Patents

Literature

327results about "Multiple-effect/fractional condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

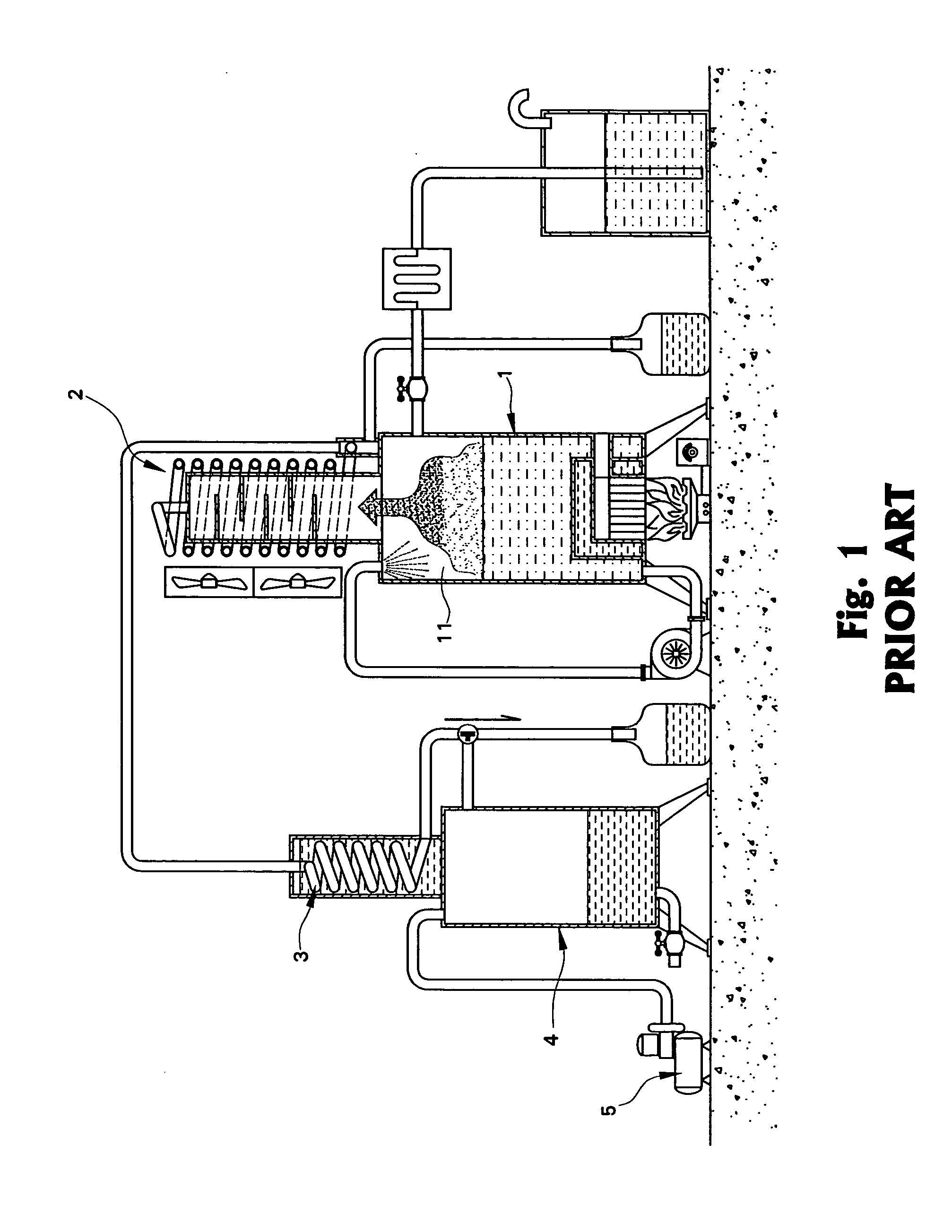

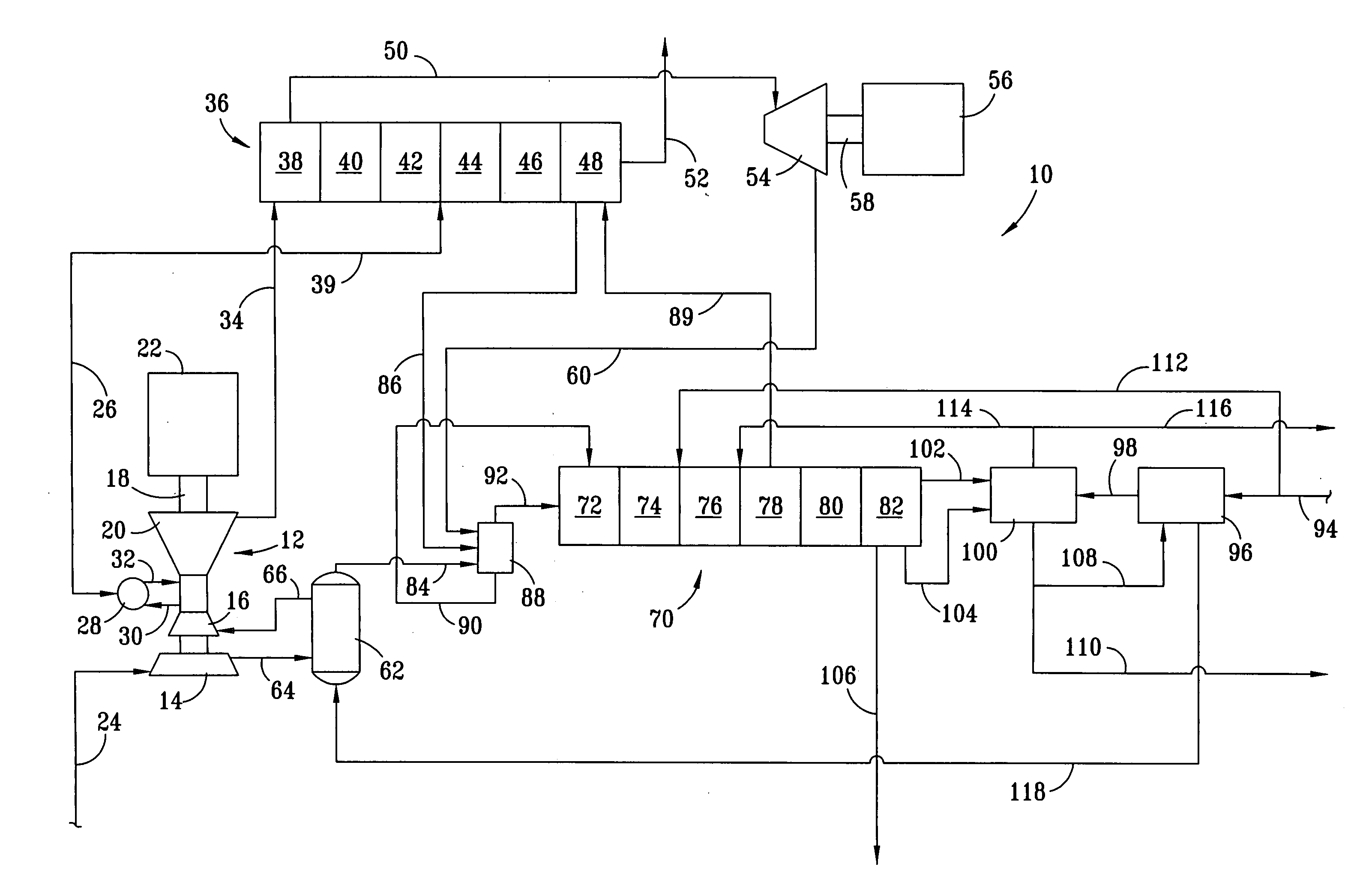

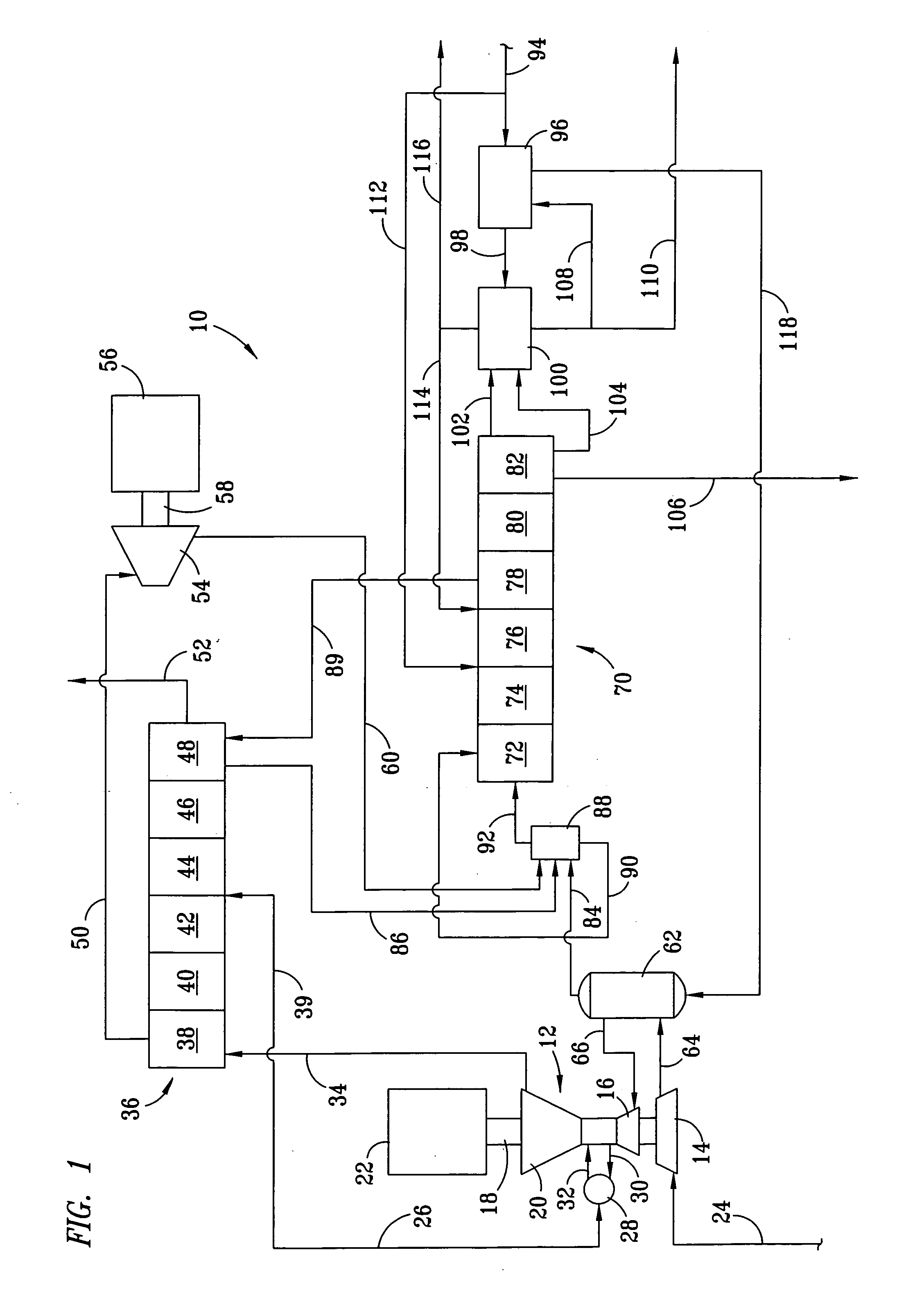

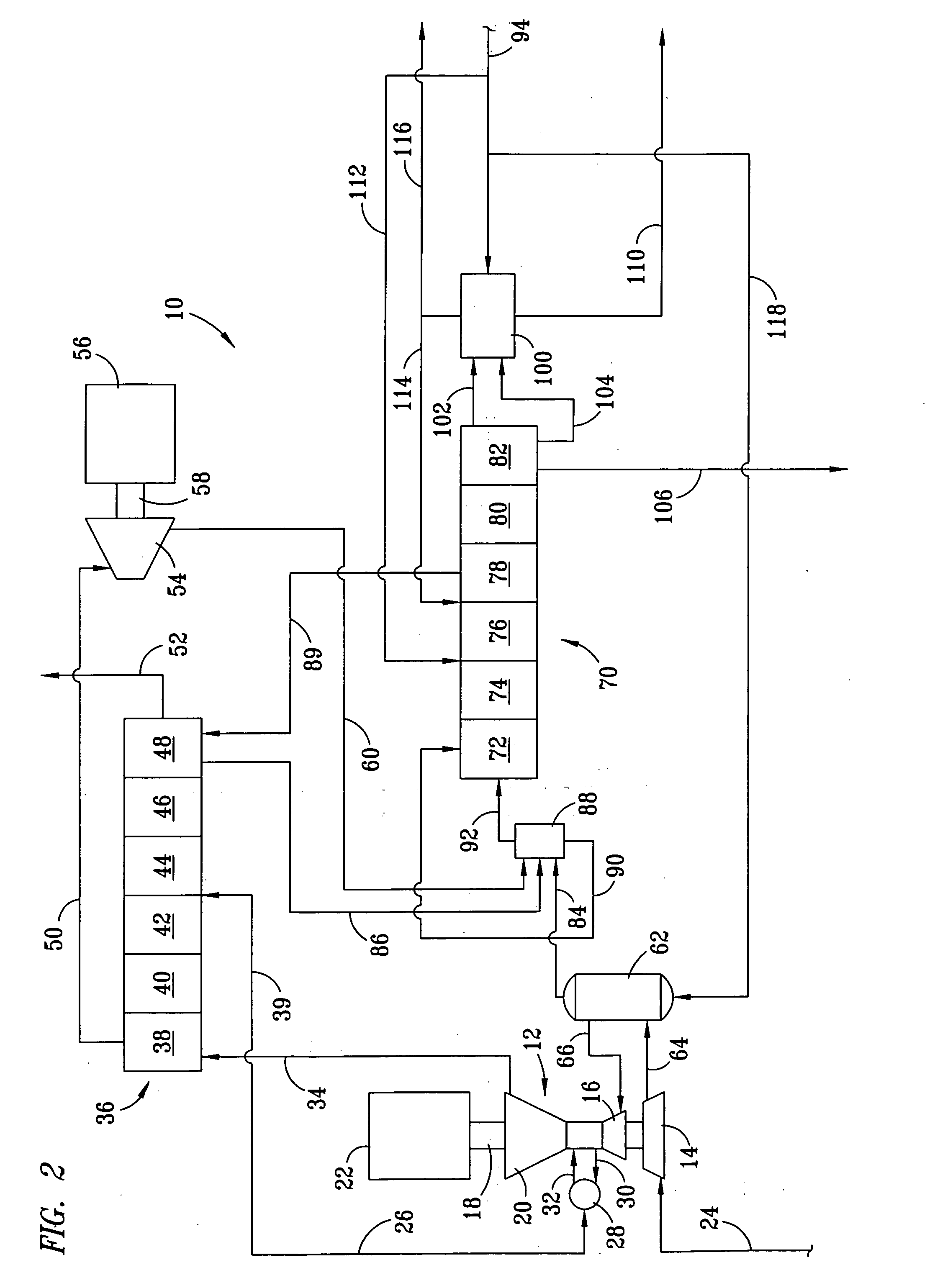

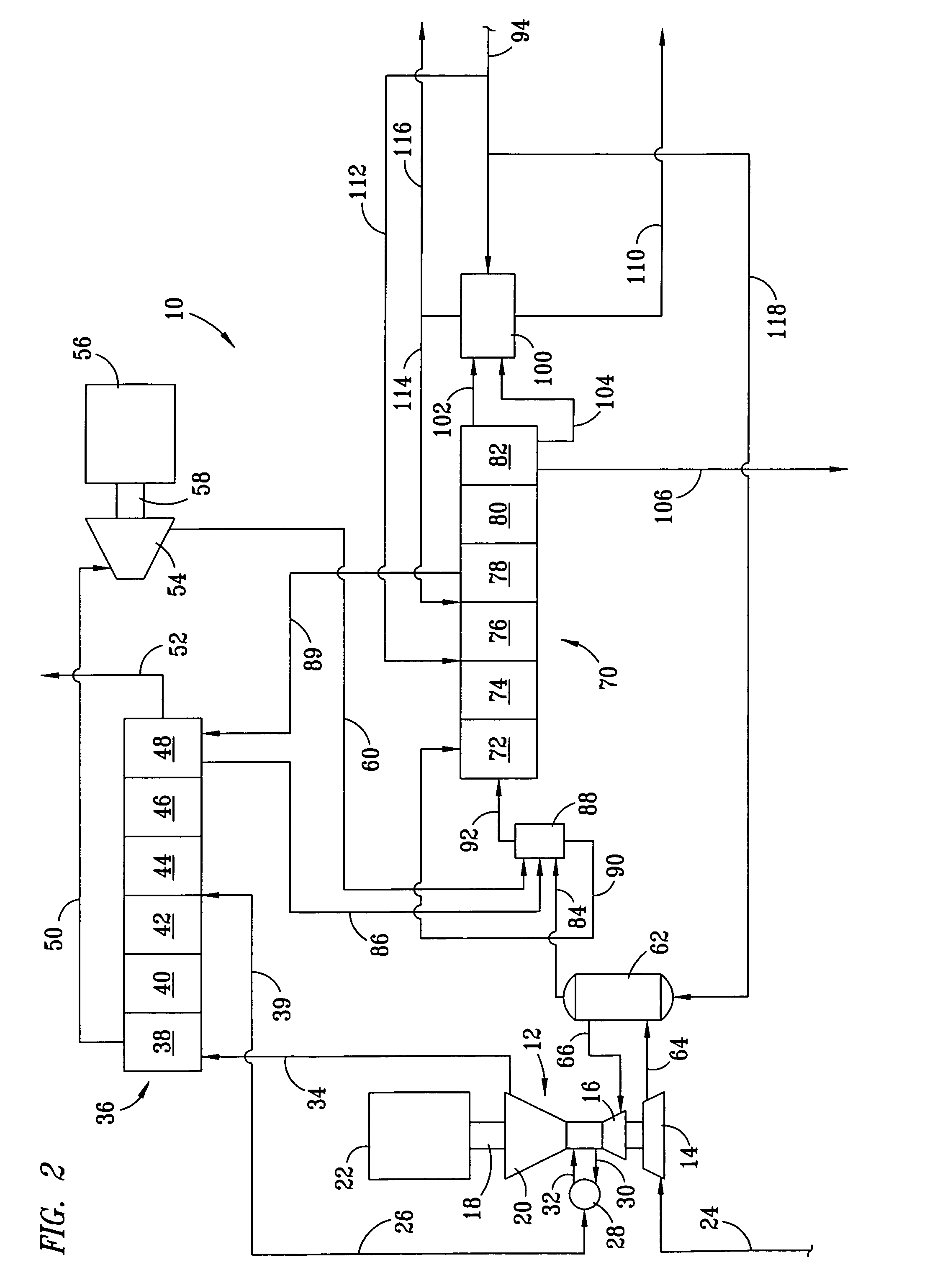

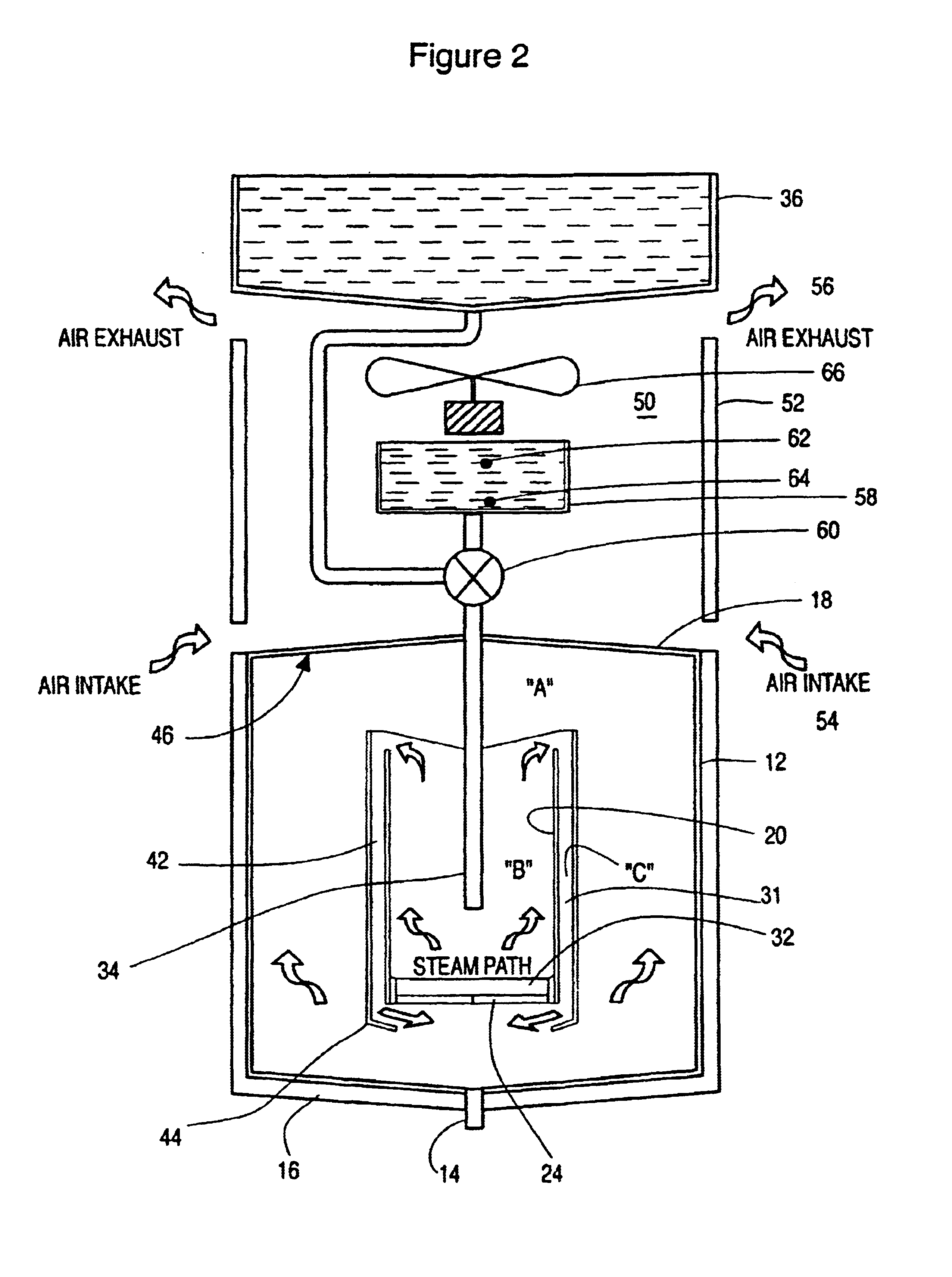

Hydraulic fracturing system and method

ActiveUS9840897B2Multiple-effect/fractional condensationSteam/vapor condensersDistilled waterHydraulic fracturing

