Patents

Literature

100results about How to "Avoid wall sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

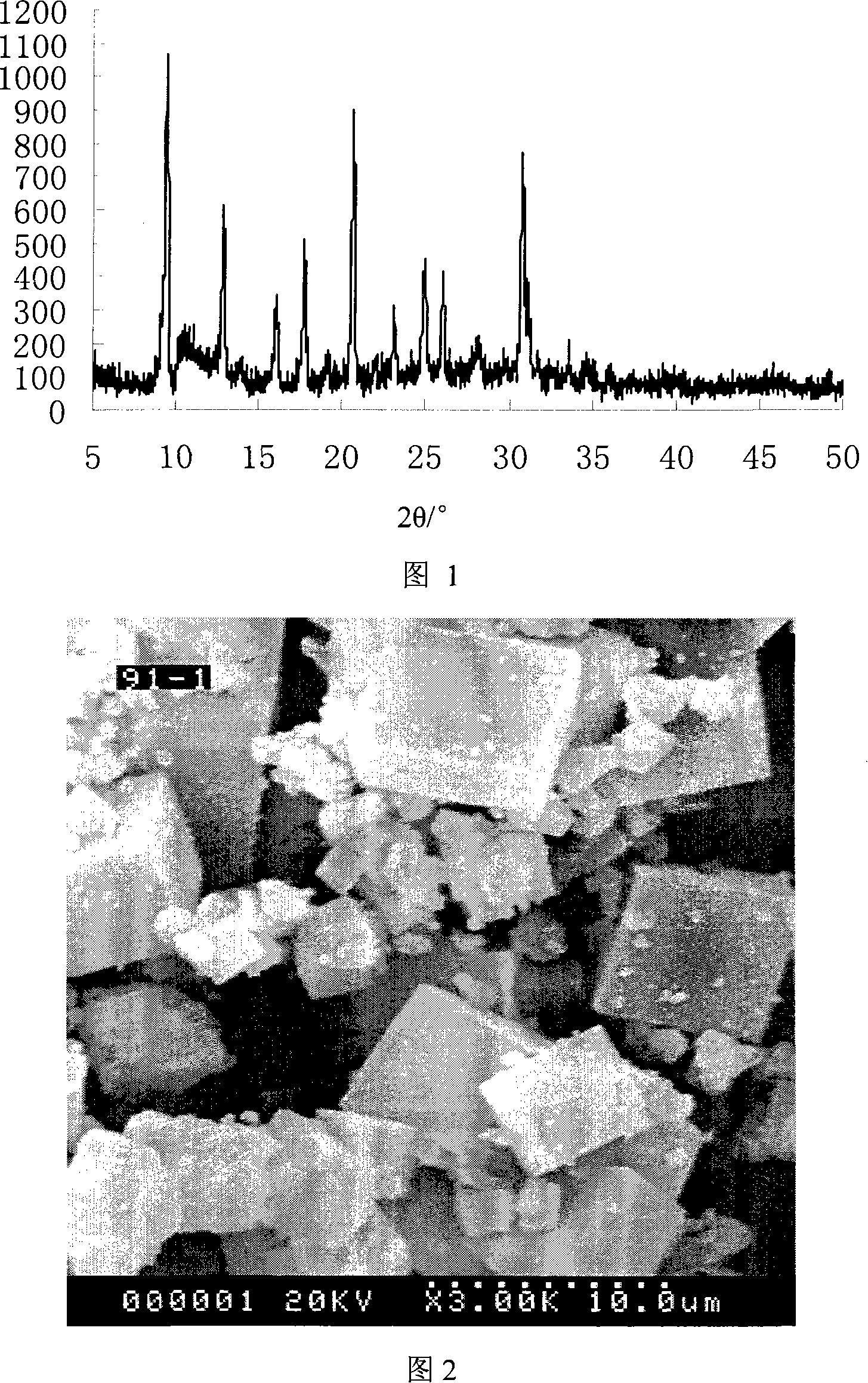

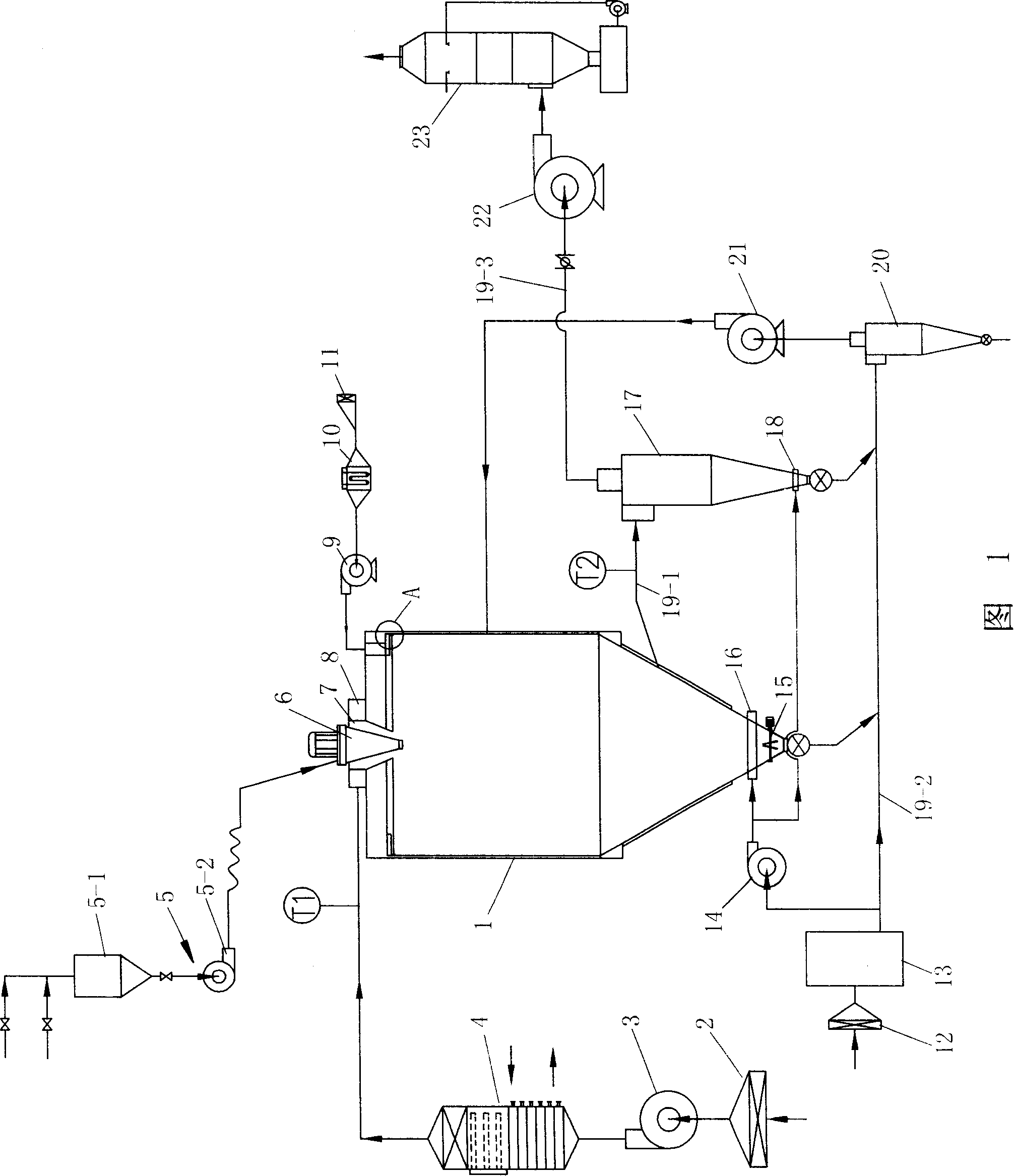

Method for preparing SAPO-34 molecular sieve by liquid phase crystallization method

ActiveCN101125665AEasy to prepareGood crystallinityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveAluminium

The invention discloses a method to prepare SAPO-34 molecule sieve through liquid phase crystallization: the precursor compounds of aluminum, silicon and phosphorous are prepared into dry gel, then the dry gel powder and a water solution of organic amine template are placed in a stainless steel high pressure vessel, and the SAPO-34 molecule sieve is synthesized through liquid crystallization. The molecule sieve after being treated can be used for a catalyst for transferring methanol into low carbon olefins. The method solves the wall sticking trouble of hydrothermal synthesis, and has the advantages of simple preparation process, good crystallization degree, simple equipments, and a normal high pressure stainless steel reaction boil can be adopted in the crystallization process, which is beneficial to industrialized mass production, and the organic amine template can be recycled.

