Patents

Literature

560results about How to "Guaranteed long-term operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

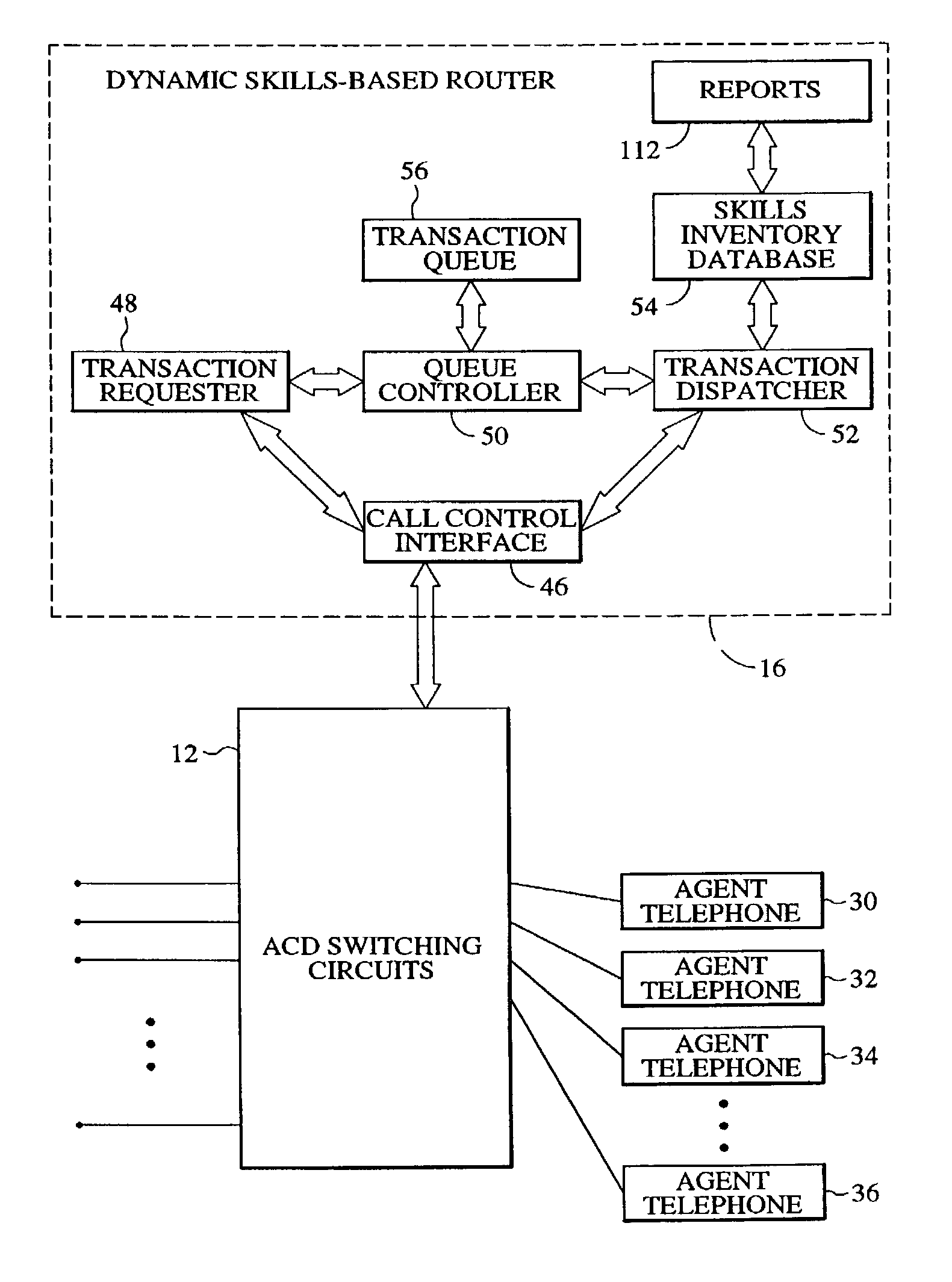

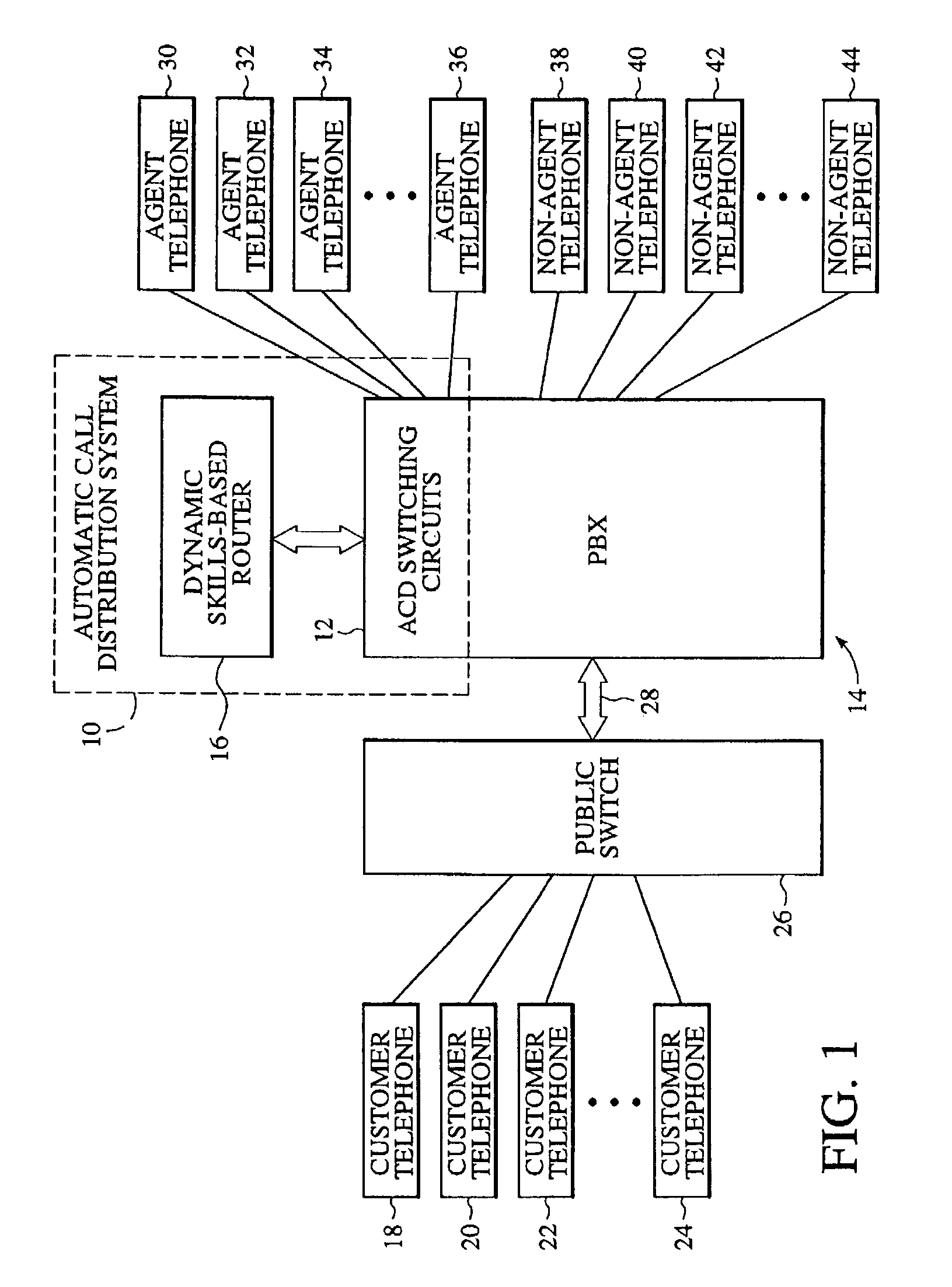

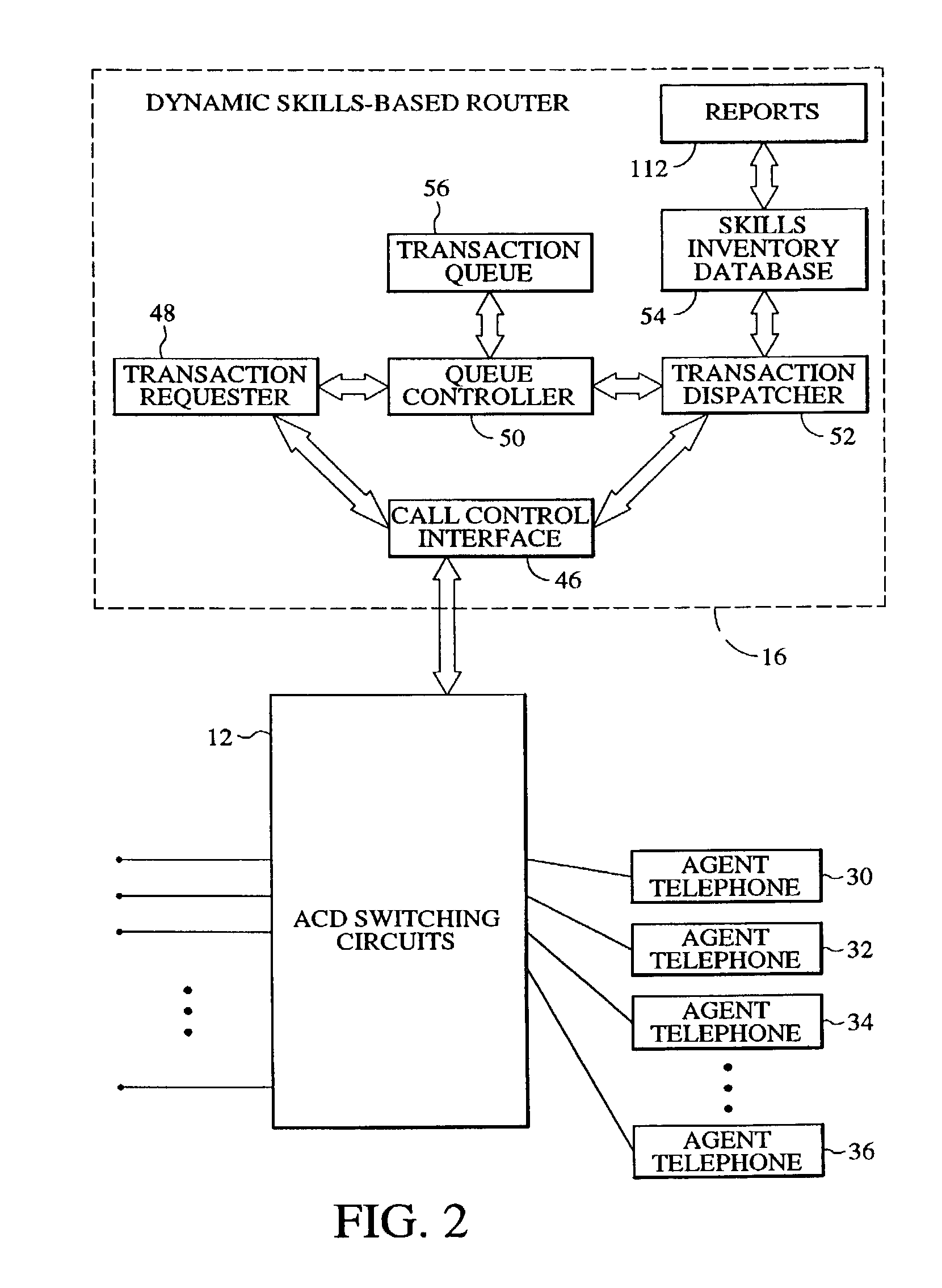

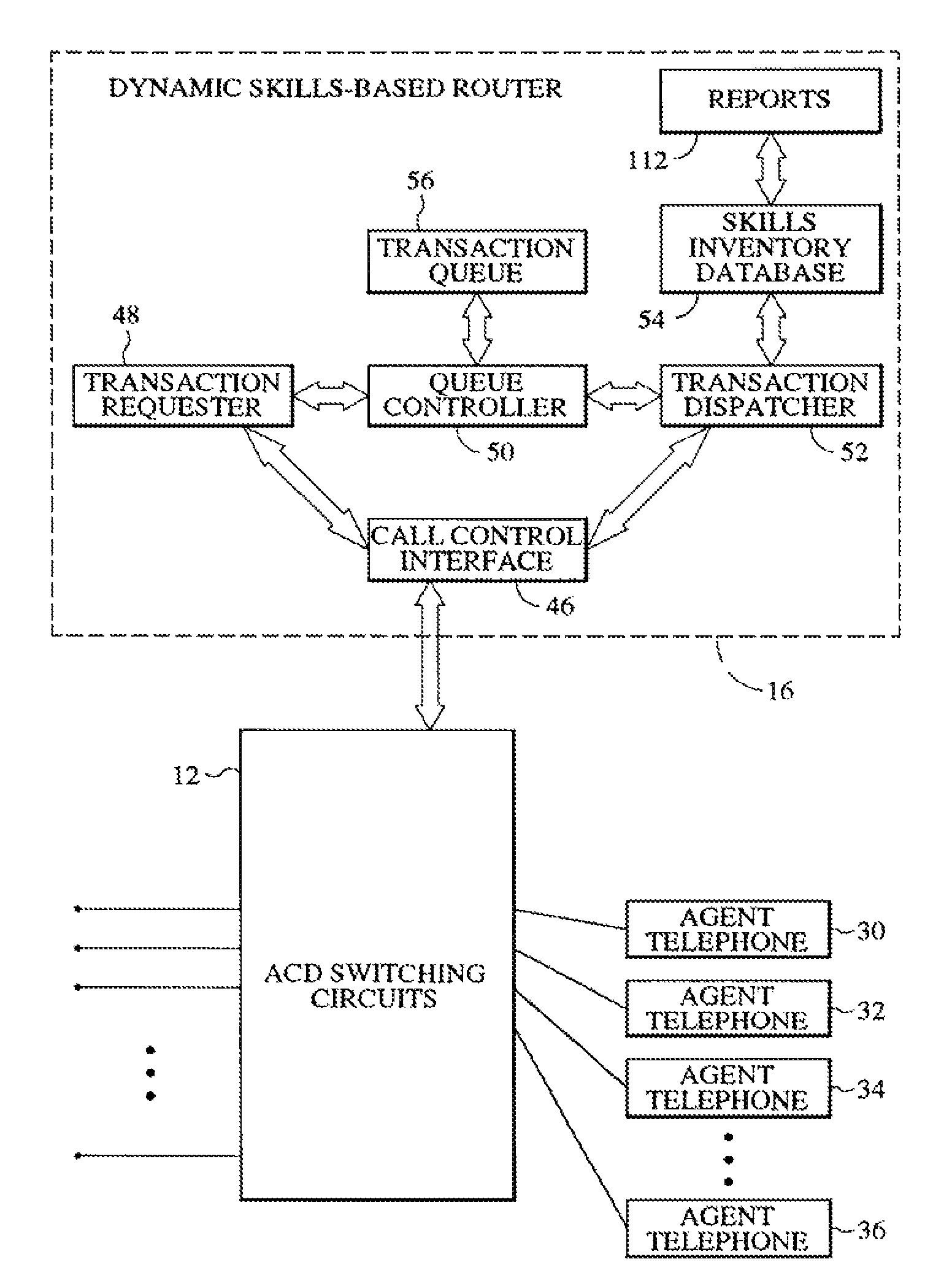

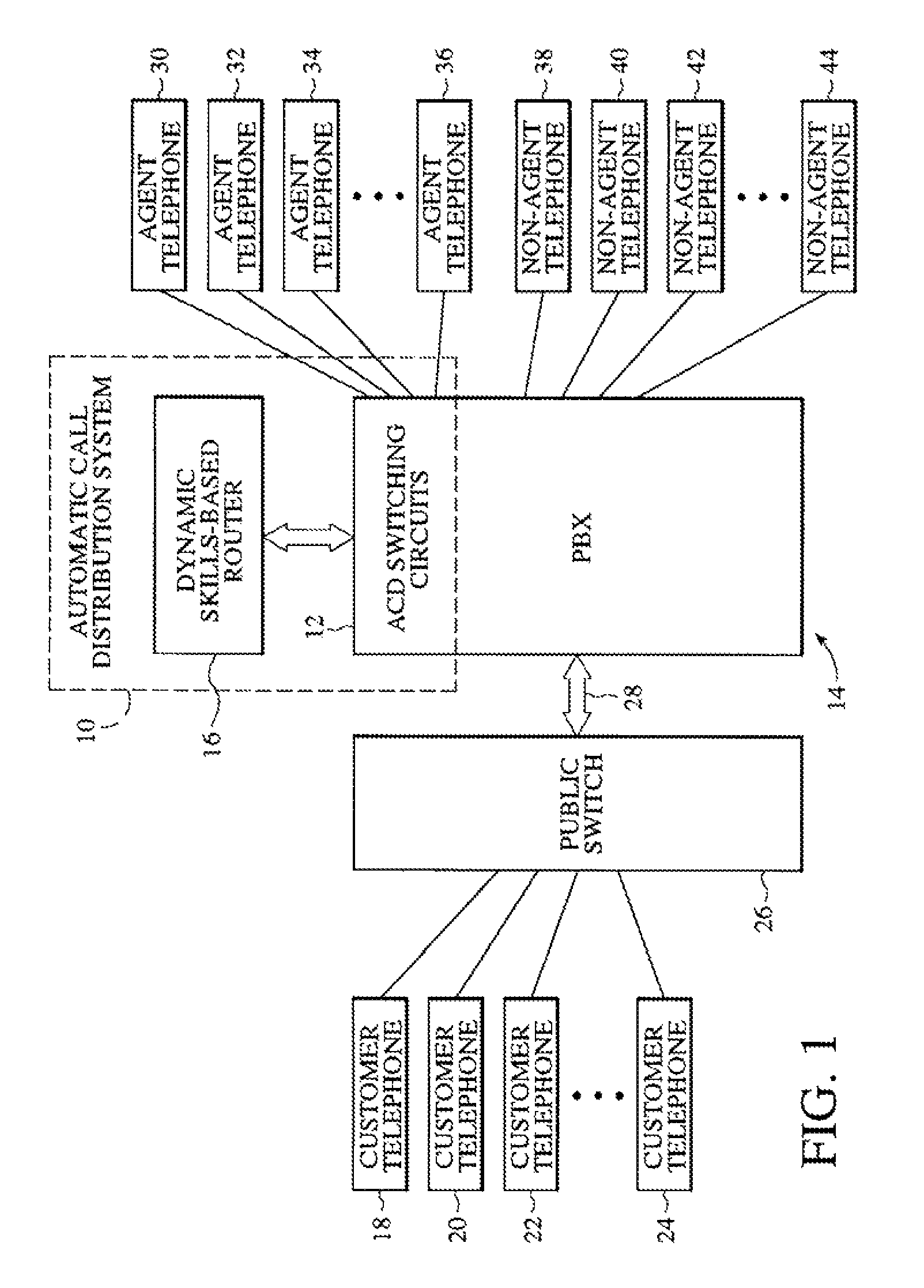

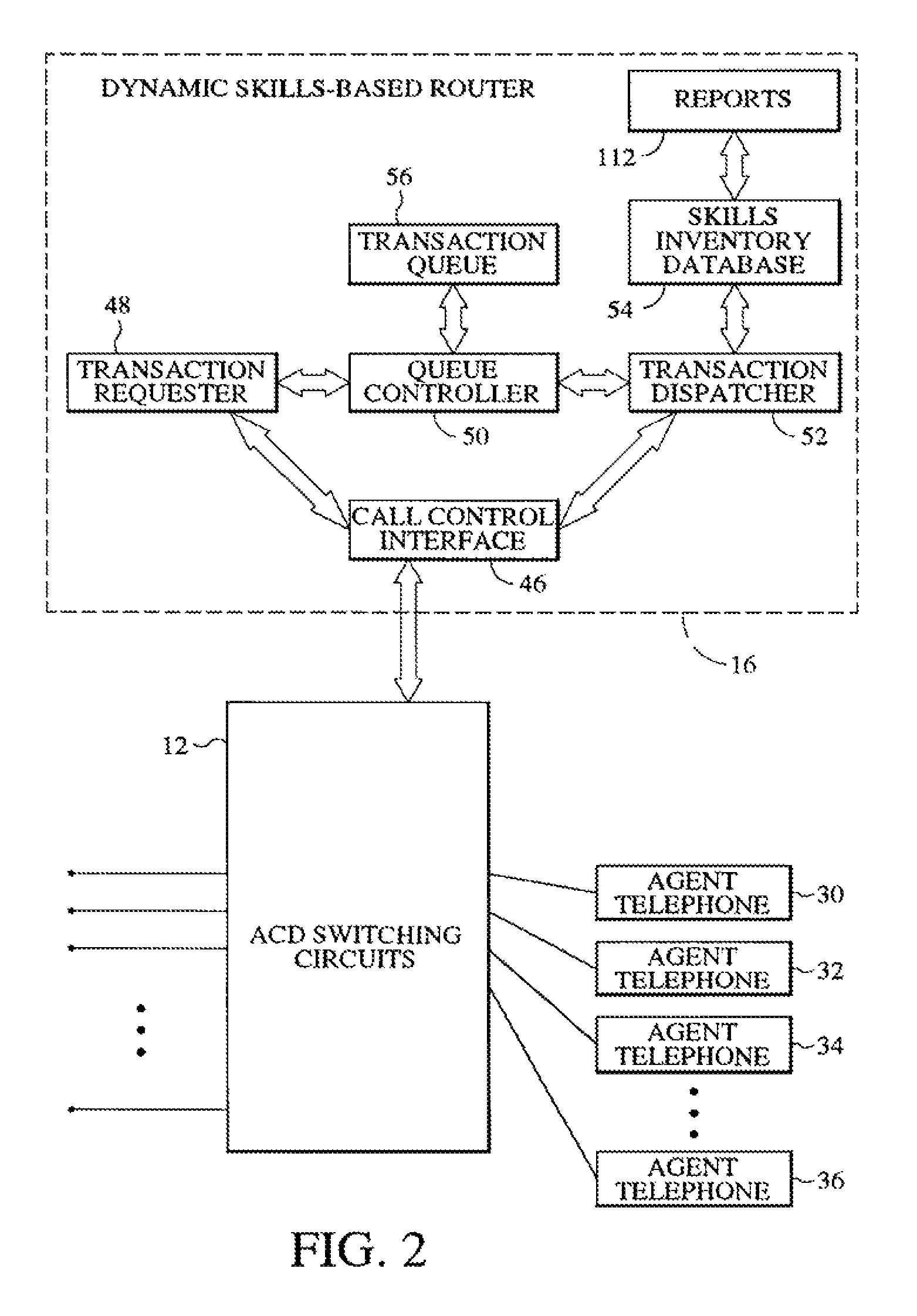

Agent training sensitive call routing system

InactiveUS7110525B1Optimize long-term call center operationHigh short-term efficiencyManual exchangesAutomatic exchangesSkill setsCall routing

A call-management method and system for distributing calls to agents, wherein each agent has a profile, e.g., defining agent skills, efficiency, etc. The call center management system implements an algorithm for selecting an agent to receive a call to optimize caller utility, call center efficiency, and agent training. Therefore, the algorithm does not seek to necessarily route a call to the agent having the skill set most suited to the call; rather, the call may be routed to an agent who needs experience in the area of the call, and thus serves as a training exercise. Skilled agents may be made available to shadow the training agent when available.

Owner:HELLER TOBY +1

Agent training sensitive call routing system

InactiveUS7916858B1Guaranteed long-term operationImprove efficiencyManual exchangesAutomatic exchangesSkill setsCall routing

A call-management method and system for distributing calls to agents, wherein each agent has a profile, e.g., defining agent skills, efficiency, etc. The call center management system implements an algorithm for selecting an agent to receive a call to optimize caller utility, call center efficiency, and agent training. Therefore, the algorithm does not seek to necessarily route a call to the agent having the skill set most suited to the call; rather, the call may be routed to an agent who needs experience in the area of the call, and thus serves as a training exercise. Skilled agents may be made available to shadow the training agent when available.

