Patents

Literature

63 results about "Cellular cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellular concrete - definition. Cellular concrete is a lightweight cement-based material, containing many gas bubbles evenly distributed in the volume, produced by blending and maturing of a mixture of cement, filler, water, agent generating cells.

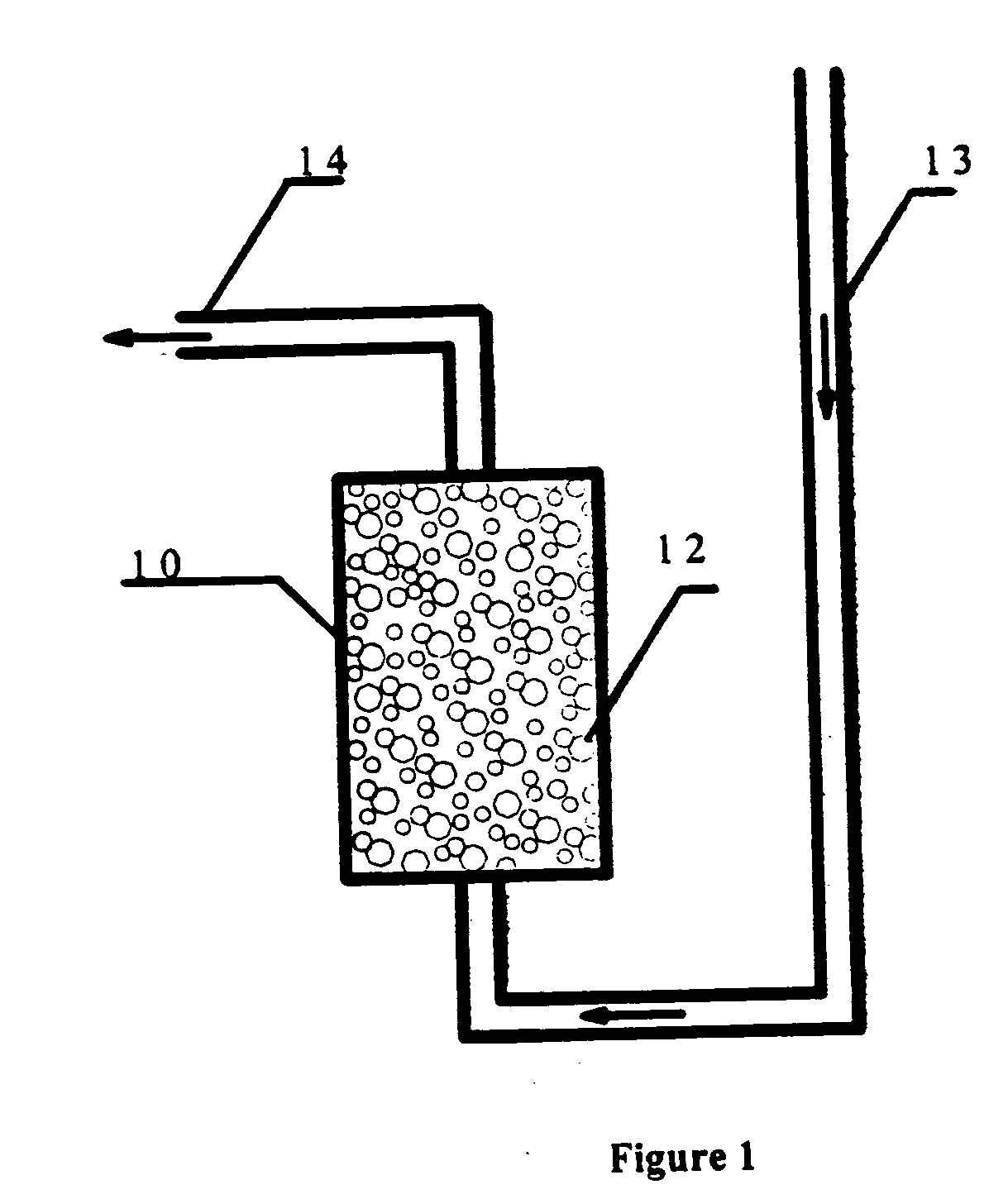

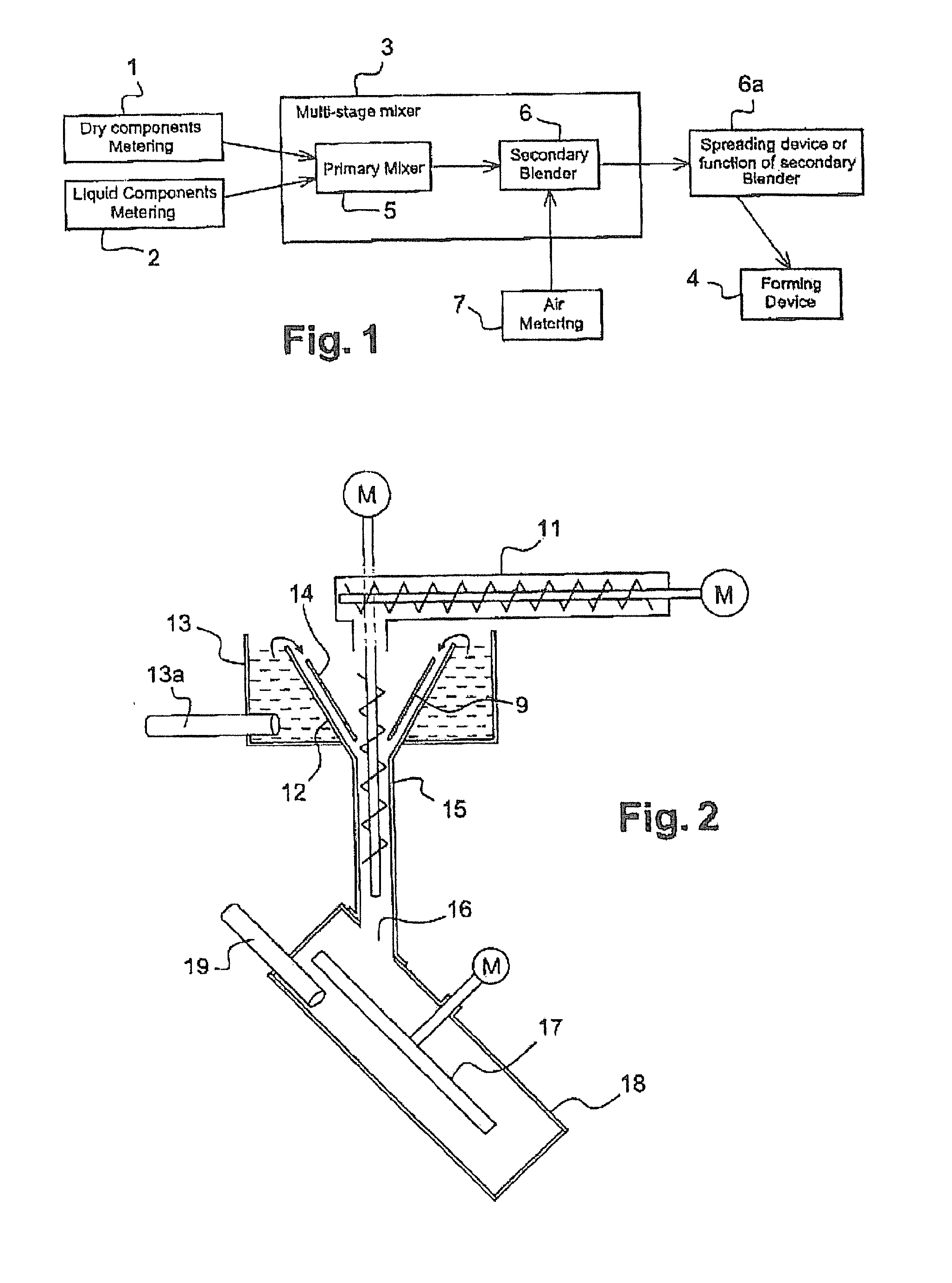

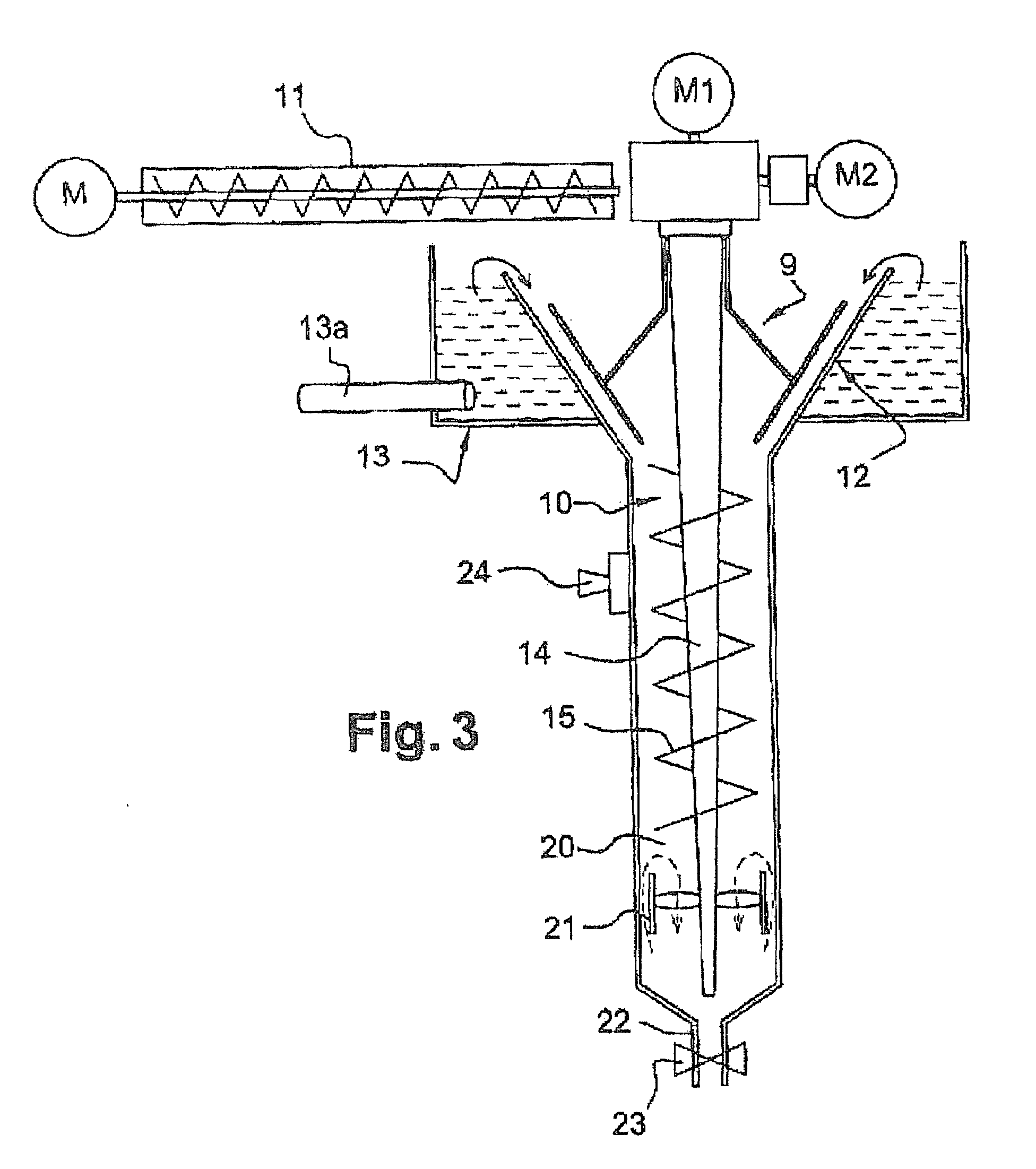

Process And Apparatus For Manufacturing Set Cellular Cement

ActiveUS20050219938A1Less foaming agentLess waterLiquid surface applicatorsTransportation and packagingFoaming agentSlurry

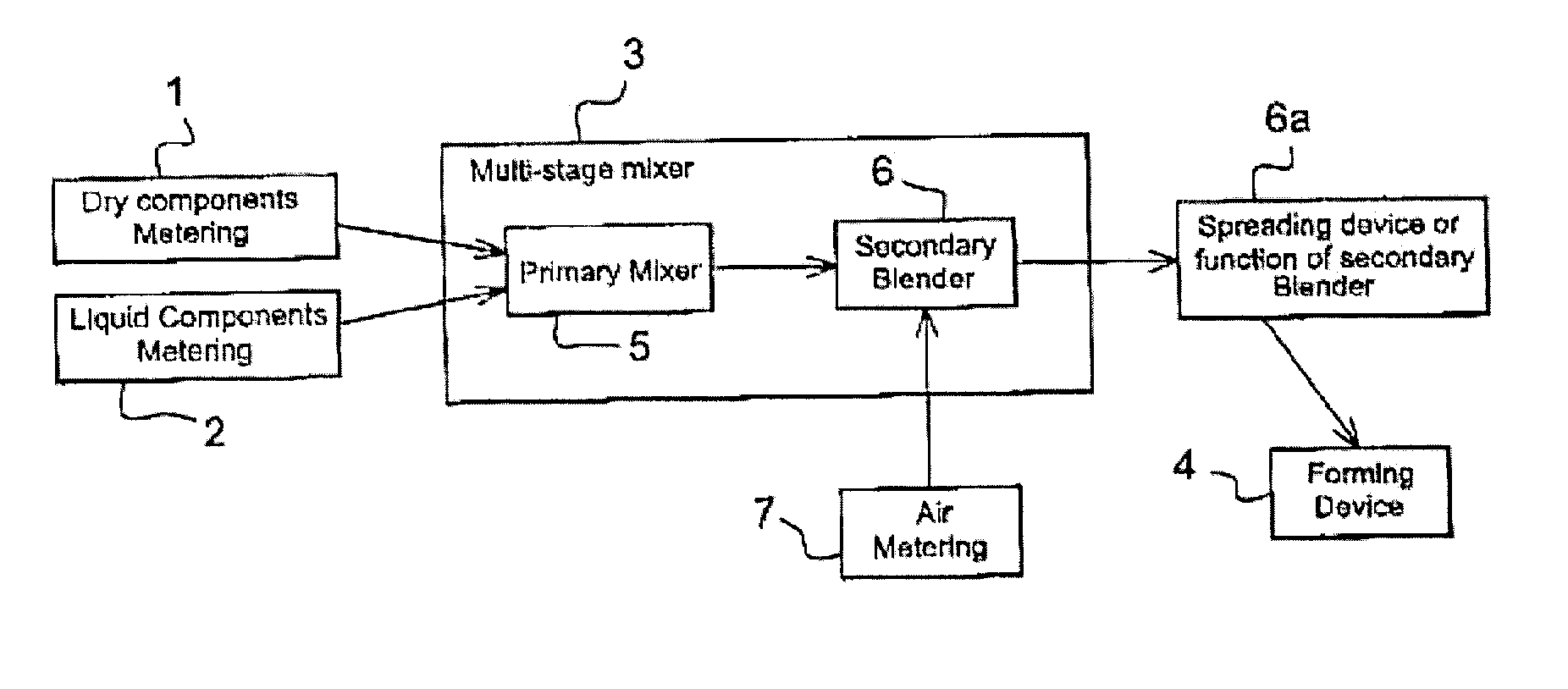

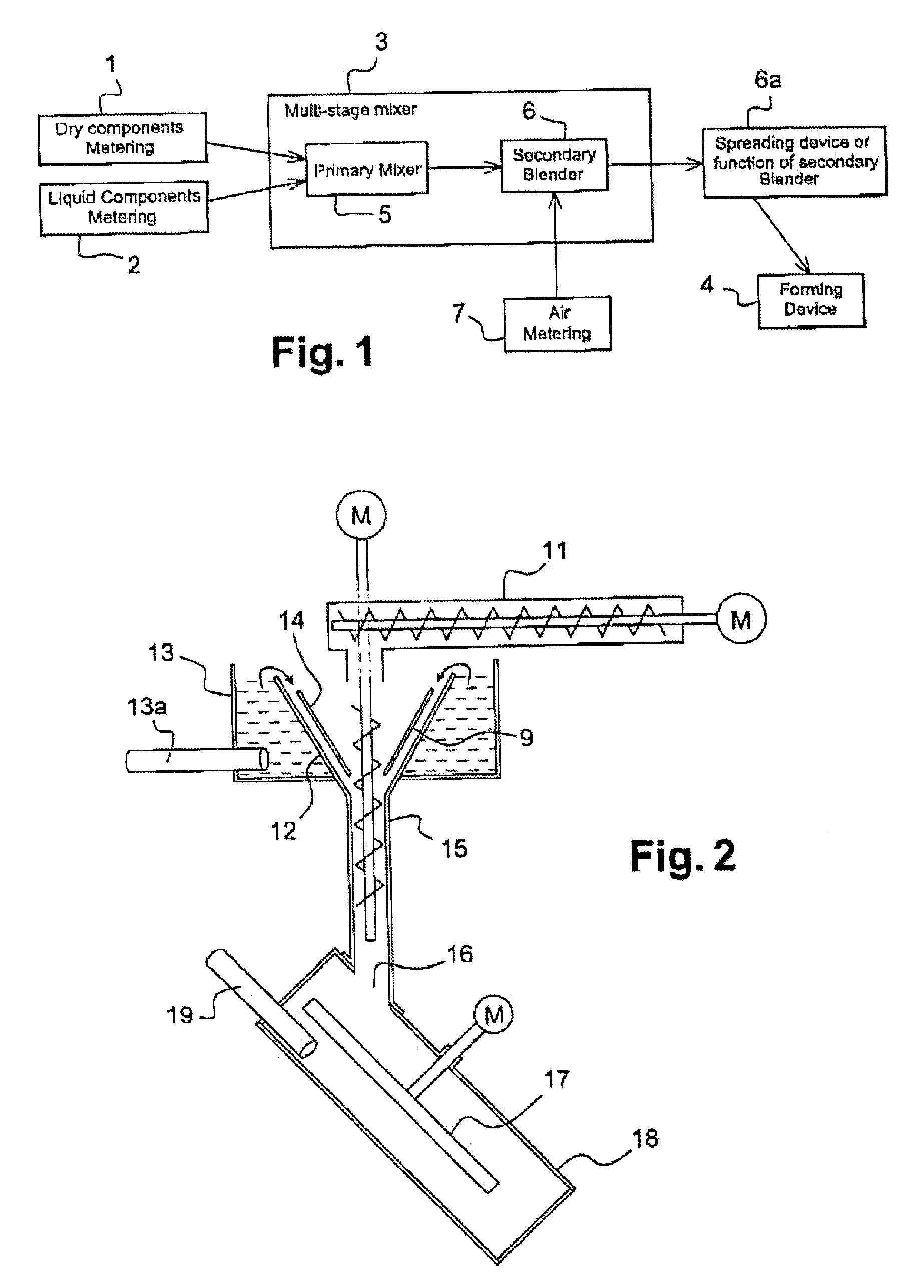

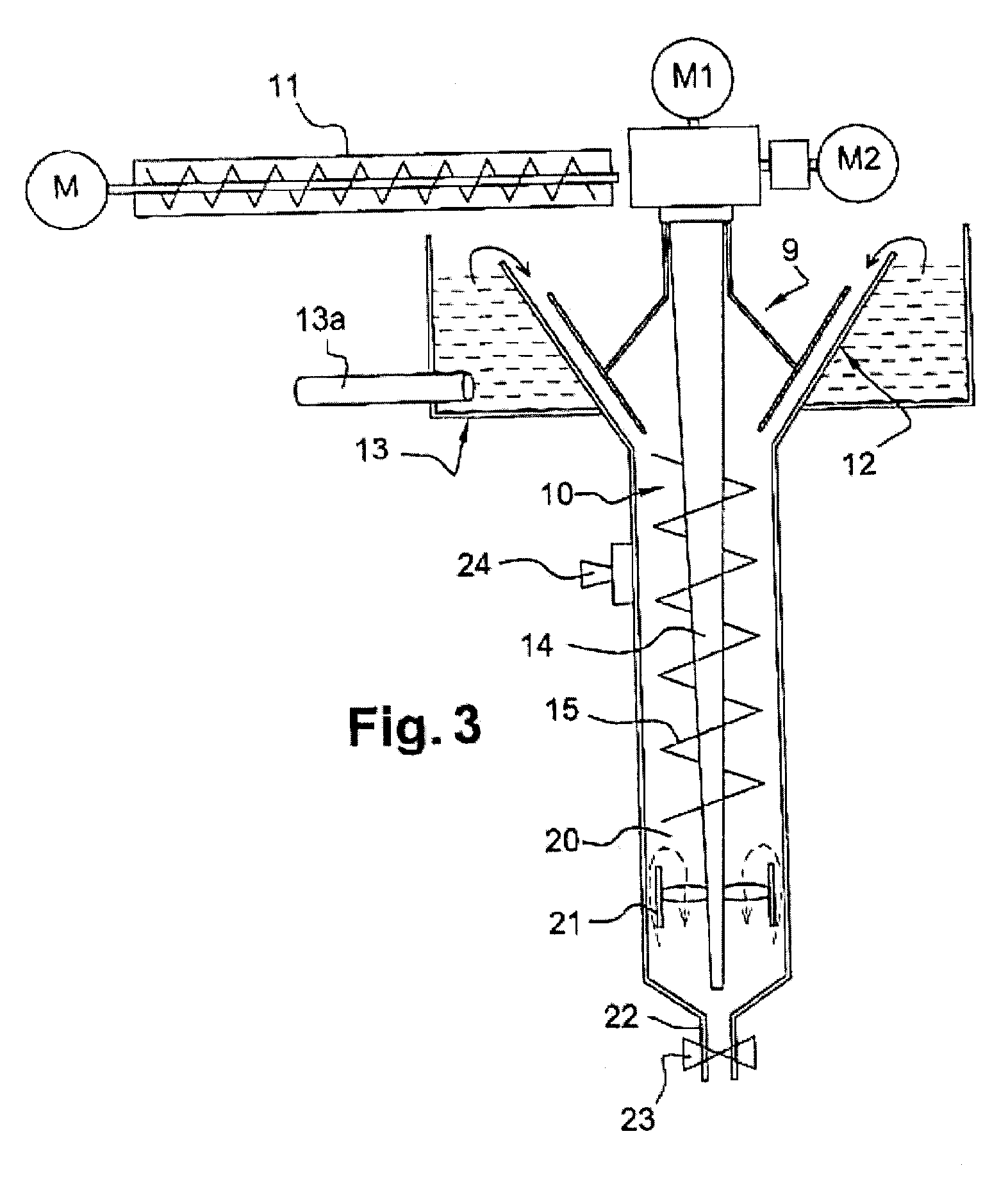

A process for manufacturing set cellular cement, including the steps of: (i) mixing cementitious material, water, foaming agent and optionally additives into a free flowing slurry having a slump of at least 100 mm; subsequently (ii) injecting and distributing air into the slurry of step (i) to form a cellular slurry; subsequently (iii) casting the cellular slurry of step (ii); and finally allowing the cellular slurry to set. And, an apparatus for carrying out the process.

