Patents

Literature

201results about How to "Low bleeding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance foaming cement and preparation method thereof

The invention relates to high-performance foaming cement, which comprises cement slurry and foams, wherein the cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 10-30 parts of gypsum powder, 10-50 parts of active admixtures, 10-40 parts of mineral admixtures, 1-5 parts of re-dispersible gelatine powder, 0.5-1.5 parts of cellulose ether, 0.2-1.0 part of water reducing agent, 0.1-0.5 part of water repellent and 40-90 parts of water; and the foams are prepared from the following components in parts by weight: 1 part of foaming agent, 0.2-0.8 part of foam stabilizer and 30-50 parts of water. A preparation method of the high-performance foaming cement comprises the steps of: (1) preparing the cement slurry; (2) preparing the foams by using a foaming machine; and (3) mixing and uniformly stirring the cement slurry and the foams according to the weight ratio of 1:(0.1-1), and pouring and molding. The high-performance foaming cement disclosed by the invention has high closed porosity and small shrinkage value, and integrates the performances of heat insulation, sound insulation, water repellent, shock resistance, fire protection, durability, low carbon and environmental protection into a whole.

Owner:辽宁际洲环保节能建材有限公司

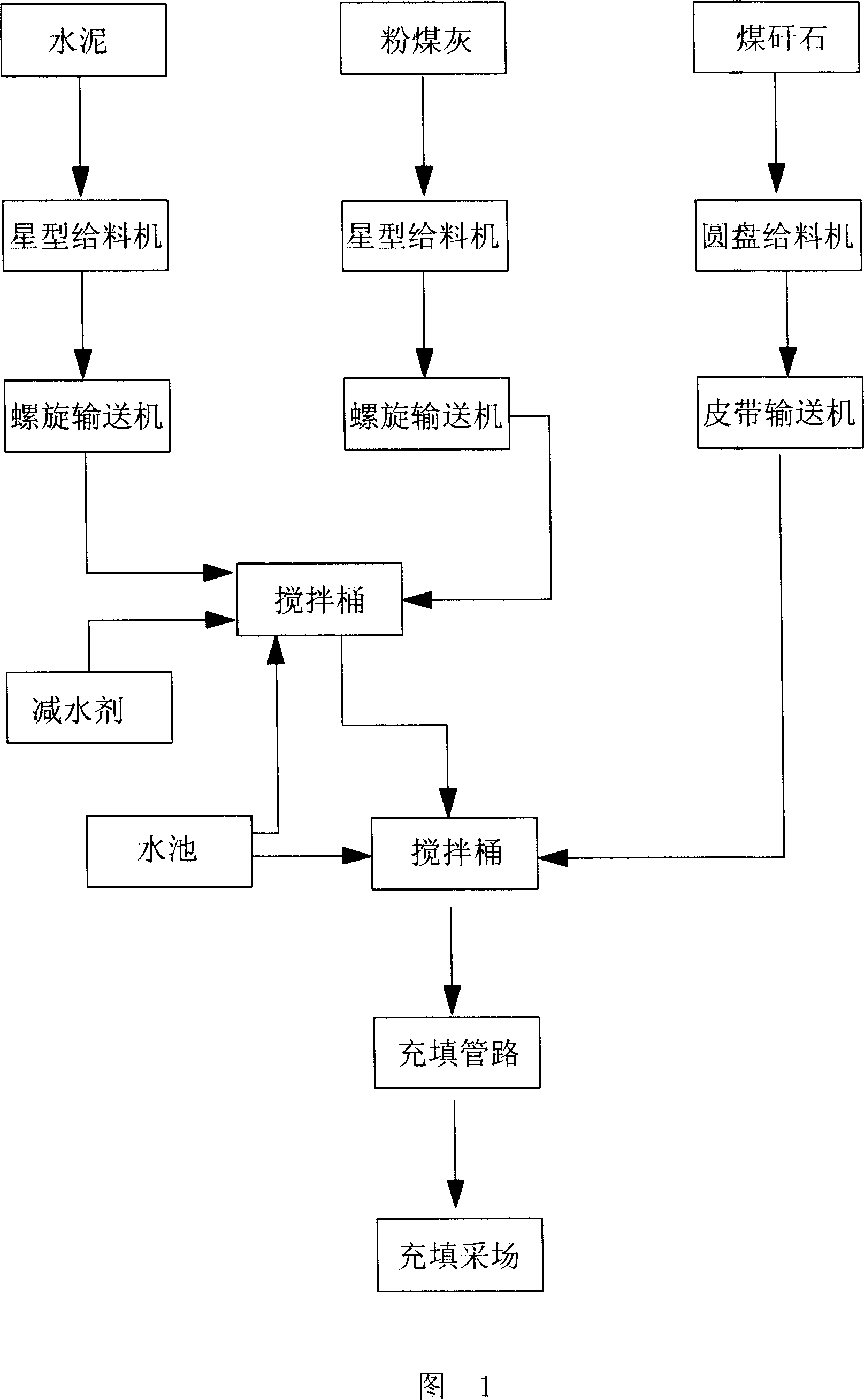

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

Paste-like backfill technology used in coal cutting area and the paste-like thereof

InactiveCN101008315AHigh content of dry ingredientsStrong dry material component contentMaterial fill-upWater leakageUltimate tensile strength

The invention relates to a paste self-flow stuff technique of coal mine and relative paste, which uses the coal gangue as main stuff. The invention is characterized in that the stuff technique comprises that mixing cement and powder coal into water to form pulp; adding coal gangue to form coal gangue suspension paste; using tube to self-flow transmit the paste into under-well stuff area to stuff the mining field. The invention uses coal gangue as main stuff material and uses self-flow stuff technique, with low cost and the application in the underground coal layer, to reduce the pollution of coal gangue. The inventive paste has high water contant and low water leakage, therefore, the stuff has high strength.

