White smoke elimination system and method

A flue gas and white smoke technology, which is applied in the fields of chemical industry and environmental protection, can solve the problems such as the inability to reduce the amount of water vapor, the inability to provide circulating cooling water, and the increase in system investment, etc., to achieve good elimination effect, low operating costs, and low investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

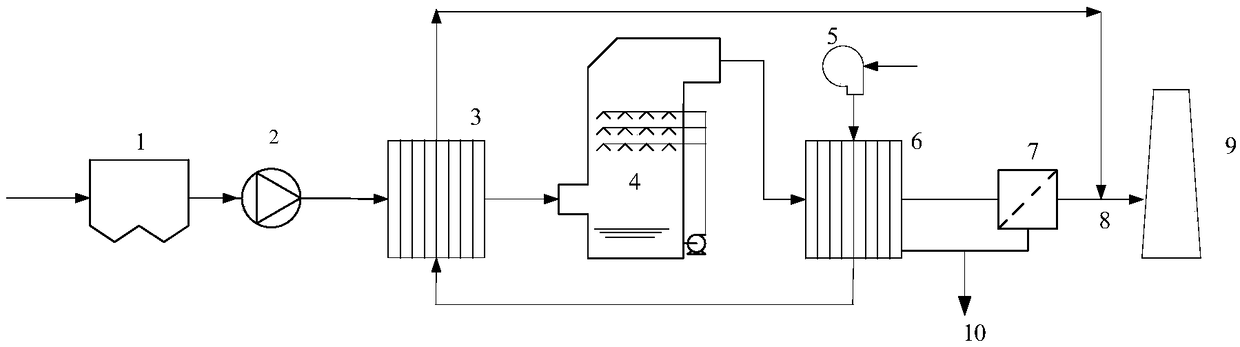

[0053] use as figure 1 In the flue gas white smoke elimination system shown, in the first flue gas condenser 3, the air exchanges heat with the flue gas, wherein the flue gas decreases from the inlet temperature of 140°C to 111°C, and the air rises from the inlet air temperature of 30°C As high as 92°C at the outlet, 4925kW of waste heat can be recovered, the moisture content of flue gas can be reduced from 14.06% to 12.58%, and the evaporation water of desulfurization tower 4 can be reduced by about 6.4t / h. After the flue gas is treated by the desulfurization tower 4, the flue gas is reduced from 53°C to 50.75°C, and the flue gas volume is reduced from 471091Nm 3 / h reduced to 463139Nm 3 / h.

[0054] In the second flue gas condenser 6, cold air is used as the cold source to cool the flue gas at the outlet of the desulfurization tower 4 from 50.75°C to 49.25°C, the temperature drops by 1.5°C, the amount of flue gas condensed water is 3.86t / h, and the flue gas condenses and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com