Energy-saving environment-friendly integrated recycling and utilization method of coal chemical gasification washing black water high-temperature flashing steam

A high temperature flash steam, energy saving and environmental protection technology, applied in chemical instruments and methods, steam condensation, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

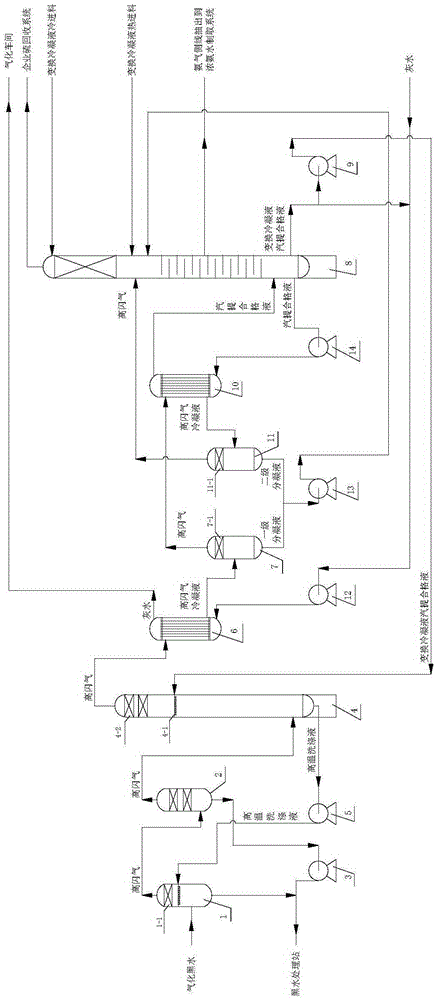

Image

Examples

Embodiment Construction

[0015] An energy-saving and environment-friendly comprehensive recycling method for high-temperature flash steam of black water washed by gasification of coal chemical industry, comprising the following steps:

[0016] A. After the gasification and washing black water at 220-280°C is decompressed to an absolute pressure of 0.8-1MPa, it enters the black water flash separator (1) for flash evaporation, producing a high-temperature flash with a pressure of 0.8-1MPa and a temperature of 170-179°C The vapor body (referred to as high-flash gas), after being washed by the high-temperature washing liquid injected by the washing liquid pump (5), goes upward through the dehydrator (1-1) in the upper section of the flash separator (1) to further remove moisture, and then from The top of the flash separator (1) is discharged and enters the flash steam secondary dehydration tank (2); the black water and high-temperature washing liquid after flashing in the flash separator (1) and the dehydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com