Owner:邸建友

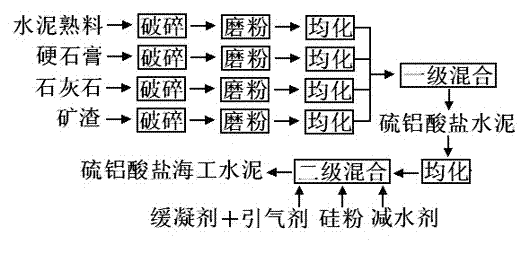

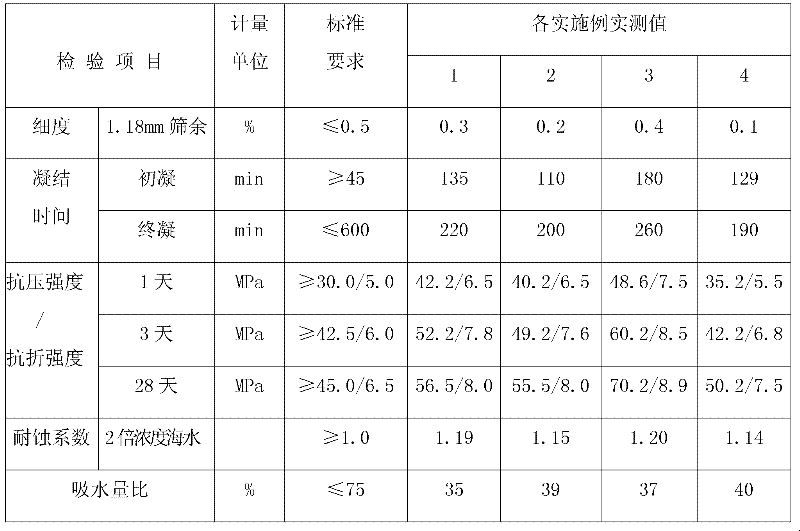

Sulphoaluminate maritime work cement and preparation method thereof

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

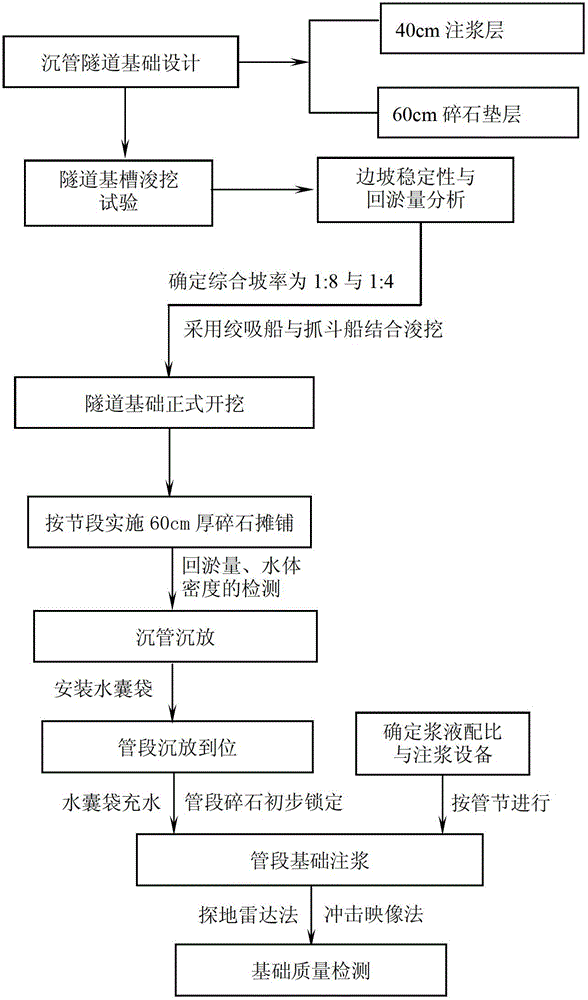

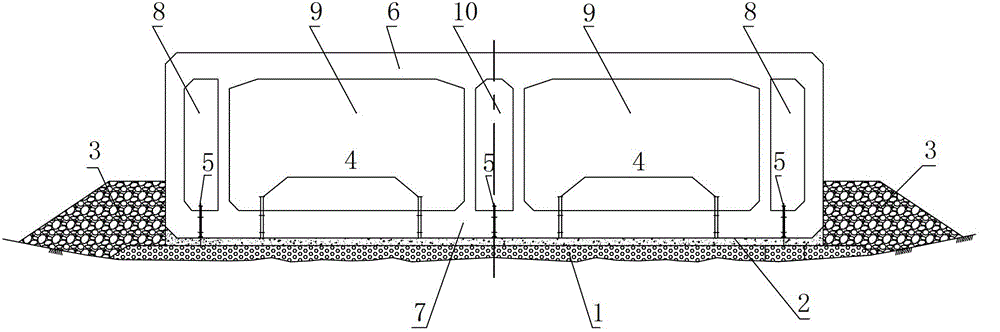

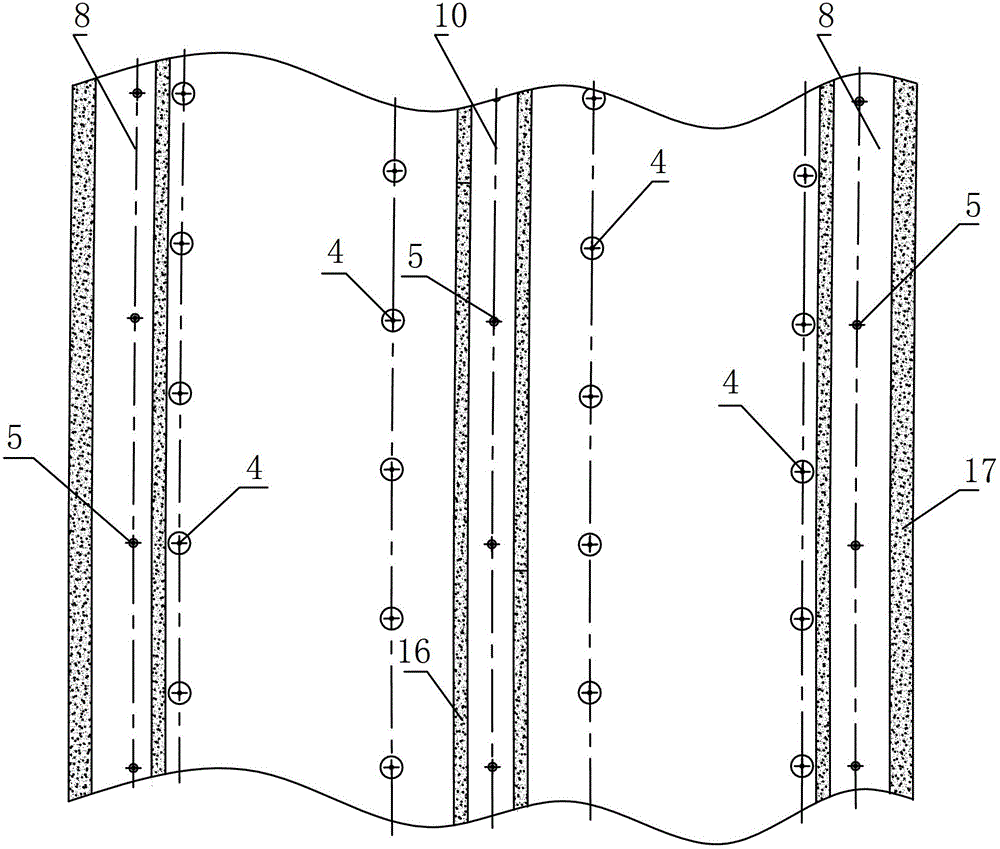

Underwater grouting grout based on soft-base large immersed tunnel foundation and grouting process thereof

The invention discloses a preparation of underwater grouting grout based on soft-base large immersed tunnel foundation and a grouting process thereof. The foundation is formed by a 60-cm thick macadam foundation base and a 40-cm thick sodium bentonite mortar foundation and is capable of meeting requirements for tunnel foundation rigidity and requirements for base seismic resistance and water flow scouring resistance. The grout is composed of cement, fine sand, coal ash and sodium bentonite. The grouting process is improved, and pipe inside grouting of embedded grouting holes is adopted. Therefore, large ships are not required to work on river face, underwater operation of divers and navigation risks are reduced, construction safety is greatly improved, and construction cost is reduced. The secondary grouting technology is first adopted in the field of the immersed tunnel to reduce uneven sedimentation in future operation stage of projects. The grouting process provides a reference guide and an experience guide for large dock projects, immersed tunnel projects, municipal administration soft earth foundation strengthening projects, high earthquake region basic project design and other similar projects.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +6

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

Retarding superplasticizer composition for roller compacted concrete

InactiveCN102659342AVC value loses quicklyVC value loss is smallRoller-compacted concreteSuperplasticizer

The invention relates to a retarding superplasticizer composition for roller compacted concrete, which is prepared from 40-80 percent of barium-containing naphthalene based superplasticizer, 10-30 percent of modified lignosulfonate, 3-7 percent of plastic retaining agent, 5-15 percent of composite retarder, 1-7 percent of layer silicate mineral material, 0.1-0.5 percent of polysiloxane and 0.1-0.2 percent of air entraining agent. The retarding superplasticizer composition does not contain alkali harmful to alkali-aggregate reaction, has a better inhibition effect to the alkali-aggregate reaction, and has the advantages of high water reducing rate, strong VC value retaining capacity, good water retaining property, small bleeding rate, remarkable retarding effect and the like, so that the prepared roller compacted concrete mixture has the characteristics of good workability, small VC value loss, small bleeding rate, long setting time, greatly reduced early hydration heat and delayed occurrence time of a hydration heat peak, so as to have better construction property, mechanical property and durability.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

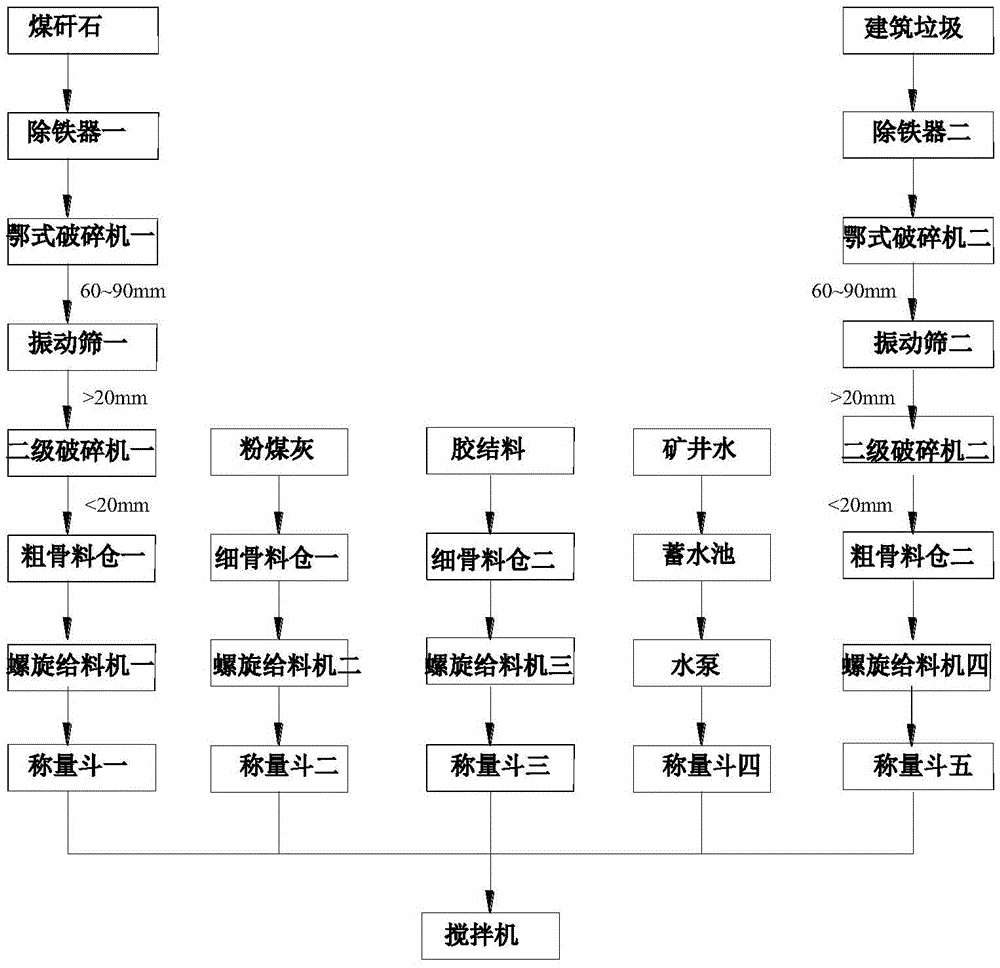

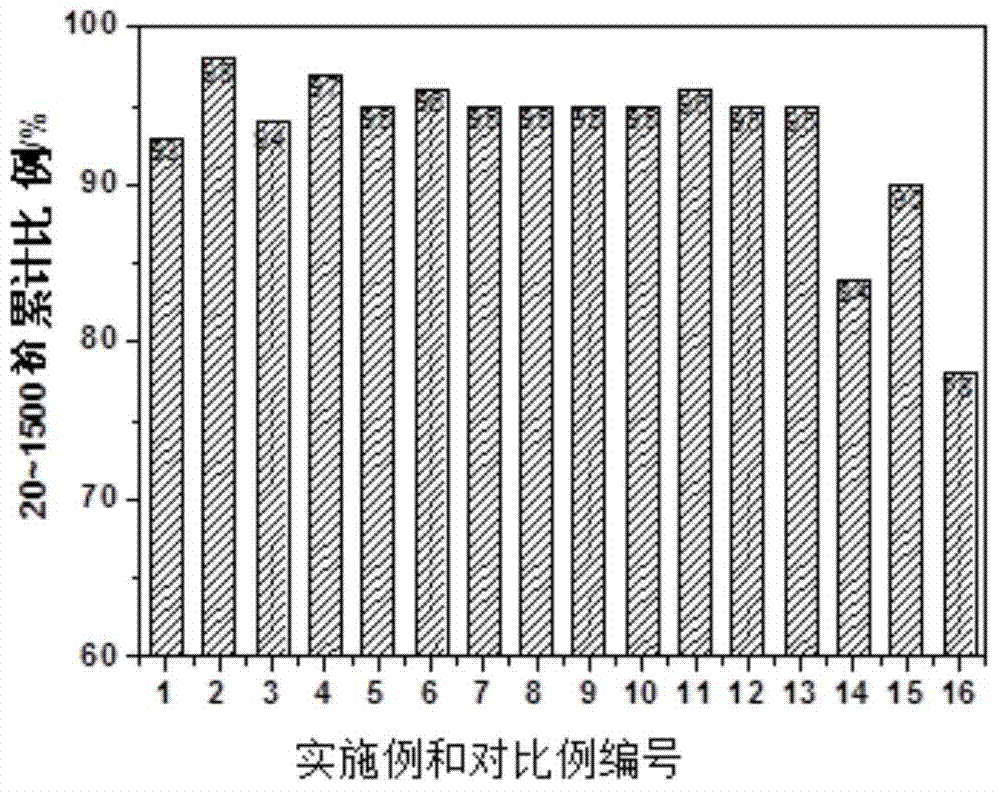

Coal mine paste-like filling material using construction waste, and preparation and filling method thereof

InactiveCN105481314AHigh strengthImprove stabilitySolid waste managementMaterial fill-upFilling materialsWater reducer

The invention provides a coal mine paste-like filling material using construction waste. The material comprises the following raw materials: a coarse aggregate containing 450-500Kg of construction waste and 400-450Kg of gangue; a fine aggregate containing 350-400Kg of fly ash and 200-250Kg of a binder; an admixture containing 6.0-12.5Kg of an accelerator and 2.0-7.5Kg of a water reducer; and 550-630Kg of mine water. According to the invention, construction waste, gangue and other wastes are used to prepare the paste-like filling material with good pumpability, low bleeding rate and degree of stratification, short setting time, high strength and stability, and low cost. The invention also provides a preparation and filling method of the coal mine paste-like filling material using construction waste.

