Patents

Literature

466results about How to "Lower surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid perfluoropolymers and medical applications incorporating same

InactiveUS20050142315A1Promote tissue growthImprove survivabilitySuture equipmentsElectrotherapyPerfluoropolyetherOxygen

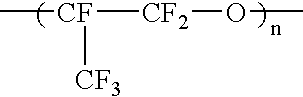

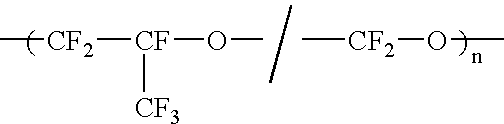

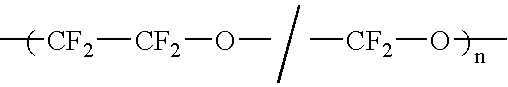

Liquid curable perfluoropolyether (PFPE) materials are provided for use as coatings, sealants, flexible fillers, and structural parts for a wide variety of medical applications, particularly where silicone has been utilized conventionally. The PFPE material is oxygen permeable and bacterial impermeable and may contain one or more pharmacological agents elutably trapped therewithin for delivery within the body of a subject.

Owner:LIQUIDIA TECH

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

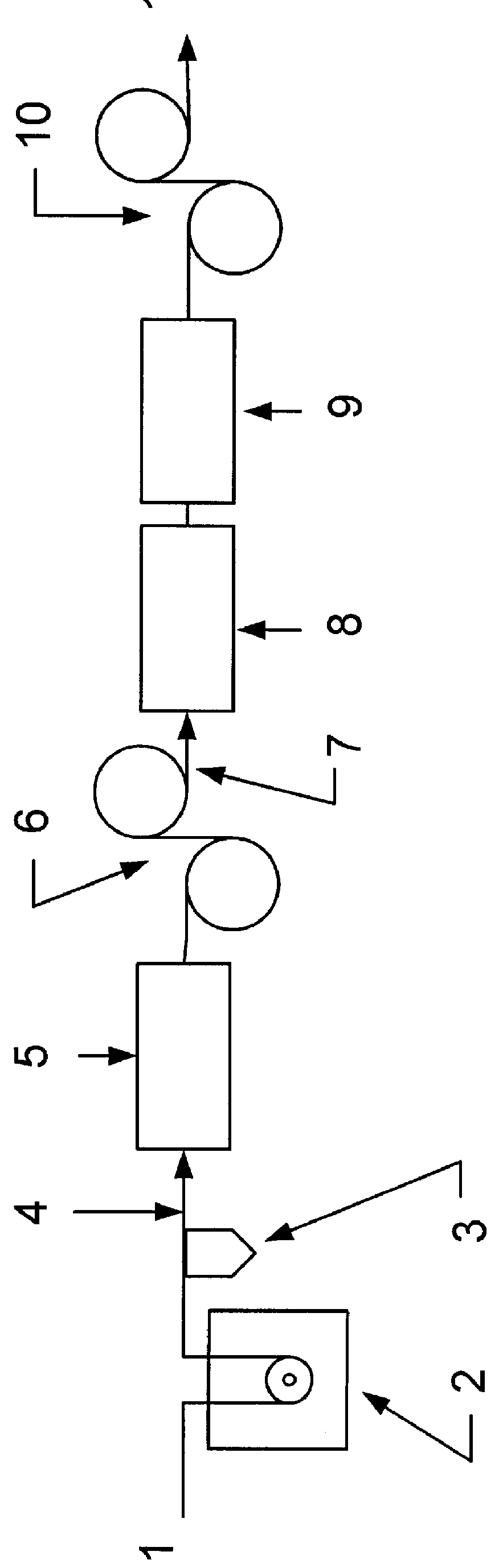

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

Integrated process and dual-function catalyst for olefin epoxidation

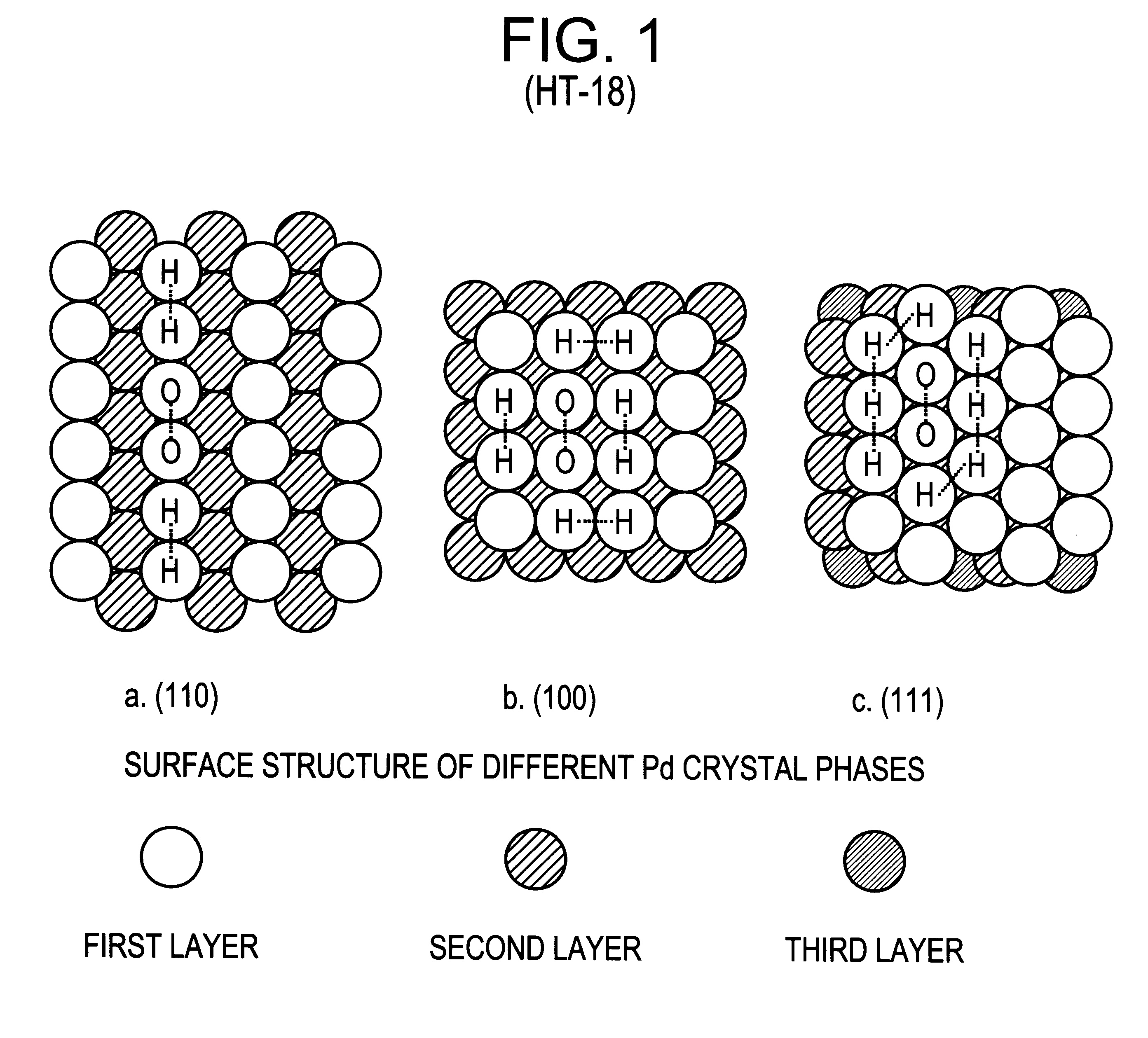

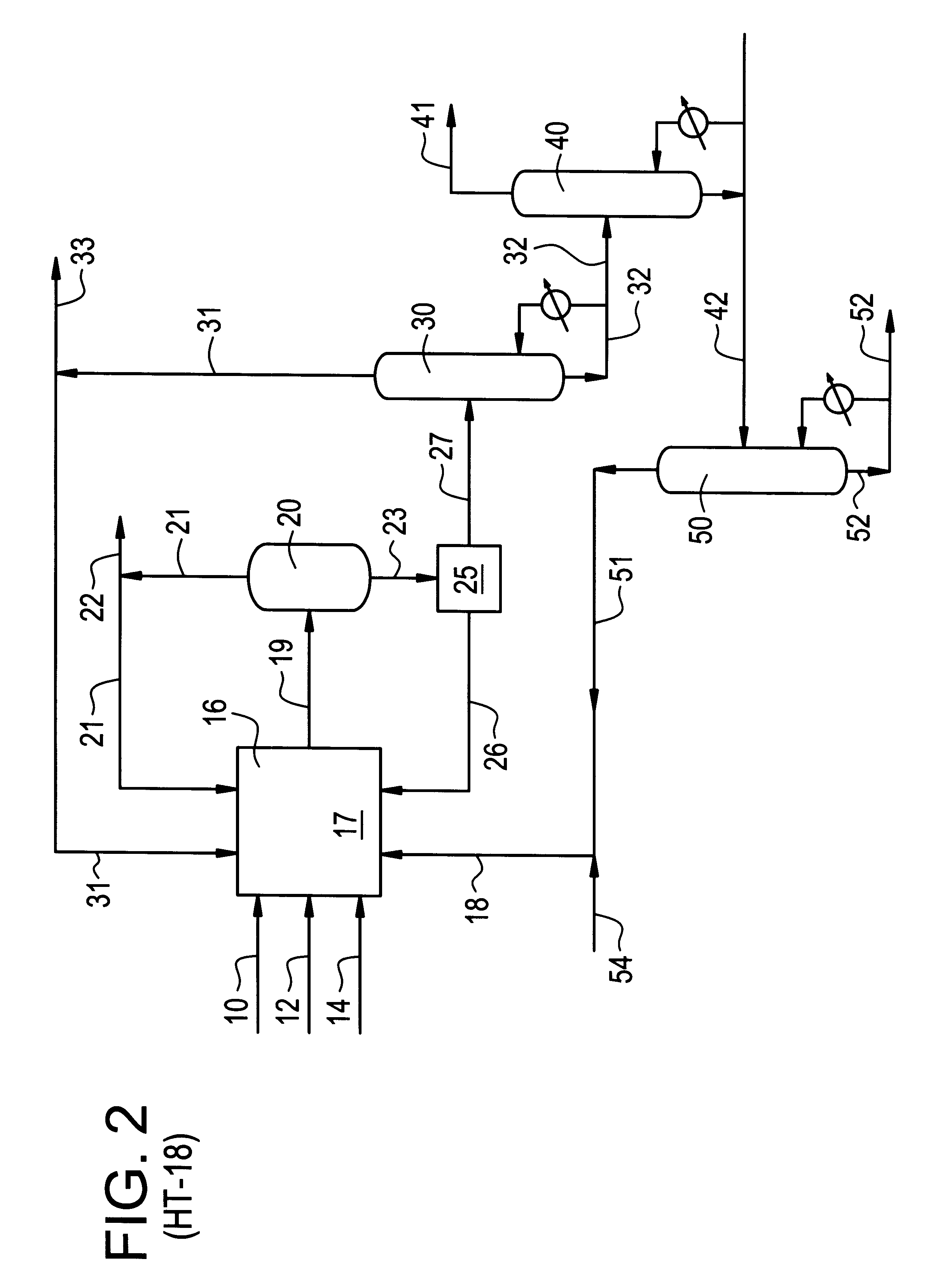

The invention discloses a dual-functional catalyst composition and an integrated process for production of olefin epoxides including propylene oxide by catalytic reaction of hydrogen peroxide from hydrogen and oxygen with olefin feeds such as propylene. The epoxides and hydrogen peroxide are preferably produced simultaneously in situ. The dual-functional catalyst comprises noble metal crystallites with dimensions on the nanometer scale (on the order of <1 nm to 10 nm), specially dispersed on titanium silicalite substrate particles. The dual functional catalyst catalyzes both the direct reaction of hydrogen and oxygen to generate hydrogen peroxide intermediate on the noble metal catalyst surface and the reaction of the hydrogen peroxide intermediate with the propylene feed to generate propylene oxide product. Combining both these functions in a single catalyst provides a very efficient integrated process operable below the flammability limits of hydrogen and highly selective for the production of hydrogen peroxide to produce olefin oxides such as propylene oxide without formation of undesired co-products.

Owner:HEADWATERS TECH INNOVATION GRP

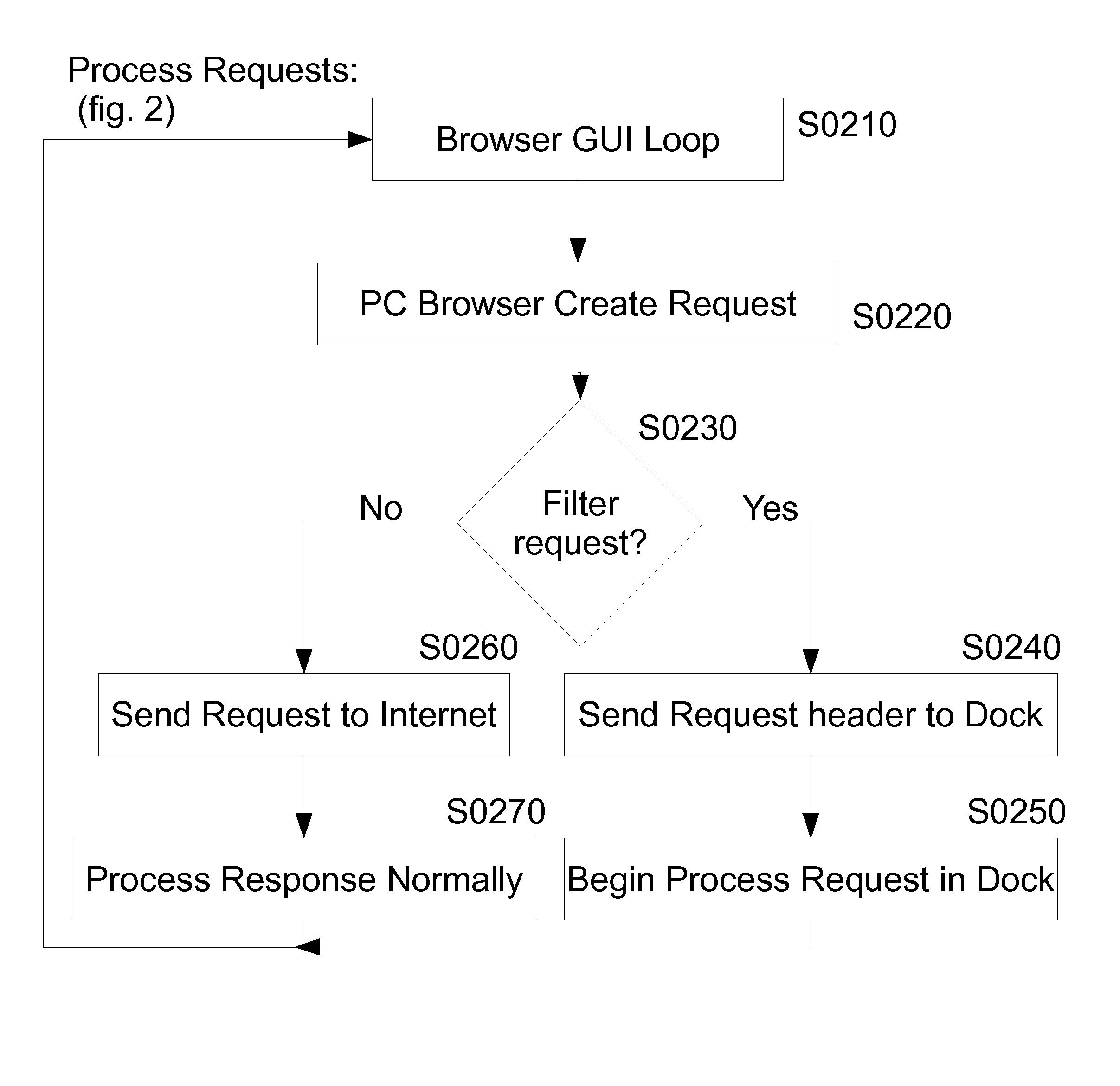

Method and apparatus for secure interaction with a computer service provider

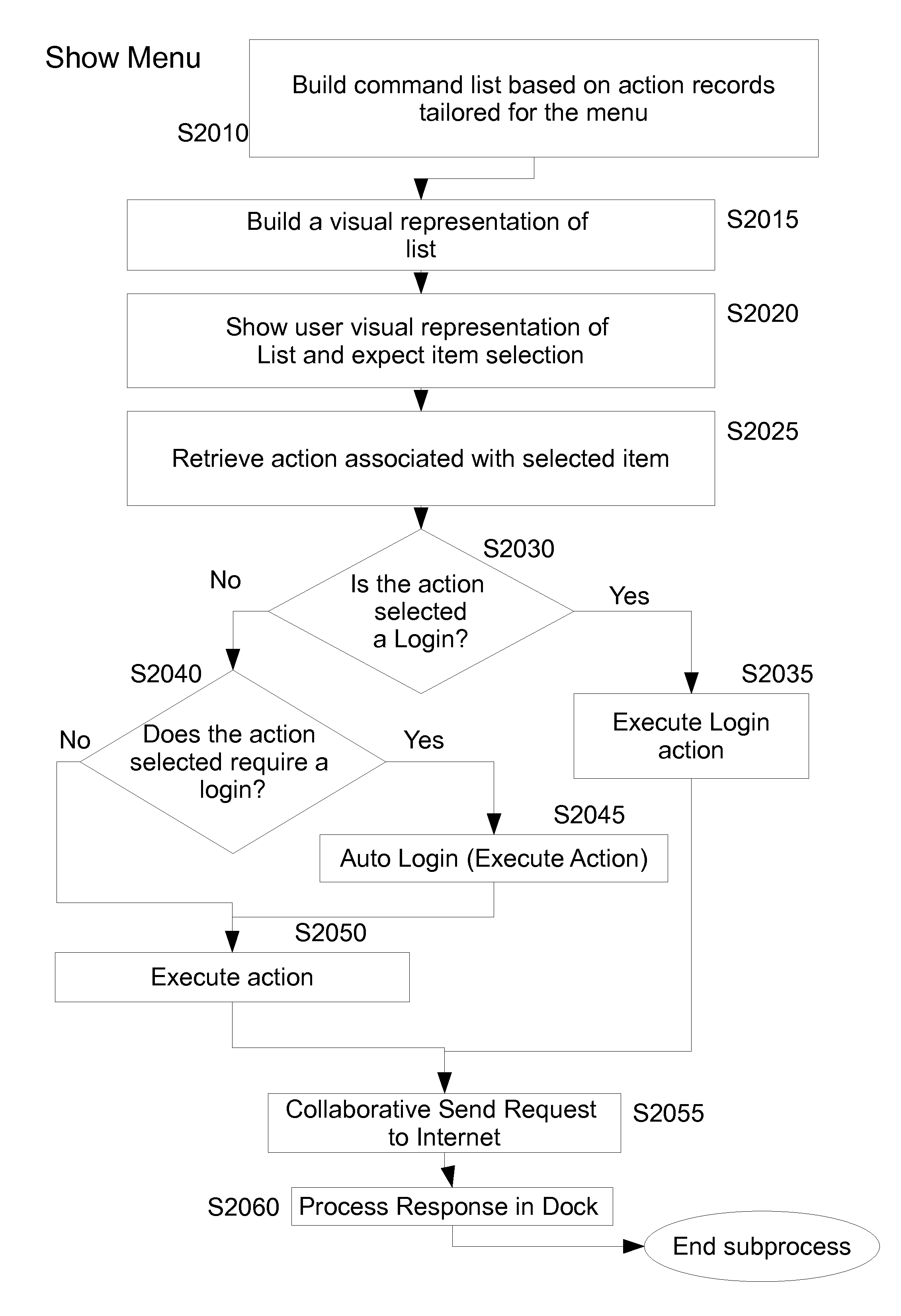

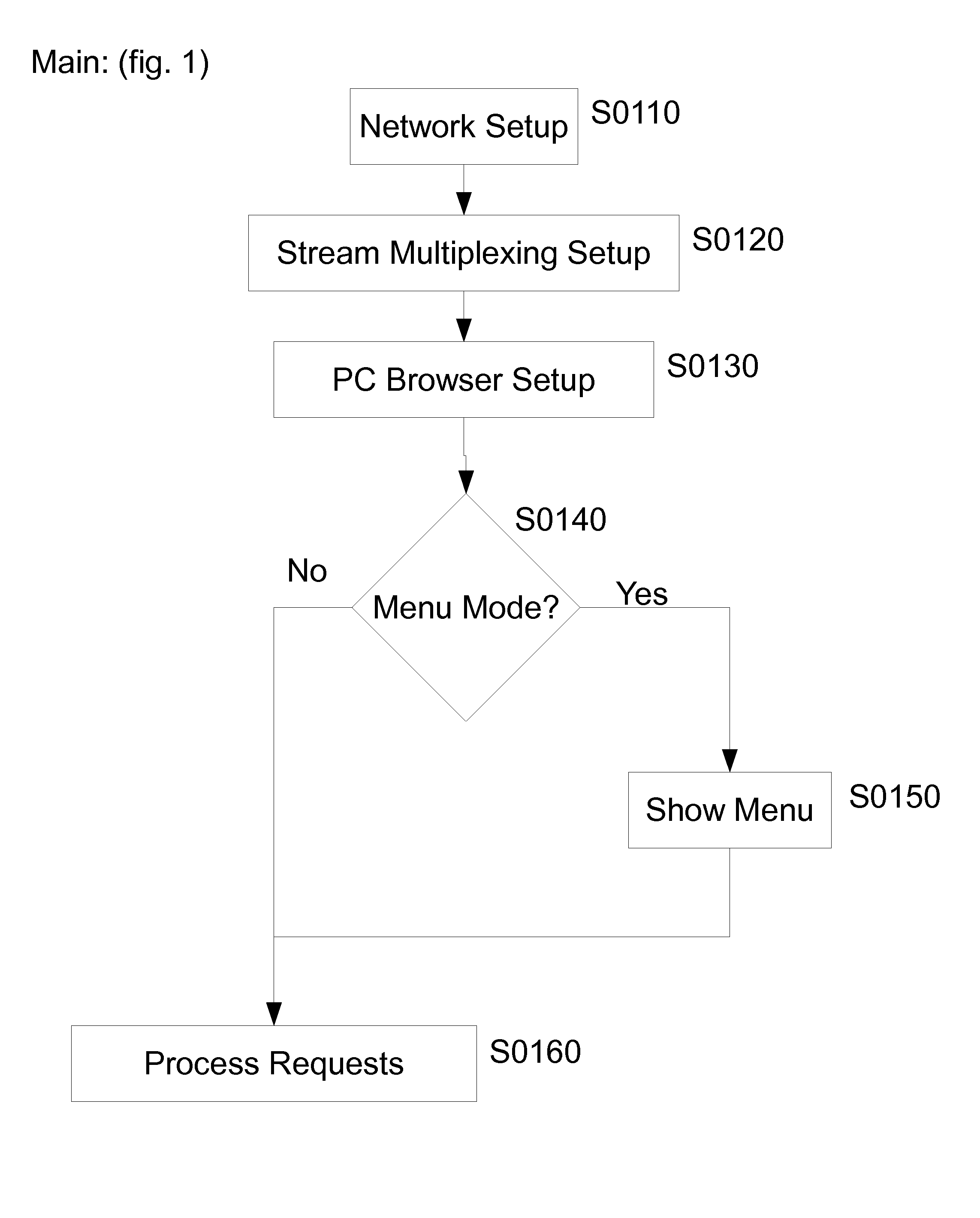

InactiveUS20140282978A1Low costEasy to useDigital data processing detailsMultiple digital computer combinationsPasswordTrusted Computing

A method for secure interaction with a website server capable of an authentication operation with a login operation checking a username and a password, is described. Standard web browsing environments are generally insecure and private information, such as passwords, are prone to theft. The proposed solution comprises securing the password used for the authentication in a trusted computing environment, such as a separate computer, without the need of revealing the password to a browser running in an untrusted computing environment, and basing the browsing on authentication data obtained as result of the login operation, that can be confirmed by the user in the trusted environment, prior of being performed.

Owner:LERNER SERGIO DEMIAN +1

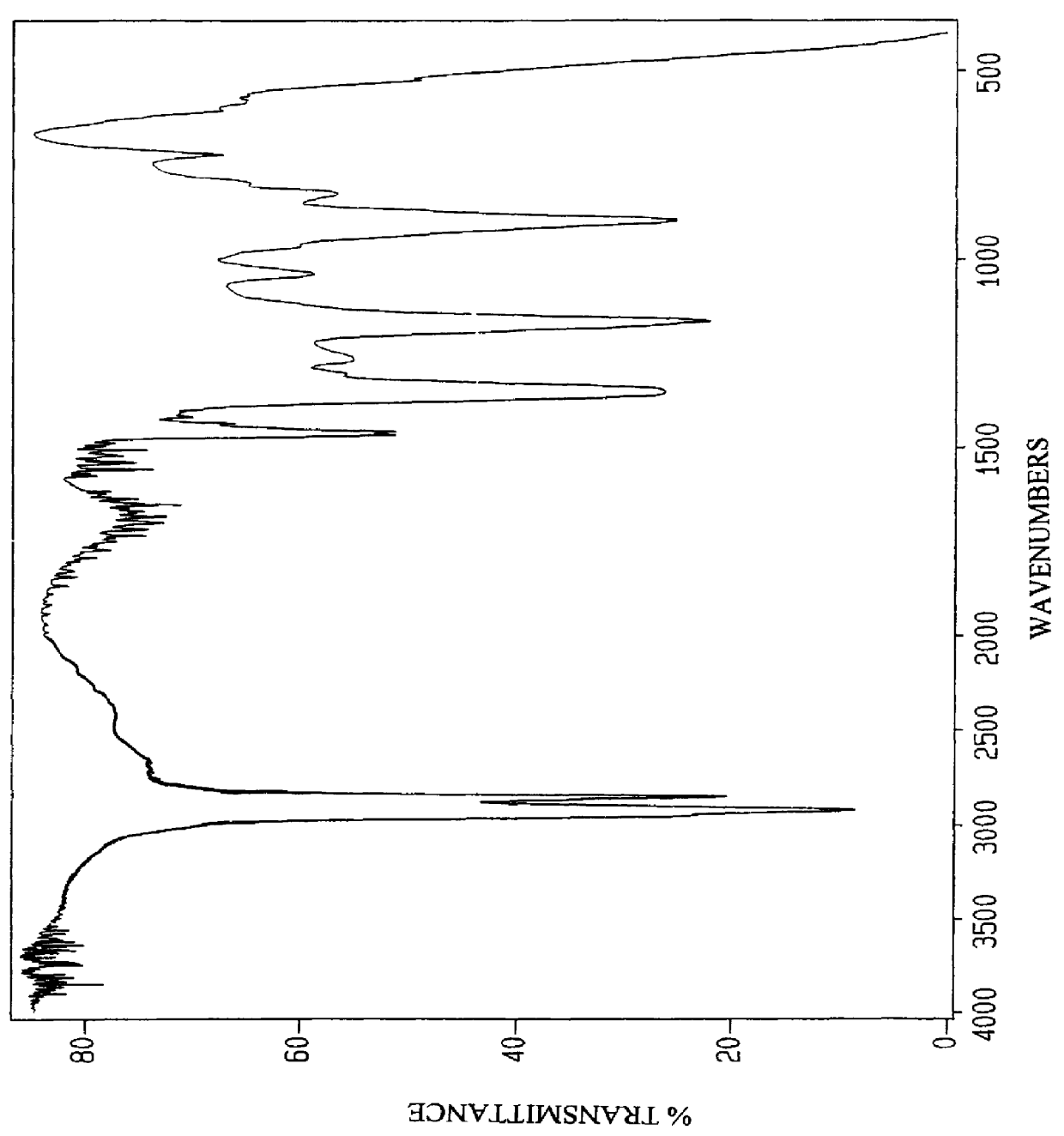

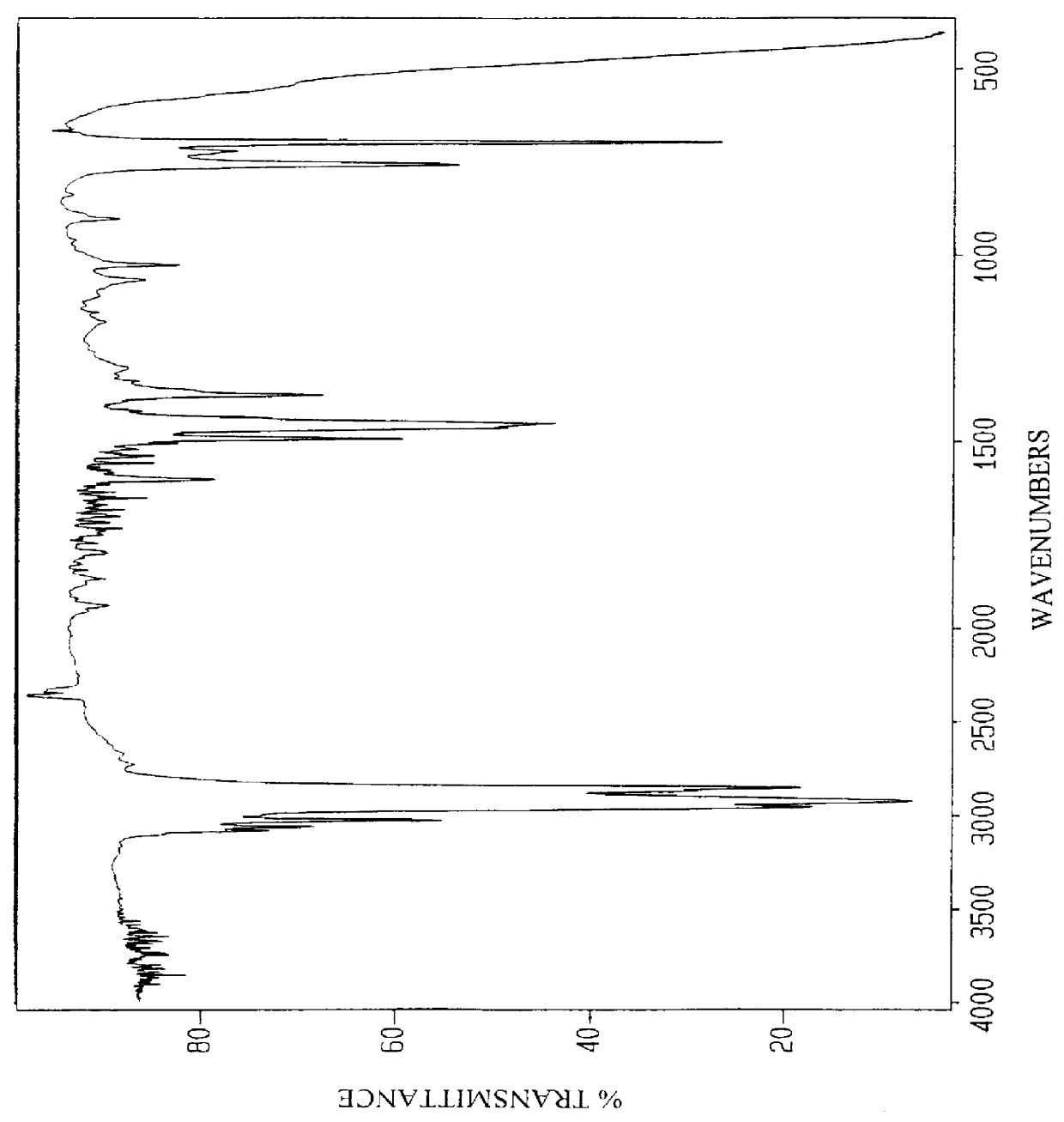

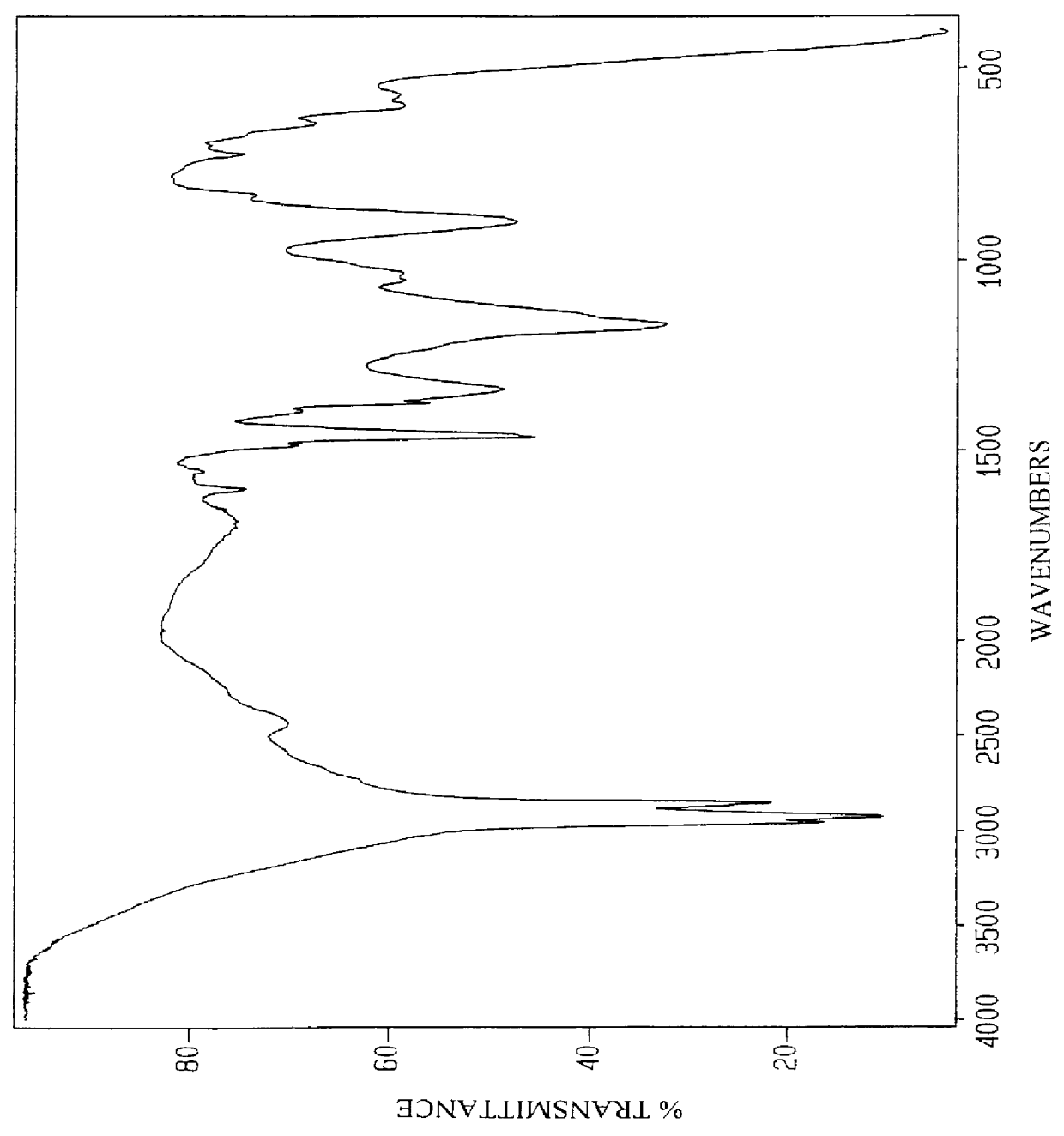

Anionic surfactants based on alkene sulfonic acid

InactiveUS6043391AIncrease productionImprove yieldGroup 3/13 element organic compoundsFlushingAlkylphenolAlpha-olefin

New anionic surfactants and methods of preparation which are derived from aromatic or substituted aromatic molecules and alkenesulfonic acid. Wherein the aryl compound is alkylated and sulfonated in one-step with an alkene sulfonic acid prior to sulfonic acid neutralization. The methods allow the functional sulfonate group to be attached to the end of the alkyl chain rather than to the aromatic ring thus allowing for selective substituted groups, either branched, linear or alkoxylated or combinations thereof to be placed on the aryl compound prior to sulfonation and alkylation. The invention uses the alkene sulfonic acid produced from thin-film sulfonation of an alpha-olefin to alkylate benzene, mono-substituted aromatic, poly-substituted aromatic, alkylbenzene, alkoxylated benzene, polycyclic aromatic, mono-substituted polycyclic aromatic, poly-substituted polycyclic aromatic, naphthalene, alkylnaphthalene, phenol, alkylphenol, alkoxylated phenol, and alkoxylated alkylphenolalkyl substituted or polysubstituted cyclic or polycyclic compounds to produce the corresponding sulfonic acid having an additional alkyl group derived from the alpha-olefin used during the thin-film sulfonation which is either linear or branched.