Owner:ETEX BUILDING PERFORMANCE INT SAS

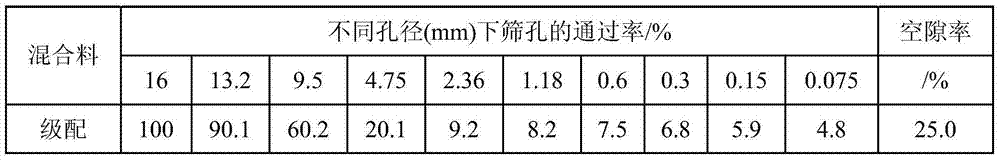

Porous cement road surface made from polymer modified cement and a construction method thereof

ActiveUS20100112329A1Reduce thicknessSimple structureIn situ pavingsLayered productsPolymer modifiedCrack resistance

A porous concrete road surface structure made from polymer modified cement and a construction method thereof are disclosed. The structure successively comprises a bottom layer, a bonding layer, a porous concrete layer and a surface treatment layer. The bonding layer is located on the bottom layer, and the porous concrete layer on the bonding layer is prepared through paving, leveling and jolting a composition mixed from broken stone, sand and a slurry mixture of polymer modified cement. The addition of polymer promotes bonding of granular materials with the slurry mixture tightly, the use of the bonding layer makes the road surface structure and the bottom layer form an integral body, and the road surface structure has high strength, good crack resistance, water resistance, ageing resistance and corrosion resistance; the use of an intermittent or single graded of particles results in large pores, makes the road surface water-penetrating, decreases noise and amount of the polymer; and, the surface treatment can improve markedly surface properties and its use according to the application can make the porous concrete layer has rigid or flexible characteristic. The porous concrete road surface can be paved, leveled and jolted by paving machine or manual labor.

Owner:YI ZHIJIAN

Functional porous cement based composite material and preparation method thereof

The invention belongs to the technical field of material science and engineering and particularly relates to a functional porous cement based composite material and a preparation method thereof. The composite material is prepared from the following raw materials: cement, aggregates, water, additives and a catalyst in a ratio of (1-1.2):(0.5-0.6): (0.2-0.8):(0-0.04):(0-0.2), wherein the content of the catalyst is not zero and the catalyst is a compound of titanium dioxide and graphene oxide. The invention provides the functional porous cement based composite material which not only has a separating function, but also has the characteristics of being photocatalytic, pollution-resistant and self-cleaning. The functional porous cement based composite material is simple in preparation process and low in cost and has wide application prospect in the technical industry of environmental protection and management.