Owner:ANHUI UNIV OF SCI & TECH

Preparing method for polycarboxylate water reducing agent

ActiveCN103159899AIncrease profitNarrow down the range of molecular weight fluctuationsHydrogenRoom temperature

The invention provides a preparing method for polycarboxylate water reducing agent. The polycarboxylate water reducing agent composed of, by weight, 30%-55% of deionized water, 35%-50% of polyoxyethylene ether, 5%-10% of carboxylic acid derivatives monomer, 0.0005%-0.002% of catalyst, 1.5%-4.5% of initiator, 0.2%-0.8% of chain transfer agent, 1.0%-2.5% of structure modifying agent and 4.5%-8.5% of alkali liquor. Under the temperature of 20-35 DEG C, the deionized water and the polyoxyethylene ether are enabled to be put in a reaction still to be dissolved, after the deionized water and the polyoxyethylene ether are fully dissolved, the carboxylic acid derivatives monomer, the catalyst, the initiator, the chain transfer agent and the structure modifying agent are enabled to be added in sequence, after stirring for 28-32 minutes, the mixed liquor still standings for 4-6 hours under room temperature, the alkali liquor is added in under a state of stirring, a potential of hydrogen (PH) value is adjusted to be 6.0-7.5, and then products are achieved.

Owner:XINJIANG DELAND

High-strength micro-expansion prestress anchoring grouting material and preparation method thereof

InactiveCN102180628AImprove rheologyGuaranteed StrengthSolid waste managementMass ratioQuality by Design

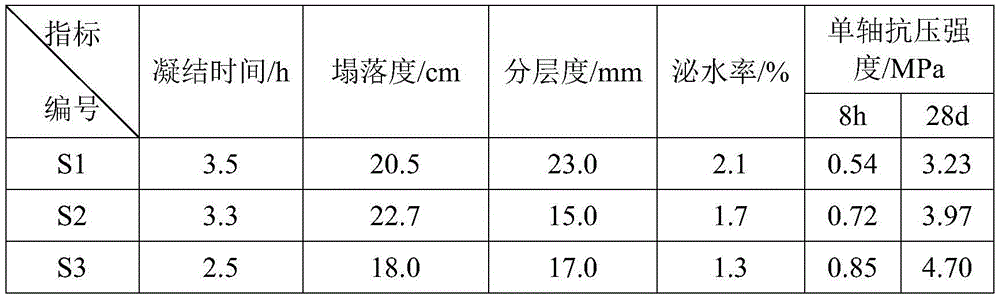

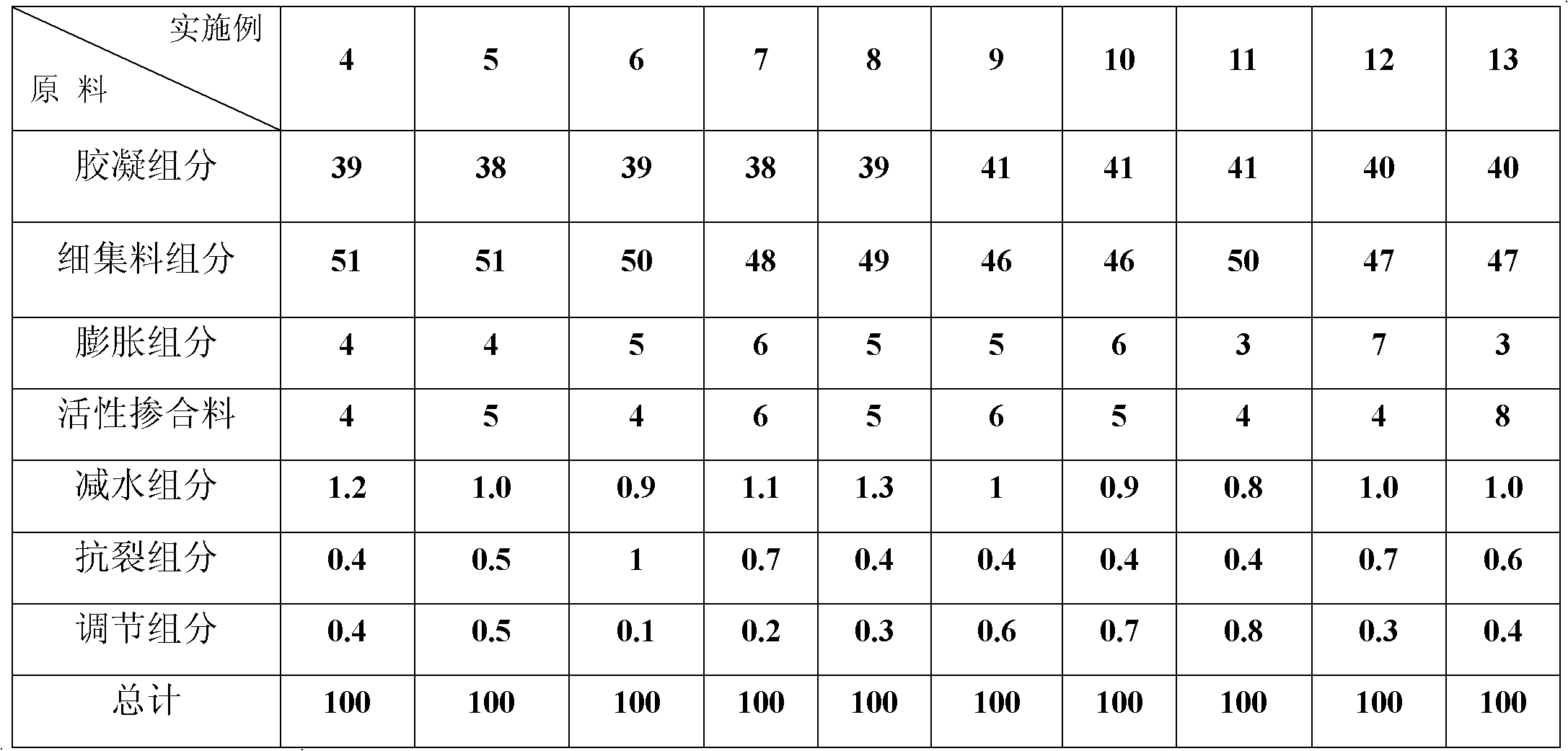

The invention discloses a high-strength micro-expansion prestress anchoring grouting material and a preparation method thereof. The material is prepared from a gelatinization component, a fine aggregate component, an expansion component, an active doped material, a water reducing component, a crack resistant component and a regulation component in a certain weight proportion. The preparation method specifically comprises the following steps: A, adding the gelatinization component, the expansion component, the active doped material, the crack resistant component and the water reducing component in a ball-mill in a designed mass ratio for commonly mixing and grinding, so as to obtain a even powder material; B, at room temperature and normal pressure, grinding until the Blaine specific surface of the material is not less than 350m<2> / kg; and C, evenly mixing and stirring the obtained in the step B with quartz sand prepared in a proportion at the room temperature and the normal pressure so as to obtain the grouting material. The method is practicable and is convenient for operation; the grouting material has high early strength and micro-expansion, thereby effectively compensating the hydration shrinkage of a cement-based material, obviously improving the adhesive strength of an anchor rod and a periphery base, effectively protecting the anchor rod from being corroded and prolonging the service of the anchor rod.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

