Patents

Literature

94results about How to "Good heat conduction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

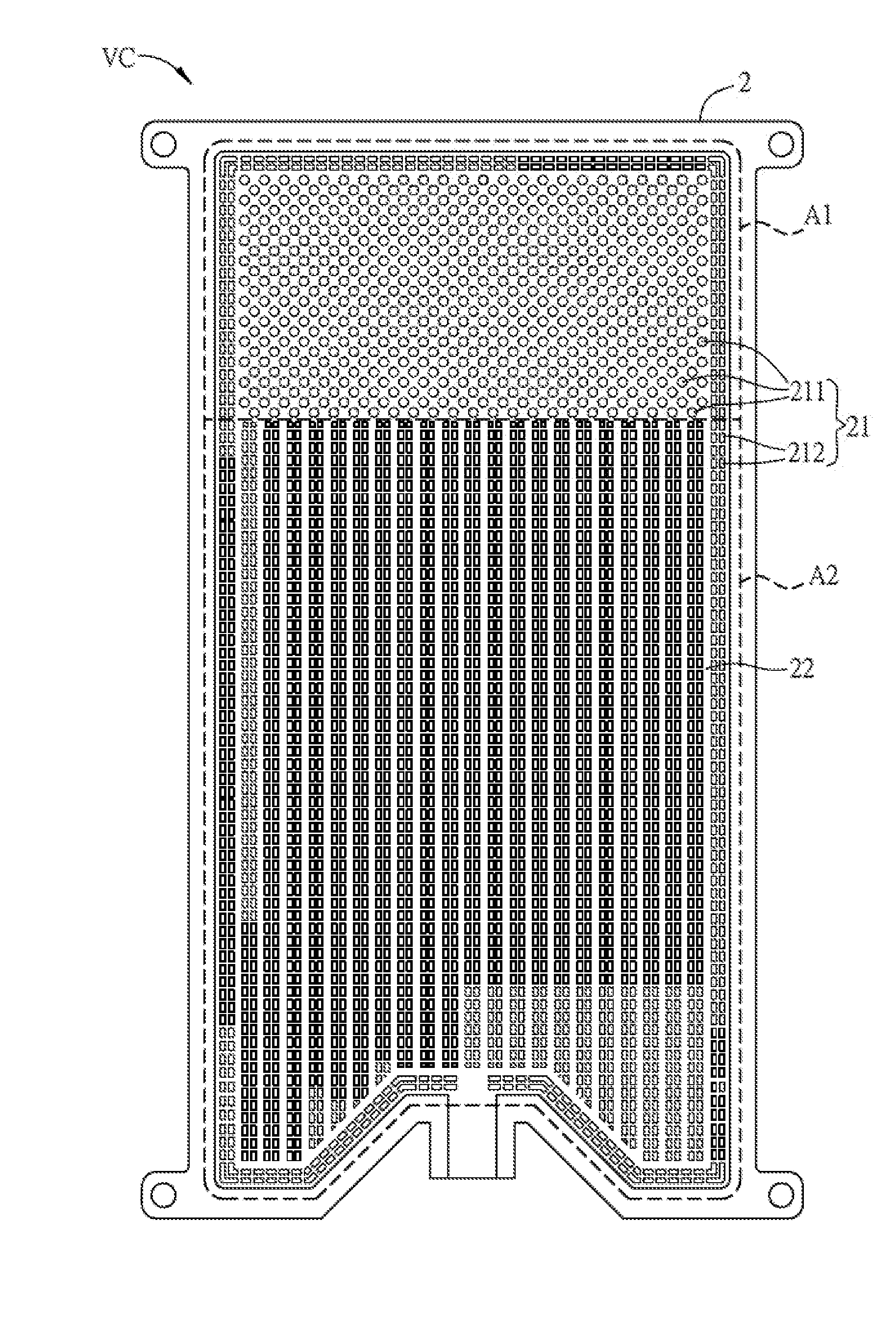

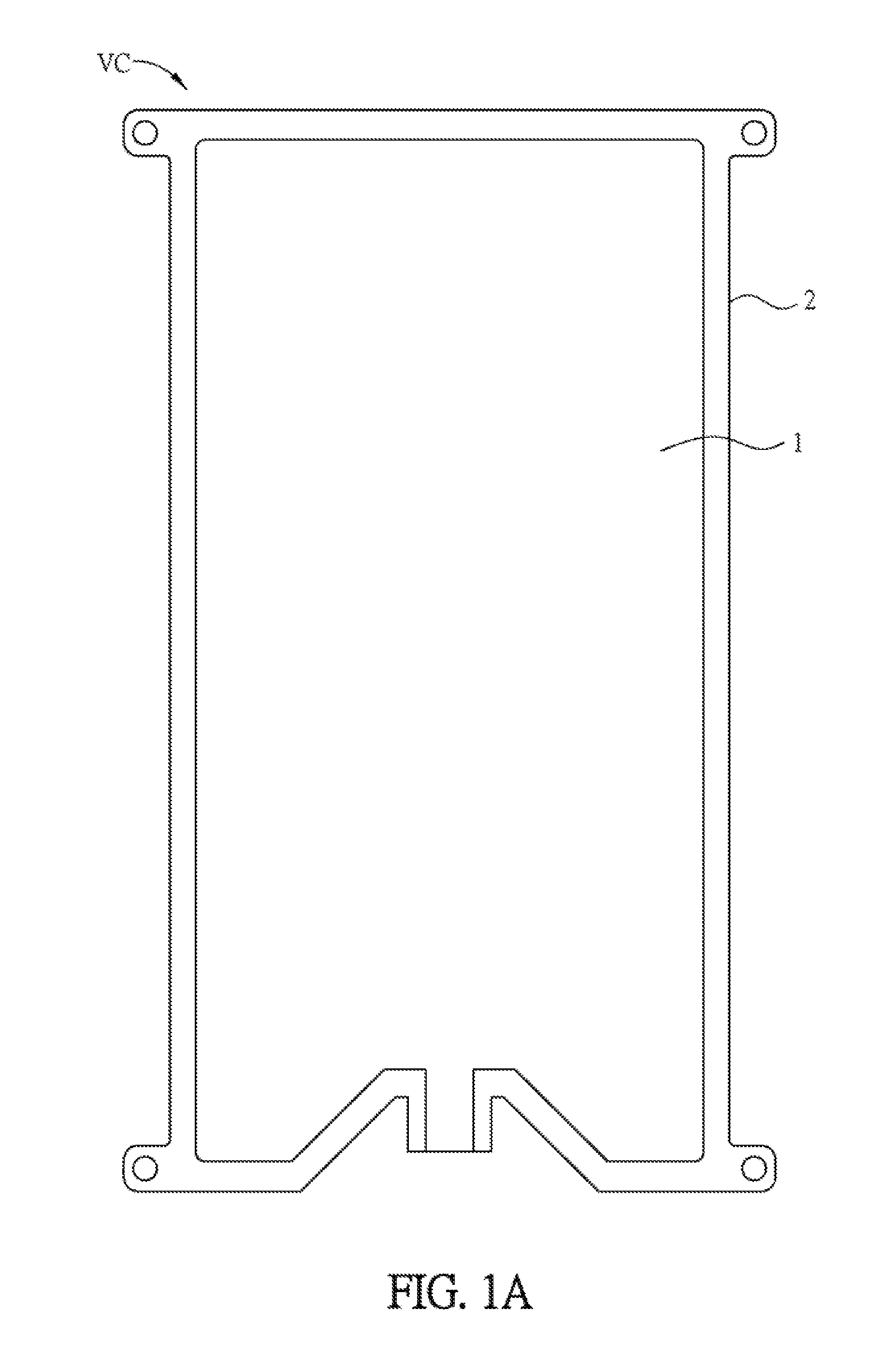

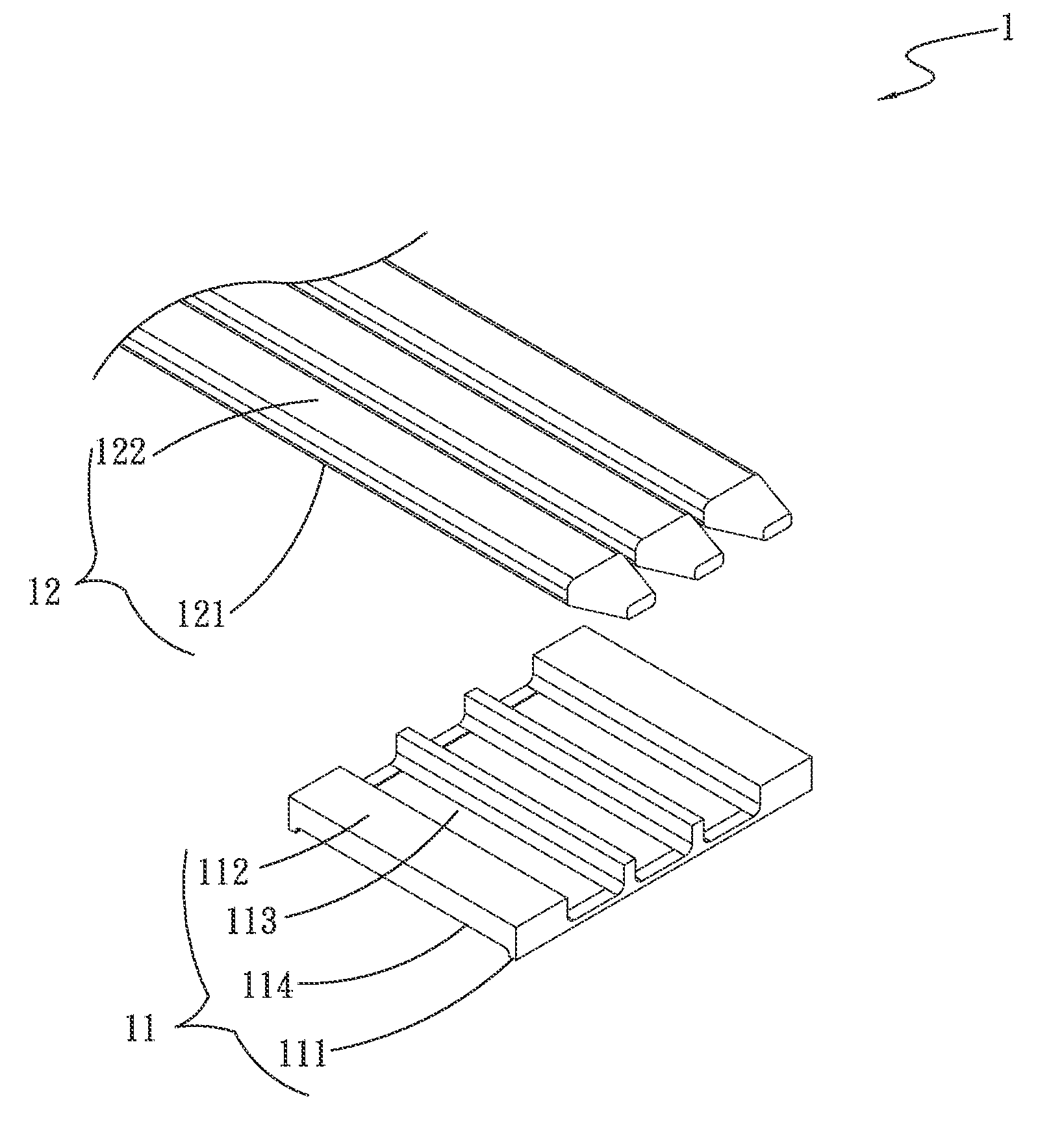

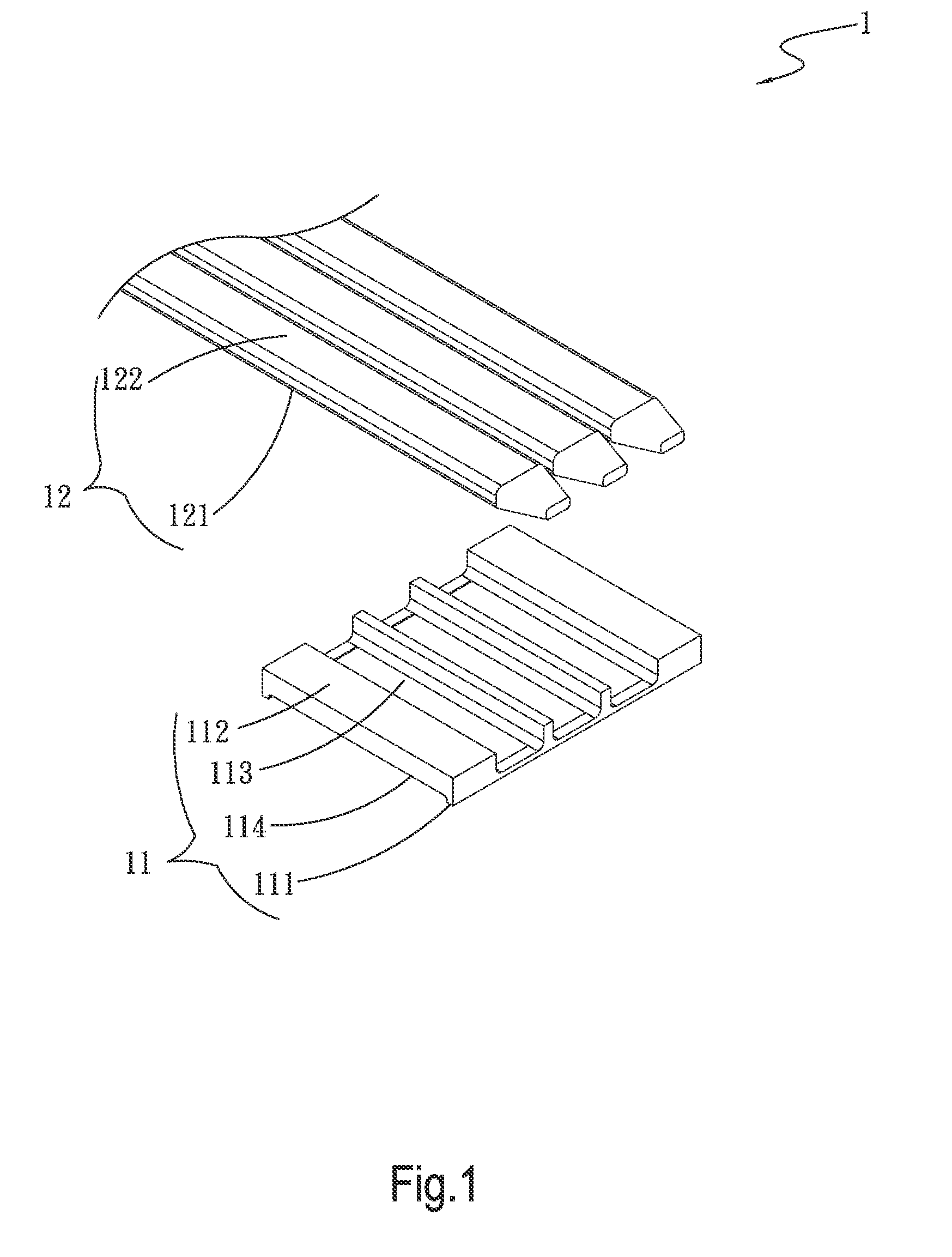

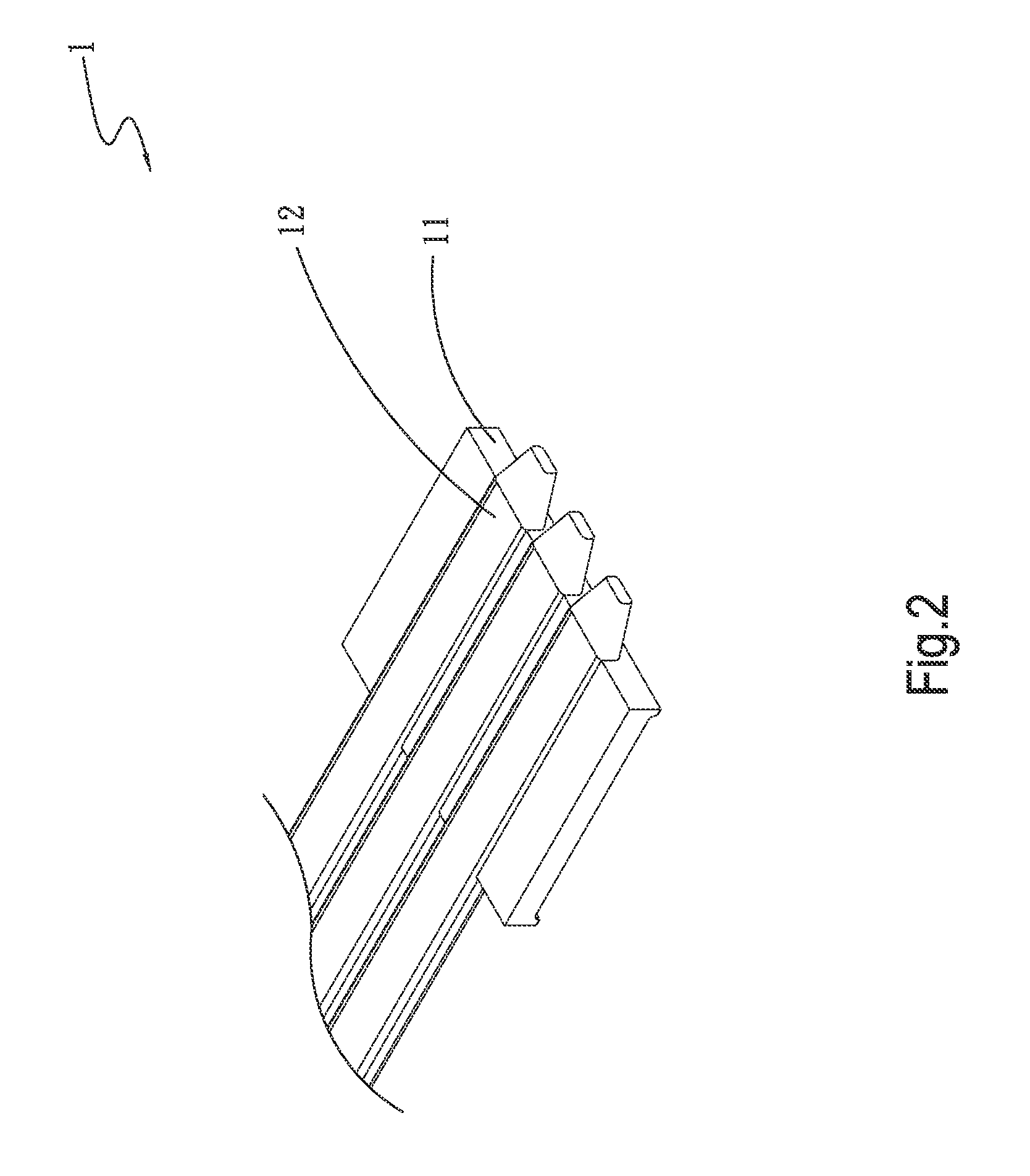

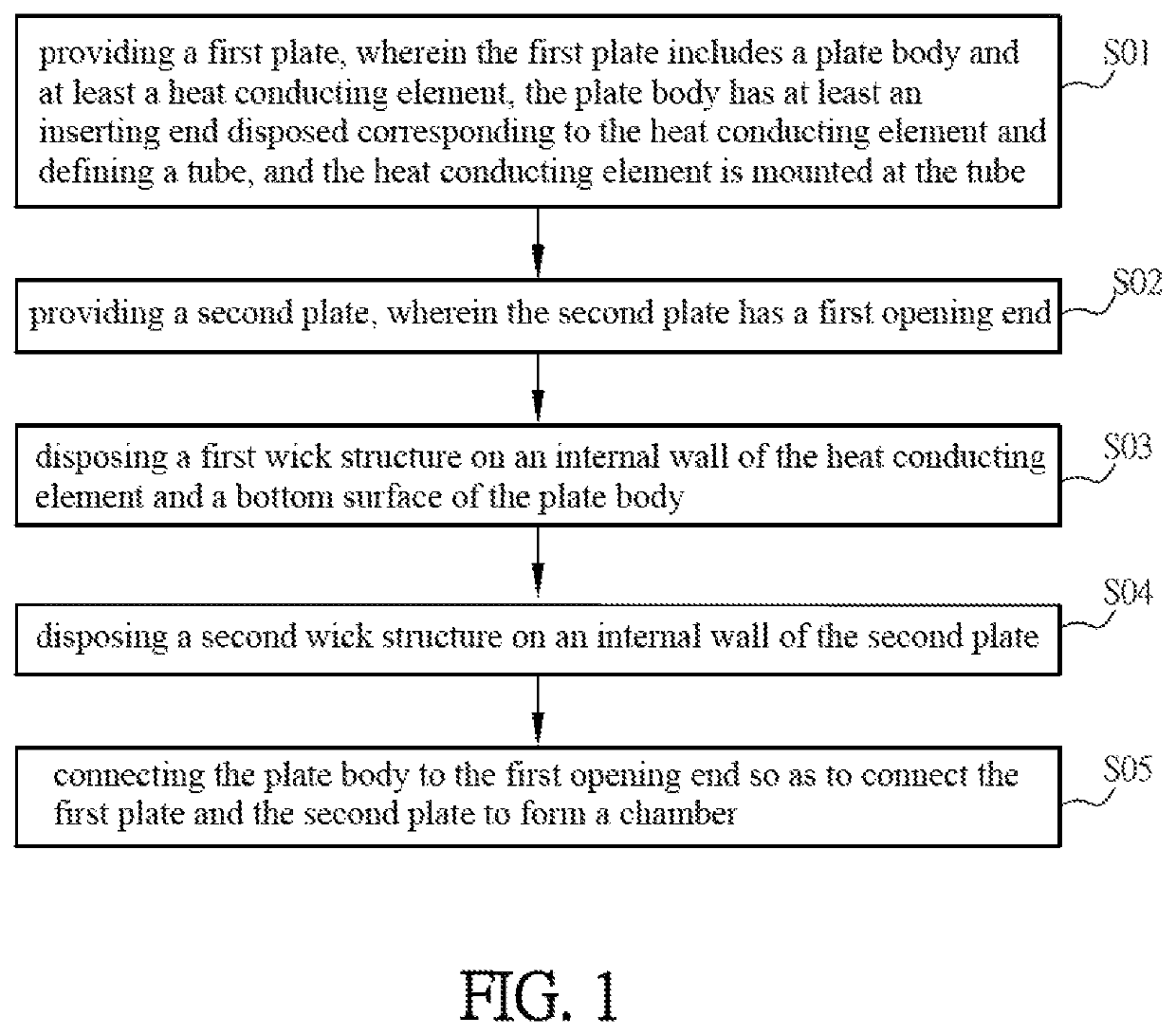

Slim vapor chamber

ActiveUS20170023308A1Improve thermal conductivitySmall sizeReinforcing meansIndirect heat exchangersEngineeringMechanical engineering

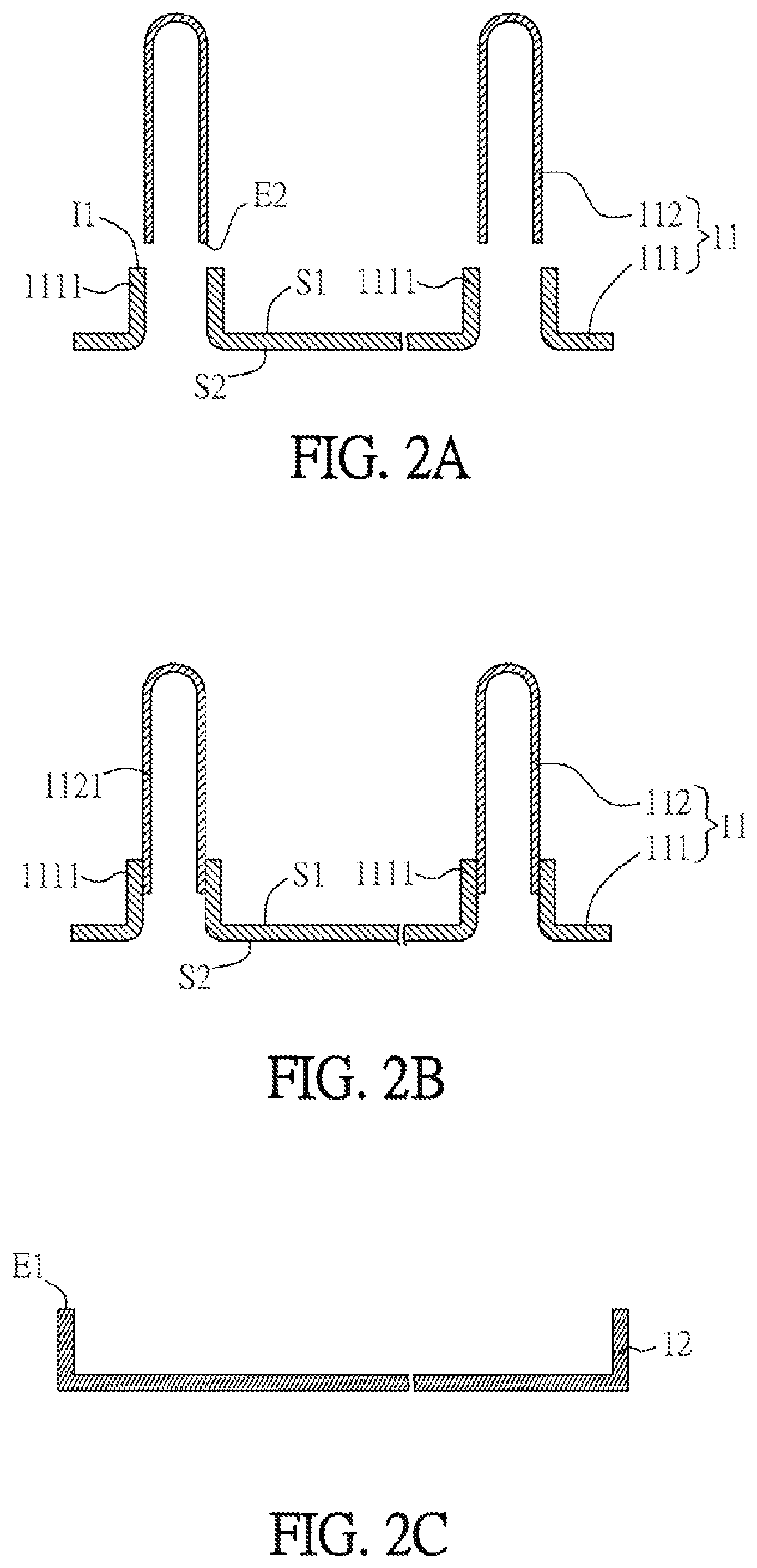

A slim vapor chamber includes a first plate, a second plate and a capillary structure. The periphery of the second plate is connected with that of the first plate to form a chamber. The capillary structure is disposed in the chamber. At least one of a side of the first plate facing the second plate and a side of the second plate facing the first plate is formed with a plurality of supporting structures, which include a plurality of supporting pillars and a plurality of supporting plates, by an etching process.

Owner:DELTA ELECTRONICS INC

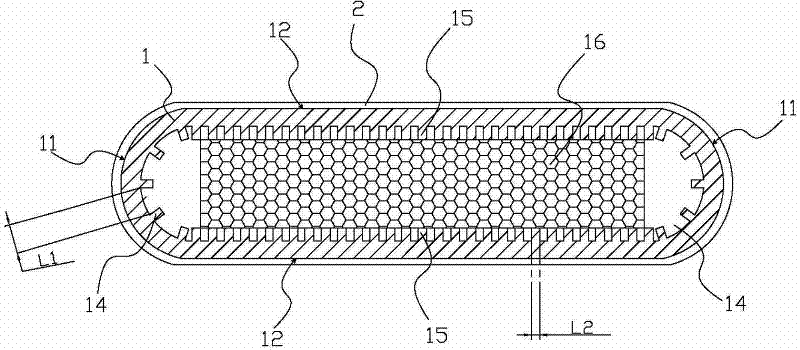

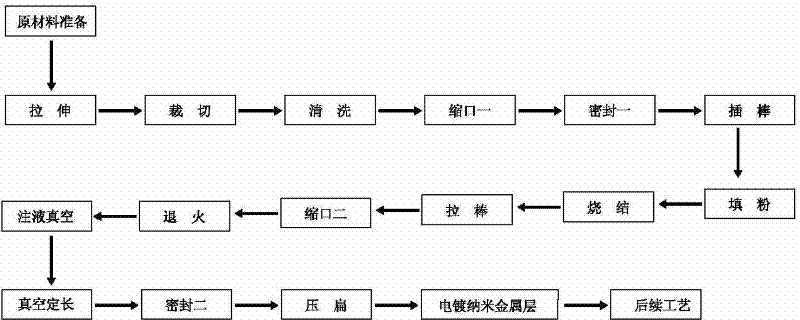

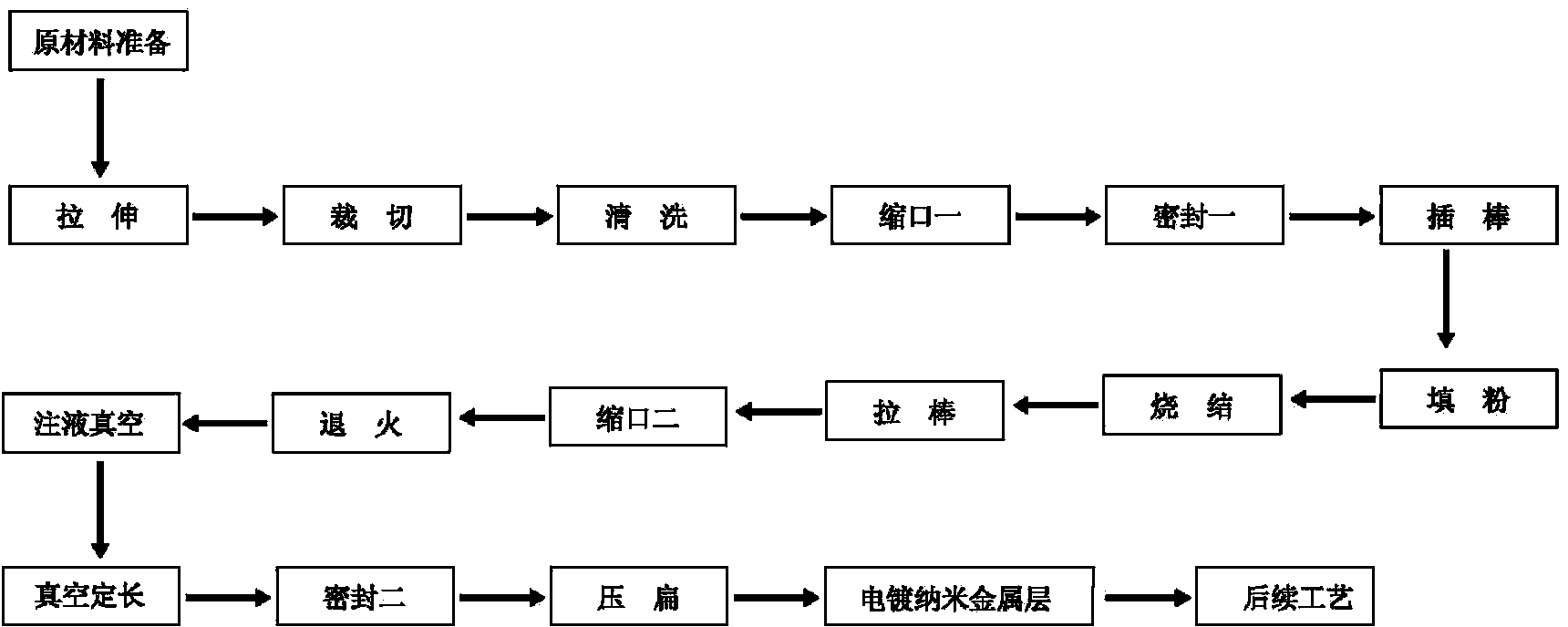

Ultrathin heat pipe and machining method thereof

ActiveCN102538528ASmall sizeGood heat conduction efficiencyIndirect heat exchangersVolumetric Mass DensityEngineering

The invention discloses an ultrathin heat pipe, comprising a flat pipe body formed by pressing. The pipe body is provided with a compression section and a smooth section; the two ends of the pipe body are sealed to form a sealed inner cavity; working solution is filled in the sealed inner cavity, the pipe body is wrapped with a nanometer metal layer, a first groove part and a second groove part are formed in the sealed inner cavity of the pipe body, and a powder sintering part is adhered on the second groove part; and the groove density of the first groove part is smaller than that of the second groove part. The invention also provides a machining method of the ultrathin heat pipe. For the ultrathin heat pipe provided by the invention, the size of the ultrathin heat pipe can be small enough, simultaneously, the heat conduction efficiency and the stability of the ultrathin heat pipe can be guaranteed, and the matched machining method is provided; and the ultrathin heat pipe can be suitable for the various fields with good heat dissipation and limited size.