Owner:HENAN POLYTECHNIC UNIV

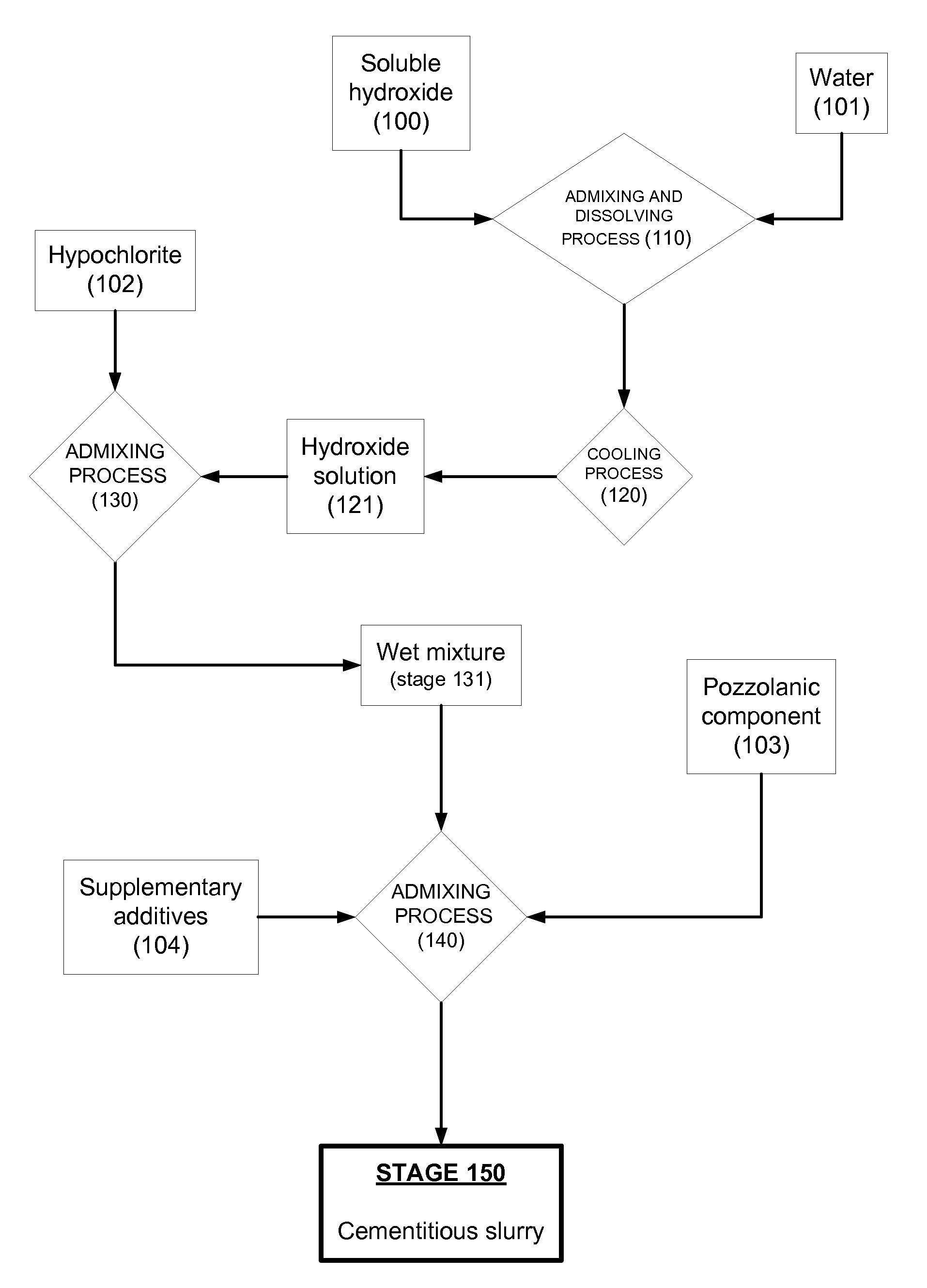

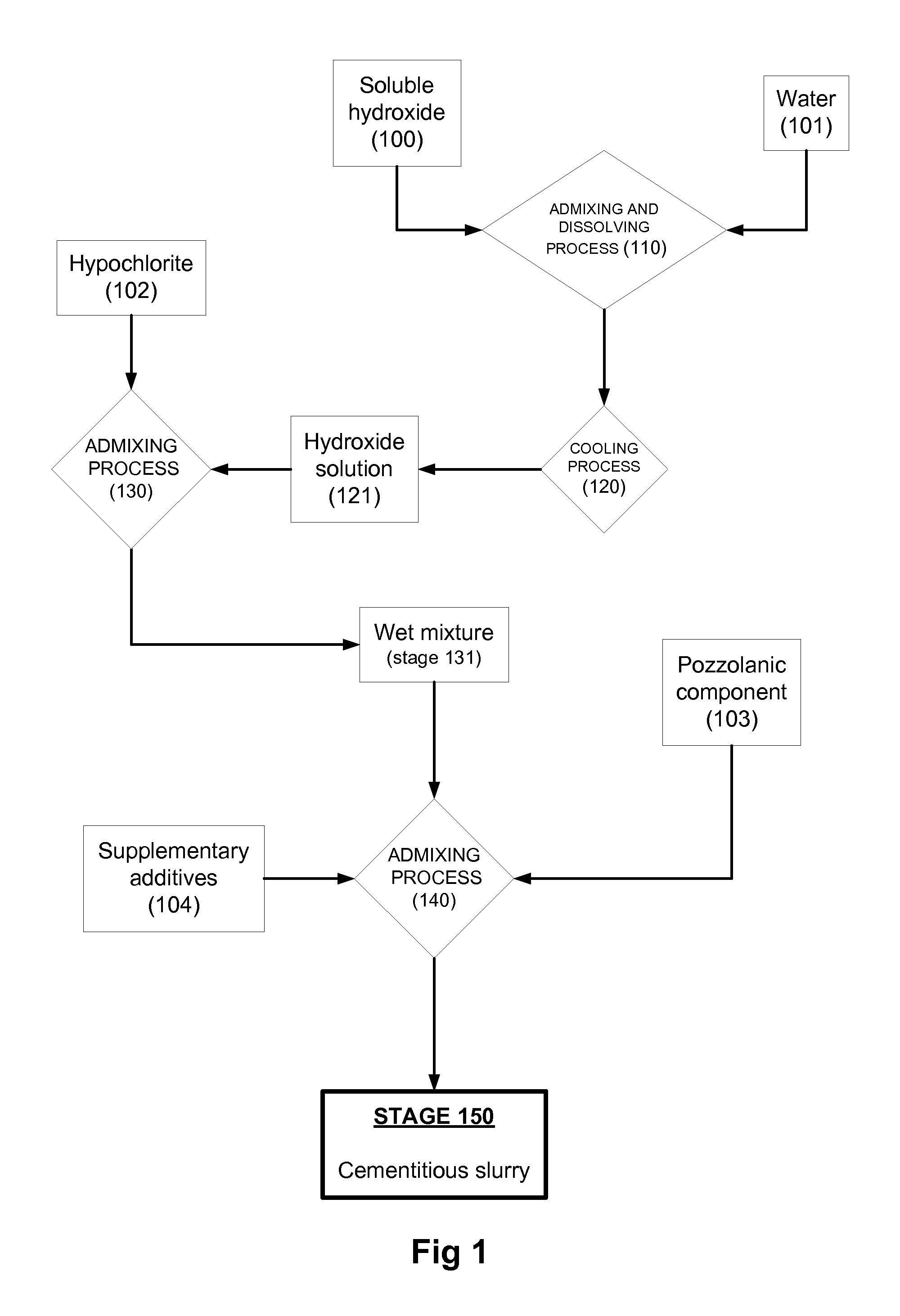

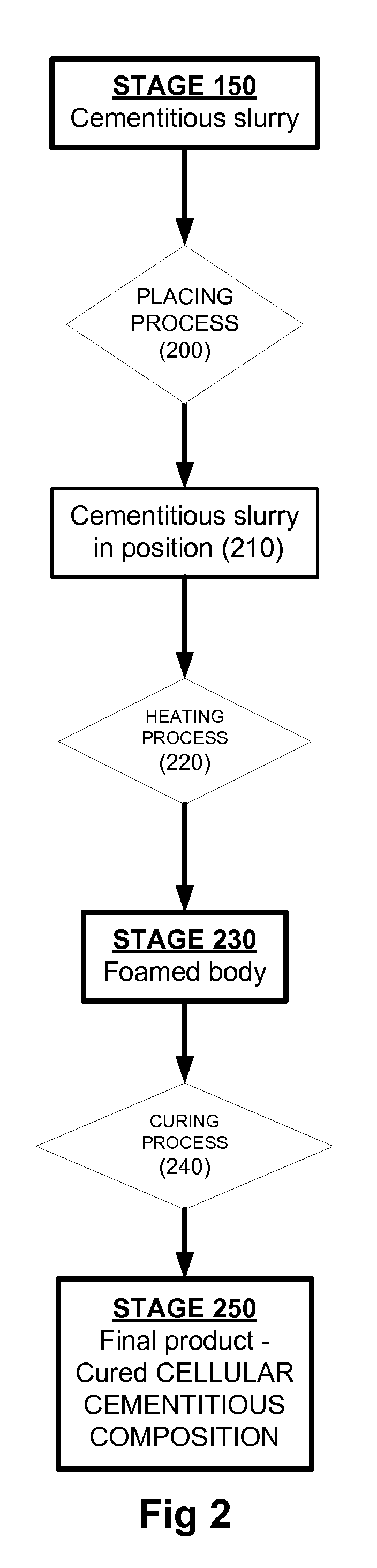

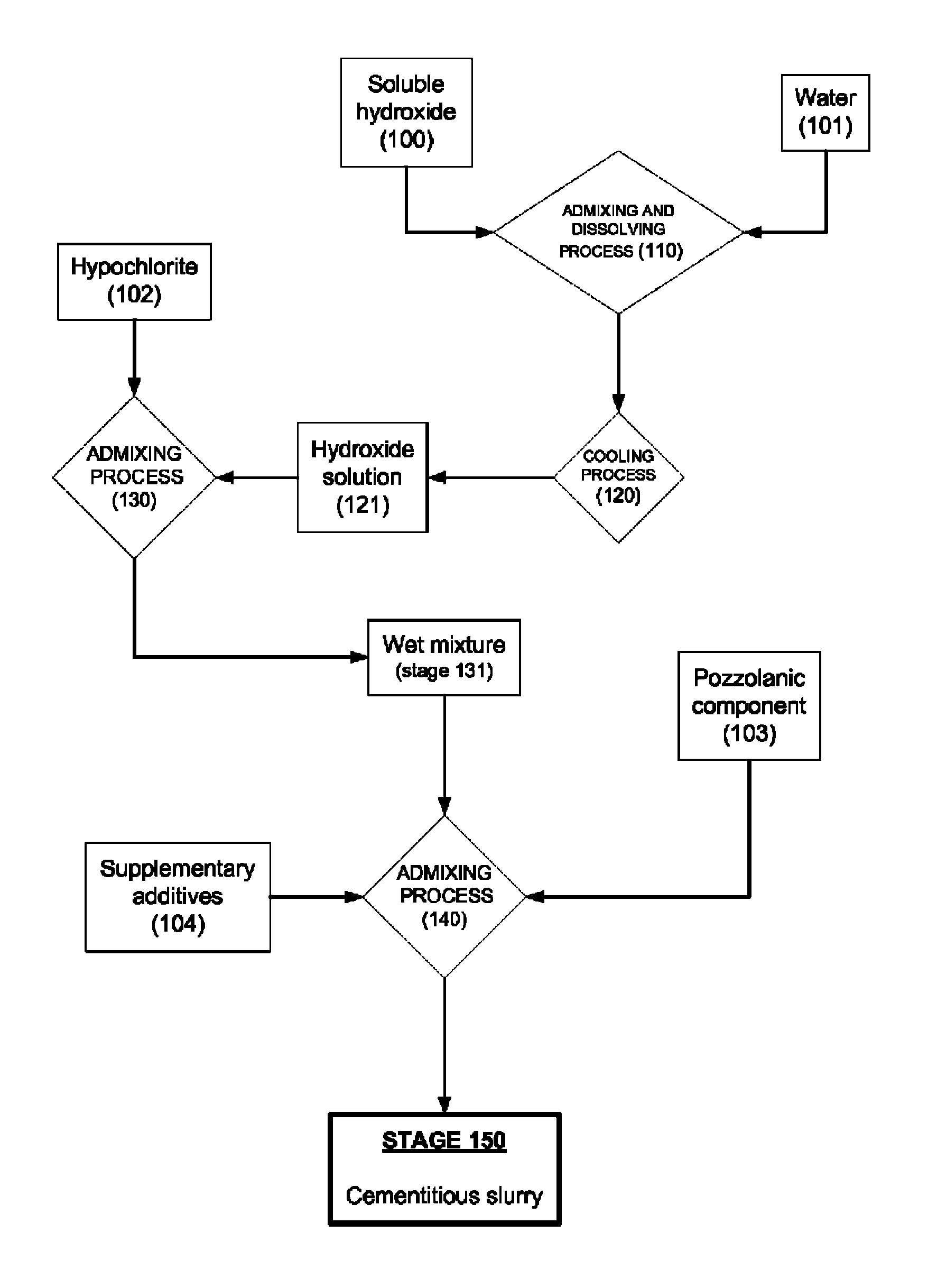

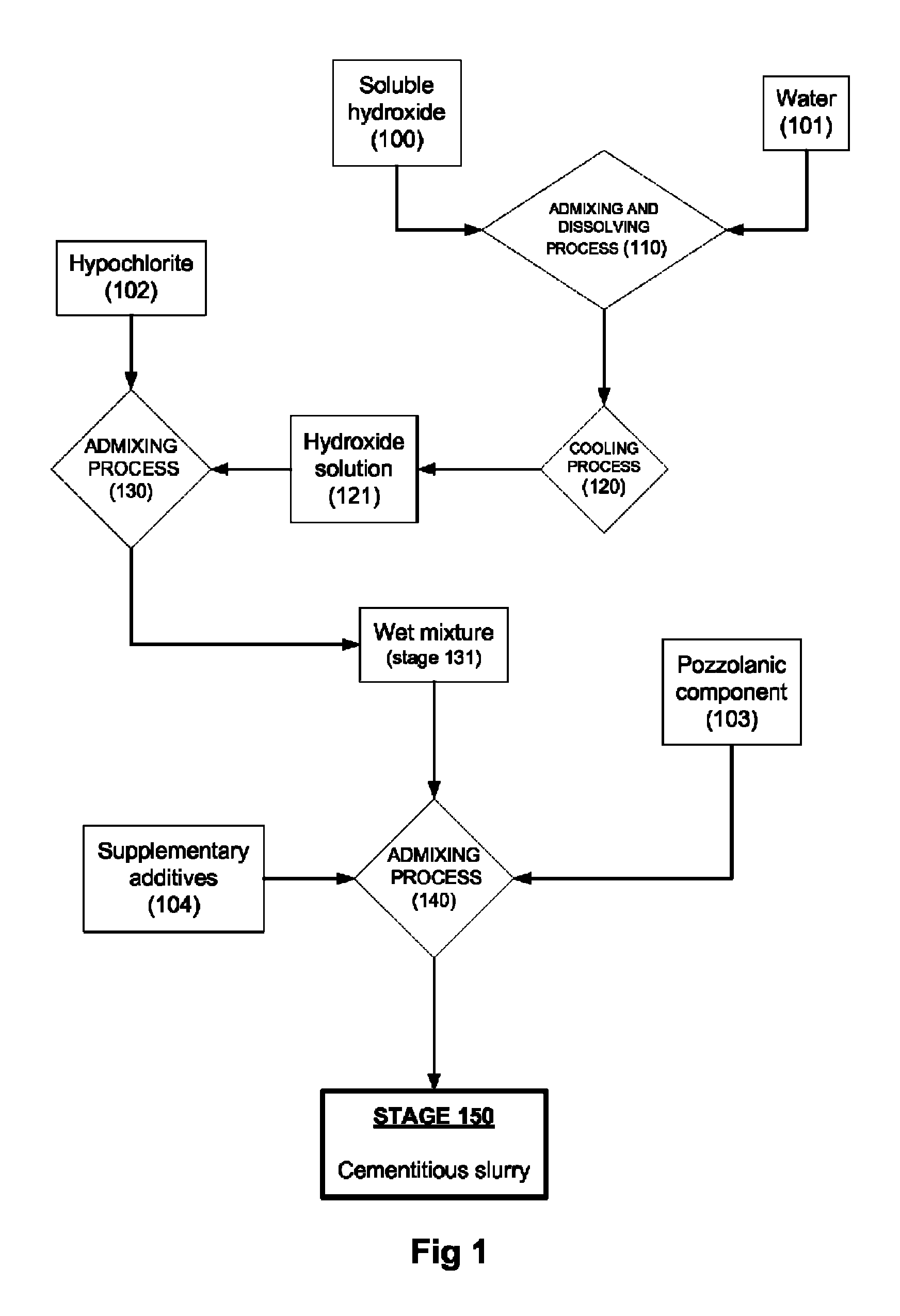

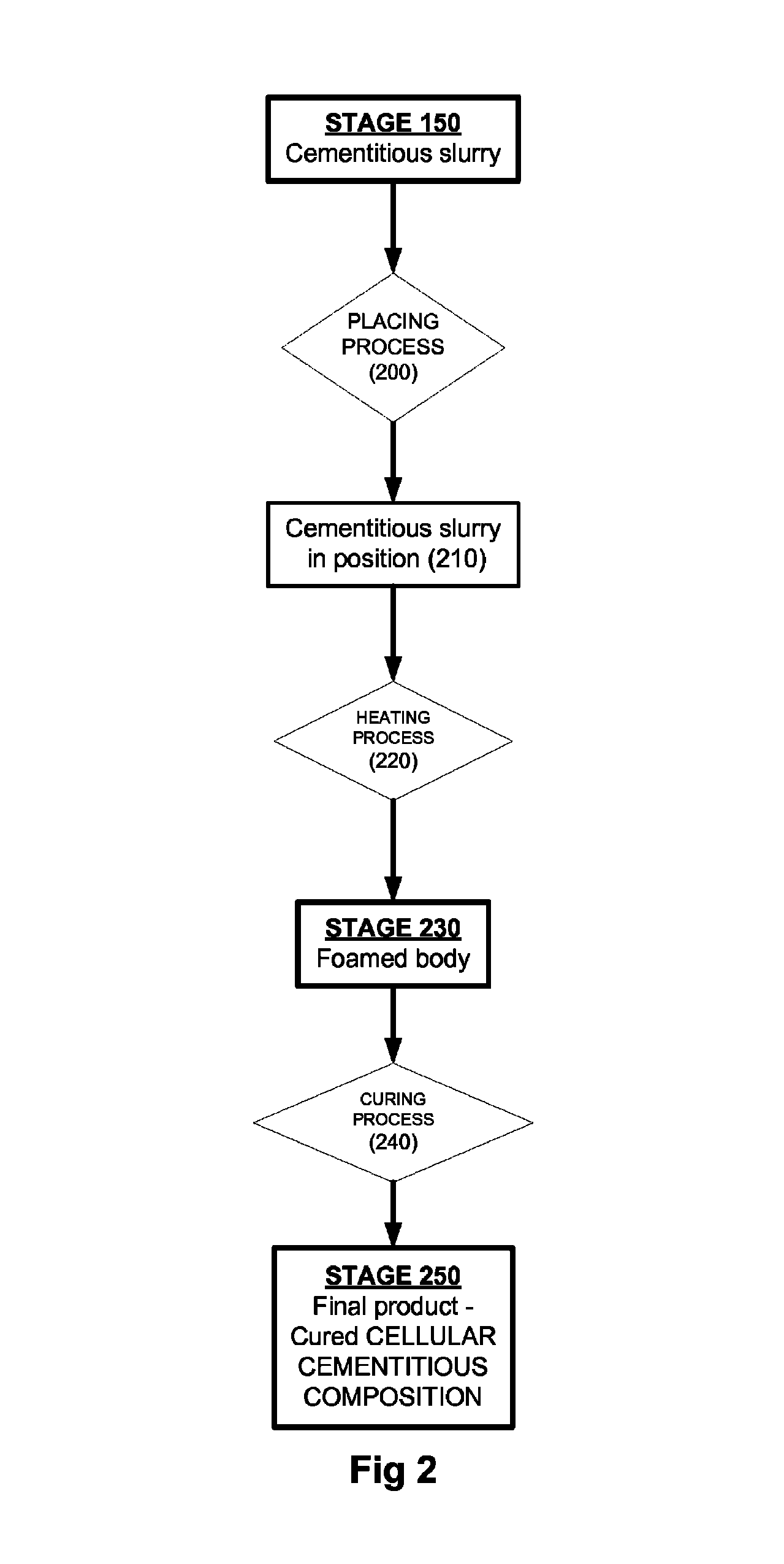

Cellular Cementitious Composition

Materials produced by foaming of particular cementitious compositions of geopolymeric or pozzolanic type in highly alkaline milieu without appreciable addition of dissolved silicate. Methods of manufacturing cementitious compositions are provided by using hypochlorite as a foaming agent therein.An aqueous cementitious slurry may be activated, first to foam, and then to set hard, by a process of applied heat, into useful materials and articles of hardened cellular cementitious composition. This process suggests advantage for a production process.

Owner:BIRCH GRANT DAVON

Porous ceramicite concrete permeable brick

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Environment friendly plant culture medium

InactiveCN1593103AEasy to get materialsSimple preparation processSolid waste disposalCultivating equipmentsBrickSlag

The invention discloses an environment friendly plant culture medium by utilizing architecture garbage and furnace slag, as well as necessary added components and auxiliary constituents, wherein the added constituents include natural nano material modified zeolite, the light material includes pearlite and vermiculite, the heavy material includes phosphorus ore, marble, granite and dolomite.

Owner:王大志

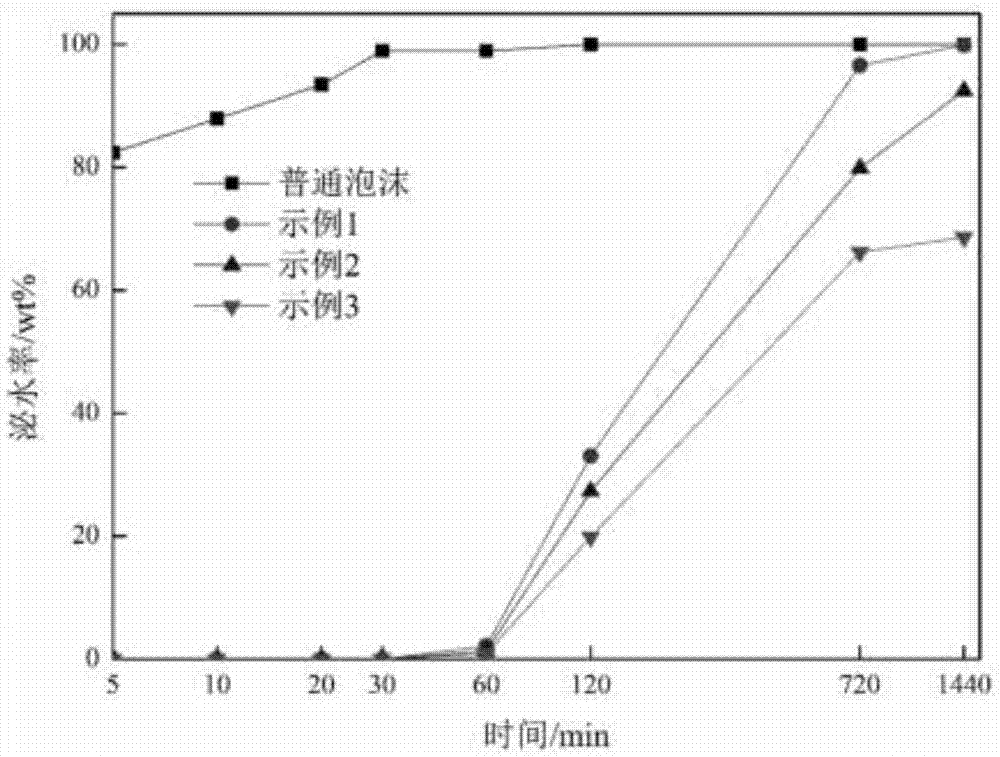

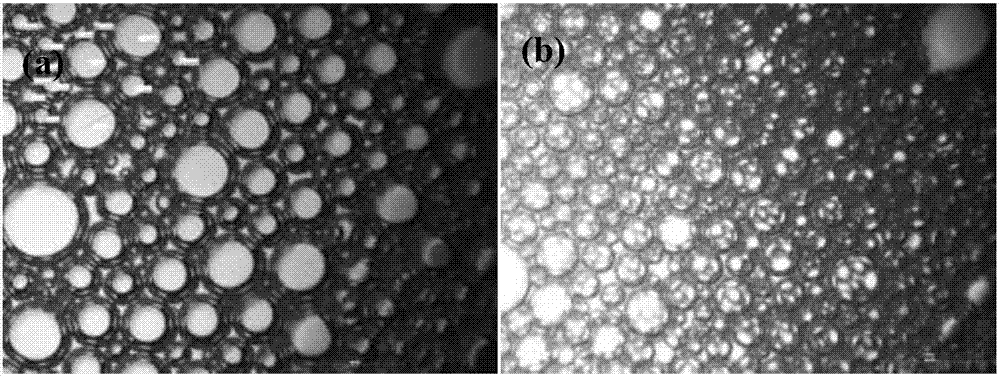

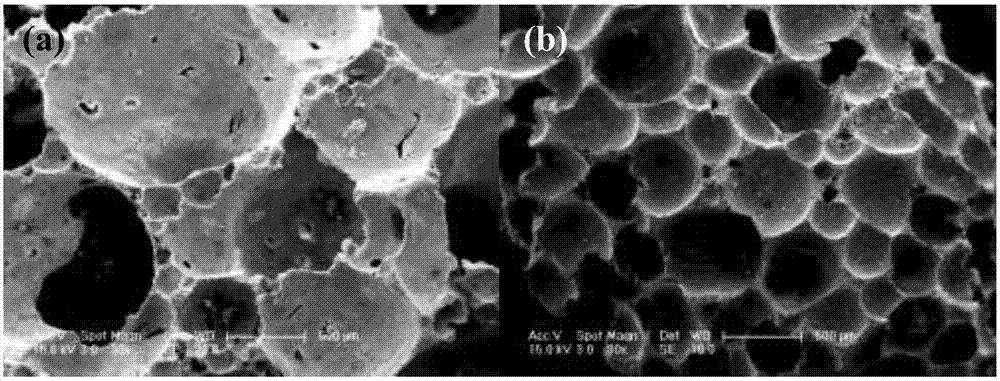

Nano-modified super-stable foam and application thereof in ultralight-density cement-based porous material

ActiveCN106866021AImprove stabilityThe improved foaming agent has good stabilityCeramicwareFoaming agentNanoparticle

The invention discloses nano-modified super-stable foam and application thereof in an ultralight-density cement-based porous material. By means of stably scattering nanoparticles into a foaming agent, foam can be wrapped by the nanoparticles after the modified foaming agent is stirred and generates the foam, the foam is converted into a gas-liquid-solid three-phase structure from a gas-liquid two-phase structure, and the stability of the foam is obviously improved. The foam prepared from the modified foaming agent has good stability and fine and uniform size; furthermore, the ultralight porous cement-based material prepared from the foam has high strength, is not prone to collapsing and solves the problems that a traditional ultralight cement-based porous material has poor performance and the like; the application of the foam is an effective method for improving performance of the ultralight cement-based material.

Owner:SOUTHEAST UNIV

New road surface structure layer

ActiveCN1587526APrevent penetrationAvoid lateral displacementIn situ pavingsHigh resistanceCrack resistance

The new type of road surface structure includes the lower porous modified cement concrete structure layer, base layer and waterproof layer set between the lower layer and the base layer. The porous cement concrete has the components of cement 200-500 weight portions, equal size crushed stone of 5-40 mm size 1000-1800 weight portions, water 100-180 weight portions, and cement modifier of 2-30 % of water. The said road surface structure has high bearing capacity, simple construction, small temperature sensitivity, high low temperature cracking resistance, good high temperature stability, proper toughness, strong impact resistance, high water resistance and excellent attenuation resistance. It is a ideal lasting road surface structure.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

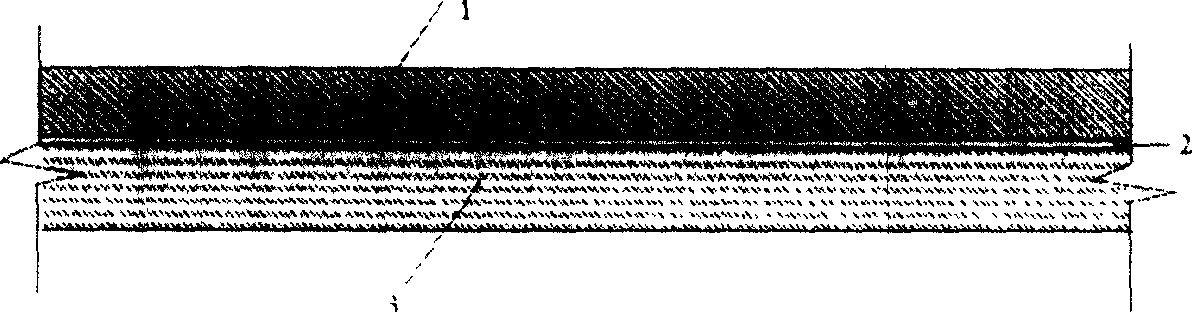

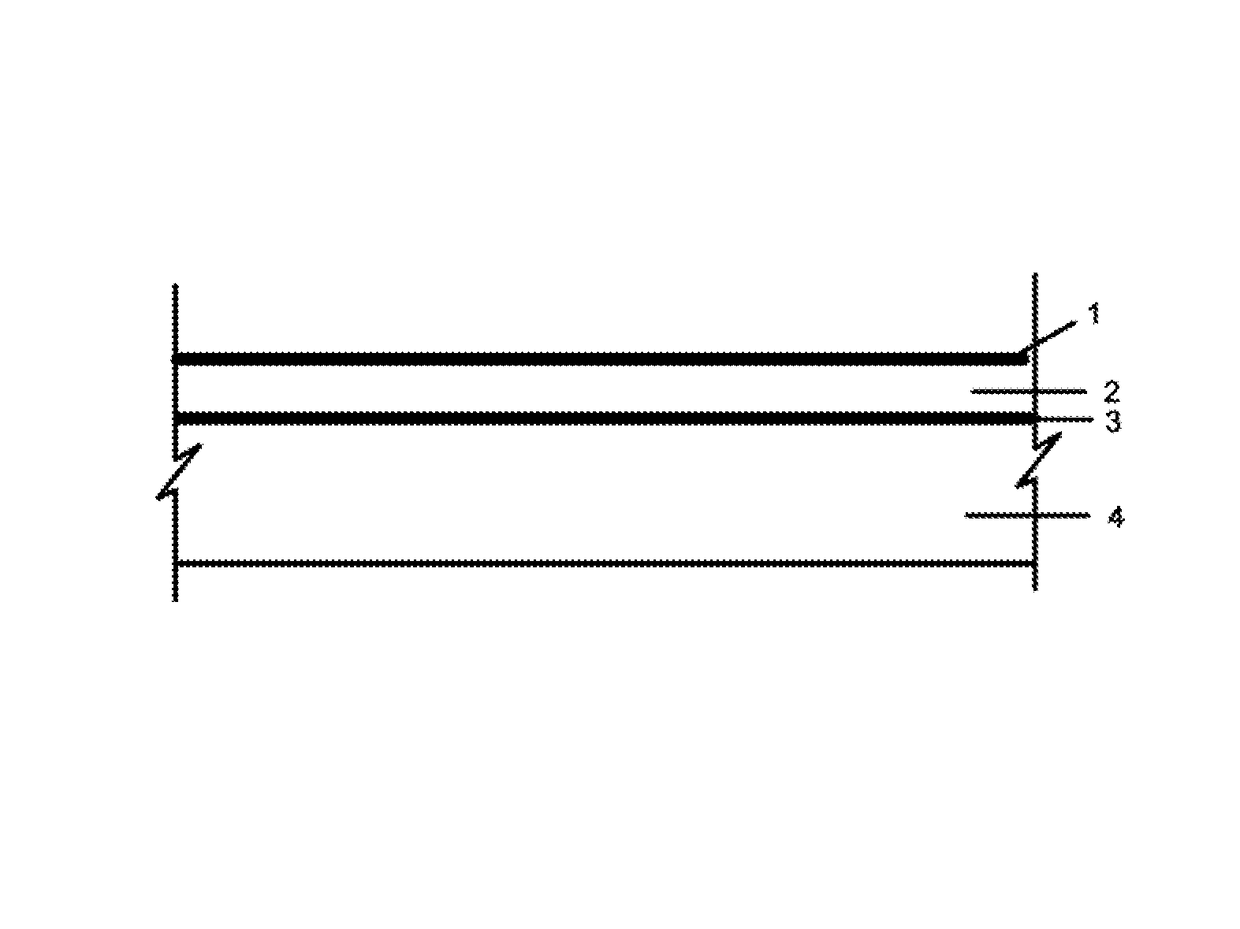

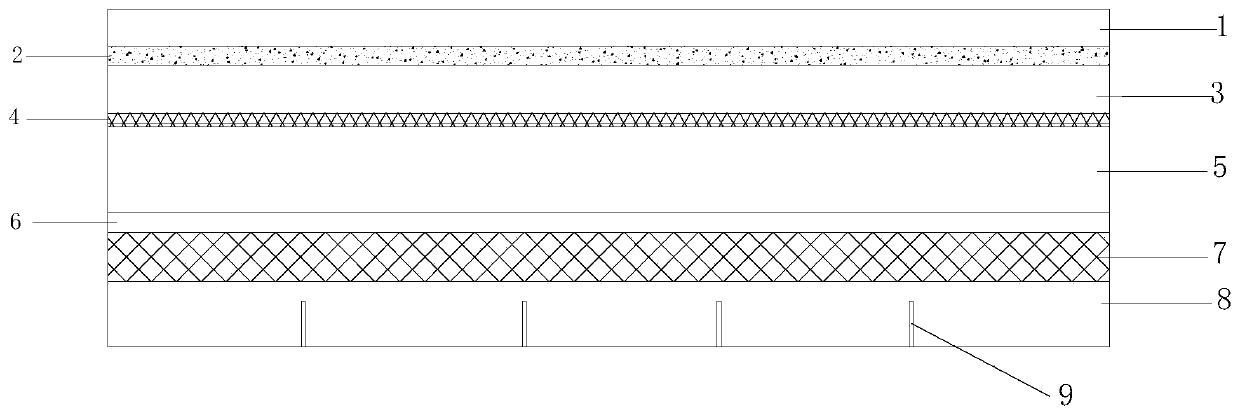

Porous cement concrete cement pavement having bond coat on rolled cement concrete and construction method therefor

ActiveCN101016717AImprove adaptabilityImprove deformation abilityIn situ pavingsCrushed stoneRoad surface

