Patents

Literature

123 results about "Exothermic process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermodynamics, the term exothermic process (exo- : "outside") describes a process or reaction that releases energy from the system to its surroundings, usually in the form of heat, but also in a form of light (e.g. a spark, flame, or flash), electricity (e.g. a battery), or sound (e.g. explosion heard when burning hydrogen). Its etymology stems from the Greek prefix έξω (exō, which means "outwards") and the Greek word θερμικός (thermikόs, which means "thermal"). The term exothermic was first coined by Marcellin Berthelot. The opposite of an exothermic process is an endothermic process, one that absorbs energy in the form of heat.

Partial boiling in mini and micro-channels

ActiveUS20060142401A1Less bubbleHigh densityOrganic compounds purification/separation/stabilisationOrganic compound preparationExothermic processChemistry

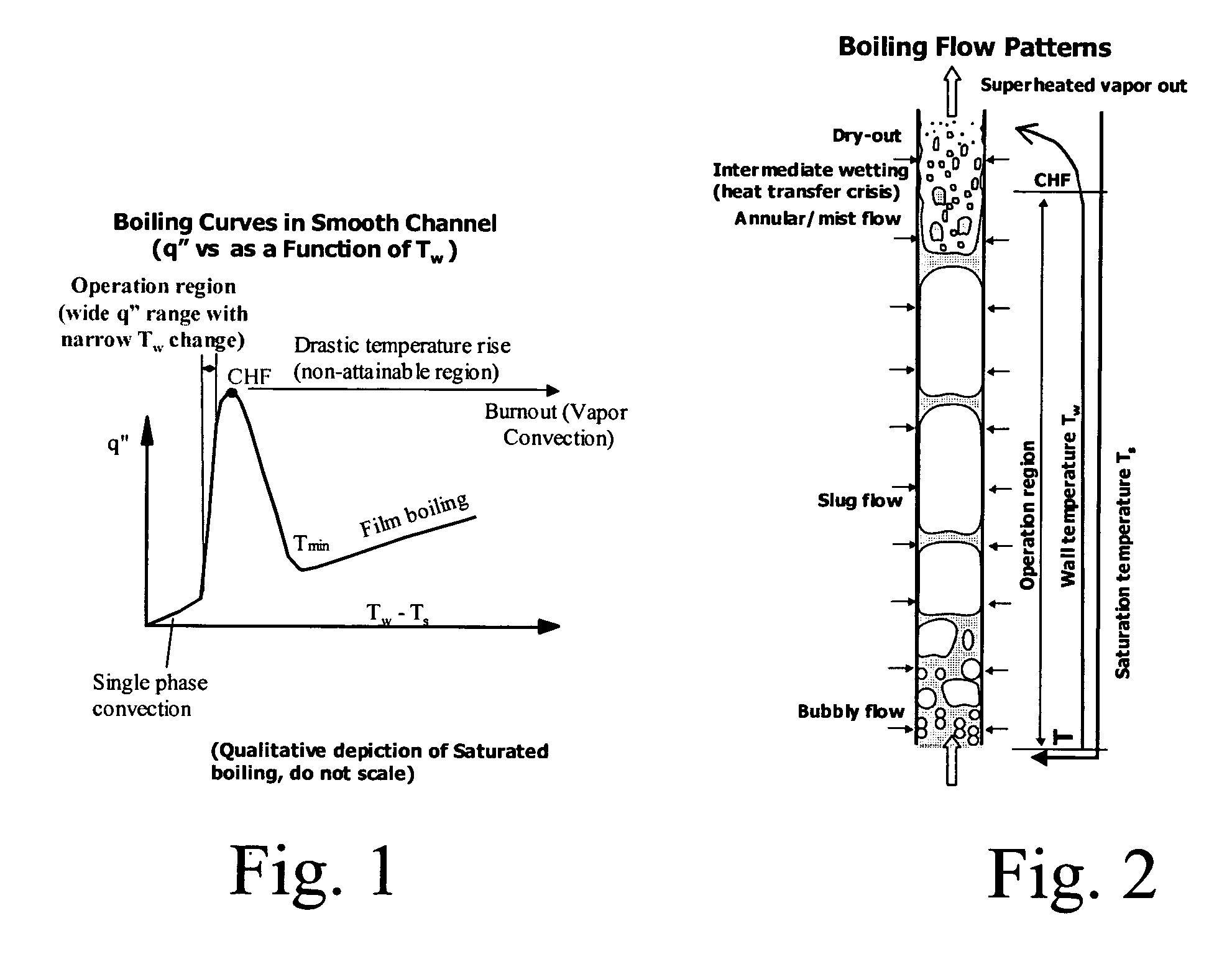

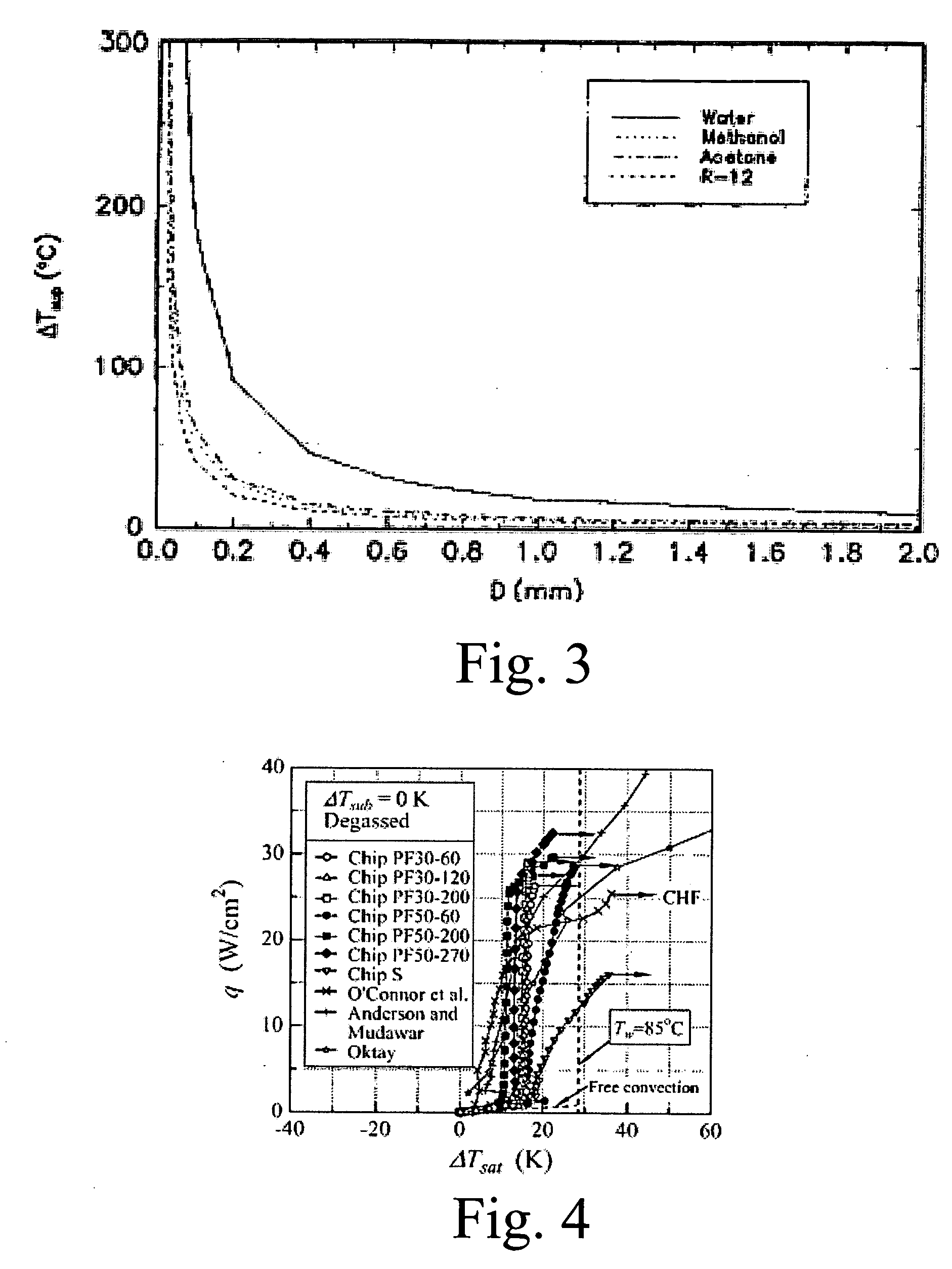

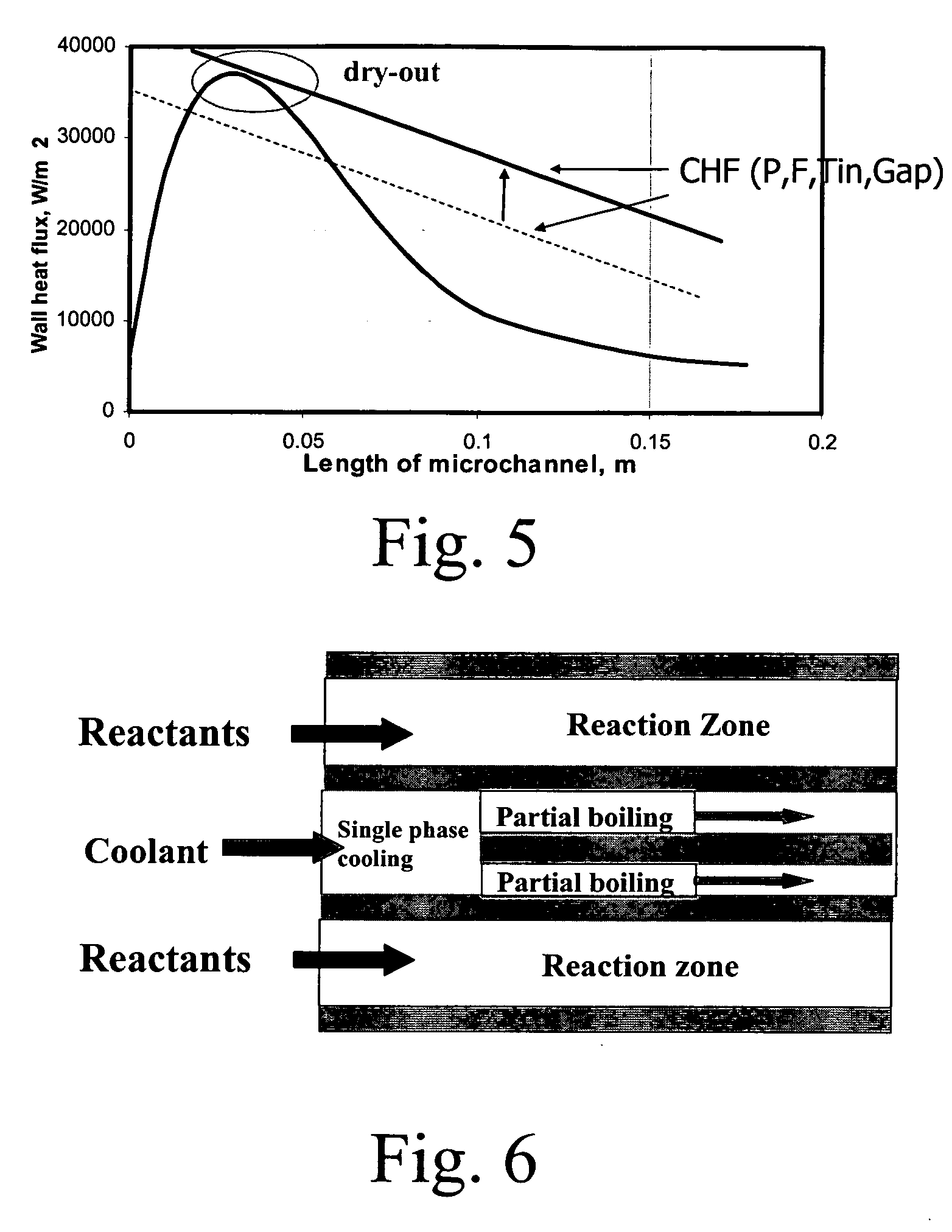

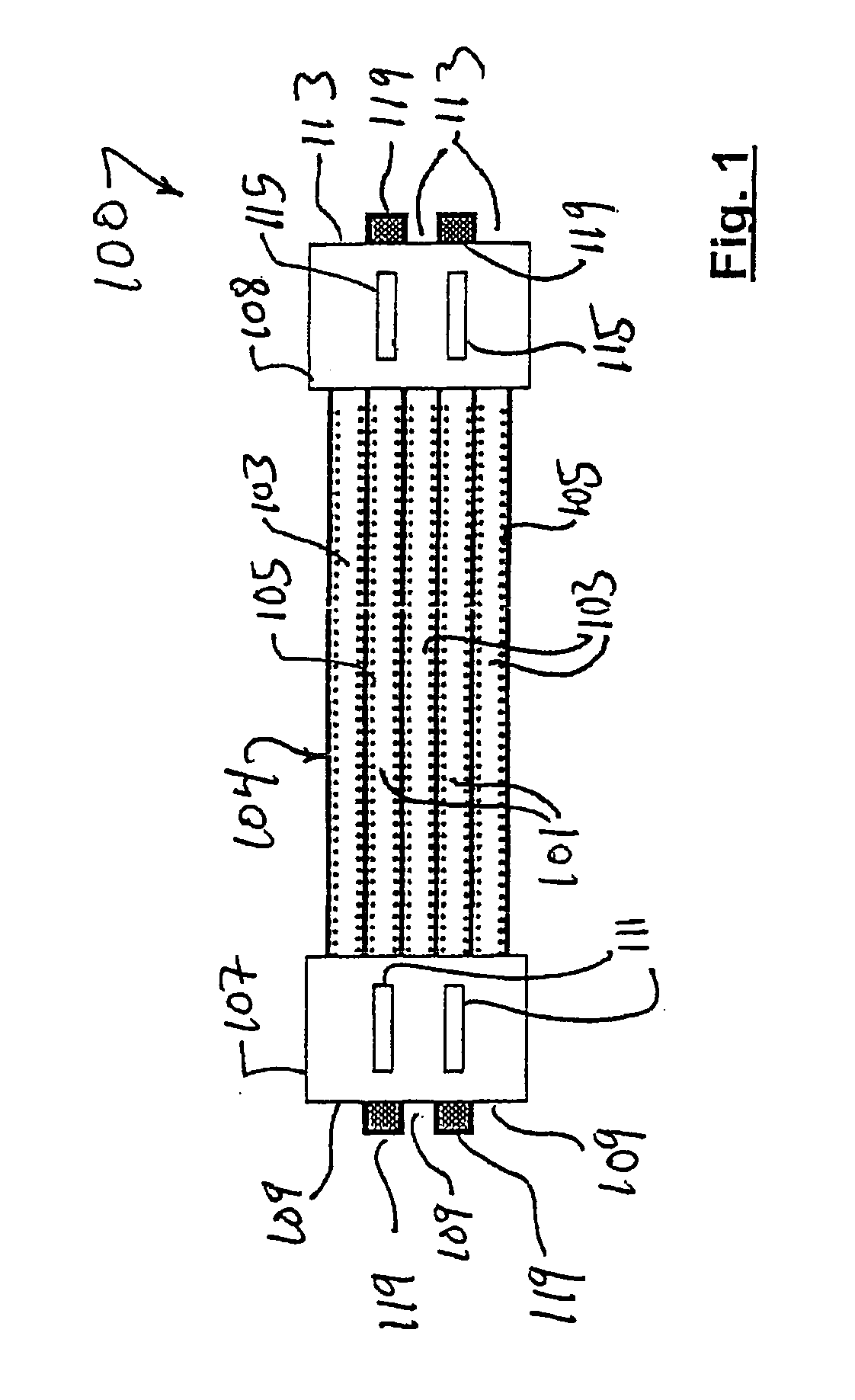

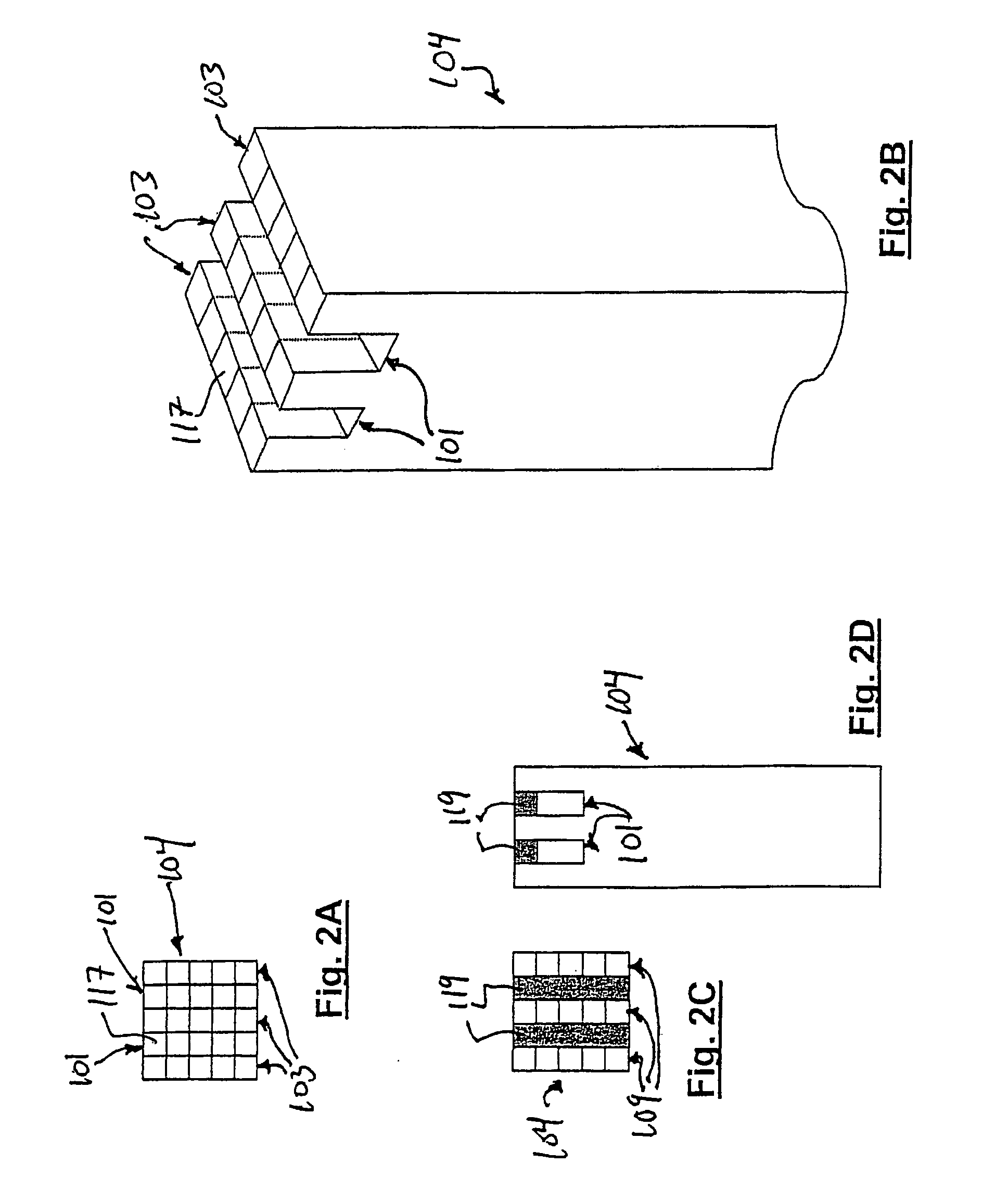

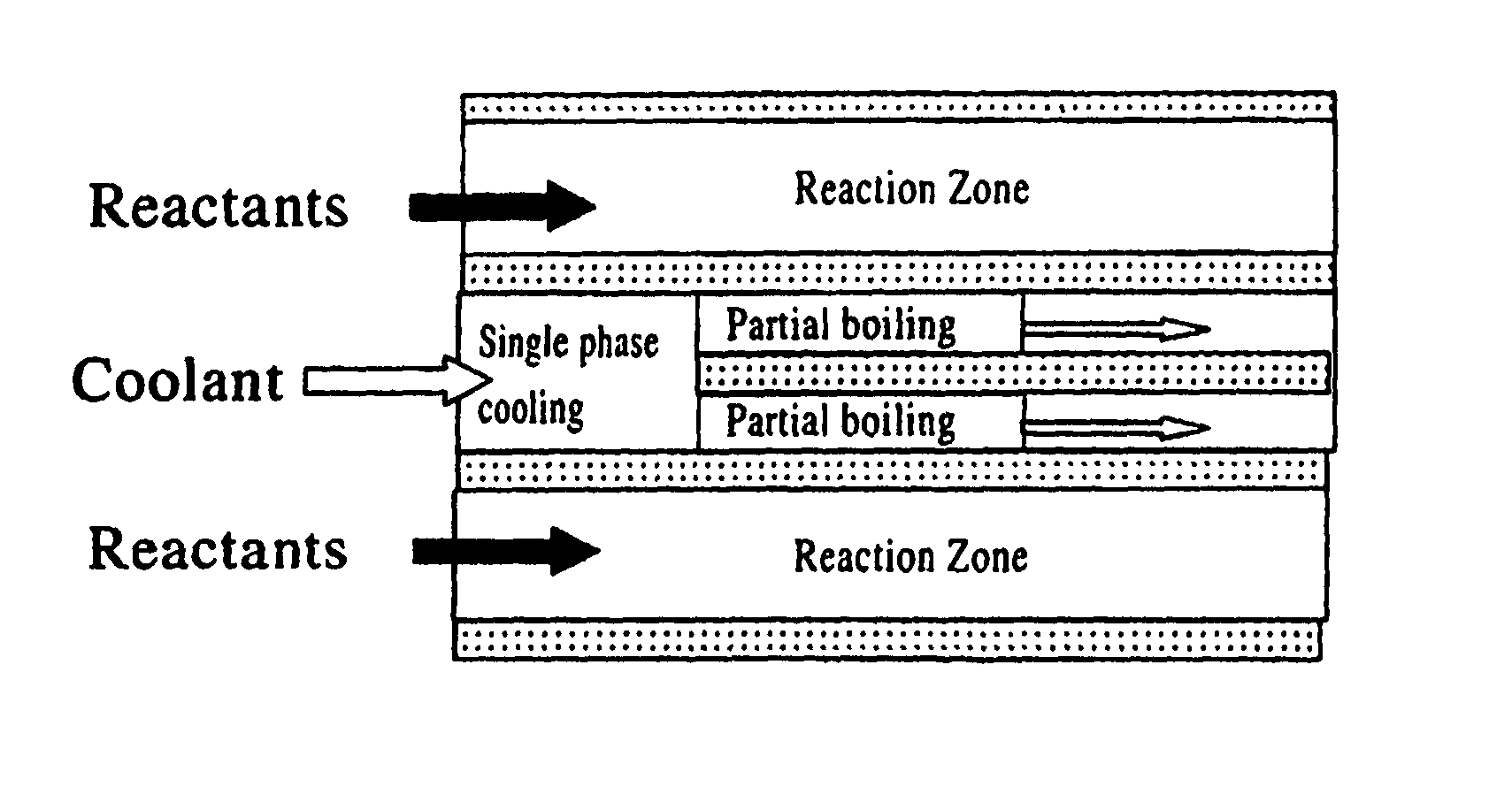

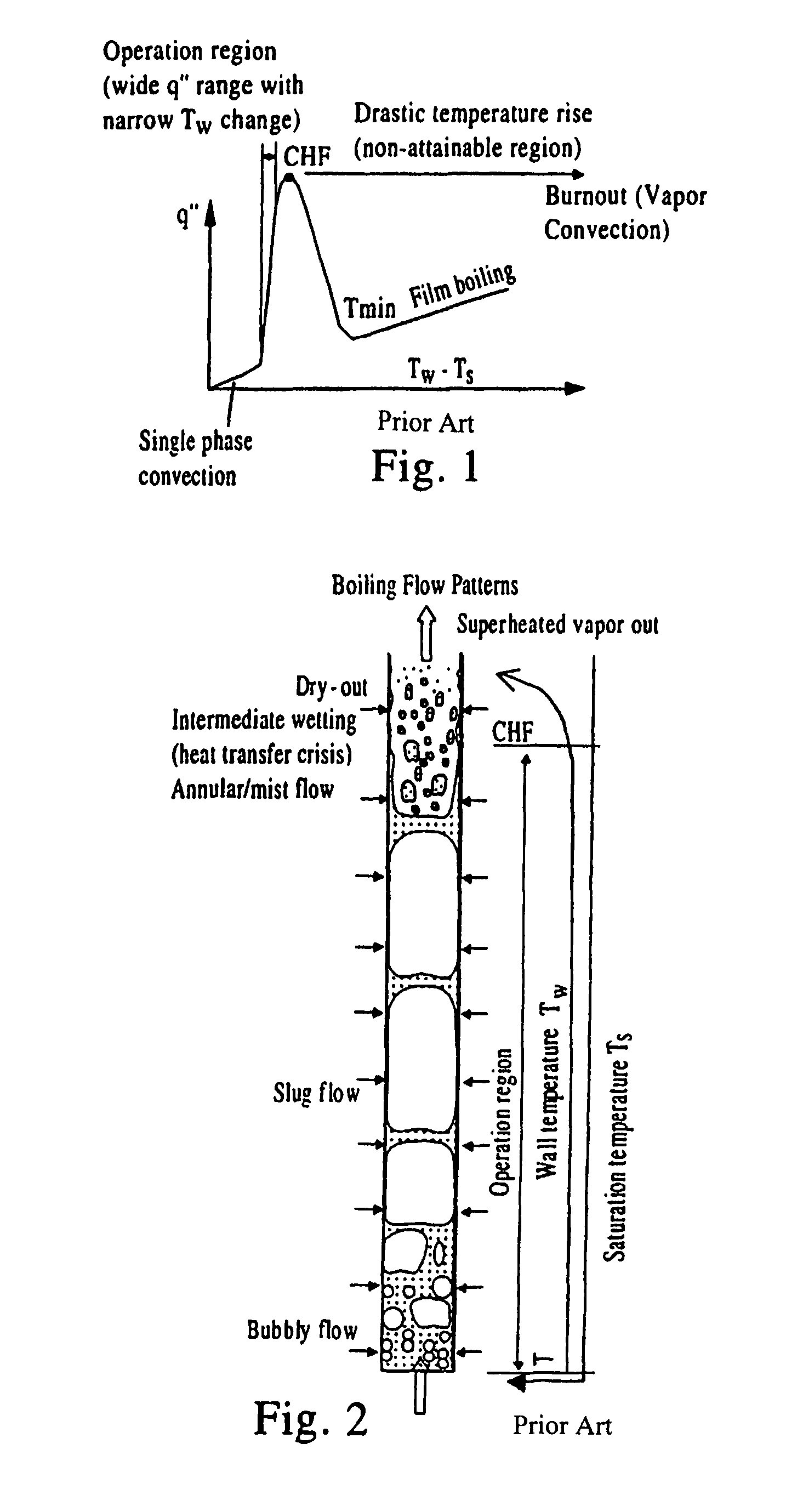

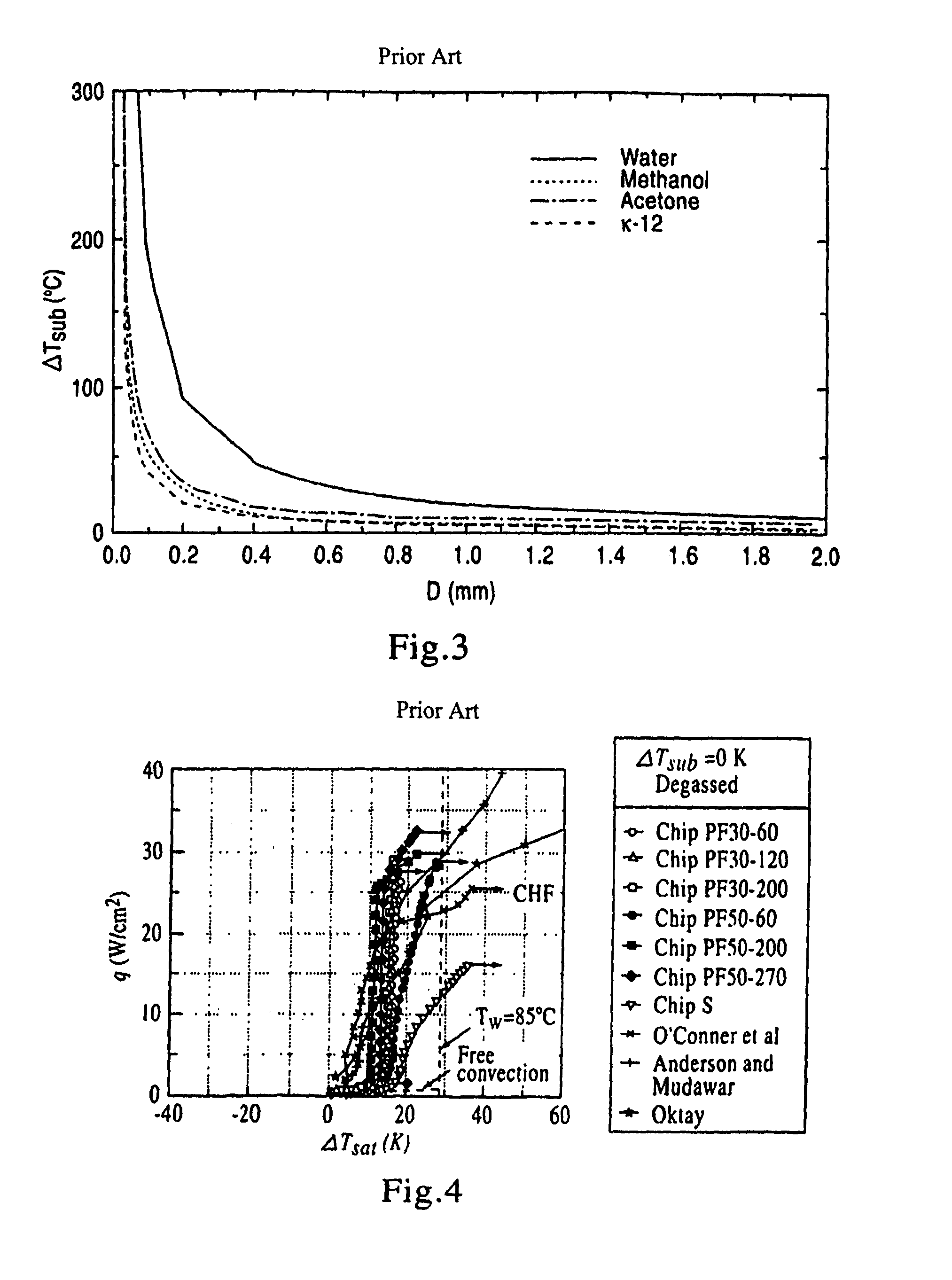

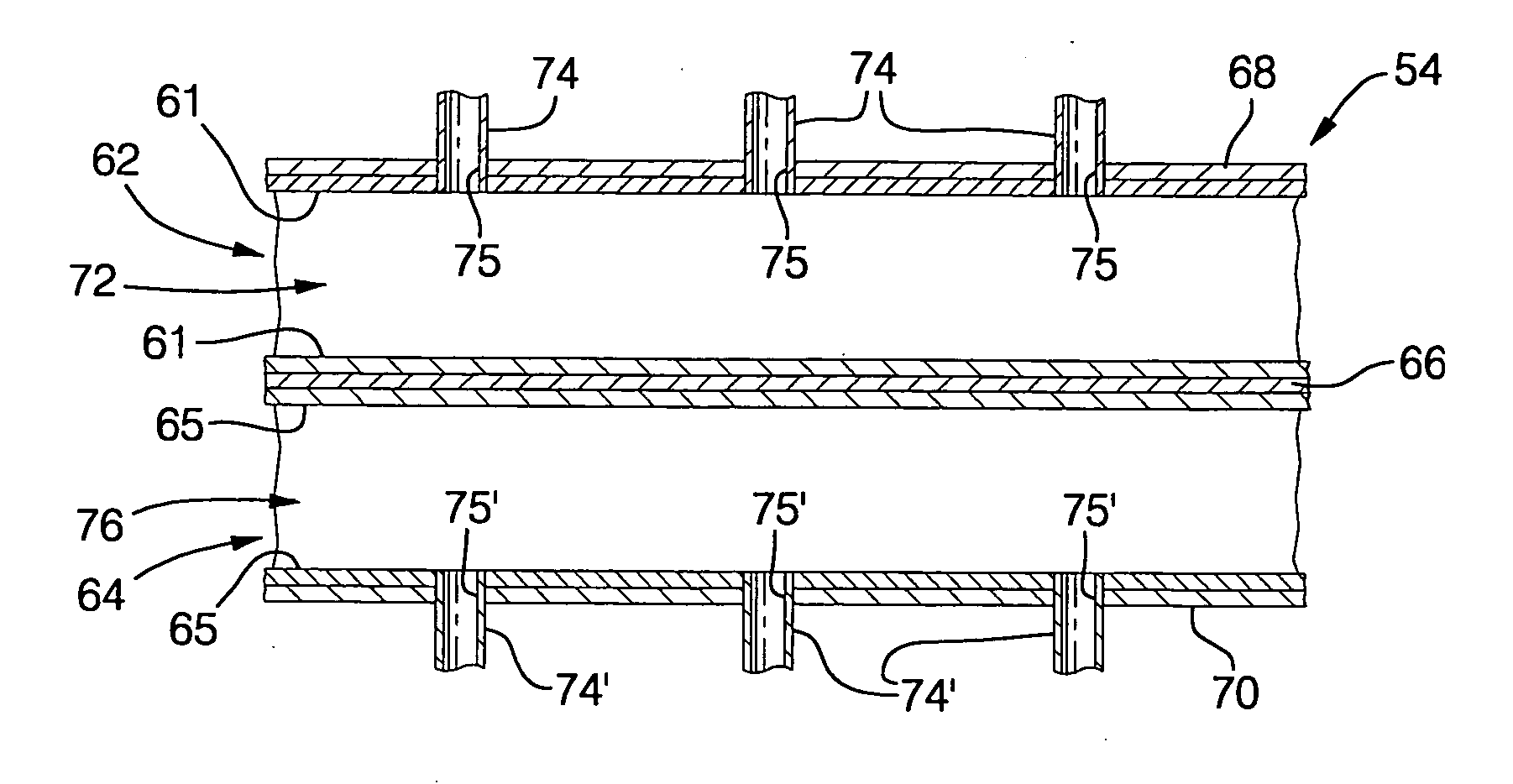

The invention provides methods, apparatus and systems in which there is partial boiling of a liquid in a mini-channel or microchannel. The partial boiling removes heat from an exothermic process.

Owner:VELOCYS CORPORATION

Thermally coupled monolith reactor

InactiveUS20070009426A1Easy to useMaximize heat transferCatalytic gas-gas reactionPhysical/chemical process catalystsChemical treatmentGas phase

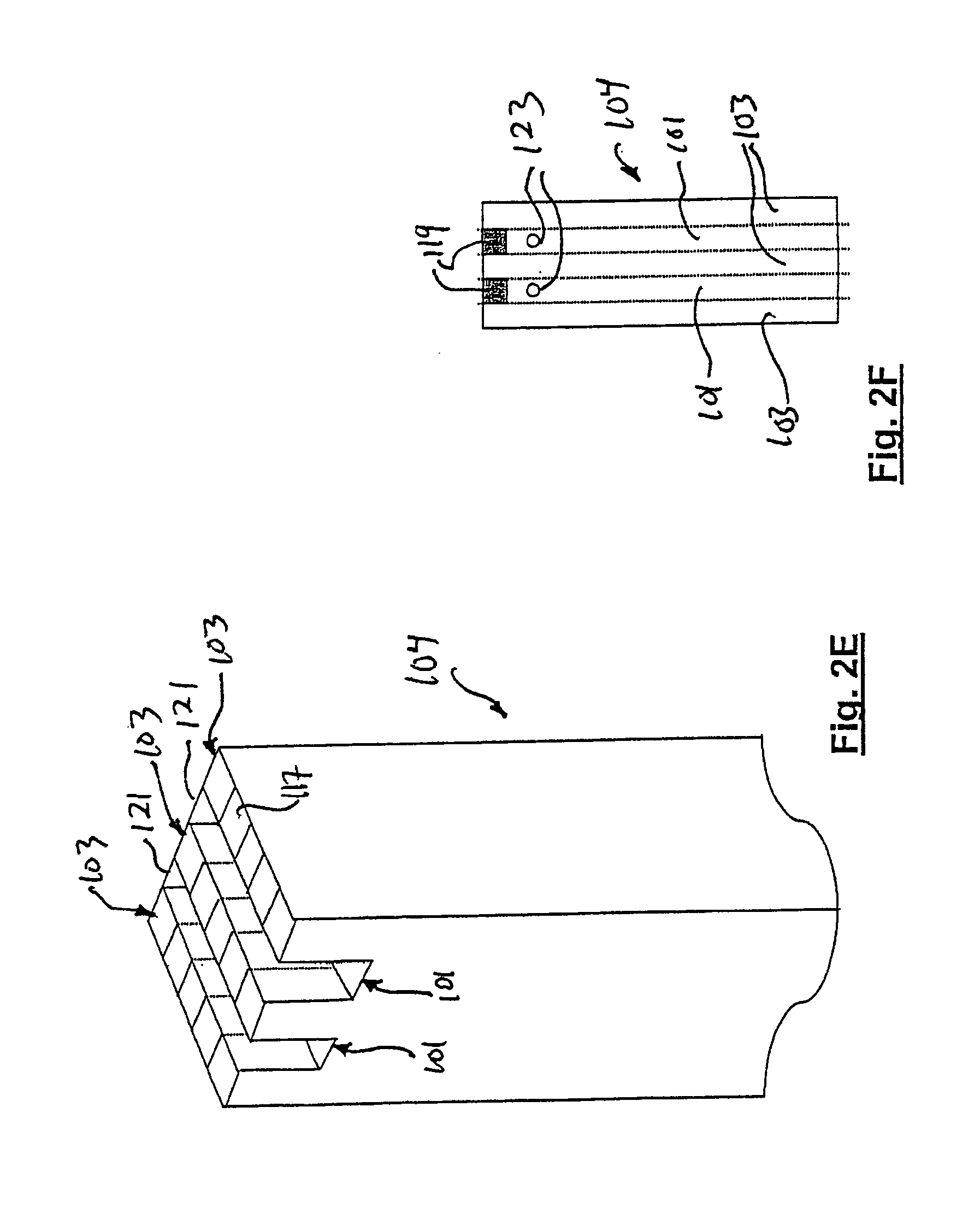

The invention comprises, in one form thereof, a chemical processing method to thermally contact an endothermic and an exothermic reaction without mixing the two streams, utilizing a thermally coupled monolith reactor (TCMR). A ceramic or metal monolith is modified to produce a structure containing at least two sets of discrete flow paths and which are separated by a number of common walls. Manifolds are arranged such that one reaction mixture flows through one set of channels and a different reaction mixture flows through the second. Catalytic material, which is active for the relevant reaction, is coated onto the inner walls of each of the sets of channels. The two reactions are chosen such that one is exothermic and one is endothermic, such that the energy required by the endothermic process is supplied directly through the dividing wall from the exothermic process occurring on the opposing side. This method of heat transfer completely decouples the gas phase hydrodynamics from the heat transfer process.