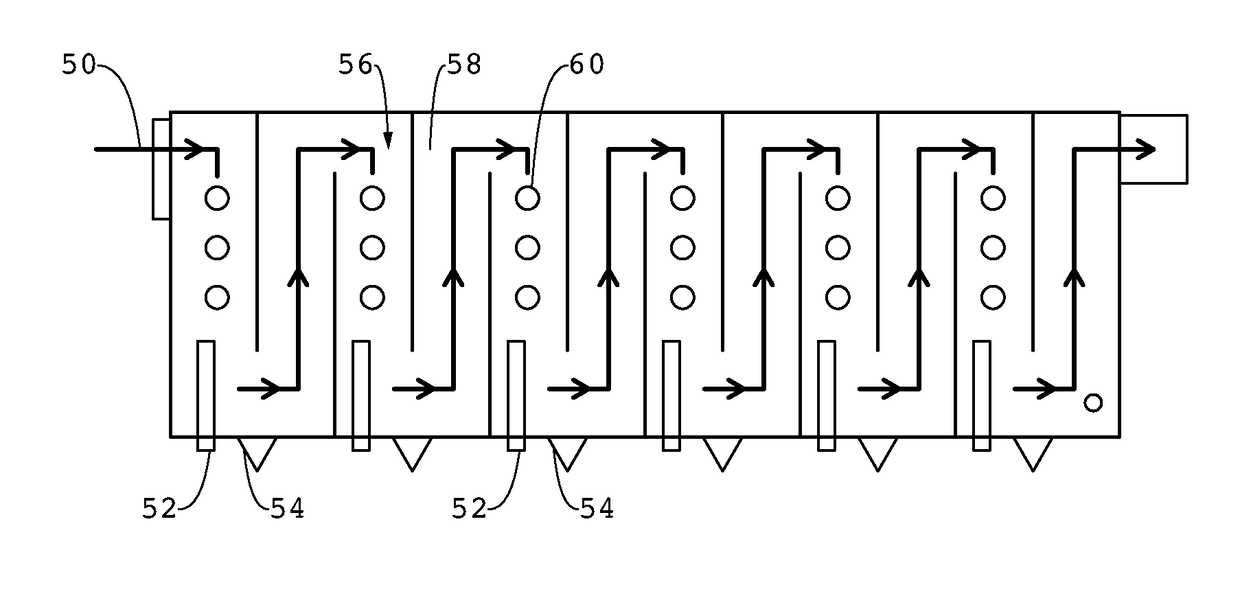

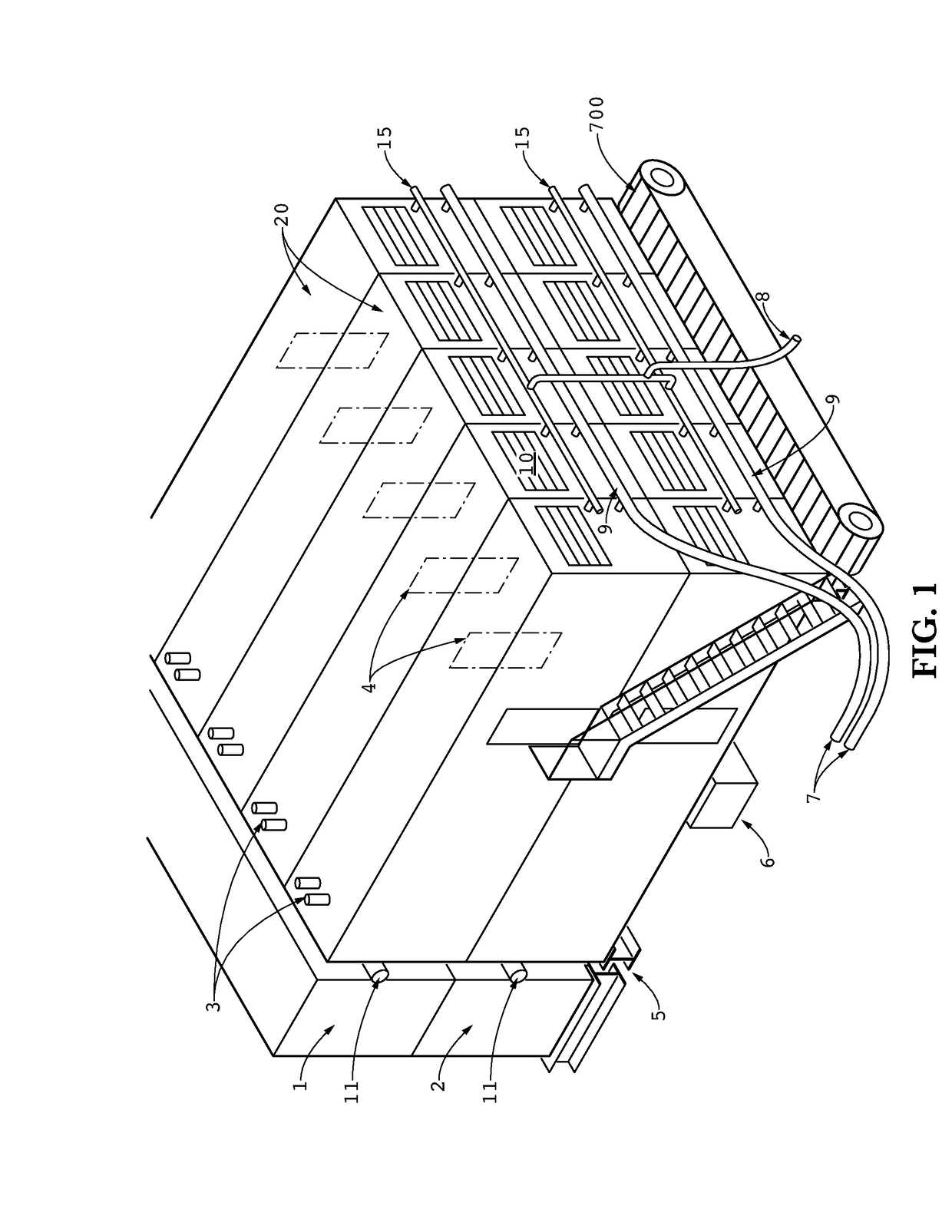

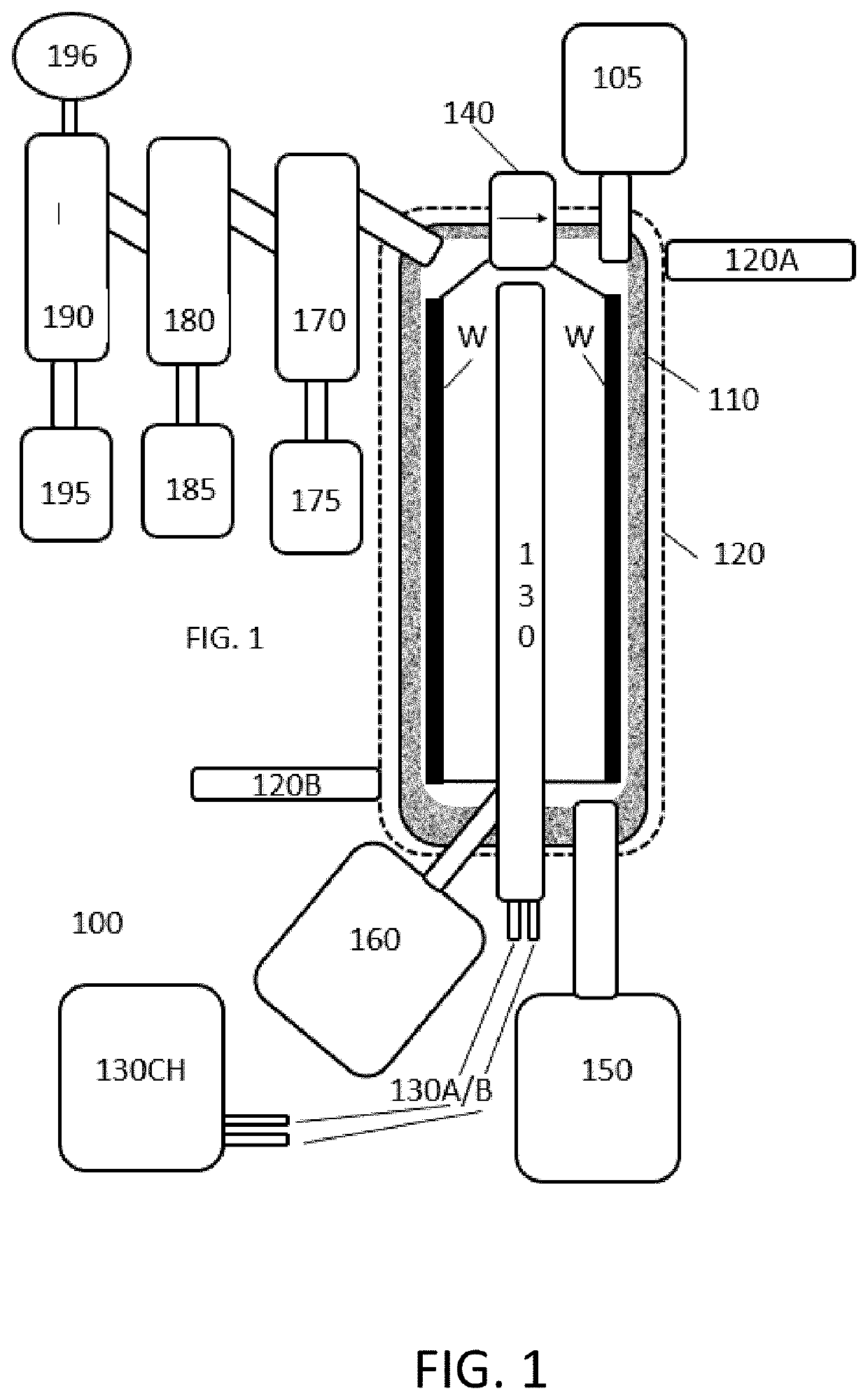

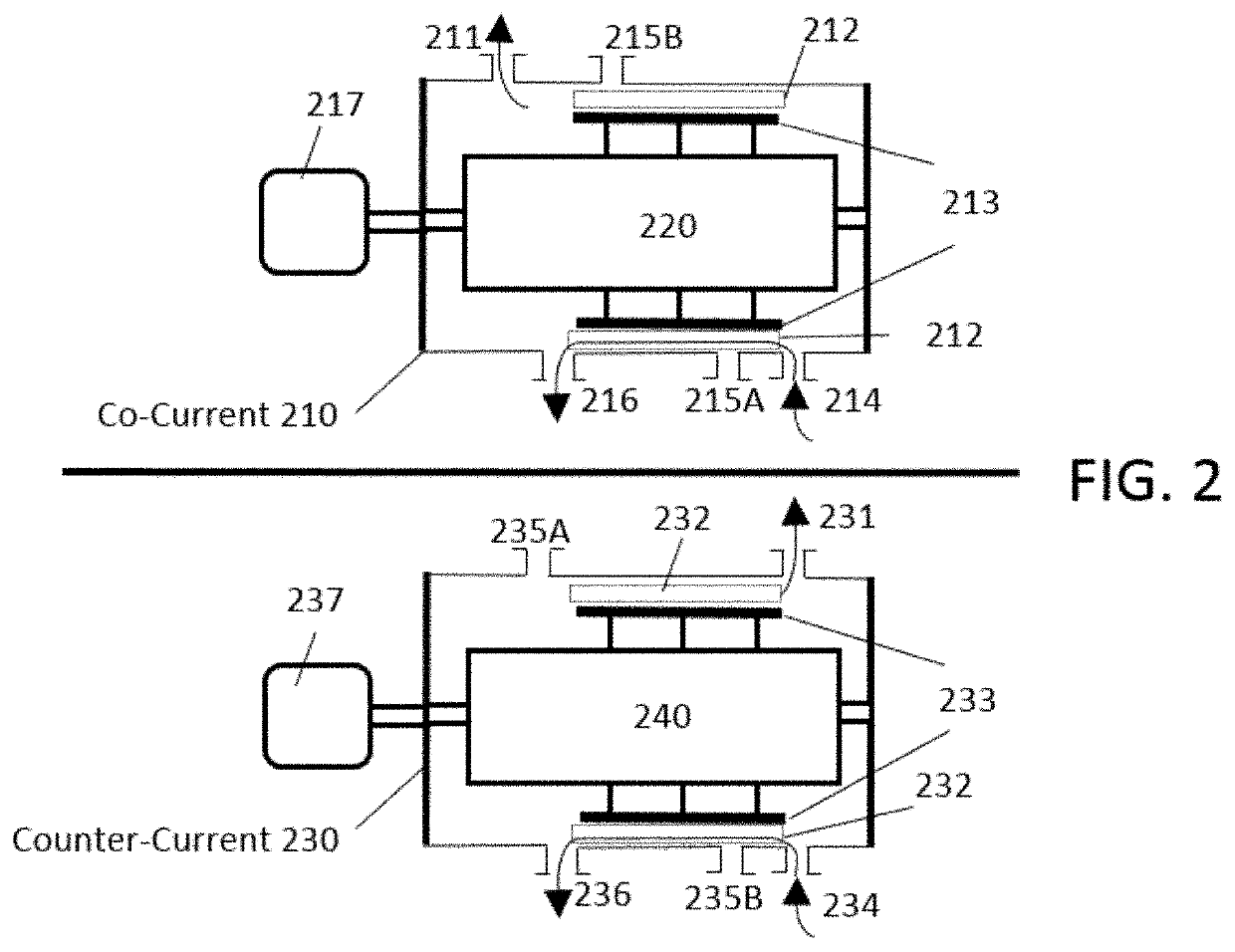

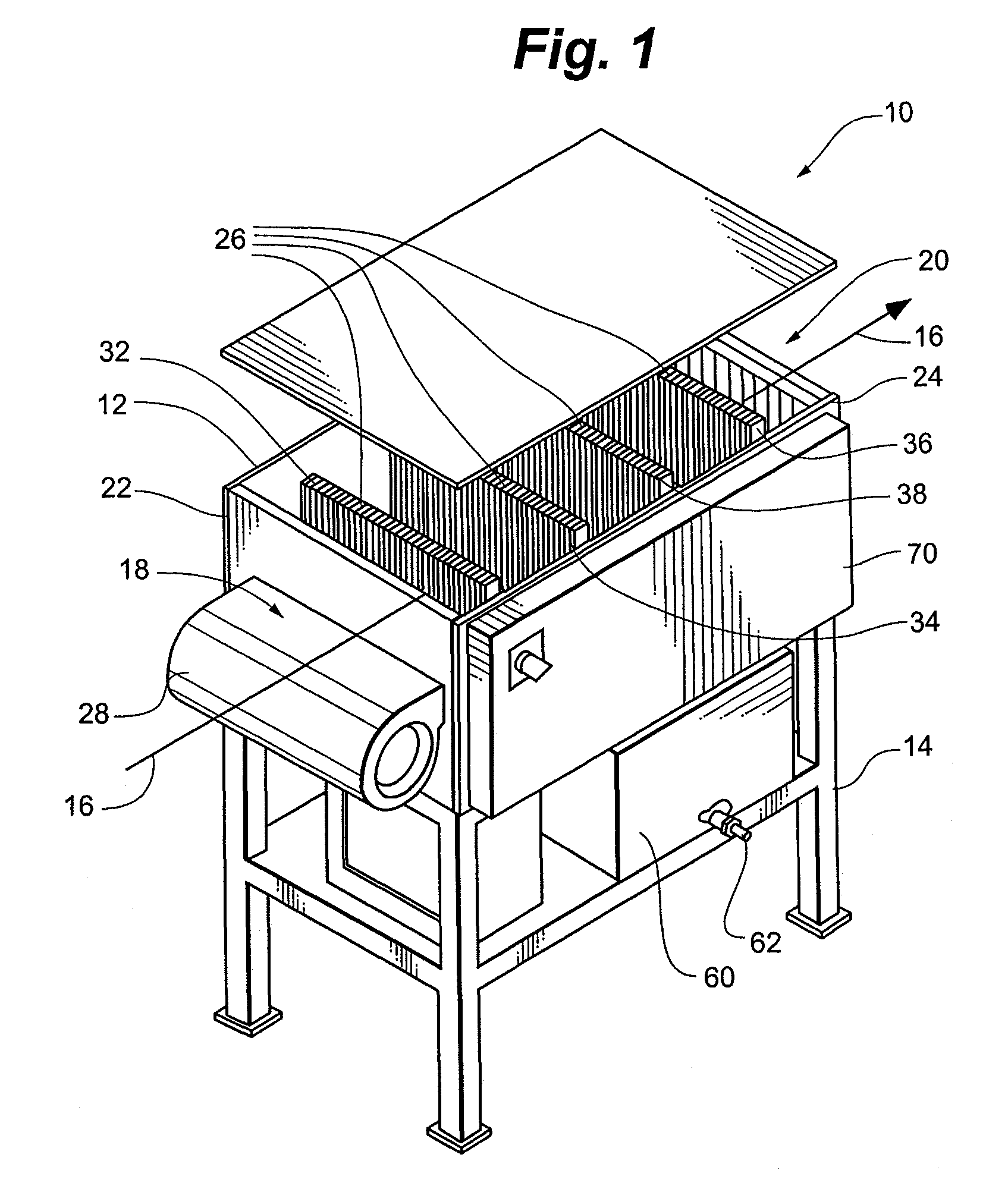

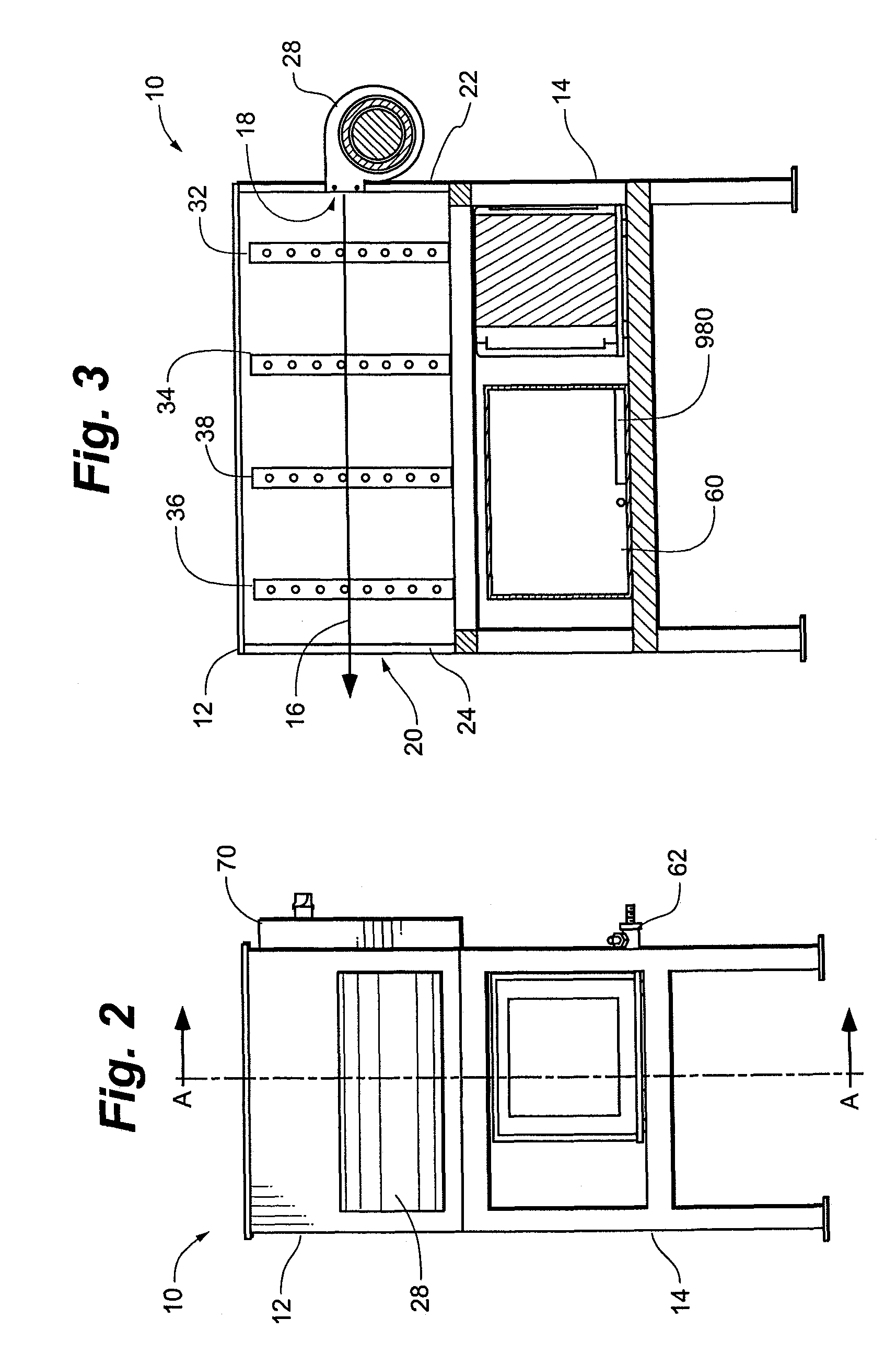

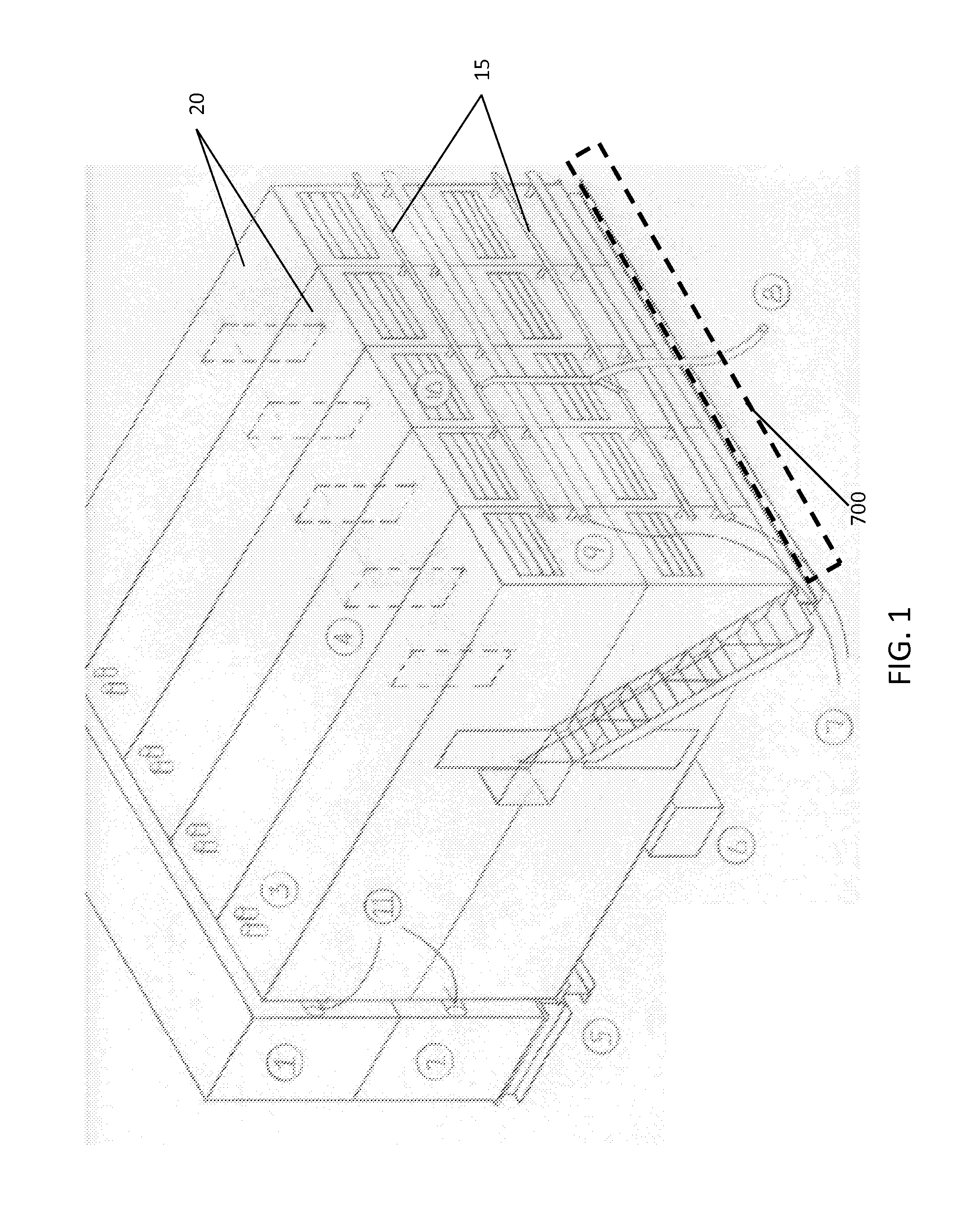

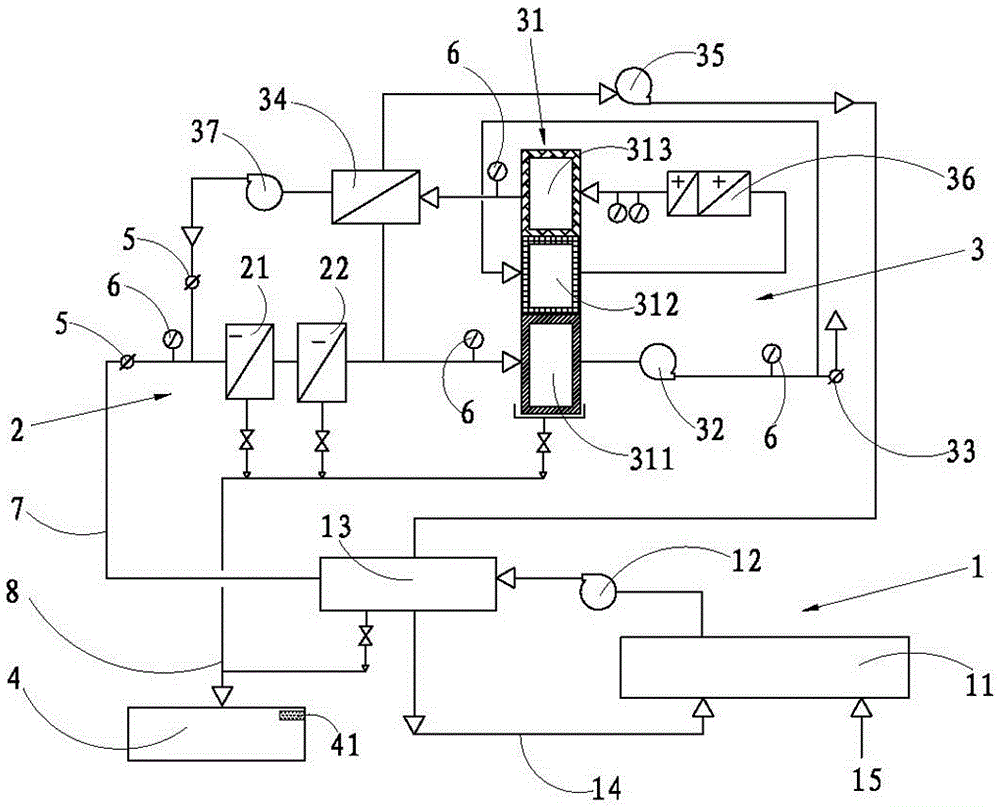

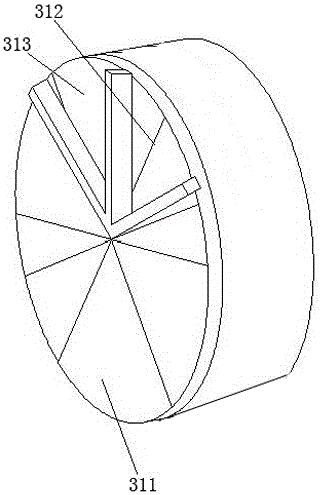

Disclosed herein is a fracturing unit for hydraulic fracturing having an engine and a fracturing pump connected to the engine through a variable speed torque converter. Also disclosed is a hydraulic fracturing system using multiple fracturing units which are sized similar to ISO containers. A hydraulic fracturing system may also force flow back water, produced water, or fresh water through a heat exchanger so that heat from the fracturing engines can be transferred to these liquids in order to vaporize them. A force cooled fractioning unit then can accept the vapor / steam in order to condense the various components and produce distilled water for re-use in the fracturing process or for release into the environment.

