Patents

Literature

2743results about "Piston rings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piston ring

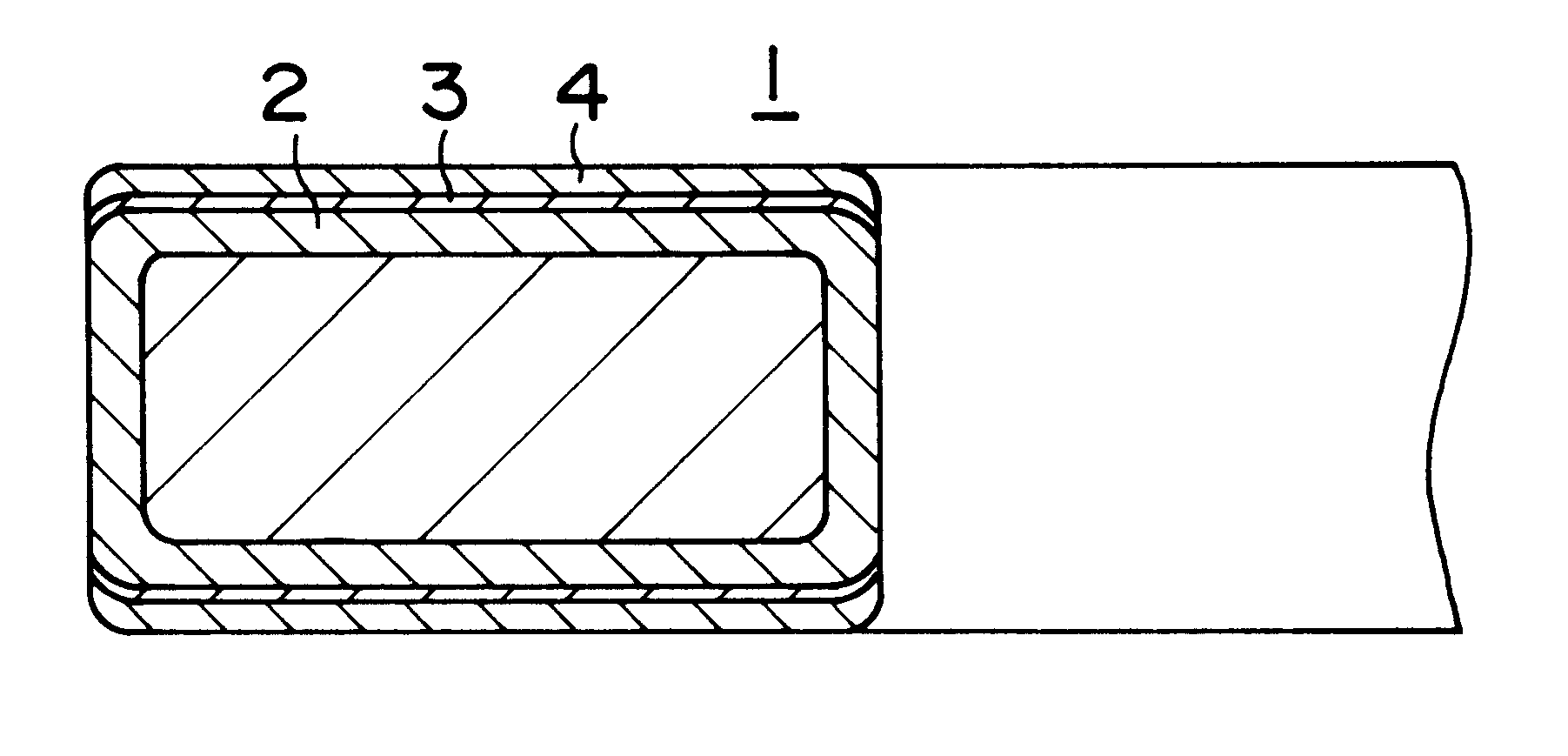

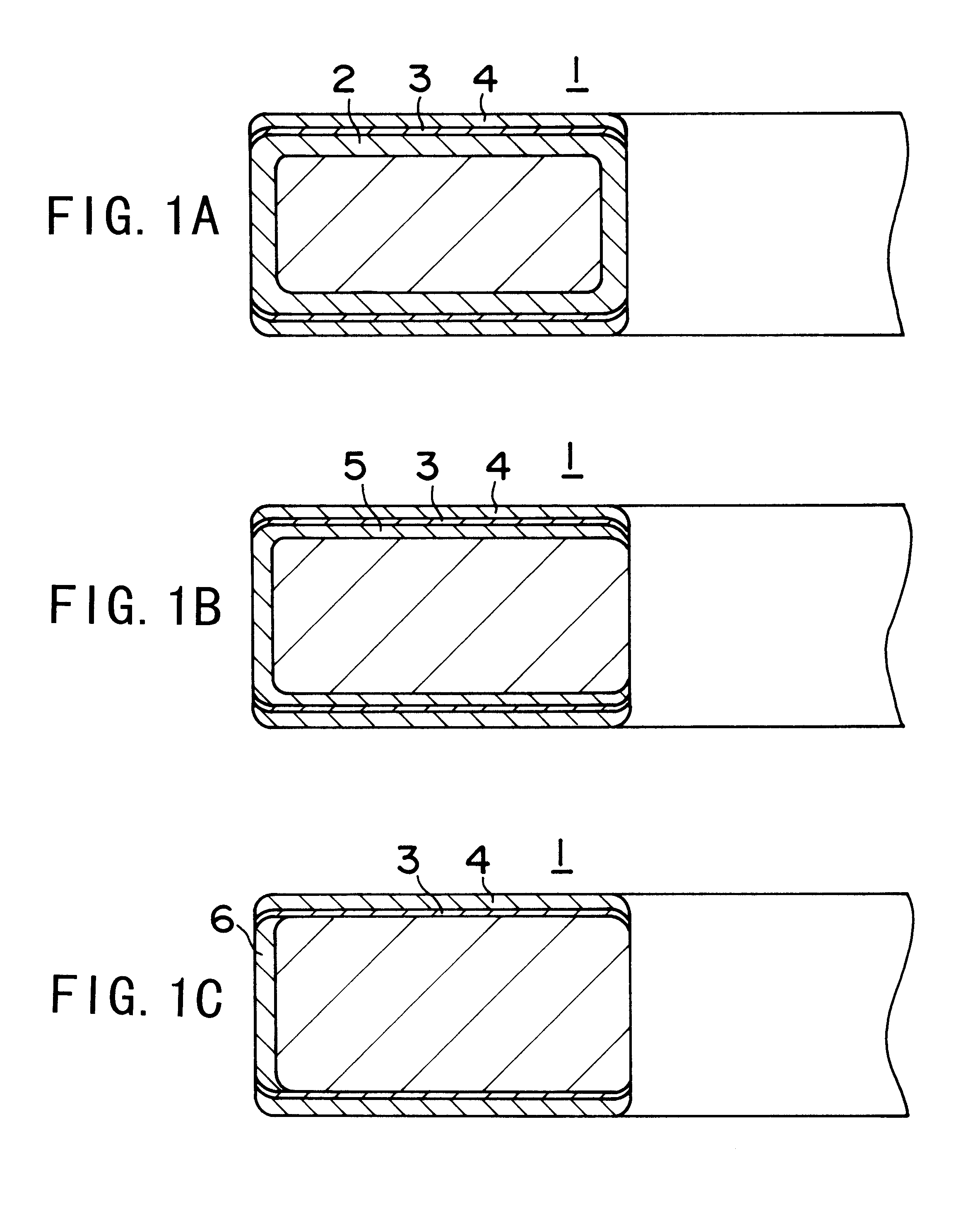

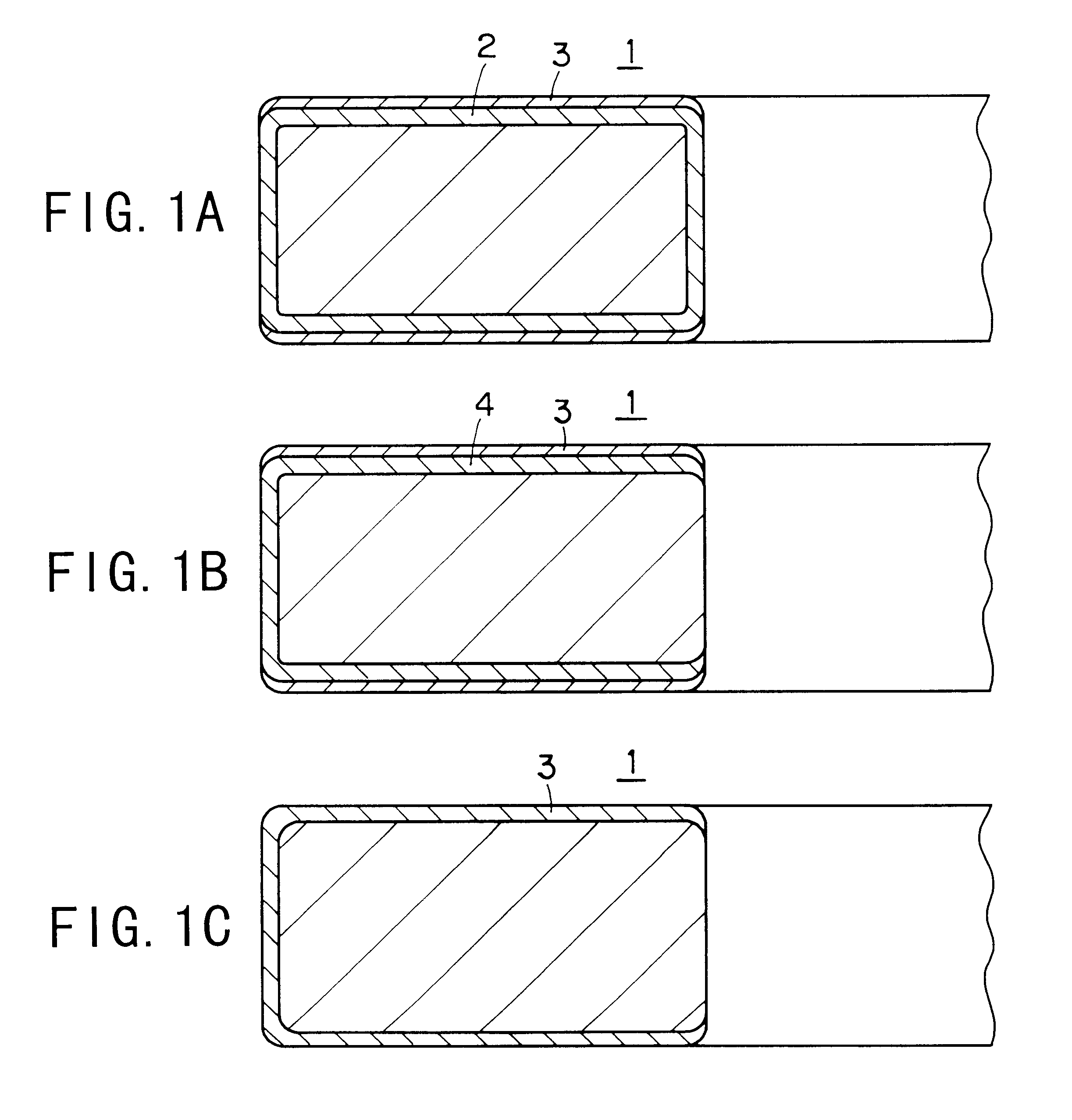

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

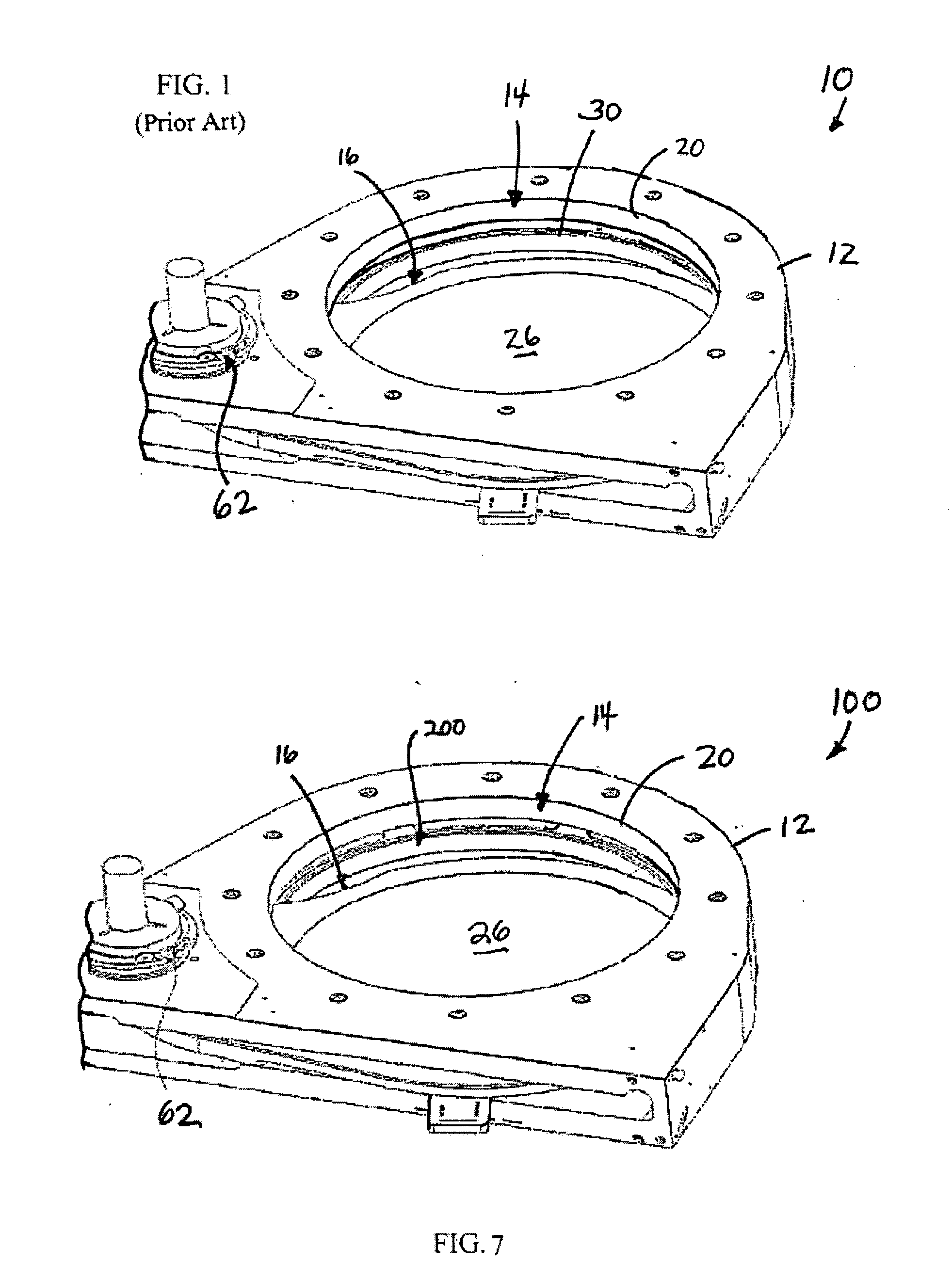

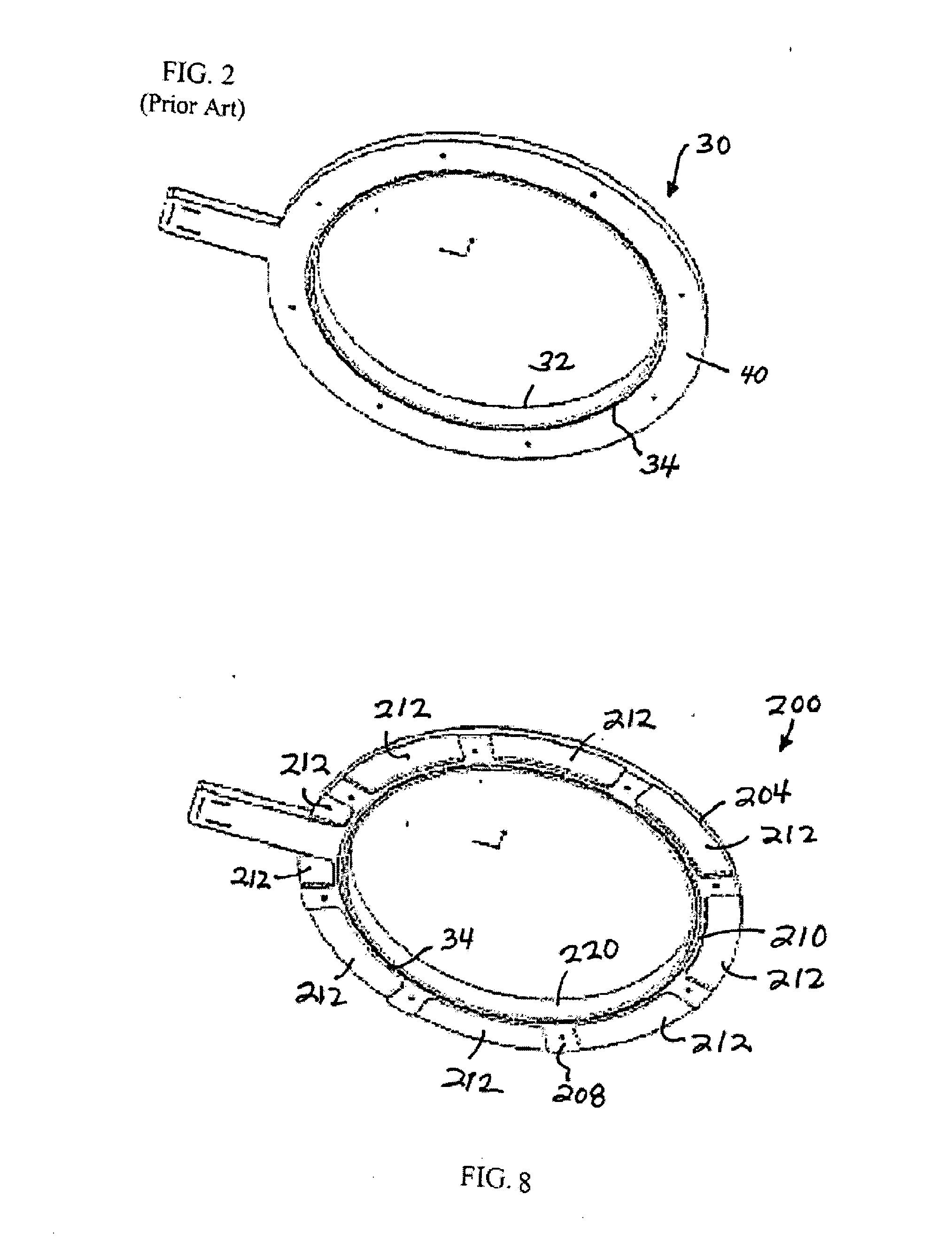

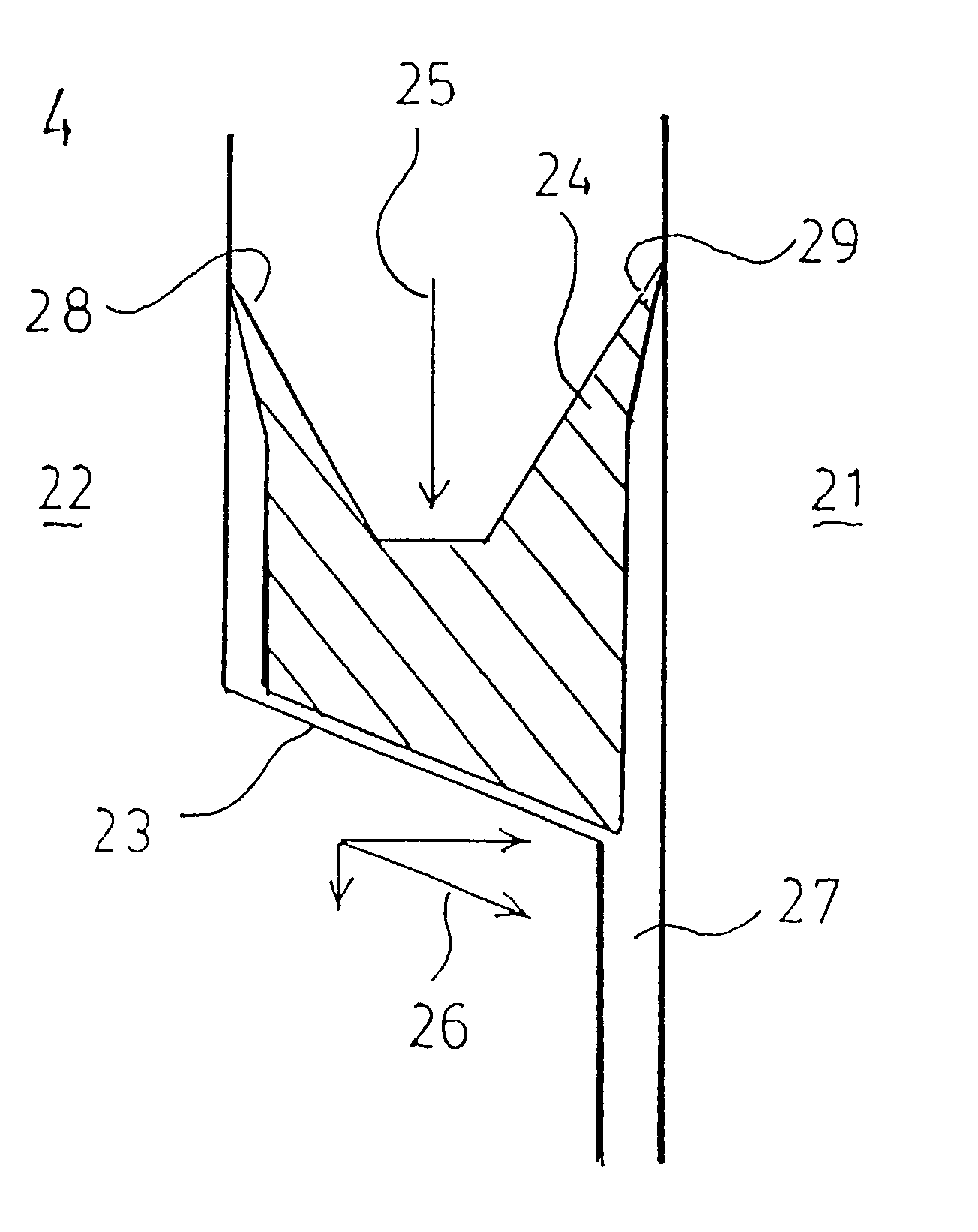

Valve assembly having improved conductance control

InactiveUS20050067603A1High conductanceEasy to controlPiston ringsBraking action transmissionSlide plateVALVE PORT

A valve assembly including a housing having a flow channel and an annular surface surrounding the flow channel, a slide plate movable to a closed position, and a seal ring positioned between the annular surface and the slide plate. The seal ring includes a first and second sides, a first surface extending between the first and the second sides and facing towards the annular surface of the housing, and a second surface axially spaced from the first surface and extending between the first and the second sides and facing towards the slide plate. The second surface includes a continuous annular sealing portion for contacting the slide plate when the seal ring is biased against the slide plate so that a fluid-tight seal can be formed between the continuous annular sealing portion and the slide plate, and at least one passageway positioned between the annular sealing portion and the second side.

