Patents

Literature

73results about How to "Shorten heat transfer time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

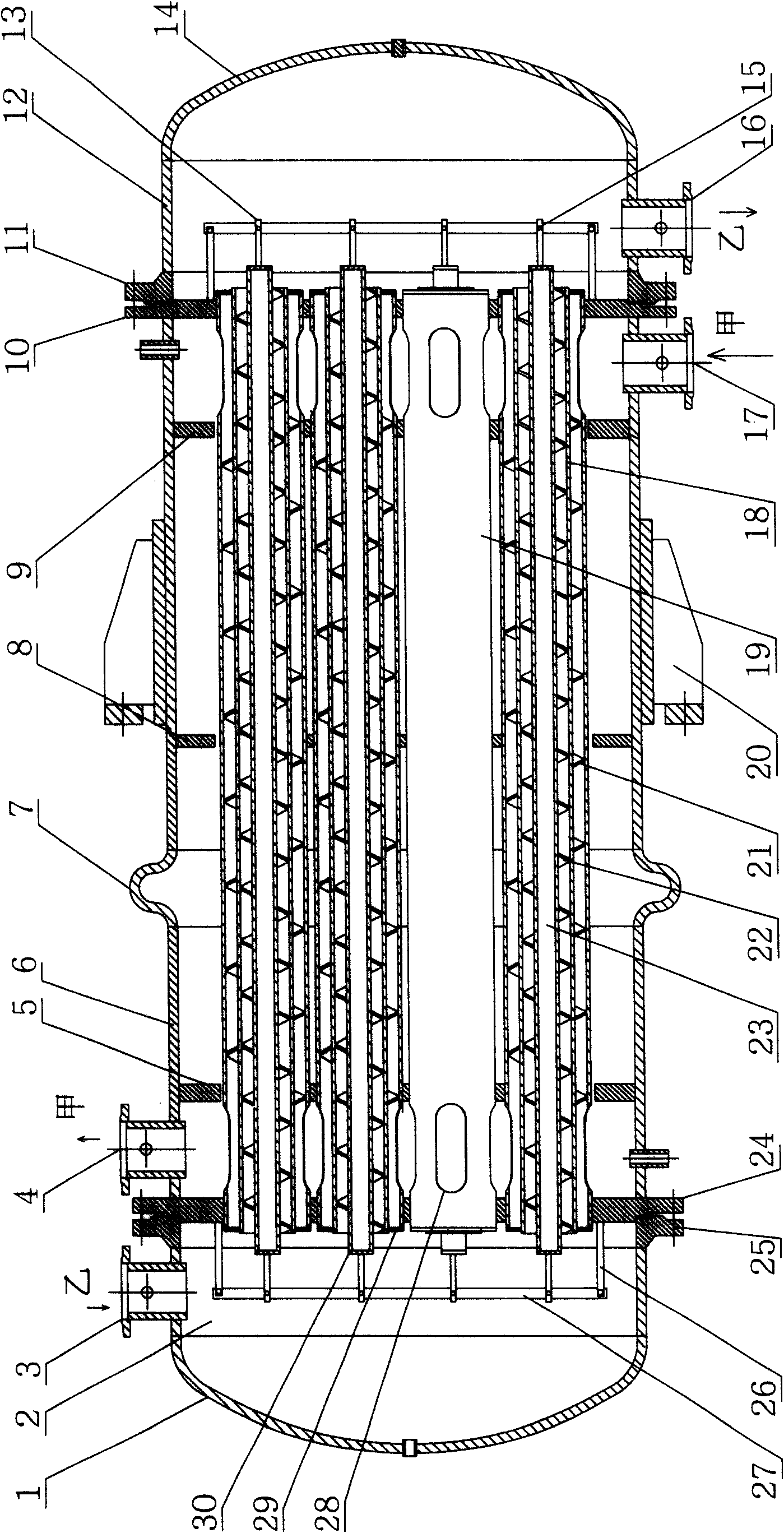

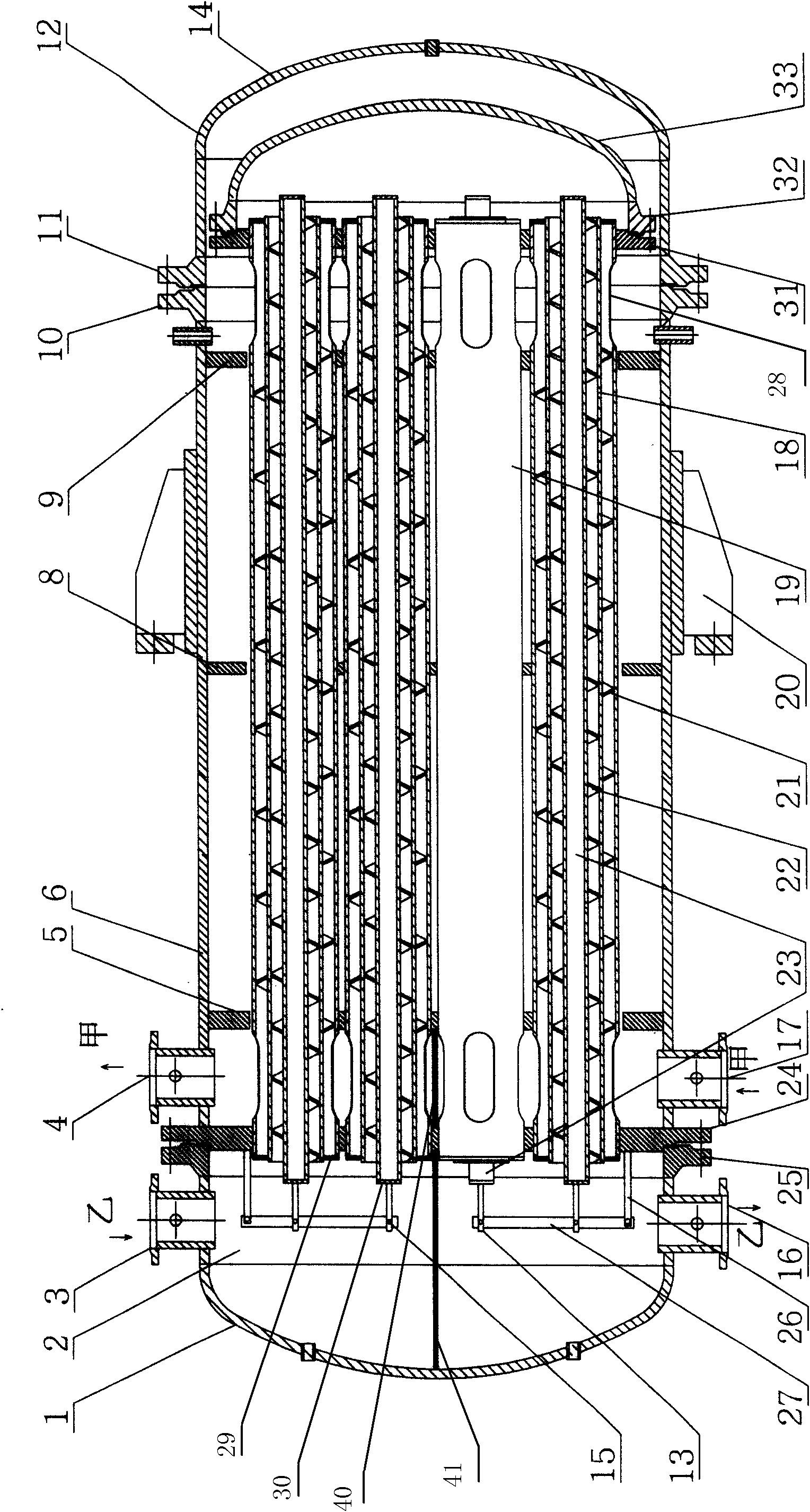

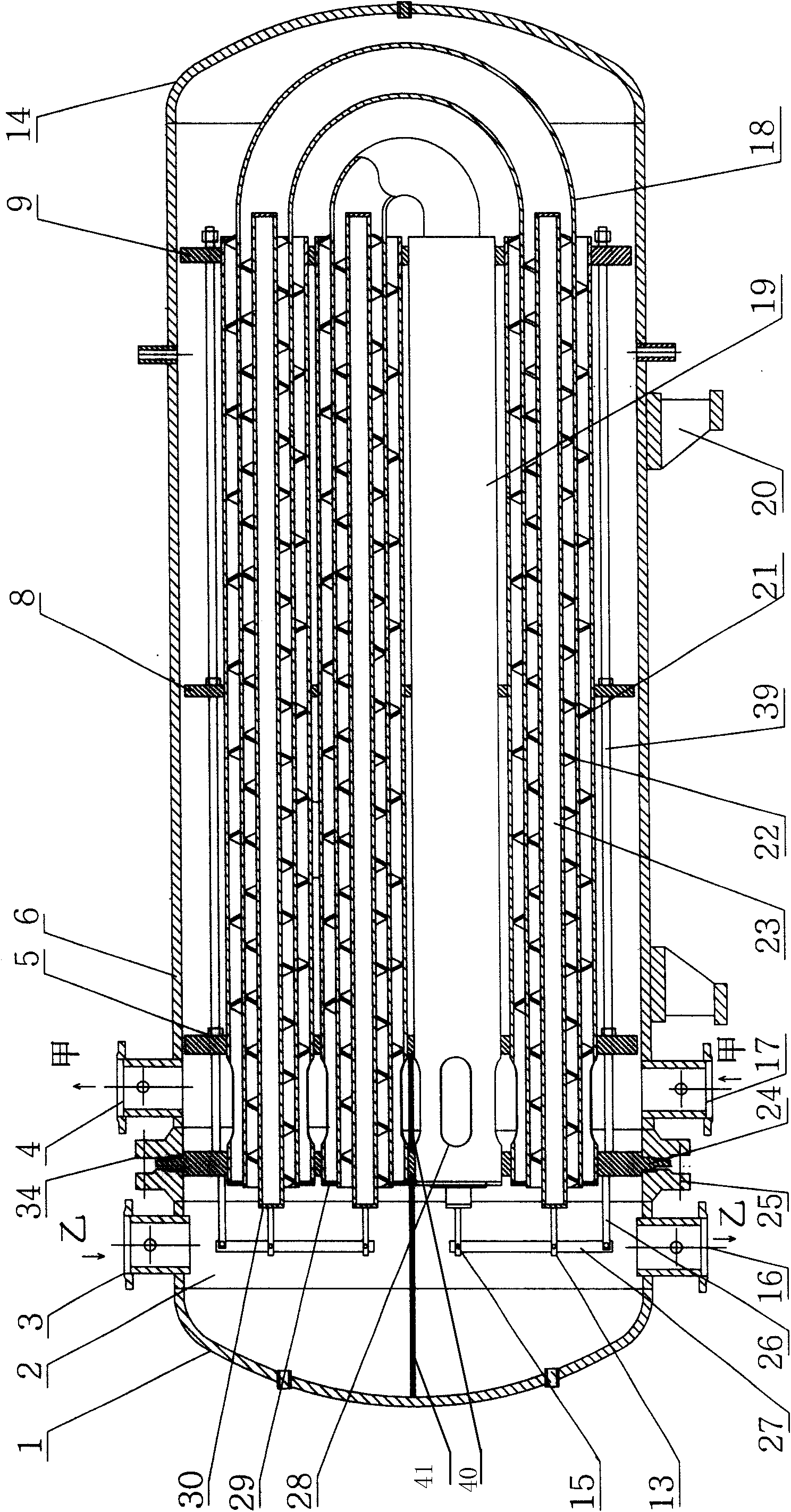

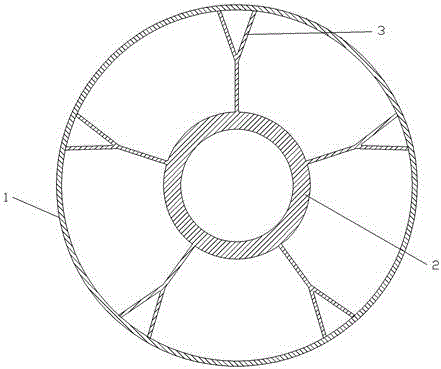

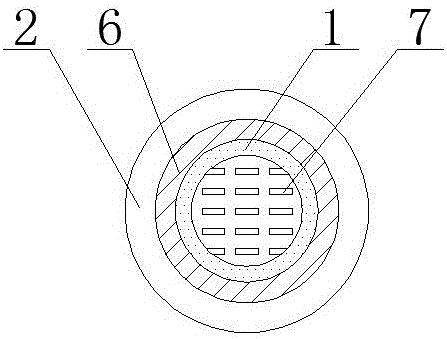

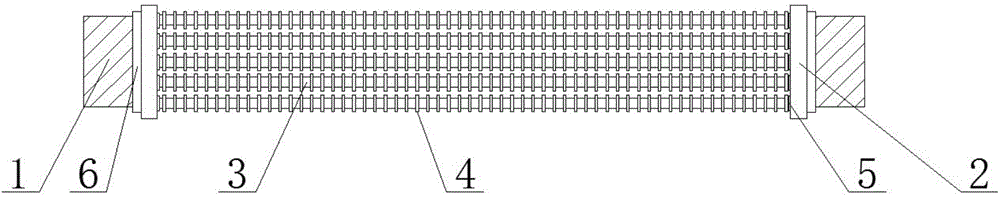

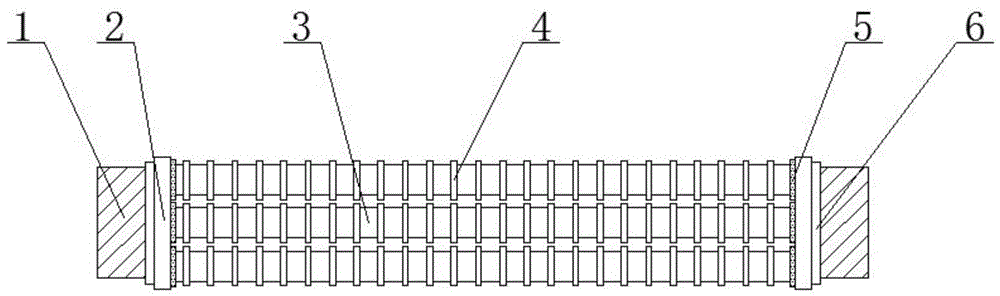

Composite sleeve double-helix heat exchanger

InactiveCN101566437AImprove circulationImprove heat transfer coefficientStationary tubular conduit assembliesViscous flowEngineering

The invention relates to a composite sleeve double-helix heat exchanger. At present, a plate type heat exchanger has high coefficient of heat transfer but can bear lower working pressure; a pipe shelltype heat exchanger is of a pressure-resisting structure but has very low coefficient of heat transfer; and a pipe type heat exchanger is formed by a single heat exchanging pipe or a heat exchange pipe bundle and has low heat transfer rate due to thick viscous flow layer of liquid inside the pipe and poor circulation state due to very low flow rate of liquid outside the pipe. In a double-helix three-sleeve heat exchanging pipe bundle of the composite sleeve double-helix heat exchanger, a middle pipe and a hollow inner pipe form an inner flow passage; inner helical blades are arranged in an annular gap of the middle pipe and the inner pipe; an outer pipe and the middle pipe form an outer flow passage; outer helical blades with opposite handedness with the inner helical blades are arranged in an annular gap of the middle pipe and the outer pipe; and two-phase liquid fast forms an annular lamella in the pipe to flow forwards in a helical scouring way. The structure not only has strong structure, but also can greatly improve the heat-transfer characteristic of the heat exchanger.

Owner:赵文阁

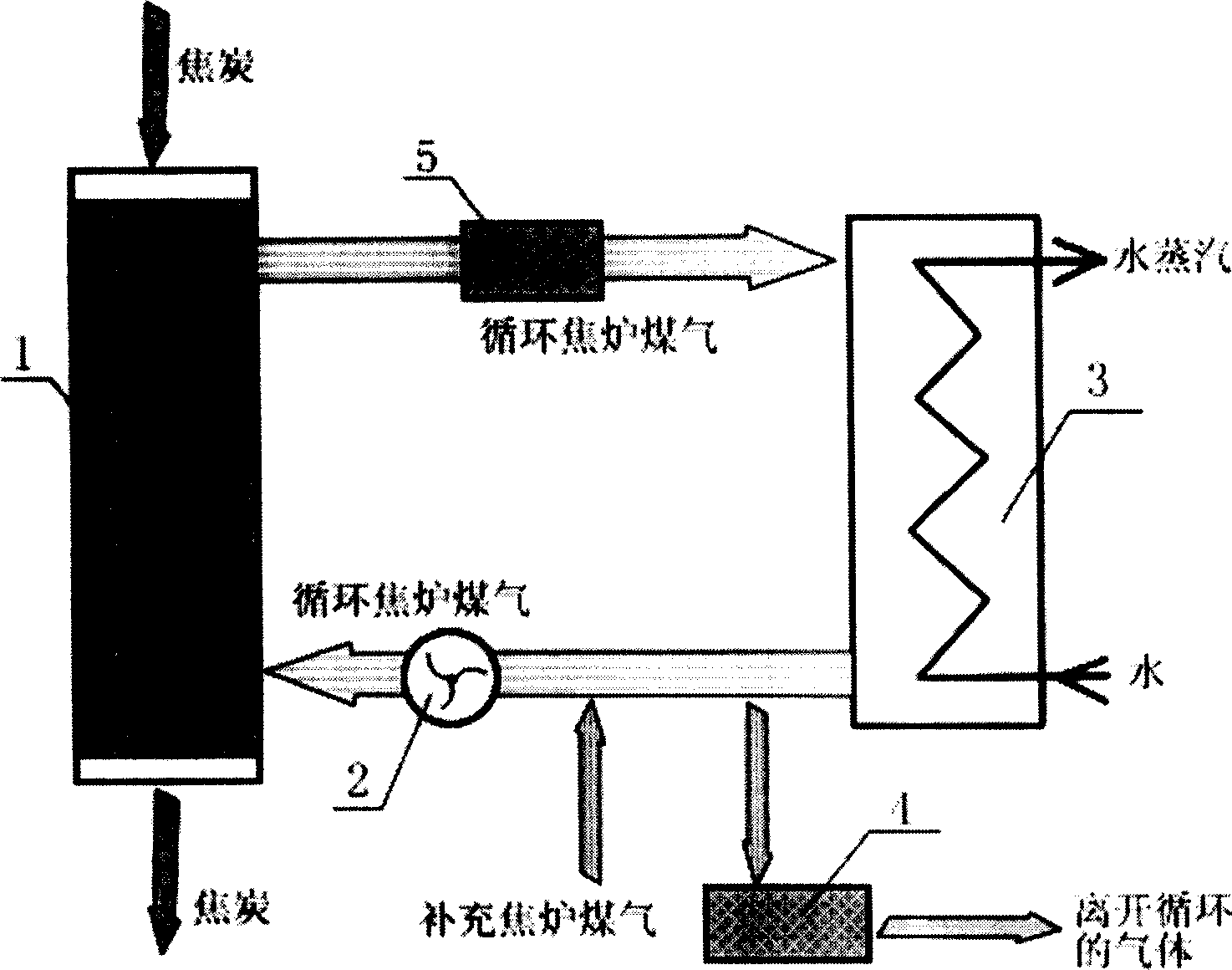

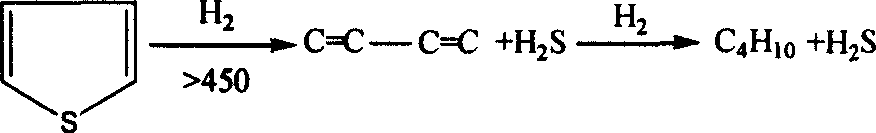

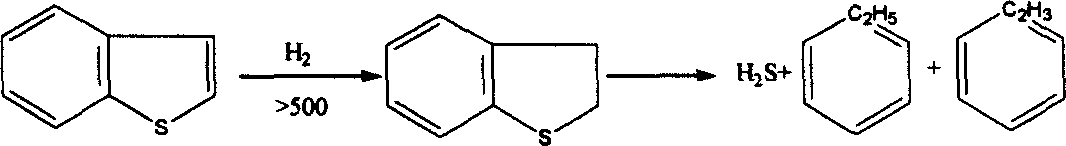

Process for dry coke quenching and coke desulfurating by coke oven gas

A process for using coke oven gas to extinguish coke and desulfurize coke features that the coke oven gas is circulated in the coke extingushing furnace, the heat-absorbing cracking reaction of methane in gas and the high heat transfer efficiency of gas can effectively extinguish to coke, and the H2 in gas can react on the sulfide and organosulfur in coke to generate H2S, so desulfurizing coke.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

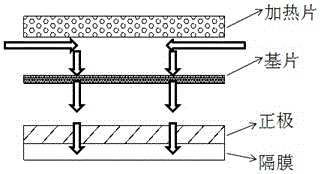

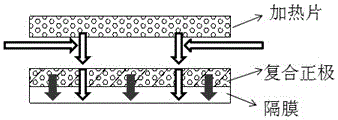

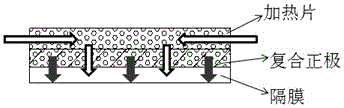

Composite positive electrode of rapidly-activated thermal battery and manufacturing method thereof

ActiveCN106207213AImprove electronic conductivityShorten the timeDeferred-action cellsPrimary cell electrodesVoltageMetal

The invention relates a composite positive electrode of a rapidly-activated thermal battery and an electrode manufacturing method. The composite positive electrode is mainly manufactured from thermal battery positive electrode powder, heating powder and a wire mesh by physical compression molding, wherein the positive electrode powder is coated with a molten salt electrolyte; the heating powder is 5-60 percent of the positive electrode powder; the wire mesh in an electrode assembly is embedded into a positive electrode layer; and the diameter of the wire mesh is 60-90 percent of a flake diameter. In a process of activating the thermal battery, the heating powder in the composite positive electrode burns, so that a positive electrode coating layer can be activated rapidly; heat transfer intermediate processes can be reduced; and the electrolyte in a diaphragm is directly heated. Moreover, the conductivity of the electrode can be improved through excessive iron in the wire mesh and the heating powder, and rapid voltage buildup is facilitated. The positive electrode has a high molding property and high heat transfer efficiency, and is suitable for a short-time rapidly-activated thermal battery design; and the activation time can be shortened greatly.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

