Patents

Literature

363results about How to "Less water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

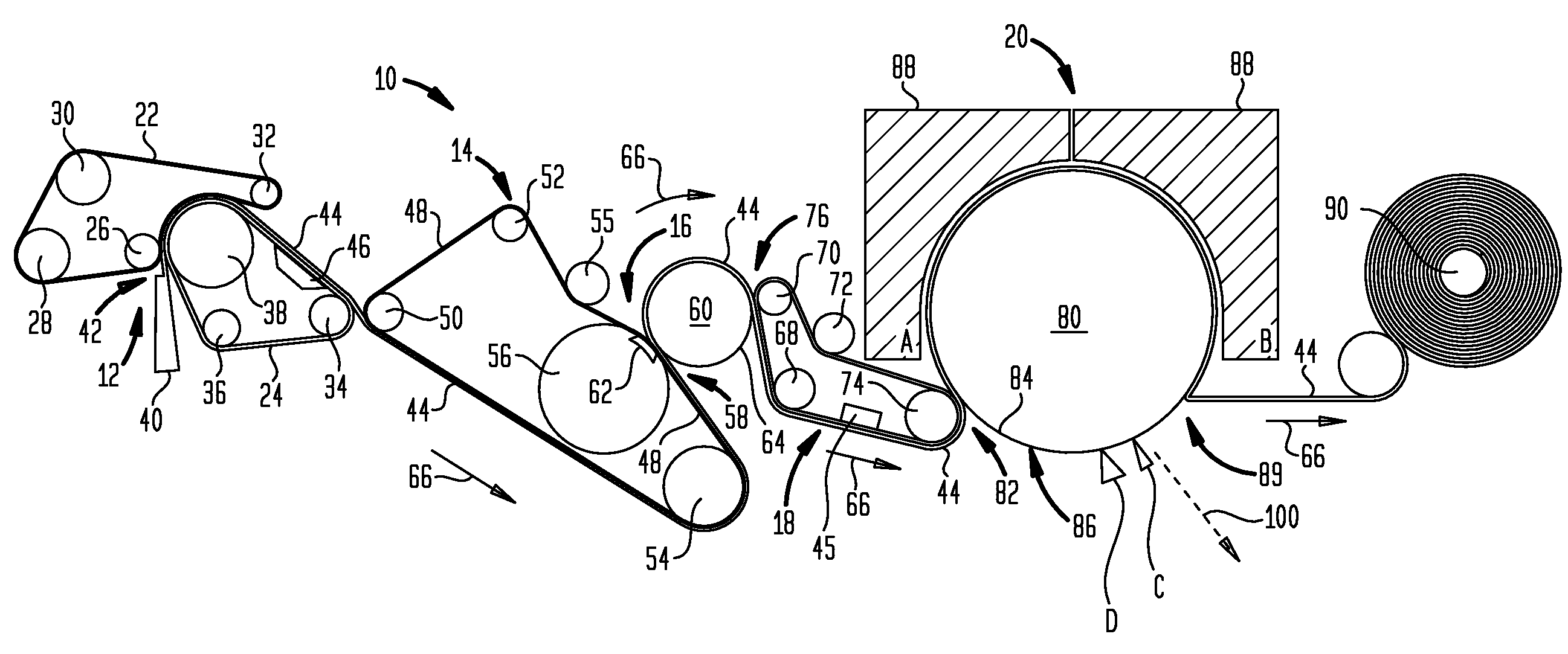

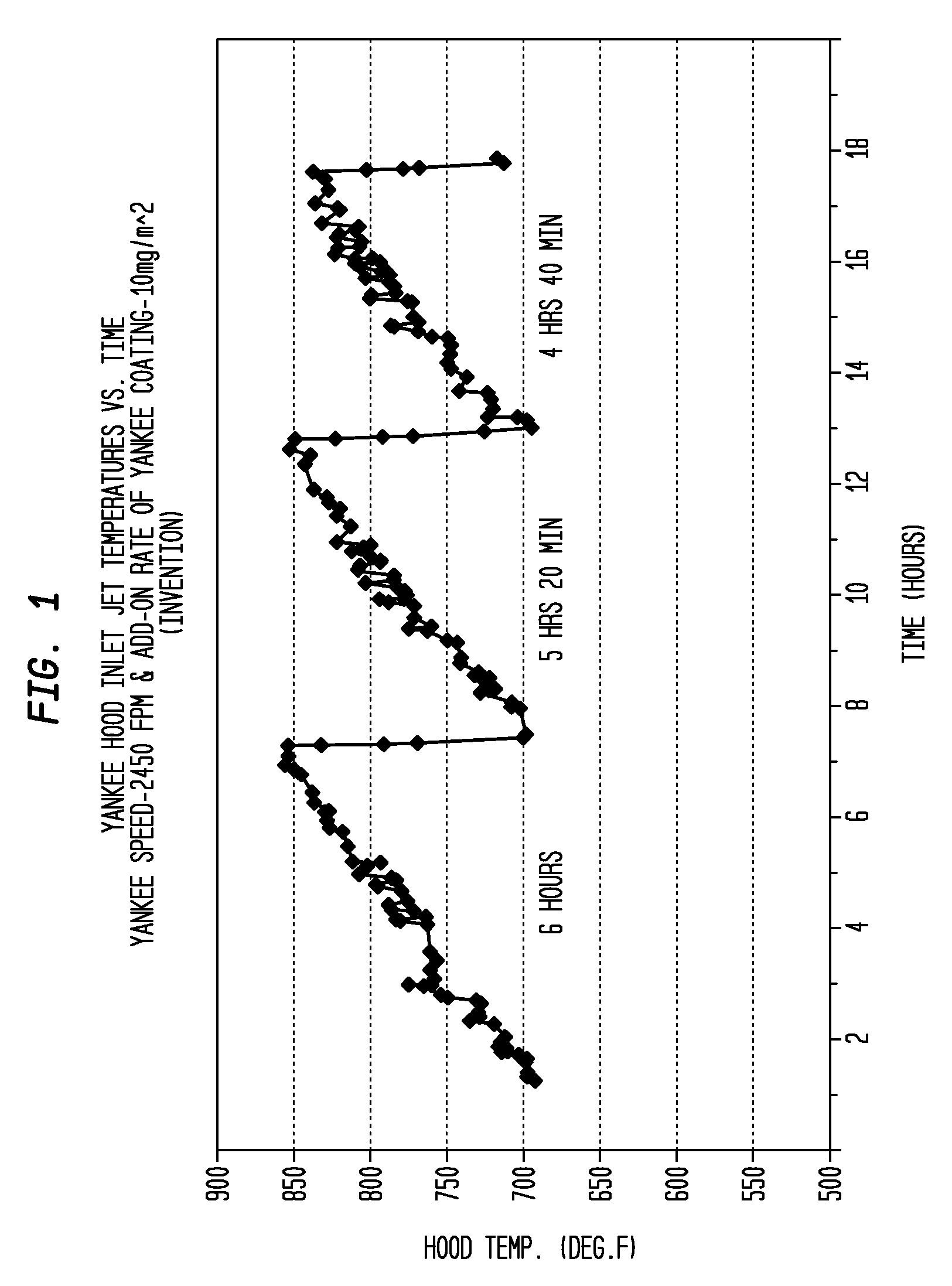

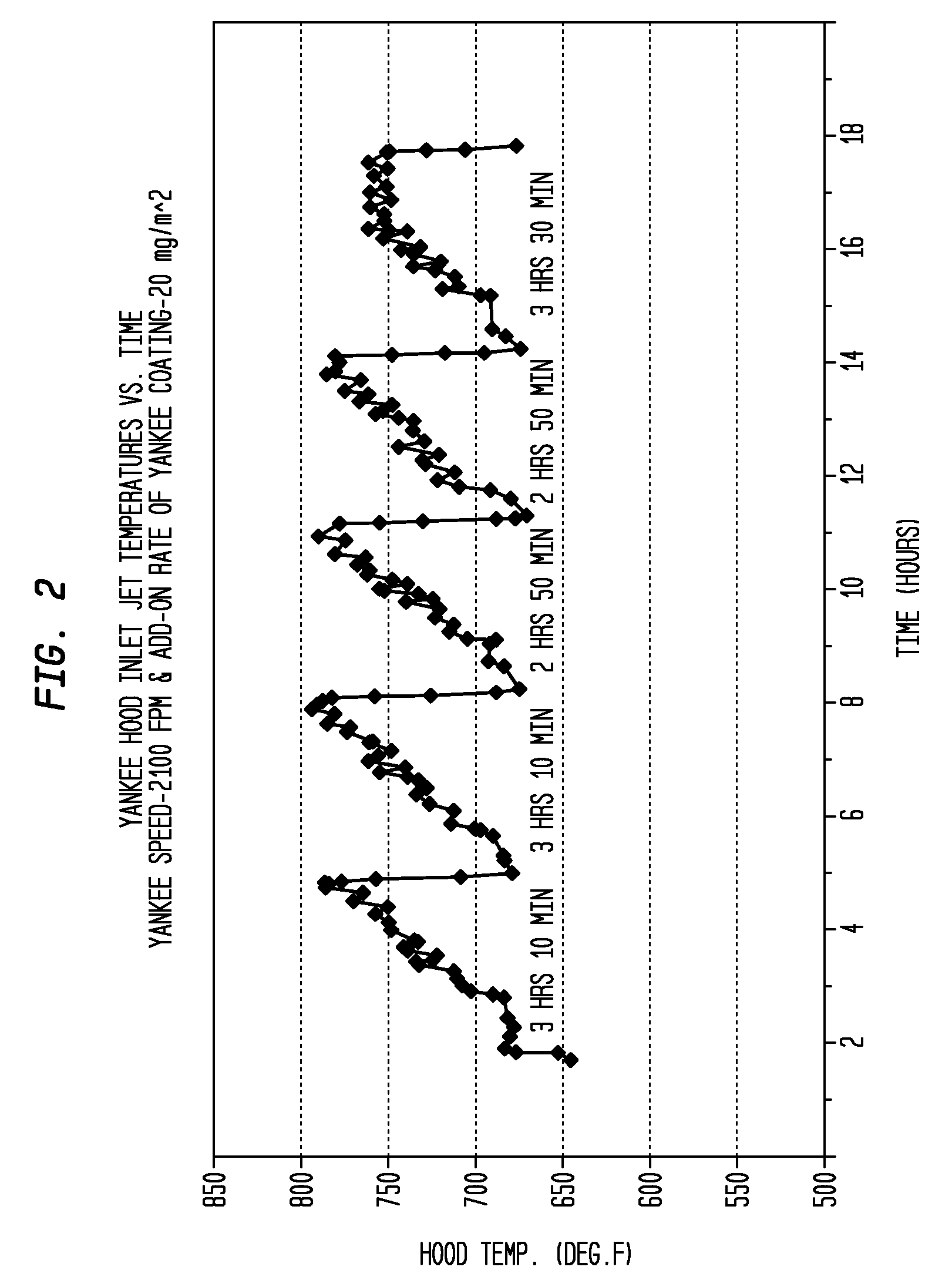

Fabric-crepe process with prolonged production cycle and improved drying

ActiveUS7608164B2Increases the amount of production available from a paper machineKeep dryNon-fibrous pulp additionDrying using combination processesAdhesiveCoating

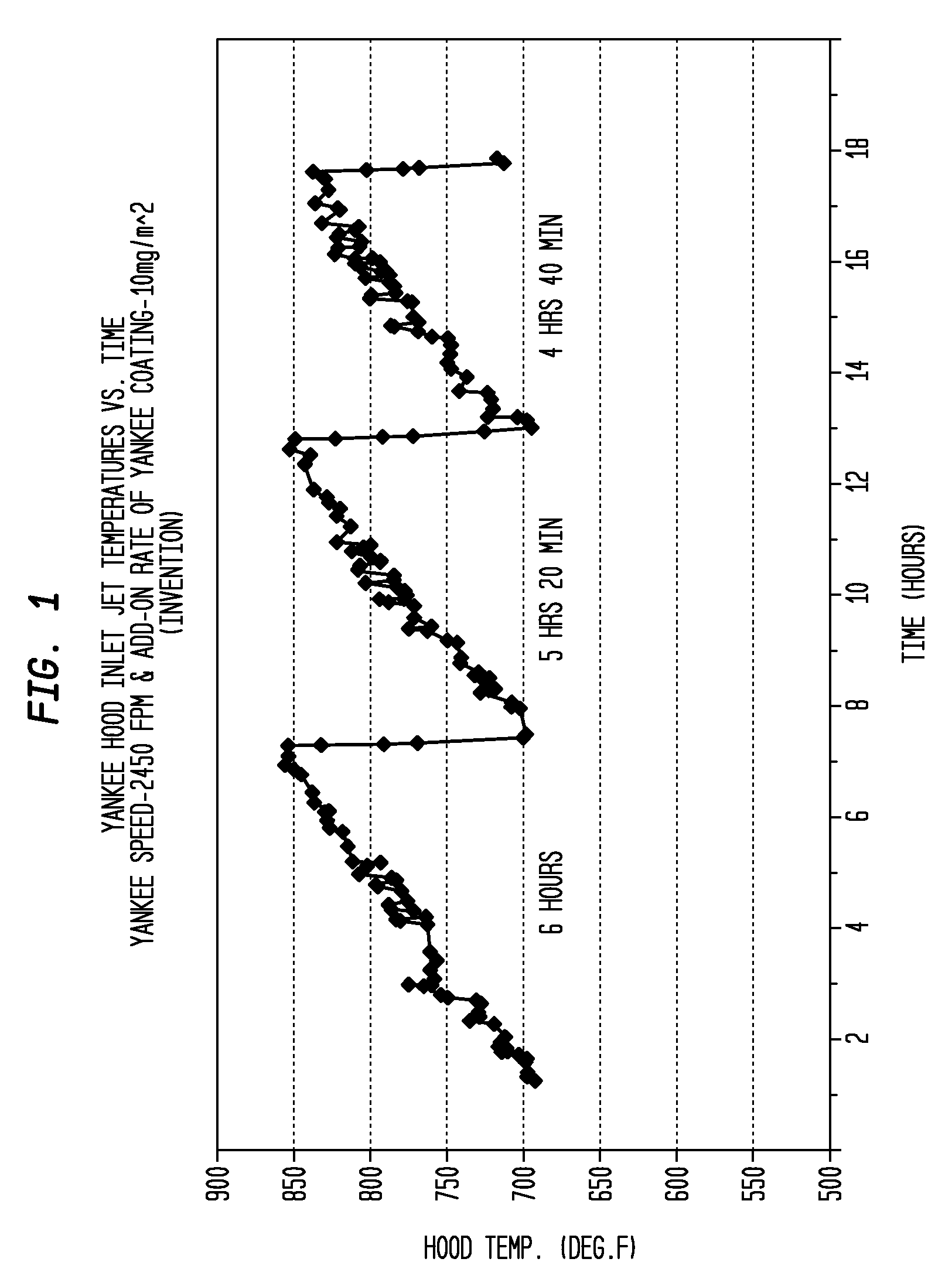

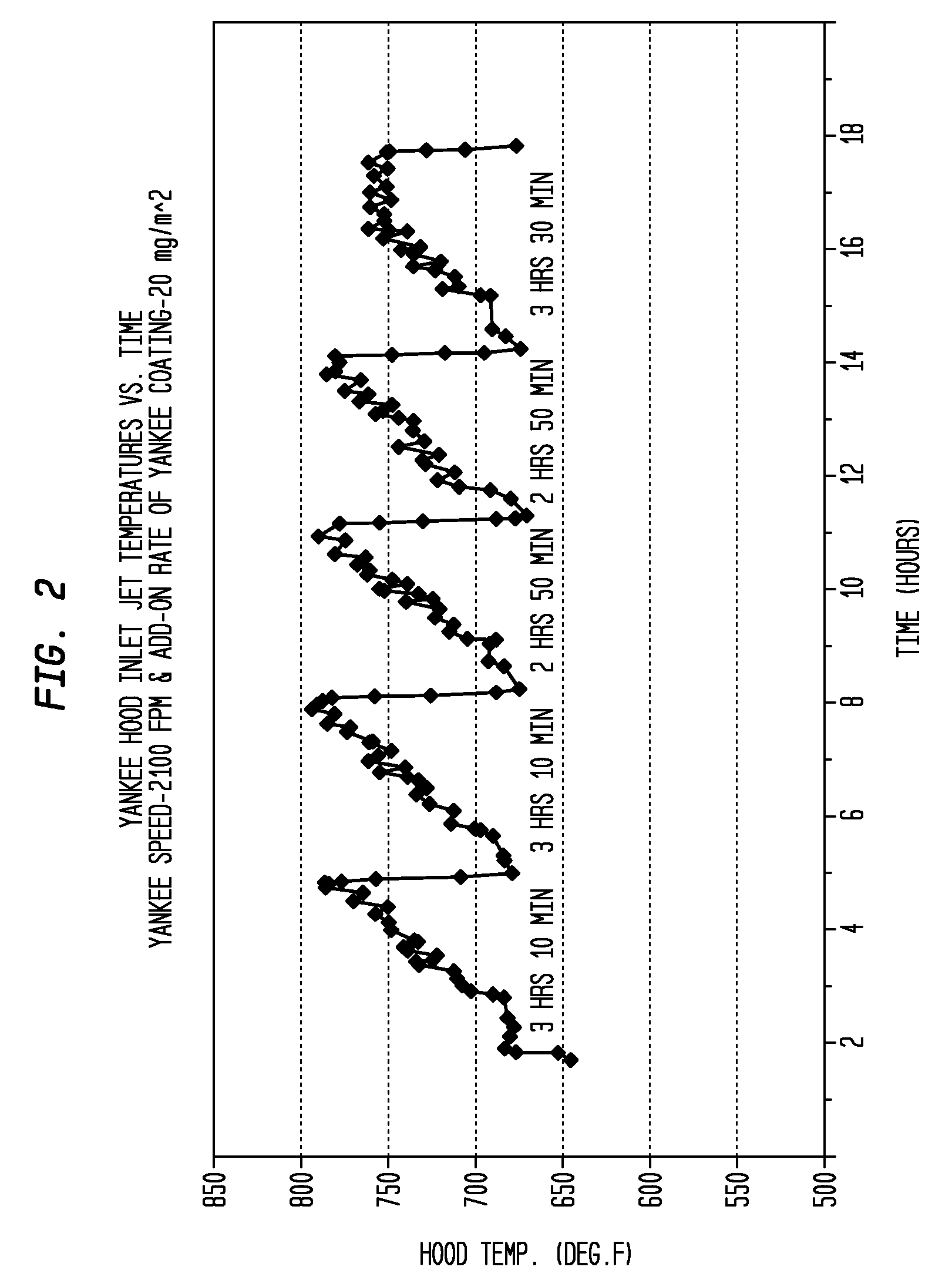

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Hydrogels for aqueous lithium/air battery cells

ActiveUS20090311567A1Impart conductivityHigh humidityFuel and primary cellsHybrid cell detailsHigh energyEnergy density

Li / air battery cells are configurable to achieve very high energy density. The cells include a protected a lithium metal or alloy anode and an aqueous catholyte in a cathode compartment. In addition to the aqueous catholyte, components of the cathode compartment include an air cathode (e.g., oxygen electrode) and a variety of other possible elements.

Owner:POLYPLUS BATTERY

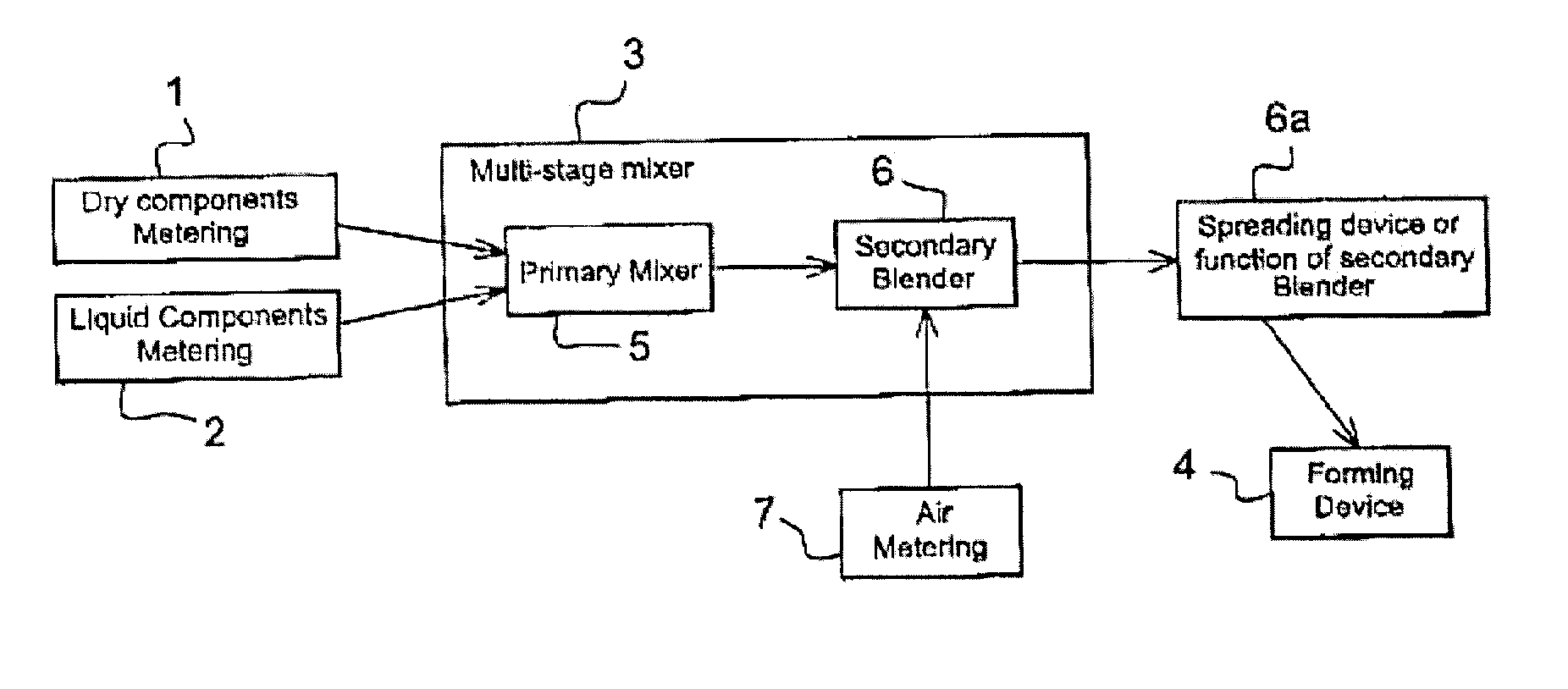

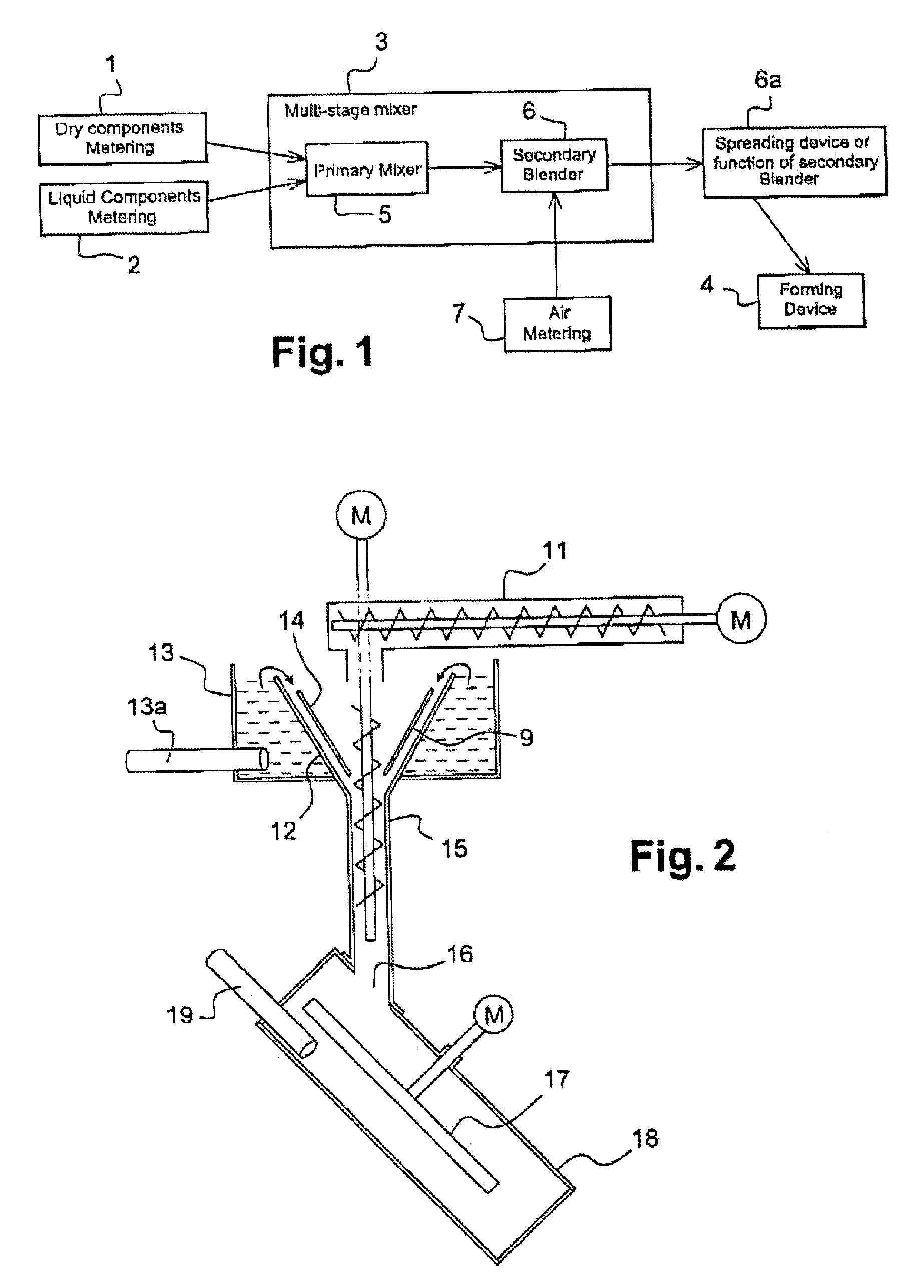

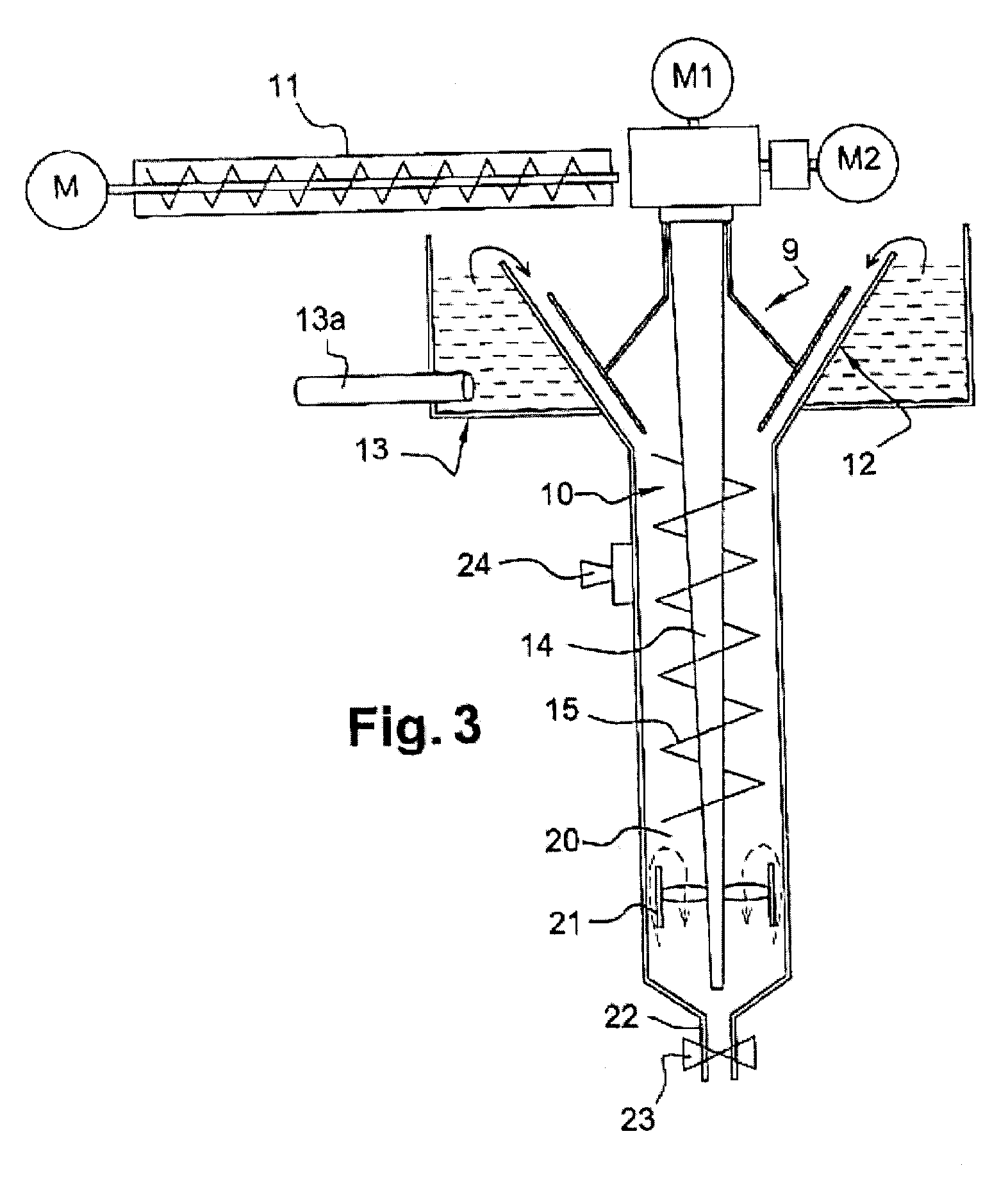

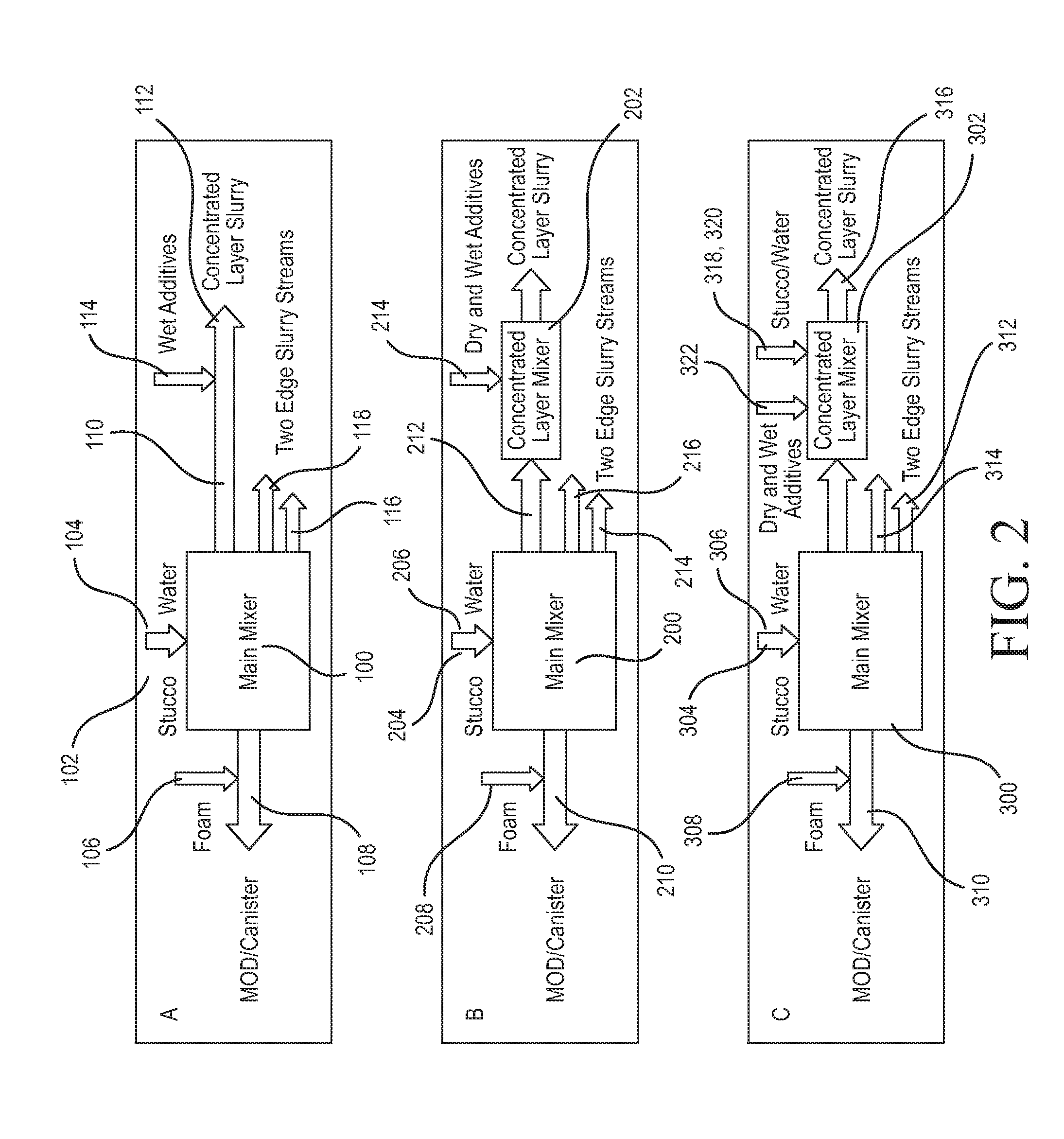

Process And Apparatus For Manufacturing Set Cellular Cement

ActiveUS20050219938A1Less foaming agentLess waterLiquid surface applicatorsTransportation and packagingFoaming agentSlurry

A process for manufacturing set cellular cement, including the steps of: (i) mixing cementitious material, water, foaming agent and optionally additives into a free flowing slurry having a slump of at least 100 mm; subsequently (ii) injecting and distributing air into the slurry of step (i) to form a cellular slurry; subsequently (iii) casting the cellular slurry of step (ii); and finally allowing the cellular slurry to set. And, an apparatus for carrying out the process.

