Patents

Literature

177results about How to "Reduce escape rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

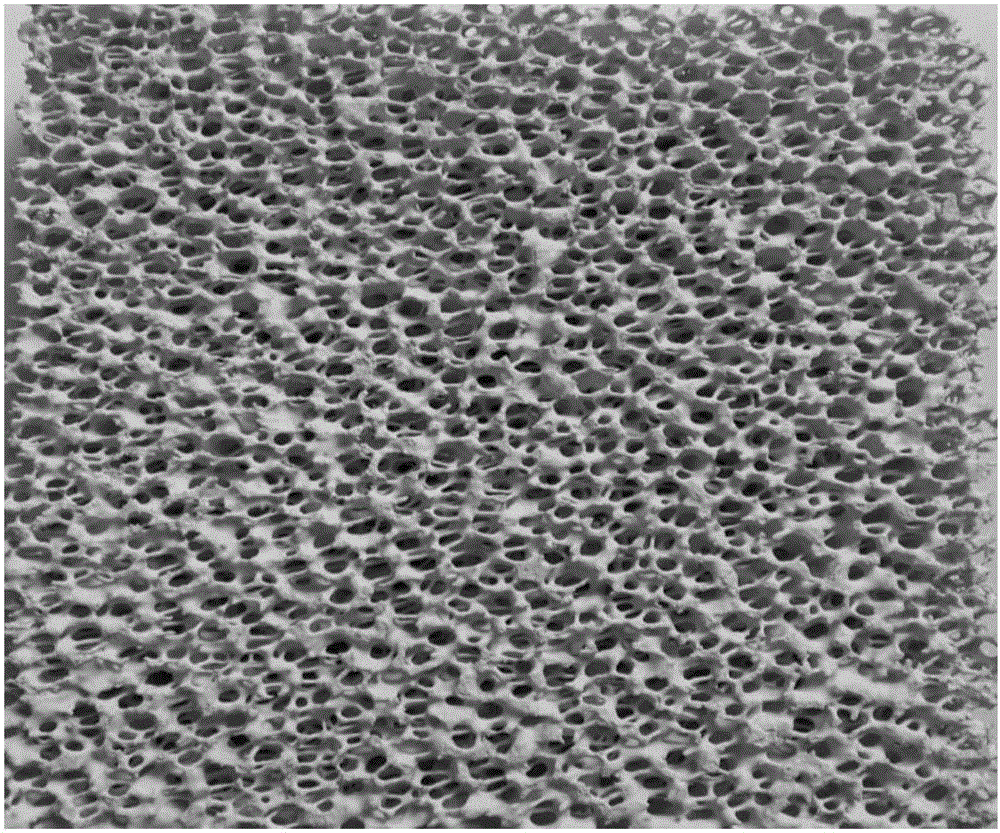

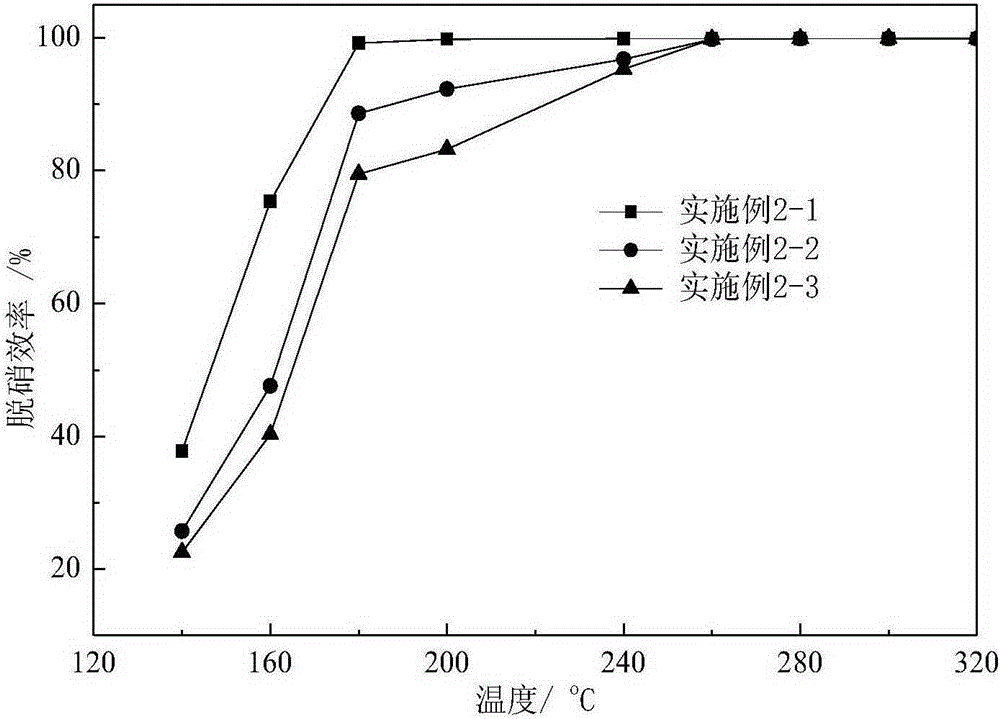

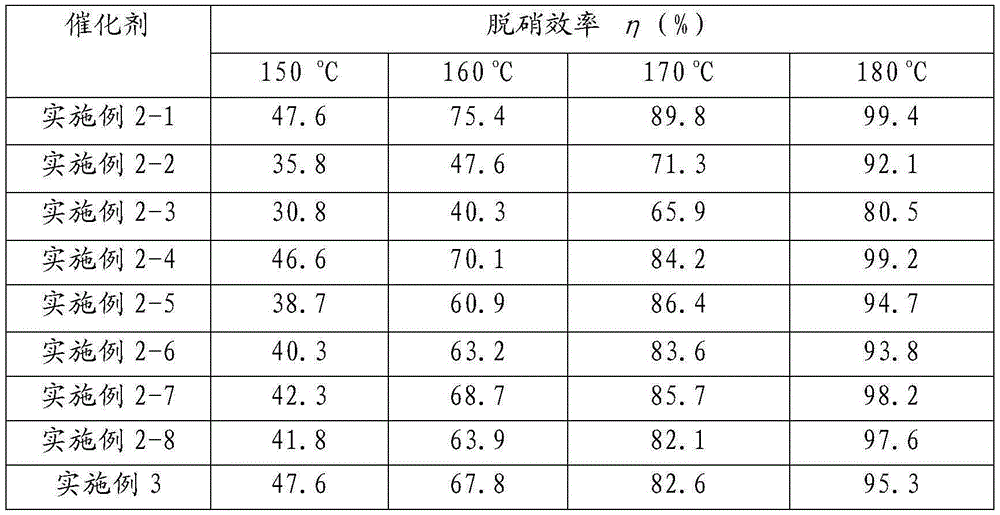

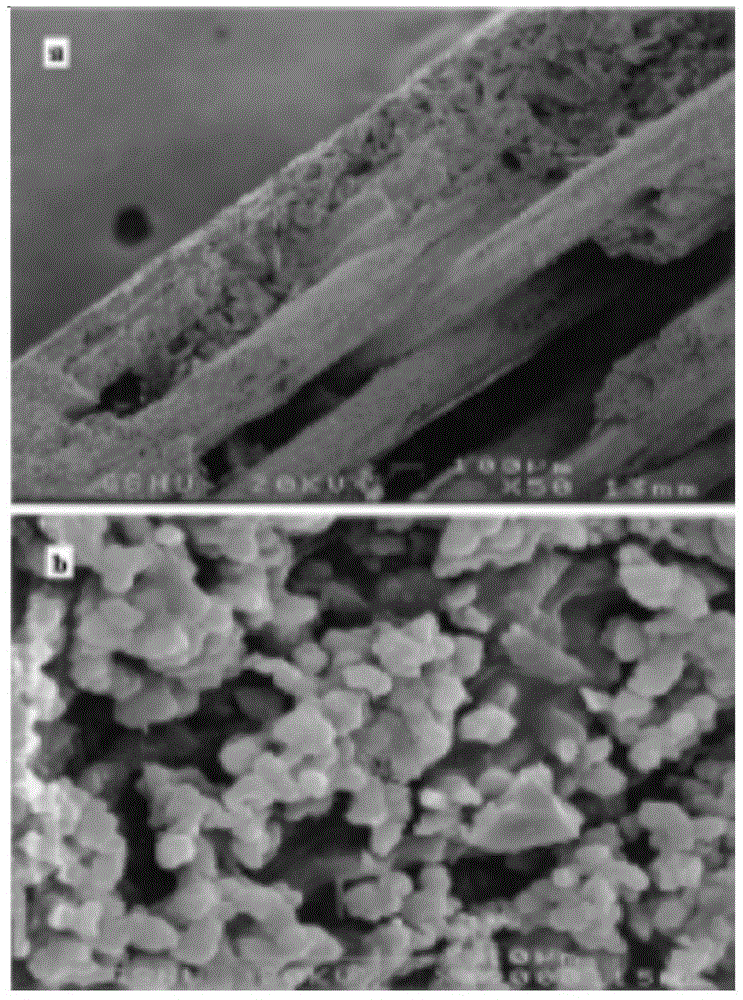

Foam-like low-temperature SCR catalyst and preparation method thereof

ActiveCN105289676AHigh low temperature activityImprove denitrification efficiencyPhysical/chemical process catalystsDispersed particle separationEngineeringReducing agent

The invention relates to a foam-like low-temperature SCR catalyst and a preparation method thereof. The catalyst is composed of a framework carrier and an active coating carried by the framework carrier. Foam ceramic of a 3D porous structure serves as the framework carrier. The active coating is composed of active components, auxiliaries and base materials. The inner portion of the foam-like low-temperature SCR catalyst is of a staggered 3D porous structure, smoke moves in ducts in a curve mode, the mixing effect of smoke and reducing agents is optimized, the utilization rate of reducing agents is increased, and ammonia escape is reduced. The catalyst has excellent low-temperature activity for NOx reduction, the removal efficiency for NOx under the condition that the smoke temperature is 170-180 DEG C is kept at 90% or above, and the catalyst has high thermal stability and sulfur-resistant capacity.

Owner:展宗城

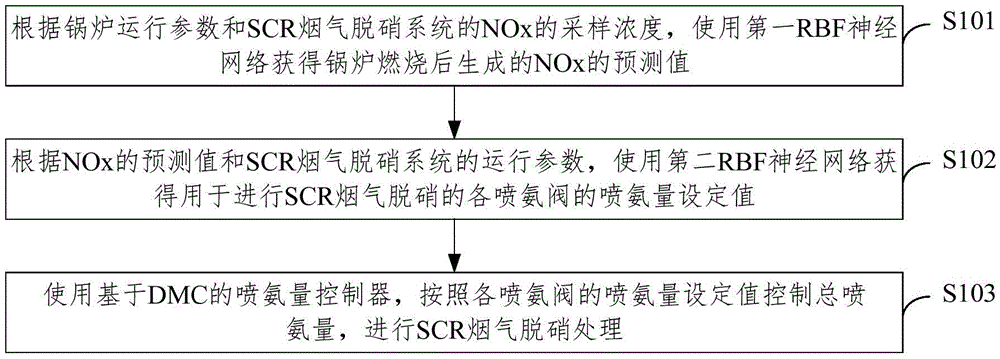

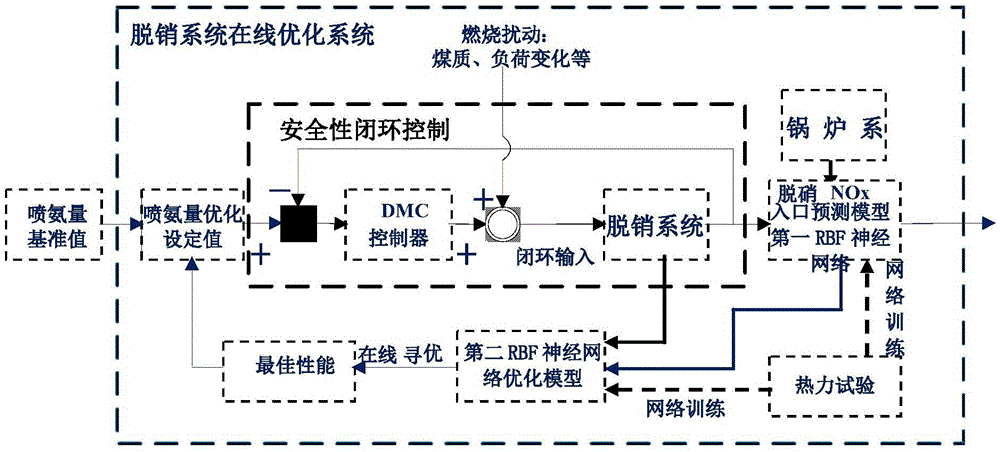

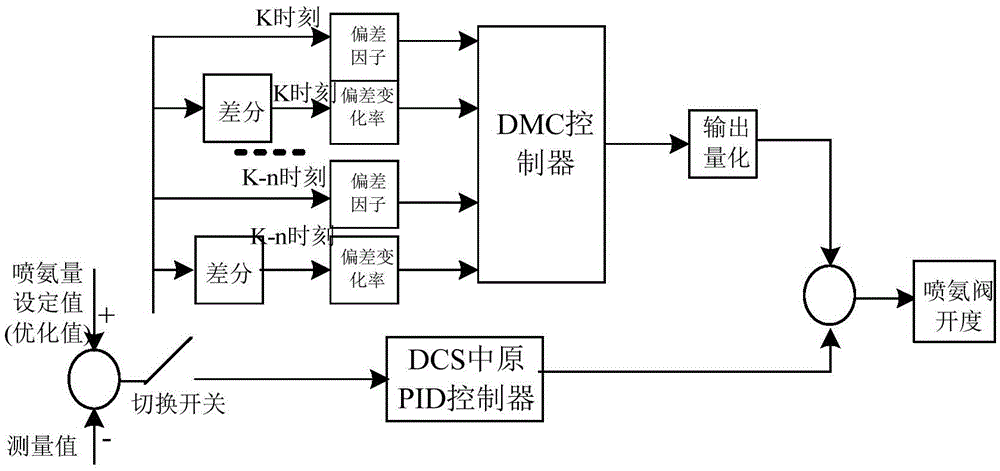

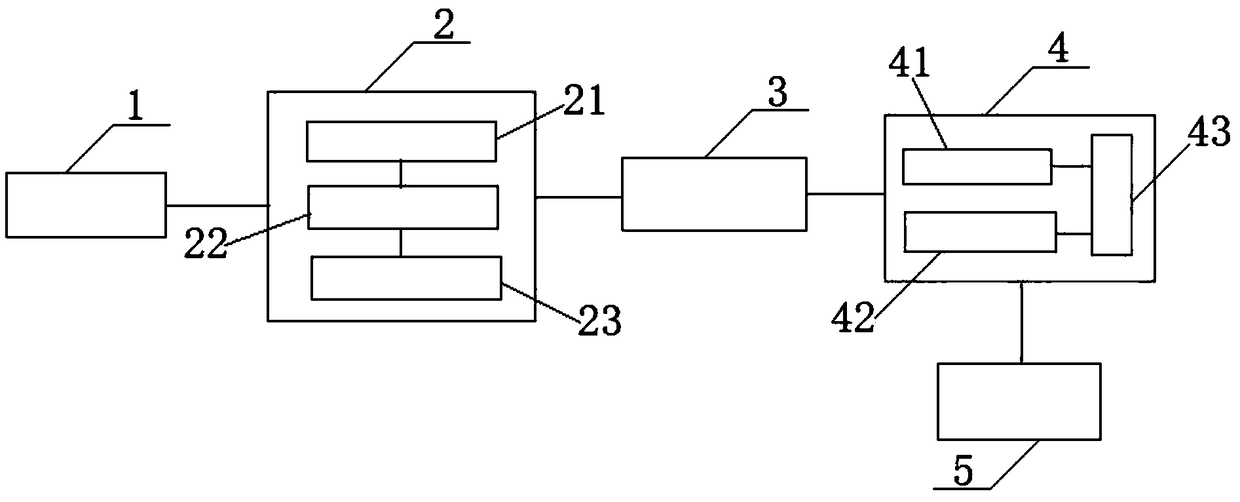

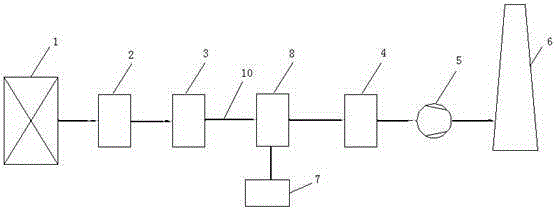

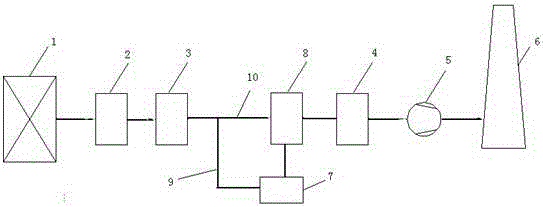

SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration system control method and apparatus. The SCR flue gas denitration system control method includes the following steps that: a first RBF neural network is adopted to obtain the predicted value of NOx generated after boiler combustion according to boiler operating parameters, the sampling concentration of NOx of an SCR flue gas denitration system; a second RBF neural network is adopted to obtain ammonia spray amount set values of ammonia spray valves for SCR flue gas denitration according to the predicted value of the NOx and the operating parameters of the SCR flue gas denitration system; and a DMC (Dynamic Matrix Control)-based ammonia spray amount controller is adopted to control total ammonia spray amount according to the ammonia spray amount set values of the ammonia spray valves so as to perform SCR flue gas denitration treatment. With the method and apparatus of the invention adopted, denitration efficiency can be effectively improved, and the escape rate of NH3 of the exit of the SCR denitration system can be reduced.