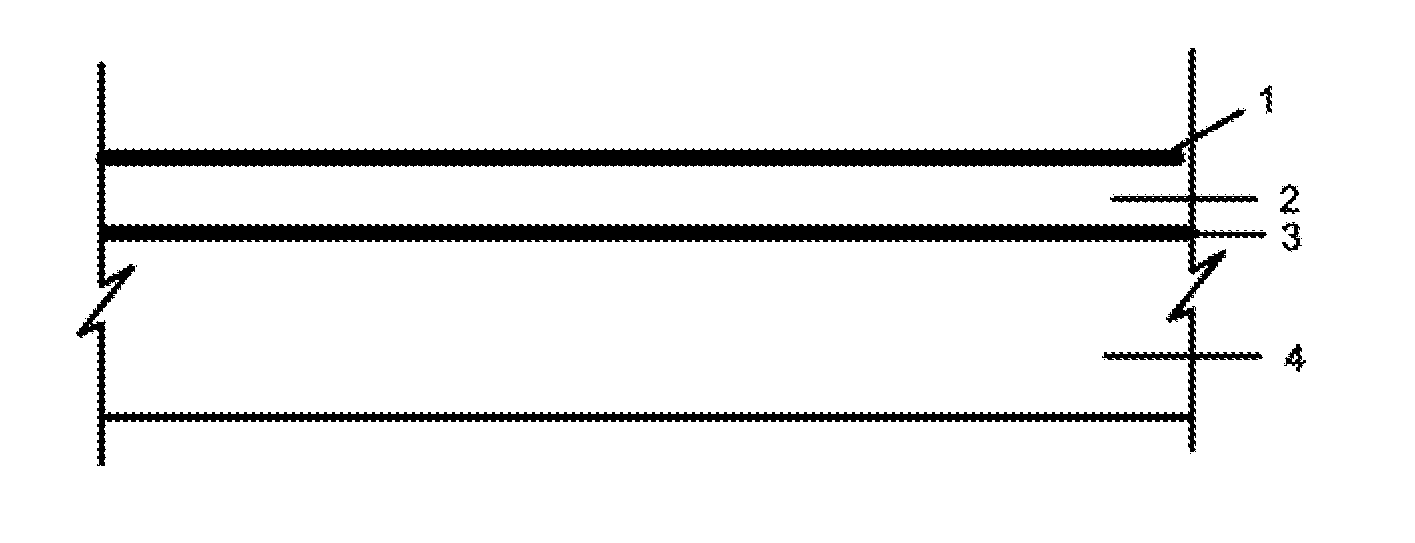

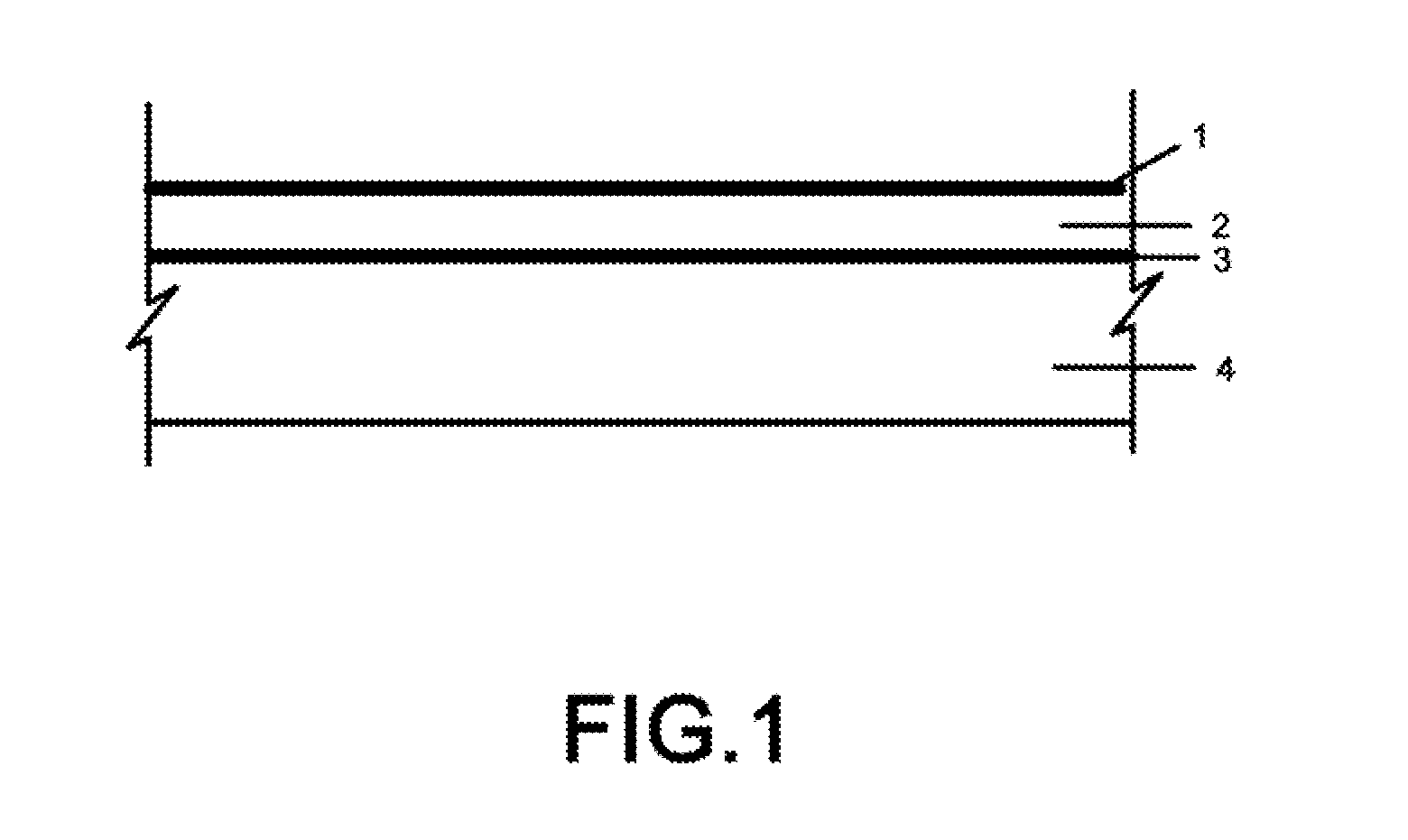

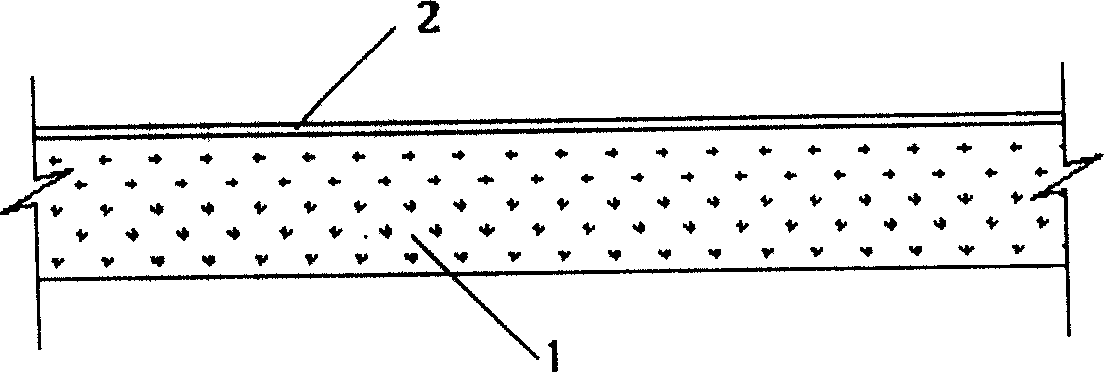

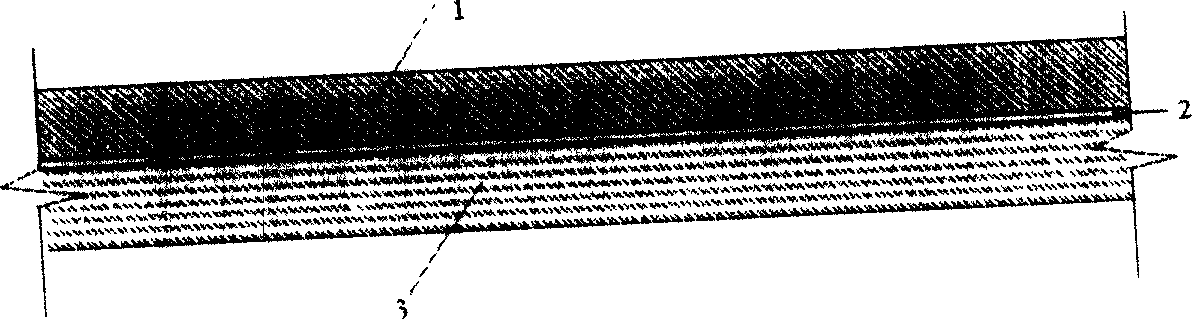

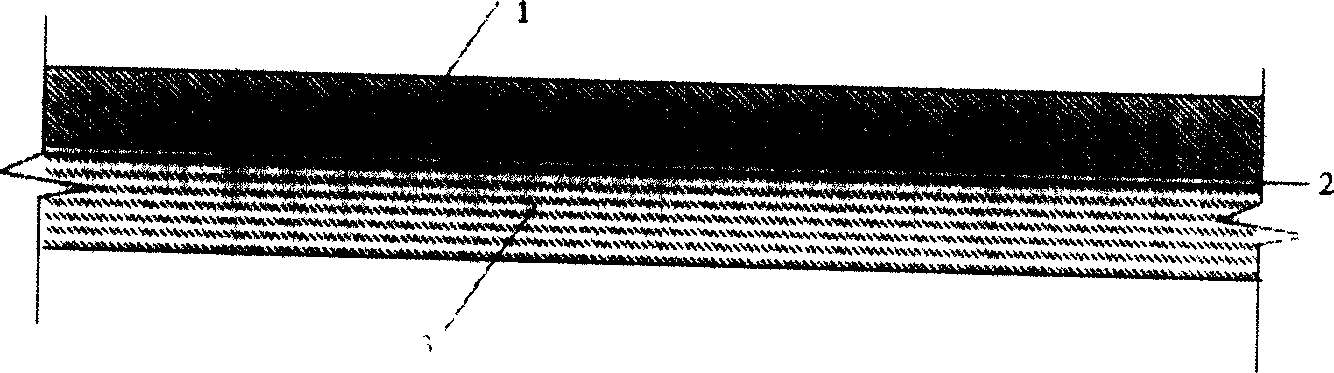

The invention relates to a porous cement concrete road which has an adhesive layer above the concrete, wherein above a cement concrete bottom layer 3, the invention mixes polymer and stuff uniformly, to form polymer mixture, then lays uniform the mixture mechanically or hand-operated on the bottom layer 3 to form an adhesive layer 2, then uses cement concrete mixer to mix uniformly cement, broken stone, sand and water to form porous cement concrete, mechanically lays porous cement concrete, flattens and presses the concrete mechanically or hand-operated to form a porous cement concrete face layer 1 to be adhered on the adhesive layer 2. The inventive cover structure has high strength, better anti-crack property, noise-reduction property or the like.

Owner:易志坚

Influent polymer cement concrete pavement structure on asphalt surface course and contracture method

ActiveCN101016716AImprove deformation abilityReduce brittlenessIn situ pavingsCrack resistanceSingle stage

A flow polymer cement concrete road above pitch face layer and relative construction comprise a pitch face layer 3 and a plated adhesive layer 2, wherein above the adhesive layer 2, the invention uses single-stage stage or intermission-stage broke stone to form porous cement concrete, to be laid and flattened, vibrates the porous cement concrete, and sprays the polymer mixture mechanically on the face of concrete, to flow the polymer mixture into the porous cement concrete, then stuffs some holes in the concrete, to form a flow polymer cement concrete face layer 1. The inventive face layer 1 has high strength, anti-crack property, waterproof property and aging resistance or the like, while the adhesive layer 2 can integrate the face layer and the pitch face layer 3, to bear force together.

Owner:易志坚

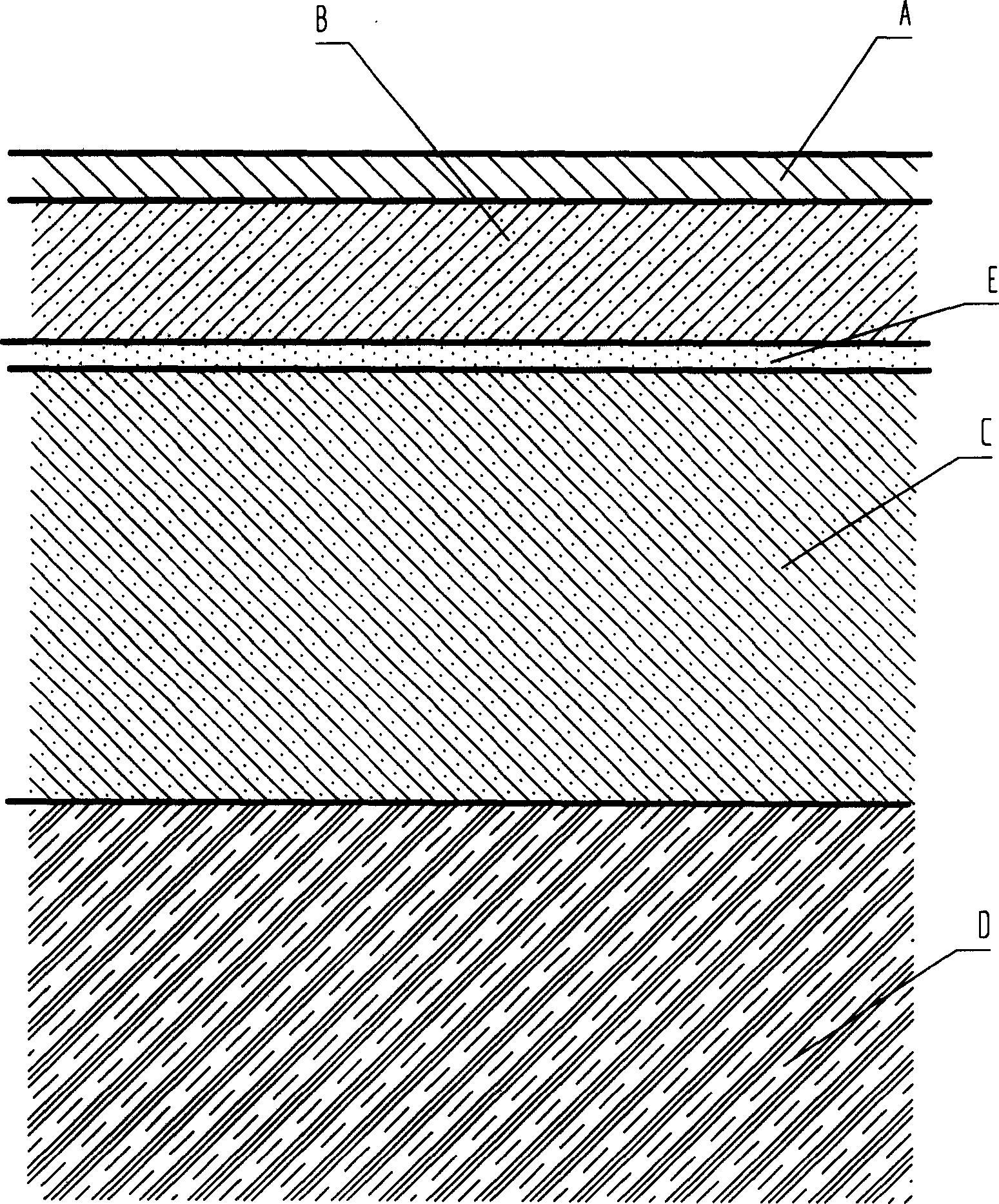

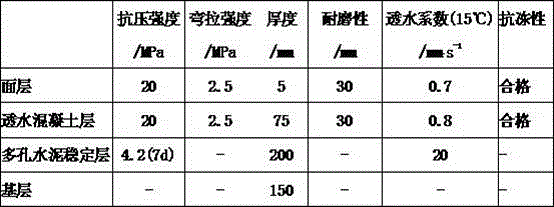

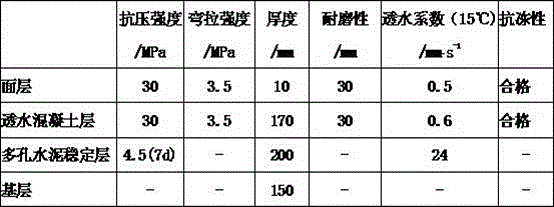

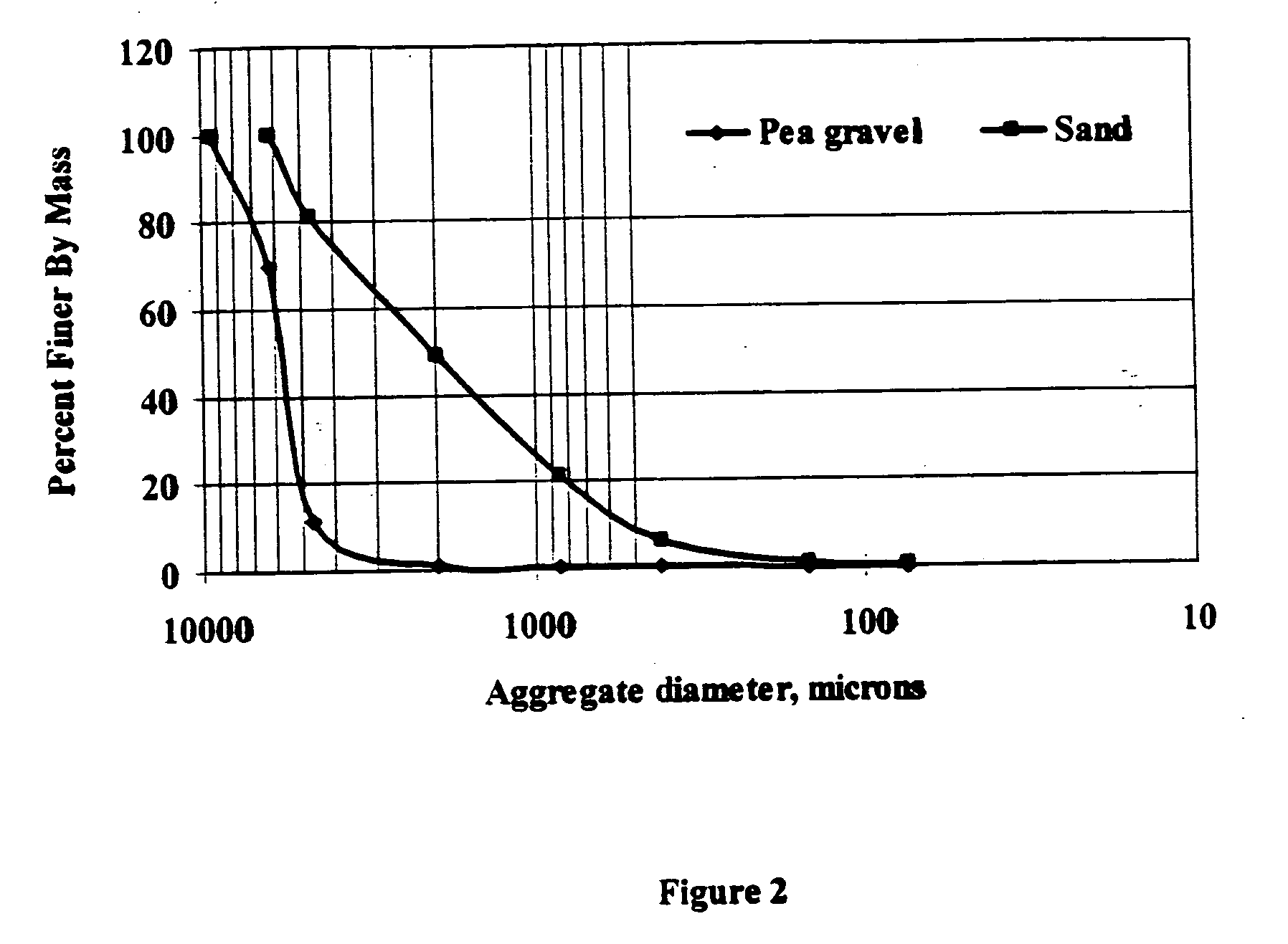

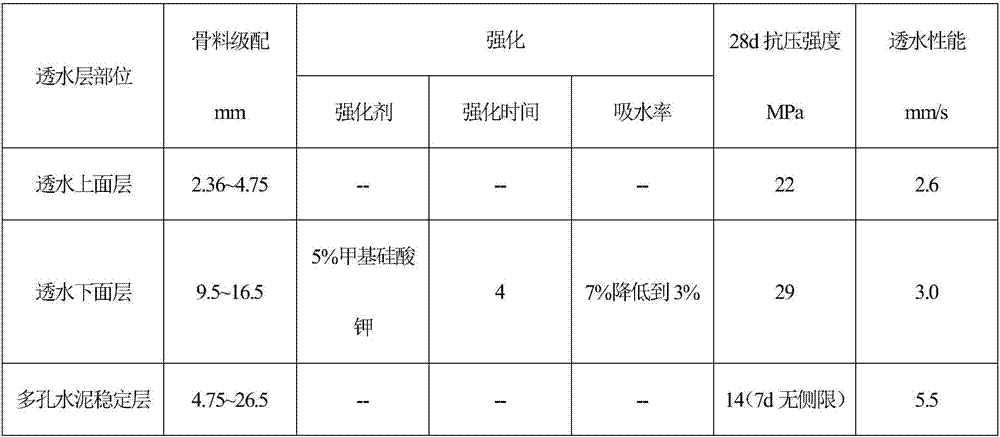

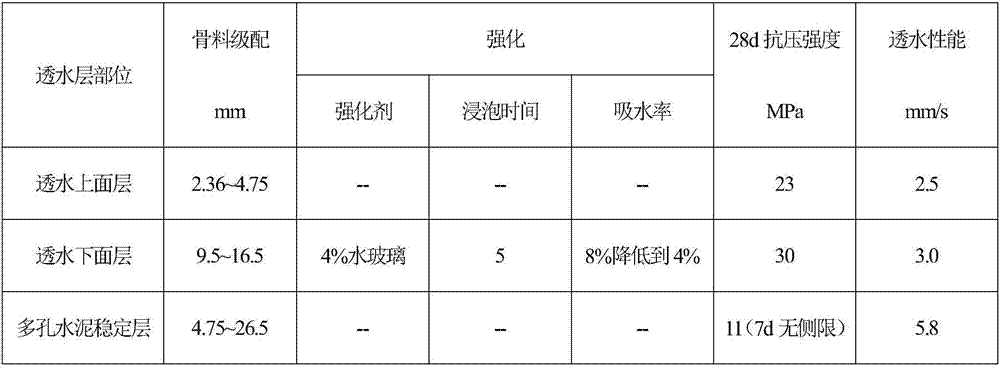

High-performance pervious concrete system prepared from construction waste and preparing method thereof

ActiveCN106116358ANo secondary by-productsReduce manufacturing costIn situ pavingsPaving gutters/kerbsSurface layerCellular cement

The invention provides a high-performance pervious concrete system prepared from construction waste and a preparing method thereof. The preparing method includes the steps that the construction waste is crushed, shaped and screened, and the construction waste is graded according to the particle size being smaller than 4.75 mm, 4.75-9.5 mm, 9.5-16 mm and 16-26.5 mm. The materials on all the layers are mixed according to the ratio, stirred uniformly and laid in the sequence of a base layer, a porous cement stable layer, a pervious concrete layer and a surface layer, the materials are rolled or rammed according to the standard after being laid on each layer, and then standard curing is carried out for 28 days to obtain the pervious concrete system. The usage amount of the construction waste in the pervious concrete system is 80-85%, the construction waste is fully used at a time, the use ratio is 100%, secondary products are avoided, and waste utilization and environment protection are achieved. The prepared pervious concrete system meets the standard about sponge city construction in China, and manufacturing cost is reduced substantially.

