Carbopol and preparation method thereof

An acrylic monomer and solvent technology, applied in the direction of adhesive types, adhesive additives, acid copolymer adhesives, etc., can solve the problem of low monomer conversion rate, high carbomer viscosity, deep carbomer hue, etc. problem, to achieve the effect of preventing and controlling high acid value, improving fat solubility, and increasing activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of preparation method of carbomer, comprises the following steps:

[0033] (1) Mix tert-butanol, sorbitol, activated carbon, and purified water evenly, add them to the reaction kettle, and stir the reaction kettle until the temperature is 65°C;

[0034] (2) After mixing the cross-linking agent and antioxidant evenly, a solution A is obtained; put the acrylic acid monomer in an alkalized microwave kettle for treatment for 5 minutes, and the microwave power is 350W; there are two high-level tanks above the reaction kettle, add acrylic acid respectively Monomer and solution A; add acrylic acid monomer and solution A dropwise to the reaction kettle, control the amount of addition so that the acrylic acid monomer and solution A are added dropwise at the same time, and the time for dropping is 4.8h;

[0035] (3) After the dropwise addition, control the temperature of the reaction kettle to rise to 90°C, and under the condition of filling...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of carbomer, comprises the following steps:

[0041] (1) Mix tert-butanol, sorbitol, activated carbon, and purified water evenly, add them to the reaction kettle, and stir the reaction kettle until the temperature is 70°C;

[0042] (2) After mixing the cross-linking agent and antioxidant evenly, a solution A is obtained; the acrylic acid monomer is put into an alkalized microwave kettle for 8 minutes, and the microwave power is 450W; there are two high-level tanks above the reaction kettle, and acrylic acid is added respectively Monomer and solution A; dropwise add acrylic acid monomer and solution A to the reaction kettle, control the amount of addition so that the addition of acrylic acid monomer and solution A is completed at the same time, and the time for dropping is 5.5h;

[0043] (3) After the dropwise addition, control the temperature of the reactor to rise to 90°C, and fill it with nitrogen to maintai...

Embodiment 3

[0048] The present embodiment provides a kind of preparation method of carbomer, comprises the following steps:

[0049] (1) Mix tert-butanol, sorbitol, activated carbon, and purified water evenly, add them to the reaction kettle, and stir the reaction kettle until the temperature is 68°C;

[0050] (2) After mixing the cross-linking agent and antioxidant evenly, a solution A is obtained; the acrylic acid monomer is put into an alkalized microwave kettle for 6 minutes, and the microwave power is 400W; there are two high-level tanks above the reaction kettle, and acrylic acid is added respectively Monomer and solution A; add acrylic acid monomer and solution A dropwise to the reaction kettle, control the amount of addition so that the acrylic acid monomer and solution A are added dropwise at the same time, and the time for dropping is 5h;

[0051] (3) After the dropwise addition, control the temperature of the reaction kettle to rise to 90°C, and fill it with nitrogen to maintai...

PUM

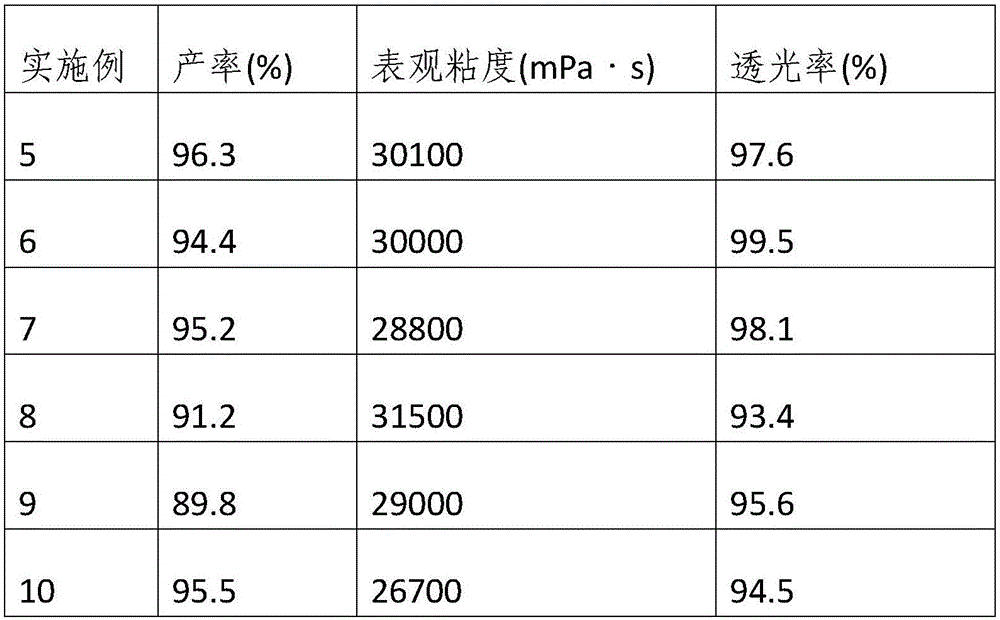

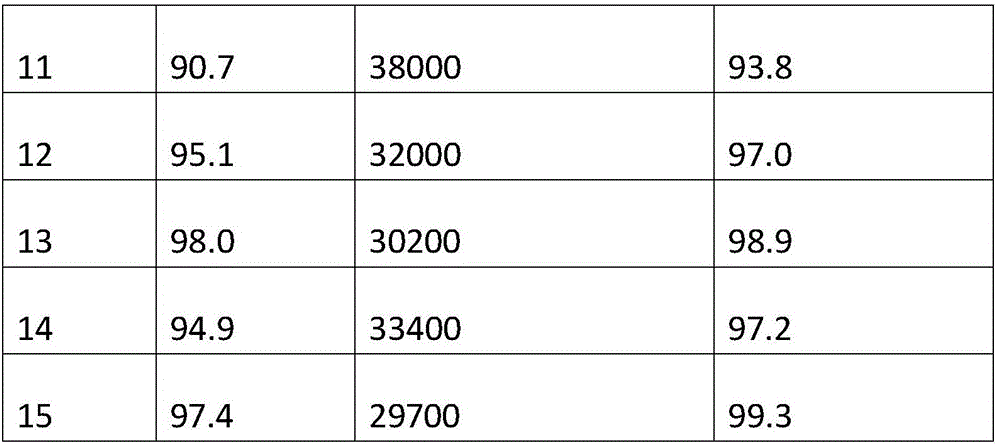

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com