Efficient energy-saving electrical oil heater

An electric heating oil heater, high-efficiency and energy-saving technology, applied in the direction of electric heating systems, household heating, heating methods, etc., can solve the problems of slow heat dissipation, single appearance, low heating efficiency, etc., to reduce the occupied space, convenient and quick to fold or The effect of expansion and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

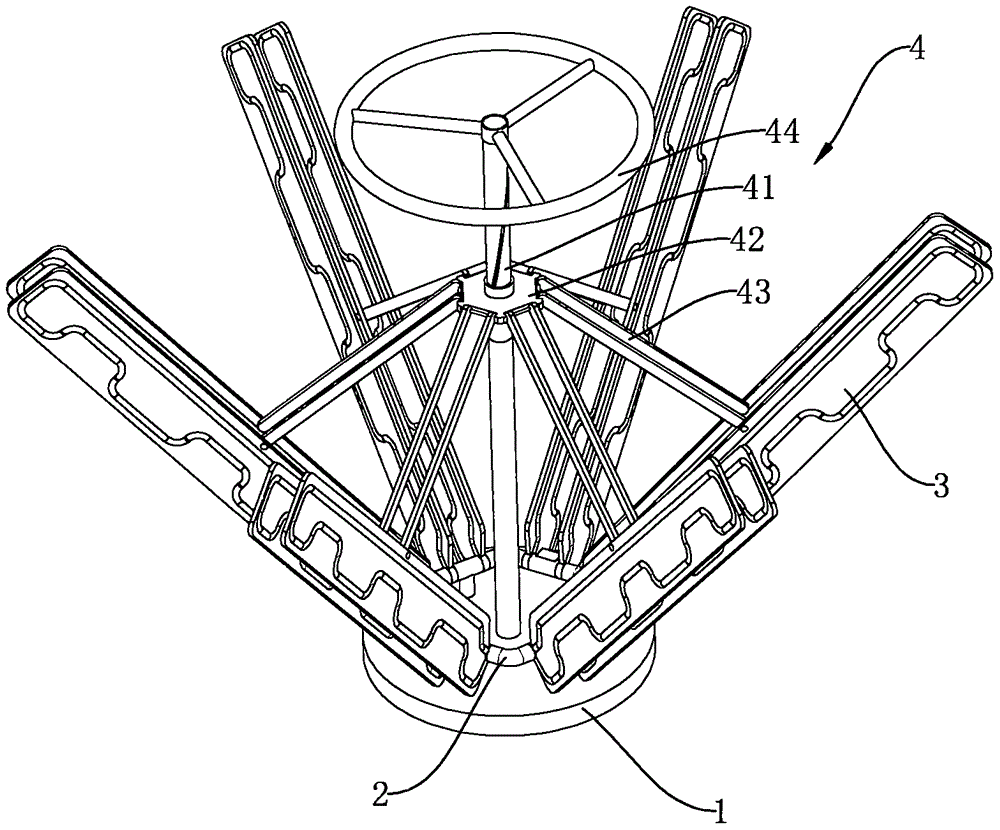

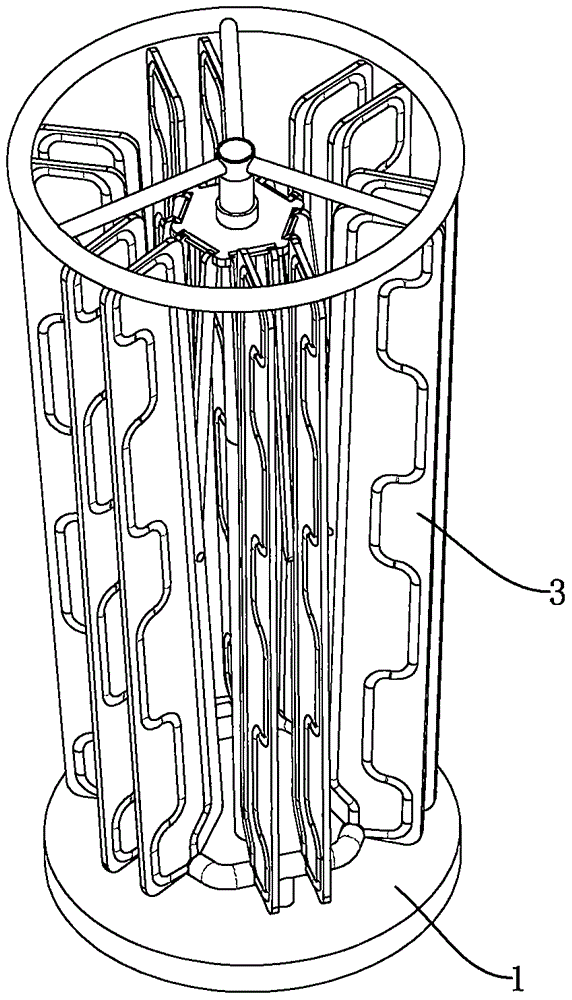

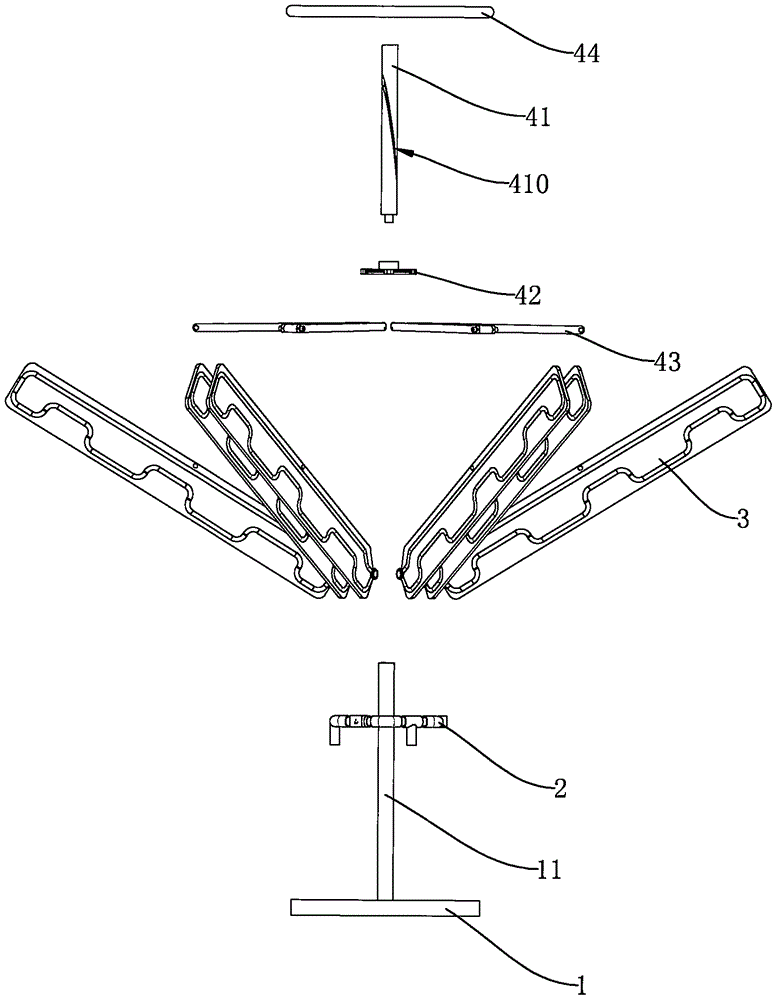

[0024] Figure 1-7 A preferred embodiment of the electric heating oil heater of the present invention is shown, and the electric heating oil heater includes a base 1 , a pipeline unit 2 , a plurality of cooling fins 3 and a control unit 4 .

[0025] The pipeline unit 2 is arranged on the base 1, and the pipeline unit 2 is surrounded by a ring shape, and each cooling fin 3 is arranged along the ring shape of the pipeline unit 2, and the lower end of each cooling fin 3 is rotatably installed on the pipeline unit 2, so that when When each cooling fin 3 rotates inward at the same time, each cooling fin 3 is in a closed state; when each cooling fin 3 rotates outward at the same time, each cooling fin 3 is in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com