Owner:SHANDONG JIANZHU UNIV

Adsorptive-filtration media for the capture of waterborne or airborne constituents

An adsorptive-filtration media for the capture of waterborne or airborne constituents. The media comprises a granular substrate and an amphoteric compound bonded to the substrate in the presence of a crystal inhibiting agent. The media can also comprise a substrate having a specific gravity of less than 1.0 and an amphoteric compound bonded to the substrate. Another media comprises a substrate with a specific surface area of greater than 0.1 m<2> / gm and an amphoteric compound bonded to the substrate. Another media includes a granular substrate and a manganese oxide amphoteric compound formed on the substrate. Also disclosed is a pavement material for the capture of waterborne constituents. The pavement material comprises a porous pavement substrate and an amphoteric compound bonded to the substrate. Also disclosed is a method for producing a porous, cementitious material. The method includes the steps of providing and thoroughly mixing cement and aggregate, mixing water with the cement and aggregate into a slurry while maintaining a water to cement ratio of less than one, initiating curing of said slurry under pressure and in the presence of steam, and continuing the curing at ambient temperature and pressure until the cementitious material is substantially dry.

Owner:UNIT PROCESS TECH

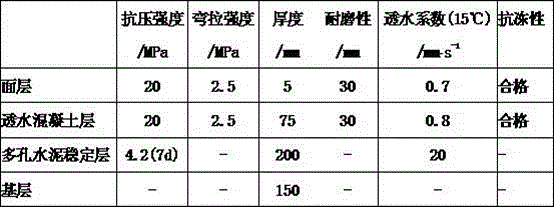

Environment-friendly all-permeable water-permeable concrete based on waste concrete and preparation method thereof

The invention provides environment-friendly all-permeable water-permeable concrete based on waste concrete and a preparation method thereof. The preparation method includes the following steps: (1) mixing and stirring 80-93% of a waste concrete regenerated aggregate, 5-15% of degradable waste plastic granules and 2-7% of dried spherical sludge granules from water plants, and after the raw materials are mixed uniformly, adding a part of blend water until the surface of the aggregate is wet; (2) successively adding a cementing material and a mixture liquid of the rest blend water and an additive, and stirring the raw materials until the surface of the mixture is bright; (3) successively paving the mixture according to the sequences of a porous cement stable layer, a water-permeable lower surface layer and a water-permeable upper surface layer, and pressing the paved mixture to form environment-friendly all-permeable colorful water-permeable concrete. The preparation method employs low-cost waste materials as raw materials and is simple in processes. The water-permeable concrete can adsorb nutrients in rainwater, is high in strength, has good water permeability, and is not liable to be blocked.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

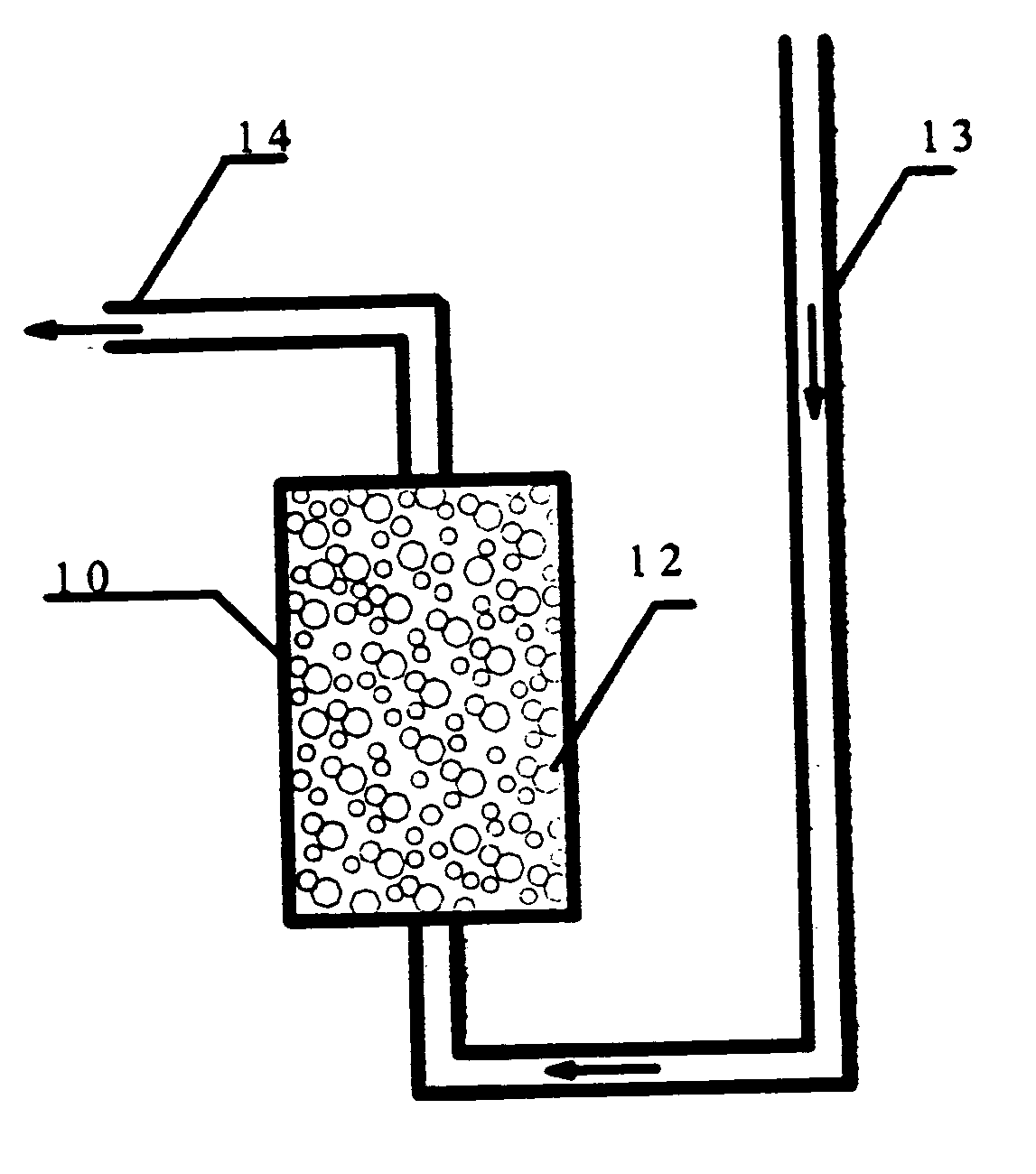

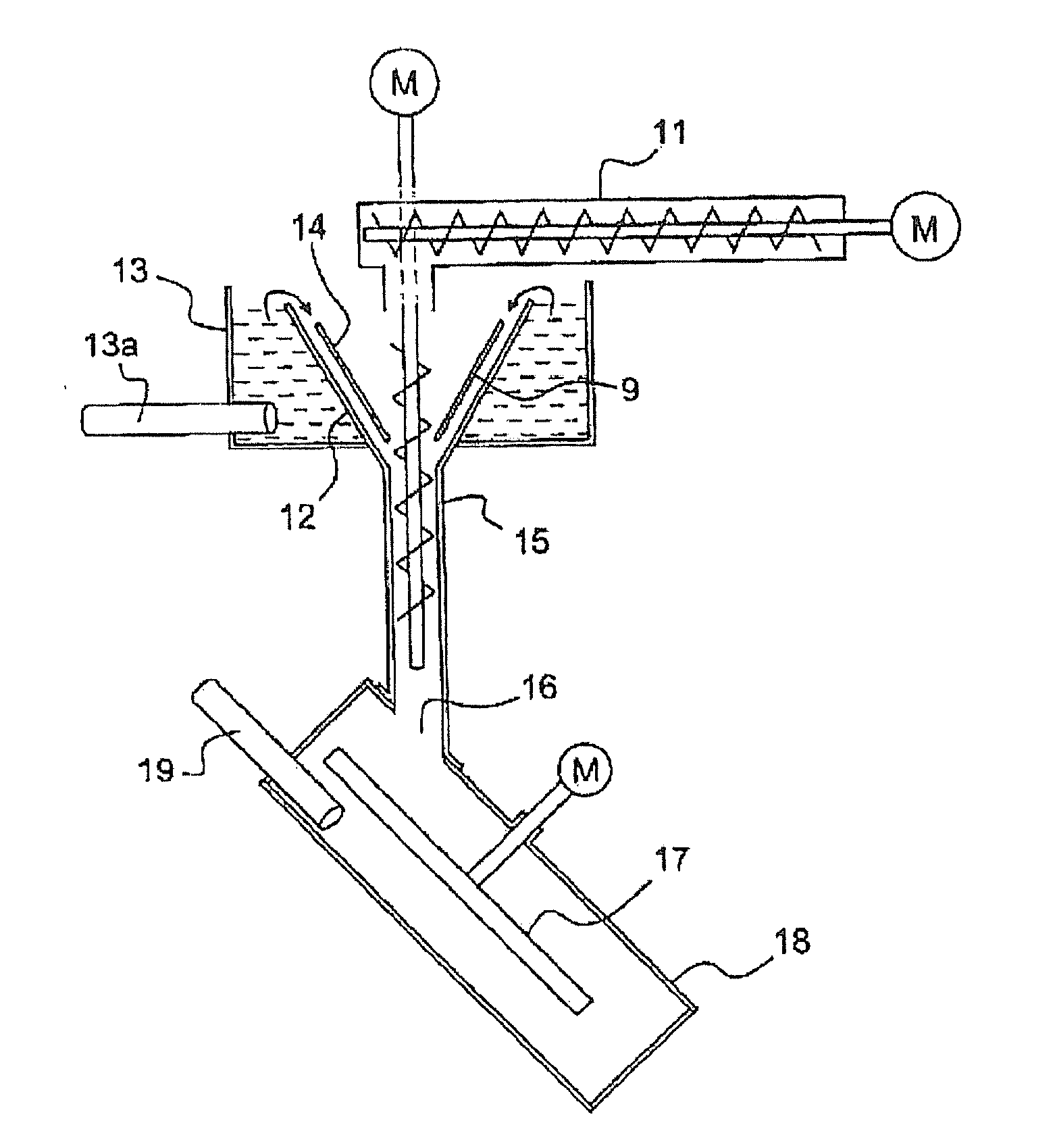

Apparatus for manufacturing set cellular cement

InactiveUS20080310248A1Less foaming agentLess waterTransportation and packagingRotary stirring mixersFoaming agentSlurry

A process for manufacturing set cellular cement, including the steps of: (i) mixing cementitious material, water, foaming agent and optionally additives into a free flowing slurry having a slump of at least 100 mm; subsequently (ii) injecting and distributing air into the slurry of step (i) to form a cellular slurry; subsequently (iii) casting the cellular slurry of step (ii); and finally allowing the cellular slurry to set. And, an apparatus for carrying out the process.

Owner:ETEX BUILDING PERFORMANCE INT SAS

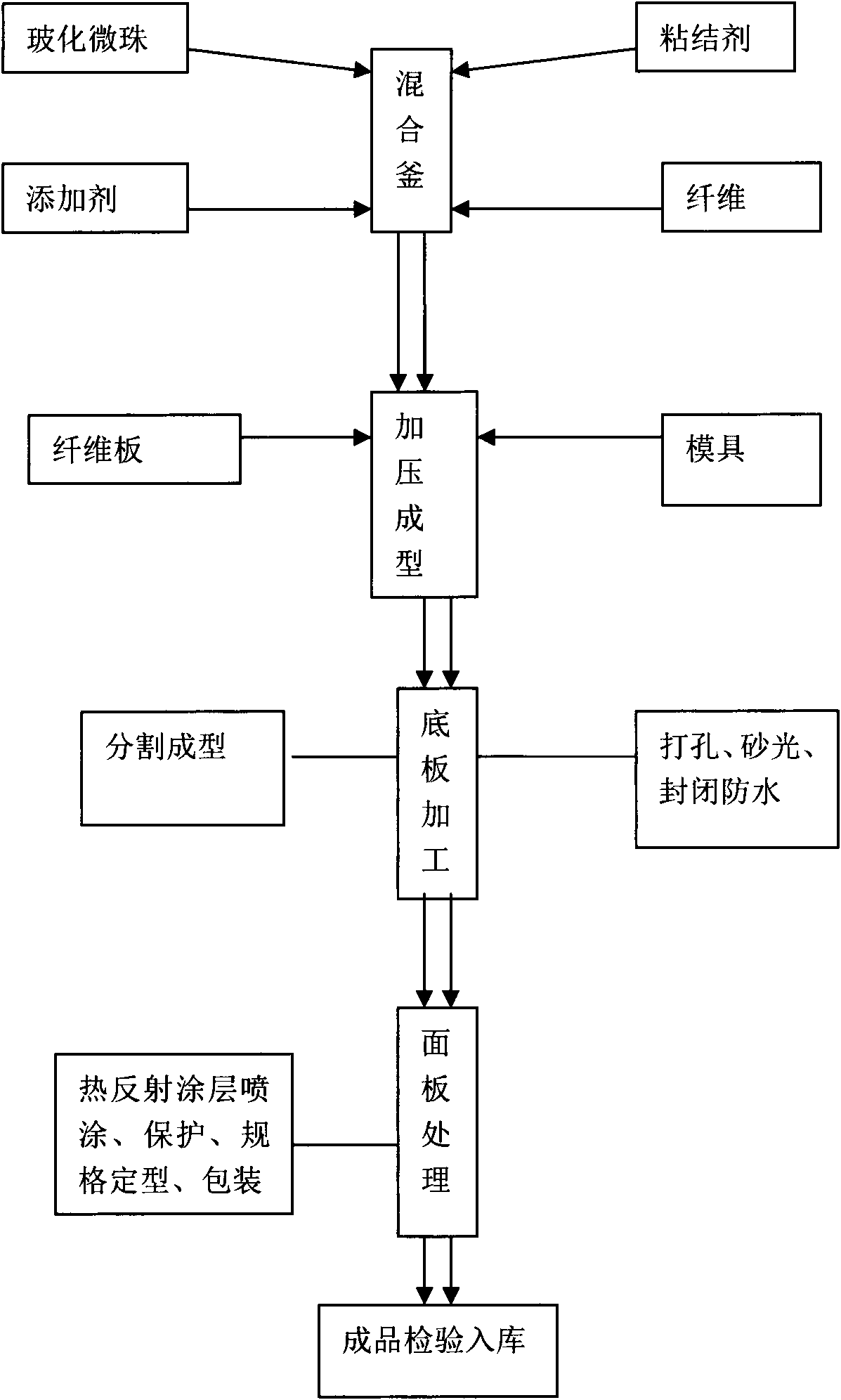

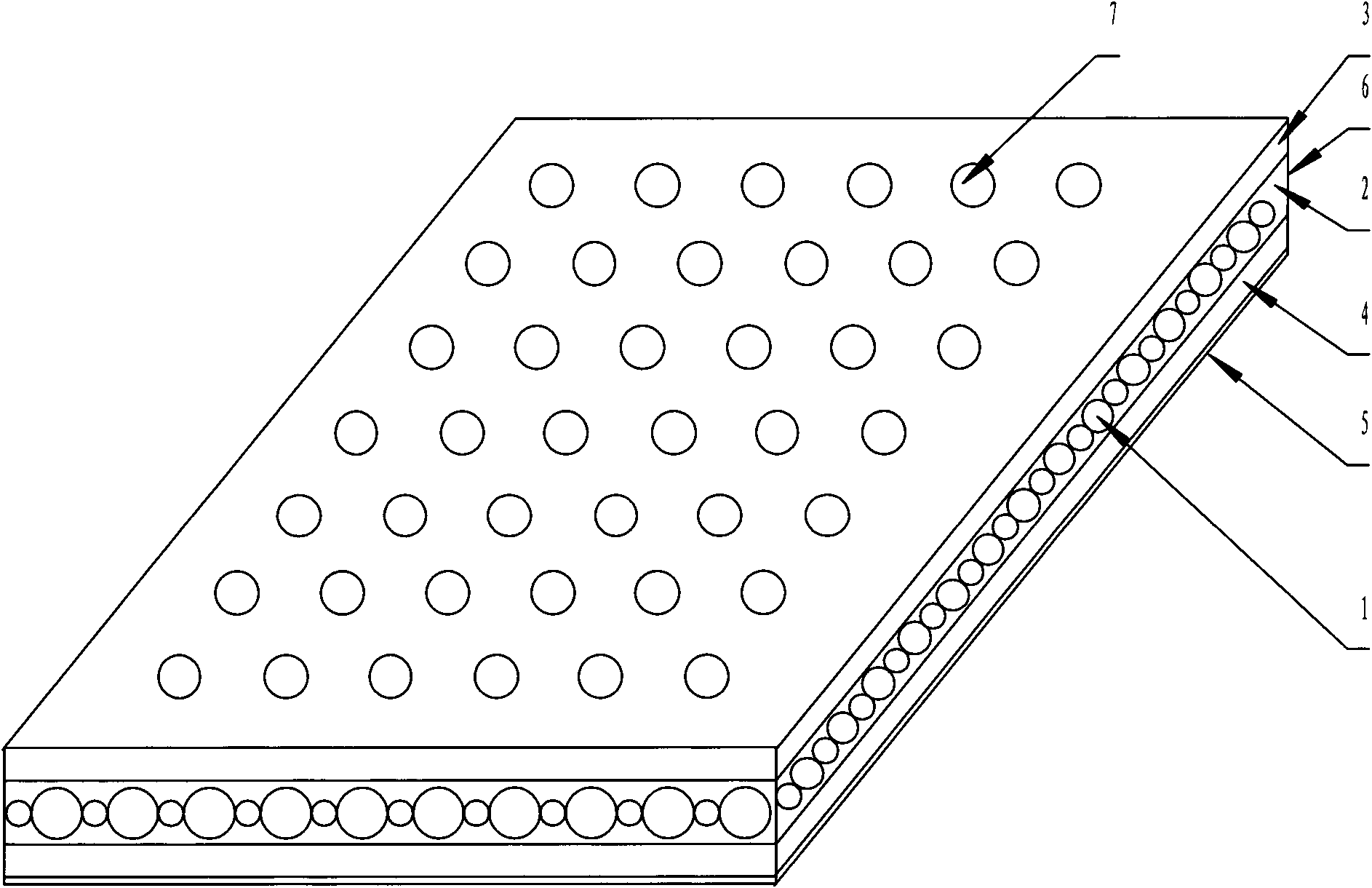

Grade A fireproof light thermal insulating decorative integrated plate and production process thereof

InactiveCN102277936ANo secondary pollution and environmental protection issuesLow thermal conductivityCovering/liningsInsulation layerThermal insulation

The invention relates to a building material, and in particular relates to a grade A fireproof light thermal insulating decorative integrated plate and a production process thereof. The integrated plate related to the invention employs a high-quality fluorocarbon coated high-density cement fibreboard as a surface decorative layer; the middle layer of the integrated plate is formed from closed cell vitrified micro-bubbles in combination with a high-strength structural adhesive through binding at the normal temperature; and the bottom layer of the integrated plate is a porous cement board. After being dried and formed, the integrated plate is 3-10 cm in thickness, and prefabricated and formed in a factory; when in use, the integrated plate is fixed to a wall body through an anchoring component and pasting mortar; and the joints are sealed by a silicone adhesive, therefore, one-step completion of thermal insulation and decoration is realized. By employing an inorganic thermal insulating aggregate which is matched with an efficient binding system, the density of the thermal insulating layer of the product is less than 150 kg / m3, and the coefficient of heat conductivity of the product is less than 0.060 W / M*K; and the compression strength and the rupture strength of the product are better than those of the XPS (Extruded Polystyrene) plate; and the integrated plate is a novel energy-saving building material.

