Patents

Literature

306results about How to "Efficient washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

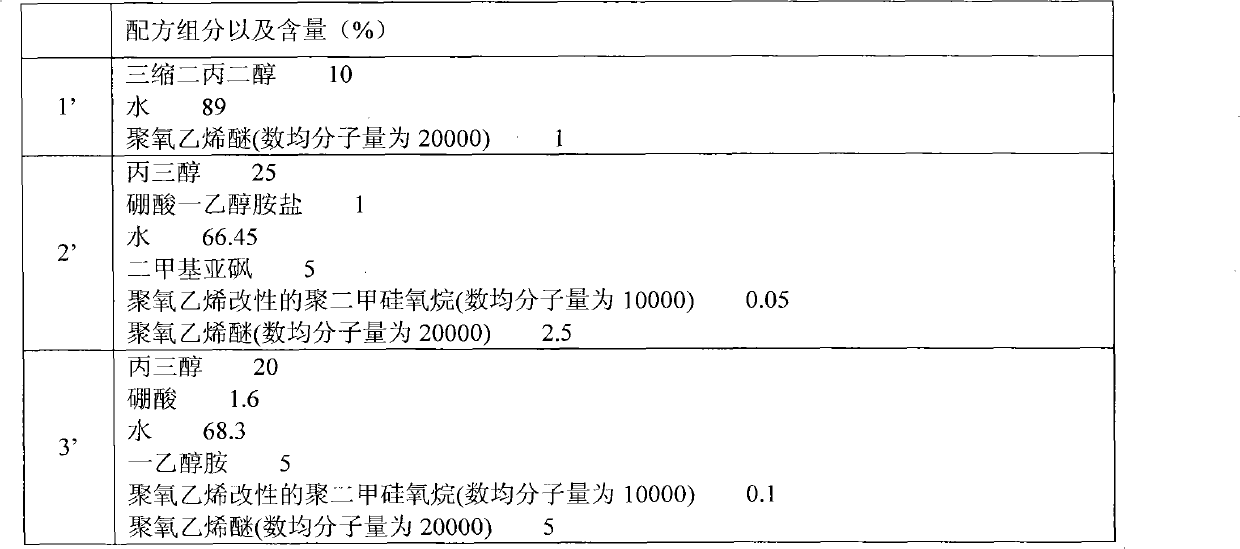

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

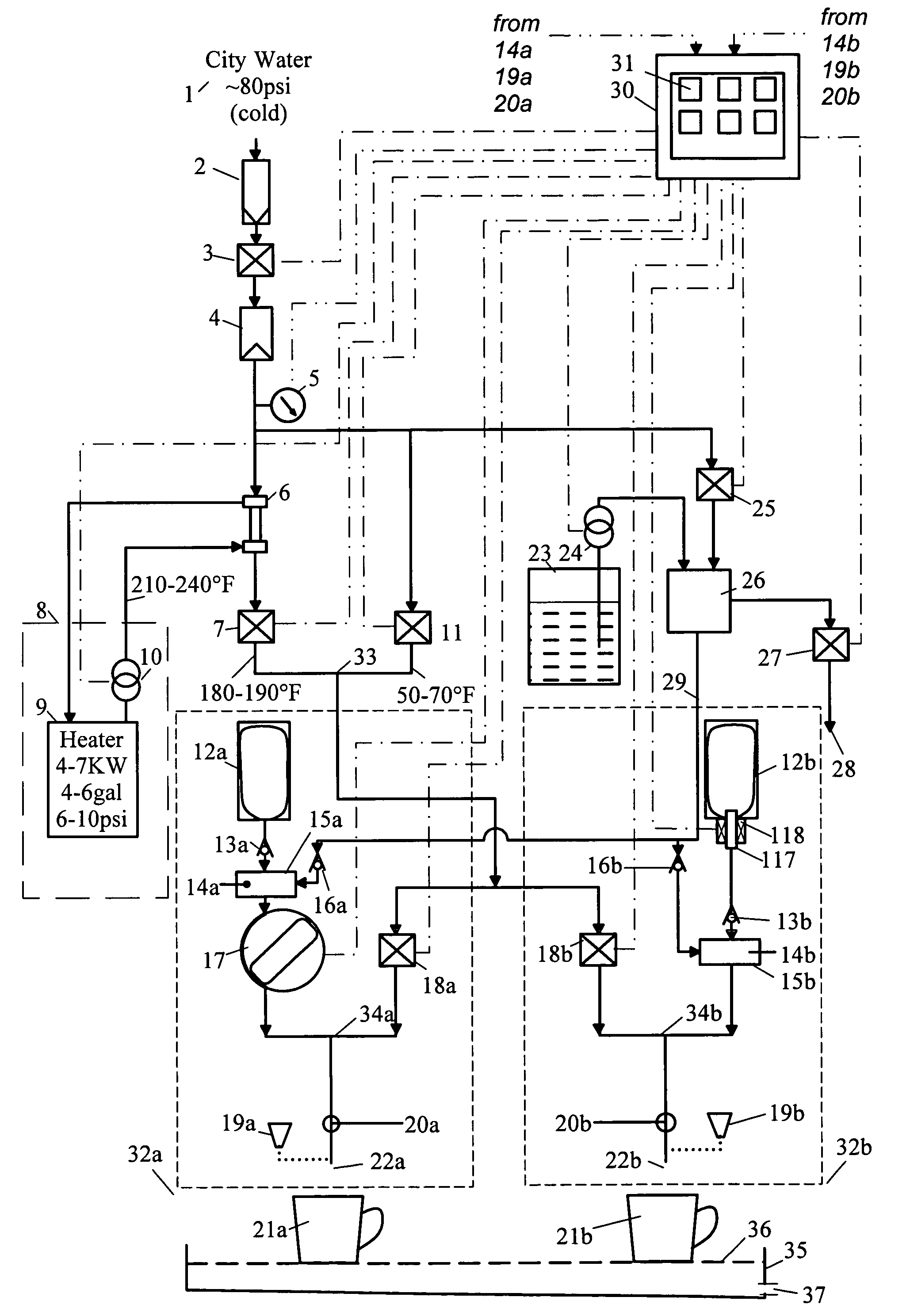

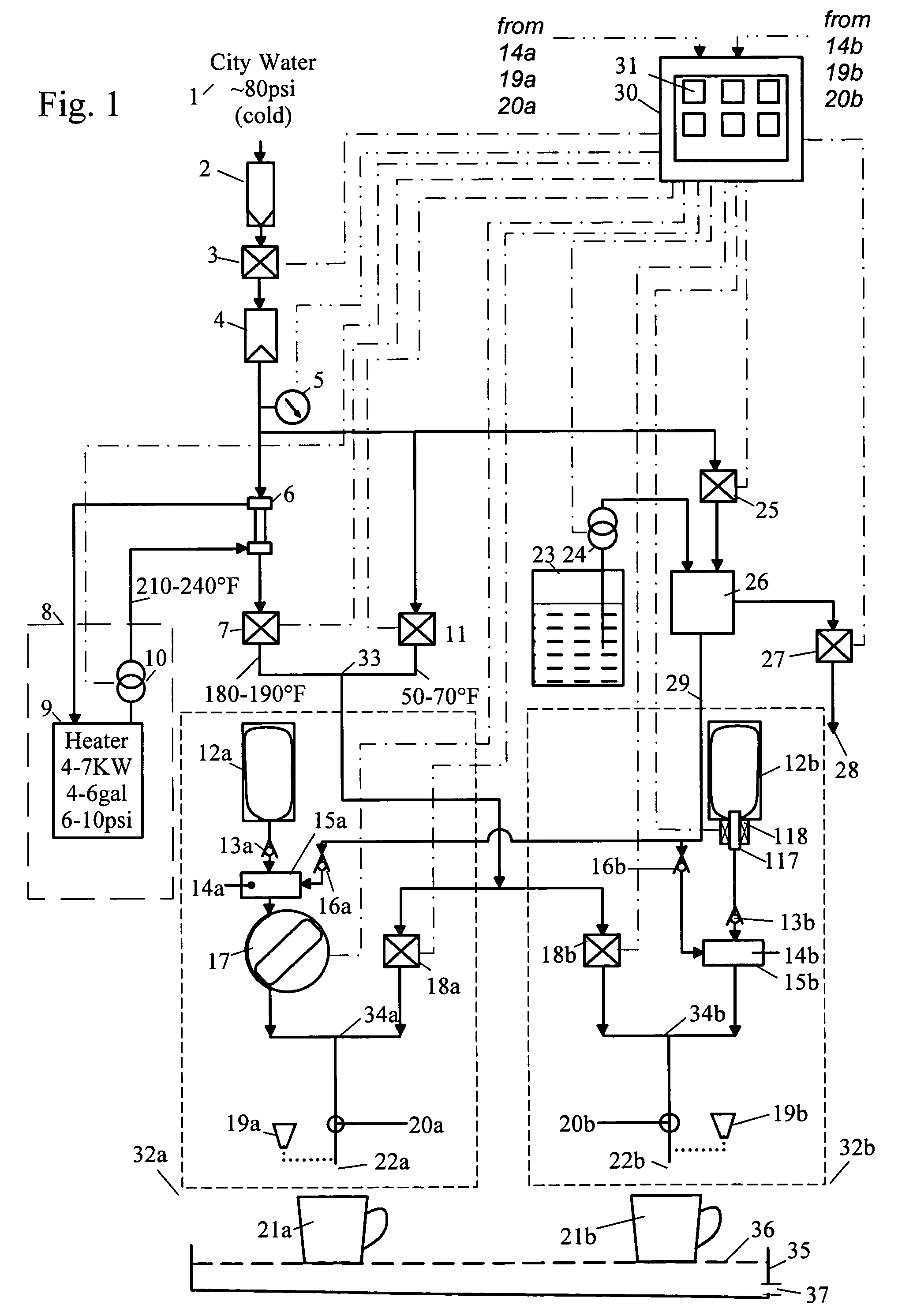

Beverage dispenser

InactiveUS7654191B2Improves aroma and look and tasteEffectively sanitizedBeverage vesselsLiquid transferring devicesWater useEngineering

A beverage dispenser and method of operation, in which incoming water for beverage preparation is heated by a liquid-to-liquid heat exchanger. The heated water may be mixed with cold water using controlled valves, to generate a selected temperature stream. This controlled-temperature stream may be mixed with beverage concentrate or sprayed over coffee grounds to brew fresh coffee.

Owner:GREENWALD TECH

Manufacture of test strips

InactiveUS6130100AEfficient washingPromote reagent stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteTest strips

A process of manufacturing test strips of the type comprising a length of porous carrier material capable of acting as a liquid flow path for a sample liquid and having at least zone downstream from a first end of the strip which zone contains an immobilized specific binding agent to act as a capture means during an assay to reveal the presence of an analyte in applied sample liquid, and in which process the specific binding agent is deposited onto a sheet of the porous carrier material which is then blocked and subdivided into a plurality of individual identical test strips, wherein blocking of the porous carrier material is achieved by applying a solution of blocking agent to the sheet upstream from the zone in an amount sufficient to ensure that the solution permeates downstream to beyond the zone. Preferably there is a plurality of zones of immobilized agent arranged in series on the strip, and wherein blocking is achieved by applying a solution of blocking agent to the sheet upstream from the first of the plurality of zones in an amount sufficient to ensure that the solution permeats downstream to beyond the last of the plurality of zones.

Owner:UNILEVER PATENT HLDG BV +1

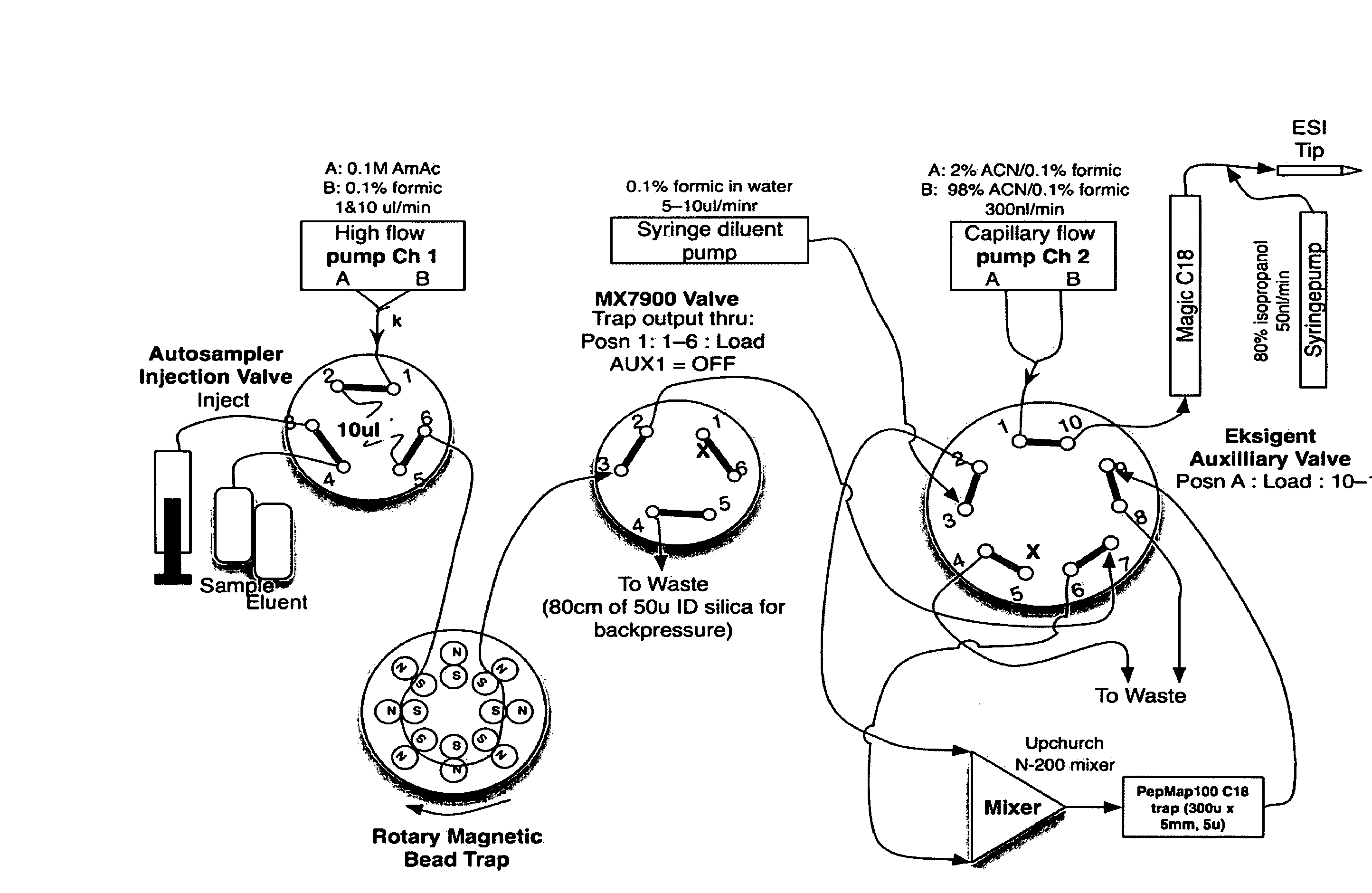

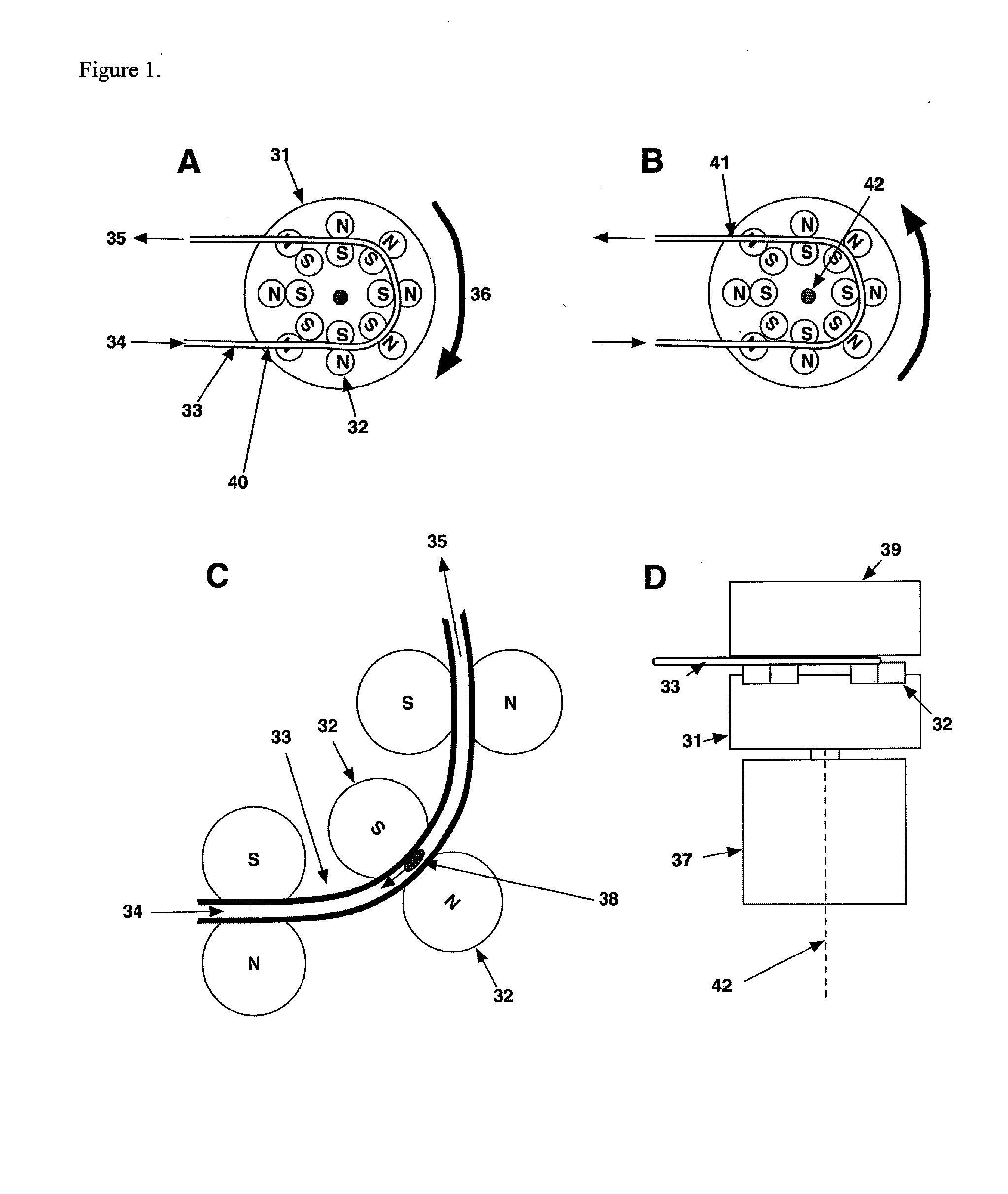

Magnetic Bead Trap and Mass Spectrometer Interface

InactiveUS20080217254A1Rapid introductionReduce lossesSludge treatmentElectrostatic separatorsAnalyteMagnetic bead

A device and method for capture of magnetic beads in a rotary magnetic bead trap is disclosed. The device allows capture, washing, elution and ejection of beads in an automated system. Analyte is eluted in a small volume in a capillary-scale fluid system compatible with LC-MS / MS analysis.

Owner:ANDERSON FORSCHUNG GROUP

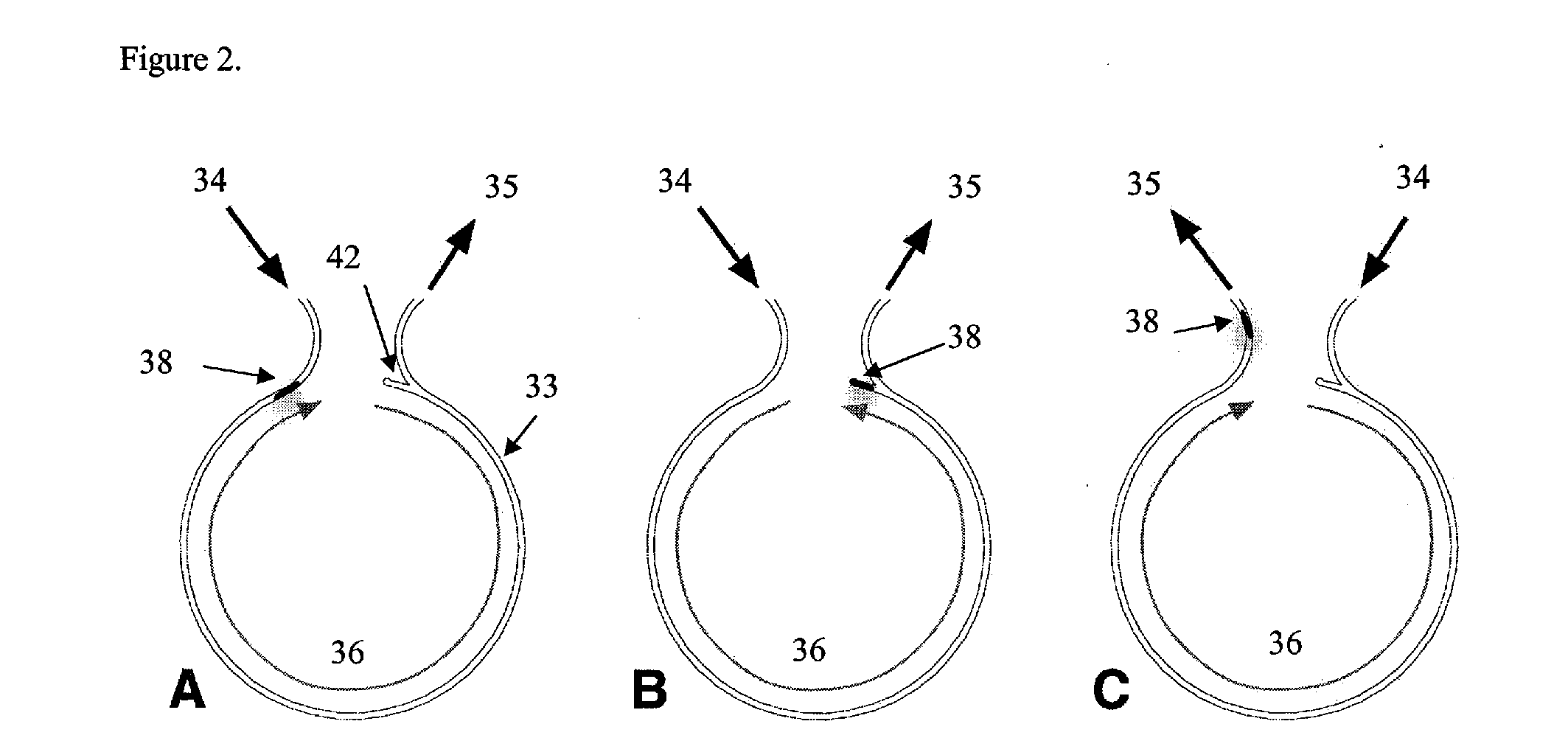

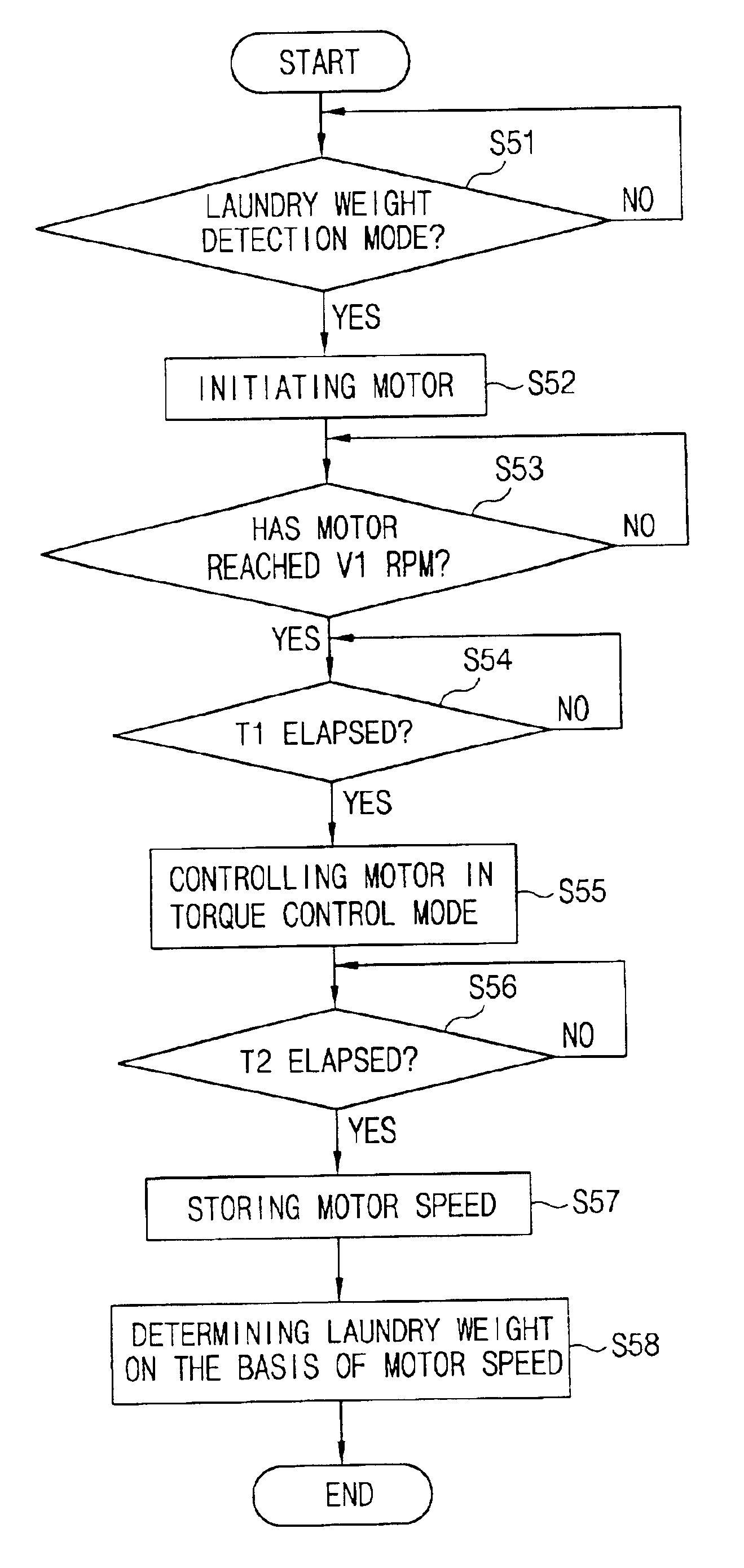

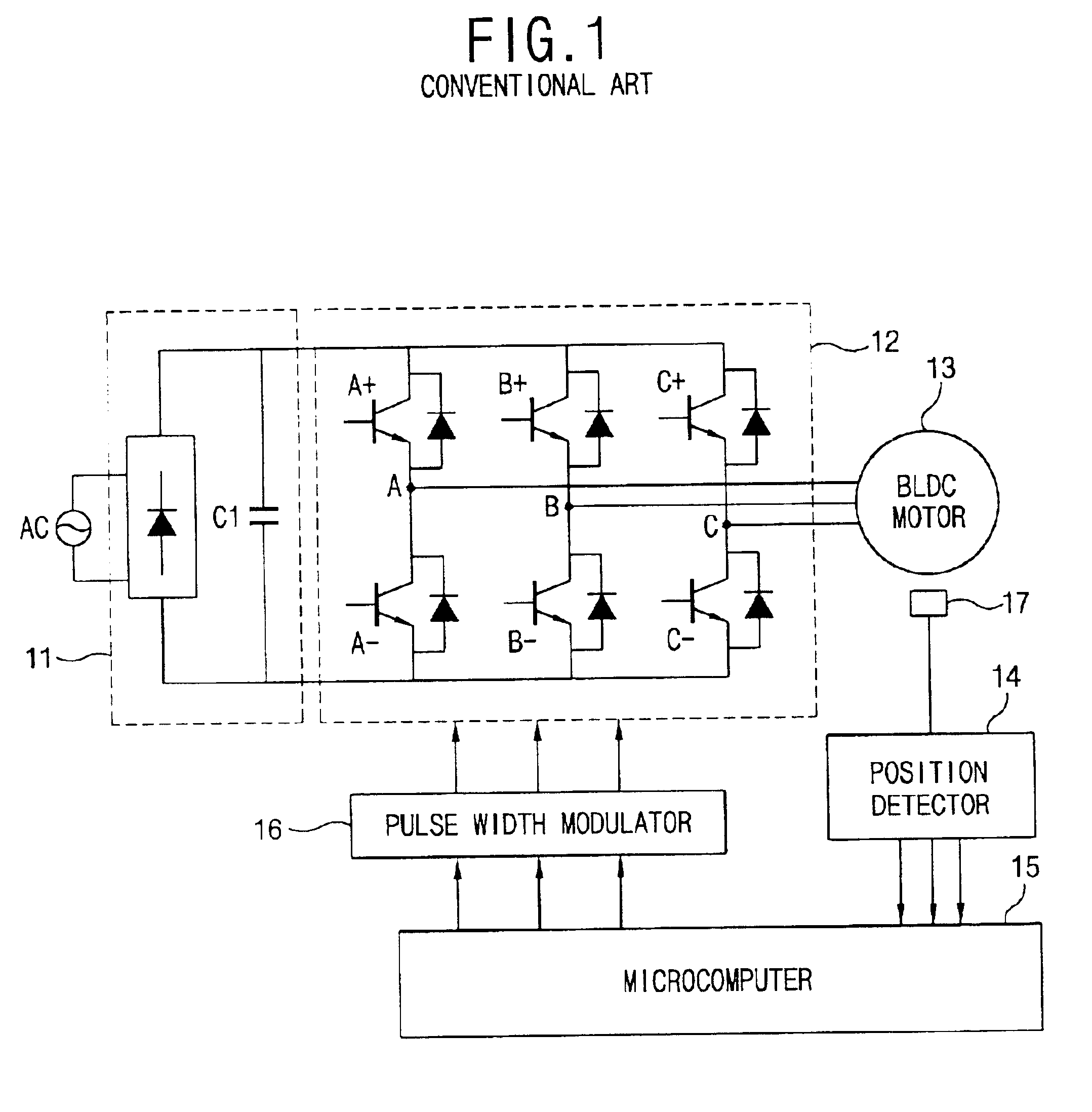

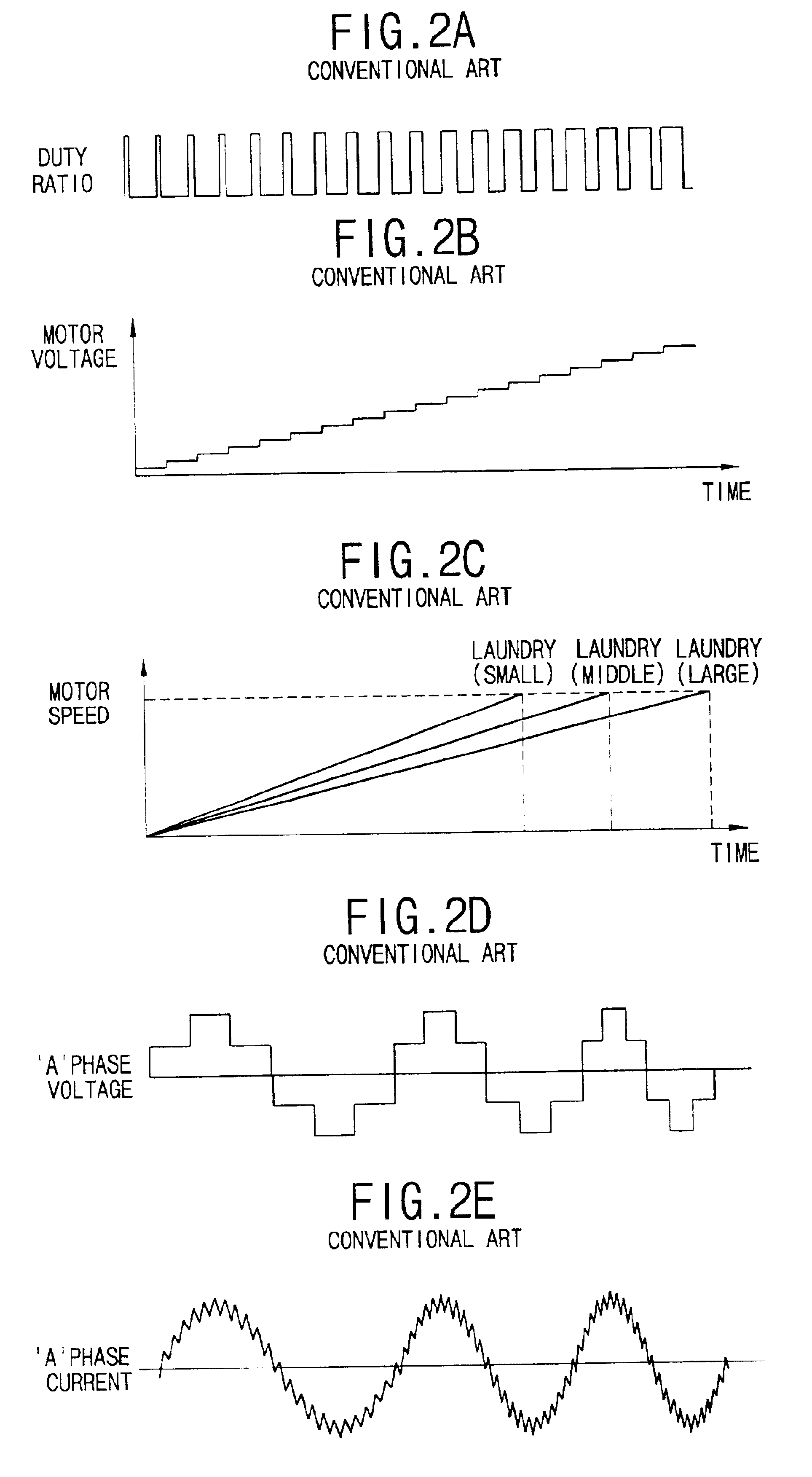

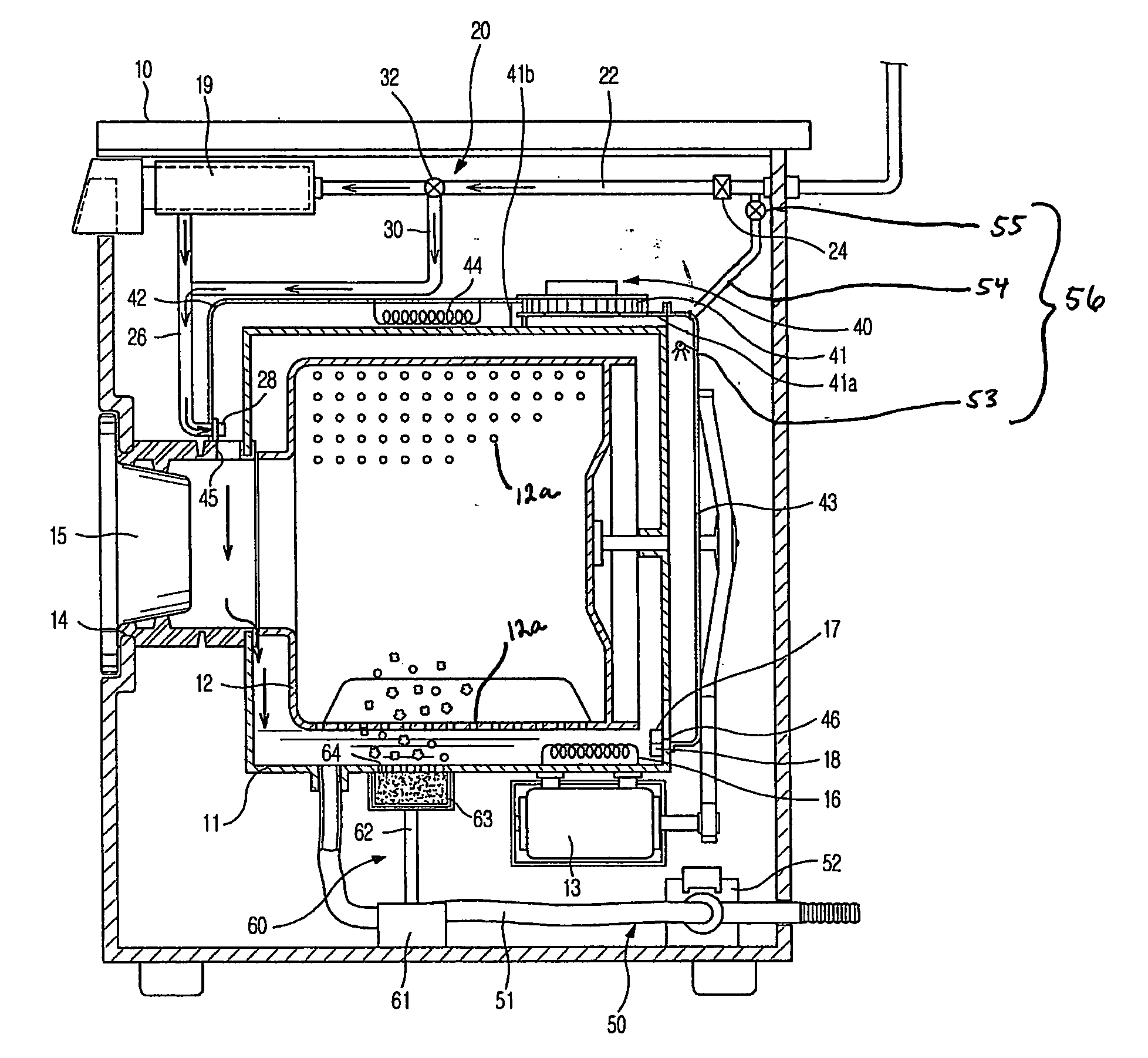

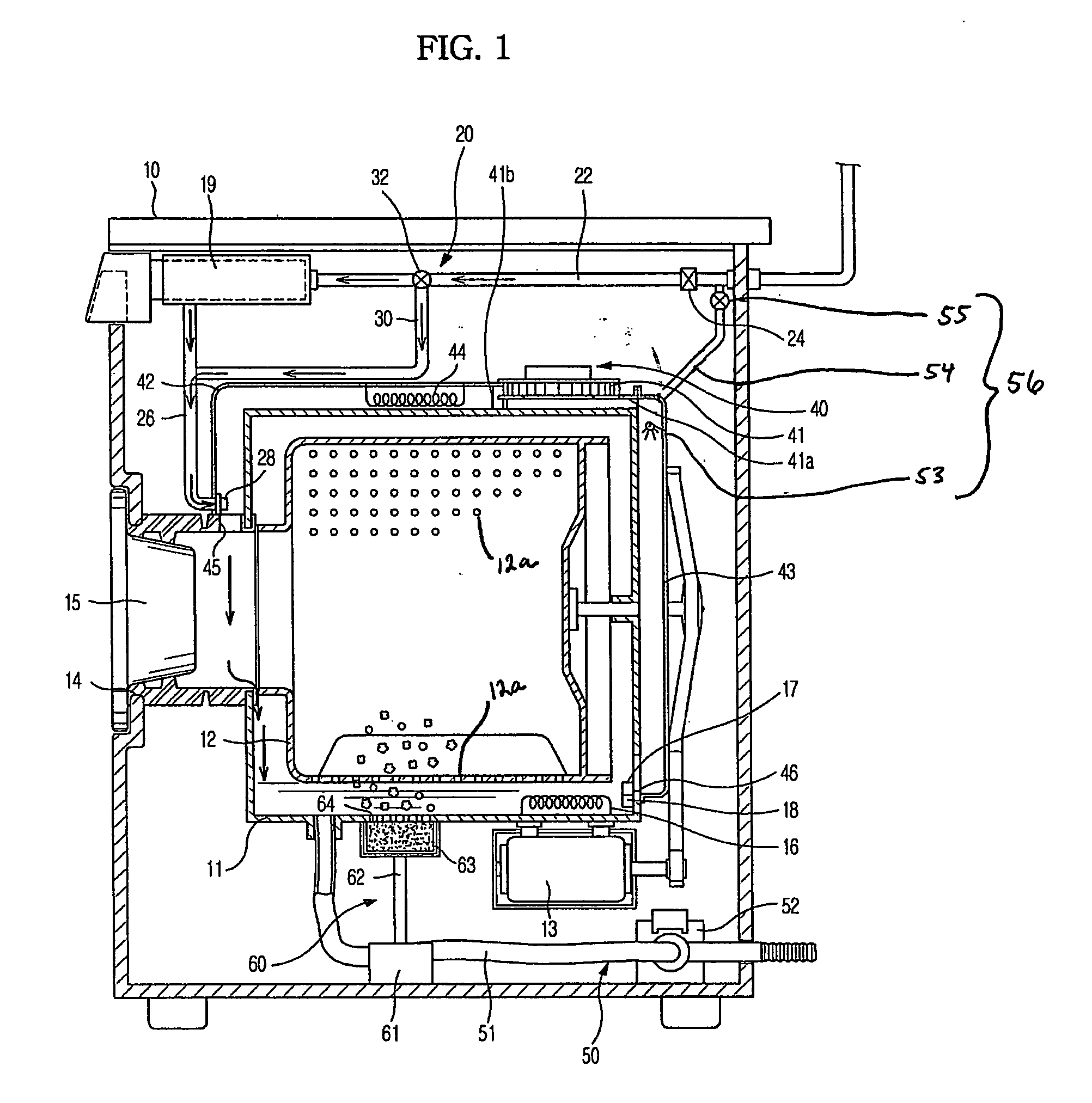

Apparatus and method for detecting laundry weight in washing machine employing sensorless BLDC motor

InactiveUS6842928B2Accurate measurementEfficient washingOther washing machinesControl devices for washing apparatusImproved methodLaundry

An improved method for detecting a laundry weight in a washing machine employing a sensorless BLDC motor is provided. The motor is rotated until the washer reaches a first speed. The washer then operates in a torque control mode for a predetermined amount of time, and a laundry weight is then determined based on a speed of the motor after the predetermined amount of time has elapsed. In this manner, laundry weight can be accurately determined and the laundry can be effectively washed. Additionally, since a washing machine employing this improved method for detecting does not require a hall sensor and its peripheral circuit manufacture is simplified, and thus cost may be reduced.