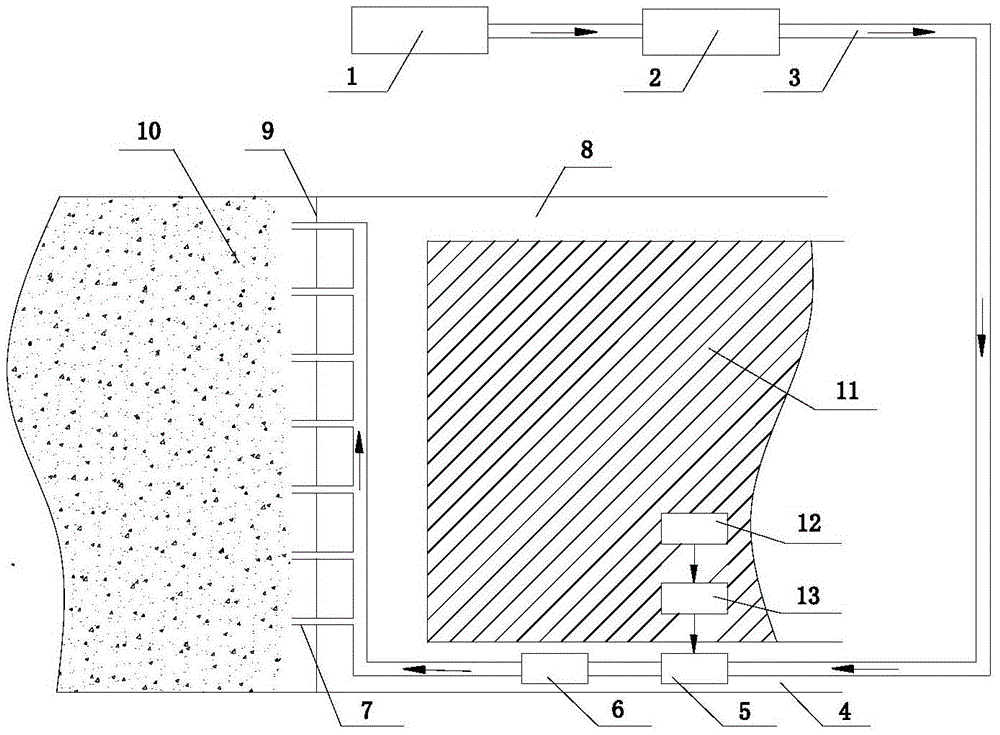

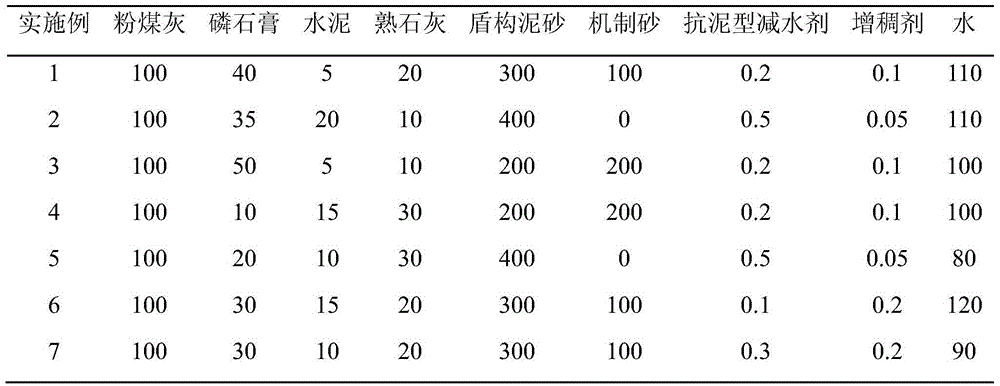

Anti-aqueous dispersion synchronous grouting material with large specific gravity and low consistence

The invention discloses an anti-aqueous dispersion synchronous grouting material with large specific gravity and low consistence. The anti-aqueous dispersion synchronous grouting material consists of the following components in parts by weight: 100 parts of coal ash, 10-30 parts of slaked lime, 5-20 parts of cement, 10-50 parts of phosphorus gypsum, 0-200 parts of machine-made sand, 200-400 parts of shield mud and sand, 0.1-0.5 part of a water reducing agent, 0.05-0.2 part of a thickening agent and 80-120 parts of water. The shield mud and sand is used for replacing river sand and bentonite in a traditional grouting material, and the shield mud and sand and machine-made sand are taken as fine aggregates, so that the problem of resource shortage for natural sand is solved; moreover, the coal ash discharged at a power station and the phosphorus gypsum produced at a phosphorus chemical plant are reasonably utilized, so that the resource utilization of industrial waste is realized. The grouting material has the characteristics of good filling property, long castable time, large specific gravity, low consistence, anti-aqueous dispersion performance, segment floating prevention and the like, is prominent in environmental protection performance and low in cost, and can be widely applied to the shield segment grouting engineering and the like.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Method for improving stability of foaming agent

The invention relates to a method for improving stability of a foaming agent. A foam stabilizing substance A, a foam stabilizing substance B, a foam stabilizing substance C and a foam stabilizing substance D are added into the foaming agent. The addition amount of the foam stabilizing substance A accounts for 0.01-5% of the total material mass. The addition amount of the foam stabilizing substance B accounts for 0.01-8% of the total material mass. The addition amount of the foam stabilizing substance C accounts for 0.01-15% of the total material mass. The addition amount of the foam stabilizing substance D accounts for 0.01-12% of the total material mass. The foaming agent defoaming and foam stabilizing principle is sufficiently analyzed, and the method for effectively improving stability of the rosin foaming agent foam is provided on the basis of a large quantity of experiment researches. According to the method, by adding the foam stabilizing substances, the purpose of improving foam stability is achieved. The method is easy to operate, low in cost and obvious in effect.

Owner:NANJING UNIV OF TECH

Efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as preparation method and application method thereof

The invention discloses an efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as a preparation method and an application method thereof. The composition comprises the following components in percentage by weight (100% in total): 1%-5% of a plasticizer, 15%-30% of a thickening agent, 30%-50% of a retarder, 10%-25% of an anti-cracking agent, 1-5% of a water-retaining agent, 5%-10% of an enhancer, and 1%-5% of a binding agent. By utilizing the composition, the workability, water-retaining property, adhesive property and cracking resistance of coating mortar can be remarkably improved, the cracking, hollowing and falling of the mortar are avoided, and various performance indexes such as the strength and permeability resistance of the mortar can be improved; and furthermore, cement can be saved, and the disadvantages of easiness in ash blasting, high shrinkage, low strength and the like of the cement mixed mortar are overcome.

Owner:四川巨星新型材料有限公司

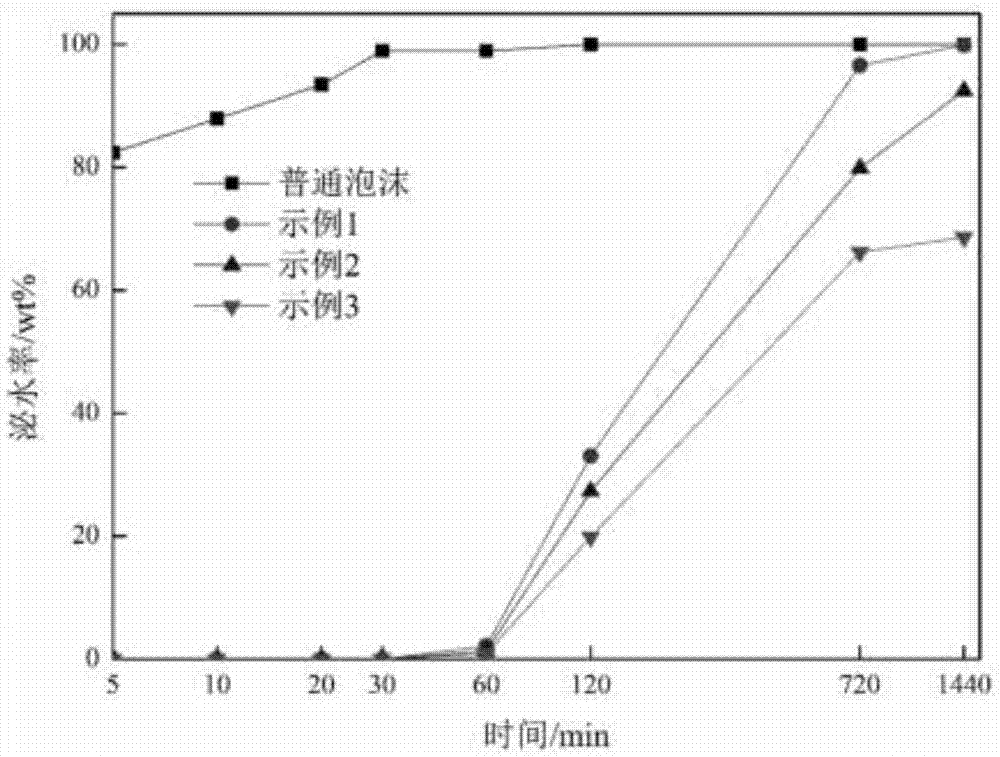

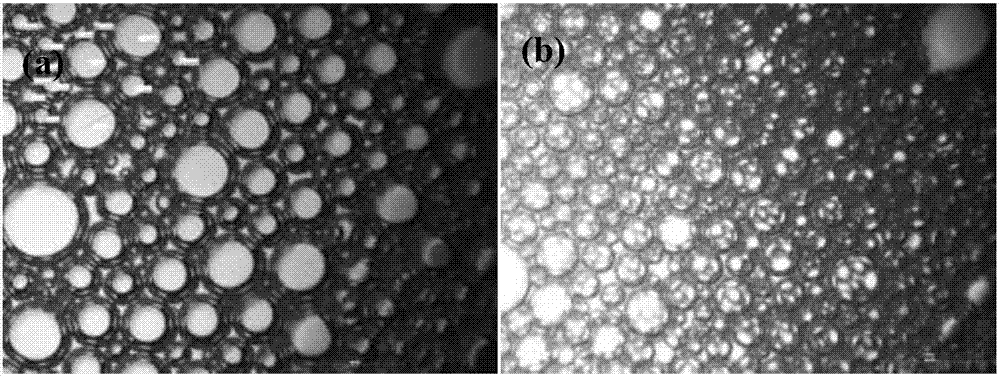

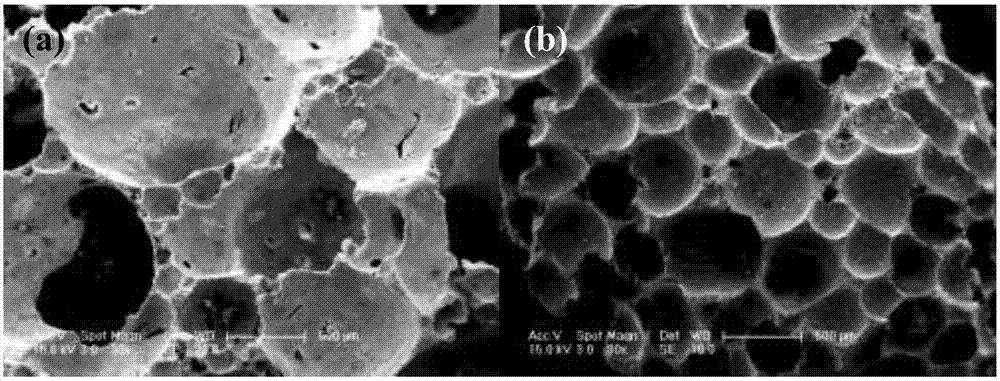

Nano-modified super-stable foam and application thereof in ultralight-density cement-based porous material

ActiveCN106866021AImprove stabilityThe improved foaming agent has good stabilityCeramicwareFoaming agentNanoparticle

The invention discloses nano-modified super-stable foam and application thereof in an ultralight-density cement-based porous material. By means of stably scattering nanoparticles into a foaming agent, foam can be wrapped by the nanoparticles after the modified foaming agent is stirred and generates the foam, the foam is converted into a gas-liquid-solid three-phase structure from a gas-liquid two-phase structure, and the stability of the foam is obviously improved. The foam prepared from the modified foaming agent has good stability and fine and uniform size; furthermore, the ultralight porous cement-based material prepared from the foam has high strength, is not prone to collapsing and solves the problems that a traditional ultralight cement-based porous material has poor performance and the like; the application of the foam is an effective method for improving performance of the ultralight cement-based material.

