VOCs recovery technology and system

A recovery system and process technology, applied in the field of VOCs recovery process and system, can solve the problems of low purification efficiency, difficulty in meeting the requirements of VOCs ultra-clean emission, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

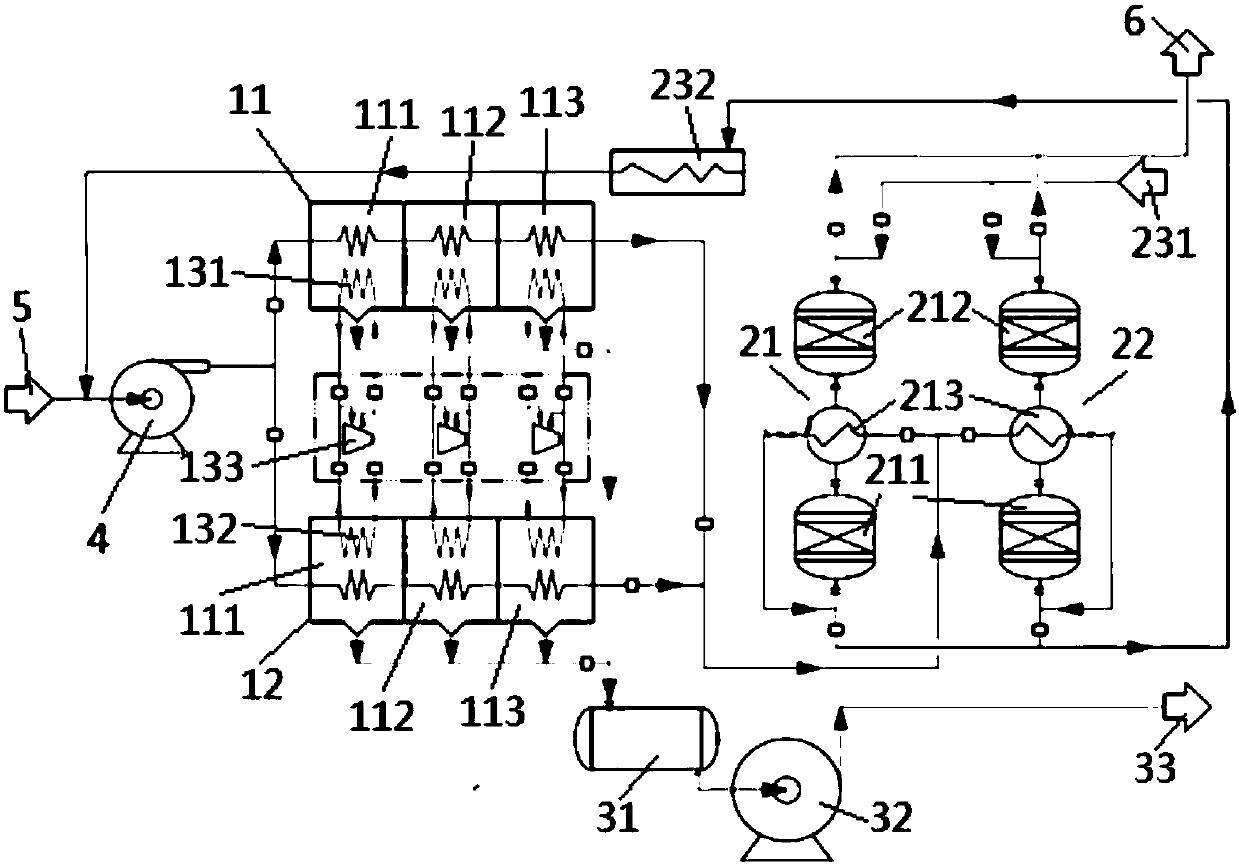

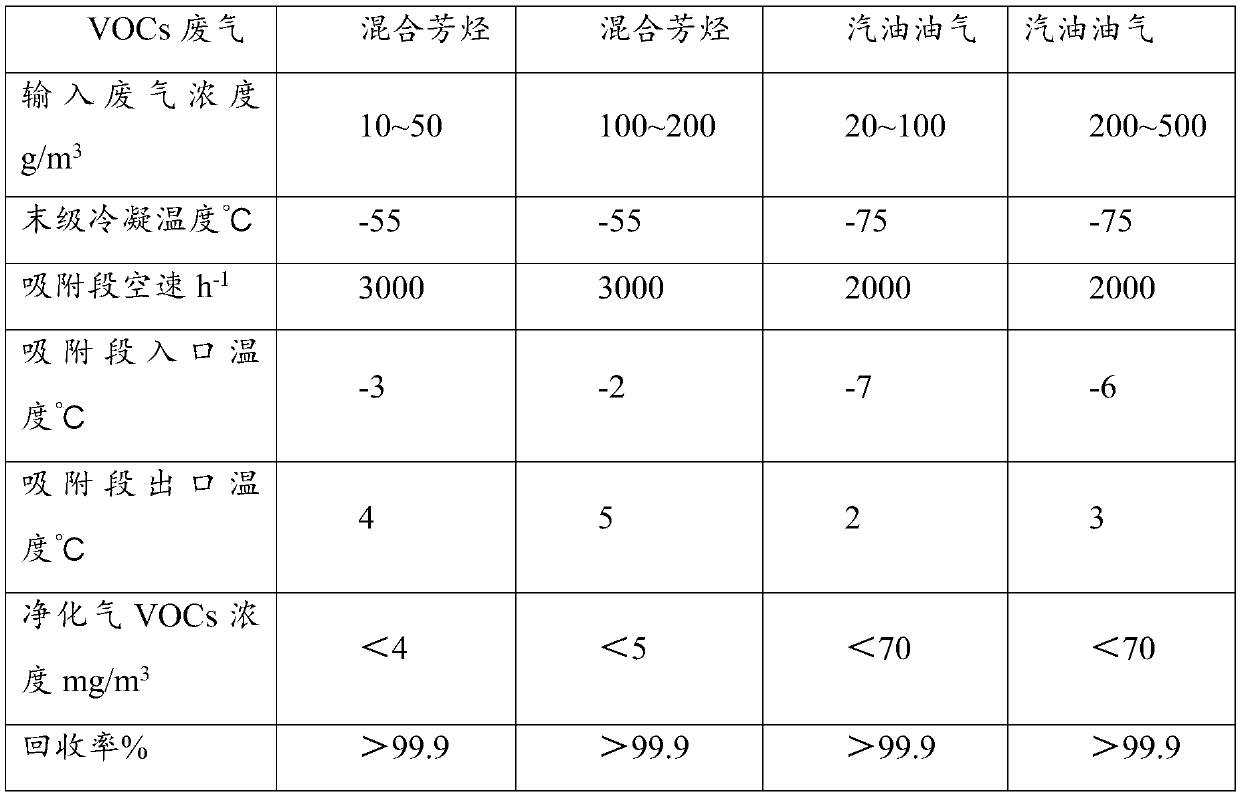

[0063] In embodiment one, a kind of VOCs recycling process comprises steps:

[0064] S100, Condensation recovery: recover part of the VOCs waste gas by condensing the VOCs waste gas;

[0065] S200, heat exchange-adsorption: sequentially perform multi-stage adsorption treatment on the non-condensable gas generated in step S100; and perform heat exchange treatment on at least one pair of adjacent non-condensable gas adsorbed in two stages, so that it enters the previous stage The adsorbed non-condensable gas can exchange heat with the non-condensable gas adsorbed in the next stage.

[0066] In this embodiment, since the adsorption process is an exothermic process, and the high temperature will often affect the adsorption efficiency, this process conducts heat transfer treatment on the non-condensable gas in two adjacent adsorption stages arranged along the flow direction of VOCs waste gas, so that The non-condensable gas adsorbed in the previous stage is cooled to the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com