Owner:HUALU ENG & TECH +1

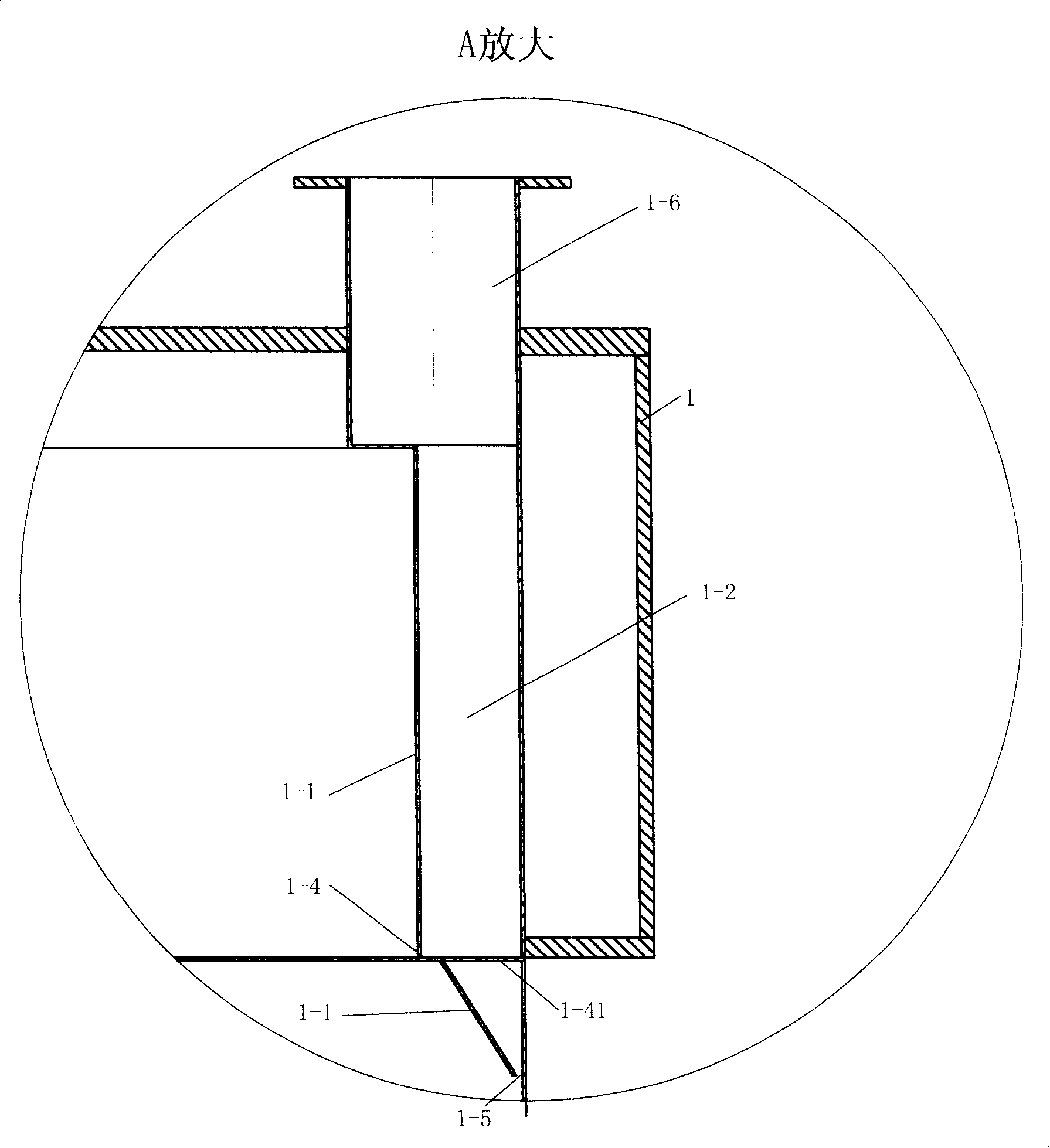

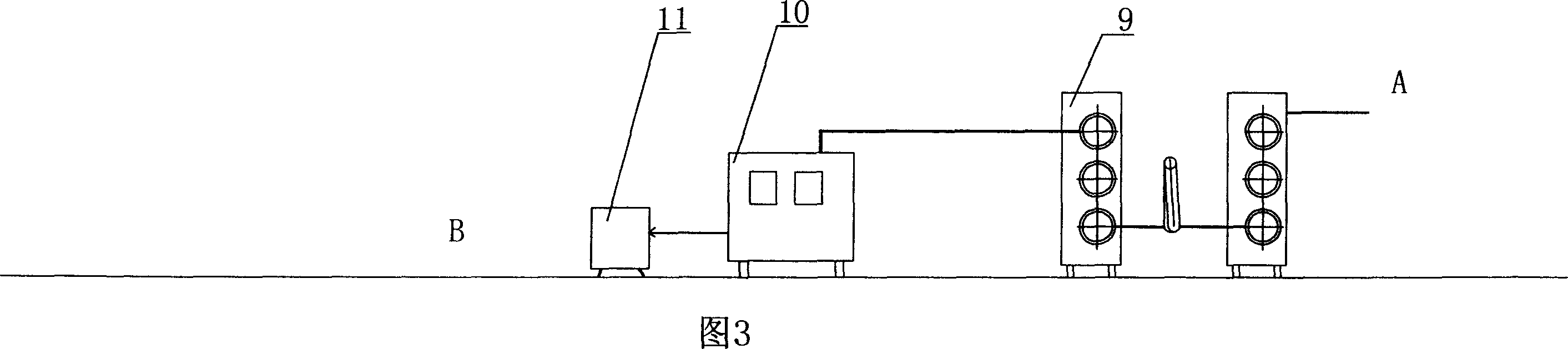

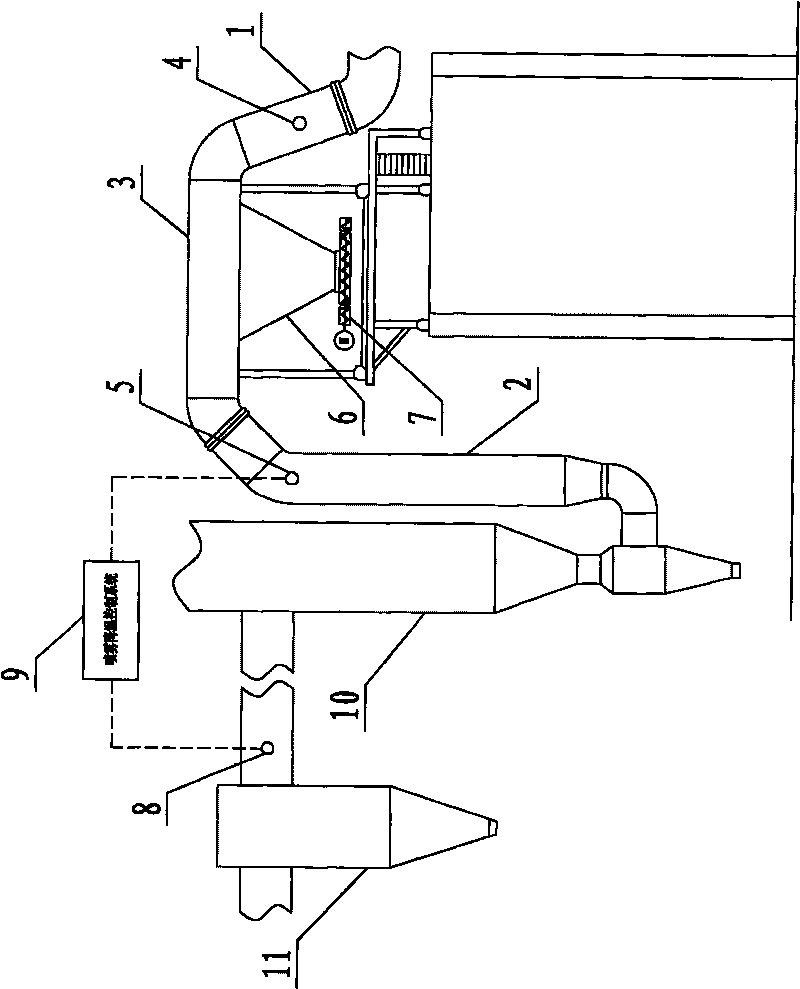

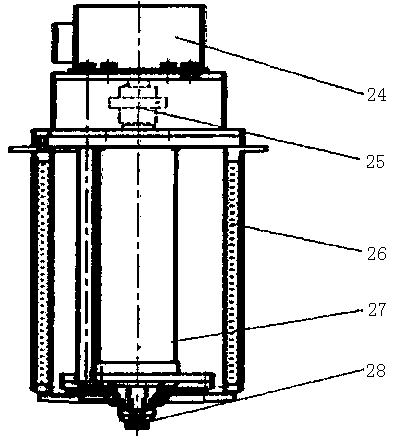

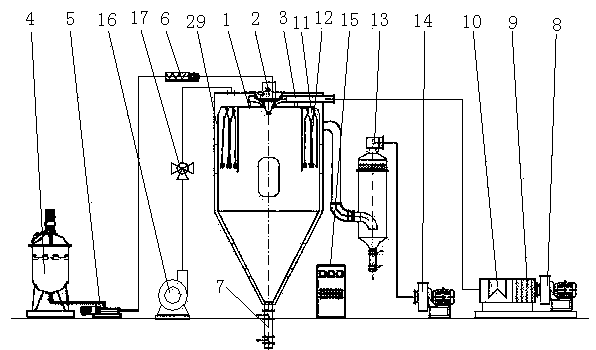

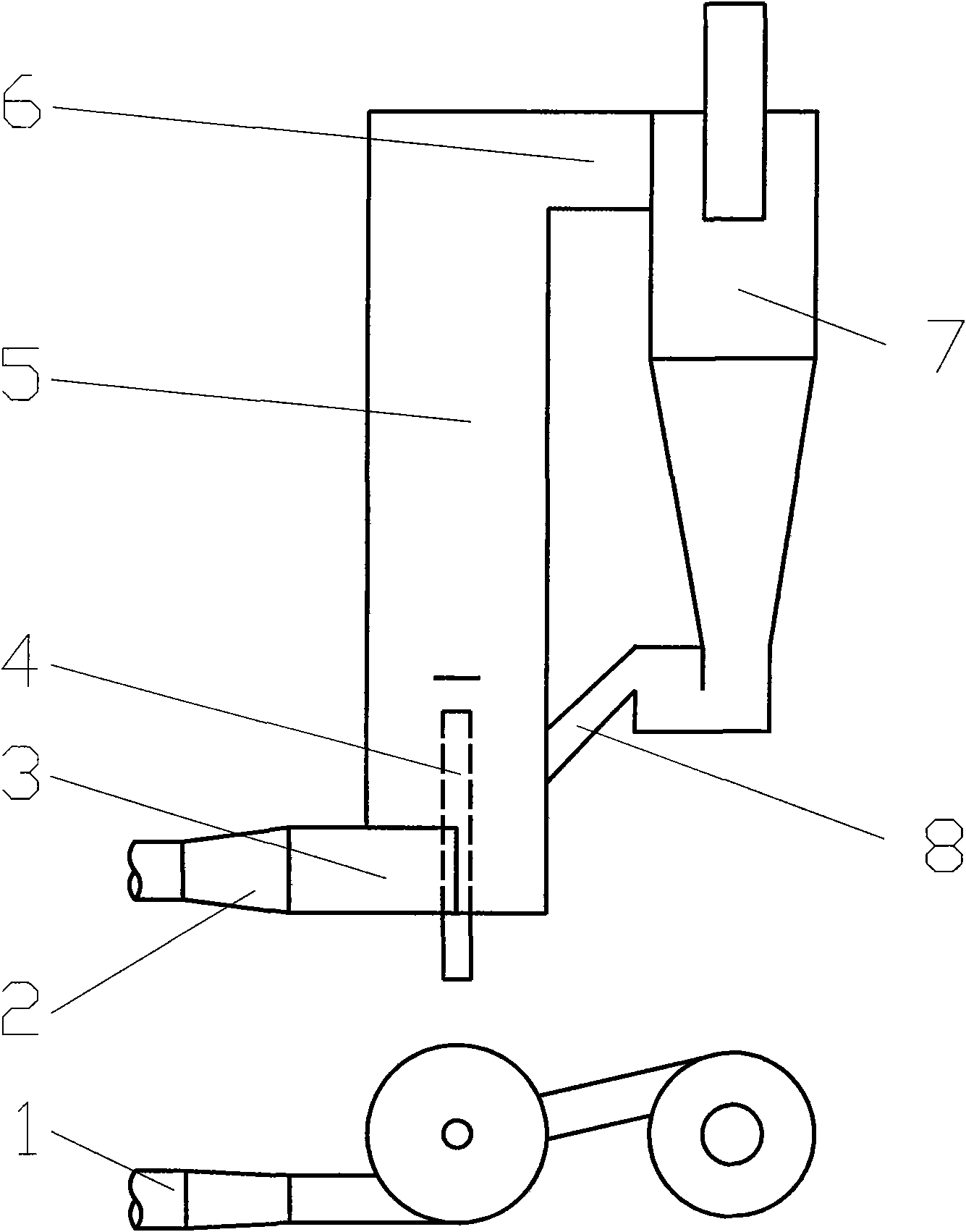

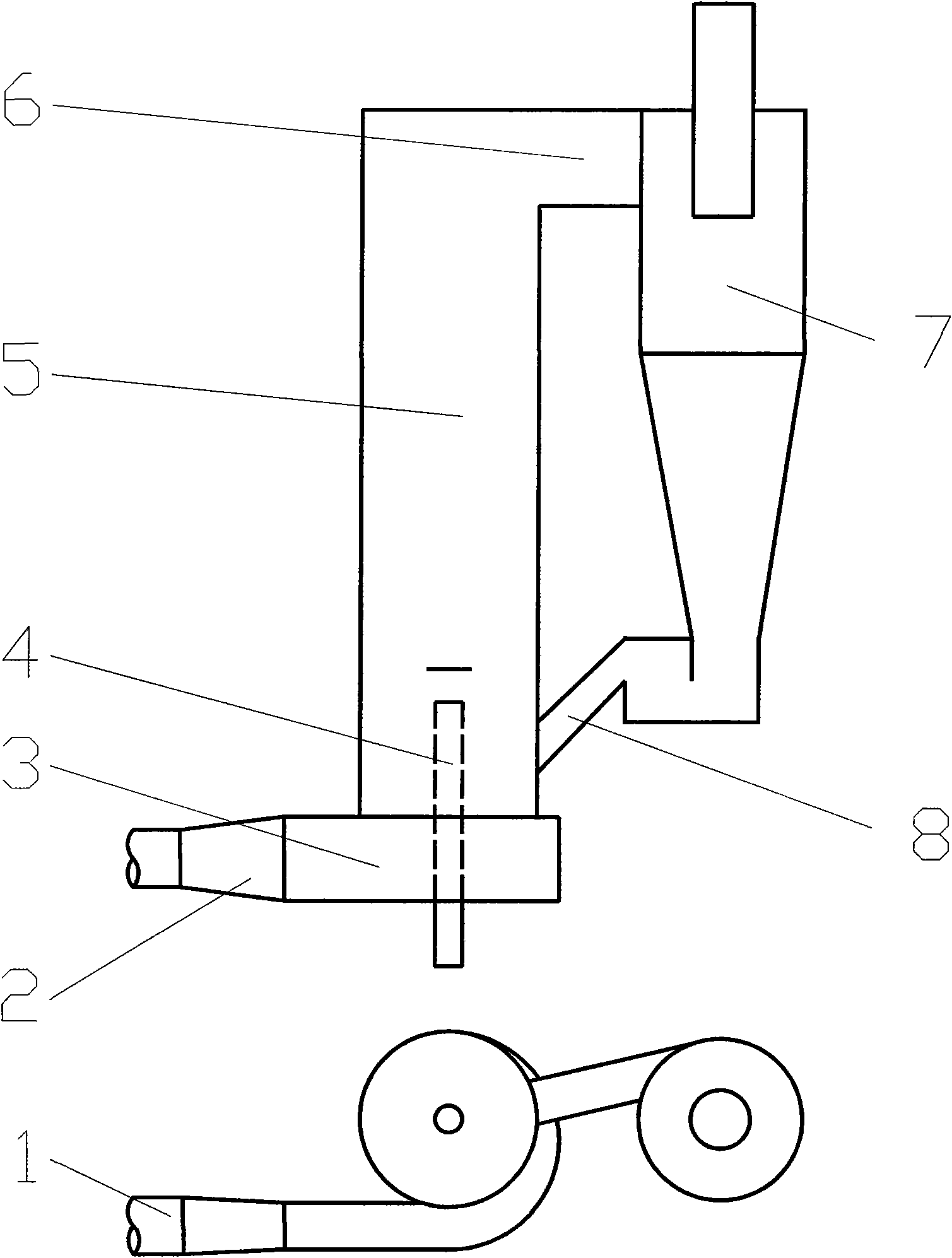

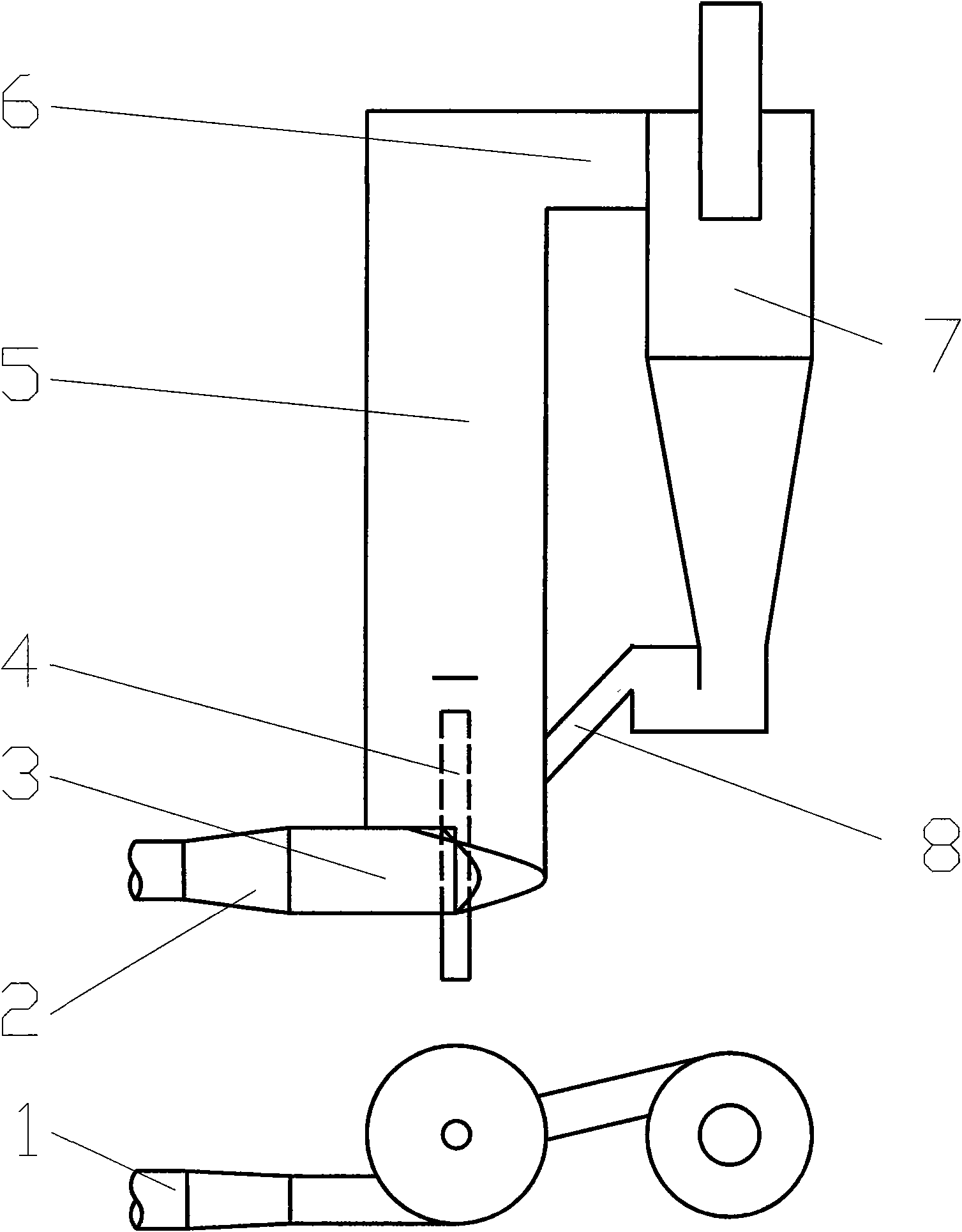

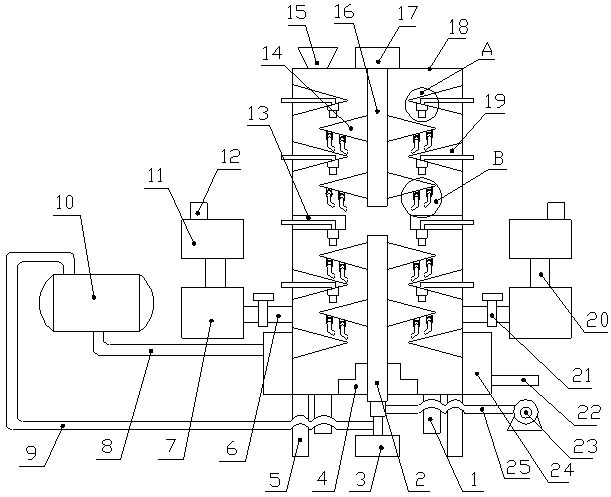

Seasoner sponging drying machine group

InactiveCN101178283AReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCycloneFeed technique

The invention comprises a material feeding device, a drying tower, a No 1 fan, a No 1 heater, a first-level cyclone separator and water-membrane dust remover. A hot air distributor and an atomizer which is arranged at the center of the hot air distributor and is connected with the material feeding device are arranged on the top of the drying tower. An air channel disk with a spiral-case shaped air channel is arranged on the top of the drying tower. The inlet of the air channel disk is connected with the output pipeline of the No1 heater, and the outlet of the spiral-case shaped air channel is connected with the inlet of the hot air distributor. A clamp sleeve is arranged in the internal tower body and near the top of the drying tower. A wall-blowing air channel is a space between the clamp sleeve and the inner side wall of the tower body. An annular clearance between the clamp bottom and the inner wall of the tower body is an air vent, and the air forms the wall-blowing air through the annular clearance. The invention adopts the air channel disk spiral air-feeding and wall-blowing feeding technique of the spiral-case shaped air channel, which not only can enhance drying efficiency but also can provide the wall-blowing air to form an air membrane in the drying tower. The air membrane can isolate powder materials from the tower wall so as to avoid a wall-sticking phenomenon.