Owner:PATENT ARMORY INC

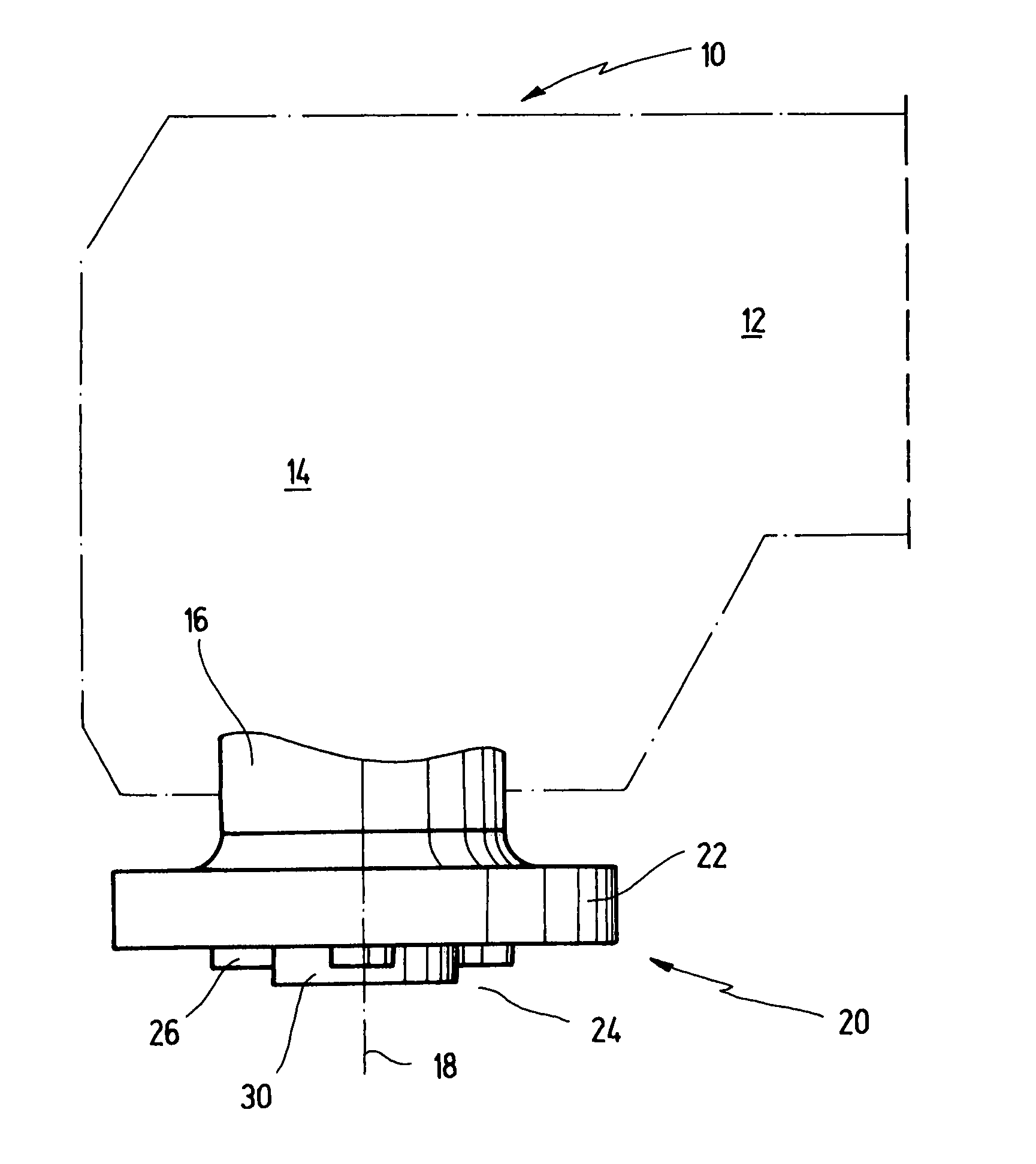

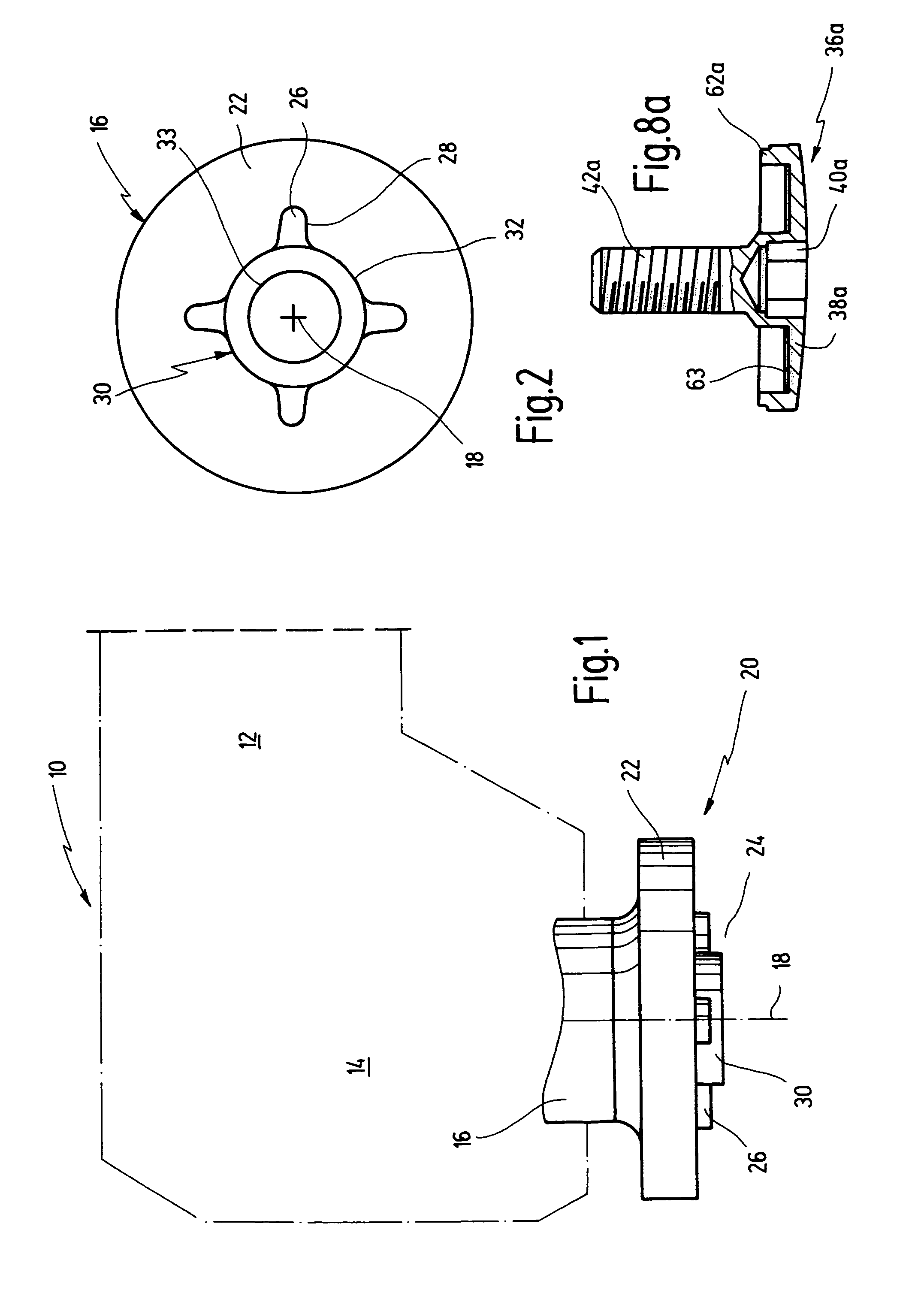

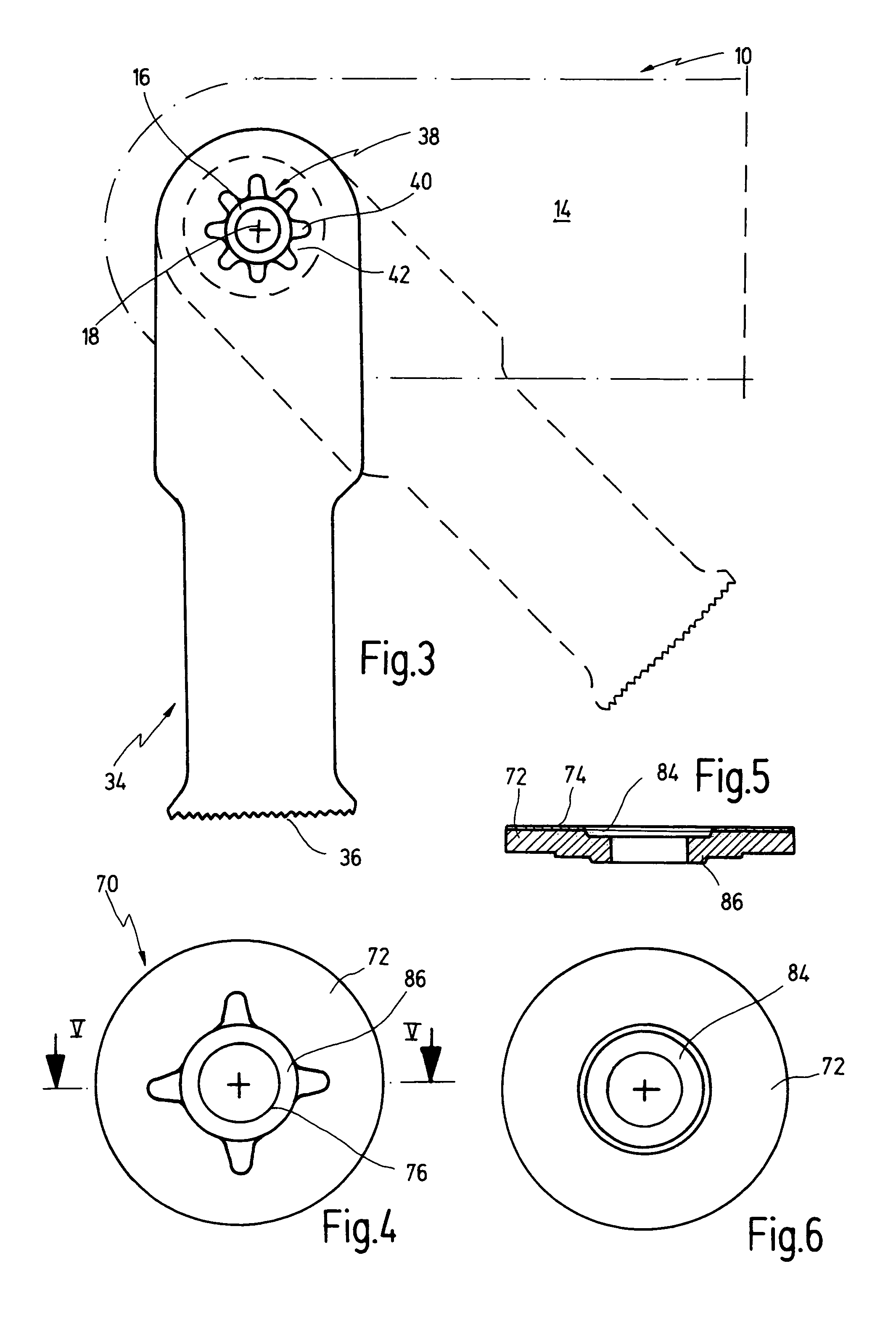

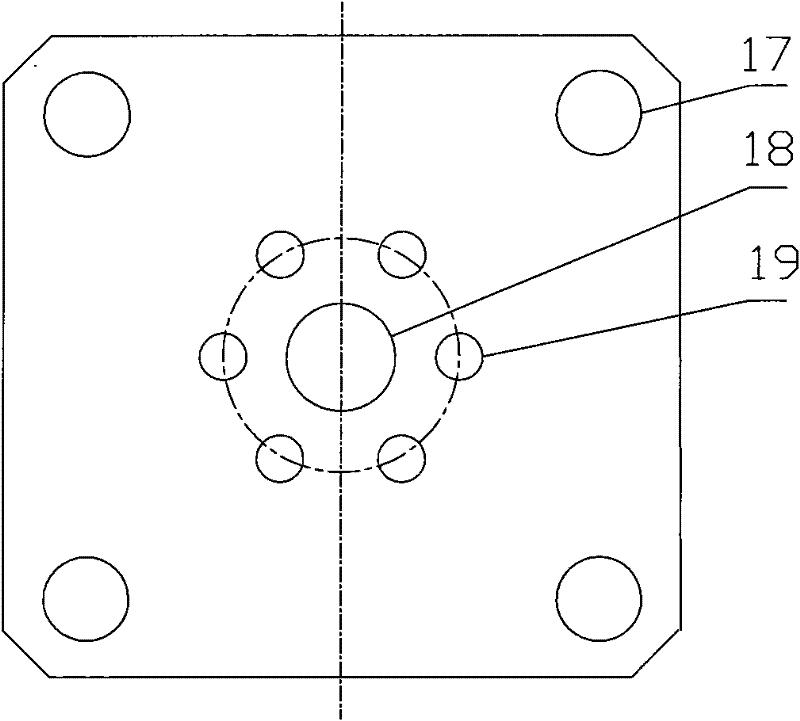

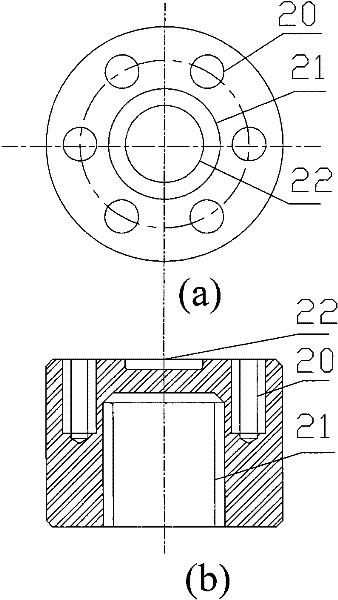

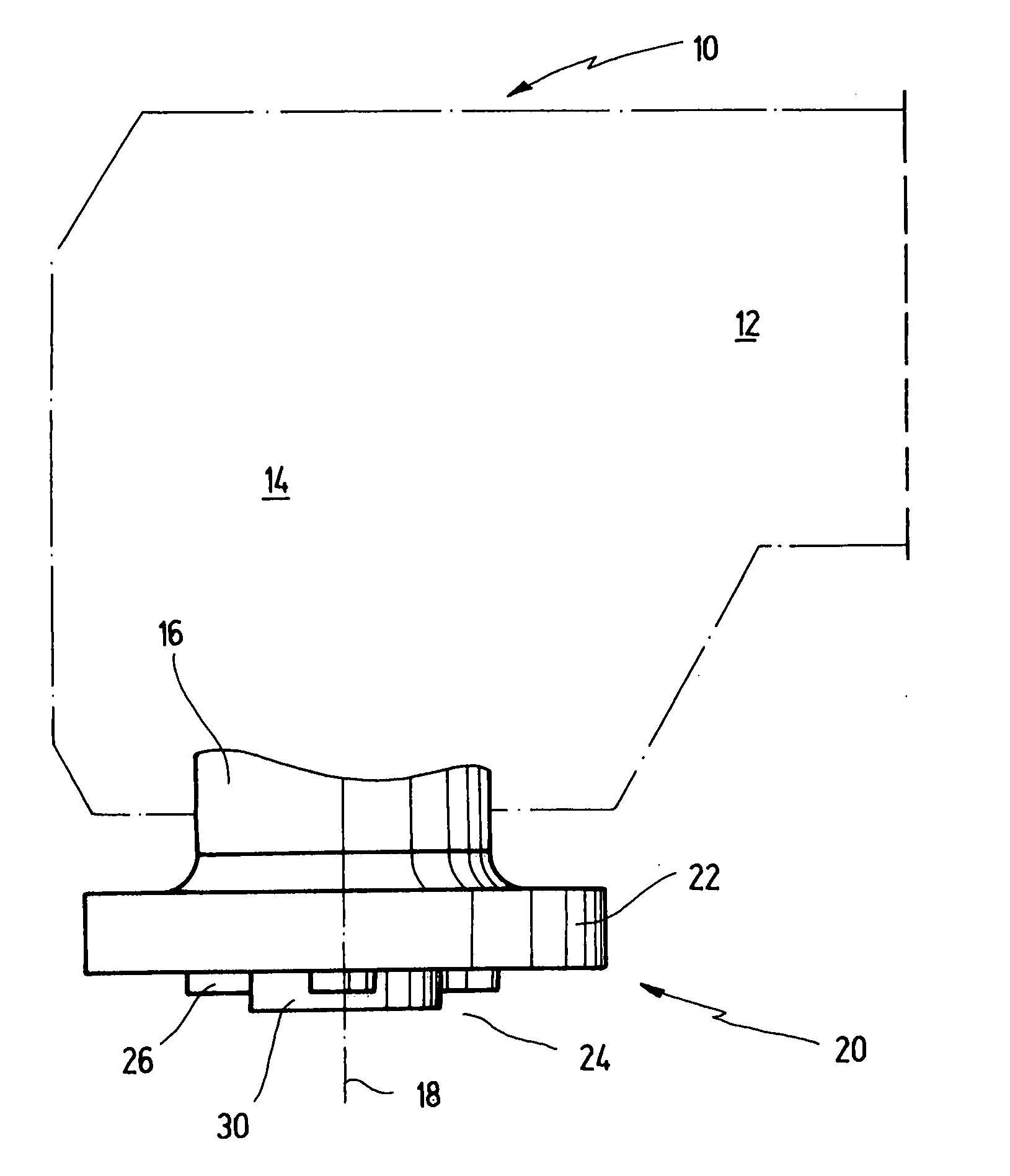

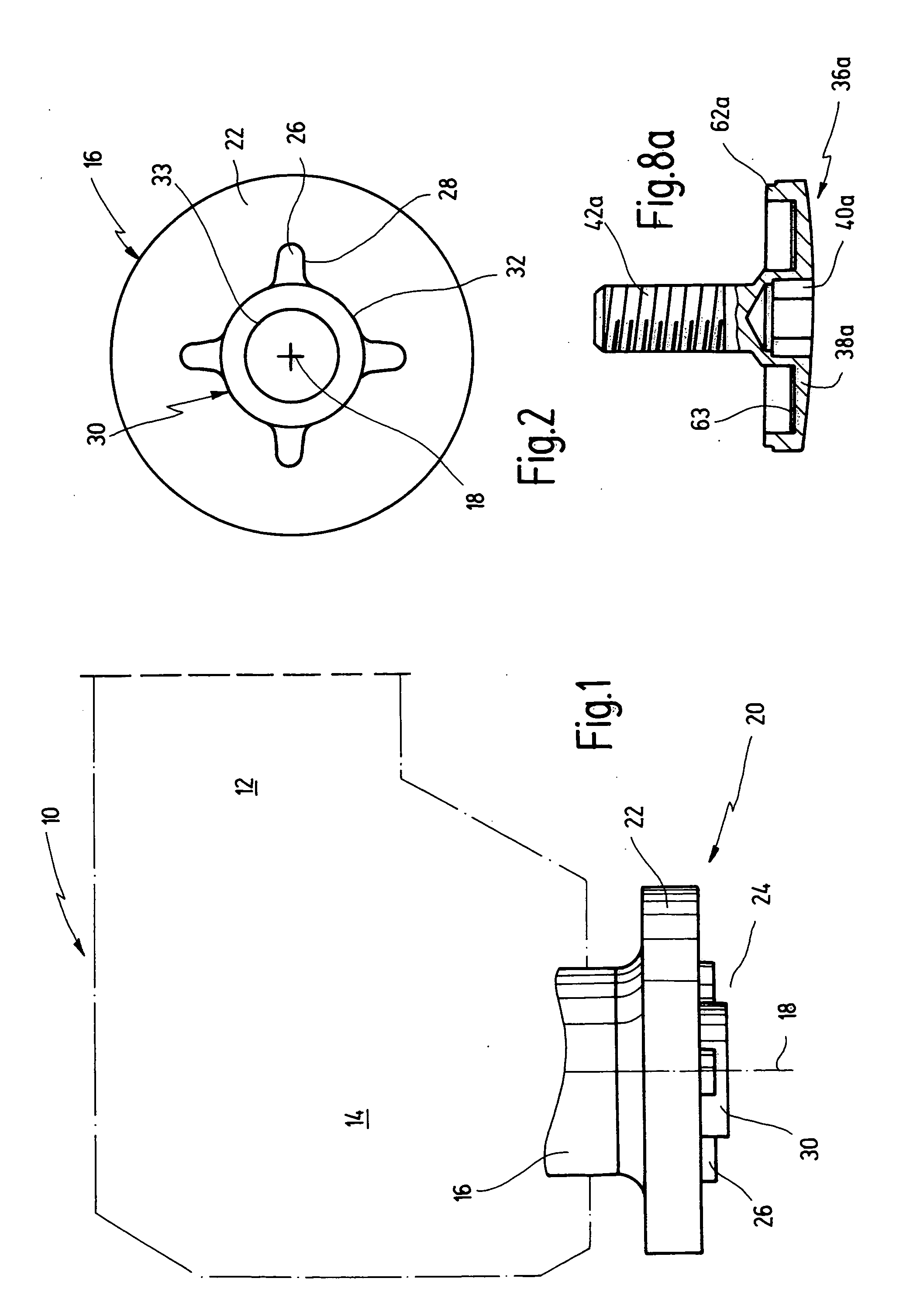

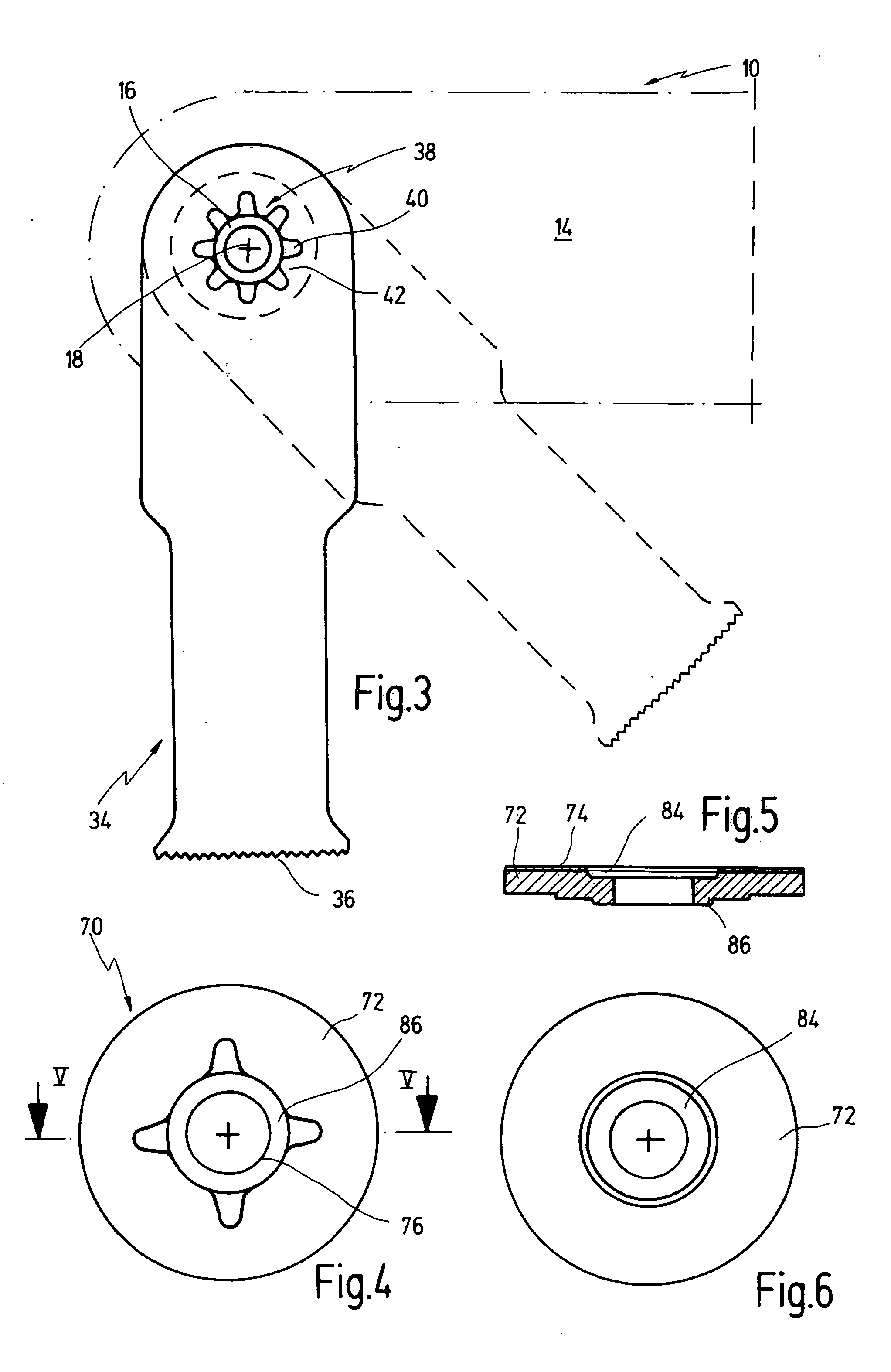

Power tool having a receptacle for securing a tool

InactiveUS6945862B2Reduce riskImprove transmittanceGrinding wheel securing apparatusMetal sawing toolsDrive shaftPower tool

A power tool having a receptacle for securing a tool to a drive shaft thereof is disclosed. The receptacle comprises a receiving opening, preferably being arranged on the tool. The receiving opening engages a securing section preferably being provided in a raised fashion on the drive shaft of the power tool, thereby effecting a positive fit. The securing section comprises a plurality of rounded tips arranged at even radial distances from said longitudinal axis, at angular intervals between each other, each rounded tip having a pair of lateral flanks extending from a common apex toward an intermediate section connecting lateral flanks of a pair of adjacent rounded tips. Preferably the receiving opening comprises a number of rounded tips which is twice the number of rounded tips provided on the raised section.