Owner:ZEROPOINT CLEAN TECH

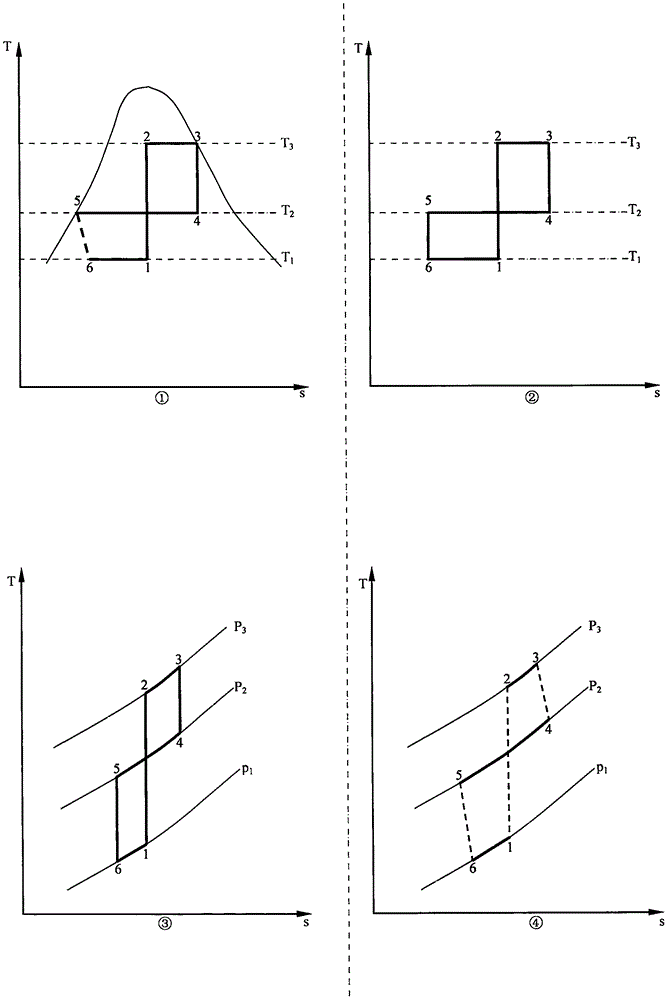

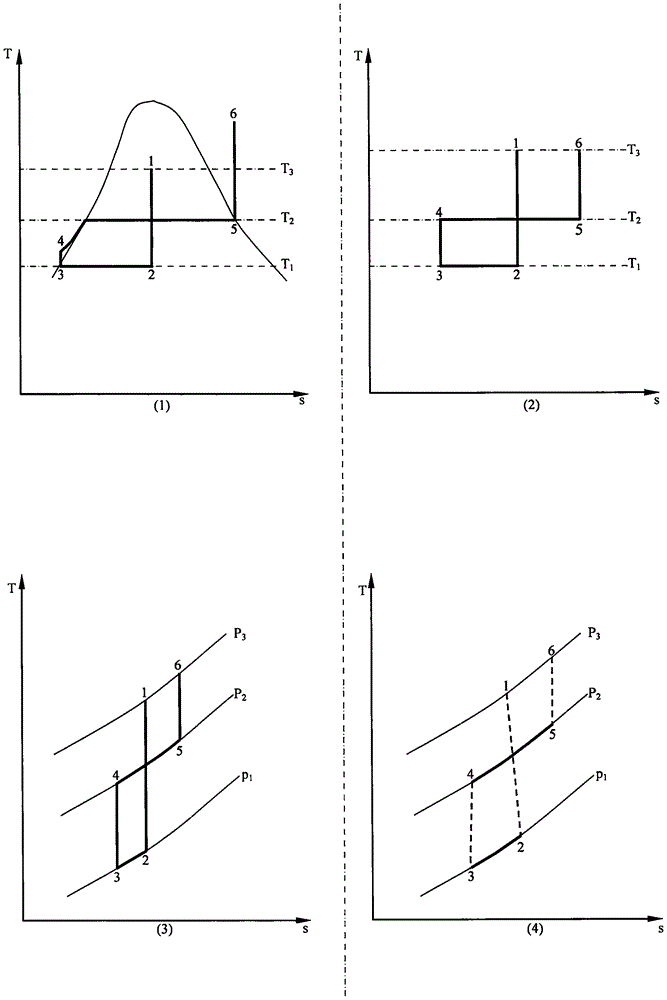

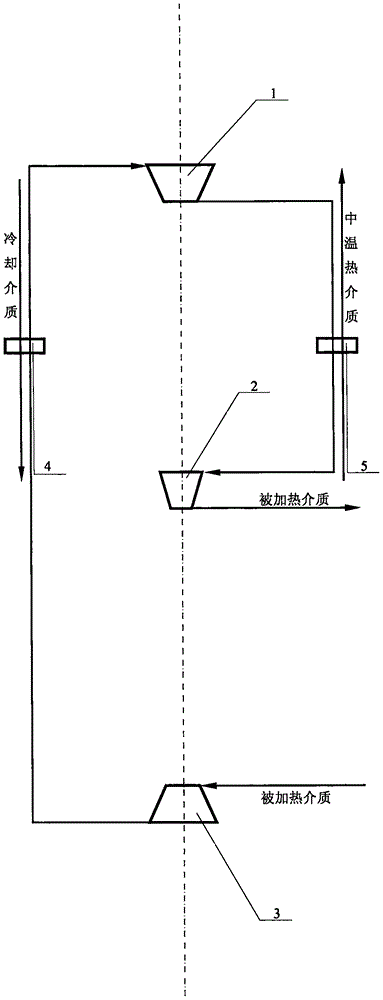

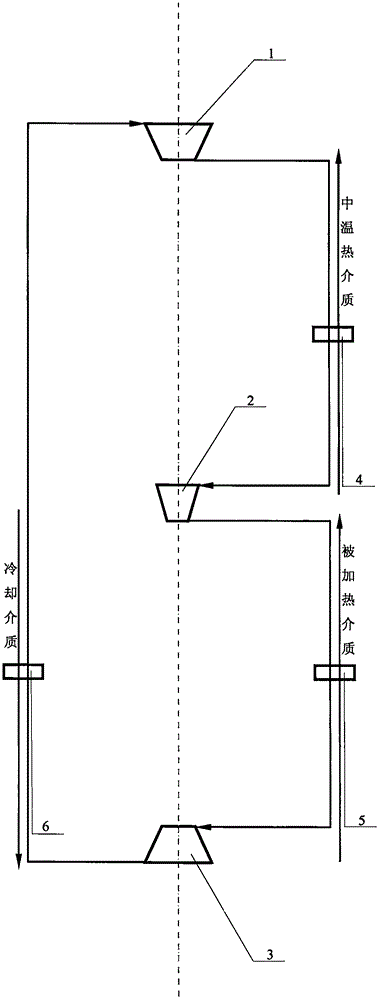

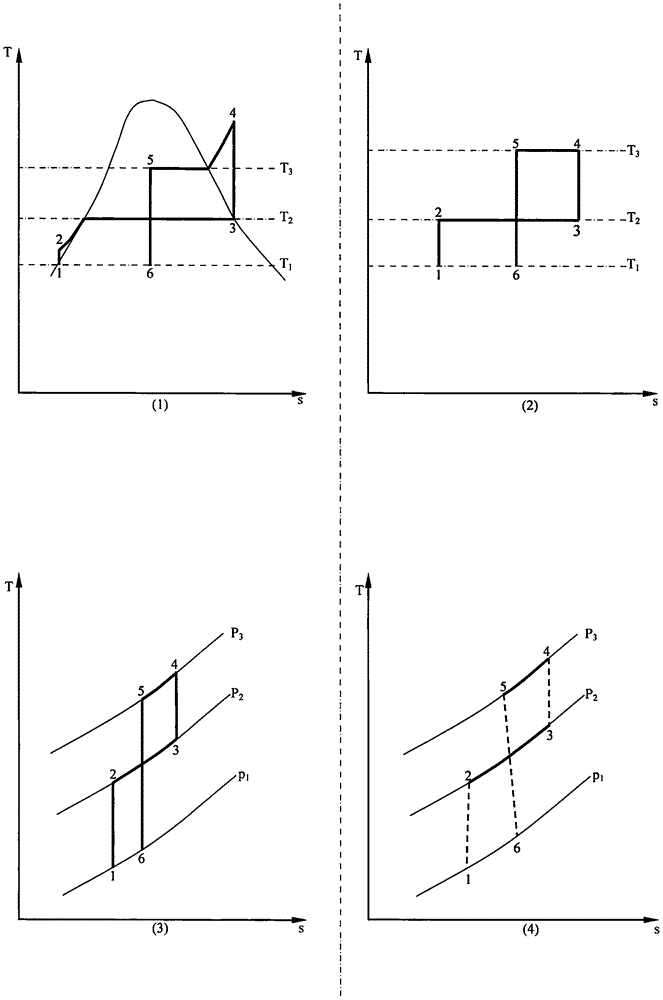

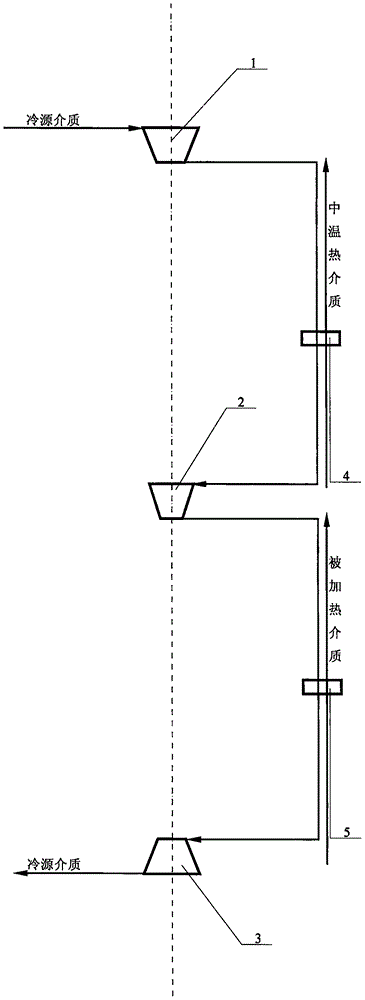

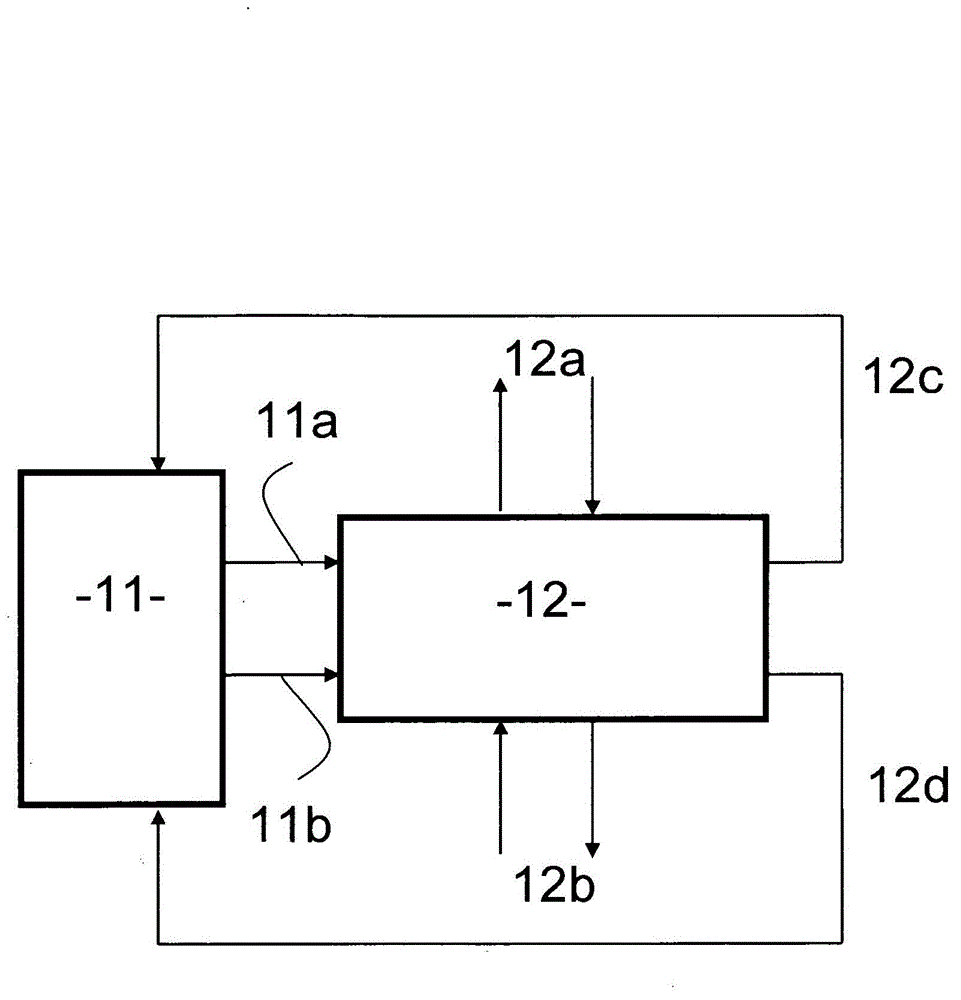

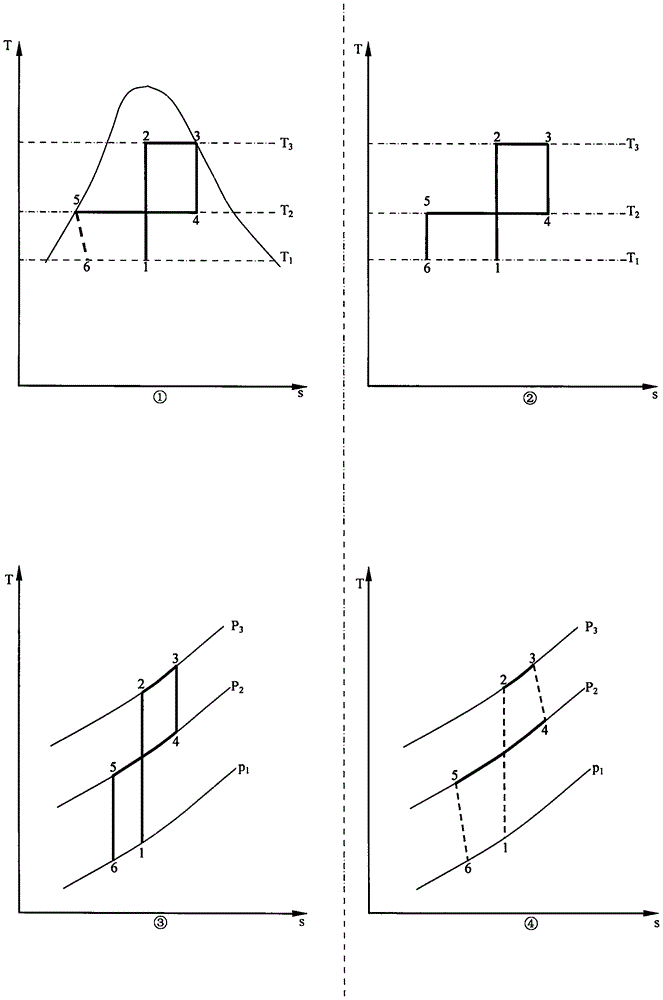

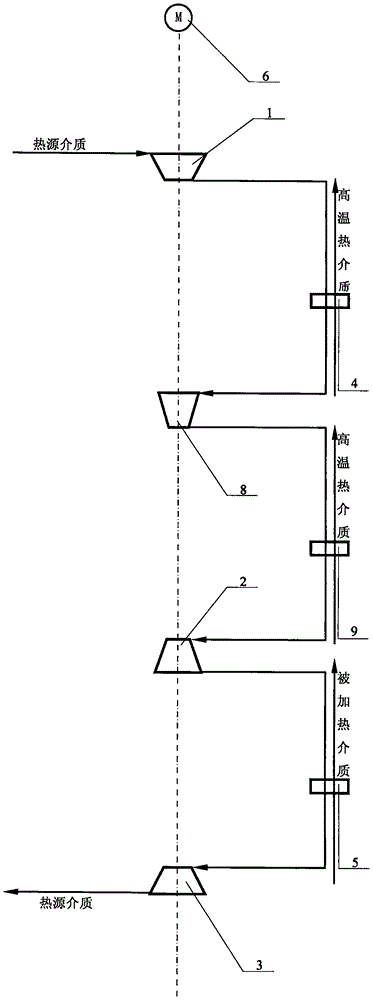

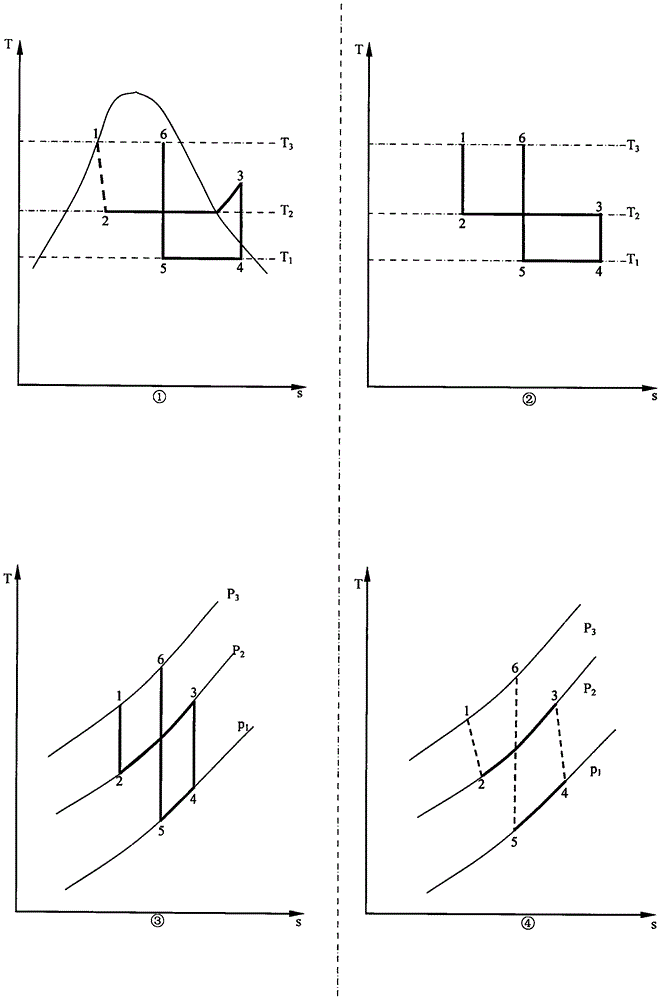

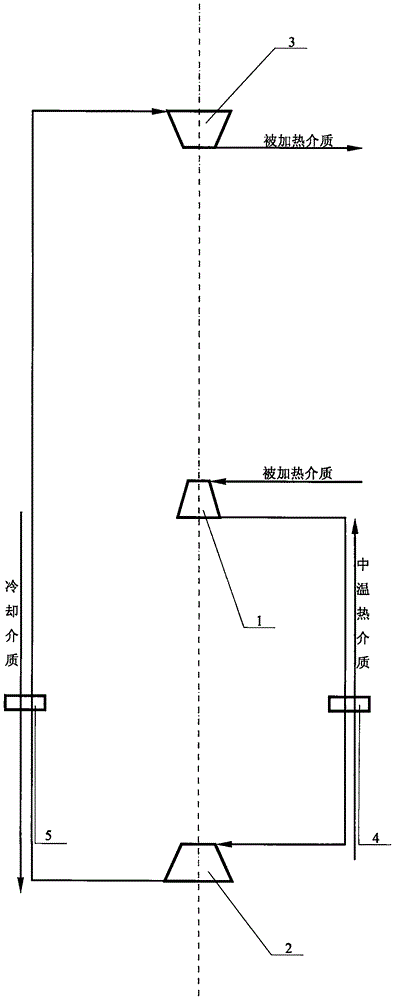

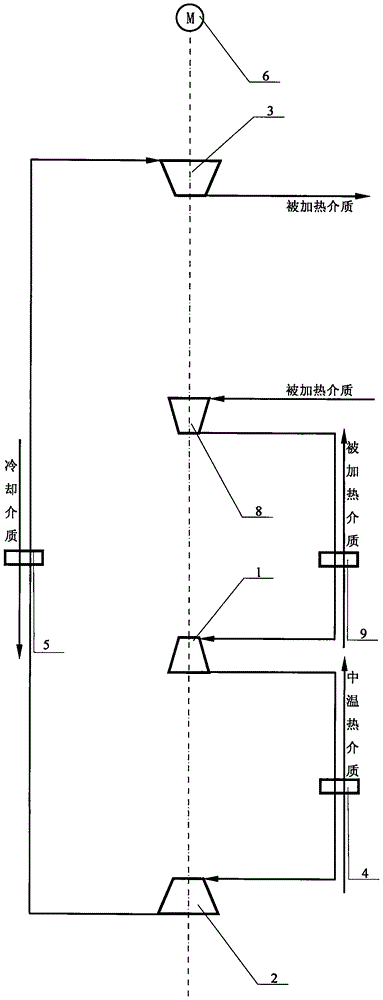

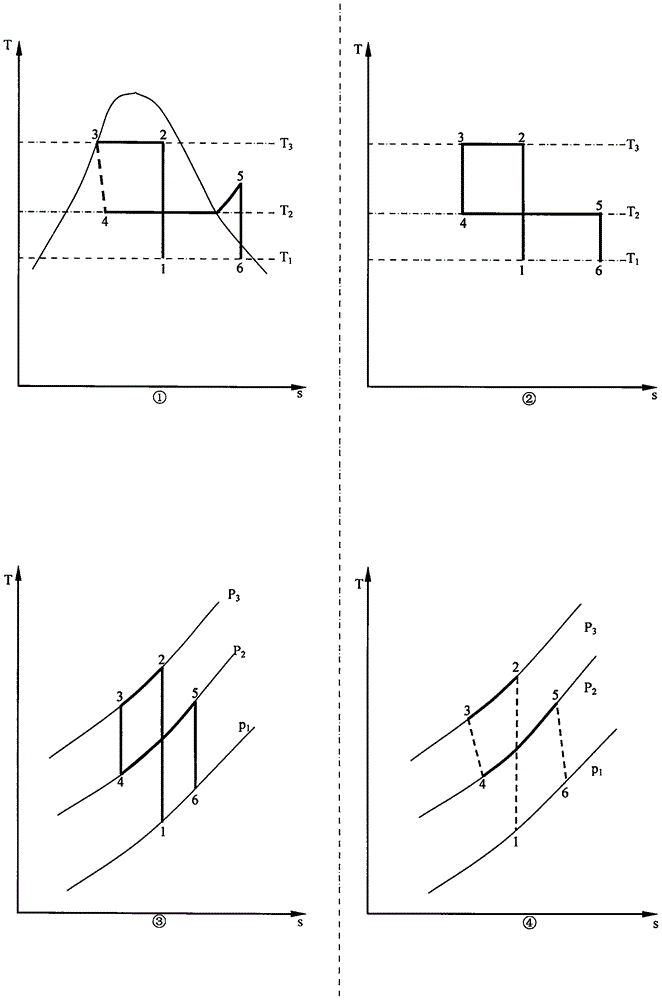

Bidirectional thermal cycle and second type of heat-driven compression heat pump

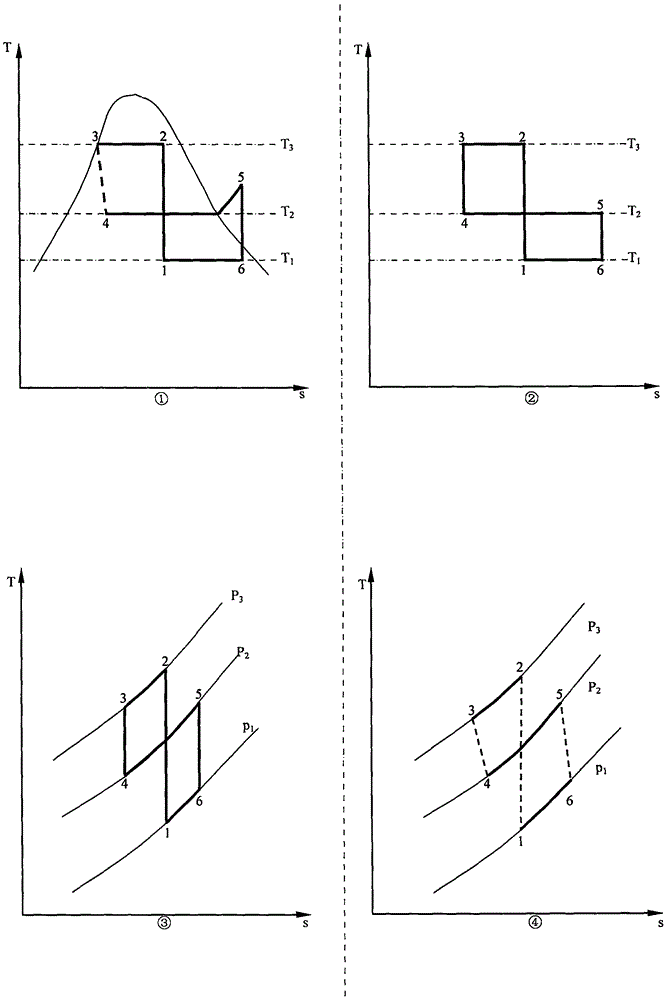

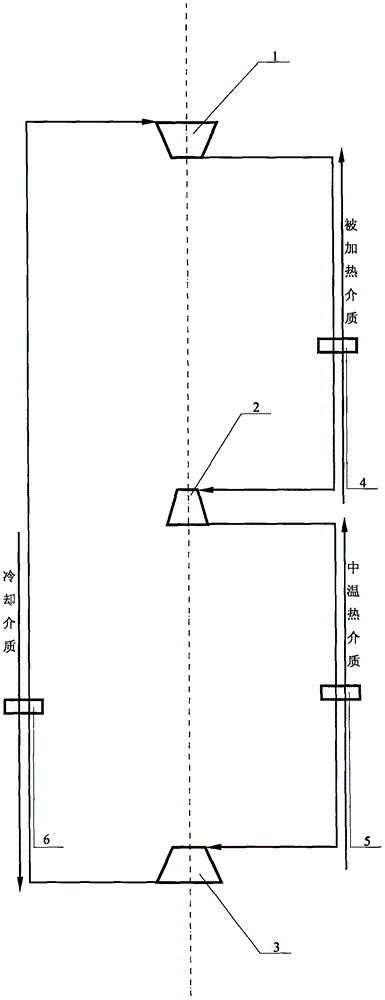

The invention provides a bidirectional thermal cycle and second type of heat-driven compression heat pump, and belongs to the power and heat pump technology field. A bidirectional thermal cycle 1234561 comprises the steps of a working medium boost process 12 that begins from a low temperature; a heat absorption process 23 that absorbs heat from a middle temperature heat source; a boost process 34 that begins from a middle temperature; a heat release process 45 that releases heat to a high temperature heat source; a pressure reduction process 56 that begins from a high temperature; a heat release process 61 that releases heat to a low temperature heat source. A compressor has cycle working medium and is communicates with a second compressor through a heat exchanger; the second compressor has the cycle working medium channel and is communicated with an expander through a heater; the expander has the cycle working medium channel and is communicated with a compressor through a cooler; the heat exchanger has a middle temperature thermal medium channel and is communicated with the outside; the heater has a heated medium channel and is communicated with the outside; the cooler has a cooling medium channel and is communicated with the outside; the expander is connected with the compressor and the second compressor, and is used to transmit power to form the second type of heat-driven compression heat pump.

Owner:李华玉

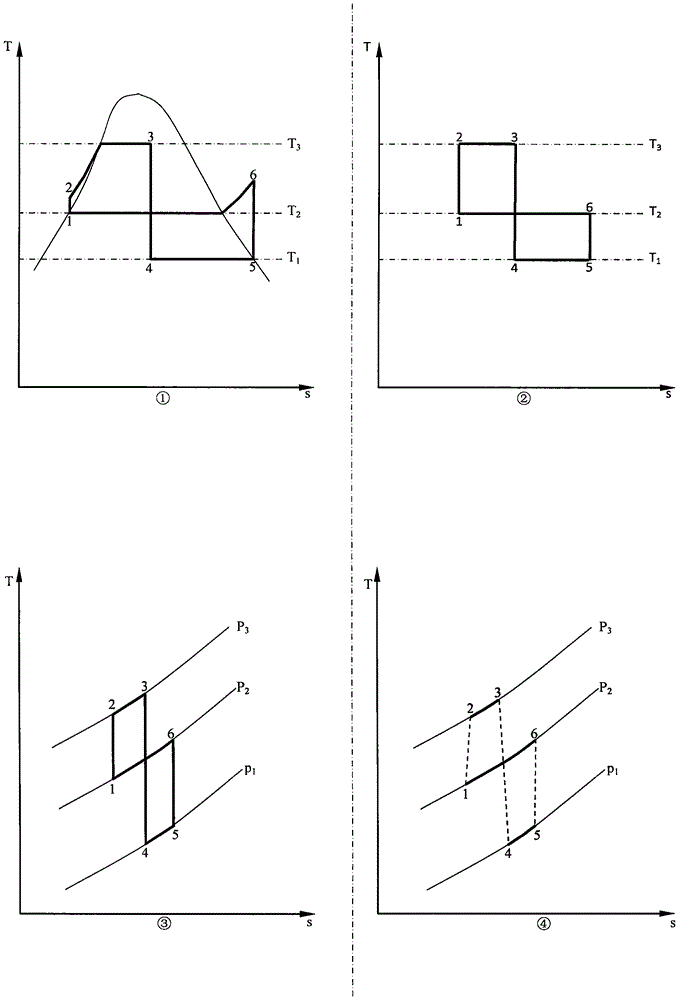

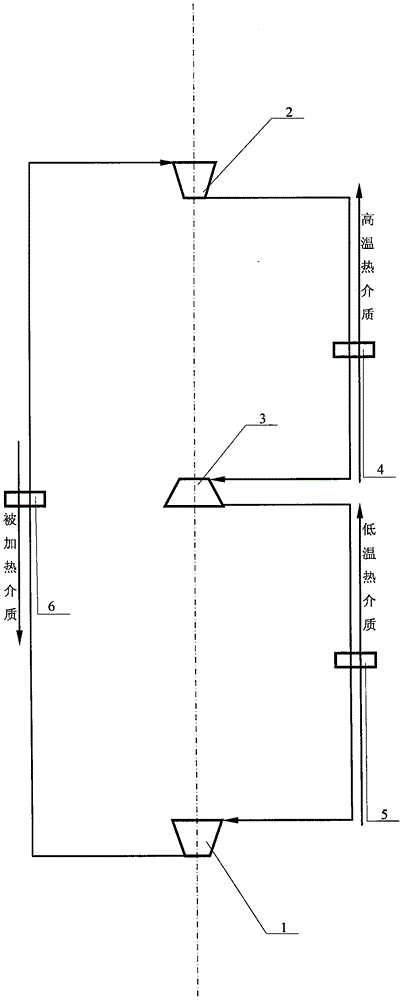

Bidirectional thermal cycle and first type of heat-driven compression heat pump

