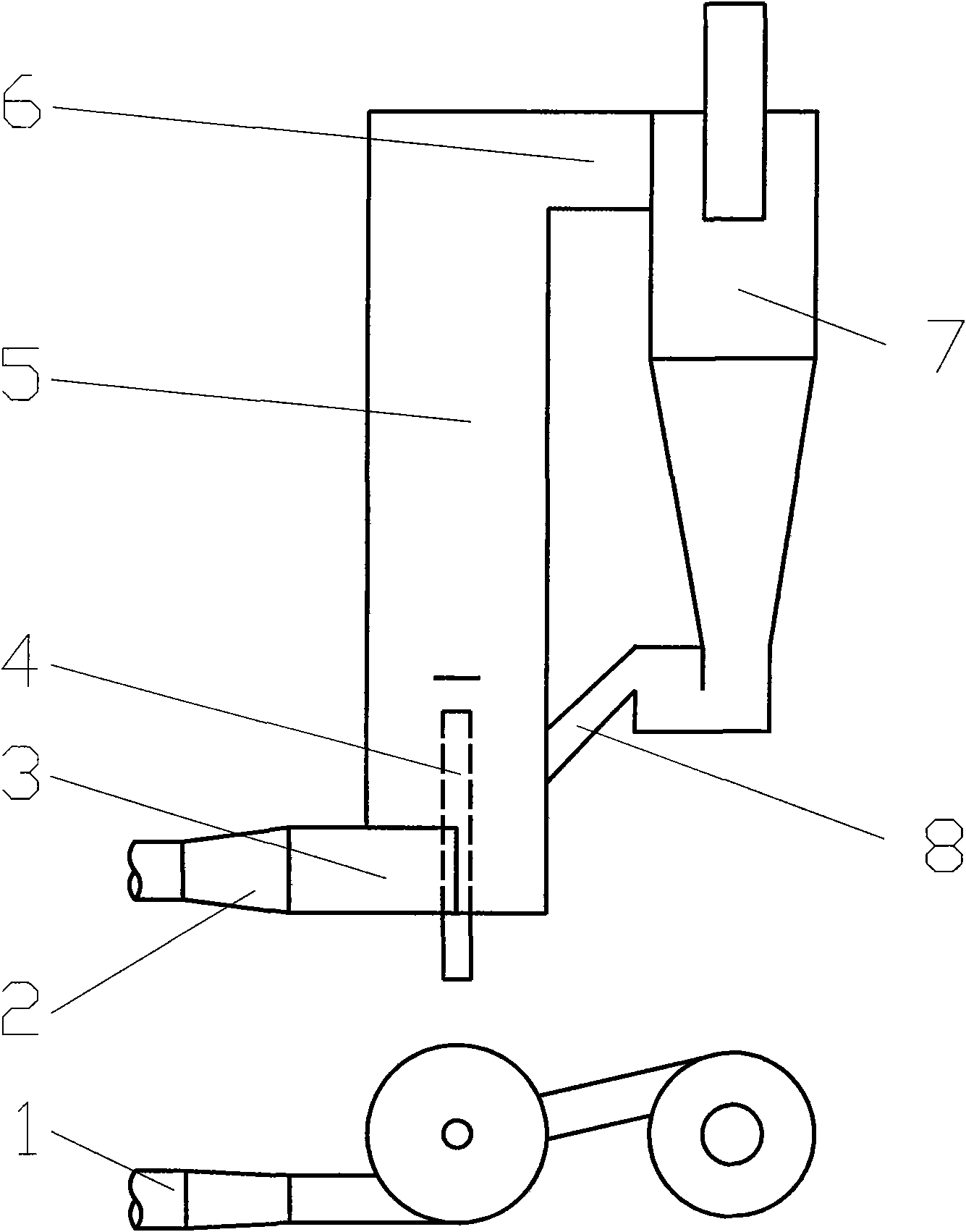

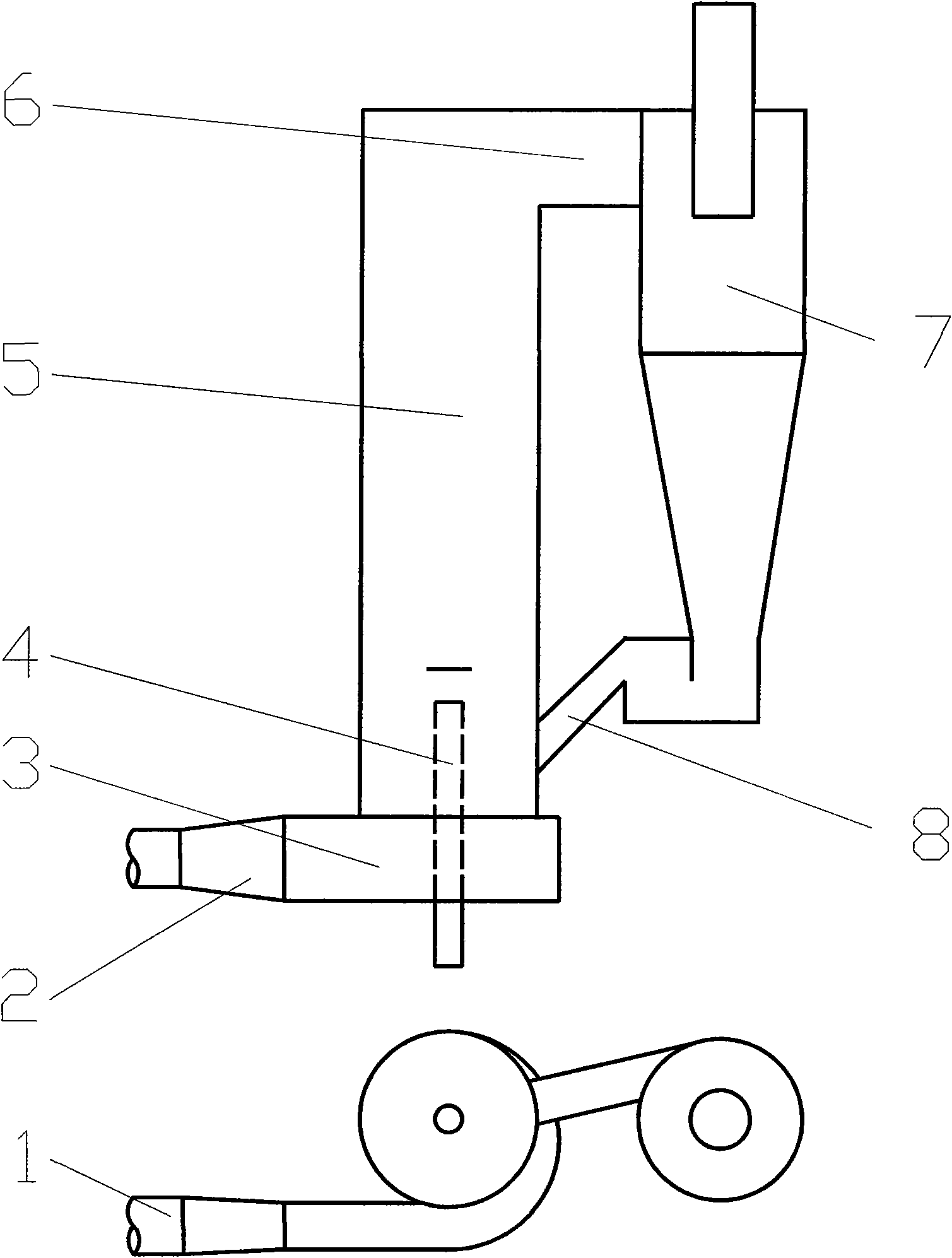

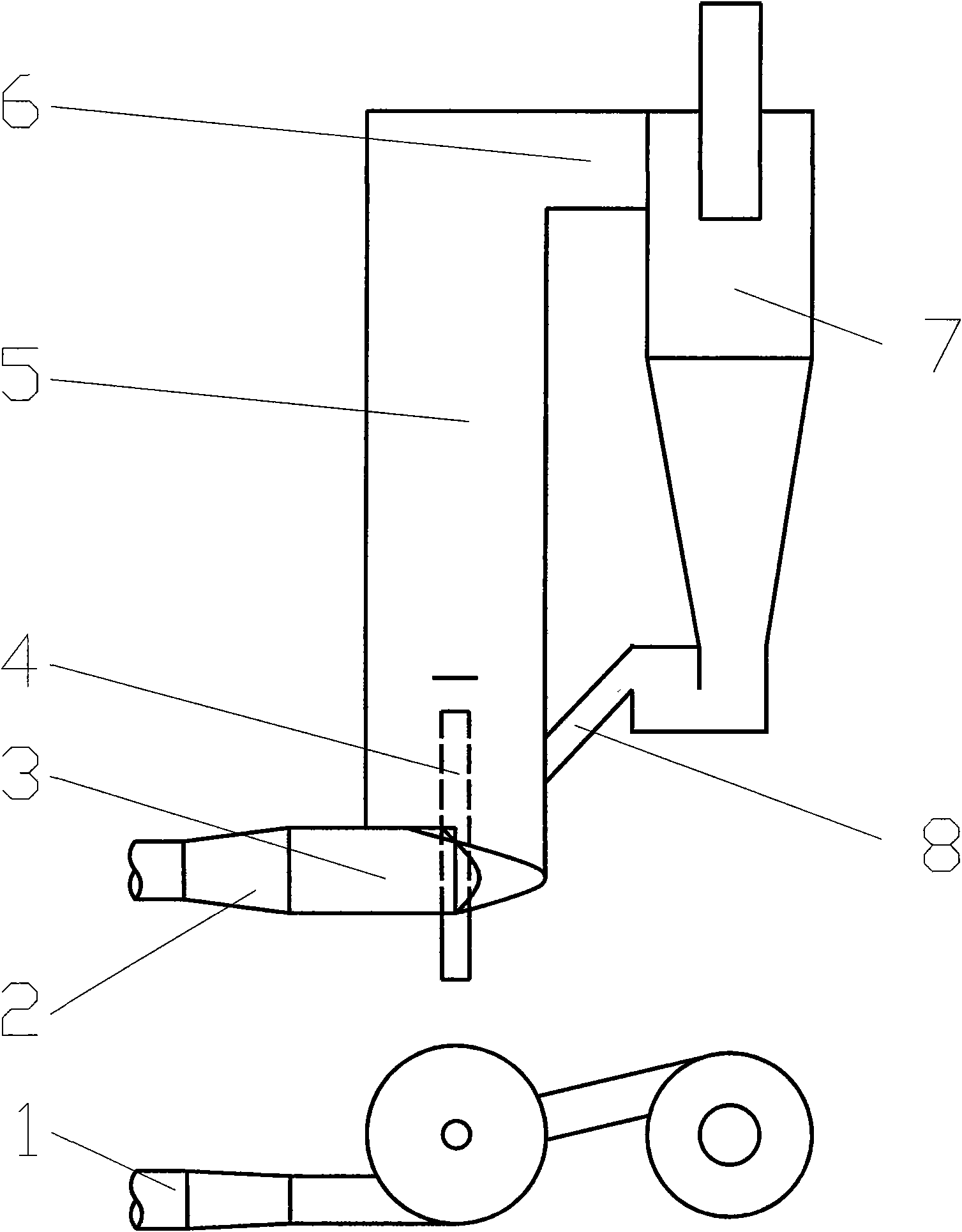

Tangential gas intake desulfurization tower of semi-dry circulating fluidized bed

A technology of circulating fluidized bed and desulfurization tower, which is applied in chemical instruments and methods, chemical/physical processes, and separation of dispersed particles. The efficiency is not high, achieving the effects of compact structure, good gas-solid contact, and reduced device height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The invention relates to a method and a device for strengthening the contact between flue gas in a circulating fluidized bed desulfurization tower and a desulfurizer to improve the utilization rate of the desulfurizer. When using a semi-dry circulating fluidized bed tangential air inlet desulfurization tower of the present invention, the flue gas enters the desulfurization tower body through the tangential air inlet structure (3) from the flue gas inlet pipe (1), and the tangential air inlet The gas structure makes a strong swirling flow field in the circulating fluidized bed desulfurization tower. The desulfurizing agent is ejected from the desulfurizing agent inlet pipe (4) located at the center of the bottom of the desulfurizing tower. Under the action of the swirling flow, the shear force and turbulence intensity of the airflow are increased, and the flue gas and the desulfurizing agent are fully contacted and mixed. Due to the effect of the swirling flow, the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com