Patents

Literature

157results about How to "Uniform concentration distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

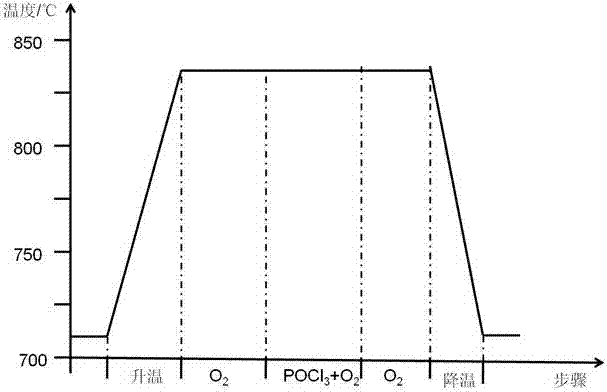

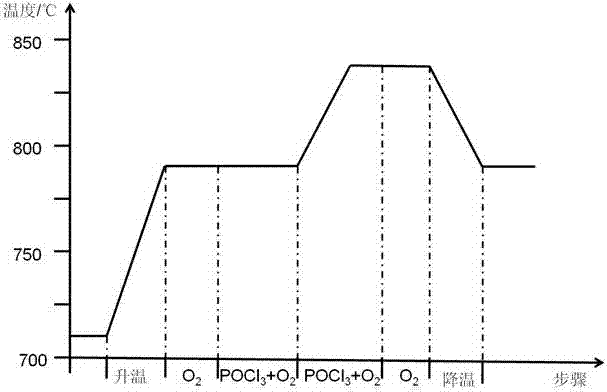

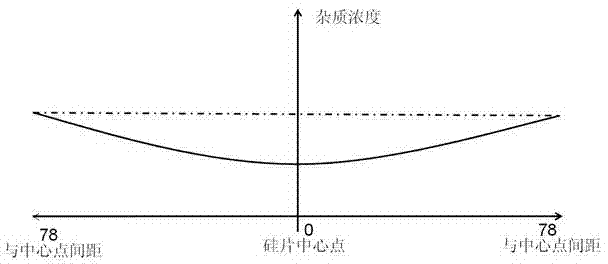

Spread method of polycrystalline silicon solar cell

InactiveCN102820383AImprove square resistance uniformityUniform concentration distributionFinal product manufactureDiffusion/dopingPre depositionSilicon chip

The invention relates to a spread method of a polycrystalline silicon solar cell. The spread method is characterized in that the spread method comprises the following processing steps of entering a boat, warming, oxidizing, spreading, redistributing, cooling and going out the boat, wherein the spreading step comprises low temperature pre-deposition and then high temperature spreading. Reaction between a phosphorus source and a silicon wafer cannot be completed under low temperature, so that the low temperature pre-deposition is carried out on low temperature source communication at a first step of spreading, the phosphorus source cannot spread (or conduct spreading with low rate) inside a silicon wafer, the phosphorus source only accumulates on the surface of the silicon wafer, and a phosphorus film with certain thickness is formed on the surface of the silicon wafer after source communication for certain time; and the high temperature spreading is carried out on high temperature source communication at a second step, phosphorus on the surface of an original silicon wafer is reacted with the silicon wafer and spreads to the inside of the silicon wafer, and spreading rates of the center point and the periphery of the silicon wafer are same. Therefore, spreading uniformity is good, concentration distribution of impurities on the surface of the silicon wafer and inside the silicon wafer body is even, sheet resistance uniformity is improved, and final photoelectric conversion efficiency of a cell sheet is improved accordingly.