Owner:C & E FEIN GMBH & CO KG

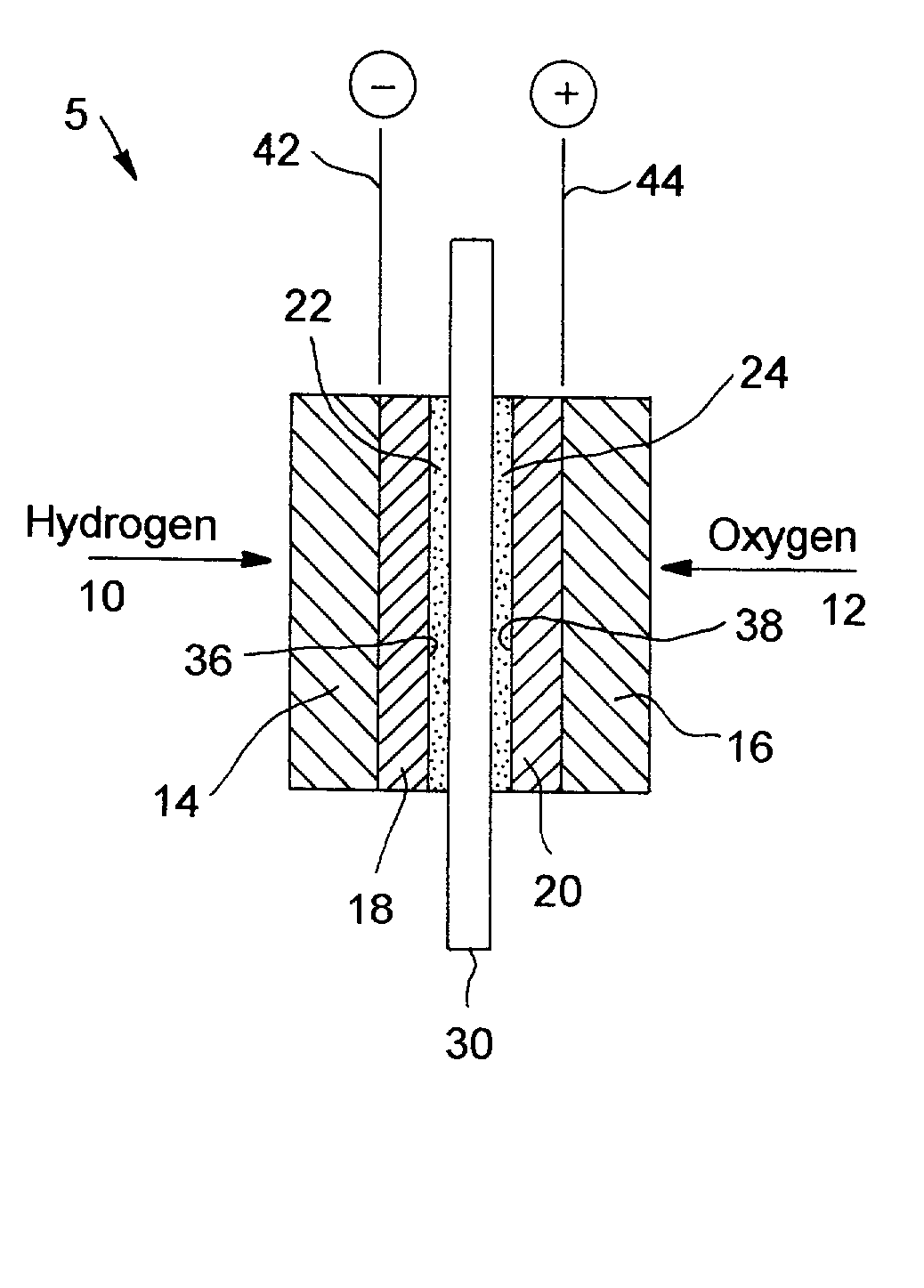

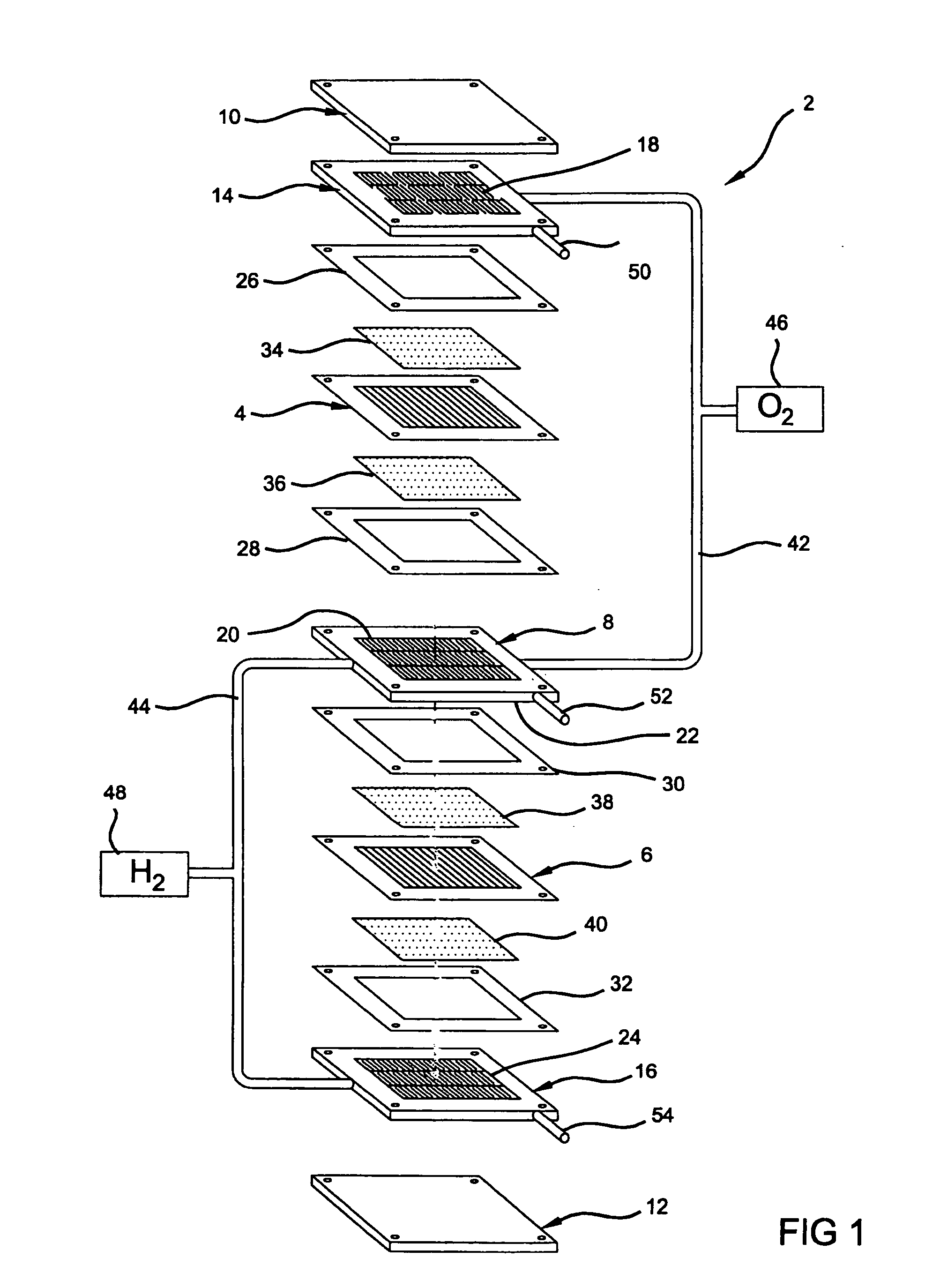

Fuel cells and other products containing modified carbon products

InactiveUS20030017379A1Decrease electrode performanceReduction of gas mass transport efficiencyOrganic diaphragmsAlkali metal halidesFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

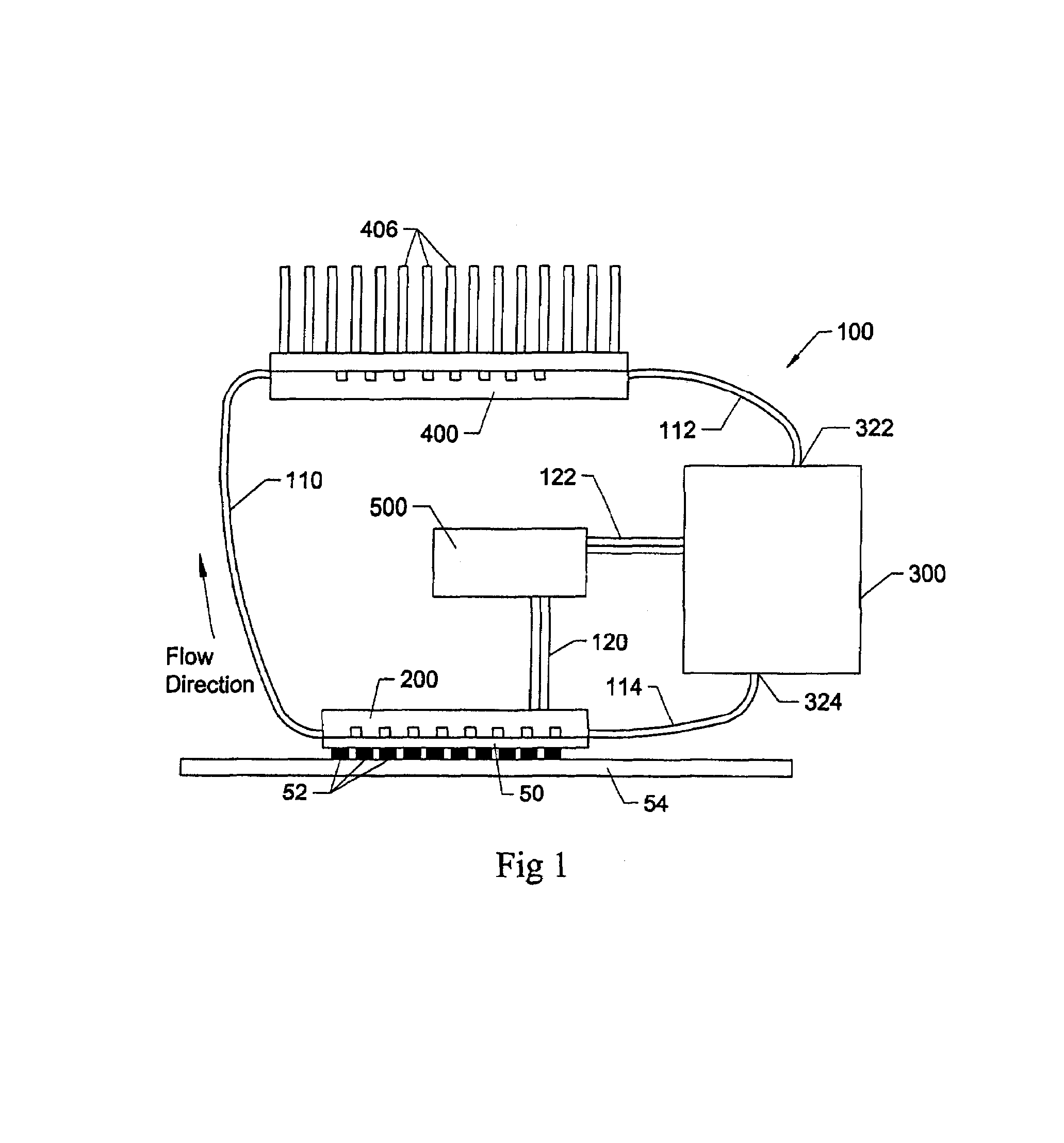

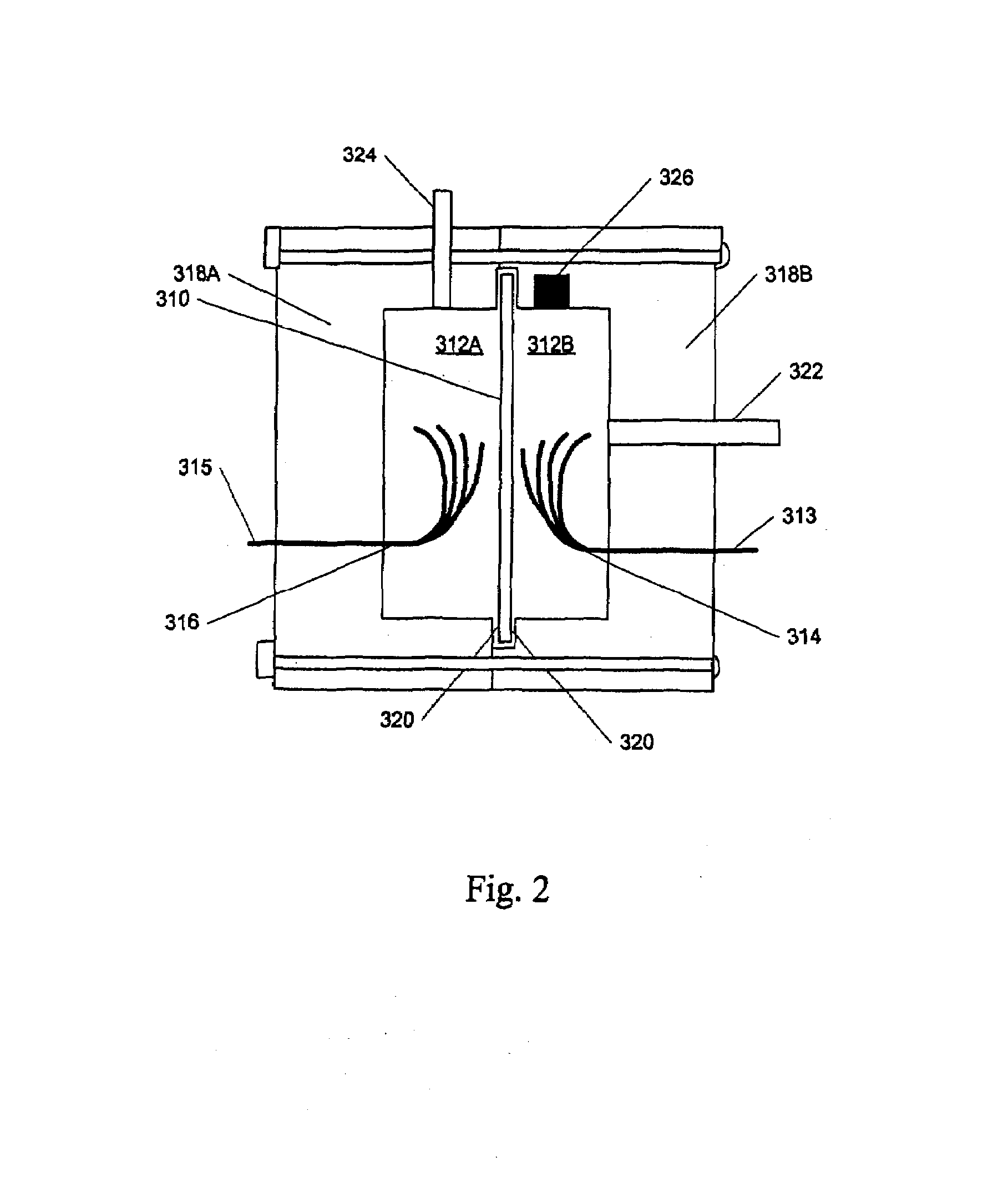

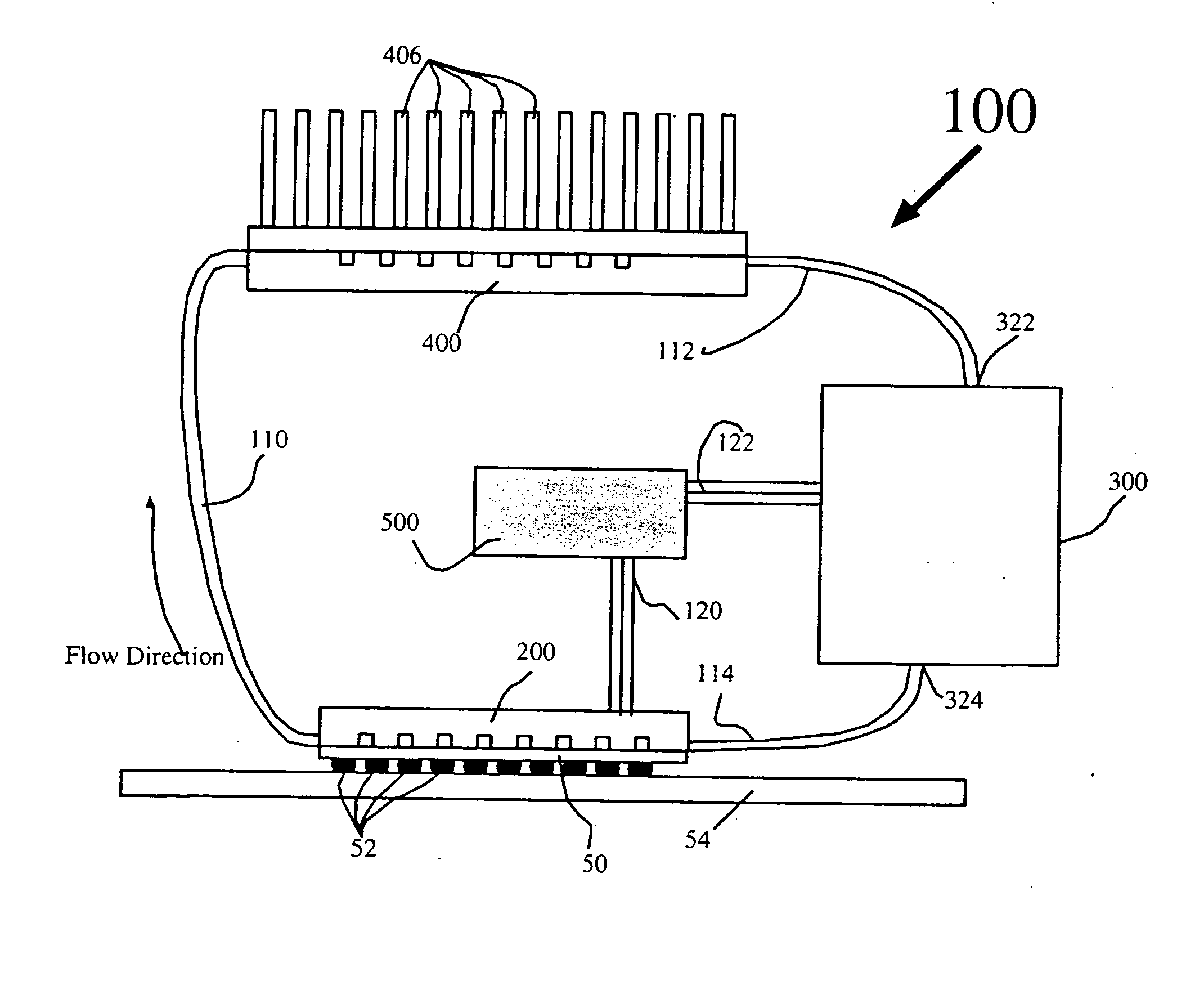

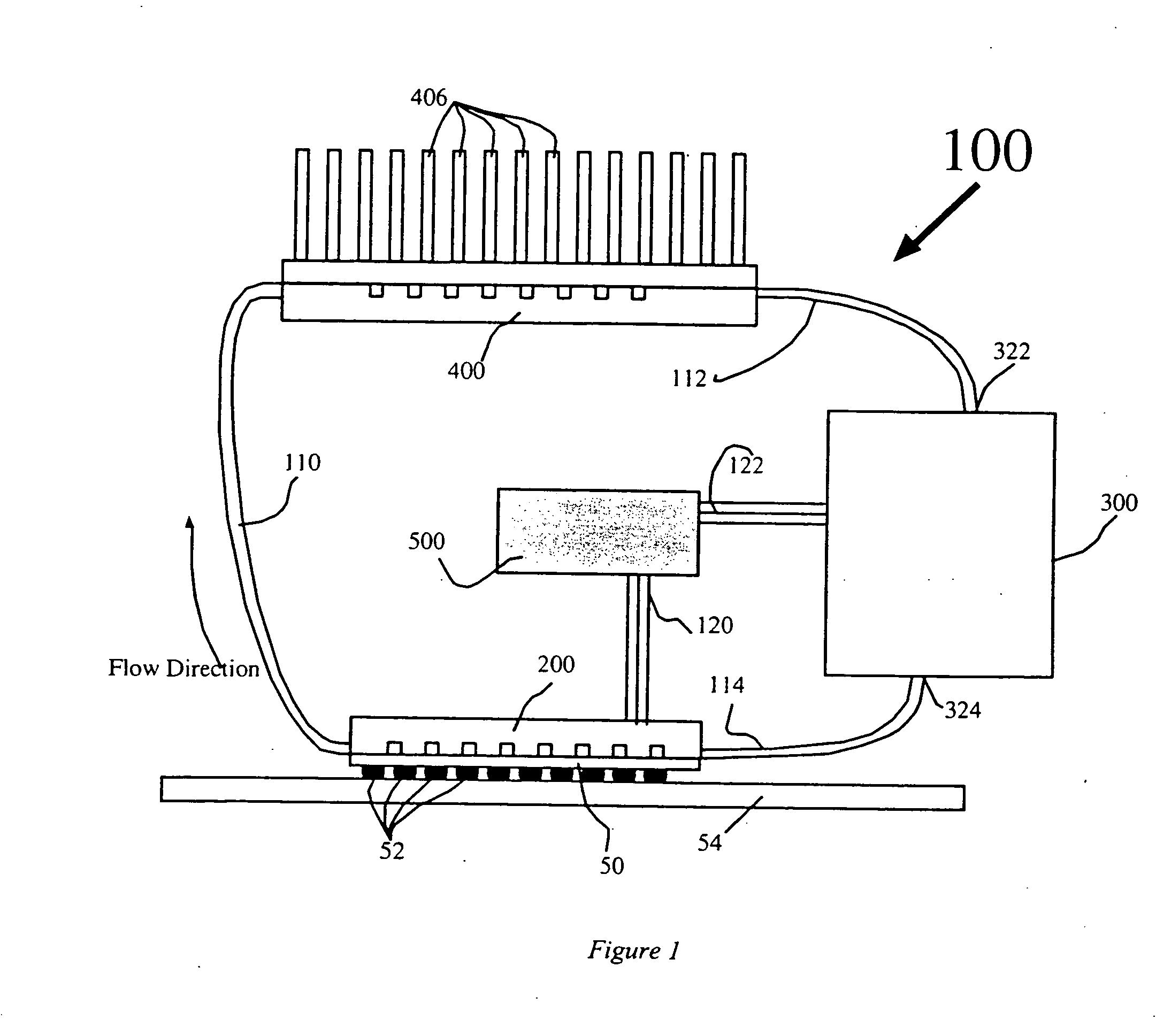

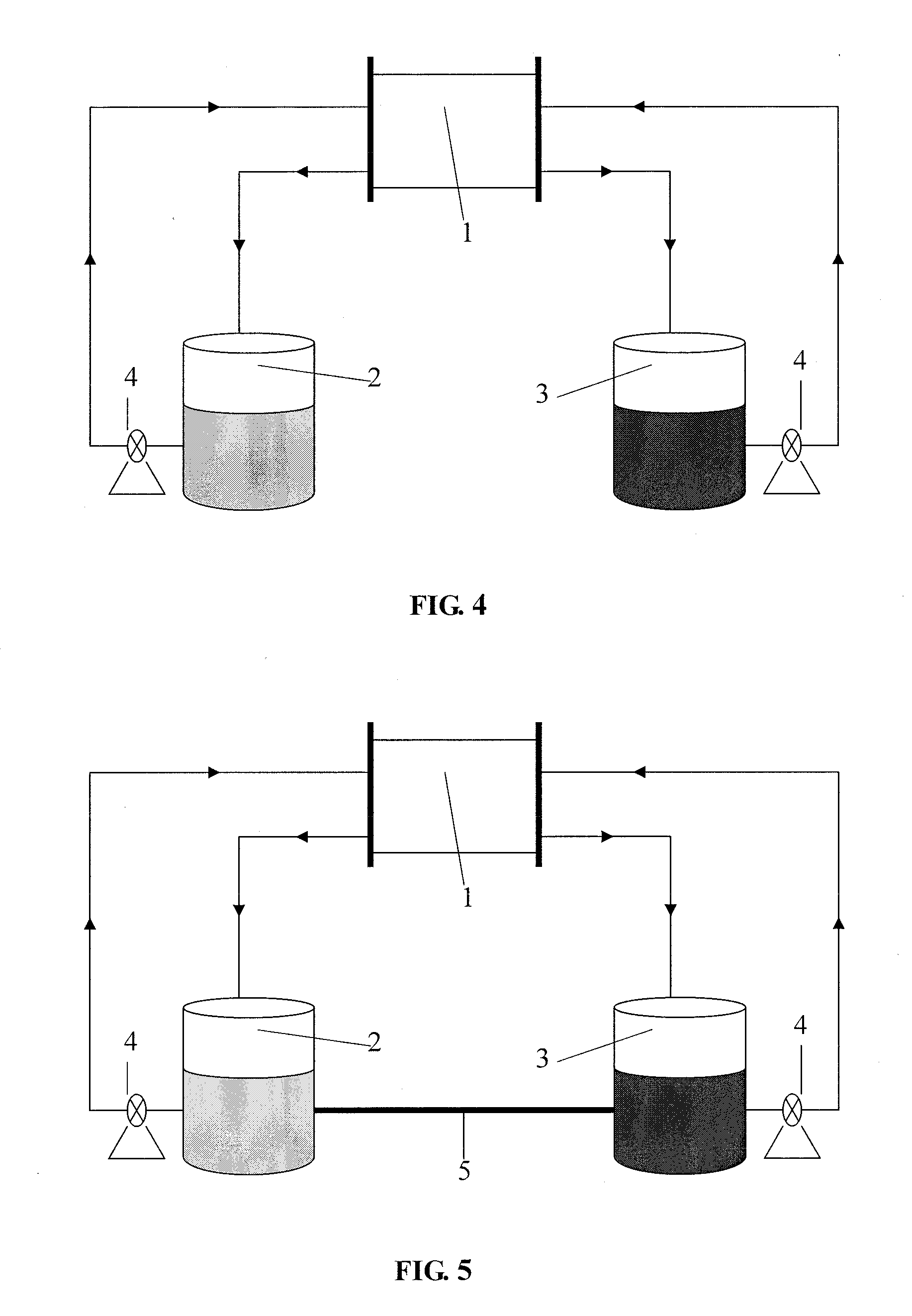

Control of electrolysis gases in electroosmotic pump systems

InactiveUS7134486B2Easy to shapeOptimize distributionFixed microstructural devicesSemiconductor/solid-state device detailsElectricityRe entry

Apparatus and methods according to the present invention preferably utilize electroosmotic pumps that are capable of generating high pressure and flow without moving mechanical parts and the associated generation of unacceptable electrical and acoustic noise, as well as the associated reduction in reliability. These electroosmotic pumps are preferably fabricated with materials and structures that improve performance, efficiency, and reduce weight and manufacturing cost relative to presently available micropumps. These electroosmotic pumps also preferably allow for control including venting or recapture of evolved gases and deposited materials, which may provide for long-term closed-loop operation. A gas permeable membrane removes and vents electrolytic gasses generated within the fluid chamber of the electroosmotic pump to ambient. A catalyst can be used to recombine electrolytic gases to form a vapor product that can be vented or condensed into a liquid state. An osmotic membrane provides for re-entry of condensed fluid to the fluid chamber.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