Owner:MKS INSTR INC

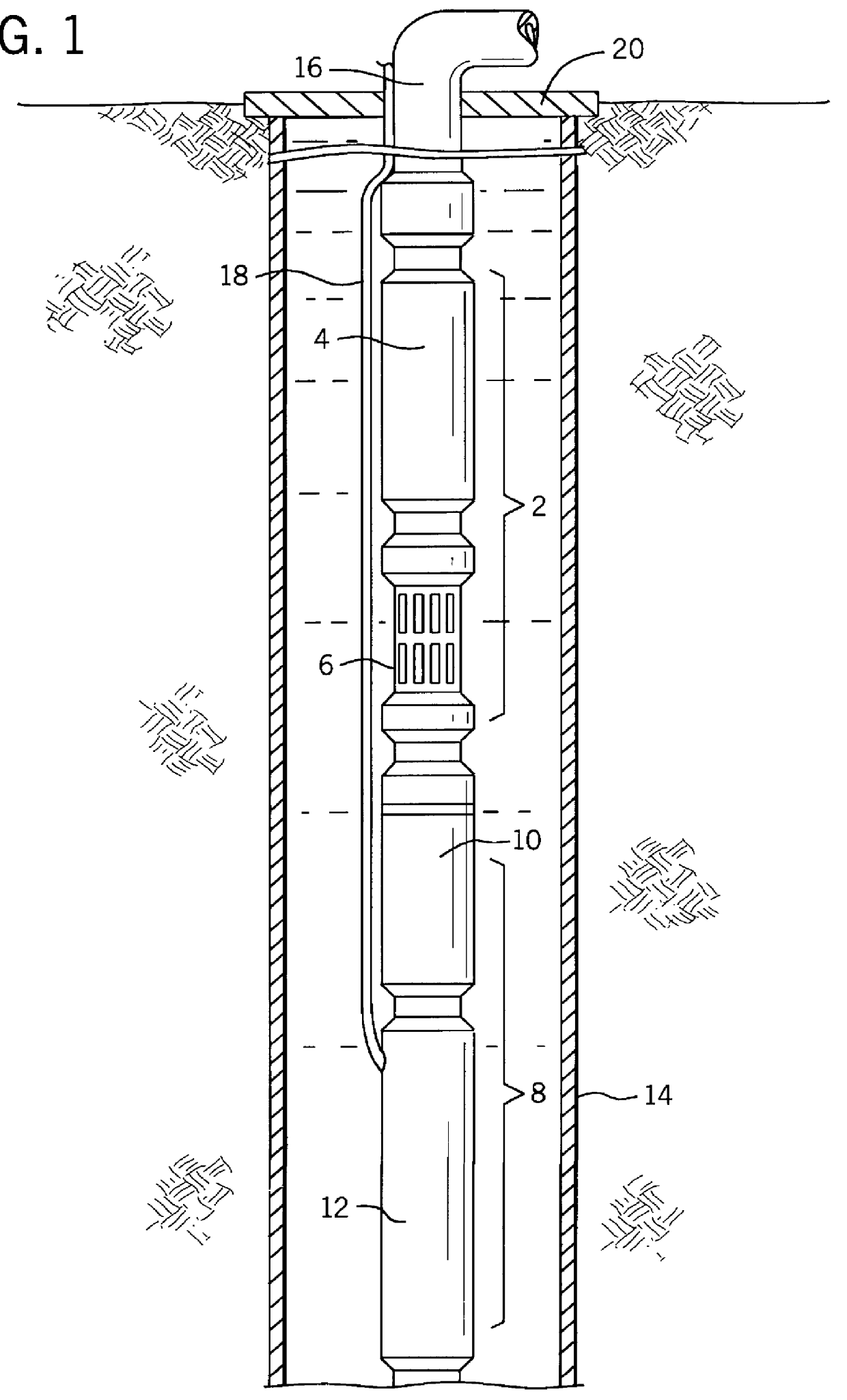

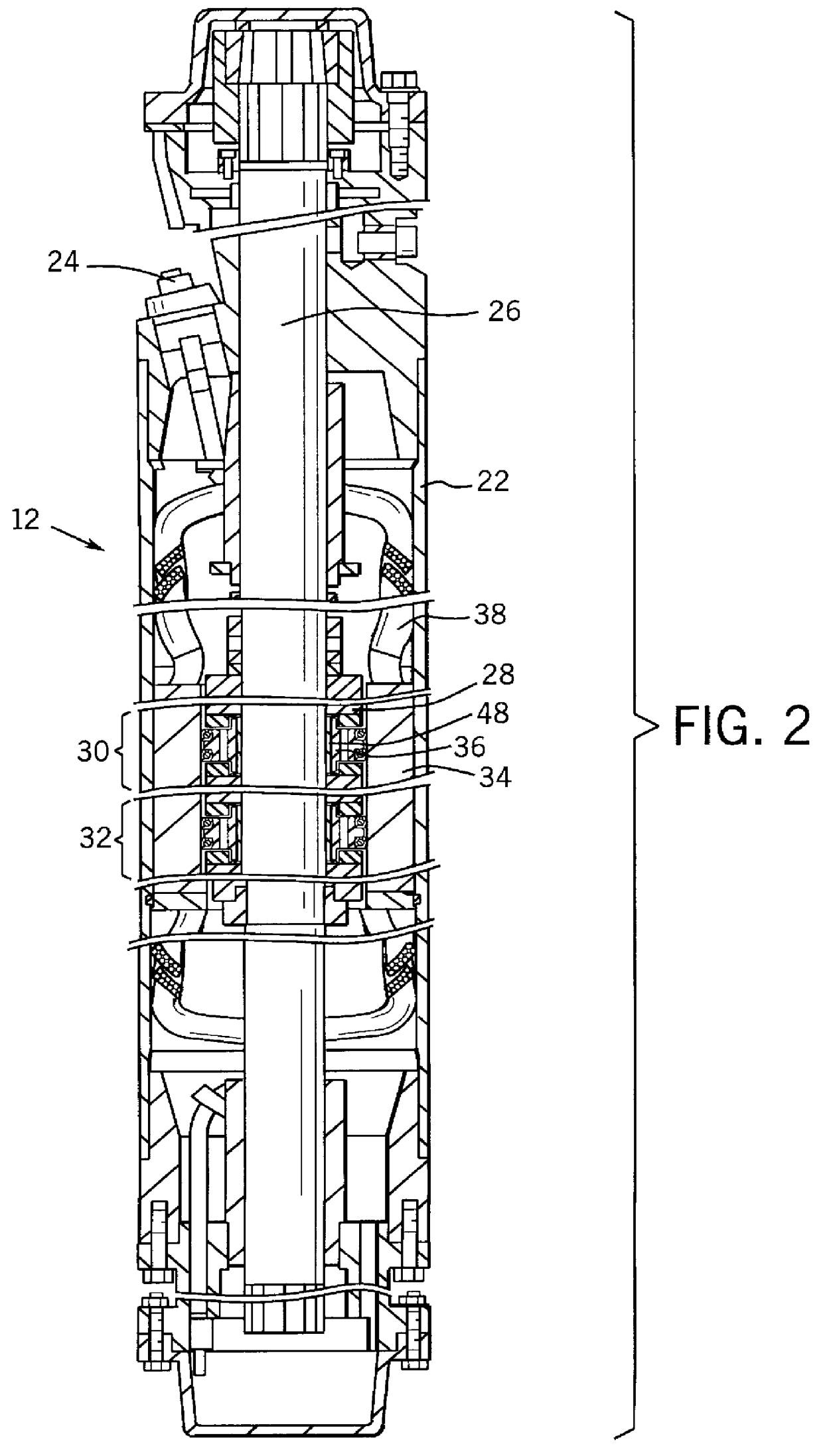

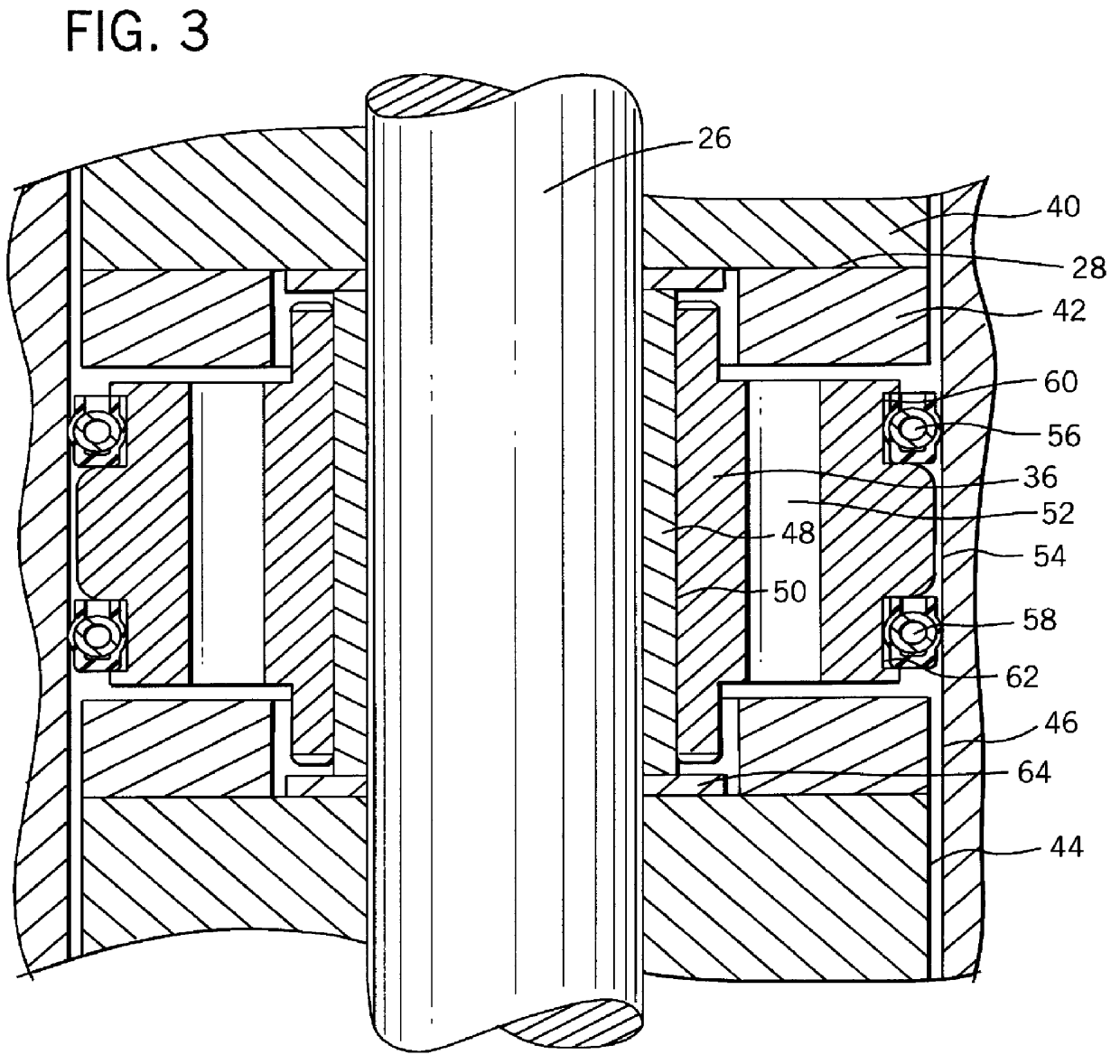

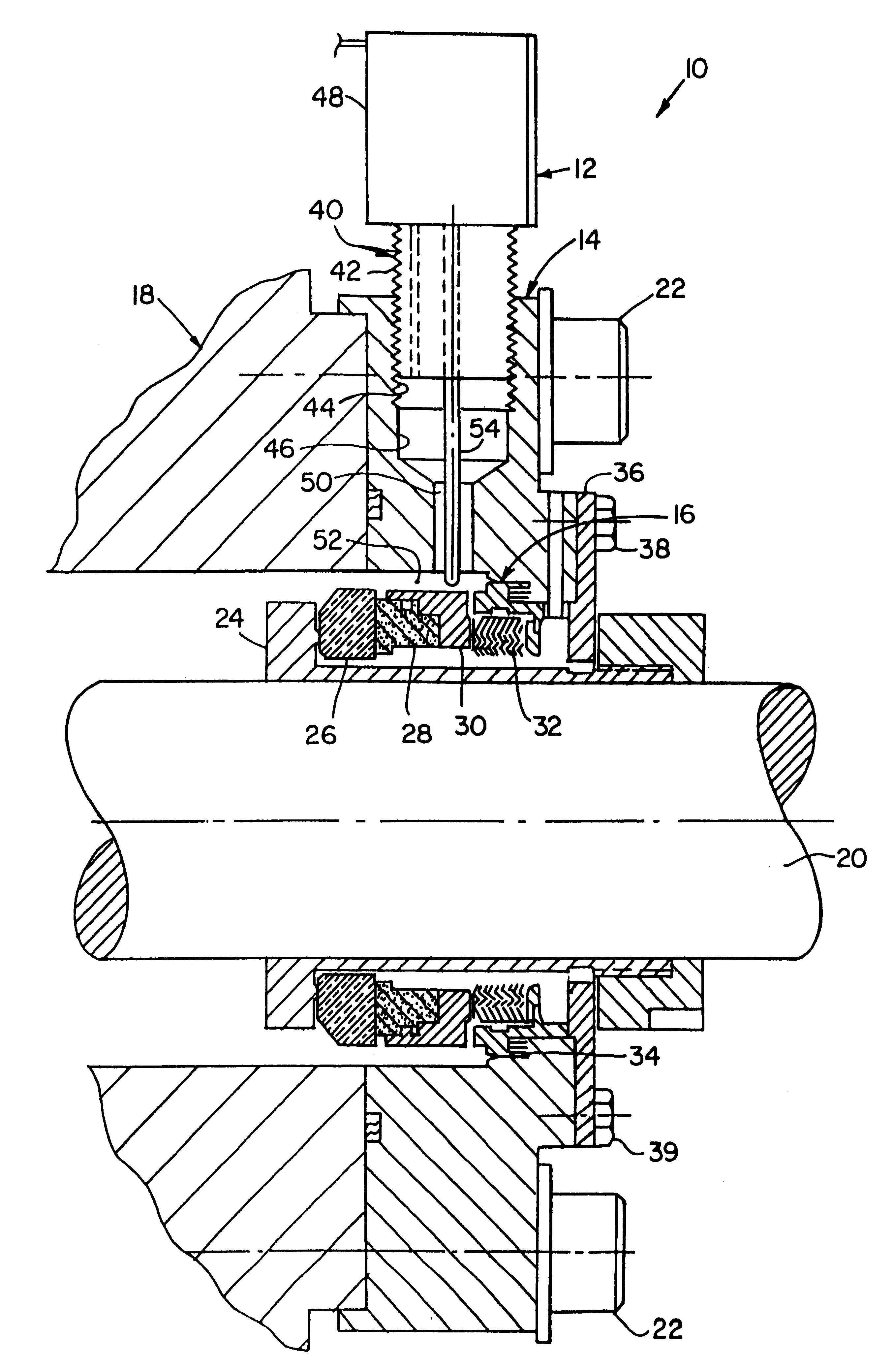

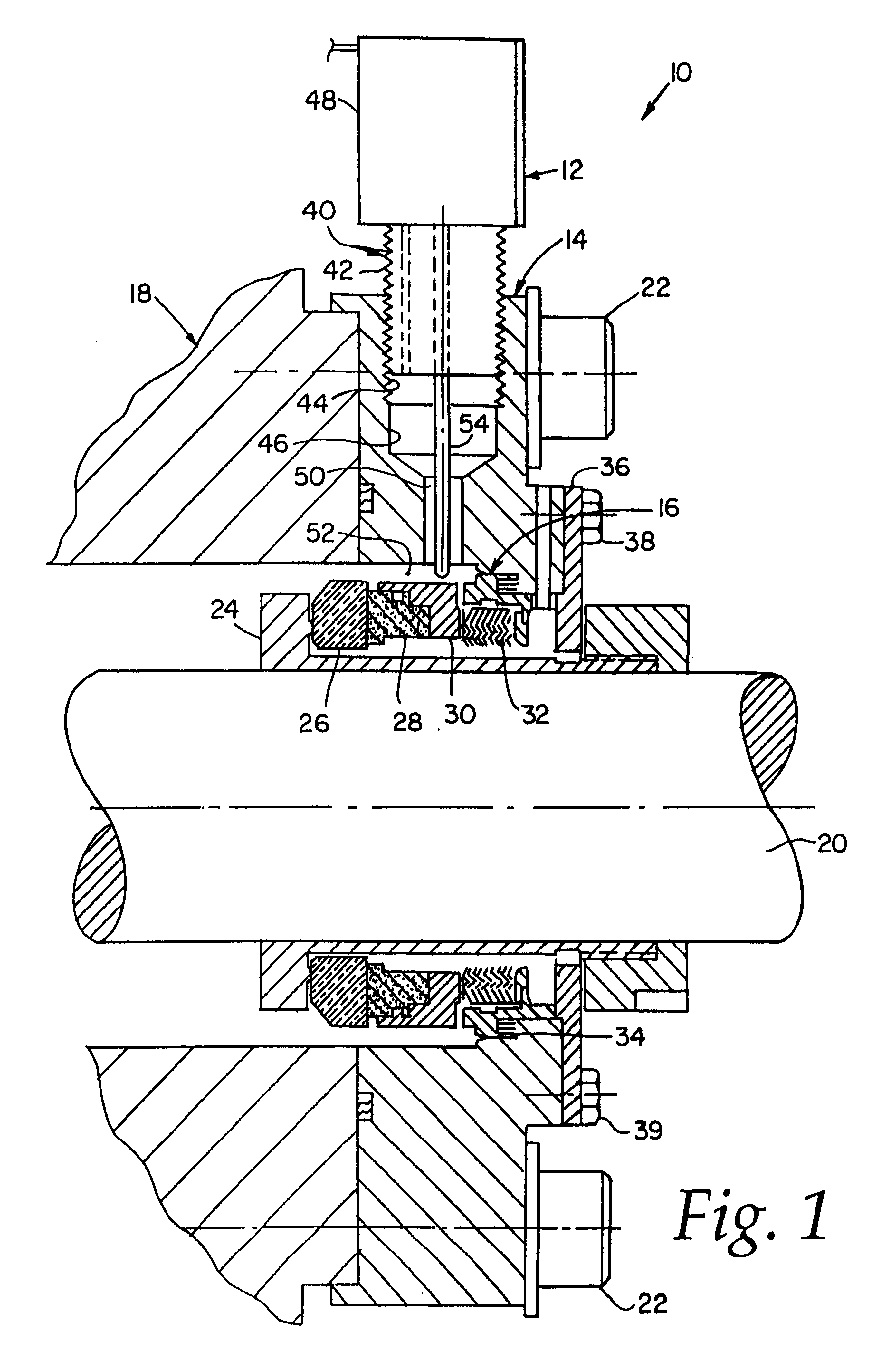

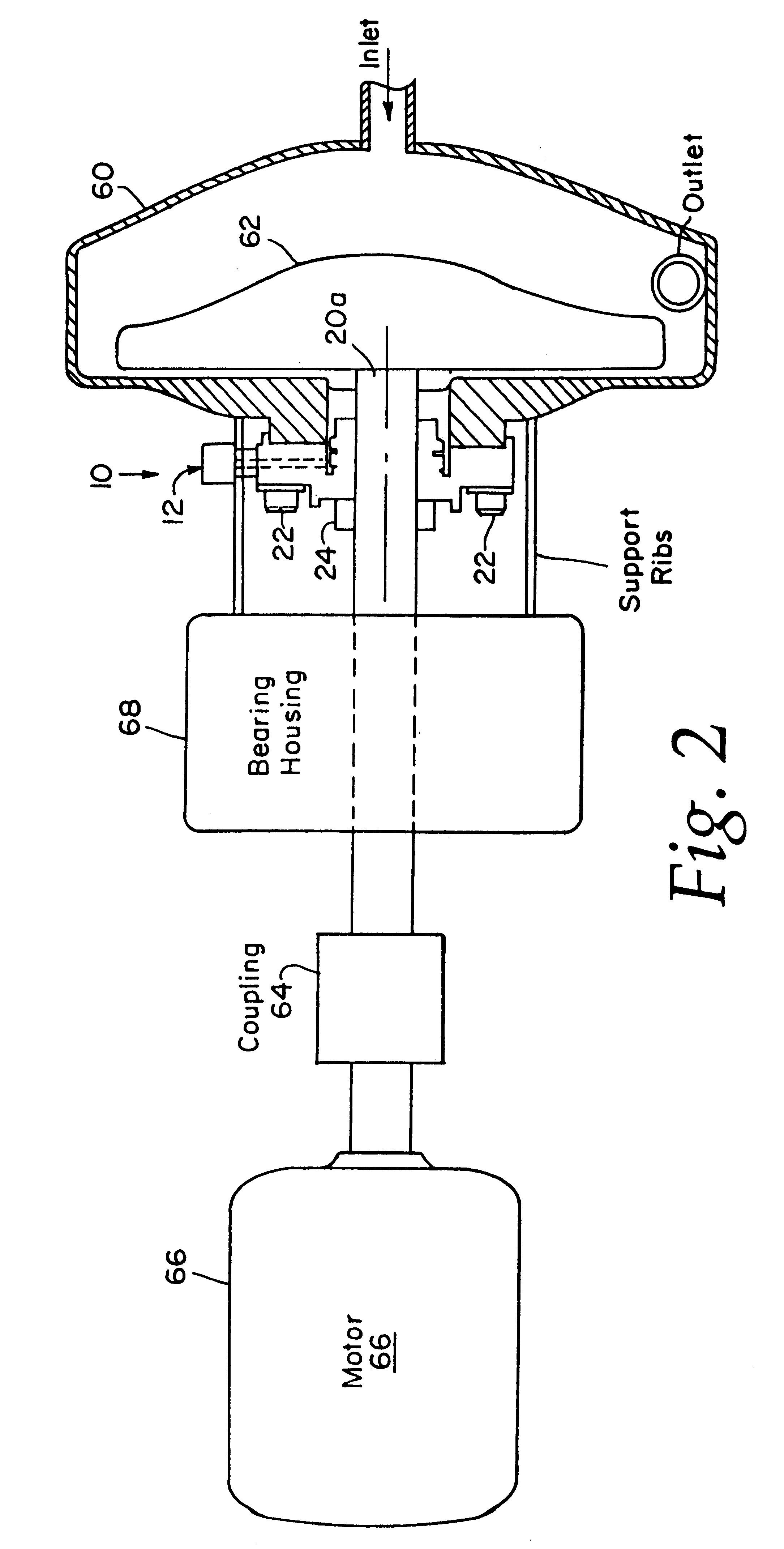

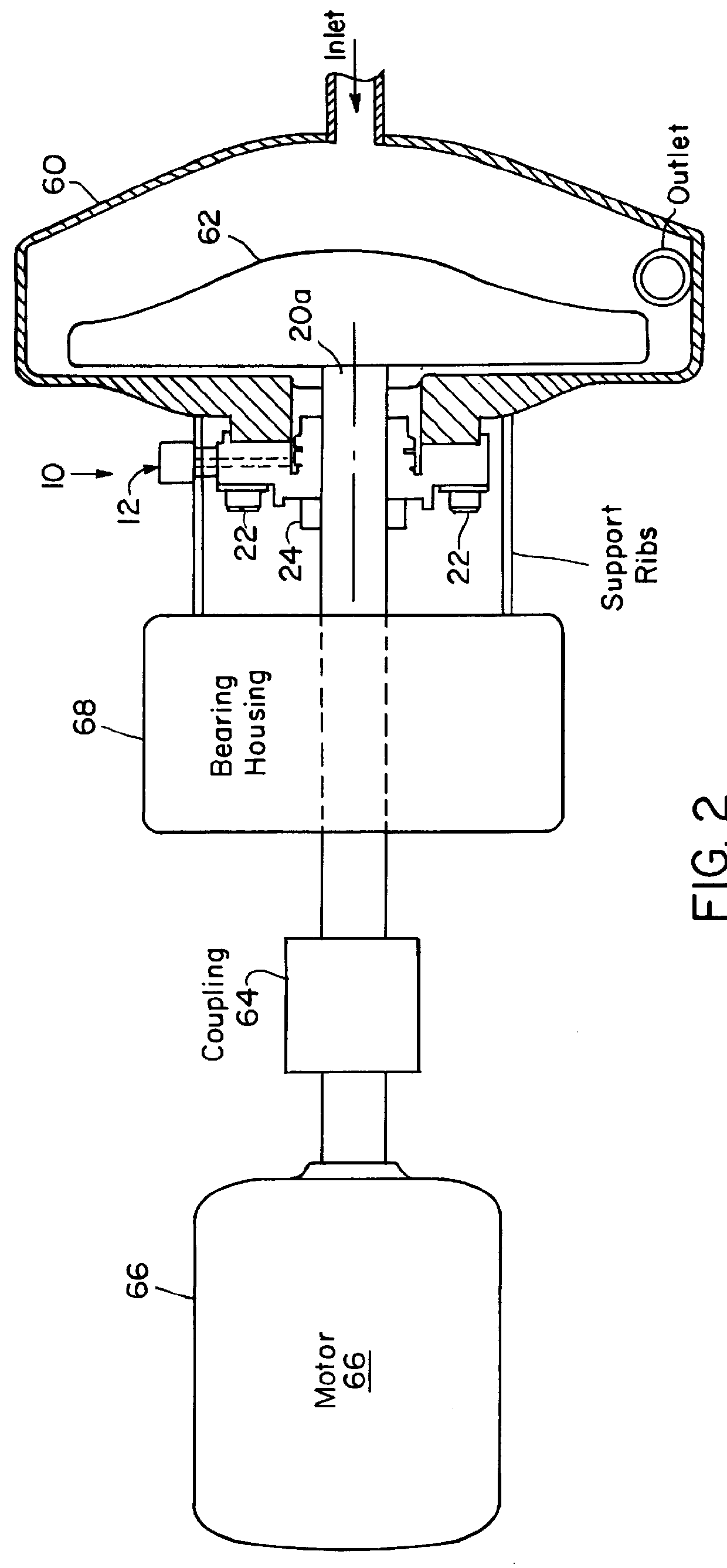

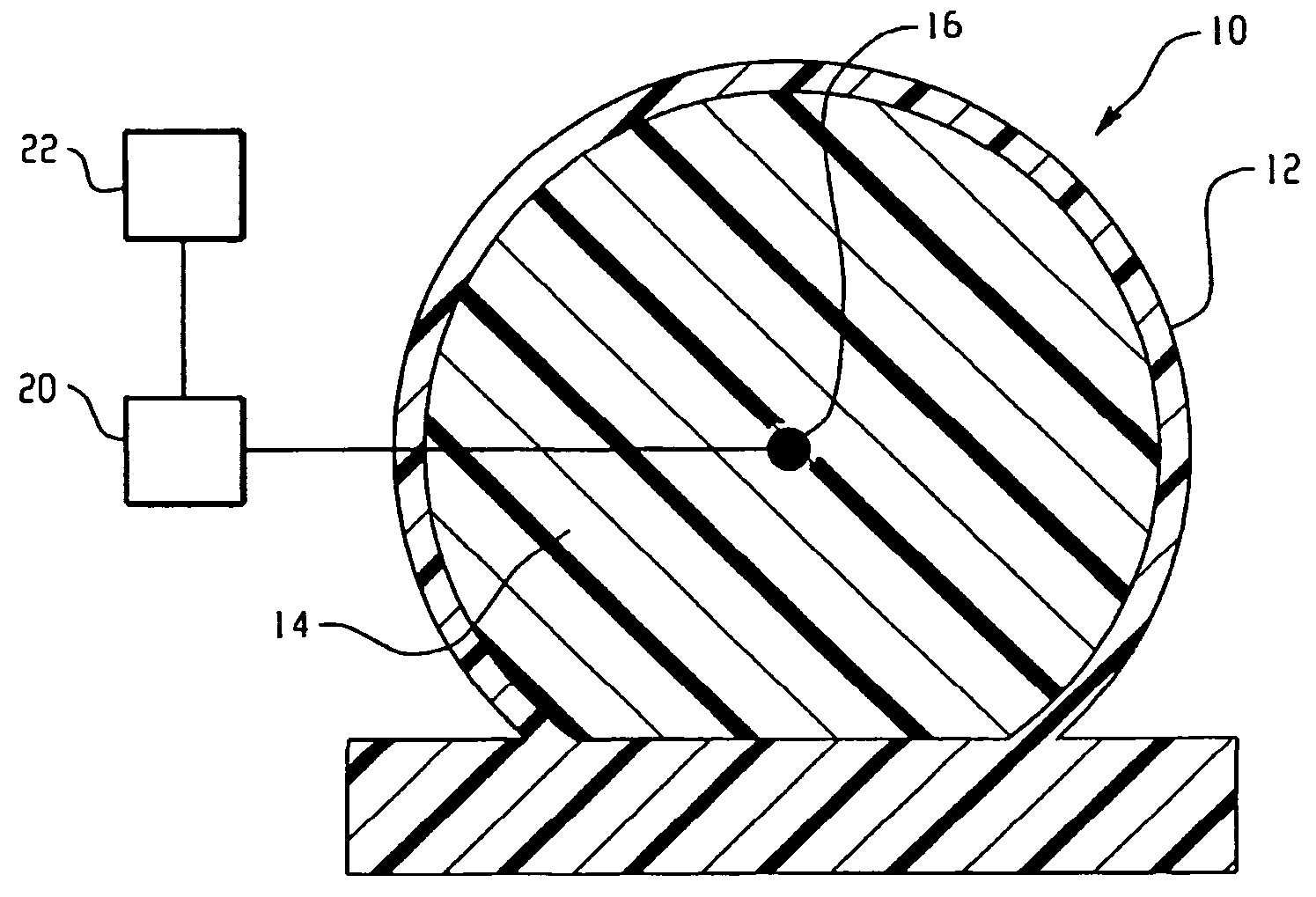

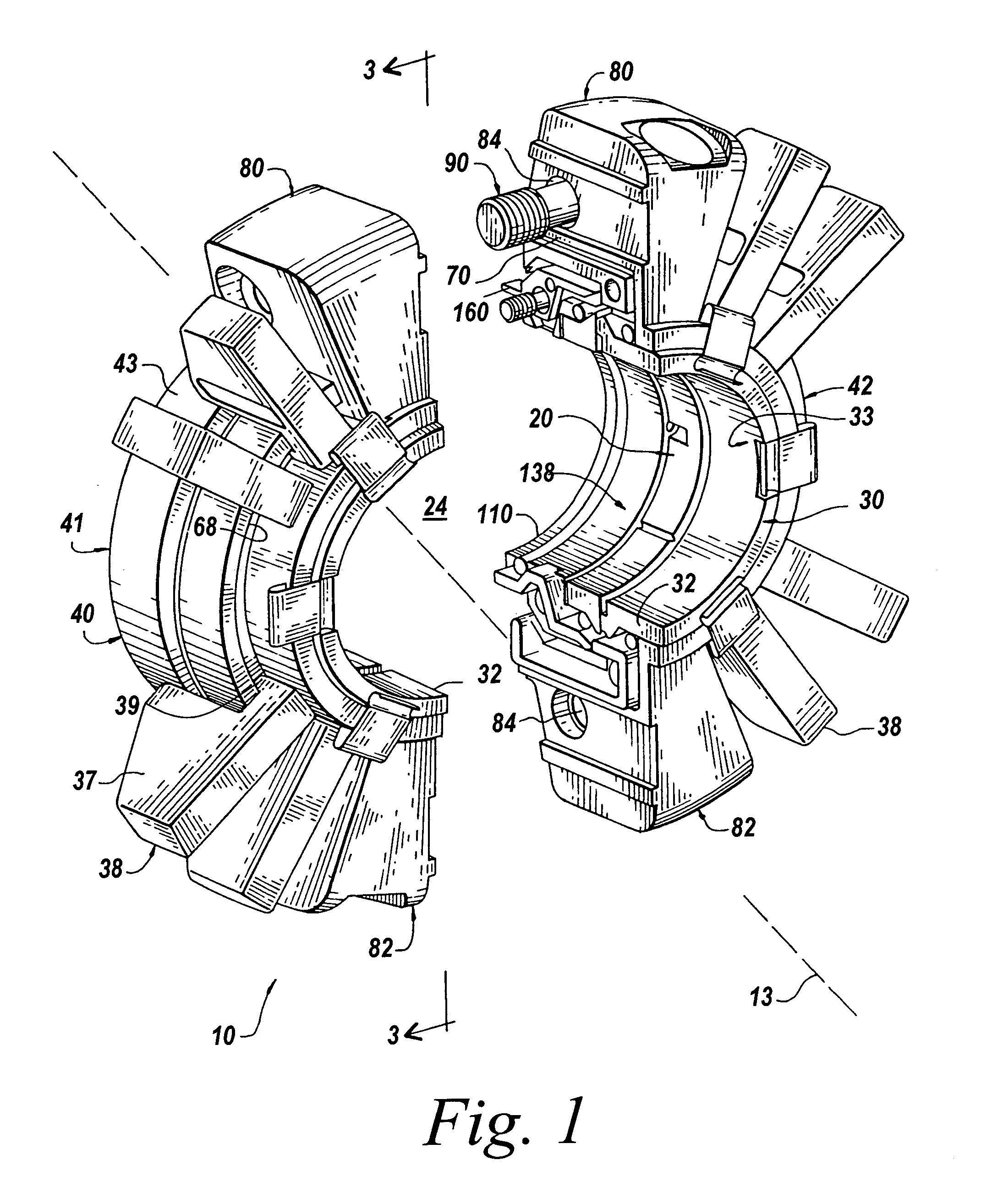

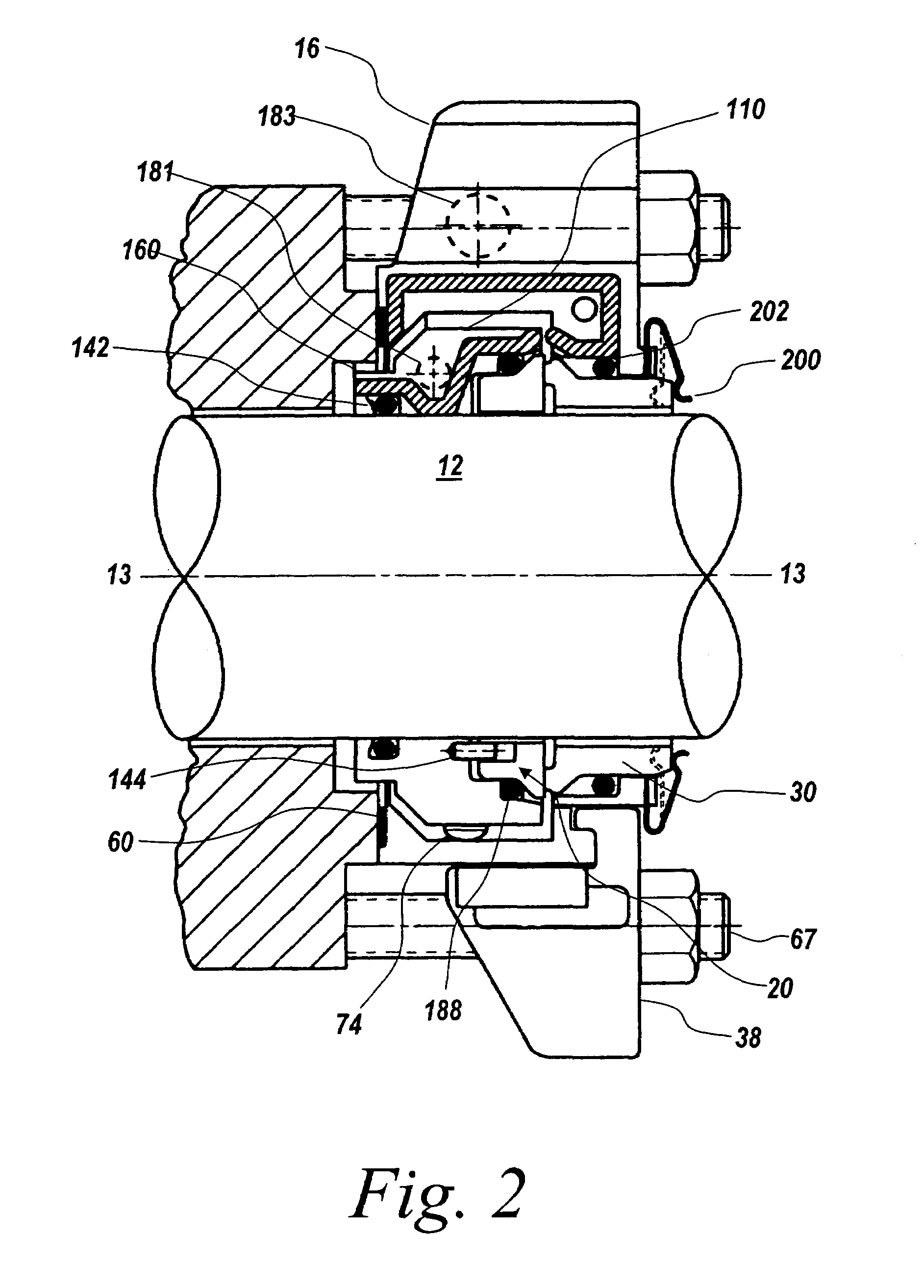

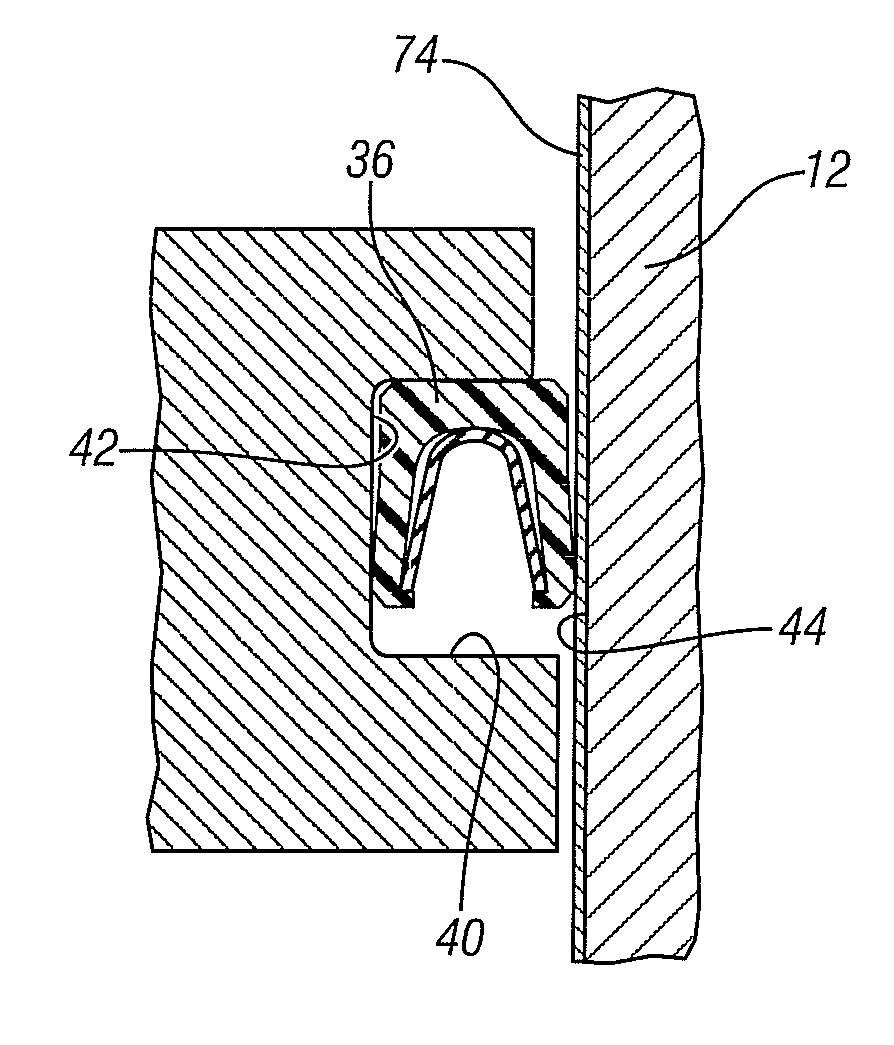

Self-centering rotor bearing assembly for submersible pump motors

The invention provides a submersible pumping system which includes a motor containing self-centering rotor bearing assemblies. Each rotor bearing assembly in accordance with the present invention includes a sleeve, a journal, and at least two seals. The journal is preferably disposed about the sleeve which is keyed to the power transmission shaft of the motor. The journal has a peripheral surface which is configured to have at least two circumferential support regions which are spaced apart from one another. Each of these circumferential support regions supports a corresponding seal. Each seal includes an interface member and an activating member. When in place in a rotor section of a submersible pump motor, the seals frictionally engage the inner surface of the stator and exert a centering force against the journal and thus against the bearing sleeve and the power transmission shaft. The seals also exert a force against the inner surface of the stator which prevents rotation of the journal when the power transmission shaft is rotating.