Owner:INNER MONGOLIA RUITE TECH

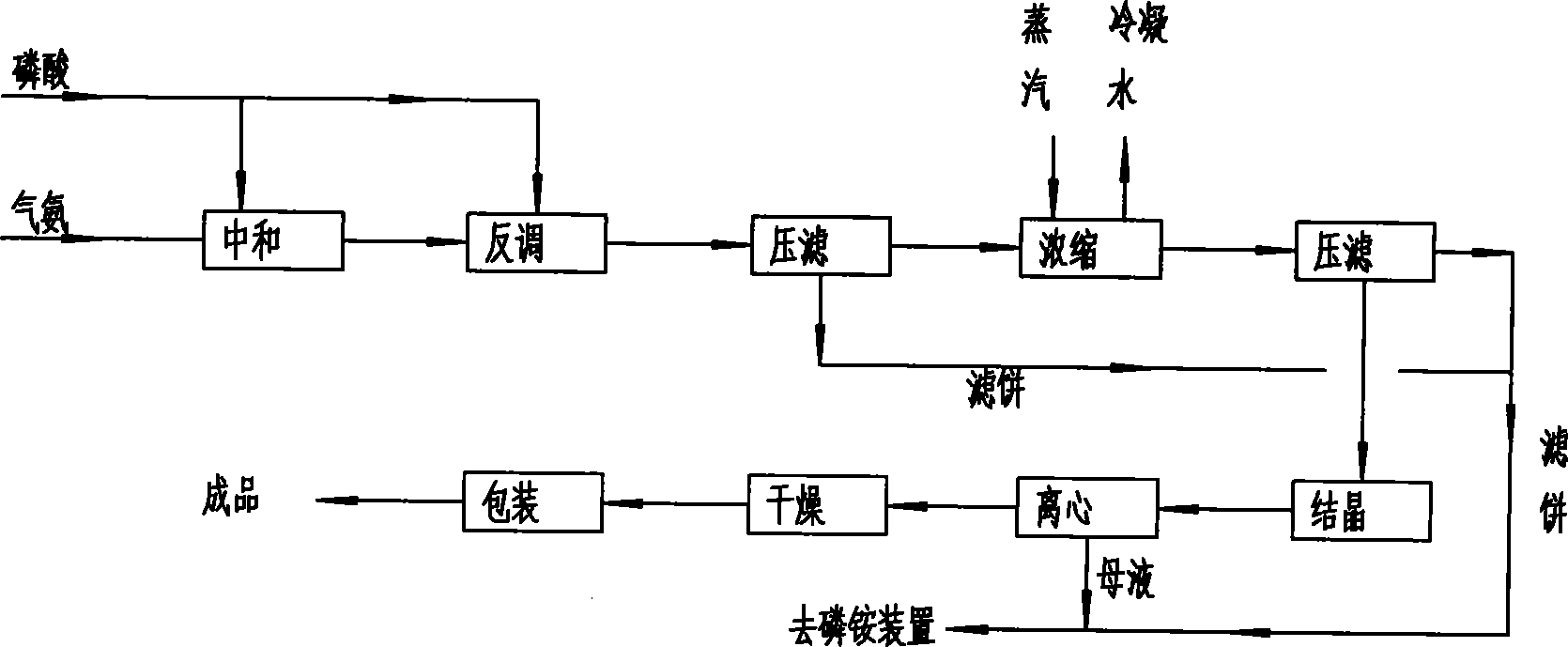

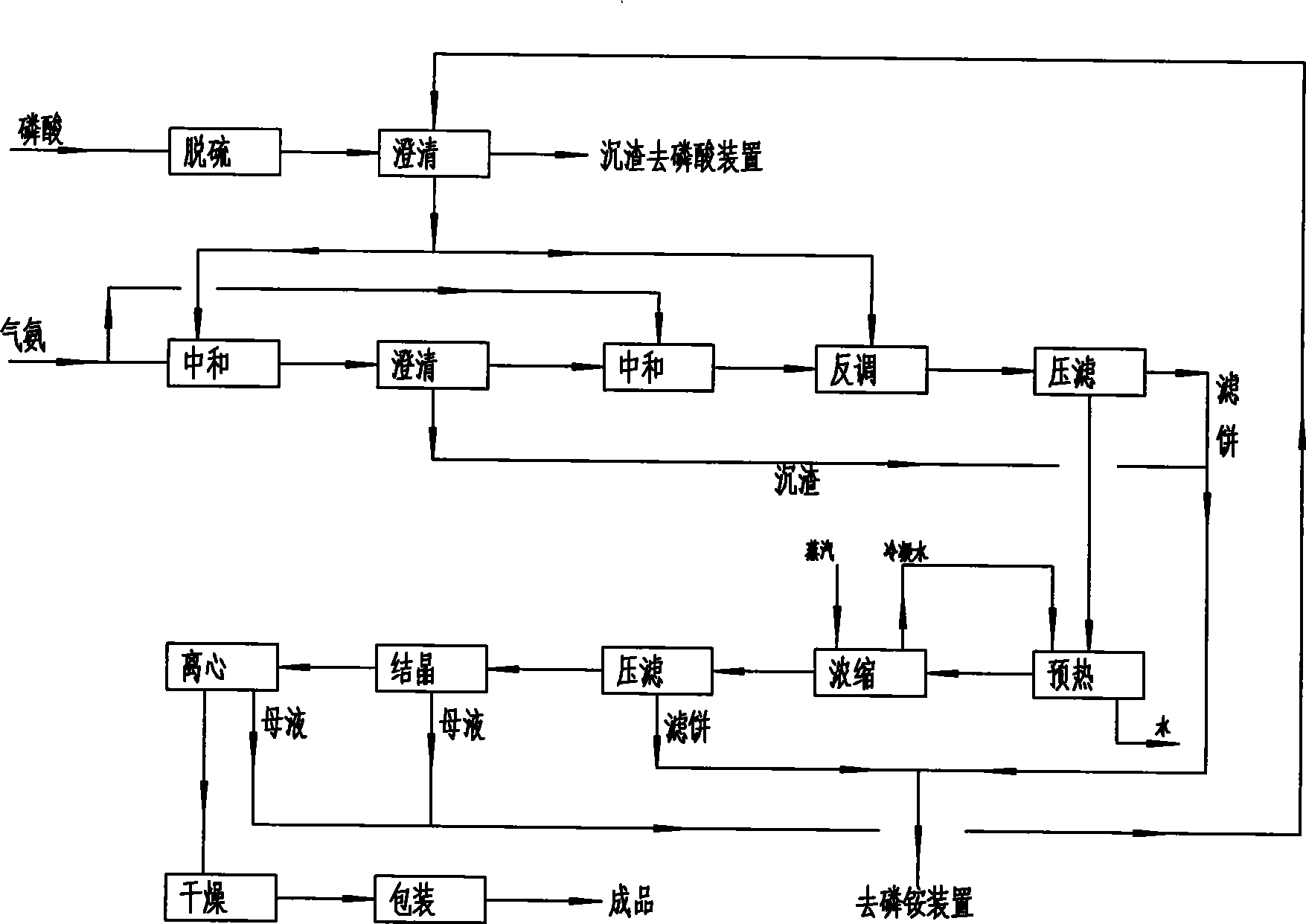

Process for continuous production of technical grade mano-ammonium phosphate with wet-process and phosphoric acid

ActiveCN101367512AReduce labor intensityReduced pressure filter loadPhosphatesPhosphatePhosphoric acid

The invention relates to a craftwork for producing the industrial-level monoammonium phosphate consecutively with the phosphoric acid by wet process, which adopts the following steps: 1) phosphoric acid and phosphorite pulp are desulfurized to get the desulfurized phosphoric acid; 2) the acid is undertaken the first neutralization action to get a neutralized material pulp clarifying solution; 3) after the second neutralization reaction, the solution is reacted with the desulfrized phosphoric acid to get a secondary neutralized material pulp with the pH value being adjusted; 4) the secondary neutralized material pulp with the pH value being adjusted is primarily filtered to get a primary filtering solution and a primary filtering mass; 5) the primary filtering solution is secondarily concentrated and press filtered to get the secondary filtering solution; 6) the obtained secondary filtering solution is dissolved through the grain refining, is cooled down in vacuum, is crystallized, is centrifugally separated and dried to get the finished product of the industrial-level monoammonium phosphate. The invention has the advantages that the operation during the production process is consecutive; the labor intensity of the worker is reduced; the leakage rate of the ammonia is low and the loss is small; the secondary neutralized raw material solution is clear solution, so that the viscosity is low and the loss of the ammonia is small; the neutralization and the press filtering load is reduced; the crystallization production capacity is large; the heat energy is adequately used, thereby reducing the consumption of the vapor.

Owner:HUBEI XIANGYUN GROUP CHEM

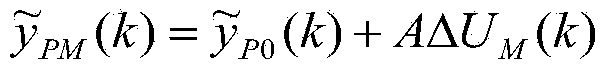

Selective catalytic reduction (SCR) denitration system and method based on constraint predictive control

ActiveCN104607042AQuick responseReduce escape rateDispersed particle separationEscape rateEngineering

The invention discloses a selective catalytic reduction (SCR) denitration system and method based on constraint predictive control. The flow of injected ammonia of the SCR denitration system is controlled by utilizing a predicting-proportioning cascade control policy; the flow of the injected ammonia is regulated by predicting the future change tendency of the concentration of NOx at an outlet of an SCR reactor and regulating the opening degree of an ammonia injection valve in advance; therefore, the defects of large inertia and delay of the SCR denitration system can be greatly overcome, the response speed of ammonia injection amount control to unit load change is increased, and the dynamic regulation quality of the SCR denitration system is improved; under the constraint predictive control, practical constrains, such as upper and lower constrains of valve opening degree, valve operation speed constrain and outlet NOx concentration constrain, are simultaneously considered and are used in parallel, so that the fact that the system performance is influenced due to saturation of execution mechanisms is avoided; based on ensuring the fact that the concentration of the NOx at the outlet reaches a target value, the ammonia injection amount is reduced as much as possible, and the operation cost and the ammonia escape rate are effectively reduced.

Owner:SOUTHEAST UNIV

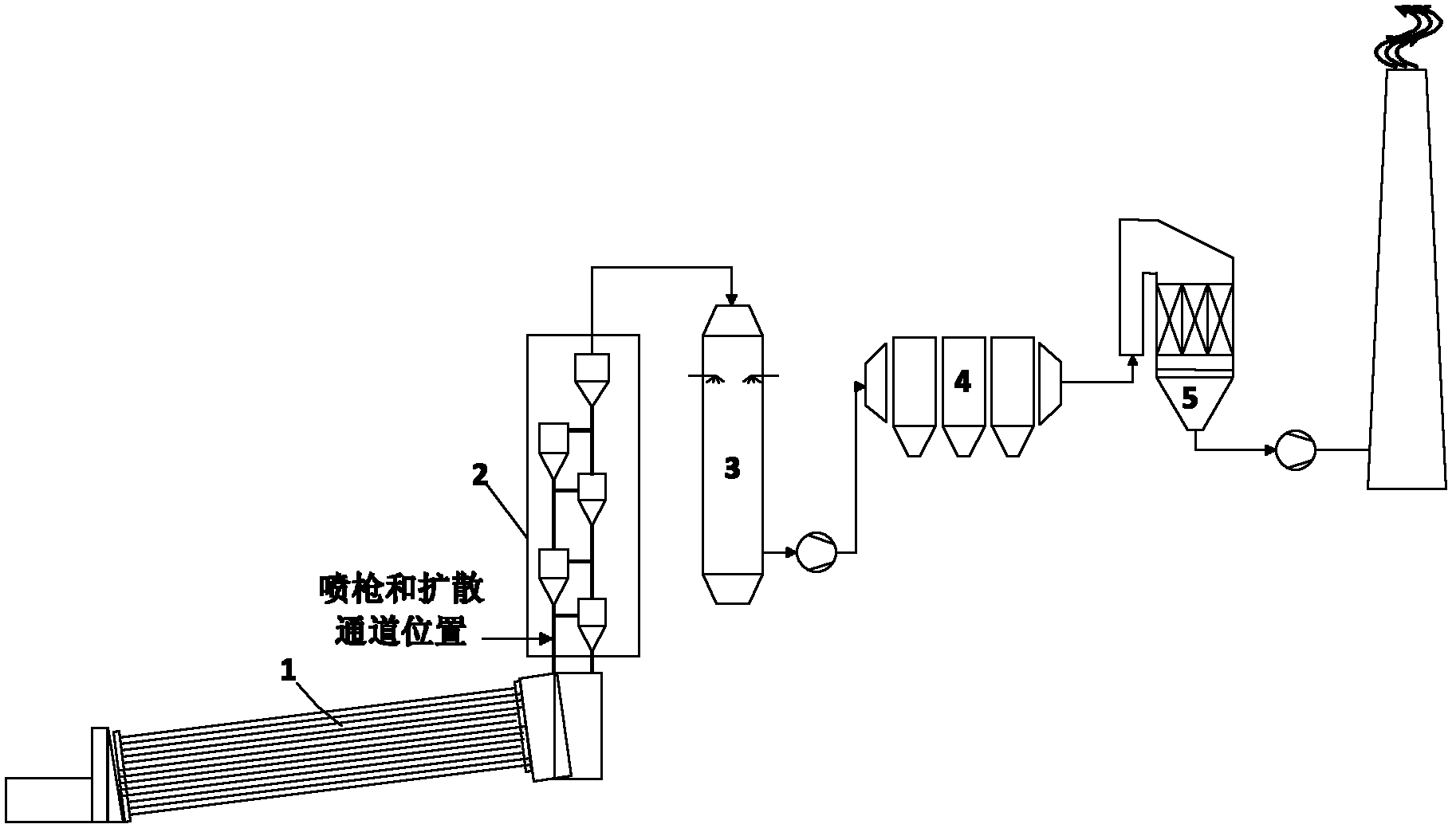

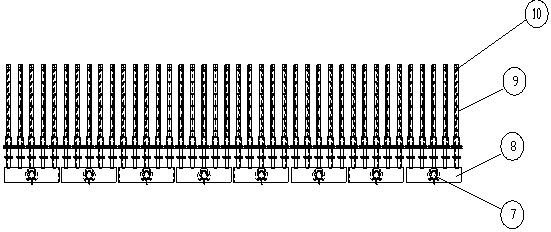

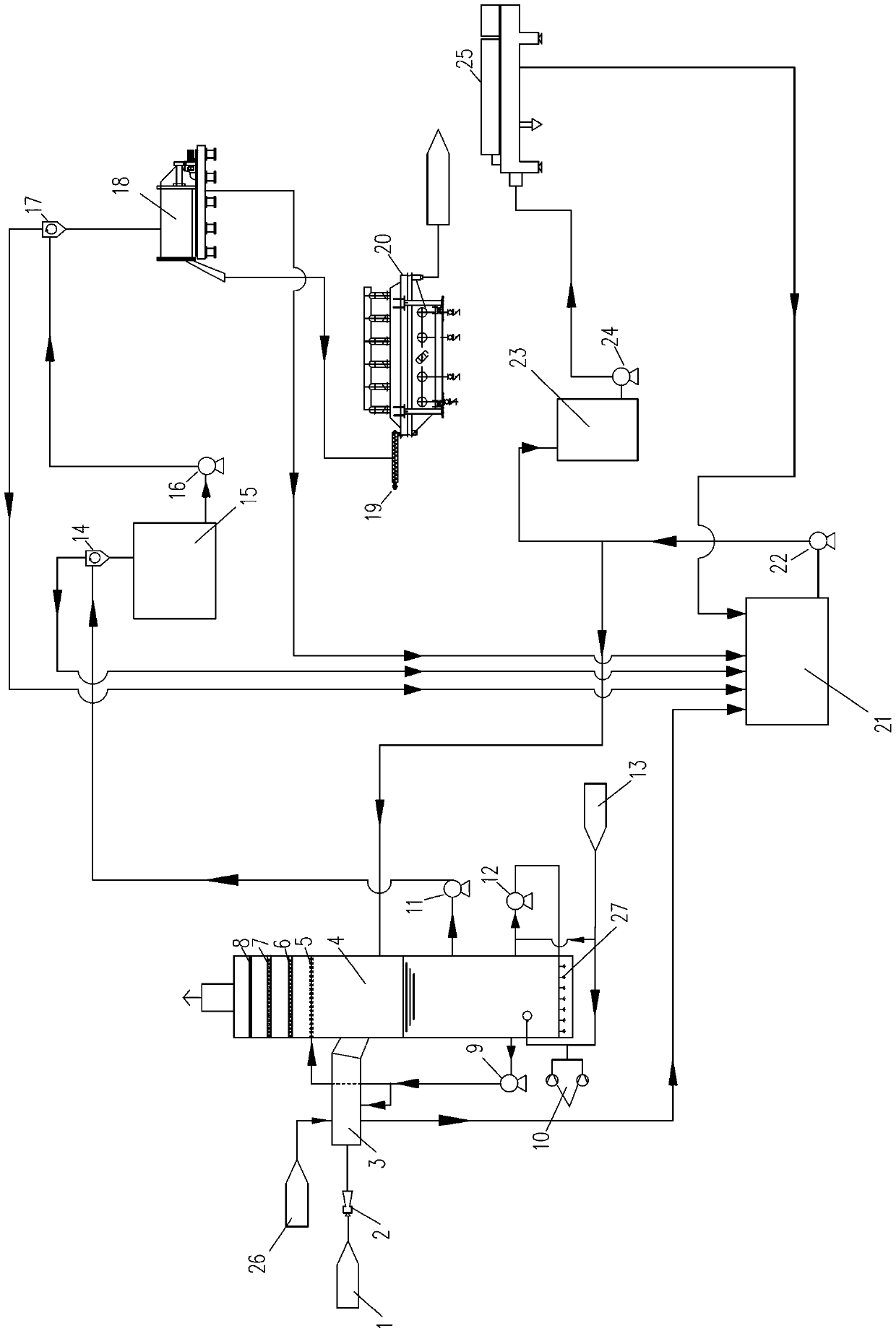

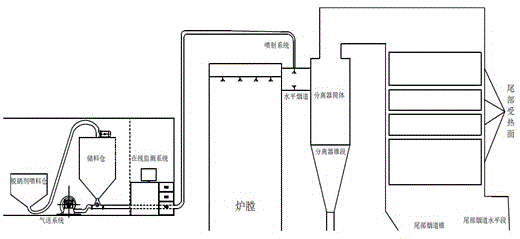

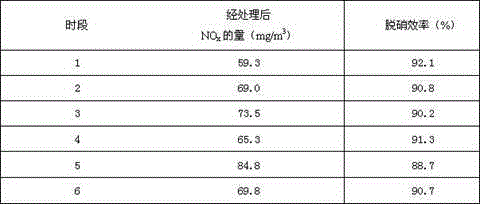

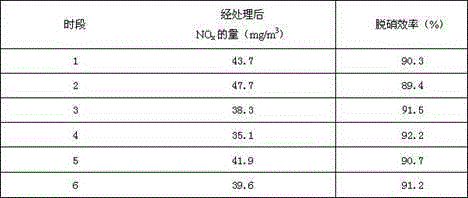

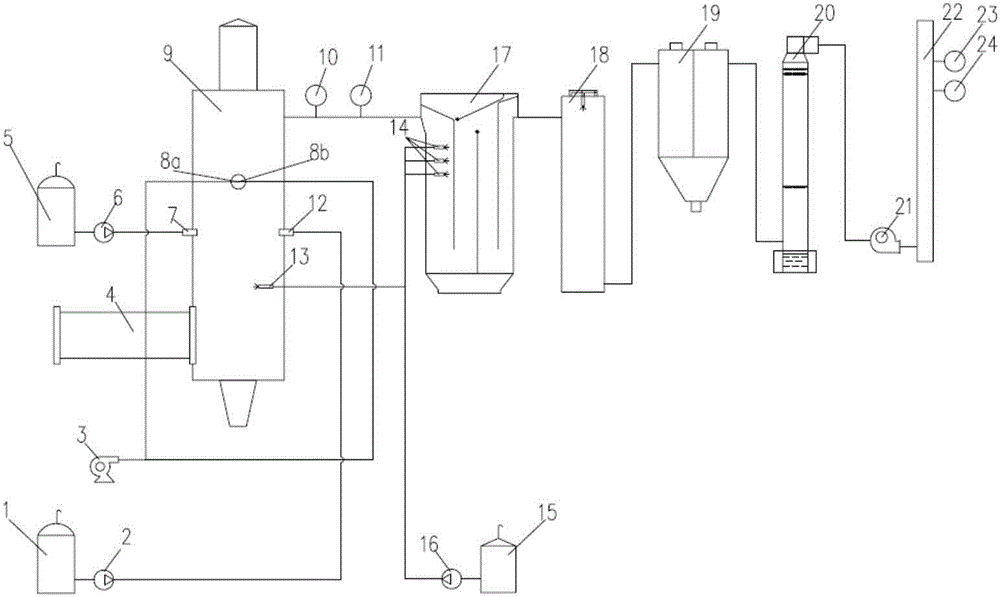

Denitration process and denitration apparatus for cement kiln flue gas

ActiveCN102512925AImprove denitrification efficiencyReduce escape rateGas treatmentDispersed particle separationDecompositionEscape rate

The invention discloses a denitration process for cement kiln flue gas. According to the process, liquefied ammonia, ammonia water or urea is used as a reducing agent and is injected into cement decomposition kiln flue gas in a temperature range of 750 to 1100 DEG C by a spray gun for a selective uncatalyzed reaction, and then the reducing agent and unreacted nitrogen oxides in the flue gas pass through an SCR reaction system installed behind a humidifying tower and a deduster together and undergo a selective uncatalyzed reaction on the surface of a specially-produced low temperature catalyst so as to realize secondary denitration. The invention also discloses a denitration apparatus used for realizing the denitration process. According to the invention, through installation of an SCR denitration system at the tail of a system, the escape rate of ammonia in an SNCR system is reduced; meanwhile, through former SNCR preliminary denitration, the volume of an SCR reactor and usage amount of the catalyst are reduced, thereby reducing cost of one-shot investment for the denitration system and improving denitration efficiency of the system. The denitration process and denitration apparatus provided in the invention are applicable to removal of nitrogen oxides in cement kiln flue gas and have wide market and application prospects.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