Owner:ETEX BUILDING PERFORMANCE INT SAS

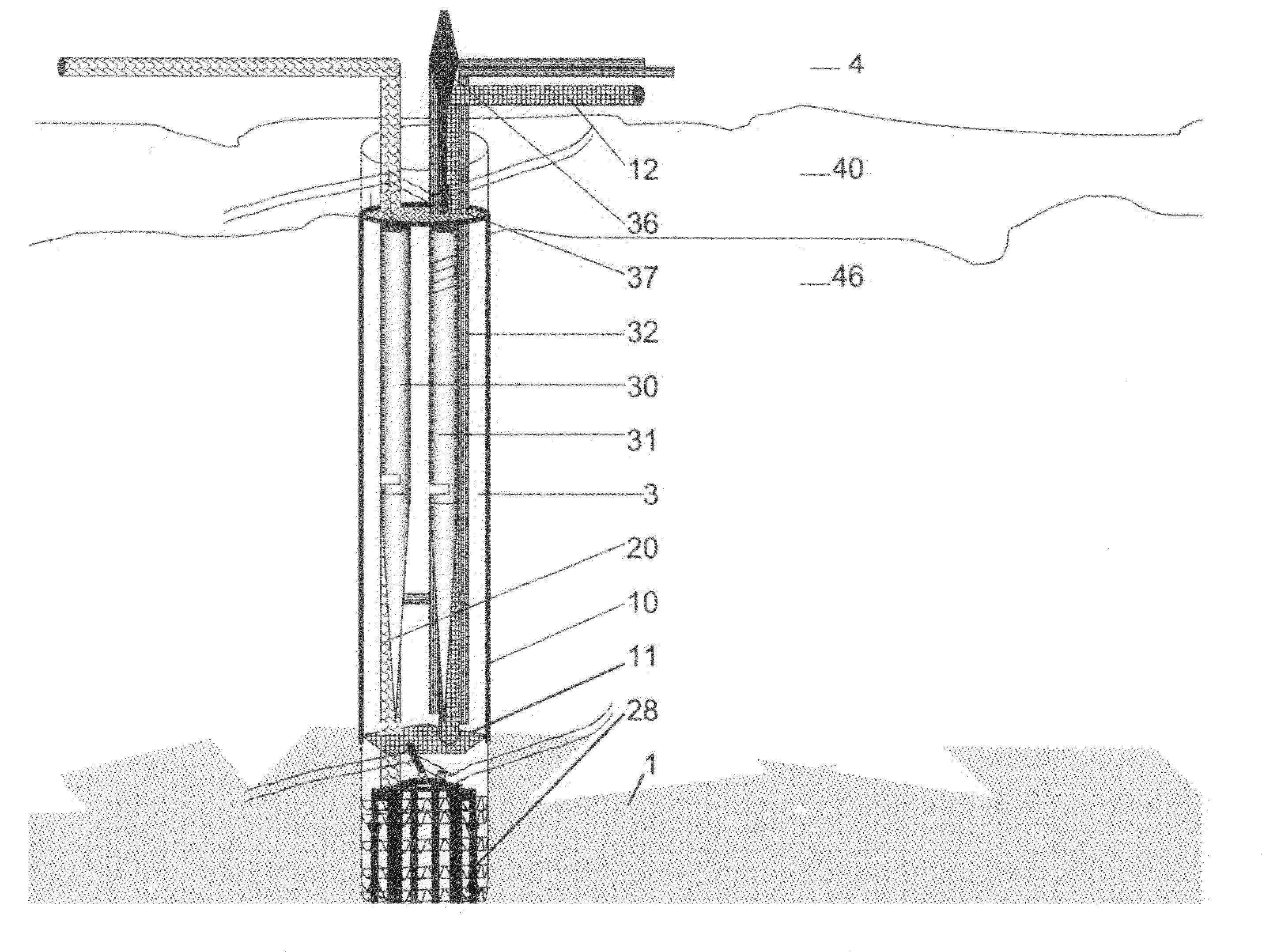

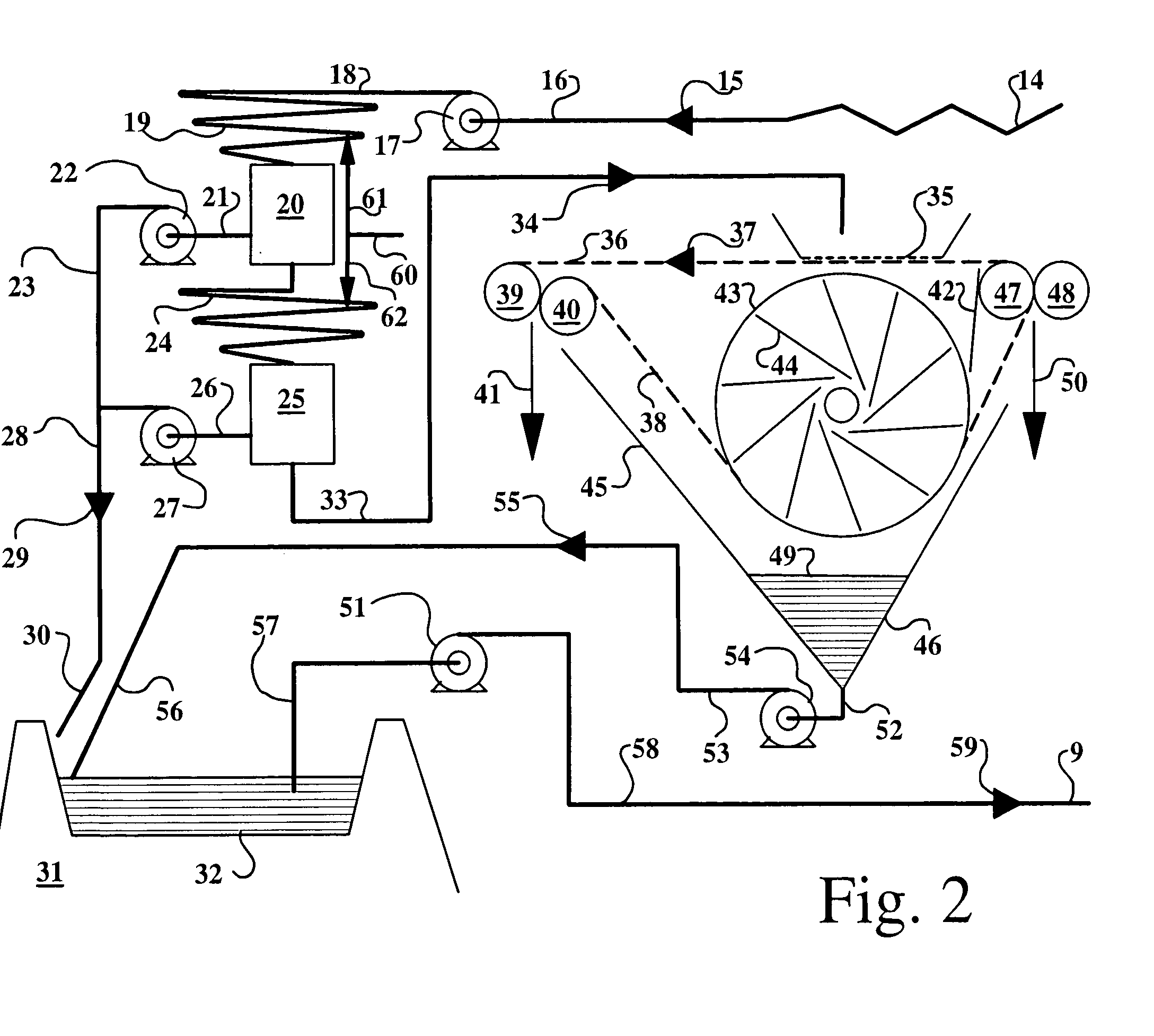

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

Adhesive composition of low molecular weight polyaminopolyamide-epichlorohydrin (PAE) resin and protein

InactiveUS20080050602A1Lower adhesive viscosityEasy to operateSynthetic resin layered productsPaper coatingEpichlorohydrinViscosity

The invention is directed to compositions containing polyamidoamine-epihalohydrin resins (PAE resins) of low molecular weight and a soy protein or lignin in which the weight ratio of protein or lignin to PAE is 100:0.1 to 0.1:100. The invention is also directed to the use of the compositions as adhesives for binding wood materials. The lower adhesive viscosity provides better handling properties, as well as allowing for less water in the adhesive formulation. The lower viscosity provides for both ease of handling of the adhesive material and the pot life if the adhesive formulation

Owner:HERCULES INC

Catholytes for aqueous lithium/air battery cells

ActiveUS20130122380A1Prevent drynessFacilitate numberFuel and primary cellsHybrid cell detailsHigh energyLithium metal

Owner:POLYPLUS BATTERY CO INC

Fabric-Crepe Process With Prolonged Production Cycle and Improved Drying

ActiveUS20080264589A1Improve productivityLower levelDrying using combination processesNon-fibrous pulp additionAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Ultra-low resistance acid-type microemulsion plugging removal and stimulation technology for low permeability oil well

ActiveCN101691839AGood dispersionStrong solubilizationFluid removalDrilling compositionSolubilityLiquid surfaces

The invention relates to a plugging removal and stimulation method for a low permeability oil well. The ultra-low resistance acid-type microemulsion is prepared by the following components: 10%-25% of acid, 5%-20% of oil, 5%-25% of alcohol, 0.5%-5% of surfactant, 0.5%-3% of inorganic salt, 0.3-1.5% of corrosion inhibitor and the balance water. The method comprises the following steps: injecting the prepared microemulsion in the oil bearing reservoir of the oil well, closing the oil well to react for 4-10h, cleaning the oil well, flowing the reaction exhaust liquor back, and completing the oilwell to perform normal production. The ultra-low resistance acid-type microemulsion used by the invention has thermodynamic stability, is a high dispersive acid-type microemulsion with good solubilization capacity, has ultra-low surface and interfacial tensions and good solubilization capacity and can increase the dispersive capacity of crude in water and the emulsification and peeling function to oil film; the microemulsion also has good dissolubility in water or oil and good fluidity due to high carrying capability and low seepage resistances so that the oil yield of the oil well is increased and the water content is reduced; the liquid surface tension in oil reservoir is reduced and the flow resistance of the crude is lowered so that the mining rate of the crude is increased and the plugging removal and stimulation of the oil well can be realized.

Owner:陕西中孚石油信息技术有限公司 +1

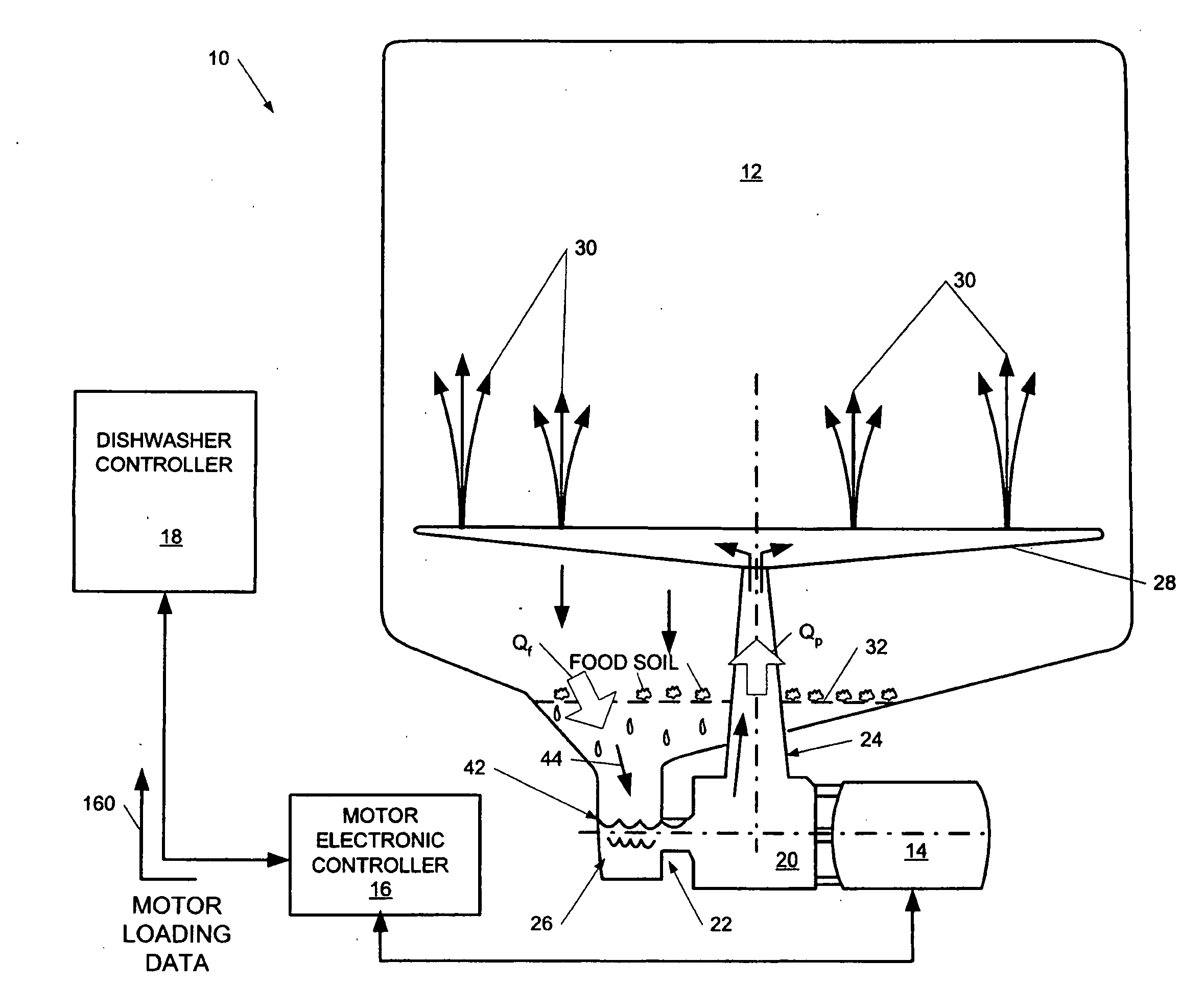

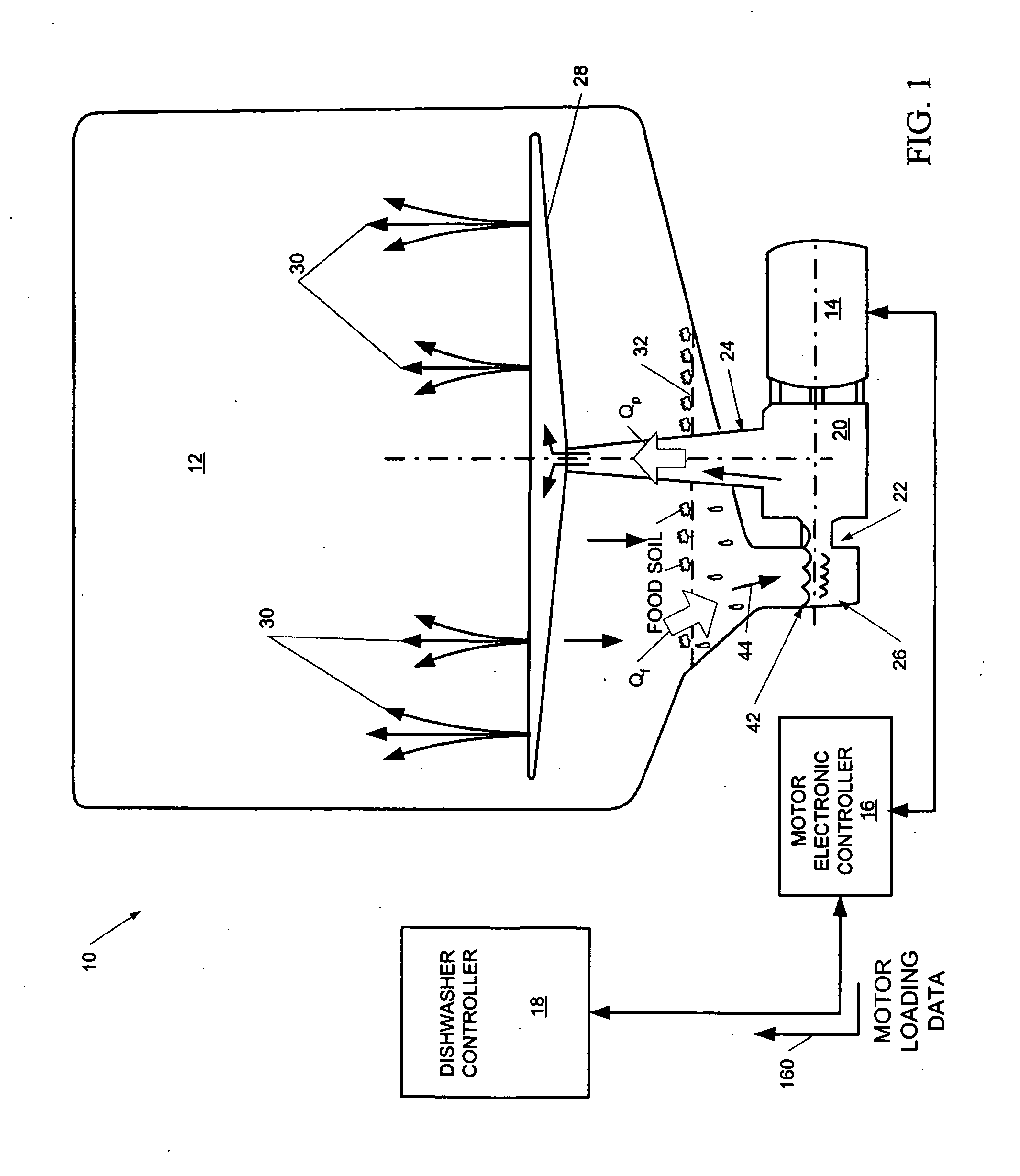

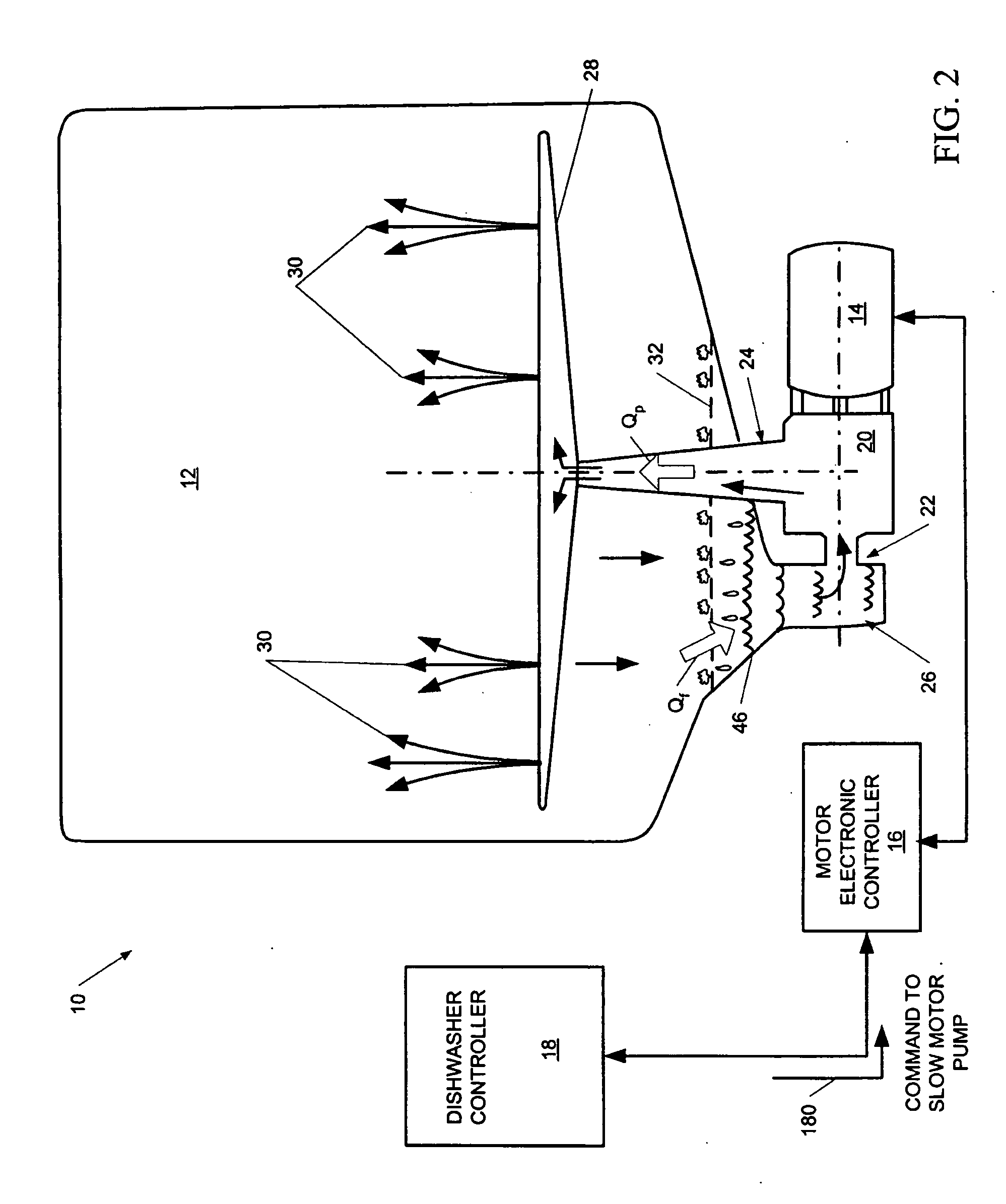

Dishwasher with controlled induction motor/pump

InactiveUS20060237044A1Easy to coverEasy to cleanAC motor controlAutomatic washing/rinsing machine detectionMotor speedMotor controller

A dishwasher having a speed-controlled induction motor coupled to a pump to drive the pump during dishwasher operation. A motor controller is connected to the induction motor to control the speed of operation of the induction motor. A dishwasher controller is connected to the motor controller for sending signals to, and receiving signals from, the motor controller during operation to control the motor speed. The flow rate of water through the pump discharge to a spray arm is controlled based on the phase of the wash cycle and the condition of the filter that blocks food debris from entering the sump. The motor speed is decreased to decrease the pump flow rate when the flow rate through the filter decreases in an early phase of the wash cycle. The motor speed is increased to increase the pump flow rate during later phases of the wash cycle. In steady state operation, the flow rate through the filter is matched to the flow rate through the pump discharge.