Owner:CAMCO INT

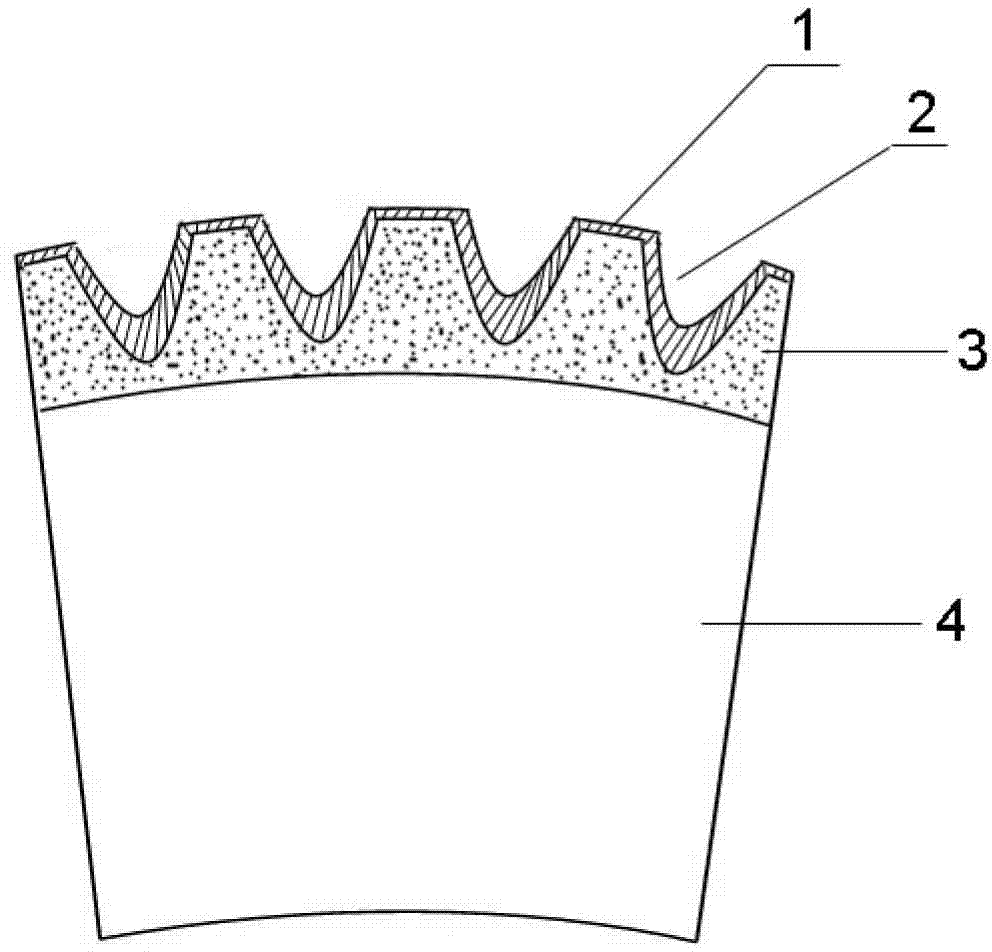

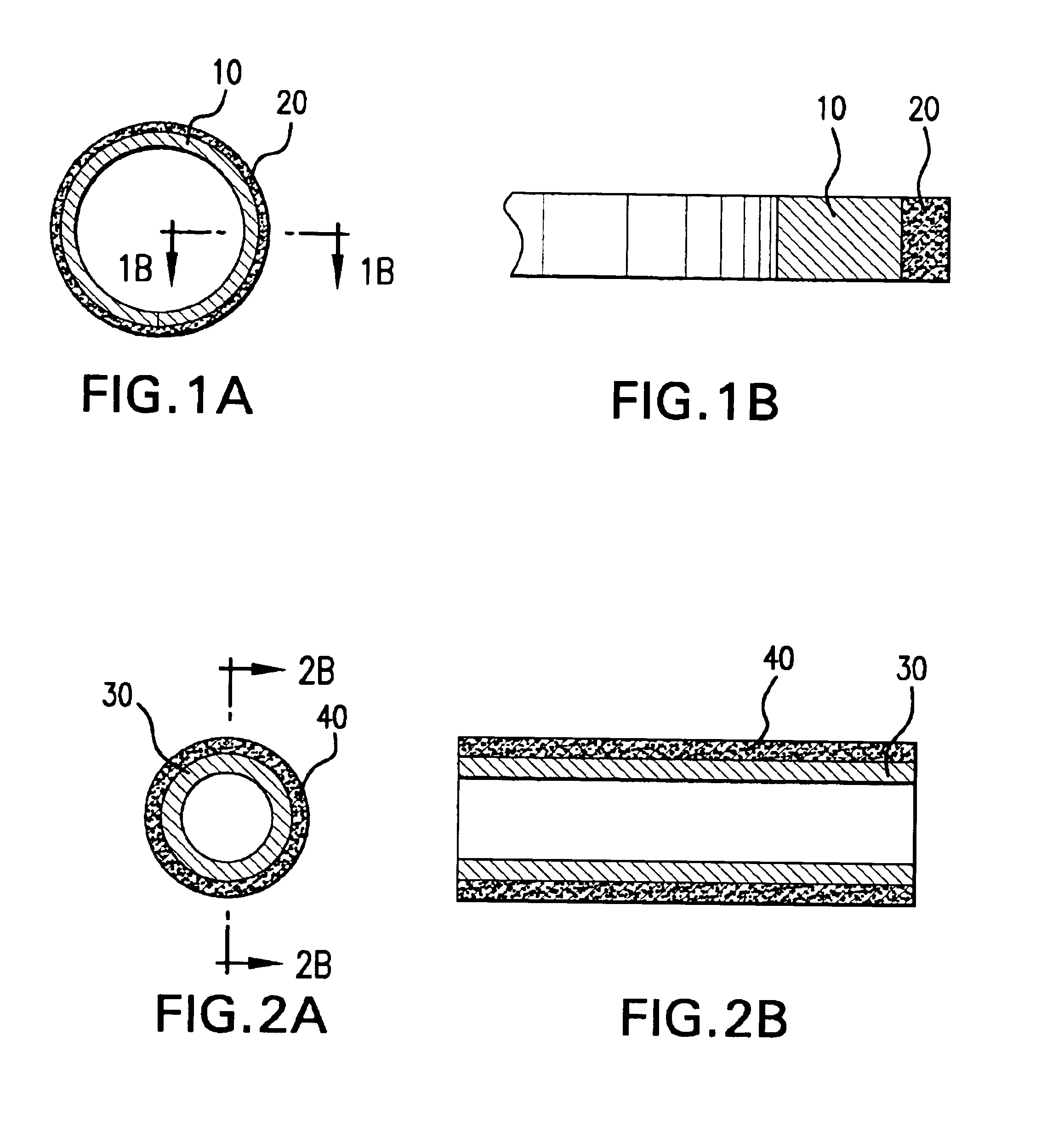

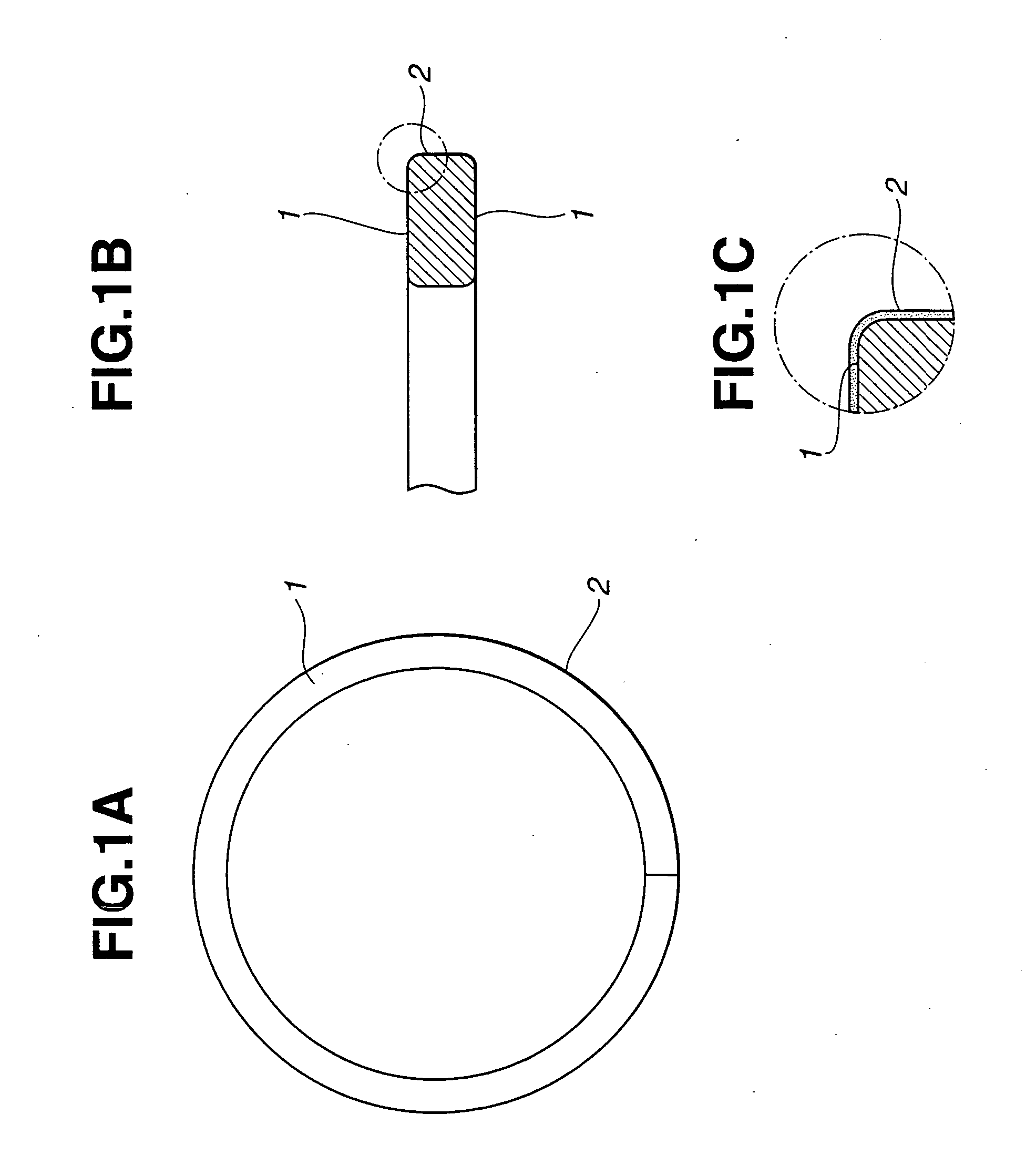

Thermally applied coating of mechanically alloyed powders for piston rings

InactiveUS6887585B2Improve the immunityTrend downMolten spray coatingPiston ringsCombustionWear resistant

The invention relates to a wear-resistant coating used for bearing surfaces and flanks of piston rings in internal combustion engines. The wear-resistant inventive coating is obtained by mechanically alloying powders which form a metallic matrix with hard material dispersoids and lubricant material dispersoids. The coating is then thermally applied to the workpieces, especially by means of high velocity oxygen fuel spraying (HVOF). The workpieces coated are bearing surfaces and parts of flanks pertaining to piston rings in internal combustion engines.

Owner:FEDERAL MOGUL BURSCHEID

Sliding member and manufacturing method thereof

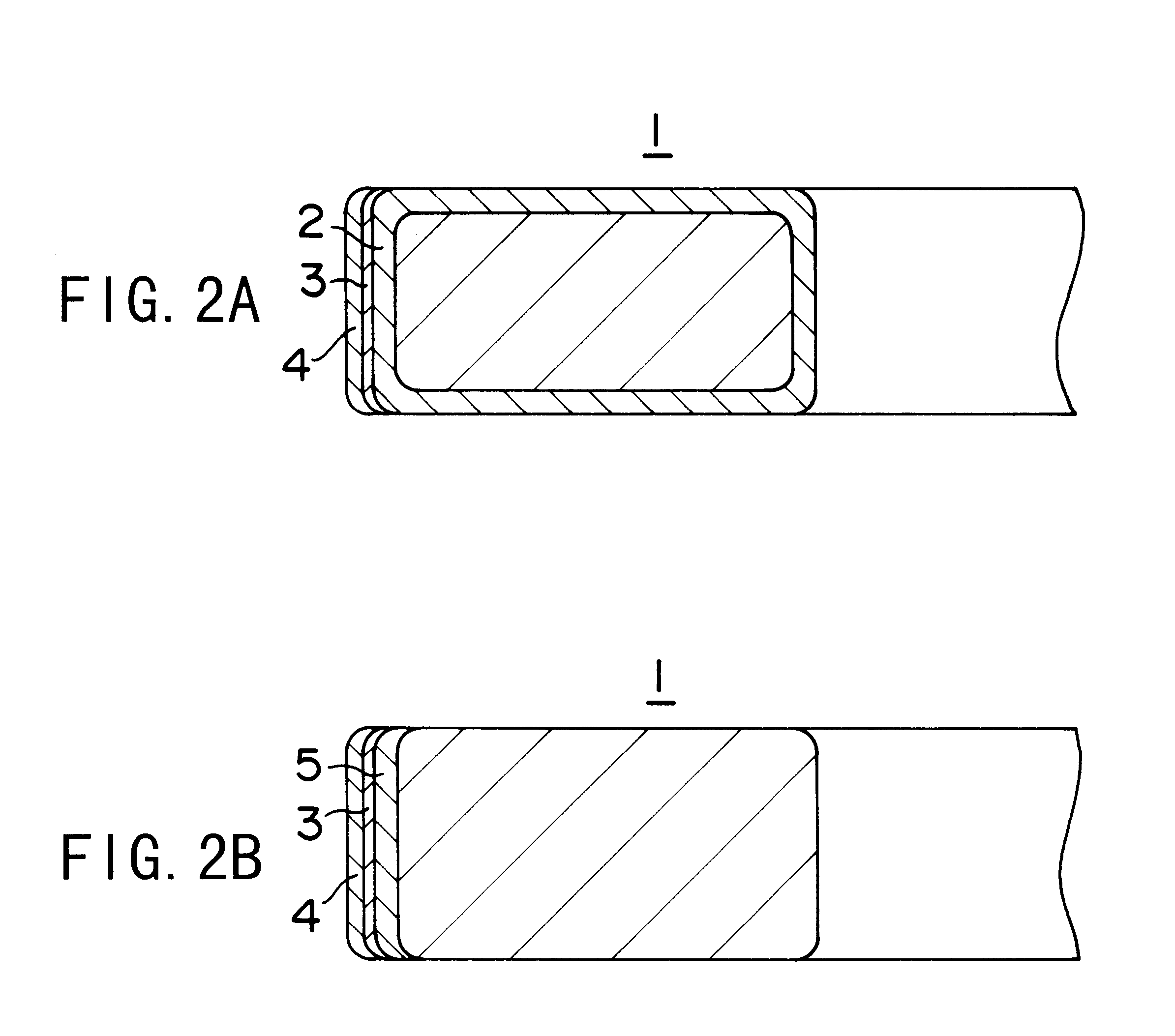

InactiveUS6279913B1Improve the immunityHigh bonding strengthPiston ringsBraking action transmissionCarbon filmDiamond-like carbon

A piston ring is formed over the entire surface with a gas nitrided layer. A diamond-like carbon film is formed in a thickness of 0.5 to 30 micrometers over the gas nitrided layer at the upper and lower surfaces. The diamond-like carbon film has a surface structure in which diamond-like carbon has been deposited in nodular shapes in sizes of 0.5 to 5 micrometers. The diamond-like carbon is configured with any one of an amorphous carbon structure, an amorphous carbon structure having partly a diamond structure, or an amorphous carbon structure having partly a graphite structure.

Owner:TEIKOKU PISTON RING CO LTD

Triple lip fork seal

InactiveUS20060103075A1Separation pointExtended service lifeEngine sealsPiston ringsReciprocating motionLip seal

A triple lip seal for reciprocating members, and especially for an inner cylindrical tube connected to a vehicle wheel and an off-road motorcycle or bicycle. The seal includes an oil side beam generally parallel to the axis of the reciprocating members and having at least two sealing lips for engaging the inner cylindrical tube and wherein the forces applied to the seal are balanced between the two lips to resist flattening of the sealing lips against the shaft and to enhance the service life of the seal. The seal also includes an air side beam having a third sealing lip engaging the inner cylindrical tube.