Owner:LG ELECTRONICS INC

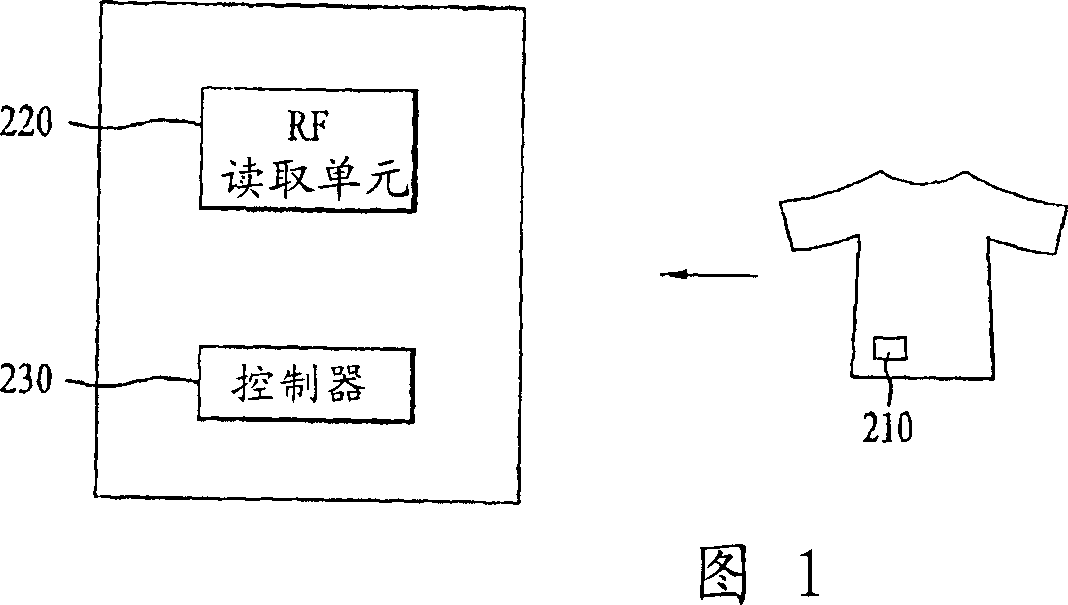

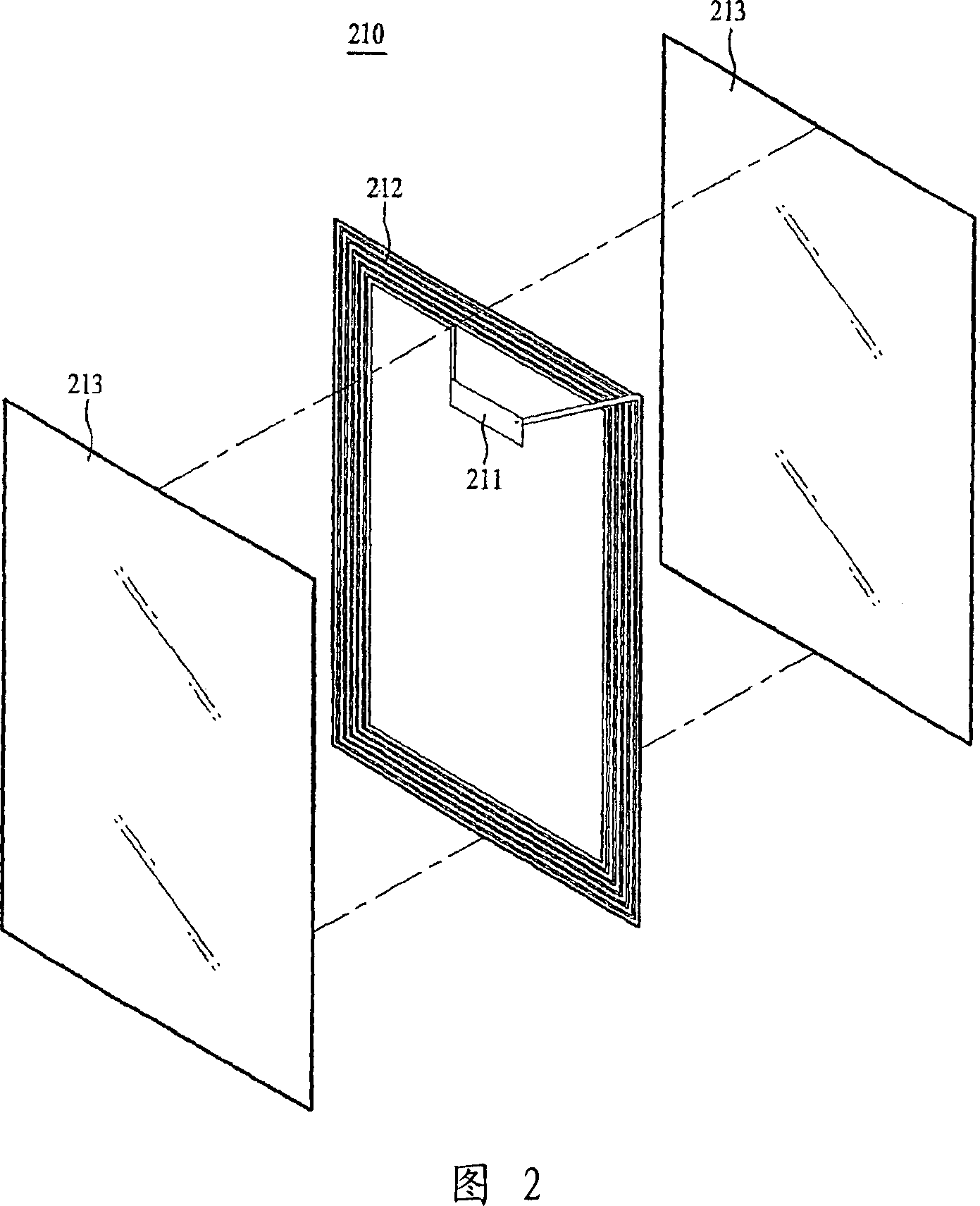

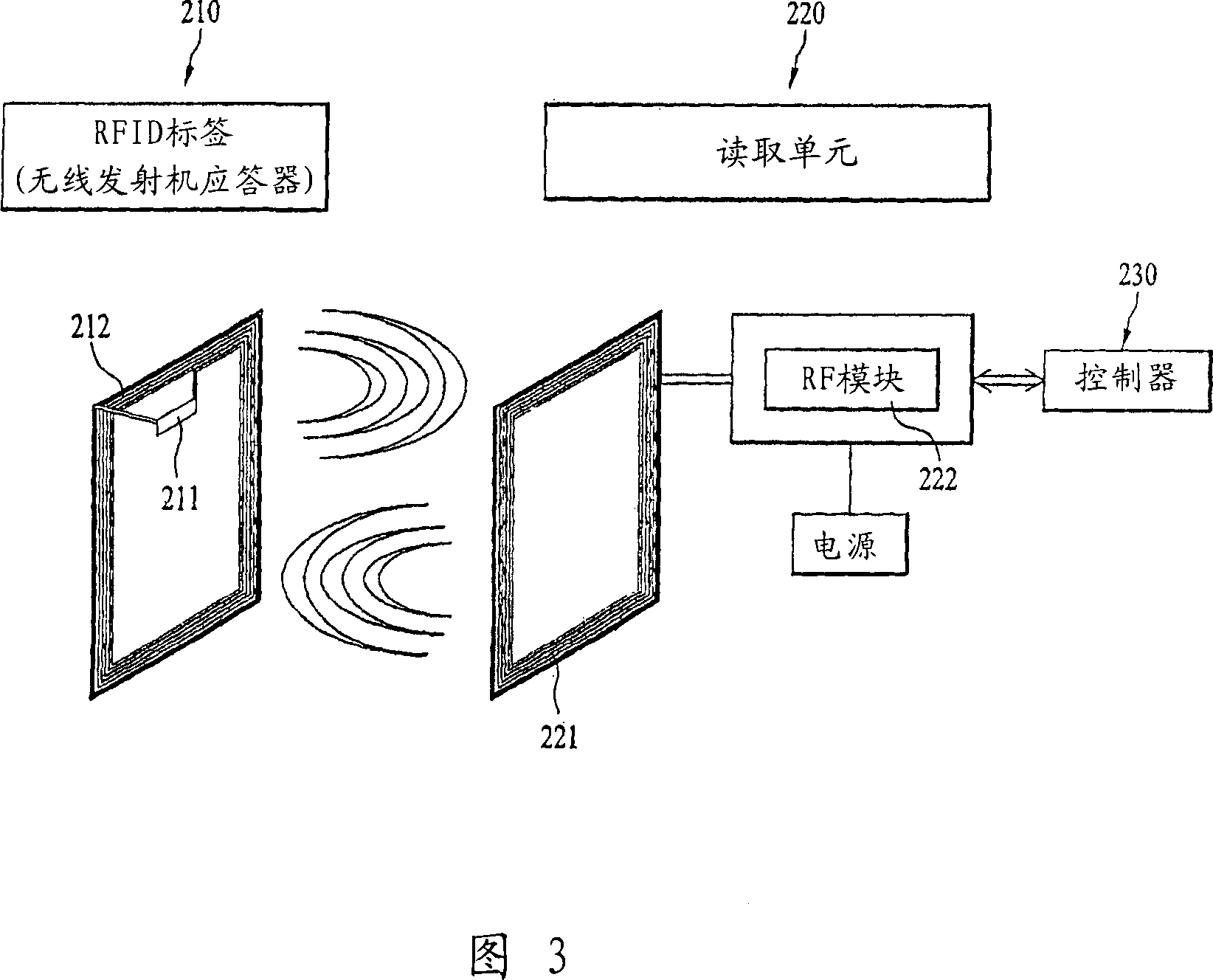

Transmitting/receiving device for washing machine and apparatus and method thereof

InactiveCN1961111AEfficient washingOptimal environmentOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

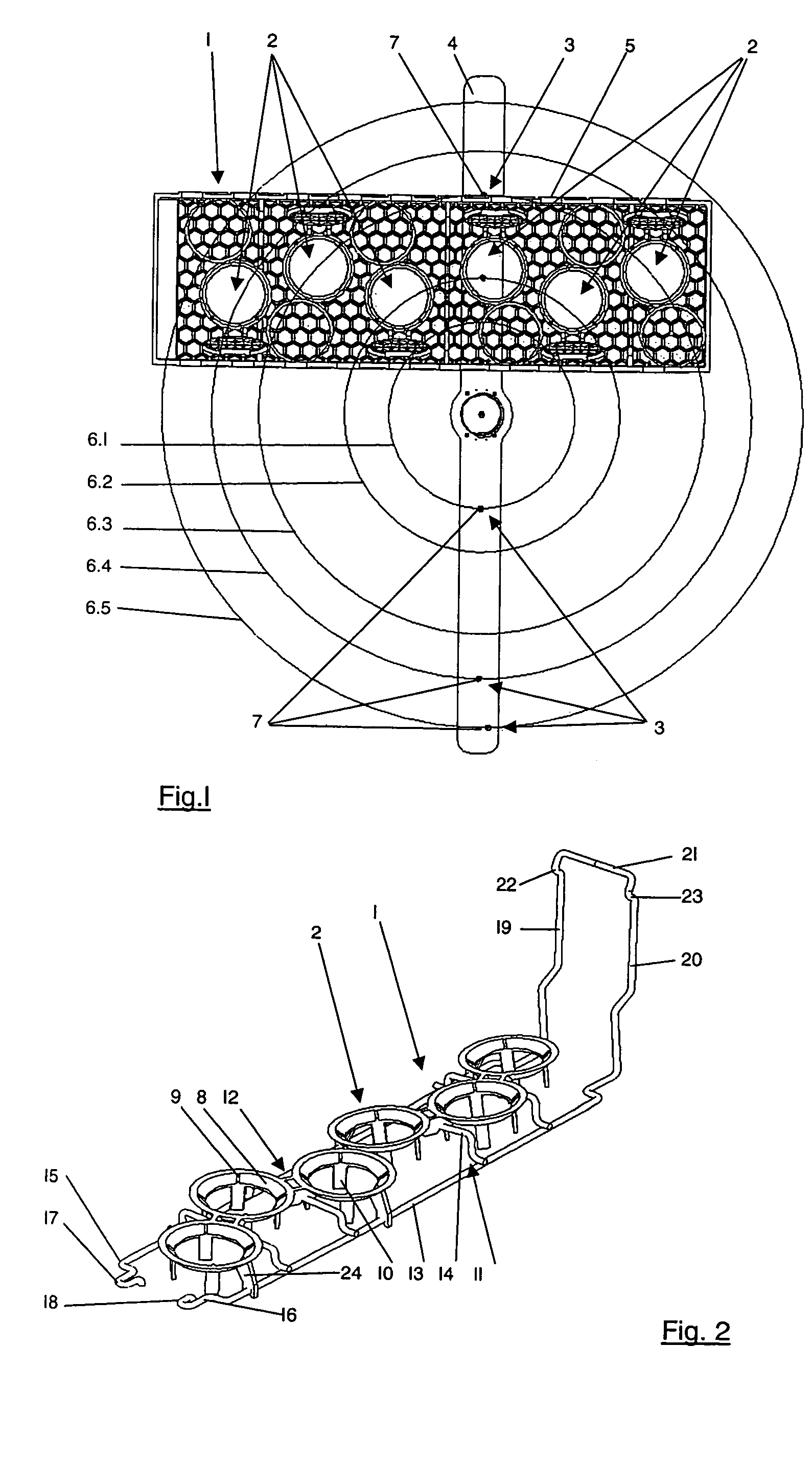

Dish basket for a dish washer

InactiveUS7478642B2Wash high hollow articlesEfficient washingTableware washing/rinsing machine detailsElectrostatic cleaningEngineeringBottle

An insert for use with a dish washer provided with a rotary spray arm having a nozzle therein and with at least one rinsing basket. The insert is provided at least one receptacle for securely supporting a bottle with its opening in alignment with the rotary path of movement of the nozzle. Protrusions are provided in the receptacle for resiliently maintaining a bottle in its position.

Owner:MIELE & CO KG

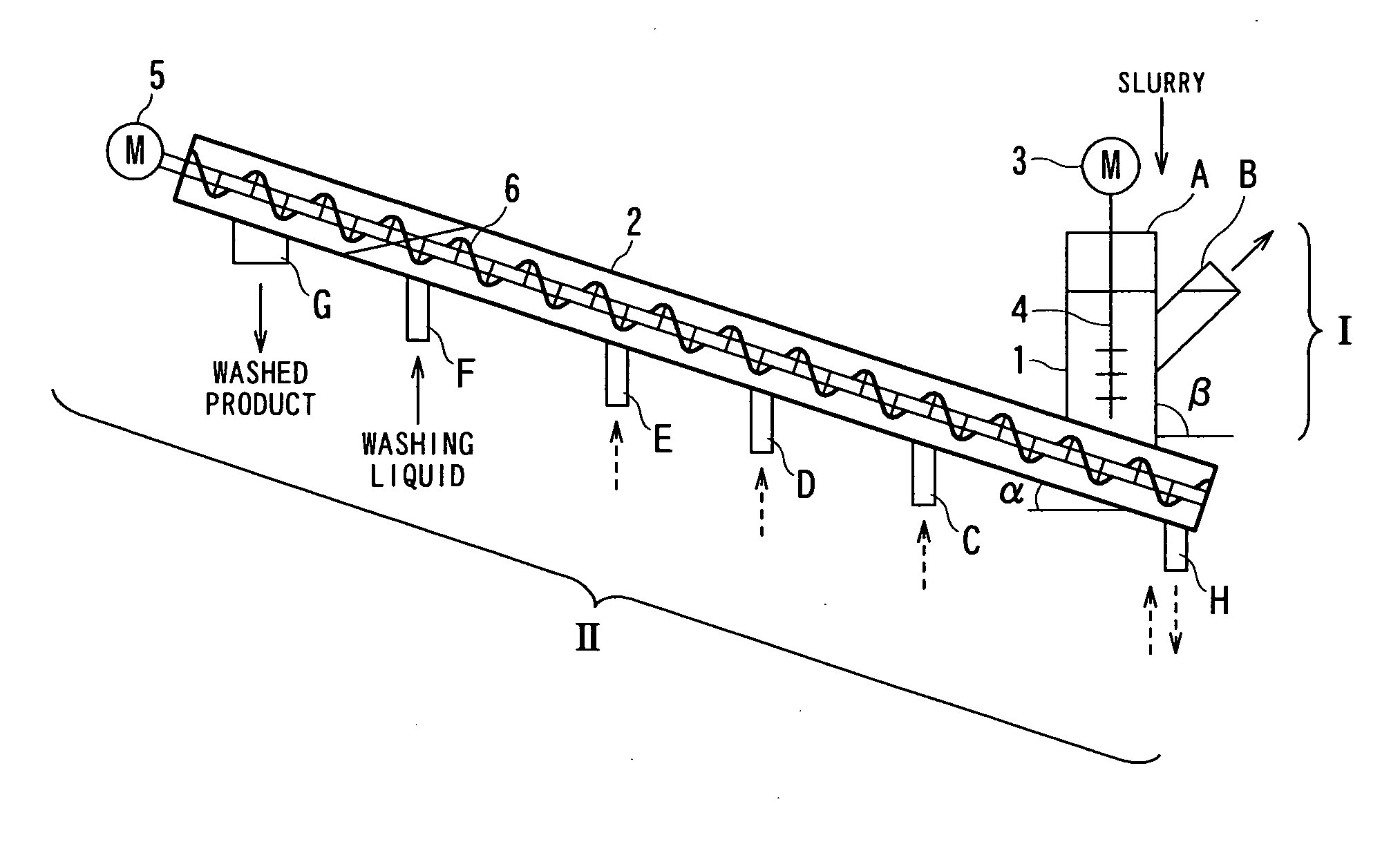

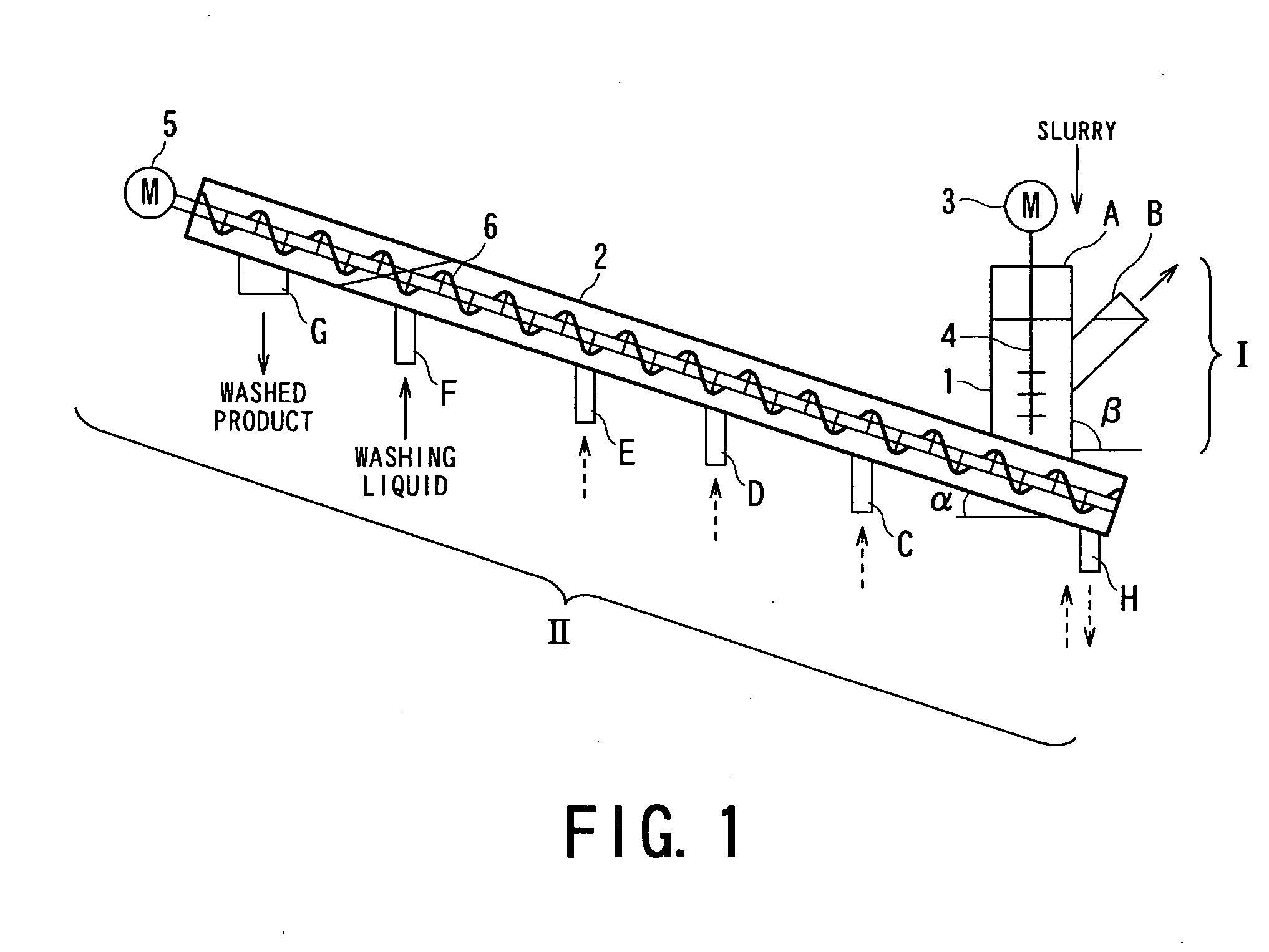

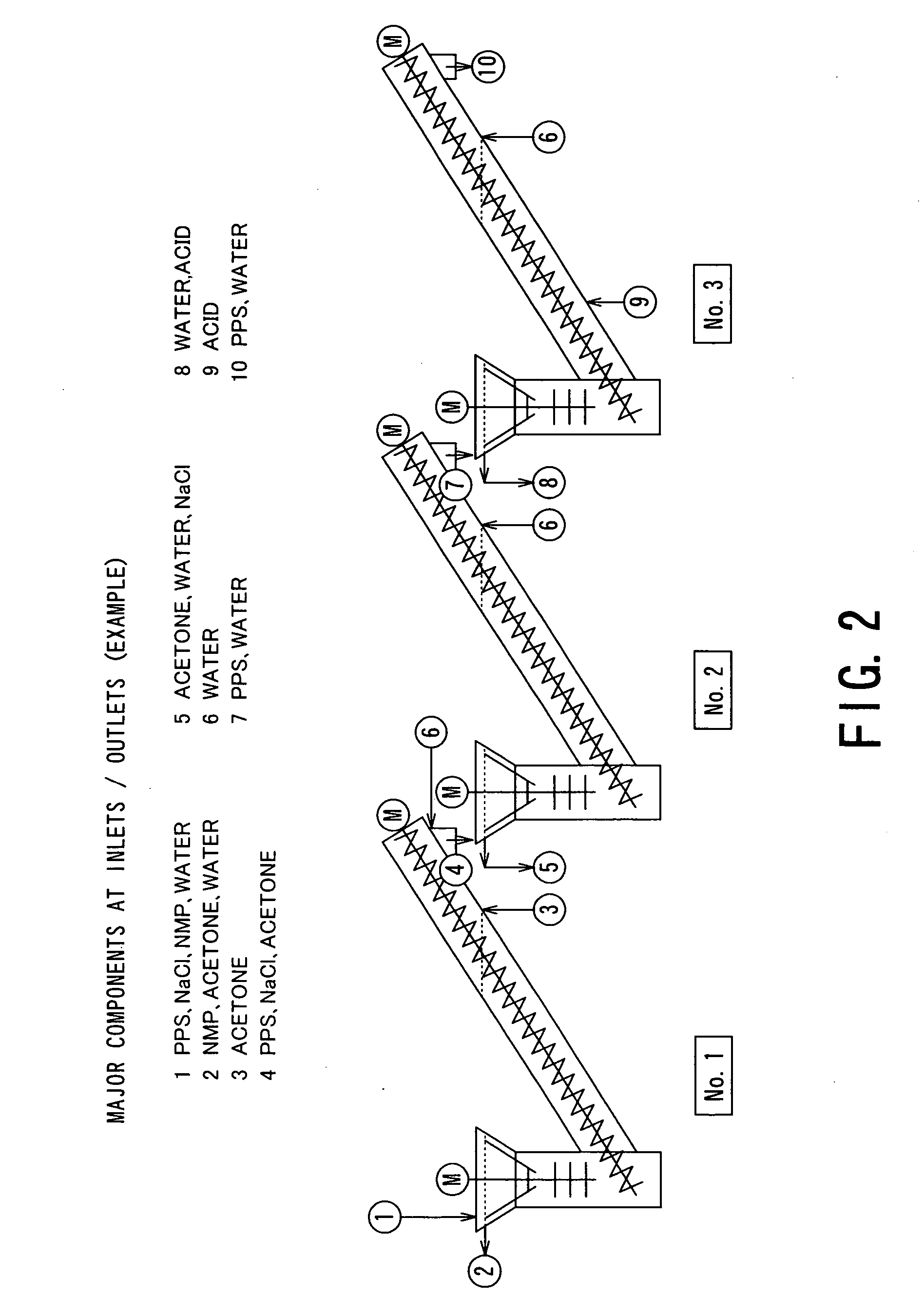

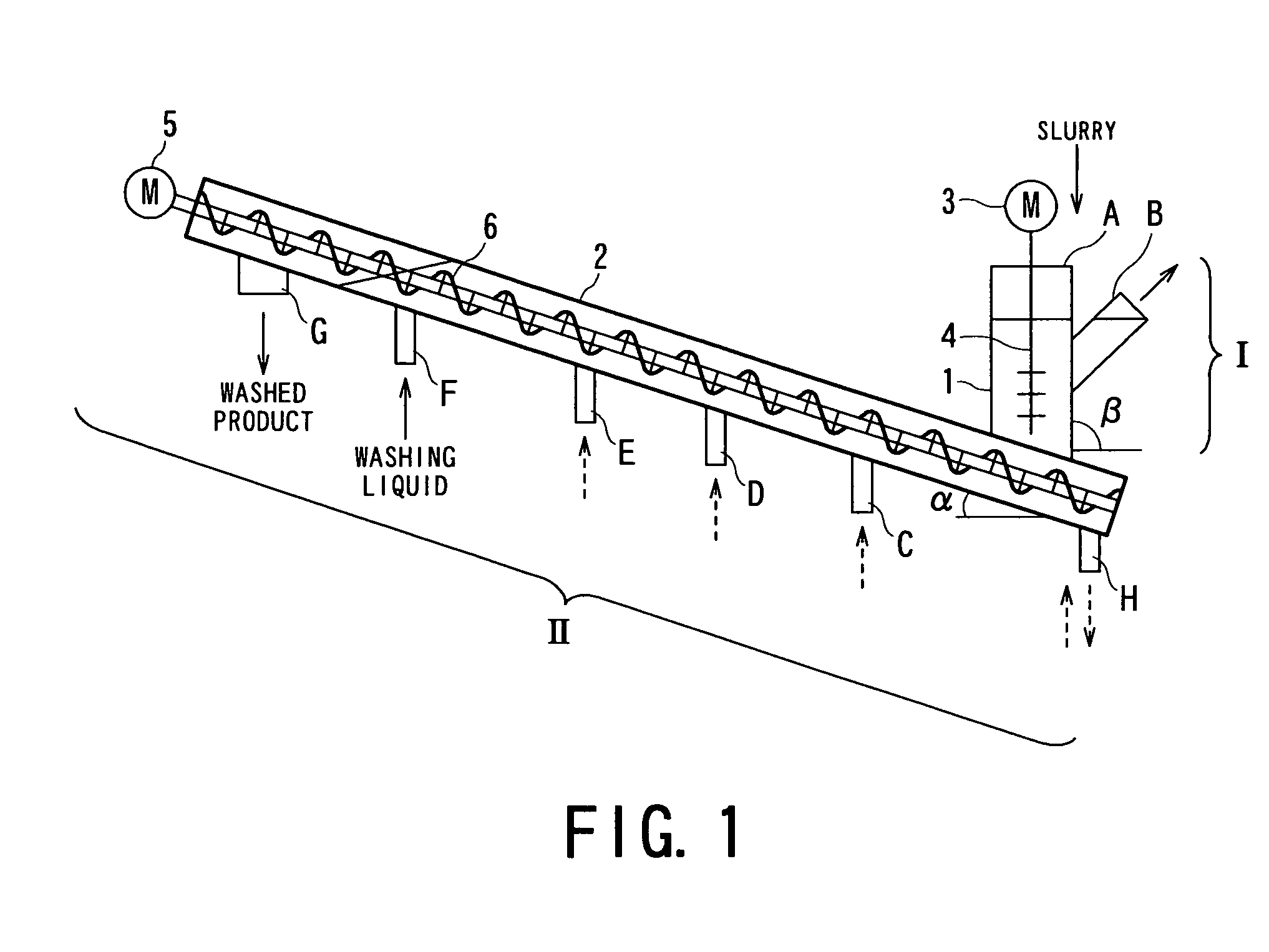

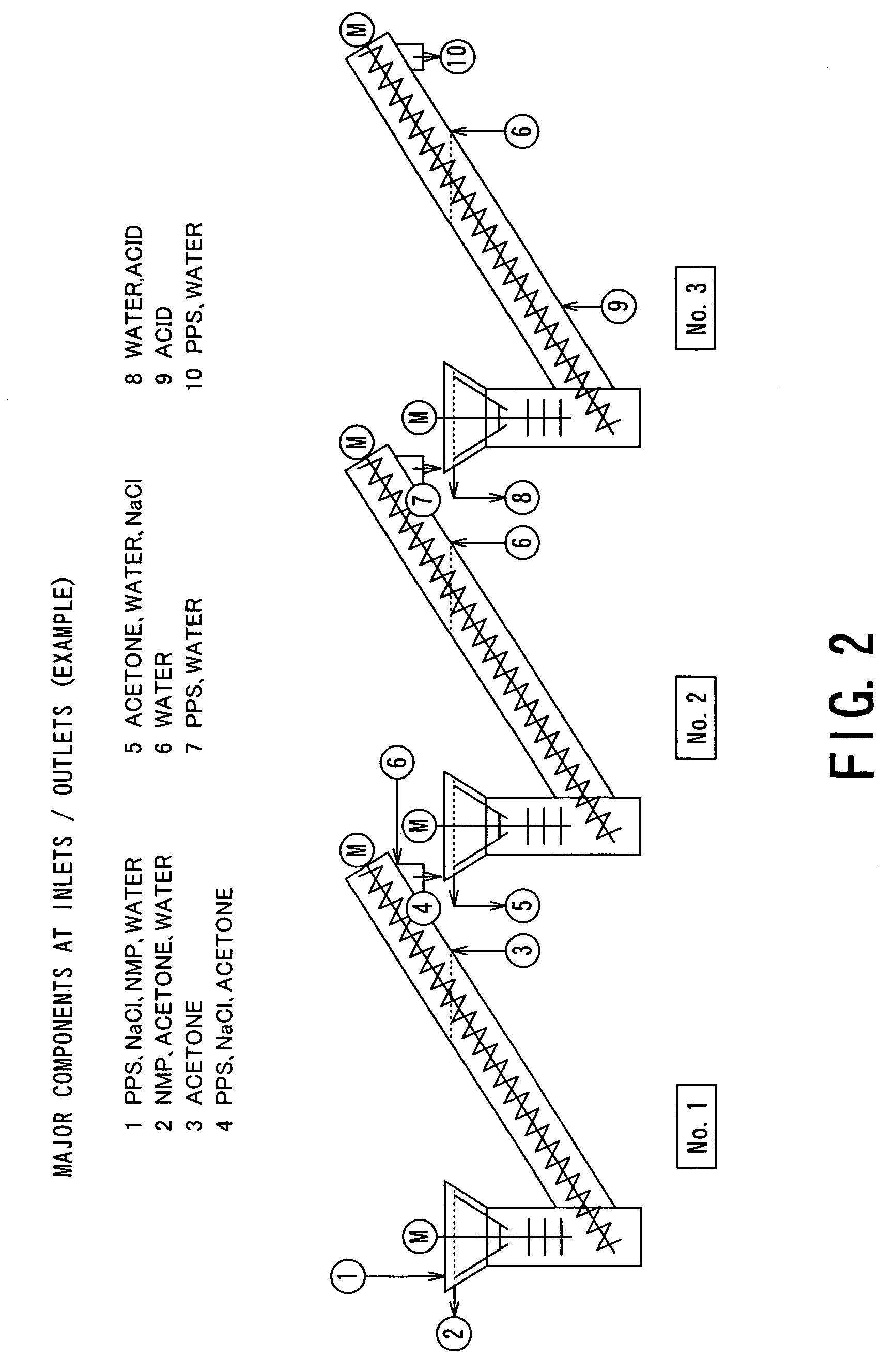

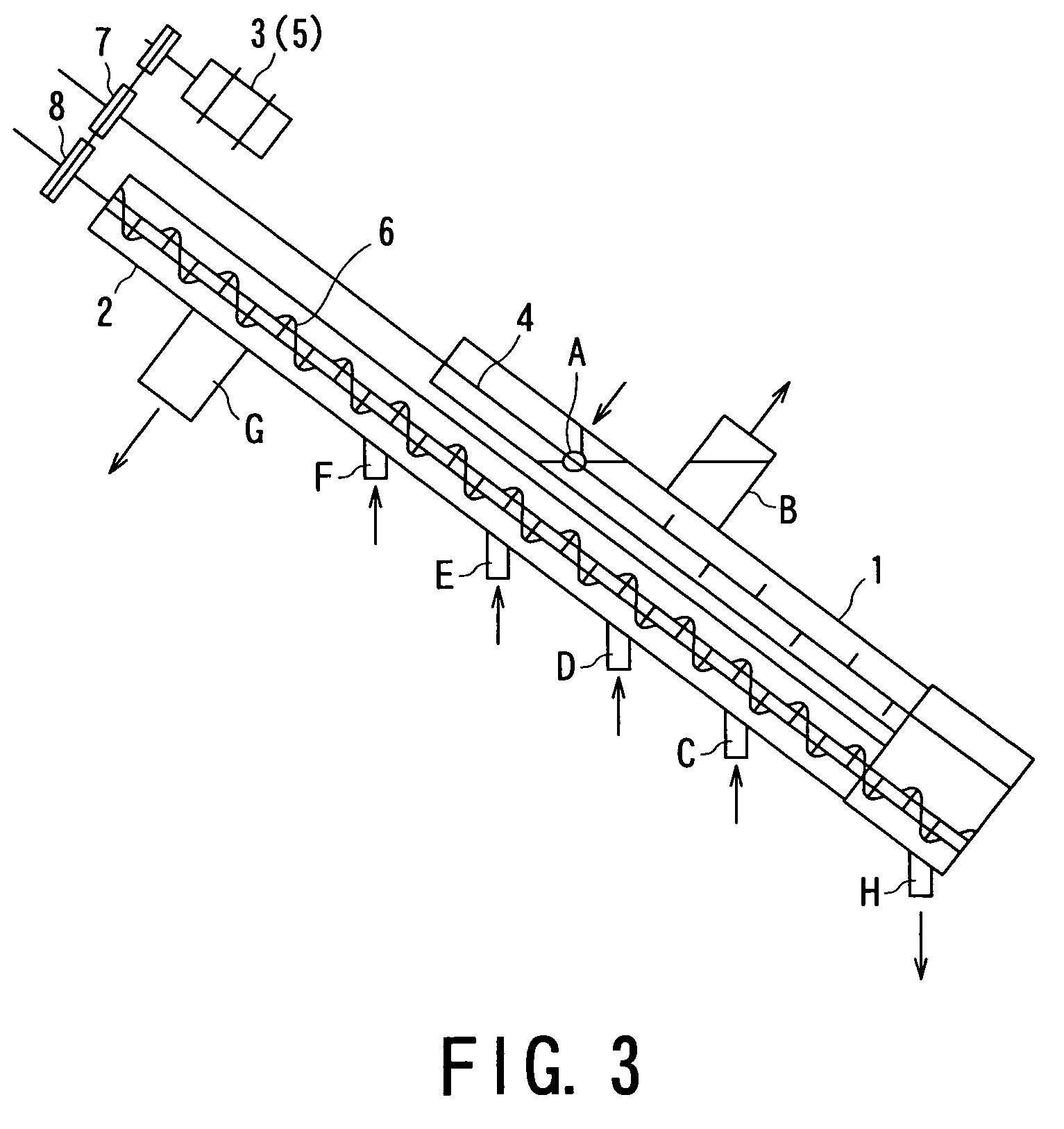

Method of continuously cleansing polyarylene sulfide

InactiveUS20050087215A1Reduce lossEfficiently removeCeramic shaping apparatusNatural resin processSolventOrganic solvent

A polymerizate slurry obtained through a reaction of an alkali sulfide source and an aromatic dihalide compound in an organic polar solvent and comprising polyarylene sulfide particles, a by-produced alkali metal salt and the polar organic solvent, is continuously contacted countercurrently with a washing liquid, thereby continuously and efficiently recovering washed polyarylene sulfide particles. Furthermore, the by-produced alkali metal salt is removed, and the polar organic solvent is recovered, efficiently.

