Complexation state mancozeb top-jet-type drying method and device thereof

A technology of mancozeb and drying method, applied in drying solid materials, botanical equipment and methods, heating to dry solid materials, etc., can solve the problems of intermittent discharge, high temperature of bag filter, and eliminate fire and explosion. , the effect of saving power consumption and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

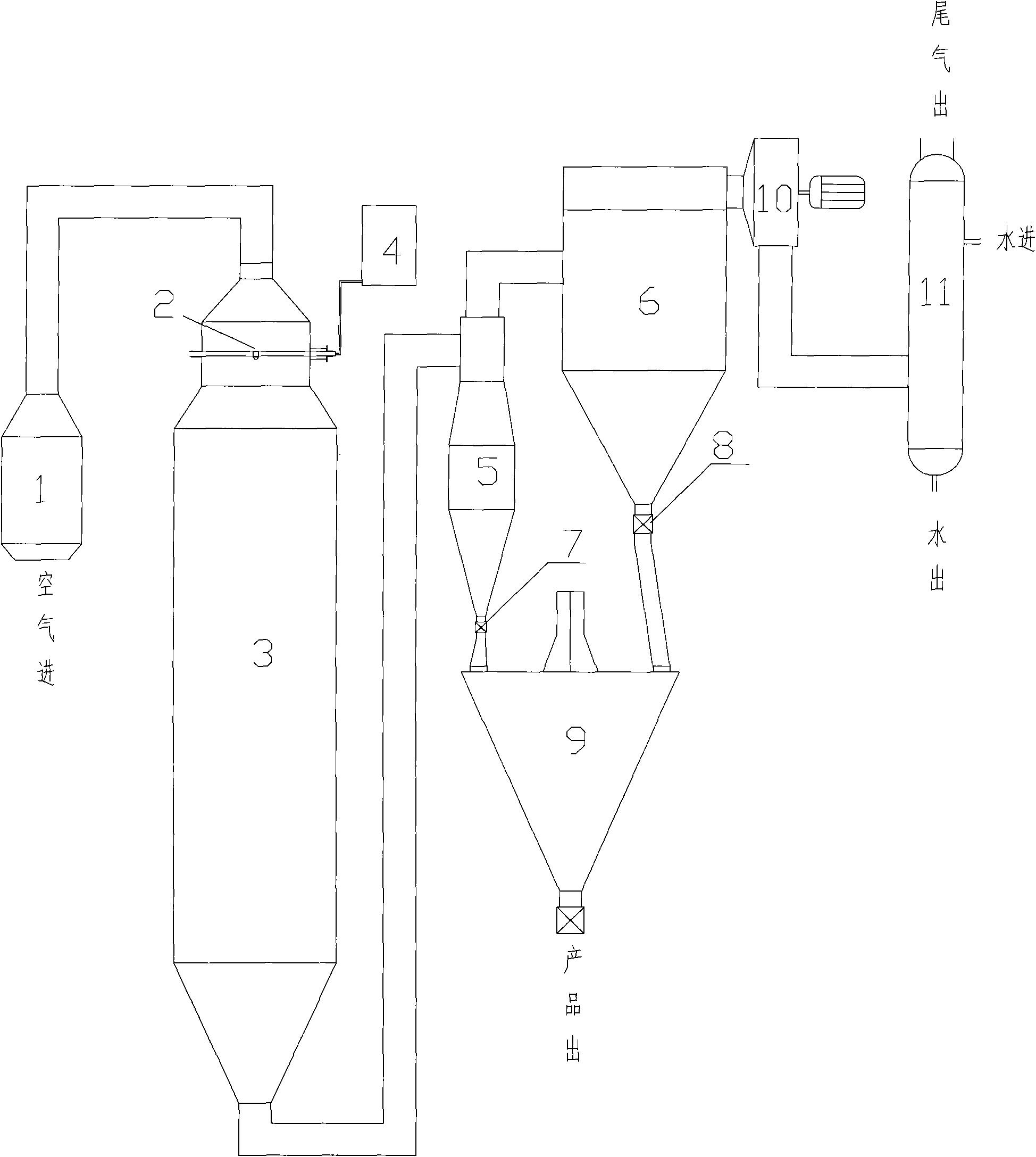

[0018] The present invention is described in detail in conjunction with accompanying drawings.