Owner:OIL CHEM TECH

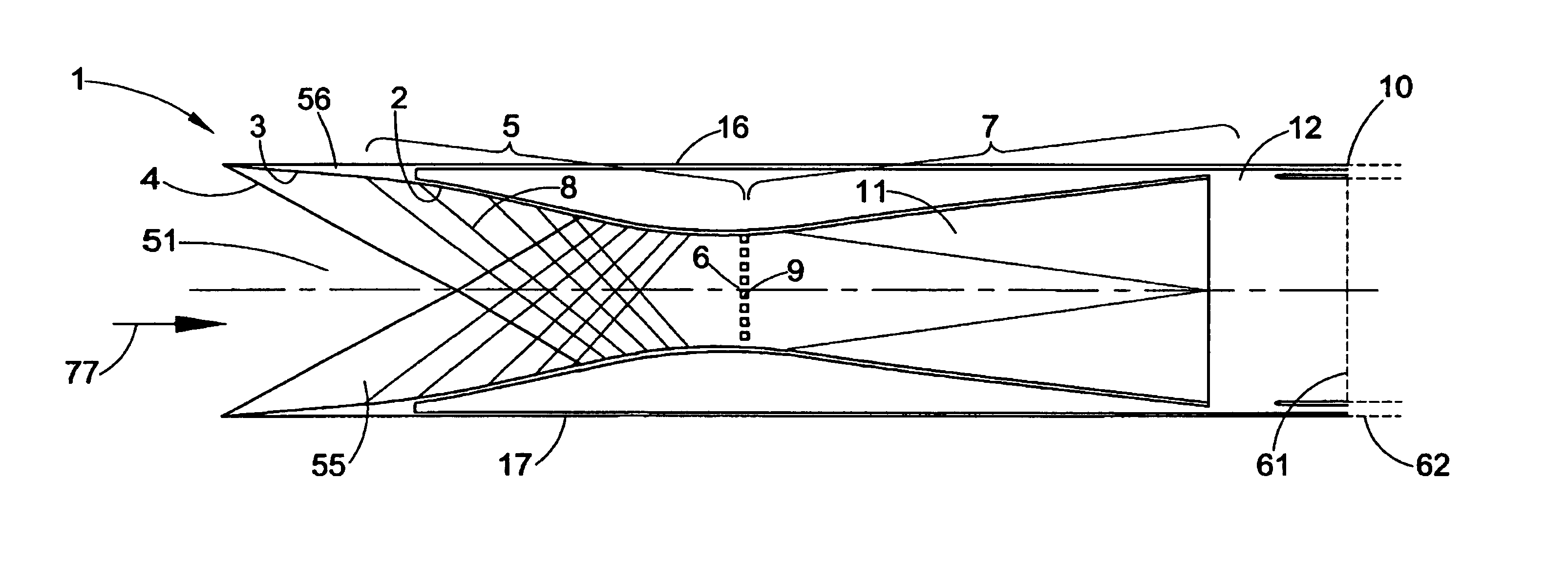

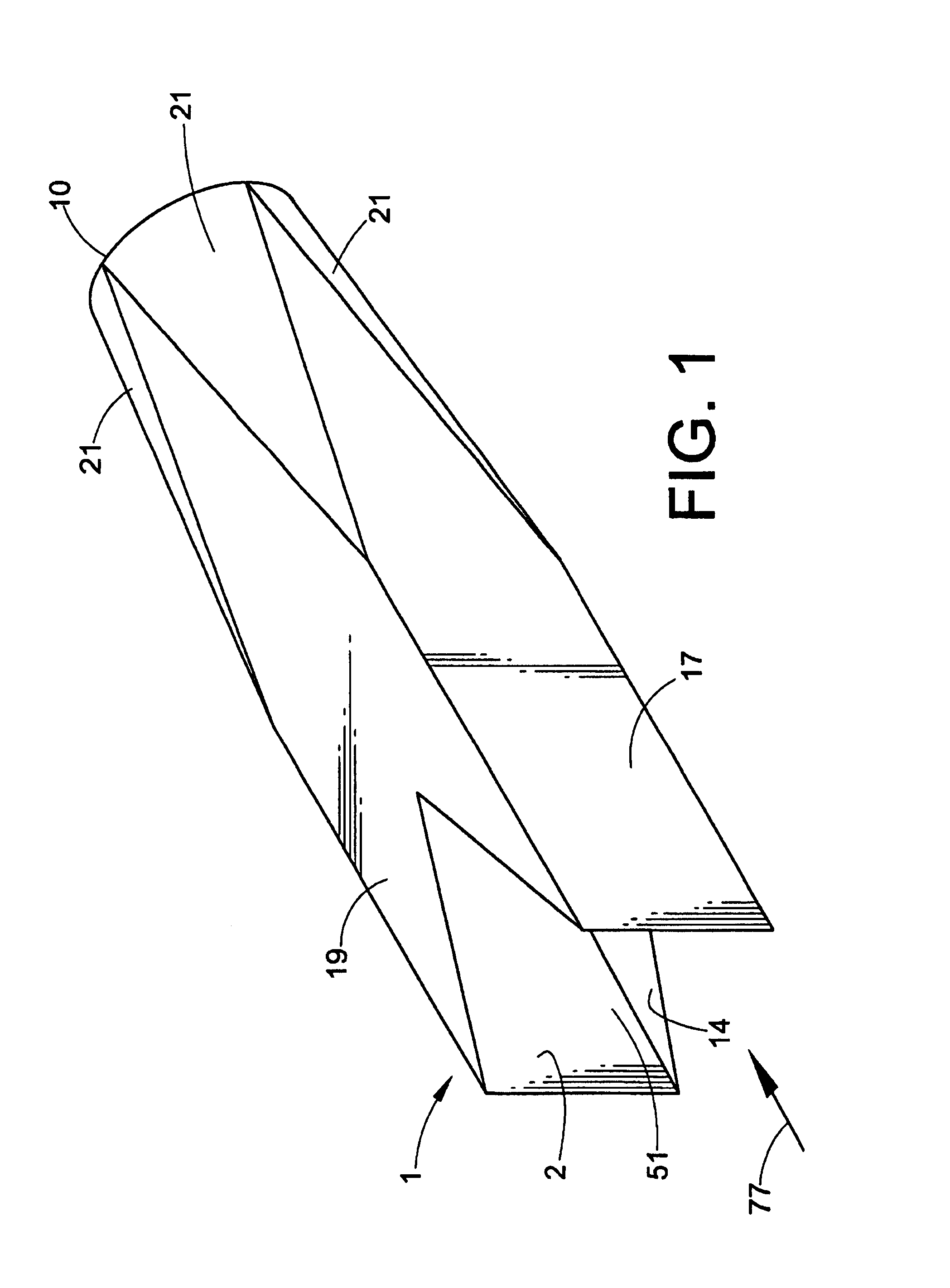

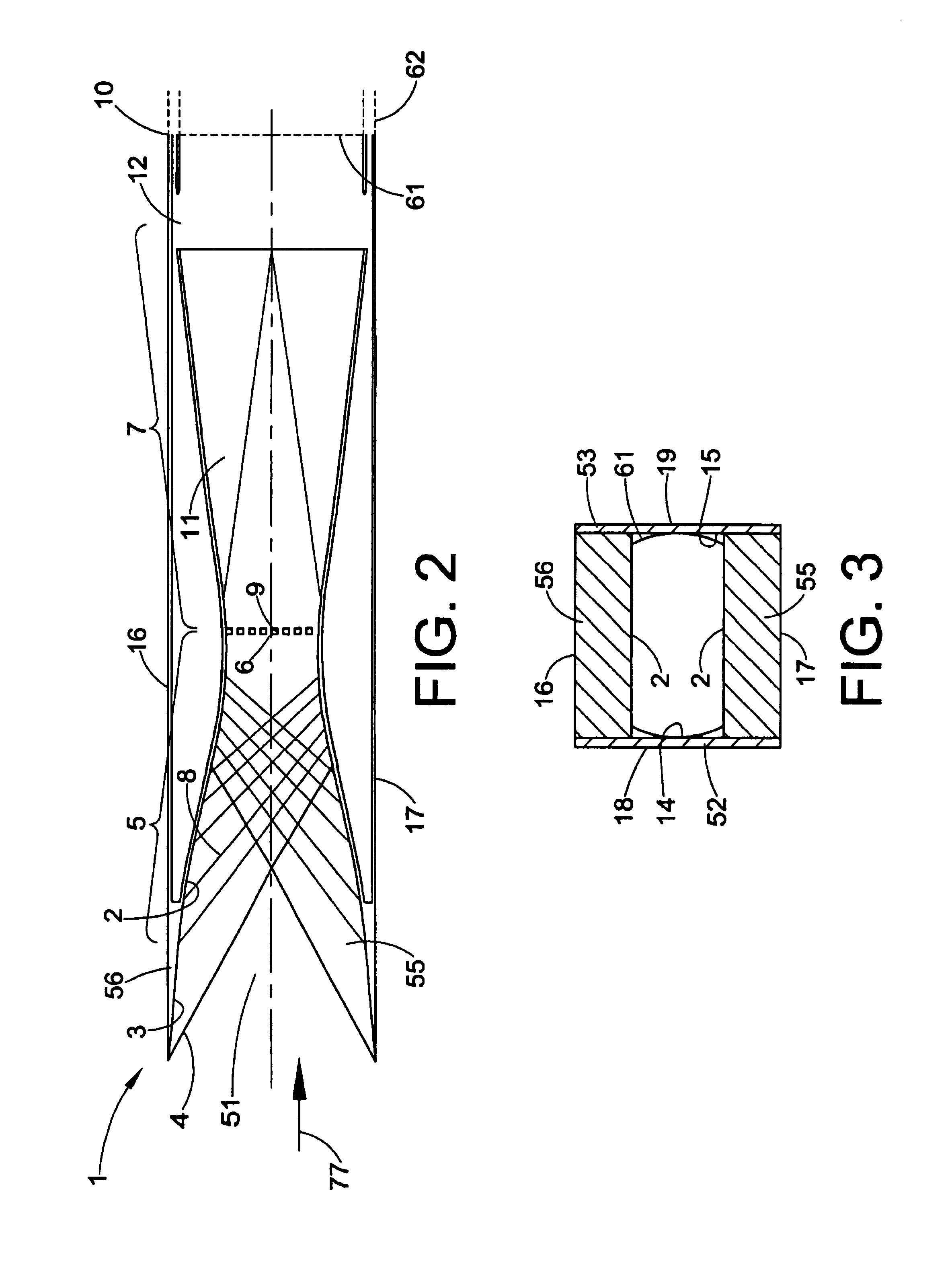

Low sonic boom inlet for supersonic aircraft

InactiveUS7048229B2Improve performanceLarge operability marginCombustion enginesEfficient propulsion technologiesThroatNacelle

All-internal compression inlets for supersonic aircraft, with variable geometry systems and shock stability bleed systems provide high performance, large operability margins, i.e. terminal shock stability that reduces the probability of inlet unstart, and contribute little or nothing to the overall sonic boom signature of the aircraft. These inlets have very high internal area contraction or compression and very low external surface angles. All shocks from the internal inlet surfaces are captured and reflected inside the inlet duct, and all of the external nacelle surfaces are substantially aligned with the external airflow. The inlet shock stability system consists of bleed regions that duct bleed airflows to variable area exits with passive or active exit area controls. This reduces the risk of inlet unstarts by removing airflow through a large open throat bleed region to compensate for reductions in diffuser (engine) corrected airflow demand. Because the stability bleed is not removed until the inlet terminal shock moves upstream over the bleed region, the necessary normal shock operability margin is provided without compromising inlet performance (total pressure recovery, and distortion).

Owner:TECHLAND RES

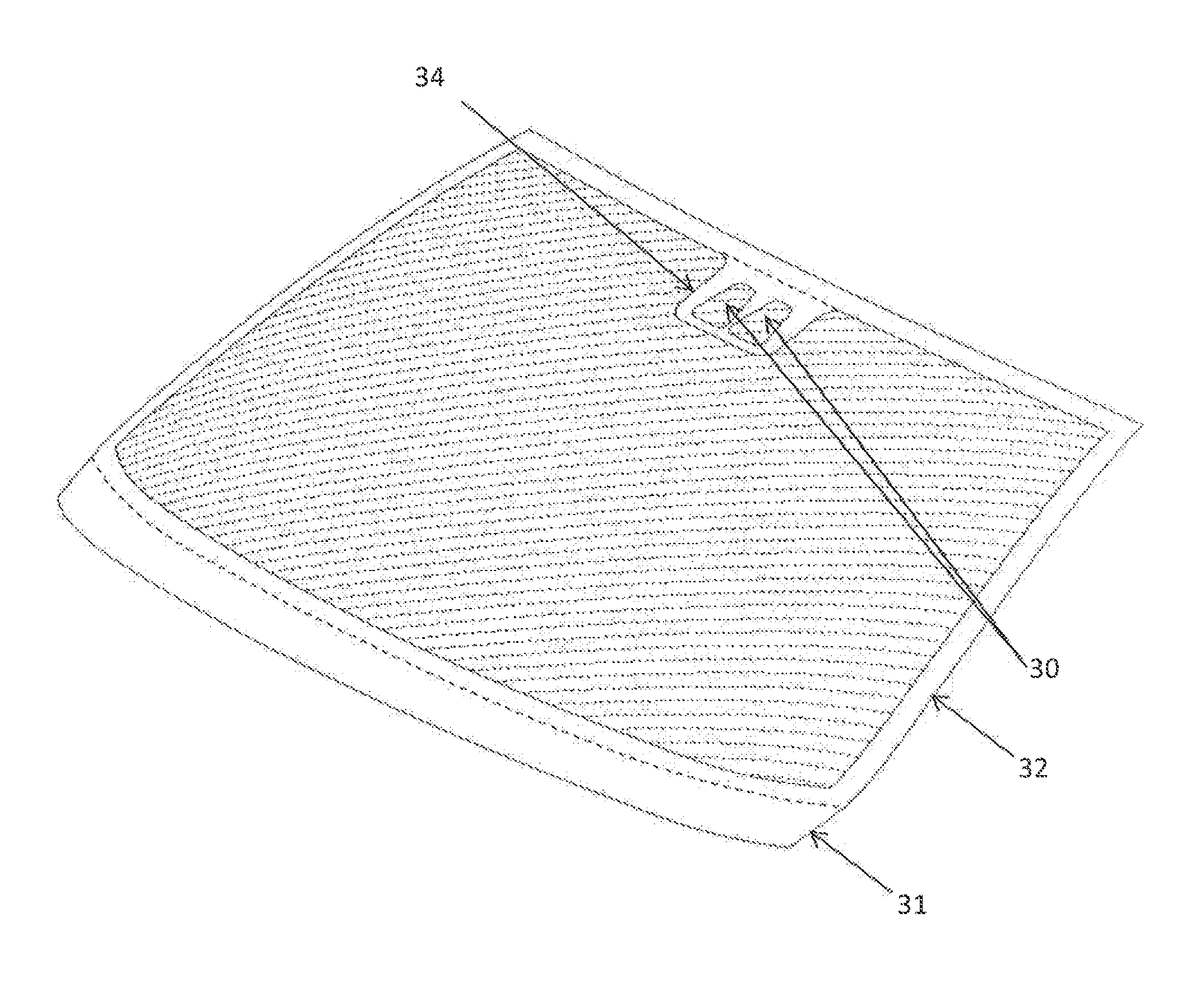

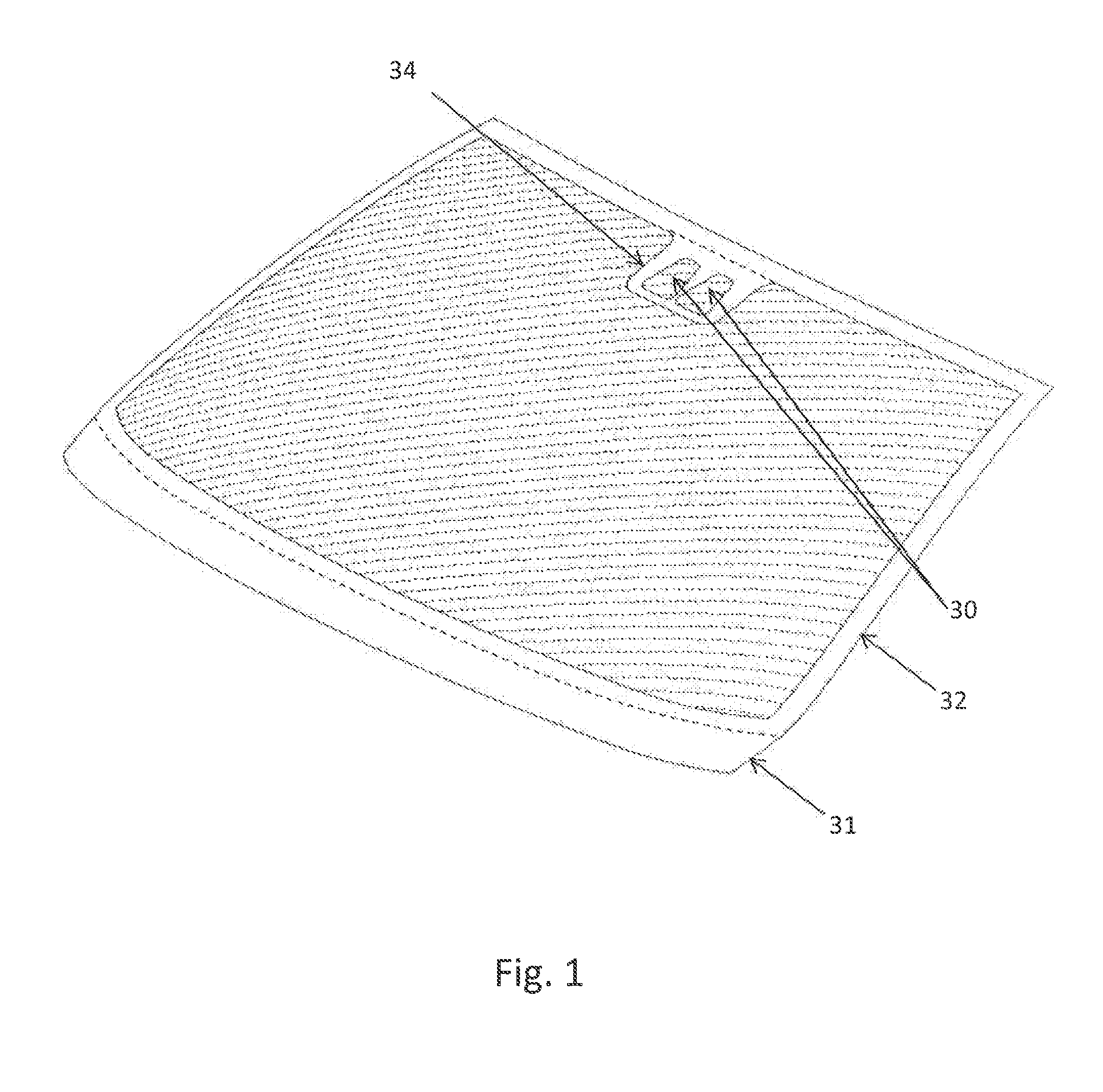

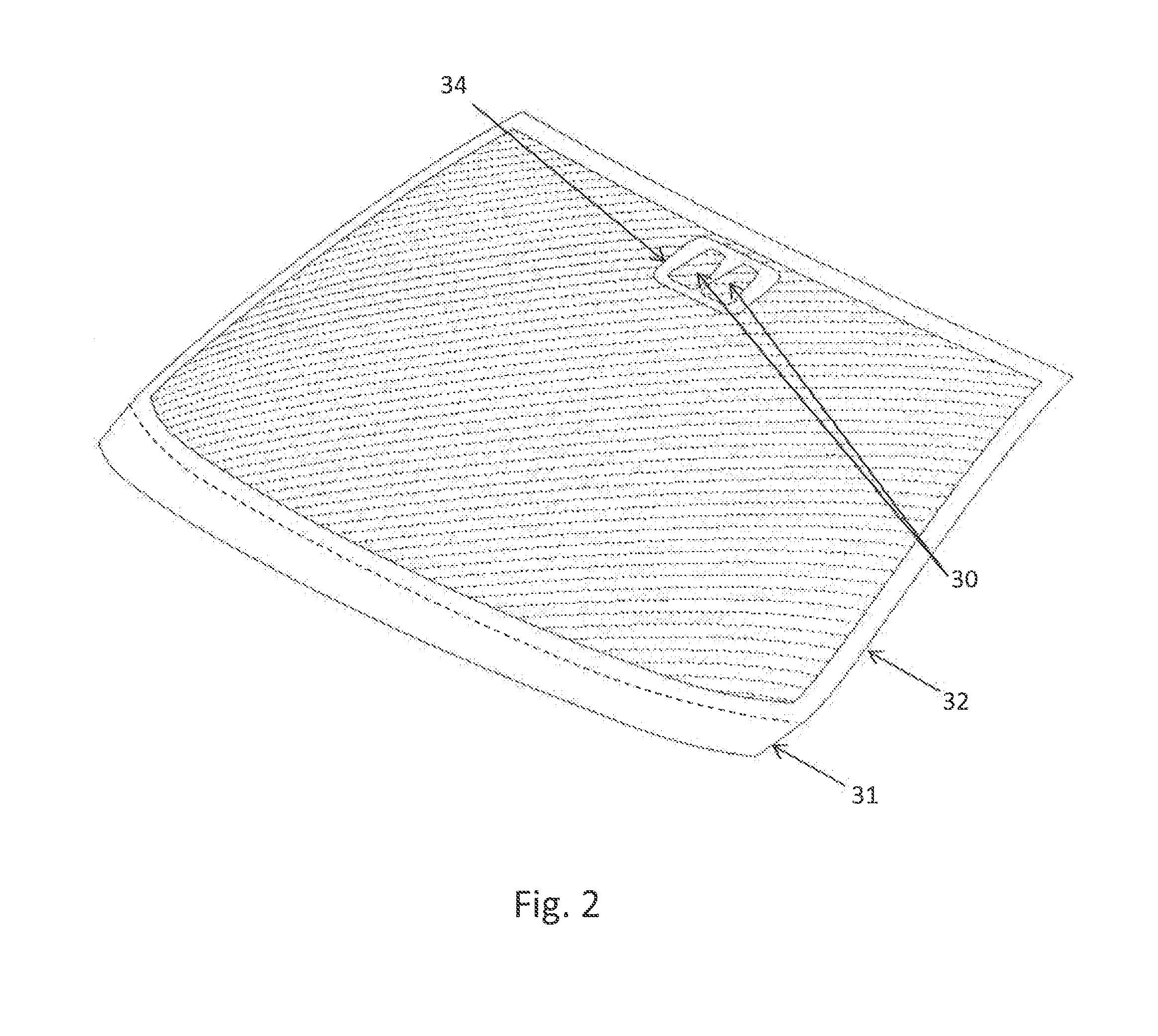

Obscuration having superior strength and optical quality for a laminated automotive windshield

ActiveUS20160243796A1Improve aestheticsAppearance differenceWindowsLamination ancillary operationsFritEngineering

Laminated automotive glazing including plastic layers and glass having an obscuration area produced by printing on the plastic layers of the laminate rather than printing and firing a black enamel frit onto the glass. This results in an obscuration having superior optical quality, higher strength and a lower probability of breakage as compared to a black enamel frit obscuration.