Owner:CLARK SEALS

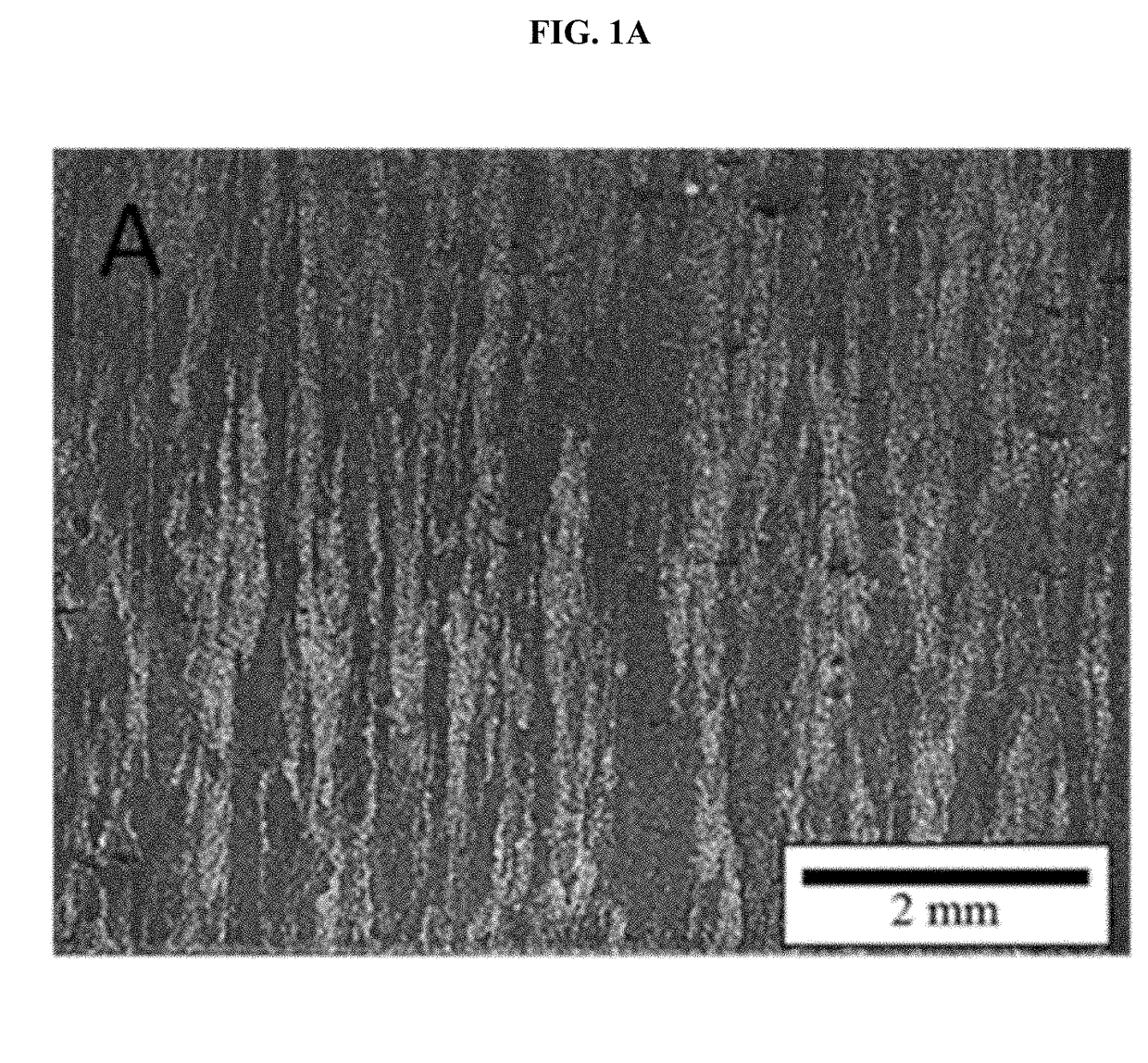

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

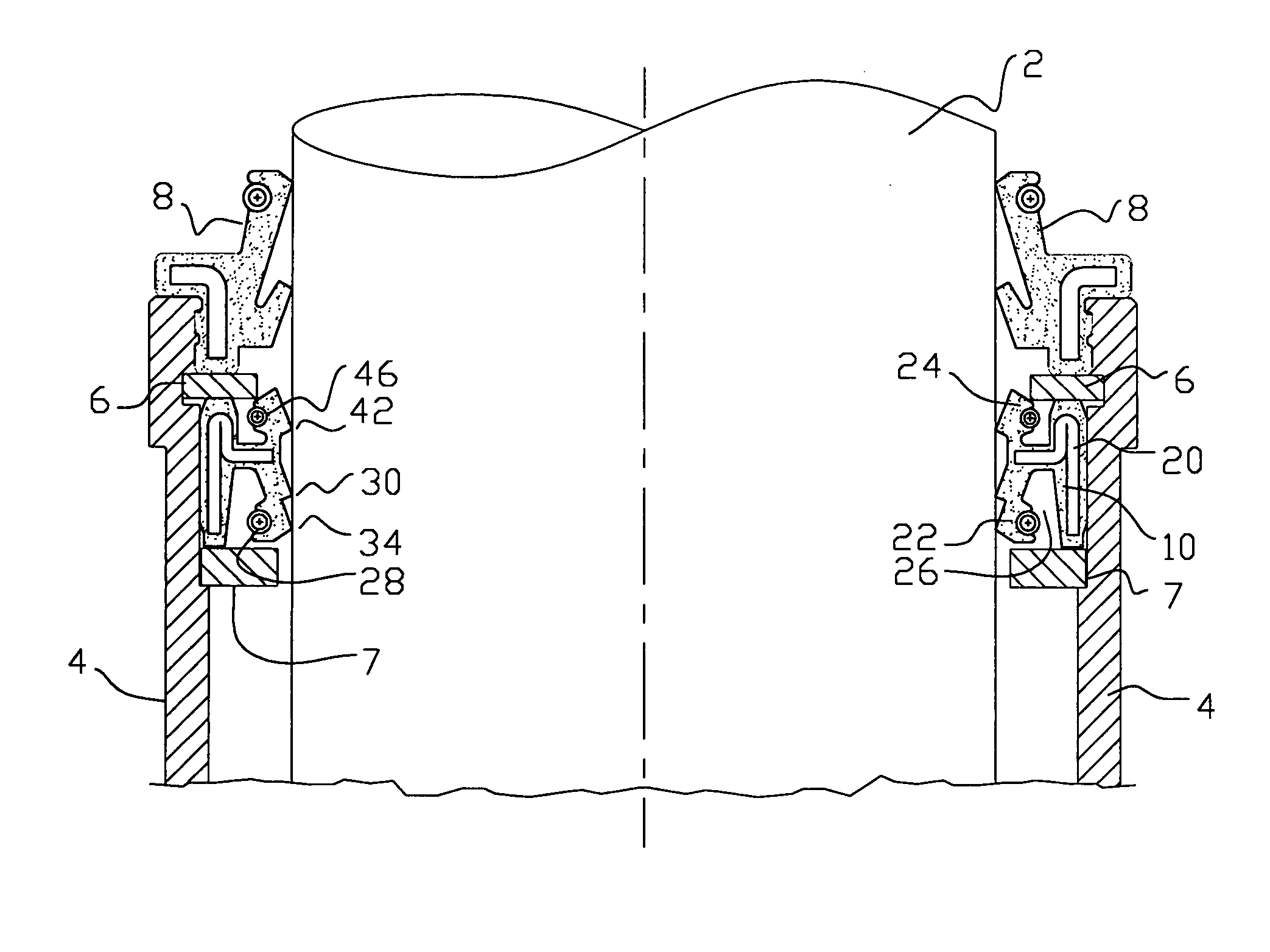

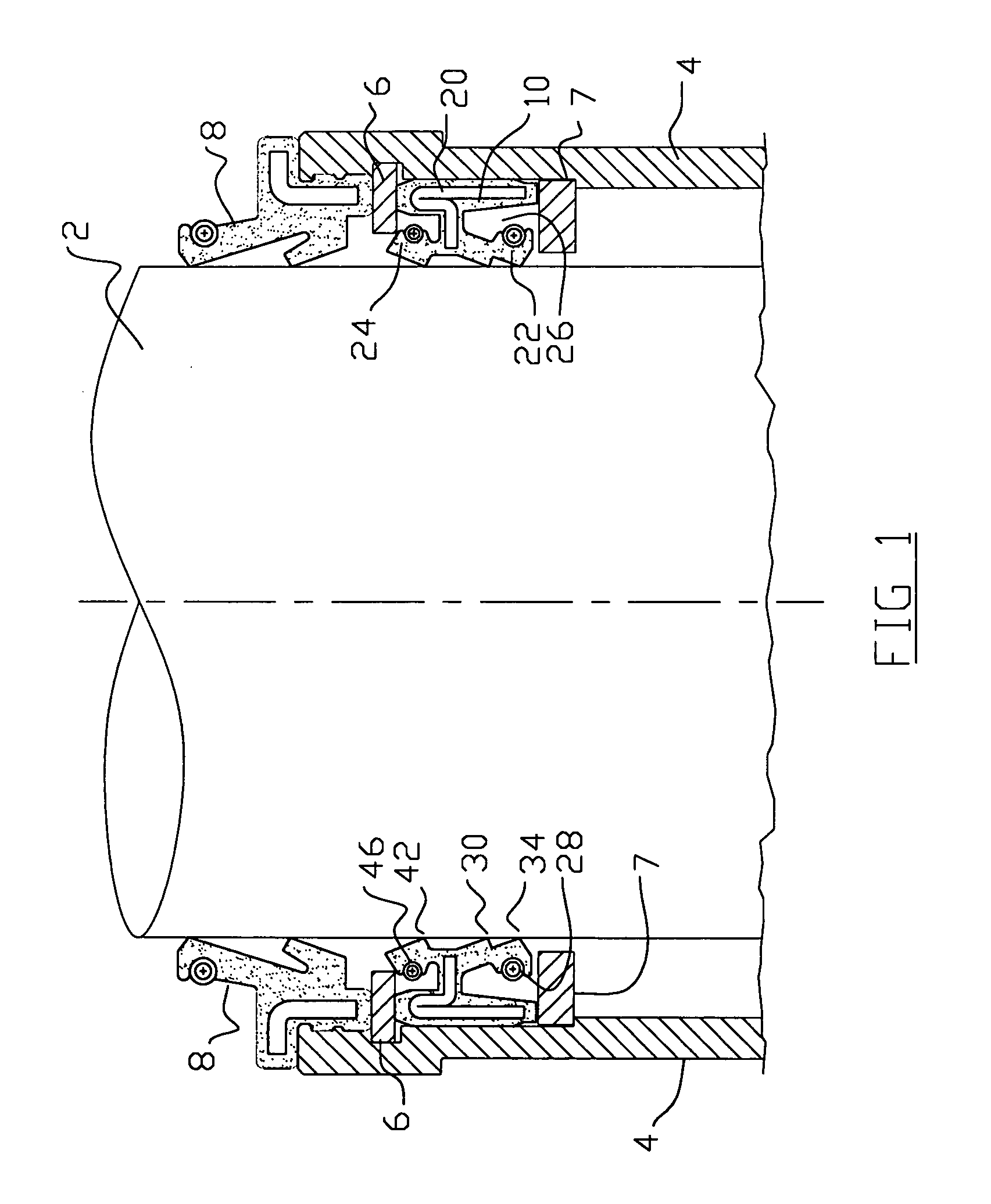

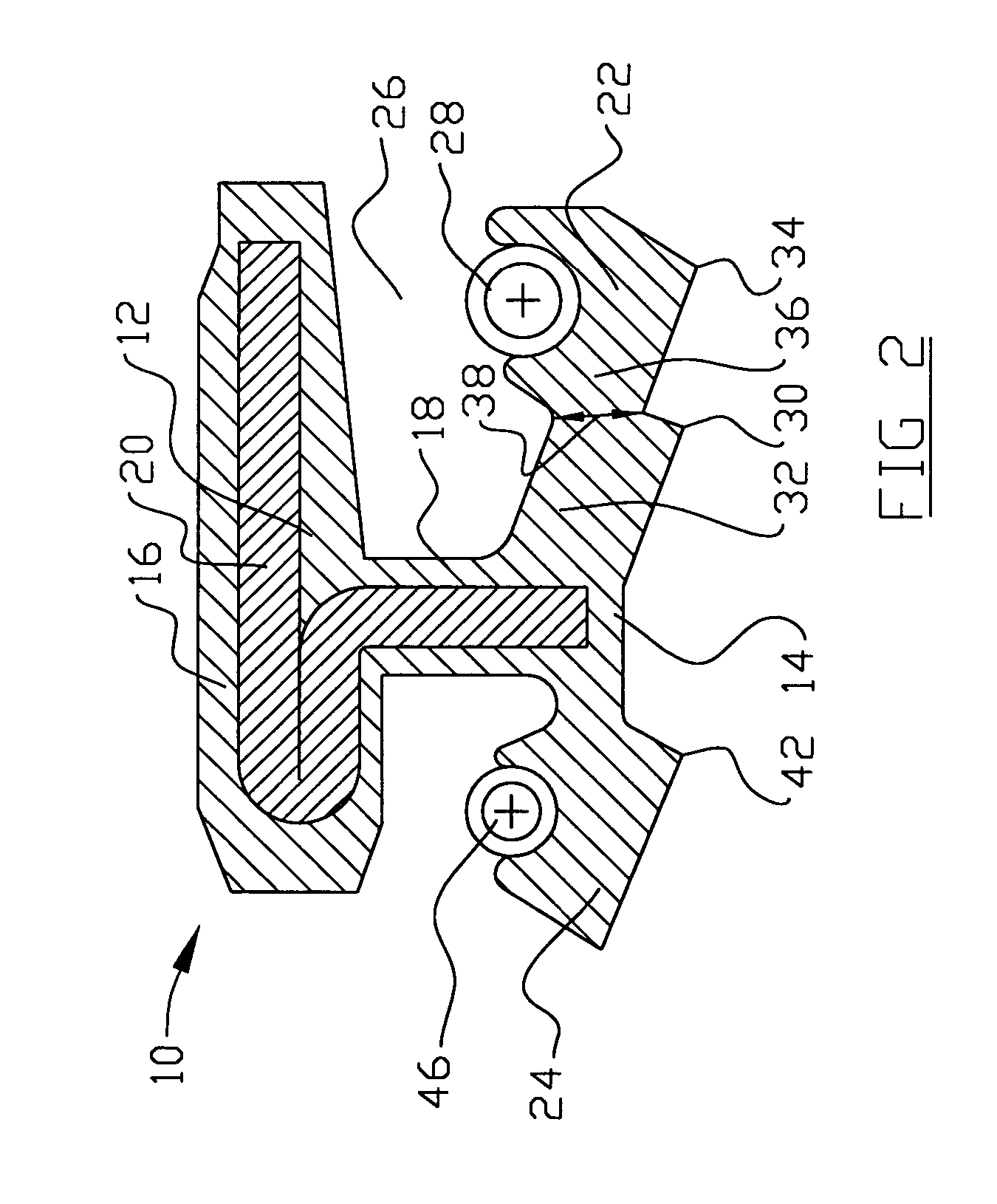

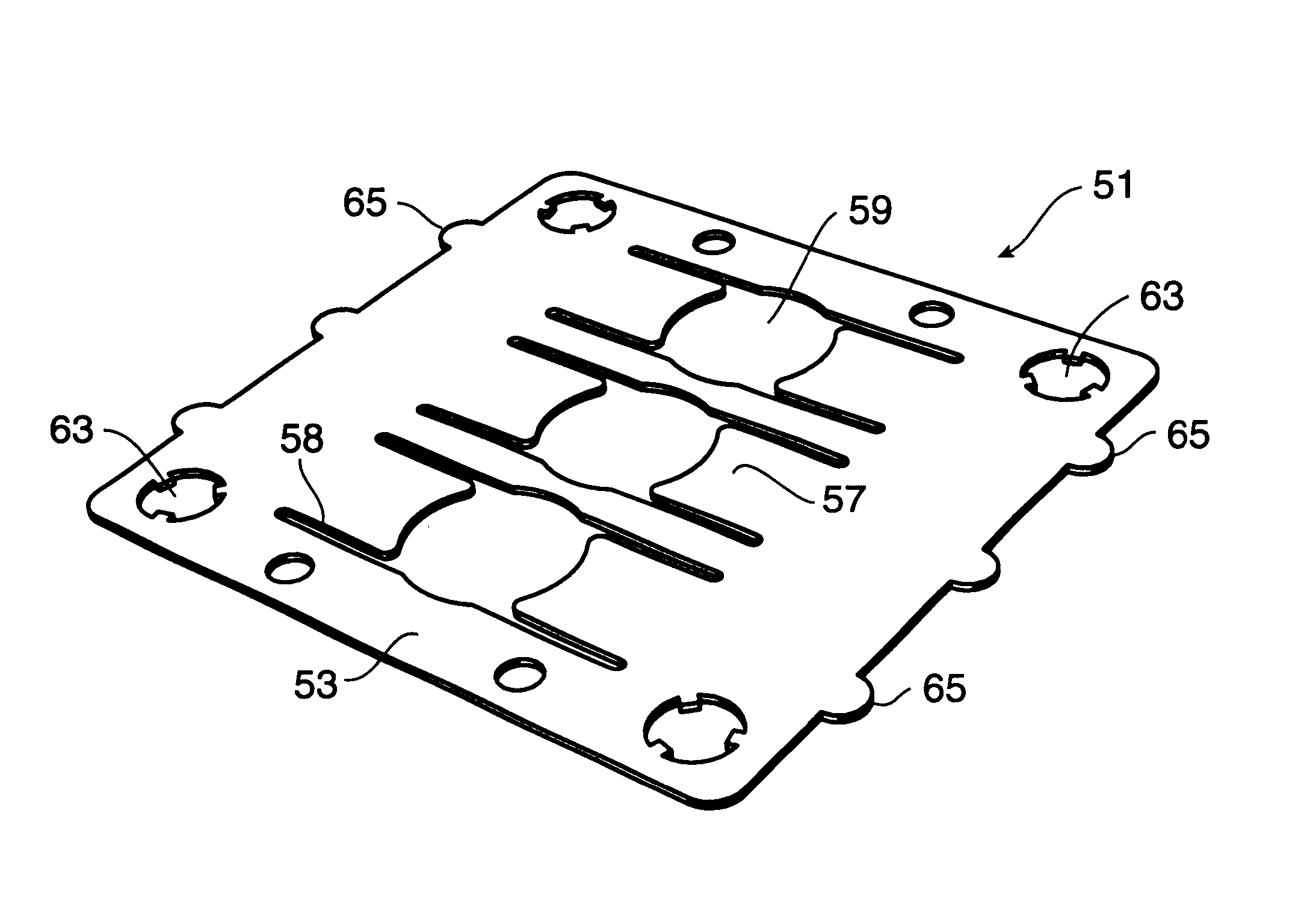

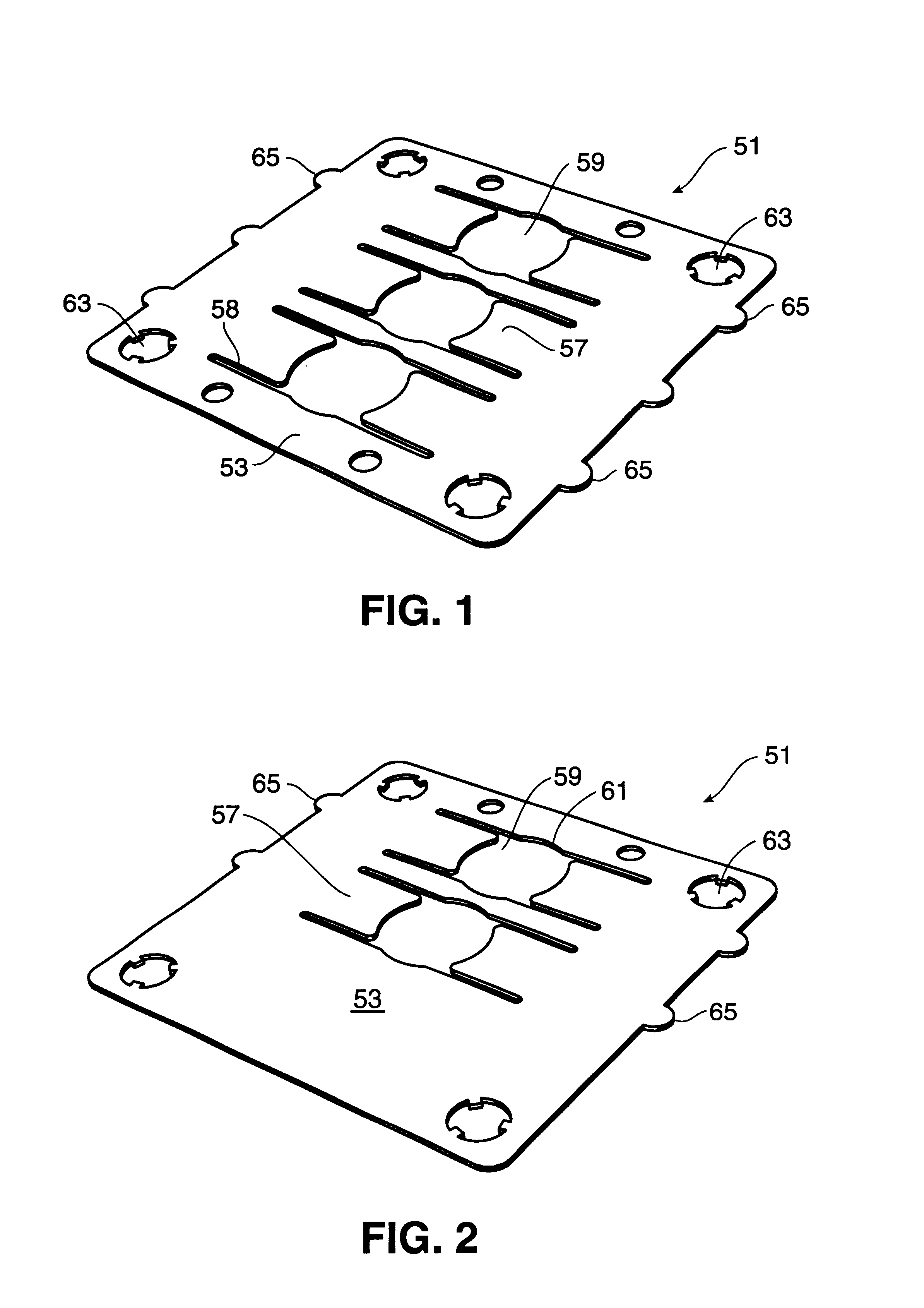

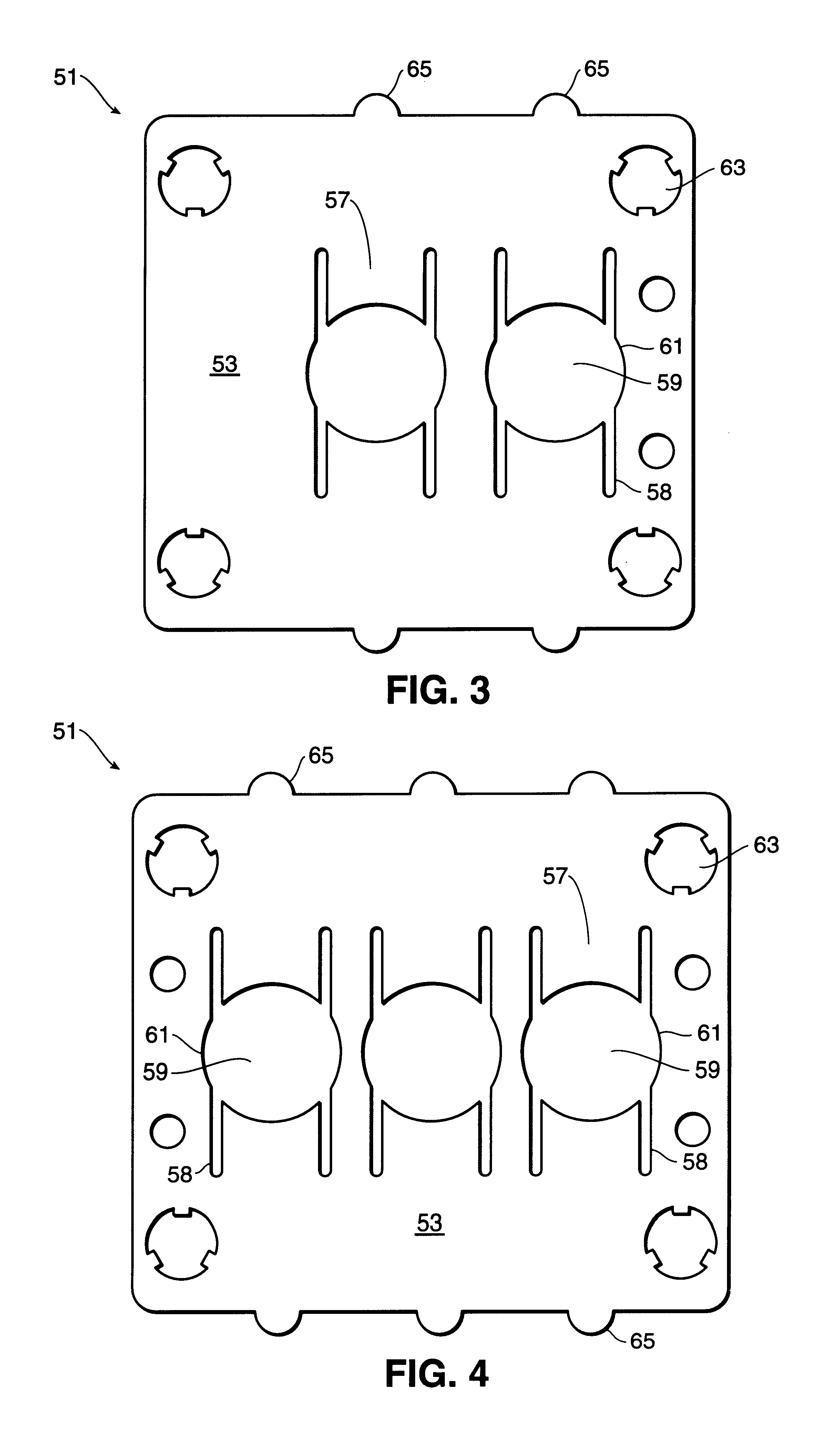

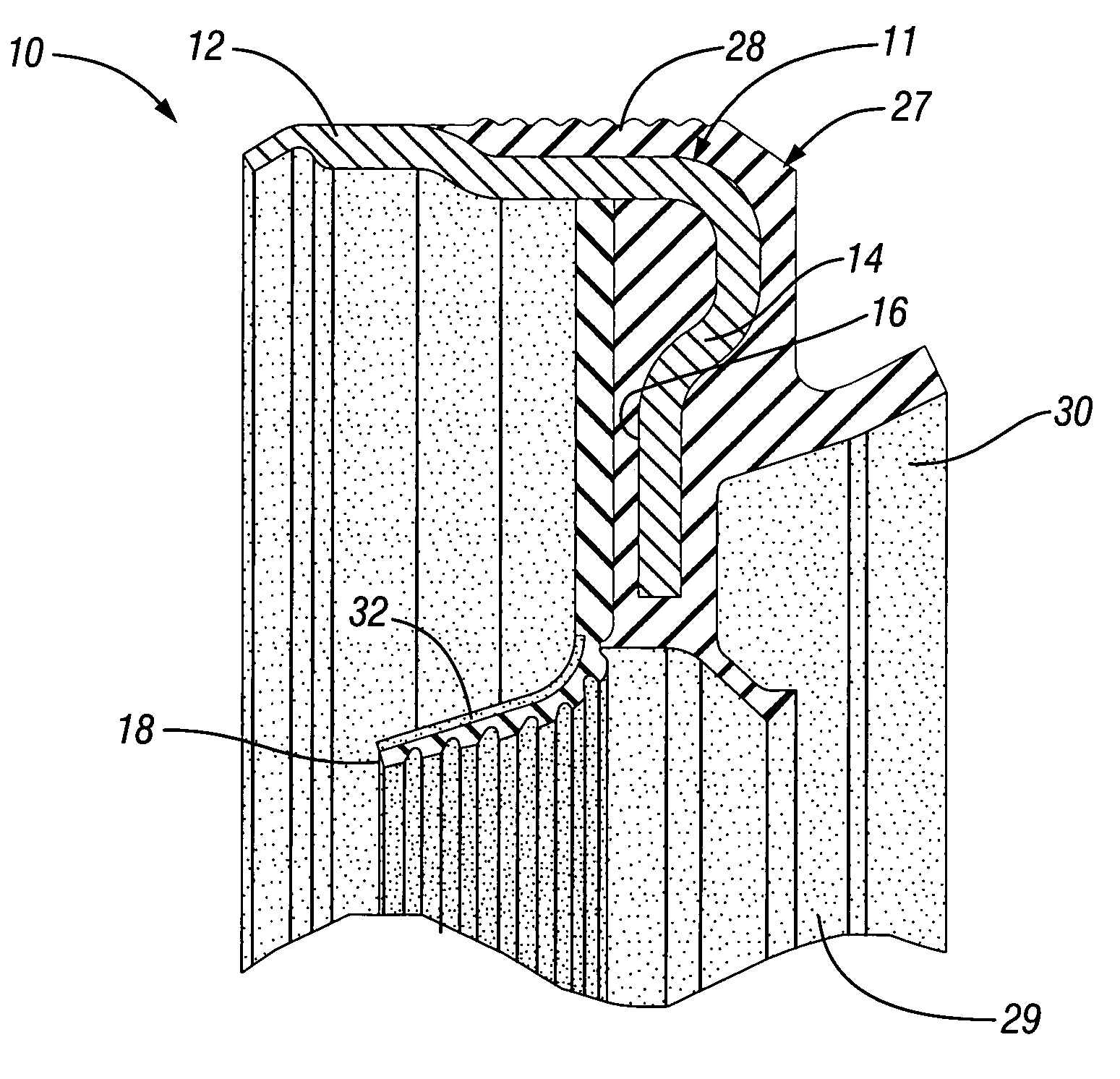

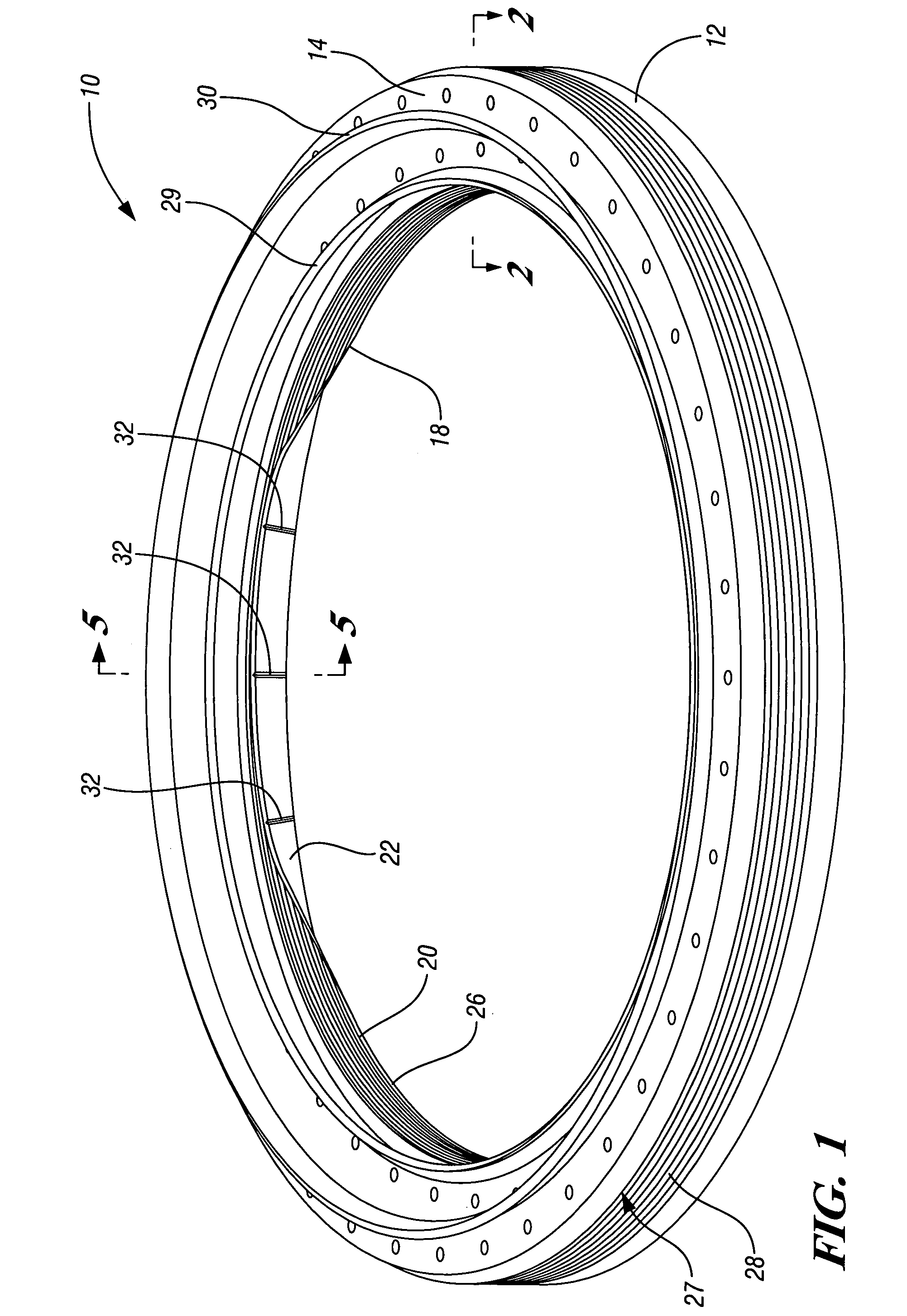

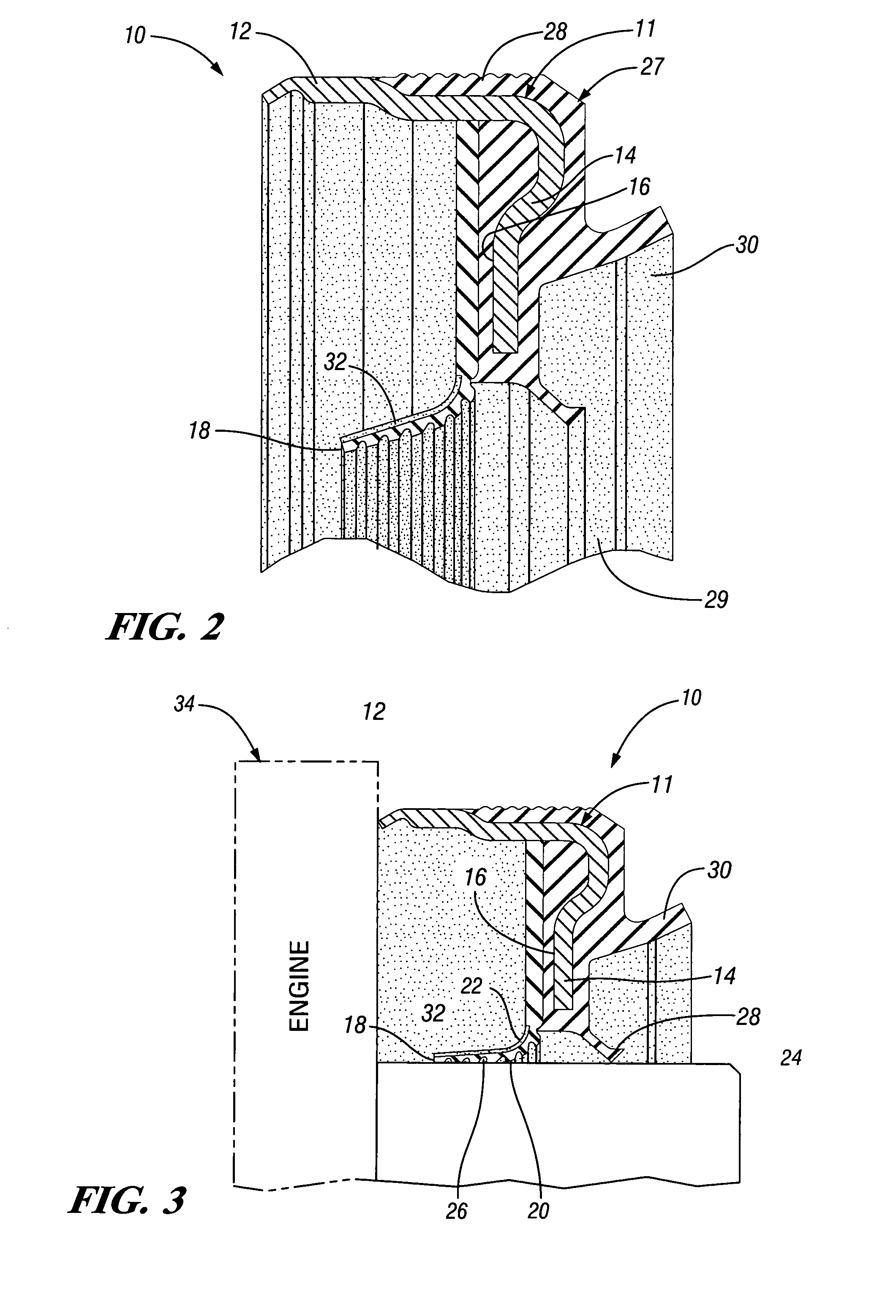

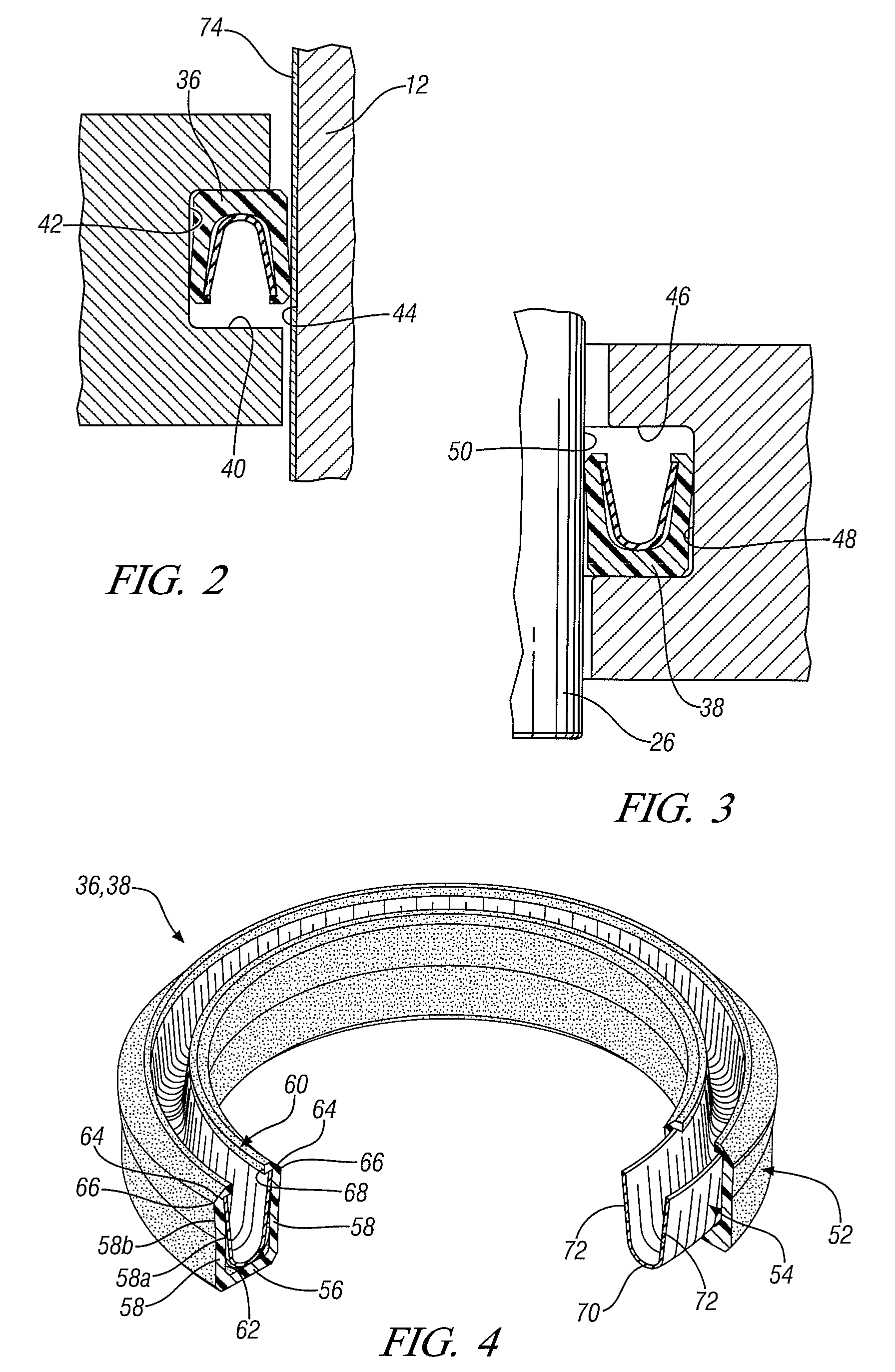

Keeper for positioning ring seals

An improved keeper for positioning ring seals is provided. The keeper includes a substantially planar sheet defining upper and lower surfaces. Projecting through the planar sheet are one or more holes configured for affixing corresponding one or more ring seals. The keeper further includes one or more nodes which extend outwardly from the planar sheet beyond the dimensions of the mating surfaces between which a sealed joint is obtained. The one or more nodes identify the position and number of holes constructed for receiving corresponding ring seals.

Owner:MICROFLEX TECH INC

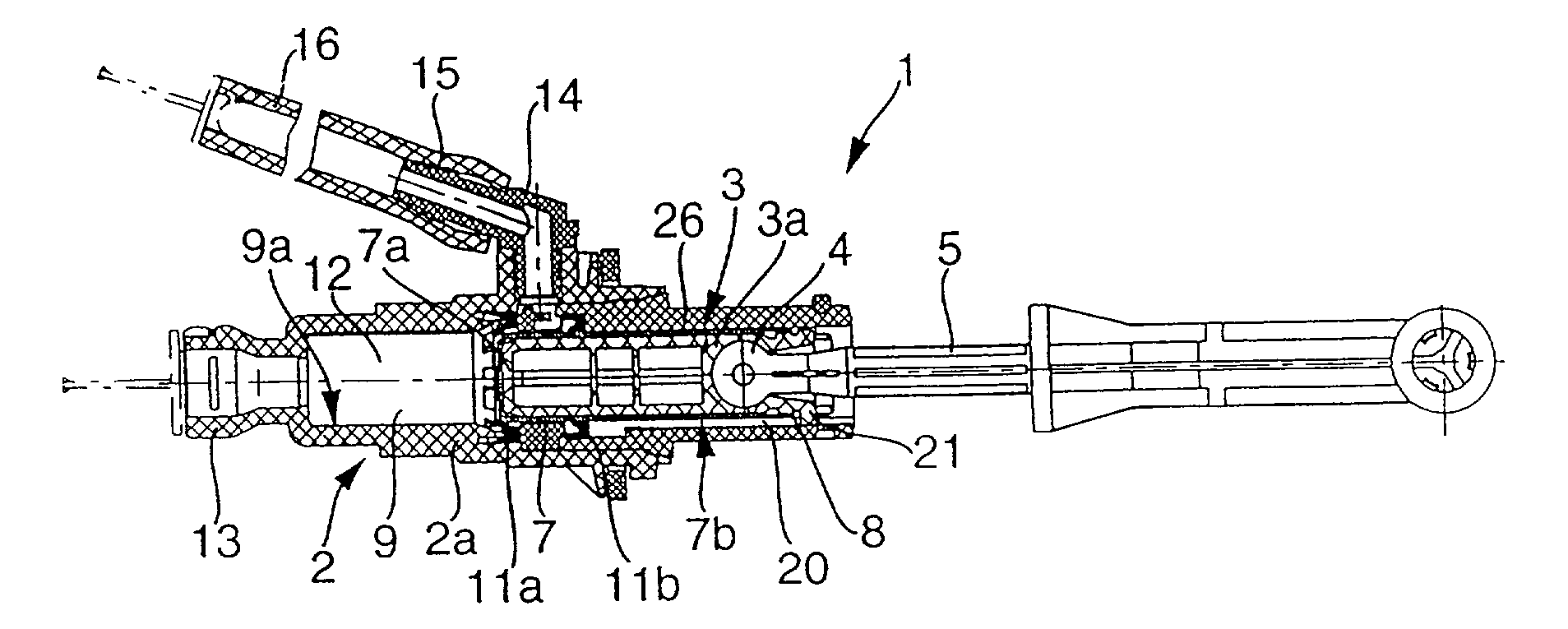

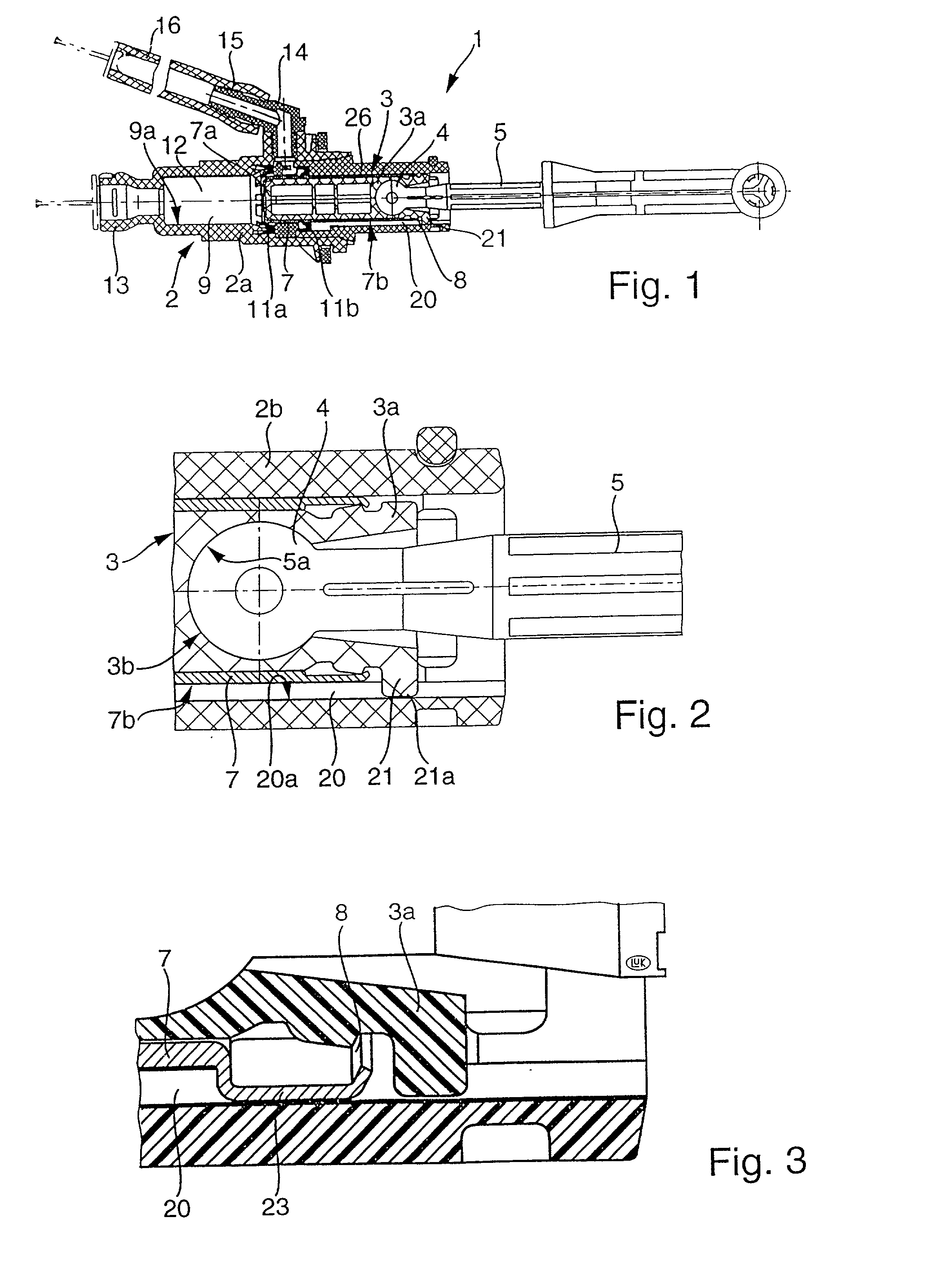

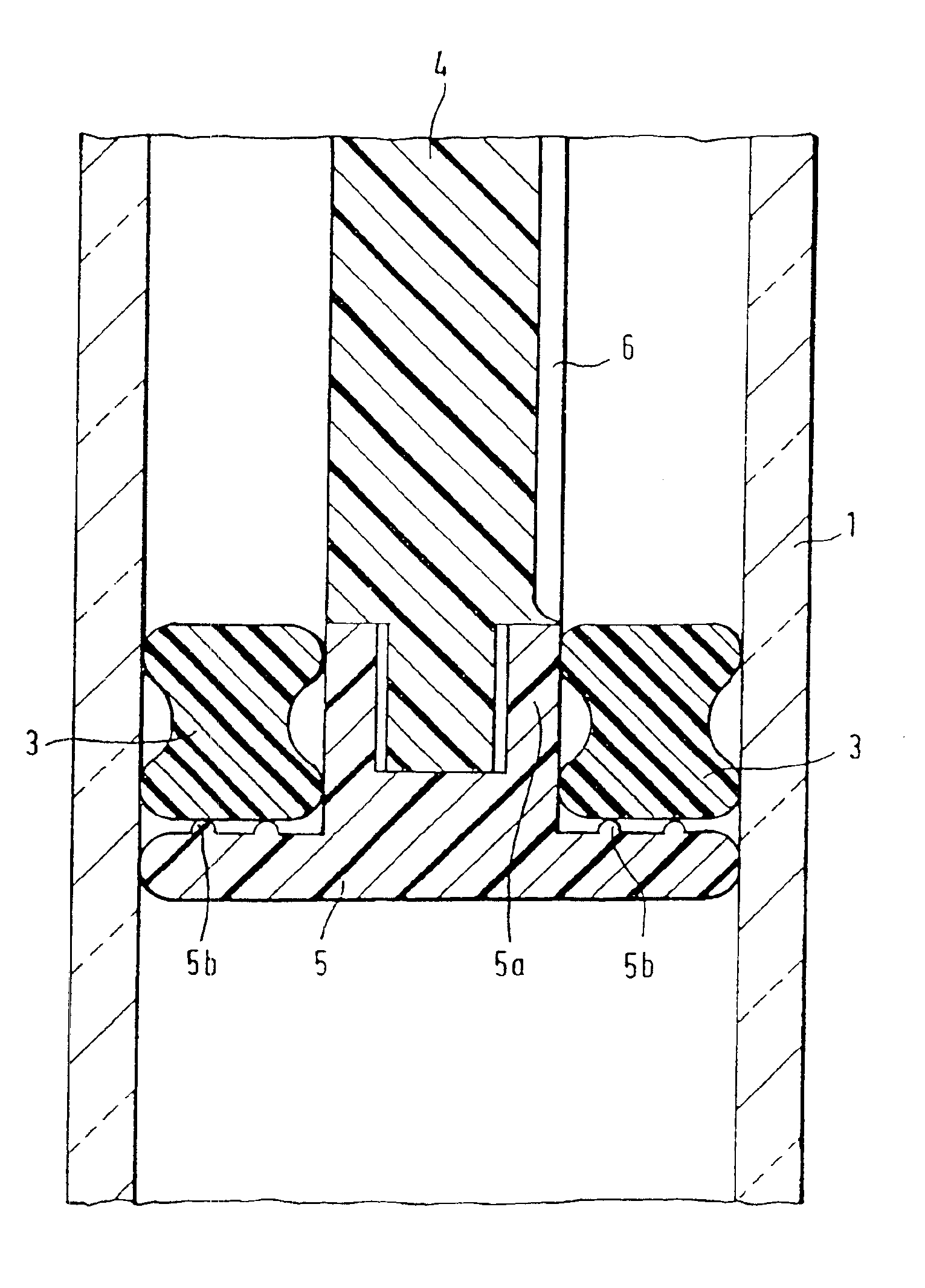

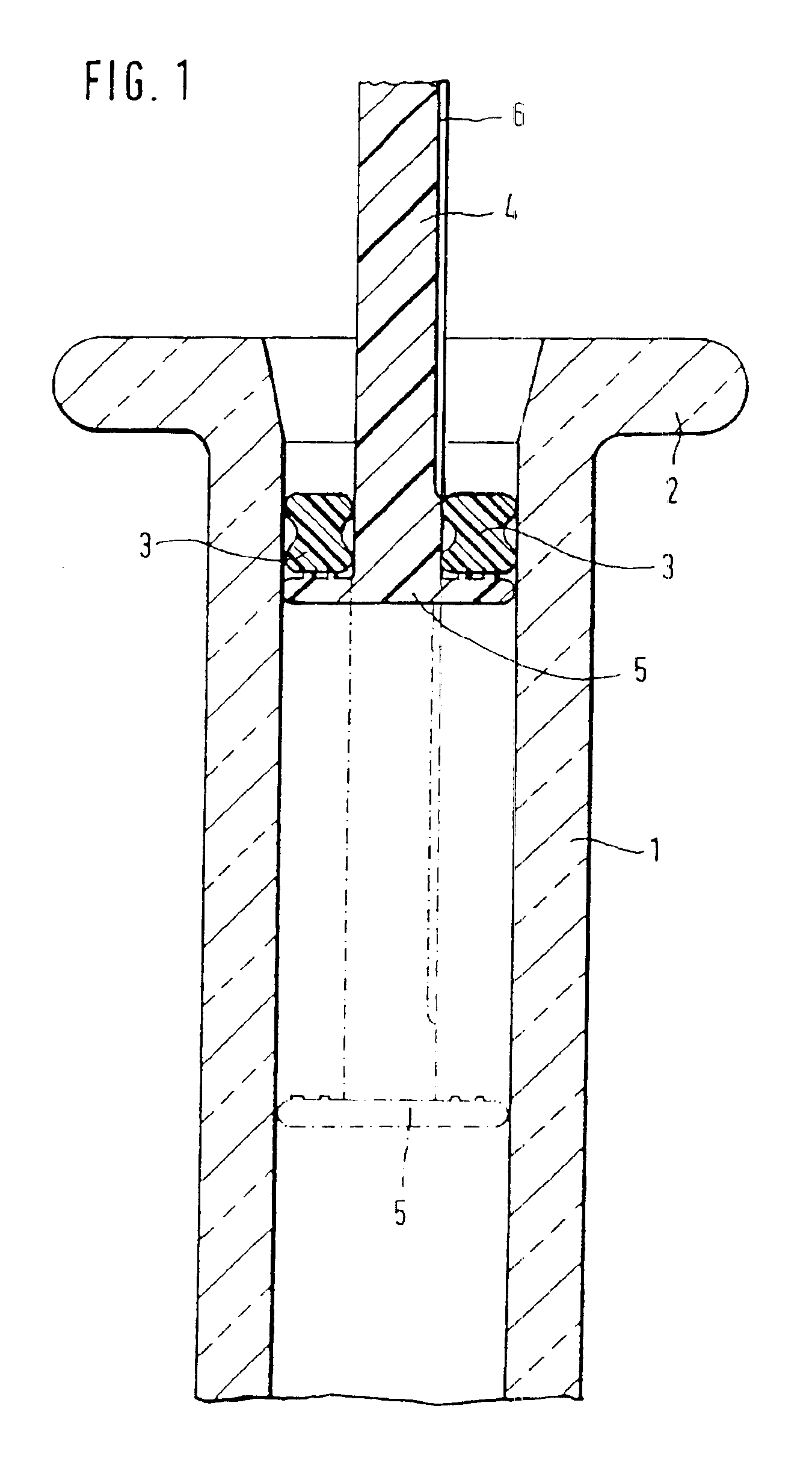

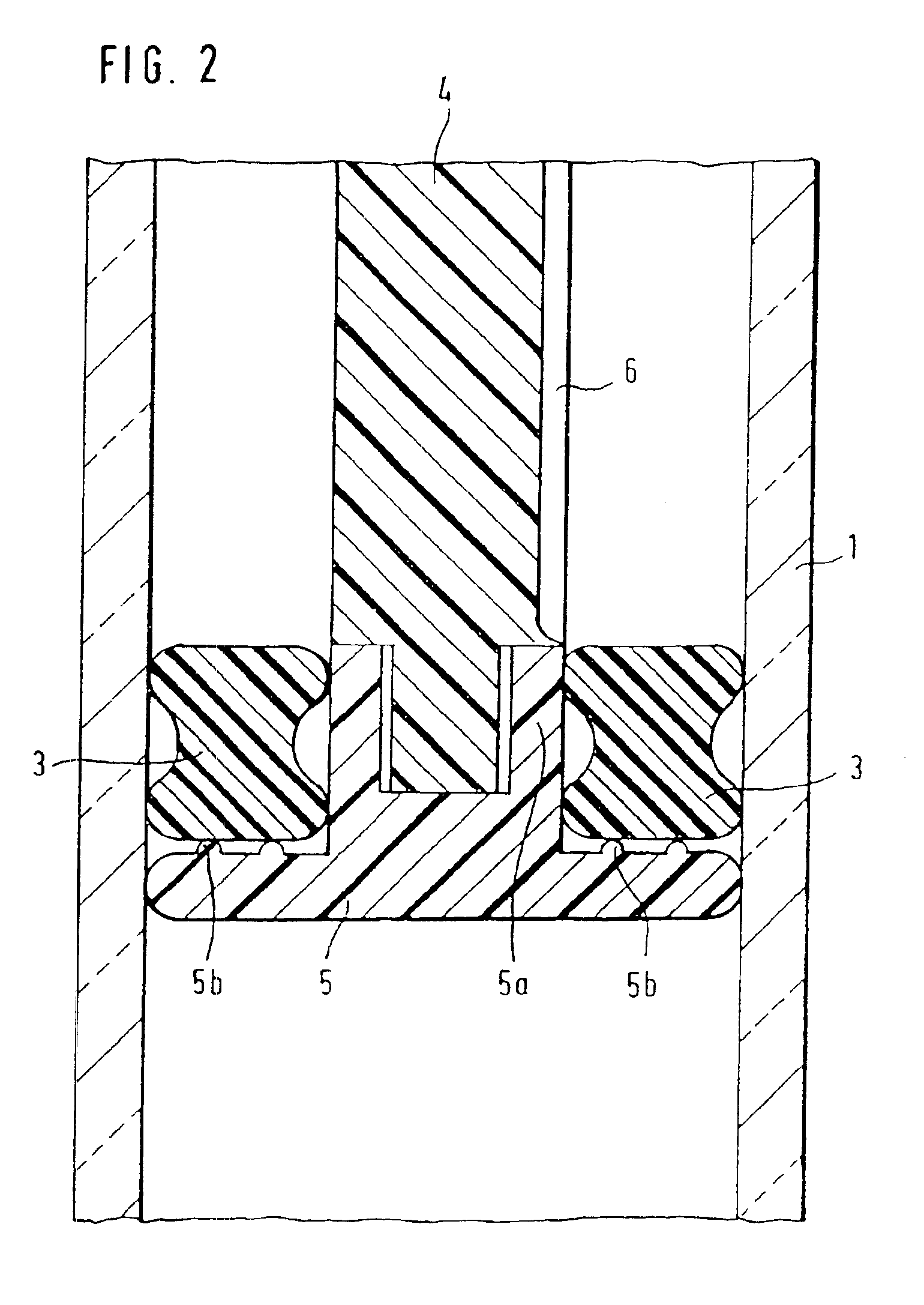

Master cylinder for use in power trains of motor vehicles

InactiveUS20020116924A1Satisfactory operationAvoid spreadingPiston ringsRotary clutchesMaster cylinderControl theory