ActiveCN105953454AMechanical apparatusCompression machines with non-reversible cycleExothermic processEngineering

The invention provides a bidirectional thermal cycle and first type of heat-driven compression heat pump, and belongs to the power, refrigeration and heat pump technology field. A bidirectional thermal cycle 1234561 comprises the steps of a working medium boost process 12 that begins from a low temperature; a heat absorption process 23 that absorbs heat from a middle temperature heat source; a boost process 34 that begins from a middle temperature; a heat release process 45 that releases heat to a high temperature heat source; a pressure reduction process 56 that begins from a high temperature; a heat absorption process 6 that absorbs heat from a low temperature heat source. A compressor has cycle working medium and is communicates with an expander through a high temperature heat exchanger; the expander has the cycle working medium channel and is communicated with a second expander through a heater; the second expander has the cycle working medium channel and is communicated with the compressor through a low temperature heat exchanger; the high temperature heat exchanger has a high temperature thermal medium channel and is communicated with the outside; the low temperature heat exchanger has a low temperature thermal medium channel and is communicated with the outside; the heater has a heated medium channel and is communicated with the outside; the expander and the second expander are connected with the compressor to transmit power to form the first type of heat-driven compression heat pump.

Owner:李华玉

Partial boiling in mini and micro-channels

ActiveUS8252245B2Stable isothermal boundary conditionLarge diameterOrganic compounds purification/separation/stabilisationOrganic compound preparationExothermic processChemistry

The invention provides methods, apparatus and systems in which there is partial boiling of a liquid in a mini-channel or microchannel. The partial boiling removes heat from an exothermic process.

Owner:VELOCYS INC

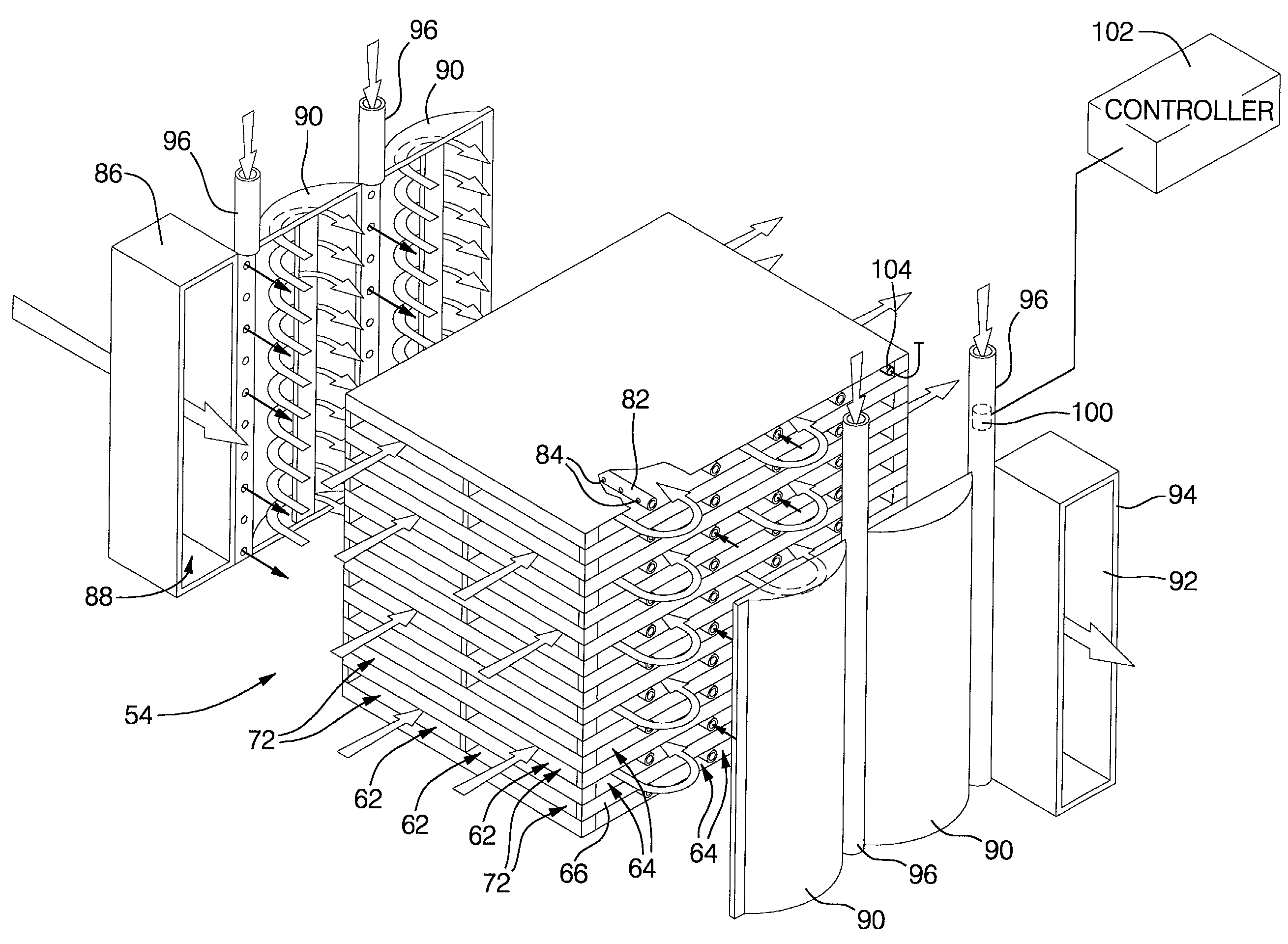

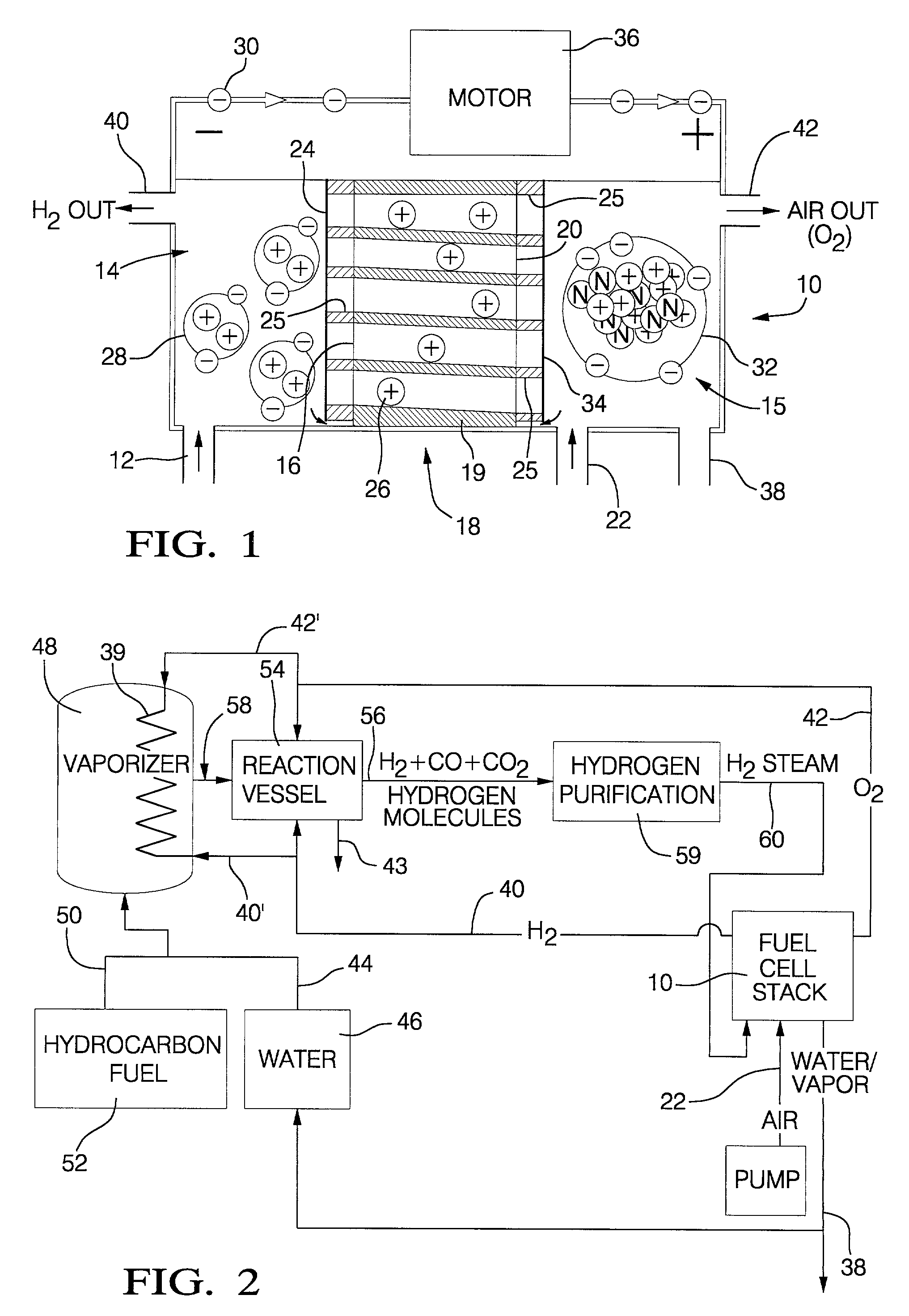

Multiple stage combustion process to maintain a controllable reformation temperature profile

