Patents

Literature

594results about How to "Improve conduction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

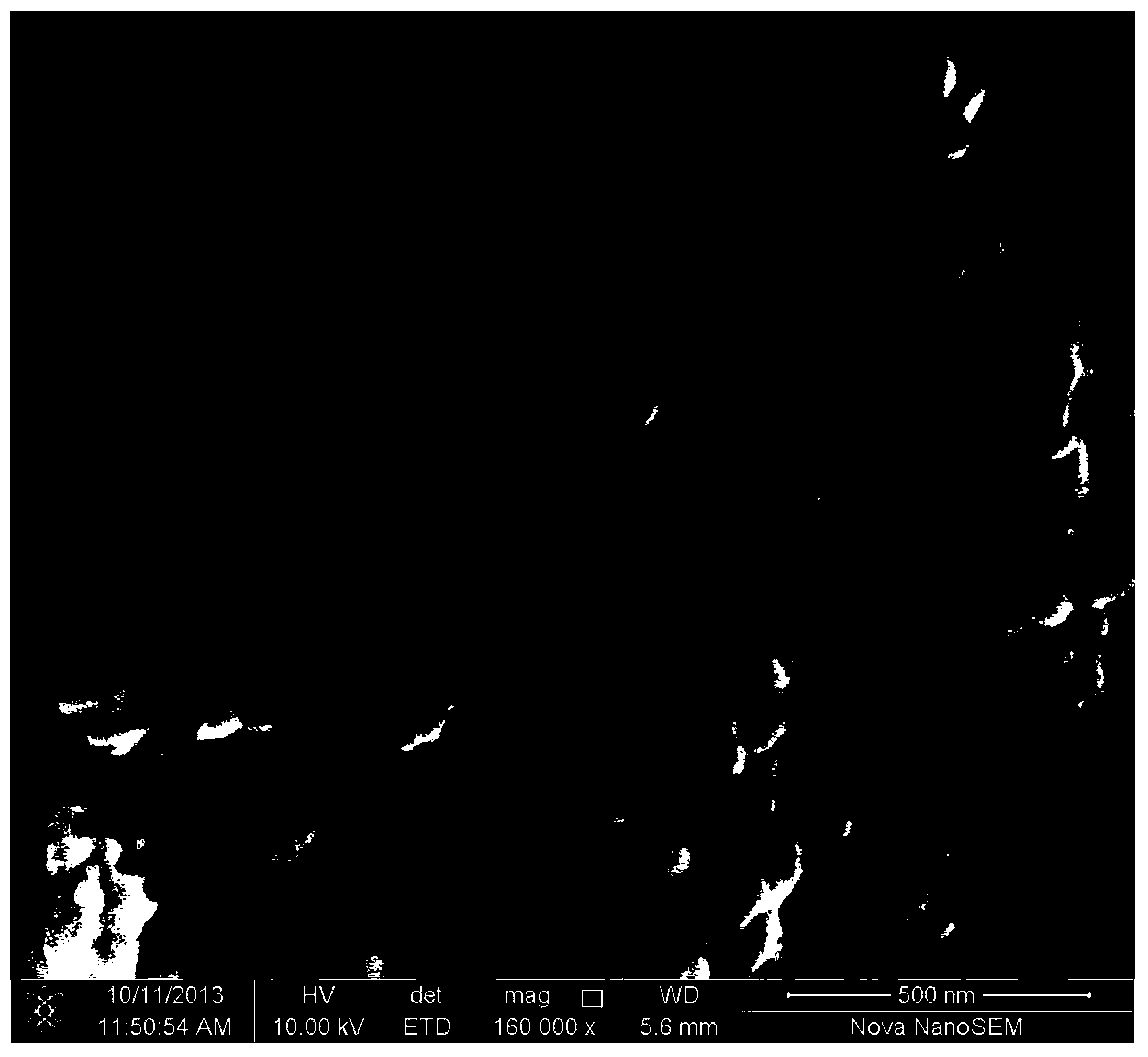

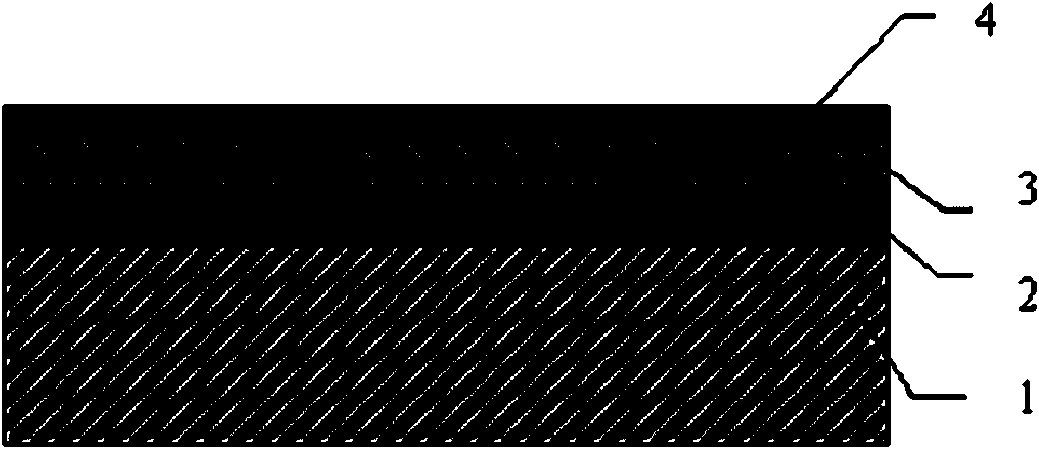

Flexible capacitive sensor fabricated by employing silver nanowire flexible electrode and fabrication method of flexible capacitive sensor

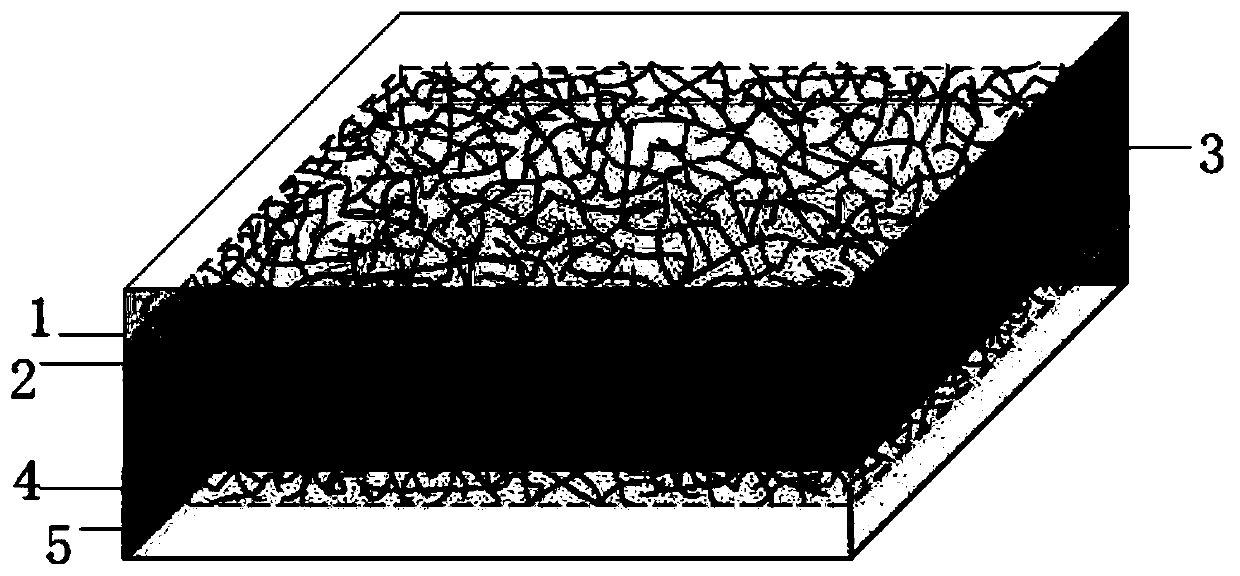

InactiveCN110455443AGood flexibilityHigh sensitivityMaterial nanotechnologyForce measurementSignal responseThin layer

The invention relates to a flexible capacitive sensor fabricated by employing a silver nanowire flexible electrode. The flexible capacitive sensor comprises an upper-layer flexible electrode plate, alower-layer flexible electrode plate and an intermediate flexible dielectric layer, wherein each flexible electrode comprises a flexible substrate, a silver nanowire electrode thin film layer, and thesilver nanowire electrode thin film layer is arranged in the flexible substrate. A fabrication method of the electrode employs a transfer printing method, the silver nanowire electrode thin film layer is fabricated in an electrode template, a flexible polymer is injected for curing, so that the silver nanowire conductive thin film layer is transferred to the flexible substrate. The flexible dielectric layer is divided into two types comprising a thin film structure and a porous structure, the thin film structure is fabricated by uniformly coating a flexible polymer prepolymer on a silicon wafer to form a thin layer, the porous structure is fabricated by a template method, the flexible polymer prepolymer is uniformly mixed with salt, a film formation structure is fabricated and cured, andthe porous dielectric layer structure is obtained after salt removal. The flexible capacitive sensor is simple in fabrication method and has favorable signal response.

Owner:BEIHANG UNIV

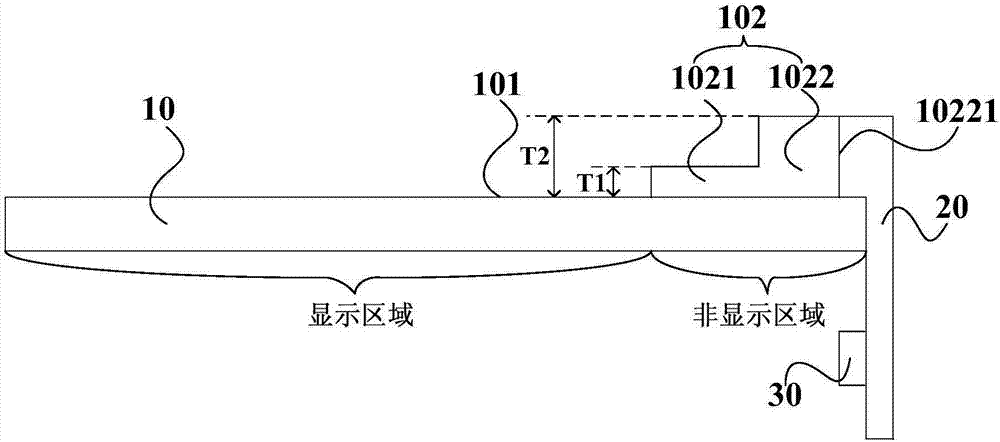

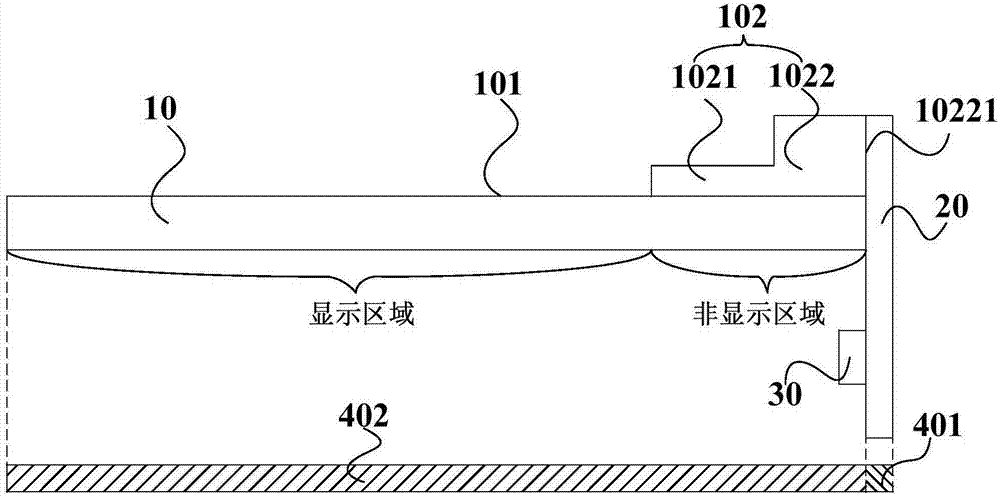

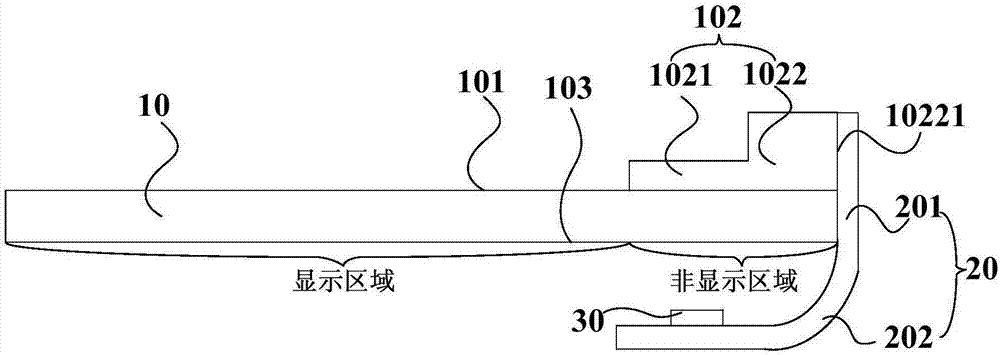

Display panel, manufacturing method thereof and display device

InactiveCN107121854ADoes not increase non-display widthImprove conduction efficiencyNon-linear opticsDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method thereof and a display device. A designed bonding pad comprises a first conductive bonding area and a second conductive bonding area, the first conductive bonding area is arranged on the surface of a first substrate, and the second conductive bonding area is arranged on the side face of the first substrate, that is, a bonding pad connected with a COF is arranged on the side face of an array substrate. On the basis, the conductive efficiency of the bonding pad and the connection stability of the bonding pad and the COF are improved on the premise of being beneficial to narrow-border design and frameless design.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

