Preparation device and process of cement-based material with regularly arranged hole structure

A technology for cement-based materials and preparation devices, applied in clay preparation devices, cement mixing devices, unloading devices, etc., can solve problems affecting actual preparation, etc., and achieve low cost, high mechanical strength and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

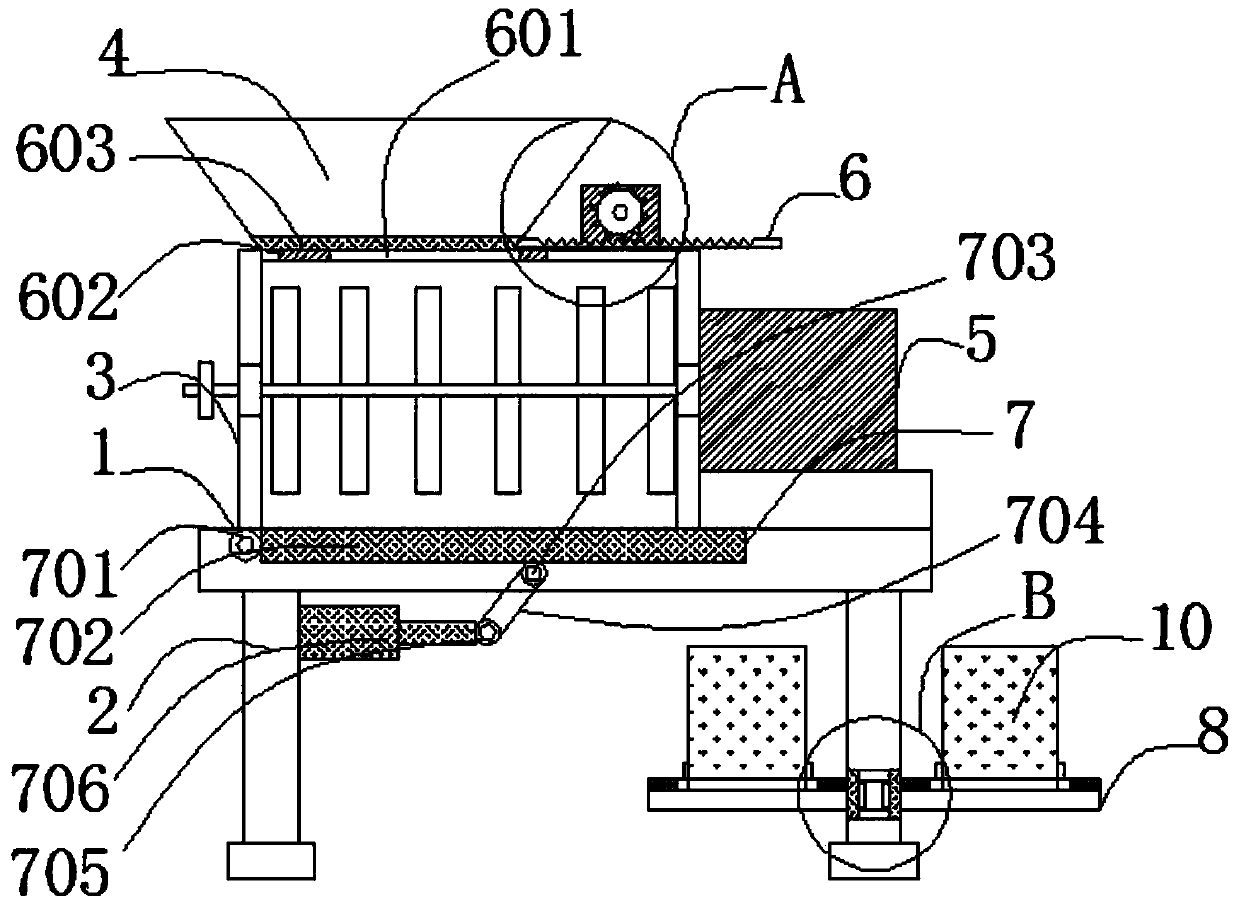

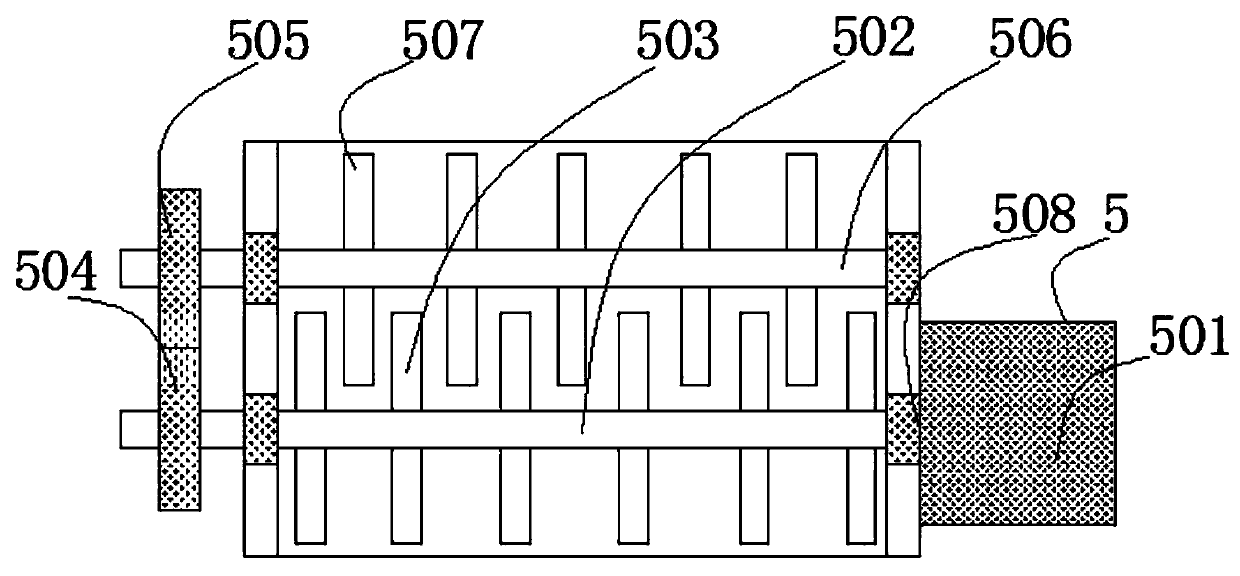

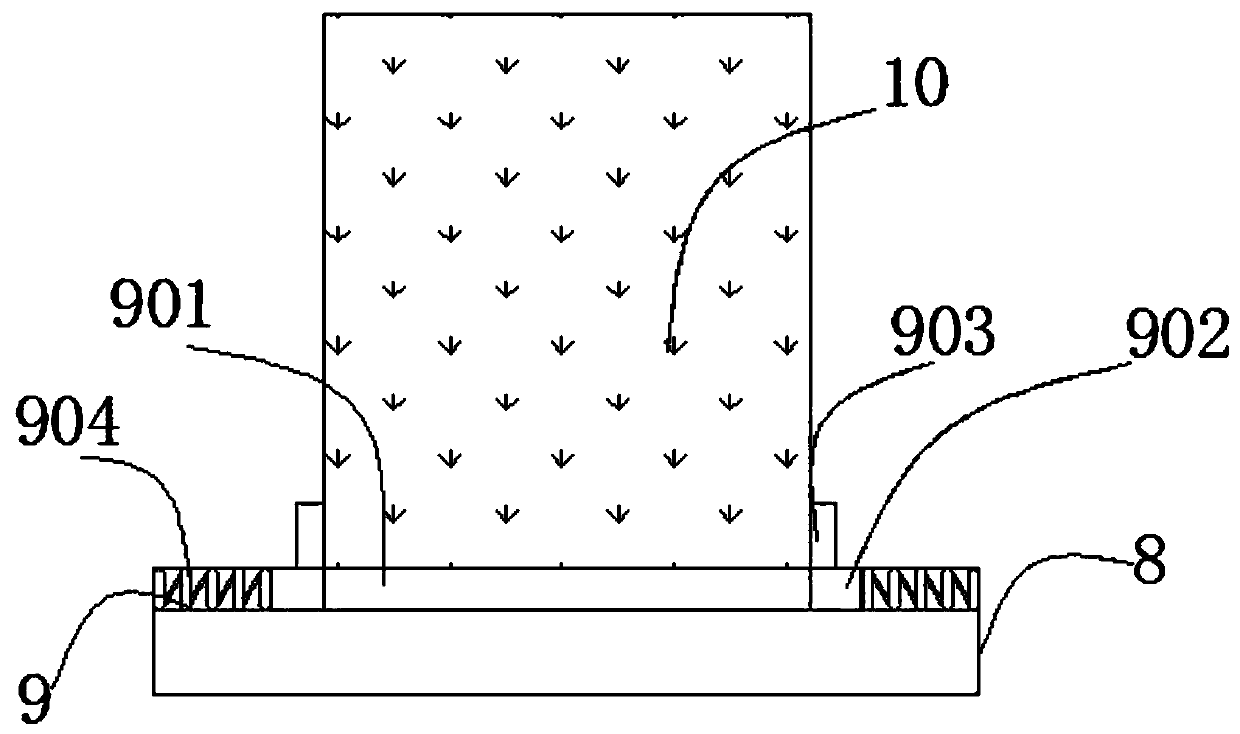

[0038] See Figure 1 to Figure 5 , The present invention provides a cement-based material preparation device with a regularly arranged hole structure, which includes a workbench 1, a bottom support 2, a mixing box 3, a feed hopper 4, a mixing mechanism 5, a first drive motor 501, a first Connecting shaft 502, first mixing blade 503, first gear 504, second gear 505, second connecting shaft 506, second mixing blade 507, bearing 508, controllable material mechanism 6, first chute 601, first sliding Block 602, partition 603, toothed rod 604, second slider 605, third gear 606, rotating shaft 607, second drive motor 608, discharge mechanism 7, first movable shaft 701, movable plate 702, second movable Shaft 703, movable rod 704, third movable shaft 705, electric push rod 706, bearing plate 8, clamping mechanism 9, second sliding groove 901, third sliding block 902, splint 903, spring 904, barrel 10, rotation The mechanism 11, the inner magnetic column 1101, the third sliding groove ...

Embodiment 2

[0052] The present invention also proposes a process for preparing cement-based materials with a regularly arranged hole structure, which mainly includes 3 steps:

[0053] Step 1: Pour the Portland cement, ordinary glass powder and tap water into the feeding funnel 4, so that the Portland cement, ordinary glass powder and tap water enter the mixing box 3.

[0054] The details of step 1 are as follows: stir and pour 100g of Portland cement, 10g of ordinary glass powder and 25g of tap water into the feed hopper 4, and then use the controllable feed mechanism 6 to determine the size of the feed inlet of the raw material into the mixing box 3 Adjustment is convenient to control the speed of raw materials entering the mixing box 3.

[0055] Step 2: The external power supply of the first driving motor 501 is activated to make the first stirring blade 503 and the second stirring blade 507 rotate to stir the raw materials put into the stirring box 3.

[0056] The detailed content of step 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com