Owner:ZHONGSHAN WEIQIANG TECH

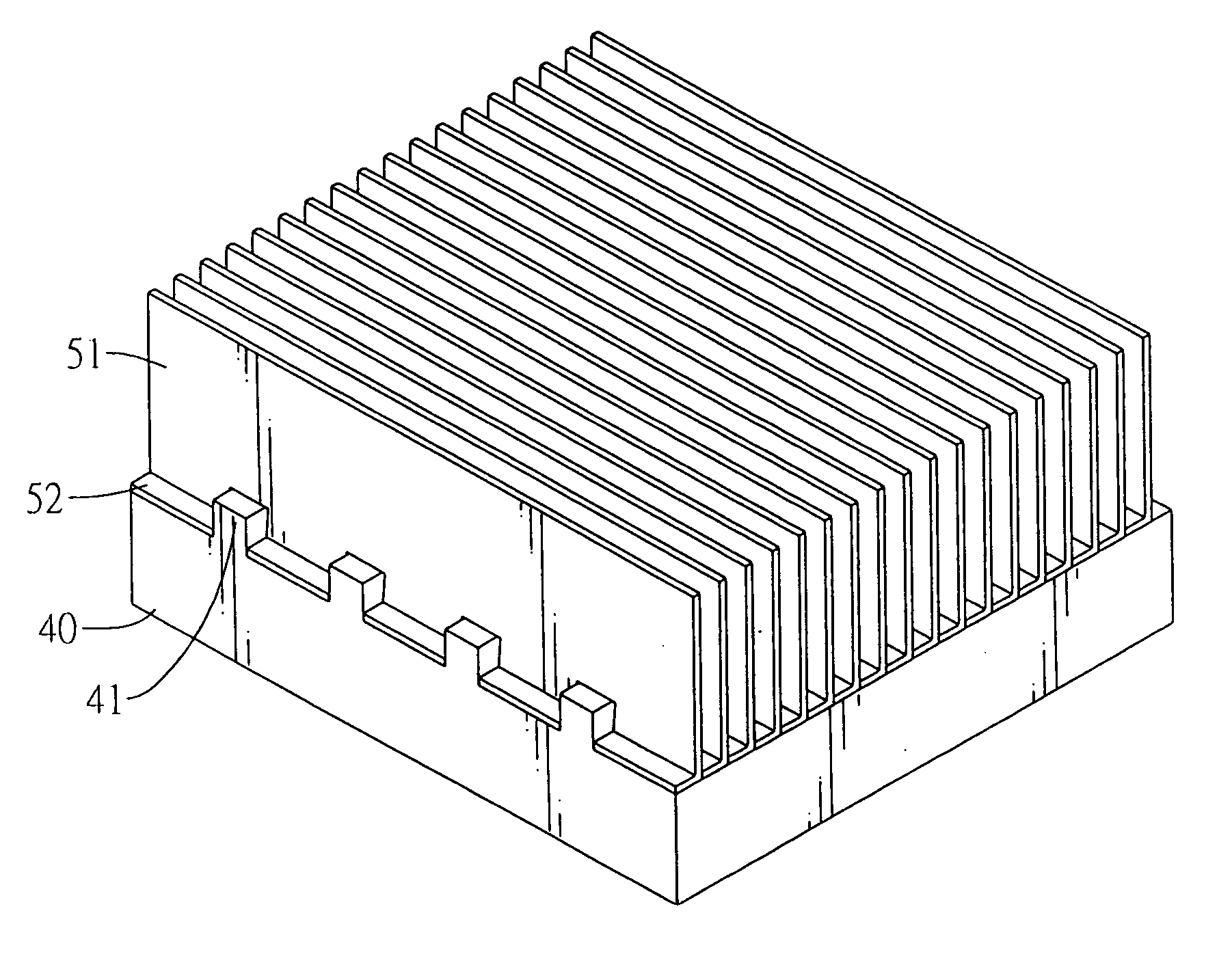

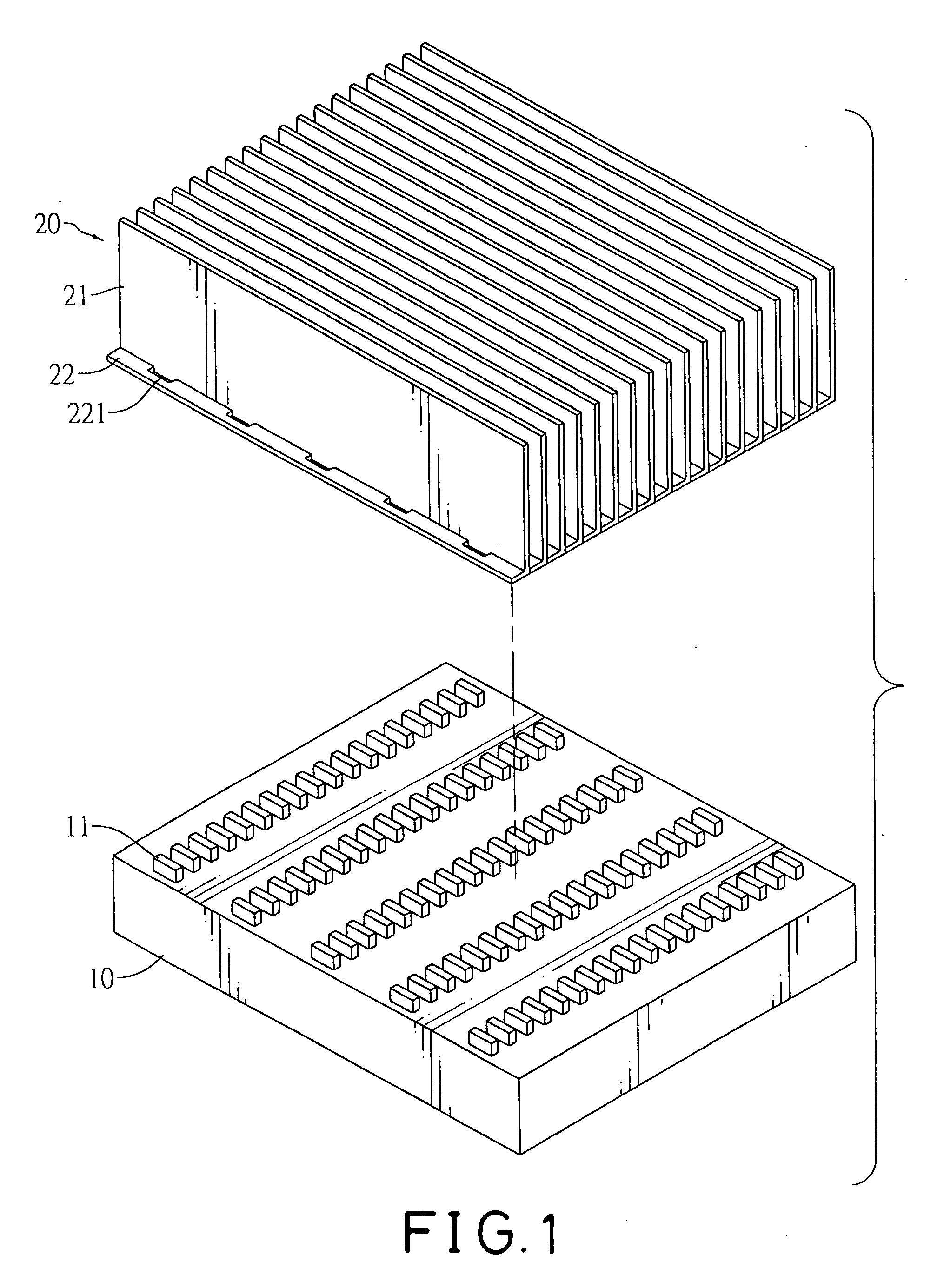

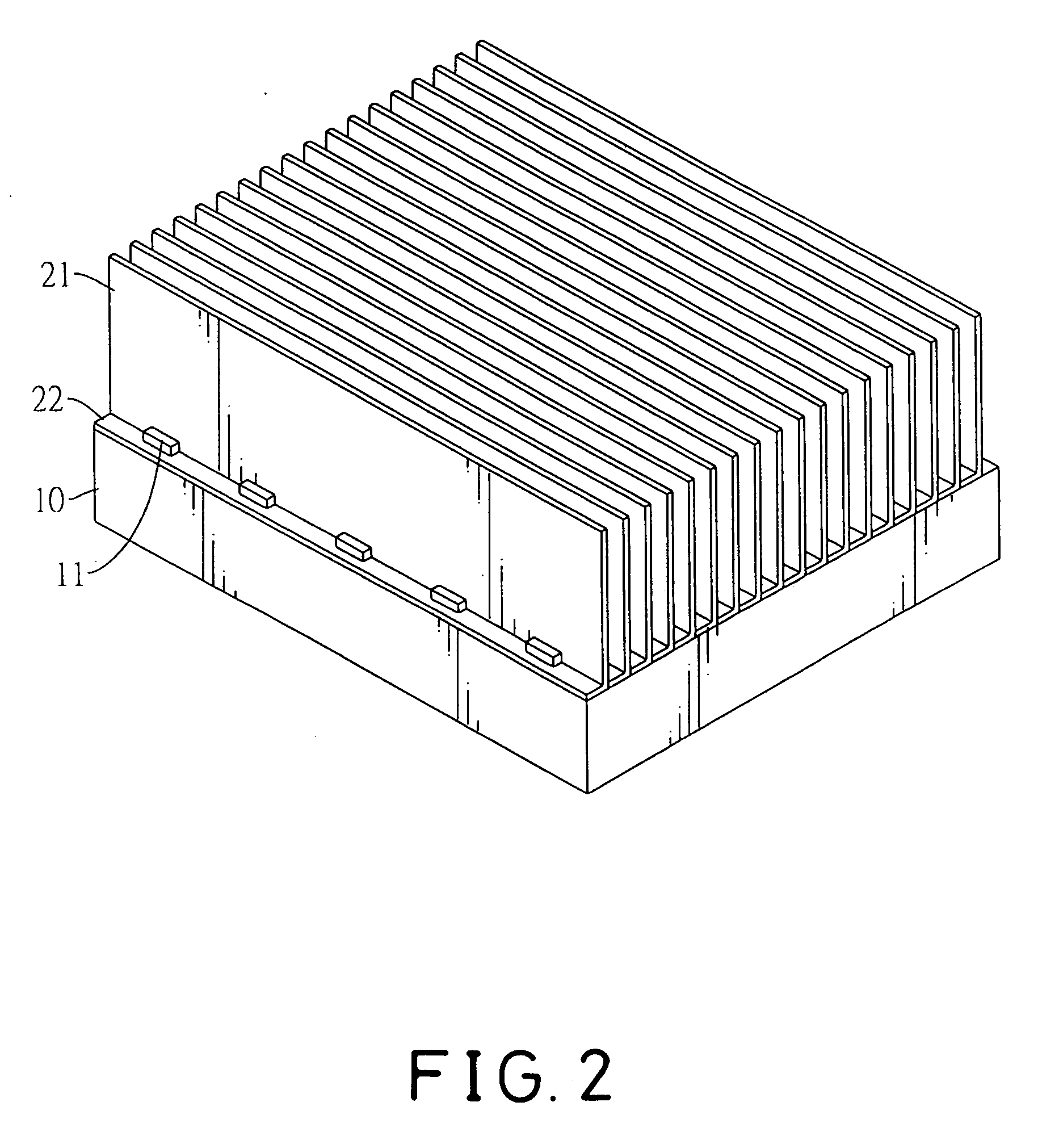

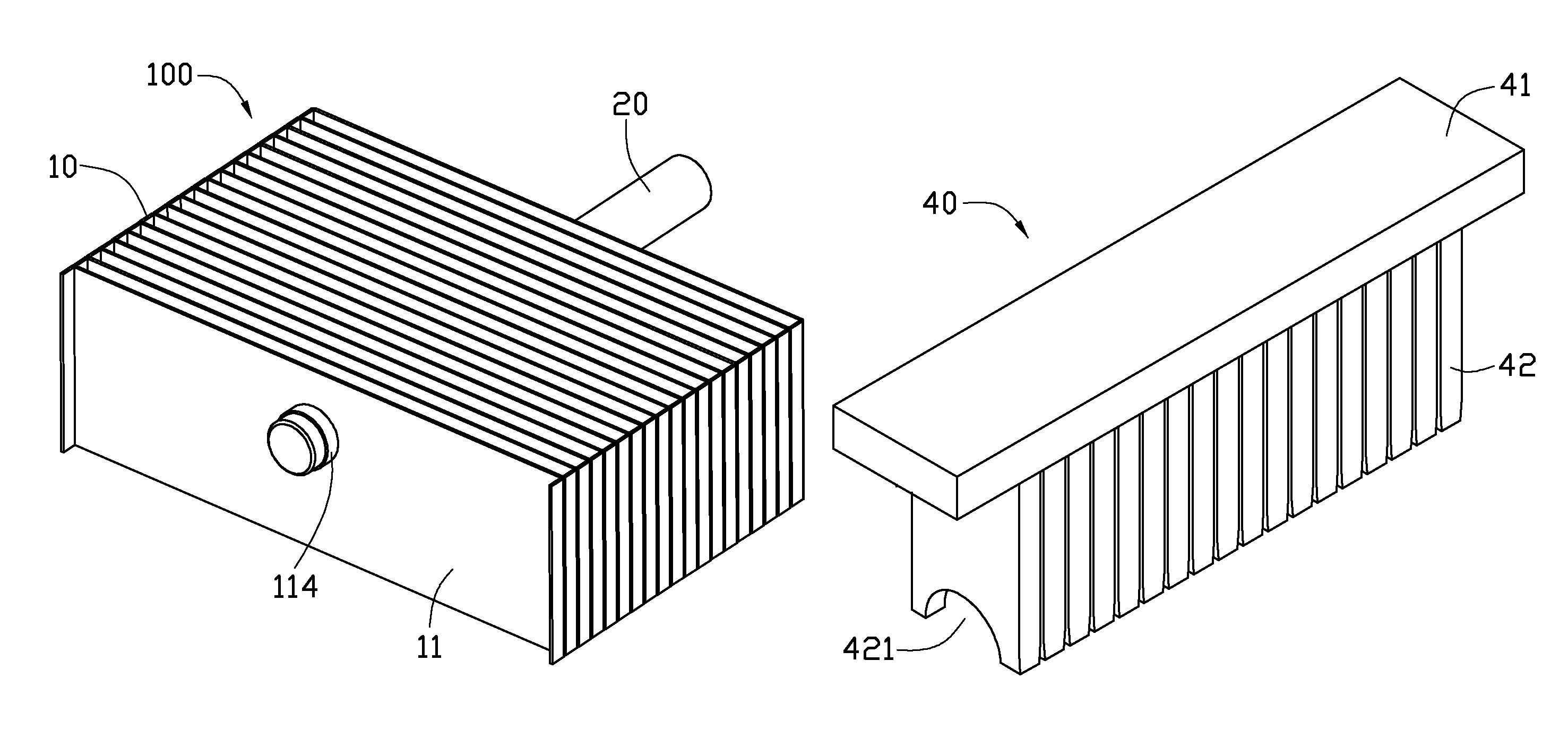

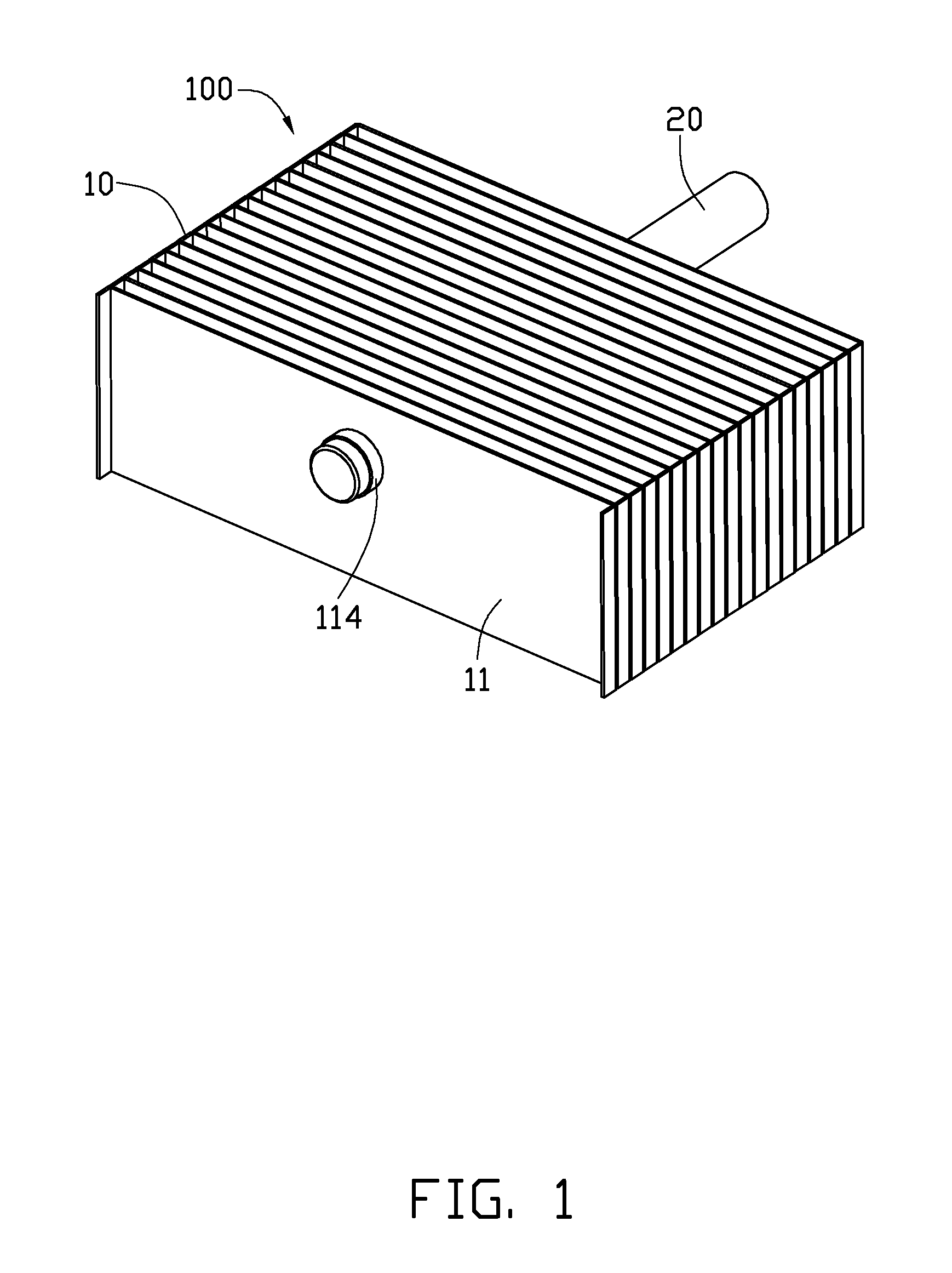

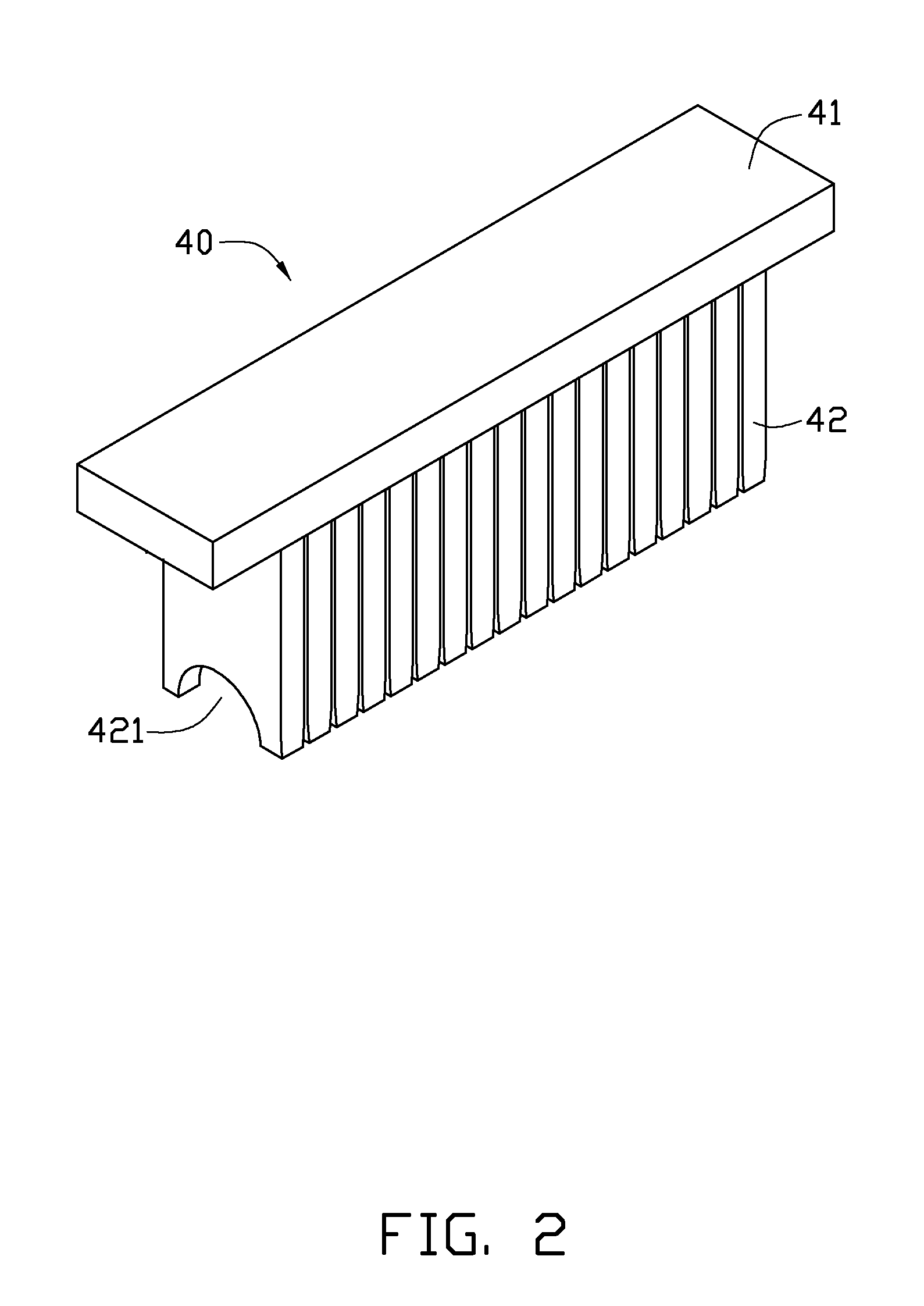

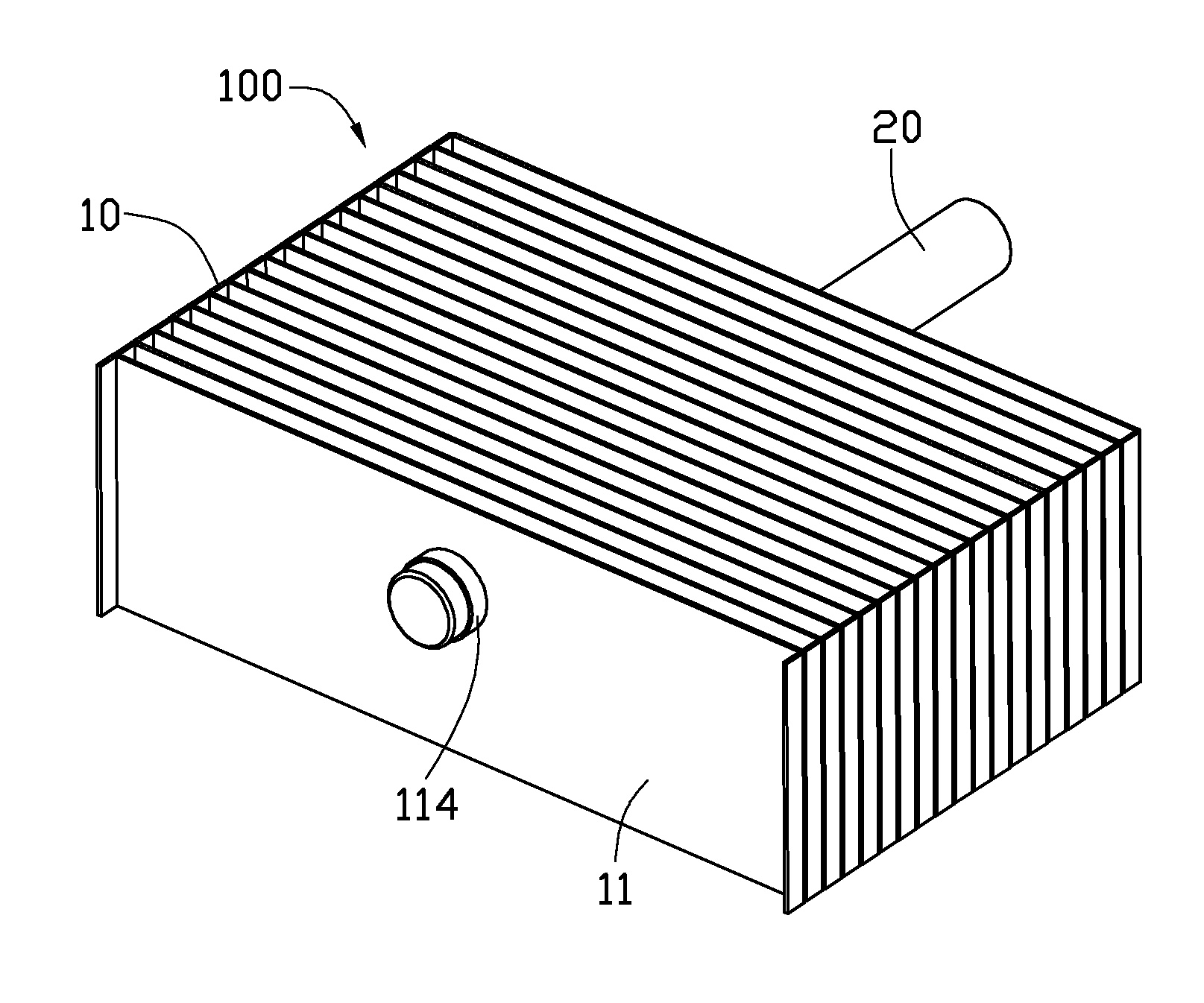

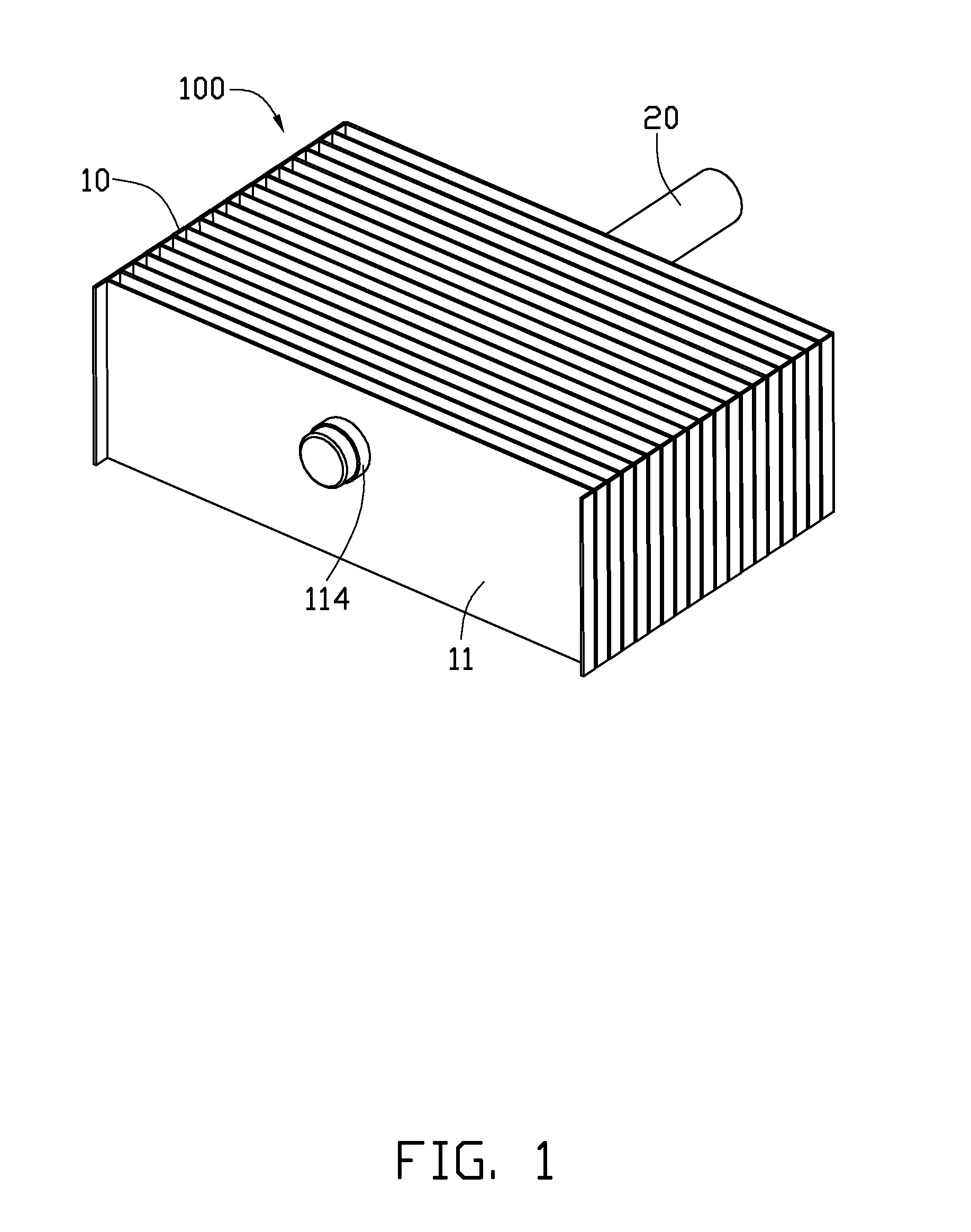

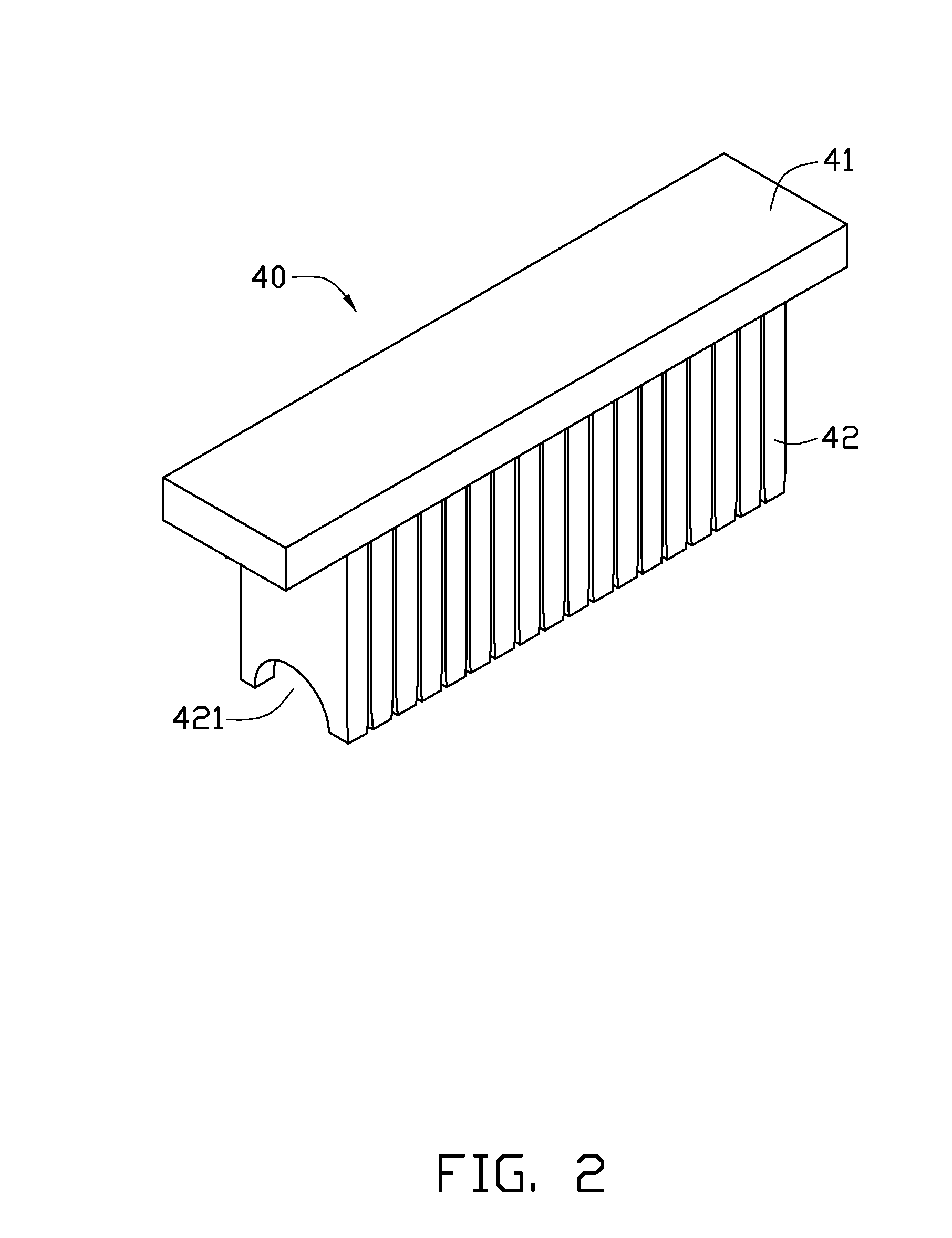

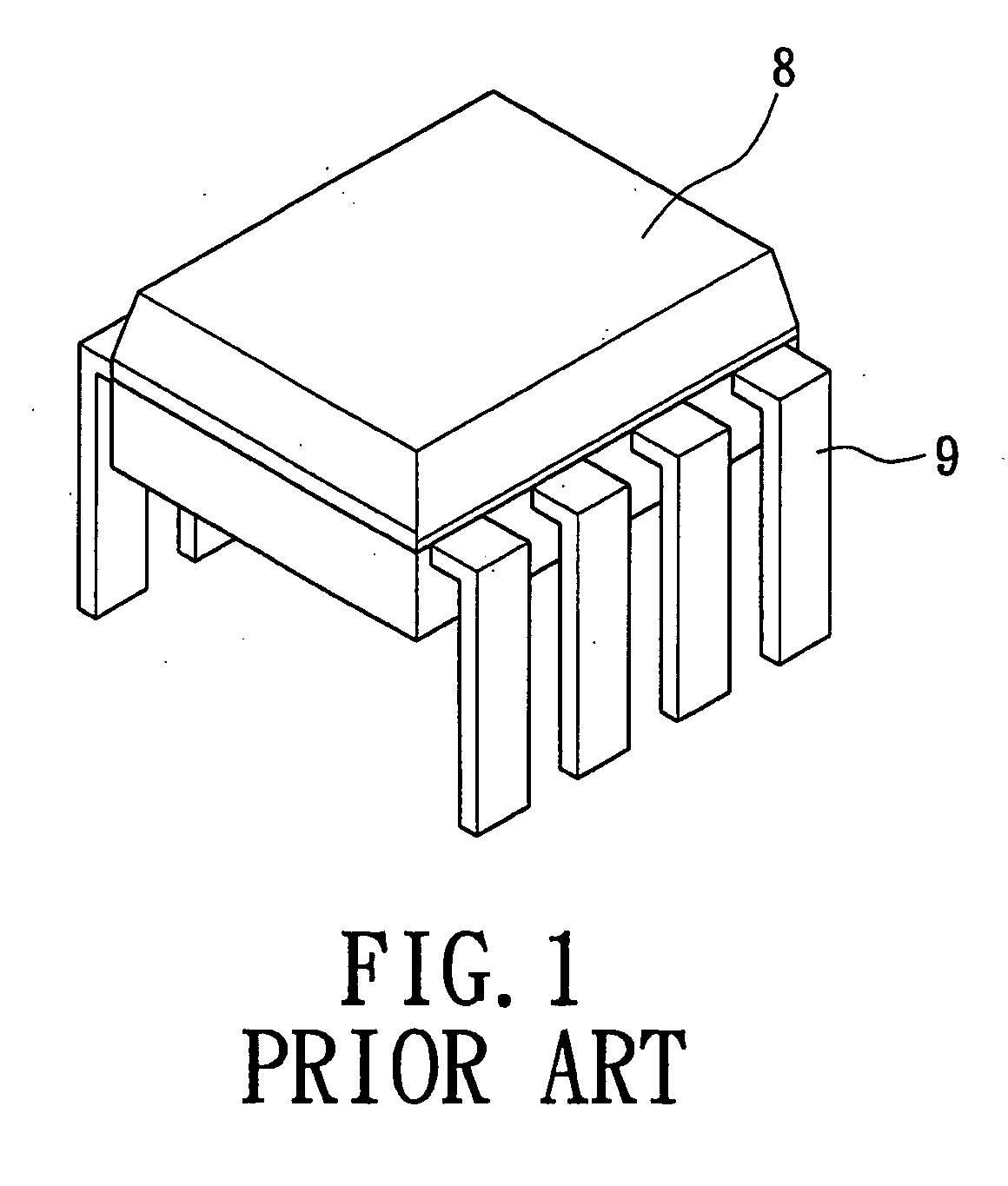

Heat sink

InactiveUS20070029068A1Good heat conduction efficiencyDissipate heat integratedSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit

