Composite electrolyte membrane, preparation method and application thereof, and solid-state lithium battery

A composite electrolyte membrane, solid electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve the problems of lithium deposition to form lithium dendrites, continuous occurrence of interface side reactions, and high interface resistance, and achieve uniform concentration distribution. , The effect of reducing interface resistance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

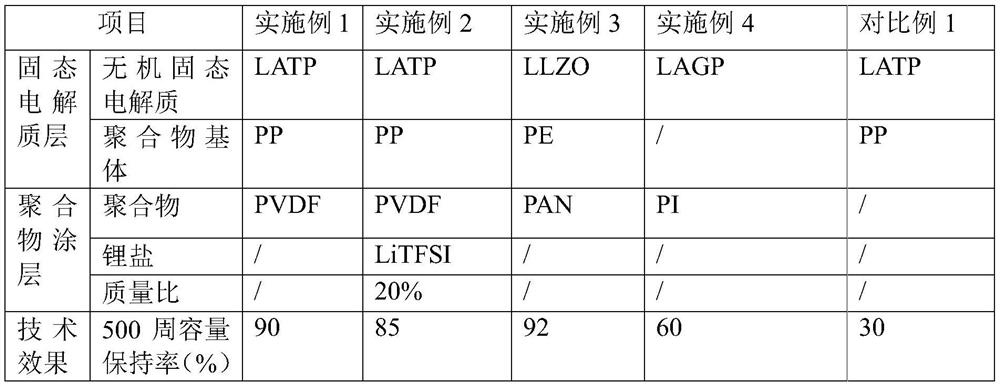

Embodiment 1

[0050] (1) Preparation of solid electrolyte layer

[0051] Mix LATP nanomaterials and NMP to obtain slurry B; apply slurry B to both sides of PP substrate (thickness 12 μm), dry, and form LATP layer with thickness 1 μm on both sides of PP substrate; obtain solid An electrolyte layer (thickness is 14 μm); wherein, the particle size of the LATP nanomaterial is 70 nm.

[0052] (2) Preparation of composite electrolyte membrane

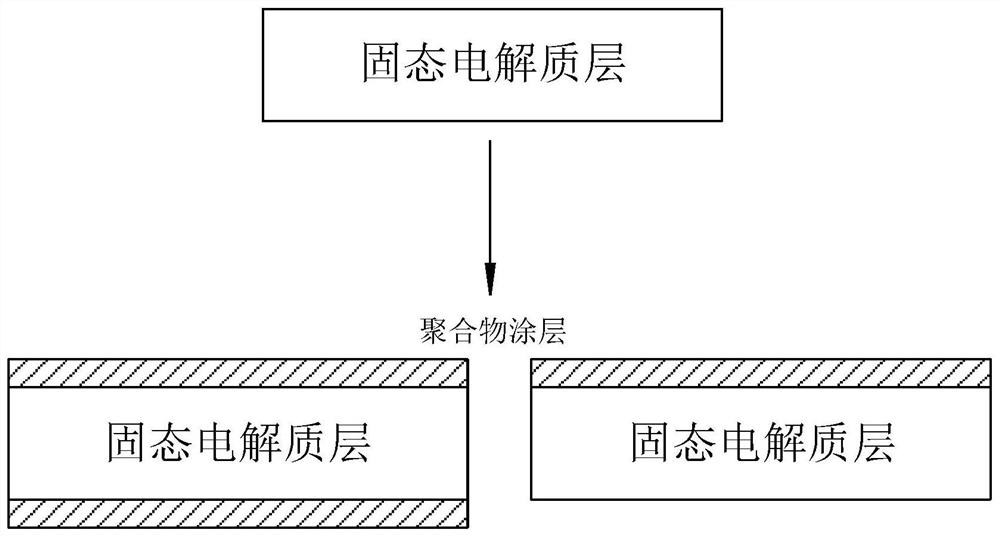

[0053] PVDF and NMP are mixed to obtain slurry A; slurry A is sprayed on both sides of the solid electrolyte layer obtained in step (1) (that is, sprayed on the LATP layer), dried, and formed on both sides of the solid electrolyte layer with a thickness of PVDF layer of 1 μm; the composite electrolyte membrane (thickness is 16 μm) is obtained, and the structure is as follows figure 1 shown.

Embodiment 2

[0055] (1) Preparation of solid electrolyte layer: same as step (1) in Example 1.

[0056] (2) Preparation of composite electrolyte membrane

[0057] Mix PVDF, LiTFSI and NMP to obtain slurry A, wherein the mass ratio of PVDF and LiTFSI is 5:1; slurry A is sprayed on both sides of the solid electrolyte layer obtained in step (1) (that is, sprayed on the LATP layer above), dry, and form a PVDF layer with a thickness of 1 μm on both sides of the solid electrolyte layer; that is, a composite electrolyte membrane (16 μm in thickness) with a structure such as figure 1 shown.

Embodiment 3

[0059] (1) Preparation of solid electrolyte layer

[0060] Mix LLZO nanomaterials and NMP to obtain slurry B; apply slurry B to both sides of a PE substrate (thickness 12 μm), dry, and form LLZO layers with a thickness of 1 μm on both sides of the PE substrate; that is, a solid Electrolyte layer (14 μm in thickness); wherein, the particle size of the LLZO nanomaterial is 70 nm.

[0061] (2) Preparation of composite electrolyte membrane

[0062] PAN and NMP are mixed to obtain slurry A; slurry A is sprayed on both sides of the solid electrolyte layer obtained in step (1) (that is, sprayed on the LLZO layer), dried, and formed on both sides of the solid electrolyte layer with a thickness of A PAN layer of 1 μm; the composite electrolyte membrane (16 μm in thickness) is obtained, and the structure is as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com