A master cylinder for use in the power train of a motor vehicle to actuate the brakes or the friction clutch is designed to avoid the generation of screeching noise and / or the transmission of stray movements to the piston rod in response to shifting of the piston relative to the housing and relative to the sealing element(s) between the piston and the housing. This can be accomplished by causing the piston to turn relative to the housing and the sealing element(s) during axial movement in the housing and / or by installing one or more dampers between the piston and the housing and / or between the piston and the piston rod. The dampers can constitute separately produced parts and / or specially configured and / or finished surfaces provided on the piston and contacting the housing and / or the sealing element(s). The invention also relates to improvements in the configuration and / or the material(s) of the piston.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Sliding structure for automotive engine

InactiveUS6886521B2Preventing cracking and separationReduce coefficient of frictionPiston ringsMolten spray coatingCarbon filmPiston ring

A sliding structure for an automotive engine includes a sliding member with a sliding portion and a lubricant applied to the sliding portion so that the sliding portion can make sliding contact with a counterpart member via the lubricant. The sliding member is either of a piston ring, a piston pin, a cam lobe, a cam journal, a plain bearing, a rotary vane and a timing chain. The sliding portion has a base made of a steel or aluminum material and a hard carbon film formed on the base to coat the sliding portion. The hard carbon film has a thickness of 0.3 to 2.0 mum, a Knoop hardness of 1500 to 4500 kg / mm2, a surface roughness Ry (mum) satisfying the following equation: Ry<{(0.75-Hk / 8000)xh+0.07 / 0.8}, where h is the thickness (mum) of the film; and Hk is the Knoop hardness (kg / mm2) of the film.