Owner:SOUTHEAST UNIV

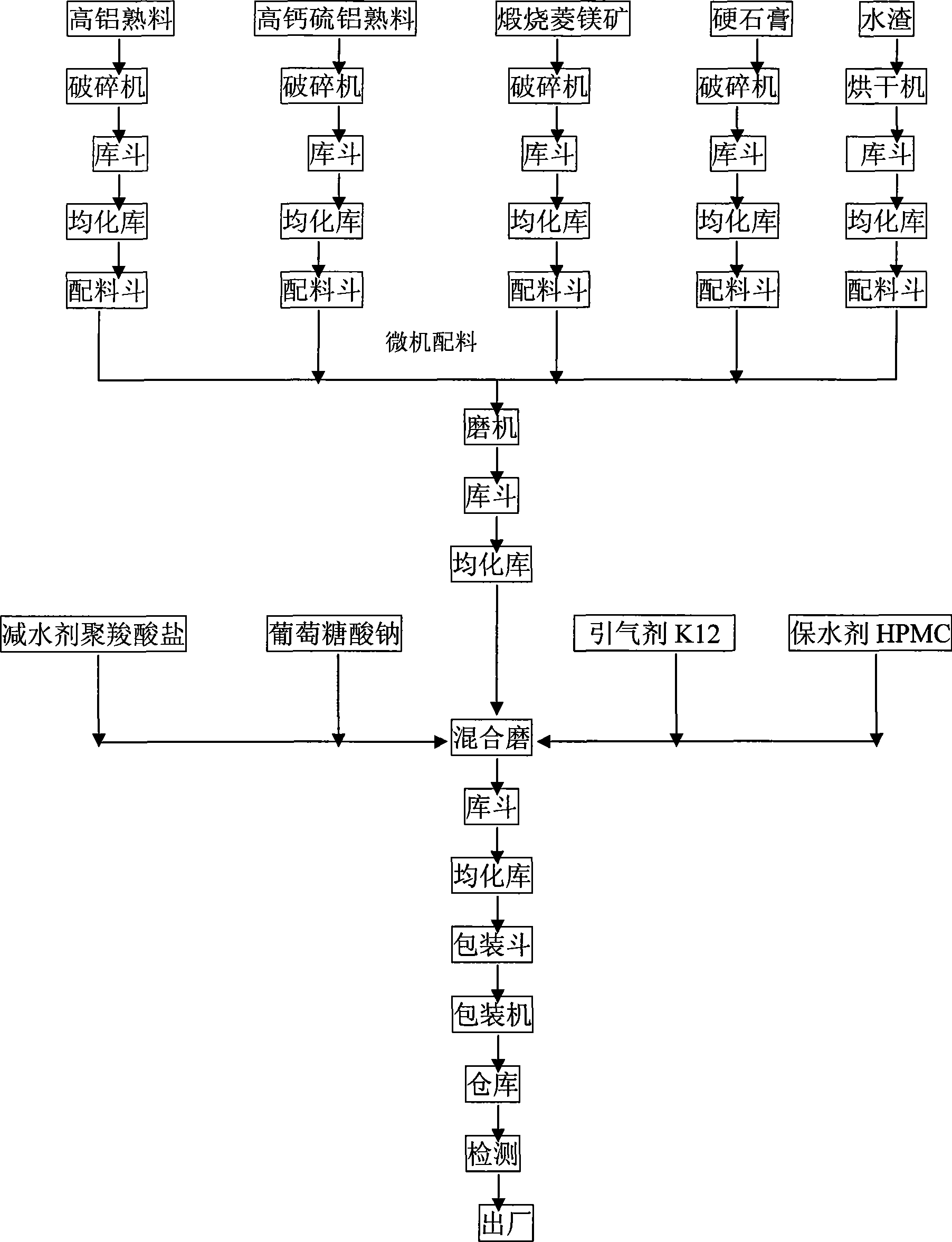

Retardation pumping type three-expansion source cement expansive material

The invention discloses a slow hardening pump deliver type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent, water retention agent, air entraining agent and retardant. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, strong suitability with concrete, balanced mechanical property after hardening, and small gradual slump loss of concrete shrinkage compensation, contributes to improving safety and durability of reinforced concrete, obviously improves the cracking resistance, volume stability, impermeability and frost resistance, and is simple and convenient to use and easy to control quality in construction. The slow hardening pump deliver type three expansion source concrete expansion agent can meet construction use requirements of commercial concrete, long distance pump-delivering concrete and mass concrete.

Owner:广西云燕特种水泥建材有限公司

High performance grouting addition for concrete with post-tensioning binding prestressing force

The invention is a special additive for post-tensioned cohesive prestressed concrete structure, prepared of the following components in weight percent: phenyl sulfonate formaldehyde high-grade condensation compound 2-10%, aluminum powder 0.005-0.05%, anhydrite 50-70%, calcined kaoline 10-20%, kaoline 10-20%, linear high-molecular anion polysaccharide 0.05-1.5%, and triterpenoid saponin 0.05-0.1%. It has multiple functions of improving both the rheological property of grouting material and the bulk stability, and after doped, it is unnecessary to compound other materials to effectively improve the rheological property of grout, largely reducing seepage water and avoiding high separation and stratification, and it can effectively compensate shrinkage in plastic and hardening state, enhancing the bulk stability of the grout. The fluidity is basically not lost in 2 hours, the grout is full and dense in the pipeline and has strong adaptability to temperature, and the economic benefits of the technique are obvious. After doped in the cement, it adopts ordinary pressure grouting technique to be able to effectively ensure the grout basal body does not seep water after grouted and the bulk of the grout does not shrink and corrode steels.

Owner:JIANGSU SOBUTE NEW MATERIALS

Cable low heat resistance protection medium and preparing method thereof

ActiveCN101764384AReduce thermal resistanceIncrease thermal resistanceCable installations on groundAlkalinityElectrical conductor

The invention discloses a cable low heat resistance protection medium with high water content, high stability, low heat resistance, environment protection and effective prevention of termite damage, and a preparation method thereof. The filling medium is prepared by mixing bentonite, fine quartz sand, water and cement, and using a small amount of tartaric acid and sodium sesquicarbonate as additives. As accounted by 100% of mass fraction, the filling medium is preferably prepared by 54%-57% of bentonite, 24%-28% of fine quartz sand, 14%-16% of water, 2.5-3.5% of cement, 0.24%-0.26% of tartaric acid and 0.24%-0.26% of sodium sesquicarbonate. Before condensation, the filling medium has the advantages of better initial liquidity, moderate alkalinity, low bleeding rate and the like. After condensation, compared with traditional material, the filling medium has the advantages of high water content and high stability, and enables the surroundings of the cable to maintain low heat resistance for long term, the heat resistance is smaller than that of soil, and the hardness is higher, therefore the current carrying amount of the cable is improved, or the running temperature of the cable conductor is reduced.

Owner:广州骏拓电力科技有限公司

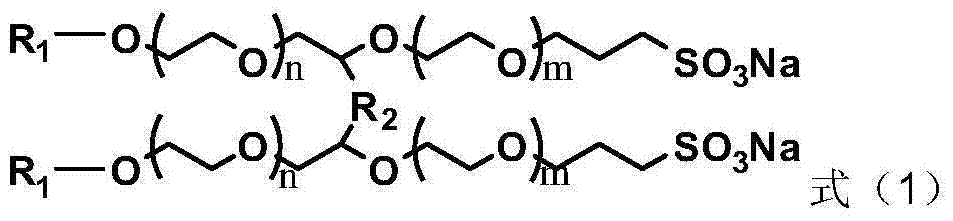

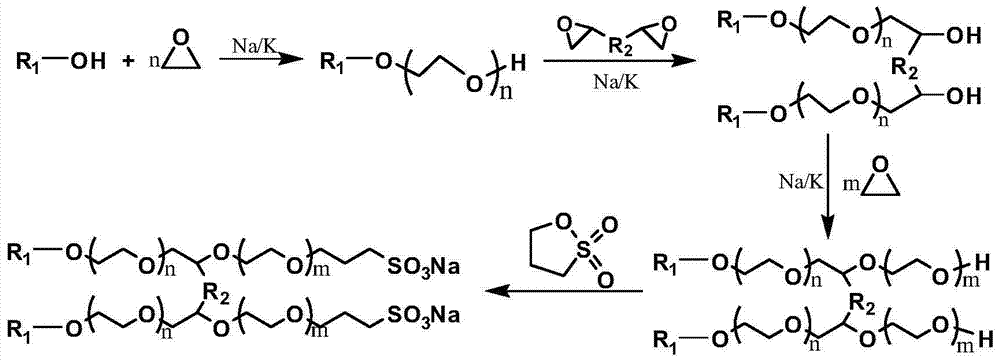

Composite concrete air entraining agent, and preparation method and application thereof

ActiveCN104496525ARemarkable foaming effectGood low temperature stabilityTransportation and packagingMixingNonionic surfactantAir content

The invention provides a composite concrete air entraining agent, and a preparation method and application thereof. The invention is characterized in that the composite concrete air entraining agent is composed of a sulfonate Gemini surfactant, a betaine amphoteric surfactant, an alkanolamide nonionic surfactant and water; and the solid content of the composite concrete air entraining agent is 20+ / -1%. The composite concrete air entraining agent has excellent air-entraining effect in concrete; and sufficient 20-150-mu m stable small bubbles can be introduced to improve the workability of the concrete (mortar), reduce the bleeding rate and sedimentation and avoid lowering the later strength of the concrete on the premise of enhancing the air content.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