Owner:LARSON KEVIN

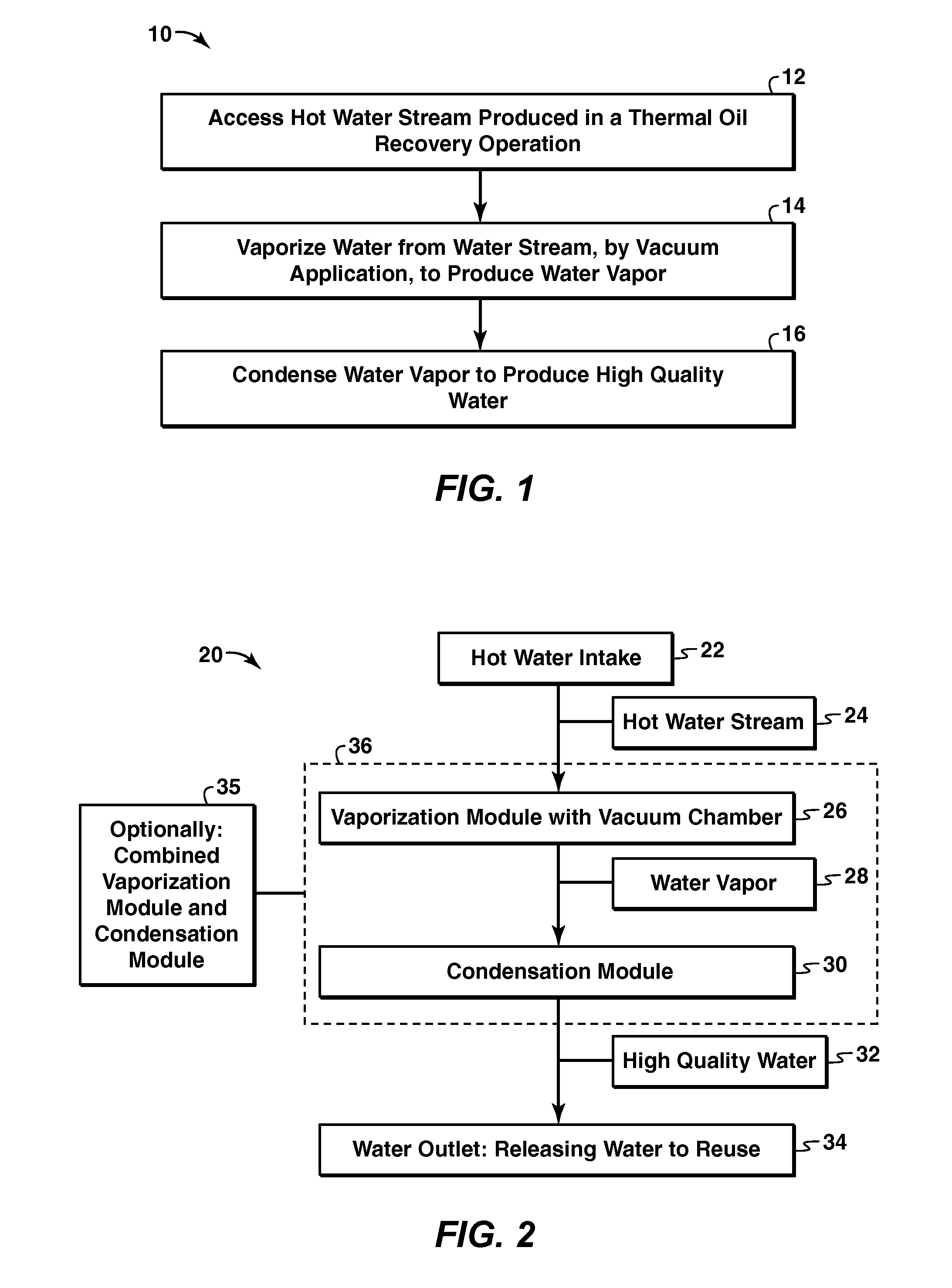

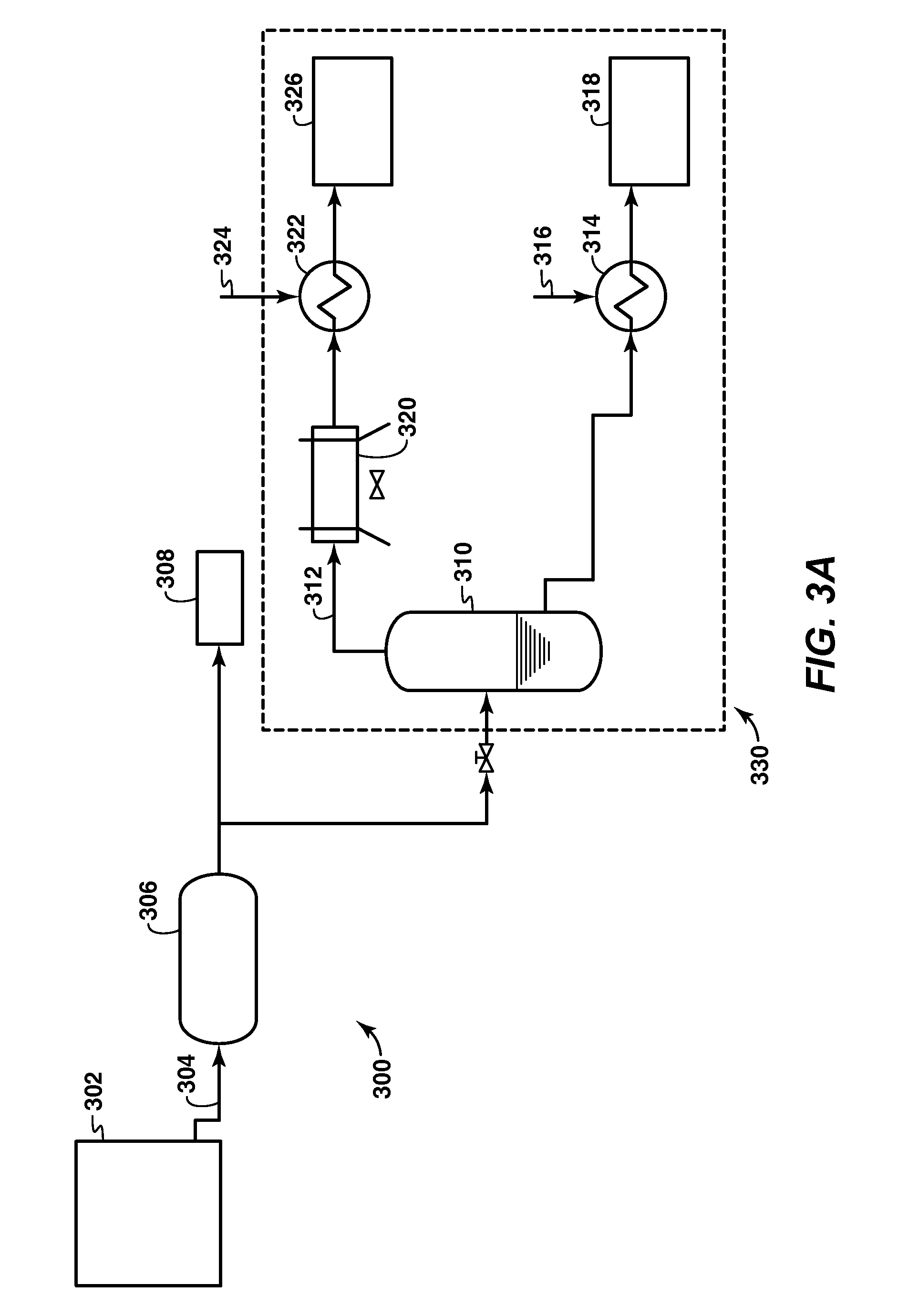

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

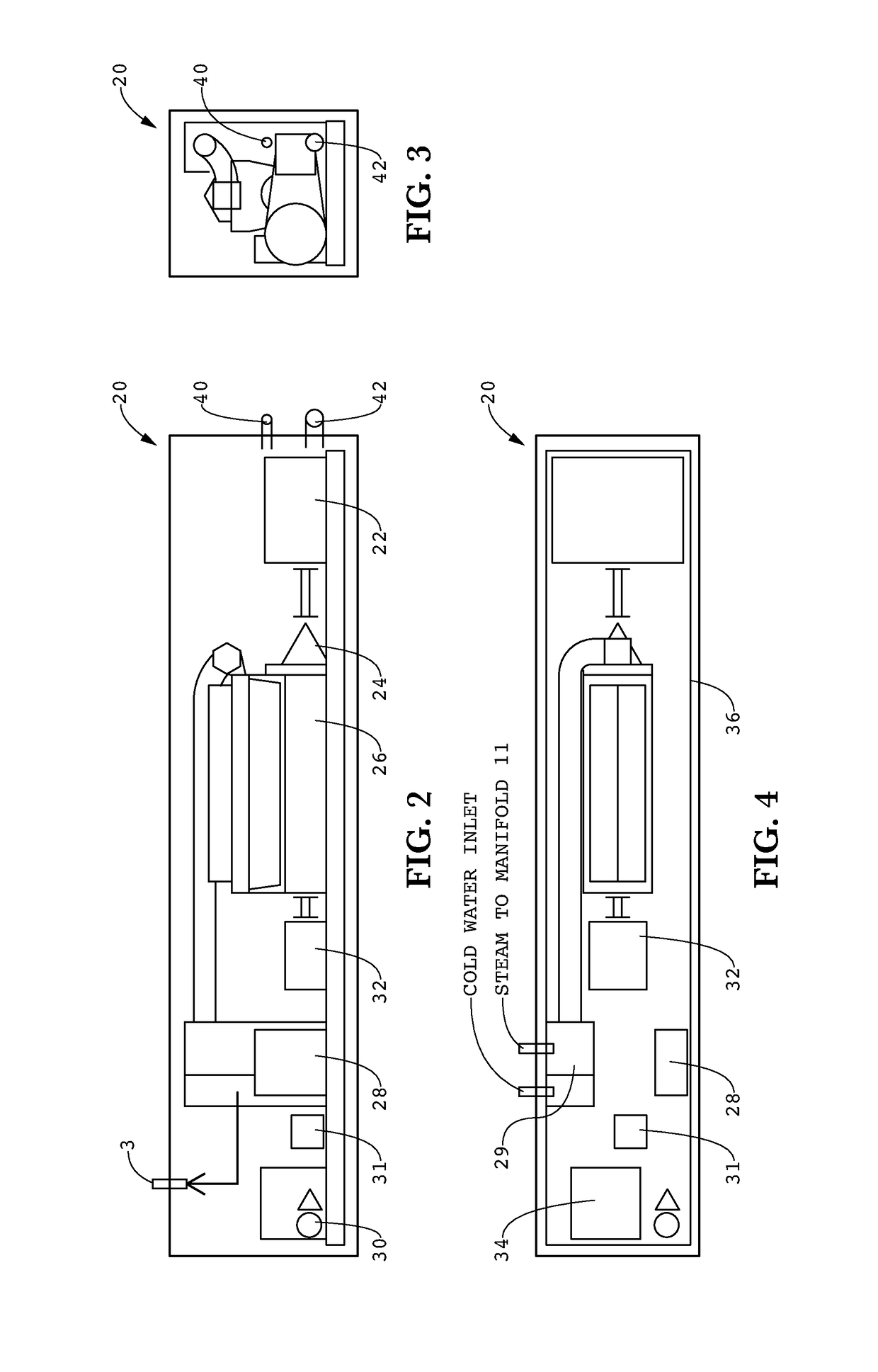

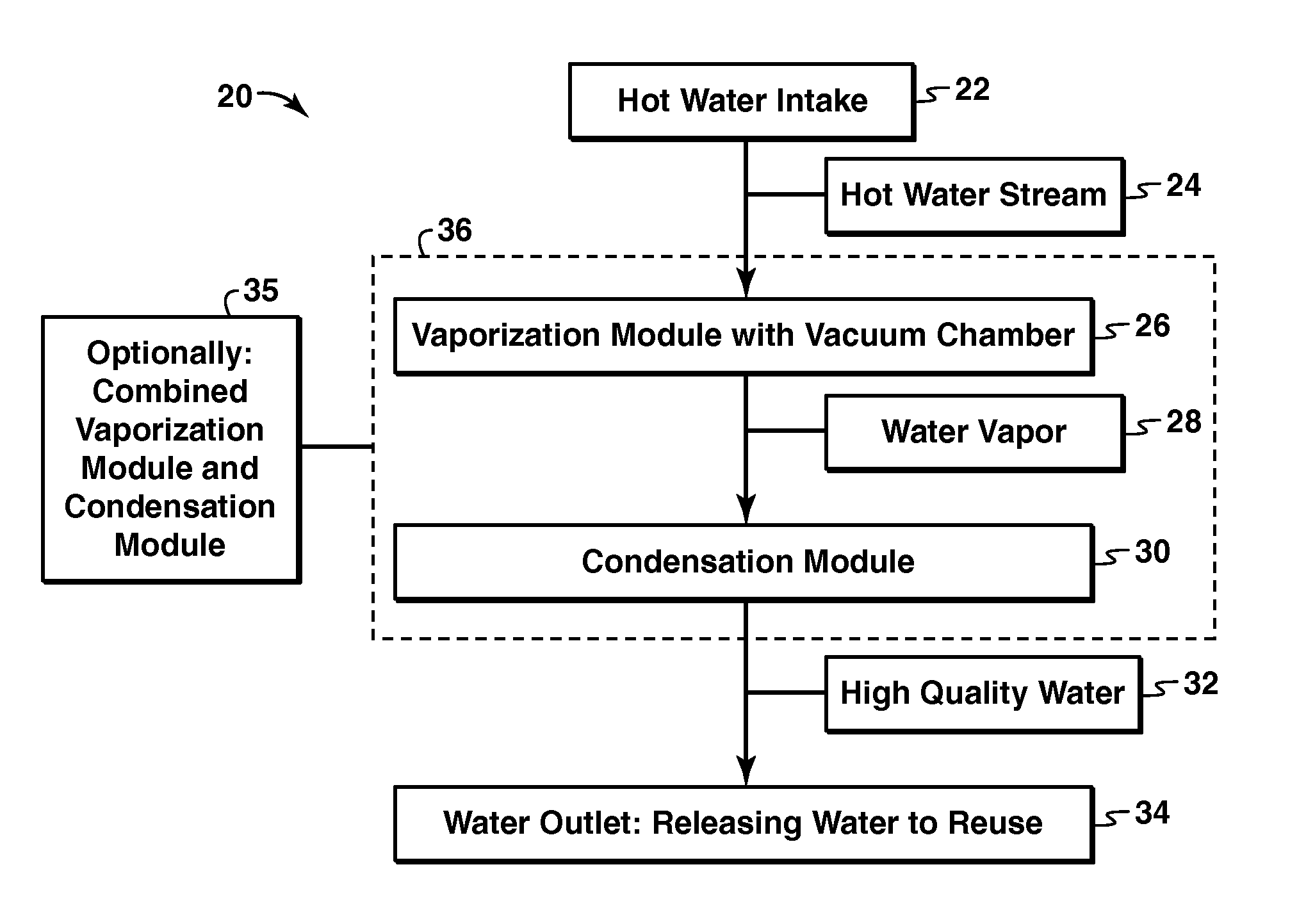

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

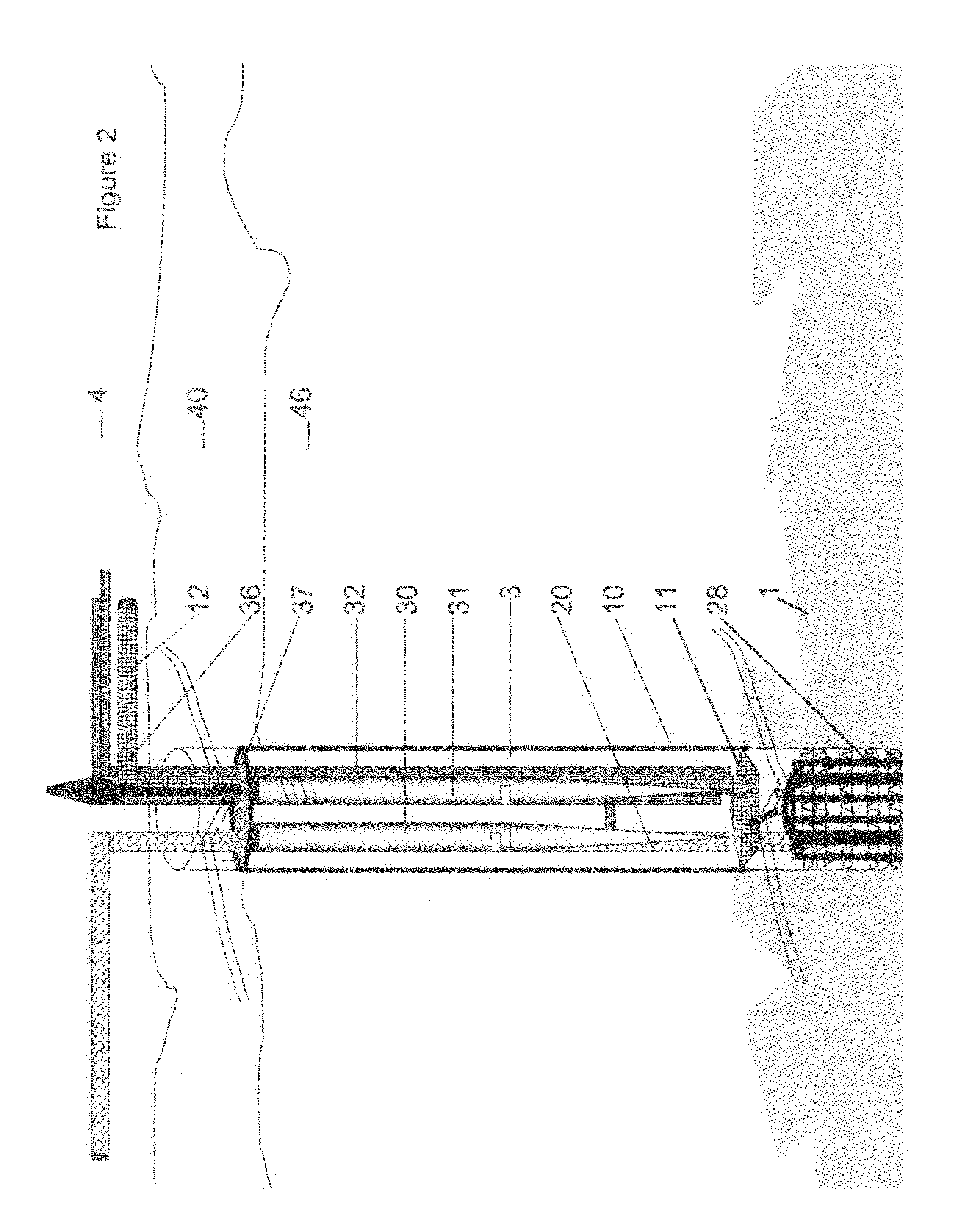

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

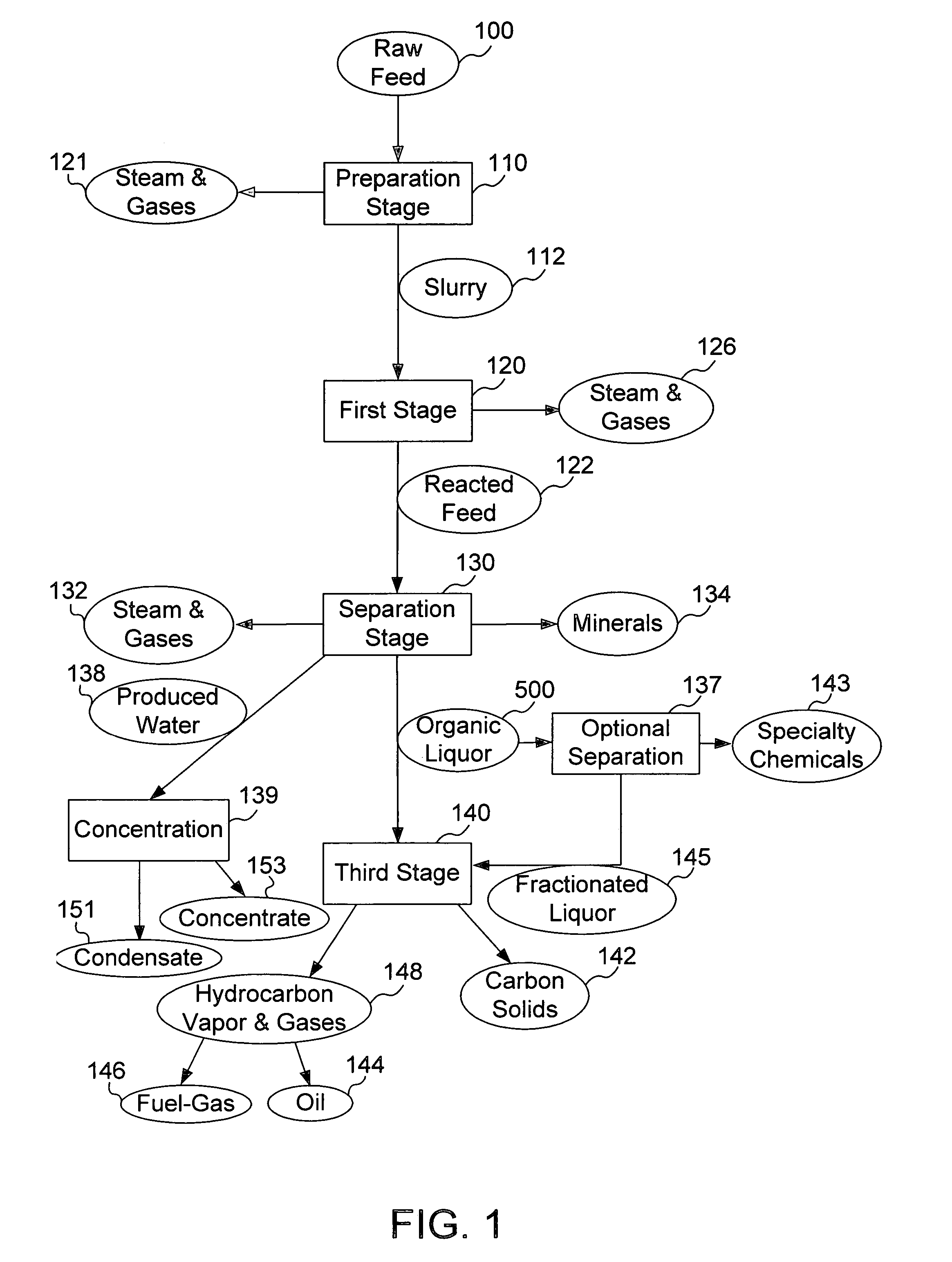

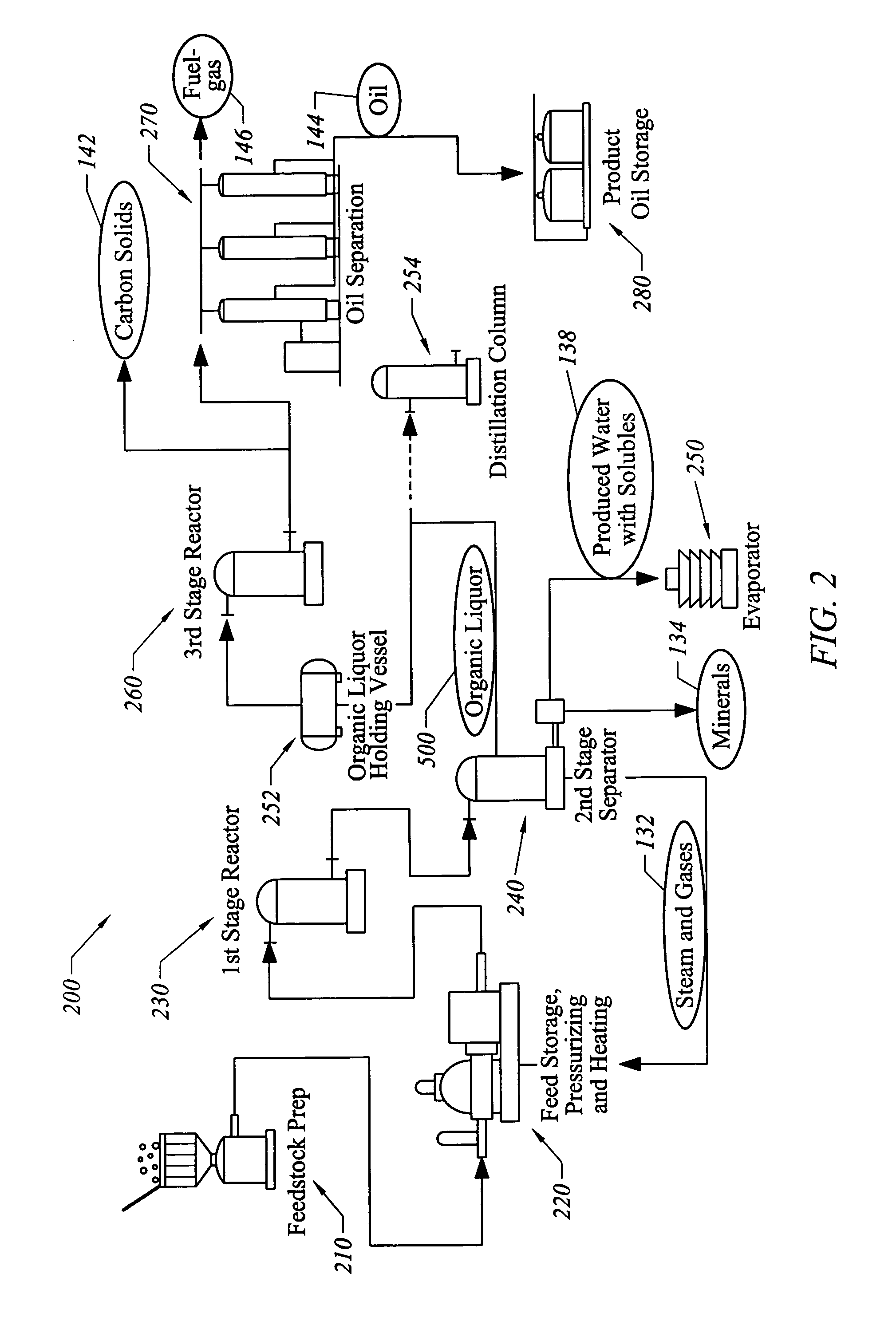

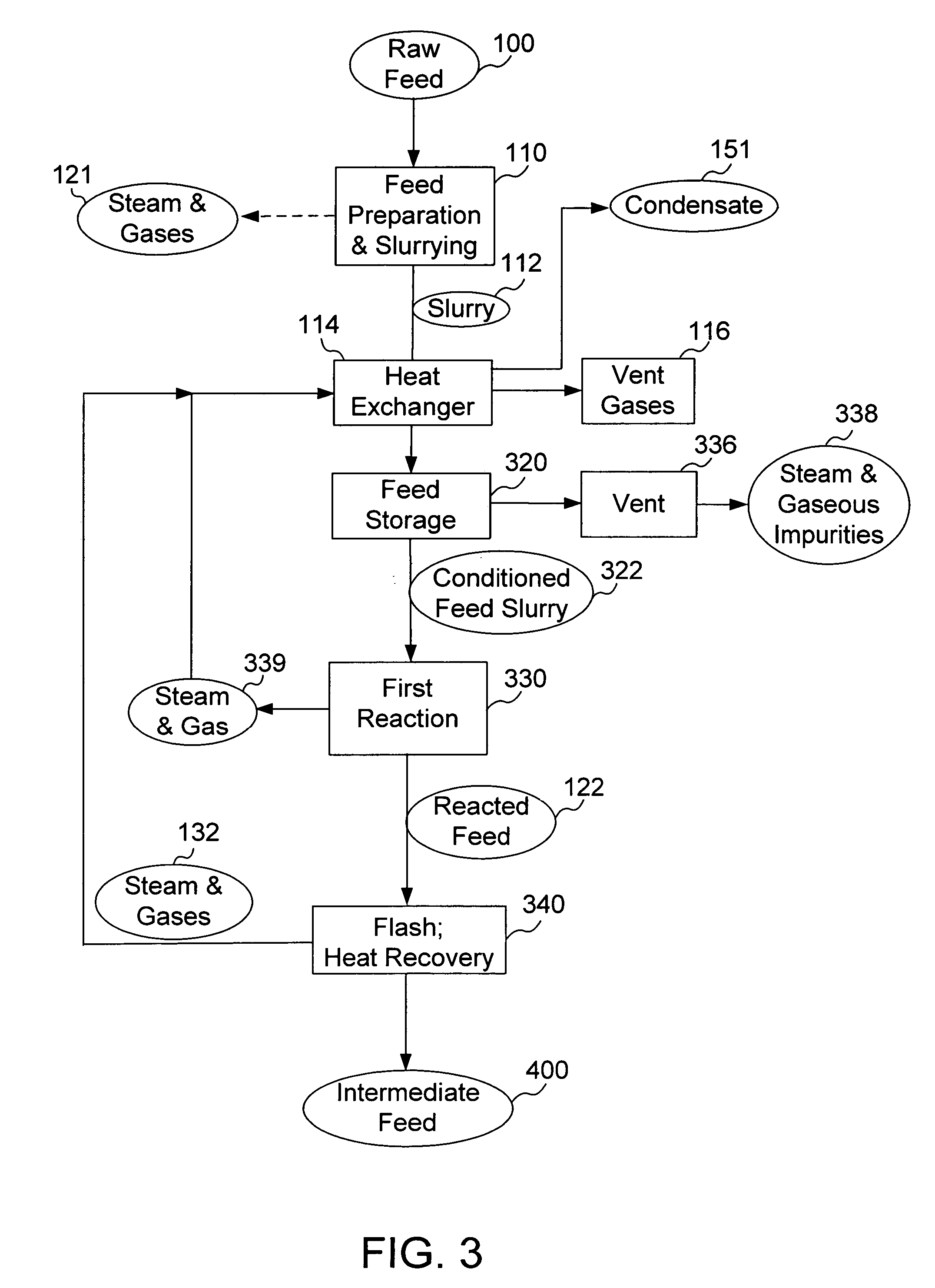

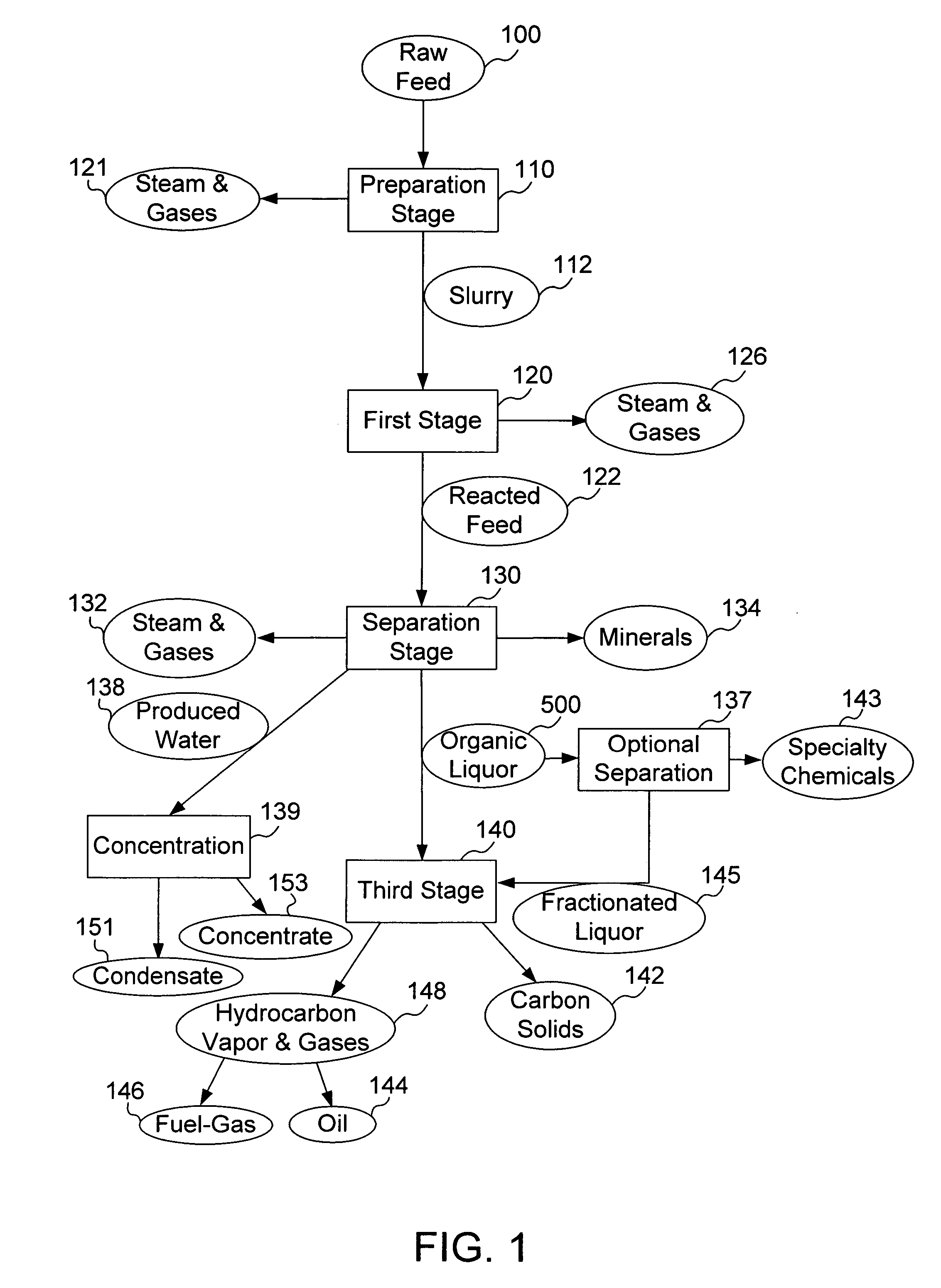

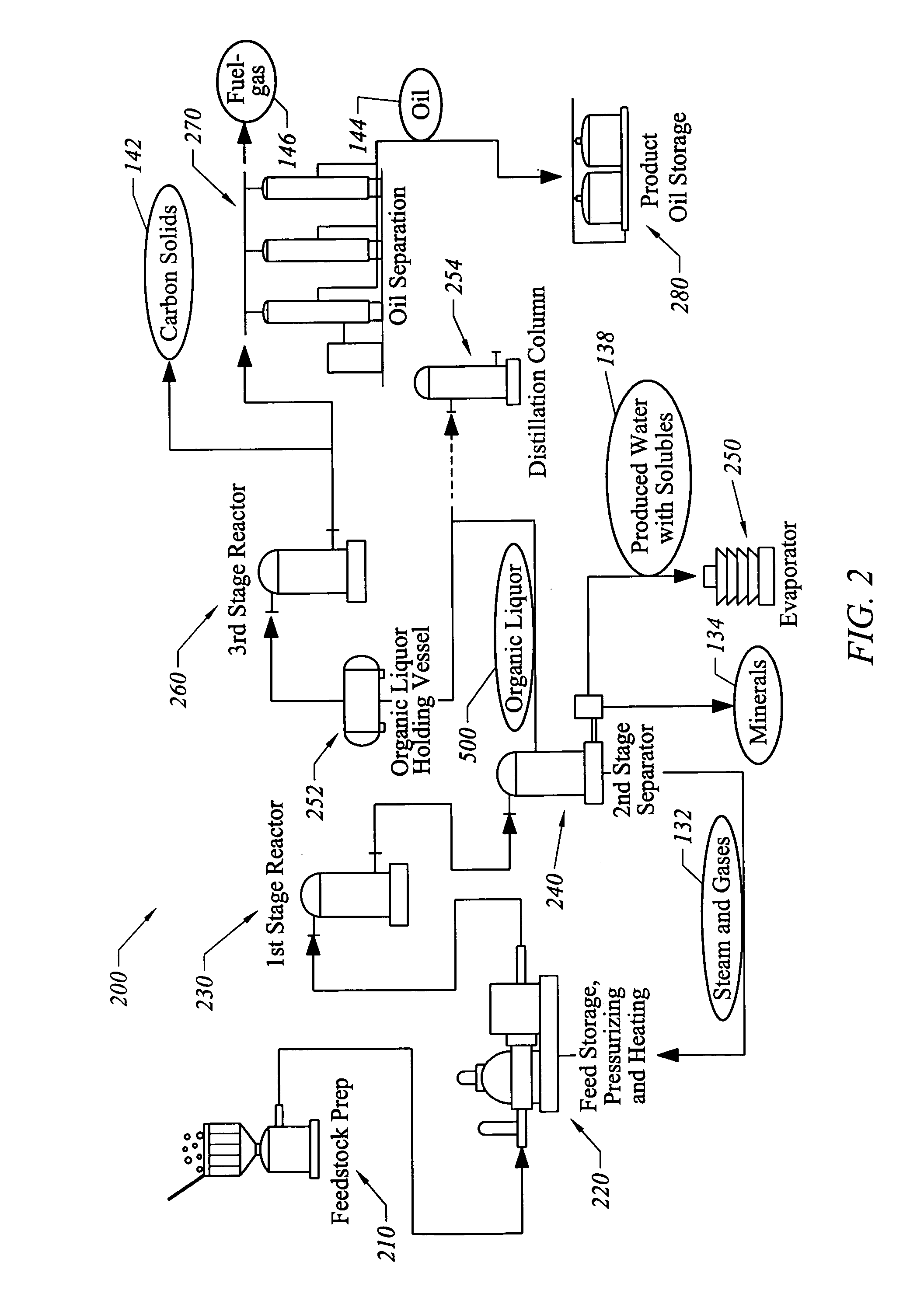

Apparatus and process for converting a mixture of organic materials into hydrocarbons and carbon solids

ActiveUS7476296B2Low viscosityInhibition formationAnimal corpse fertilisersMultiple-effect/fractional condensationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

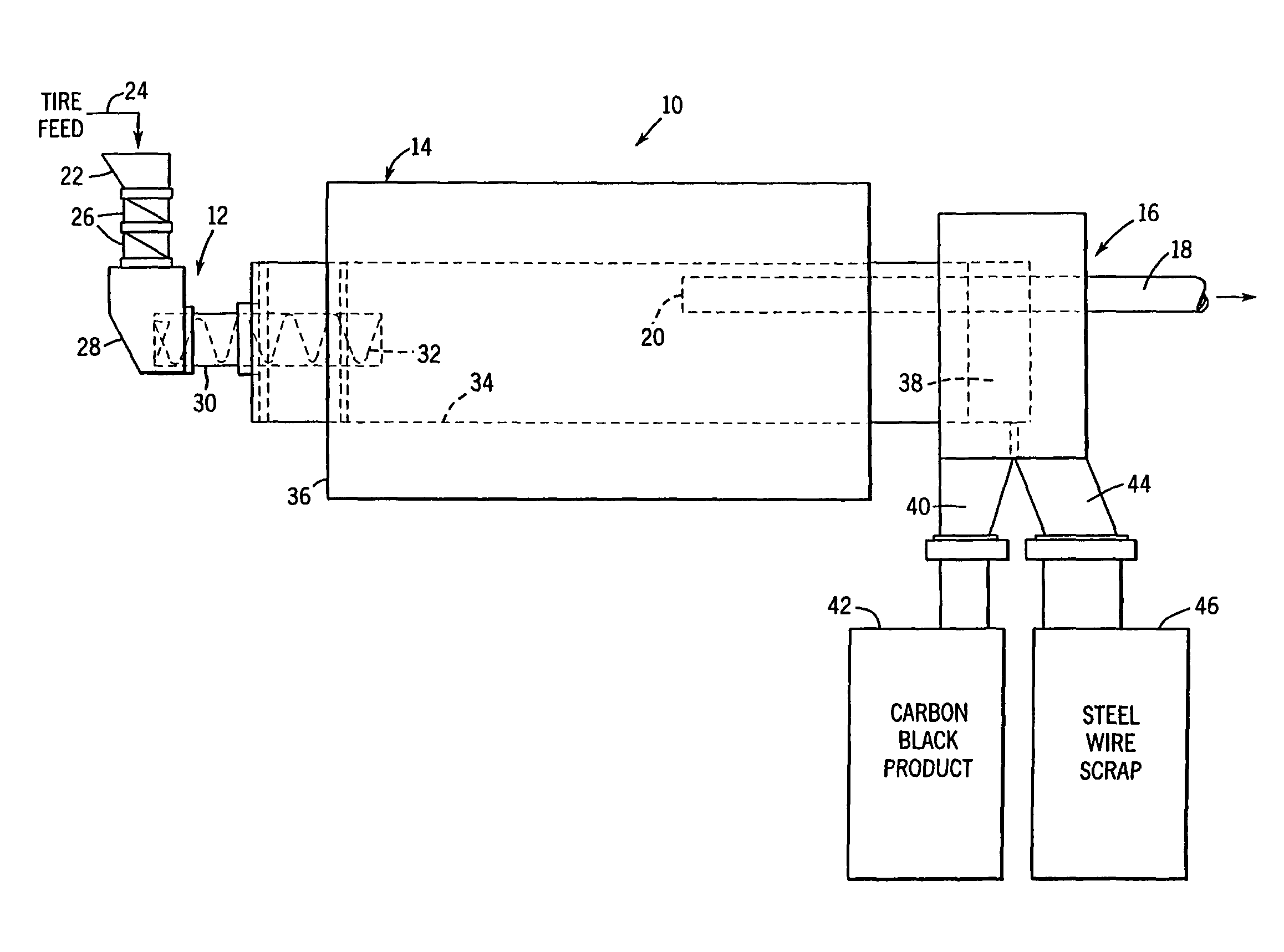

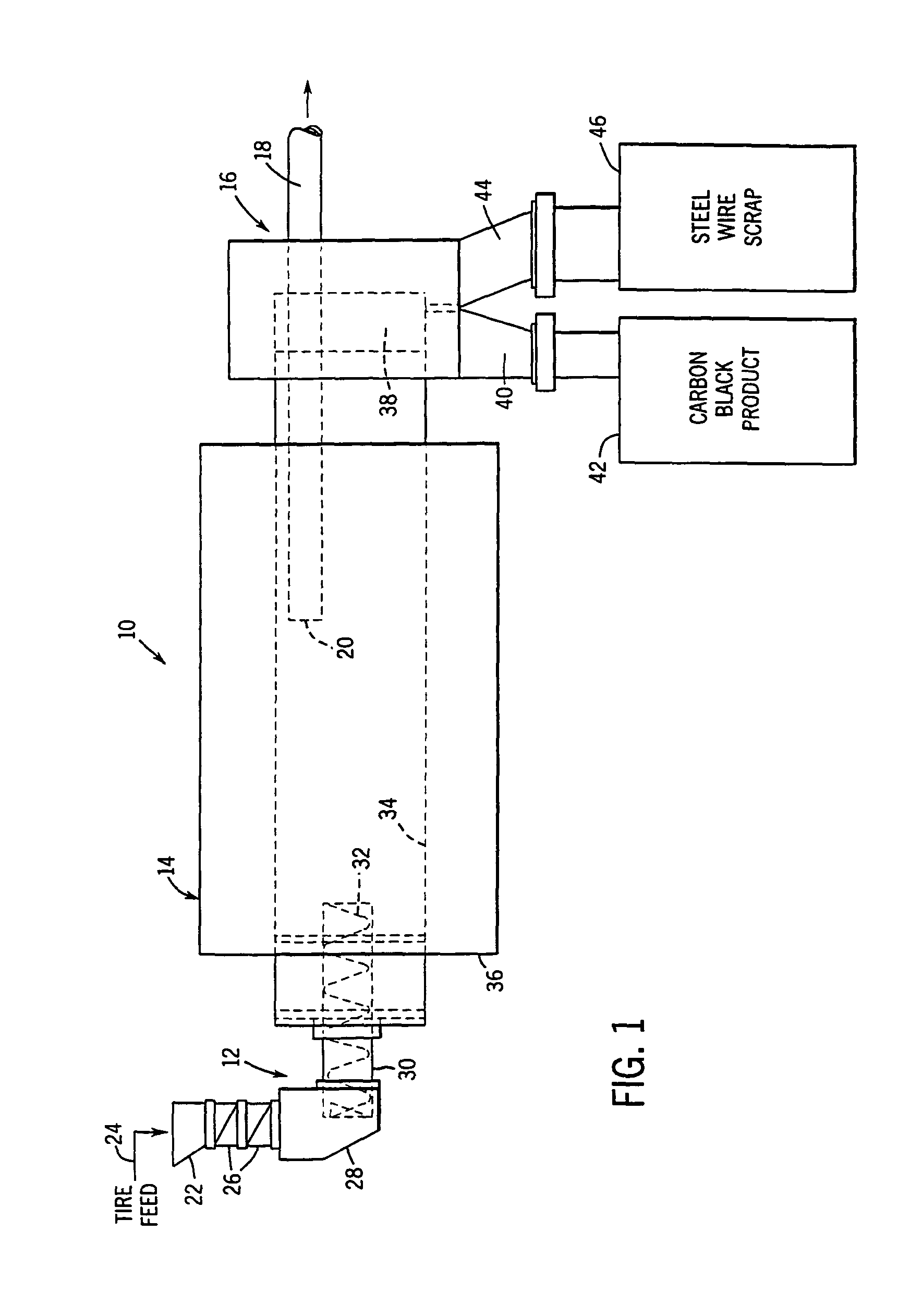

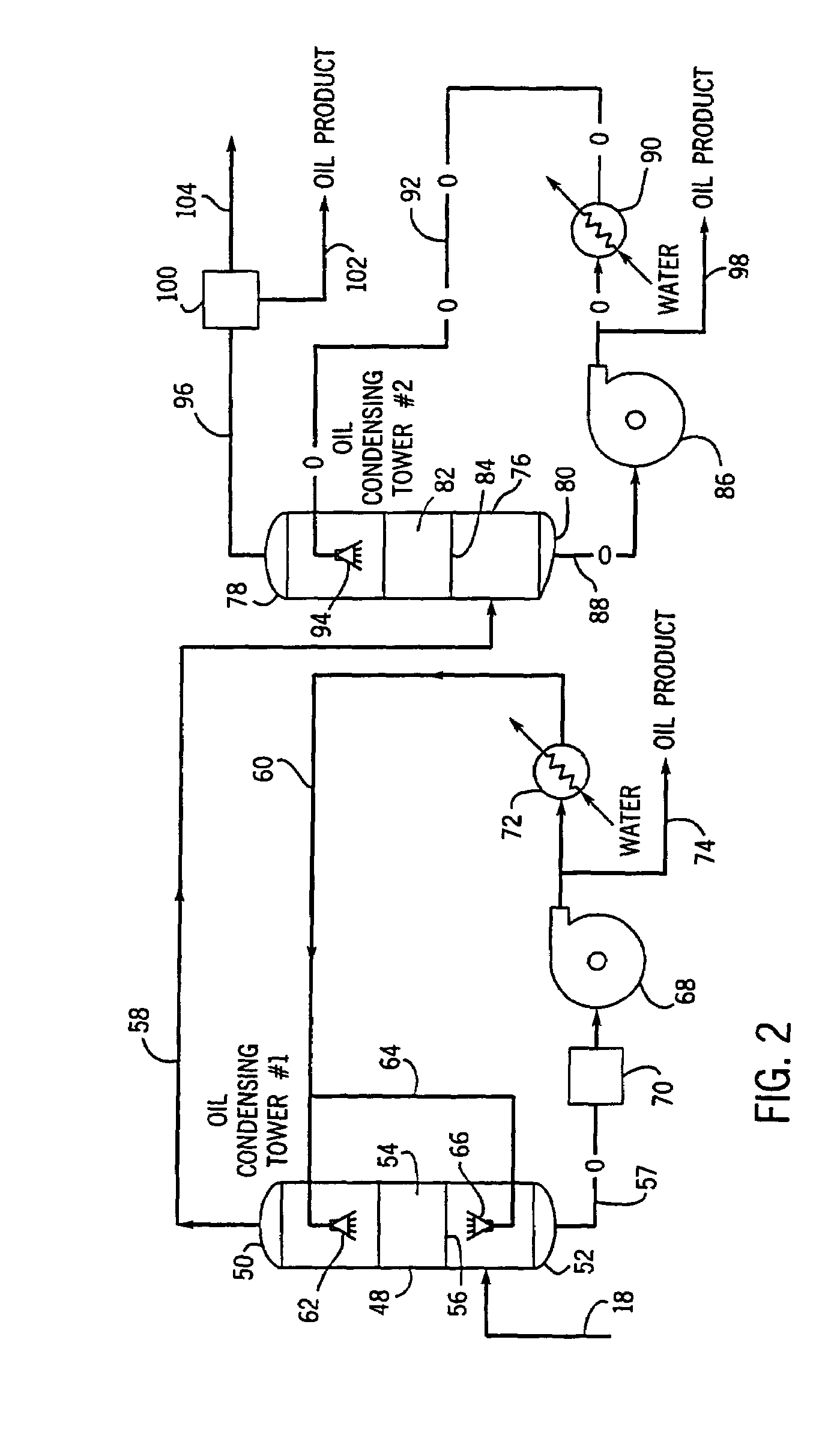

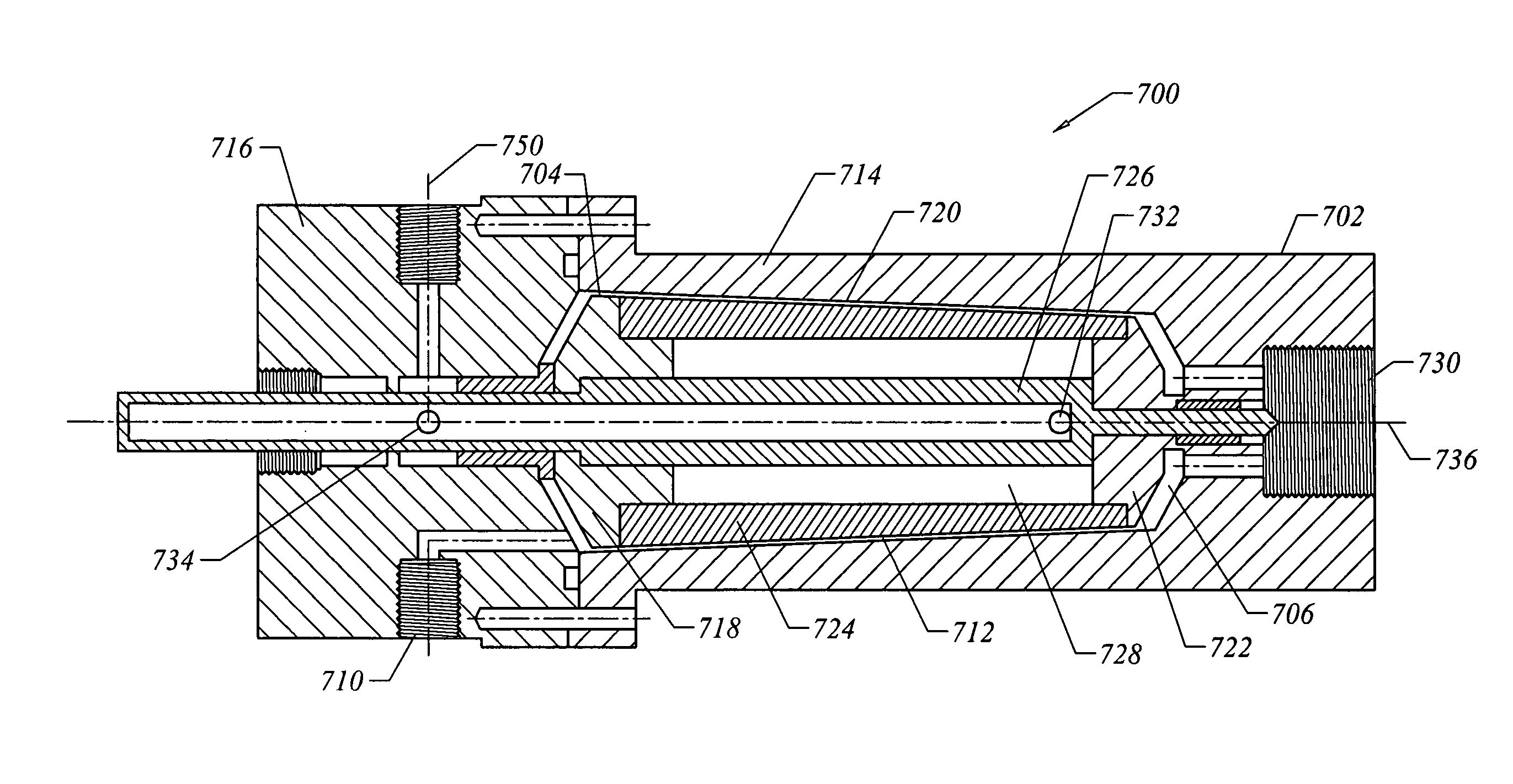

Condensation and recovery of oil from pyrolysis gas

InactiveUS7101463B1Large specific surface areaTemperature controlMultiple-effect/fractional condensationDirect heating destructive distillationWater vaporProduct gas

A system and process for the recovery of oil from the pyrolysis of material containing hydrocarbons such as shredded vehicle tires. The system utilizes a pair of sequentially positioned packed towers to recover at least 95% of the oil contained in the pyrolysis gases. The first packed tower operates above the dew point of the water vapor in the pyrolysis gases to insure that no water is condensed and obtain a primary oil fraction having oil with a high flash point of about 60° C. or greater and a primary vapor fraction containing additional oils, fuel gases and water vapor. The primary vapor fraction is fed to the second packed tower which operates below the dew point of the water vapor to condense the water and oil having a low flash point of 34° C. or below, and provide a secondary vapor fraction containing valuable fuel gases.