Owner:VIKING RANGE

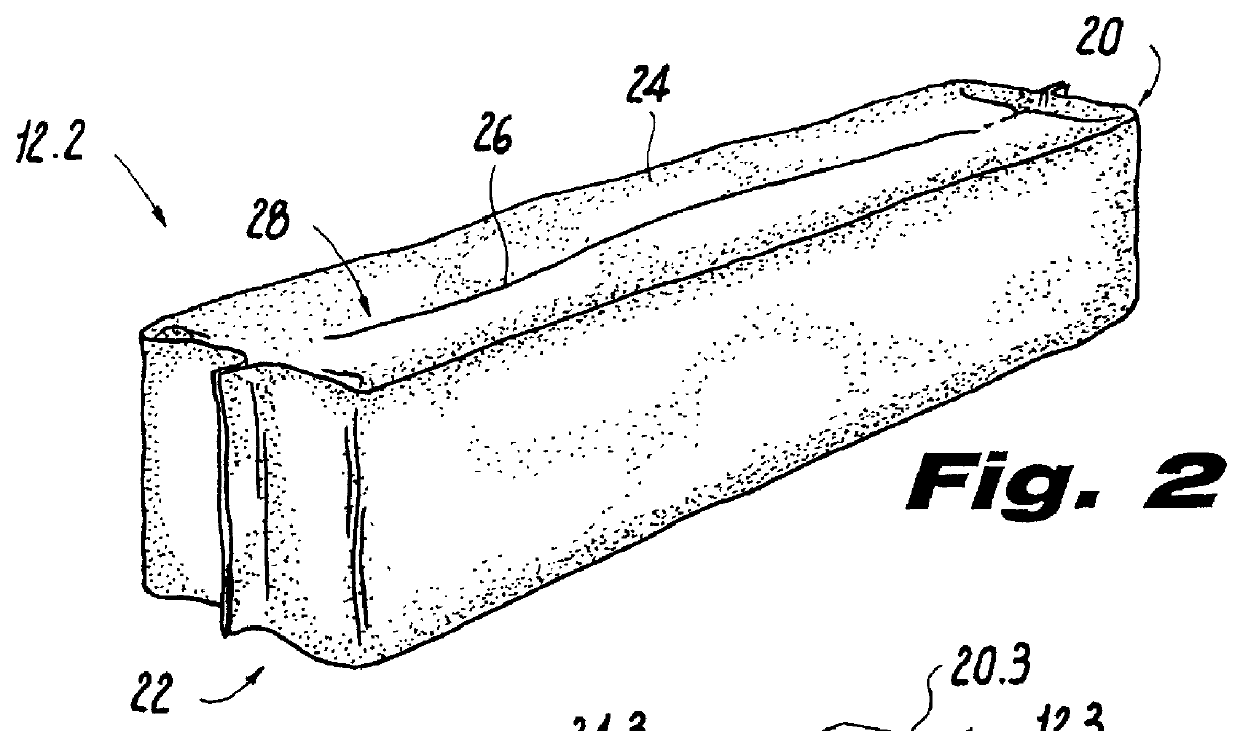

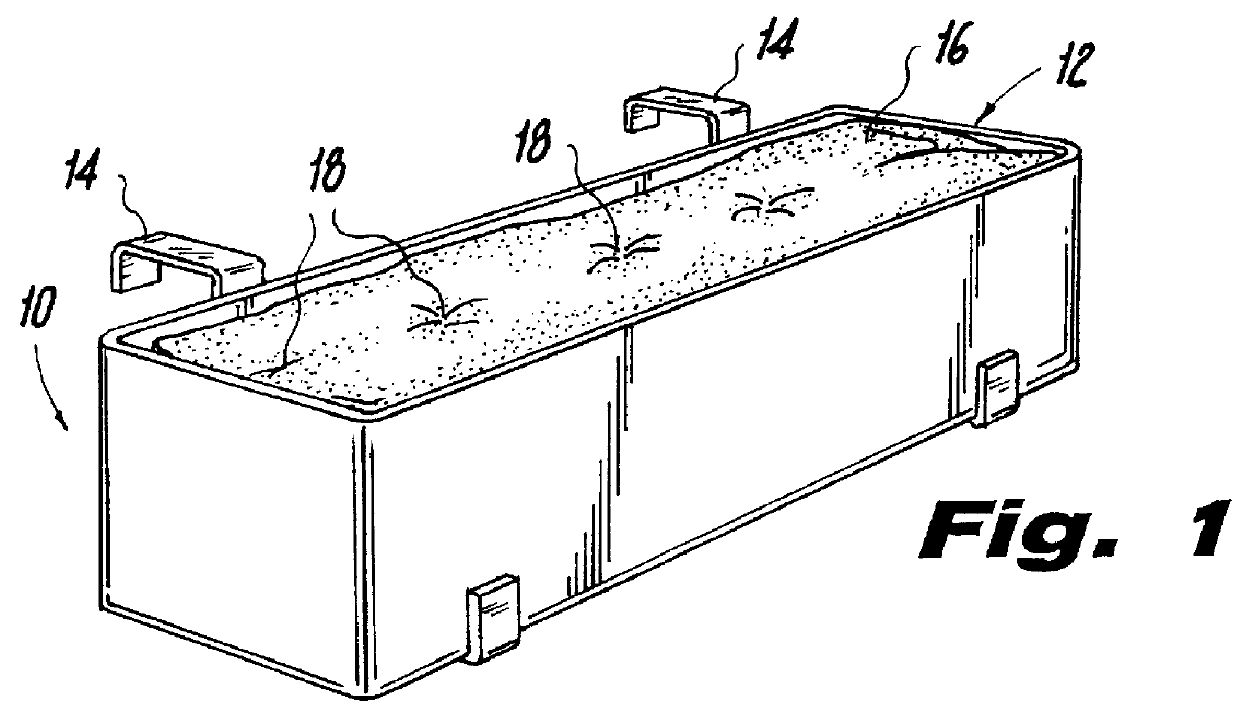

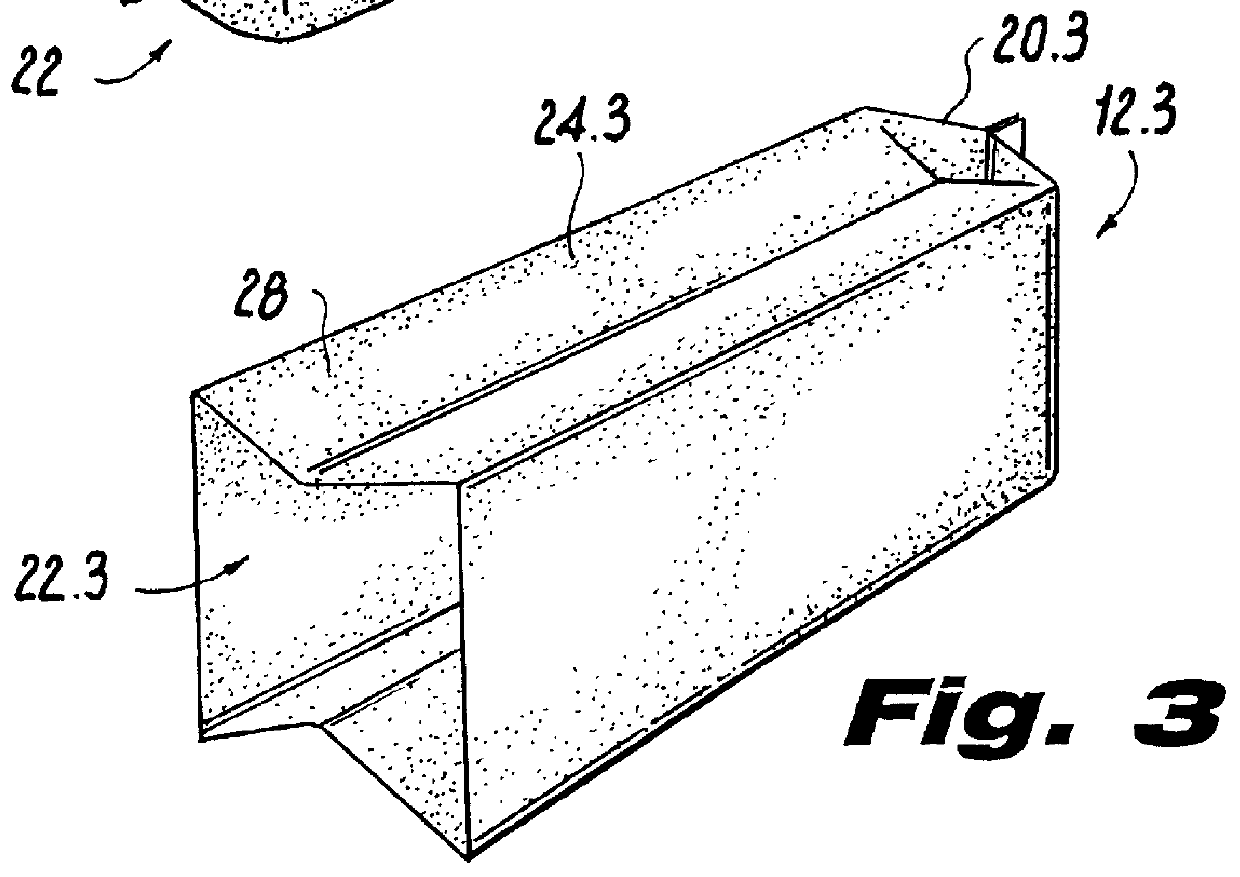

Plant growth bag for use in a flower box

InactiveUS6016628ARaise the possibilityPrevents rapid drying outCultivating equipmentsReceptacle cultivationGrowth plantPlant growth

PCT No. PCT / DE96 / 00133 Sec. 371 Date Oct. 27, 1997 Sec. 102(e) Date Oct. 27, 1997 PCT Filed Jan. 31, 1996 PCT Pub. No. WO96 / 25844 PCT Pub. Date Aug. 29, 1996A planting substrate in the form of a soil-like mixture for flower boxes (10) is characterized in that the planting substrate is available filled in a bag (12), the bag skin of which consists of a plastic foil which has poor transparency and is water-permeable from the outside, and the shape of the bag (12) is or can be adapted to the inner cross-section of the flower box (10) in such a manner that the bag (12) has room in the flower box (10) in terms of size.

Owner:LOTHAR DEDDEN +1

Composite blocking remover and method for removing blockage of compact sandstone reservoir pressing crack commissioning horizontal well in composite manner

ActiveCN103740353AGood retarding performanceDecontamination of reservoirCleaning apparatusDrilling compositionSolid phasesOrganic acid

The invention discloses a composite blocking remover and a method for removing blockage of a compact sandstone reservoir pressing crack commissioning horizontal well in a composite manner. The composite blocking remover comprises a preposition liquid, a main treating fluid, an active blocking remover and a subsequent fluid. The preposition liquid is composed of organic acid, inorganic acid, a stabilizer, an oxidizing agent, a chelating agent, a corrosion inhibitor, polyol ether and water. The main treating fluid is composed of organic acid, inorganic acid, the stabilizer, the oxidizing agent, a fluorine carbon surfactant and water. The active blocking remover is composed of a zwitterionic surfactant, the stabilizer and water. The subsequent fluid is water. The composite blocking remover can remove the blockage of routine colloid, asphalt mass and inorganic solid phase particles, and can remove the damage of water blocking and crude oil emulsification by pertinency, and has the advantages of good slow performance, effectively preventing secondary deposition pollution such as the iron ion deposition and acid sludge generation, the horizontal well near-well and deep reservoir pollution can be effectively released, the oil well production power is recovered, and the recovery efficiency can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

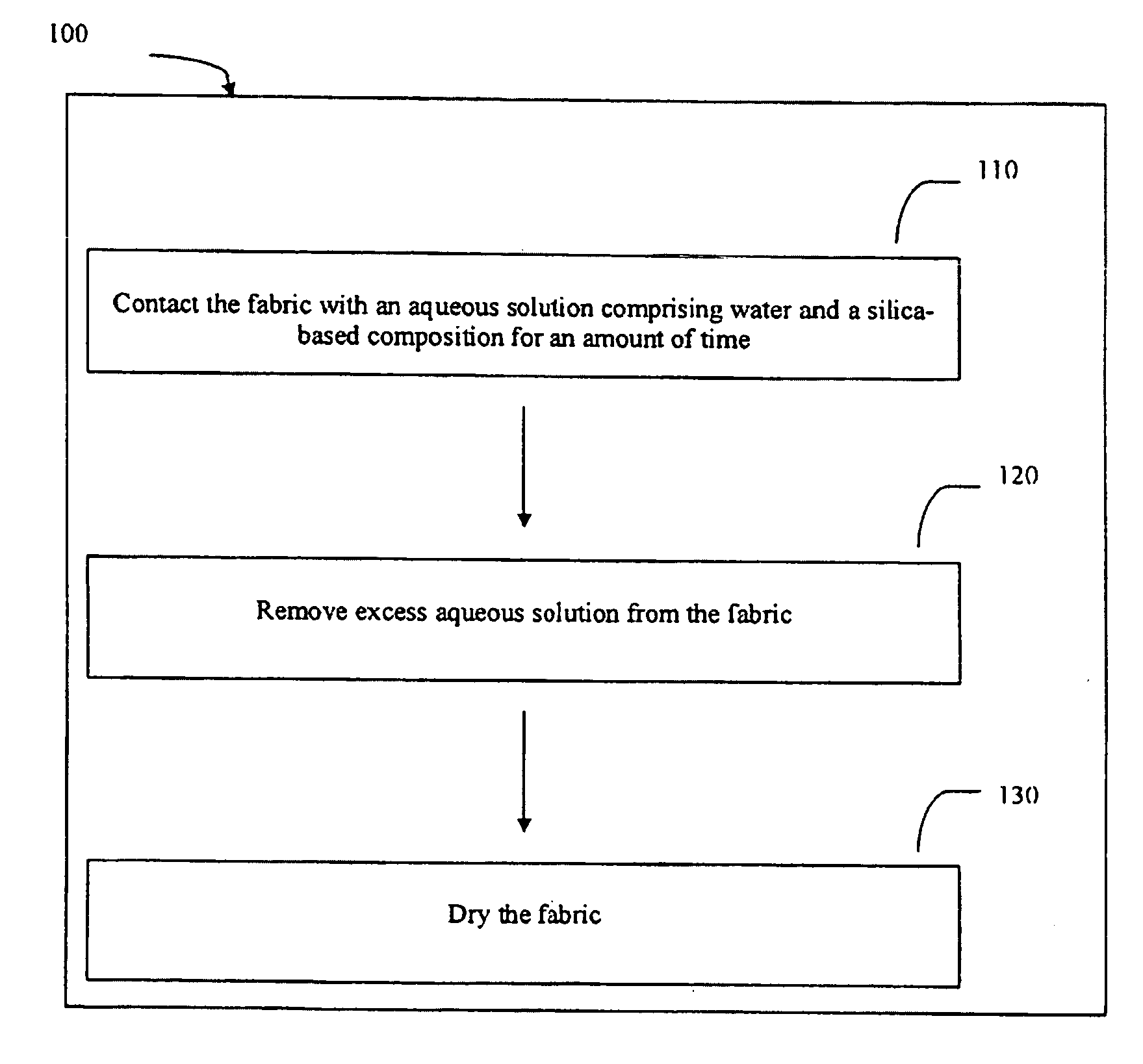

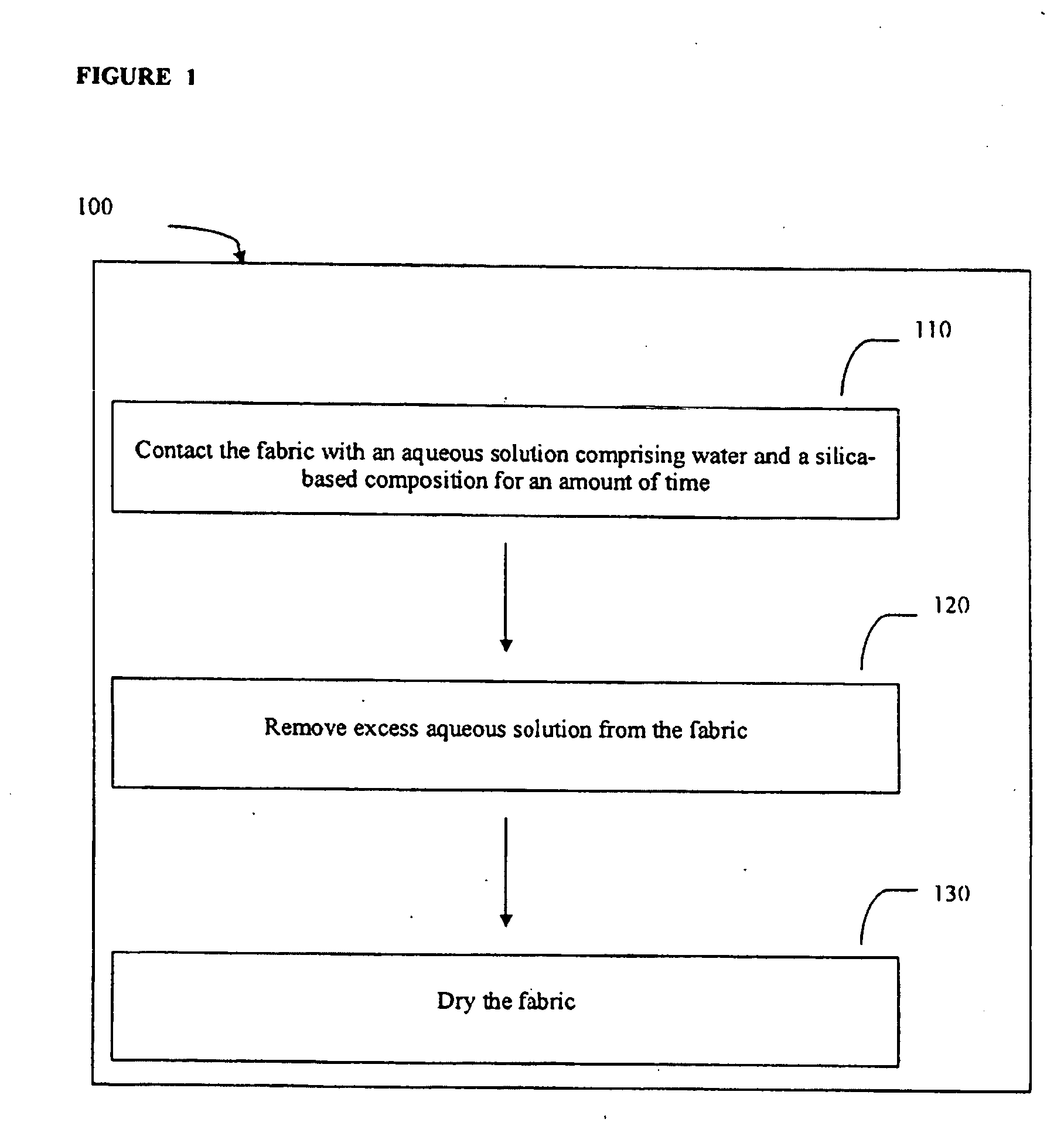

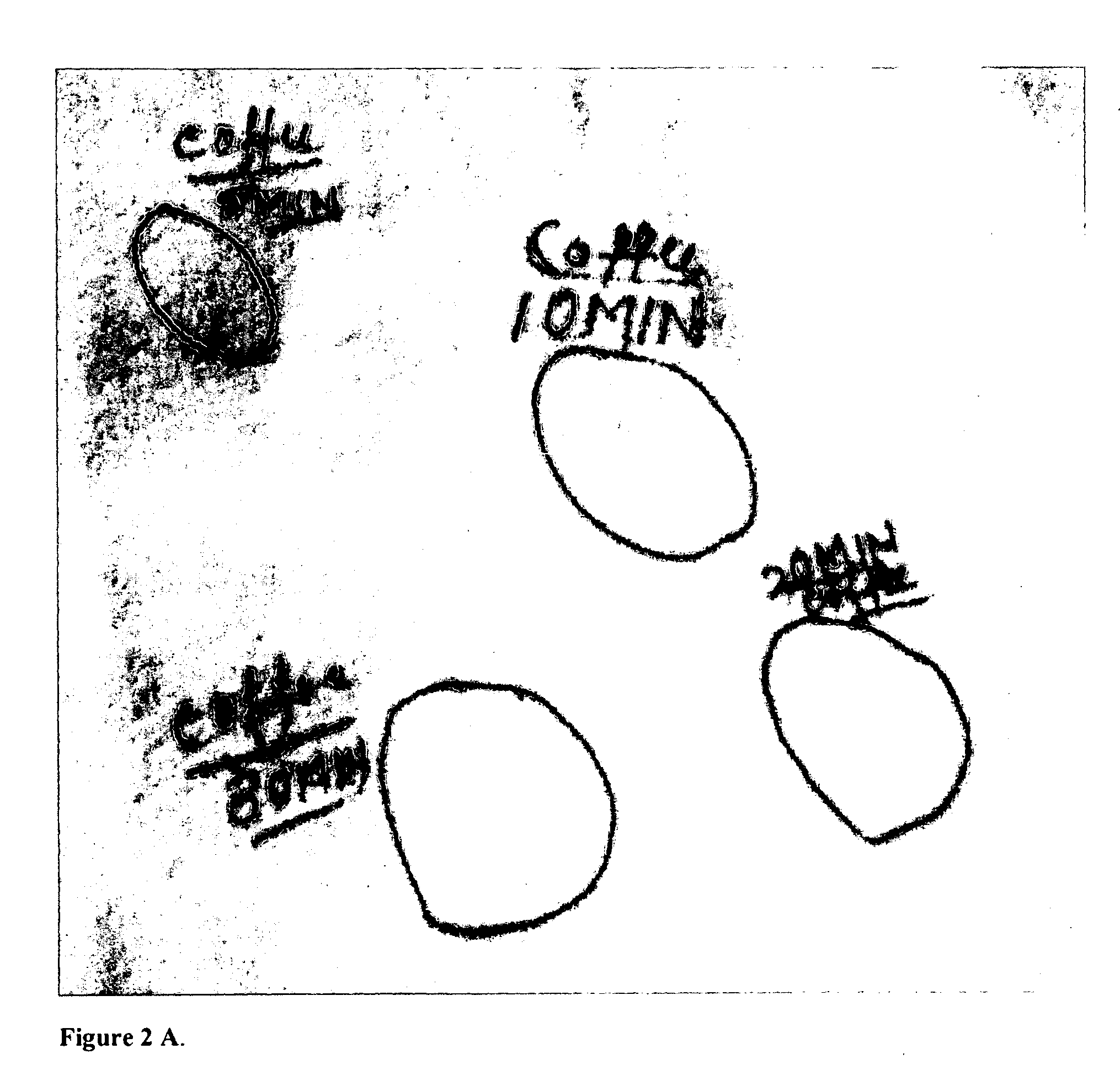

Methods and compositions for improving the surface properties of fabrics, garments, textiles and other substrates

InactiveUS20090206296A1Optical property easeImprove smoothnessDetergent mixture composition preparationDetergent solventsSilanesSolvent

The present invention discloses the use of organosilanes as a semi-permanent surface treatment for fabrics, textiles, and other materials. The present invention discloses a composition for this treatment comprising an organosilane, a catalyst, water, and a solvent. The present invention further discloses methods for improving water repellency and for providing other enhanced benefits to a substrate wherein the methods include contacting the substrate with a solution of water and a silane-based composition, removing excess solution from the substrate, and drying the substrate.