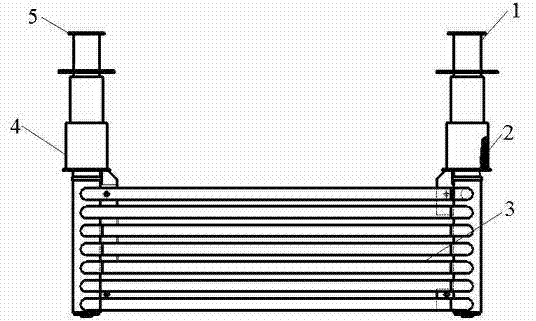

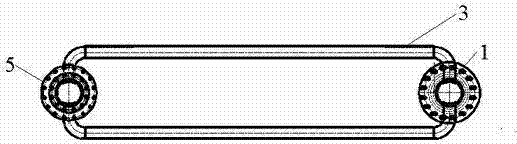

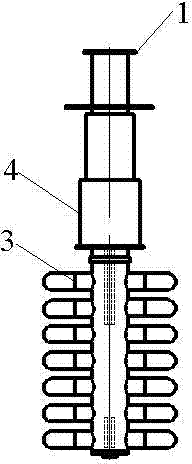

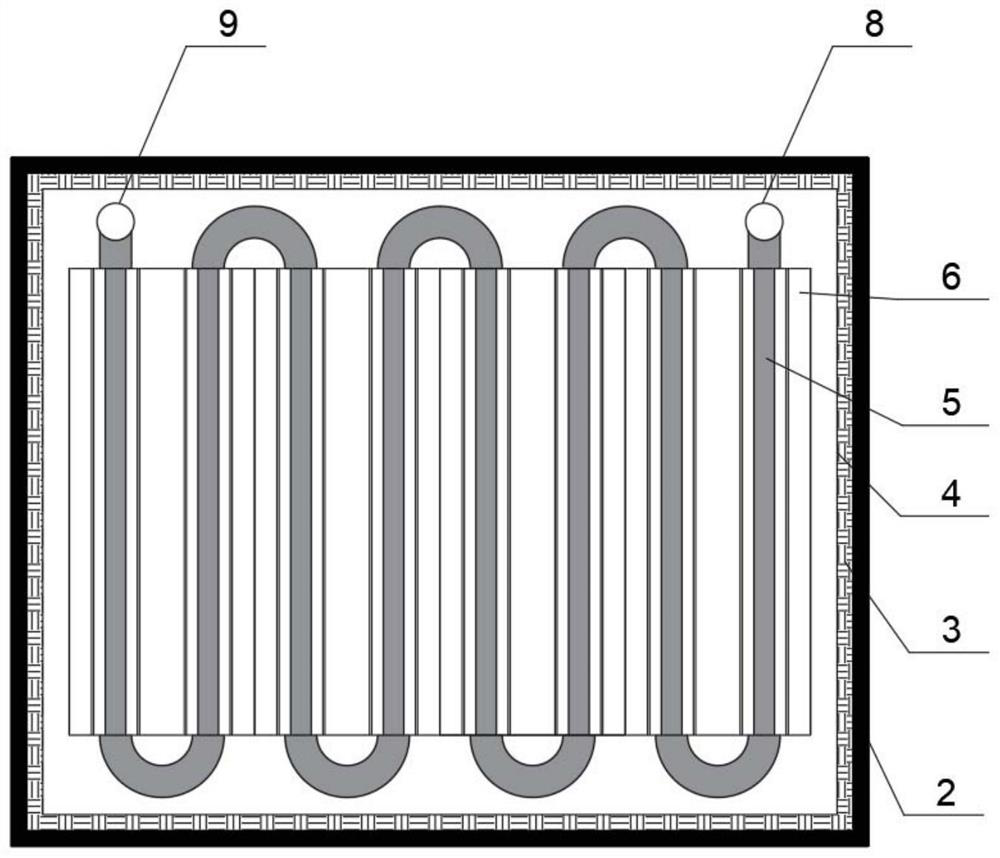

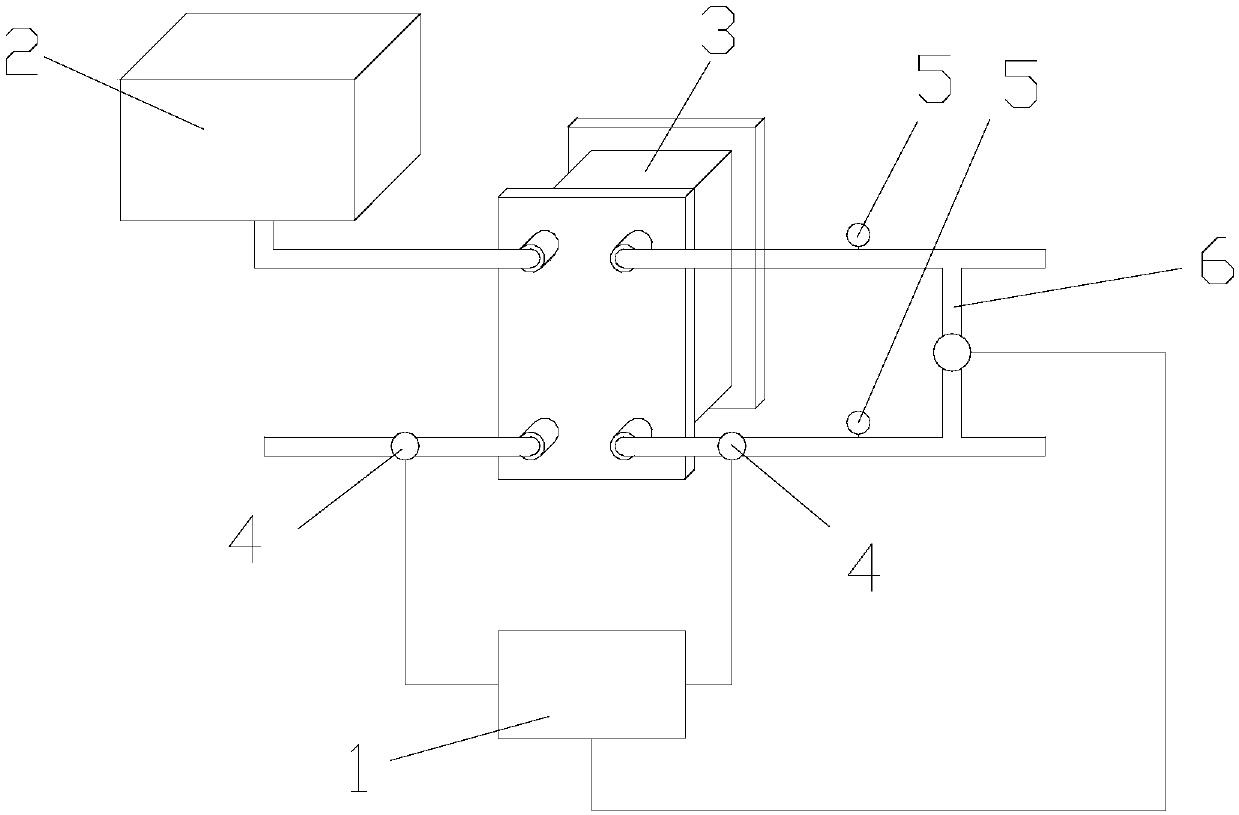

Device for heat exchange of electrolytic bath

InactiveCN102492964AShorten heat transfer timeImprove heat transfer efficiencyElectrolysis componentsCooling coilMagnesium

The invention relates to a device for heat exchange of an electrolytic bath, which comprises an air inlet tube, an air outlet tube, stainless steel sleeves and a cooling coil. A heat exchanger is perpendicularly mounted below a cover of a magnesium collection compartment of the electrolytic bath and integrated with the cover of the electrolytic bath. The air inlet tube and the air outlet tube are respectively connected with the cover. The cooling coil is in a multi-set structure and subjected to temperature resistance and corrosion resistance treatment. The outer sleeves for the air inlet tube and the air outlet tube between the level of electrolyte and the bottom of the cover are made of anticorrosion or stainless steel materials, and castables are cast between each stainless steel sleeve and the corresponding one of the air inlet tube and the air outlet tube. Safe and reliable temperature regulation and control for the electrolytic bath are realized by the heat exchanger physically, damage of mass balance, chemical balance and thermal balance of the electrolyte in the electrolytic bath can be reduced, operation is facilitated, operation safety of the electrolytic process is ensured, current efficiency of the electrolytic bath is improved, product quality and mass are improved, operation stability of the electrolytic bath is guaranteed effectively, and energy consumption of an electrolytic system is reduced.

Owner:洛阳双瑞万基钛业有限公司

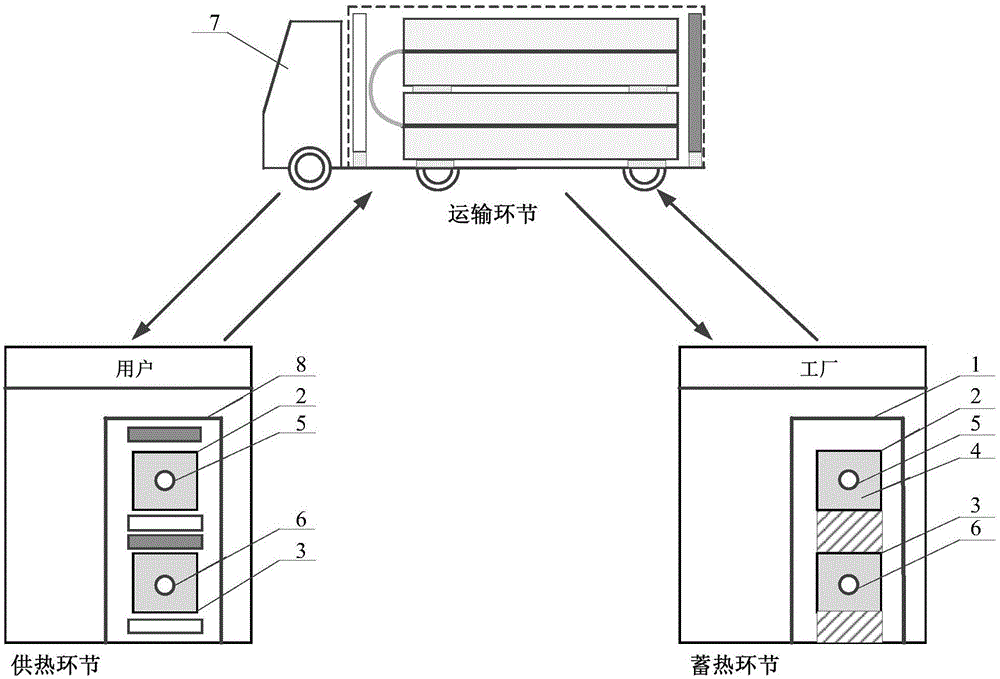

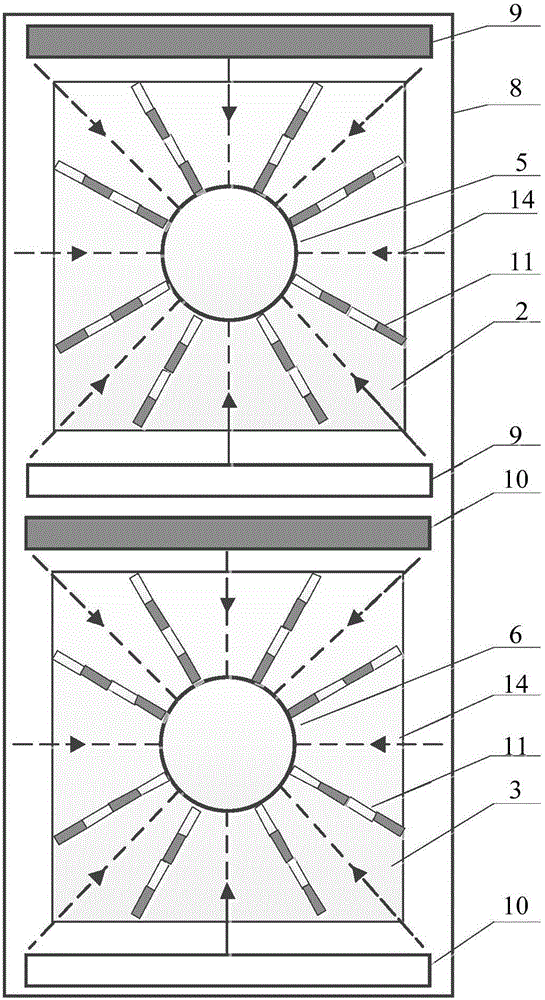

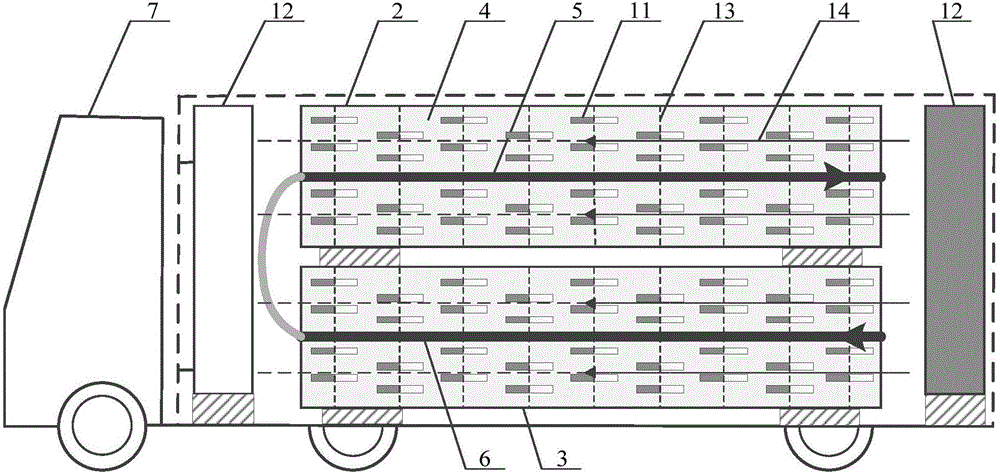

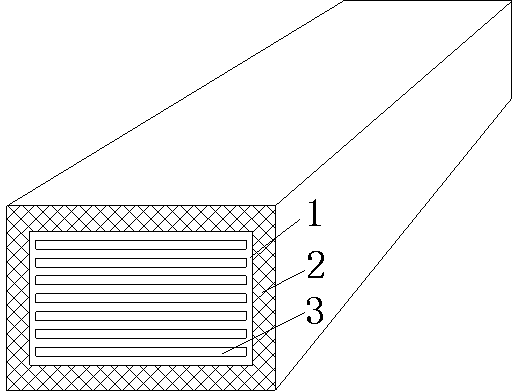

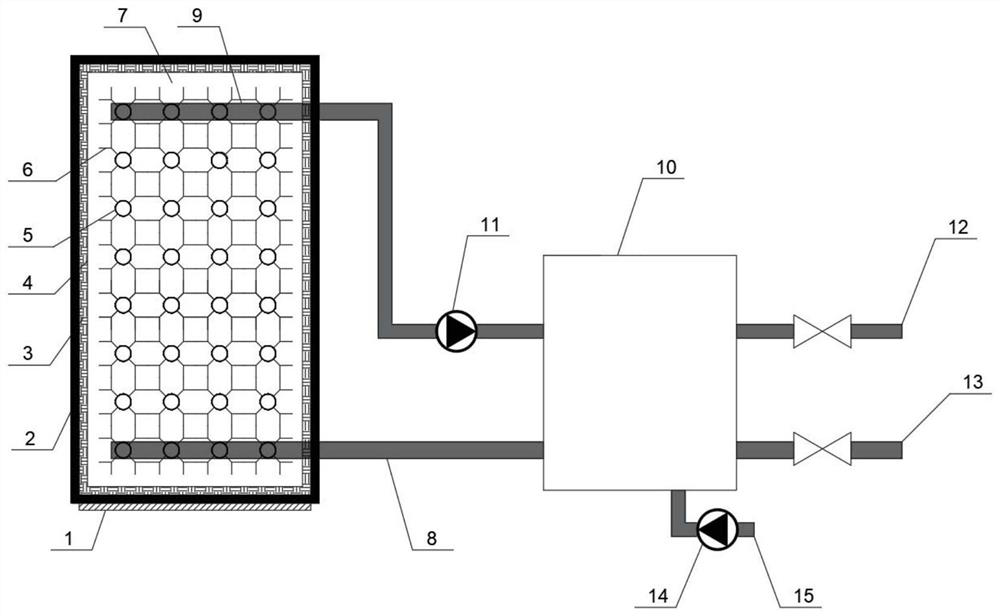

Magnetic particle based directional adjusting system for mobile heat supplying and staged heat transferring performances and method thereof

ActiveCN106839848AShorten heat transfer timeIncrease heating timesHeat storage plantsHeat conductingExothermic process

The invention discloses a magnetic particle based directional adjusting system for mobile heat supplying and staged heat transferring performances and a method thereof. The system is applied to the field of mobile heat supplying. The system comprises a heat storing room, a heat supplying room, a conveying device, heat storing chambers, magnetic particles, positioning wires and a radial / axial magnetic field generating device. According to the system, a heavy-duty device, the heat storing chambers and heat exchanging pipelines are used for continuously absorbing industrial waste heat from the heat storing chamber and conveyed to heat releasing chambers to release and supply heat to a user, thus achieving trans-time-and-space utilization of industrial waste heat as well as achieving energy conservation and emission reduction; the radial magnetic field generating device and the magnetic particles are utilized to form a radial heat conducting channel to improve the phase change heat transfer in the heat absorbing / releasing process, so that the heat exchange time can be saved, and the heat supplying frequency each day can be improved, and as a result, the payback period can be reduced, and the cost can be decreased; the heat conducting channel can be cut off through the axial magnetic field generating device, thus the heat loss in the conveying process can be decreased, the effective heat supplying quantity can be improved, and as a result, the cost is further decreased.

Owner:ZHEJIANG UNIV

Active heat regenerator for room temperature magnetic refrigerator

InactiveCN103822412APrevent oxidation and corrosionShorten heat transfer timeSuperheatersHeat flowBoiling point

The invention discloses an active heat regenerator for a room temperature magnetic refrigerator. The active heat regenerator comprises an insulated housing and a magnetocaloric working medium bed layer arranged inside the insulated housing, wherein the magnetocaloric working medium bed layer is internally provided with mutually parallel micro channels for a heat exchange fluid flowing through linearly and uniformly along the length direction; the heat exchange fluid is a low boiling point fluid, such as R410a, R134a, R407a or R290, that the boiling temperature after pressurization is 20-30 DEG C. The active heat regenerator has the effects and advantages that the heat exchange efficiency of the active heat regenerator is furthest improved, the boiling heat-transfer characteristic is effectively utilized, and the heat convection coefficient between the heat exchange fluid and a magnetocaloric working medium is greatly improved, thus the cold / heat flow time is reduced, and the running efficiency of the room temperature magnetic refrigerator is improved. Moreover, an organic low boiling point working medium is introduced, so that the problem that active rear metals corrode during the machine running process is effectively solved. Therefore the room temperature magnetic refrigerator keeps a smooth and efficient running state during a long-time running process.

Owner:SOUTH CHINA UNIV OF TECH

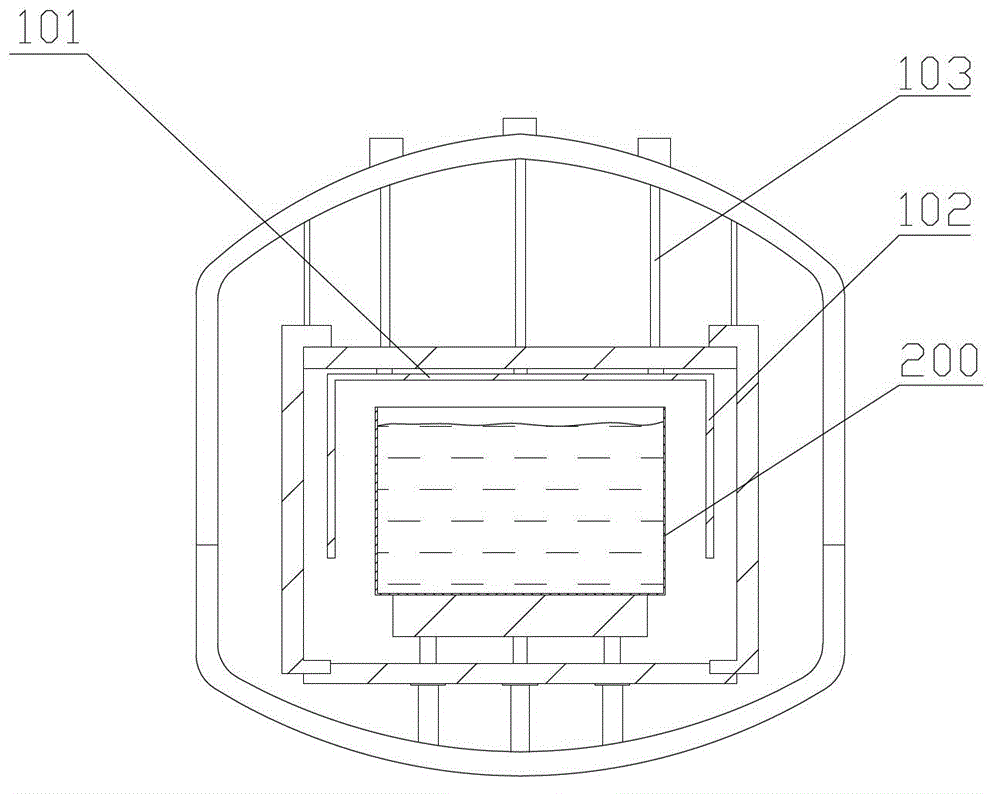

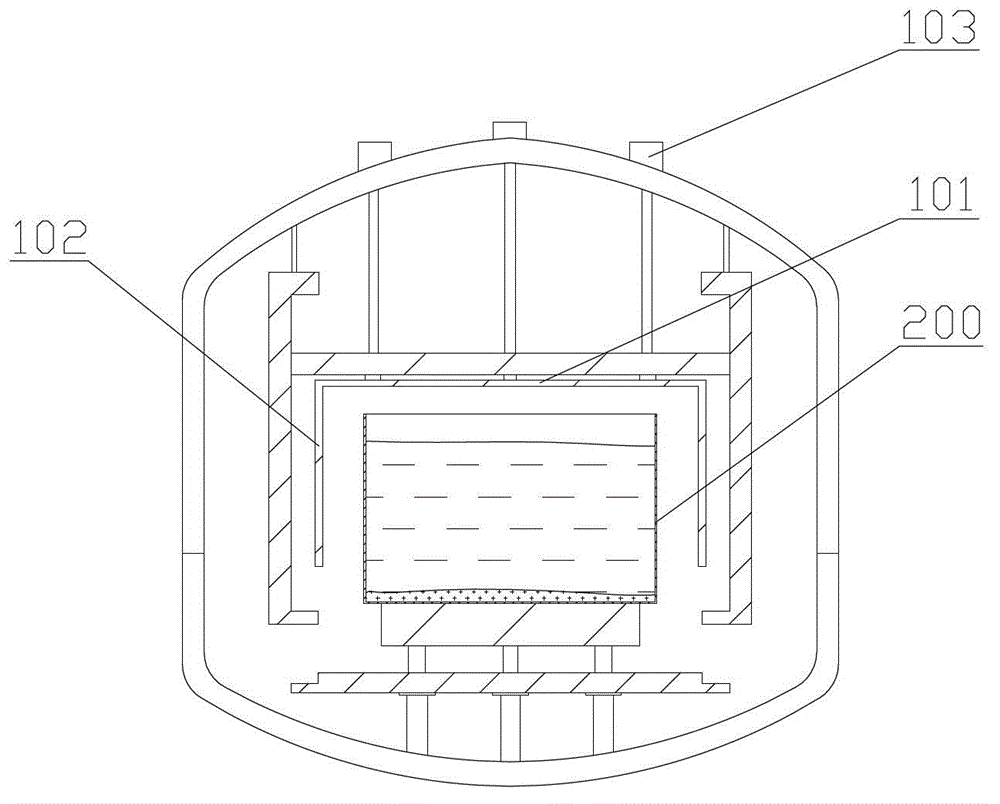

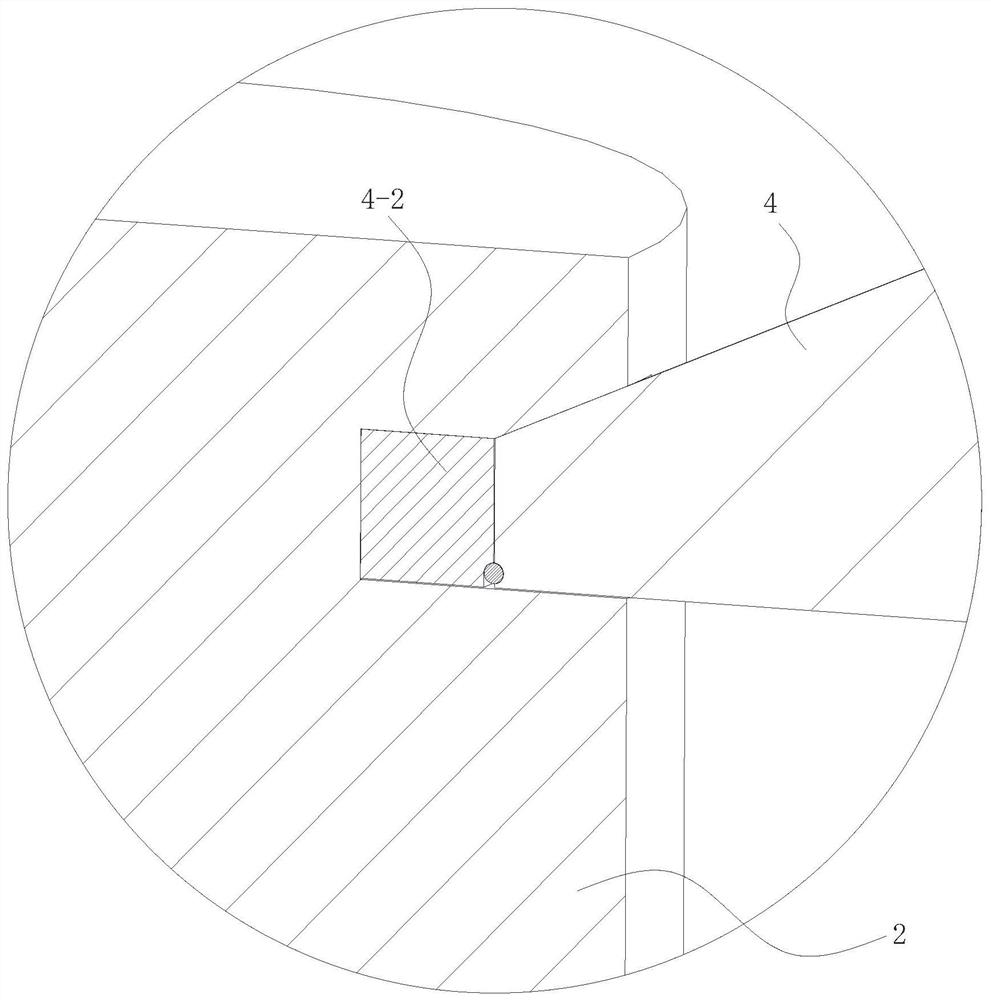

Polycrystalline silicon ingot production furnace and crucible thereof

ActiveCN102912414AQuality improvementIncrease temperaturePolycrystalline material growthFrom frozen solutionsHeating timeCrucible