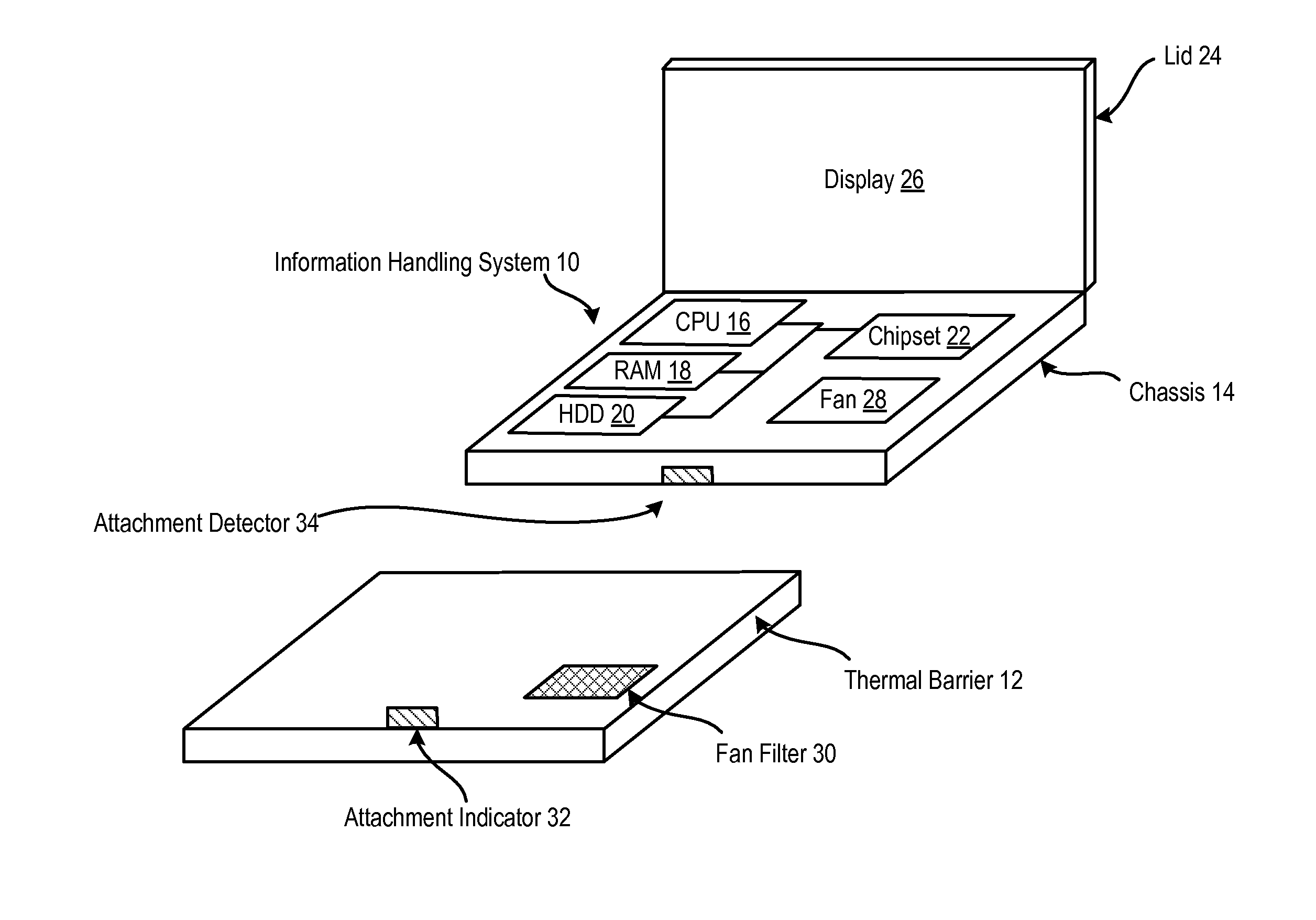

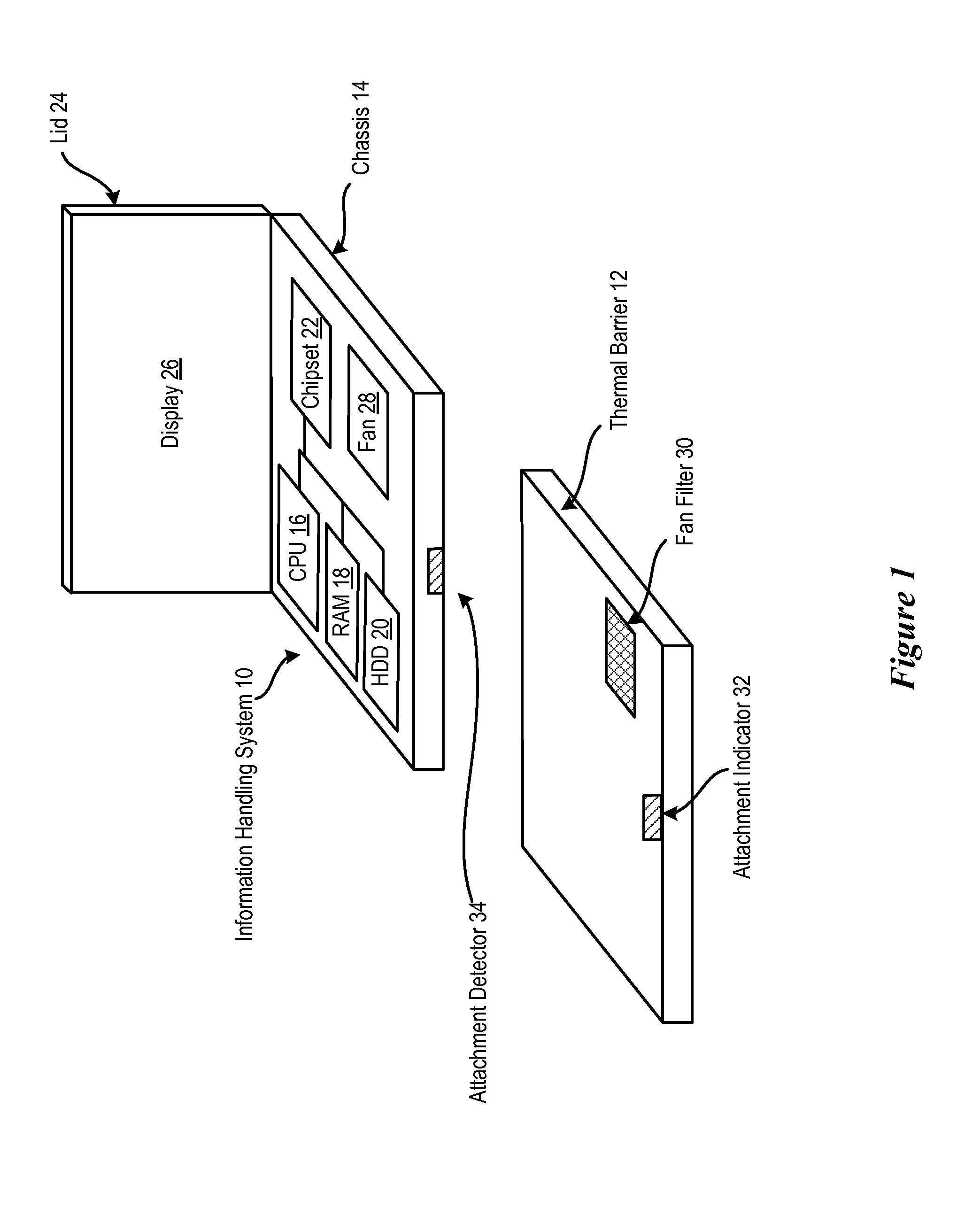

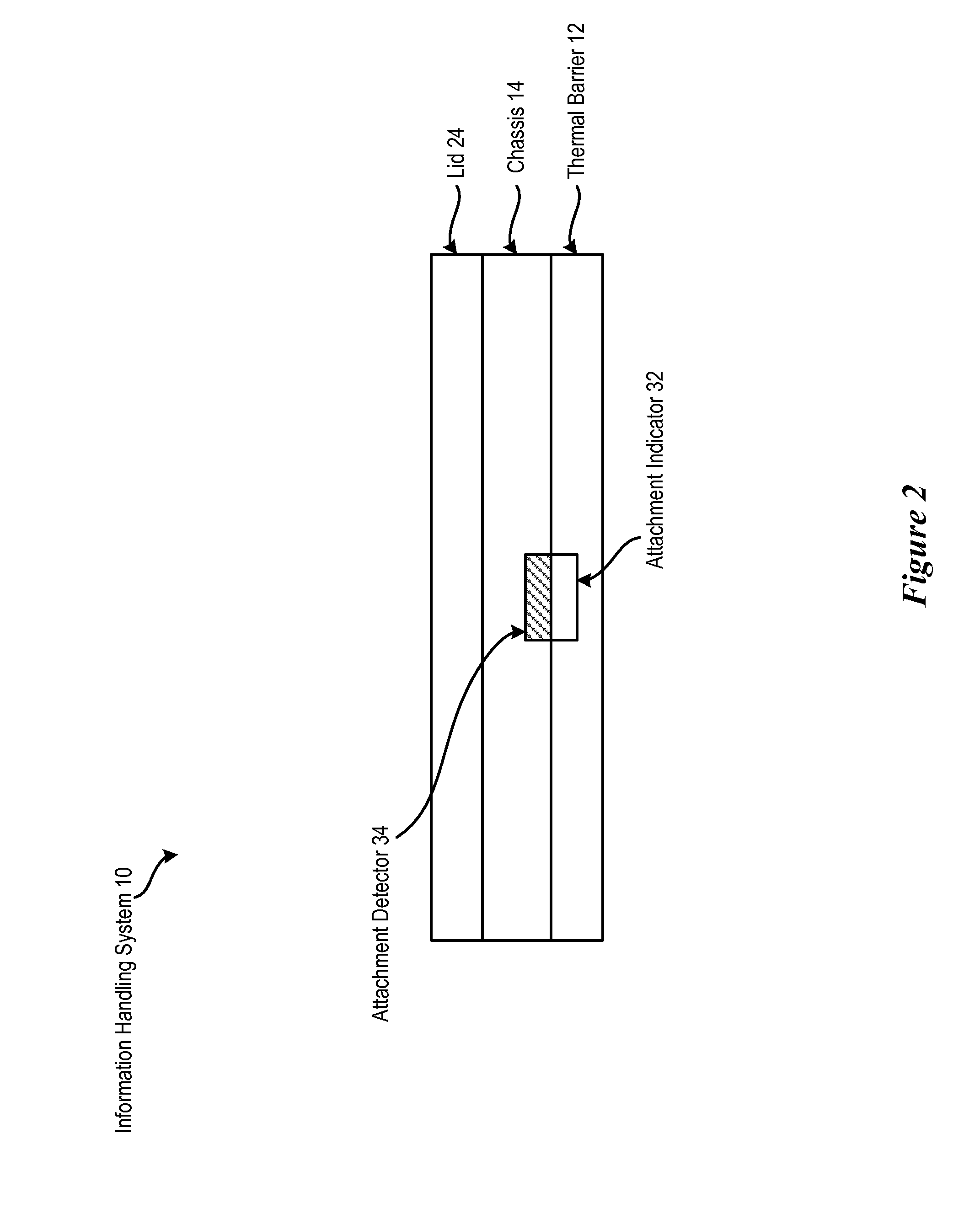

System and Method for Portable Information Handling System Parallel-Wall Thermal Shield

ActiveUS20090323275A1Reduce disadvantagesReduce problemsEnergy efficient ICTDigital data processing detailsThermal energyEngineering

An information handling system's thermal management is selectively altered by coupling a thermal barrier to the bottom surface of the information handling system chassis so that an air channel insulates against the passage of thermal energy from the bottom surface. A vent opening in a side of the thermal barrier allows airflow through the air channel to a vent opening of the information handling system. The airflow through the air channel cools the base of the thermal barrier so that an end user will experience reduced thermal energy if the information handling system rests on the end user, such as in the end user's lap.

Owner:DELL PROD LP

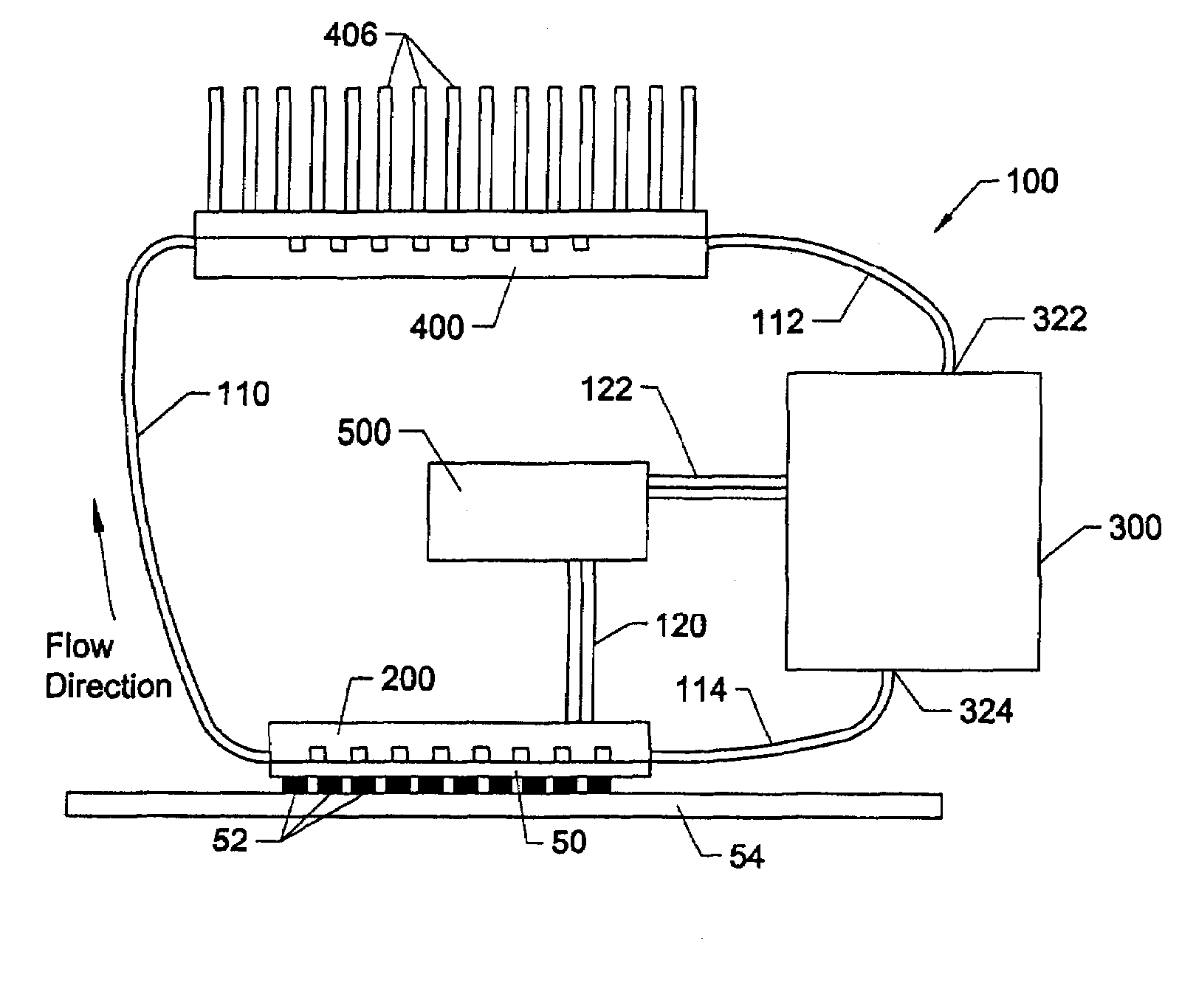

Electroosmotic microchannel cooling system

InactiveUS20050098299A1Easy to shapeOptimize distributionPump componentsDomestic cooling apparatusElectricityClosed loop

Apparatus and methods according to the present invention preferably utilize electroosmotic pumps that are capable of generating high pressure and flow without moving mechanical parts and the associated generation of unacceptable electrical and acoustic noise, as well as the associated reduction in reliability. These electroosmotic pumps are preferably fabricated with materials and structures that improve performance, efficiency, and reduce weight and manufacturing cost relative to presently available micropumps. These electroosmotic pumps also preferably allow for recapture of evolved gases and deposited materials, which may provide for long,-term closed-loop operation. Apparatus and methods according to the present invention also allow active regulation of the temperature of the device through electrical control of the flow through the pump and can utilize multiple cooling loops to allow independent regulation of the special and temporal characteristics of the device temperature profiles. Novel microchannel structures are also described.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Process for coking full fraction oil hydrogenation refining

InactiveCN1458233AImprove product propertiesDiesel properties improvedHydrocarbon oils refiningProcess engineeringHeating energy

The present invention is one process of hydrofining coked full fraction oil. Based on available process of hydrofining coked full fraction oil, new hydrogen of the system is used in further refining of diesel oil, so that diesel oil is refined under ideal thermodynamic and dynamic conditions. This results in high product quality, flexible, economic and practical technological process, less investment increment, fully utilization of heat energy and low operation cost. The present invention is suitable for reforming and constructing coked full fraction oil hydrofining apapratus.