Owner:KUREHA KAGAKU KOGYO KK

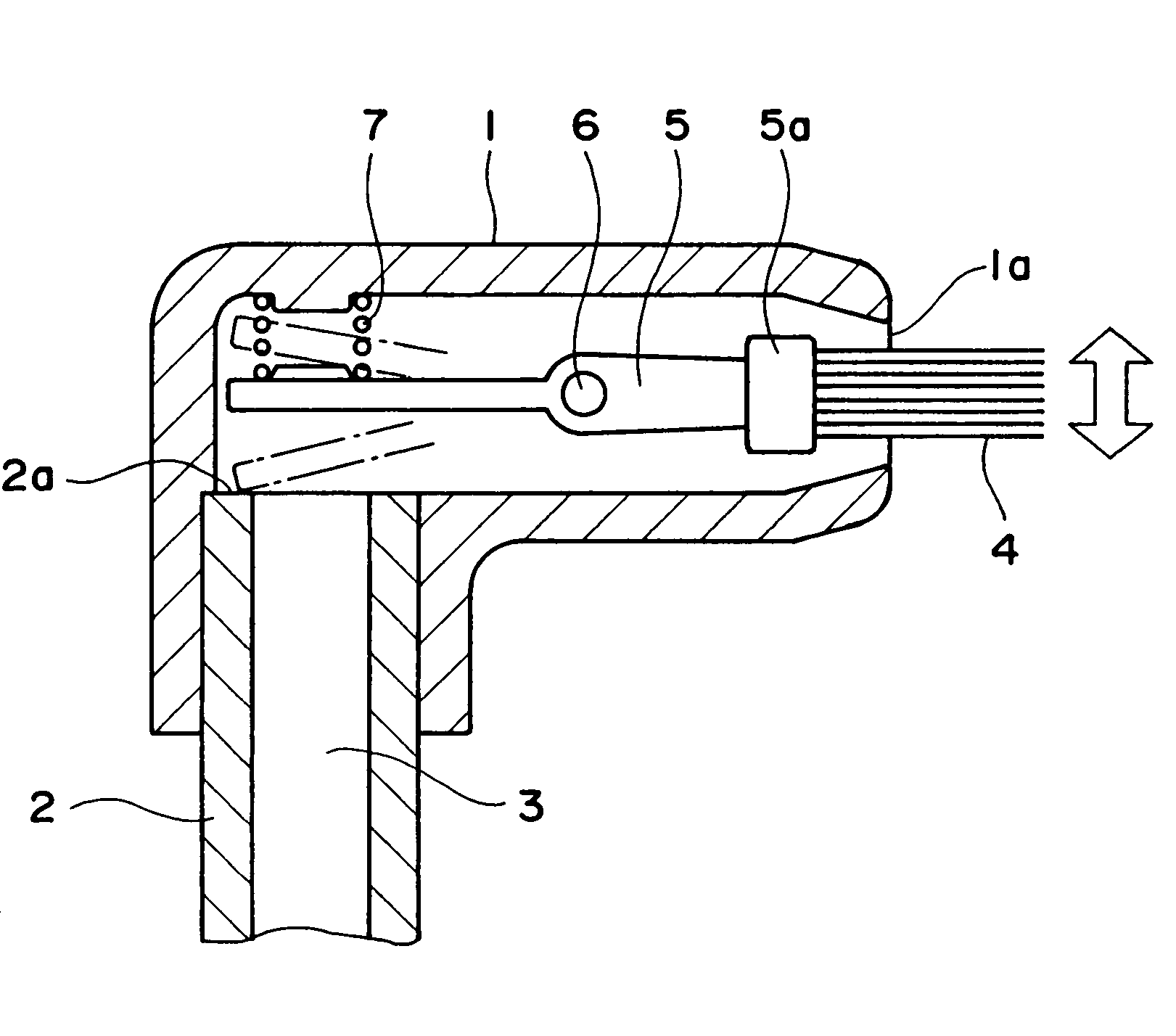

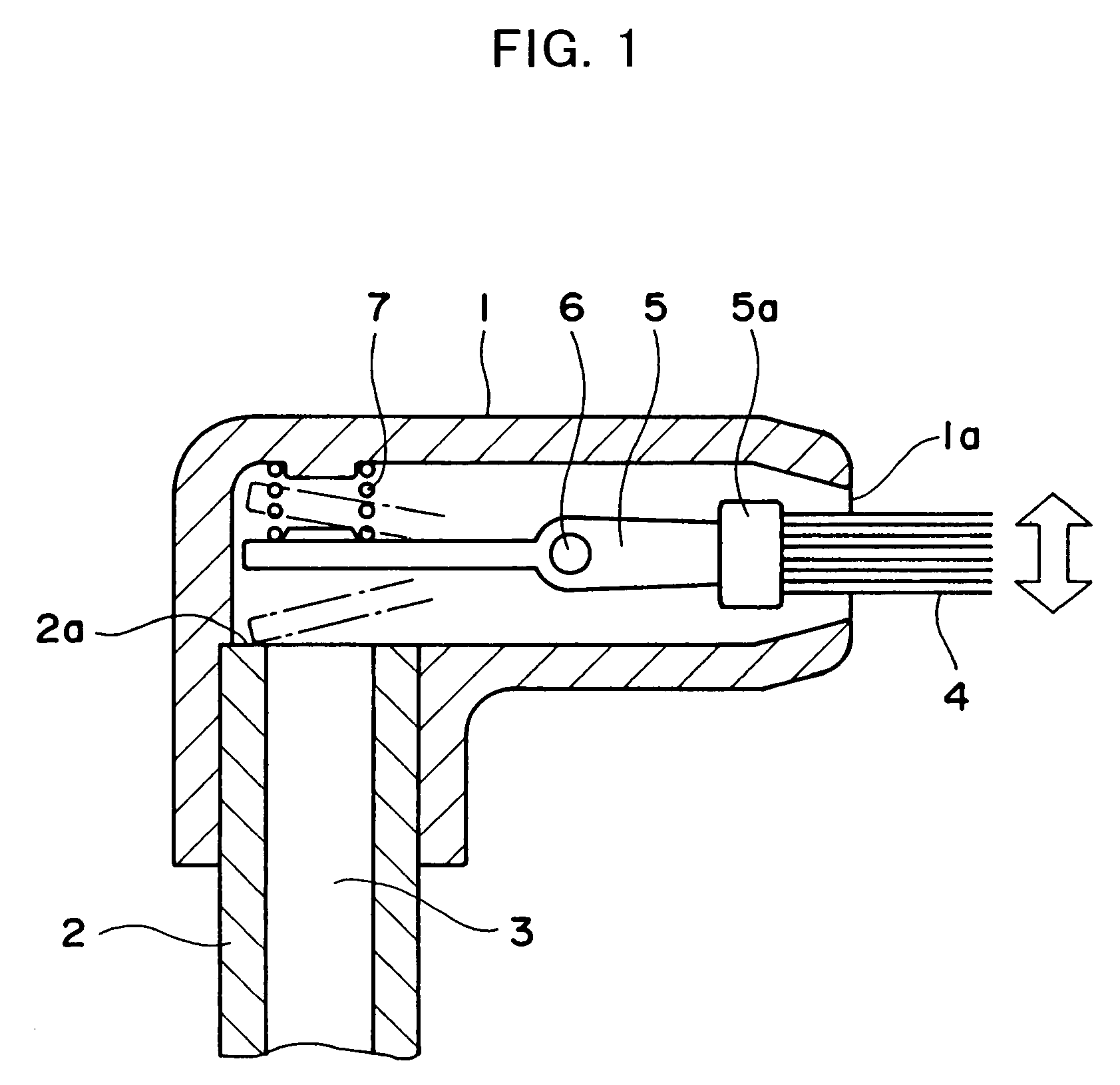

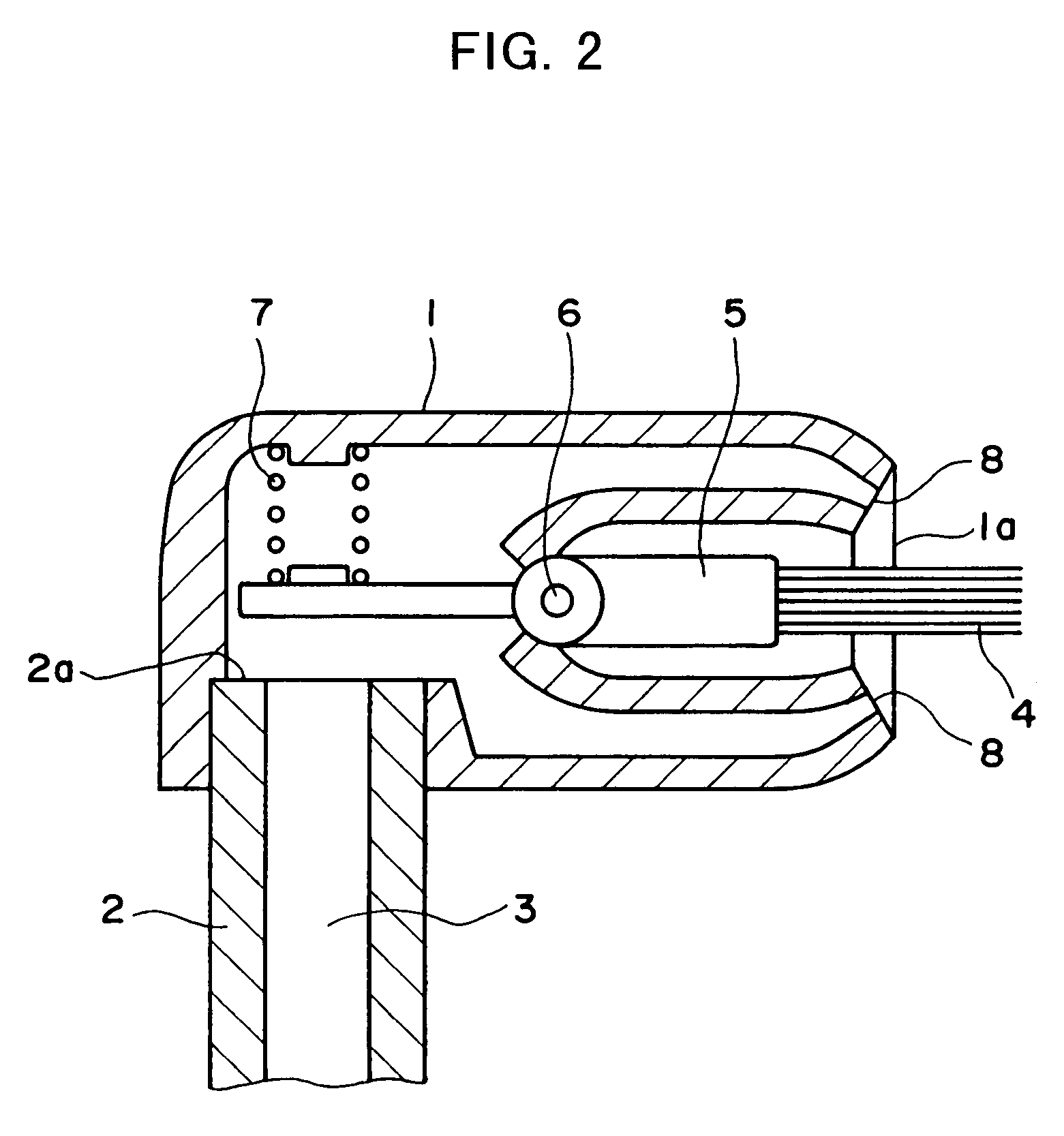

Tooth brusher

A safe brushing is realized without sticking the gum if the bristle tips are once inserted in a pocket of a tooth by using a system having a brush of which the bristle tips automatically vibrate in a direction at right angles with the direction of length of the bristles. A brush lever 5 having a brush 4 is swingingly supported in the nozzle 1, a flow passage 3 leading to a blow-out port 1a at an end of a nozzle 1 is partly bent, and a resilient member 7 is provided at the bent portion to urge the brush lever 5 in a direction opposite to the direction of flow of water, so that the brush lever 5 oscillates reciprocally due to the resilient force produced by the resilient member 7 and the pressure of water flow, causing the bristle tips of the brush 4 to oscillate in a direction at right angles with the direction of length of the bristles outside the nozzle 1.

Owner:RICOH ELEMEX CORP

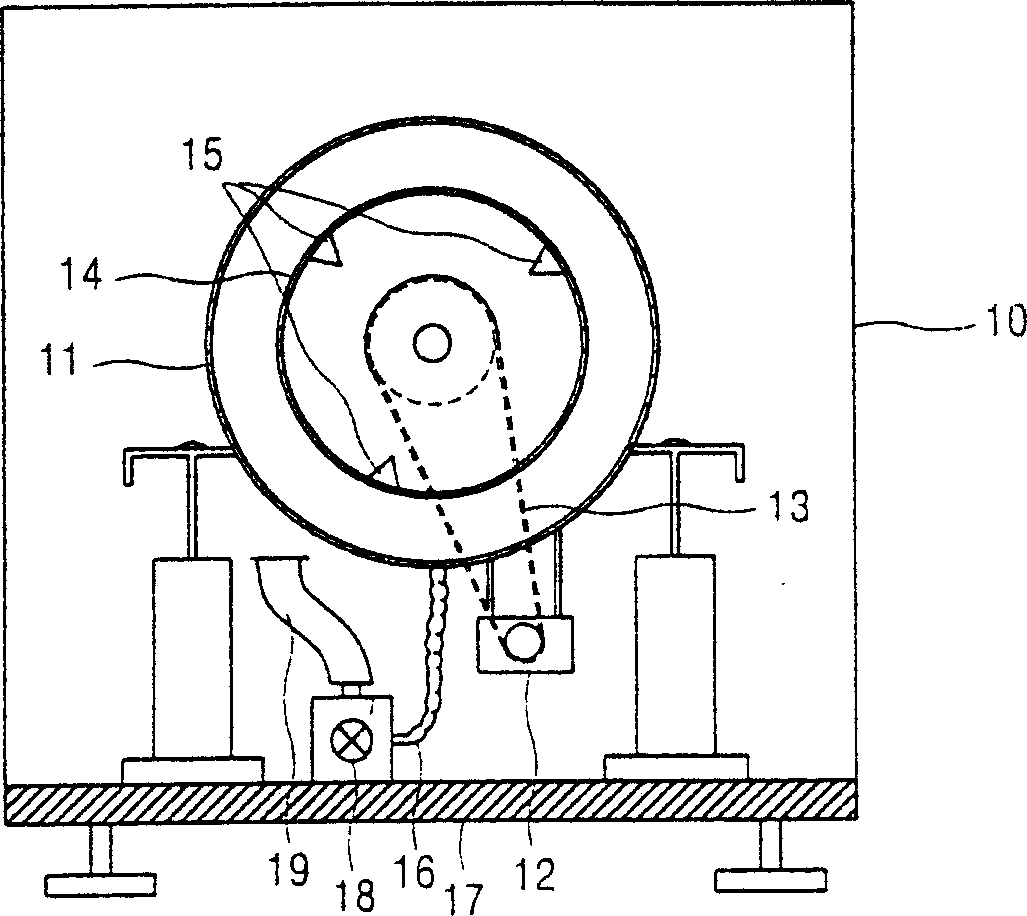

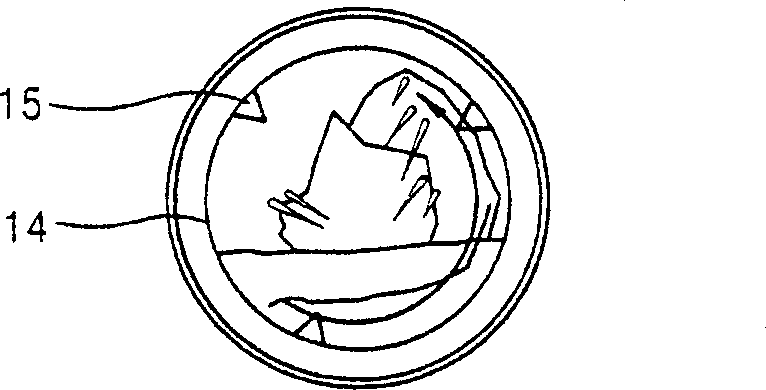

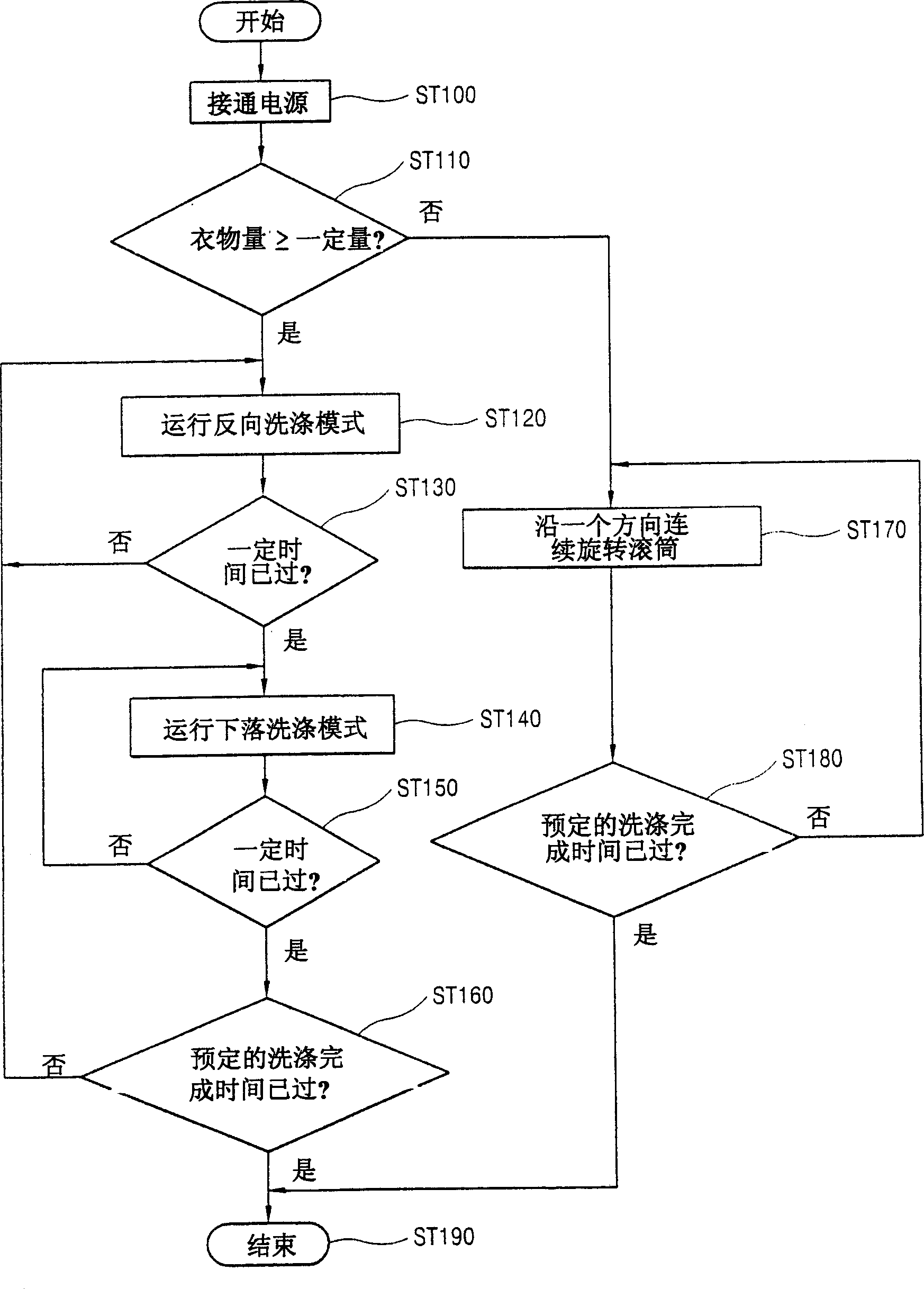

Washing method of drum type washing machine

InactiveCN1521311AEfficient washingOther washing machinesControl devices for washing apparatusEngineeringProper time

In a washing method of a drum type washing machine, a large amount of the laundry can be more effectively washed by effectively transmitting a mechanical force to the laundry by repeatedly and forcedly rotating a drum forward (or clockwise) or backward (or counterclockwise) for a short predetermined time. Through continuous rotation of the drum of the drum type washing machine, a falling washing is performed such that the laundry in the drum is washed by falling by a gravity, or a reversing washing is performed such that the laundry is washed by repeatedly rotating the drum forward (or clockwise) or backward (or counterclockwise) for a short predetermined time, thereby improving energy efficiency through economizing a washing time and washing water according to the amount of the laundry, and also preventing a waste of power by driving a heater at a proper time.

Owner:LG ELECTRONICS INC

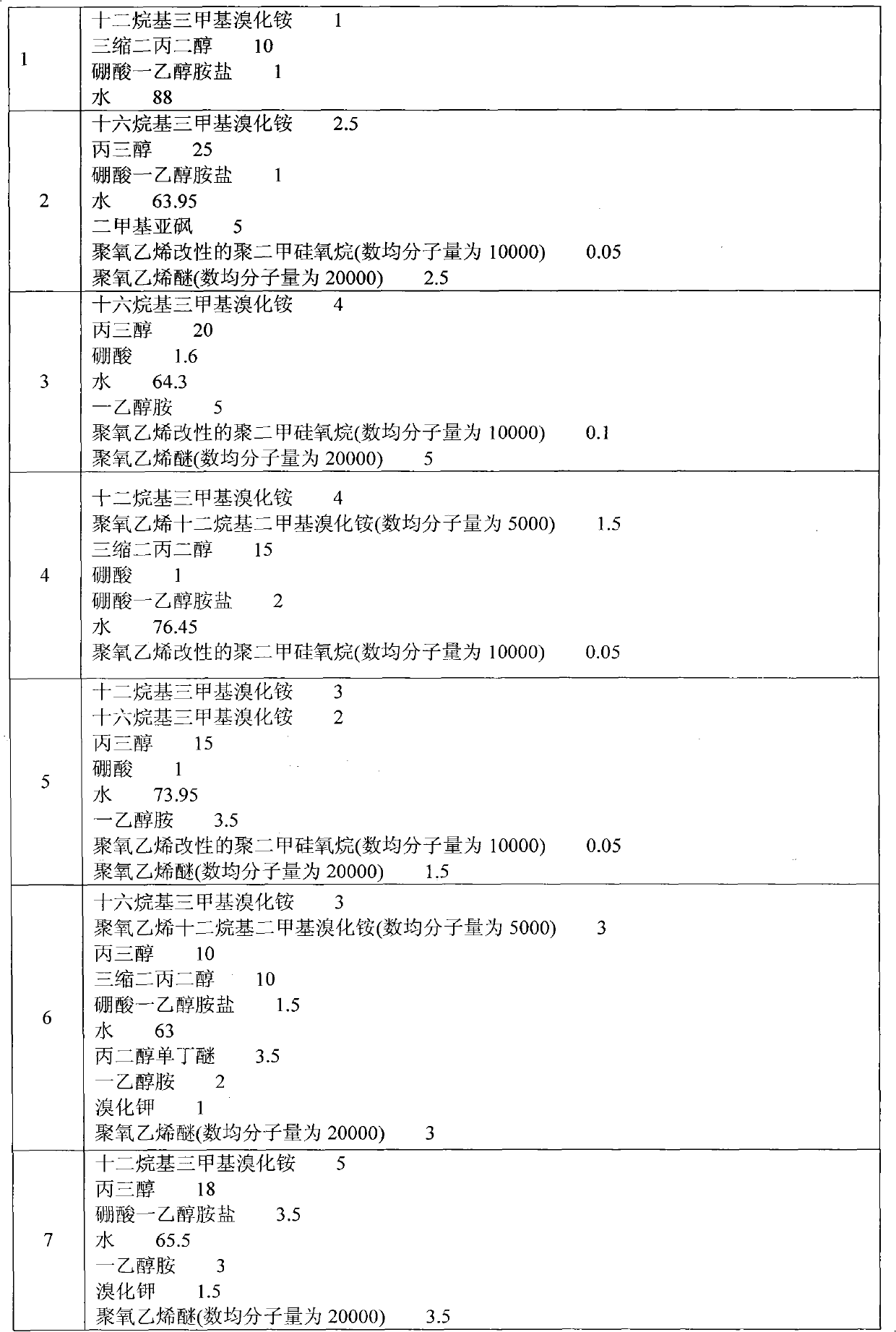

Water-based glass grinding fluid

InactiveCN102559354AImprove cooling effectImprove the lubrication effectLubricant compositionAlcoholActive agent

The invention discloses a water-based glass grinding fluid which comprises a brominated alkyl quaternary ammonium salt surfactant, organic alcohol, a corrosion inhibitor and water. The water-based glass grinding fluid has excellent properties of cooling, lubricating, washing, corrosion preventing and the like, and has a better chemical dressing function on a diamond grinding tool; and according to the water-based glass grinding fluid, the grinding precision can be remarkably improved, the service life of the grinding tool is prolonged, and the greasy blockage of the grinding tool is effectively prevented. The water-based glass grinding fluid has good glass grinding efficiency, excellent chemical stability and low cost, has no harm to the health, does not pollute the environment, is convenient for use, and can be widely applied to the grinding and cleaning processes of various kinds of glass.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

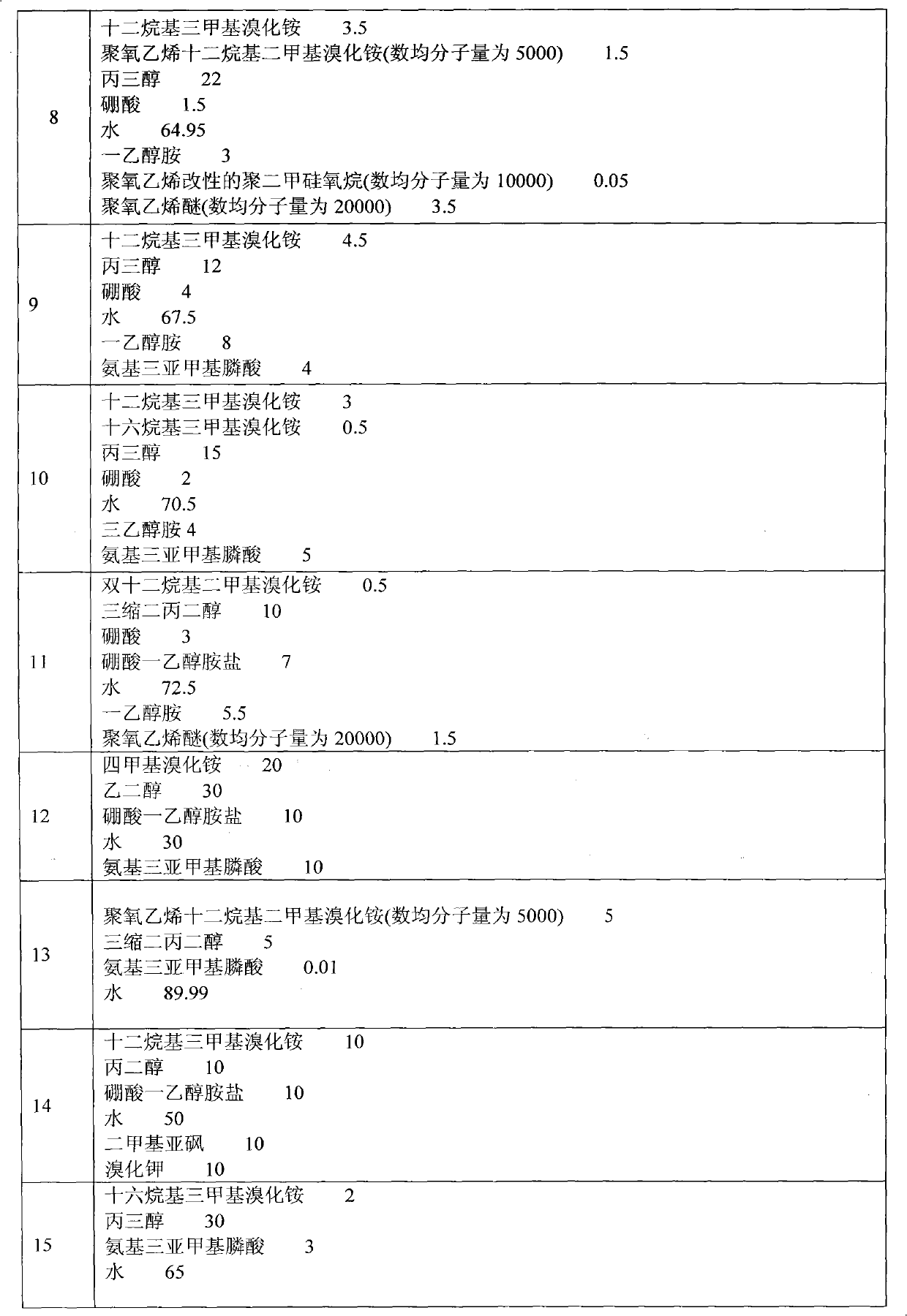

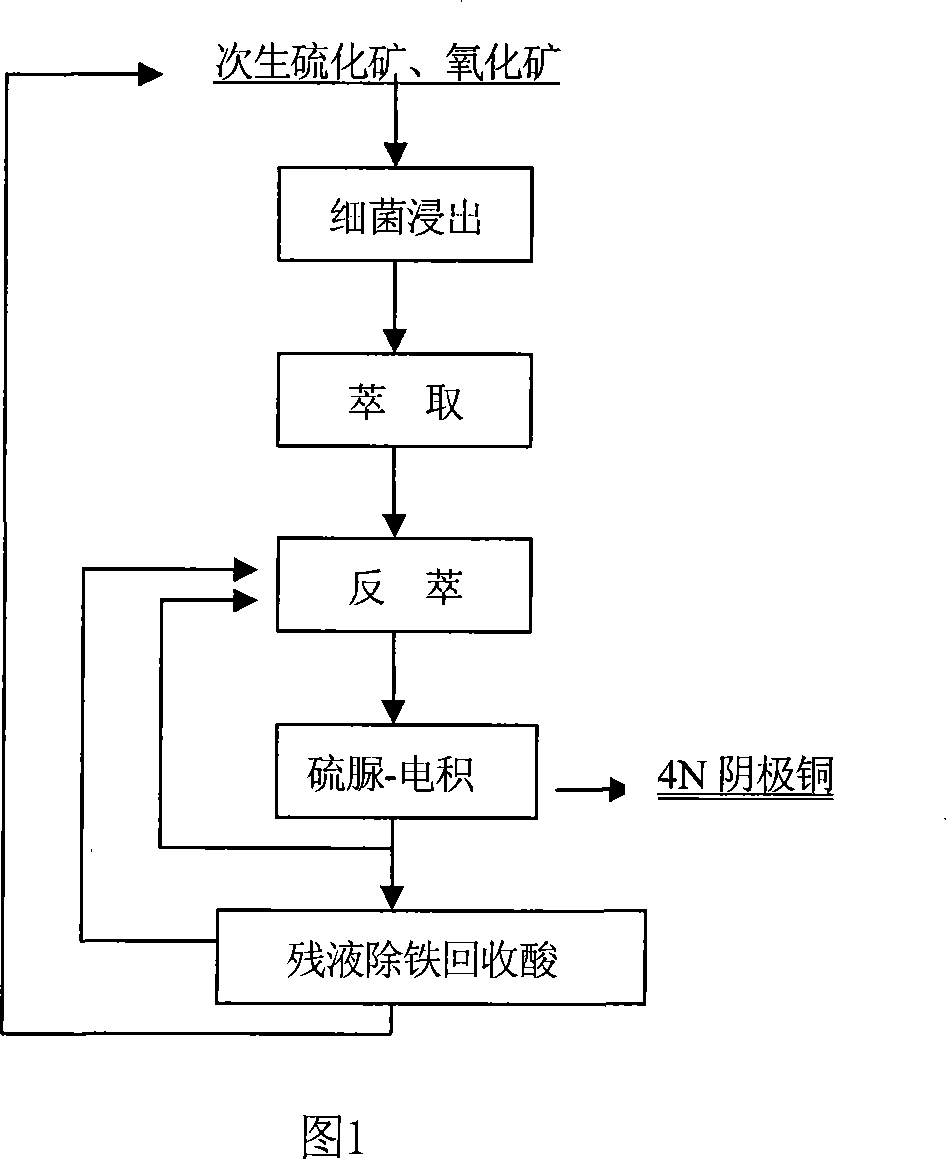

Method of preparing high purity copper by bacteria leaching primary sulfide ore

InactiveCN101033508AEnhanced synergistic leachingIncrease leaching ratePhotography auxillary processesProcess efficiency improvementSulfurThin layer

The invention relates to a method of preparing high pure copper from the leachate of primary sulfide ore bacteria, including: it leaches the primary sulfide ores and its mixture by using the mixture of middle and mesophilic bacterias. It filters and extracts the bacterial leaching solution, and conducts thin-layer wash-condensate, coalescence phase, and back-extraction electrowinning for the organic phase load. The invention uses hybrid strains of bacteria and sub-culture techniques to enhance the synergy of the bacterial leaching role and the minerals leaching rate, uses gelatin and other additives without sulfur element to reduce the sulfur impurities.