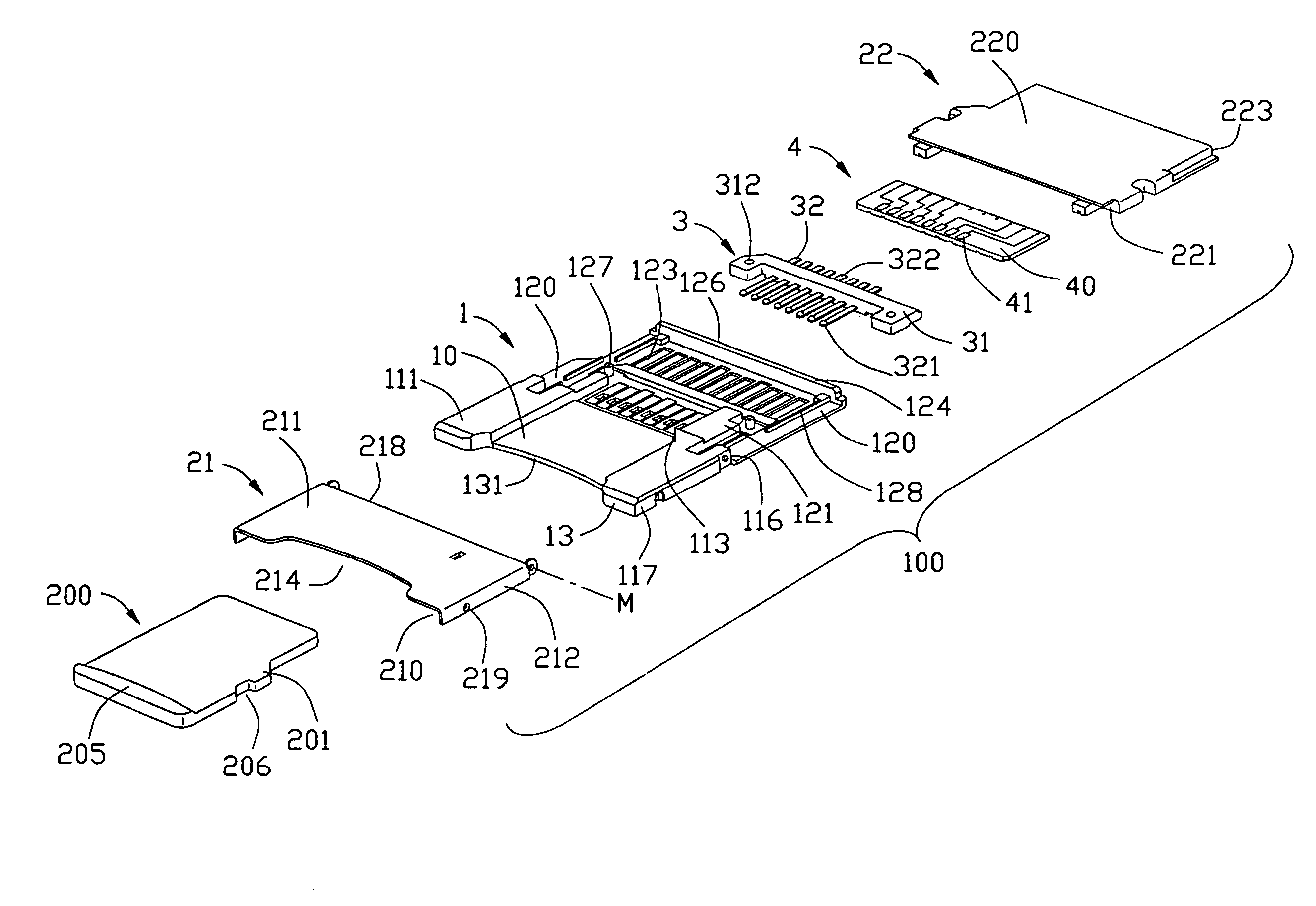

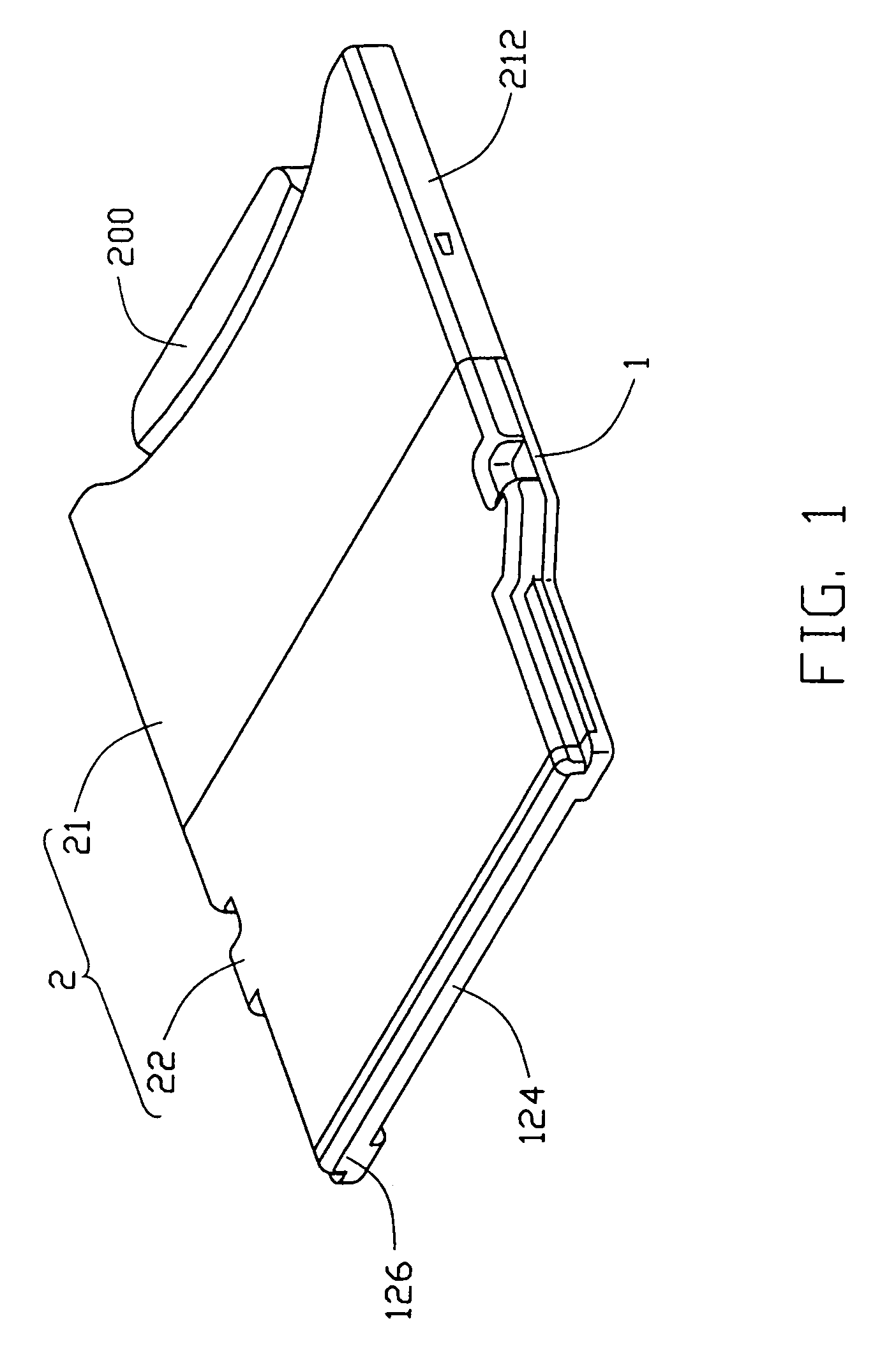

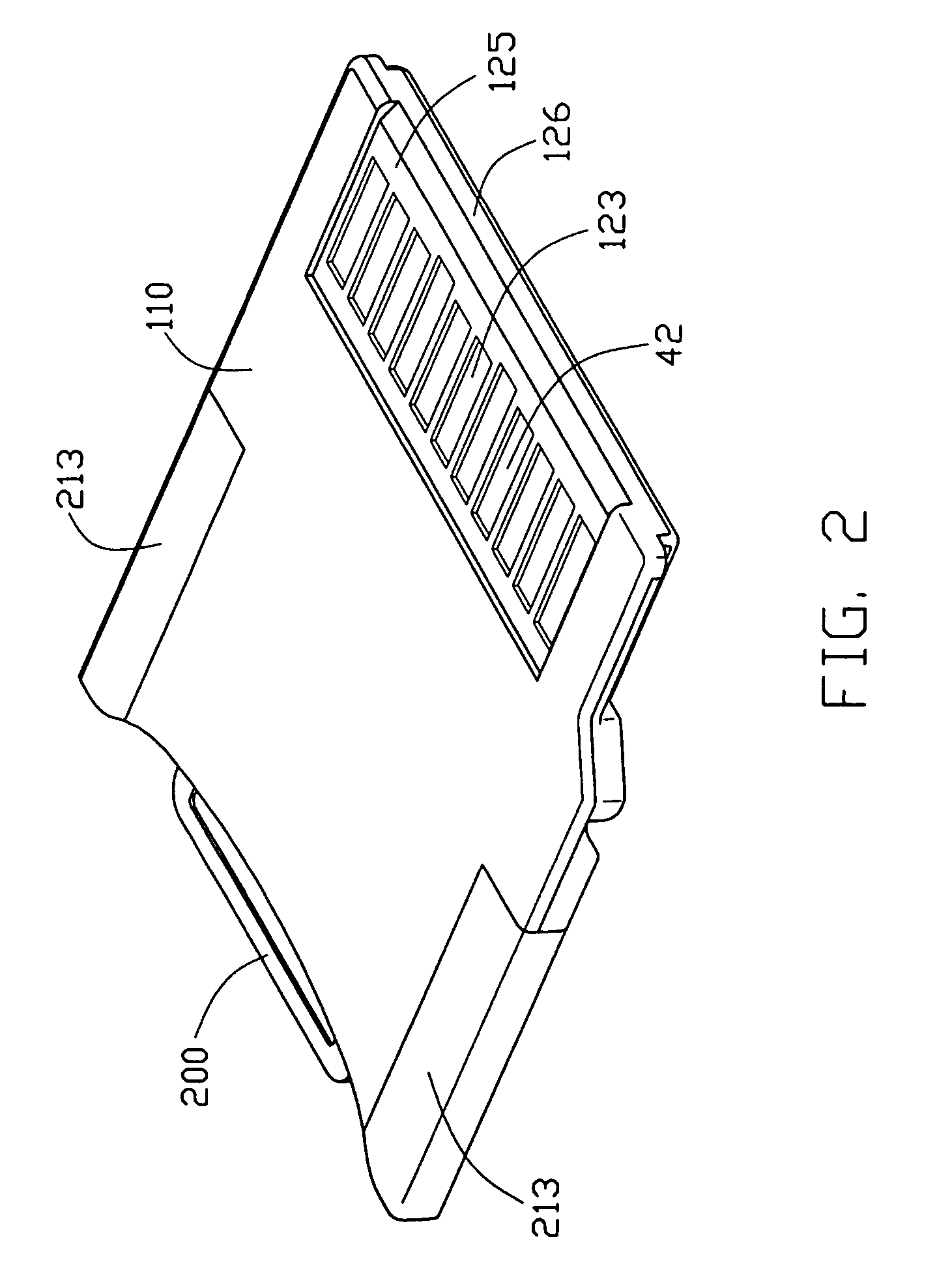

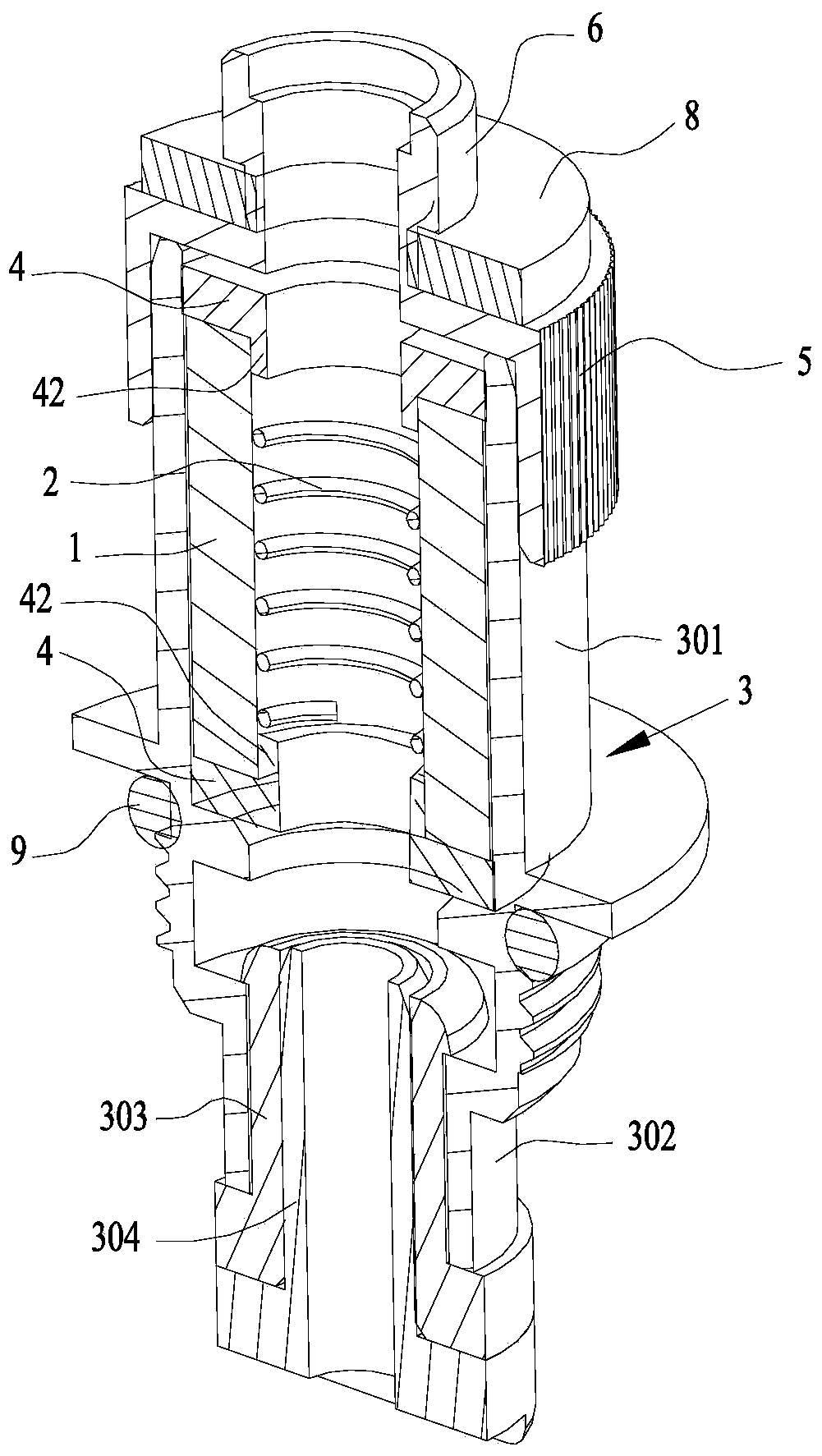

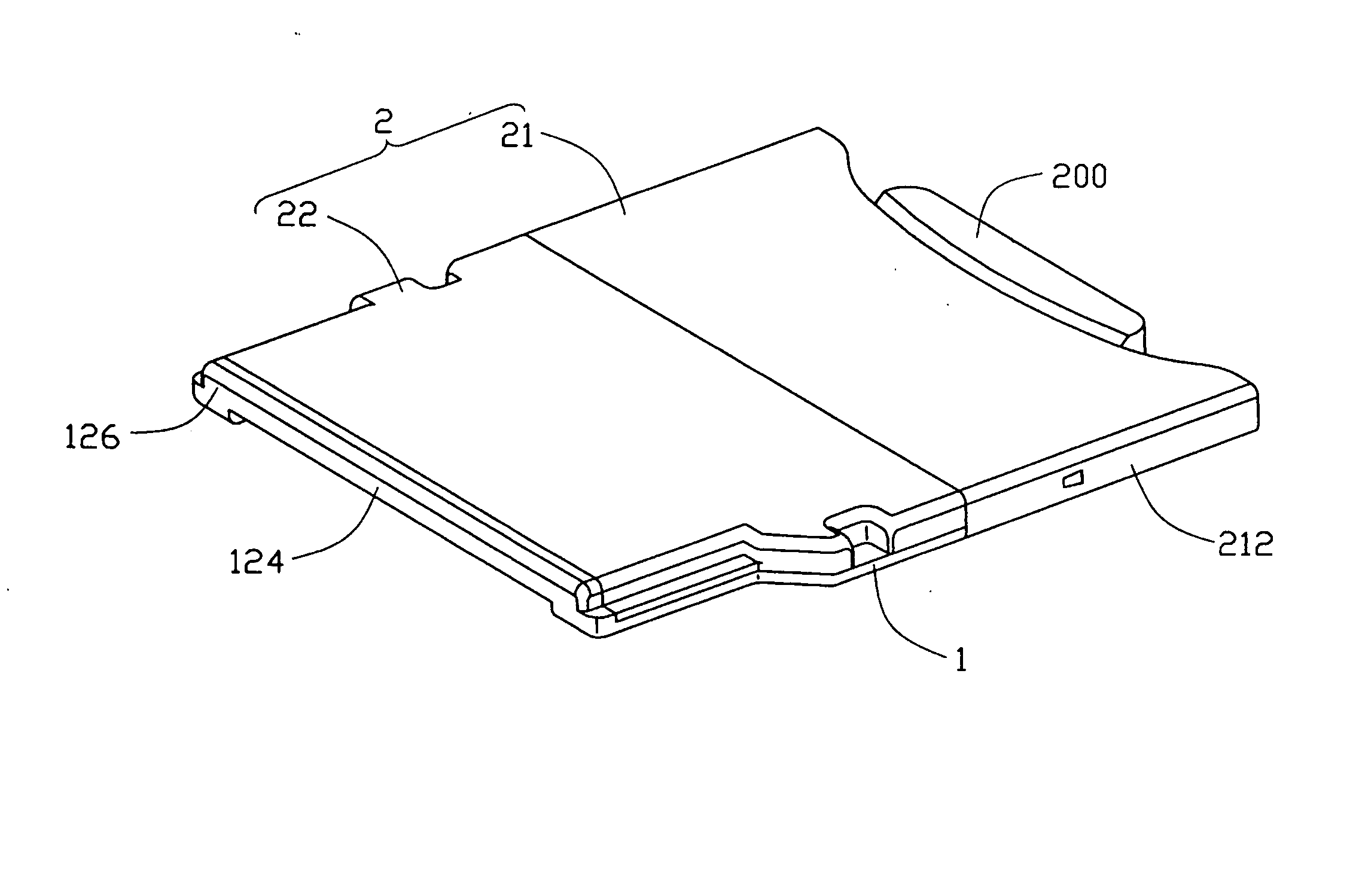

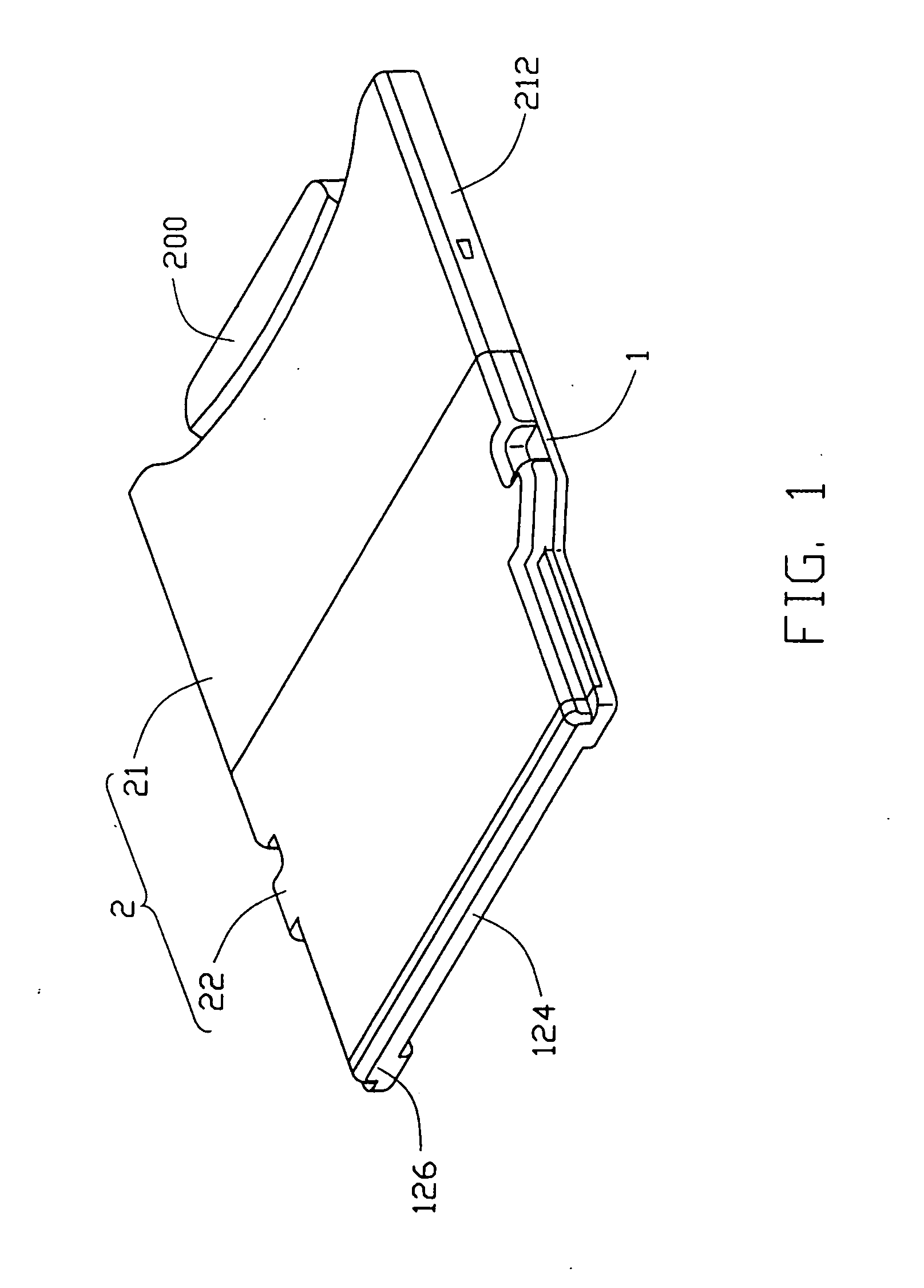

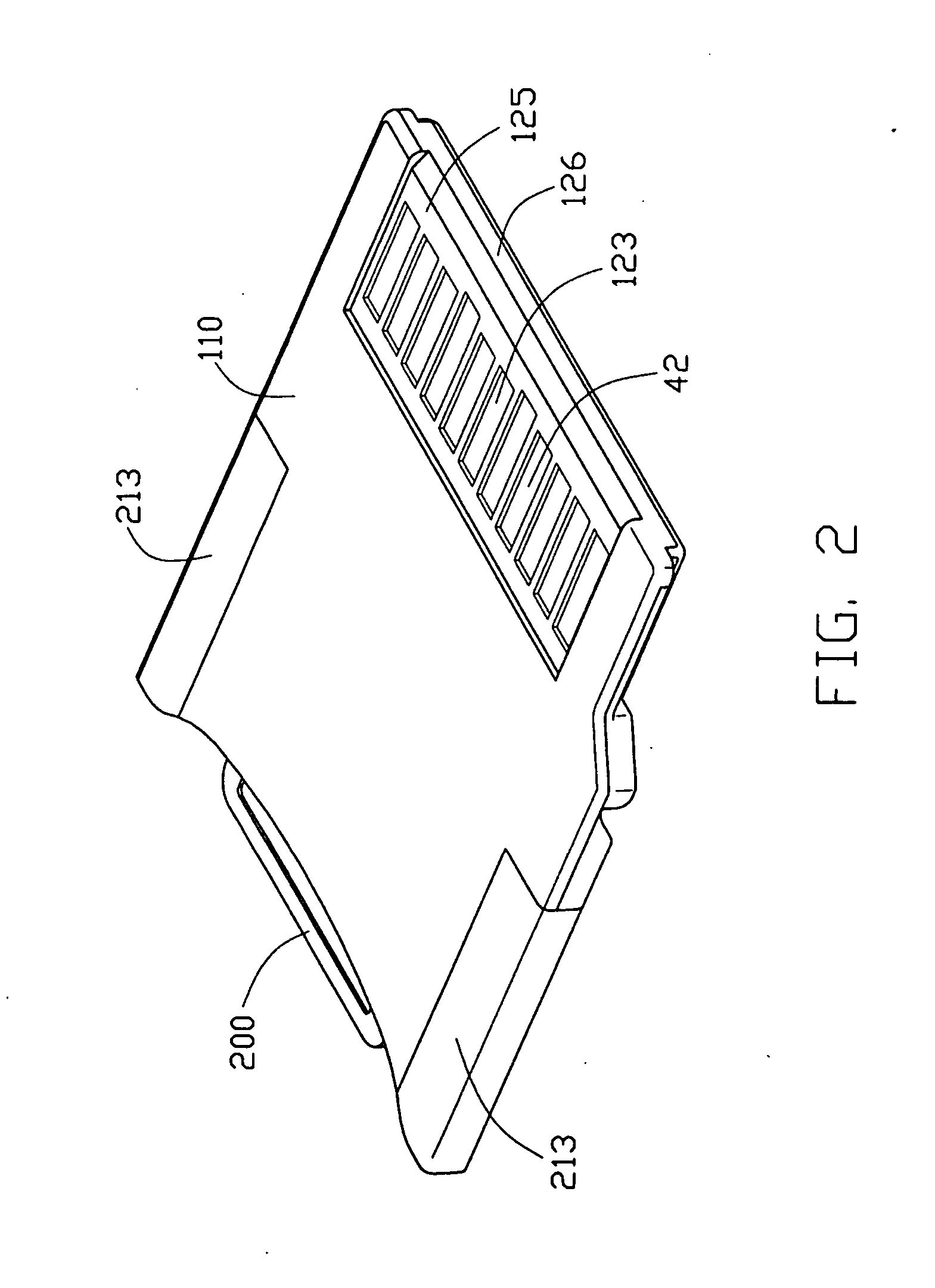

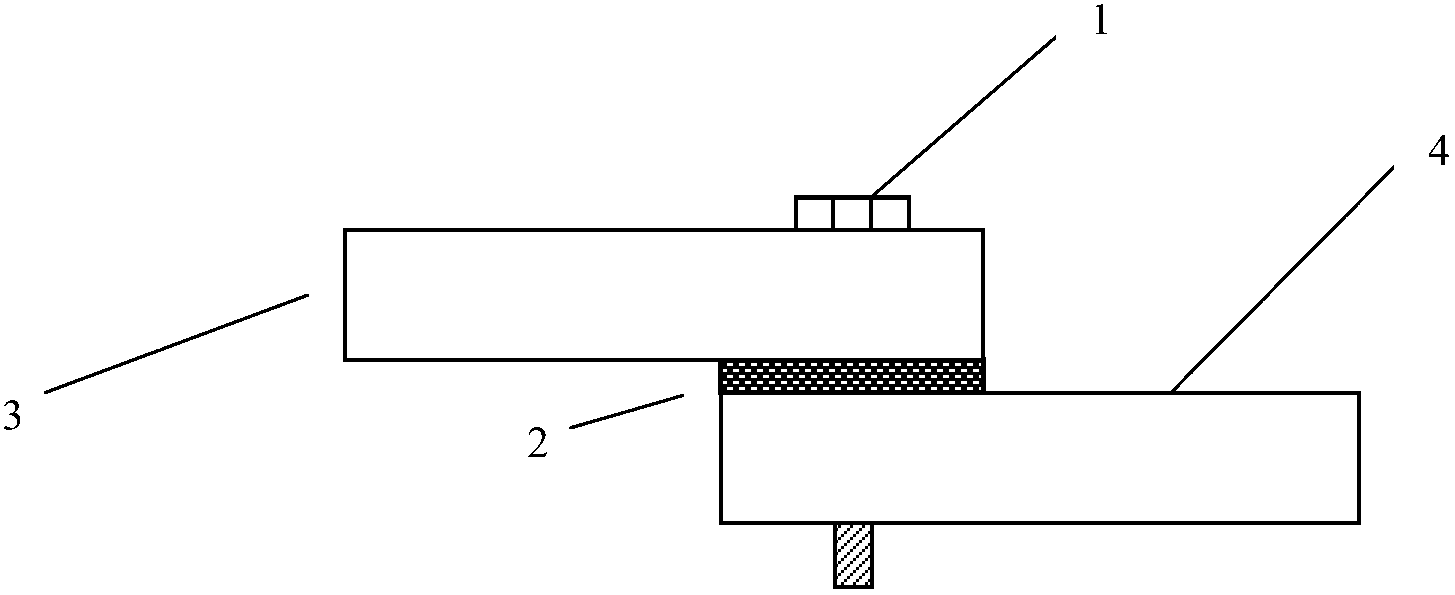

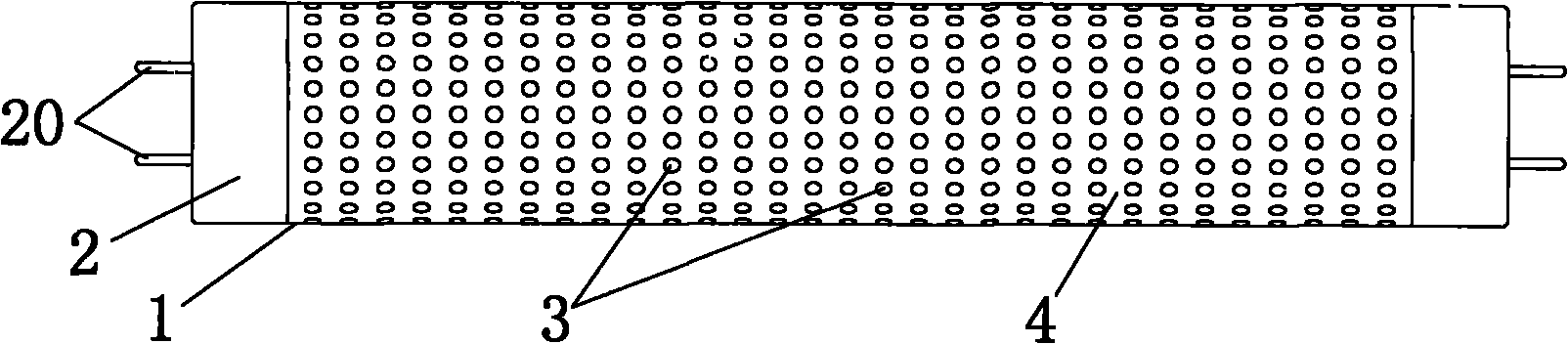

Memory card adapter

InactiveUS7320622B2Simple processImprove conduction efficiencyCoupling contact membersTwo-part coupling devicesEngineeringMemory cards

A memory card adapter (100) comprises an upper cover (2), an insulating lower cover (1), a conductive member (4) and a conductive terminals module (3) fixed on the insulating lower cover. The upper cover comprises a resin cover (22) and a metal cover (21). The lower insulating cover engages with the metal cover with a mini memory card receiving space (10) formed therebetween. The conductive terminals module comprises a plurality of conductive terminals (32) electrically connecting with the conductive member and a resin beam (31) to retain the conductive terminals therein. The mini memory card (200) is accommodated in the mini memory card receiving space and electrically connecting with the conductive terminals. Due to the arrangement of the conductive terminals module with the conductive member and the insulating lower cover, the whole assembly of the adaptor is highly simplified and the conduction efficiency is increased.

Owner:HON HAI PRECISION IND CO LTD

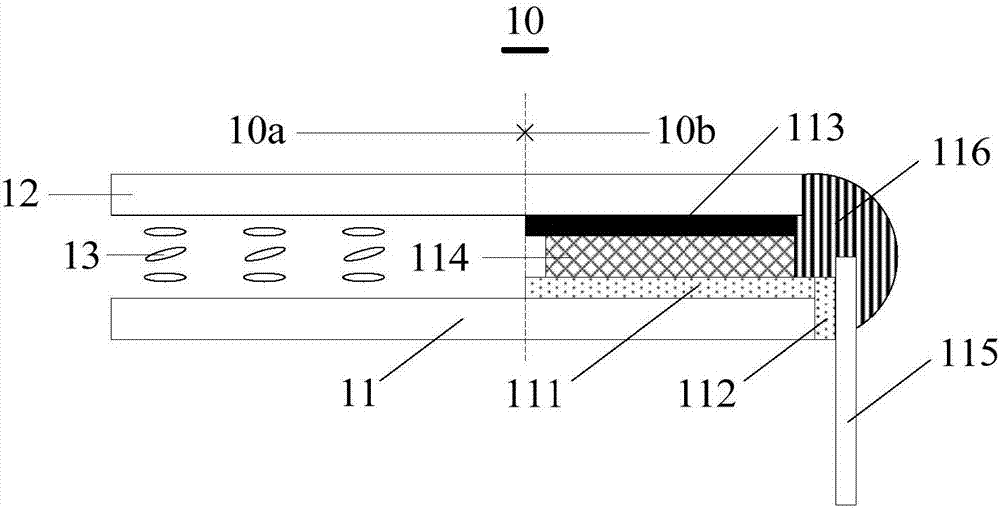

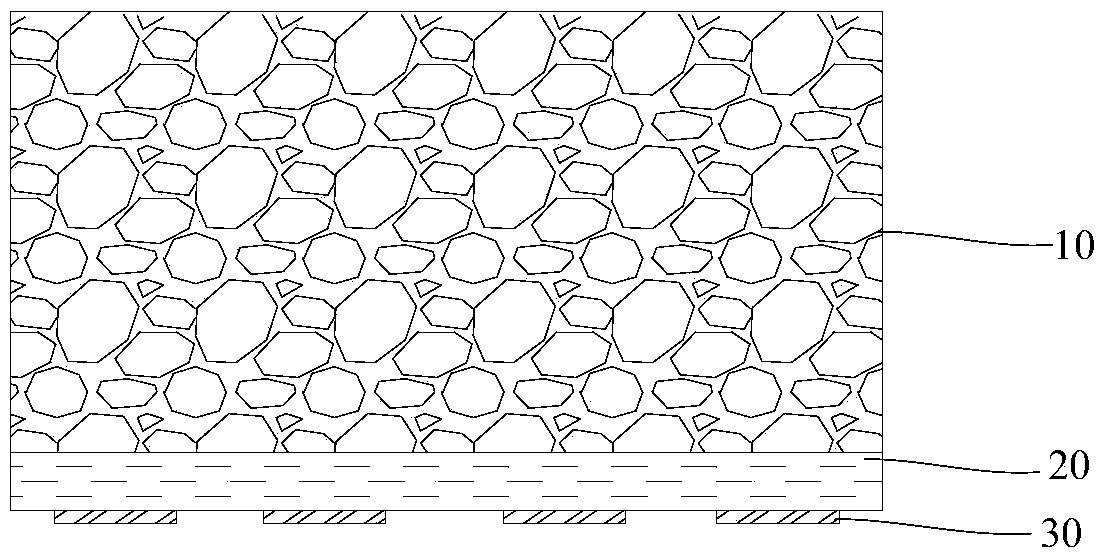

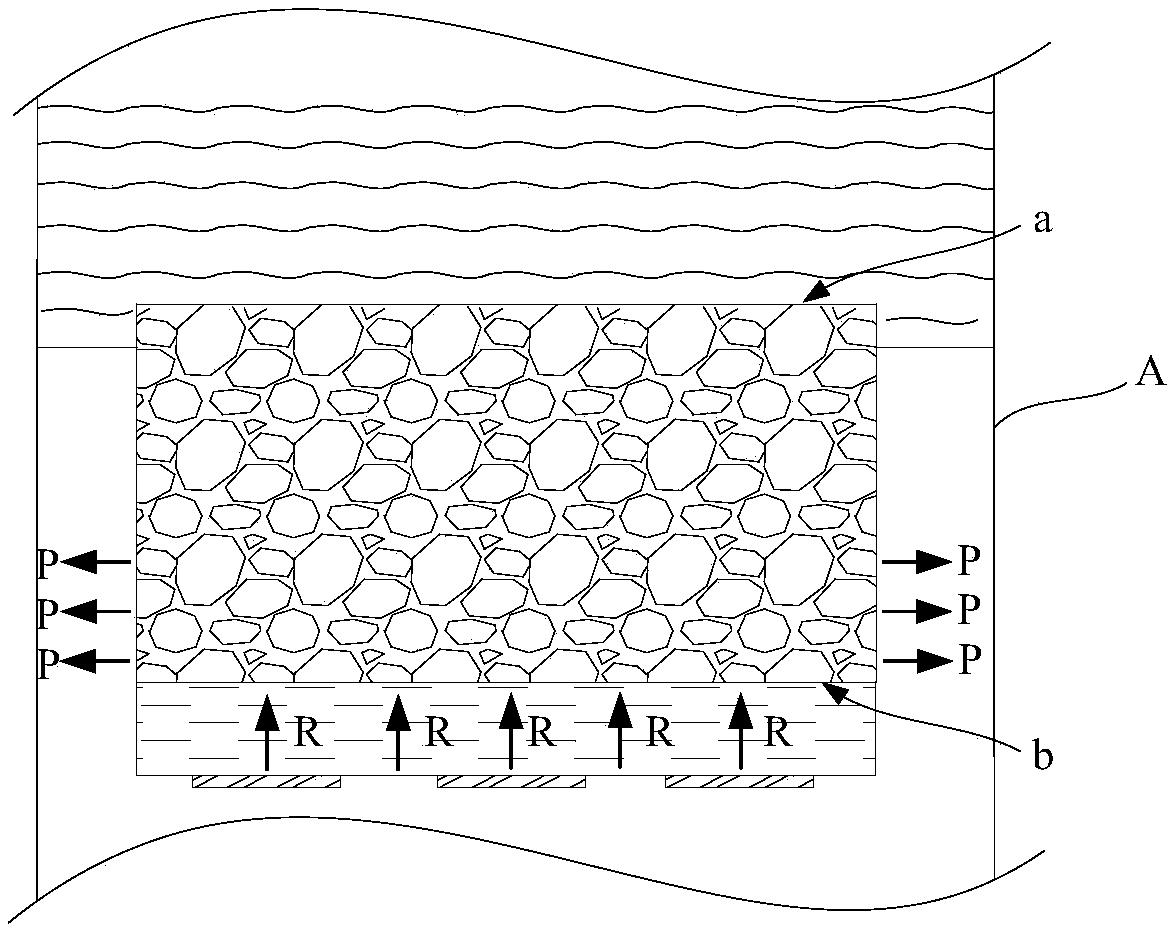

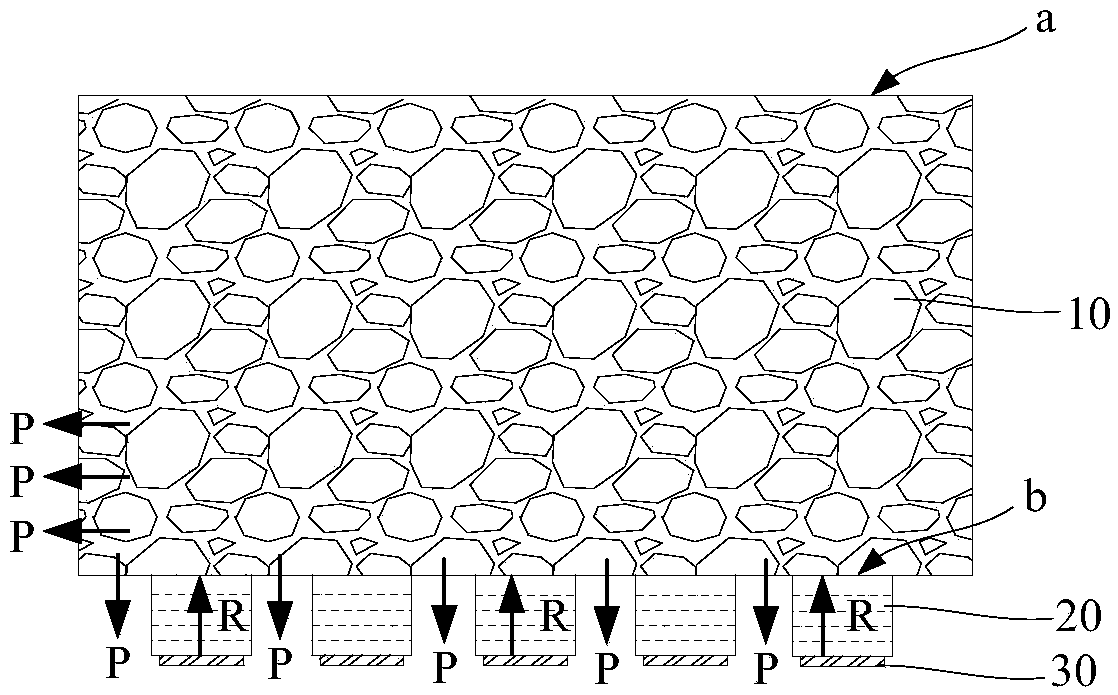

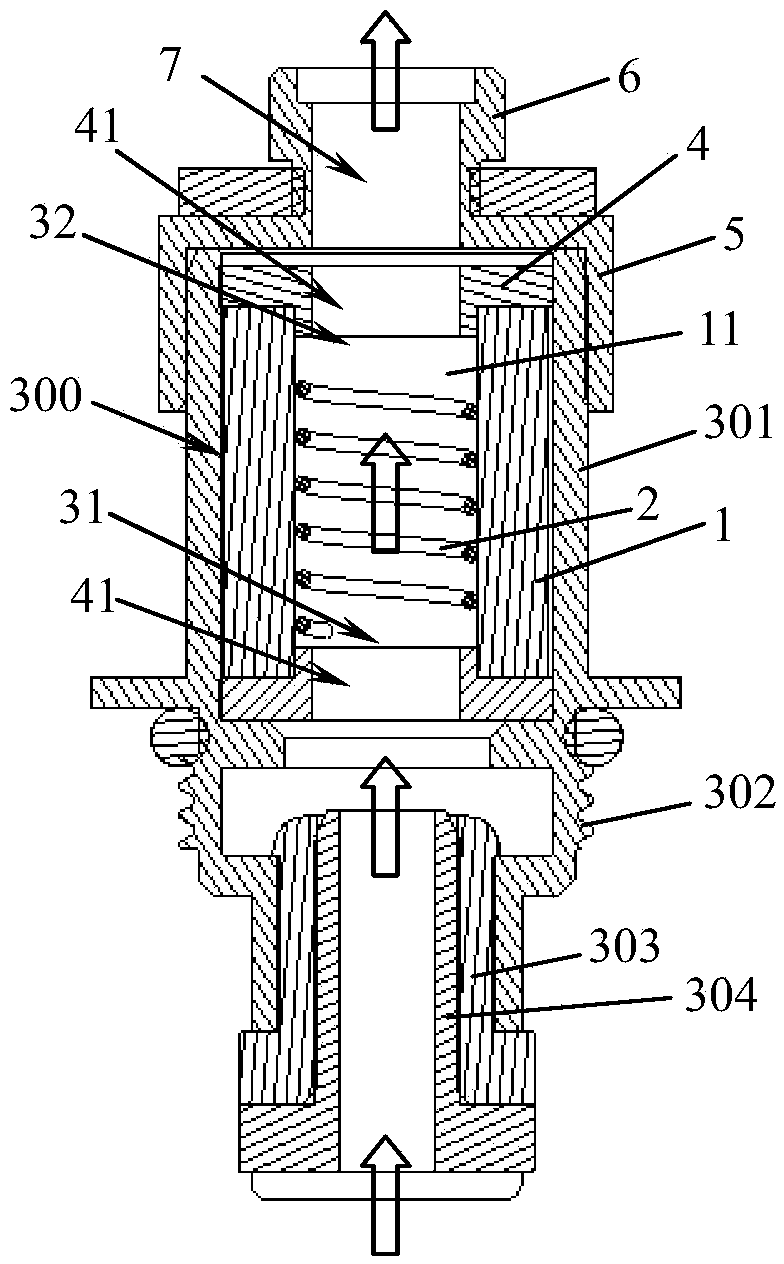

Preparation method of atomization component and electronic cigarette atomizer

InactiveCN109527657AImprove conduction efficiencyImprove flatnessTobacco devicesElectrical resistance and conductanceTar

