Water-based glass grinding fluid

A glass grinding fluid, water-based technology, applied in the field of grinding fluid, can solve the problems of inability to improve the grinding precision and the service life of the abrasive tool, can not be satisfied at the same time, and the glass grinding efficiency is insufficient, and achieve excellent chemical stability , good chemical sharpening effect, excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

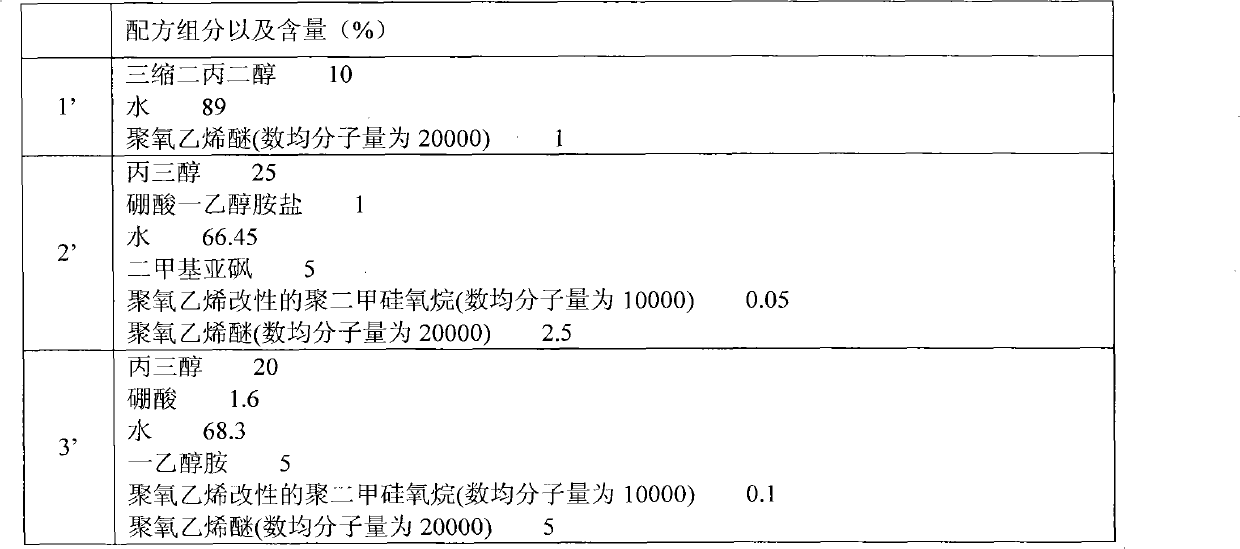

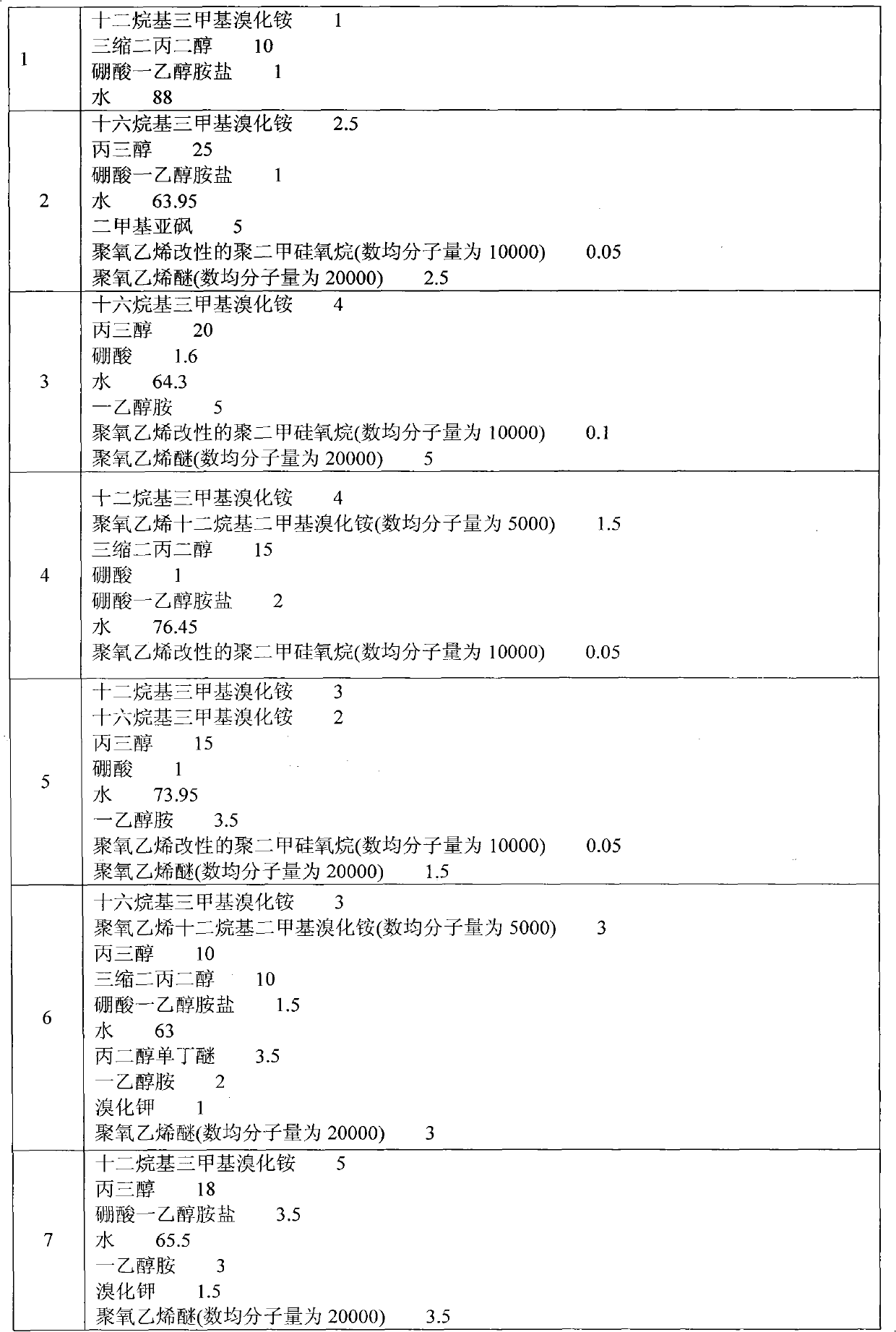

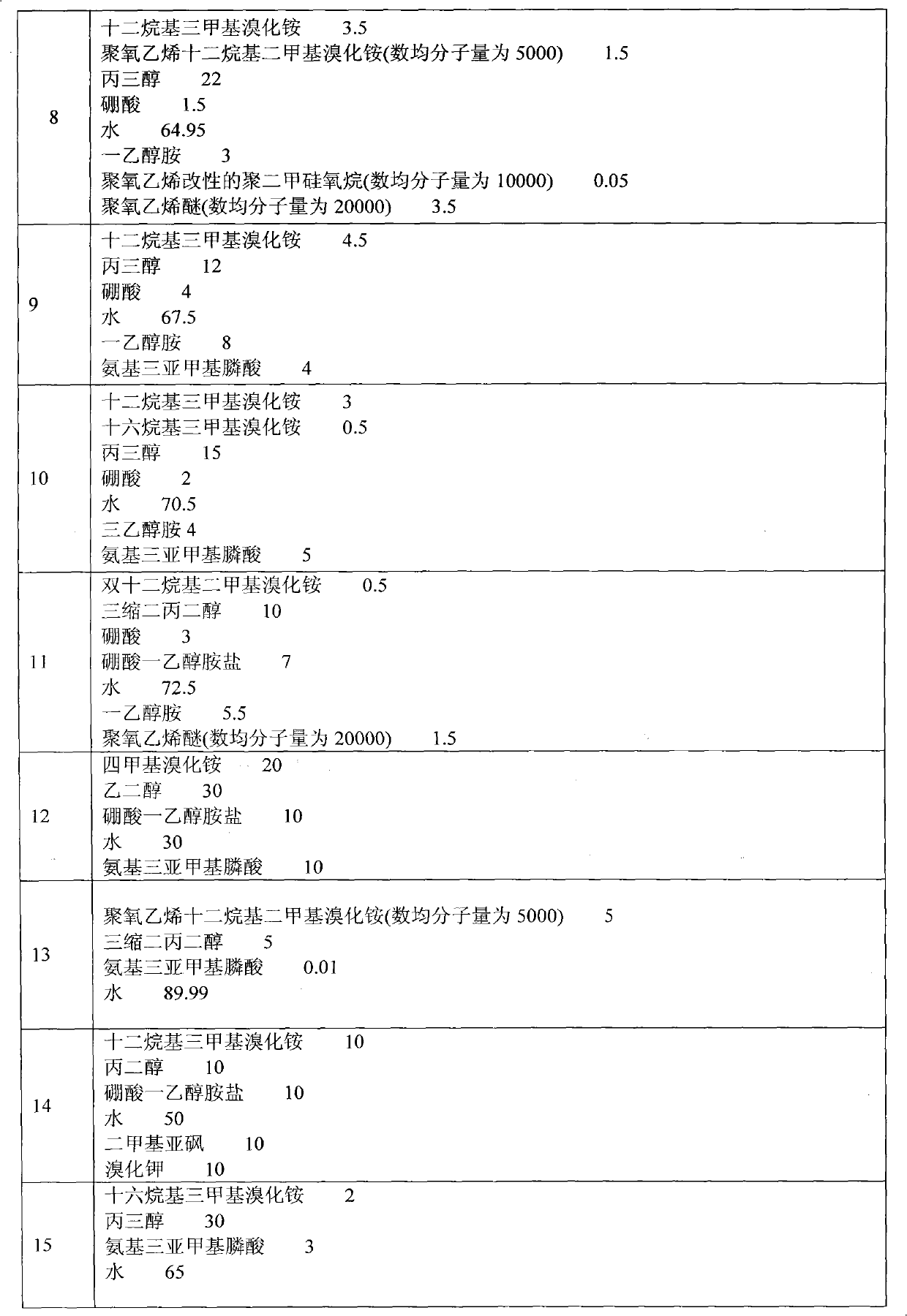

[0041] The beneficial effects of the present invention will be further described below through preferred effect examples of the present invention, but the present invention is not limited to the scope of the described examples. In the following examples, the percentages are all mass percentages.

[0042] Effect embodiment contrasts water-based glass grinding fluid 1'~3' and water-based glass grinding fluid 1~10 of the present invention

[0043] Table 1 provides the formulas of comparative water-based glass grinding fluids 1'~3' and cleaning agent compositions 1~10 of the present invention. According to the components listed in Table 1 and their contents, simply mix them uniformly to obtain Various water-based glass grinding fluids.

[0044] Table 1 compares the components and contents of water-based glass grinding fluid 1'~3' and water-based glass grinding fluid 1~10 of the present invention

[0045]

[0046]

[0047]

[0048]

[0049] Among the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com