Owner:CENT SOUTH UNIV

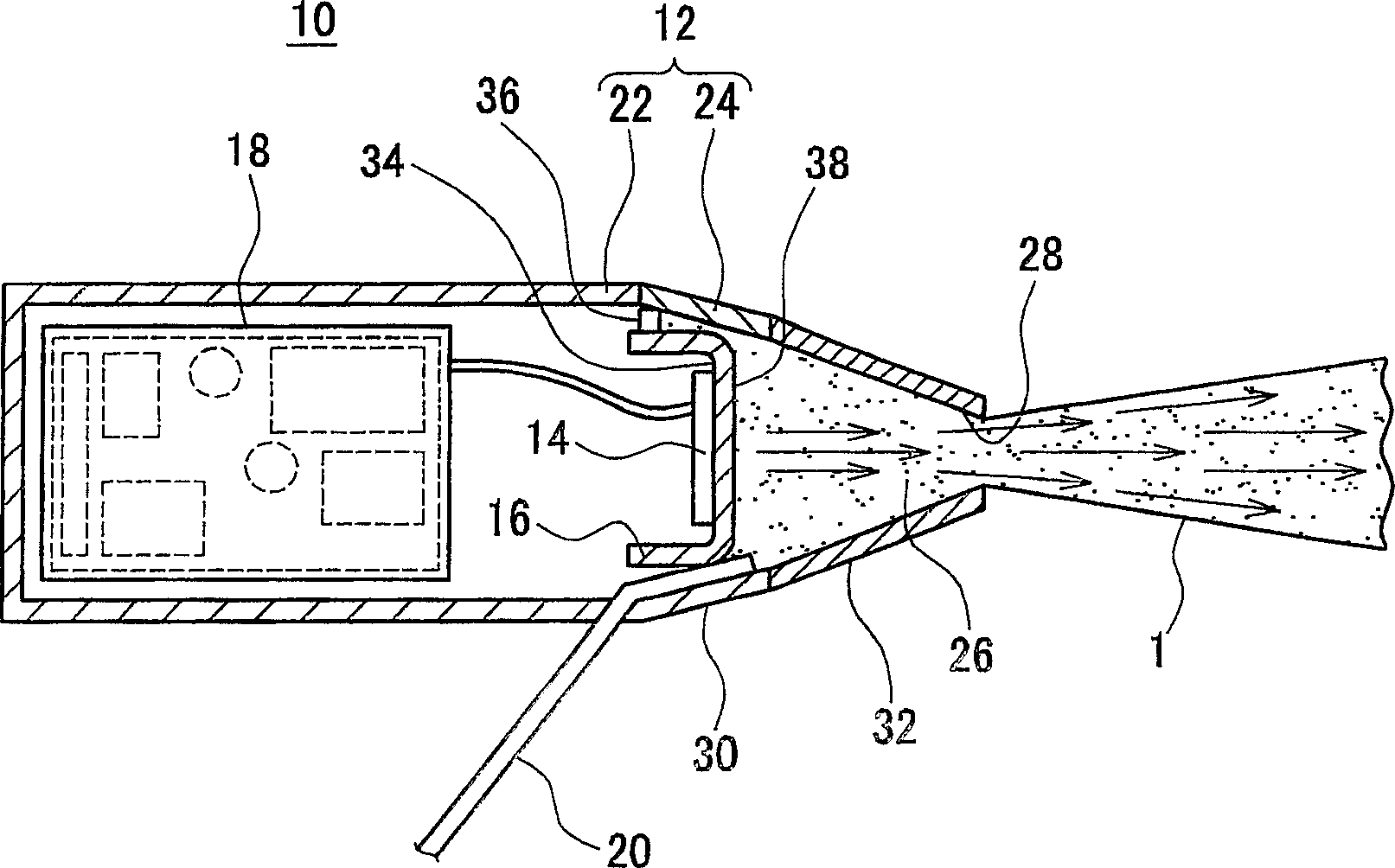

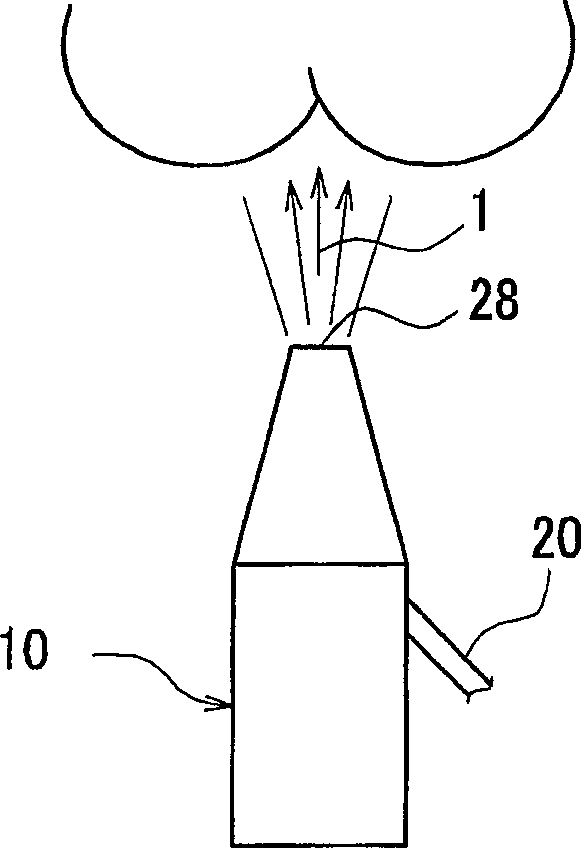

Ultrasonic washing device

InactiveCN1750783AImprove conduction efficiencyReduce outputBathroom accessoriesSpray nozzlesVibration amplitudeEngineering

In an ultrasonic washer for washing by splaying washing toward an object to be washed or a portion to be washed from a front end of a nozzle, a part of an ultrasonic wave propagation member connected to an ultrasonic transducer is protruded into a cavity of the nozzle into which the washing is filled in order to propagate ultrasonic vibration generated by the ultrasonic transducer to the washing efficiently. Furthermore, the ultrasonic wave propagation member is formed so that a cross-sectional area becomes gradually smaller as approaching to the front end thereof, so that the ultrasonic vibration is converged to the end face of the ultrasonic wave propagation member. Still furthermore, a length of the ultrasonic transducer and the ultrasonic wave propagation member is made to be integral multiplication of a half-wavelength of ultrasonic standing wave oscillation, and the end face of the ultrasonic wave propagation member from which the ultrasonic wave is emitted to the washing is disposed at a position of antinode of the ultrasonic standing wave oscillation where the amplitude becomes the largest.

Owner:MATSUSHITA ELECTRIC WORKS LTD

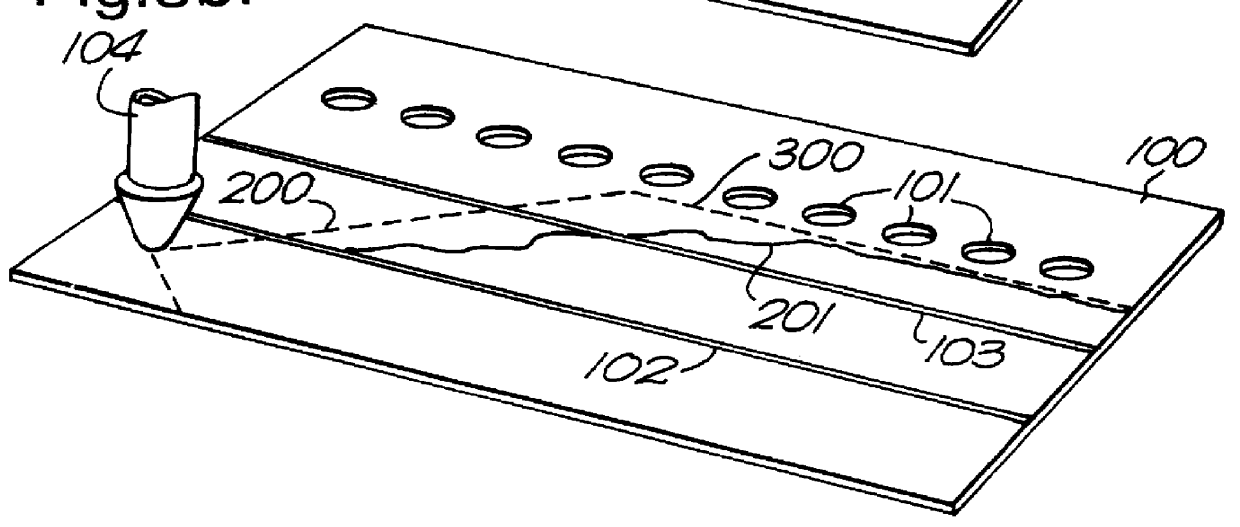

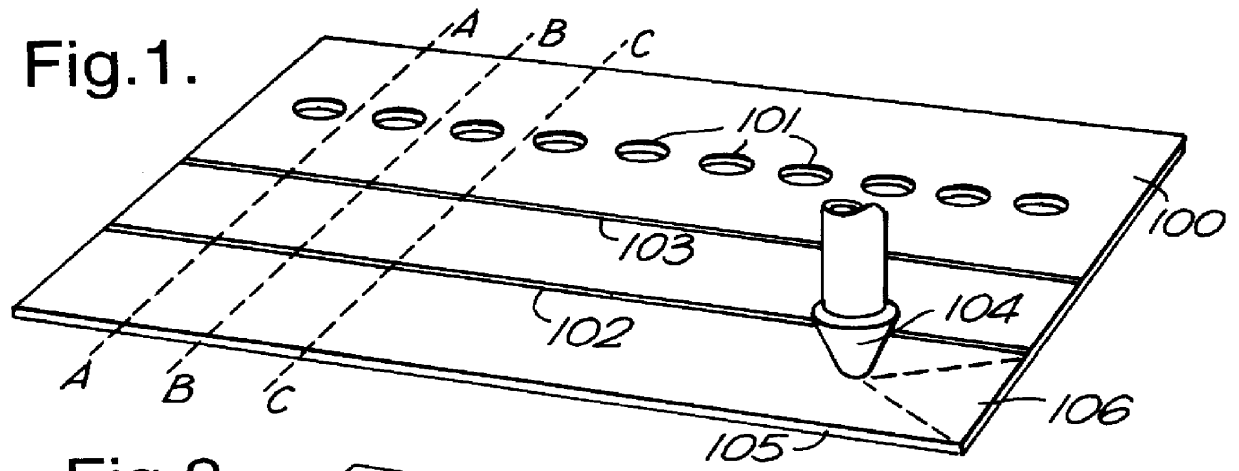

Apparatus and method for transferring samples from a source to a target

InactiveUS20060266130A1Efficient washingWithdrawing sample devicesWater/sewage treatment by magnetic/electric fieldsActuatorControl theory

A transfer unit for transferring a sample from a source vessel to a target vessel. The transfer unit includes a transfer device having a pin tip with a central bore terminating at a bottom wall, an actuating element movably disposed in the pin tip bore, an actuator rod for moving the actuating element and a compensating device connected between the actuating element and the actuator rod. The actuator rod moves the actuating element between a first position adjacent the tip bottom wall and a second position away from the bottom wall. Movement of the actuating element causes a sample in proximity to the pin tip to be alternately collected and released from the pin tip. Such movement also defines a stroke length for the actuator rod, wherein the compensating device compensates for any variations in the actuator rod stroke length. The transfer unit further includes a tip ejector for removing the disposable tips from the transfer device and a tip loading station for applying the tips to the transfer device.

Owner:FESTO CORPORATION

Apparatus for transferring samples from source vessels to target vessels

InactiveUS20070214900A1Efficient washingWithdrawing sample devicesMagnetic separationEngineeringSpecific volume

A transfer unit for transferring a sample from a source vessel to a target vessel. In one embodiment of the invention, an actuator plate within the transfer unit, has a plurality of individually activated electromagnets disposed therein; wherein activation of any of said electromagnets results in translation and mating of the electromagnetic pin of said electromagnet into a respective though-hole associated with an individual actuator rod, for selective activation of said actuator rod and its terminal actuating element. The terminal actuating element can be a magnet for attraction of magnetic particles from within a sample, or a piston for pippetting a specific volume of liquid sample.

Owner:PORAT AMIR +1

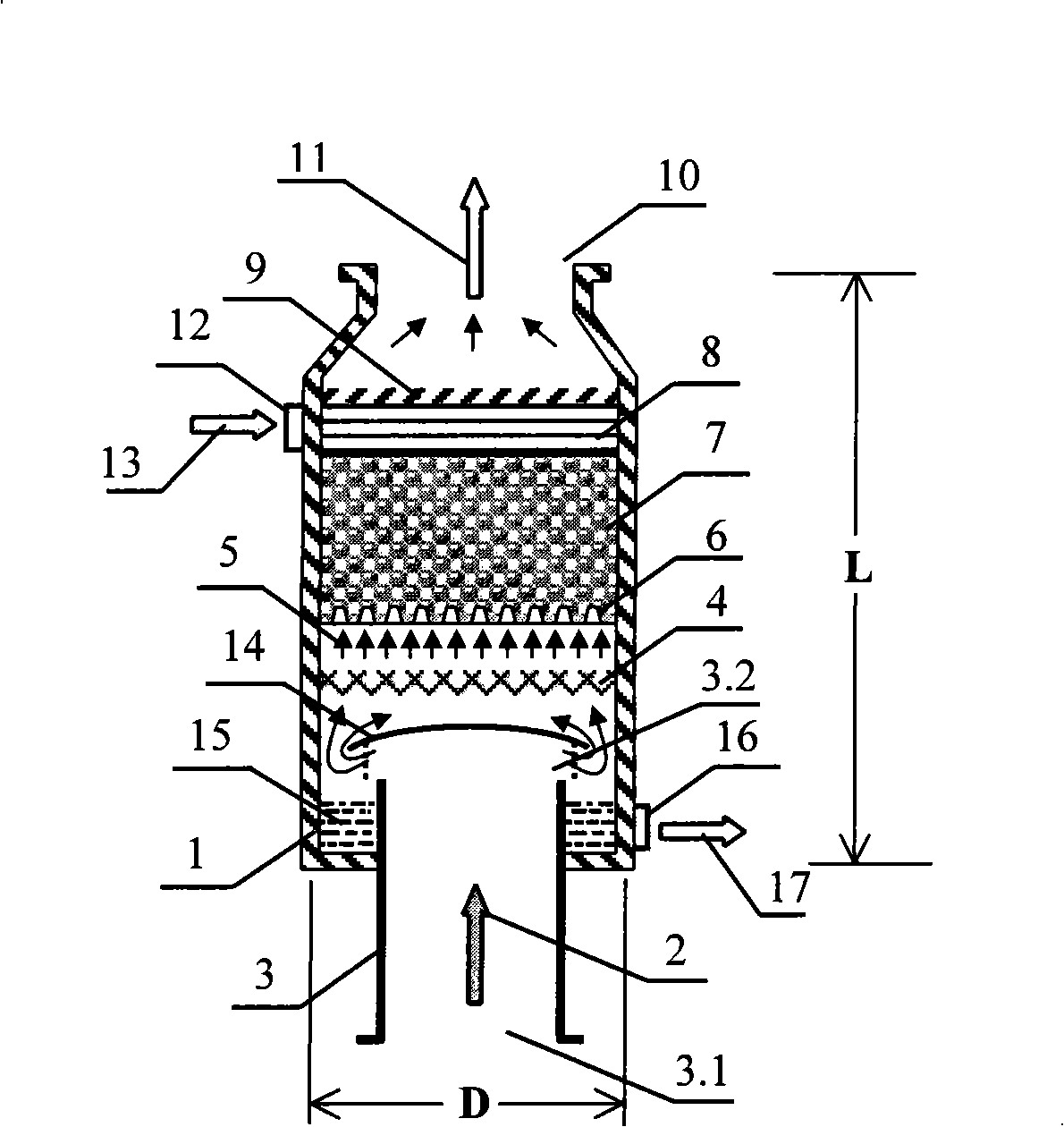

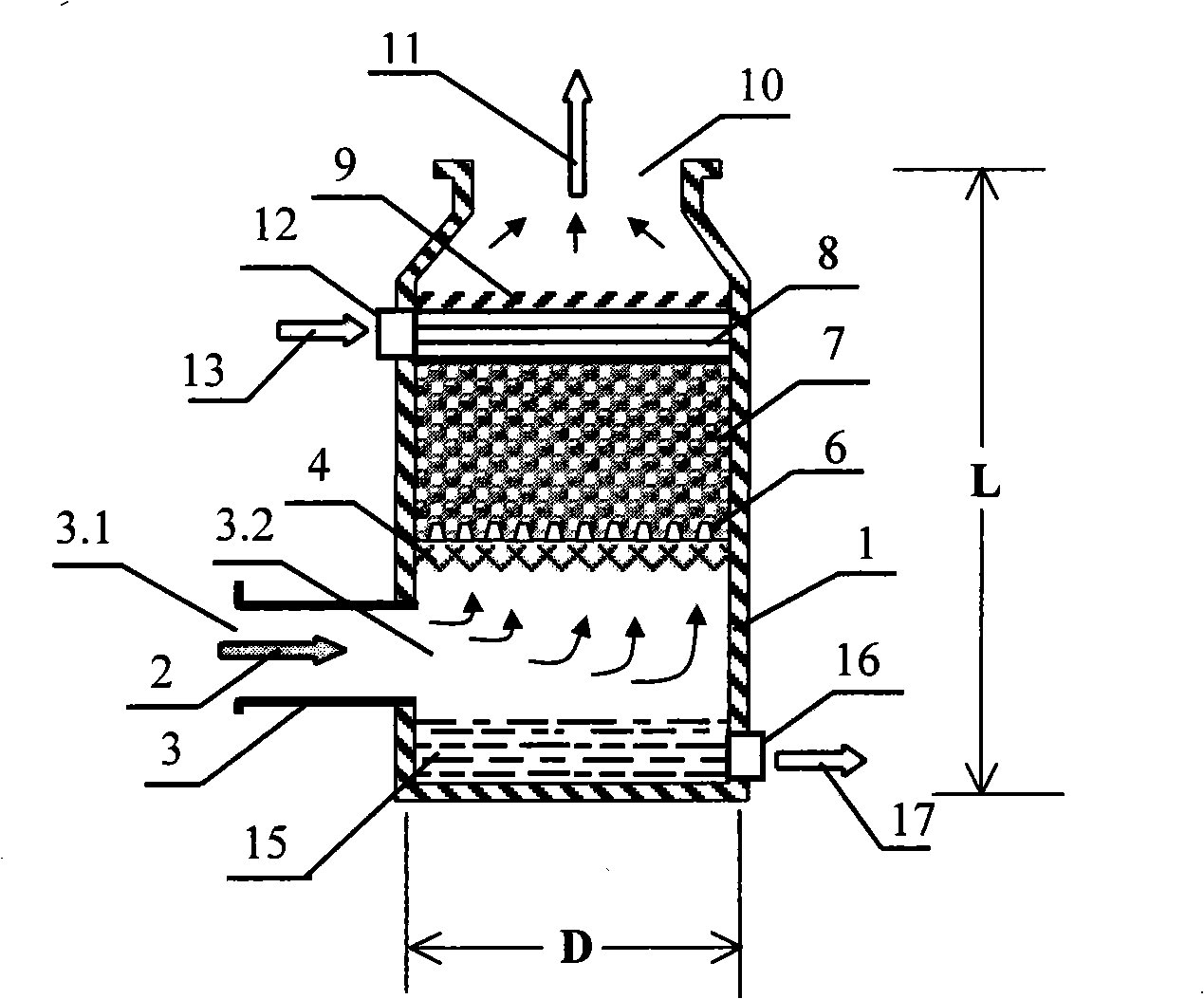

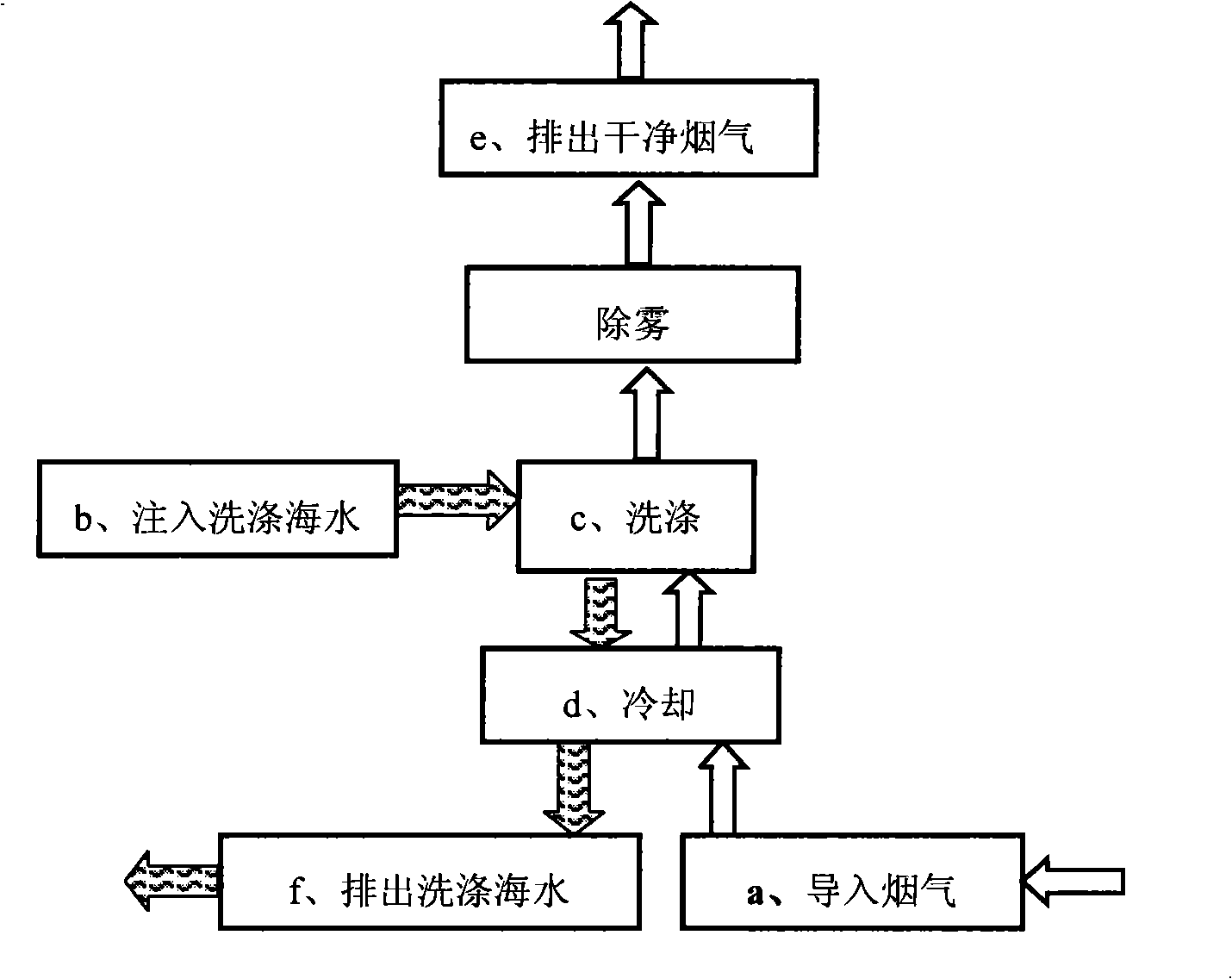

Sea boat smoke evacuation washing device and its washing method

InactiveCN101288823AGood technical effectEfficient washingDispersed particle separationSeawaterProcess engineering

The invention relates to a sea boat smoke exhaust washing device and a washing method. The device comprises a shell, a washing layer which is arranged at the upper part in the shell, a liquid collecting pool which is arranged at the lower part in the shell, a shell internal flue gas guide-in port arranged between the washing layer and the liquid collecting pool, a washing seawater inlet which is arranged above the washing layer and the cooler of the flue gas passage which is arranged between the shell external flue gas inlet and the washing layer; the method comprises the steps such as guiding in the flue gas, cooling and injecting the washing seawater and washing, etc. The invention provides the high-effect smoke exhaust absorption washing device and method which are suitable for high smoke temperature and narrow space of the sea boat, and has the advantages of high exhaust reduction efficiency, low running energy consumption, small volume and long service life.

Owner:武汉晶源环境工程有限责任公司

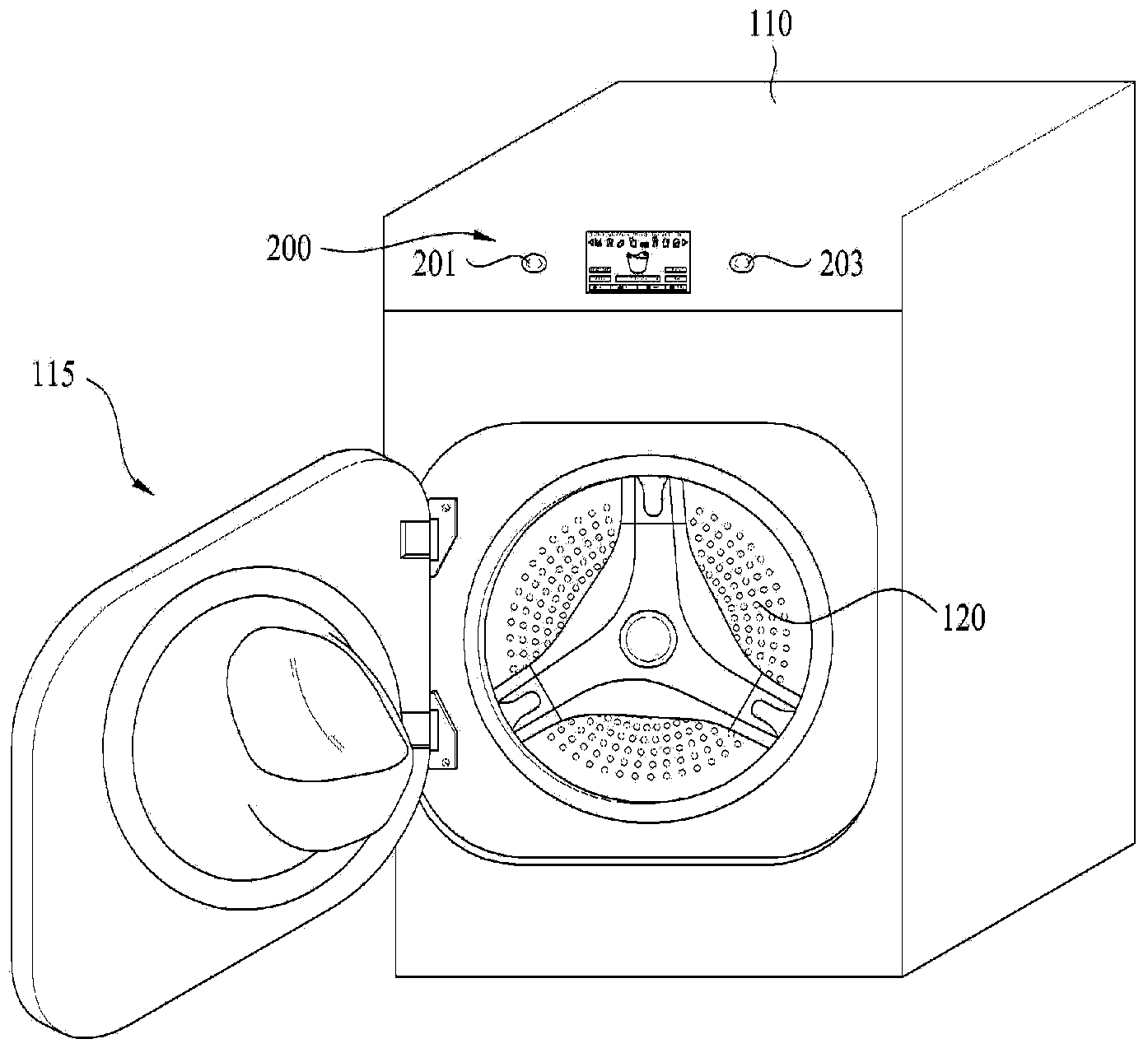

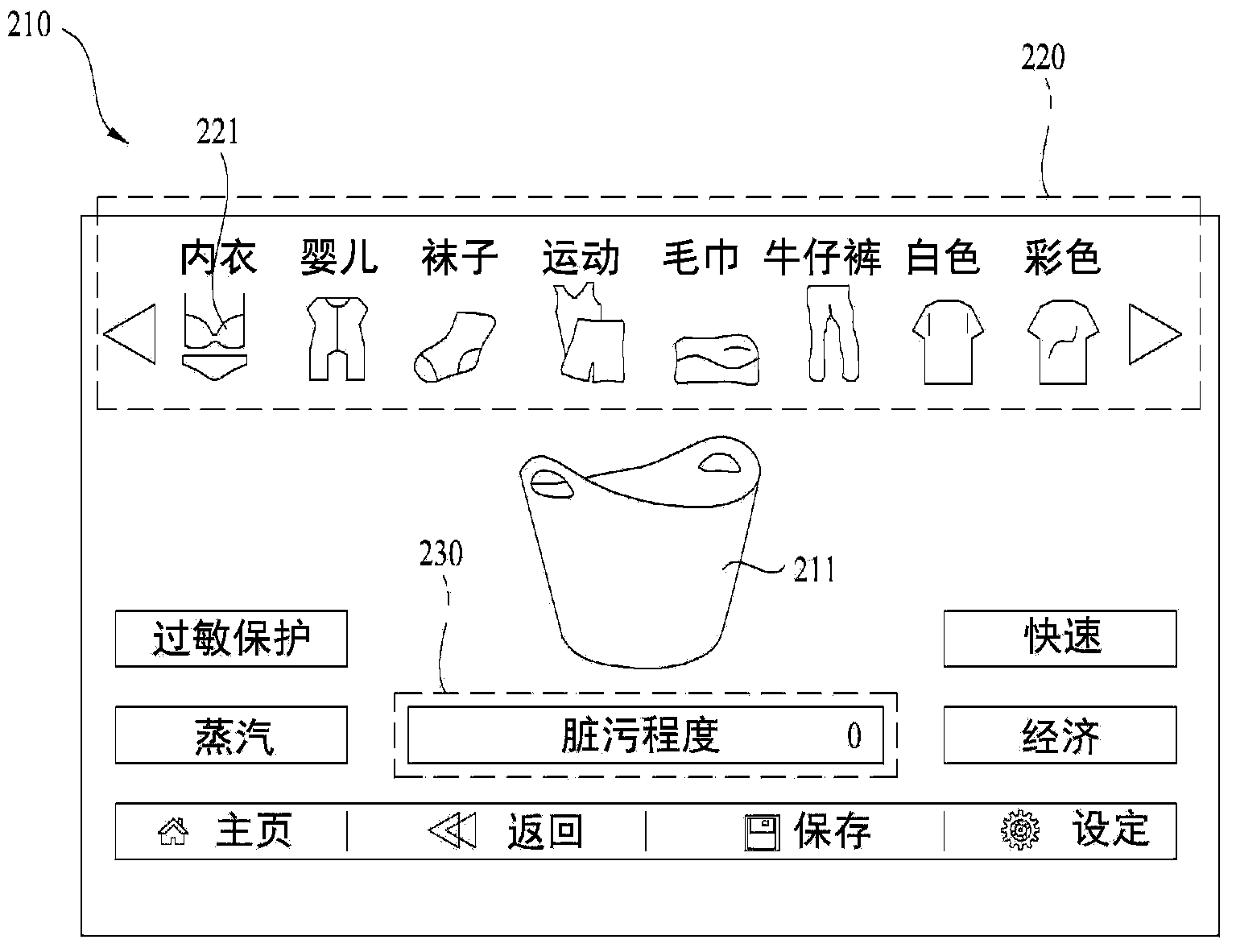

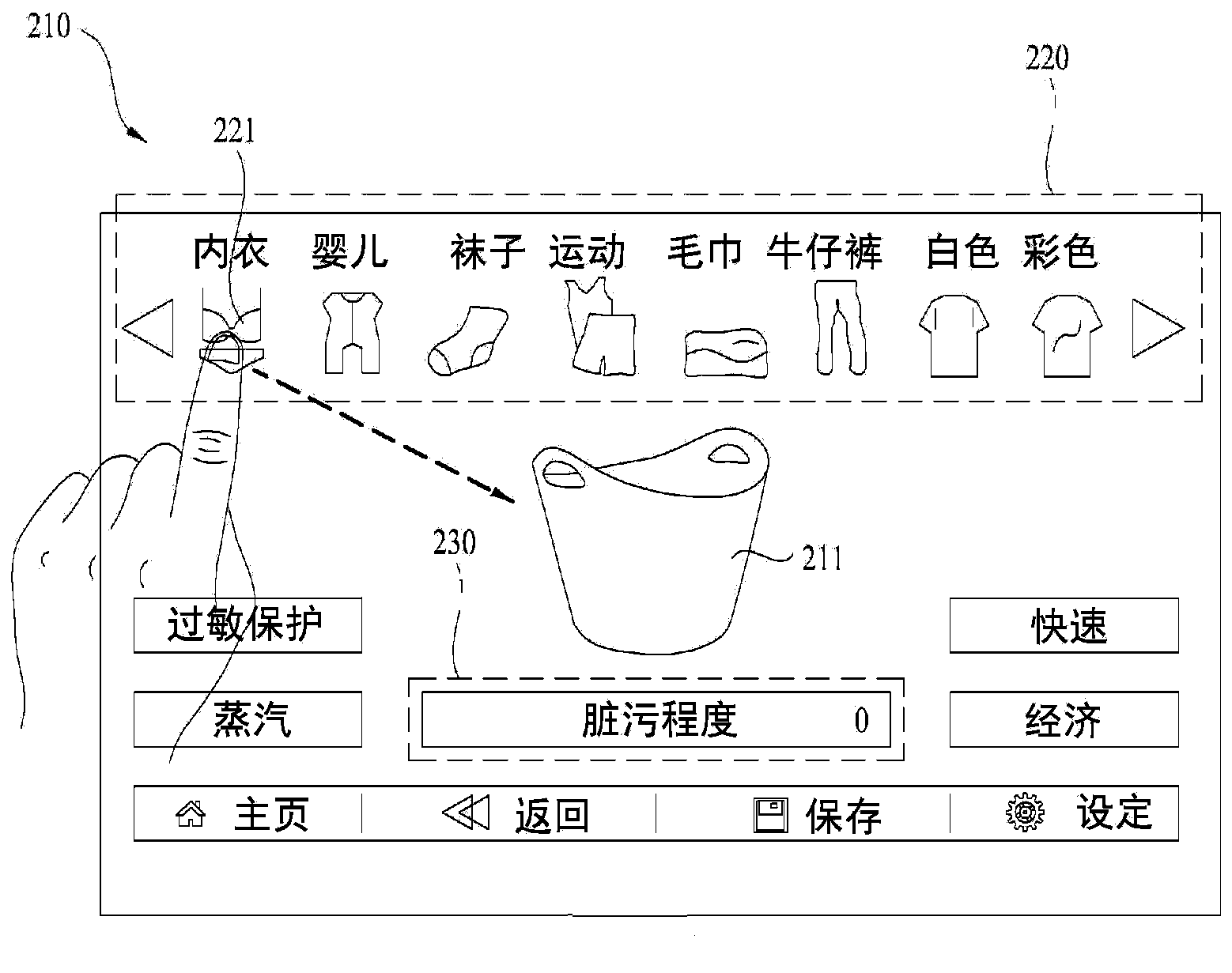

Control panel and laundry machine having the same, further method for controlling the same

InactiveCN103502522AEfficient washingOther washing machinesControl devices for washing apparatusProcess engineeringControl unit

Owner:LG ELECTRONICS INC

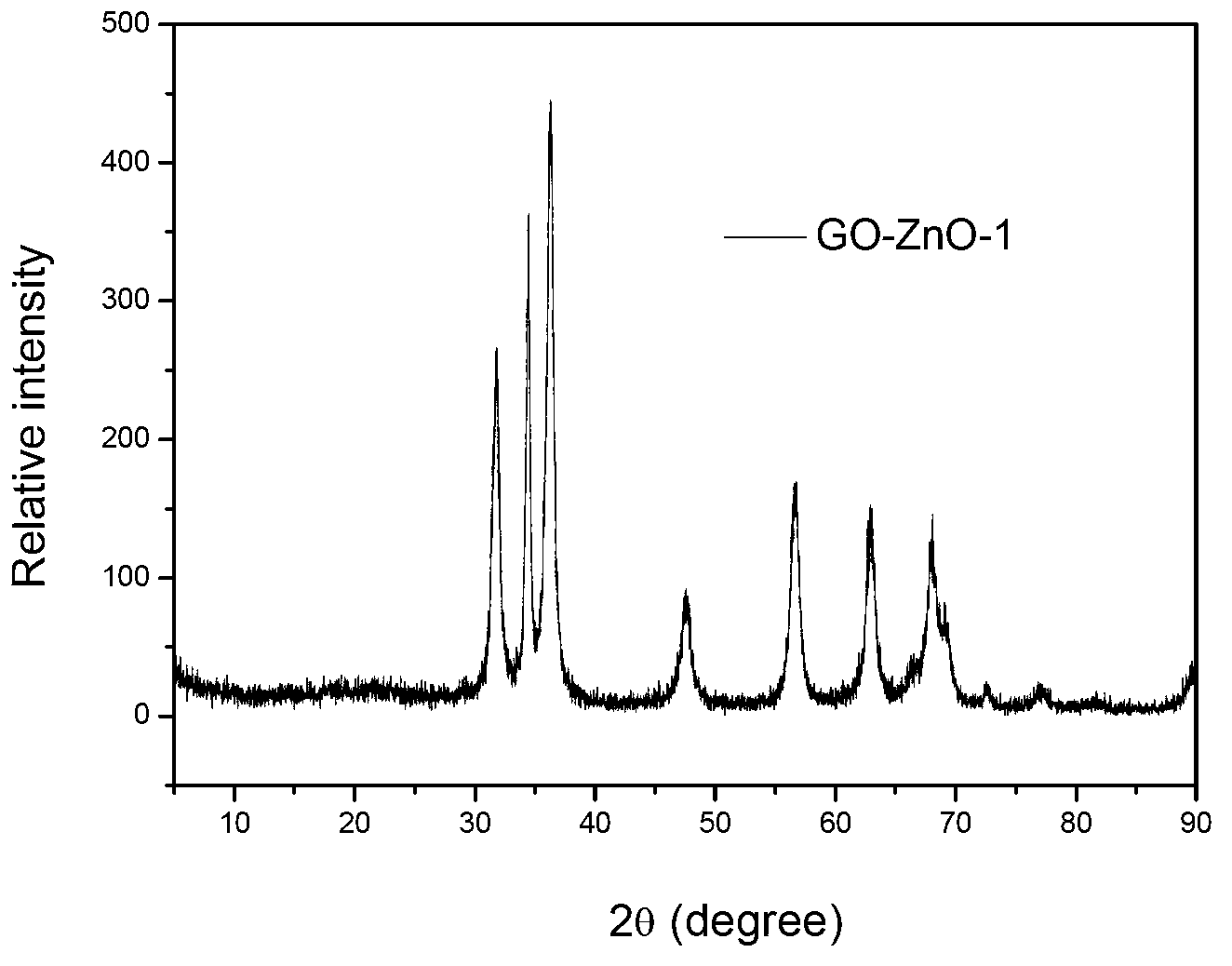

Graphene oxide loaded nanometer zinc oxide antibacterial agent, preparation method and applications thereof

ActiveCN103283781AEvenly dispersedEfficient washingBiocideDisinfectantsCentrifugationBiocompatibility Testing

The invention belongs to the field of inorganic antibacterial materials, and discloses a graphene oxide loaded nanometer zinc oxide antibacterial agent, a preparation method and applications thereof. The preparation method comprises the following steps: dissolving a surfactant P123 and graphene oxide in distilled water, adding a NaOH solution, adding solid zinc nitrate, and stirring until the solid is dissolved; carrying out a reaction for 16-18 h at a temperature of 60-85 DEG C under stirring, carrying out centrifugation washing on the obtained reaction solution with distilled water, and collecting precipitate; and dissolving the precipitate in distilled water to obtain a liquid antibacterial agent, or carrying out vacuum drying on the precipitate for 36-48 h at a temperature of 40-75 DEG C to obtain a solid antibacterial agent. According to the present invention, a suitable dispersant is selected to uniformly disperse the nanometer zinc oxide particles on the surface of the graphene oxide, such that the product has good stability; and the graphene oxide loaded nanometer zinc oxide antibacterial agent belongs to a water-soluble inorganic antibacterial agent, such that practical application is convenient, the use process is simple, and characteristics of good stability, good biocompatibility, and good antibacterial property are provided.