Owner:JIANGSU XIANFENG DRYING ENG

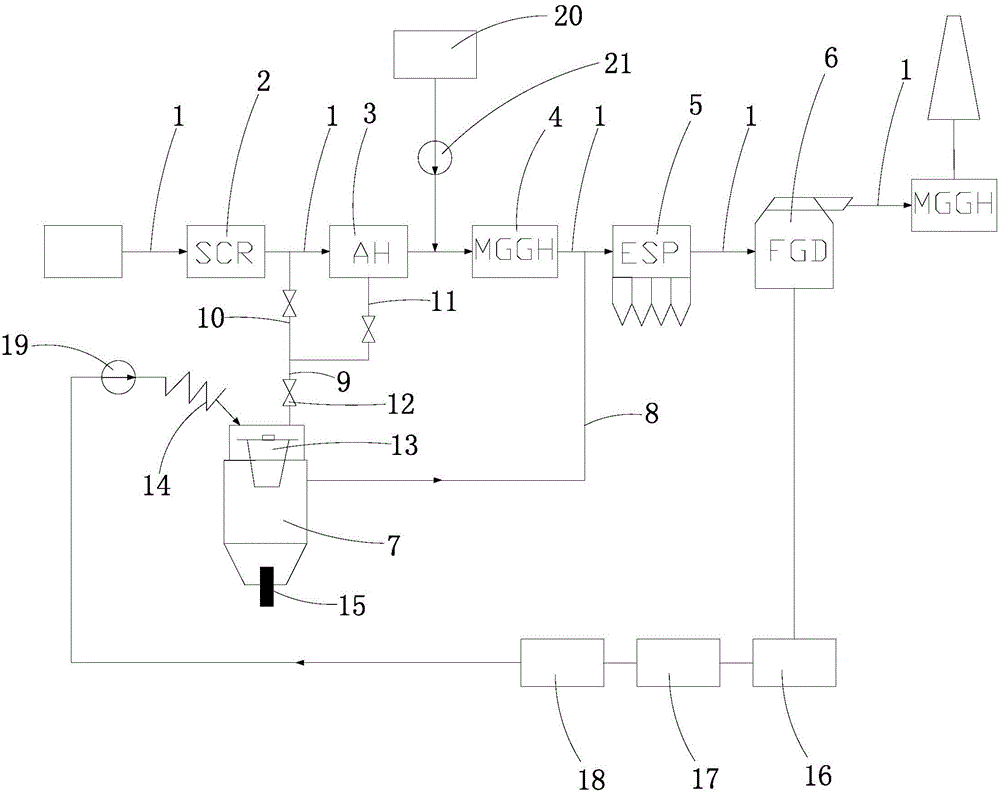

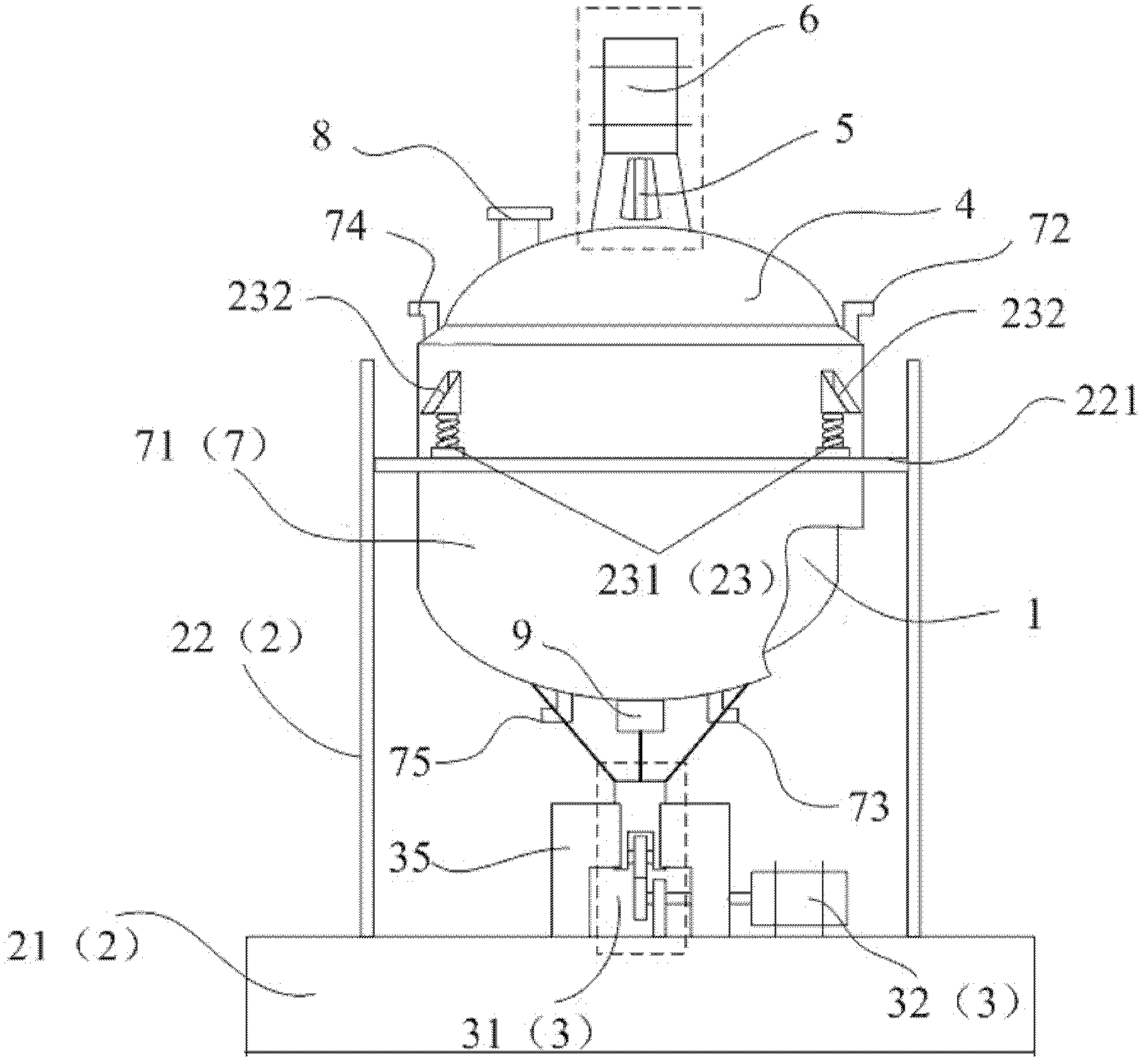

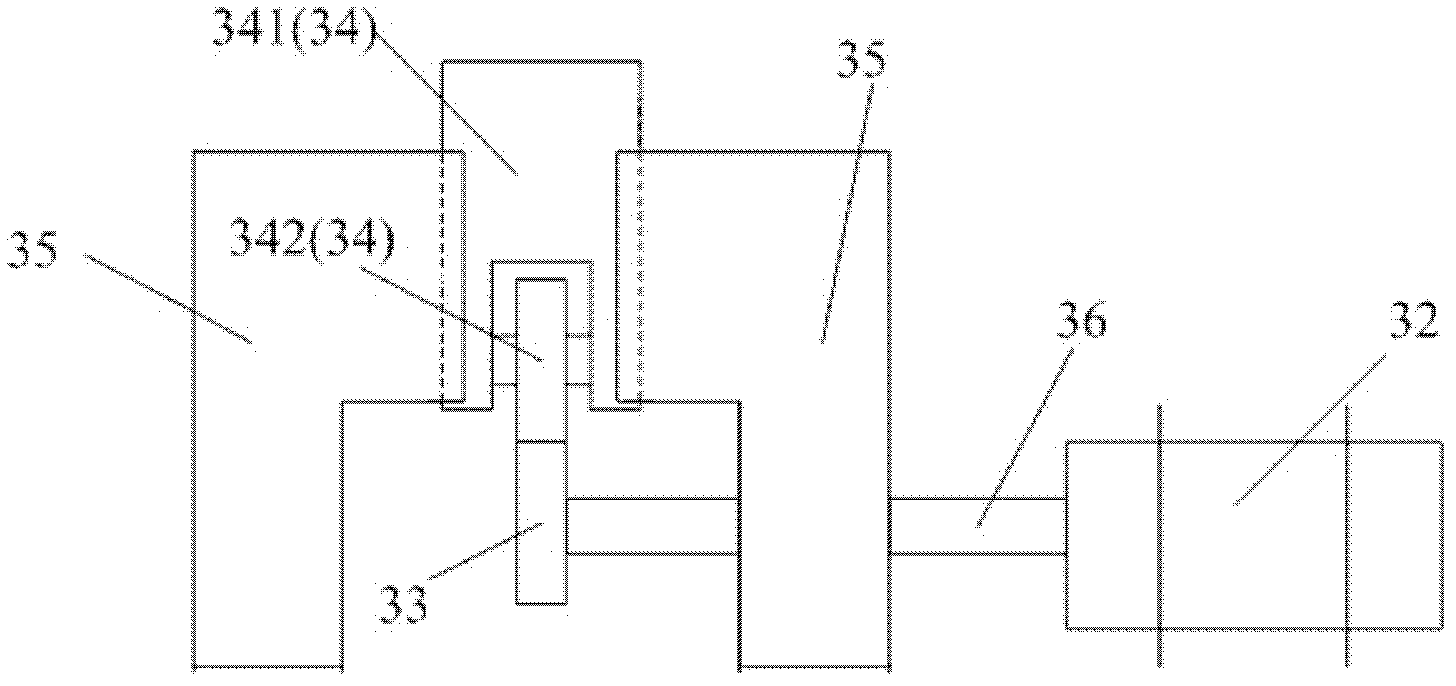

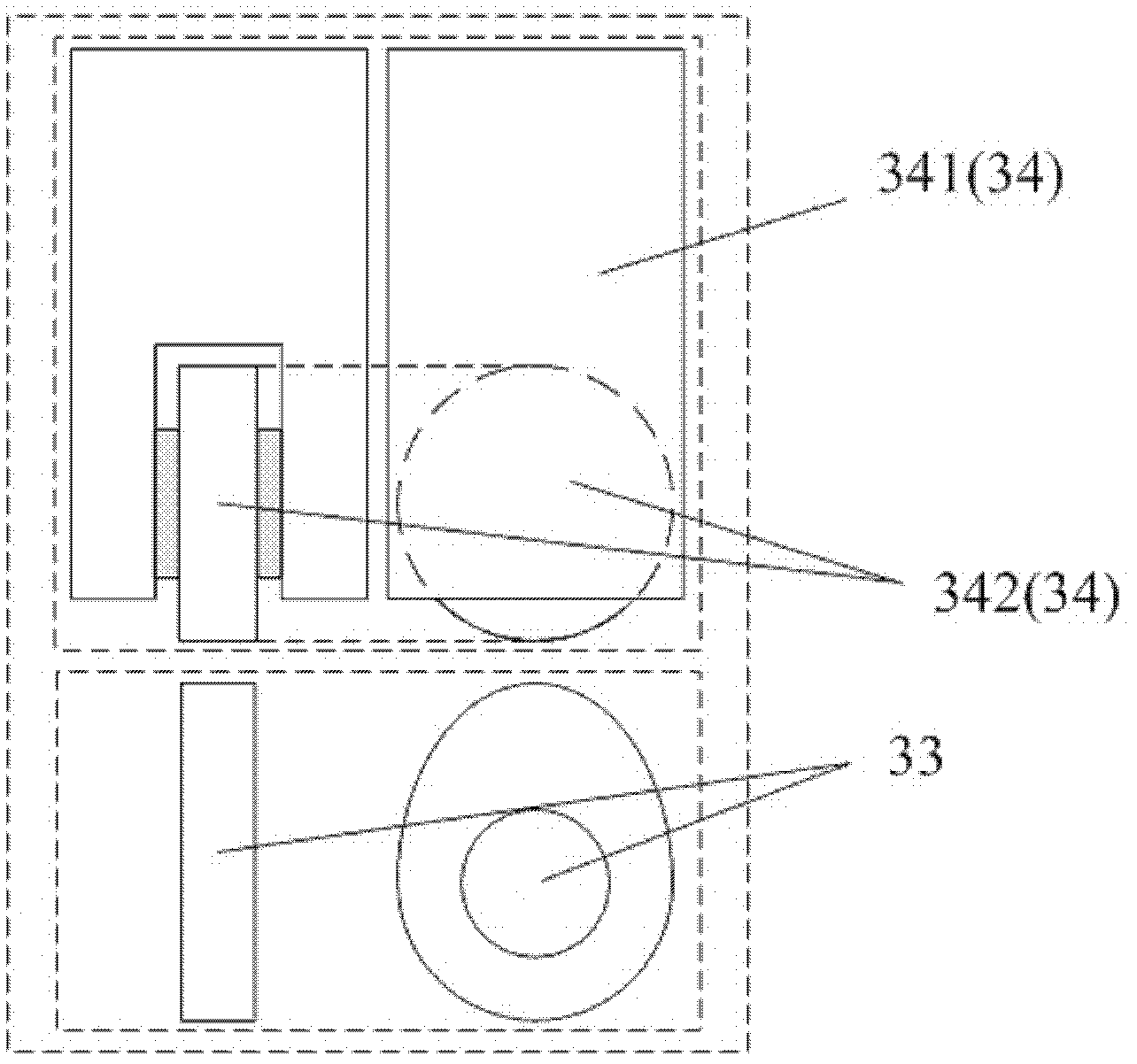

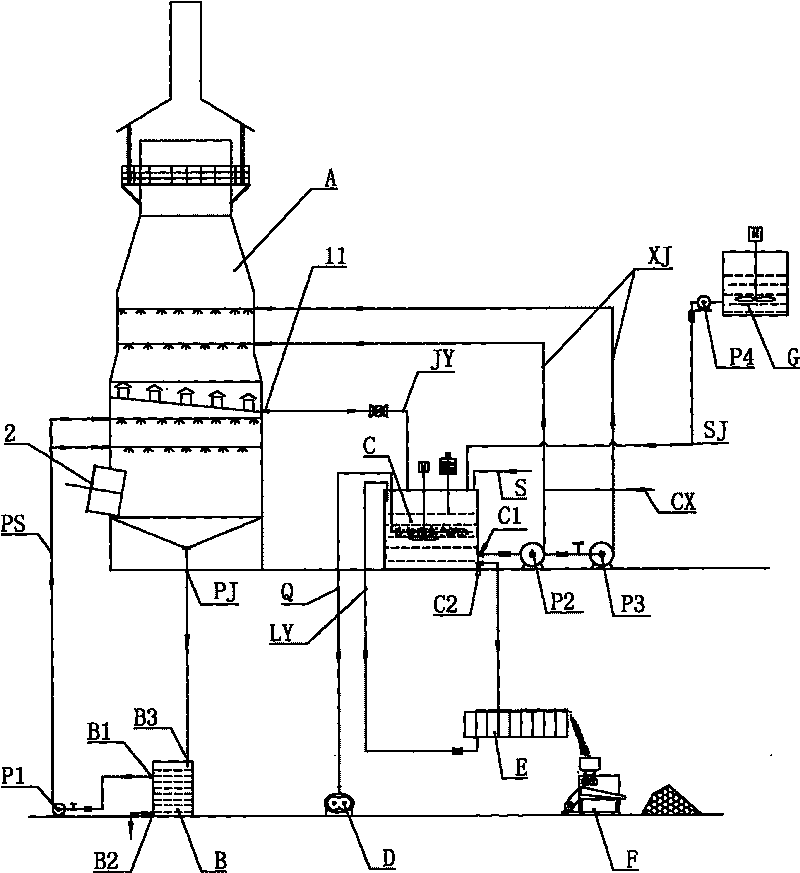

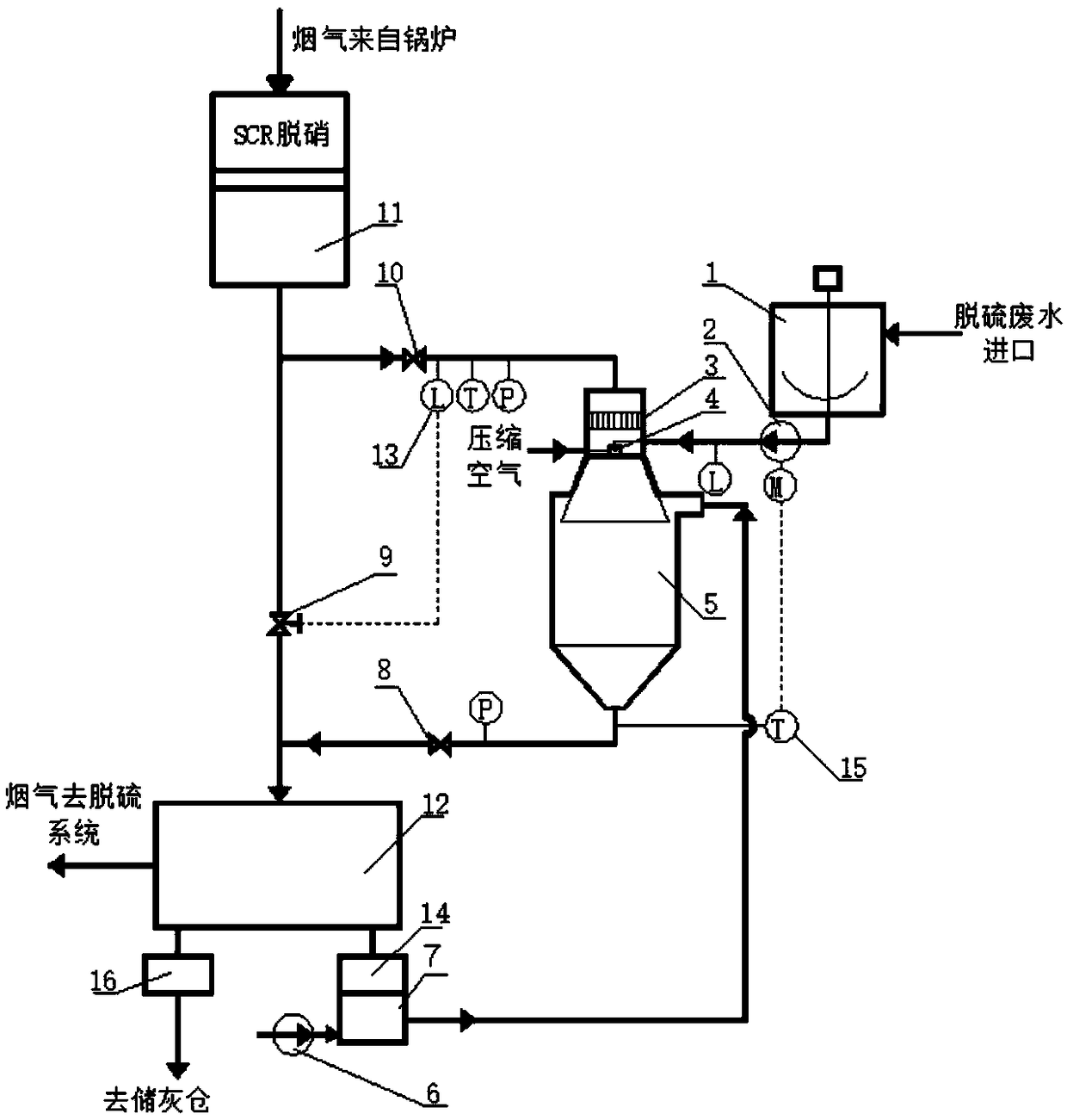

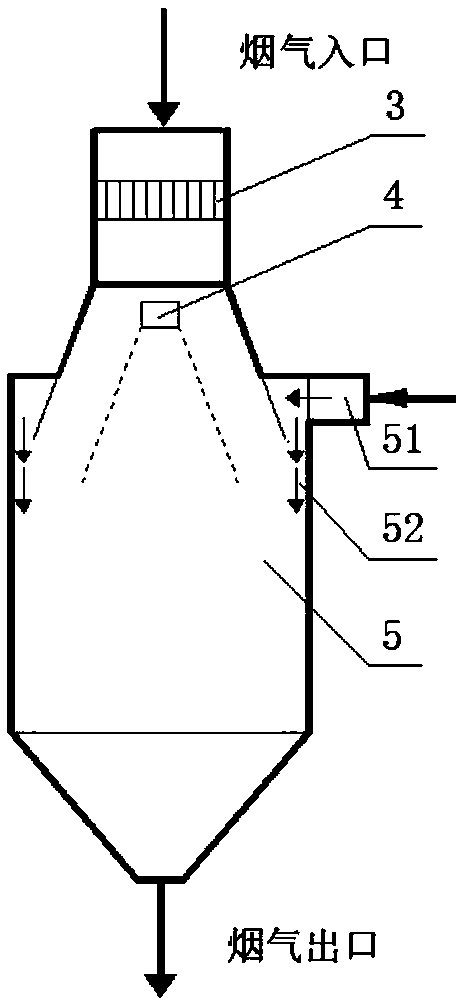

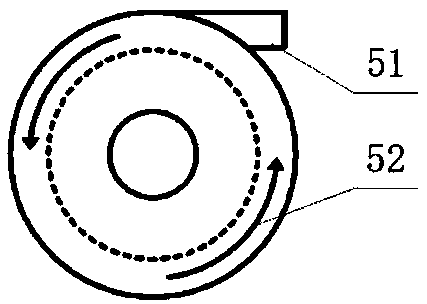

Device and method for mixed smoke evaporation to dryness of desulfuration wastewater

ActiveCN105692745AAvoid wall stickingGuaranteed service lifeWater contaminantsWater/sewage treatmentAir preheaterWastewater

The invention relates to a device and method for mixed smoke evaporation to dryness of desulfuration wastewater. The wall attaching phenomenon or the flue blocking phenomenon exists in an existing mode of boiler smoke evaporation to dryness of desulfuration wastewater, and the desulfuration efficiency is low. The device comprises a mixed gas evaporation to dryness desulfuration part and a gas tempering desulfuration part. The mixed gas evaporation to dryness desulfuration part comprises a drying tower, a wastewater preprocessing pipeline and a mixed gas pipeline. The drying tower is communicated with a flue main pipe through a tail gas pipe. The mixed gas pipeline comprises a main pipe, a first branch pipe and a second branch pipe which is communicated with external air and flows through an air preheater. Smoke and heated external air are mixed and sent into the drying tower so that evaporation to dryness can be conducted on desulfuration wastewater. The wall attaching phenomenon during mixed smoke evaporation to dryness of desulfuration wastewater is effectively solved, the service life of the drying tower is ensured,the influences of external air to boiler efficiency can be effectively reduced,the desulfuration efficiency is effectively improved, the desulfuration wastewater volume can be decreased, the workloads of evaporation work are relieved, and the heat loss for evaporation of desulfuration wastewater is reduced.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

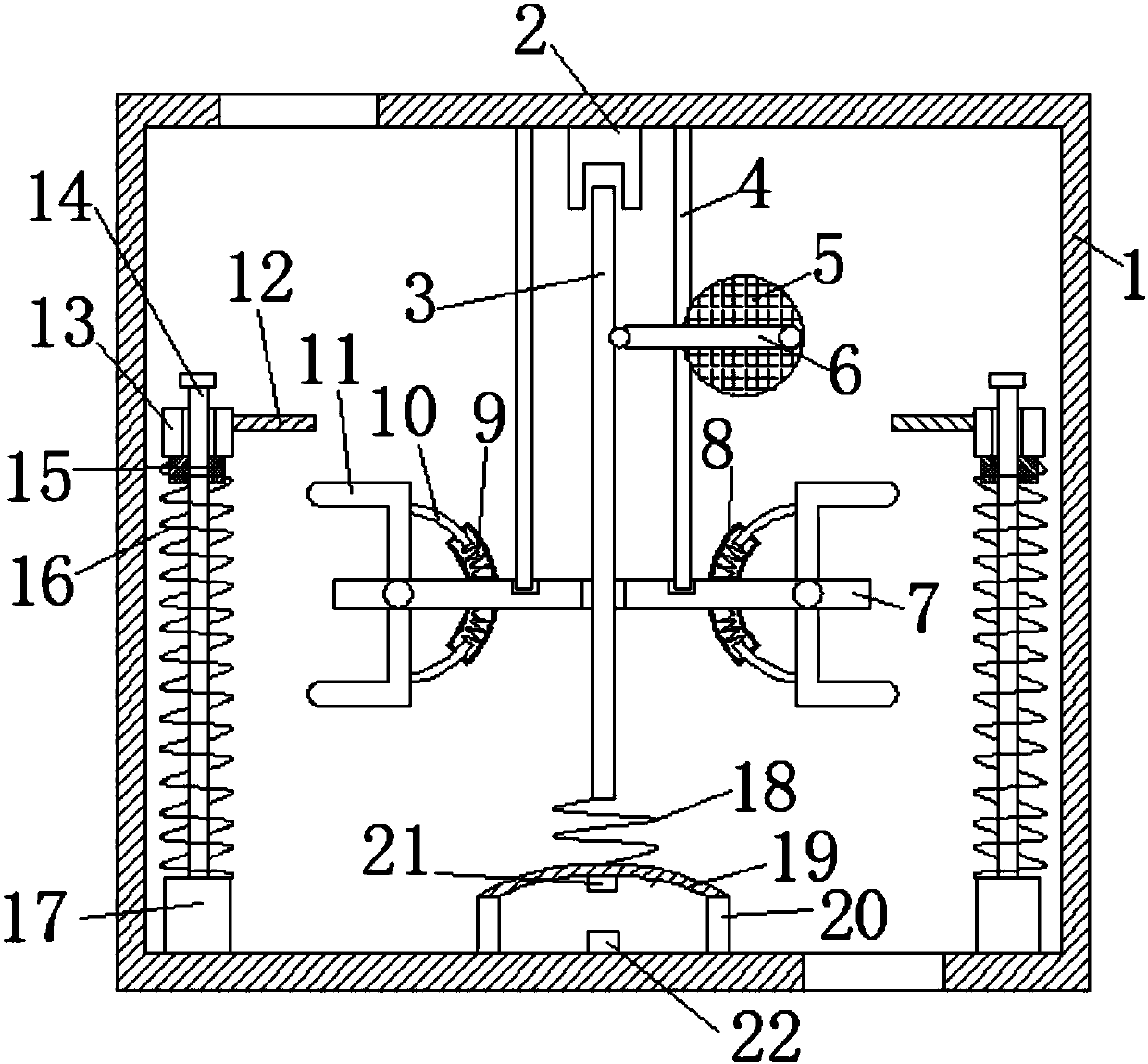

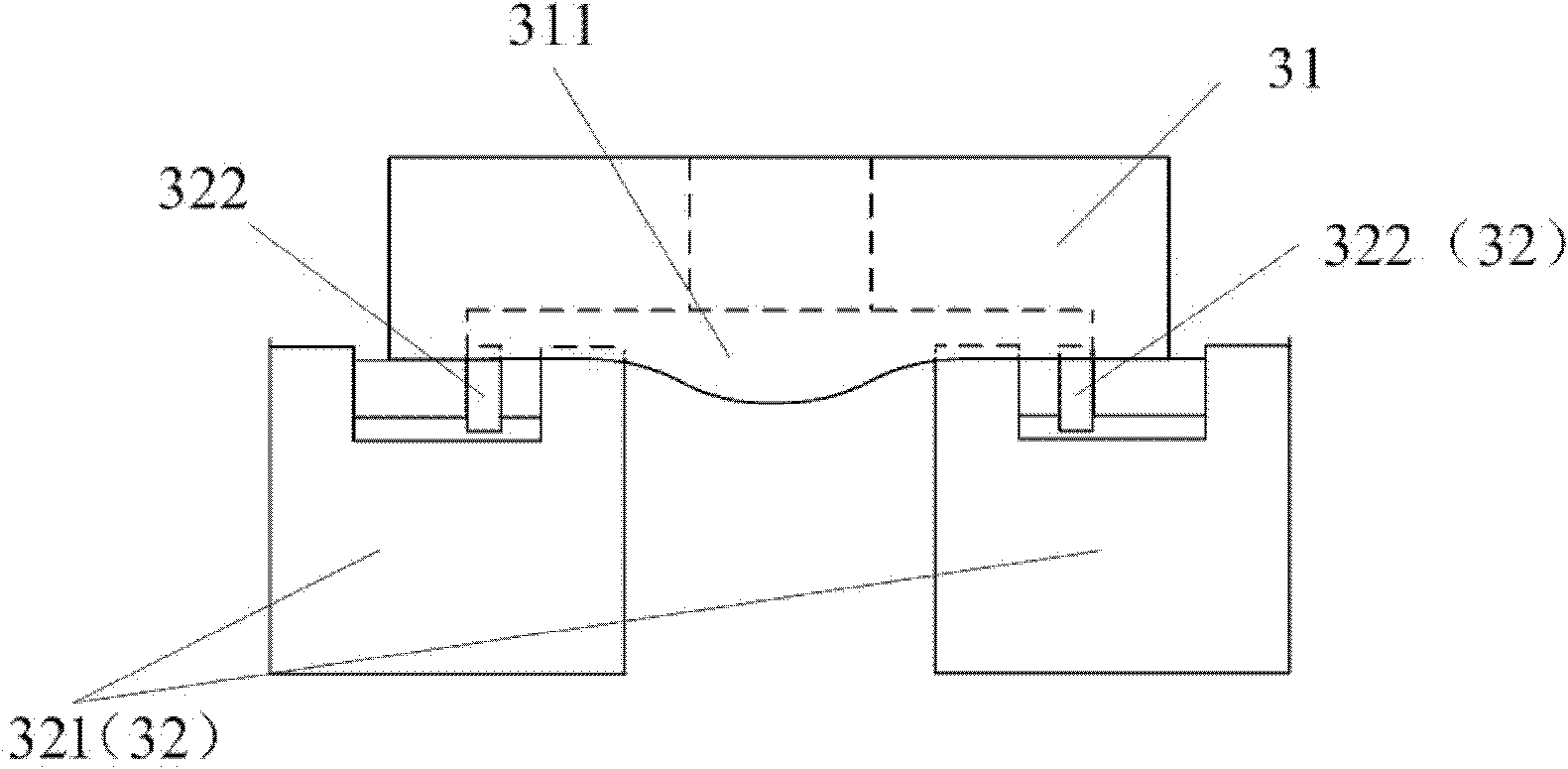

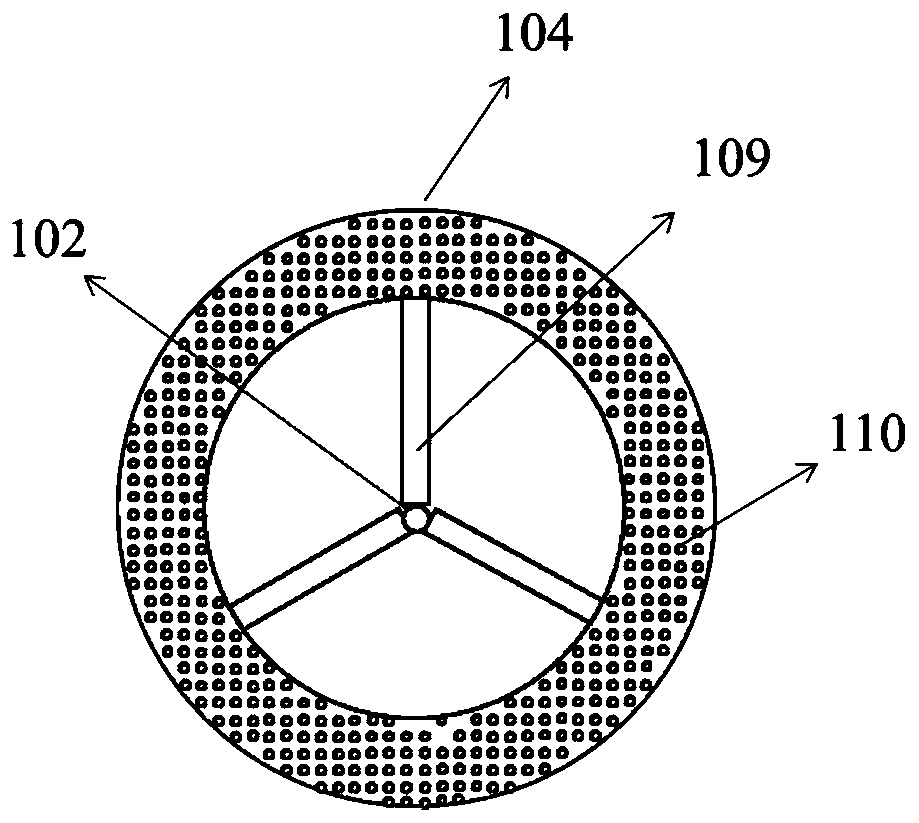

Stirred tank

ActiveCN103007865AStir wellAvoid Stirring Dead ZonesMixersChemical/physical/physico-chemical stationary reactorsBiochemical engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Wall-adhering-preventing concrete mixer

InactiveCN107584669AAvoid wall stickingSimple structureMixer accessoriesCement mixing apparatusCircular discElectrical conduction

The invention discloses a wall-adhering-preventing concrete mixer. The wall-adhering-preventing concrete mixer comprises a box body, wherein a feeding hole is formed in a top wall of the box body; a discharging hole is formed in a bottom plate of the box body; the wall-adhering-preventing concrete mixer is simple in structure; when an external power supply is switched on, a motor is switched on, and a round plate rotates; a twist rod moves up and down under the limitation effect of a concave frame, so that a rotary table rotates back and forth; the twist rod moves up and down to pull a third spring, so that a metal resilient sheet is periodically bent upwards and bent downwards, and furthermore, a first electrical conduction sheet and a second electrical conduction sheet are in periodic contact; an electromagnet is periodically powered on and powered off, and a rubber block moves up and down on a sliding rod; on one hand, an inner side wall of the box body is abraded by the rubber block, and a concrete wall-adhering phenomenon is prevented; on the other hand, an extruding rod extrudes a stirring blade, so that the stirring blade swings leftwards and rightwards when the stirring blade rotates along the rotary table, and a stirring range is increased.

