Synchronous shielding grouting material composite admixture

A composite admixture and synchronous grouting technology, applied in the field of building materials, can solve the problems of exacerbating the floating of segments, increasing the proportion of groundwater, labor-consuming and time-consuming, etc., to reduce the bleeding rate and stratification, and improve the resistance Water dispersibility, the effect of improving overall performance

Active Publication Date: 2019-11-26

CCCC WUHAN HARBOR ENG DESIGN & RES +2

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] For water-rich strata with large permeability coefficient, the traditional synchronous grouting material will be diluted by groundwater after injection during shield construction, and the expected synchronous grouting effect cannot be achieved, especially in the case of high water pressure. Synchronous grouting The slurry material is more easily diluted, which leads to the destruction of the material structure. The grouting material cannot be condensed quickly, but instead increases the proportion of groundwater, which further intensifies the floating of the segment, especially in the case of a sudden change in the formation. Due to the equipment conditions of the slurry, the adjustment of equipment and pipelines on site is not only labor-intensive and time-consuming, but also cannot respond to the problem of segment floating in a timely and effective manner, resulting in unstable posture of the shield machine and a great safety risk

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0044] The preparation method of shield synchronous grouting material comprises the following steps:

[0045] Step 1. Add the weighed cement, fly ash and river sand into the mixer for dry mixing for 1-2 minutes to make it mix evenly.

[0046] Step 2: Add the compound admixture into the mixer, and dry stir for 1-2 minutes to make it evenly mixed

[0047] Step 3: Add water into the blender and stir for 3-5 minutes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

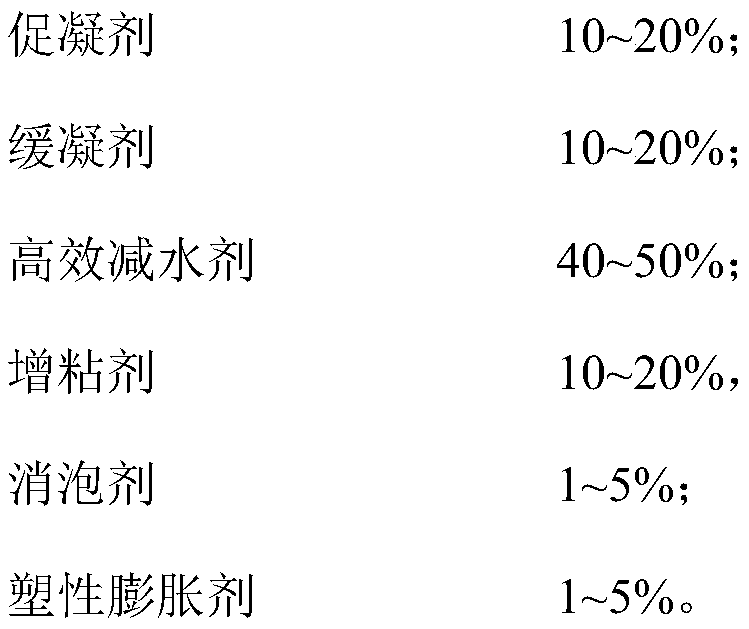

The invention discloses a synchronous shielding grouting material composite admixture which comprises the following raw materials in percentage by mass: 10-20% of a coagulant, 10-20% of a retarder, 40-50% of an efficient water reducer, 10-20% of a tackifier, 1-5% of a defoaming agent and 1-5% of a plasticity expander. The admixture has the effects that in a high-pressure water-enriched stratum environment, on premise that equipment and pipelines are not changed, the curing time can be adjusted, the working performance loss is small within the curing time, and good water dispersibility resistance, efficient filling and rapid curing can be achieved.

Description

technical field [0001] The invention relates to the field of building materials. More specifically, the invention relates to a composite admixture for shield synchronous grouting materials. Background technique [0002] The synchronous grouting technology is that when the shield is advanced to the end of the shield and the segment is separated from the segment, an over-excavated gap appears on the back of the segment. In order to avoid deformation of the ground and cause destructive effects on adjacent structures, the After the tail of the shield is detached, it is a construction method of filling the back of the segment with consolidating grout. The main purpose of synchronous grouting is: (1) to fill the gap in the shield tail building in time, support the rock mass around the segment, and effectively control the surface settlement; (2) ensure the early stability of the segment lining and the sealing of the gap, and prevent the (3) As the first line of defense for lining...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/24C04B28/04C04B111/70

CPCC04B28/04C04B40/0039C04B2111/00724C04B2111/70C04B2201/50C04B22/064C04B22/08C04B22/10C04B24/10C04B24/06C04B2103/302C04B24/24C04B24/005C04B24/129C04B18/08C04B14/06

Inventor 沈尔卜韩晓明李顺凯吴克雄刘华黄文杰朱金彭钟函

Owner CCCC WUHAN HARBOR ENG DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com