Owner:SOUTHERN ILLINOIS UNIVERSITY

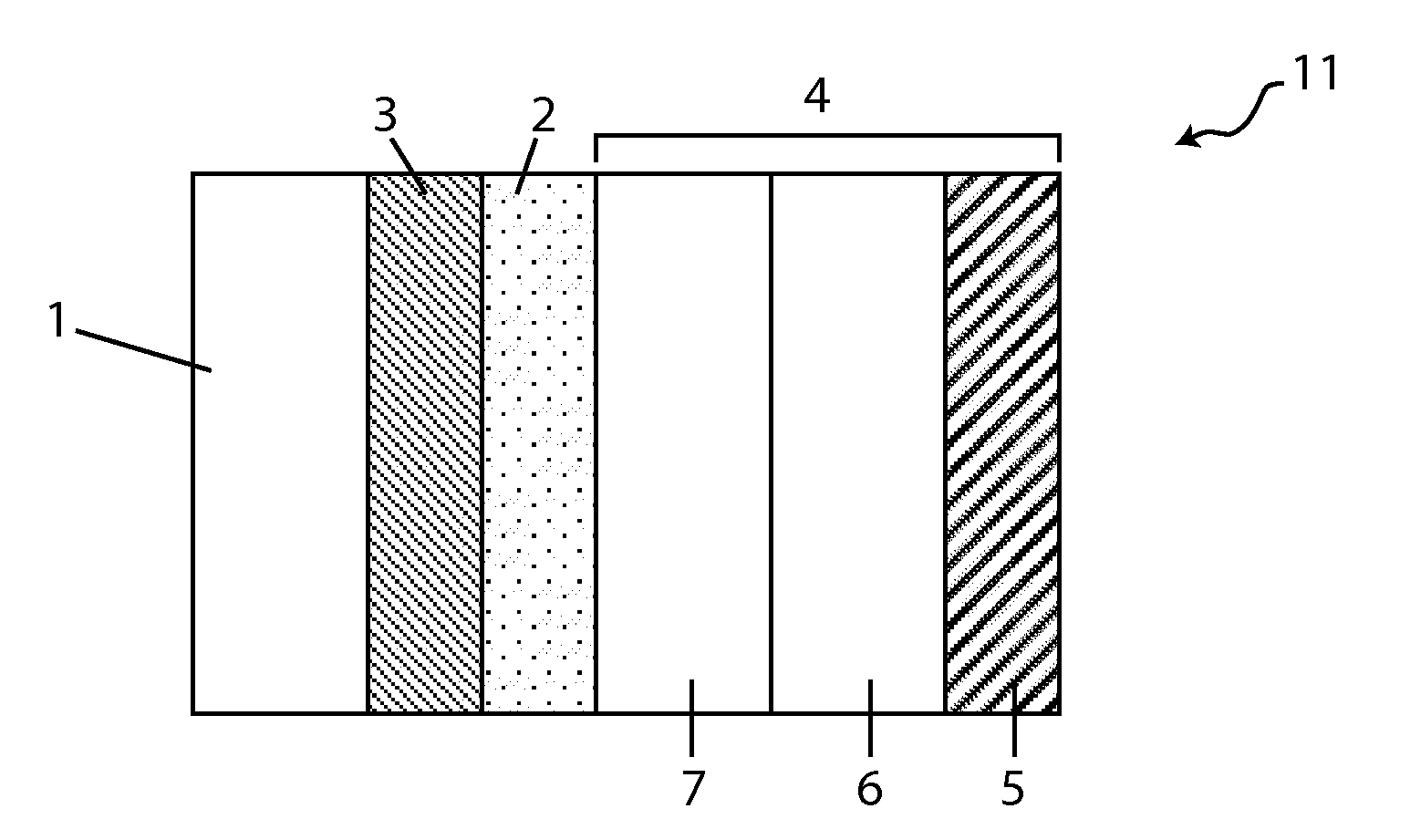

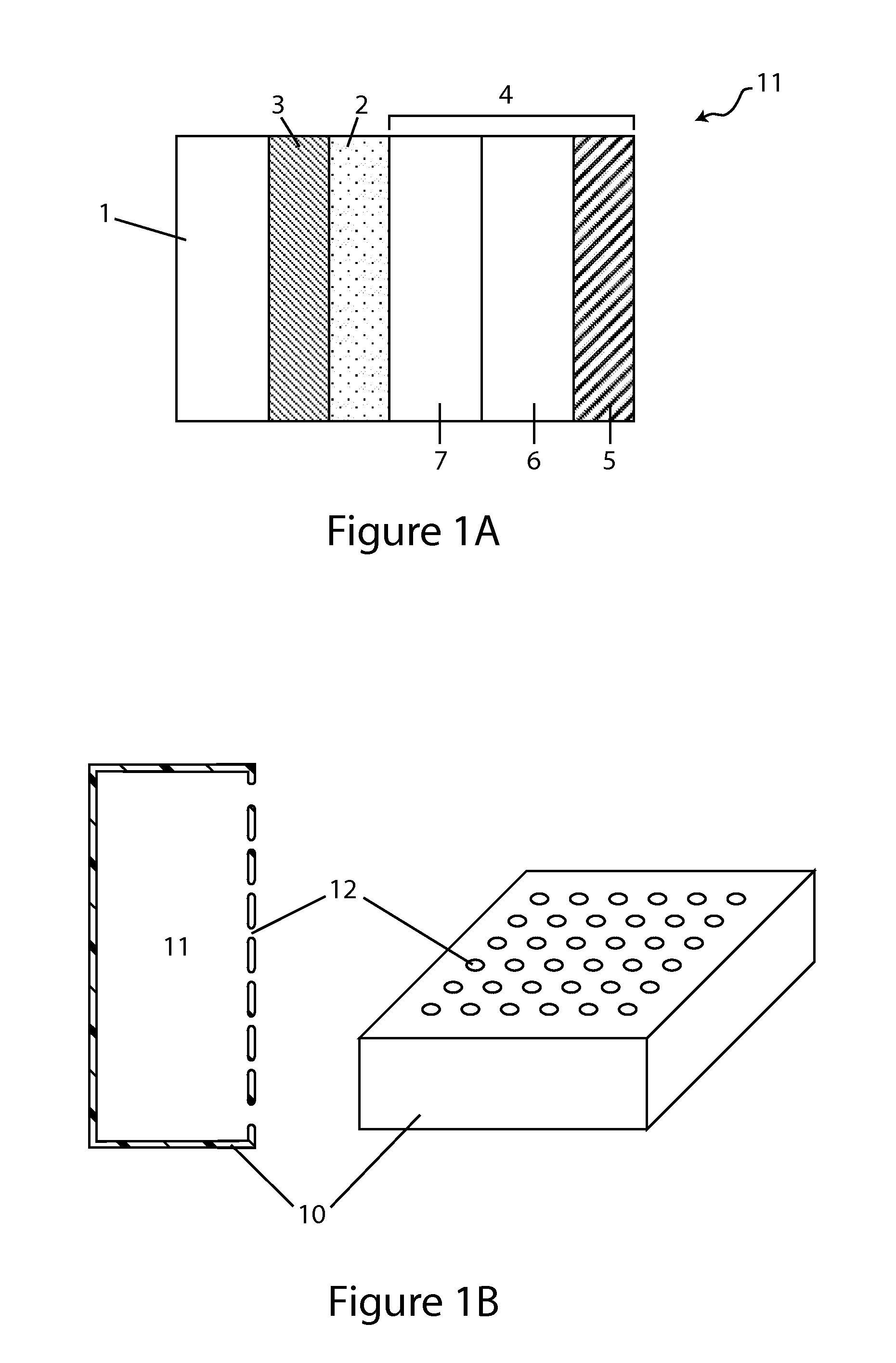

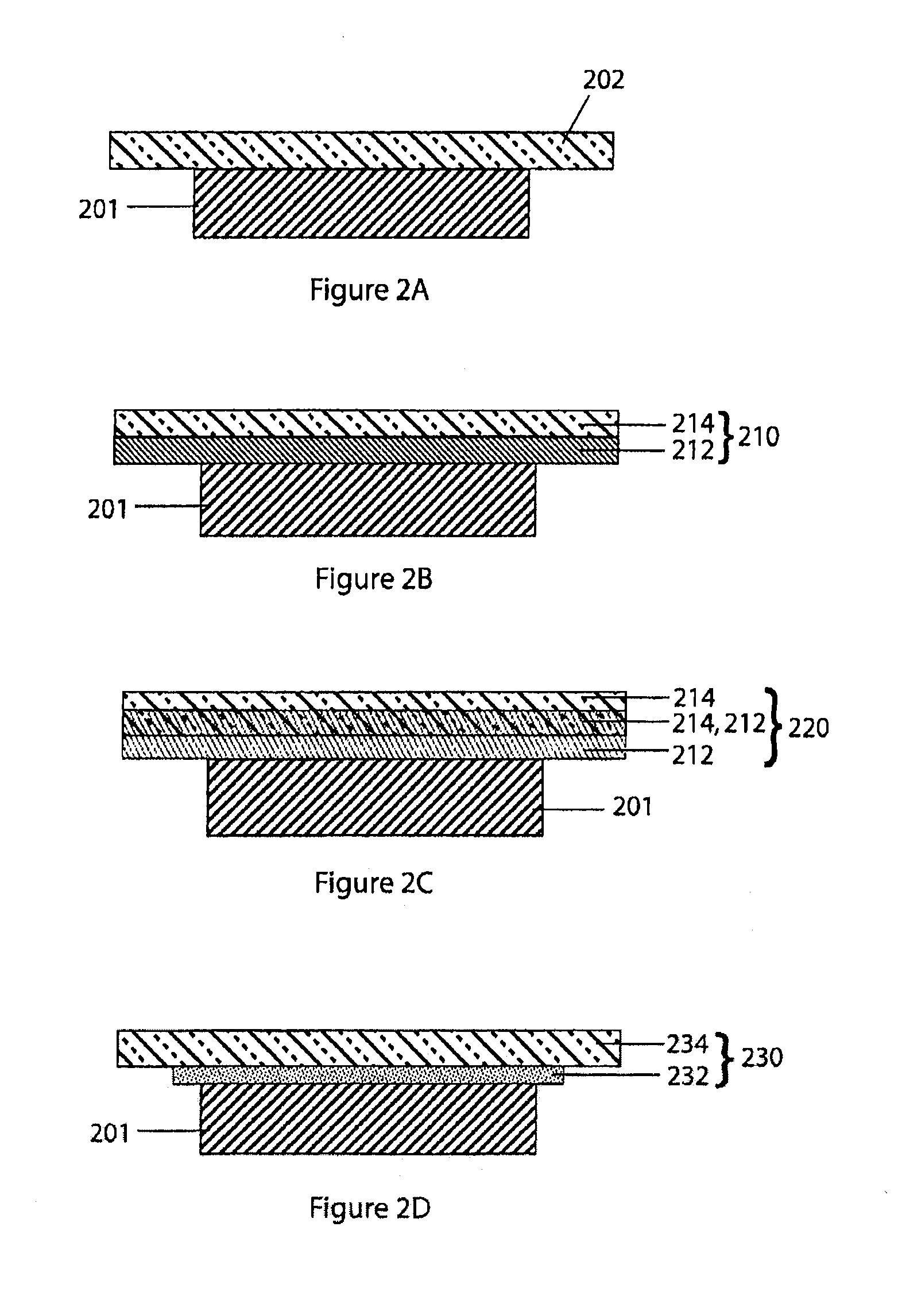

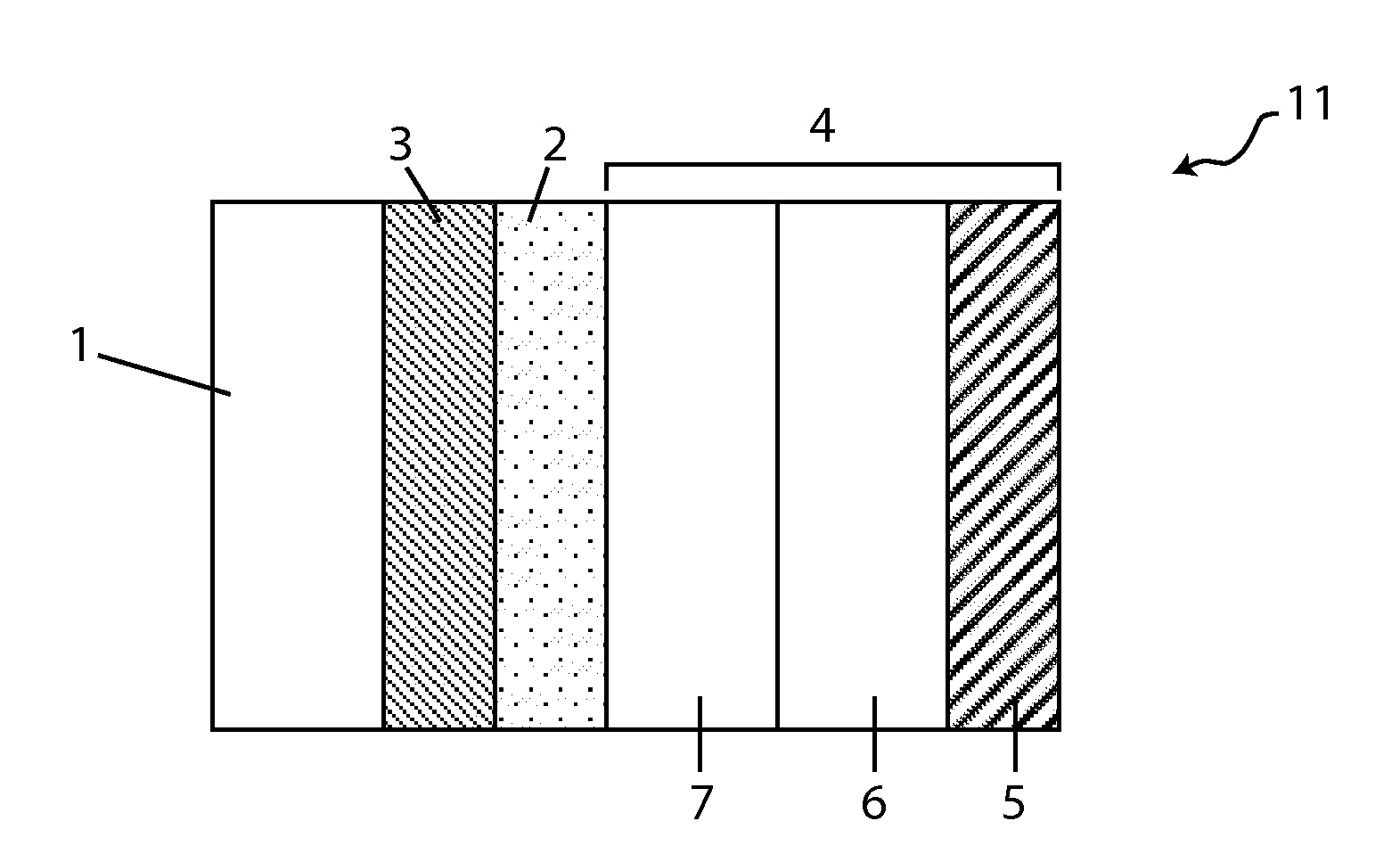

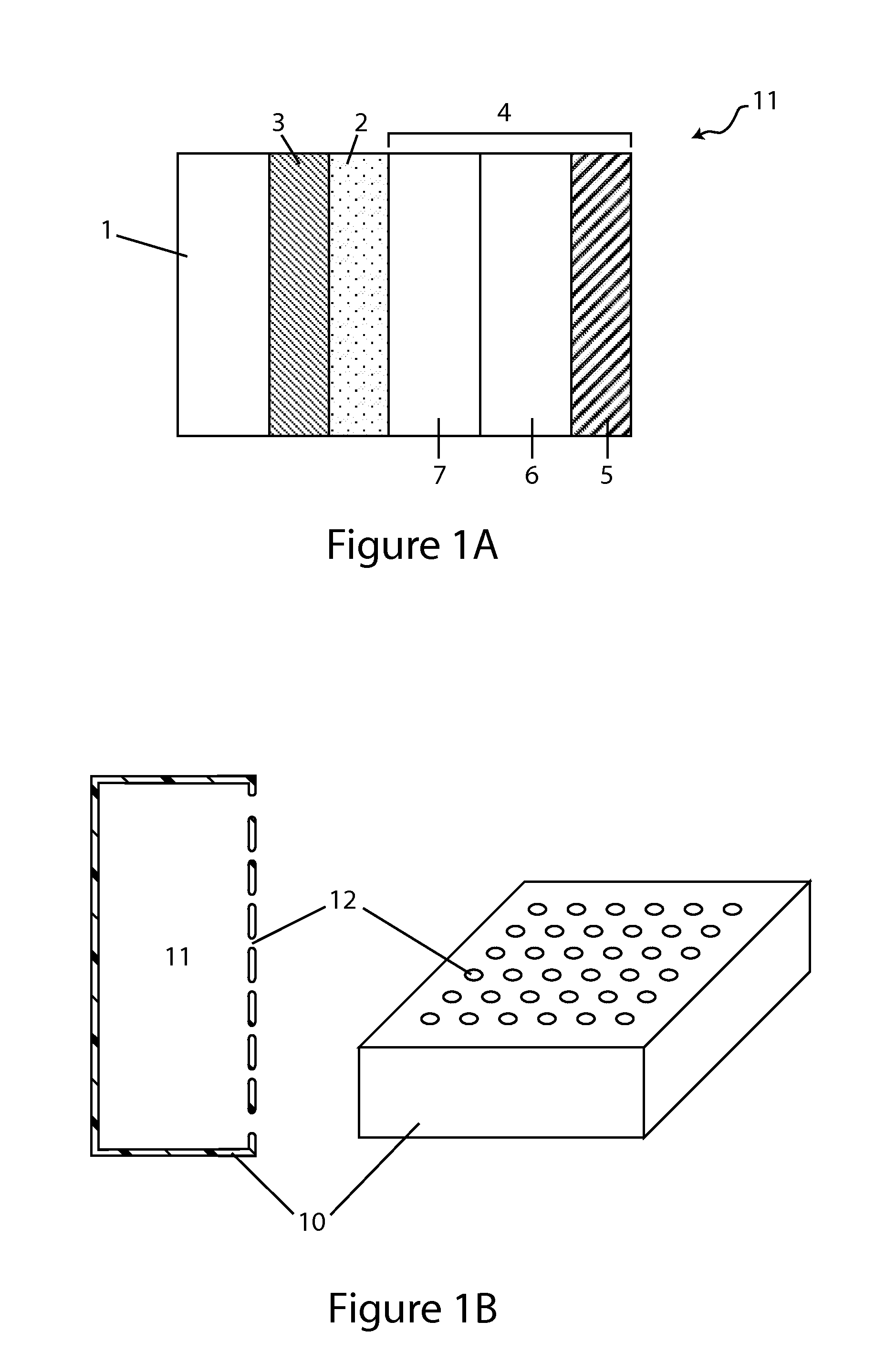

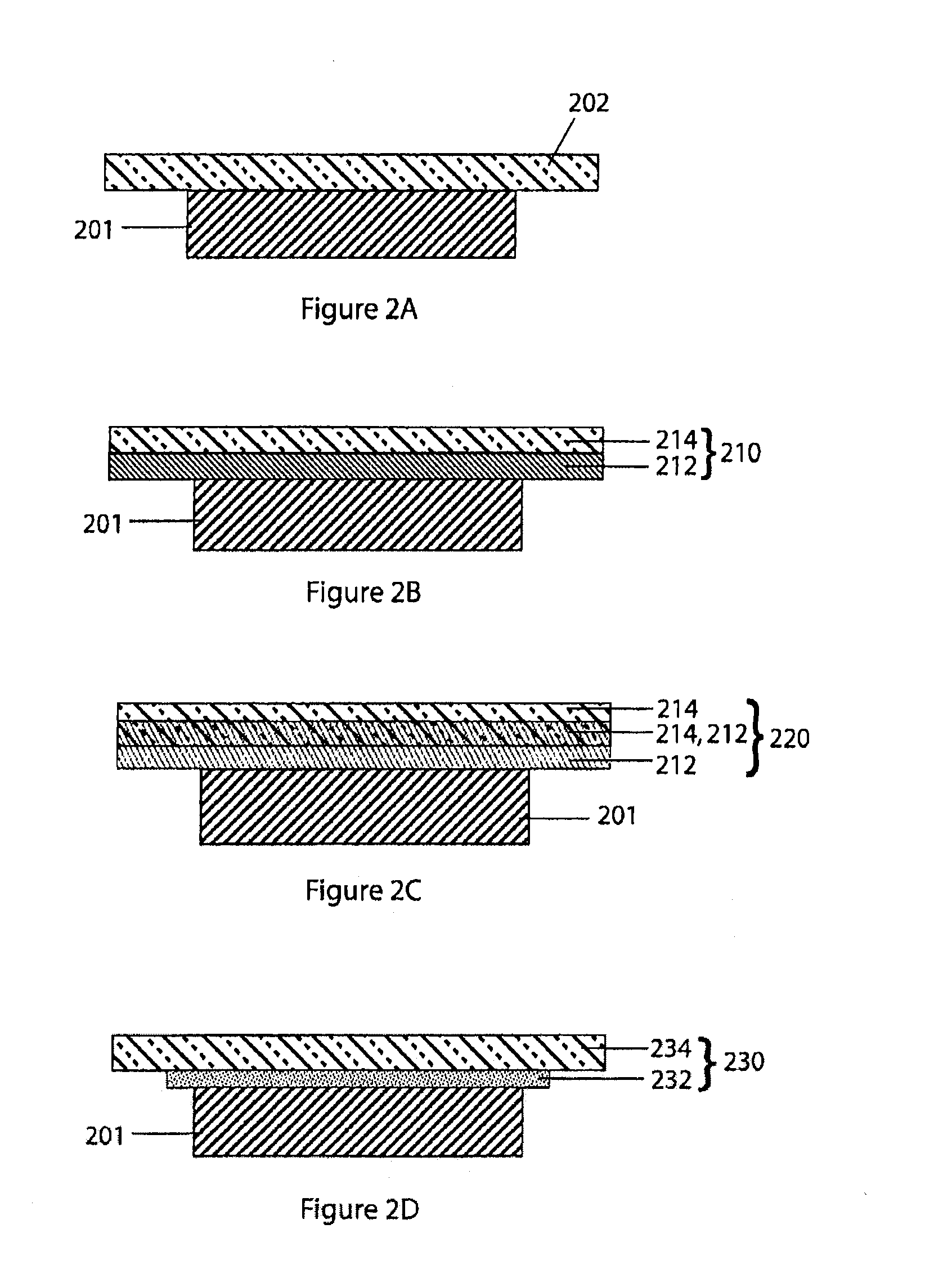

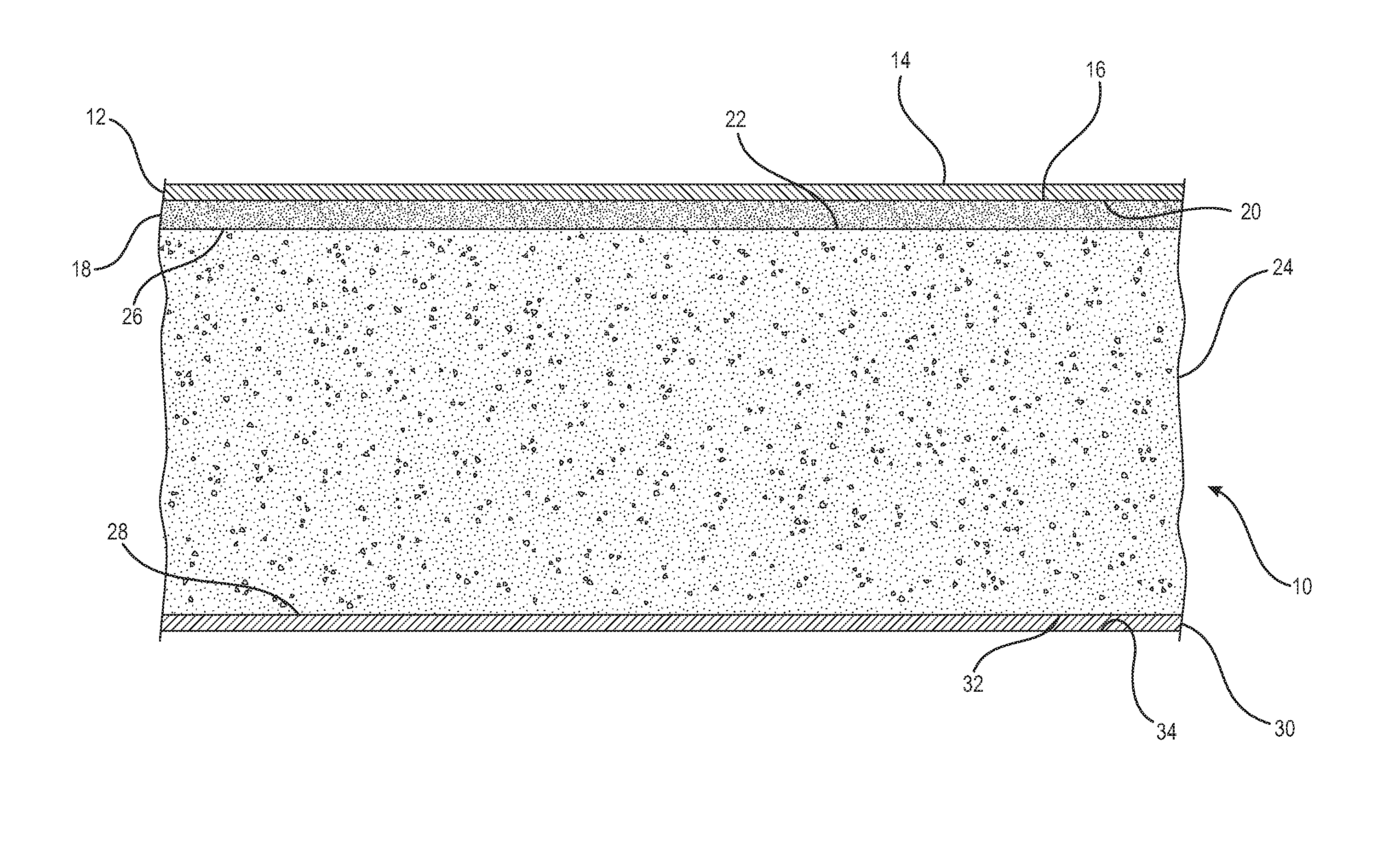

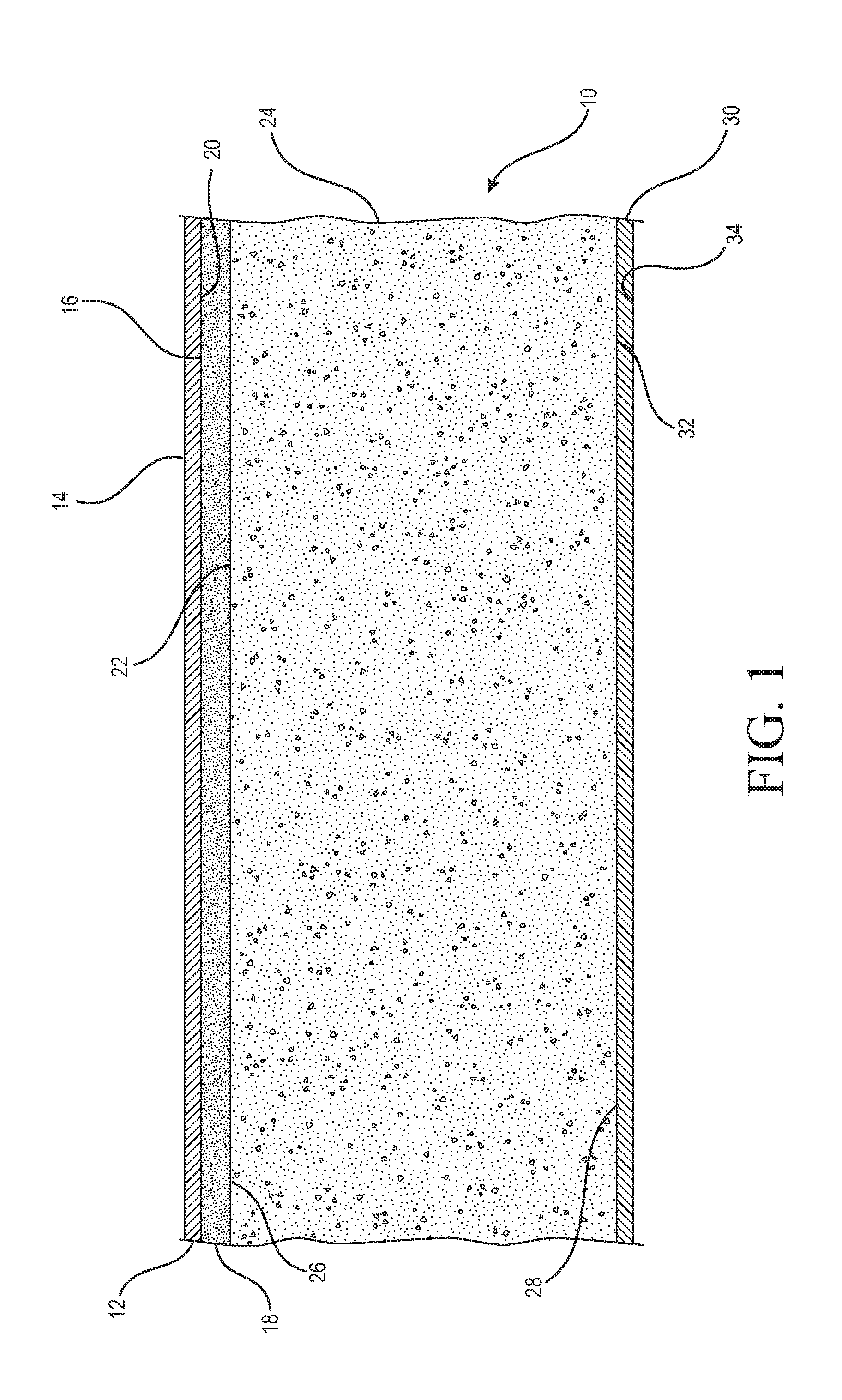

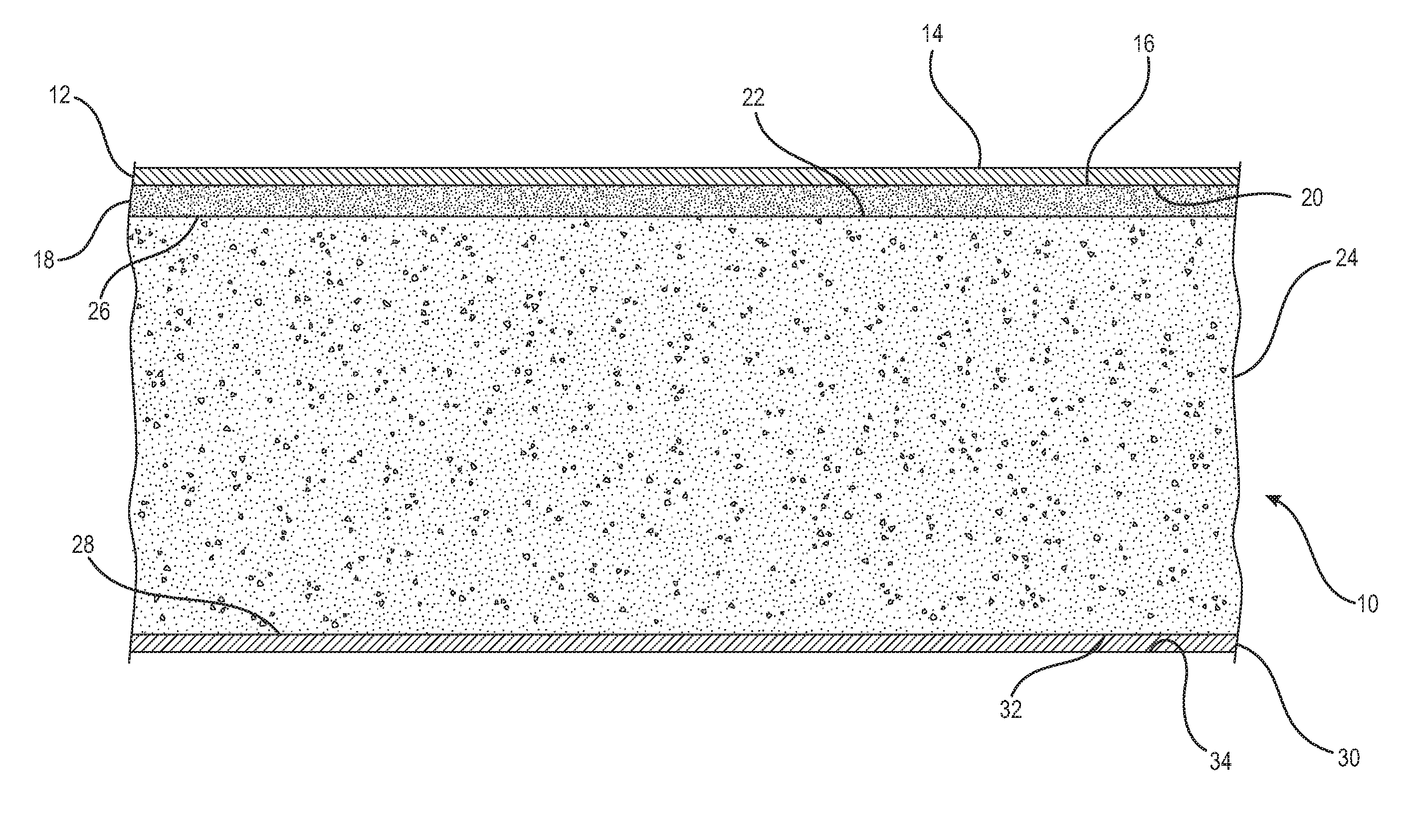

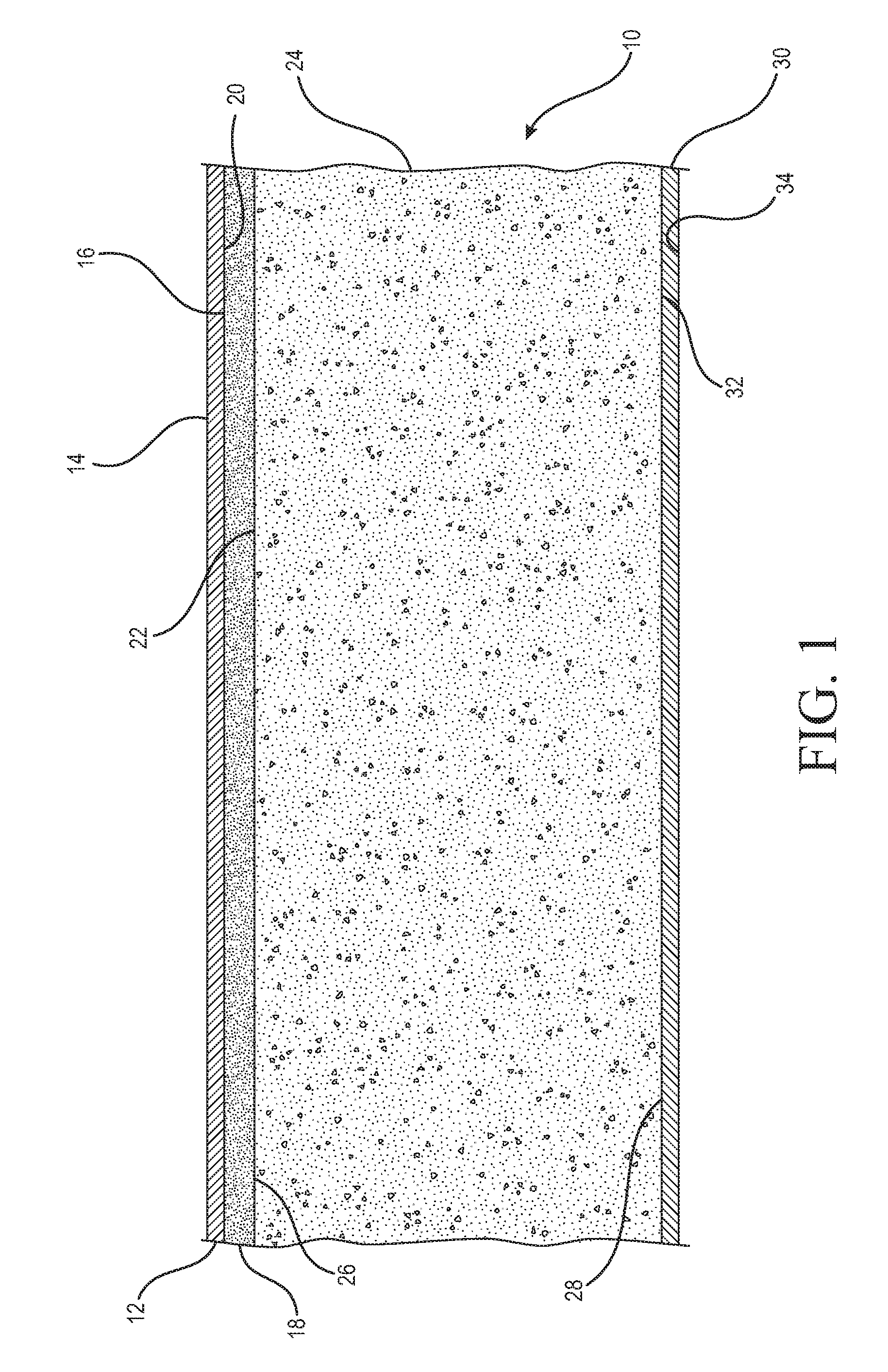

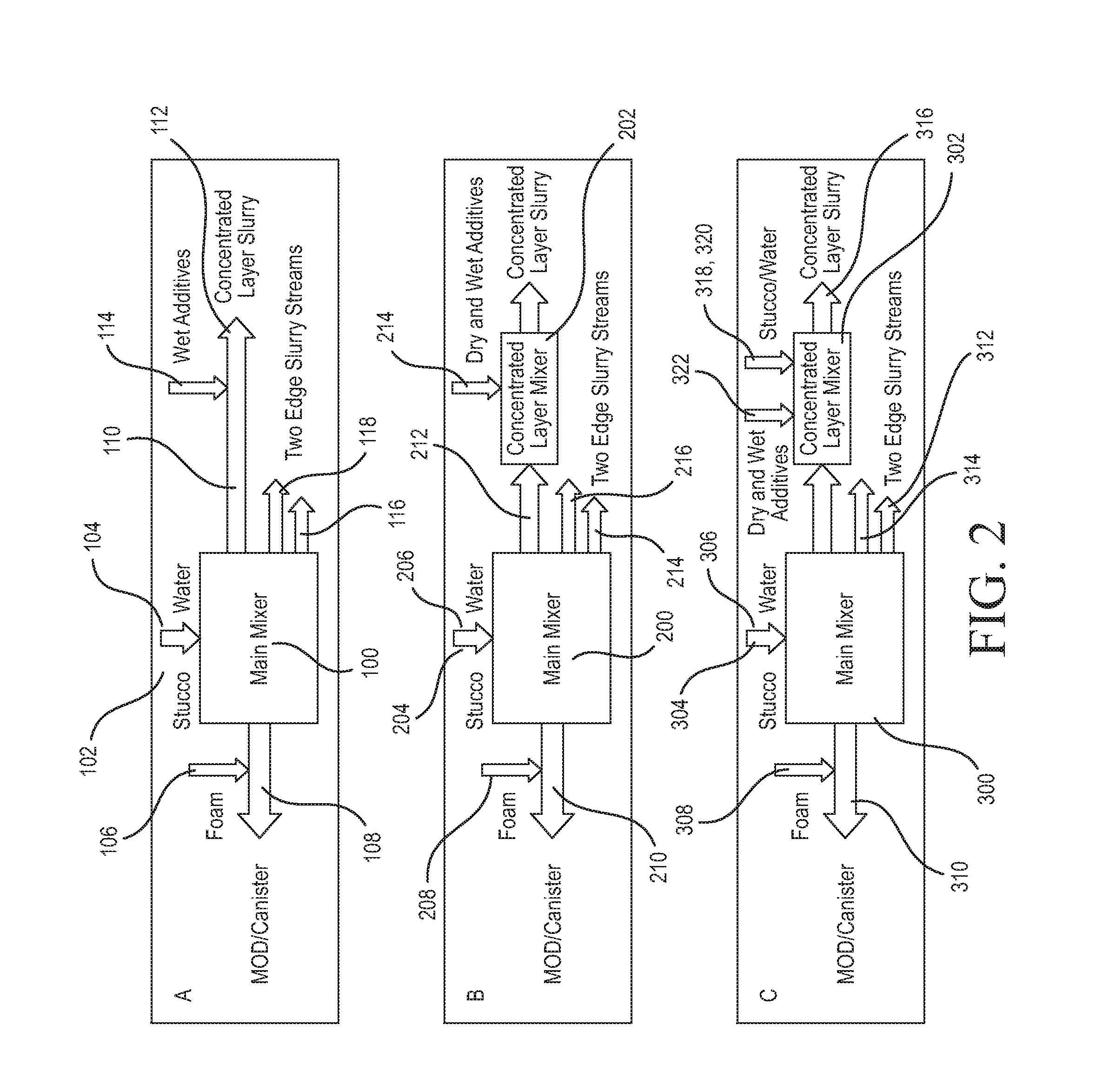

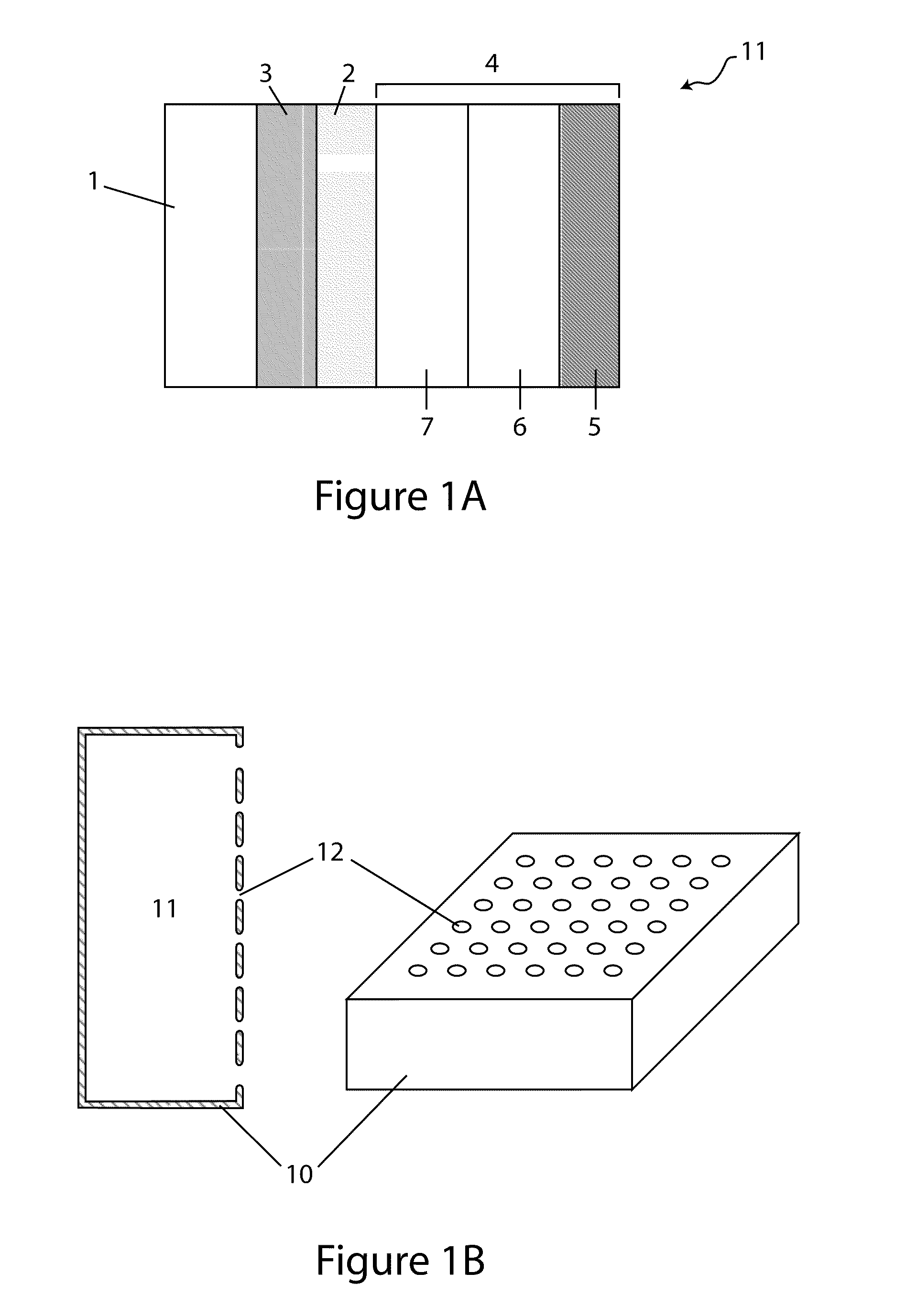

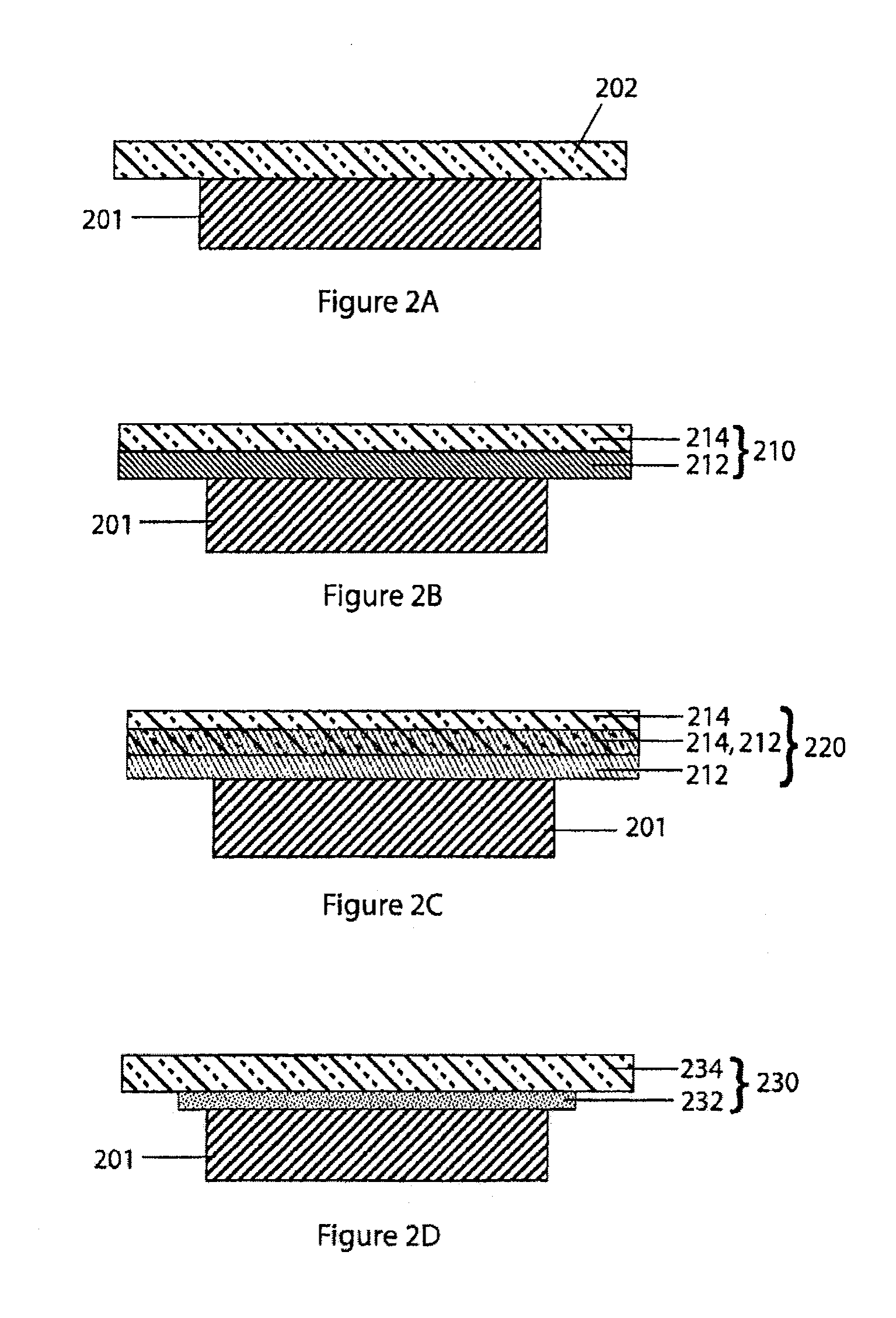

Composite gypsum board and methods related thereto

ActiveUS20160375655A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a board core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

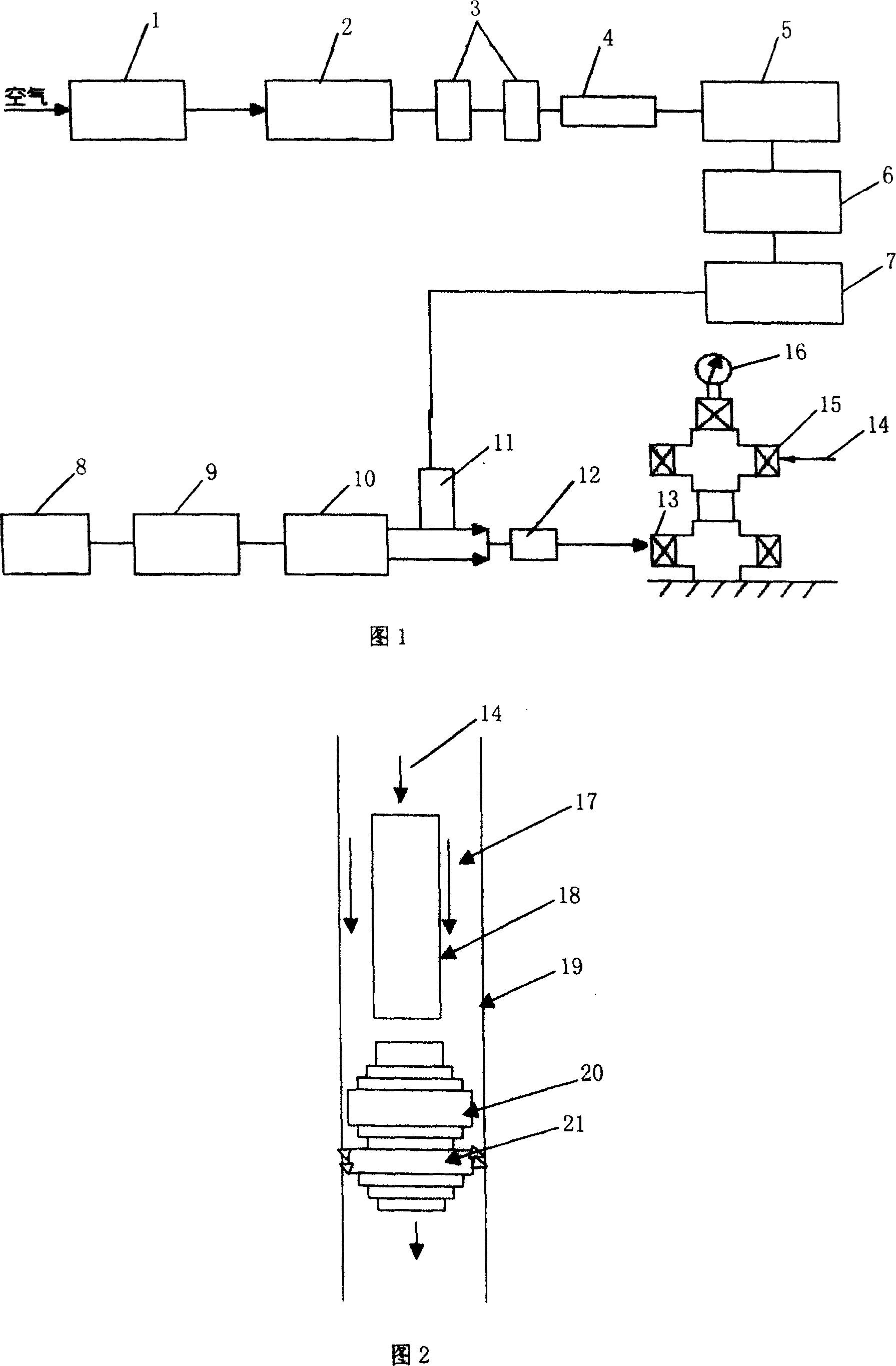

Thermal production well filling vapor and nitrogen foam profile control technique

InactiveCN101016835AExpand the affected volumeIncrease crude oil productionFluid removalChemistryNitrogen gas

The invention relates to a thermal developing well pouring steam nitrogen foam adjusting method comprising steam, nitrogen and foaming agent pouring method and nitrogen generating pouring method, wherein the steam is poured via an oil tube, the nitrogen and the foaming agent are poured in via a muffle, while the mass ratio between the foaming agent, steam is 1:250-500, the mass ratio between the nitrogen and the stem is 50-80:1, the pouring speed is steam at 10-13t / h, foaming agent at 0.1-0.5t / h, and nitrogen at 900-1000Nm3 / h. And the invention uses four-section plug pouring process, while the first section plug pours nitrogen via the muffle for 12h at 900-1000Nm3 / h, the second section plug pours the steam via the oil tube for 24h at 10-13t / h, and the third section plug pours steam via the oil tube and pours nitrogen and foaming agent via the muffle at 10-13t / h, 900-1000Nm3 / h, and 0.1-0.5t / h for 2h, the fourth section plug stops pouring foaming agent and holds the pouring speed of the nitrogen and the steam for 12h, repeats the steps of four section plugs until preset demand, closes the well, then opens well to produce.