Owner:AGP AMERICA

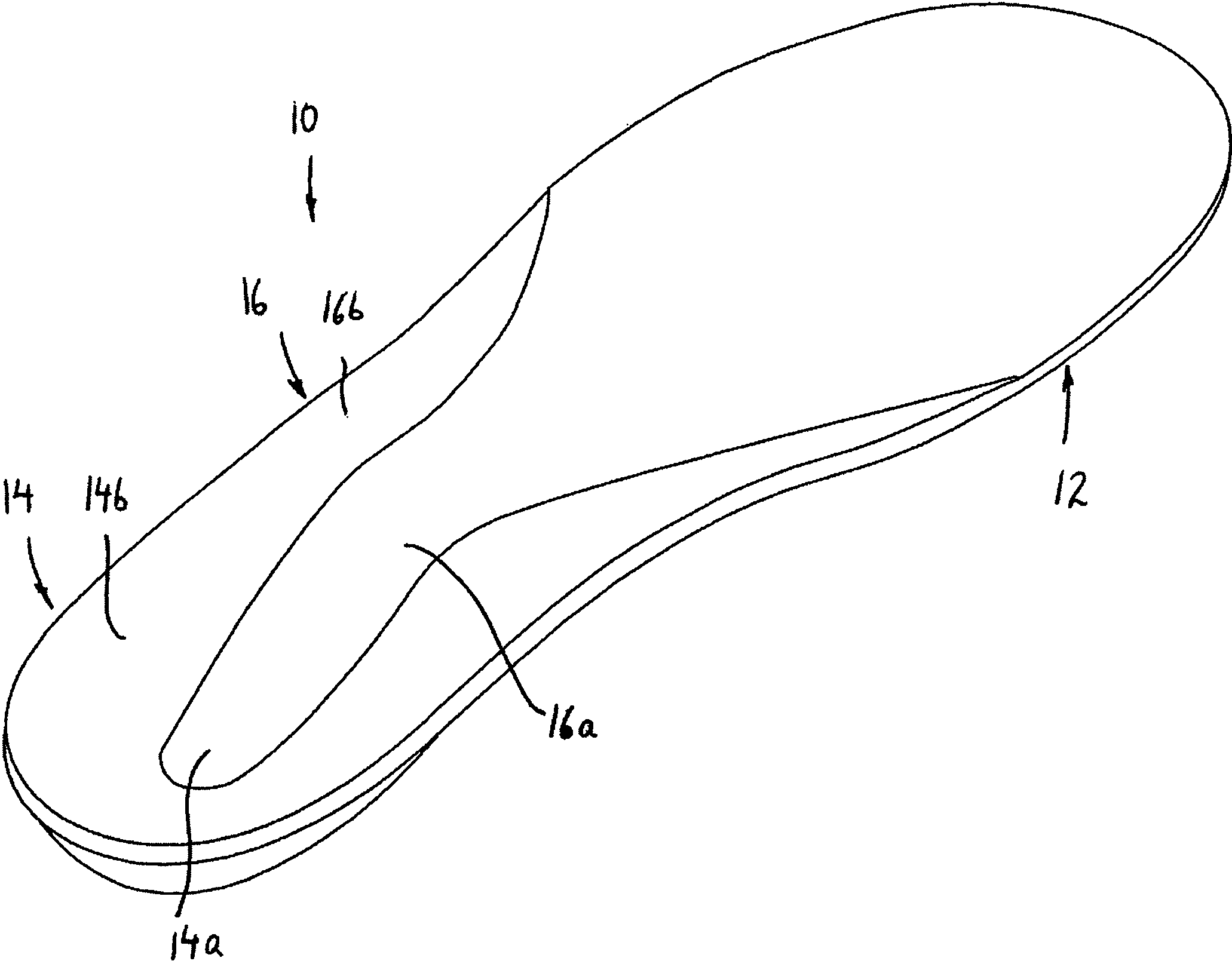

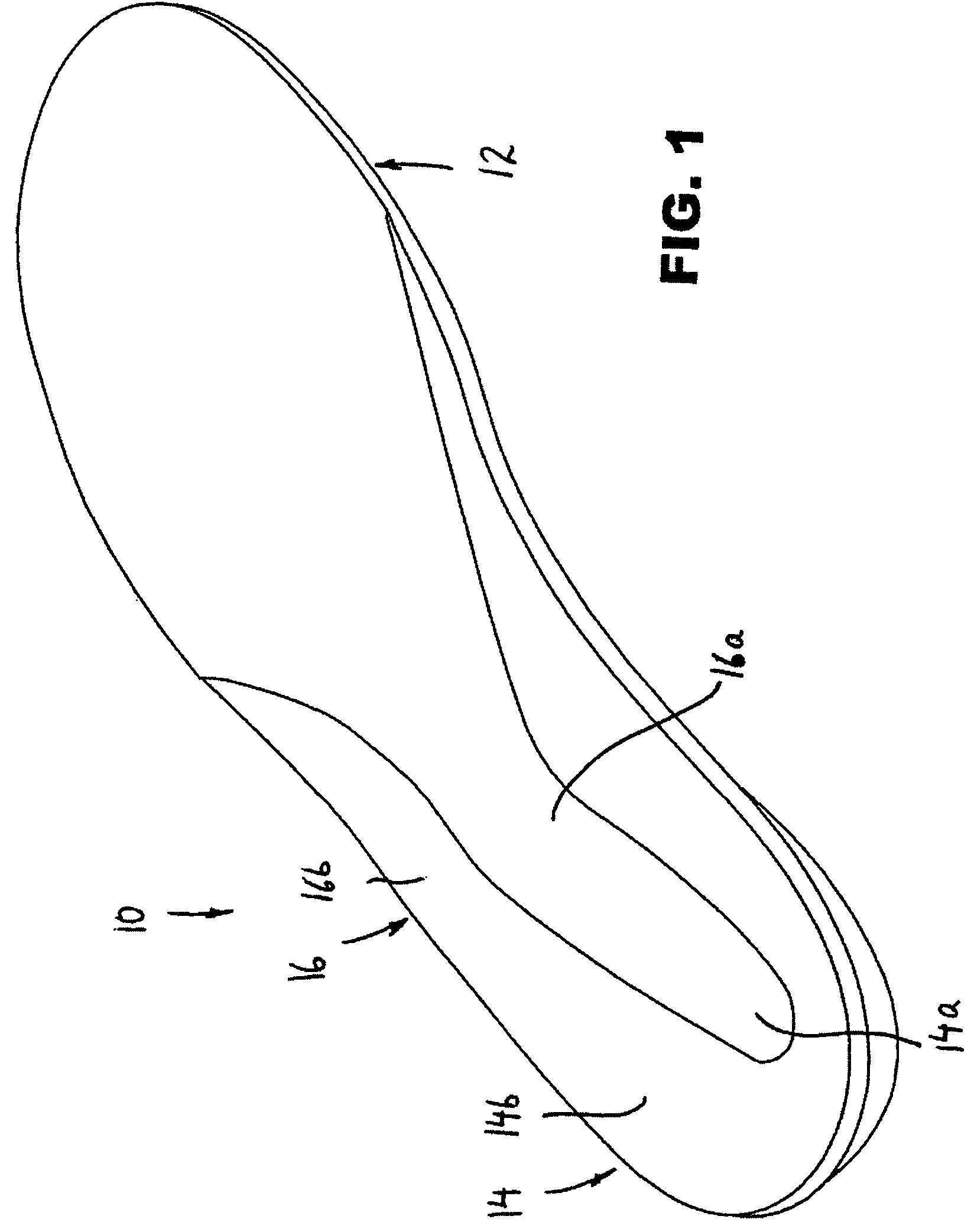

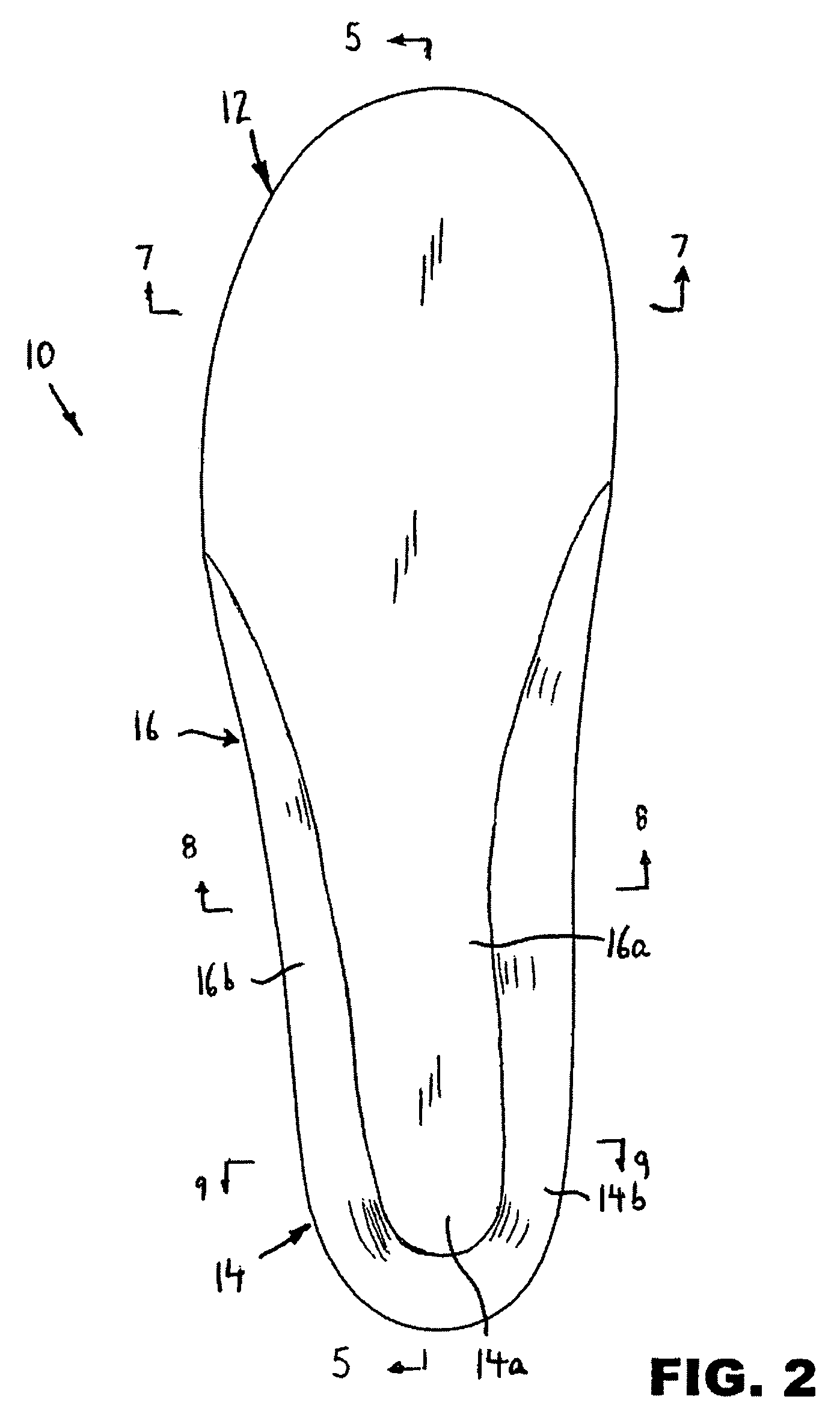

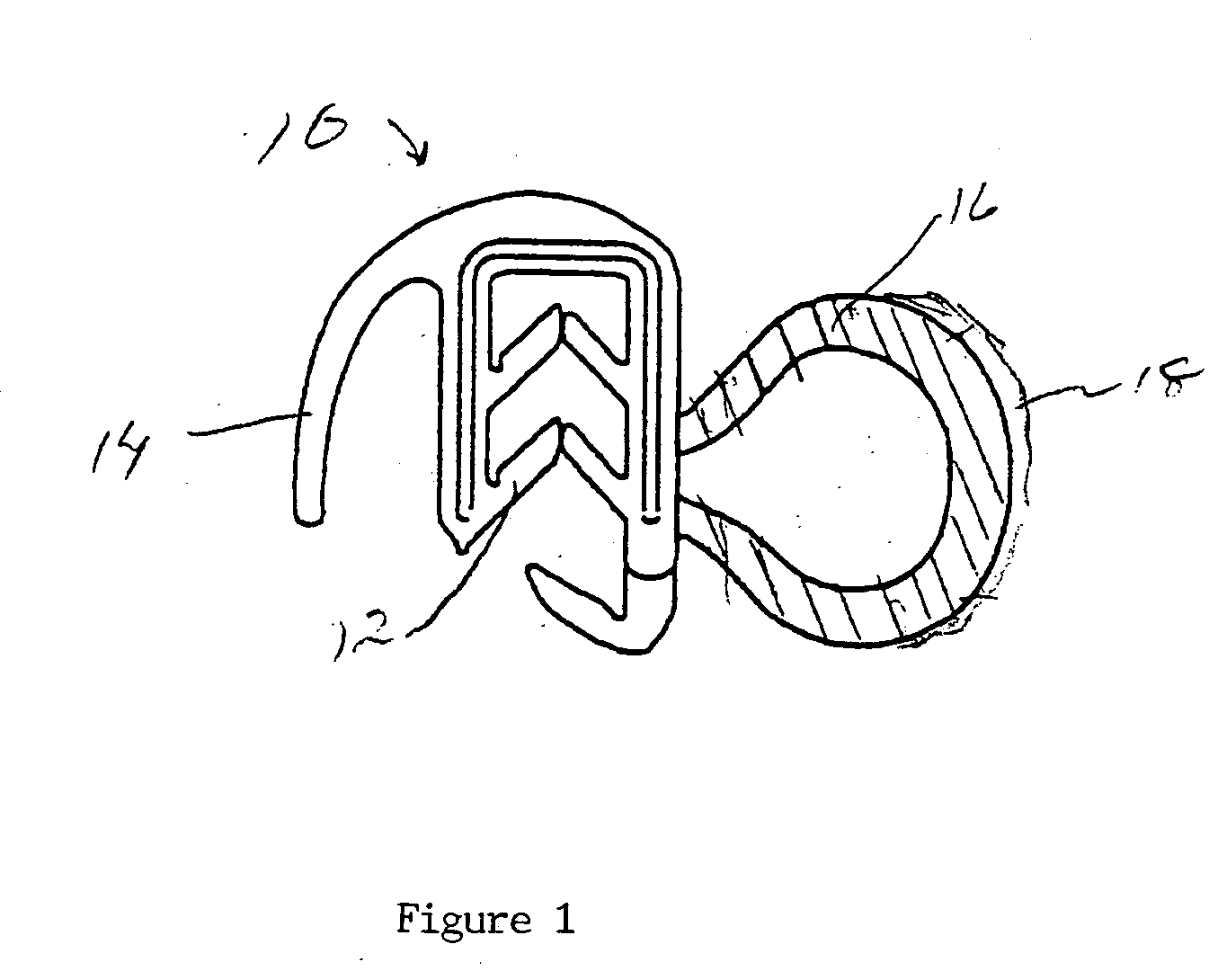

Heel insert

A removable insole for insertion into footwear, includes a forefoot portion, a heel portion, and an arch portion connecting together the forefoot and heel portions. At least one of the forefoot portion, heel portion and arch portion is formed by a lower layer of a resilient material which provides a cushioning function, and an upper layer positioned and secured on top of the lower layer and formed of a material having a Shore “000” hardness of less than about 45, and a tear strength greater than about 6.3 lb / in.

Owner:MSD CONSUMER CARE INC

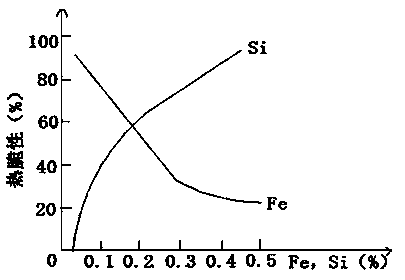

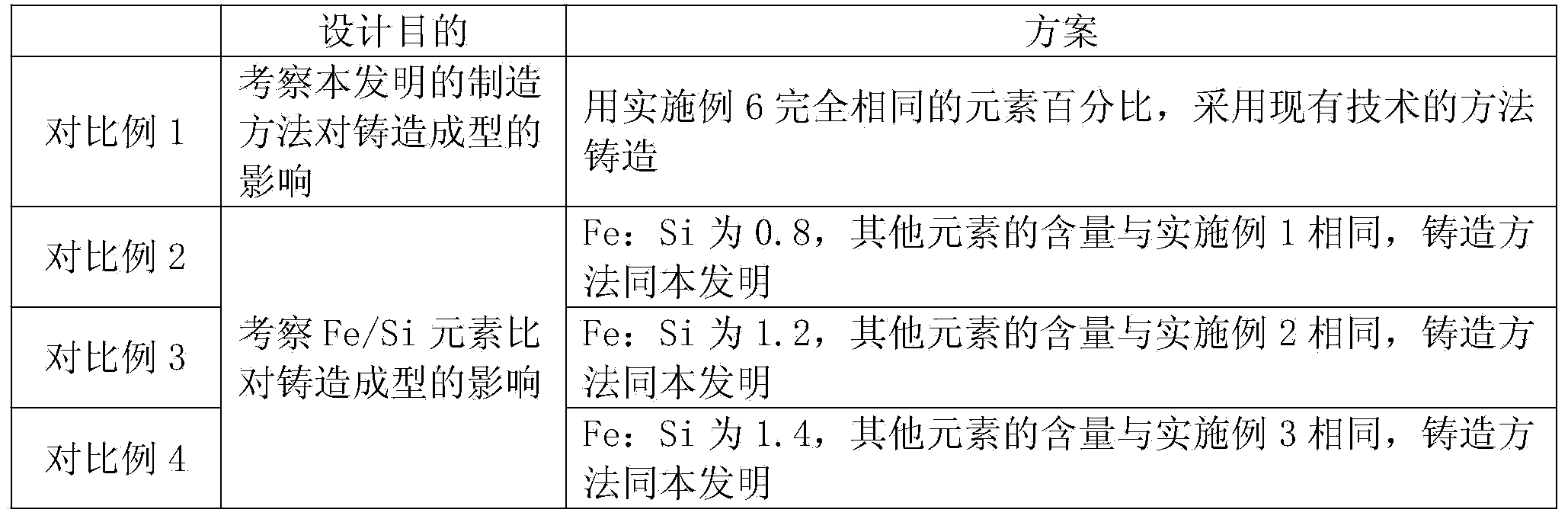

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

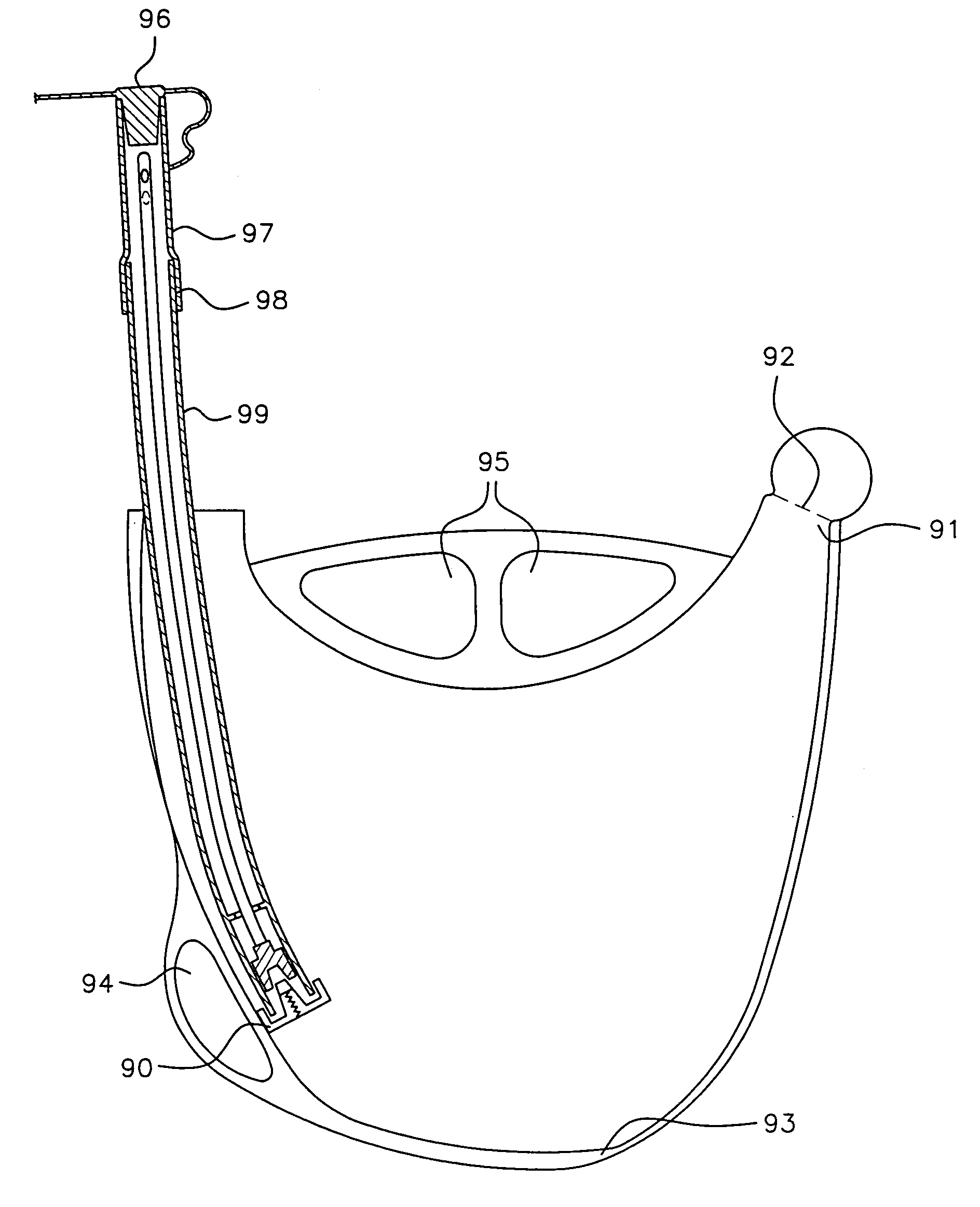

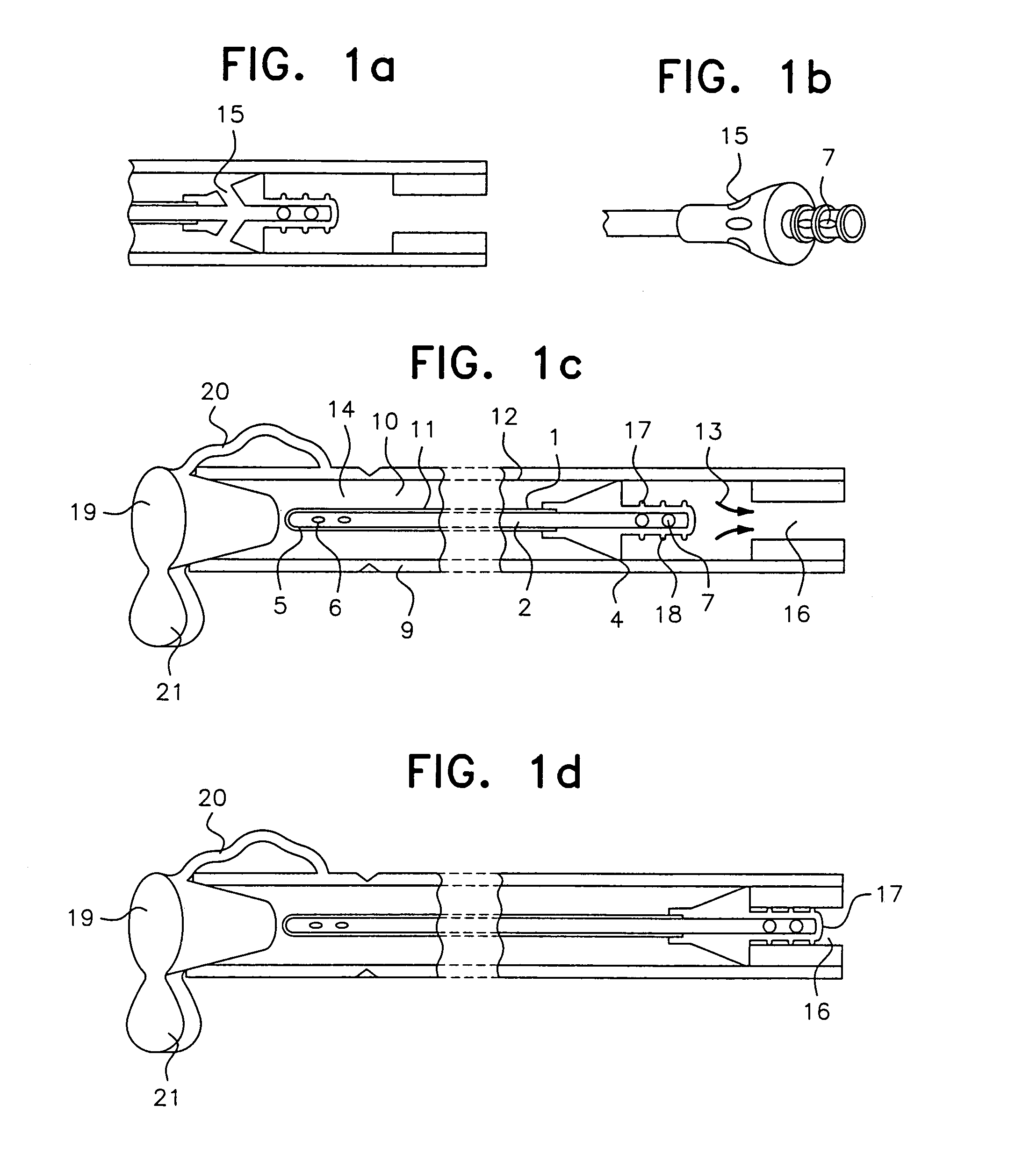

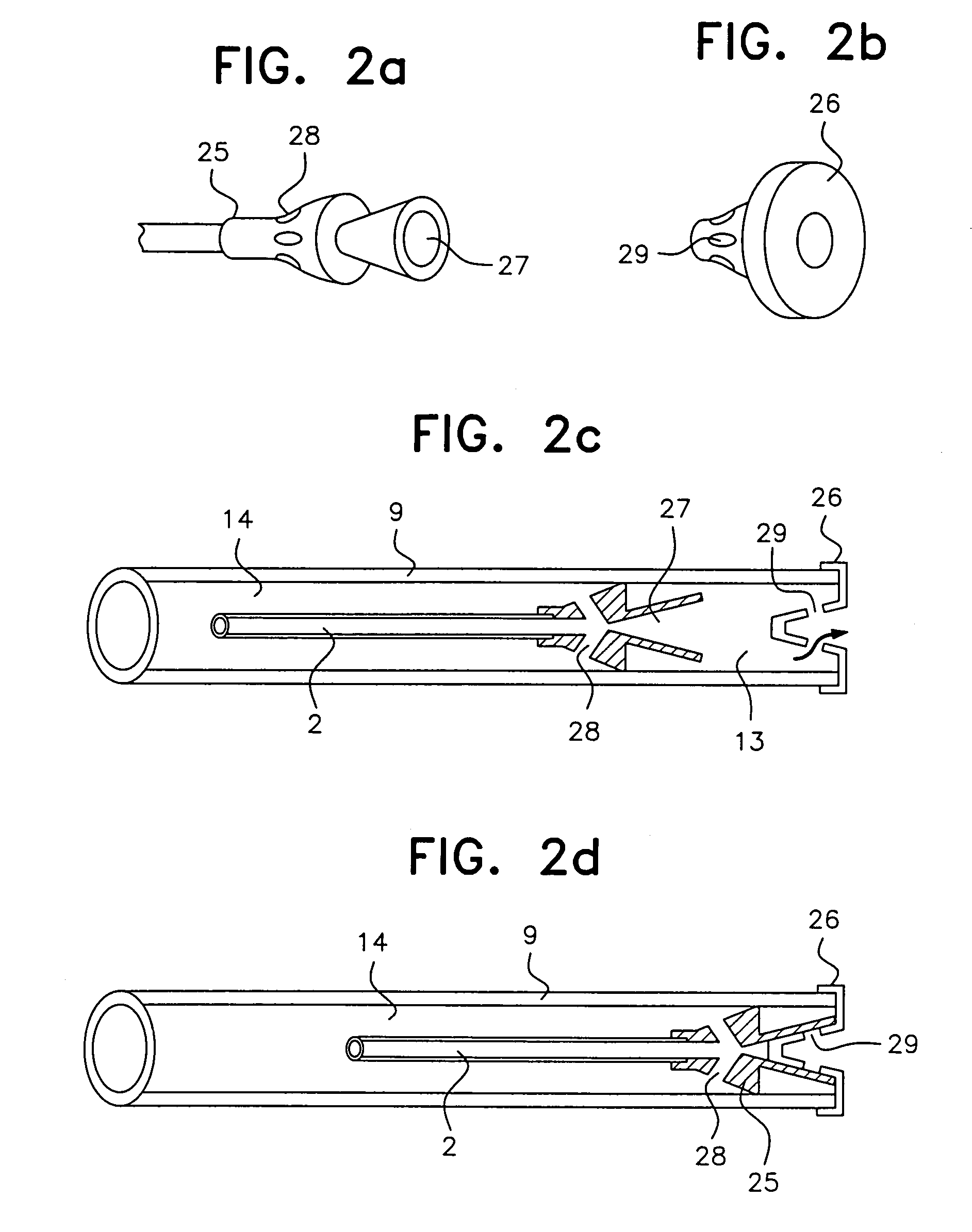

Catheter assembly including a catheter applicator

The present invention is a catheter assembly allowing for non-contaminated insertion of a catheter into a urinary canal. The assembly includes a package for the catheter and an applicator to be used for guiding the catheter into the urinary canal without touching the catheter by holding the catheter via walls of the applicator. The assembly further comprises clamping means for pressing the walls of the applicator into engagement with the catheter. The present invention further relates to an applicator with integrated clamping means to be used with the assembly.

Owner:COLOPLAST AS

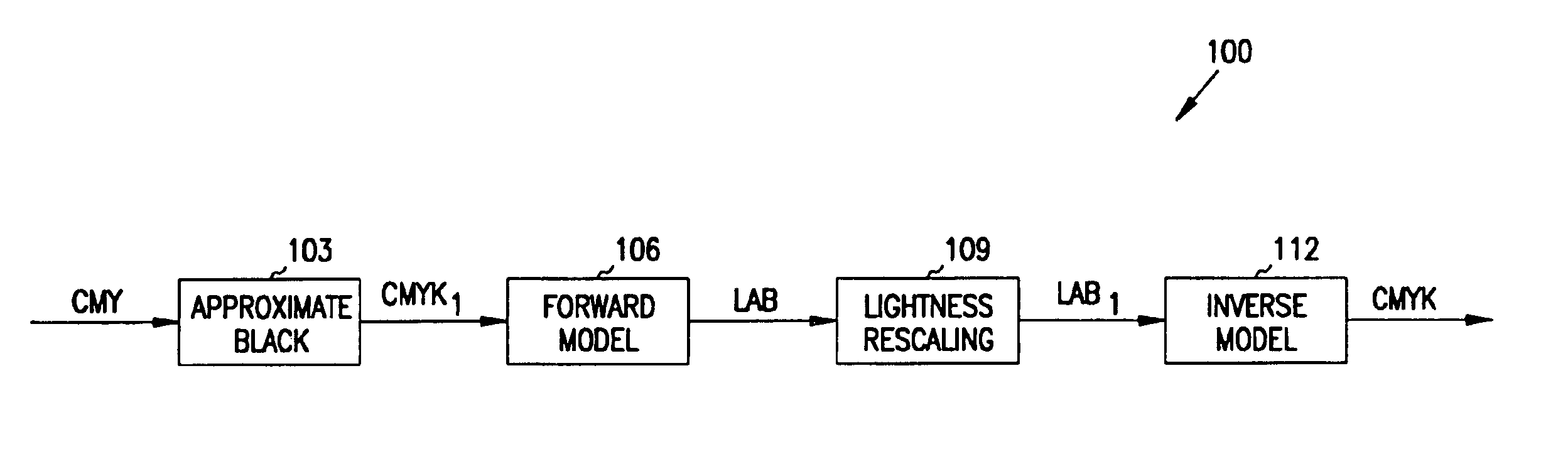

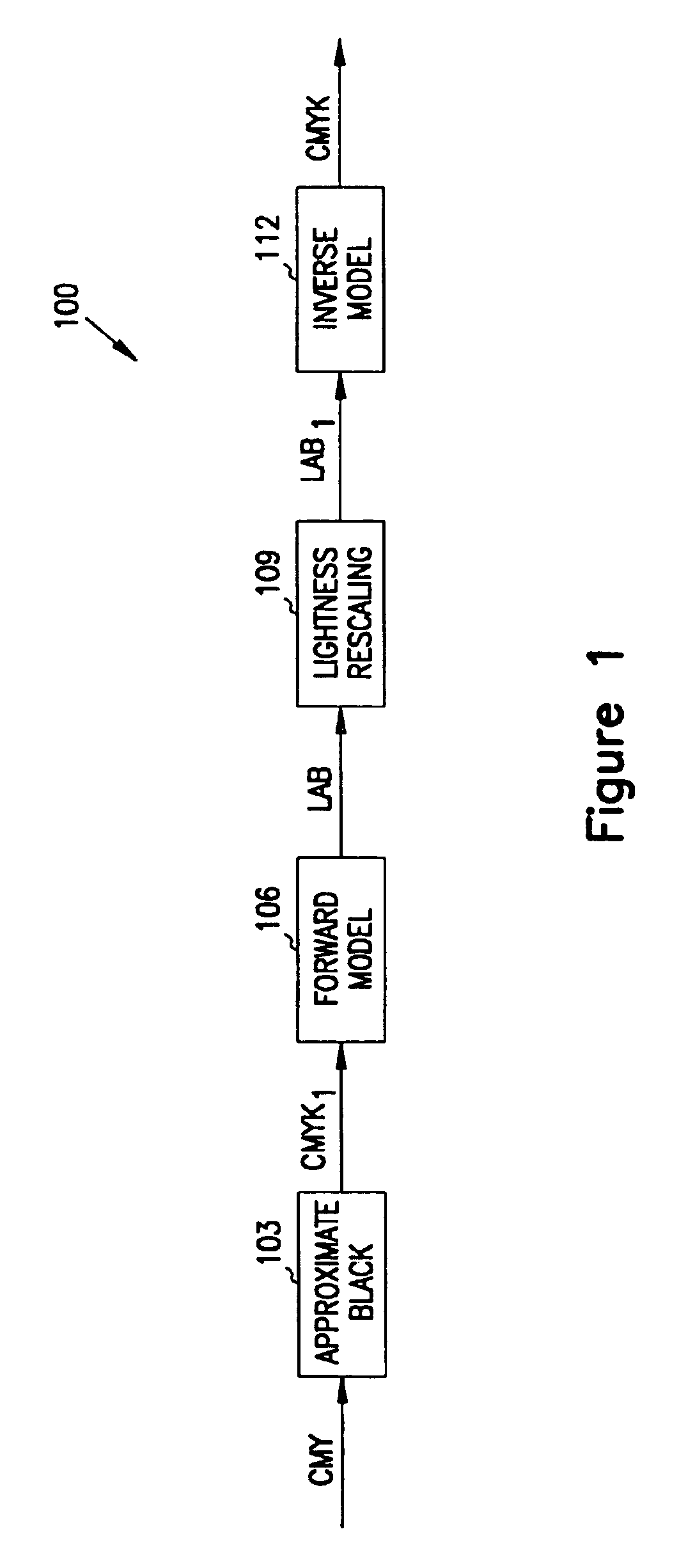

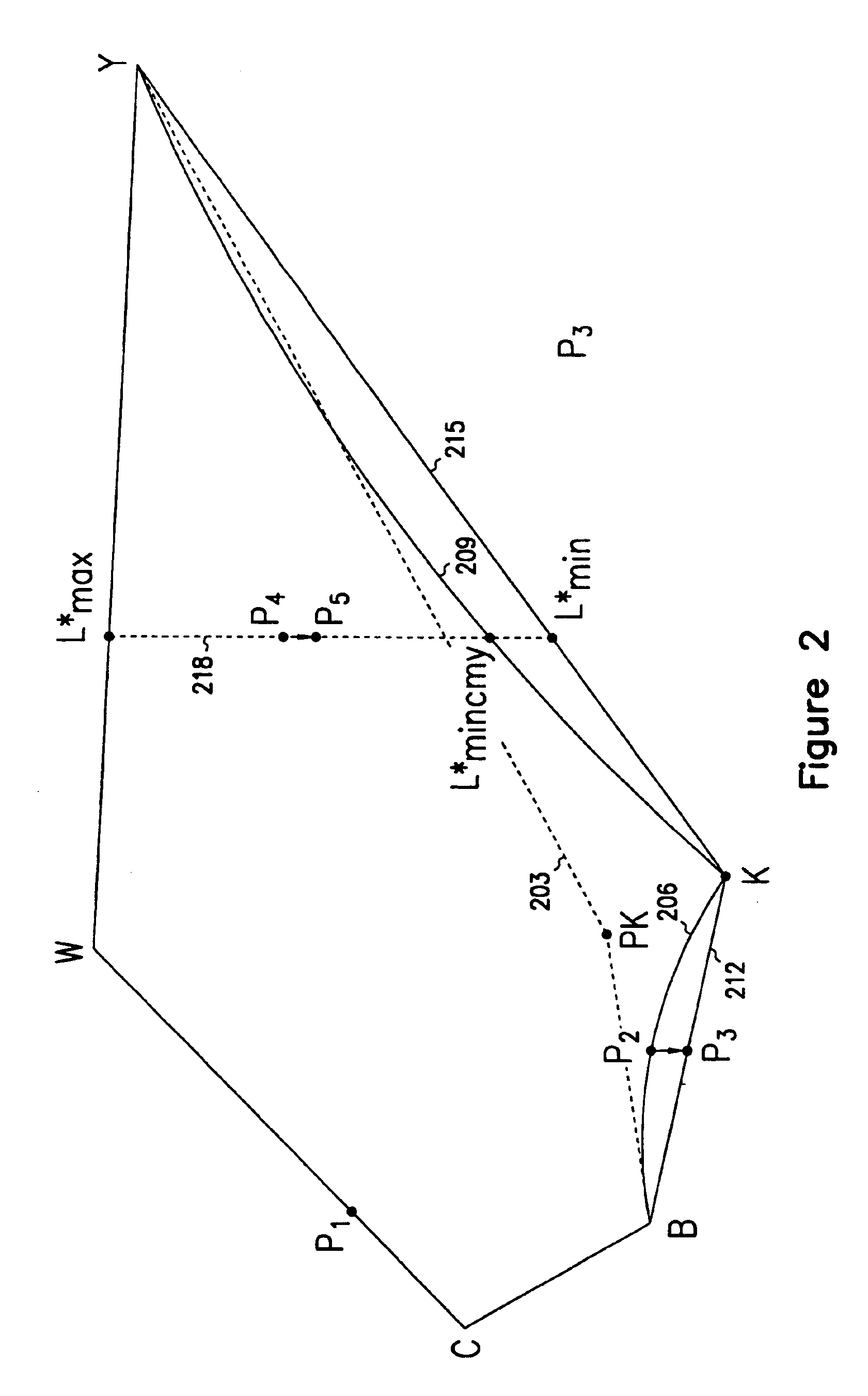

Method and apparatus for expanding a color gamut

InactiveUS6867883B1Upper surfaceLower surfaceDigitally marking record carriersDigital computer detailsGamutGeometric distortion

A color gamut in a first color space is expanded to utilize a larger gamut in a second color space. The gamut in the first color space is first converted by black generation or geometric distortion to a gamut in a second color space. The gamut in the second color space is converted by forward mapping to a gamut in a third color. The gamut in the third color space is expanded by linear rescaling. Finally, the linearly rescaled gamut is mapped to a gamut in the second color space through inverse modeling to form a final color gamut. The final color gamut utilizes the gamut available in the second color space, which is larger than the gamut available in the first color space.