Owner:METSO MINERALS IND INC

Apparatus for separating particulates from a suspension, and uses thereof

InactiveUS7179379B2Stir wellDiscouraging decarboxylation reactionMultiple-effect/fractional condensationAnimal corpse fertilisersParticulatesSpeciality chemicals

The present invention includes an apparatus for separating particulates from a fluid in a suspension, comprising: a housing defining a frusto-conically shaped inner chamber with an inner wall, an inlet and a first outlet communicating with the chamber, and a second outlet; and a spinning assembly with a hollow interior mounted in the chamber, the assembly being shaped to define an annular gap with the chamber inner wall, the hollow interior communicating with the second outlet, and the hollow interior communicating with the annular gap for flow of fluid materials from the gap into the interior and out of the second outlet in response to rotation of the spinning assembly. The separator finds application in the preparation of waste products such as municipal sewage sludge for processes that produce useful materials including gas, oil, specialty chemicals, fertilizer, and carbon solids, in reliable purities and compositions, and with high energy efficiency.

Owner:AB CWT LLC

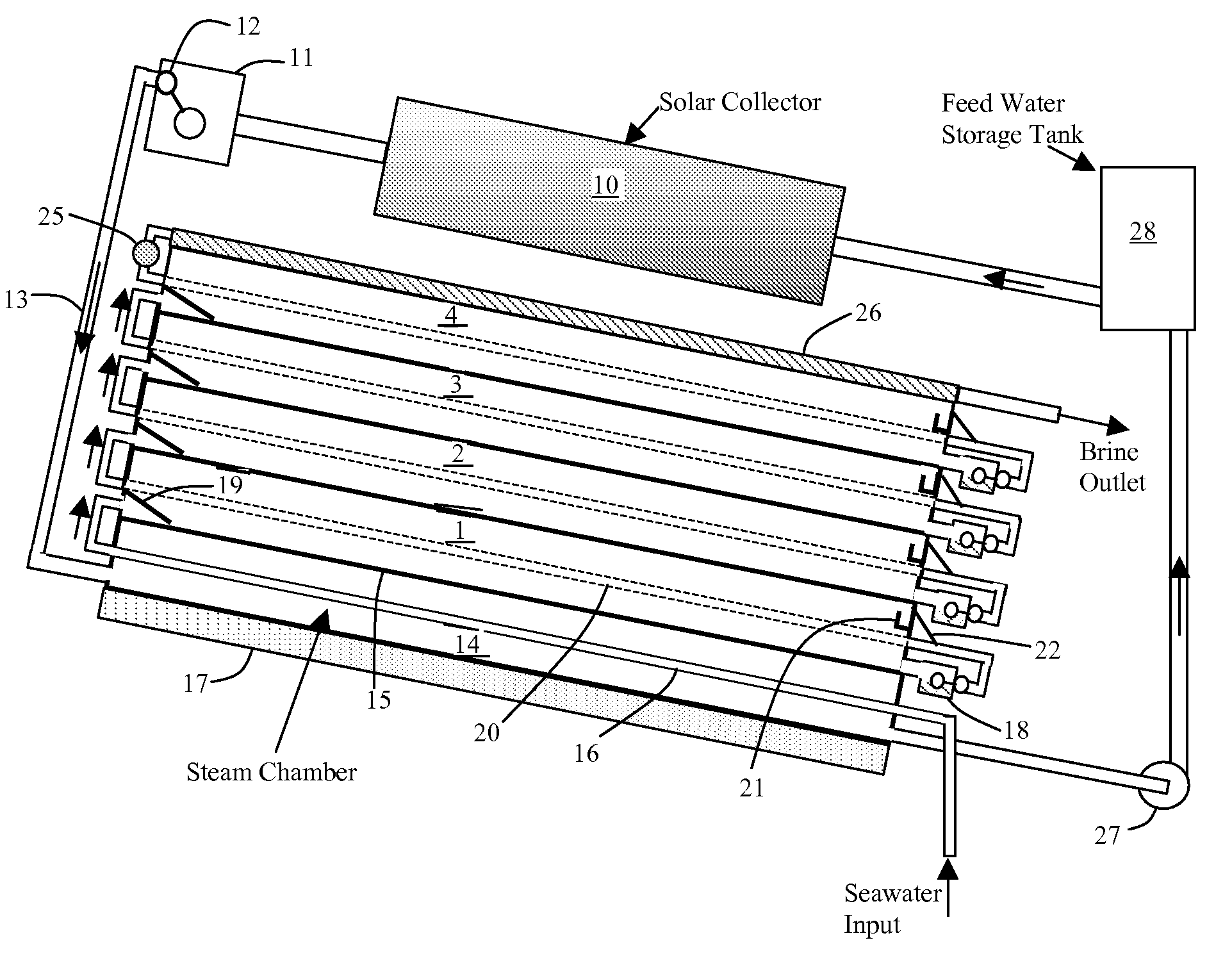

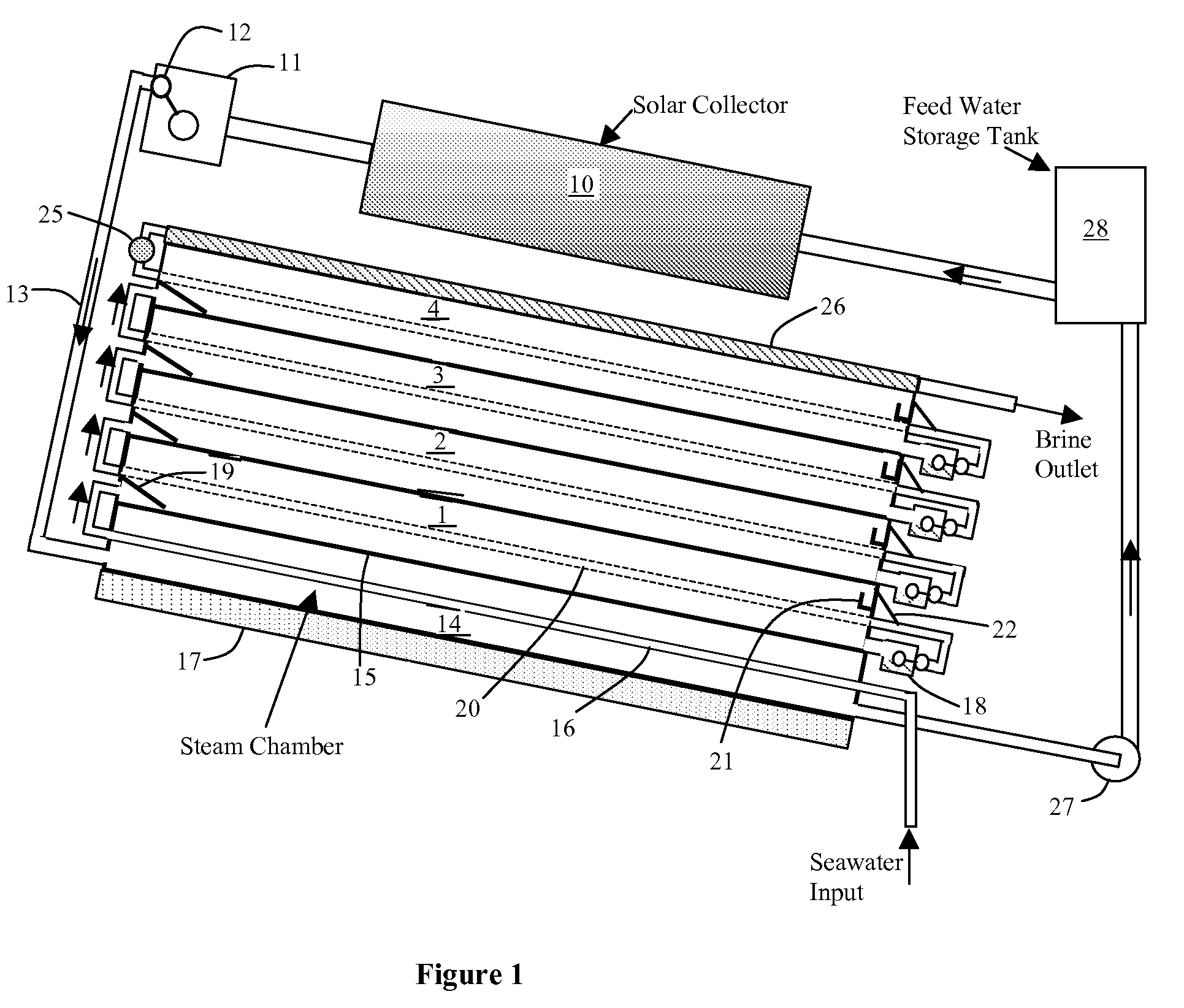

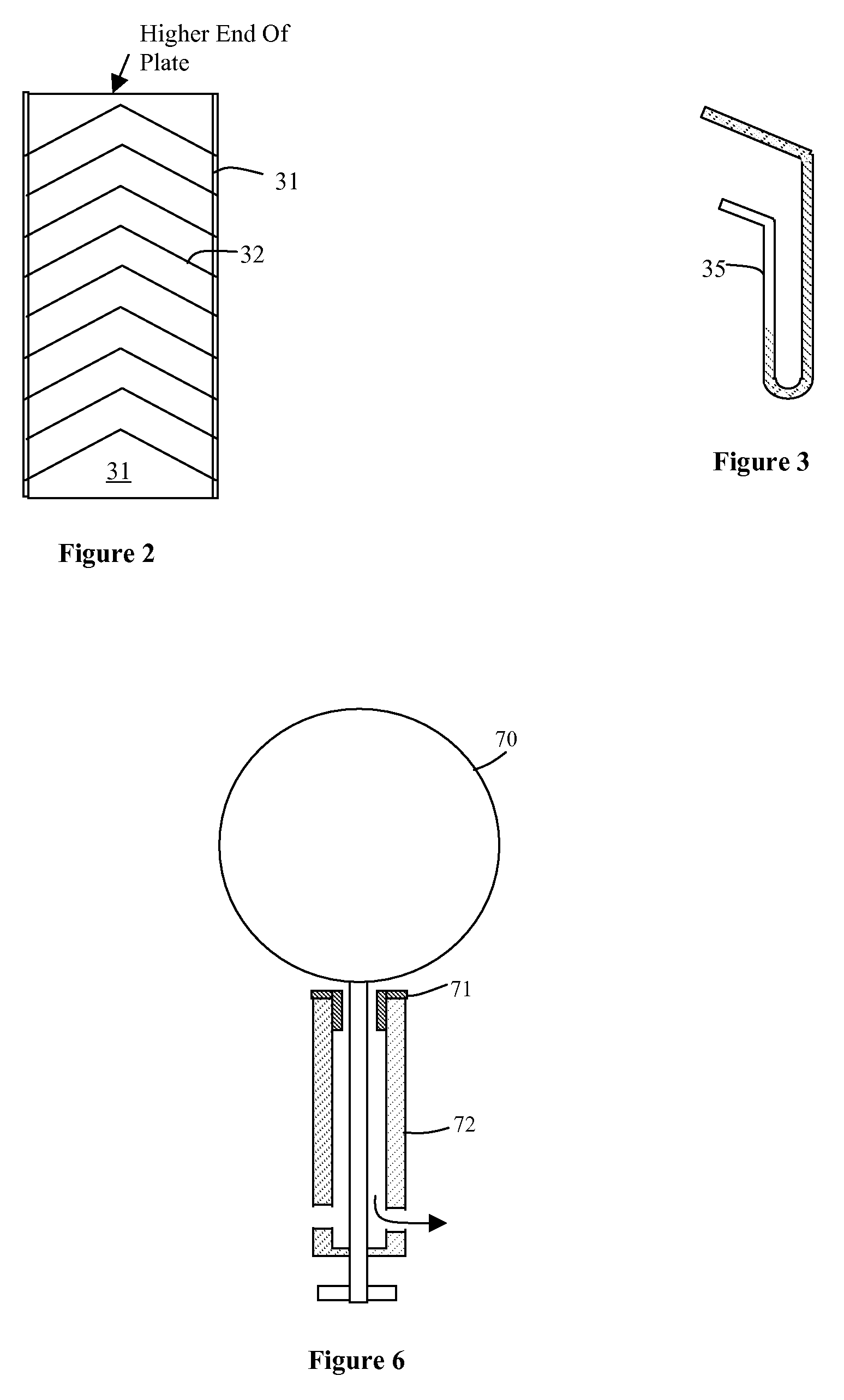

Solar-powered desalination system

InactiveUS20070193870A1Easy to useExcessive numberGeneral water supply conservationMultiple-effect/fractional condensationSaline waterParallel plate

Owner:PRUEITT MELVIN L

Solar distilling apparatus for alcohol

InactiveUS20060037853A1Reduce the temperatureFermented solutions distillation/rectificationGeneral water supply conservationAlcoholSteam condensation

A distilling apparatus for alcohol includes an evaporation tank having a compartment for receiving fermented alcoholic liquid. A heating tube is mounted in the compartment for heating the fermented liquid into steam. A condensing device is communicated with the evaporation tank for receiving and condensing steam from the evaporation tank. A collecting tank is communicated with the condensing device for collecting condensed liquid from the condensing device. A negative pressure creating device creates a negative pressure in the evaporation tank, allowing the fermented alcoholic liquid in the evaporation tank to evaporate at a low temperature. A solar energy collecting device includes a solar energy collector and a water tank containing water heated by the solar energy collector. Hot water in the water tank flows into the heating tube for heating the fermented alcoholic liquid in the evaporation tank.

Owner:ROAN TONY +1

Method for producing a distillate stream from a water stream containing at least one dissolved solid

A method and a system to produce a distillate stream from an aqueous stream containing at least one dissolved solid by a distillation process using at least one of a heated aqueous stream from a turbine system intercooler and a stack heater as a heat source.

Owner:BLACK & VEATCH HLDG

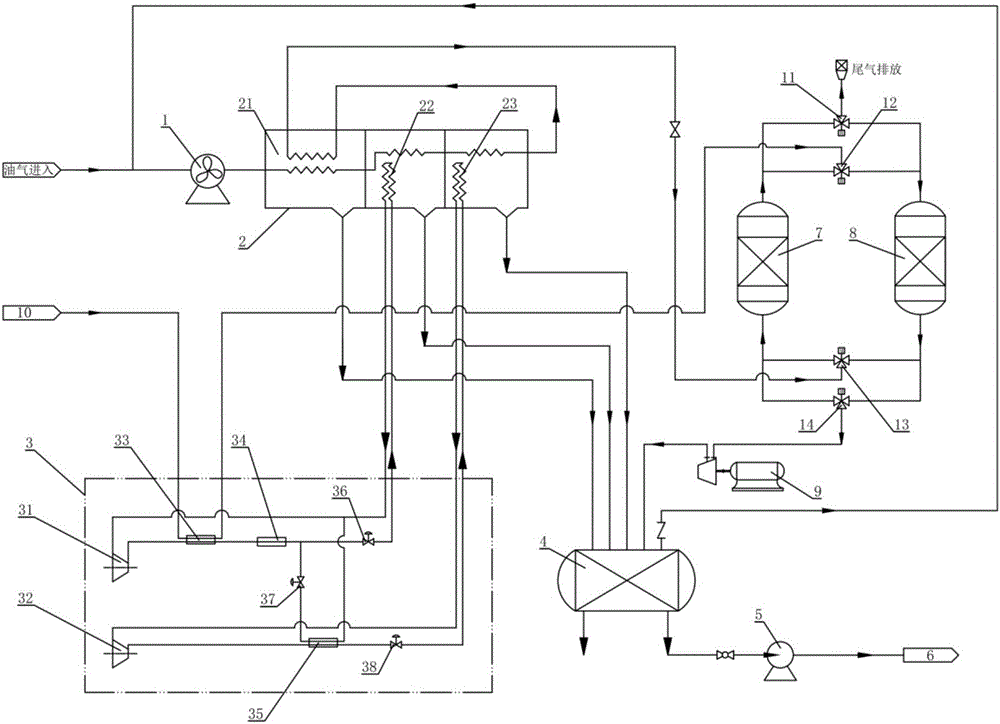

Oil gas recovery device and method

InactiveCN106166399AReduce energy consumptionEliminate potential safety hazardsGas treatmentMultiple-effect/fractional condensationAutomatic controlDesorption

The invention relates to an oil gas recovery device, comprising an anti-exposure centrifugal fan, a cold box, a refrigeration unit, a liquid storage tank, a liquid return pump, an oil storage tank, a first adsorption tank, a second adsorption tank, a vacuum pump, a nitrogen making unit, and Including the PLC automatic control system; the oil and gas are first transported into the cold box by the anti-exposure centrifugal fan, and the liquid oil condensed by the pre-cooling part, the first-level condensing part and the second-level condensing part of the cold box is sent to the liquid storage tank, and then returned to the storage tank. The liquid pump is sent to the oil storage tank for recovery; the oil and gas from the secondary condensing part are sent to the first adsorption tank after the heat is raised by the pre-cooling part, and the first adsorption tank and the second adsorption tank are cycled for adsorption and desorption. When the first adsorption tank or the second adsorption tank enters the desorption stage, the vacuum pump is turned on, and when the vacuum degree of the adsorption tank reaches the set value, the hot nitrogen gas is turned on to desorb the oil and gas with the hot nitrogen gas. By utilizing the advantages of the condensation method and the adsorption method to optimize the combination, the purpose of reducing energy consumption and eliminating potential safety hazards is achieved.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

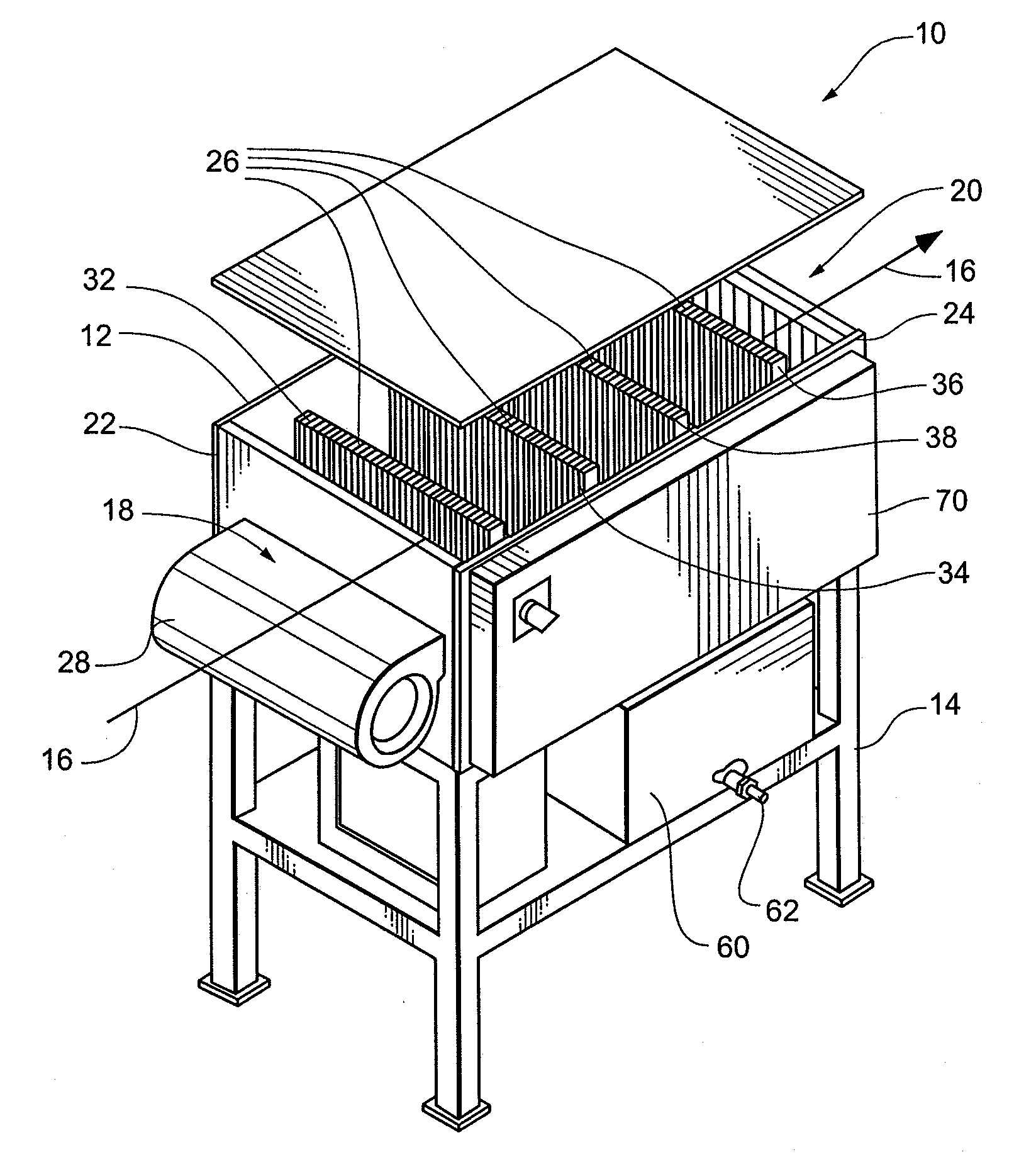

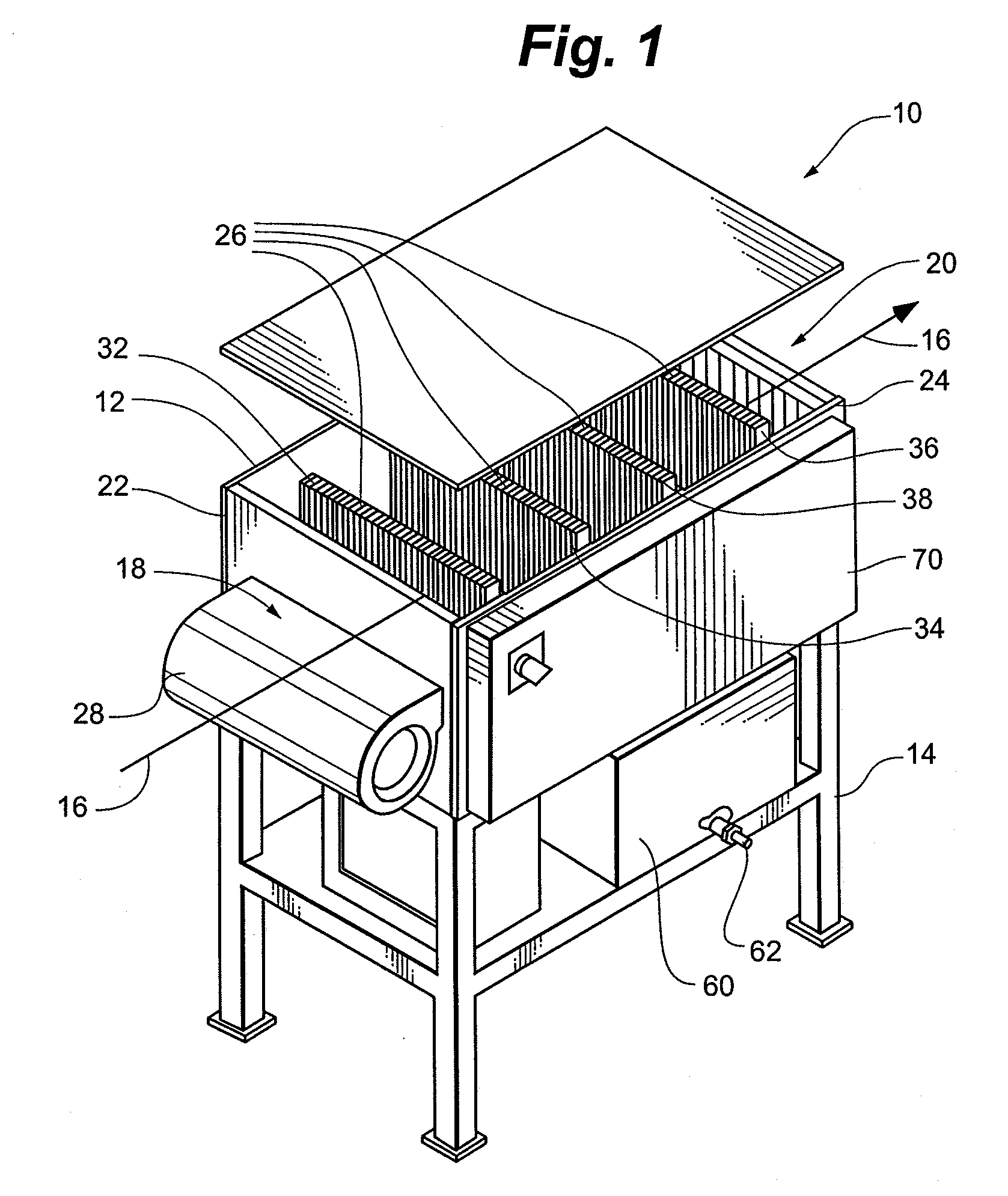

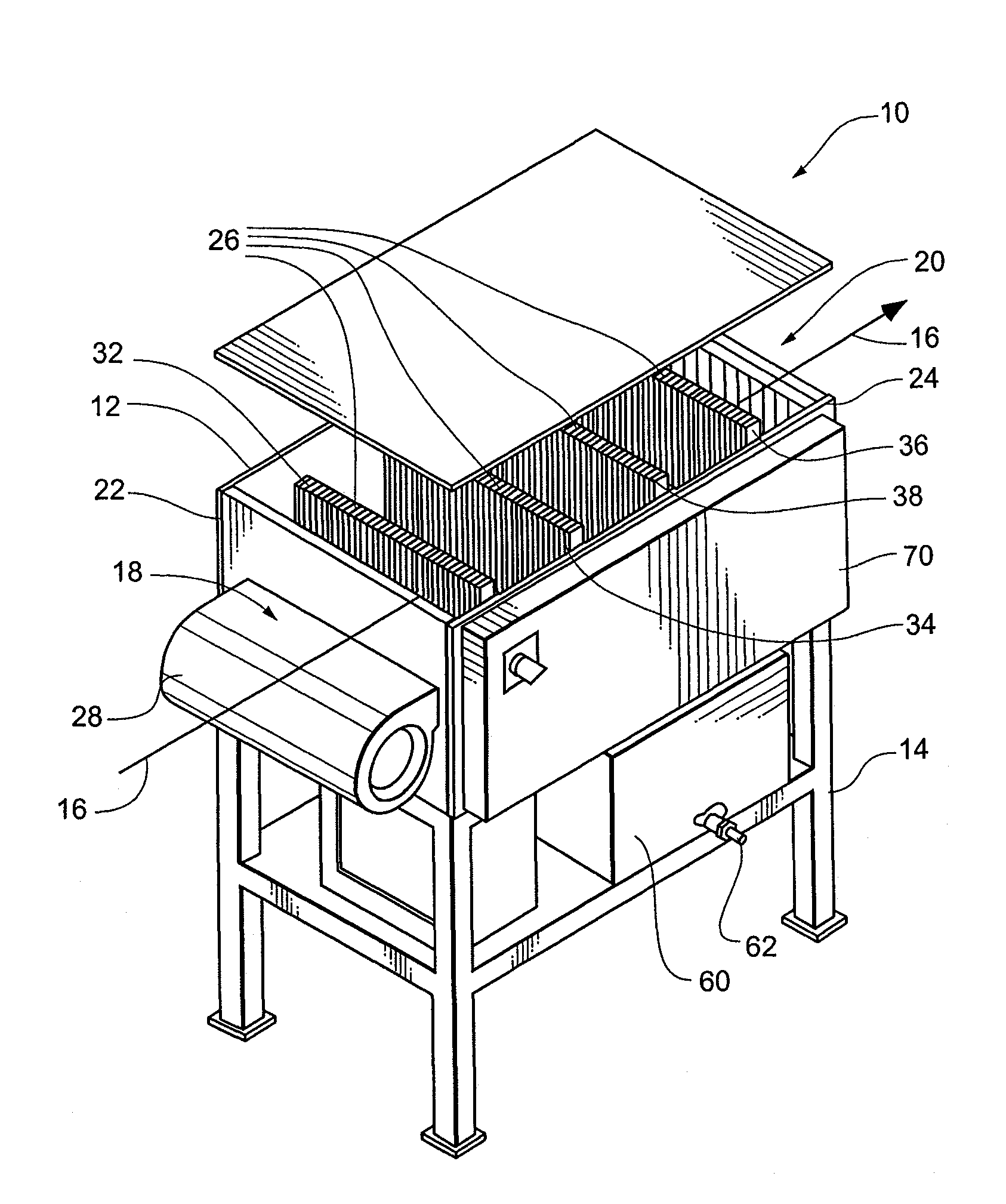

Machines and Methods for Removing Water From Air

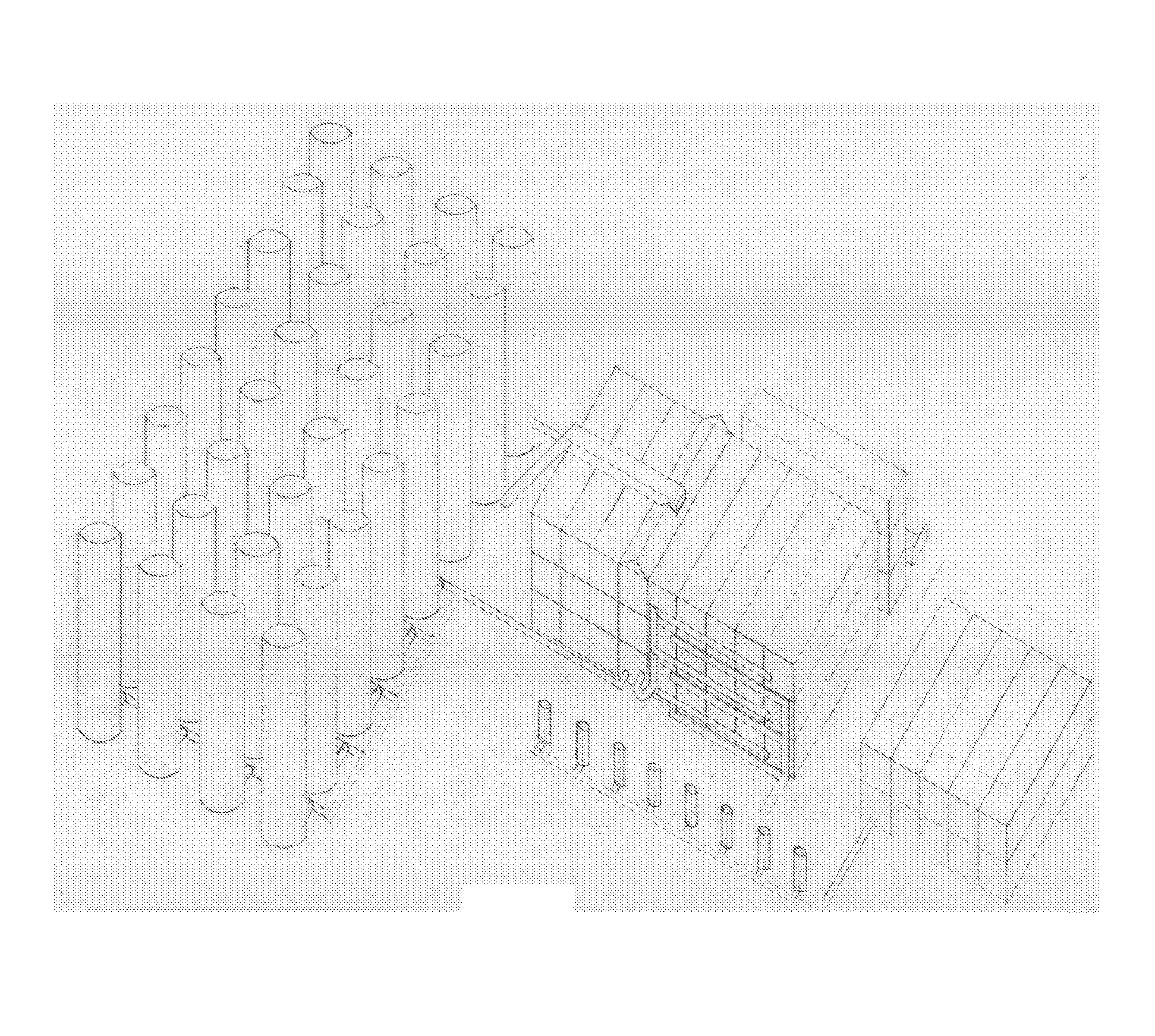

InactiveUS20090293513A1Water/sewage treatment by irradiationLighting and heating apparatusAtmospheric airEnvironmental engineering

The invention provides machines and methods for extracting water from atmospheric air. Also provided are bladed core heat exchangers.

