Optical module assembly with inner heat dispassion channel and composite heat dispassion structure thereof

A technology of heat dissipation channel and heat dissipation structure, which is applied in the coupling of optical components, optical waveguides, light guides, etc., can solve the problem of large emission power and overall power consumption, no existing heat dissipation channels in the heat dissipation path, and can not meet the heat dissipation requirements of high-speed broadband optical modules, etc. problem, to achieve the effect of improving the heat dissipation efficiency and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

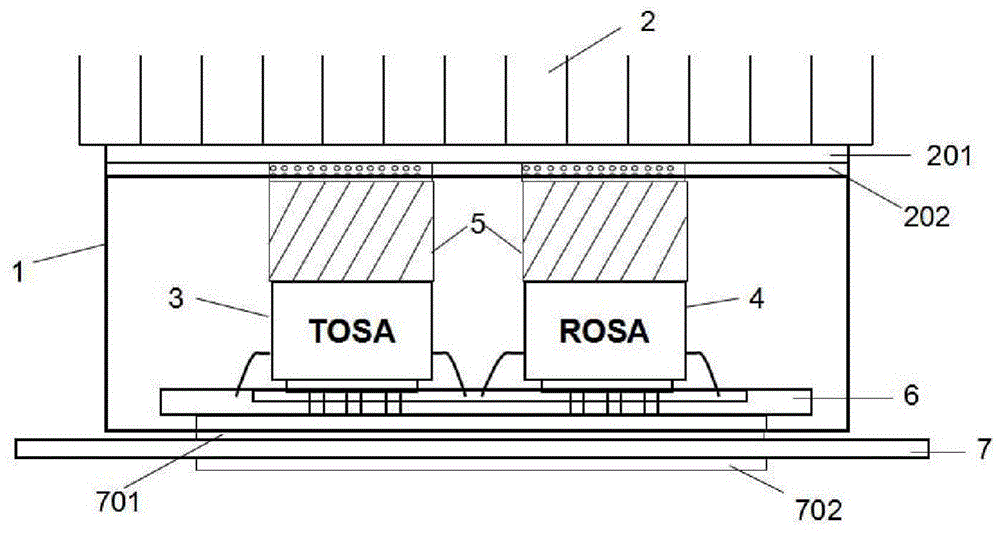

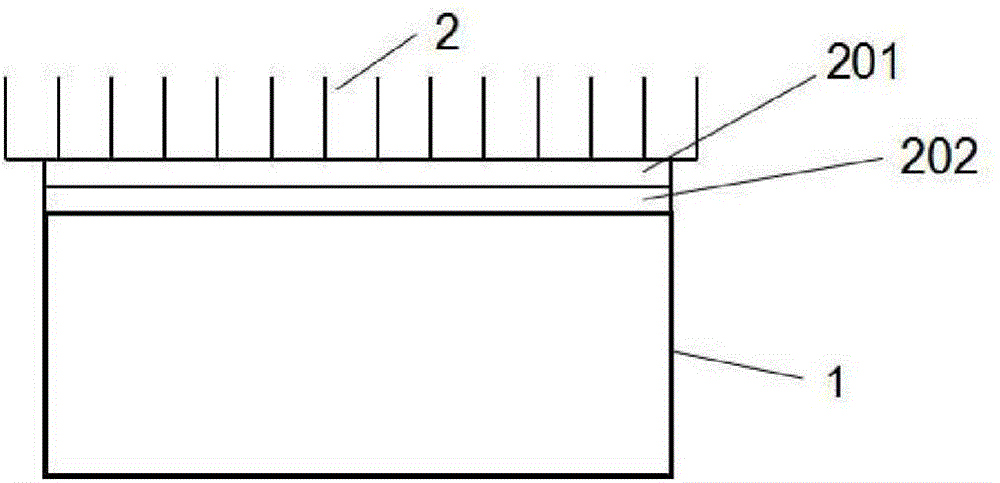

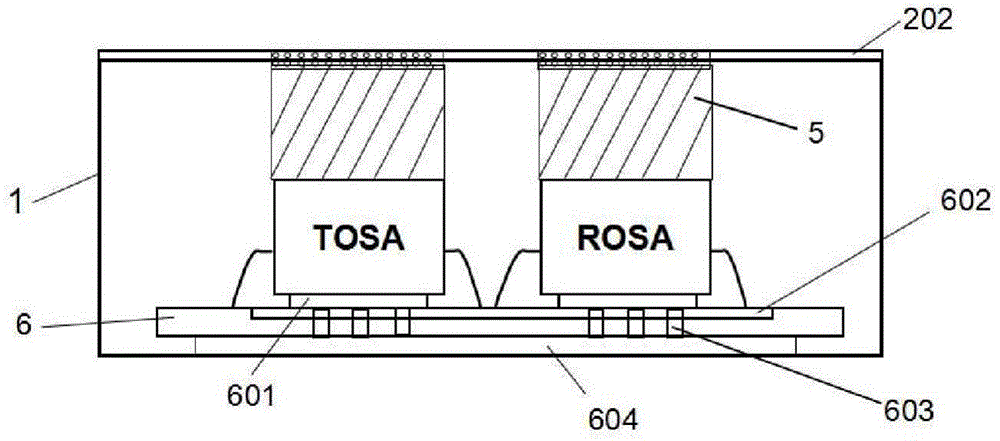

[0027] figure 1 As shown, heat conduction units are arranged between the internal components of the module, between the components and the module package shell, and between the module package shell and the external structural parts to form two upper and lower heat dissipation channels. The heat generated inside the module passes through the heat conduction unit from the inside Conduction to the top and bottom focuses on solving the heat dissipation problem between the internal components of the module. By adding a heat conduction unit inside the module, the heat generated by the heat source is quickly and evenly conducted upwards and downwards, thereby improving the overall cooling effect of the module.

[0028] combine figure 1 and image 3 As shown, the composite heat dissipation structure includes an optical module packaging shell 1, a TOSA transmitting component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com