A heat sink has a base and multiple fins. The fins are attached to the base, and each fin has a radiating surface and a conducting surface. The conducting surface is formed on the radiating surface and has at least one side abutting the base. The base is attached to an integrated circuit to dissipate heat from the integrated circuit. Because at least one of the two sides of the conducting surfaces is in full contact with the base, more heat is conducted from the base to the fins. Therefore the heat sink can cool the integrated circuit effectively.

Owner:BIN PEY

Tube fin brazing process and internal tube heating soldering machine for

InactiveCN101318245AUnchanged structureEasy to operateHeating appliancesMetal working apparatusCrystal structureEngineering

The invention discloses a tube fin brazing process and an in-tube heating brazing machine and is characterized in that a finned tubular pipe welding element well filled with solders is placed on a bracket and the surfaces of welding elements to be brazed are chemically cleaned; a rod type electric heating tube extends into the pipe to perform in-tube radiation heating to firstly moisten and apply the solders at the external wall of the pipe to fill the brazing gaps and then transfer the temperature to a finned folding edge by liquid solders; the metallurgical bonding is formed between the solders and the pipe as well as the folding edge by the atomic diffusion and solution. By adopting the in-tube heating brazing machine which consists of a machine stand, the bracket which is arranged at the front end of the machine stand and a heating tube holder arranged at the bracket, the tube fin brazing process and the in-tube heating brazing machine have the advantages of simple and convenient operation, minimal investment, no limitation to the geometric shapes of the brazed elements, no damage to the surfaces of the brazed elements and no change of the crystal structures in metals and solve the problems that the fins reach the brazing temperature before the pipes and the temperature is not easily controlled, and the brazing can not completely penetrate and fill the connection gaps and the brazing effect is bad, and the problems are caused by the traditional brazing heating ways.

Owner:AECC AERO SCI & TECH CO LTD

Method For Connecting Heat-Dissipating Body And Heat Pipe And Structure Thereof

InactiveUS20080121377A1Low costTightnessSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A method for connecting a heat-dissipating body and a heat pipe and the structure thereof are used to improve the efficiency of heat conduction. The structure includes a heat-dissipating body and a heat pipe. The central position of the heat-dissipating body is provided with an accommodating trough for accommodating the heat pipe. A plurality of corresponding slots extends outwardly from the periphery of the trough. The other end of the slot is connected to a through hole. Tools are disposed in the slots to widen the slots and thus the periphery of the trough, so that the inner diameter of the trough is larger than the outer diameter of the heat pipe. After the heat pipe penetrates into the trough, the tools are removed, so that the inner wall surface of the trough abuts tightly against the outer circumferential surface of the heat pipe. Thus, the optimal efficiency of heat conduction between the heat pipe and the heat-dissipating body can be achieved.

Owner:CPUMATE INC +1

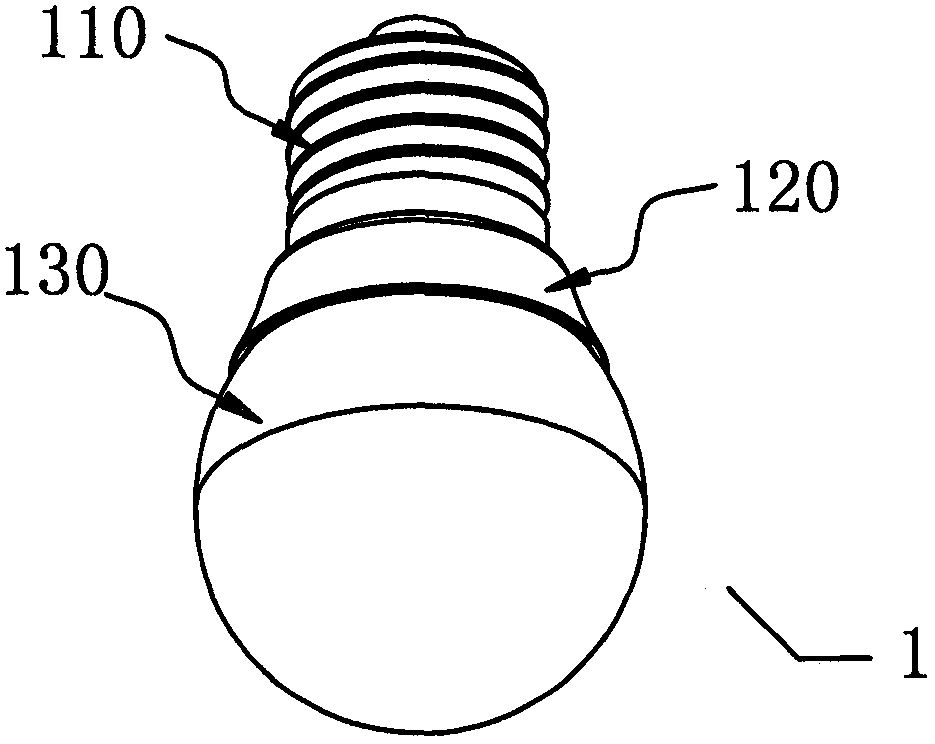

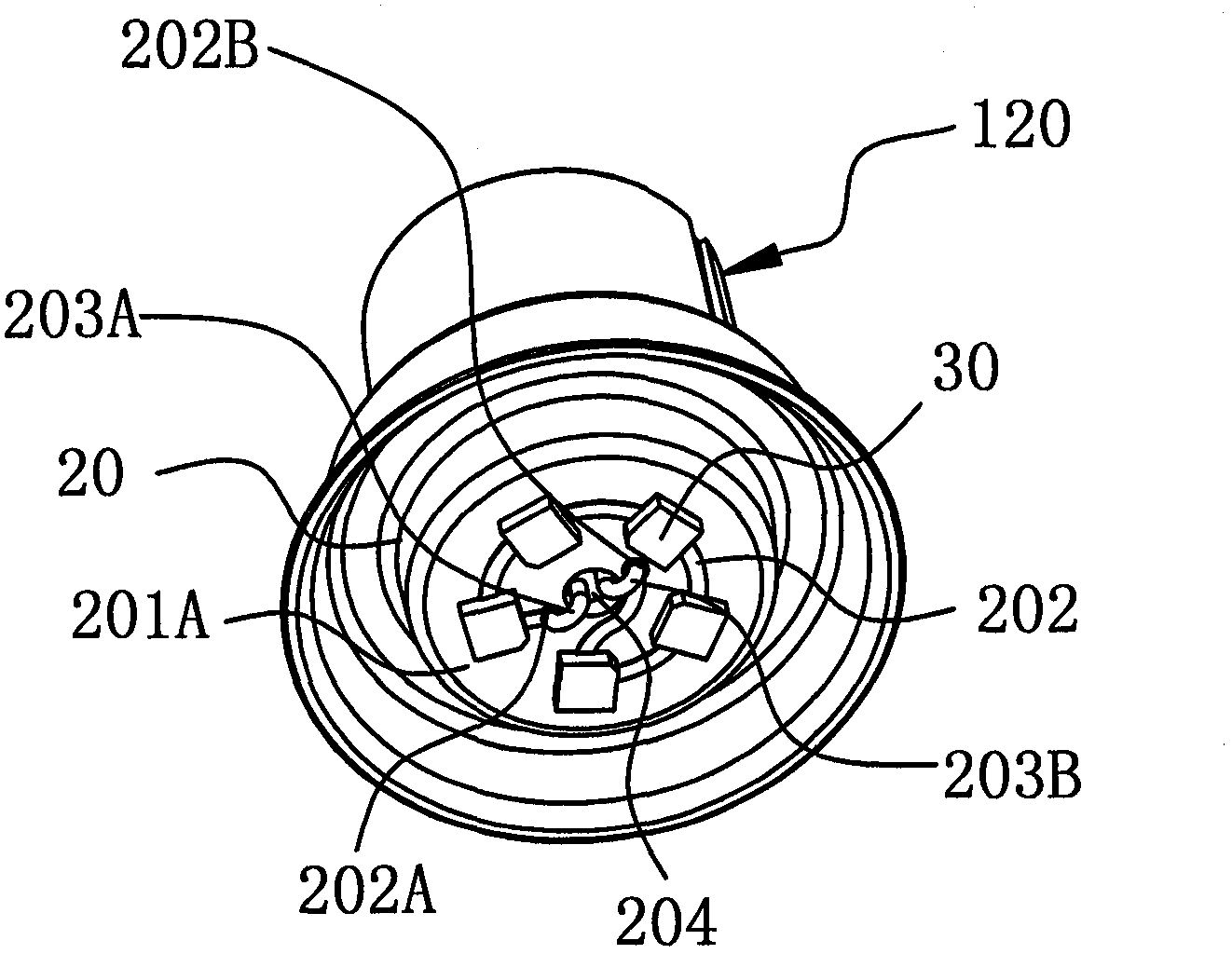

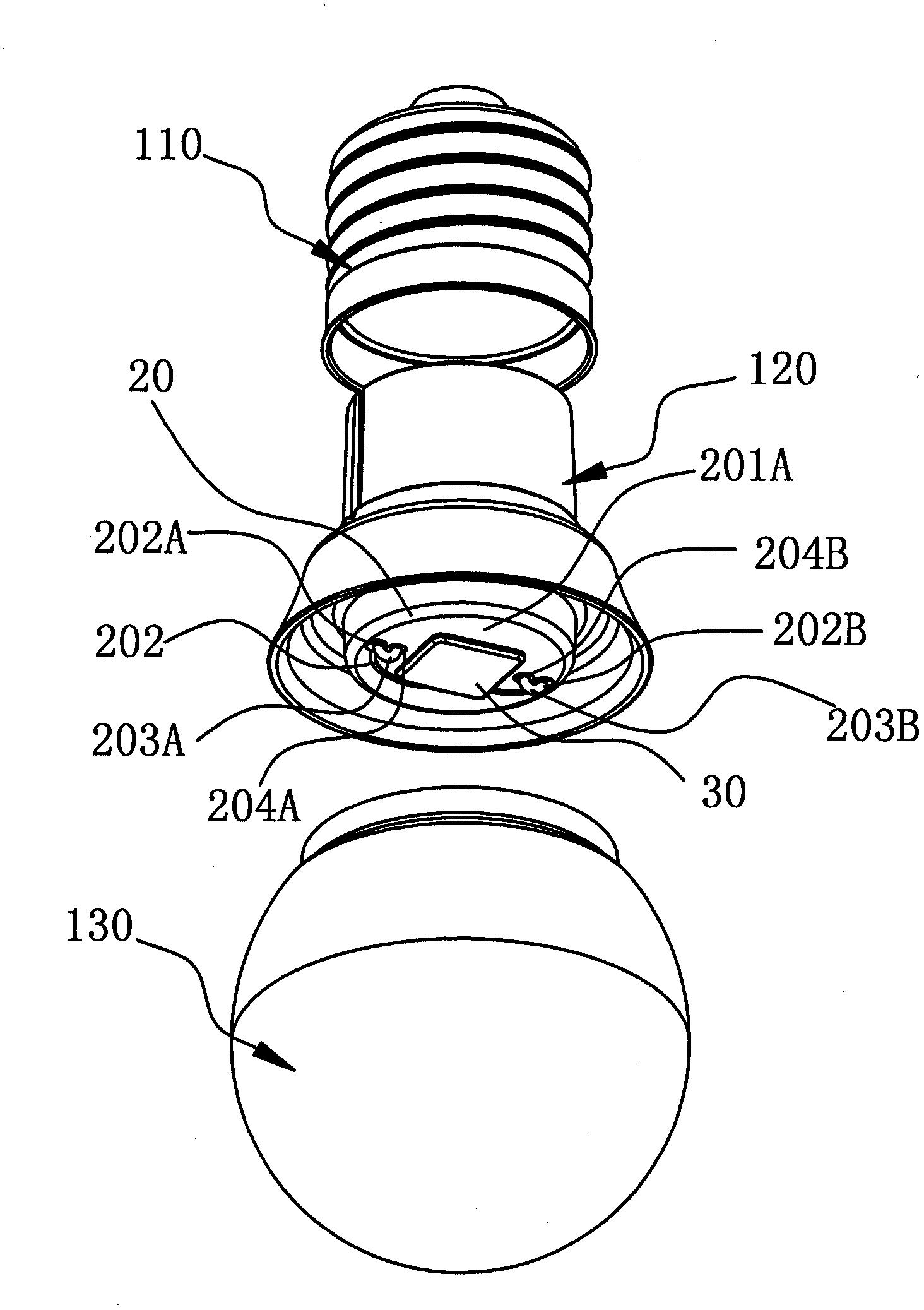

Light emitting diode (LED) lamp wick and lighting device with LED as light source

InactiveCN103104828ALower assembly costsReduce logistics costsPlanar light sourcesPoint-like light sourceEffect lightEngineering

The invention relates to the semiconductor lighting technology, in particular to a light emitting diode (LED) lamp wick and a lighting device with an LED as a light source. The purpose is to provide the LED lamp wick suitable for being fitted to a lamp housing to provide a lighting device which is good in heat dissipating effect and low in production cost. One more purpose is to provide the lighting device with the LED as the light source, and the lighting device with the LED as the light source has the advantages of being both good in heat dissipating effect and low in production cost.

Owner:赵依军 +1

Thermal module structure and manufacturing method thereof

InactiveUS20130020055A1More assembledImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A thermal module structure and a manufacturing method thereof. The thermal module structure includes a base and a heat pipe. The base has a first channel and a first recessed section in communication with the first channel. The heat pipe is correspondingly disposed in the first channel. According to the thermal module structure, the heat pipe can directly contact heat source and directly connect with the base without brazing. Therefore, the manufacturing cost is greatly lowered.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

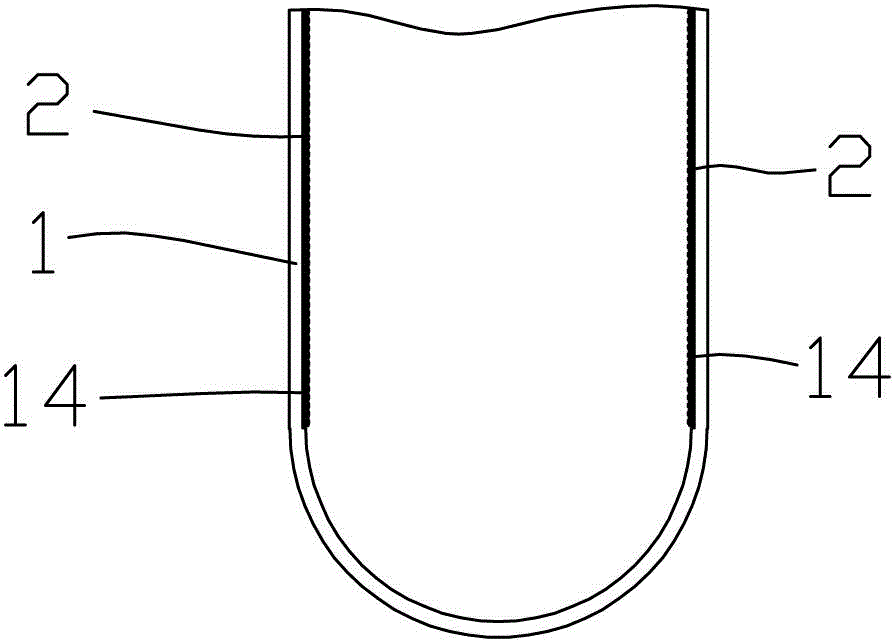

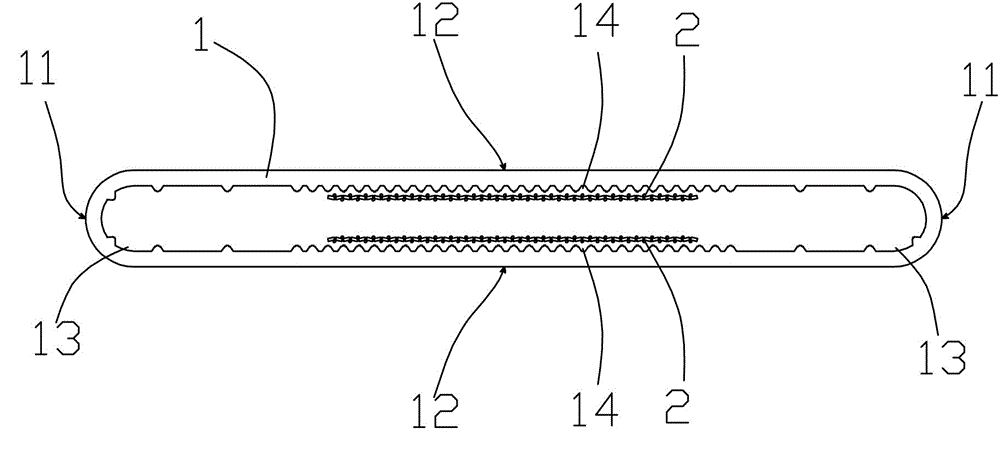

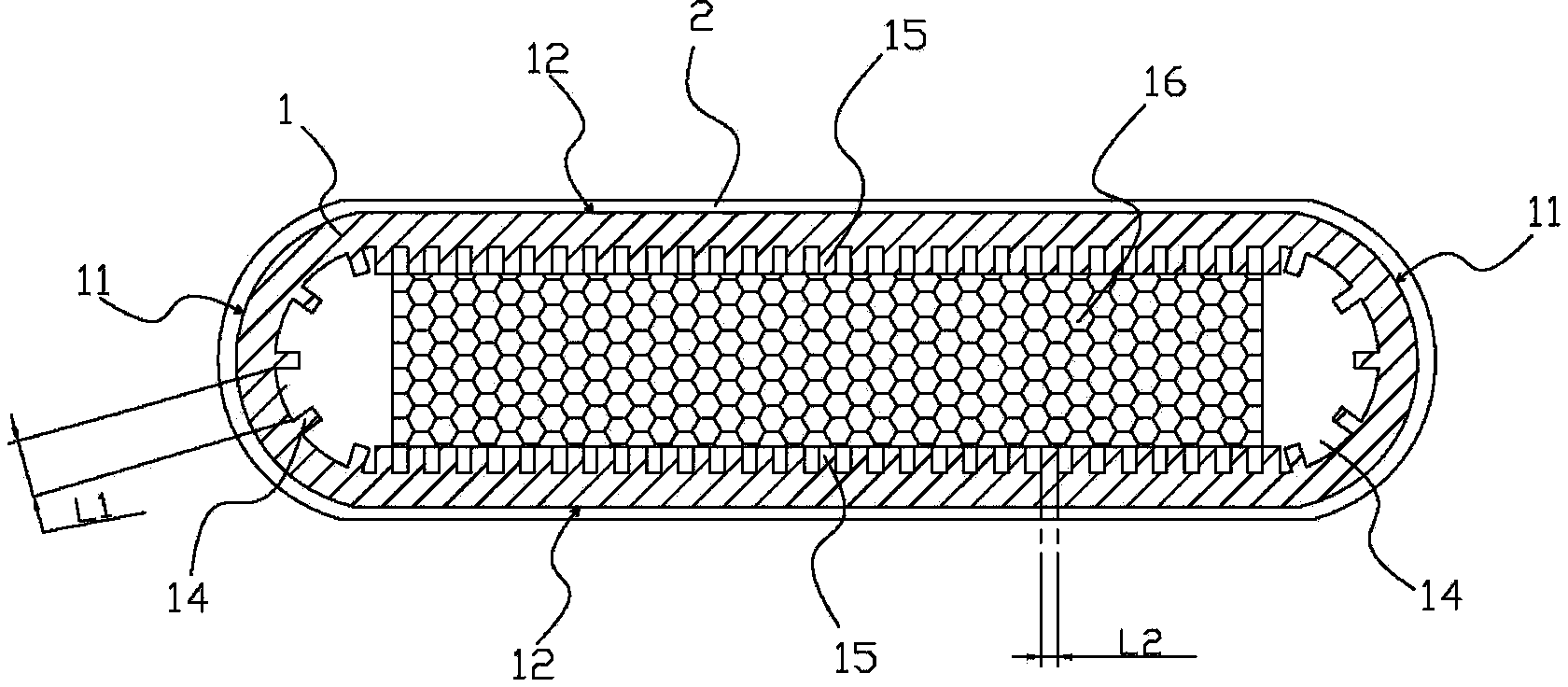

Ultra-thin heat pipe and manufacturing method thereof

ActiveCN103940274AGood heat conduction efficiencyImprove stabilityIndirect heat exchangersWorking fluidEngineering

The invention discloses an ultra-thin heat pipe. The ultra-thin heat pipe comprises a pipe body which is pressed to be in a flat shape, and the pipe body is provided with a compressed section and a smooth section. The two ends of the pipe body are sealed to form a closed inner cavity. The closed inner cavity is filled with working fluid, a first groove portion and a second groove portion are formed in the closed inner cavity of the pipe body, and a powder sintering portion adheres onto the second groove portion. The groove density of the first groove portion is lower than the groove density of the second groove portion, a metal net adheres onto the second groove portion, and the metal net and the second groove portion are combined together through sintering. The invention further provides a manufacturing method of the ultra-thin heat pipe. The size of the ultra-thin heat pipe can be manufactured to be as small as possible, meanwhile, the ultra-thin heat pipe can guarantee good heat conduction efficiency and stability, and the matched manufacturing method of the ultra-thin heat pipe is provided; the ultra-thin heat pipe and the manufacturing method of the ultra-thin heat pipe are applicable to various fields where good heat dissipation is needed and the size is limited.

Owner:ZHONGSHAN WEIQIANG TECH

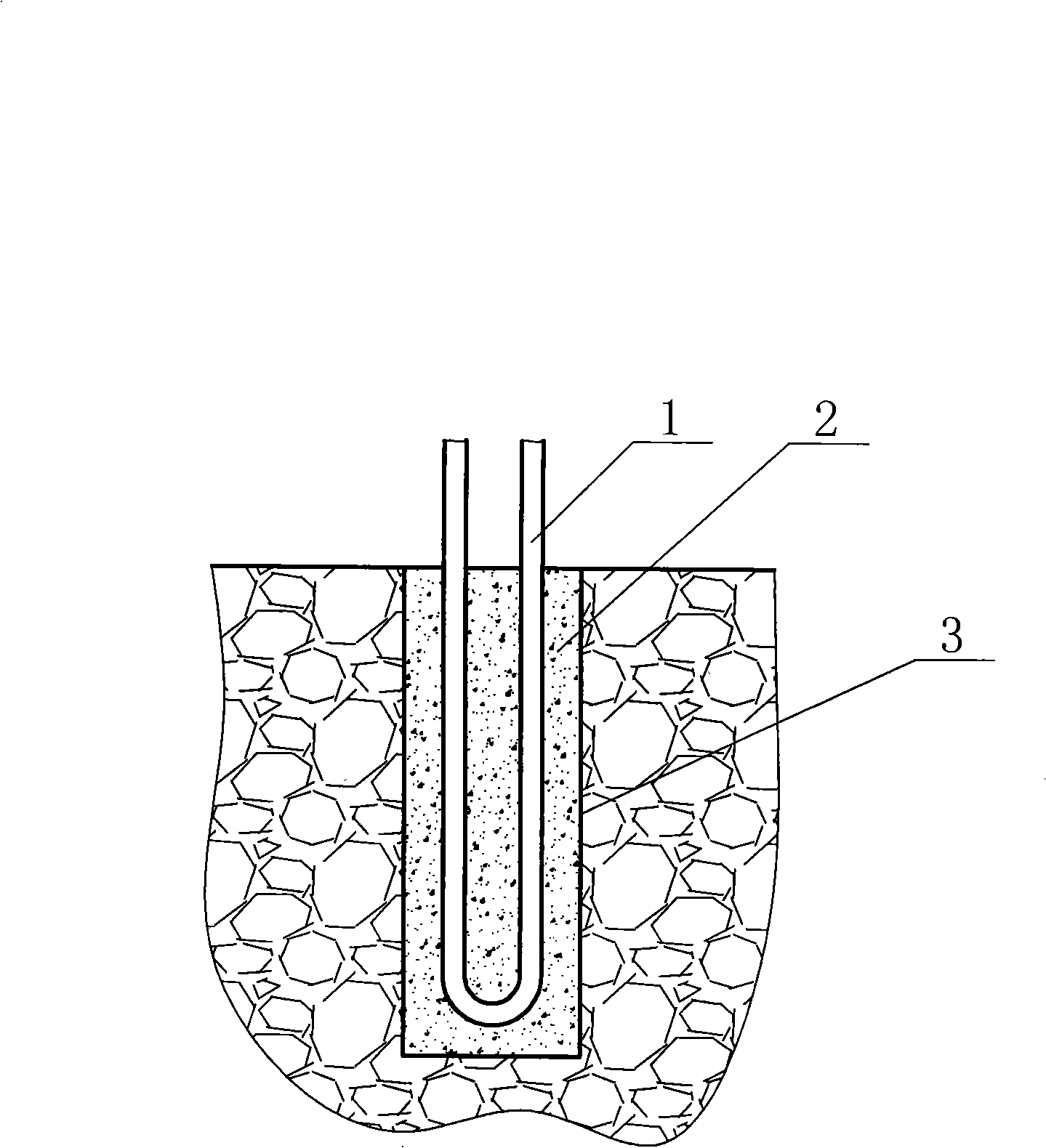

Back-filling material for ground-source heat pump ground-burying tube hole drilling

InactiveCN101343533AReduce thermal resistanceGood chemical stabilityOther heat production devicesGeothermal energy generationAluminateEngineering

The invention discloses a ground source heat pump buried pipe drill hole recharging material, the weight percentage of the recharging material components are as followings: graphite occupies 5 percent to 80 percent, and inorganic particles occupy 20 percent to 95 percent, wherein the inorganic particles are mainly composed of silicate, carbonate, or an inorganic mixture of granular or powdery aluminate. If unprocessed and much impurities composed graphite is adopted, and because the purity of the graphite is only 25 percent, inorganic particles are not need to be added when recharging is performed, and only the unprocessed graphite and water are mixed for recharging directly. The mass ratio of the graphite composed in the interior of the material is no less than 5 percent, thus the heat transfer coefficient K of the recharging material is above 10, the heat transfer coefficient of ground source heat pump buried pipe drill hole recharging material in the prior art is between 1.5 and 3, the heat transfer coefficient of the recharging material of the invention is more than 3 times of the heat transfer coefficient of the recharging material in the prior art, the heat changing efficiency between U-shaped pipe and the surrounding rocks and ground can be improved, thereby, the heat changing efficiency and the energy efficiency ratio of the ground source heat pump are improved.

Owner:GAO XIUMING

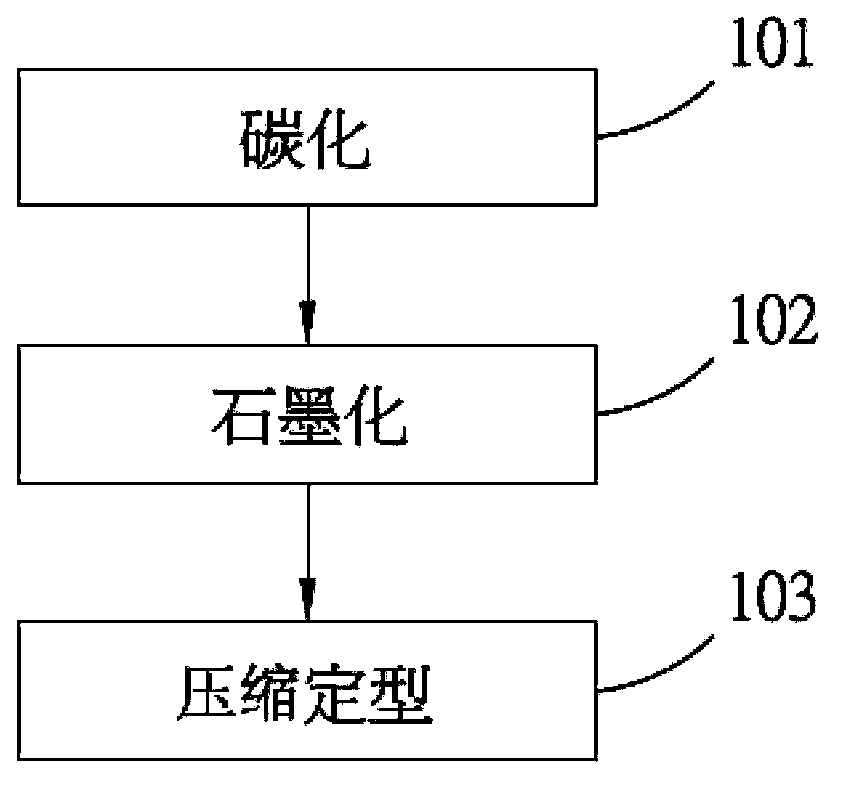

Artificial graphite heat radiation substrate and making method thereof

InactiveCN103770433AReduce equipment costsReduce material costsGraphiteLaminationCvd graphenePolymer substrate

A making method of an artificial graphite heat radiation substrate comprises the following steps: applying a pressure of 0.1kg / cm<2> or less to a polymer sheet in inert gas environment, and gradually heating to obtain a condensed carbonization membrane; gradually heating the condensed carbonization membrane to obtain a graphite membrane composed of a plurality of layers of graphene; and stacking a plurality of the graphite membranes along a stacking direction, and carrying out compressing fixation of the graphite membranes by a predetermined pressure in the stacking direction. Compared with present making methods, the making method disclosed in the invention has the advantages of process simplification, production cost reduction and easy processing; and the artificial graphite heat radiation substrate made through the making method has a good heat conduction effect.