Owner:SUN YAT SEN UNIV

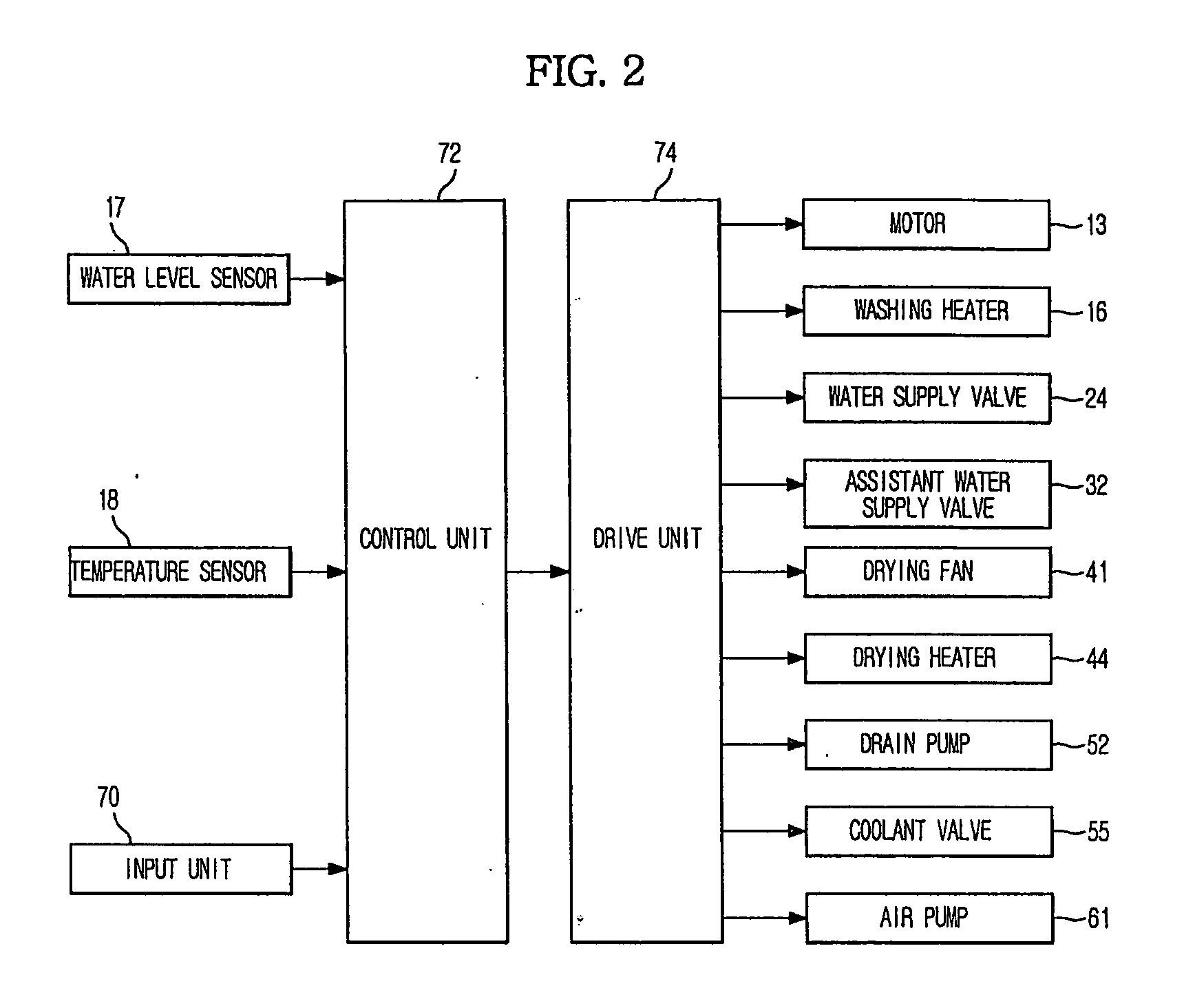

Washing machine and controlling method

ActiveUS20090064421A1Reduce water consumptionImprove washing efficiencyOther washing machinesControl devices for washing apparatusProcess engineering

Disclosed are a washing machine and a controlling method, capable of maintaining an optimal temperature for efficient generation of foam to perform foam washing that uses a large amount of foam in washing laundry, thereby accomplishing optimal washing efficiency. The controlling method for the washing machine according to the present invention comprises supplying washing water with detergent required to generate foam, generating foam using detergent water which is a mixture of the washing water and the detergent, transmitting heat to the generated foam by heating the detergent water, and washing laundry using the foam.