Owner:NISSAN MOTOR CO LTD

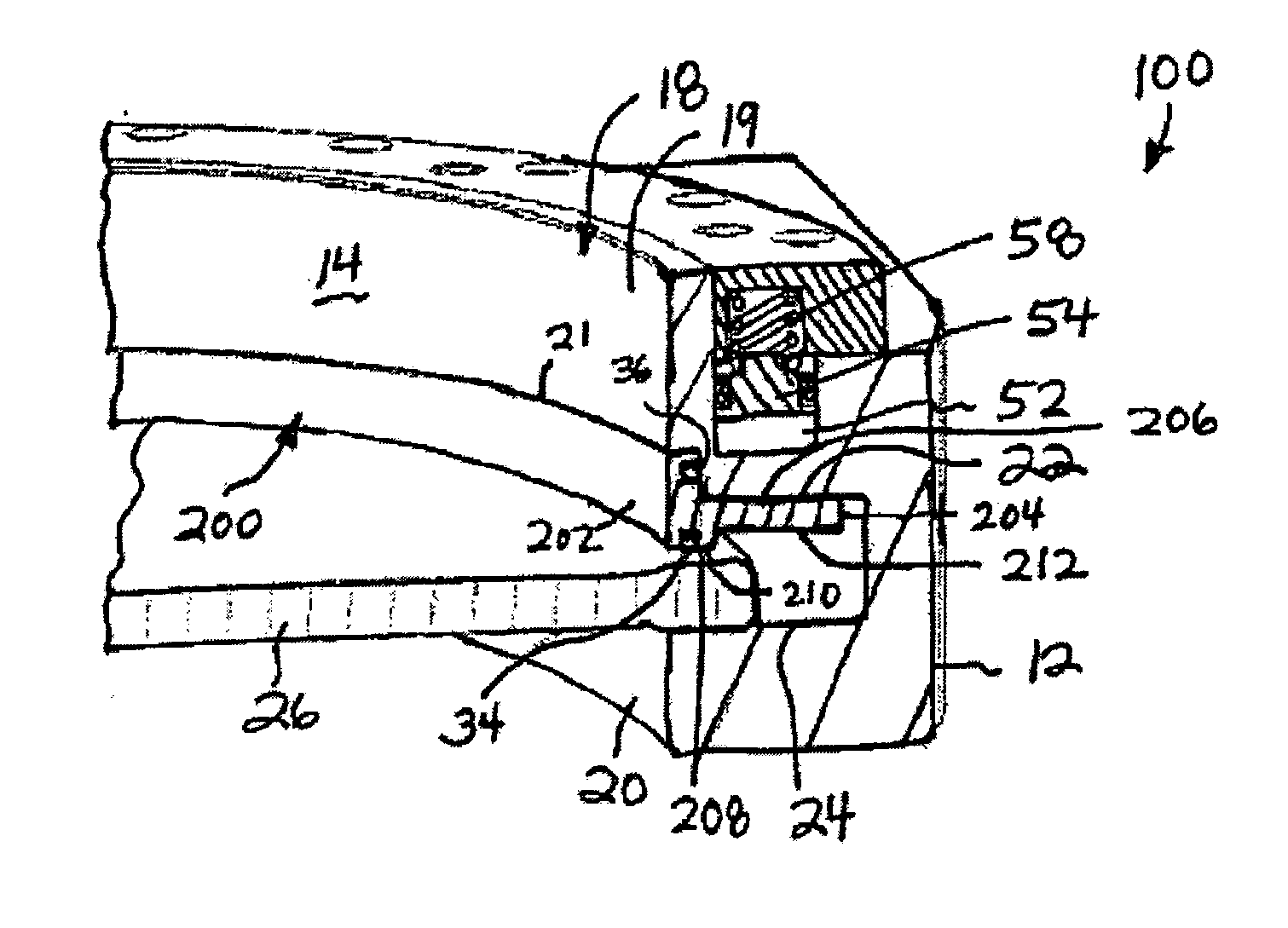

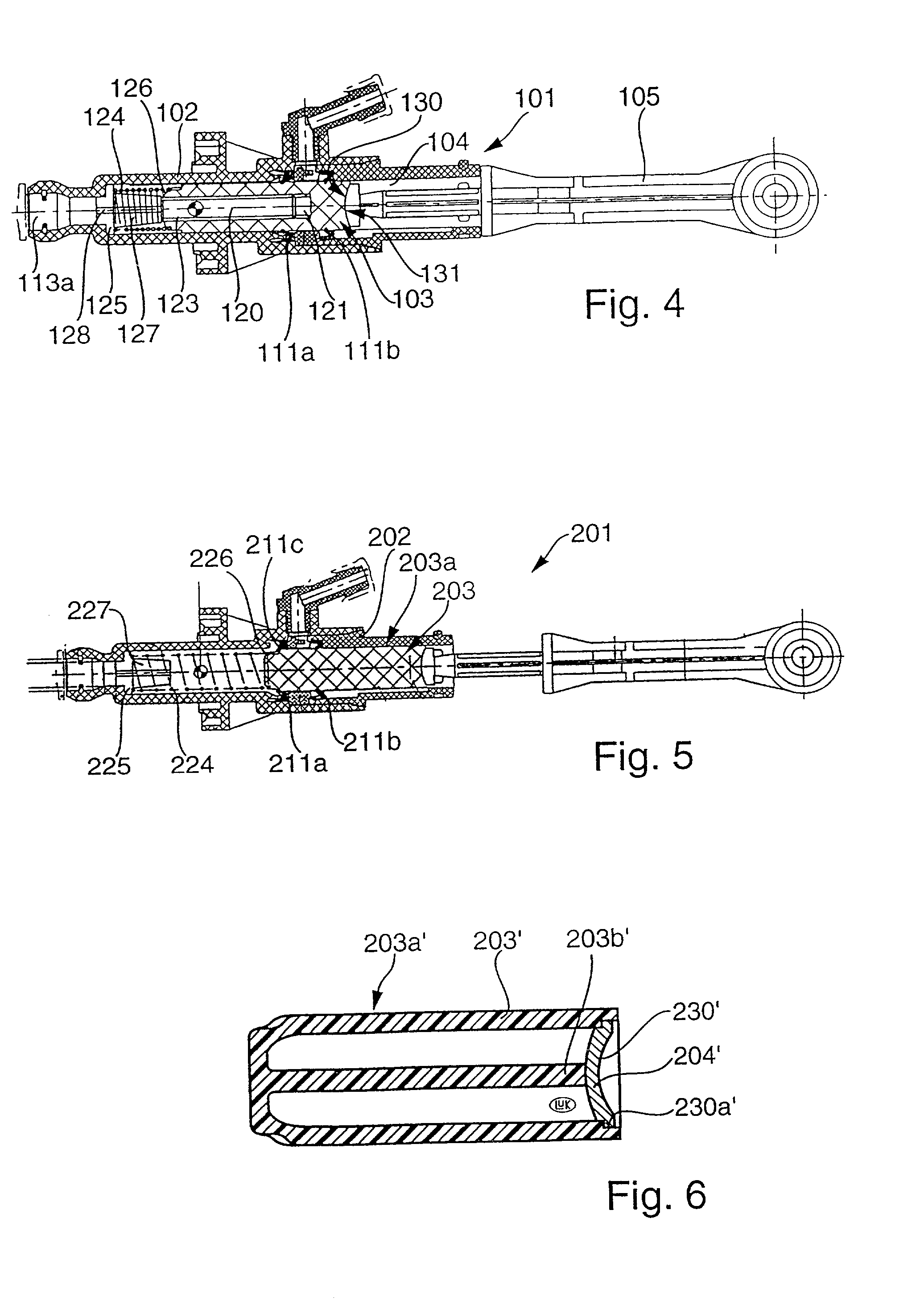

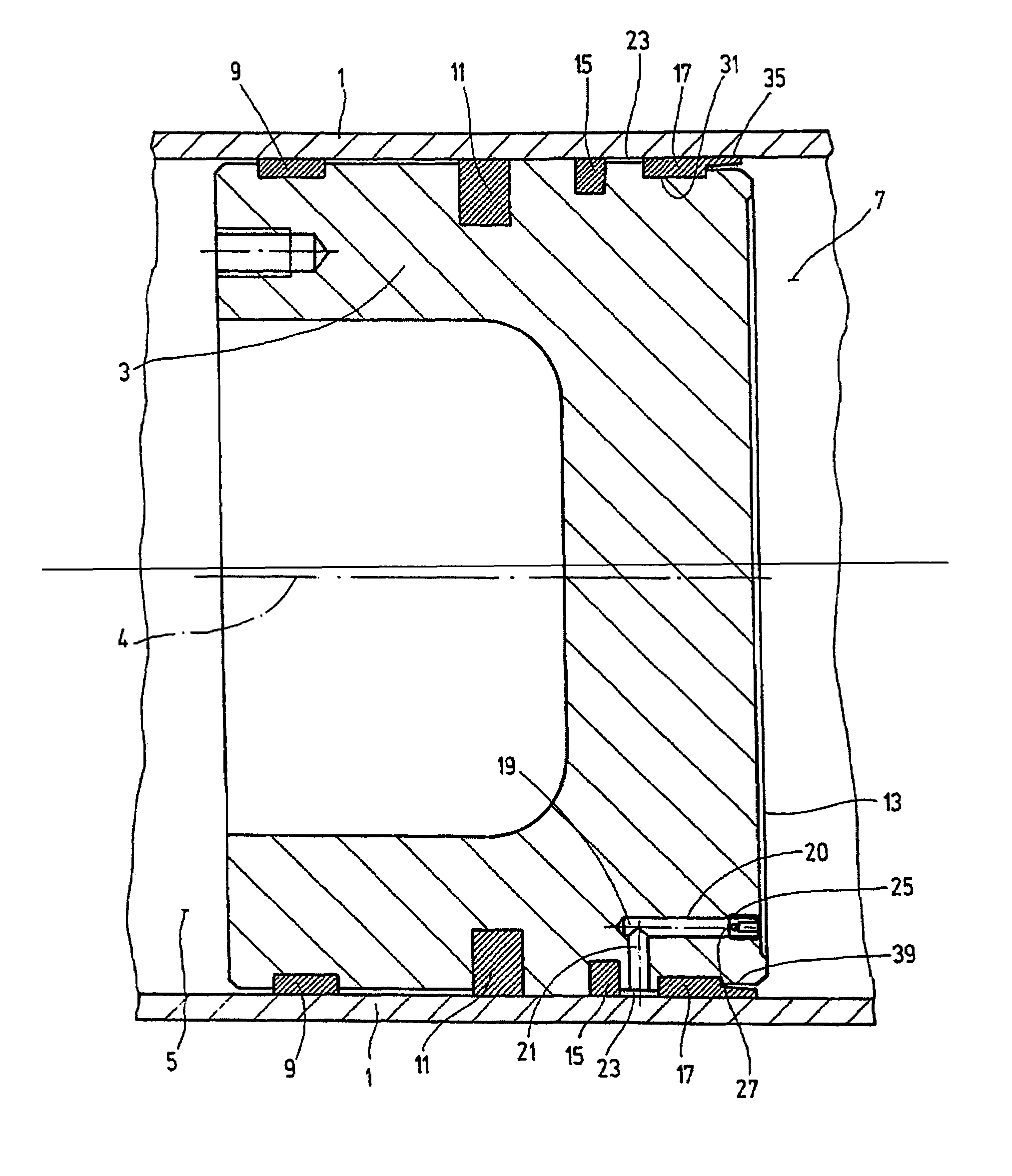

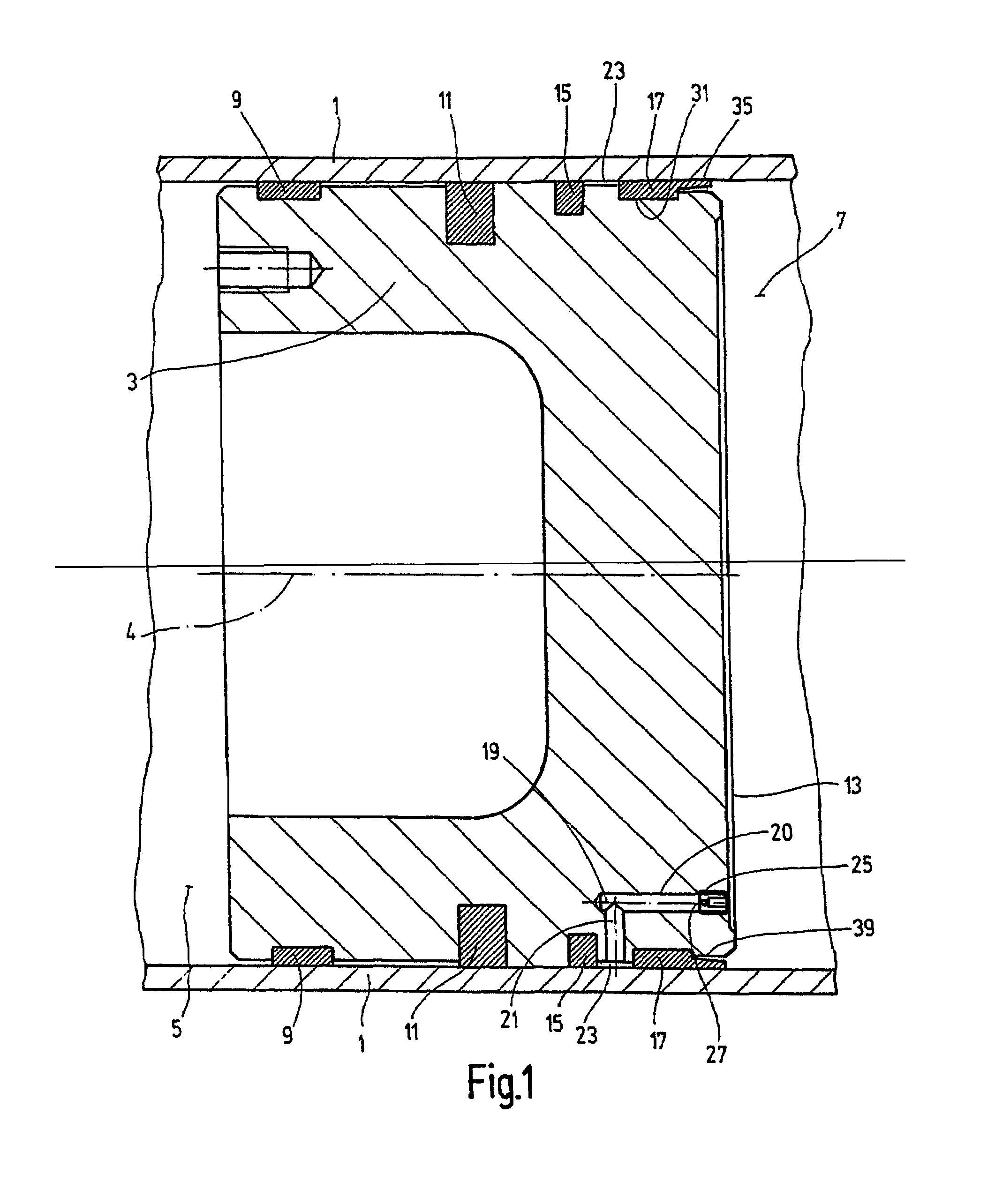

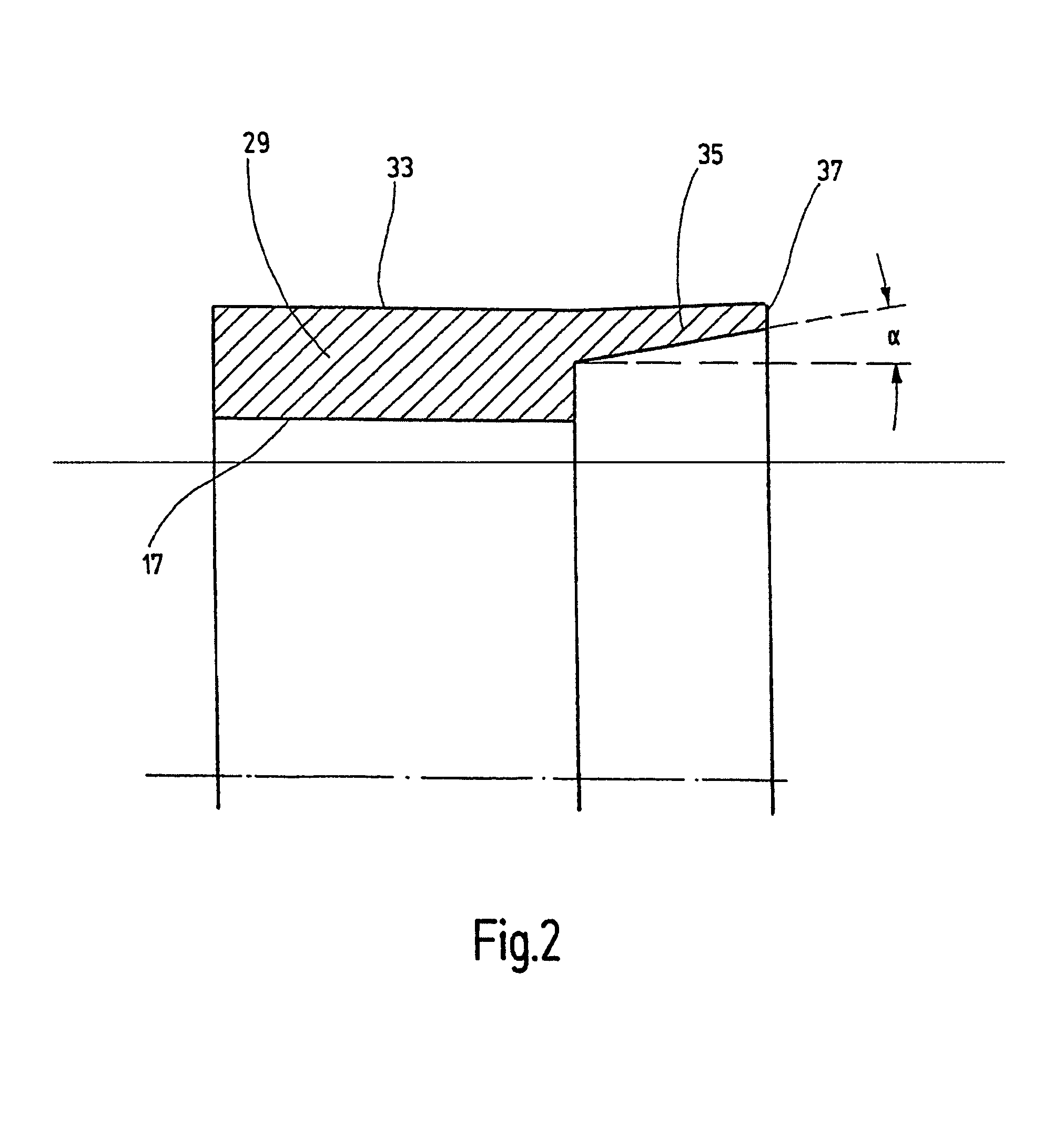

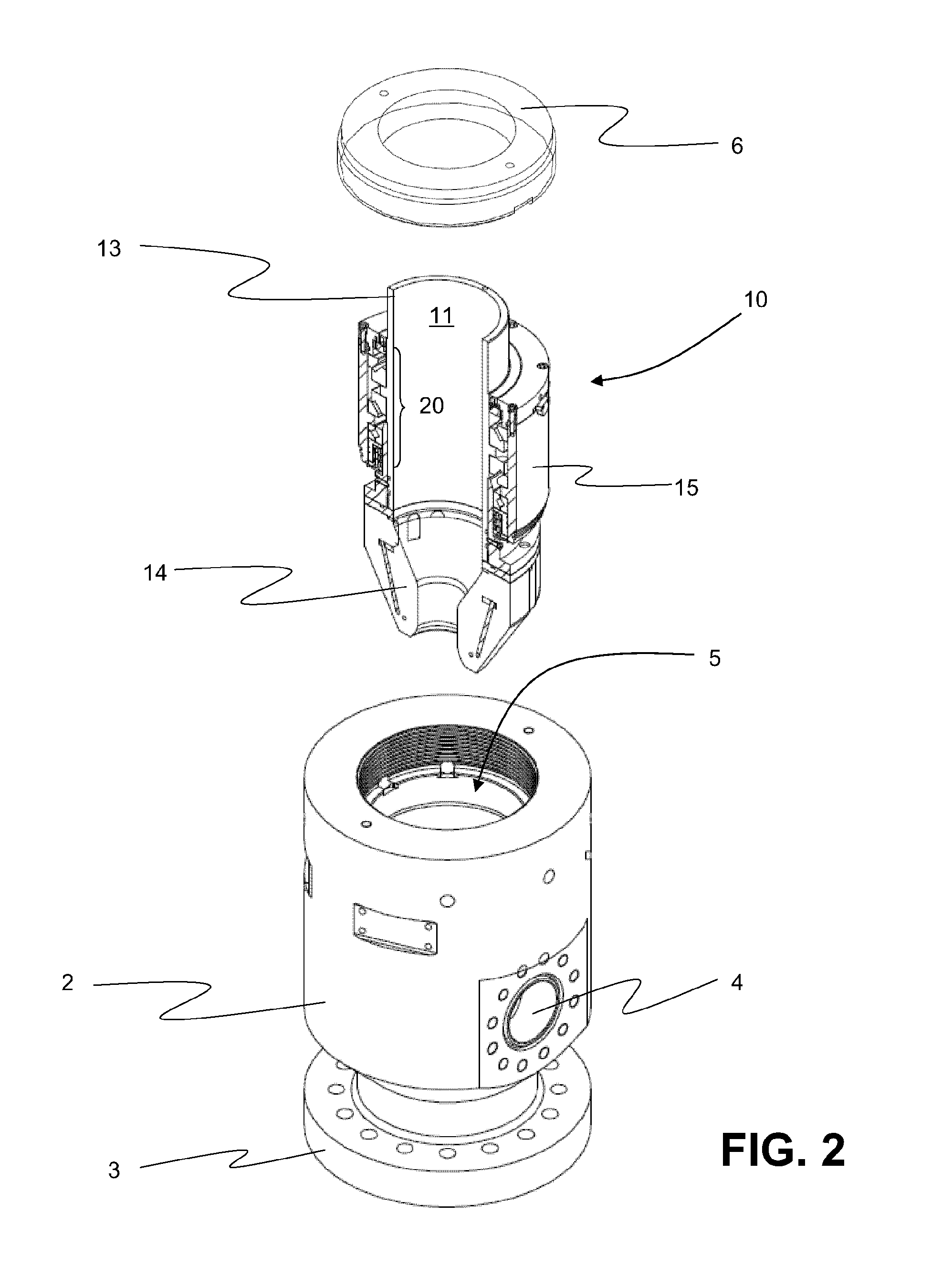

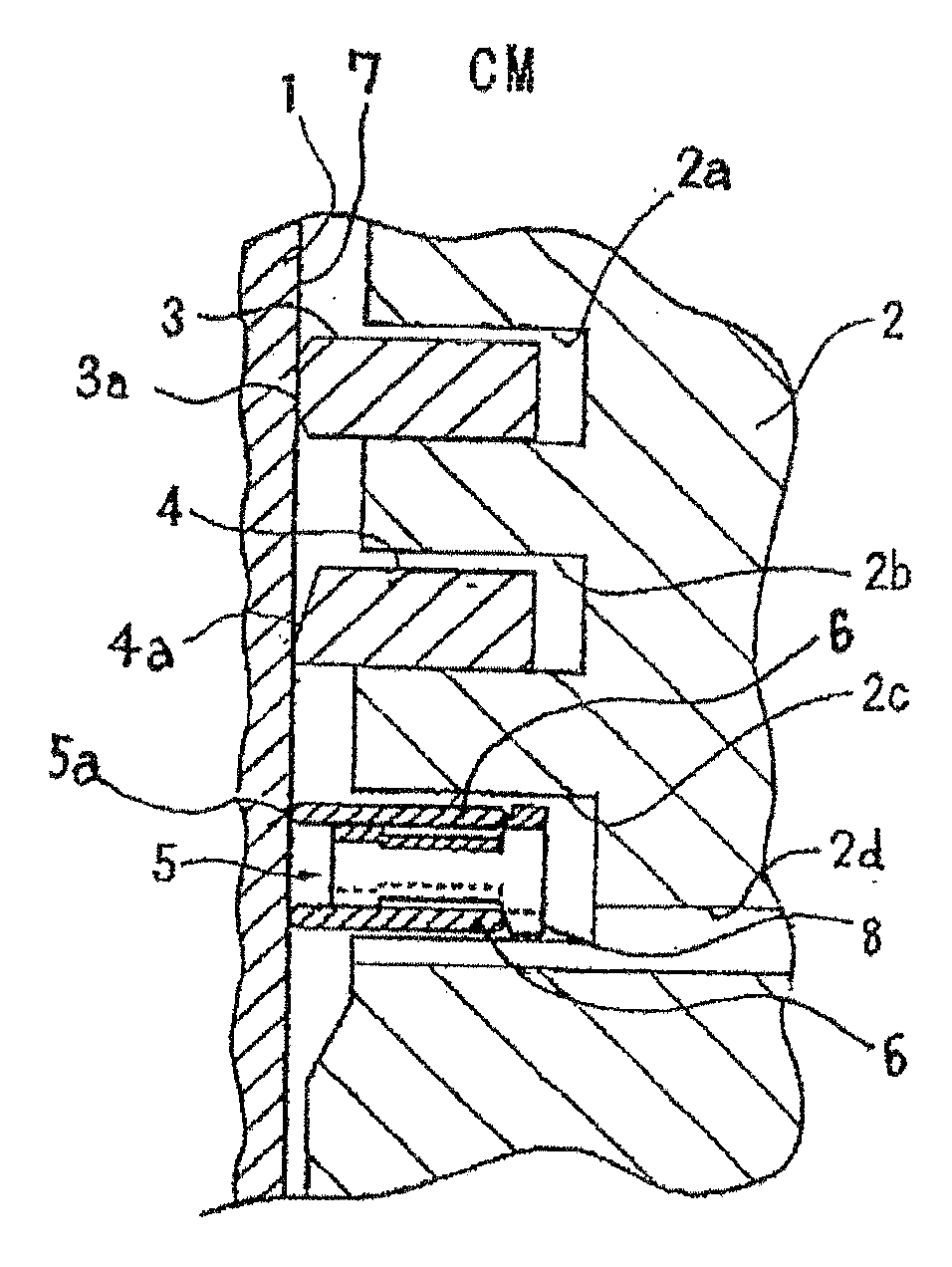

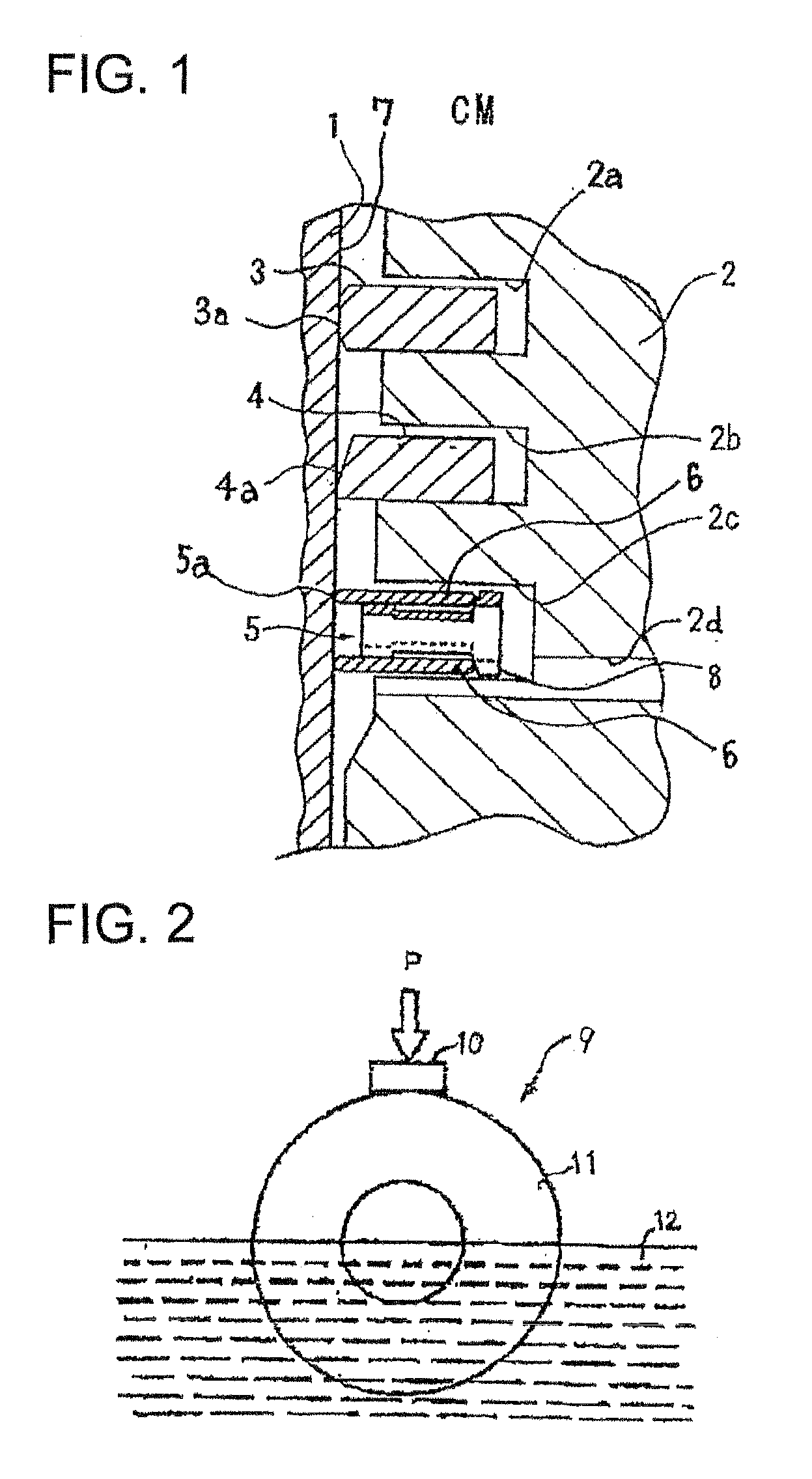

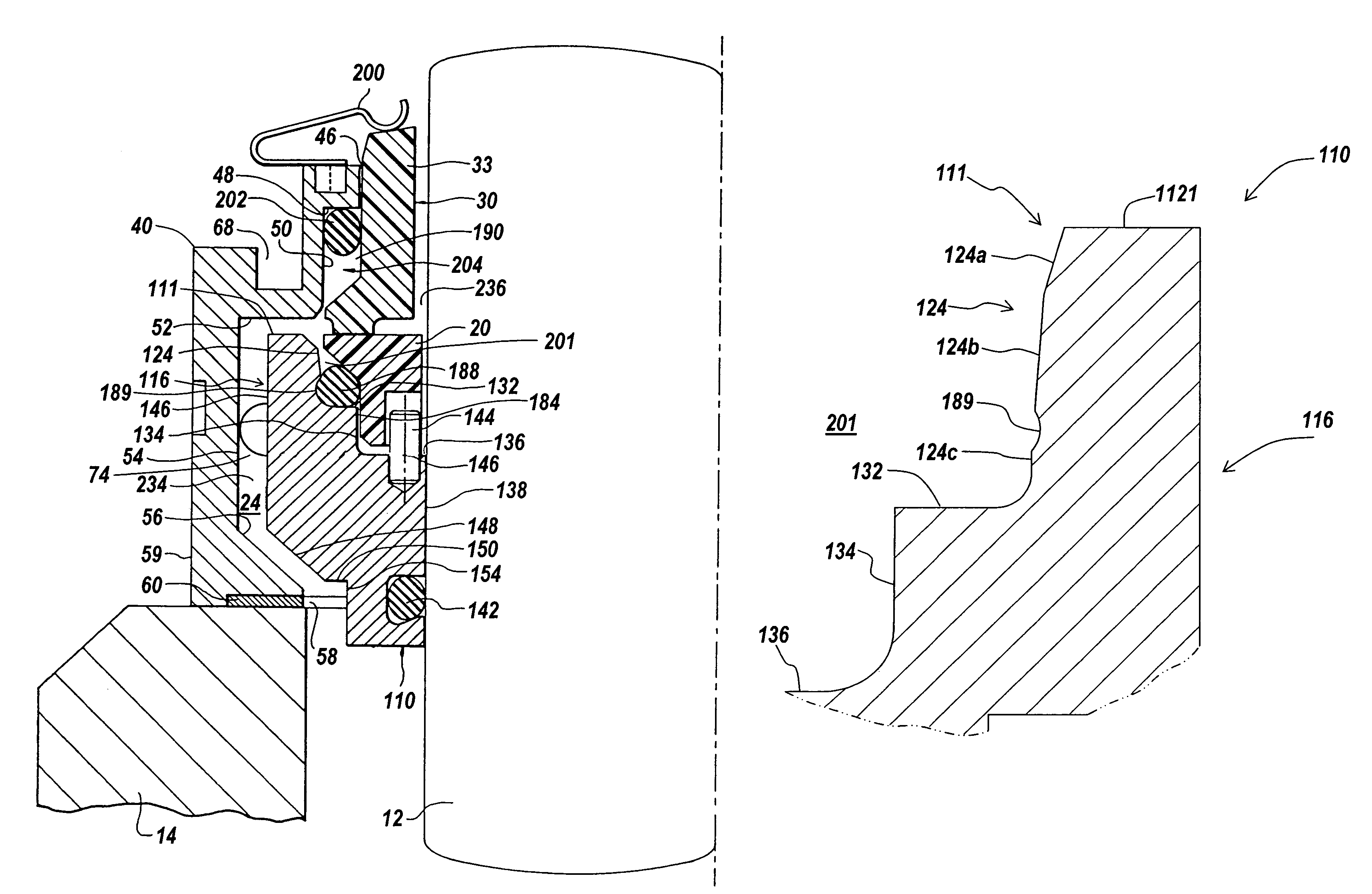

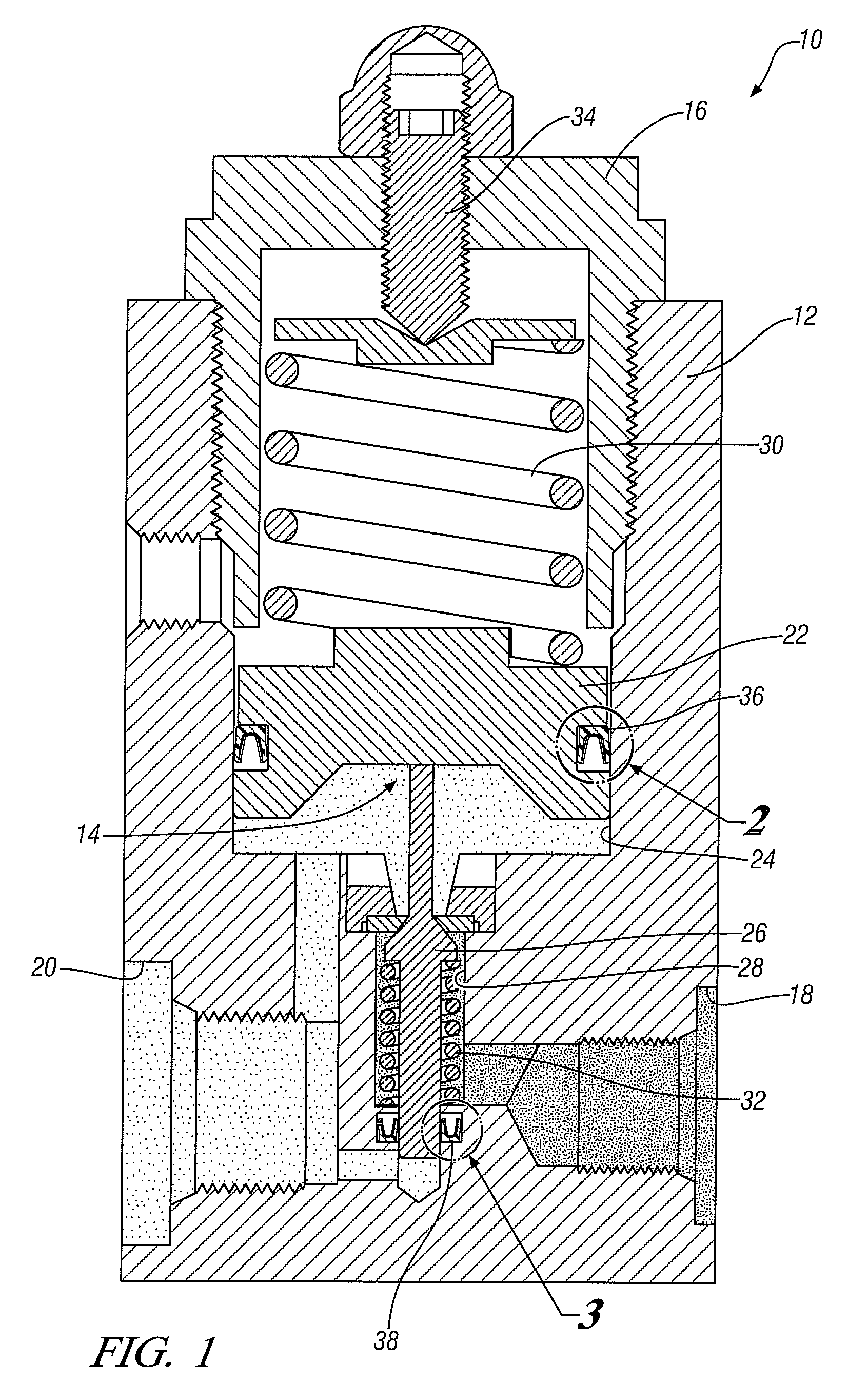

Hydraulic accumulator

ActiveUS7322377B2Guaranteed long-term operationReduction of the passage cross-sectionPiston ringsBraking action transmissionMechanical engineeringPiston

A hydraulic accumulator includes a piston (3) capable of moving in an accumulator housing (1) in its axial direction and separating a gas side (5) from a liquid side (7) of the accumulator housing (1). Guide elements (9, 17) designed to co-operate with the accumulator housing wall (1), as well as at least one sealing element (15), are arranged at the periphery of the piston. The sealing element is arranged offset in the axial direction relative to the guide elements (9, 17), and is located between the guide elements. In the piston (3), a pressure compensating channel (19) forms, at the piston periphery, a liquid flow path between the liquid side (7) and a space (2) located between the guide element (17) nearest to the liquid side (7) and the sealing element immediately next in the axial direction. A device (25) reducing the cross-section of the passage of the pressure compensating channel (19) is located in it.

Owner:HYDAC TECH GMBH

Metering receptacle

InactiveUS6960195B2Improve the lubrication effectPiston ringsInfusion syringesEngineeringMechanical engineering

A metering receptacle has an elongate hollow body which at one end has a closable exit opening, and which at the other end is closable by way of a plastic plunger stopper. The plunger stopper is at the same time longitudinally displaceable in the hollow body by way of a plunger rod. The metering receptacle is configured such that the plunger stopper is formed of two parts, with a sealing stopper part of plastic which is rigidly positionable in the elongate hollow body and has a centric bore for the passage of the plunger rod, and with a longitudinally displaceable plunger part of lubricious plastic which is connected to the plunger rod.

Owner:TRANSCOJECT

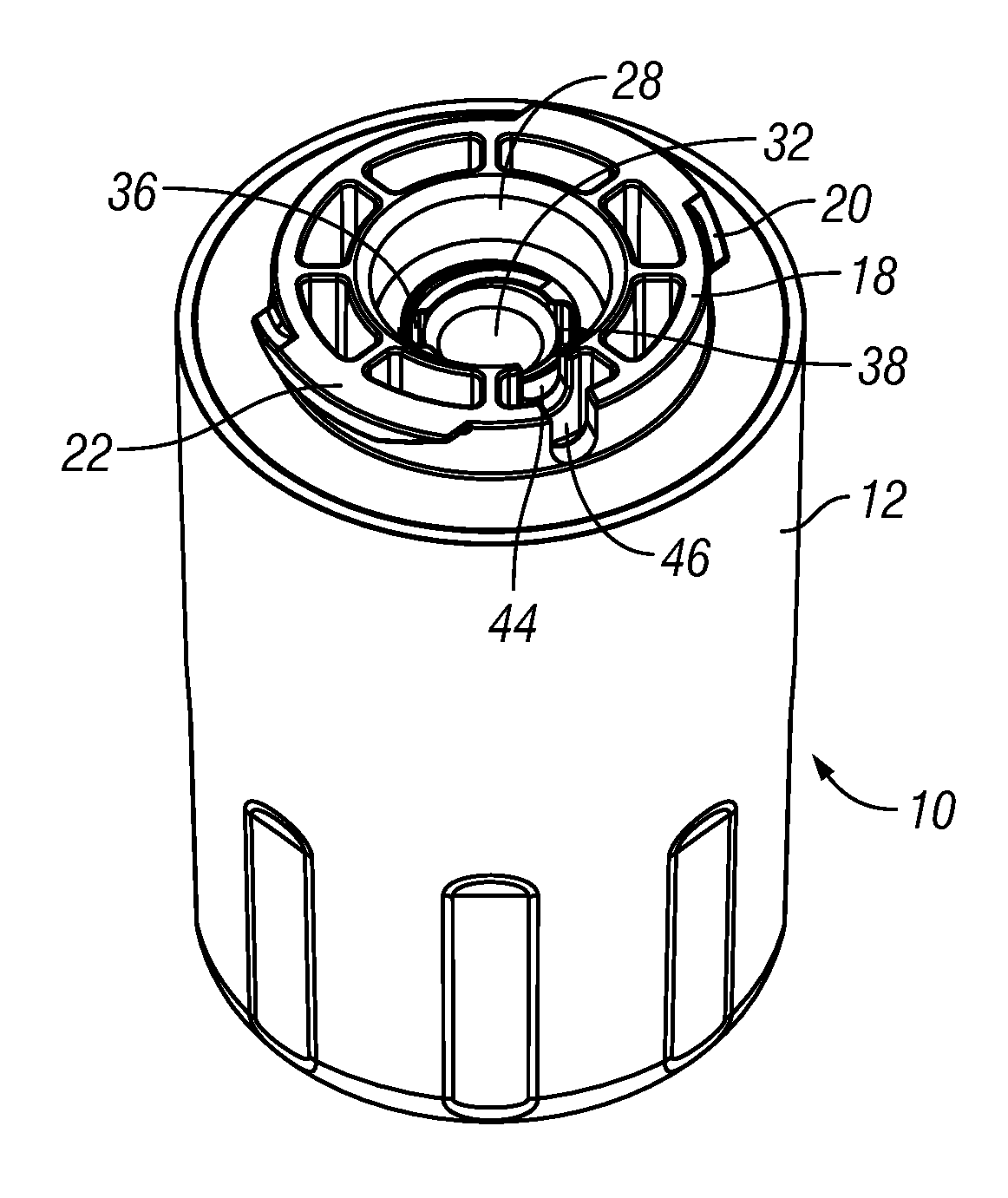

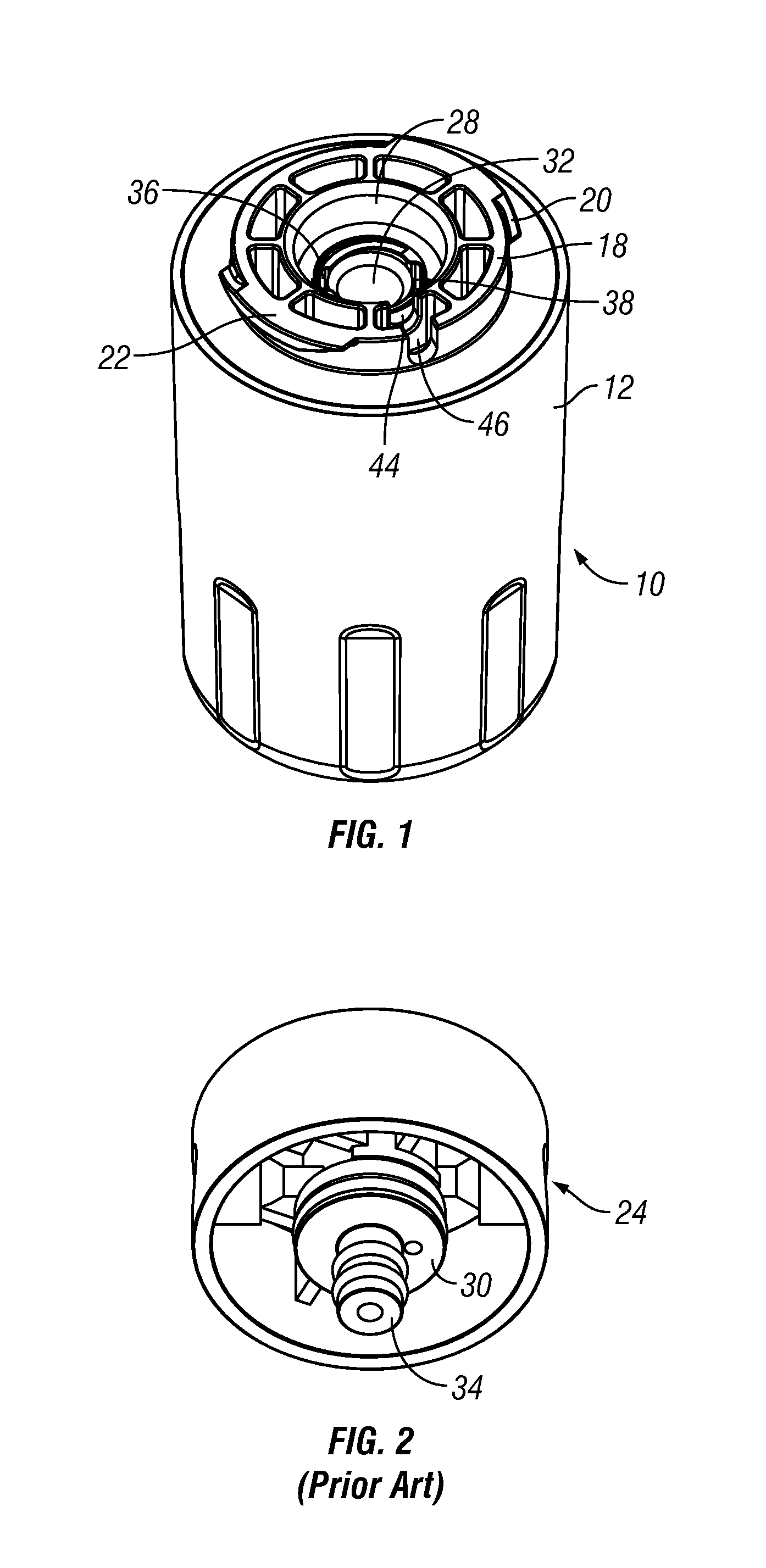

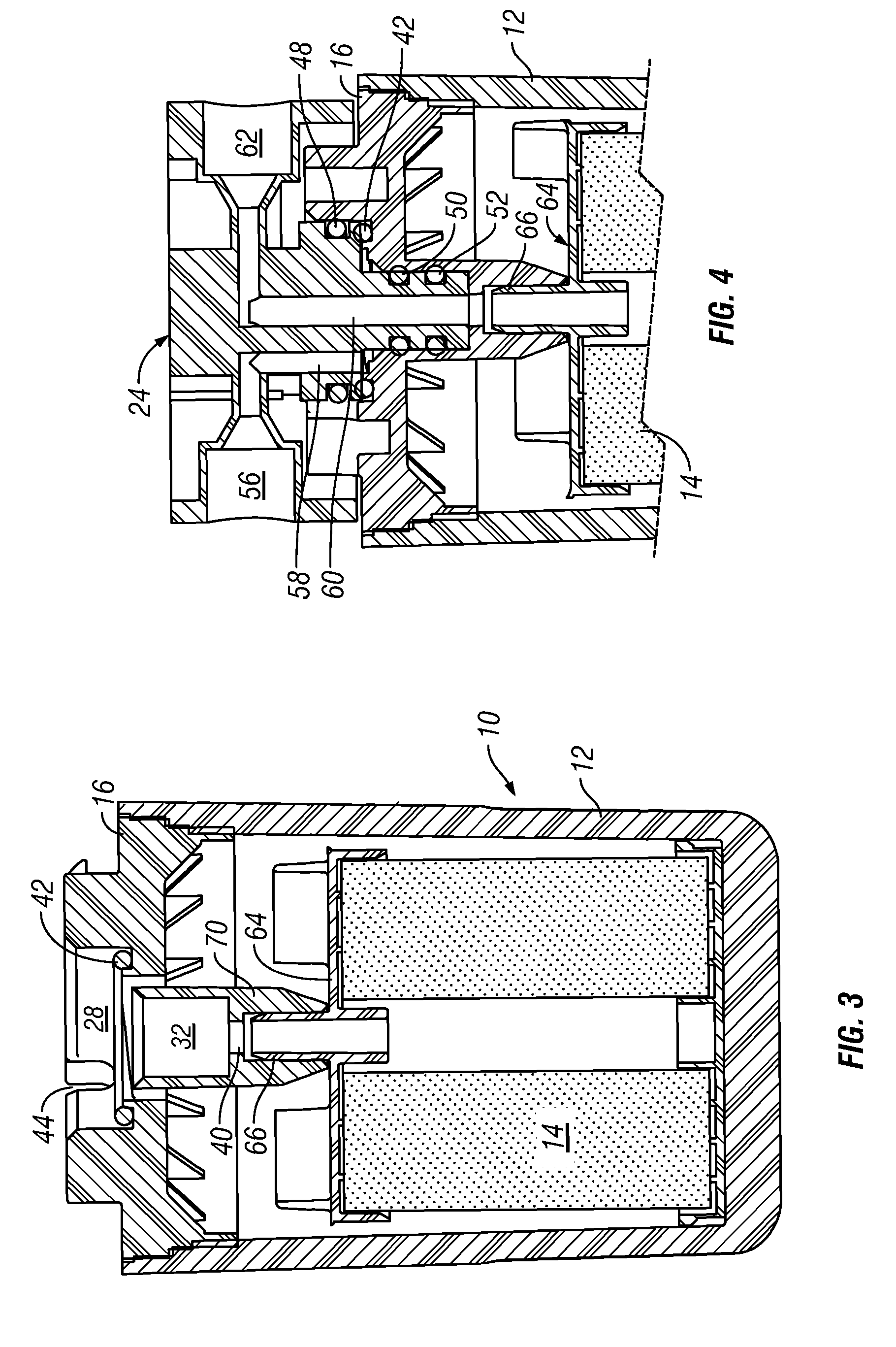

Refrigerator water filter cartridge with leakage indicator

ActiveUS8216463B1Improve manifold-to-cartridge water sealEasy to correctEngine sealsPiston ringsWater filterFiltration

A water filter cartridge particularly suited for a water filtration system incorporated into refrigerators includes an outer housing, a water filtration media inside the housing, and a cap affixed to an end of the housing to thereby enclose the filtration media. A portion of the cap defines a large cylindrical cavity having a channel formed therein which is positioned so that an O-ring provides a substantially water-tight seal when the filter cartridge is in an operative position in a manifold. The O-ring prevents water from otherwise flowing through the channel and externally of the water filtration system. Under normal water pressure the water filtration system will immediately visually exhibit a substantial leak if the filter cartridge is coupled to the manifold of the water filtration system in the operative position without the O-ring being positioned in the large cylindrical cavity.

Owner:BAIRD MICHAEL T

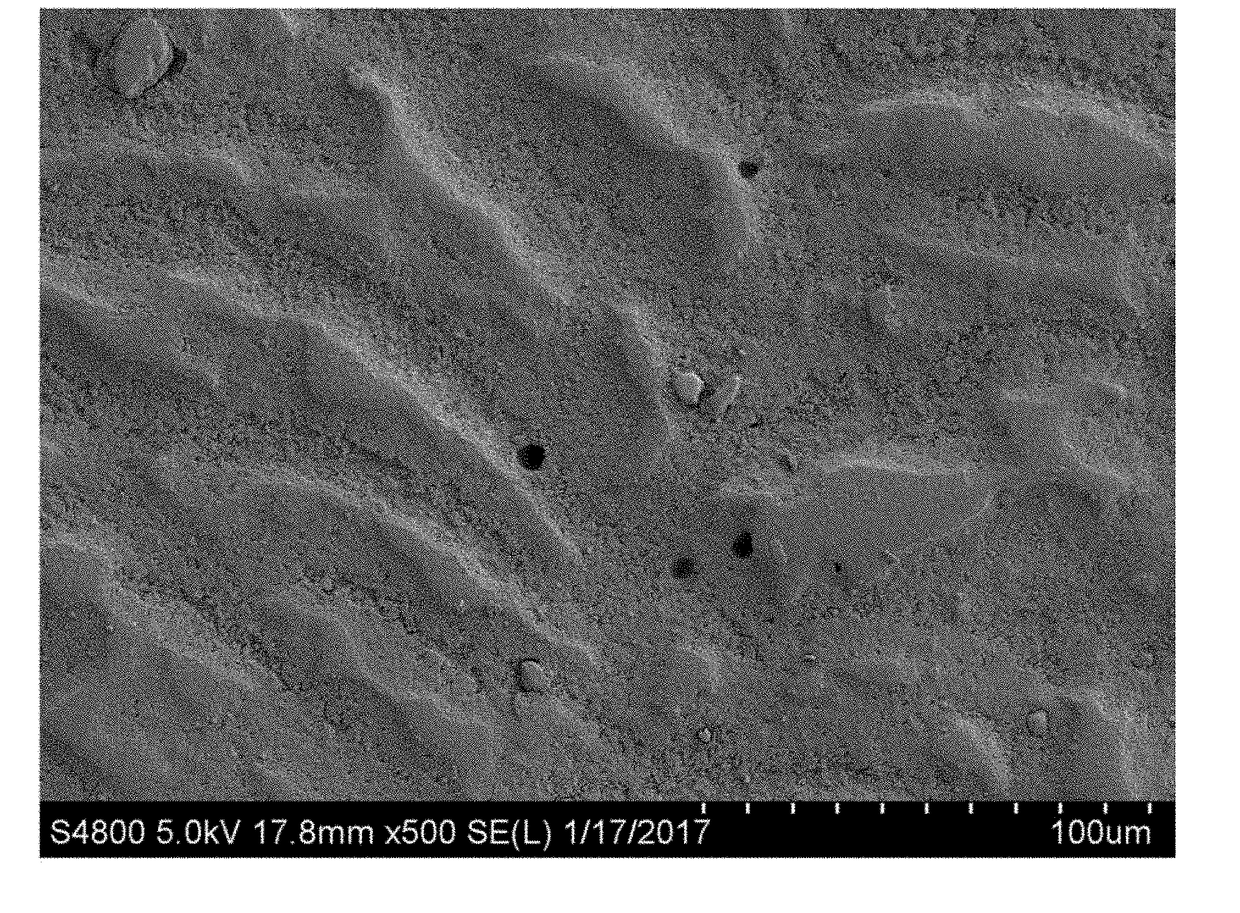

Additive manufacturing with nanofunctionalized precursors

Some variations provide a process for additive manufacturing of a nanofunctionalized metal alloy, comprising: providing a nanofunctionalized metal precursor containing metals and grain-refining nanoparticles; exposing a first amount of the nanofunctionalized metal precursor to an energy source for melting the precursor, thereby generating a first melt layer; solidifying the first melt layer, thereby generating a first solid layer; and repeating many times to generate a plurality of solid layers in an additive-manufacturing build direction. The additively manufactured, nanofunctionalized metal alloy has a microstructure with equiaxed grains. Other variations provide an additively manufactured, nanofunctionalized metal alloy comprising metals selected from aluminum, iron, nickel, copper, titanium, magnesium, zinc, silicon, lithium, silver, chromium, manganese, vanadium, bismuth, gallium, or lead; and grain-refining nanoparticles selected from zirconium, tantalum, niobium, titanium, or oxides, nitrides, hydrides, carbides, or borides thereof, wherein the additively manufactured, nanofunctionalized metal alloy has a microstructure with equiaxed grains.