The invention provides an electronic cigarette atomizer, which comprises an oil storage cavity used for storing smoke tar and an atomizing component used for sucking the smoke oil from the oil storagecavity and heating and atomizing the smoke oil; the atomizing component comprises a porous ceramic layer, a compact ceramic layer and a heating element which are sequentially stacked; the porous ceramic layer has a first surface opposite to the compact ceramic layer and a second surface opposite to the first surface; the compact ceramic layer is bonded to at least a portion of the first surface and the second surface is configured as an oil-absorbing surface in contact with the smoke oil. With the adoption of the electronic cigarette atomizer provided by the invention, the smoke oil is soakedand absorbed and conducted in the laminating direction of the porous ceramic layer and the compact ceramic layer in the atomizing component, so that the conduction efficiency of the smoke oil is greatly improved; the smoothness and bond stability of the heating element are better so that the problems that the resistance of the heating element is unstable to float and cannot be conducted even whenthe heating element is broken are solved; and the whole working stability and the service life can be obviously improved.

Owner:SHENZHEN FIRST UNION TECH CO LTD

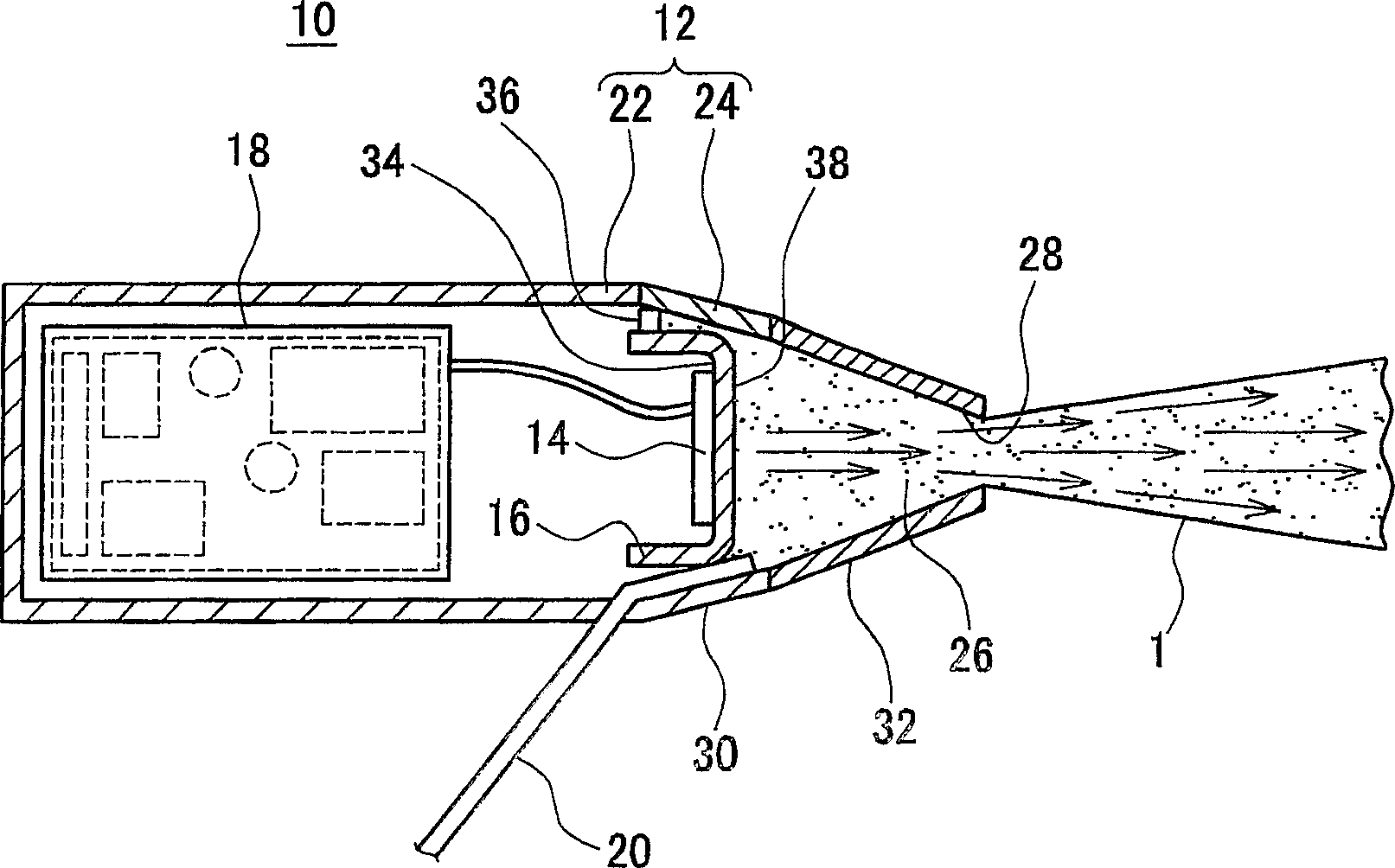

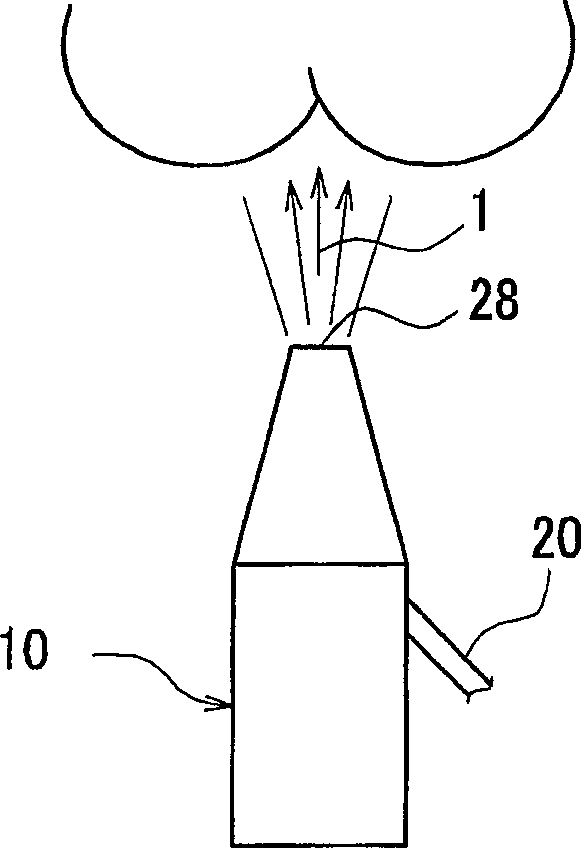

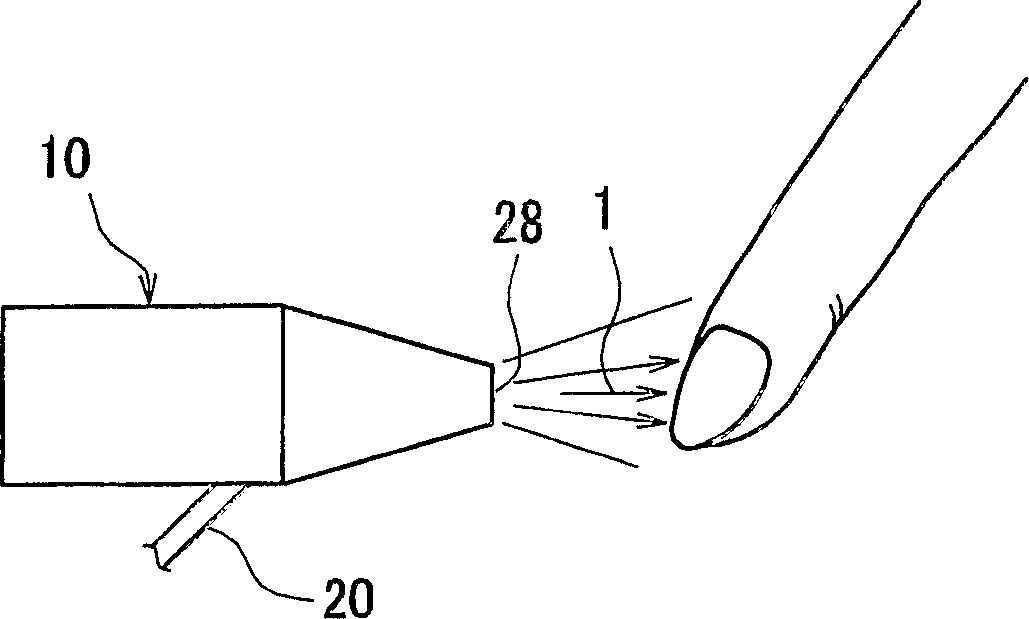

Ultrasonic washing device

InactiveCN1750783AImprove conduction efficiencyReduce outputBathroom accessoriesSpray nozzlesVibration amplitudeEngineering

In an ultrasonic washer for washing by splaying washing toward an object to be washed or a portion to be washed from a front end of a nozzle, a part of an ultrasonic wave propagation member connected to an ultrasonic transducer is protruded into a cavity of the nozzle into which the washing is filled in order to propagate ultrasonic vibration generated by the ultrasonic transducer to the washing efficiently. Furthermore, the ultrasonic wave propagation member is formed so that a cross-sectional area becomes gradually smaller as approaching to the front end thereof, so that the ultrasonic vibration is converged to the end face of the ultrasonic wave propagation member. Still furthermore, a length of the ultrasonic transducer and the ultrasonic wave propagation member is made to be integral multiplication of a half-wavelength of ultrasonic standing wave oscillation, and the end face of the ultrasonic wave propagation member from which the ultrasonic wave is emitted to the washing is disposed at a position of antinode of the ultrasonic standing wave oscillation where the amplitude becomes the largest.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

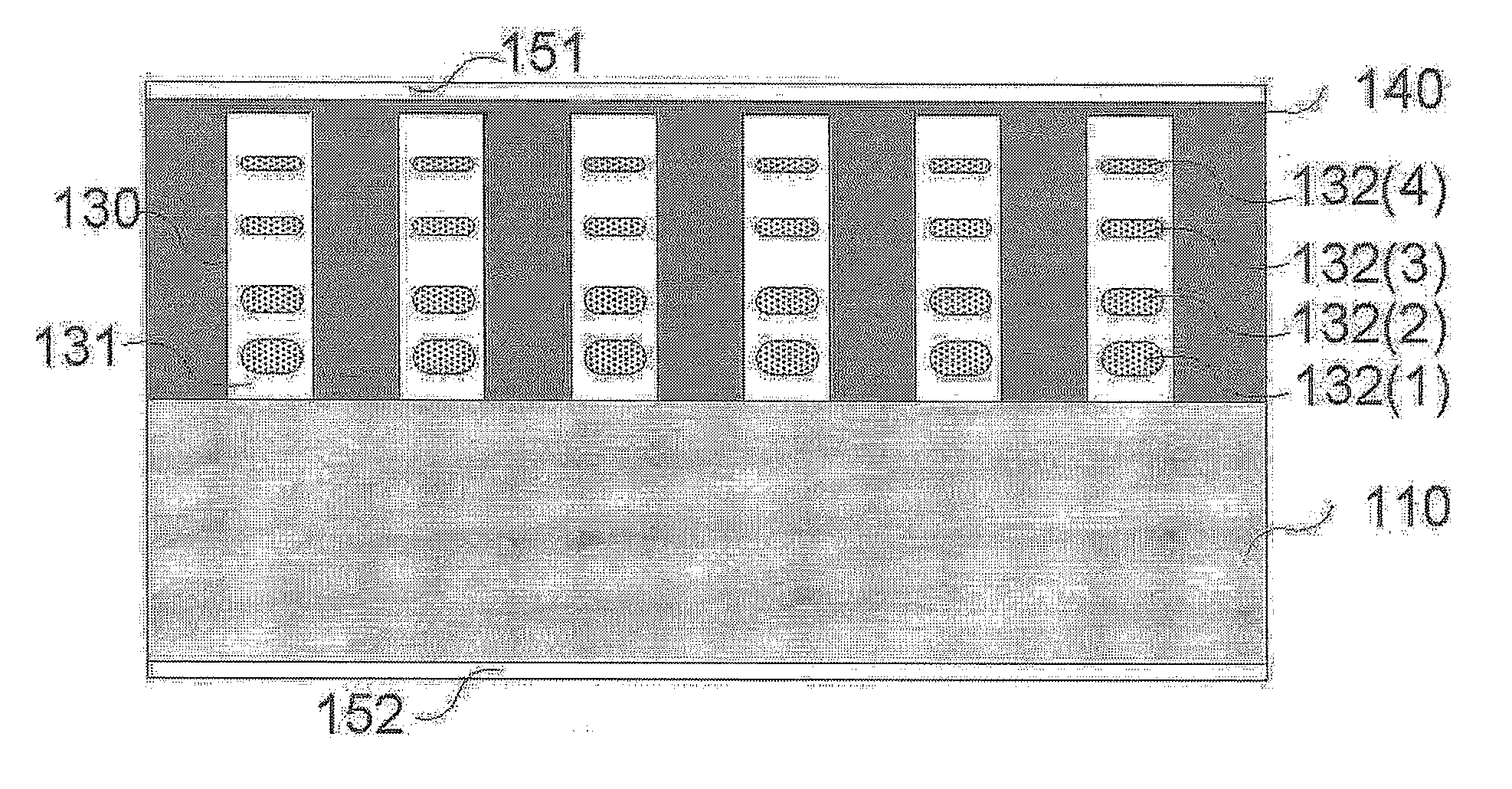

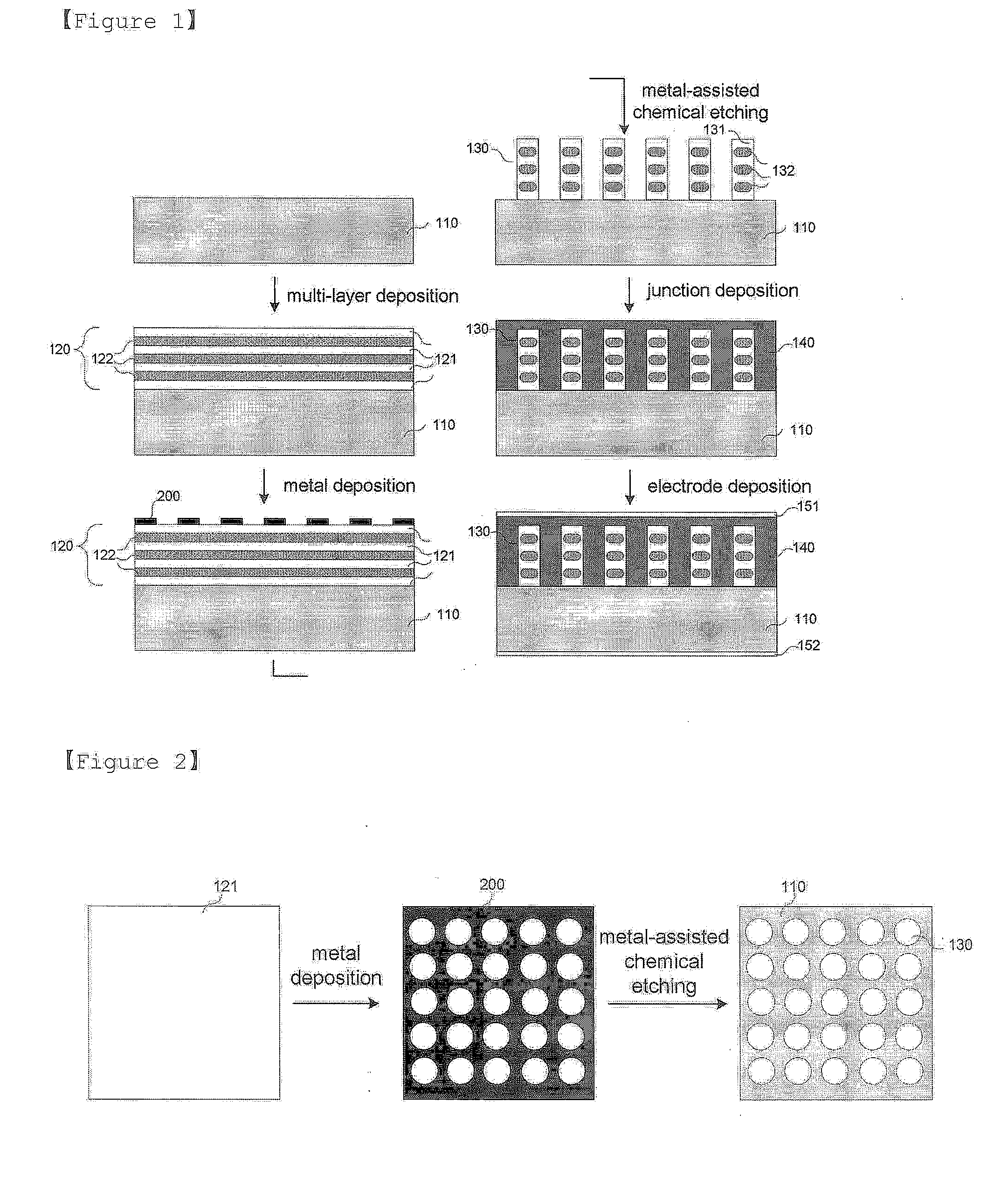

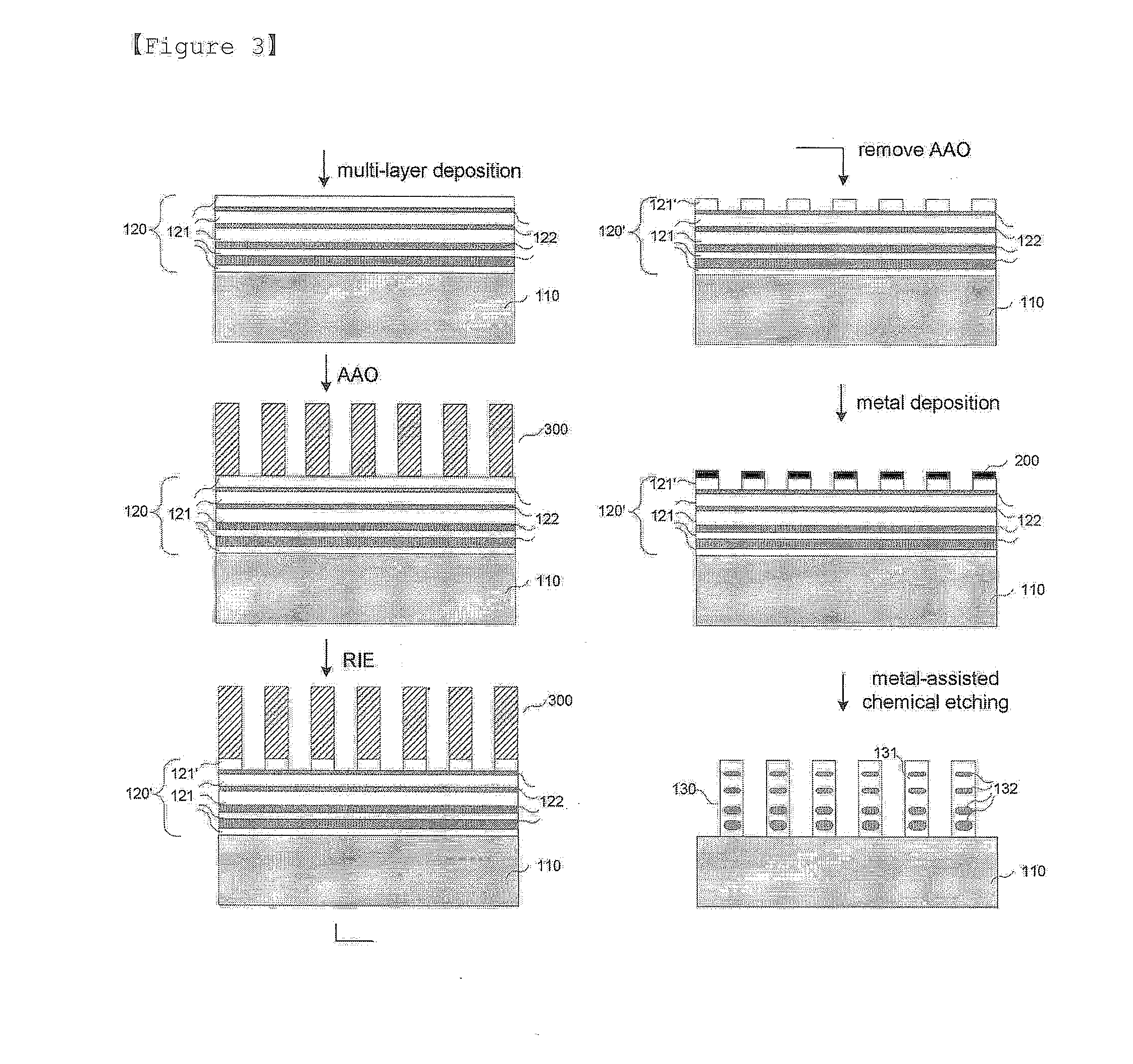

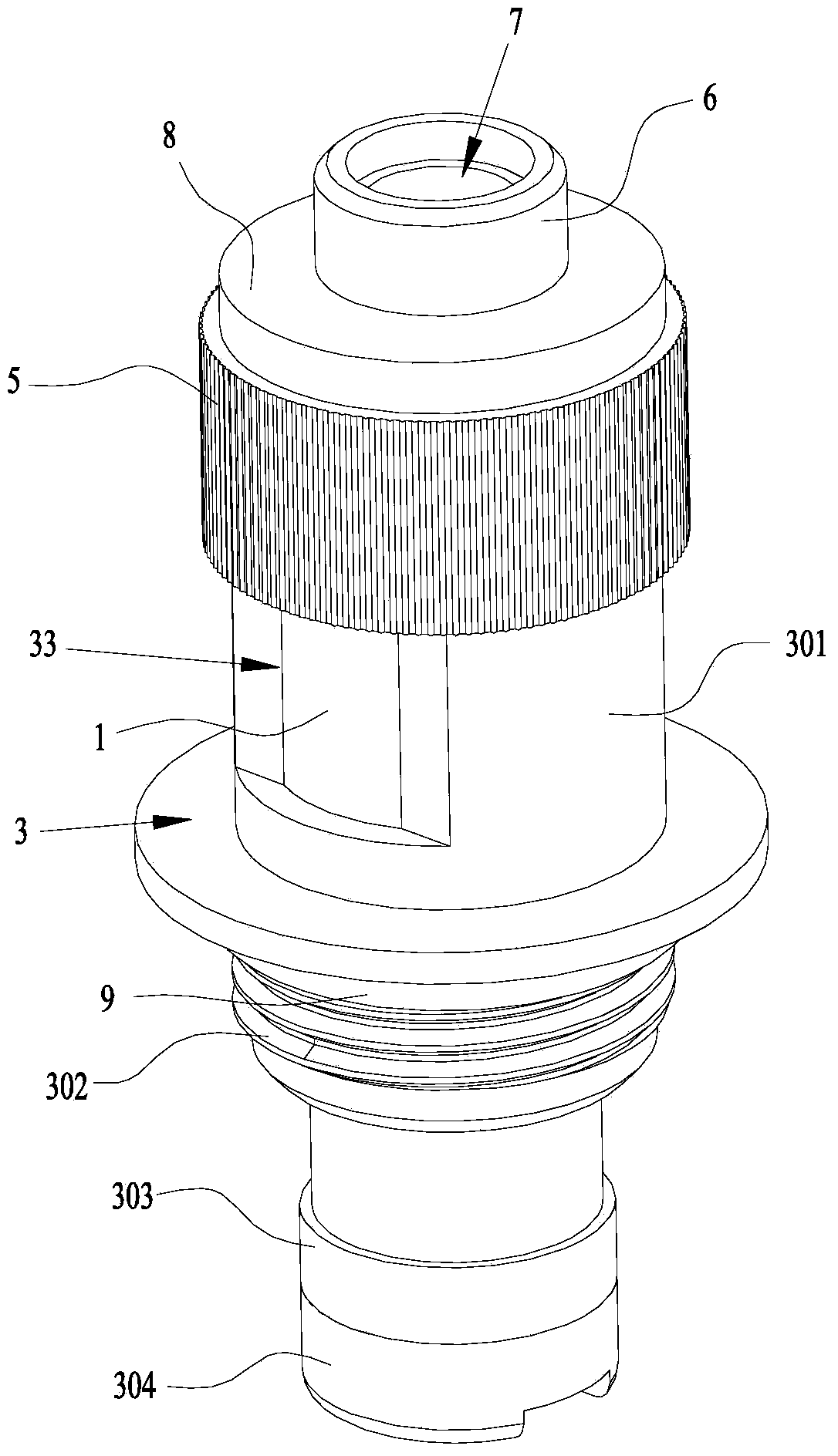

Solar Cell Having Quantum Dot Nanowire Array and the Fabrication Method Thereof

InactiveUS20110146774A1Light absorption can be maximizedConduction of electron be improvedFinal product manufactureSolid-state devicesHeterojunctionInfrared

The present invention relates to a solar cell having quantum dot nanowire array and the fabrication method thereof. The solar cell according to the present invention includes quantum dot nanowire array with a heterostructure including matrix and semiconductor quantum dots, and p-type and n-type semiconductor and electrodes each contacting the quantum dot nanowires. With the solar cell according to the present invention, the band gap energy of the semiconductor quantum dot can be easily controlled, the semiconductor quantum dots having different sizes are provided in the quantum dot nanowire so that the photoelectric conversion can be performed in the wide spectrum from visible rays to infrared rays, the quantum dot is embedded in the high density quantum dot nanowire array so that light absorption can be maximized, and the quantum dot nanowire contact p-type and n-type semiconductor over a wide area, conduction efficiency of electrons and holes can be improved.