Owner:SAMSUNG ELECTRONICS CO LTD

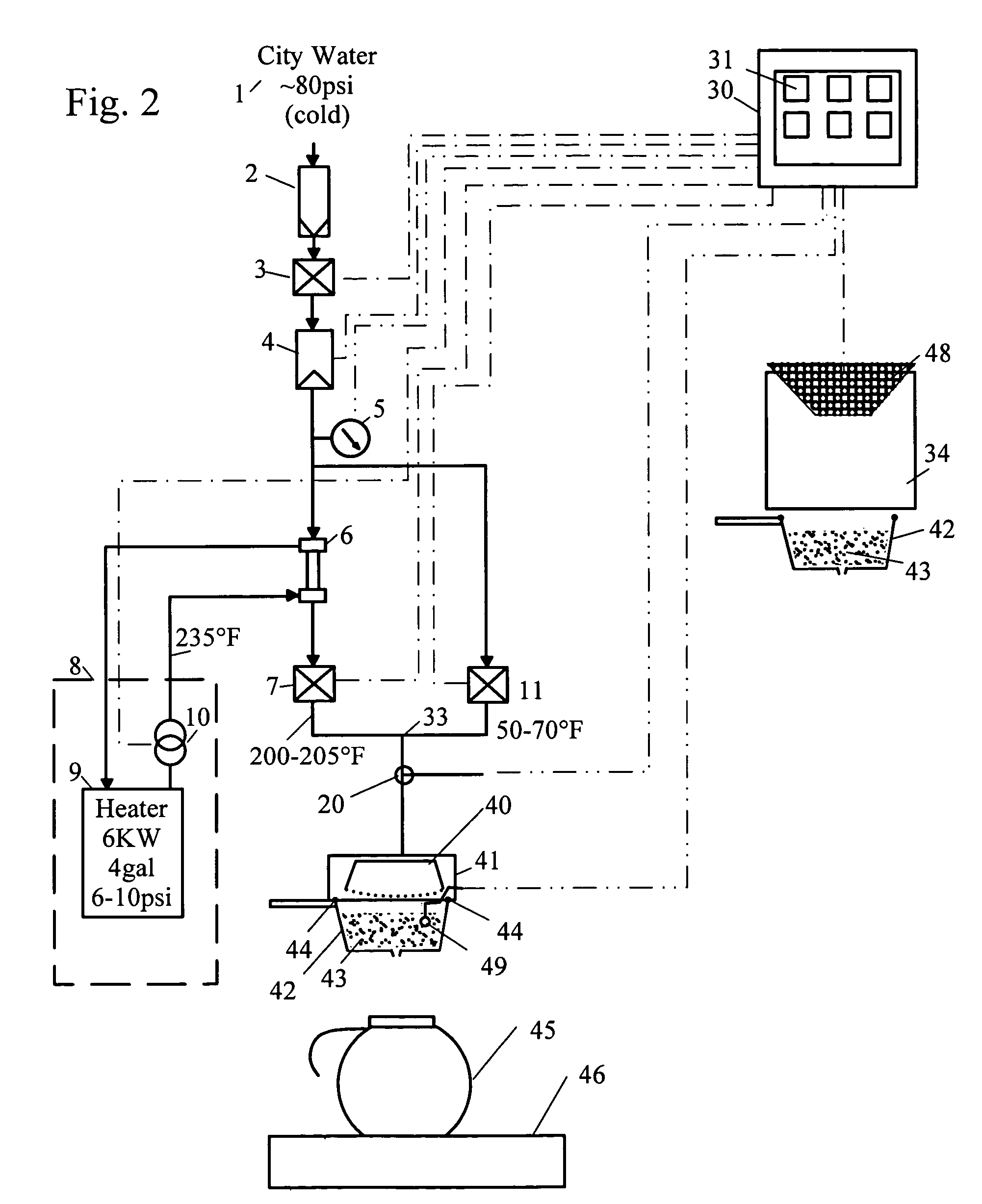

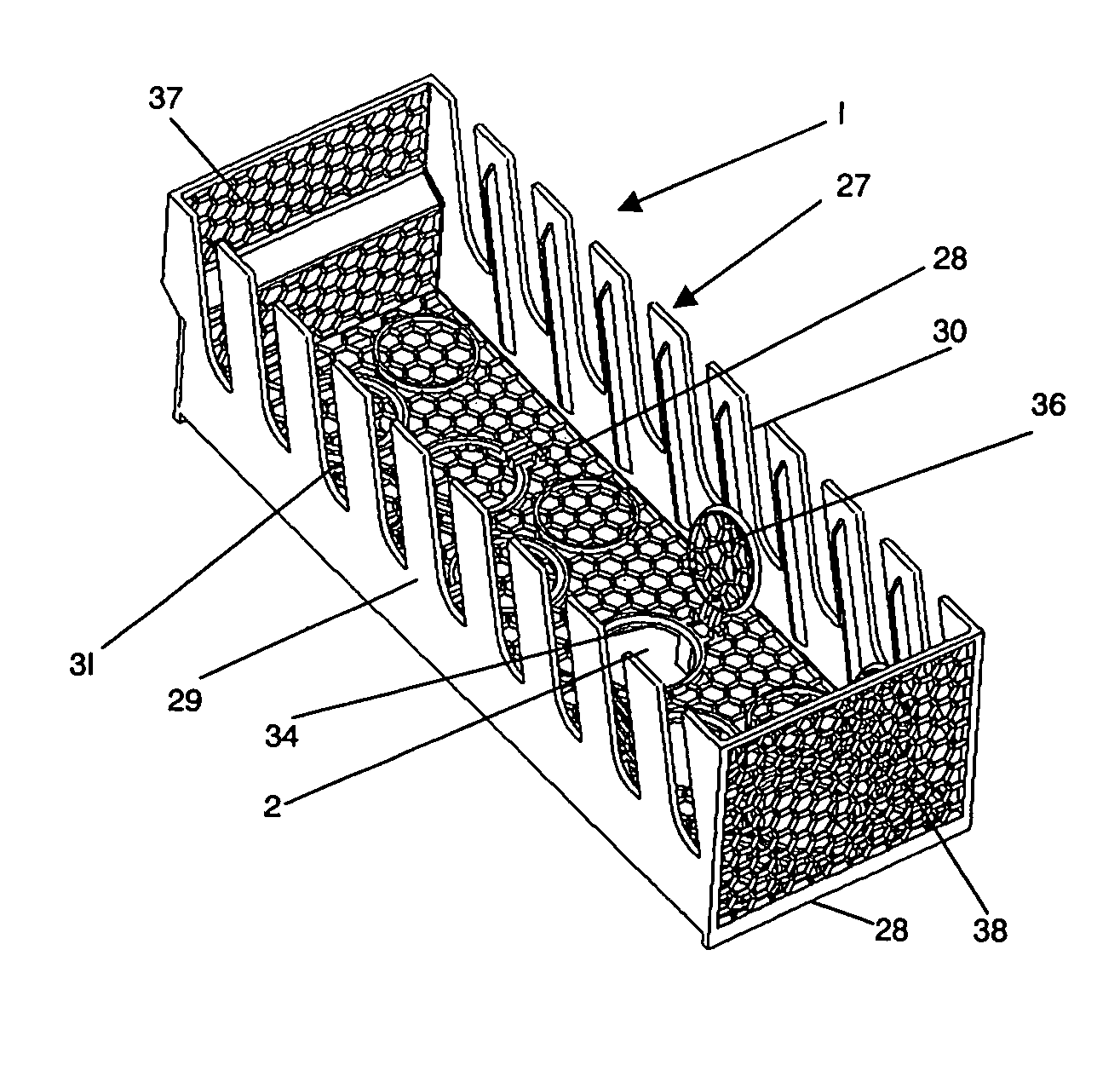

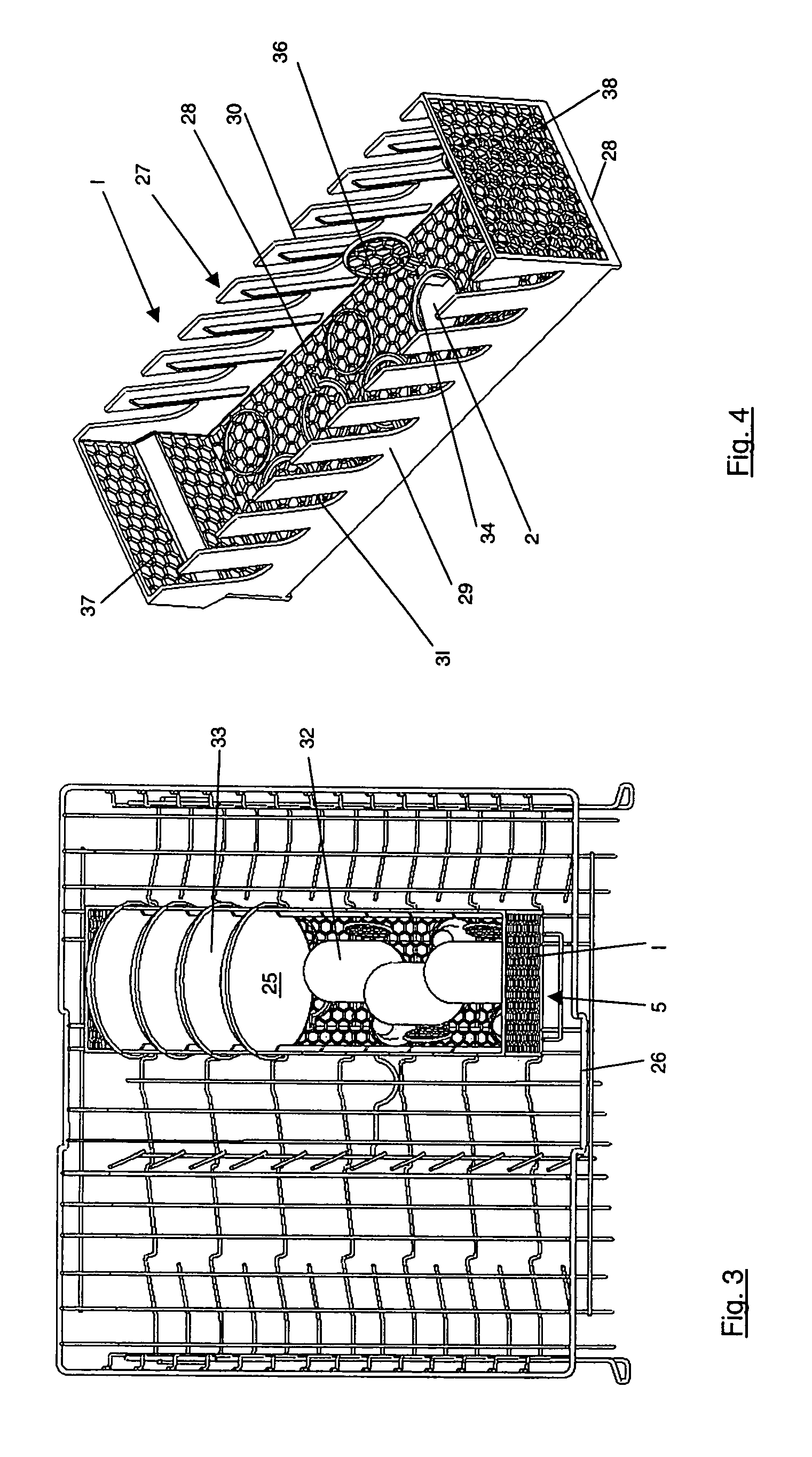

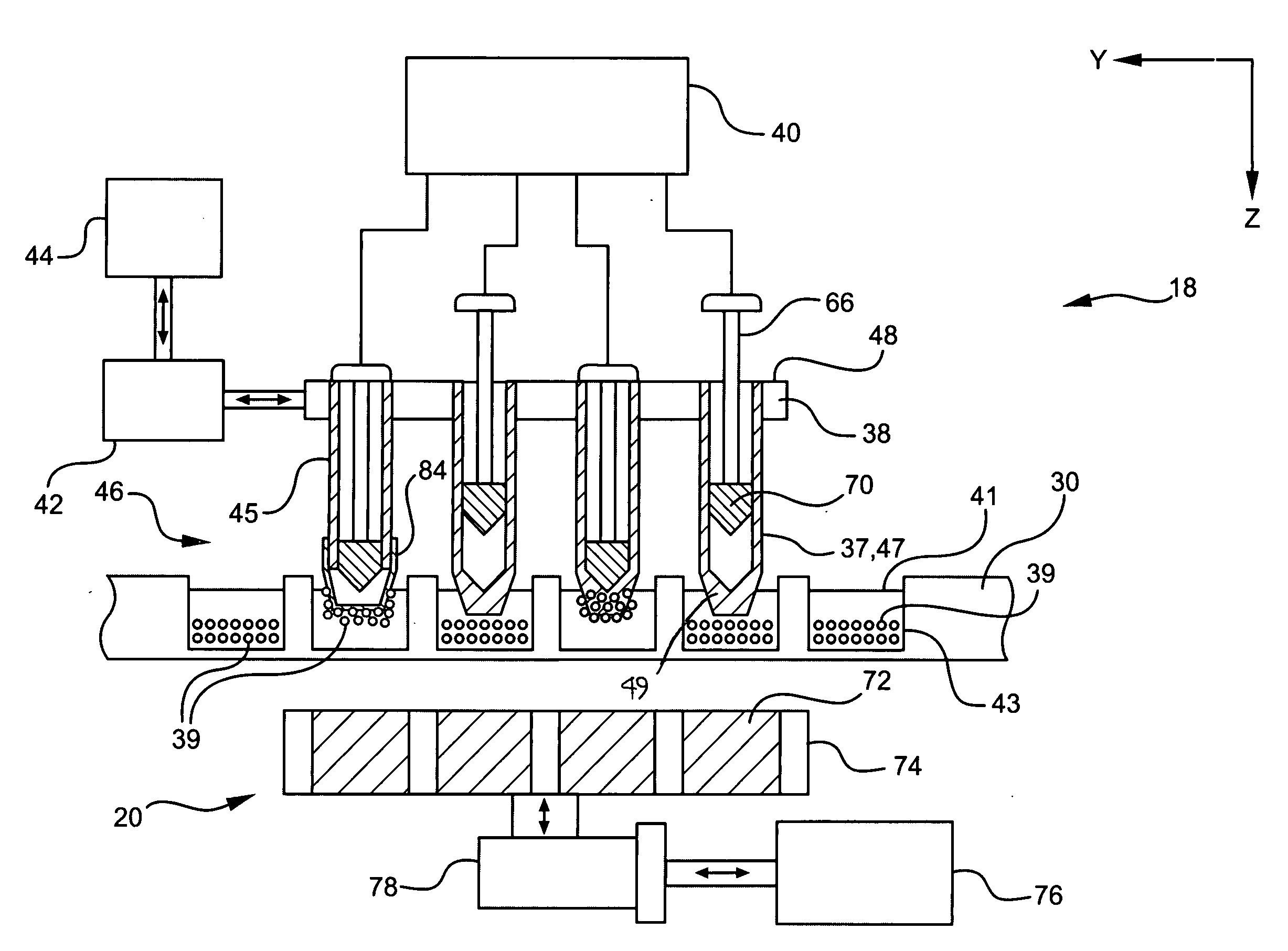

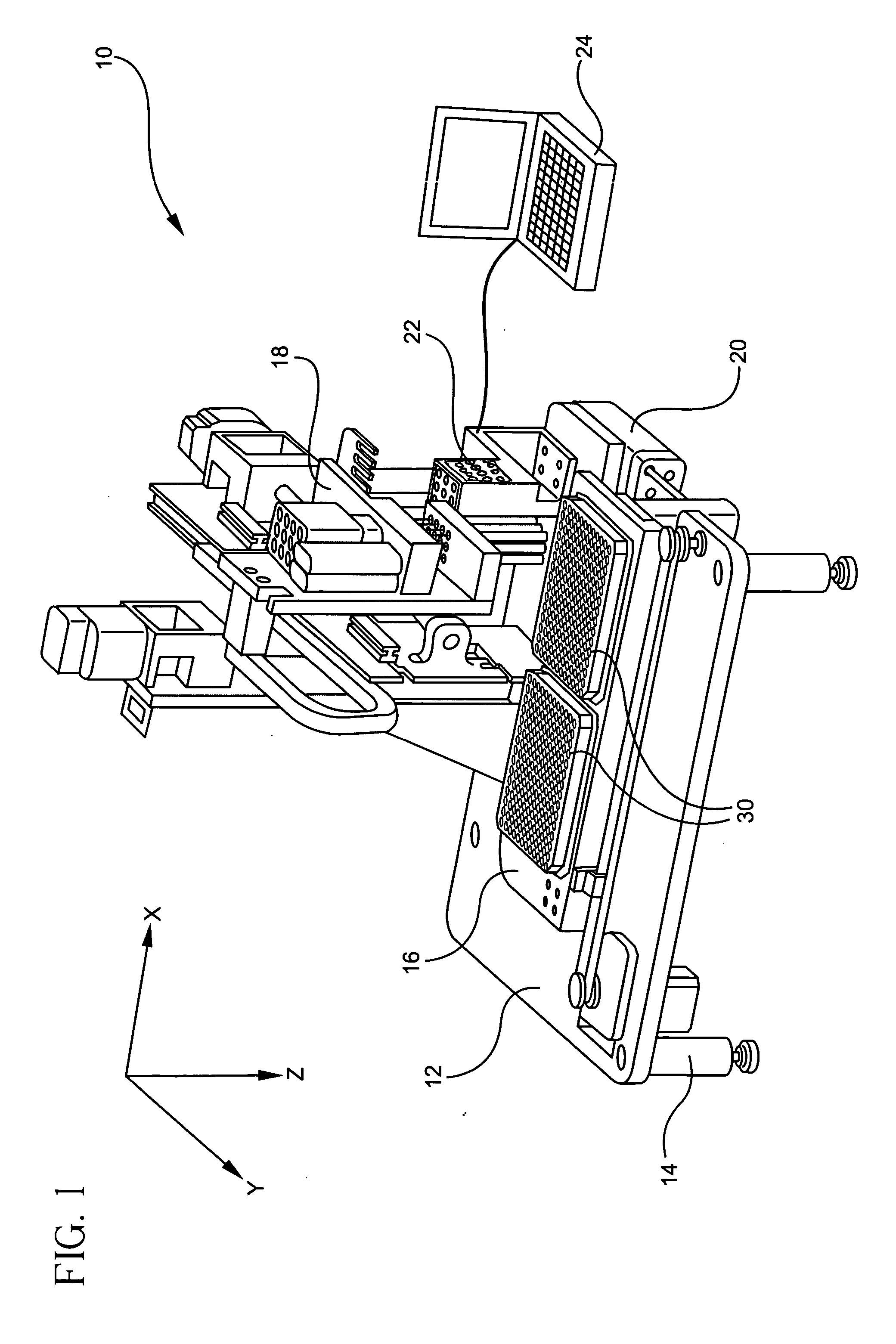

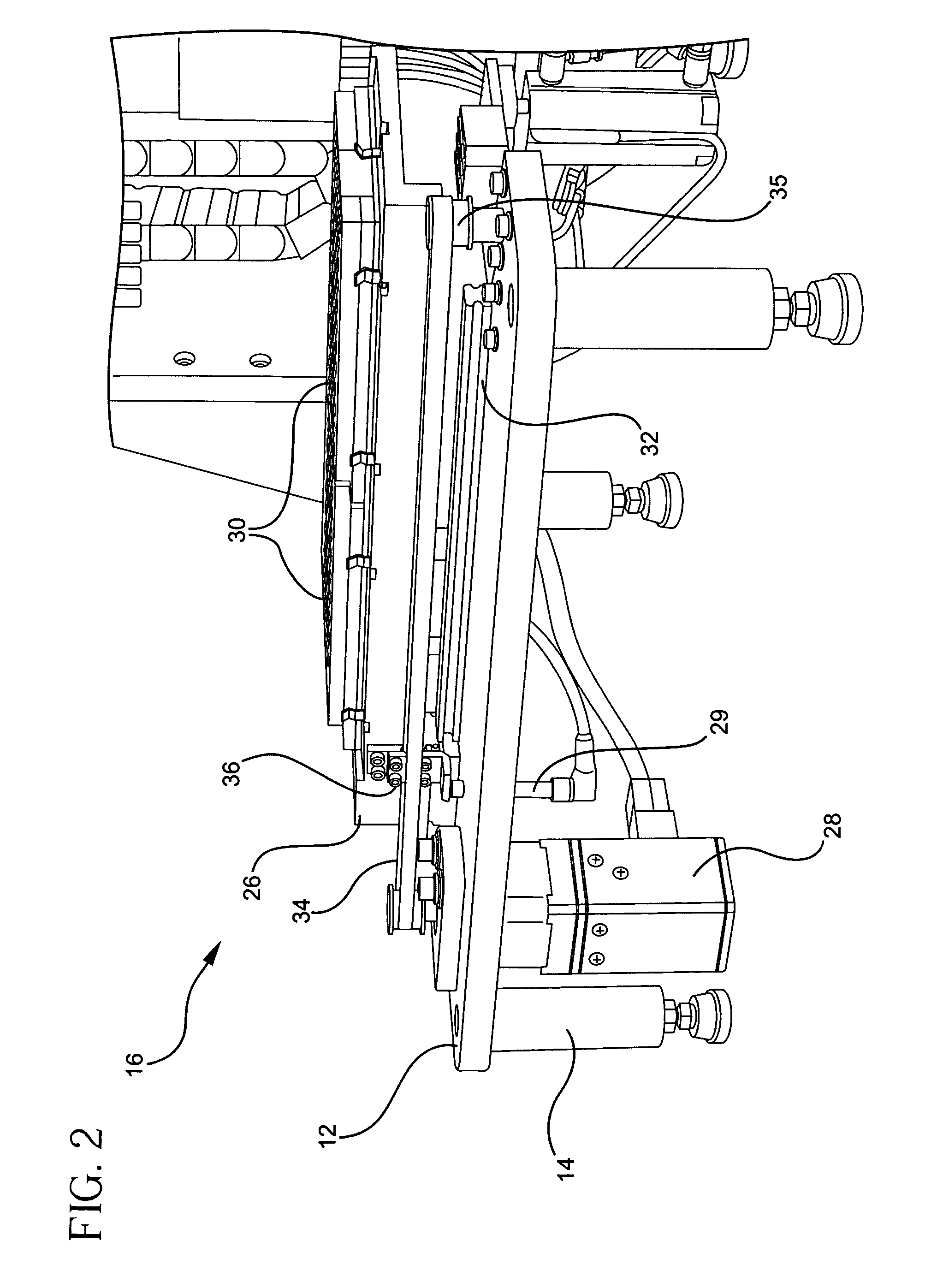

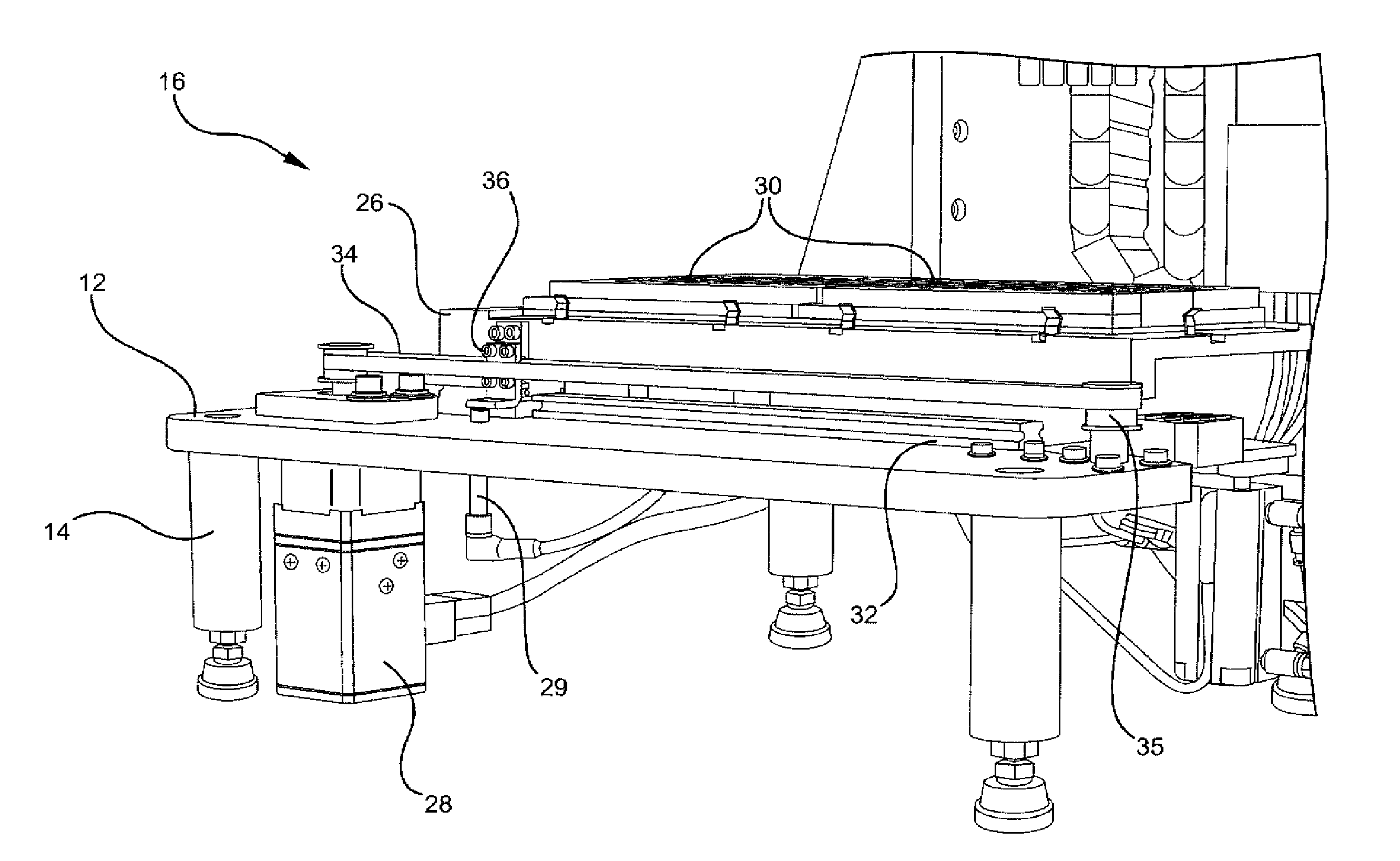

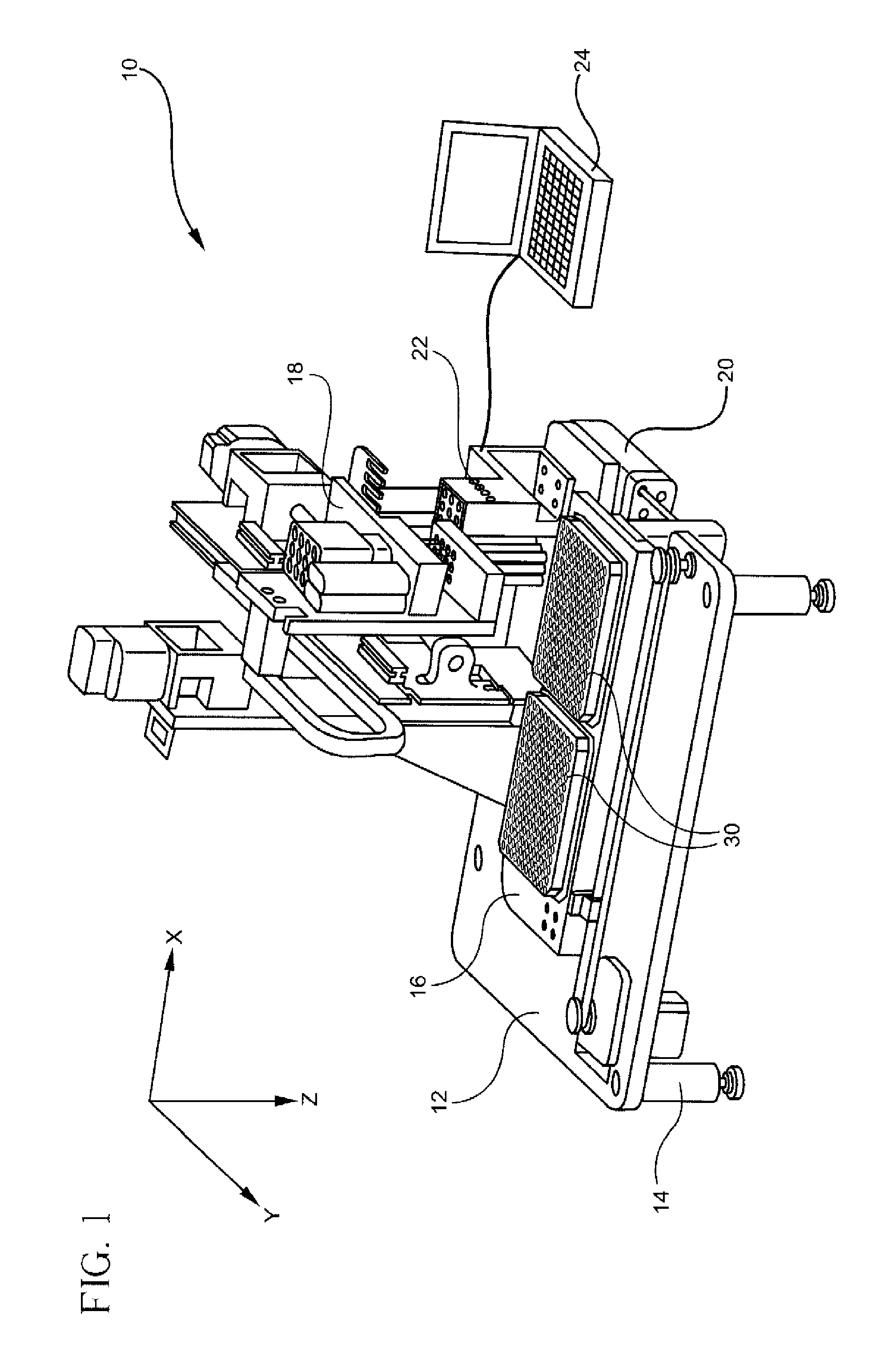

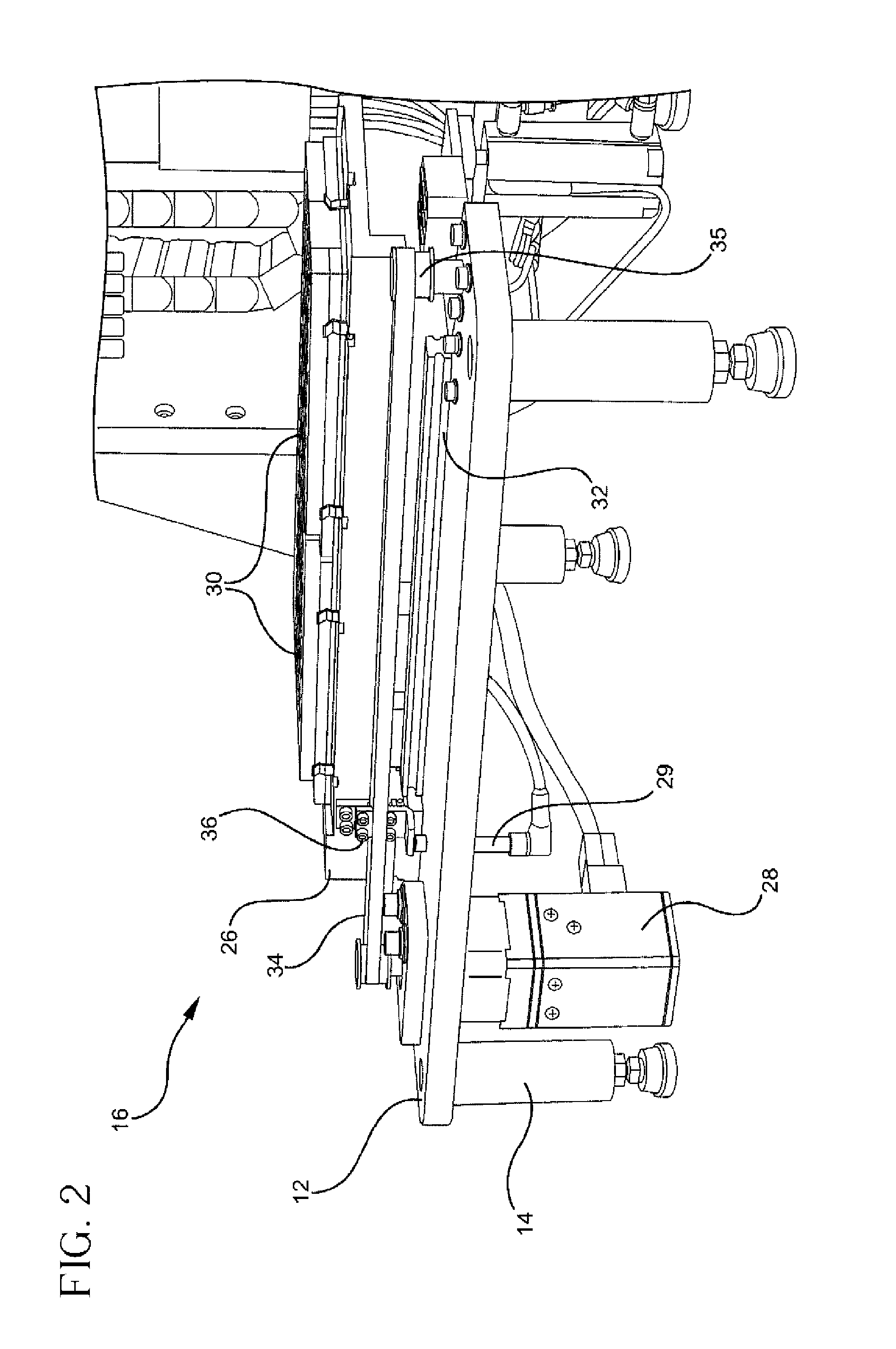

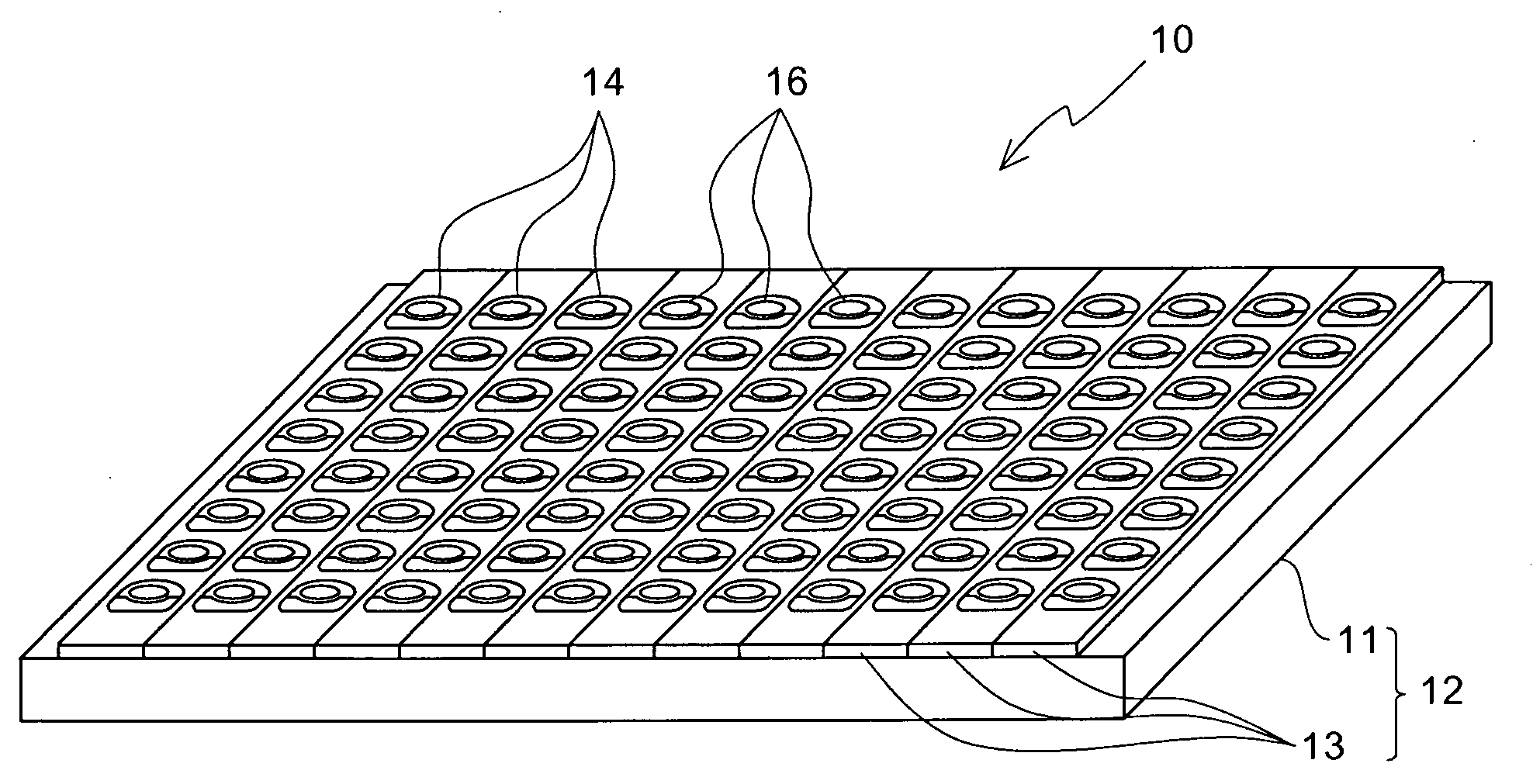

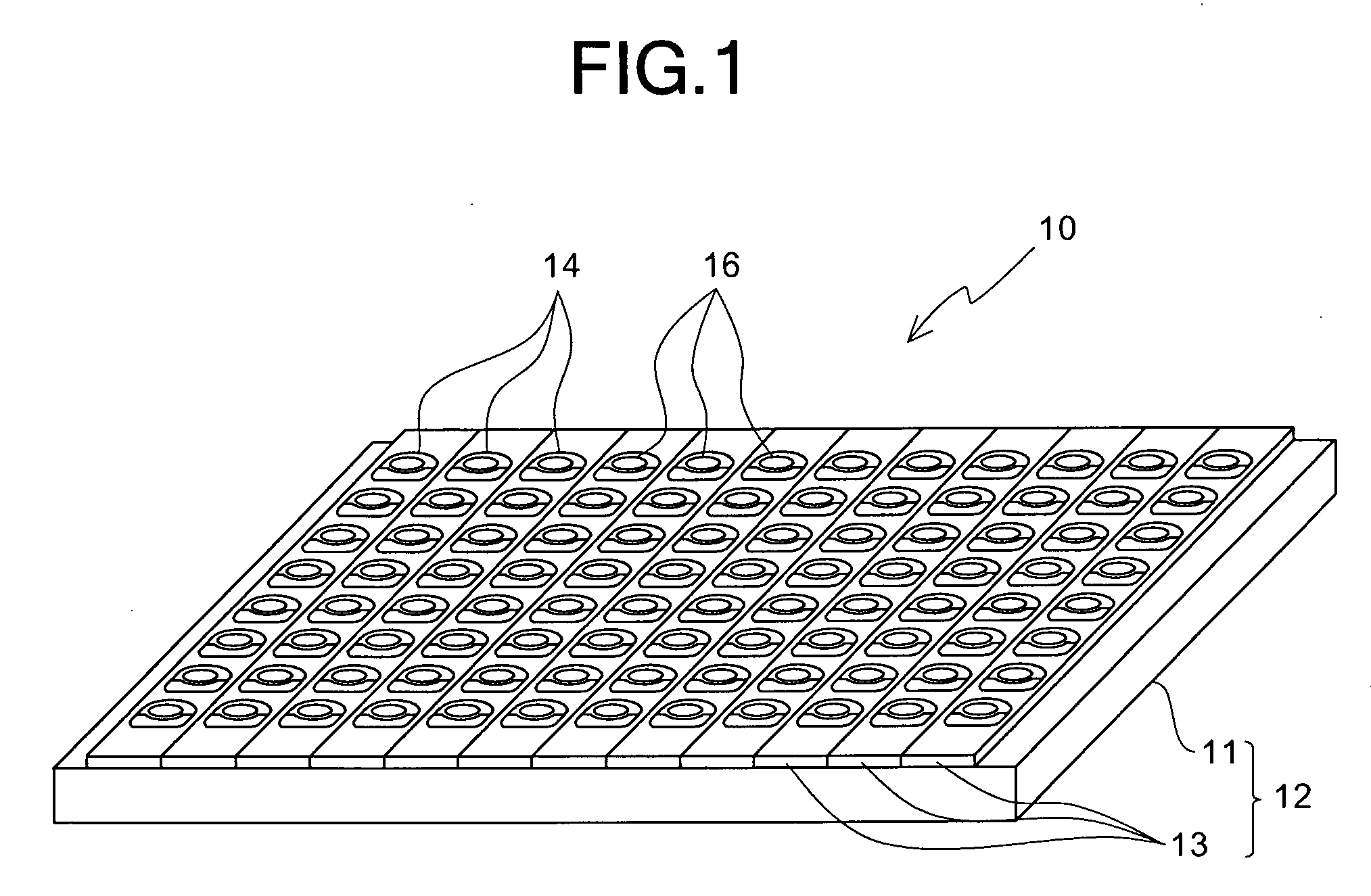

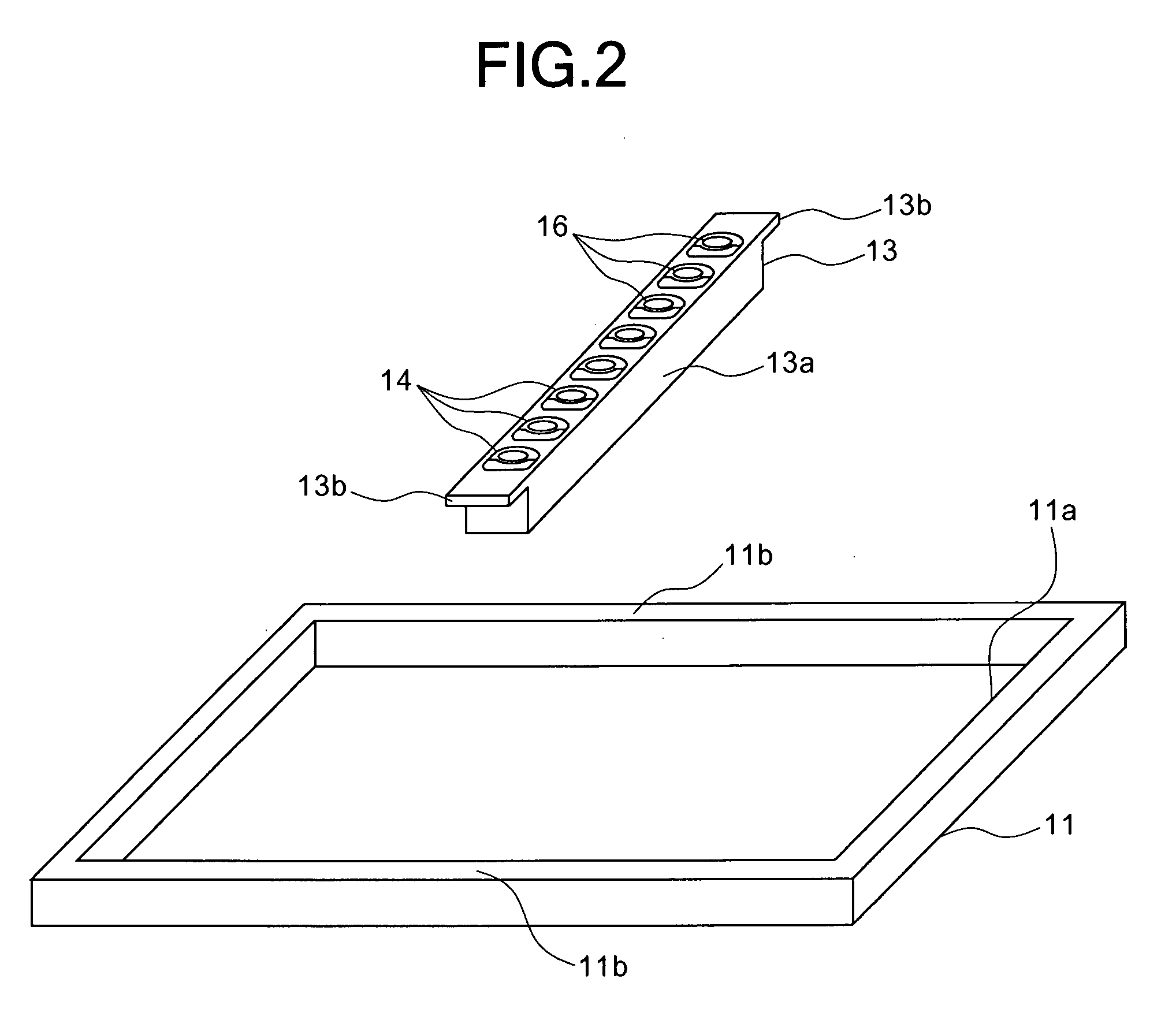

Fluid handling apparatus and fluid handling unit for use therein

InactiveUS20070217955A1Improve reaction efficiencyHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsFluid handlingEngineering

A fluid handling apparatus 10 has a plurality of fluid handling subassemblies 16 arrayed on a plate body 12. Each of the fluid handling subassemblies includes: an injecting section 26 for injecting a fluid; a fluidized section 28 for allowing the fluid to continuously flow downwards; a fluid housing chamber 30 for receiving the fluid from the fluidized section; a wall portion 20 formed between the fluid housing chamber and the fluidized section; slits 20b for allowing the fluid to enter the fluid housing chamber; and a surface-area increasing means 22 for increasing the area of a contact surface with the fluid in the fluidized section. The slits extend from a lower end positioned in the vicinity of the lower end of the fluidized section, to an upper end higher than the upper end of the fluidized section, for allowing the injecting section and fluidized section to be communicated with the fluid housing chamber.

Owner:ENPLAS CORP

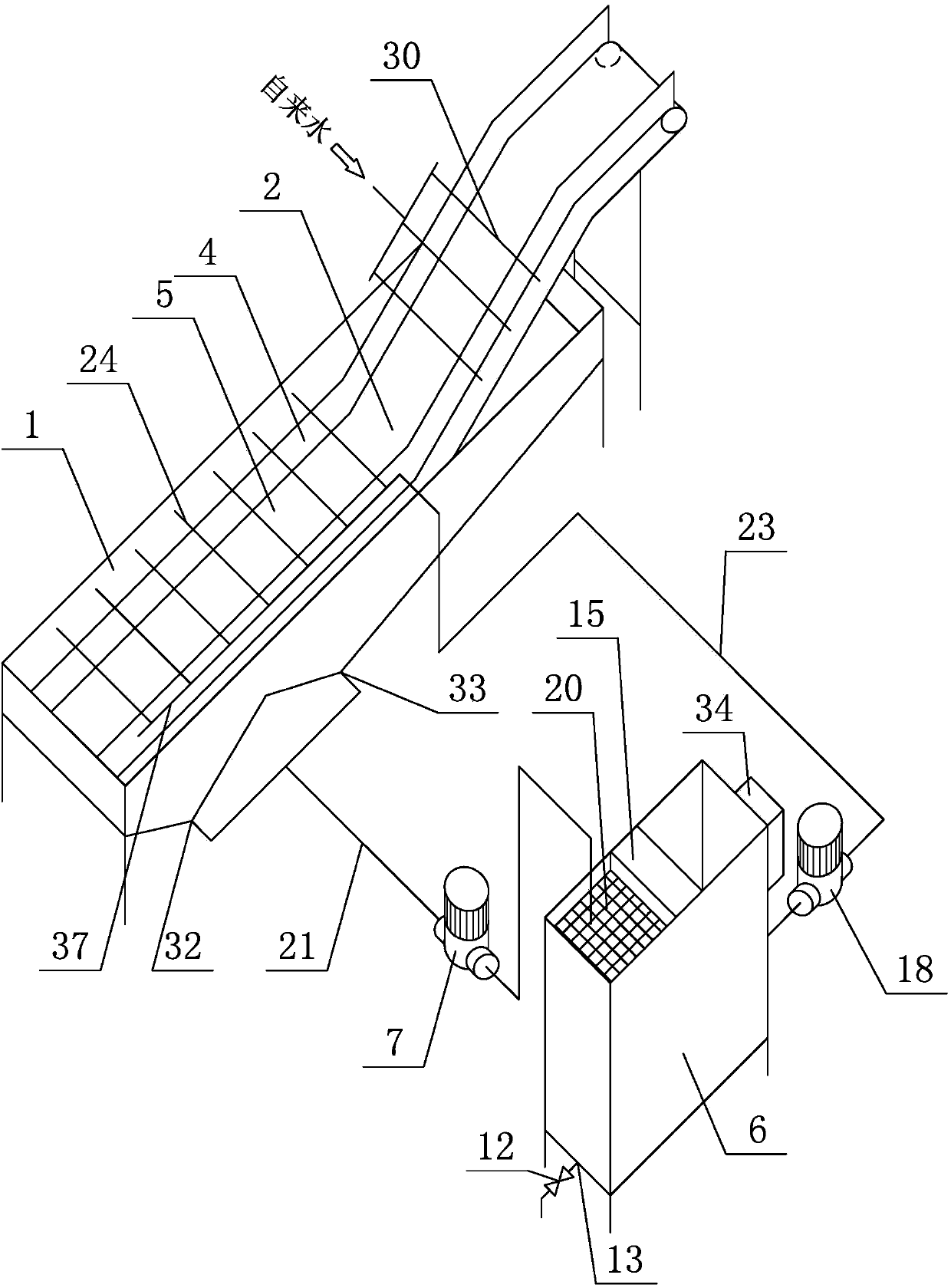

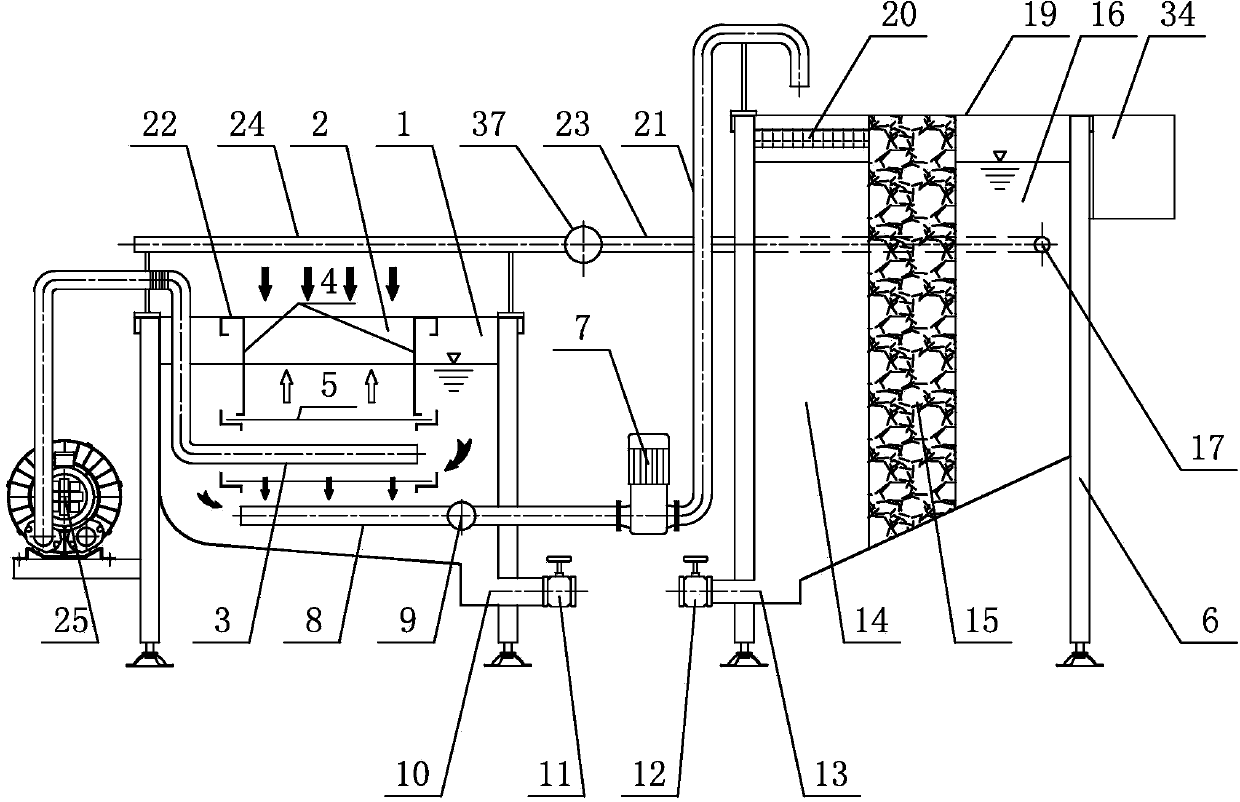

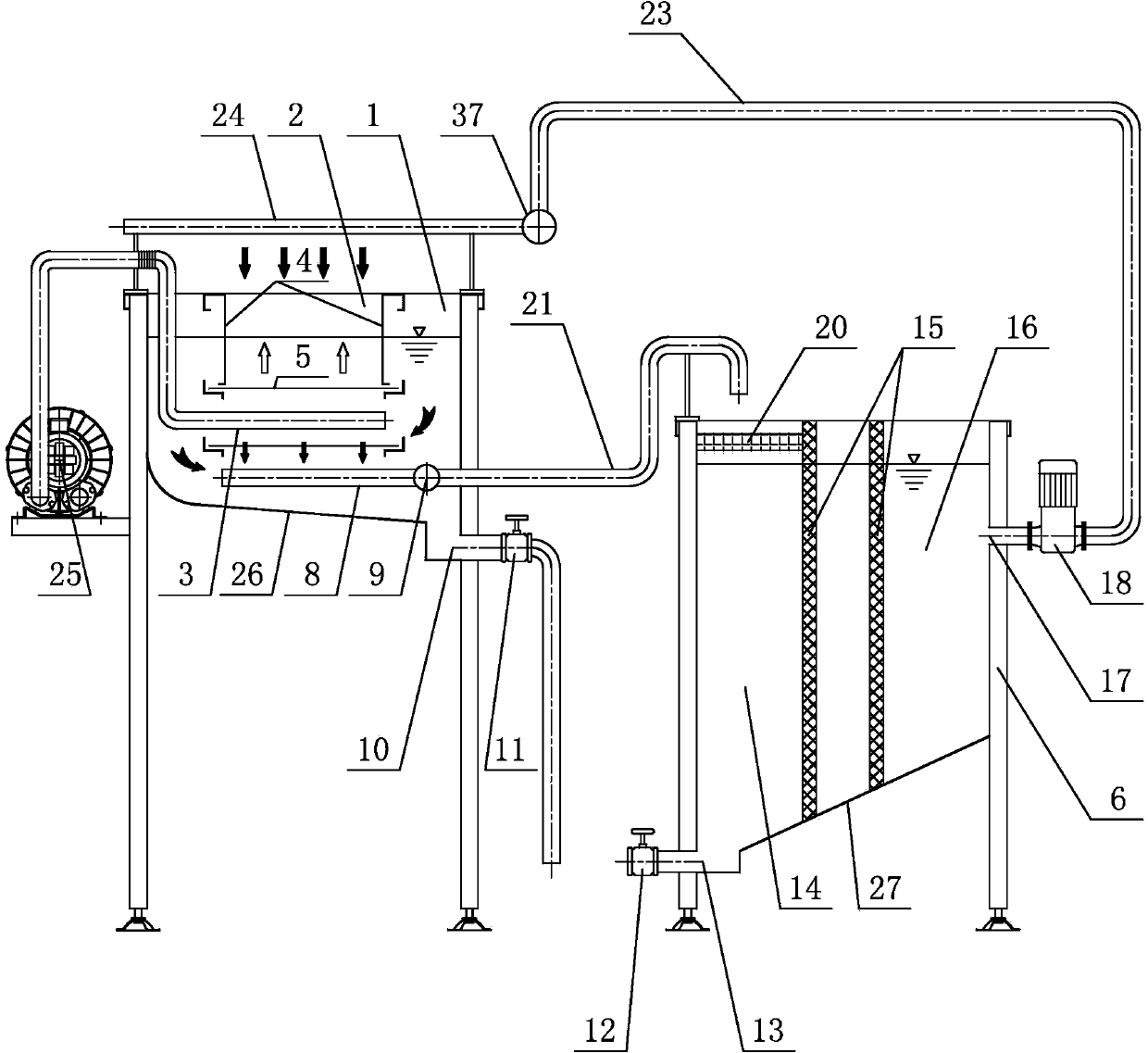

Efficient cleaning device

ActiveCN103433228AImprove water qualityEasy to cleanMultistage water/sewage treatmentCleaning using liquidsHigh concentrationSludge

Disclosed is an efficient cleaning device. The efficient cleaning device comprises a cleaning pool, a material cleaning groove, a circulating water treating pool, a connecting pipeline and the like. Gas can be fed into the material cleaning groove to conduct bubble-type washing on materials. Enough purified water is added into the material cleaning groove to spray and flush the materials. The water and sewage penetrate through the material cleaning groove and then are sucked by a water intake formed nearby. Water of the water intake flows into the circulating water treating pool through the pipeline or a water pump and the pipeline. Impurities or sludge or high-concentration sewage can be filtered or discharged from a sewage discharging valve. The purified water obtained after being treated can flow back through the pipeline or be conveyed back to the cleaning pool or the material cleaning groove by the water pump and the pipeline to form recycling of the water. Meanwhile, the materials can be washed under the environment with cleaner water. The circulating water treating pool is independent of the cleaning pool and is provided with a filtering device, a fine filtering layer and the like, water treatment like sediment or filtering or medicine adding or ozone disinfection or sterilization and disinfection can be carried out on the water. The efficient cleaning device is suitable for fixation of materials like fruits and vegetables or continuous cleaning.

Owner:与进智能科技(昆山)有限公司

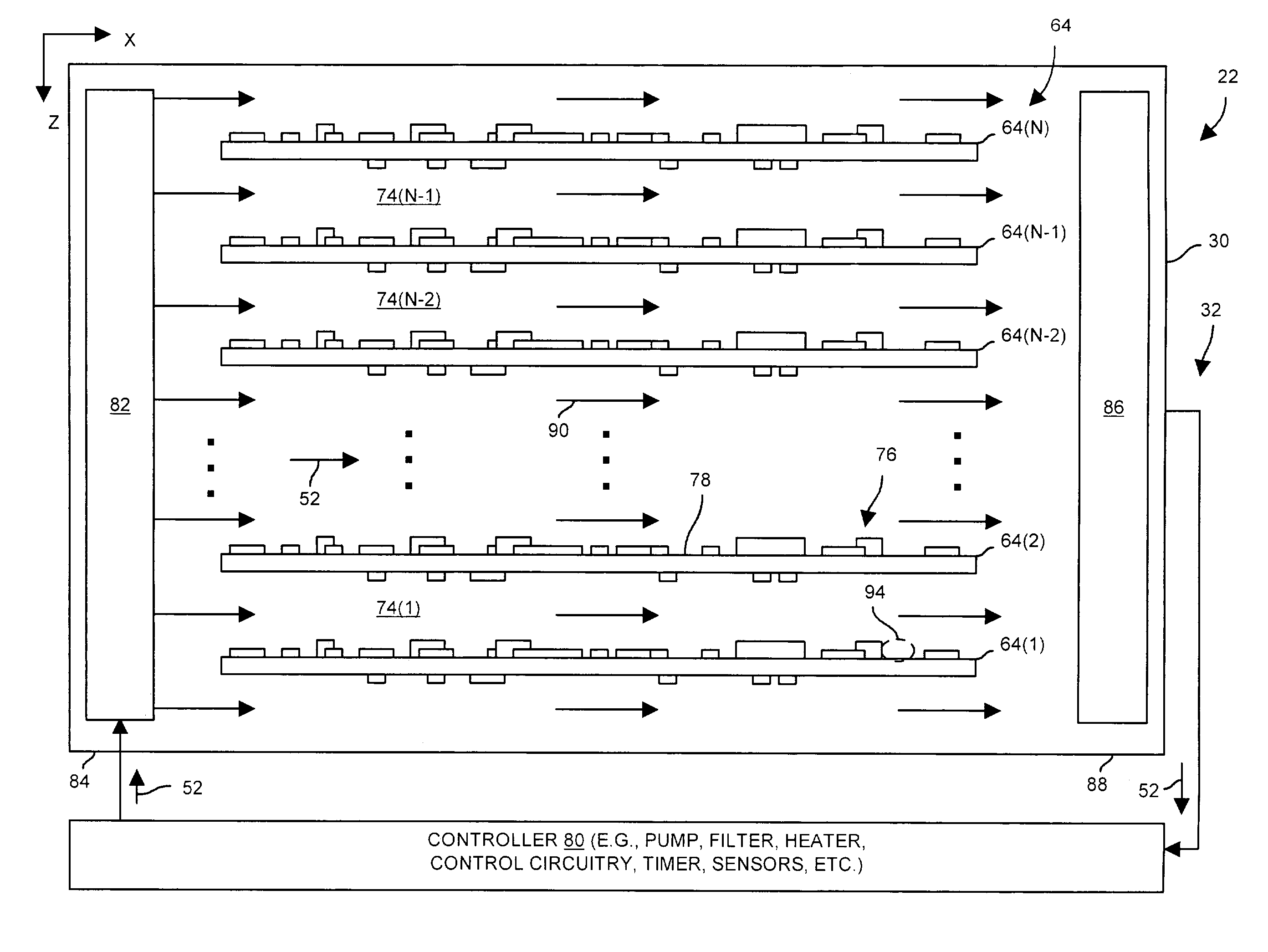

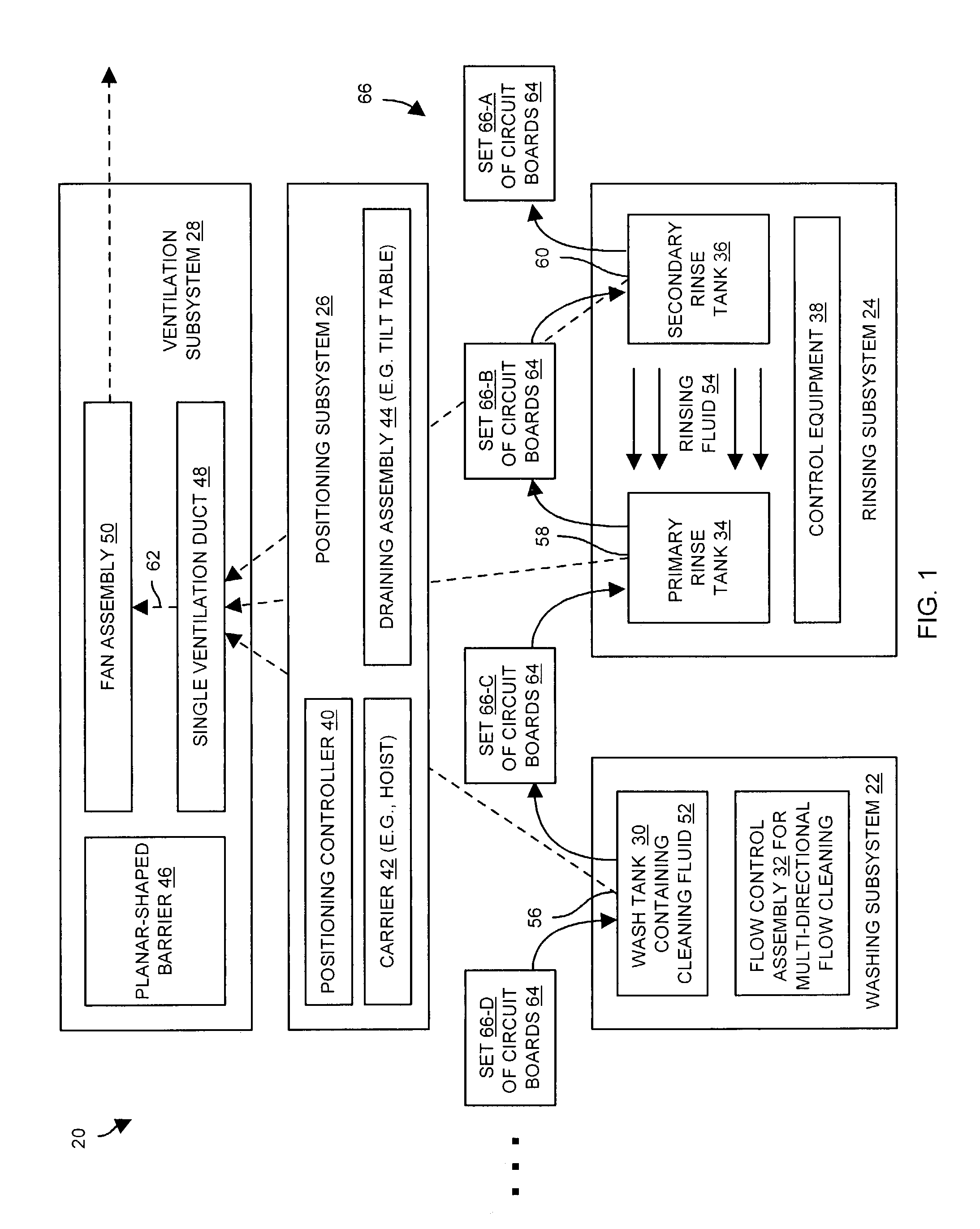

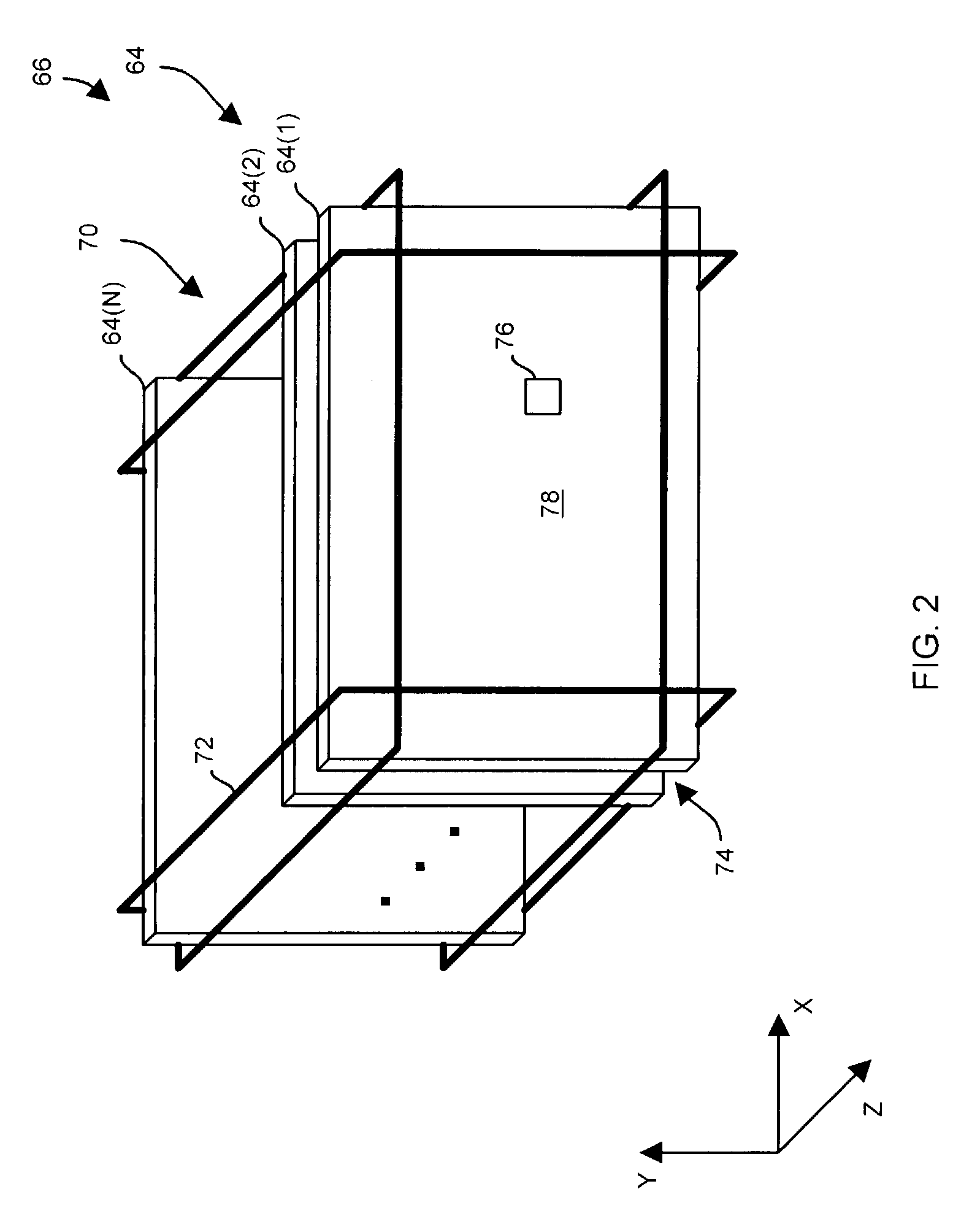

Systems and methods for processing a set of circuit boards

ActiveUS7252100B1Reduce the amount of energyReduce the amount of timeElectrostatic cleaningStacked spaced PCBsHandling systemElectrical and Electronics engineering