Owner:JIANGYIN XINHUI SOLAR ENERGY

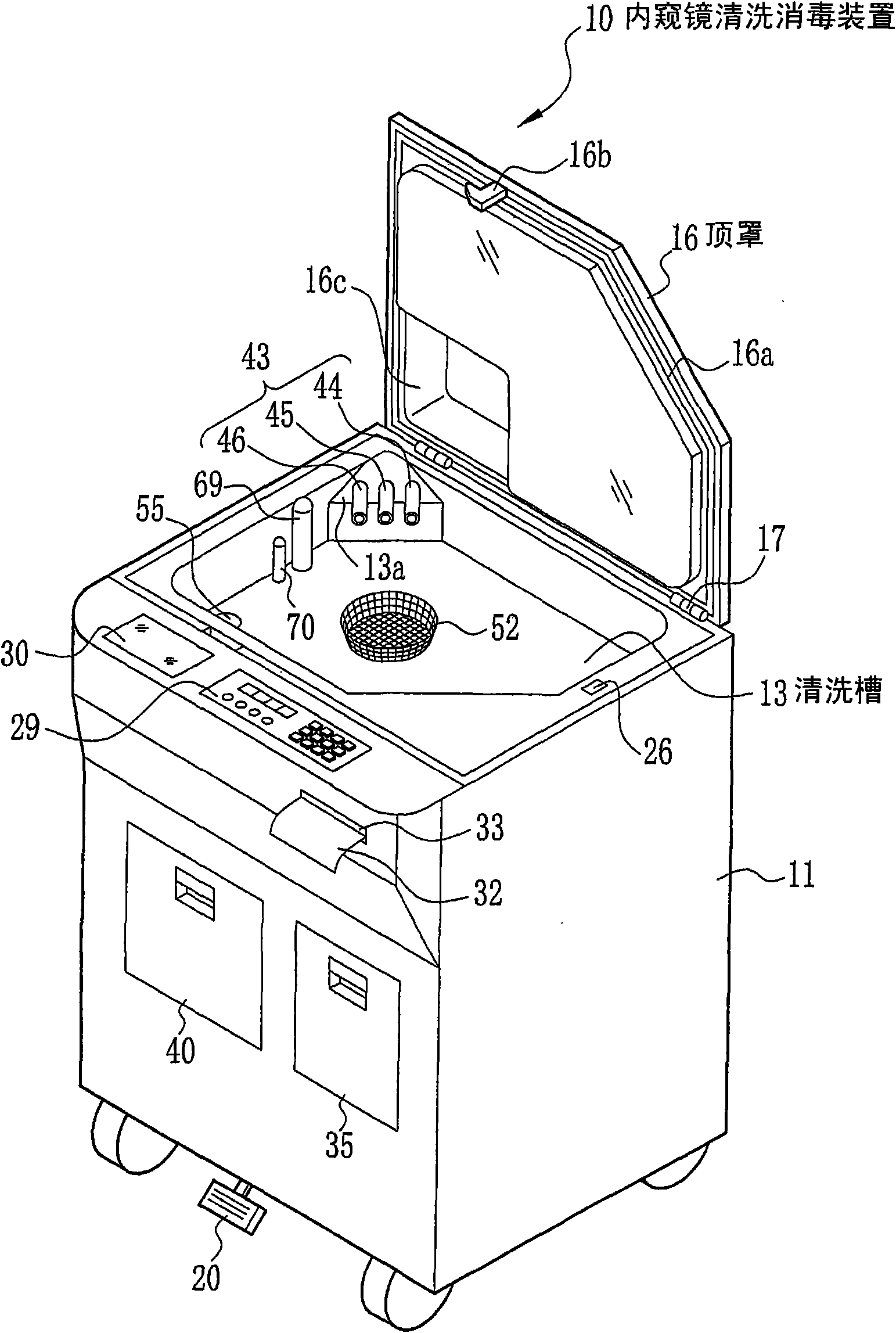

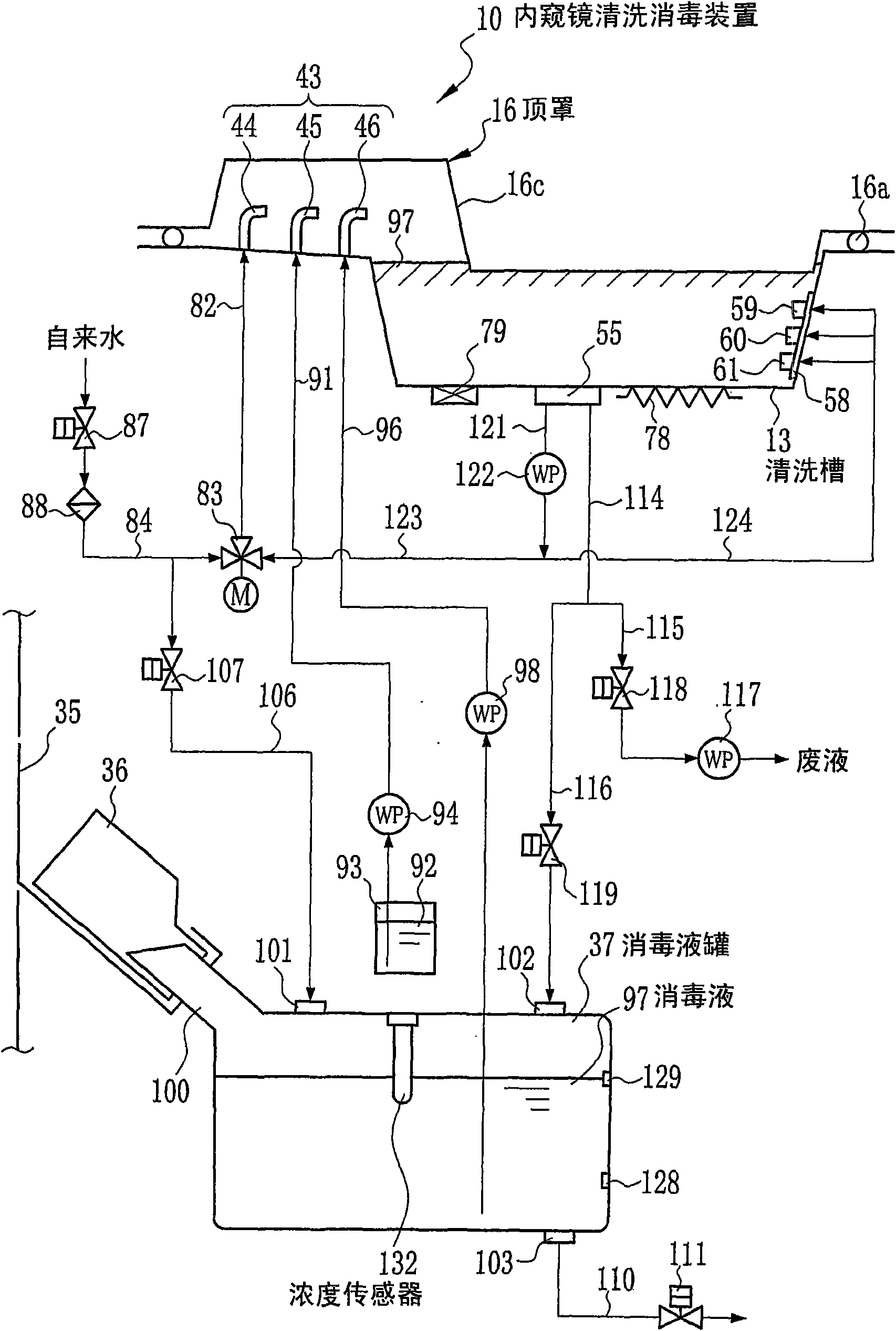

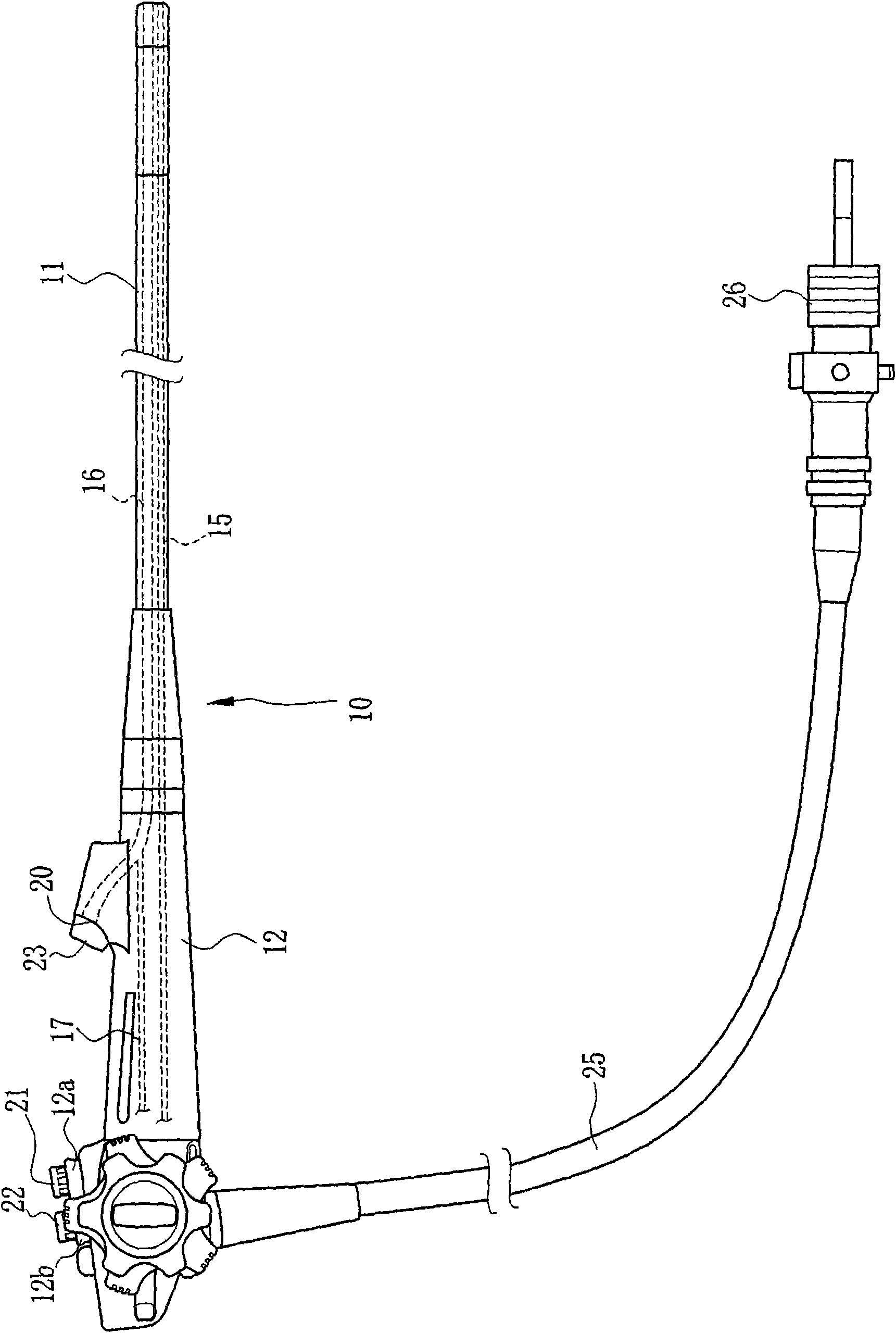

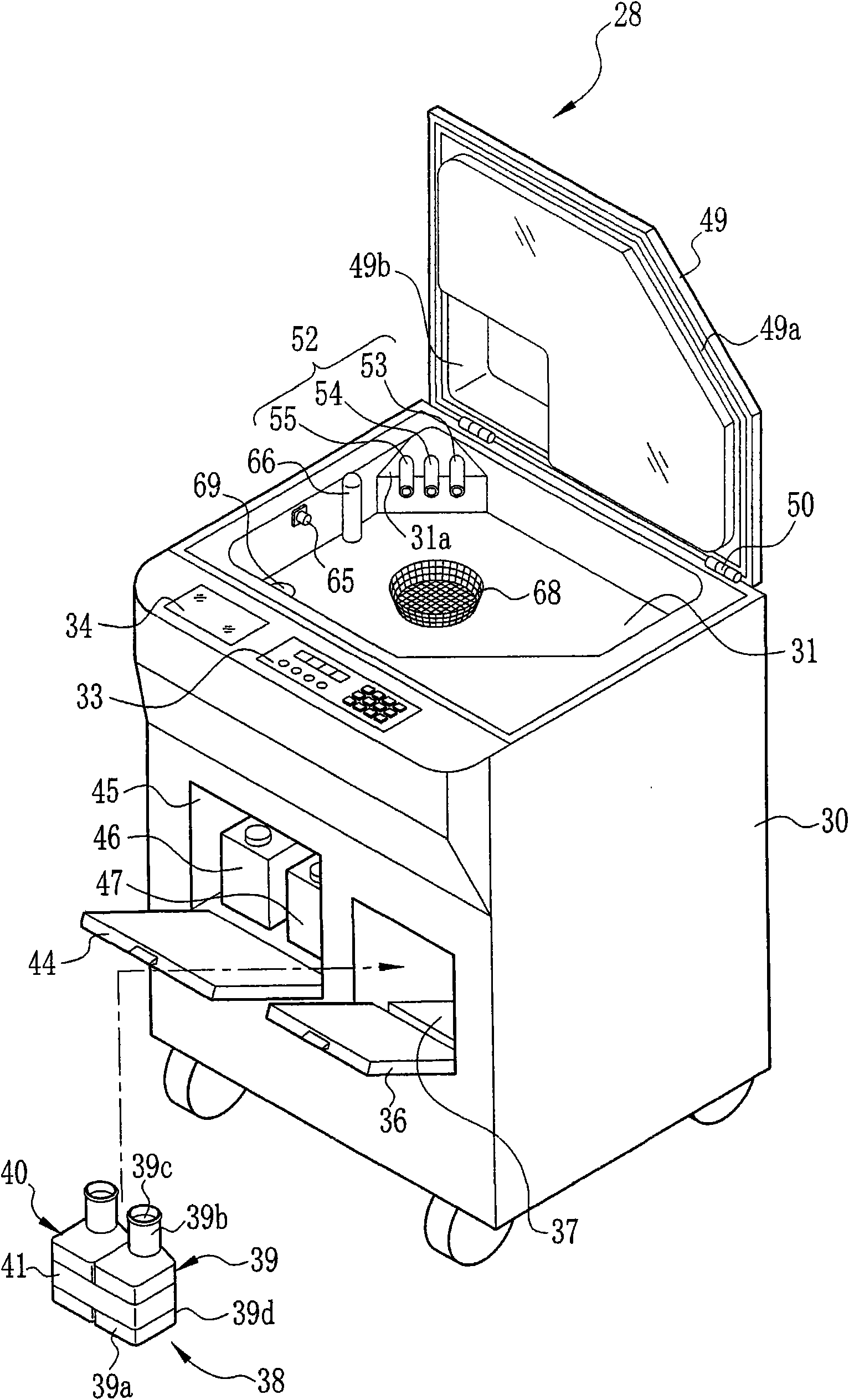

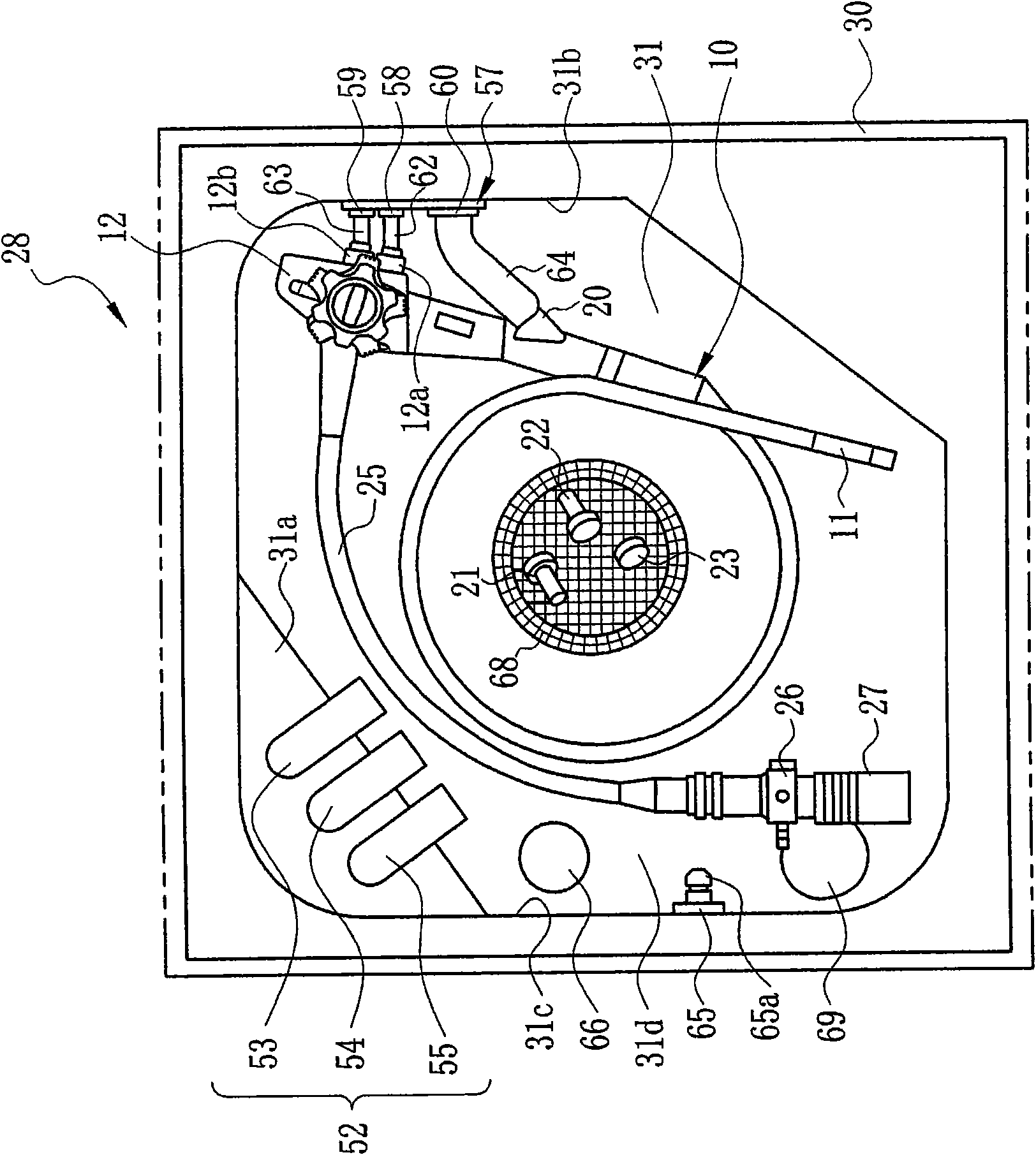

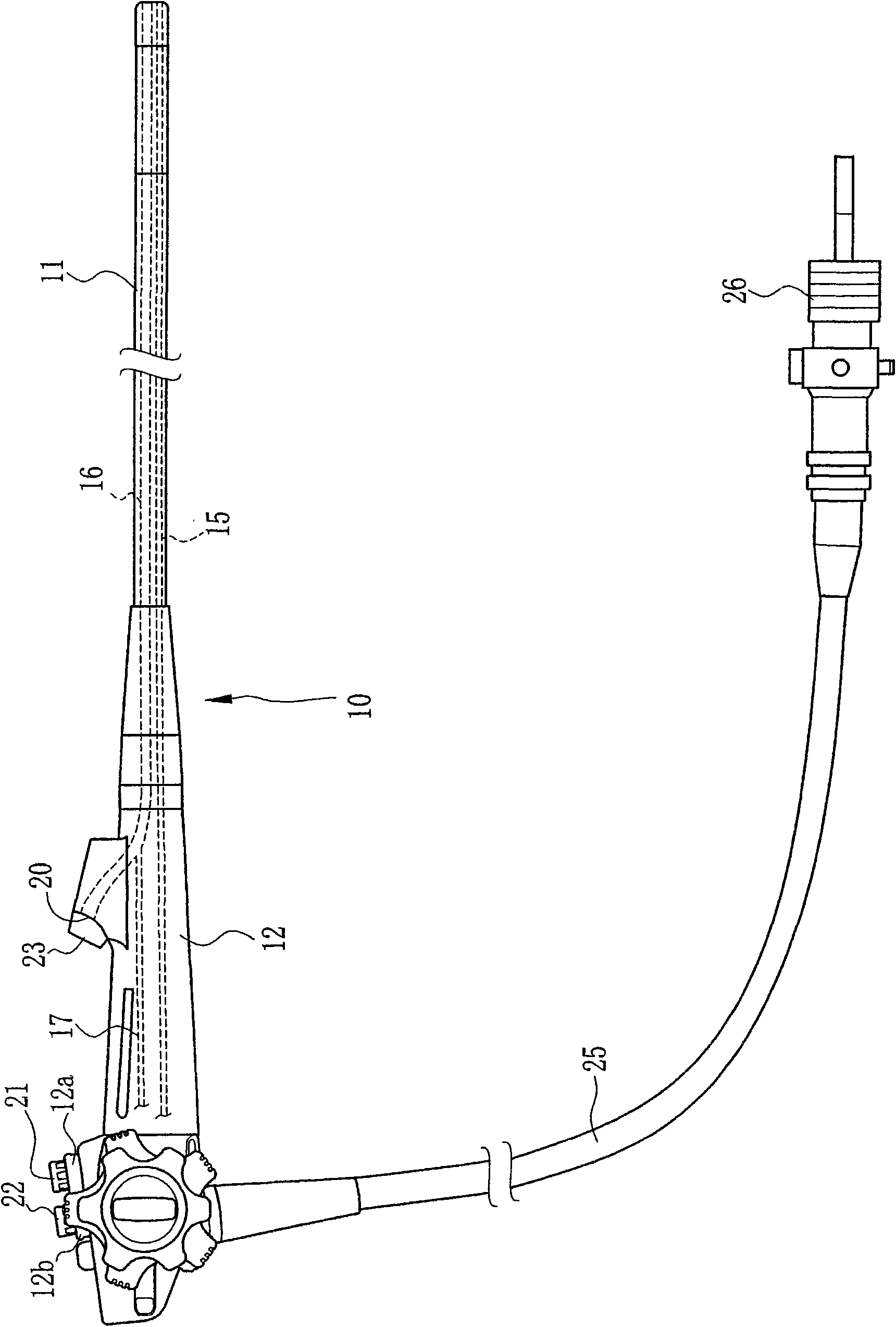

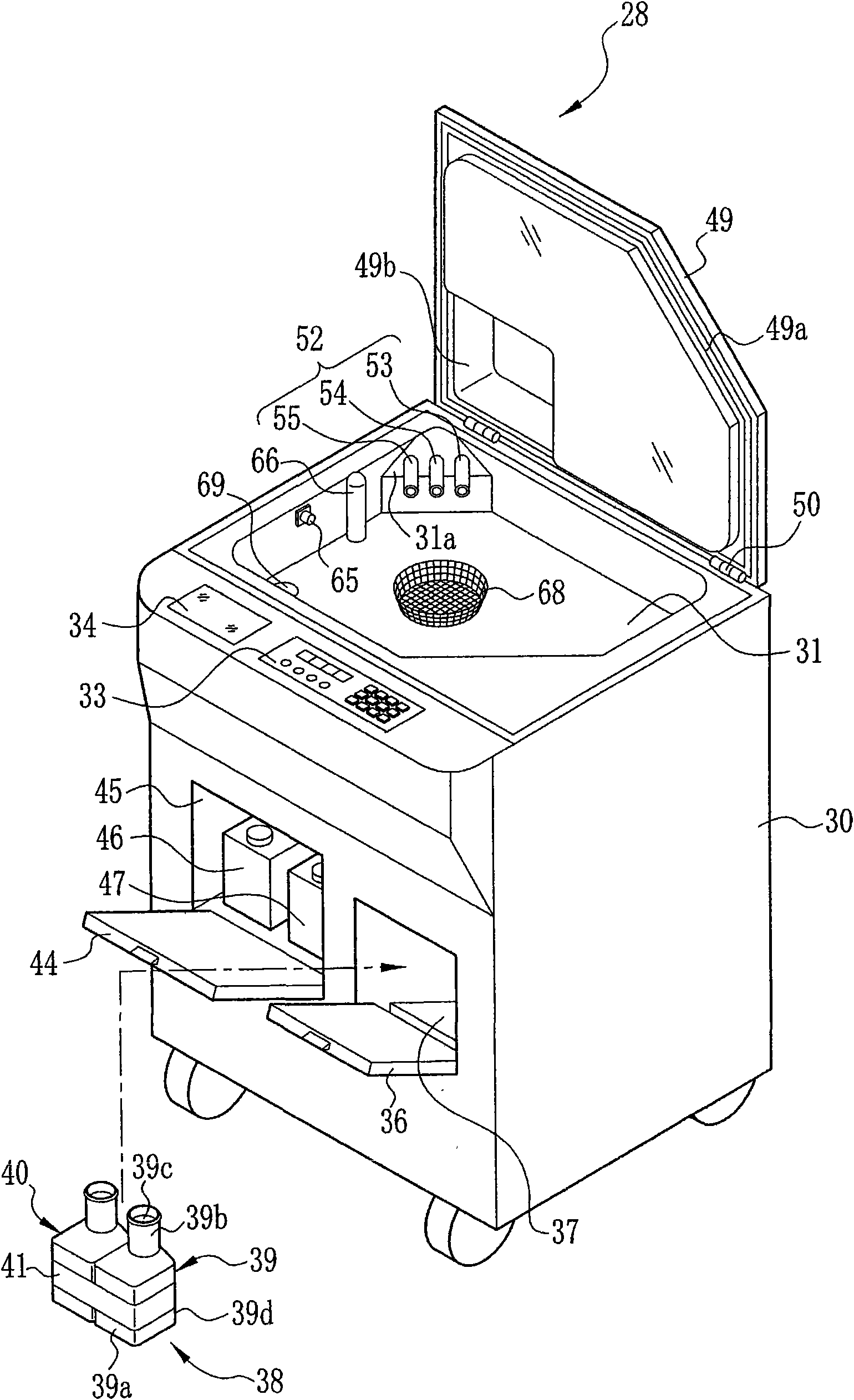

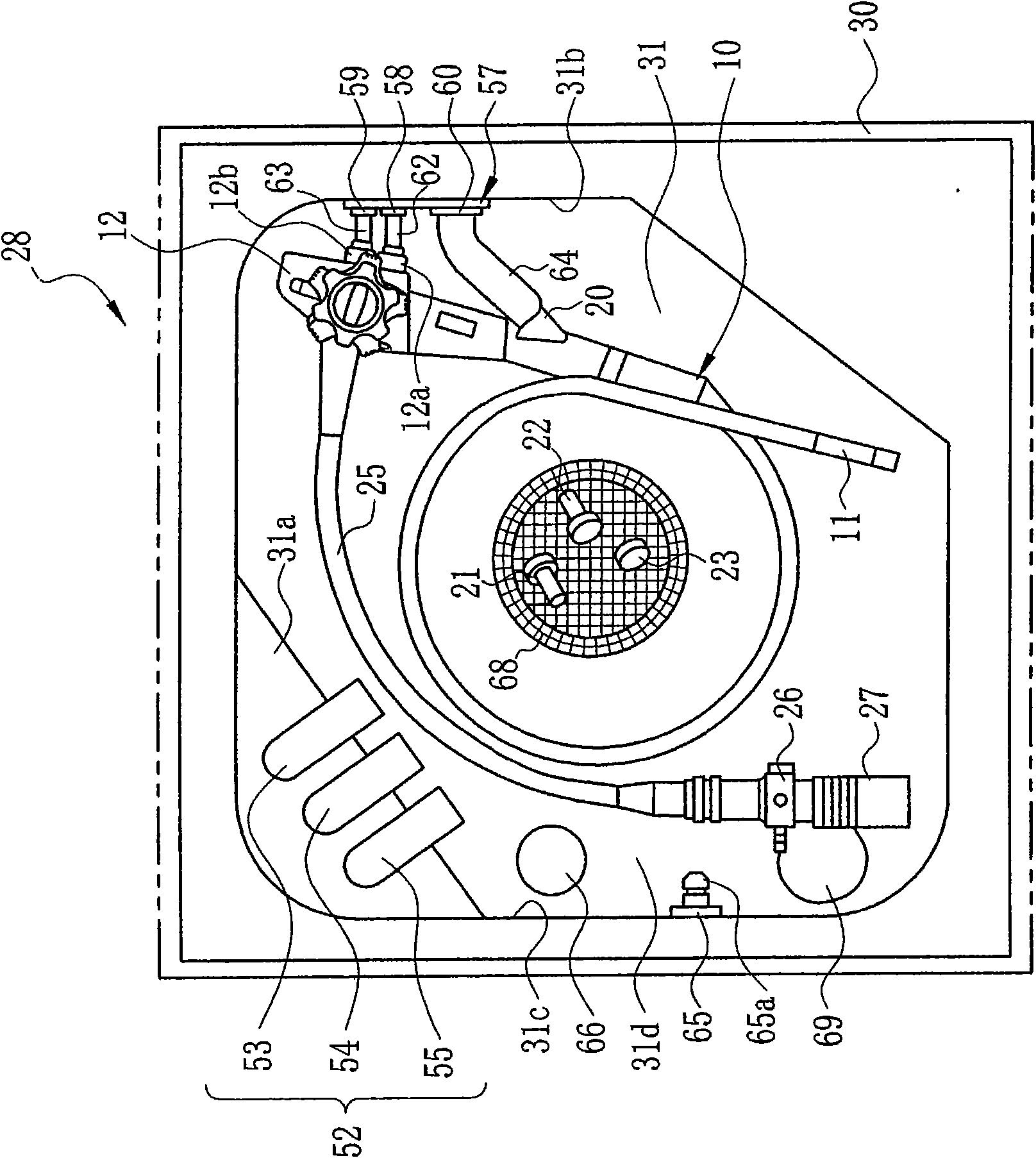

Disinfection device

InactiveCN101664560AAccurate measurementReduce the burden onLavatory sanitoryChemicalsInput controlEngineering

The invention provides a disinfection device. The disinfection liquid is recovered from a cleaning slot to a disinfection tank after the completion of the cleaning disinfection processing of the endoscope in the cleaning slot. After the recovery of the disinfection liquid, a concentration measurement control portion (157) measures the concentration of the disinfection liquid at the concentration sensor (132). The concentration measured by the concentration sensor (132) is inputted into a determination portion (158), and it is determined whether it is suitable for performing disinfection for the endoscope within the range of the concentration value. An input control portion (161) outputs the cleaning information including the determination result to each output target. The cleaning controlportion (155) removes the locking mechanism (23) of the top cover of the cleaning slot when the determination result is appropriate. When the determination result is not appropriate, the locking stateof the locking mechanism is maintained before the further disinfection of the endoscope by the novel disinfection liquid. In another embodiment, when the determination result is not appropriate, rawliquid is supplied to the disinfection liquid into the disinfection liquid tank.

Owner:FUJIFILM CORP

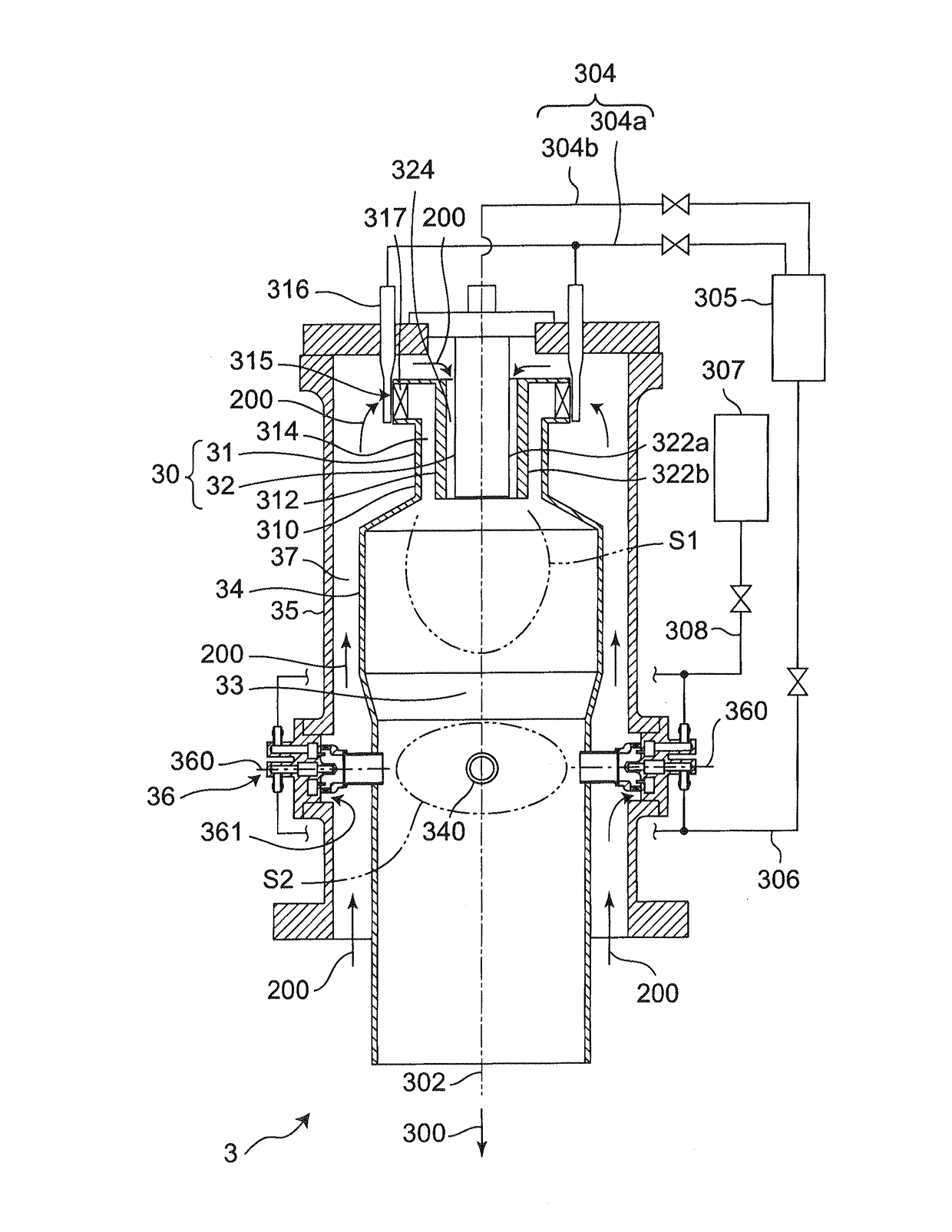

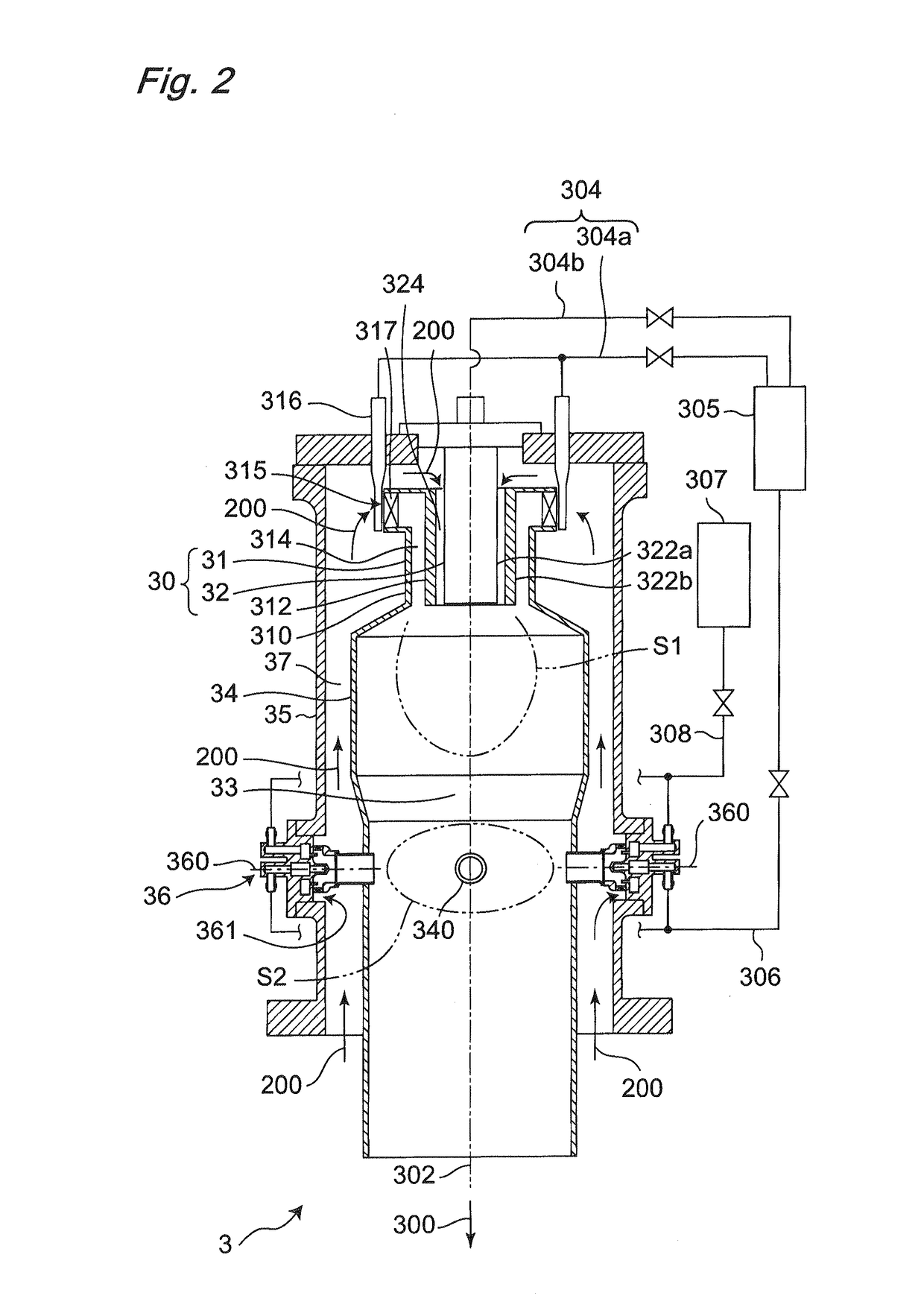

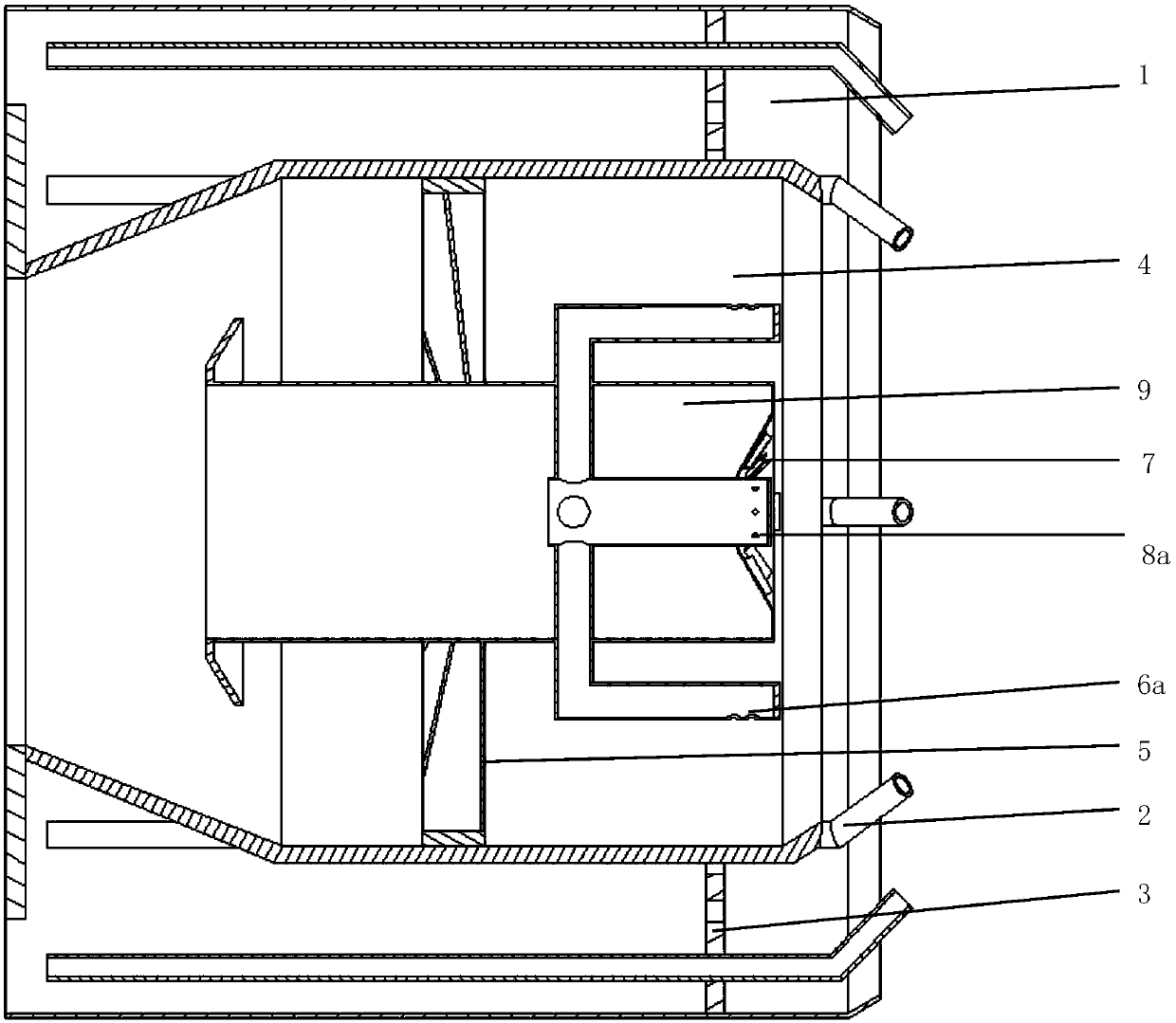

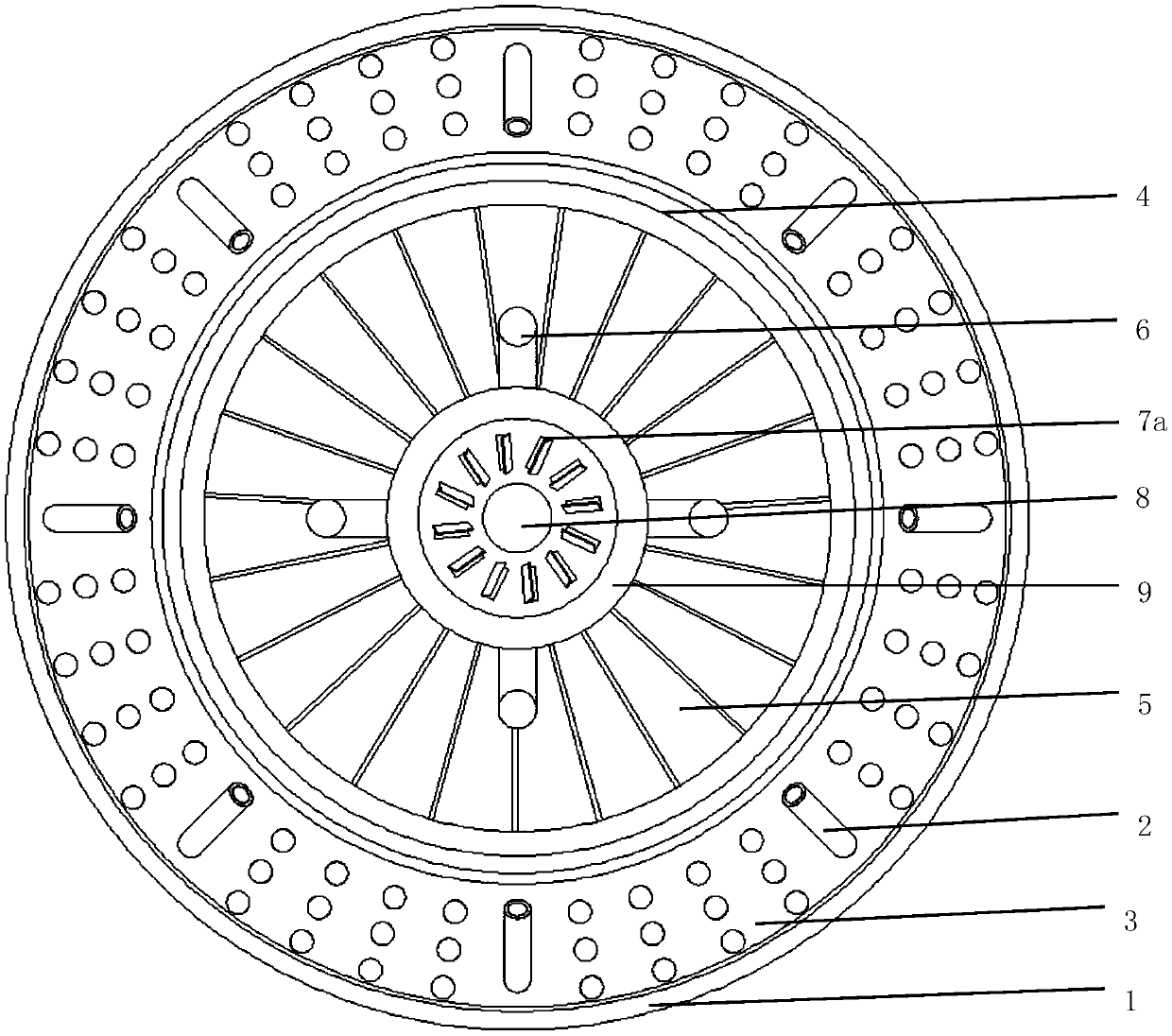

Burner, combustor, and gas turbine

ActiveUS20170356656A1Suppressing emission amountUniform concentration distributionBurnersContinuous combustion chamberExhaust gasSpecific gravity

The present invention provides a burner, a combustor equipped with the burner, and a gas turbine, with which it is possible to premix a first hydrocarbon-based fuel (for example, natural gas), a second fuel (for example, hydrogen gas), and combustion air, and to spray into the combustion chamber of the combustor a thin and uniform concentration distribution of the premixed air, and with which it is possible to suppress the amount of NOx discharged. On the upstream side of the premix flow path, hydrogen gas is sprayed from second fuel spray nozzles, which project into the premix flow path, into the flow of the combustion air flowing toward the center from the outer edge of an outer cylinder, whereby a primary air-fuel mixture having a uniform concentration distribution is generated without affecting a low-speed region of the combustion air. Natural gas is then sprayed from first fuel spray nozzles into the primary air-fuel mixture, whereby the natural gas, which has a high specific gravity, and the primary air-fuel mixture are adequately mixed in a stirring fashion, and a secondary air-fuel mixture (premixed air) is generated that is lean and has a more uniform concentration distribution than the first air-fuel mixture. By combusting this type of premixed air in the combustion chamber, NOx in the combustion exhaust gas can be suppressed.

Owner:KAWASAKI HEAVY IND LTD

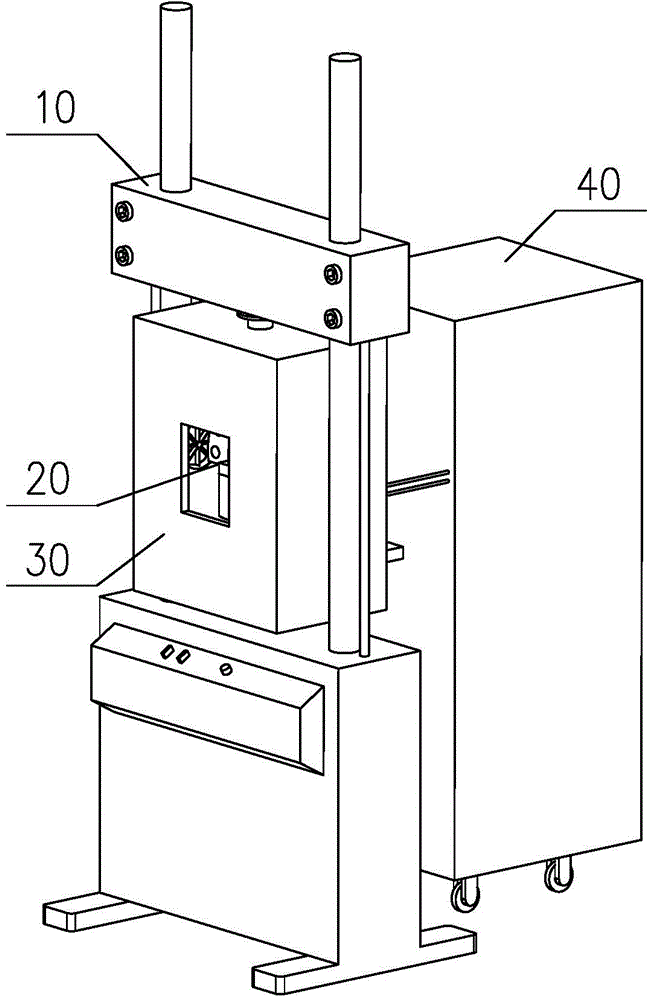

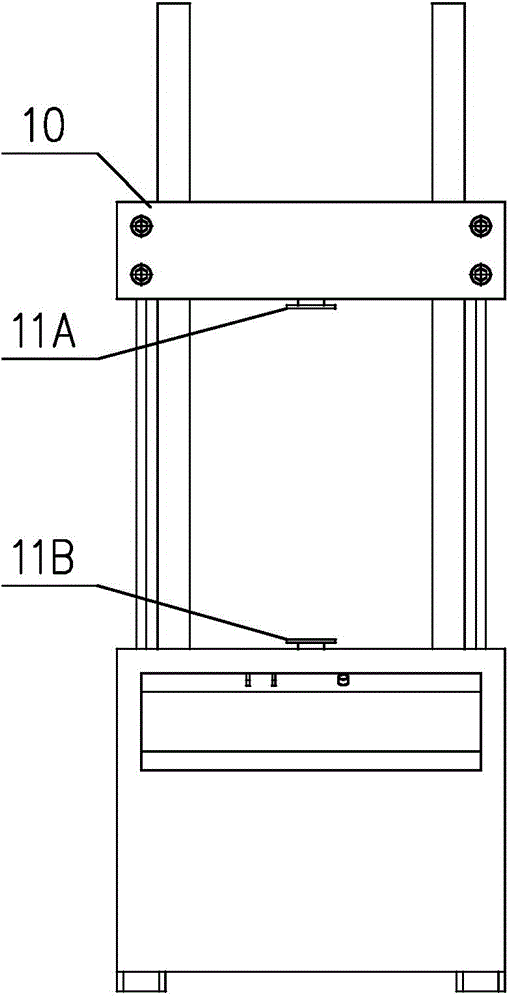

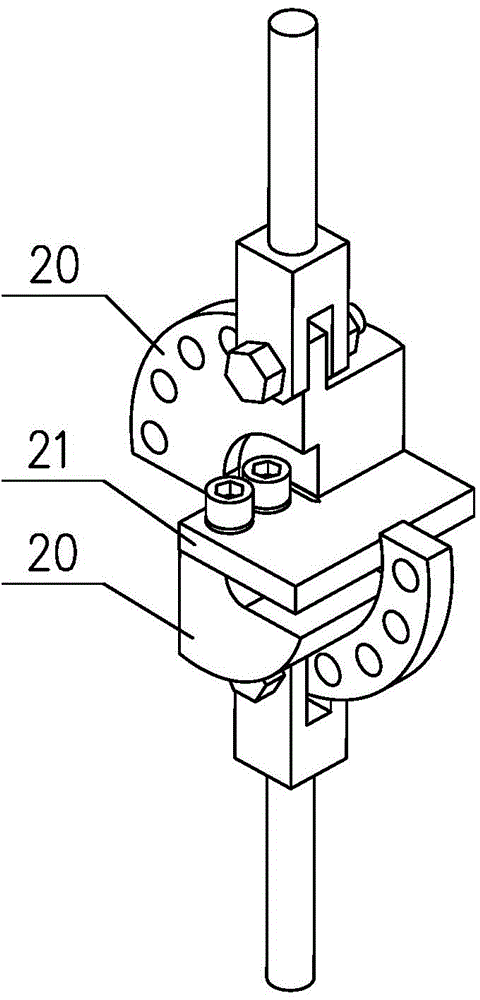

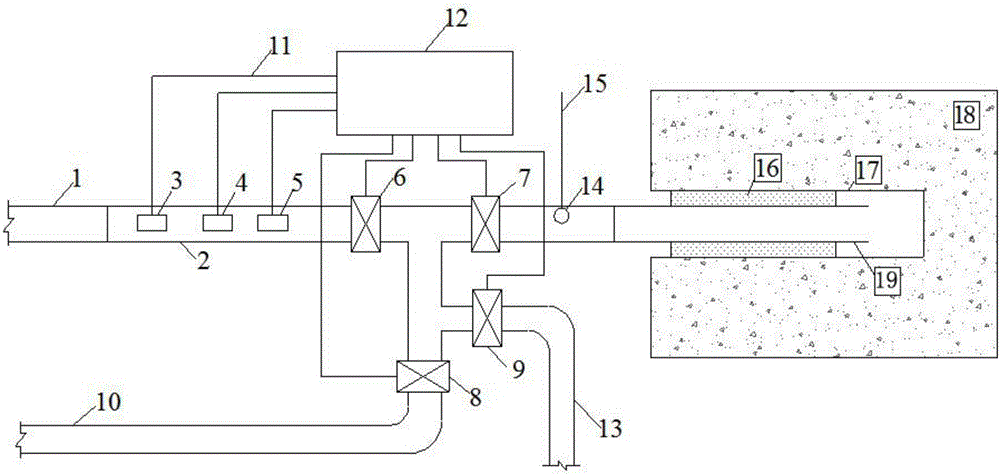

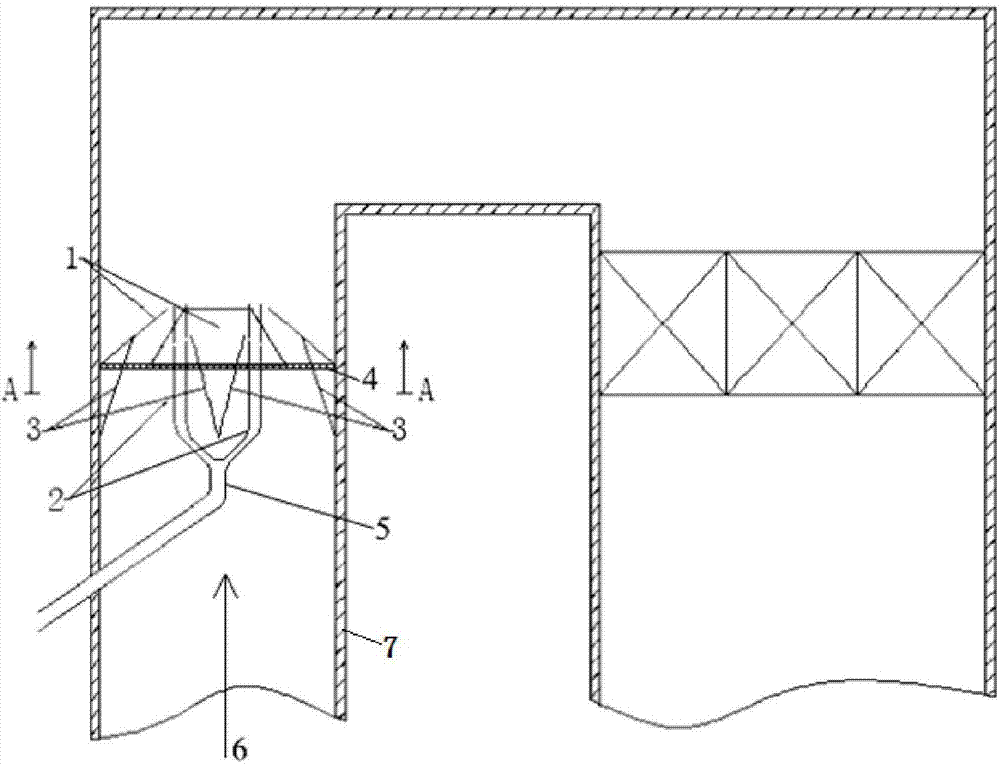

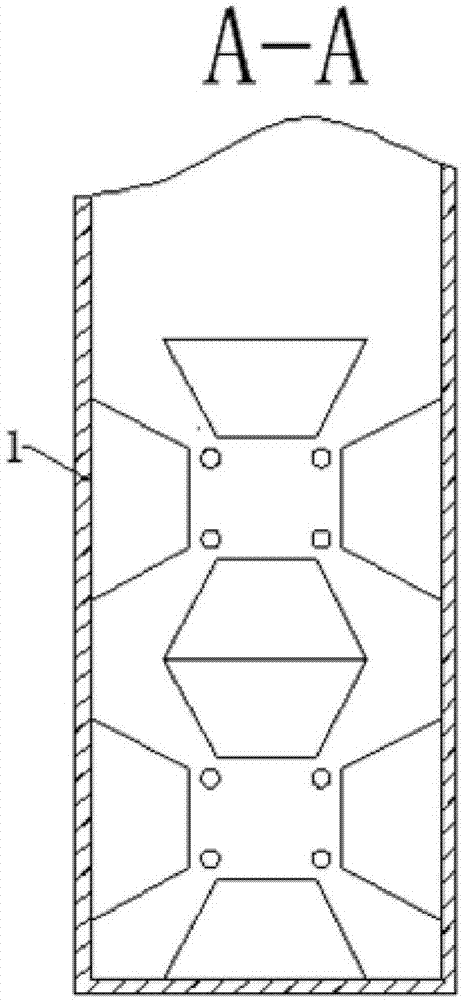

Test system for extension of multi-axis and salt-spray corrosion fatigue crack

ActiveCN104931407AContinuous, stable and reliable supplyFacilitated DiffusionWeather/light/corrosion resistanceStrength propertiesFatigue loadingFracture mechanics