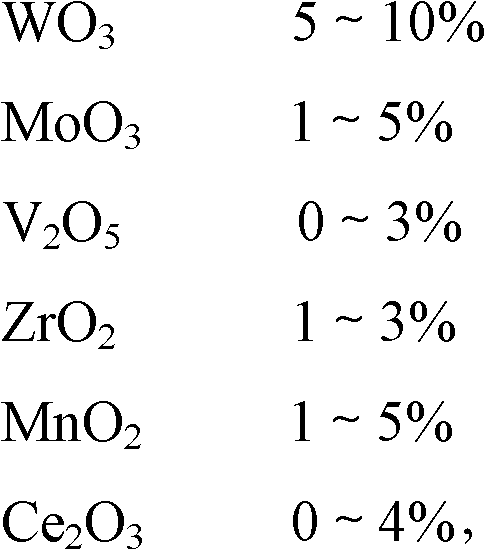

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

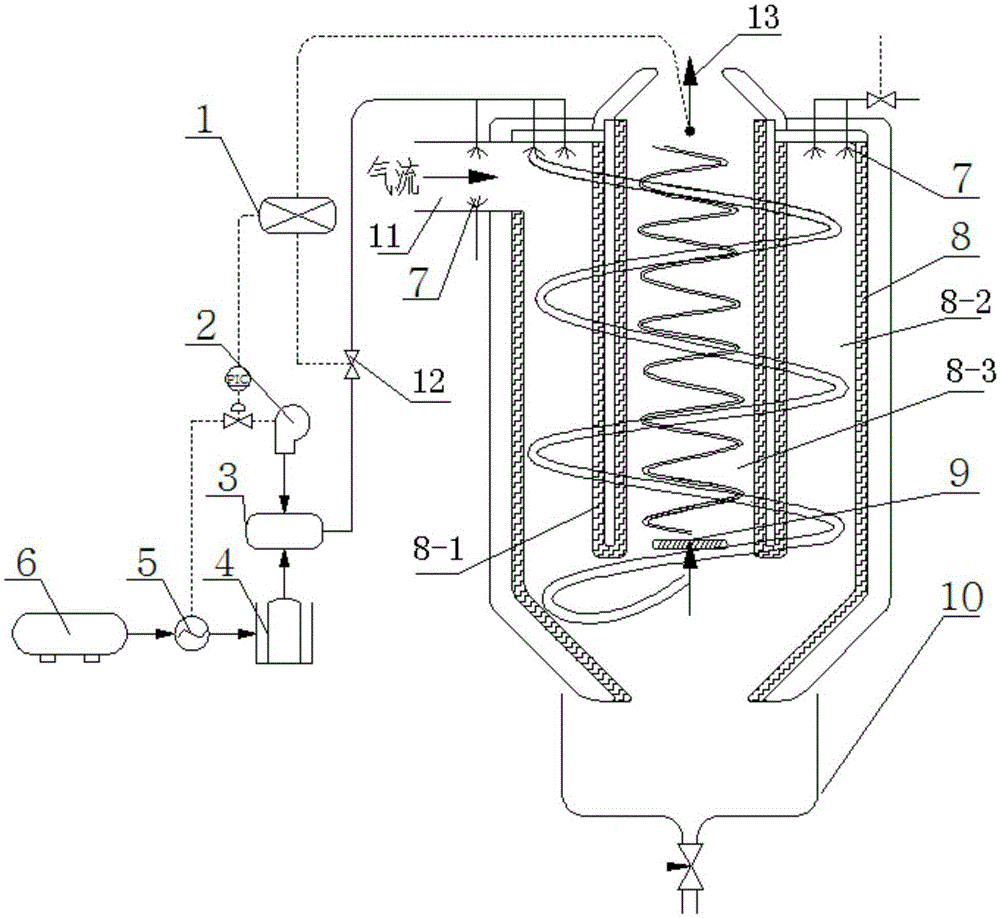

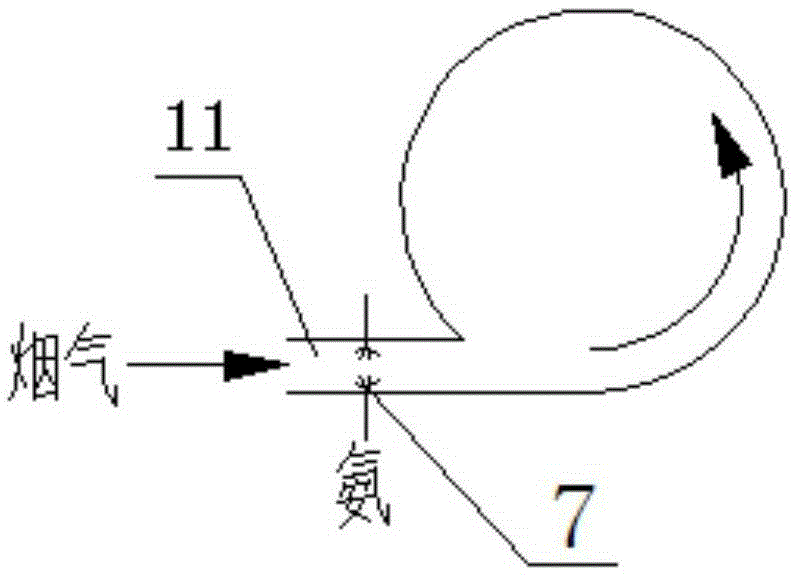

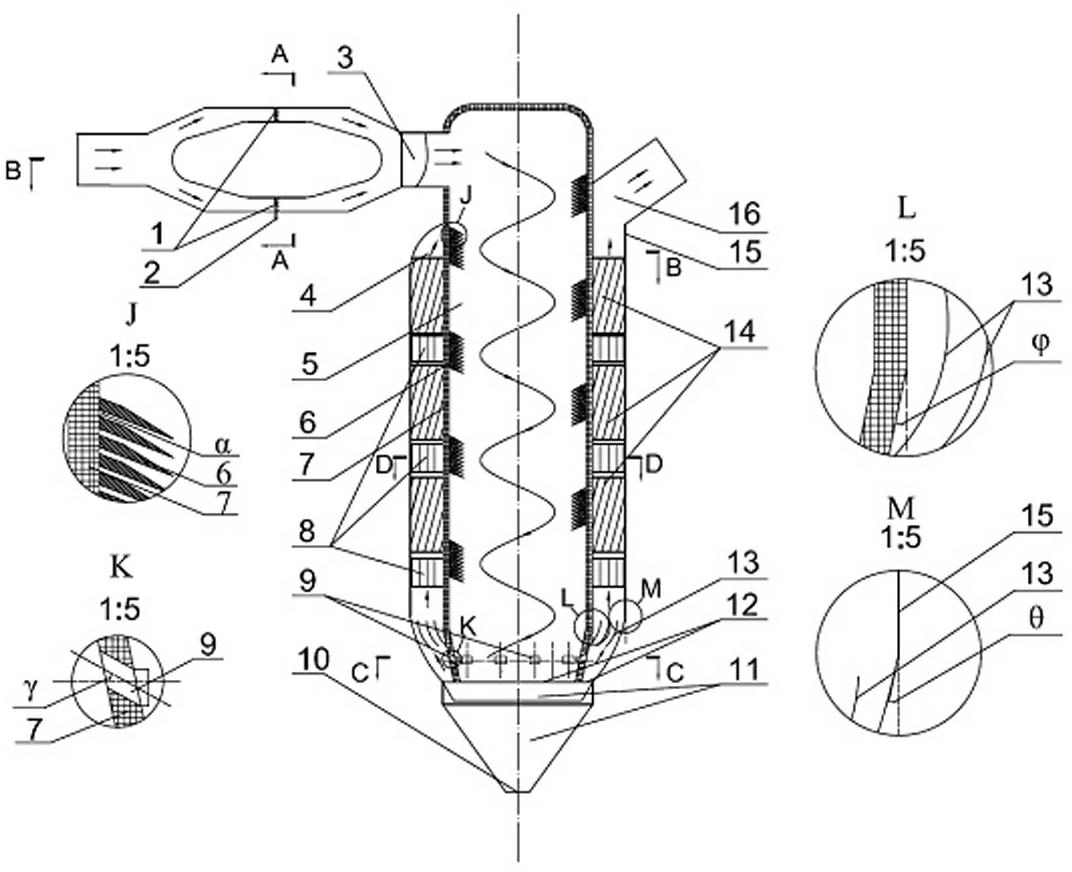

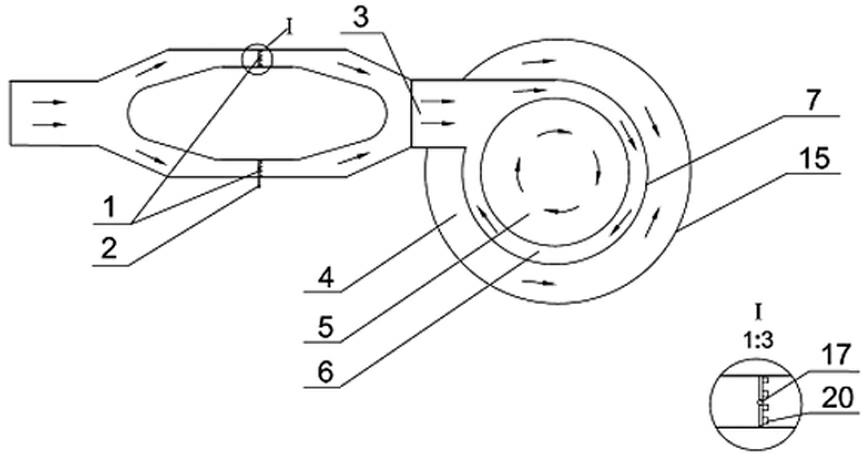

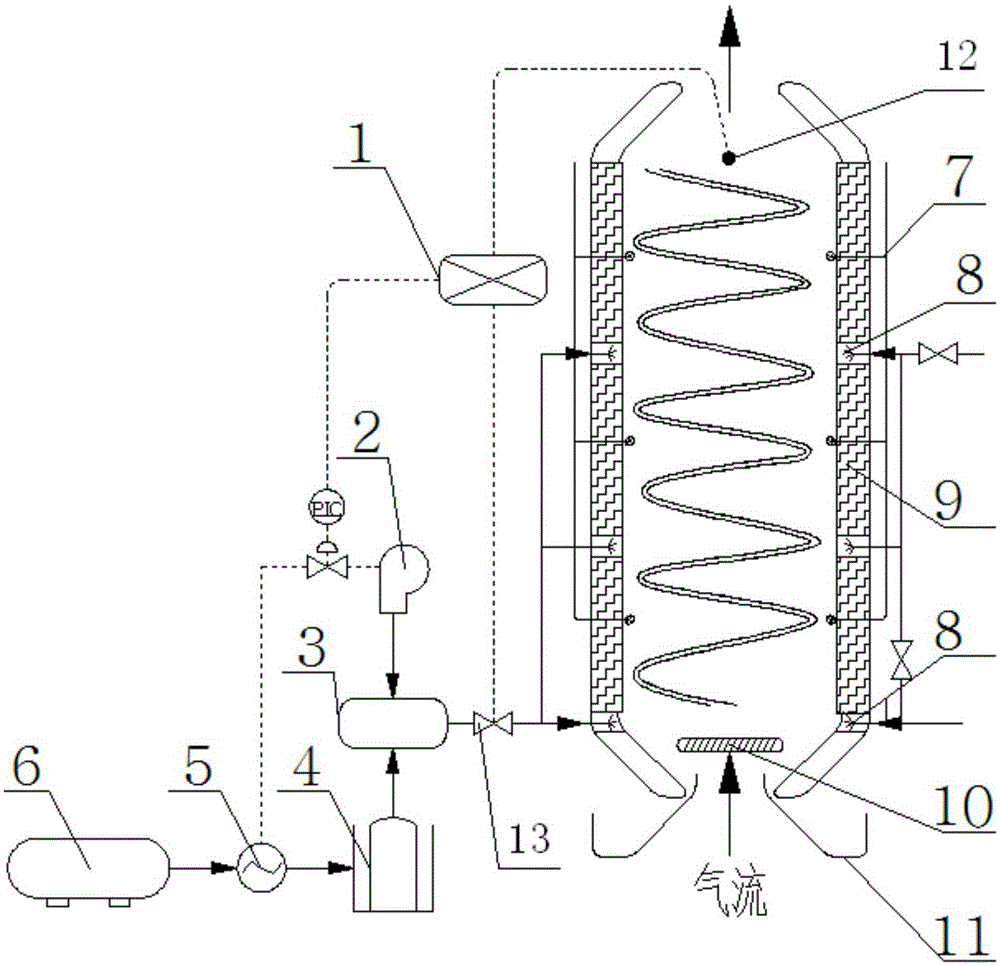

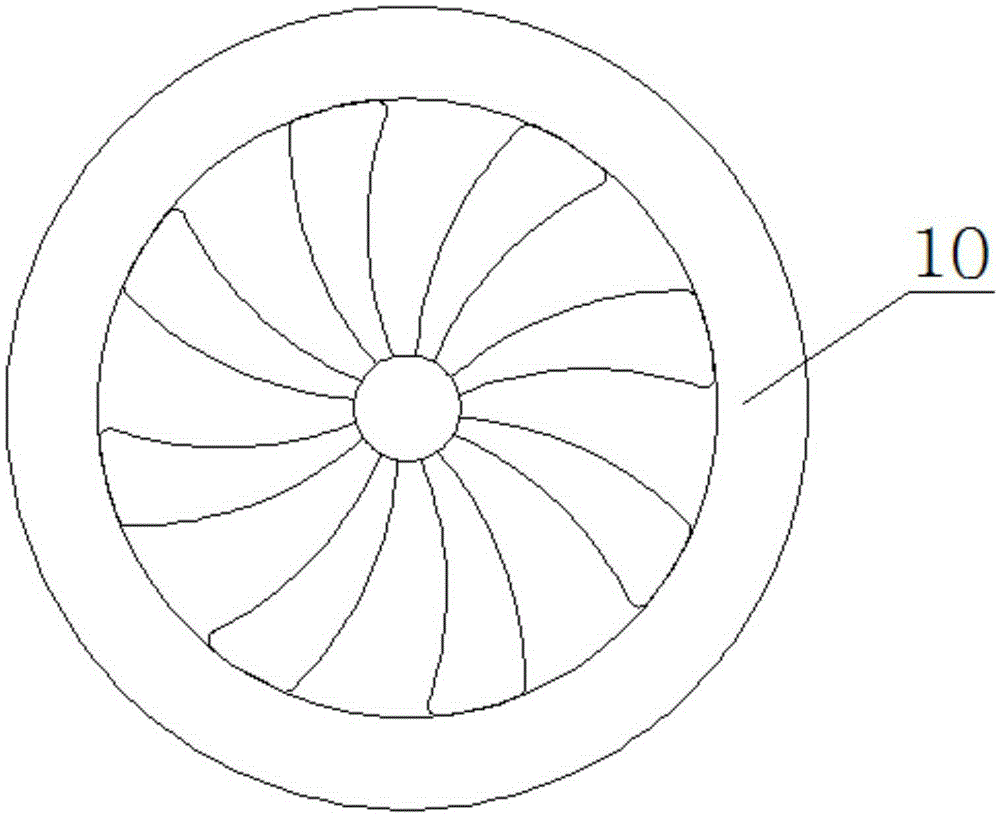

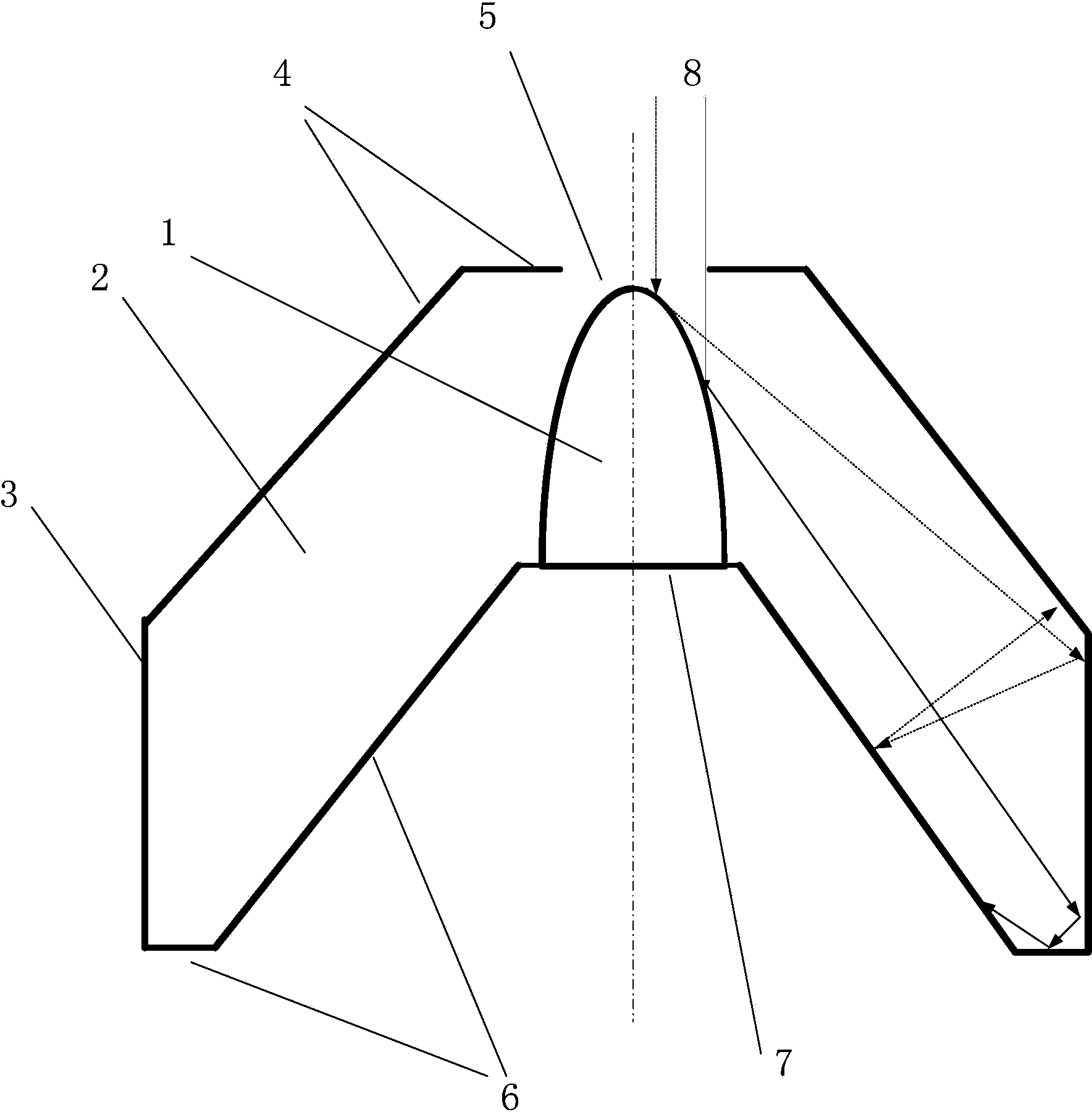

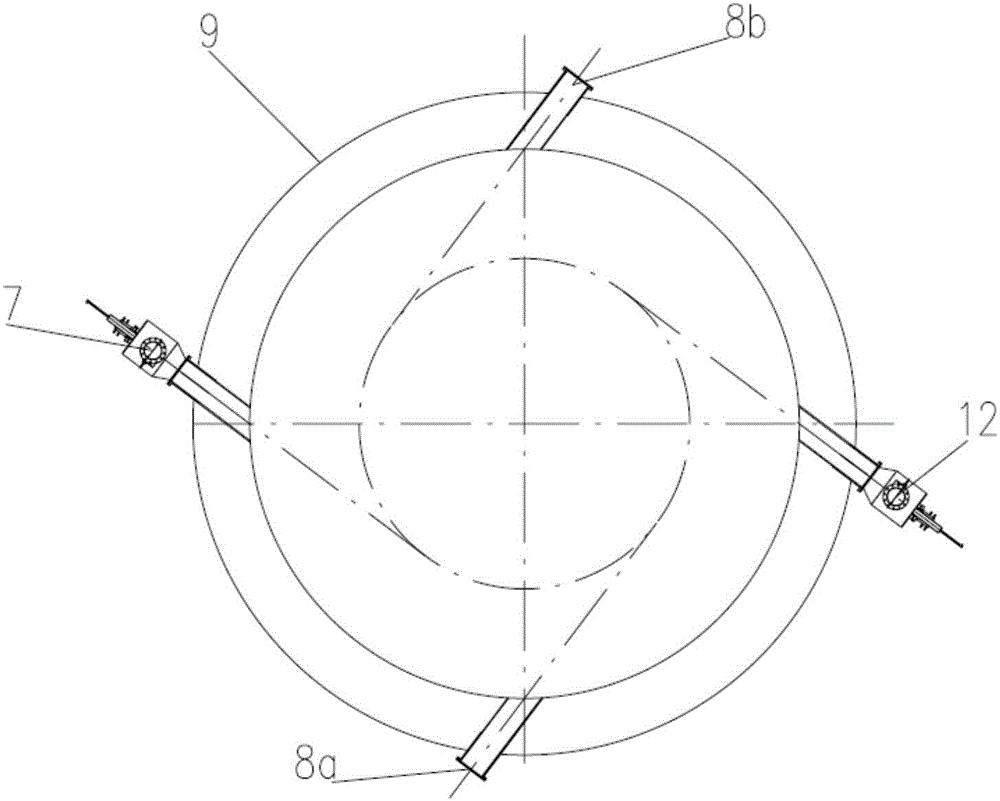

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

Denitration ammonia spraying control method based on multi-variable correction

ActiveCN109062053AReduce volatilityReduce excess spaceDispersed particle separationAdaptive controlAmmoniaComputer science