The invention discloses a polycrystalline silicon ingot production furnace comprising a top heater and a side heater which are arranged in a furnace chamber, and further comprising a central heater arranged in the furnace chamber and used for heating middle polycrystalline silicon materials in a crucible. Because the central heater is arranged in the middle of the furnace chamber of the polycrystalline silicon ingot production furnace, the central heater emits heat at the same time while the top heater and the side heater emit heat, the temperature of the polycrystalline silicon materials in the crucible rises quickly, the heat transmission distance between the polycrystalline silicon materials in the outer side of the crucible and the polycrystalline silicon materials in the middle of the crucible is shortened simultaneously, the heat transmission time is reduced, and energy loss caused by overlong heating time is avoided. In addition, the central heater is arranged, so that the temperature difference between the polycrystalline silicon materials in the middle of the crucible and the polycrystalline silicon materials in the outer side of the crucible is reduced, and the quality of the polycrystalline silicon ingots are ensured. The invention also discloses the crucible for the polycrystalline silicon ingot production furnace.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

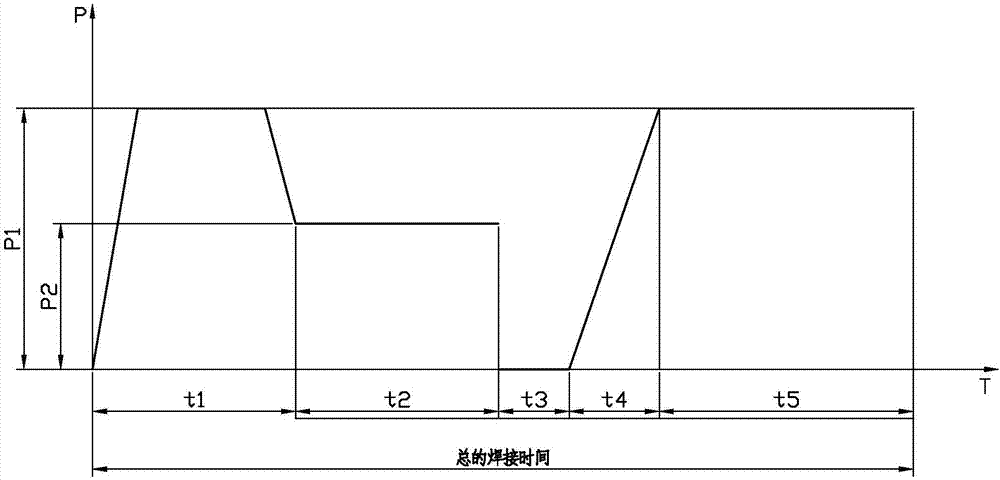

Manufacturing method for sweat soldering PVC pipe fitting

ActiveCN107498883AIncreasing the thicknessHigh strengthPipe connection arrangementsSiphonsPipe fittingFree cooling

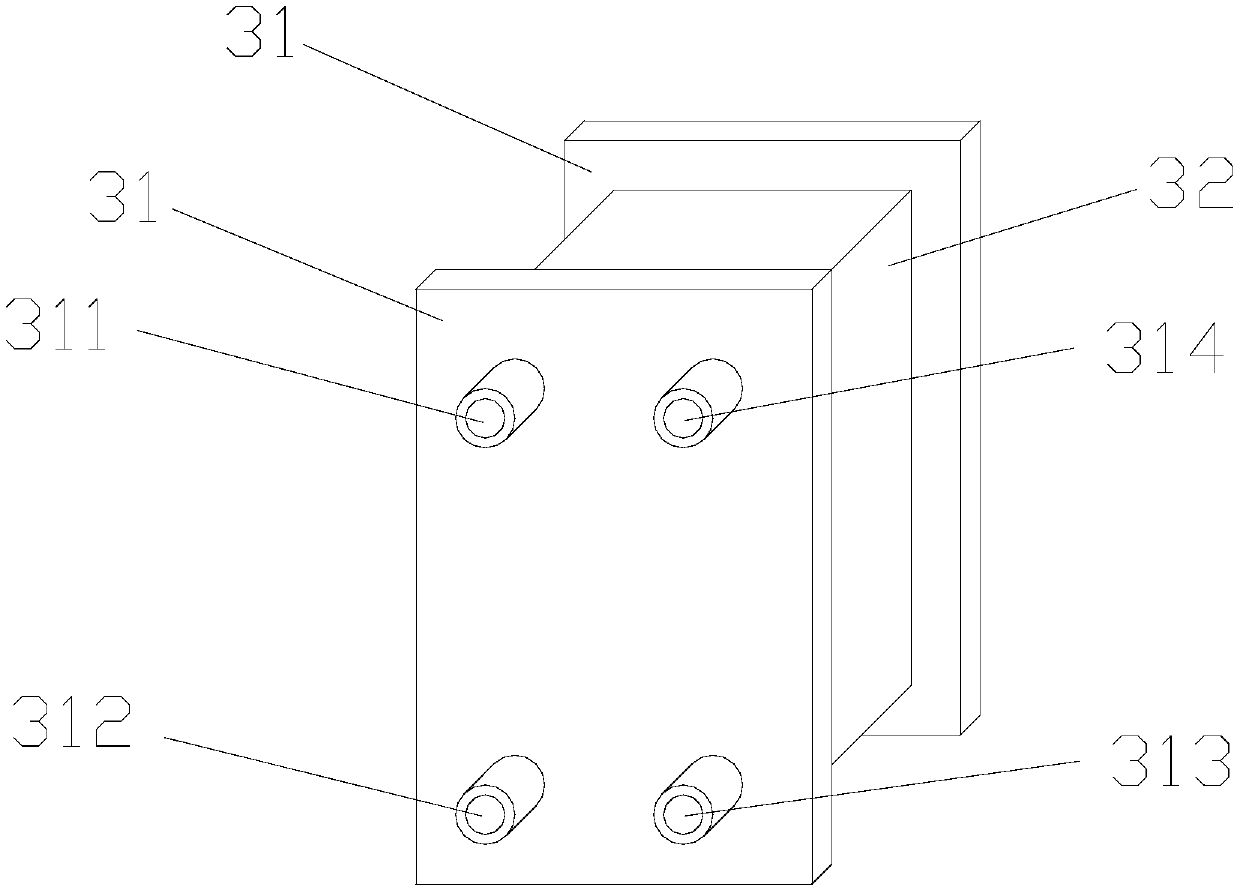

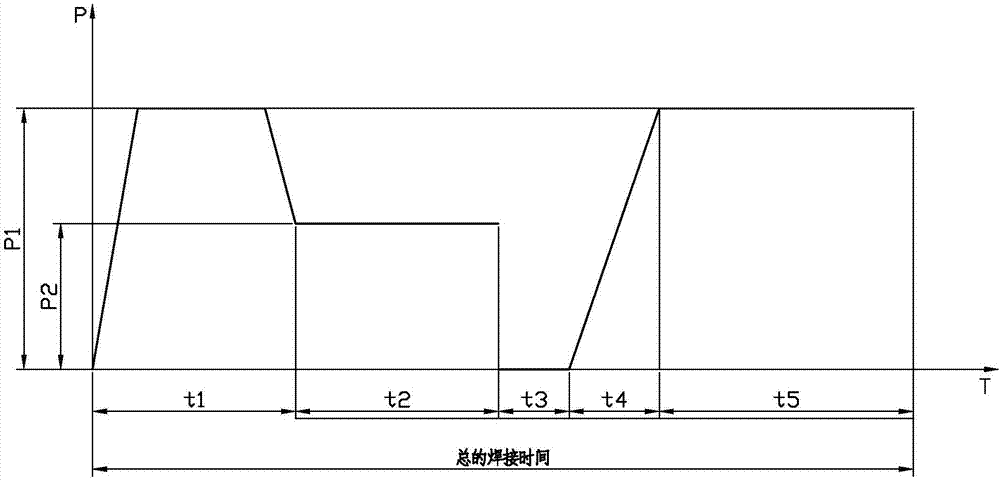

The invention relates to a manufacturing method for a sweat soldering PVC pipe fitting. The manufacturing method comprises the following steps that a multi-angle pipe cutter is used for cutting a tubular object into required lengths and angles; the cut tubular objects are put on a fixture of a soldering machine and fixed well; the end faces to be soldered of the two tubular objects are treated to be smooth; the end faces are gathered, the centring situation is checked, misalignment edges of the two end faces to be soldered do not exceed 10% of the wall thickness, or otherwise the clamping force of the fixture is used for carrying out adjustment, and the two end faces to be soldered are treated again to be smooth; a heating plate of the soldering machine is arranged between the two pipe ends, pressure P1 is gradually exerted within t1 so that the pipe ends can be heated on the heating pipe, and after uniform soldering beads are formed, the pressure is gradually reduced to P2, P2 is kept, heat absorbing is carried out; the pipe ends are loosened, the heating plate is taken out, and the pipe ends are gathered again; the pressure is gradually increased to P1 from 0, soldering portions of the pipes form uniform flanges inwards and outwards; and the pressure P1 is kept, and the soldering portions are naturally cooled.

Owner:JIANGSU HUASHENG PLASTIC

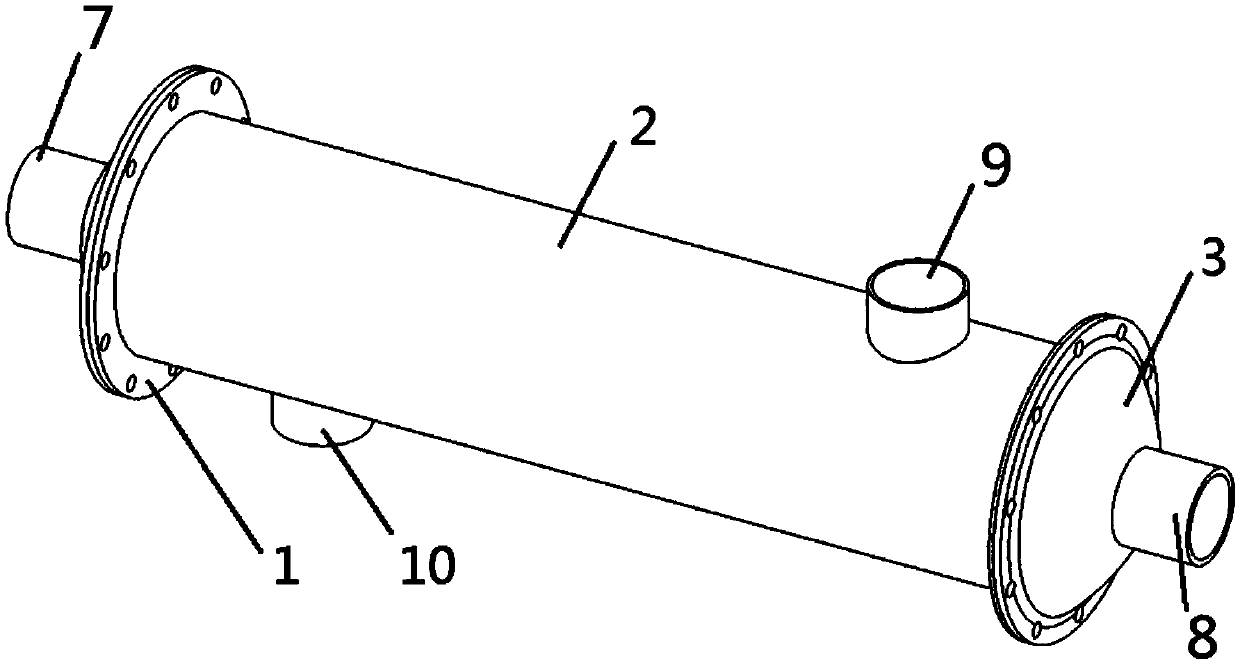

Shell-tube-type phase-change energy storage heat exchanger

InactiveCN107631657AReduce volumePromote mutual disturbanceHeat storage plantsEngineeringPhase change

The invention discloses a shell-tube-type phase-change energy storage heat exchanger. The shell-tube-type phase-change energy storage heat exchanger comprises a heat exchanger shell cylinder, a heat source fluid inlet and a heat source fluid outlet, wherein the heat source fluid inlet and the heat source fluid outlet are formed in the two sides of the heat exchanger shell cylinder; the upper sidewall and the lower side wall of the heat exchanger shell cylinder are provided with a phase-change material filling port and a phase-change material discharging port correspondingly; and a plurality groups of heat exchange round tubes of which the two ends communicate with the heat source fluid inlet and the heat source fluid outlet correspondingly are arranged in the heat exchanger shell cylinder, and fins are evenly distributed on the outer wall of each heat exchange round tube. According to the shell-tube-type phase-change energy storage heat exchanger, by designing arrangement of the heatexchange round tubes, the heat exchanger fully adapts to the flowing and heat exchanging characteristics in the heat exchange process of a phase-change material, a temperature field and a velocity field achieve the synergistic effect, the heat exchange uniformity is improved, and the heat exchange rate is increased; furthermore, by additionally arranging the fins, the heat exchange area of the heat exchanger is effectively increased, the heat exchange coefficient is increased, and convection heat exchange is enhanced; in addition, by designing arrangement of the fins, the flow guiding effect of the fins is fully utilized, mutual disturbance among multiple tube bundles is enhanced, convergency and circulation of a liquid-phase area are promoted, the heat exchange rate is increased, and theheat exchange efficiency is improved.

Owner:XI AN JIAOTONG UNIV

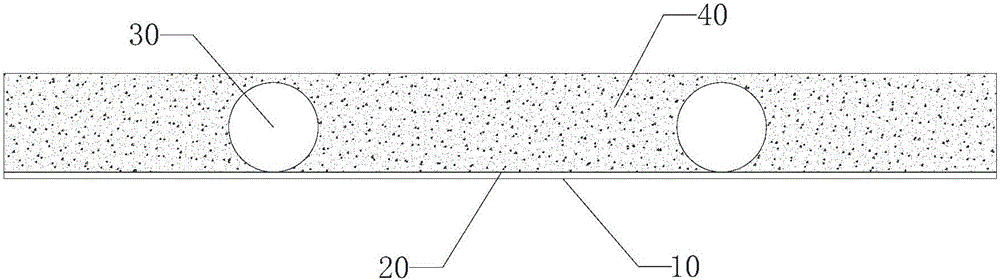

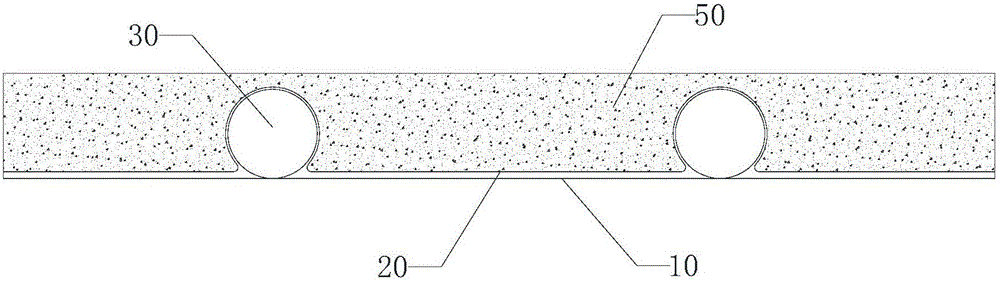

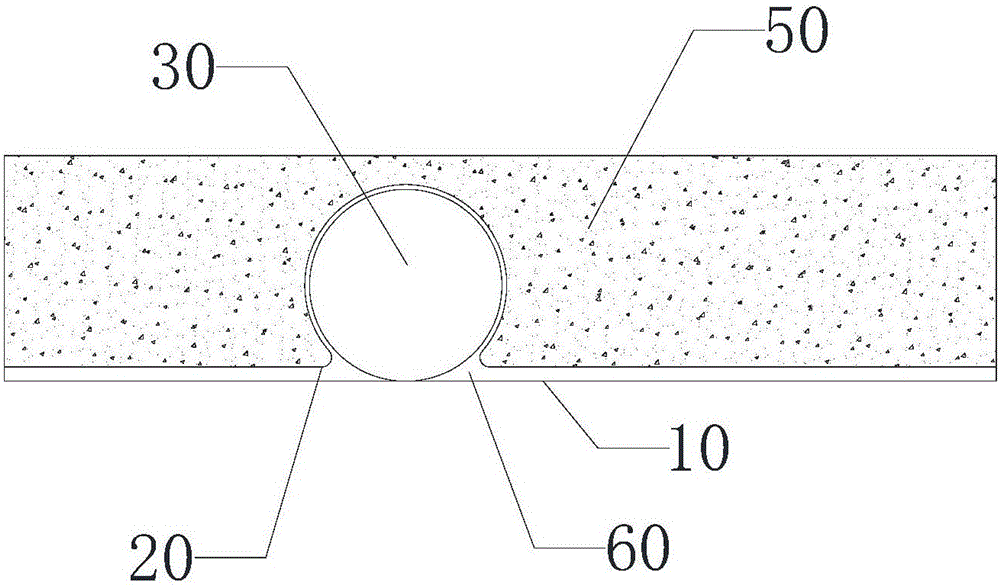

Steam-water heat exchange sleeve

InactiveCN104634139AProcess stabilityIncrease the heat exchange areaStationary tubular conduit assembliesTubular elementsThermodynamicsWater flow

Owner:李静

Radiation module and air conditioning system with same

InactiveCN105805927AEasy to passUniform deliveryMechanical apparatusSpace heating and ventilation safety systemsHeat conductingEngineering

The invention provides a radiation module and an air conditioning system with the same, wherein the radiation module includes a radiation plate, a graphene heat conducting film and a heat exchange tube; the radiation plate has a first surface and a second surface oppositely arranged; the graphene heat conducting film is arranged on the second surface; and the heat exchange tube is contacted with the graphene heat conducting film to exchange heat with the radiation plate through the graphene heat conducting film. The radiation module can solve the problems of long heat exchange time between the radiation plate and a copper tube and low radiation efficiency in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