The invention relates to a test system for the extension of a multi-axis and salt-spray corrosion fatigue crack. The test system comprises a fatigue tester for providing I-type, II-type, III-type and compound fatigue loads required by a test for a test sample through a pull-cut-twist multi-axis loading fixture, and further comprises a salt-spray corrosion environmental box, wherein the salt-spray corrosion environmental box comprises a salt-spray corrosion box body and a salt-spray pre-occurrence box body which are mutually communicated through a pipeline; the salt-spray pre-occurrence box body conveys air and salt water required by salt-spray forming to the salt-spray corrosion box body; the salt-spray corrosion box body provides a required salt-spray corrosion environment for the fatigue crack extension test; both the pull-cut-twist multi-axis loading fixture and the fatigue crack extension test sample are positioned in the salt-spray corrosion box body. Through the adoption of the test system, the fatigue crack extension rate and other fracture mechanics parameters under the combined action of multi-axis loads and the salt-spray corrosion environment can be measured relatively well, and thus the material selection design and the service life evaluation for marine engineering equipment serving in the salt-spray corrosion environment and under a complex stress state can be supported.

Owner:HEFEI GENERAL MACHINERY RES INST +1

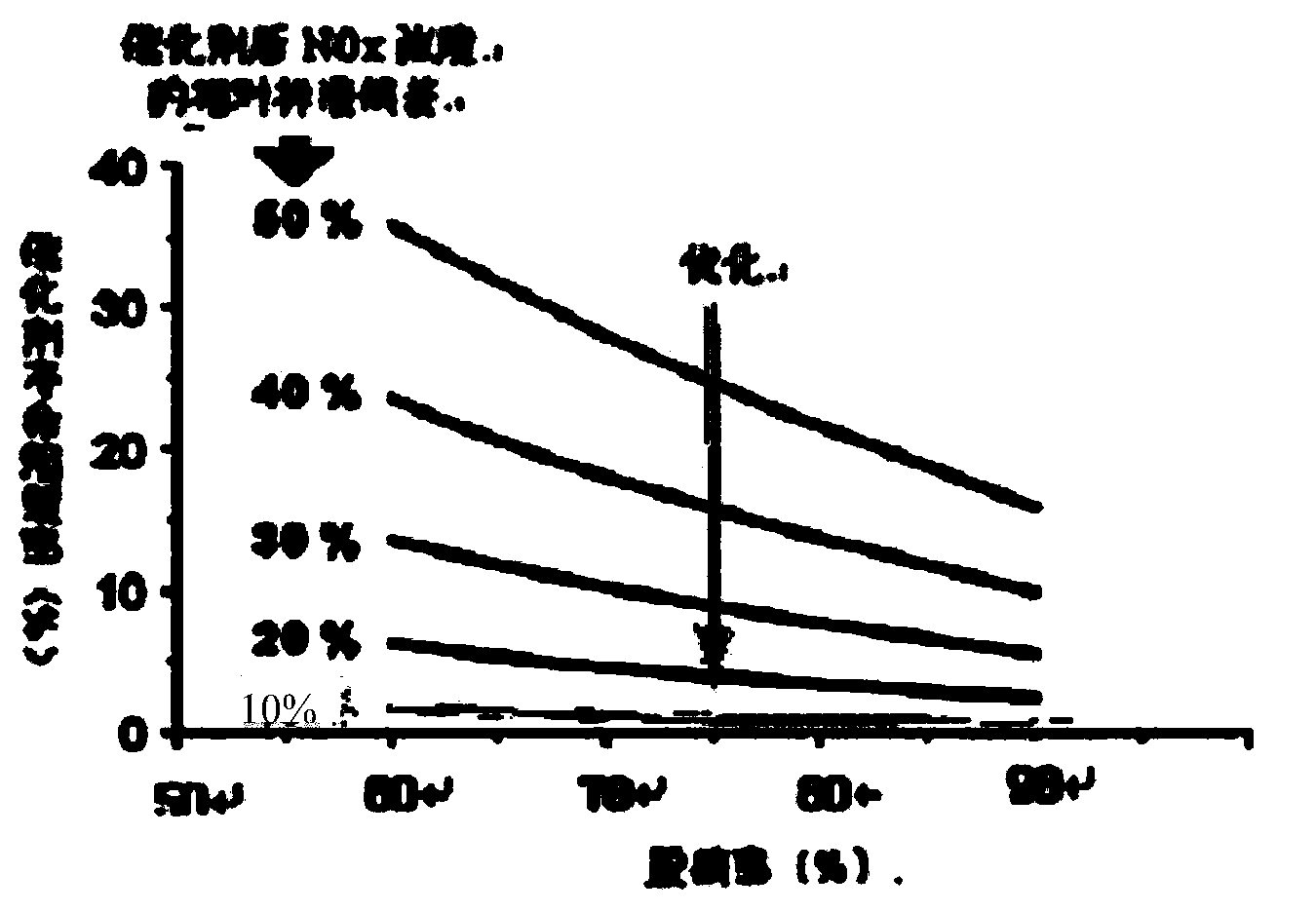

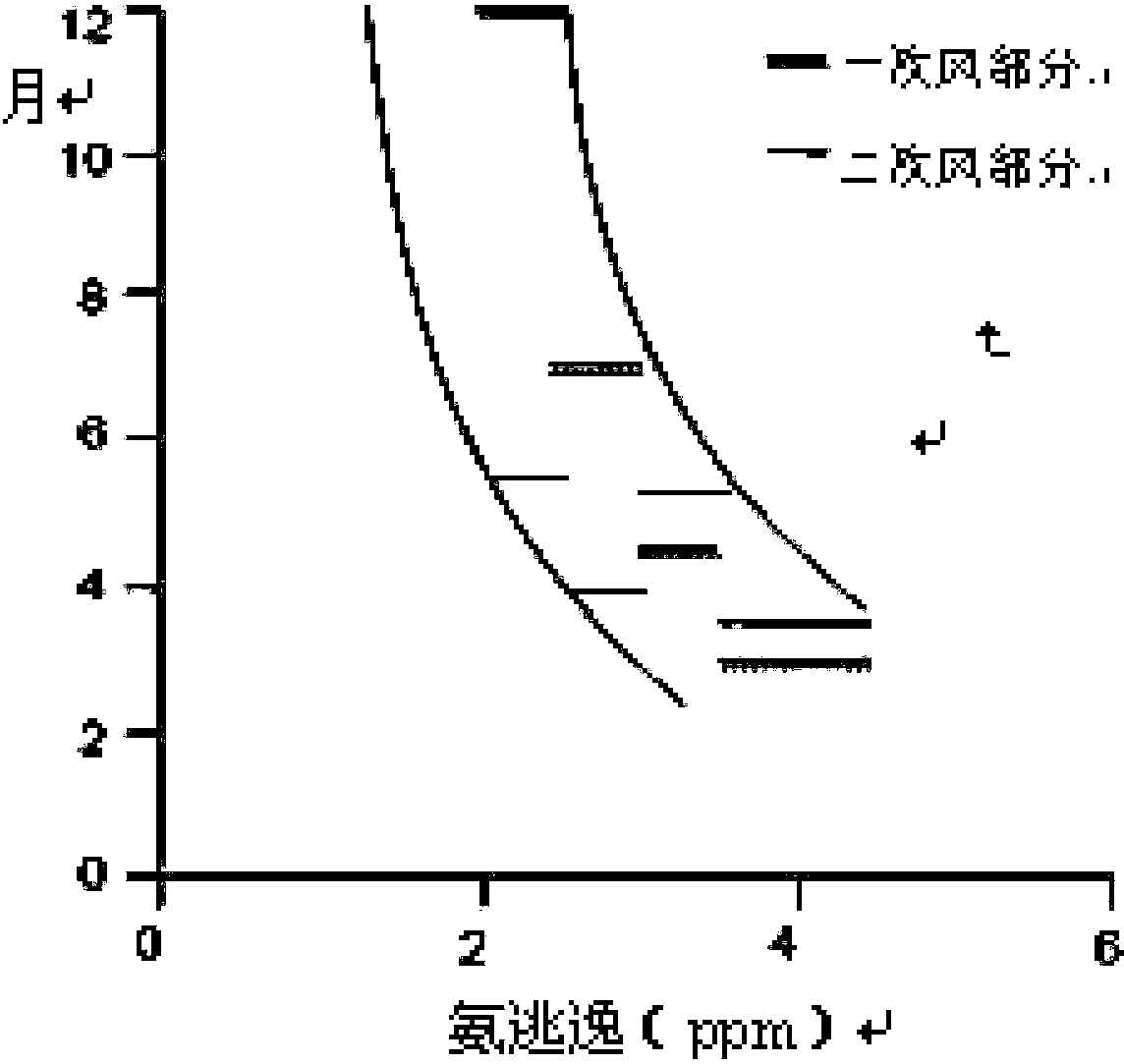

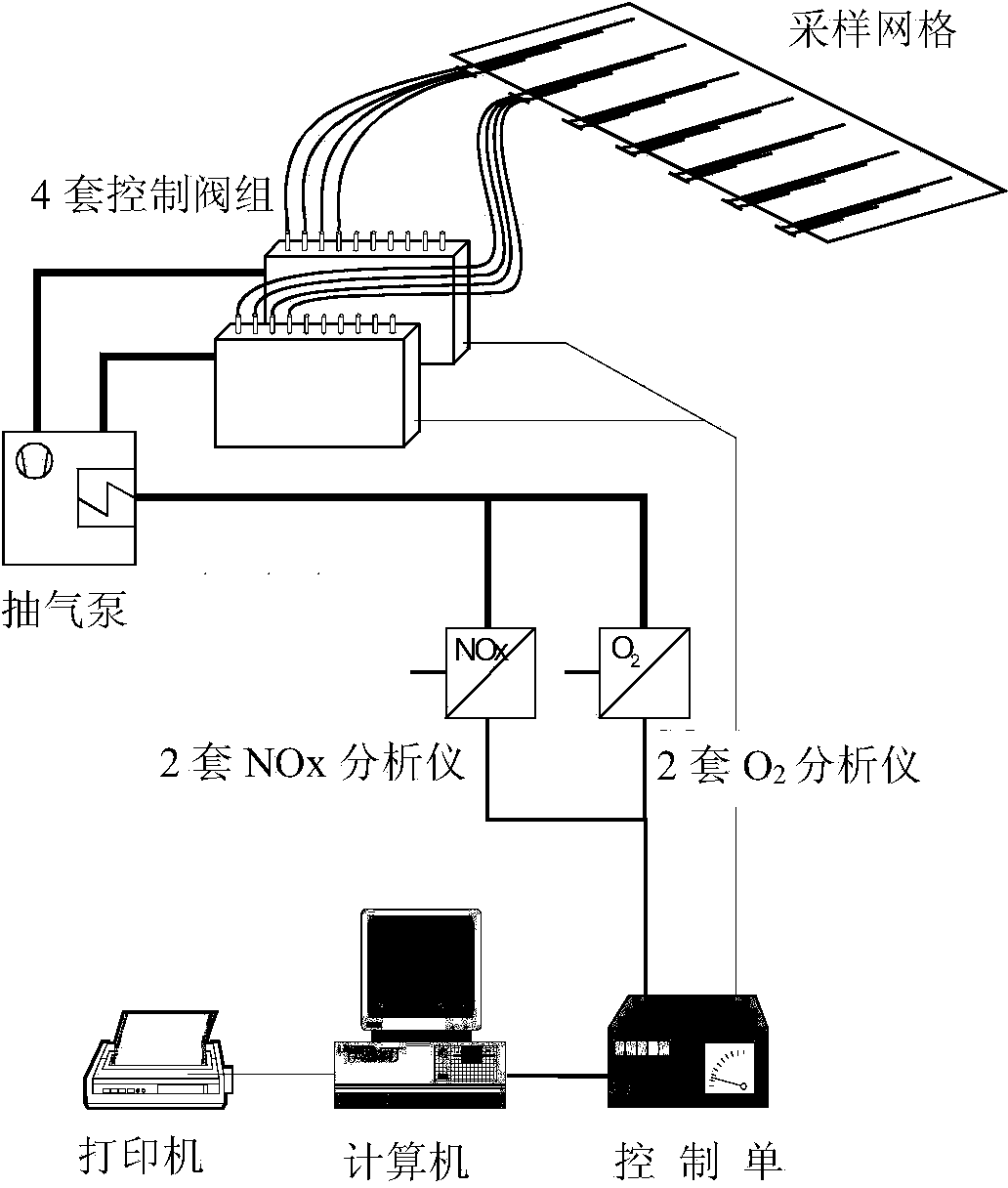

Method for improving denitration rate of SCR (Selective Catalytic Reduction) denitration system of power station boiler

InactiveCN103521073AReduced service lifeReduce availabilityDispersed particle separationSystem safetyValve opening

The invention discloses a method for improving the denitration rate of an SCR (Selective Catalytic Reduction) denitration system of a power station boiler. The method comprises the following steps: (1) measuring concentration distribution of NOx at the outlet of an SCR denitration reactor; (2) calculating the unevenness Cv of concentration distribution of NOx according to the measuring result in the step (1); (3) when Cv is greater than 20%, adjusting the valve opening in an area corresponding to an ammonia injection grid according to the concentration distribution of NOx at the outlet of the SCR denitration reactor; (4) repeating the steps (1) to (3) until Cv is less than or equal to 20%. Through optimization and adjustment by the invention, the evenness of distribution of NOx at the outlet of the SCR denitration reactor is remarkably improved, and the relative standard deviation of NOx is reduced from 46.4% to 14.8%. On the premise of ensuring that ammonia escape does not exceed standard, the denitration rate is improved from 77% to 83%. The method disclosed by the invention has important guiding meaning and engineering application value to safe, efficient and stable operation of the SCR denitration system of the power station boiler.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

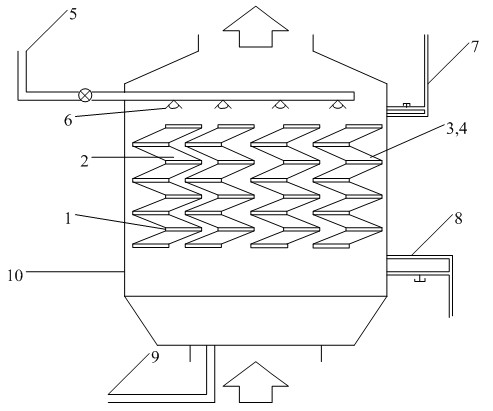

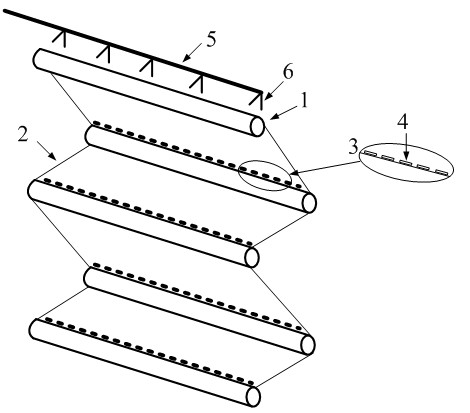

Solution dehumidifying and regenerating device

InactiveCN102147134ASolving Corrosion ProblemsReduce volumeLighting and heating apparatusAir conditioning systemsEngineeringMachining process

The invention discloses an internal cold / internal heat type solution dehumidifying and regenerating device. A plurality of zigzag connected heat and mass transfer units consisting of reducing templates (2) and internal cold / internal heat pipes (1) are arranged in a shell (10), an inlet pipe (7) is arranged above the shell, and an outlet pipe (8) is arranged below the shell; a dehumidifying solution inlet pipe (5) is arranged above the heat and mass transfer units, a solution distributor (6) is arranged on the dehumidifying solution inlet pipe (5), and the bottom of the shell (10) is provided with a dehumidifying and regenerating solution delivery pipe (9). A dehumidifying solution flows into a pipeline through a solution inlet header pipe and is sprayed to the reducing templates to be in direct contact with wet air for carrying out a heat and mass transfer process so that the purpose of air dehumidifying or solution regenerating is achieved; and internal heat / internal cold branch pipes play a role of strengthening the heat and mass transfer process, thus the solution dehumidifying and regenerating efficiency is greatly improved. The internal cold / internal heat type solution dehumidifying and regenerating device has the advantages of simple machining process, low cost and easiness in production and manufacture.

Owner:SOUTHEAST UNIV

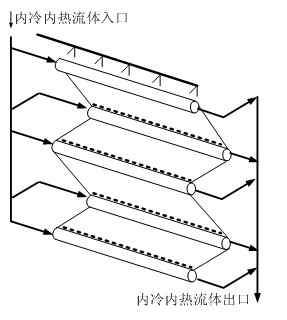

Gas explosion coal seam permeability increasing extraction method in borehole in later period of induction extraction

ActiveCN105927268AUniform concentration distributionPromote fissure developmentDust removalFire preventionUltrasound attenuationDetonation

Provided is a gas explosion coal seam permeability increasing extraction method in a borehole in the later period of induction extraction. The method comprises: inserting a gas extraction pipe (7) into a borehole; a down-hole negative pressure extraction main pipeline (1) and the pipeline of a three-way ball valve (5) being provided with a gas density monitoring device (2), a carbon monoxide monitoring device (3), and a temperature monitoring device (4), a gas extraction pipe being provided with a spark generator (6), when the gas density monitoring device monitors that gas density in the gas extraction pipe is in the range of 9%-10%, the spark generator switching on to make gas in the borehole blast; extracting gas in the borehole; when carbon monoxide density in the extracted gas is monitored to exceed a warming value or the temperature of the extracted gas exceeds the warming value, injecting water into the borehole to prevent coal spontaneous combustion. The method uses the natural attenuation characteristics of the density of a gas extraction borehole to induce repeated detonation, cracks of coal mass on the periphery of a hole wall are developed, and coal seam gas permeability is improved continuously. The method is suitable to be used for a high-gas low permeability coal seam.

Owner:CHINA UNIV OF MINING & TECH

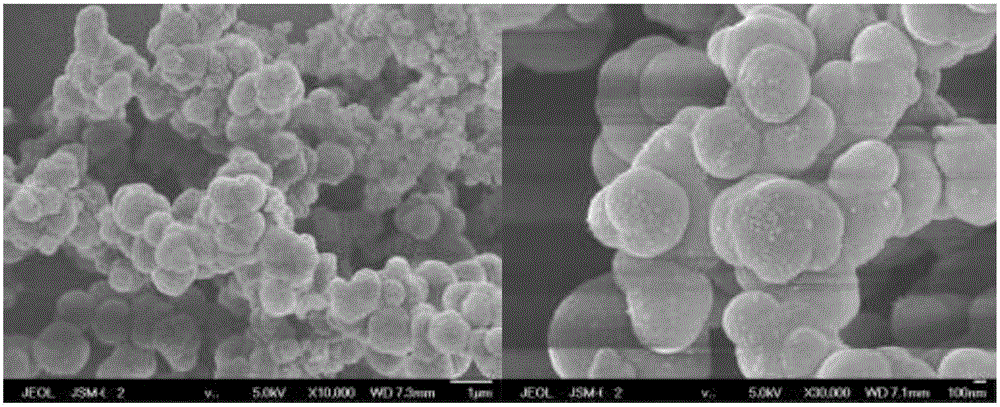

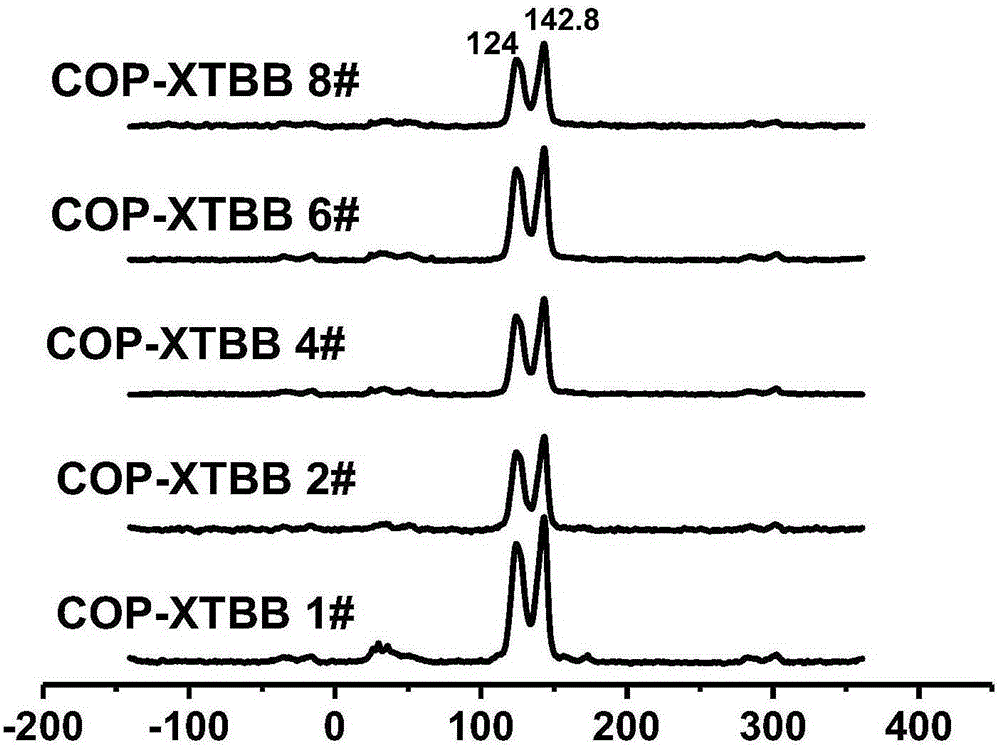

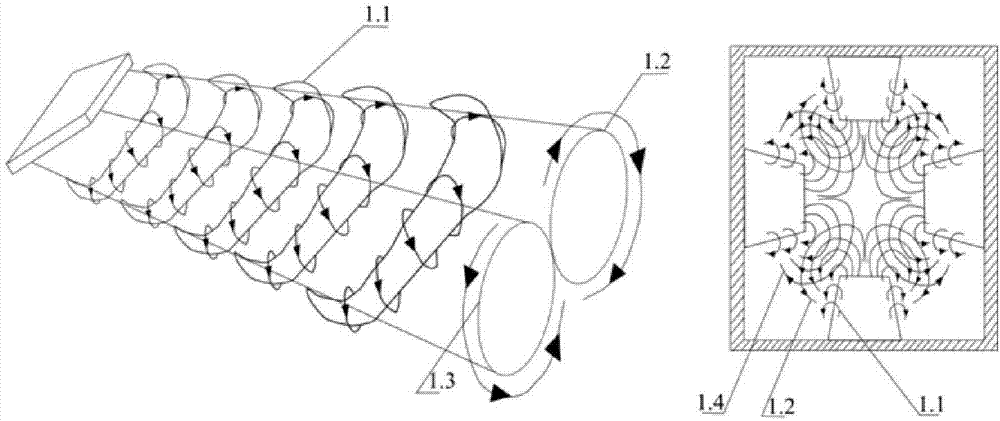

Method for preparing porous covalent organic material by using ultra-gravity method

The invention discloses a method for preparing a porous covalent organic material by using the ultra-gravity method, and belongs to the technical field of preparation of porous covalent organic materials. The method comprises the following steps: under a high gravity field, the micromixing and mass transferring process is strengthened, materials in a cavity of a preferable over-gravity rotary bed are sucked into a rotor of the rotary bed through a rotating inner spiral pipe, and the materials are sheared by, mixed and reacted with a filler rotating at a high speed in the rotor. Compared with reaction under a normal gravity filed, the method is greatly increased in reaction rate, and shortened in reaction time; besides, as for reaction systems sensitive to air, the water-free and oxygen-free reaction condition can also be achieved without a glove box, and compared with low-dosage preparation in the glove box, the method is greater in preparation amount and higher in production efficiency.