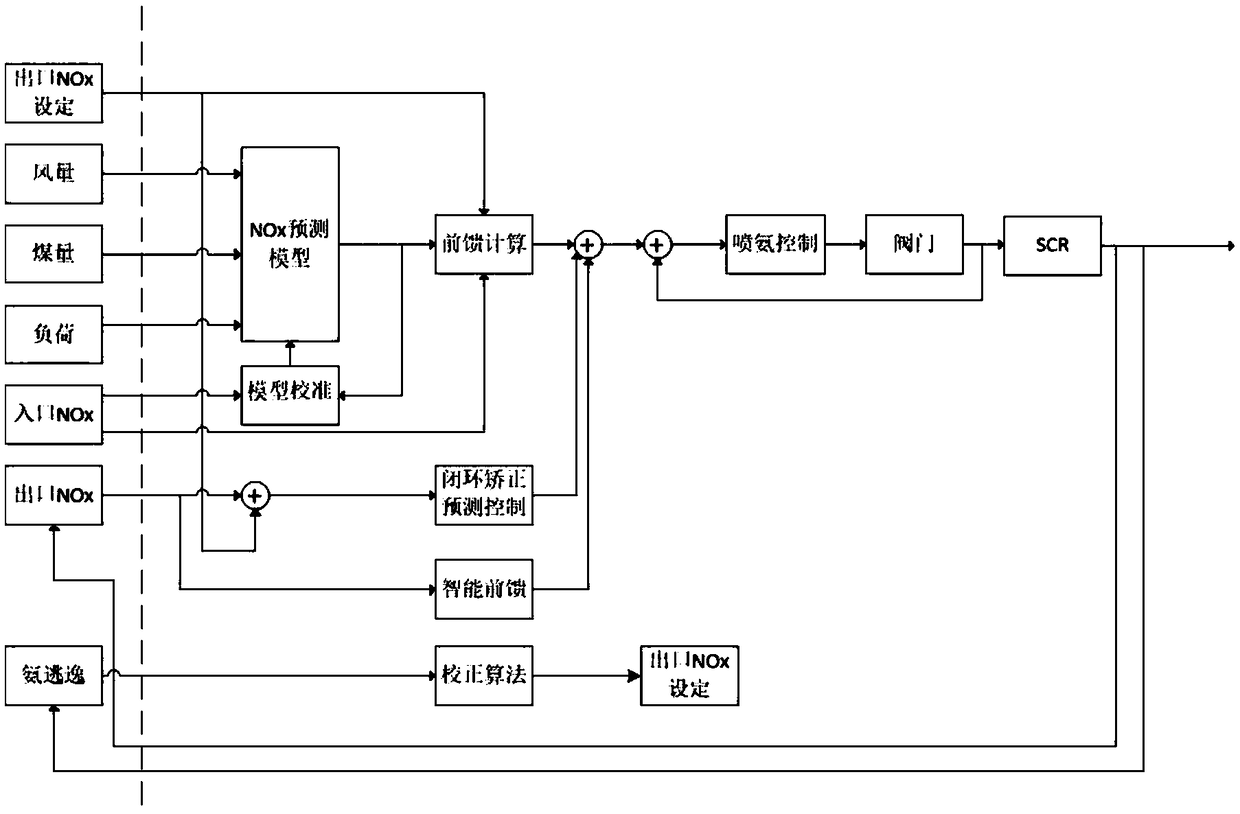

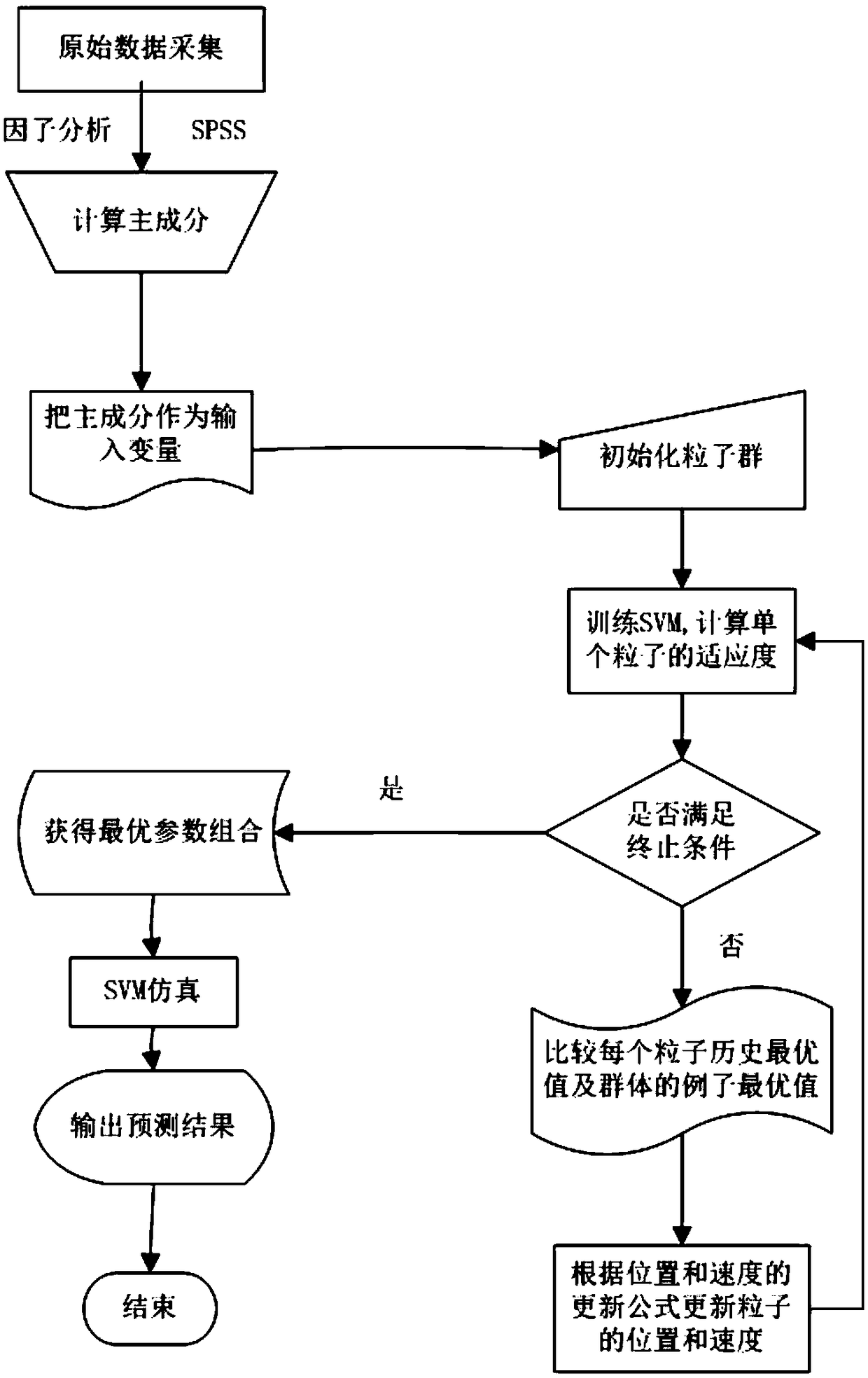

The invention relates to a denitration ammonia spraying control method based on multi-variable correction, belongs to the technical field of ammonia spraying control of a denitration system of a thermal power generating set, and solves the problem that NOx fluctuation in an outlet of an SCR system in the prior art is severe. The method comprises the steps of acquiring measurement data and workingcondition information of a denitration system instrument in real time; constructing a NOx content prediction model at the inlet of the SCR denitration system, and predicting the NOx content at the inlet of the SCR system at the current moment; and carrying out ammonia spraying amount feedforward control and prediction correction on the basis of the predicted NOx content at the inlet of the SCR system and the measured data, generating an ammonia spraying amount control instruction at the current moment, controlling an ammonia spraying adjusting valve and adjusting the ammonia spraying amount. According to the method, the NOx content precision prediction model of the SCR inlet denitration system and the intelligent feedforward control method are adopted, so that NOx fluctuation at the outletof the SCR denitration system and space deviation are greatly reduced under the premise that smoke NOx emission satisfies the environmental protection index, the average value of the outlet NOx is increased, the ammonia spraying amount is reduced, the ammonia escape level is reduced, and the denitration cost is lowered.

Owner:JIANGSU GUOXIN JINGJIANG POWER GENERATION CO LTD +1

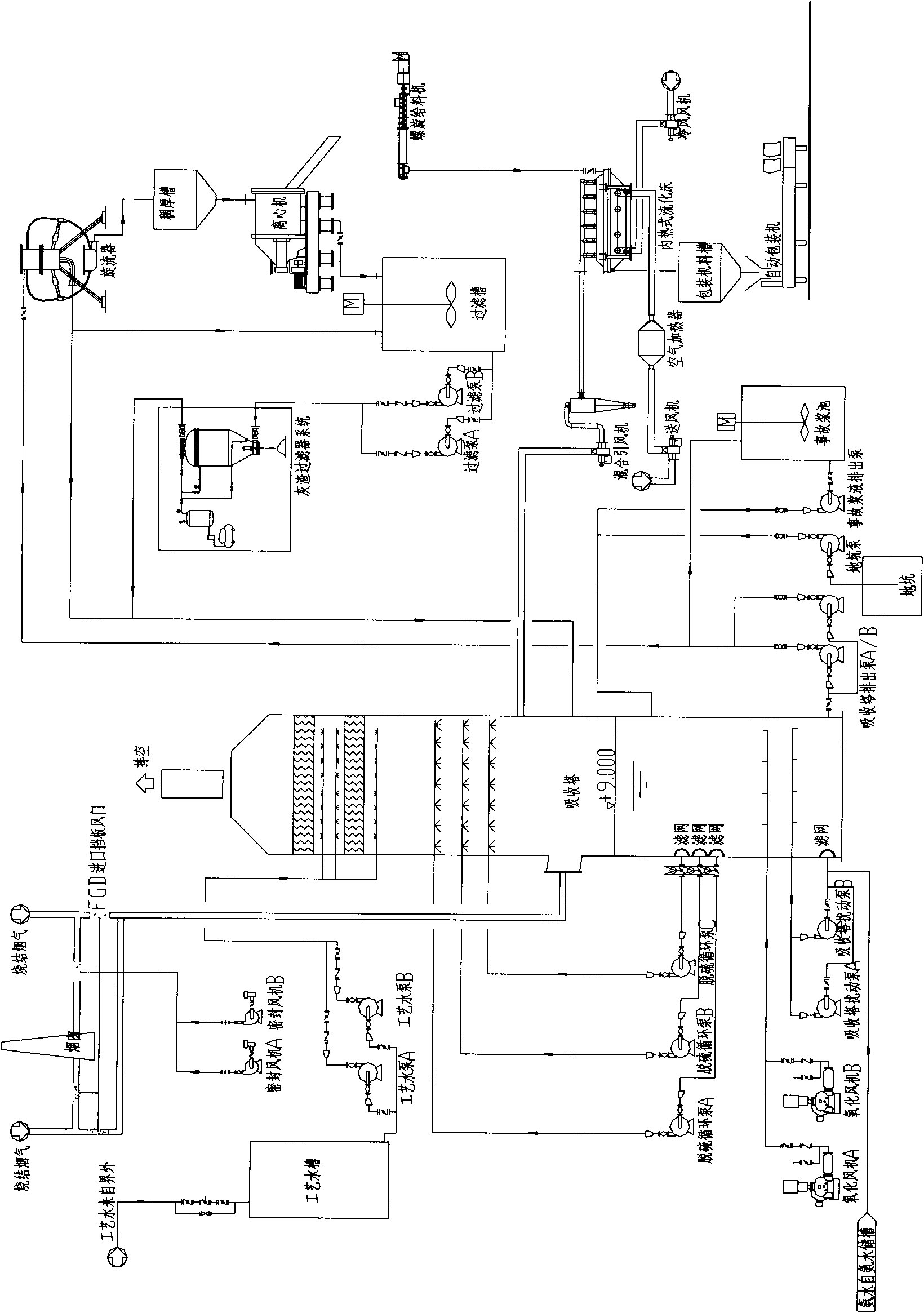

Flue gas desulfurization process suitable for sintering machine of steel mill

InactiveCN101862583AHigh desulfurization rateLow running costDispersed particle separationProcess engineeringSteel mill

The invention discloses process technology suitable for removing a sulfur dioxide byproduct, namely, ammonium sulfate chemical fertilizer in flue gas produced by a sintering machine of a steel mill and suitable for the characteristics of large sintering flue gas amount, large flue temperature fluctuation, high moisture content, high dust content and the like. The process comprises the following steps of: allowing sintering flue gas to enter from the middle of an absorption tower, wherein the flue gas is reversely contacted with absorption liquid; removing sulfur dioxide from the flue gas in a contacting process; exhausting the flue gas through a chimney on the top of the tower after the flue gas flows through a demister on the top of the tower; introducing compressed air and ammonia water into the absorption liquid, wherein ammonium sulfate in solution is saturated and 5 percent of crystal is separated out along with continuous absorbing and oxidizing processes; and rotating, filtering and drying ammonium sulfate crystal-containing suspension to obtain a finished product. Since the absorption, oxidation and condensation of the sintering flue gas are completed in the absorption tower at the same time, the process has the characteristics of refined flow, high desulfurization efficiency and high byproduct quality.

Owner:高翀

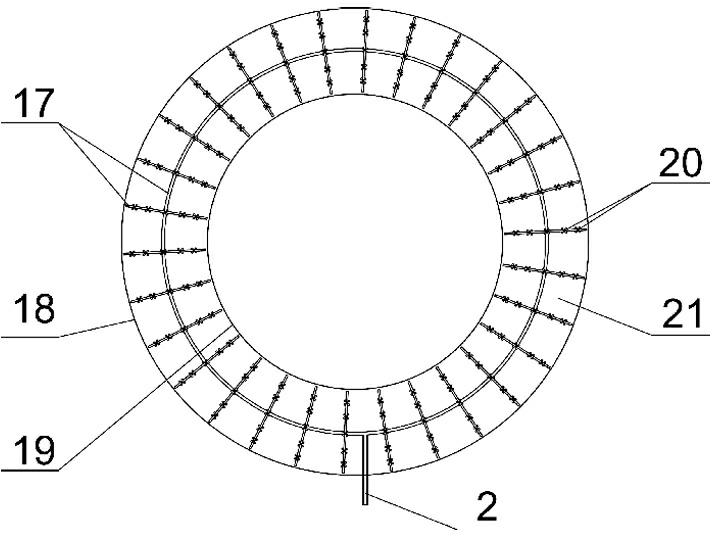

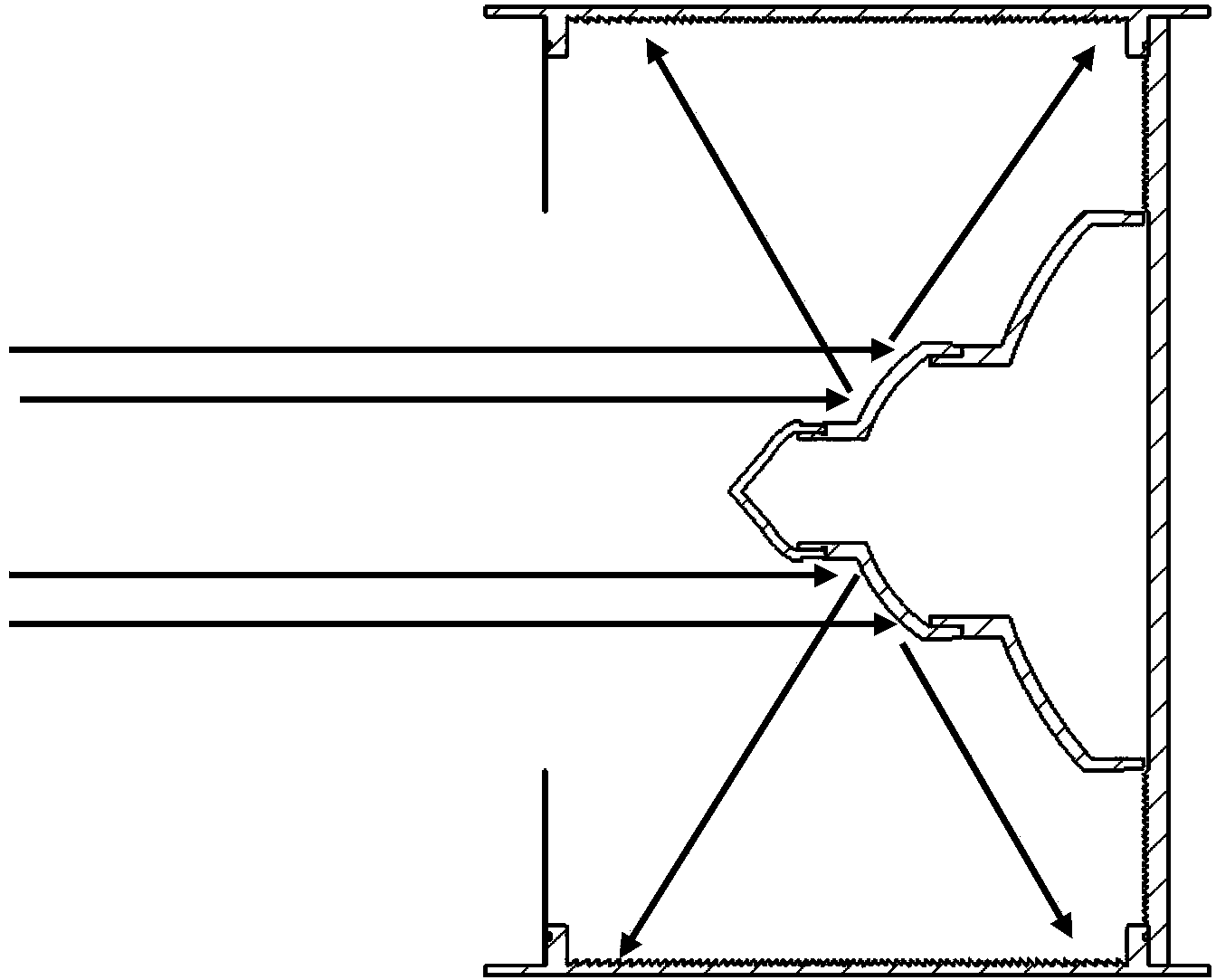

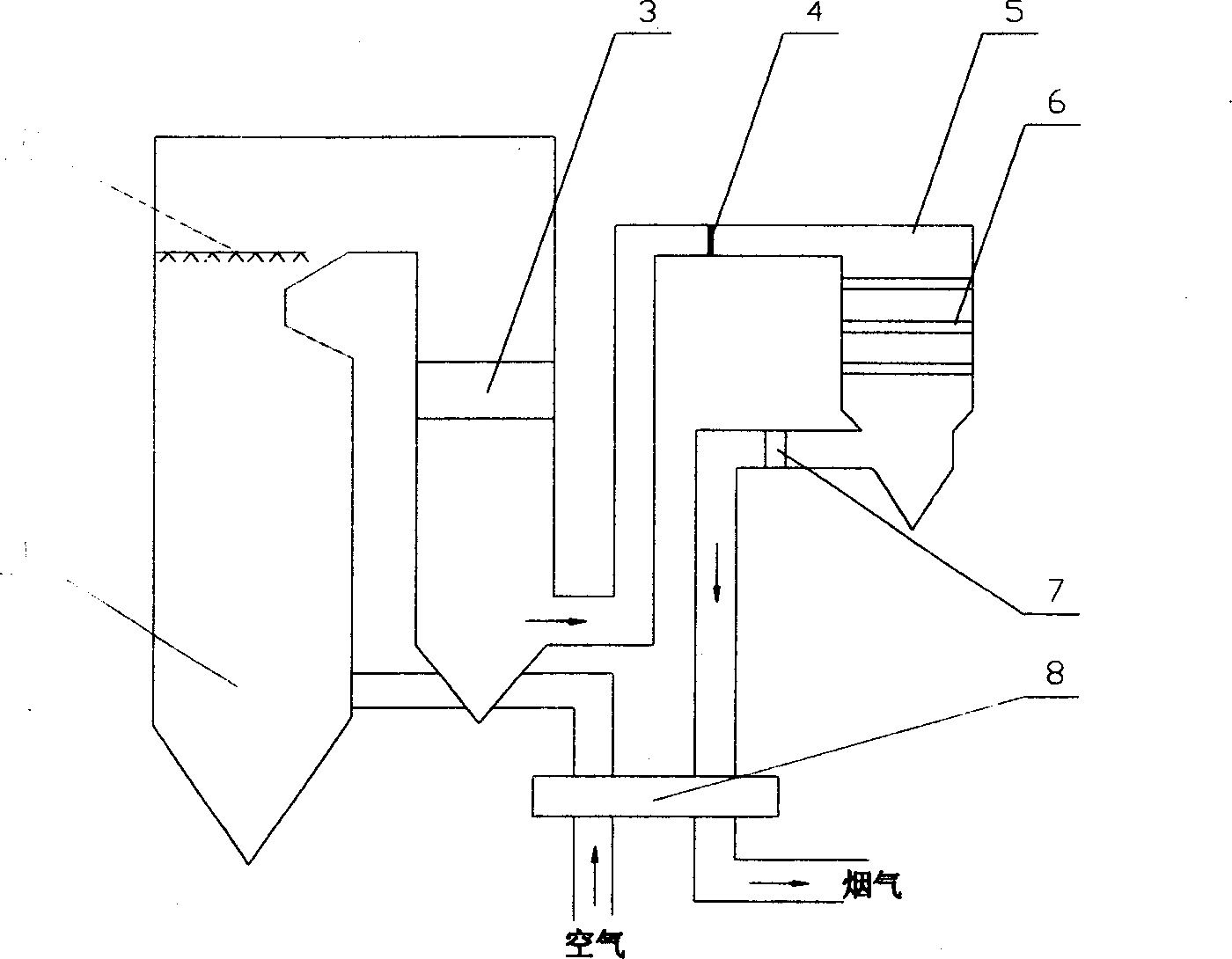

Dedusting-denitrating integrated device

ActiveCN102614779ASimple structureSimple control systemDispersed particle filtrationFlue gasProcess engineering