Owner:KOREA RES INST OF STANDARDS & SCI

Heating assembly for electronic cigarette

ActiveCN104068476ALong-term efficient heating workImprove reliabilityTobacco devicesEngineeringElectronic cigarette

The invention discloses a heating assembly for an electronic cigarette. The heating assembly comprises a liquid guide ceramic body, a heating wire and a fixed seat, wherein an accommodating cavity is formed in the fixed seat, the liquid guide ceramic body is fixed in the accommodating cavity, an inlet and an outlet which are communicated with the accommodating cavity are formed in the both ends of the fixed seat, a cigarette liquid inlet communicated with the accommodating cavity is opened in the sidewall of the fixed seat, a fixing hole penetrates in the liquid guide ceramic body, an orifice at one end of the fixing hole is opposite to the inlet, and an orifice at the other end of the fixing hole is opposite to the outlet; and the heating wire is fixed in the fixing hole, in contact with the wall of the fixing hole, and electrically connected with the fixed seat. The heating assembly disclosed by the invention is high in atomization efficiency and reliability, and moreover, the generated cigarette smoke is good in taste.

Owner:SHENZHEN KANGER TECH CO LTD

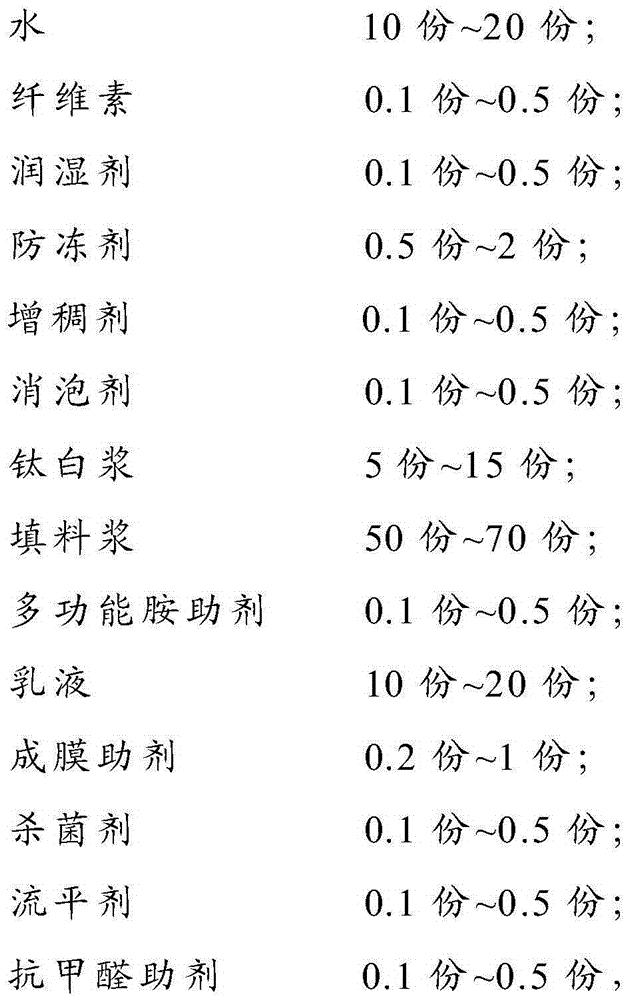

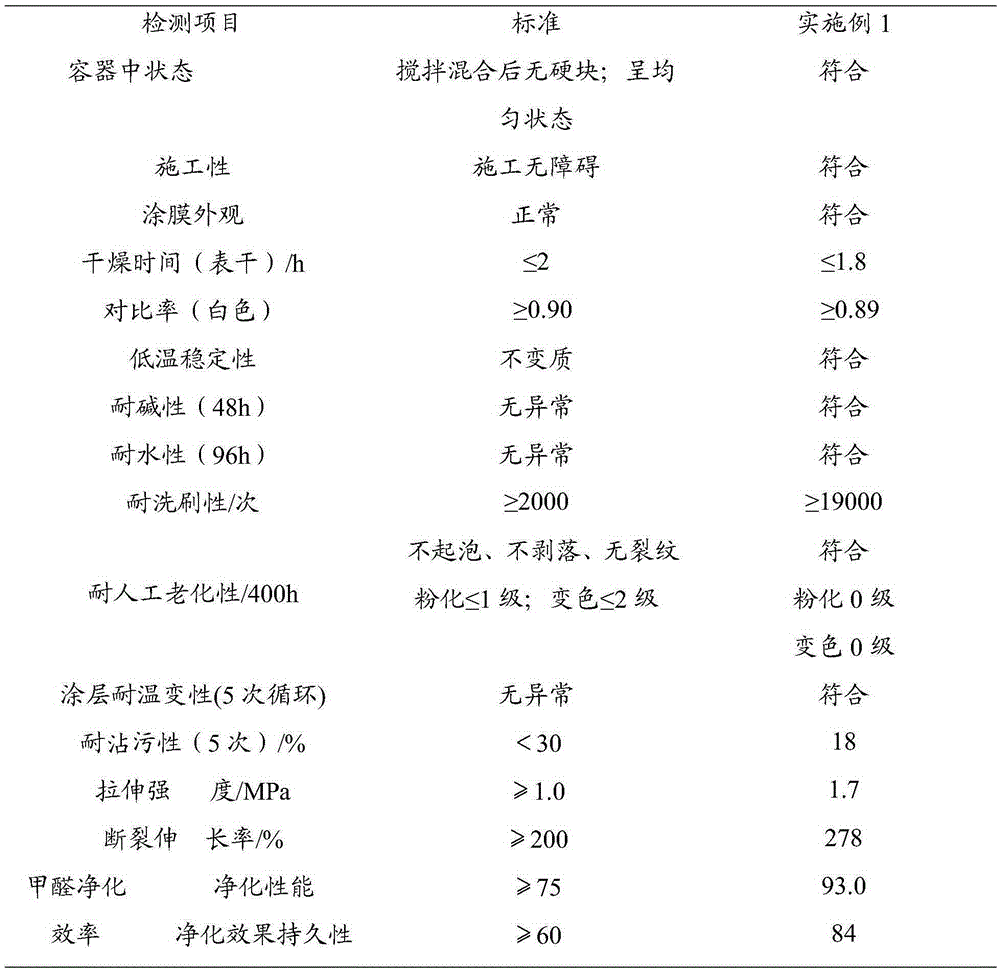

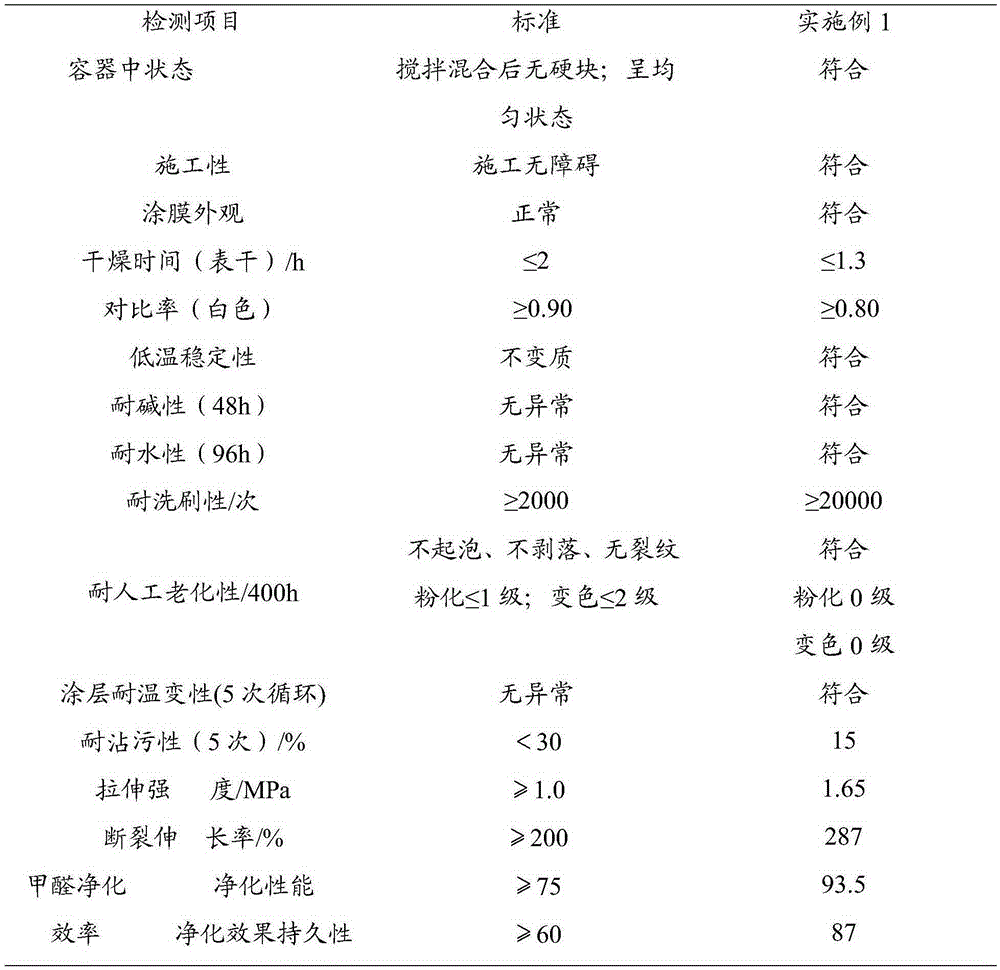

Graphene formaldehyde-resisting paint and preparing method thereof

InactiveCN105315814AImprove conduction efficiencyImprove photocatalytic activityAntifouling/underwater paintsPaints with biocidesWater basedPhotocatalytic reaction

The invention belongs to the field of chemical engineering paint and particularly relates to graphene formaldehyde-resisting paint and a preparing method thereof. The graphene formaldehyde-resisting paint is prepared from water, cellulose, a wetting agent, an anti-freezing agent, a thickening agent, a defoaming agent, titanium dioxide pulp, padding pulp, a multifunctional amine assistant, emulsion, a coalescing agent, a sterilizing agent, a flatting agent and a formaldehyde resisting agent, wherein the formaldehyde resisting agent is a mixture of graphene and nanometer titania. According to the graphene formaldehyde-resisting paint and the preparing method thereof, a traditional formulation is improved, graphene serves as a photocatalytic carrier by means of the light transmittance of graphene, and thus the efficiency of a photocatalytic reaction is greatly improved. Meanwhile, graphene is added to nanoscale titania, the absorption rate of visible light is increased, and the electron conduction efficiency is improved. In addition, due to the addition of graphene, the wear-resisting property of the water-based emulsion paint is improved.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Memory card adapter

InactiveUS20070111604A1Improve conduction efficiencySimple processCoupling contact membersTwo-part coupling devicesEngineeringMemory cards

A memory card adapter (100) comprises an upper cover (2), an insulating lower cover (1), a conductive member (4) and a conductive terminals module (3) fixed on the insulating lower cover. The upper cover comprises a resin cover (22) and a metal cover (21). The lower insulating cover engages with the metal cover with a mini memory card receiving space (10) formed therebetween. The conductive terminals module comprises a plurality of conductive terminals (32) electrically connecting with the conductive member and a resin beam (31) to retain the conductive terminals therein. The mini memory card (200) is accommodated in the mini memory card receiving space and electrically connecting with the conductive terminals. Due to the arrangement of the conductive terminals module with the conductive member and the insulating lower cover, the whole assembly of the adaptor is highly simplified and the conduction efficiency is increased.

Owner:HON HAI PRECISION IND CO LTD

Method for reducing contact resistance based on low-melting-point metal and oxide thereof

ActiveCN103066475AReduce contact resistanceImprove efficiencyLine/current collector detailsMetal/alloy conductorsIndiumRubidium

The invention relates to a method for reducing contact resistance based on low-melting-point metal and an oxide thereof. By coating the low-melting-point metal and the oxide thereof between electric terminals connected with machinery, the contact resistance between the mechanical electric terminals is reduced effectively. The invention further relates to a conductive paste composing of the low-melting-point metal and the oxide thereof. The oxide takes 0.05% to 50% of the total weight of the conductive paste. The low-melting-point metal is one type or a combination of any two types selected from sodium, potassium, lithium, rubidium, cesium, gallium, indium, mercury, lead bismuth alloy, gallium-base binary alloy, gallium-base complex alloy, indium-base alloy, bismuth-base alloy, mercury-base alloy and sodium-potassium alloy which are lower than 200 DEG C in melting point. With the compound of the low-melting-point metal and the oxide thereof as the conducting medium, the method for reducing contact resistance can effectively reduce the contact resistance between the electric terminals connected with the machinery, significantly reduce the contact resistance heat effect, improve transmission efficiency of electric energy and prolong the service life of the machinery. The method for reducing contact resistance based on the low-melting-point metal and the oxide thereof can be widely applied to the technical fields of electric power and energy.

Owner:郭瑞

Array substrate and display panel

ActiveCN107422553AReduce widthImprove connection strengthStatic indicating devicesNon-linear opticsFlexible circuitsEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Electrocondution slurry and preparation method and application of electrocondution slurry

InactiveCN103839605AAvoid affecting charge transportGuaranteed normal transmissionNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkMoisture resistance

The invention discloses electrocondution slurry and a preparation method and application of the electrocondution slurry. The slurry comprises, by mass percent, 30-40% of silver-graphene composite materials, 30-48% of organic resin, 5-10% of cross-linking agents and 12-26% of thinning agents. The method that the silver-graphene composite materials are prepared are as follows: graphite oxide and organic silver are added to a mixed system formed by organic solvents and deionized water, and ultrasonic dispersion is carried out on the mixture; hydrazine hydrate is dripped to the mixed system while the mixed system is stirred; after stirring is carried out for 20-30 min at room temperature, the temperature rises to 60-70 DEG C, reaction is conducted for 2-3 h, the mixture is cooled to be at the room temperature, filtered and rinsed by the deionized water, vacuum drying is carried out on the mixture, and the silver-graphene composite materials are obtained. The electrocondution slurry can meet the demands of photovoltaic devices for the electrical property under low silver content conditions and is suitable for flexible substrates, good in temperature and moisture resistance and excellent in filament printing performance, adhesive force of the electrocondution slurry and substrate ITO materials is high, and production cost of the slurry is remarkably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

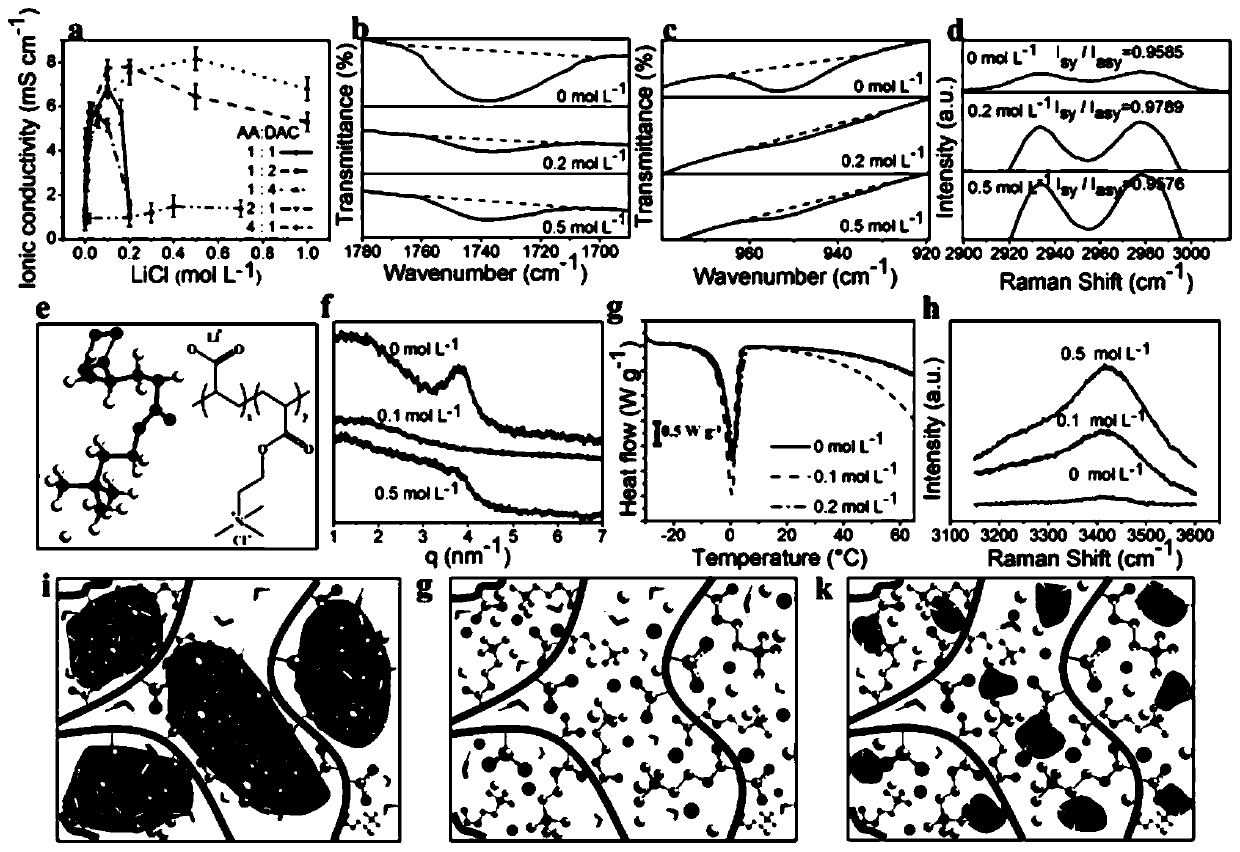

Amphoteric gel polymer electrolyte with good performance and preparation and application thereof

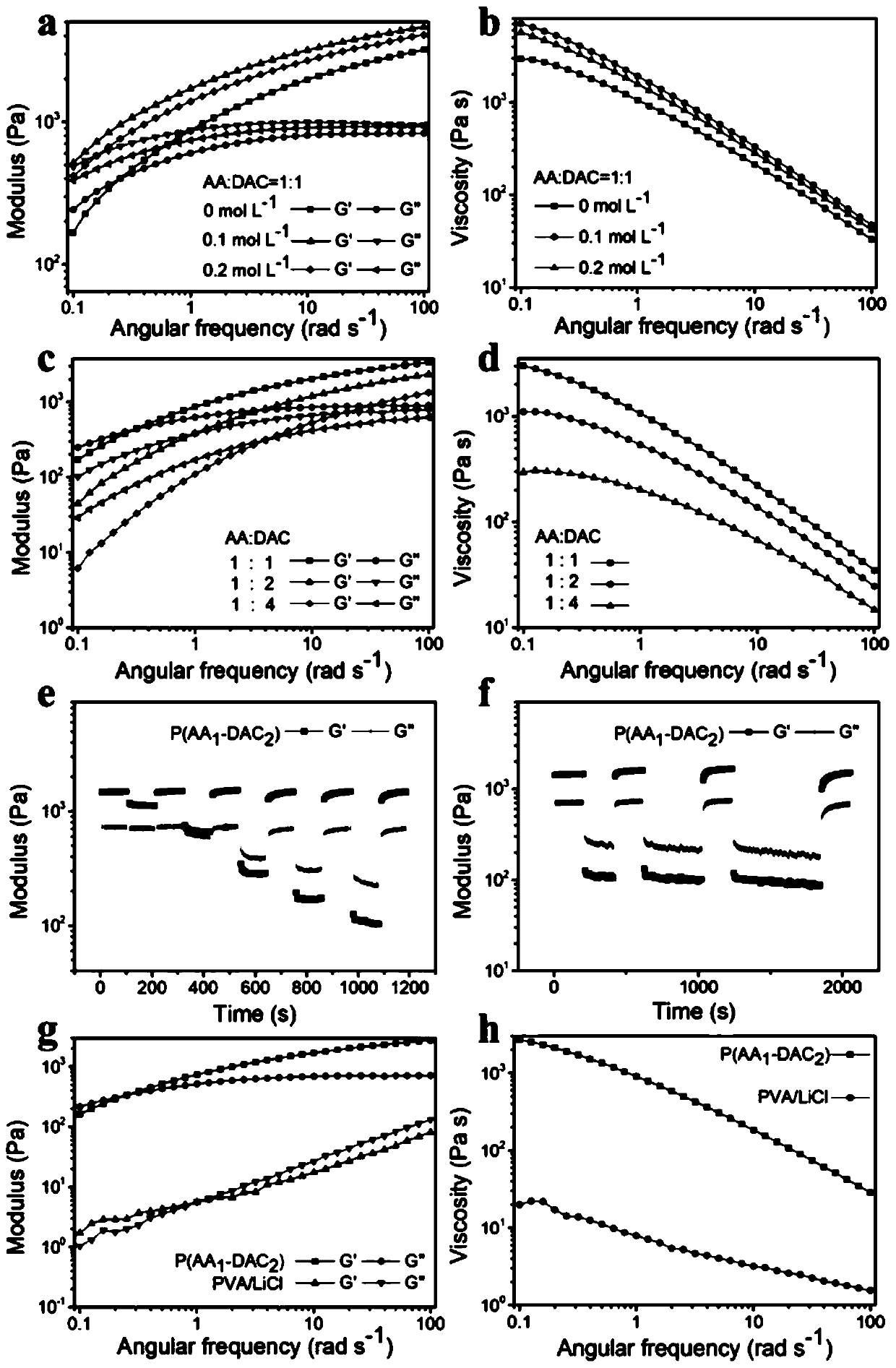

ActiveCN109935476AInhibit migrationReduce interface resistanceHybrid capacitor electrolytesHybrid/EDL manufactureCapacitancePolymer science

The invention relates to an amphoteric gel polymer electrolyte with good performance and preparation and application thereof. A series of zwitterionic gel electrolytes are prepared in the invention. An amphoteric gel electrolyte with high mechanical strength and a conductivity of 8.2 mScm-1 can be prepared by controlling the ratio of monomers and the concentration of lithium salt. The interfacialresistance between an electrode and the electrolyte is greatly reduced by immersing an AC electrode into a monomer solution for in-situ polymerization. The AC electrode with the in-situ polymerized electrolyte has a large area capacitance of 297mF cm-2 at a current density of 0.8 mA cm-2 and can remain 70% after 7000 cyclic tests. Remarkably, the combined solid capacitor not only have an area energy density up to 6.6 mWh cm-2 and a power density up to 2.4 W cm-2, but also have a good self-healing property. The work of the invention provides a new idea for the field of gel electrolytes, and obtains a zwitterionic gel electrolyte having great application potential in energy storage equipment.

Owner:QILU UNIV OF TECH

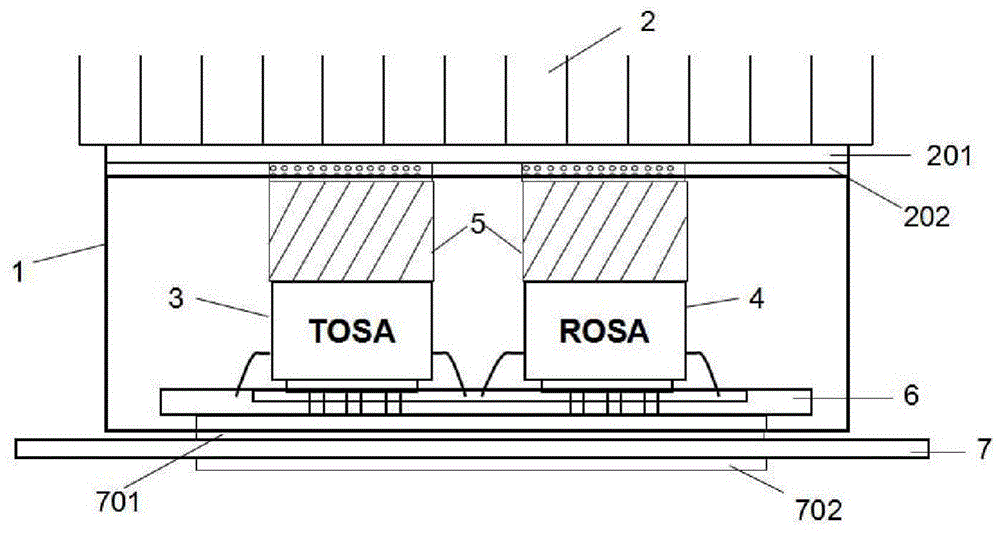

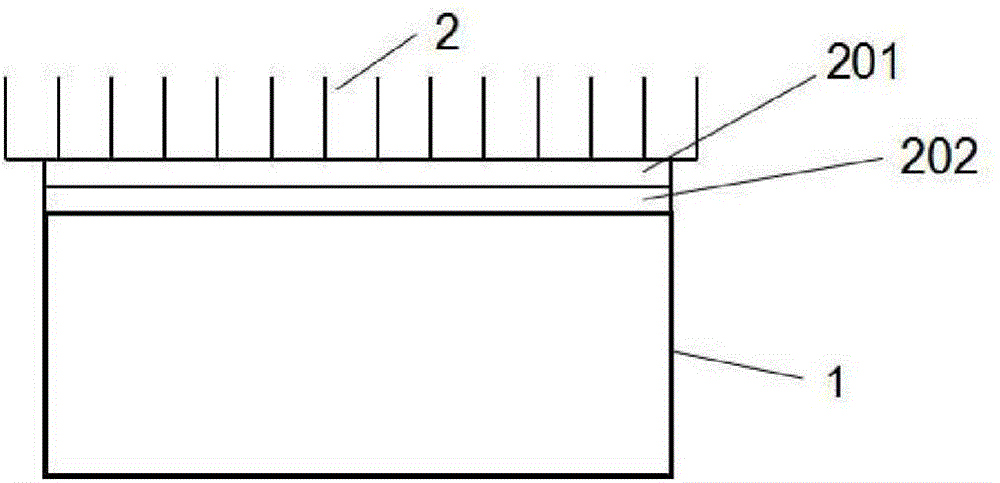

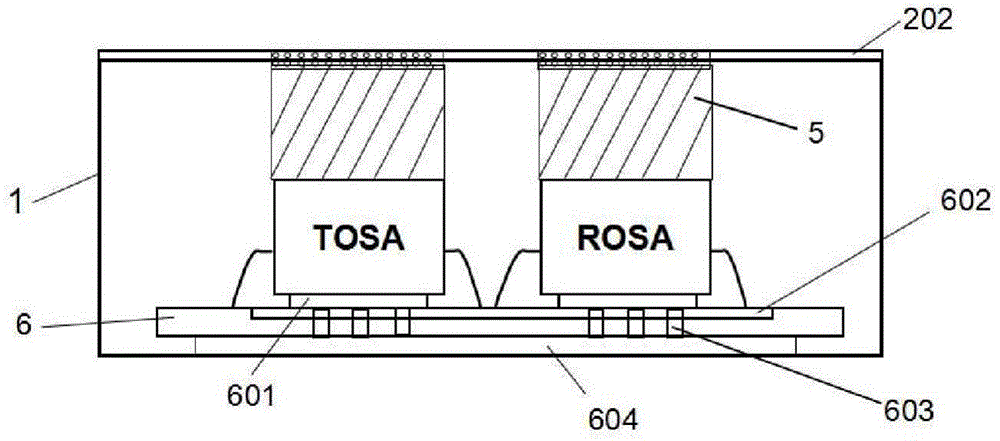

Optical module assembly with inner heat dispassion channel and composite heat dispassion structure thereof

InactiveCN104793300AImprove cooling effectImprove cooling efficiencyCoupling light guidesOptical ModuleCooling effect

The invention discloses an optical module assembly with an inner heat dispassion channel and a composite heat dispassion structure thereof. The optical module assembly comprises an optical module packing housing, a cooling fin on the top of the module, a TOSA (transmitter optical subassembly), a ROSA (receiver optical subassembly) and an inner circuit board. The TOSA and the ROSA are fixedly arranged on the inner circuit board, a thermal pad is arranged on the top of the TOSA and the ROSA. The upper surface of the thermal pad is closely contacted with the optical module packing housing, and the lower surface of the optical module packing housing is connected with the outer big PCB board. By arranging two cooling channels up and down inside the optical module, a cooling path is increased and heat generated by the inner assembly can be quickly transmitted upward and downward to external environment through thermal conductive units. Compared with the prior art, the optical module assembly with the inner heat dispassion channel and composite heat dispassion structure has better cooling effect.