Owner:HUGETEMP ENERGY

Thermally conductive resin composition and thermally conductive sheet including the same

ActiveUS8912278B2Solve high hardnessLower surfaceSolid-state devicesSpecial tyresPolymer chemistryFluorine

Owner:VALQUA LTD

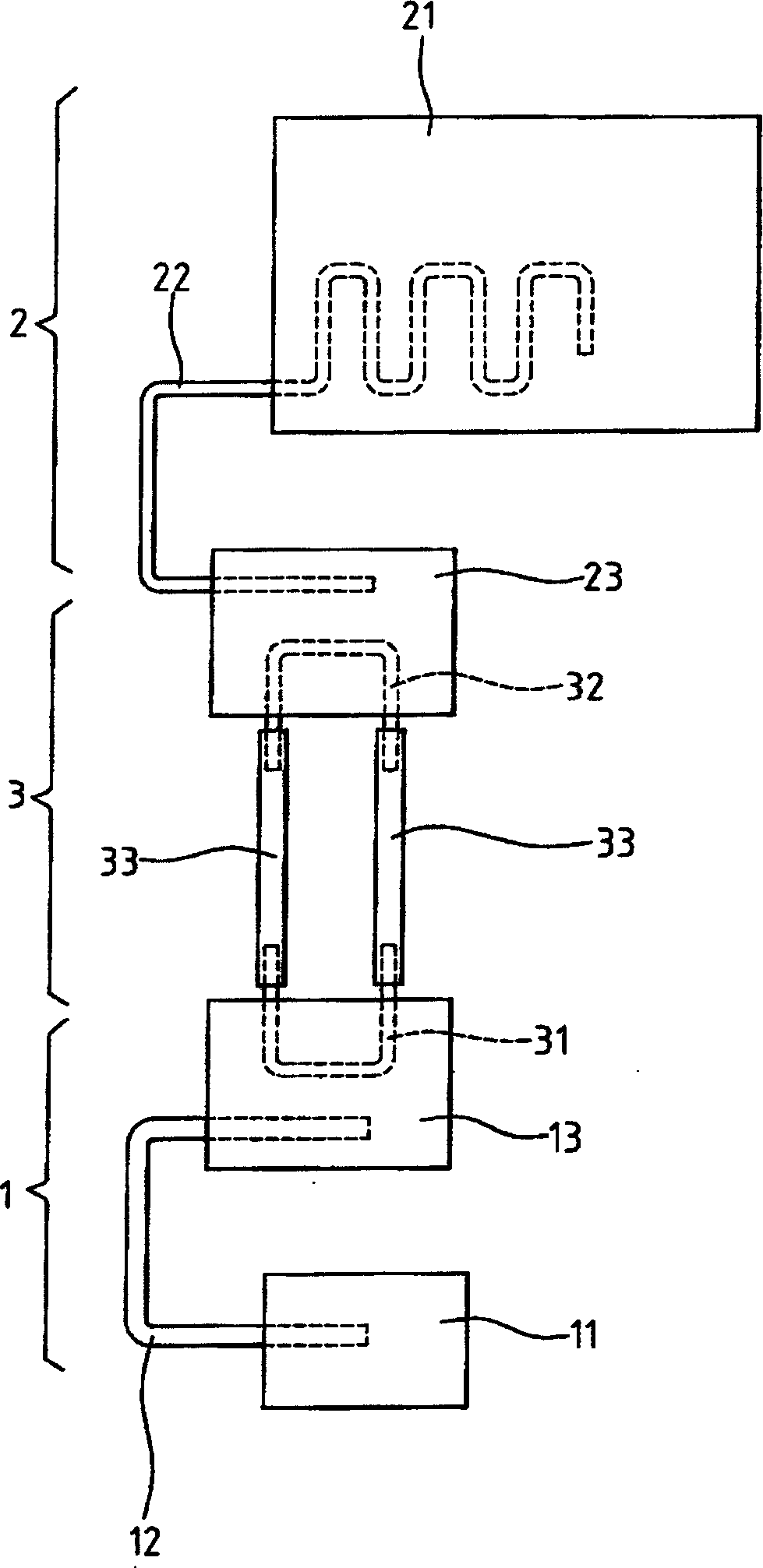

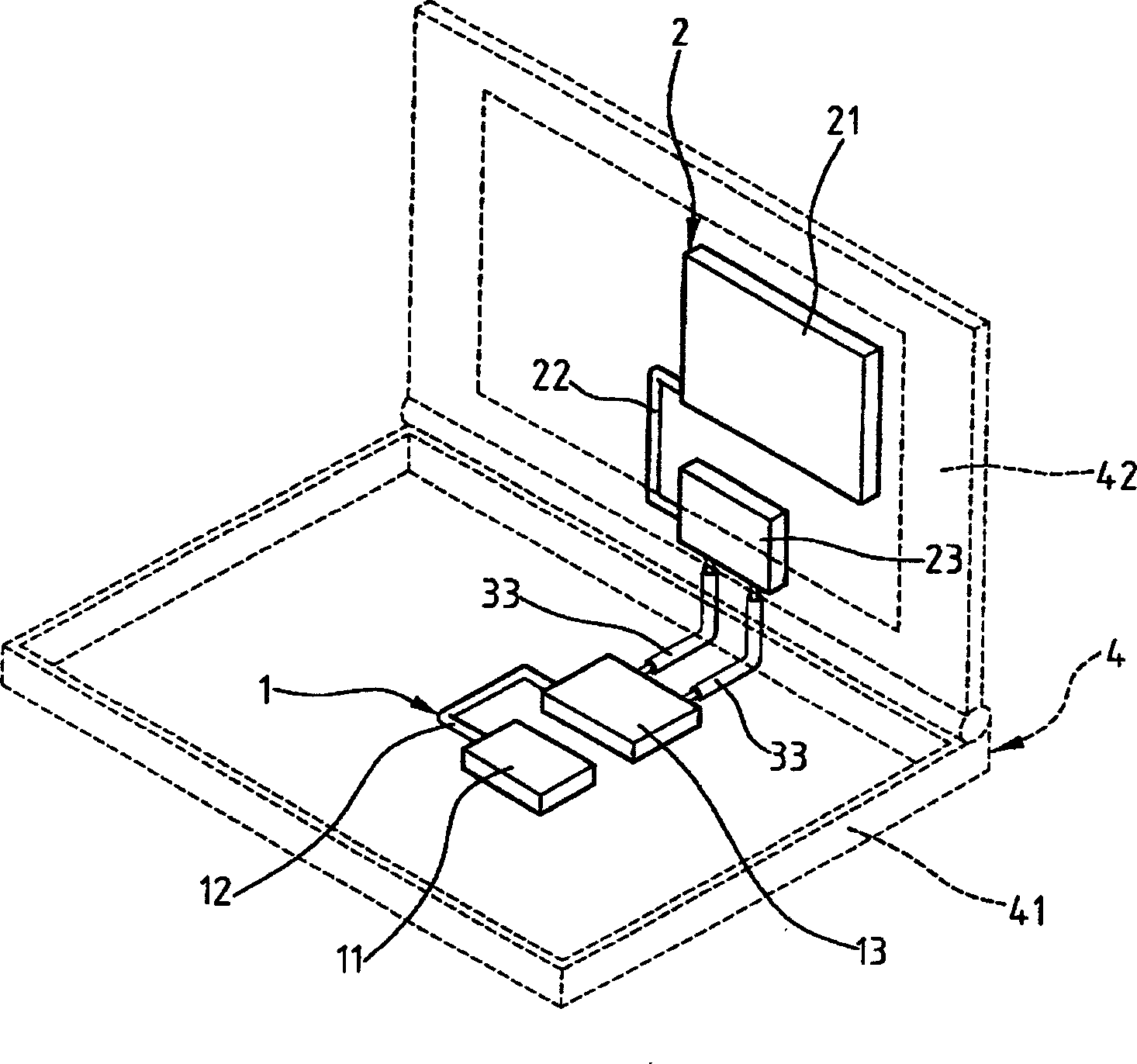

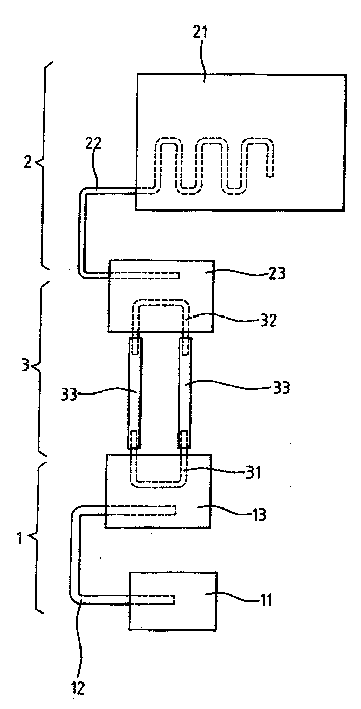

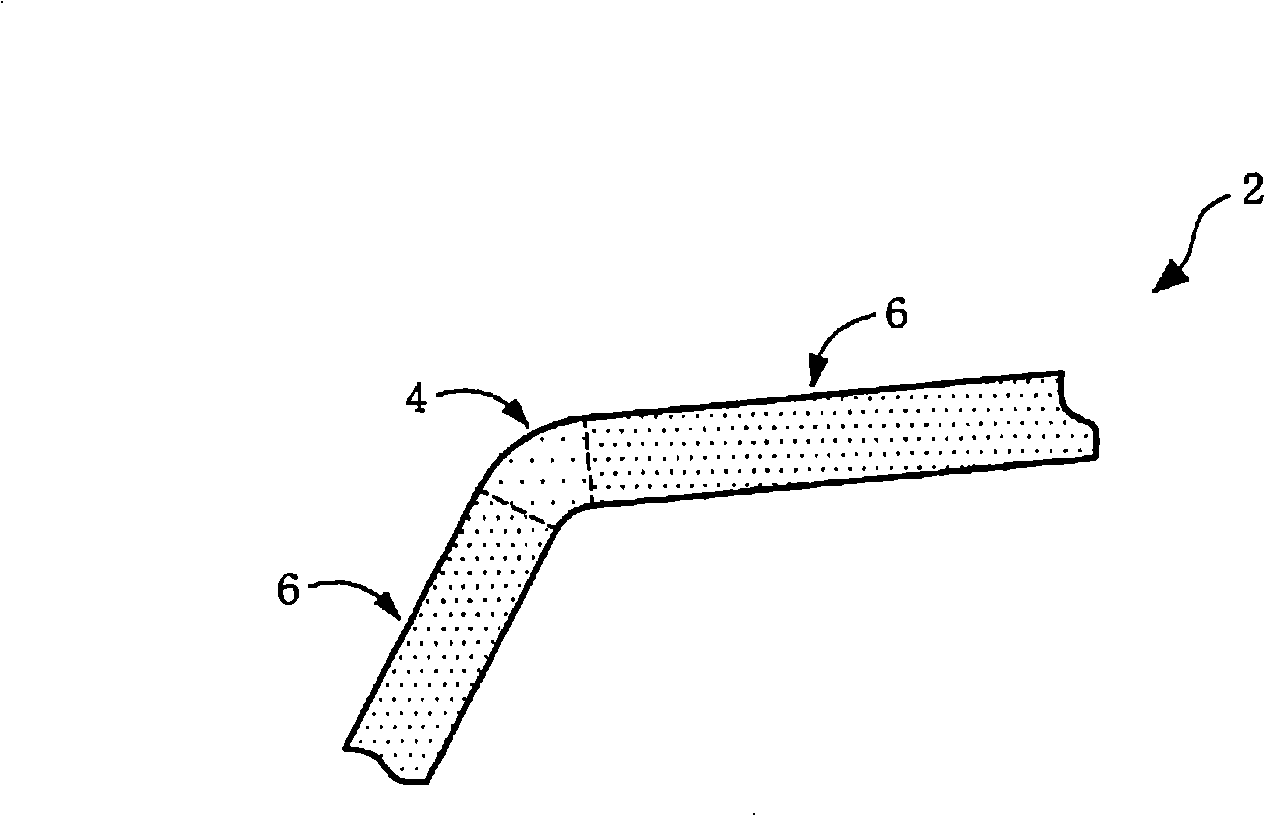

Repeatedly bend heat conducting & radiating module group with flexible pivot

InactiveCN1549079AReduce manufacturing costGood heat conduction efficiencyDigital data processing detailsSemiconductor/solid-state device detailsHeat conductingClosed loop

The flexible heat conducting and dissipating module includes one heat accepting end device, one heat dissipating end device and one flexible heat conducting device. The heat accepting end device is heat conducting tube or other heat conducting body connected between the heat source and the first pedestal; the heat dissipating end device is heat conducting tube or other heat conducting body connected between the heat dissipater and the second pedestal; and the flexible heat conducting pipe is connected between the first pedestal and the second pedestal to constitute closed loop. The flexible heat conducting pipe is filled with heat conducting liquid, and after absorbing heat in the heat accepting end, the heat conducting liquid forms heat convection inside the flexible pipe to conduct heat to the heat dissipating end. In this way, heat is transferred and dissipated via flexible path.