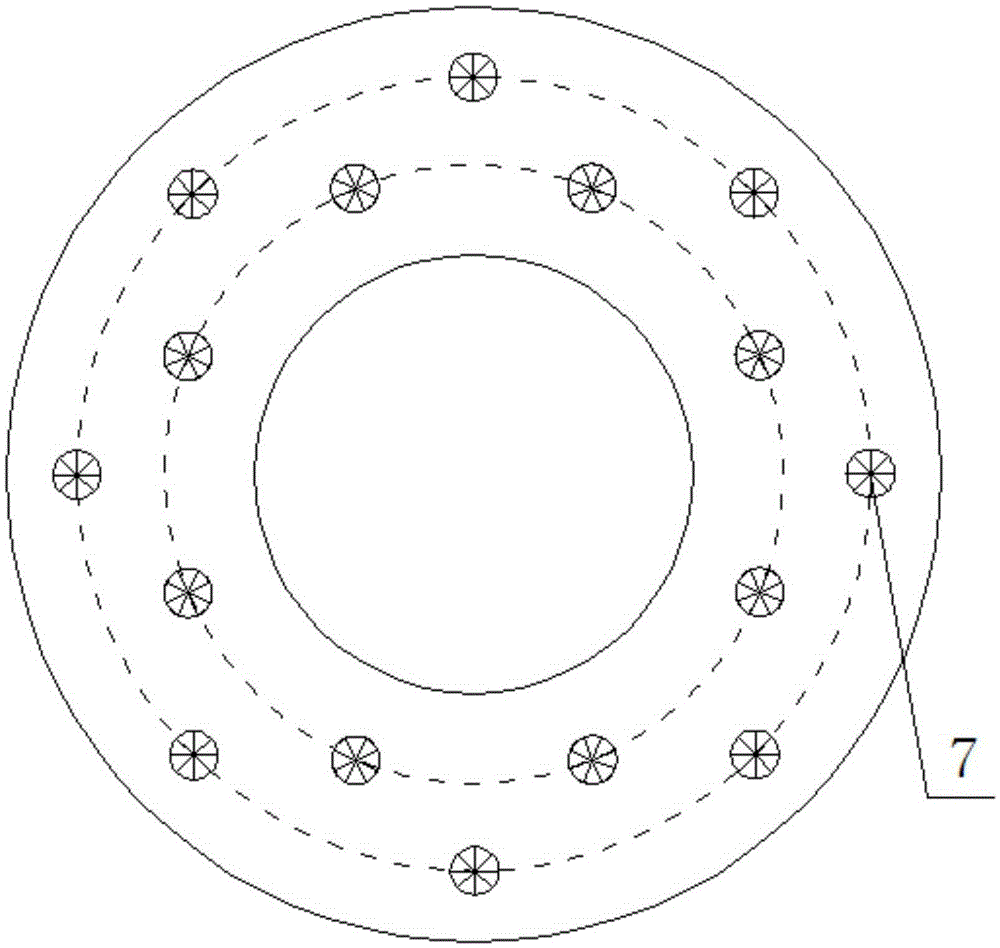

The invention discloses a dedusting-denitrating integrated device which comprises a flue gas channel, a mixed flue gas inlet and a shell consisting of an outer cylinder and an inner cylinder, and a ash hopper at the bottom of the shell, wherein the inner cylinder is mainly used for dedusting and ammonia mixing, the outer cylinder is mainly used for containing a denitrating catalyst bed, the crosssection of the flue gas channel is ring-shaped, and ammonia spray grilles are distributed in the flue gas channel in a radial manner so that the required NH3-to-NO ratio can be reached more easily. The device provided by the invention can be used for dedusting before carrying out denitrating, a catalyst can be effectively prevented from being worn, poisoned and blocked and the service life of thecatalyst can be prolonged. Under the condition that the length of the device is not increased, the ammonia mixing time is prolonged and ammonia mixing can be performed fully; heat absorbing spiral plates and cooling rectifier plates are arranged in both the inner cylinder and the outer cylinder to share heat of flue gas at the inlet, and therefore the heat loss of flue gas can be reduced, the denitrating efficiency can be improved and the catalyst is prevented from being sintered and inactivated under the action of superheated flue gas.

Owner:HUNAN UNIV

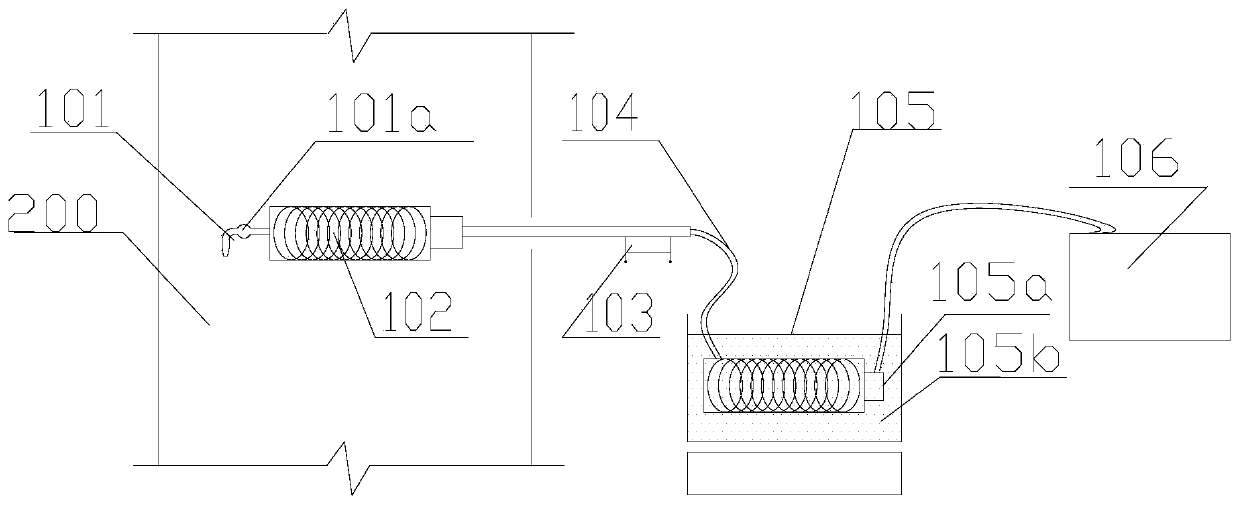

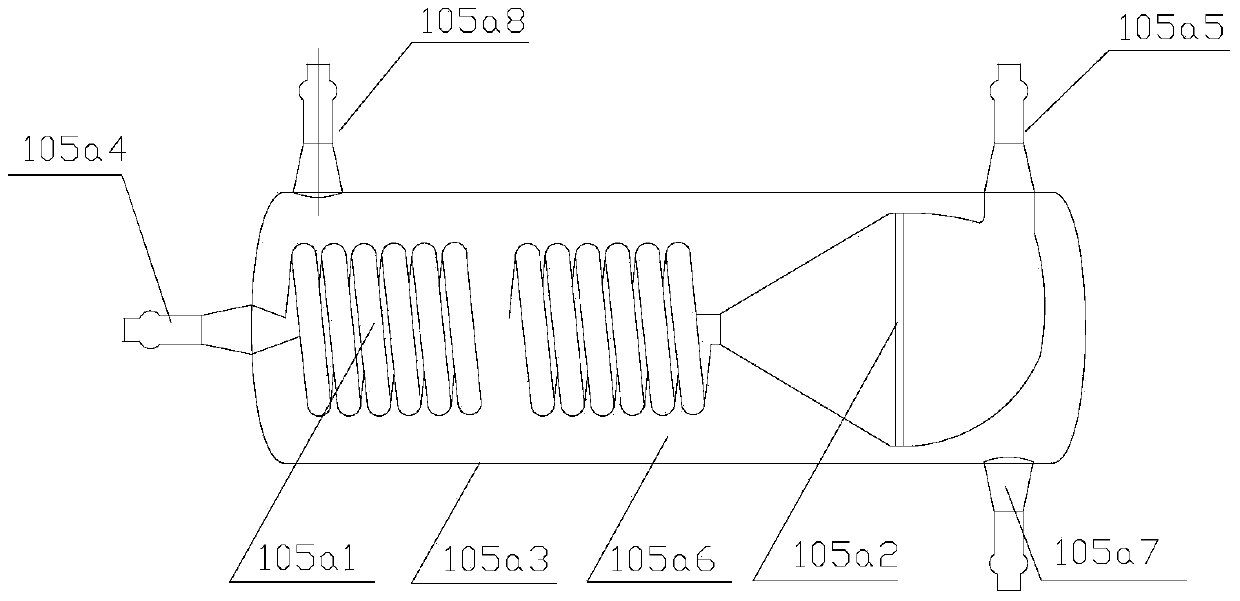

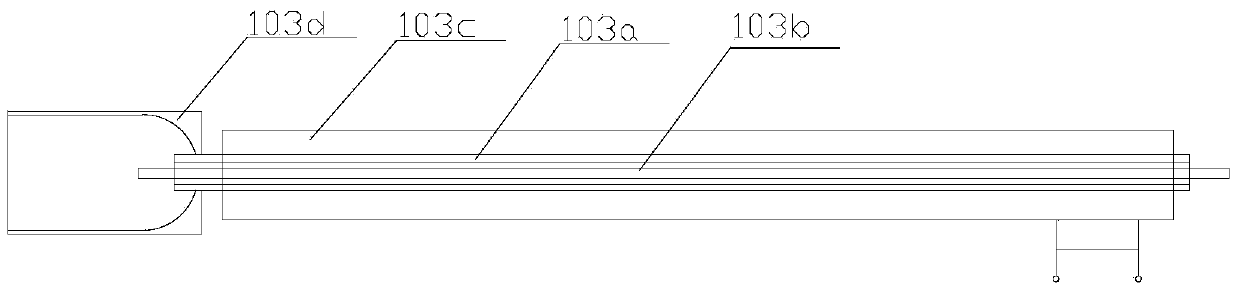

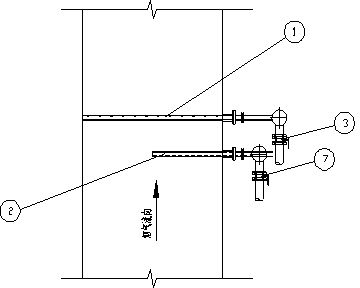

Polymorphic sampling system and method for sulfur trioxide in exhaust of stationary pollution source

ActiveCN103439152AIn-depth studyReduce escape rateWithdrawing sample devicesPreparing sample for investigationWater bathsAcid corrosion

The invention discloses a polymorphic sampling system and method for sulfur trioxide in exhaust of a stationary pollution source. The polymorphic sampling method comprises the following steps: according to the form of SO3 in the exhaust, based on a selective condensation principle, collecting aerosol-state SO3 in the exhaust by adopting a front-stage collector under the temperature of the exhaust; and enabling the temperature of the exhaust flowing in a rear-stage collector to be reduced below an acid dew point through a water bath or water bath circulation so that the original gaseous SO3 under the temperature of the exhaust is transformed into the aerosol-state SO3 to be deposited in the rear-stage collector so as to realize the purpose that the aerosol-state SO3 and the gaseous SO3 are respectively measured. According to the scheme provided by the invention, the aerosol-state SO3 and the gaseous SO3 in the exhaust can be distinguished, and respectively quantified; a proportion of the aerosol-state SO3 to the gaseous SO3 is calculated, and the total concentration of the SO3 can also be measured. The measured concentration of the aerosol-state SO3 and the gaseous SO3 under the temperature of the exhaust provides basic data for researching acid corrosion at the tail of a boiler; meanwhile, the polymorphic sampling system can be applied to detection of SO3 emission concentration of exhaust of other pollution sources.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

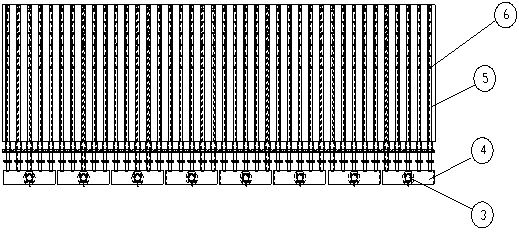

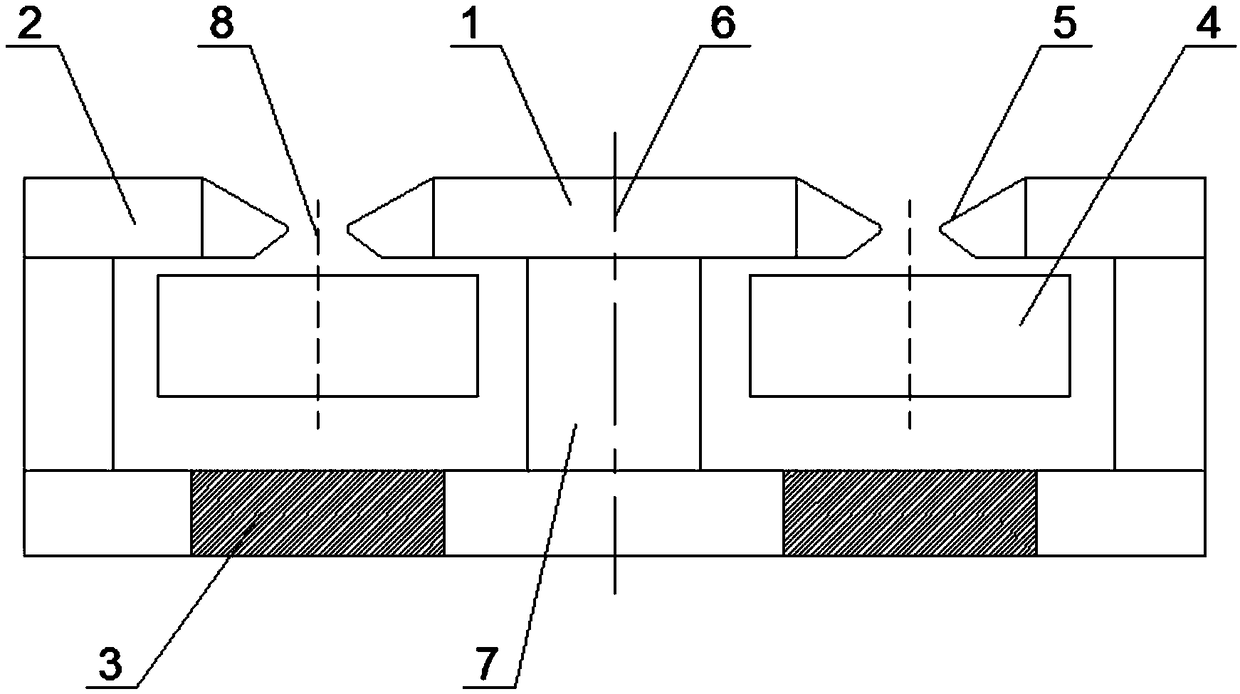

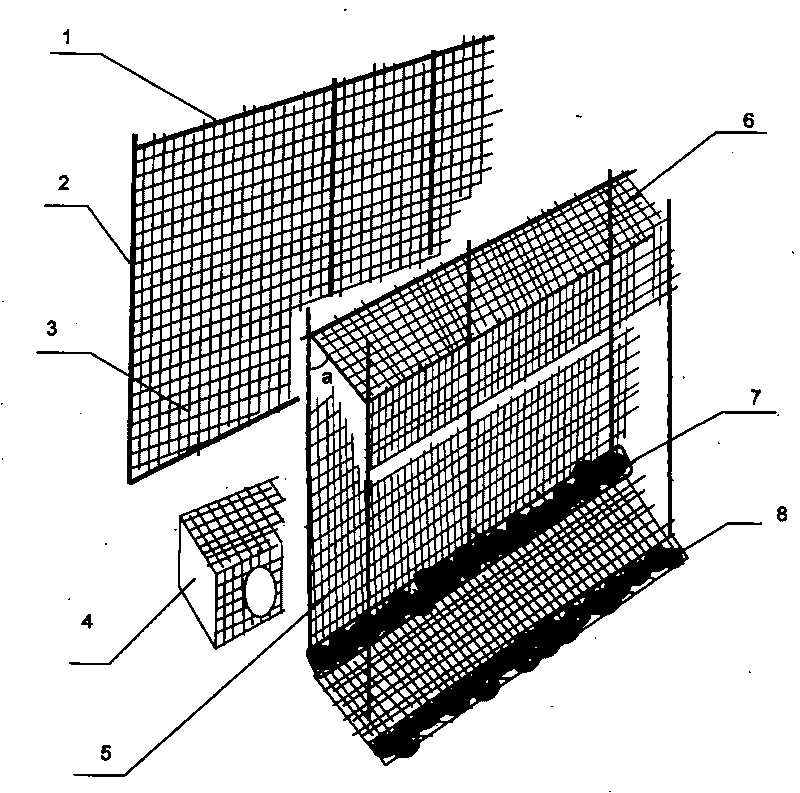

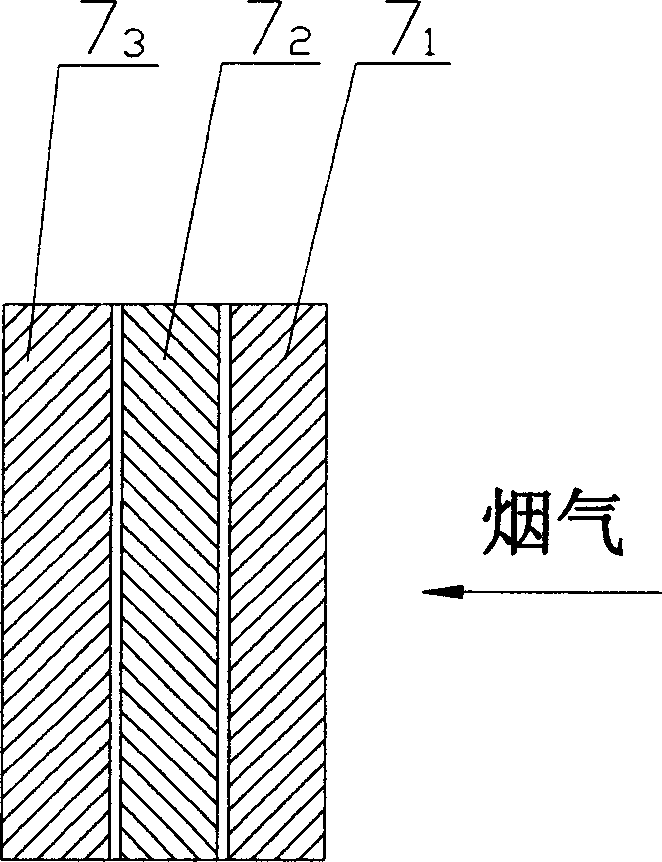

Zoning-regulating double-layer ammonia injection grid applied to selective catalytic reduction denitrification device for industrial flue gas

InactiveCN102527233AReduce escape rateImprove the mixing effectDispersed particle separationChemical industryDenitrification

The invention relates to the technical field of selective catalytic reduction denitrification of industrial flue gas, in particular to a zoning-regulating double-layer ammonia injection grid applied to a selective catalytic reduction denitrification device for industrial flue gas. In order to solve the problems that the ammonia distribution on a flue section of the conventional ammonia injection grid is quite non-uniform, which affects the denitrifying efficiency and increases the escape rate of ammonia, and the like, the zoning-regulating double-layer ammonia injection grid applied to the selective catalytic reduction denitrification device for the industrial flue gas divides the flue section into two equal subzones; the ammonia injection function of one subzone (1 / 2 of the flue section area) is realized by an upper ammonia injection grid and the ammonia injection function of the other subzone is realized by a lower ammonia injection grid; and according to the distribution rules of the flow rates of the flue gas in the two flue section subzones and different concentrations of NOx in the flue gas, the ammonia injection amount of each subzone is regulated and controlled by an ammonia injection regulating valve, so that the ammonia injection amount is adjustable on different zones of the flue section, the uniform mixing effect of the ammonia and nitrogen oxides in the flue gas is optimized, the denitrifying efficiency is improved, and the escape rate of the ammonia is effectively reduced. The uniform zoning-regulating double-layer ammonia injection grid applied to a selective catalytic reduction denitrification device for industrial flue gas has a good uniform mixing effect of the nitrogen oxides in the flue gas and the ammonia, improves the denitrifying efficiency, effectively reduces the escape rate of the ammonia, and is applicable to NOx selective catalytic reduction denitrification devices in coal burning, metallurgy, chemical industry and other industries.

