Multilayer planetary roller mill

A technology of planetary rollers and mills, applied in grain processing, etc., can solve the problems of low critical speed of the mill, low energy utilization rate, and inability to increase the speed of the mill, and achieve high grinding efficiency, improved grinding efficiency, and improved grinding work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

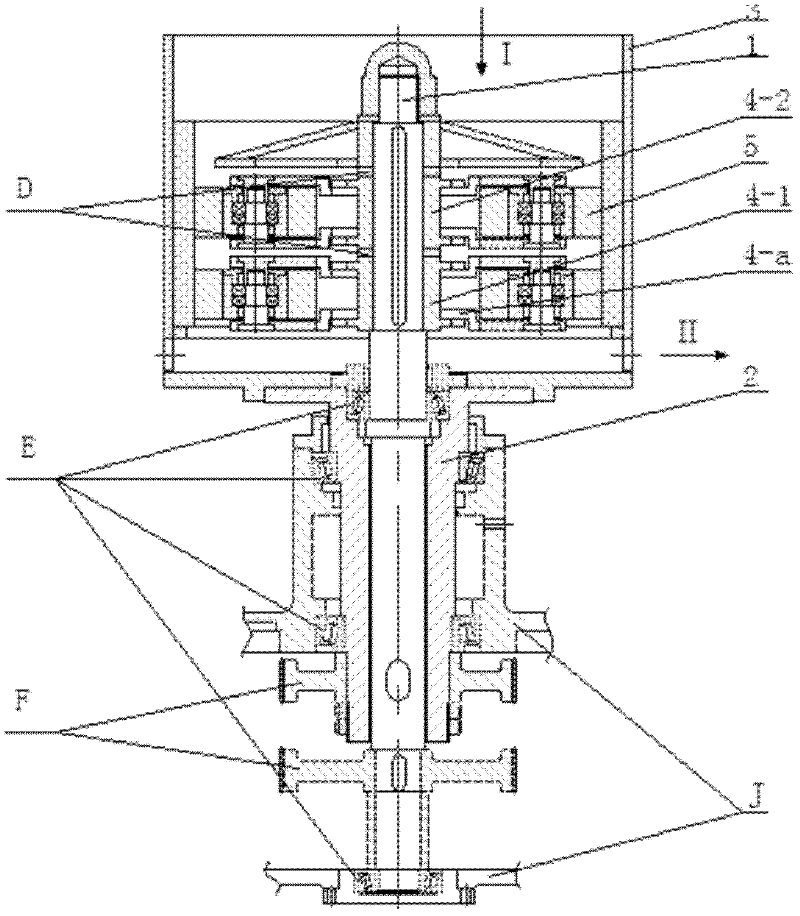

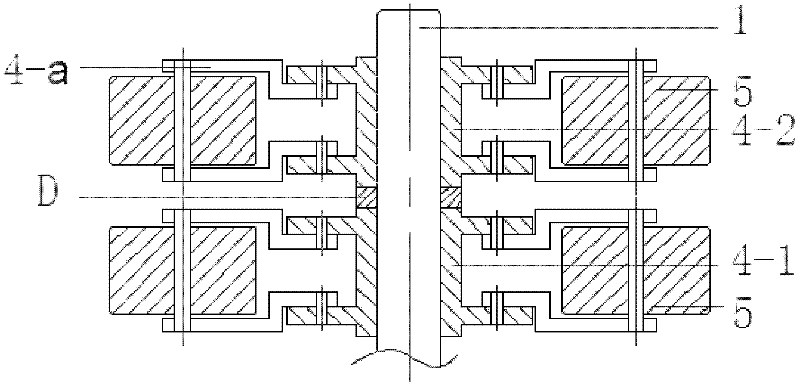

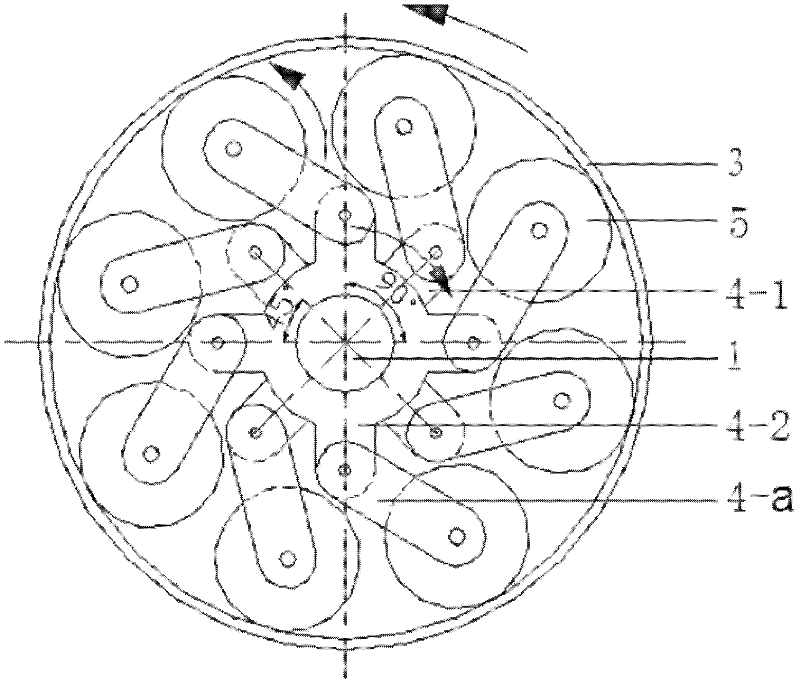

[0020] Now in conjunction with accompanying drawing, further illustrate how the present invention is implemented:

[0021] The multilayer planetary roller mill of the present invention comprises a frame, a central rotating shaft, a hollow rotating shaft, a grinding cylinder, a grinding roller frame and a grinding roller.

[0022] The grinding roller frame of this design is a multi-layer connection frame arranged at axial intervals, and a plurality of connection chains can be arranged at radial intervals of each layer of connection frame, and each connection chain is respectively connected with the grinding roller.

[0023] Taking a grinding roller stand with two layers of connecting frames, each layer of connecting frames is respectively provided with four connecting chains at radial intervals as an example to further illustrate the implementation of the present invention. (like figure 1 , 2 、3)

[0024] The grinding cylinder 3 is fixedly connected with the hollow shaft 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com