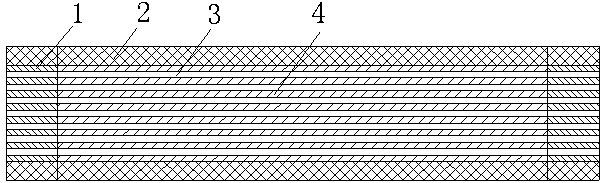

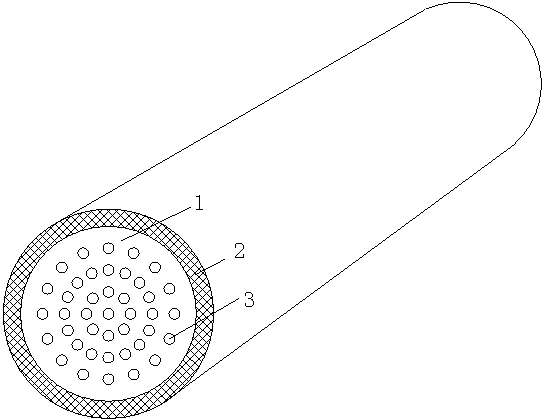

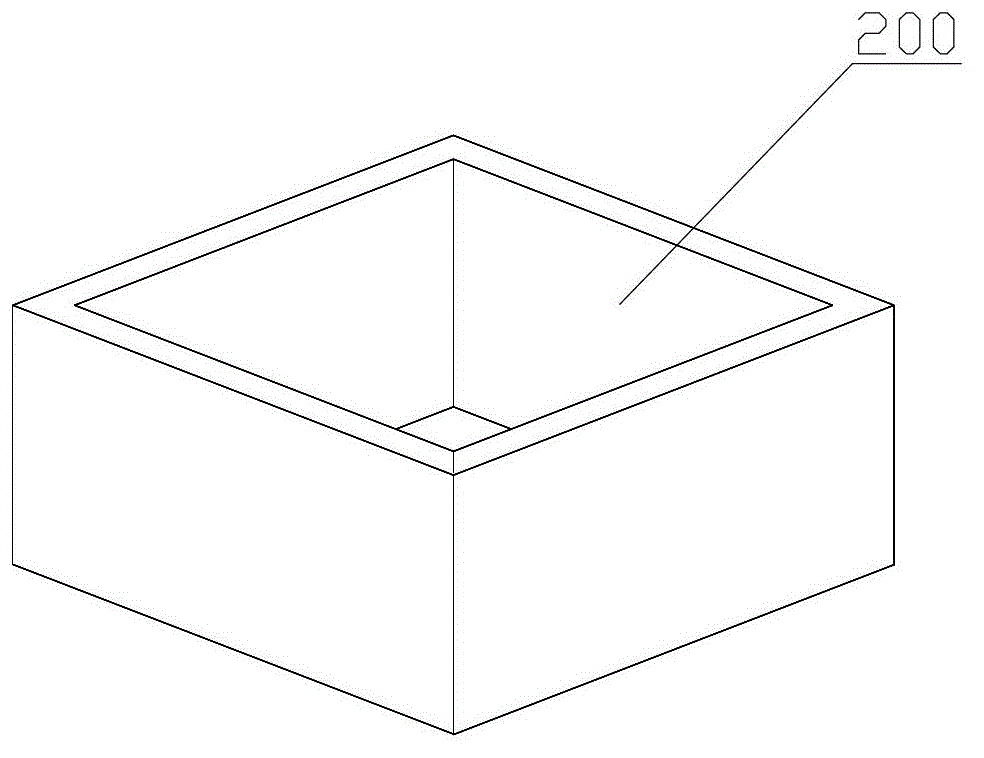

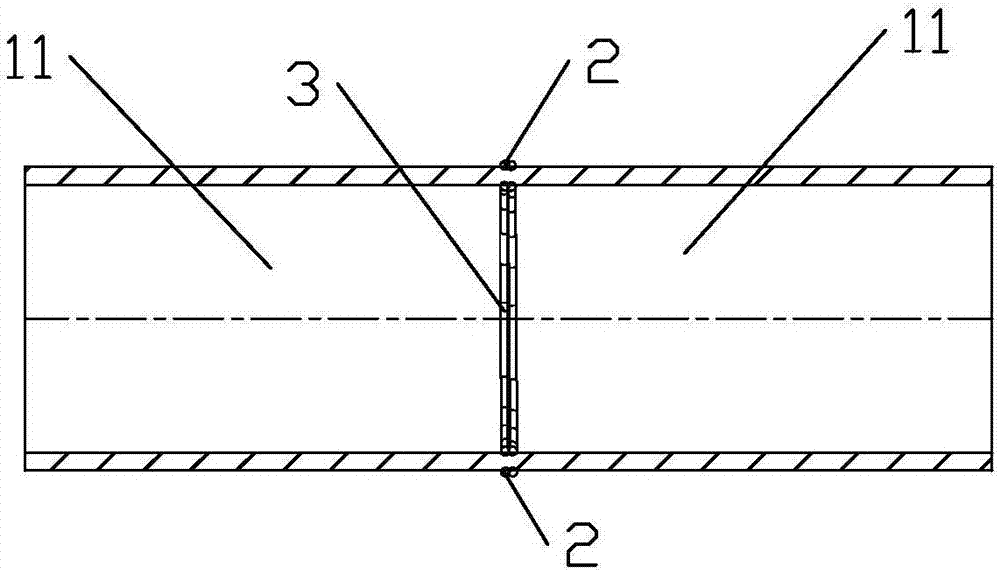

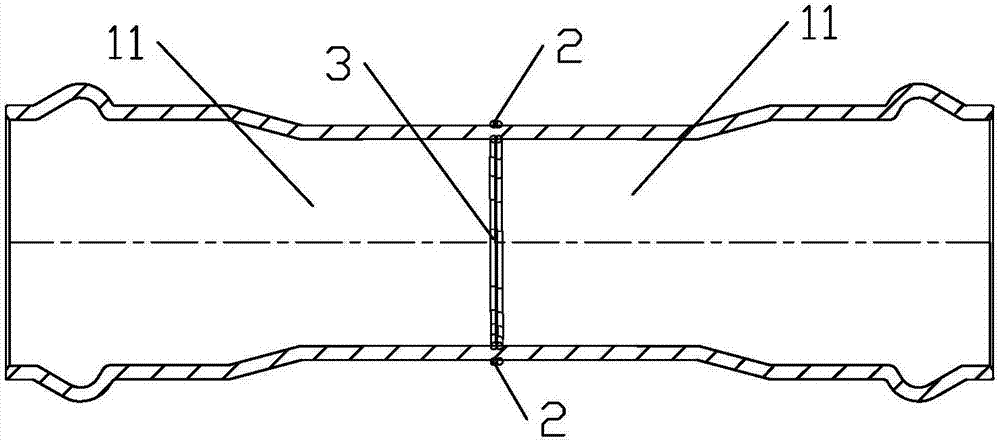

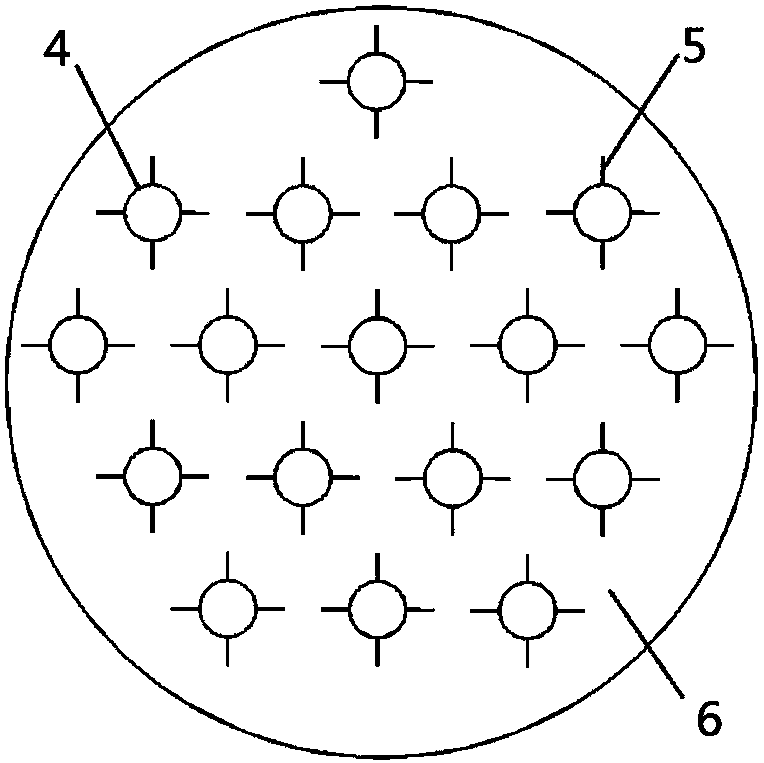

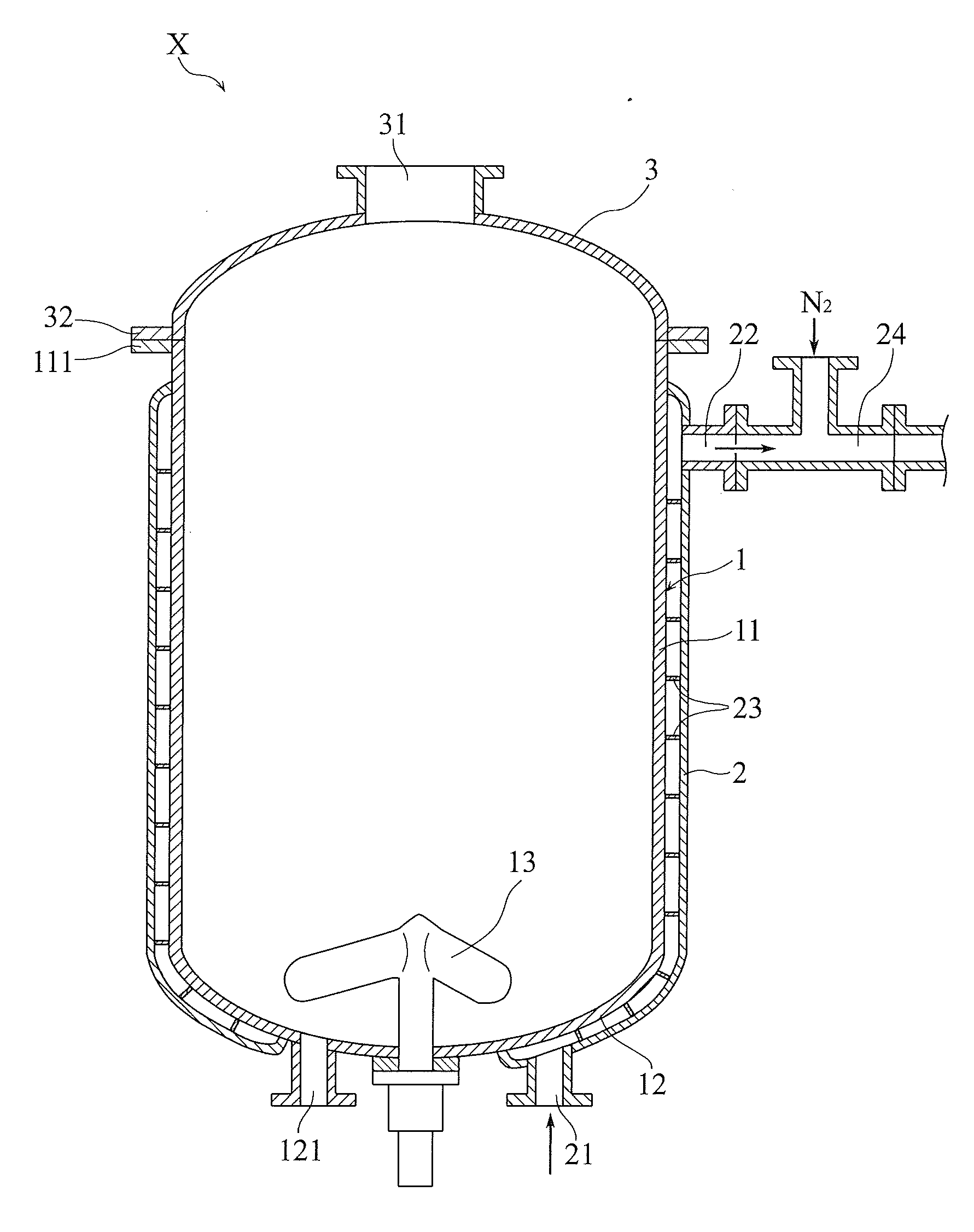

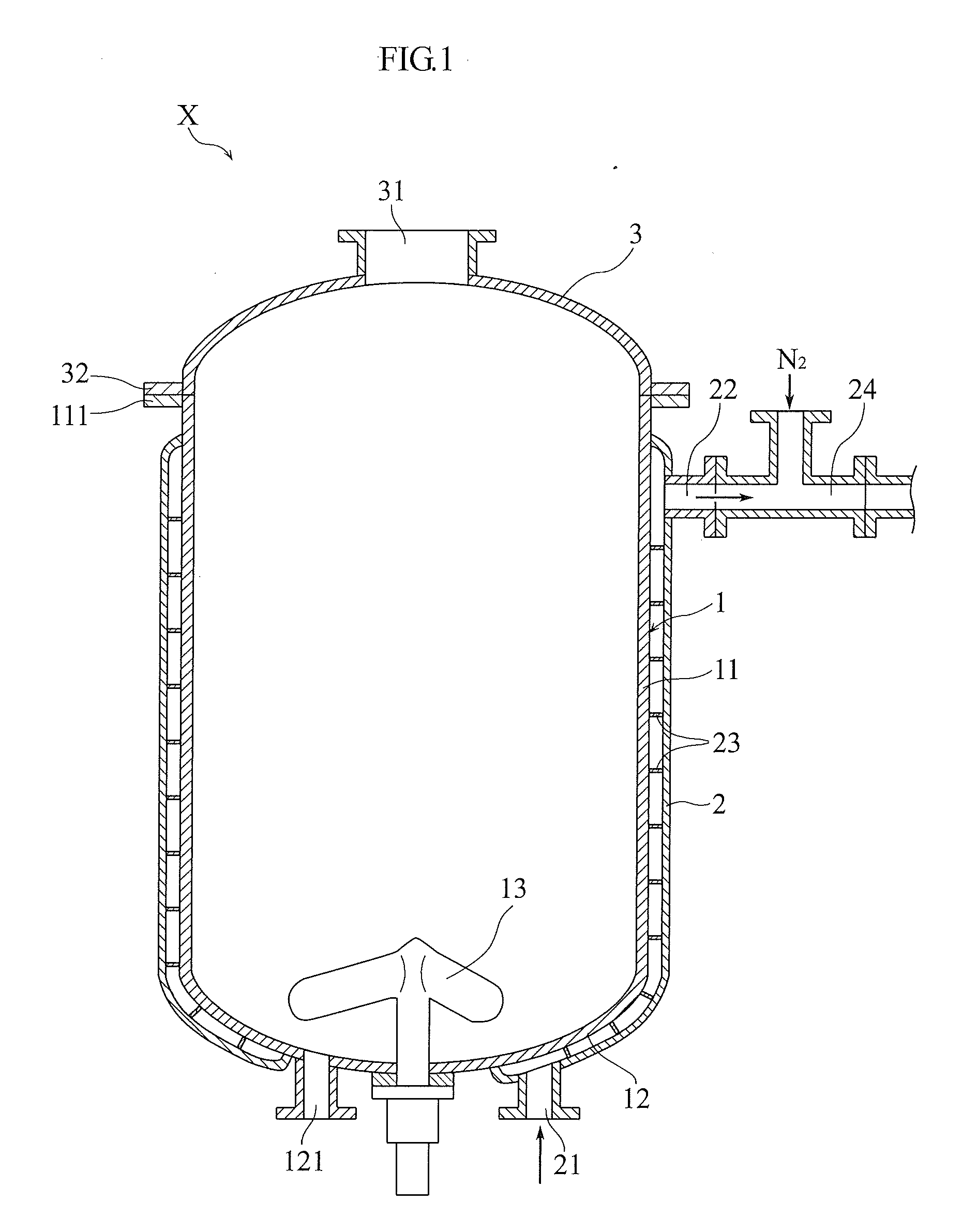

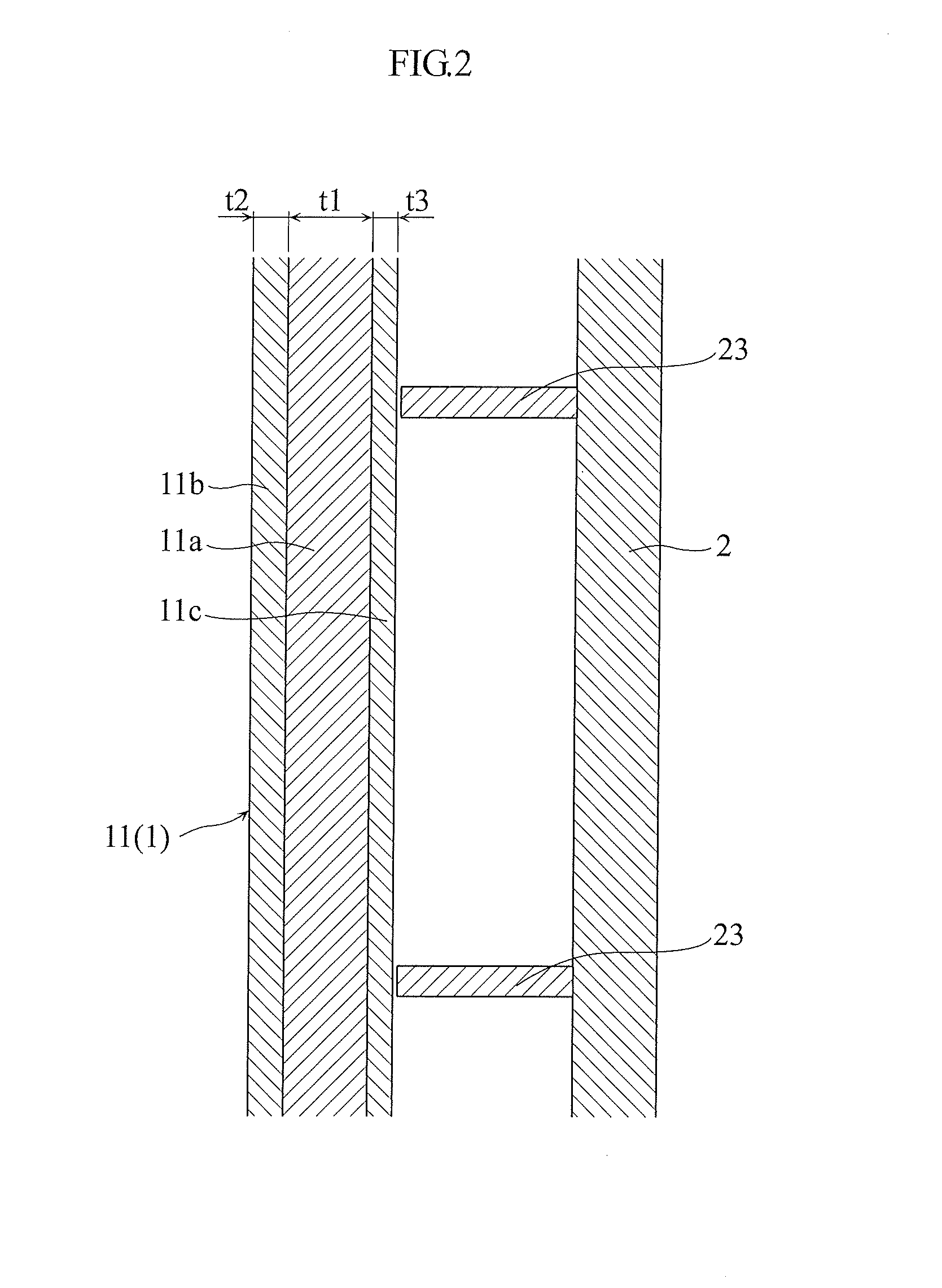

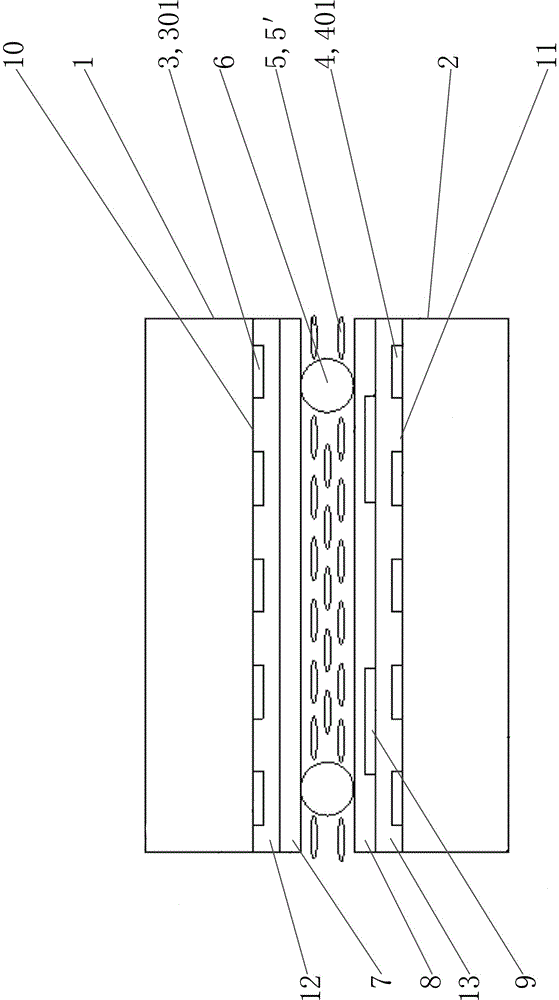

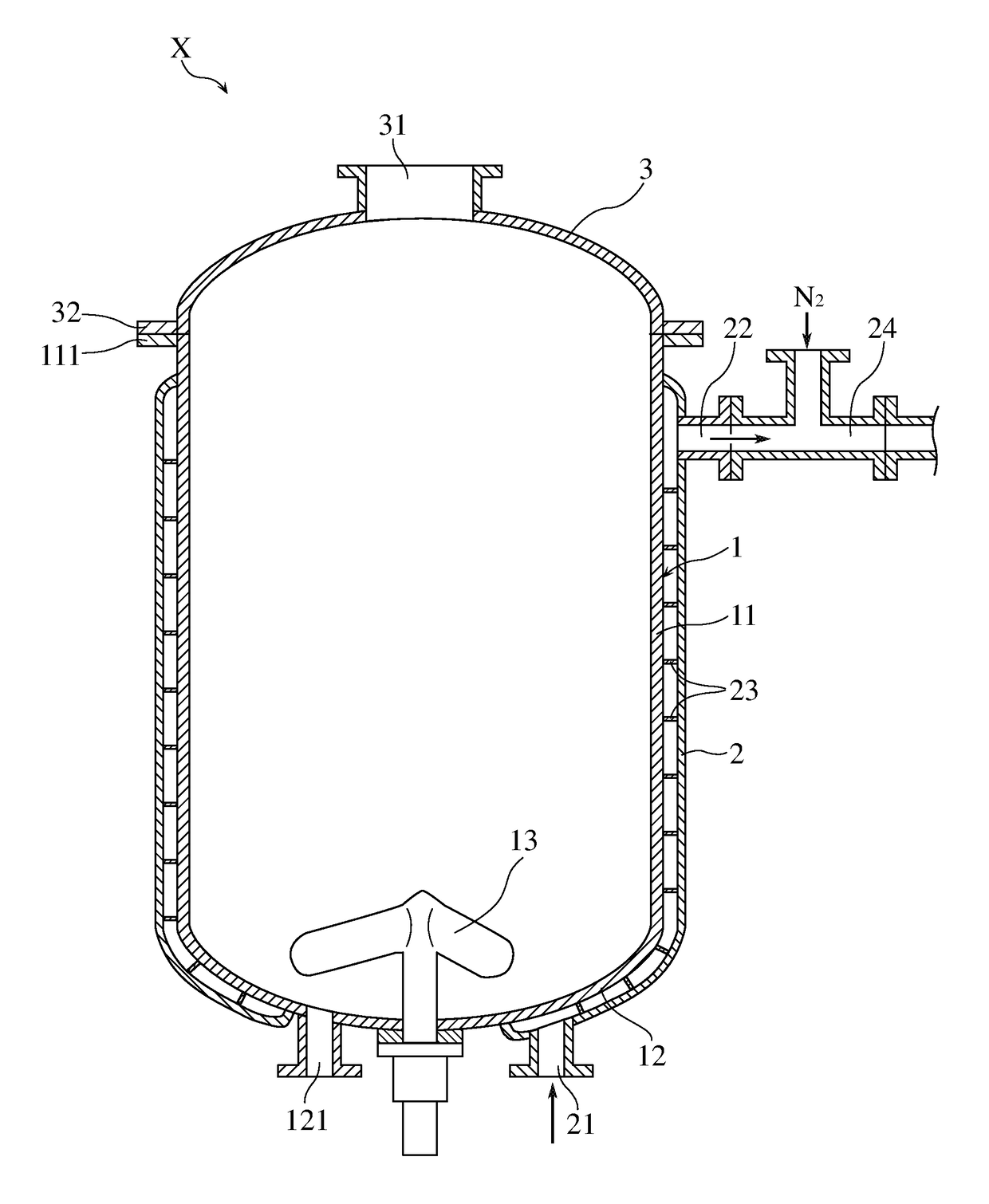

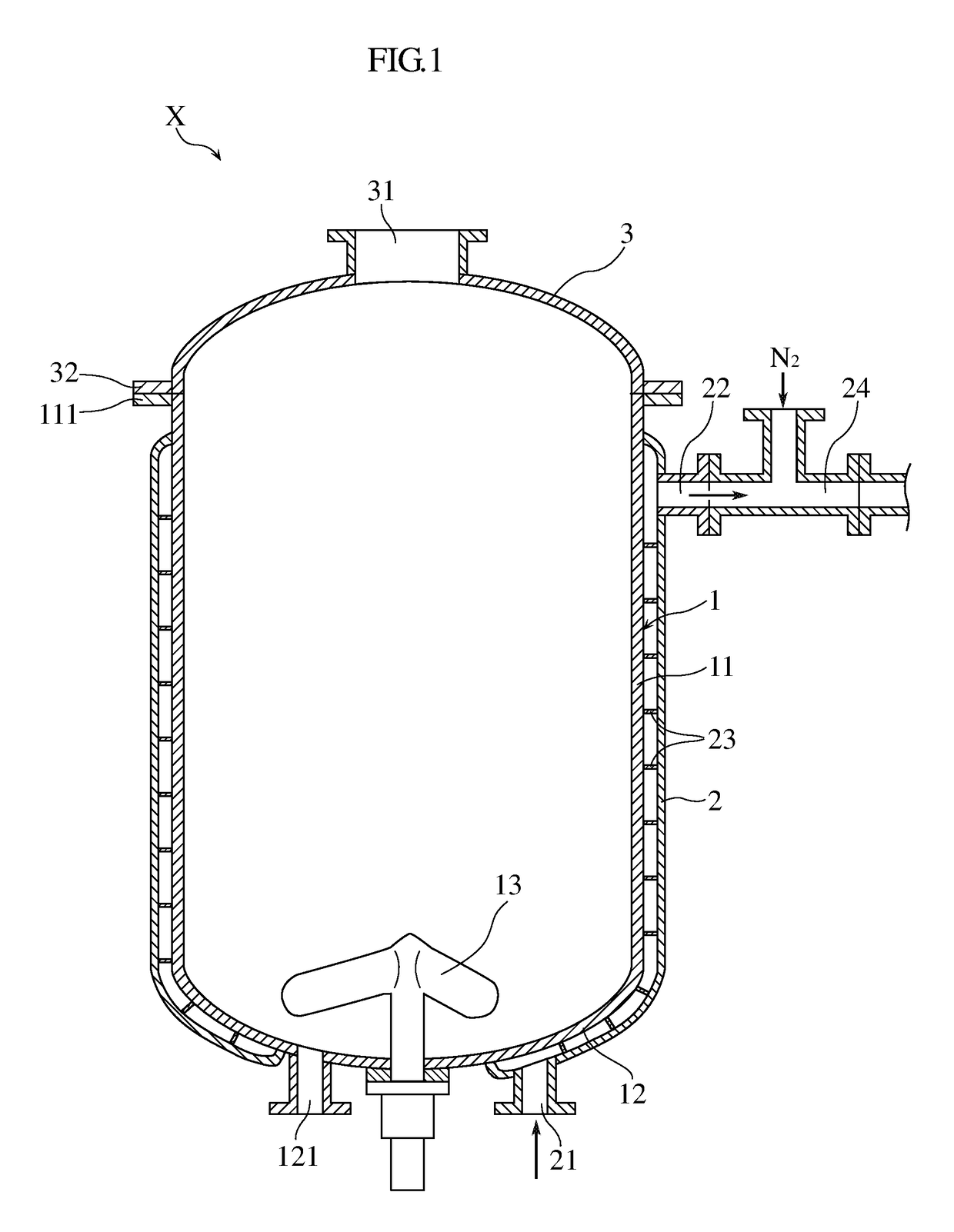

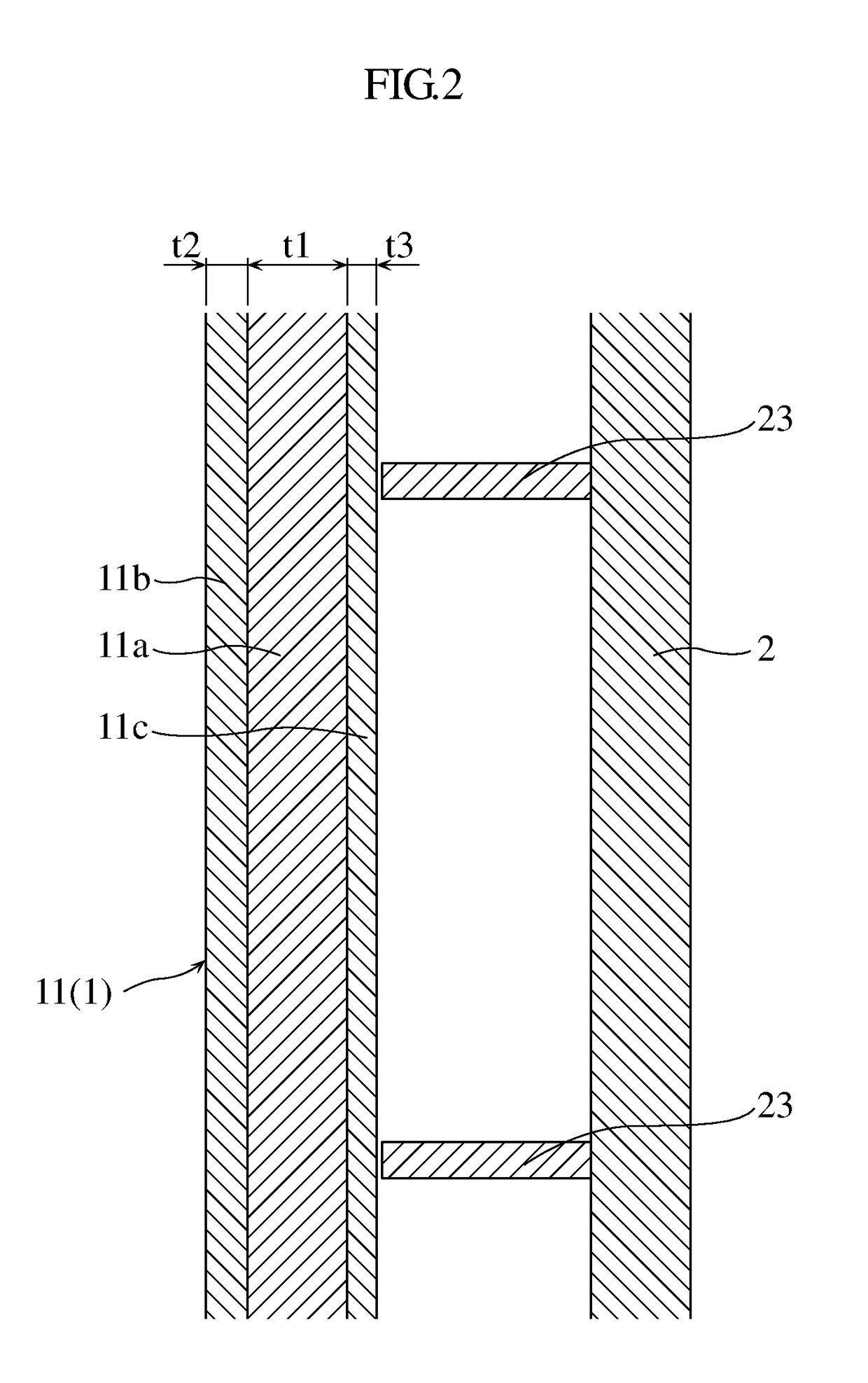

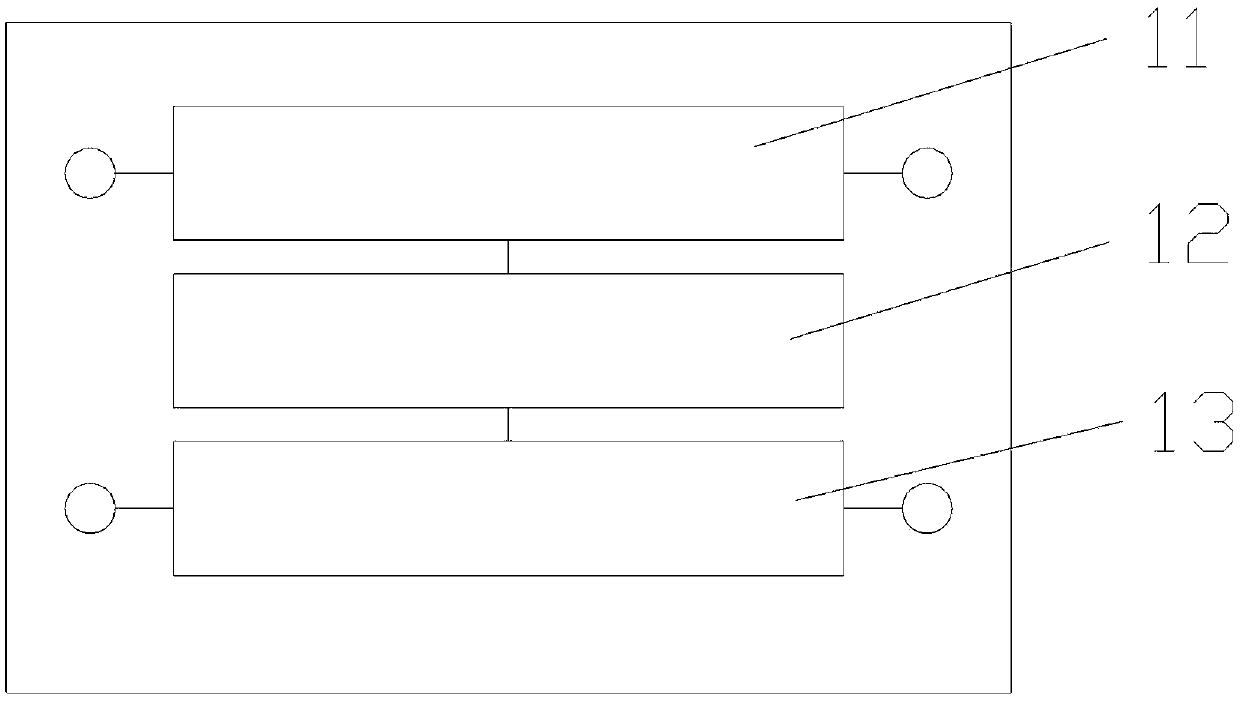

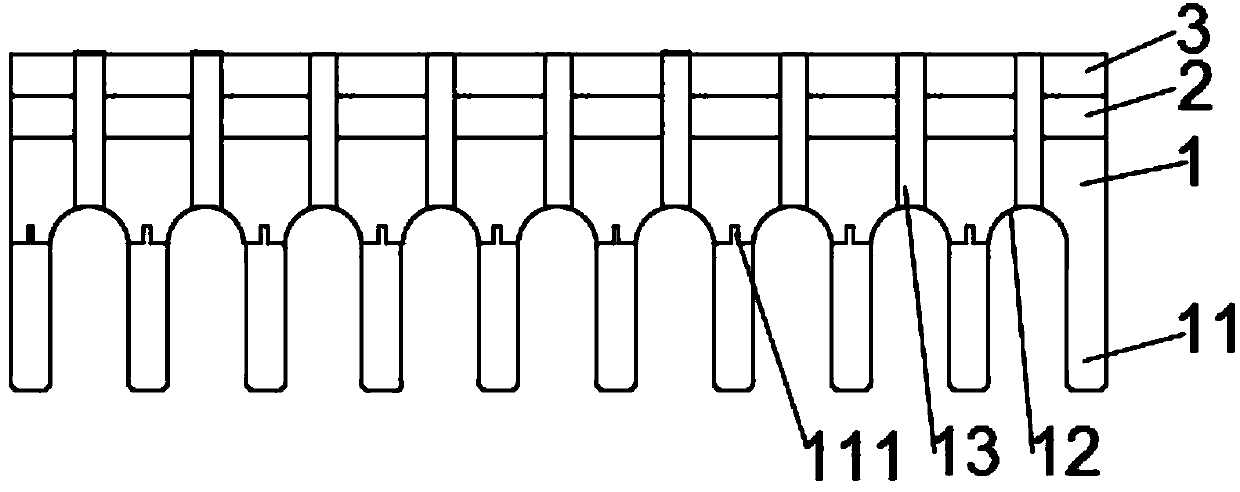

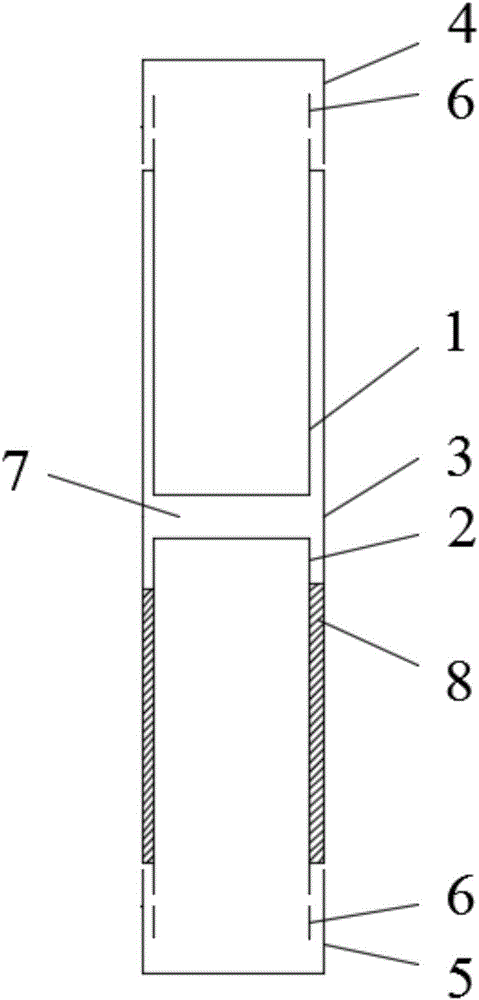

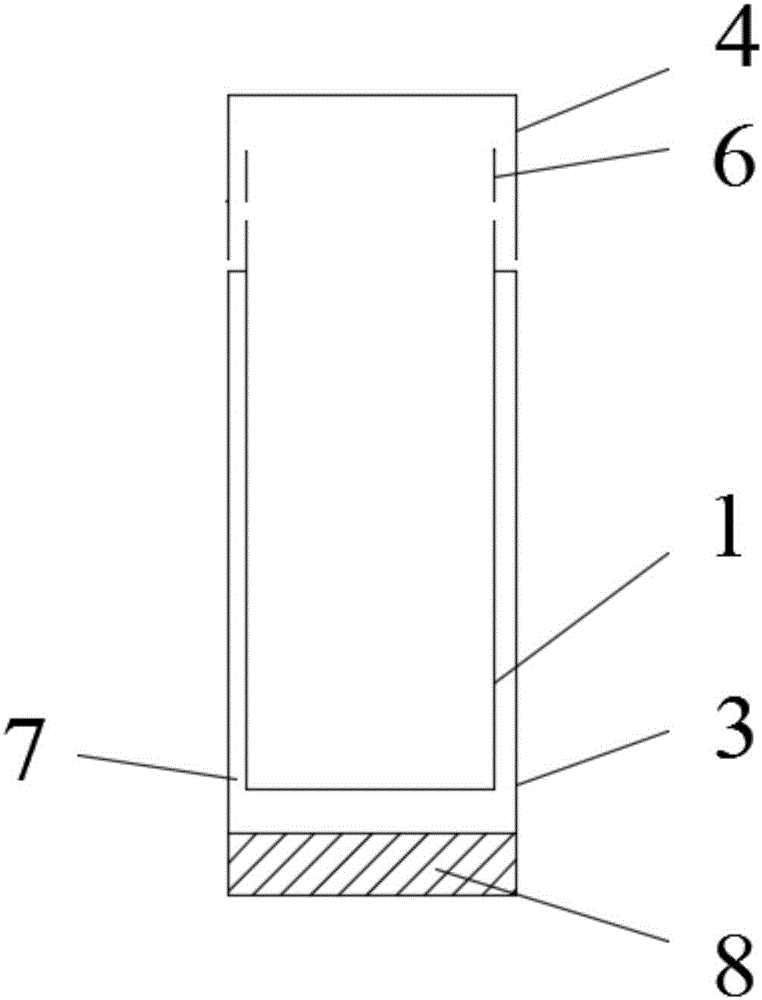

Polymerization reactor and method for producing water absorbent resin

InactiveUS20150080539A1Shorten heat transfer timeMaintain reliabilityChemical/physical/physico-chemical stationary reactorsCorrosion resistantProduced water

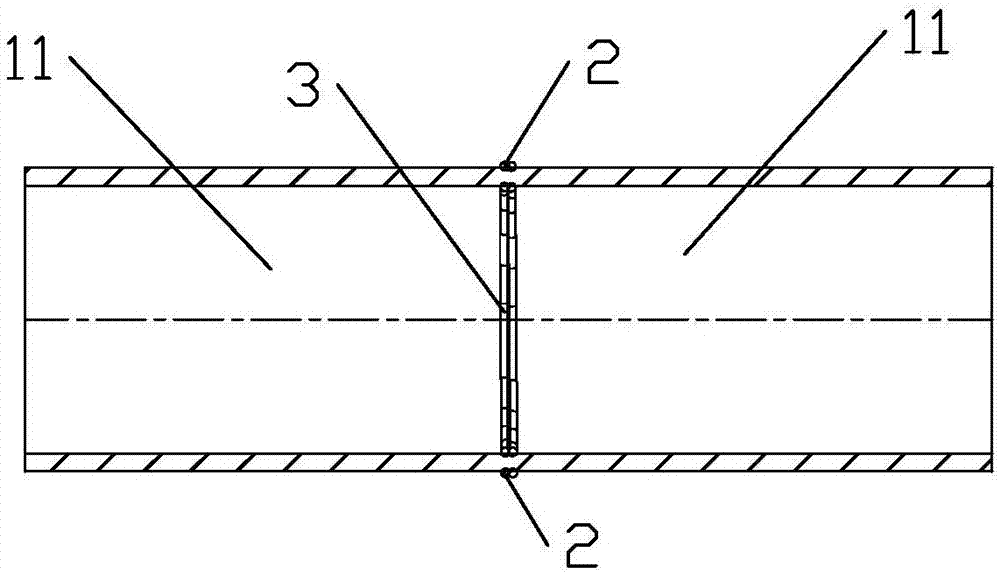