Owner:LEXMARK INT INC

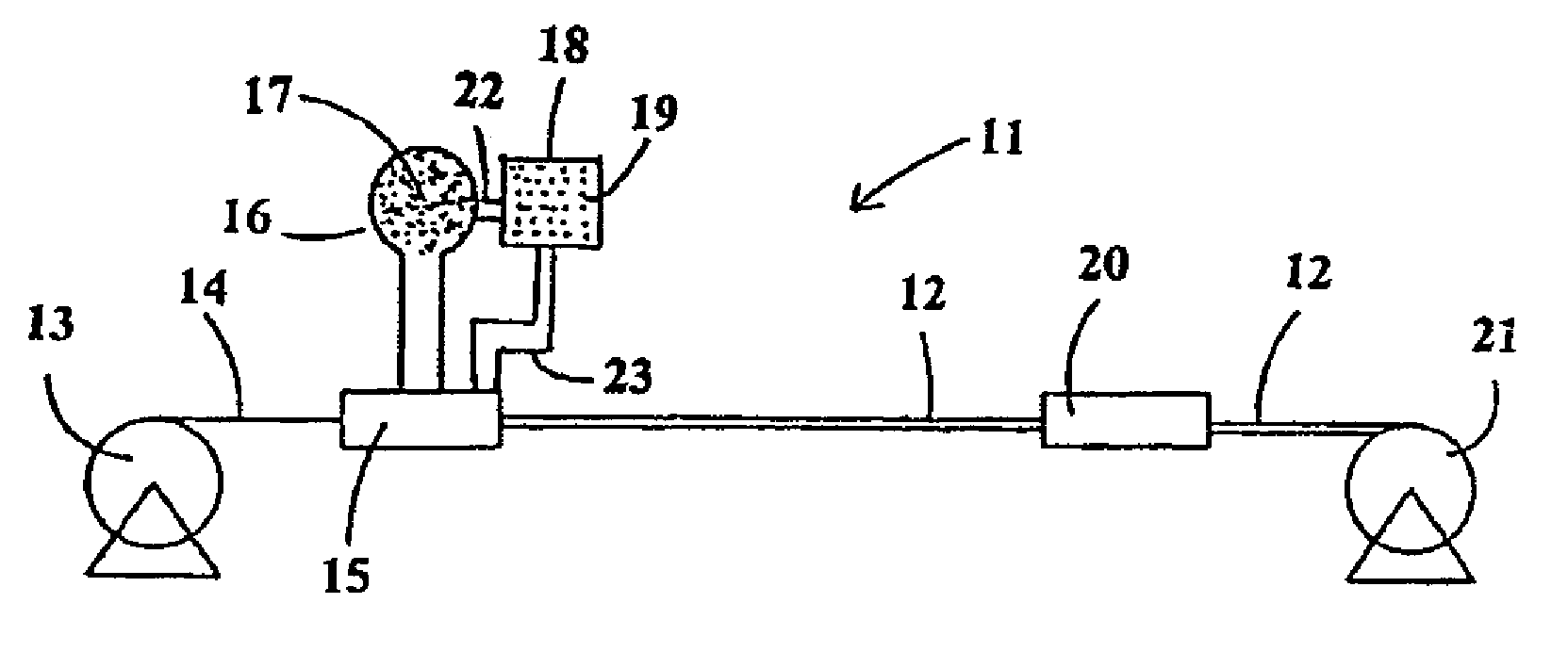

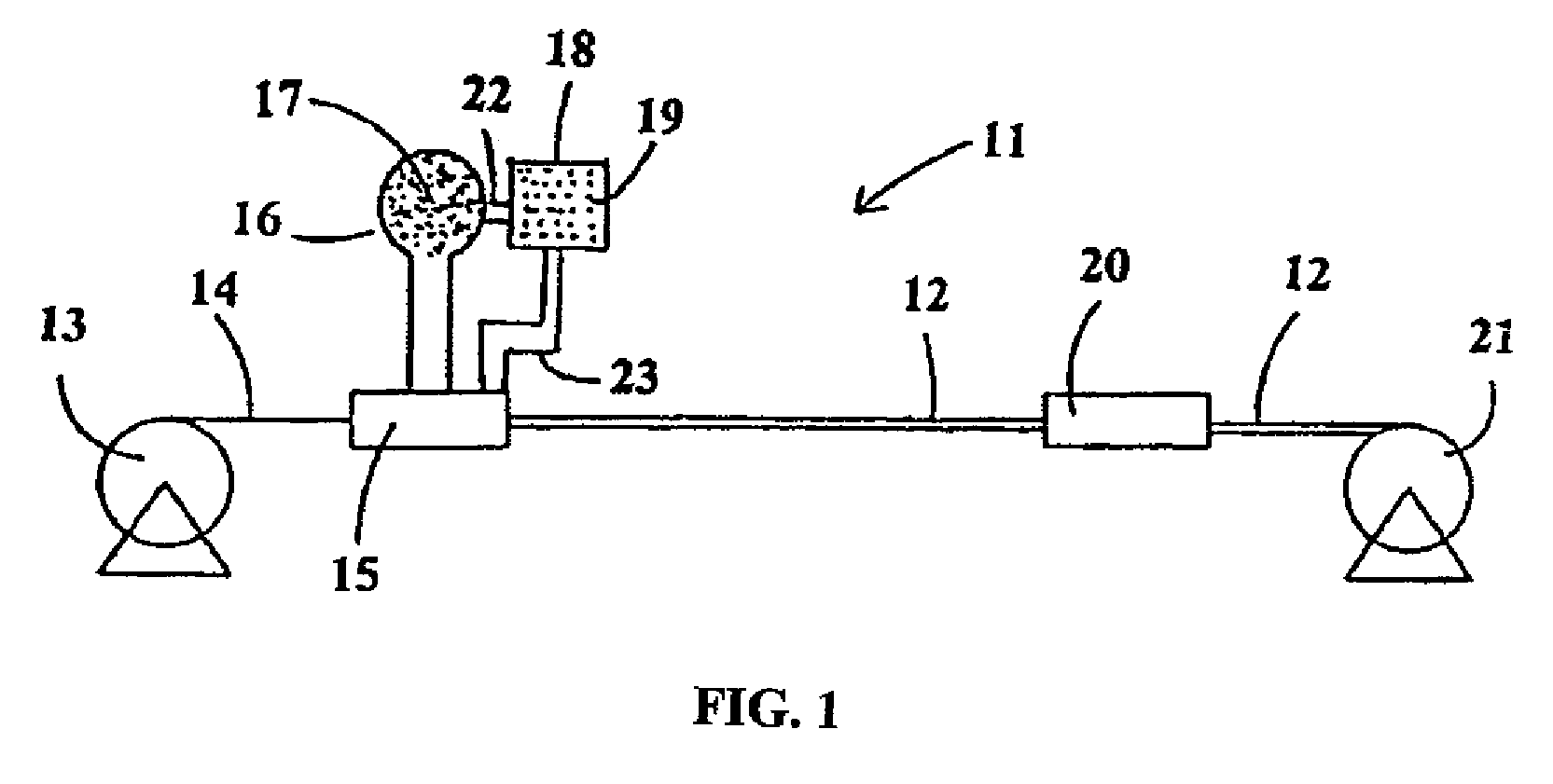

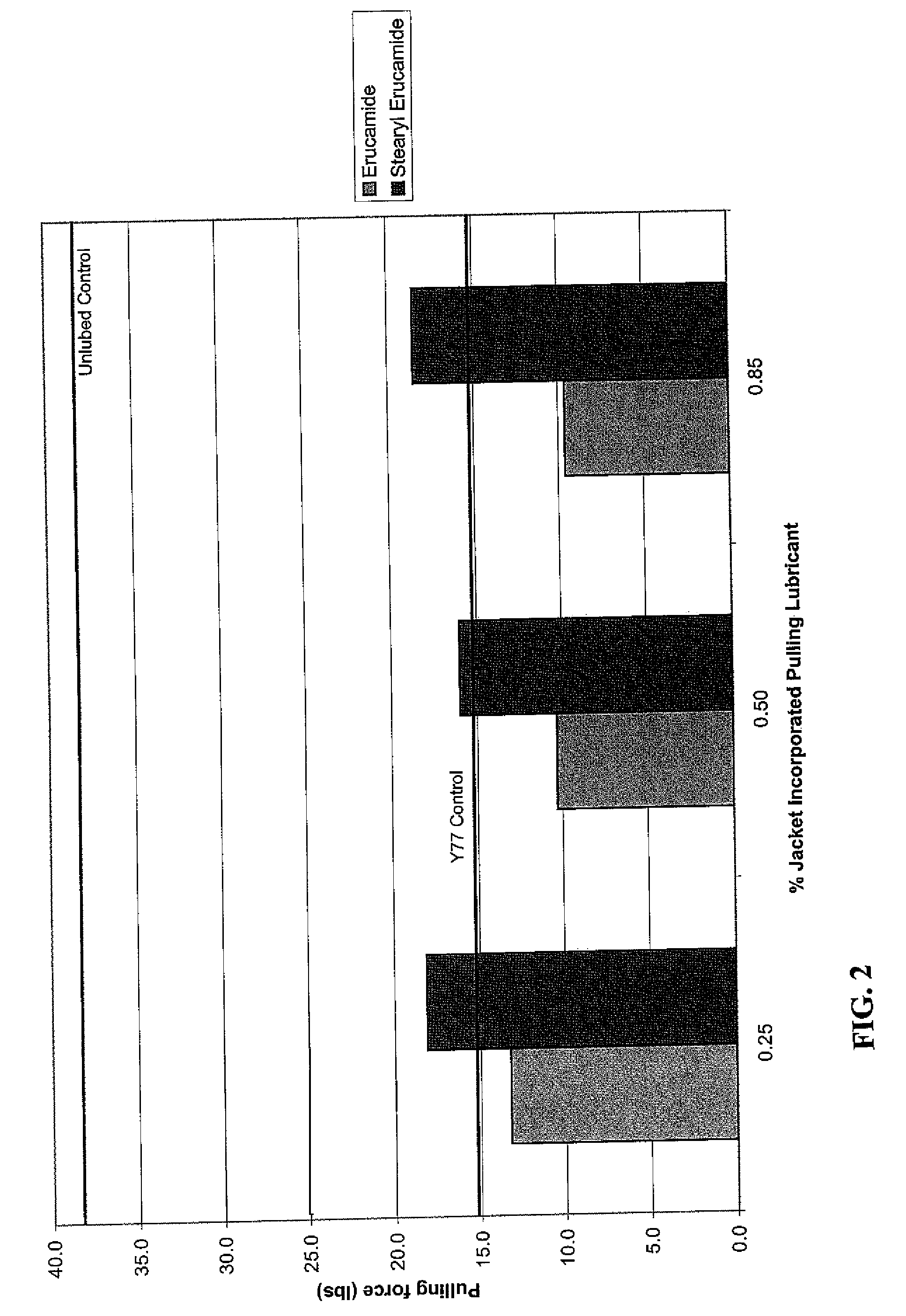

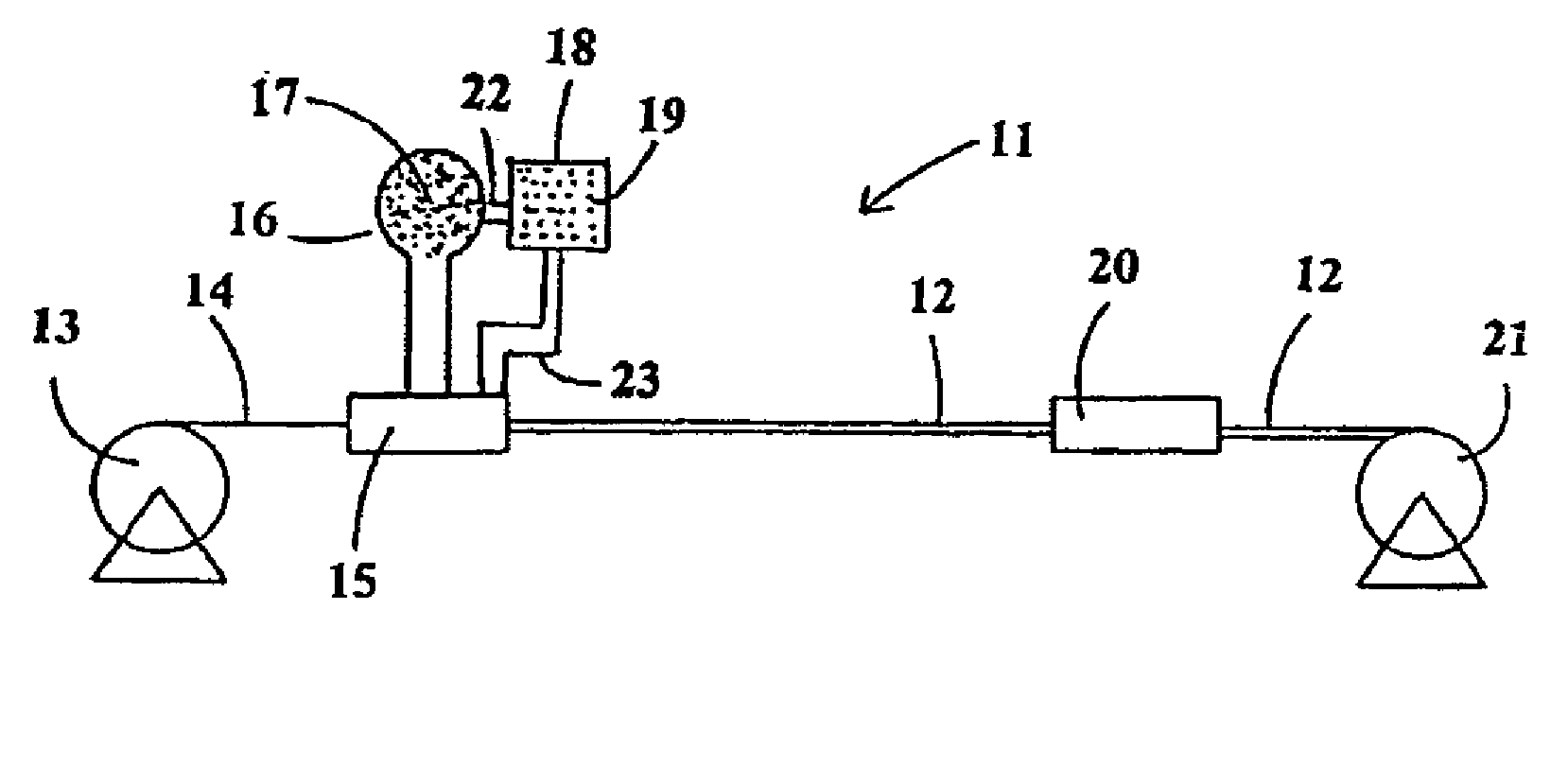

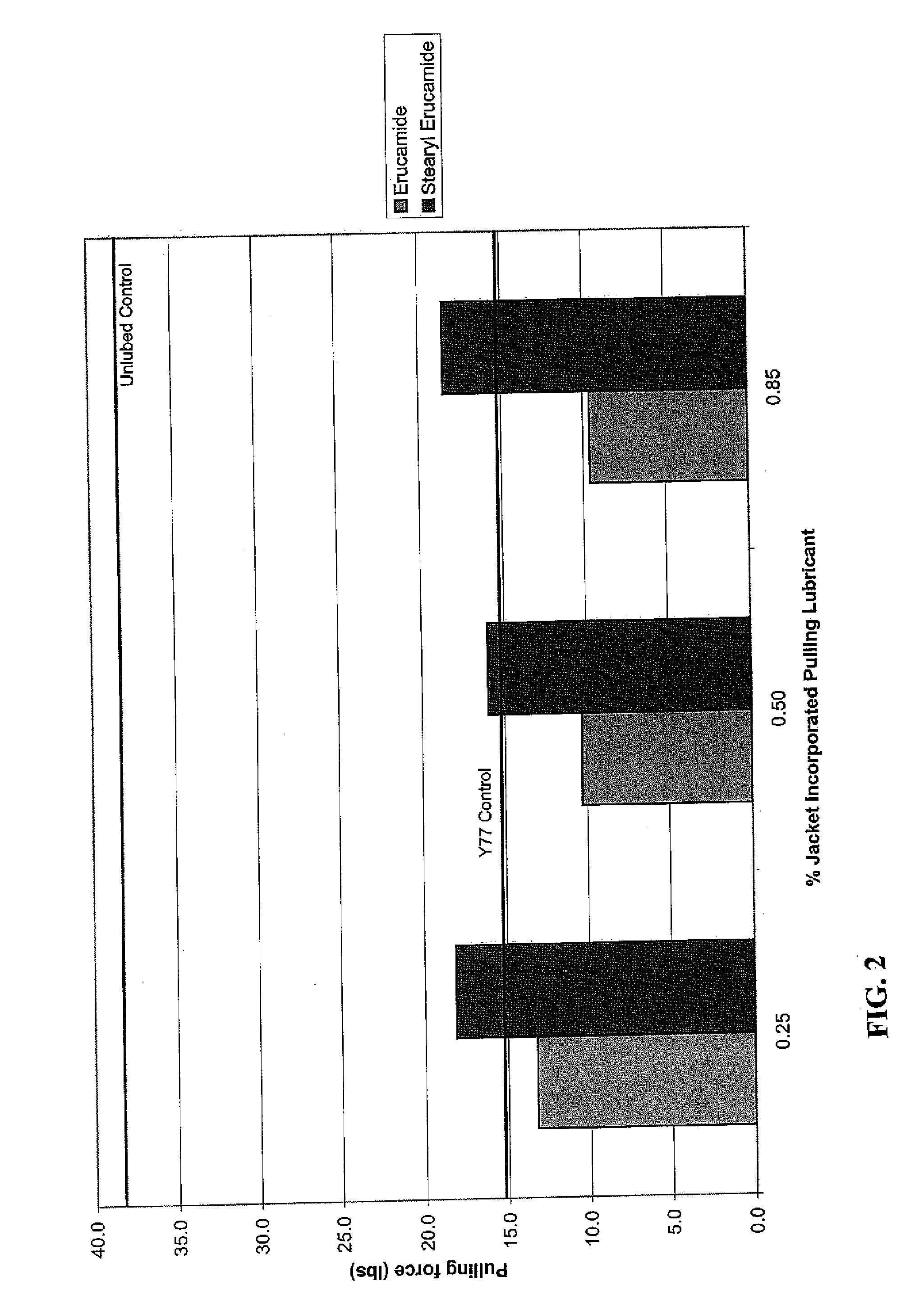

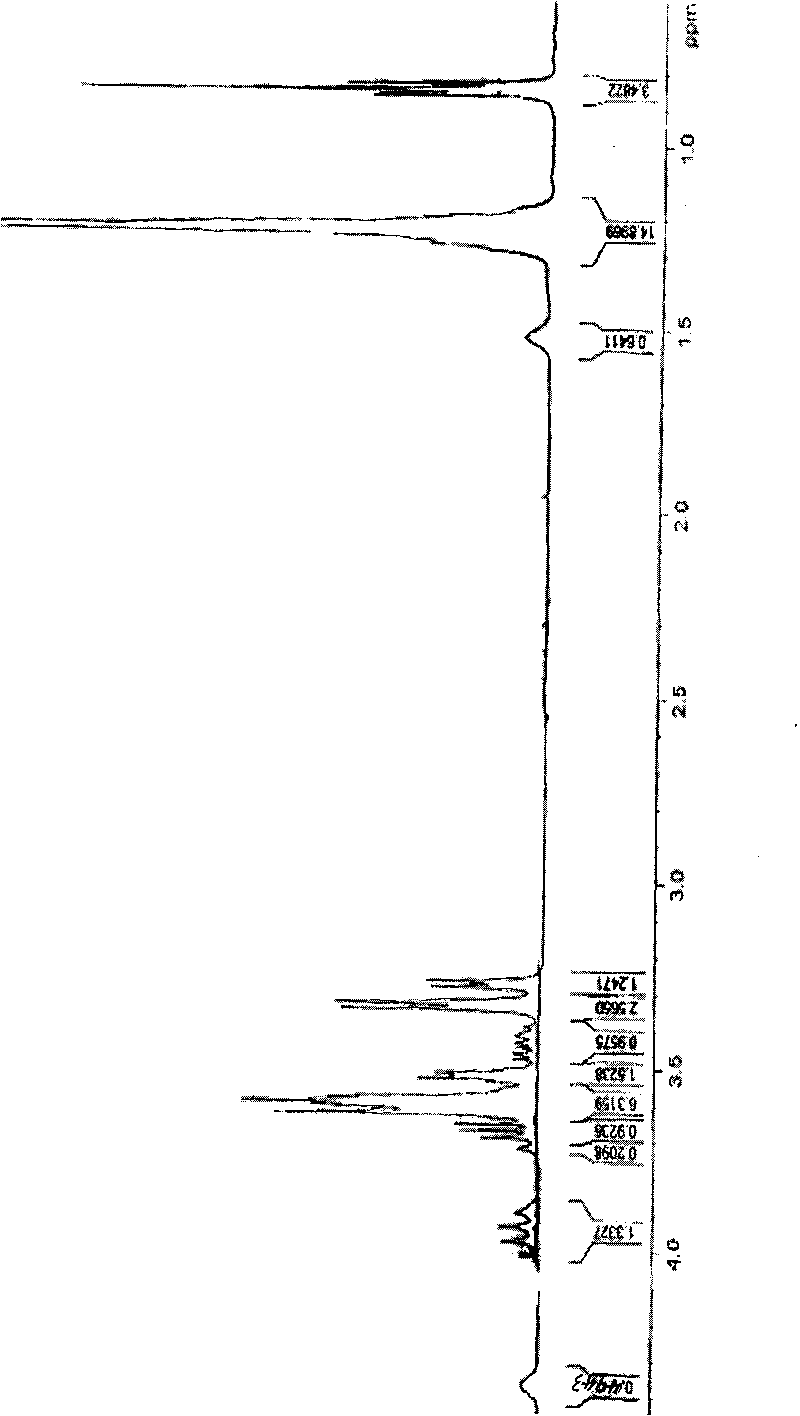

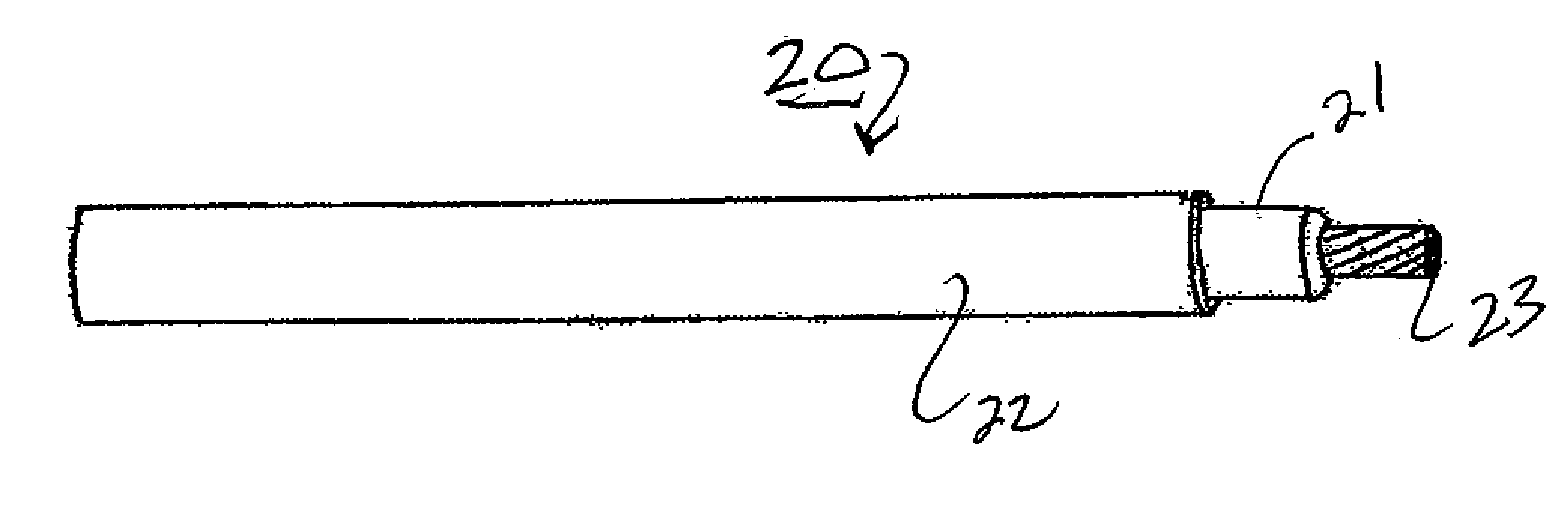

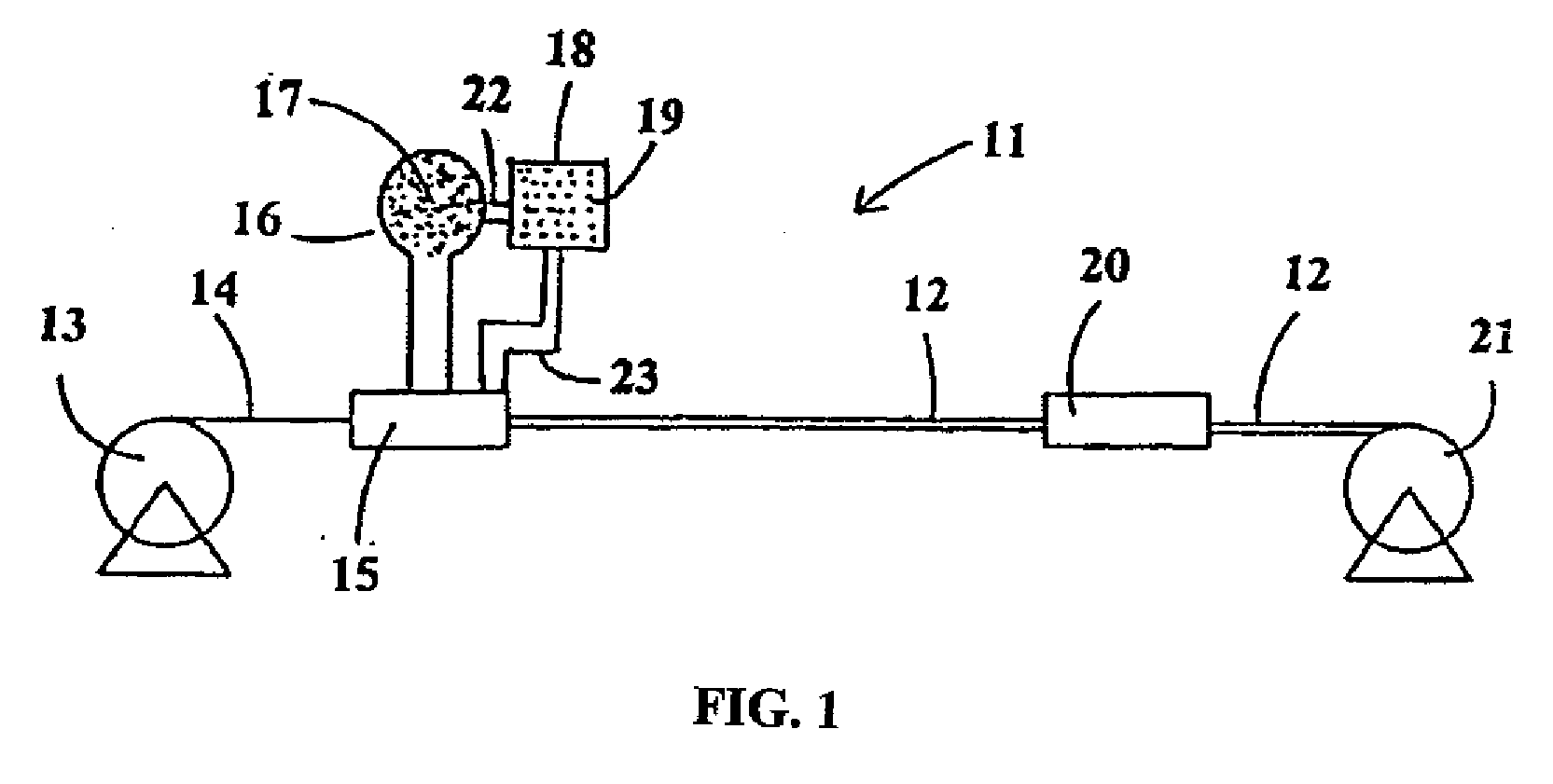

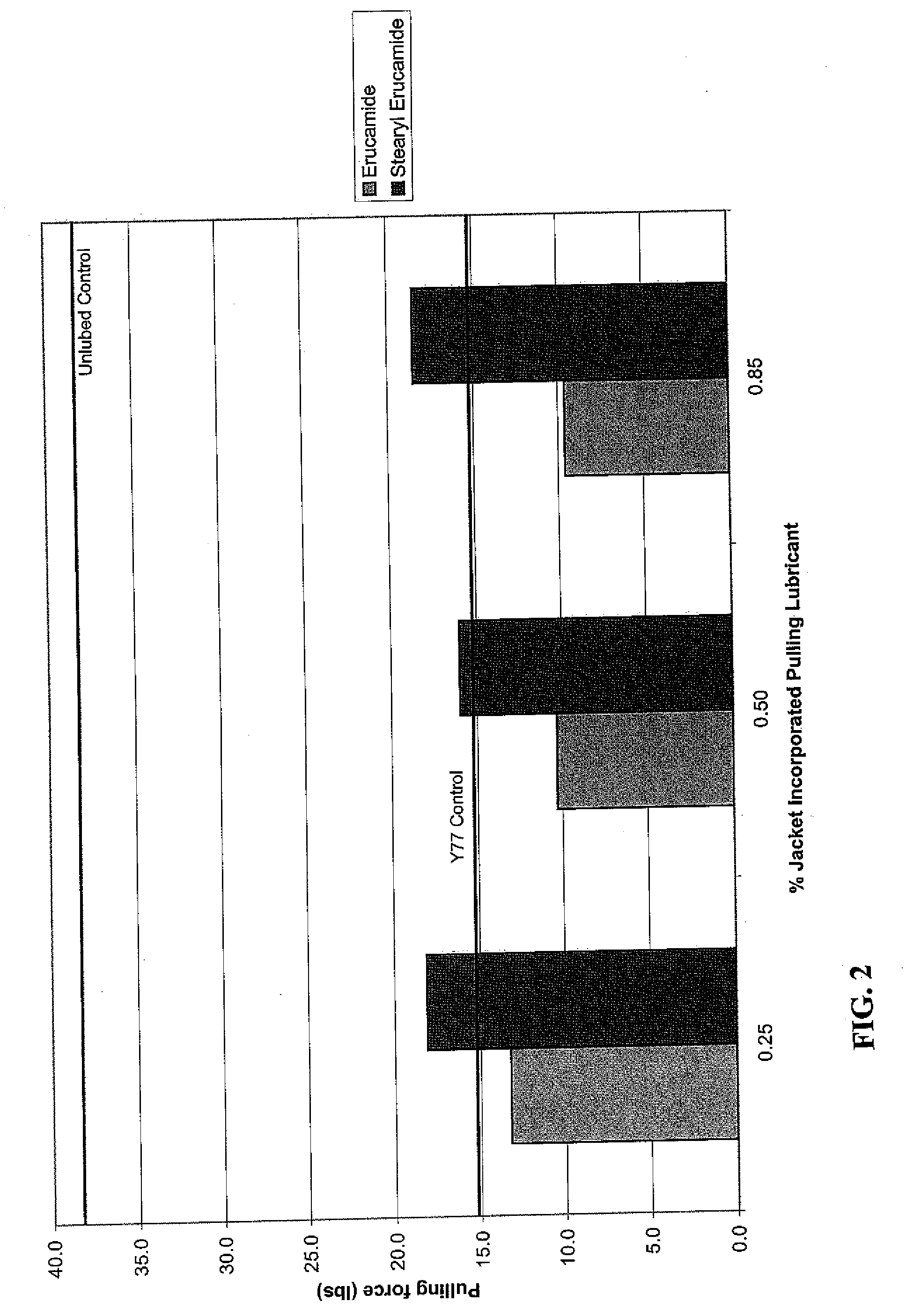

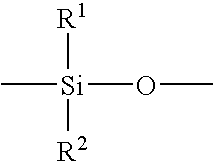

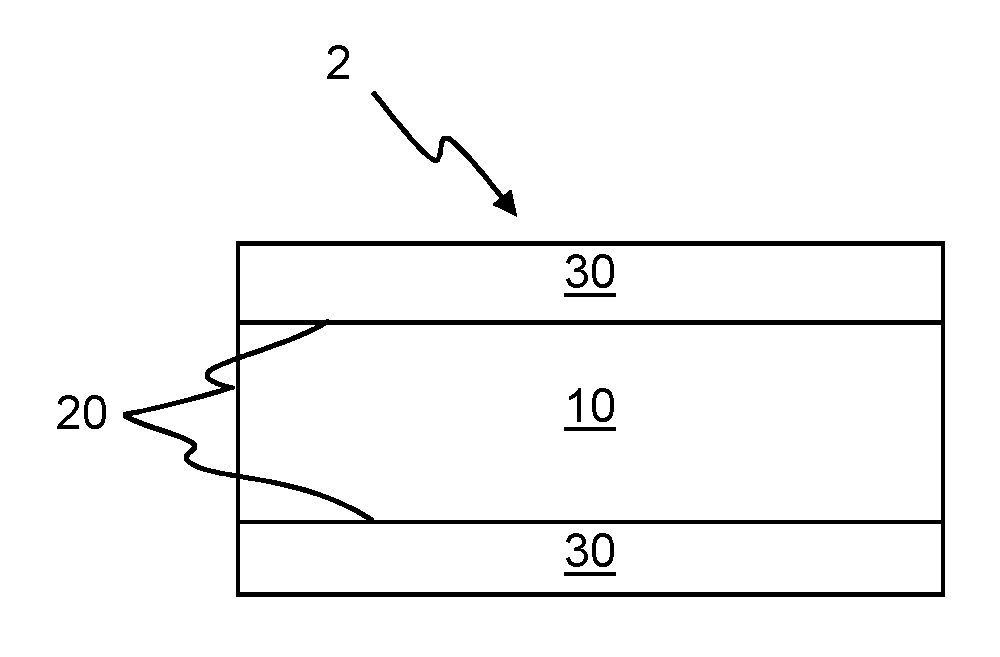

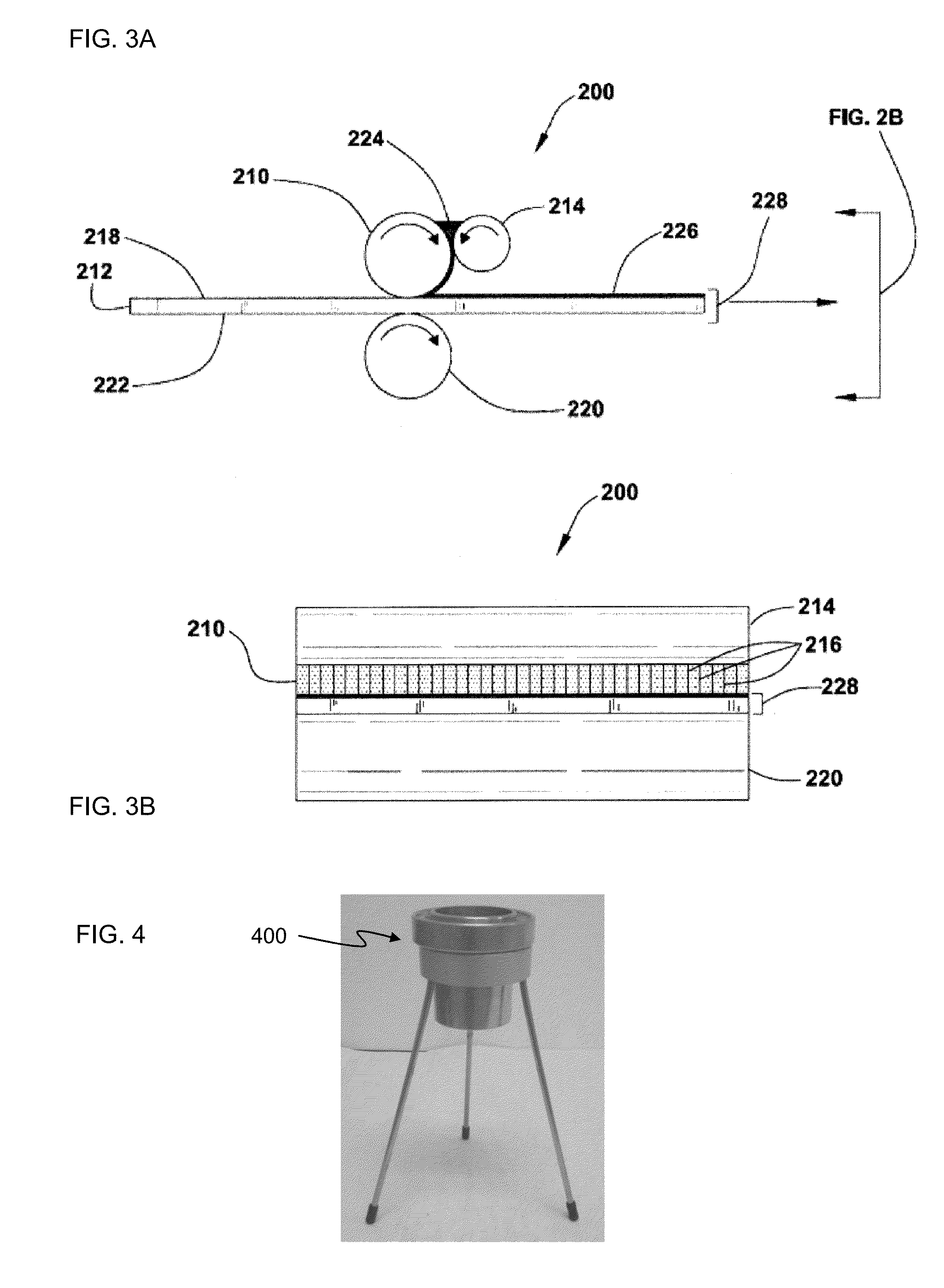

Method of manufacturing THHN electrical cable, and resulting product, with reduced required installation pulling force