Owner:SOUTHEAST UNIV

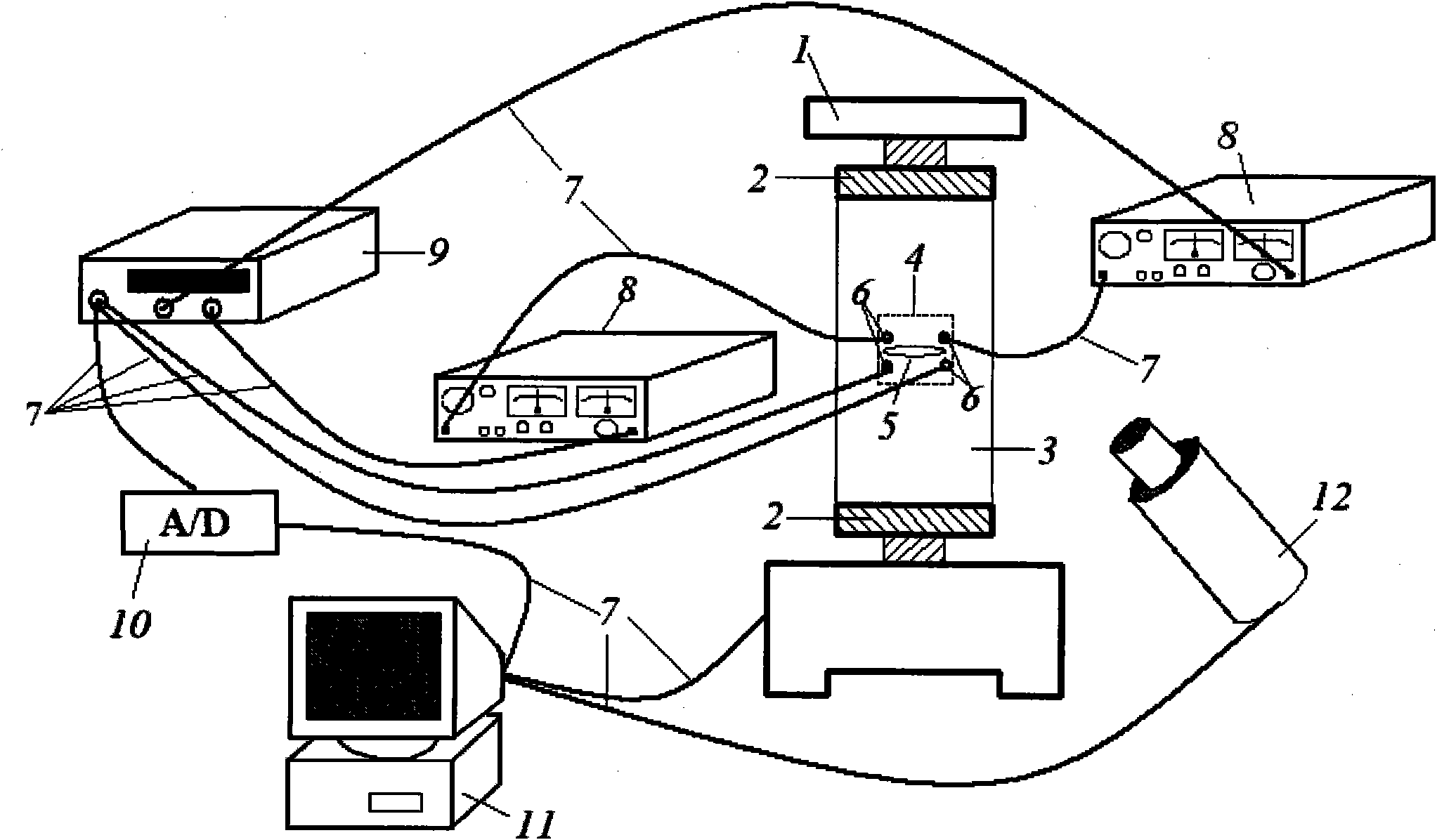

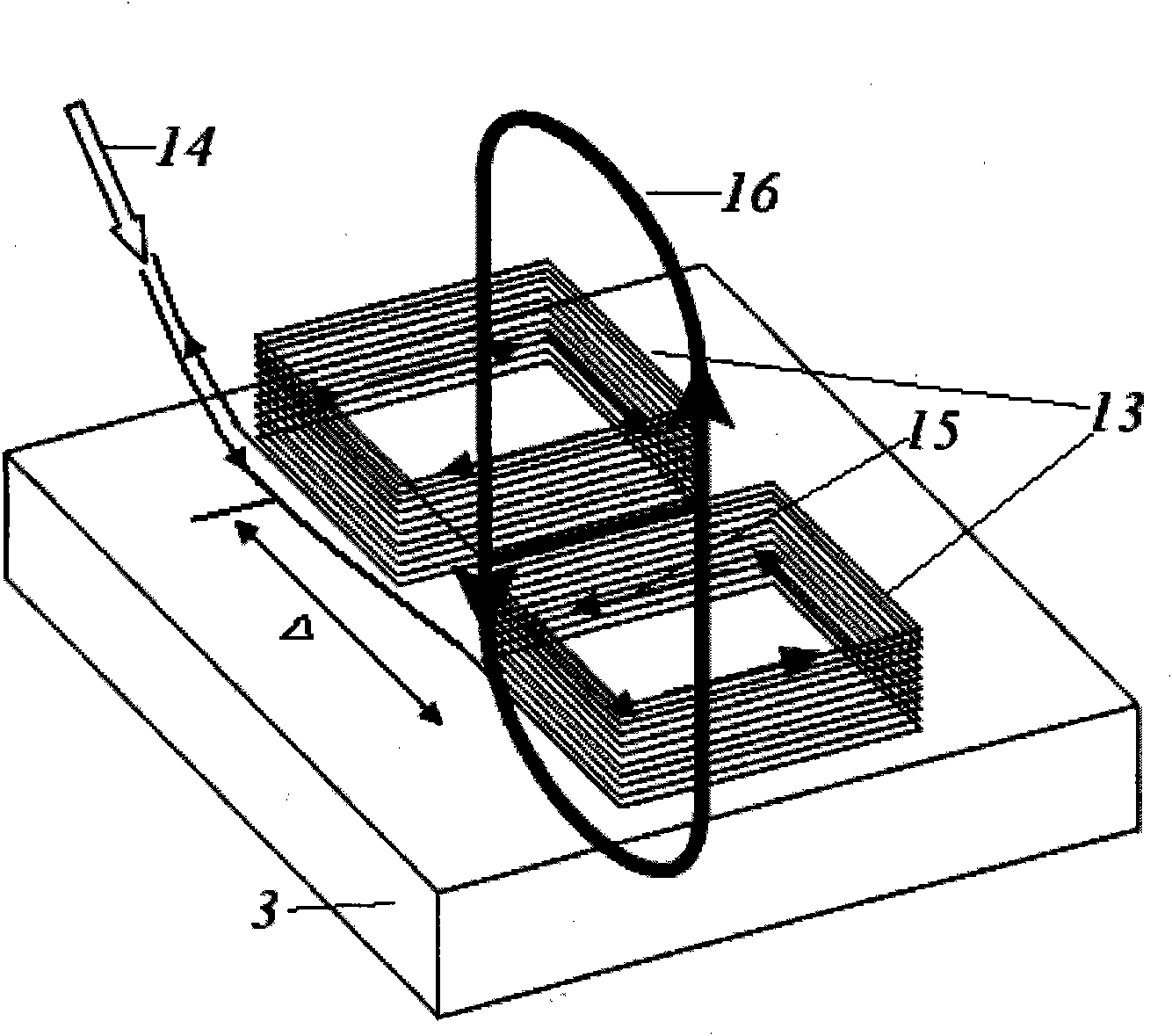

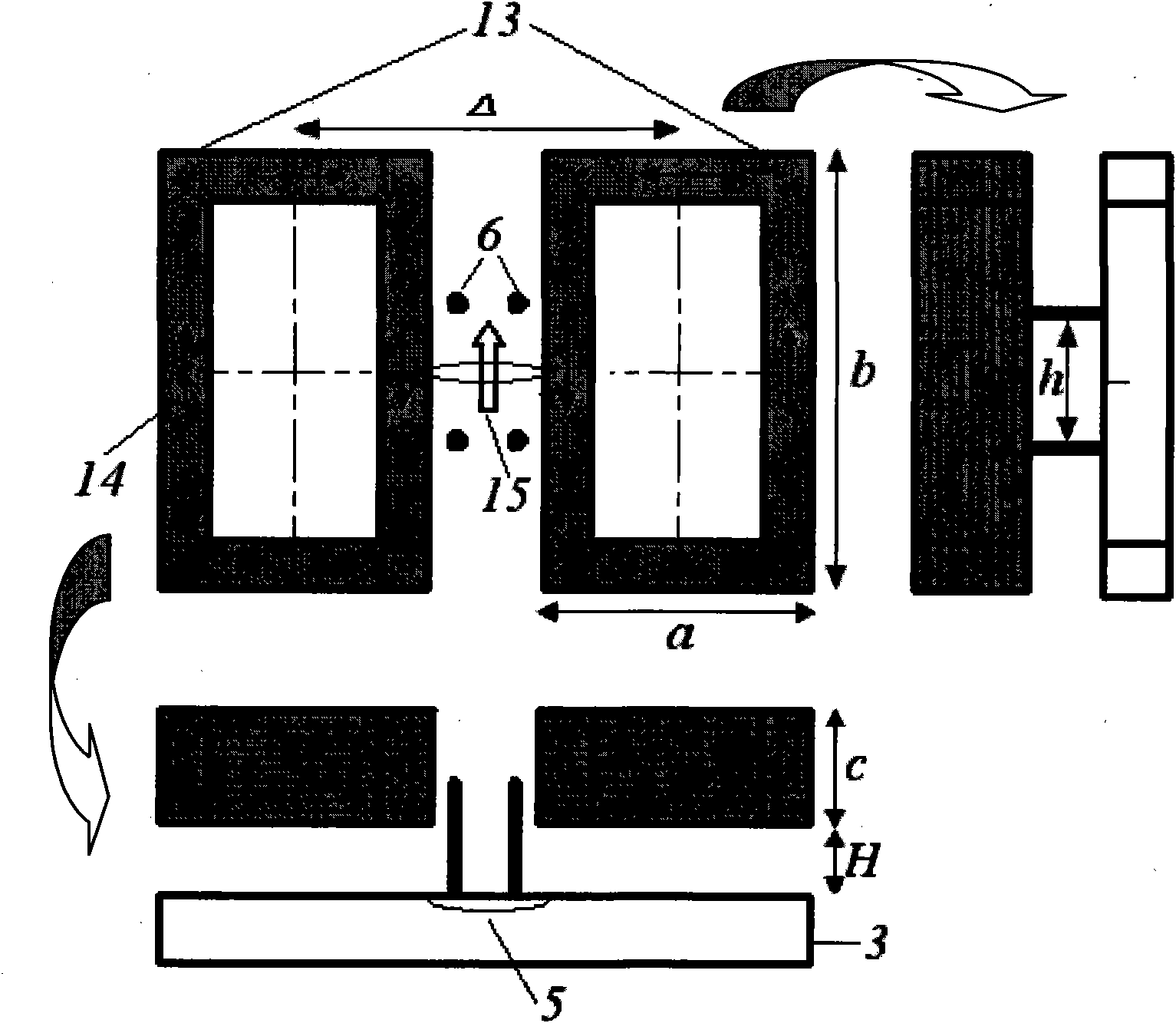

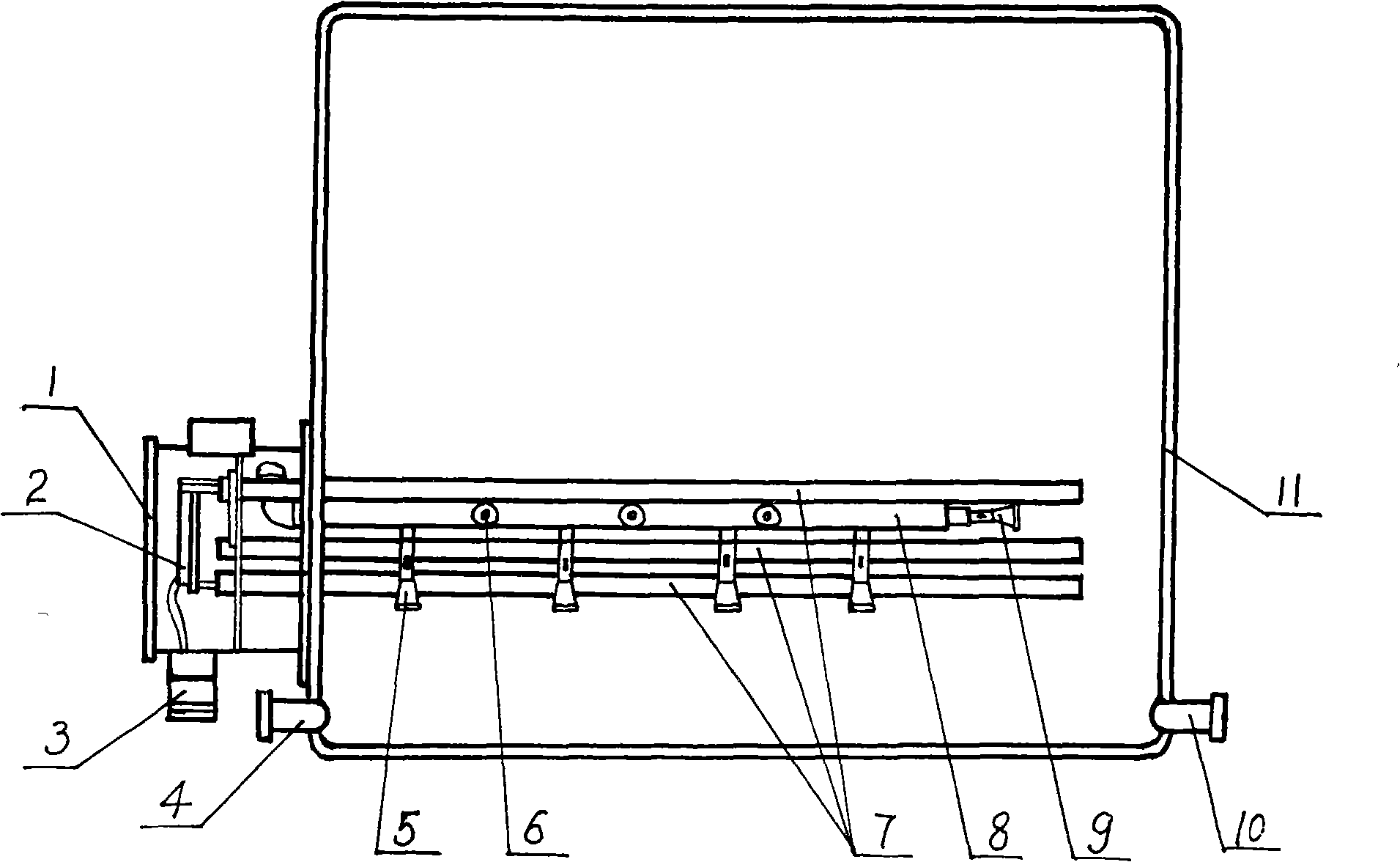

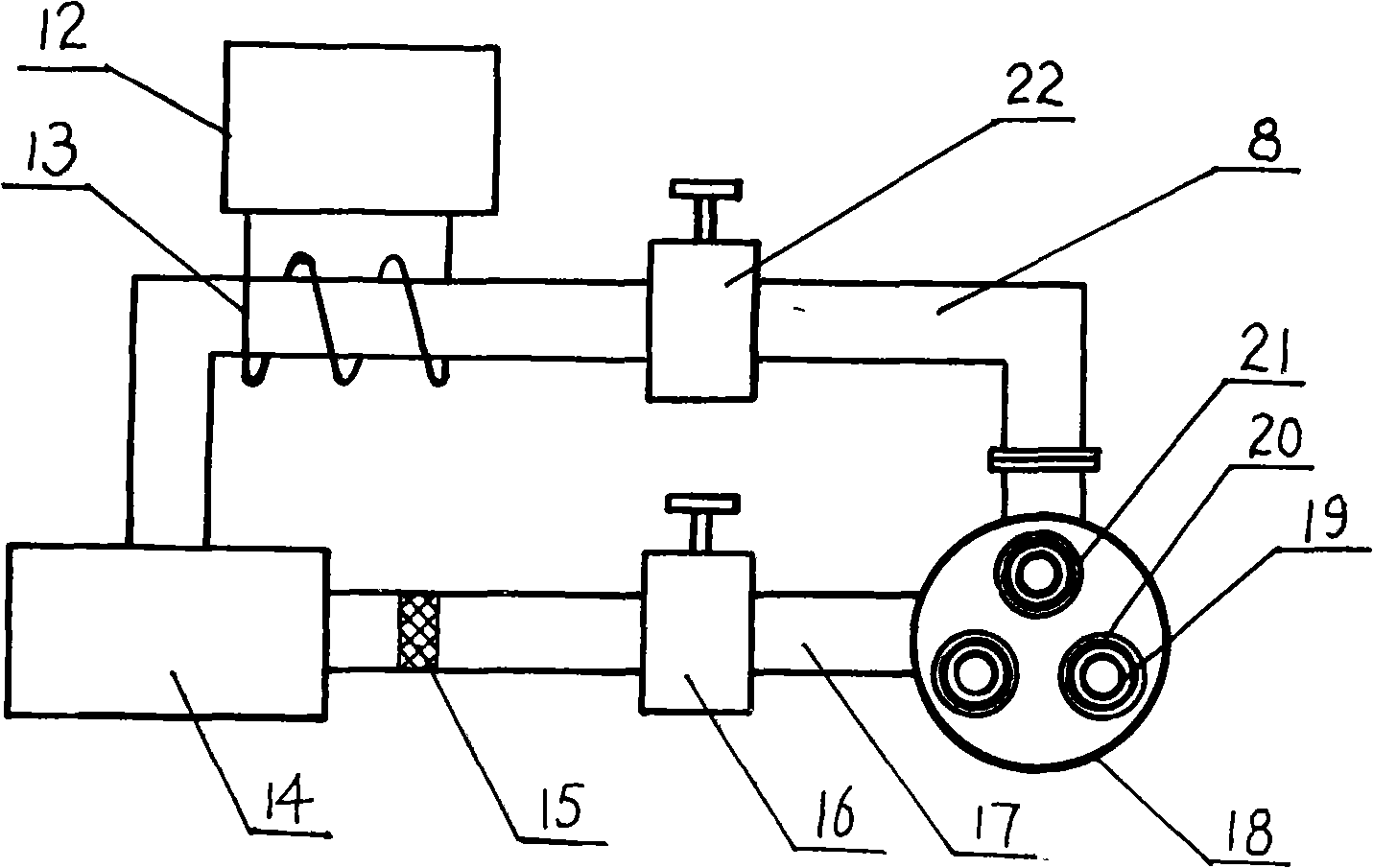

Device and method for reckoning fatigue crack propagation rate of flat alloy by AC potentiometry

InactiveCN101832970AImprove conductivityIsolation of high resistance interferenceMaterial magnetic variablesPotential measurementAlloy

The invention provides a device and a method for reckoning the fatigue crack propagation rate of a flat alloy by AC potentiometry, relating to the field of detecting material fatigue performance. The method comprises the following steps: in the process of a tension-tension fatigue test, two pairs of probes are arranged on the surface of a flat alloy sample, and the sample monitors electric potential change at the two sides of a crack in real time by an AC potentiometry sensor thereon when the fatigue crack propagates; the electric potential change is transmitted to a dual-trace oscilloscope by an amplifier; the dual-trace oscilloscope displays the electric potential oscillogram of the propagation of the two ends of the crack; and the electric potential oscillogram is input to a computer by an A / D converter, and is analyzed by a bundled software to obtain fatigue propagation rate such as the fatigue crack propagation rate and the like. The device of the invention mainly comprises a fatigue-testing machine, sample fixtures, the AC potentiometry sensor, potential measurement probes, lead wires, a signal amplifier, the dual-trace oscilloscope, the A / D converter, a CCD image acquisition system and the computer. The invention is applicable to research on the fatigue crack propagation behavior of the alloy.

Owner:JIANGSU UNIV

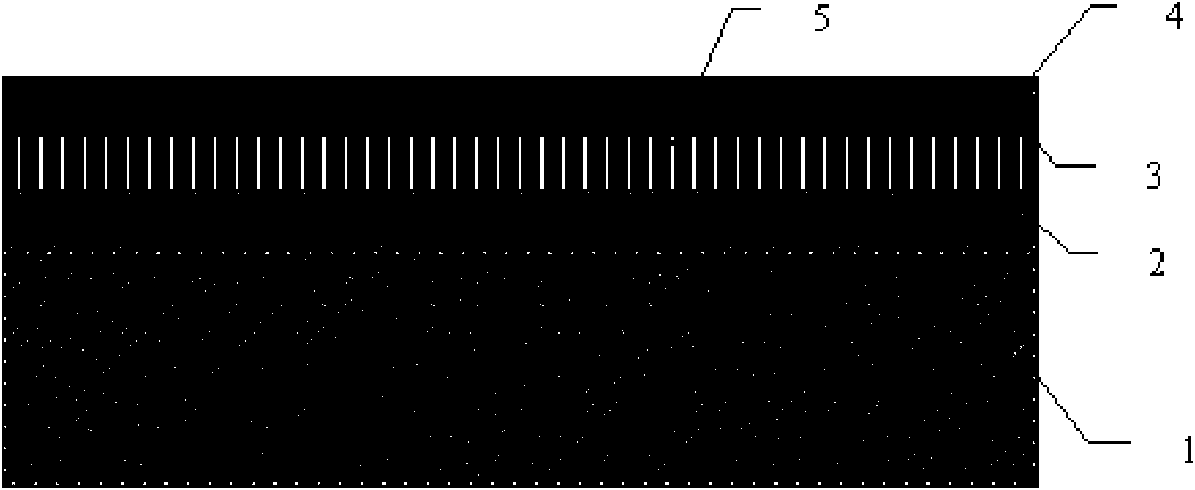

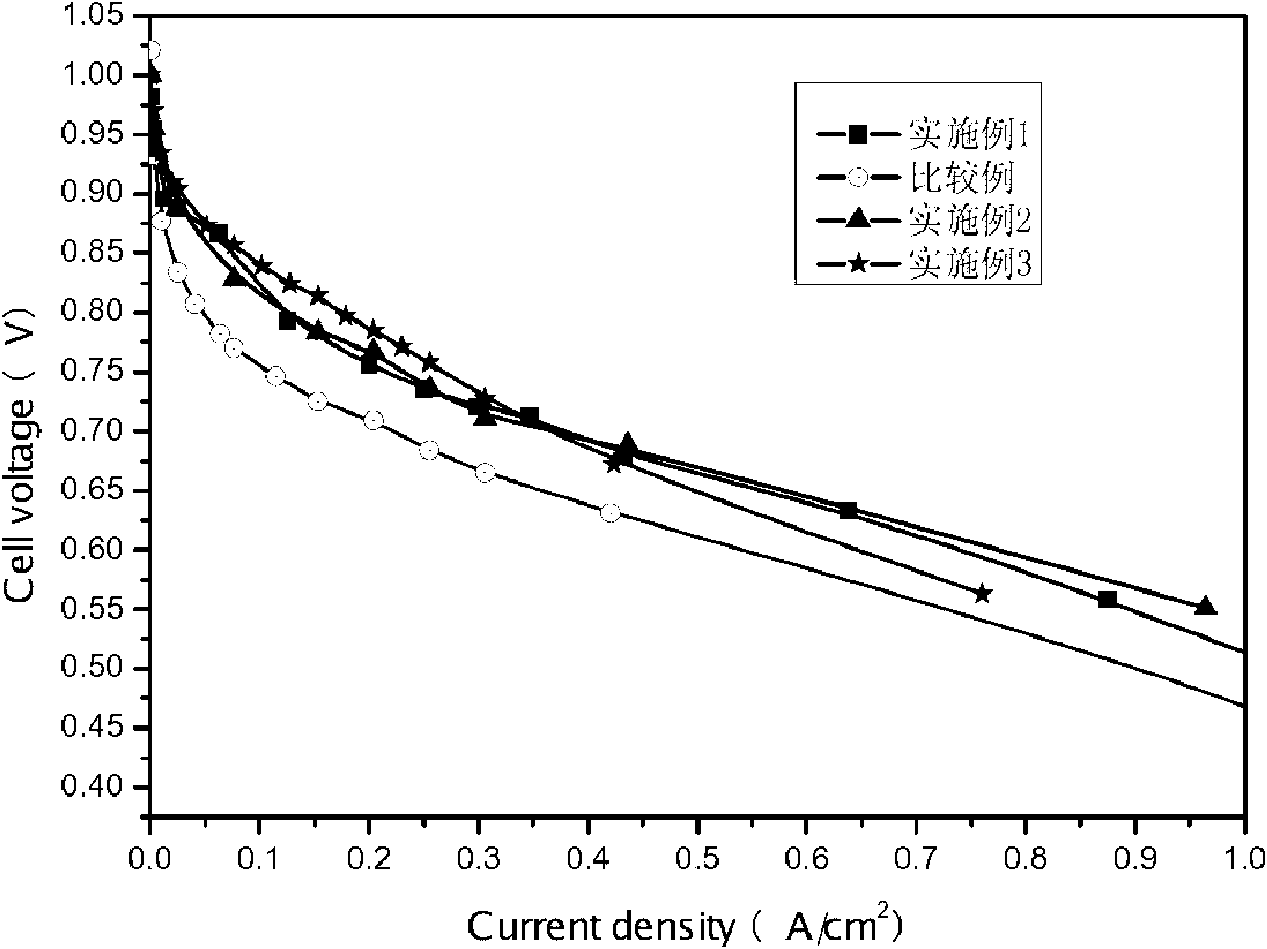

Fuel cell film electrode and preparation method thereof

ActiveCN101557001AImprove flatnessNo slurry penetration issuesCell electrodesCell component detailsPtru catalystMaterials science

The invention discloses a fuel cell film electrode and a preparation method thereof. The film electrode comprises a gas diffusion layer and catalysis layers, wherein, the catalysis layer is of multilayer composite structure and is mainly composed of a catalytic active metal, a water repellent and a conductive ion polymer, wherein, the conductive ion polymer has different contents among the catalysis layers; the multilayer composite structure has at least two layers, wherein, the first layer is a partial hydrophobic catalysis layer while the second layer is a hydrophilic catalysis layer. The invention further discloses a preparation method of the fuel cell film electrode, wherein, the diffusion layer is prepared by the dry method, the inventive film electrode structure has better water-gasmanagement ability, more uniform and stabler mass transfer and excellent electron and proton conducting ability, thus increasing the utilization rate of catalysts and enhancing electric output performance of the fuel cell.