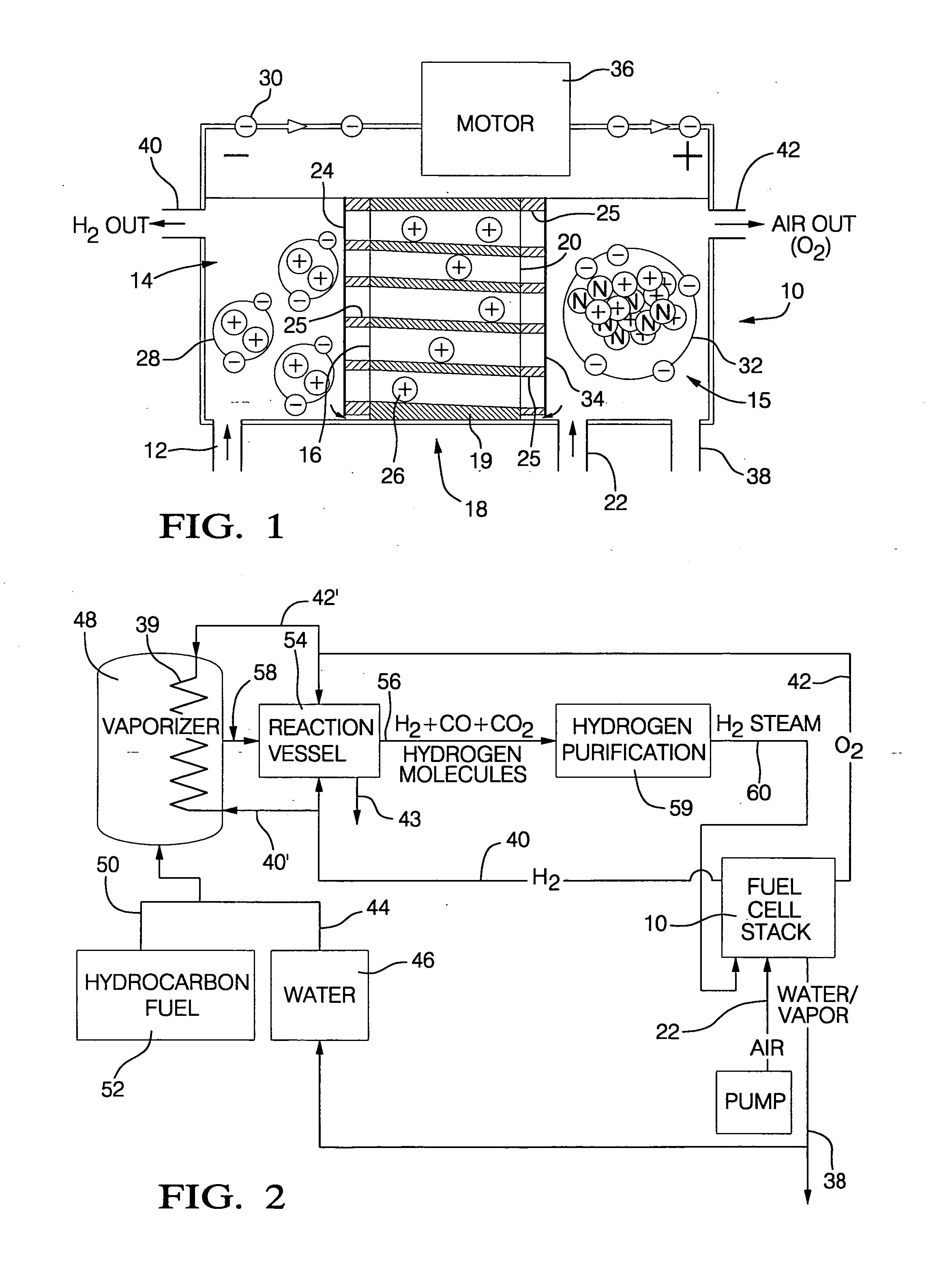

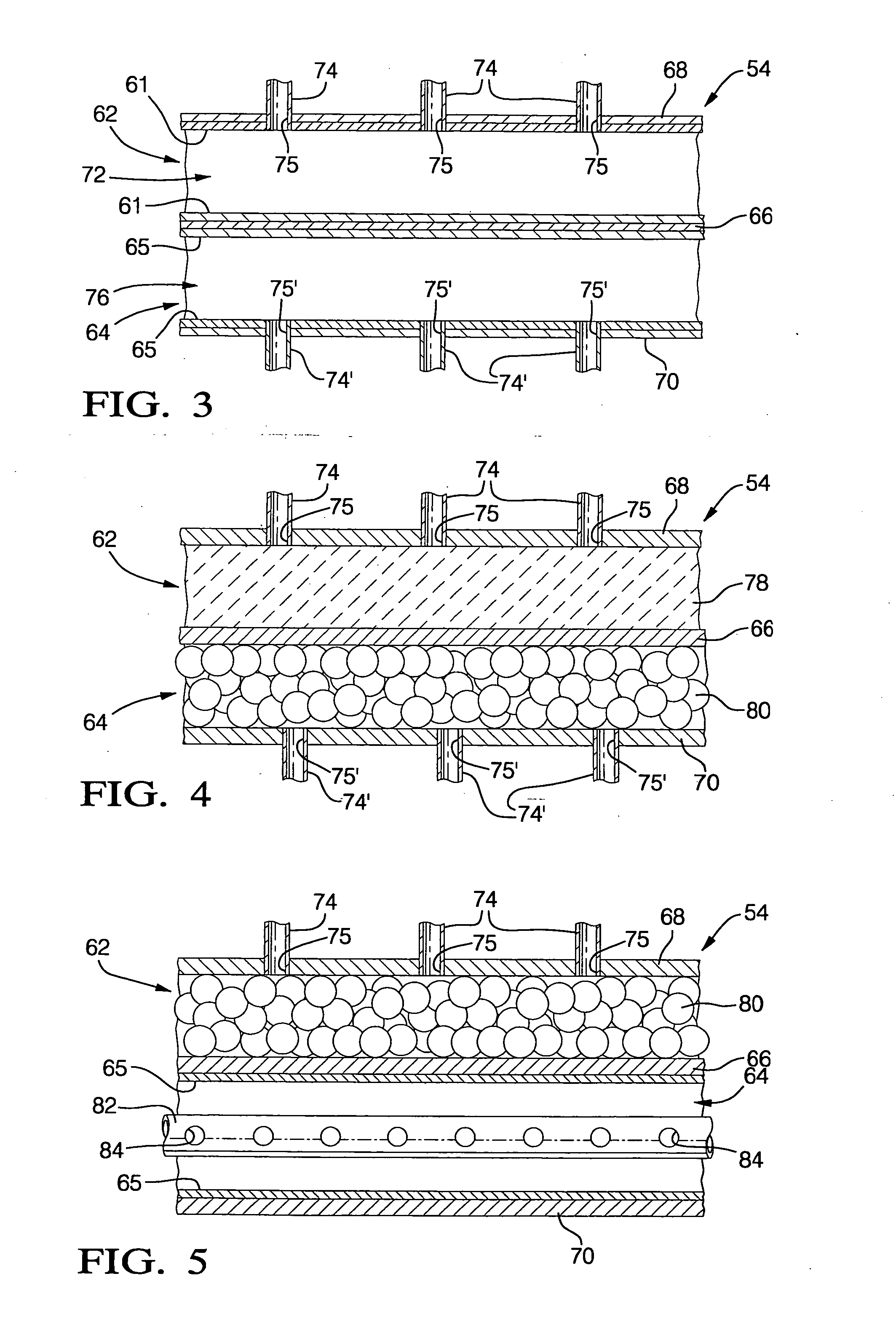

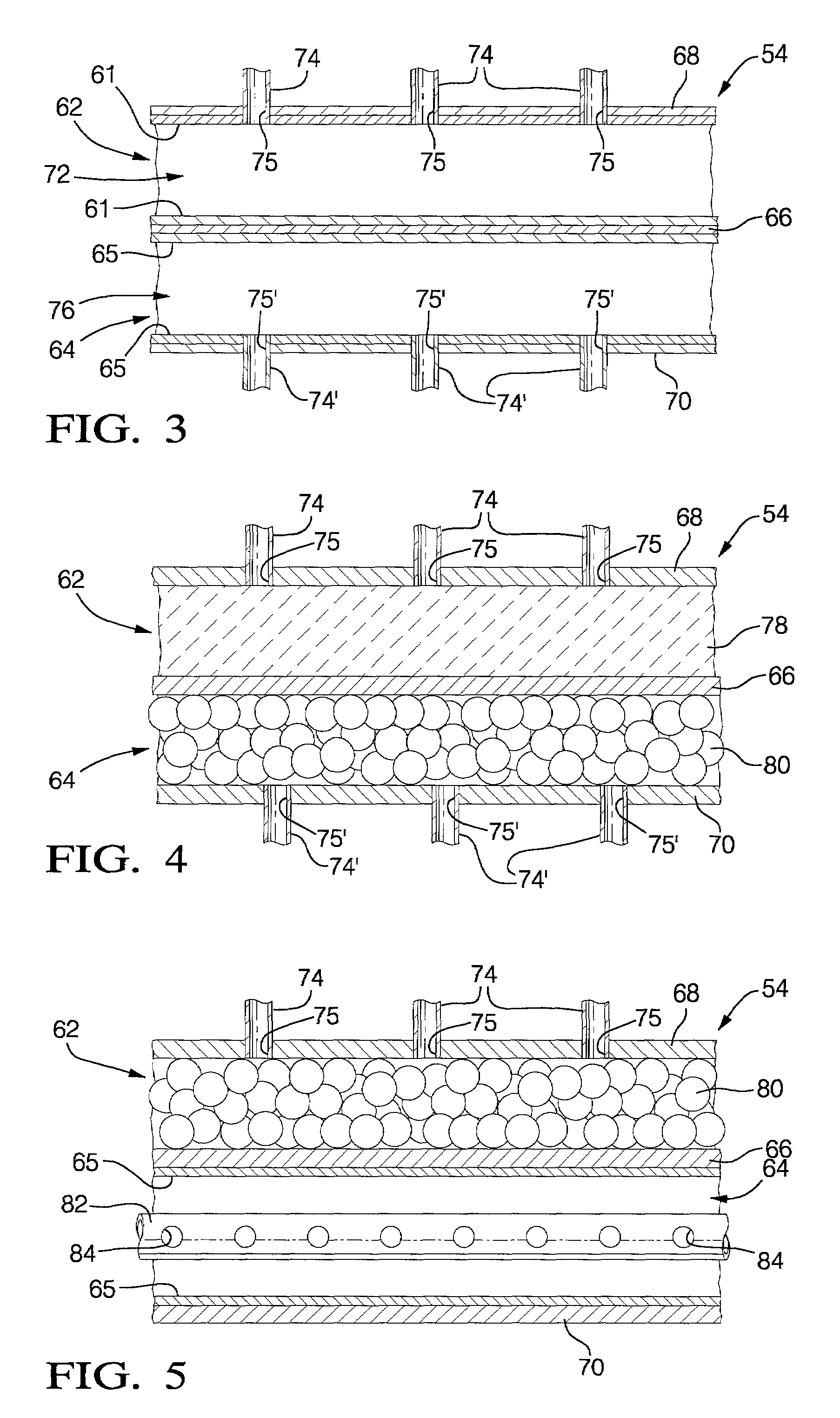

InactiveUS20050048333A1Uniform exchangeGenerate uniformFuel cells groupingFuel cell auxillariesFuel cellsWorking fluid

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

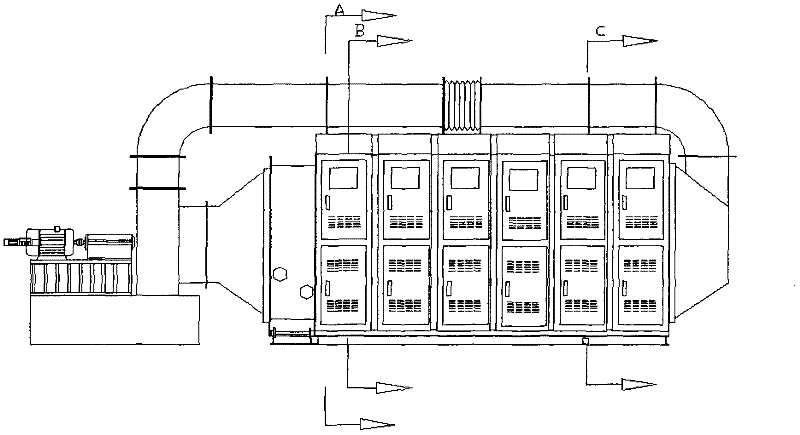

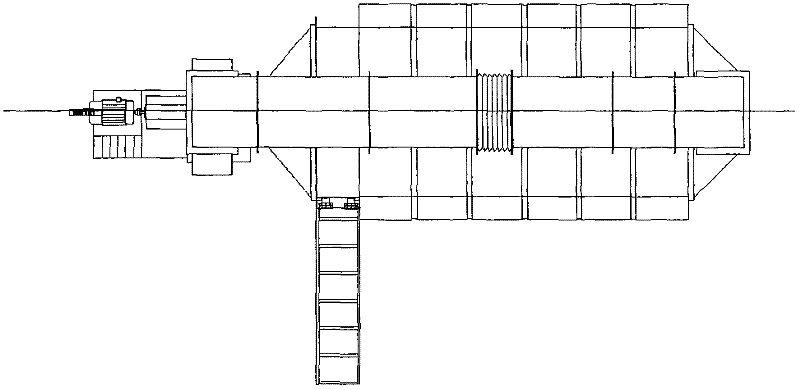

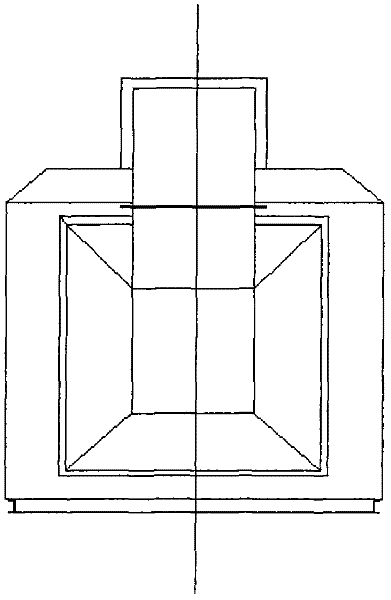

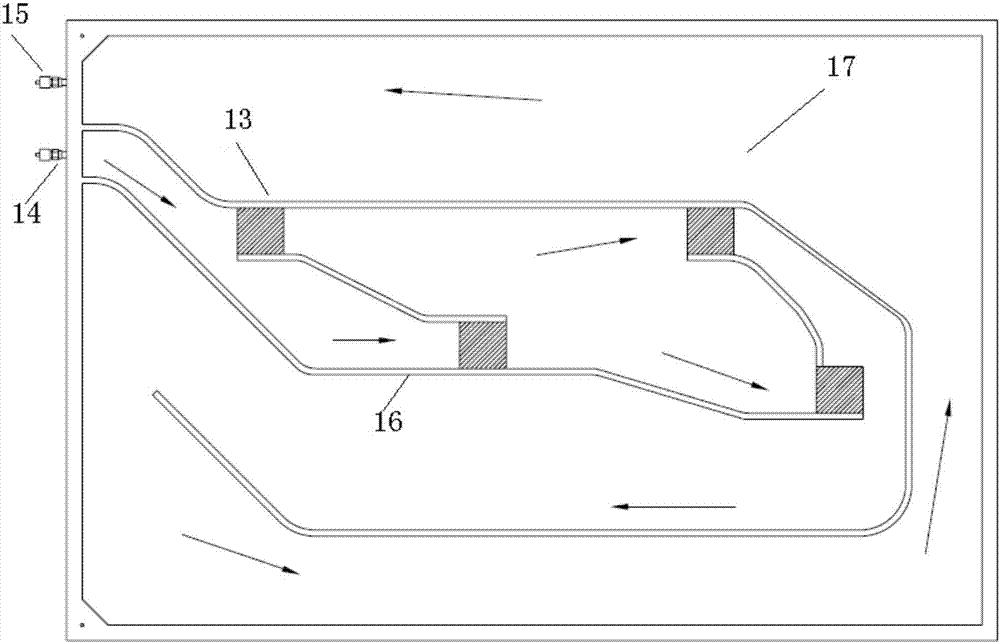

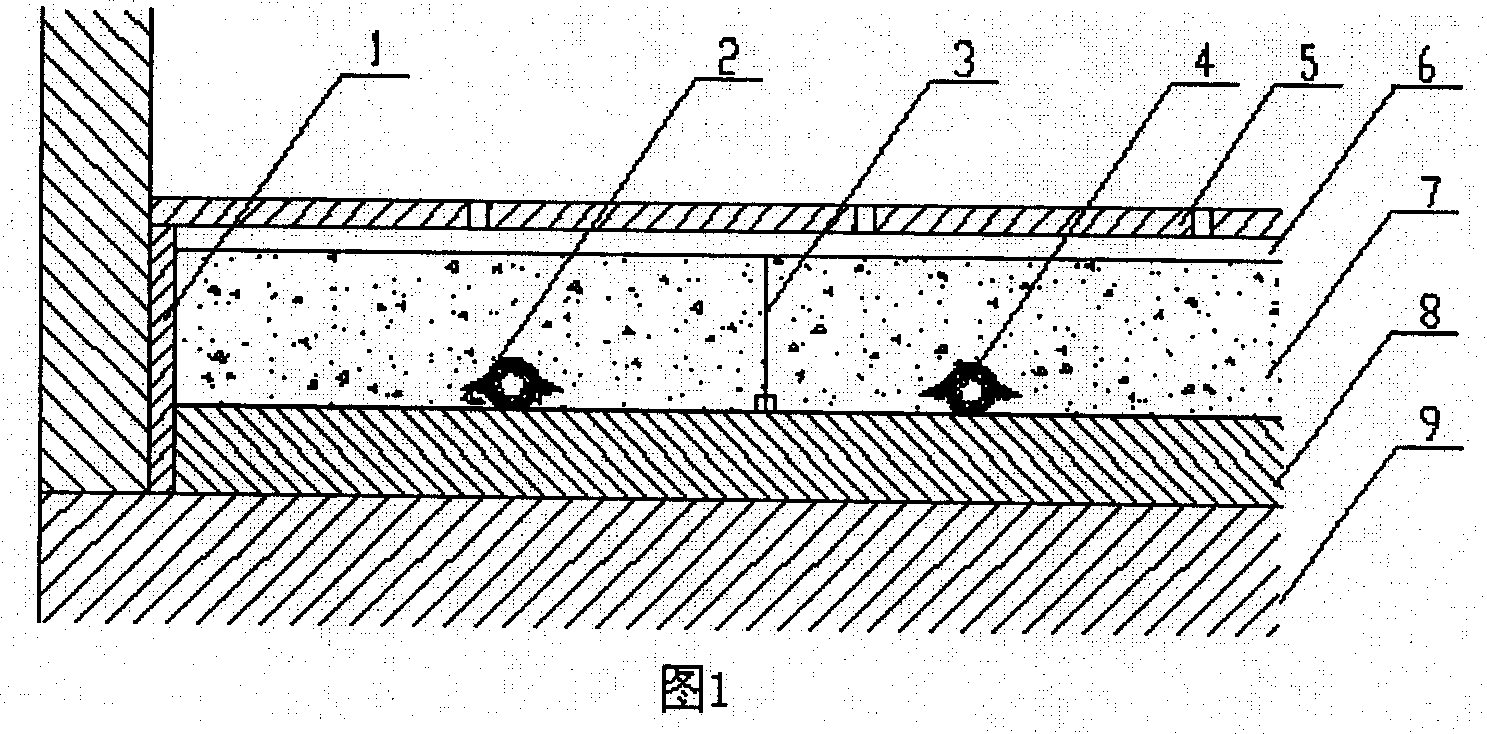

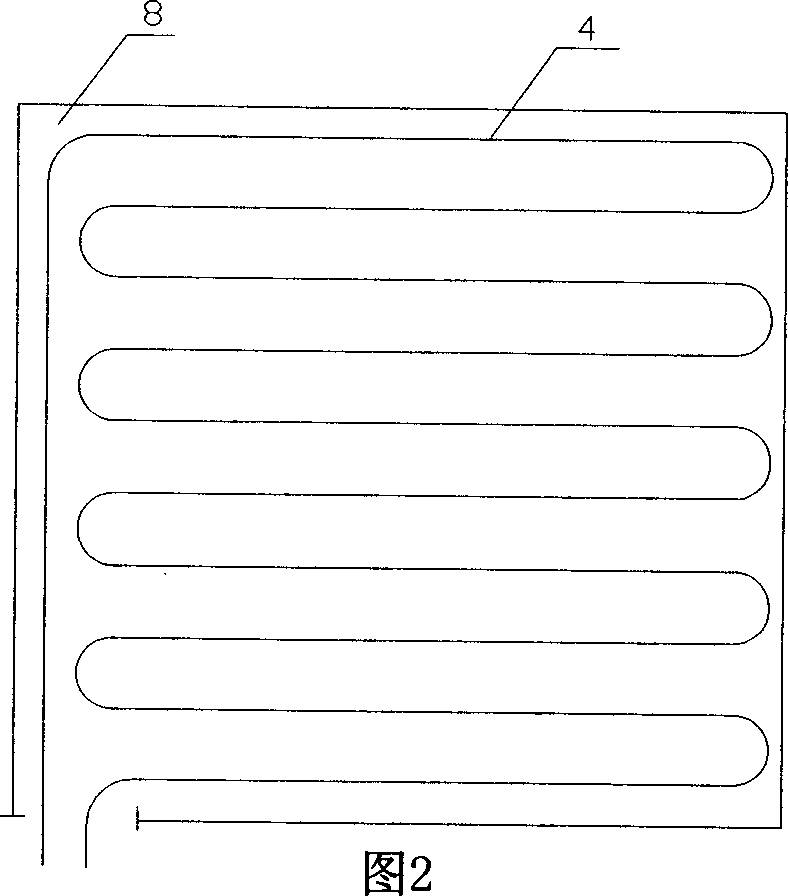

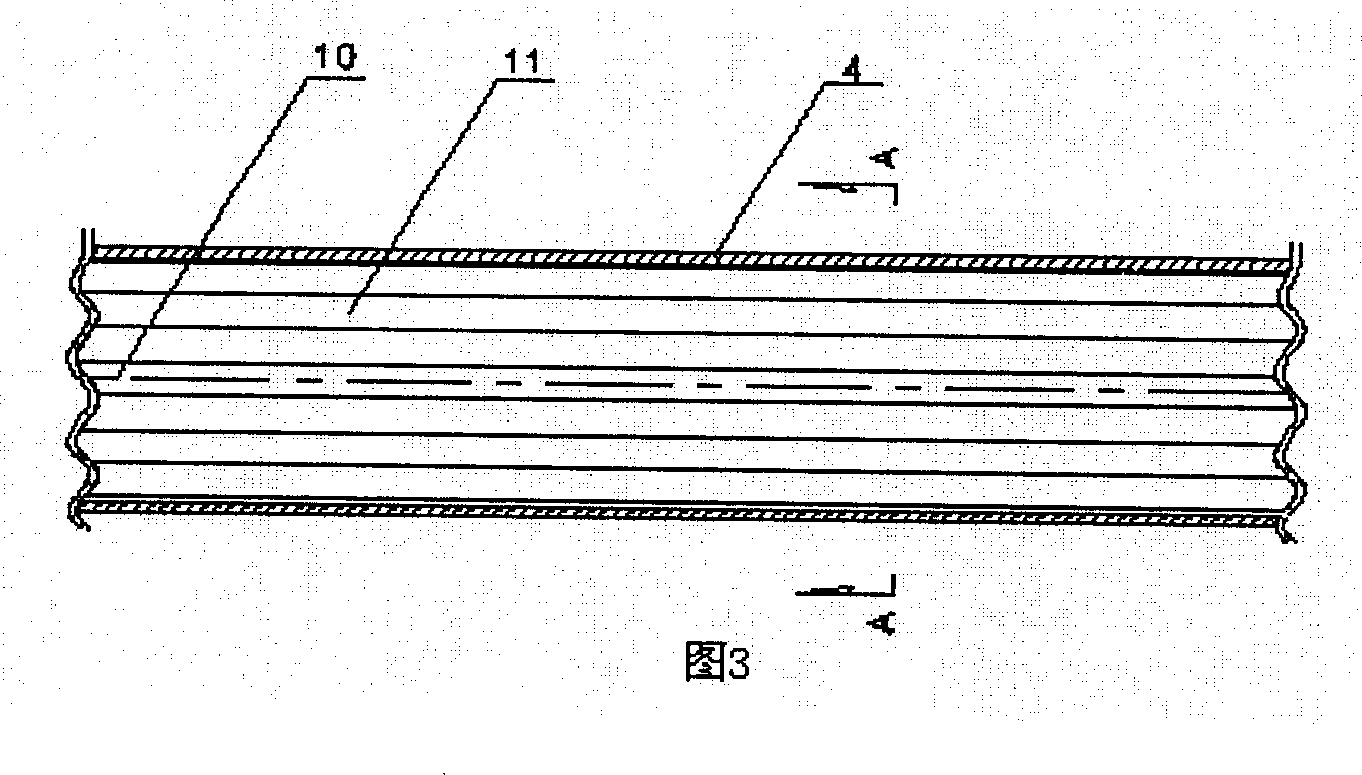

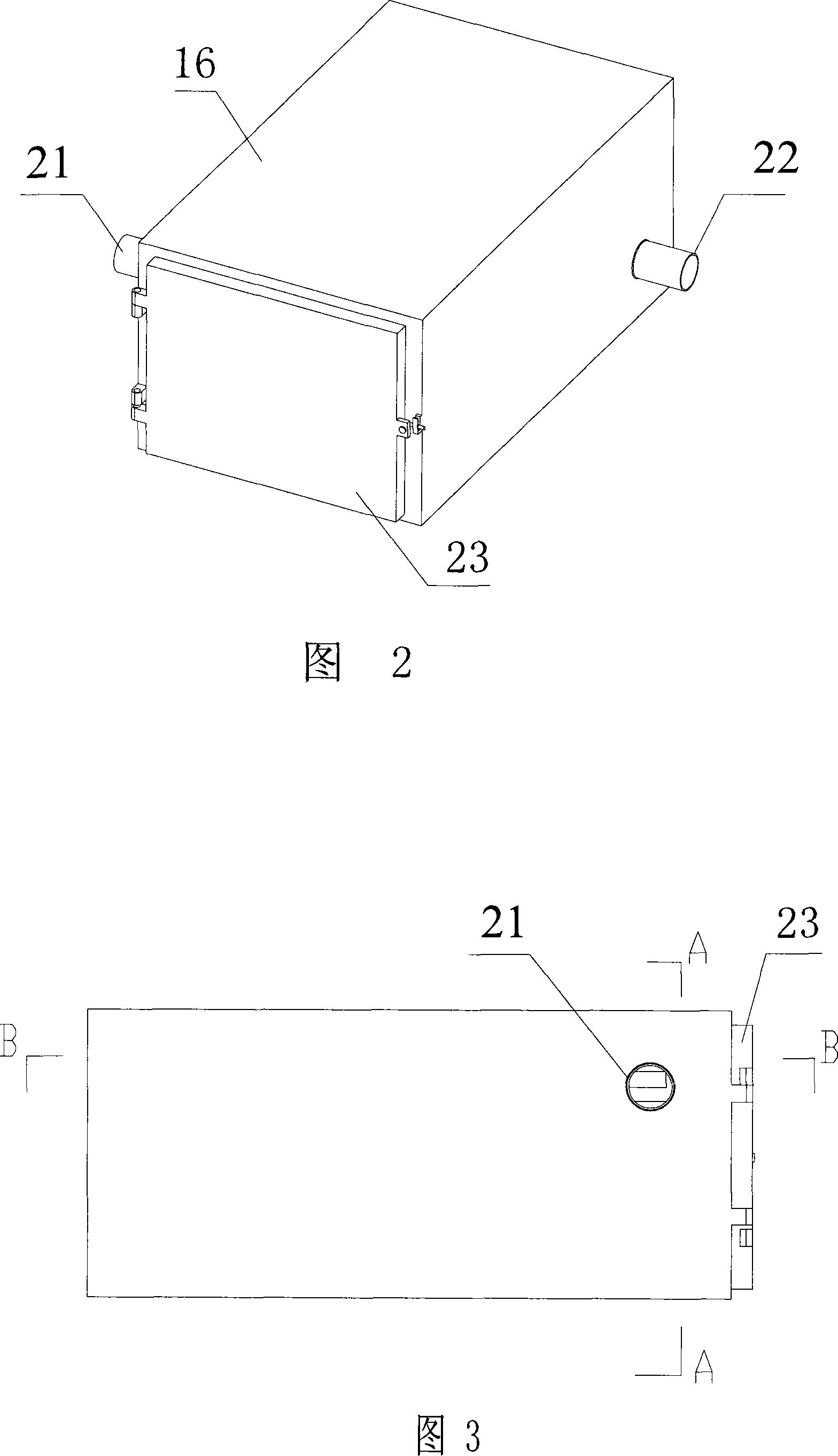

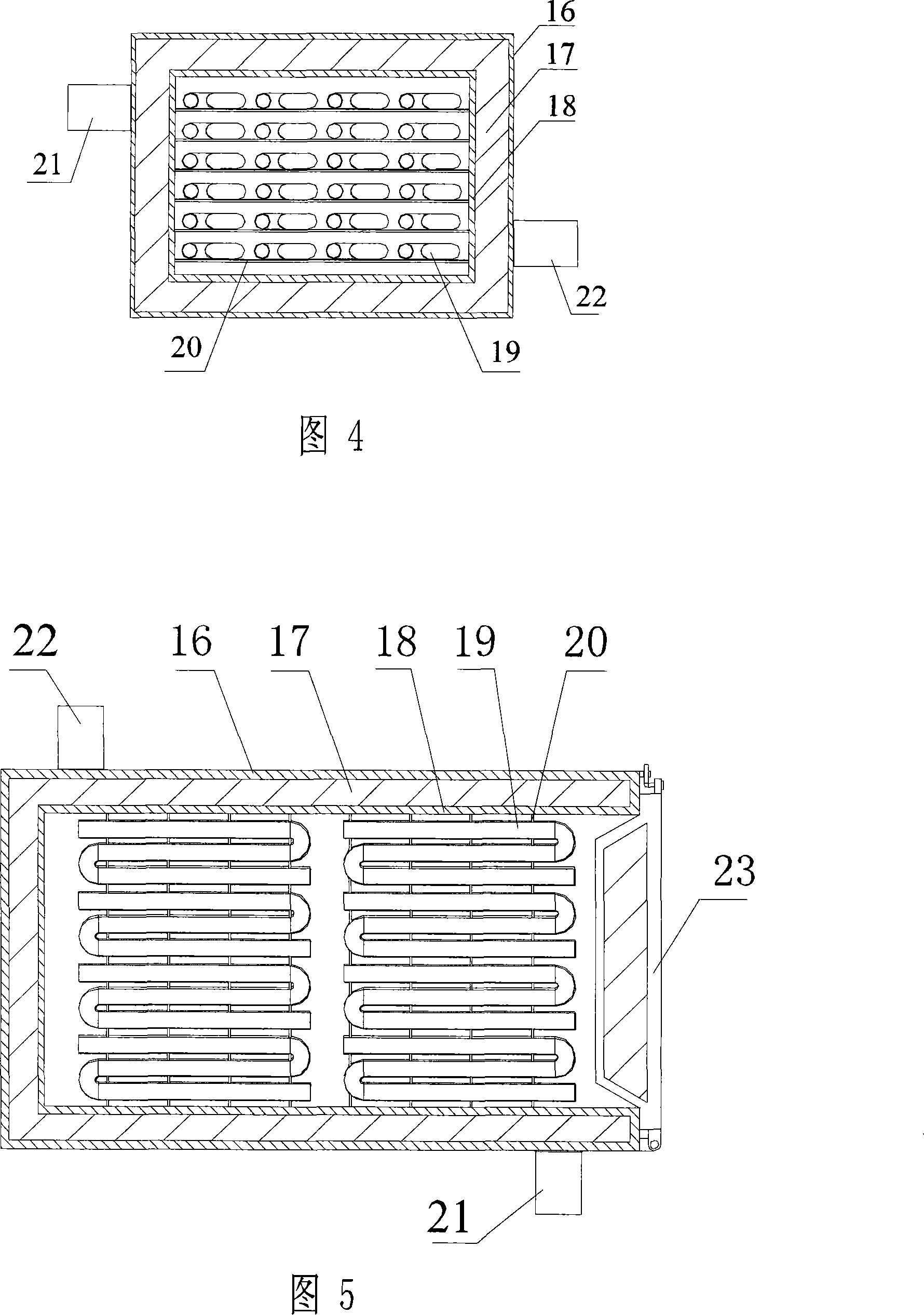

Solid energy storage electric boiler and heat exchanging structure thereof

InactiveCN102175018AUniform and effective conductionRuntime controlSteam generation heating methodsHeat storage plantsBrickExothermic process

The invention aims to overcome the defects of the existing heating plants, such as a boiler, and to provide a solid energy storage electric boiler and a heat exchanging structure thereof. A heat storage brick is utilized as a heat storage medium for the solid energy storage electric boiler, and a high-capacity heat exchanging structure with a controllable exothermic process. Particularly, the heat exchanging structure comprises a heat storage structure, a heat insulation material layer, a heat insulation wall with holes, a heat exchanger and an outer shell; two ends of the outer shell are provided with air openings; the heat storage structure, the heat insulation wall with holes and the heat exchanger are arrayed in the outer shell; the heat insulation material is placed among the heat storage structure, the heat insulation wall with holes and the outer shell; and the heat exchanging structure also comprises an air door, a fan and a circulation outer air duct.