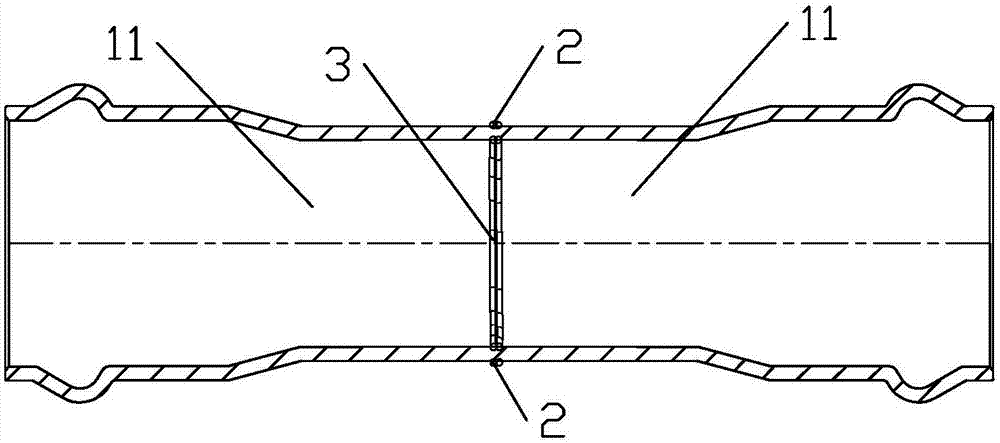

A polymerization reactor of the present invention includes a container body 1 and a jacket 2 covering the outer surface of the container body 1 and defining a passage for passing a cooling / heating medium between itself and the outer surface of the container body. The container body 1 is made of a clad metal plate including a support metal layer 11a having an inner surface at an inner side of the container body and an outer surface at an outer side of the container body, and an inner corrosion-resistant metal skin layer 11b bonded to the inner surface of the support metal layer and being smaller in thickness than the support metal layer.

Owner:SUMITOMO SEIKA CHEM CO LTD

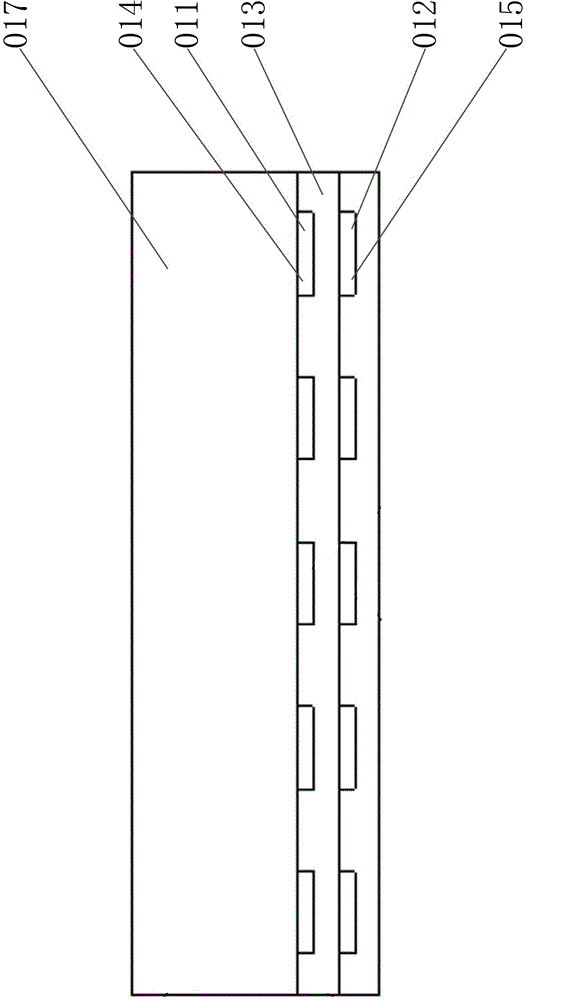

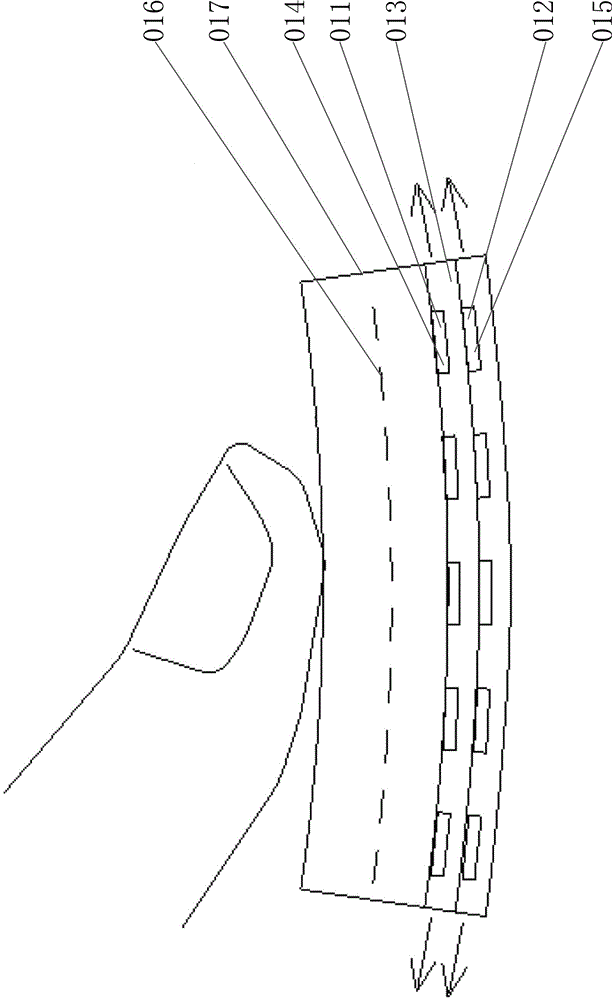

Mechanical induction plate

ActiveCN105675183AShorten heat transfer timeShorten the timeForce measurementElectrical resistance and conductanceDifferential signaling