Owner:CHINA PETROLEUM & CHEM CORP +1

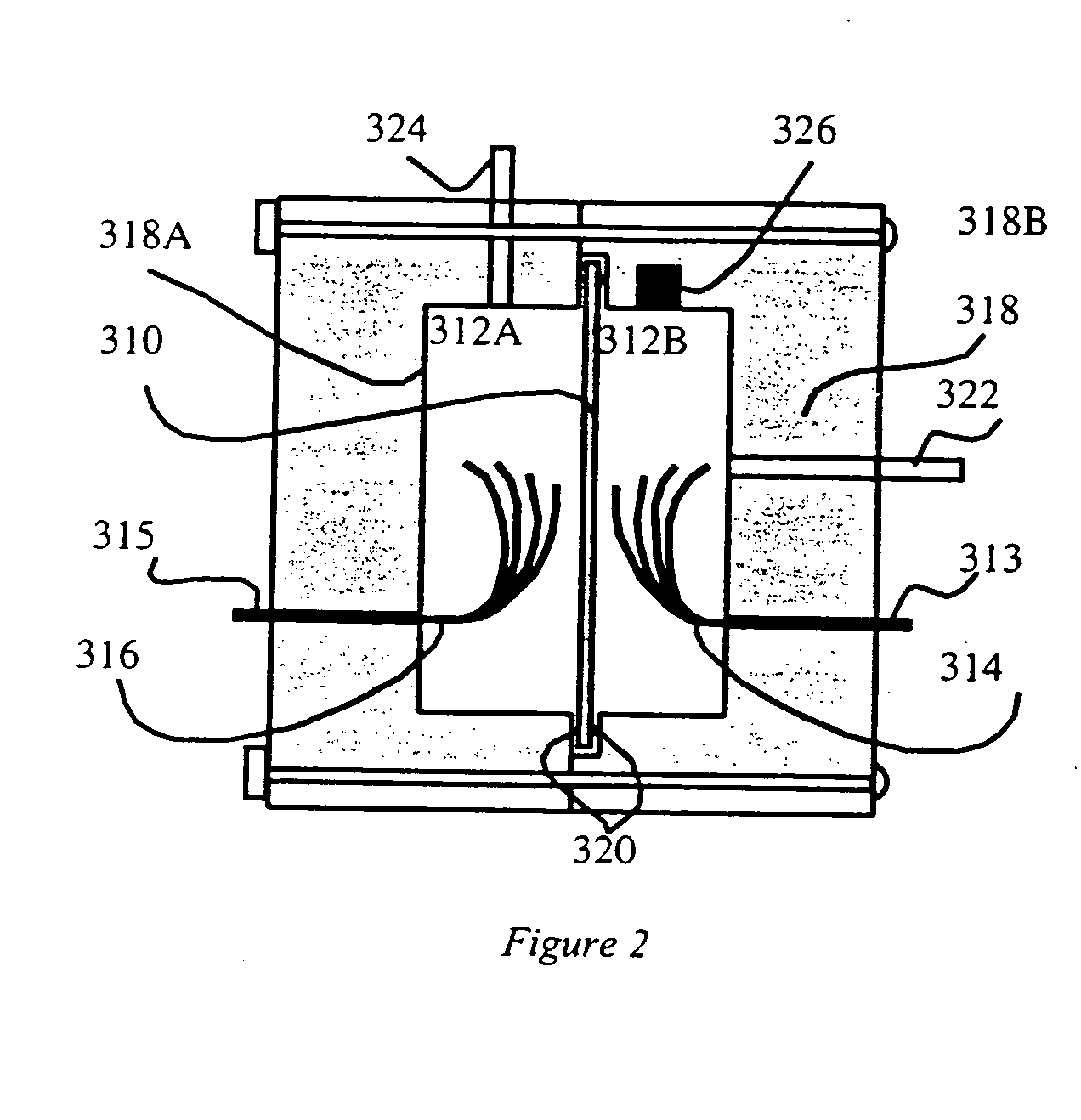

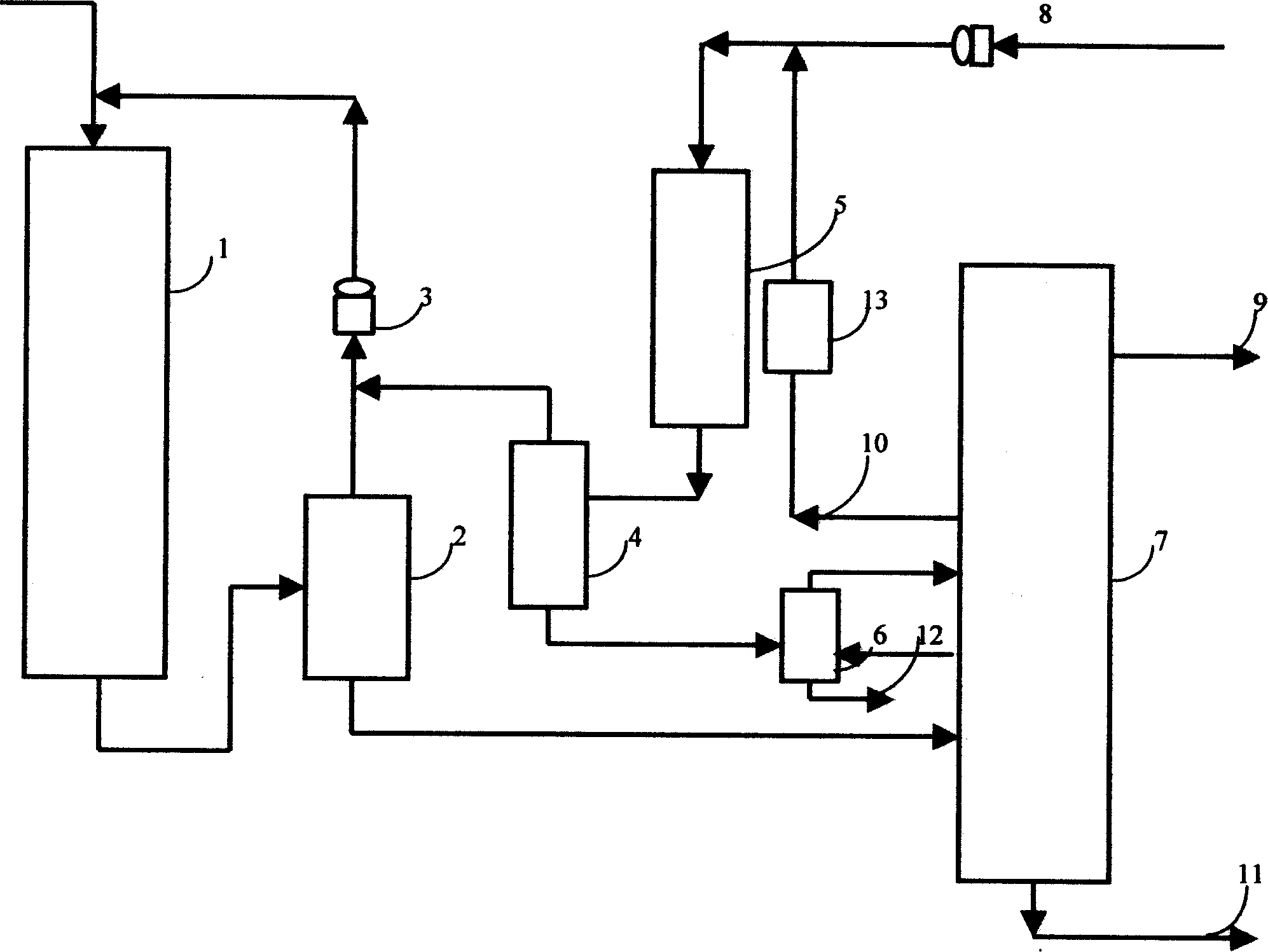

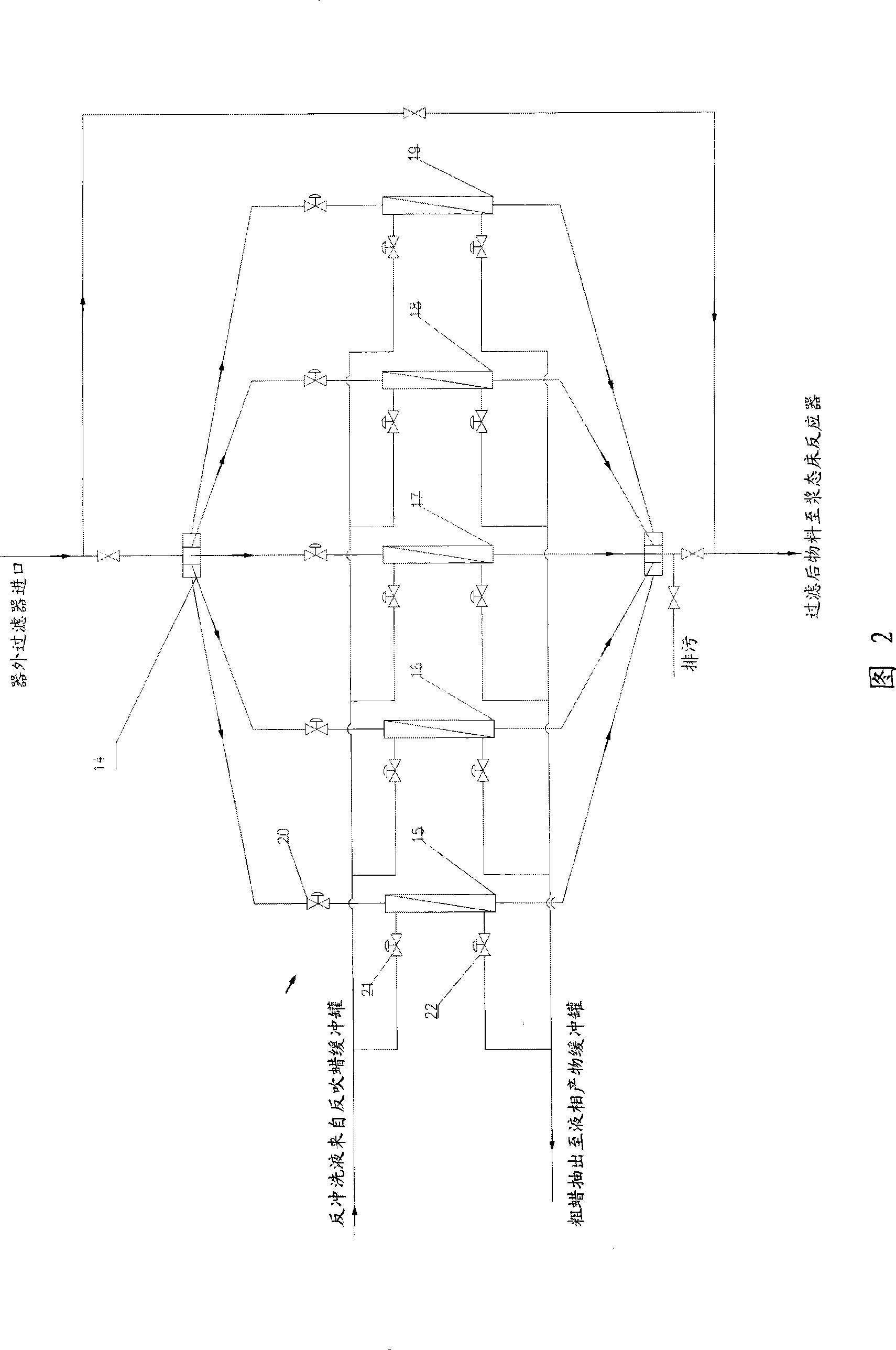

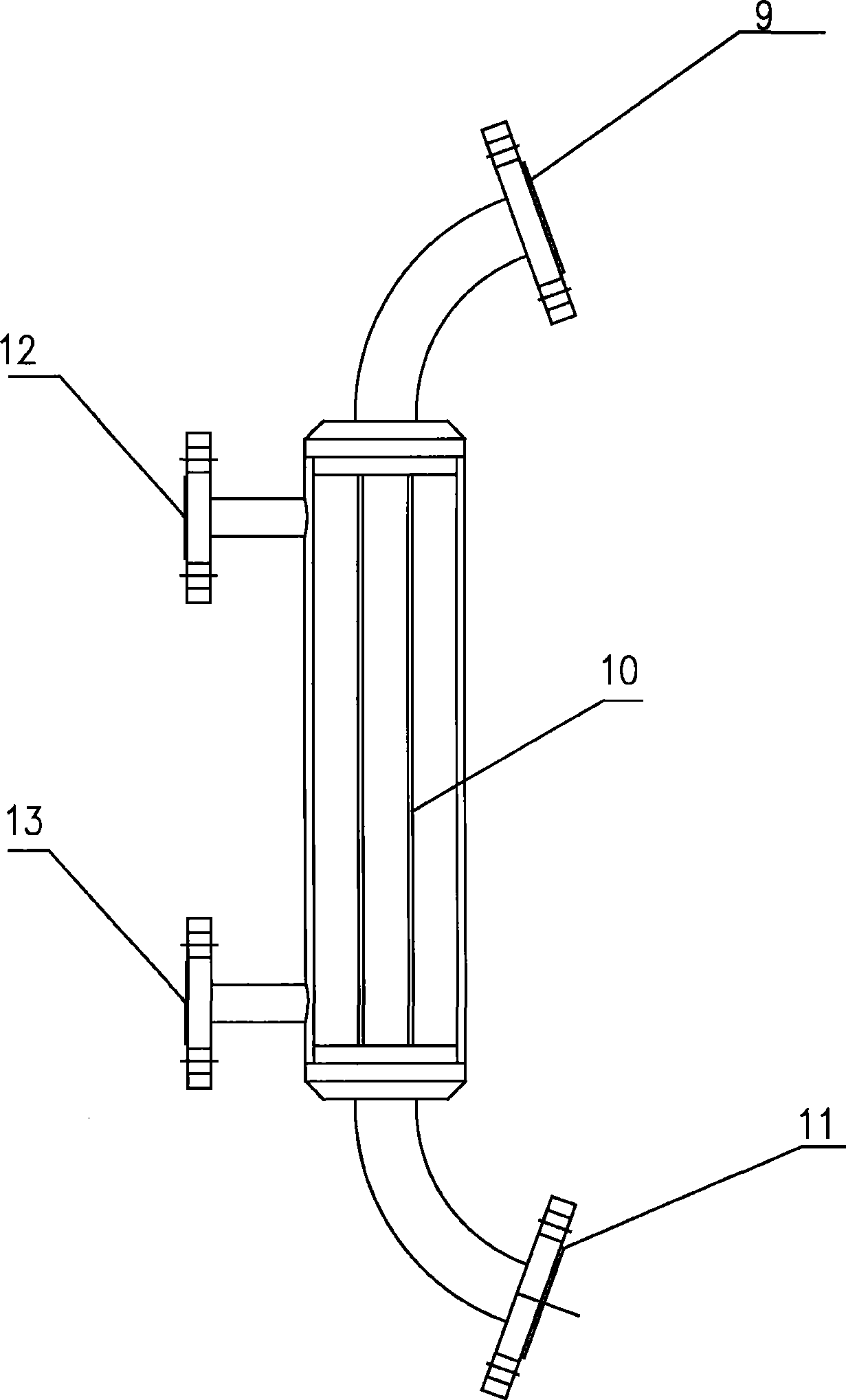

Wax extraction automatic filter, backwashing system of Ft synthetic pulp bed reactor

ActiveCN101417219AAvoid damageReduce the pressure on fine filtrationHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionWaxSlurry reactor

The invention discloses a wax extraction automatic filtration and backwashing system used for Fischer-Tropsch synthesis slurry reactor, comprising a filter unit and a backwashing unit, wherein, the filter unit comprises a slurry buffer tank, a wax device external filter (30), a coarse wave outcome buffer tank (4), a wax fine filter (5) and a wax product buffer tank (6); and the backwashing system comprises a washing wax pump (7) and a backwashing wax buffer tank (8). The wax extraction automatic filtration and backwashing system has the advantages of reasonable structure, short flow, low energy dissipation, avoiding the blocking or reverse flowing, reducing the damage of catalyst grains, and achieving the stable and continuous running of the Fischer-Tropsch synthesis slurry reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

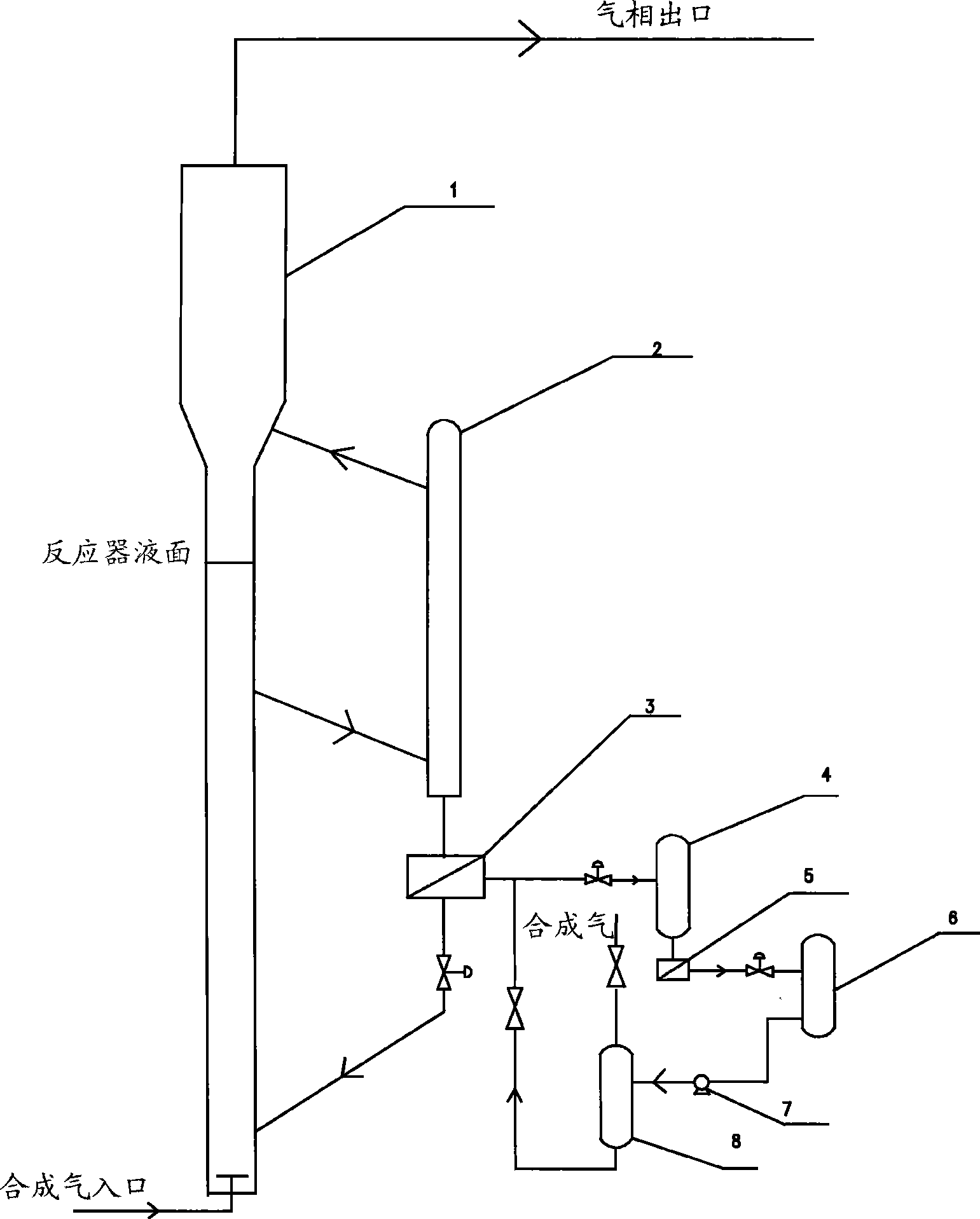

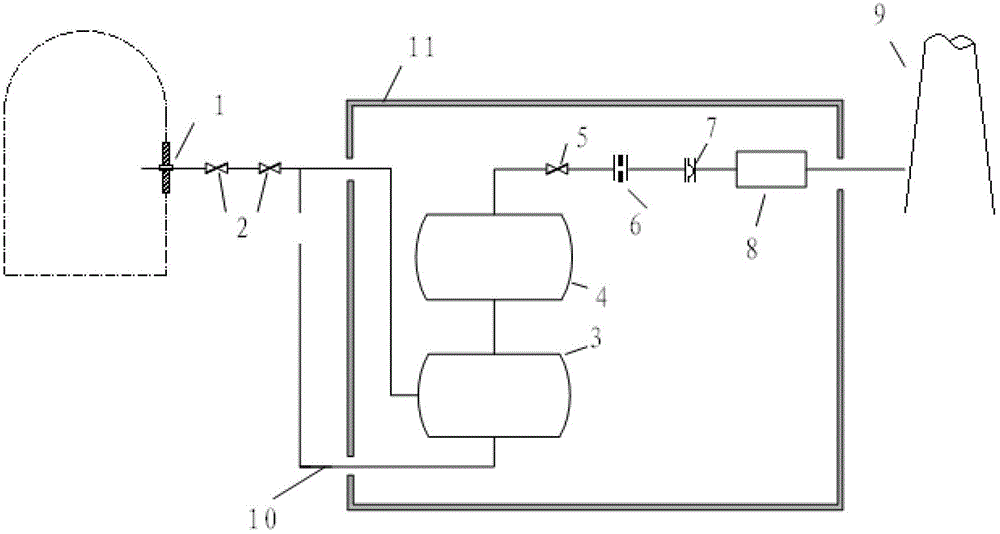

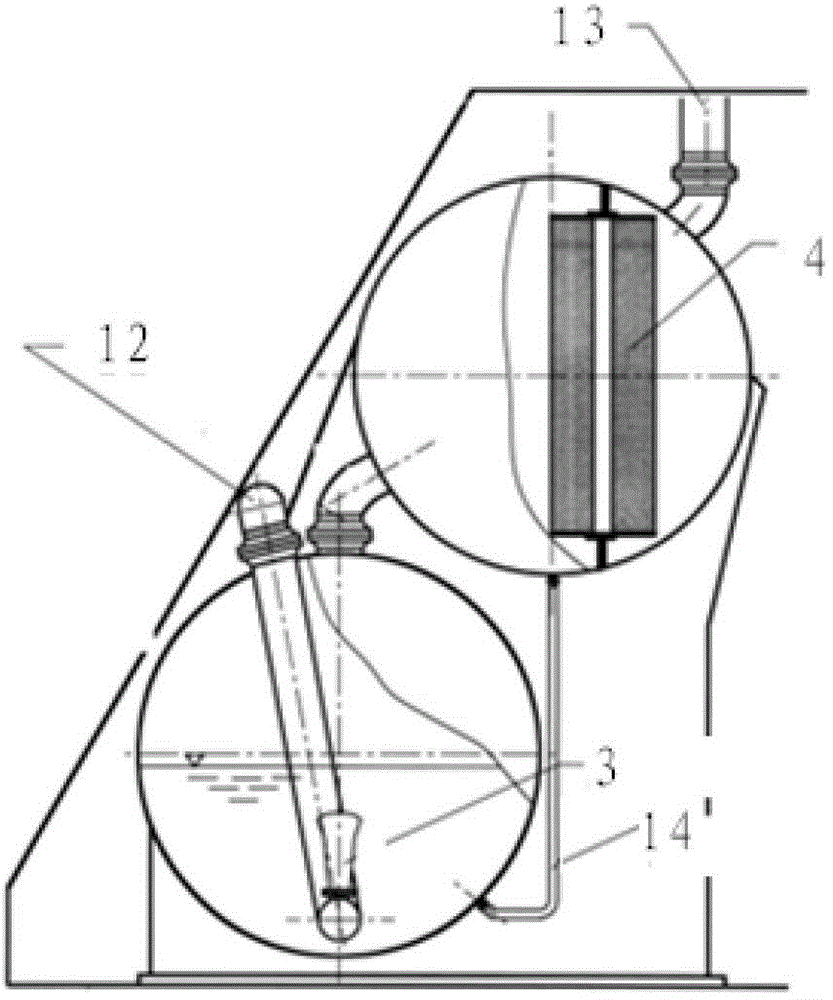

Containment filtering and discharging system

InactiveCN102723114AImprove filtering effectAccumulated radioactivityNuclear energy generationEmergency protection arrangementsLiquid wasteRadioactive agent

The invention relates to a containment filtering and discharging system. As a shielding plant (11) is arranged outside a containment, a discharging and filtering sub system is arranged in the shielding plant (11), a water washing filter (3) and a metal fiber filter (4) connected with each other in sequence are arranged in the discharging and filtering sub system and the water washing filter (3) is provided with a waste liquid returning pipeline (10), gases discharged by the containment are doubly filtered by the water washing filter (3) and the metal fiber filter (4), and the waste liquid accumulated in the water washing filter (3) self-flows into the containment through the waste liquid returning pipeline (10) under the effect of gravity force. Therefore, according to the invention, serious accidents occurred in pressurized-water reactor nuclear power stations are eased, overpressure failure of the containment is prevented, radioactive substances released to the environment are reduced, safeties of the surrounding environment and personnel are protected, and the safety of the nuclear power stations are greatly improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Alumina support containing silicon and titanium and preparation method thereof

ActiveCN1768945AImprove pore structureLarge specific surface areaCatalyst carriersPore distributionAluminium hydroxide

The invention discloses property-transformation alumina carrier which contains titanium and silica agent and its relative preparing method. Said silica agent is added in the sol process of aluminum hydroxide to improve the specific surface, pore diameter and pore capacity of alumina; after the sol process, individually using acid agent and alkali agent to adjust the pH value of mixed paste solution for several times to make the attained alumina with more centralized pore distribution; the titanium agent is added after the sol process and before the aging process, to improve the surface acid property, surface acid amount and B acid amount of carrier. In addition, the surface of alumina is modified by titanium to decrease the interactive condition between active metal and carrier, which can apply the diffusion of active metal components in the catalyst. The property transformation of said invention can be used as catalysis material when processing oil, especially as the catalyst carrier of hydrogenation treatment and hydrogenation transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

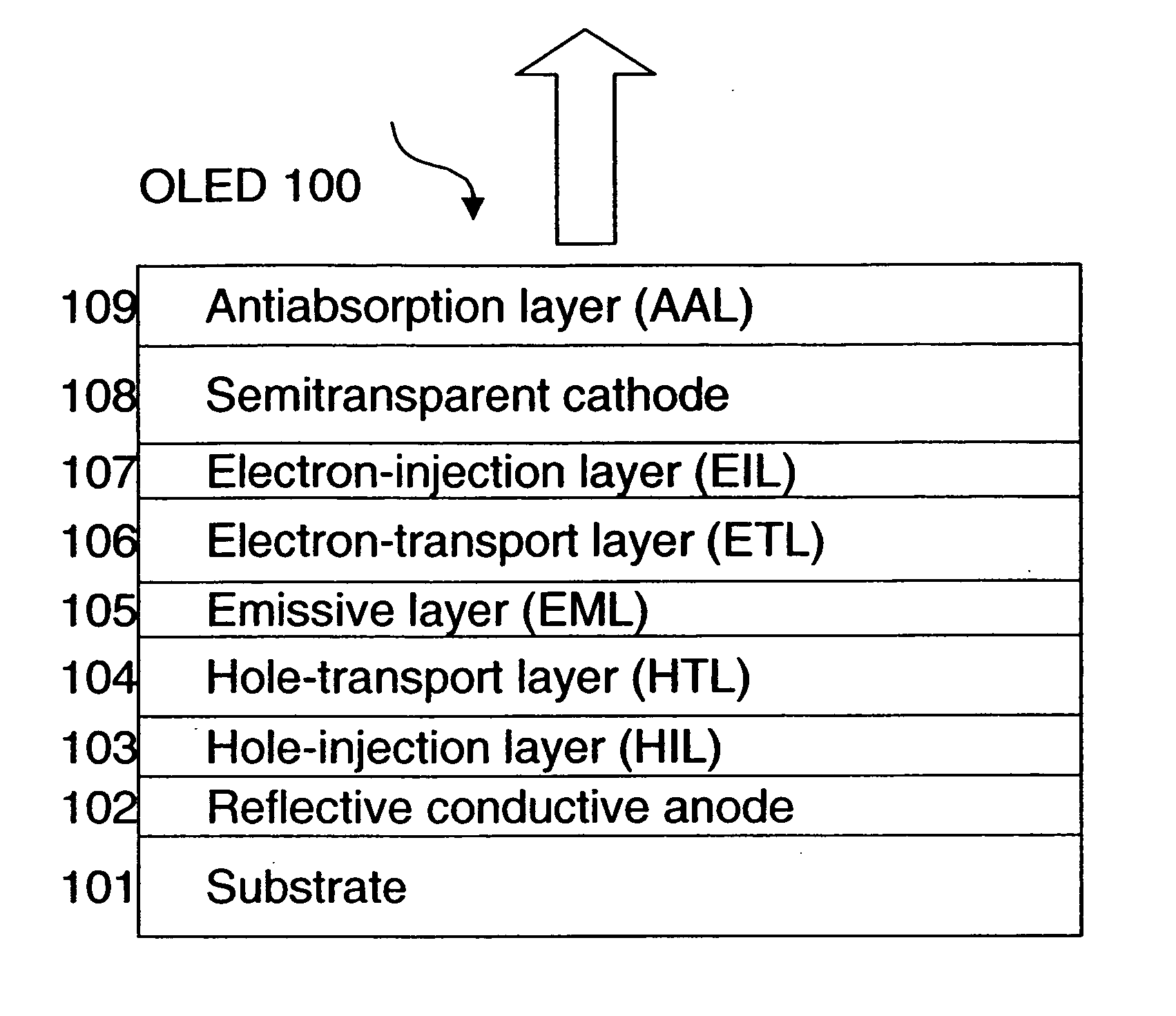

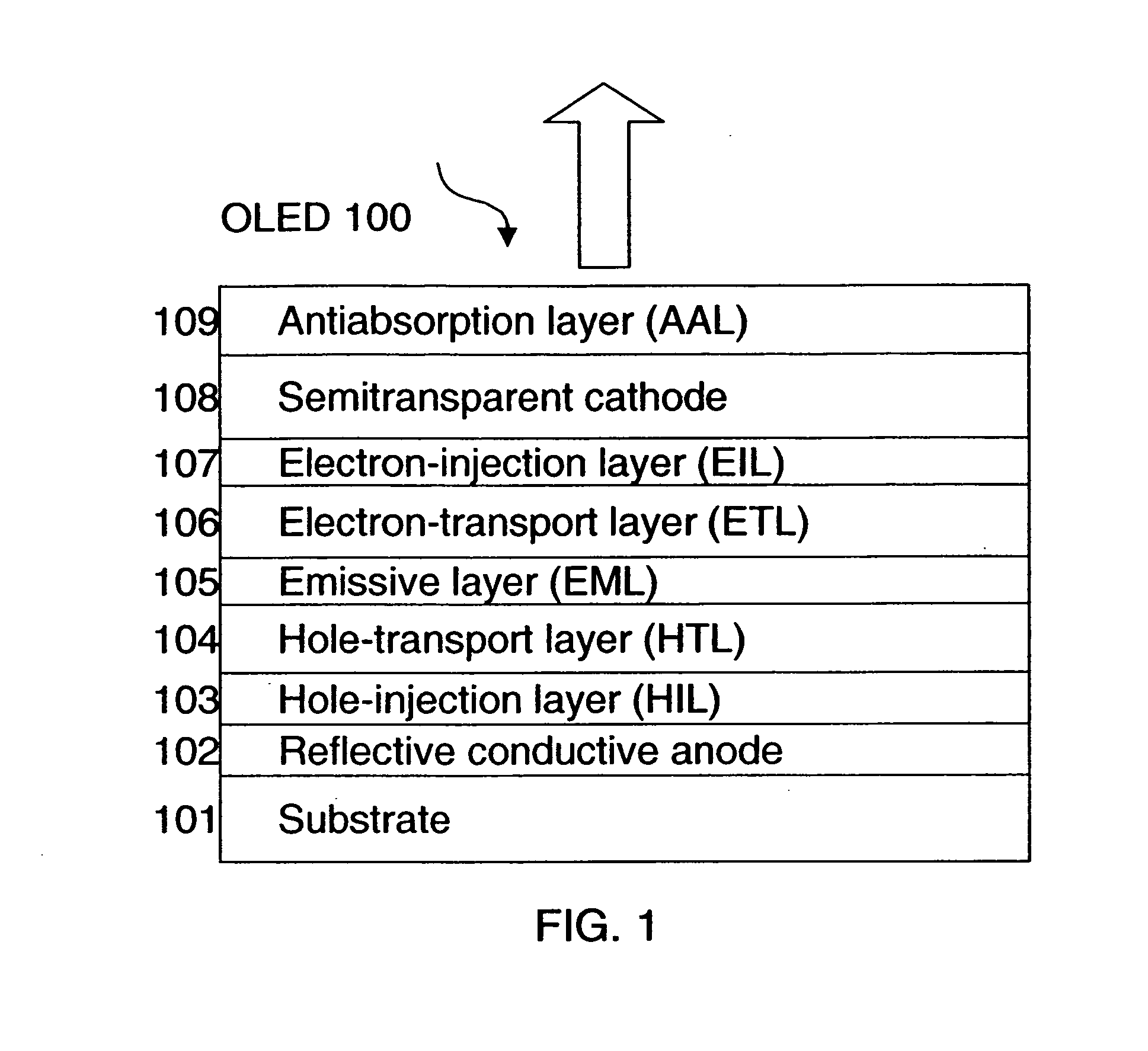

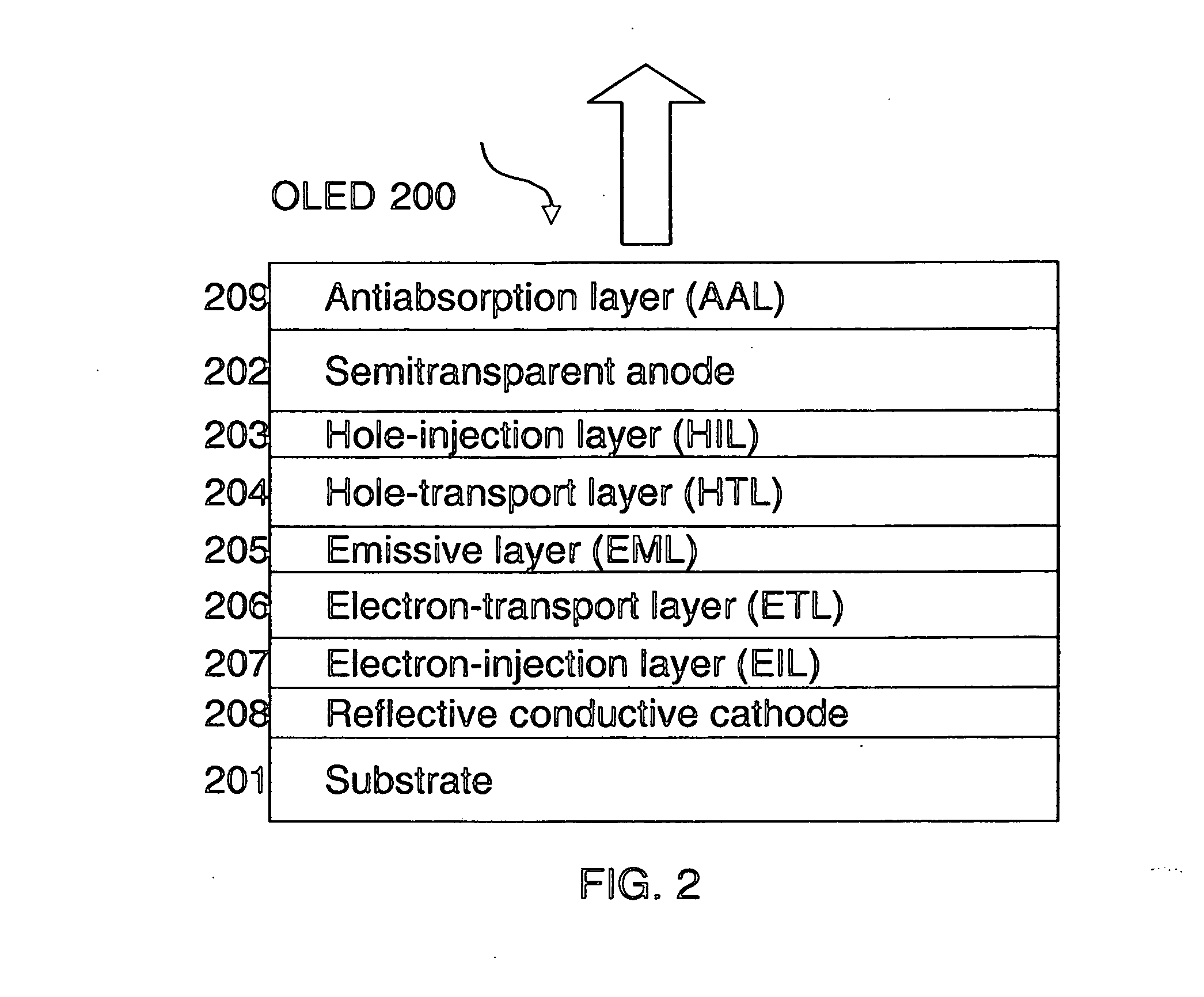

Top-emitting OLED device with improved stability

InactiveUS20070222371A1High yieldIncreased lateral electrical conductivityDischarge tube luminescnet screensLamp detailsFree energiesMetal alloy

A top-emitting OLED device including a substrate; a reflective and conductive first electrode including a metal or metal alloy or both formed over the substrate; at least one organic layer formed over the first electrode and including an emissive layer having electroluminescent material; and a semitransparent, reflective and conductive second electrode provided over the organic layer, wherein the second electrode includes a first layer having material M, wherein M is a metal, and a second layer providing an anti-absorption function in contact with the first layer and having a compound M′X , wherein M′ is a ‘metal and X is a non-metal, wherein M′X has a free energy of formation [equal to or ]more negative than the free energy of formation of MX.