Owner:北京蓝景圣诺尔能源科技有限公司 +1

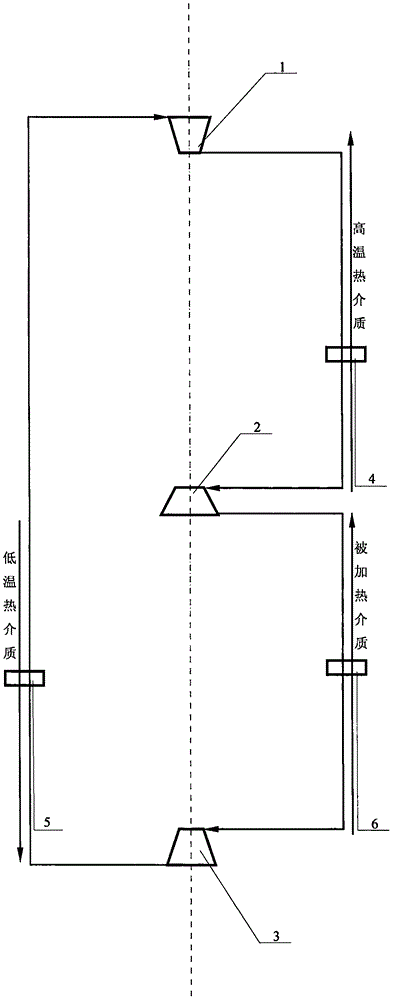

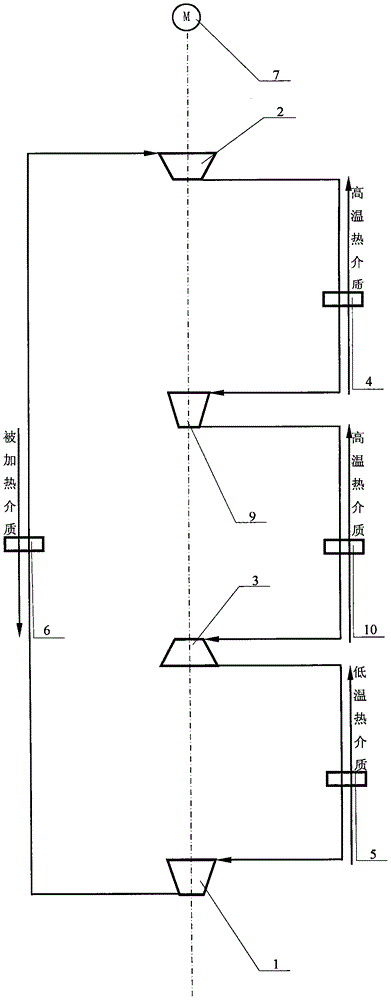

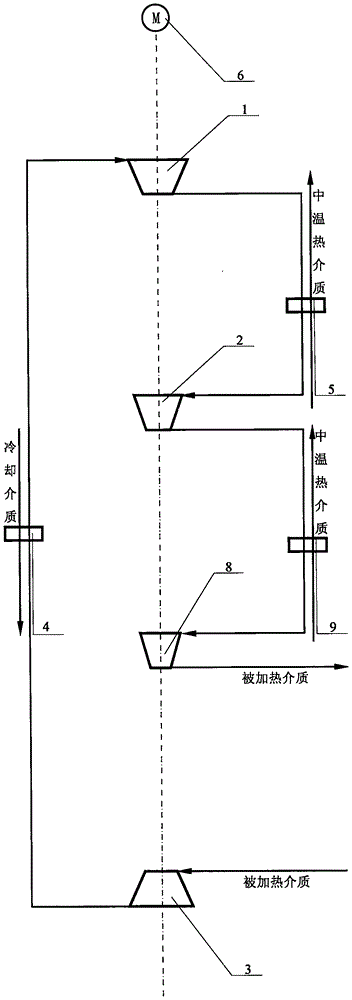

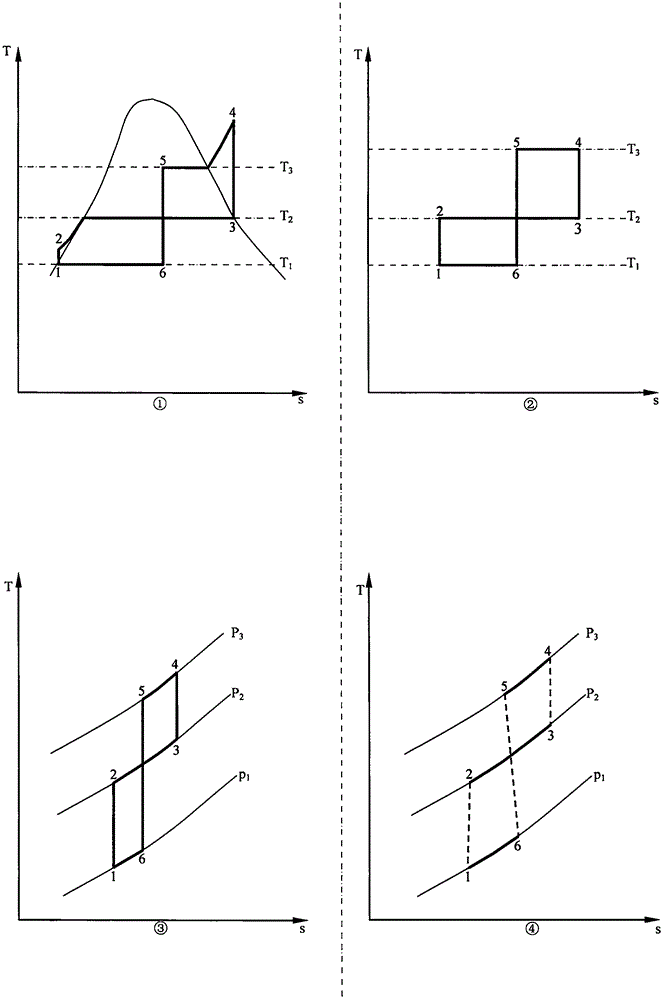

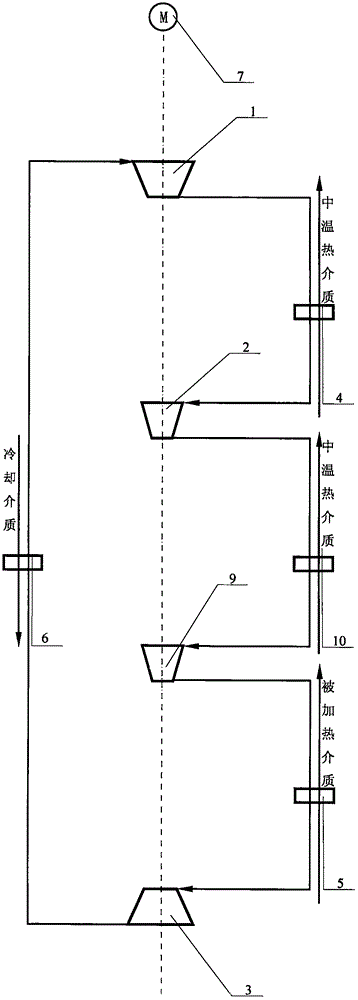

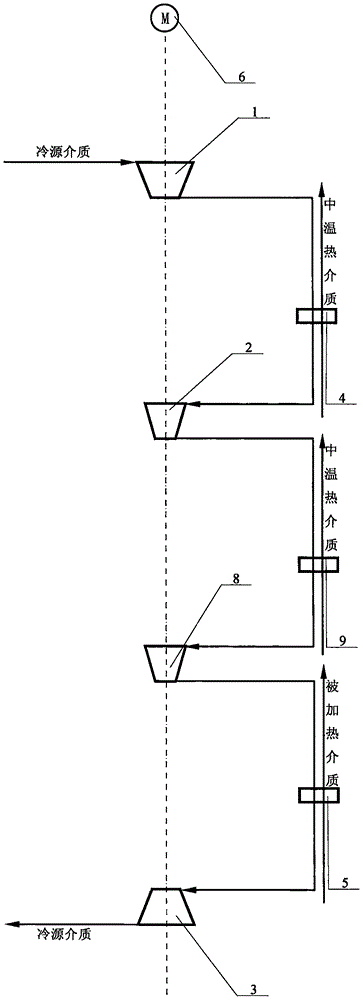

Dual-way thermodynamic cycle and first-type thermal-drive compression heat pump

ActiveCN105953453ACompression machines with non-reversible cycleFluid circulation arrangementThermodynamic cycleEngineering

The invention provides a dual-way thermodynamic cycle and a first-type thermal-drive compression heat pump and belongs to the technical field of dynamics, refrigeration and heat pumps. The dual-way thermodynamic cycle 1234561 is composed of a course 12 in which a working medium is boosted from a middle temperature, a course 23 in which the working medium absorbs heat from a high-temperature heat source, a course 34 in which the working medium is decompressed from a high temperature, a course 45 in which the working medium absorbs heat from a low-temperature heat source, a course 56 in which the working medium is boosted from a low temperature, and a course 61 in which the working medium releases heat to a middle-temperature heat source. A compressor is equipped with a circulating medium channel which communicates with a second compressor by a heat supply device; the second compressor is equipped with a circulating medium channel which communicates with an expansion machine via a high-temperature heat exchanger; the expansion machine is equipped with a circulating medium channel which communicates with the compressor via a low-temperature heat exchanger; the high-temperature heat exchange is equipped with a high-temperature thermal medium pipeline which communicates with the external environment; the low-temperature heat exchange is equipped with a low-temperature thermal medium pipeline which communicates with the external environment; the heat supply device is equipped with a heated medium pipeline which communicates with the external environment; and the expansion machine is connected to the compressor and the second compressor and transmits power. In this way, the first-type thermal-drive compression heat pump is formed.

Owner:李华玉

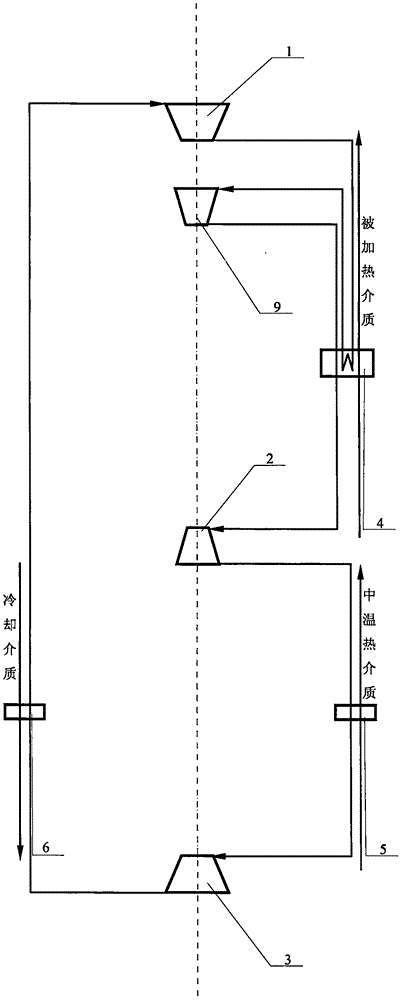

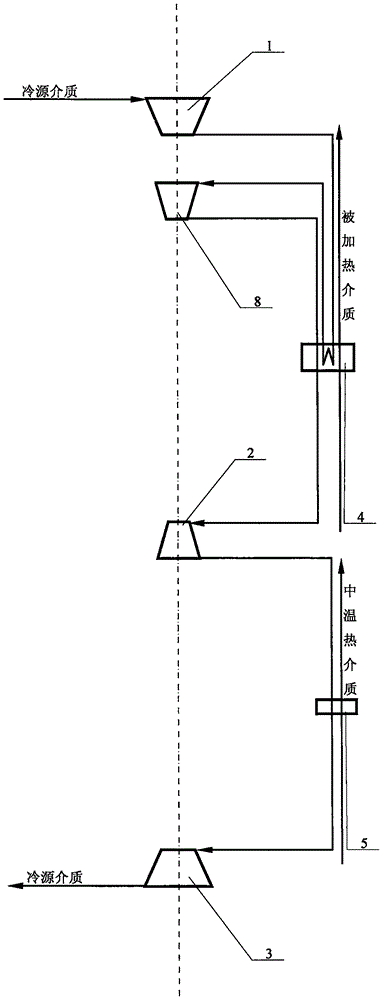

Open-type bidirectional thermodynamic cycle and second-class thermally-driven compression heat pump

ActiveCN105865068ACompression machines with non-reversible cycleFluid circulation arrangementThermodynamic cycleChiller

The invention provides an open-type bidirectional thermodynamic cycle and a second-class thermally-driven compression heat pump belonging to the technical fields of heat energy utilization and heat pumps. The open-type bidirectional thermodynamic cycle is formed by a process 12 of heated medium pressure reduction beginning from a high temperature, a process 23 of releasing heat towards a low-temperature heat source, a process 34 of pressure rise beginning from a low temperature, a process 45 of absorbing heat from a medium-temperature heat source and a process 56 of pressure rise beginning from a medium temperature. The outside communicates with an expansion machine by virtue of a heated medium channel; the expansion machine communicates with a compressor through a cooler by virtue of a heated medium channel; the compressor communicates with a second compressor through a heat exchanger by virtue of a heated medium channel; the second compressor communicates with the outside by virtue of a heated medium channel; the cooler communicates with the outside by virtue of a cooling medium channel; the heat exchanger communicates with the outside by virtue of a medium-temperature heat medium channelA heated medium channel which communicates with an expansion machine is arranged at the outside; the expansion machine is provided with a heated medium channel which communicates with a compressor through a cooler; the compressor is provided with a heated medium channel which communicates with a second compressor through a heat exchanger; the second compressor is provided with a heated medium channel which communicates with the outside; the cooler is provided with a cooling medium channel which communicates with the outside; the heat supply device is provided with a heated medium channel which communicates with the outside; the heat exchanger is internally provided with a medium-temperature heat medium channel which communicates with the outside; and the expansion machine is connected with the compressor and the second compressor and is used for transmitting power, so that the second-class thermally-driven compression heat pump is formed.

Owner:李华玉

Method for directly preparing porous metal product by molten salt electrolysis

The invention discloses a method for directly preparing a porous metal product by molten salt electrolysis. The method comprises the following step of: performing molten salt electrolysis for 4 to 30 hours in the presence of argon shielding gas under such conditions that a metal blank is used as cathode, graphite as anode and CaCl2 is used as electrolyte, to obtain a porous metal product with a porosity of 15 to 78%. The temperature of electrolysis is 850 DEG C to 1200 DEG C, the voltage of electrolysis is 2.8 V to 3.8 V, and the metal blank is prepared from metal oxide powders as raw materials by the conventional method in which a pore-forming agent is added prior to pressing and sintering. The porous metal product is prepared by molten salt electrolysis of the metal blank. Since the deoxidation process is an exothermic process, the temperature is increased to produce a sintering effect during cathode reduction, as a result, the strength of the product is increased. Besides, the sintering effect as local sintering effect has a small impact on deformation of the product.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Bidirectional thermal cycle and second type of heat-driven compression heat pump

The invention provides a bidirectional thermal cycle and second type of heat-driven compression heat pump, and belongs to the power and heat pump technology field. A bidirectional thermal cycle 1234561 comprises the steps of a working medium boost process 12 that begins from a low temperature; a heat absorption process 23 that absorbs heat from a middle temperature heat source; a boost process 34 that begins from a middle temperature; a heat release process 45 that releases heat to a high temperature heat source; a pressure reduction process 56 that begins from a high temperature; a heat release process 61 that releases heat to a low temperature heat source. A compressor has cycle working medium and is communicates with a second compressor through a heat exchanger; the second compressor has the cycle working medium channel and is communicated with an expander through a heater; the expander has the cycle working medium channel and is communicated with a compressor through a cooler; the heat exchanger has a middle temperature thermal medium channel and is communicated with the outside; the heater has a heated medium channel and is communicated with the outside; the cooler has a cooling medium channel and is communicated with the outside; the expander is connected with the compressor and the second compressor, and is used to transmit power to form the second type of heat-driven compression heat pump.

Owner:李华玉

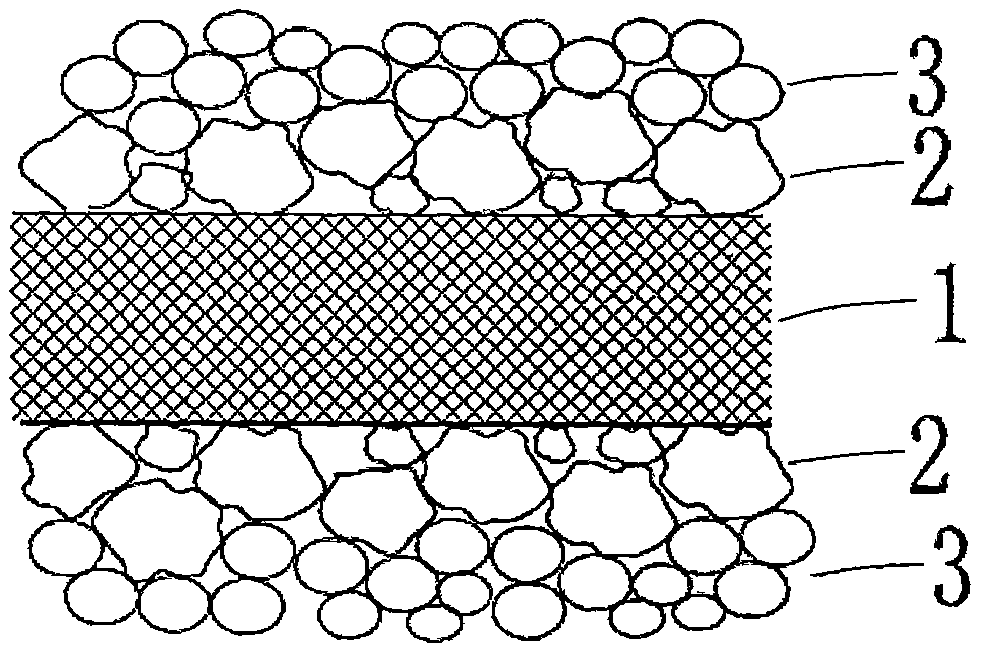

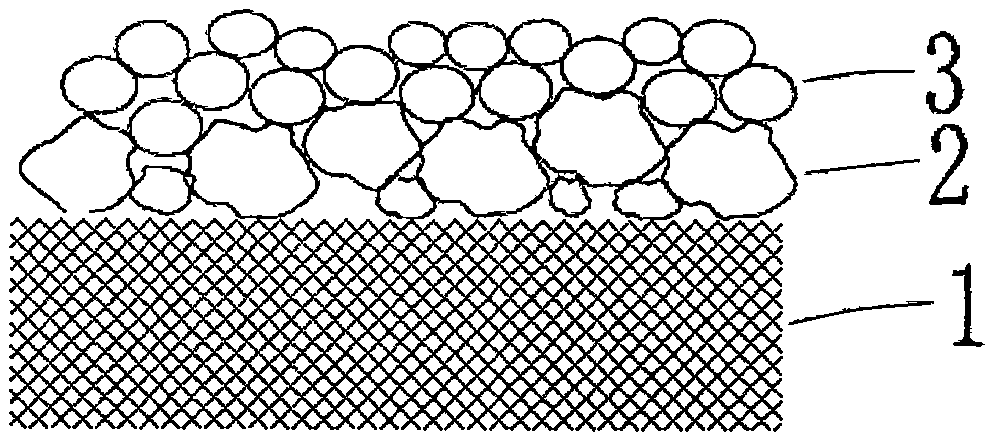

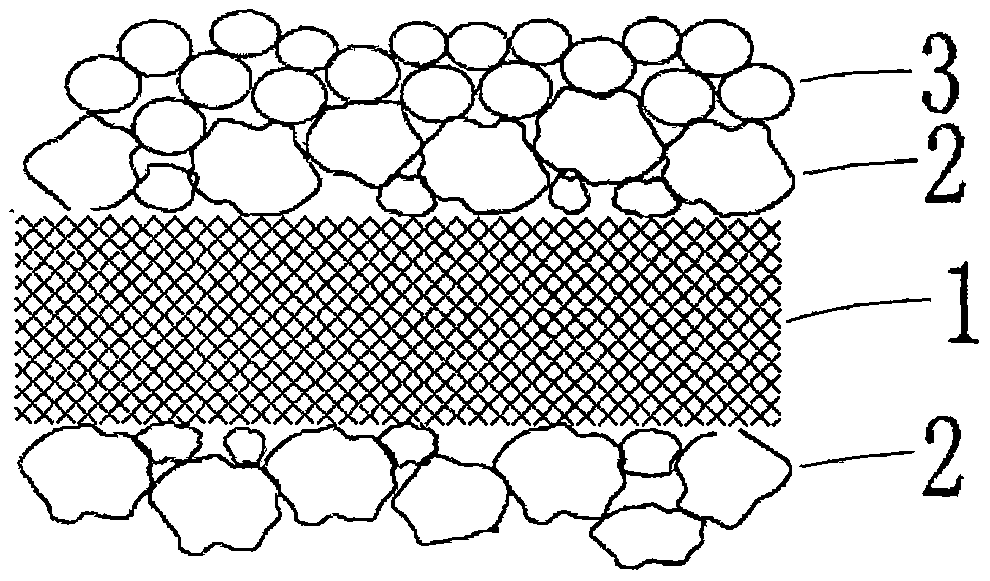

Thermal shutdown heat-resistant high-safety coated and modified membrane and preparation method thereof

PendingCN108550766AHigh membrane rupture temperatureAvoid short circuitCell seperators/membranes/diaphragms/spacersSecondary cellsWater basedMicrosphere

The invention discloses a thermal shutdown heat-resistant high-safety coated and modified membrane, which comprises a base membrane, wherein a ceramic / resin coating and a polymer microsphere coating are arranged at one side or two sides of the base membrane; the ceramic / resin coating is prepared from the following components in percentages by mass: 30-60wt% of an inorganic ceramic material, 25-66wt% of deionized water, 3-10wt% of heat-resistant resin and 1-5wt% of a catalytic polyaddition organic matter; and the polymer microsphere coating is prepared from the following components in percentages by mass: 3-20wt% of polymer microspheres, 60-93wt% of deionized water, 3-10wt% of a water-based binder, 0.5-5wt% of a water-based wetting agent and 0.5-5wt% of a water soluble dispersant. The prepared thermal shutdown heat-resistant high-safety coated and modified membrane has a trigger effect of achieving thermal shutdown of the membrane at relatively low temperature, the thermal shutdown temperature of the membrane is lower than 130 DEG C, the thermal shutdown mechanism can be triggered at relatively low temperature in a thermal runaway exothermic process of a lithium-ion battery, the internal resistance of the battery is increased by two orders of magnitude after thermal shutdown, and further lithium ion exchange in the battery is prevented to reduce the generated heat.

Owner:CANGZHOU MINGZHU PLASTIC +2

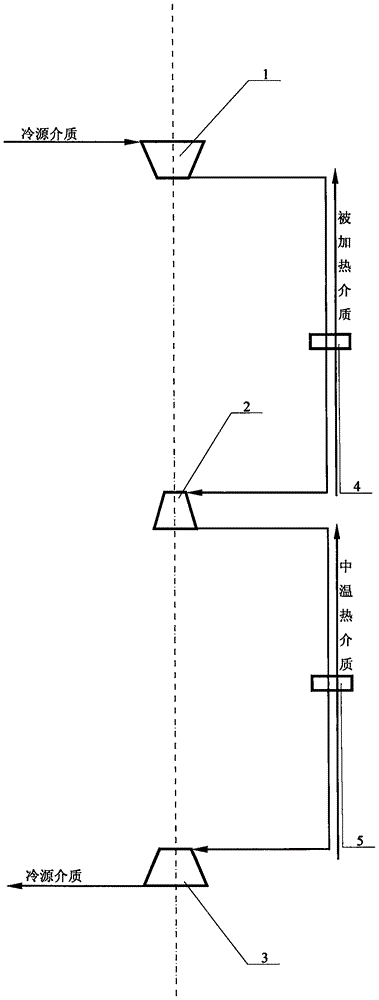

Open-type bidirectional thermodynamic cycle and second-class thermally-driven compression heat pump

ActiveCN105865067AMechanical apparatusCompression machines with non-reversible cycleExothermic processEngineering

The invention provides an open-type bidirectional thermodynamic cycle and a second-class thermally-driven compression heat pump belonging to the technical fields of heat energy utilization and heat pumps. The open-type bidirectional thermodynamic cycle is formed by a process 12 of cold source medium pressure rise beginning from a low temperature, a process 23 of absorbing heat from a medium-temperature heat source, a process 34 of pressure rise beginning from a medium temperature, a process 45 of releasing heat towards a high-temperature heat source and a process 56 of pressure reduction beginning from a high temperature. The outside communicates with a compressor by virtue of a cold source medium channel; the compressor communicates with a second compressor through a heat exchanger by virtue of a cold source medium channel; the second compressor communicates with an expansion machine through a heat supply device by virtue of a cold source medium channel; the expansion machine communicates with the outside by virtue of a cold source medium channel; the heat exchanger communicates with the outside by virtue of a medium-temperature heat medium channel; the heat supply device communicates with the outside by virtue of a heated medium channelA cold source medium channel which communicates with a compressor is arranged at the outside; the compressor is provided with a cold source medium channel which communicates with a second compressor through a heat exchanger; the second compressor is provided with a cold source medium channel which communicates with an expansion machine through a heat supply device; the expansion machine is provided with a cold source medium channel which communicates with the outside; the heat exchanger is internally provided with a medium-temperature heat medium channel which communicates with the outside; the heat supply device is provided with a heated medium channel which communicates with the outside; and the expansion machine is connected with the compressor and the second compressor and is used for transmitting power, so that the second-class thermally-driven compression heat pump is formed.