Owner:HANERGY TECH

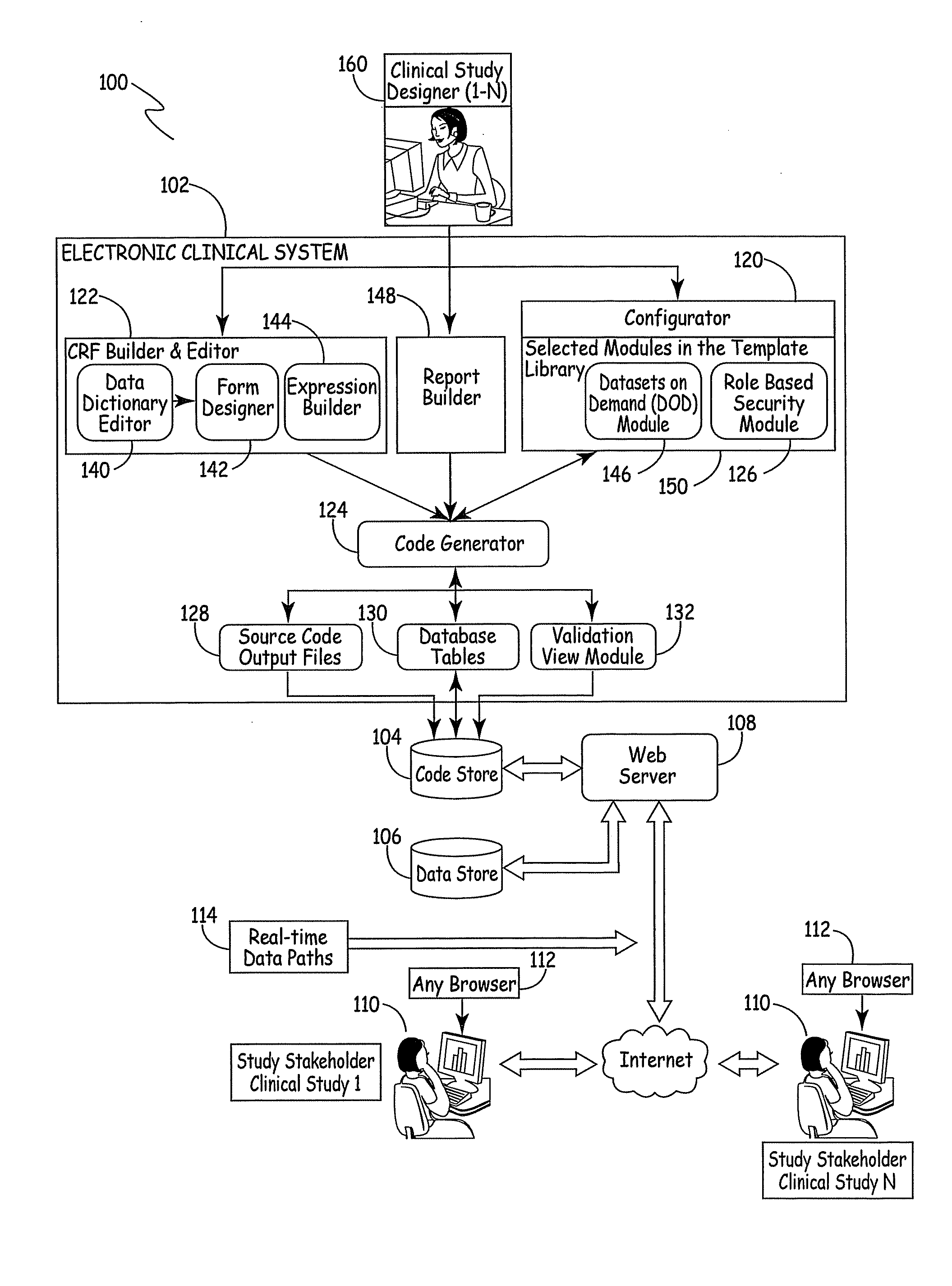

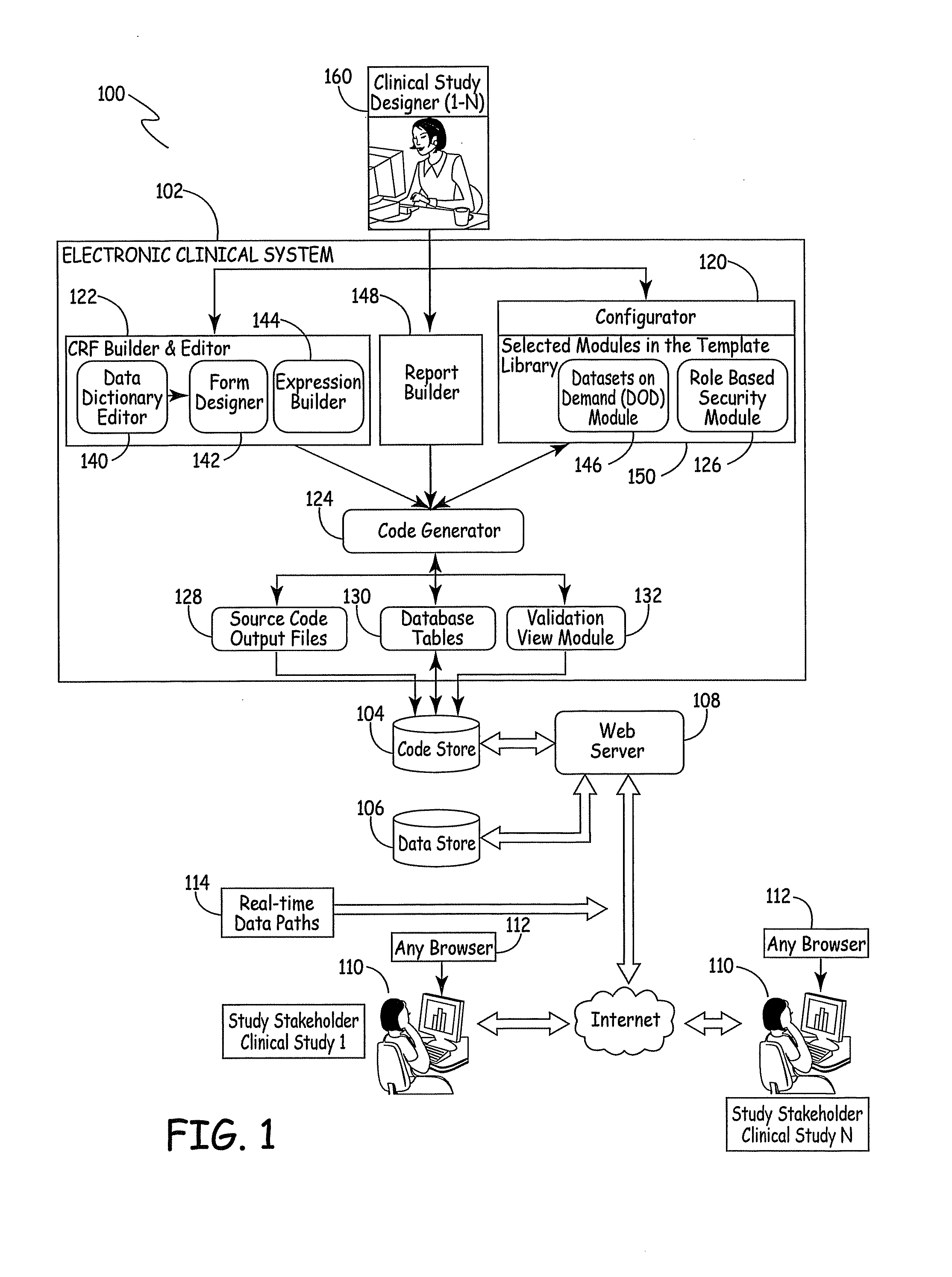

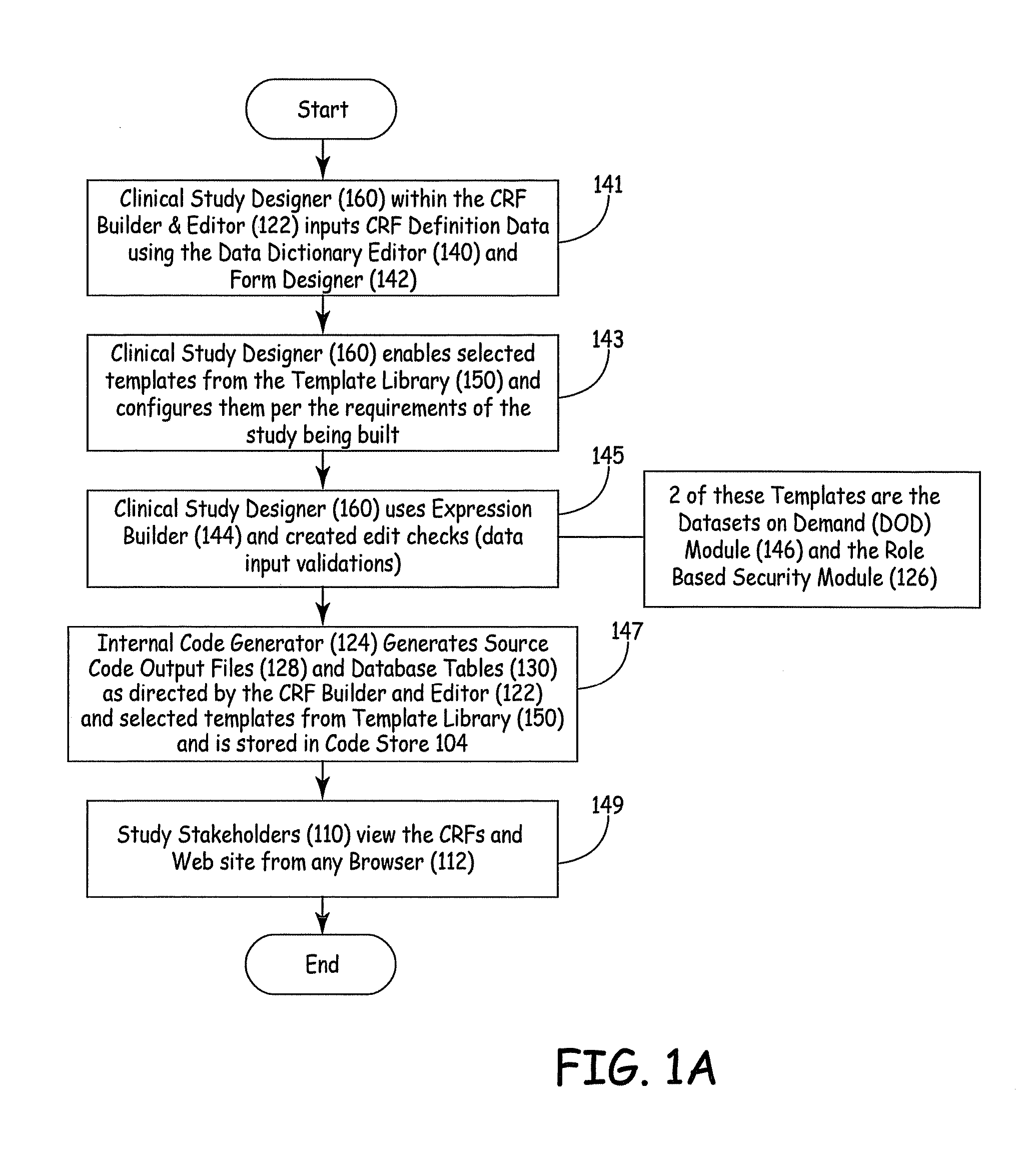

Electronic Clinical Study Site Generation System

InactiveUS20090083703A1OptimizationWell representedComputer-assisted medical data acquisitionOffice automationWeb siteClinical study

An electronic clinical system receives protocol information from a clinical study or trial designer and automatically generates source code modules and a data model for a website used in conducting the study or trial. The source code modules are used in automatically generating and exposing case report forms for use by the clinical sites participating in the study.

Owner:MEDNET SOLUTIONS INC

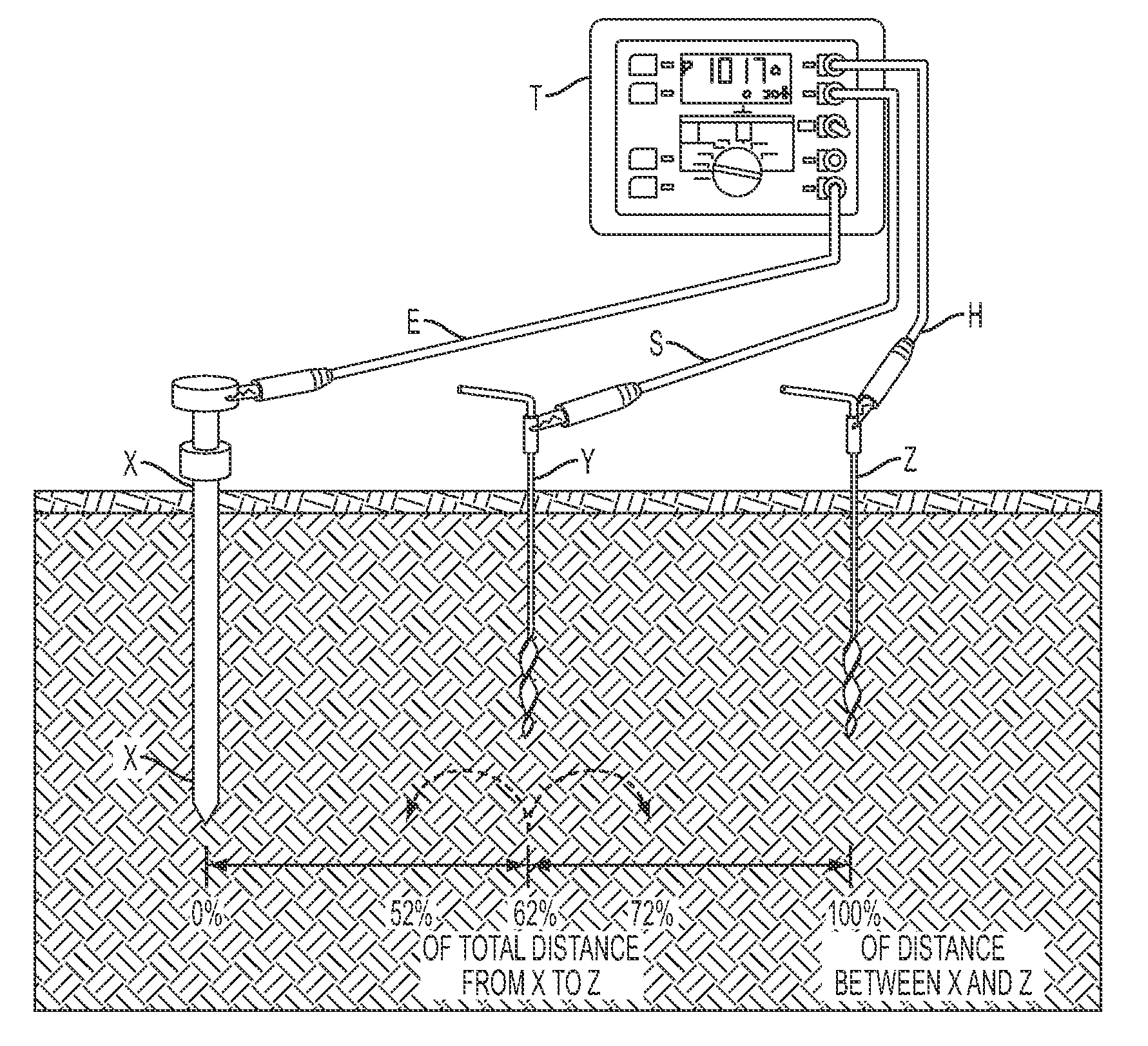

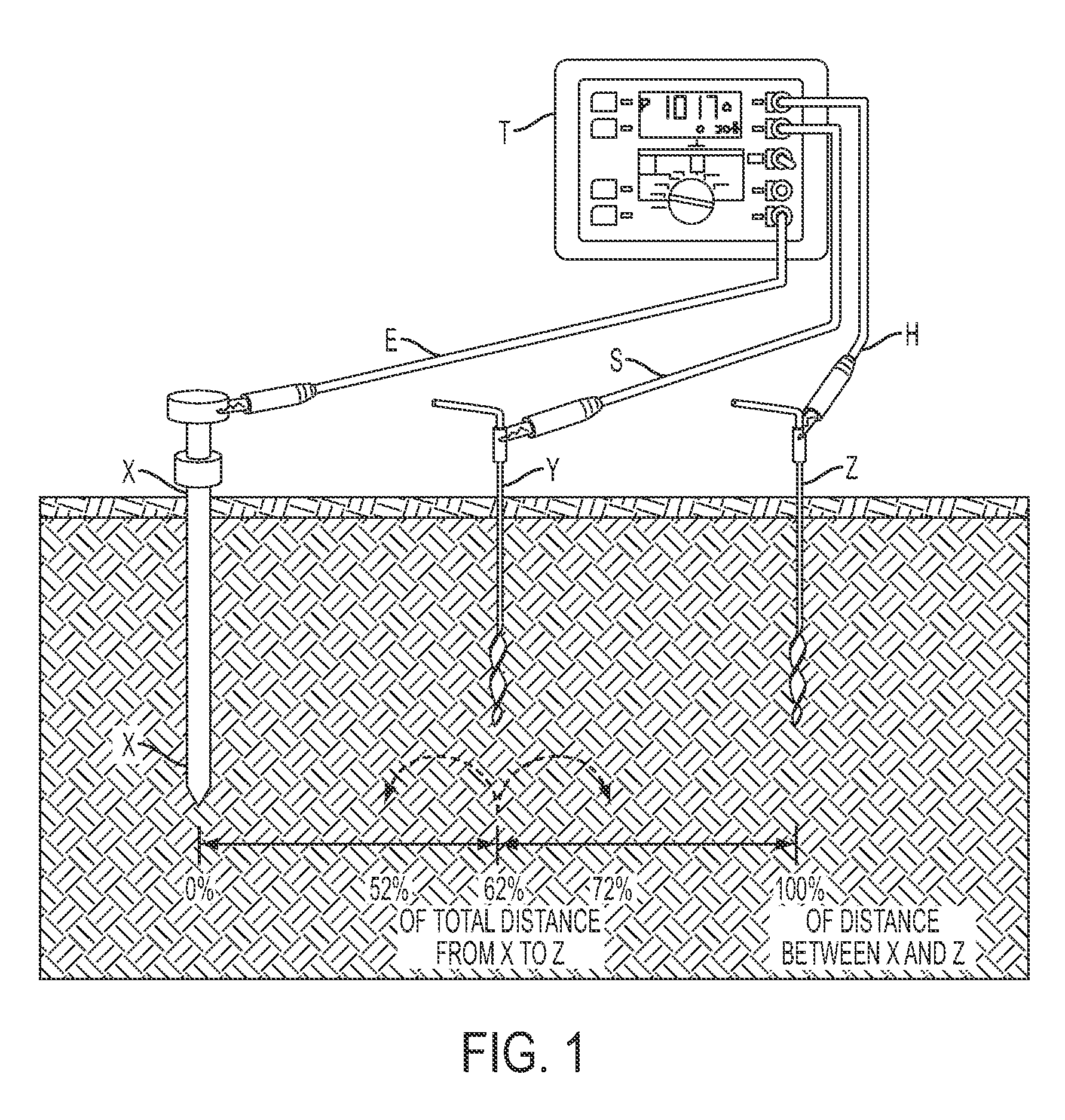

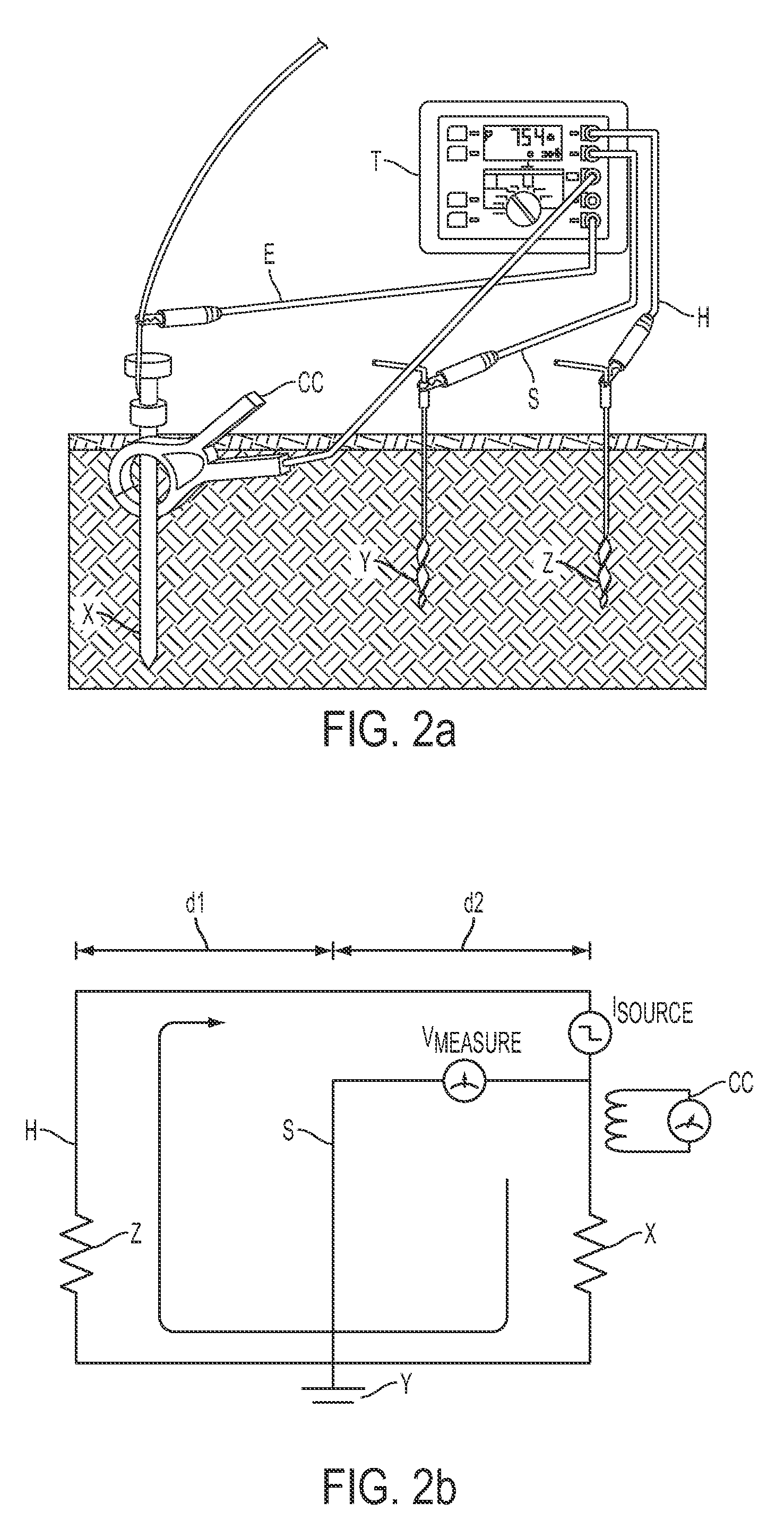

Method of measuring earth ground resistance of a pylon

InactiveUS20110121844A1Extra costExtra laborEarth resistance measurementsElectrical testingElectrical resistance and conductanceEngineering

The present invention relates generally to a facilitated method for accurately measuring the earth ground resistance of a ground rod, in particular a footing of a pylon acting as a ground rod or a ground rod attached to the footings of a pylon, and obtaining an overall value for the resistance of the pylon i.e. all footings in parallel, and all pylons connected in parallel thereto. A method of determining the earth ground resistance of two or more pylon footings is provided according to the present invention, comprising conducting selective measurements of each footing of a pylon consecutively and wherein true values for the resistance of each footing measured are calculated. According to the present invention the testing means is connected directly to two auxiliary electrodes which are placed at predetermined distances from the pylon, and a current measurement means which is placed around a pylon footing in order to measure a the current flowing along the footing.

