Novel polycarboxylate water reducer, preparation method and application thereof

A technology of water reducer and polycarboxylate, applied in the field of new polycarboxylate water reducer, can solve the problems of low initial fluidity of polycarboxylate water reducer, inconvenient engineering construction, difficult to meet practical application, etc., and achieve low cost , Reduce the time loss, and the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 48g (0.02mol) polyalkoxyalkylene long-chain unsaturated monomer (BAPP, weight average molecular weight is 2400) is dissolved in the four-neck round bottom flask that 100g deionized water is housed; 4.32g (0.06mol) acrylic acid ( AA) was dissolved in 30g deionized water to form solution A; 0.236gL-ascorbic acid (Vc) and 0.5g sodium methacrylate (SMA) were dissolved in 24g deionized water to form solution B;

[0054] Nitrogen (N 2 ) for 30 minutes to remove oxygen, then heat up to 70°C, add 1.5g hydrogen peroxide (30% aqueous solution) into the reaction flask at one time, then add solution A and solution B dropwise, keep warm for 1 hour after the addition is completed, and add 0.08g trimethylol propane triacrylate (TMPTA), and then keep warm for 3 hours to obtain polycarboxylate superplasticizer (solution).

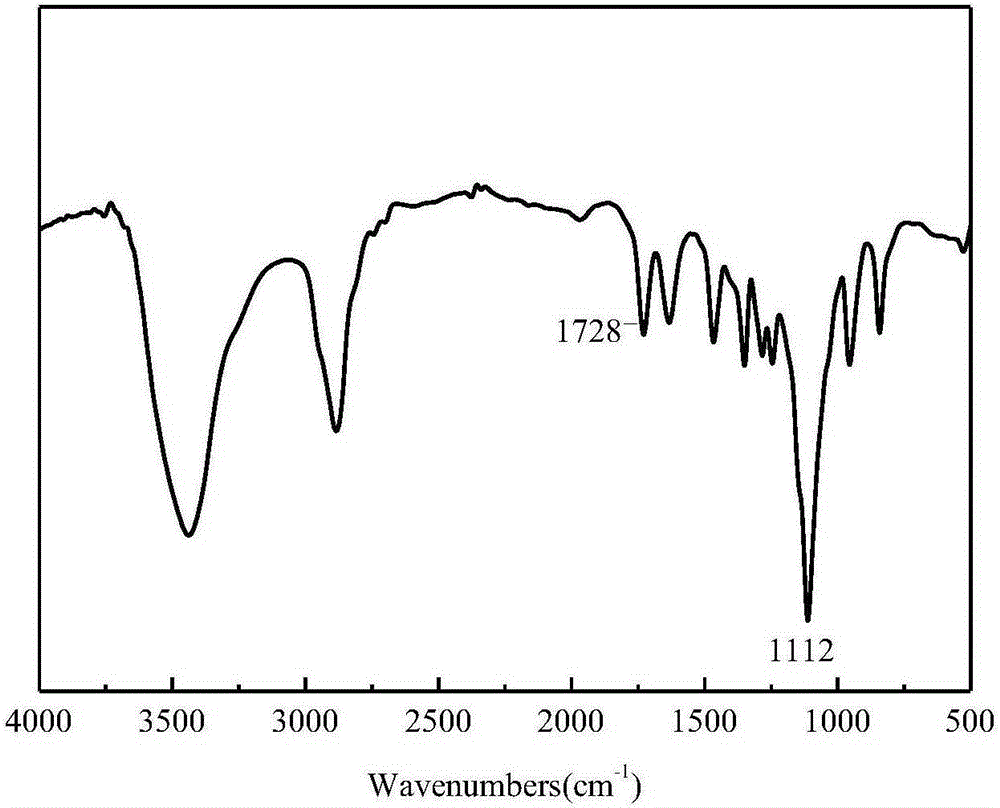

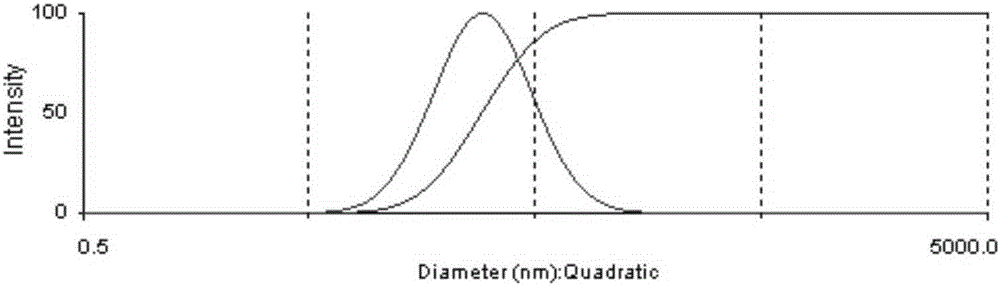

[0055] In order to determine its structure, the polycarboxylate water reducer synthesized in Example 1 of the present invention was tested by FTIR and dynamic light...

Embodiment 2

[0060] 48g polyalkoxyalkylene long-chain unsaturated monomer (BAPP, weight average molecular weight is 2400) is dissolved in the four necked round bottom flask that 100g deionized water is housed; 4.32g acrylic acid (AA) is dissolved in 30g deionized water Make solution A; 0.236gL-ascorbic acid (Vc) and 0.5g sodium methacrylate (SMA) are dissolved in 24g deionized water to make solution B;

[0061] Nitrogen (N 2 ) for 30 minutes to remove oxygen, then raise the temperature to 70°C, add 1.5g hydrogen peroxide (≥30% aqueous solution) into the reaction bottle at one time, then add solution A and solution B dropwise, keep warm for 1 hour after the addition is completed, and add 0.16g trihydroxy Methyl propane triacrylate (TMPTA), and then keep warm for 3 hours to obtain polycarboxylate superplasticizer (solution).

[0062] In order to determine its structure, FTIR, dynamic light scattering and other tests were carried out on the polycarboxylate water reducer synthesized in Exampl...

Embodiment 3

[0067] 48g polyalkoxyalkylene long-chain unsaturated monomer (BAPP, weight average molecular weight is 2400) is dissolved in the four necked round bottom flask that 100g deionized water is housed; 4.32g acrylic acid (AA) is dissolved in 30g deionized water Make solution A; 0.236gL-ascorbic acid (Vc) and 0.5g sodium methacrylate (SMA) are dissolved in 24g deionized water to make solution B;

[0068] Nitrogen (N 2 ) for 30 minutes to remove oxygen, then raise the temperature to 70°C, add 1.5g hydrogen peroxide (≥30% aqueous solution) into the reaction flask at one time, then add solution A and solution B dropwise, keep warm for 1 hour after the addition is completed, and add 0.24g trihydroxy Methyl propane triacrylate (TMPTA), and then keep warm for 3 hours to obtain polycarboxylate superplasticizer (solution).

[0069] In order to determine its structure, tests such as FTIR and dynamic light scattering were carried out on the polycarboxylate water reducer synthesized in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com