Owner:湘潭市龙腾节能科技有限公司

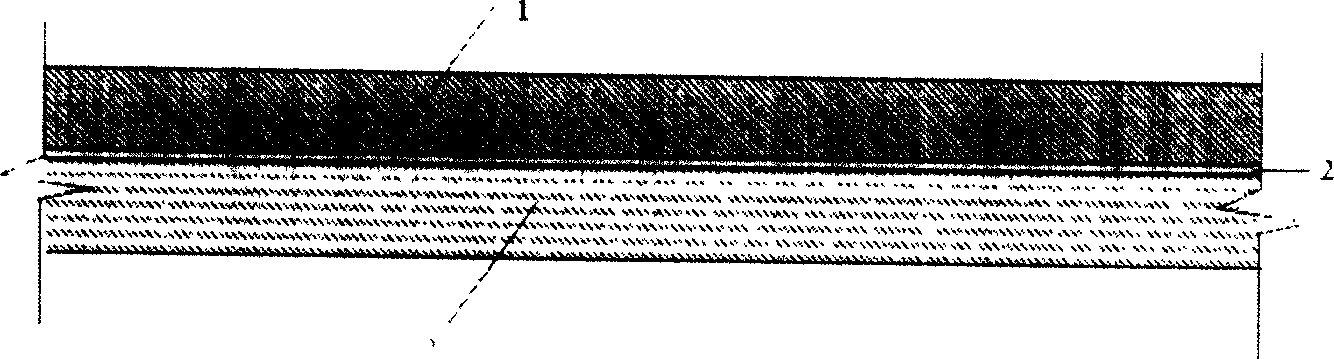

Color pavement formed by spraying on honey-combed cement concrete facing and construction method therefor

ActiveCN101016714AImprove deformation abilityImprove crack resistanceIn situ pavingsCrushed stoneRoad surface

A colorful road plated with porous cement concrete face and relative construction first mix polymer, broken stone, sand, cement, and water uniformly to form porous cement concrete face layer 1, then mix uniformly the colorful face material, and plate colorful face material on the face of porous cement concrete face layer 1 to form a colorful face layer 2, while the colorful face layer 2 is adhered with the porous cement concrete face layer 1, to form a colorful road. The inventive road has high strength, better deformation property, abrasion resistance or the like, while the color can adjust via different fields.

Owner:易志坚

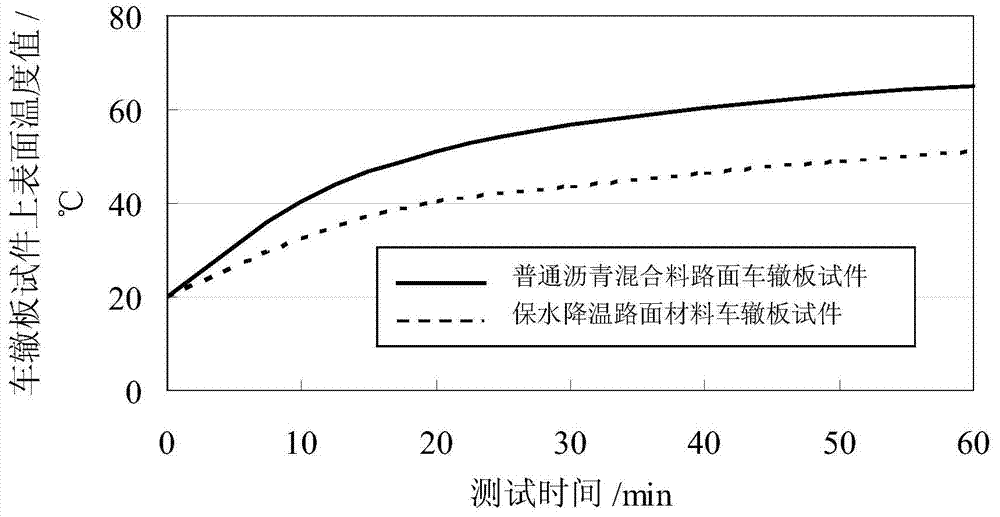

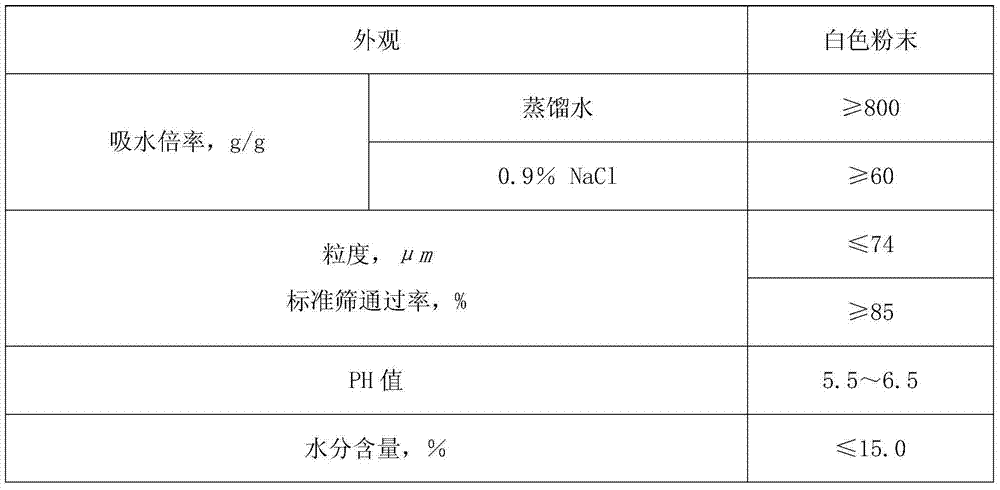

Water-retaining and cooling pavement material and application thereof

The invention discloses a water-retaining and cooling pavement material and an application thereof. The water-retaining and cooling pavement material is prepared from expanded perlite powder, cement, sepiolite powder, quartz sand powder, water-absorbent resin and a water reducing agent in an appropriate mass ratio. The water-retaining and cooling pavement material is applied to surfacing, and porous asphalt mixture or a porous cement concrete material with the void ratio of 20-30% is combined, so that finishing strength and performance of the pavement material are improved, and the aim of lowering temperatures of a pavement and a pavement surface is achieved.

Owner:CHANGAN UNIV

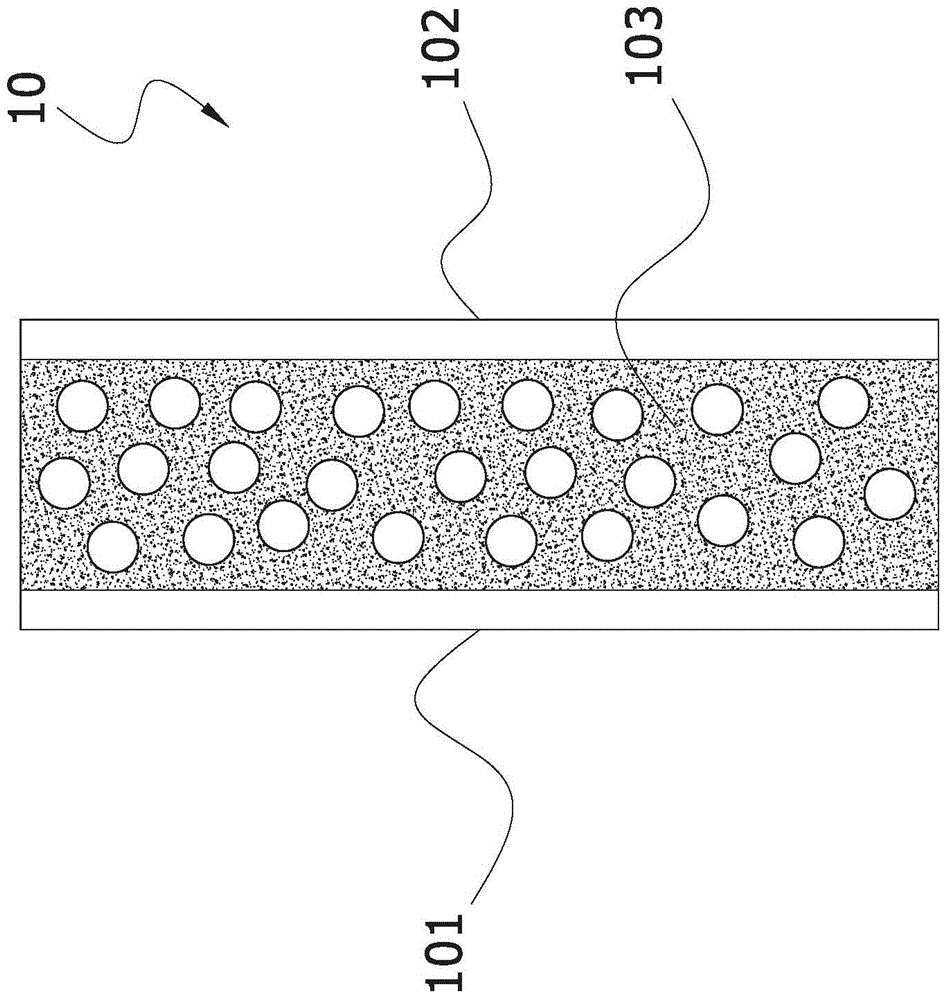

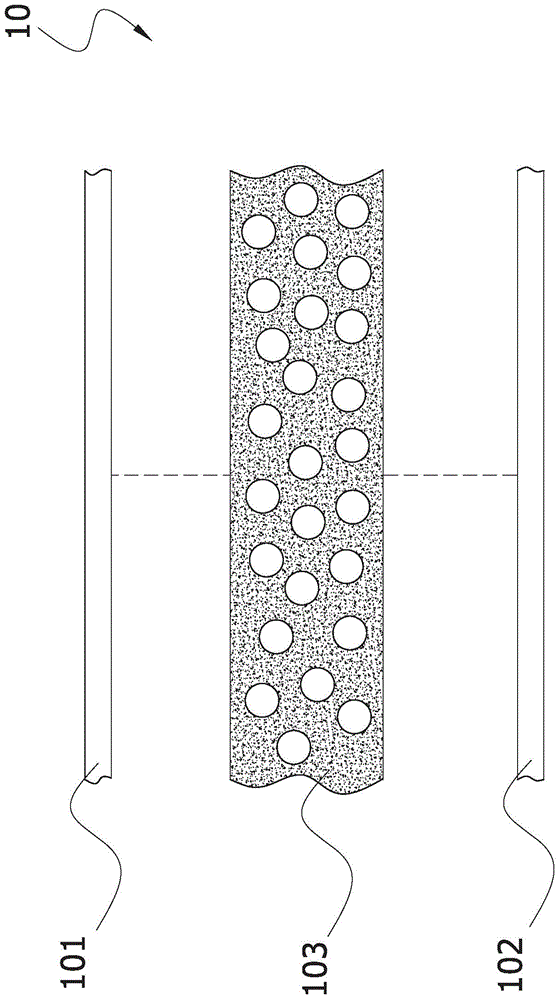

Porous cement road surface made from polymer modified cement and a construction method thereof

ActiveUS8470437B2Simple structureEasy constructionIn situ pavingsLayered productsCrack resistancePolymer modified

A porous concrete road surface structure made from polymer modified cement and a construction method thereof are disclosed. The structure successively comprises a bottom layer, a bonding layer, a porous concrete layer and a surface treatment layer. The bonding layer is located on the bottom layer, and the porous concrete layer on the bonding layer is prepared through paving, leveling and jolting a composition mixed from broken stone, sand and a slurry mixture of polymer modified cement. The addition of polymer promotes bonding of granular materials with the slurry mixture tightly, the use of the bonding layer makes the road surface structure and the bottom layer form an integral body, and the road surface structure has high strength, good crack resistance, water resistance, ageing resistance and corrosion resistance; the use of an intermittent or single graded of particles results in large pores, makes the road surface water-penetrating, decreases noise and amount of the polymer; and, the surface treatment can improve markedly surface properties and its use according to the application can make the porous concrete layer has rigid or flexible characteristic. The porous concrete road surface can be paved, leveled and jolted by paving machine or manual labor.

Owner:YI ZHIJIAN

Porous cement-based photocatalytic material and preparation process thereof

ActiveCN102989522ANo secondary pollutionHigh porosityCatalyst carriersCellular cementPhoto catalysis

The invention discloses a porous cement-based photocatalytic material and a preparation process thereof. The porous cement-based photocatalytic material is prepared from a porous cement-based carrier, an interface processing agent and a photocatalytic agent. The preparation method comprises the following steps of pre-treatment of the porous cement-based carrier, interface activation treatment of the porous cement-based carrier, dispersion of the photocatalytic agent, loading of the photocatalytic agent and post-treatment of materials. The porous cement-based photocatalytic material and the preparation process thereof have the advantages that an ultrasonic pore opening manner is adopted to improve the through-hole rate of a porous cement-based material; a manner of combining the interface treatment and the negative-pressure loading is used for activating the surface property of the porous cement-based material and improving the loading amount and the uniformity, so as to improve the photocatalytic efficiency and the long-period activity; and furthermore, a coordination effect of the porous cement-based material and the photocatalytic material is combined to improve the treatment capability on harmful gas.

Owner:WUHAN UNIV OF TECH

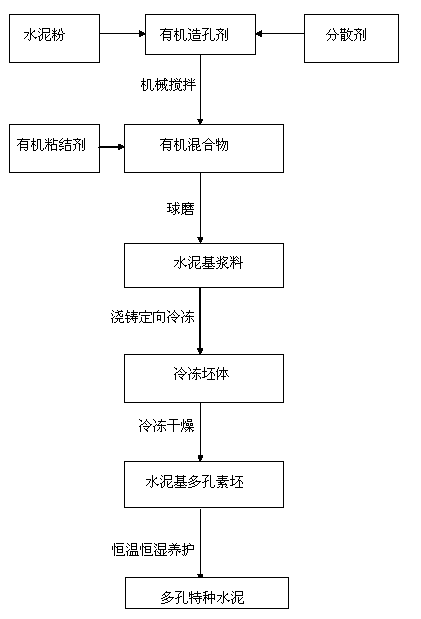

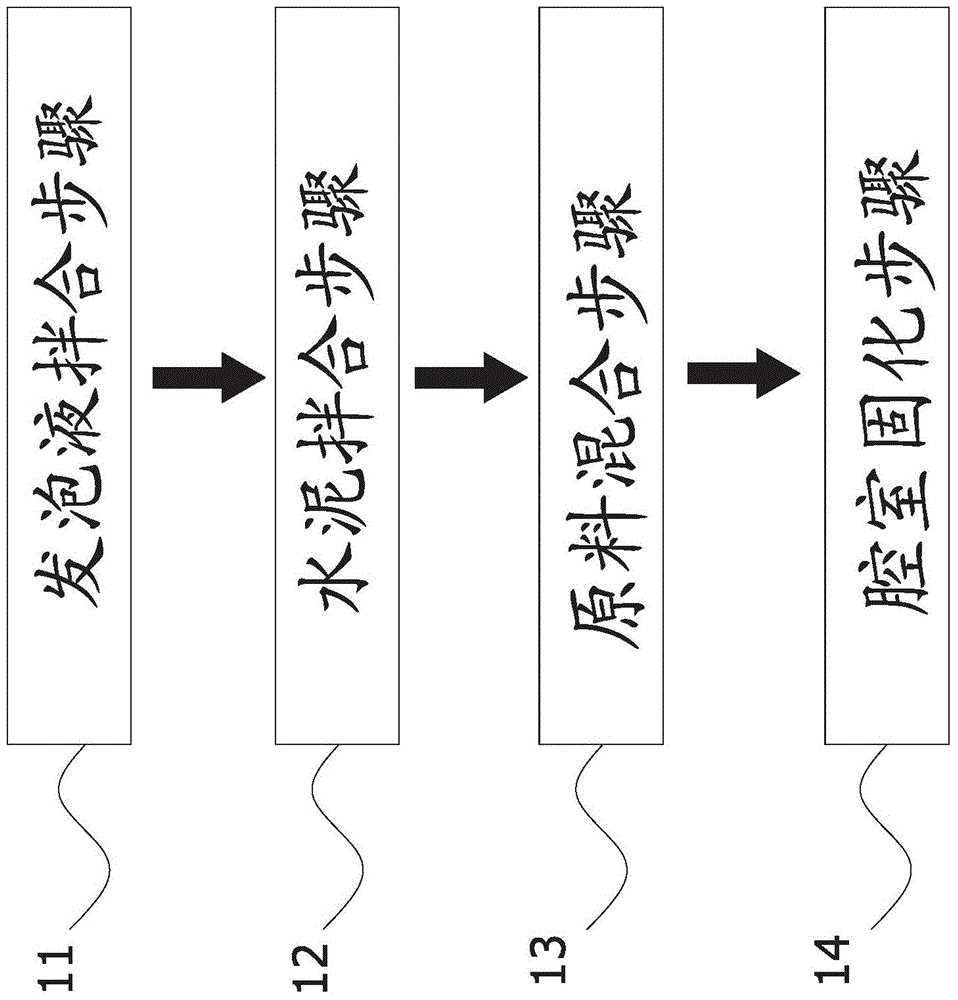

Preparation method of directional porous special cement

ActiveCN103739306BImprove performanceReduce the degree of collapseCeramicwarePorosityEconomic benefits

The invention relates to a preparation method of cement, and in particular relates to a preparation method of directional porous special cement, which belongs to the technical field of a porous material manufacturing method. The preparation method comprises the following four steps of preparation of cement-based slurry, manufacturing of frozen green body, manufacturing of cement-based porous biscuit, and maintaining of the biscuit. According to the preparation method, the process is simple, and the cost is low; the method for preparing the directional porous special cement has the advantages that the opening porosity of the prepared porous material is 50-80% and the average aperture is 0.1-500 micrometers; various organic binders and the dosage are selected, the collapse degree of the biscuit can be reduced and the strength of the biscuit can be improved, and the performance of the final style is affected; as the porous material is prepared by directional freezing, the shape of special pore can be obtained easily and the style with complex shape can be obtained easily; due to the adoption of the method for maintaining in a constant-temperature constant-humidity box to obtain the final style, more energy is saved, the environment is protected, the economic benefit is preferable, and the damage to a sample is slight.