Owner:HRL LAB

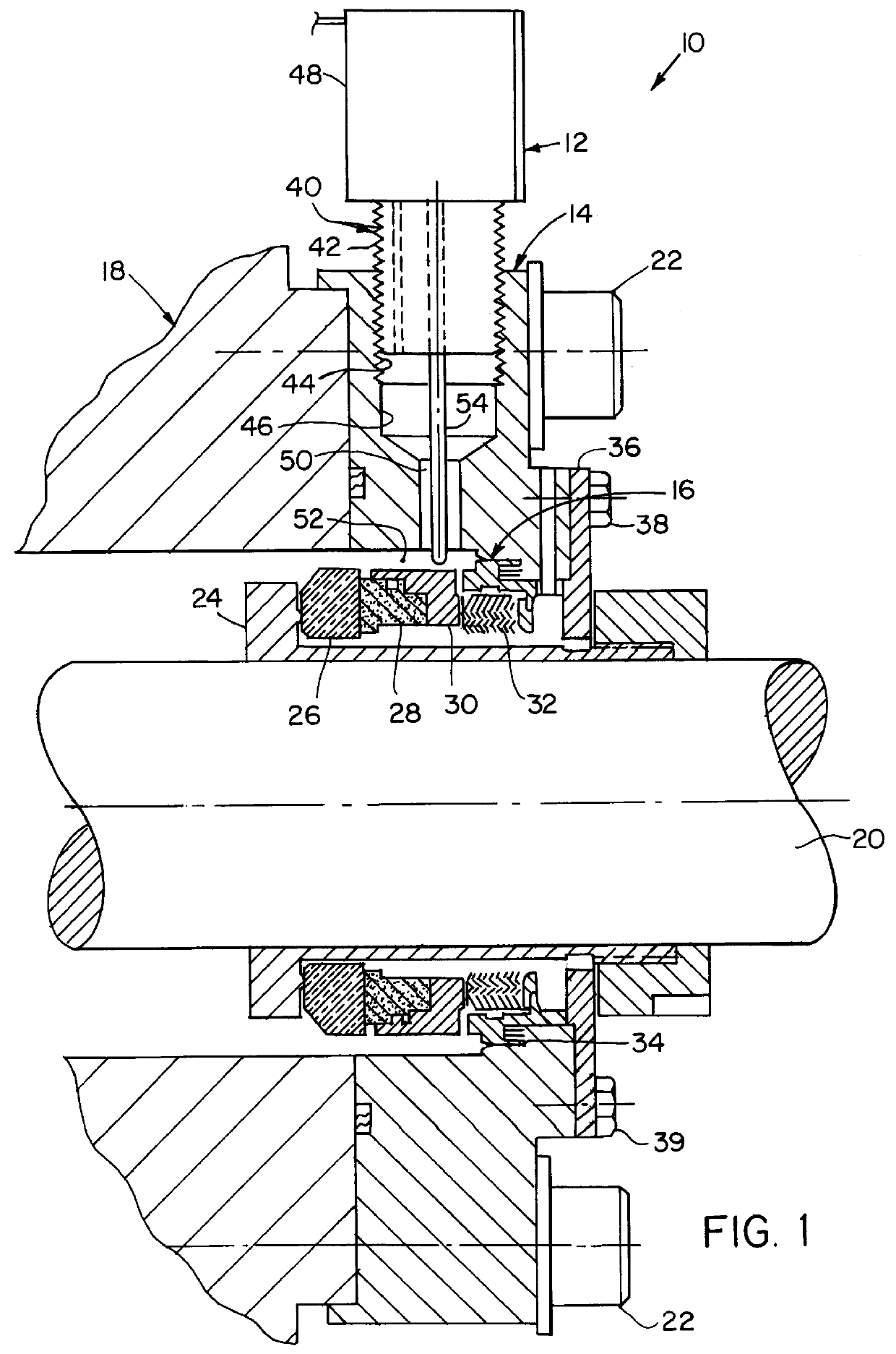

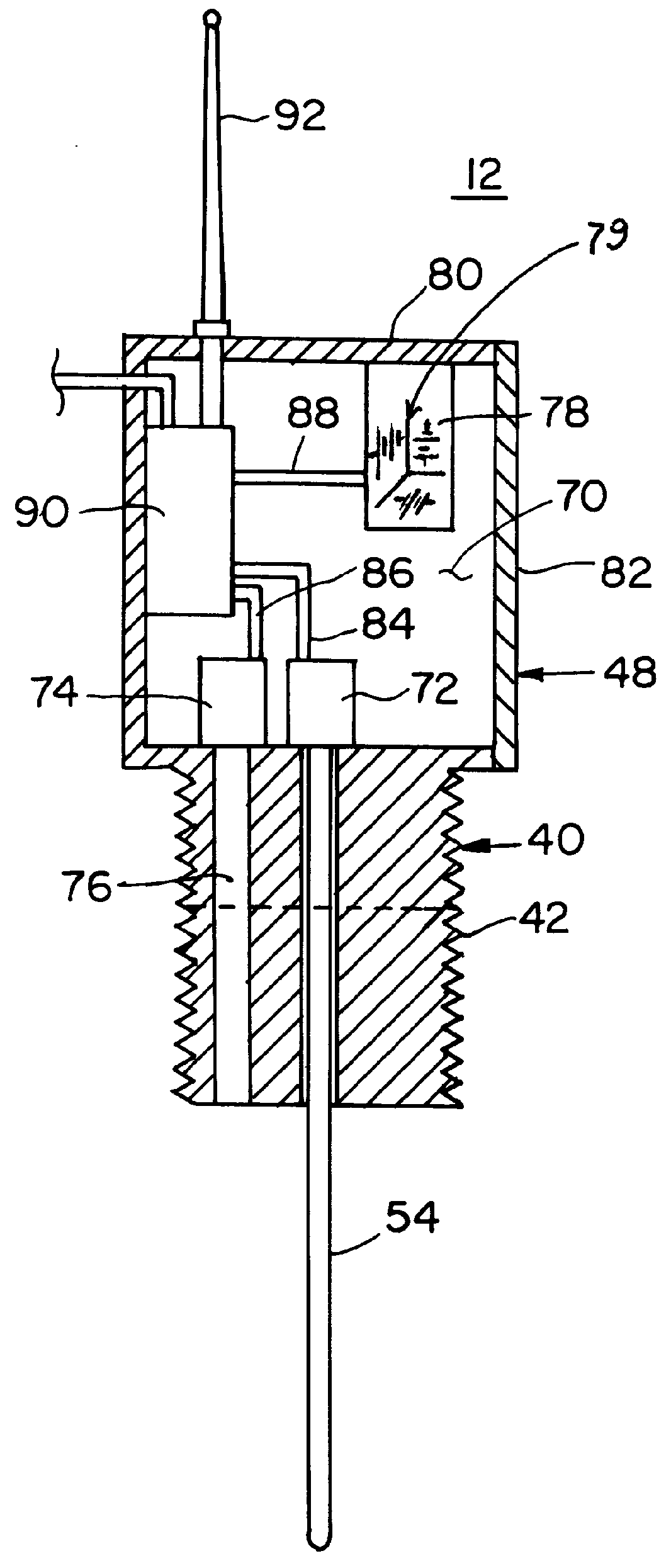

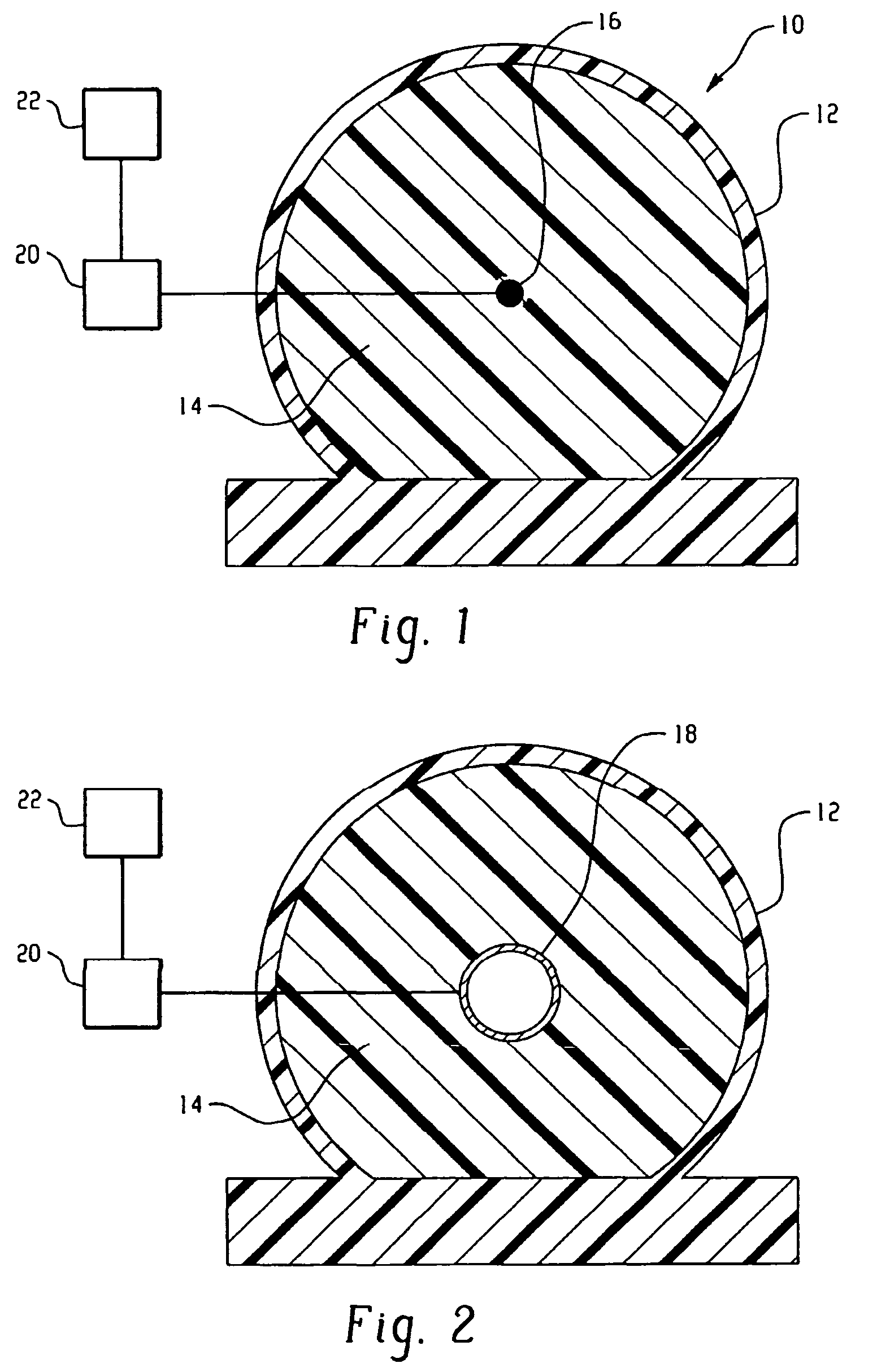

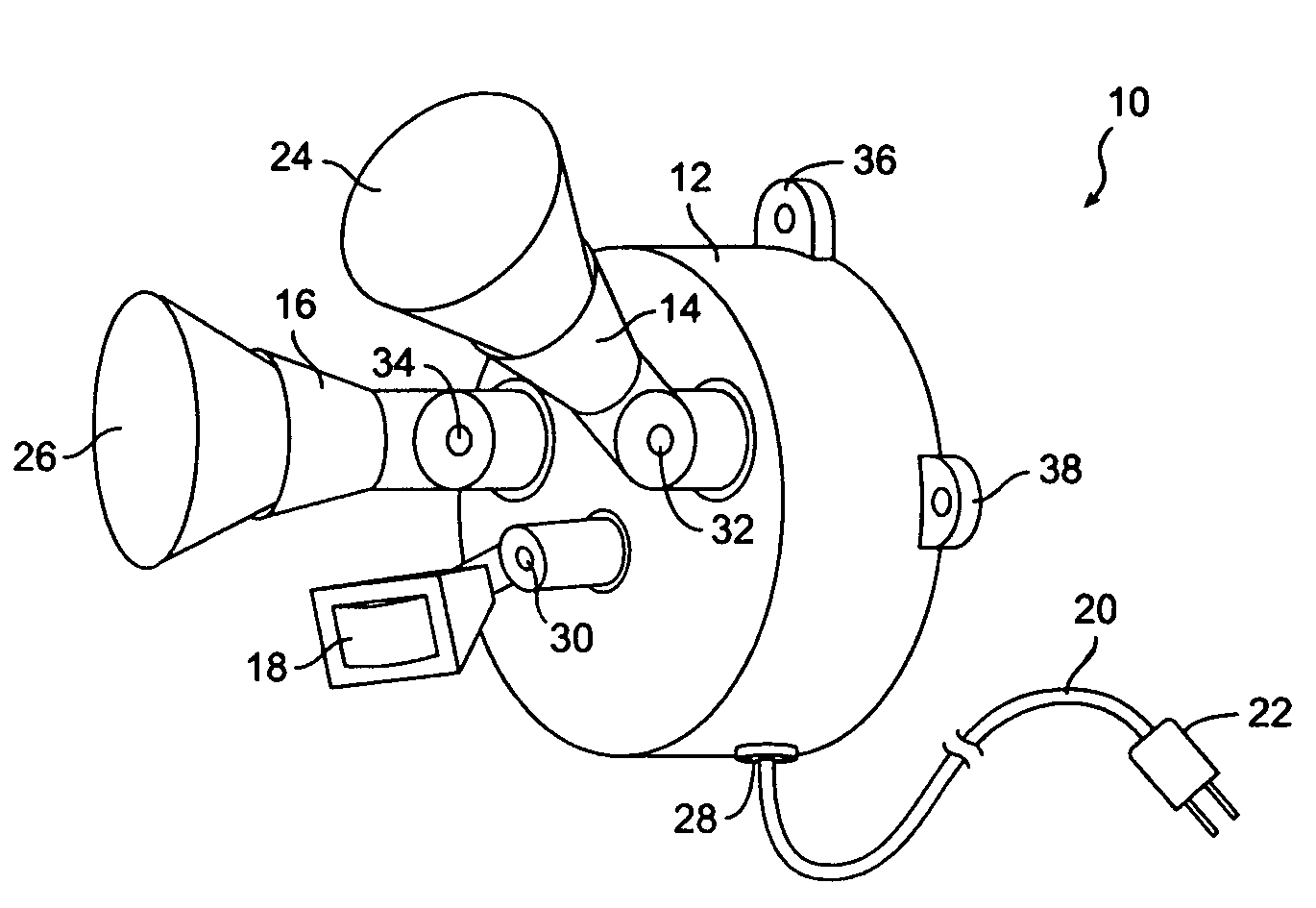

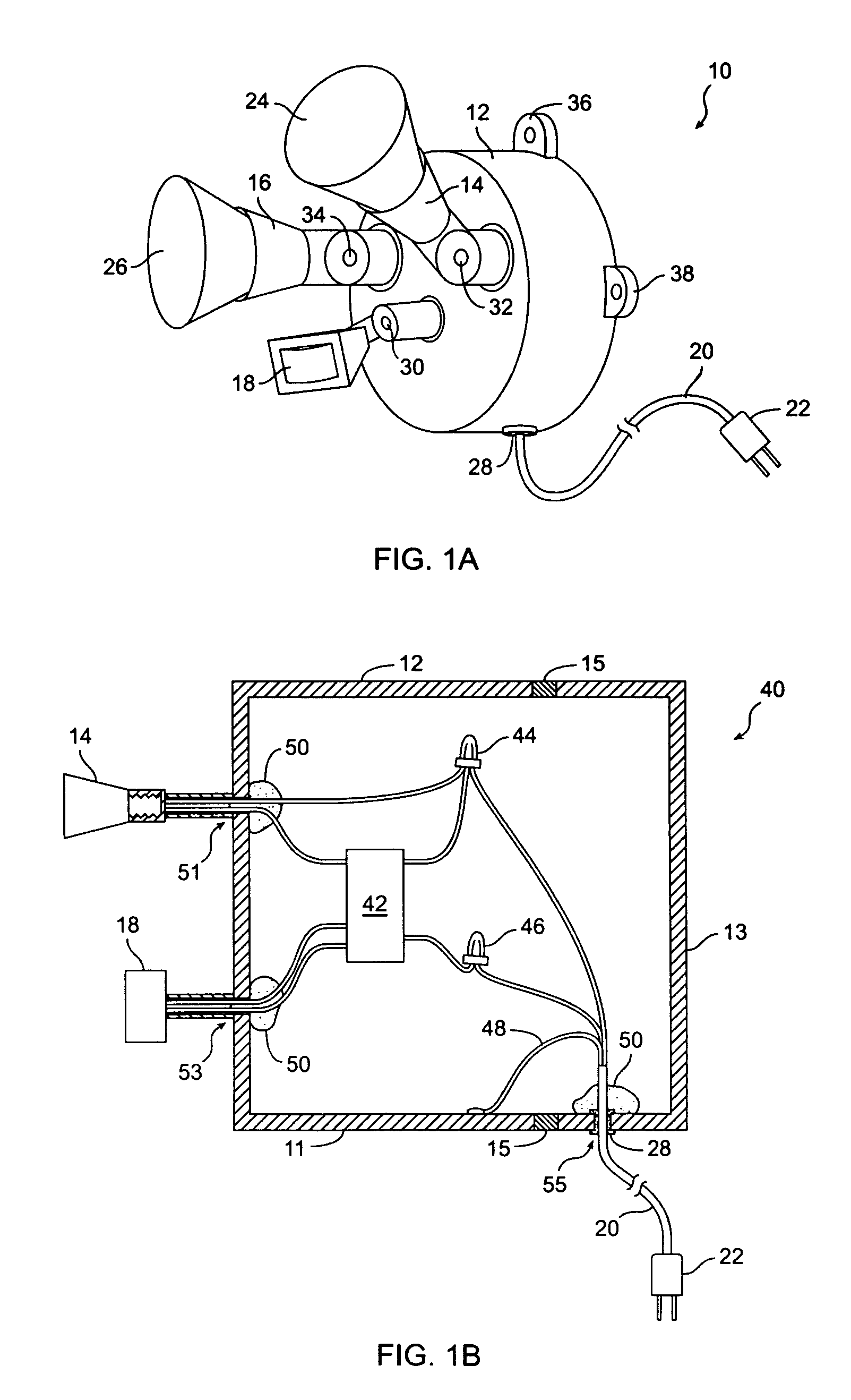

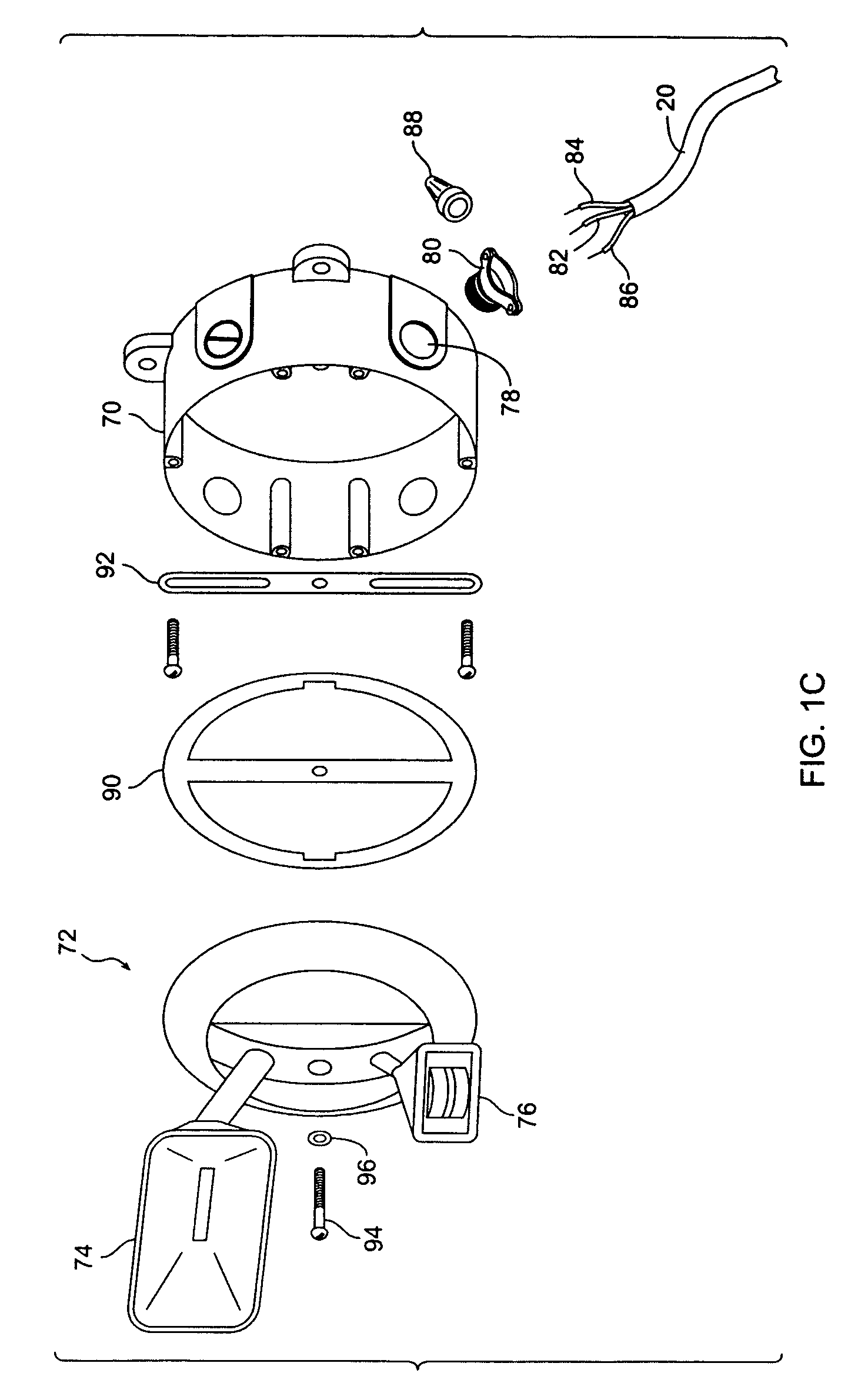

Monitoring seal system

InactiveUS6626436B2Prevent liquid leakageEngine sealsPiston ringsEngineeringElectrical and Electronics engineering

A monitoring seal system comprises a seal housing, a seal assembly, a temperature sensor and a controller. The seal assembly sealingly engages a rotary shaft to prevent fluid leakage between the shaft and the housing. The seal assembly has at least one seal. The seal has a primary ring and a mating ring. The temperature sensor senses the temperature in the vicinity of the seal. The controller determines whether an upset condition has occurred based on at least the temperature in the vicinity of the seal.

Owner:JOHN CRANE INC

Rotary shaft monitoring seal system

InactiveUS6082737AEasy to installEasy to operateEngine sealsPiston ringsMechanical engineeringFluid leakage

A rotary shaft monitoring seal system includes a seal housing; a seal assembly in the housing for sealingly engaging a rotary shaft to prevent fluid leakage between the shaft and the housing; a monitoring port in the housing; and a detector assembly mounted in the port for sensing conditions in the vicinity of the seal assembly.

Owner:EG&G +1

Seals for hydraulic assemblies

InactiveUS6494465B1Reduce usageImprove sealing propertiesEngine sealsPiston ringsMetallic materialsEngineering

Owner:CURTISS WRIGHT FLOW CONTROL CORP

Seal cleaning and lubricating bearing assembly for a rotating flow diverter

ActiveUS20090161997A1Reduce differential pressureExtend your lifeEngine sealsPiston ringsFlow diverterLubricant

A rotating flow diverter has a lubricated sealed bearing assembly for isolating bearing elements from wellbore fluids under pressure. The sealed bearing assembly is supported between an outer bearing housing and an axially rotatable quill. The bearing assembly further has bearing elements with a bearing lubricant under pressure and a seal assembly. The seal assembly has at least one sealing element which comprises a body, the body having an outer peripheral wall, an inner sealing surface having a plurality of sealing lips and an annular cavity, and a loading ring for compressionally fitting within the annular cavity to urge the sealing surface radially inwardly for sealing engagement with tubulars.

Owner:OPTIMAL PRESSURE DRILLING SERVICES

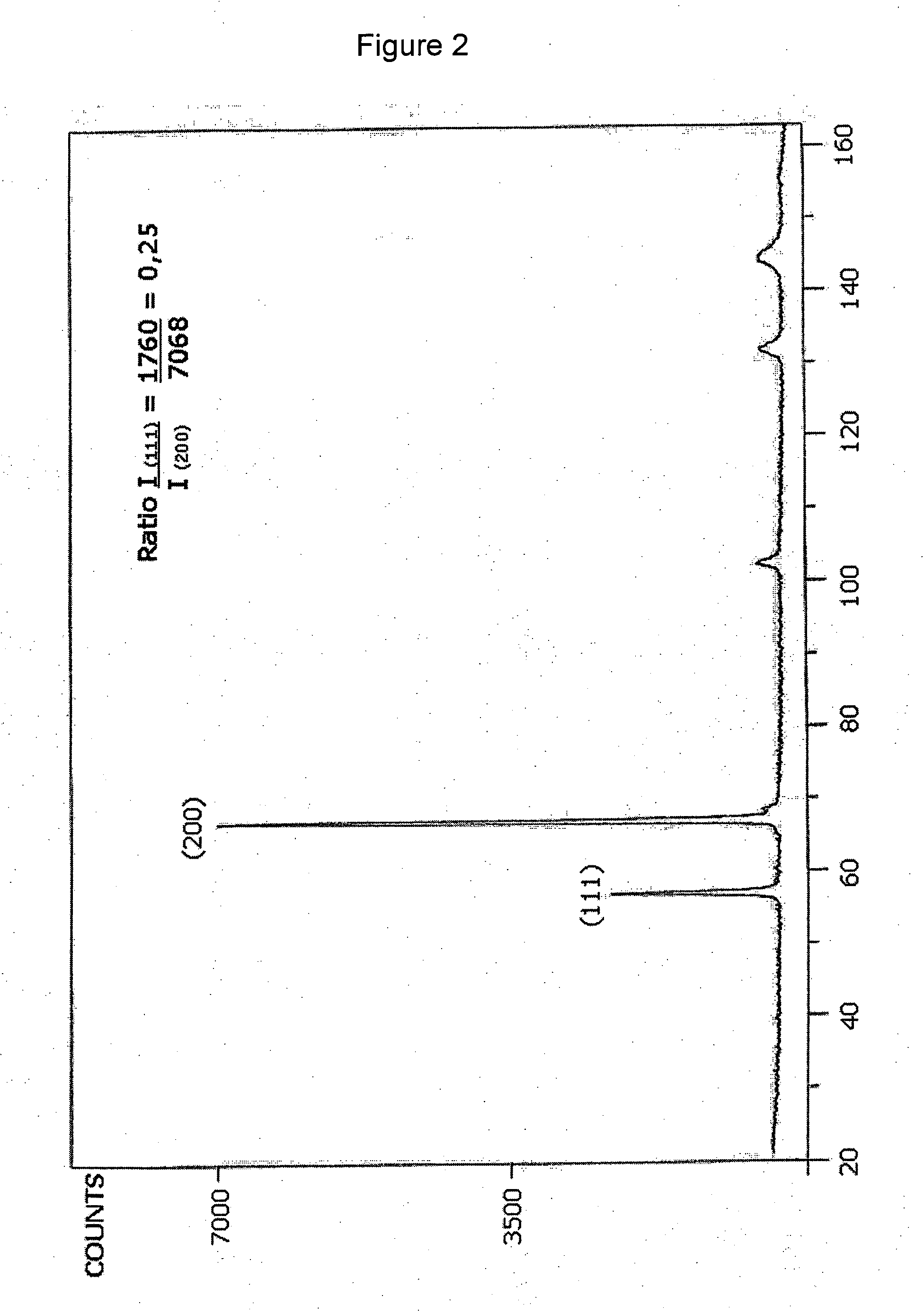

Piston ring for internal combustion engines

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

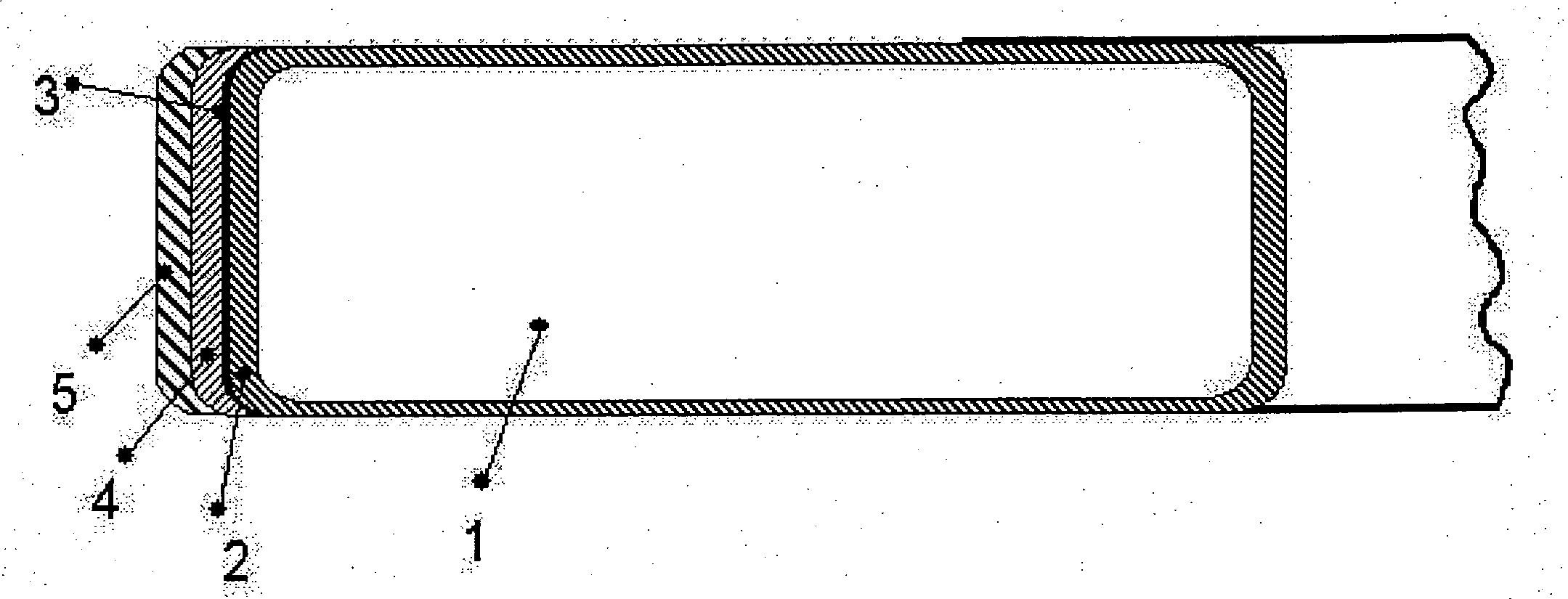

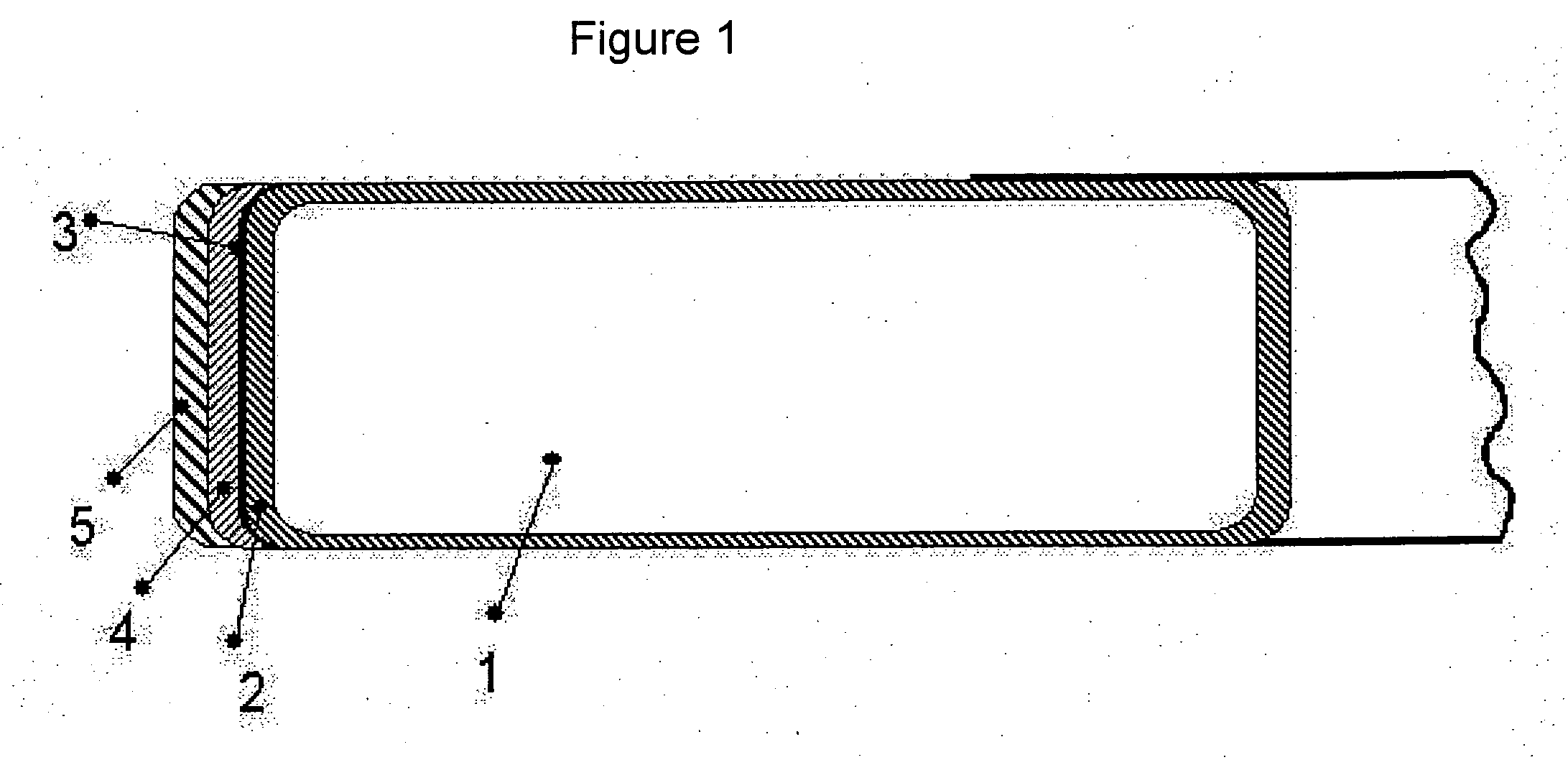

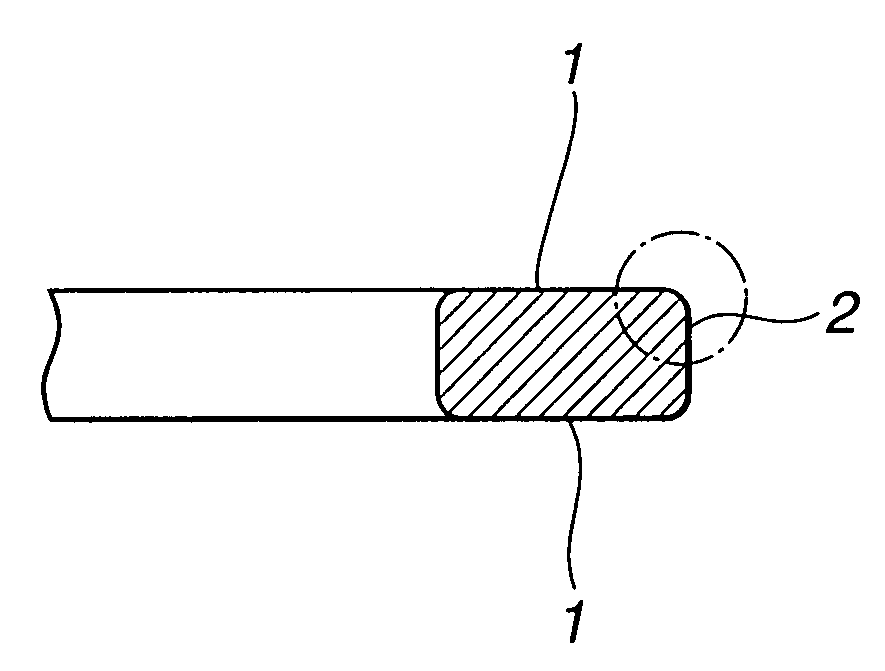

Sliding element, in particular piston ring, having a coating and process for producing a sliding element

ActiveUS20130140776A1Increase valueProducibilityPiston ringsBraking action transmissionPiston ringMetal

A sliding element, in particular piston ring, has on at least one running surface, from the inside outwards, a coating having a metal-containing adhesive layer and a ta-C type DLC layer with a thickness of at least 10 μm.In a process for the production of a sliding element, in particular a piston ring, coating with a metal-containing adhesive layer and a ta-C type DLC layer in a thickness of at least 10 μm is carried out.

Owner:FEDERAL MOGUL BURSCHEID

Radial lip seal

A radial lip seal including an annular support with a radially extending portion having an inner periphery. An annular seal lip formed of elastomeric material such as polytetrafluoroethylene is connected to the inner periphery. The lip has an inner side adapted to seal a circumferential surface of a shaft and an outer side. The outer side of the lip has a plurality of grooves or protrusions to vary the diameter of the lip. The varied diameter creates a substantial leak between the outer side of the lip and the circumferential surface. The leak created is sufficient to be detected by a low-pressure air test.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Reversible thermally expandable and/or contractible seal assemblies