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD

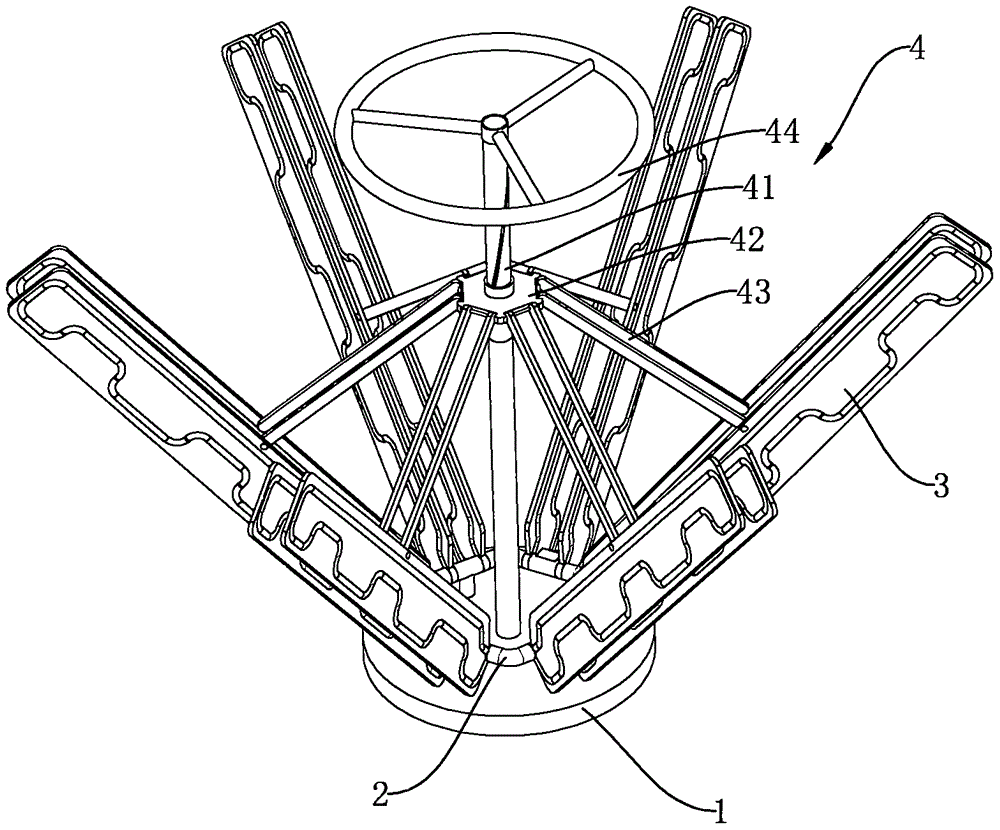

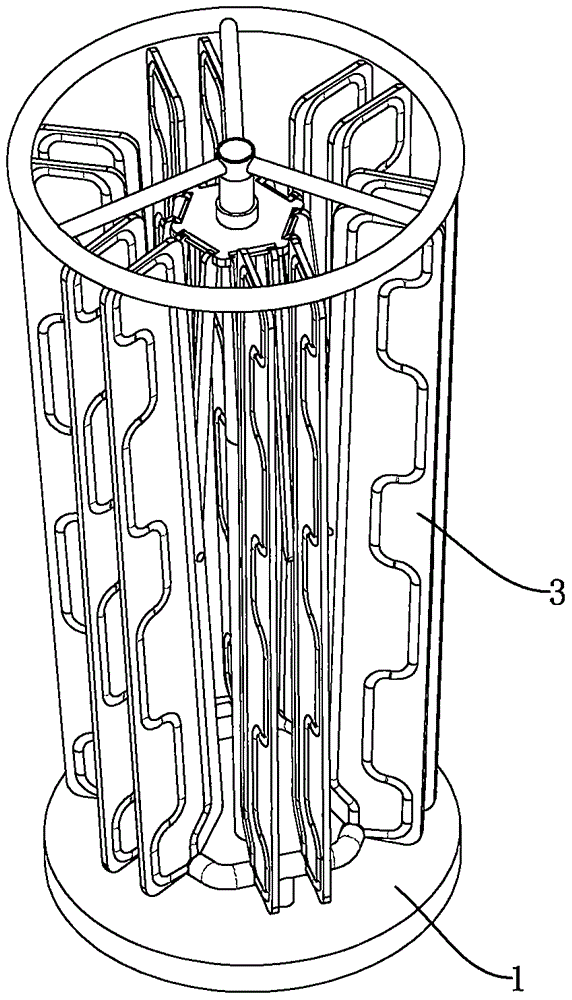

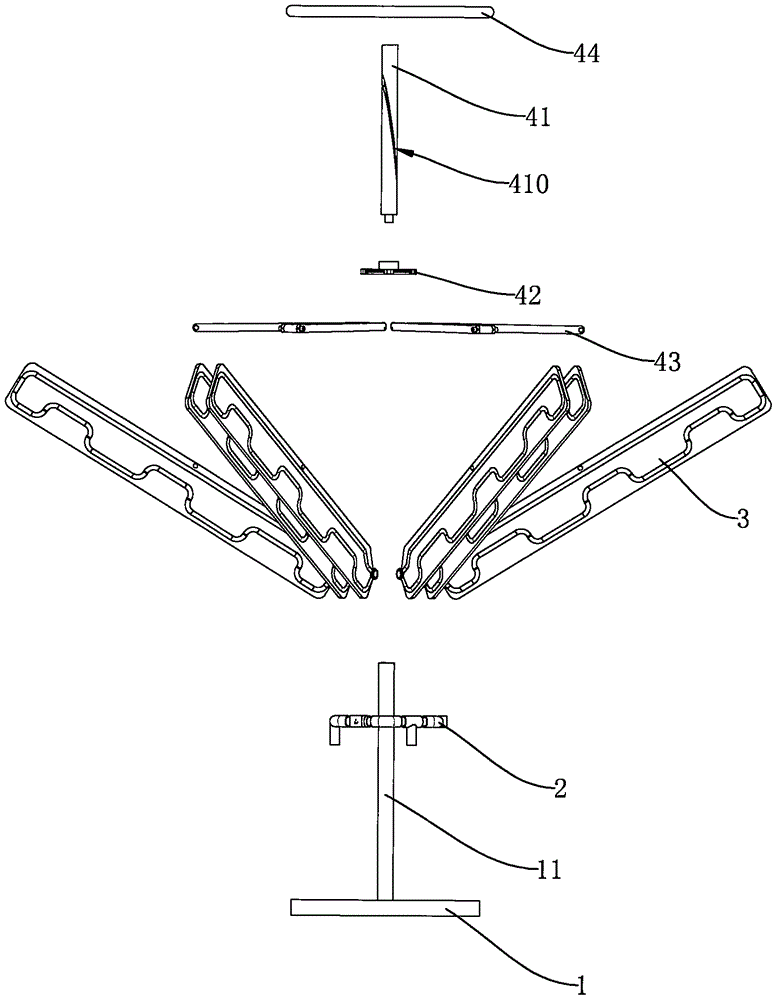

Efficient energy-saving electrical oil heater

ActiveCN105202616AReduce interactionImprove cooling efficiencyLighting and heating apparatusElectric heating systemEngineeringHeat sink

The invention provides an efficient energy-saving electrical oil heater. The efficient energy-saving electrical oil heater comprises a base, a pipeline unit, a plurality of heat sinks and a control unit, wherein the pipeline unit is arranged on the base, the pipeline unit forms a ring shape in a surrounding mode, the heat sinks are installed on the pipeline unit in a rotary mode along the ring shape, the control unit comprises a rotary rod, a control block and a plurality of connecting rods, the rotary rod is arranged on the base in a rotary mode, a rail is arranged on the side wall of the rotary rod, the rail extends upwards in a spiral mode along the side wall of the rotary rod, the control block is arranged on the rotary rod in a sleeving mode, and the control block extends towards the rail to form a clamping block so that the control block can move up and down when the rotary rod rotates; one end of each connecting rod is hinged to the control block, and the other end of each connecting rod is hinged to the corresponding heat sink; when the control block moves to the lowermost end of the rail, the heat sinks rotate outwards to be totally open; when the control block moves to the uppermost end of the rail, the heat sinks rotate inwards to be totally closed.

Owner:NINGBO AOTIAN ELECTRICAL APPLIANCES

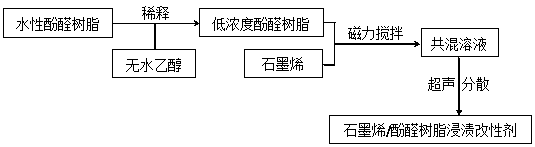

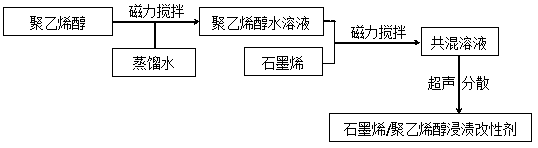

Preparation method of high-heat-conductivity veneer graphene impregnated modified wood

ActiveCN109795000AReduce porosityImprove thermal conductivityPressure impregnationWood impregnation detailsPorosityHeating time

The invention provides a preparation method of high-heat-conductivity veneer graphene impregnated modified wood, which mainly comprises the following steps: 1) preparing a graphene impregnation modifier by taking graphene as a heat-conductivity filler; 2) sorting a veneer, polishing the surface and side edges of the veneer, and drying to obtain a veneer test piece; 3) immersing the veneer test piece in the impregnation modifier, taking out the veneer test piece after vacuum impregnation and normal pressure impregnation, and draining the veneer test piece to obtain the graphene impregnatied modified veneer with improved heat conductivity. The method has the advantages that 1) the porosity of the wood is effectively reduced, so that the density and stability of the wood are enhanced while the heat conductivity of the wood is improved; 2) the heating time of the wood is shortened, the heat transfer efficiency is improved, and the energy consumption is reduced; 3) the wood can be used as abase material to be applied to the production of a ground heating floor, is suitable for various heating modes, and has the advantages of energy saving, consumption reduction, uniform heat dissipation, stable structure and the like.

Owner:NANJING FORESTRY UNIV +1

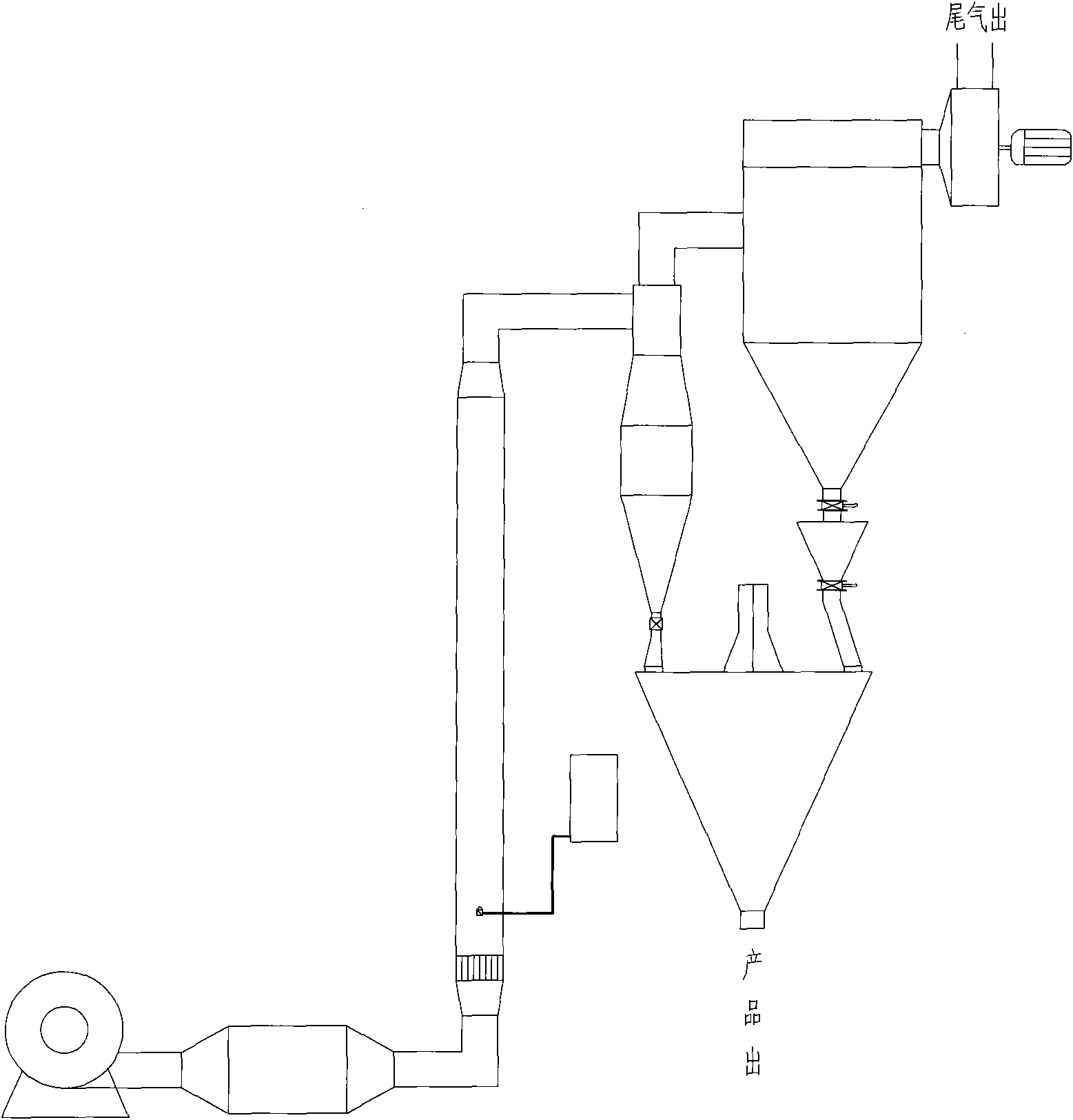

Novel coke stove based on wet-method quenching

PendingCN108611106AQuality improvementImprove qualityCoke quenchingEnergy inputNitrogenMechanical stability

The invention discloses a novel coke stove based on wet-method quenching. The novel coke stove comprises a quenching section as well as a dry distillation section, wherein a plurality of nozzles are arranged at the bottom of the quenching section; the nozzles are divided into two parts; one part of the nozzles are communicated with a nitrogen inlet tube; the other part of the nozzles are communicated with an ammonia water inlet tube; the dry distillation section is arranged above the quenching section; the quenching section comprises an upper section and a lower section which are connected together; the upper section is directly connected with the dry distillation section, is provided with a water cooling wall and is used for carrying out radiation heat exchange with red hot semi-coke at the dry distillation section; a steam outlet tube of the water cooling wall is fed into a power plant through a waste heat boiler; the lower section is an inert gas quenching section. Quenching of cokeis carried out with nitrogen and ammonia water in a spraying manner, so that the quality of the coke is greatly improved, the red coke can be slowly cooled by using a circulated inert gas in a quenching process, cracks caused by water spraying in wet-method quenching can be avoided, the coke is subjected to mechanical pellet shaping in a dry quenching furnace, the uniformity of coke blocks is improved, and the mechanical stability of the coke is improved.

Owner:YULIN UNIV

Polymerization reactor and method for producing water absorbent resin

ActiveUS20170282146A1Efficient productionShorten heat transfer timeChemical/physical/physico-chemical stationary reactorsEngineeringProduced water

A polymerization reactor of the present invention includes a container body 1 and a jacket 2 covering the outer surface of the container body 1 and defining a passage for passing a cooling / heating medium between itself and the outer surface of the container body. The container body 1 is made of a clad metal plate including a support metal layer 11a having an inner surface at an inner side of the container body and an outer surface at an outer side of the container body, and an inner corrosion-resistant metal skin layer 11b bonded to the inner surface of the support metal layer and being smaller in thickness than the support metal layer.

Owner:SUMITOMO SEIKA CHEM CO LTD

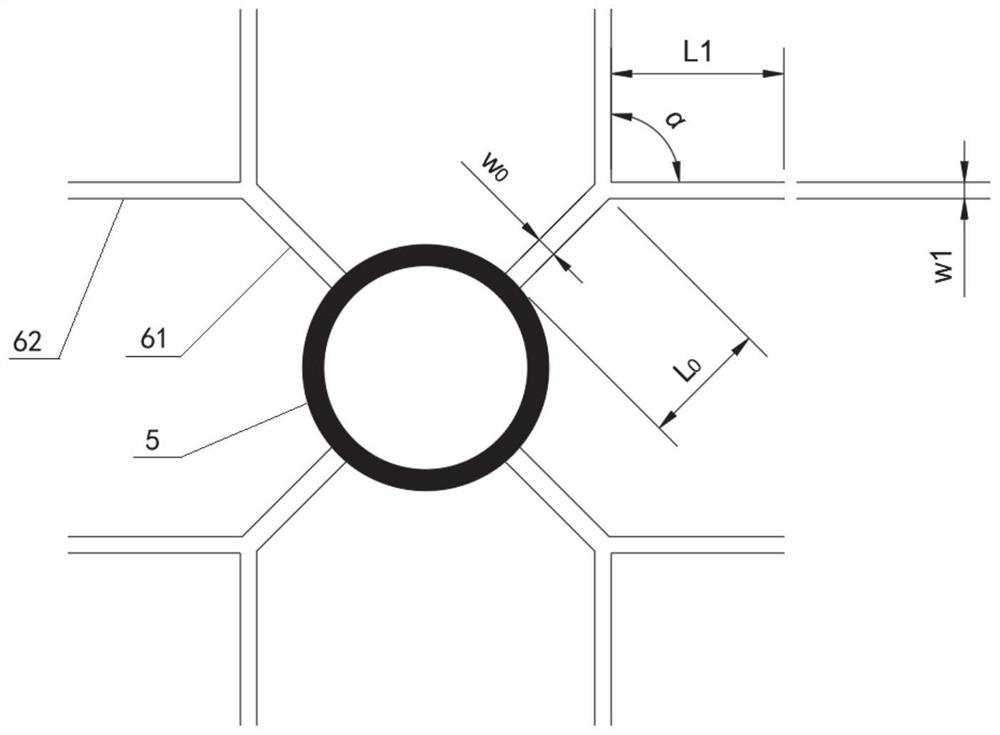

Phase change cold storage device for air conditioner

InactiveCN113218016AEasy to passReduce dosageHeat storage plantsAir conditioning systemsThermodynamicsEnhanced heat transfer

The invention relates to a phase change cold storage device for an air conditioner. The phase change cold storage device comprises a box body, a plurality of heat exchange coil pipes connected in parallel are arranged in the box body, each heat exchange coil pipe extends in an S-shaped bent shape in the length direction of the box body, fractal fins are arranged on the pipe wall of each heat exchange coil pipe, the fractal fins are of a forked structure evenly distributed along the circumference of the pipe walls, the forked structures between the adjacent heat exchange coil pipes are correspondingly connected to form a uniformly arranged net-shaped structure, and the box body is filled with a phase change material. According to the phase change cold storage device, the fractal fins are bionic step-by-step forked tree-shaped structure fins, compared with a common flat plate type fin structure, the fractal fins have the advantages that the heat exchange area is large, heat can be better transferred to the area away from the heat exchange coil pipes, the heat exchange time is greatly shortened, the cold storage and release time is prolonged, compared with other foam metal and other complex enhanced heat transfer forms, the structure is simpler, the price is low, and a better enhanced heat transfer effect is achieved with a smaller amount of metal.

Owner:SOUTHEAST UNIV

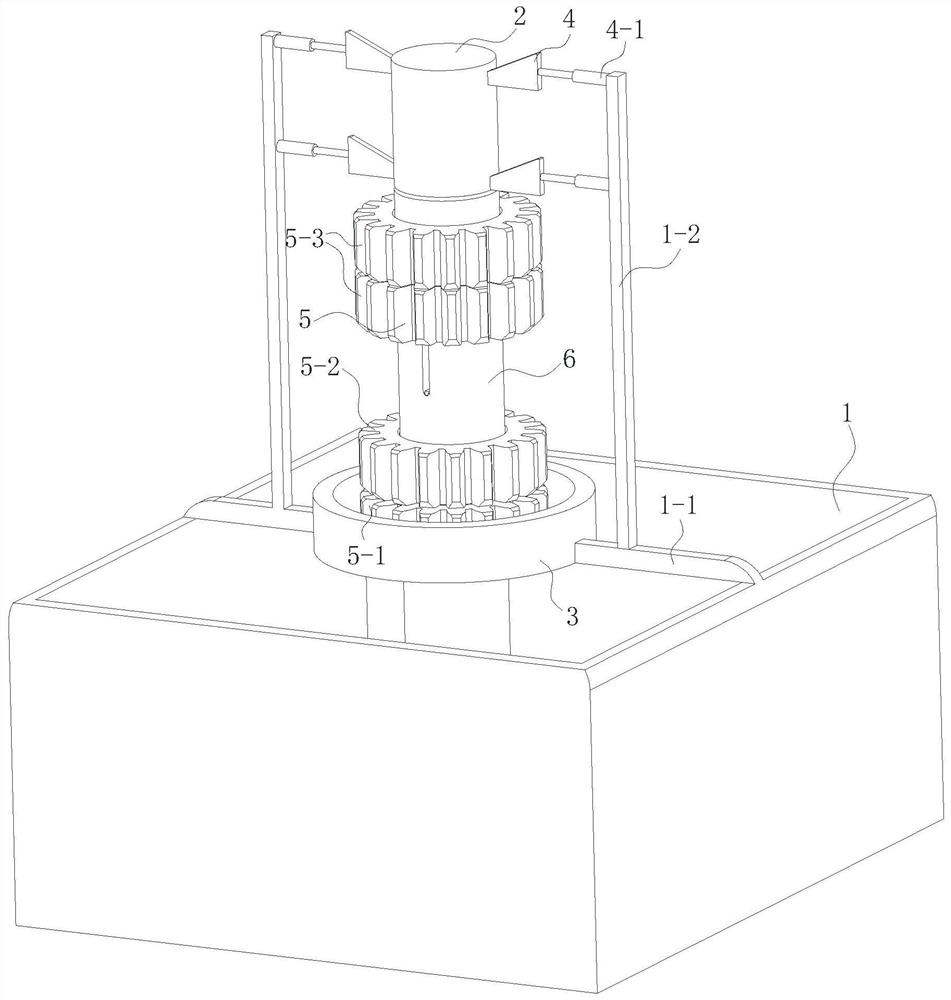

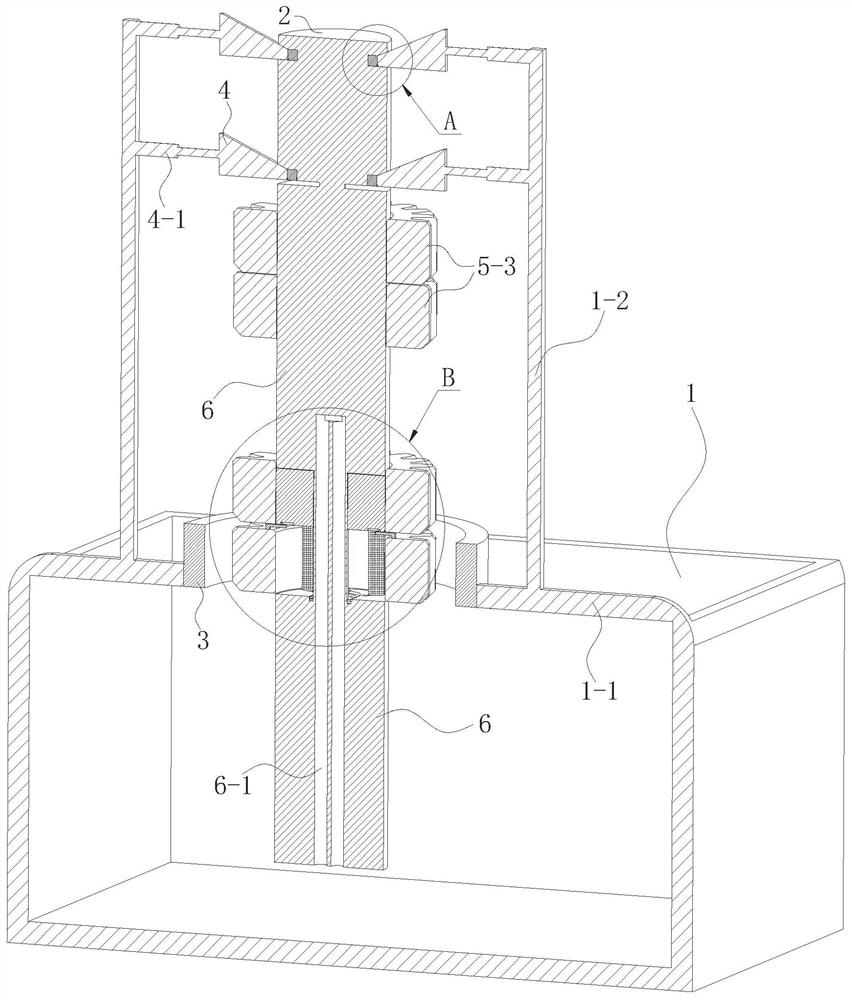

Quenching equipment for gear machining and quenching process of quenching equipment

InactiveCN113462876APrecision quenchingQuality improvementFurnace typesIncreasing energy efficiencyGear wheelInduction heater

The invention discloses quenching equipment for gear machining in the technical field of gear machining. The quenching equipment comprises a cooling pond, a high-frequency magnetic induction heater, gears and a rotating shaft, and is characterized by further comprising a fixed shaft, wedge-shaped supporting plates, an electromagnet, an annular limiting rod, a sliding column and a limiting connecting rod; the high-frequency magnetic induction heater is fixedly installed at the upper end of the cooling pond, the four wedge-shaped supporting plates are vertically distributed in pairs and symmetrically arranged above the high-frequency magnetic induction heater relative to the axis of the high-frequency magnetic induction heater, the wedge-shaped supporting plates are all connected with the fixed shaft in a clamped mode, and the fixed shaft and the high-frequency magnetic induction heater are coaxial; the lower end of the rotating shaft is rotationally mounted at the lower end of the fixed shaft, and the multiple gears sleeve the rotating shaft; and the wedge-shaped supporting plates, the electromagnet, the annular limiting rod, the sliding column and the limiting connecting rod are all mounted on the rotating shaft and used for controlling the positions of the gears on the rotating shaft. Compared with a conventional method for controlling the quenching degree through time, the quenching time is controlled through the quenching degree, so that the quality of the gears is stable, and the quality is high.