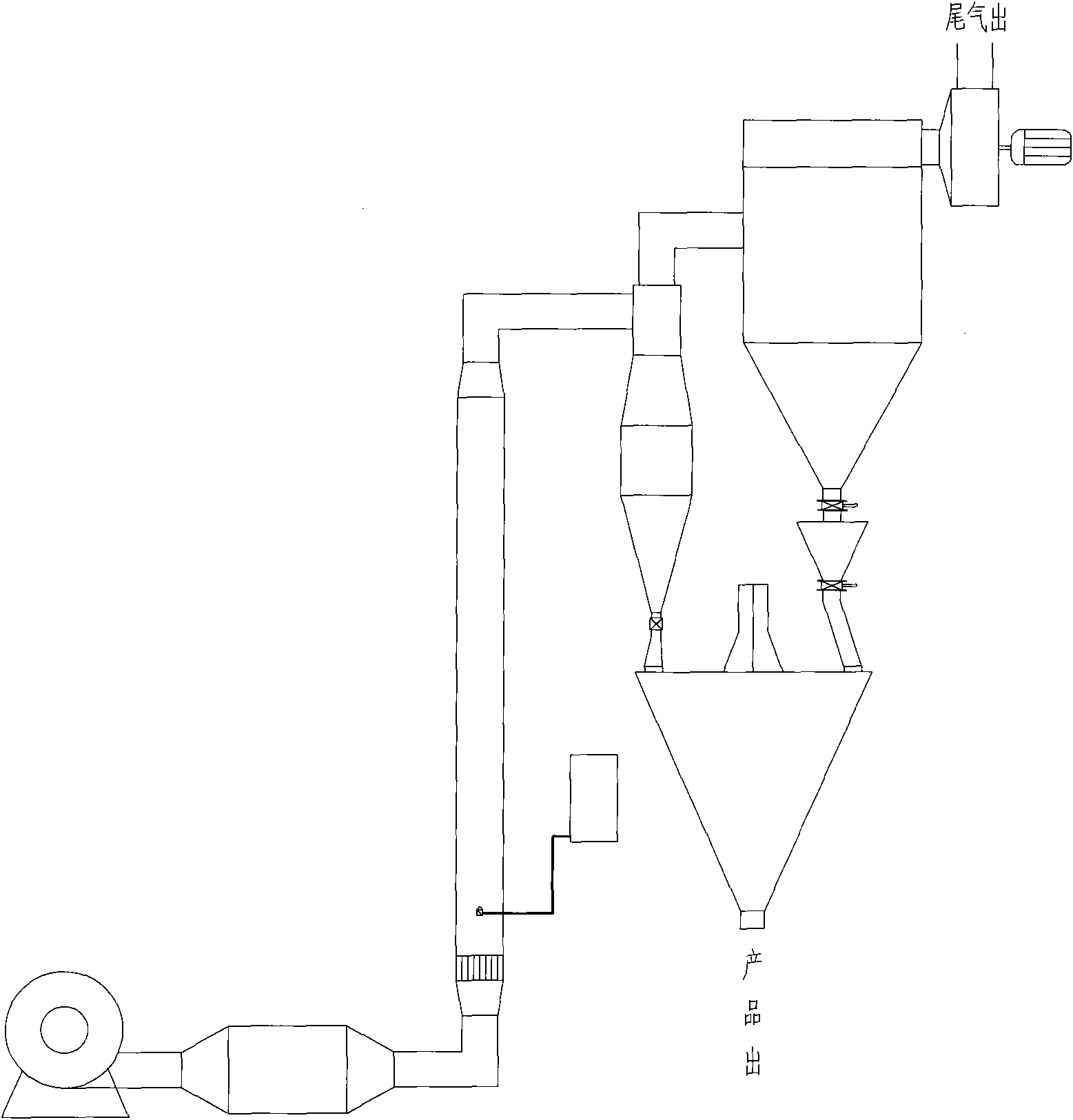

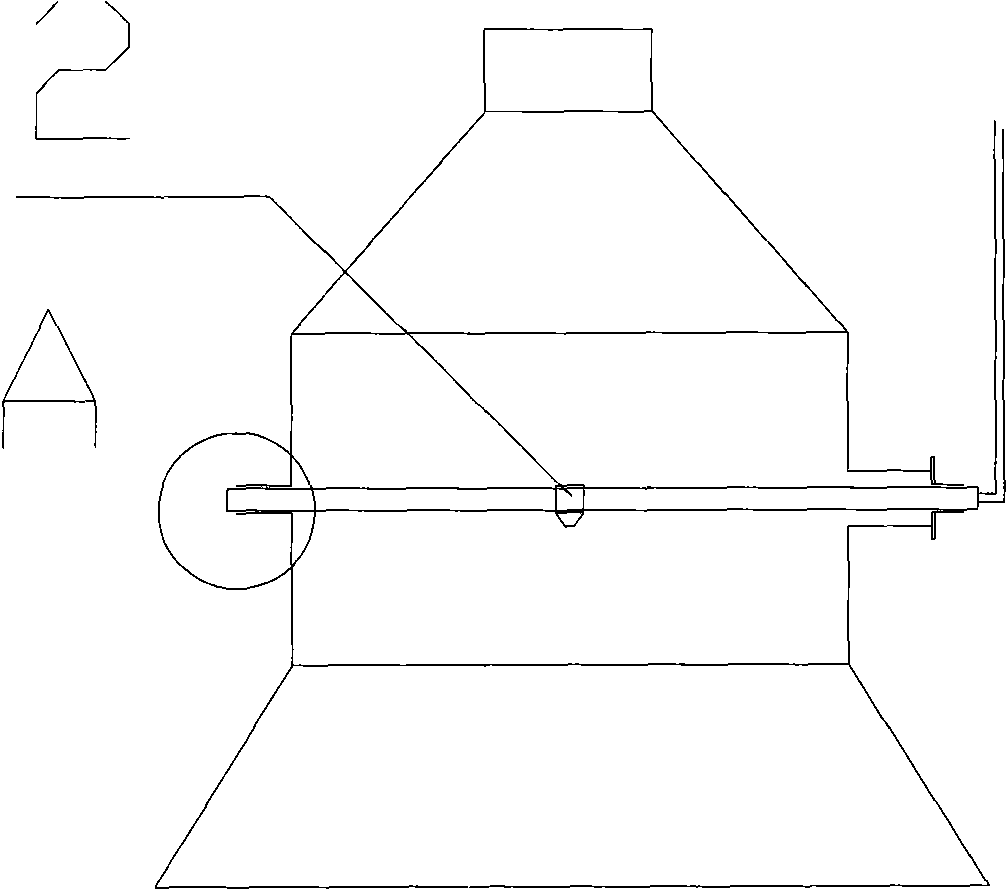

[0019] Such as figure 1 As shown, a complexed mancozeb top-spray drying method, the complexed slurry enters the spray drying tower 3 and is atomized in the spray drying tower 3 by compressed air, and is heated with the heated air. After mass exchange, the dried dry material is separated by the cyclone separator 5 and then enters the dry product bin 9, and a small amount of unseparated material is captured by the bag filter and enters the dry product bin 9 to obtain a complex state Mancozeb wettable powder, the slurry with good complexation reaction enters from the top of the spray drying tower 3, and moves downward in the spray drying tower 3 in a swirling flow. The drying temperature is 200-230°C, and the pressure of compressed air is 0.4MPa. ~0.6MPa, the outlet temperature of the spray drying tower 3 is ≤80°C, the angle at which the material comes out of the atomizer 2 during a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com