Owner:EASTMAN KODAK CO

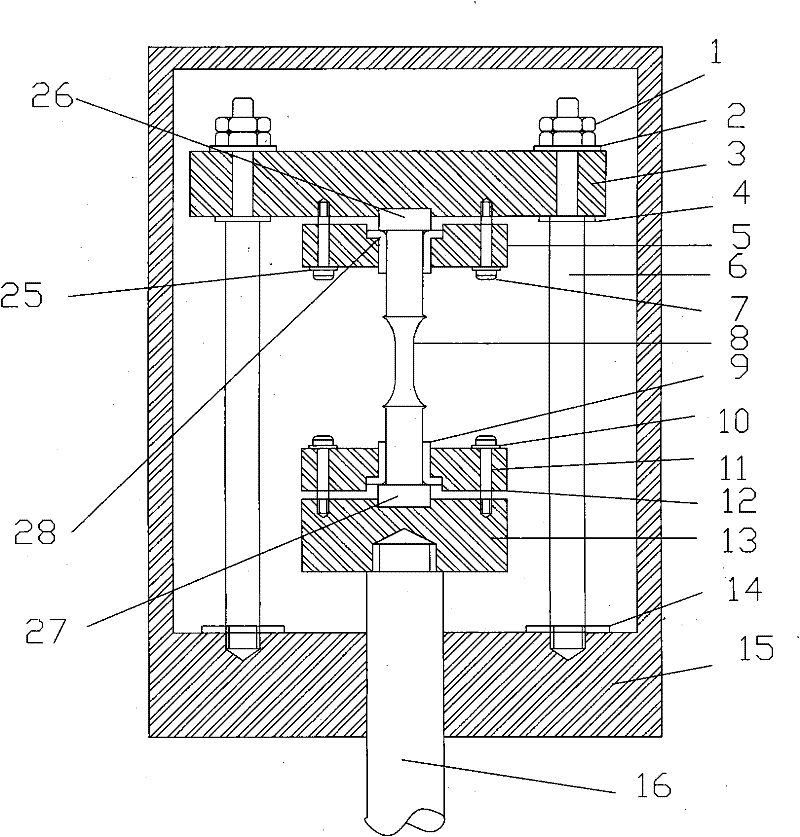

Fatigue test sample clamp with high temperature resistance, high pressure resistance and aqueous corrosion resistance and usage method thereof

ActiveCN102346113AGood strengthSimple structureWeather/light/corrosion resistanceStrength propertiesTemperature resistanceAqueous corrosion

The invention belongs to the material test technical field, to be more exactly, relates to a fatigue test sample clamp with high temperature resistance, high pressure resistance and aqueous corrosion resistance and an usage method thereof, which solves the problems of high temperature irresistance, high pressure irresistance, aqueous corrosion, large screw thread slit and poor centering in the current sample clamp. The clamp is provided with a column, a platform, an upper press cap, a lower press cap and a conversion adapter; the lower part of the column of the clamp is fixed on a cover of anautoclave, the upper part of the column of the clamp is fixed on the platform, and respectively and tightly pressed by lock nuts, the lower part of the conversion adapter is connected with a stretching shaft of a fatigue machine, through elevating the stretching shaft, an upper convex plate and a lower convex plate of the test sample are respectively placed in a platform groove and a conversion adapter groove, two dimidiate semirings are pressed on upper convex plate and the lower convex plate of the test sample, the upper press cap and the lower press cap are sleeved, the press cap bolts arescrewed for fixing two ends. The fatigue test sample clamp can be used in the autoclave for carrying out various fatigue tests (stress-stress, stress-tension, tension-tension and the like) under the high temperature high pressure solution environment, and has the advantages of simple structure and low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Power tool having a receptacle for securing a tool

InactiveUS20050095966A1Increase surface pressureReliable engagementGrinding wheel securing apparatusMetal sawing toolsDrive shaftPower tool

A power tool having a receptacle for securing a tool to a drive shaft thereof is disclosed. The receptacle comprises a receiving opening, preferably being arranged on the tool. The receiving opening engages a securing section preferably being provided in a raised fashion on the drive shaft of the power tool, thereby effecting a positive fit. The securing section comprises a plurality of rounded tips arranged at even radial distances from said longitudinal axis, at angular intervals between each other, each rounded tip having a pair of lateral flanks extending from a common apex toward an intermediate section connecting lateral flanks of a pair of adjacent rounded tips. Preferably the receiving opening comprises a number of rounded tips which is twice the number of rounded tips provided on the raised section.

Owner:C & E FEIN

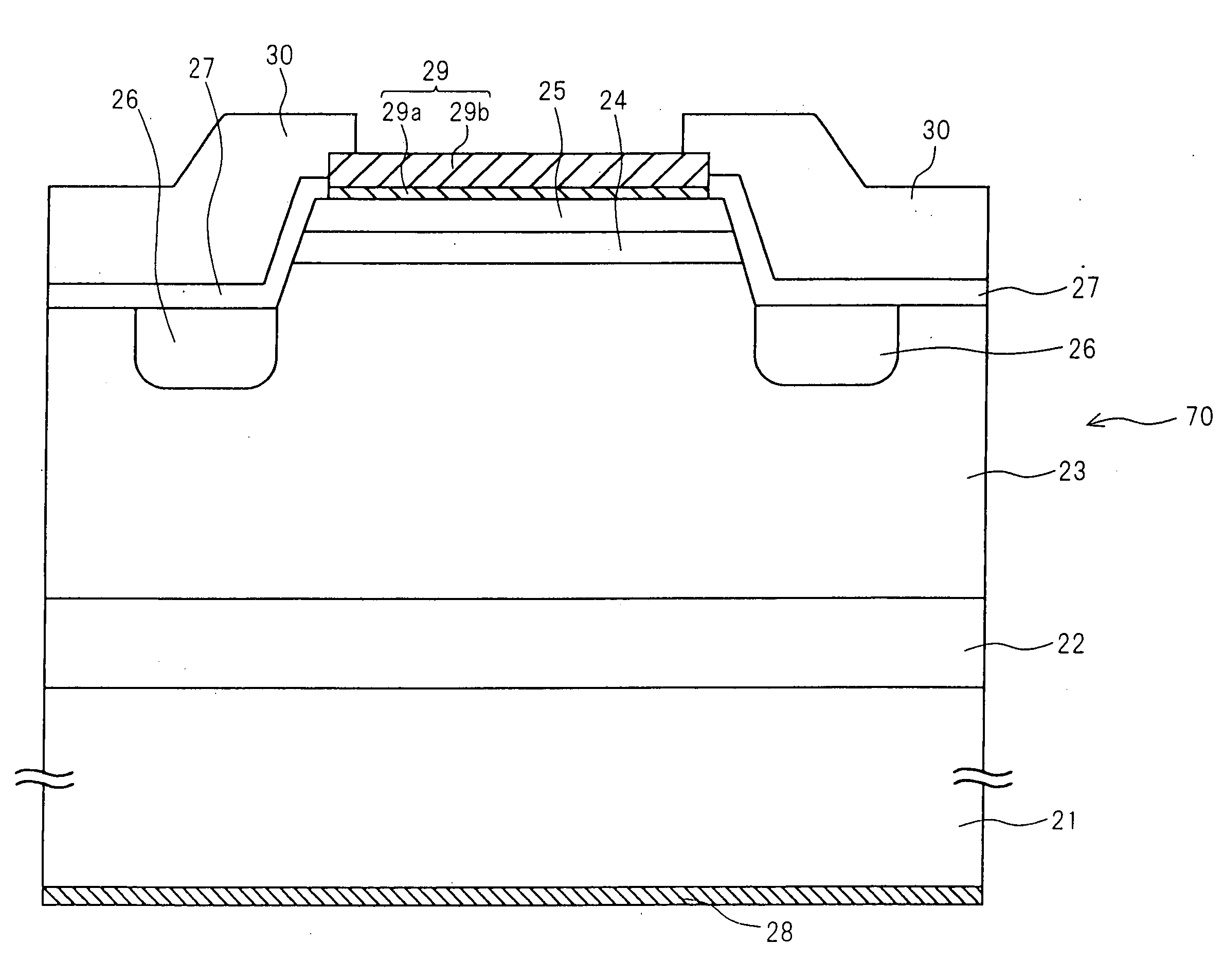

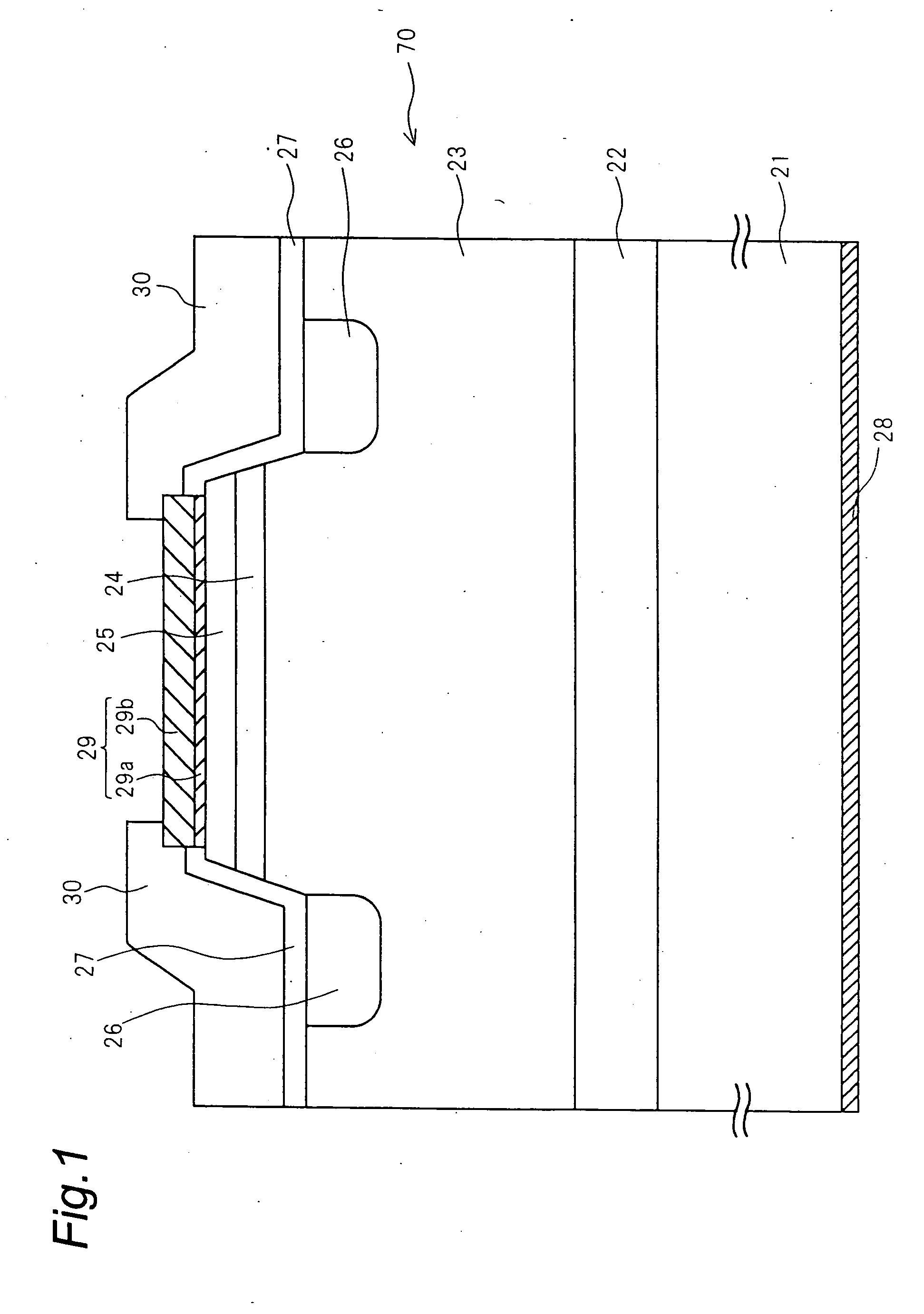

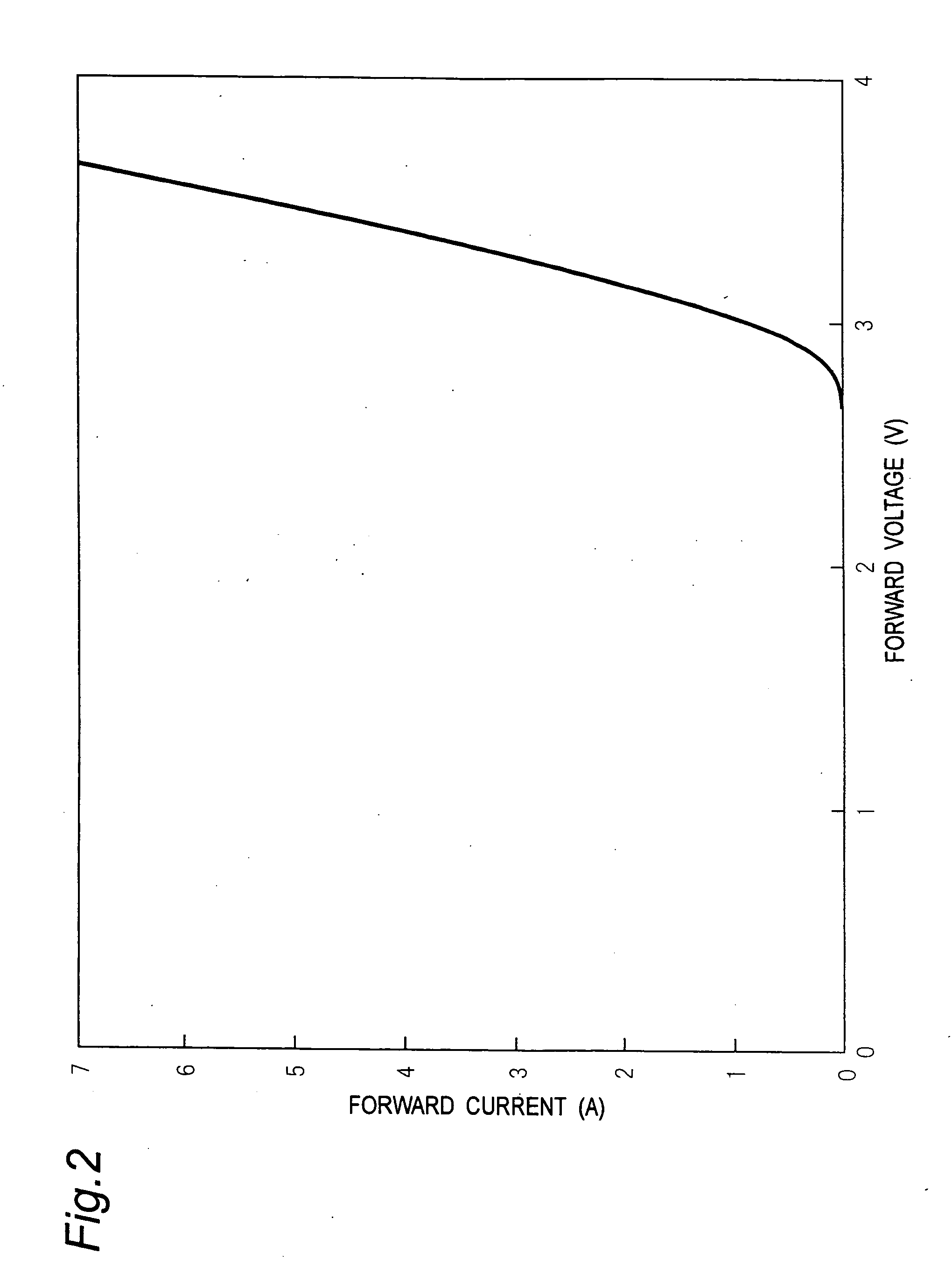

Silicon carbide semiconductor device and manufacturing method therefor

ActiveUS20070090370A1Fine surfaceForward voltage can be preventedTransistorSemiconductor/solid-state device detailsDopantDevice material

With a view to preventing increases in forward voltage due to a change with the lapse of time of a bipolar semiconductor device using a silicon carbide semiconductor, a buffer layer, a drift layer and other p-type and n-type semiconductor layers are formed on a growth surface, which is given by a surface of a crystal of a silicon carbide semiconductor having an off-angle θ of 8 degrees from a (000-1) carbon surface of the crystal, at a film growth rate having a film-thickness increasing rate per hour h of 10 μm / h, which is three times or more higher than conventional counterparts. The flow rate of silane and propane material gases and dopant gases is largely increased to enhance the film growth rate.