Owner:SULLIVAN SHAUN E

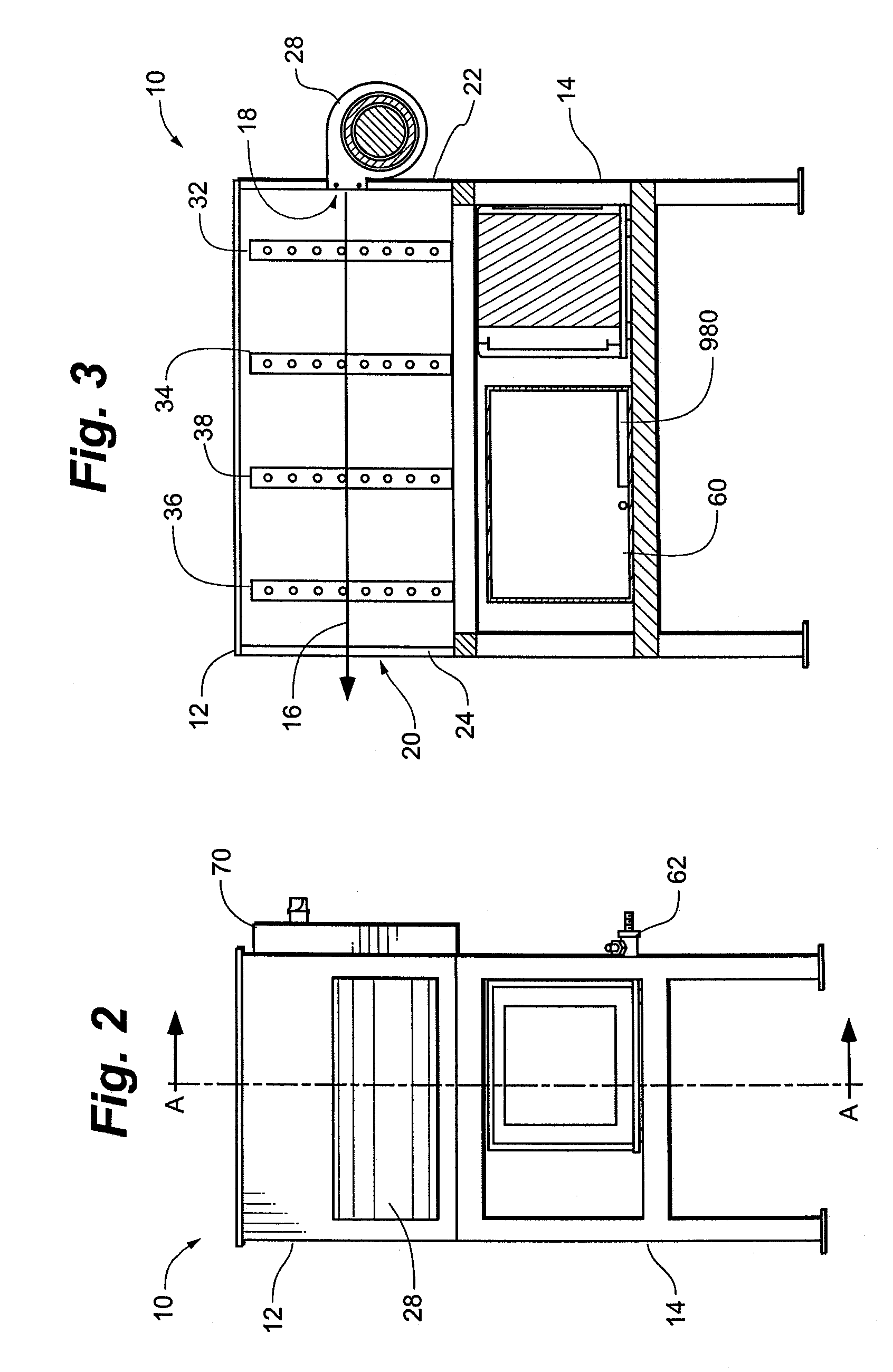

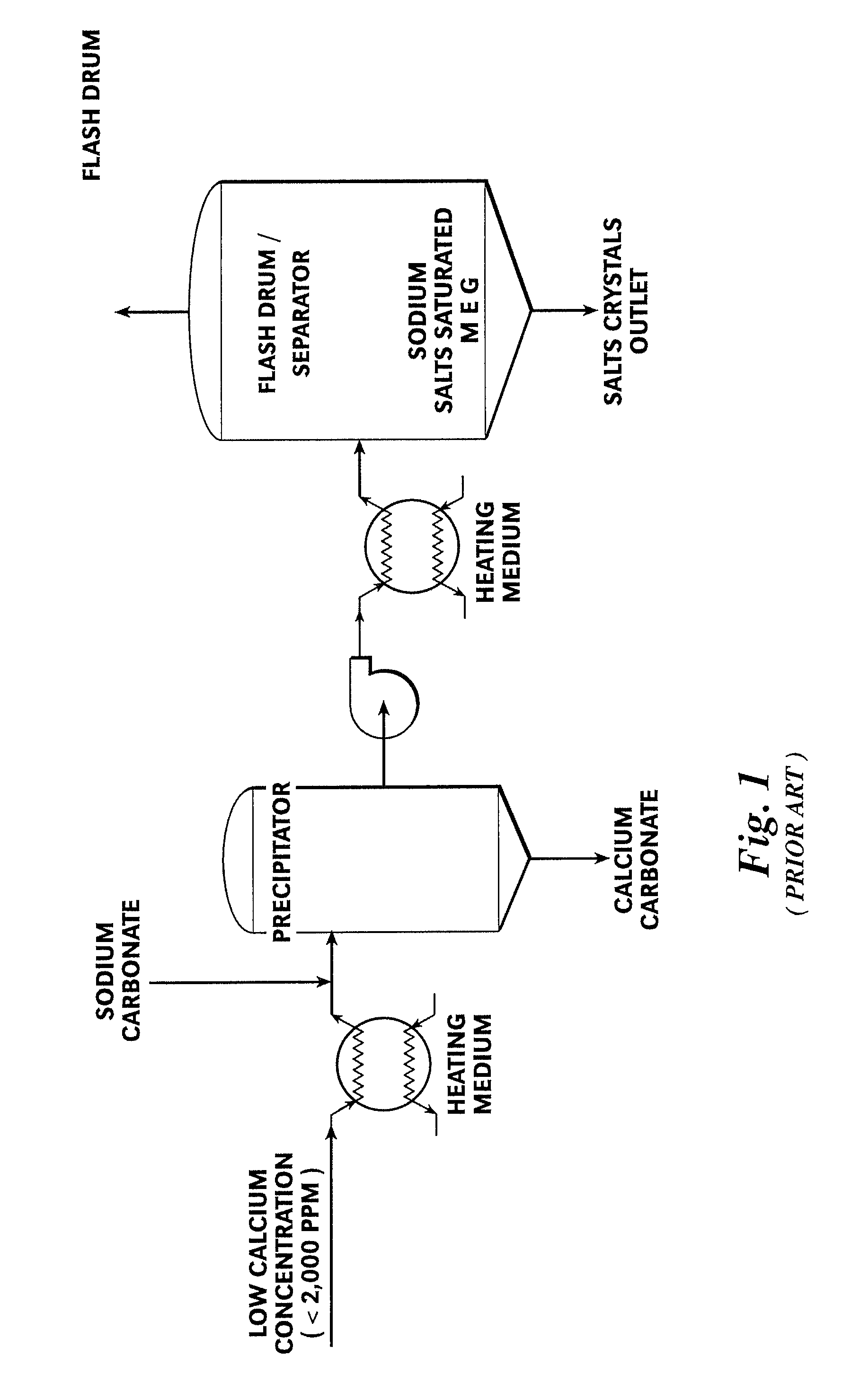

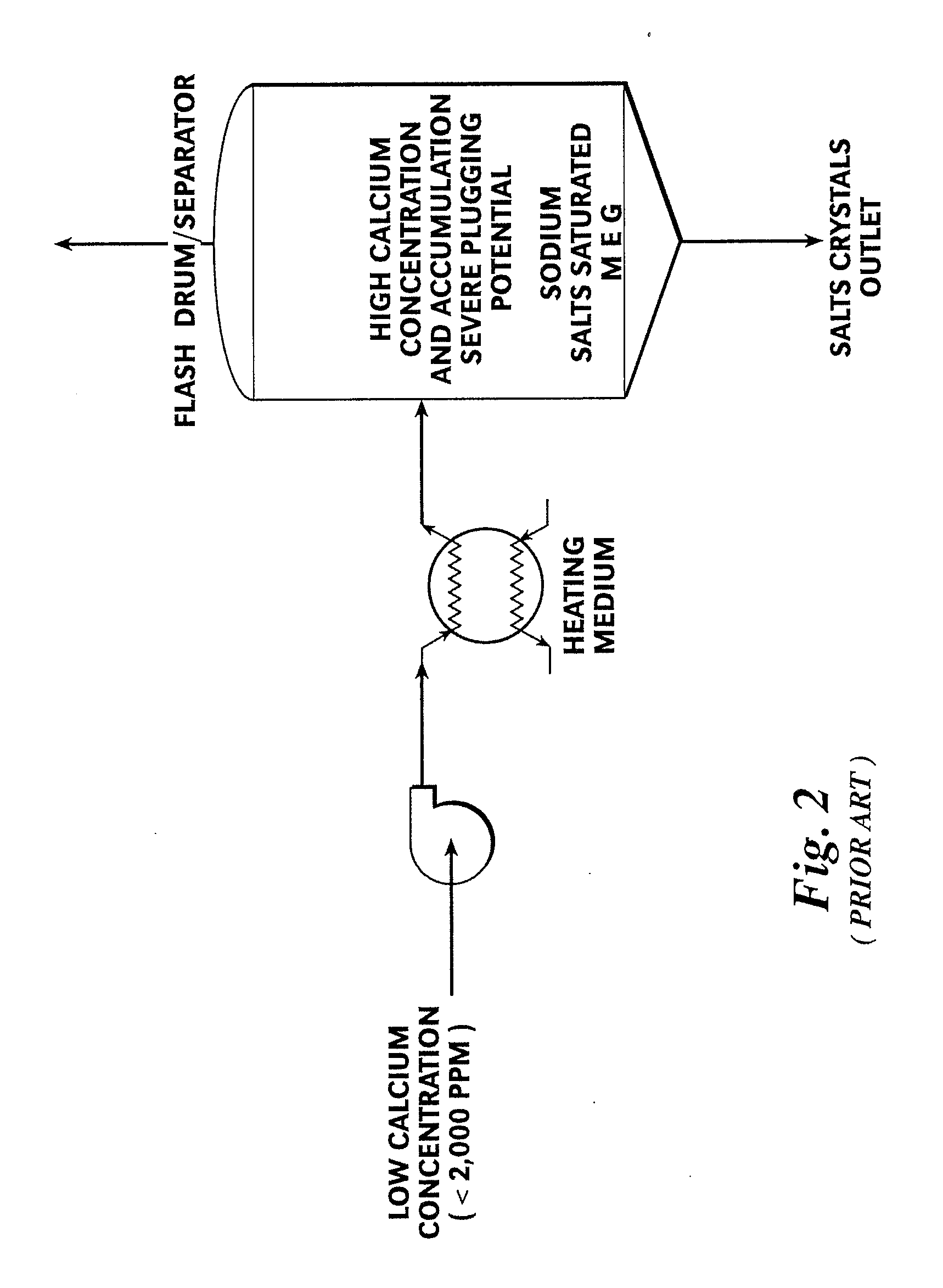

Process Scheme to improve Divalent Metal Salts Removal from Mono Ethylene Glycol (MEG)

ActiveUS20130118989A1Less floor-space/volumeSpeed reactionGas treatmentMultiple-effect/fractional condensationStream flowDivalent metal

A MEG reclamation process includes the step of increasing above 2,000 ppm the divalent metal salts concentration of a rich (wet) MEG feed stream flowing into a precipitator. The increasing step includes routing a salts-saturated MEG slipstream from the flash separator it to the precipitator. The slipstream may be mixed with a fresh water feed stream, a portion of the rich MEG feed stream, or some combination of the two. The rich MEG feed stream also may be split into two streams, with a portion of the stream being heated and routed to the flash separator and the other portion being combined as above with the removed slipstream. The process can be performed on the slipstream after dilution and prior to entering the precipitator or after being loaded into the precipitator. Removal of the insoluble salts may be done in either a batch or continuous mode.

Owner:CAMERSON INT CORP

Method for producing a distillate stream from a water stream containing at least one dissolved solid

A method and a system to produce a distillate stream from an aqueous stream containing at least one dissolved solid by a thermal distillation process using at least one of a heated aqueous stream from a turbine system intercooler and a stack heater as a heat source.

Owner:BLACK & VEATCH HLDG

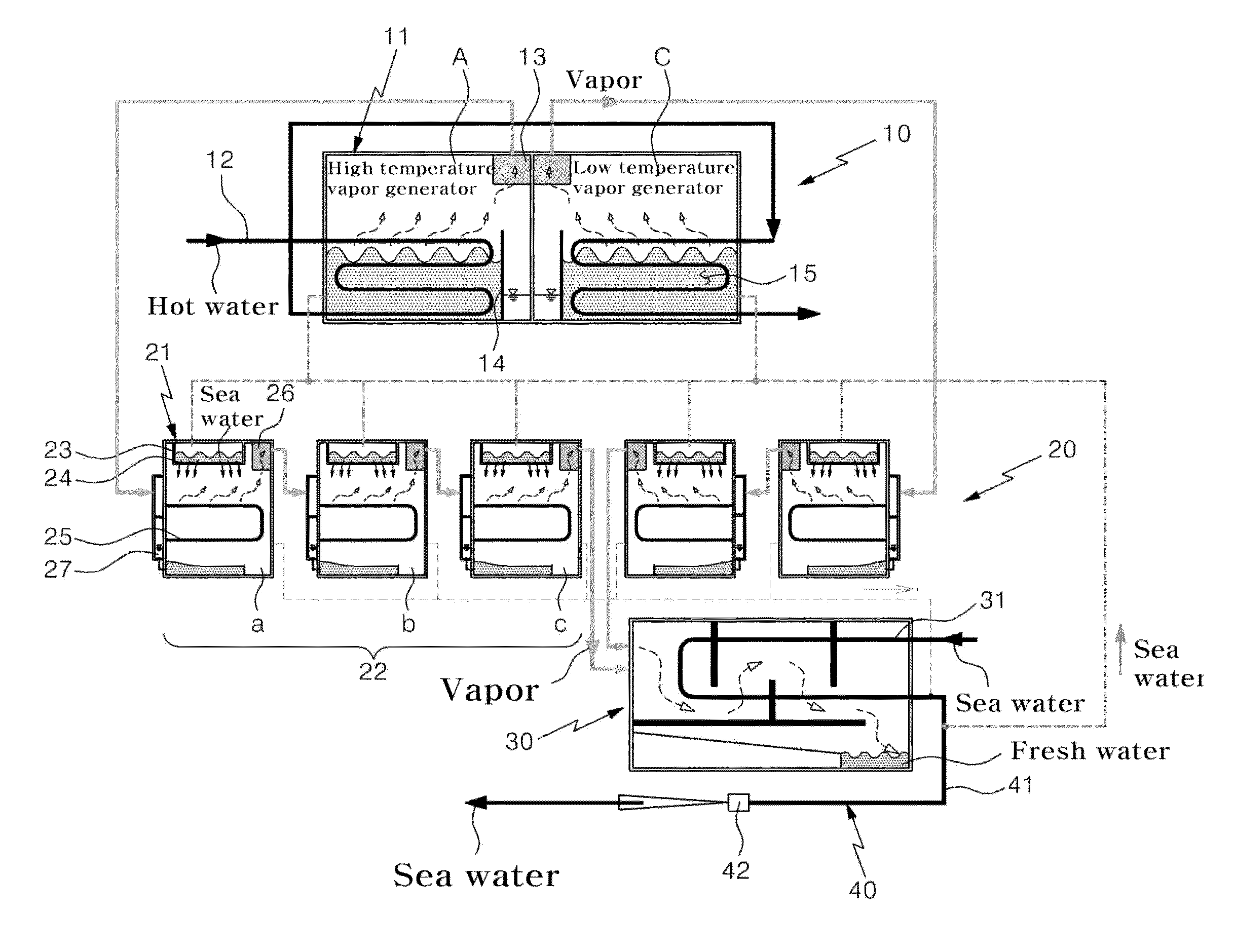

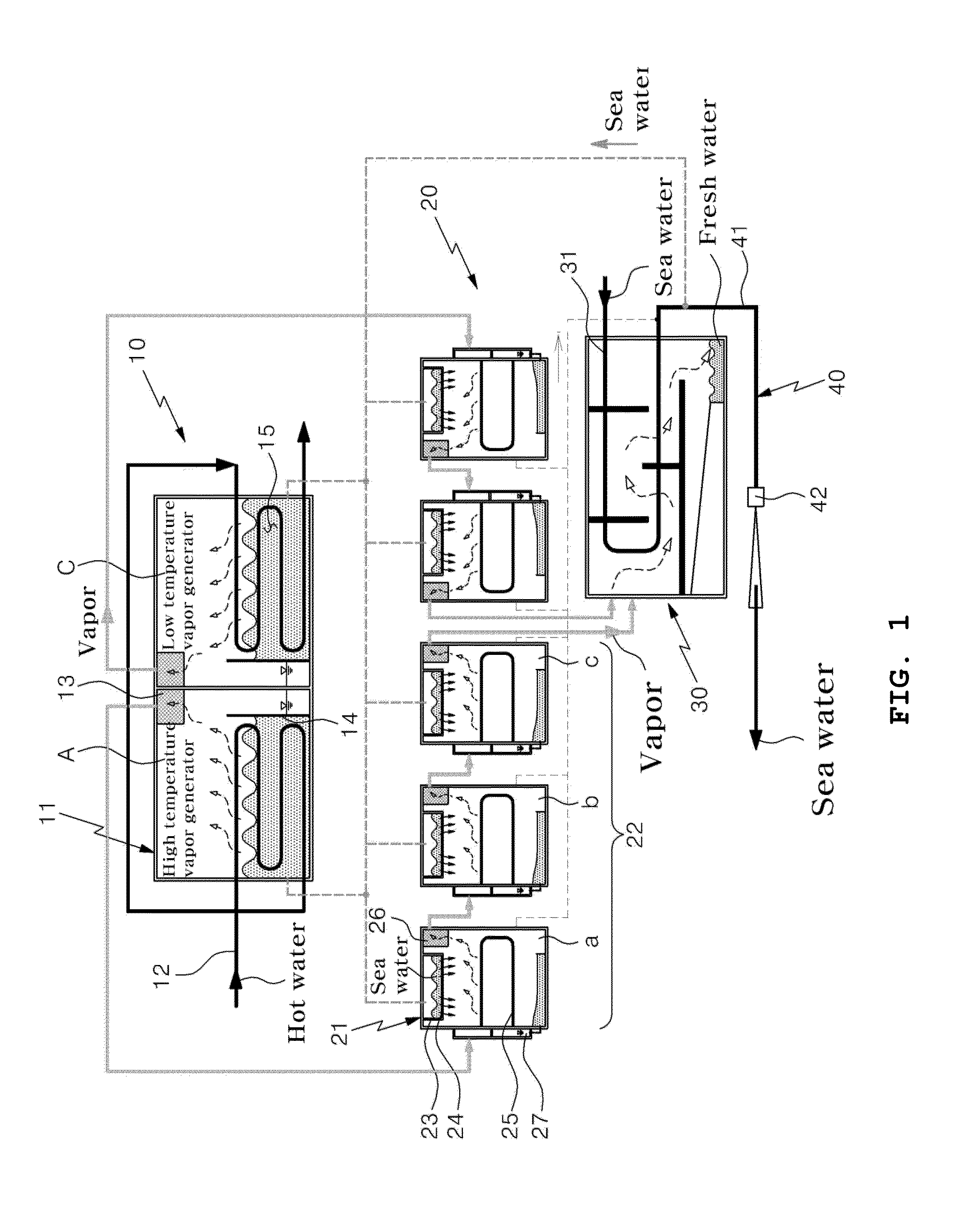

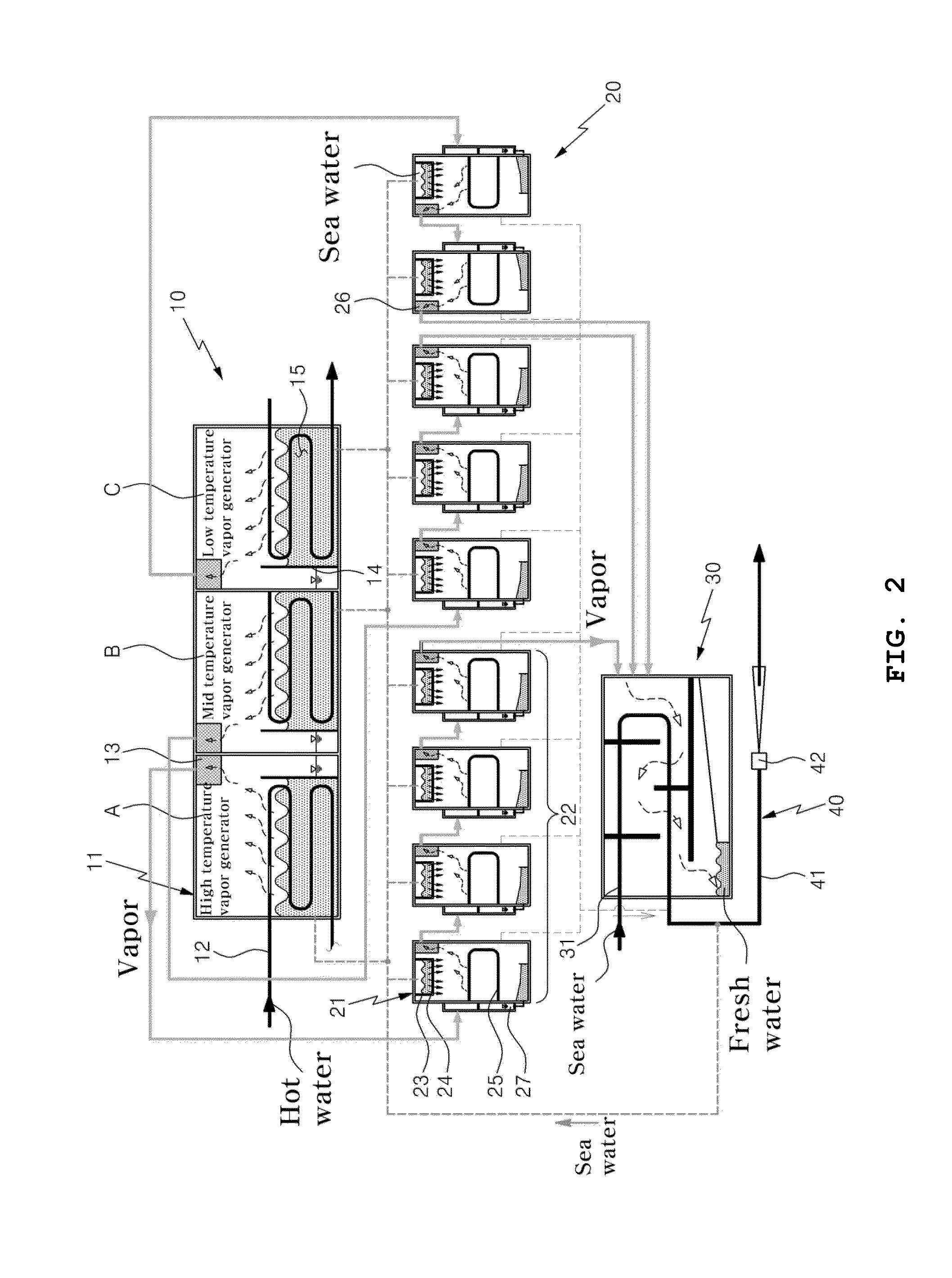

Evaporative desalination device of multi stage and multi effect using solar heat

ActiveUS20130270100A1Increased freshwater productionEconomic feasibilityGeneral water supply conservationSeawater treatmentLiquid stateDesalination

Disclosed is an evaporative desalination device of multi-stage and multi-effect using solar heat constructed in multi stage and multi effect as a desalination device that is capable of not only increasing fresh water output but also resolving a problem of conventional desalination device having series structure as well, through constructing: a multi stage vapor generator that generates vapor by passing a hot water supply pipe successively through a plurality of vapor generators to evaporate sea water inside thereof; a multi effect vapor generator that uses vapor in the respective vapor generators as heat source and forms a plurality of evaporator groups; and a discharge unit that condenses vapor in the multi effect generator by sea water to discharge fresh water in liquid state, and returns and supplies portions of discharged sea water to the multi stage vapor generator and the multi effect evaporator.

Owner:KOREA INST OF ENERGY RES

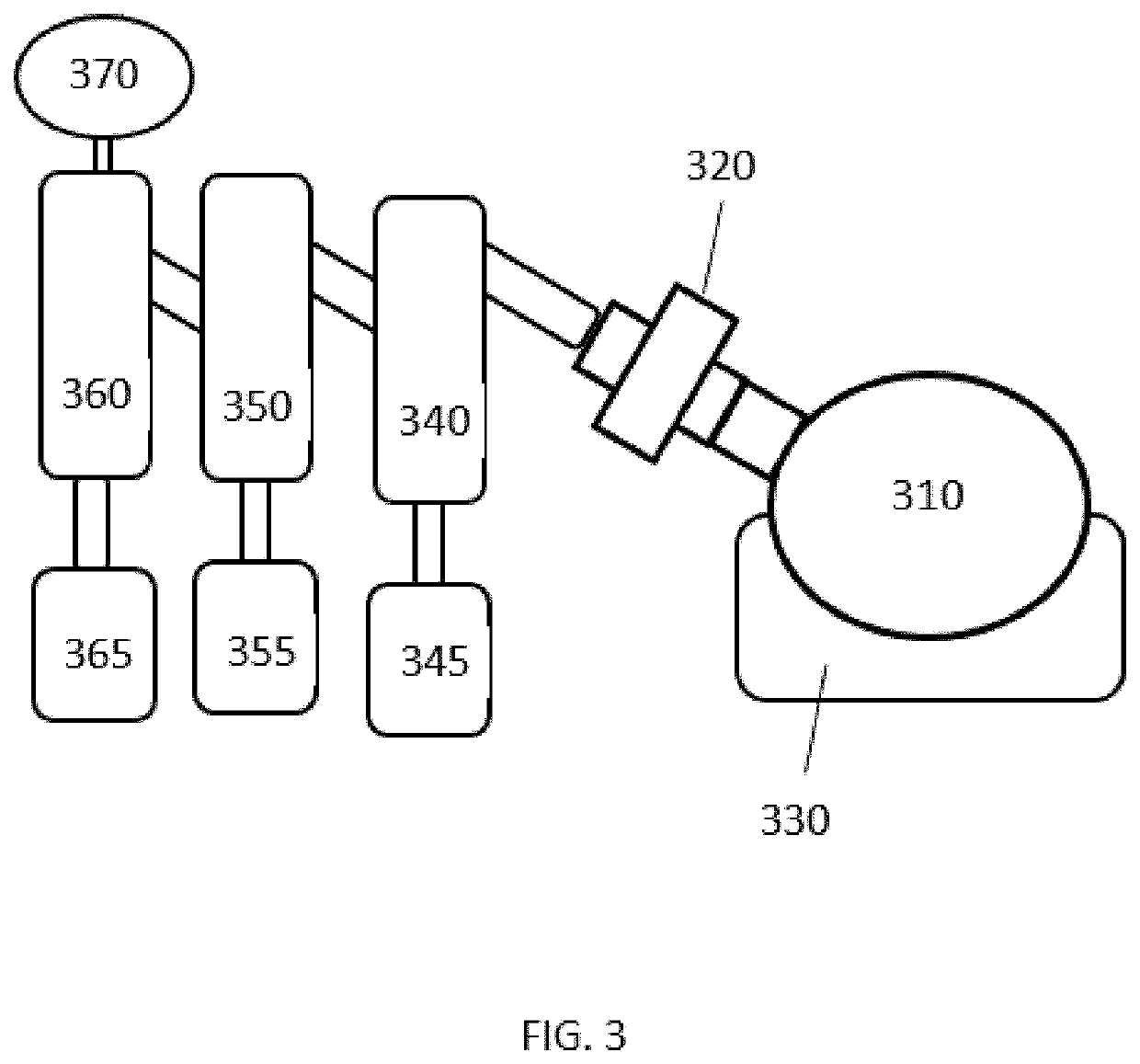

Method and apparatus for sharing co-generated energy when processing essential elements derived from plant matter

Methods and apparatus consistent with the present disclosure may provide electrical energy and thermal to extraction or separation equipment. Methods and apparatus consistent with the present disclosure may extract and concentrate essential elements plant matter. An amount of wasted heat energy collected from a engine that powers an electrical generator may be provided to an evaporation or separation process when electrical power is provided to extraction or separation processing equipment. Computers or electronics that control equipment consistent with the present disclosure may be remotely controlled via a mobile electronic device, when desired. Such computers or electronics may receive sensor data related to the operation of plat matter extractors, related separation equipment, or other equipment may be used to manage a production line. As such, methods and apparatus consistent with the present disclosure may extract essential elements from cannabis plant matter and process those essential elements into cannabis extracts or isolates.