Owner:黄林枢

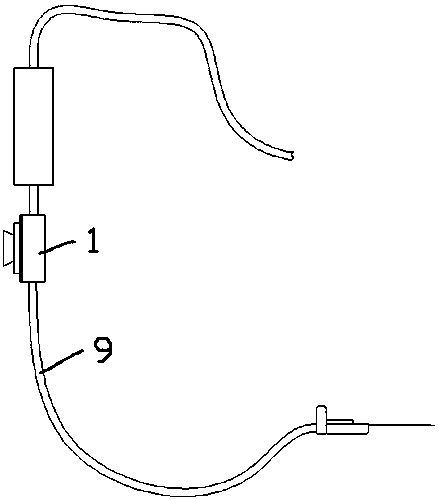

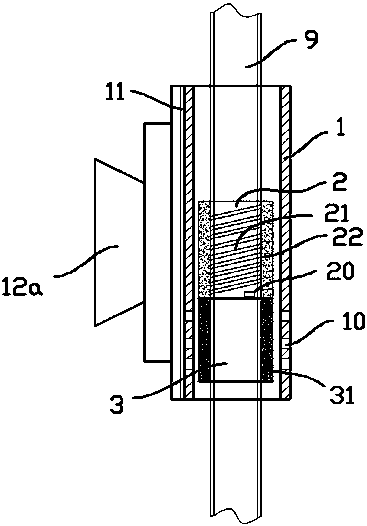

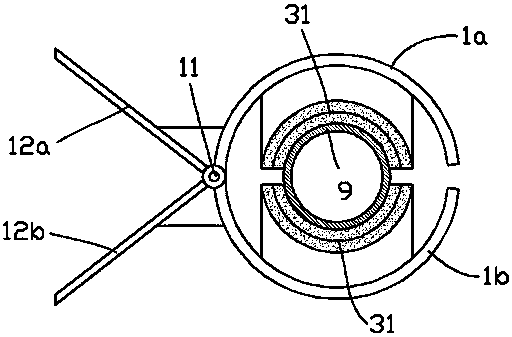

Reminding type medical infusion heating device

InactiveCN111529835AShorten heat transfer timeReduce cooling effectMedical devicesIntravenous devicesCold sideEngineering

The invention provides a reminding type medical infusion heating device. The reminding type medical infusion heating device comprises a tubular shell clamped outside an infusion tube, wherein the interior of the tubular shell at least comprises a constant-temperature cavity and a refrigerating cavity from top to bottom; a temperature sensor and a heating device which are jointly coupled to a heating control module are arranged in the constant-temperature cavity, so that a liquid medicine flowing through the constant-temperature cavity is kept at a preset temperature; an arc-shaped semiconductor chilling plate capable of being clamped on the surface of the infusion tube in a wrapping mode is arranged in the refrigerating cavity, and the cold face of the semiconductor chilling plate is keptin heat conduction contact with the infusion tube. The device not only can heat the liquid medicine, but also can enable a patient to sense the infusion speed in real time.

Owner:仲杏英

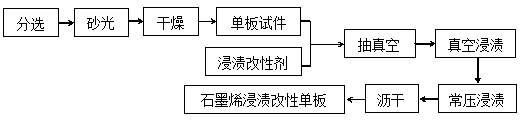

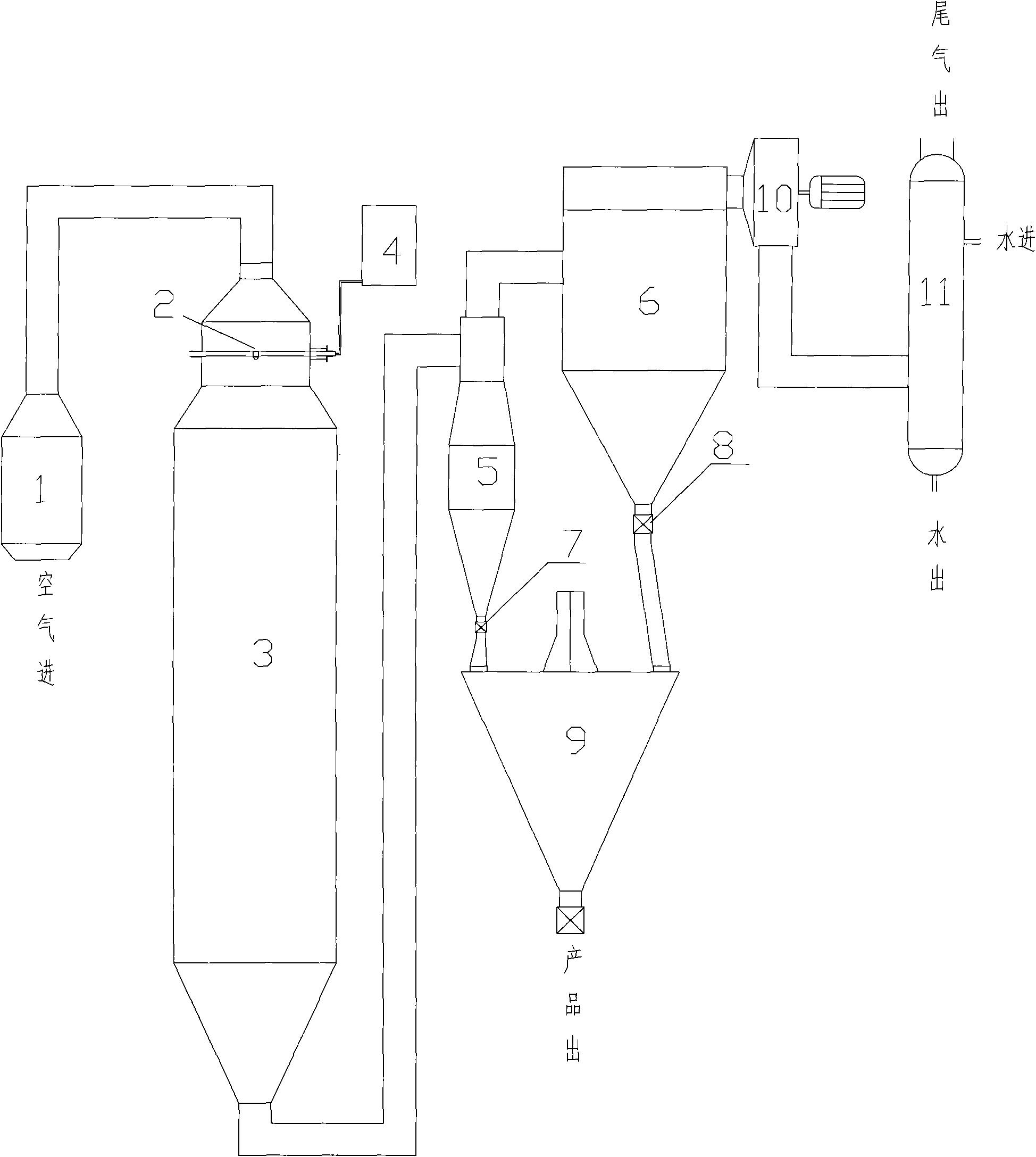

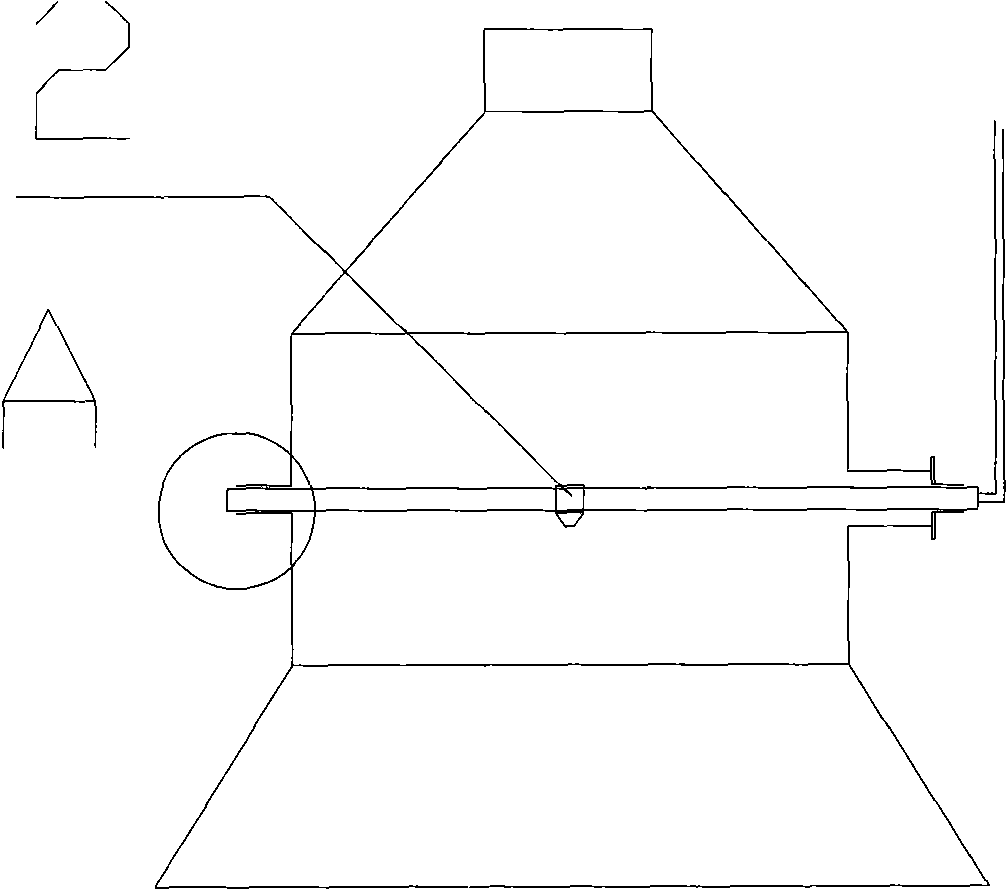

Complexation state mancozeb top-jet-type drying method and device thereof

InactiveCN101629776AAvoid wall stickingEliminate unsafe factors such as fire and explosionBiocideDrying solid materials with heatComing outAtmospheric air

The invention discloses a complexation type mancozeb top-jet-type drying method. In the invention, sizing agents after complex reaction enter from the top of a spray drying tower, and move downwards in a rotational flow mode in the spray drying tower; the drying temperature is 230 DEG C, the pressure of compressed air is from 0.4 MPa to 0.6 MPa, and the outlet temperature of the spray drying tower is less than or equal to 80 DEG C; and the angle of the materials coming out of an atomizer during atomization is from 50 degrees to 60 degrees. Atmosphere is communicated to an inlet of a heat interchanger, an outlet is connected with an inlet of the spray drying tower, an outlet of the spray drying tower is connected with an inlet of a cyclone separating device, and the airflow type atomizer is fixed at the top end of the drying tower by an atomizer fixing device, wherein the atomizer fixing device comprises a fixing rod, an axial fixing bolt, three radial fixing bolts, three sealing gland fixing bolts and a sealing gland. The axial fixing bolt is arranged at the end of the fixing rod, the three radial fixing bolts are uniformly distributed around the fixing rod and are perpendicular to the fixing rod, the three sealing gland fixing bolts are uniformly distributed at the circumference of the fixing rod and are 3 to 10 centimeters away from the axial direction of three radial fixing bolts.

Owner:LIMIN CHEM CO LTD

Water pumping and compressed air energy storage system and method for storing energy and heat by utilizing geothermal well

ActiveCN114754519ARun fastGuaranteed uptimeHeat pumpsGeothermal energy generationWater storageCombustion chamber

The invention discloses a water pumping compressed air energy storage system and method for storing energy and heat through a geothermal well. The water pumping compressed air energy storage system comprises a compressor unit, a heat exchanger, a combustion chamber unit and an expansion unit. An outlet of each stage of compressor is connected with a heat exchanger, the heat exchanger is connected with a cold water storage pool and a hot water storage pool, the heat exchanger is further connected with a combustion chamber unit and a first geothermal well, and a combustion chamber is arranged in the combustion chamber unit. An outlet of the first geothermal well is sequentially connected with a third heat exchanger, a variable frequency water pump, a fourth heat exchanger and a second geothermal well, the fourth heat exchanger is further connected with an under-pressure water turbine, and the under-pressure water turbine is connected with the third heat exchanger. The compressor air energy storage system, the underground geothermal well, the variable frequency water pump and the pressurized water turbine are mutually coupled, low-grade compression heat and exhaust waste heat of the expansion machine during energy storage are utilized, the energy utilization efficiency is improved, and meanwhile the effect of improving the geothermal recovery function is achieved.

Owner:XI AN JIAOTONG UNIV

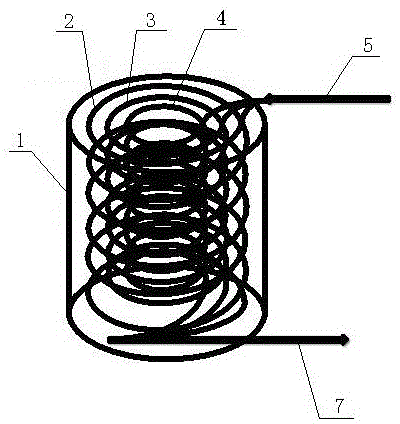

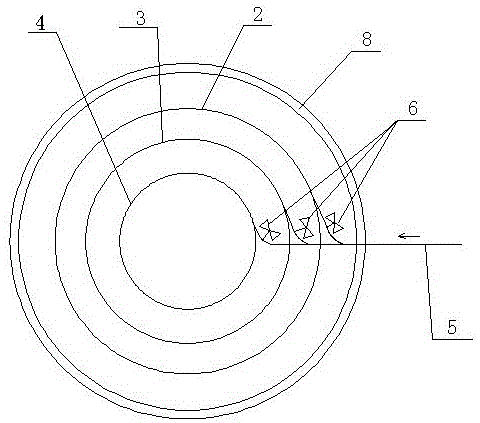

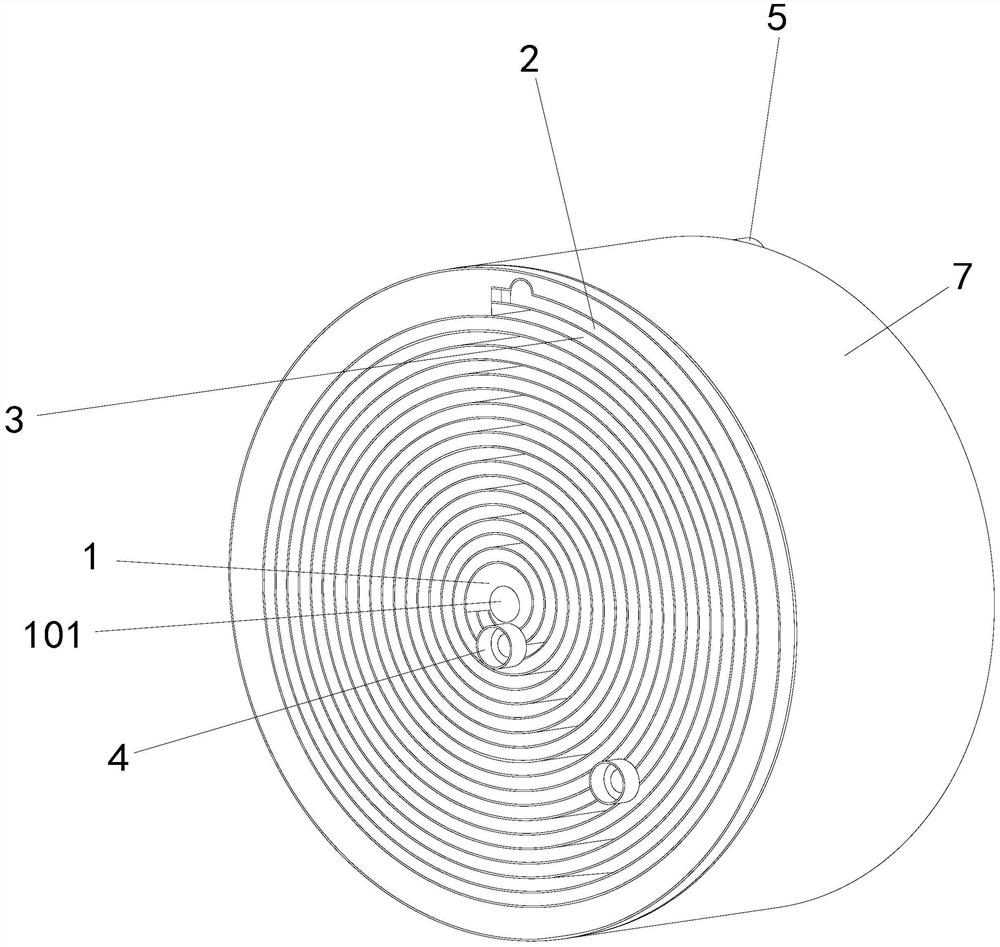

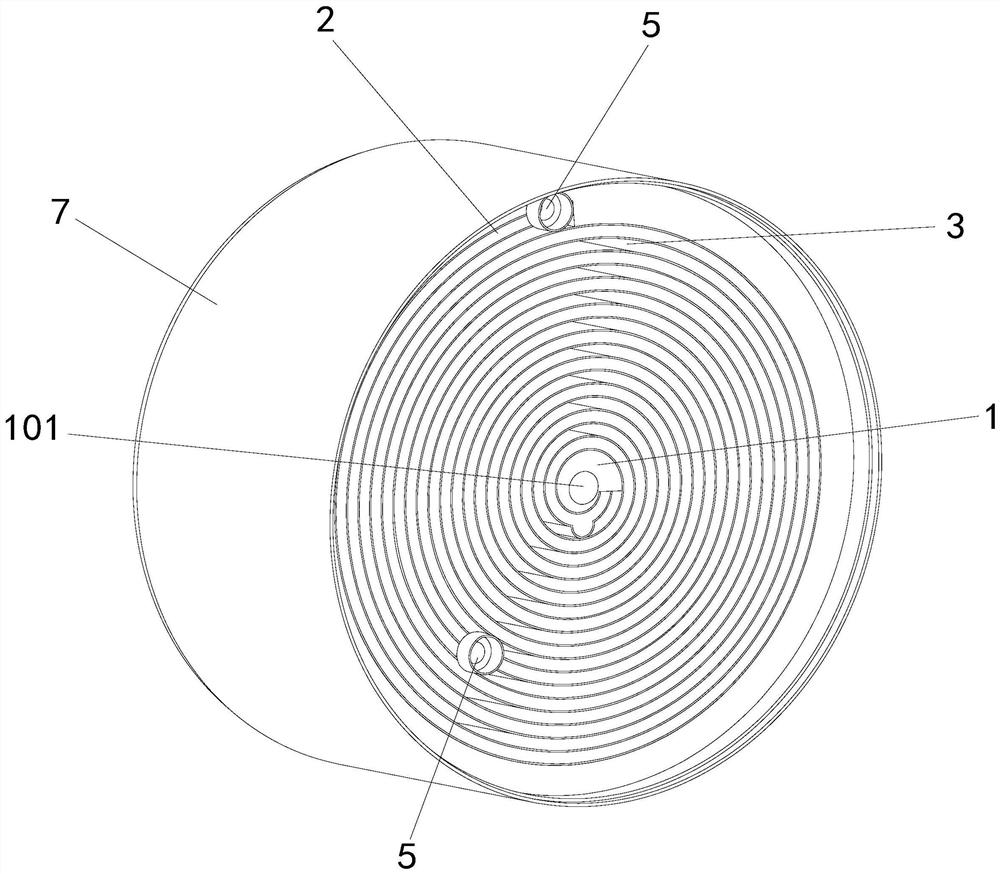

Multilayer cylindrical spiral pipe solar storage tank

InactiveCN105129264AAchieve innovationRealize the purpose of energy savingTank wagonsHeat transfer efficiencyEngineering

The invention relates to a multilayer cylindrical spiral pipe solar storage tank. A tank body of the multilayer cylindrical spiral pipe solar storage tank is cylindrical, three cylindrical spiral heat transfer pipeline layers are arranged on the tank body from inside to outside, namely, an outer cylindrical spiral heat transfer pipeline layer, a middle cylindrical spiral heat transfer pipeline layer and an inner cylindrical spiral heat transfer pipeline layer, and each cylindrical spiral heat transfer pipeline layer penetrates in the tank body from top to bottom. A fluid inlet pipe is divided into three inlet branch pipes, each branch pipe is provided with an adjusting valve, and the three inlet branch pipes are connected with inlets of the cylindrical spiral heat transfer pipeline layers respectively and are in one-to-one correspondence with the inlets. Outlets of the three cylindrical spiral heat transfer pipeline layers are gathered to an outlet manifold at the bottom of the tank body, and the outlet manifold extends out of the tank body. A heat preservation layer is arranged on the outer wall of the tank body. By means of the multilayer spiral pipe distribution structure, the heat transfer efficiency of a system is improved, the heat transfer time of the system is shortened, and energy saving of the system is achieved.