Owner:BEIJING LONDIAN HONGTAI ENVIRONMENTAL TECH

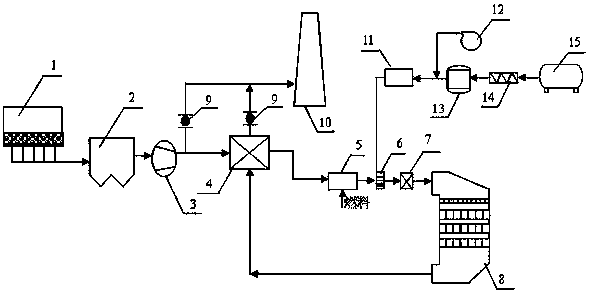

Sintering and pelletizing flue gas SCR denitration and dioxin removal apparatus

ActiveCN103463976AStable removalEfficient removalDispersed particle separationNitrogen removalEscape rate

Owner:宝武水务科技有限公司 +1

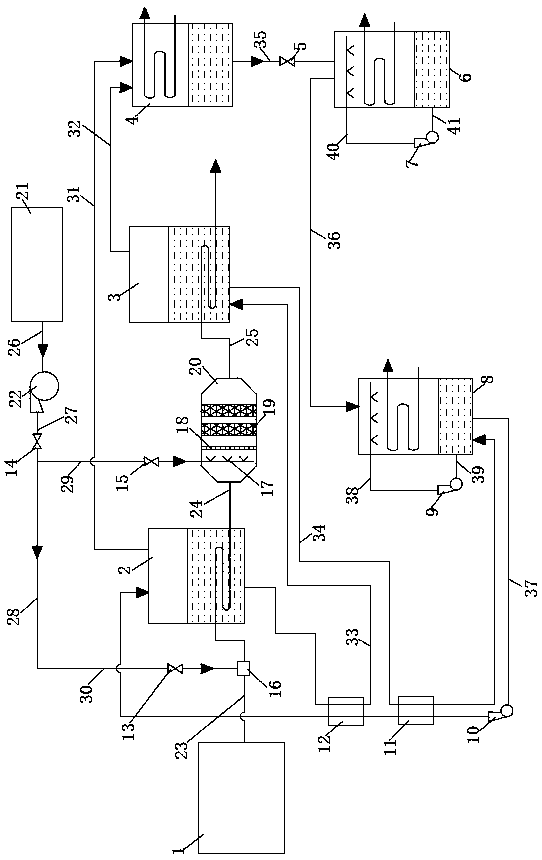

Coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process

InactiveCN105214478AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationAir quality improvementFlueFlue-gas desulfurization

The invention provides a coke oven flue waste gas desulfurization and denitrification and waste heat recovery integrated process. Coke oven flue waste gas is subjected to an SCR reaction under the effect of a low-temperature SCR denitrification catalyst to remove nitric oxides in flue waste gas, a sodium-based dry powder absorbent is sprayed to flue waste gas for desulfurization after waste heat is recovered through a waste heat boiler, and desulfurized flue waste gas is discharged up to standard after dust removal is conducted through a filter. The process is free of waste water, waste gas emission and heating, denitrification can be directly conducted, the absorbent can be recycled, investment is reduced, and energy is saved.

Owner:CHENGDU HUAXITANG INVESTMENT

Desulfurization system and desulfurization process thereof

InactiveCN103252158AReduce consumptionUniform flow rateDispersed particle separationEscape rateSaturated water vapor

The invention discloses a desulfurization system comprising a tower body, wherein a smoke inlet is arranged in the middle of the tower body; a pure smoke outlet is arranged at the top of the tower body; a slurry pool for containing slurry is formed on the lower part of the tower body; the slurry pool is provided with a mixed liquid outlet; a slurry spraying layer, a rising air gap and a clean water spraying layer are sequentially arranged from the smoke inlet to the pure smoke outlet from bottom to top; the bottom of the slurry pool is respectively connected with an oxidization mechanism and an ammonia supplying mechanism; and the desulfurization system further comprises a slurry circulating mechanism and a clean water circulating mechanism. The invention further provides a desulfurization process; and the process is low in water consumption amount so that the amount of saturated steam in pure smoke is reduced by 30-40% and consumption of external clean water is reduced. According to the desulfurization system and the desulfurization process disclosed by the invention, the operation cost is low; and the consumption of the steam is 20% of that of an ammonia-fertilizer method process and the consumption of power is 40% of that of the ammonia-fertilizer method process. The escaping rate of ammonia is low; the content of the ammonia in the pure smoke is less than 8mg / Nm<3>; no three wastes are discharged; and secondary pollution to an environment is not caused.

Owner:九美科技有限公司

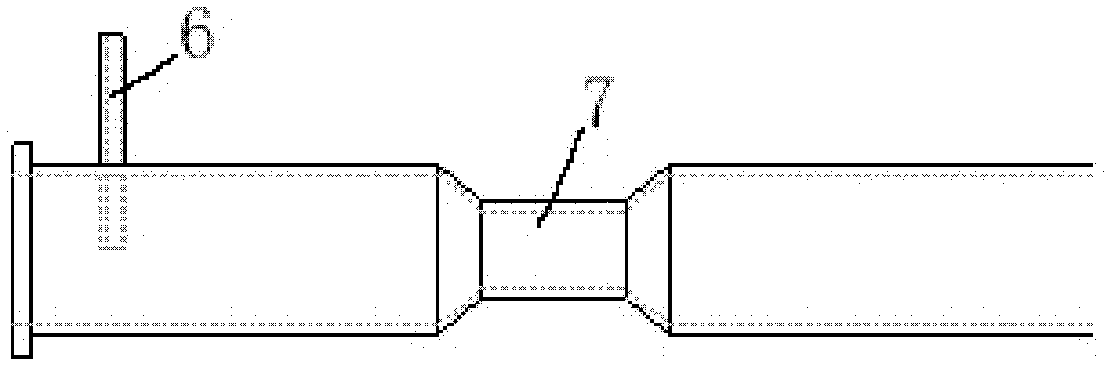

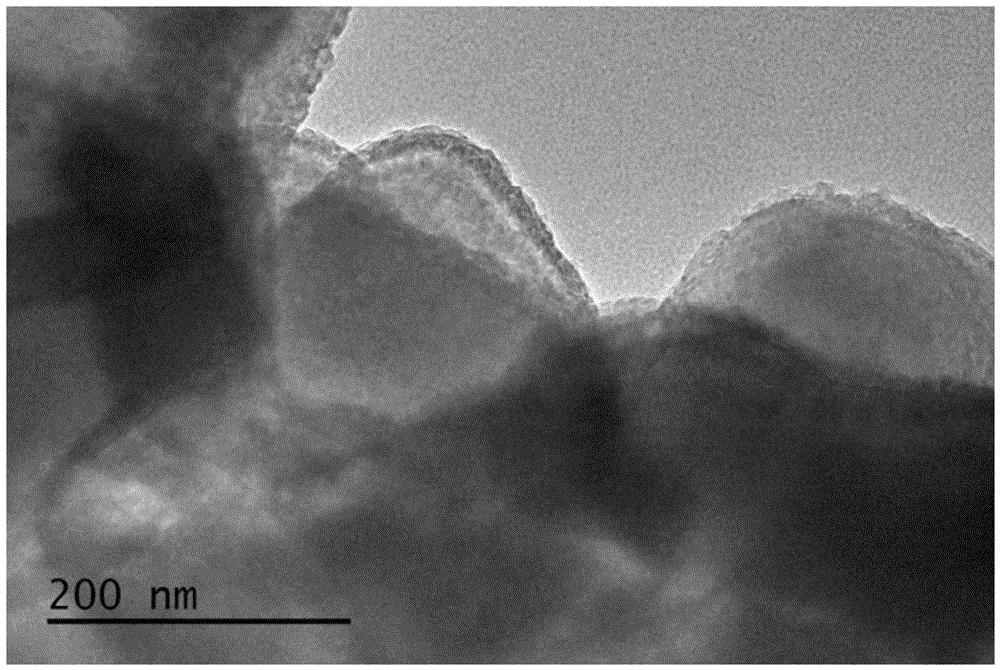

Preparation method of denitration and dedusting difunctional ceramic filter

ActiveCN105536528AIncrease the active specific surfaceReduce manufacturing costGas treatmentDispersed particle filtrationTungstenTitanium

The invention relates to a denitration and dedusting difunctional ceramic filter, and a preparation method and an application thereof. The preparation method of the denitration and dedusting difunctional ceramic filter includes the following steps: (1) with a titanium salt solution as a precursor, growing a TiO2 ultra-thin film in ceramic filter pores in situ by a precipitation method; and (2) loading the TiO2 ultra-thin film obtained in the step (1) with vanadium and tungsten, and thus obtaining the denitration and dedusting difunctional ceramic filter. The SCR denitration catalyst ultra-thin film is precipitated and grown in situ in the ceramic filter pores, is uniformly dispersed in nanometer scale, has adjustable thickness, and is firmly combined with a ceramic filter substrate; the prepared catalytic ceramic filter enables the NOx conversion rate to reach 80% of the limiting conversion rate and the ammonia escape rate to be less than 5 ppm with the NH3 / NOx ratio of 0.8 and in a wide temperature range of 180-420 DEG C; and at the same time, under the same pressure drop condition with an original filter, the catalytic ceramic filter can have the dust removal efficiency reaching more than or equal to 99%.

Owner:NANJING WEIHENG EXPERIMENTAL EQUIP CO LTD

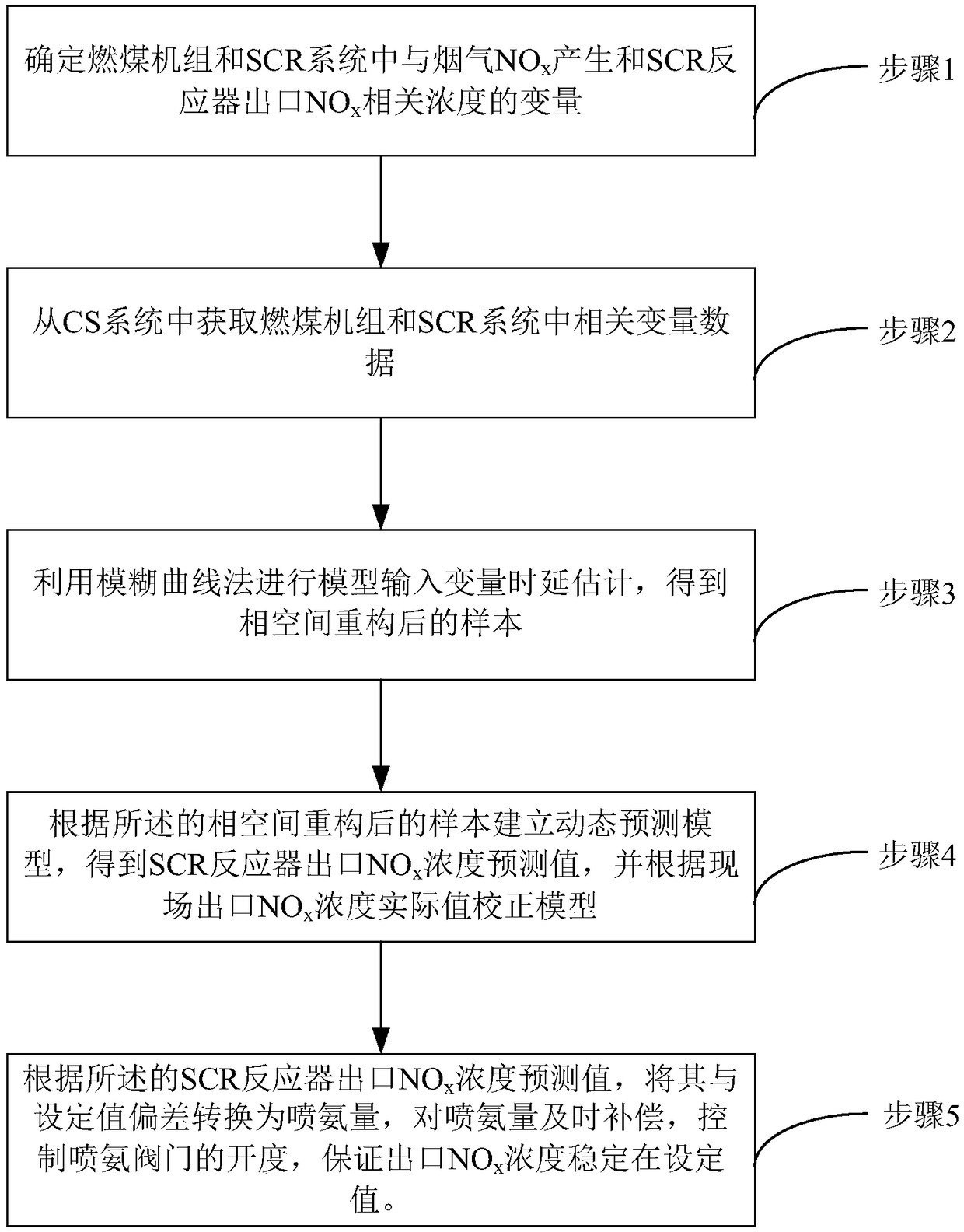

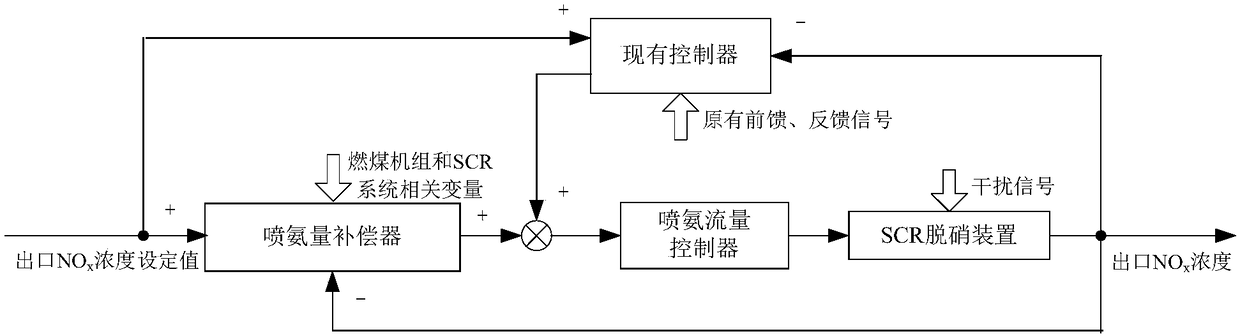

SCR flue gas denitration optimization control system and method based on ammonia spraying amount compensator

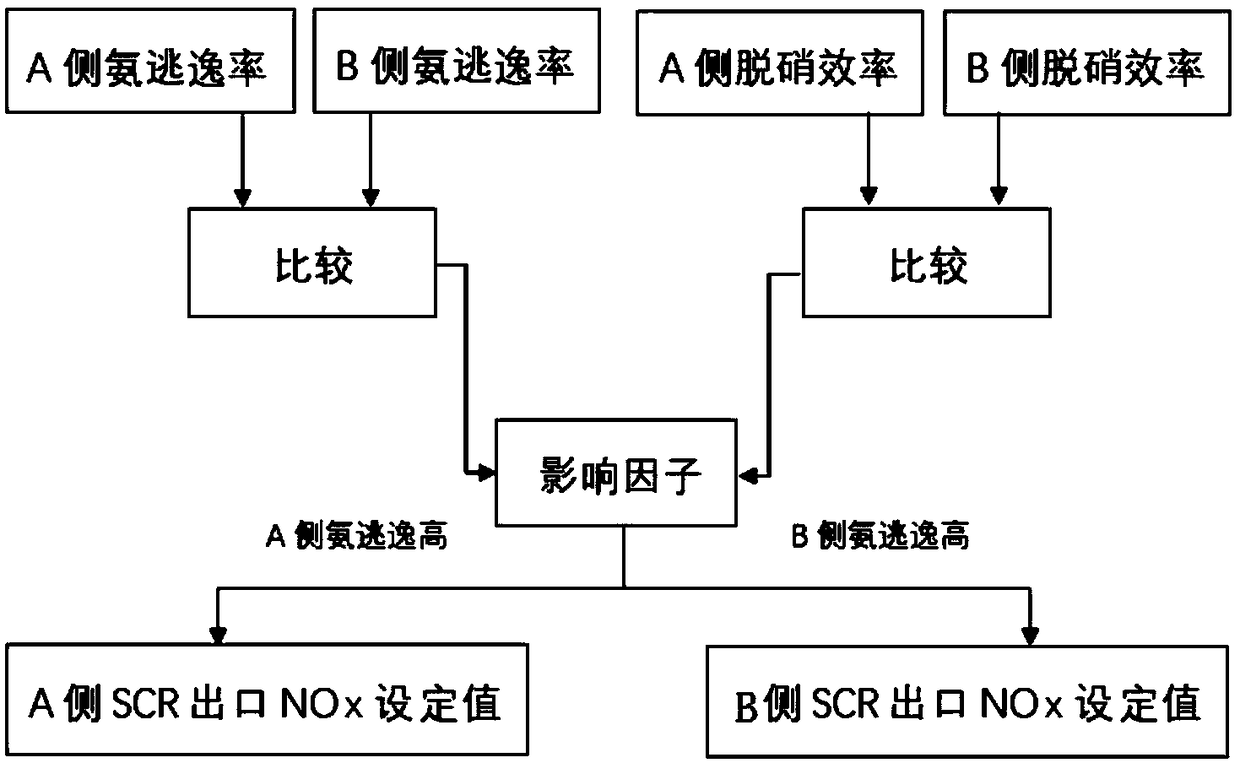

ActiveCN109343349AReduce escape rateReduce adverse effectsTotal factory controlAdaptive controlControl systemFlue gas

The invention discloses an SCR flue gas denitration optimization control method based on an ammonia spraying amount compensator. The method comprises the following steps of 1, determining variables related to the flue gas NOx generation and the outlet NOx concentration of an SCR reactor in a coal-fired unit and an SCR system; 2, acquiring related variable data in the step 1 from a DCS system; 3, performing input variable time delay estimation of a model by utilizing a fuzzy curve method, so that a sample after phase space reconstitution is obtained; 4, building an outlet NOx concentration dynamic prediction model according to the sample after the phase space reconstitution in the step 3, obtaining an outlet NOx concentration prediction value of the SCR reactor, and correcting the outlet NOx concentration dynamic prediction model according to an actual value of the field outlet NOx concentration; and 5, according to the outlet NOx concentration prediction value of the SCR reactor, obtained in the step 4, converting a deviation between the outlet NOx concentration prediction value of the SCR reactor and a set value into an ammonia spraying amount, timely compensating the ammonia spraying amount, and controlling the opening degree of an ammonia spraying valve to ensure that the outlet NOx concentration is stabilized to be the set value.