Owner:JOHN FLUKE MFG CO INC

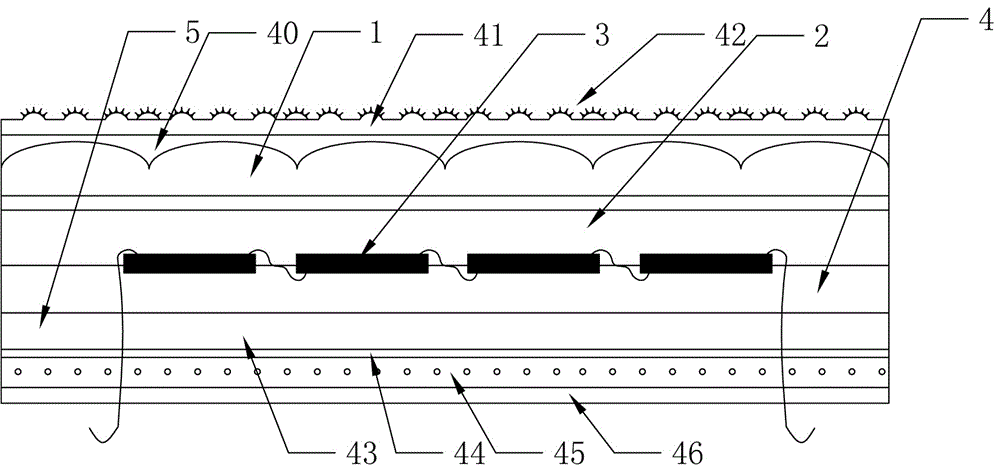

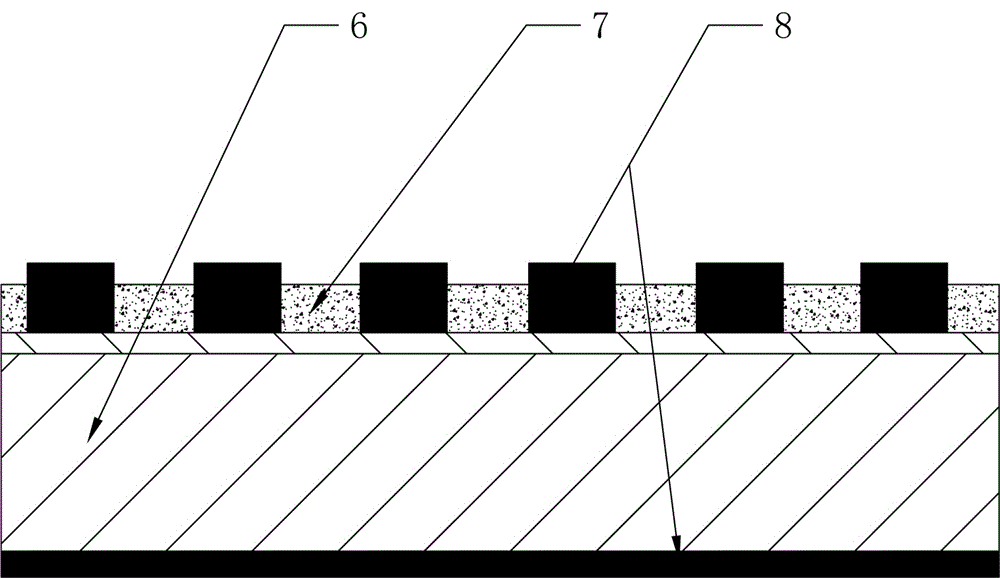

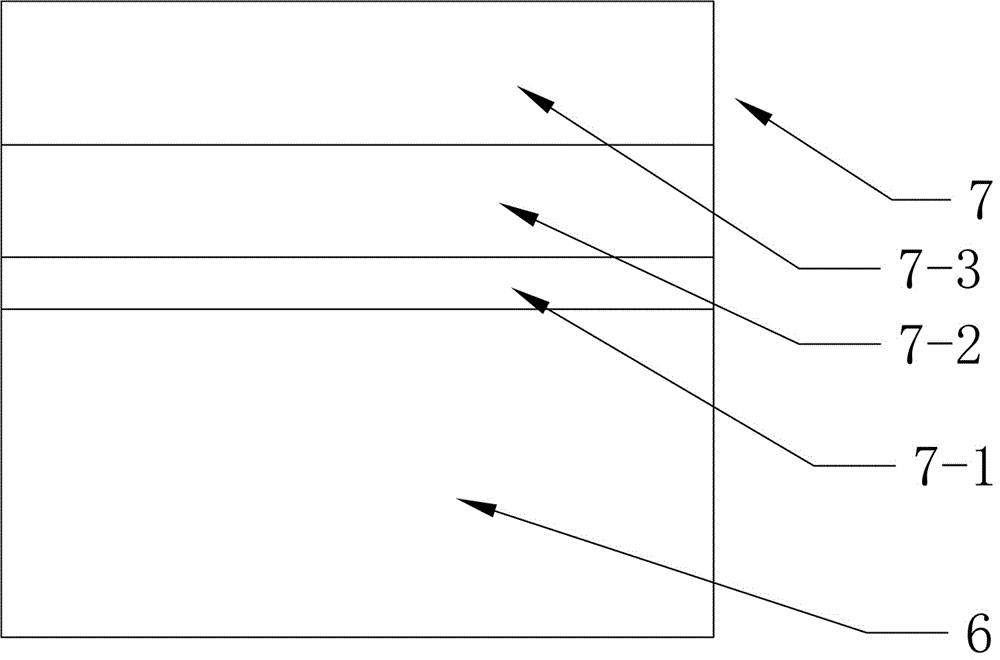

Solar panel component and processing technology

ActiveCN106206758AReduce widthReduce thicknessFinal product manufacturePhotovoltaicsEngineeringPhotoelectric conversion

The invention discloses a solar panel component and a processing technology. The solar panel component mainly comprises components, wherein the components comprise a battery piece, a glass layer, a backboard and a frame on the outer side, wherein the upper end of the battery piece is provided with a silicon nitride passivation antireflection layer; the electrode grid lines of the battery piece are formed in a way that fragmented main grid lines and grouped thin grid lines are arranged in parallel and are connected by auxiliary grid lines; and the frame comprises an integral frame and a detachable frame. By use of the solar panel component and the processing technology provided by the invention, the internal laminated structure and the external frame structure of the solar panel are improved to lower power loss, improve a photoelectric conversion rate and prolong the service life of the solar panel component.

Owner:九州方园新能源股份有限公司

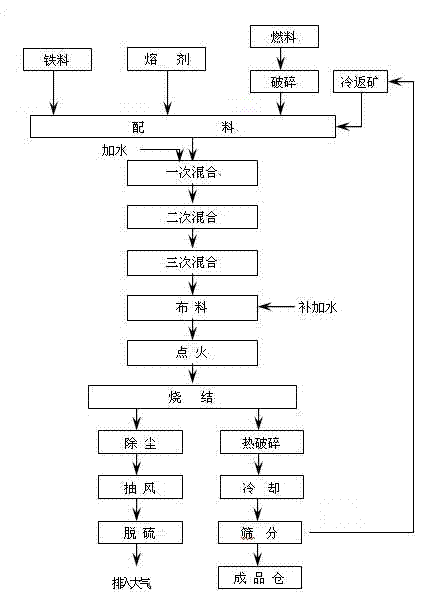

Isothermal sintering process of iron ore powder

The invention, relating to the field of iron ore powder sintering in metallurgy production system, particularly discloses an isothermal sintering process of iron ore powder, comprising uniformly mixing, distributing materials, igniting, sintering by air draft, cooling, and granulating to obtain a finished agglomerate, wherein in the step of distributing materials of a sintering machine, an atomization spray device is used for adding water to the sintering mixture; small water addition is adopted in material distribution of the middle and upper portion of the mixture material layer on the sintering machine, the water content is 6-6.5%; the water content of the lower portion of the material layer is raised by 1.0-2.0%, thus the water content reaches 7-8.5%. According to the invention, under the condition of applying thick material layer sintering technology, the water contents of the middle and lower portions of the sintering material layer are properly raised, the heat exchange efficiency of the sintering material layer is raised, the hot permeability deterioration at different height positions of the mixture in the sintering process is improved, the agglomerate quality deterioration is effectively avoided, the yield and quality of the agglomerate are raised, and the sintering solid burn-up is reduced.

Owner:山东德钧精工机械有限公司

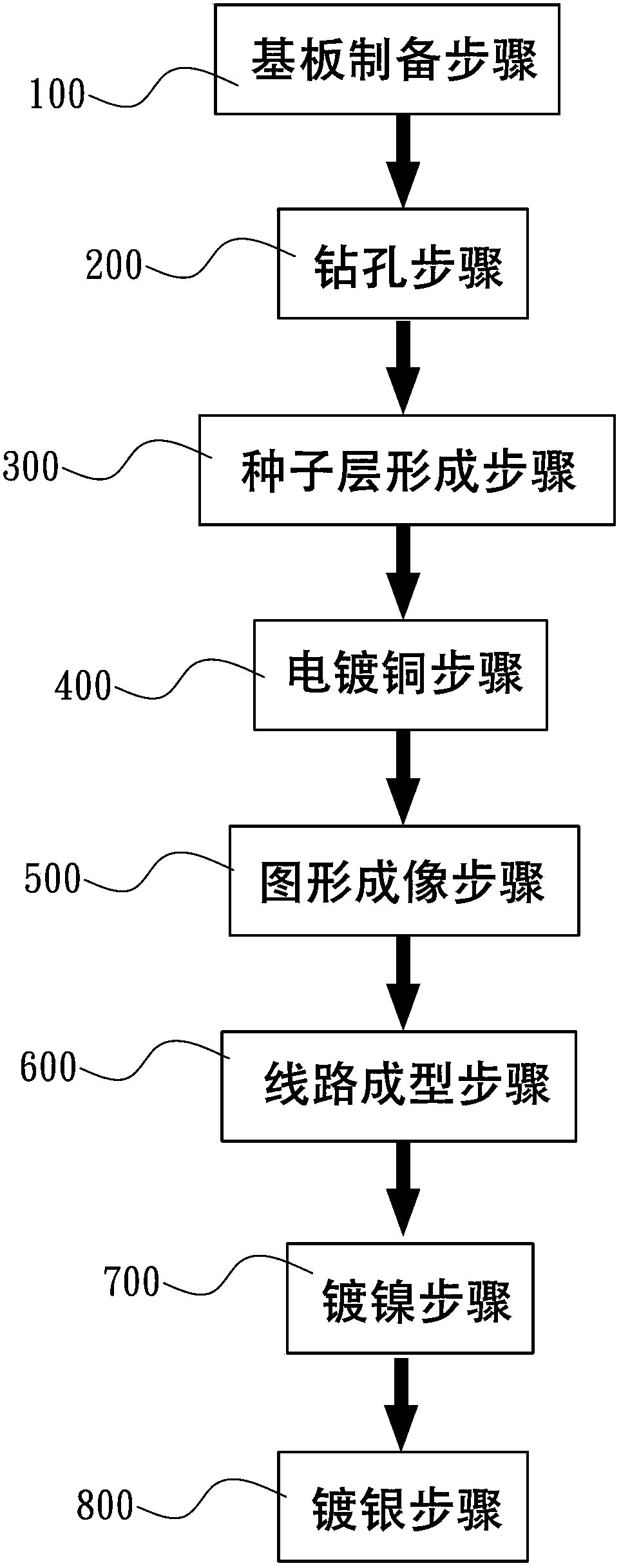

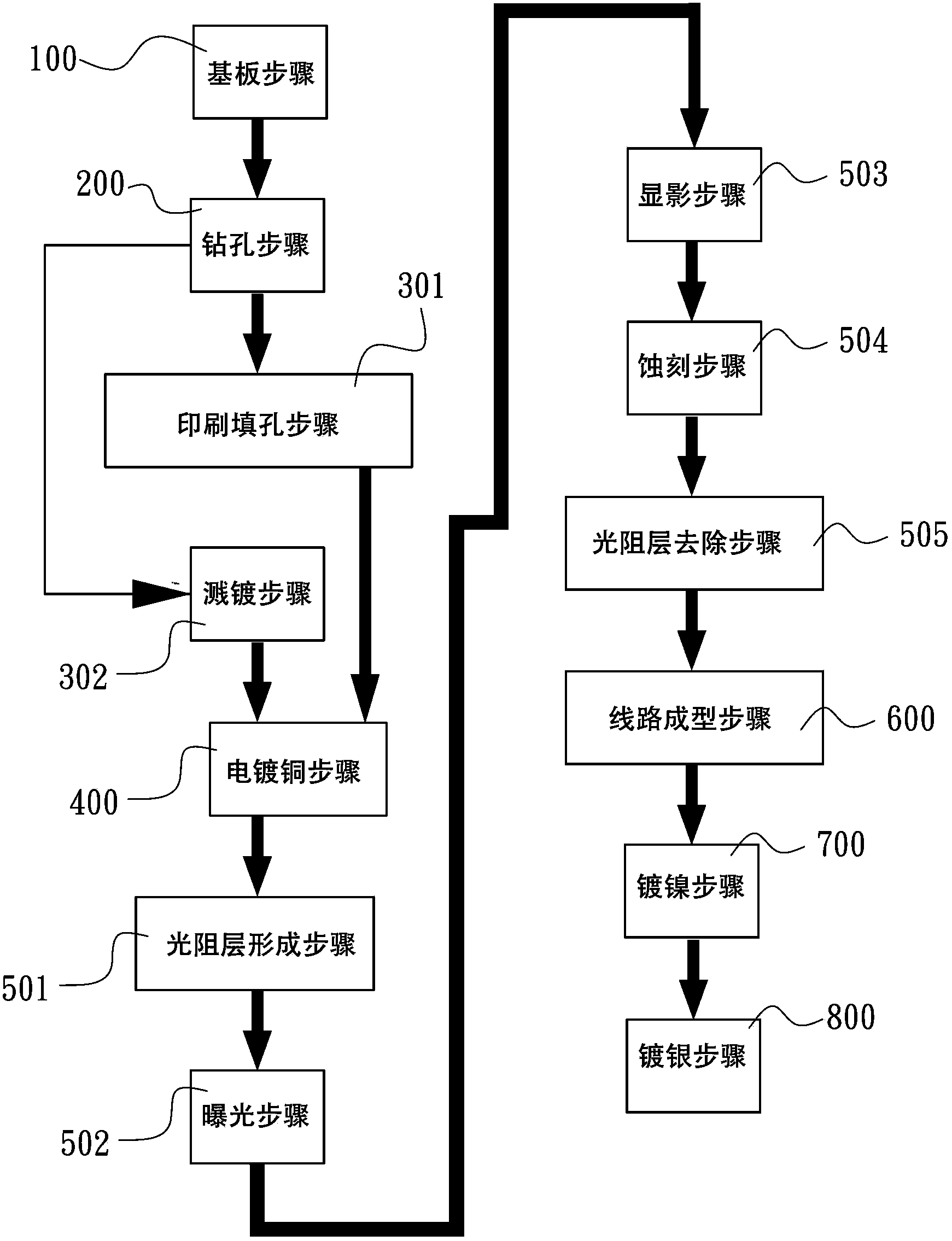

Forming method for conductive jack of ceramic heat dissipation substrate

InactiveCN103429010AGood heat conduction efficiencyLow costConductive pattern reinforcementPrinted element electric connection formationSilver colloidPhysical property

The invention relates to a forming method for a conductive jack of a ceramic heat dissipation substrate. The method comprises the following steps of a substrate preparing step, a hole drilling step, a printing silver colloid hole filling step, a sputtering coating step, an electro-coppering step, a photoresistance layer forming step, an exposing step, a development step, an etching step, a photoresistance layer removing step, a line moulding step, a nickel plating / sputter coating step, and a silver plating step. On the basis of the forming steps, a conductive jack with the advantages of ideal heat conduction efficiency, low cost, and stable physical property can be manufactured.

Owner:TA I TECH

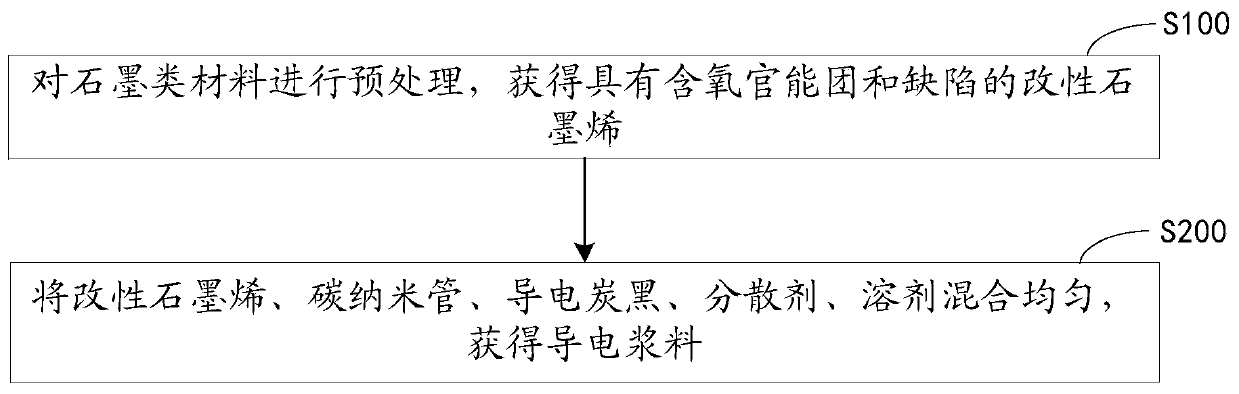

Conductive paste, preparation method and application thereof, and battery

InactiveCN110620237AImprove conduction efficiencyIncrease profitCell electrodesNon-conductive material with dispersed conductive materialConductive pasteCarbon nanotube

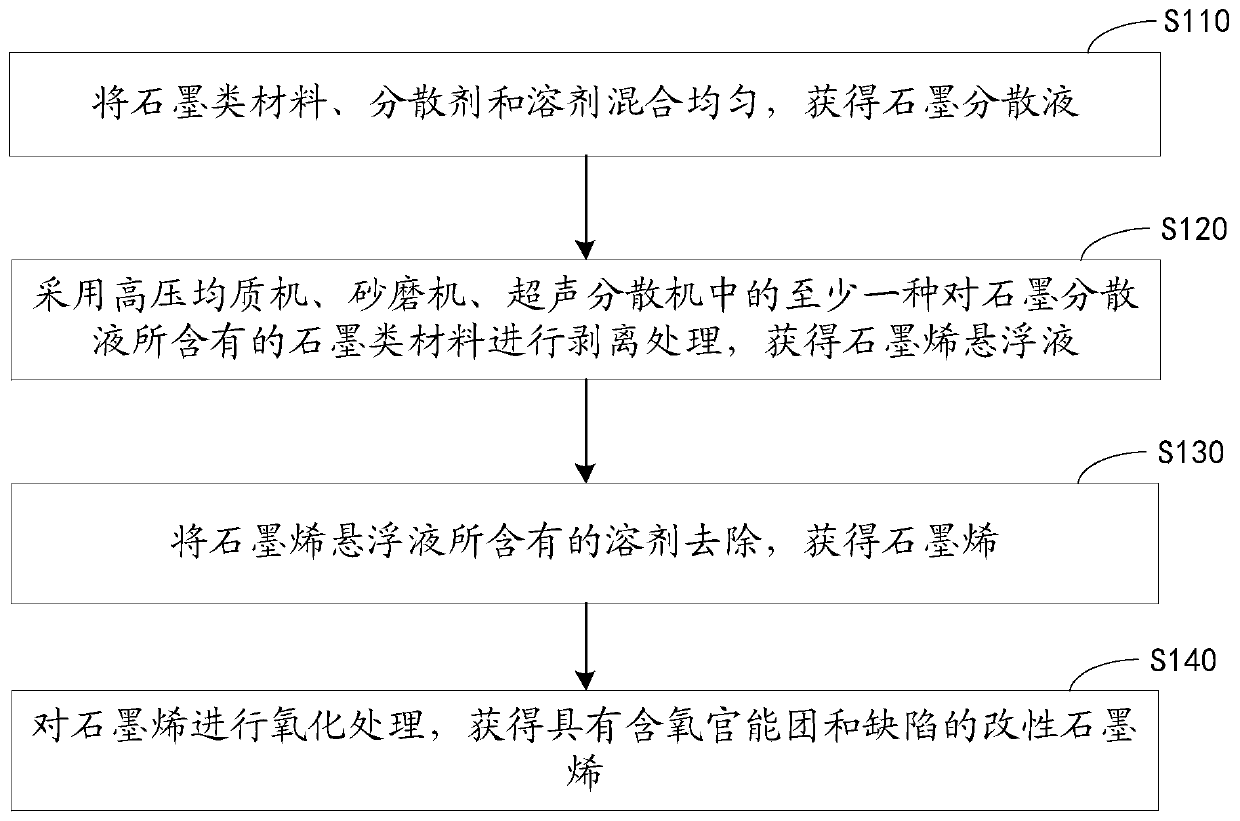

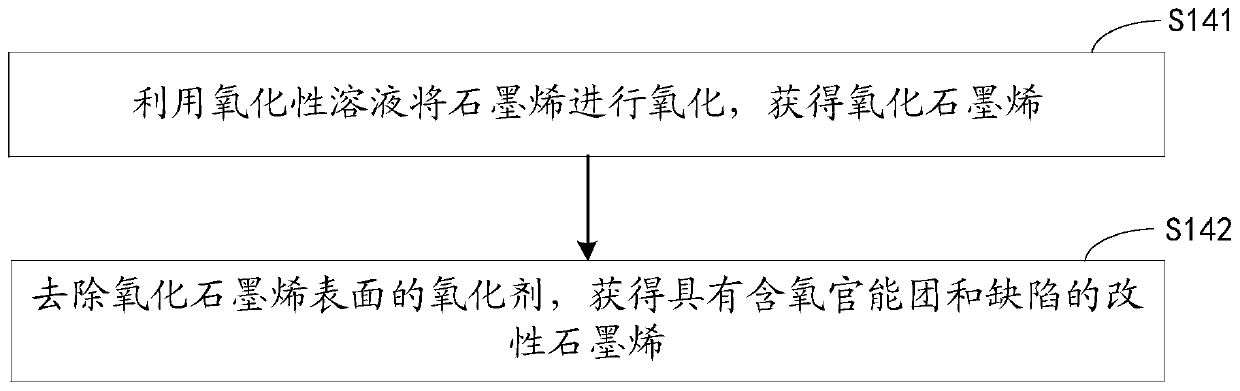

The invention discloses conductive paste, a preparation method and application thereof and a battery, relates to the technical field of batteries, and aims to improve the comprehensive performance ofcharging and discharging of the battery. The conductive paste comprises modified graphene, carbon nanotubes, conductive carbon black, a dispersing agent and a solvent, wherein the modified graphene has oxygen-containing functional groups and defects. The preparation method of the conductive paste comprises the following steps: pretreating a graphite material to obtain modified graphene with oxygen-containing functional groups and defects; and uniformly mixing the modified graphene, carbon nanotubes, conductive carbon black, the dispersing agent and the solvent to obtain the conductive paste. The invention is used for the battery.

Owner:ENN GRAPHENE TECH CO LTD

Energy-saving explosion-proof electric heater for pot

InactiveCN101492114ABreak the mode of temperature rise and viscosity dropSolve the many disadvantages that existLarge containersTank wagonsThermal energyEnergy transfer

The invention relates to an energy saving explosion prevention electric heater for pots, which is provided with a heating device which extends into a pot from the outside of the pot and a flow jet and heat transfer device, wherein the flow jet and heat transfer device consists of a flow jet pump and a flow jet pipe which is connected with the flow jet pump and extends into the pot. A liquid inlet of the flow jet pump is communicated with a liquid storage pot through a liquid suction pipe, and the part of the flow jet pipe extending out of the pot is provided with an electromagnetic scale preventing and scale removing device. The heating device consists of a plurality of electric heating components, and is arranged in a lower position in the liquid storage pot parallel to the flow jet pipe, wherein the electric heating components and the part of the flow jet pipe extending out of the pot are coated with an explosion prevention box, and the inside of the explosion prevention box is provided with a heating monitoring device. The energy saving explosion prevention electric heater can prevent the surface of the electric heater from scaling and coking effectively, and has the advantages of high heat energy transfer speed, high electric heat efficiency, long service life, obvious energy saving effect, good explosion prevention safety performance, convenient operation and maintenance, and the like.

Owner:NANYANG YITONG EXPLOSION-PROOF ELECTRIC CO LTD

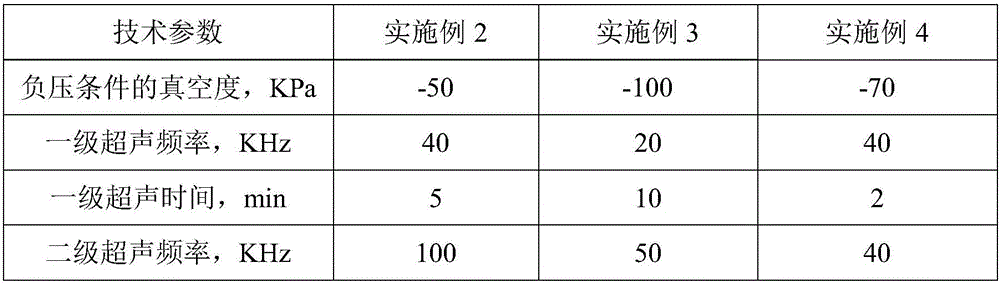

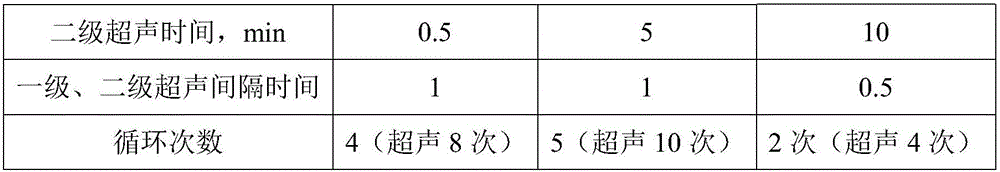

Method for eliminating foreign gas in lithium-ion battery

ActiveCN105742742AImprove conduction efficiencyReduce energy lossFinal product manufactureSecondary cell gas removalLithium electrodeEngineering

The invention discloses a method for eliminating a foreign gas in a lithium-ion battery. The method comprises the following steps: in the formation process or after formation, carrying out ultrasonic treatment on the lithium-ion battery and pumping out escaping foreign gas under the condition of keeping a negative pressure in the lithium-ion battery. According to the method for eliminating the foreign gas in the lithium-ion battery, in the formation process or after formation, an ultrasonic wave is applied to the lithium-ion battery under the condition of the negative pressure; bubbles attached to a pole piece and a membrane surface are broken by the defoaming effect of the ultrasonic wave; and the foreign gas dissolved into an electrolyte escapes in a form of micro-bubbles by the cavitation effect of the ultrasonic wave. According to the method, the gas which is dissolved into the electrolyte and generated in the formation process of the lithium-ion battery and the micro-bubbles which are attached to the pole piece and the membrane and between the pole piece and the membrane can be eliminated; the quality of an SEI film of the lithium-ion battery is improved; and the production efficiency of the lithium-ion battery is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Low smoke antiflaming high shield cable sheath material

ActiveCN103897292AAvoid generatingAvoid catalytic decompositionRubber insulatorsPlastic/resin/waxes insulatorsShielded cableAntioxidant

The invention discloses a low smoke antiflaming high shield cable sheath material. The low smoke antiflaming high shield cable sheath material is prepared from the following raw materials in parts by weight: 45-60 parts of poly vinyl chloride resin base material, 40-50 parts of ethylene-vinyl acetate rubber, 1.5-2.3 parts of multifunctional rare earth thermal stabilizer, 1.5-1.8 parts of zinc borate, 21-24 parts of main plasticizer, 4-6 parts of secondary plasticizer dioctyl sebacate, 2-4 parts of secondary stabilizer calcium stearate, 0.6-0.9 part of antioxidant, 11-13 parts of filing modification material, 0.3-0.5 part of lubricating agent stearic acid, 0.7-1.2 part of conductive carbon black, 3-6 parts of graphite powder and 30-45 parts of magnesium hydroxide. The low smoke antiflaming high shield cable sheath material has excellent antiflaming effect and excellent conductive and shielding properties and can release less smoke and harmful gas when being burned.