Owner:BEIJING UNIV OF CHEM TECH

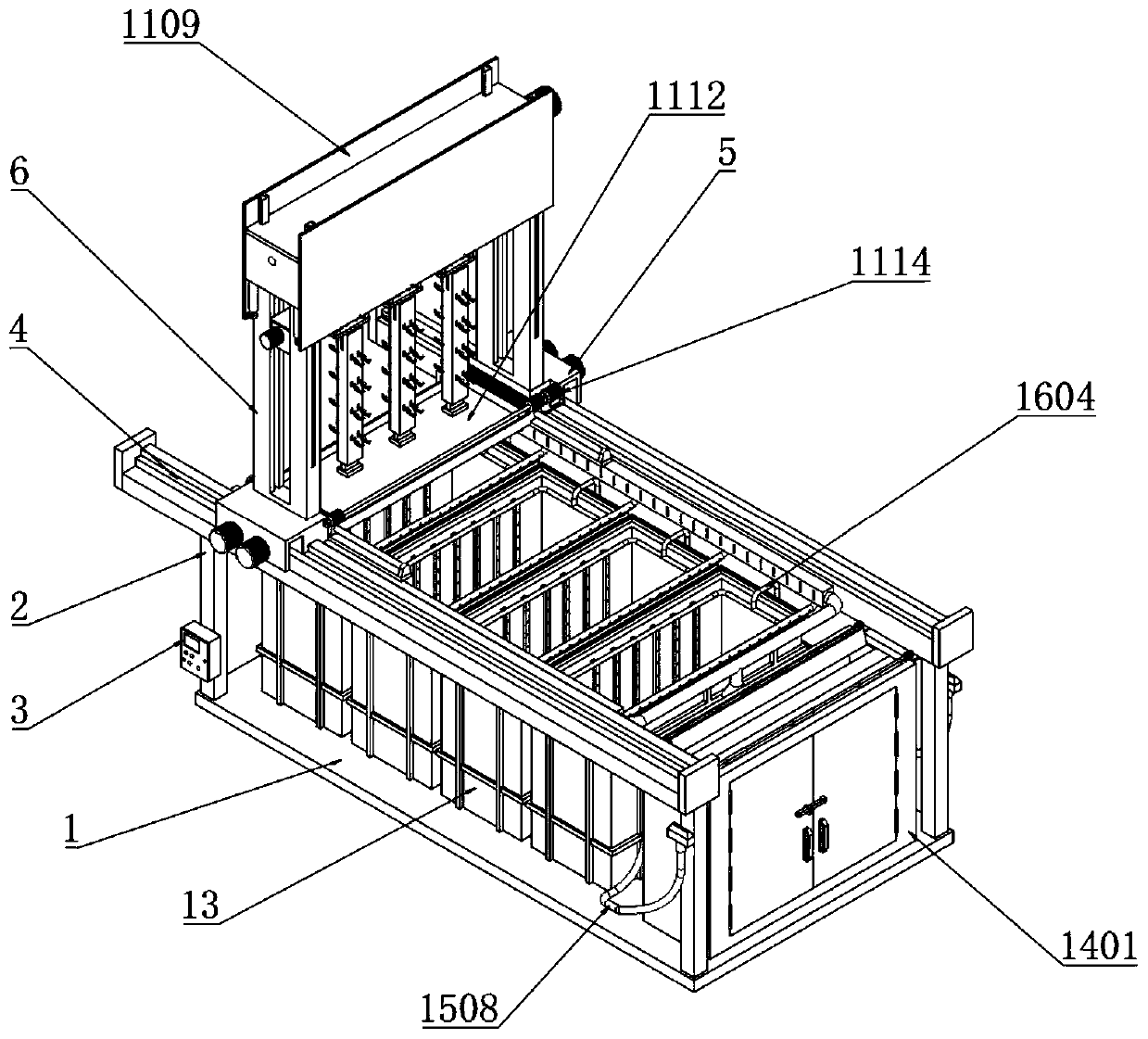

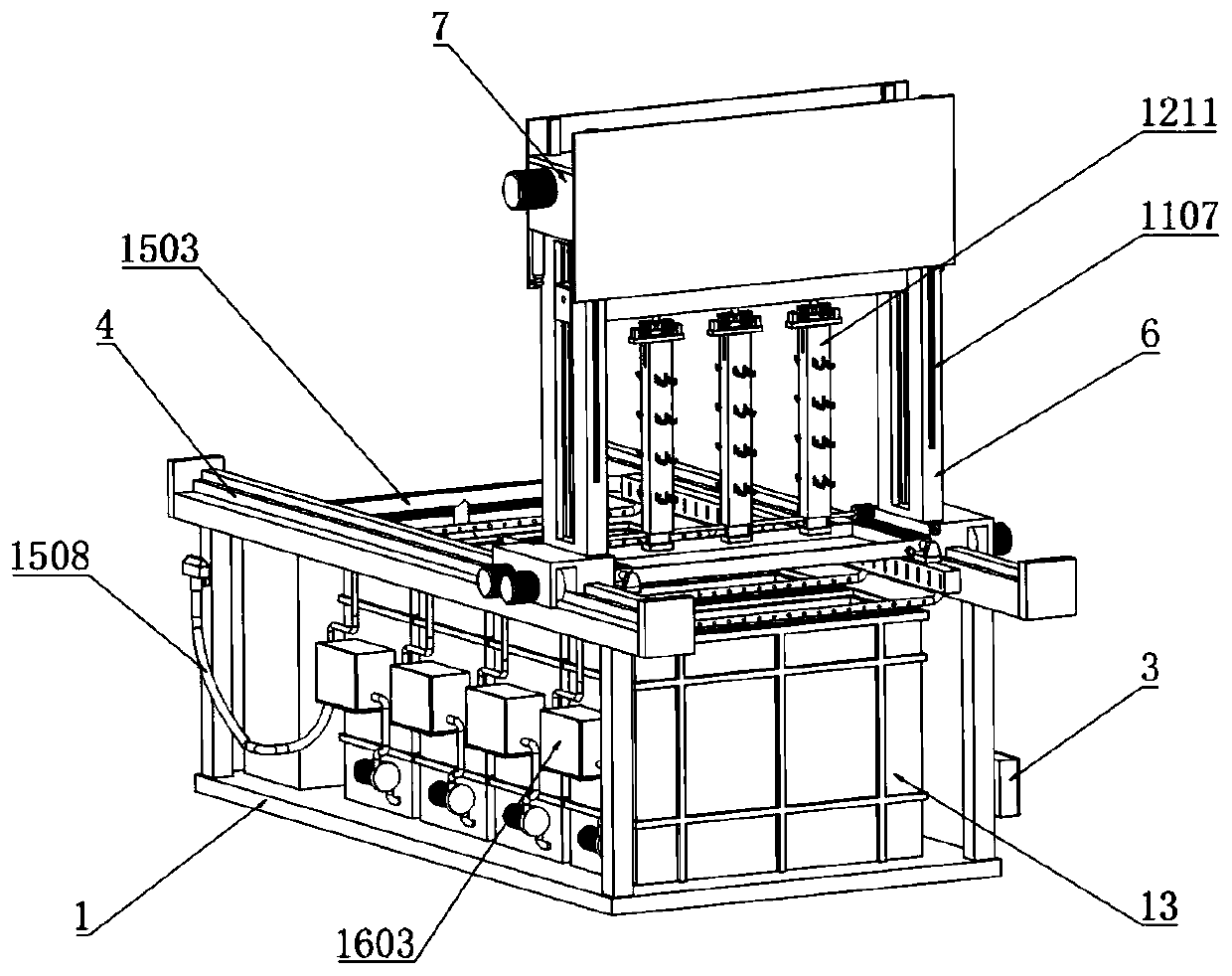

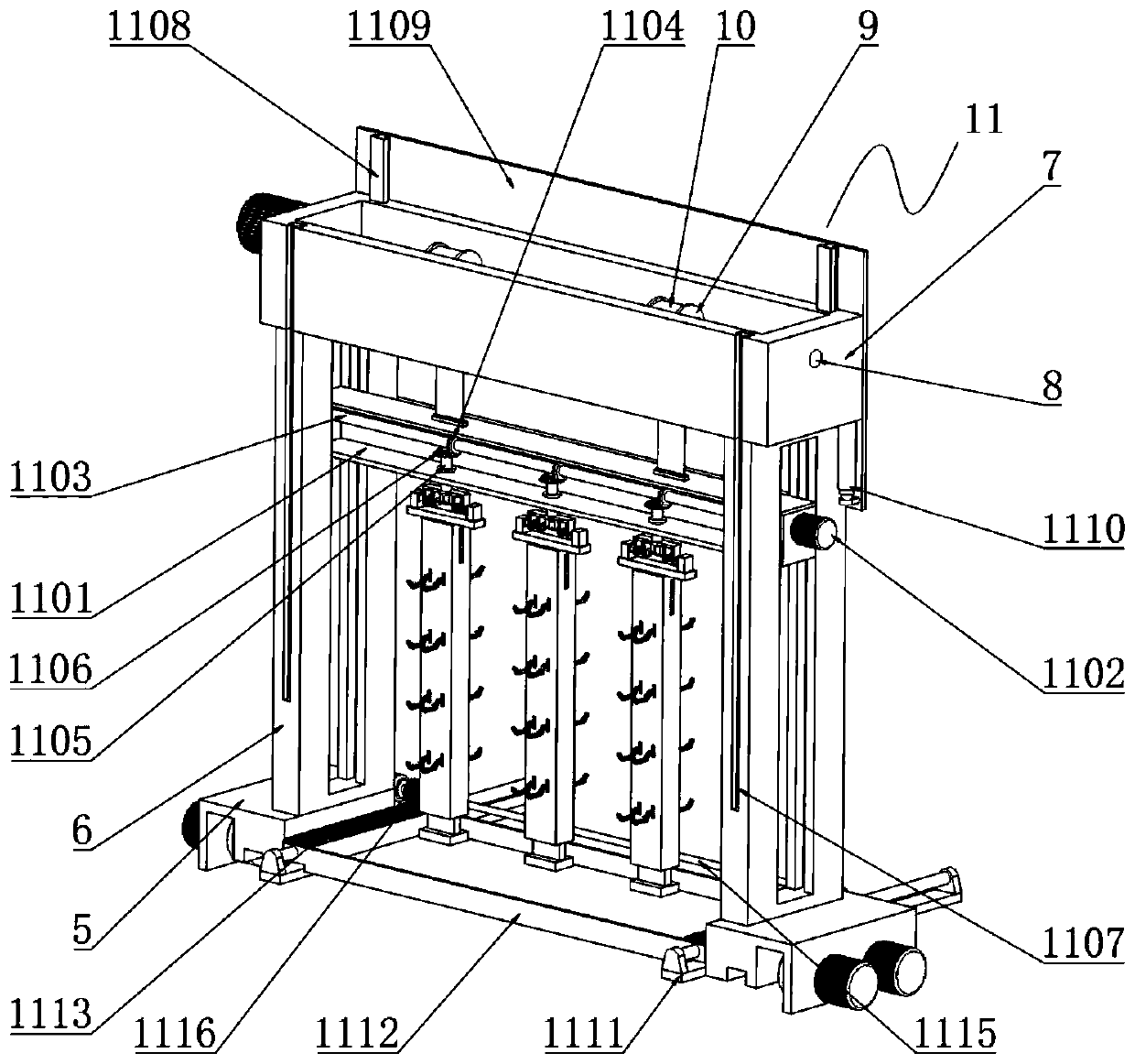

Full-automatic anti-residue automatic electroplating device

InactiveCN111501084AScientific and reasonable structureEasy to useCellsTanksMetallurgySurface cleaning

The invention discloses a full-automatic anti-residue automatic electroplating device. The full-automatic anti-residue automatic electroplating device comprises an installation bottom plate, wherein support bottom columns are fixedly connected to four corners of the top end of the installation bottom plate, support sliding rails are fixedly connected to the top ends of the support bottom columns,belt winding rollers are fixedly connected to the position, corresponding to the inner position of a lifting installation box, of the outer side of a lifting rotating shaft, and a surface cleaning mechanism is fixedly connected to the position, corresponding to the inner positions of support vertical plates, of the bottom end of a traction belt. A rotating motor drives a transmission rotating shaft and transmission bevel gears to rotate, the transmission bevel gears drive rotating vertical shafts and rotating bevel gears to rotate, then workpieces are driven to rotate through material hangingmechanisms, and in the rotating process of the workpieces, electroplate liquid and washing liquid left on the surfaces of the workpieces are separated from the workpieces under the action of centrifugal force, so that residual electroplate liquid and washing liquid are effectively prevented from being left on the workpieces and affecting next layer of electroplating of the workpieces, and the coating quality of the workpieces is improved.

Owner:刘理仁

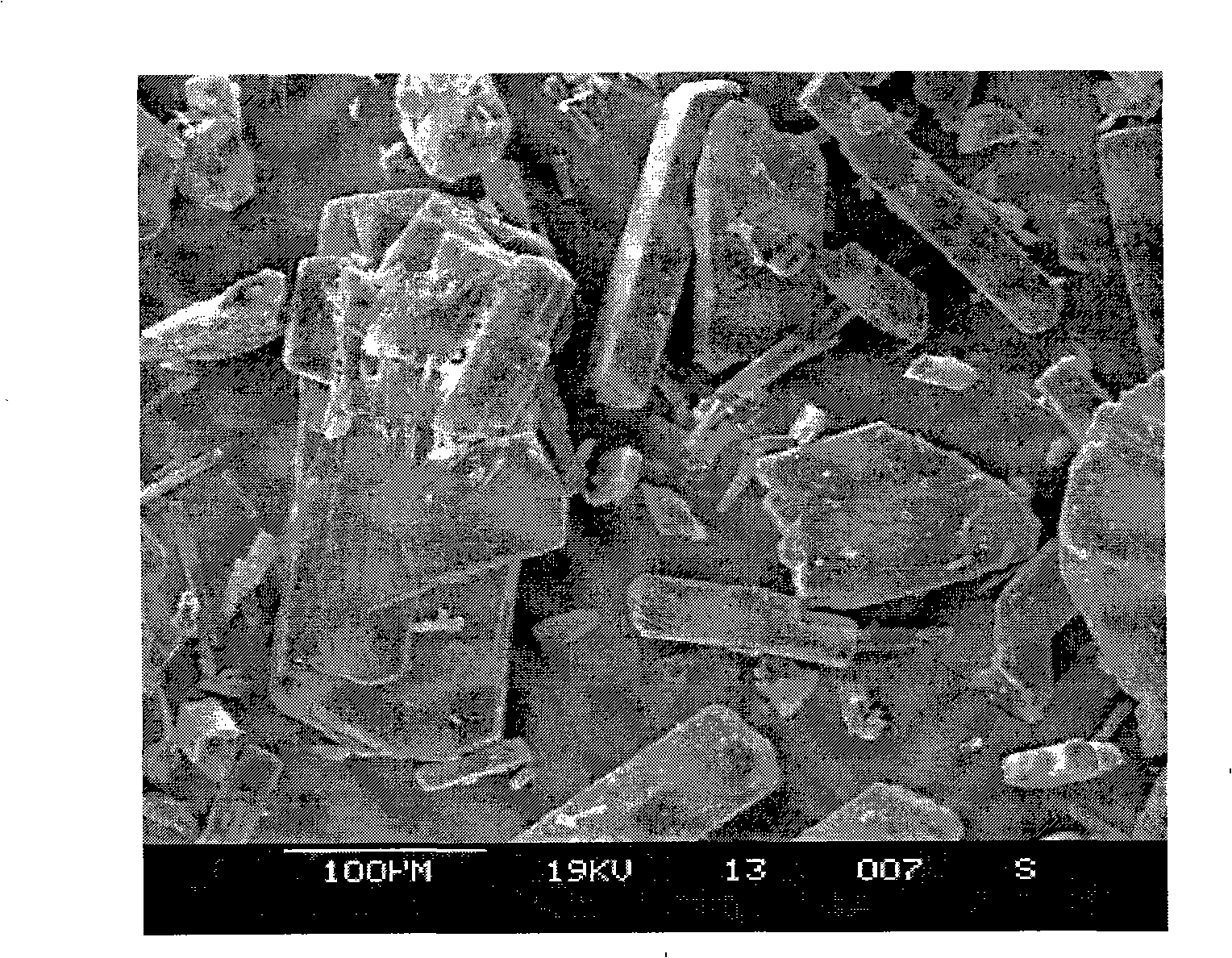

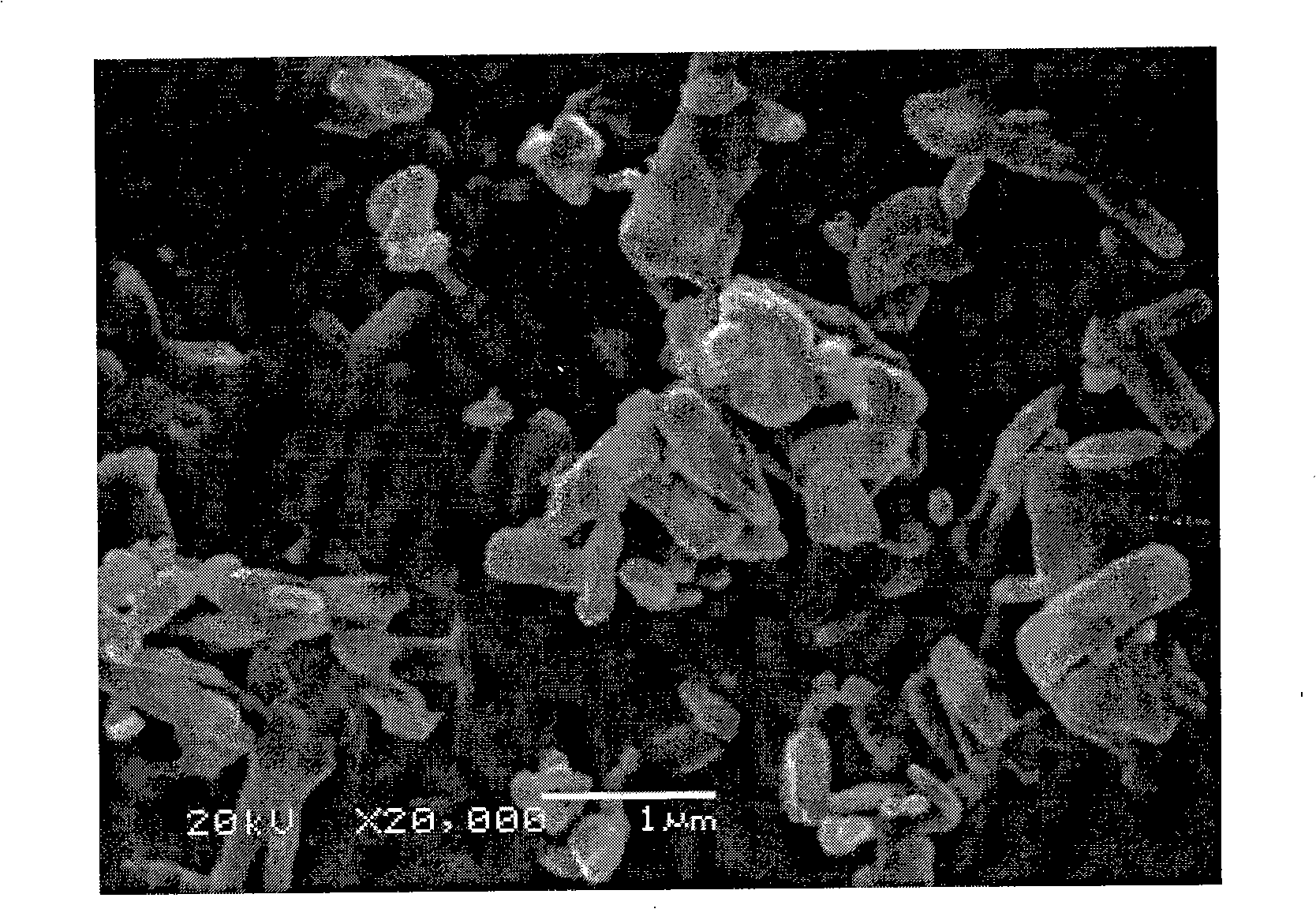

Polyethylene-polystyrene resin and preparation method thereof

ActiveCN101704929APhase separation does not occurUniform concentration distributionPre irradiationFunctional monomer

The invention relates to a polyethylene-polystyrene resin and a preparation method thereof. The preparation method comprises the following steps of: performing pre-irradiation treatment on polyethylene resin by using beta rays or gamma rays; adding the polyethylene resin after the pre-irradiation treatment, a dispersing agent, a functional monomer, an emulsifying agent, a nucleating agent and a homopolymerization inhibiting agent into a reactor to perform suspension graft polymerization reaction for a certain period of time at a certain temperature; and filtering, washing and drying a suspension graft product to obtain the polyethylene-polystyrene resin. The concentrations of macromolecular peroxides generated by the pre-irradiation are distributed evenly, so side reactions such as monomer homopolymerization, polymer crosslinking and / or degradation and the like caused by a micromolecule chemical initiator are avoided; the percent grafting ratio reaches 21 to 42 percent; the homopolymerization inhibiting agent reduces the homopolymerization of the monomer in the suspension grafting process; and the polyethylene-polystyrene resin has the tensile strength of more than 22 MPa, breaking elongation of over 90 percent and elastic modulus of more than 480 MPa, and has good mechanical properties such as strength, tenacity, impact strength and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