Owner:HOSPODOR ANDREW DAVID +1

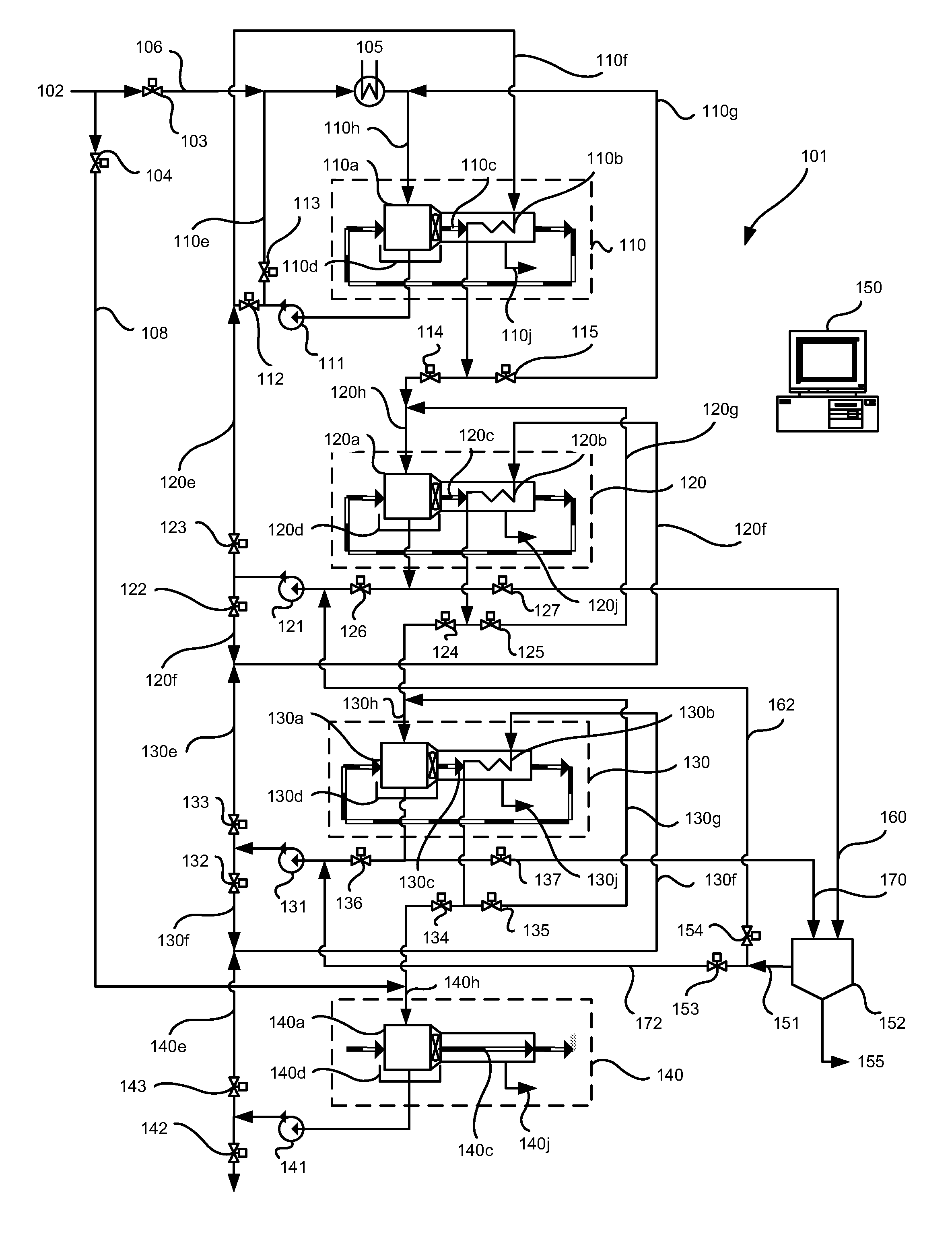

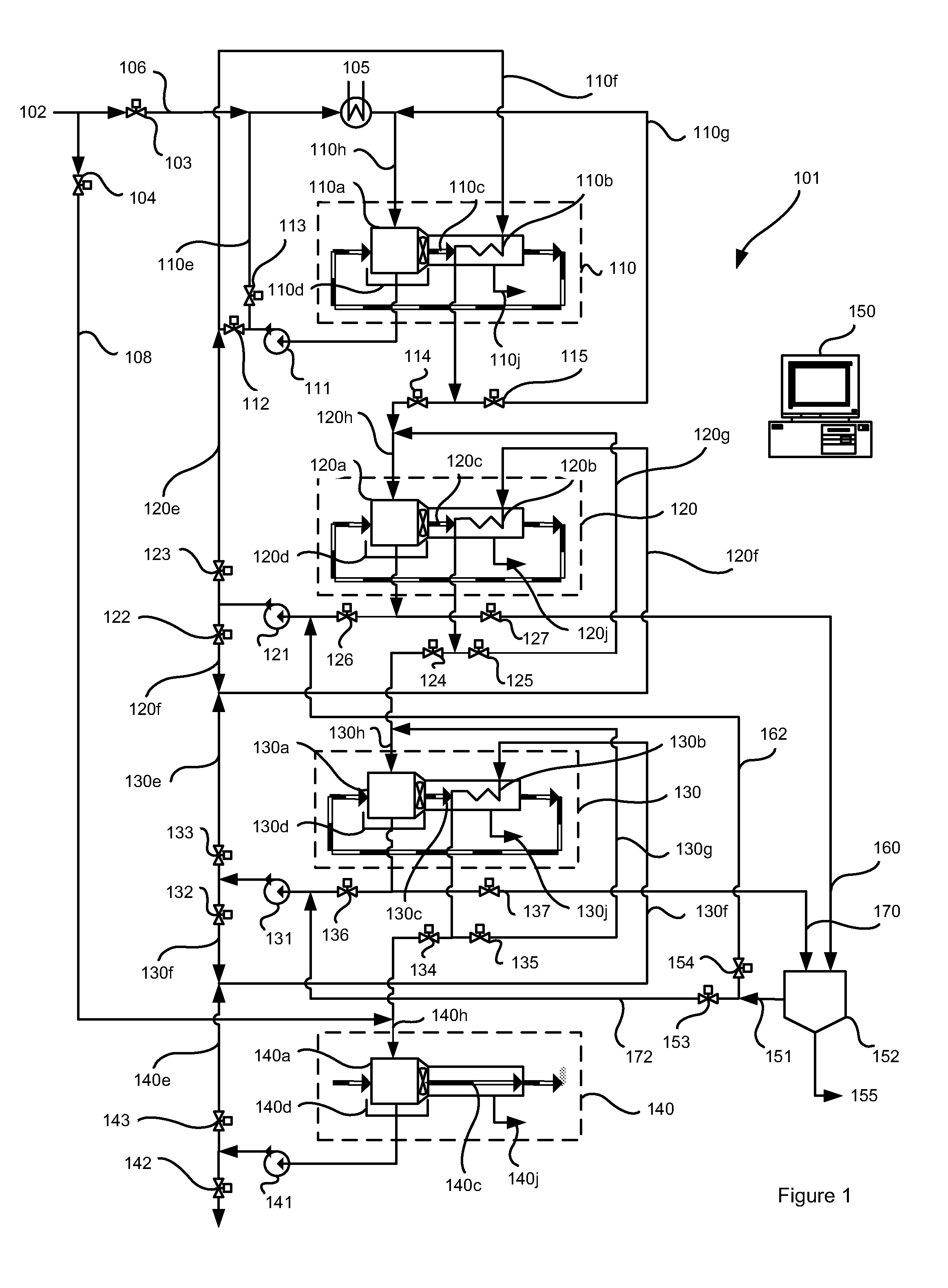

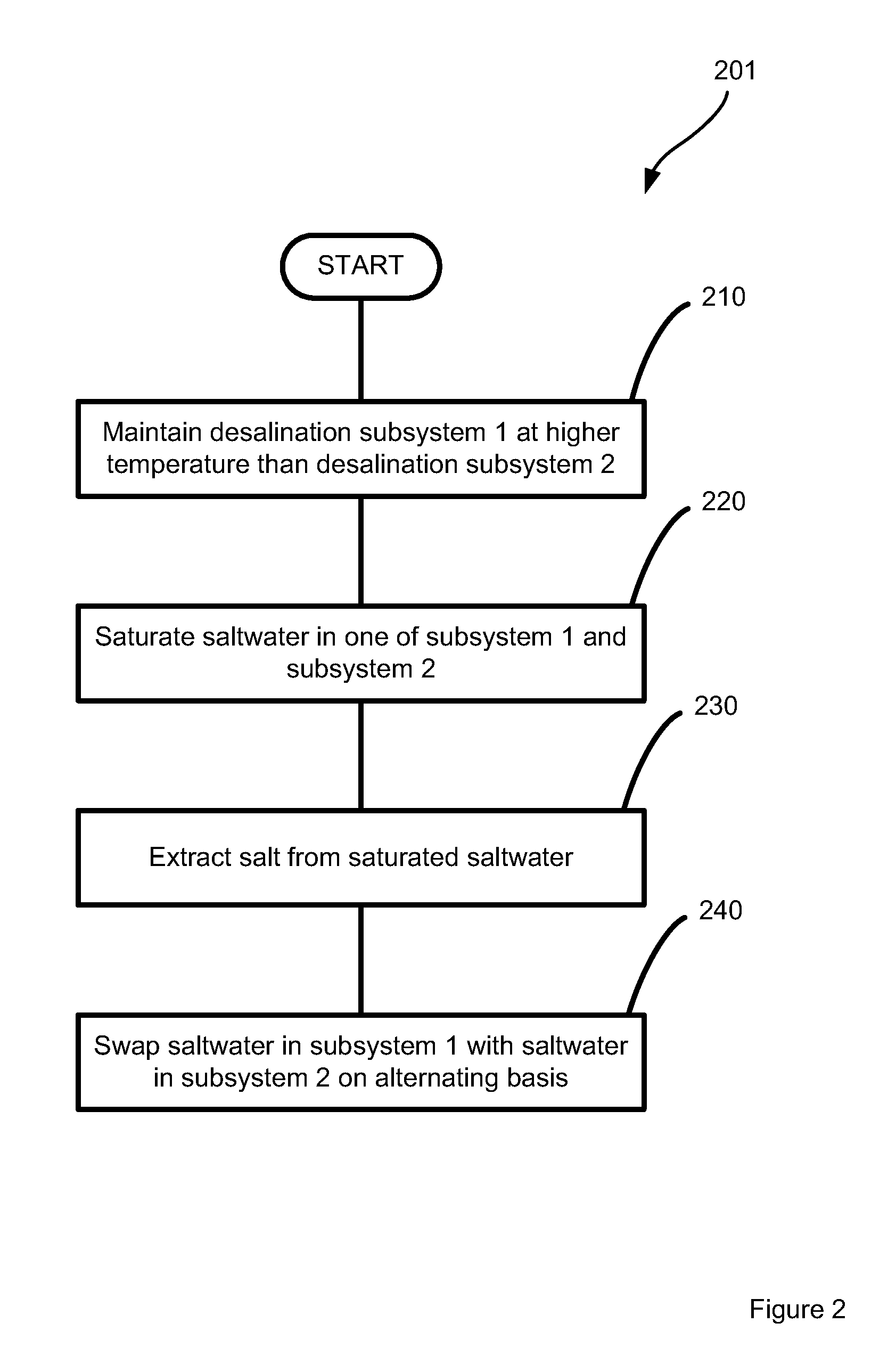

Multiple effect concentration swap de-scaling system

ActiveUS9266747B1Reduce problem sizeWaste water treatment from quariesGeneral water supply conservationSaline waterEngineering

A multistage thermal desalination system, together with its associated method of use, allows de-scaling of subsystems exposed to saturated saltwater by alternating the saturation stage of the process between two neighboring physical desalination stages. The desalination system is provided with at least one transfer conduit, at least one pump, and valving to permit saltwaters being desalinated by higher and lower stage desalination subsystems to be swapped. By replacing the saturated saltwater in a higher salt concentration desalination subsystem with lower salt concentration saltwater, the scaling in higher salt concentration desalination subsystem is reduced while the saturation load is placed on another of the desalination subsystems.

Owner:SALTWORKS TECH INC

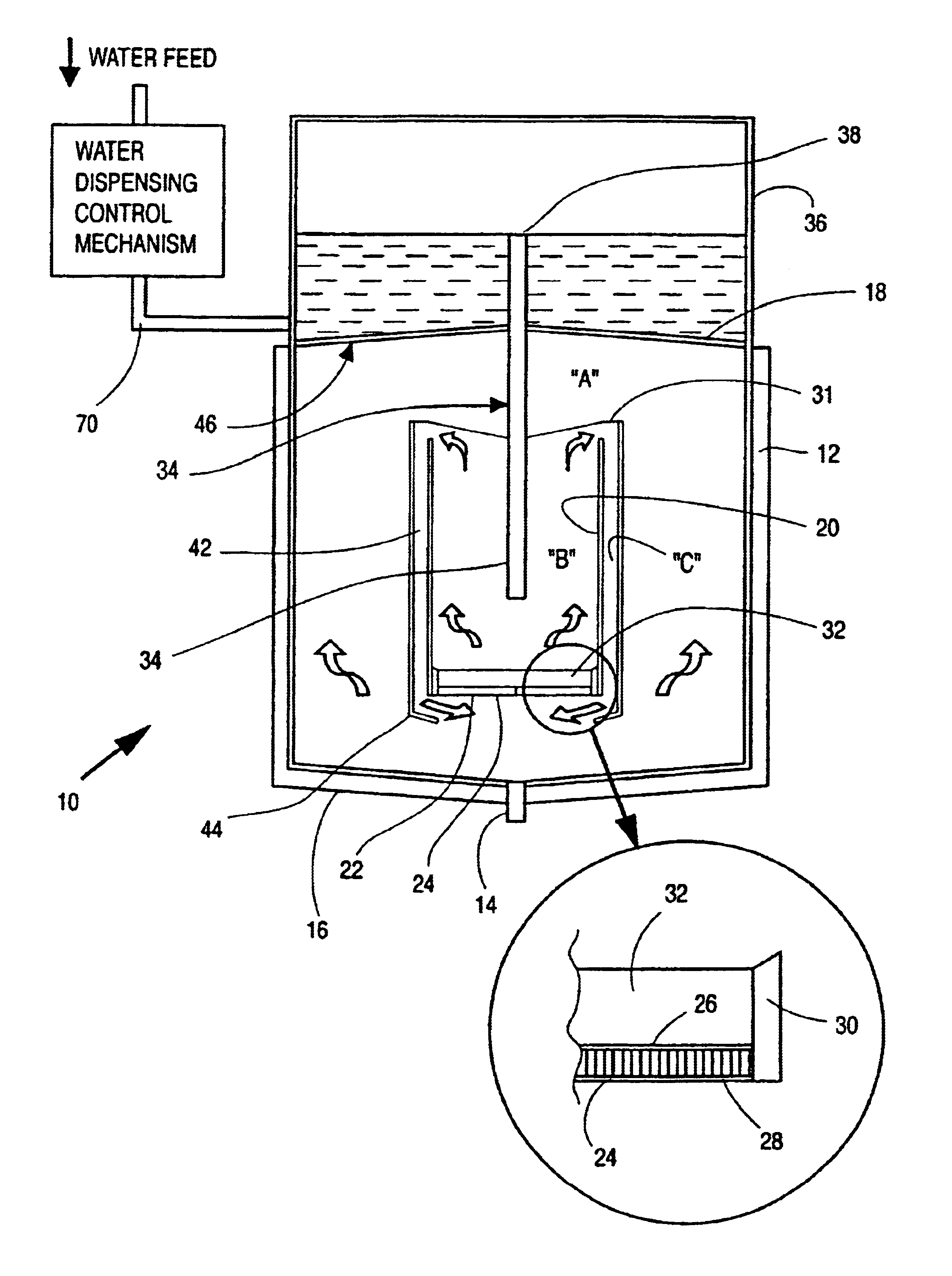

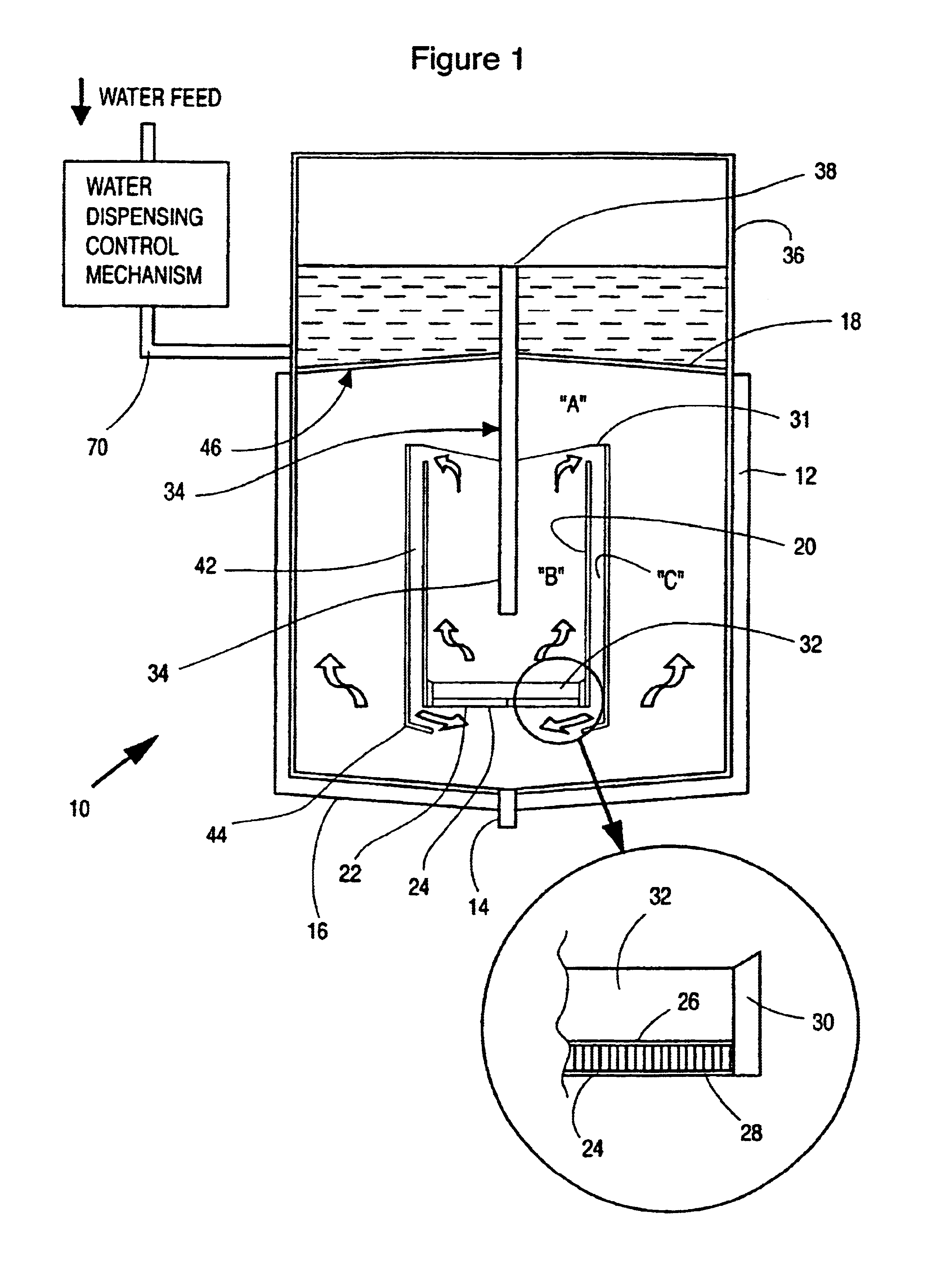

Apparatus and process for purifying a liquid by thermoelectric peltier means

InactiveUS6805774B2Avoid overall overheatingEasy to condenseThermo-electric condensationDistillation regulation/controlElectricityMarine engineering

A continuous process and apparatus is provided for treating an impure liquid to produce purified liquid. The process includes electrically activating a thermoelectric module (24) to provide a first module heated surface (26) and a module cooler surface (28); feeding the impure liquid to the first module heated surface (26) to produce vapor of the liquid; and transferring the vapor to the module cooler surface (28), to effect heat transfer to the module cooler surface (28). The process further includes (a) directing a first portion of the vapor adjacent to or onto the module cooler surface (28) to effect heat transfer to the module cooler surface to produce a first condensed liquid; (b) directing a second portion of the vapor to condenser means (18) having a second cooler surface (46) remote from the module cooler surface (28) to effect heat transfer to the second cooler surface (46) to produce a second condensed liquid; and (c) collecting the first and second condensed liquids.

Owner:DABLEH YOUSSEF HANNA

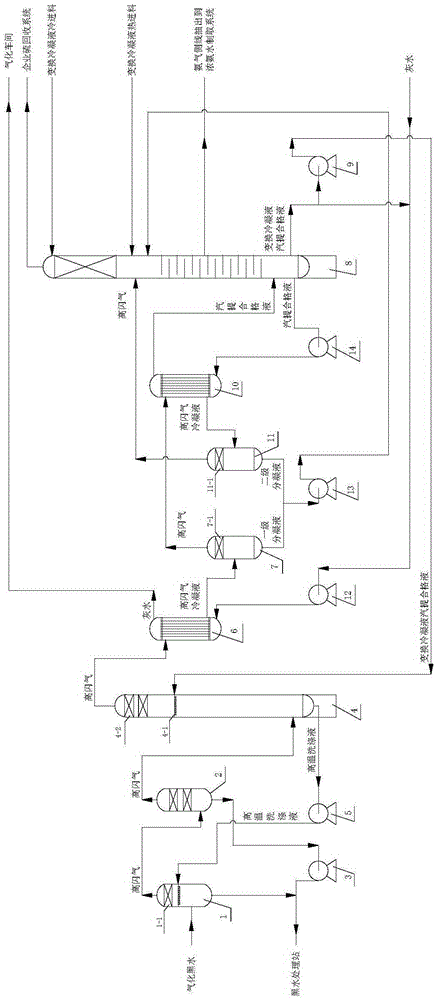

Energy-saving environment-friendly integrated recycling and utilization method of coal chemical gasification washing black water high-temperature flashing steam

ActiveCN105366751ATake advantage ofEfficient separationGas treatmentMultiple-effect/fractional condensationAdditive ingredientReboiler

The invention relates to an energy-saving environment-friendly integrated recycling and utilization method of coal chemical gasification washing black water high-temperature flashing steam. According to the energy-saving environment-friendly integrated recycling and utilization method, gasification washing black water is subjected to vacuum flashing so as to obtain high-temperature flashing steam with a temperature ranging from 170 to 179 DEG C, the high-temperature flashing steam is delivered into a second stage dehydration tank for dehydration, and then is delivered into a washing tower for full washing and dehydration; the high-temperature flashing steam is delivered into a grey water heat exchanger to heat grey water, and then is delivered into a stripping tower reboiler to heat column reactor steam stripping qualified liquid; un-condensed high-temperature flashing steam is delivered into a stripping tower for ingredient separation and recycling; and high-temperature flashing steam obtained from a first stage fractional condenser and a second stage fractional condenser is delivered into the stripping tower for steam stripping, separating, and recycling; and at last, scaling ingredients in the high-temperature flashing steam are moved completely, full utilization of the high-temperature flashing steam is realized, grey water is diluted, so that scaling caused by recrystallization is not caused, and complete recycling of grey water is realized.

Owner:郑州和易环保科技有限公司

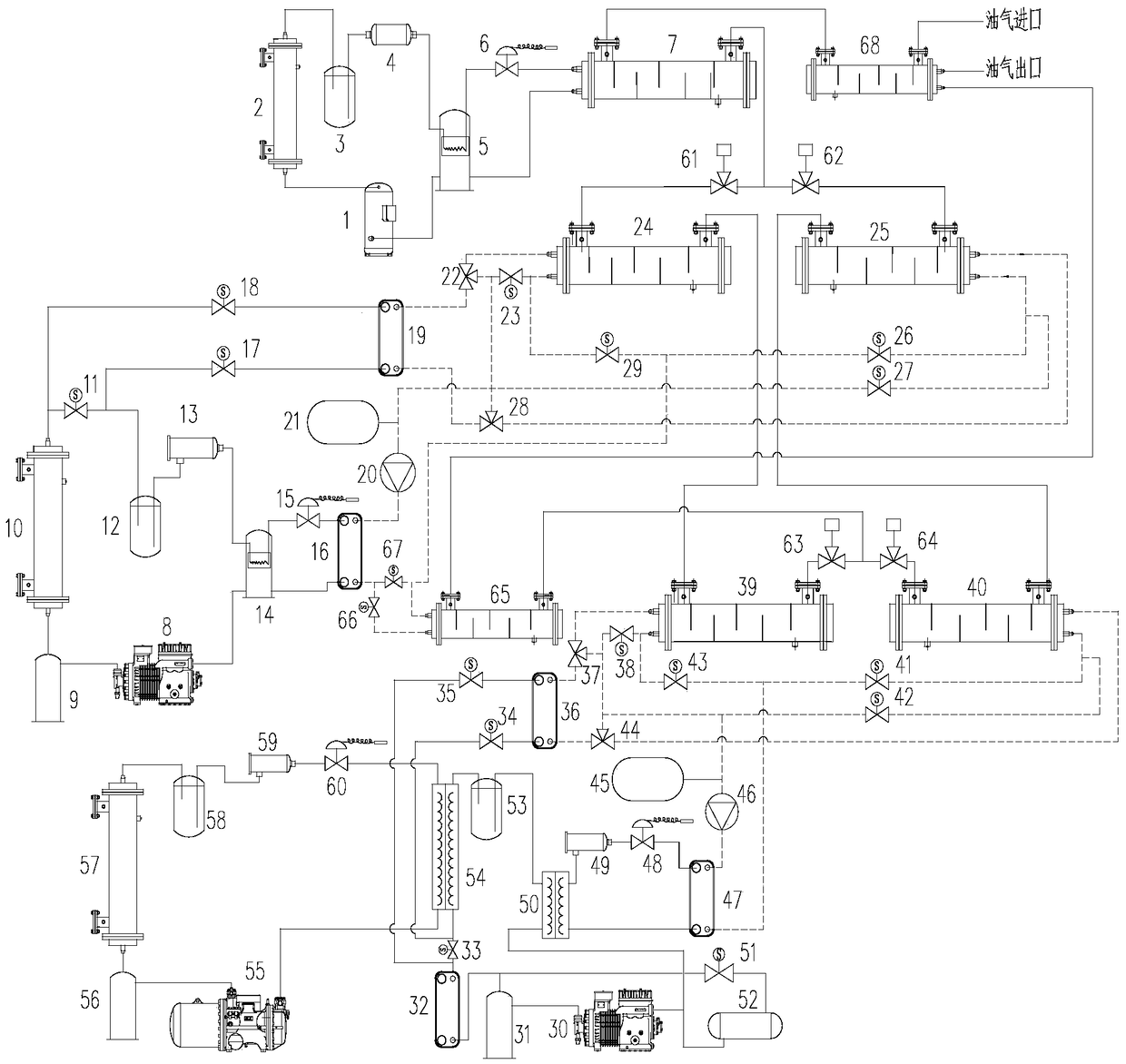

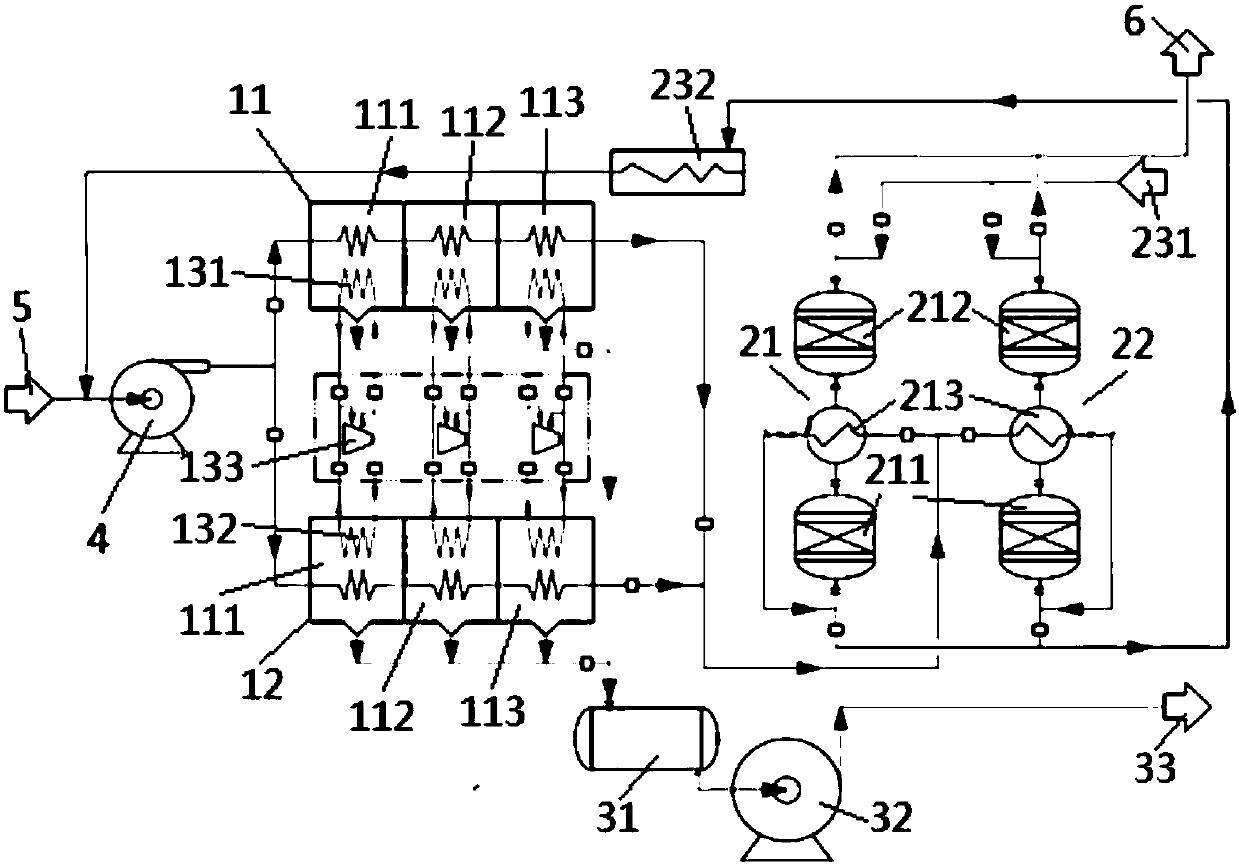

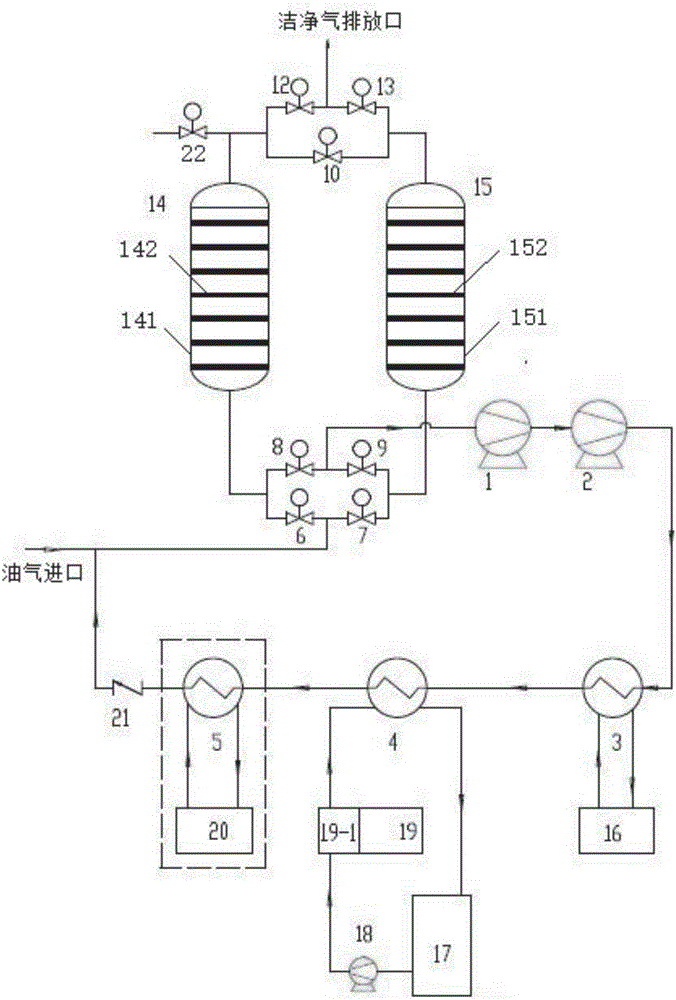

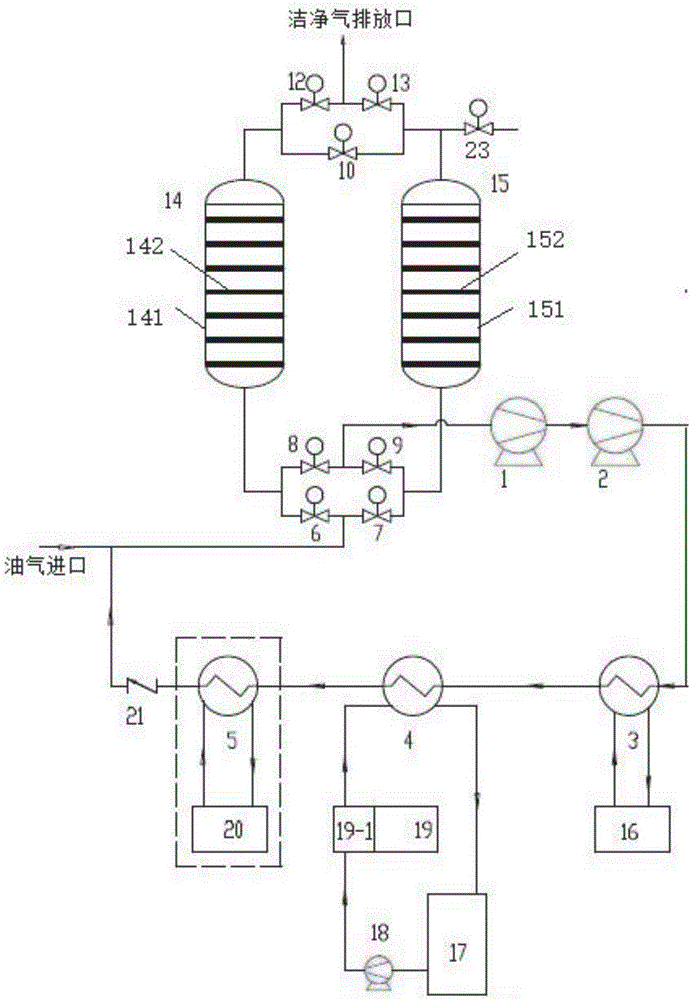

Indirect condensation type oil-gas recovery unit with self-defrosting function

PendingCN109157861AWith self-defrosting functionImprove reliabilityMultiple-effect/fractional condensationLow voltageRefrigerant

The invention discloses an indirect condensation type oil-gas recovery unit with a self-defrosting function. The unit comprises a primary direct-expansion type condensing system, a secondary indirectcondensing system, a third indirect condensing system and a waste cold recovery system connected through an oil-gas pipeline. By organically combining a direct-expansion type refrigerating technologywith an indirect condensing technology, secondary and third systems easy to be frozen and condensed have low voltage and oil deficient problems as a refrigerant migrates easily as the refrigerating and defrosting modes are switched. By adopting the indirect condensing technology, a refrigerant system of a compressor is in a single refrigerating cycle all the way, so that the problem that the refrigerant migrates is solved thoroughly, and therefore, the low voltage of the system and oil deficiency of the compressor are further solved, and the operating reliability of the condensing unit is improved greatly.

Owner:NANJING WUZHOU REFRIGERATION GRP

Machines and methods for removing water from air

InactiveUS7886547B2Water/sewage treatment by irradiationLighting and heating apparatusAtmospheric airEnvironmental engineering

The invention provides machines and methods for extracting water from atmospheric air. Also provided are bladed core heat exchangers.