Owner:张宇洋

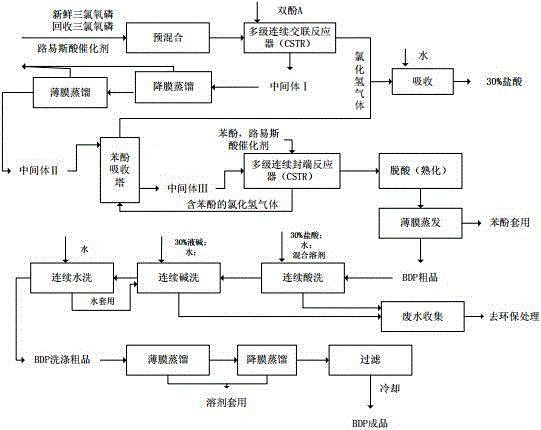

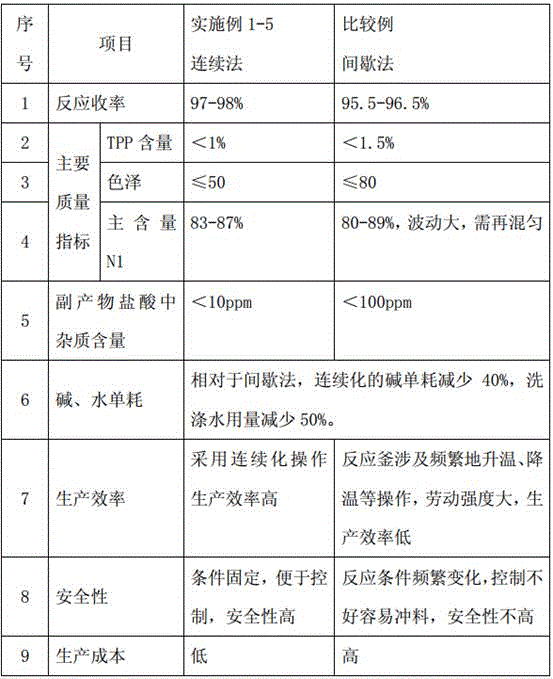

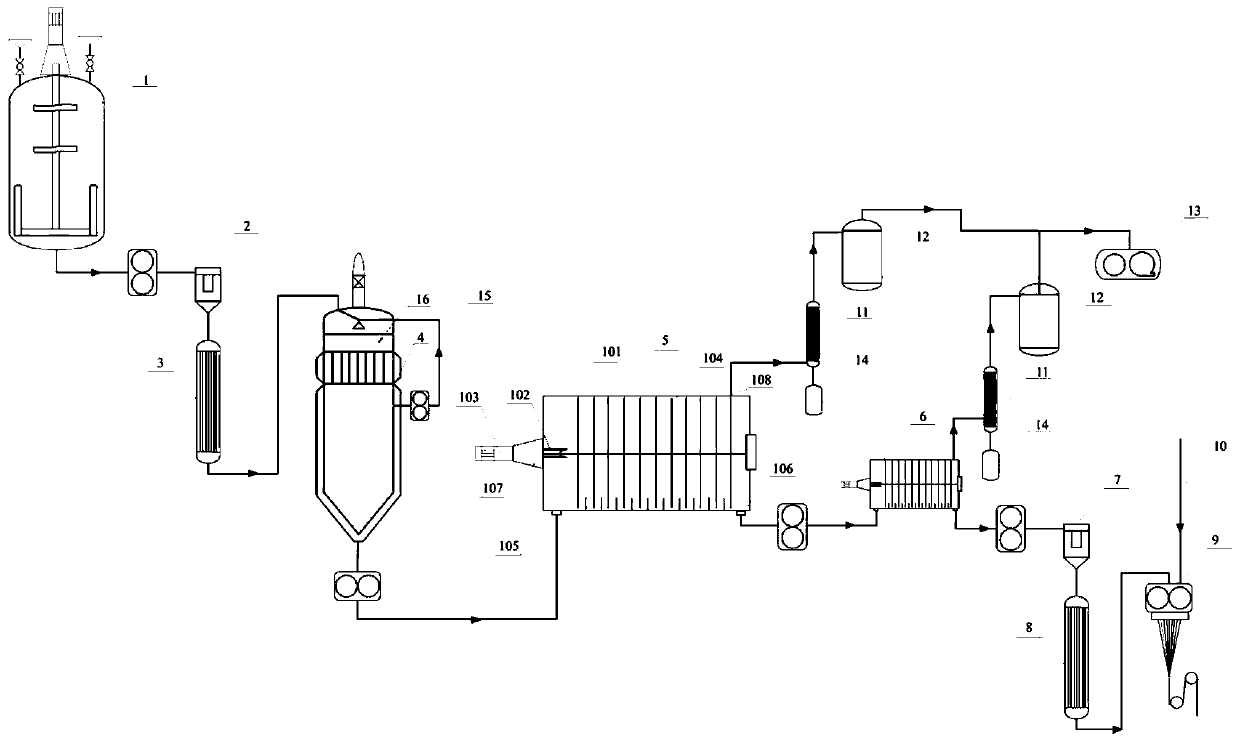

Continuous preparation method for bisphenol A-di(diphenyl phosphate)

ActiveCN106496264AReduce labor intensityMeets requirementsGroup 5/15 element organic compoundsCustomer requirementsDiphenyl phosphate

The invention discloses a continuous preparation method for bisphenol A-di(diphenyl phosphate). The continuous preparation method for the bisphenol A-di(diphenyl phosphate) comprises a multistage crosslinking reaction process, a continuous phosphorus oxychloride recycling process, a continuous multistage end capping reaction and phenol recycling process, a continuous crude product refining process, and a continuous solvent recycling and filtering process. The BDP is prepared by the continuous processes, the production cost is reduced, the labor intensity of operators is greatly reduced, the labor efficiency is improved, and the product yield is greatly improved, so the lot production quality is stable, and the production is safe and environment-friendly. The yield is improved by 1-1.5%, the color number is improved below 50, and the TPP is controlled to be 1%, and is reduced by 50% compared by an original intermittence device. The high-end customer requirement is satisfied, and the quality index fluctuation of each product is small.

Owner:ZHEJIANG WANSHENG

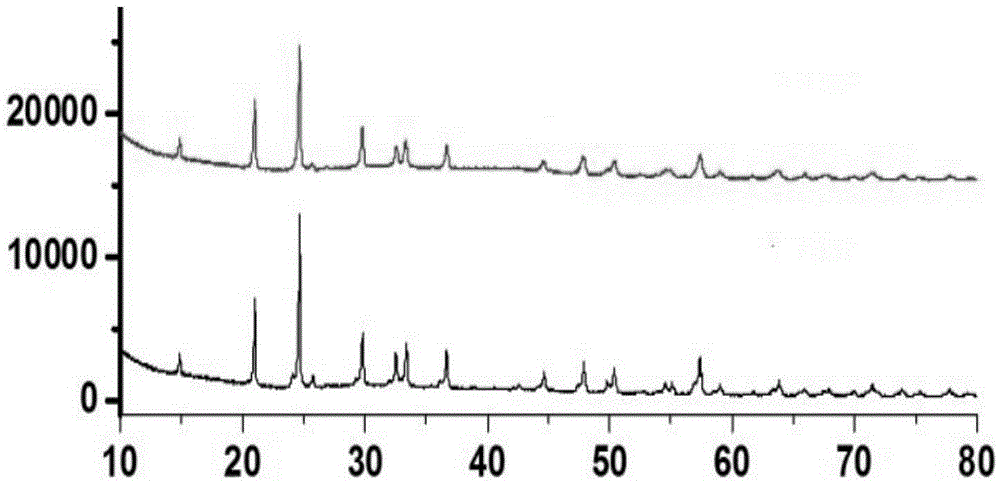

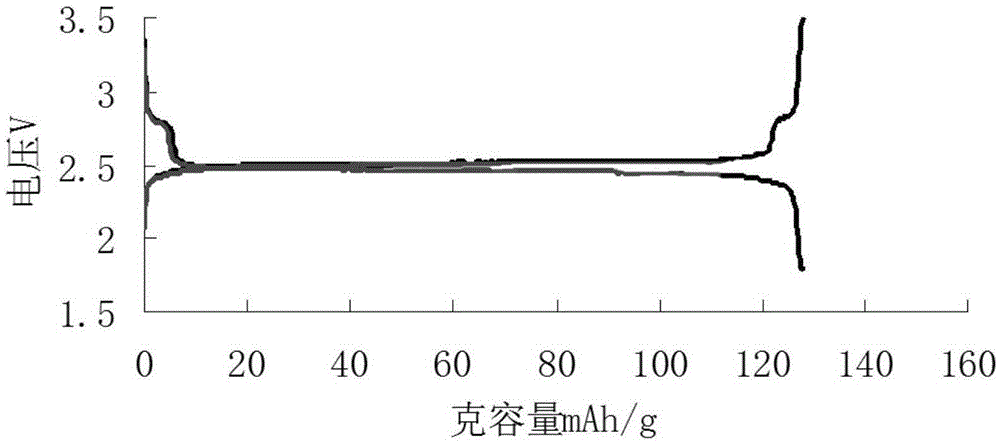

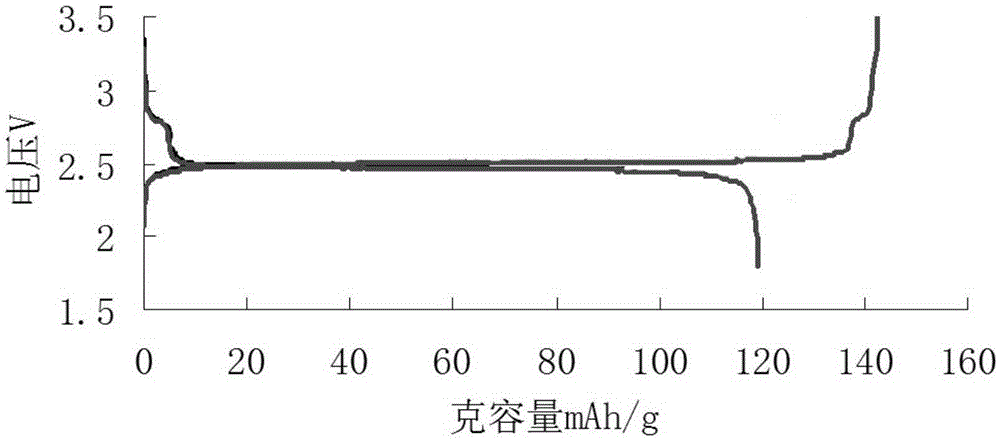

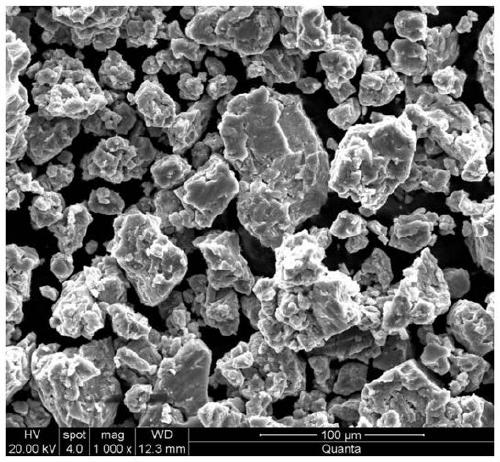

Preparation method of lithium titanium phosphate anode material

ActiveCN106299267AAvoid wall stickingImprove conductivityCell electrodesSecondary cellsAqueous electrolyteSlurry

The invention belongs to the technical field of green energy source material, and more specifically relates to a preparation method of a lithium titanium phosphate anode material of lithium ion batteries taking an aqueous solution as the electrolyte. According to the preparation method, a primary carbon source with a relatively high glass transition temperature is added into a slurry so as to avoid adhering on the wall in spray drying process caused by adding of an organic carbon source completely; carbon sources are added in two times, a secondary carbon source is added in a second time after an initial precursor is formed, and the secondary carbon source is mixed with the initial precursor at a high speed, adoption of composite carbon sources is capable of achieving excellent carbon coating effect on the surface of lithium titanium phosphate; electrical conductivity among the LiTi2(PO4)3 particles is increased via coating by the secondary carbon source, the electrical conductivity of LiTi2(PO4)3 is increased obviously, and carbon coated LiTi2(PO4)3 possesses excellent cycling stability in aqueous electrolyte. The production process is continuous; product characteristics are uniform; quality is stable; the preparation method is simple and convenient, and is suitable for industrialized production.

Owner:江西省金锂科技股份有限公司

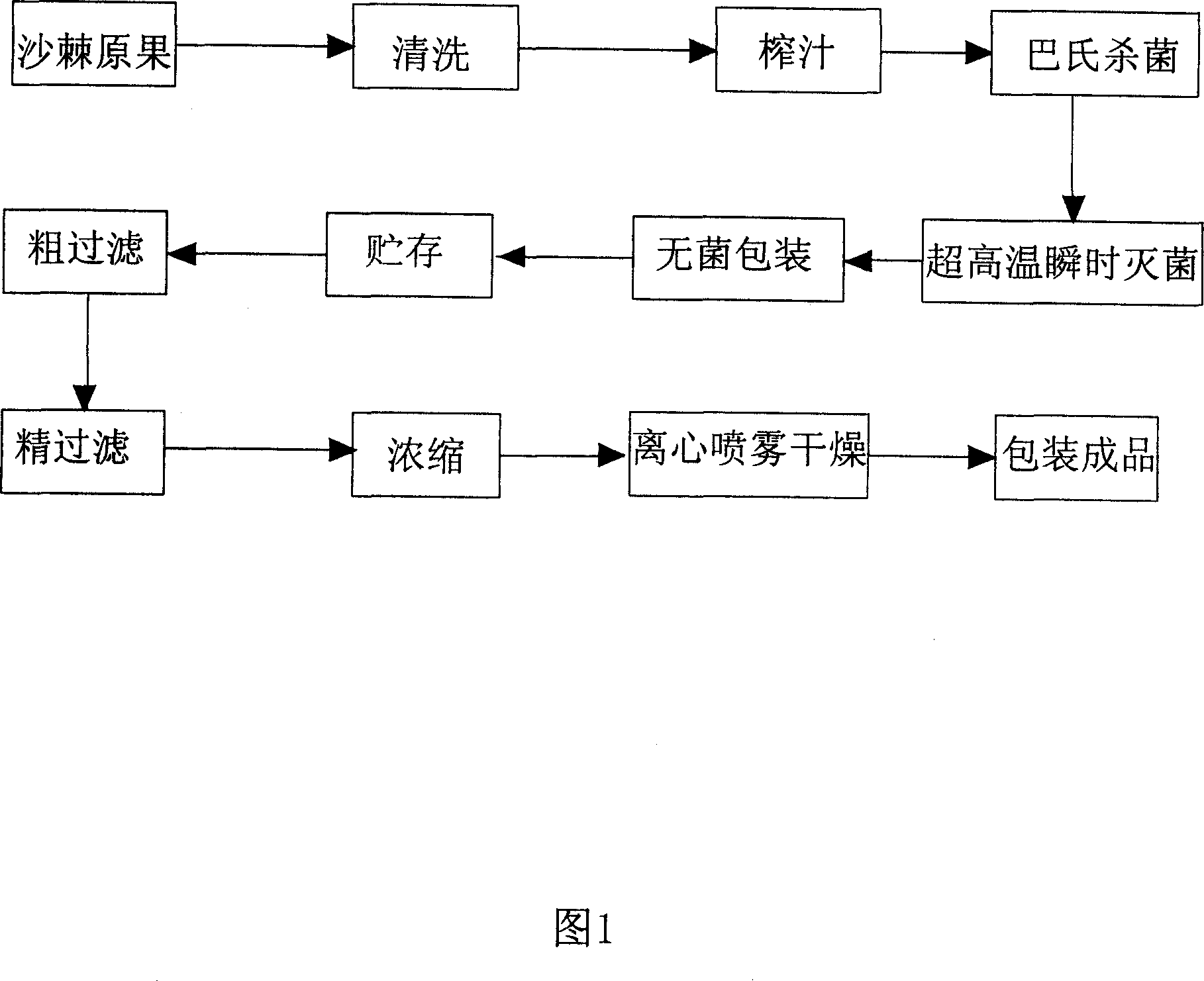

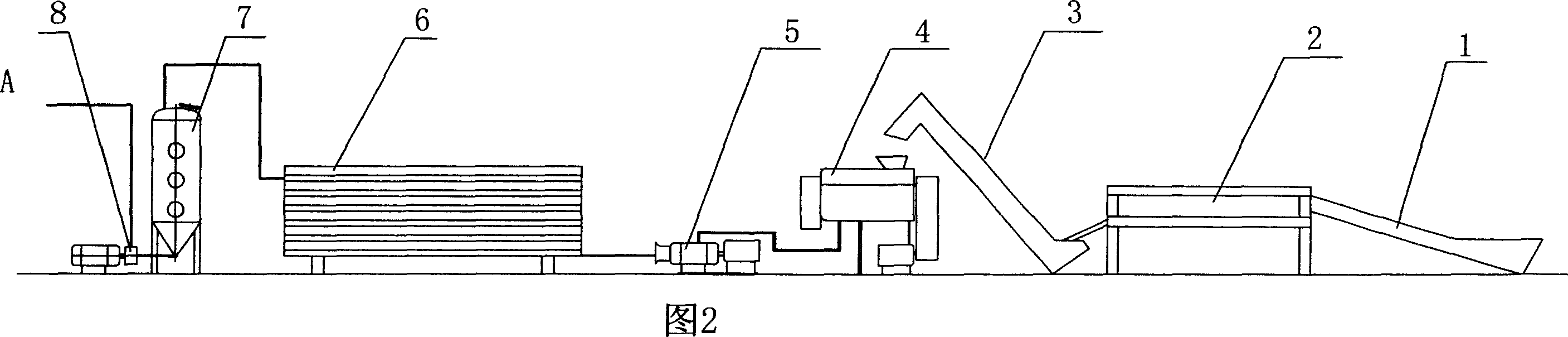

Preparation method of seabuckthorn fruit powder and production equipment thereof

The invention relates to a method for finely processing sea-buckthorn powder, wherein said method comprises that: washing sea-buckthorn; putting sea-buckthorn into compressor to be compressed; disinfecting sea-buckthorn slurry in disinfector at high temperature; potting, and storing; filtering via eccentric machine, filtering, concentrating at vacuum, using feeding screw pump to feed material into high-speed eccentric atomizer, to be put into drying tower; drying and packing. Compared with present technique, the invention has simple device, while the hot wind distributor at upper part of tower is connected to feeding pump to feed dry powder into tower, to avoid adhering sea-buckthorn powder on wall. The invention can hold nourishment and active components of sea-buckthorn fruit.

Owner:宝得瑞(河北)健康产业有限公司

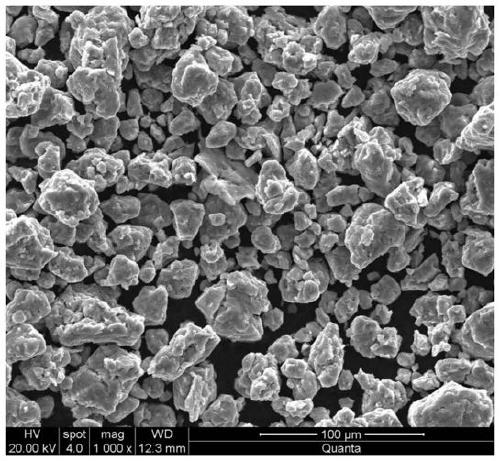

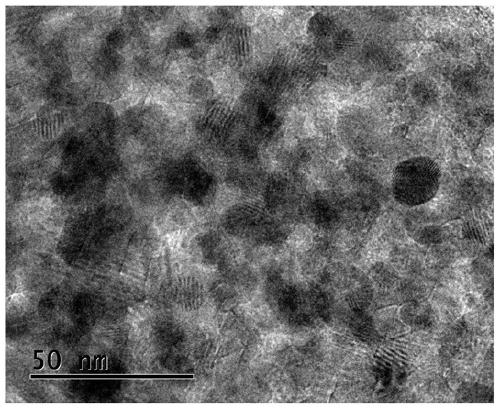

Nano-magnesium-based composite hydrogen storage material and preparation method thereof

ActiveCN109972010AEnhanced reversible hydrogen storage propertiesHigh recovery rateCell electrodesRare-earth elementIngot

The invention relates to a nano-magnesium-based composite hydrogen storage material and a preparation method thereof. The material comprises a main component of magnesium, and simultaneously comprisesa plurality of catalysts of mixed rare earth, carbonyl nickel powder and graphite so as to improve the low-temperature hydrogen absorption performance of the material. The material has a nanocrystalstructure, the grain size is 20-50 nanometer, and the material has excellent low-temperature hydrogen absorption dynamics performance. The preparation method comprises the following steps of firstly,carrying out vacuum smelting on pure magnesium and a certain amount of mixed rare earth by adopting a vacuum induction melting method to prepare a brittle magnesium-rare earth alloy ingot with magnesium doped with rare earth elements in situ; and then mixing the obtained alloy with carbonyl nickel powder, graphite powder and inert organic grinding aid, and further preparing a high-capacity magnesium-based composite hydrogen storage material through a mechanical ball milling method. The preparation method of the material overcomes a wall sticking phenomenon in a mechanical ball milling processof the magnesium-based hydrogen storage alloy, so that the material recovery rate is improved, and the high-capacity magnesium-based composite hydrogen storage material with excellent low-temperaturehydrogen absorption performance is obtained.

Owner:HEBEI UNIV OF TECH

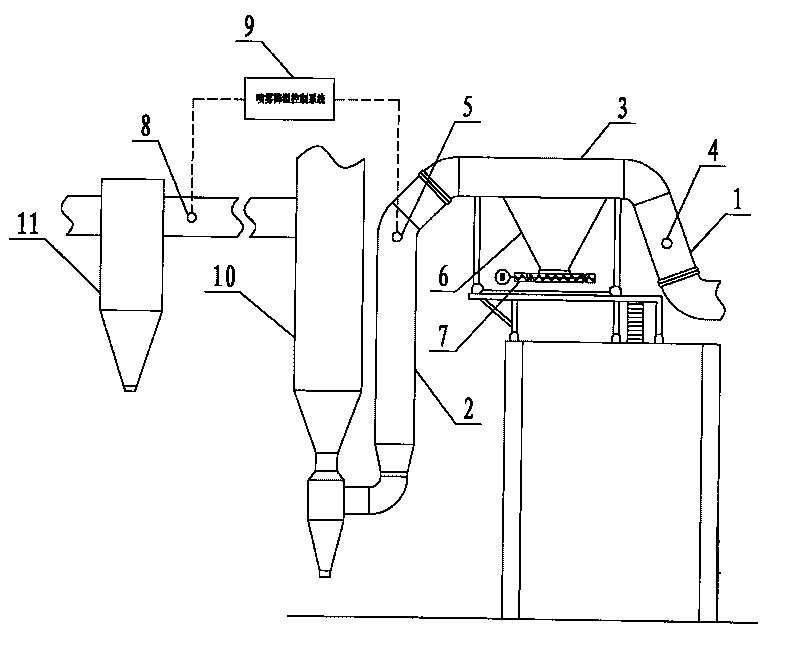

Quenching device for processing smoke generated by burning garbage and smoke processing system thereof

ActiveCN101701716AReduce maintenance costsReduce flow rateDispersed particle filtrationLighting and heating apparatusSprayerBaghouse

The invention relates to a quenching device for processing smoke generated by burning garbage and a smoke processing system thereof. The quenching device is provided with an inlet pipeline, a quenching pipeline, an outlet pipeline, a spray cooling controller and a temperature measurer, wherein a first sprayer is installed on the inlet pipeline, and the water spraying quantity of the first sprayer is fixed; a second sprayer is installed on the outlet pipeline, and the water spraying quantity of the second sprayer is regulated and controlled by the spray cooling controller according to the temperature data fed back by the temperature measurer; the quenching pipeline is communicated with an ash bucket arranged below the quenching pipeline; the smoke processing system is provided with an acid removing tower and a bag-type dust remover; the outlet pipeline of the quenching device is communicated with an inlet end of the acid removing tower; and the temperature measurer is installed on a pipeline that the acid removing tower is connected with the bag-type dust remover. By adopting the quenching device and the smoke processing system of the invention, ash can not be deposited on an inner wall of the acid removing tower easily, the maintenance cost is lower, and the quenching device has simple installation and lower manufacturing cost.