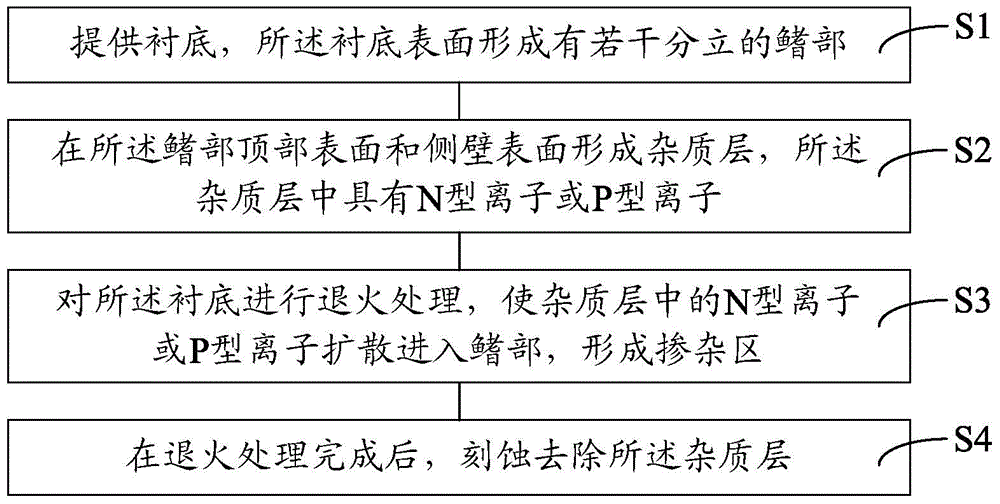

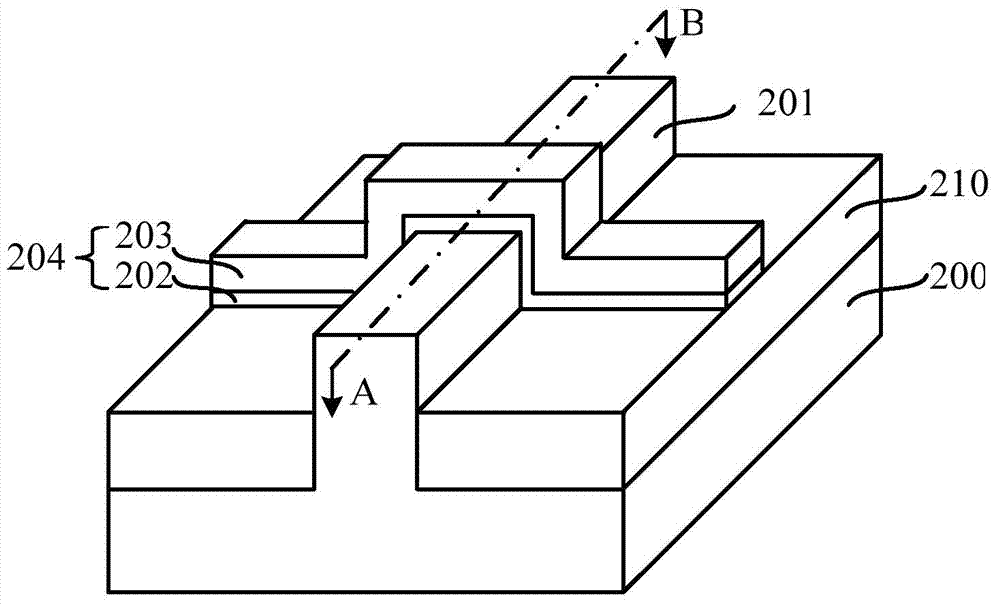

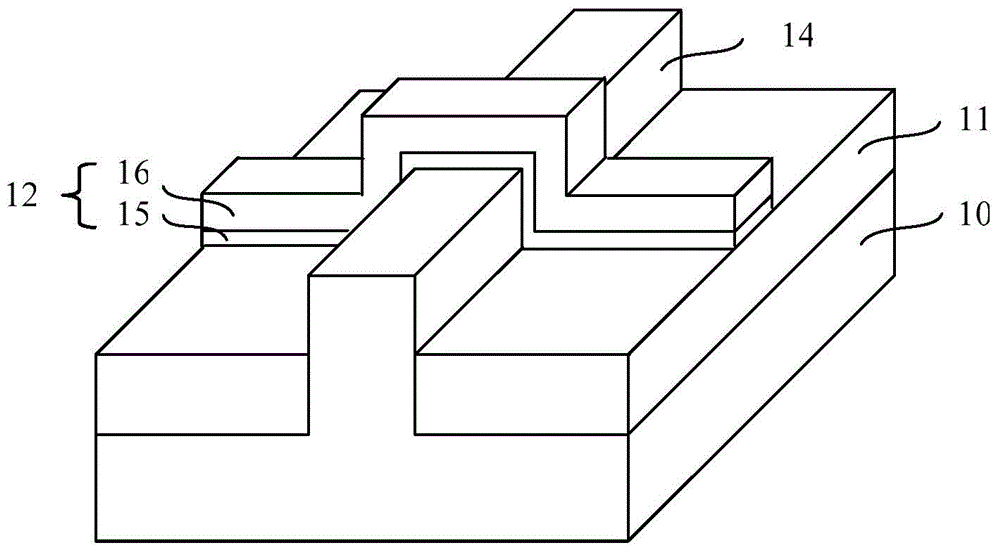

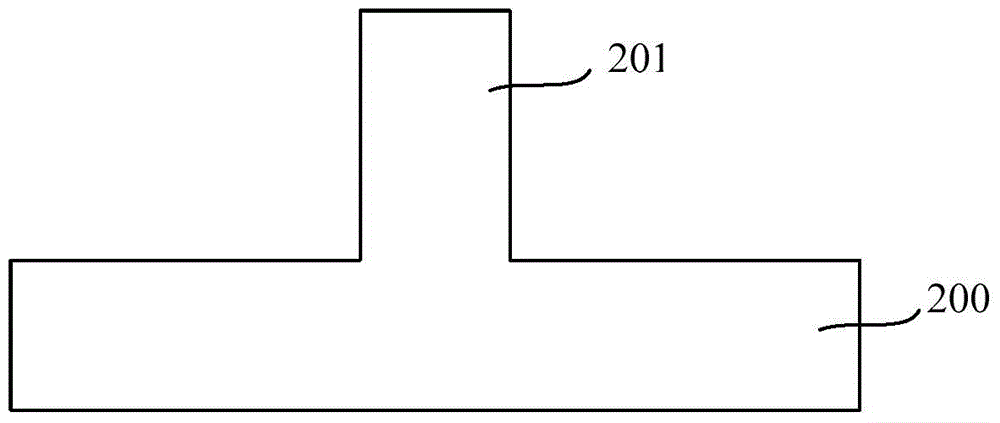

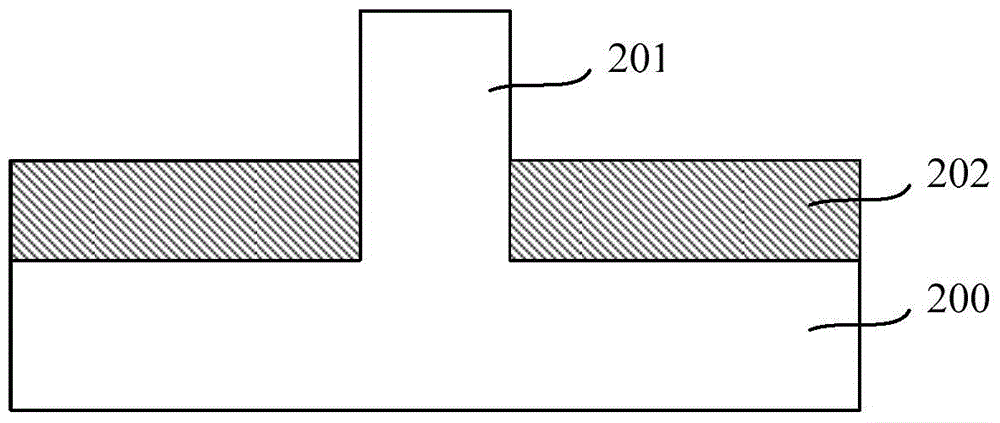

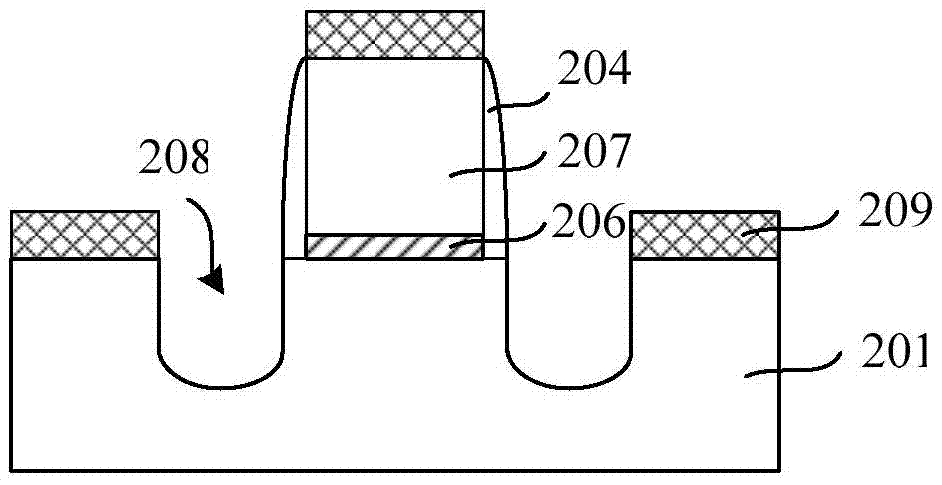

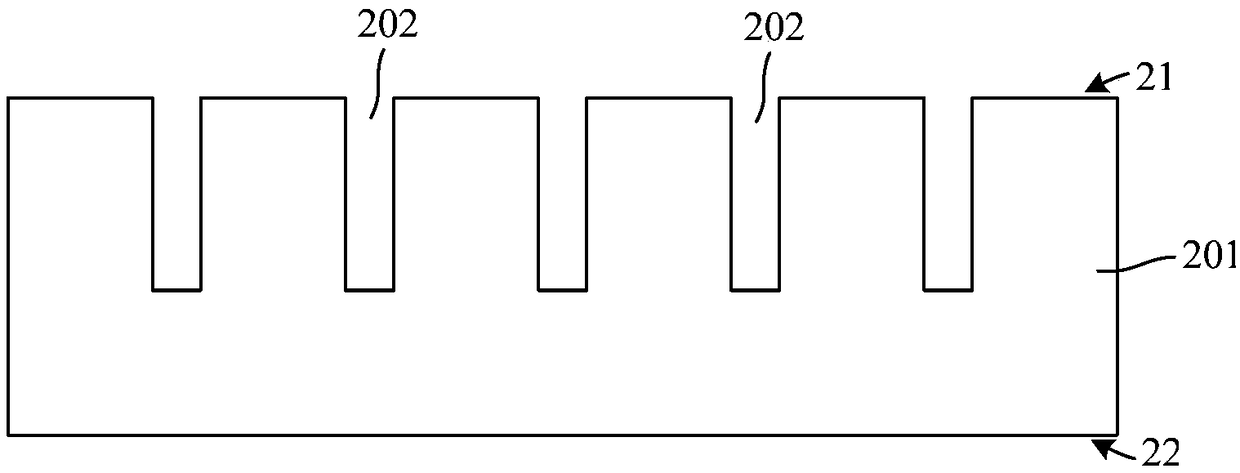

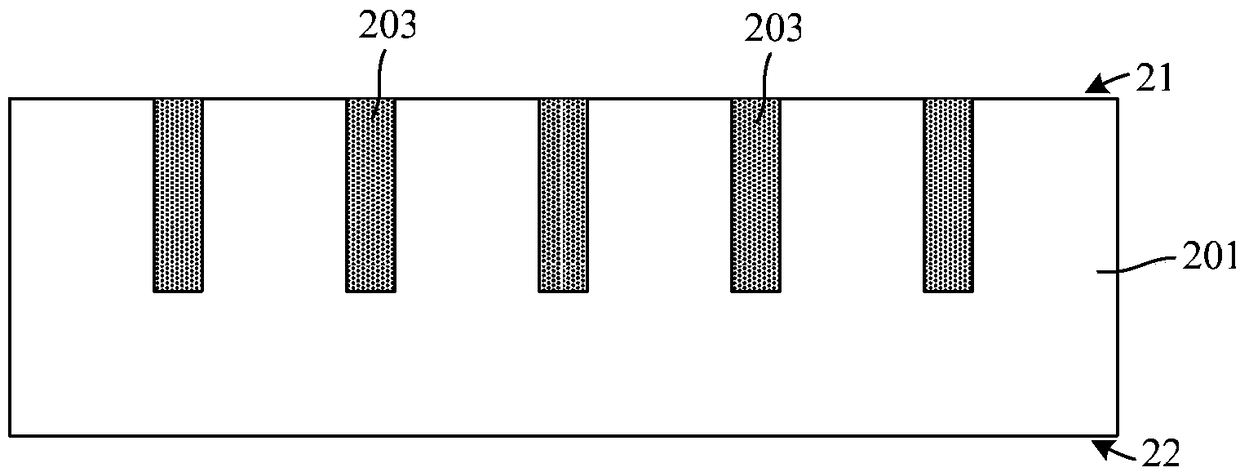

Formation method for fin type field-effect transistor

ActiveCN105336621AIntegrity guaranteedImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesIsolation layerEngineering

A formation method for a fin type field-effect transistor is disclosed. The formation method comprises the steps of providing a substrate, wherein a plurality of separated fin parts are formed on the surface of the substrate; forming a separating layer on the surfaces of the side walls and the top parts of the fin parts, wherein the etching speed on the separating layer and the etching speed on the fin parts in an etching process are different; forming an impurity layer on the surface of the separating layer, wherein the impurity layer has atoms with the same material as the fin parts ; the impurity layer is further provided with N type ions or P type ions; performing annealing treatment on the substrate to enable the N type ions or the P type ions in the impurity layer to be diffused into the fin parts through the separating layer to form a doping region in the internal of the fin parts; the impurity layer is converted into an intrinsic layer; taking the separating layer as the etching stop layer and etching off the intrinsic layer; and etching off the separating layer until the top parts and the side wall surfaces of the fin parts are exposed. The concentration uniformity of the formed doping region is improved, the amorphization problem on the fin parts caused by the ion implantation technology is avoided, the completeness of the sizes of the fin parts is kept, and the electrical property of the fin type field-effect transistor is optimized.

Owner:SEMICON MFG SOUTH CHINA CORP

Polyethylene-polystyrene foam and preparation method thereof

ActiveCN101824198AUniform concentration distributionAvoid homopolymerizationPre irradiationFunctional monomer

The invention relates to a polyethylene-polystyrene foam, which is formed in a way that polystyrene is grafted on a molecular chain of polyethylene to connect the polyethylene with the polystyrene by a covalent chemical bond, wherein the grafting ratio mass percent of the grafted polystyrene is 25-60%, and the volume density of the polyethylene-polystyrene foam is 27-208kg / m<3>. The preparation method comprises the following steps: carrying out pre-irradiation treatment on the polyethylene; and adding the polyethylene after the pre-irradiation treatment, dispersant, functional monomer, emulsifying agent, nucleating agent and homopolymerization depressor to a reaction vessel to be subject to suspension graft polymerization reaction, adding foaming agent, cooling the reaction product, filtering, washing with water, drying, and heating to obtain the polyethylene-polystyrene foam. The polyethylene-polystyrene foam has the advantages of excellent mechanical property, favorable rebound elasticity, good stress cracking resistance, high impact absorbing capacity and the like, combines the flexibility of polyethylene foam and the rigidity of polystyrene foam, and is used in the fields of vehicles, buildings, packaging, heat preservation, heat insulation and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

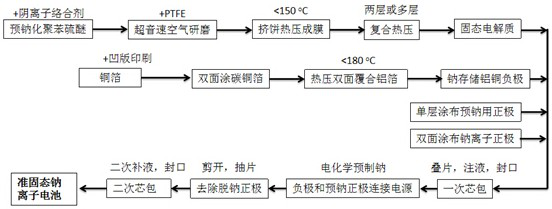

Manufacturing method of high-energy-density quasi-solid-state sodium ion battery

ActiveCN112290081AImprove thermal stabilityNon-flammableSolid electrolytesFinal product manufactureSolid state electrolyteElectrolytic agent

The invention relates to the field of new energy and discloses a manufacturing method of a high-energy-density quasi-solid-state sodium ion battery, and the method comprises two main technological processes of pre-preparing sodium and removing secondary packaging of a positive electrode for pre-preparing sodium. According to the pre-preparing sodium process, under the action of an electric field,a positive electrode for sodium prefabrication is subjected to single-layer coating, and uniform sodium plating is formed on the surface of a porous aluminum foil by compounding a sodium ion polyethylene and polyphenylene sulfide-based composite solid electrolyte, so that nucleation and growth of metal sodium are uniform, and dendritic crystal generation is inhibited. The sodium-ion polyethylene polyphenylene sulfide-based composite solid electrolyte can be tightly adhered to a sodium storage aluminum-copper negative electrode after sodium is prefabricated, and can be easily separated from a single-layer coated positive electrode for pre-sodium, the positive electrode for pre-sodium after sodium removal is taken out, the internal damage of a battery cell cannot be caused, and secondary vacuumizing and sealing are performed. The battery manufactured by the method has good flame retardant property and good thermal stability, the electrolyte injection amount is reduced, combustibles in the battery are also reduced, and the safety performance of the battery is improved.

Owner:东莞奥创能源科技有限公司

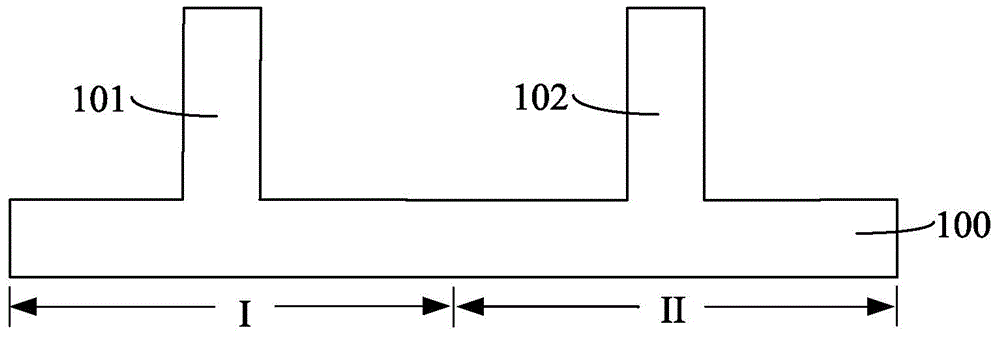

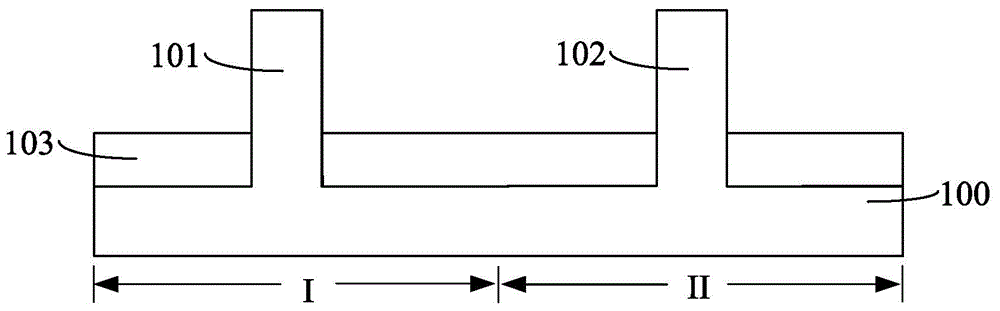

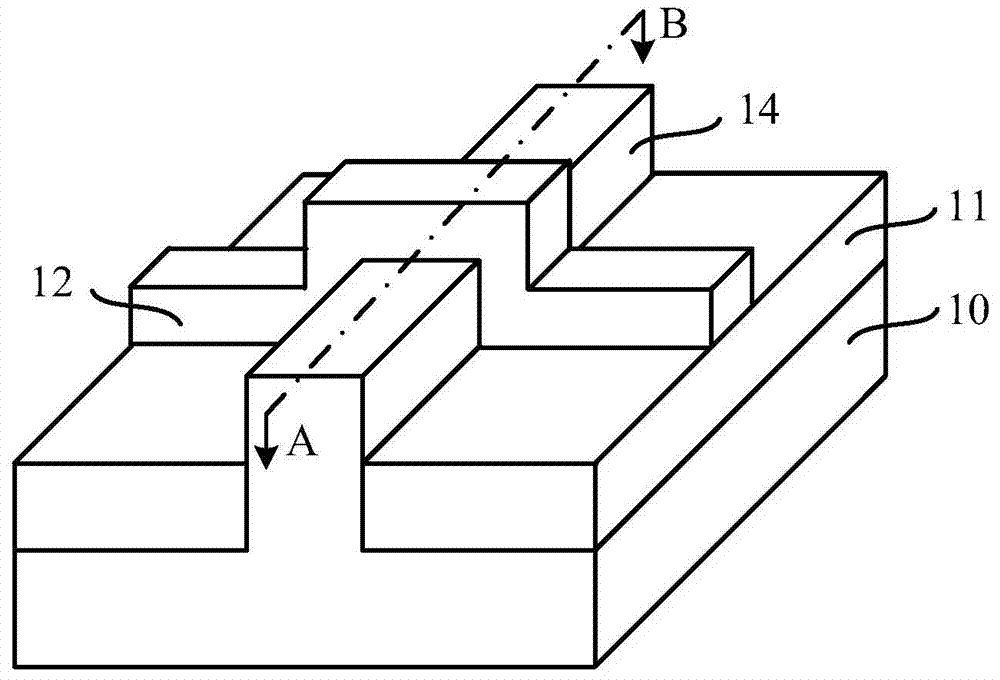

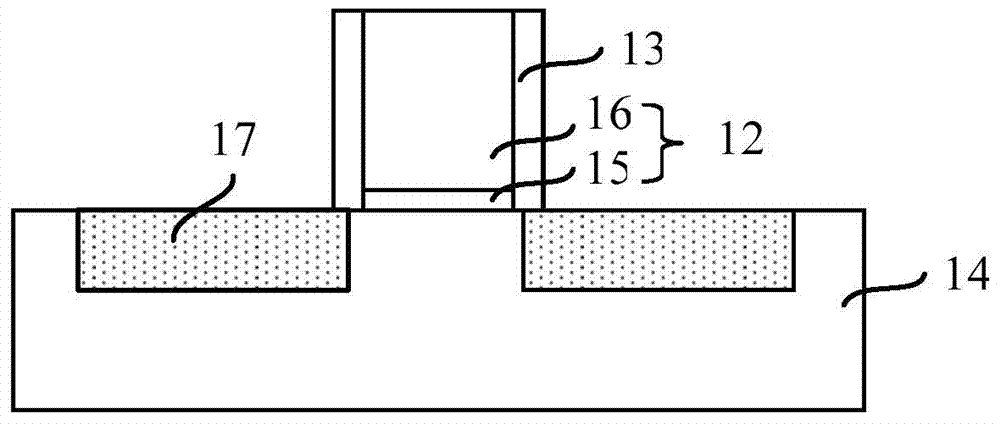

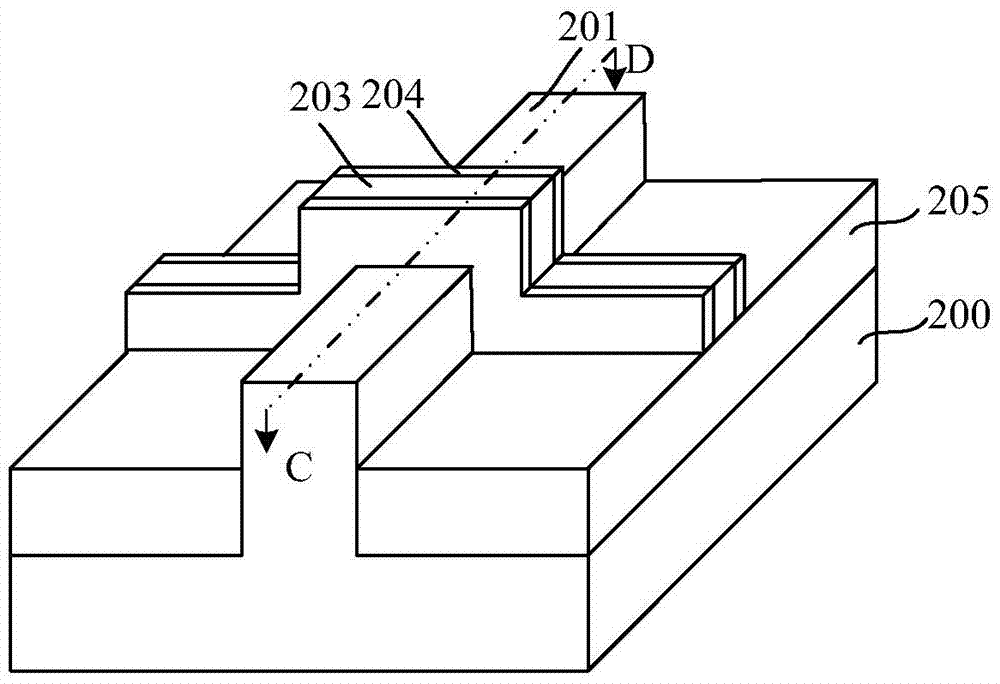

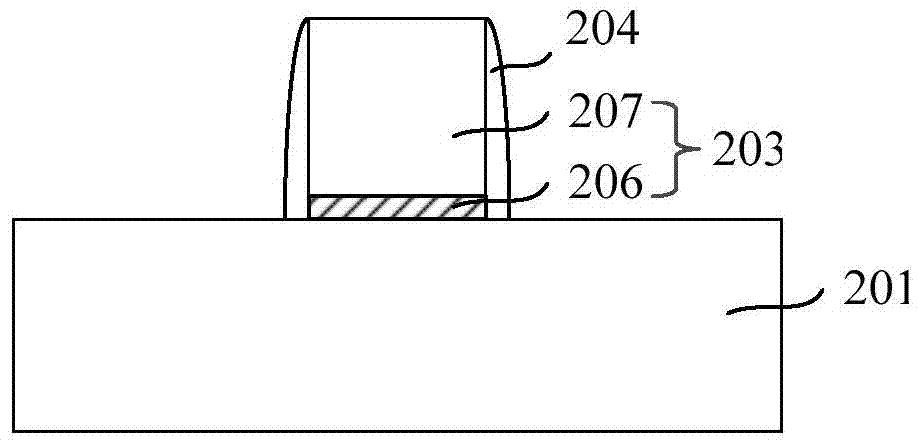

Fin type field-effect transistor and forming method thereof

ActiveCN104752211AUniform concentration distributionImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorSemiconductor package

Provided are a fin type field-effect transistor and a forming method thereof. The forming method of the fin type field-effect transistor comprises the steps of providing a semiconductor substrate, forming a fin portion on the semiconductor substrate, forming gate electrode structures on the surfaces of the top and the side wall of the fin portion and forming side walls on two side walls of each gate electrode structure; etching the fin portions on two sides of each gate electrode structure and forming grooves in the fin portions on the two sides of each gate electrode structure; forming first semiconductor layers on the side walls and bottoms of the grooves, wherein foreign ions are doped in the first semiconductor layers; forming second semiconductor layers on the first semiconductor layers and forming grooves in the second semiconductor layers, wherein foreign ions are doped in the second semiconductor layers, and the concentration of the foreign ions doped in the second semiconductor layers is higher than that of the foreign ions are doped in the first semiconductor layers. The foreign ions doped in the first semiconductor layers and the second semiconductor layers are evenly distributed, and the performance of the fin type field-effect transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