InactiveUS7749024B2Reduce coefficient of frictionLower surfaceRelieving strain on wire connectionLiquid organic insulatorsElectrical conductorPull force

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

Method of manufacturing electrical cable, and resulting product, with reduced required installation pulling force

ActiveUS20100230134A1Reduce coefficient of frictionLower surfaceLine/current collector detailsLiquid organic insulatorsNylon materialElectrical conductor

Disclosed is type THHN cable having a reduced surface coefficient of friction, and the method of manufacture thereof, in which the central conductor core and insulating layer are surrounded by a nylon sheath. A high viscosity, high molecular weight silicone based pulling lubricant for THHN cable, or alternatively, erucamide or stearyl erucamide for small THHN gauge wire, is incorporated, by alternate methods, with the nylon material from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

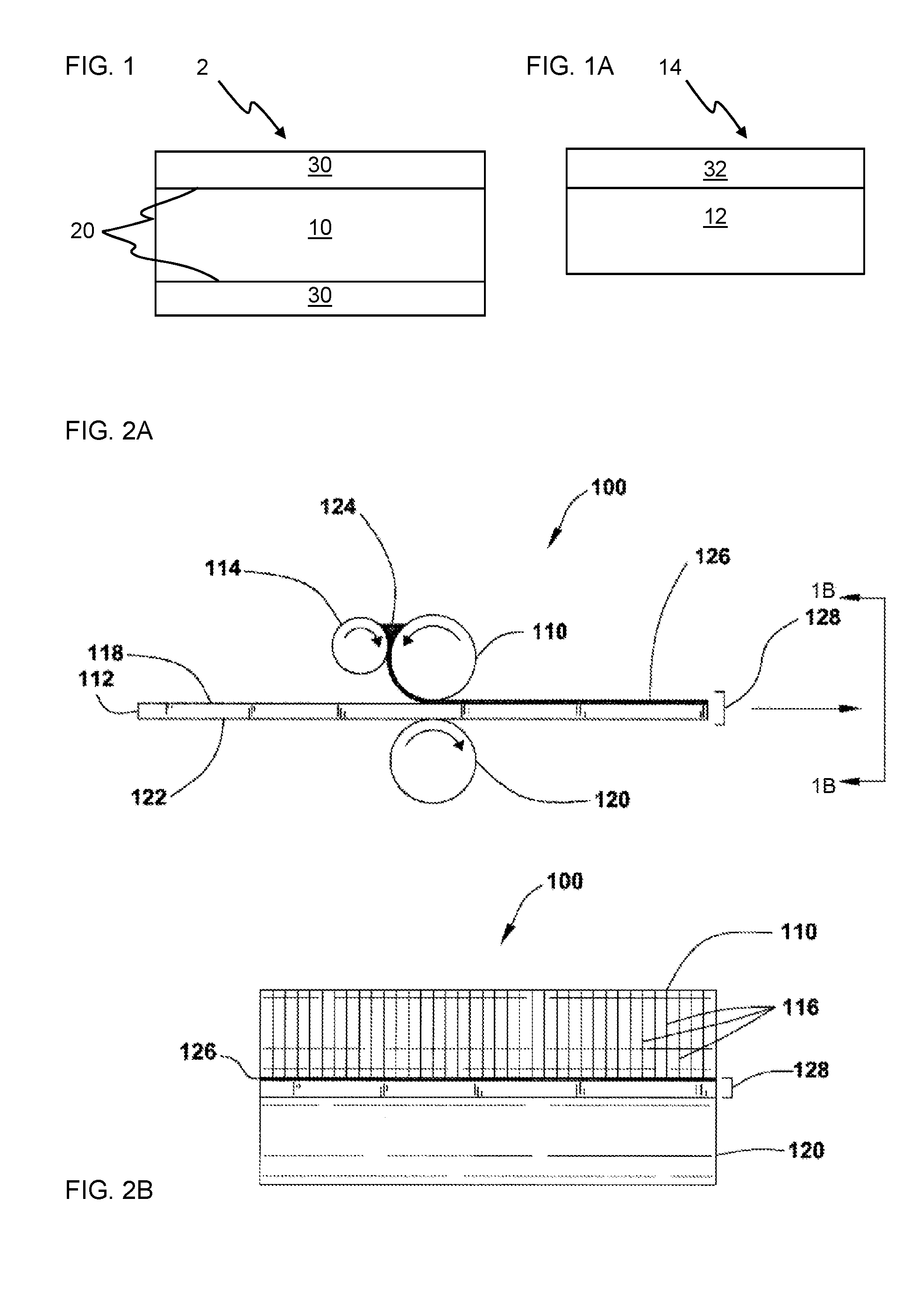

Light module and flat panel display including the light module

InactiveUS6871975B2Easy to assembleStructure simple and easyShow cabinetsMechanical apparatusOptical ModuleLight guide

A light module and a flat panel display including the light module. The light module includes a printed circuit board having a first surface and a second surface; a first light source disposed on the first surface of the printed circuit board; a second light source disposed on the second surface of the printed circuit board; and a light guiding plate disposed adjacent to the printed circuit board, for guiding light emitted from the first and / or the second light sources to a first surface of the light guiding plate.

Owner:INNOLUX CORP

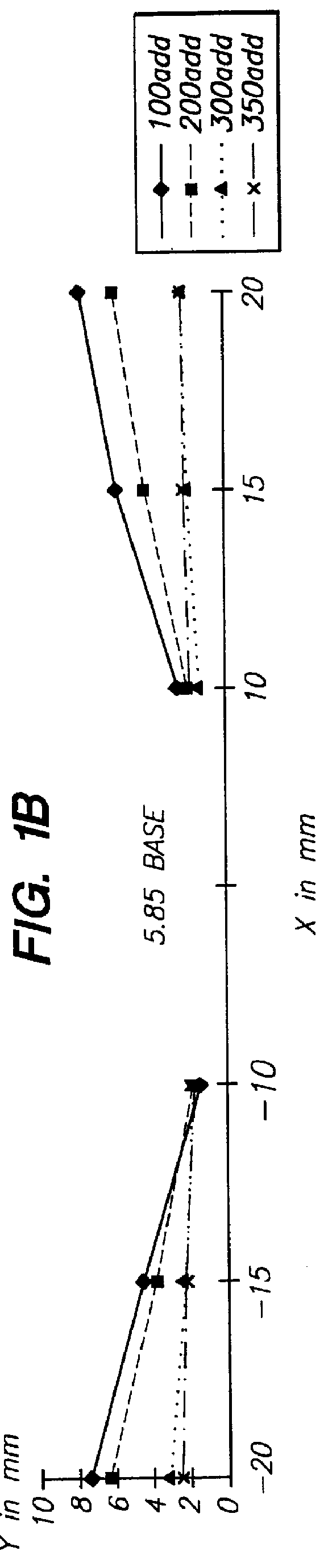

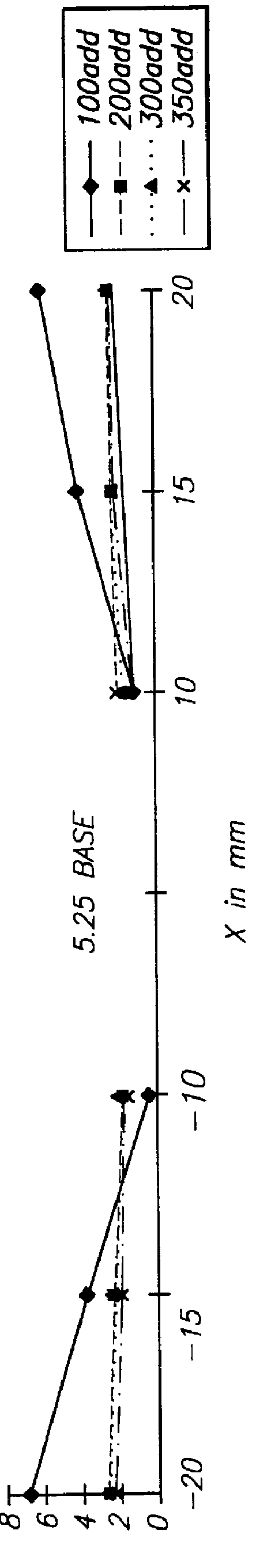

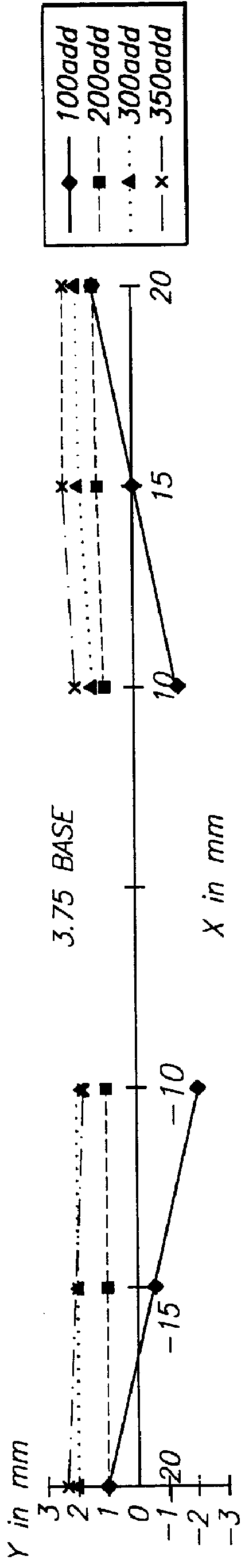

Progressive lens elements and methods for designing and using same

InactiveUS6074062ALower surfaceImprove performanceSpectales/gogglesOptical partsMultifocal lensesAstigmatism

A series of progressive ophthalmic lens elements, each lens element including a lens surface having an upper viewing zone having a surface power to achieve a refracting power corresponding to distance vision; a lower viewing zone having a greater surface power than the upper viewing zone to achieve a refracting power corresponding to near vision; a corridor of relatively low surface astigmatism connecting the upper and lower zones, said corridor having a surface power varying from that of the upper viewing zone to that of the lower viewing zone; the progressive ophthalmic lens series including a first set of lens elements having a base curve(s) suitable for use in providing a range of distance prescriptions for a first category of patient; and a second set of lens elements having a base curve(s) suitable for use in providing a range of distance prescriptions for a second category of patient; each lens element within a set differing in prescribed addition power and including a progressive design, in at least one of the upper and lower viewing zones, depending upon the addition power of the lens element; the lens elements in the first set differing substantively in progressive design from the corresponding lens elements in the second set due to the differences in base curve(s).

Owner:CARL ZEISS VISION AUSTRALIA HO

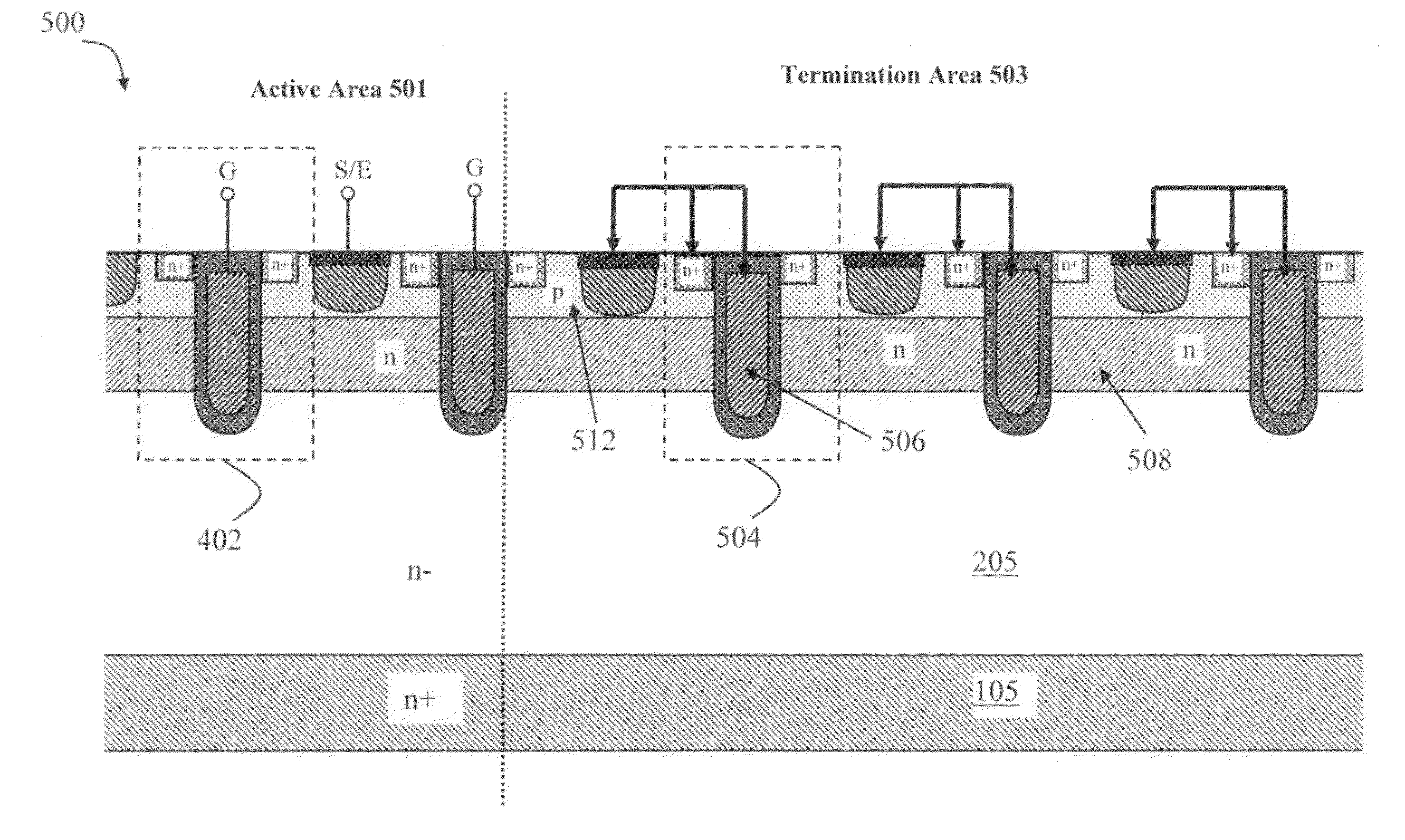

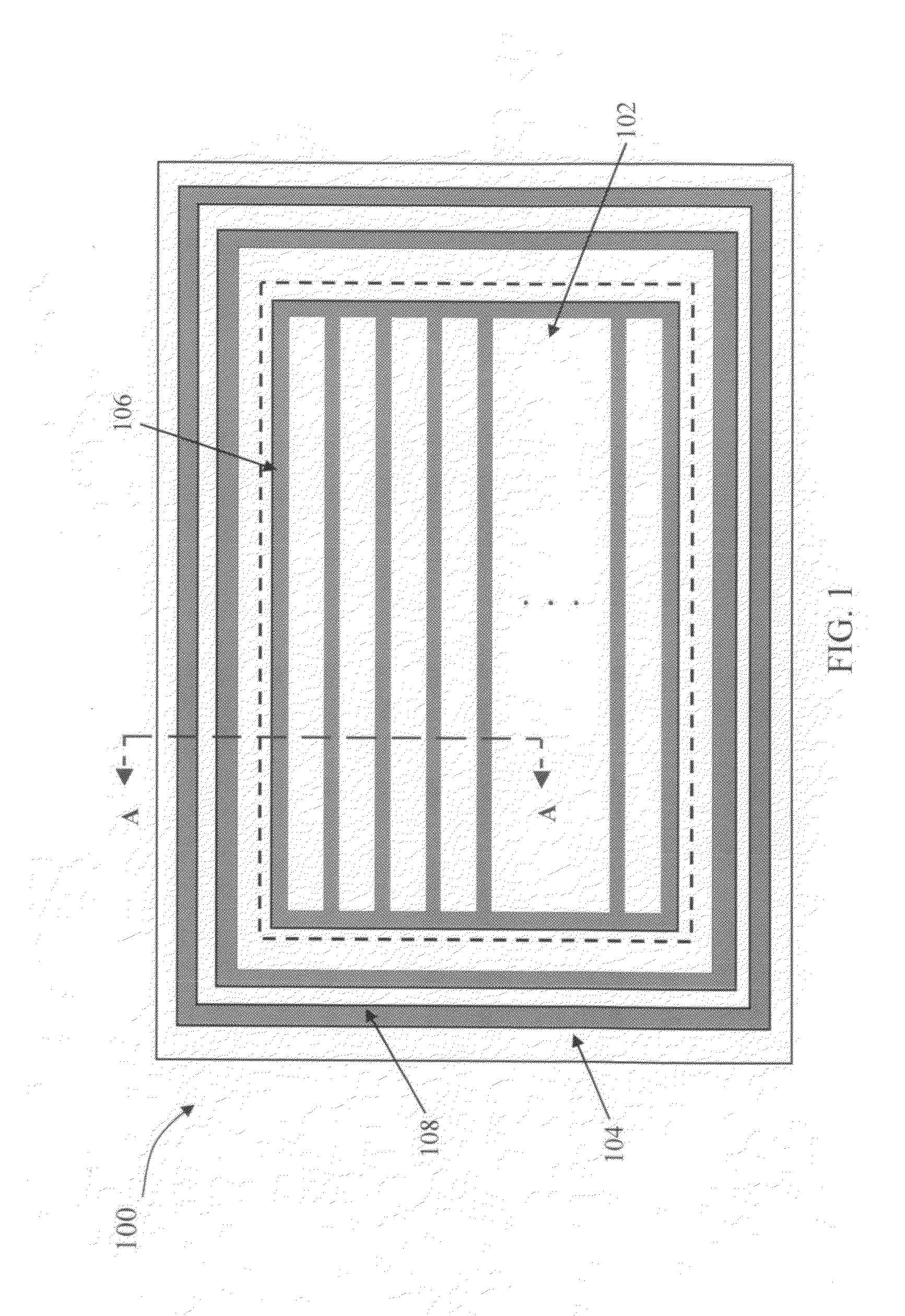

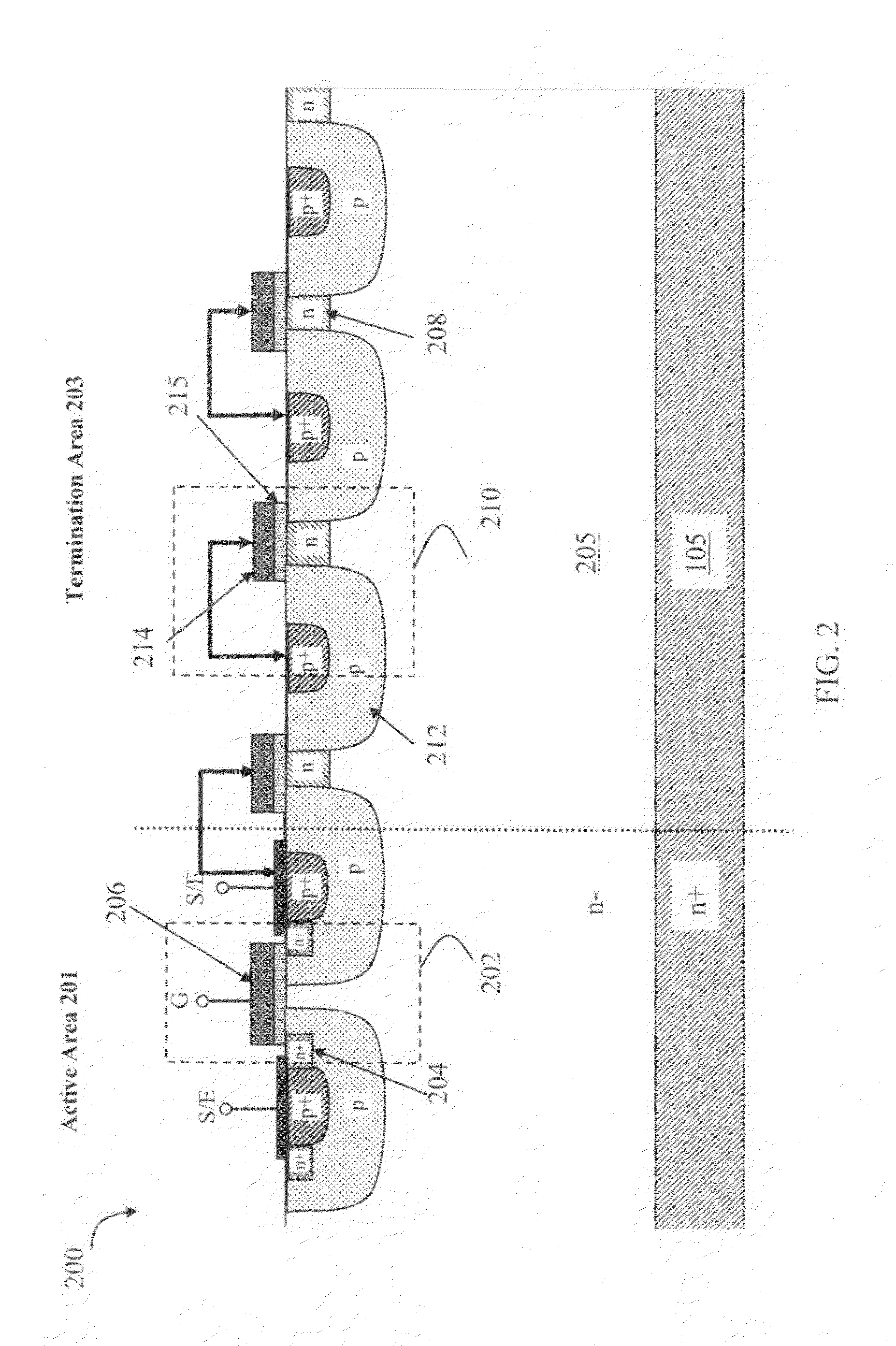

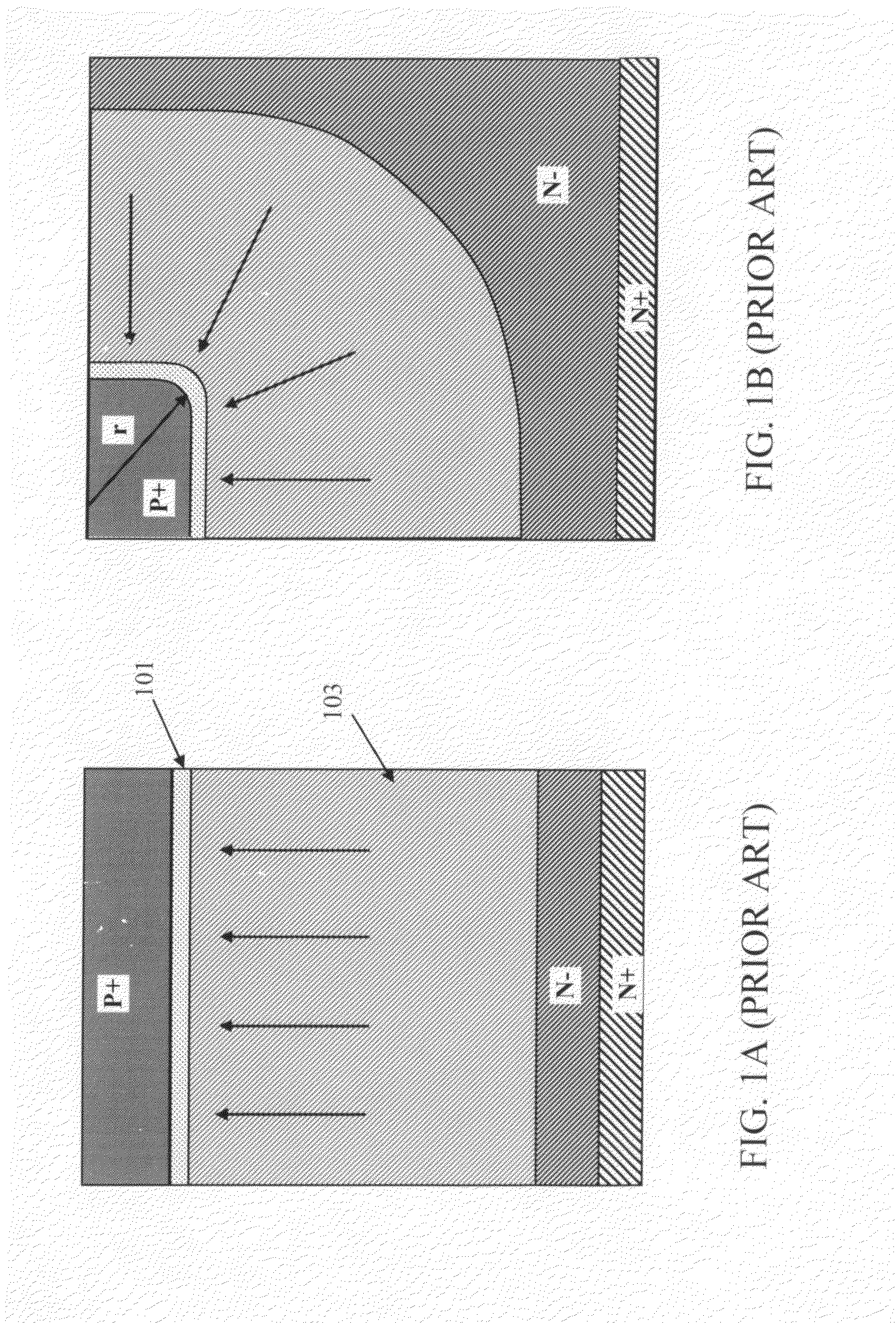

Semiconductor device with field threshold MOSFET for high voltage termination

ActiveUS20130020635A1Reduce electrical field crowding effectSurface electric fieldTransistorSolid-state devicesMOSFETActive cell

This invention discloses a semiconductor power device disposed in a semiconductor substrate comprising a lightly doped layer formed on a heavily doped layer and having an active cell area and an edge termination area. The edge termination area comprises a plurality P-channel MOSFETs. By connecting the gate to the drain electrode, the P-channel MOSFET transistors formed on the edge termination are sequentially turned on when the applied voltage is equal to or greater than the threshold voltage Vt of the P-channel MOSFET transistors, thereby optimizing the voltage blocked by each region.

Owner:ALPHA & OMEGA SEMICON INC

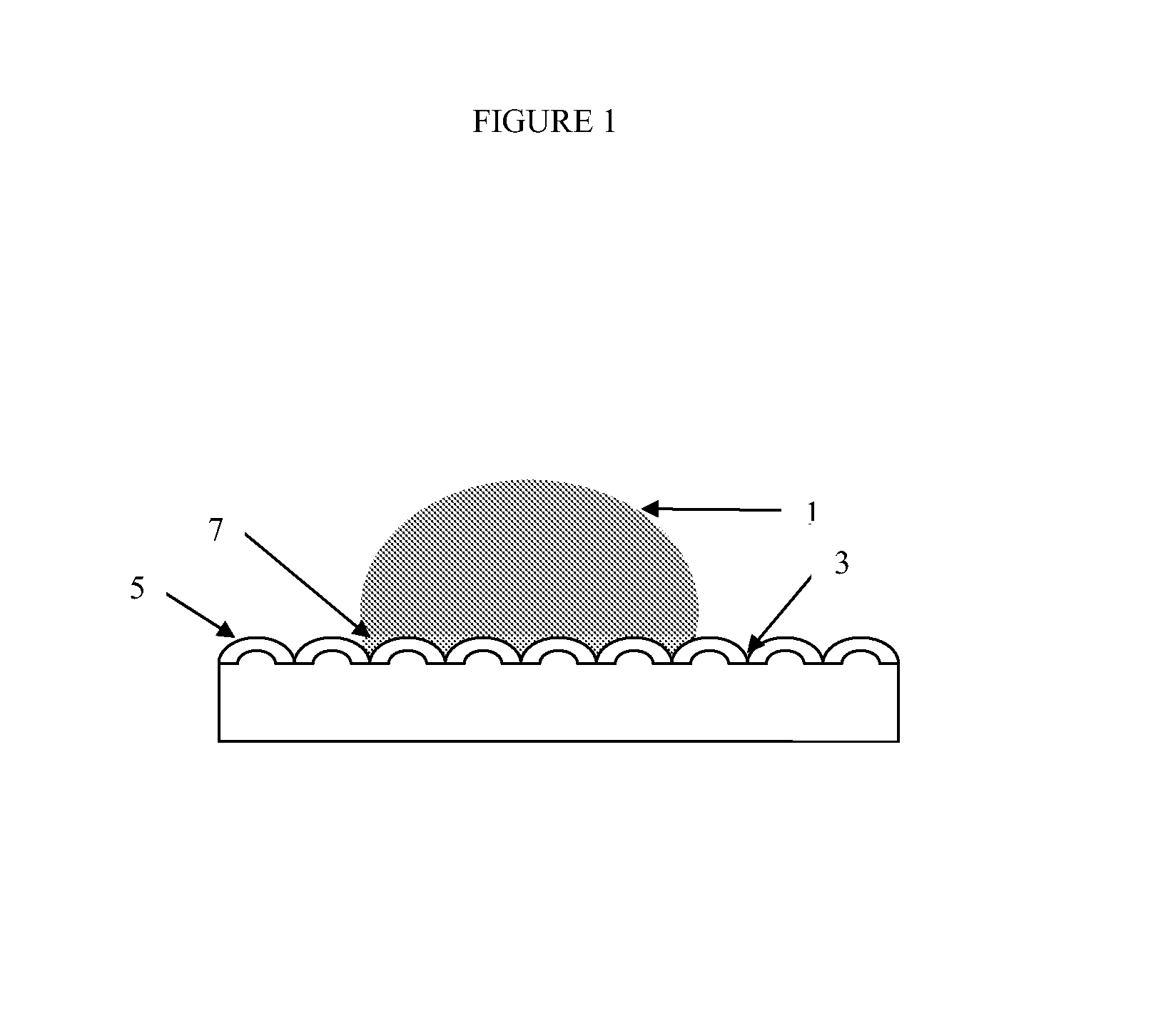

Modified surface energy non-woven filter element

InactiveUS20140275692A1Improve hydrophobicityImprove surface roughnessMembrane filtersHydrocarbonsEngineeringFilter element

A non-woven low surface energy filter element designed to have improved removal of a dispersed liquid phase from a continuous liquid phase is disclosed.

