Method for preparing SAPO-34 molecular sieve by liquid phase crystallization method

A technology of SAPO-34 and molecular sieves, which is applied in the field of preparation of SAPO-34 molecular sieves, can solve problems such as small synthesis range, low crystallinity, complex equipment, etc., and achieve industrial scale production, good crystallinity, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

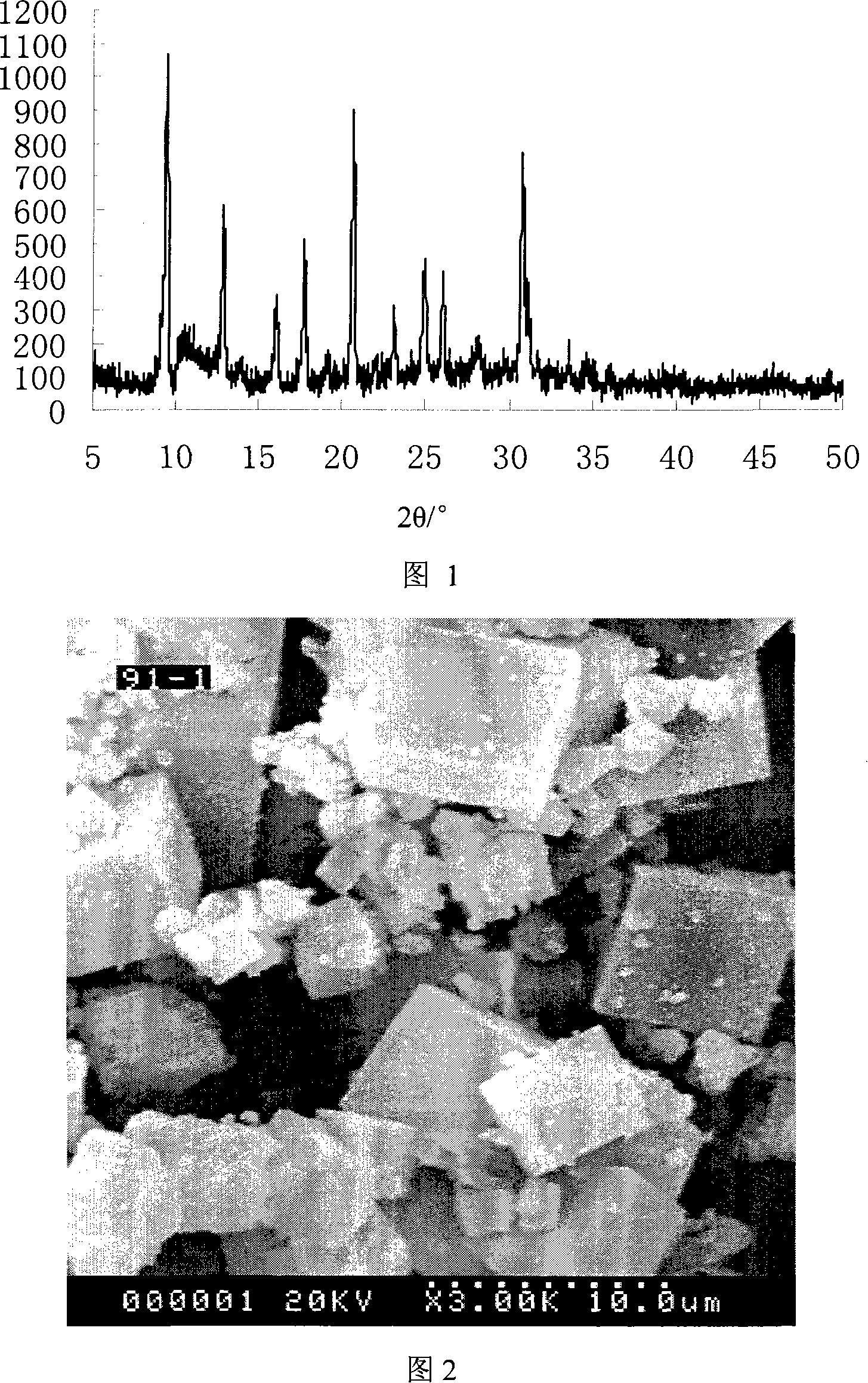

Embodiment 1

[0020] Mix 23.06g 85% orthophosphoric acid with 25ml H 2 O fully mixed, under vigorous stirring, add 32.57g of pseudo-boehmite into the mixed solution of phosphoric acid and water, add 25g of water, stir for 2h, then add 13.61g of SiO 2 26.45% silica sol. Wherein the molar composition of adding each component is: Al 2 o 3 :P 2 o 5 : 0.6SiO2 2 .

[0021] After stirring and reacting at room temperature for 2 h, the reaction temperature was gradually increased to 80° C., and the stirring reaction was continued for 6 to 18 h. With the evaporation of water during the reaction, the viscosity of the system gradually increases until finally it becomes dry glue. Grind the obtained dry glue into powder, take 24g of the powder and a mixed solution of 45.8g morpholine and 53.2g water (volume ratio is 1:1) and fully mix them under stirring, place in a stainless steel autoclave, and seal the autoclave Then crystallize at 180°C for 5 days. Finally, after cooling the autoclave to ro...

Embodiment 2

[0024] Mix 23.06g of 85% phosphoric acid with 25ml of H 2 O mixed thoroughly, under vigorous stirring, 32.57g of aluminum hydroxide was gradually added to the aqueous solution of phosphoric acid within 2h, and after stirring for 2h, 13.61g of SiO 2 26.45% silica sol. Prepare the precursor sol after stirring and reacting at room temperature for 4 hours, gradually increase the reaction temperature to 90°C, continue stirring and reacting for 4-6 hours, then place the precursor sol in the oven, and evaporate the water until it becomes a dry gel .

[0025] Grind the obtained dry glue into powder, take 24g of the powder and a mixed solution of 45.8g morpholine and 53.2g water (volume ratio is 1:1) and fully mix them under stirring, place in a stainless steel autoclave, and seal the autoclave Then crystallize at 180°C for 5 days. Finally, after cooling the autoclave to room temperature, the resulting mixture was fully washed with water, filtered, dried at 120°C for 4 hours, and ca...

Embodiment 3

[0028] According to the method and steps of Example 1, but changing the amount of silica sol, the molar ratio of each component in the precursor sol is respectively:

[0029] Al 2 o 3 :P 2 o 5 : SiO 2 =1:1:0.4, the rest are the same as in Example 1. The obtained sample was determined by X-diffraction, and the result was similar to Example 1, all of which were SAPO-34 molecular sieves, but the intensity of individual diffraction peaks was slightly different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com