Owner:LIOU JIUN-FU

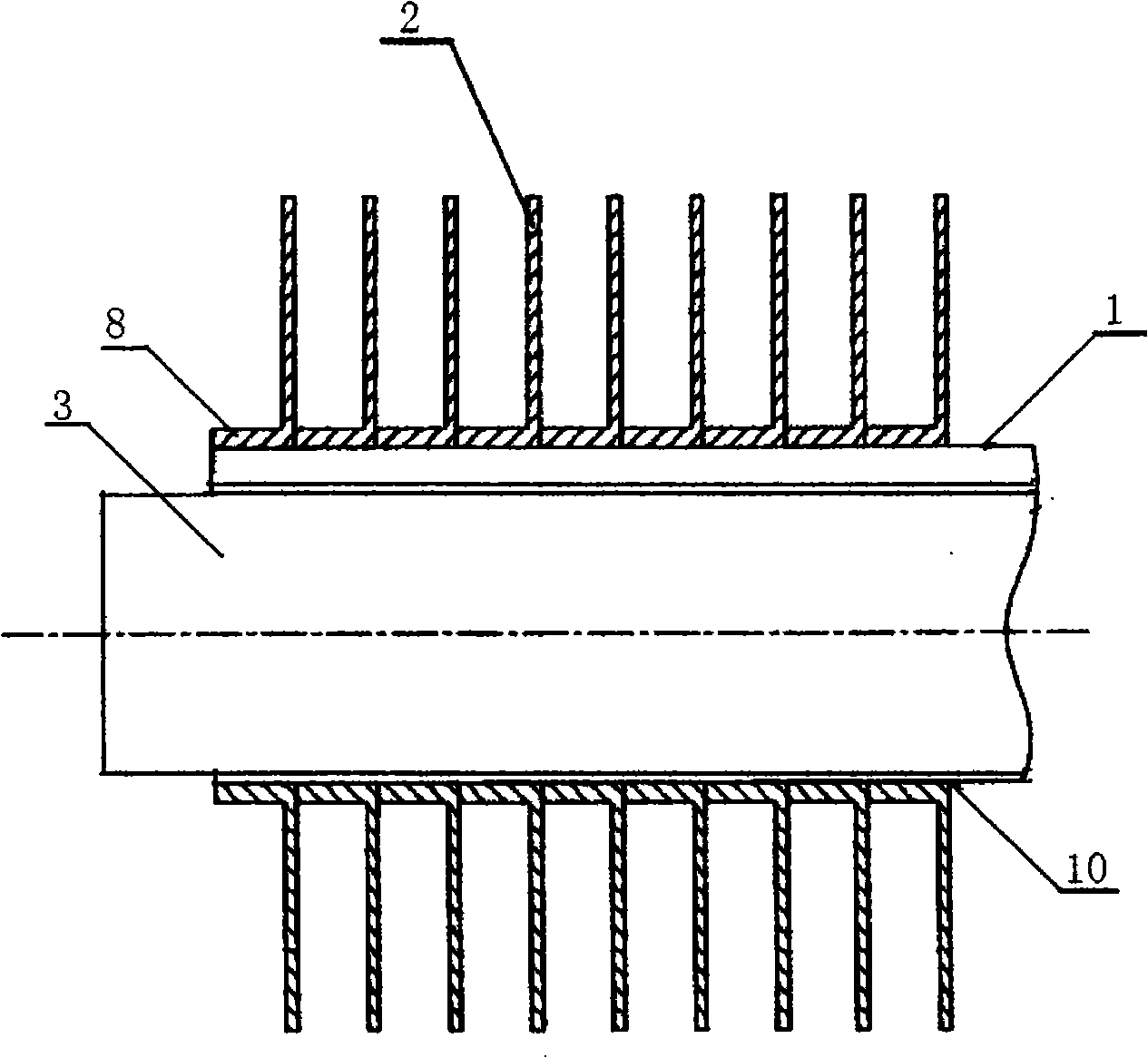

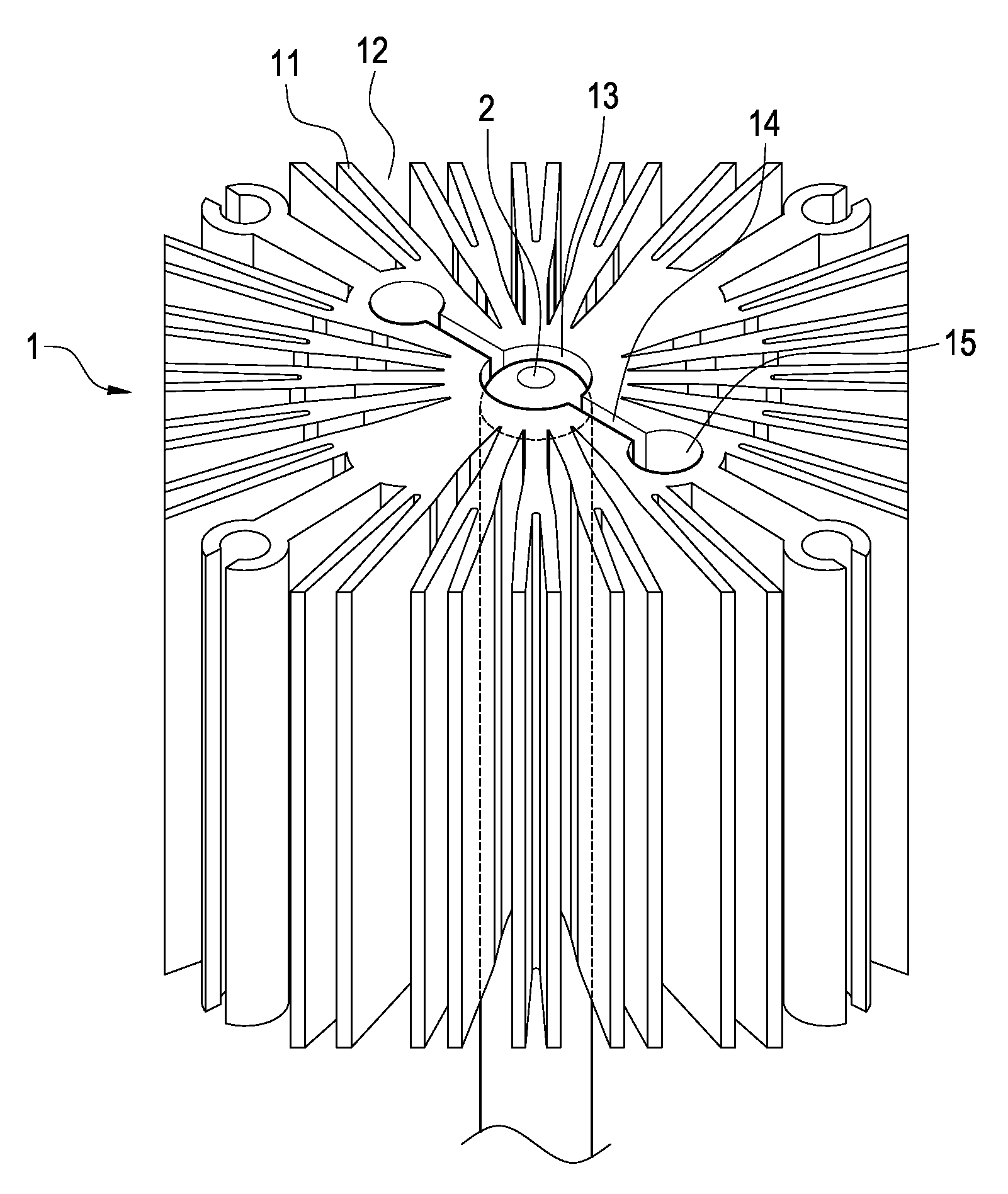

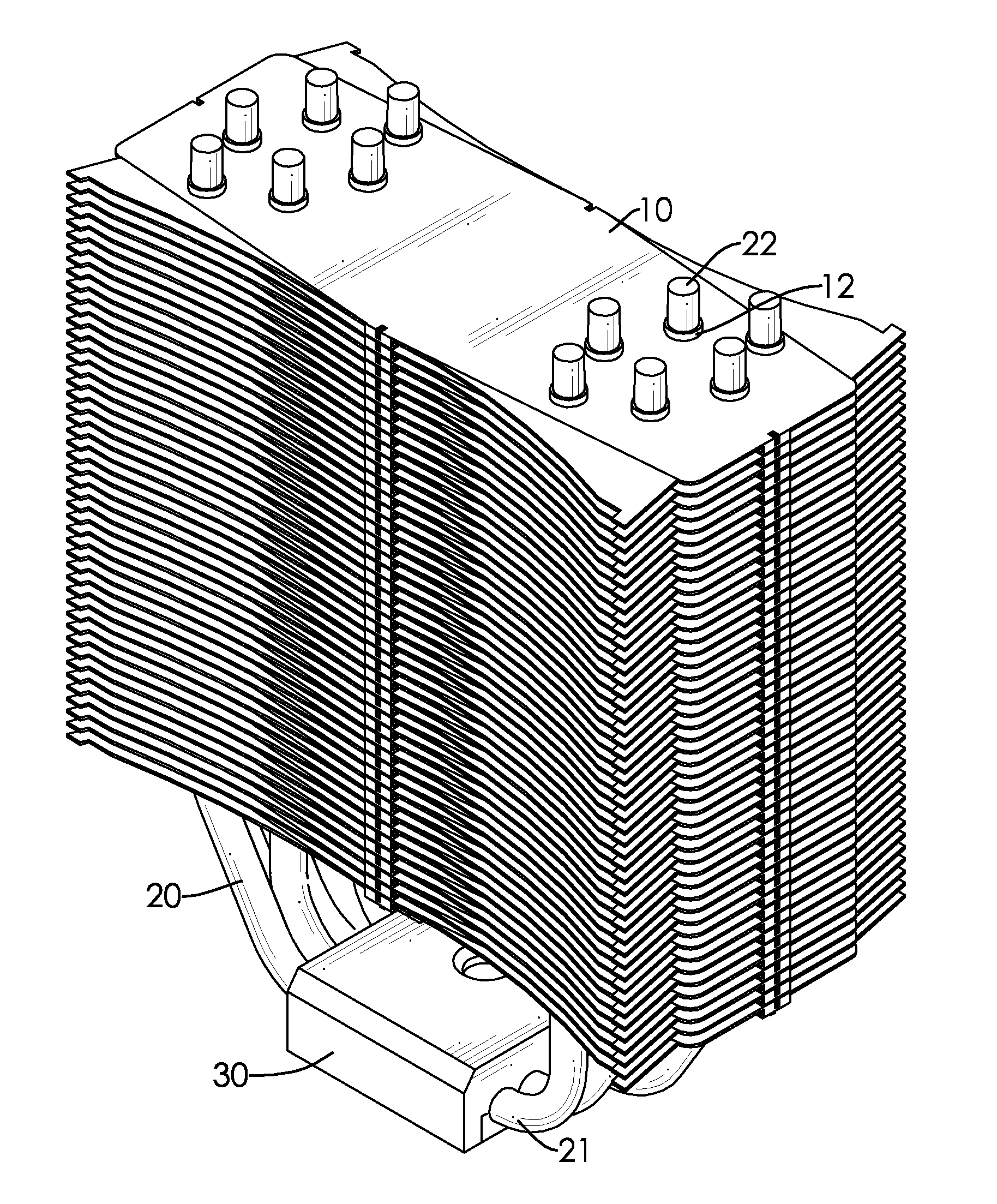

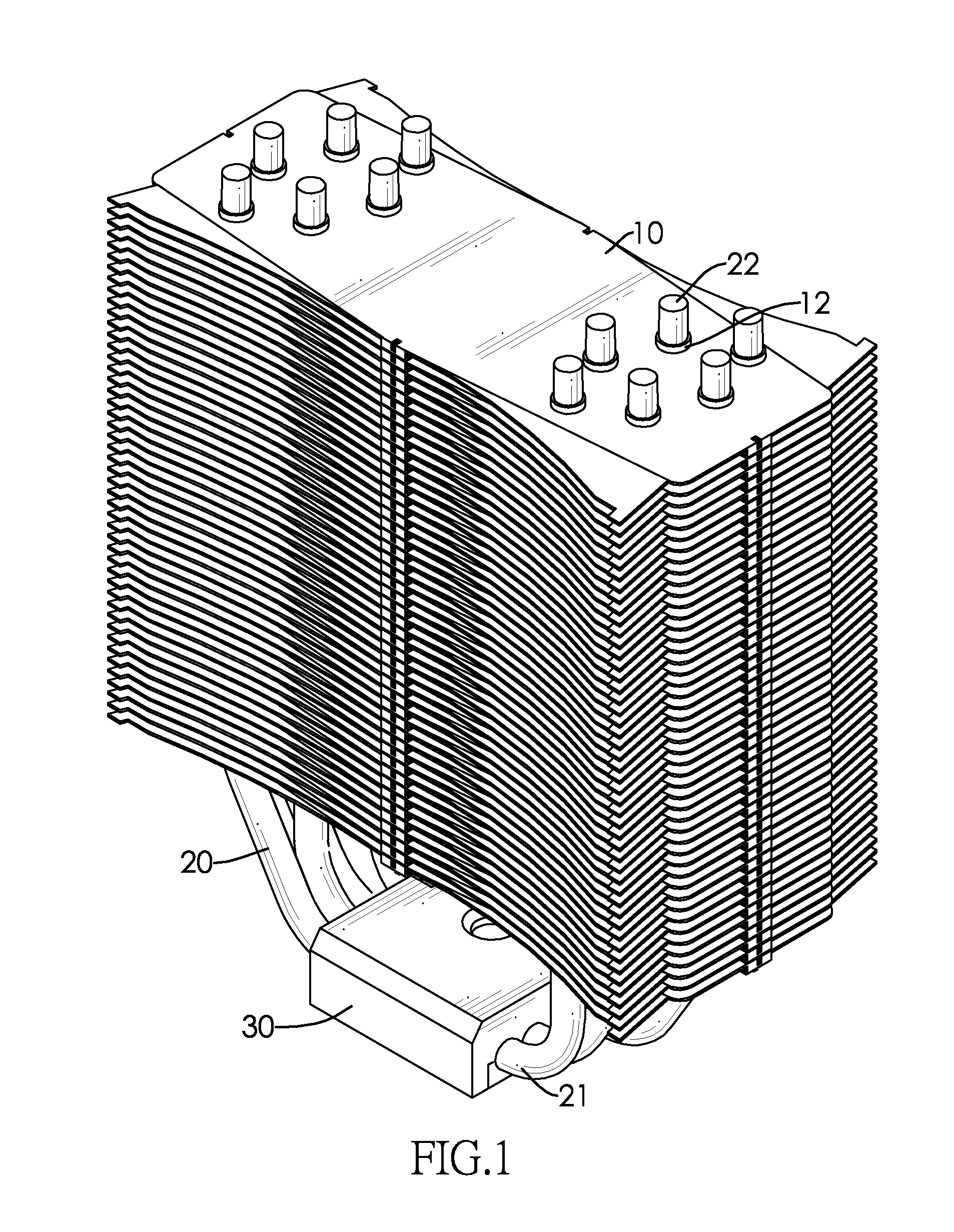

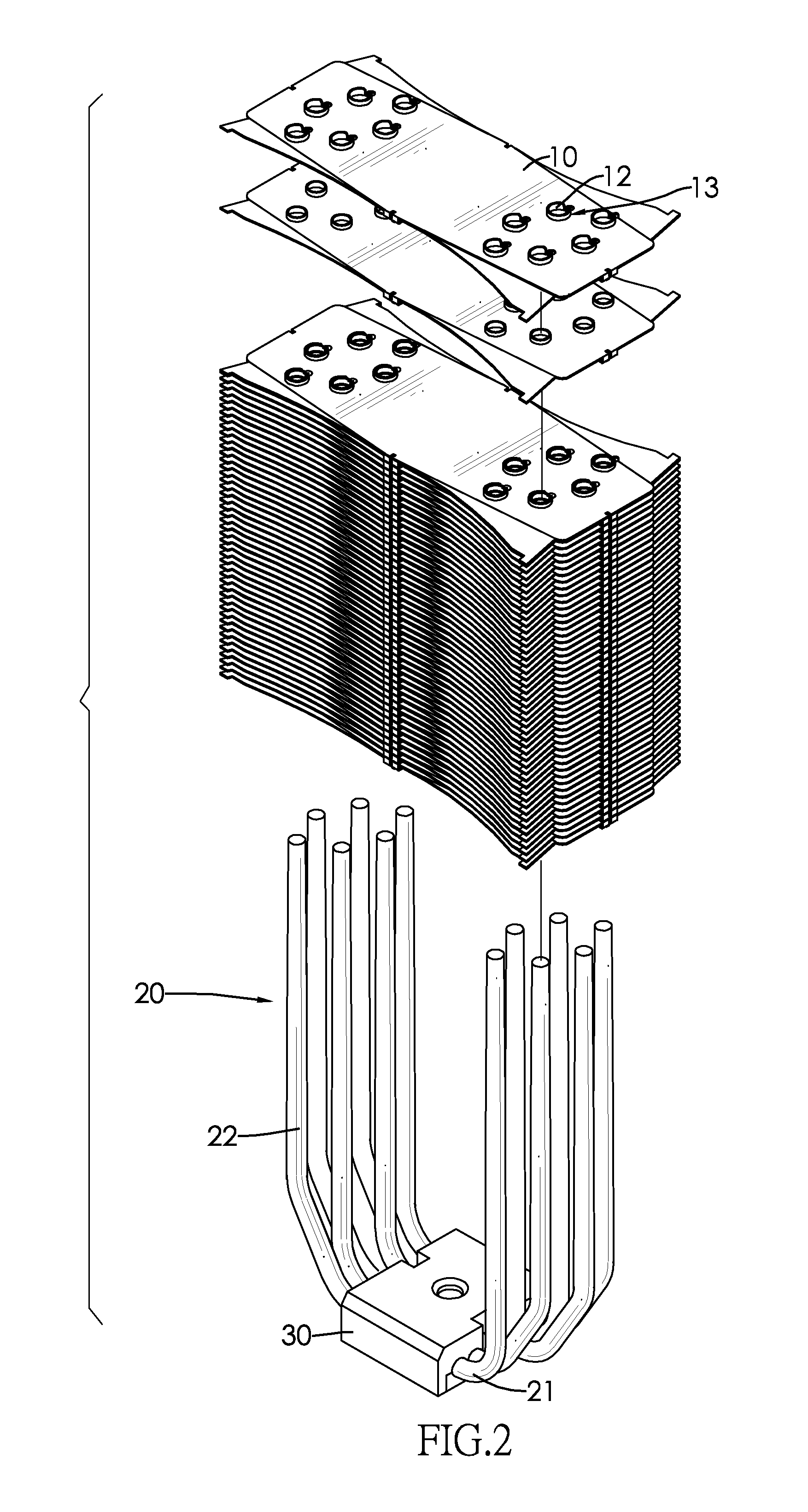

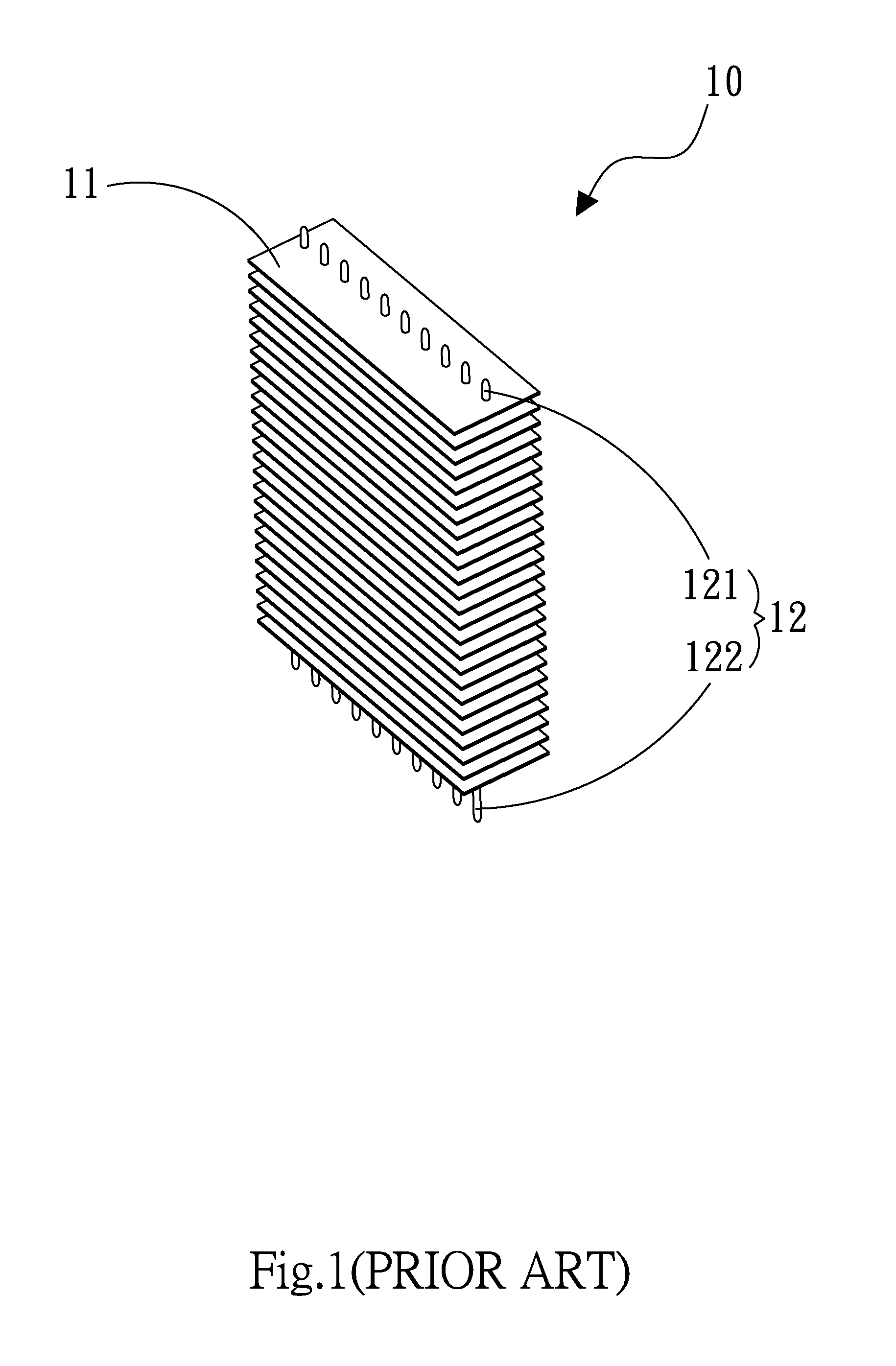

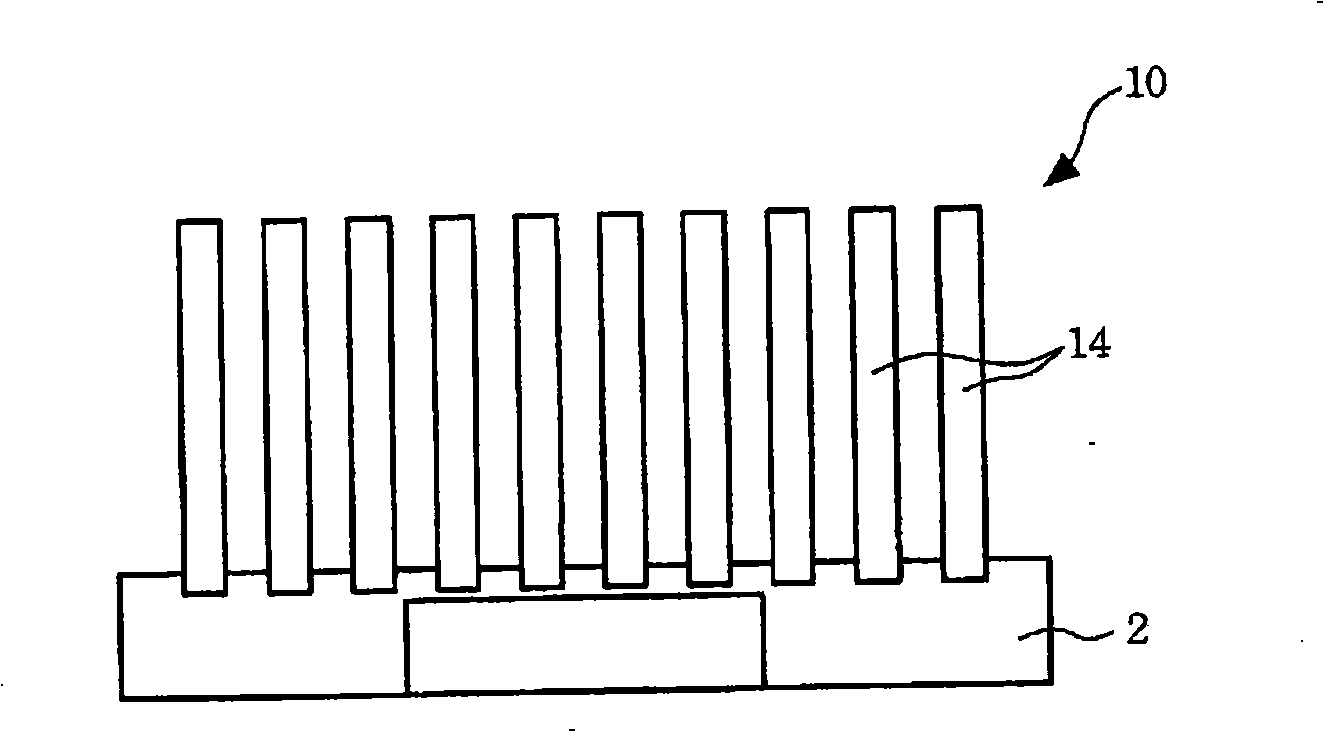

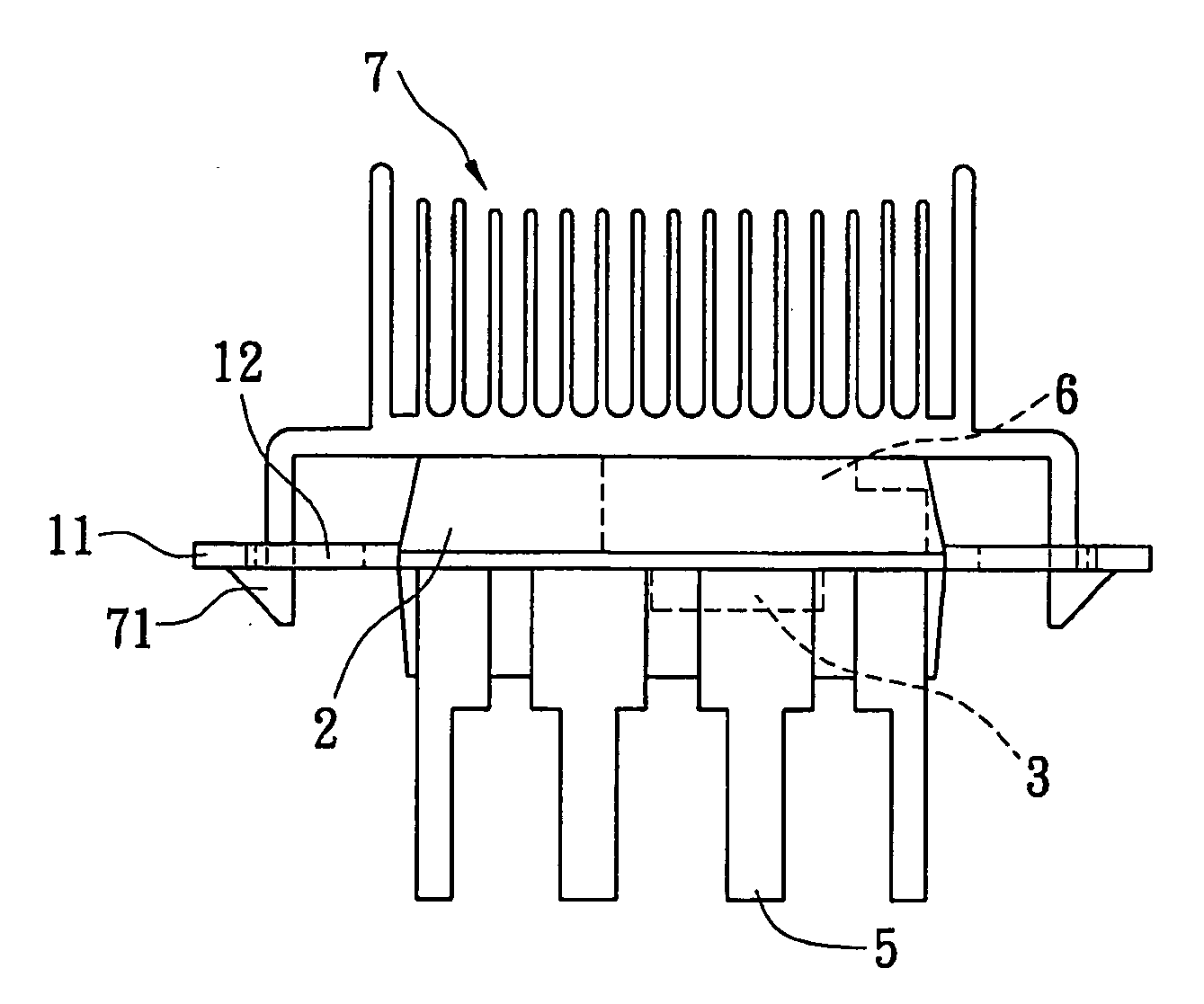

Heat sink

InactiveUS20110214842A1Good heat conduction efficiencyEfficiently dissipatedIndirect heat exchangersLaminated elementsEngineeringHeat pipe

A heat sink has a fin set and at least one heat pipe. The fin set has multiple stacked fins and at least one tapered tube. Each fin has at least one protrusion. The at least one protrusion protrudes from each fin and each protrusion has an internal surface. The at least one tapered tube is defined through corresponding protrusions of the fins. The at least one heat pipe has at least one tapered arm and a pipe wall. The tapered arm corresponds to and is mounted through a corresponding tapered tube of the fin set. The pipe wall of the heat pipe abuts the internal surfaces of corresponding protrusions of the fins tightly so heat can be dissipated efficiently during use.

Owner:LEA MIN TECH

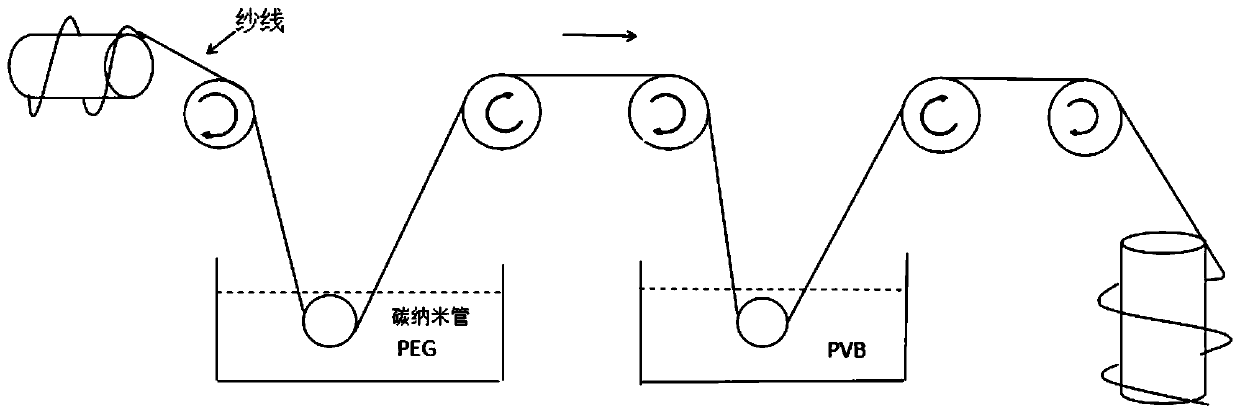

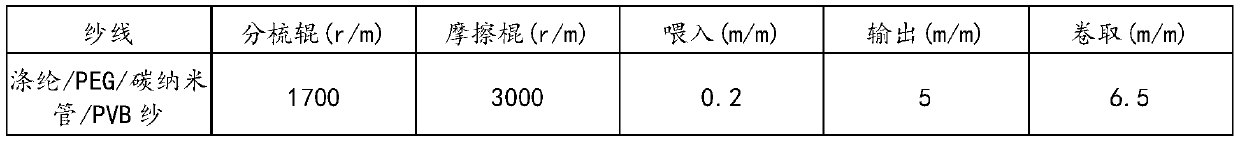

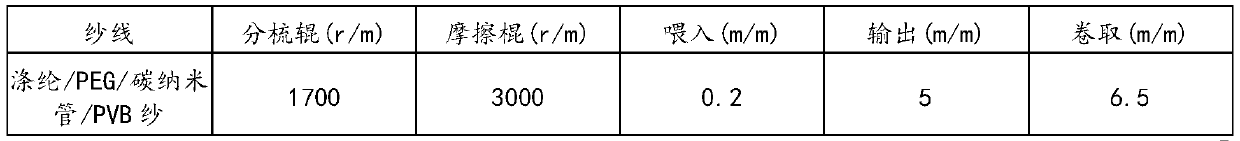

Friction-spun phase-change antistatic composite yarn and preparation method thereof

The invention relates to a friction-spun phase-change antistatic composite yarn and a preparation method thereof. The method comprises the following steps of 1, sequentially impregnating a polyester yarn in a mixture of polyethylene glycol (PEG) and carbon nanotubes, and a polyvinyl butyral (PVB) solution to obtain a polyester-PEG-carbon nanotube-PVB composite yarn; and 2, taking the polyester-PEG-carbon nanotube-PVB composite yarn as a core yarn and common synthetic fibers as wrapping fibers, and performing friction spinning to prepare the polyester-PEG-carbon nanotube-PVB-synthetic fiber composite yarn. The composite yarn has the advantages that 1, the composite yarn is high in phase change enthalpy value, good in heat storage effect, high in heat transfer efficiency and good in antistatic property; 2, the preparation method is simple, economical and rapid; 3, the service life is long, and the thermal cycle performance is stable; 4, the phase change temperature is adjustable; and 5,the raw material applicability is good, and the problem that a core yarn is difficult to prepare by ring spinning after non-uniform PEG sizing can be solved.

