Nano-modified super-stable foam and application thereof in ultralight-density cement-based porous material

A nano-particle modification and foam technology is applied in the field of thermal insulation to achieve the effect of improving stability, good strength and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1250

[0031] Example 1 250kg / m 3 dry density

[0032] Weigh raw materials according to the following weight: (kg)

[0033] Cement: 600, fly ash: 300, silica fume: 100, polycarboxylate superplasticizer: 5, water: 350, foaming agent: 40. The cement is Onoda P·Ⅱ52.5 cement, the fly ash is secondary fly ash, the silica fume is Elkem silica fume, and the water reducer is polycarboxylate water reducer produced by Jiangsu Subote New Material Co., Ltd. The water rate is 40%, and the composition of the blowing agent is mainly shown in Table 2.

[0034] The composition of table 2 embodiment 1 nano blowing agent

[0035]

[0036]

[0037] The preparation steps of the cement-based porous material modified by nanotechnology are:

[0038] 1) Add 0.5% nanoparticles to the sodium hydroxide solution and stir for 5 minutes, then add 0.3% dispersant and heat to 45°C and stir for 10 minutes. After the stirring is completed, perform ultrasonic treatment on the prepared suspension in an ultraso...

Embodiment 2

[0041] Example 2 200kg / m 3 dry density

[0042] Weigh raw materials according to the following weight: (kg)

[0043] Cement: 600, fly ash: 300, silica fume: 100, polycarboxylate superplasticizer: 5, water: 350, foaming agent: 50. The properties of the raw materials are as in Example 1, and the composition of the blowing agent is mainly shown in Table 3.

[0044] The composition of table 3 embodiment 2 nano blowing agent

[0045] serial number component name Mass % 1 nanoparticles 0.8 2 Dispersant 0.5 3 Surfactant A 1 4 Surfactant B 2.5 5 sodium hydroxide 0.07 6 Deionized water 94.73

[0046] The preparation steps are as in Example 1.

Embodiment 3

[0047] Example 3 150kg / m 3 dry density

[0048] Weigh raw materials according to the following weight: (kg)

[0049] Cement: 600, fly ash: 300, silica fume: 100, polycarboxylate superplasticizer: 5, water: 350, foaming agent: 60. Raw material properties are as in Example 1. The composition of the blowing agent is mainly shown in Table 4.

[0050] The composition of table 4 embodiment 3 nano blowing agent

[0051] serial number component name Mass % 1 nanoparticles 1 2 Dispersant 0.8 3 Surfactant A 2 4 Surfactant B 2 5 sodium hydroxide 0.09 6 Deionized water 93.61

[0052] The preparation steps are as in Example 1.