Owner:OCEAN UNIV OF CHINA

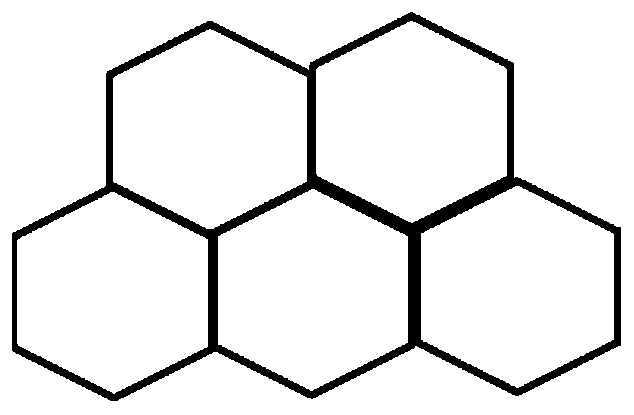

Road structure of urban intersection, bus station and bus lane

PendingCN111118999AMitigate the impact on driving safetyImproves rutting resistanceIn situ pavingsClimate change adaptationFiberWaste rubber

The invention discloses a road structure of an urban intersection, a bus station and a bus lane. The road structure comprises a surface layer, a middle surface layer, a lower surface layer, a base layer and a sub-base layer from top to bottom, a rubber asphalt stress absorption layer is arranged between the lower surface layer and the base layer, and the surface layer is composed of a semi-flexible material SFA13 sprayed with a stone exposing agent of 4-6 cm; the middle surface layer is formed by a semi-flexible material SFA16 doped with a phase change energy storage material of 6-8cm; the lower surface layer is made of an EME20 high-modulus asphalt mixture of which the thickness is 8-10cm; the base layer is composed of C-B-1 cement stabilized graded broken stones or gravels doped with bagasse fibers, waste rubber powder and water-absorbent resin sodium polyacrylate of 18-20cm, and the subbase layer is composed of 15-18cm fabricated regular hexagonal prism-shaped porous cement concrete. By integrating and optimizing the pavement structure, the water stability, the crack resistance and the durability of the road structure are improved, the rut resistance, the skid resistance and thefatigue resistance of the pavement are improved, the urban heat island effect is relieved to a certain extent, and the recycling of wastes is realized.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

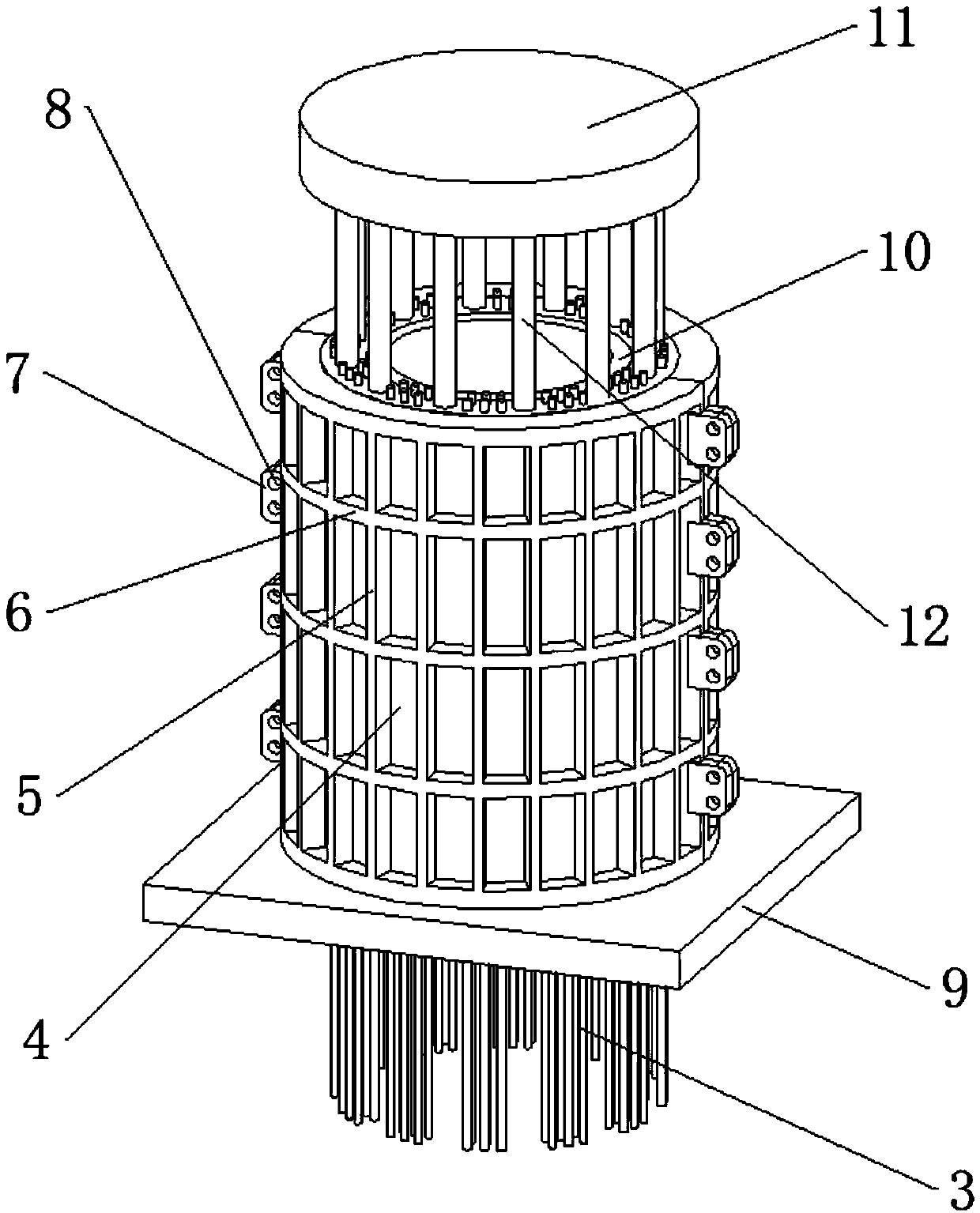

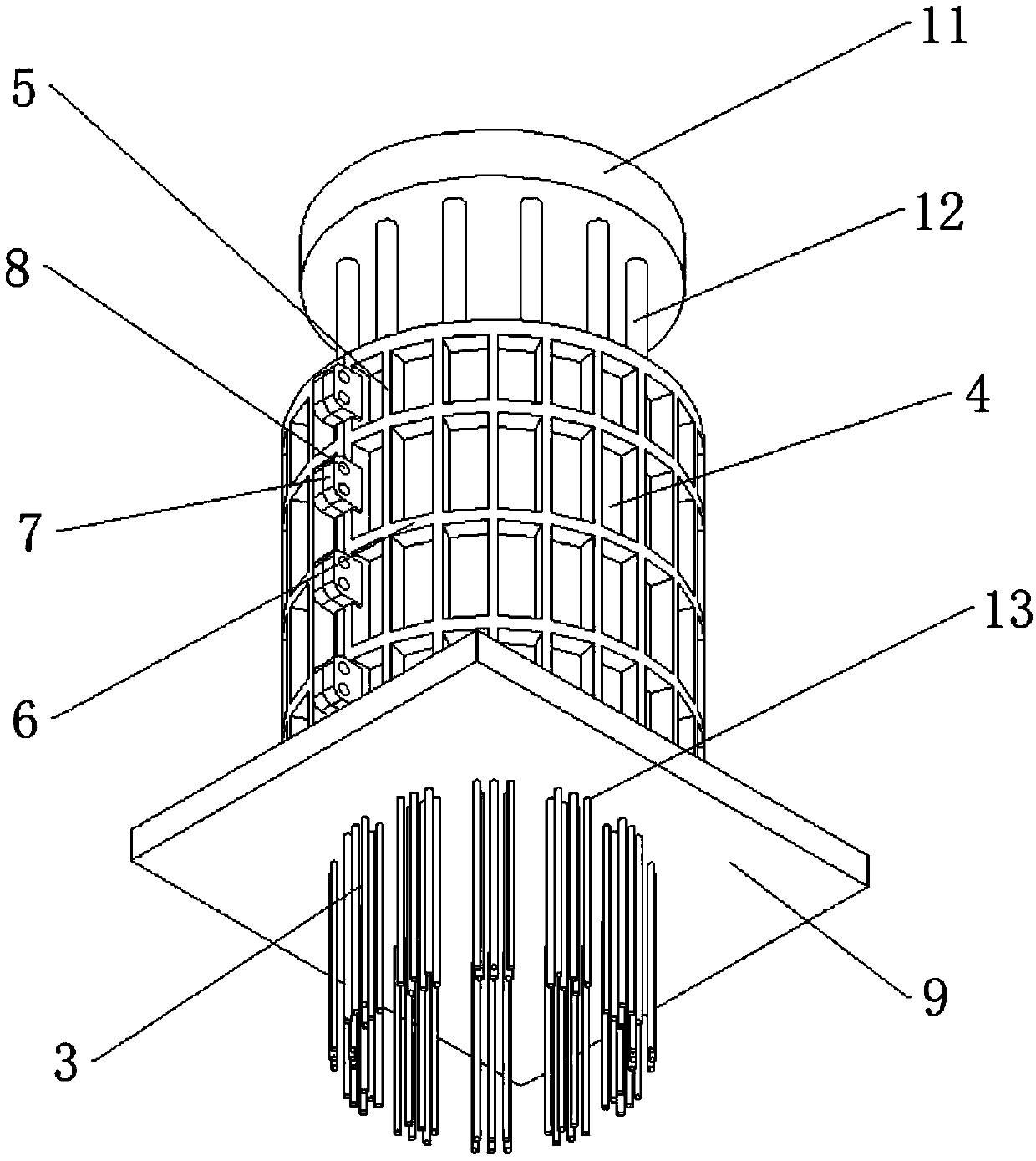

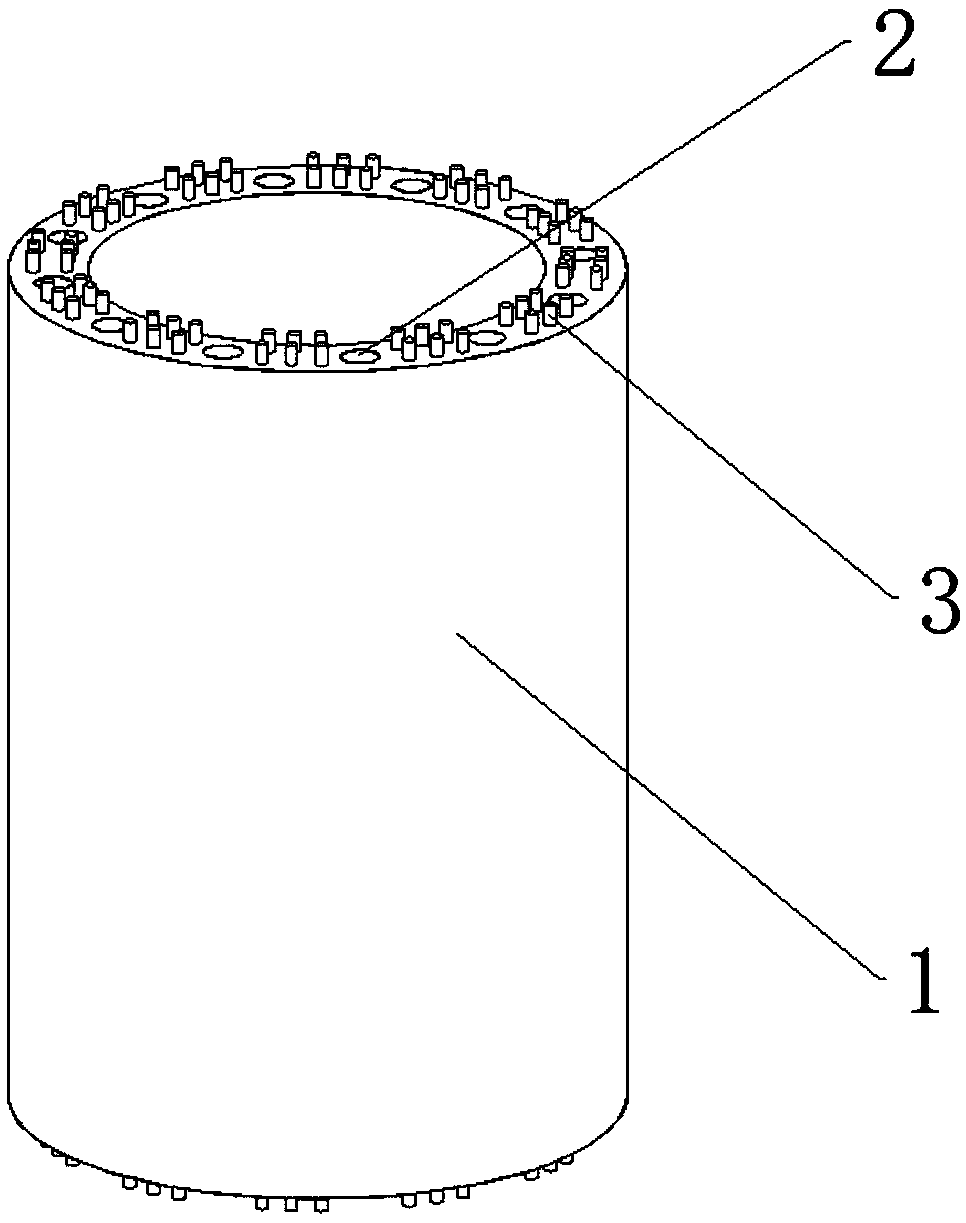

Honeycombed cement pipe and manufacturing process thereof

ActiveCN109676752AHigh strengthReduce usageCeramic shaping plantsAuxillary shaping apparatusCellular cementUltimate tensile strength

The invention discloses a honeycombed cement pipe and a manufacturing process thereof, and belongs to the technical field of the honeycombed cement pipe. The honeycombed cement pipe comprises a honeycombed cement pipe, wherein a plurality of through holes which are uniformly distributed are formed in the honeycombed cement pipe and are penetrated up and down; the interior of the honeycombed cementpipe is fixedly connected to a plurality of steel bars which are evenly distributed; the diameters of the steel bars are 4-8mm; the material of the honeycombed cement pipe is concrete; the strength grade of the concrete is C30; the raw materials of the concrete comprise water, cement, sand, stone and concrete additives; the cement surplus coefficient of the concrete is 1.00; the maximum particlesize of the coarse aggregate is 20mm, collapsbillity is 35-50 mm, and sand rate is 28-30%; and by reasonably adding multiple pores in the production process of the cement pipe, the strength of the cement pipe is greatly enhanced, the usage amount of the cement material is greatly reduced, the solidification time is greatly reduced, the production efficiency is improved, and the weight of the cement pipe is reduced, and the transportation cost can be substantially reduced.

Owner:林飘飘

Influent polymer cement concrete pavement structure on cement concrete and construction method therefor

ActiveCN101016718AImprove deformation abilityReduce brittlenessIn situ pavingsSingle stageCrushed stone

A flow polymer cement concrete road above cement concrete and relative construction comprise a cement concrete bottom layer 3 and a plated adhesive layer 2, wherein above the adhesive layer 2, the invention uses single-stage stage or intermission-stage broke stone to form porous cement concrete, to be laid and flattened, vibrates the porous cement concrete, and sprays the polymer mixture mechanically on the face of concrete, to flow the polymer mixture into the porous cement concrete, then stuffs some holes in the concrete, to form a flow polymer cement concrete face layer 1. The inventive face layer 1 has high strength, anti-crack property, waterproof property and aging resistance or the like, while the adhesive layer 2 can integrate the face layer and the pitch face layer 3, to bear force together.

Owner:易志坚

High-efficiency paper base sound-absorbing material and preparation thereof

InactiveCN1472725AImprove sound absorptionPromote absorptionSound proofingSound producing devicesFiberAcoustic absorption

The material is fabricated by paper made multihole base material covered with foaming cement slurry in water-proof type. The triangle and polygon cavities formed by inserting paper to each other can arrest sound wave and light aggregate cement slurry body can carry on diffuse reflection and further absorption. The fabricated material can arrest sound wave into independent cavities and to use different sizes of hole seams and fibre distributed on mutihole cement and light aggregate to absorb sound wave and consume sound energy for sound wave of 100-2000 Hz frequency with average sound absorption coefficient up to 0.6.