Owner:李华玉

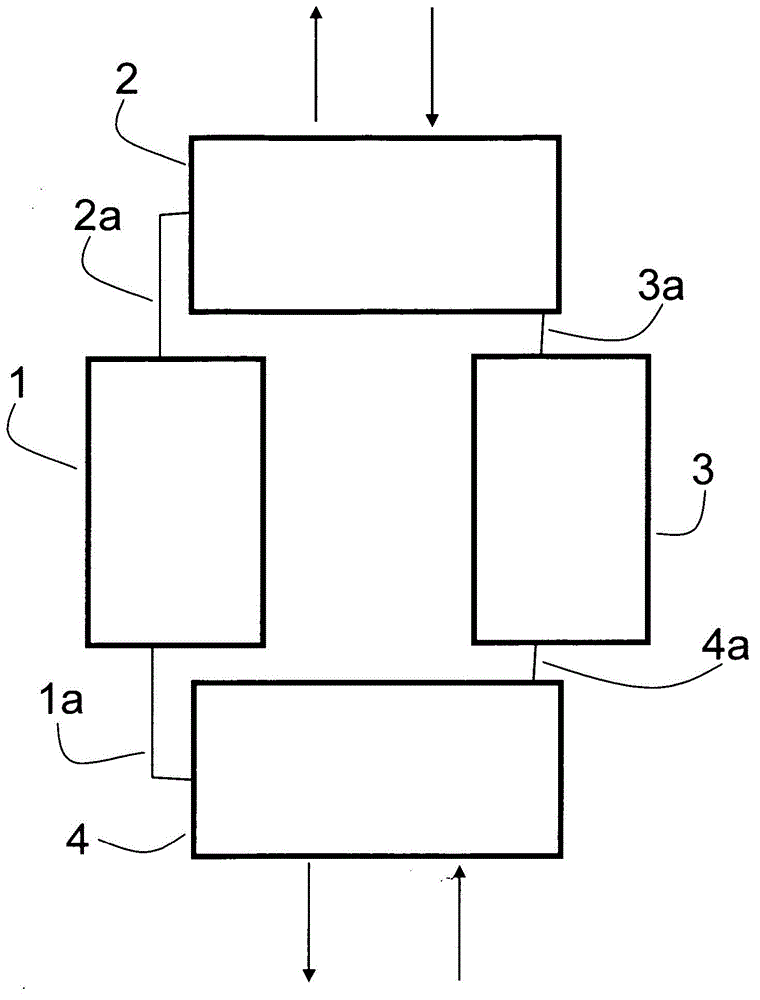

Method and apparatus for storing and releasing heat by means of a phase change material

InactiveCN102803889ALow costEliminate temperature limitationsHeat storage plantsStorage heatersExothermic processEngineering

The invention relates to a method for storing and releasing heat by means of a phase change material. In said method, a phase change is caused in a first heat exchanging device (4) by supplying heat during a charging process in a storage medium comprising a phase change material in order to store the heat as latent heat in the storage medium, and a phase change is caused in the storage medium while heat is dissipated during a discharging process in the first or another heat exchanging device (2). The invention is characterized in that at least predominantly non-encapsulated phase change material is used as storage medium, the storage medium is fed to the first heat exchanging device (4) as a fluid stream or particle stream during the charging process and is discharged when the phase change has been completed, the storage medium is fed to the first or another heat exchanging device (2) as a fluid stream during the discharging process and is discharged from the heat exchanging device as a fluid stream or particle stream when the phase change has been completed, the storage medium is temporarily stored in a first storage tank (1) following the charging process and / or in the first or another storage tank (3) following the discharging process,; and the storage medium is actively conveyed and heat is exchanged during the phase change as the charging process and / or the discharging process take / s place. The invention further relates to an apparatus for storing and releasing heat by means of a phase change material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

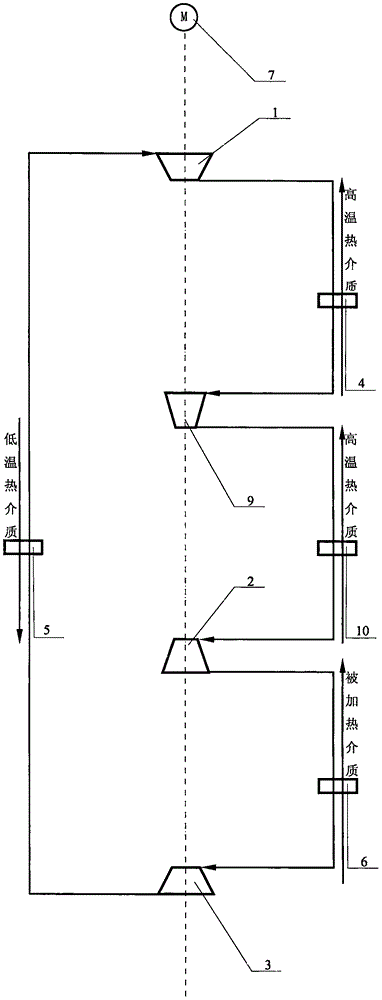

Open type bidirectional thermal cycle and first kind thermal driving compression heat pump

The invention provides an open type bidirectional thermal cycle and first kind thermal driving compression heat pump, and belongs to the power, refrigeration and heat pump technical field; a boost process 12 of a low temperature thermal medium from low temperature, a heat absorption process 23 from a high temperature heat source, a pressure reduction process 34 from high temperature, a heat release process 45 to a middle temperature heat source and a pressure reduction process 56 from middle temperature can form the open type bidirectional thermal cycle; an external heat source medium channel is connected with a compressor; the compressor uses the heat source medium channel to connect with an expander through a high temperature heat exchanger; the expander uses the heat source medium channel to connect with a second expander through a heater; the second expander uses the heat source medium channel to connect with the outer side; the high temperature heat exchanger is connected with the outer side through a high temperature thermal medium channel; the heater is connected with the outer side through a heated medium channel; the expander and the second expander are connected with the compressor so as to transfer power, thus forming the first kind thermal driving compression heat pump.

Owner:李华玉

Pump-driven two-phase circuit device for heat dissipation of high heat flux electronic device

ActiveCN107454797AMeet job needsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsHeat fluxEvaporation

The invention provides a pump-driven two-phase circuit device for heat dissipation of a high heat flux electronic device. Heat is collected and transported by using an endothermic process in evaporation and an exothermic process in condensation during a circulation flow process of a working medium. An evaporator for the circuit device comprises micro-channels and fins. In an area of high heat flux, the micro-channels are used to dissipate heat and increase a heat transfer coefficient of a partial area, while in an area of low heat flux, the fins are used. Due to great area difference between the micro-channel area and the fin area in the evaporator, when the working medium in the micro-channels enters the fin area, volume quickly expands and temperature of the working medium reduces, so as to help heat dissipation of the device in the fin area. By using different structures and with little resources, heat dissipation problems of devices with different powers are solved. The pump-driven two-phase circuit device for heat dissipation of the high heat flux electronic device can adapt to heat dissipation of electronic devices with different heat flux densities and can satisfy working requirements of electronic devices with a heat flux density of 50 W / cm<2> or above.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Composite phase-change heat-storage heating method and heating apparatus

InactiveCN1731028AImprove heat storage capacityReduce volumeCentral heating with accumulated heatLighting and heating apparatusElectricityPhase change

The new composite phase changing heat accumulating heating technology includes adding heat accumulating pipe and heat accumulating capsule into traditional electric heating set and filling heat medium in the gaps. The heat accumulating medium takes phase change while being heated and cooled to form one latent heat accumulating process. The heat medium acts as the fluid medium for heat transfer between the heated surface and the heat accumulating medium to strengthen the heat transfer inside the heat accumulating medium on one hand, and takes temperature change as one sensible heat process accompanying the heat accumulating and releasing on the other hand. The technology of the present invention can strengthen the heat transfer process inside heat accumulating medium, raise heat accumulating capacity and decrease size of heat accumulating apparatus.

Owner:BEIJING UNIV OF TECH

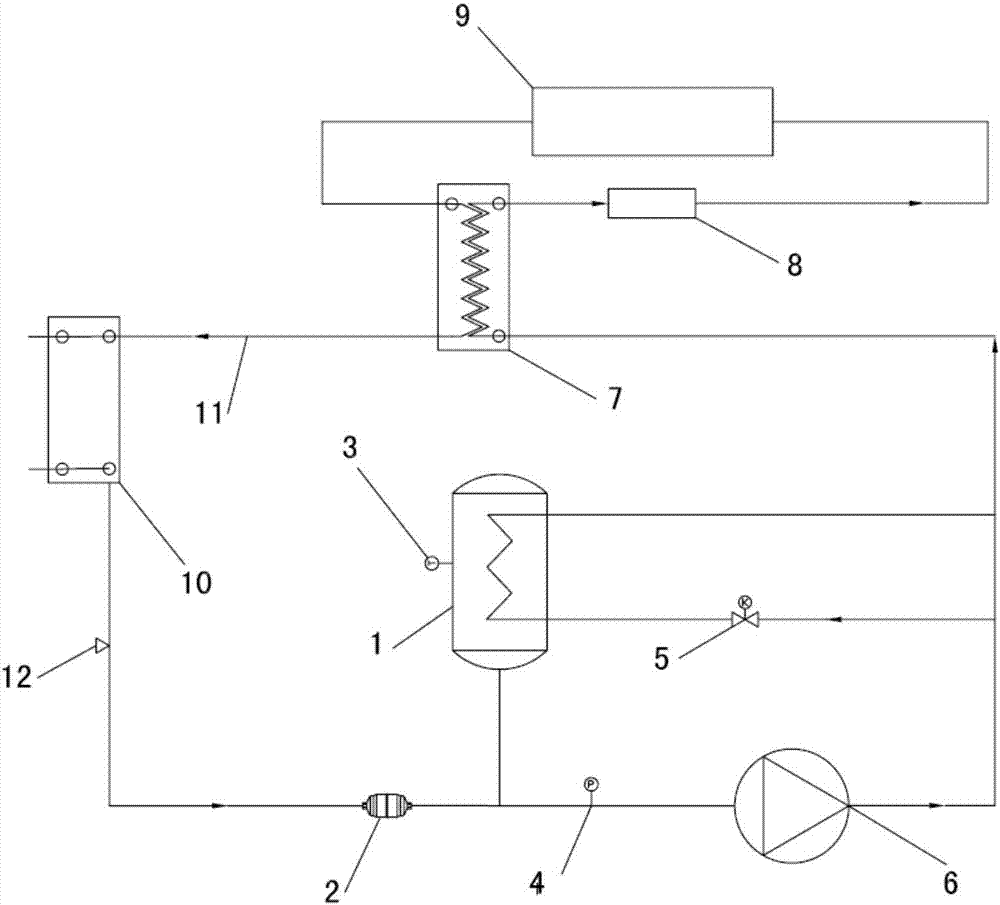

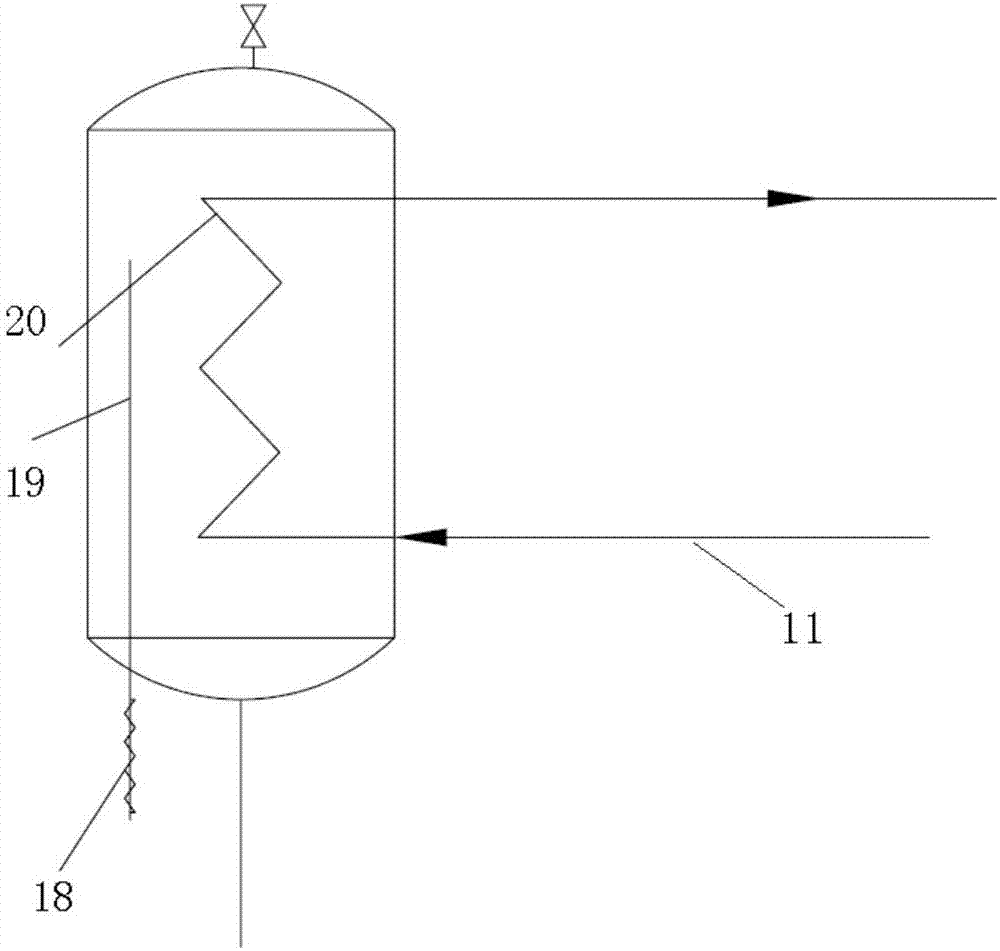

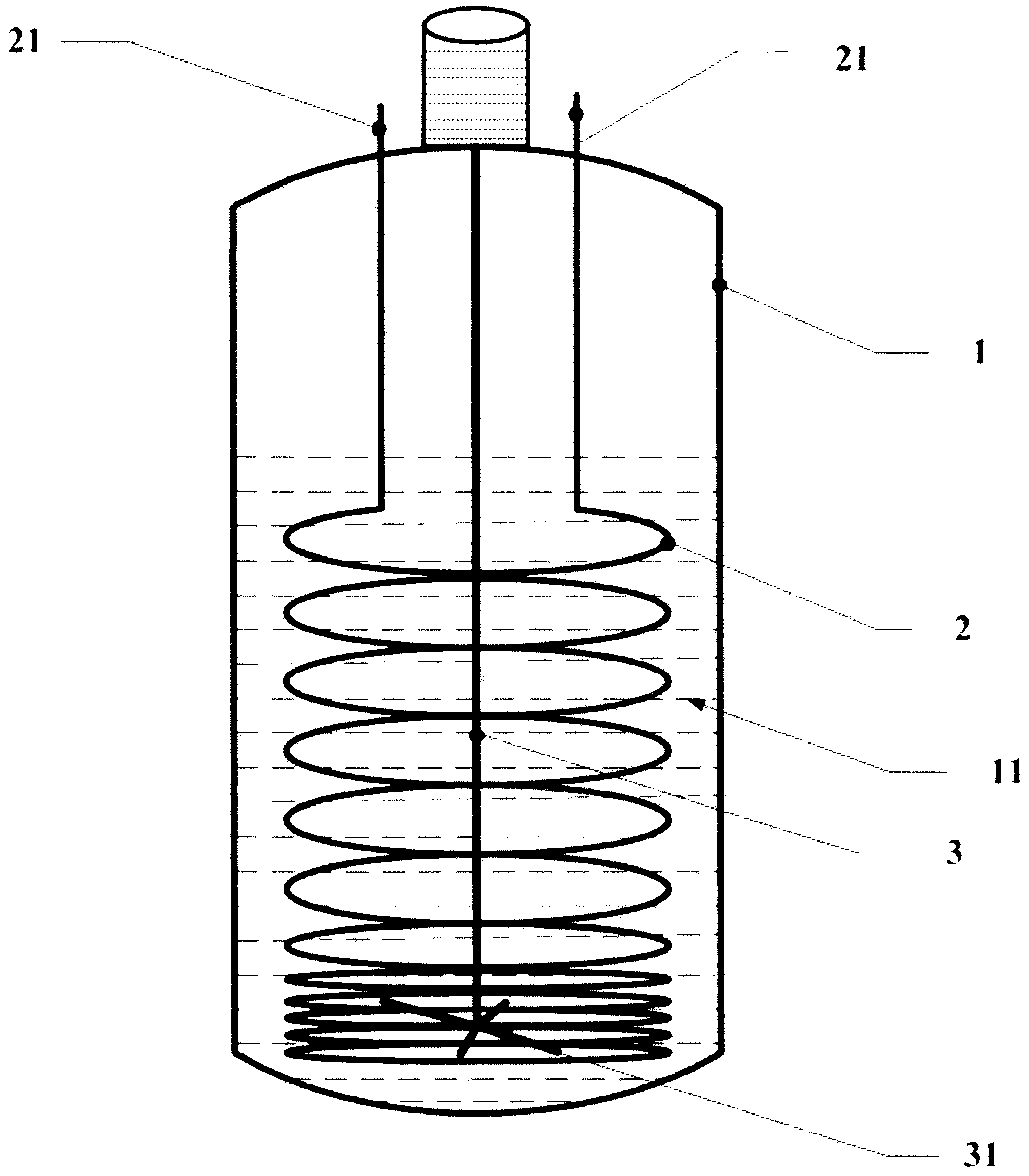

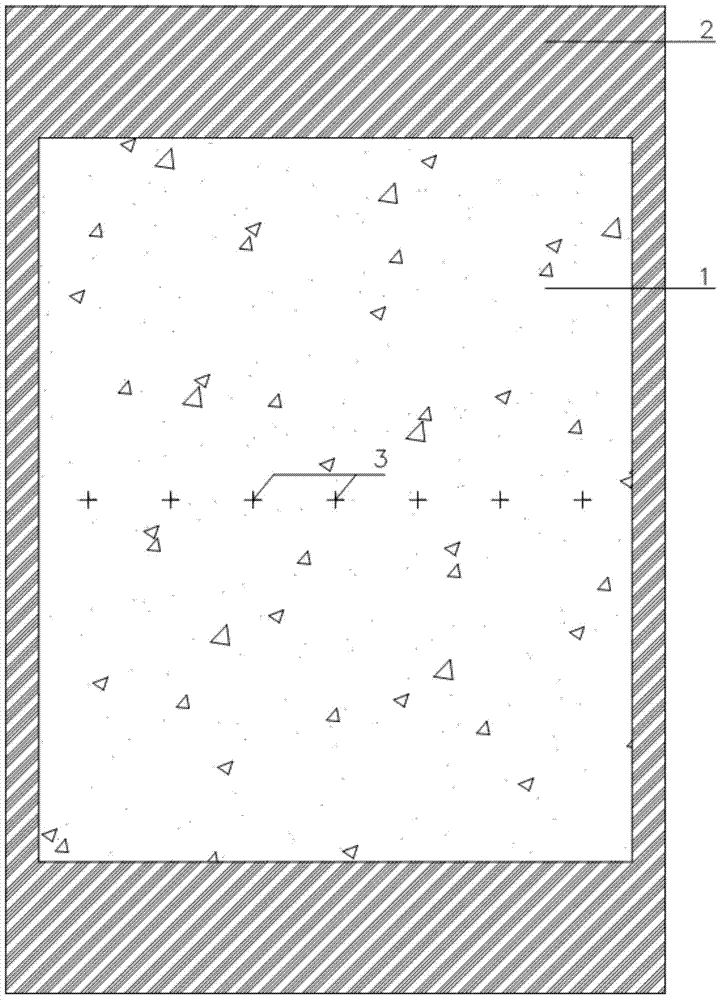

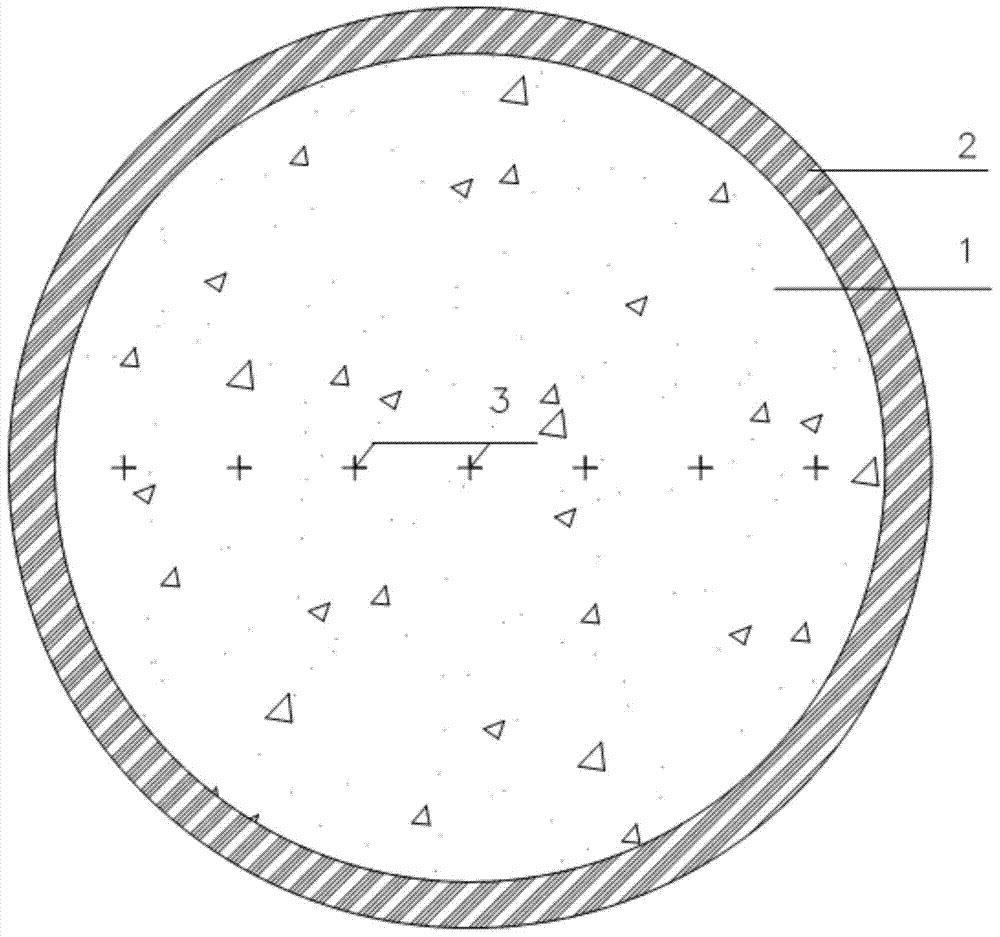

Inorganic phase change heat storage device capable of reducing phase separation

InactiveCN103913087AExtended service lifePrevent subsidenceHeat storage plantsExothermic processHeat storage material

The invention provides an inorganic phase change heat storage device capable of reducing phase separation. The inorganic phase change heat storage device comprises a container (1), an inorganic phase change heat storage material (11), heat exchange tubes (2) and a stirrer (3); the inorganic phase change heat storage device is so structured that the heat exchange tubes (2) and the stirrer (3) are mounted in the container (1), the stirrer (3) is arranged between the heat exchange tubes (2), and the rest space part of the container (1) is filled with the inorganic phase change heat storage material (11). The phase separation generated by the inorganic phase change heat storage material (11) in the repeated heat storage and release process by virtue of stirring of the stirrer (3), and the service life of the heat storage device is prolonged; meanwhile, heat exchange can be strengthened and the heat release speed can be increased.

Owner:杨春花

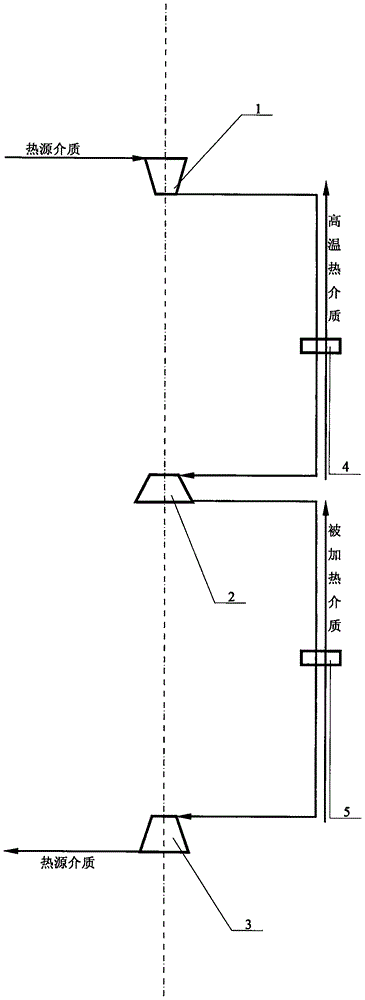

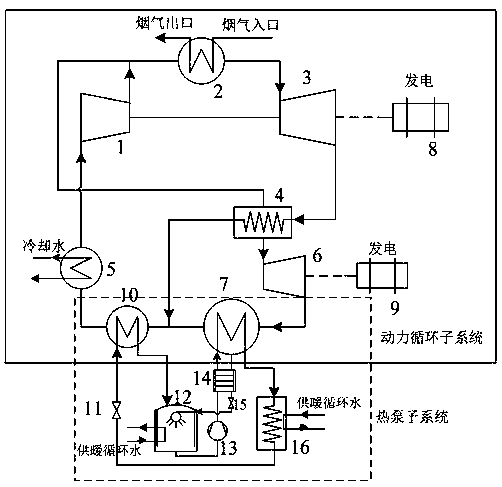

Transcritical carbon dioxide power cycle and absorption heat pump combined heat and power cogeneration system for high temperature flue gas waste heat recovery

ActiveCN108775266AImprove heat transfer matchingImprove utilization efficiencySteam engine plantsTranscritical cyclePower cycle

The invention discloses a CO2 power cycle and absorption heat pump combined heat and power cogeneration system for high temperature flue gas waste heat recovery. The CO2 power cycle and absorption heat pump combined heat and power cogeneration system realizes combined heat and power cogeneration by integrating high and low temperature power cycle and absorption heat pump cycle. The power cycle uses CO2 as the working medium, the endothermic process is located at the supercritical pressure, the exothermic process to a cold source is located at the subcritical pressure, and a transcritical cycleform is achieved. The high-temperature power cycle uses high-temperature flue gas as a heat source, and the low-temperature power cycle absorbs heat from dead steam of the high-temperature power cycle. An absorption heat pump system uses low-temperature power cycle high-temperature dead steam as a driving heat source and a low-temperature dead steam as a low temperature heat source, the waste heat resources are fully used as far as possible, and the COP of the absorption heat pump cycle is increased. The CO2 power cycle and absorption heat pump combined heat and power cogeneration system improves the heat exchange matching between the circulation and the variable temperature heat source, effectively utilizes the recycled dead steam heat, realizes the cascade utilization of different tasteresidual heat energy, and improves the overall energy utilization efficiency of the system.