A circuit board processing system includes a wash tank configured to contain cleaning fluid, and a positioning subsystem configured to immerse a set of circuit boards into the wash tank. The system further includes a flow control subsystem having (i) a first set of nozzles disposed within the wash tank, (ii) a second set of nozzles disposed within the wash tank, and (iii) a controller. The controller is configured to direct the cleaning fluid through the first set of nozzles to provide a flow of the cleaning fluid in a first direction relative to the set of circuit boards. The controller is further configured to direct the cleaning fluid through a second set of nozzles to provide a flow of the cleaning fluid in a second direction relative to the set of circuit boards after providing the flow of the cleaning fluid in the first direction.

Owner:EMC IP HLDG CO LLC

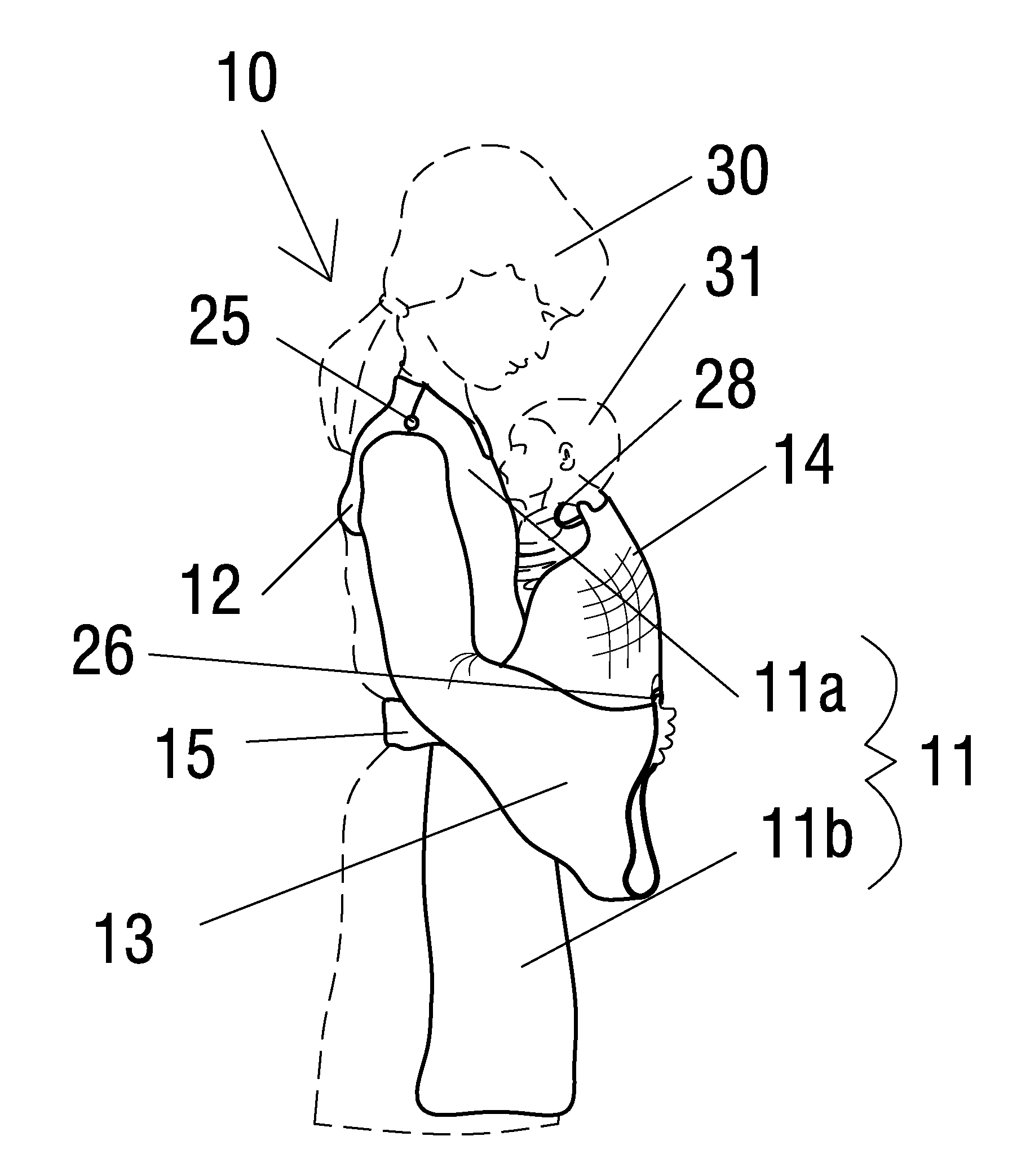

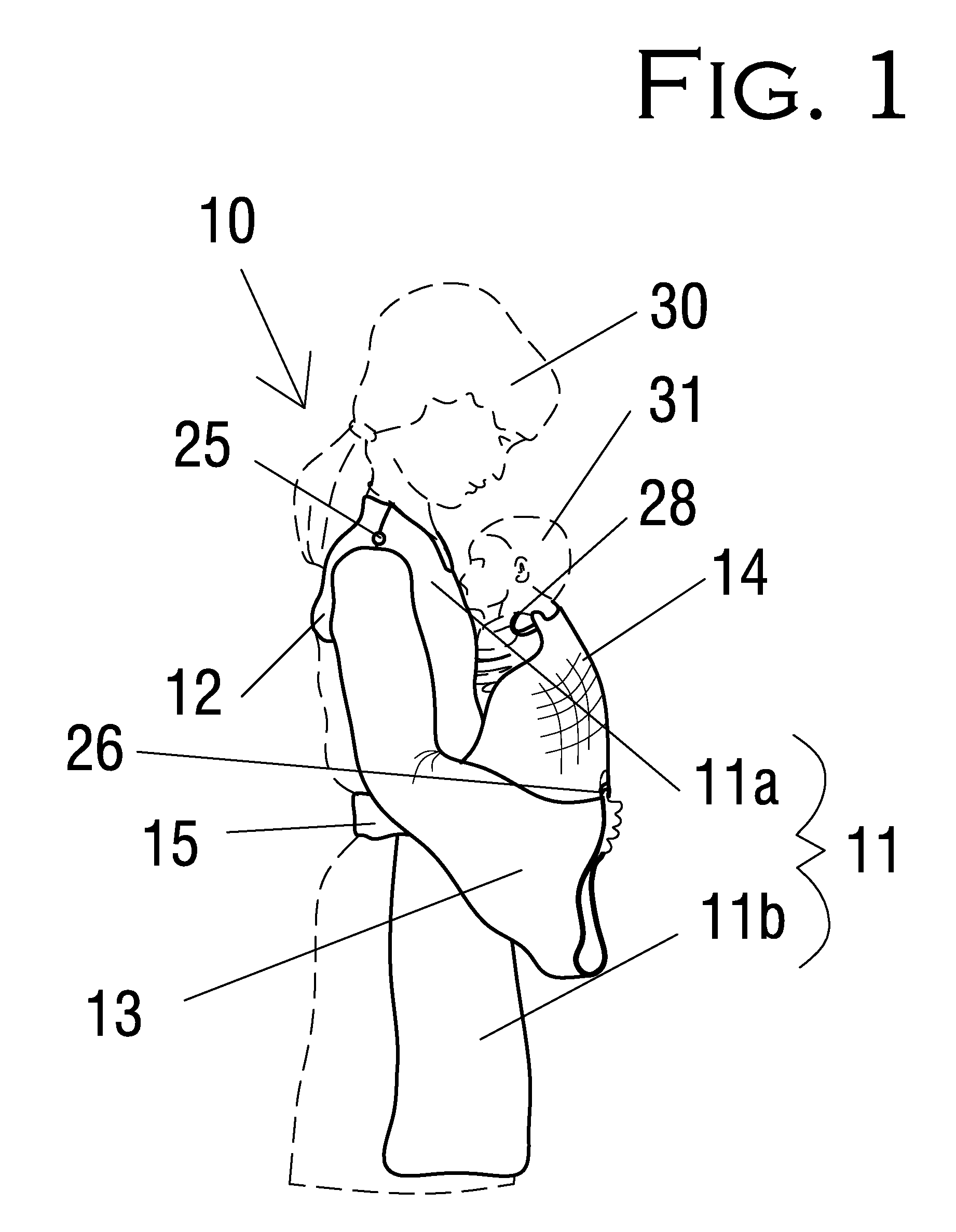

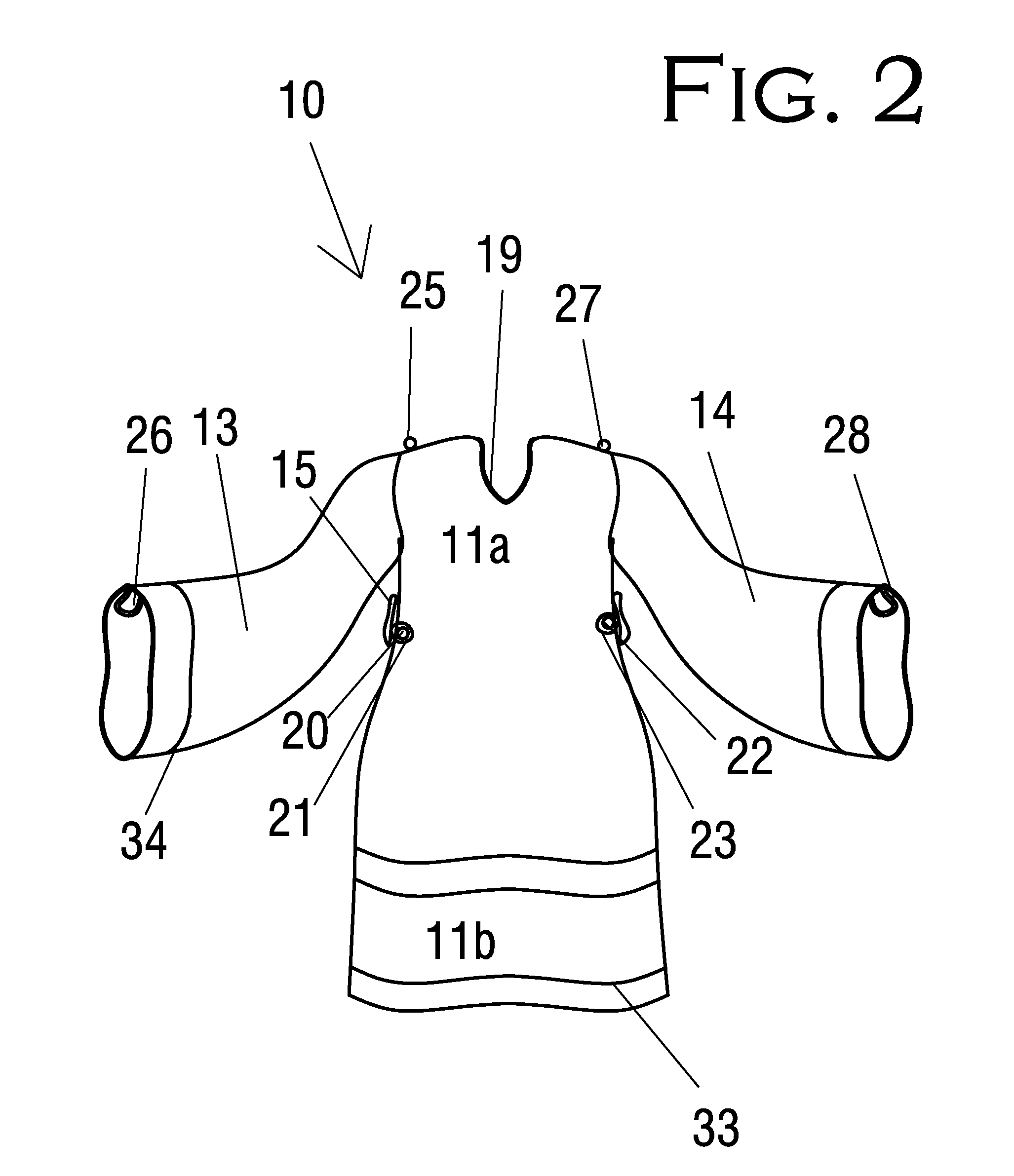

Combination user protection and baby safety towel

InactiveUS7634818B1Improve convenienceImprove securityBaby linensProtective garmentUser protectionEngineering

A combination user protector and baby safety towel is provided including a long front fabric member, a short back fabric member, two long sleeve fabric members, a belt fabric member, complementary belt-attachment members, and complementary sleeve-securing button and loop members. The front and sleeve fabric members are a soft, absorbent fabric.Each sleeve is positionable. The loop engages the button to retract the sleeve for washing the baby. The sleeve is held extended for drying the baby by insertion of the user's thumb into the loop.The combination user protector and baby safety towel allows the user to draw a wet baby out of a bath and immediately and conveniently wrap and dry the baby in the extended sleeve fabric members while cuddling the baby on the front fabric member. Thus safety and convenience are increased while the user's clothing is protected from wetness.

Owner:TRUJILLO LESTHER +1

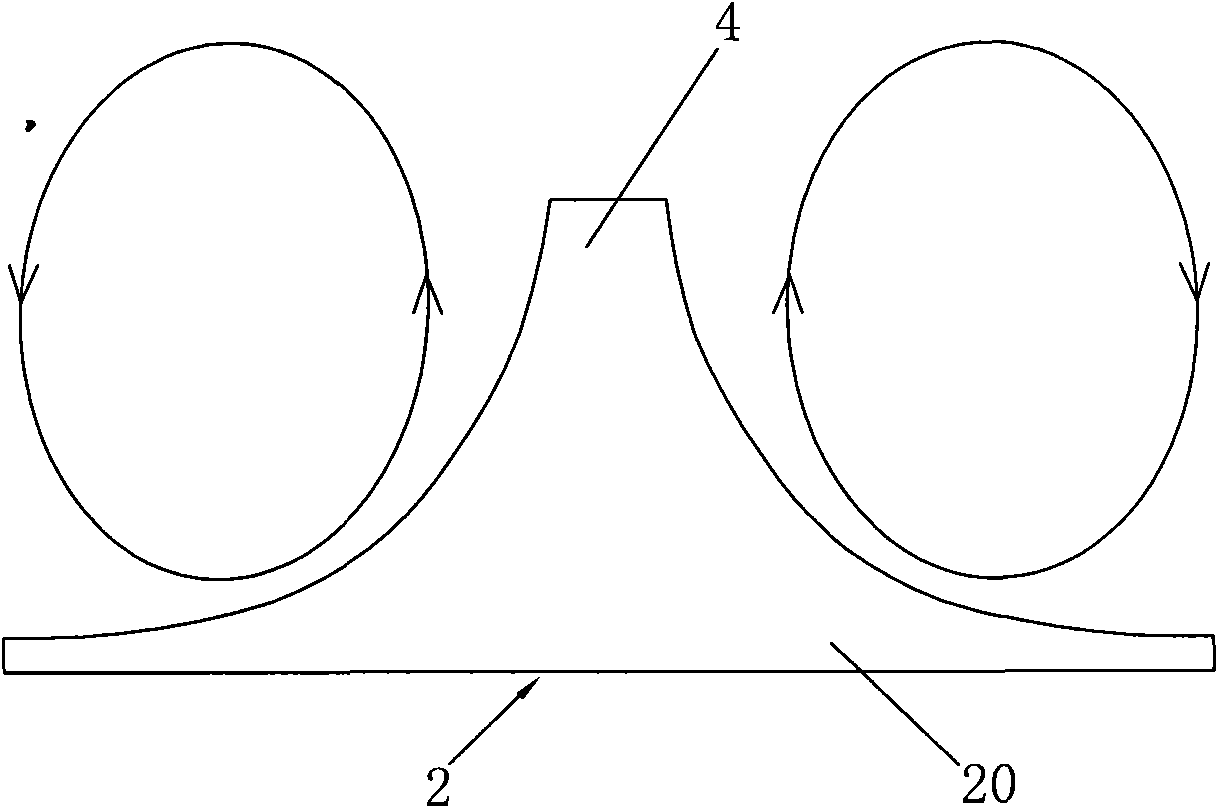

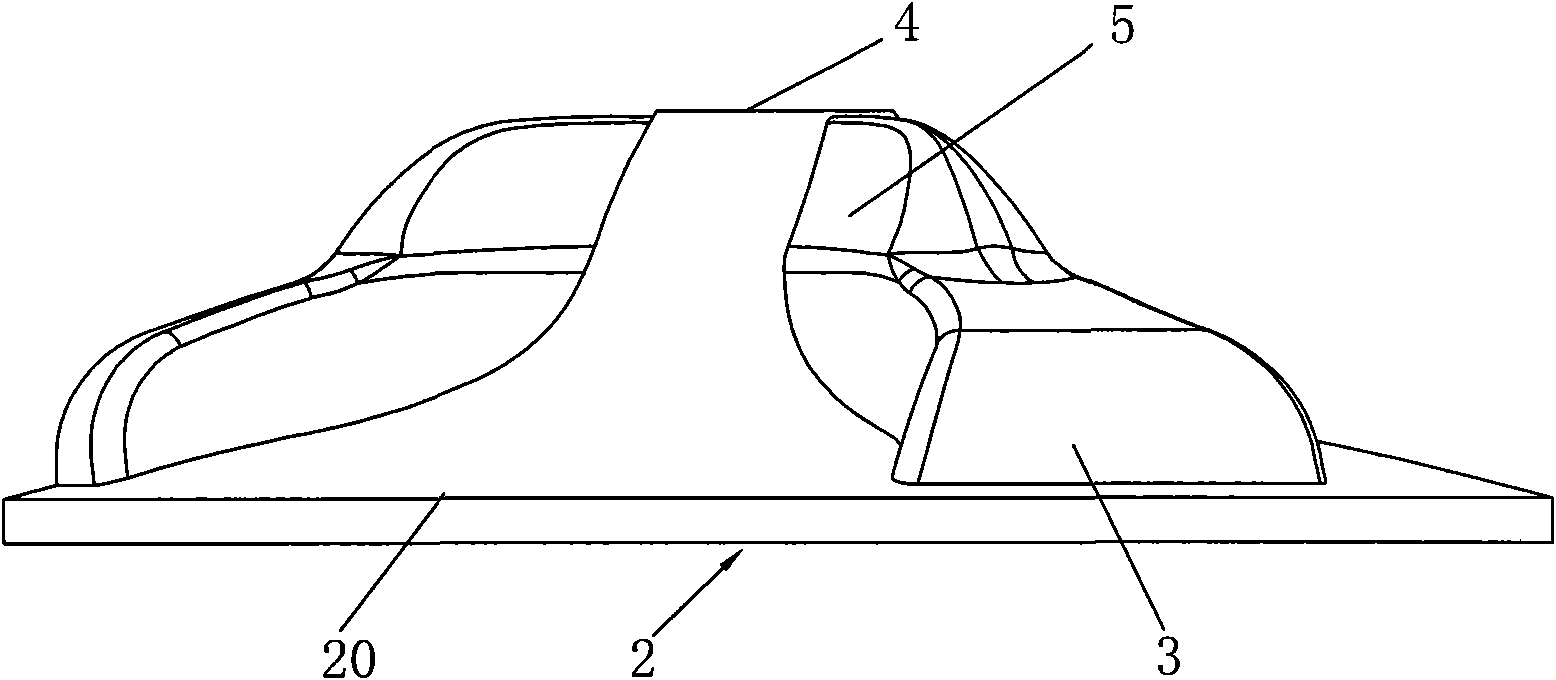

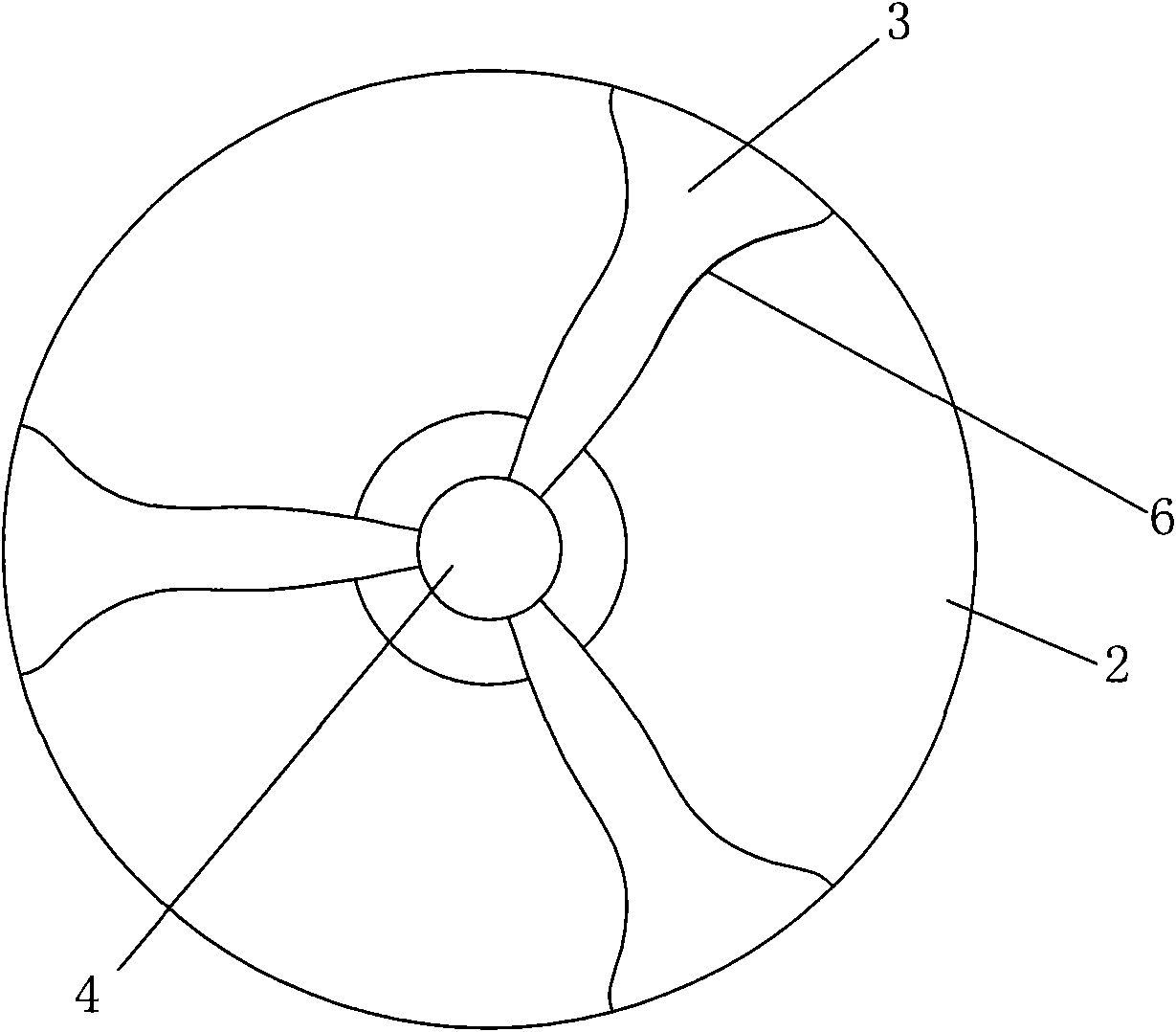

Washings overturned washing method by impeller of washing machine

ActiveCN101851835ASave waterHigh stress frequencyWashing machine with receptaclesTextiles and paperImpellerEngineering

The invention discloses a washings overturned washing method by an impeller of a washing machine. In the method, impeller vanes are arranged on the impeller in the radial direction, and an upward raised impeller neck is arranged on the position of a central axis. The washings overturned washing comprises a forward moving process and a backward moving process: when the washings are on the bottom of an inner barrel and move towards the center of the impeller, the washings moving mode is that washings make spiral ascending motion upwards along the impeller vanes while revolving around the central axis, and move upwards along the impeller vanes to the impeller neck in the center of the impeller; when the washings move to the top of the impeller neck, the washings move upwards due to inertia; after short upcast, the washings make external overturn revolution under the action of centrifugal force and bottom washings until the washings reach the position of inner barrel wall far away from the center of the impeller, and then the washings are pulled downwards by the washings on the bottom and the washings contacted with the impeller until the washings reach the bottom of the barrel; and while the washings move, the washings make overturned motion. The washing method has the characteristics of comprehensiveness, sufficiency, repetition and high efficiency.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Method of continuously cleansing polyarylene sulfide

InactiveUS7094867B2Effective recoveryEfficient removalCeramic shaping apparatusNatural resin processOrganic solventSulfide

A polymerizate slurry obtained through a reaction of an alkali sulfide source and an aromatic dihalide compound in an organic polar solvent and comprising polyarylene sulfide particles, a by-produced alkali metal salt and the polar organic solvent, is continuously contacted countercurrently with a washing liquid, thereby continuously and efficiently recovering washed polyarylene sulfide particles. Furthermore, the by-produced alkali metal salt is removed, and the polar organic solvent is recovered, efficiently.

Owner:KUREHA KAGAKU KOGYO KK

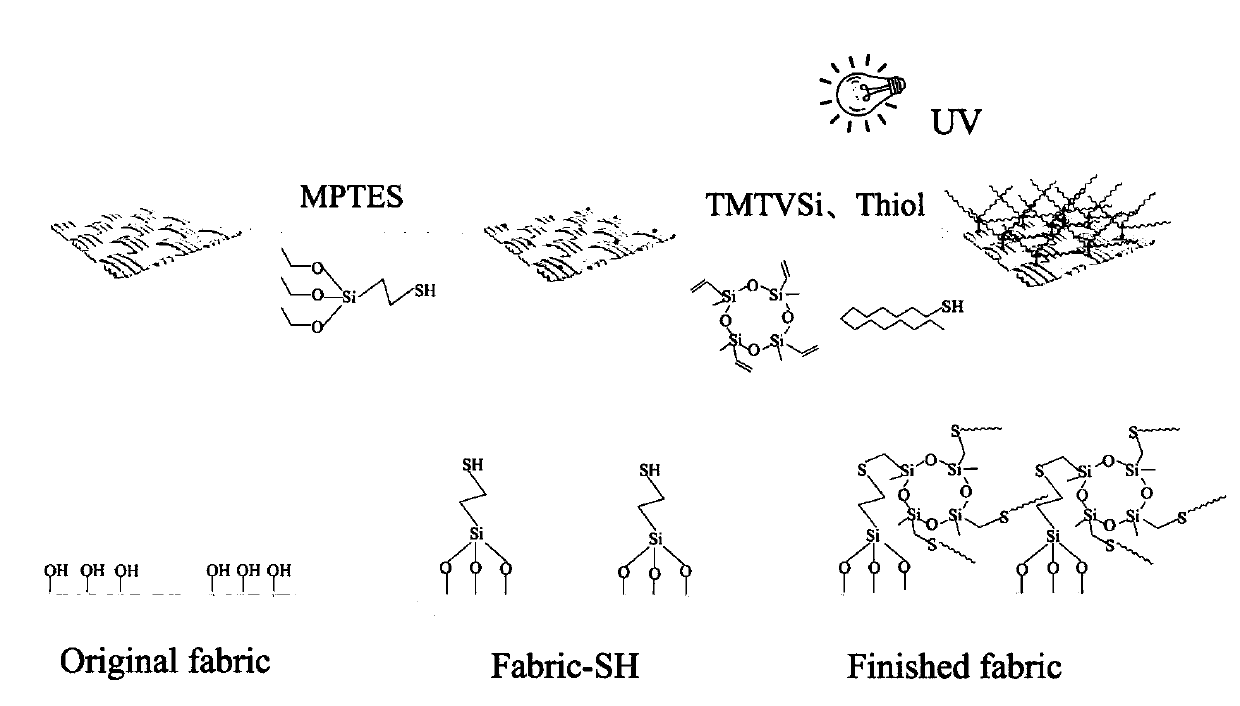

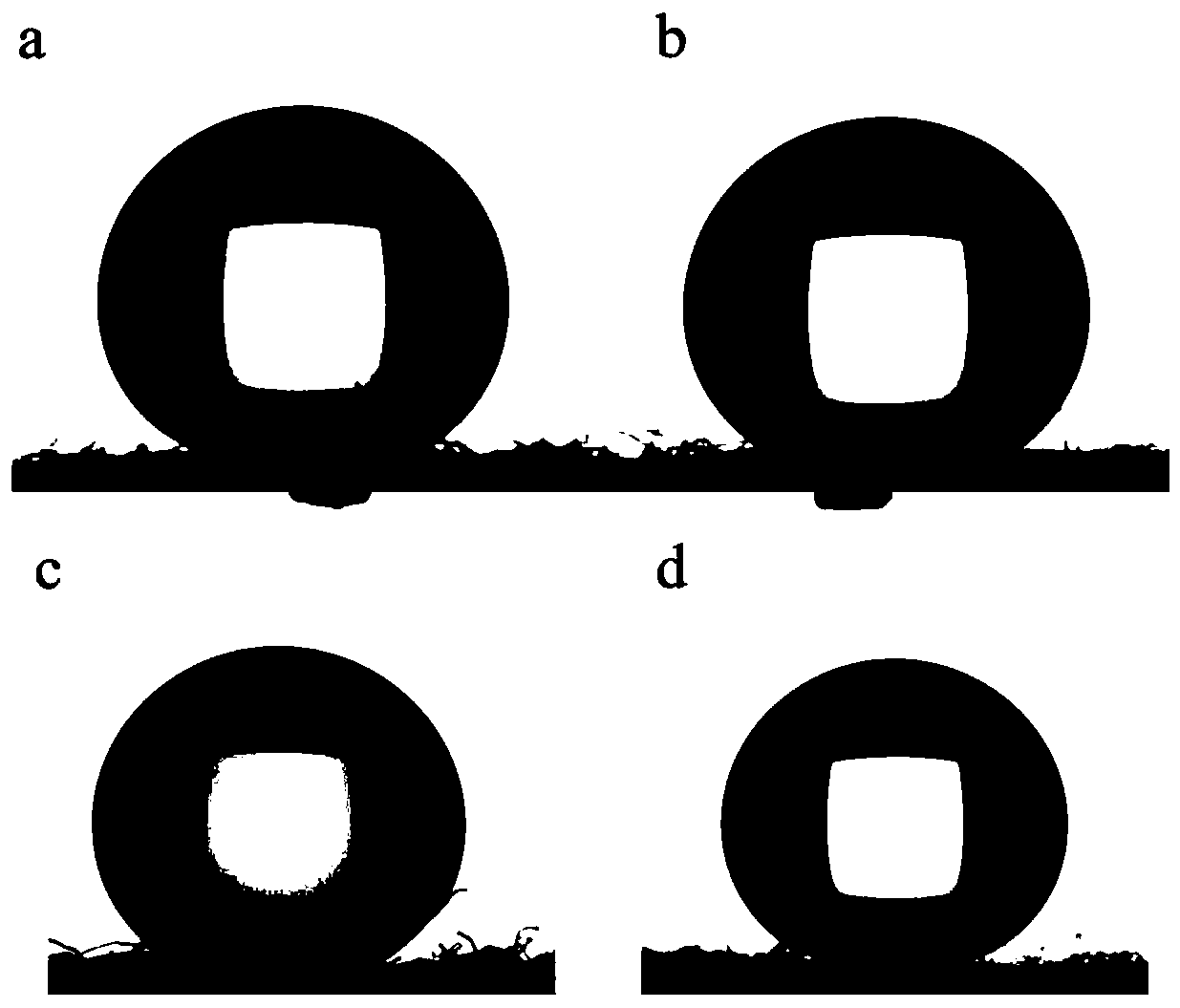

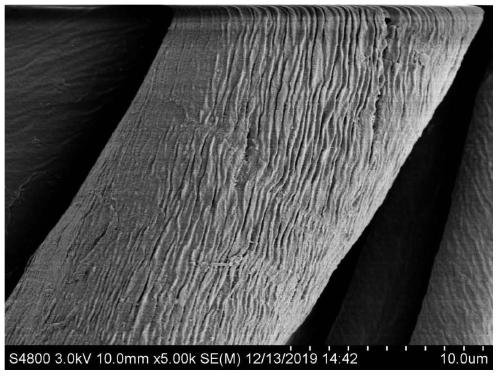

Method for preparing superhydrophobic cotton textile by thiol-ene click chemistry modification