Owner:WUHAN TEXTILE UNIV

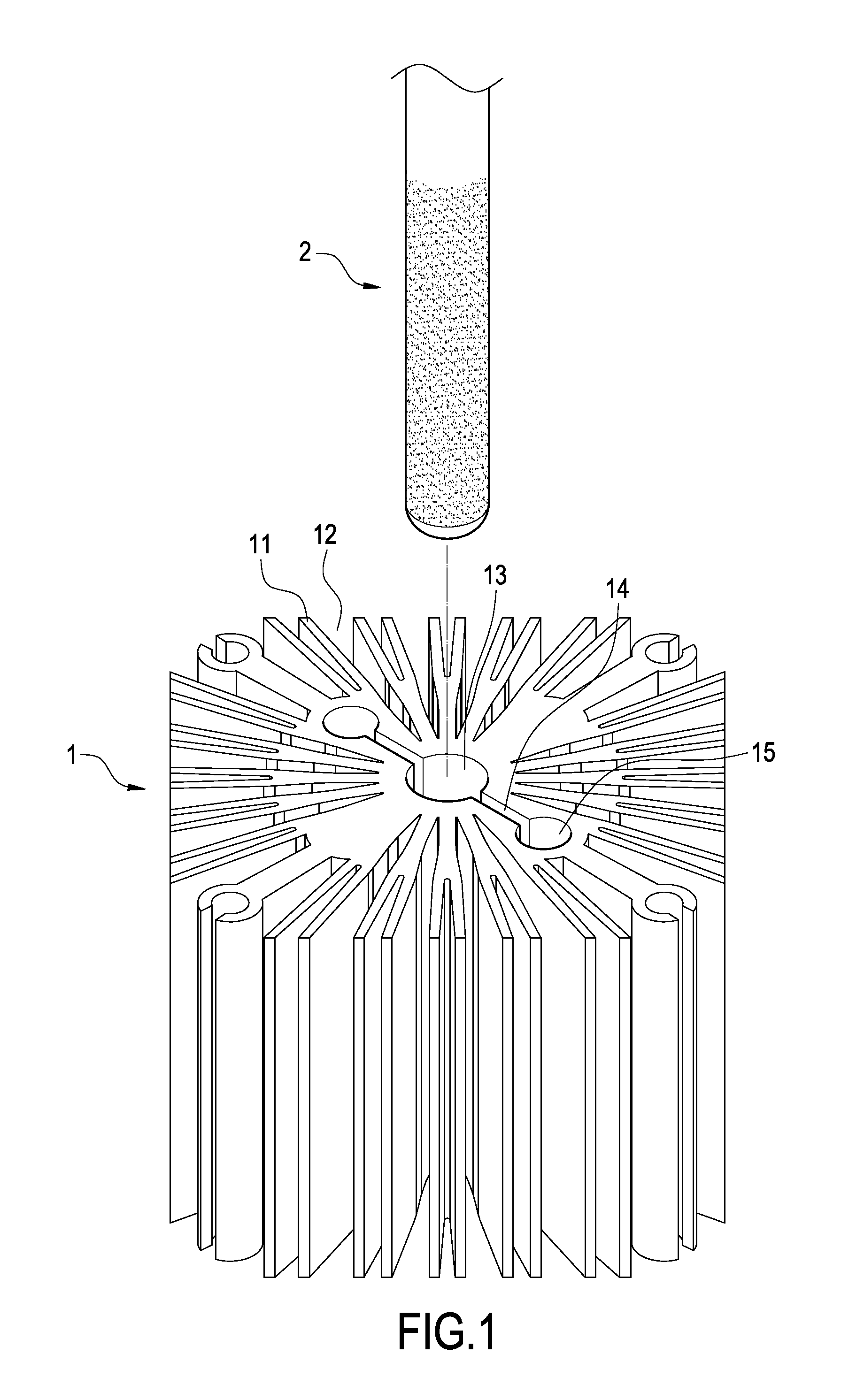

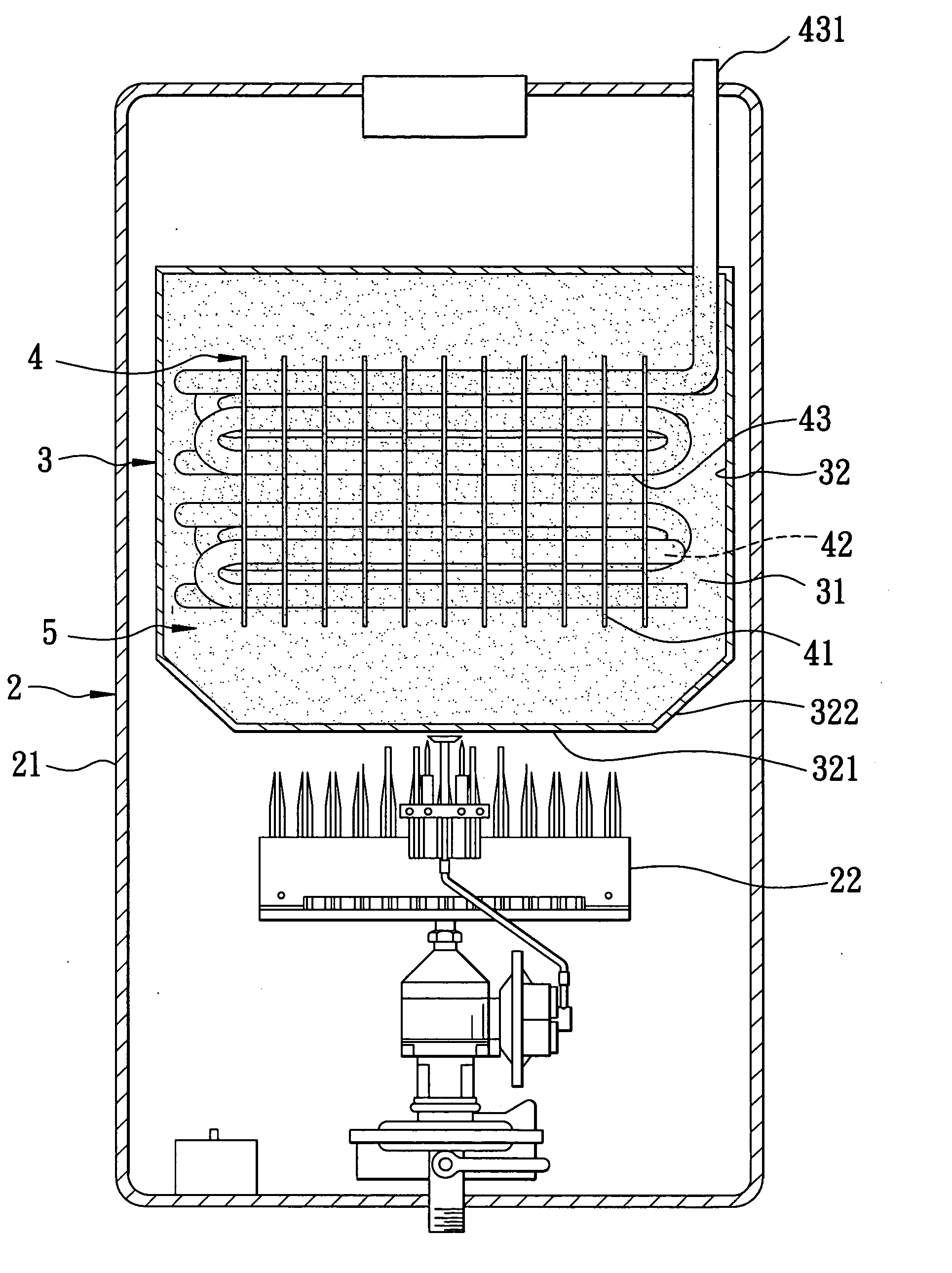

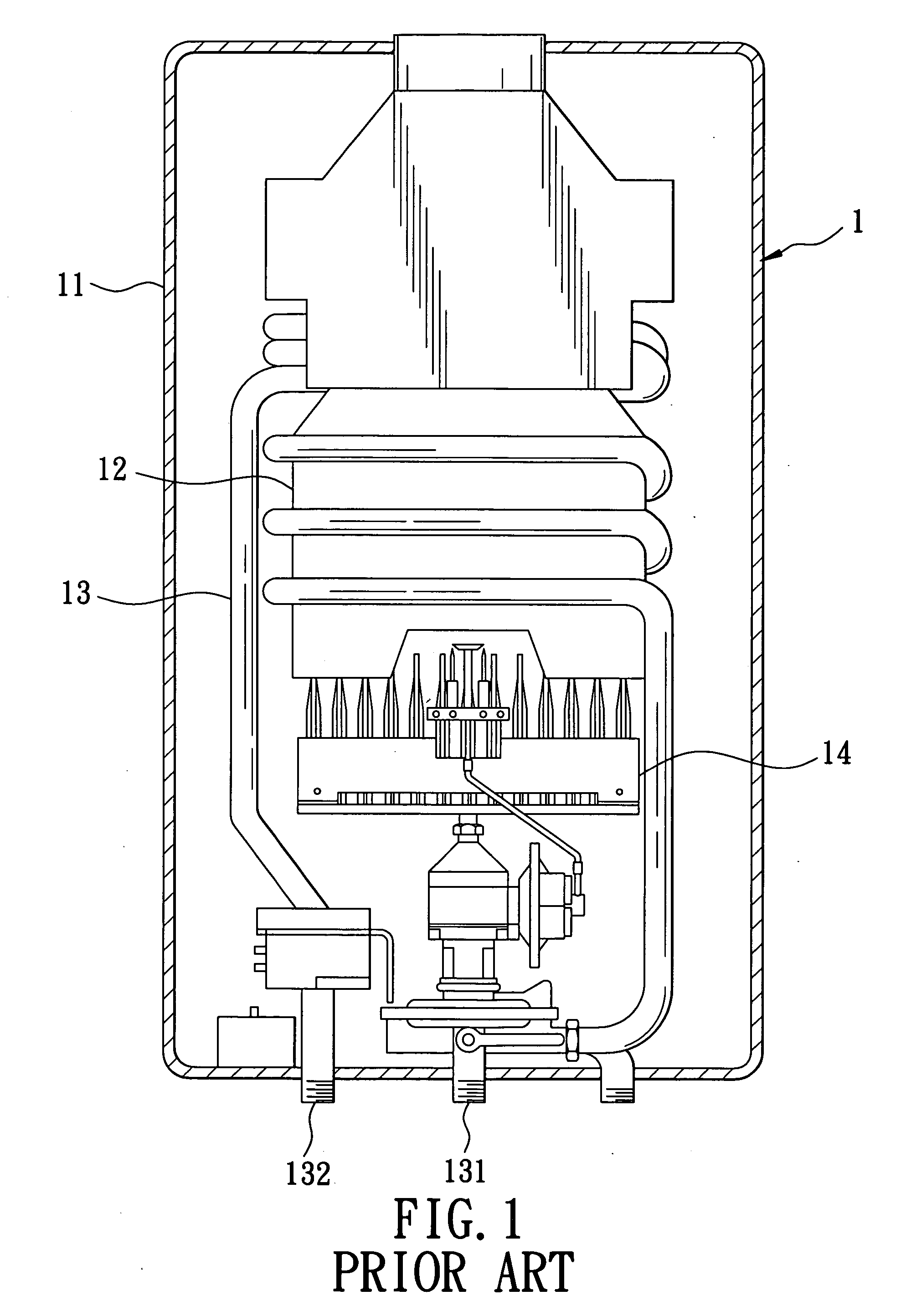

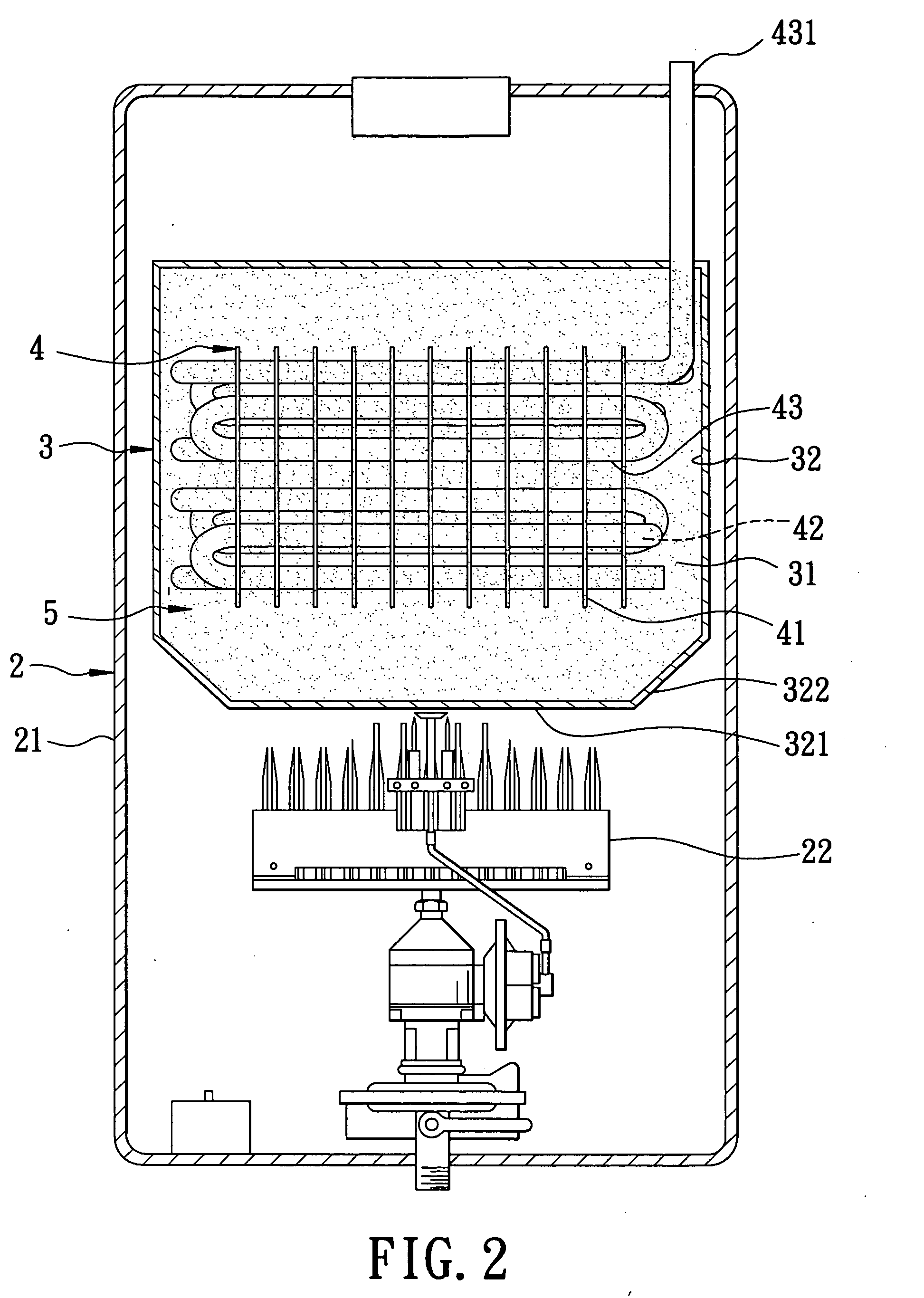

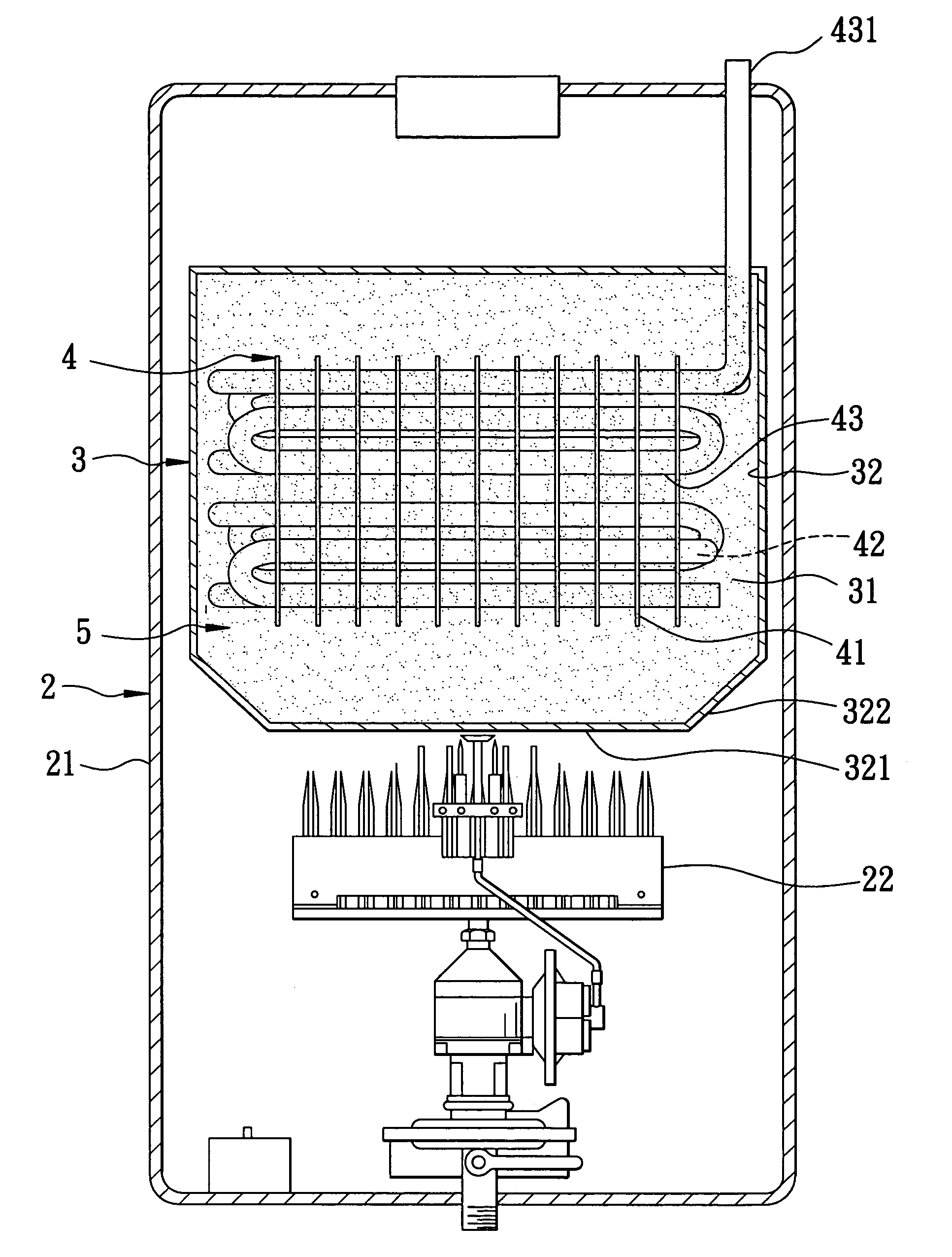

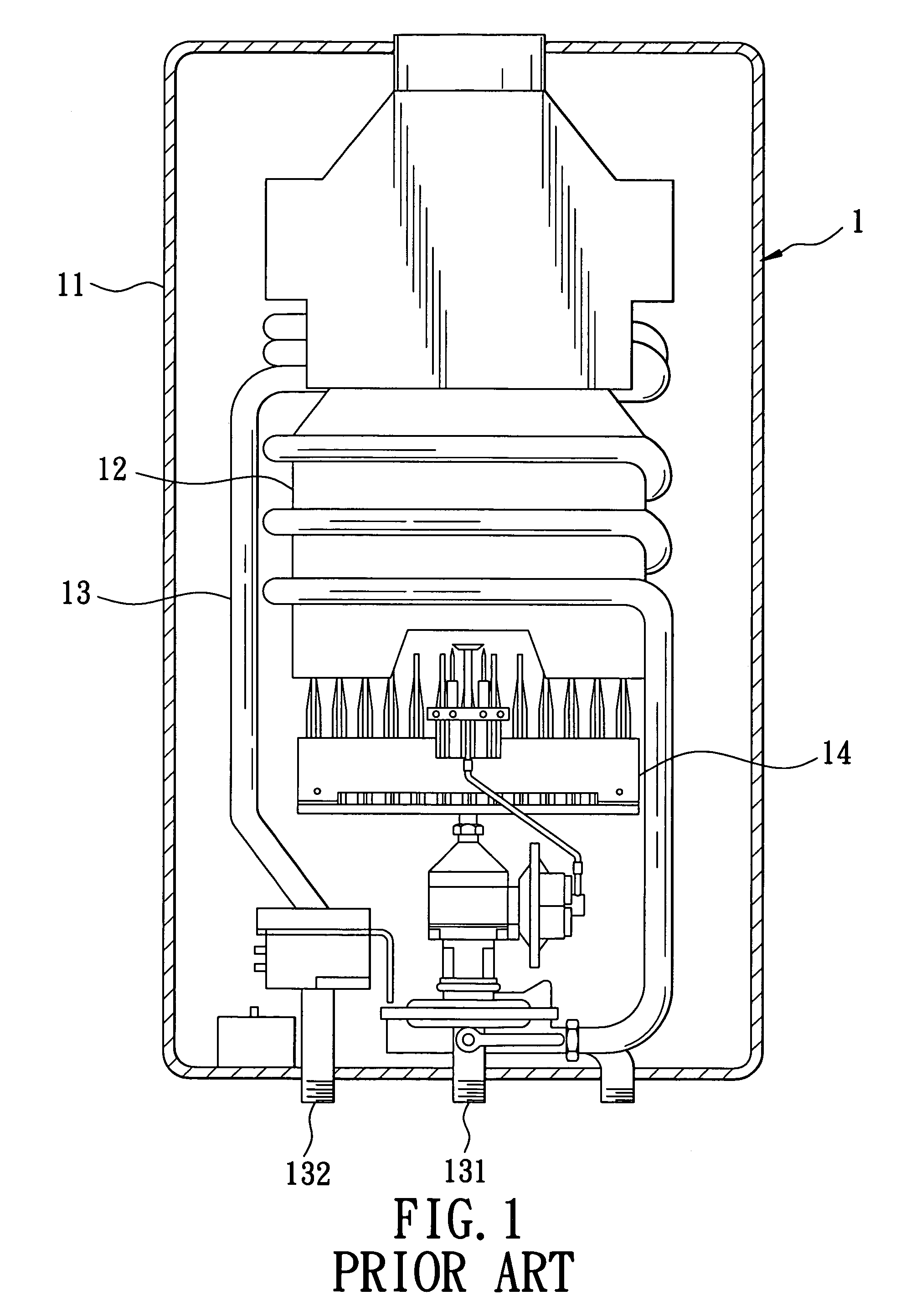

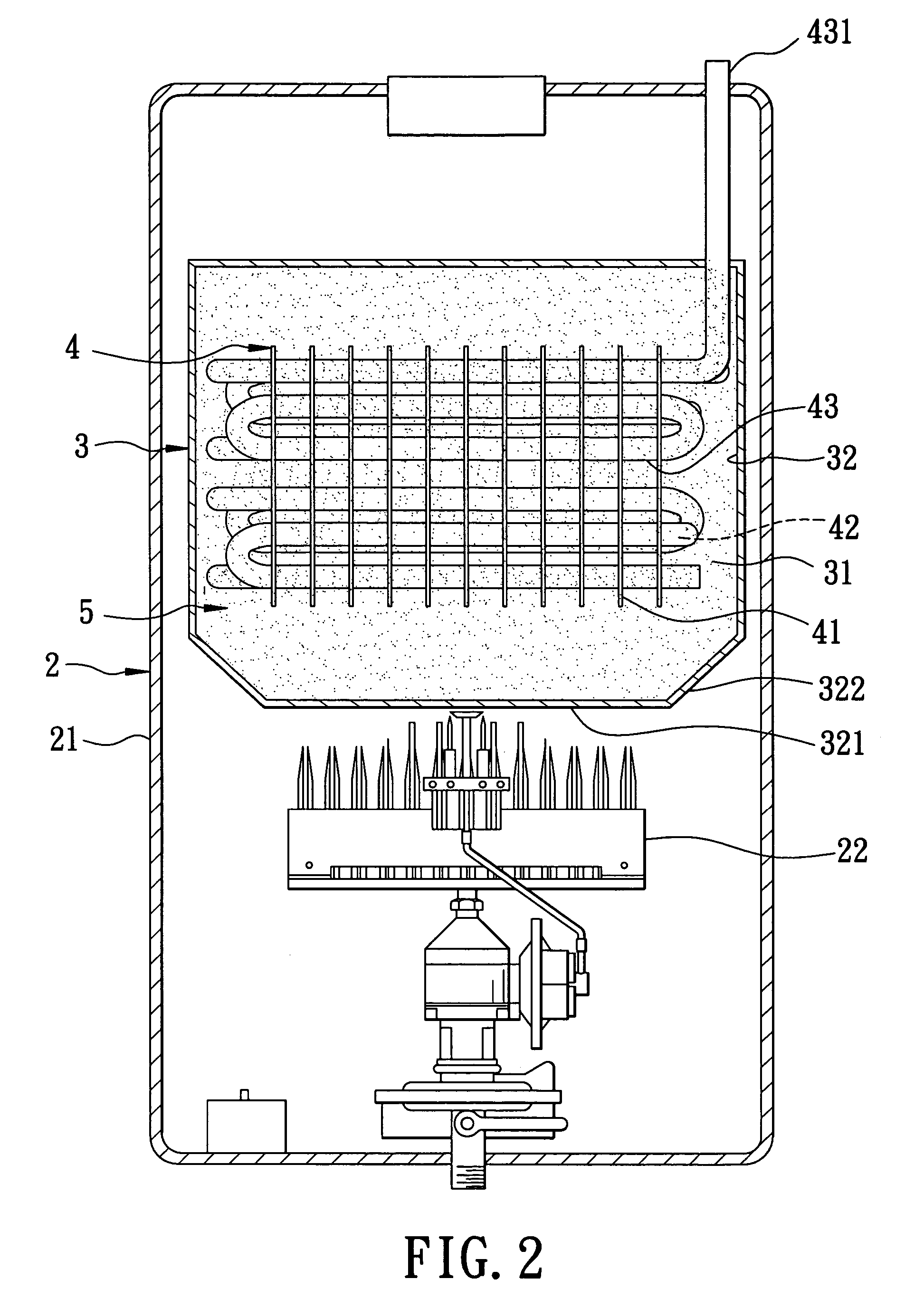

Heat conducting assembly for a water heater, and method for making the heat conducting assembly

InactiveUS20070133963A1Good heat conduction efficiencyReduce energy consumptionCooking vesselsBeverage vesselsHeat conductingEngineering

In a heat conducting assembly for a water heater and a method for making the heat conducting assembly, there is provided a heat-conductive housing which has inner wall surfaces that cooperate to confine a sealed chamber. A heat-conductive unit is disposed in the sealed chamber. Heat-conductive particles are disposed in the sealed chamber, and are caused to accumulate on the inner wall surfaces of the heat-conductive housing and outer wall surfaces of the heat-conductive unit for heating water in the heat-conductive unit.

Owner:LUO CHIN KUANG

Heat conducting assembly for a water heater, and method for making the heat conducting assembly

InactiveUS7319814B2Good heat conduction efficiencyReduce energy consumptionCooking vesselsBeverage vesselsHeat conductingEngineering

In a heat conducting assembly for a water heater and a method for making the heat conducting assembly, there is provided a heat-conductive housing which has inner wall surfaces that cooperate to confine a sealed chamber. A heat-conductive unit is disposed in the sealed chamber. Heat-conductive particles are disposed in the sealed chamber, and are caused to accumulate on the inner wall surfaces of the heat-conductive housing and outer wall surfaces of the heat-conductive unit for heating water in the heat-conductive unit.

Owner:LUO CHIN KUANG

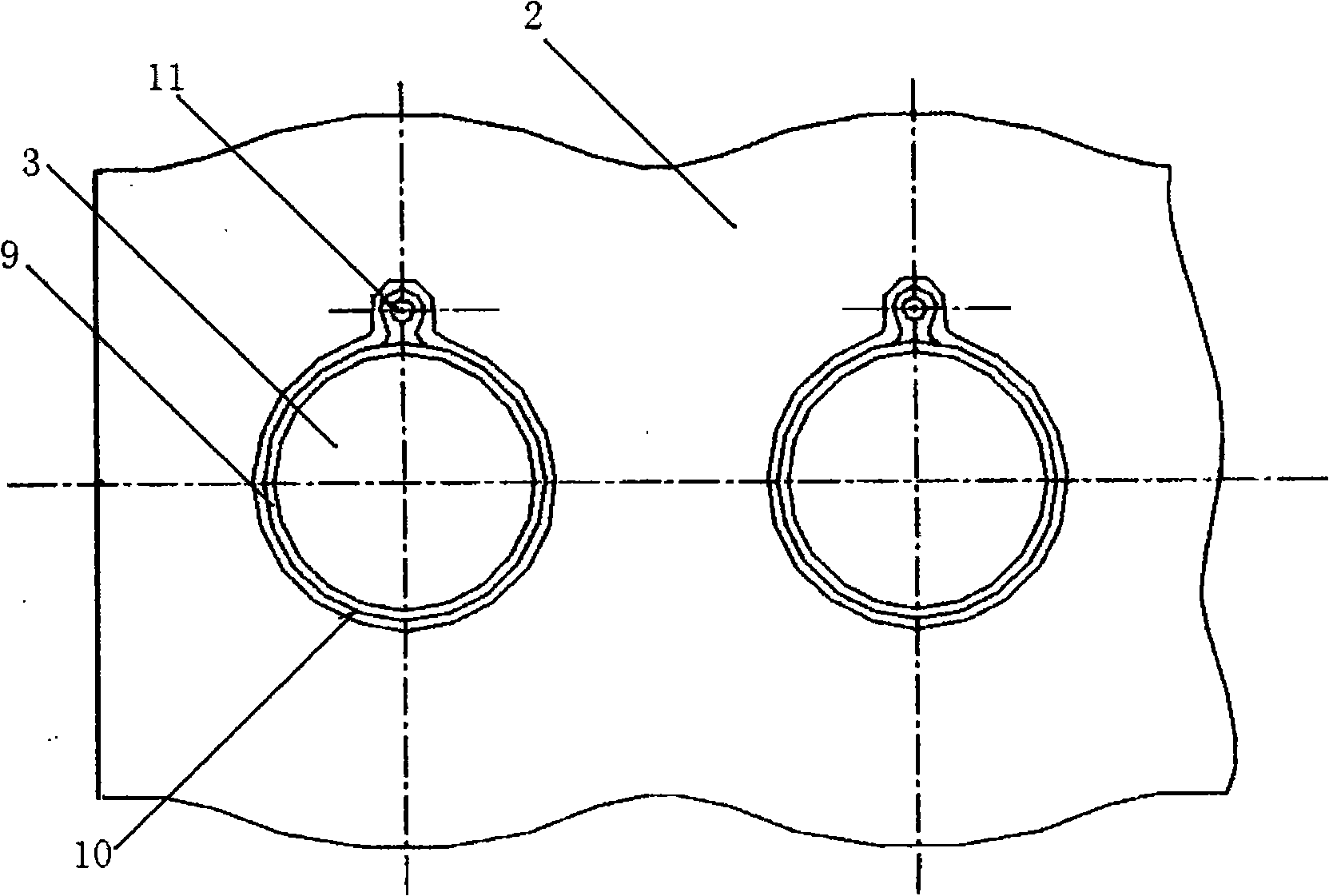

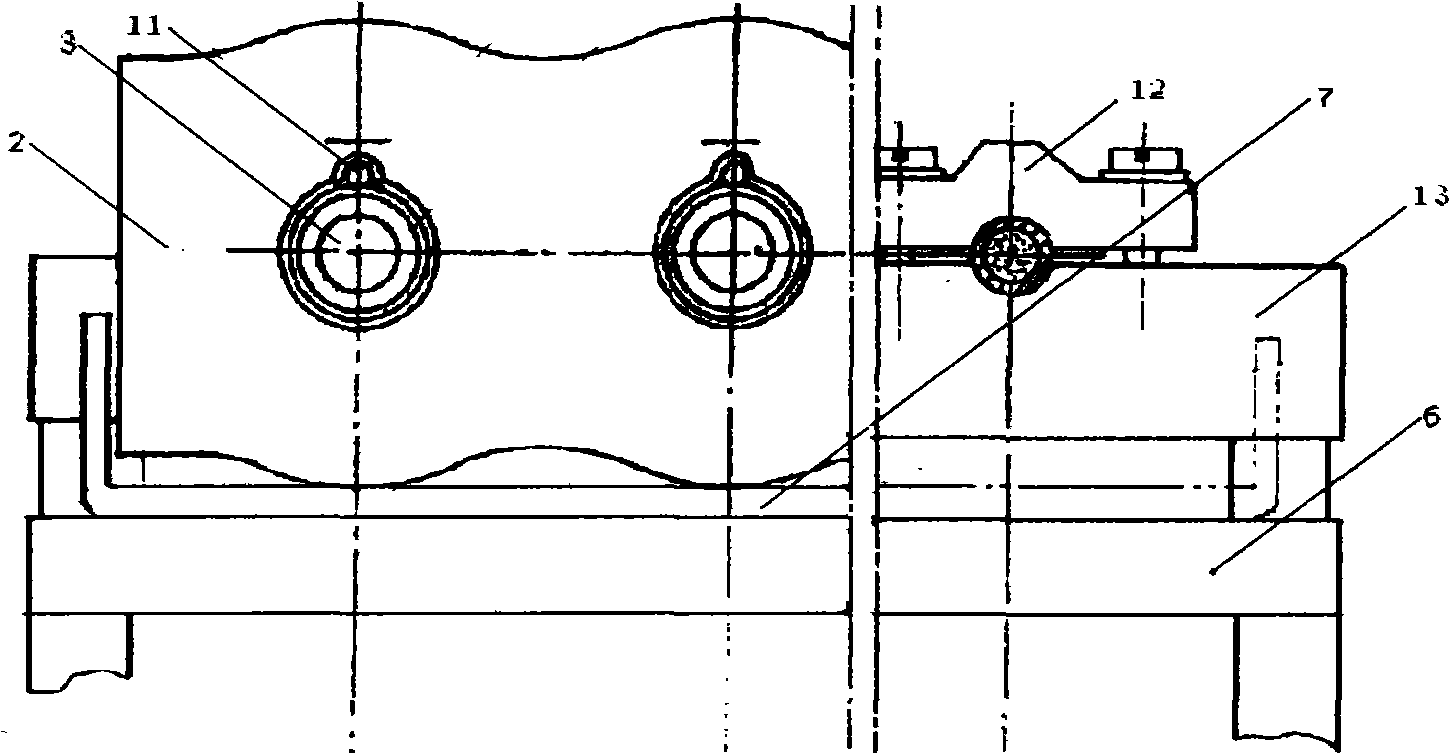

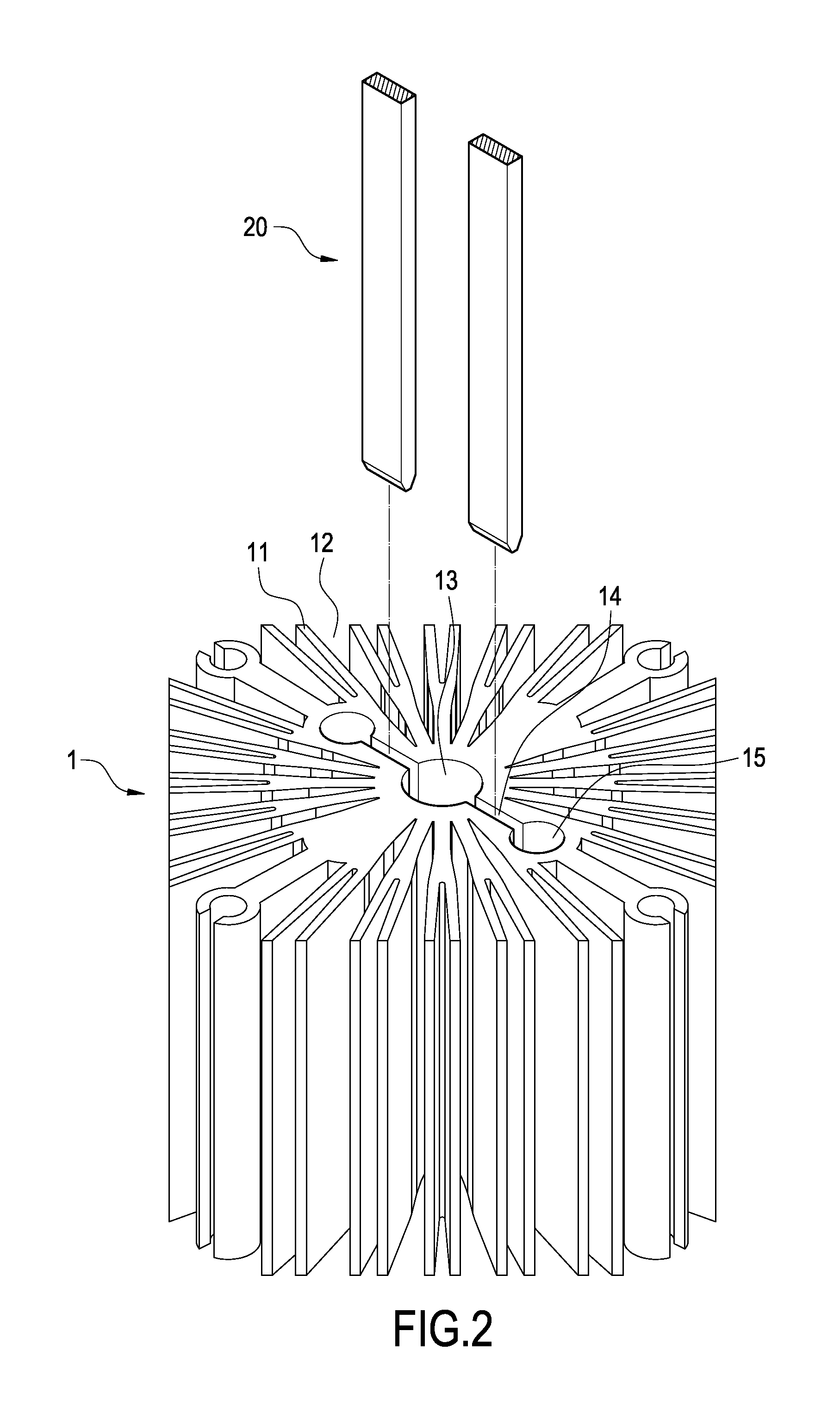

Method for manufacturing heat dissipating apparatus

InactiveUS8656590B2Good heat conduction efficiencySemiconductor/solid-state device detailsSolid-state devicesPunchingHeat pipe

An exemplary method for manufacturing a heat dissipation apparatus includes, firstly, providing a fin assembly including a stack of fins spaced from each other. Each fin defines a through hole therein, and includes a collar formed at an edge of the through hole. Then a heat pipe is provided, and inserted in the through holes of the fins. Next, two opposing punching tools are provided. Each punching tool defines a series of recesses. The subassembly of the heat pipe and fins is positioned between the two punching tools, with the collar of each fin located between two corresponding recesses of the two punching tools. The two punching tools punch the collars of the fins from two opposite sides of the collars. Thereby, the collars shrink inwardly and press the heat pipe to deform until the heat pipe is fittedly mounted in the collars of the fins.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

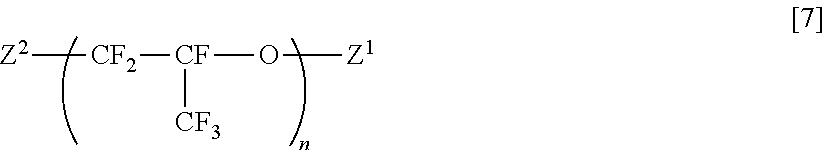

Thermally conductive resin composition and thermally conductive sheet including the same

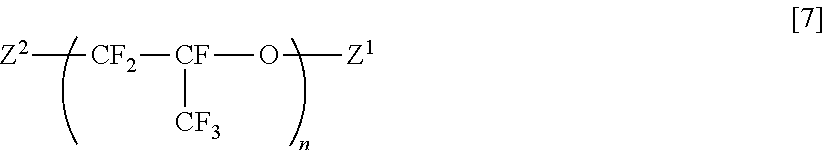

ActiveUS20130240778A1Improve heat resistanceGood low hardnessSolid-state devicesHeat-exchange elementsPolymer chemistryFluorine

A thermally conductive resin composition containing (A1) a fluorine-based compound having one to two terminal SiH group(s), in which a content of molecules having two such groups is 60 to 100 mole %, (B1) a fluorine-based compound having one to two terminal alkenyl group(s), in which a content of molecules having two such groups is 60 to 100 mole %, (A2) a fluorine-based compound in which a content of molecules having two terminal SiH groups is 0 to 40 mole %, (B2) a fluorine-based compound in which a content of molecules having two terminal alkenyl groups is 0 to 40 mole %, and (C) a thermally conductive filler, and satisfying, in connection with the content of the fluorine-based compounds, relation of [(A1)+(B1)] / [(A2)+(B2)]=20 / 80 to 80 / 20 and (A1) / (B1) and (A2) / (B2)=20 / 80 to 80 / 20, as well as a thermally conductive sheet including the same are provided.

Owner:VALQUA LTD

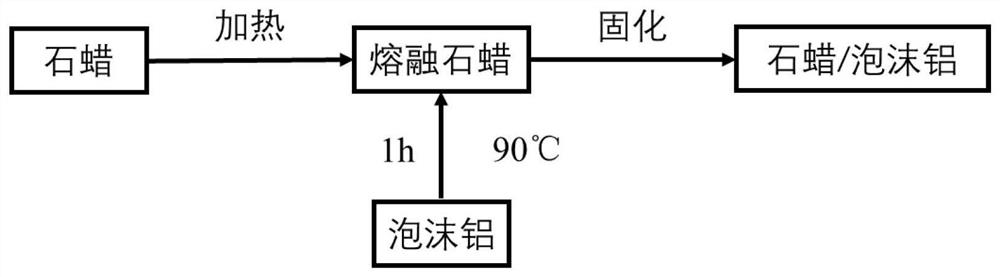

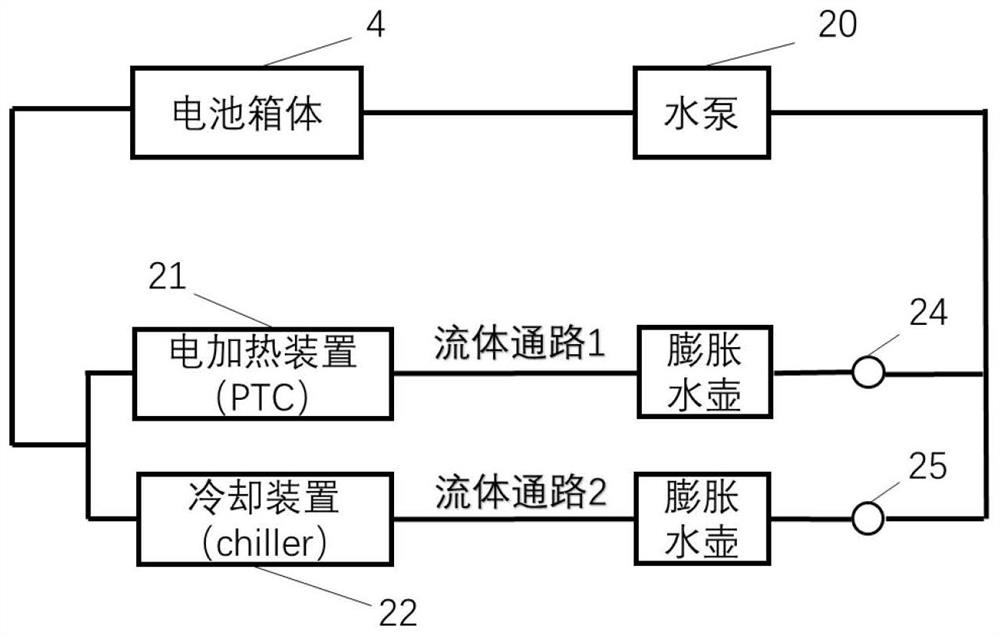

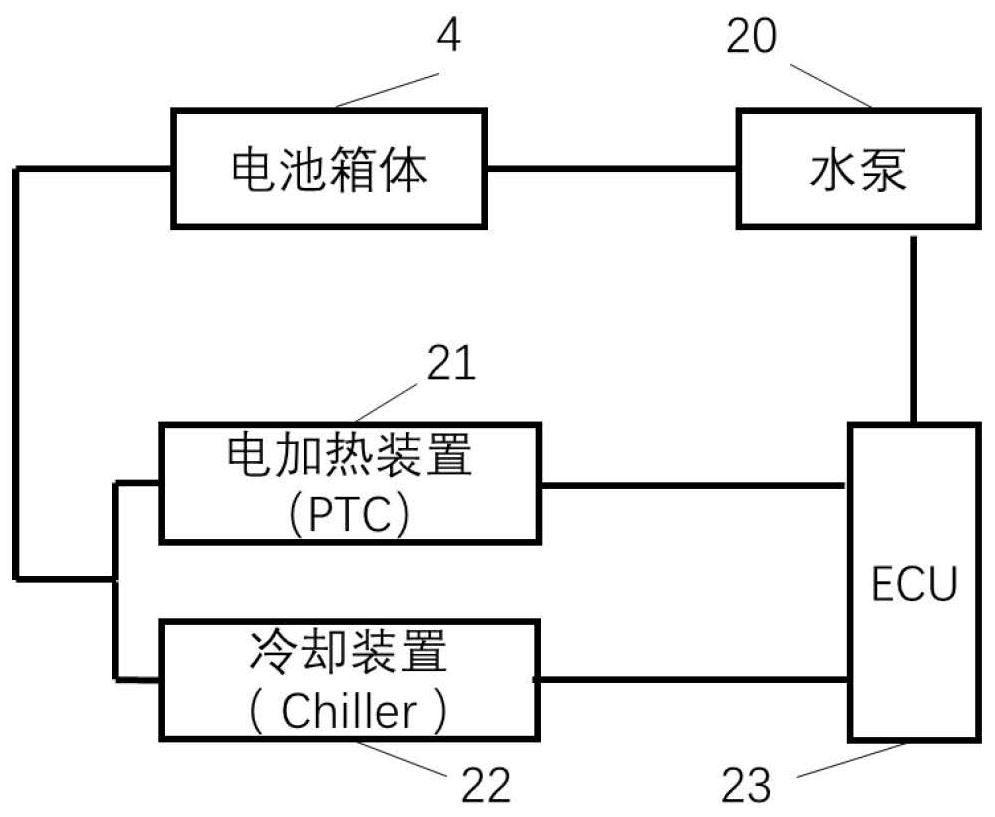

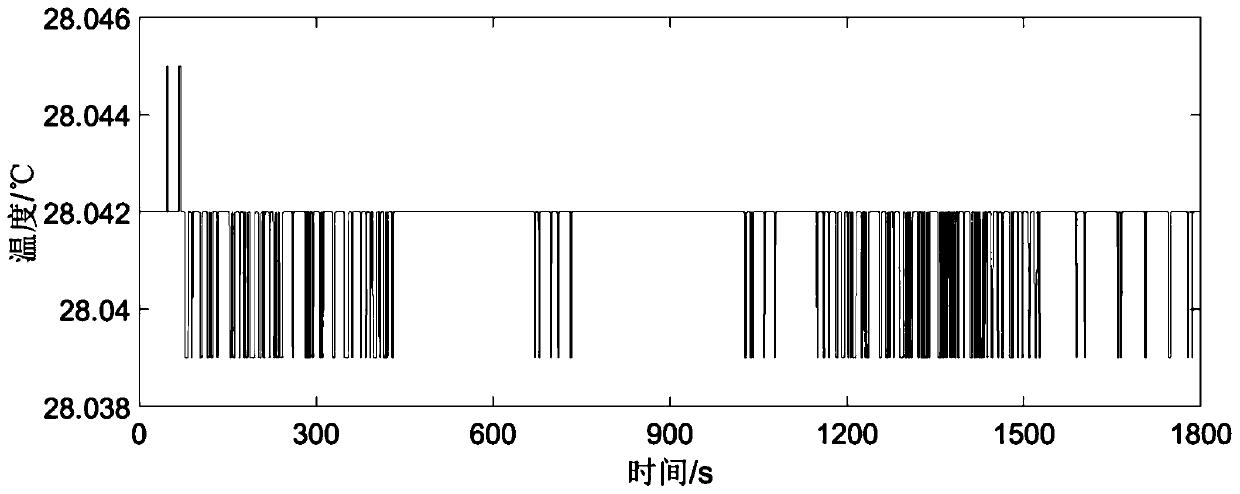

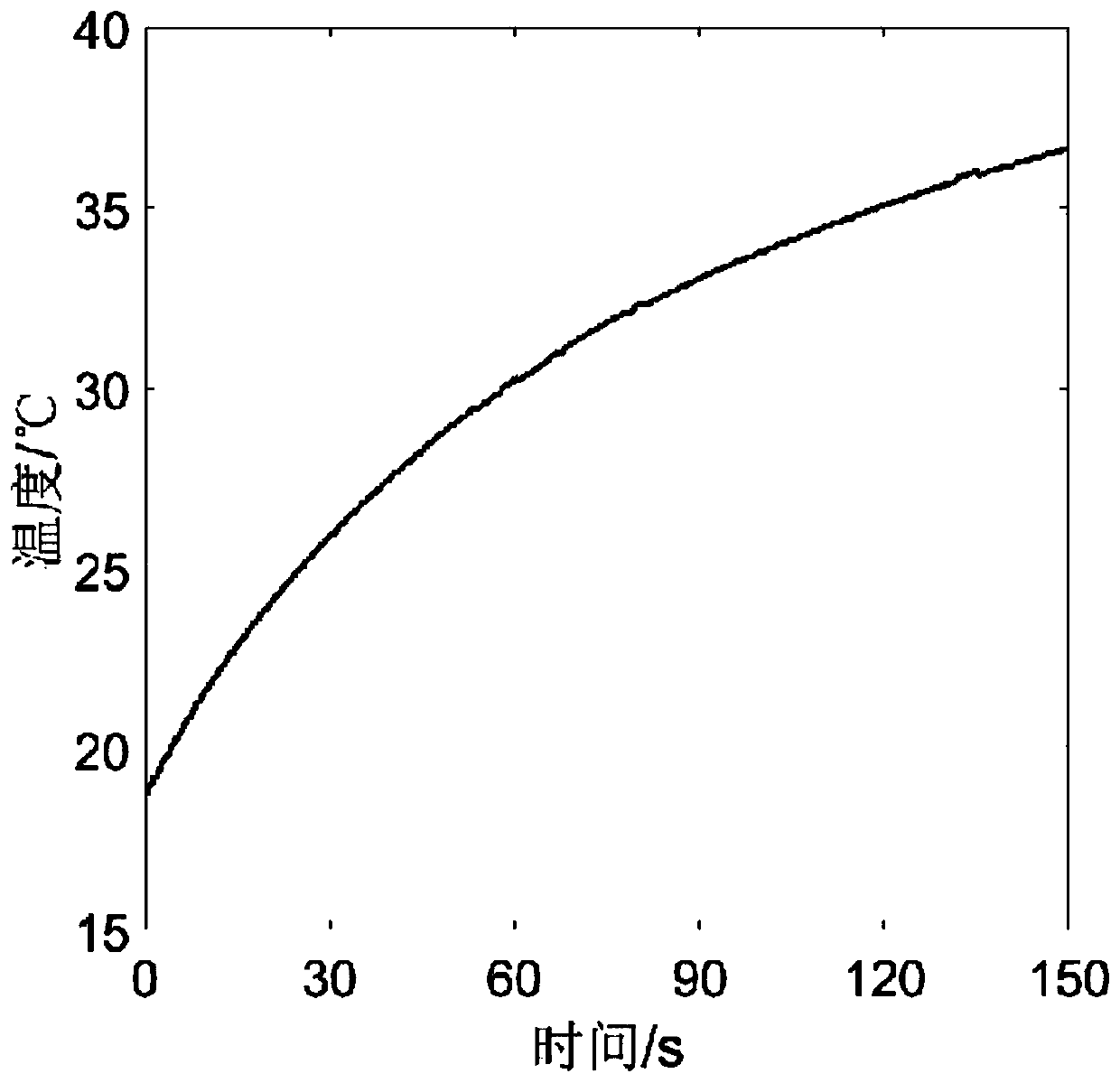

Electric vehicle battery temperature management system based on mixing of composite phase change material and liquid cooling