Owner:PARKER HANNIFIN FILTRATION US INC

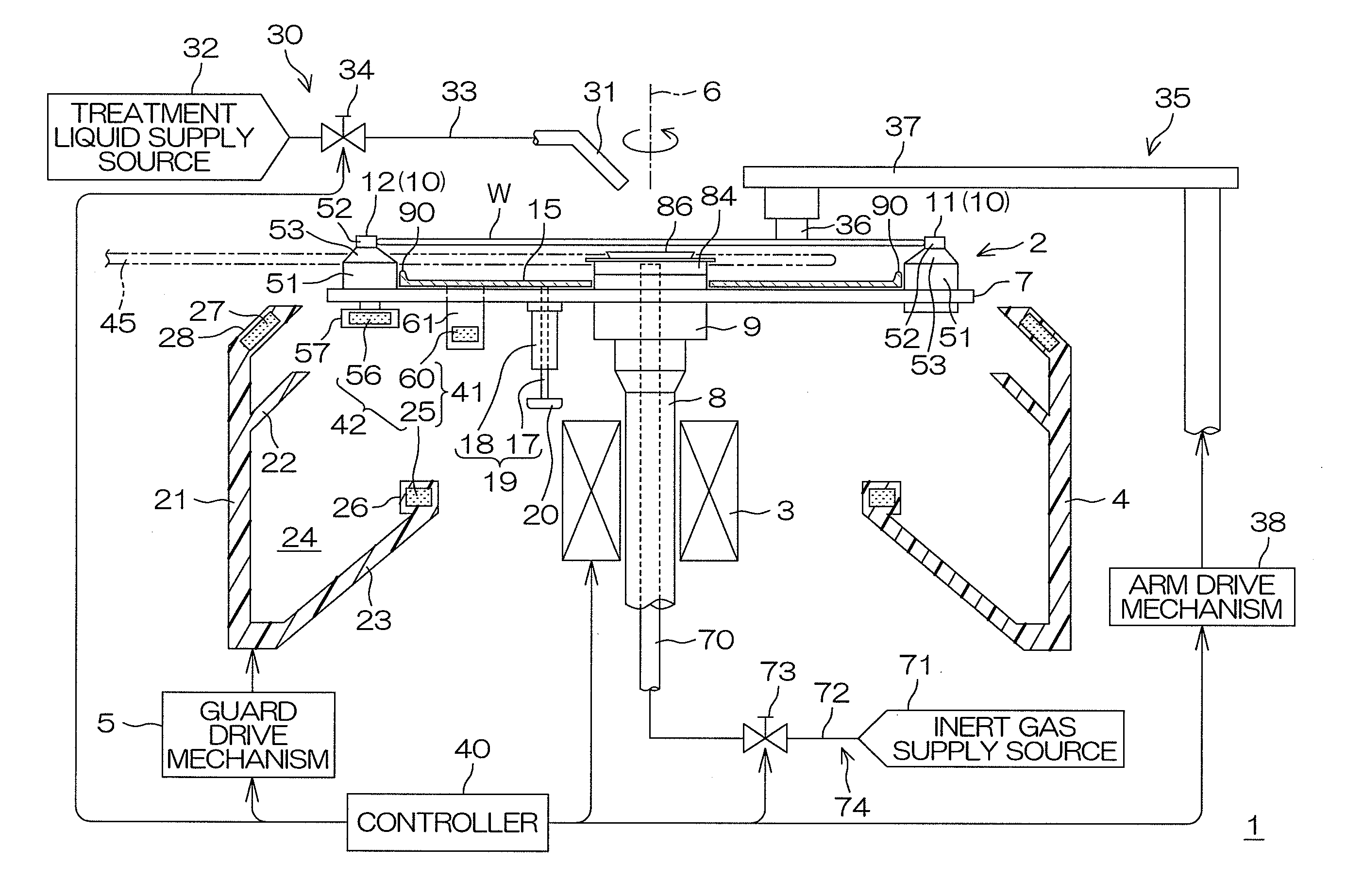

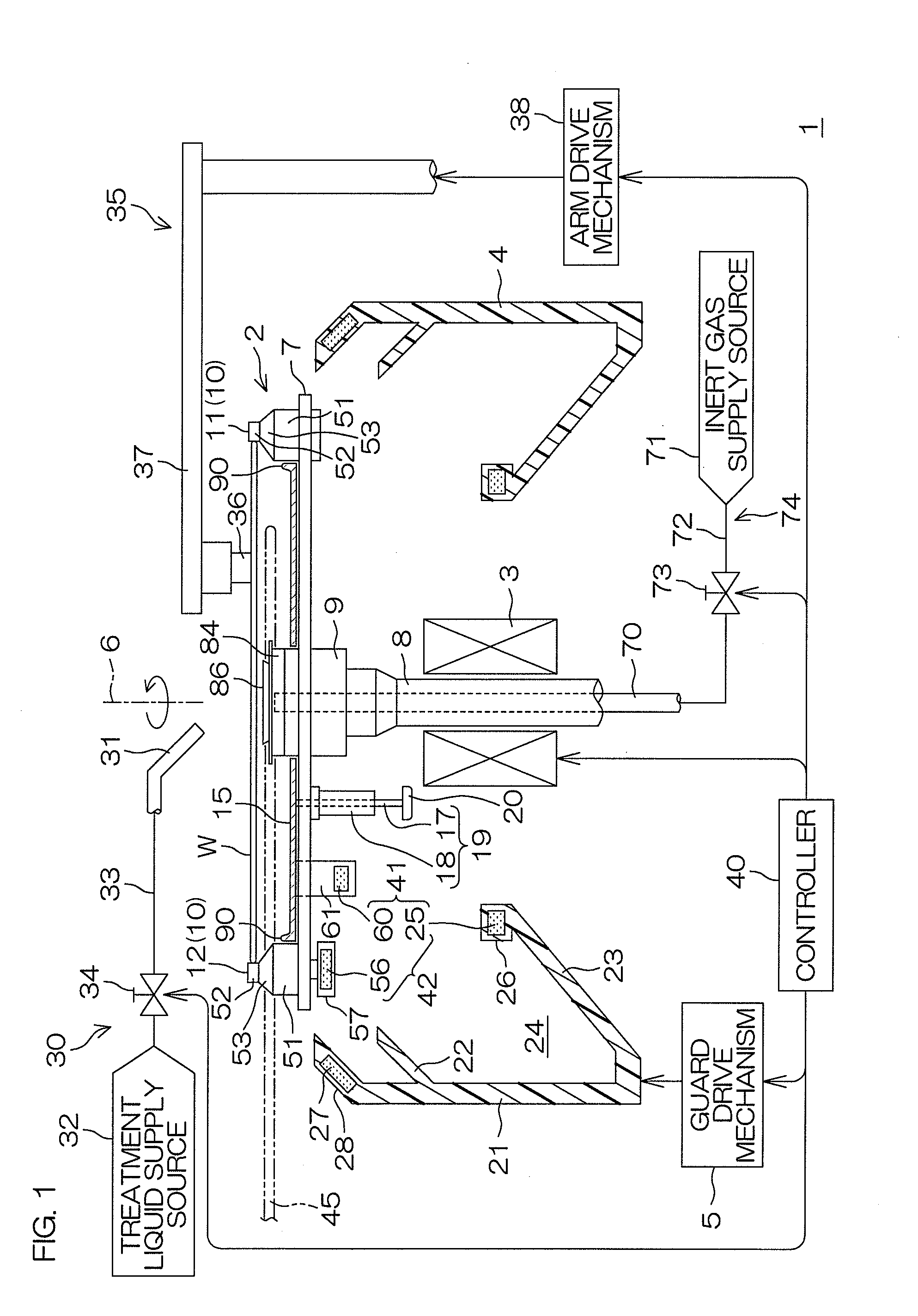

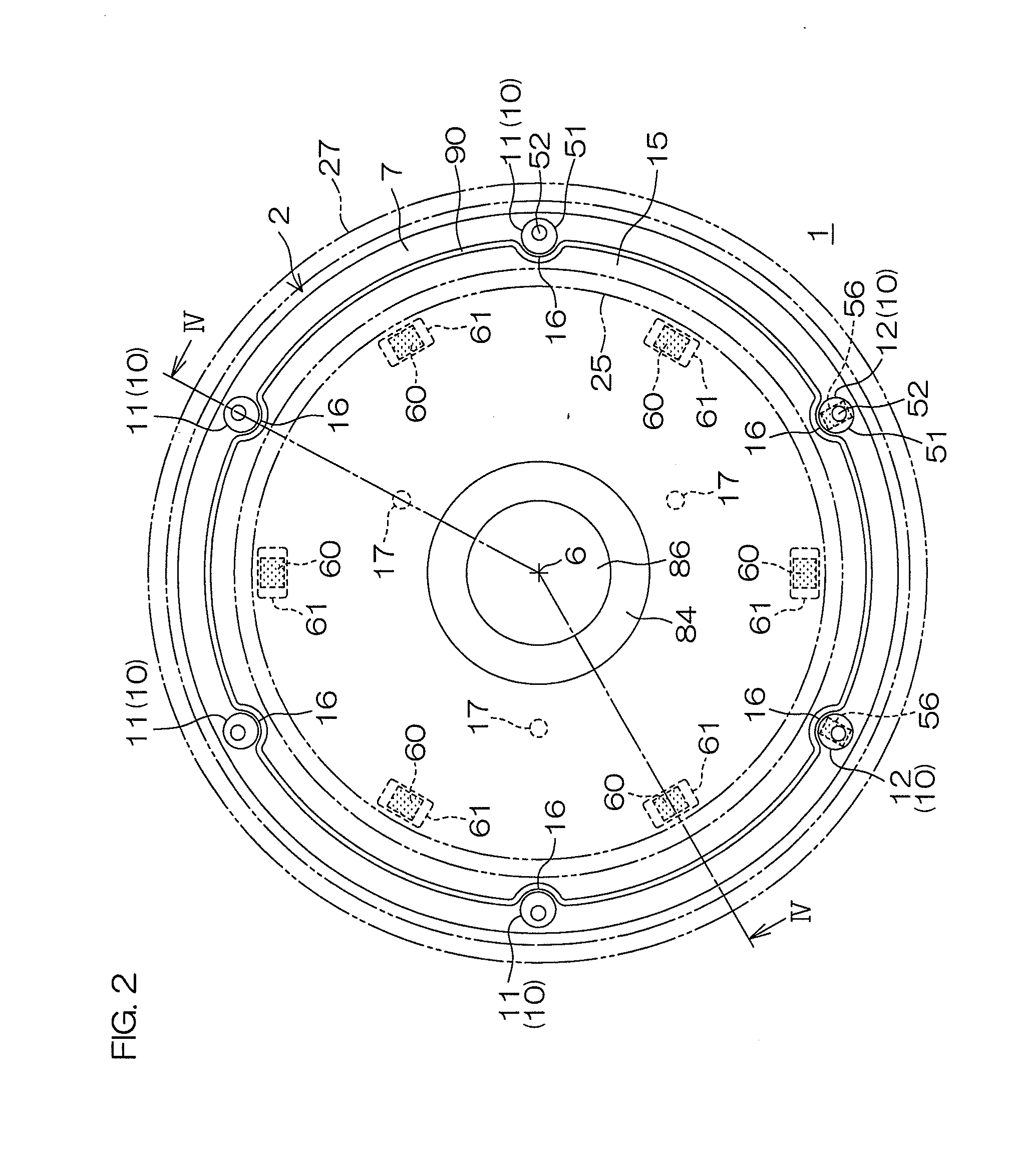

Substrate holding and rotating device, substrate treatment apparatus including the device, and substrate treatment method

ActiveUS20130152971A1Convenient ArrangementAvoid stickingSemiconductor/solid-state device manufacturingWork holdersEngineeringMagnetic levitation

A substrate holding and rotating device includes: a turntable rotatable; a rotative drive unit which rotates the turntable; a holding member which is provided on the turntable and horizontally holds a substrate in upwardly spaced relation to the turntable; a vertically movable protection disk disposed between the turntable and a substrate holding position; and a magnetic levitation mechanism including a first magnet attached to the protection disk, an annular second magnet which generates a repulsive force with respect to the first magnet, a support member which non-rotatably supports the second magnet, and a relative movement mechanism which moves the support member and the turntable relative to each other.

Owner:DAINIPPON SCREEN MTG CO LTD

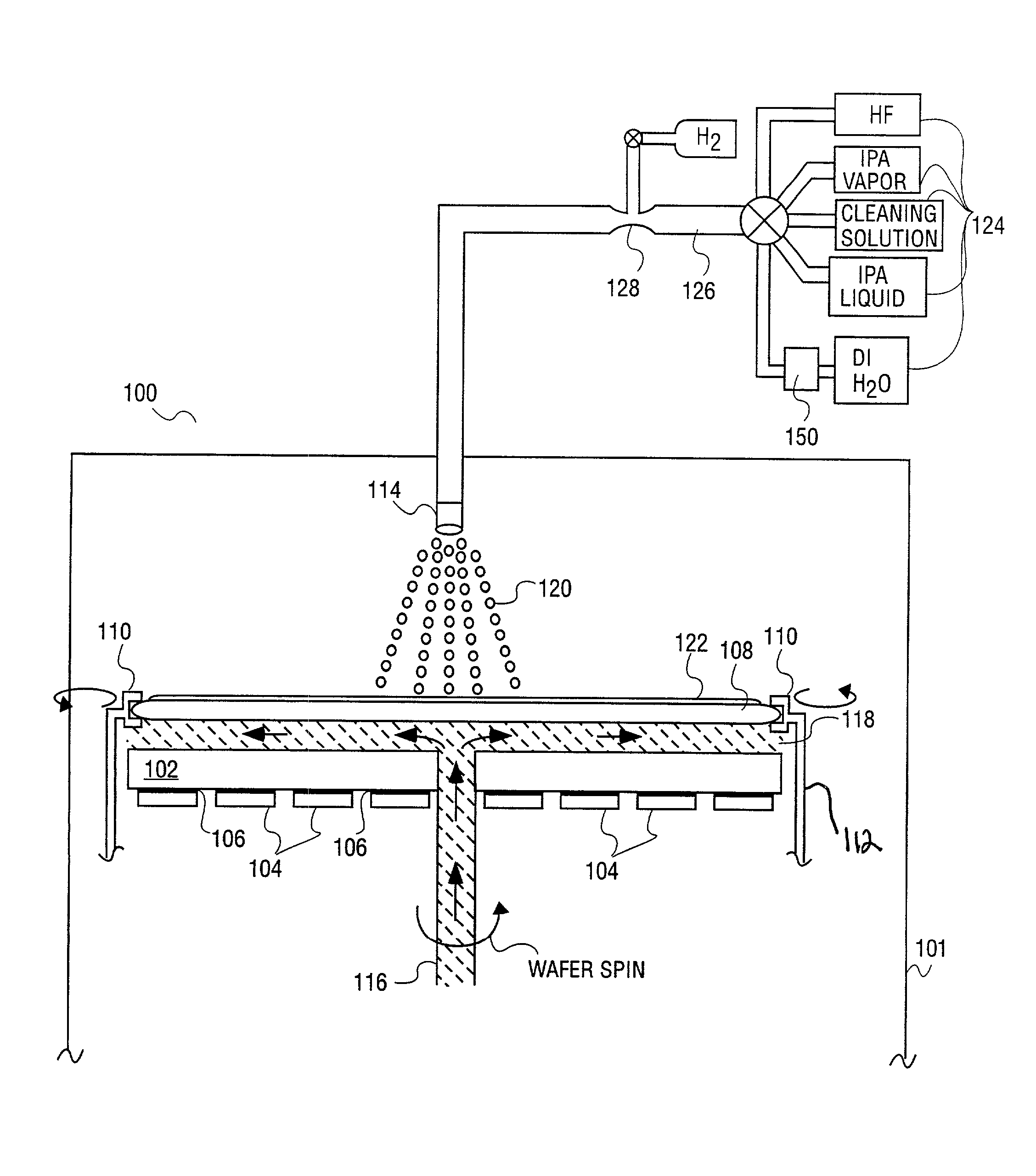

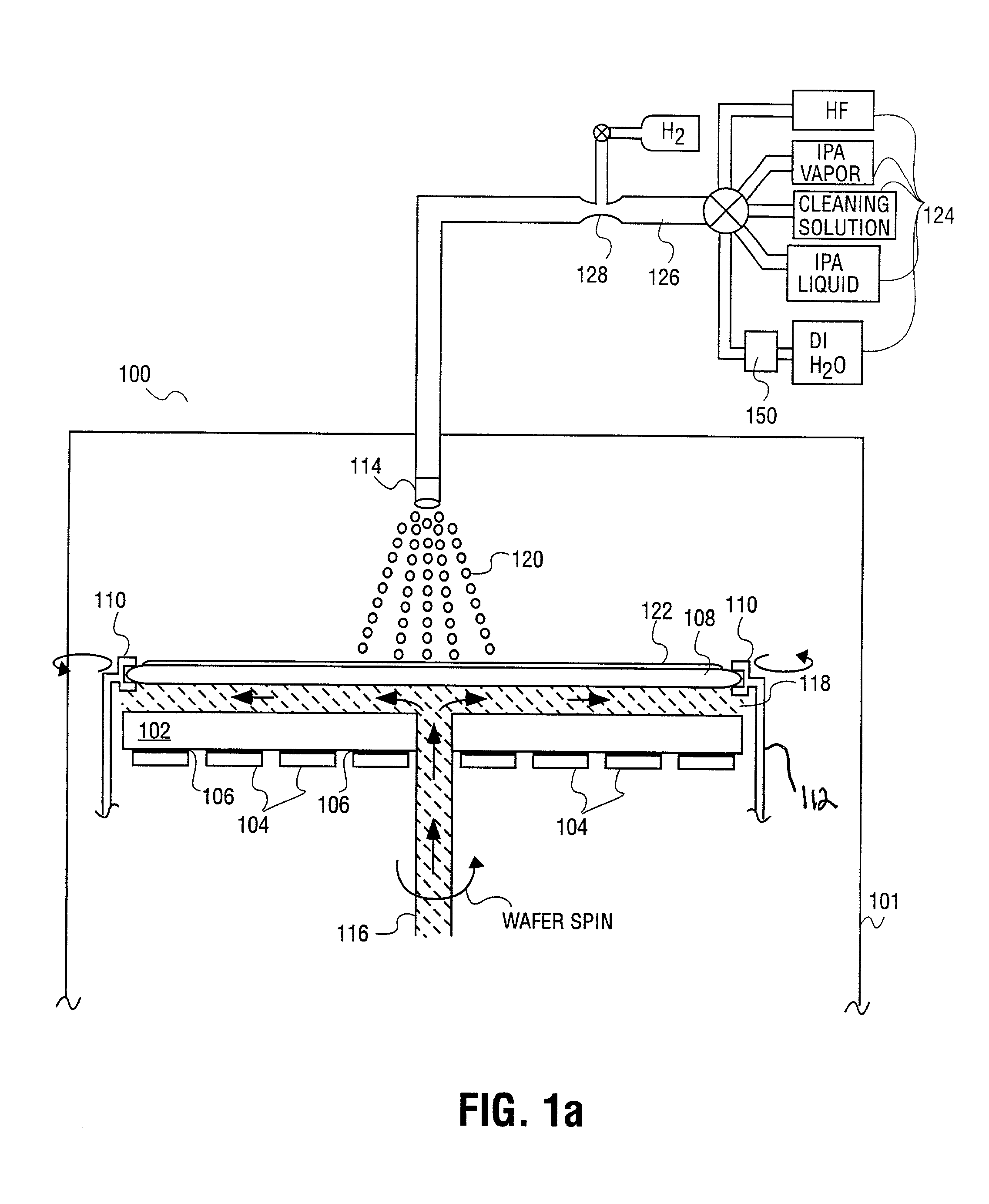

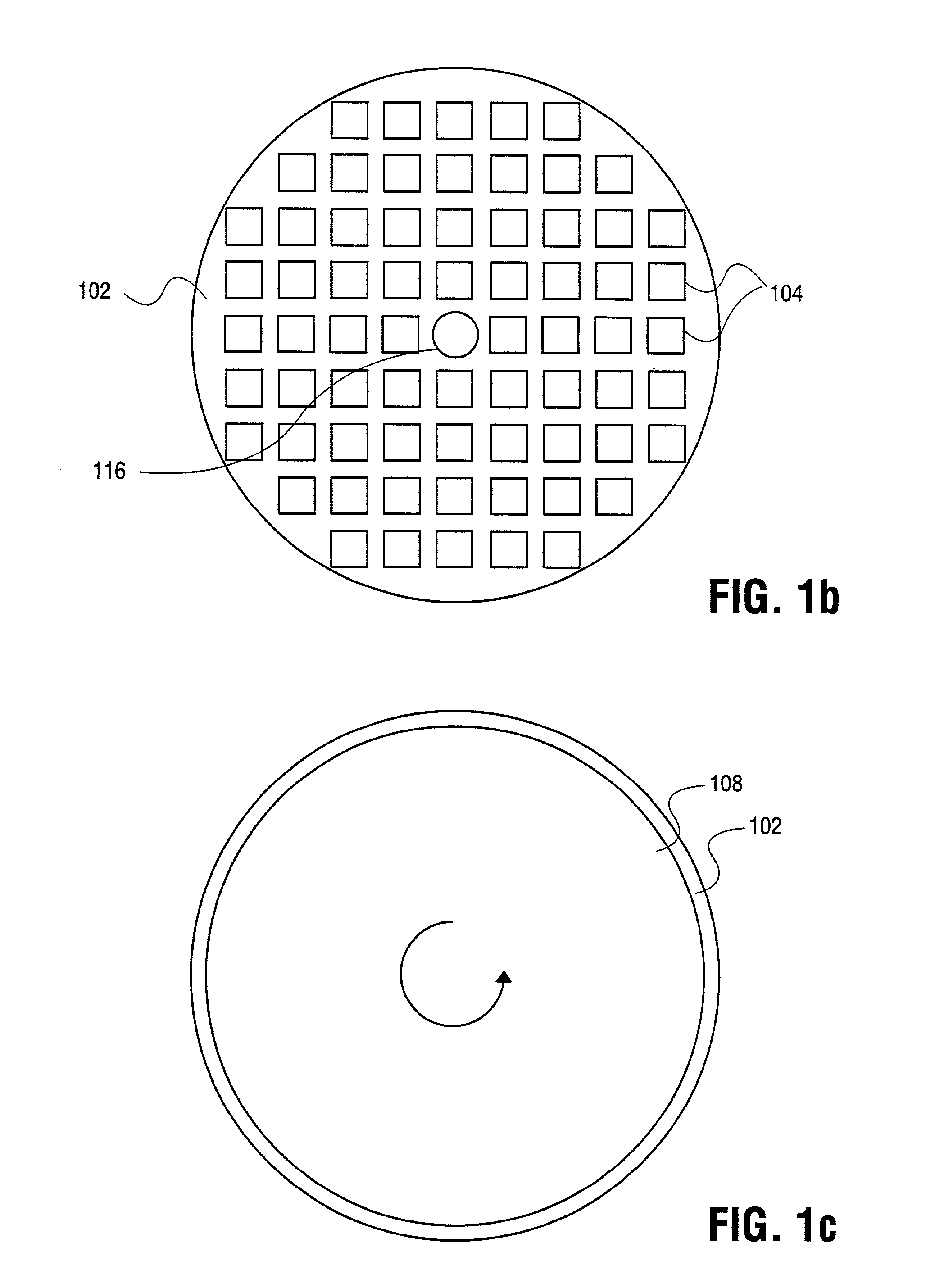

Assisted rinsing in a single wafer cleaning process

InactiveUS20020062840A1Small thicknessDecreases rinsingElectrostatic cleaningSemiconductor/solid-state device manufacturingRoom temperatureCentrifugal force

The present invention is a method of assisting the rinsing of a wafer in a single wafer cleaning apparatus. According to the present invention, after exposing a wafer to a cleaning and / or etching solution, the cleaning or etching solution is removed from the wafer by spinning the wafer and dispensing or spraying DI water onto the wafer as it is spun. The centrifugal force of the spinning wafer enhances the rinsing of the wafer. In order to enhance the rinsing of the wafer, in an embodiment of the present invention a solution having a lower surface tension than water, such as but not limited to isopropyl alcohol (IPA) is dispensed in liquid or vapor form onto the wafer after the DI water. In a specific embodiment of the present invention, the vapor of a solution with a lower surface tension than DI water, such as IPA vapor, is blown on the wafer in order to break up the DI water bulging up at the center of the spinning wafer. In another embodiment of the present invention, a gas such N2, is blown for a short period of time onto the center of the wafer to break up the DI water bulging up at the center of the spinning wafer. In yet another embodiment of the present invention, acoustic or sonic waves are applied to the wafer as it spins in order to help diffuse the DI water from the wafer. And in still yet another embodiment of the present invention, the DI water which is dispensed onto the spinning wafer is heated to a temperature above room temperature and preferably between 60-70° C. to enhance the diffusion of water from the wafer. The low surface tension liquid, acoustic application, gas blowing, and heated DI water can be used alone or in combination with one another into enhance the rinsing of a wafer and thereby decrease the rinsing time of a single wafer process to less than 20 seconds.