Owner:常州市武进东方除尘设备有限公司

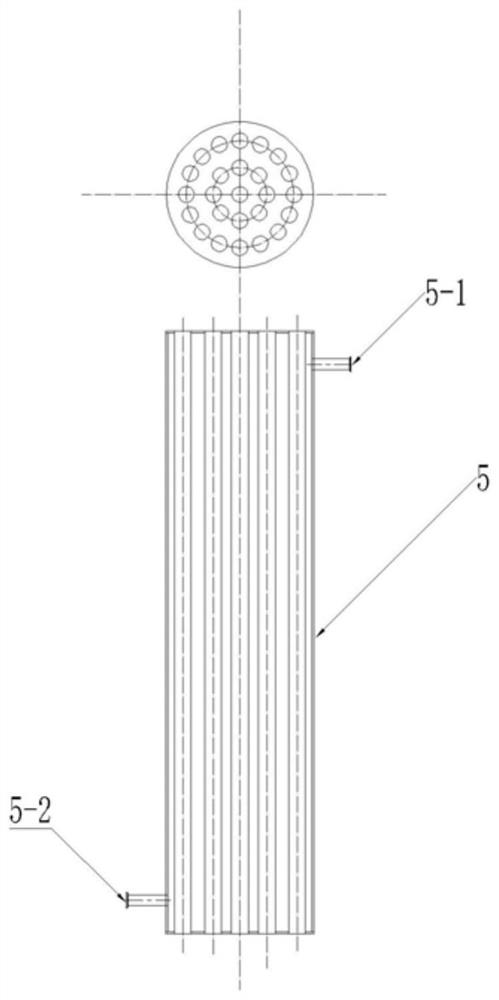

Convenient-to-clean solid catalyst atomization drying system

ActiveCN104399263ASimple structureExtended service lifeEvaporator accessoriesCatalyst activation/preparationPtru catalystAir filter

The invention relates to a convenient-to-clean solid catalyst atomization drying system which comprises a drying tower of a vertical cylindrical structure, an electric high-speed centrifugal atomizer, a feeding device, a heating device, an air moisture cooling device, a discharging device, a waste gas recovery device, a cleaning device and an intelligent control cabinet, wherein the electric high-speed centrifugal atomizer is arranged on the inner central axial line at the top of the drying tower; the feeding device is connected to a feed opening in the drying tower; an air filter is arranged at the front end of the heating device; the discharging device is arranged at the bottom of the drying tower; a refrigeration dehumidifier is arranged at the front end of the air moisture cooling device; the waste gas recovery device is used for delivering waste gas to the periphery of the outer side of a tower body of the drying tower through a waste gas recovery tower; the cleaning device comprises a clear water tank and a rotating cleaning device; the intelligent control cabinet is used for automatically controlling the whole working process of the system in a centralized way. The whole system is convenient to control and manage and high in drying efficiency, and has good energy-saving effects, and the pollution to the atmospheric environment caused by the waste gas is avoided.