Owner:THE KANSAI ELECTRIC POWER CO +1

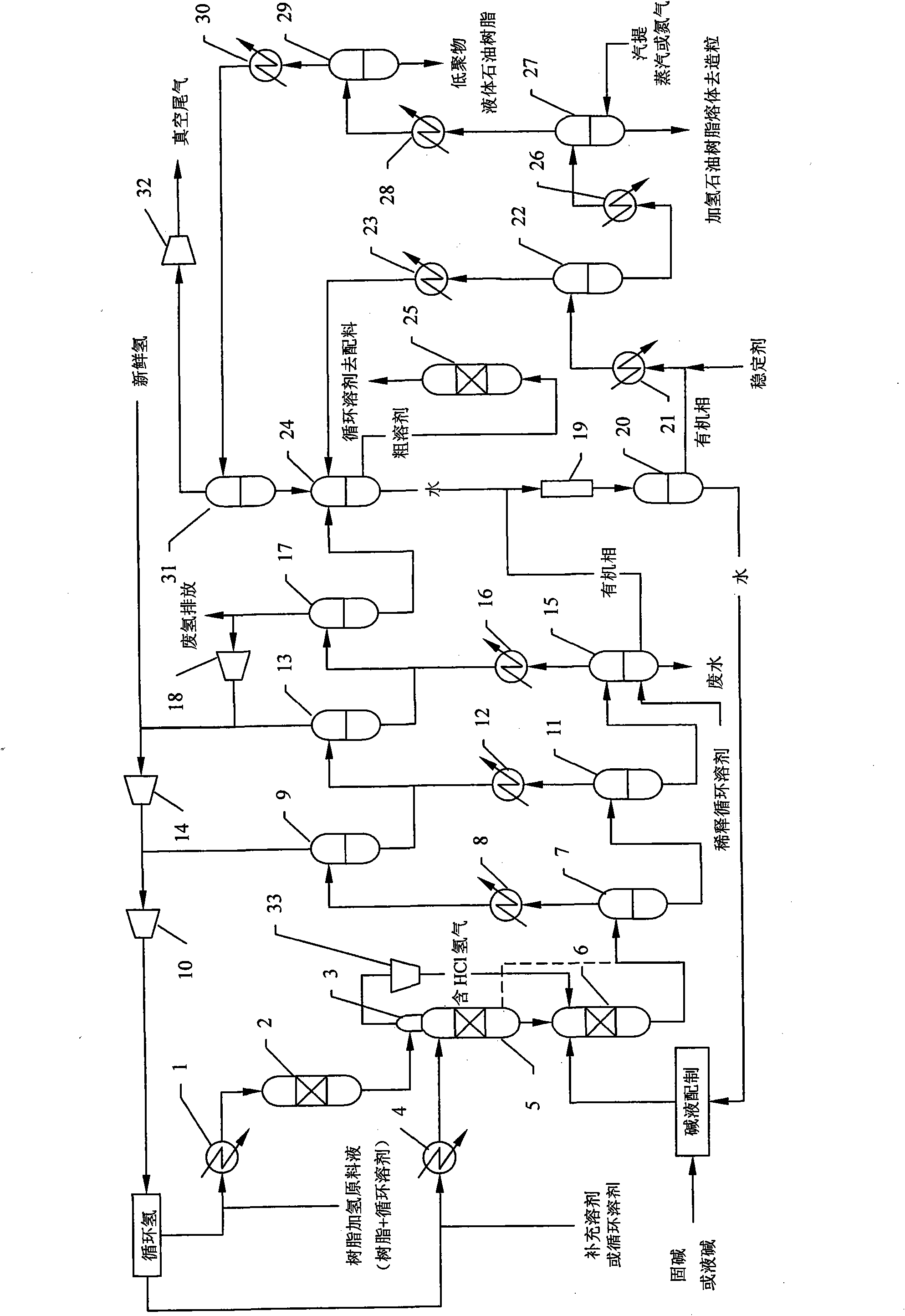

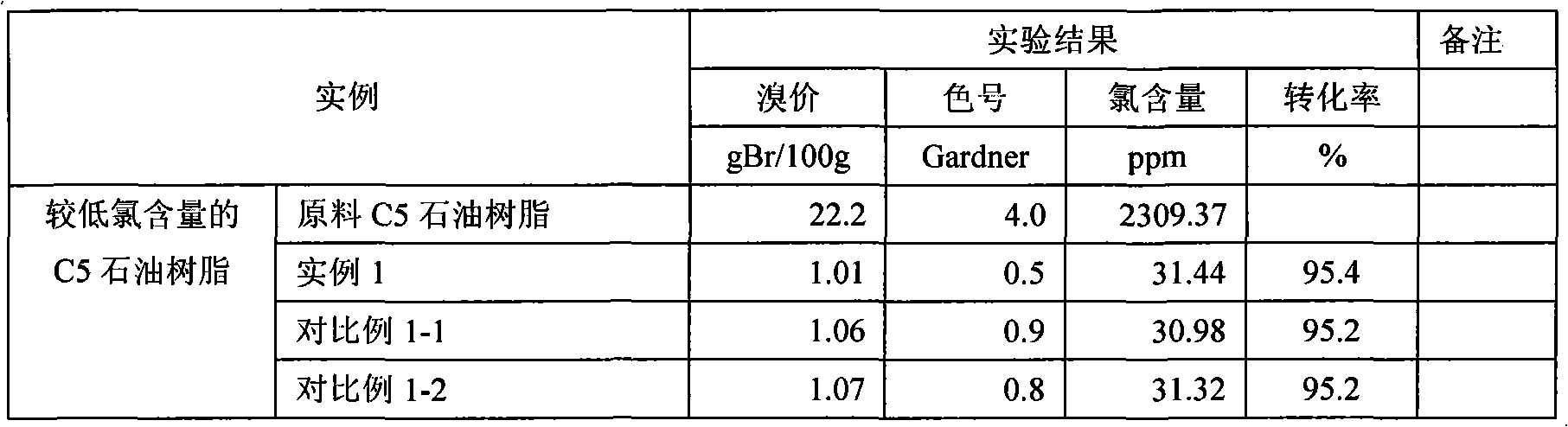

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

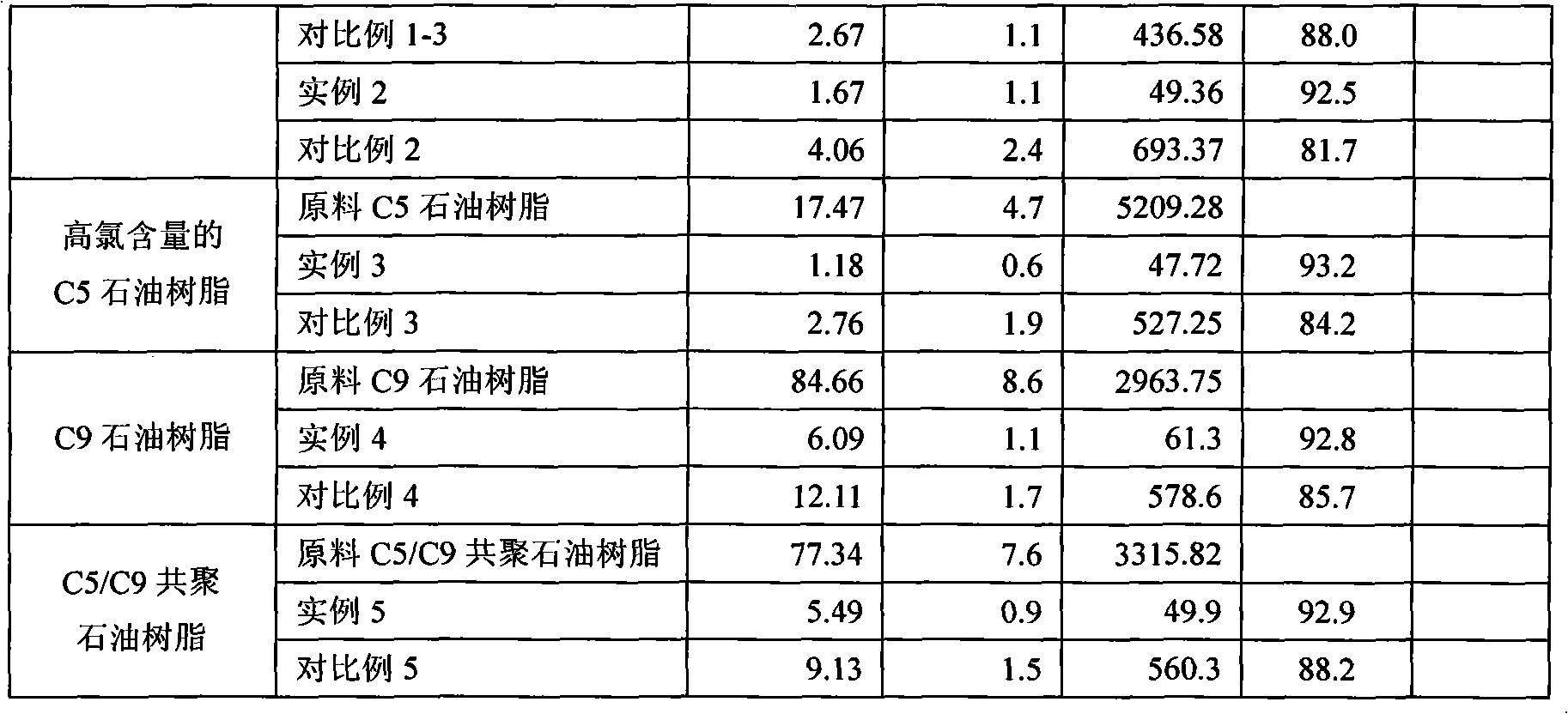

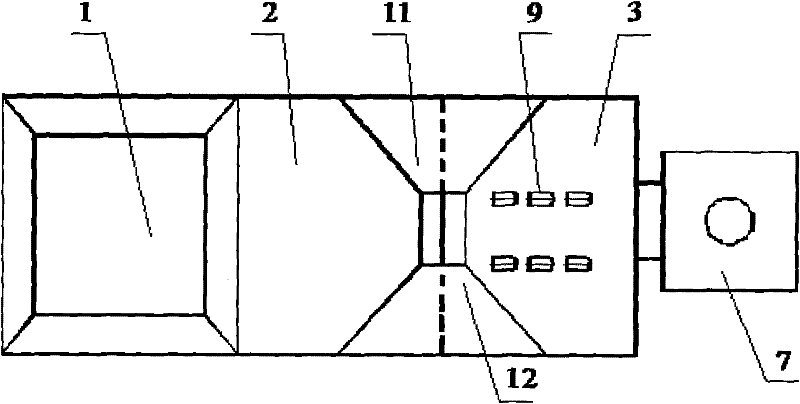

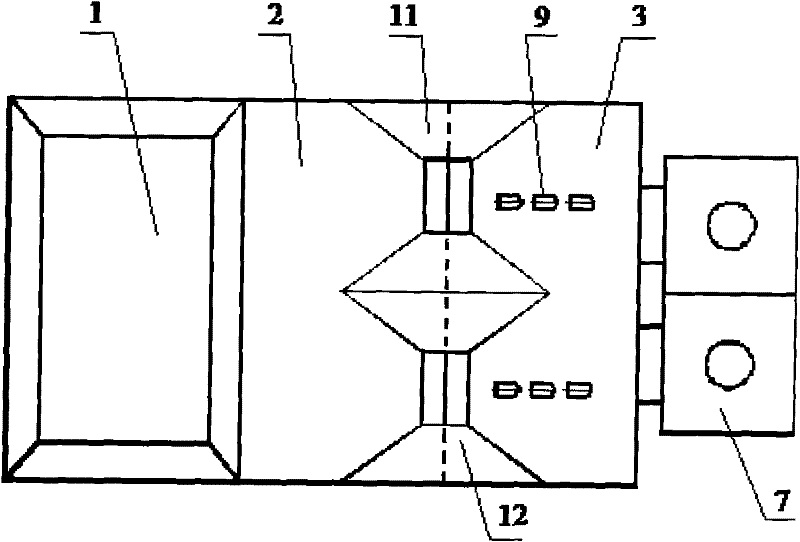

Multipath circulating fluidized bed boiler

ActiveCN101749696AGuaranteed separationGuaranteed long-term operationFluidized bed combustionIncinerator apparatusCombustion chamberPulp and paper industry

The invention discloses a multipath circulating fluidized bed boiler, which comprises a main combustion chamber, an auxiliary combustion chamber and an ash chamber which are parallel to the main combustion chamber, a tail flue, and a coal economizer and a centrifugal separator arranged in the tail flue; the bottom of the auxiliary combustion chamber is inclined to the ash chamber and the inclination angle alpha is between 30 and 60 degrees; the bottom of the ash chamber is inclined to the auxiliary combustion chamber and the inclination angle beta is between 45 and 75 degrees; a material falling passage is reserved between the bottom surface of the ash chamber and the bottom surface of the auxiliary combustion chamber; an asymmetrical inertia separation circulating device is formed by the bottom surfaces of the mutually inclined auxiliary combustion chamber, an inclined plate I and an inclined plate II fixed on the two sides, and the material falling passage; a flow area of the bottom of the ash chamber A2 is no more than half of a flow area A1 of the bottom of the auxiliary combustion chamber; and the bottom surface of the ash chamber is provided with a loose blast cap. The multipath circulating fluidized bed boiler can ensure the smooth conveying of materials and the required material separating amount, prevent the materials from accumulating on the bottom of the combustion chambers for a long time, and ensure smooth circulating, so that a combustion device normally operates for a long term.

Owner:TSINGHUA UNIV +1

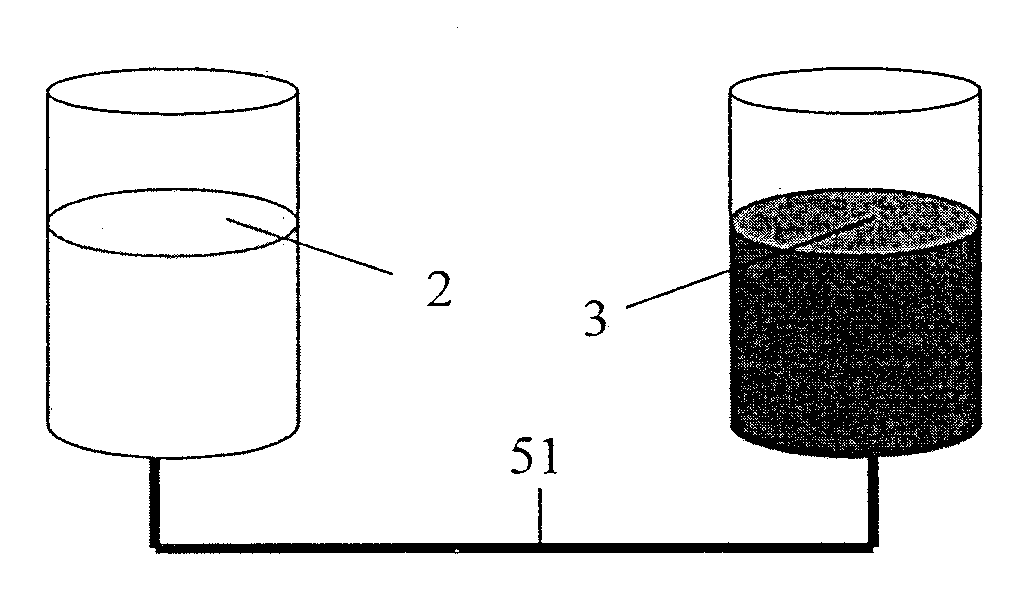

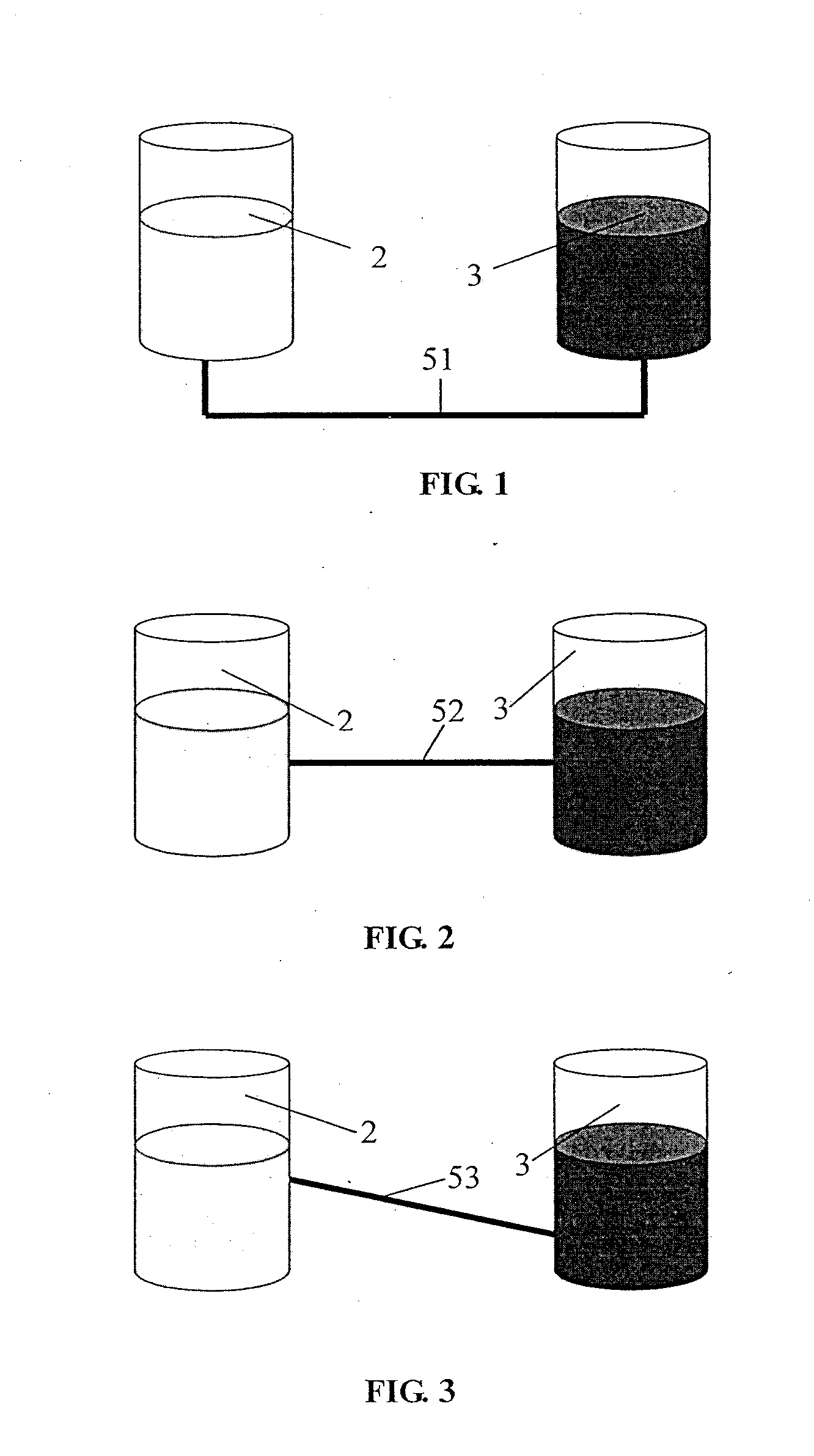

Redox flow battery and method for operating the battery continuously in a long period of time

ActiveUS20110300417A1Inhibition of capacity fadingReduce frequencyReactant parameters controlElectrolyte stream managementElectrical batteryDiameter ratio

The present invention provides a redox flow battery comprising a positive electrolyte storage tank and a negative electrolyte storage tank, wherein the positive electrolyte storage tank and the negative electrolyte storage tank is kept to be in liquid communication through a pipe, wherein the length-to-diameter ratio of the pipe for the liquid communication is not less than about 10. The present invention also provides a method for operating the redox flow battery continuously in a long period of time.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

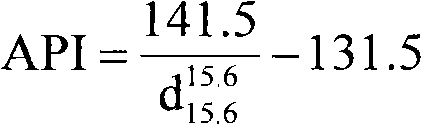

Heavy crude oil hydrocracking method

The invention relates to a heavy crude oil hydrocracking method. In the method, heavy crude oil is sequentially subjected to the steps of a hydrogenation protective agent, a hydrodemetallization agent, a hydrodesulfurization agent I, a hydrocracking agent and a hydrodesulfurization II in the presence of hydrogen, wherein the filling weight percentage of the hydrogenation protective agent, the hydrodemetallization agent, the hydrodesulfurization agent I, the hydrocracking agent and the hydrodesulfurization agent II are respectively 2-20%, 10-78%, 10-78%, 5-50% and 5-50% by taking an integral catalyst as a reference. According to the method provided by the invention, the heavy crude oil with the API (American Petroleum Institute) degree smaller than 20 can be processed to obtain hydrogenated crude oil with enhanced API and reduced viscosity, and moreover, the operating period of a hydrogenation processing device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

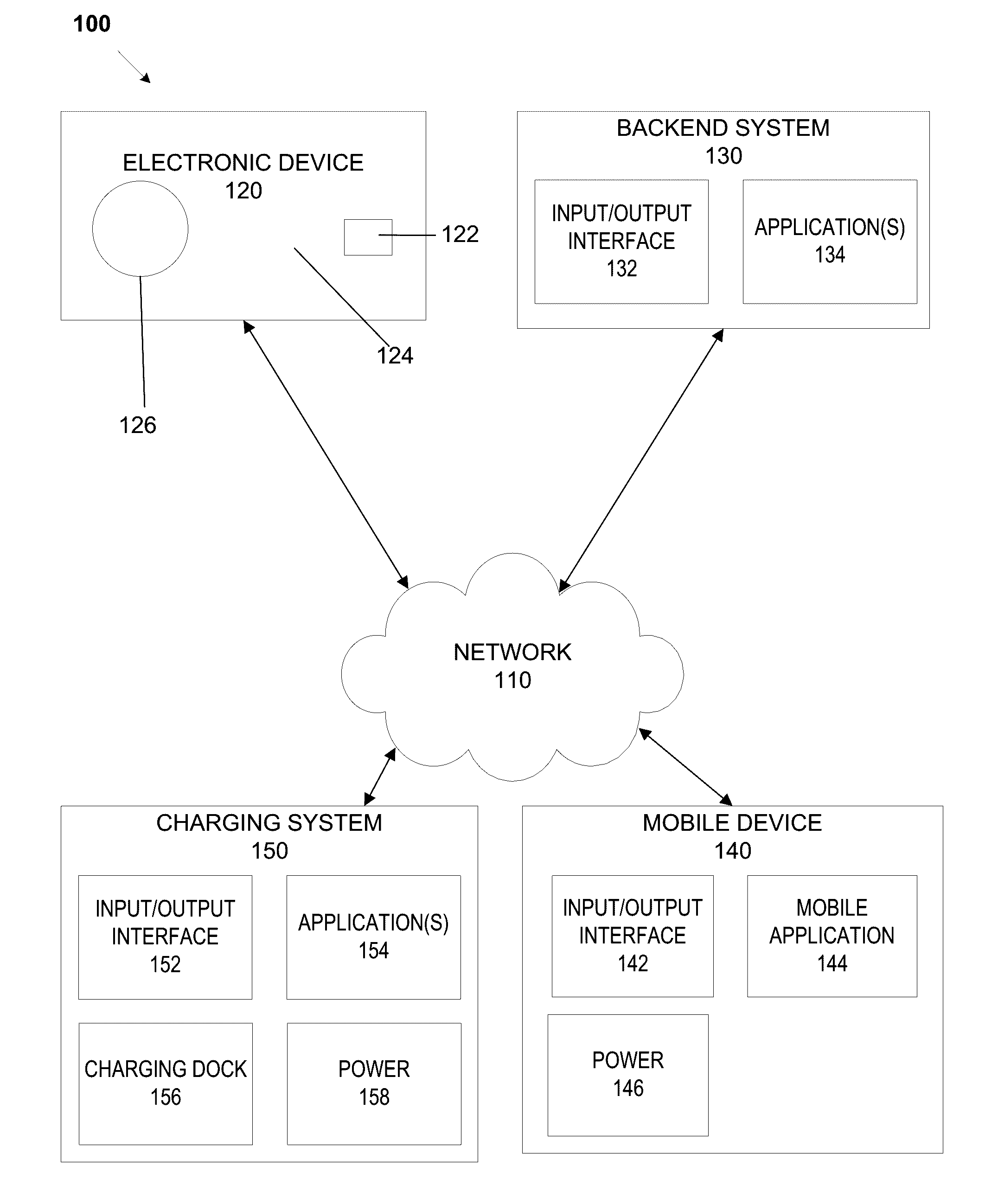

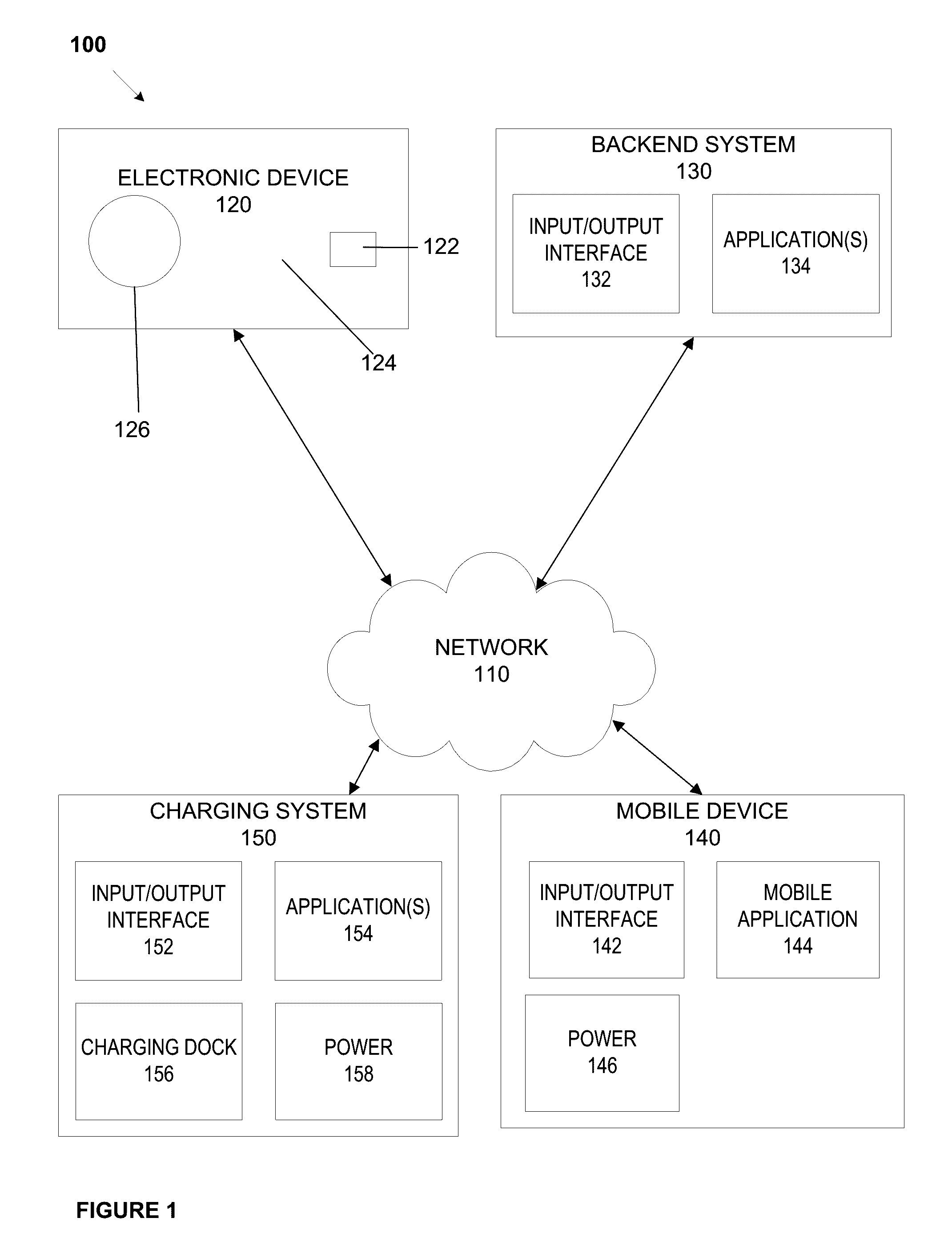

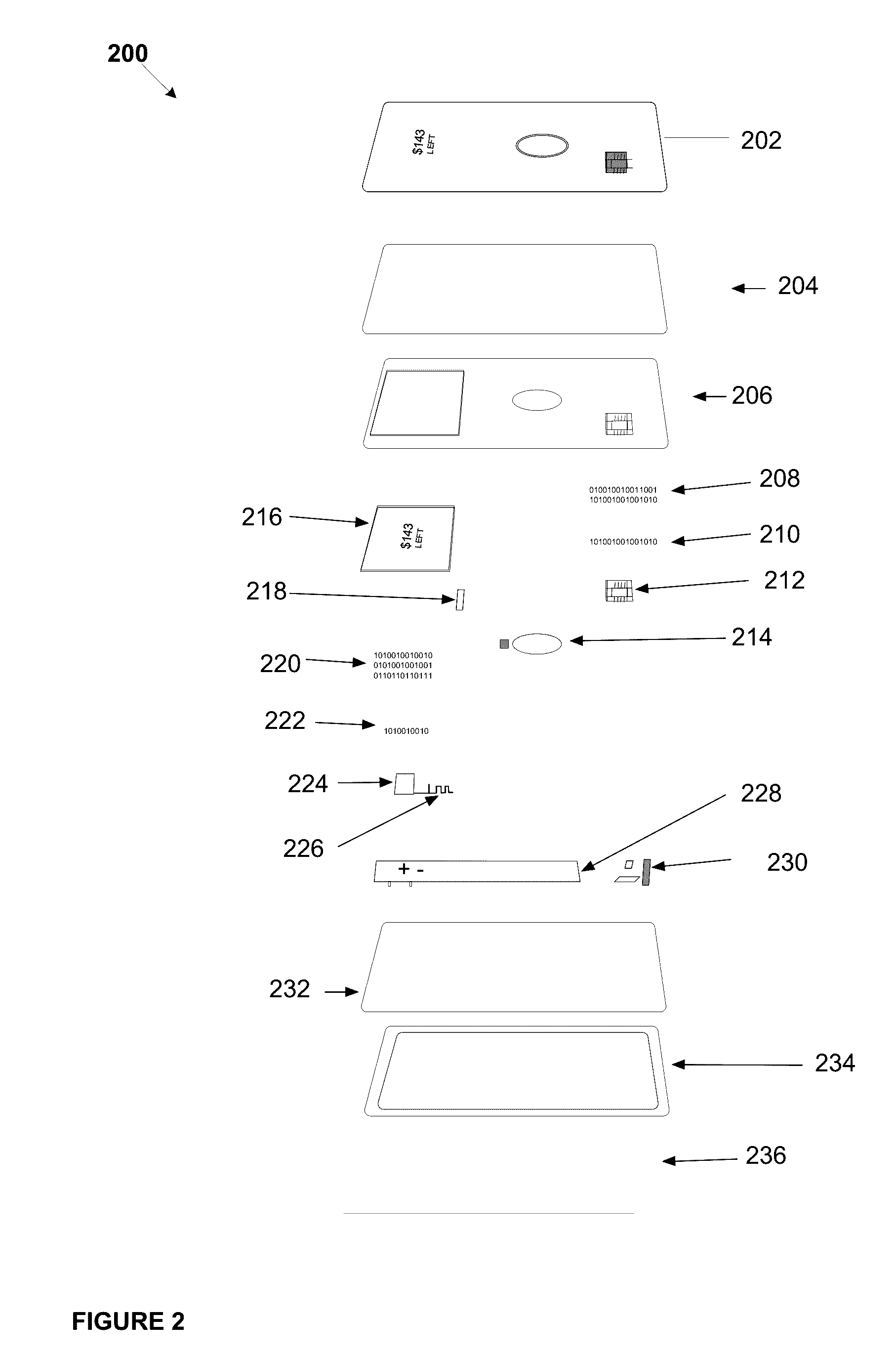

Dynamic transaction card power management

ActiveUS20160308371A1Fast timeLower levelBatteries circuit arrangementsAc-dc network circuit arrangementsEngineeringComputer terminal

A printed circuit board (“PCB”) with a power source. The PCB and power source combination may be inserted into a small electronic device, such as a dynamic transaction card, which may include a dynamic transaction card or a EuroPay-MasterCard-Visa (“EMV”) card. For example, a PCB may be manufactured to attach a battery as a power source to one side of a PCB such that the integrated battery directly connects with at least a portion of the PCB side. A rapid energy storage device may also be utilized as a power source. Energy may be harvested from an EMV terminal to charge or recharge a dynamic transaction card or EMV card powered by a rapid energy storage device when the card is inserted into the terminal.