Owner:NORTHEAST GASOLINEEUM UNIV

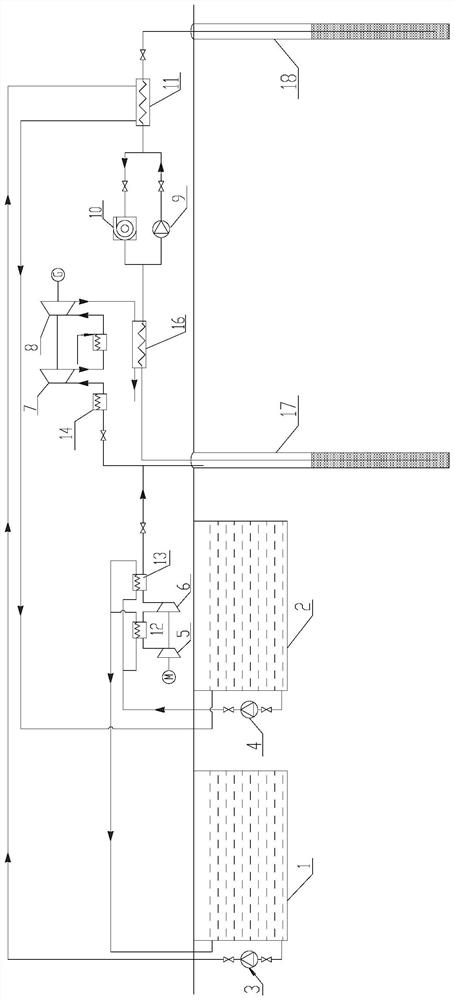

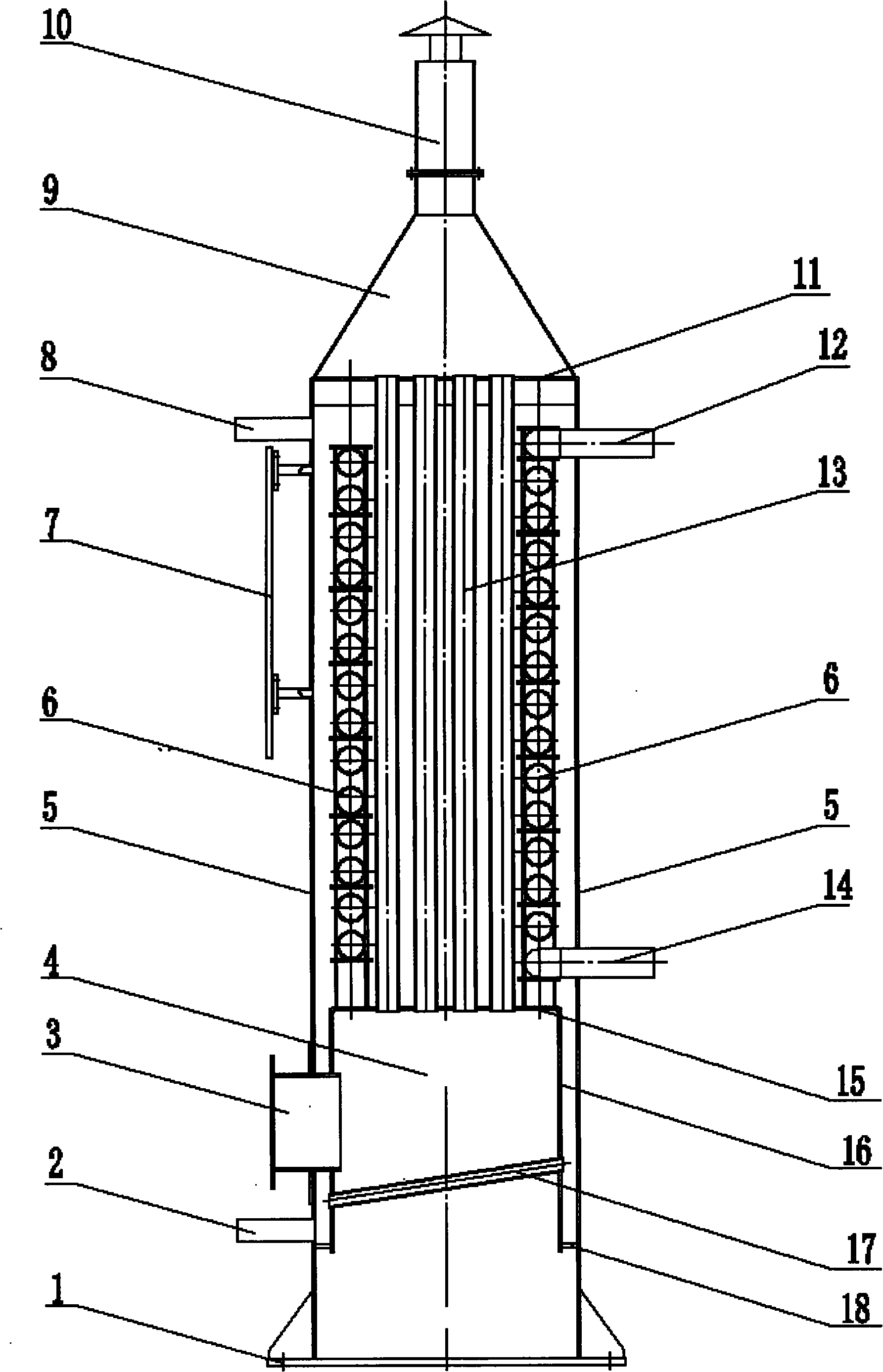

Flue gas waste heat recovery and heat exchange system

PendingCN109520333AImprove heat transfer efficiencyReduce security risksCombustion technology mitigationStationary plate conduit assembliesBusiness efficiencyFlue gas

The invention relates to a flue gas waste heat recovery and heat exchange system which perform heat exchange on waste heat water and heat supply water to recover waste heat in flue gas and reach efficient heat exchange on water. The flue gas waste heat recovery and heat exchange system comprises a control unit, a water tank used for storing the waste heat water, a waste heat exchange device and acirculation pump; the control unit is arranged outside a pipeline, is used for controlling the pipeline and can perform detection on a detection difference before and after heat exchange on heat supply water in the pipeline and controls the pipeline to reach a corresponding state after the pipeline starts to run; the waste heat exchange device is connected with the water tank and is used for performing heat exchange on the waste heat water and the heat supply water; and the circulation pump is connected with the waste heat exchange device and is sued for controlling a circulation pump for running of the waste heat water and the heat supply water in the pipeline. The flue gas waste heat recovery and heat exchange system uses the waste heat to cool flue gas when the flue gas is not treated,can reach the maximum heat exchange efficiency, performs heat exchange on the waste heat water and the heat supply water without causing dangers due to leakage at the same time, lowers the safety hidden dangers in the system and is high in recovery energy efficiency ratio.

Owner:启明星宇节能科技股份有限公司

Manufacturing method for PVC straight-through pipe and PVC straight-opening reducer tee joint

ActiveCN107504306AIncreasing the thicknessHigh strengthBranching pipesDomestic articlesFree coolingReducer

The invention relates to a manufacturing method for a PVC straight-through pipe and a PVC straight-opening reducer tee joint. The manufacturing method comprises the following steps that pipe-shaped objects are cut into required lengths and angles through a multi-angle pipe sawing machine; the cut pipe-shaped objects are placed on a welding machine clamp and well fixed; the to-be-welded end faces of the two pipe-shaped objects are treated to be level and smooth; the end faces are folded, the centering situation is checked, the staggered edges of the two to-be-welded end faces are no more than 10% of the wall thickness, and otherwise, adjusting is conducted through the clamping force of the clamp and the end faces are treated to be level and smooth again; a welding machine heating plate is placed between the two pipe ends, the pressure P1 is gradually exerted within the time T1, so that the pipe ends are pressed on the heating plate to be heated, after uniform welding beads are formed, the pressure is gradually decreased to be P2 and maintained to be P2, and heat is absorbed; the pipe ends are released, the heating plate is taken out, and then the pipe ends are folded again; the pressure is gradually increased from 0 to P1, so that the pipe welding parts inwards and outwards form uniform turned edges; and the pressure P1 is maintained, so that the welding parts are naturally cooled.

Owner:JIANGSU HUASHENG PLASTIC

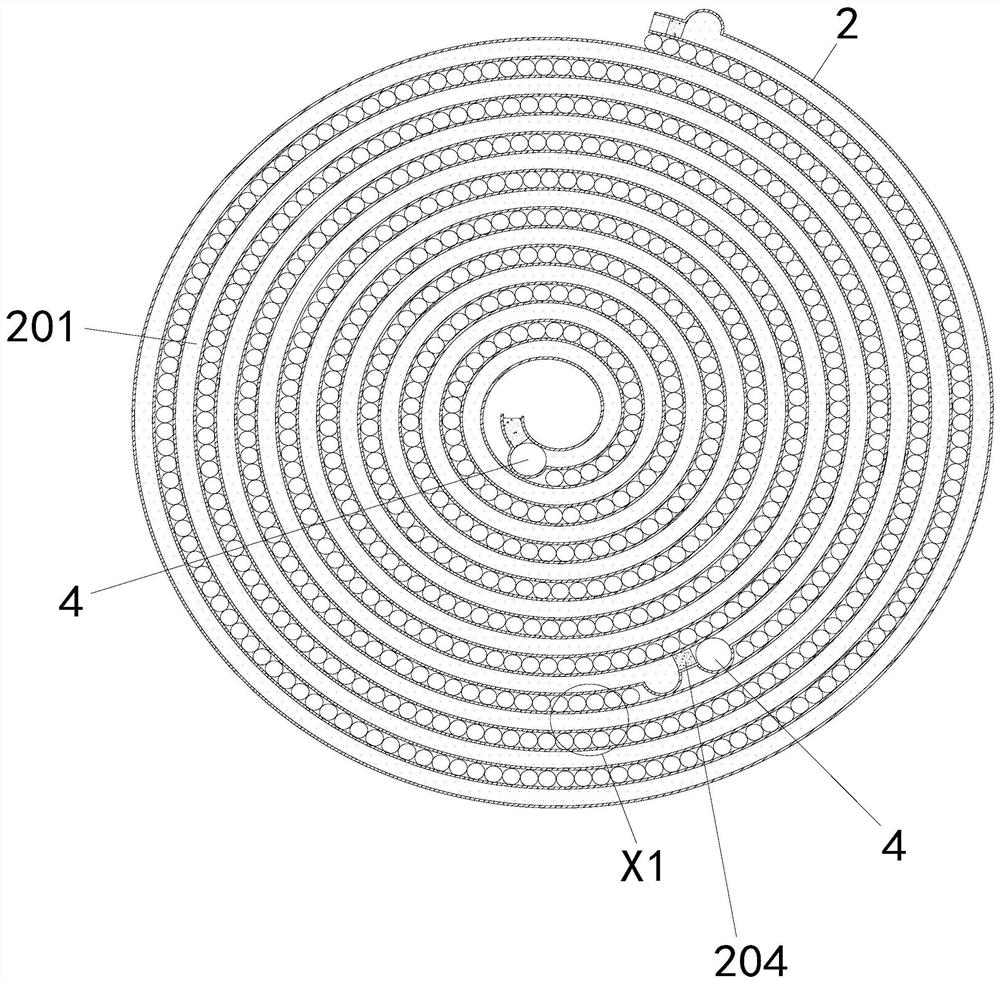

Spiral heat exchanger

PendingCN112378280AImprove heat transfer effectReduce the difficulty of cleaningHeat exchanger casingsStationary plate conduit assembliesMechanical engineeringMechanics

The invention relates to a spiral heat exchanger. The spiral heat exchanger comprises a mandrel with the axis extending leftwards and rightwards, and liquid flowing winding belts which are spirally wound around the periphery of the mandrel by at least two circles and internally provided with spiral liquid channels; and the liquid flowing winding belts of any two adjacent ring layers are spaced bya certain distance, so that a spiral air flowing channel which is through left and right is formed, a liquid channel separation strip which extends left and right is arranged in each liquid flowing winding belt, the liquid channel separation strips separate the spiral liquid channels into a plurality of liquid flow branch channels which are sequentially arranged in the spiral direction and are isolated from one another, the inner side end and the outer side end of each liquid flow branch channel in the spiral direction are provided with a first liquid inlet and outlet connector and a second liquid inlet and outlet connector respectively, wherein the first liquid inlet and outlet connectors and the second liquid inlet and outlet connectors are in communication through the liquid flow branchchannels. The heat exchanger is large in heat exchange amount and high in heat exchange efficiency.

Owner:SHANGHAI XINGYE MATERIALS TECH CO LTD

Assembled heat sink

InactiveCN107644856AImprove cooling effectImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesChemical factorEngineering

The invention relates to the field of electrical technologies, and in particular relates to an assembled heat sink. According to the assembled heat sink provided by the invention, a graphene heat dissipation film layer can accelerate the heat dissipation effect and the heat conduction performance of the heat sink; the heat transfer time between the heat sink and an electrical component is shortened; the heat dissipation effect is improved; a corrosion-resistant protective film layer is arranged to improve the corrosion resistance of the surface of the heat sink body; the graphene film layer isprotected; the graphene film layer is prevented from being damaged by physical or chemical factors, and the service life is not affected; heat dissipation through-holes are arranged, which greatly improves the heat dissipation function of the heat sink; the heat sink is detachably assembled on the heat sink body, which is easy for maintenance and replacement; and the assembled heat sink has the advantages of simple and reasonable structure, simple preparation process and low production cost.

Owner:BIHE ELECTRIC TAICANG CO LTD

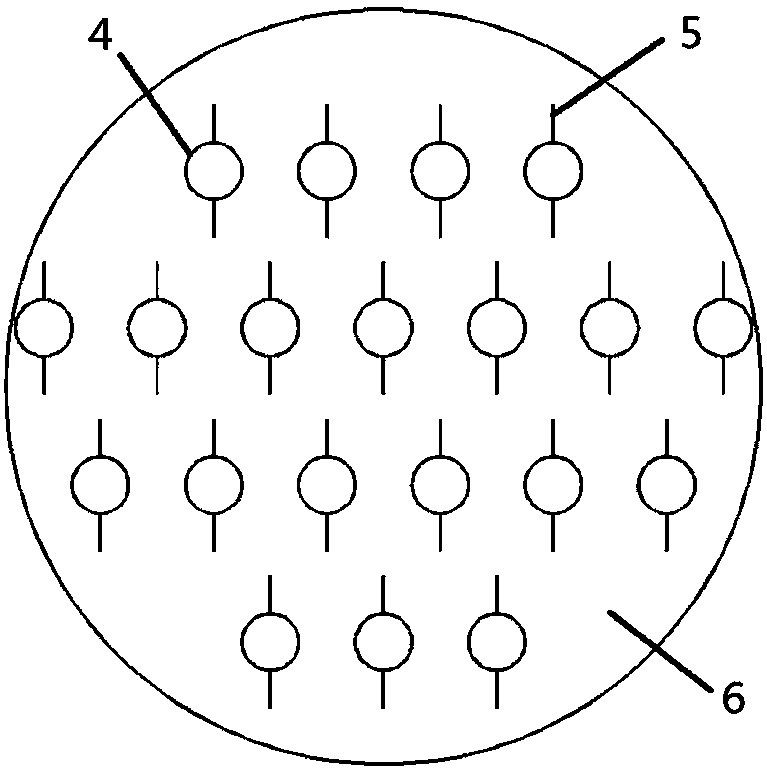

Heat exchange pipe for petrochemical machinery

ActiveCN106500530AEasy to maintain normal operationIncrease contact areaHeat exhanger sealing arrangementHeat exchanger casingsRubber ringCapillaria obsignata

The invention provides a heat exchange pipe for petrochemical machinery. The heat exchange pipe comprises capillary heat exchange pipe bodies, the capillary heat exchange pipe bodies are provided with capillary pipe heat exchange fins, and the two ends of the capillary heat exchange pipe bodies are both provided with input and output buffer pipes. The portions, close to the two ends of the capillary heat exchange pipe bodies, of the interiors of the input and output buffer pipes are both provided with internal heat exchange fluid input and output pipe openings. The connection positions of the capillary heat exchange pipe bodies and the input and output buffer pipes are provided with capillary pipe sealing rubber ring, the ends, away from the capillary heat exchange pipe bodies, of the input and output buffer pipes are provided with threaded connection pipe heads, and the sides, close to the input and output buffer pipes, of the threaded connection pipe heads are provided with connection pipe head sealing rings. The strip-shaped capillary heat exchange pipe bodies are distributed in an array manner, the contact areas of heat exchange fluid and the pipe bodies are increased, thereby raising the heat exchange speed and improving heat exchange efficiency, and it is convenient to protect normal operation of the petrochemical machinery; meanwhile, the capillary heat exchange pipe bodies are evenly provided with the capillary pipe heat exchange fins, so that heat exchange efficiency is further enhanced.

Owner:江苏泽楚建设有限公司

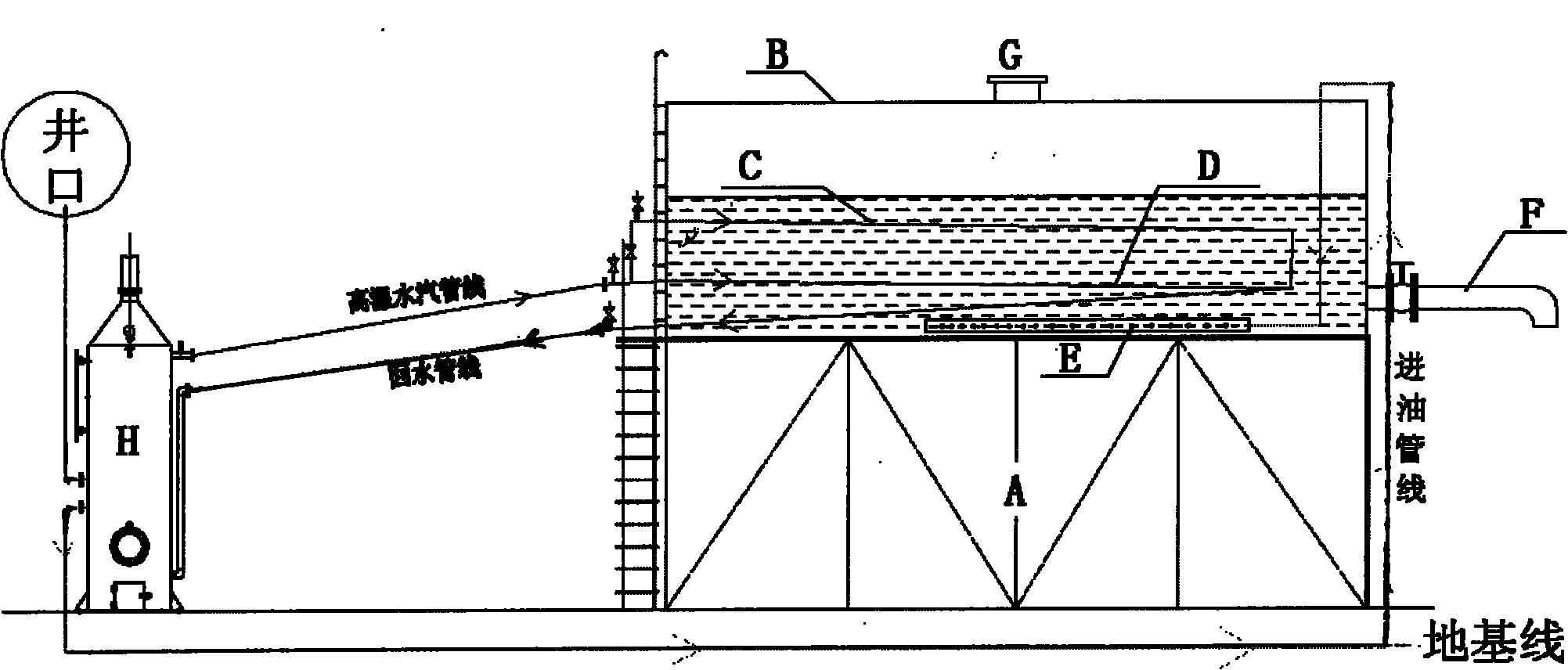

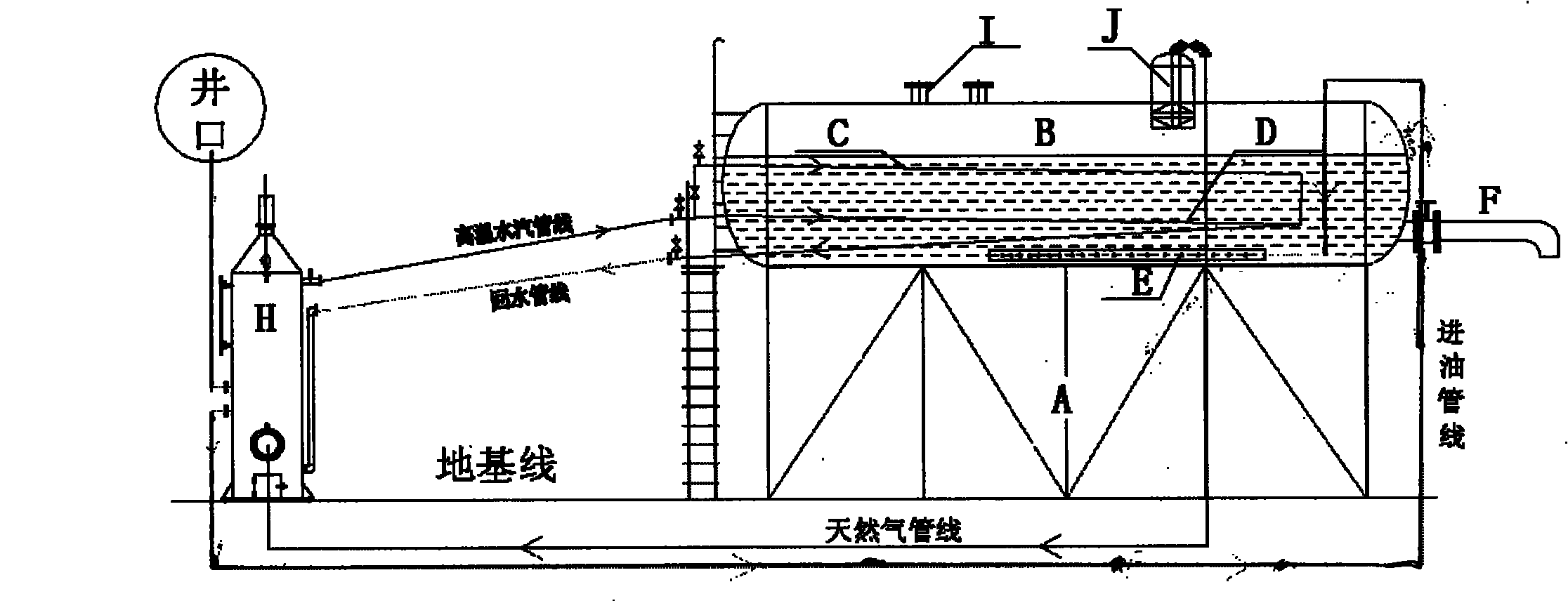

Natural circulation phase change heating storage tank

The invention relates to a natural circulation phase-change heating oil storage tank. The technical scheme is as follows: the natural circulation phase-change heating oil storage tank consists of a phase-change heating furnace, an oil storage tank and a pipeline system, wherein the phase-change heating furnace is connected with the oil storage tank by the pipeline system; the oil storage tank comprises two forms such as a normal pressure tank or a bearing and separating tank; the pipeline system consists of a crude oil pipeline, a gas pipeline and water-vapor circulation pipelines, and the crude oil pipeline and the gas pipeline are laid under a foundation line; the water-vapor circulation pipelines are erected from the air, and are divided into an upper layer and a lower layer, wherein the upper layer is high-temperature water-vapor tank inlet pipelines and the lower layer is a condensed water return pipeline. When in working, phase change is utilized for heat transferring so as to realize backflow naturally without needing a forced circulation system such as a hot water pump and the like, and the heat efficiency reaches or exceeds that of the 'heart-burn' structure; the matched heating furnace combines the advantages of a water jacket furnace and a pipe type furnace, and is equipped with a single-well coiled pipe; especially, a hearth adopts a water-cooling wall structure, and a fire grate adopts water-cooling pipes without using refractory bricks, so that the volume is smaller, the weight is light, the heat loss is less, and the heat efficiency is high. The heating furnace can achieve the purpose of burning three types of fuels such as coal, gas and oil simultaneously.

Owner:刘凯

Heat preservation container capable of quickly transferring heat and preparing method of heat preservation container

InactiveCN106263966ARapid coolingShorten heat transfer timeNon-pressured vesselsDrinking vesselsEngineeringPhase change

The invention relates to a heat preservation container capable of quickly transferring heat and a preparing method of the heat preservation container. The heat preservation container capable of quickly transferring heat comprises a hot container, a cold container and a shell wrapping the outer surfaces of the two containers. A vacuum cavity is defined by the hot container, the cold container and the shell. The lower half part of the vacuum cavity is filled with a heat transfer medium, and the height of the heat transfer medium in the vacuum cavity is lower than the bottom of the hot container. The preparing method comprises the steps that the containers are welded to the shell, a process opening is reserved, and the sealed cavity is formed by the shell and the outer surfaces of the containers; the sealed cavity is vacuumized through the process opening, and the heat transfer medium is injected into the cavity through the process opening after vacuumizing is finished, wherein the height of the heat transfer medium in the vacuum cavity is lower than the bottom of the hot container; the process opening is sealed. The heat preservation container can preserve heat and can also quickly transfer heat through the phase change of the heat transfer medium, the heat transfer time is greatly shortened, and cooling is fast; the preparing method is simple, and the processing cost is low.

Owner:苏州图卡节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com