Owner:南京净微环保科技有限公司

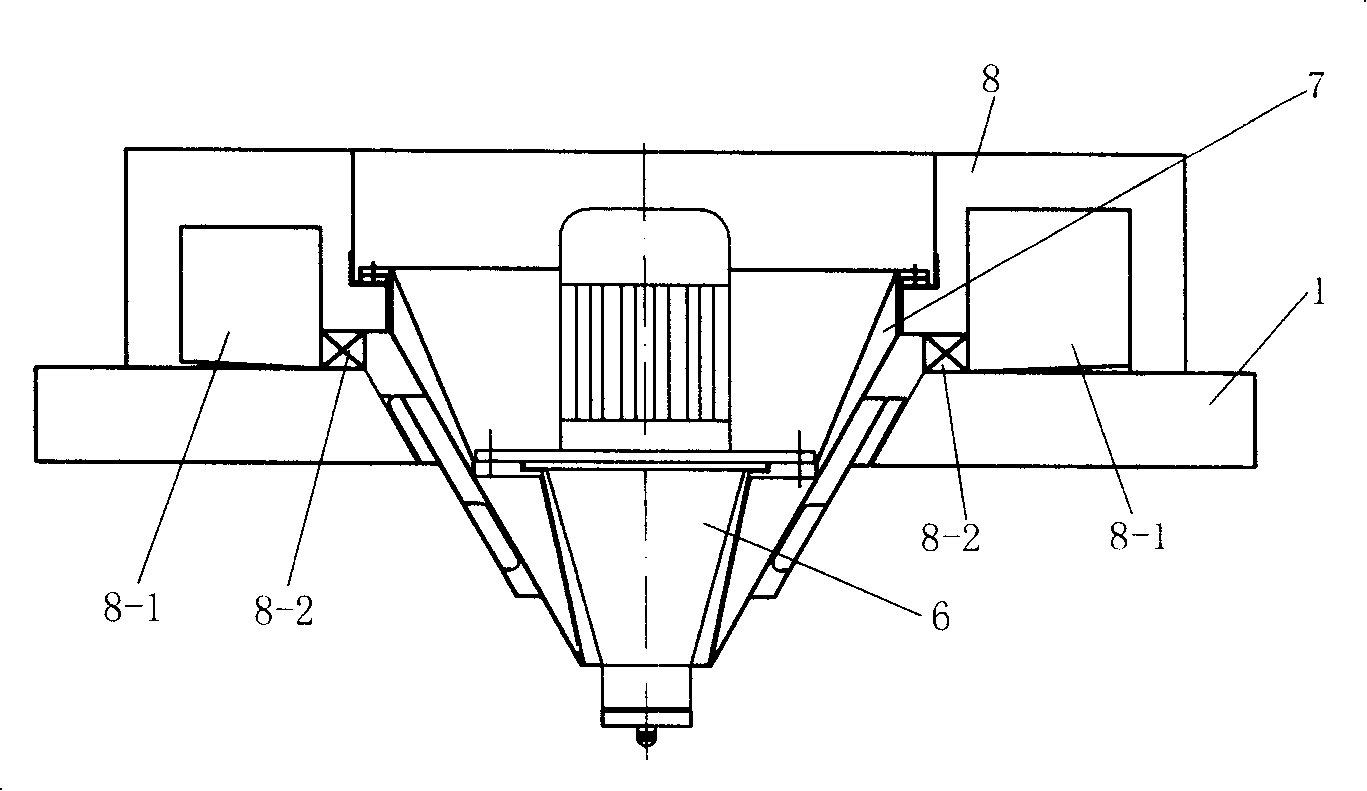

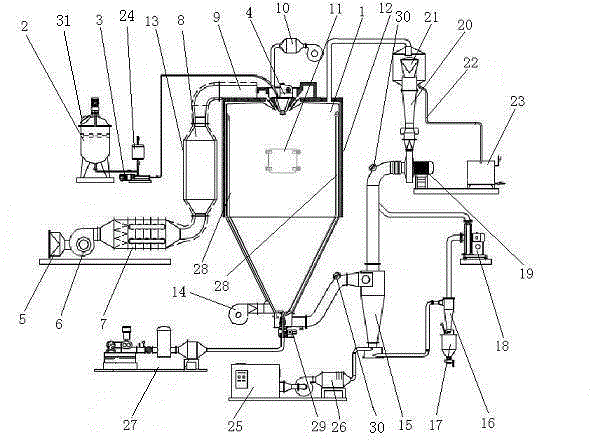

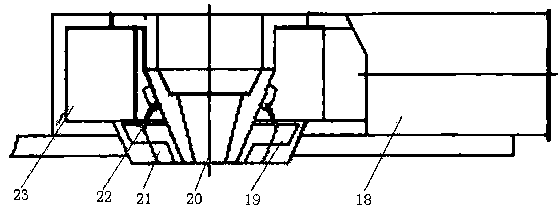

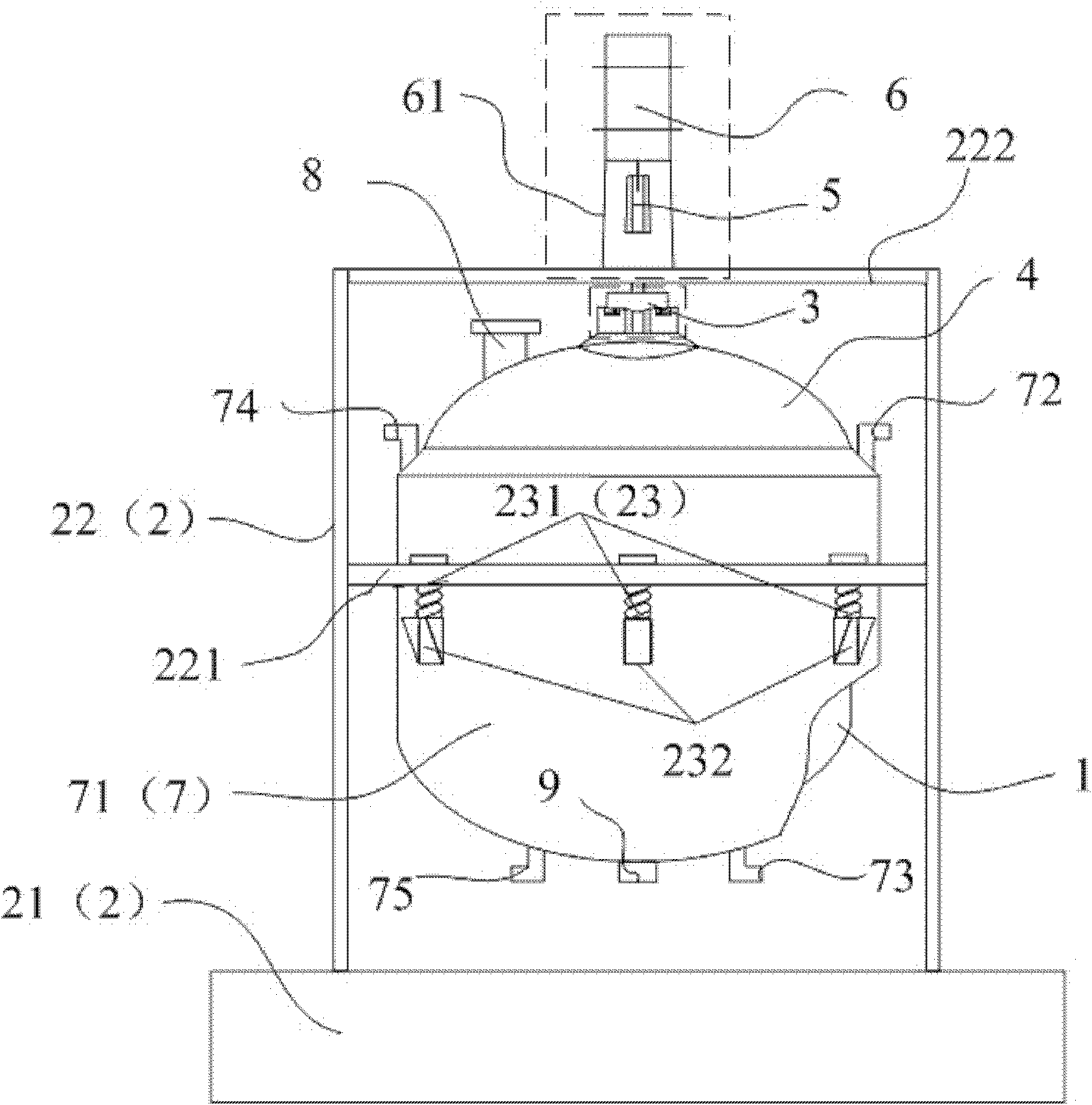

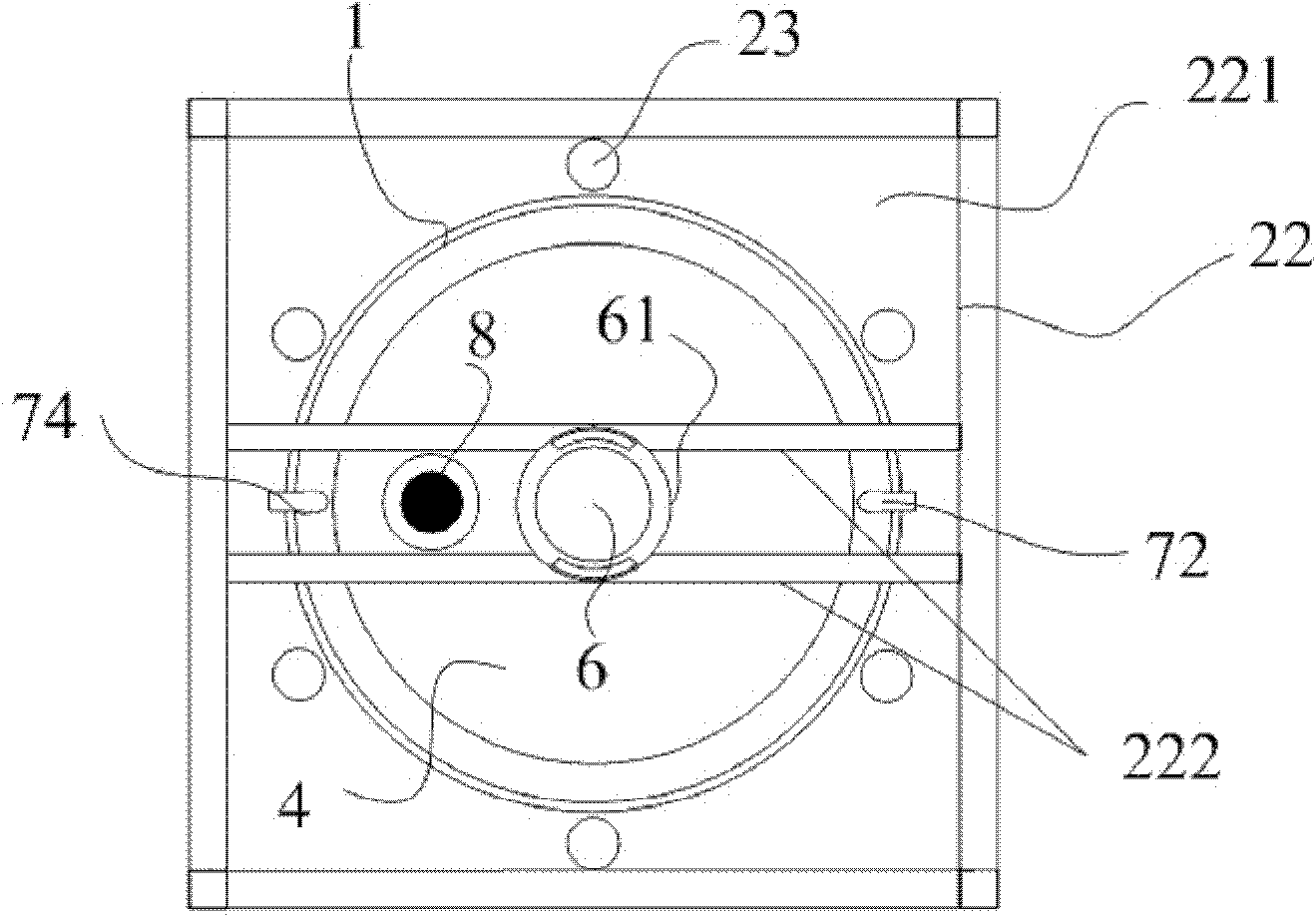

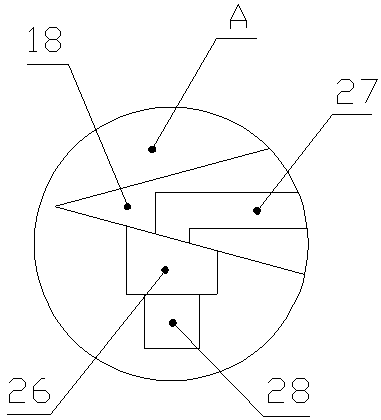

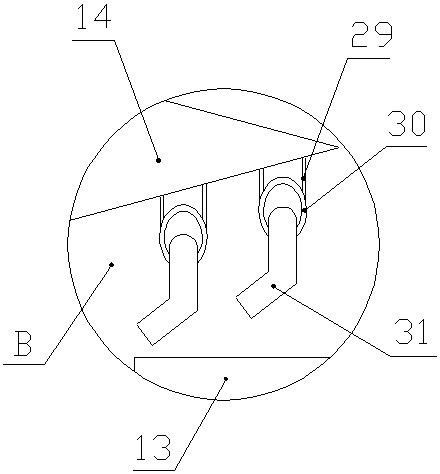

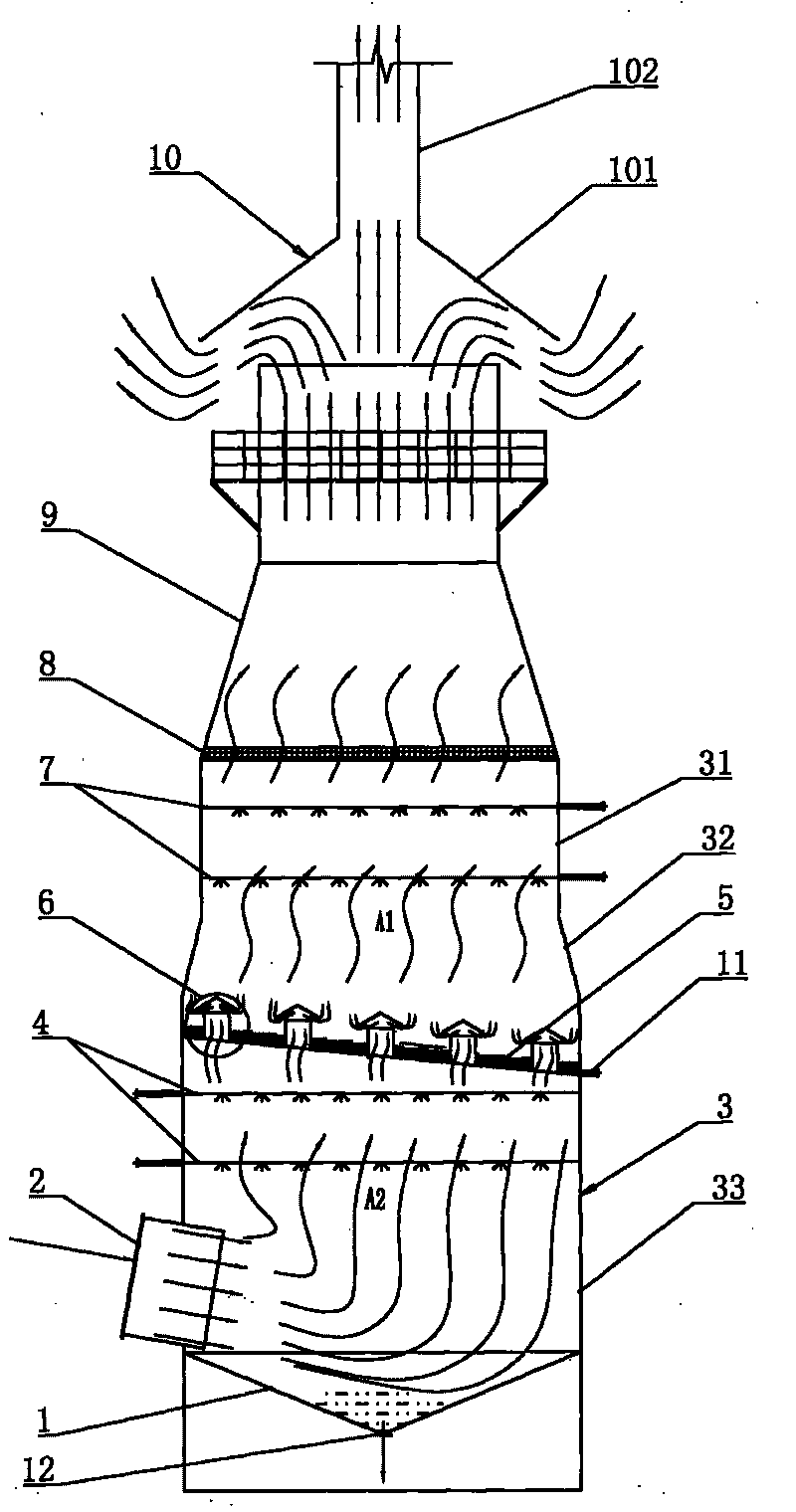

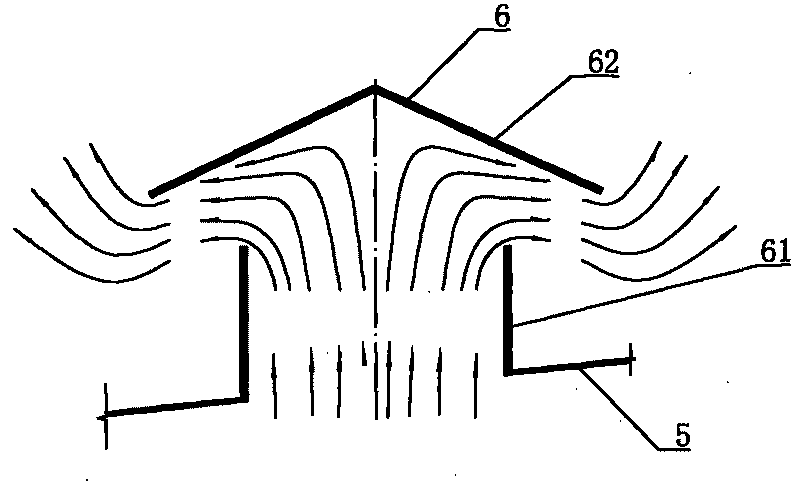

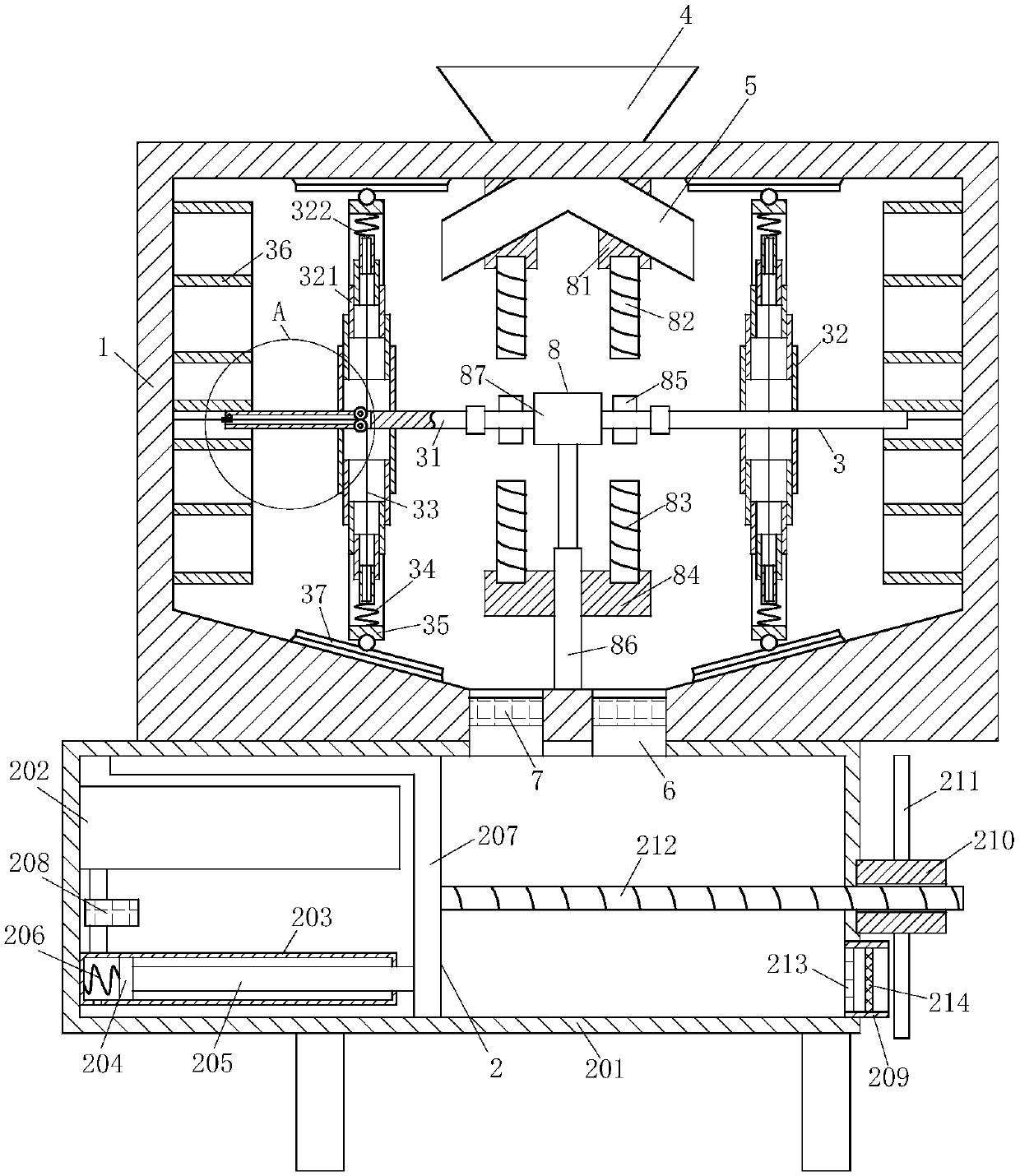

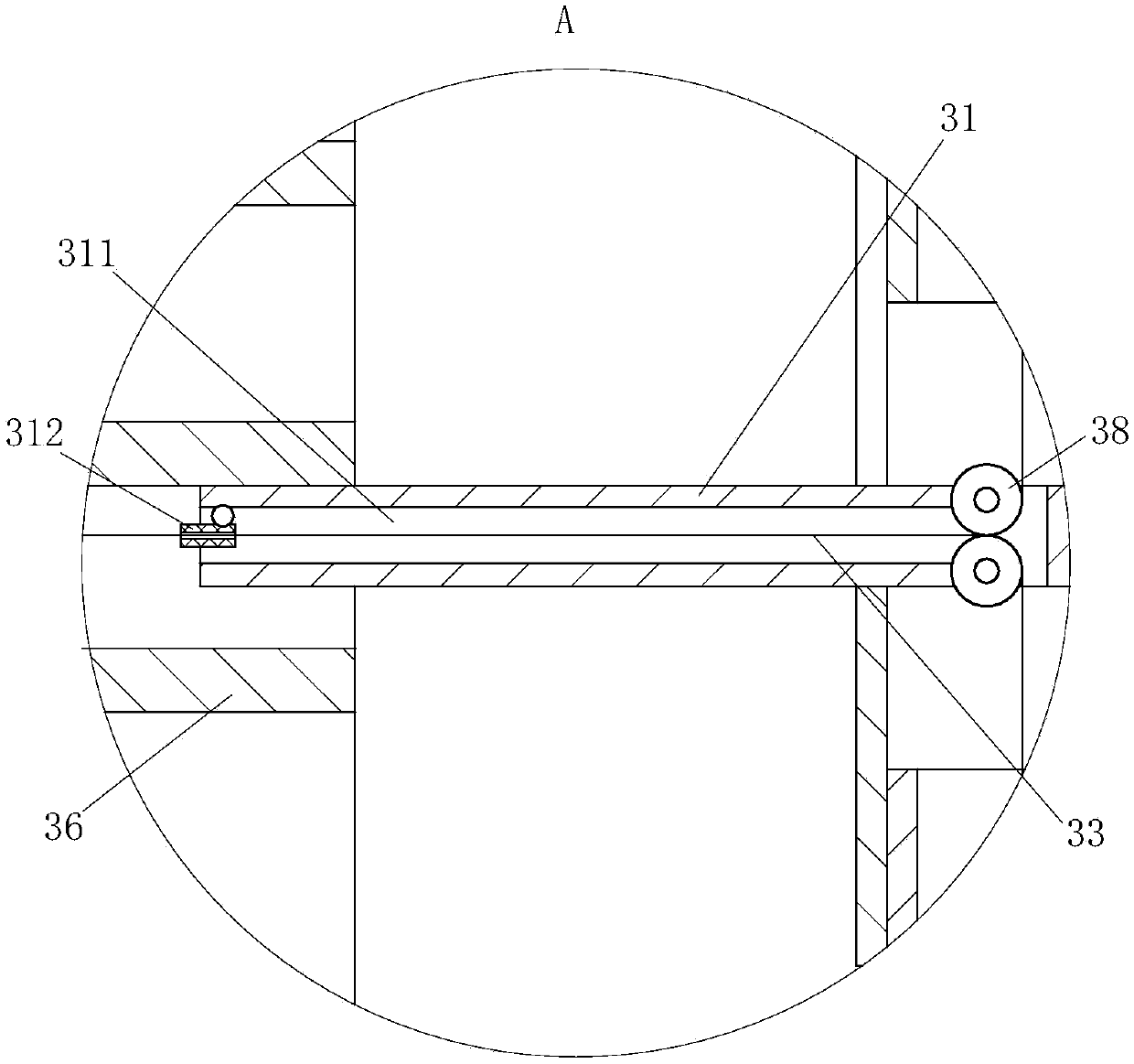

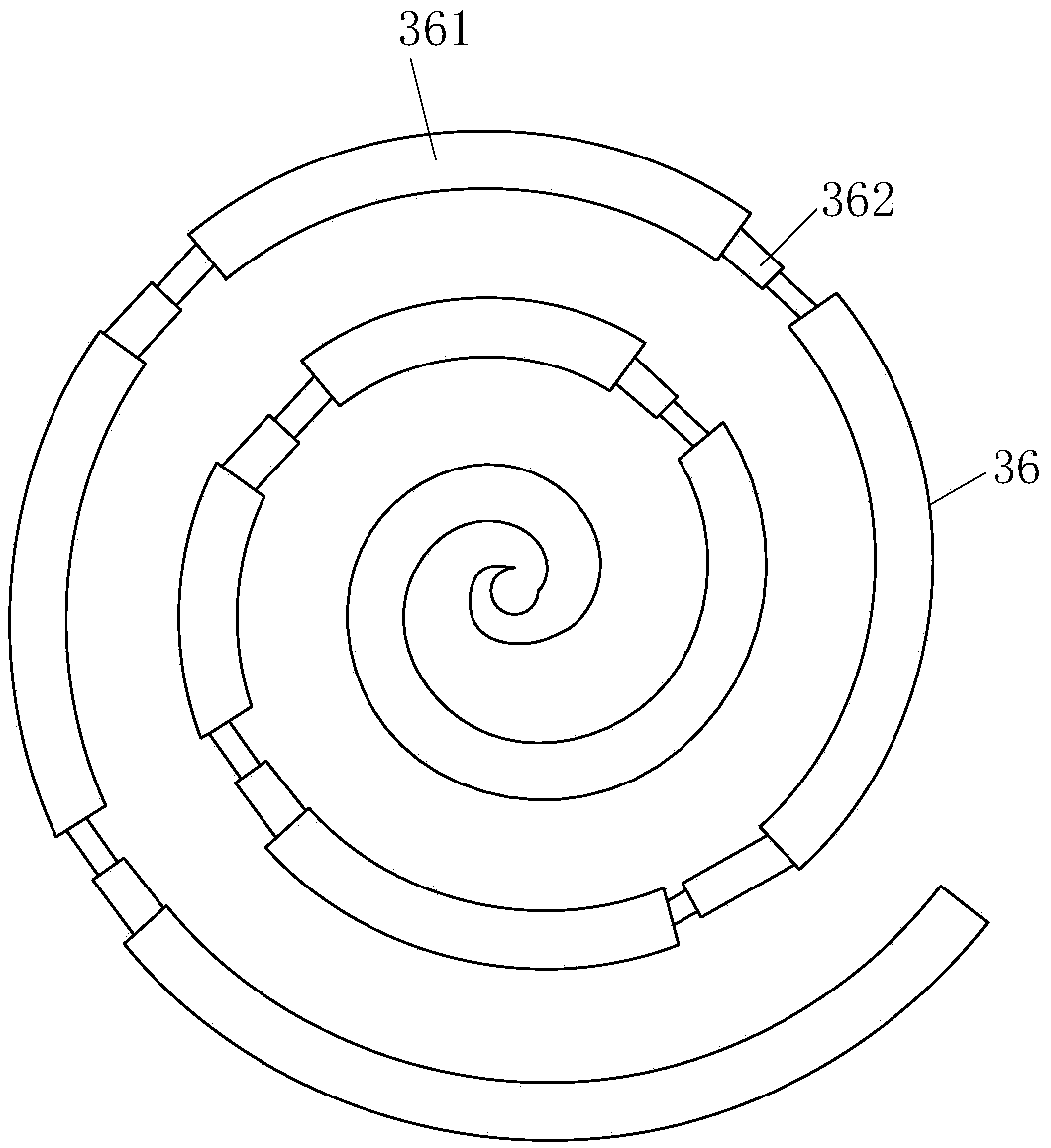

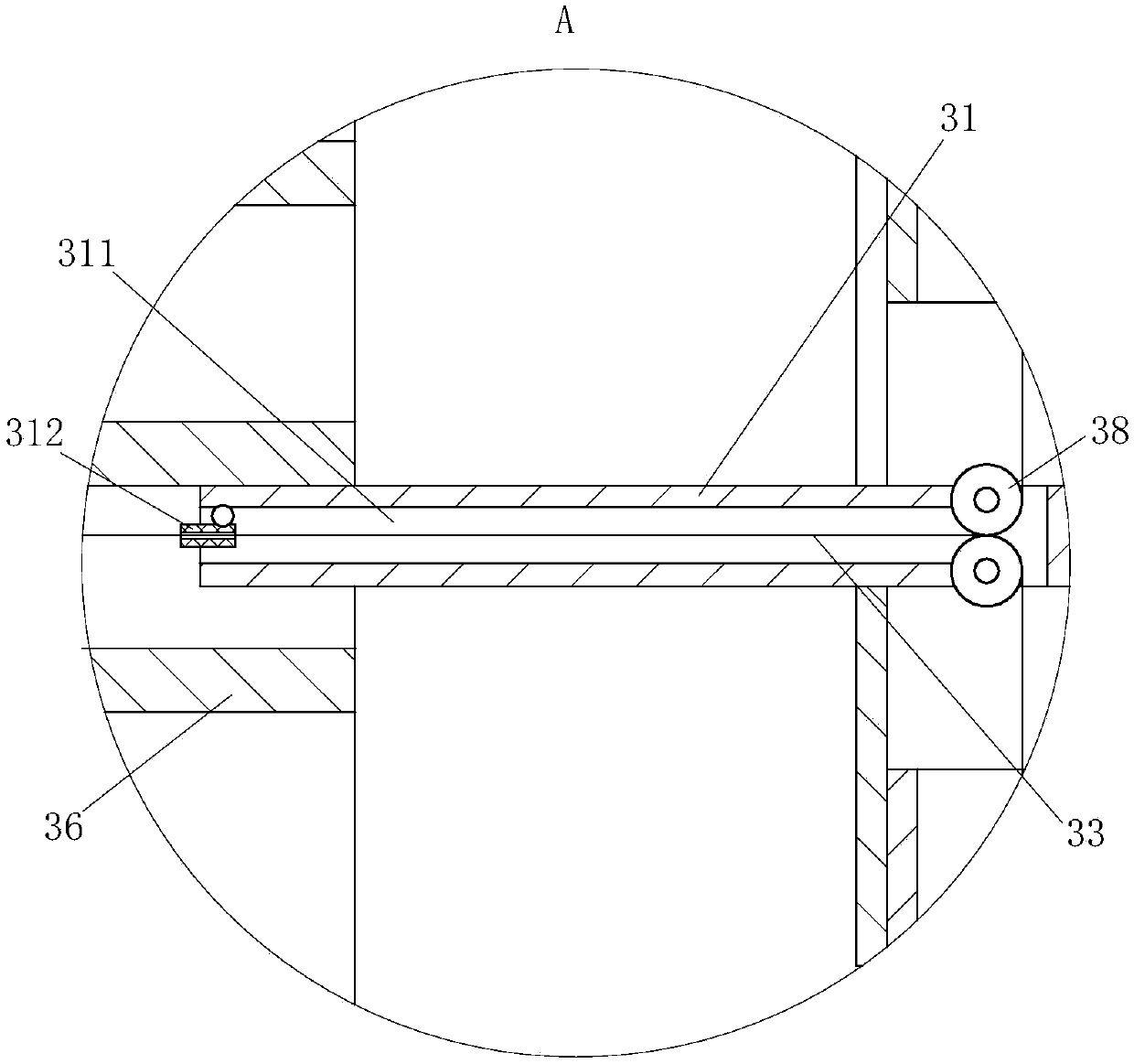

Centrifugal spray drying apparatus capable of preventing catalyst from adhering to walls

ActiveCN105363231AIngenious structural designLow costEvaporator accessoriesEvaporation by sprayingDust controlSpray dried

The present invention relates to a centrifugal spray drying apparatus capable of preventing a catalyst from adhering to walls. The apparatus comprises a centrifugal drying tower, a feeding apparatus, a heating apparatus, a cooling feeding device, a dust removal and evacuation apparatus and an intelligent control box; the middle of the top of the drying tower is provided with a volute hot air distributor and a variable frequency centrifugal atomizer, a heating apparatus is connected to an air inlet of the volute hot air distributor via a hot air pipeline, the cooling feeding device is mounted on the bottom of the drying tower, the upper side wall of the inside of the drying tower is provided with a cloth filter chamber, the bottom of the cloth filter chamber is open, the outer side of the drying tower is provided with a cooling sandwich layer, and the intelligent control box is connected to the variable frequency centrifugal atomizer, a material conveying pump, the heating apparatus, the cooling feeding device, an air outlet fan, an induced draft fan and an electric butterfly valve via wires, and working parameters of the whole drying apparatus are controlled accurately. The apparatus is high in drying speed and simple and stable in operation, and the circumstance that materials are adhered to walls is avoided, so that drying quality of the catalyst and the continuity of the drying operation are improved.

Owner:南京净微环保科技有限公司

Stirring tank

ActiveCN103007864AStir wellAdjustable temperatureMixersChemical/physical/physico-chemical stationary reactorsBiochemical engineeringEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

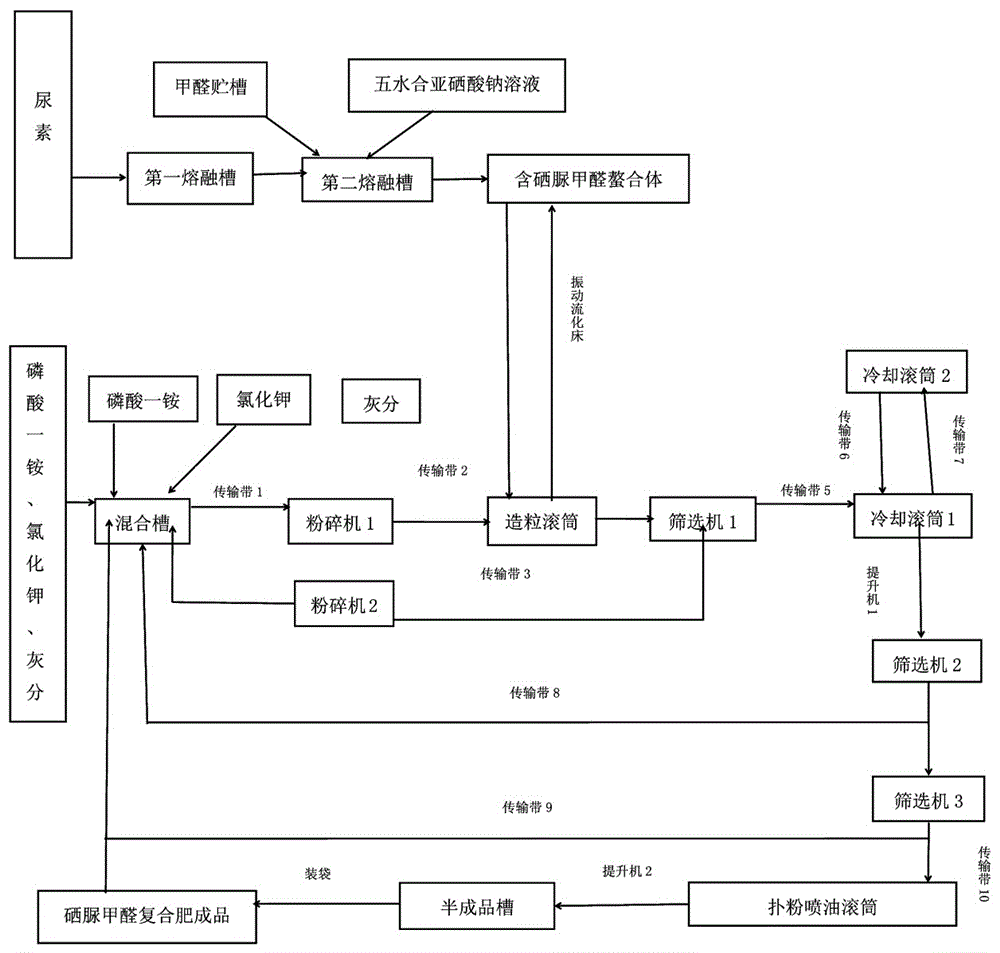

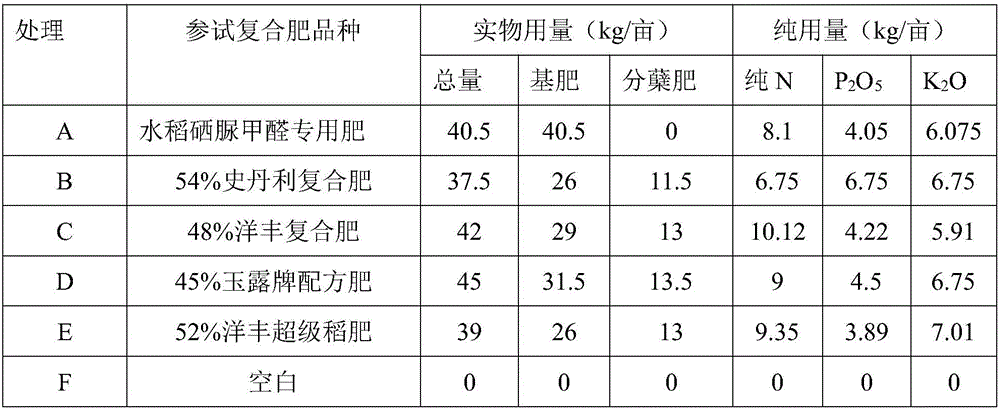

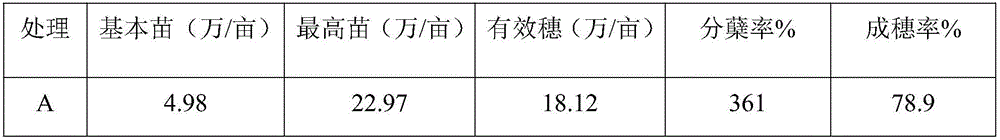

Special selenourea slow-release composite fertilizer for rice and production technology of fertilizer

InactiveCN106187386APromote growthFully absorbedAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium Selenite PentahydrateMelting tank

The invention provides a special selenourea slow-release composite fertilizer for rice. The fertilizer is prepared from, by weight percentage, urea, potassium chloride, monoammonium phosphate, sodium selenite pentahydrate, water and ash. The slow-release composite fertilizer further comprises synergist and a dispersion agent. A preparation method includes the steps that formaldehyde is conveyed into a urea melting tank, and sodium selenite pentahydrate is added for reaction to generate a selenourea formaldehyde chelate solution. High-temperature selenourea formaldehyde chelate is sprayed into mist from top to bottom and enters a cylinder granulation device, synergist and the dispersion agent are sequentially heated to 50-80 DEG C, then enter the cylinder granulation device of a fluidized bed and are mixed with smashed blocky fertilizer to form selenourea formaldehyde fertilizer particles, and the special selenourea slow-release composite fertilizer for rice is obtained. The fertilizer is scientific in ratio and comprehensive in nutrient, can gradually and continuously provide nutrients for rice crops, can make nutrients fully absorbed by rice, remarkably promotes rice growth, and remarkably increases the utilization rate of the fertilizer.

