Paste-like backfill technology used in coal cutting area and the paste-like thereof

A paste-like, stope-like technology, applied in the paste-like field, can solve the problems of low water content, high filling body strength, and low production cost, so as to reduce pollution and impact, high content of dry material components, and low filling cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

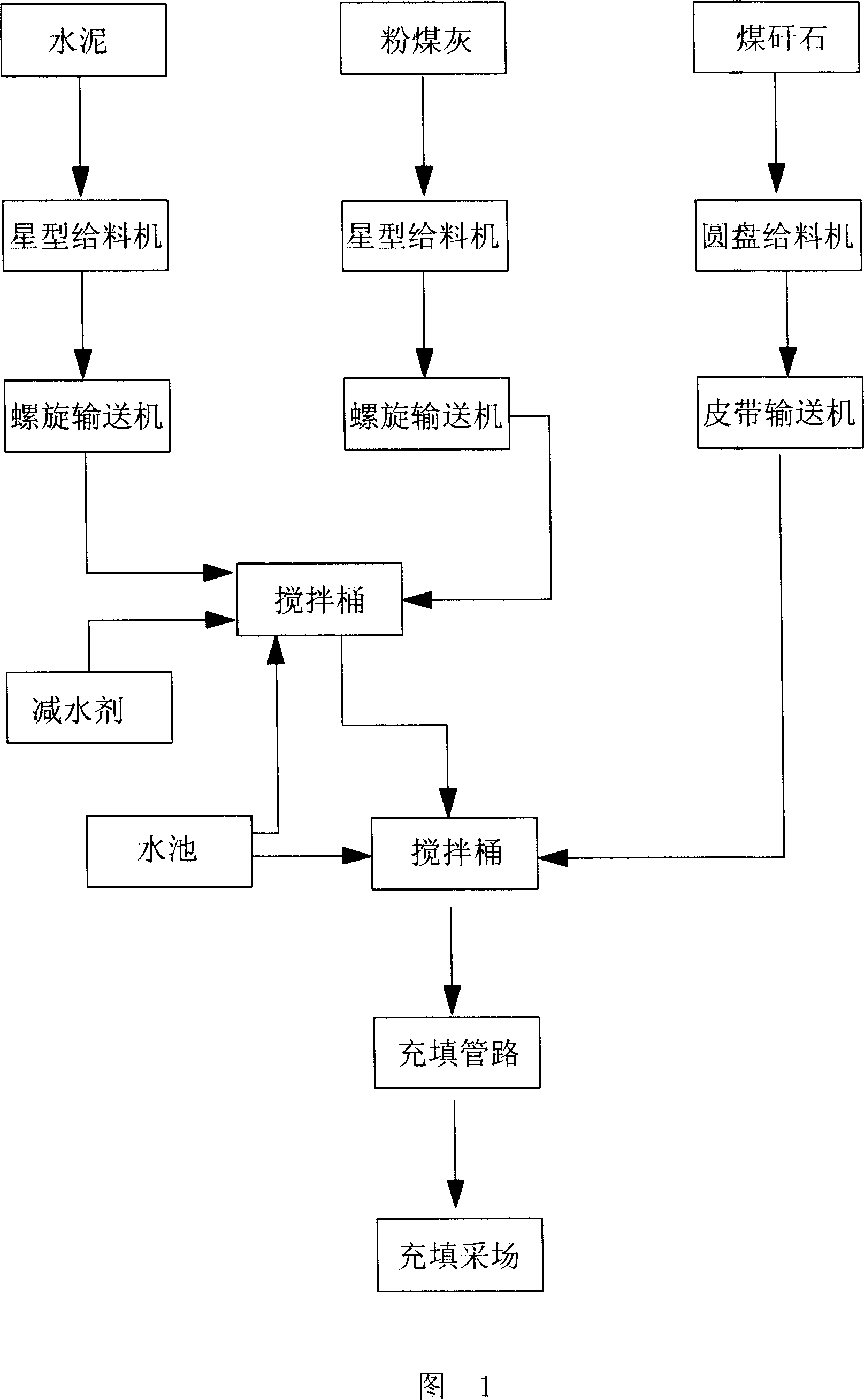

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Carry out the preparation of similar paste with ordinary portland cement, fly ash and coal gangue as the dry component of paste, wherein coal gangue adopts the vitrified coal gangue ( Tao gangue for short), and fresh gangue with particle size less than 5mm after coarse crushing and fine crushing (referred to as new gangue 1 and new gangue 2). The physical and mechanical measurement results are shown in Table 2.

[0028] The particle size percentage composition of different filler components in table 1

[0029] filler

name

5~2

mm

2~0.5

mm

0.5~0.25

mm

0.25~0.075

mm

0.075~0.05

mm

0.05~0.005

mm

<0.005

mm

Tao gangue

12.0

33.0

15.0

20.0

5.0

13.5

1.5

New gangue 1

77.0

10.0

2.0

1.0

2.0

7.5

0.5

New gangue 2

16.0

31.5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com