Owner:山西山安蓝天节能科技股份有限公司

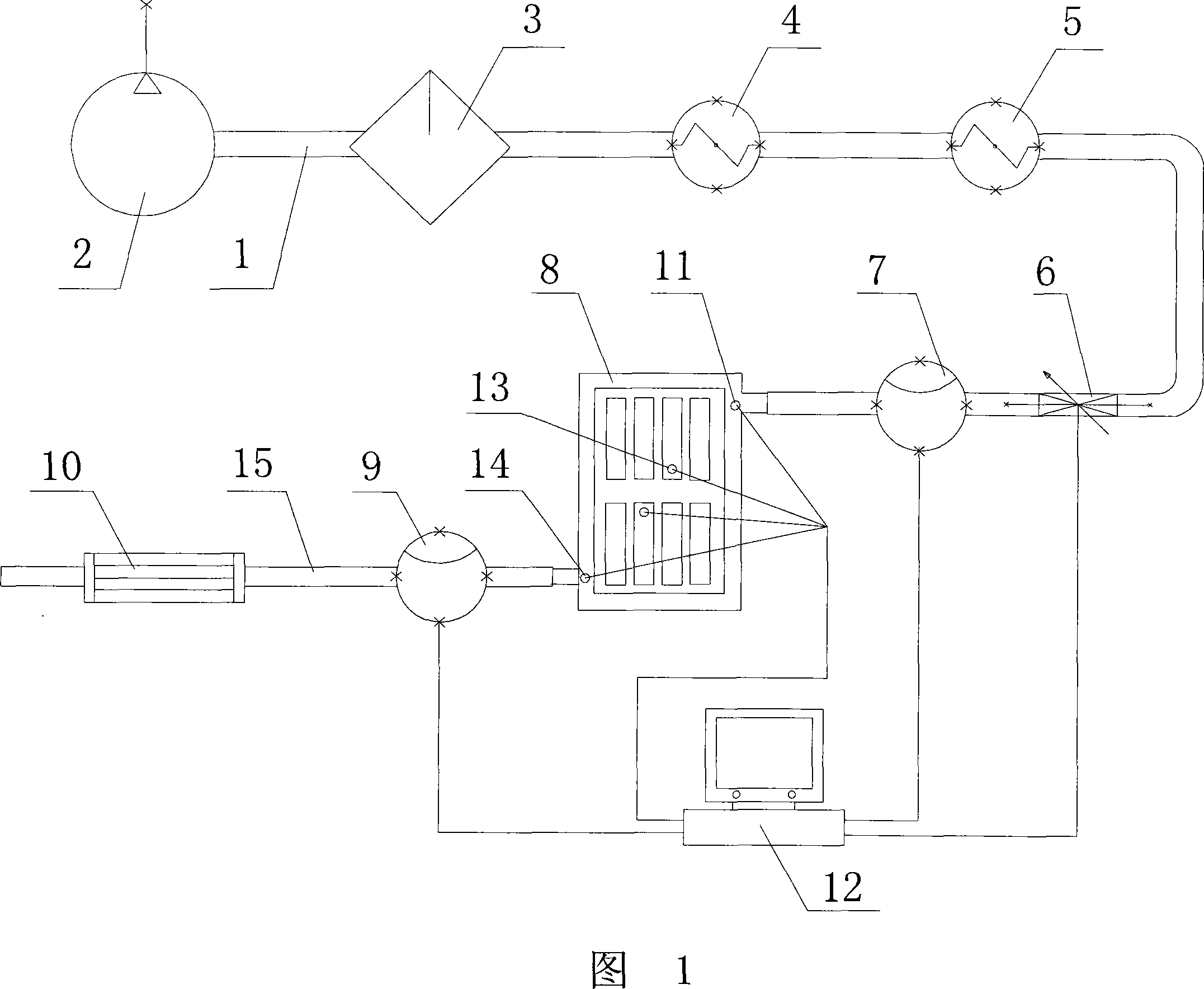

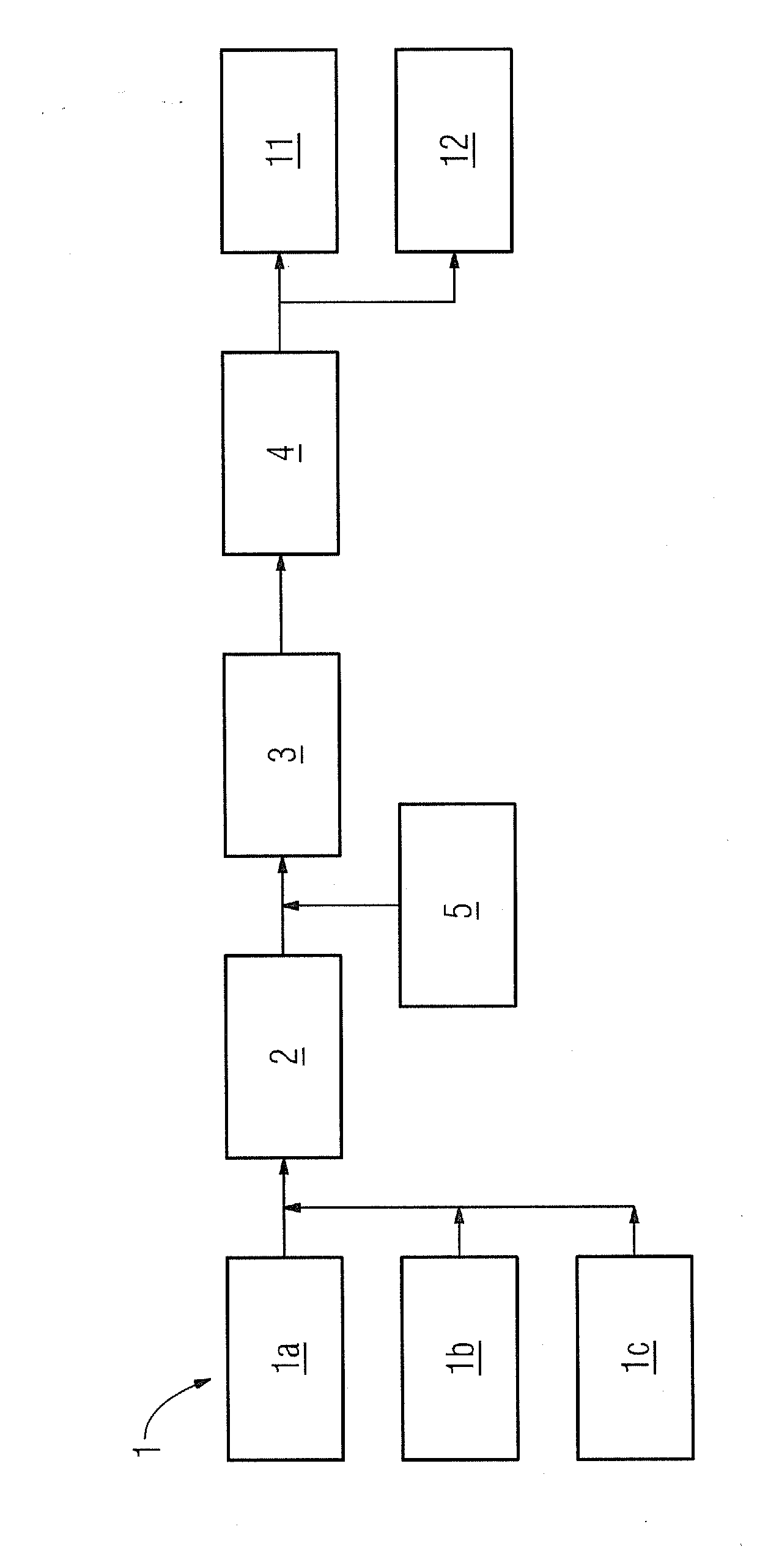

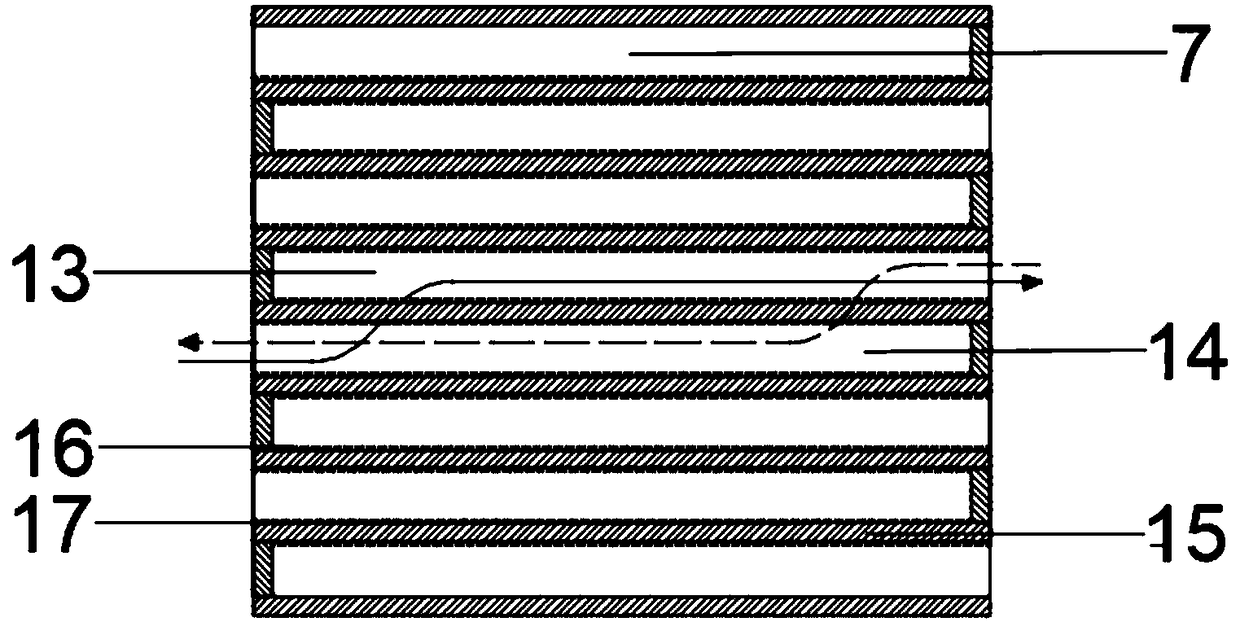

Apparatus for testing and evaluating heat-filling and heat-discharging process of thermal storage device

The invention relates to a device for detecting and evaluating the performance index in the processes of heat charge and heat release of a heat capacitor in the solar thermal power generation. The device for detecting and evaluating the processes of the heat charge and heat release of the heat capacitor is characterized in that the device comprises a first conduit (1), an air compressor (2), an air-drying filter (3), an air preheater (4), an air heater (5), an electrical control flow adjusting valve (6), a first flow indicator (7), a second flow indicator (9), a first temperature pressure sensor (11), a computer (12), a second temperature pressure sensor (13), a third temperature pressure sensor (14) and a second conduit (15), wherein, the first conduit (1) is provided with the air-drying filter (3), the air preheater (4), the air heater (5), the electrical control flow adjusting valve (6) and the first flow indicator (7) in sequence; the second conduit (15) is provided with the second flow indicator (9). The device has simple structure and easy operation and can detect and evaluate the index of the heat accumulation efficiency, the security and the durability in the processes of heat charge and heat release of the heat capacitor.

Owner:WUHAN UNIV OF TECH

Open type two-way thermal circulation and second-class thermal driving compression heat pump

The invention provides open type two-way thermal circulation and a second-class thermal driving compression heat pump, and belongs to the technical field of heat energy utilization and heat pumps. A pressure reducing process 12 from high temperature of a heated medium, a heat source heat sucking process 23 from medium temperature, a pressure reducing process 34 from medium temperature, a heat releasing process 45 to a low-temperature heat source and a pressure increasing process 56 from low temperature form the open type two-way thermal circulation; the external communicates with an expander by a heated medium channel; the expander also communicates with a second expander through a heated medium channel by a heat exchanger; the second expander communicates with a compressor through a heated medium channel by a cooler; the compressor communicates with the external through a heated medium channel; the heat exchanger communicates with the external through a medium-temperature heat medium channel; the cooler communicates with the external through a cooling medium channel; and the expander and the second expander are connected with the compressor for transmitting power to form the second-class thermal driving compression heat pump.

Owner:李华玉

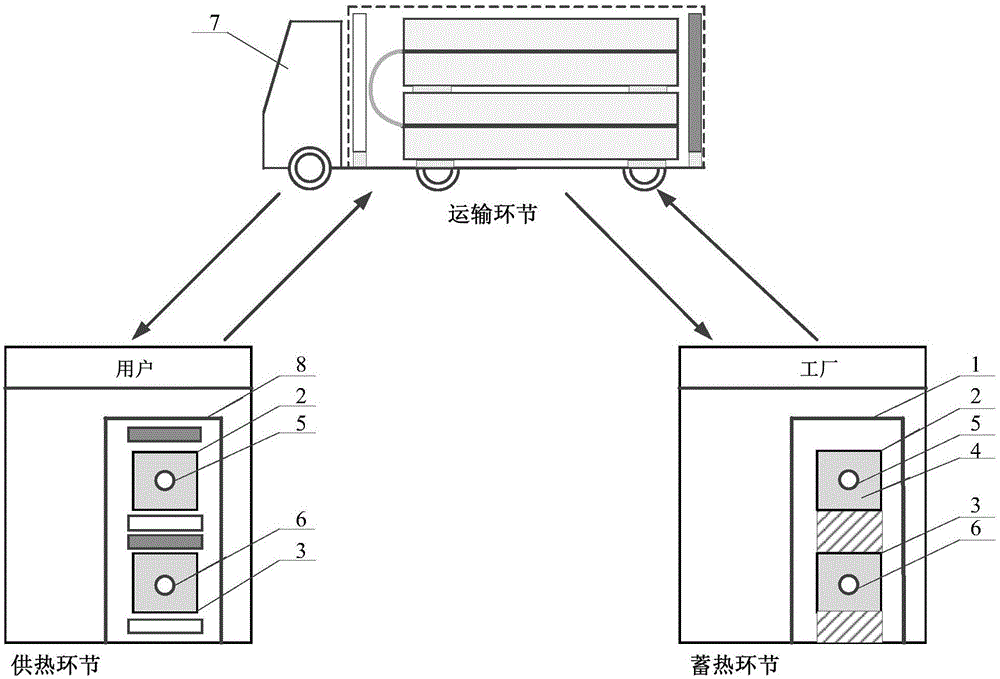

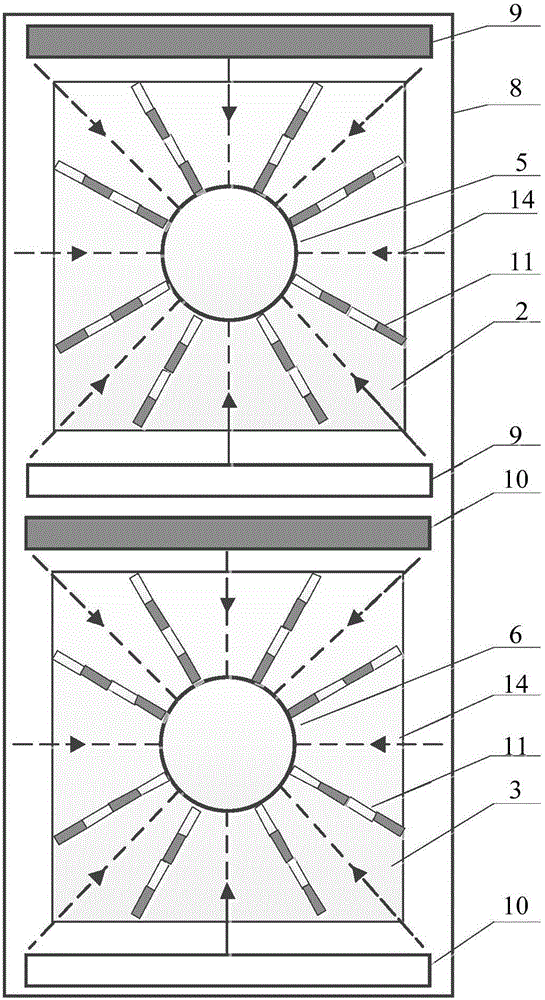

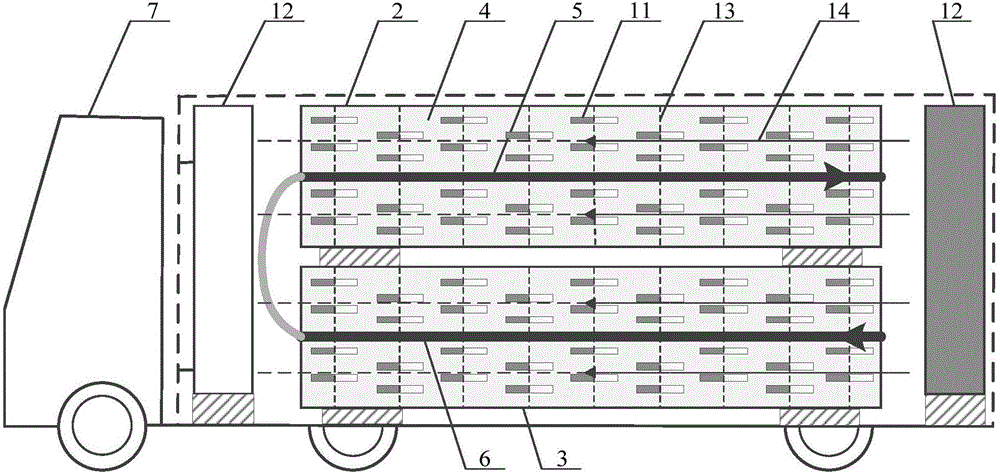

Magnetic particle based directional adjusting system for mobile heat supplying and staged heat transferring performances and method thereof

ActiveCN106839848AShorten heat transfer timeIncrease heating timesHeat storage plantsHeat conductingExothermic process

The invention discloses a magnetic particle based directional adjusting system for mobile heat supplying and staged heat transferring performances and a method thereof. The system is applied to the field of mobile heat supplying. The system comprises a heat storing room, a heat supplying room, a conveying device, heat storing chambers, magnetic particles, positioning wires and a radial / axial magnetic field generating device. According to the system, a heavy-duty device, the heat storing chambers and heat exchanging pipelines are used for continuously absorbing industrial waste heat from the heat storing chamber and conveyed to heat releasing chambers to release and supply heat to a user, thus achieving trans-time-and-space utilization of industrial waste heat as well as achieving energy conservation and emission reduction; the radial magnetic field generating device and the magnetic particles are utilized to form a radial heat conducting channel to improve the phase change heat transfer in the heat absorbing / releasing process, so that the heat exchange time can be saved, and the heat supplying frequency each day can be improved, and as a result, the payback period can be reduced, and the cost can be decreased; the heat conducting channel can be cut off through the axial magnetic field generating device, thus the heat loss in the conveying process can be decreased, the effective heat supplying quantity can be improved, and as a result, the cost is further decreased.

Owner:ZHEJIANG UNIV

Multiple stage combustion process to maintain a controllable reformation temperature profile

InactiveUS7081312B1Uniform exchangeGenerate uniformHydrogen separation using solid contactCell electrodesWorking fluidFuel cells

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Open type bidirectional thermal cycle and second kind thermal driving compression heat pump

ActiveCN105910324ACompression machines with non-reversible cycleFluid circulation arrangementThermal energyEngineering

The invention provides an open type bidirectional thermal cycle and second kind thermal driving compression heat pump, and belongs to the heat energy utilization and heat pump technical field; a boost process 12 of a cold source medium from low temperature, a heat release process 23 to a high temperature heat source, a pressure reduction process 34 from high temperature, a heat absorption process 45 from a middle temperature heat source and a pressure reduction process 56 from middle temperature can form open type bidirectional thermal cycle; an external cold source medium channel is connected with a compressor; the compressor uses the cold source medium channel to connect with an expander through a heater; the expander uses the cold source medium channel to connect with a second expander through a heat exchanger; the second expander is connected with the outer side through the cold source medium channel; the heater is connected with the outer side through a heated medium channel; the heat exchanger is connected with the outer side through a middle temperature medium channel; the expander and the second expander are connected with the compressor so as to transfer power, thus forming the second kind thermal driving compression heat pump.

Owner:李华玉

Method for producing a synthetic material, in particular a synthetic fuel or raw material, an associated device and applications for said method

A method and a device of producing a synthetic material are provided. Water (H20) is converted into hydrogen (H2) and oxygen (O2) using a high-temperature electrolysis, water vapor (H20D) being formed during the high-temperature electrolysis. Carbon dioxide (CO2) is added to the hydrogen (H2) and water vapor (H2OD). The mixture of carbon dioxide (CO2), hydrogen (H2) and water vapor (H2OD) is subjected to a catalytic reaction, wherein, through the catalytic reaction, the hydrogen (H2), the water vapor (H2OD) and the carbon dioxide (CO2) are transformed into a synthetic gas (H2 / CO / CO2 / H2O / CH4). Exothermic processes are executed during the transforming into the synthetic gas.

Owner:SIEMENS AG

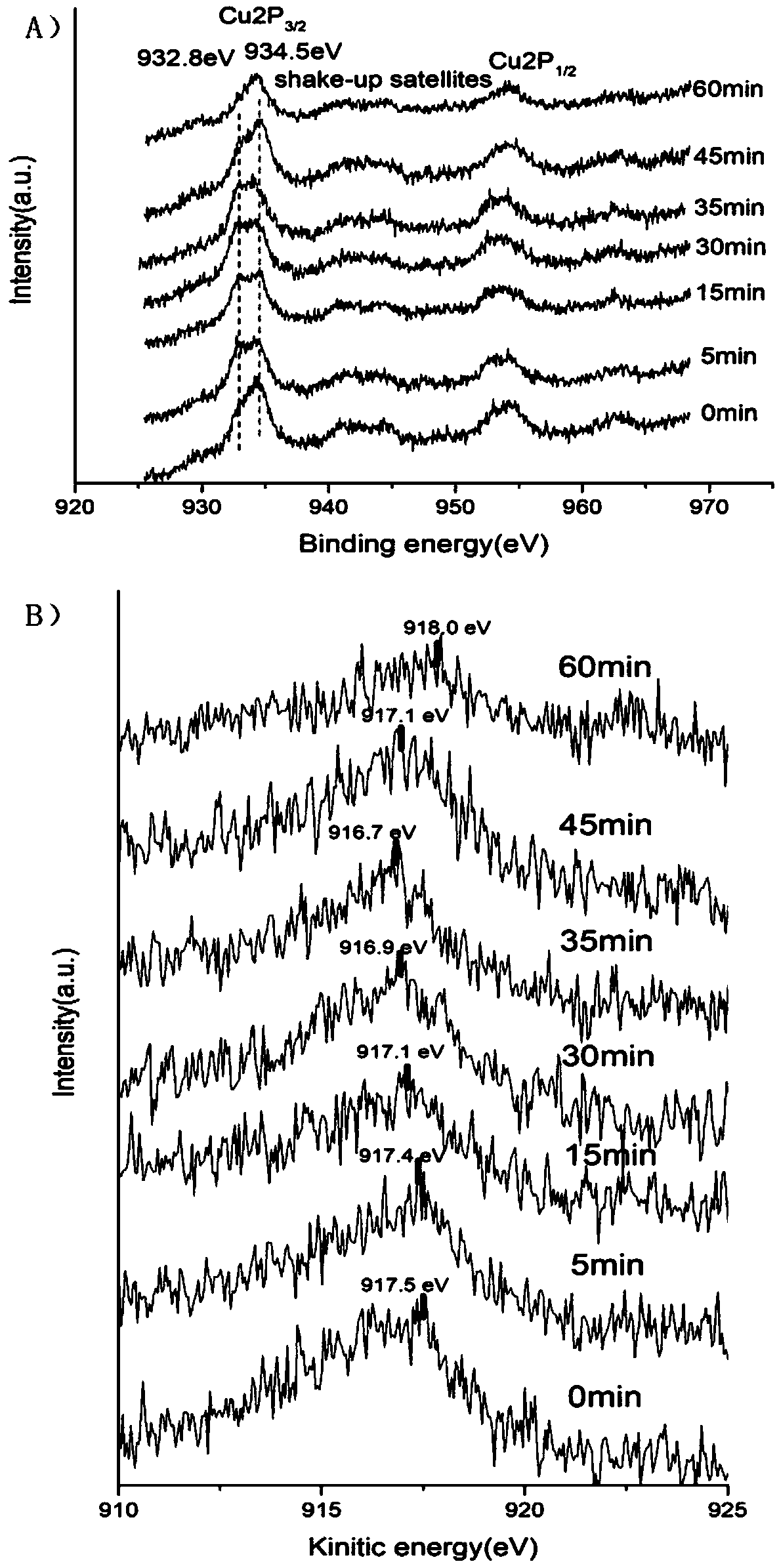

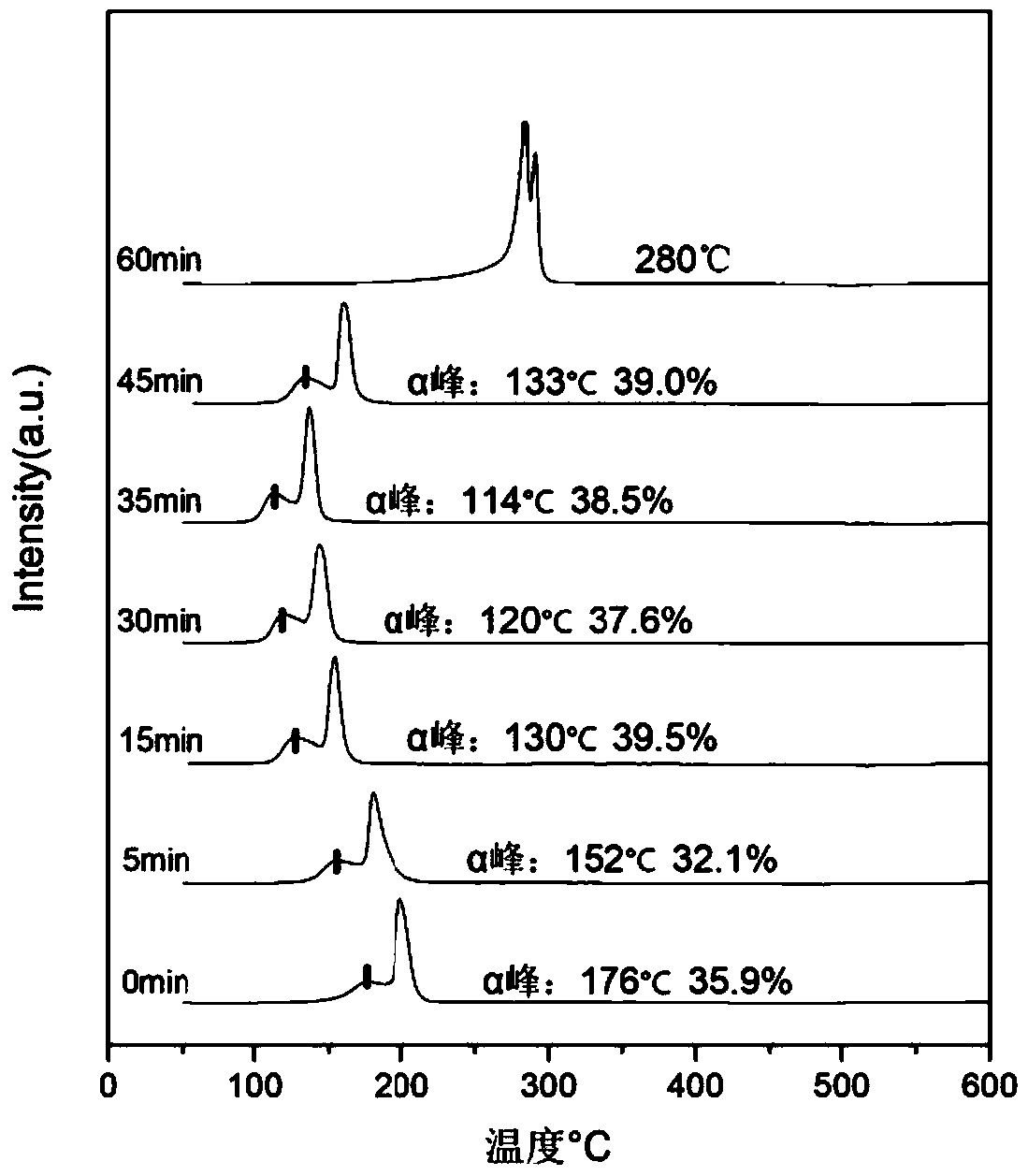

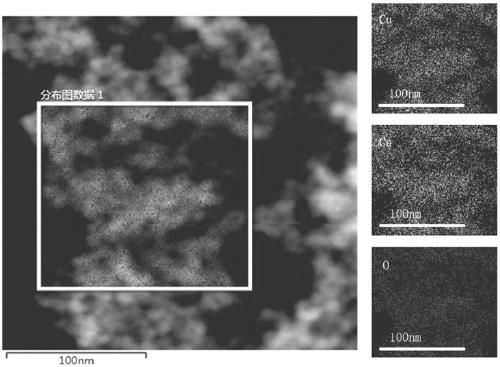

Method for preparing supported copper oxide catalyst by using cerium oxide as carrier

ActiveCN108927163AIncrease satietySimple structureHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsFreeze-dryingCerium(IV) oxide

The invention relates to an ultrasonic assisted method for preparing a supported copper oxide catalyst by using cerium oxide as a carrier. An excess amount of an alkali is added to an aqueous solutionof a copper salt and a cerium salt, and the alkali dissolving process is an exothermic process; the copper salt forms a copper hydroxide precipitate, and is further converted into small copper oxideparticles by using the exothermic process; the cerium salt forms a cerium hydroxide precipitate, and forms cerium oxide having a hole structure in an exothermic environment; the obtained sample is sonicated for a certain period of time to generate local high-temperature and high-pressure "hot spots" in order to promote the copper oxide enter holes of the cerium oxide and form mixed oxides; and centrifugal washing, freeze drying and high temperature calcination are carried out to obtain the final catalyst. The close combination and interaction between copper oxide and the cerium oxide carrier and partial unsaturated coordination of the copper oxide part make defective copper oxide having good redox ability formed, so the complete oxidation of carbon monoxide under hydrogen-rich conditions at a low temperature in a wide window range by the catalyst is achieved.