Owner:SINOPEC SHENGLI OILFIELD

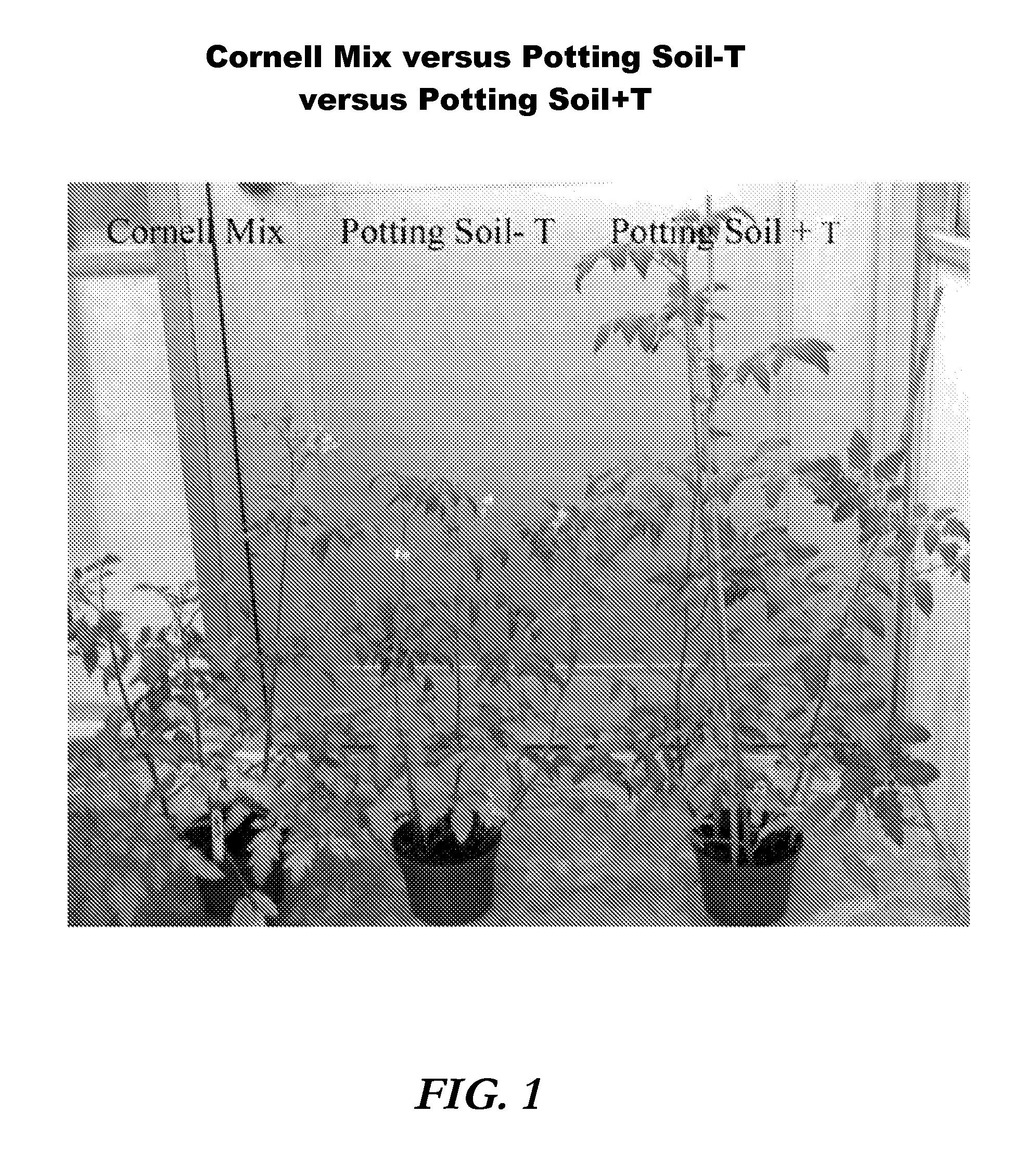

Plant propagation medium and methods of making and using it

ActiveUS20130055635A1Easy to useIncrease in mediumSeed and root treatmentExcrement fertilisersPlant propagationMoisture

The present invention provides a plant propagation medium, the improvement comprising a manure having a moisture content of 10 to 35 wt % with a salt level sufficient to achieve a conductivity of less than 0.35 dS / m. Also disclosed is a method of manufacturing a manure product and the manure product itself.

Owner:CORNELL UNIVERSITY

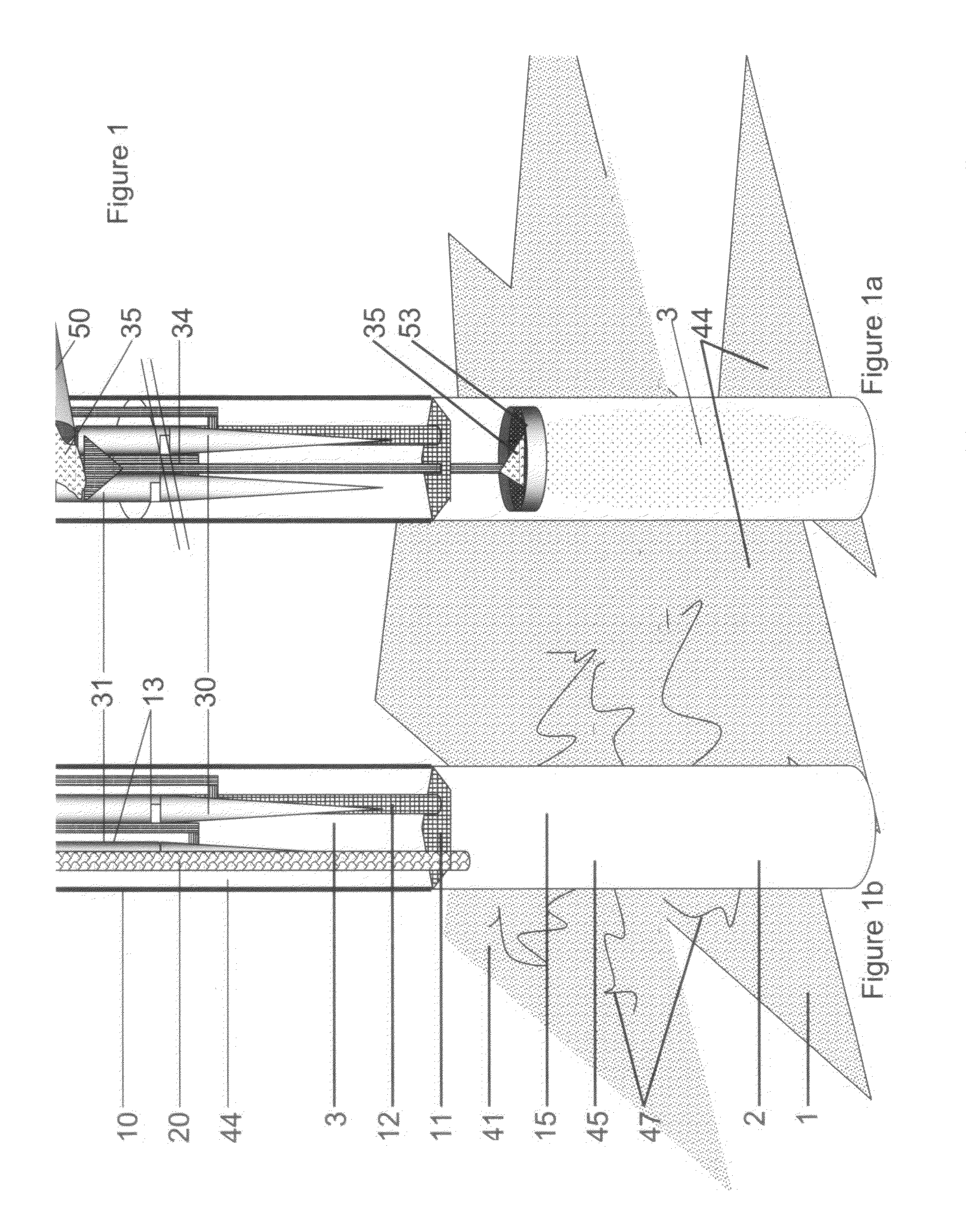

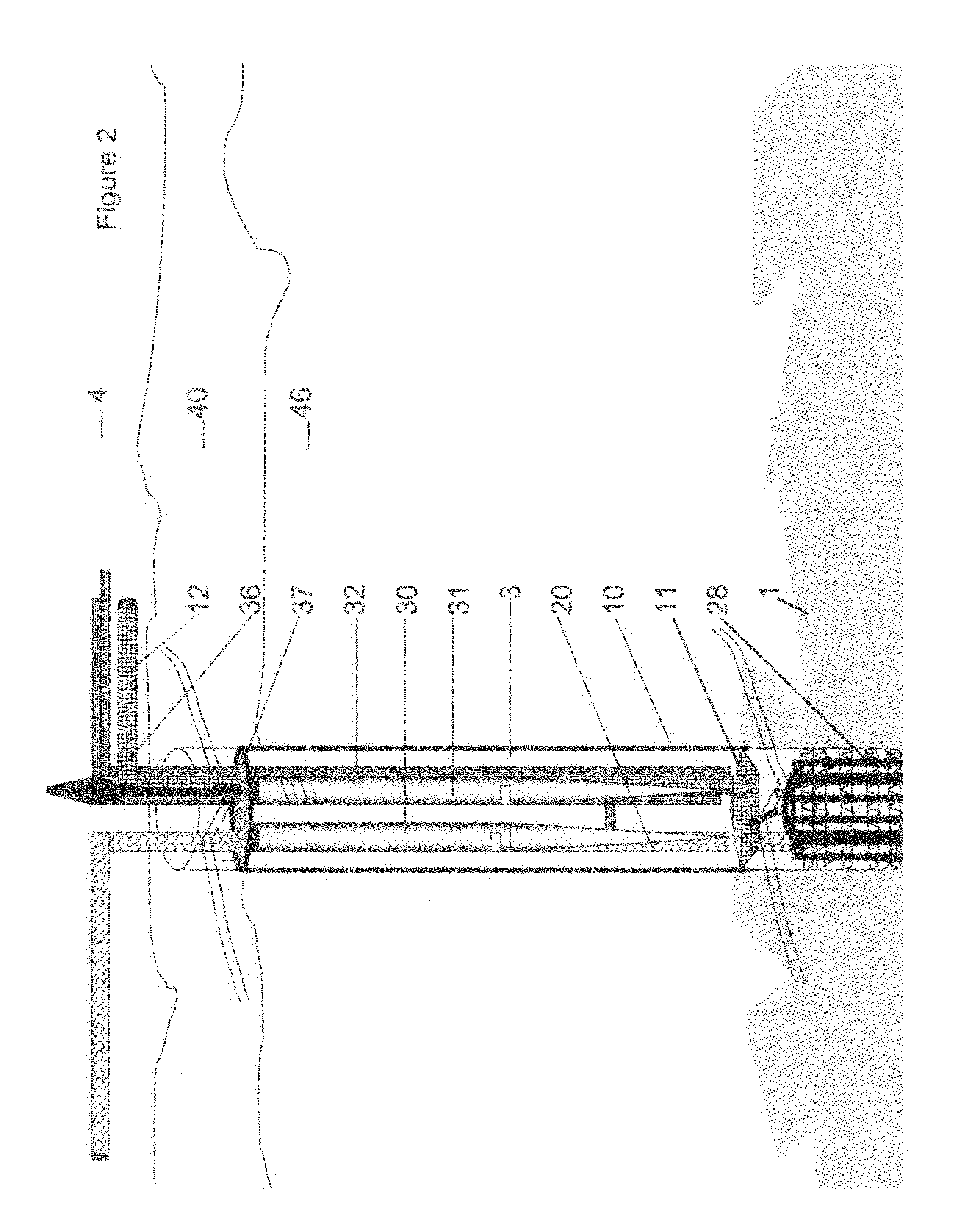

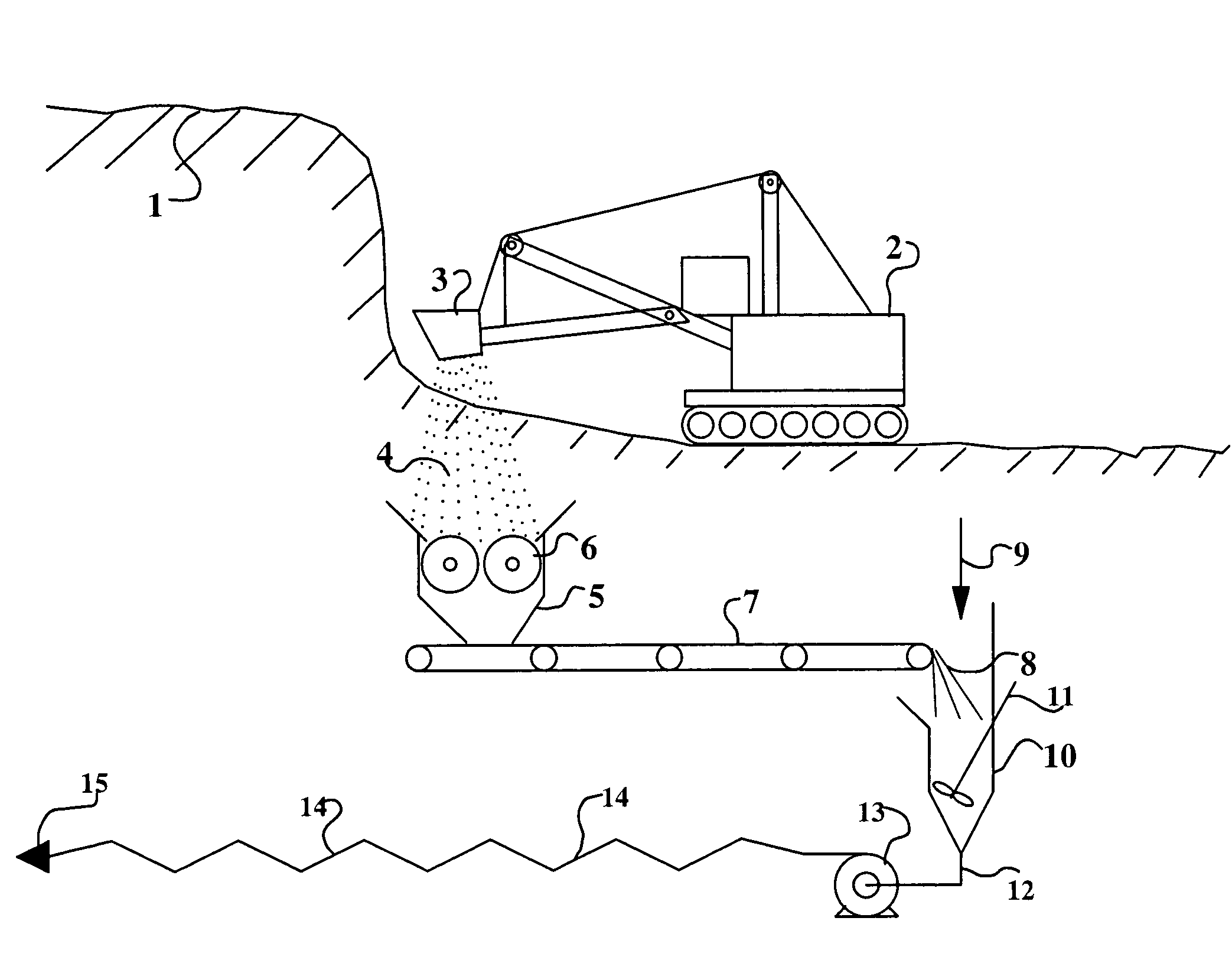

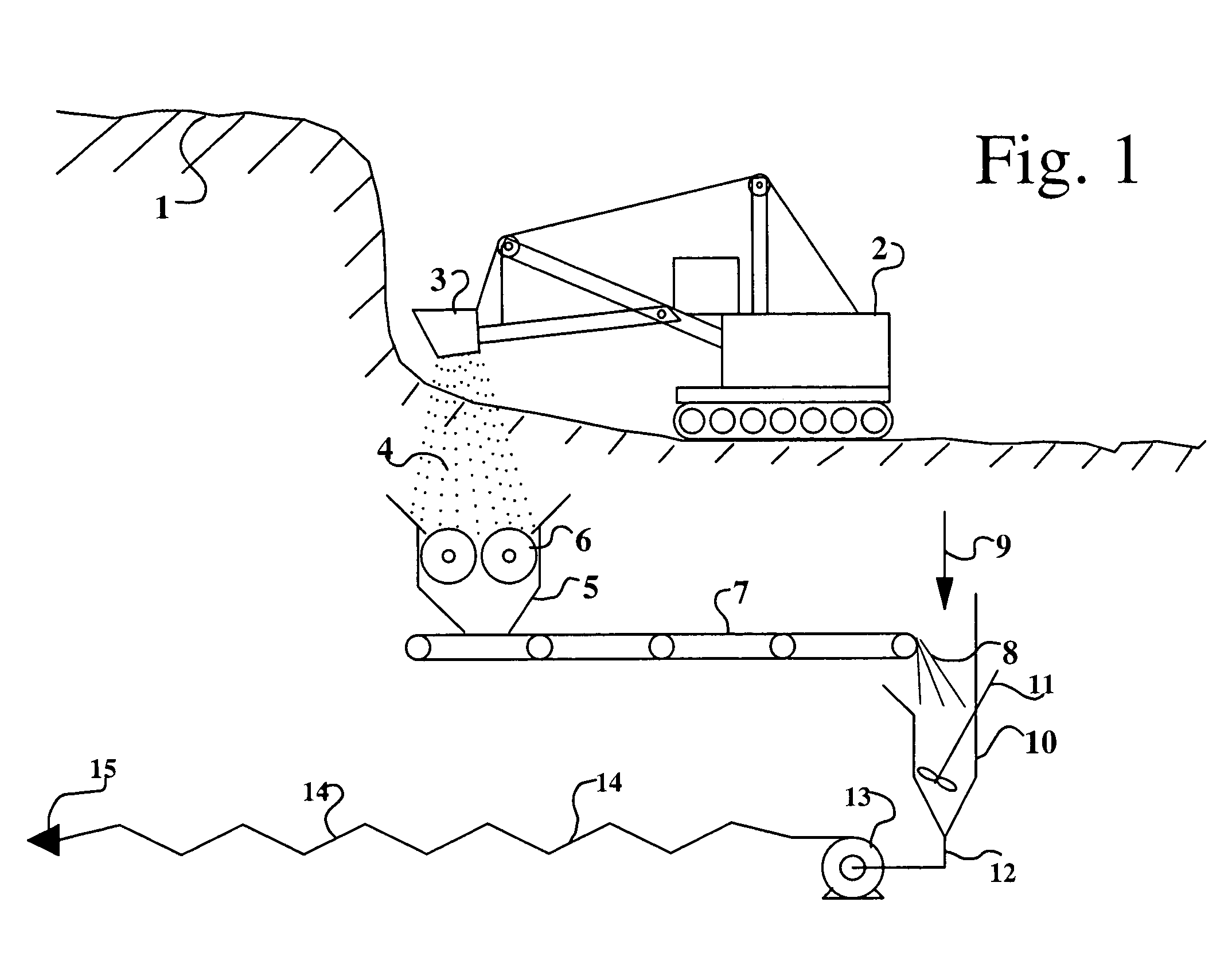

Isoelectric separation of oil sands

InactiveUS20090139906A1Reduced effectivenessReduce recoveryWater/sewage treatmentLiquid hydrocarbon mixture productionSlurryFroth flotation

A process and system for substantially isoelectric separation of an oil sand slurry is disclosed and described. The process can include mining oil sand, crushing the oil sands, forming a slurry of the oil sands, and transporting the oil sands slurry to a sinusoidal pipe. The sinusoidal pipe acts to digest the slurry from which bitumen can be separated using a hydrocyclone. Overflow from the hydrocyclone can be further treated using a revolving oleophilic device from which bitumen is recovered. Various optional further treatments can be used to dewater and / or further treat the bitumen and other process streams. The use of caustic soda, long-term tailing ponds, and froth flotation can be avoided resulting in an effective production of oil using less water than currently conventional processes.