ActiveCN113314783ASpeed up the melting processGood heat conduction efficiencySecondary cellsVehicular energy storageTemperature controlElectrical battery

The embodiment of the invention discloses an electric vehicle battery temperature management system based on liquid cooling and composite phase change material mixing. The battery temperature management system comprises a composite phase change material, a battery box body and a heat exchange system. The lithium ion battery columns are arranged in the battery box body in a layered and staggered manner, vertical snakelike three-layer hollow metal plates are arranged among the layers, and the outer layer is a phase-change material filling shell layer; and the middle layer is a heat exchange fluid channel and is communicated with the corresponding hollow box wall. According to the battery temperature management system, temperature monitoring is conducted through the temperature sensors near the electrodes, the real-time temperature can be transmitted to the vehicle-mounted electronic control unit ECU, then heat preservation treatment can be conducted on the battery through the heat exchange system when the temperature of the battery is too high or too low, the battery is made to be within the constant temperature range, and the battery temperature management system has wide application prospects. The battery temperature management system has the main technical characteristics of high heat conduction efficiency, uniform temperature distribution and stable temperature control effect.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Manufacturing method of heat conducting device

ActiveUS10663231B2Prevent subsidenceGood heat conduction efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

Owner:DELTA ELECTRONICS INC

Optical interference light source device of current-temperature control semiconductor laser and measurement system thereof

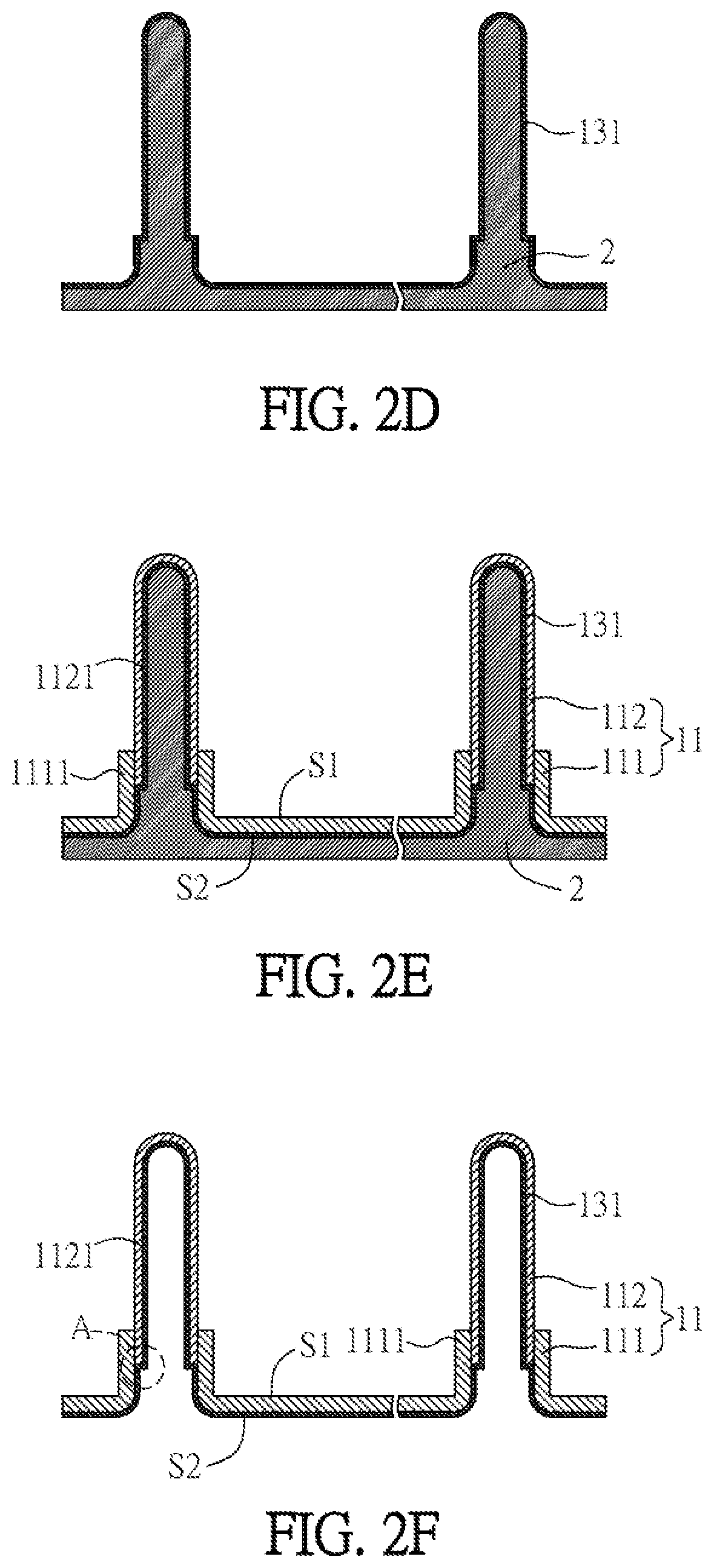

PendingCN110011178AChange temperatureRealize regulationLaser detailsSemiconductor laser structural detailsTemperature controlPower flow

The invention discloses an optical interference light source device of a current-temperature control semiconductor laser. The optical interference light source device comprises a heating panel, an annular semiconductor cooling piece, a semiconductor laser, a PCB, a head sensor and a fixed plate, the centers of the two sides of the PCB are respectively provided with a first circular windowing copper area and a second circular windowing copper area, and the first circular windowing copper area is in contact with the second circular windowing copper area through a via hole; the lower end of the housing of the semiconductor laser is connected with the first circular windowing copper area through heat conducting silicone grease, and the cooling surface of the annular semiconductor cooling pieceis connected with the first circular windowing copper area through the heat conducting silicone grease; the heating surface of the annular semiconductor cooling piece is connected with the heating panel through the heat conducting silicone grease; the heat sensor is arranged on the first circular windowing copper area to detect the temperature of the first circular windowing copper area. The present invention further discloses a measurement system. The structure is simple, the thermal conductivity is good, the temperature control precision is high and the output wavelength of the laser is stable.

Owner:GUANGDONG UNIV OF TECH

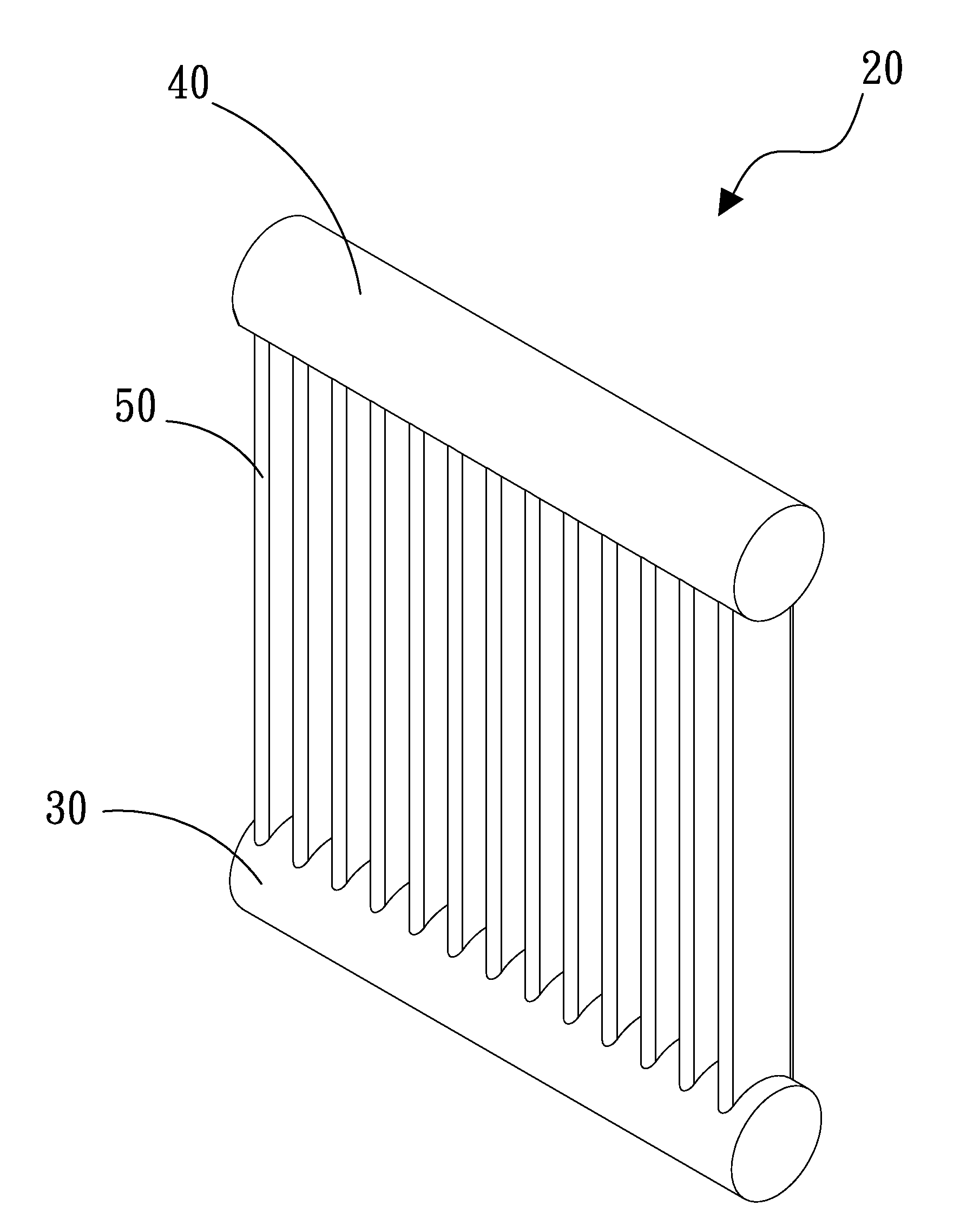

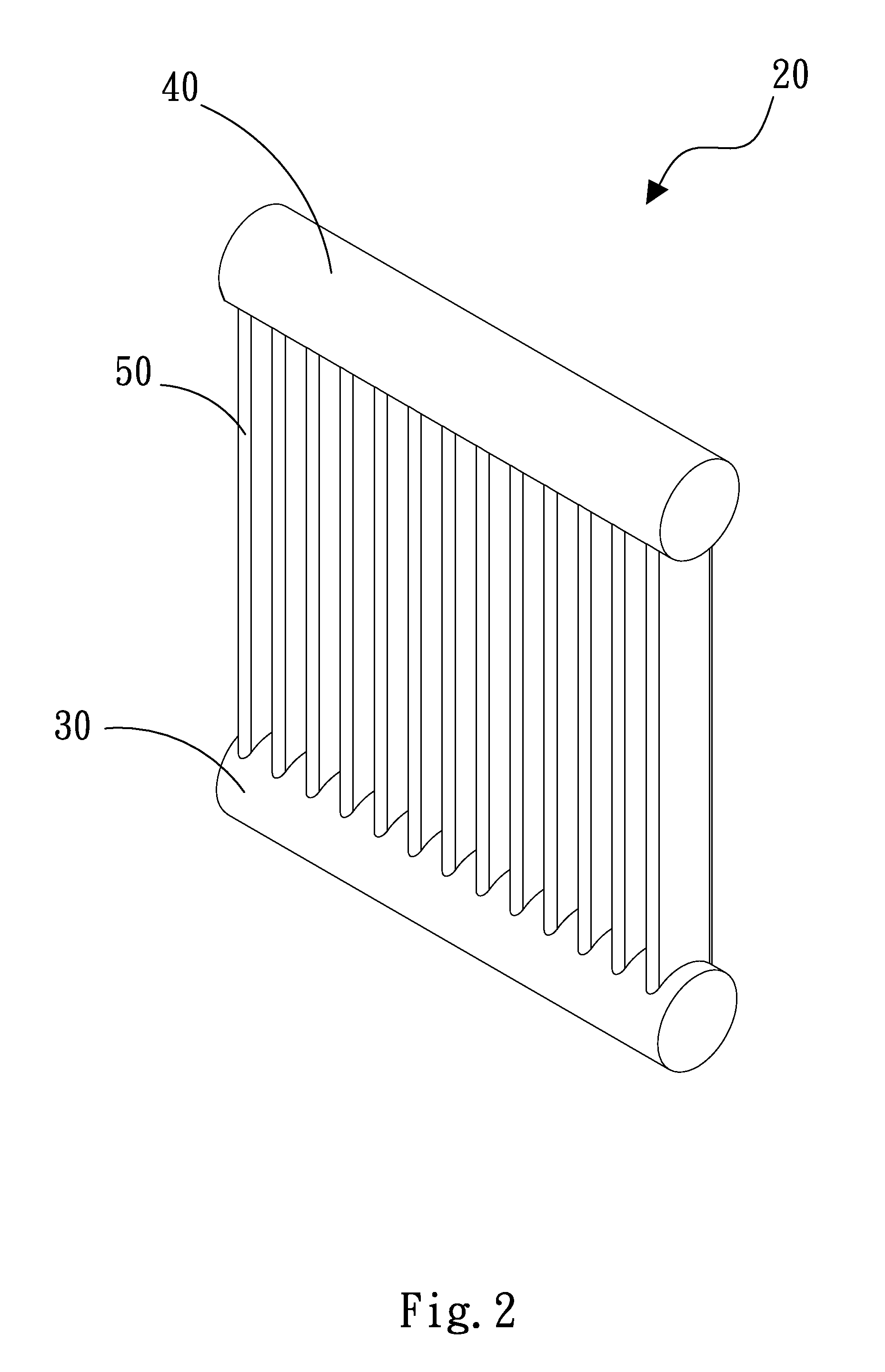

Heat dissipation device and manufacturing method thereof

InactiveUS20120255716A1Light weightGood heat conduction efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidLiquid state

A heat dissipation device and a manufacturing method thereof. The heat dissipation device includes a first chamber defining a first cavity, a second chamber defining a second cavity, and multiple connection members each defining a passageway. First and second ends of the connection members are respectively connected with the first and second chambers in communication with the first and second cavities through the passageways. A working fluid is contained in the first cavity. When the working fluid is heated, the working fluid is evaporated into vapor. The vapor passes through the passageways into the second cavity. After reaching the second cavity, the vapor is condensed into liquid state. Then, the liquid goes back into the first cavity through the passageways to complete a working cycle and achieve heat dissipation effect.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

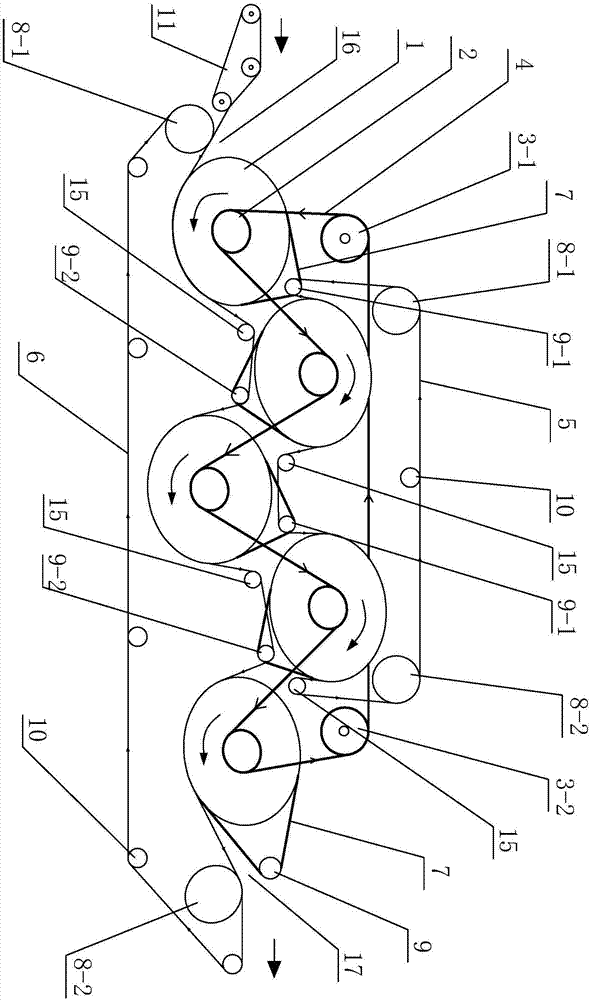

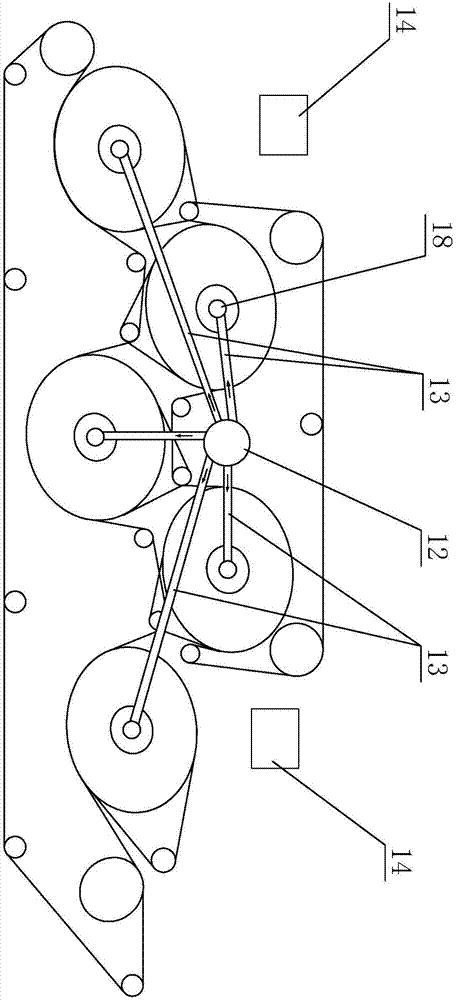

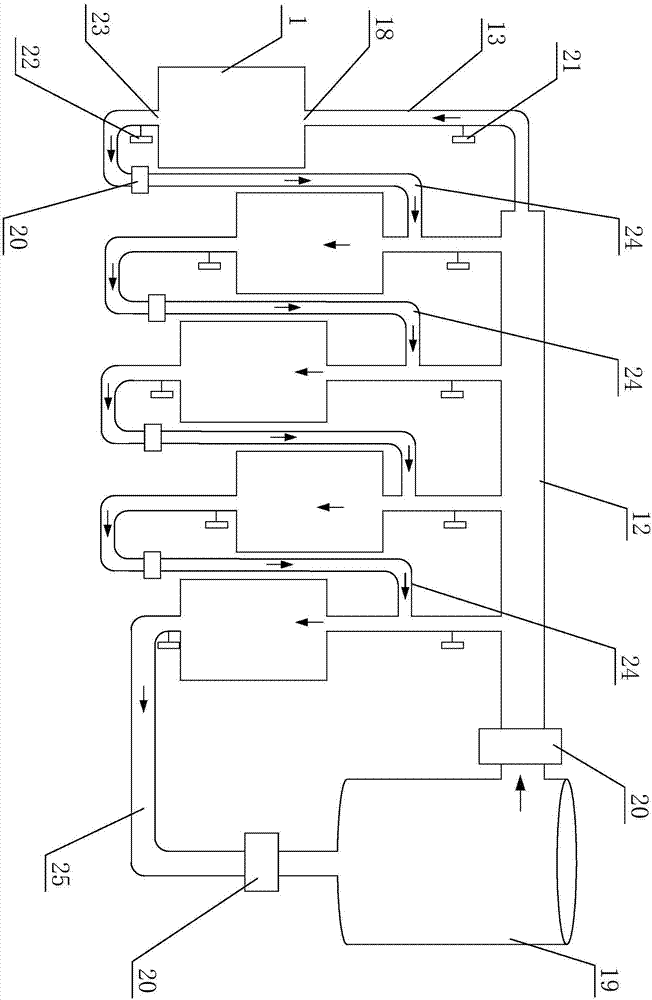

Drying machine for wood chips

InactiveCN107300313AImprove drying efficiencyReduce lossesDrying machines with progressive movementsDrying solid materialsHeat carrierDrive motor

The invention discloses a drying machine for wood chips. The drying machine comprises a conveyor belt, a dynamic chain, N heating rollers arranged at intervals sequentially and a heat circulating device providing heat carriers to the heating rollers; each heating roller is provided with one roller, a first driving shaft is arranged above the first heating roller, a second driving shaft is arranged above the Nth heating roller, and each of the first driving shaft and the second driving shaft is connected with a driving motor; one end of the dynamic chain is mounted on the first driving shaft while the other end winds the rollers sequentially and the second driving shaft to return to the first driving shaft, and the conveyor belt is mounted between a feed inlet and a discharge outlet and is arranged on outer side walls of the heating rollers through positioning roll shafts sequentially, wherein N is a positive integer greater than or equal to 3. Compared with the prior art, the drying machine has the advantages of simple structure, low energy consumption, rapid drying and high drying efficiency.

Owner:许珍

Ultrathin heat pipe and manufaturing method thereof

ActiveCN102538528BSmall sizeGood heat conduction efficiencyIndirect heat exchangersVolumetric Mass DensityEngineering

The invention discloses an ultrathin heat pipe, comprising a flat pipe body formed by pressing. The pipe body is provided with a compression section and a smooth section; the two ends of the pipe body are sealed to form a sealed inner cavity; working solution is filled in the sealed inner cavity, the pipe body is wrapped with a nanometer metal layer, a first groove part and a second groove part are formed in the sealed inner cavity of the pipe body, and a powder sintering part is adhered on the second groove part; and the groove density of the first groove part is smaller than that of the second groove part. The invention also provides a machining method of the ultrathin heat pipe. For the ultrathin heat pipe provided by the invention, the size of the ultrathin heat pipe can be small enough, simultaneously, the heat conduction efficiency and the stability of the ultrathin heat pipe can be guaranteed, and the matched machining method is provided; and the ultrathin heat pipe can be suitable for the various fields with good heat dissipation and limited size.

Owner:ZHONGSHAN WEIQIANG TECH CO LTD

Method for manufacturing heat dissipating apparatus

InactiveUS20120317811A1Good heat conduction efficiencySemiconductor/solid-state device detailsMetal-working apparatusPunchingEngineering

An exemplary method for manufacturing a heat dissipation apparatus includes, firstly, providing a fin assembly including a stack of fins spaced from each other. Each fin defines a through hole therein, and includes a collar formed at an edge of the through hole. Then a heat pipe is provided, and inserted in the through holes of the fins. Next, two opposing punching tools are provided. Each punching tool defines a series of recesses. The subassembly of the heat pipe and fins is positioned between the two punching tools, with the collar of each fin located between two corresponding recesses of the two punching tools. The two punching tools punch the collars of the fins from two opposite sides of the collars. Thereby, the collars shrink inwardly and press the heat pipe to deform until the heat pipe is fittedly mounted in the collars of the fins.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

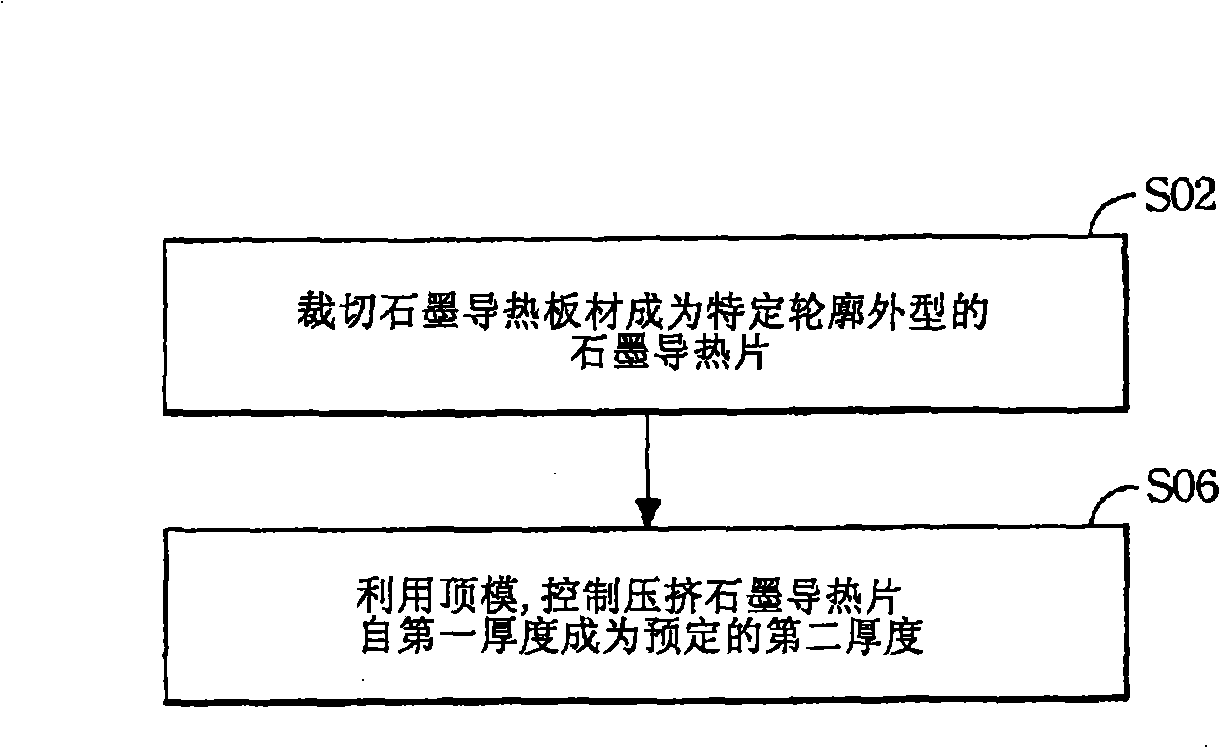

Processing method of graphite heat-conducting fin

InactiveCN101336064AHigh densityFirm insertionCooling/ventilation/heating modificationsMetal layered productsHeat conductingGraphite

The invention discloses a processing method of graphite heat conducting fins, using a group of male dies and female dies to clamp and press the graphite conduction plate to become the graphite heat conducting fins with specific contour exterior, and using holderups arranged between the male dies and the females dies, controlled to continue to press a first thickness to a scheduled second thickness of the graphite heat conducting fins, thereby advancing density of the graphite and improving conduction efficiency. Furthermore, the bent graphite heat conducting fins are extruded, to reinforce the problems of hard conduction at the loose bending. In addition, after the heat conducting fins are tabled on the surfaces of the graphite heat conducting fins, the graphite heat conducting fins are extruded again, causing the conducting fins more fixedly connected with the surfaces of the graphite heat conducting fins.