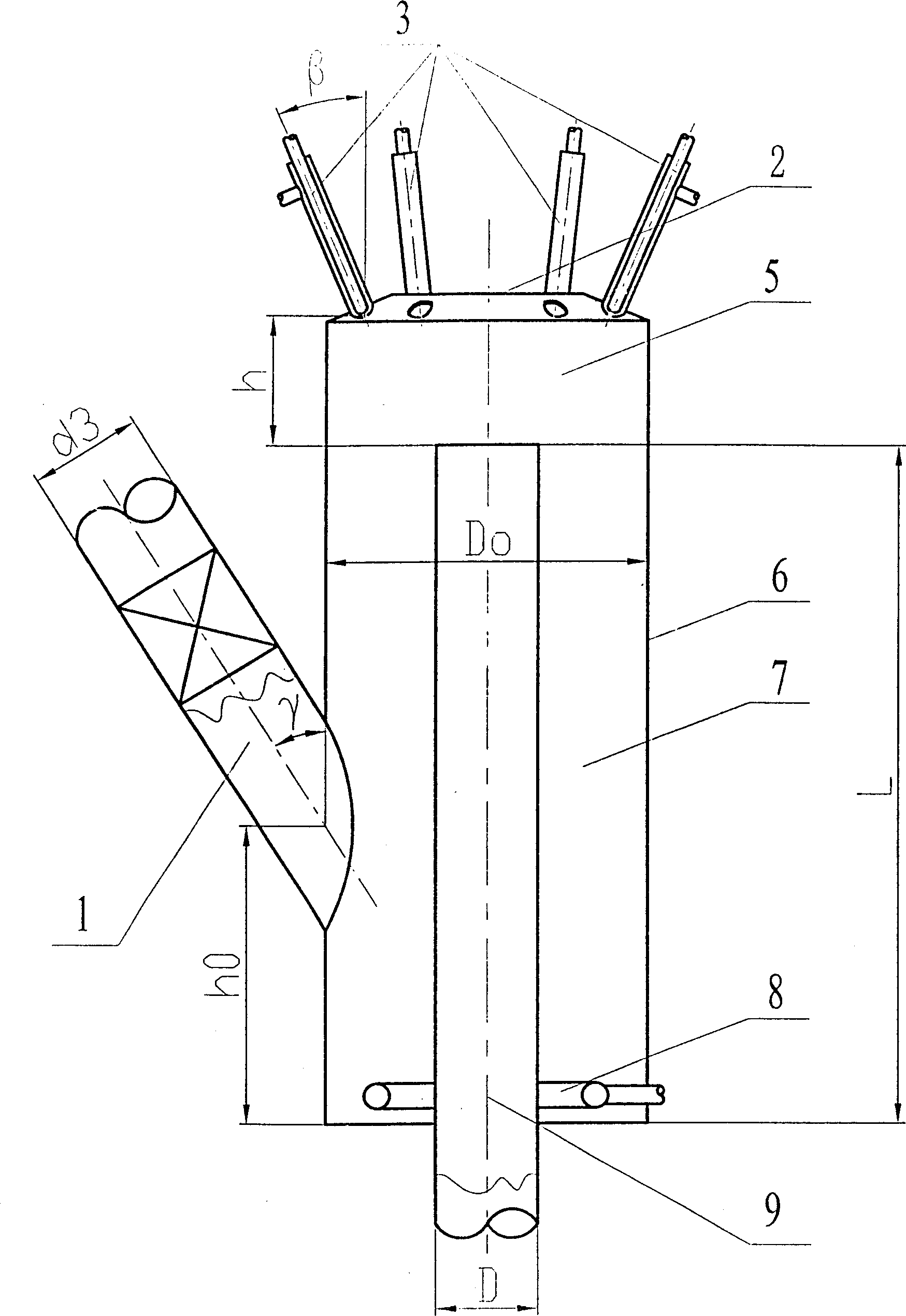

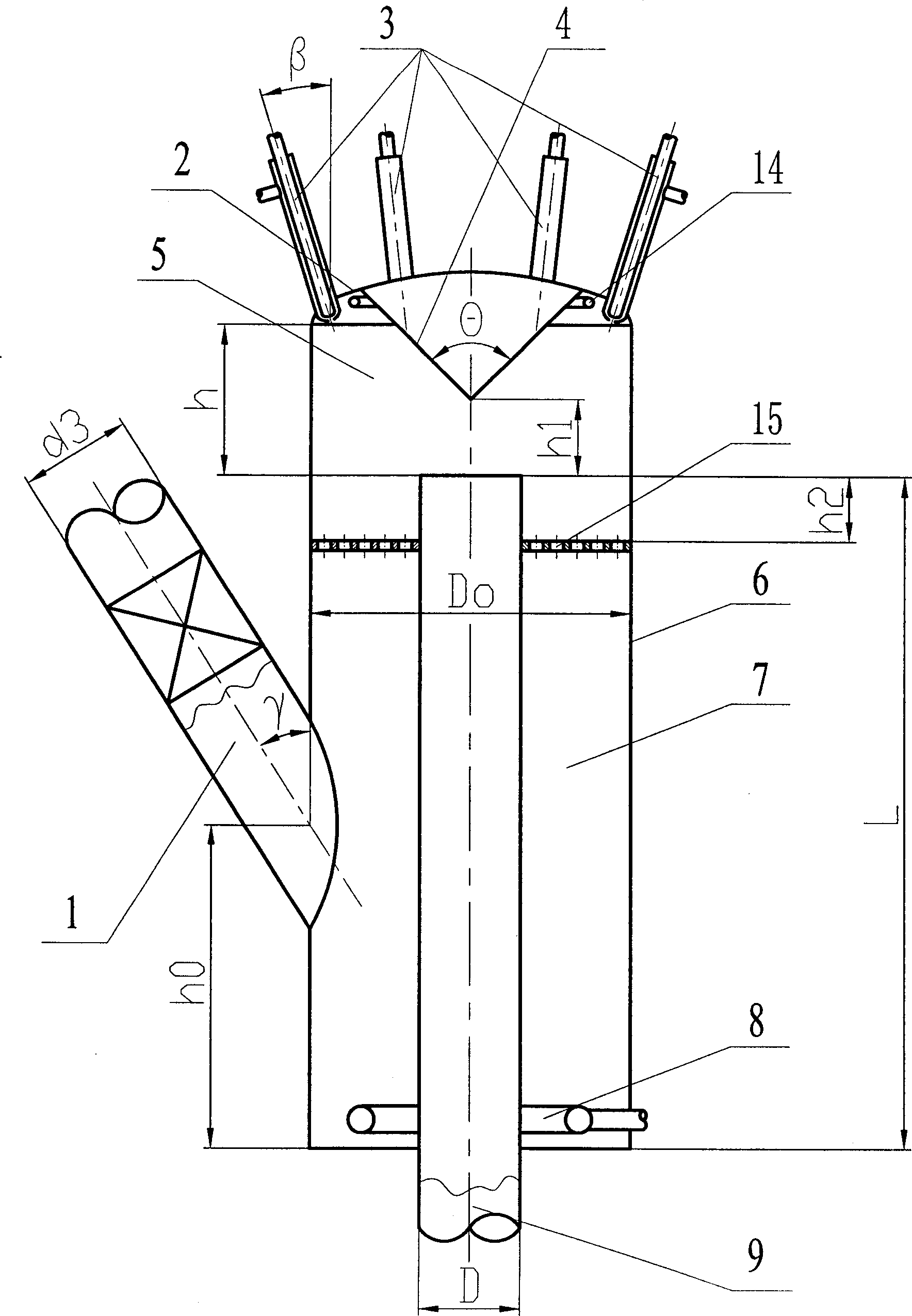

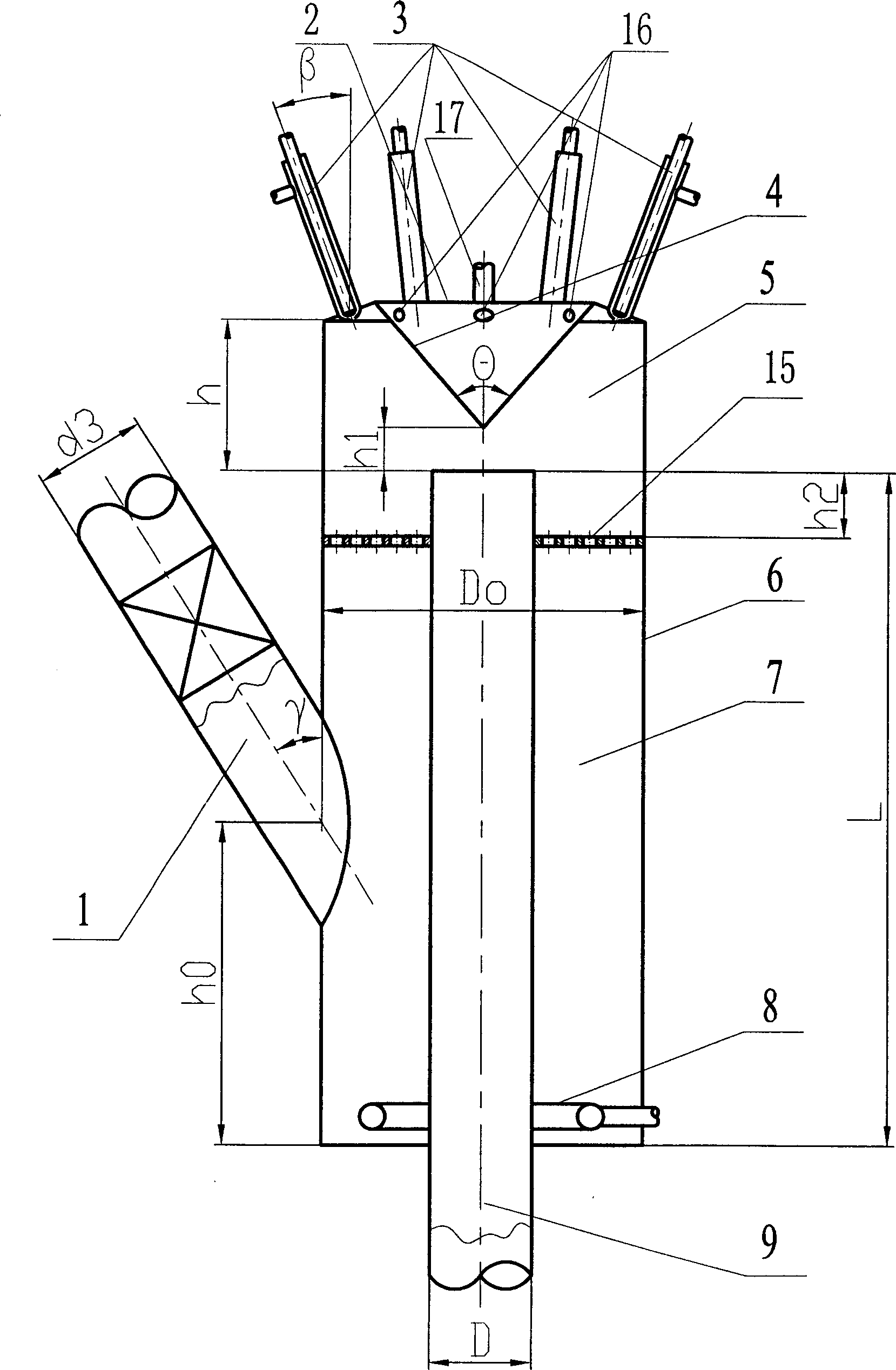

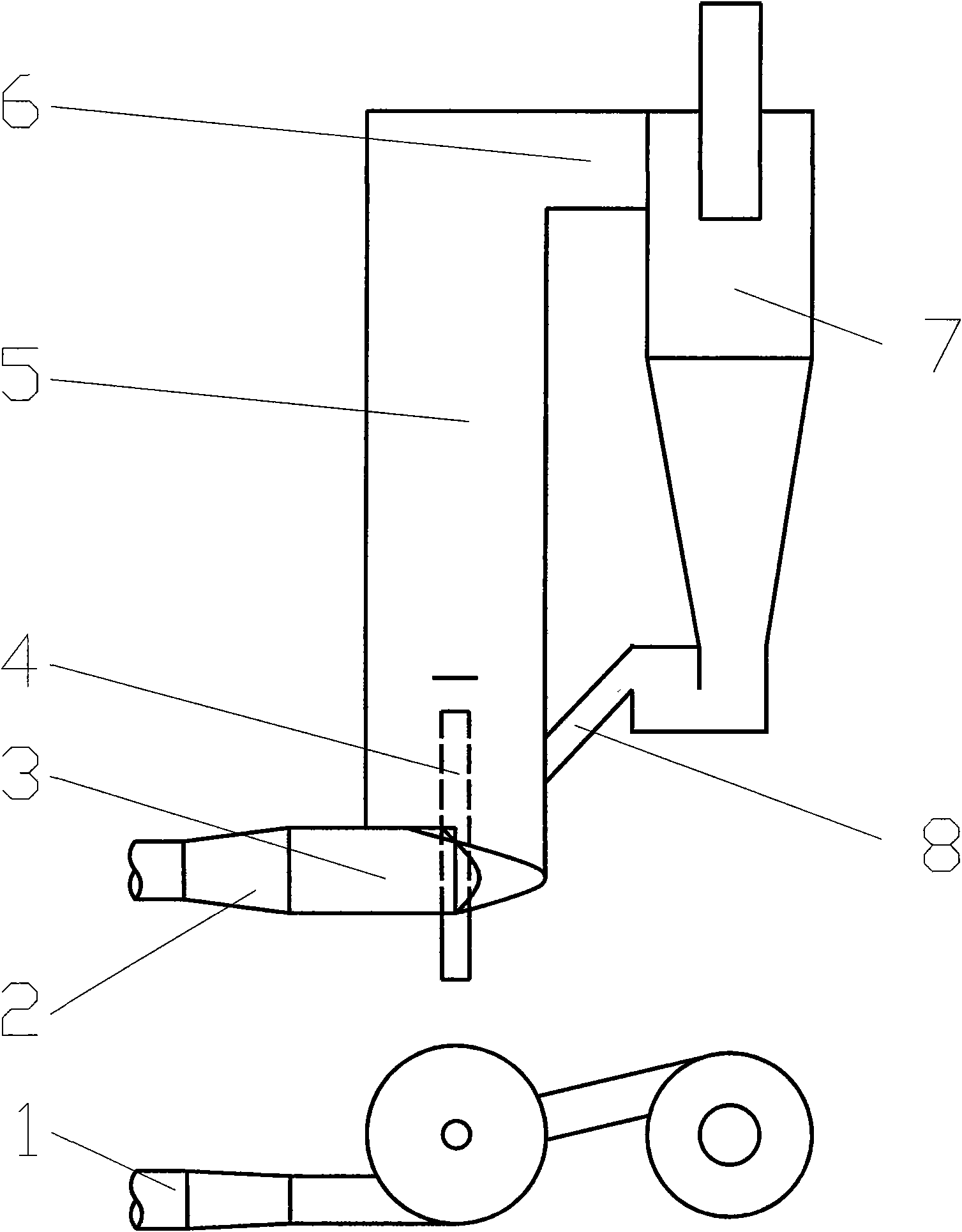

Desending catalytic cracking reactor and its application

InactiveCN1453334AImprove atomization effectImprove contact efficiencyCatalytic crackingDistributorChemical engineering

The descending catalytic cracking reactor includes the members of: catalyst conveying pipe, reactor top cover, material nozzle, outer reactor cylinder, medium pre-lifting distributor and descending reaction pipe. The descending reaction pipe and the outer reactor cylinder are set vertically and coaxially; the upper end of the outer reactor cylinder is connected to the top hermetically to constitute the cavity over the inlet of the descending reaction pipe as the material atomizing chamber, the outer reactor cylinder has its bottom connected hermetically to the outer wall of the descending reaction pipe; the upper section of the descending reaction pipe is inside the outer reactor cylinder while the lower section extends beyond the bottom of the cylinder; the material nozzle is set on thetop cover; the catalyst conveying pipe is connected to the outer cylinder and communicated to the catalyst pre-lifting area; and the medium pre-lifting distributor is set in the bottom of the catalyst pre-lifting area.

Owner:CHINA PETROLEUM & CHEM CORP +1

Honeycomb catalyst carrier and method for production thereof

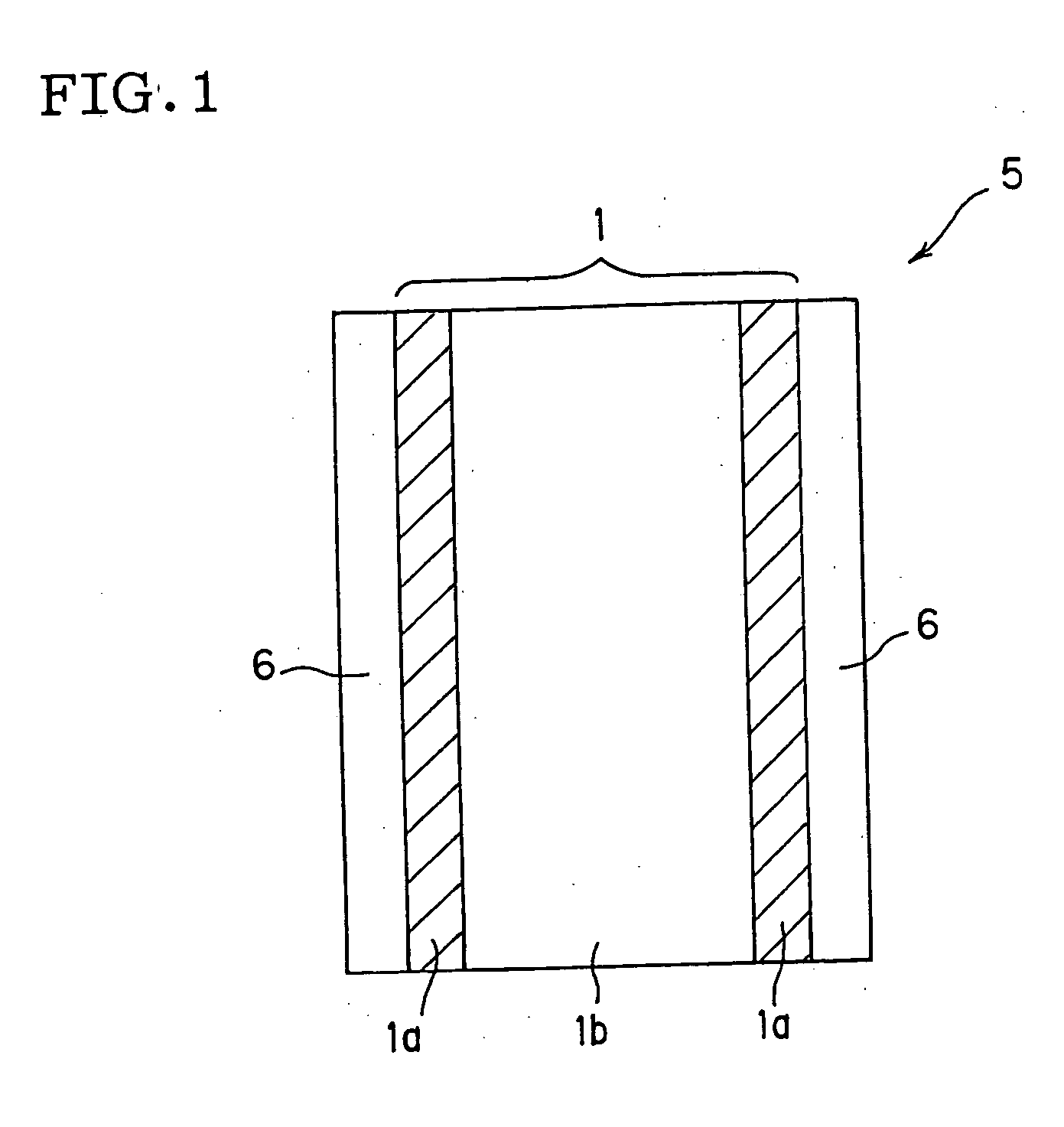

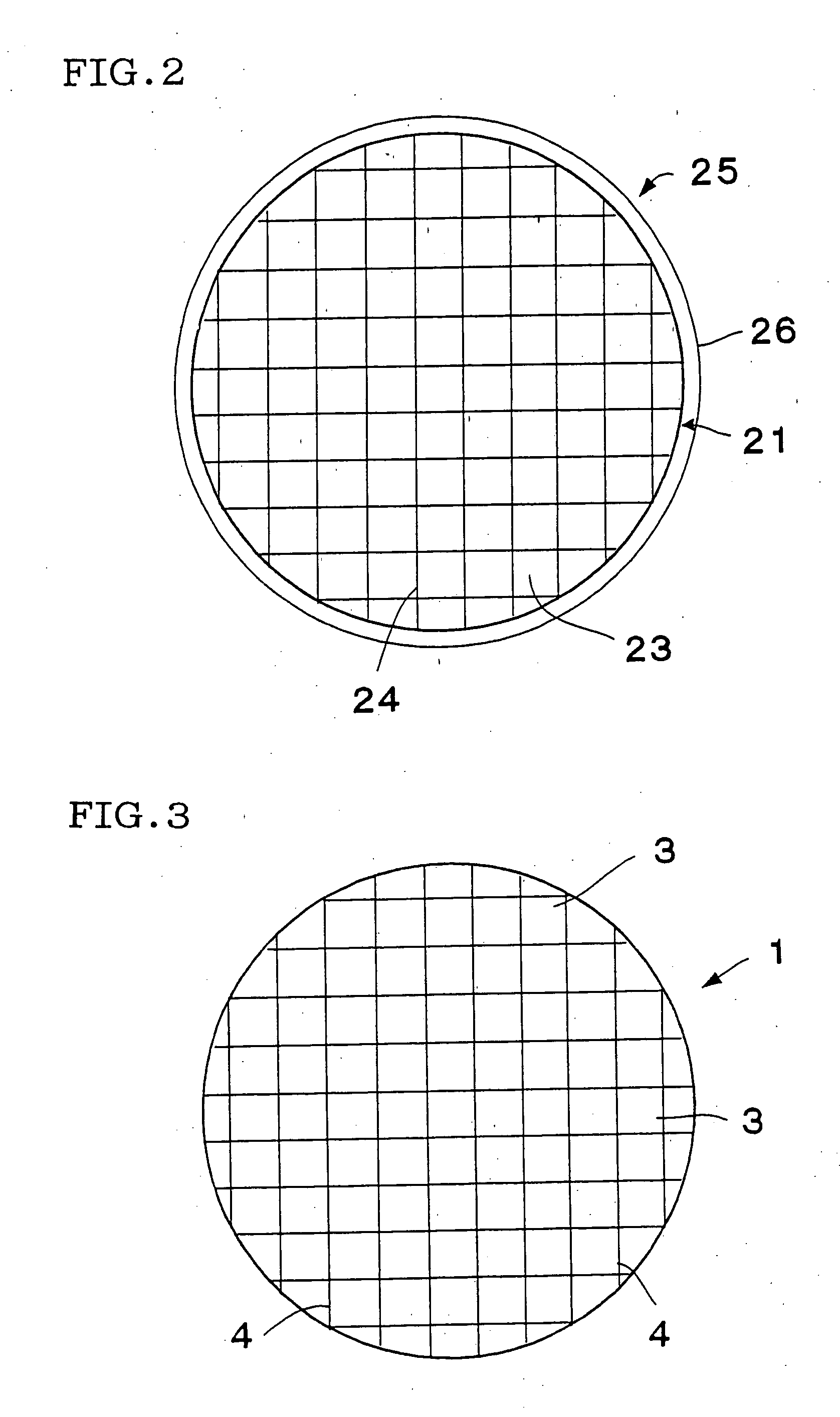

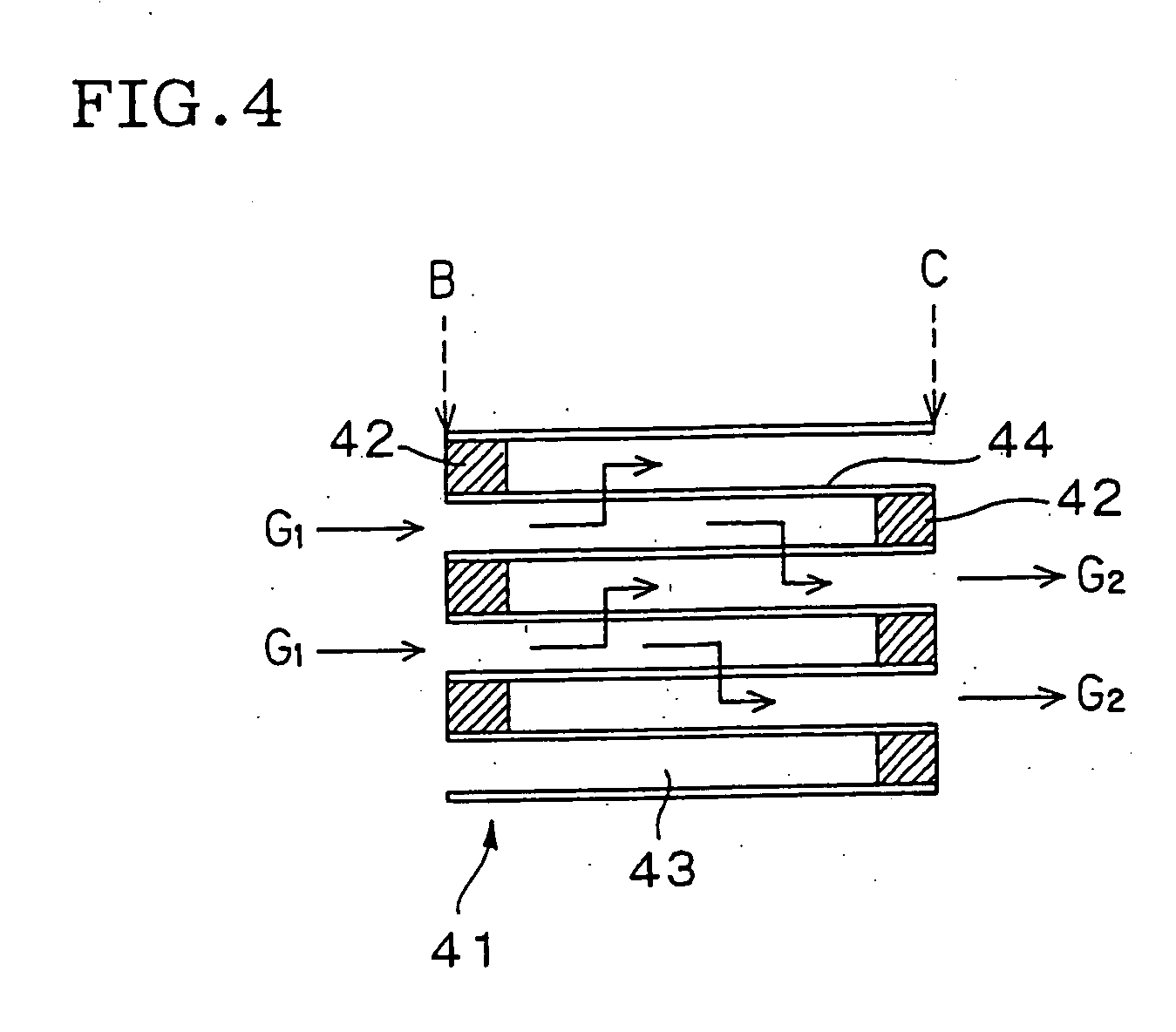

InactiveUS20050261128A1Uniform concentration distributionInhibit generation of crackCatalyst carriersInternal combustion piston enginesHoneycombEngineering

A honeycomb catalyst carrier 5 of the present invention includes: a honeycomb formed cell structure 1 which is composed of a porous material having a large number of pores and has cells each functioning as a fluid passage; and an outer wall 6 composed of a porous material disposed so as to cover an outer periphery of the cell structure 1. An impregnated part 1a impregnated with a water-insoluble organic material which disappears by burning or an inorganic material is formed in an outermost peripheral part, which has a given thickness, of the porous material of the cell structure 1.

Owner:NGK INSULATORS LTD

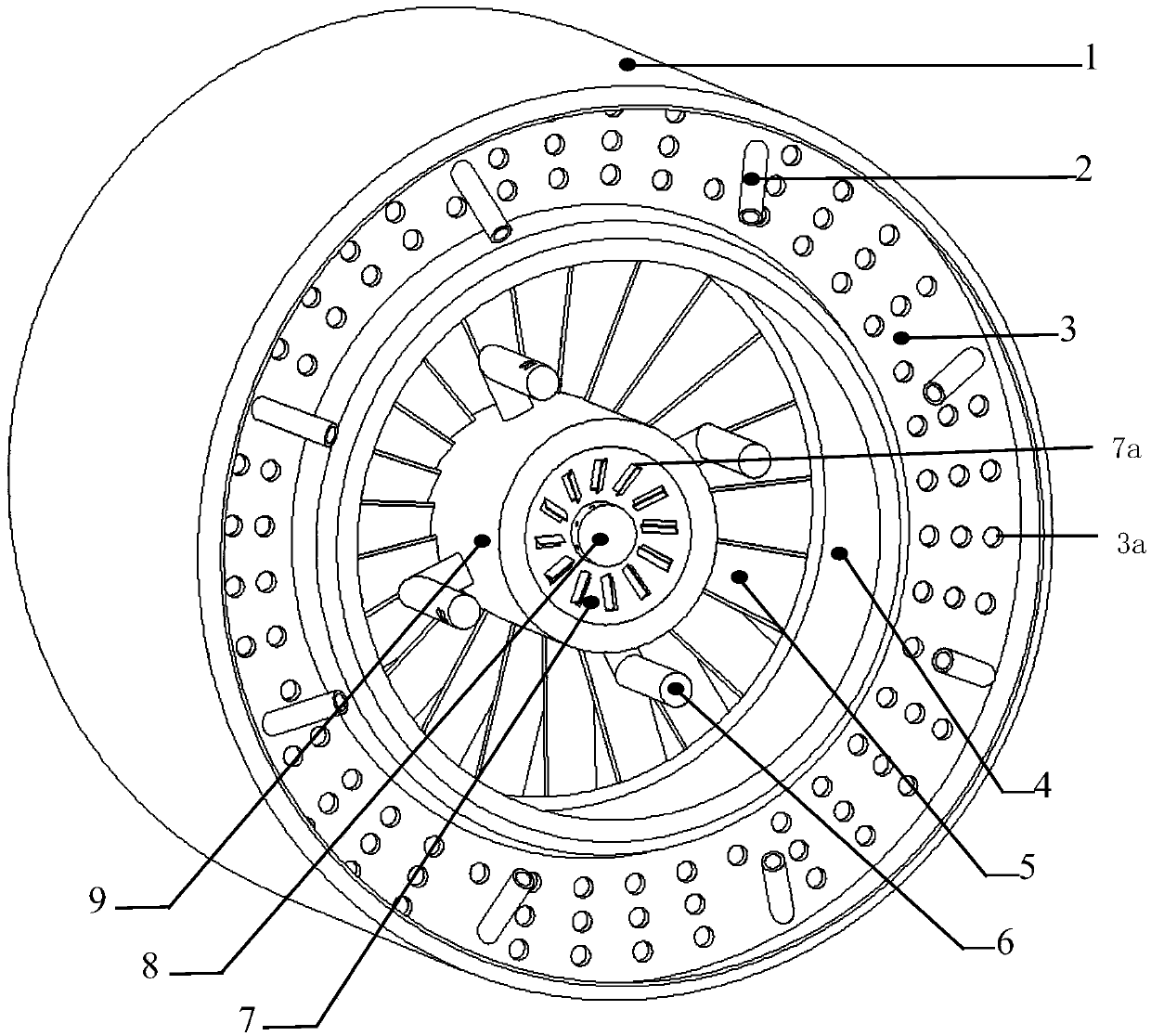

Multistage gas reverse swirl burner

PendingCN109611835AEfficient mixingStable combustion characteristicsPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPollutant emissionsEngineering

The invention discloses a multistage gas reverse swirl burner. The multistage gas reverse swirl burner comprises a fuel spraying pipe and an air guide barrel set; the air guide barrel set comprises afirst-stage air guide barrel, a second-stage air guide barrel and a third-stage air guide barrel, the air outlet end of the first-stage air guide barrel is provided with a flame stabilizing disc to output first-stage swirl gas, the first-stage air guide barrel is sleeved with the second-stage air guide barrel, the second-stage air guide barrel is provided with multiple second blades to output second-stage swirl gas, the first-stage swirl gas and the second-stage swirl gas are opposite in swirl direction, the second-stage air guide barrel is sleeved with the third-stage air guide barrel, the third-stage air guide barrel is provided with a porous plate to output high-speed straight-through flow gas, the fuel spraying pipe set comprises a first-stage fuel spraying pipe, a second-stage fuel spraying pipe and a third-stage fuel spraying pipe, the first-stage fuel spraying pipe is located on the first-stage air guide barrel to spray fuel to the first-stage swirl gas, the second-stage fuel spraying pipe is located on the second-stage air guide barrel to spray fuel to the second-stage swirl gas, and the third-stage fuel spraying pipe is located on the third-stage air guide barrel. The airand gas mixing degree can be greatly improved, gas mixing is more uniform, combustion is more sufficient, and pollutant emission is lower.

Owner:HUAQIAO UNIVERSITY

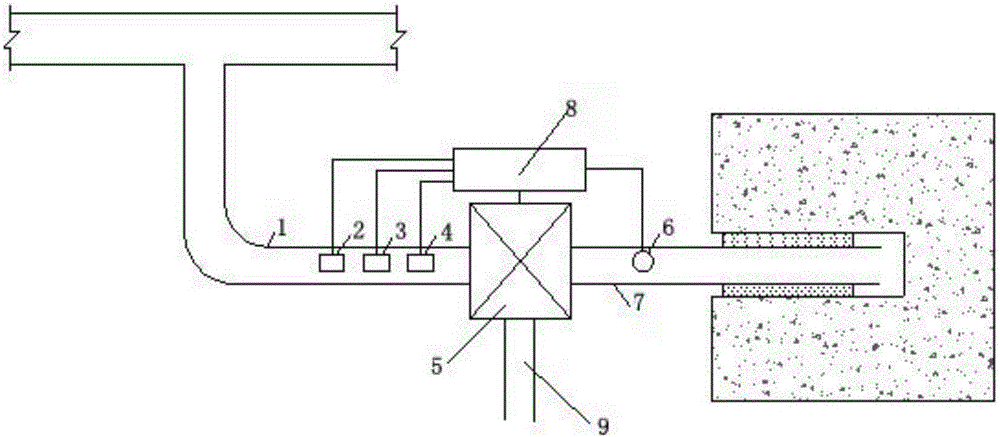

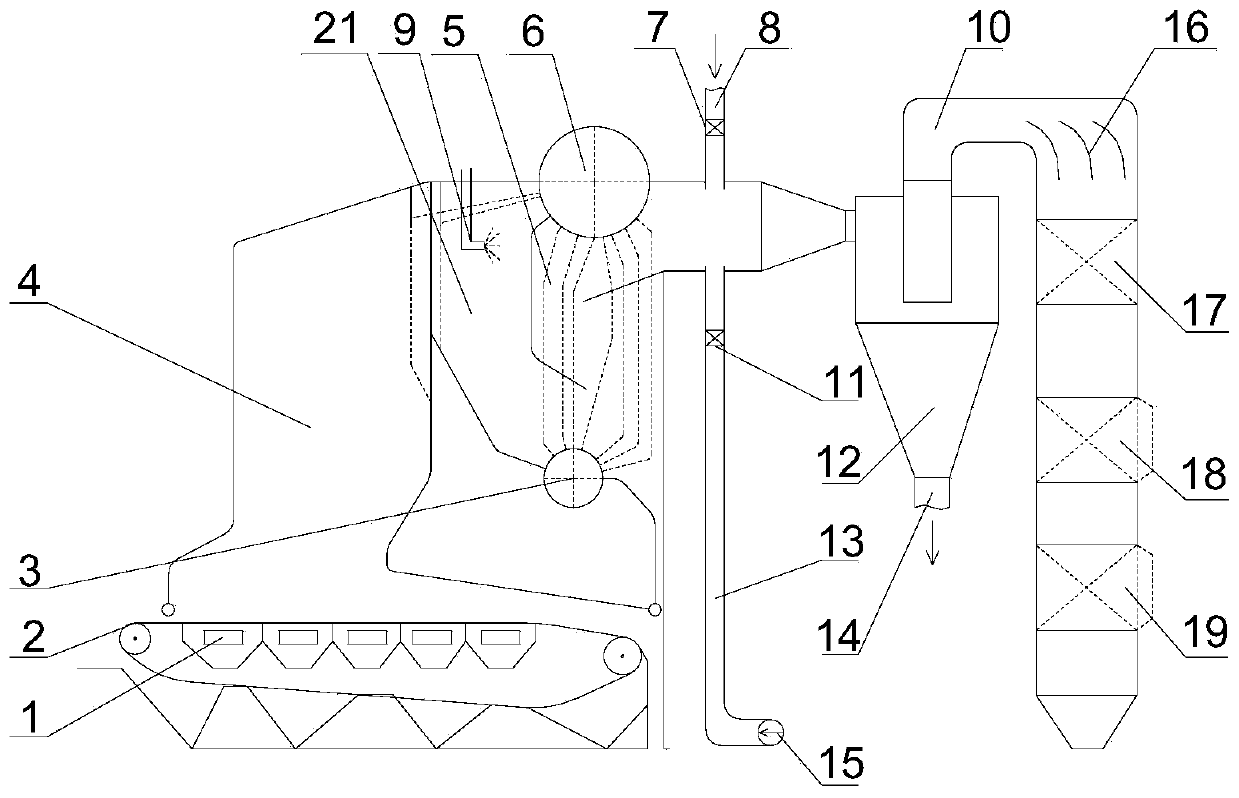

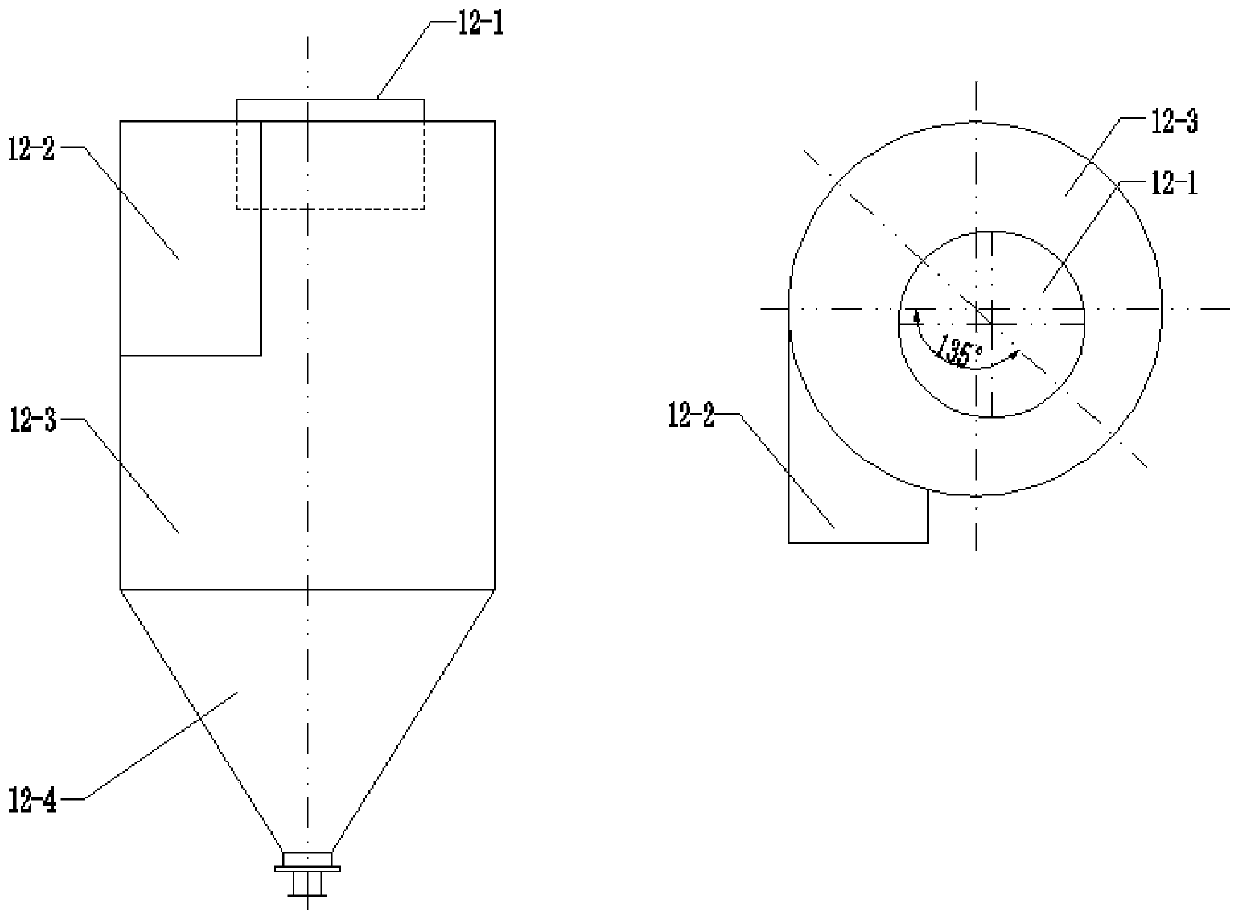

System and process for coal seam permeability improvement by inducing hole drilling extraction later-period gas burning explosion

ActiveCN105909302ALong extraction cycleIncrease extraction concentrationGas removalWater dischargeEngineering

The invention relates to a system and process for coal seam permeability improvement by inducing hole drilling extraction later-period gas burning explosion. The left end of a connecting pipe (2) is connected with a first gas extraction pipe (1); the right end of the connecting pipe is connected with a sealed gas extraction drilling hole (17); a third electromagnetic valve (8) is arranged on a water conveying pipe (10); a water discharging pipe (13) is arranged on a pipeline for connecting the third electromagnetic valve and the connecting pipe; a fourth electromagnetic valve (9) is arranged on the water discharging pipe; a first electromagnetic valve, a second electromagnetic valve, the third electromagnetic valve, the fourth electromagnetic valve, a temperature sensor, a methane sensor and a carbon monoxide sensor are connected with an intelligent controller (12) through connecting wires (11); and an electric spark igniter (14) is connected with an external power supply switch through a conducting wire. The system has the advantages that the operation is simple; the real-time monitoring can be realized; the manual coal seam burning explosion permeability improvement induction is realized; the gas permeability of a coal seam can be improved in a short time; and the problems of high-gas low-permeability coal seam gas extraction difficulty and fast extraction concentration reduction are solved.