Owner:DATANG ENVIRONMENT IND GRP

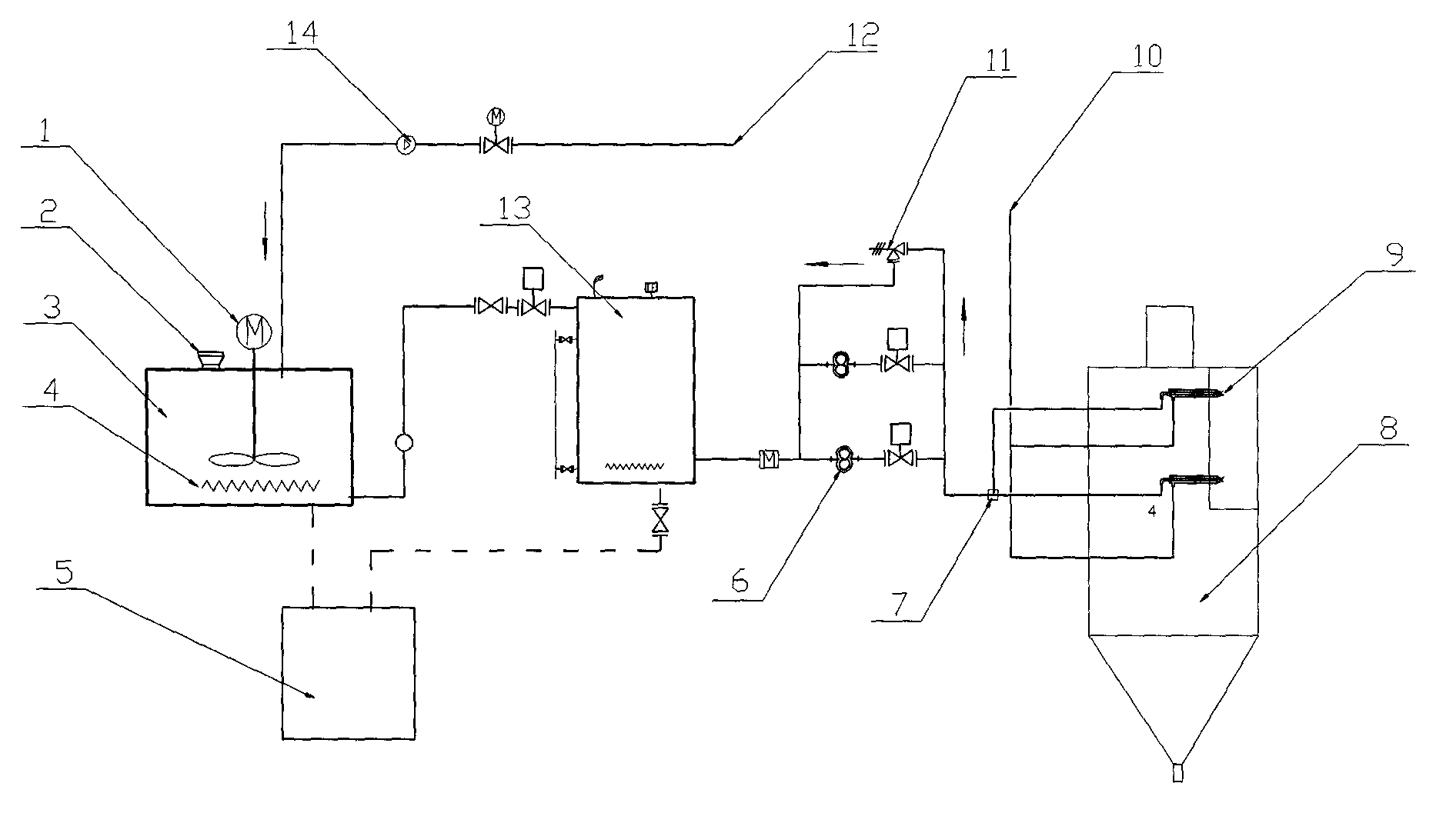

Flue gas ammonia desulfurization and deslagging system

InactiveCN102989306AReduce escape rateProblems that reduce qualityDispersed particle separationFiltration circuitsCycloneSmall footprint

The invention discloses a flue gas ammonia desulfurization and deslagging system. The flue gas ammonia desulphurization and deslagging system comprises a flue gas desulfurization sub-system, an ammonium sulfate separation sub-system and an ammonium sulfate deslagging sub-system; the flue gas desulfurization sub-system comprises an absorption tower and a flue gas pre-dedusting cooling device arranged at the position of a flue gas inlet of the absorption tower; the ammonium sulfate separation sub-system comprises a primary cyclone, a secondary cyclone, a dehydration centrifugal machine and a fluidized drying bed which are sequentially connected with one another; the ammonium sulfate deslagging sub-system comprises a filtrate tank, a mixing dosing tank and a filter press which are sequentially connected with one another; and a slurry outlet of the absorption tower is connected with the primary cyclone, a purified liquor outlet of the primary cyclone, a purified liquor outlet of the secondary cyclone and a liquid outlet of the dehydration centrifugal machine are connected with the filtrate tank, and accordingly, the three sub-systems are connected into a whole. By means of the flue gas ammonia desulfurization and deslagging system, ammonia escape amount can be reduced, the phenomenon of acid rain can be effectively relieved, utilization ratios of absorbents are increased, recovery rates of ammonium sulfate products are increased, qualities of the ammonium sulfate products are improved, occupied space areas are small, space is saved, and the system can be generally used in ammonia flue gas desulfurization of thermal power generation and sintering flue gases.

Owner:武汉钢铁有限公司

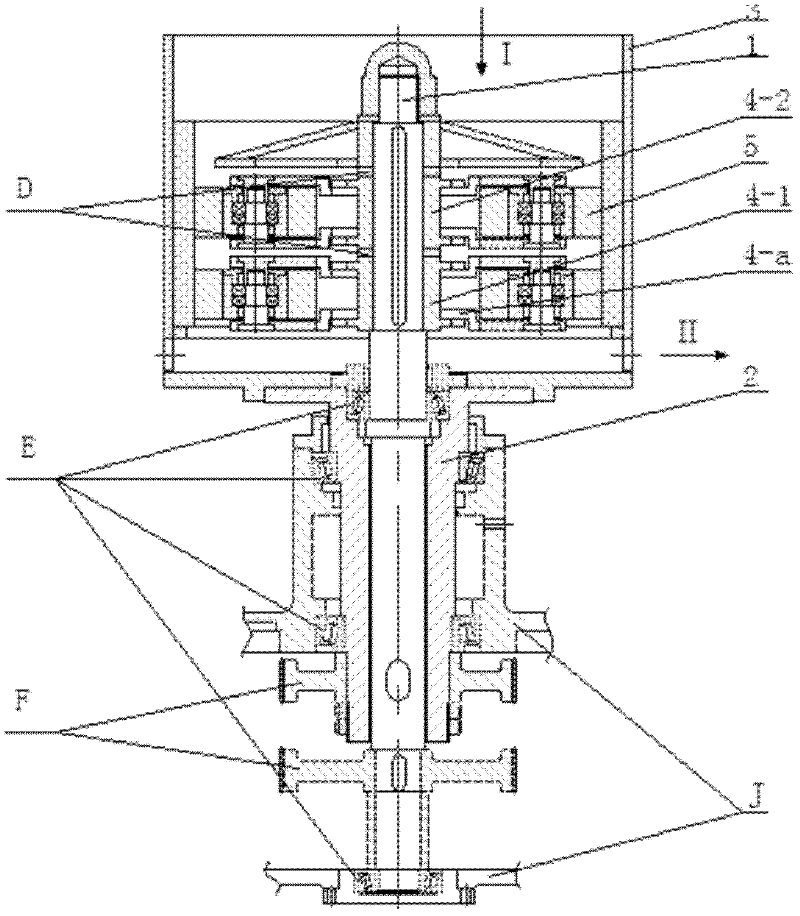

An ion source that reduces the rate of electron escape

ActiveCN109065429AReduce escape rateReduced chance of bombardmentIon beam tubesEscape rateMagnetic poles

The invention discloses an ion source capable of reducing an electron escape rate, including an anode ring, inner cathode and outer cathode, the anode ring, the inner cathode and the outer cathode areeach axisymmetric, a soft magnetic column is fixed in the middle of the yoke of the outer cathode, one end of the soft magnetic column passes through the center of the inn hole of the anode ring andis connected with the middle of the inner cathode, the longitudinal cross-sectional shape of the magnetic pole shoe of the inner cathode is mirror symmetrical with the longitudinal cross-sectional shape of the magnetic pole shoe of the outer cathode of the corresponding position, and an annular cathode gap is formed between the magnetic pole shoe of the inner cathode and the magnetic pole shoe ofthe outer cathode, the anode ring is directly opposite to the lower part of the cathode gap, two permanent magnets are arranged on the magnetic yoke of the outer cathode, the two permanent magnets aresymmetrical with respect to the soft magnetic column, and the two permanent magnets are respectively positioned directly below the opposite sides of the anode ring. By increasing the symmetrical magnetic field, the invention improves the uniformity of the magnetic field distribution on both sides of the cathode gap, can reduce the escape rate of electrons and effectively reduce the bombardment probability of the electrons on the cathode magnetic pole shoe.

Owner:成都极星等离子科技有限公司

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

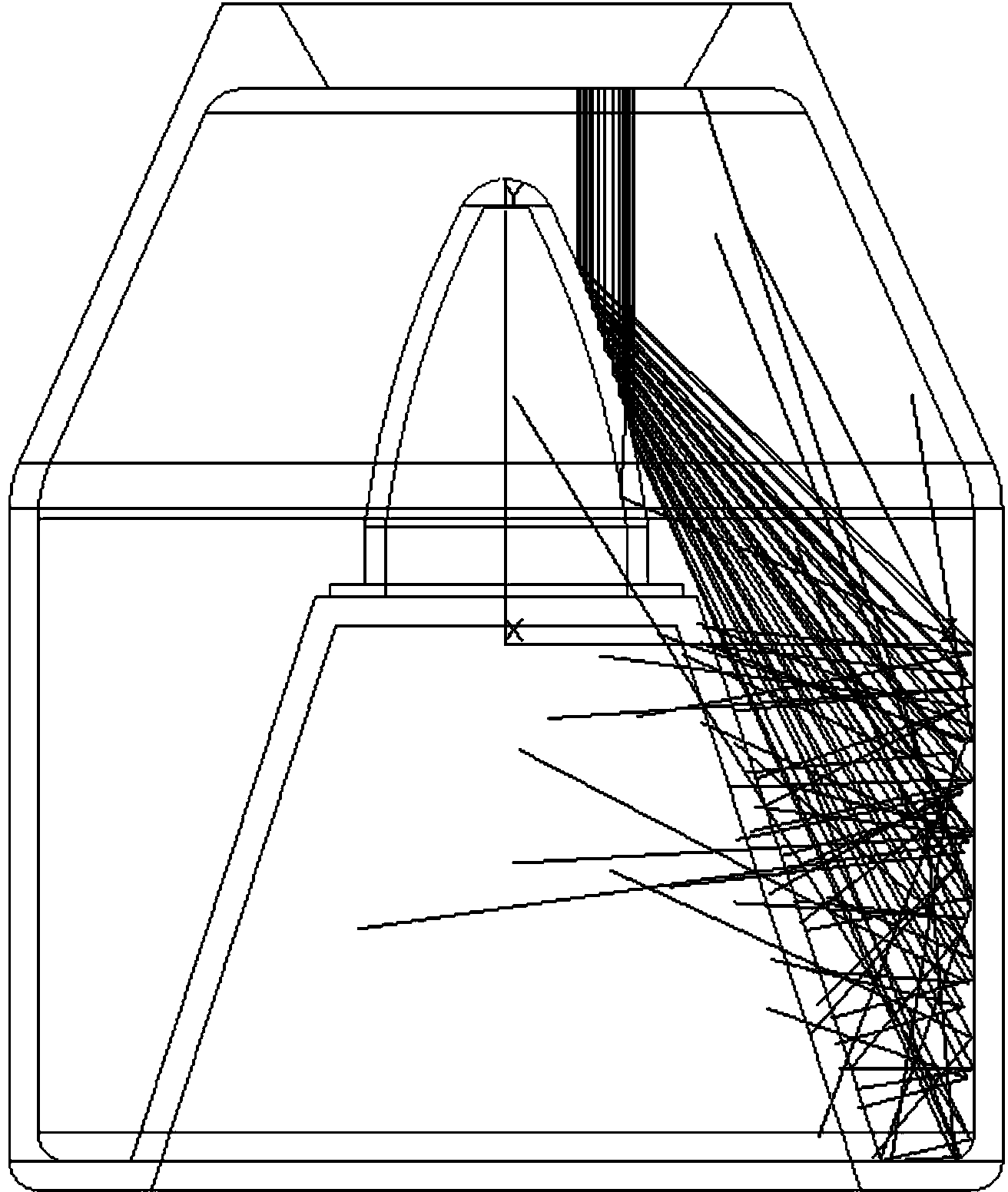

Total absorption superlaser energy meter

ActiveCN104048755AReduce laser power densityIncrease light receiving areaPhotometryLaser power densityCollimated light

The invention disclose a total absorption superlaser energy meter which comprises a reflection cone and an absorption cavity, wherein the generatrix of the reflection cone is arc-shaped, the absorption cavity is formed by sealed connection of a base plate, an inner lateral plate, an absorption cylinder and a cover plate, the whole structure of the absorption cavity is concave, the wall of the absorption cylinder is arranged on the light path of a superlaser beam after the superlaser beam is reflected through the reflection cone, and the absorption cylinder is located behind the reflection cone in the front and back direction. According to the total absorption superlaser energy meter, the incident collimated light beam is reflected onto the wall of the absorption cylinder in an axial and circumferential two-dimensional beam expansion mode, the power density of laser irradiating on the wall of the absorption cylinder is reduced greatly, the light receiving area of the reflection cone is increased at the same time, and the laser irradiation bearing capacity of the reflection cone is improved; furthermore, due to the adoption of the cavity structure, the probability that the reflection cone is polluted by dust is effectively reduced, and meanwhile, the exit escape rate of laser is reduced and measurement accuracy of the energy meter is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

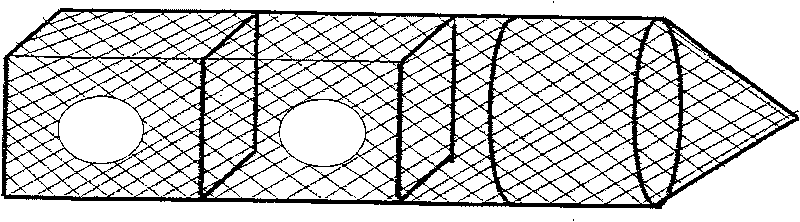

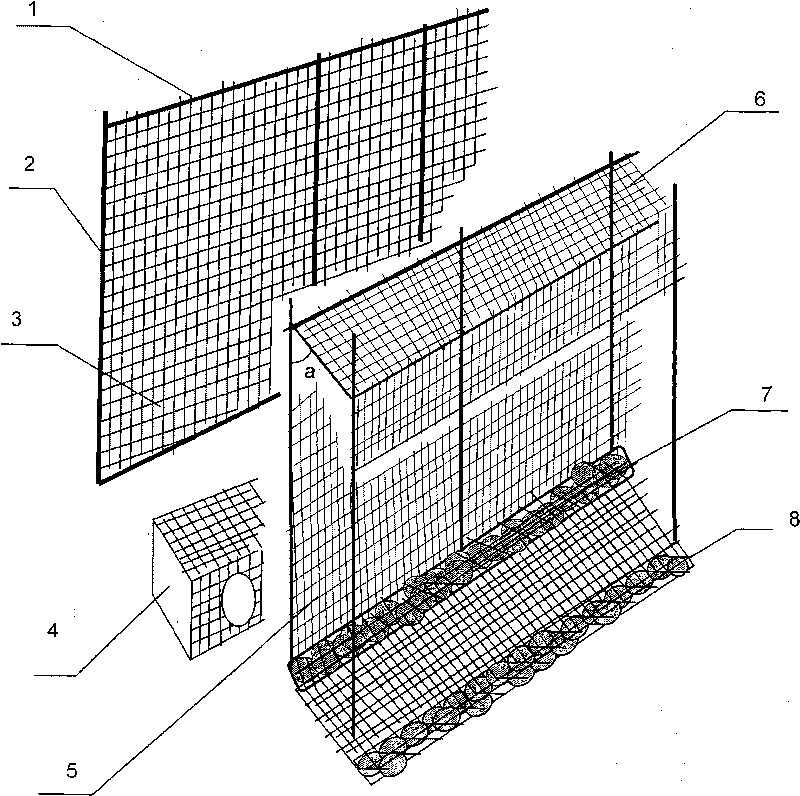

Combined netting gear for culturing river crabs in purse seine in lake

InactiveCN101715748APrevent escapeReduce escape rateClimate change adaptationPisciculture and aquariaSludgeAquatic product

The invention belongs to the technical field of aquaculture, and in particular relates to a combined netting gear for culturing river crabs in purse seine in a lake, which is combined by a purse net, galion meshes and other netting gears to prevent river crabs from escaping. An outer purse net and an inner purse net are both fixed on a mao bamboo pile; the bottom of the inner purse net, a main galion mesh and an auxiliary galion mesh are fixed together and sunk into mud; the upper end of the inner purse net is provided with a gamma-shaped reverse covering net (an escape preventing net); the bottom of the outer purse net is inserted into substrate sludge by a ground anchor for fixing; cage meshes are arranged at the water bottom in the middle of the inner purse net and the outer purse net. The combined netting gear has the advantages that the escape of the river crabs can be effective prevented by using two layers of purse nets; the upper end of the inner purse net is provided with the reverse covering net, so that even if the river crabs can creep up to the upper end of the inner purse net and finally reach the reverse covering net, the river crabs can also drop into a purse seine region; the arrangement of the main galion mesh and the auxiliary galion mesh ensures that meshes cannot drift under the condition that the purse nets encounters heavy storm.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