Owner:KRUYER JAN

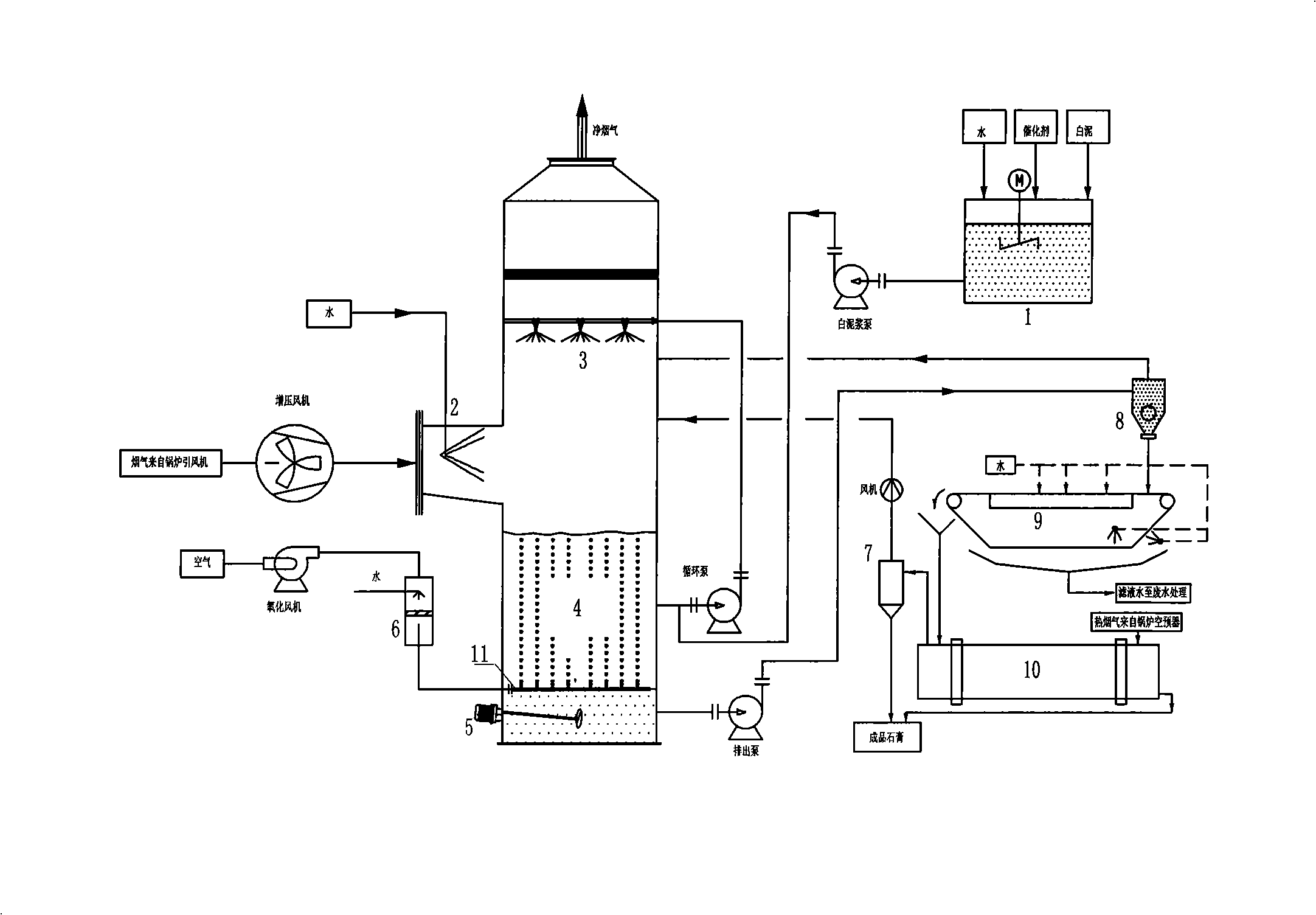

Method for preparing gypsum by removing boiler flue gas sulphur dioxide with white slime from ammonia alkali factory

ActiveCN101343077AIncrease production capacityAchieve economyCalcium/strontium/barium sulfatesSulfateCatalytic oxidation

The invention discloses a method for removing sulfur dioxide in fumes with the by-product of gypsum produced by white mud in the ammonia-soda factory. With such method adopted, the efficiency of removing the sulfur dioxide is more than 95 percent, the purity of the by-product of the gypsum is more than 85 percent, and the water content of the gypsum is less than 4 percent. The method is realized by the following technical proposal: white mud slurry is used as an absorbent for removing the sulfur dioxide; in the spray tower absorbing zone, the white mud slurry reacts with the sulfur dioxide to generate calcium sulfite and calcium bisulfite; the calcium sulfite and the calcium bisulfite are catalyzed and oxidized into calcium sulfate in the oxide crystallization pool; the calcium sulfate is crystallized into gypsum; and gypsum slurry is concentrated, washed and dehydrated, and dried, and then changed into the finished product of gypsum. The method for removing the sulfur dioxide in fumes, which uses waste to restrict waste, not only realizes clean production and circular economy in the ammonia-soda industry, but also provides a more economical sulfur dioxide removing method for surrounding power plants in the ammonia-soda industry, thereby realizing bidirectional treatment of the waste. Furthermore, the by-product of the gypsum has wide commercial prospect after dried.

Owner:GUANGDONG NANFANG SODA ASH IND

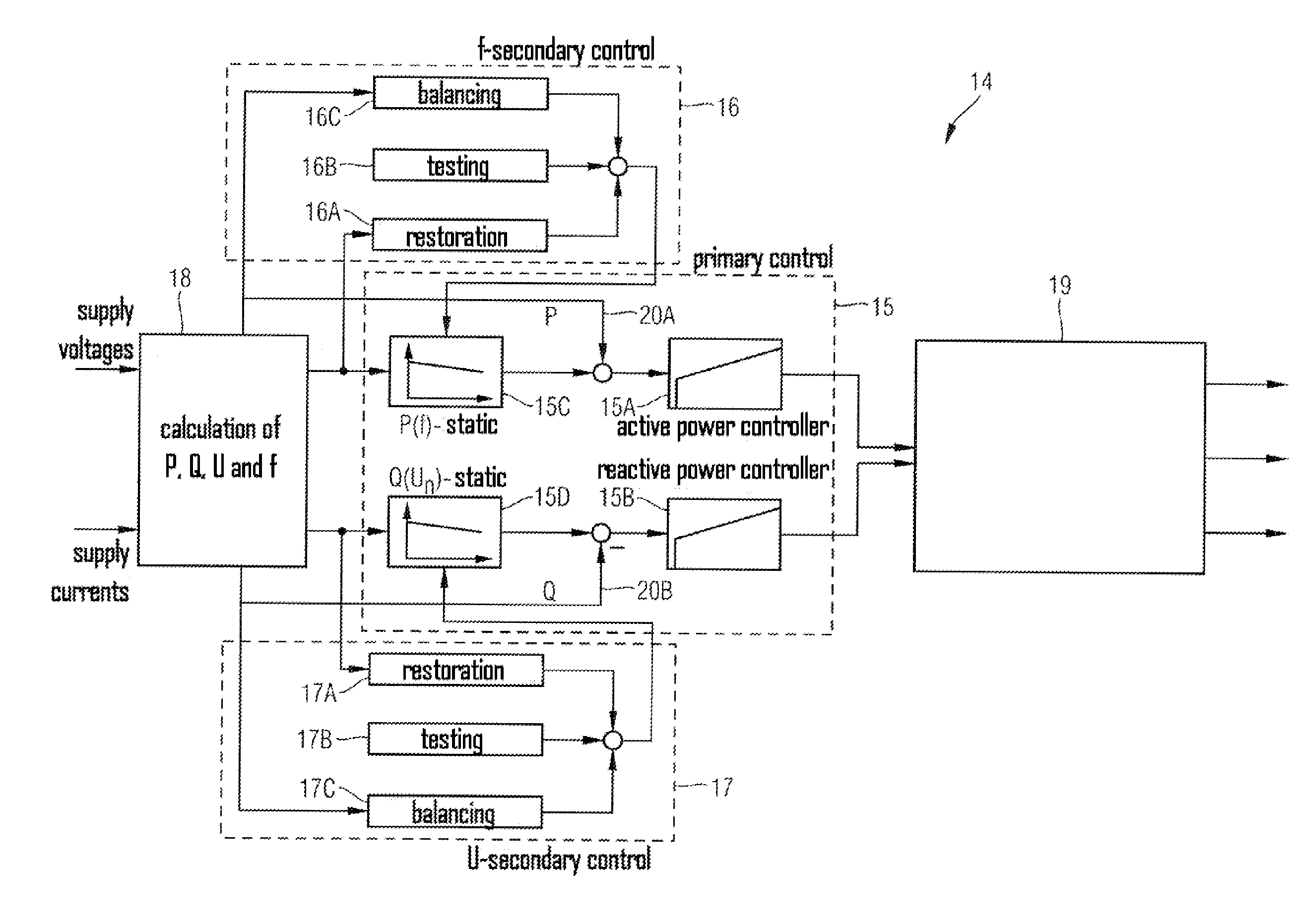

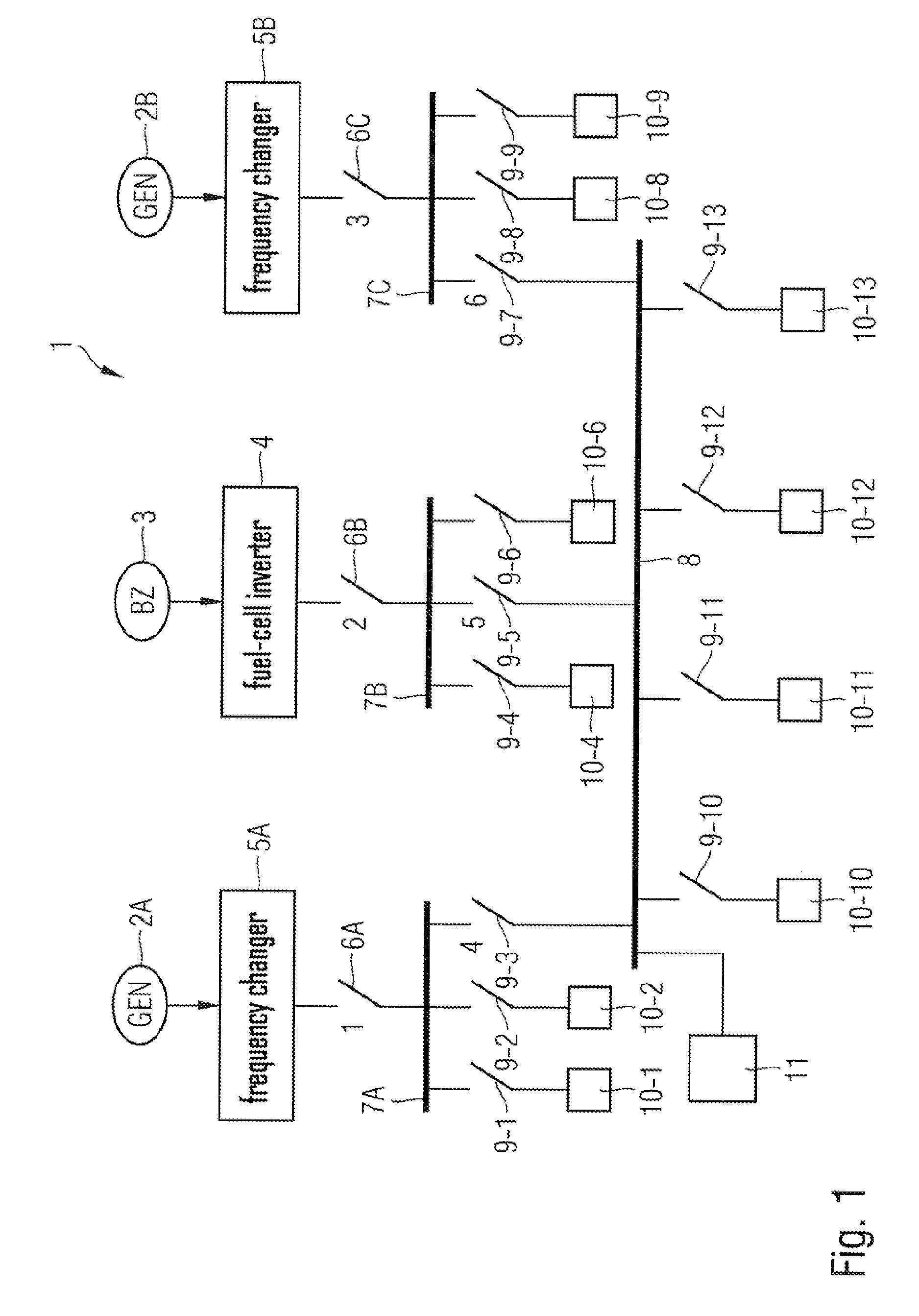

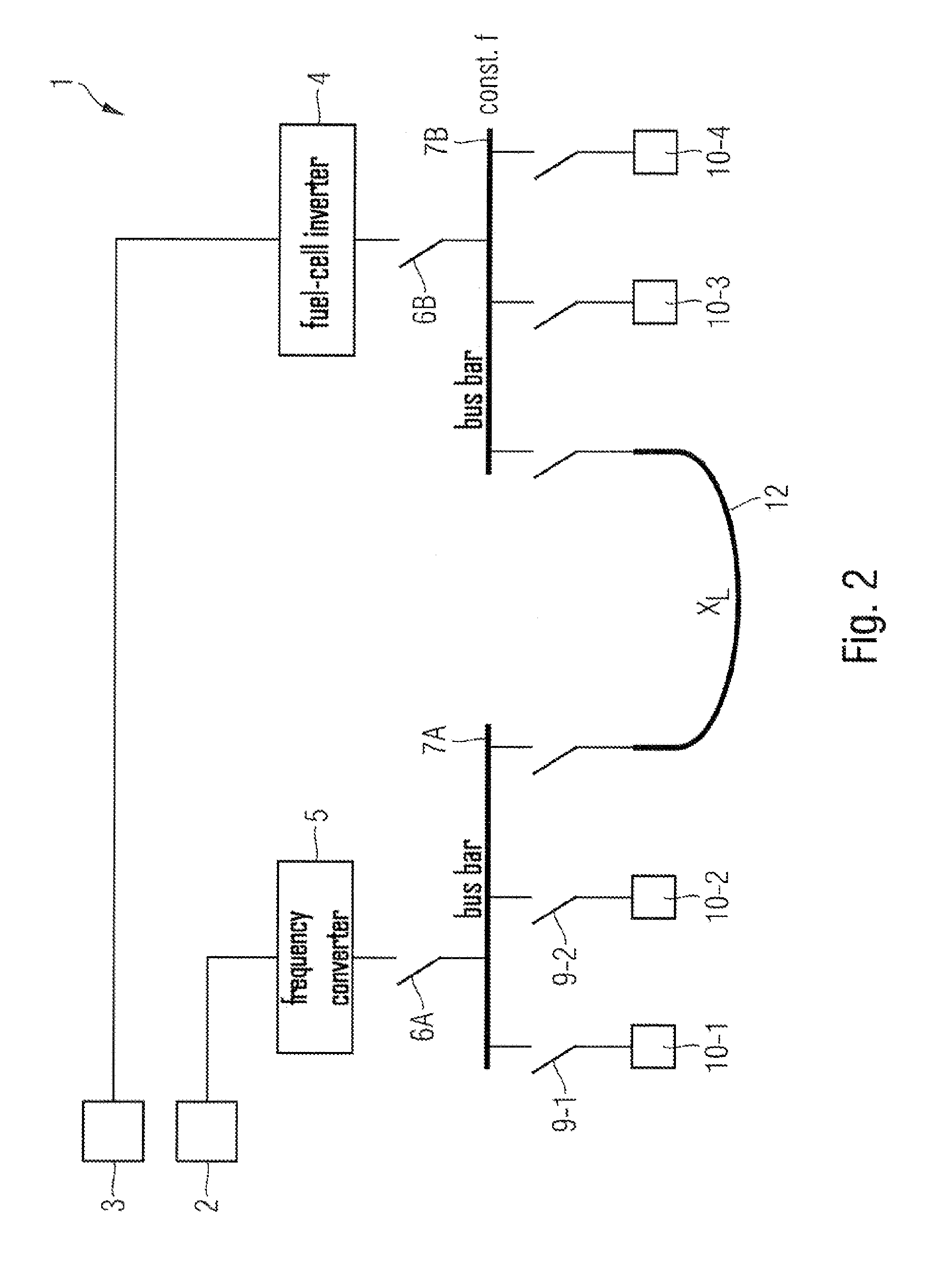

Method and device for providing an electrical system alternating voltage in an aircraft

InactiveUS20110210606A1Improve efficiencyImprove stabilityDc network circuit arrangementsElectric devicesFrequency changerFuel cells

The present invention provides a method and a device for providing a three-phase electrical system alternating voltage for an electrical system of an aircraft, a plurality of voltage sources being provided which comprise at least one engine generator and a further voltage source, in particular a fuel cell, comprising one or more frequency converters for converting an alternating voltage of variable frequency provided by the respective engine generator into a first output alternating voltage and comprising at least one cyclo-inverter for cyclo-inverting a voltage provided by the respective further voltage source into a second output alternating voltage which is synchronous with the first output alternating voltage and constitutes the electrical system alternating voltage.