Owner:史丹利化肥当阳有限公司

Tangential gas intake desulfurization tower of semi-dry circulating fluidized bed

InactiveCN101612523AUniform concentration distributionIncreased turbulence intensityDispersed particle separationChemical/physical processesFluidized bedFlue gas

The invention relates to a tangential gas intake desulfurization tower of flue gas desulfurization technology of a semi-dry circulating fluidized bed. The tower is characterized in that: a flue gas intake structure is tangentially connected with the desulfurization tower, a desulfurizer inlet is positioned at the central position of the bottom of the desulfurization tower, a feed back inlet is positioned at the lower part of the desulfurization tower and a flue gas outlet is positioned at the top of the desulfurization tower. The tangential gas intake desulfurization tower has the advantages of causing the flue gas to form strong rotating flow in the desulfurization tower, improving turbulent intensity of gas flow, maintaining full contact between a desulfurizer and the flue gas, and intensifying desulfurization reaction process and greatly improving the utilization ratio of the desulfurizer; and the tangential flue gas intake structure can help effectively lower pressure drop of the system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing polyester-nylon composite fibers by melt direct spinning

ActiveCN111394831AReduced extractables contentQuality assuranceTextile/flexible product manufactureChemical/physical/physico-chemical stationary reactorsPolyesterFiber

The invention relates to the field of nylon materials, and discloses a method for preparing polyester-nylon composite fibers by melt direct spinning. The method comprises the following steps of 1) burdening, specifically, heating and mixing caprolactam, an end-capping reagent, water and a catalyst to obtain a mixture; 2) ring opening; 3) pre-polycondensation, specifically, carrying out a pre-polycondensation reaction and devolatilization; 4) final polycondensation, specifically, carrying out a final polycondensation reaction and devolatilization; 5) devolatilizing before spinning; and 6) spinning, specifically, directly conveying nylon melt and polyester melt which are devolatilized before spinning to a composite spinning assembly, performing extruding, cooling, oiling, stretching and winding to obtain the polyester-nylon composite fibers. By means of the method, direct spinning after nylon melt polymerization can be achieved, slices do not need to be prepared in advance, and the content of hot water extractables and cyclic dimers in the nylon melt can be effectively controlled; and composite spinning is carried out on the nylon melt and the polyester melt to obtain the polyester-nylon composite fibers in different composite forms.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Limestone powder calcining furnace

The invention discloses a limestone powder calcining furnace which comprises a furnace body, wherein the left side and the middle of the upper surface of the furnace body are connected with a feedinghopper and a motor B respectively; a motor A is arranged below the furnace body; output shafts of the motor A and the motor B are respectively connected with a stirring shaft A and a stirring shaft B;stirring blades are connected to the stirring shaft A and the stirring shaft B; high-temperature belts are connected to the middle of the inner side wall of the furnace body; the upper and lower parts of the inner side wall of the furnace body are connected with guide plates; the lower surfaces of the guide plates and the high-temperature belts are connected with material blowing devices; the lower surfaces of the stirring blades are connected with poking devices; the outer side of the stirring shaft A is connected with a discharge tower through a bearing; the outer side of the lower part ofthe furnace body is sleeved by a cooling sleeve; the lower part of the right side of the cooling sleeve is connected with a liquid inlet pipe; the upper part of the left side of the cooling sleeve isconnected with the inlet end of a steam drum through a liquid outlet pipe; the outlet end of the steam drum is connected with the stirring shaft A through a steam pipe; and the left side and the rightside of the lower surface of the furnace body are connected with discharge tubes. The limestone powder calcining furnace has the advantages of thorough calcination, wall adhesion prevention, high discharge efficiency, energy conservation and environment protection.

Owner:河南越尔环保科技有限公司

Desulfurization and purification method and equipment for unpowered sintering machine by using two-step method

InactiveCN101695620ASystem resistance is smallReduce power consumptionCombination devicesFlue gasPurification methods

The invention relates to desulfurization and purification method and equipment for an unpowered sintering machine by using a two-step method. The rear part of an induced draft fan of the sintering machine is provided with a desulfurization reaction tower which is divided into a water-washing dedusting zone and a desulfurization reaction zone. The purification treatment comprises the following steps: firstly, dust particulates in flue gas are removed in the water-washing dedusting zone, and then the flue gas enters into the desulfurization reaction zone through a bubble cap flue gas ascension pipe; and secondly, sulfur dioxide in the flue gas closely contacts a desulfurizer solution sprayed from top to bottom in the desulfurization reaction zone to react, and the flue gas is discharged into air after the sulfur dioxide is removed. The desulfurization reaction tower with low resistance can work by using the induced draft fan of the original sintering machine without an additional relay air blower to achieve the unpowered purpose. Compared with the traditional desulfurization device, the invention has the advantages of high desulfurization rate, low manufacturing cost, low operation cost, high degree of automation, simple operation, capability of continuous operation and safe and stable operation.

Owner:山西长林能源科技有限公司

Preparation method of low-fluorine euphausia superba unshelled shrimp meal

The invention discloses a preparation method of low-fluorine euphausia superba unshelled shrimp meal. The preparation method comprises the following steps: 1. carrying out unshelling treatment on euphausia superba fished into a boat to obtain euphausia superba meat; 2. carrying out heat treatment on the euphausia superba meat at 60-90 DEG C for 5-20 minutes; 3. centrifuging and dehydrating the euphausia superba meat and carrying out vacuum drying; and 4. crushing the dried shrimp meat by a crushing machine and sieving the crushed dried shrimp meat with a 20-mesh sieve to obtain the euphausia superba unshelled shrimp meal. The preparation method of the low-fluorine euphausia superba unshelled shrimp meal applicable to the boat is established for the first time and the water content of the prepared shrimp meal is lower than 10%; and the content of fluorine is lower than 300mg / kg and the appearance color is better. The preparation method has the technical innovations that 1. the euphausia superba unshelled shrimp meal is prepared from the euphausia superba unshelled meat and the fluorine content is low; 2. the drying time is short and the production efficiency is improved; 3. conditions are moderate, the stability of grease in the shrimp meal is kept and the quality of the shrimp meal is improved; and 4. a wall sticking phenomenon is avoided by adopting a drying container with a teflon coating.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for producing polyethylene

The invention provides a method for producing polyethylene. The method comprises the following steps: adding reaction materials into a high-pressure polyethylene reactor; carrying out a first-stage polymerization reaction on the reaction materials at 302-307 DEG C to obtain a first polymerization product; and carrying out a second-stage polymerization reaction on the first polymerization product at 285-290 DEG C to obtain the polymerization product polyethylene. According to the method, the reaction temperatures of the first-stage reaction and the second-stage reaction in a high-pressure polyethylene reaction are adjusted, and the reaction temperatures of the two stages are relatively controlled to be in a range of 302-307 DEG C and in a range of 285-290 DEG C, so that the molecular weightof the polymer obtained in the first-stage reaction is reduced, the viscosity of the materials of the first-stage reaction is reduced, the flowability is enhanced, and thus the occurrence of adhesionto a wall is avoided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

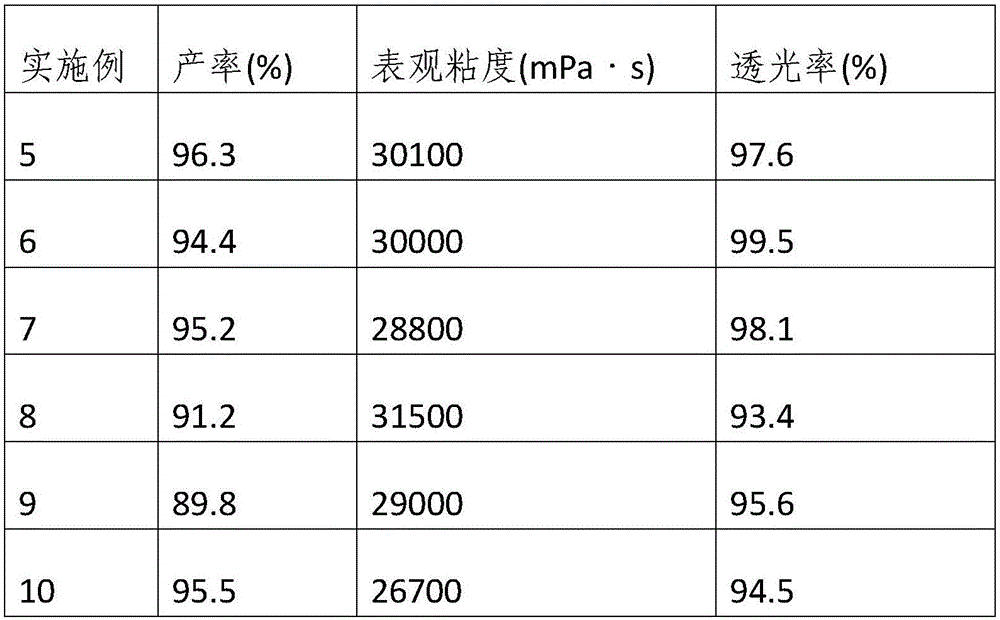

Carbopol and preparation method thereof

InactiveCN106632803AIncrease activation energyPrevent reversible reactionsNon-macromolecular adhesive additivesAcid polymer adhesivesActivated carbonAntioxidant

The invention relates to the technical field of resin materials, in particular to carbopol and a preparation method thereof. The carbopol is prepared by taking acrylic acid as a monomer and matching with an initiating agent, a corss-linking agent, an assistant, purified water, a solvent and activated carbon, wherein the solvent is prepared from tertiary butanol and sorbitol; the assistant is prepared from an antioxidant and a chain modifier. According to the preparation method disclosed by the invention, abnormal phenomena of wall sticking and instable acid values are effectively prevented; by utilizing the preparation method disclosed by the invention, the yield and the light transmittance of a product are better, the thickening effect is good, the odor is low, and the product also has good mechanical performance.

Owner:贵州省欣紫鸿药用辅料有限公司

Film pressure thermal dehydration method and equipment for high-moisture sludge

InactiveCN102108001ADecrease the concentration gradientMoisture migration path is shortSludge treatment by de-watering/drying/thickeningSludge dewateringMoisture

The invention discloses a film pressure thermal dehydration method and equipment for high-moisture sludge, and belongs to the technical field of sludge dehydration. The method is characterized by comprising the following steps of: spreading the sludge subjected to conventional mechanical dehydration into a film of 1 to 10mm, regulating hot extrusion temperature and pressure for partition wall hot extrusion dehydration, separating out moisture in a liquid form, and further applying the sludge after the moisture is separated out. The invention has the advantages that: the energy consumption is low, and the energy utilization rate is high; in the dehydration process, seamless compression is adopted, and a wall-sticking phenomenon of conventional equipment is avoided, so that the whole dehydration process is smooth and feasible; and the process flow is simple and high in feasibility, other substances are not introduced, and the further treatment and recycle of the sludge are not influenced.

Owner:DALIAN UNIV OF TECH

Potassium tripolyphosphate preparation method

ActiveCN1799997ASolve the difficulty of mixing and dischargingPrevent stickingPhosphorus compoundsPhosphoric acidChemistry

The invention discloses a making method of potassium tripolyphosphate, which comprises the following steps: proceeding one-step potassium tripolyphosphate synthetic process through high temperature of peroxyphosphoric acid and anhydrous potassium carbonate; producing the needed potassium tripolyphosphate through mixing, neutralizing, drying, grinding, sintering and disintegrating by twin-screw plodder. The invention simplifies the flow path and saves the equipment investment, which improves the conversion rate and quality.

Owner:YUNNAN CHEM RES INST

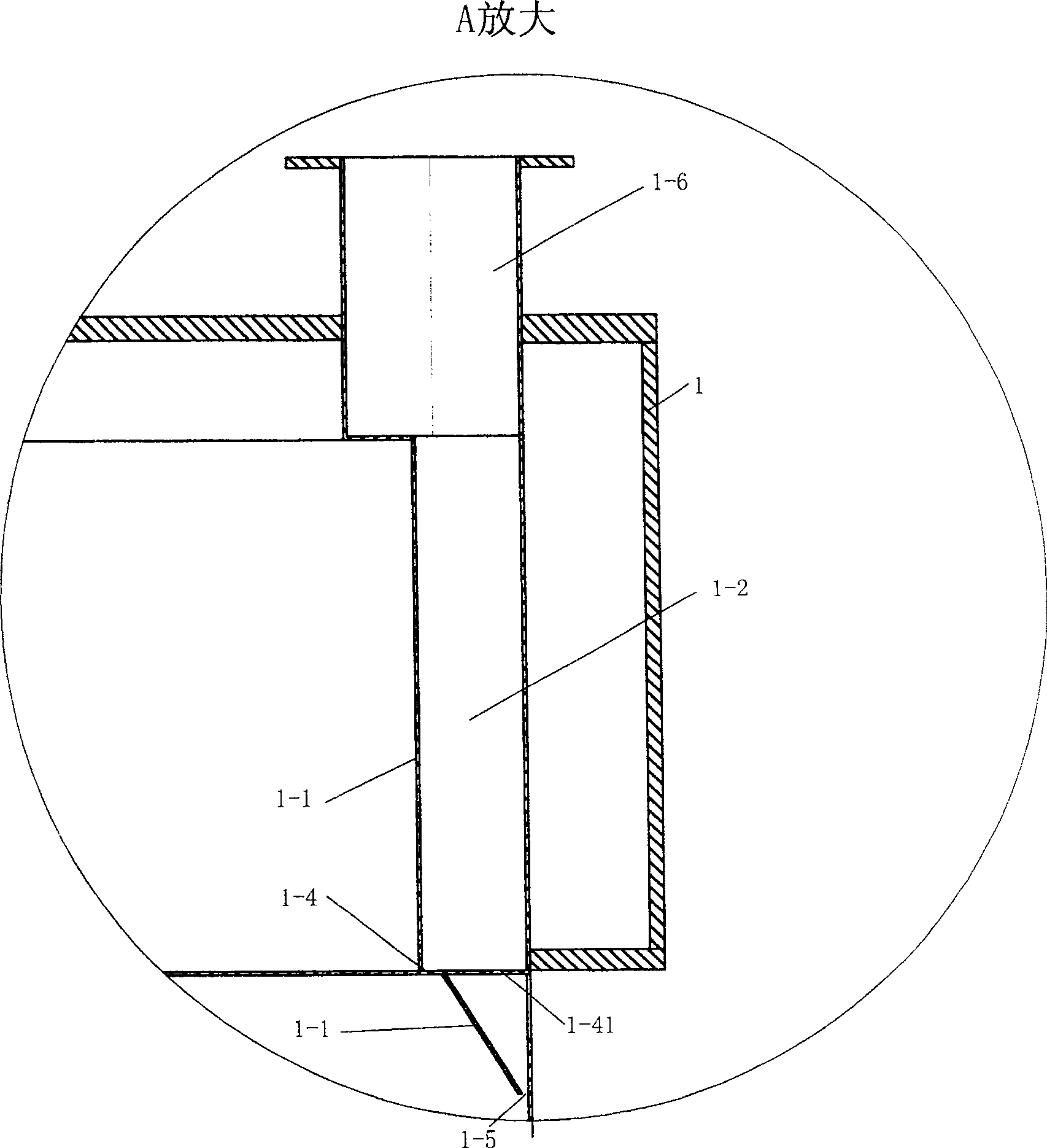

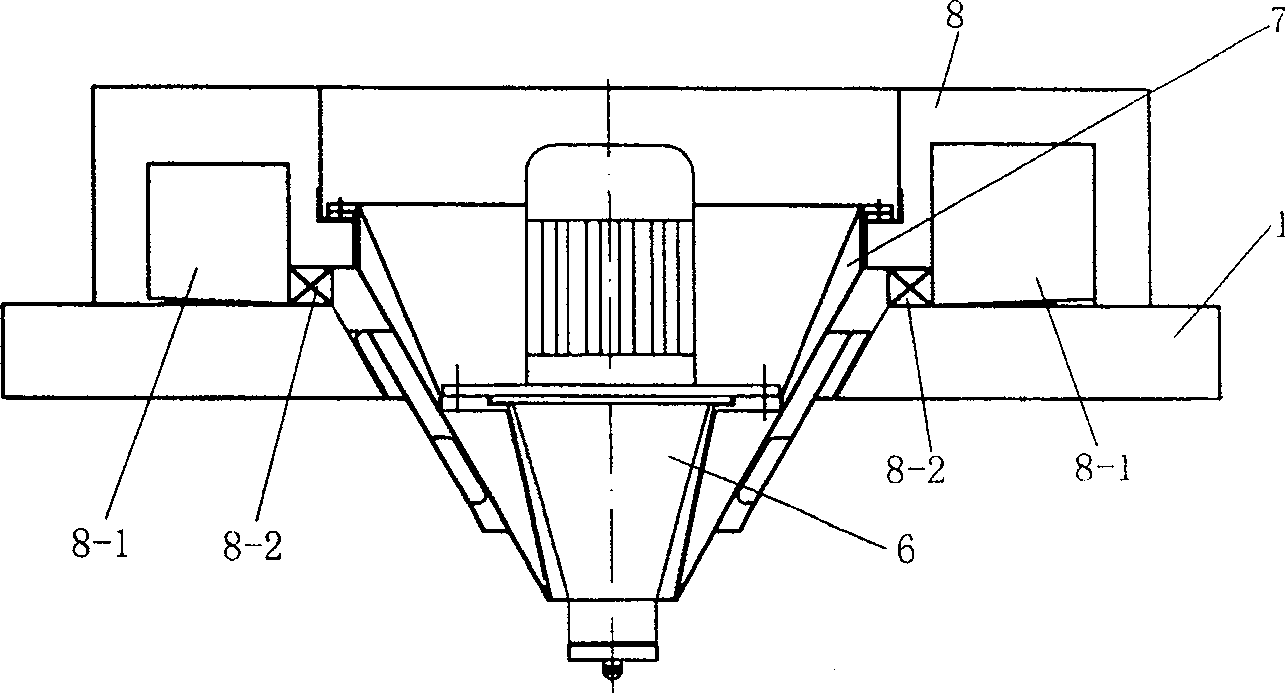

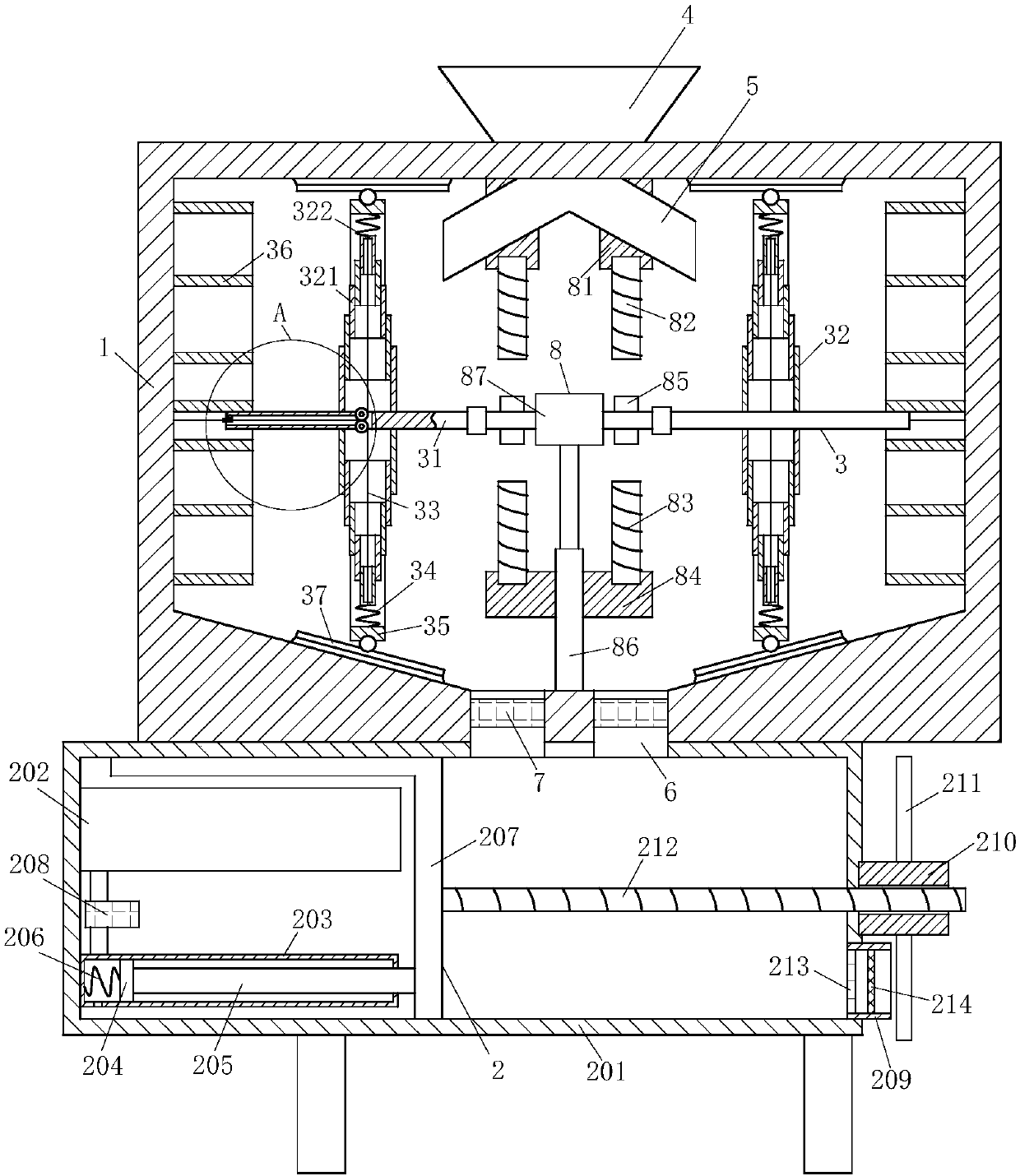

Inorganic waste refined recycling equipment

InactiveCN109593586AEfficient mixingAvoid wall stickingSolid fuelsWaste based fuelBiochemical engineeringSolid fuel

The invention belongs to the technical field of environment-friendly equipment, and particularly relates to inorganic waste refined recycling equipment. The equipment comprises a shell, an extrusion mechanism, a mixing mechanism, a feed opening, a feed pipe, a delivery channel, a first electromagnetic switch, a drive device and a controller, wherein the controller is used for controlling the equipment to work; the shell has a cylindrical structure which is horizontally arrangement, the conical inner bottom wall of the shell is convenient for material flow-out; coal ash, adhesive and solid fuelcan be efficiently and uniformly mixed in the shell due to the two-axis motor, a stirrer, a first wall scraper and a second wall scraper, and materials attached to the shell are constantly scrapped and mixed once again to avoid the phenomenon of wall sticking; and the mixture of coal ash, adhesive and solid fuel is directly extruded into cake which can be burnt more easily due to the extrusion mechanism, so that the processing time is saved, and the production efficiency is improved.