Owner:APPLIED MATERIALS INC

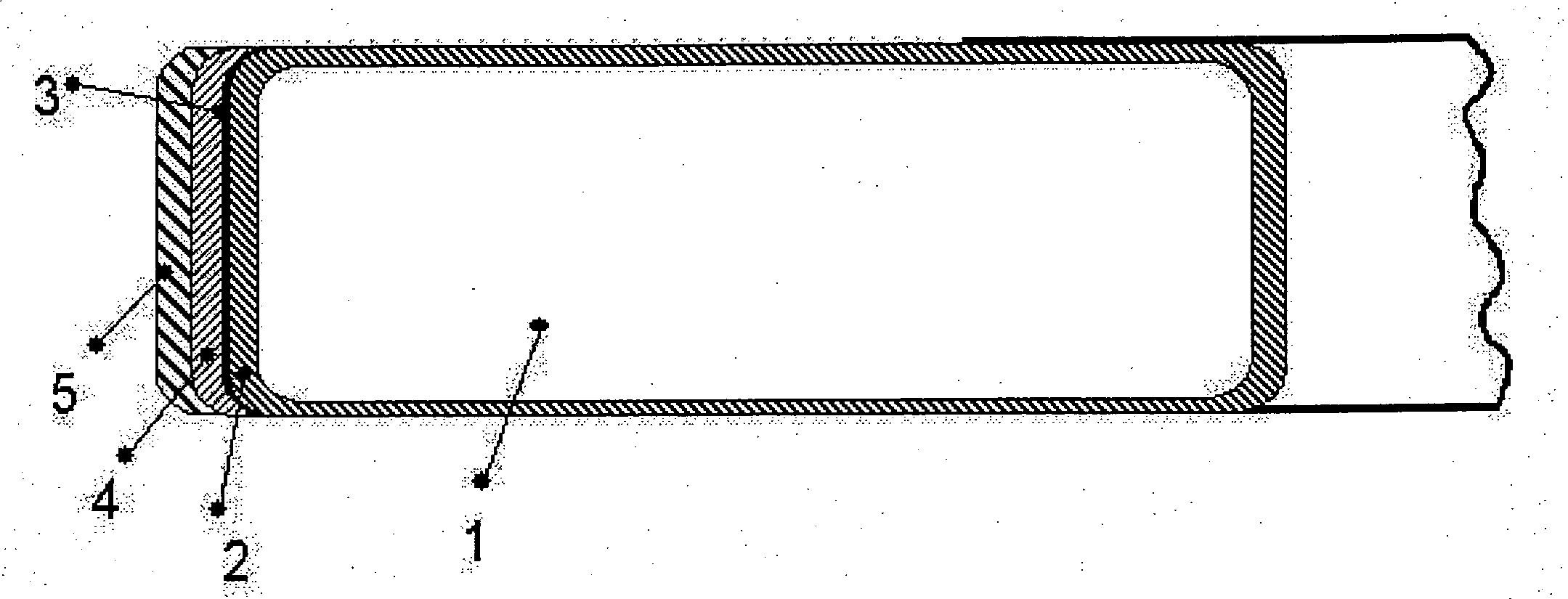

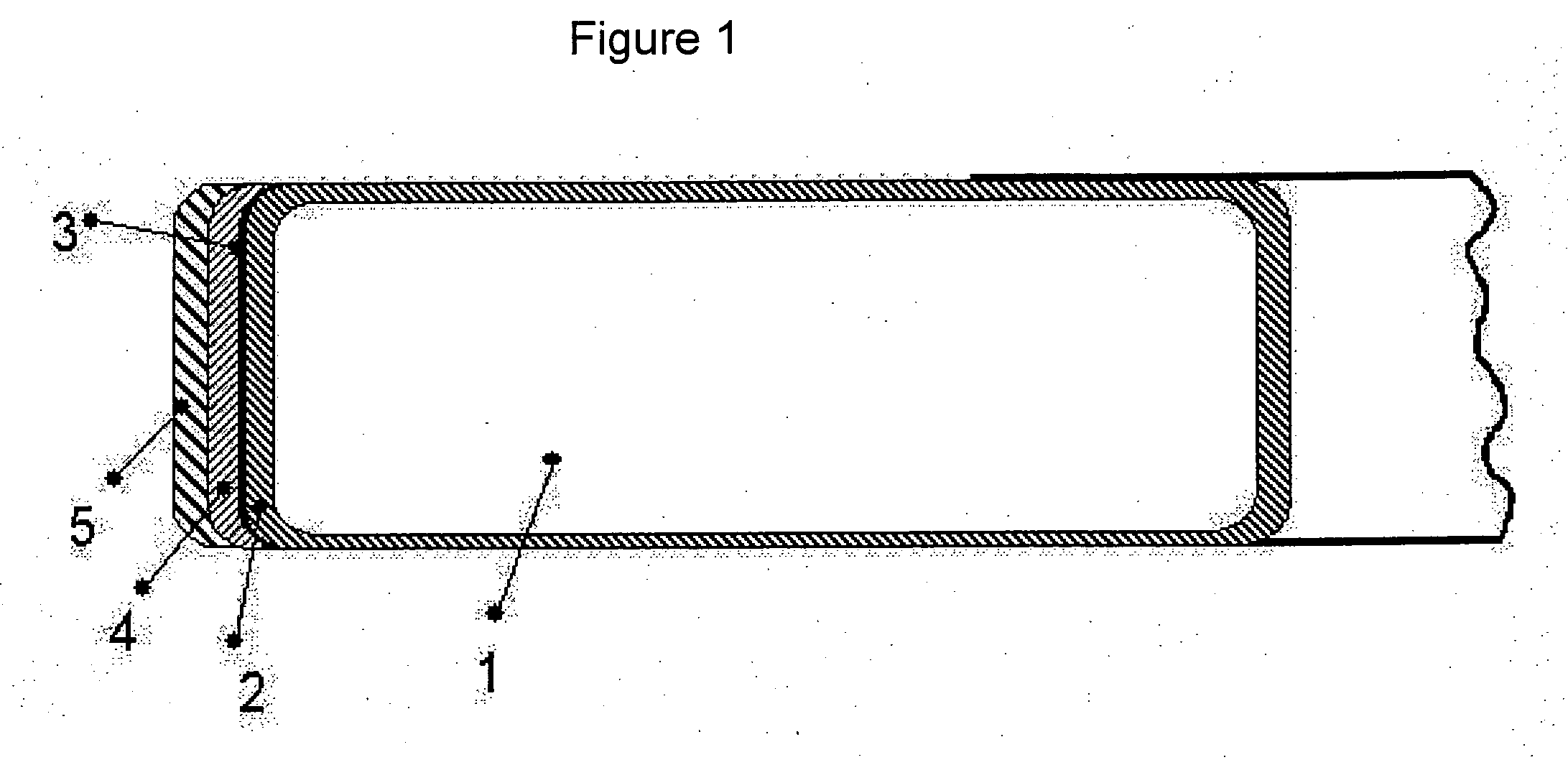

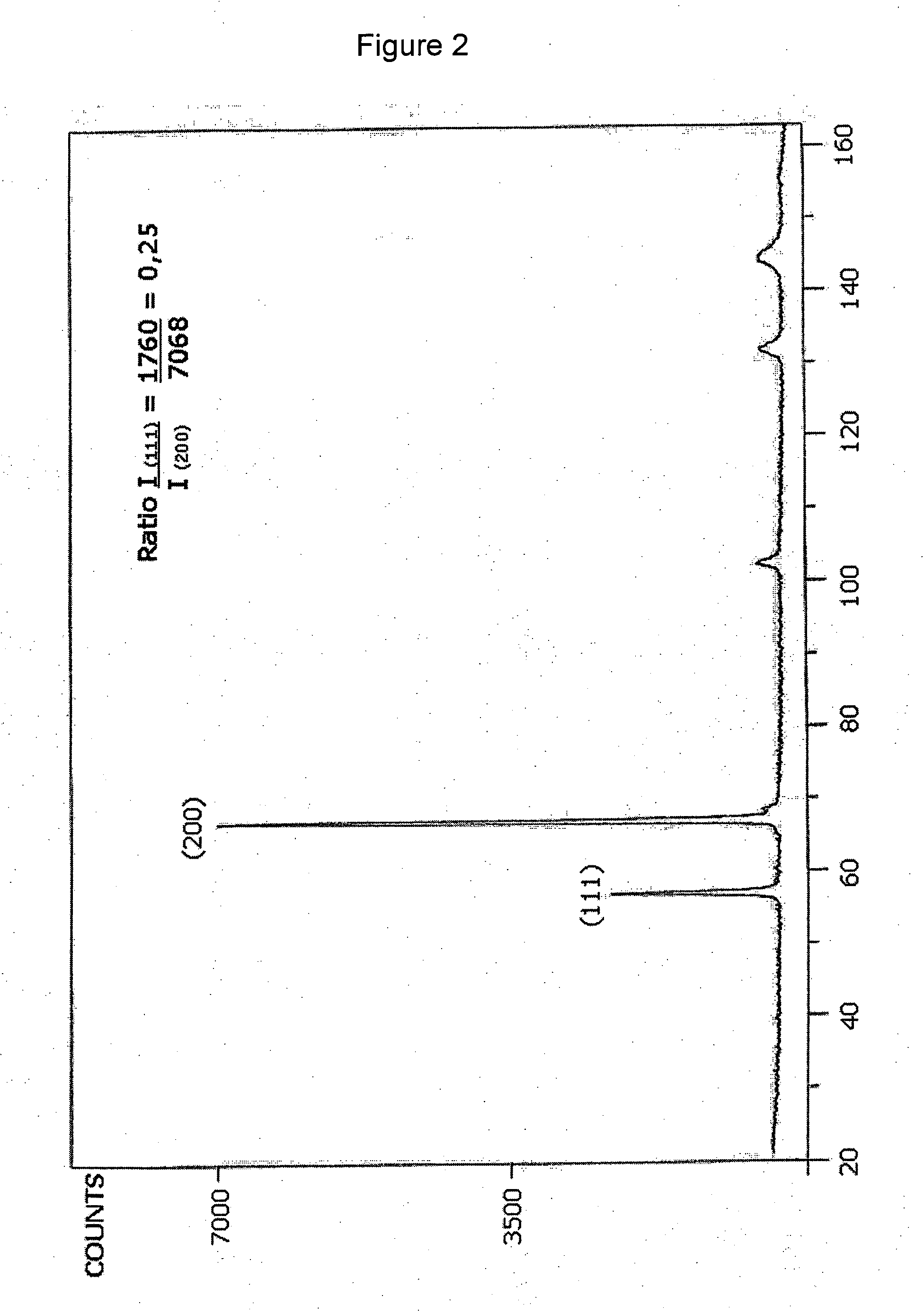

Piston ring for internal combustion engines

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

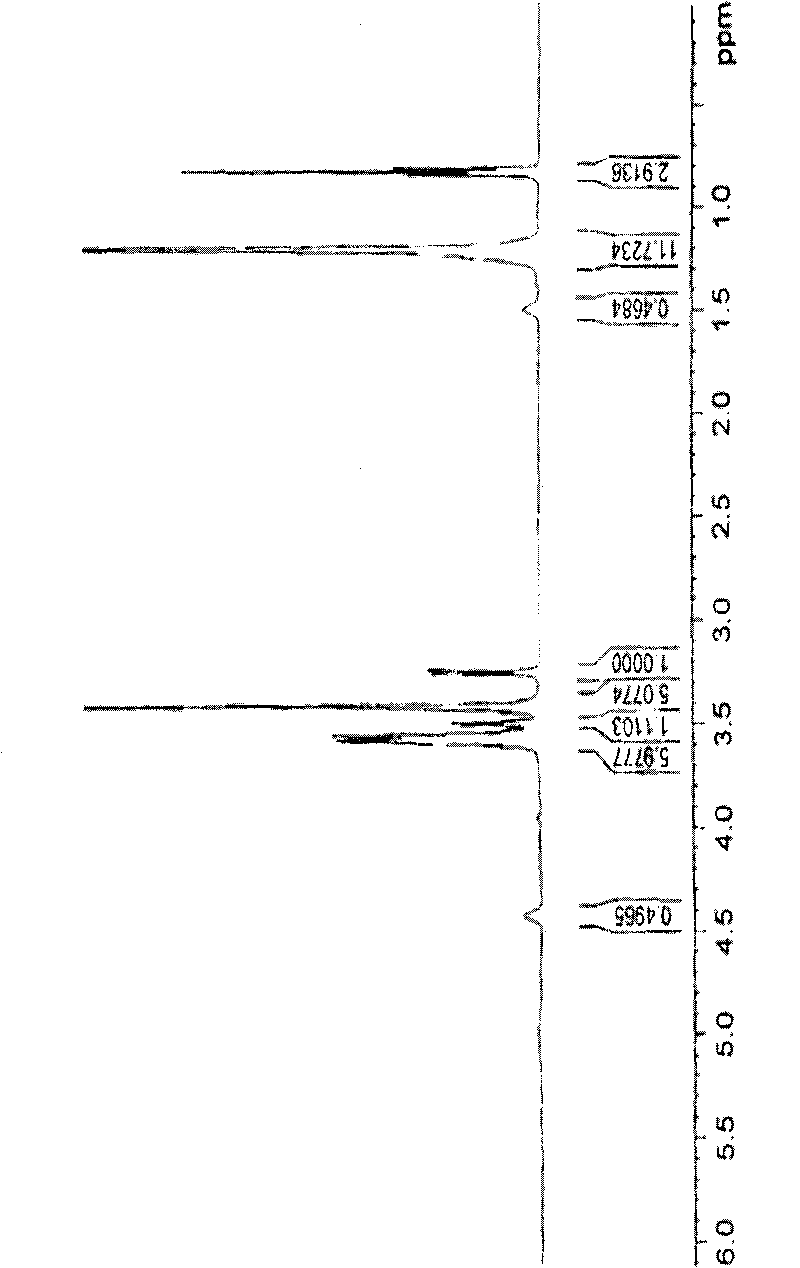

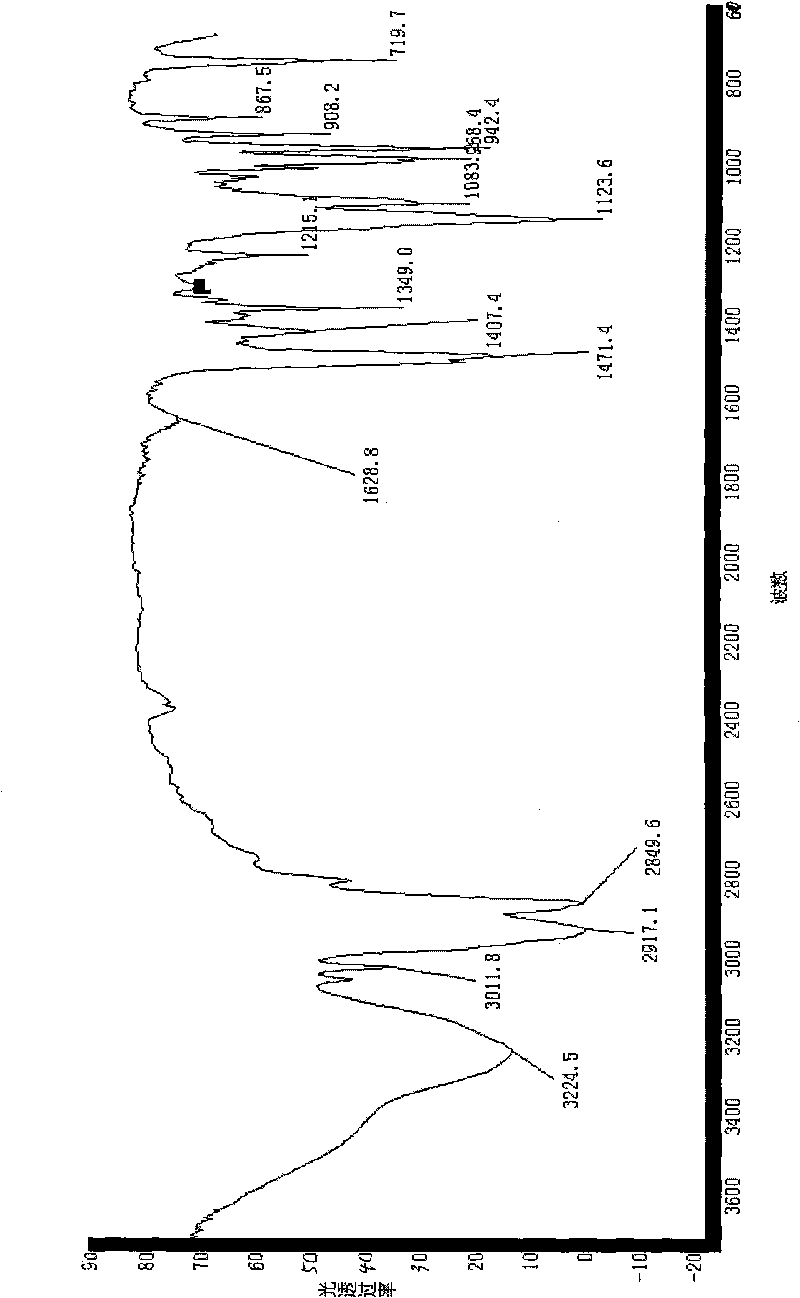

Method for preparing anti-pollution chitosan-nonwoven cloth composite porous filter membrane

InactiveCN101497002AImprove mechanical stabilityGood chemical stabilitySemi-permeable membranesWater bathsNonwoven fabric

The invention discloses a method for preparing an antipollution chitosan-nonwoven fabric composite porous filter membrane and belongs to the technical field of microfilter and ultrafilter composite membranes. The method is characterized in that the method adopts nonwoven fabric with nominal aperture of between 0.1 and 10 microns as a base membrane; a crosslinking agent is adopted to carry out pretreatment on the base membrane; 0.1 to 10 mass percent amylose is dissolved in an acetic acid solution; the crosslinking agent and a hole formation agent are added into the acetic acid solution; after the crosslinking reaction, a casting film liquid is obtained; at negative pressure, the casting film liquid is evenly coated on the surface and pores of the porous base membrane; and after treatment by a sodium hydroxide solution and a hot water bath, the antipollution chitosan-nonwoven fabric composite porous filter membrane is formed. The method has the advantages that the prepared composite membrane has good mechanical performance and chemical stability; and the surface of the membrane is levelled and smooth. The composite membrane has dual functions of hydrophile and antibiosis, can lighten adsorption of pollutants on the surface of the membrane, inhibit the growth and reproduction of thalli on the surface of the membrane, and keep the penetrating performance of the membrane and is widely applied to the water treatment process of various fields.

Owner:DALIAN UNIV OF TECH

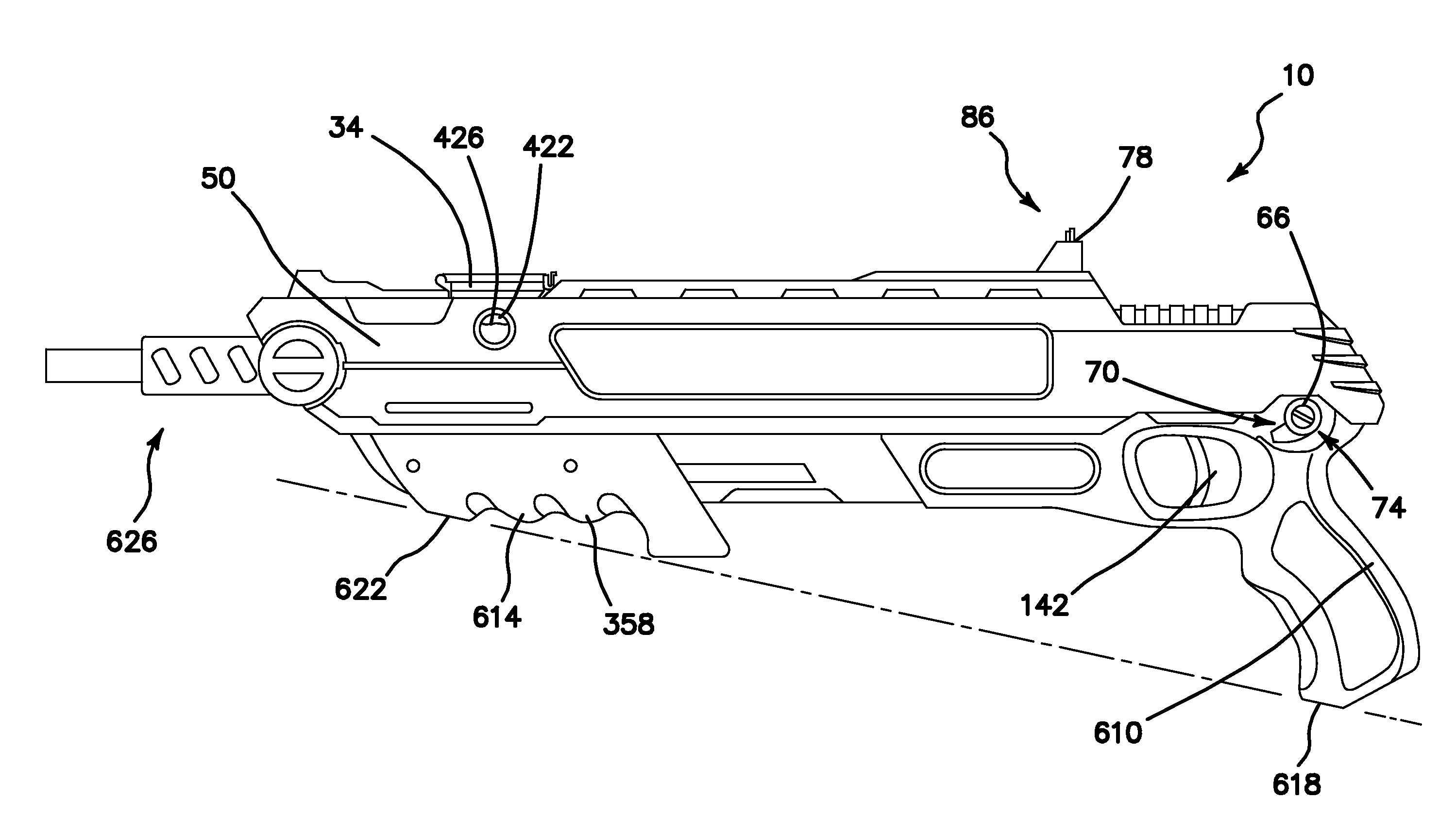

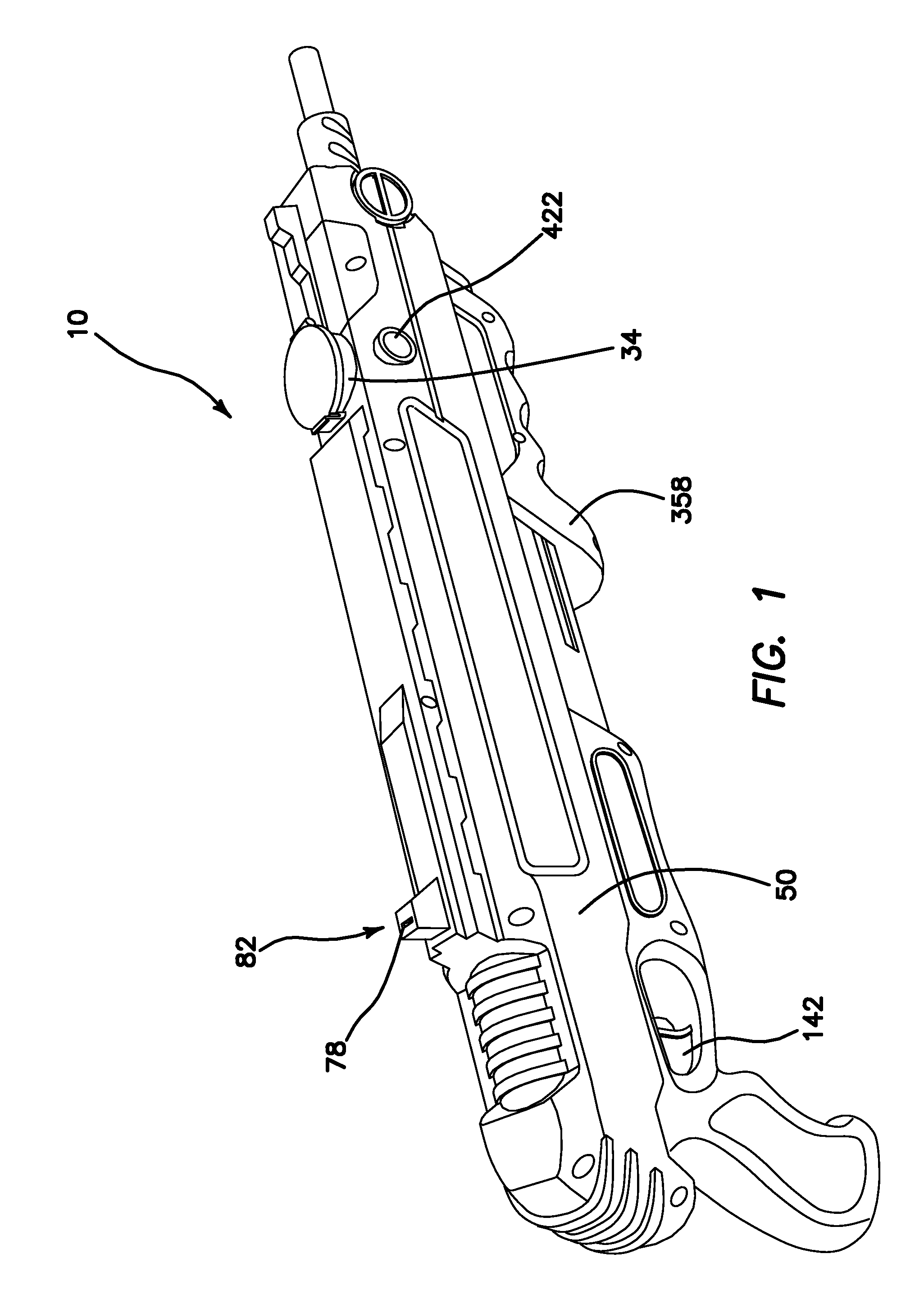

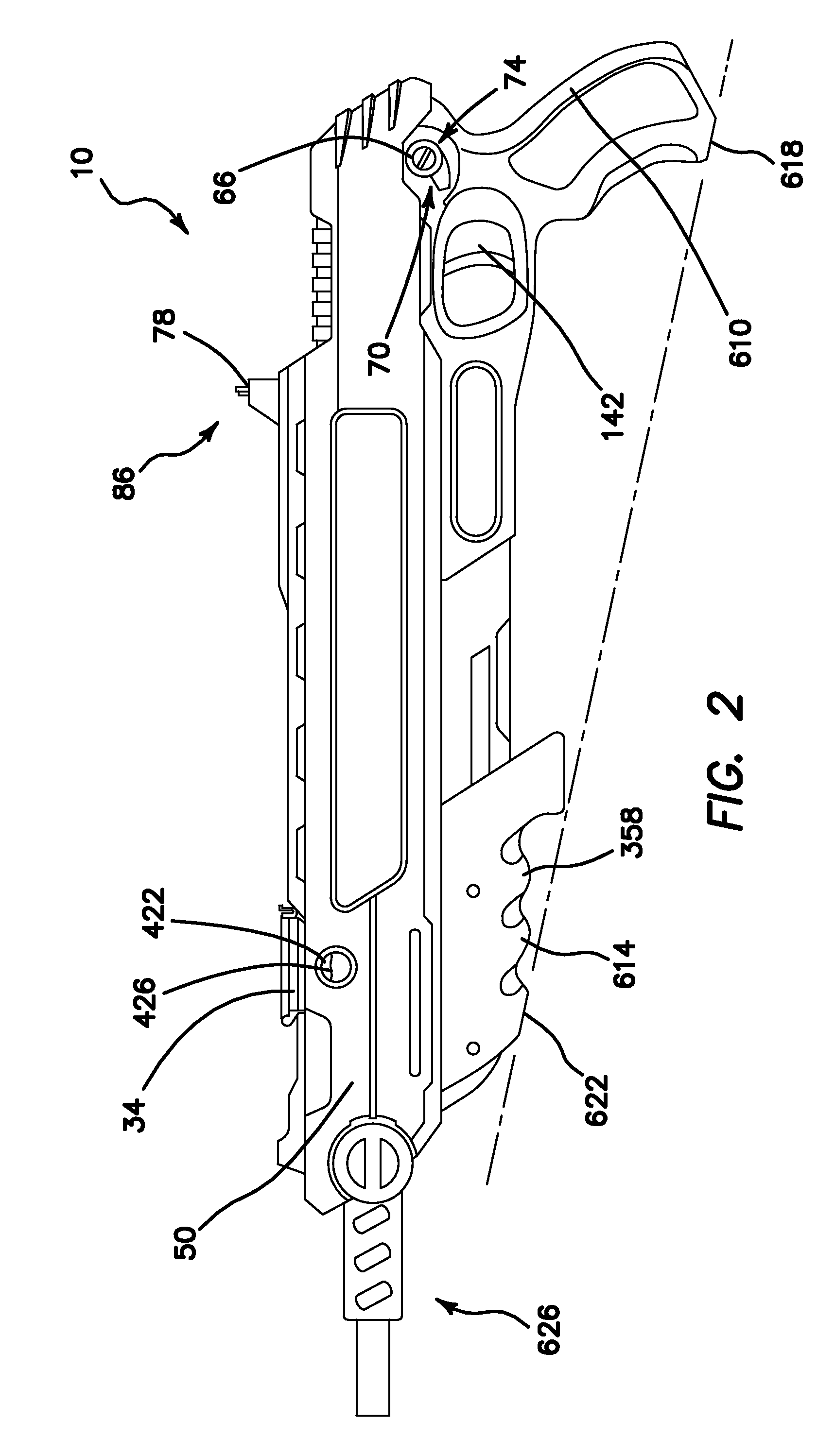

Bug killing gun

ActiveUS8251051B2Inhibition of activationLower surfaceProjectileSafety arrangementEngineeringGas release

A bug killing gun includes a compressed gas source fluidly connected to a chamber connected to a barrel. A compressed gas release mechanism is connected to the compressed gas source. A projectile storage magazine stores particulate projectiles and is located adjacent the chamber. A projectile loading mechanism moves the projectiles into the chamber from the magazine. A cocking mechanism is mechanically connected to the compressed gas source, the compressed gas release mechanism, and the projectile loading mechanism. A stock houses and supports the compressed gas source, the compressed gas release mechanism, the barrel, the chamber, the projectile storage magazine, the cocking mechanism and the projectile loading mechanism. When the gun is cocked, the projectile loading mechanism loads a predetermined quantity of the particulate projectiles into the chamber. When the compressed gas release mechanism is activated the projectiles are ejected from the chamber into the barrel and expelled from the gun.

Owner:MAGGIORE LOREN

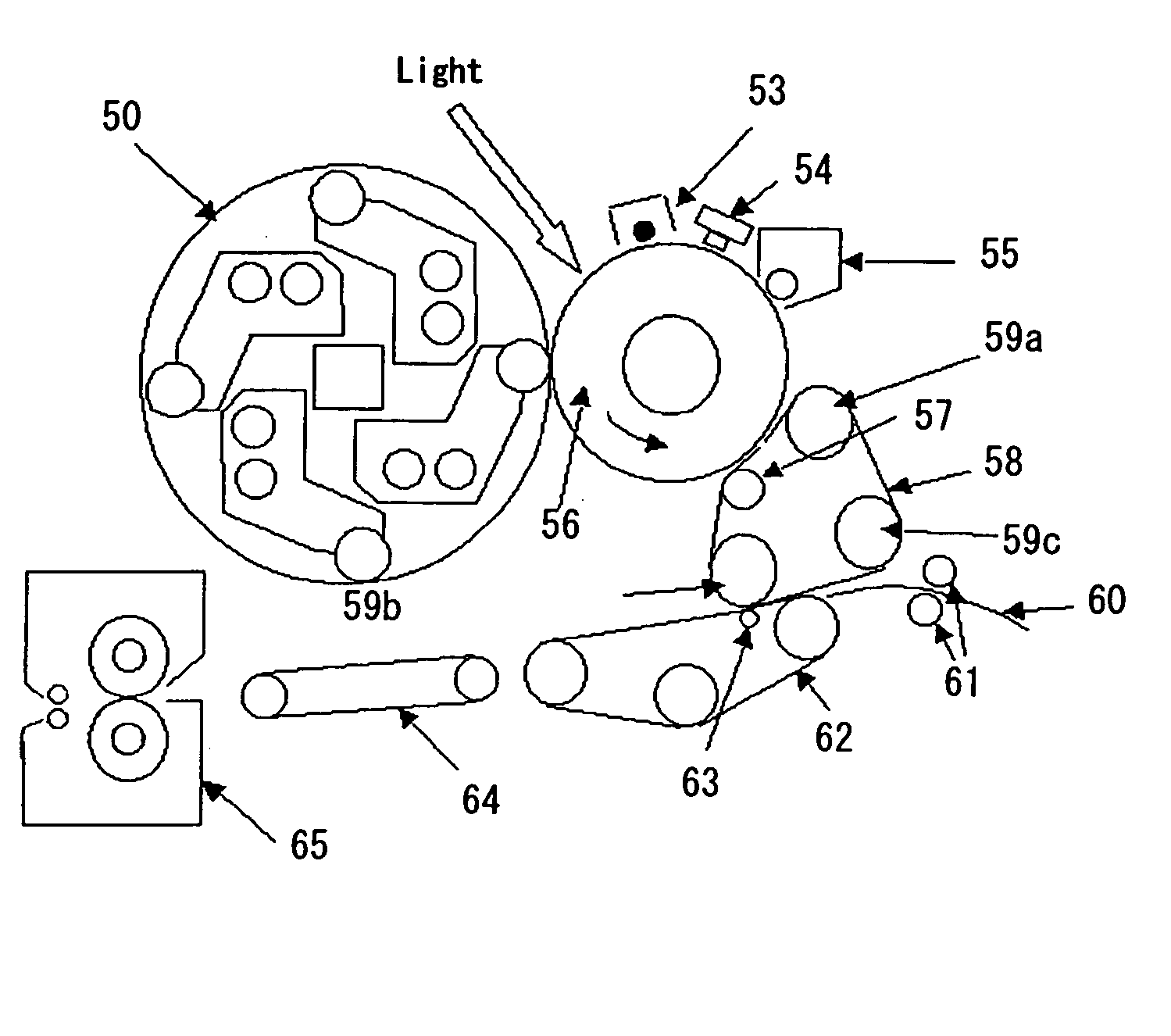

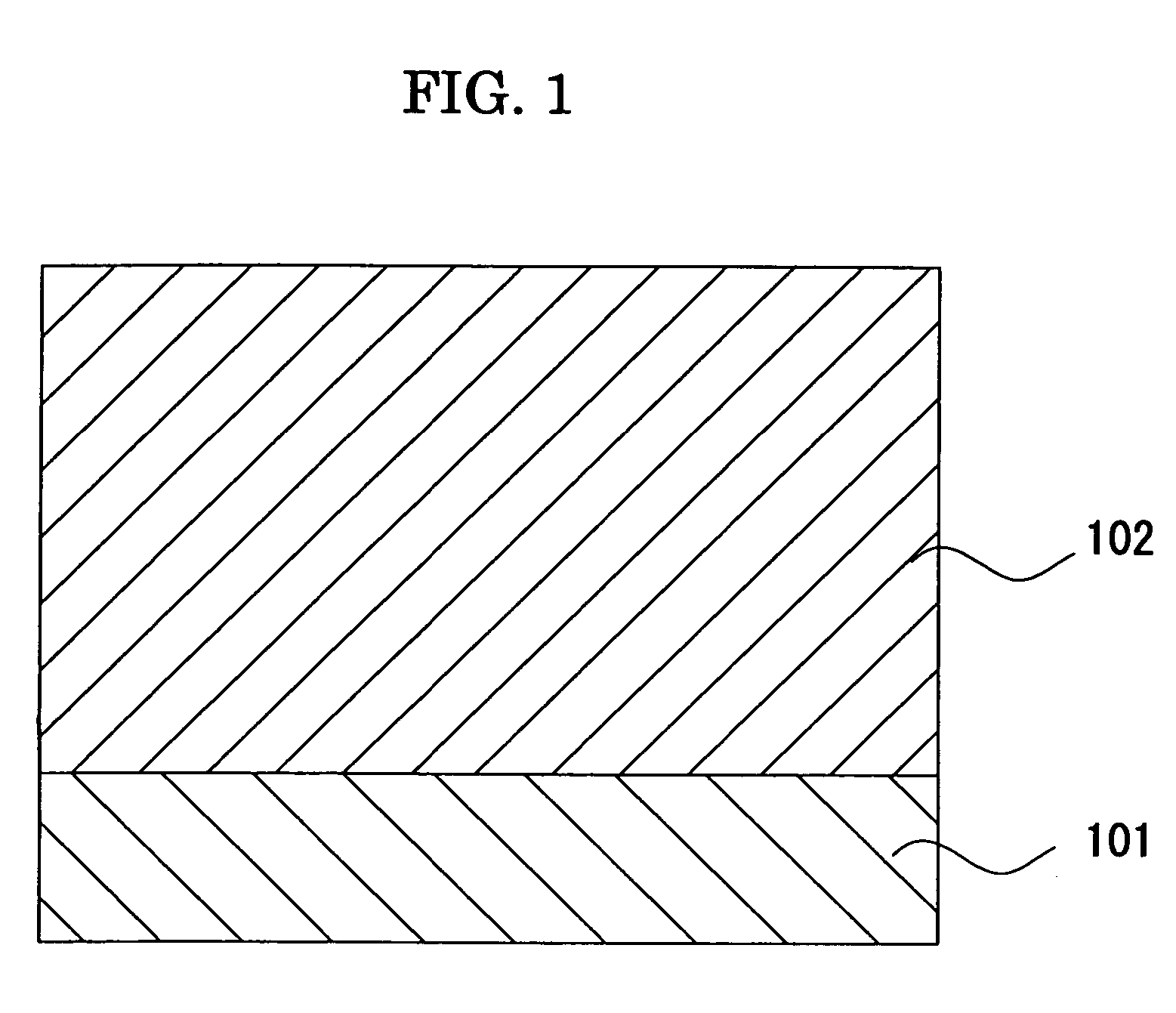

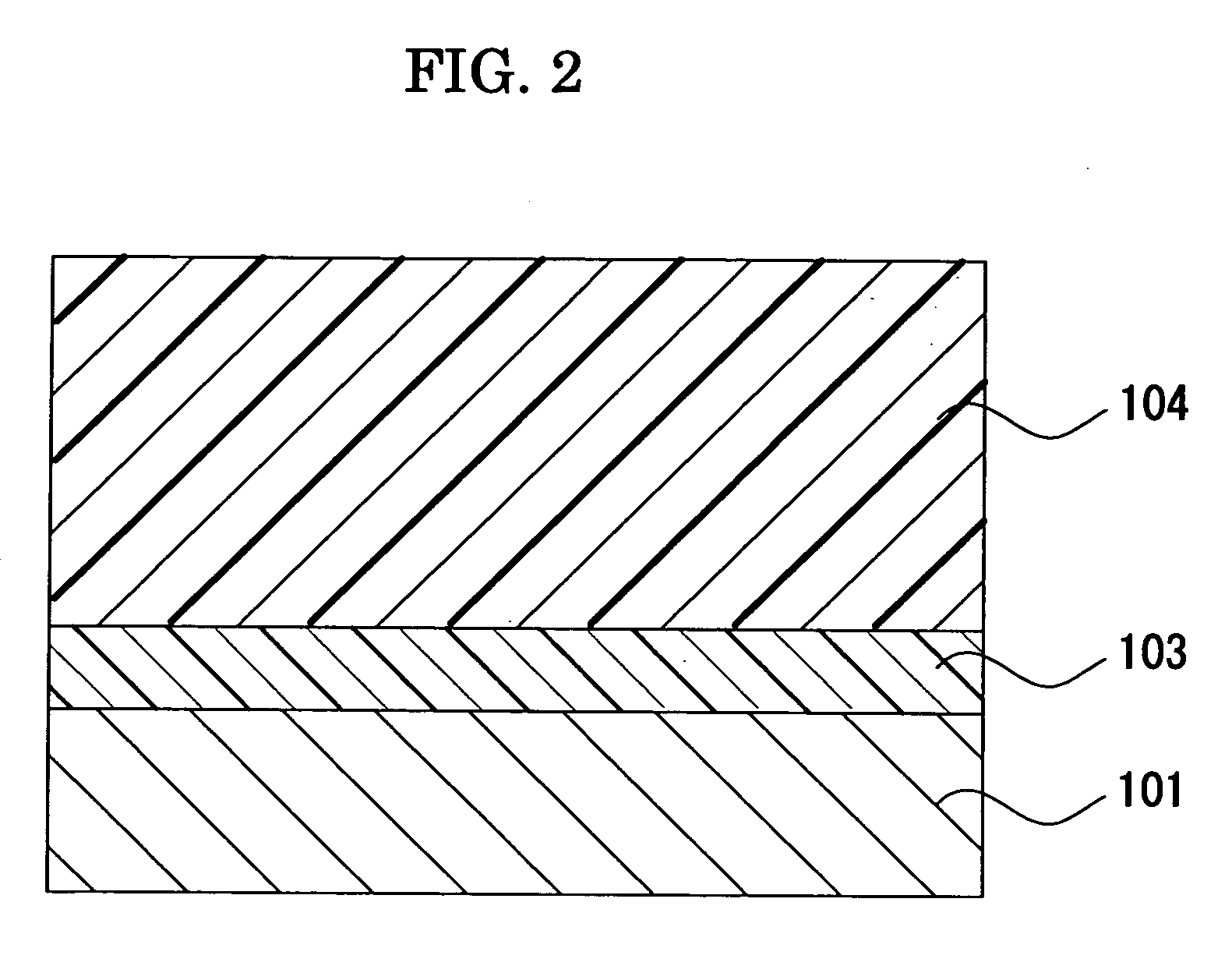

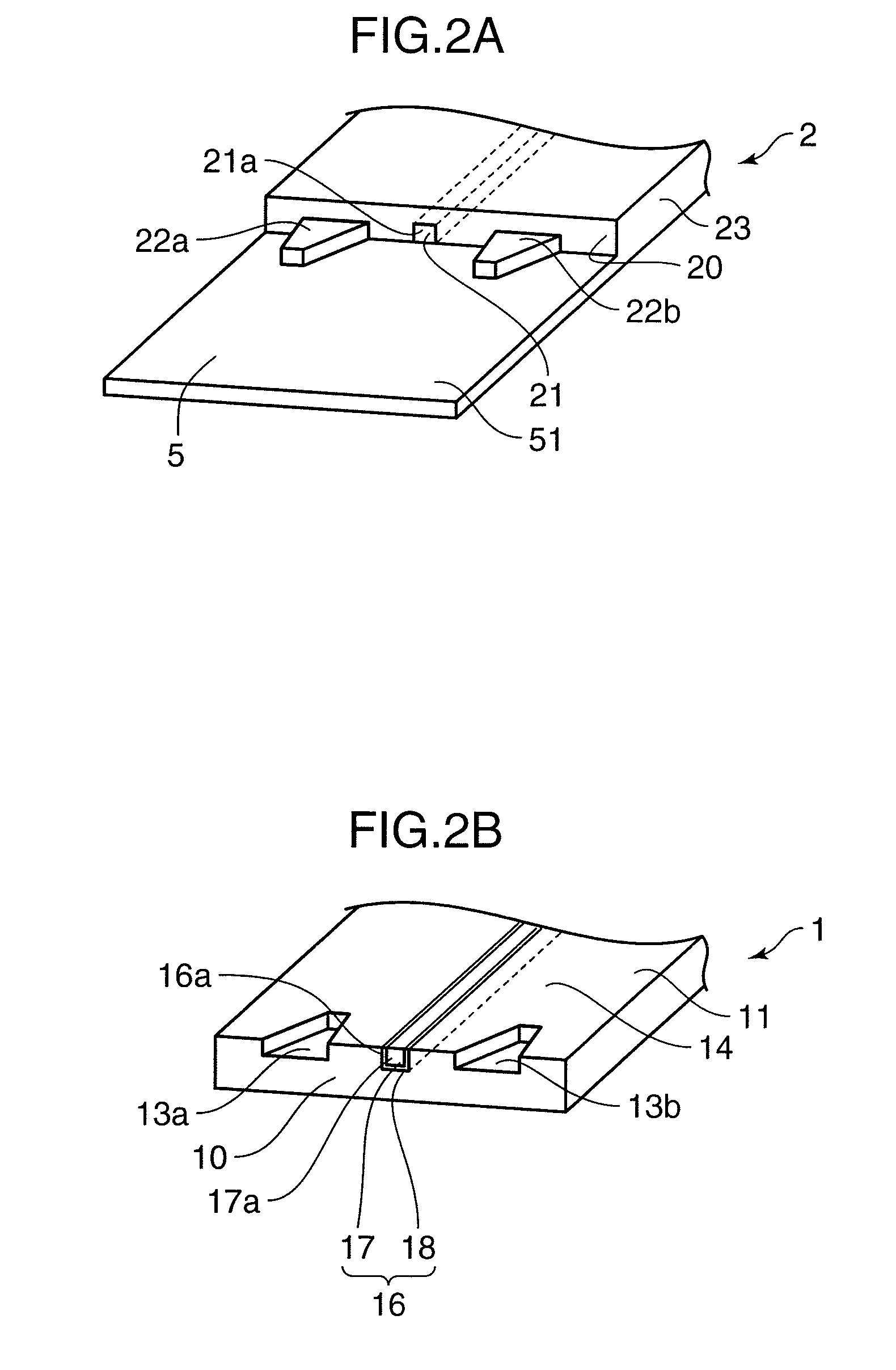

Image forming apparatus, image forming process, and process cartridge for image forming apparatus

ActiveUS20050130050A1Low coefficient of frictionSurface energy is lowElectrographic process apparatusDevelopersSurface energyLight exposure

Disclosed is an image forming apparatus for lowering friction coefficient and lowering surface energy of photoconductor surface in particular, which comprises an electrophotographic photoconductor, charging unit, light exposure unit, developing unit, transferring unit, and fixing unit, the electrophotographic photoconductor comprises a photosensitive layer on a conductive support and fluoropolymer fine particles at the outermost layer, a part of the fluoropolymer fine particles are exposed above the surface of the outermost layer in configurations of primary particles and secondary particles formed by flocculation of plural primary particles, and sum of area ratios of particles in the configurations of the primary particles and the secondary particles, each particles having an average diameter D of 0.15 μm≦D≦3.0 μm as respective projected figures of exposed portion above the surface of the outermost layer, is 10% to 60% based on the entire surface area of the outermost layer, and wherein the binder resin in the outermost layer comprises a polyalylate copolymer resin having a structural unit of alkylene-aryldicarboxylate.