Owner:CHINA UNIV OF MINING & TECH +1

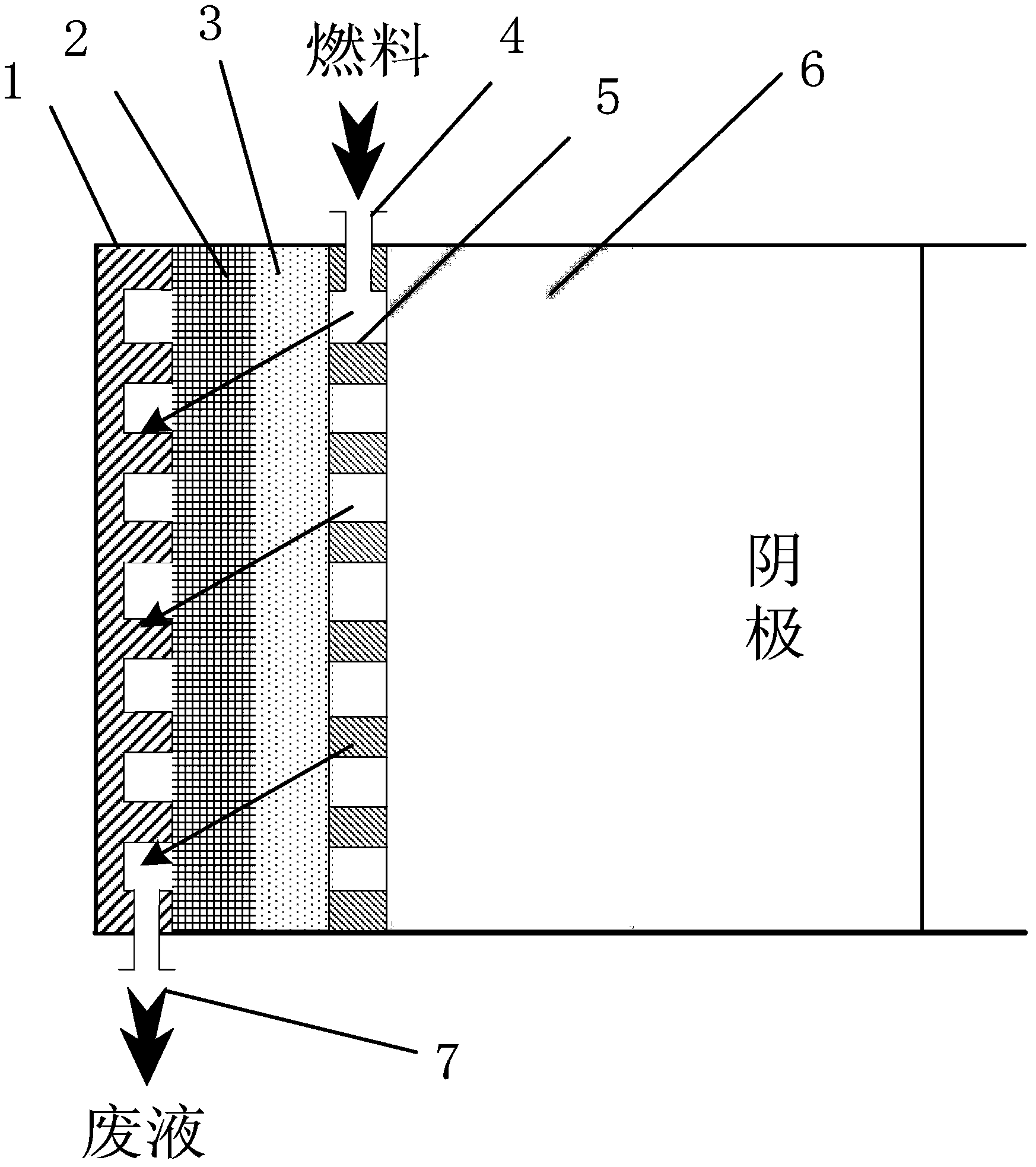

Direct alcohol fuel cell electrode with internal flow field

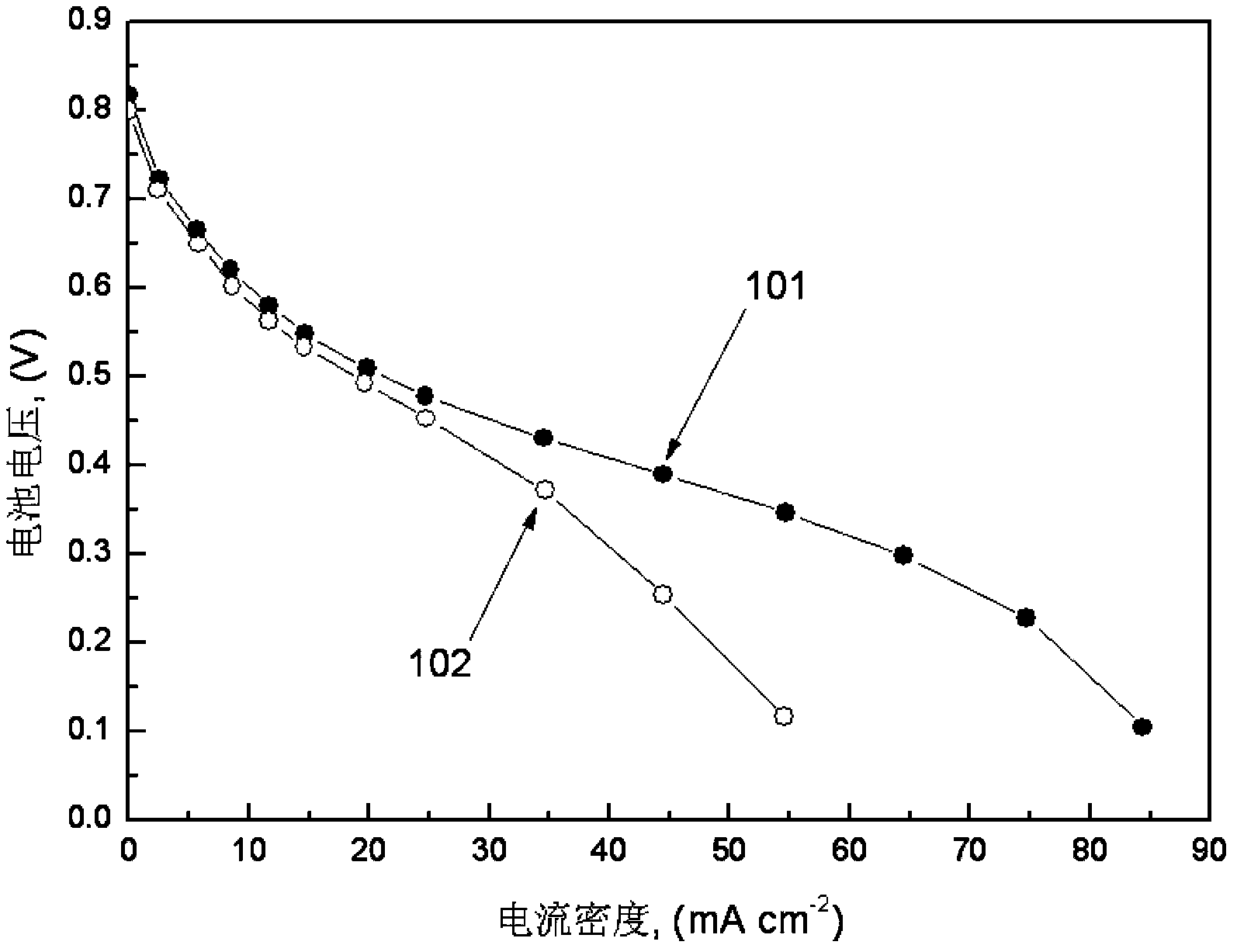

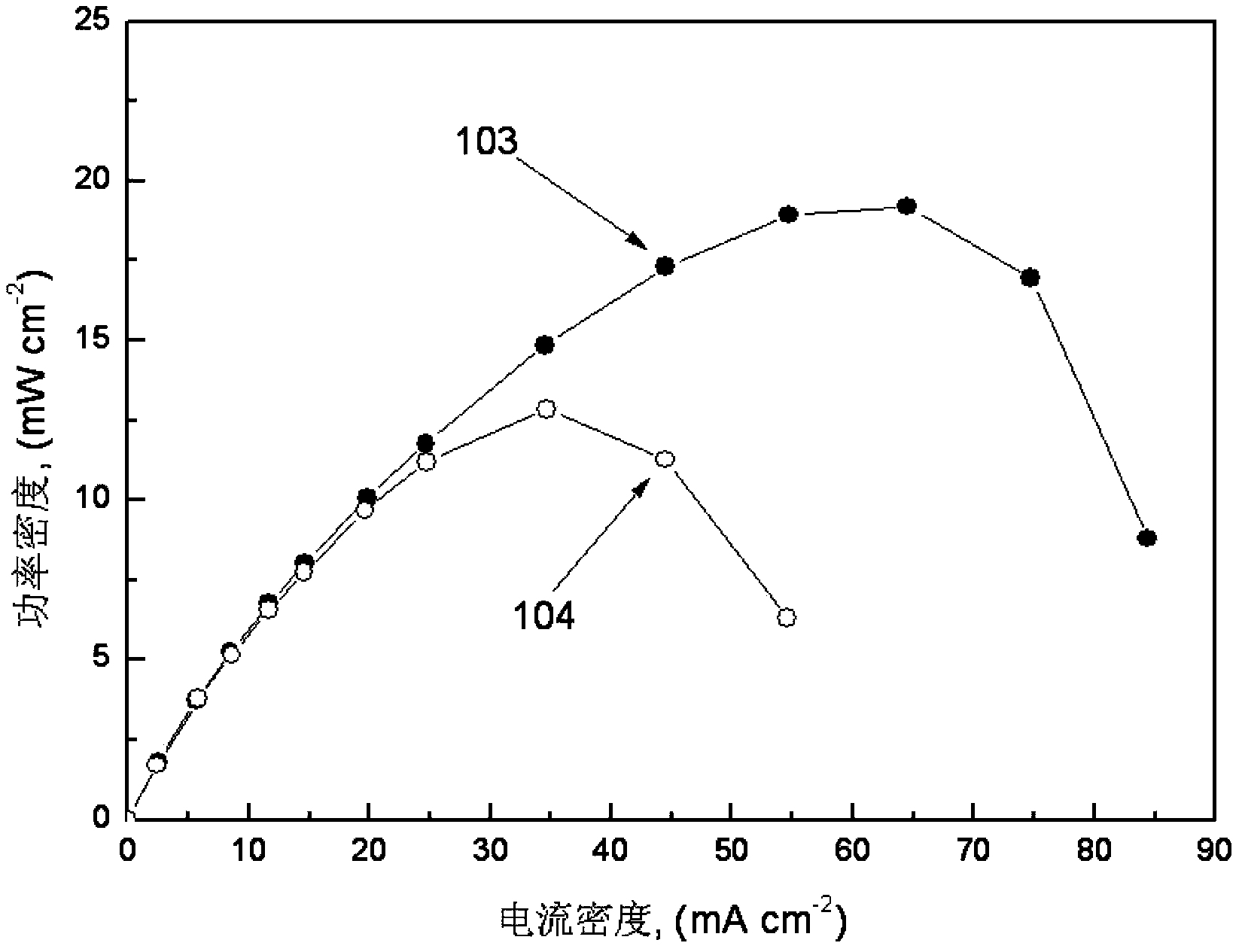

ActiveCN103367774AImprove conductivityUniform concentration distributionCell electrodesFuel cell detailsCounter currentMixed fuel

The invention belongs to the field of fuel cells, and relates to a direct alcohol fuel cell electrode with an internal flow field, which has the advantages that fuel transfer resistance is small, electrolyte concentration in a diaphragm is high, concentration distribution of reactants is uniform, and discharge property is good. The direct alcohol fuel cell electrode comprises a flow field, a diffusion layer, catalysis layers and the diaphragm, wherein the diffusion layer, the catalysis layers and the diaphragm are sequentially arranged from outside to inside, the internal flow field with a fuel inlet is arranged between the catalysis layers and the diaphragm to ensure that a mixed fuel firstly enters the internal flow field; because the internal flow field is in contact with the diaphragm, the concentration of the electrolyte in the diaphragm is high, thus the conductivity of the diaphragm is increased; a mixture of the internal flow field enters the catalysis layers and generates a chemical reaction between the catalytic layers, products obtained after the reaction penetrate through the diffusion layer to reach an external flow field for being discharged. Due to a downstream conveying mode of the reactants and the products, the defects of uneven distribution of fuels upstream and downstream, large transfer resistance of the fuels, low concentration of the electrolyte in the diaphragm, and the like in a countercurrent conveying mode adopted by a conventional process are overcome, the cell property is greatly improved, and a good application prospect is achieved.

Owner:XIAN ACTIONPOWER ELECTRIC

Tangential gas intake desulfurization tower of semi-dry circulating fluidized bed

InactiveCN101612523AUniform concentration distributionIncreased turbulence intensityDispersed particle separationChemical/physical processesFluidized bedFlue gas

The invention relates to a tangential gas intake desulfurization tower of flue gas desulfurization technology of a semi-dry circulating fluidized bed. The tower is characterized in that: a flue gas intake structure is tangentially connected with the desulfurization tower, a desulfurizer inlet is positioned at the central position of the bottom of the desulfurization tower, a feed back inlet is positioned at the lower part of the desulfurization tower and a flue gas outlet is positioned at the top of the desulfurization tower. The tangential gas intake desulfurization tower has the advantages of causing the flue gas to form strong rotating flow in the desulfurization tower, improving turbulent intensity of gas flow, maintaining full contact between a desulfurizer and the flue gas, and intensifying desulfurization reaction process and greatly improving the utilization ratio of the desulfurizer; and the tangential flue gas intake structure can help effectively lower pressure drop of the system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

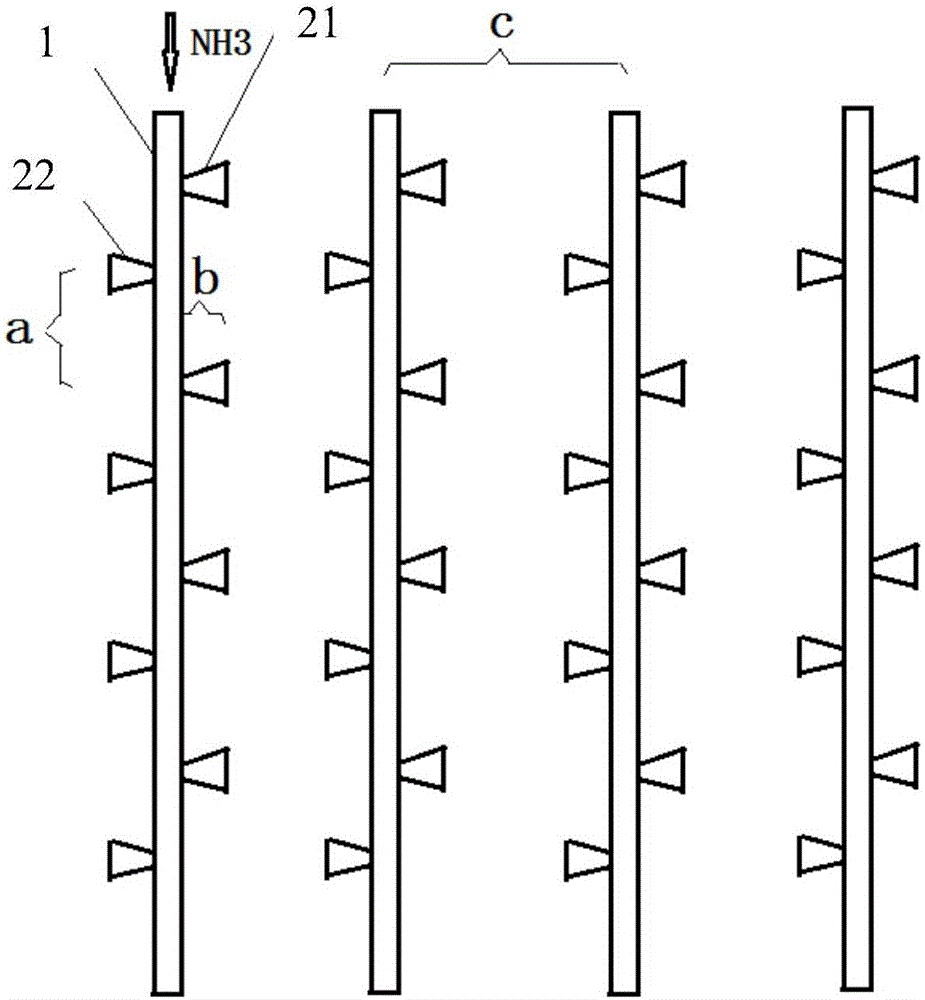

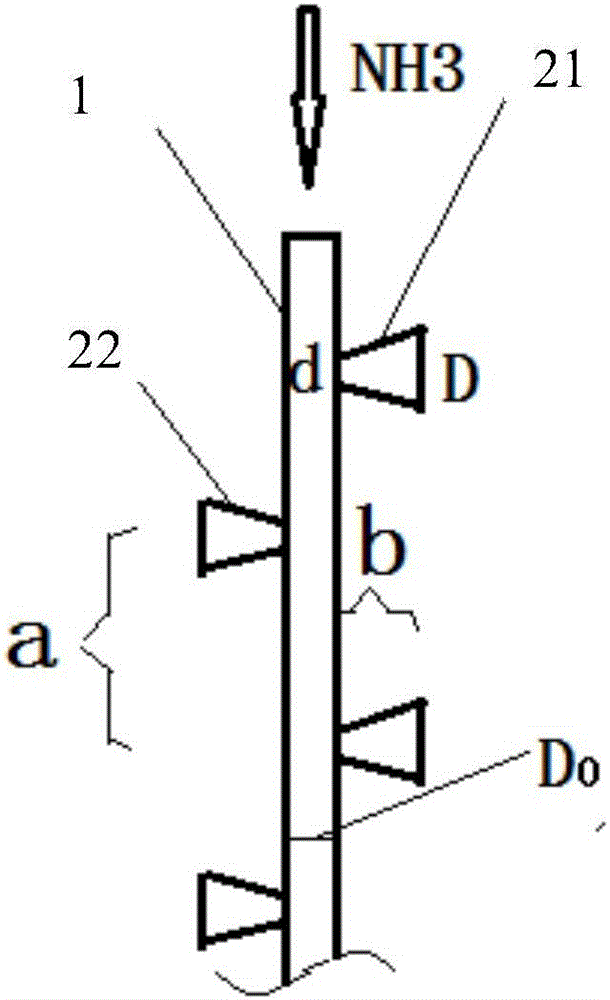

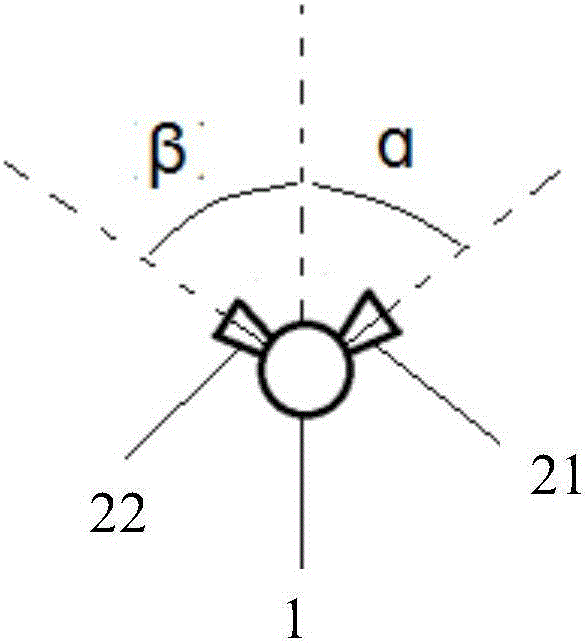

Ammonia spraying grating device

PendingCN106823797AFacilitated Diffusion MixingImprove concentration field distributionGas treatmentDispersed particle separationFlue gasPhysical chemistry

The invention discloses an ammonia spraying grating device, which comprises multiple ammonia spraying main pipes (1) and multiple ammonia spraying branch pipes, wherein the multiple ammonia spraying main pipes (1) are arranged in parallel in the same section perpendicular to the flow direction of a flue gas; the multiple ammonia spraying branch pipes are communicated with the ammonia spraying main pipes (1); the ammonia spraying main pipes (1) are provided by multiple jet holes; the ammonia spraying branch pipes are perpendicularly inserted into the ammonia spraying main pipes respectively through the jet holes; an ammonia gas is diffused and sprayed out from the ammonia spraying main pipes through the ammonia spraying branch pipes to be mixed with the flue gas. The ammonia spraying grating device provided by the invention can be used for effectively promoting the diffusion mixing between the ammonia gas and the flue gas, ameliorating the distribution of the concentration field of the ammonia gas and improving reaction efficiency; the mixed ammonia gas is sprayed out from the ammonia spraying main pipes through the ammonia spraying branch pipes; the effect that the mixed ammonia gas is subjected to diffusion through the ammonia spraying branch pipes is obvious; the sprayed out ammonia gas can be sufficiently mixed with the flue gas through a short distance; the concentration distribution of the ammonia gas is quite uniform.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

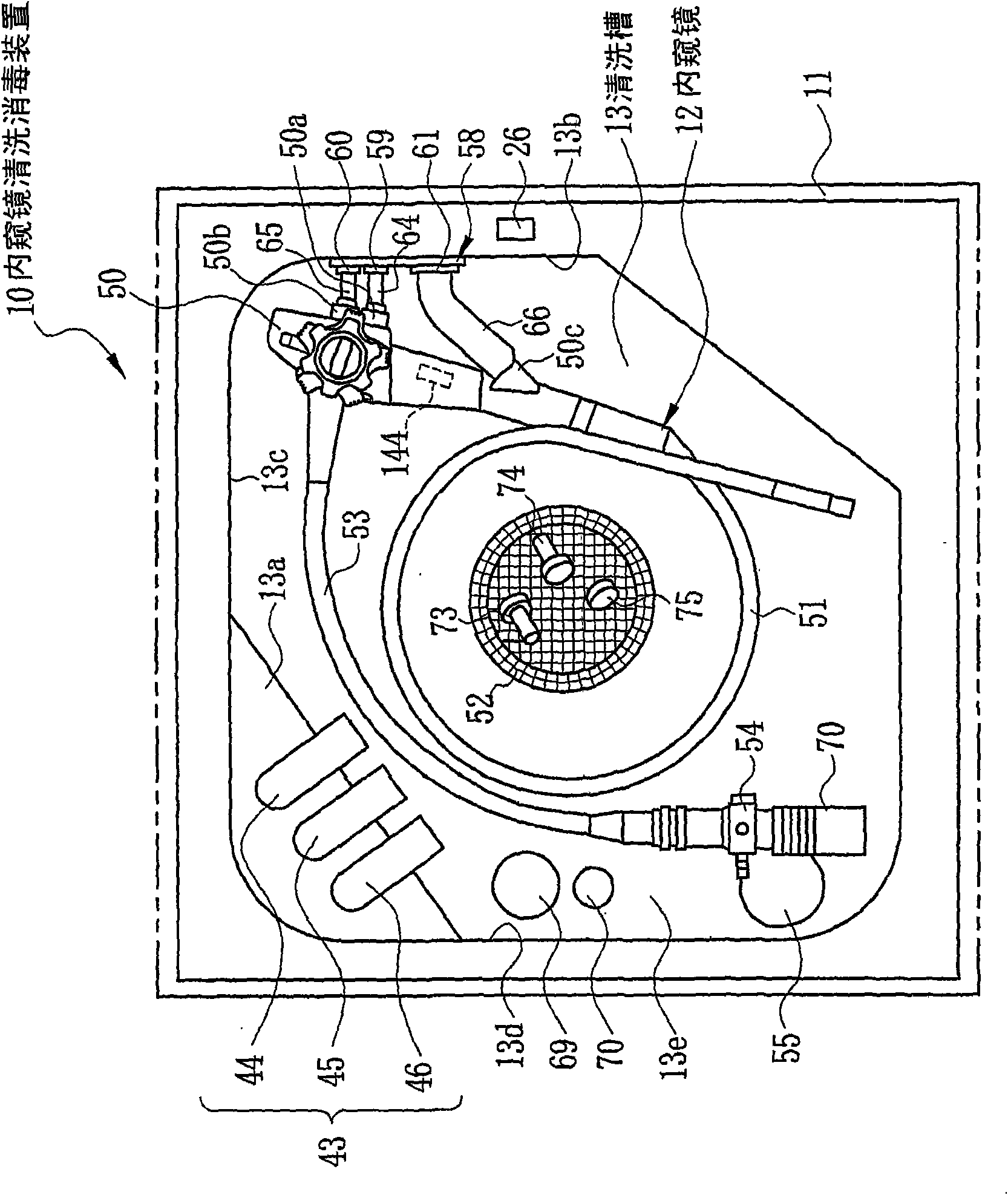

Endoscope cleaning and disinfecting device and method for preparing disinfection liquid used for the endoscope cleaning and disinfecting device

The invention provides an endoscope cleaning and disinfecting device and a method for preparing disinfection liquid used for the endoscope cleaning and disinfecting device, reduces the odor of peracetic acid leaked from bottle when replacing disinfection liquid. In the invention, a first bottle (39) containing peracetic acid condensed liquid (132) is installed in a first bottle installation unit (108); the condensed liquid (132) flows through a condensed liquid injection path (110), and is supplied to a disinfection liquid can (87); when a condensed liquid sensor (118) detects the condensed liquid (132) surface, bottle cleaning fluid (136) is injected from a bottle cleaning nozzle (112) to the first bottle (39); and the bottle cleaning fluid in the first bottle (39) is supplied to the disinfection liquid can (87) through the condensed liquid injection path (110). Thus, the condensed liquid (132) is diluted by water, i.e. the bottle cleaning fluid (136), and prepared into the disinfection liquid (86) with predetermined concentration.