ActiveCN111188183AImprove hydrophobicityLower surface energyPhysical treatmentLight resistant fibresFiberPolymer science

The invention discloses a method for preparing a superhydrophobic cotton textile by thiol-ene click chemistry modification. The method comprises the following steps of Step 1, pretreating cotton fabrics so that thiol groups are introduced to the fiber surfaces; Step 2, grafting thiol silane onto the surfaces of the pretreated cotton fabrics; and Step 3, soaking the cotton fabrics grafted with thethiol silane into a mixed solution prepared from ethyl acetate, 2,4,6,8-Tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane, octadecanethiol and benzoin dimethyl ether to take a reaction through UV irradiation, and after the reaction is completed, performing cleaning and drying to obtain the superhydrophobic cotton textile. The invention also discloses the superhydrophobic cotton textile prepared bythe method. The superhydrophobic cotton textile prepared by the method provided by the invention has the advantages that hydrophobic substances are grafted onto the surfaces of the fabrics in a chemical bond form; and the performance of resisting acid, alkali, water washing, friction, UV irradiation and the like of the superhydrophobic textiles can be improved.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

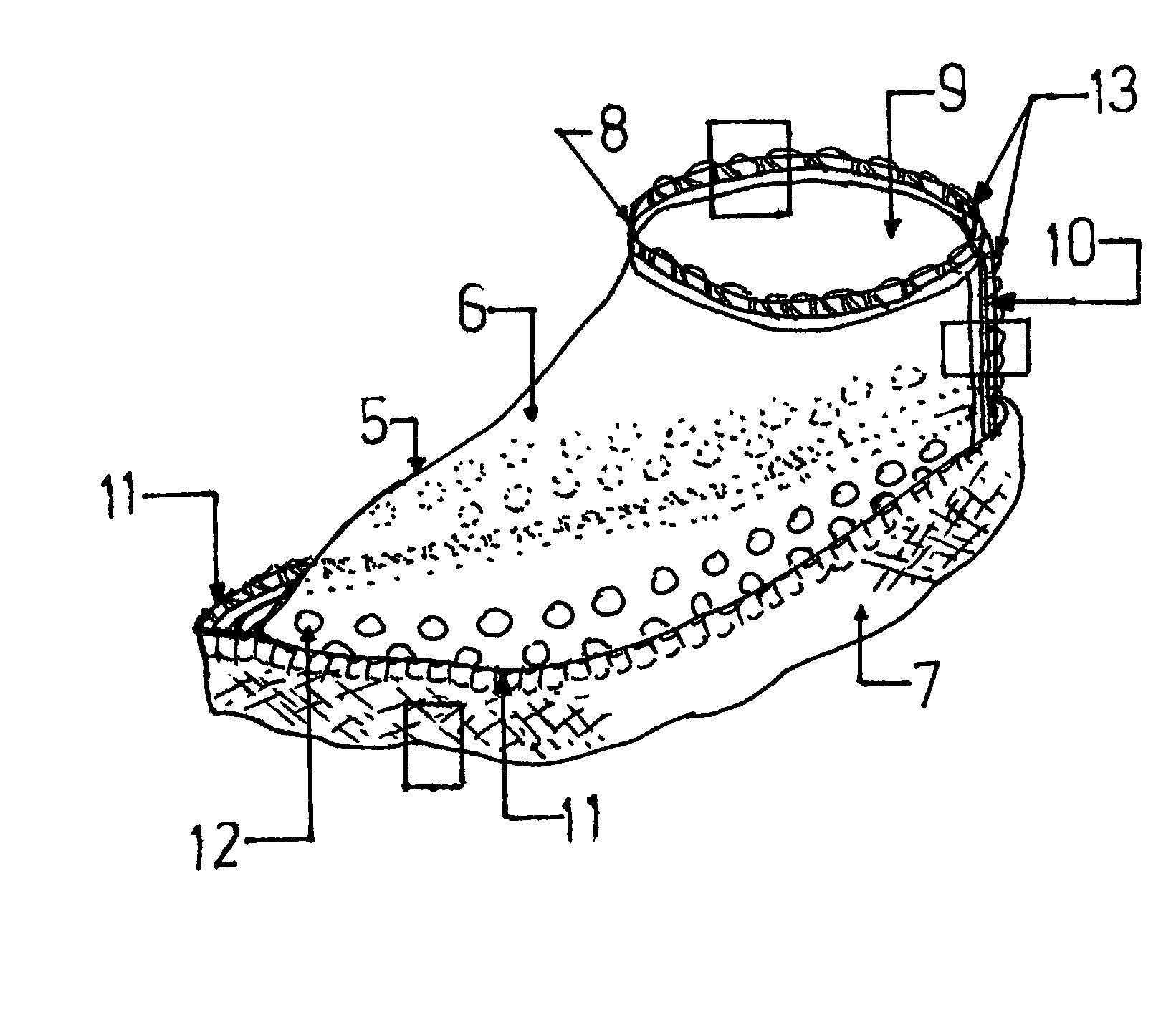

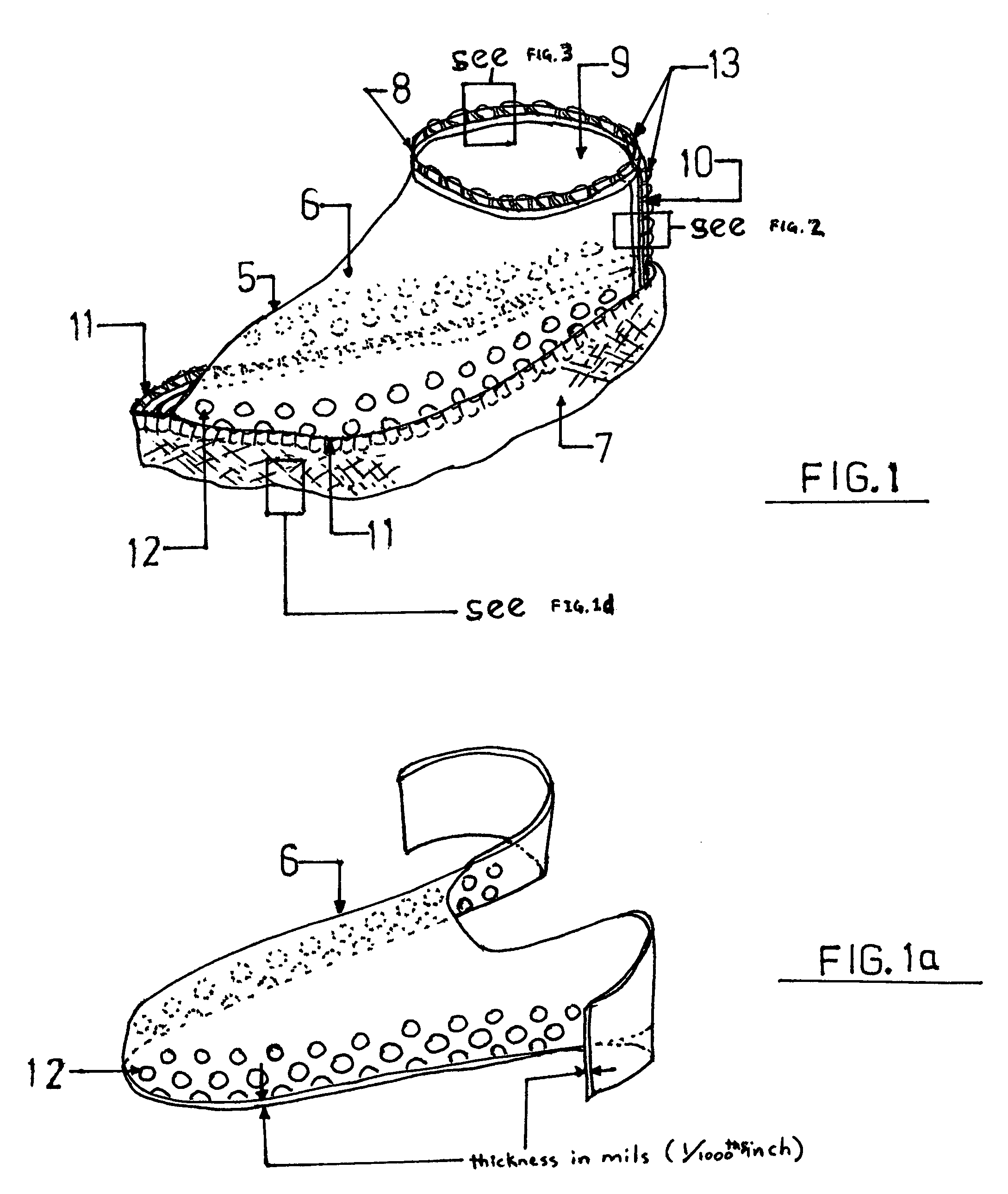

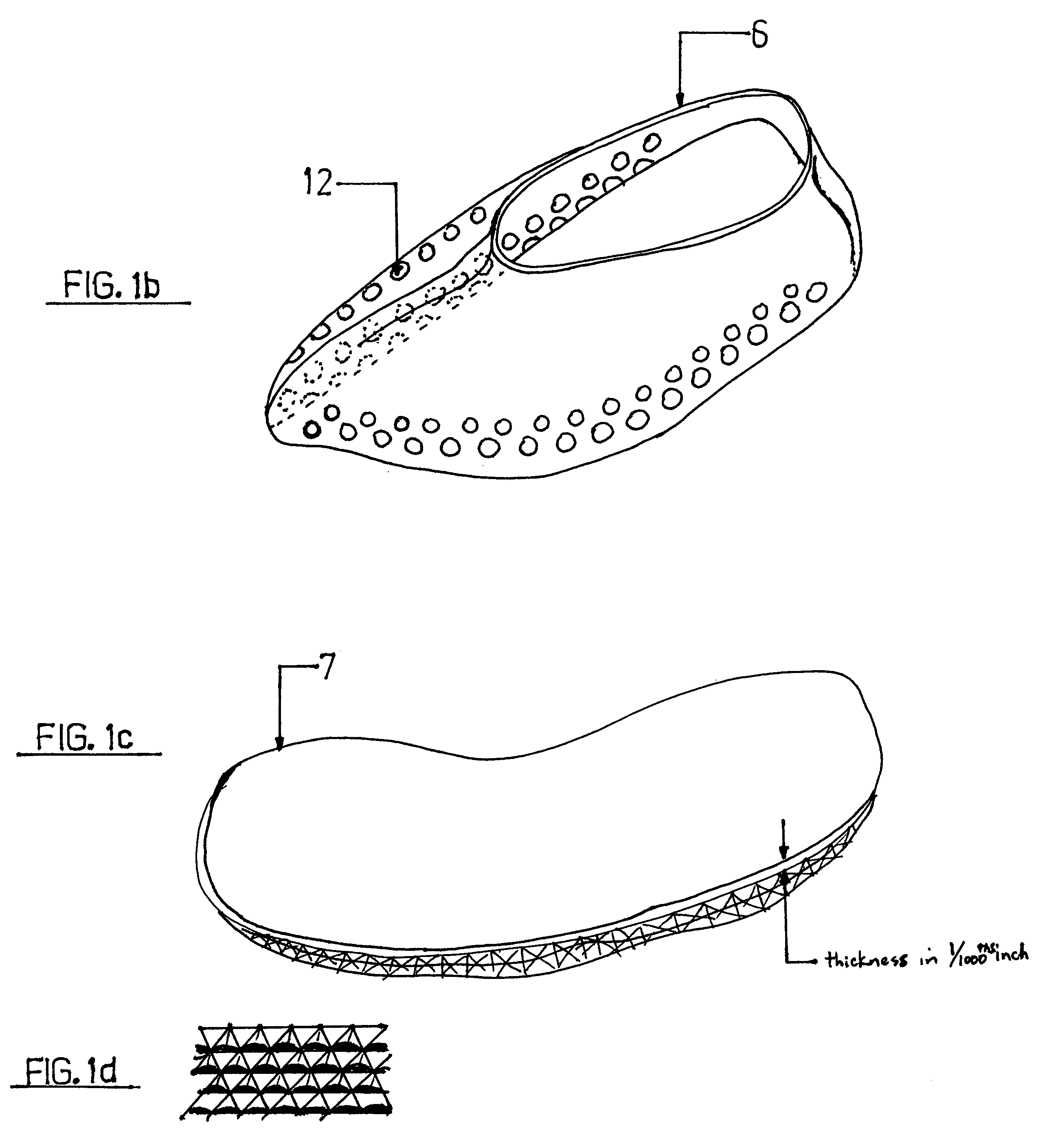

Disposable and non-disposable foot cap

Thin, lightweight footwear made of a polyethylene material that is composed of a top part and a sole part that are sewn together such that when fitted properly to the wearer's foot the footwear encompasses the foot and extends to the level of the ankle. The top part is porous allowing the ingress and egress of soap and water. The sole has slip resistance properties due to the material from which it is made and the texture of its outer surface. The finished product can be folded and compressed for storage, then later unfolded and worn without the folding adversely affecting its intended function of providing a barrier between the wearer's feet and the tub or shower floor on which the wearer stands while the wearer showers.

Owner:THOMAS JEFF C C

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

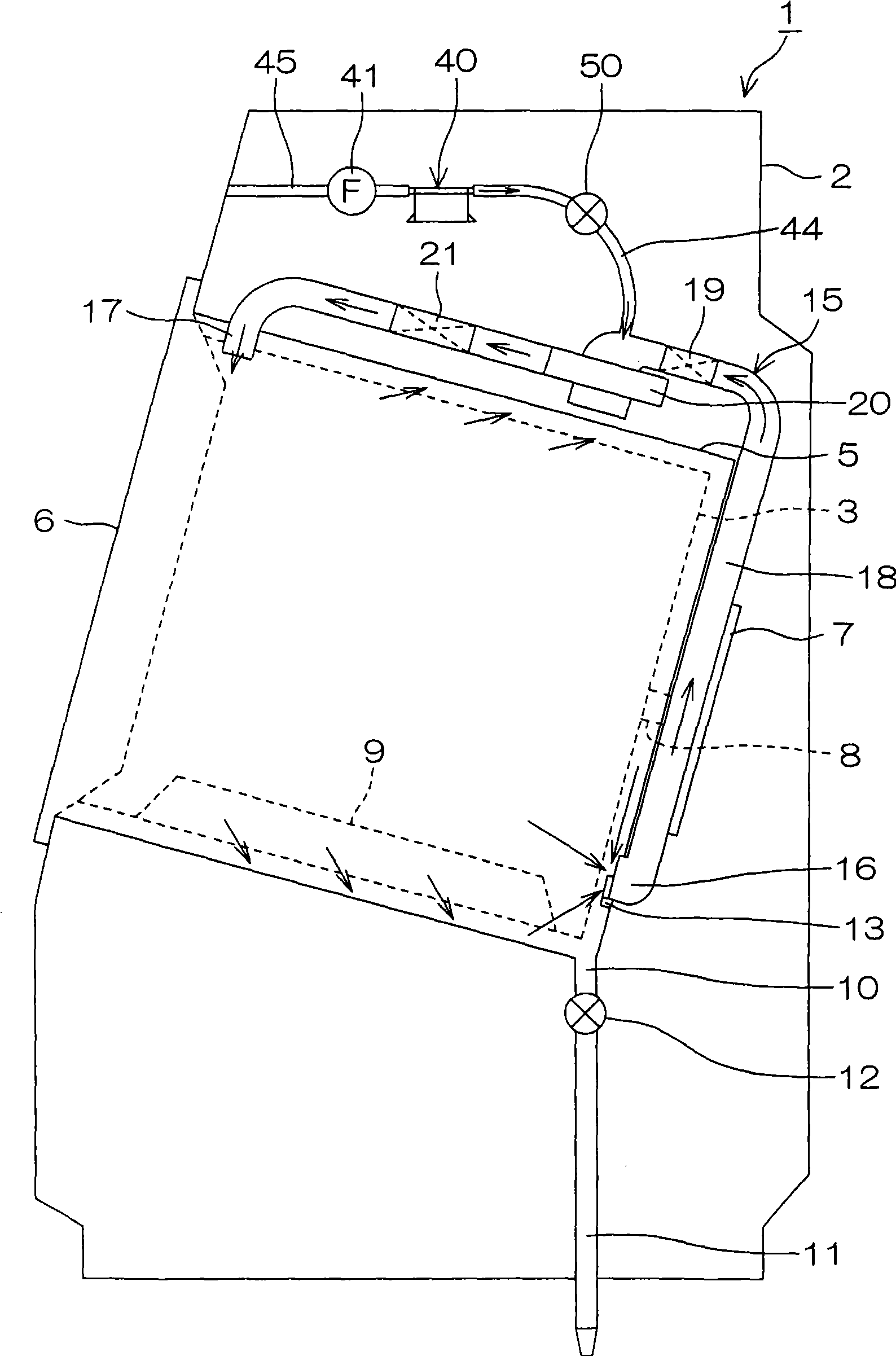

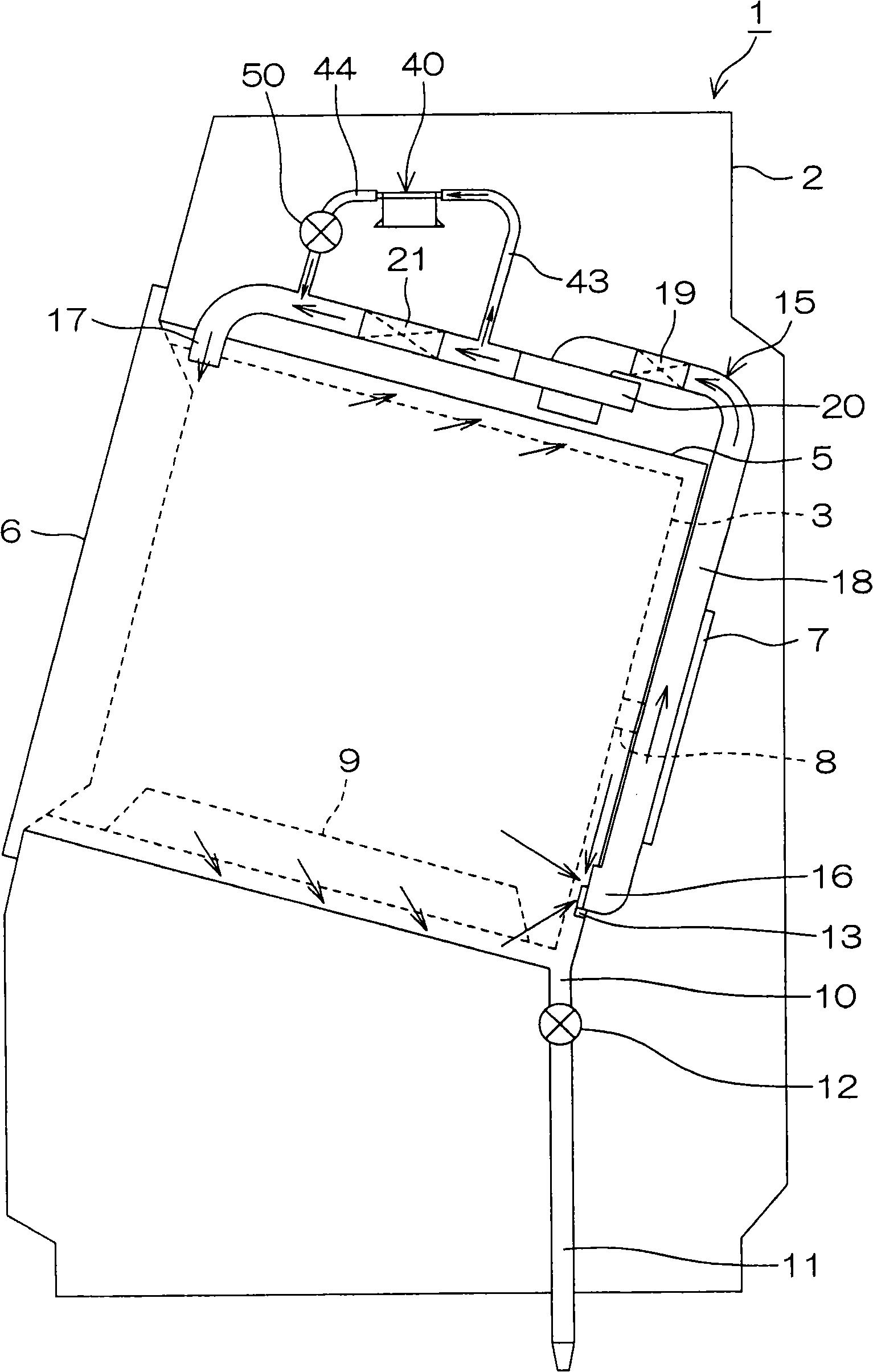

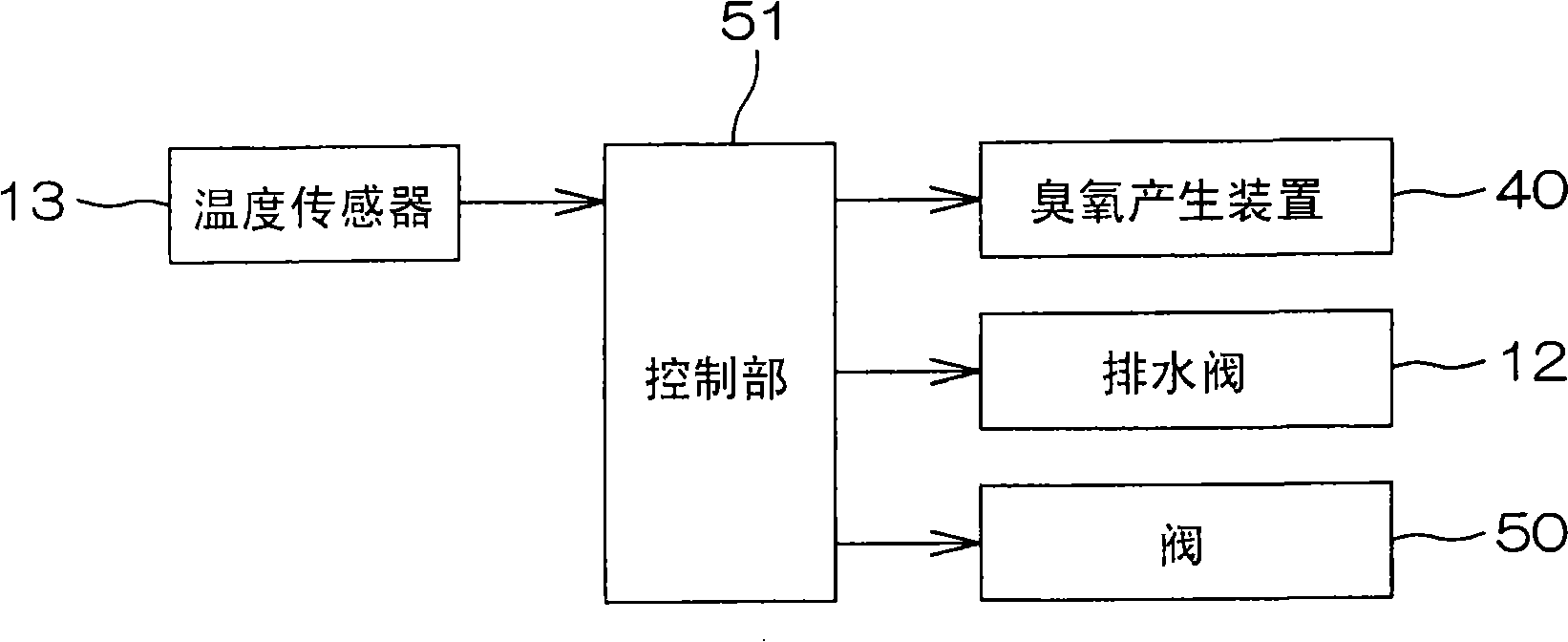

Cloth drier, washing machine, and washing machine with cloth drying function

ActiveCN101283139AEfficient washingOther washing machinesWashing machine with receptaclesOzone generatorSafety control

This invention provides a cloth drier, which is improved in the effect of washing, deodorizing and sterilization of clothes by ozone and can allow an ozone generation element to be easily replaced, or allow ozone to be safely regulated, and a washing machine and a washing machine with a cloth drying function. An ozone generator (40) applies silent discharge to an introduced air to generate ozone. This ozone is sucked into a drying air duct (15) by a blower (20) and the rotation of a drum (3) and is mixed into air heated by a heater (21), and the mixture is supplied through an inlet (17) into the drum (3). This allows ozone to be supplied into clothes to be dried, and the clothes are effectively deodorized and sterilized. Since the ozone generator (40) is disposed away from the drying air duct (15), the ozone generation element can be easily replaced. After the completion of drying, there is no ozone within the drum (3) due to an oxidation reaction, and, thus, there is no possibility that the user is influenced by ozone when the user takes the clothes out of the drum (3).

Owner:HAIER GRP CORP +1

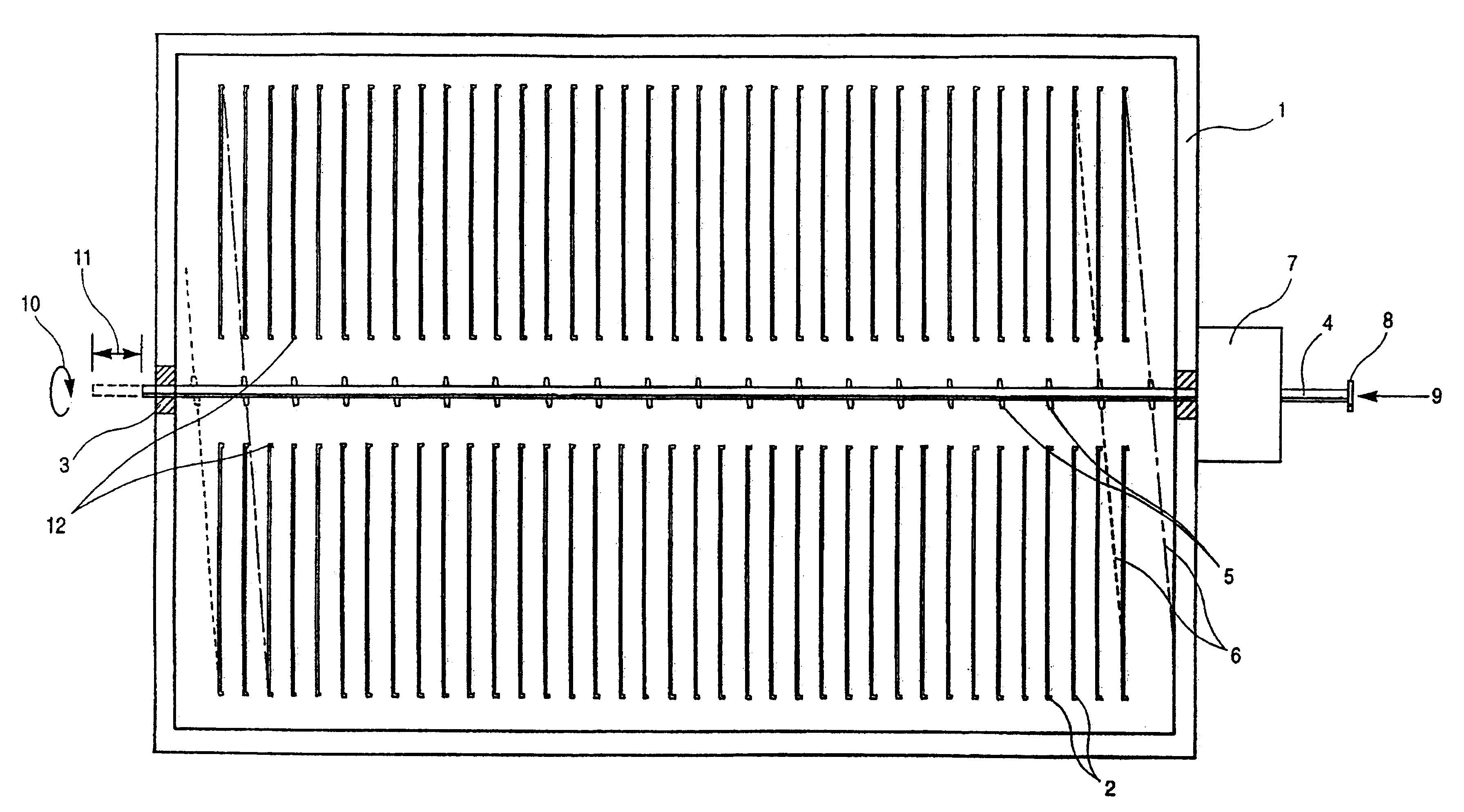

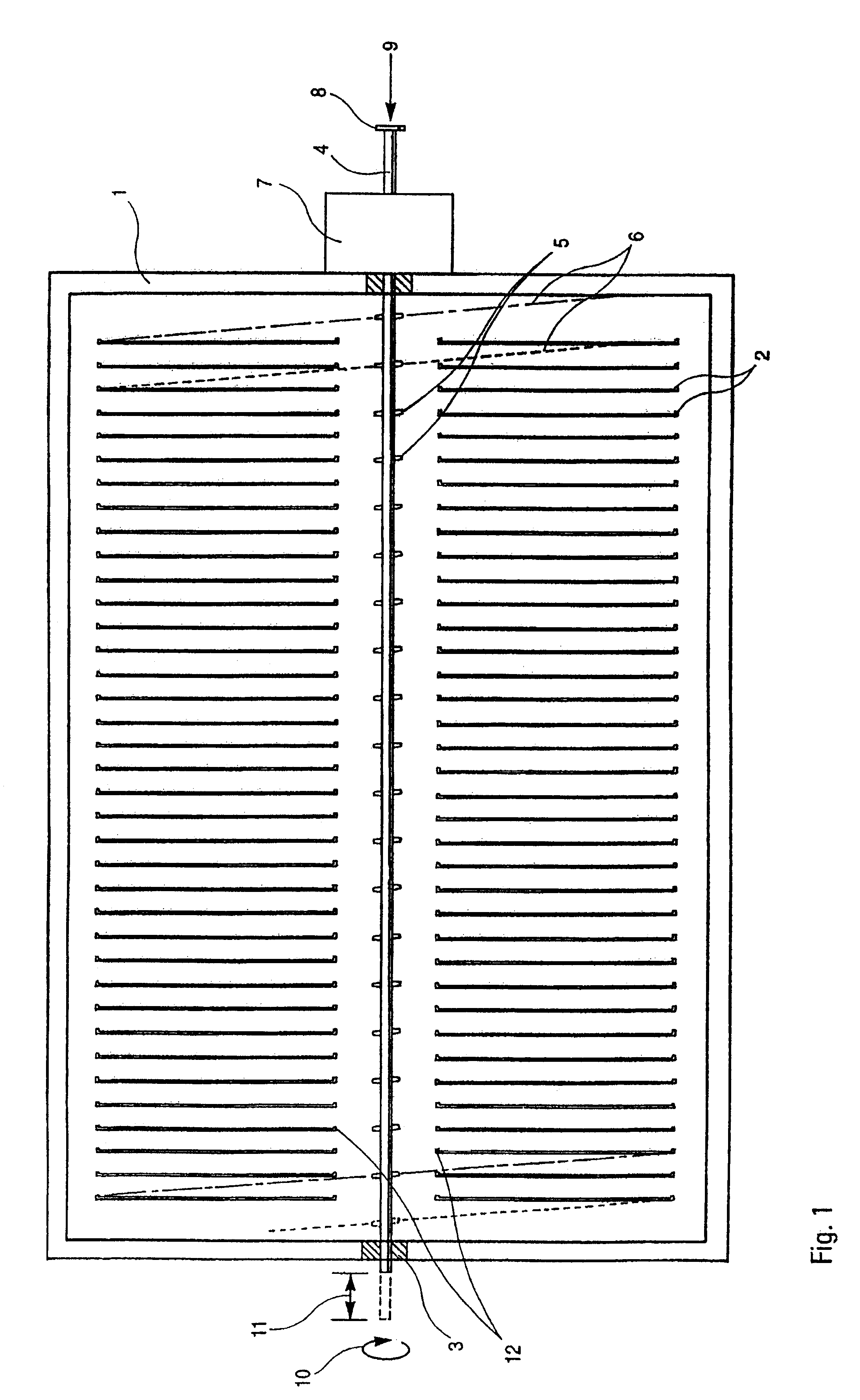

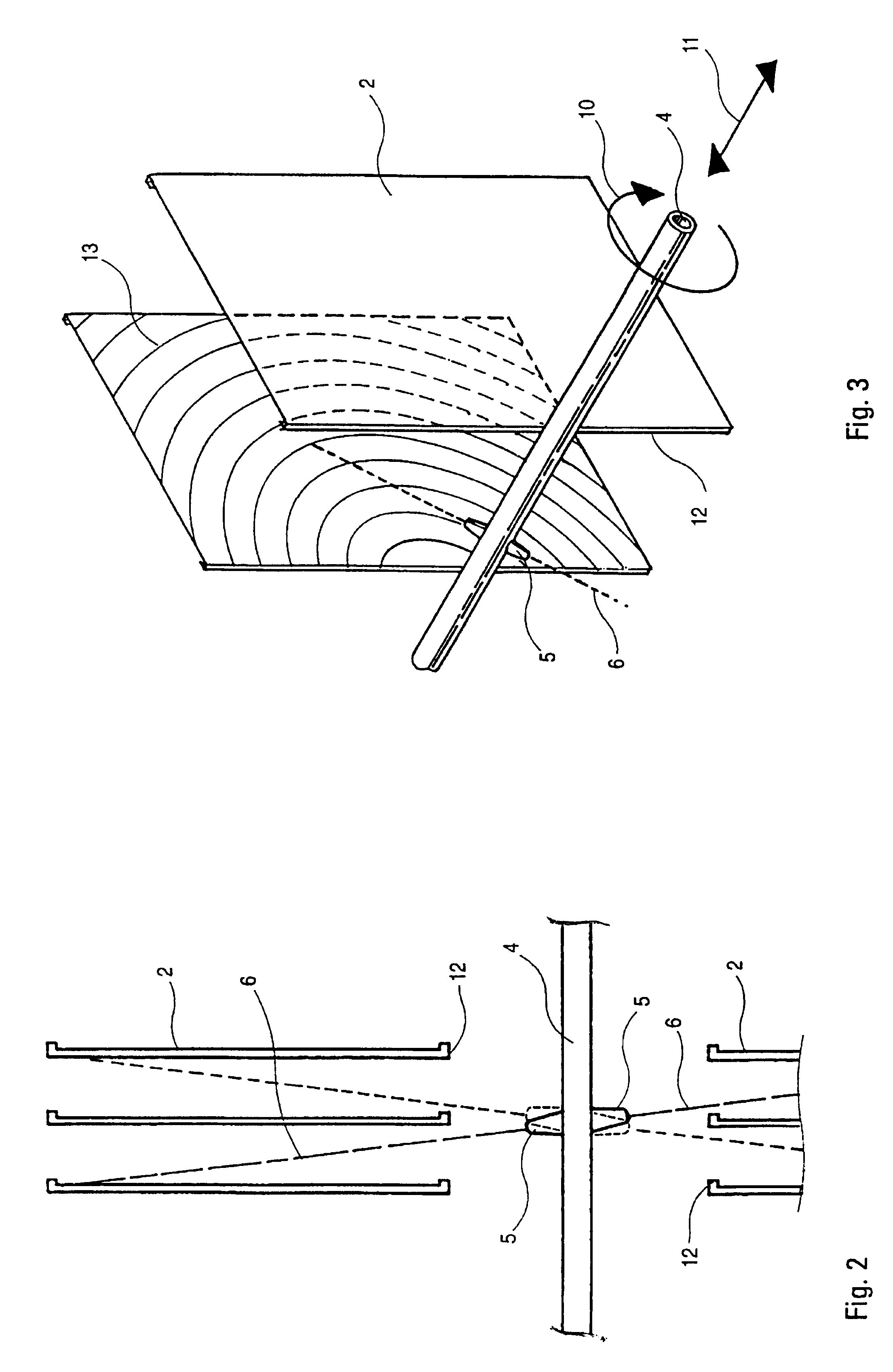

Method and rinsing equipment for the cleaning of especially filter plates in an electro-filter

InactiveUS6533841B1Easy to cleanImprove efficiencyMovable spraying apparatusElectrode constructionsEngineeringStructural engineering

Filter plates in an electro-filter are cleaned using nozzles which, during spraying, are displaced longitudinally with the side edges of the filter plates while at the same time being rotated. The nozzles are mounted in a plane slightly different from the plane of the filter plates to enable the spray jets to reach the furthermost areas of the plates when the nozzles are at the greatest angle of incidence during washing.

Owner:ORECO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com