Owner:ZHEJIANG UNIV

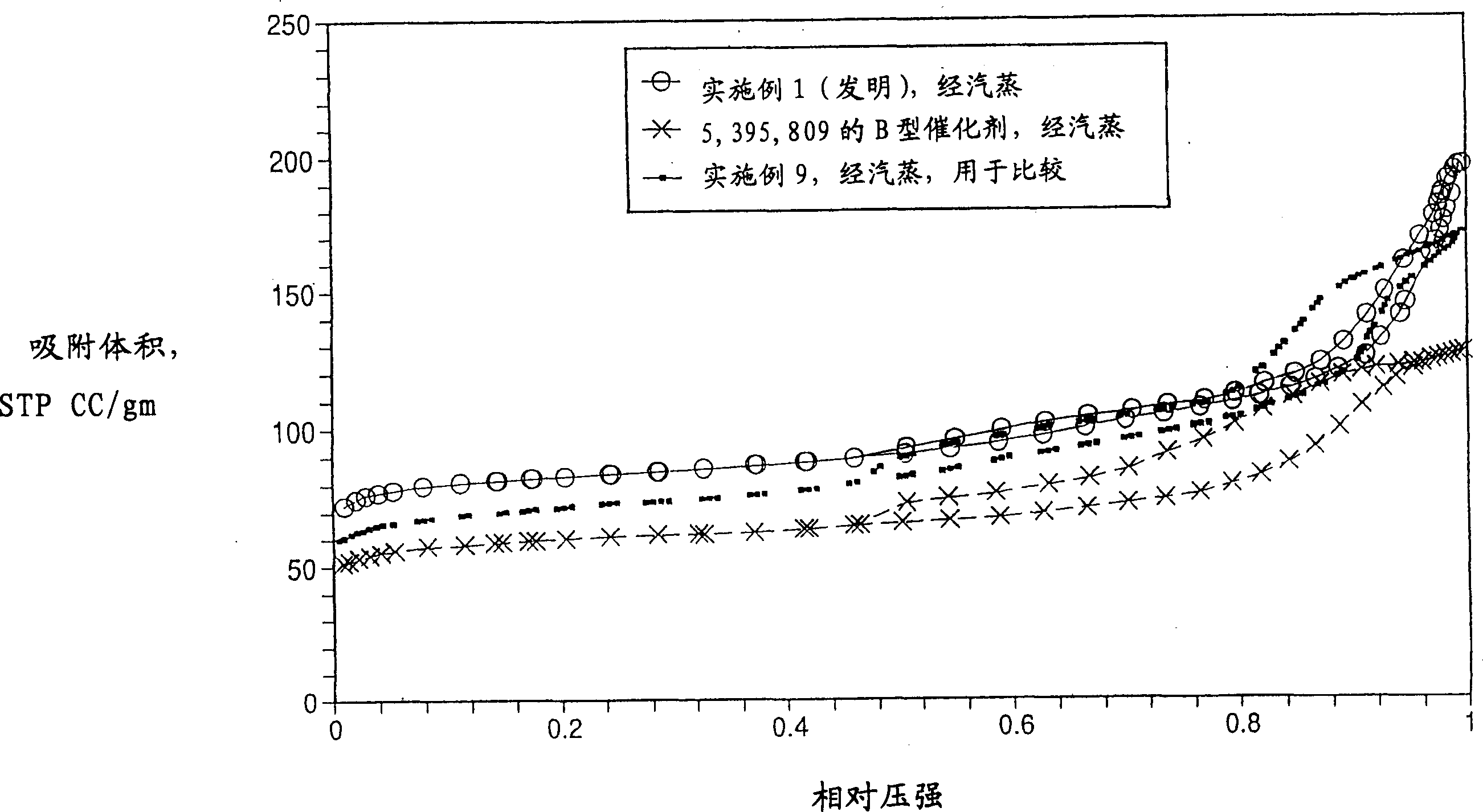

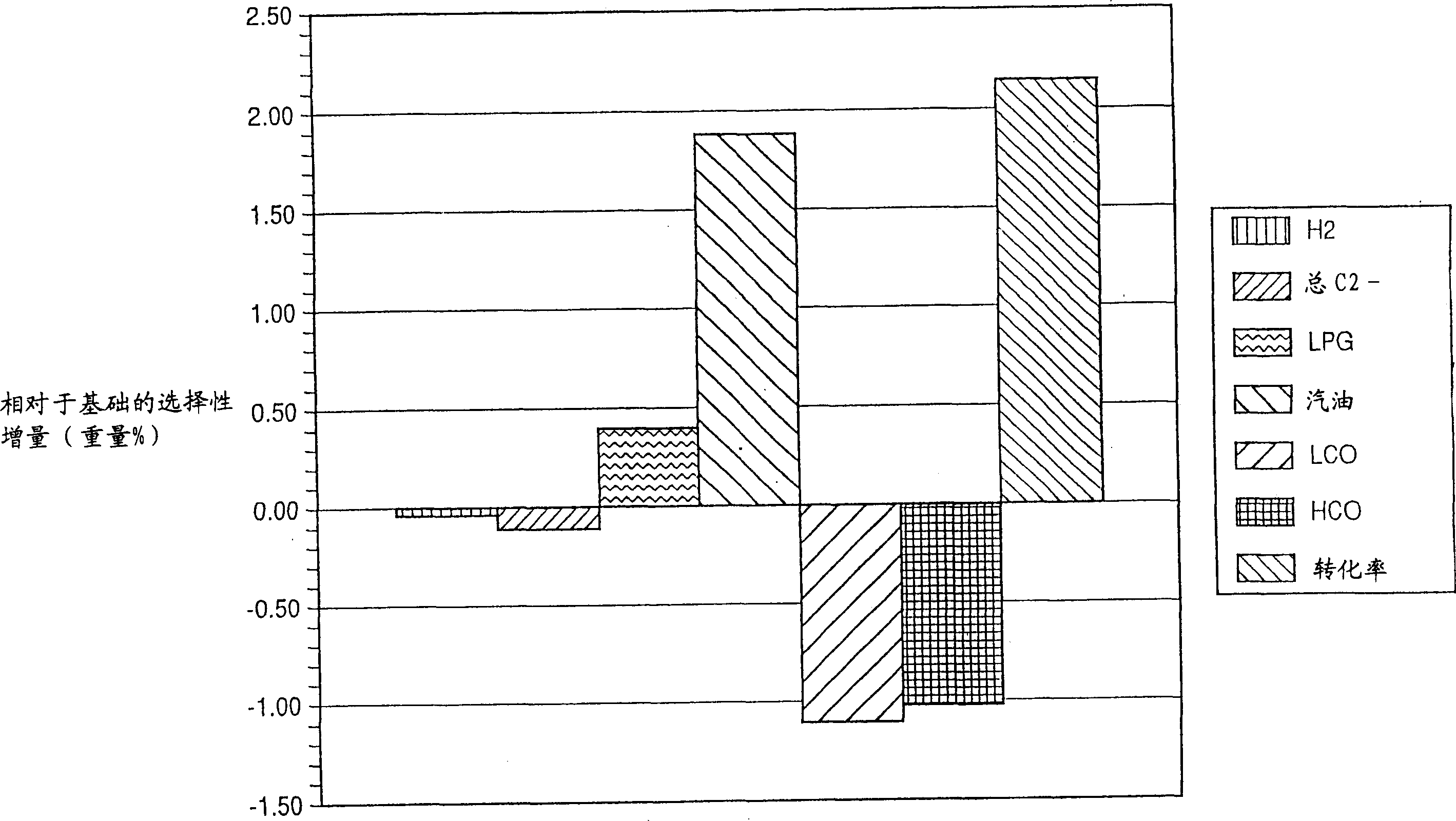

Structurally enhanced cracking catalysts

A zeolite microsphere FCC catalyst with a novel morphology comprising a macroporous porous matrix and a free coating of crystalline zeolite on the matrix pore walls. The catalyst is formed from microspheres comprising metakaolin and kaolin calcined to undergo its exothermic process, wherein the kaolin calcined to undergo its exothermic process is made from kaolin having a high pore volume. The kaolin with high pore volume may be ground fine kaolin or ground kaolin with an initial slurry point of less than 57% solids.

Owner:ENGELHARD CORP

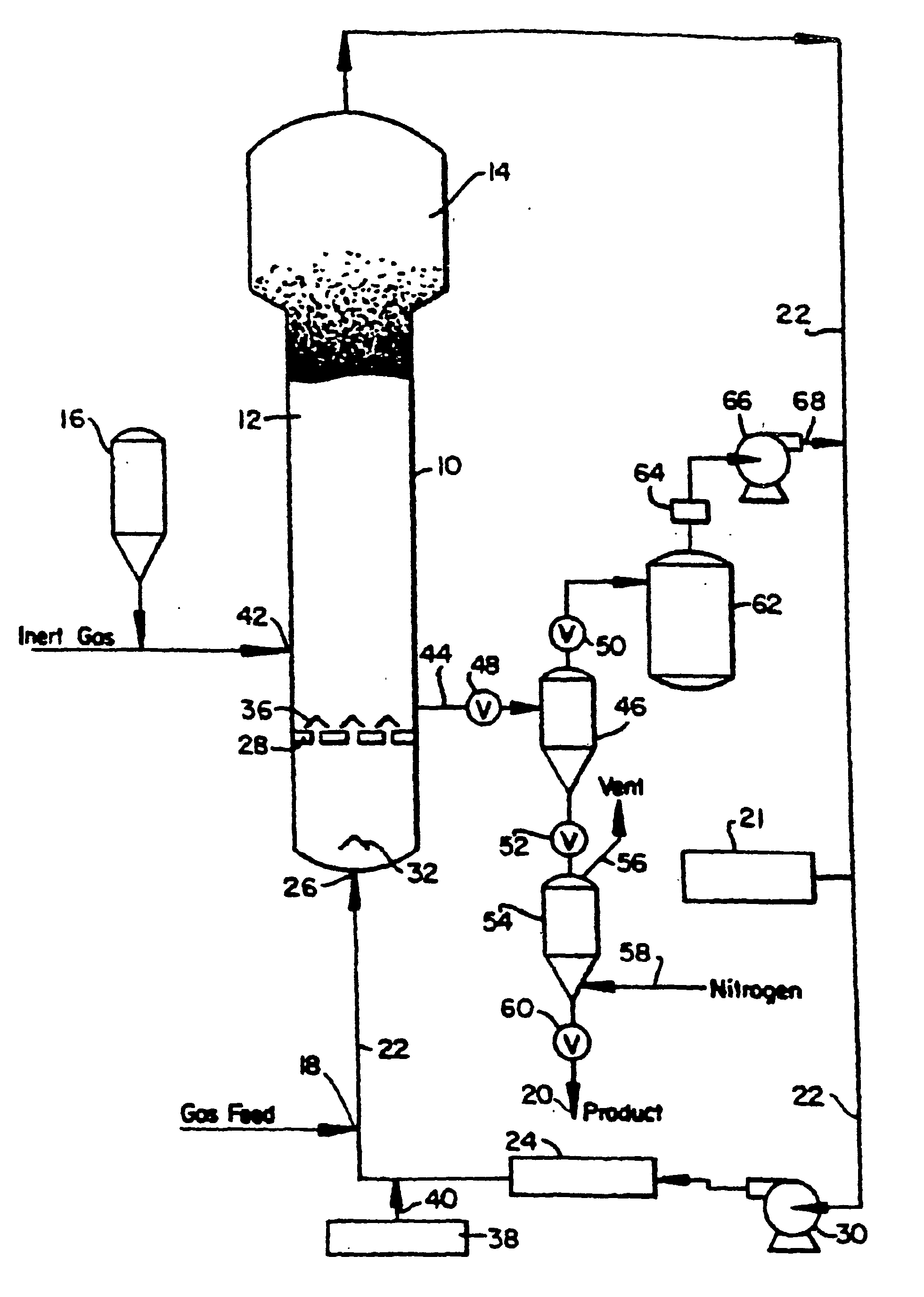

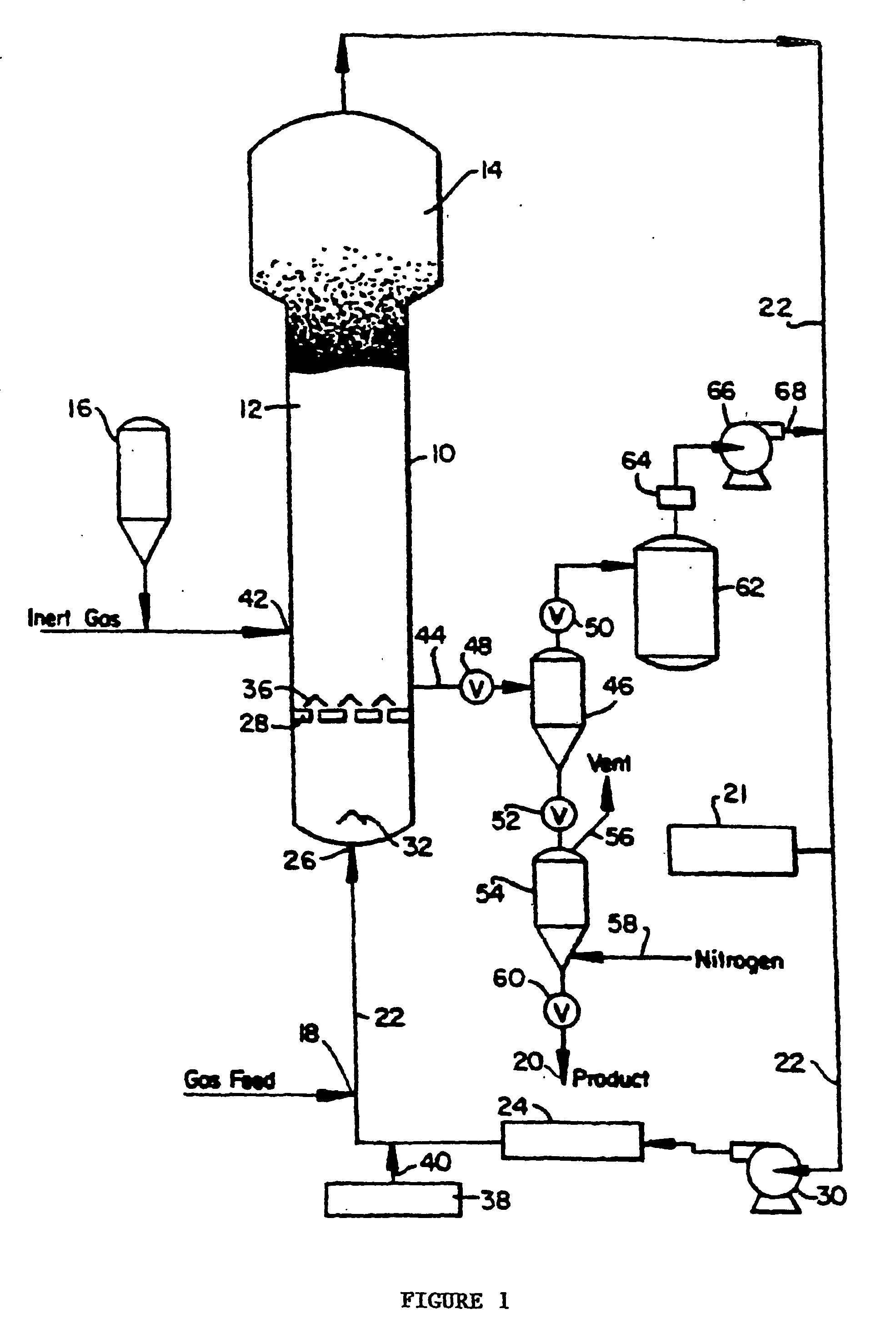

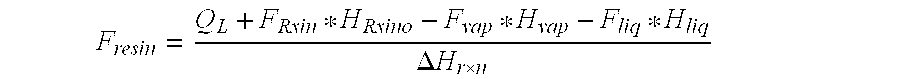

Gas phase polymerization and method of controlling same

A process for controlling a continuous gas phase exothermic process in a reactor comprising: (i) effecting a gas phase exothermic reaction under a set of operating conditions in the presence of a cooling agent, the cooling agent having a pre-selected concentration and feed rate of an induced cooling agent; (ii) determining a maximum production rate (I) without regard to limitations due to the cooling agent under the operating conditions; (iii) determining a maximum production rate (II) with regard to limitations due to the cooling agent under the operating conditions; (iv) calculating an optimal concentration of the induced cooling agent such that the difference between (I) and (II) is minimized; and (v) adjusting the feed rate of the induced cooling agent to achieve the concentration value calculated in (iv).

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

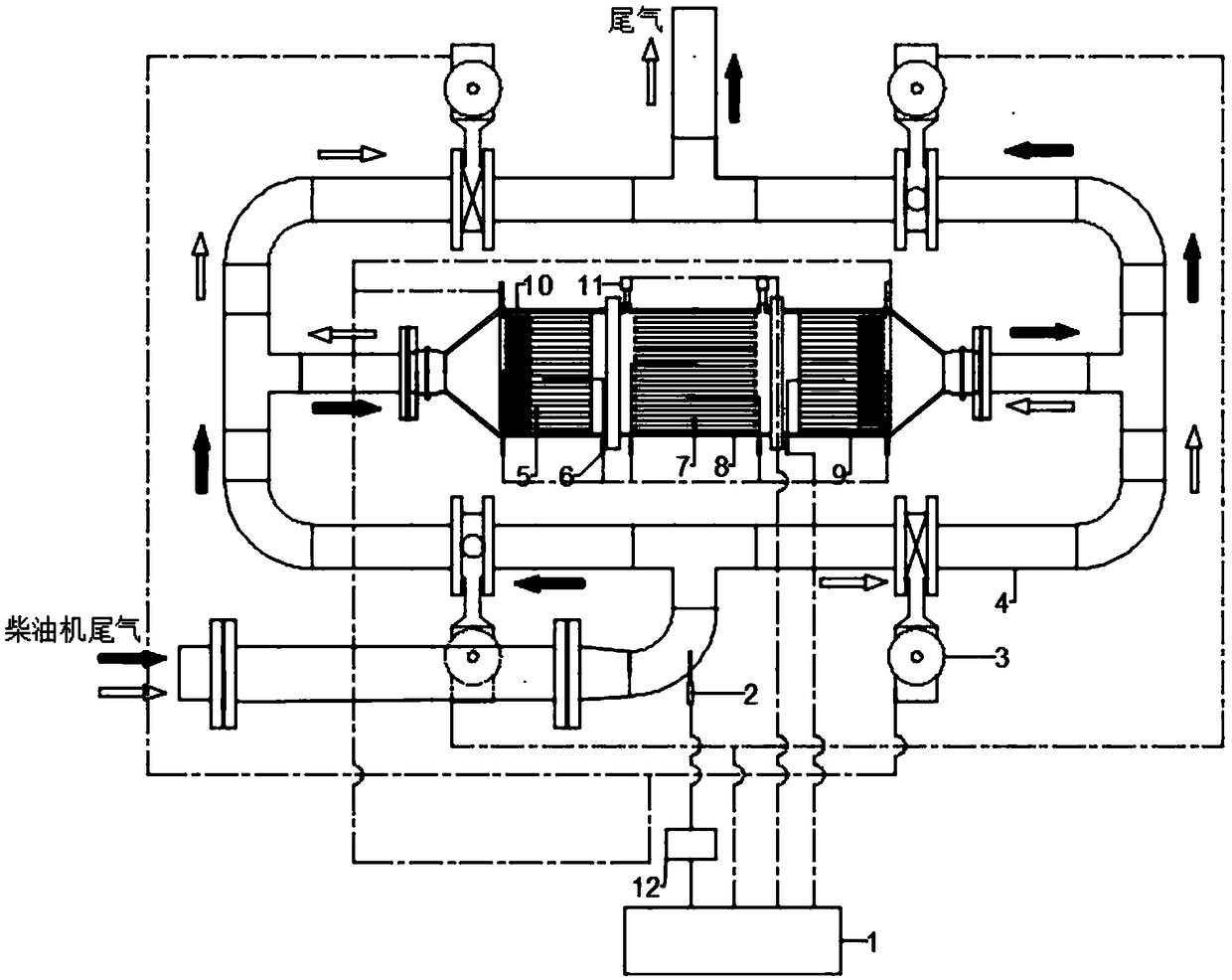

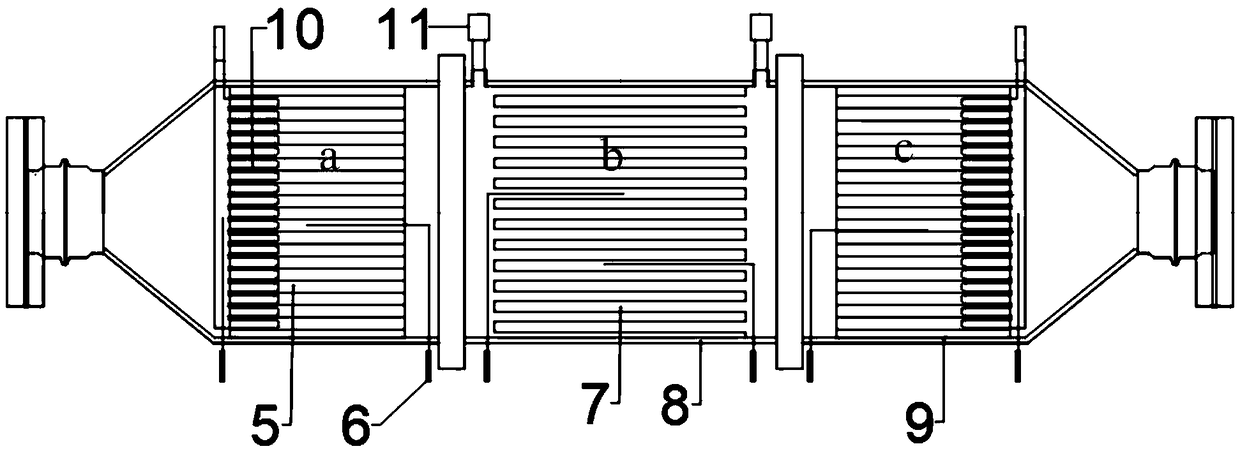

Diesel engine pollutant treatment system and method

PendingCN109356690AGood removal effectExhaust apparatusSilencing apparatusParticulatesChemical reaction

The invention belongs to the technical field of diesel engine particulate matter emission control post-treatment and particularly relates to a diesel engine pollutant treatment system and method. According to the diesel engine pollutant treatment system, periodic reversing pipeline connection DOC+CDPF+DOC is adopted, by means of control of a control system, the treatment system capable of performing periodic reversing is formed, the system makes own filter bodies and honeycomb ceramic carriers inside the DOC+CDPF+DOC perform self-sustaining heat storage and exothermic processes utilizing chemical reactions generated by organic pollutants in tail gases or replenishing trace amount of atomized fuel oil, and trace amount of atomized oil droplet is controlled to be sprayed into a pipeline, thetemperature inside the DOC+CDPF+DOC system is maintained between 500-650 DEG C, chemical reaction residue, incombustible inorganic salt and other ashes accumulated on a wall flow type passage are removed utilizing reverse flowing, particle catcher DPF continuous regeneration can be realized, and meanwhile, particulate matter, CO, HC and soluble organic matter SOF can be disposed.

Owner:DALIAN MARITIME UNIVERSITY

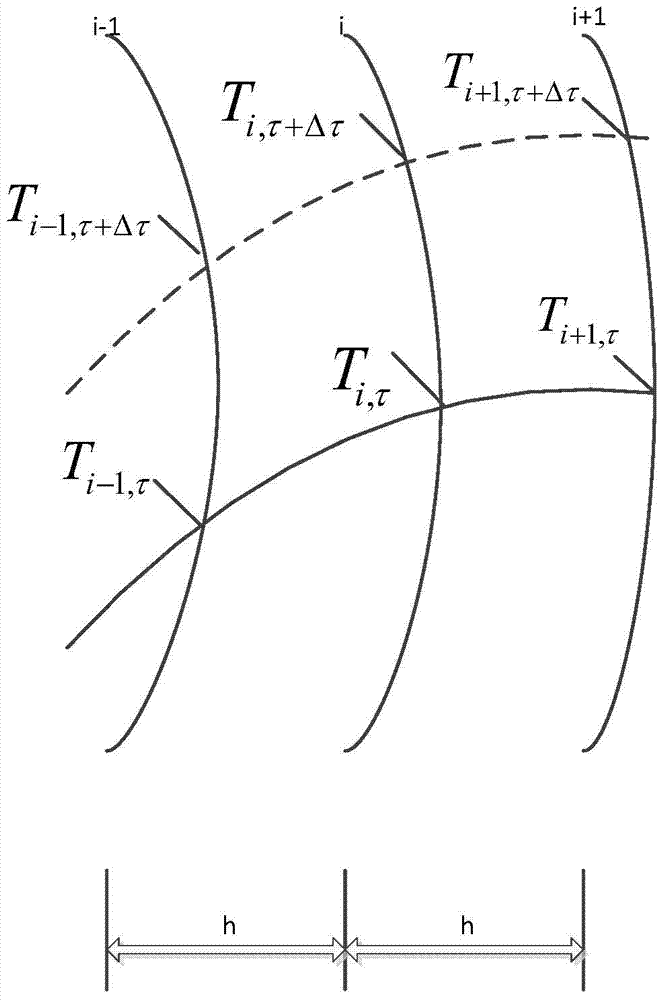

Method for inverting adiabatic temperature rise of concrete

InactiveCN103926271AReflect exothermic processSimple formulaMaterial heat developmentExothermic processEngineering

A method for obtaining adiabatic temperature rise of concrete relates to method for measuring and acquiring temperature by the use of temperature sensors and a temperature acquisition module and inverting adiabatic temperature rise by measured temperature calculation. By arranging temperature sensors along the radial direction at different positions on the same section of concrete, temperatures of concrete at different measuring points and at different times are measured; a temperature field is calculated through difference; and inversion of adiabatic temperature rise is optimized by the utilization of measured temperature and calculated temperature. Instead of getting down to reducing heat radiation of concrete, temperature of concrete during the process of heat radiation is measured to invert adiabatic temperature rise. Through data analysis, it proves that a later exothermic process of concrete can be well reflected.

Owner:TSINGHUA UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com