Owner:RICOH KK

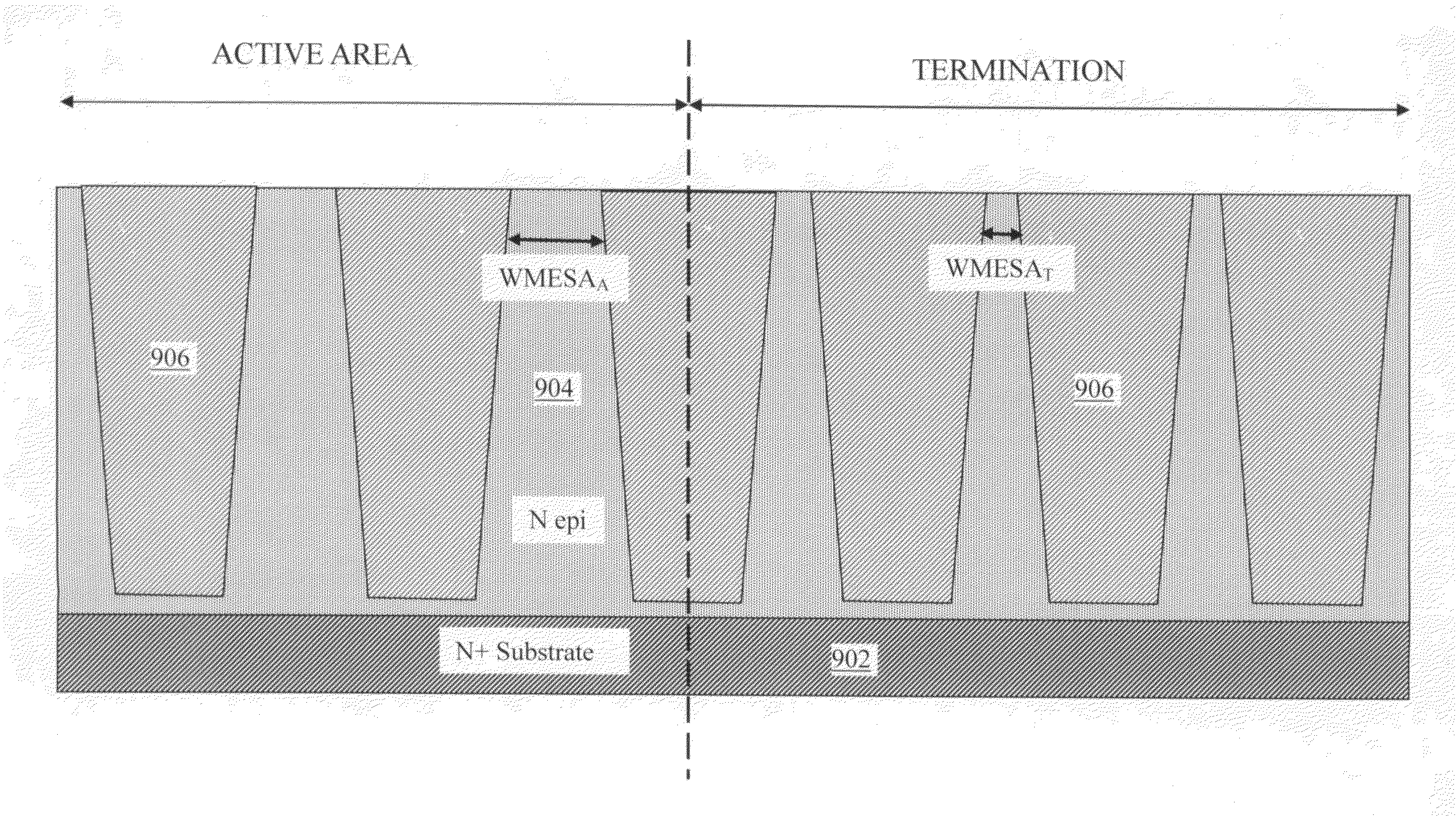

Configuration and method to generate saddle junction electric field in edge termination

ActiveUS20120248566A1Reduce electrical field crowding effectSurface electric fieldSemiconductor/solid-state device manufacturingSemiconductor devicesActive cellEngineering

This invention discloses a semiconductor power device disposed in a semiconductor substrate and having an active cell area and an edge termination area the edge termination area wherein the edge termination area comprises a superjunction structure having doped semiconductor columns of alternating conductivity types with a charge imbalance between the doped semiconductor columns to generate a saddle junction electric field in the edge termination.

Owner:ALPHA & OMEGA SEMICON INC

Alkyl group polyoxyethylene ether surface active agent with Guerbet structure and preparation method and application thereof

ActiveCN101745343AGood water solubilityLow critical micelle concentrationTransportation and packagingMixingChemical structureSolubility

The invention relates to an alkyl group polyoxyethylene ether surface active agent with a Guerbet structure and a preparation method and the application thereof, which is applied to the tertiary oil recovery technology; alpha-olefin with dialkyl, which is obtained by catalyzing dimerization by the alpha-olefin with short carbon chain, is used as starting material, and after a series of the chemical reaction, the corresponding alkyl group polyoxyethylene ether surface active agent with the Guerbet structure is prepared; the surface active agent comprises a quaternary ammonium cationic surfactant of alkyl polyoxyethylene ether hydroxypropyl and a carboxylic acid oxyneurines amphoteric surfactant of alkyl group polyoxyethylene ether hydroxypropyl, a special molecular structure determines the alkyl group polyoxyethylene ether surface active agent to have good water solubility, low critical micelle concentration, good surface or interface tensile force reduction capacity and high-efficiency foaming capacity, ultra-low oil-water interface tensile force (10-3mN / m) is formed between the brine solution energy and crude oil, therefore, the alkyl group polyoxyethylene ether surface active agent which is used as an effective oil displacement agent has application potential in the tertiary oil recovery; the surface active agent has the following chemical structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Electrical cable having a surface with a reduced coefficient of friction

InactiveUS20070243761A1Reduce coefficient of frictionMinimizing required installation pulling forceLiquid organic insulatorsSecuring/insulating coupling contact membersElectrical conductorFrictional coefficient

Owner:SOUTHWIRE CO LLC

Aqueous dispersion coating composition having noise and/or friction abatement properties

InactiveUS20070134502A1Dry noise valueReduce interior noiseSynthetic resin layered productsPolyurea/polyurethane coatingsStatic friction coefficientPolymer science

An aqueous dispersion coating for rubber and polymer substrates comprises a blend of a polysiloxane and a curable polyurethane and various additives such as a urethane crosslinking agent, a heat resistant filler, and the like. The aqueous dispersion coating reduces the noise upon contact or movement of the coated substrate with an article and maintains the initial static coefficient of friction therewith over a period of time. A desired end use is as a coating on vehicle weatherstrips such as for doors, trunks, and other enclosing articles.

Owner:LORD CORP

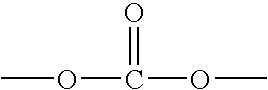

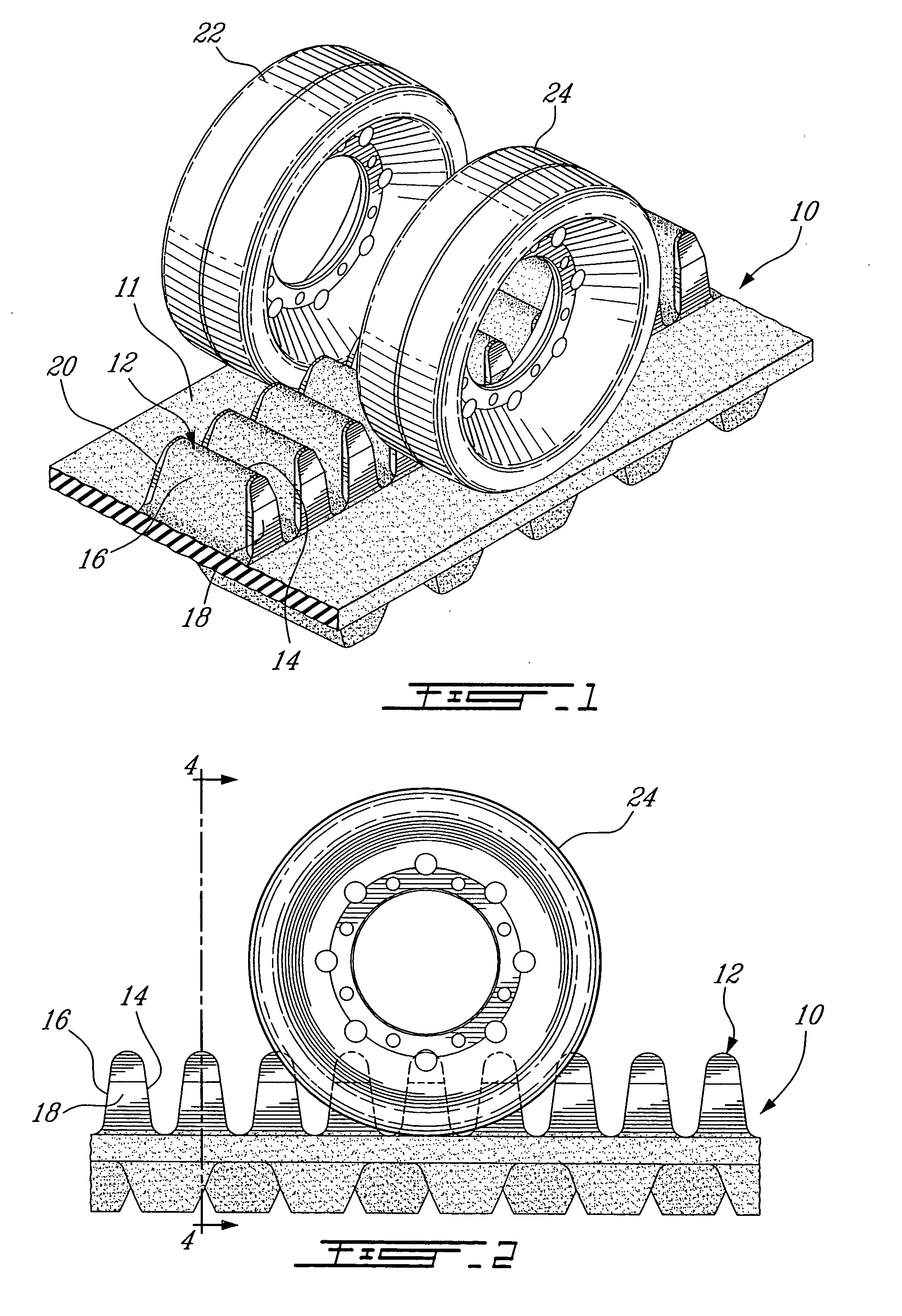

Track with low friction reinforced guide blocks

InactiveUS20050103540A1Reduce frictionLow heat generationEndless track vehiclesScroll wheelLow friction

The endless track of a track-propelled vehicle has an inner face provided with a series of longitudinally spaced guide blocks; the guide blocks have, on an opposite side faces thereof, pads made of low friction resin material to contact the mid rollers of the track assembly.

Owner:CAMOPLASY INC

Hydrophobic finish compositions with extended flow time retention and building products made thereof

ActiveUS20160264461A1Improve water resistanceLow costConstruction materialSolid waste managementFiberBuilding product

Disclosed are hydrophobic finish compositions and cementitious articles made with the hydrophobic finish compositions. In some embodiments, the article is a waterproof gypsum panel surface reinforced with inorganic mineral fibers that face a flexible and hydrophobic cementitious finish possessing beneficial waterproofing properties. These waterproof gypsum panels have many uses, such as, tile backer board in wet or dry areas of buildings, exterior weather barrier panel for use as exterior sheathing, interior wall and ceiling, and roof cover board having water durability and low surface absorption. The flexible and hydrophobic cementitious finish can include fly ash, film-forming polymer, preferably silane compound (e.g., alkyl alkoxysilane), an extended flow time retention agent including either one or more carboxylic acids, salts of carboxylic acids, or mixtures thereof, and other optional additives. Preferably a pre-coated non-woven glass fiber mat is employed to provide the inorganic mineral fibers for the surface reinforcement.

Owner:UNITED STATES GYPSUM CO

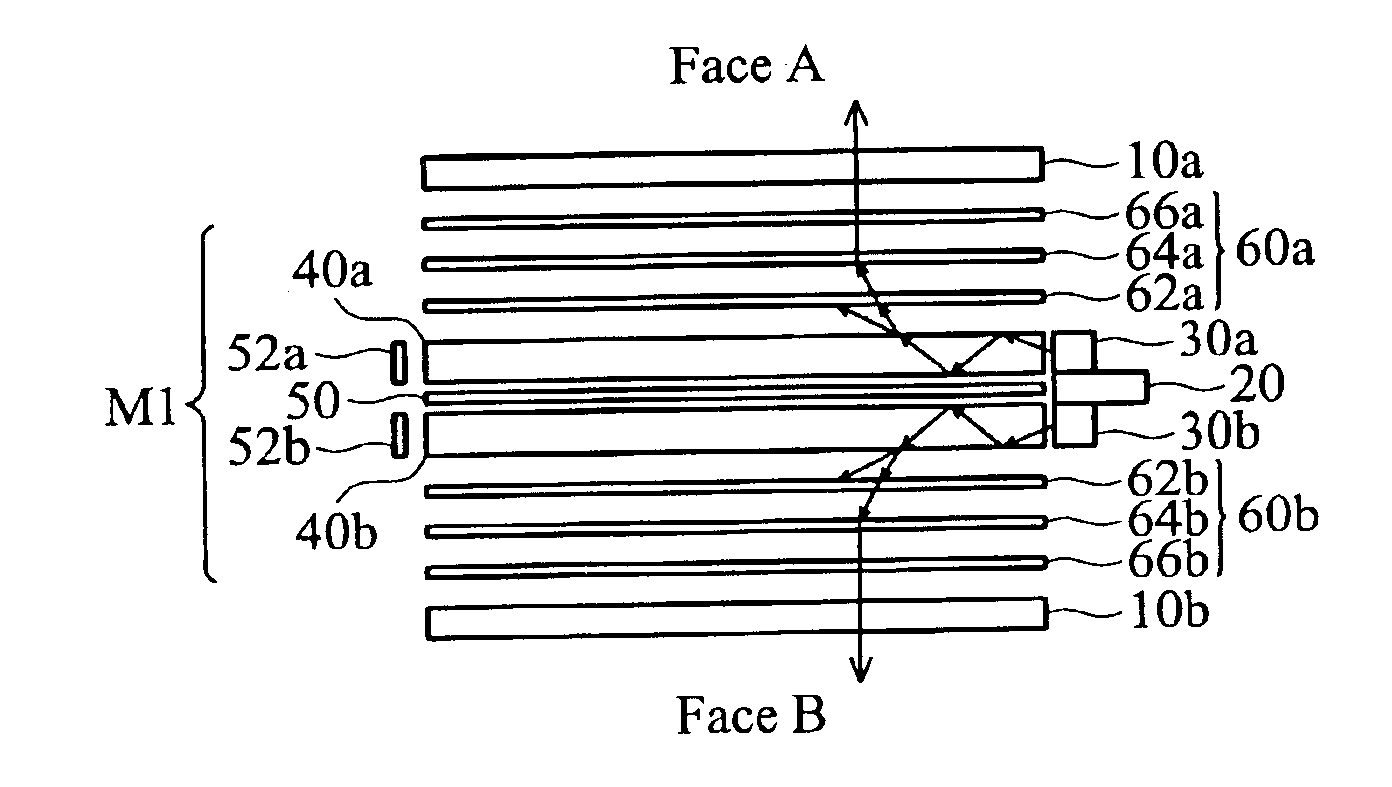

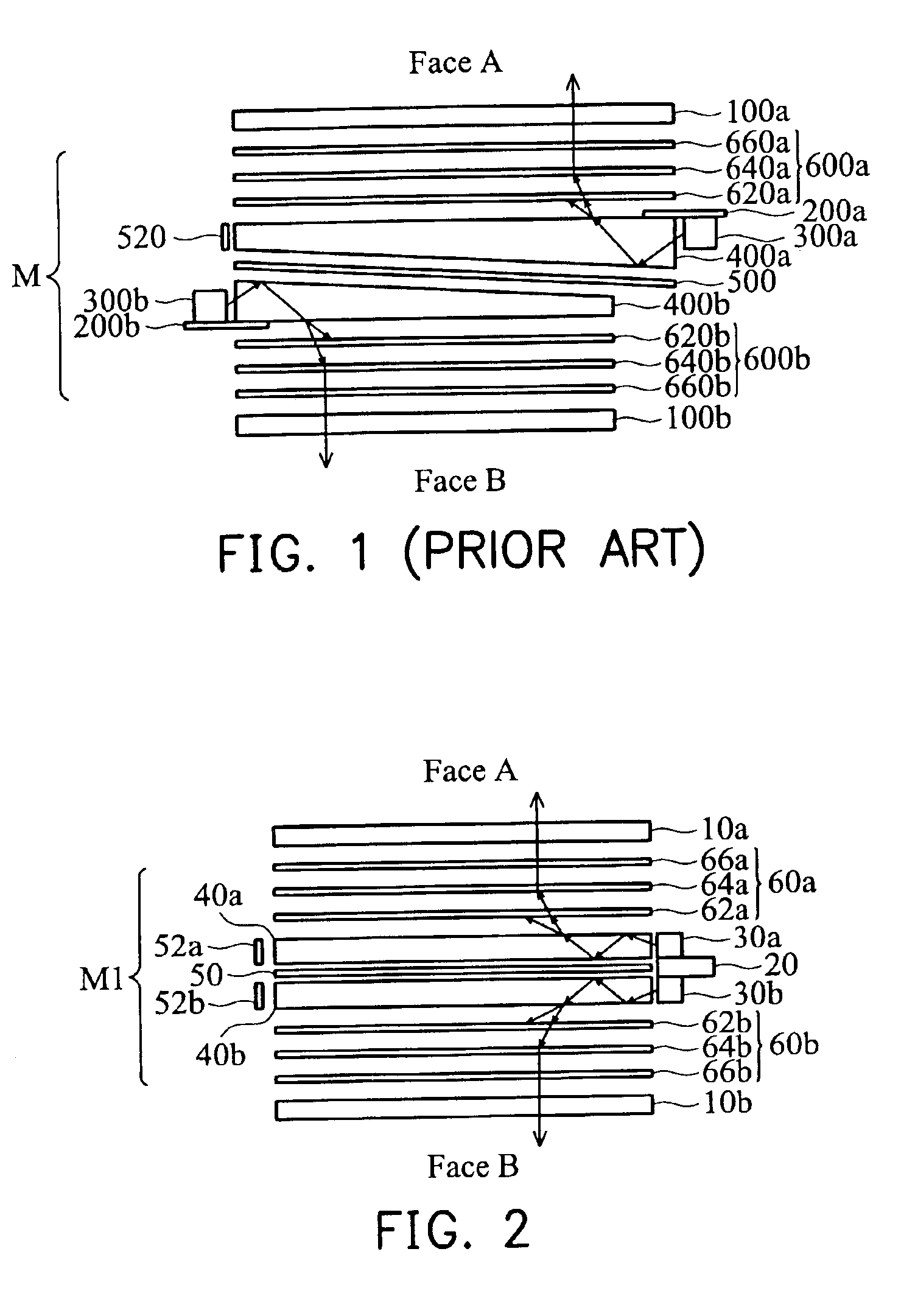

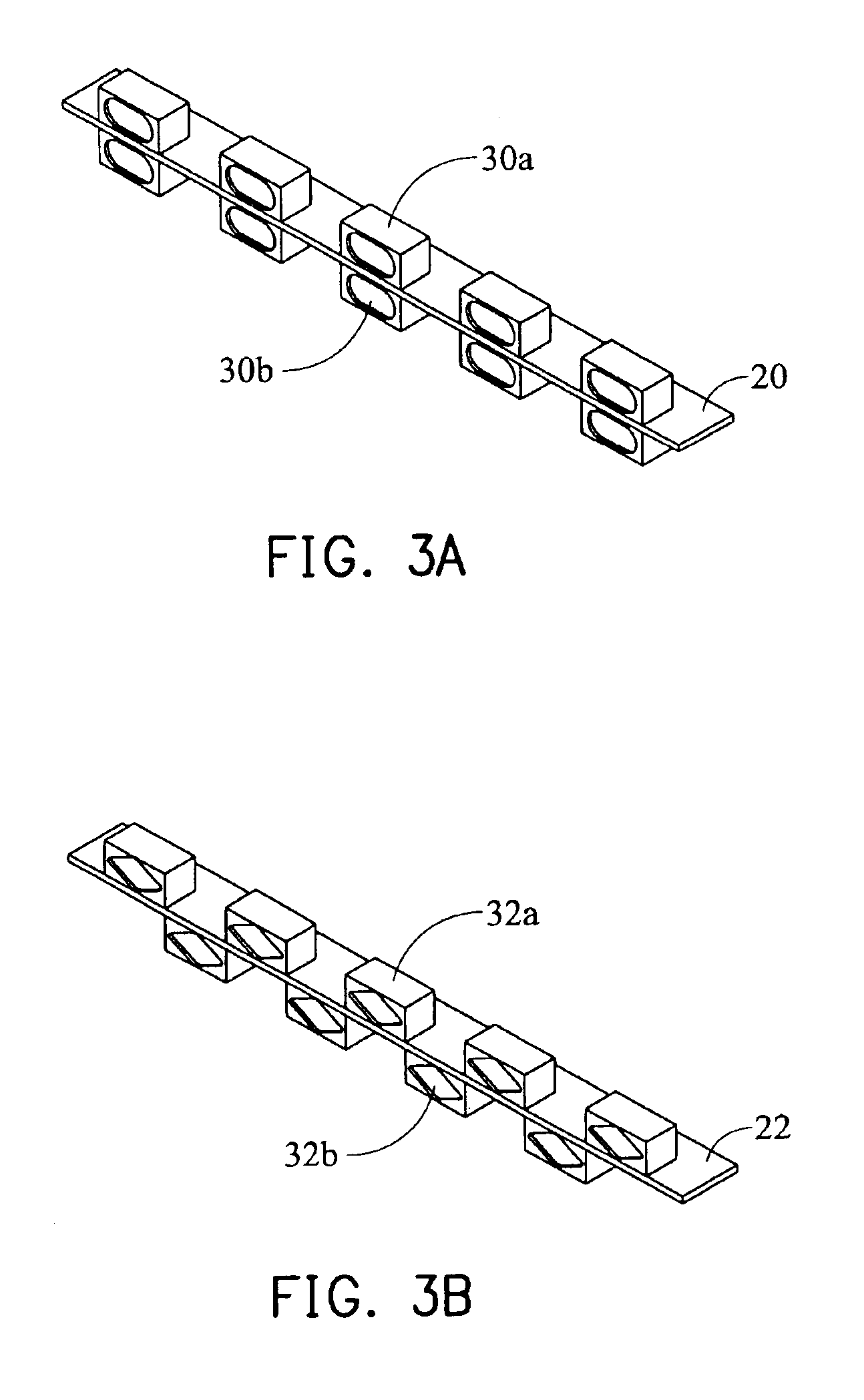

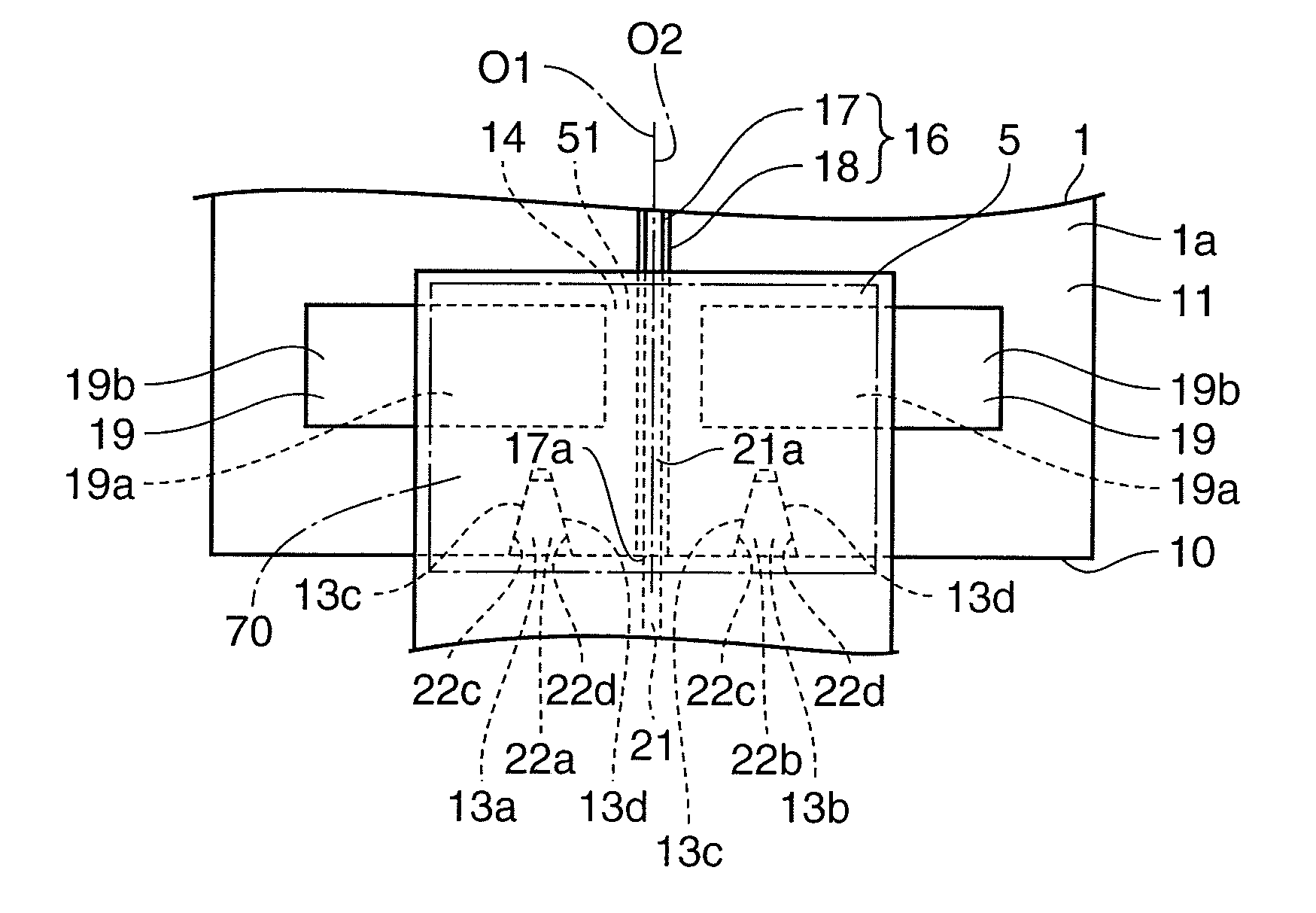

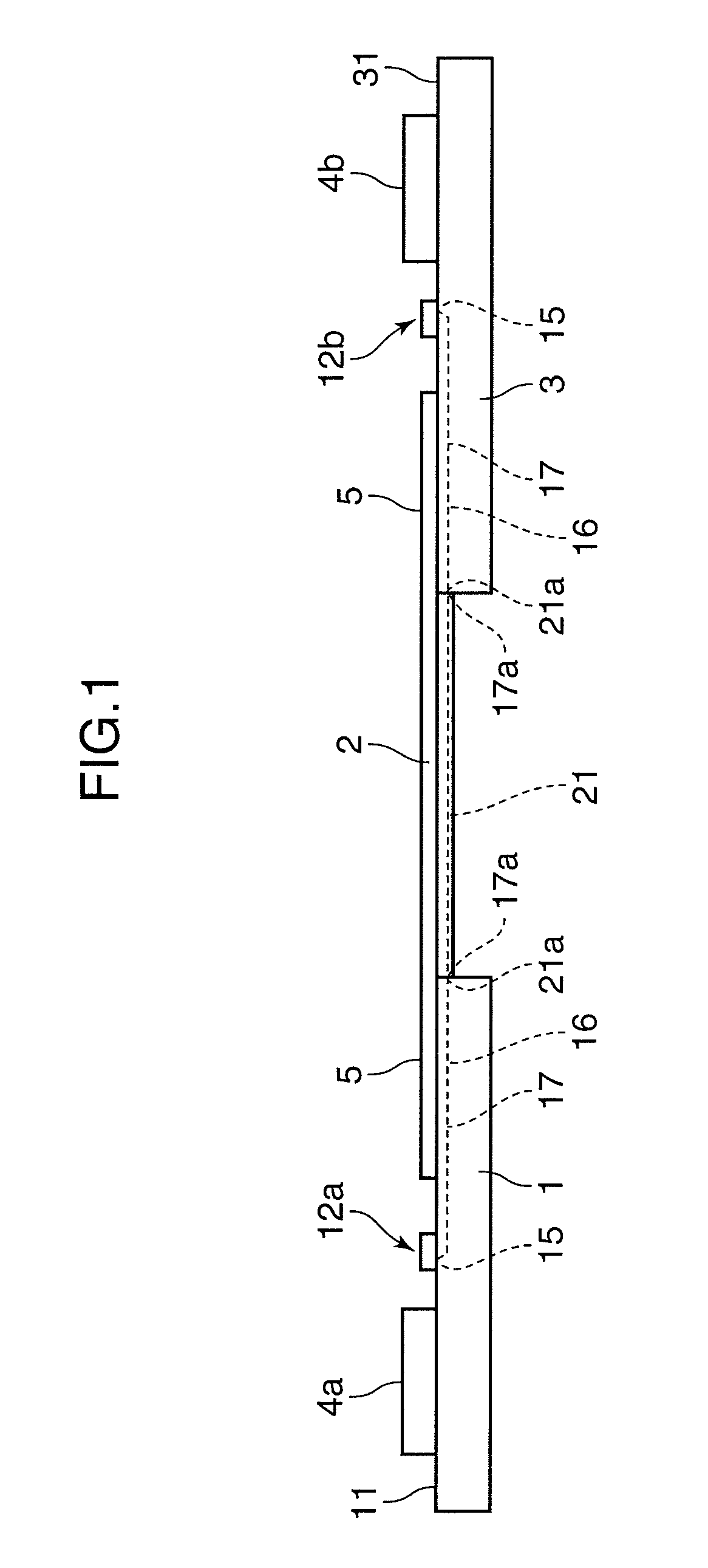

Optical module

InactiveUS20100220957A1High bonding strengthReduce riskCoupling light guidesOptical waveguide light guideOptical ModuleLap joint

An optical module includes an emitter-side mounting substrate, a receiver-side mounting substrate and an external waveguide substrate. The mounting substrate is provided with a waveguide having a core and a pair of fitting recesses. The external waveguide substrate is provided with an external waveguide having a core, a pair of fitting tabs and a lap joint portion. As the fitting tabs are fitted into the respective fitting recesses, the mounting substrate and the external waveguide substrate are joined together, the two cores are aligned with each other, and the lap joint portion is positioned to overlap the mounting substrate.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com