Owner:GM GLOBAL TECH OPERATIONS LLC

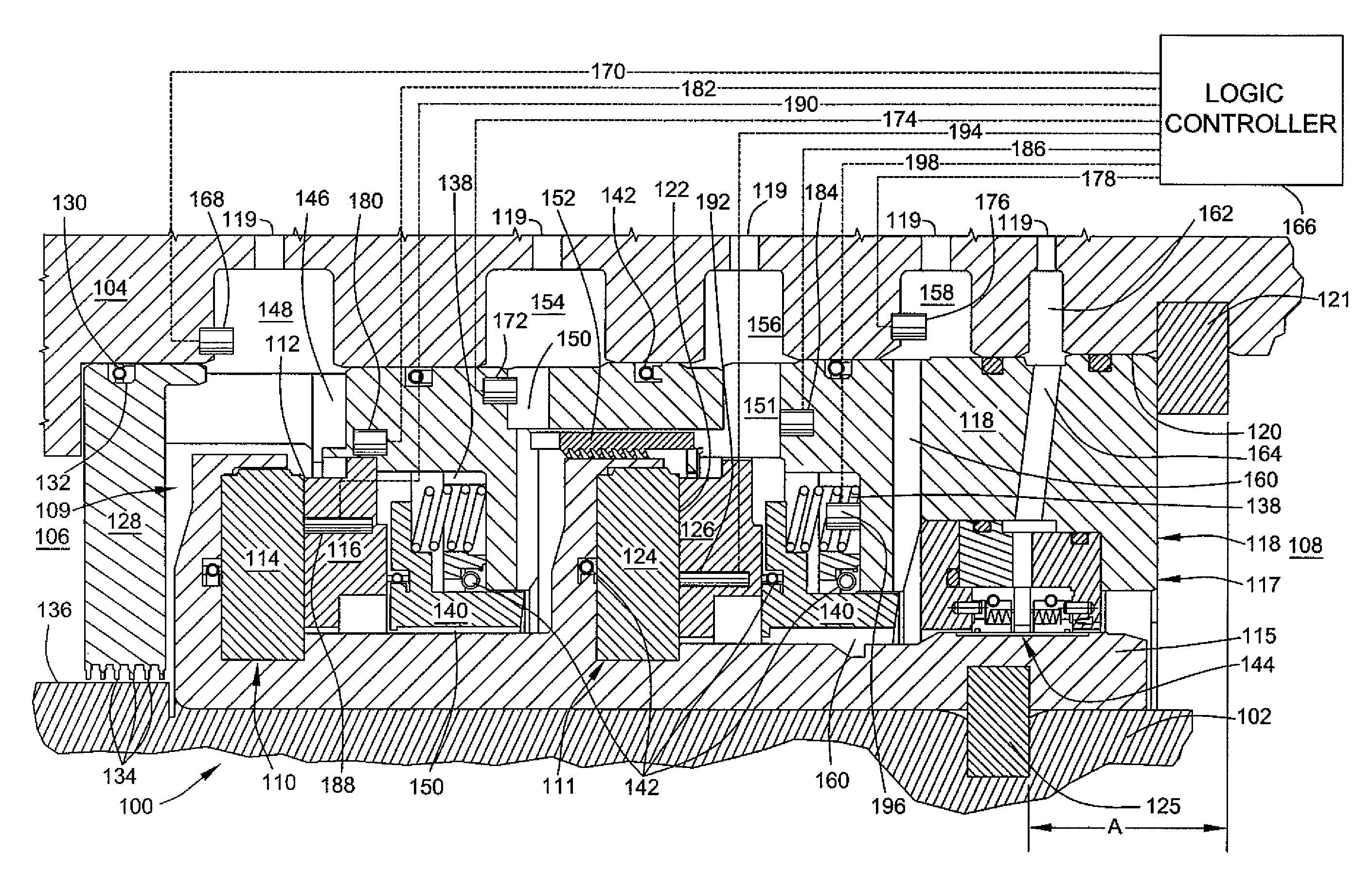

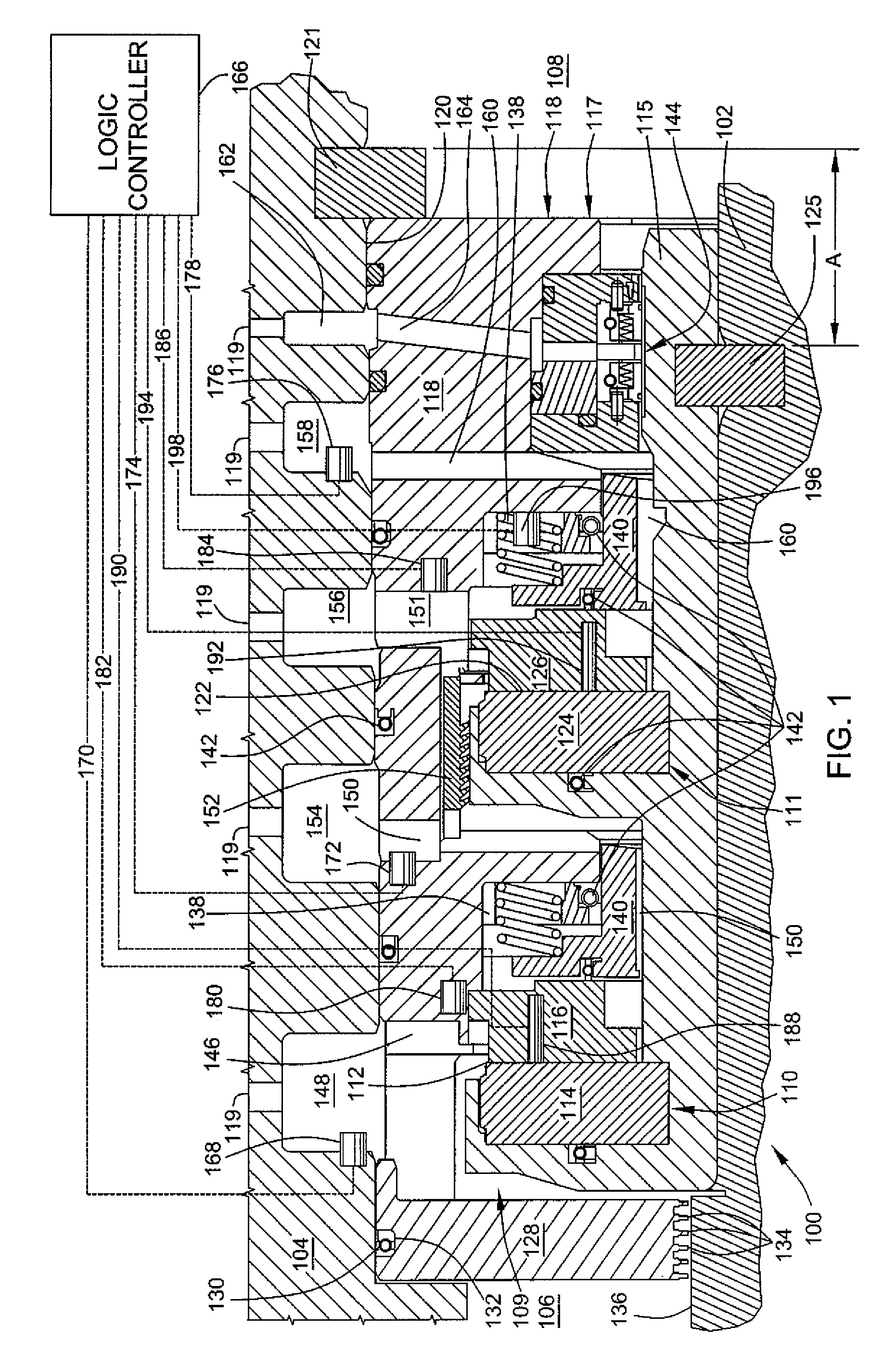

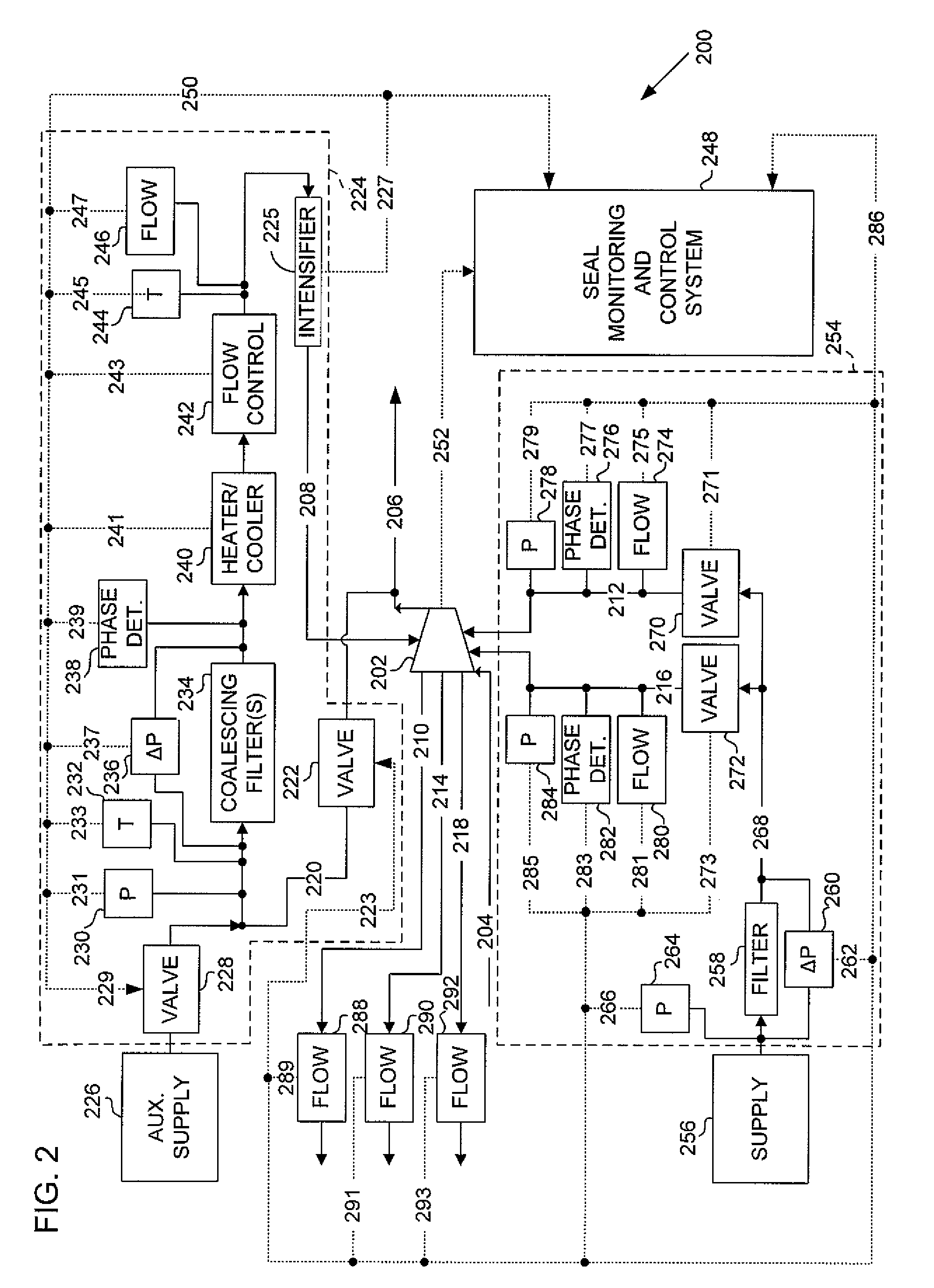

Seal monitoring and control system

A seal monitoring and control system for a gas lubricated non-contacting seal includes various sensors providing signals to a programmable logic control system. The control system is disposed to determine a presence of an anomalous operating condition of the seal, for example, based on phase, relative position of rotor to stator or other signals in combination provided by the various sensors to provide an output signal, which in one embodiment performs at least one mitigating process to correct the anomalous operating condition by adjusting at least one operating parameter of the seal.

Owner:JOHN CRANE INC

Combination of a cylinder liner and a piston ring

InactiveUS20080053396A1Reduce wearImprove the immunityPiston ringsCylinder headsPiston ringSurface roughness

The disclosed is a combination of a cylinder liner and a piston ring which contacts to a inner circumference surface of the cylinder liner at the pressure of 0.03 to 0.2 MPa, wherein the composition of the cylinder liner includes, silicon: 23.0 to 28.0% by weight, magnesium: 0.80 to 2.0% by weight, copper: 3.0 to 4.5% by weight, iron: 0.25% by weight or less, nickel: 0.01% by weight or less, and the rest: unavoidable impurities and aluminum, and wherein surface roughness profile of the inner circumference surface has Rz 0.5 to 1.0 μm, Rk=0.2 to 0.4 μm, Rpk=0.05 to 0.1 μm, Rvk=0.08 to 0.2 μm, meanwhile, wherein the composition of a piston ring includes carbon: 0.6 to 0.7% by weight, chrome: 13 to 14% by weight, molybdenum: 0.2 to 0.4% by weight, silicon: 0.25 to 0.50% by weight, manganese: 0.2 to 0.5% by weight, and the rest: unavoidable impurities and iron, and wherein carbides with the diameter of 5.0 μm and less are contained at the area rate of 4 to 10%, and the surface roughness of an outer circumference sliding surface is Rz=0.8 μm or less, and RPk=0.15 μm or less.

Owner:NIPPON PISTONRING CO LTD

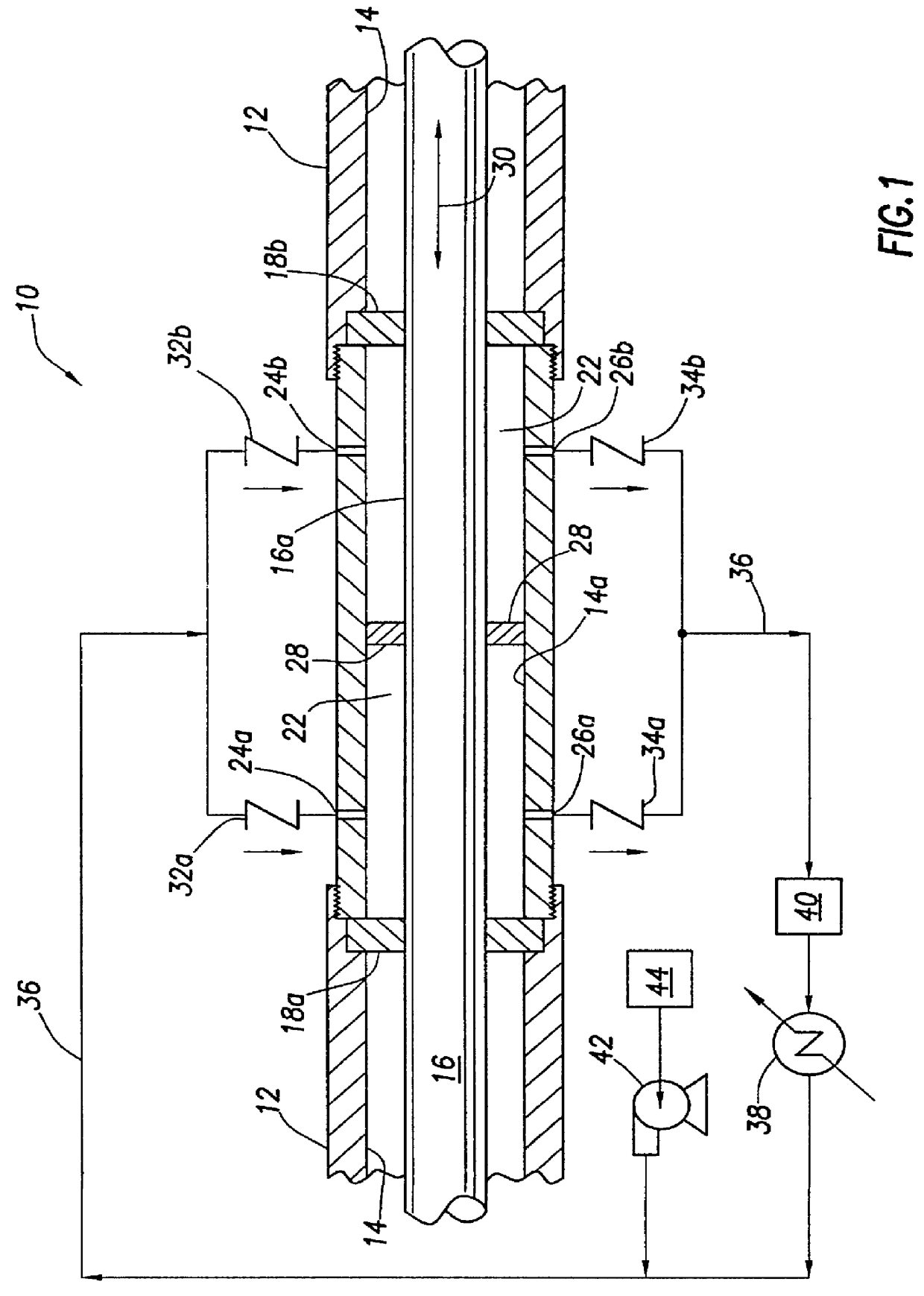

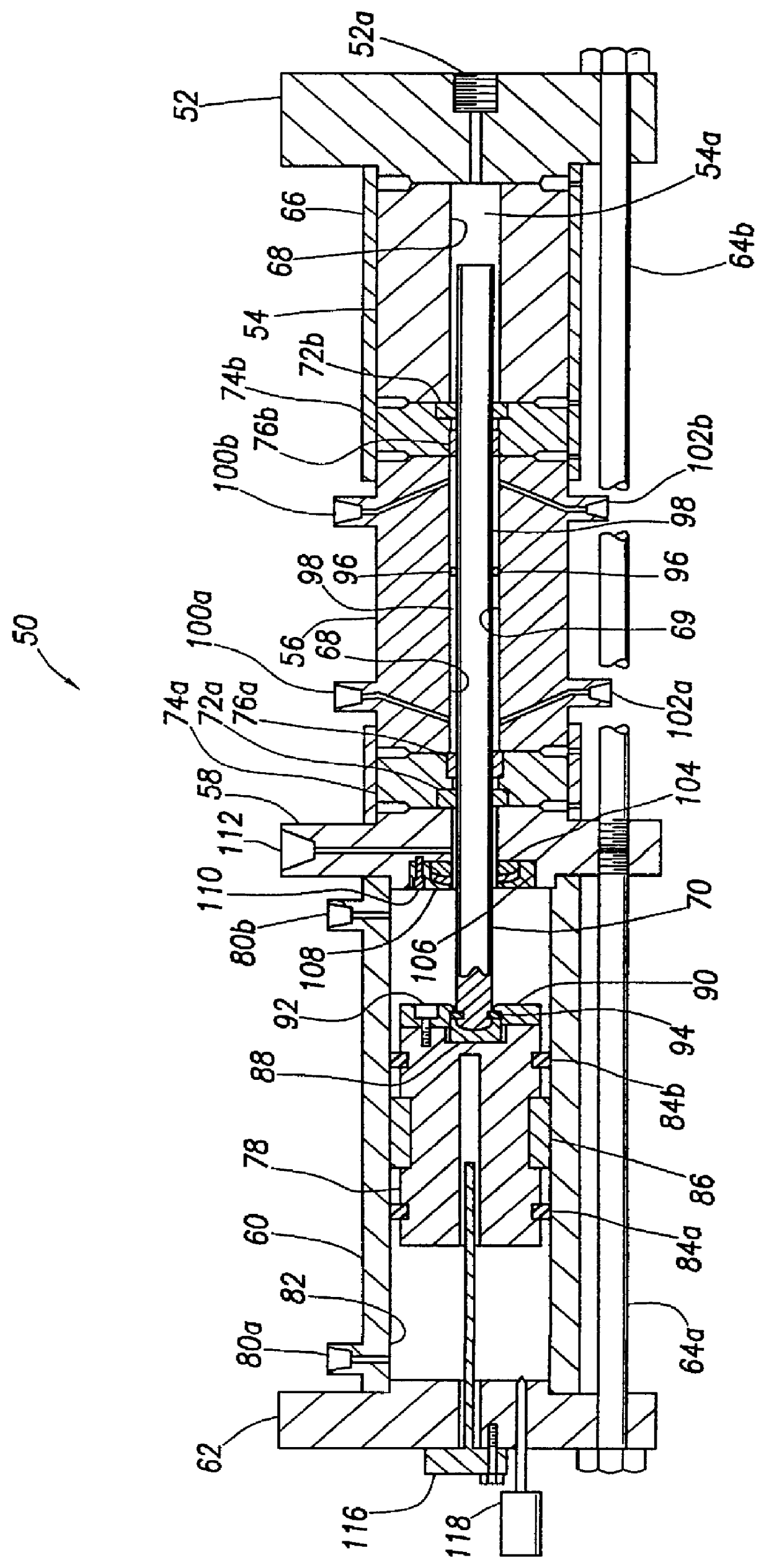

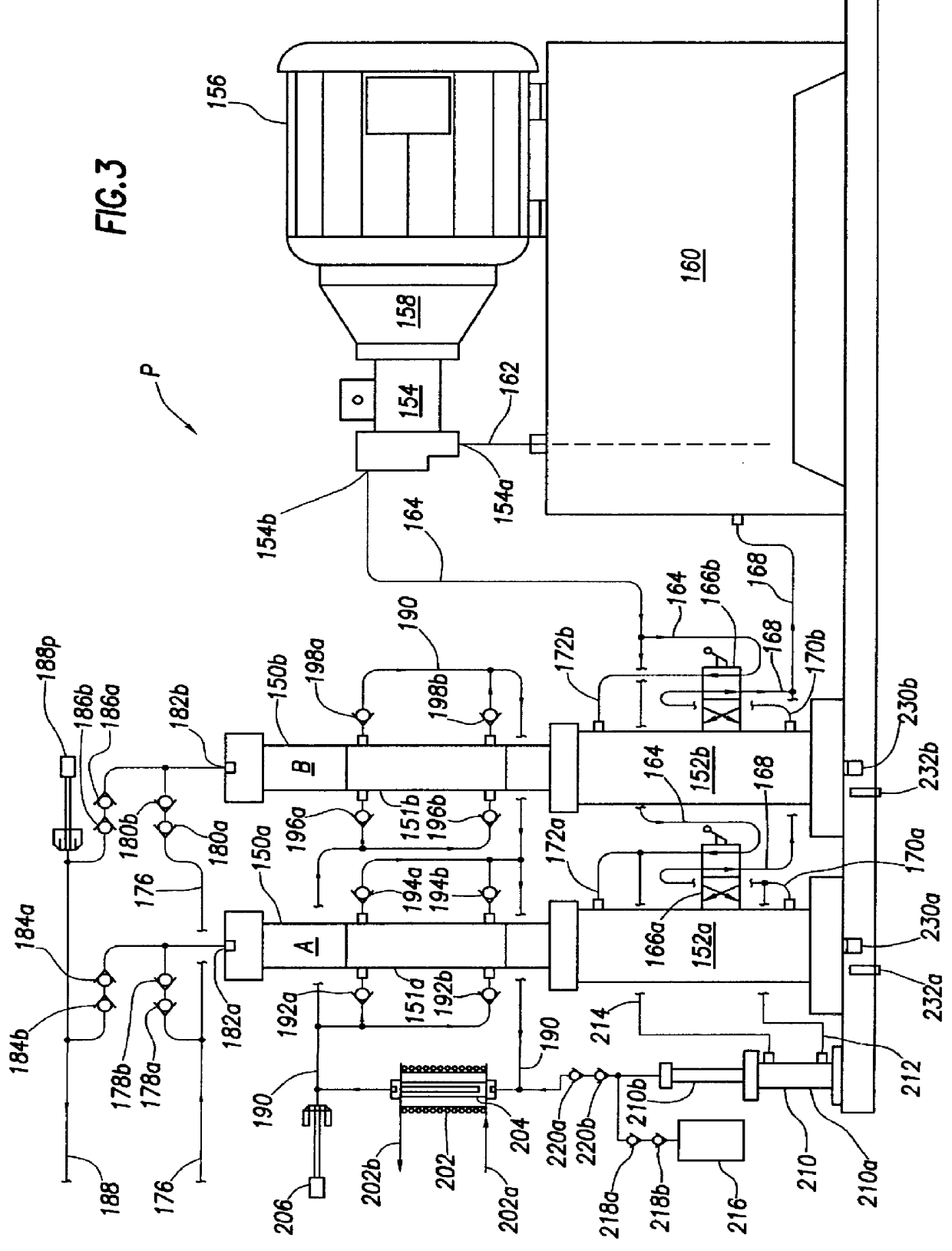

Barrier fluid seal, reciprocating pump and operating method

A barrier fluid seal assembly is provided for a reciprocating rod, where the reciprocation of the rod is used to pump barrier fluid through a barrier fluid chamber. The rod has first and second seals, and the barrier fluid chamber is located between the seals. Barrier fluid pressure is maintained higher than process fluid pressure so that if there is leakage past the seals, then it is barrier fluid that leaks, which keeps the seals clean and flushed. A reciprocating pump may incorporate the barrier fluid seal assembly for sealing around a plunger. A method of operating first and second reciprocating pumping cylinders provides bumpless transfer of pumping from one pumping cylinder to the other pumping cylinder. Motion controls, such as a controller using a position transducer for a hydraulic piston and a servo-valve for providing hydraulic fluid to the hydraulic piston, are used to compress liquid process fluid in one pumping cylinder prior to beginning its pumping stroke. A total plunger speed is determined for plungers in pumping cylinders A and B, and total plunger speed is held essentially constant prior to hand-off of pumping from one pumping cylinder to another pumping cylinder. The speed of one plunger is increased before it enters its pumping stroke while the speed of the other plunger is decreased an equal amount as it reaches the end of its pumping stroke.

Owner:TEXAS PRESSURE SYST

Portable sensing light

InactiveUS6956493B1Low costImprove moisture resistanceEngine sealsPiston ringsMotion sensingEngineering

A motion-sensing light includes a power cord with a plug to be plugged into an electrical outlet. In one embodiment, the light is moisture-resistant, allowing the light to be used outdoors with a suitable electrical outlet. The light may be mounted on a wall with nails or screws, hung from a hook, or a mounting bracket that holds the lamp in a desired orientation, yet allows removal and re-insertion of the light.

Owner:YOUNGBLOOD TENA

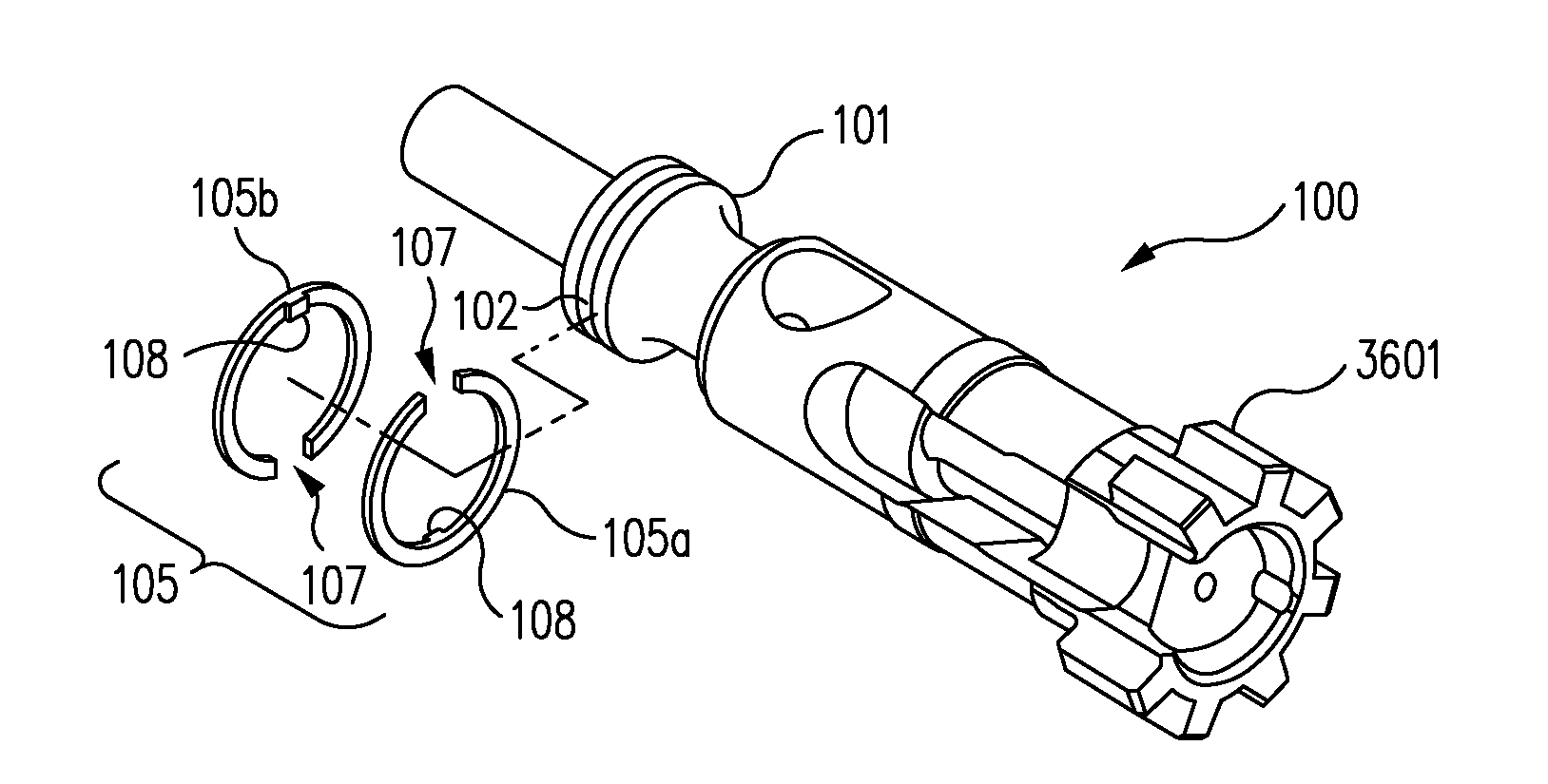

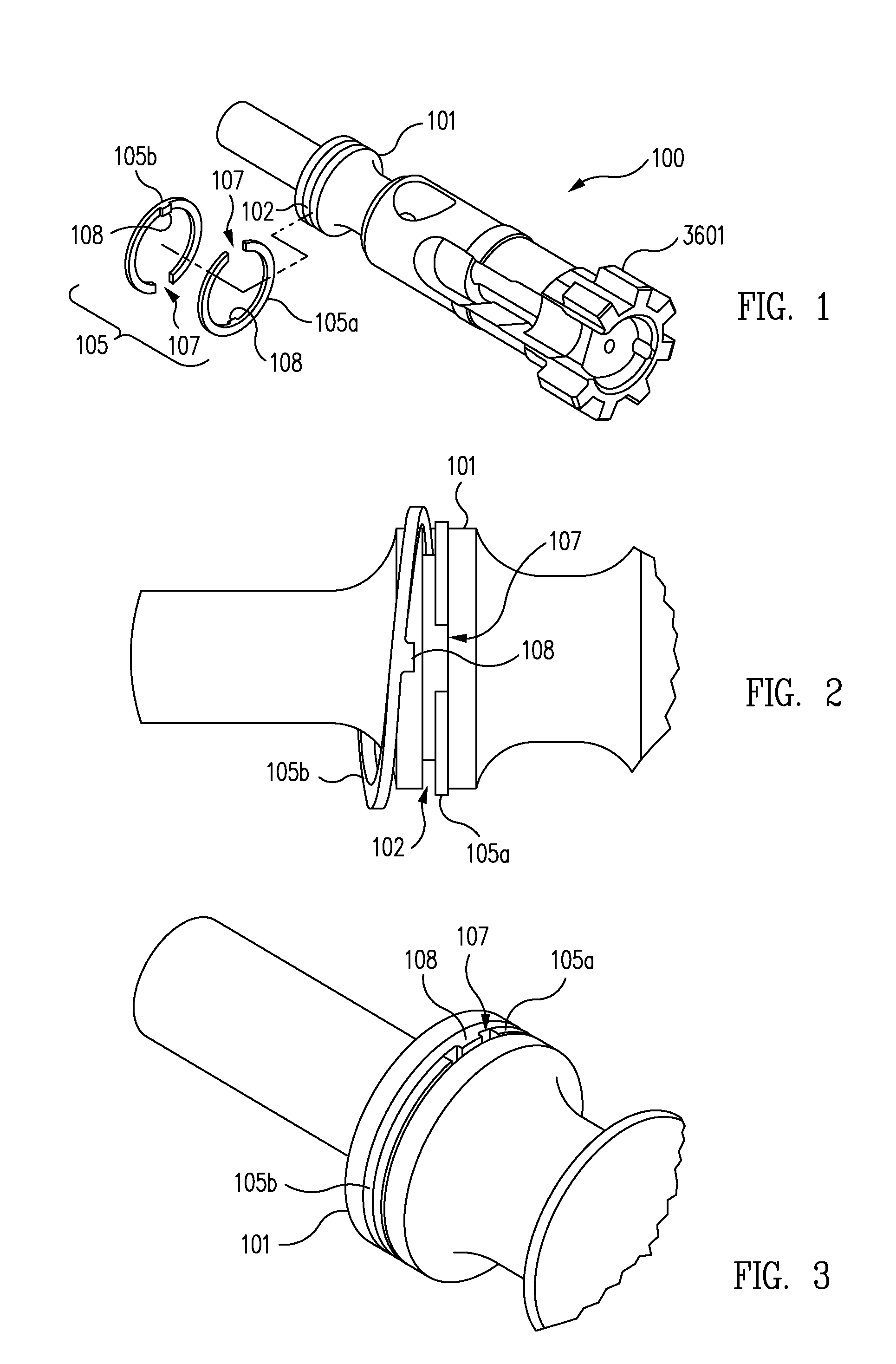

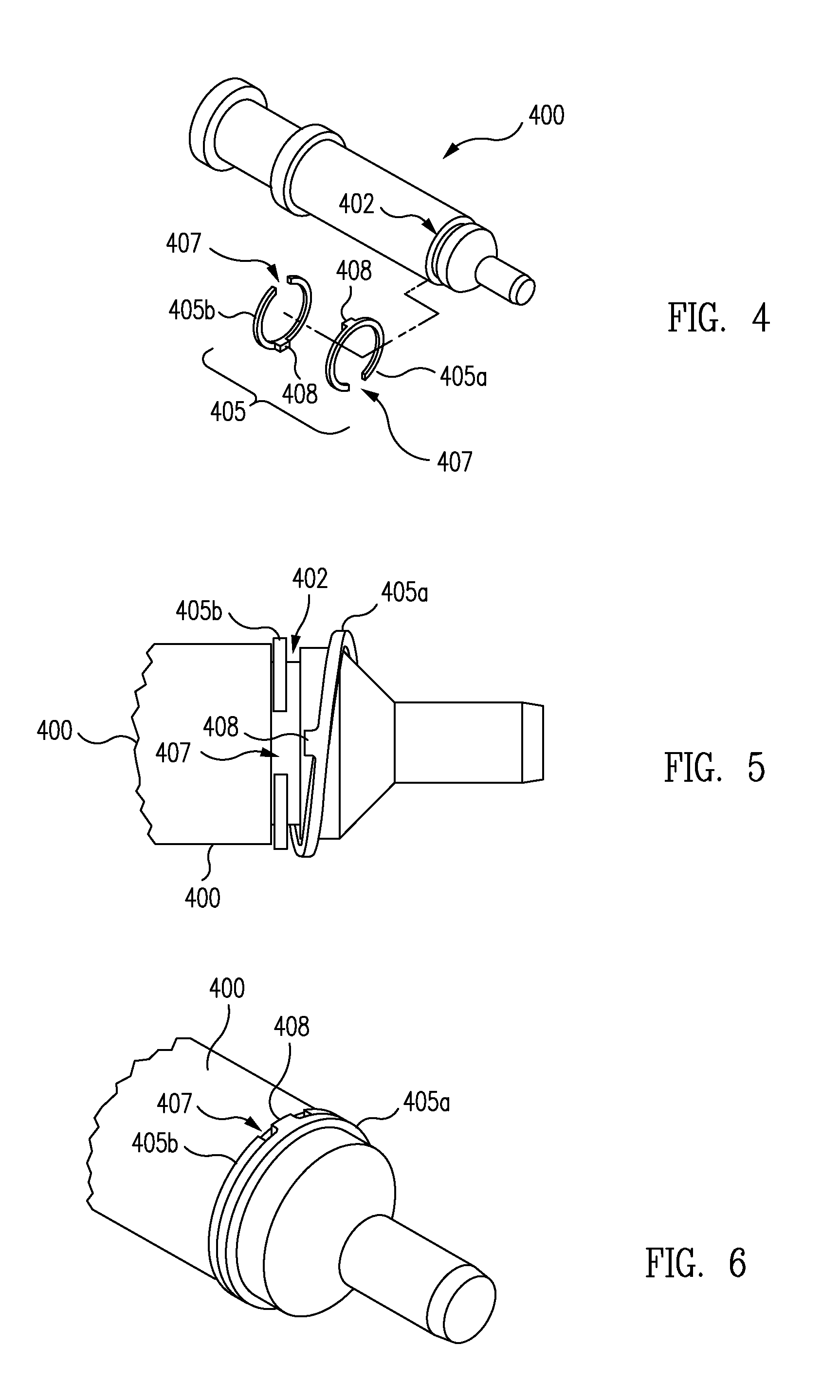

Firearm

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is at least approximately 1.3 times that of a standard M16 / M4. A piston can be formed on the bolt and can have a plurality of rings that are configured to cooperate with the piston to mitigate gas leakage past the piston. Each of the rings can have a key formed thereon and a gap formed therein such that the gap of one ring is configured to receive at least a portion of the key of another ring. The bolt carrier can have a double cut cam.

Owner:ARMWEST

Mechanical seal assembly

A split mechanical composite seal assembly for providing a seal between a rotating shaft and a static surface. The split mechanical composite seal assembly includes first and second axially adjacent annular seal elements. The first and second seal elements each include a sealing edge contacting the shaft to provide a respective seal between the first and second seal element and the shaft. A static housing receives the first and second seal elements and engages the static surface to provide a static stationary seal, while concomitantly providing a flex region that engages the seal elements to form a dynamic seal therewith. A holder assembly receives one seal element and may include a double-angled lead-in to facilitate installation of the seal element. The holder assembly may include a detent groove for receiving and retaining an O-ring disposed about the seal element. The static housing may comprise two mating segments having overlapping surfaces.

Owner:A W CHESTERTON

Seal performance for hydrogen storage and supply systems

InactiveUS8251373B2Increase forceImprove sealingEngine sealsElectrolysis componentsSurface roughnessElectrochemistry

The performance and durability of static and dynamic seals for hydrogen storage and supply systems has been improved by utilizing a spring-energized and plastic coated radial seal in combination with at least a mating surface that has been treated by one of a variety of procedures. These procedures include applying to the mating surface a low-friction, hard, and hydrogen impervious coating, chemically polishing the mating surface, and electrochemically polishing the mating surface. Each of these procedures significantly reduces, on a microscopic scale, the surface roughness of the mating surface. The seal can thus form a tighter and more gas-tight seal with the smoother mating surface so as to decrease the loss of hydrogen gas across the seal. The smoother mating surface can also improve seal life by reducing seal surface wear.

Owner:GM GLOBAL TECH OPERATIONS LLC

Sliding member and production process thereof

ActiveUS20050100701A1Excellent low-friction characteristicIncreased durabilityPiston ringsVacuum evaporation coatingCarbon coatingMetallurgy

There is provided a sliding member including a base body and a hard carbon coating formed on the base body to define a sliding surface for sliding contact with an opposing member under lubrication according to one embodiment of the present invention. The hard carbon coating has an outermost surface portion lower in hydrogen content than a remaining portion thereof, or an outermost coating layer lower in hydrogen content than at least one other coating layer.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com