Owner:AIRBUS OPERATIONS GMBH

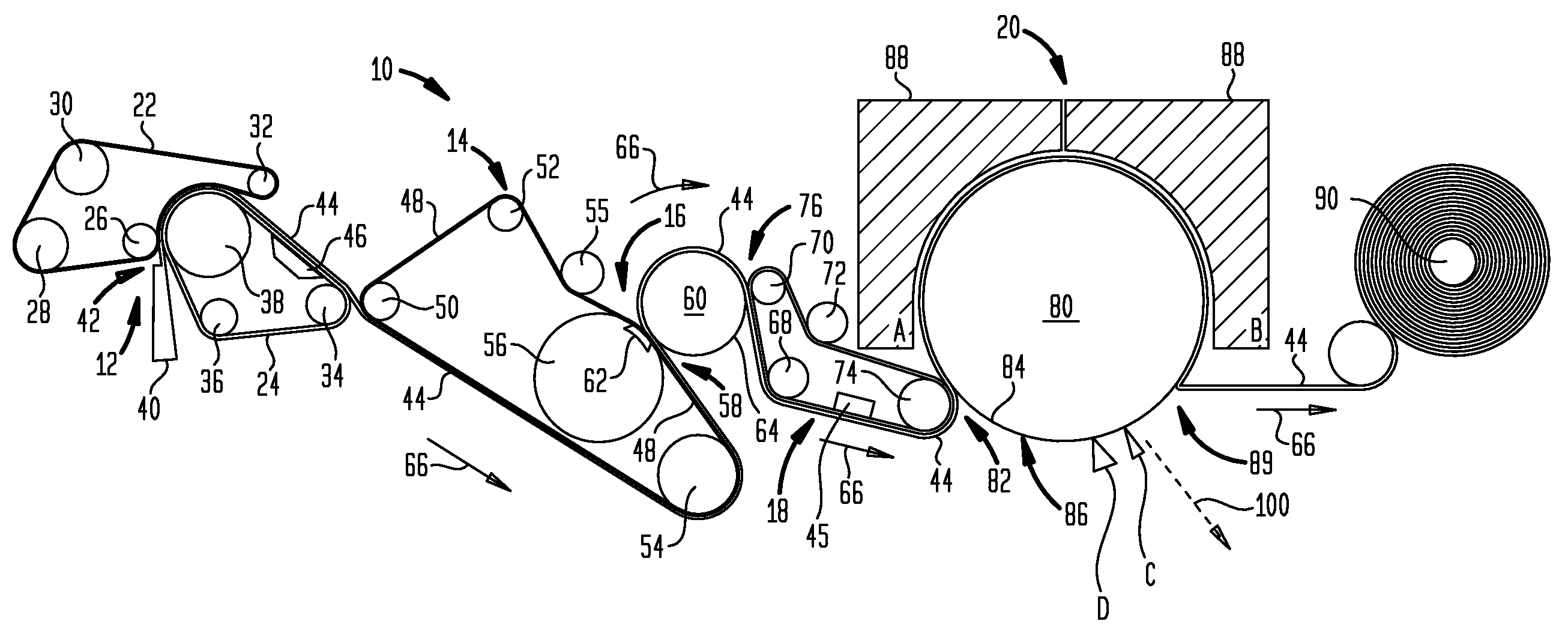

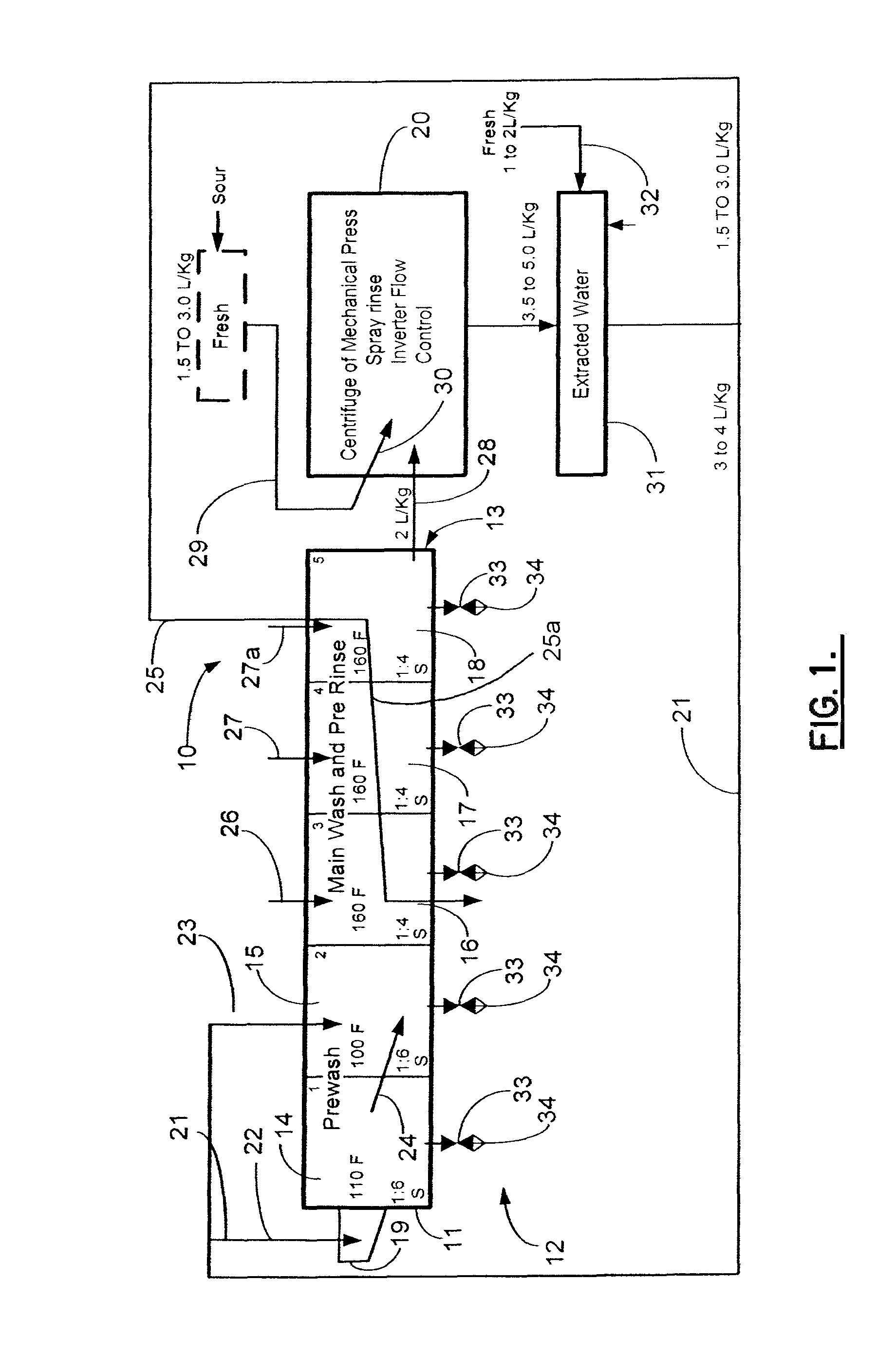

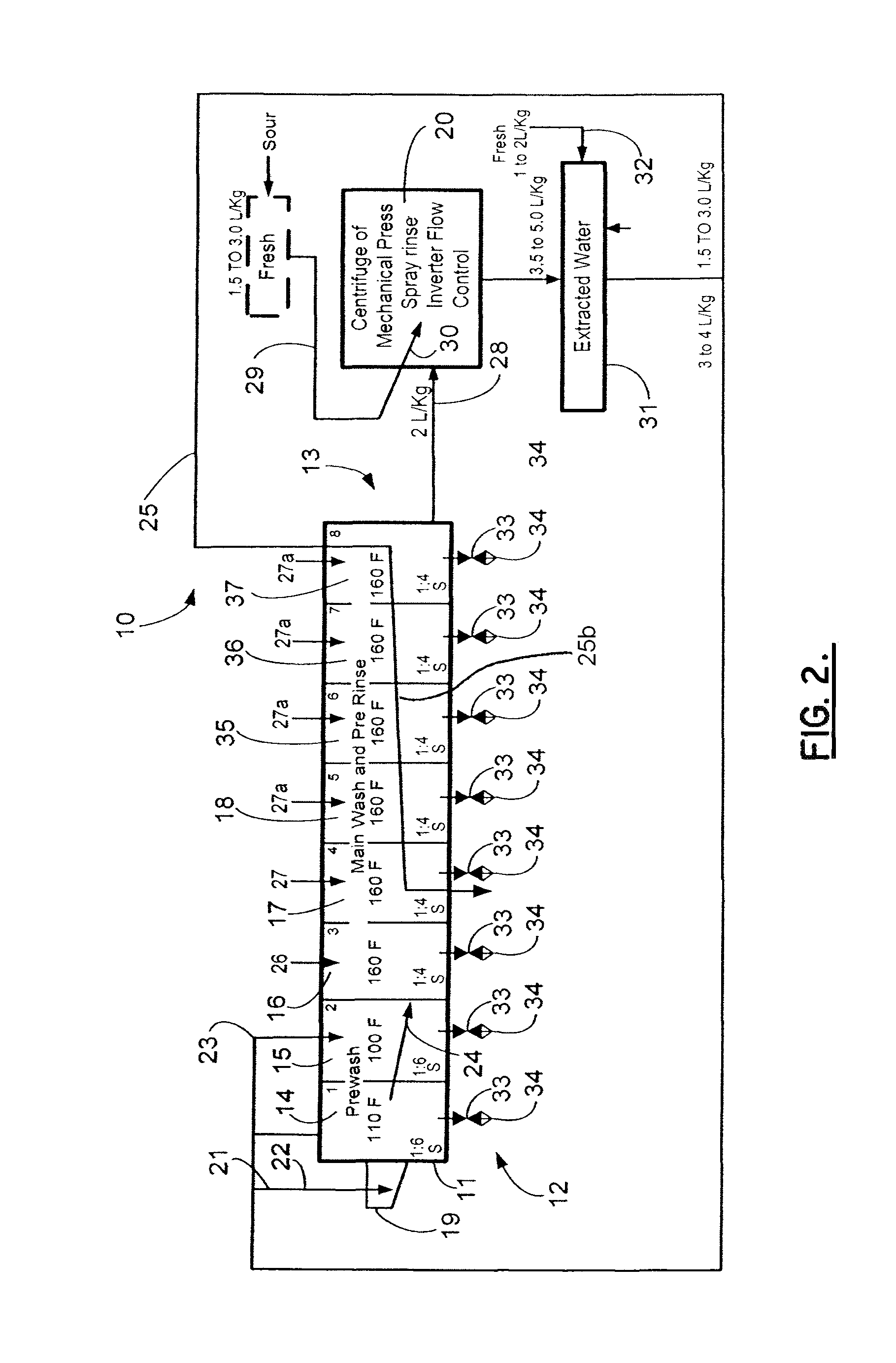

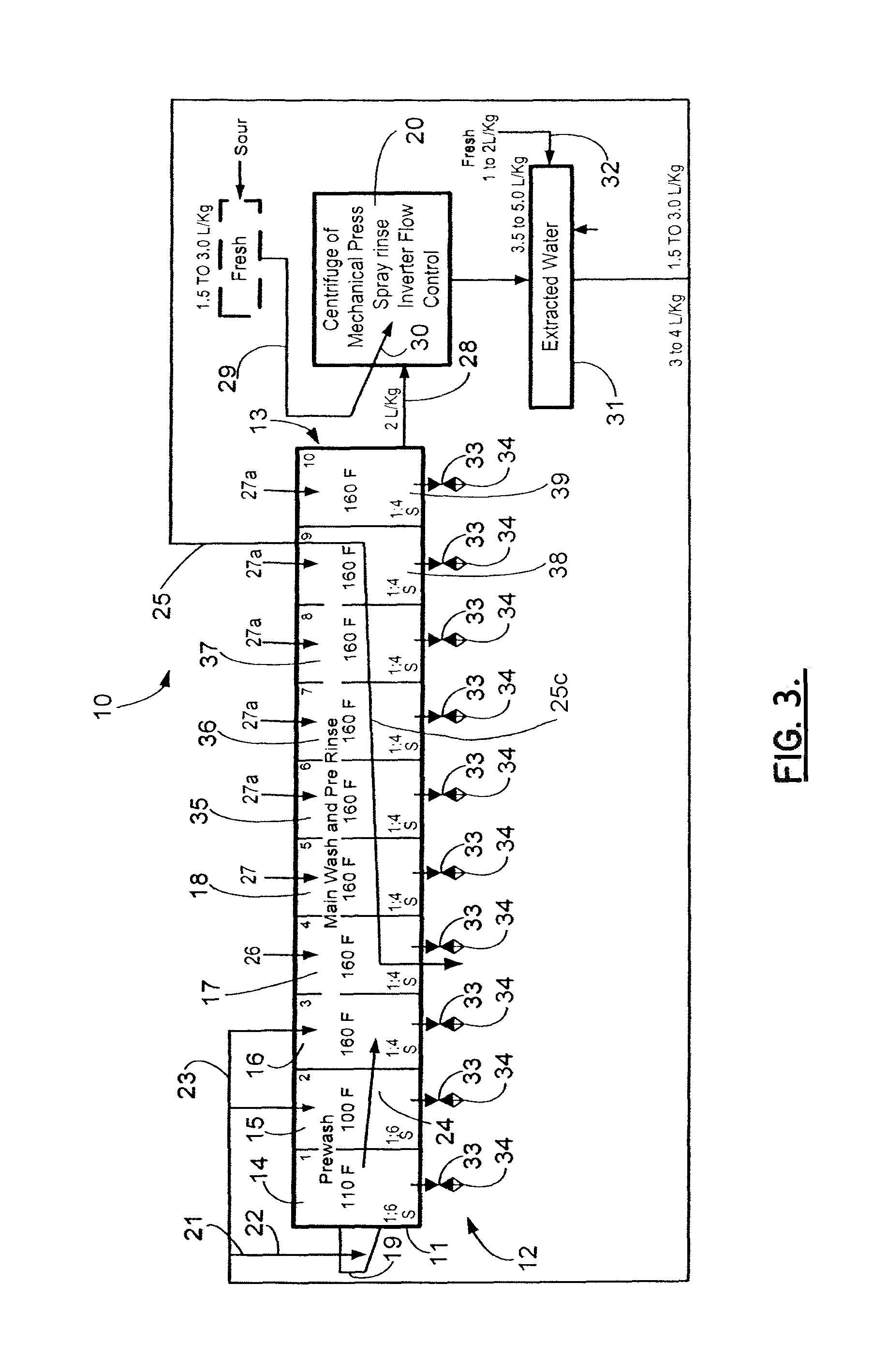

Integrated continuous batch tunnel washer

ActiveUS7971302B2Reduce water consumptionSave spaceOther washing machinesDetergent compounding agentsChemical treatmentCounter flow

A method of washing fabric articles in a tunnel washer includes moving the fabric articles from the intake of the washer to the discharge of the washer through first and second sectors that are a pre-wash zone. In the pre-wash zone, liquid is counter flowed in the wash interior along a flow path that is generally opposite the direction of travel of the fabric articles. The fabric articles are transferred to a main wash zone, and a washing chemical is added to the main wash zone. At about the same time, counter flow is reduced or stopped. The main wash zone can be heated as an option. After a period of time (for example, between about 20 and 120 seconds) counter flow is increased. The increased counter flow after chemical treatment amounts to either an intermediate rinse or a pre-rinse depending upon which module or zone the goods occupy. The pre-rinse ensures that the fabric articles are substantially free of soil or the majority of any soil when they are transferred to an extractor for final removal of excess water.

Owner:PELLERIN MILNOR

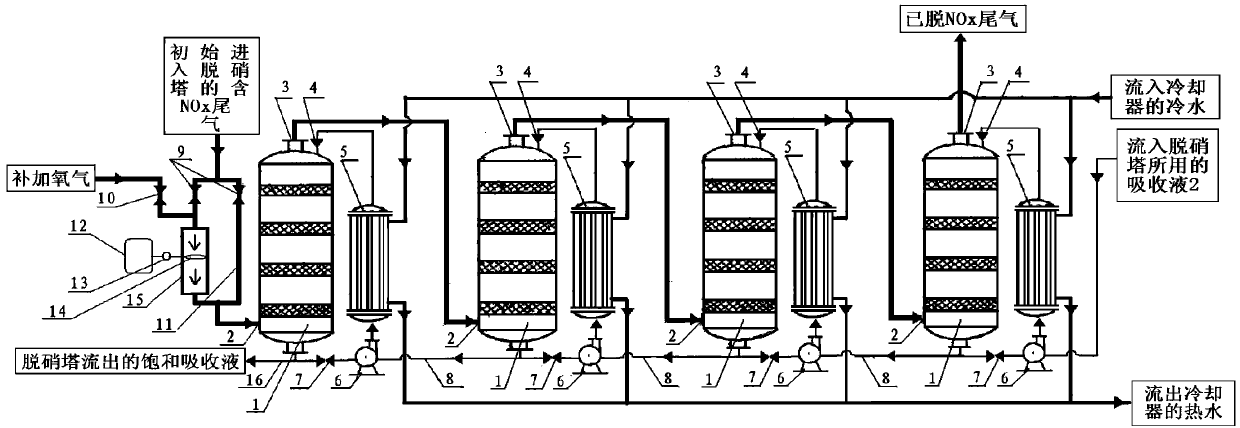

Desulfurization and denitrification method for tail gas, used equipment and product application thereof

InactiveCN105080307AReduce material costsLow costOther chemical processesDispersed particle separationCorrosion preventionChemistry

The present invention discloses a desulfurization and denitrification method for tail gas, used equipment and product application thereof. According to the method provided by the present invention, an oxidative catalyst is not used in a desulfurization column or a denitration column, or a small amount of the oxidative catalyst with a simplified formula added is used outside the desulfurization column and the denitration column, so that the cost is reduced significantly. The oxidative catalyst is not used in the desulfurization column or the denitration column to avoid the severe corrosion of the desulfurization column and denitration column texture by the material, so that the texture cost of the desulfurization column and the denitration column is reduced significantly; The volume of the processed material is small: only 30%-10% of the material in volume in the desulfurization column and the denitration column, and the cost for equipment corrosion prevention is lowered, so that a small amount of the oxidative catalyst used and a simplified formula can be facilitated.

Owner:陈汇宏 +2

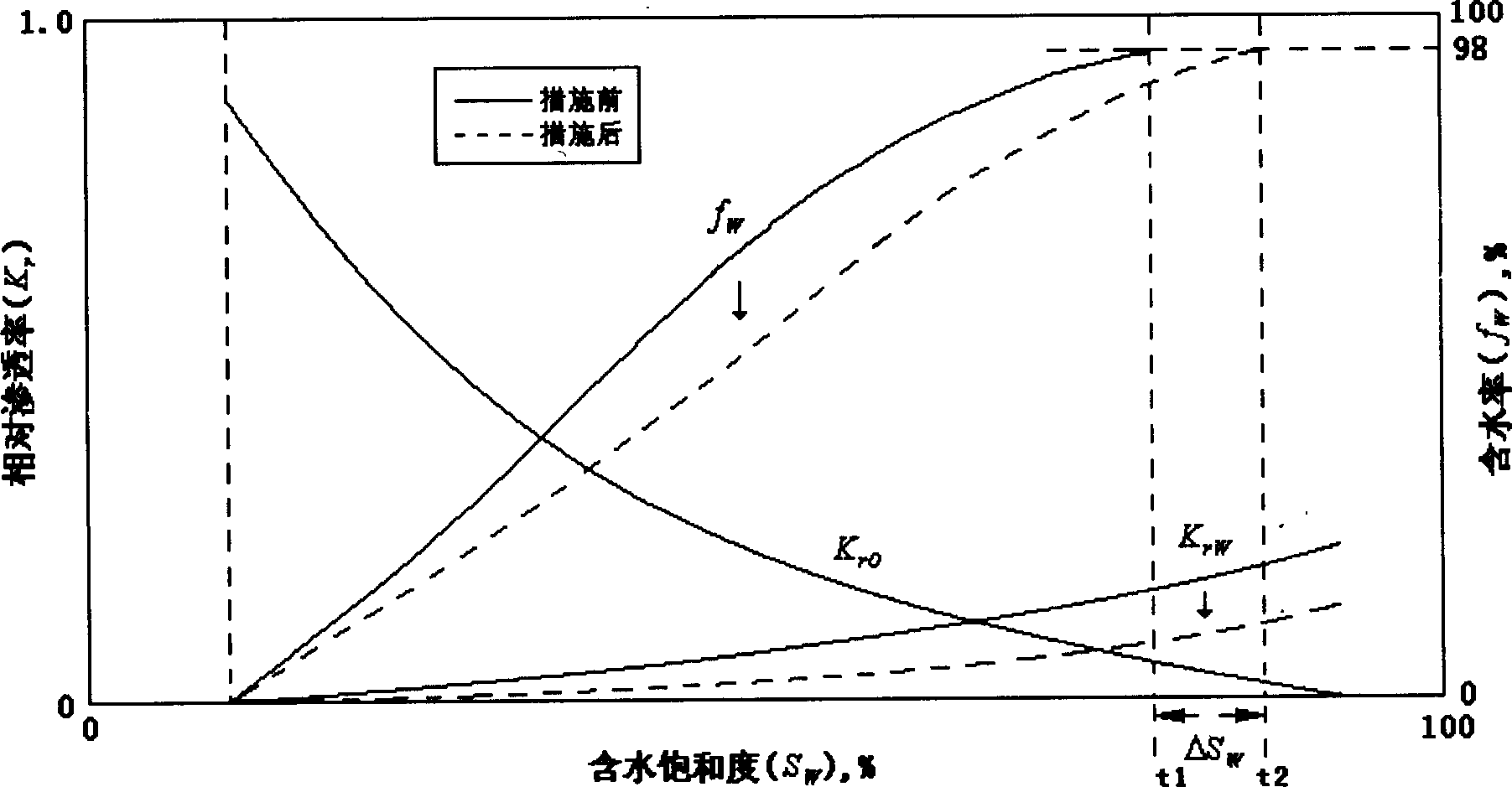

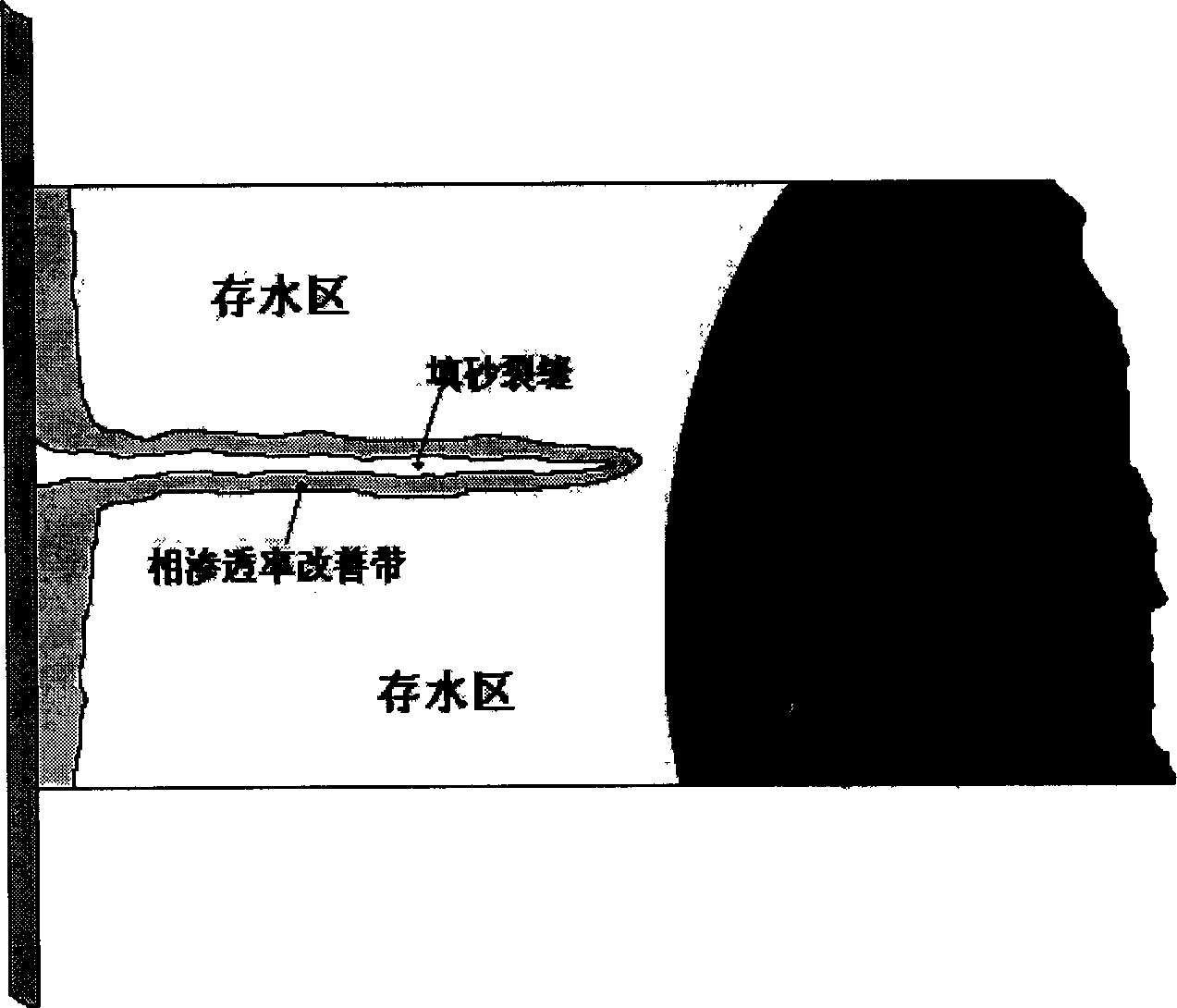

Fracturing method for improving recovering ratio by phase permeability improver

InactiveCN1614193AReduce water contentIncrease fluid productionFluid removalHydraulic fracturingOil water

A fracturing method for increasing the recovering rate of oil well by use of phase permeability improver features that the hydraulic fracturing method is used to generate artificial crack and the phase permeability improver is filled in the stratum via oil well to form a phase permeability improved zone around the artificial crack, which has the selectivity to the osmotic oil-water flow, reducing the relative permeability of water.

Owner:DAQING OILFIELD CO LTD

Method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material

ActiveUS8052953B2Reduce solubilityEasier the sugars precipitateSugar derivativesSugar crystallisationCelluloseOrganic solvent

Owner:CHEN PEIHAO

Method for carrying out profile control on fracture-type oil reservoir

The invention relates to a method for carrying out profile control on a fracture-type oil reservoir, which comprises the following steps of injecting 0.1 to 0.3 percent of zwitterionic polymer solution into an oil layer; suspending and carrying expansion-retarding 0.2 to 1.0 percent of salt-resistance high-intensity water-absorbent resin particles by a zwitterionic gel profile control agent and injecting the obtained product into a fracture of the oil layer; injecting 30 to 50m<3> of acrylamide gel; suspending 0.2 to 0.5 percent of water insoluble solid particles by the zwitterionic gel profile control agent and injecting the obtained product into the fracture; and alternately injecting 1,000m<3> of partially hydrolyzed polyacrylamide solution with a molecular weight of 15 million, degree of hydrolysis of 10 to 20 percent and 1,000m<3> of petroleum sulfonate surfactant solution, wherein the concentration of the hydrolyzed polyacrylamide solution is 0.05 to 0.15 percent and the concentration of the petroleum sulfonate surfactant solution is 0.2 to 0.5. According to the method, profile control and flooding effects of the fracture-type oil reservoir can be improved; water content of a fracture main direction oil well is reduced; and yield of crude oil of a fracture side direction oil well is increased.

Owner:PETROCHINA CO LTD

Composite gypsum board and methods related thereto

ActiveUS20160375651A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a hoard core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

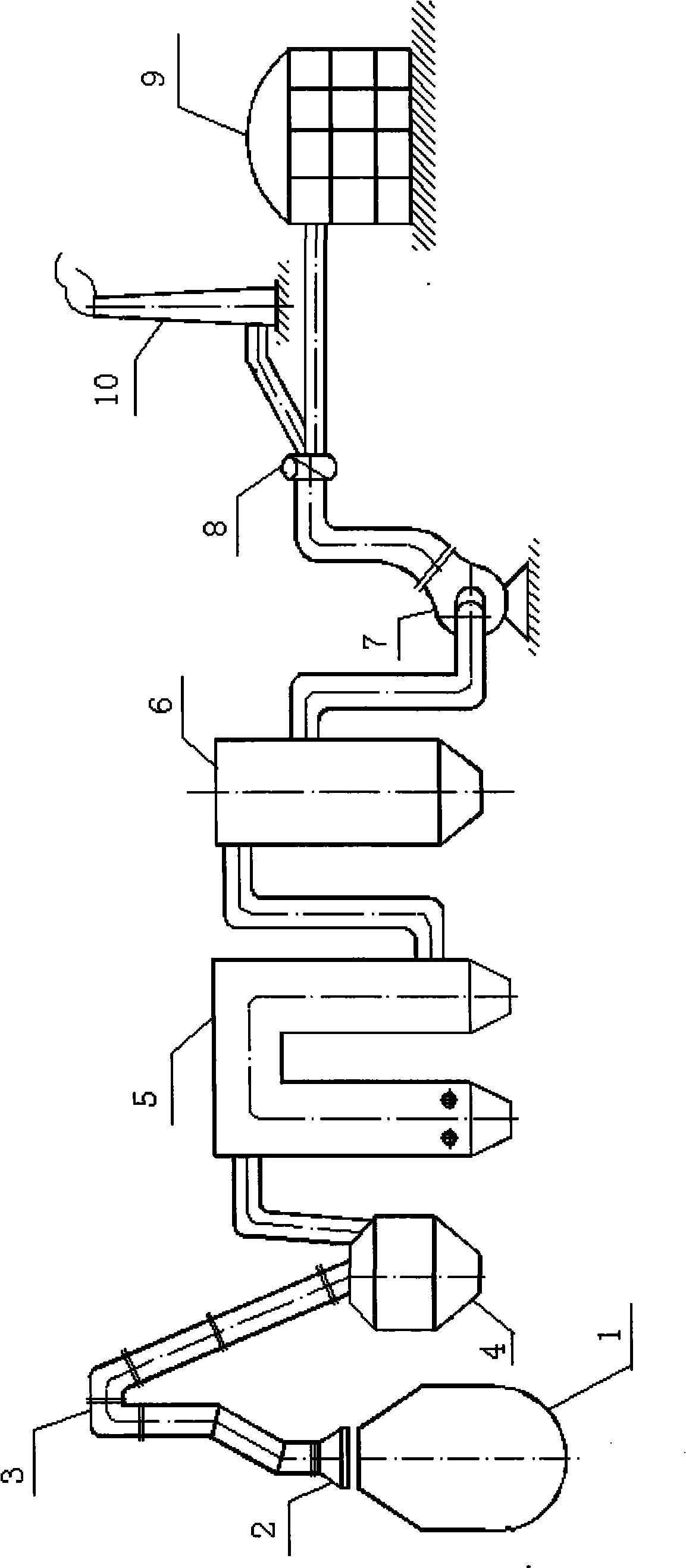

Full dry purification and residual heat utilization equipment and method for converter gas

InactiveCN101492756ALess dustLess waterIncreasing energy efficiencyManufacturing convertersSuperheated steamMoisture

The invention provides devices for purifying converter gas by dry process and using afterheat of the converter gas and a method thereof. In a converting period, waste gas exhausted from the converter is cooled by a movable gas hood and a vaporizing cooling duct, then is sent into a gravity dust collector to reduce dust content thereof, is conducted into a flue and then to an afterburning afterheat boiler; the afterburning afterheat boiler generates overheated vapor by using large quantity of sensible heat of the converter gas and sends the converter gas after being cooled into a bag dust collector through the flue to purify; the purified converter gas is sent to a draft fan to be pressurized through the flue, then passes through a three-way valve, and is sent to a converter gas cabinet; in a non-blowing period of the converter, converter gas is not generated; afterburning afterheat boiler burns a certain amount of blast furnace gas to stabilize load thereof and vapor yield. The three-way valve is switched to cause the afterheat boiler waster gas exhausted from the draft fan to flow to a waste gas discharging chimney. The converter gas processed by the method and devices has very low dust and moisture contents and is an ideal purified gas. During the operation process, large quantity of industrial water is saved, and large quantity of secondary energy is recycled.