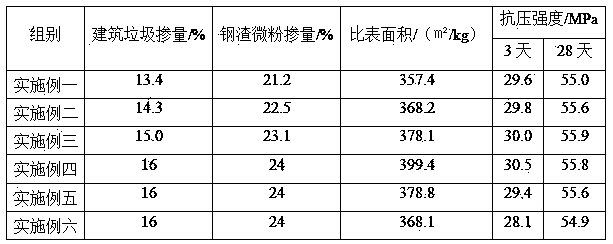

Method for producing green ecological cement resistant to seawater corrosion by using construction wastes

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using construction wastes. The cement comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinkers, 5-20 parts of construction wastes, 20-25 parts of steel slag powder, 0.06-0.08 part of compound activating agent, 2-5 parts of early strength agent, 0.3-0.5 part of water reducing agent, 0.005-0.007 part of air entraining agent and 0.3-0.5 part of retarder. The production method is characterized by breaking, grinding and homogenizing the construction wastes, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Method for producing seawater corrosion-resistant green ecological cement from stone waste

ActiveCN104291717AReduce stone dust pollutionWide variety of sourcesCement productionScrapCorrosion resistant

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste. The seawater corrosion-resistant green ecological cement comprises the following raw materials in parts by weight: 30-40 parts of stone waste, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of a complex activator, 2-4 parts of an early-strength agent, 0.3-0.5 part of a water-reducing agent, 0.005-0.007 part of an air entraining agent, and 0.3-0.5 part of a retarder; and the production method comprises the following steps: respectively crushing the stone waste, sulphate aluminum cement clinker, complex activator and early-strength agent, grinding, homogenizing, then mixing and homogenizing according to a proportion, then adding the water-reducing agent, air entraining agent and the retarder, mixing and homogenizing to obtain the seawater corrosion-resistant green ecological cement. The seawater corrosion-resistant green ecological cement has the excellent properties of being high-strength, seawater corrosion-resistant, seawater scouring-resistant and the like besides the performances of common cement, and is especially applicable to underground engineering, ports, wharfs and other engineering corroded by erosion media.

Owner:广西云燕特种水泥建材有限公司

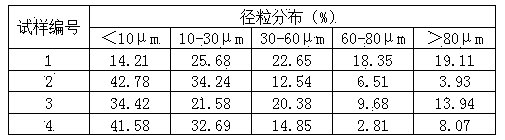

Efficient mortar plasticizer base material and its efficient mortar plasticizer composition

This invention relates to a basic material of a high efficient mortar DBP to be prepared by the following method: a, adding 11-14% rosin polymers into 45-55% water of 80-120deg.C slowly and mixing them in a kettle continuously to be solved fully, then adding 4-6% inorganic alkali and dissolving them completely under the 60-80deg.C constant to the complete reaction, b, adding 8-10% sulfosalt while mixing, 1-2% polyalcohol under 40-60 deg.C constant to the complete reaction, c, adding 10-11% DBP to be dissolved fully under 30-50 deg.C to be cooled to normal temperature, d, spraying and drying them to powder particles then to be matched with 3-5% DBP and 9-11% silicon powder to get the basic material of high efficient mortar DBP. This invention also relates to its compound.