Owner:SULLIVAN SHAUN E

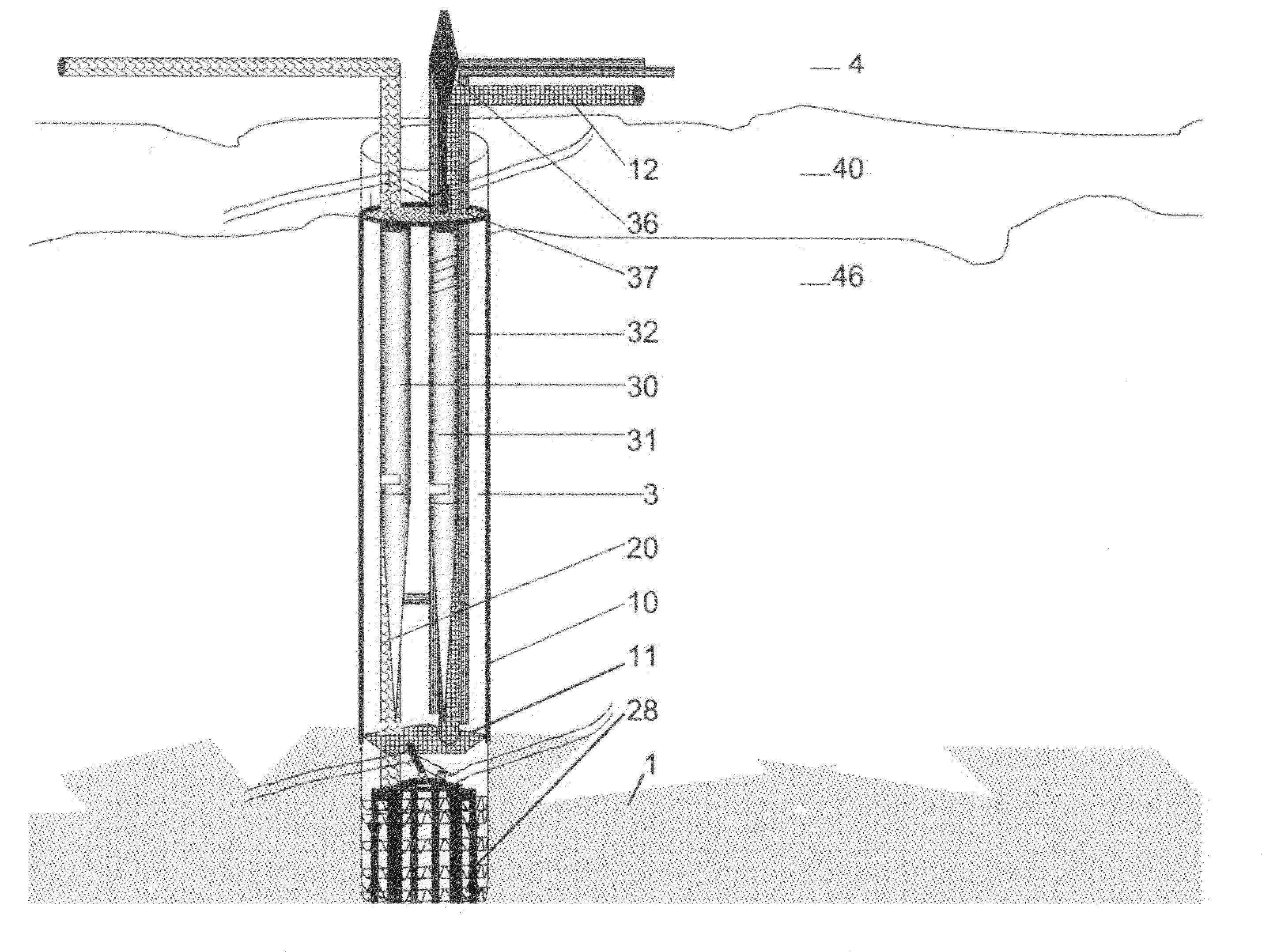

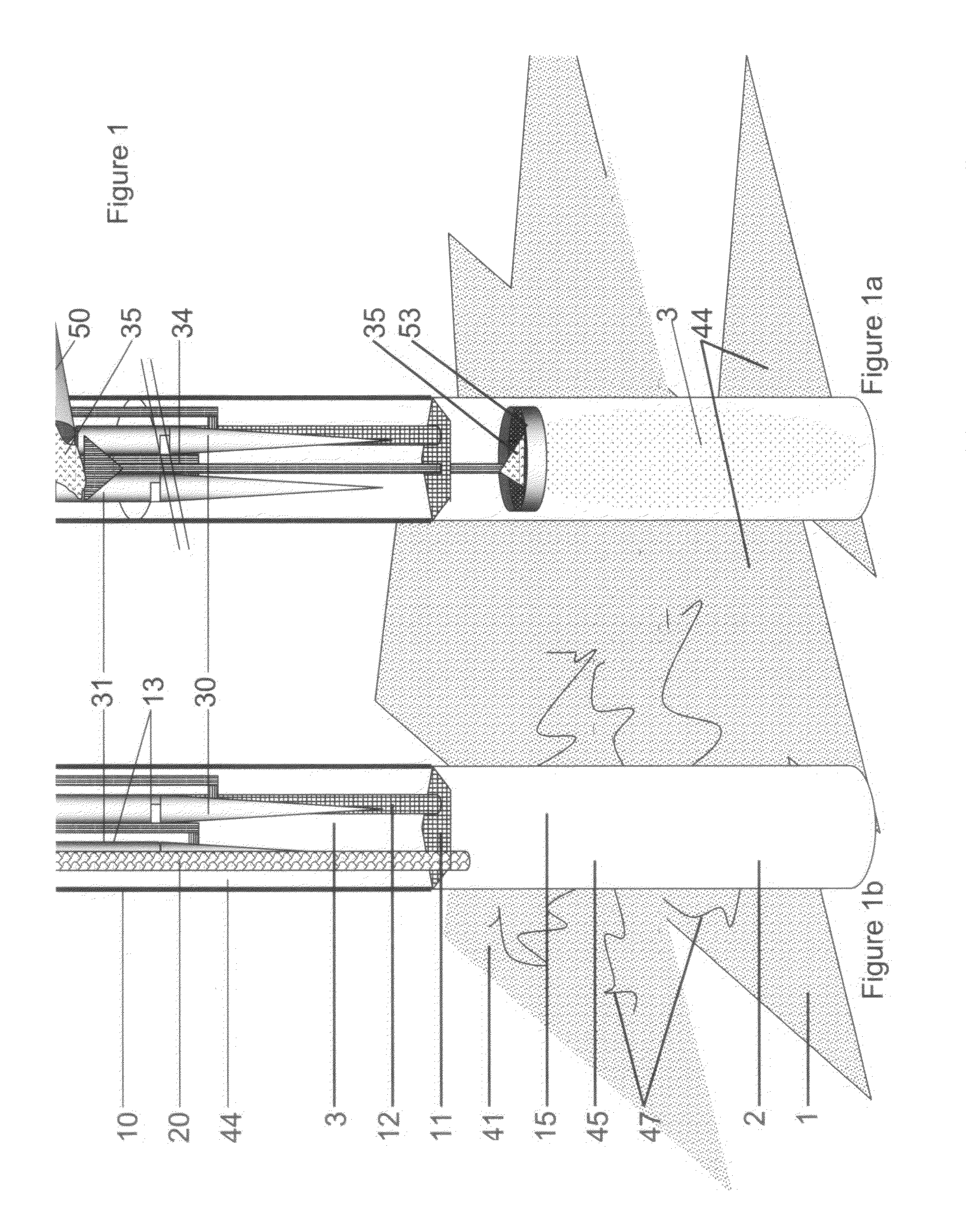

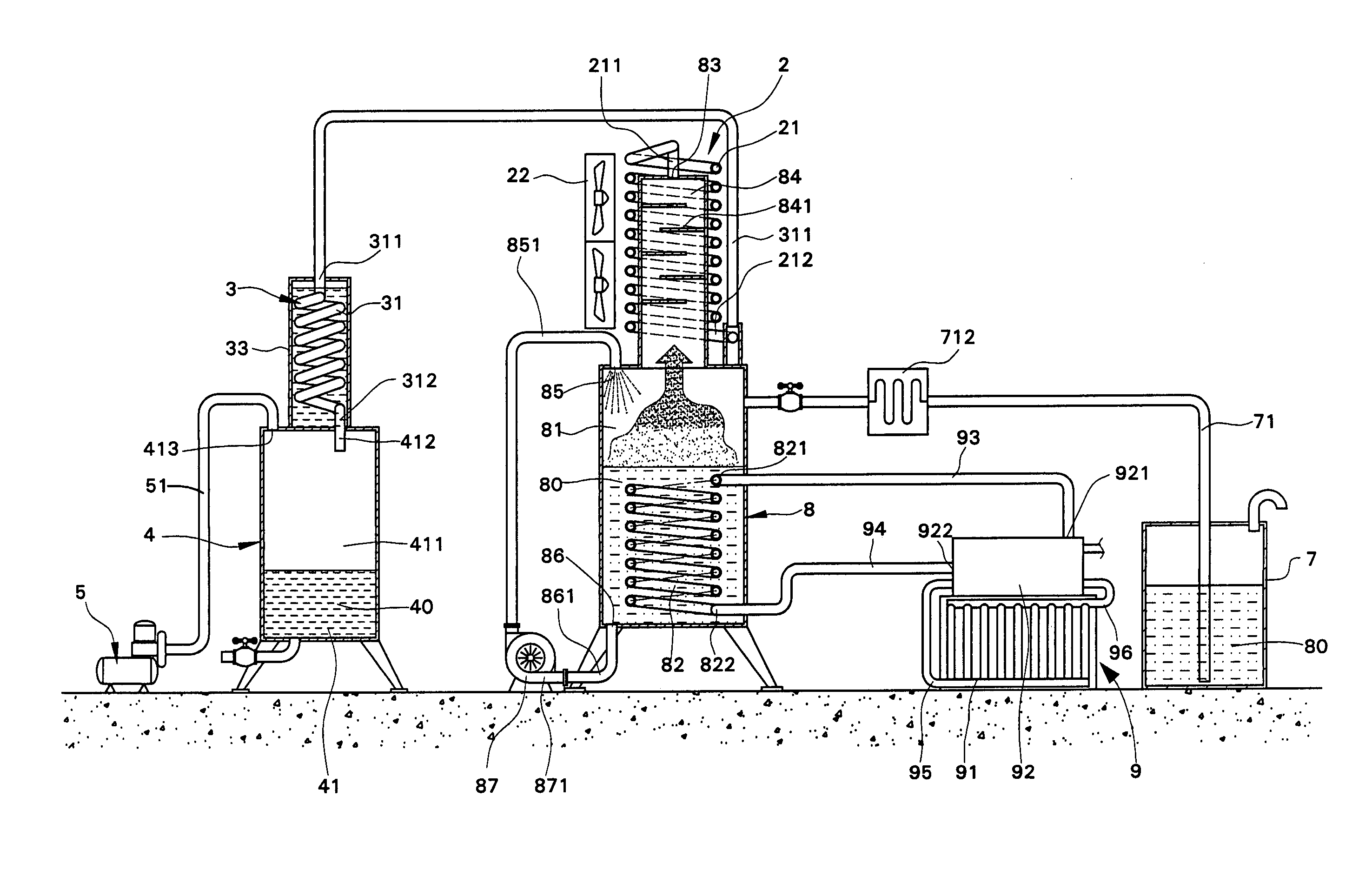

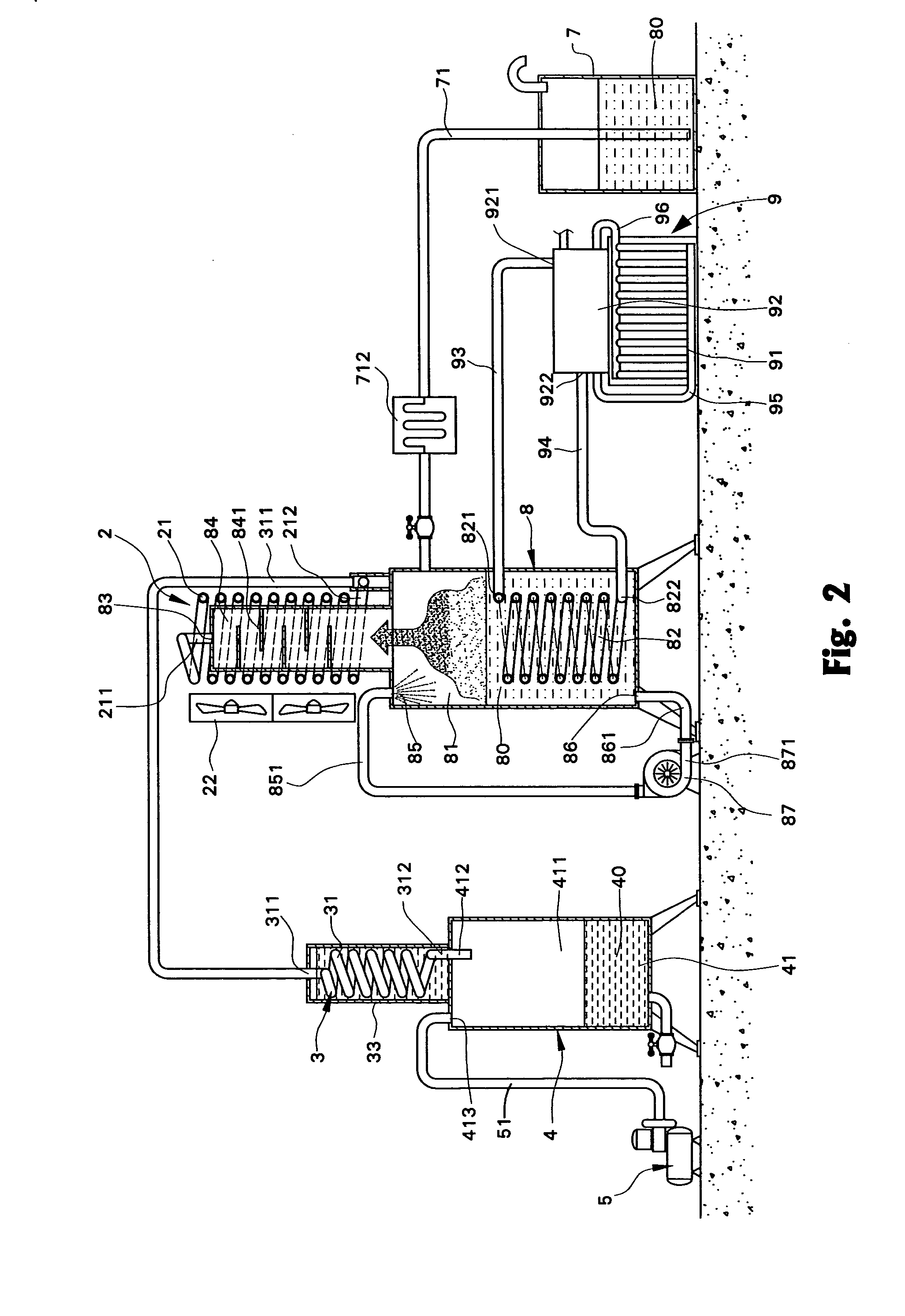

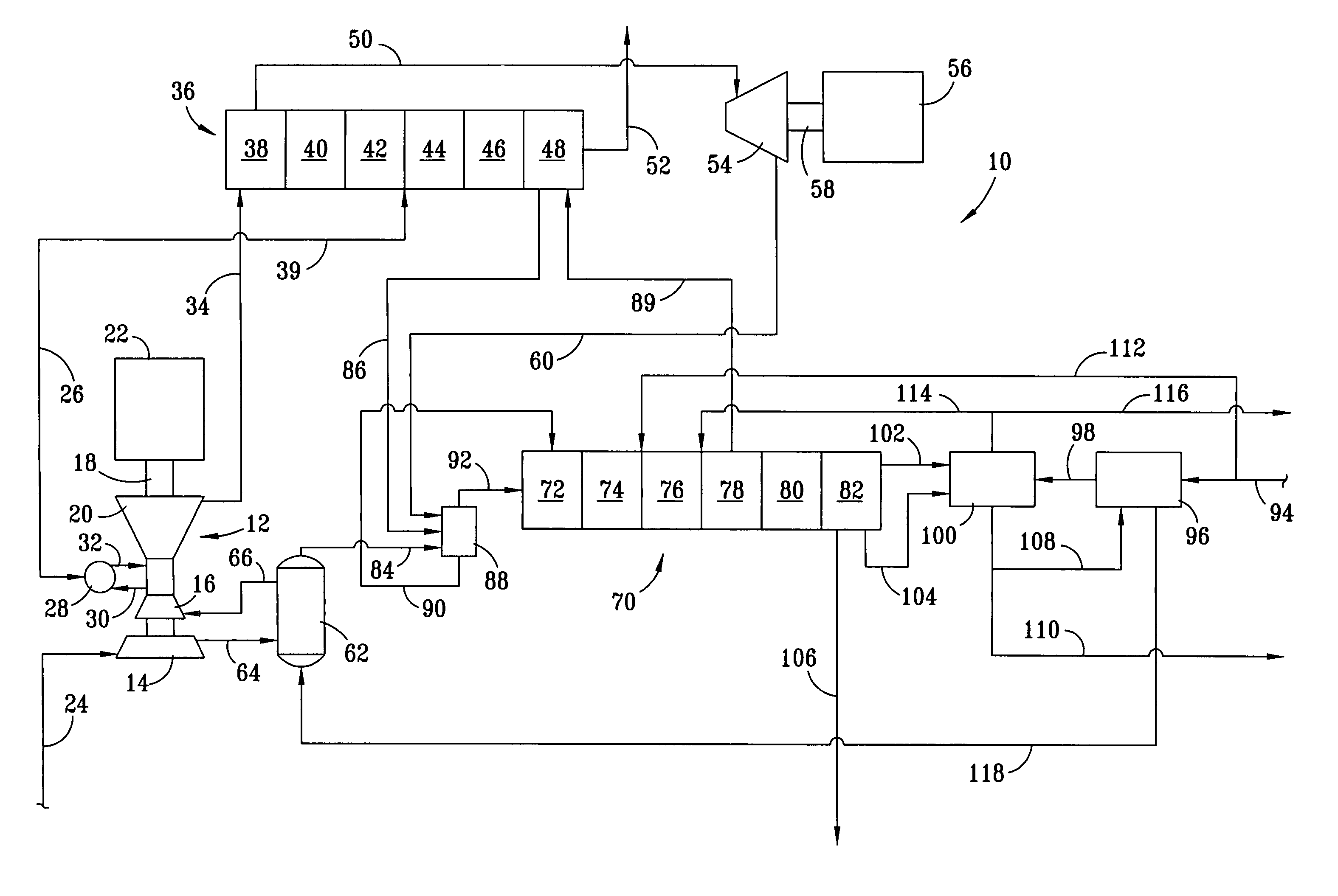

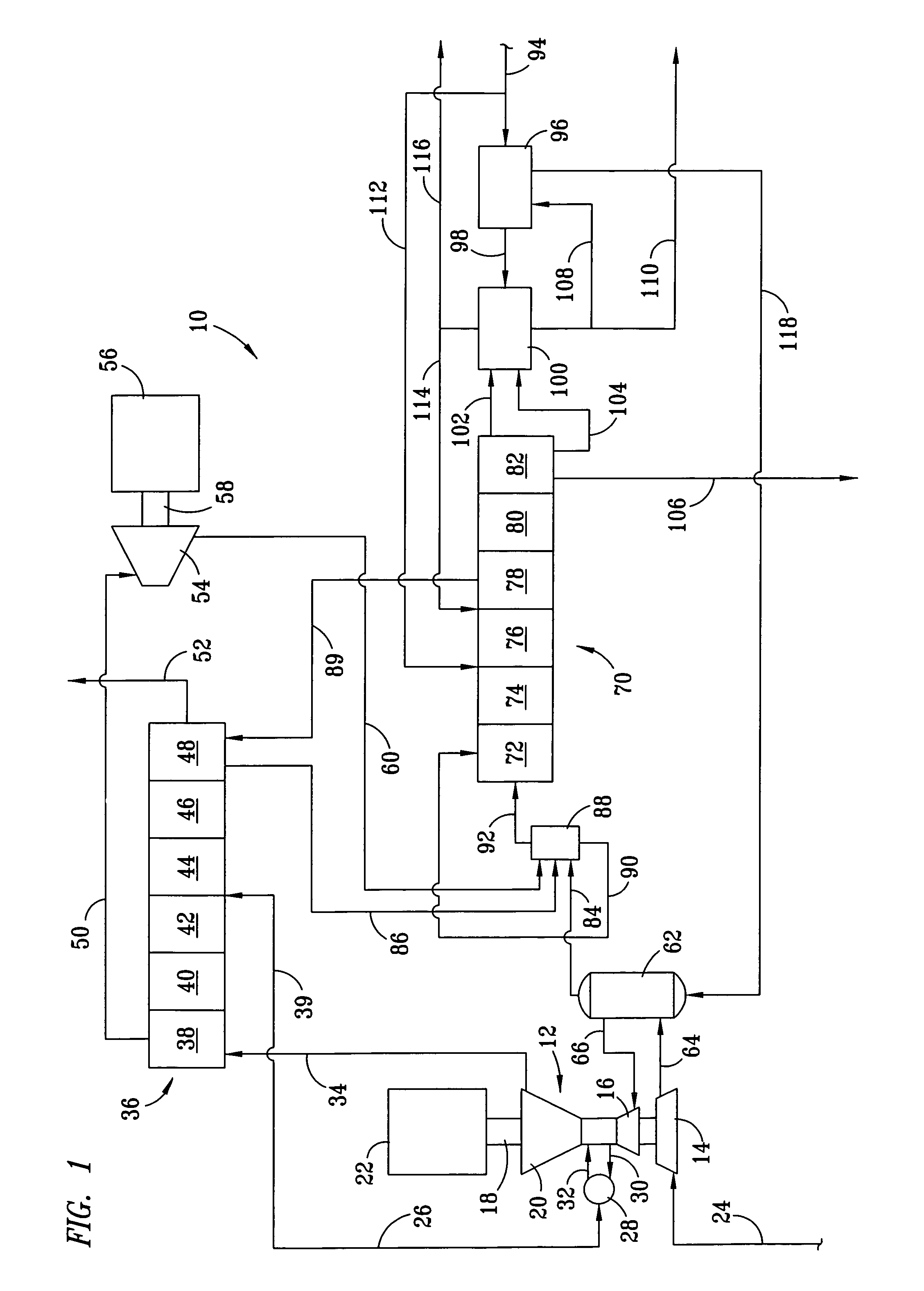

Hydraulic fracturing system and method

ActiveUS20150083235A1Valve members for heating/coolingMultiple-effect/fractional condensationDistilled waterFresh water

Disclosed herein is a fracturing unit for hydraulic fracturing having an engine and a fracturing pump connected to the engine through a variable speed torque converter. Also disclosed is a hydraulic fracturing system using multiple fracturing units which are sized similar to ISO containers. A hydraulic fracturing system may also force flow back water, produced water, or fresh water through a heat exchanger so that heat from the fracturing engines can be transferred to these liquids in order to vaporize them. A force cooled fractioning unit then can accept the vapor / steam in order to condense the various components and produce distilled water for re-use in the fracturing process or for release into the environment.

Owner:LARSON KEVIN

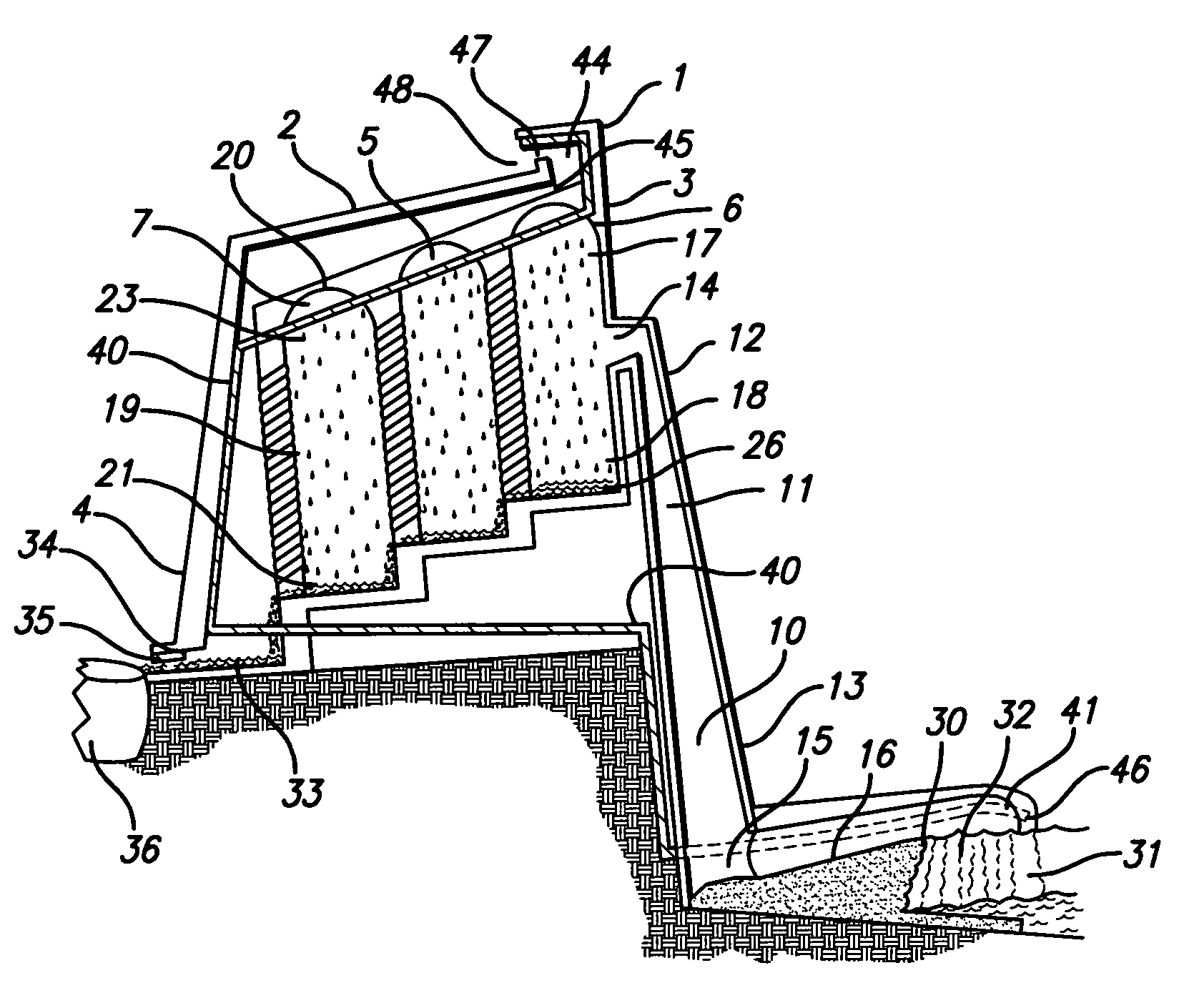

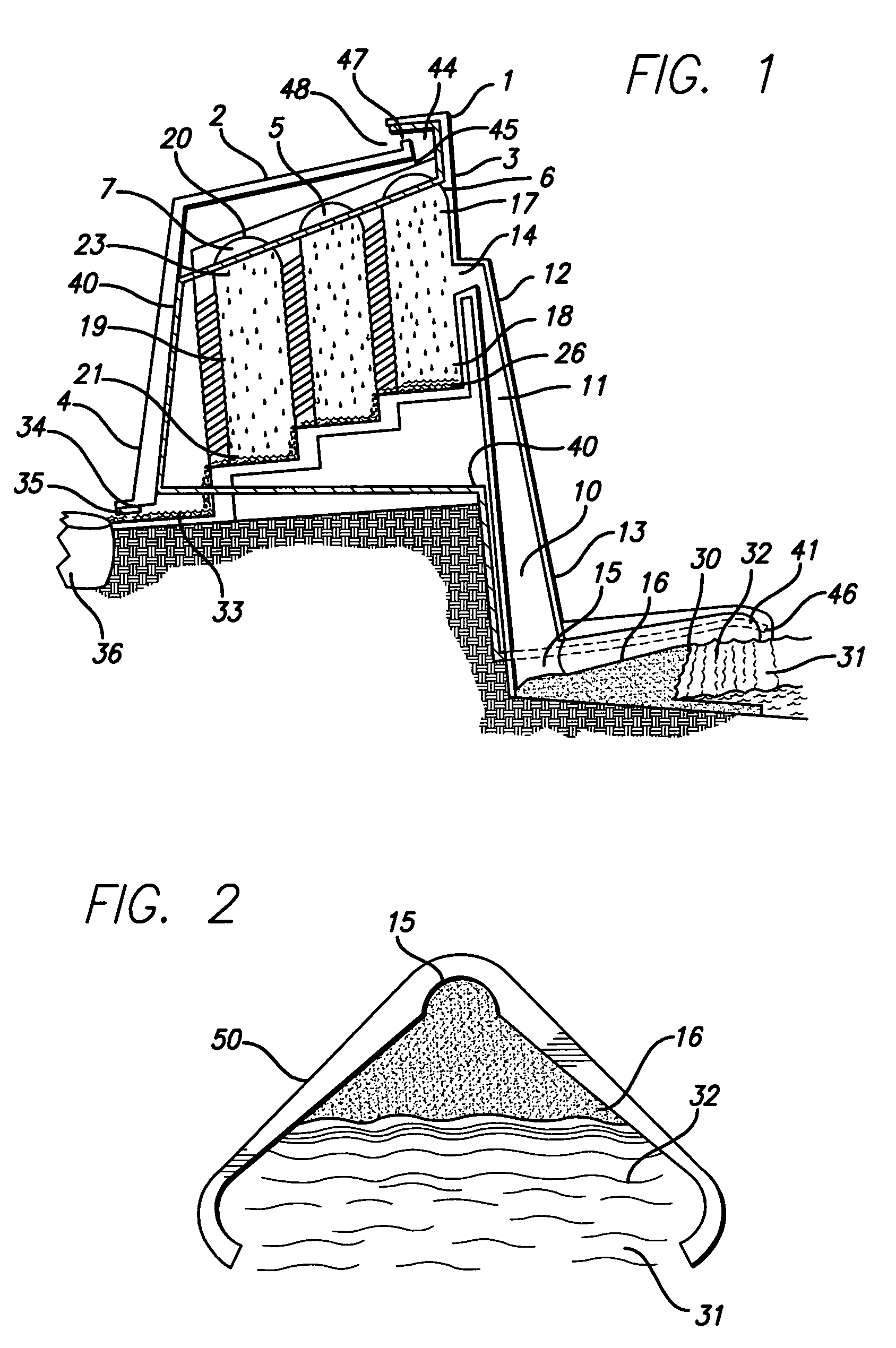

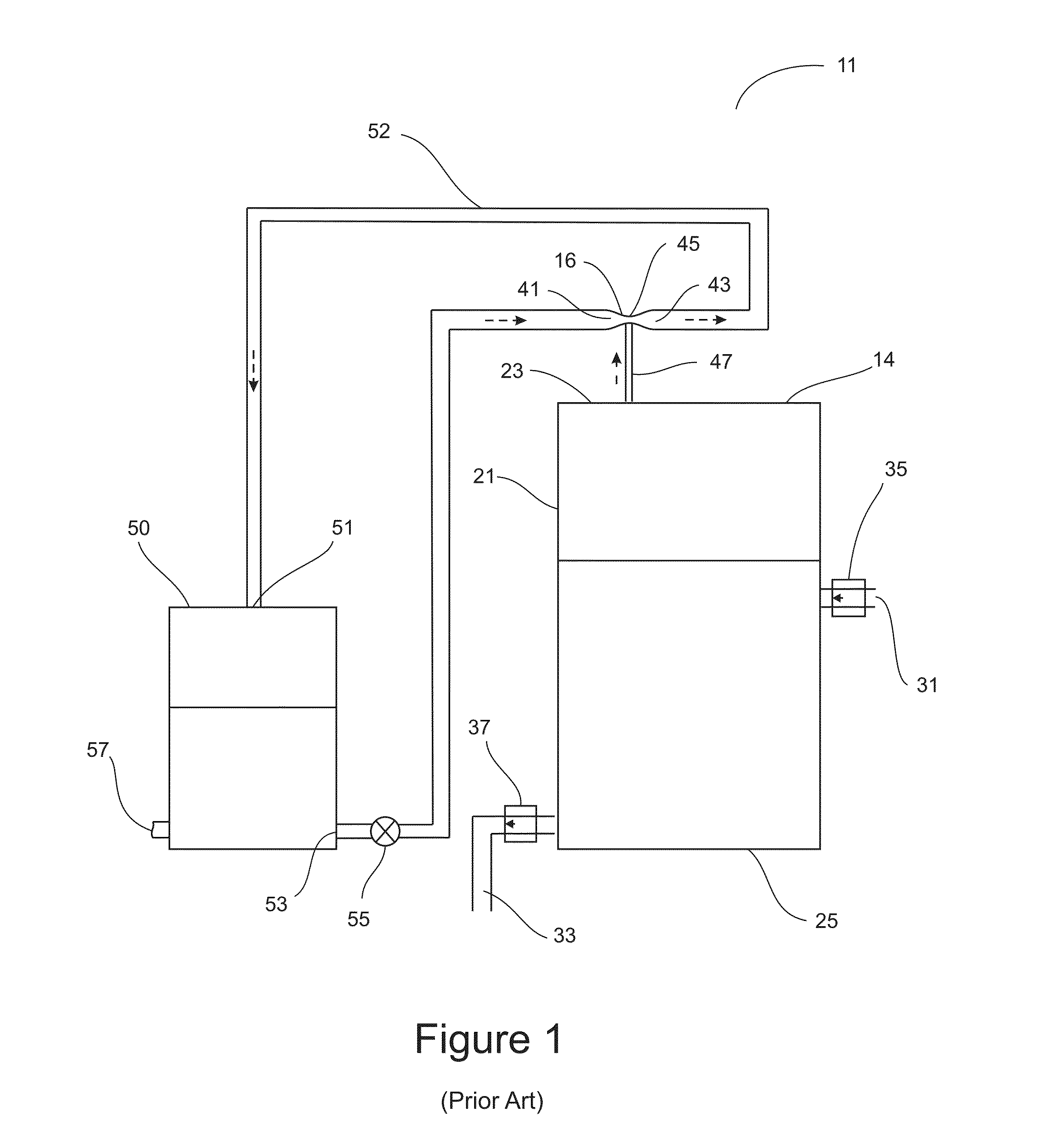

Process and structure for superaccelerating nature, producing a continuous supply of fresh water from salt water by using solar, wind, and wave energy

InactiveUS7527711B2Without any measurable waste productLow additional costAuxillariesGeneral water supply conservationSaline waterSalt water

A continuous supply of fresh water achieved through desalinization by a system of Venturi shafts to increase the velocity and pressure of air flow allowing for increased condensation and processing of evaporated water through a structure (1) that incorporates a blackened evaporation surface (16), concave Venturi wind walls (50), a vertical Venturi wind shaft (10), condensation chambers (5) connected by horizontally stacked hollow cylinders (61), a heat transfer duct (40) that draws cool air from a water body, vents hot air through an air exhaust port (48), and a water drainage port (35) that flows water to a reservoir (36).