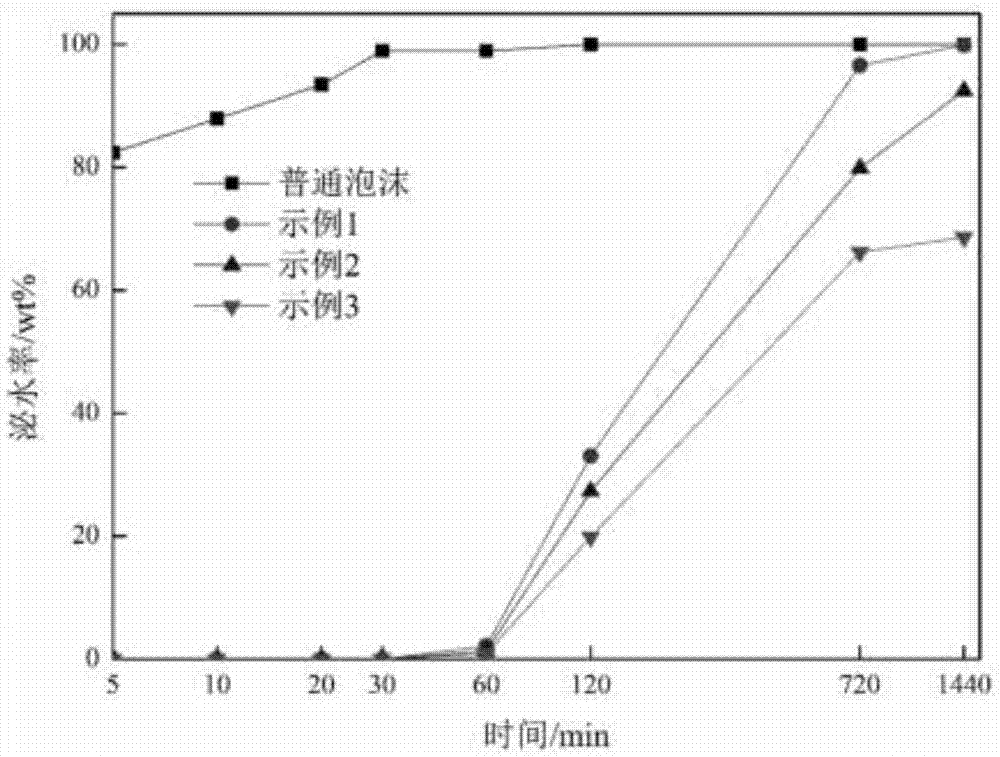

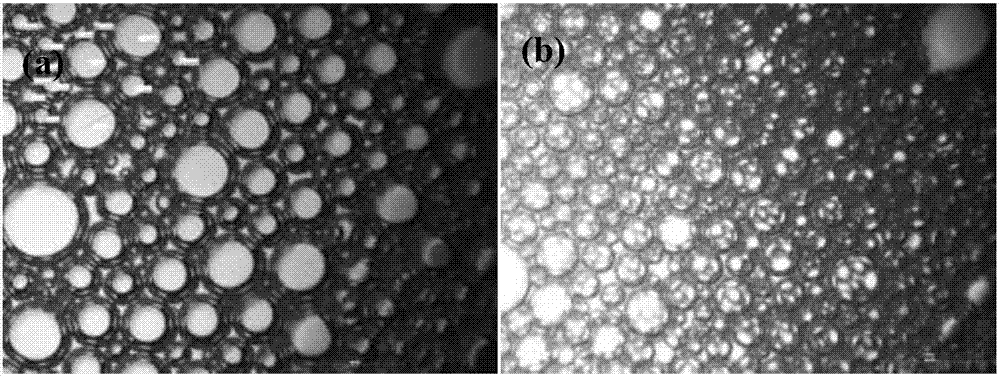

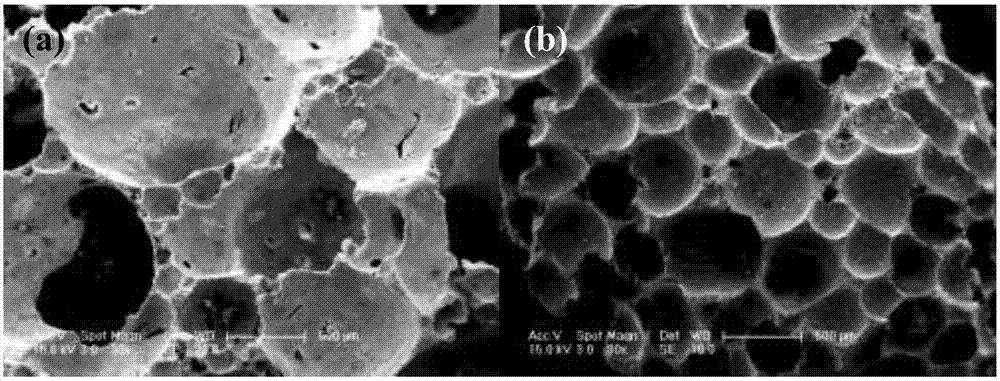

[0053] The bleeding rate of the foam prepared by the present invention is as follows figure 1 As shown, the shape of the bubble is as figure 2 shown.

[0054] Depend on figure 1 As shown, the stability of the air bubbles improved by nanoparticles is significantly improved, and the mass bleeding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com