Owner:四川铁科新型建材有限公司

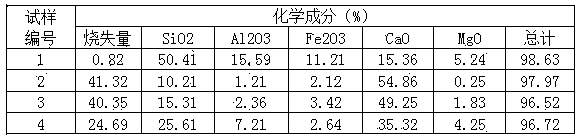

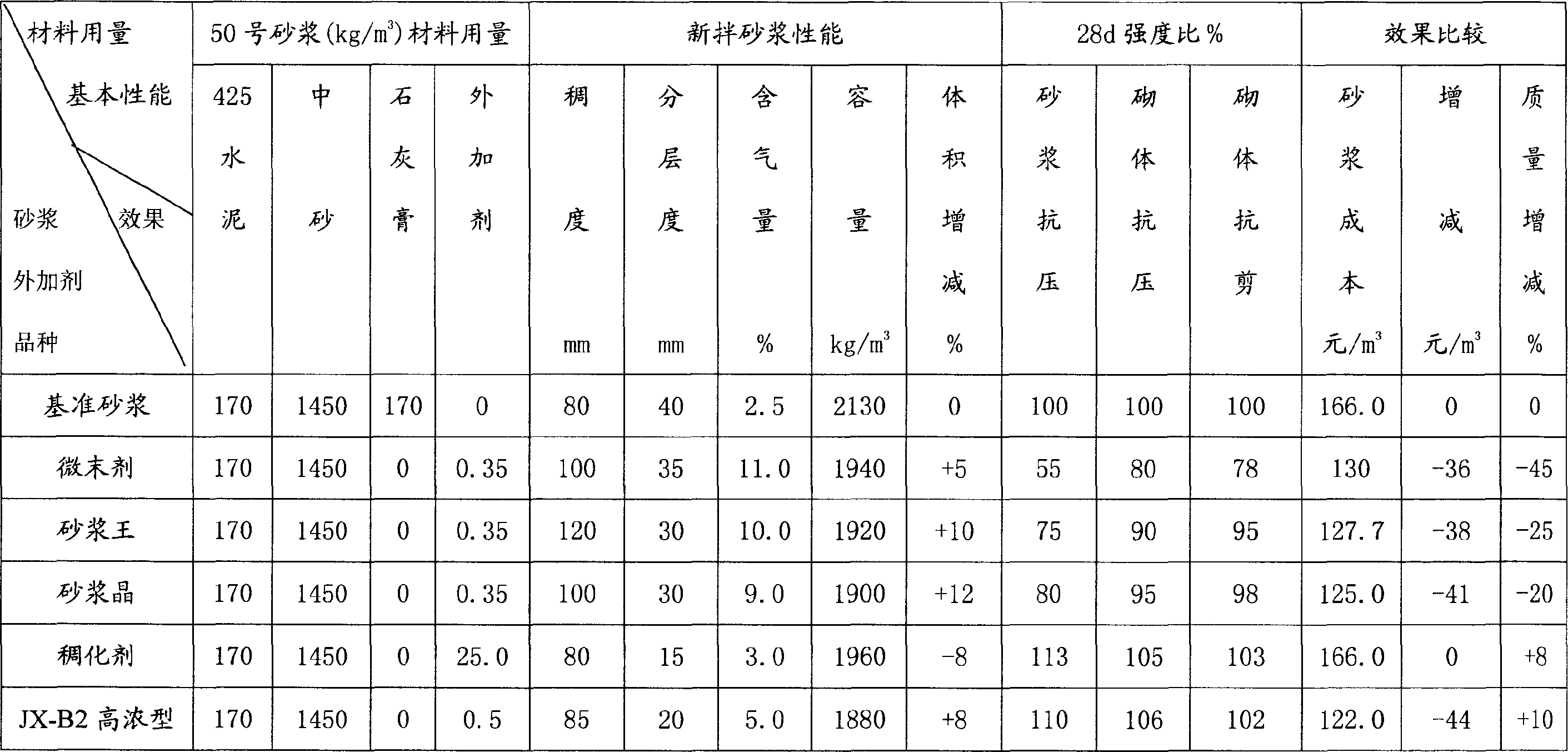

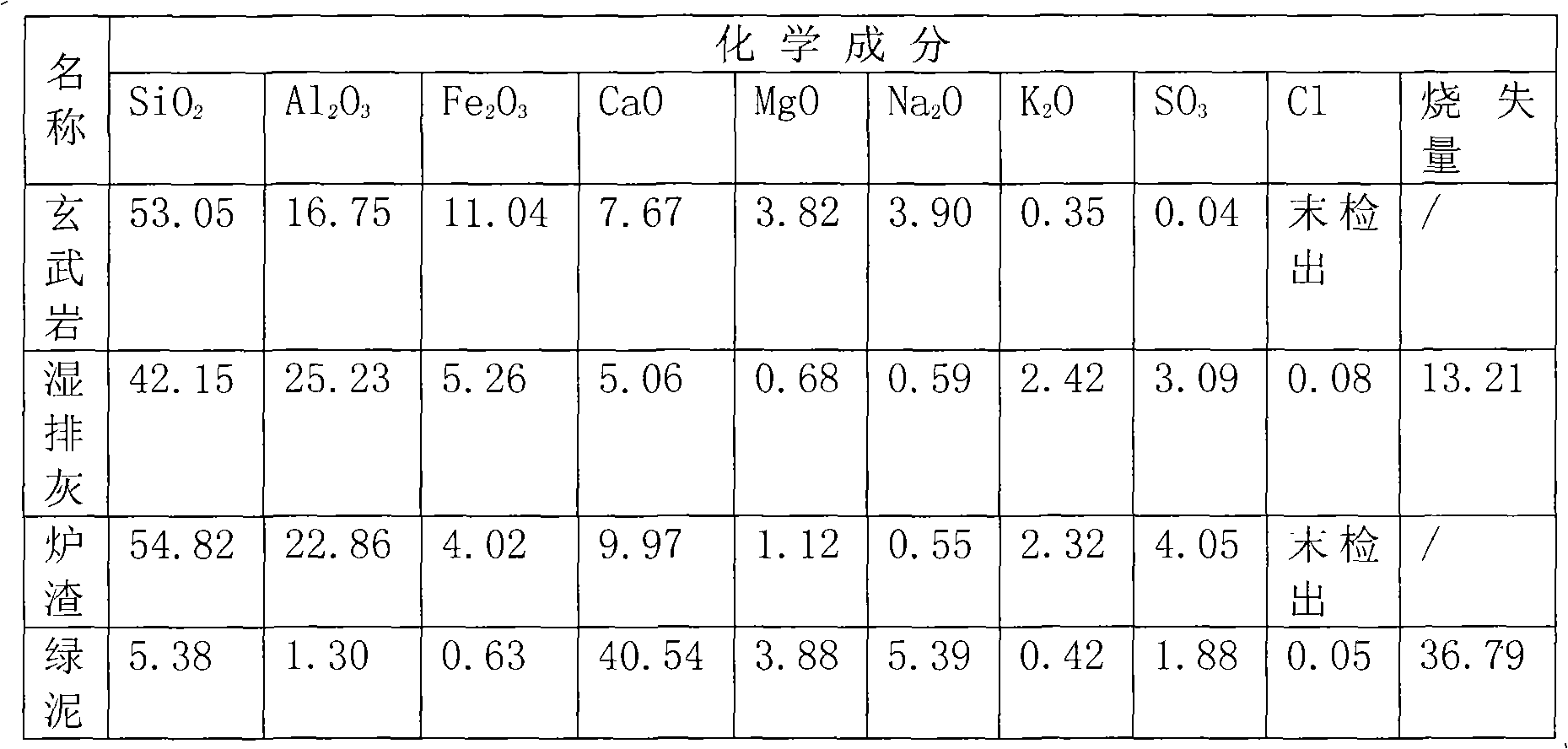

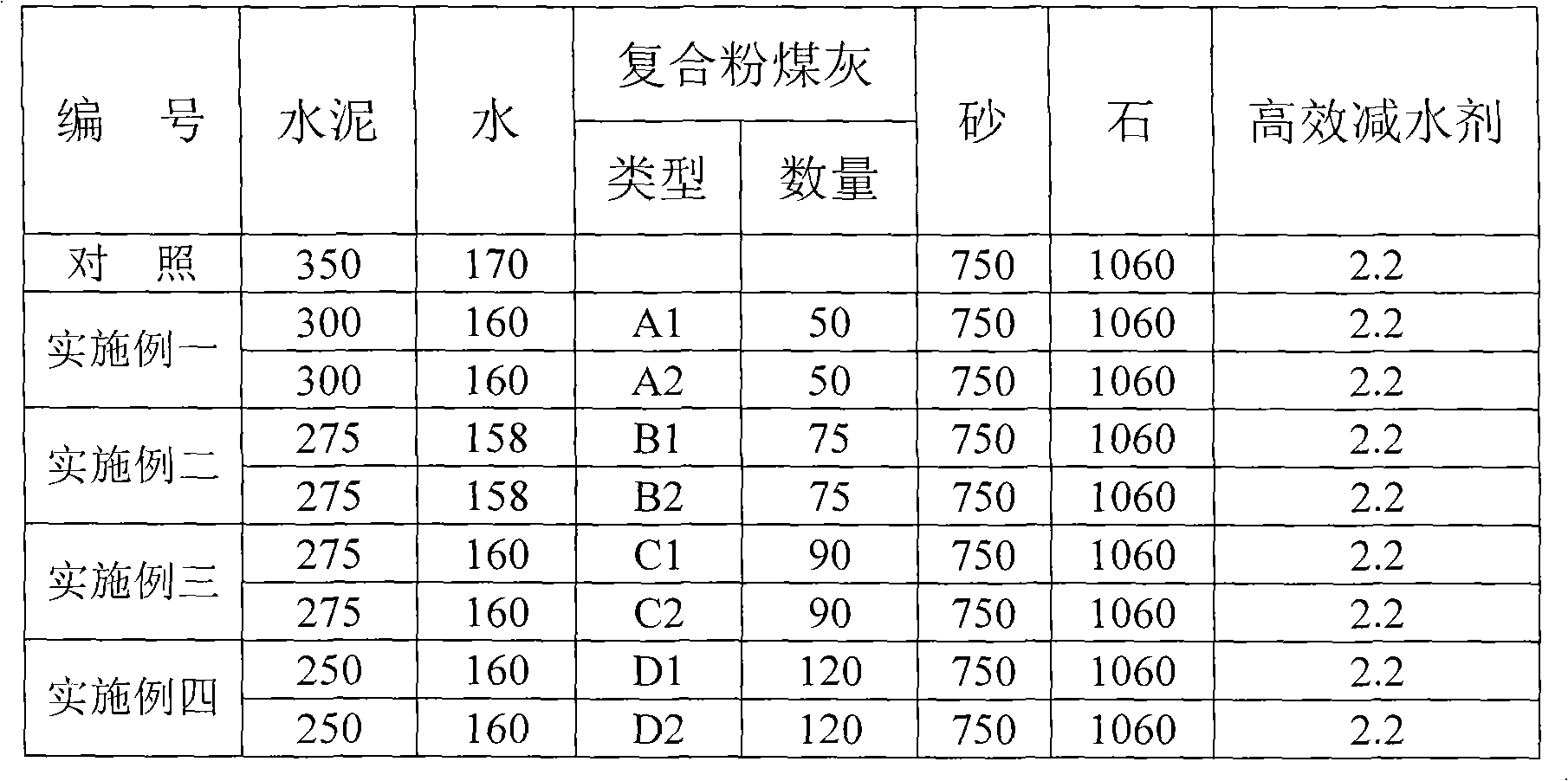

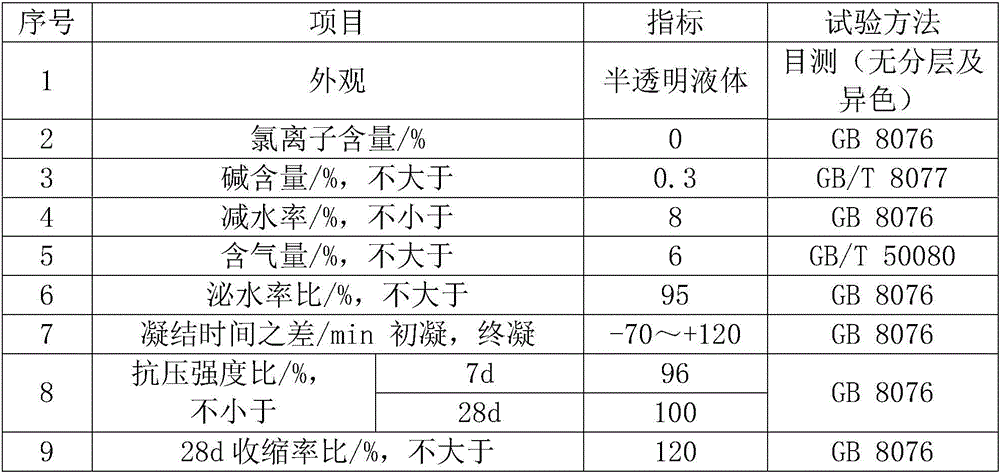

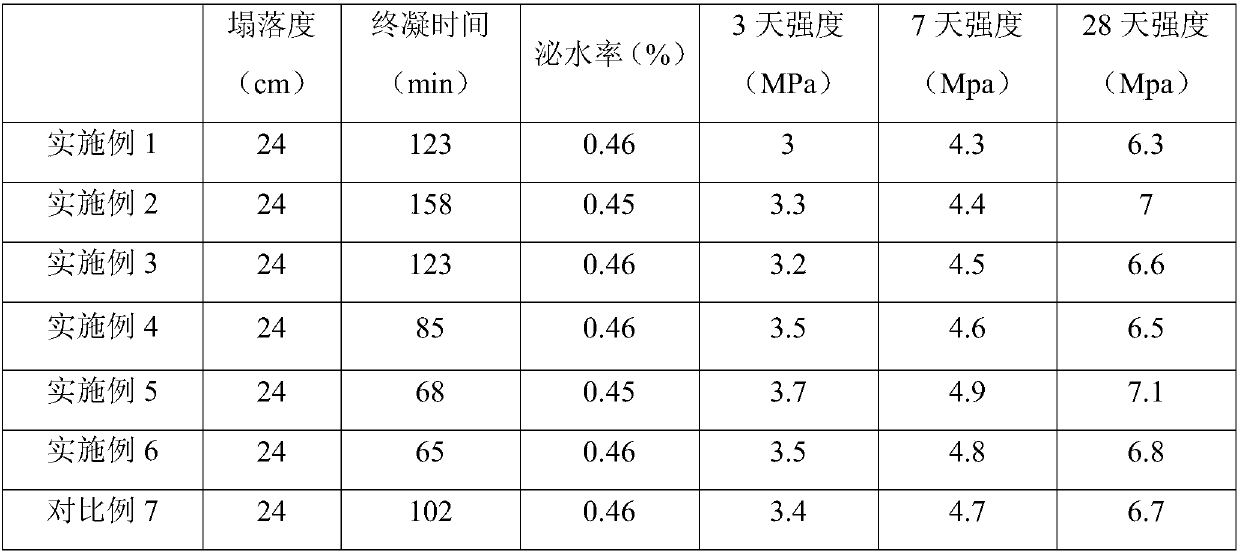

Compound green mud coal ash for concrete

The invention relates to compound green mud coal ash for concrete. The compound green mud coal ash for concrete is prepared by the following steps: mixing basalt macadam with a grain size less than 50 millimeters, wet coal ash with a moisture content of 15 to 25 percent, hearth slag and green mud; grinding the mixture into powder; controlling the fineness being 45 microns and the residue on a square hole screen being less than 15 percent; and drying during the grinding process, thereby causing the moisture content of the ground powder to be less than 0.5 percent. The production process is simple; a large amount of easily obtained industrial wastes, such as wet coal ash, hearth slag, green mud, and the like, are taken as raw materials; the cost is low; a part of cement in the concrete can be replaced by the obtained compound coal ash; the early strength of the concrete and the mild property of the concrete can be efficiently increased; the expanding degree of the newly mixed concrete can be increased; the bleeding rate is reduced; the resource and energy source are saved; the industrialized production is boosted; a large amount of industrial wastes can be treated; and the environmental protection and the energy saving and emission reduction are boosted.

Owner:洋浦固体废物处理有限公司

Hydrolyzed animal blood meal cement foaming agent and its application in lightweight cement preparation

Belonging to the technical field of cement preparation, the invention specifically relates to a cement foaming agent with animal blood meal as a raw material and its application in lightweight cement preparation. The cement foaming agent is prepared by the steps of: in an alkaline solution, adding animal blood meal about 3%-5% of the weight of the alkaline solution, stirring the mixture for 4-8h and conducting hydrolyzation; then adjusting the reaction system to neutral, and stopping hydrolyzation, then removing waste residue by centrifugation or filtering, thus obtaining a foaming agent stock solution; adjusting the pH of the foaming agent stock solution to 8-9, adding a chelating agent, a stabilizing agent and a surfactant for stirring, thus obtaining a hydrolyzed animal blood meal cement foaming agent. The cement foaming agent prepared in the invention has table performance, high foam expansion rate, as well as low bleeding rate, and can generate foams with an average diameter of 0.5mm-3mm and independent pores. Lightweight cement products prepared by the cement foaming agent of the invention have low density, enclosed pores, different densities, low thermal conductivity, low sound absorption rate as well as good fire resistance and waterproofness, and are free of condition restriction and easy to implement.