Owner:石宏扬

Method for producing vital wheat gluten by using slice flash evaporation-circulation drying technology

The invention discloses a method for producing vital wheat gluten by using a slice flash evaporation-circulation drying technology, and belongs to the technical field of food processing. Wheat flour is used as a raw material, high-purity wet gluten is prepared through the steps of dough kneading, curing, homogenizing, three-phase separation, washing and the like, drying treatment is conducted through the slice flash evaporation-circulation drying technology, and efficient production of the vital wheat gluten is achieved. According to the method, the energy consumption and cost of dehydration and drying can be effectively reduced, the wall sticking phenomenon of wet gluten in the dehydration and drying process is avoided, the equipment loss and failure rate are reduced, the uniformity of the product is improved, and the method can be applied to the fields of green low-carbon production of high-quality vital wheat gluten and food thereof.

Owner:JIANGNAN UNIV

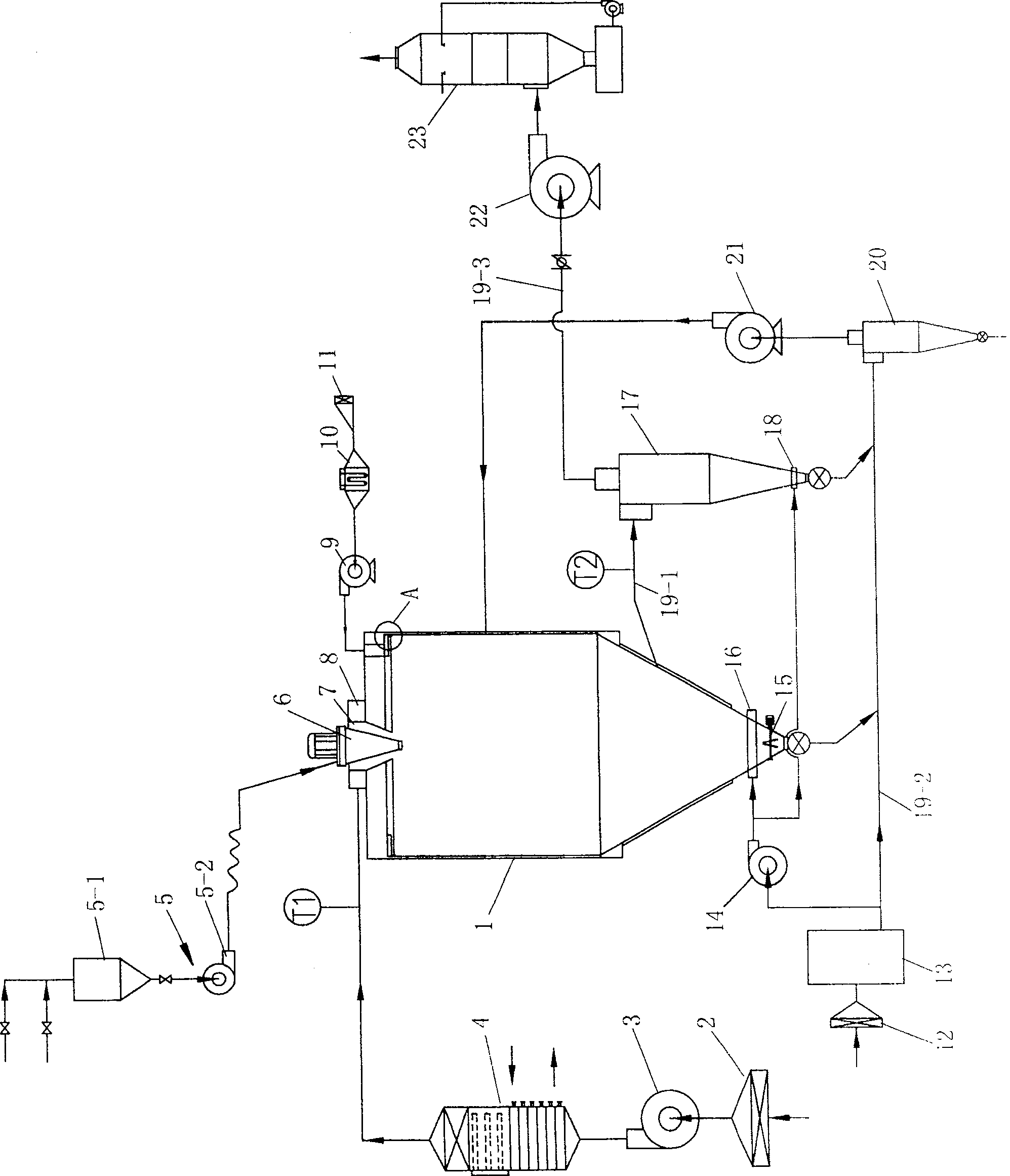

Bypass flue gas spray drying desulphurization waste water processing apparatus and method thereof

ActiveCN108640188AUnlikely to cause blockageNo foulingGeneral water supply conservationWaste water treatment from gaseous effluentsFlue gasStraight tube

The invention discloses a bypass flue gas spray drying desulphurization waste water processing apparatus and a method thereof. The apparatus comprises an air-flow spraying tower, a flue gas wind distributor arranged at the upper part of the air-flow spraying tower and connected with the air-flow spraying tower, an air-flow nozzle arranged at a central line in the air-flow spraying tower, a waste water pot connected with an air-flow nozzle feed inlet, a deduster connected with the lower part of the air-flow spraying tower, a first ash bin and a second ash bin respectively connected with two ends of the lower part of the deduster, a positive air seal machinery connected with an ash outlet of the second ash bin, and a Roots blower and an air-outlet pipe connected with the lower part of the positive air seal machinery. A fly ash inlet is arranged at the top of a straight tube of the air-flow spraying tower, the fly ash inlet and the straight tube of the air-flow spraying tower are tangentially connected, and the fly ash in the air-flow spraying tower spirally downward sprays. The operation cost is low, no fouling and wall scaling is generated, the system operation is reliable, operation of a boiler main body is not influenced, and the operation is stable and reliable.

Owner:SOUTHEAST UNIV +1

Seasoner sponging drying machine group

InactiveCN100523685CReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCyclonePulp and paper industry

The invention includes a feeding device, a drying tower, a No. 1 fan, a No. 1 heater, a first-stage cyclone separator and a water film dust collector; a hot blast distributor is installed at the central hot blast inlet of the drying tower top and installed in the center of the hot blast distributor. And the atomizer connected with the feeding device, the top of the drying tower is provided with an air channel plate with a volute-shaped air channel, the inlet of the air channel plate is connected to the output pipeline of No. 1 heater, and the outlet of the air channel plate is connected to the The inlet connection of the hot air distributor; there is a jacket near the top of the drying tower body, the space between the jacket and the inner wall of the tower body is the air inlet channel for sweeping the wall, and the ring between the bottom of the jacket and the inner wall of the tower body The gap is the air outlet, and the wind passes through the annular gap to form a wall-sweeping wind. The invention adopts the air duct spiral cutting and wall-sweeping air inlet technology, which not only improves the drying efficiency, but also forms a wind film on the drying tower wall by providing the wall-sweeping wind. , The air film isolates the powder from contacting the tower wall to prevent the phenomenon of sticking to the wall.

Owner:JIANGSU XIANFENG DRYING ENG

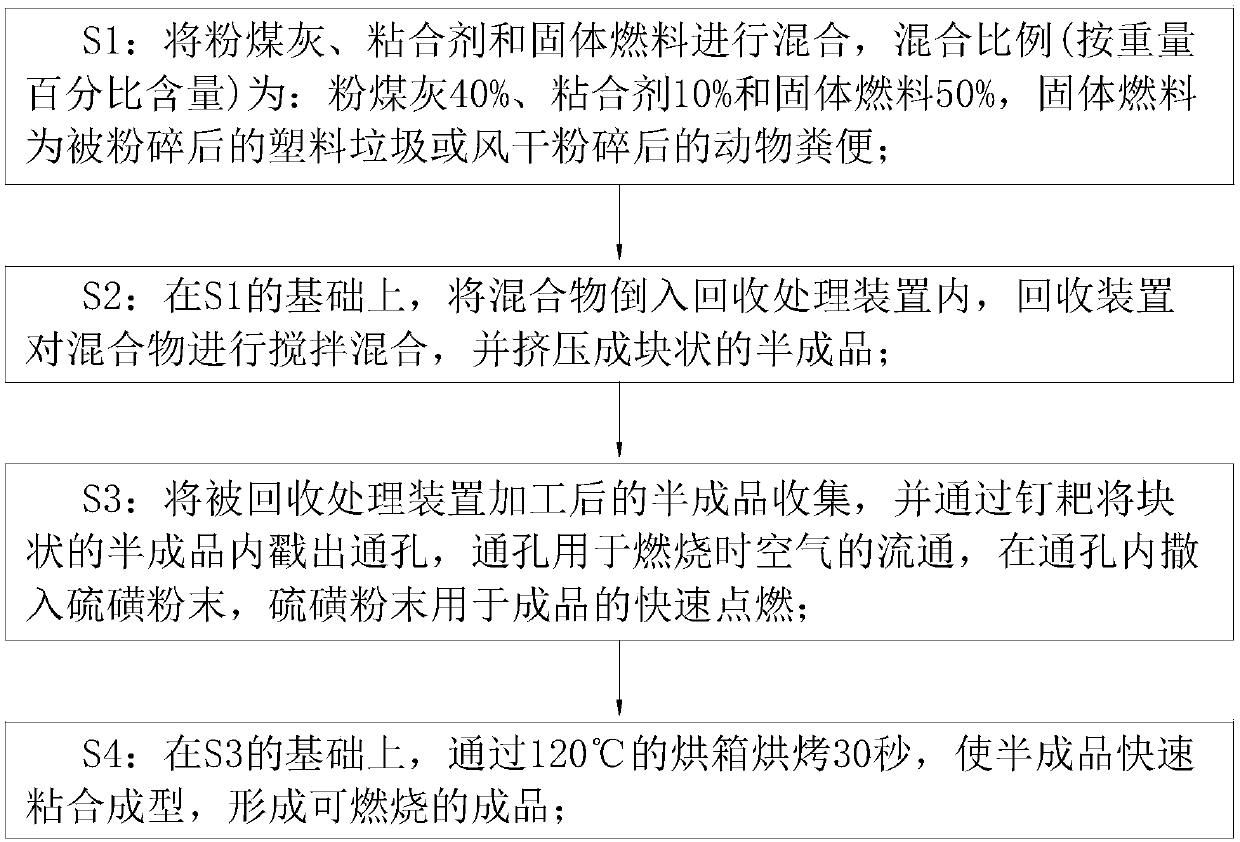

Recycling process of pulverized coal ash

The invention belongs to the technical field of environment protection and particularly relates to a recycling process of pulverized coal ash. A recycling device used by the recycling process comprises a shell and also comprises an extruding mechanism, a mixing mechanism, a feeding opening, a feeding pipe, a conveying channel, a first electromagnetic switch, a driving device and a controller, wherein the controller is used for controlling operation of equipment; the shell is of a horizontally arranged cylindrical structure; an inner bottom wall of the shell is conical; the pulverized coal ashis bonded with solid fuels through adhesives and is treated by the recycling device; about 1-25% of effective heat value in the pulverized coal ash can be fully reused, so that the coal energy can bereused; meanwhile, plastic wastes and animal wastes can be used as the solid fuels, so that the wastes are further used, and the resources are saved; through holes are poked on finished blocks, and sulfur powder are sprinkled into the through holes; the ignition points of finished products are reduced; the finished products can be rapidly ignited; meanwhile, the combustion of the finished productsis more complete.

Owner:石宏扬

Processing method of low-hygroscopicity waxberry fruit powder

The invention discloses a processing method of a low-hygroscopicity waxberry powder, belonging to the technical field of fruit and vegetable food processing. A method of juicing waxberry fruits, modifying low-molecule sugar and performing spray-drying is adopted and comprises the following specific steps: screening a waxberry fruit raw material, cleaning, blanching for performing enzyme deactivation, mashing, juicing, modifying the low-molecule sugar, adding a drying aid, performing spray-drying, and packaging. According to the processing method, by adopting a novel process of modifying the low-molecule sugar, the hygroscopicity resistance of the waxberry fruit powder is improved; by adopting a spray-drying processing method, the dewatering time of the waxberry fruit juice is short, nutritional ingredients are well preserved, and the qualities of color, taste and the like are good. The processing method has the advantages of simple equipment, simplicity and convenience in operation, and reliability in running, and is capable of greatly reducing the quality deterioration during processing, so that the quality of the waxberry fruit powder is remarkably improved.

Owner:TAIZHOU UNIV

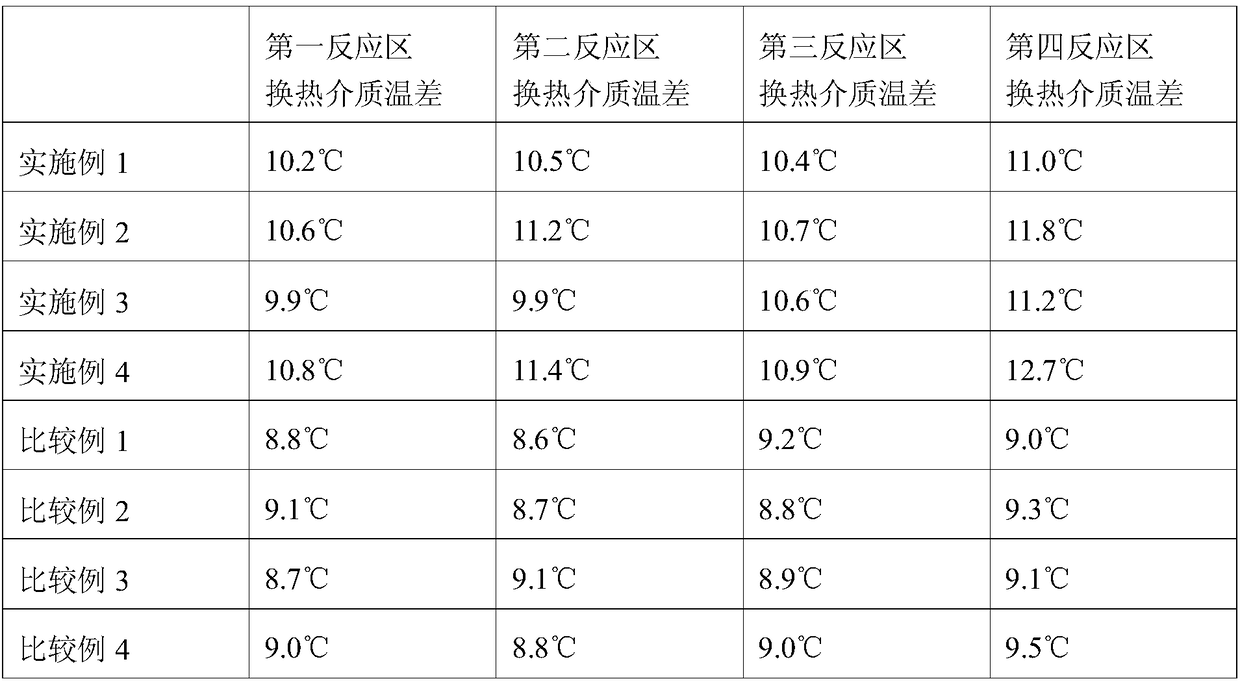

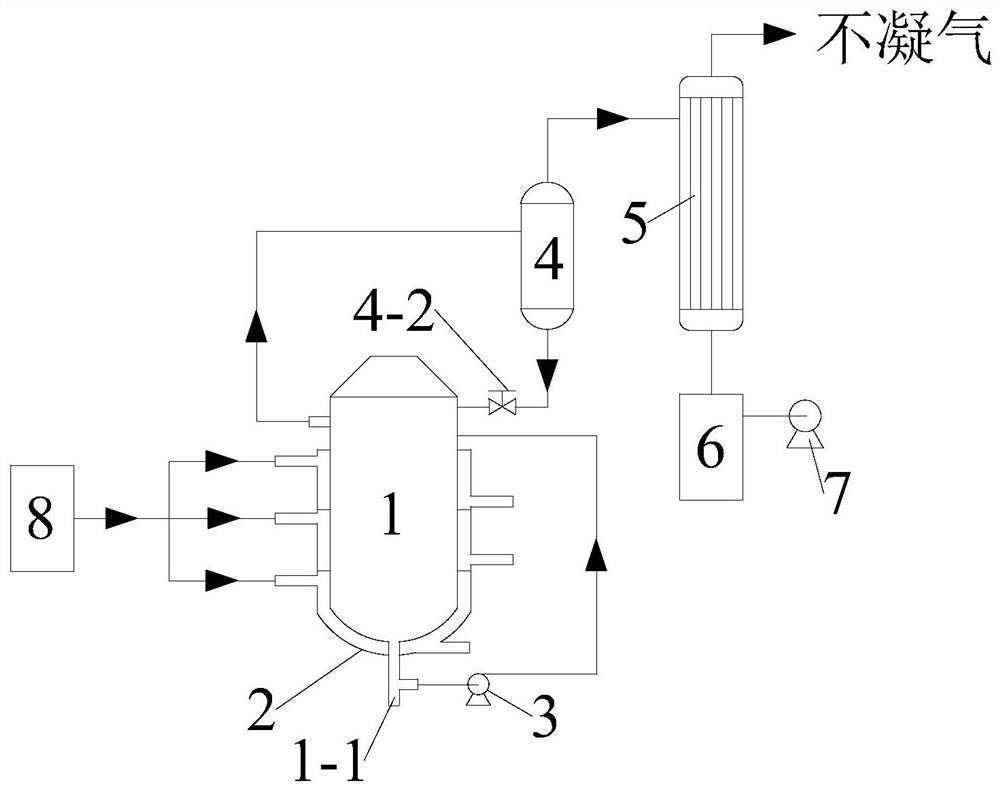

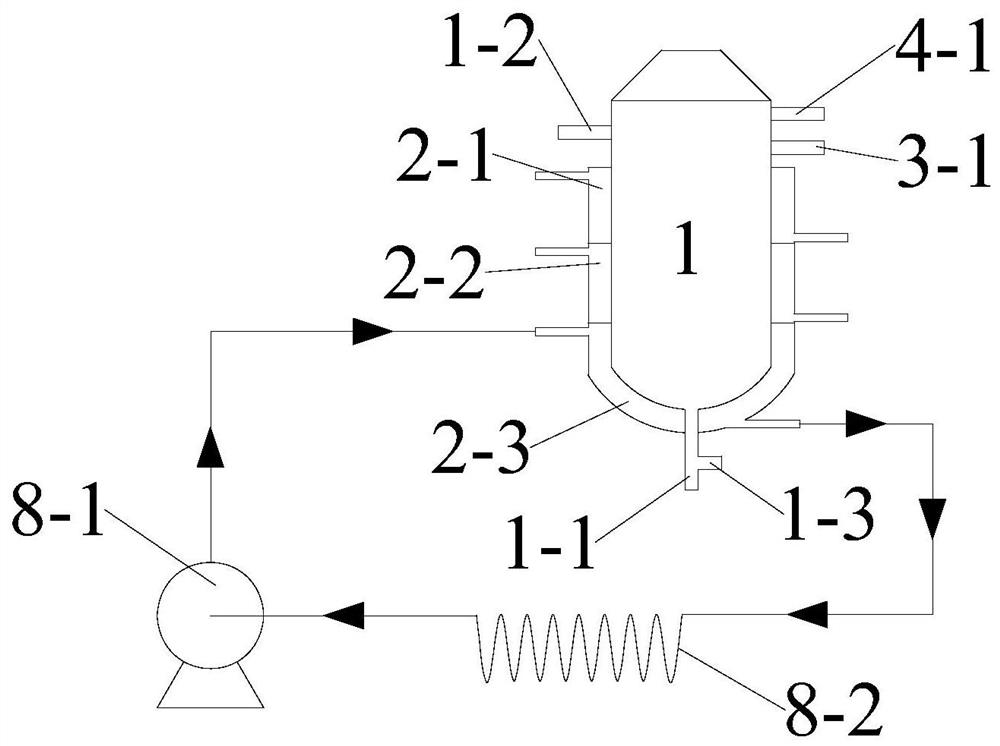

Anti-wall-sticking efficient vacuum concentration device and application thereof

PendingCN111803977AIncrease the dispersion specific surface areaImprove transfer efficiencyEvaporator accessoriesEvaporator regulation/controlVapor–liquid separatorEngineering

The invention relates to an anti-wall-sticking efficient vacuum concentration device and an application thereof. The anti-wall-sticking efficient vacuum concentration device comprises an evaporation chamber, a circulating delivery pump, a gas-liquid separator, a condenser, a liquid collector, a vacuum pump and a heat source supply device, the circulating delivery pump is used for circulating a to-be-concentrated solution flowing out of the bottom of the evaporation chamber to the circulating solution inlet in the top of the evaporation chamber, the evaporation chamber is provided with a liquidlevel monitoring part and a heat exchange jacket, the heat exchange jacket is divided into at least two cavities which are distributed from top to bottom by partition plates, each cavity is independently provided with a heat source inlet and a heat source outlet, and the liquid level monitoring part is used for monitoring the liquid level in the evaporation chamber and controlling opening and closing of the heat source inlet and the heat source outlet. According to the anti-wall-sticking efficient vacuum concentration device, the wall sticking phenomenon of materials can be reduced while thevacuum concentration efficiency is improved without a stirring device, the structure is simple, the energy consumption is low, and the quality and the activity of a concentrated product are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com