Owner:DESAL LLC

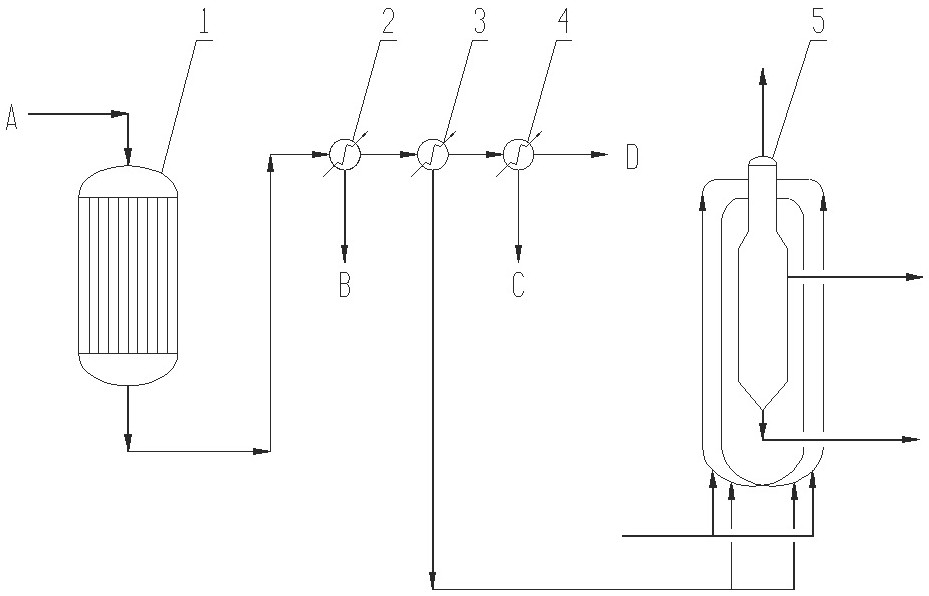

NMP gas recovery system and technology thereof

InactiveCN105797420AReduce reheatingImprove recycling ratesOrganic chemistryMultiple-effect/fractional condensationActivated carbonResource recovery

The invention belongs to the technical field of industrial production waste gas recovery, and particularly relates to a recovery system for N-methyl pyrrolidone in lithium battery industrial waste gas treatment and a technology of the recovery system. The recovery system comprises a precooling and exchanging unit, a condensing unit, an adsorption and regeneration unit and an NMP waste liquor recovery tank which are sequentially connected, and the precooling and exchanging unit and the condensing unit are both connected with the NMP waste liquor recovery tank. Compared with the prior art, according to the NMP gas recovery system, equipment is simple, the technological process is short, no activated carbon adsorbent is used, eluting tower waste liquor is not generated, and the primary recovery rate of NMP can reach 99% or above; the production environment is effectively improved, personnel body health is prevented from being harmed, the cost of enterprise consumables is reduced, and the resource recovery utilization rate is increased.

Owner:DONGGUAN TAFEL NEW ENERGY TECH CO LTD +1

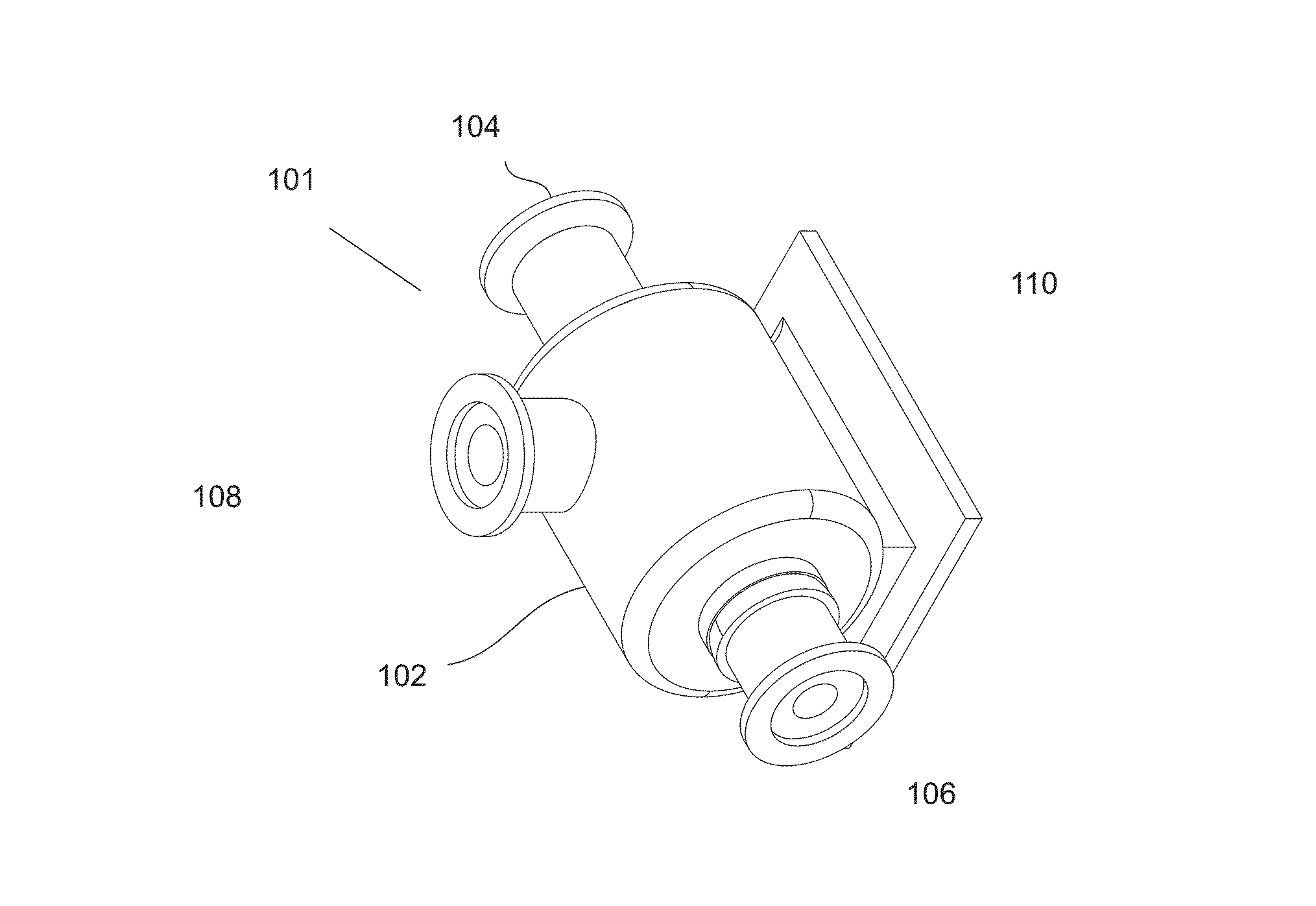

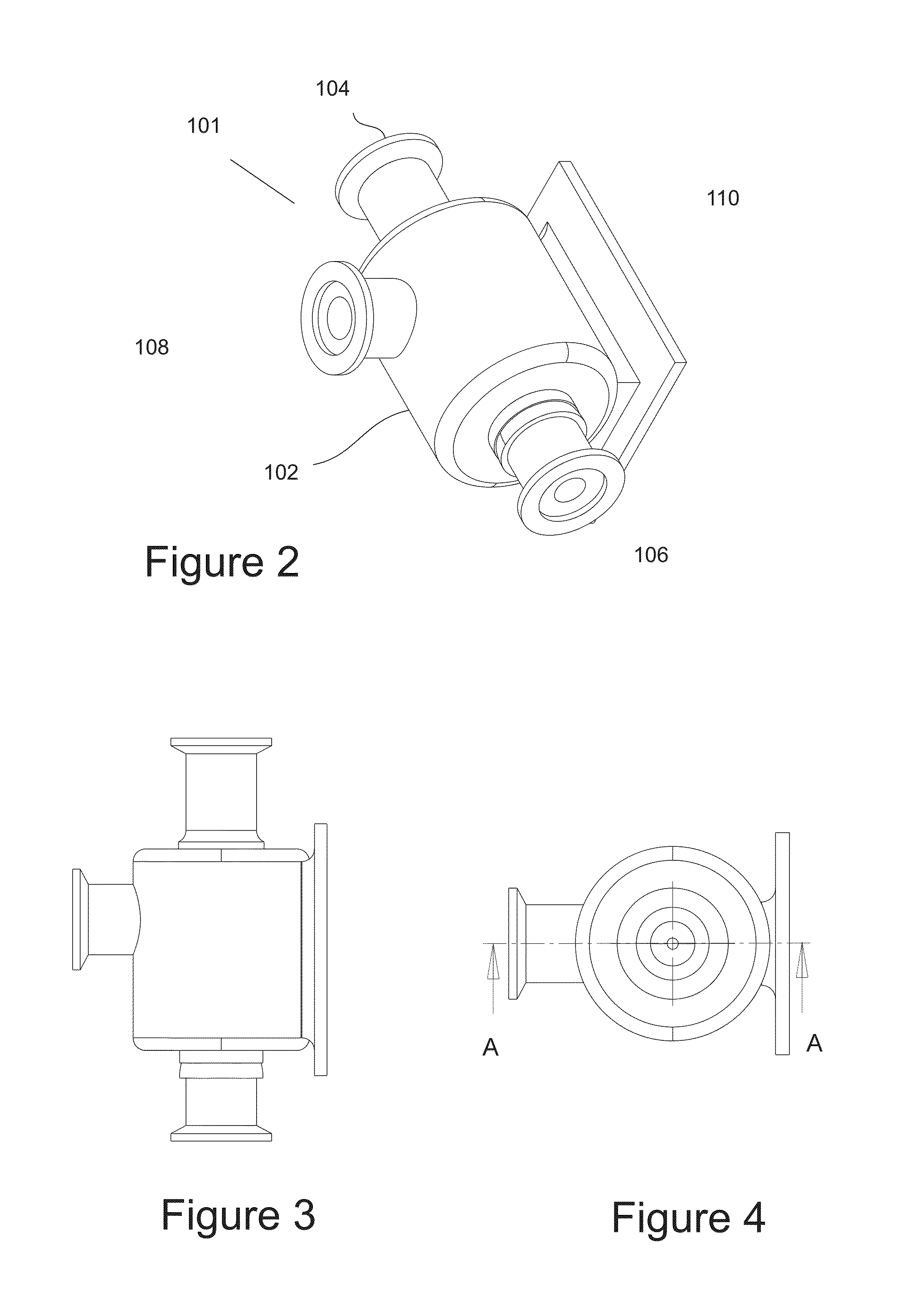

Vacuum Condenser

InactiveUS20160271519A1Reduce pressureIncrease productionVacuum condensationMultiple-effect/fractional condensationEngineeringOperating temperature

A vacuum condenser adapted to reduce pressure in an enclosure containing a secondary liquid and thereby cause the accelerated production of vapor from the secondary liquid by the passage of a primary liquid through the vacuum condenser and whereby the vapor produced is absorbed by the primary liquid within the vacuum condenser by being entrained and condensed within the primary liquid wherein the vacuum condenser is configured to cause the operating temperature of the secondary liquid within the enclosure to maintain a stable minimum temperature for a predetermined substantial rate of production of vapor.

Owner:HARMAN JAYDEN DAVID +4

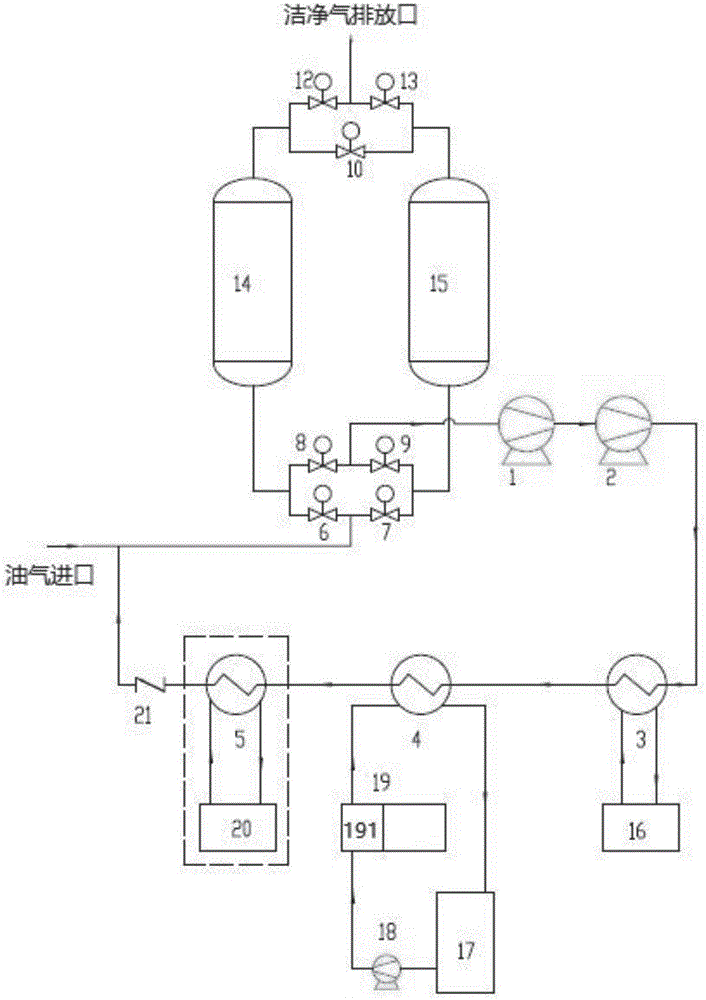

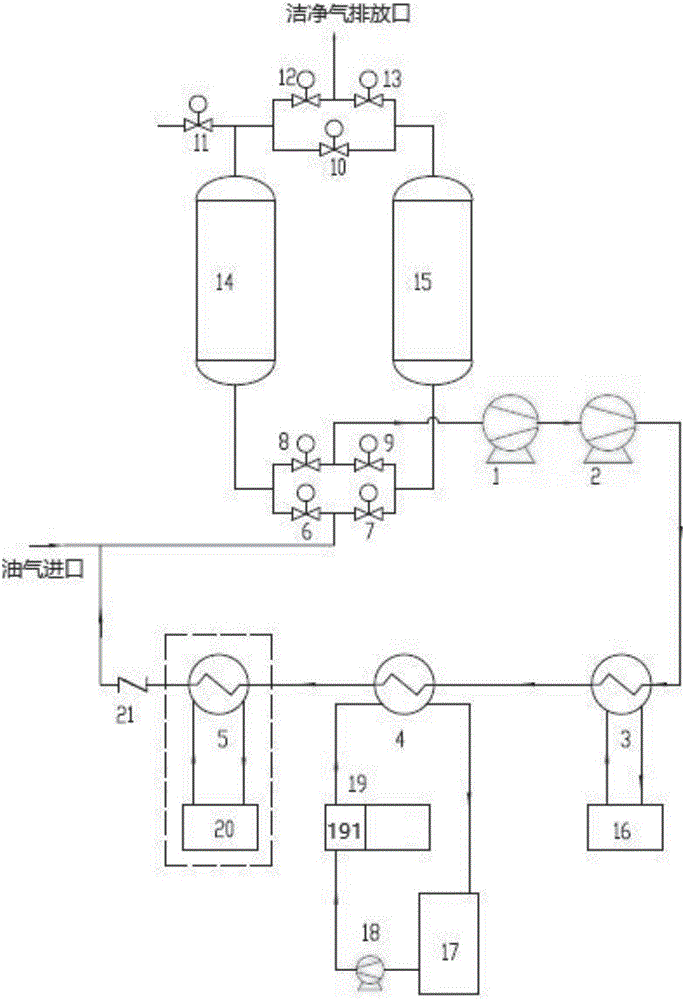

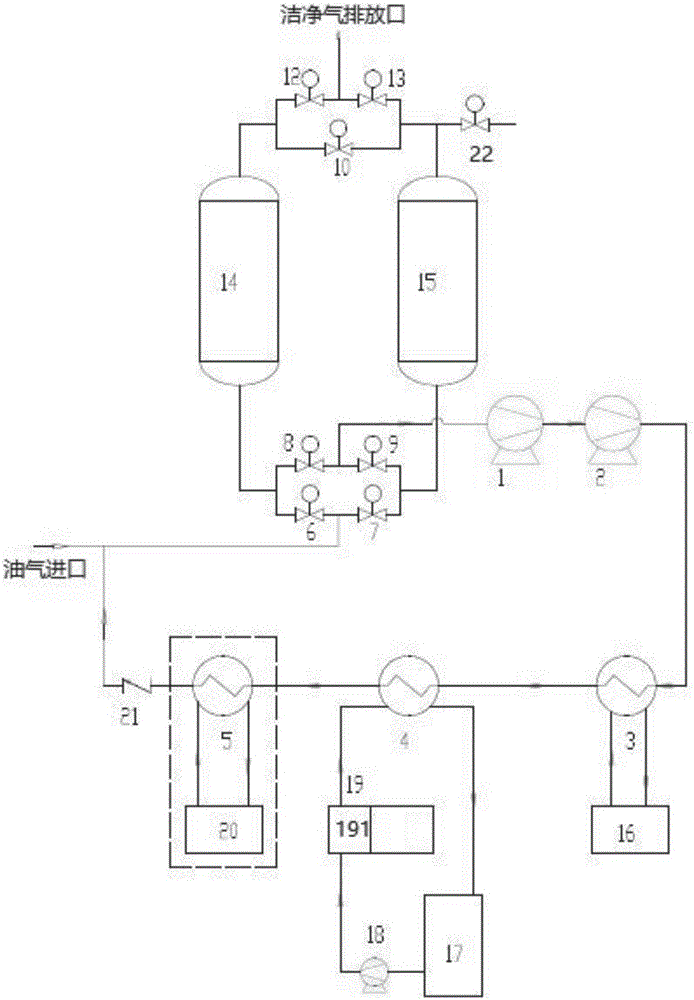

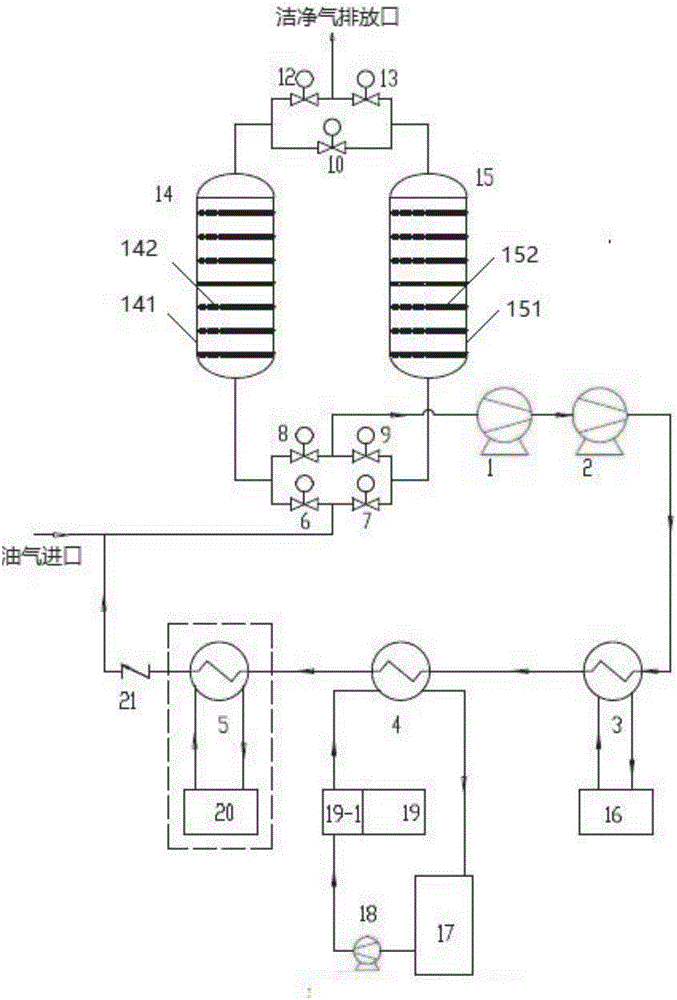

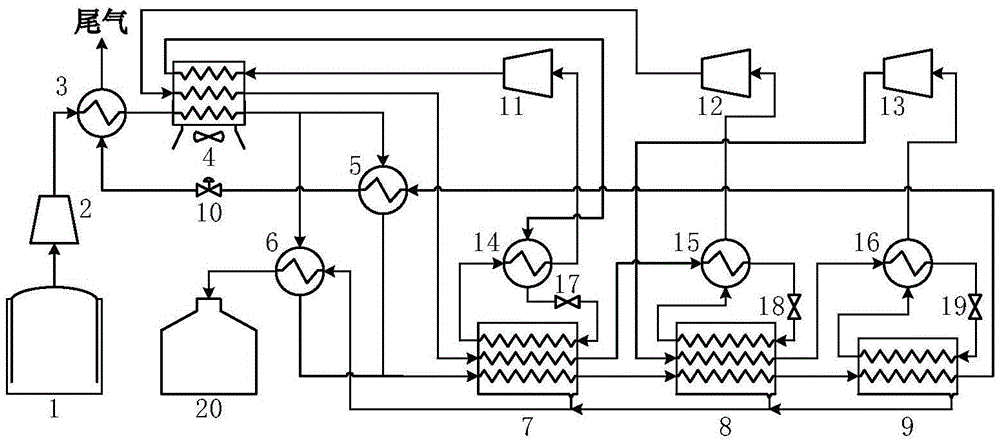

Adsorption and condensation type oil gas recovery device and adsorption and condensation type oil gas recovery process by self-adsorptive heat regeneration

ActiveCN106807179ALess investmentReduce energy consumptionGas treatmentMultiple-effect/fractional condensationInlet valveCheck valve

The invention discloses an adsorption and condensation type oil gas recovery device and an adsorption and condensation type oil gas recovery process by self-adsorptive heat regeneration. The adsorption and condensation type oil gas recovery device by the self-adsorptive heat regeneration comprises an oil gas inlet, a first valve group, a Roots vacuum pump, a dry vacuum pump, a primary oil gas condenser, a secondary oil gas condenser, a tertiary oil gas condenser, a check valve, an adsorption tank group, a second valve group and a clean gas discharge outlet. The first valve group comprises a gas inlet valve group and a vacuum valve group, wherein the gas inlet valve group and the vacuum valve group which are in parallel connection are arranged below the adsorption tank group. The second valve group comprises a gas discharge valve group and a balanced purge valve, wherein the gas discharge valve group and the balanced purge valve are in parallel connection and arranged over the adsorption tank group. The balanced purge valve, the adsorption tank group, the vacuum valve group, the Roots vacuum pump, the dry vacuum pump, the primary oil gas condenser, the secondary oil gas condenser, the tertiary oil gas condenser and the check valve are connected in sequence, and then the check valve is connected with the oil gas inlet. The oil gas inlet is sequentially connected with the gas inlet valve group, the adsorption tank group, the gas discharge valve group and the clean gas discharge outlet.

Owner:上海聚宸新能源科技有限公司

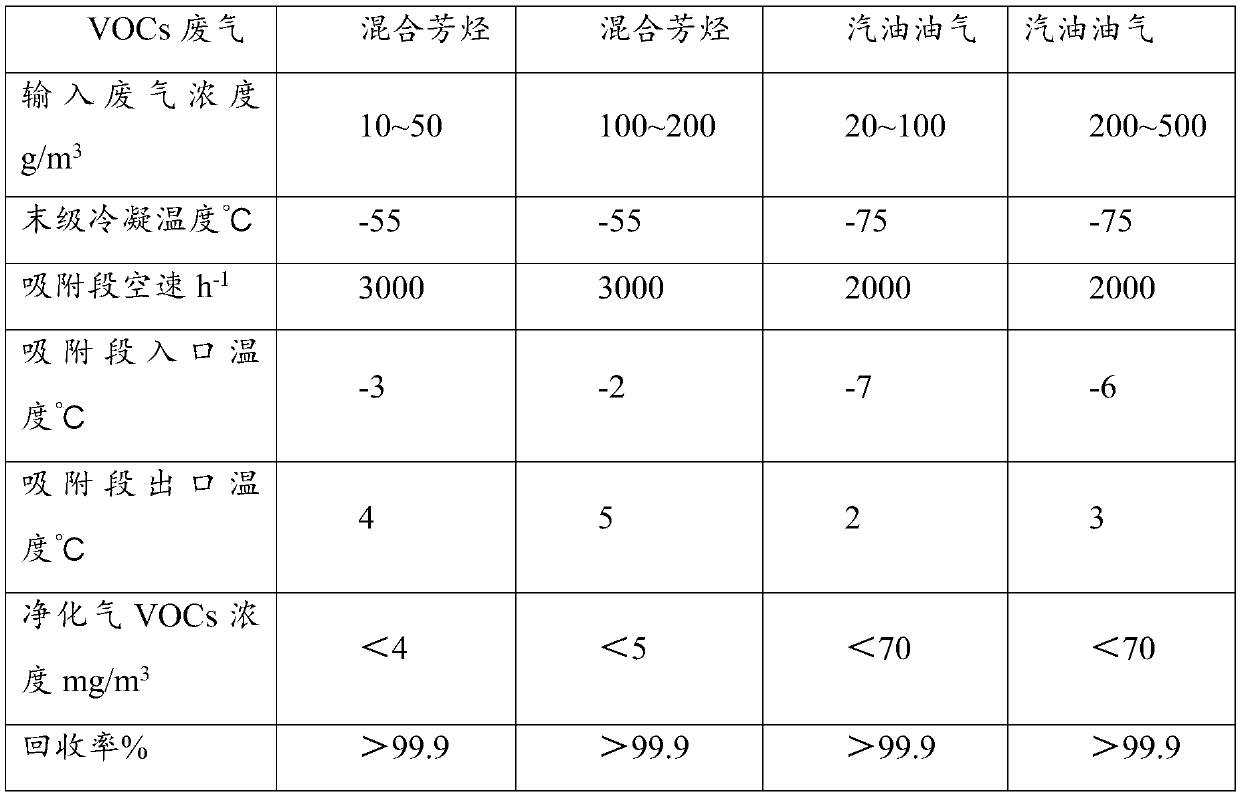

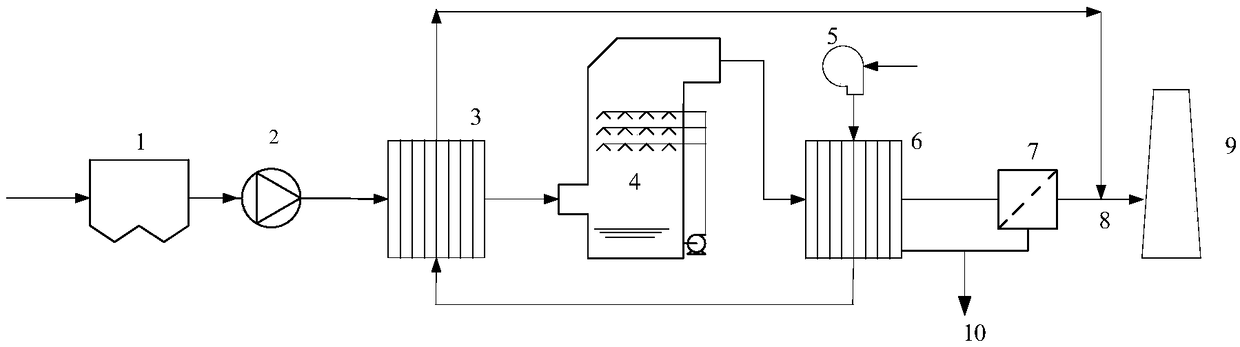

VOCs recovery technology and system

ActiveCN108043064AAchieve recyclingReduce safety concernsGas treatmentMultiple-effect/fractional condensationResource utilizationPositive response

The invention discloses a VOCs recovery technology and system. The VOCs recovery system includes a condensation device and an adsorption device; the condensation device is in serial connection with the adsorption device, so that VOCs waste gas is discharged after being treated by the condensation device and the adsorption device in sequence; the adsorption device includes an adsorption structure which includes at least two adsorption tanks which are in serial connection in sequence; a heat exchanger is arranged between at least one pair of adjacent adsorption tanks, so that non-condensable gasentering the former adsorption tank exchanges heat with non-condensable gas entering the latter adsorption tank in the heat exchanger. The VOCs recovery technology and system are good in environmental protection performance and high in resource utilization rate and treating efficiency, wherein the cold energy recovering during heat exchanging is a positive response to the environment protection national policy of China; at the same time, discharged tail gas reaches national discharging standards and even local VOCs discharging standards.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

Method and device for producing hexamethylenediamine from caprolactam

ActiveCN112812020AHydrogenation benefitsControl not to be hydrogenatedAmino compound purification/separationOrganic compound preparationPtru catalystHexamethylenediamine

The invention discloses a method and a device for producing hexamethylenediamine from caprolactam, ammonia gas and caprolactam are subjected to ammoniation and dehydration reaction under the action of a catalyst, and the obtained ammoniation and dehydration reaction product is subjected to three-stage condensation separation; caprolactam obtained through secondary condensation and 6-aminocapronitrile condensate are subjected to a hydrogenation reaction under the action of a catalyst, a mixture containing hexamethylenediamine and caprolactam obtained through the reaction is separated to obtain hexamethylenediamine, and water accounting for 5%-500% of the total weight of the condensate is added in the hydrogenation reaction process to serve as a hydrogenation reaction diluent. According to the method, the caprolactam aqueous solution is used as the 6-aminocapronitrile hydrogenation reaction diluent, ethanol does not need to be added as the diluent, and generation of by-products N-Et-HMD, BHT and tar is reduced. The ammoniation dehydration reaction liquid is not subjected to rectification separation, so that the energy consumption is reduced.

Owner:宁波迦尔新材料技术有限公司

Adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and oil vapor recovery method

ActiveCN106731445ALess investmentReduce energy consumptionGas treatmentMultiple-effect/fractional condensationRecovery methodExhaust valve

The invention discloses an adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and an oil vapor recovery method. The device comprises an oil vapor inlet, a first valve set, an adsorption tank set, a second valve set, a clean gas exhaust port, a vacuum pump set, a first-level oil vapor condenser, a second-level oil vapor condenser, a third-level oil vapor condenser and a check valve, wherein the first valve set is composed of a gas inlet valve set under the adsorption tank set and a vacuum valve set in parallel connection with each other; the second valve set is composed of an exhaust valve set above the adsorption tank set and a blow-down valve set in parallel connection with each other; the blow-down valve set, the adsorption tank set, the vacuum valve set, the vacuum pump set, the first-level oil vapor condenser, the second-level oil vapor condenser, the third-level oil vapor condenser and the check valve are connected in turn; the check valve is connected with the oil vapor inlet; the oil vapor inlet is connected with the gas inlet valve set, the adsorption tank set, the exhaust valve set and the clean gas exhaust port in turn; a solid-liquid phase variable energy storage substance is filled into the adsorption tank set.

Owner:上海聚宸新能源科技有限公司

Pressurizing multi-grade condensation type oil gas recycling method

ActiveCN105536282AImprove energy efficiency ratioTake advantage ofMultiple-effect/fractional condensationLiquid hydrocarbon mixture recoveryRecovery methodAtmospheric layer

The invention discloses a pressurizing multi-grade condensation method for recycling oil gas. An air compressor is used for pressurizing the oil gas; cold quantity needed by each grade is provided for a pressurizing oil gas cooler through air cooling heat exchangers and a three-grade overlapping type refrigeration system. The pressurized oil gas passes through the air cooling heat exchangers and then is divided into two paths to be subjected to heat exchange with two heat exchangers which are arranged in parallel to recycle the cold quantity in liquid-state oil and tail gas respectively; then the oil gas sequentially passes through cooling heat exchangers of 2 DEG C, -30 DEG C and -80 DEG C, and the liquid-state oil and the tail gas are condensed and separated grade by grade. The tail gas is throttled to normal pressure before being exhausted to an atmospheric layer, and is subjected to heat exchange with the oil gas from the cooling heat exchangers to recycle the cold quantity again. The method disclosed by the invention has the three advantages that the water removing rate and the oil gas recycling rate can be easily improved after pressure is improved; the two parallel heat exchangers can be used for improving a heat transferring temperature difference and the cold quantity in the liquid-state oil and the tail gas is recycled to the greatest extent; the air cooling heat exchangers also can be used as overlapped refrigerating cycle condensers, so that a refrigerating system is relatively compact and efficient.

Owner:SOUTHEAST UNIV

White smoke elimination system and method

PendingCN108434924AReduce moisture contentImprove elimination effectMultiple-effect/fractional condensationDispersed particle separationTowerFlue

The invention relates to the technical fields of chemical engineering and environmental protection, in particular to a white smoke elimination system and a method. Specifically, the white smoke elimination system comprises a first smoke condenser, a desulfurizing tower, a second smoke condenser, a fan, a demister, a smoke-air mixing flue and a chimney, wherein a smoke outlet of the first smoke condenser is connected with an inlet of the desulfurizing tower, an outlet of the desulfurizing tower is connected with a smoke inlet of the second smoke condenser, a smoke outlet of the second smoke condenser is connected with an inlet of the demister, an outlet of the demister is connected with a smoke inlet of the smoke-air mixing flue, and an outlet of the smoke-air mixing flue is connected withthe chimney; an outlet of the fan is connected with an air inlet of the second smoke condenser, an air outlet of the second smoke condenser is connected with an air inlet of the first smoke condenser,an air outlet of the first smoke condenser is connected with an air inlet of the smoke-air mixing flue, and an outlet of the smoke-air mixing flue is connected with the chimney.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com