Owner:JILIN UNIV

High-compactness cement paste for vacuum grouting and manufacturing method thereof

The invention provides high-compactness cement paste for vacuum grouting and a manufacturing method thereof, and belongs to the technical field of pre-stress engineering. The manufacturing method comprises the following steps of 1, preparing 300 parts by weight of portland cement, 2.7 to 3.9 parts by weight of a polycarboxylic acid water reducer, 1.5 to 2.4 parts by weight of a polycarboxylic acid retarder, 93 to 99 parts by weight of water and 3 to 6 parts by weight of a paste thixotropic agent, 2, pouring water into a paste agitator tank, and simultaneously, adding the polycarboxylic acid water reducer and the polycarboxylic acid retarder into the paste agitator tank, and uniformly mixing, 3, adding cement with stirring and continuously stirring to obtain retarded paste, wherein the total time of feeding and stirring is in a range of 4 to 6 minutes, 4, putting the retarded paste into a paste storage tank with a stirrer and standing for 1 hour, and 5, starting the stirrer for stirring, adding the paste thixotropic agent into the retarded paste with stirring, and after addition of the paste thixotropic agent, sequentially stirring for 15 to 30 seconds to obtain thixotropic paste. The thixotropic paste can realize single-step grouting formation of a pipe having a high bending degree and thus work efficiency and construction quality are greatly improved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

Multifunctional concrete synergist

The invention belongs to the technical field of concrete admixtures, and in particular relates to a multifunctional concrete synergist, which is made of the following raw materials in parts by weight: 26-42 parts of diisopropylethanolamine, 2-8 parts of pentaerythritol, lignin sulphon 15-26 parts of sodium nitrate, 8-16 parts of cetyltrimethylammonium hydroxide, 1-6 parts of xanthan gum, 5-13 parts of alkyl glycoside, 40-80 parts of water. The multifunctional concrete synergist of the present invention can fully hydrate the 20-30% cement that cannot function normally, reduce the amount of cement, and at the same time, can also enhance the strength of concrete, improve the durability and anti-thawing performance of concrete, and improve the impermeability Sex, reduce concrete cracks, improve bleeding, and has multiple functions.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Semi-hydrated phosphogypsum filling material and preparation method thereof

The invention belongs to the field of mine filling materials and in particular relates to a semi-hydrated phosphogypsum filling material and a preparation method thereof. The filling material preparedfrom semi-hydrated phosphogypsum is high in strength, excellent in fluidity and low in bleeding rate. The invention provides the semi-hydrated phosphogypsum filling material and the preparation method thereof. The filling material comprises the following components in parts by weight: 49-80 parts of semi-hydrated phosphogypsum, 30-50 parts of dehydrate phosphogypsum, 1-5 parts of quick lime and 0.001-0.003 part of a coagulant or a retarder. The preparation method comprises the following steps: drying semi-hydrated phosphogypsum, weighing dried semi-hydrated phosphogypsum, quick lime, dehydrate phosphogypsum and the coagulant or retarder according to a proportion, uniformly mixing, and adding water, thereby obtaining the semi-hydrated phosphogypsum filling slurry. The filling material disclosed by the invention effectively utilizes the by-product, namely dehydrate phosphogypsum, is high in strength, excellent in fluidity and excellent in bleeding rate and can be widely applied to the field of mine filling.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Concrete water-retaining agent

The invention belongs to the technical field of concrete admixtures, in particular to a concrete water-retaining agent, made from the following materials according to parts by weight: 30-50 parts of hydroxypropyl methylcellulose, 10-18 parts of diatomaceous earth, 5-15 parts of glyceryl monostearate, 3-15 parts of calcium sulfoaluminate and 2-10 parts of alkyl glycoside. The concrete water-retaining agent of the invention has high water-retaining rate and stable properties and can improve the strength, cracking resistance and durability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of enhanced polycarboxylate superplasticizer

The invention discloses a preparation method of an enhanced polycarboxylate superplasticizer. Compared with a conventional solution polymerization method, the preparation method has the advantages ofhigh reaction speed, no need of heating, narrow molecular weight distribution and lower cost as well as simplicity and convenience in operation, easiness in industrial production and broad applicationprospect. A photoinitiator is adopted as a main substance, so that the reaction speed is improved, and high polymerization speed and high conversion rate of a product are realized; the prepared polycarboxylate superplasticizer has stable performance; a molecular structure of the prepared polycarboxylate superplasticizer is a comb type structure; a main chain contains a polar group, and a side chain contains a nitrogen-containing group; the enhanced polycarboxylate superplasticizer has good dispersity in concrete, and further early strength and late strength of the concrete are remarkably improved; the enhanced polycarboxylate superplasticizer has the characteristics of excellent working performance, good durability, low bleeding rate and good economic and social benefits.

Owner:KZJ NEW MATERIALS GROUP CO LTD

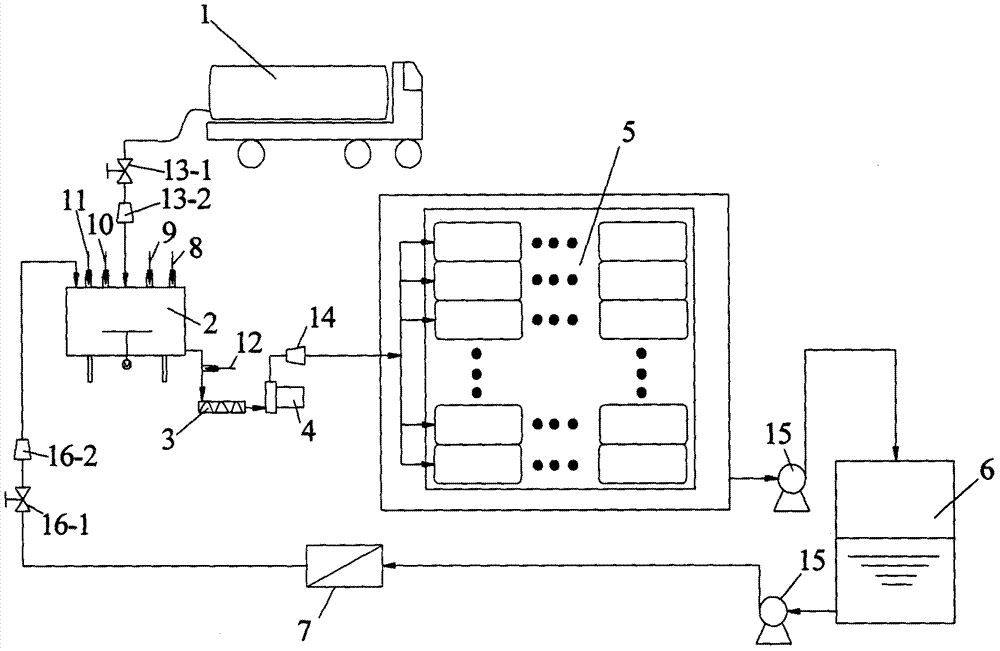

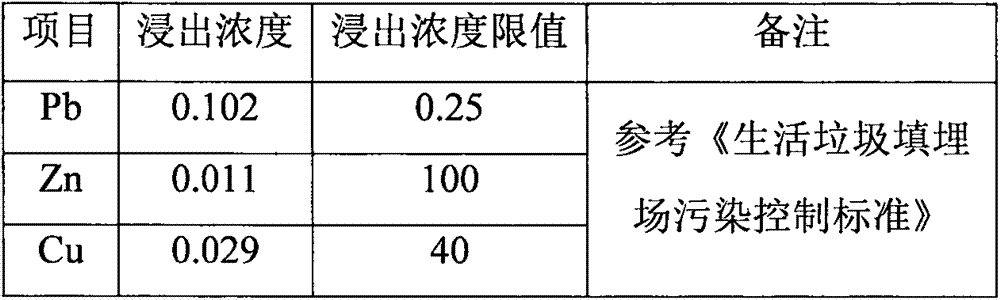

High-concentration wet filling mold bag treatment method and system for municipal solid waste incineration fly ash

ActiveCN107150060AImprove storage capacity utilizationReduce disposal costsSolid waste disposalFurniture waste recoveryDetoxicationHigh concentration

The invention discloses a high-concentration wet filling mold bag treatment method for municipal solid waste incineration fly ash. Fly ash homogenization, heavy metal stabilization, dioxin detoxication, rapid hydration consolidation and landfill integration treatment are achieved through the three links of fly ash thick paste or cream preparing, high-pressure pumping or filling and mold bag water segregation or hydration consolidation, no dust pollution or wastewater discharge or ammonia smell dissipation is generated in the treatment process, discharge of fly ash landfill leachate can be greatly reduced, and meanwhile municipal and industrial sludge, silt, river sediment and the like can be collaboratively treated; the consolidated fly ash in a mold bag meets the relevant national standard requirements, and landfill treatment can be conducted on the consolidated mold bag. The invention further discloses a high-concentration wet filling mold bag treatment system for the municipal solid waste incineration fly ash. Accordingly, the defects in large-scale industrial application of traditional dry landfill for the fly ash and a low-concentration slurry filling mold bag treatment method for the fly ash can be avoided, environment-friendly, economic and safe fly ash treatment is achieved, solid waste such as sludge is collaboratively and safely treated, and the method and system can be applied to large-scale industrial production.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Micro-fine particle high-silicon tailings grouting material

The invention discloses a micro-fine particle high-silicon tailings grouting material. The material is obtained by mixing the following raw materials of high-silicon tailings, 1-10% of lime, 1-10% ofgypsum, 1-5% of calcium chloride, granulated blast furnace slag and water, wherein the ratio of the water weight to the total weight of the high-silicon tailings, the lime, the gypsum, the calcium chloride and the granulated blast furnace slag is 0.5-1.5. Accordingly, the micro-fine particle high-silicon mine tailings serve as the main raw material, the lime, the gypsum and the calcium chloride are adopted as activators, the granulated blast furnace slag serves as a performance adjusting agent, mechanochemical and chemical activation methods are adopted, the low-cost green grouting material isobtained, and the grouting material has the advantages of being high in compressive strength, low in bleeding rate, good in grout stability and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com