Retarding composite limestone powder admixture

A limestone powder and admixture technology, applied in the field of building materials, can solve problems such as loss of concrete slump over time, waste of resources, and adverse environmental effects, to solve the shortage of fly ash, reduce loss over time, and prolong condensation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

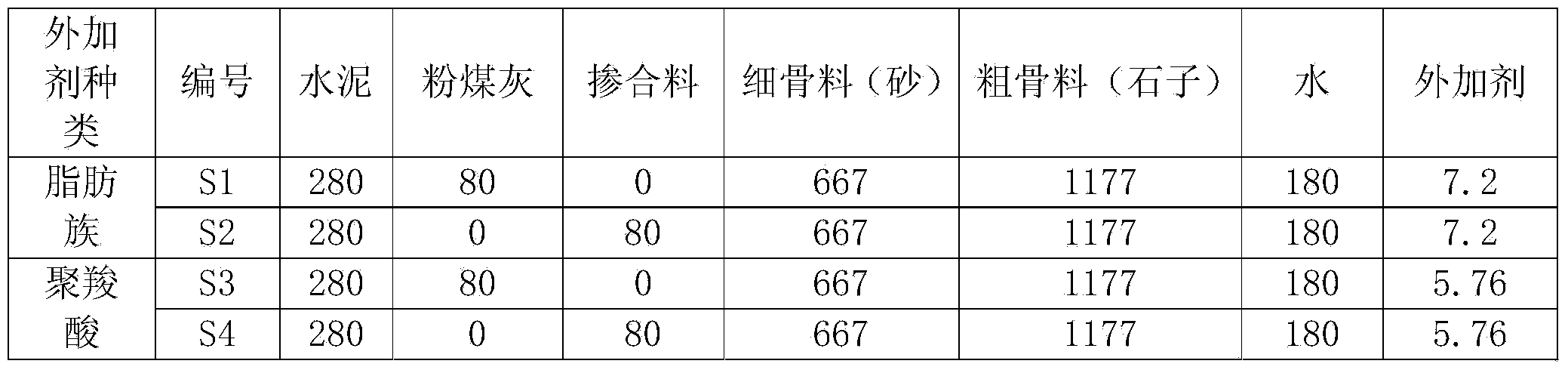

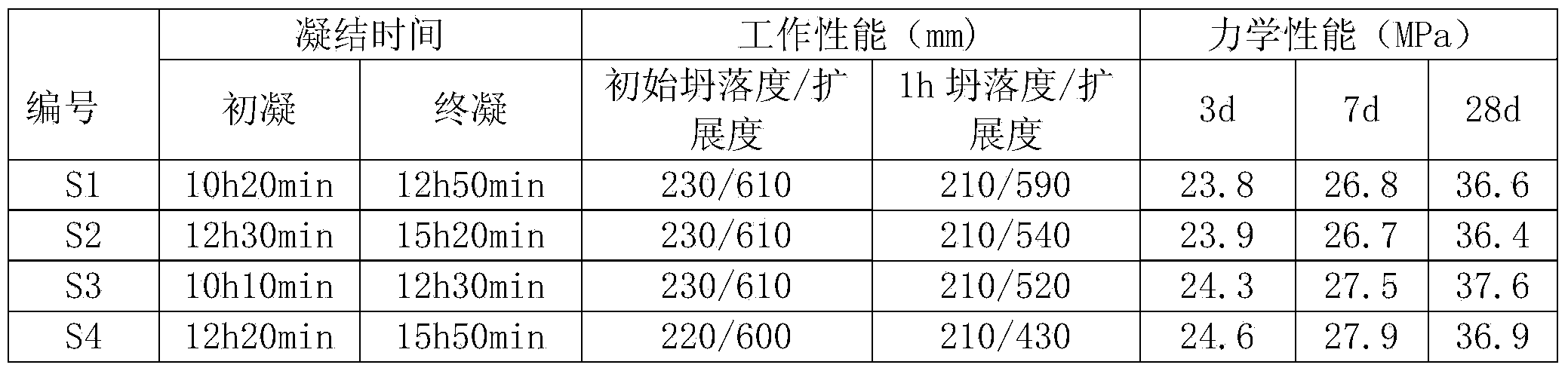

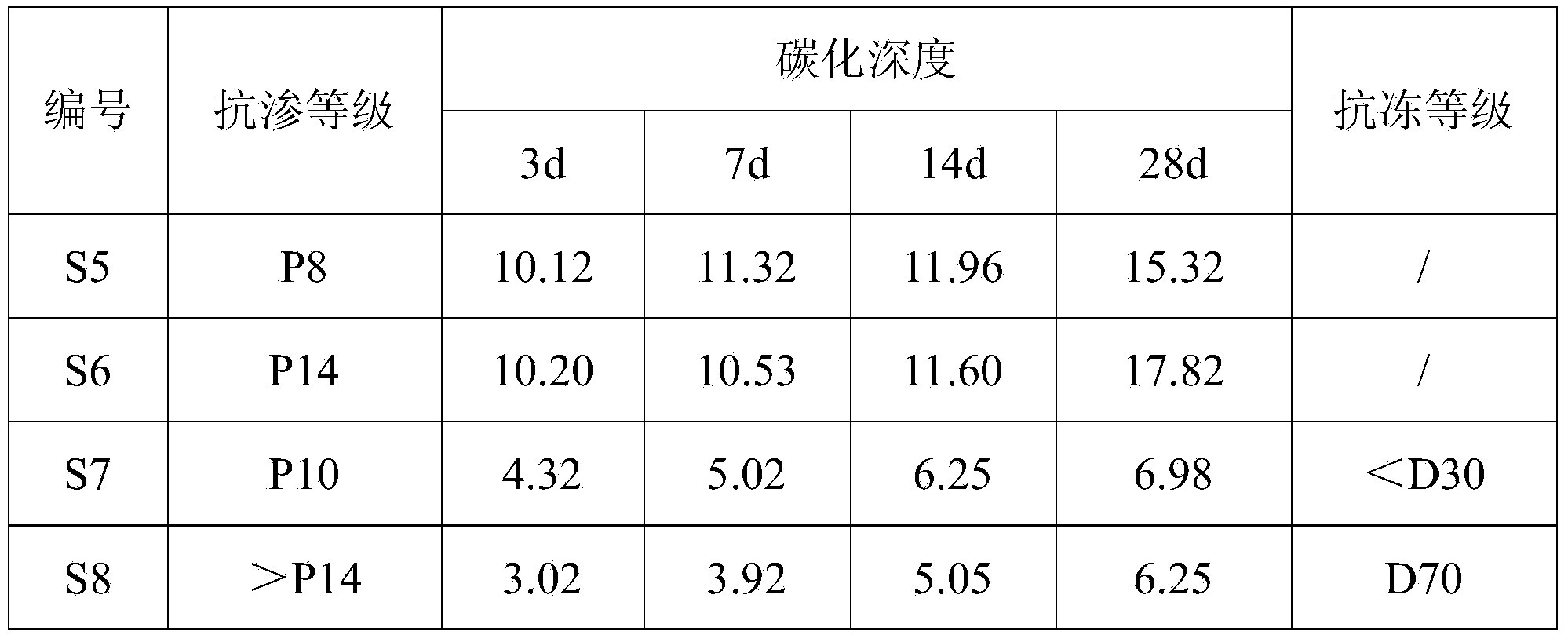

Method used

Image

Examples

Embodiment 1

[0015] Each component will be taken according to the following weight percentage proportioning,

[0016] Limestone: 80%, steel slag 15%, phosphorus slag: 4%, triethanolamine: 1%

[0017] The above-mentioned components are mixed uniformly and then ground into fine powder, the specific surface area of which is more than or equal to 350㎡ / kg to obtain the admixture.

Embodiment 2

[0019] Each component will be taken according to the following weight percentage proportioning,

[0020] Limestone: 75%, steel slag 20%, phosphorus slag: 3%, triethanolamine: 2%

[0021] The above components are mixed evenly and ground into fine powder, the specific surface area of which is ≥350m 2 / kg to obtain the admixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com