Owner:FUJIFILM CORP

N type fin type field effect transistor and formation method thereof

InactiveCN105448986AImprove the ability to resist punch-throughEnhanced resistance to penetrationSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorSemiconductor

An N type fin type field effect transistor and a formation method thereof. The formation method of N type fin type field effect transistor includes the following steps: a semiconductor substrate is provided which has a protruding fin part, the fin part includes a bottom region and an upper region which are adjacent to each other, and the bottom region is located under the upper region; an ion implantation technology is performed, B ions and F ions are implanted into the fin part, and an implantation region is formed in the bottom region of the fin part; after the ion implantation technology, an annealing process is performed, the B ions and F ions in the implantation region are activated, and a doping region is formed in the bottom region of the fin part; after the annealing process is performed, a gate structure which stretches across and covers surfaces of side wall and top parts of the fin part is formed; and a source region and a drain region are formed in the fin part at two sides of the gate structure. The method provided by the invention improves a capability of resisting source leakage punchthrough of the fin type field effect transistor by preventing diffusion of boron ions in the doping region.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Tangential double vortex SCR mixer

ActiveCN103933858AReduce escape rateSolve the problem of insufficient reconstruction space and insufficient ammonia mixing distanceFlow mixersDispersed particle separationEscape rateFlue gas

The invention discloses a tangential double vortex SCR mixer. The mixer comprises a flue, the cross section of the flue is equidistantly provided with a support beam, the support beam divides the cross section of the flue into a plurality of mixer unit zones, the mixer unit zones comprises a mixer unit, the mixer unit comprises a group of trapezoidal plates, a group of nozzles, the support beam and support rods, the bottom edges of the trapezoidal plates are connected with the support beam, one ends of the support rods are fixed on the trapezoidal plates, the other ends of the support rods are fixed on the inner wall of the flue in order to form a certain angle between the support rods and flue gas, each of the nozzles is arranged between adjacent trapezoidal plates, and the nozzles of the group share a gas supply pipeline. The mixer makes a reducing agent to reach a catalyst upper layer and to be uniformly distributed, so the ammonia escape rate of ammonia at an SCR outlet is reduced, and the denitration efficiency is improved, thereby problems of insufficient reconstruction space and insufficient ammonia mixing distance of service sets in a power plant are effectively solved.

Owner:SOUTHEAST UNIV +1

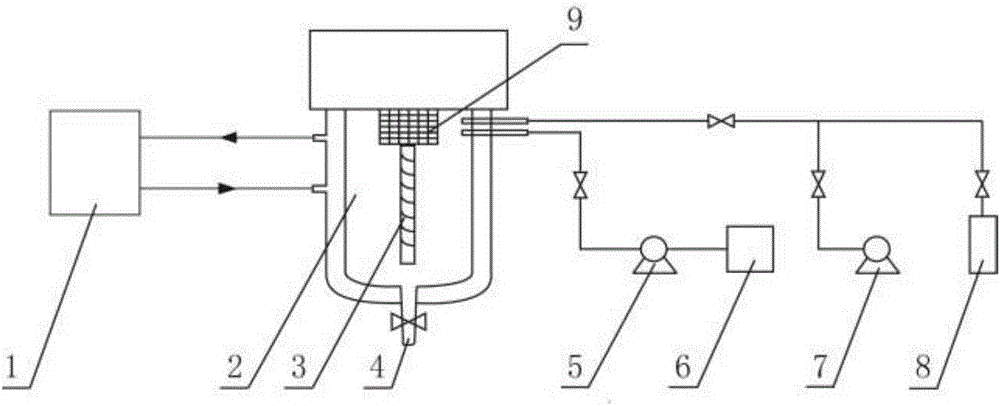

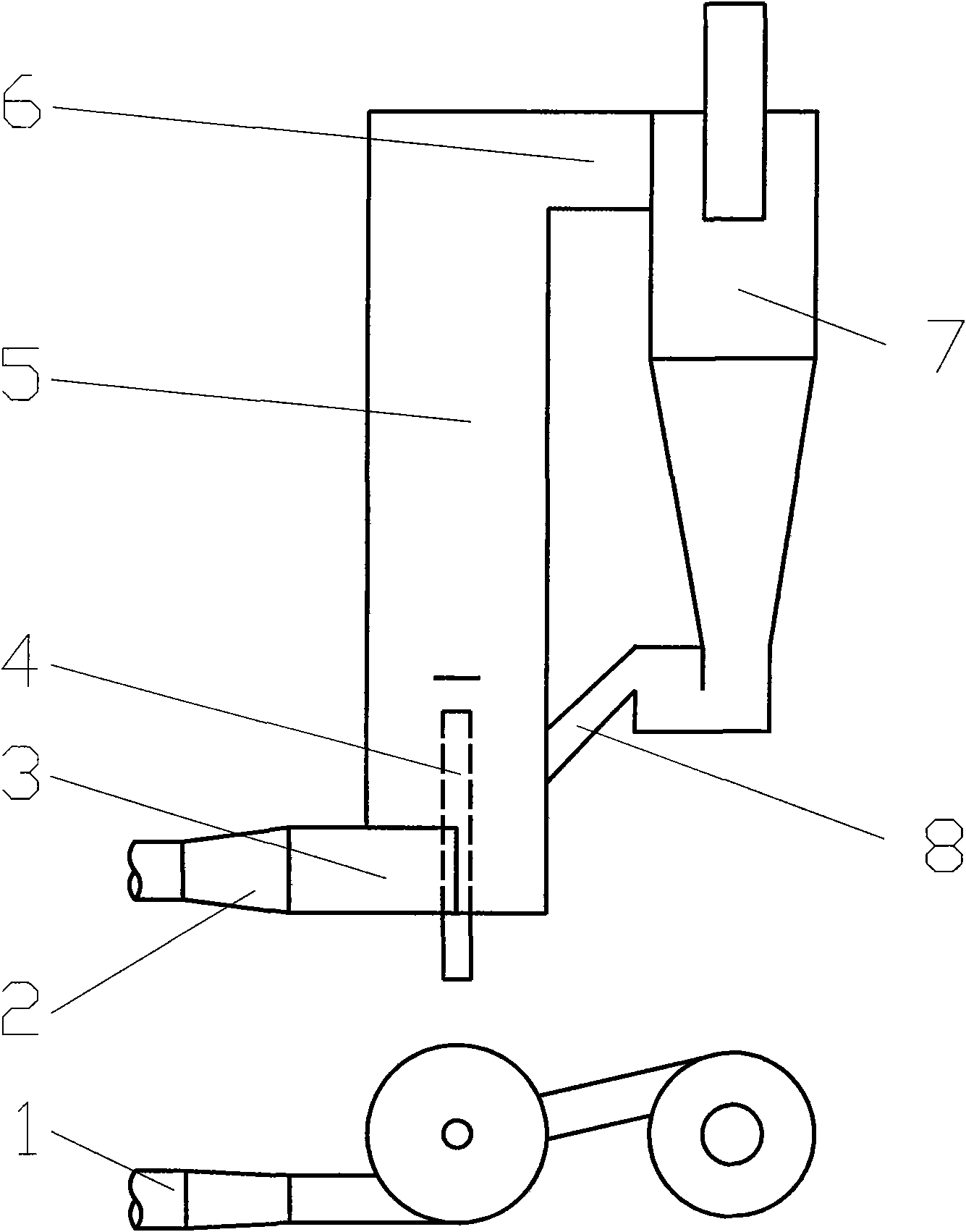

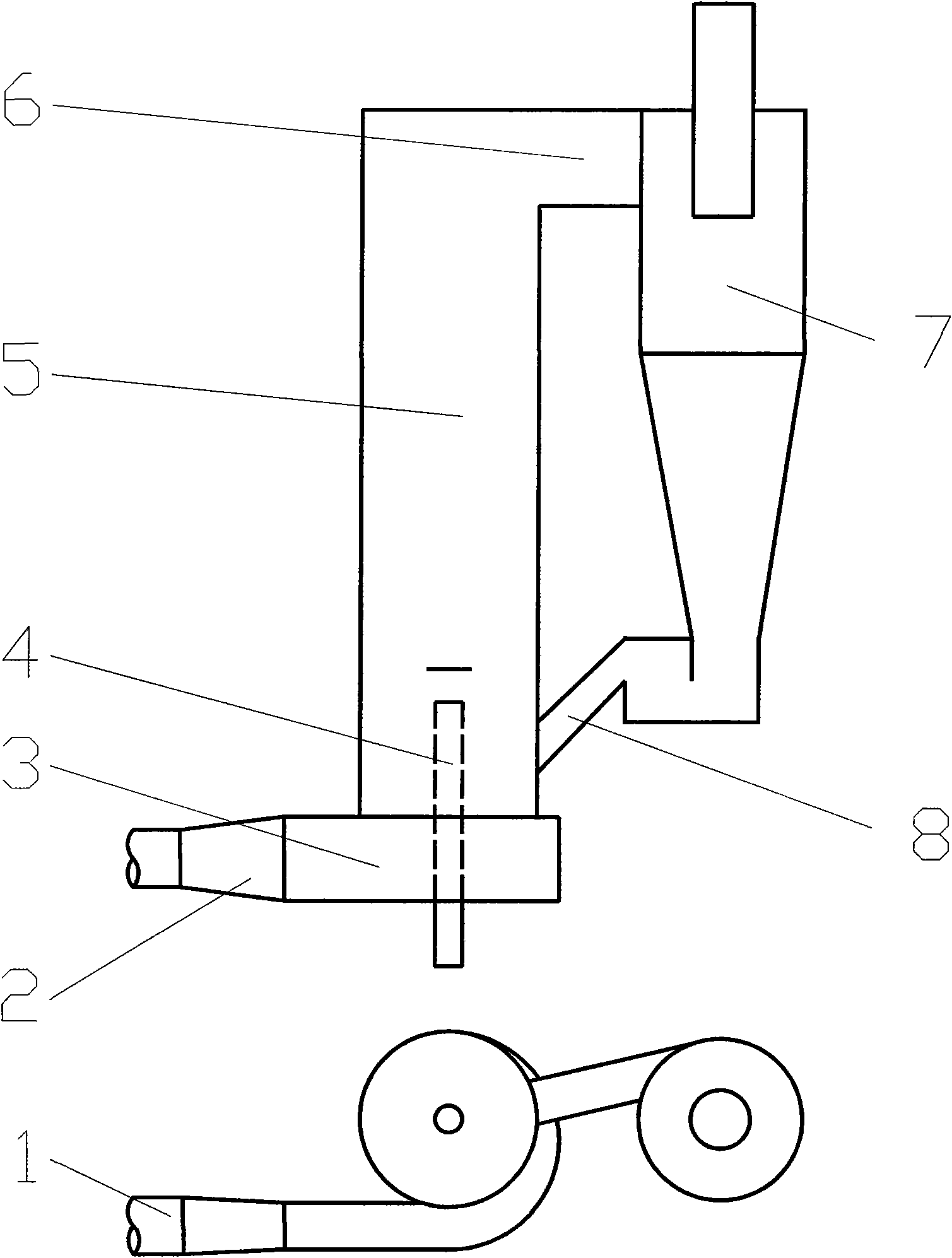

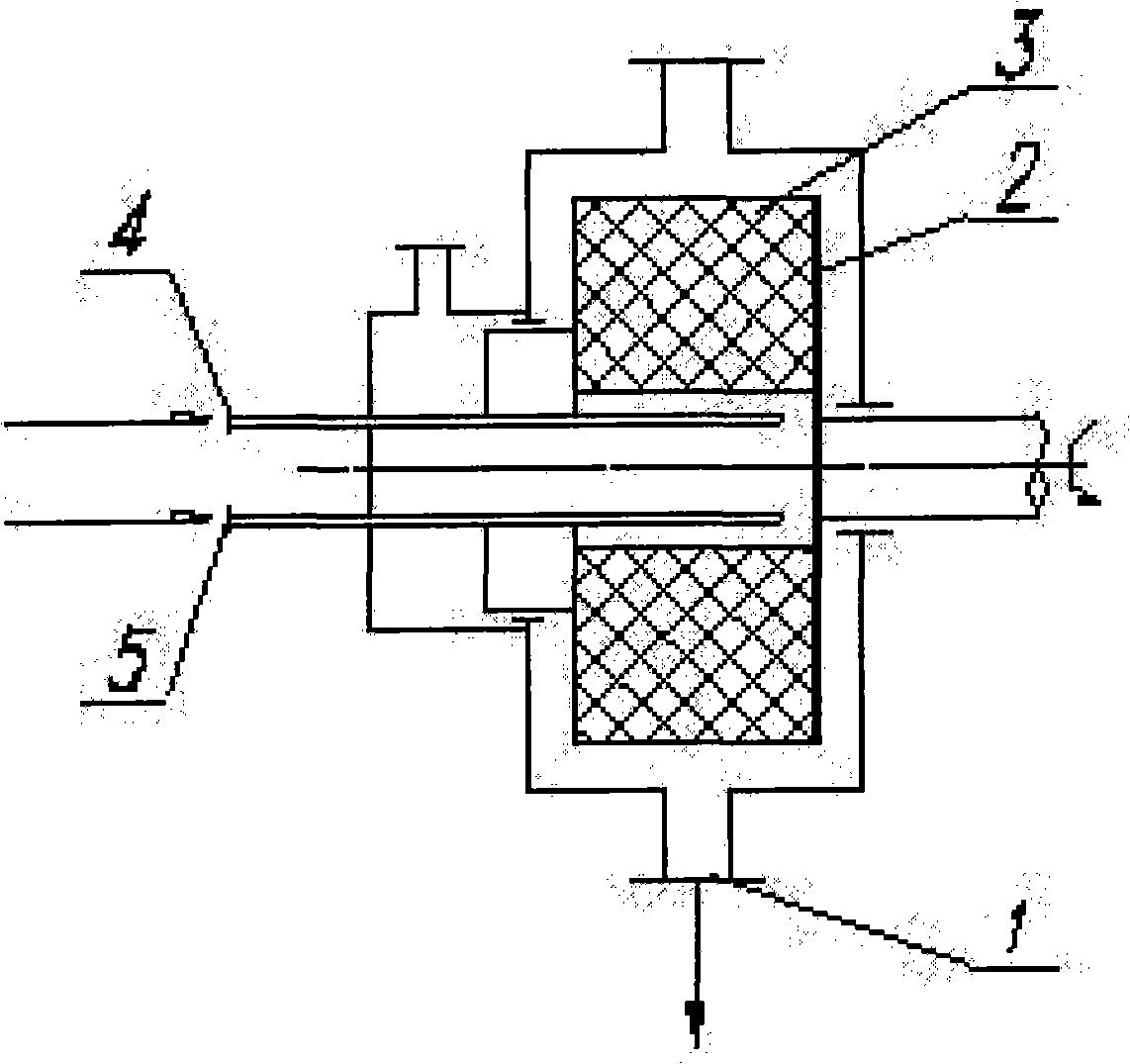

Method of preparing ultra-fine danazol powder

InactiveCN101292958AFine granularityUniform compositionPowder deliveryOrganic active ingredientsUltra fineDesolvation

A preparation method of ultra-fine danazol powder belongs to the method of drug micronization. The method is that danazol solution and desolvation are first put into a supergravity rotating bed through a solution entrance 4 and a desolvation entrance 5 respectively at the same time, and the recrystallized danazol paste by the desolvation flows out from a discharge hole 1; the danazol paste is collected, filtered and dried to obtain the ultra-fine danazol powder. The method can obtain the ultra-fine danazol powder of controlled average grain size, controlled shape and narrow grain size distribution.

Owner:BEIJING UNIV OF CHEM TECH +1

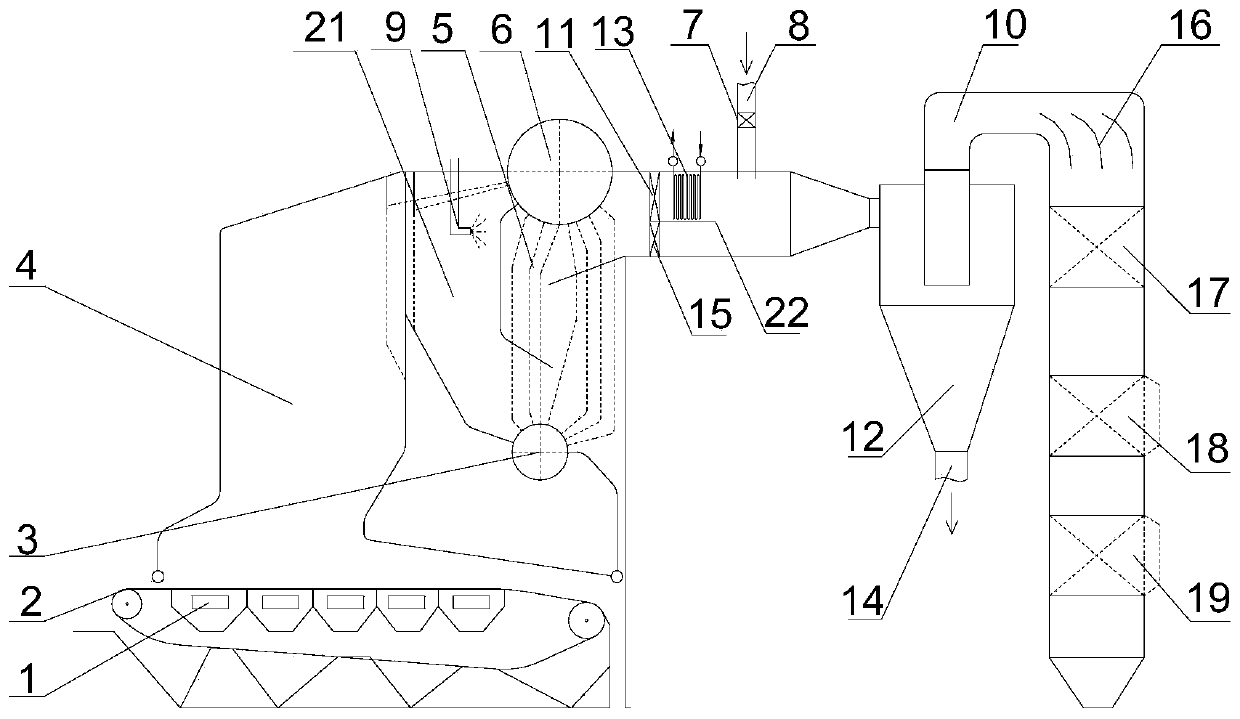

SCR inlet flue gas pre-treatment system and method

PendingCN110038433AUniform sectionSection NH

<sub>3</sub>

evenly distributedDispersed particle separationSolid fuel combustionAir preheaterHandling system

The invention relates to an SCR inlet flue gas pre-treatment system and method, relates to boiler pollutant control technology, and are used for new construction or renovation projects of ultra-cleanNOx emission of grate-firing coal-fired boilers. The SCR inlet flue gas pre-treatment system comprises a temperature regulating system, a urea solution or ammonia water solution ejector, and a cycloneequalization system. The system adopts a heating way of extracting high-temperature flue gas from a hearth outlet and then introducing the high-temperature flue gas into a cyclone tube, and a coolingway of adding a temperature-regulating economizer or extracting low-temperature flue gas from flue gas at a boiler dust collector outlet or an air preheater outlet and then introducing the low-temperature flue gas into the cyclone tube through a cold flue, and the average temperature of SCR inlet flue gas is controlled within the working range of catalysts. A urea solution is ejected in a burnoutchamber through the urea solution ejector; an ammonia water solution is ejected at an inlet pipe of a cyclone separator through the ammonia water solution ejector; NH3 is produced under the action ofthe high-temperature flue gas and mixed into the flue gas. Under the combined action of a flow equalization board and the cyclone tube, the flue gas and NH3 are mixed uniformly to achieve the effectsof equal temperature, equal concentration field and equal velocity, thereby meeting the requirements on the temperature, concentration field and velocity field at an SCR inlet.

Owner:HARBIN INST OF TECH

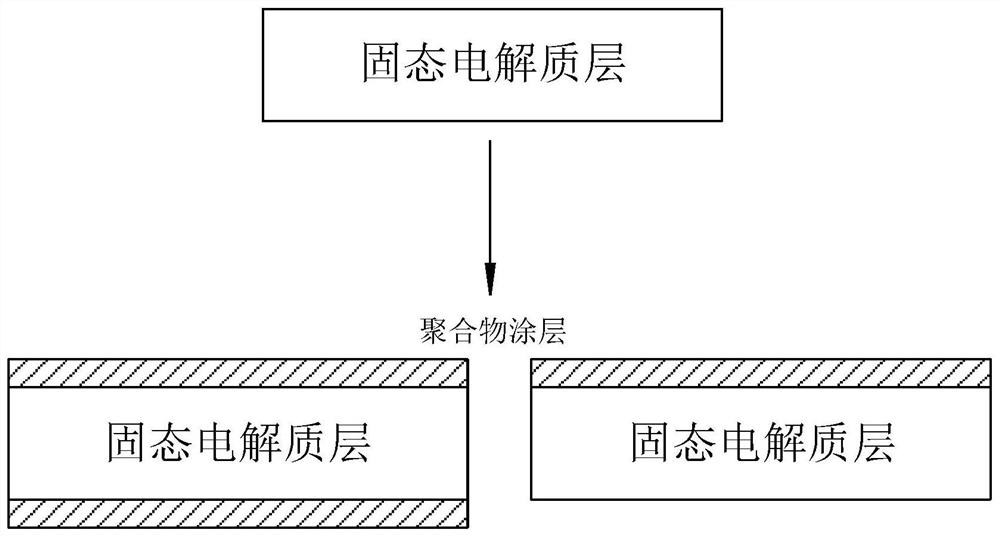

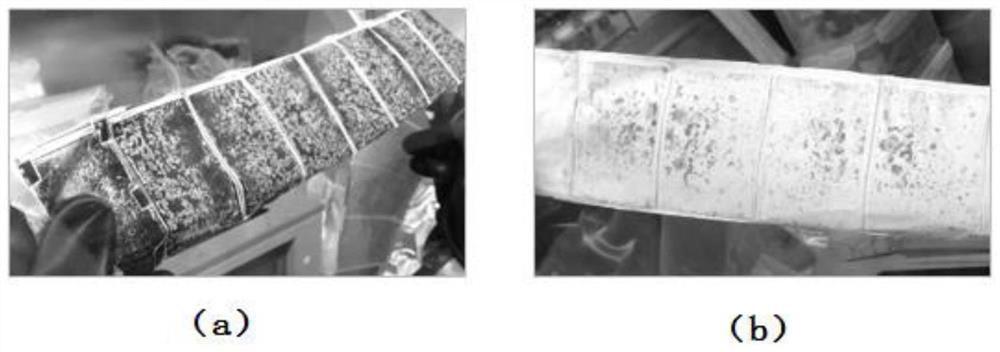

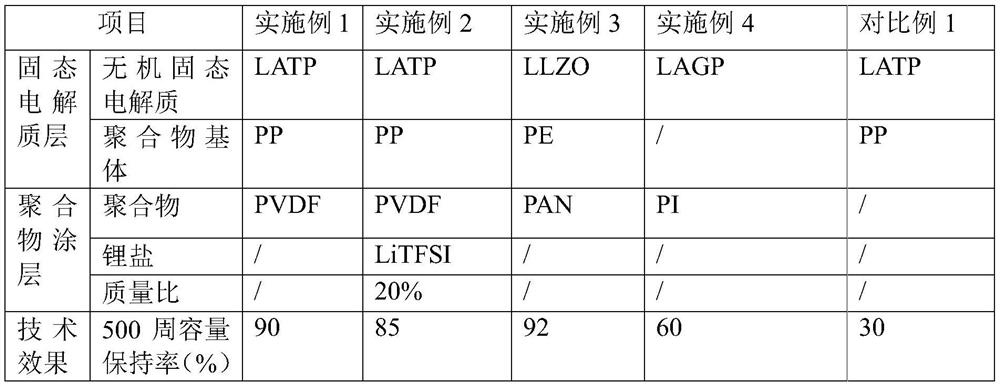

Composite electrolyte membrane, preparation method and application thereof, and solid-state lithium battery

ActiveCN112838266AImprove performanceImprove solid-solid contact problemsSolid electrolytesSecondary cells servicing/maintenanceSolid state electrolyteComposite electrolyte

The invention discloses a composite electrolyte membrane, a preparation method and application thereof, and a solid-state lithium battery. The composite electrolyte membrane comprises a solid electrolyte layer, wherein one side or two sides of the solid electrolyte layer are coated with a polymer coating; the solid electrolyte layer includes an inorganic solid electrolyte. The composite electrolyte membrane can reduce interface resistance, inhibit interface side reaction and relieve lithium deposition; the solid-state lithium battery based on the composite electrolyte membrane is good in cycle performance and good in safety.

Owner:SHANGHAI ELECTRICGROUP CORP

Formation method of fin-type field effect transistor

ActiveCN106856170ASpread evenlyEvenly distributedSemiconductor/solid-state device manufacturingSemiconductor devicesImpurity ionsEngineering

The invention provides a formation method of a fin-type field effect transistor. The method comprises: a semiconductor substrate is provided and a protruding fin part is formed on the semiconductor substrate; a gate structure stretching across and covering the side wall of the partial fin part and the top surface is formed; the fin part at the two sides of the gate structure is etched to form grooves; sacrificial layers doped with impurity ions are formed on the side walls and the bottom surface of the grooves; annealing is carried out on the sacrificial layers doped with impurity ions and thus the impurity ions in the sacrificial layers are diffused in the fin part in contact with the grooves to form a doping region; and then the sacrificial layers are removed. With the method, the impurity ions in the doping region can be distributed uniformly and the position of the doping region becomes accurate, so that an effect of preventing hot carrier injection or preventing punchthrough between source and drain regions can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A method for forming a back-illuminated image sensor

ActiveCN109192741AReduce manufacturing costWon't hurtSolid-state devicesRadiation controlled devicesEtchingBoron containing

A method for forming a back-illuminated image sensor includes: a semiconductor substrate includes a first side and a second side opposite to the first side; Etching the semiconductor substrate on thefirst side to form a plurality of trenches in the semiconductor substrate on the first side; Forming a boron-containing silicon glass layer in the trench, the surface of the boron-containing silicon glass layer being lower than the surface of the semiconductor substrate on the first side; Performing an annealing process to diffuse boron ions in the boron-containing silicon glass layer into a semiconductor substrate between adjacent trenches to form a doping stopping layer; Filling the trench with an isolation material to form a deep trench isolation structure; Forming a pixel of an image sensor on a semiconductor substrate on a first side, the pixel sensing light incident from a second side; Using a doped stop layer and a boron-containing silicon glass layer as a stop layer to thin the semiconductor substrate from a second side of the semiconductor substrate. The doped stop layer and the boron-containing silicon glass layer are removed by wet etching. The above method is simple in process.

Owner:淮安西德工业设计有限公司

Endoscope cleaning and disinfecting device and method for preparing disinfection liquid used for the endoscope cleaning and disinfecting device

InactiveCN101564545APrevent aging and crystallizationPrevent agingLavatory sanitoryCleaning using liquidsChemistryEndoscopic washing

The invention provides an endoscope cleaning and disinfecting device and a method for preparing disinfection liquid used for the endoscope cleaning and disinfecting device, prevents the aging of disinfection liquid can and crystal precipitation caused by condensation liquid. In the invention, dilution liquid (132) is supplied to a supplied to a disinfection liquid can (87) through a dilution path (100), a second waste liquid path (96); when a dilution liquid sensor (118) detects the dilution liquid (132), the supply of the dilution liquid (132) is stopped; a bottle component (38) containing condensed disinfection liquid (134) is accepted by a bottle installation unit (108). Thus, the condensed liquid (134) does not contact the disinfection liquid can (87) directly, but is supplied to the disinfection liquid can (87) by a condensed liquid injection path (110), and is prepared into the disinfection liquid with predetermined concentration in the disinfection liquid can (87).

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com