Owner:洪进富

Thermal electricity conversion based on the heat extracted from underground coal fires

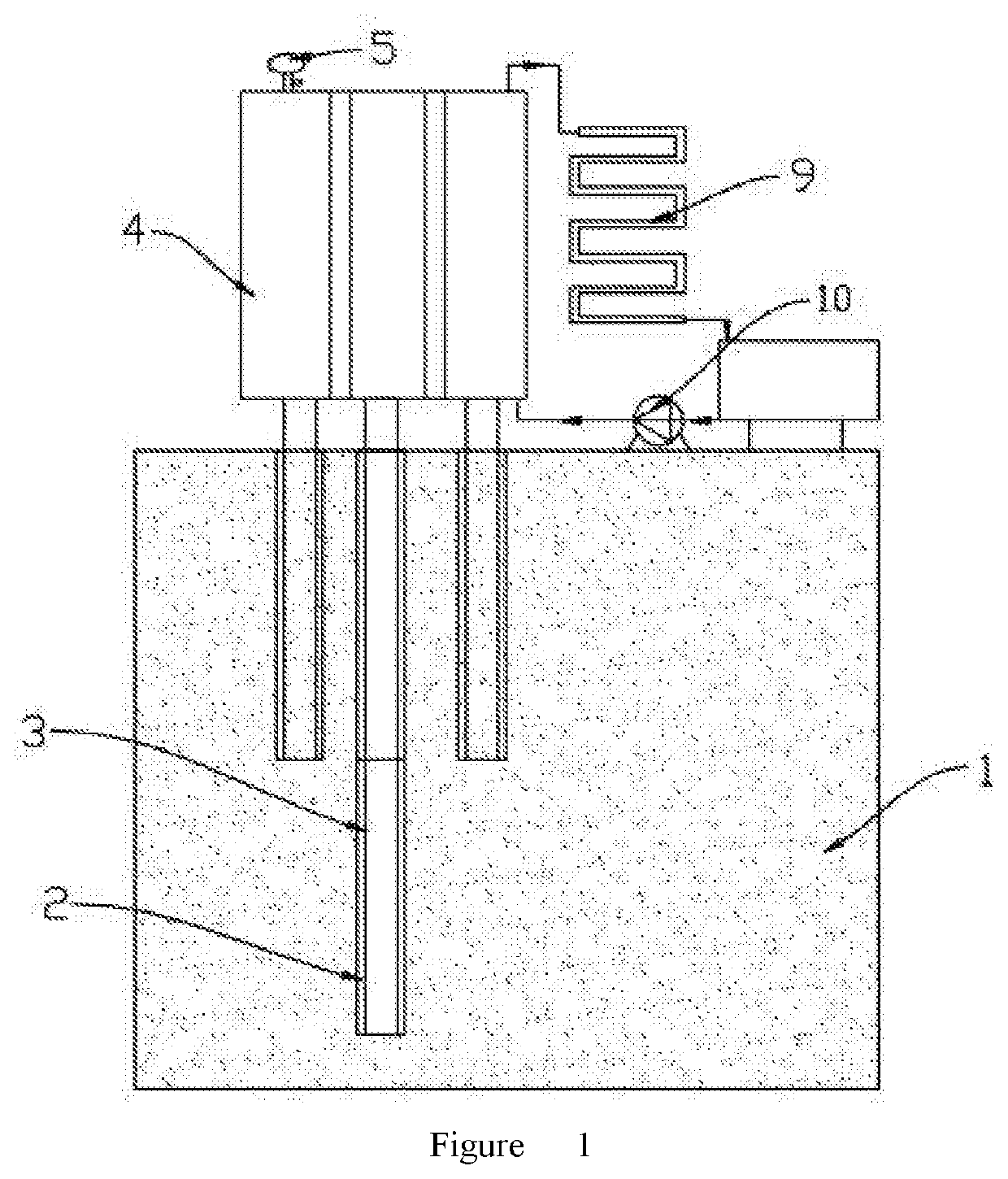

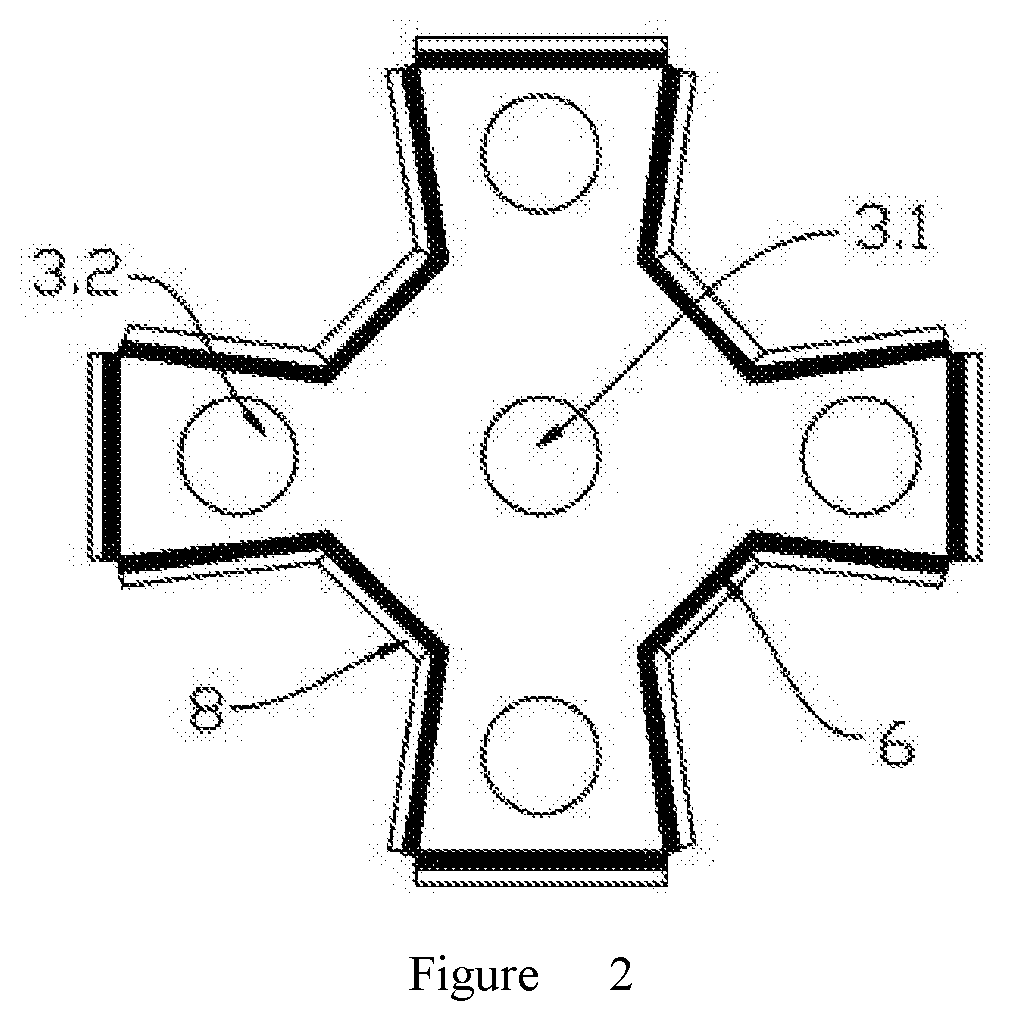

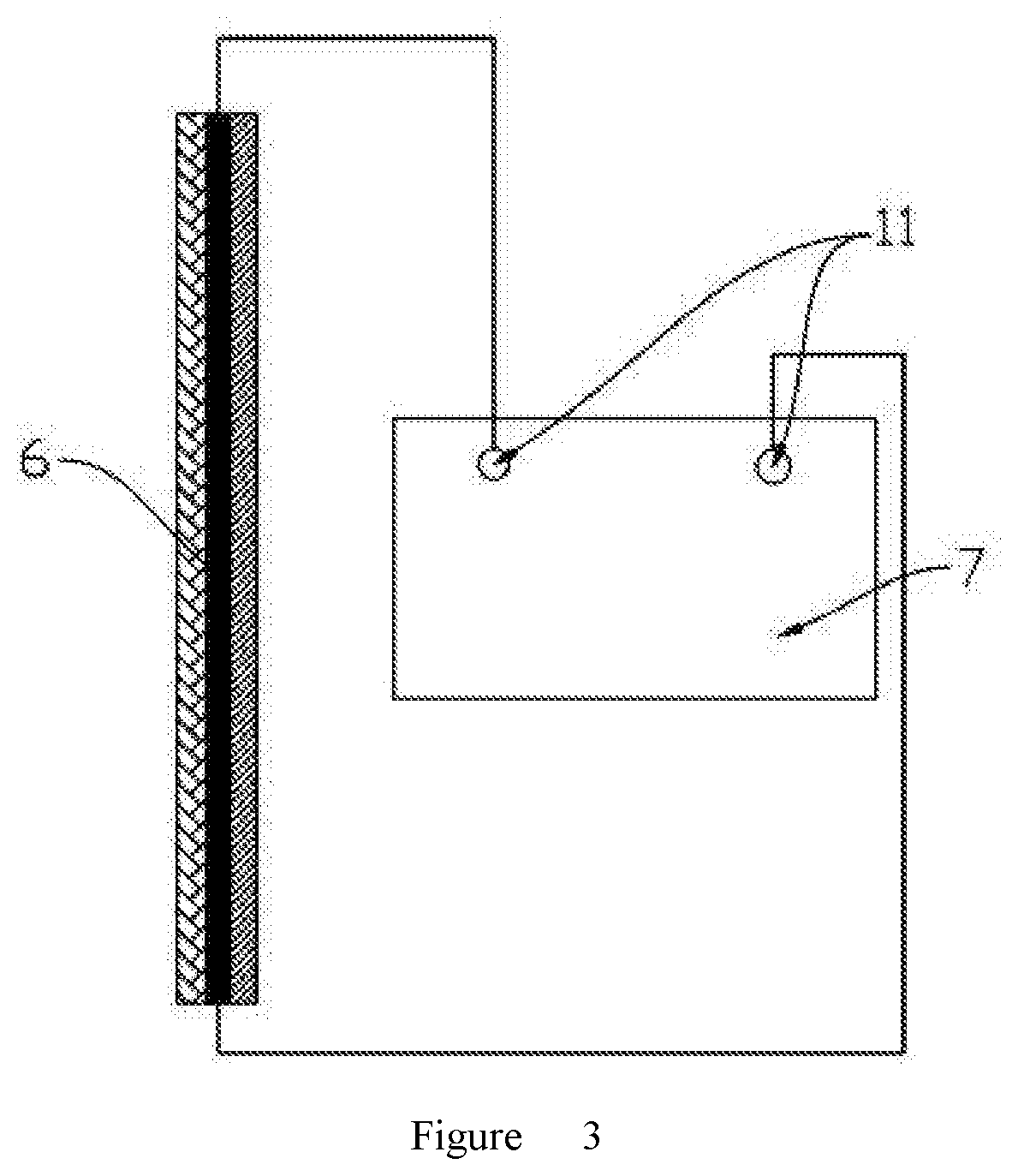

InactiveUS20200036303A1Improve thermal conductivityEfficient thermal energyBatteries circuit arrangementsThermoelectric device with peltier/seeback effectChipsetMechanical engineering

Thermal electricity conversion based on the heat extracted from underground coal fires, comprising a coalfield fire area (1), coalfield drill holes (2), underground heat conduction pipelines (3) and a heat conduction container (4) which is provided with a pressure relief device (5) thereon and further comprises thermoelectric power generation chip sets (6) and a storage battery (7), wherein the thermoelectric power generation chip sets (6), having cold-side radiator pipes (8) provided on outer sides thereof, are provided on an outer side wall of the heat conduction container (4). The thermoelectric power generation chip sets in the invention are directly attached on the heat conduction container, so that the system is simple in structure without redundant components and high in heat conduction efficiency. The thermoelectric power generation chip sets, having the cold side radiator pipes on outermost layers thereof, are surface mounted so that the contact area among heating media, refrigerants and the thermoelectric power generation chip sets, and the thermal energy of the subsurface fire may be utilized efficiently. The thermoelectric power generation system is simple in process and may be well adapted to the engineering operating environment in the coalfield fire area.

Owner:CHINA UNIV OF MINING & TECH

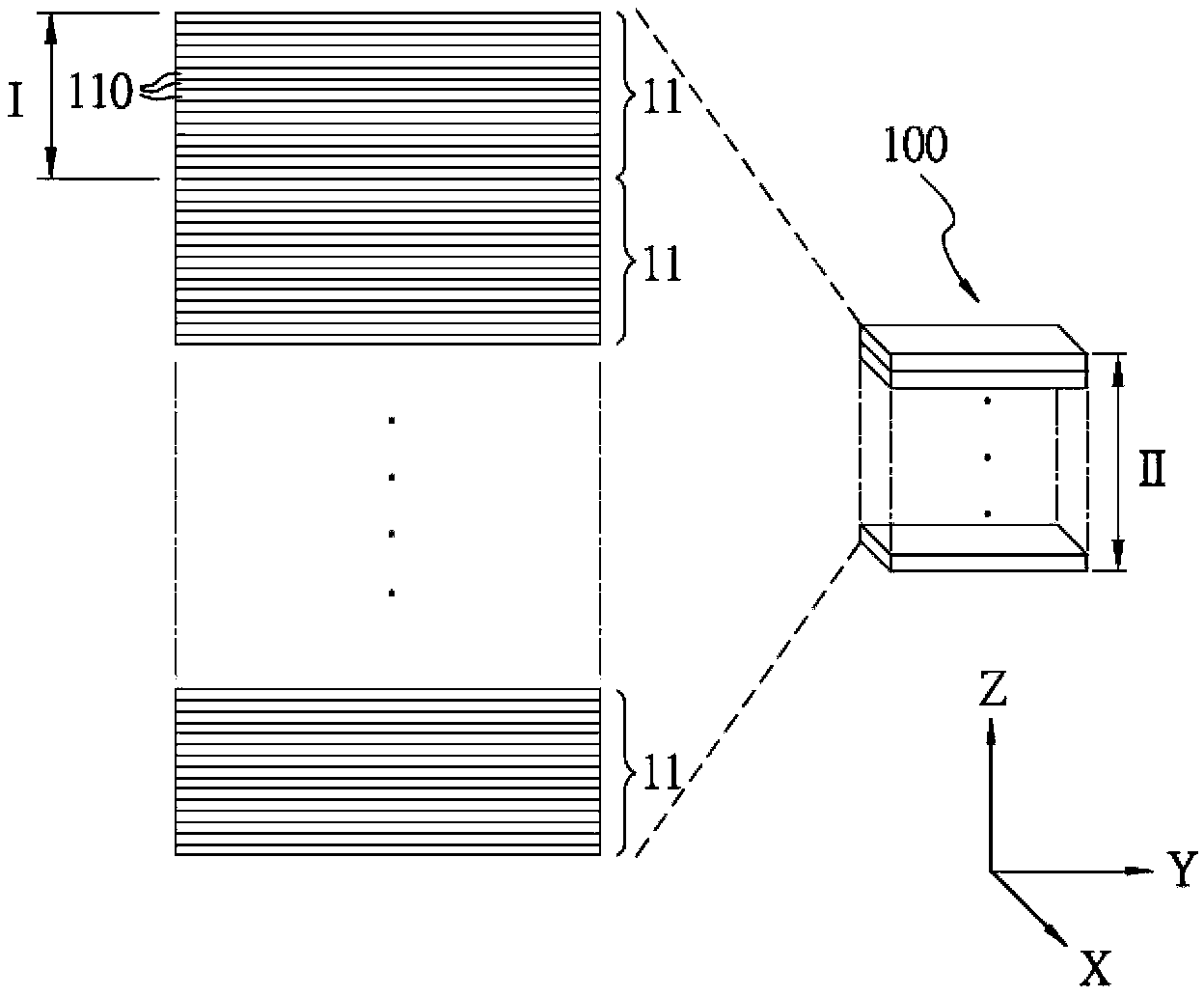

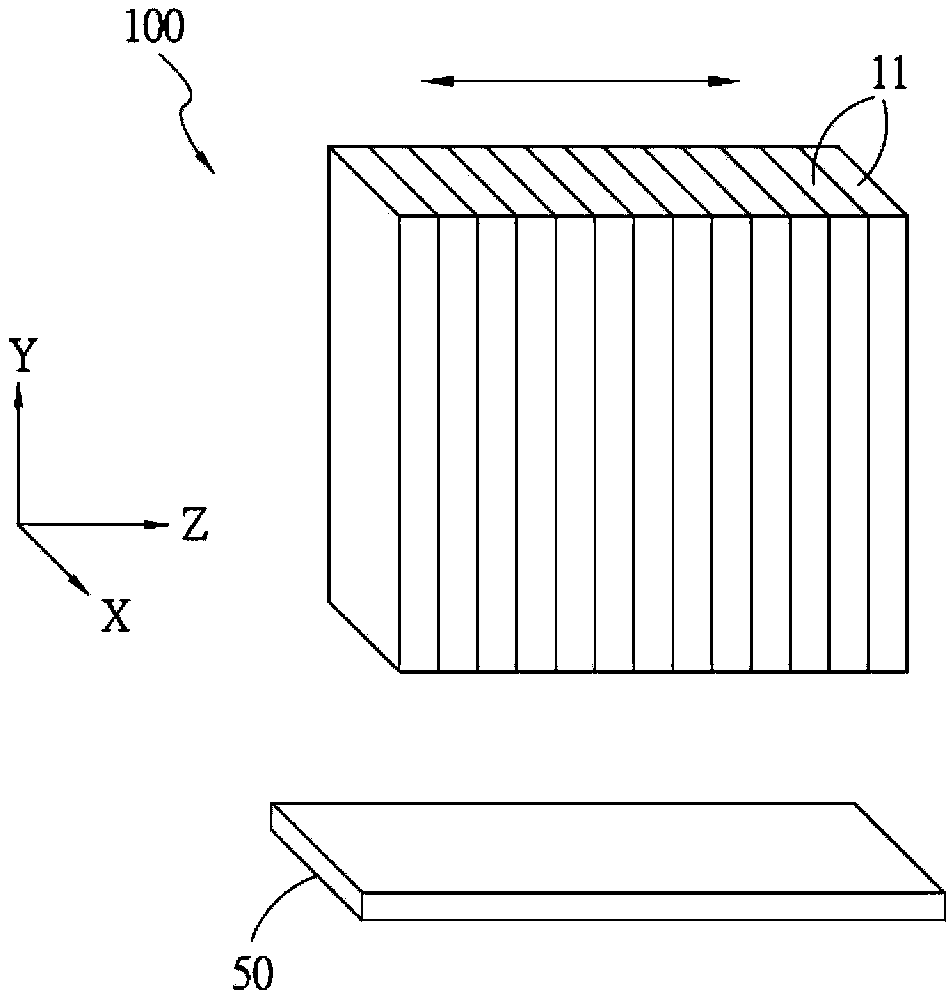

High-heat-flux graphite heat conduction film module stacking method

ActiveCN112040722AImprove thermal efficiencyReduce the chance of scalding the human bodyCooling/ventilation/heating modificationsDoped grapheneHeat flux

The invention provides a high-heat-flux graphite heat-conducting film module stacking method. The method comprises the following steps of taking a plurality of graphite film raw materials; and stacking the graphite film raw materials on an operation table in sequence to form a graphite film module. The thick graphite film raw materials is a high-power heat-conducting graphite film and is a high-power graphite film raw material formed by burning an ultra-thick PI film (more than or equal to 125 microns) prepared by doping graphene and carbon nanotubes into traditional polyimide, and the thin graphite film raw material is a graphite film formed by burning a conventional polyimide material. The thick graphite film raw material is tightly attached to a heat source, so that the purposes of vertical high-heat-flux heat conduction and horizontal high-energy heat storage of heat energy of the heat source are achieved. The thin graphite film raw material plays a role in heat homogenization, thethick graphite film raw material and the thin graphite film raw material are bonded through glue with a certain thickness, due to the thermal resistance effect of the glue, the high heat conduction efficiency of the heating end can be improved through the high-power graphite film module, and it is guaranteed that when heat conduction is conducted in electronic equipment, a shell of the electronicequipment cannot be overheated, and a human body cannot be scalded.

Owner:SUZHOU KANRONICS ELECTRONICS TECH CO LTD +1

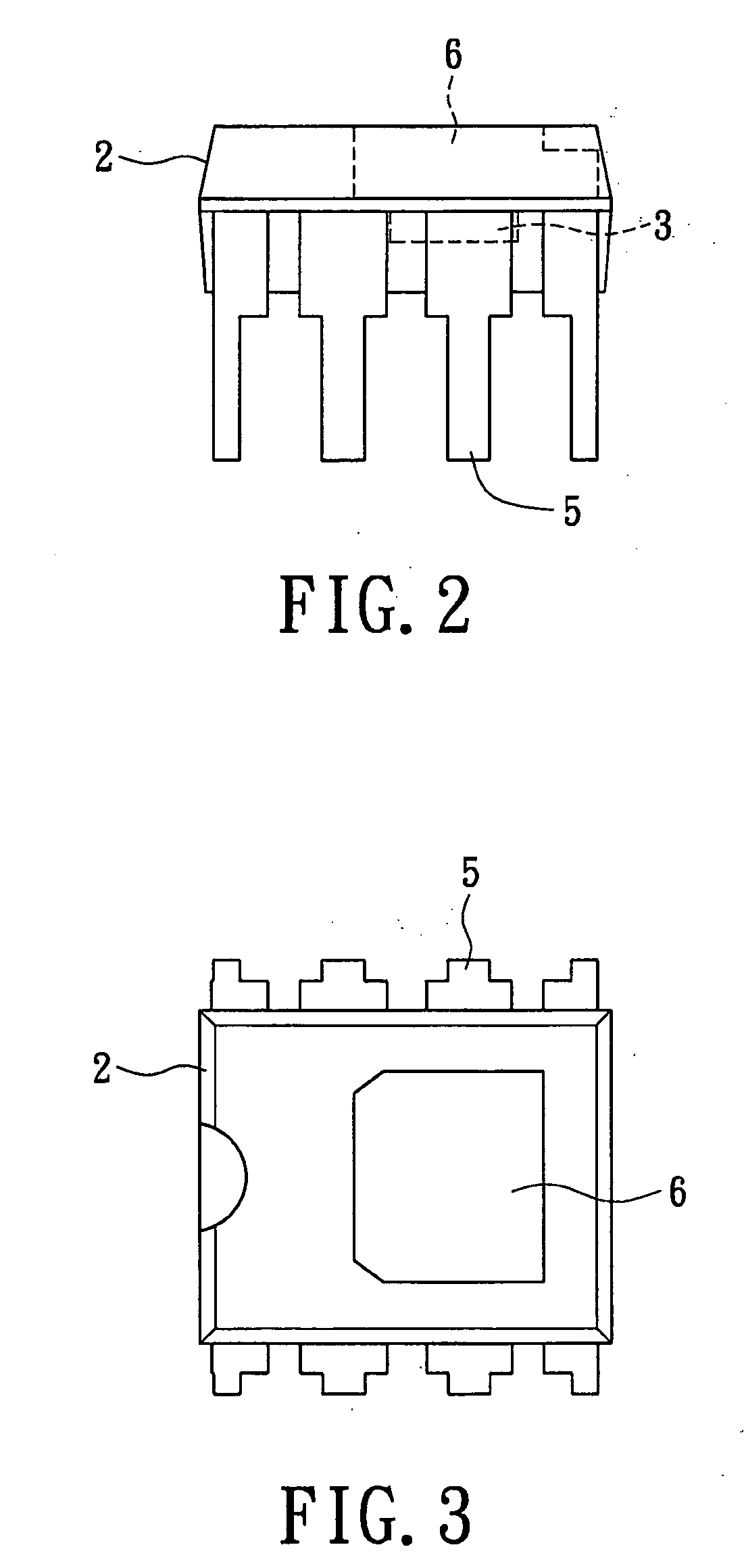

Chip package structure

InactiveUS20070132074A1Easy to optimizeGood heat conduction efficiencySemiconductor/solid-state device detailsSolid-state devicesChip carrierHeat spreading

An improved chip package structure includes a chip carrier, a chip, a plurality of pins, a plurality of leads, a package body and a heat spreader. The chip is fixed on the chip carrier. The leads are electrically connected between the chip and the pins. The package body is packaged outside the chip carrier, the chip and the leads. The heat spreader is disposed in the package body. The heat spreader contacts the chip carrier, and is partially exposed out of a face (top face) of the package body. Heat generated by the chip can thus be transmitted to a heatsink via the chip carrier and the heat spreader so as to discharge a large amount of heat generated by the chip to the outside. The improved chip package structure has a good heat conduction efficiency and an effectively enhanced heat spreading efficiency.

Owner:NIKO SEMICON

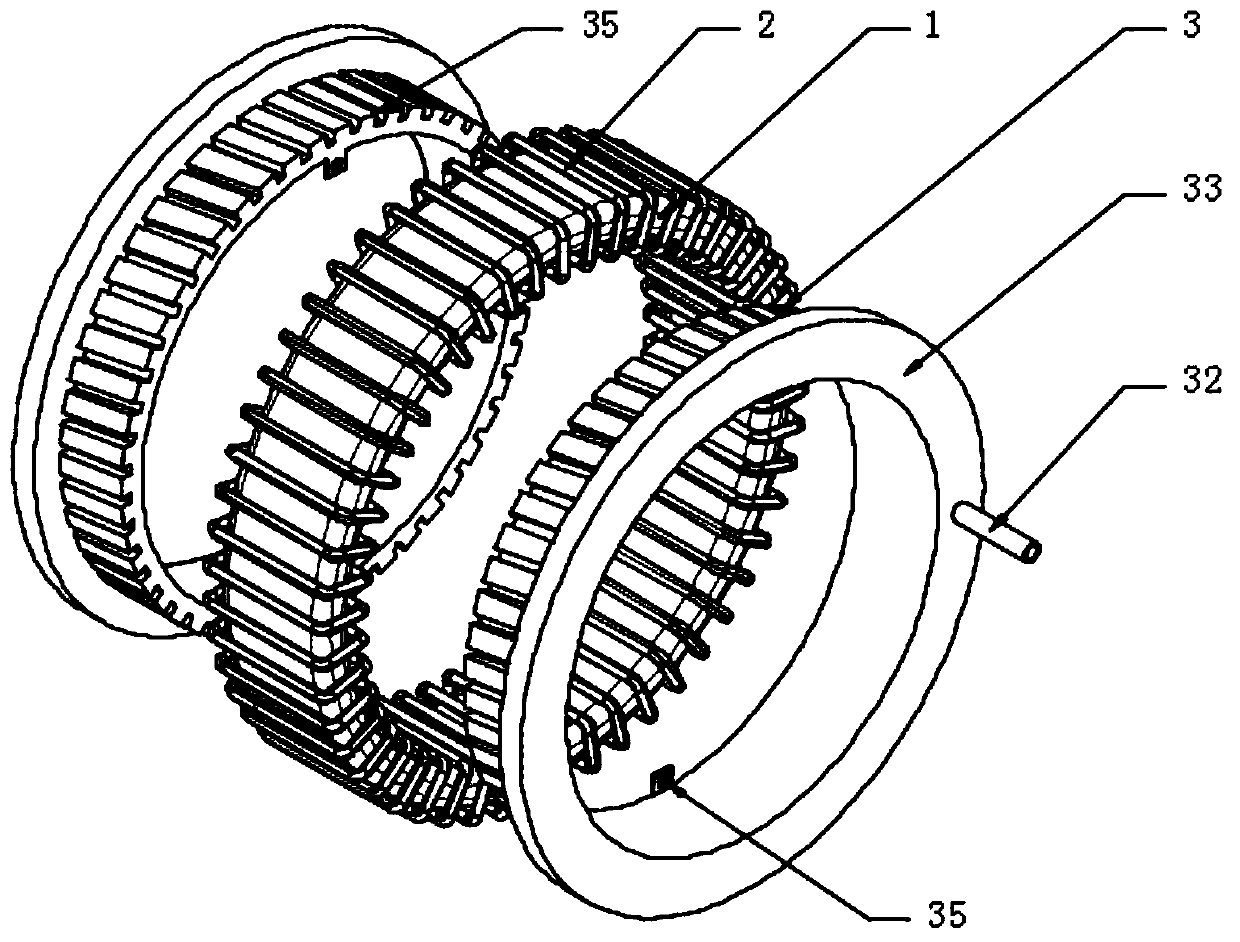

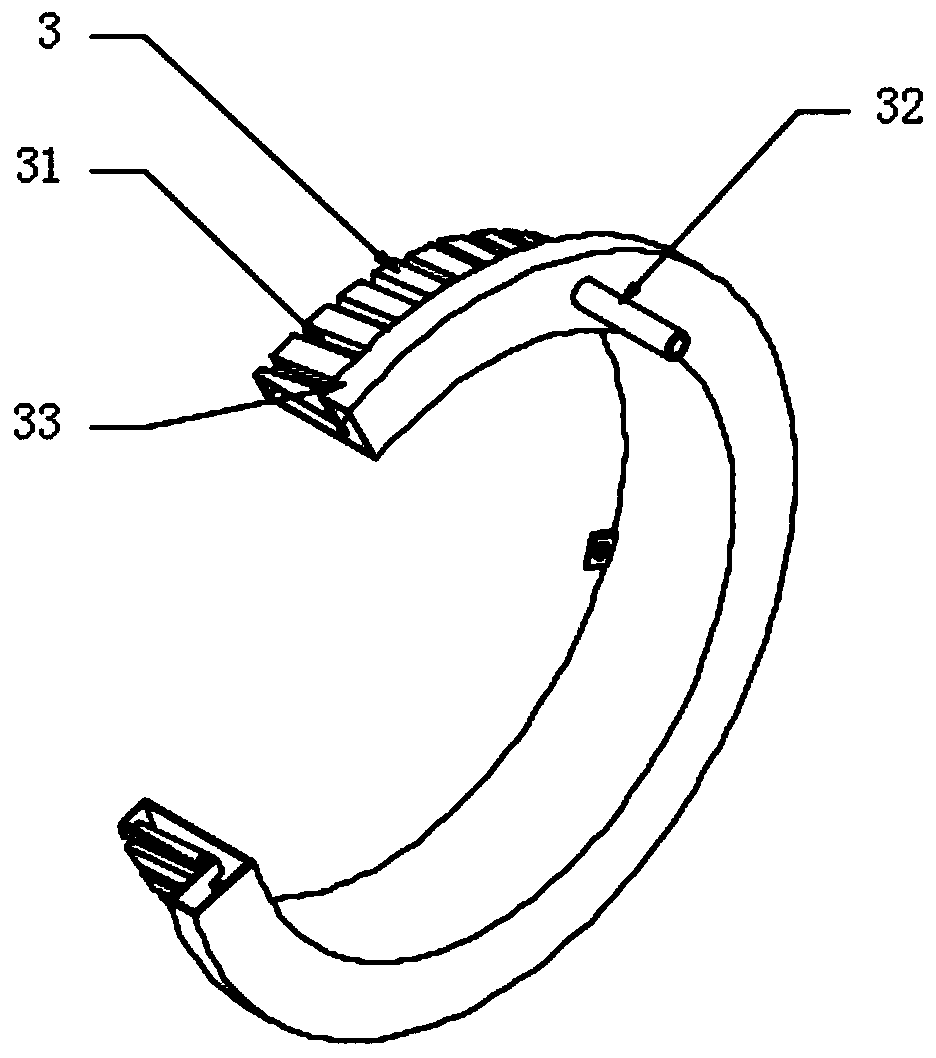

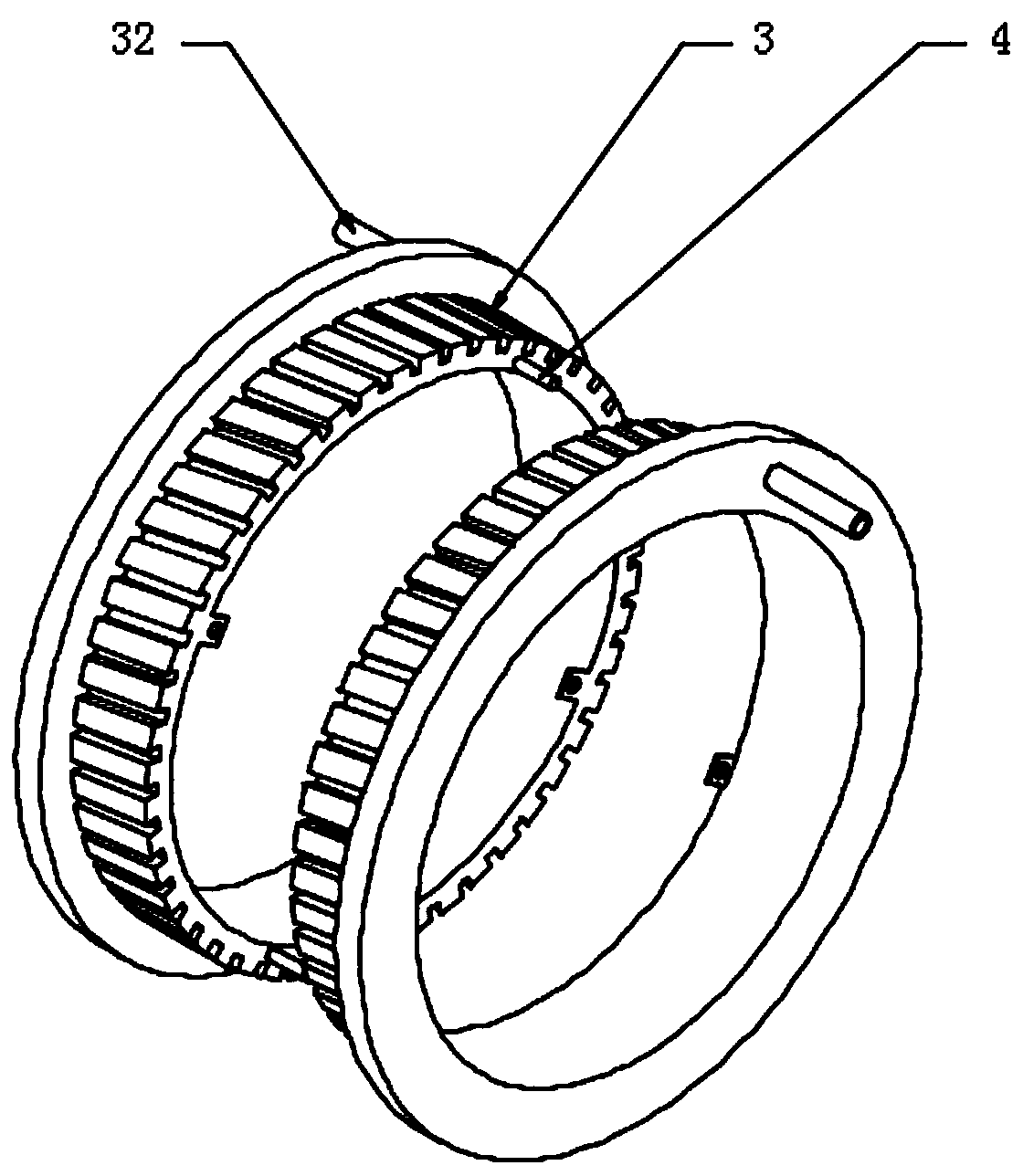

Power coil with built-in cooling structure

PendingCN110648822AIncrease contact areaAchieve snap-fit connectionTransformers/inductances coils/windings/connectionsEngineeringWire wrap

The invention discloses a power supply coil with a built-in cooling structure. The power supply coil comprises an annular iron core and a winding coil wound on the annular iron core, and further comprises two annular heat dissipation sleeves sleeved at two ends of the annular iron core, and grooves with helical gear teeth are formed in the outer surface walls of the annular heat dissipation sleeves. The winding coil wound on the annular iron core is distributed at intervals, the two ends of the annular iron core are sleeved with the two annular heat dissipation sleeves, the grooves are formedin the outer surface walls of the annular heat dissipation sleeves, the winding wire of the winding coil is clamped into the grooves, so when the two annular heat dissipation sleeves and the winding coil are mounted, the two annular heat dissipation sleeves only need to be oppositely inserted from two sides of the winding coil and then rotate reversely, and buckling connection of the two annular heat dissipation sleeves is achieved by means of guiding of the winding coil, so the spliced heat dissipation sleeves are convenient to install and detach, the contact area of the heat dissipation sleeves with the winding coil is increased, and the heat conduction effect is improved.

Owner:YAXIN (HUAIHUA) ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com