Owner:江苏鑫海腾线缆有限公司

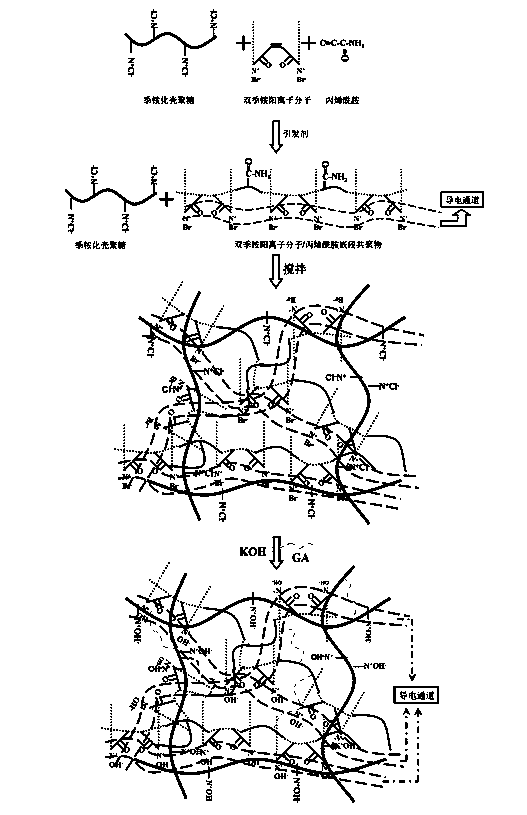

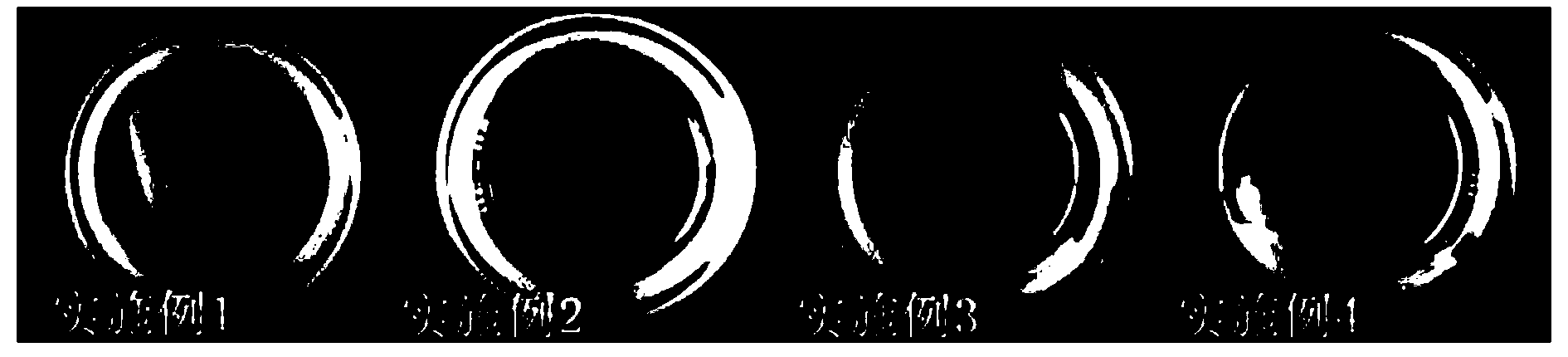

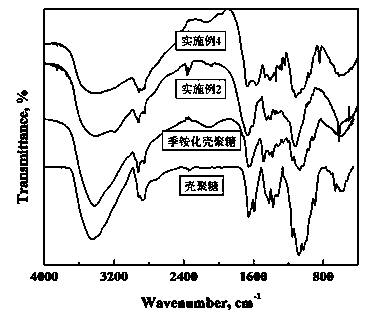

Double-quaternary ammonium positive ion molecule introduced anion-exchange membrane and preparation method thereof

InactiveCN103554526AImprove conduction efficiencyImprove conductivityFuel cell detailsQuaternary ammonium surfactantIon-exchange membranes

The invention belongs to the technical field of fuel cells, and particularly relates to a double-quaternary ammonium positive ion molecule introduced anion-exchange membrane and a preparation method thereof. The double-quaternary ammonium positive ion molecular introduced anion-exchange membrane is a membrane having a full-interpenetrating network structure, which is formed by the crosslinking between amino groups in quaternized chitosan and amino groups in a double-quaternary ammonium positive ion molecule / acrylamide block polymer, the mutual crosslinking of the amino groups in the quaternized chitosan and the crosslinking of the amino groups in the double-quaternary ammonium positive ion molecule / acrylamide block polymer. The preparation method comprises the following steps: preparing the quaternized chitosan, then introducing double-quaternary ammonium positive ion molecules and preparing the membrane. The double-quaternary ammonium positive ion molecule introduced anion-exchange membrane has the advantages that a reverse U-shaped channel formed in an anionic membrane structure is used for constructing an ordered and continuous microphase zonal structure for OH<-> migration and facilitates the improvement of the conduction efficiency of OH<-> in the solution, the conductivity of the OH<-> is improved while the ion exchange capacity and the moisture content are not increased, and the mechanical property is improved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

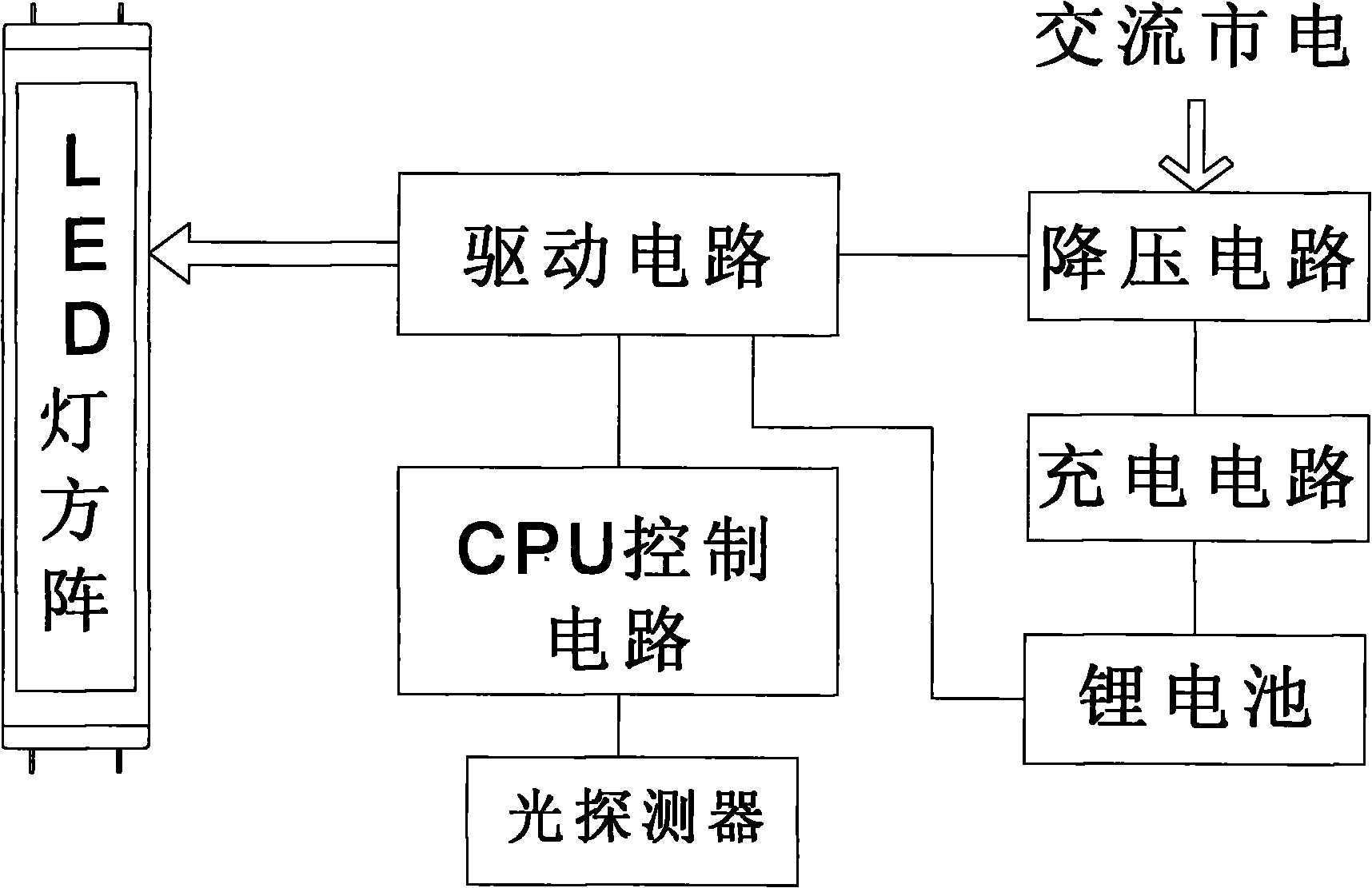

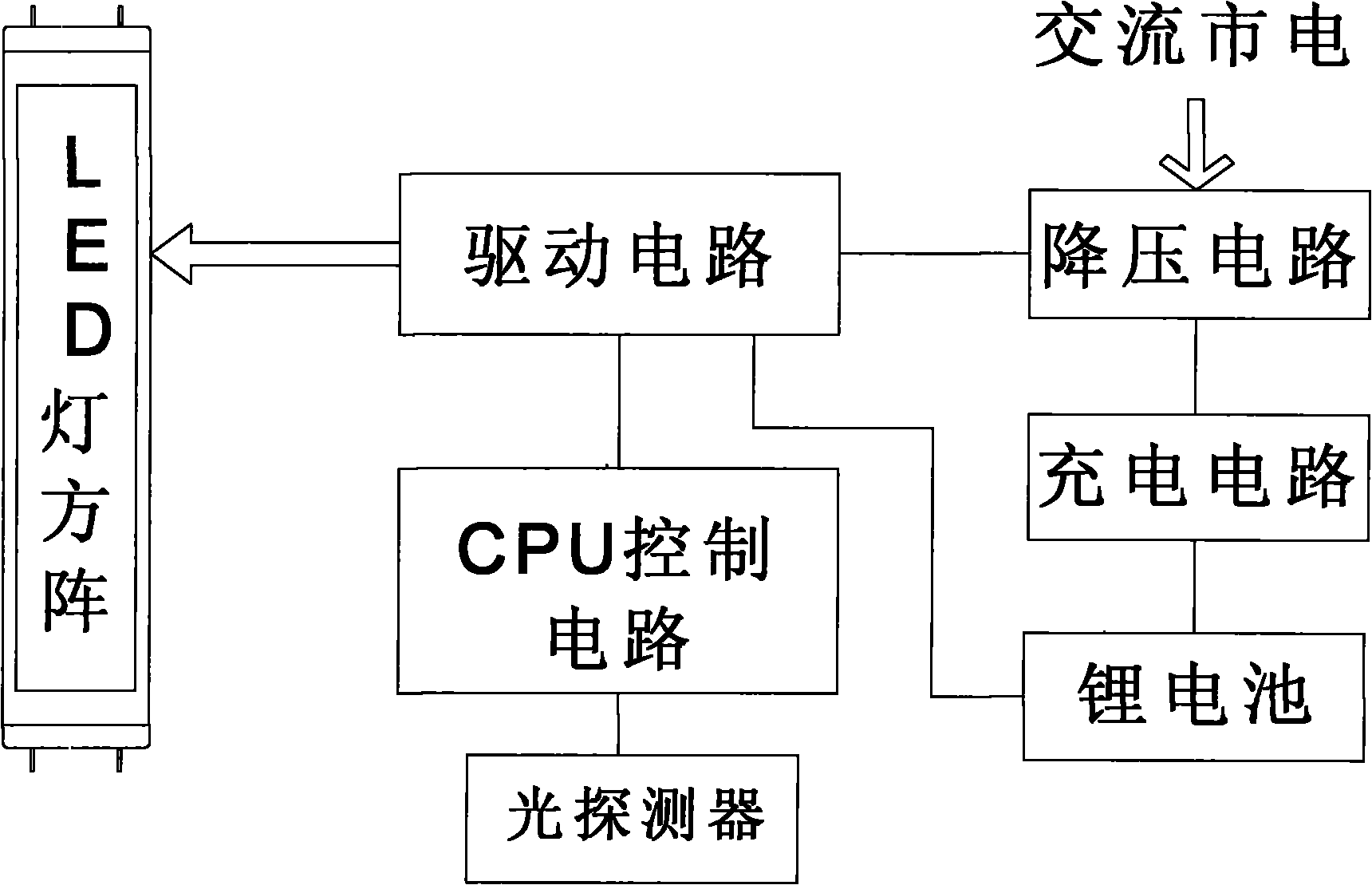

Energy-saving LED fluorescent lamp device

InactiveCN101769450AIncrease savingsHigh light conversion efficiencyBatteries circuit arrangementsPoint-like light sourceControl signalEngineering

The invention discloses an energy-saving LED fluorescent lamp device with better energy-saving effect, which comprises an LED lamp, a PCB, a lamp tube, a fluorescent lamp cap, a fluorescent lamp holder electrode and a circuit system, wherein the circuit system of the LED fluorescent lamp device comprises a voltage reduction circuit, a drive circuit, a CPU control circuit and a light detector, ambient light information is collected by the light detector and sent to a CPU, the intensity of the ambient light information is judged by the CPU, and then a corresponding control signal is output to the drive circuit to regulate the size of a constant current value, i.e. regulating the light brightness of the LED lamp, thereby the purposes of automatically regulating the light brightness of the LED lamp, saving energy and lowering consumption are achieved. Through the scheme, the light brightness of the LED lamp can be automatically regulated according to environments under the control of the CPU control circuit, and the energy saving ratio can be increased from 60 percent to 80 percent.

Owner:李艳

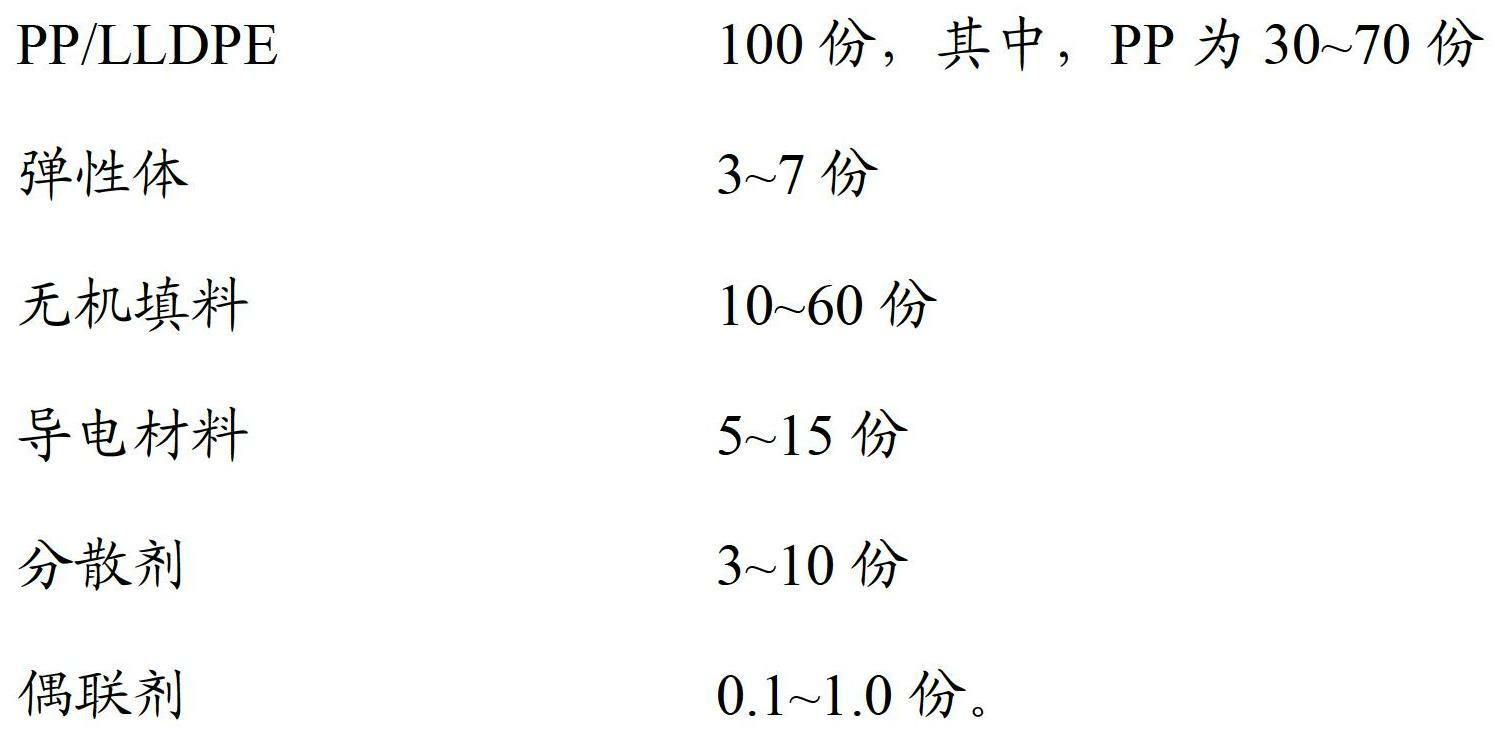

Anti-static alloy composite material and preparation method thereof

The invention discloses an anti-static alloy composite material and belongs to the technical field of high polymer materials. The anti-static alloy composite material comprises the following components of, by weight, 100 parts of polypropylene (PP) / linear low density polyethylene (LLDPE), 3-7 parts of elastomers, 10-60 parts of inorganic fillers, 5-15 parts of conducting materials, 3-10 parts of dispersing agents and 0.1-1.0 parts of coupling agents, wherein the PP is 30-70 parts. The invention further discloses a preparation method of the anti-static alloy composite material, which includes the following steps of mixing the PP, the LLDPE, the elastomers, the inorganic fillers, the dispersing agents and the coupling agents in a mixer, and adding the mixtures into a hopper of an extruder; adding the conducting materials into a feed barrel of the extruder form a side feeding port of the feed barrel of the extruder; subjecting the mixtures to plasticization, vacuum-pumping exhausting, extruding, cooling and granule-cutting, and obtaining the anti-static alloy composite material. According to the anti-static alloy composite material and the preparation method thereof, the problems that prepared products are not provided with performances of warpage prevention, low temperature resistance and anti-stativity on the premise of having basic mechanical properties and heat resistance when the PP, the LLDPE and the elastomers are mutually added in prior art are solved.

Owner:ZHEJIANG SANWEI ANTI ELECTROSTATIC EQUIP

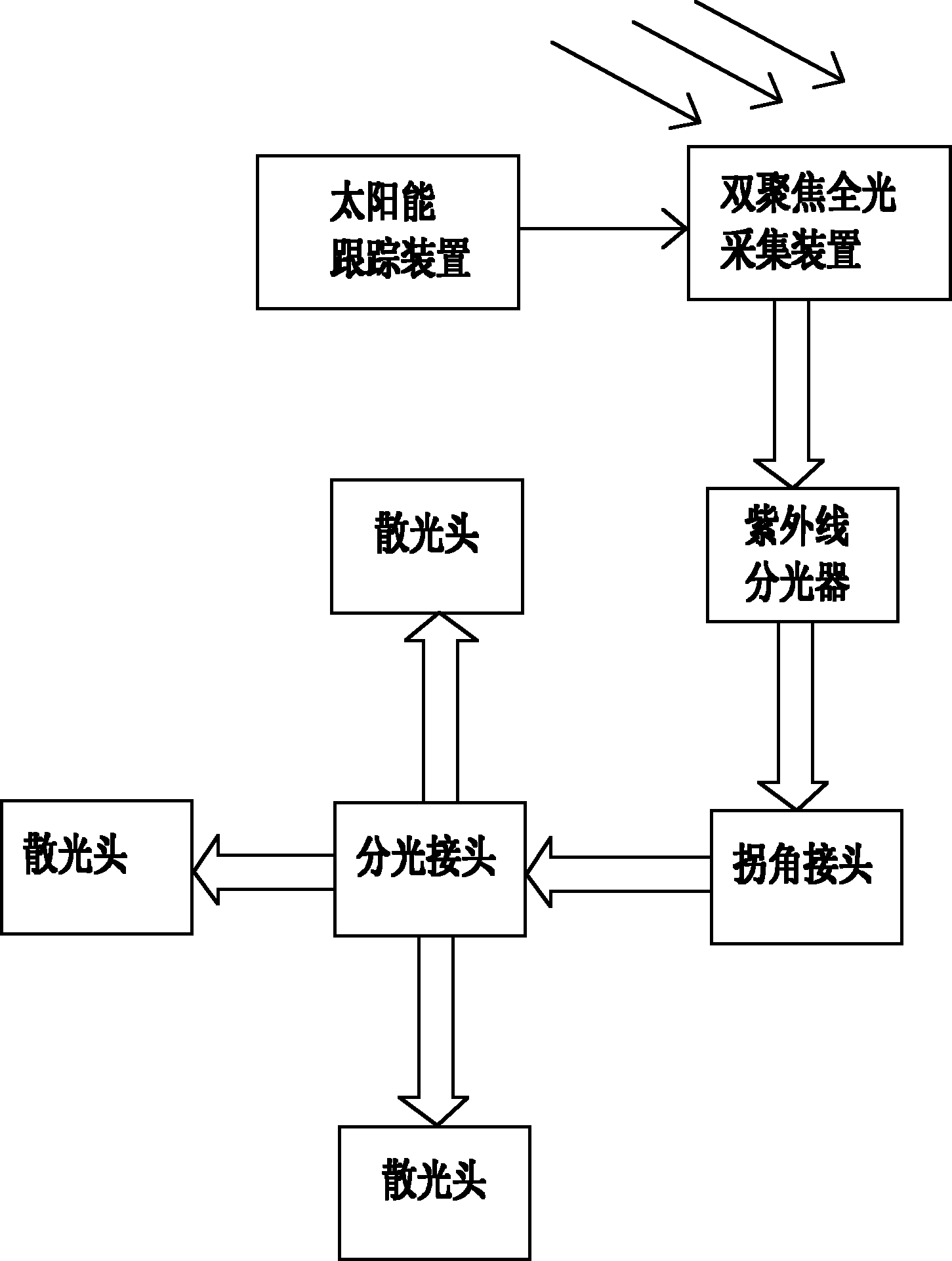

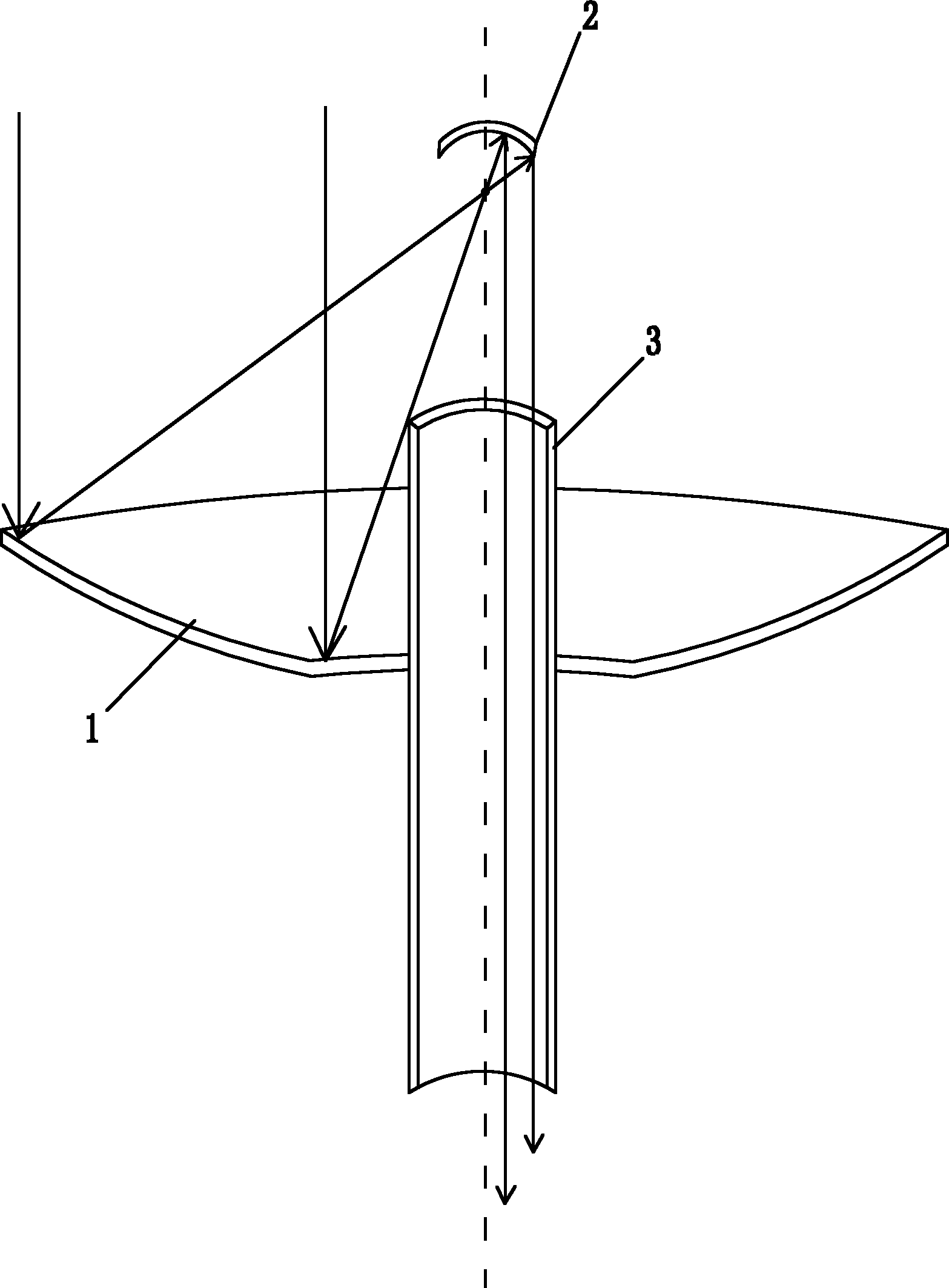

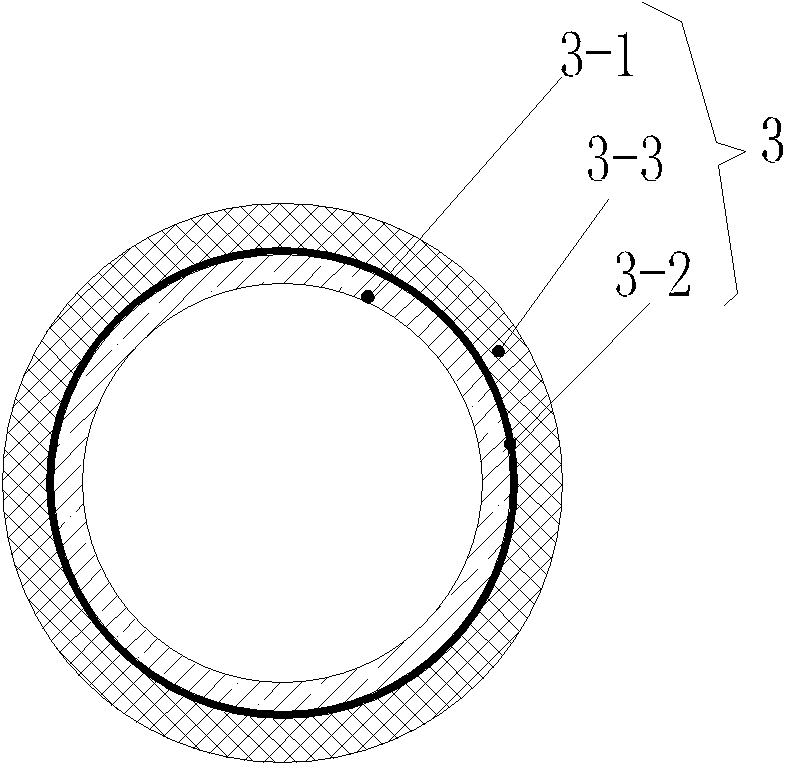

Sunlight full-light guidance lighting system

InactiveCN101922672ALow costFlexible installationMechanical apparatusLight guides for lighting systemsHigh energyLight guide

The invention relates to a sunlight full-light guidance lighting system, which comprises a dual-focus full-light collection device. The dual-focus full light collection device comprises an annular parahboloidal mirror, a spherical concave mirror and a full-light light guide pipe; sunlight is reflected and focused by the annular parahboloidal mirror and reflected again by the concave mirror and enters the full-light light guide pipe; and the full-light light guide pipe comprises a glass tube, a reflecting mirror film arranged on the outer wall of the glass tube, and a plastic sleeve in close fit with the outer periphery of the reflecting mirror film. The sunlight full-light guidance lighting system has the advantages of low manufacturing cost and flexible installation, can be conveniently independently installed or combined into a movable type, a wall mounting type, an eave mounting type and an overhead mounting type according to different requirements for lighting, sunshine and lighting of application places, is particularly suitable for high-power and high-energy level light density sunlight lighting systems in different fields such as civil, public and underground projects, industry, agriculture, planting and breeding.

Owner:CHANGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com