Owner:WUHAN UNIV OF TECH

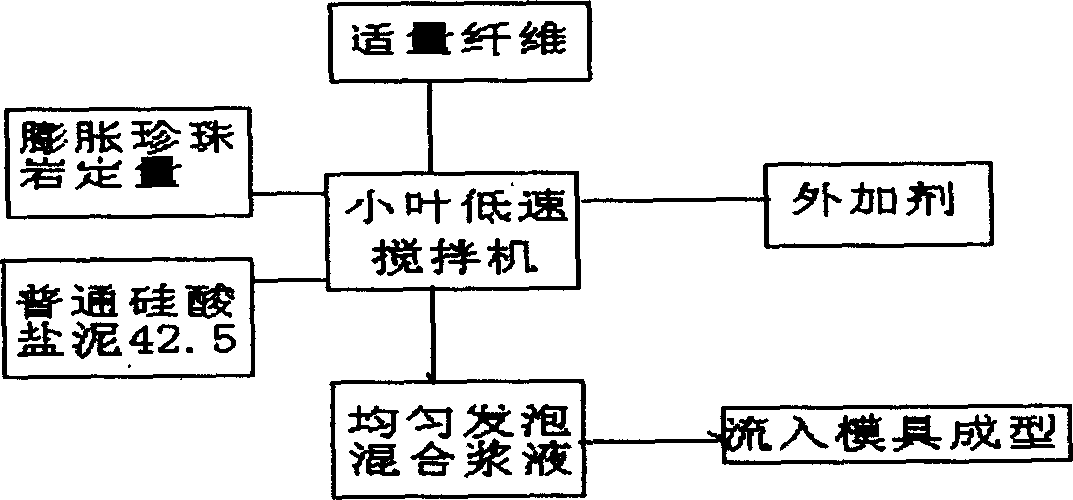

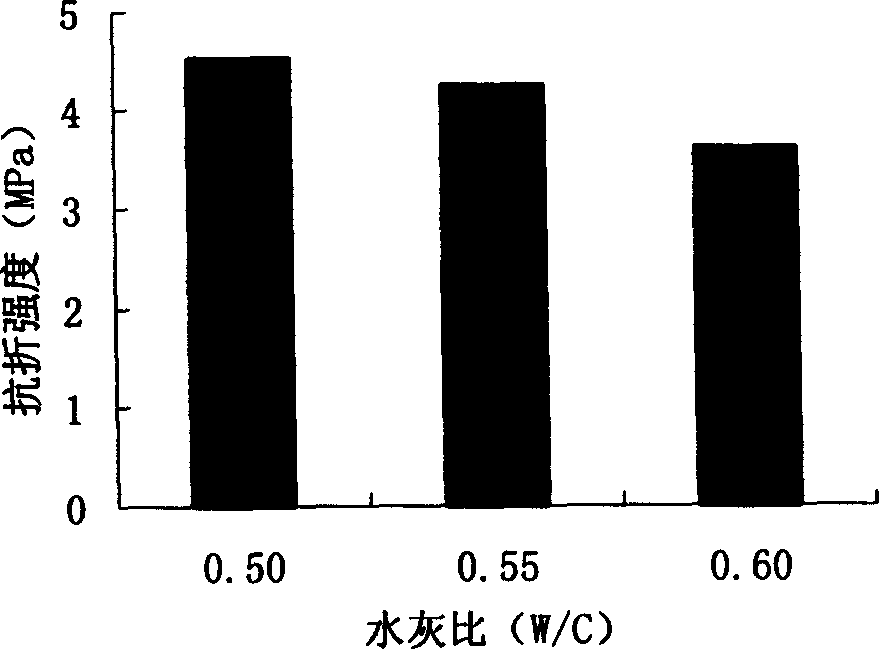

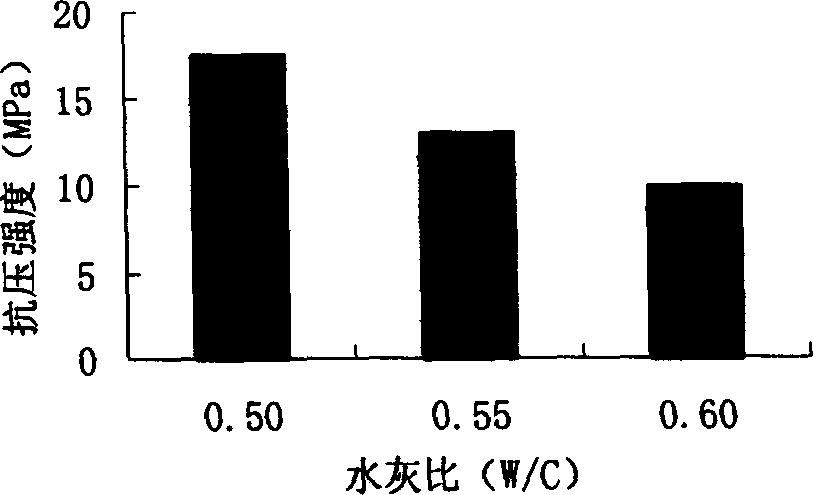

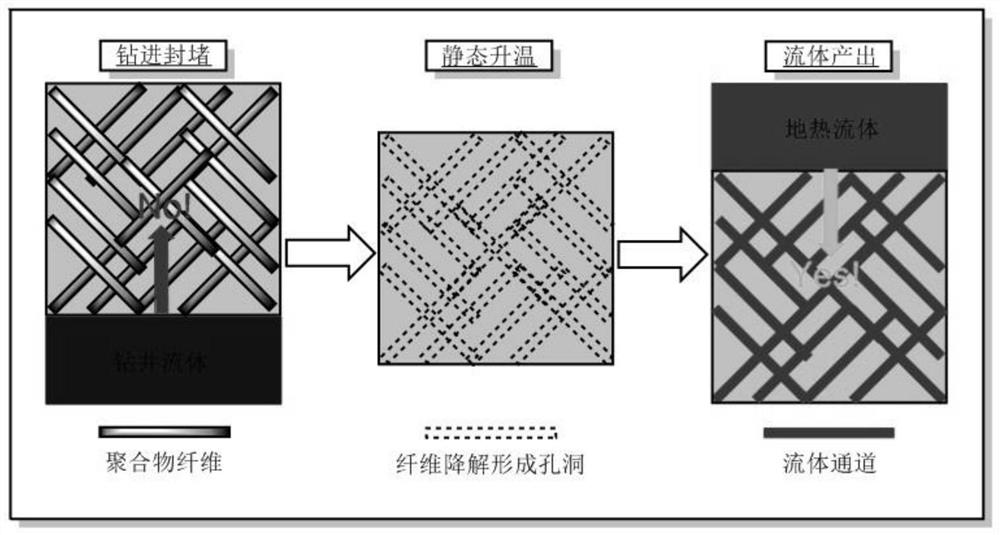

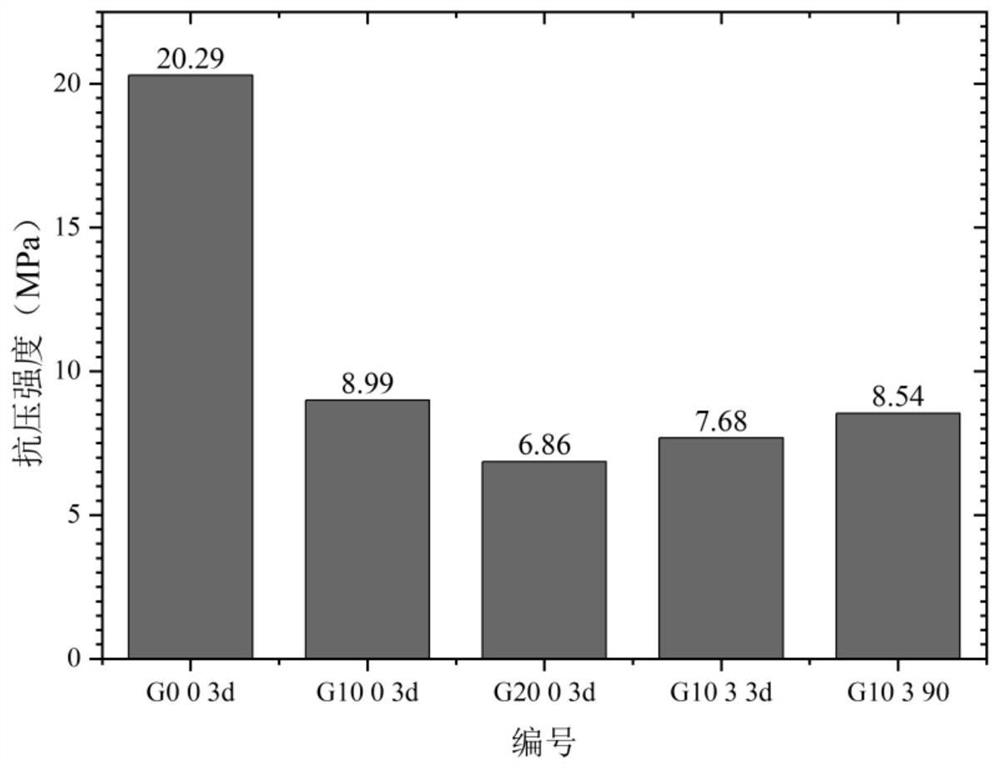

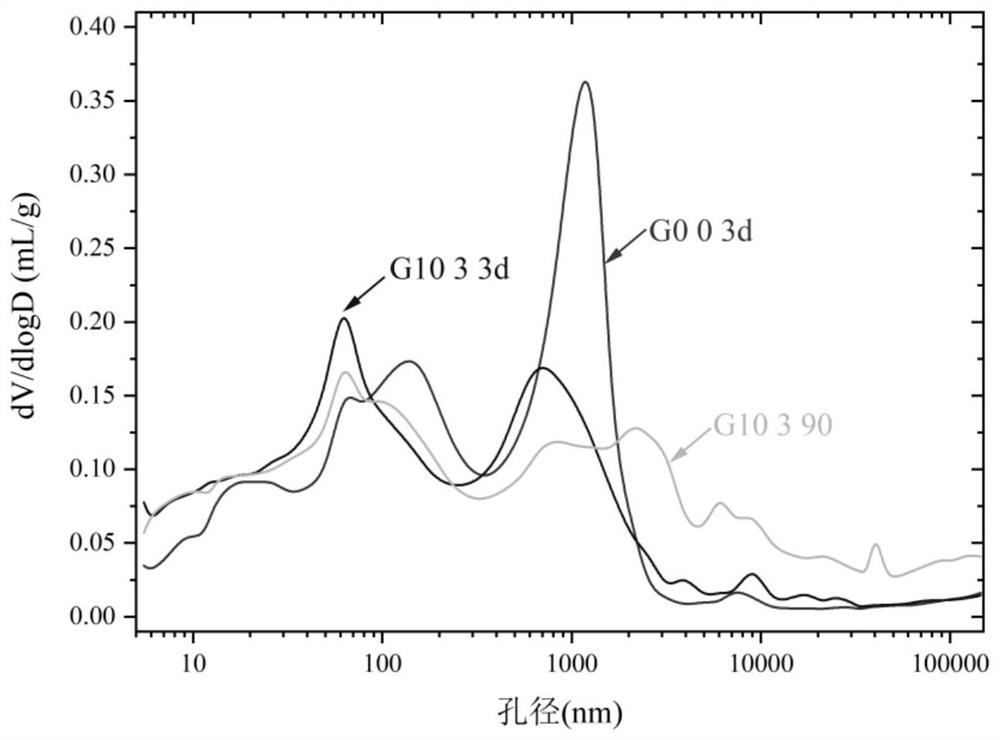

Temporary plugging type high-water-permeability porous cement-based material suitable for medium-low temperature geothermal wells and preparation method thereof

ActiveCN112408881AEffective blockingReduce intensityDrilling compositionCeramicwareTap waterWell drilling

The invention provides a temporary plugging type high-permeability porous cement-based material suitable for a medium-low temperature geothermal well and a preparation method thereof. The preparationmethod comprises the following steps: 1, drying and stirring raw materials at a low speed by utilizing a cement paste stirrer; 2, continuously starting the cement paste stirrer filled with the uniformly mixed raw materials, and adding tap water into the cement paste stirrer; 3, stirring the raw materials and water at a low speed, a stop speed and a high speed through a cement paste stirrer; 4, injecting the prepared slurry into a cubic triple test mold for maintenance; and 5, soaking the porous cement-based material in hot water to form the high-water-permeability porous cement-based material.The invention aims at vast medium and low temperature geothermal resources in China, wherein based on the temperature change rule in the development process, a porous material is formed after well drilling is finished while effective leaking stoppage is achieved and hole wall stability is guaranteed, the time cost of acidifying blockage removal measures or the risk of accidents caused by the factthat broken cement blocks deposit at the bottom of a well is reduced, and economic benefits are improved. Therefore, the development of geothermal energy in China is facilitated to a certain extent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Cellular cementitious composition

A cementitious slurry and method of making the cementitious slurry comprising mixing a pozzolanic component, a foaming agent of hypochlorite, and a hydroxide solution of soluble hydroxide dissolved in water, whereby the slurry is foamed and hardened into a cellular cementitious composition.

Owner:BIRCH GRANT DAVON

Porous cement concrete cement overlay having bond coat laying on bituminous surface and construction method therefor

ActiveCN101016720AImprove adaptabilityImprove deformation abilityIn situ pavingsCrushed stoneCellular cement

The invention relates to a porous cement concrete road which has an adhesive layer above a pitch face layer, wherein above the pitch face layer 3, the invention mixes polymer and stuff uniformly, to form polymer mixture, then lays uniform the mixture mechanically or hand-operated on the pitch face layer 3 to form an adhesive layer 2, then uses cement concrete mixer to mix uniformly cement, broken stone, sand and water to form porous cement concrete, mechanically lays porous cement concrete, flattens and presses the concrete mechanically or hand-operated to form a porous cement concrete face layer 1 to be adhered on the adhesive layer 2. The inventive cover structure has high strength, better anti-crack property, noise-reduction property or the like.

Owner:易志坚

Fireproofing heat-insulating door with porous cement structure and manufacturing method thereof

InactiveCN104453640ALight weightAvoid burn penetrationFireproof doorsLaminationFoaming agentFireproofing

The present invention provides a fireproofing heat-insulating door with a porous cement structure and a manufacturing method thereof. The fireproofing heat-insulating door mainly comprises a first plate layer, a second plate layer and a foaming cement layer. The foaming cement layer is arranged between the first plate layer and the second plate layer, and includes a plurality of chambers. A layer of film is formed on the surface of each chamber, and the interior of each chamber is filled with gas. The manufacturing method of the door includes: mixing a foaming agent, methylcellulose and water to obtain a foaming liquid; mixing raw cement material with water to obtain cement paste; mixing the foaming liquid and the cement paste to obtain foaming cement paste; pouring the foaming cement paste into the space between the first plate layer and the second plate layer; curing the foaming cement plate to form the foaming cement player; and fixing and combining the first plate layer, the second plate layer and the foaming cement layer. According to the present invention, the foaming cement layer includes a plurality of chambers, and all the chambers are filled with gas, so that the foaming cement layer has the light-weight, fireproofing and heat insulating effects, and can effectively blocking flames when a fire breaks out, thereby preventing the fire from spreading rapidly.

Owner:永安矿物科技实业有限公司

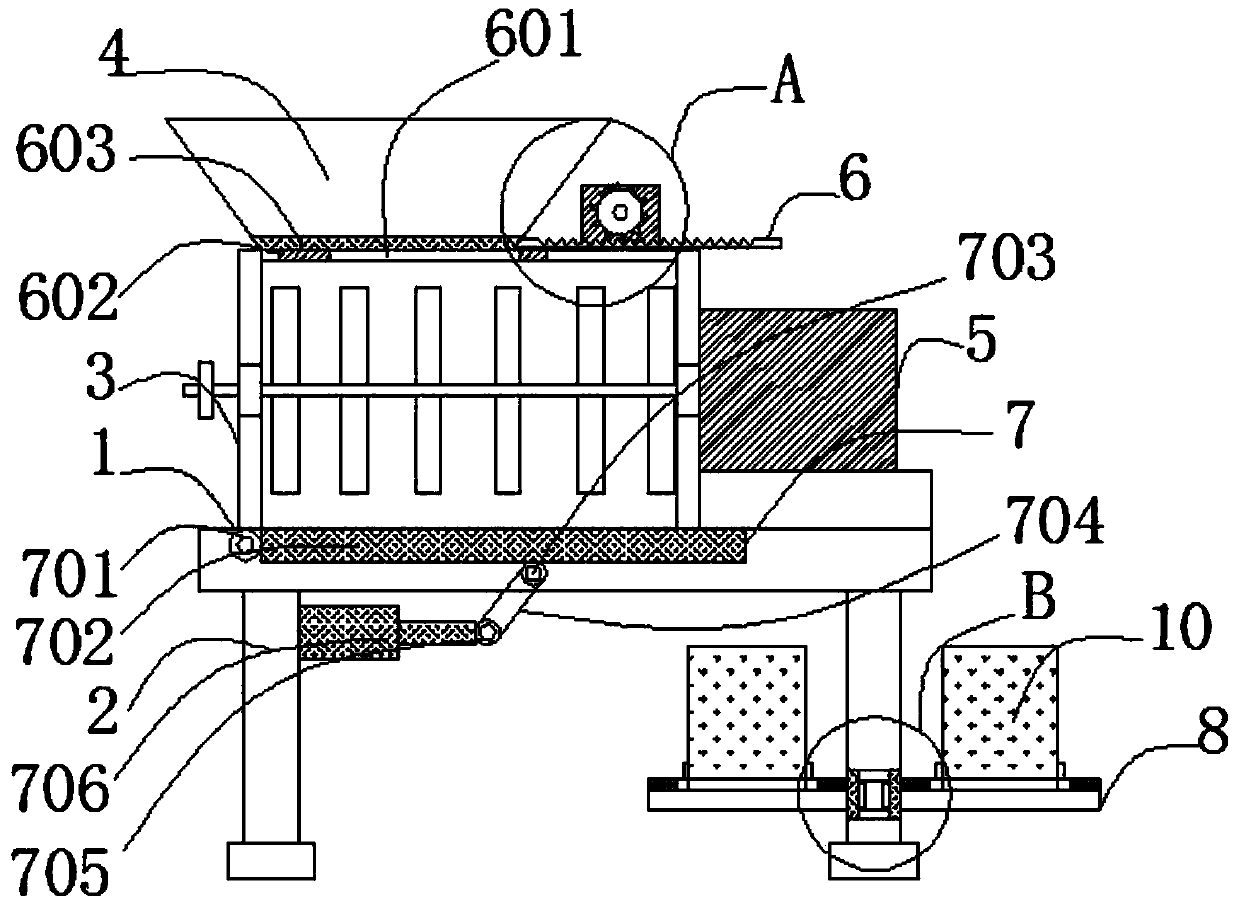

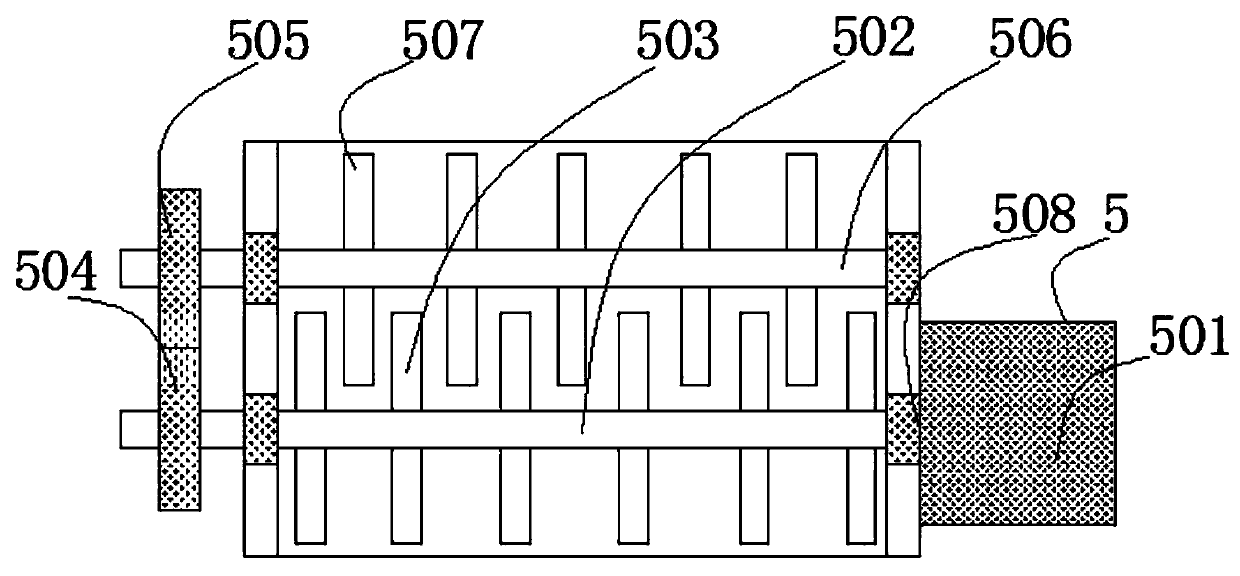

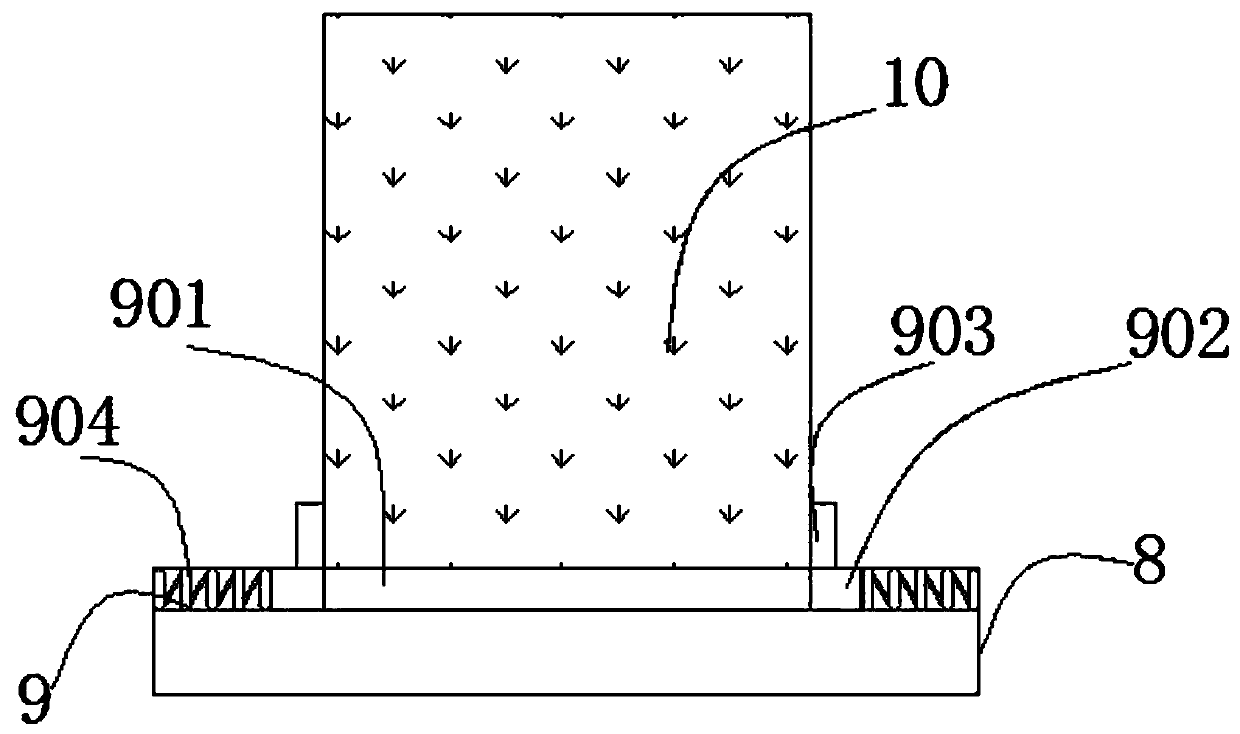

Preparation device and process of cement-based material with regularly arranged hole structure

InactiveCN110936493AEasy to prepareLow costDischarging apparatusCement mixing apparatusElectric machineryCellular cement

The invention relates to a preparation device and process of a cement-based material with a regularly arranged hole structure. The preparation device comprises a workbench, the bottom end of the workbench is fixedly connected with a bottom support, and a stirring box is fixedly mounted at the top end of the workbench. The top end of the stirring box is fixedly connected with a feeding funnel. According to the preparation device and process of the cement-based material, under the action of the stirring mechanism, after materials are discharged through the feeding funnel and enter the stirring box, an externa power source of a first driving motor can be started, a first stirring blade connected with a first connecting shaft rotates, meanwhile a first gear connected with the exterior of the first connecting shaft drives a second gear engaged with one side to rotate, and therefore a second connecting shaft drives a second stirring blade to rotate; and stirring is carried out in the mannerthat the first stirring blade and the second stirring blade intersect, the raw materials are better in effect and more even, the effect of the cement-based material in the use process is better, and holes of the porous cement-based material are evenly arranged.

Owner:JIANGXI UNIV OF TECH

Porous cement concrete cement overlay having bond coat laying on cement concrete and construction method therefor

ActiveCN101016719AImprove adaptabilityImprove deformation abilityIn situ pavingsCrushed stoneCellular cement

The invention relates to a porous cement concrete road which has an adhesive layer above the concrete, wherein above a cement concrete bottom layer 3, the invention mixes polymer and stuff uniformly, to form polymer mixture, then lays uniform the mixture mechanically or hand-operated on the bottom layer 3 to form an adhesive layer 2, then uses cement concrete mixer to mix uniformly cement, broken stone, sand and water to form porous cement concrete, mechanically lays porous cement concrete, flattens and presses the concrete mechanically or hand-operated to form a porous cement concrete face layer 1 to be adhered on the adhesive layer 2. The inventive cover structure has high strength, better anti-crack property, noise-reduction property or the like.

Owner:易志坚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com