Owner:袁长胜

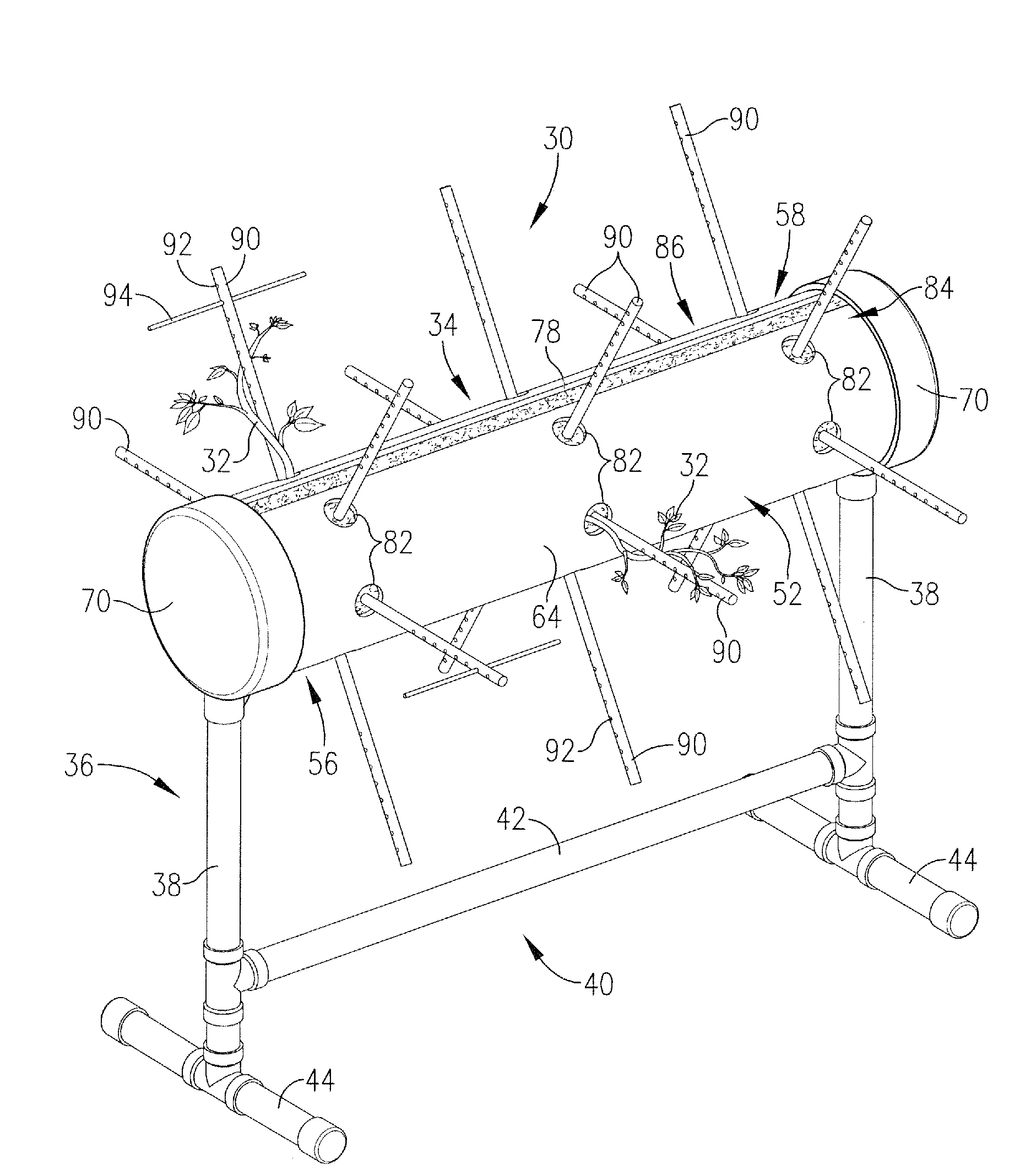

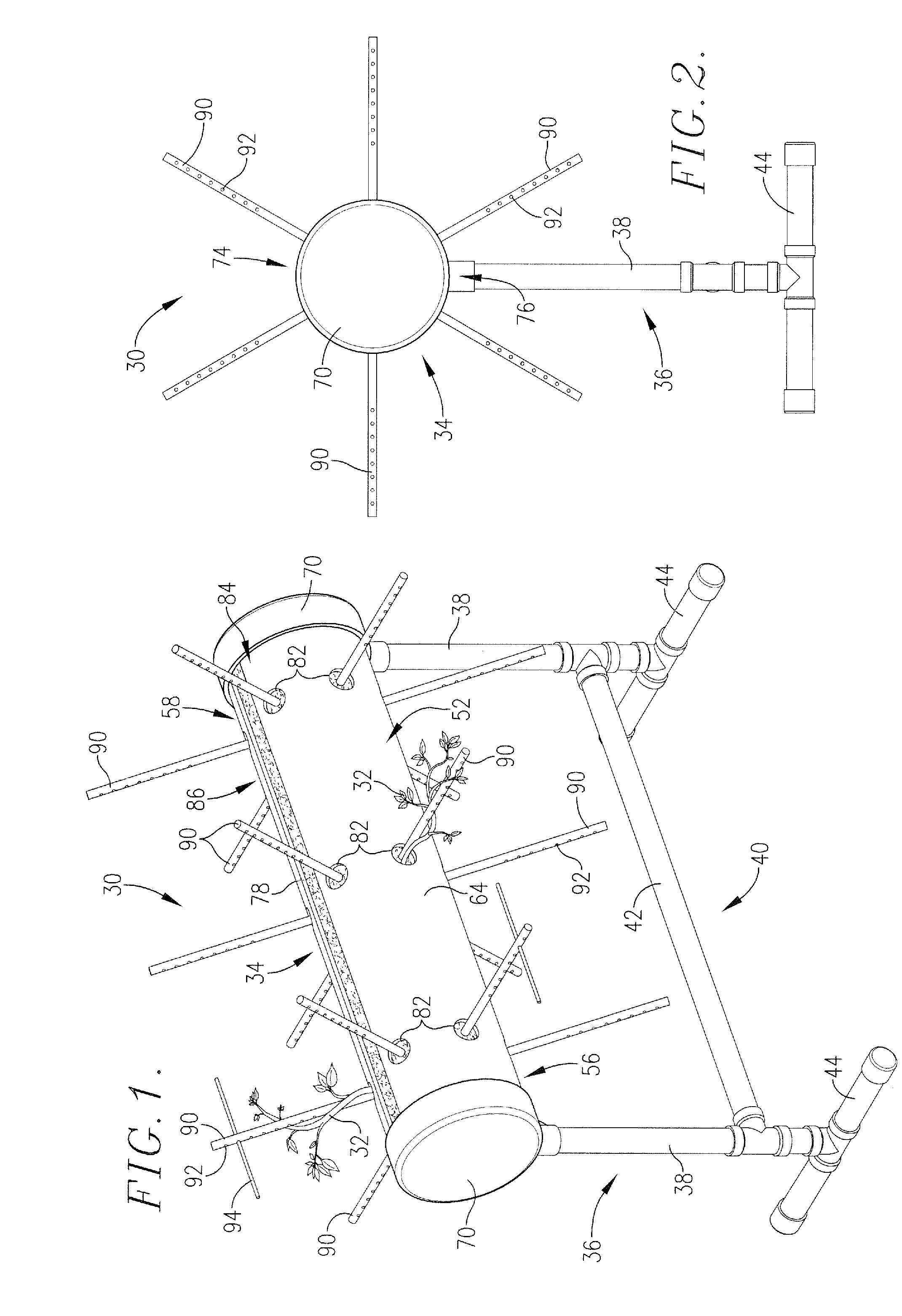

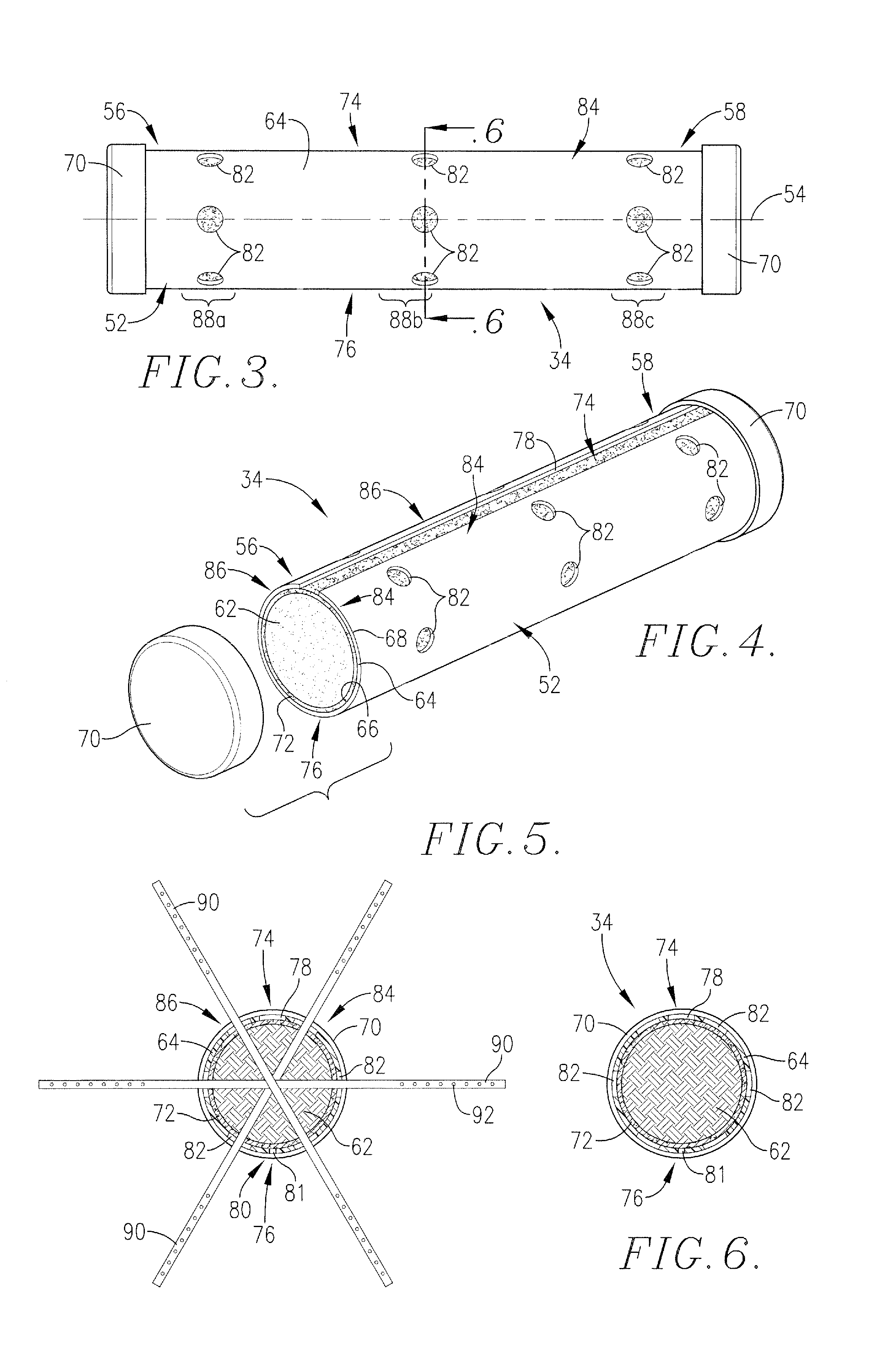

Method and apparatus for growing plants

ActiveUS20110016782A1Less waterAvoid oversaturationWatering devicesAgriculture gas emission reductionGrowth plantAbove ground

A plant growing assembly is configured to grow a plurality of plants in multiple directions above a ground surface. The assembly includes a growing container and a support structure for elevating the container above the ground surface. The container presents a generally hollow body to retain a plant-growing medium and the plurality of plants. The body extends along an axis to present opposite axial end margins and a radial peripheral wall. The wall defines a plurality of discrete plant-receiving ports extending therethrough, and disposed generally radially about the wall. A method of growing plants above ground in substantially opposite directions from one another is also disclosed.

Owner:GROW TUBE

Composite high polymer flocculant for coking wastewater and preparation method thereof

InactiveCN106335988AReduce secondary pollutionWide variety of sourcesWater/sewage treatment by flocculation/precipitationCoking wastewaterIron(II) chloride

The invention discloses a composite high polymer flocculant for coking wastewater and a preparation method thereof. The composite high polymer flocculant adopts non-ionic modified starch, cationic modified starch, anionic modified starch, and amphoteric modified starch as the raw materials, in the presence of an initiator and under a weak acid condition, the raw materials undergo graft copolymerization with acrylamide, acrylic acid, methacrylic acid, acrylonitrile, acrylic ester, styrene, methylene acrylamide, maleic anhydride and other monomers to obtain a modified starch graft copolymer, and the copolymer is blended with an inorganic flocculant ferric sulfate, ferric silicate, ferric chloride, ferrous sulfate and ferrous chloride to obtain the composite high polymer flocculant. The composite high polymer flocculant has the characteristics of long molecular chain, compact floccules, wide source of raw materials, low price, biodegradability, and little secondary pollution, etc., and is a real efficient and environment-friendly flocculant. During use, the dosage of the composite high polymer flocculant accounts for 0.1-1% of the volume fraction of the treated coking wastewater, the COD removal rate of the treated coking wastewater reaches 85% or more, the decolorization rate is 95% or more, and the removal rate of suspended solids reaches 95% or more.

Owner:TIANJIN ZHONGFU ENG TECH

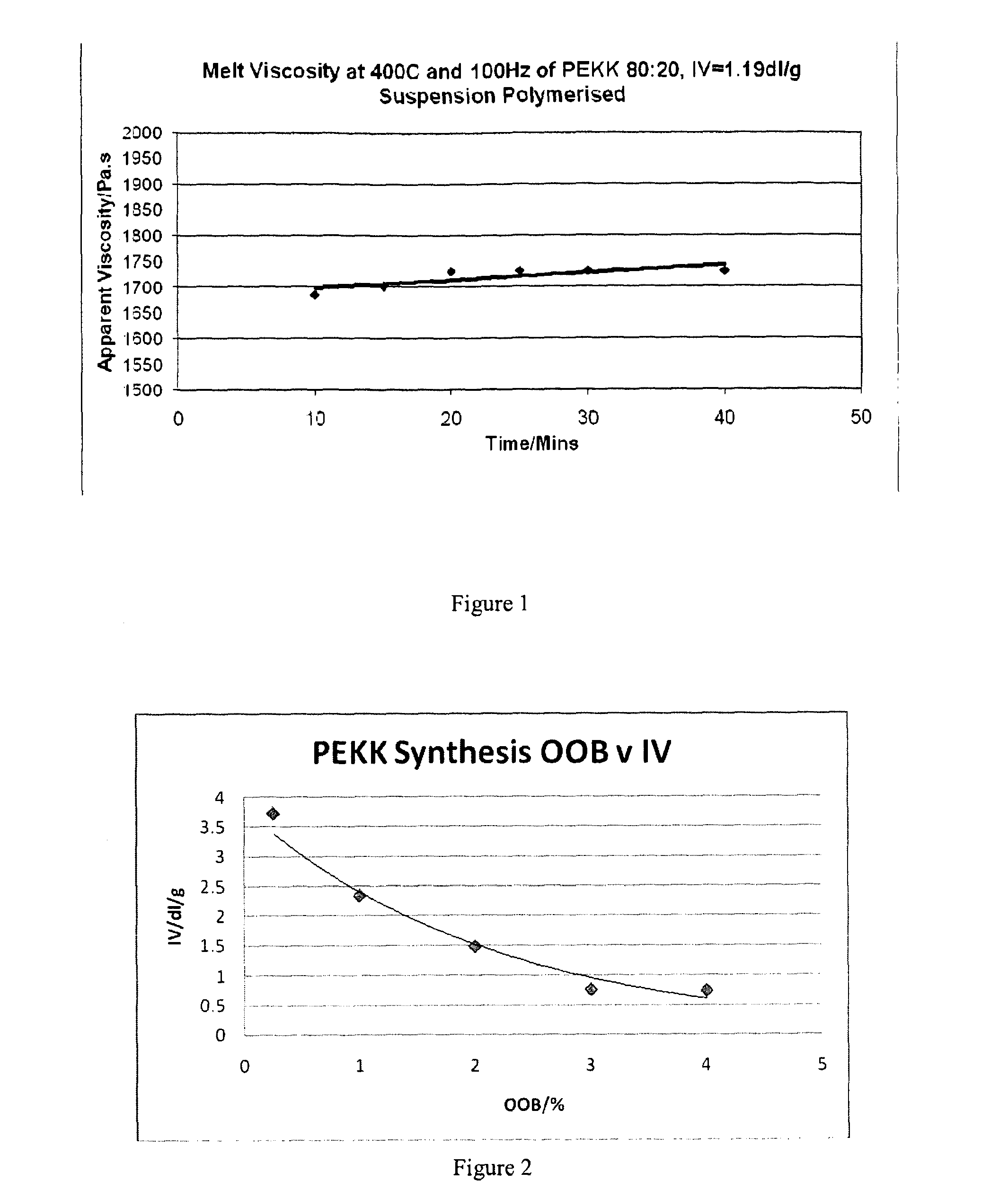

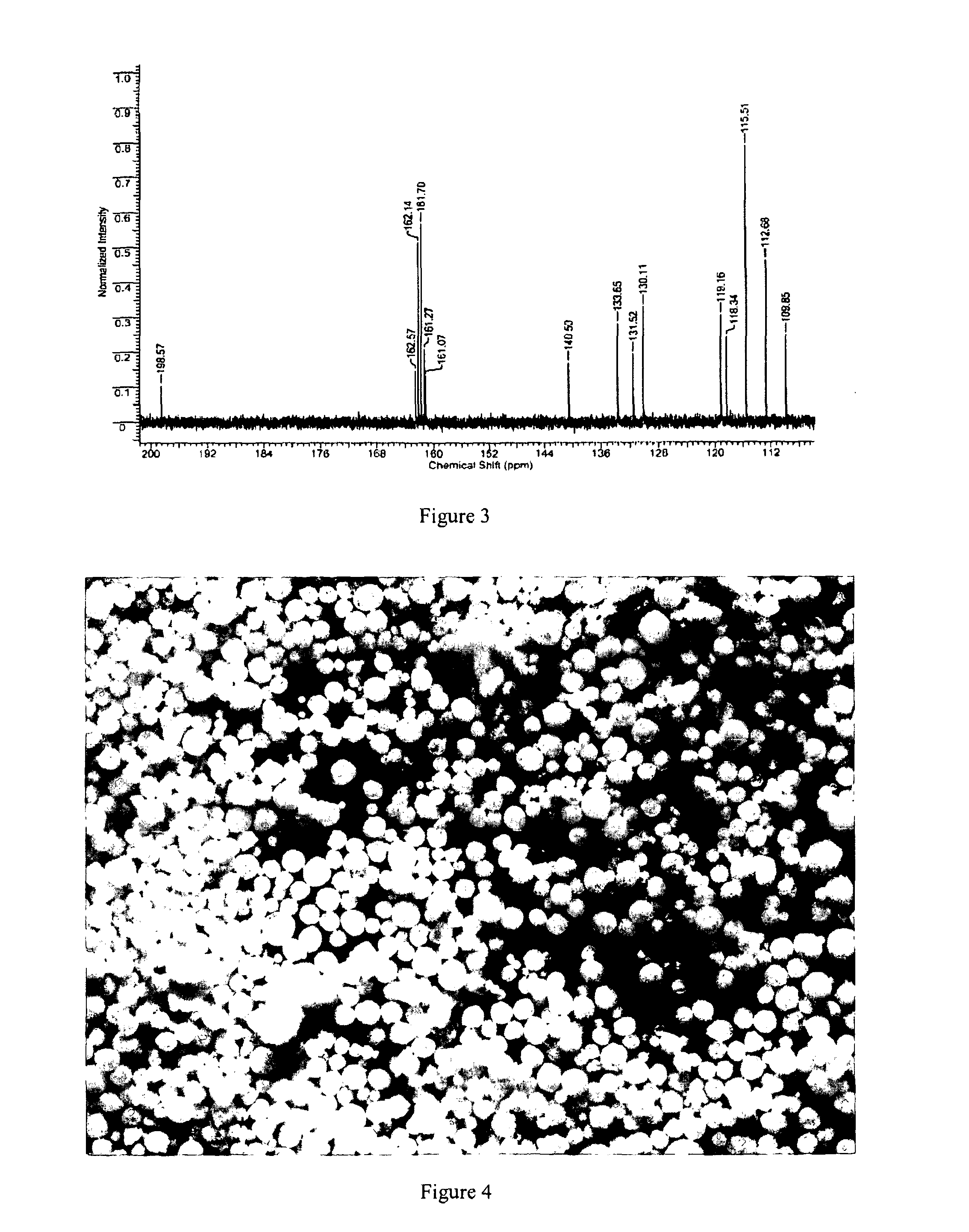

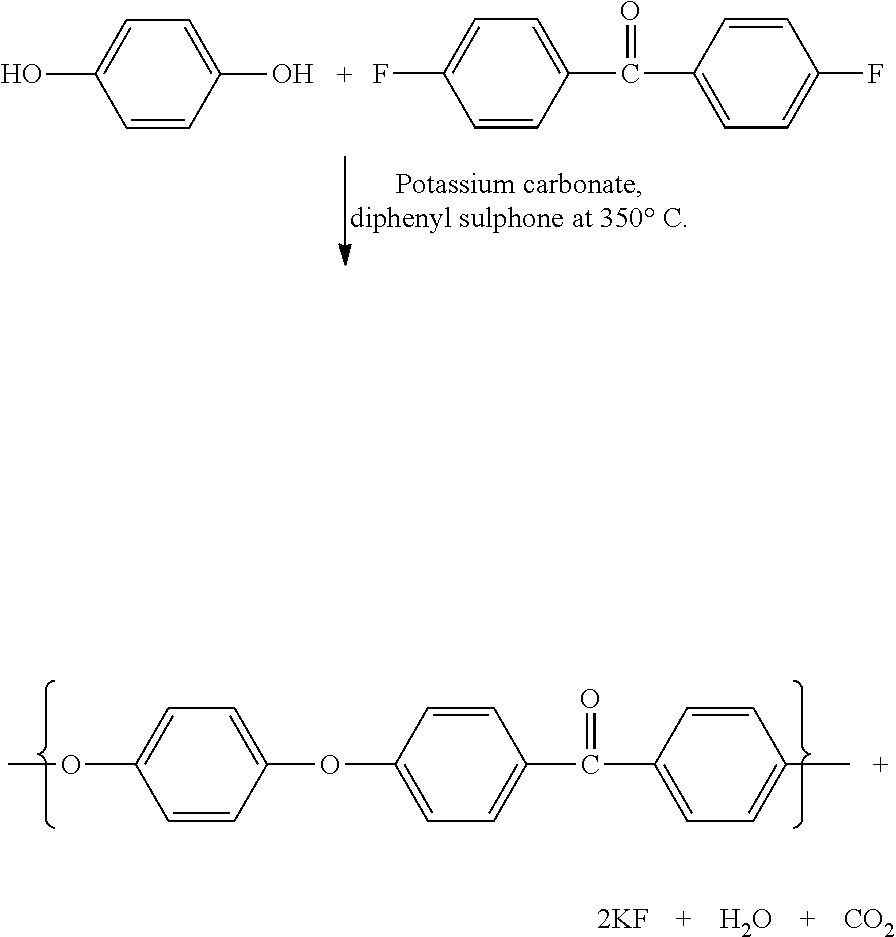

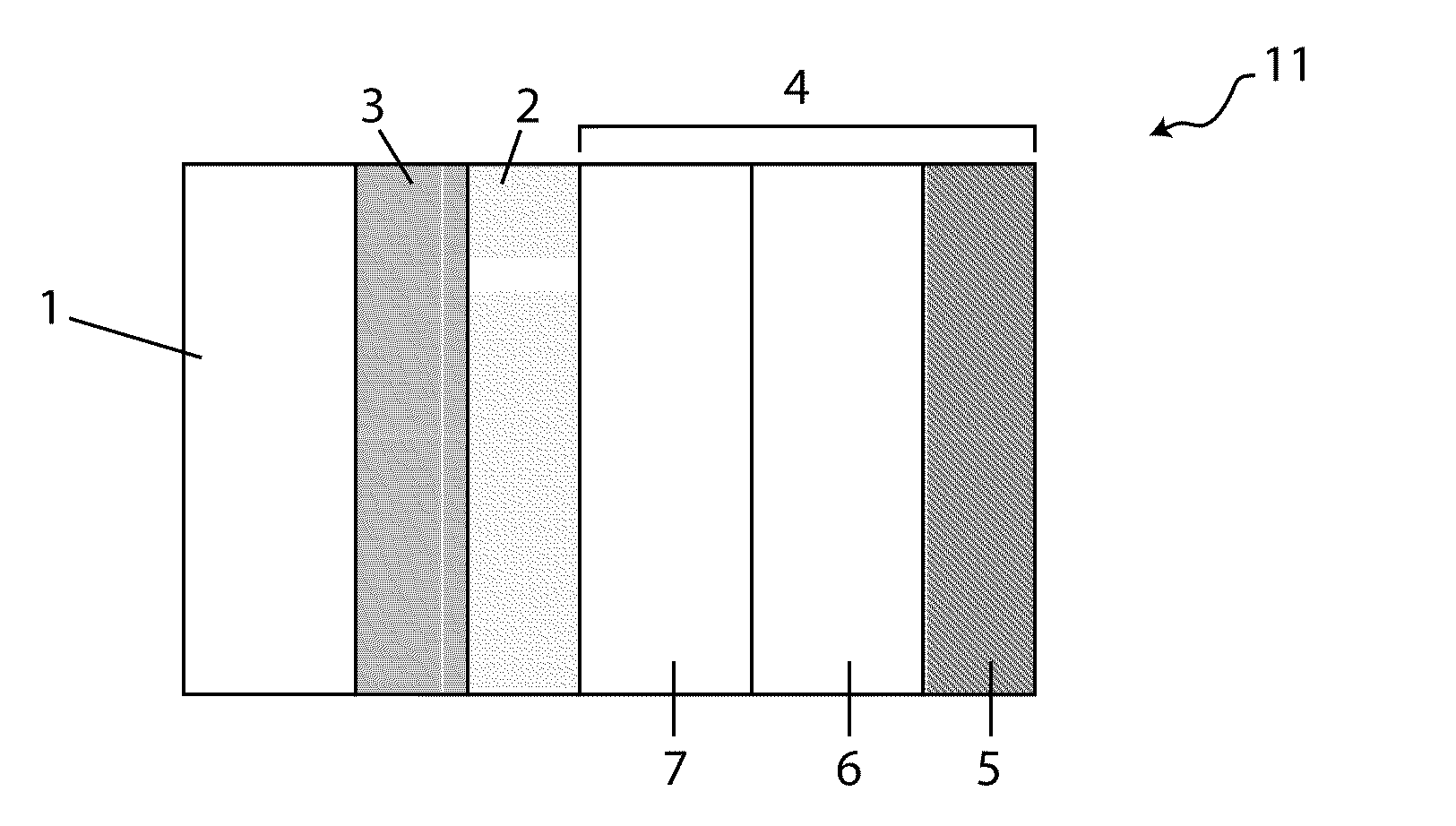

Method for preparing poly (ether ketone ketones)

ActiveUS9023468B2Reduce the amount of waterLower the volumeMonocomponent polyethers artificial filamentSynthetic resin layered productsAromatic moietyEther

A method of preparing a poly (ether ketone ketone) consisting essentially of the repeat unit:—Ar—O—Ar—C(═O)—Ar—C(═O)—wherein each Ar is independently an aromatic moiety is provided. The method may comprise the step of polymerising a monomer system in a reaction medium comprising: (a) a Lewis acid; and (b) a controlling agent comprising an aromatic carboxylic acid, an aromatic sulphonic acid, or a derivative thereof.

Owner:OXFORD PERFORMANCE MATERIALS

High energy density aqueous lithium/air battery cells

InactiveUS20090311603A1Impart conductivityHigh humidityFuel and primary cellsElectrode manufacturing processesChemistryHigh energy

Li / air battery cells are configurable to achieve very high energy density. The cells include a protected a lithium metal or alloy anode and an aqueous catholyte in a cathode compartment. In addition to the aqueous catholyte, components of the cathode compartment include an air cathode (e.g., oxygen electrode) and a variety of other possible elements.

Owner:POLYPLUS BATTERY

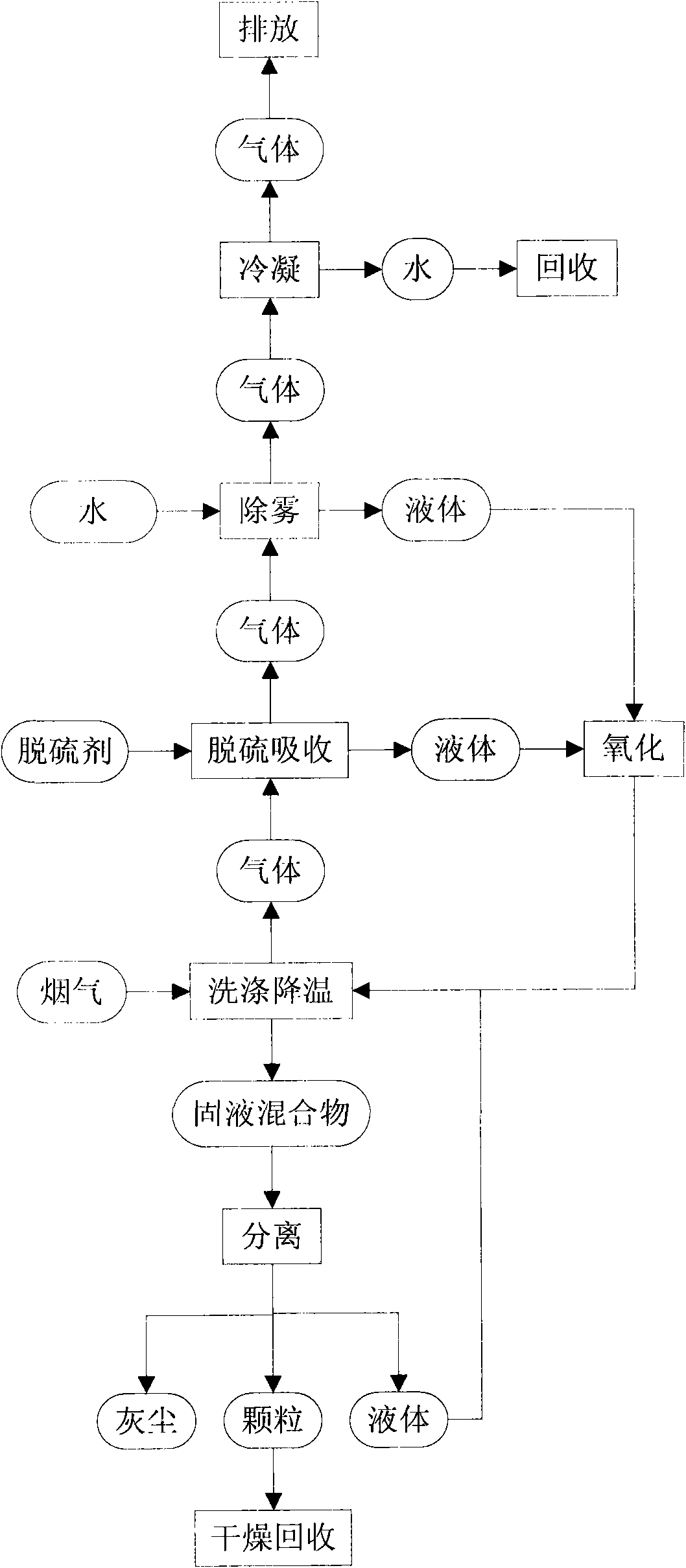

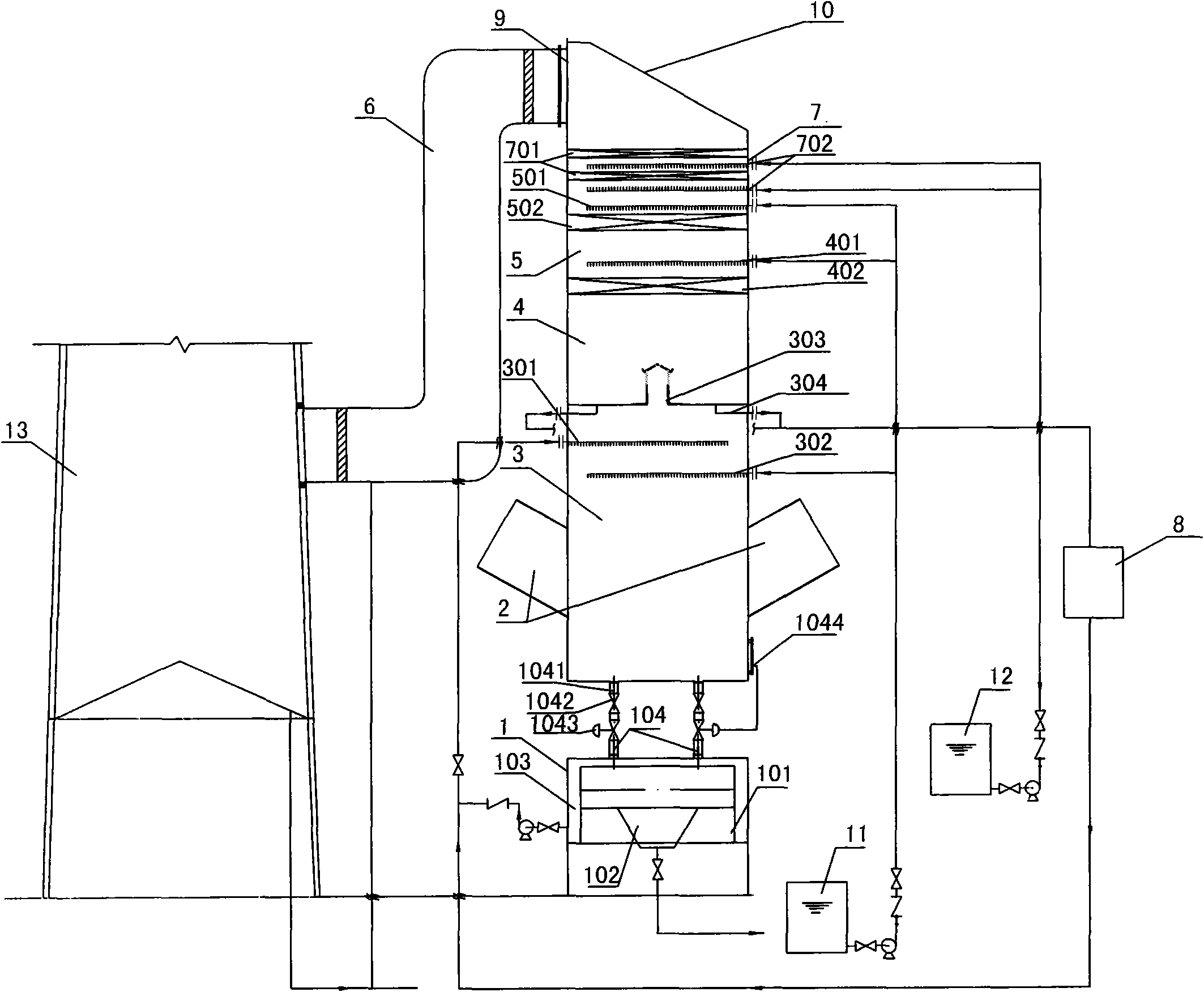

Flue gas desulfurization method and device

ActiveCN102151470ALess waterLess water droplet contentCombination devicesProcess engineeringEnvironmental engineering

The invention discloses a flue gas desulfurization method. The method is characterized by comprising the following steps of: 1) washing and cooling: washing and cooling the flue gas entering a desulfurization tower; 2) separation: separating the dust-containing solid-liquid mixture obtained in the step 1) into dust, ammonium salt granules and ammonium sulfate-containing aqueous solution; 3) absorption: spraying a desulfurizing agent to the purified flue gas obtained in the step 1), and performing gas-liquid countercurrent contact; 4) demisting: removing dust, mist foam and liquid drops entrained in the gas through a demister; and 5) condensation: delivering the gas from the demister to a condensation device, condensing the gas and discharging the condensed gas. The invention also discloses a desulfurization device for the flue gas desulfurization method. The desulfurization device comprises the condensation device, the desulfurization tower, an oxidation device, a desulfurizing agent supply device and a water supply device. The method provided by the invention purifies the flue gas; the discharged gas contains little water, dust and ammonia; byproducts such as ammonium sulfite, ammonium sulfate and the like can be produced; and equipment cost and operating cost for desorption and hydrolysis of urea waste solution are saved at the same time.

Owner:山东华鲁恒升集团德化设计研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com