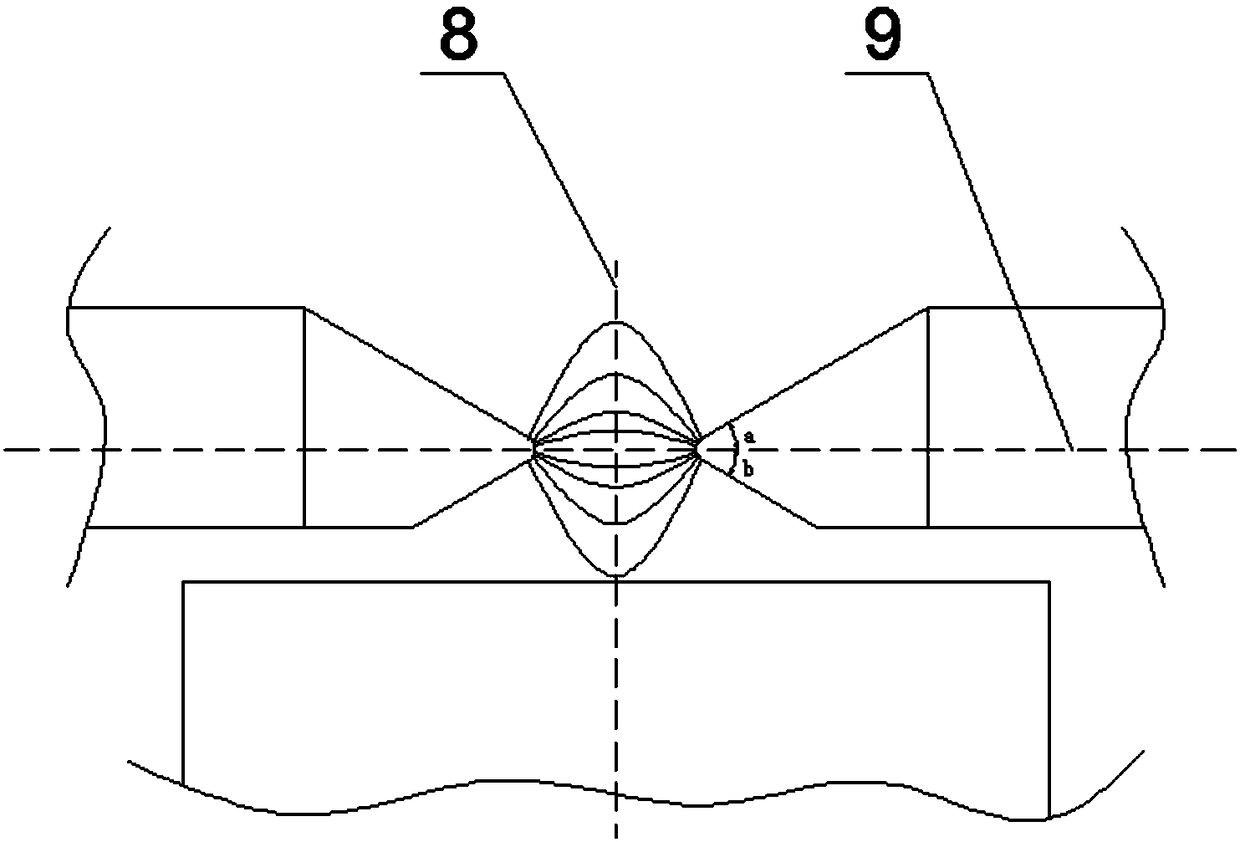

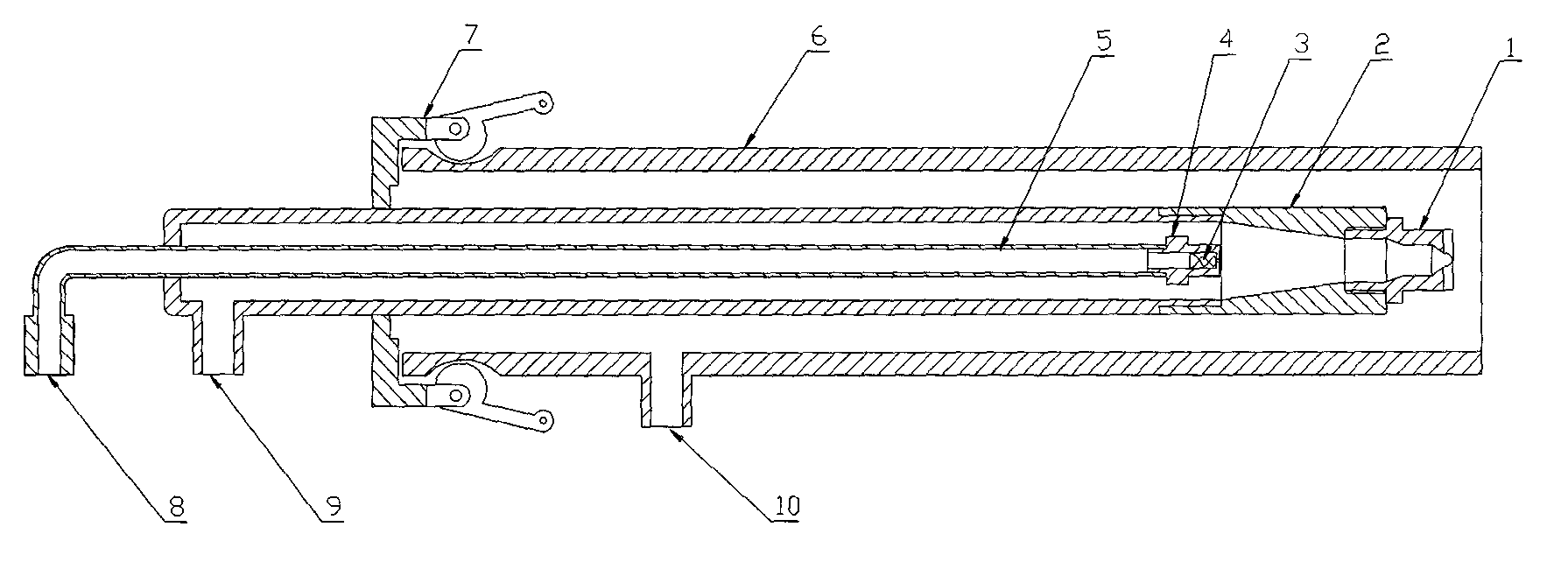

Double-atomization spray gun for SNCR (selective non-catalytic reduction) denitration system

InactiveCN103657385AReduce escape rateEasy to controlDispersed particle separationSpray nozzlesAgricultural engineeringEconomic benefits

The invention discloses a double-atomization spray gun for an SNCR (selective non-catalytic reduction) denitration system. The double-atomization spray gun comprises a reducer solution pipeline, a mechanical conical spraying nozzle, a compressed air sleeve, a fan-shaped air atomization nozzle, a protection sleeve and quick-connecting flanges, wherein the spray gun adopts a method of combining direct reducer solution atomization and secondary compressed air atomization, so that the atomization effect is relatively good; a compressed air flow and a reducer flow are independently adjustable and low in correlation, so that the control is relatively convenient and simple. The spray gun disclosed by the invention is connected with the sleeves by the quick-connecting flanges, the nozzle is connected with the spray gun by a thread, so that the connection and the replacement are convenient. The double-atomization spray gun is convenient to manufacture, low in cost, wide in application range, easy to popularize and implement, and good in economic benefits.

Owner:杨建华

Nitric oxide efficient control system and control method of gas internal combustion engine

ActiveCN108049946AReduce escape rateImprove uniformityInternal combustion piston enginesExhaust apparatusExternal combustion engineLithium bromide

The invention relates to a nitric oxide efficient control system and control method of a gas internal combustion engine. An outlet of the internal combustion engine is communicated with a first-stageammonia spraying device through a No.1 pipeline; the first-stage ammonia spraying device communicates with one end of a No.2 pipeline; the other end of the No.2 pipeline passes through a high-pressuregenerator; the other end of the No.2 pipeline is communicated with an inlet of an SCR reactor; an outlet of the SCR reactor is communicated with one end of a No.3 pipeline; the other end of the No.3pipeline passes through a low-pressure generator; a reducing agent storage groove is communicated with a dilution fan through a No.4 pipeline; one end of the No.5 pipeline is communicated with the dilution fan; one end of a No.6 pipeline and one end of a No.7 pipeline are communicated with the other end of the No.5 pipeline; the other end of the No.6 pipeline is communicated with the first-stage ammonia spraying device; the other end of the No.7 pipeline is communicated with the second-stage ammonia spraying device. The ammonia-nitrogen ratio distribution uniformity degree is improved; the denitration efficiency is improved; the ammonia escape rate is reduced; the refrigeration effect of a lithium bromide refrigeration unit is not influenced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

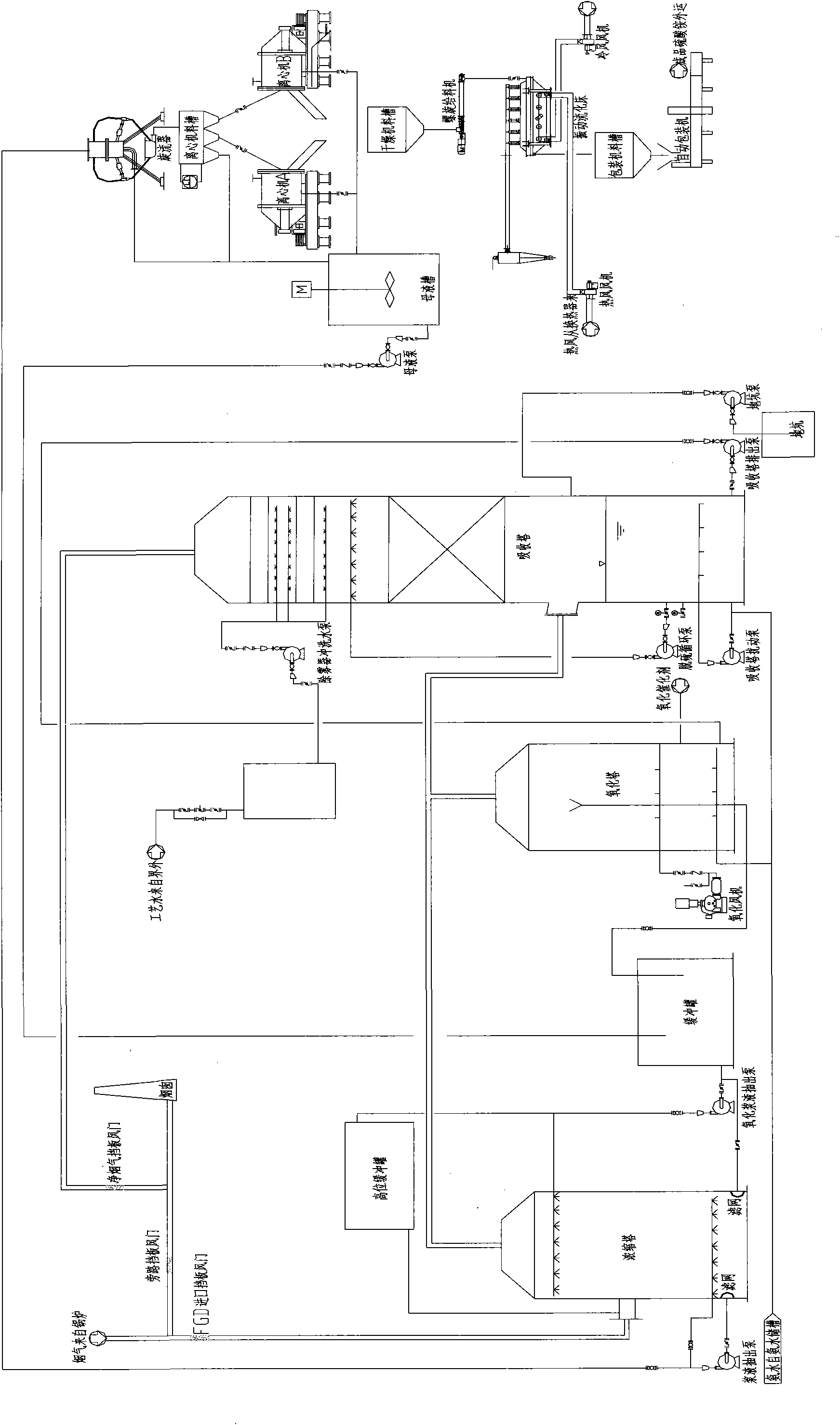

Process and device for carrying out flue gas denitrification by utilizing solid organic denitrifying agent

InactiveCN104383808AEnsure personal health and safetyWill not cause secondary pollutionDispersed particle separationSuperheaterChemical agent

The invention discloses a process and a device for carrying out flue gas denitrification by utilizing a solid organic denitrifying agent. According to the process, an organic denitrifying reducing agent is sprayed into a reaction area at the fume temperature of 500-950 DEG C and gasified and is subjected to selective uncatalyzed reaction with NOx contained in smoke gas, so that the purpose of denitrification is achieved. The core device of the process is highly-integrated integral equipment, is designed according to unit system and mainly comprises a denitrifying agent delivery supply system, a metering distribution system, a fluidic system, a gas delivery system, a chemical agent injection system and an on-line monitoring system. According to the smoke gas denitrification technology of the solid organic denitrifying agent, no change needs to be made on a boiler, and only the injection system needs to be added to the position at the fume temperature of 500-950 DEG C and between the smoke gas outlet of the boiler and a superheater. The process and the device which are disclosed by the invention have the characteristics of low operating cost, high safety, obviousness in denitrification effect and the like.

Owner:天津天和环能科技有限公司

Separation tower type boiler flue gas desulfurization process

InactiveCN101862582AHigh desulfurization rateLow running costDispersed particle separationEvaporationHeat energy

The invention discloses a process technology for removing sulfur dioxide from boiler flue gas to produce an ammonium sulfate fertilizer. High-temperature flue gas is firstly cooled by a concentrating tower and then enters a desulfurizing tower (absorption tower), and the flue gas is desulfurized together with an ammonium sulfite solution in the desulfurizing tower and is exhausted. Desulfurized ammonium sulfite solution is sent to an oxidizing tower so that ammonium sulfite is thoroughly converted into ammonium sulfate, the ammonium sulfate enters the concentrating tower to perform countercurrent heat exchange with the flue heat, so that water in the ammonium sulfite solution is evaporated. After the concentration reaches supersaturation, ammonium sulfate crystals are separated out, and a suspension containing the ammonium sulfate crystals is spirally flowed, centrifuged and dried into the finished product. The invention effectively utilizes the low-grade heat energy of the flue gas, and the ammonium sulfate evaporation system is saved; oxidation is adopted outside the desulfurizing tower, so that the oxidation is more thorough; the desulfurizing tower is a packed tower, the specific surface area is increased, the liquid-air ratio is low, the circulating volume of the absorbing liquid is reduced, and the equipment saves more energy; and the absorbing liquid controls not to crystallize at low concentration, and the phenomena of bias current and packing collapse caused by packing crystallization are avoided.

Owner:北京九州美电环保工程有限公司 +2

Combined denitration method and combined denitration device for flue gas of hazardous waste incineration system

ActiveCN106215664AImprove denitrification efficiencyReduce injection volumeGas treatmentDispersed particle separationLiquid wasteCombustion chamber

The invention relates to a combined denitration method and a combined denitration device for flue gas of a hazardous waste incineration system, belonging to the technical field of flue gas denitration of industrial hazardous waste incineration systems. According to the method and the device, to-be-processed organic liquid waste and a secondary combustion chamber auxiliary fuel, namely light diesel oil are used as re-combusting fuels for carrying out graded reduction removal on NOX in flue gas by combining with the characteristics of reburning denitration and selective non-catalytic reduction (SNCR), so that the denitration efficiency can be substantially improved, the NOX in the flue gas can meet the emission standard, the utilization rate of a reducing agent can be increased, the spraying amount of ammonia water can be reduced, and the production run cost can be lowered; meanwhile, primary hazardous waste incineration system equipment is modified slightly, so that the investment is low; and the emission load of the NOX in the flue gas can be effectively reduced, and the denitration efficiency can reach about 90%, so that the method and the device have wide market promotion and use values.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

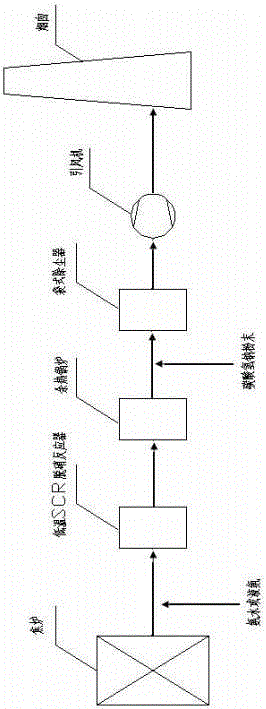

Integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery

InactiveCN105169943AMuch waste heat recoveryIncrease evaporationDispersed particle filtrationSteam generation using hot heat carriersPulverizerFlue-gas desulfurization

The invention provides an integrated system for coke oven flue gas desulfurization and denitrification and waste heat recovery. The integrated system comprises a coke oven, a low-temperature SCR denitrification system, a waste heat boiler, a flue, a pulverizer, a filtering system and a chimney. The coke oven, the low-temperature SCR denitrification system, the waste heat boiler, the filtering system and the chimney are sequentially connected through the flue, a dry powder absorbent inlet is formed in the portion, between the waste heat boiler and the filtering system, of the flue and is connected with an outlet of the pulverizer through a pipeline, and an absorbent inlet is formed in the pulverizer. The system is free from waste water and gas emission and capable of directly carrying out denitrification without heating, absorbent can be used circularly, investment can be reduced, and energy can be saved.

Owner:CHENGDU HUAXITANG INVESTMENT

Method for reducing ammonia escaping rate of flume denitration outlet

InactiveCN1788827AReduce escape rateReduce the impactDispersed particle separationAir quality improvementChemistryMolecular sieve

The method of lowering the escapement rate of ammonia in the outlet of fume denitrator is to perform secondary treatment of denitrated fume before it enters to the air preheater. One molecular sieve reactor is set before the air preheater to eliminate unreacted ammonia completely or partially to lower the escapement rate of ammonia. The molecular sieve reactor is filled with elite, active carbon or artificially synthesized molecular sieve, and the molecular sieve has homogeneous pore size in 2.8-3.8 angstrom. The apparatus of the present invention can well control the escapement rate of ammonia, reduce the influence on the downstream apparatus, avoid secondary pollution, simplify the ammonia spaying set and its control system, and lower investment cost and running cost.

Owner:徐海涛 +2

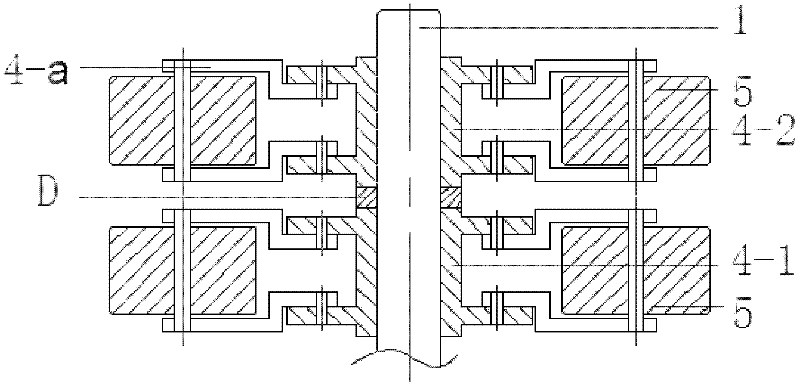

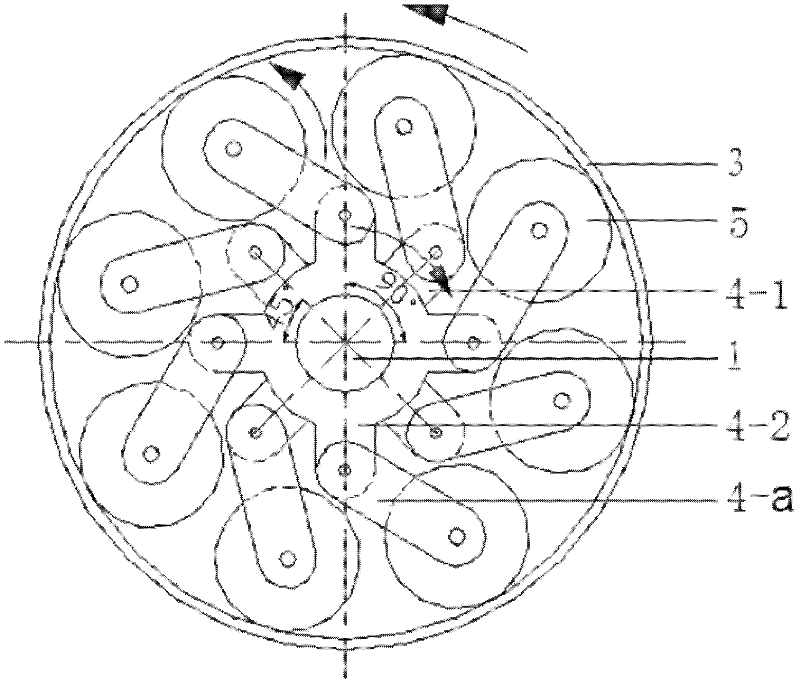

Multilayer planetary roller mill

InactiveCN102327798AImprove grinding efficiencyReduce escape rateGrain treatmentsRoller millEscape rate

The invention relates to a multilayer planetary roller mill, which belongs to the field of powder grinding processing equipment. In the multilayer planetary roller mill, a grinding cylinder is fixedly connected with a hollow rotating shaft, a grinder roll bracket is a multilayer connecting bracket which is axially arranged at intervals, each layer of connecting bracket is movably connected with grinder rolls through connecting chains which are uniformly arranged in the radial direction at intervals, a central rotating shaft passes through a central axis of the grinder roll bracket to be fixedly connected with the grinder roll bracket, the central rotating shaft is sleeved inside the hollow rotating shaft to be integrally arranged inside the grinding cylinder, the central lines of the two rotating shafts are overlapped, the central rotating shaft and the hollow rotating shaft are respectively connected with a power device and rotate in reverse directions, and the grinder rolls rotate in opposite directions with the grinding cylinder inside the grinding cylinder. On one hand, the grinder rolls are driven by the grinder roll bracket and affected by the friction force with the grinding cylinder to obtain a higher speed than that of the grinding cylinder, and on the other hand, multilayer and multi-angle grinding working surfaces which are formed through the grinder rolls which are movably connected with the multilayer connecting bracket, the grinding working efficiency of the materials can be adequately improved and the escaping rate of the materials can be reduced.

Owner:武汉宇格电力设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com