Owner:CAPITAL ONE SERVICES

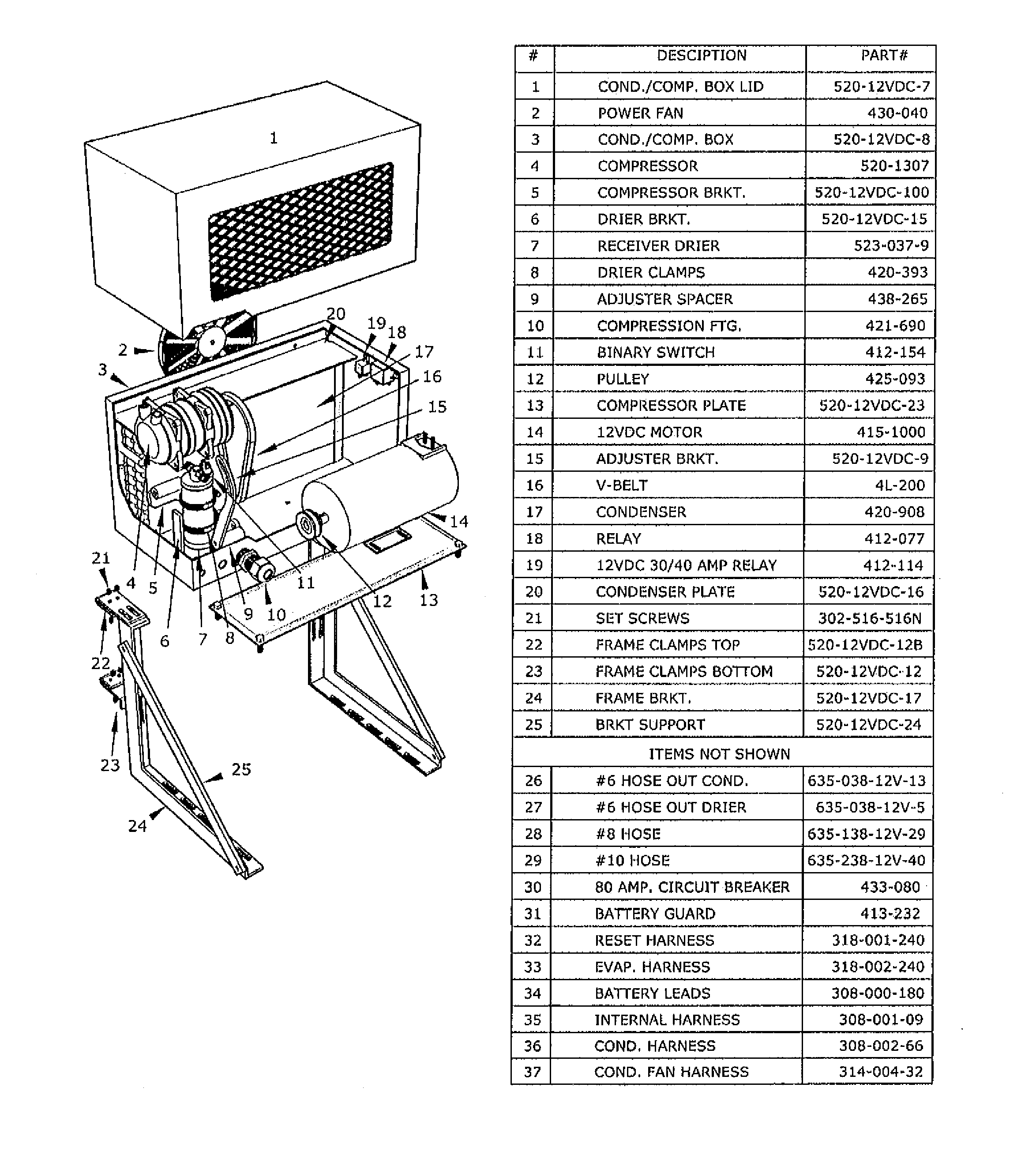

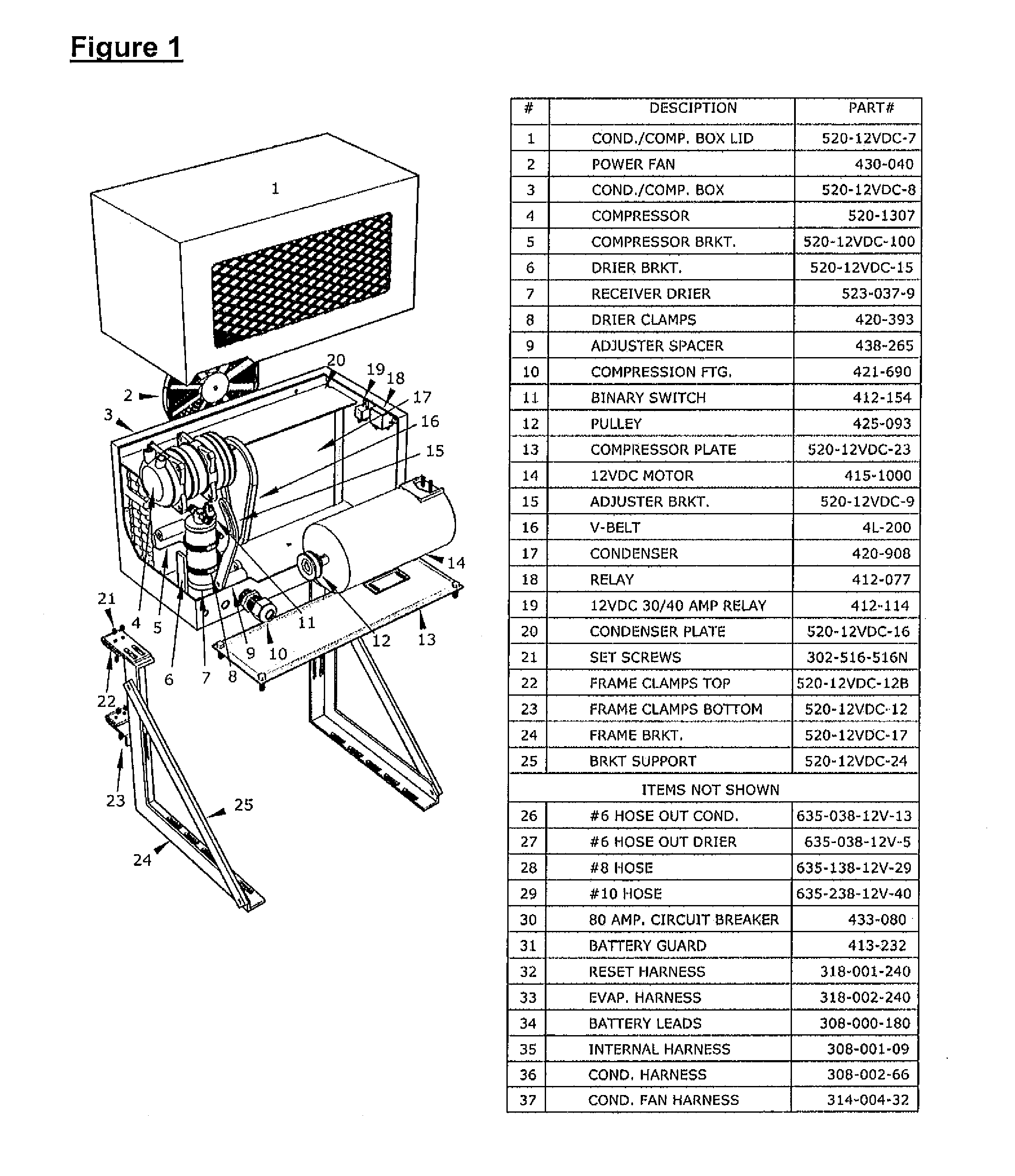

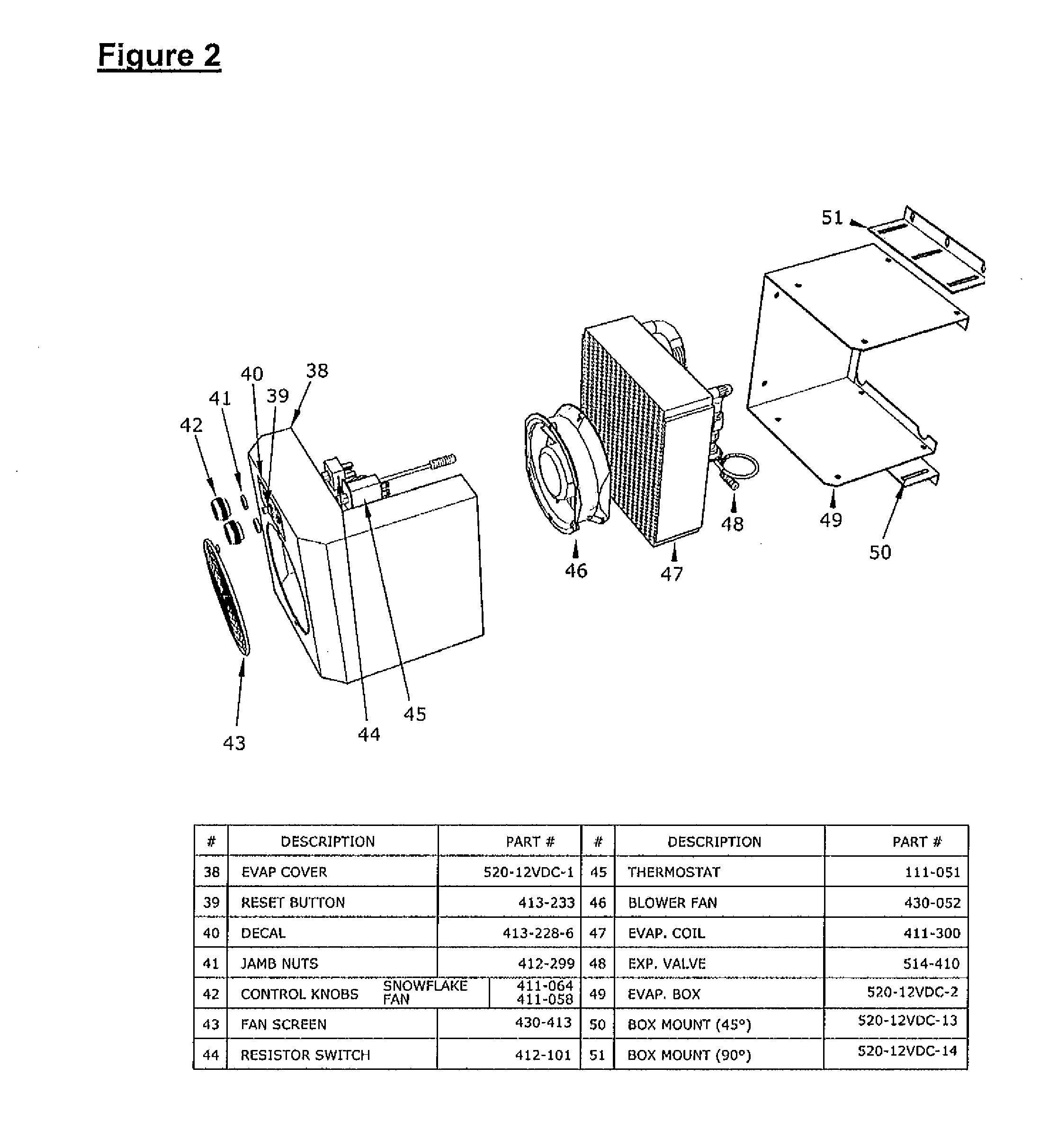

Truck Air Conditioner for Keeping Cabin Temperature Comfortable Independently of the Vehicle Engine

InactiveUS20110016894A1Minimizes battery draw-downGuaranteed long-term operationAir-treating devicesCompression machines with non-reversible cycleCost effectivenessAir conditioning

This disclosure provides a new high-efficiency air conditioning system for cooling a motor vehicle control cabin. Various components of the system have been optimized (including the motor, the drive train and the condenser) in a way that minimizes battery draw-down, and allows long-term operation on battery power alone. The main engine of the vehicle can be shut down during loading or when the driver is resting overnight, and does not need to be restarted for 8 hours or more. The air conditioning system of this invention enhances the driver's comfort and alertness after resting, decreases vehicle weight, and substantially reduces air pollution and noise. The invention has the added benefits of reducing fuel consumption and wear and tear on the truck's engine, thereby sustaining considerable cost benefit for the fleet operator.

Owner:HAMMOND AIR CONDITIONING

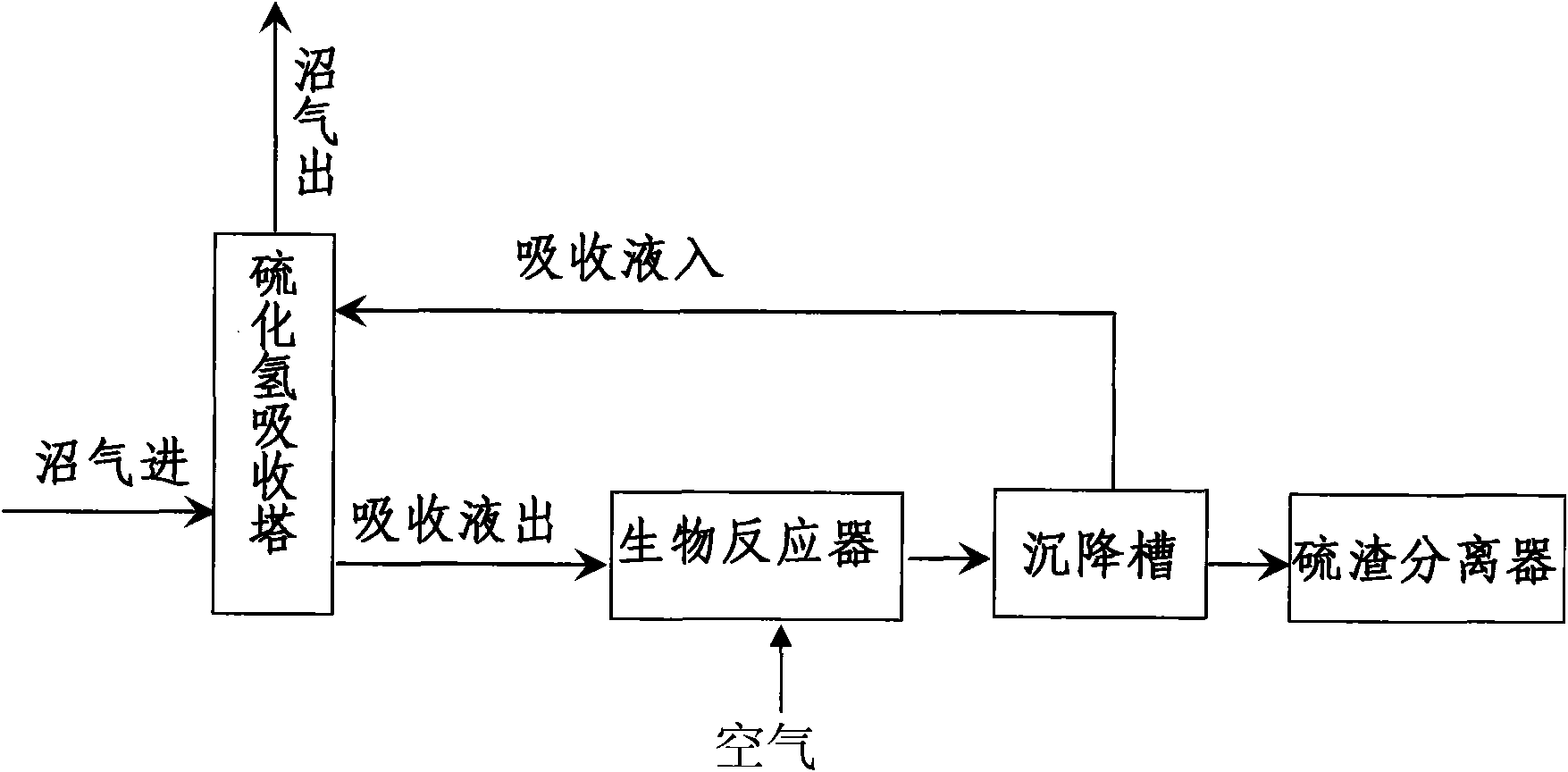

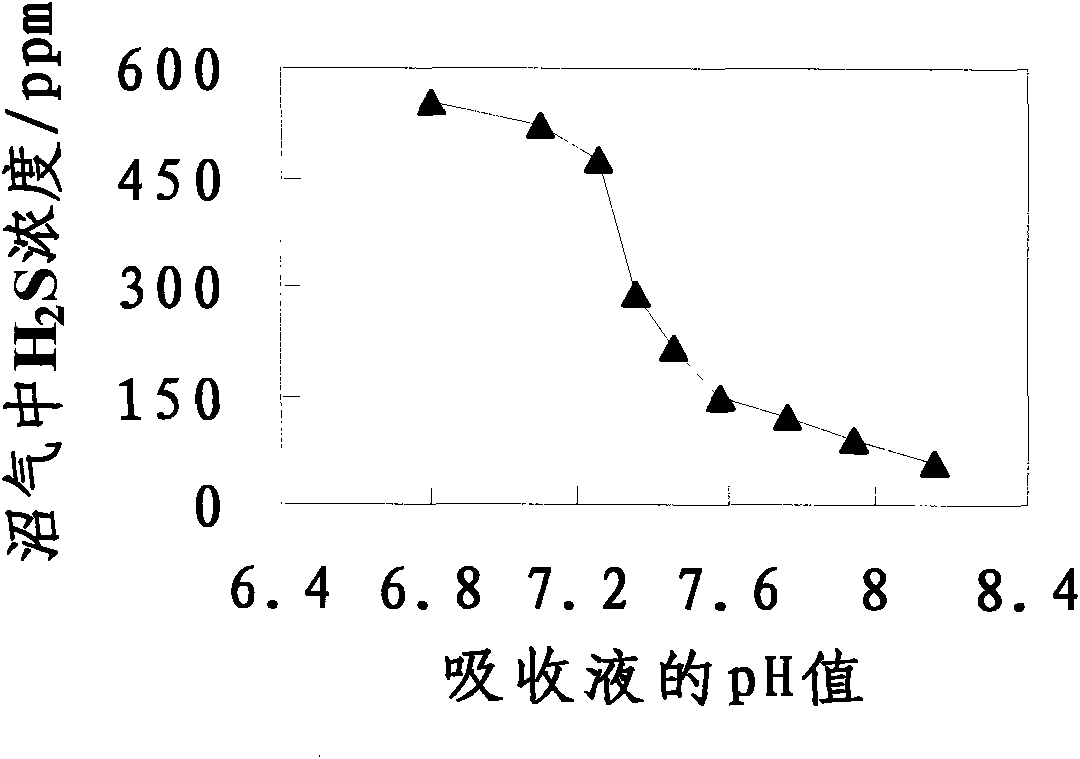

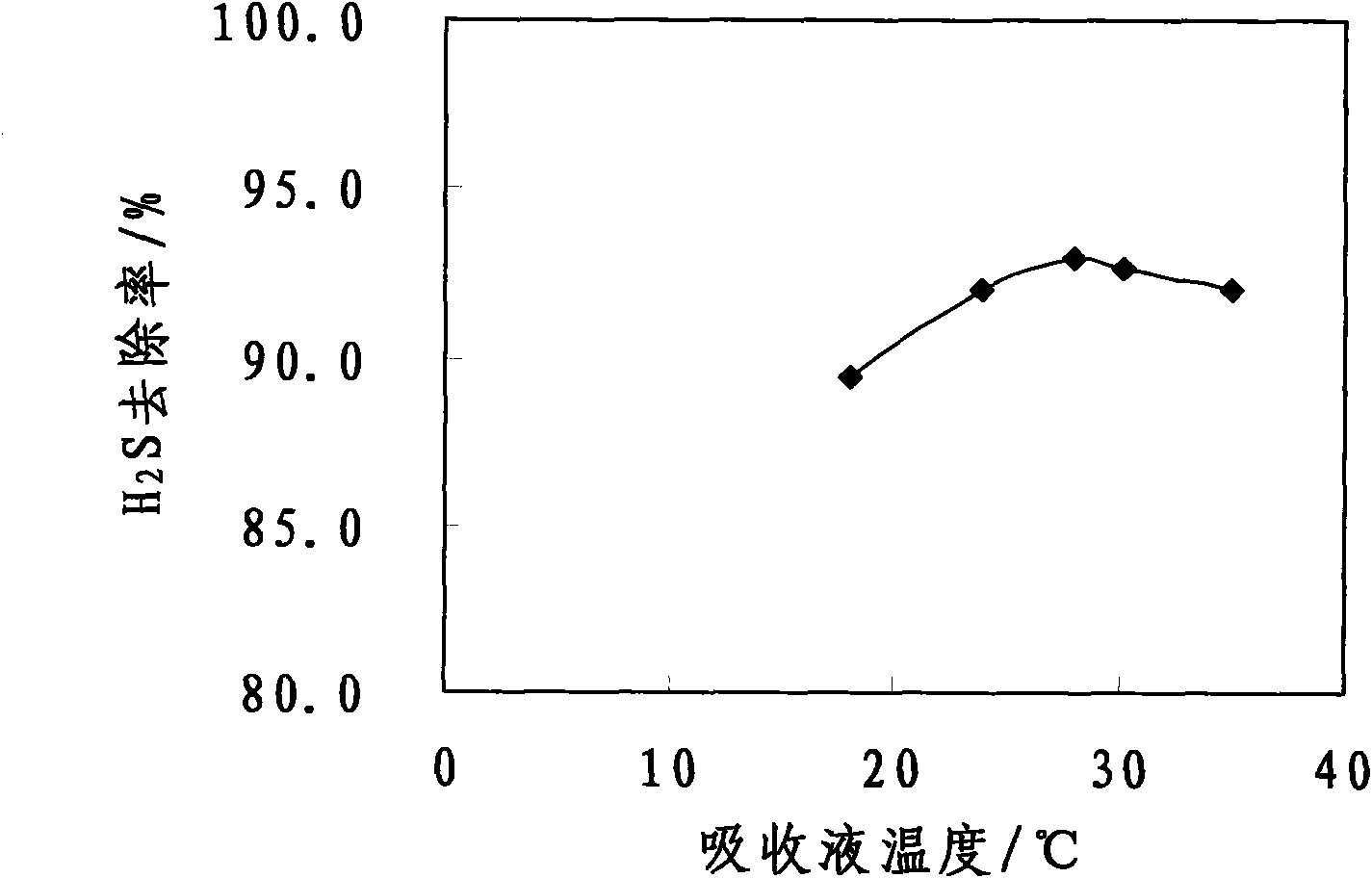

Biological desulfurization process for biogas

A biological desulfurization process for biogas comprises the following steps: contacting and reacting absorption solution which has a pH value of 7.5 to 8.0 and contains biological desulfurizing bacteria with the biogas first; aerating the reaction solution and keeping the dissolved oxygen concentration of the reaction solution between 0.50 and 1.25 mg / L; transforming sulfur element in the adsorption solution into monomer sulfur; and recycling the absorption solution which is obtained after the settlement separation of the monomer sulfur and maintains the dissolved oxygen concentration of 0.05 to 1.25 mg / L. The process avoids further desulfurization by a dry method or wet method and is simple and convenient to operate.

Owner:李旭源

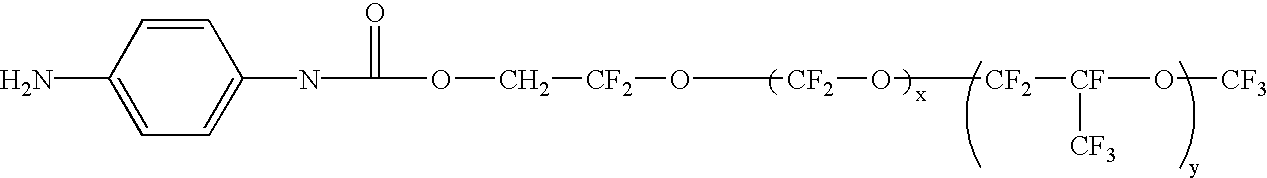

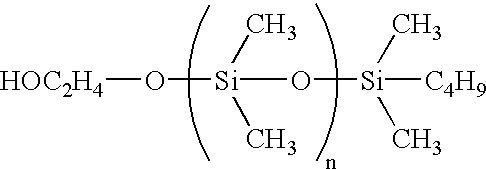

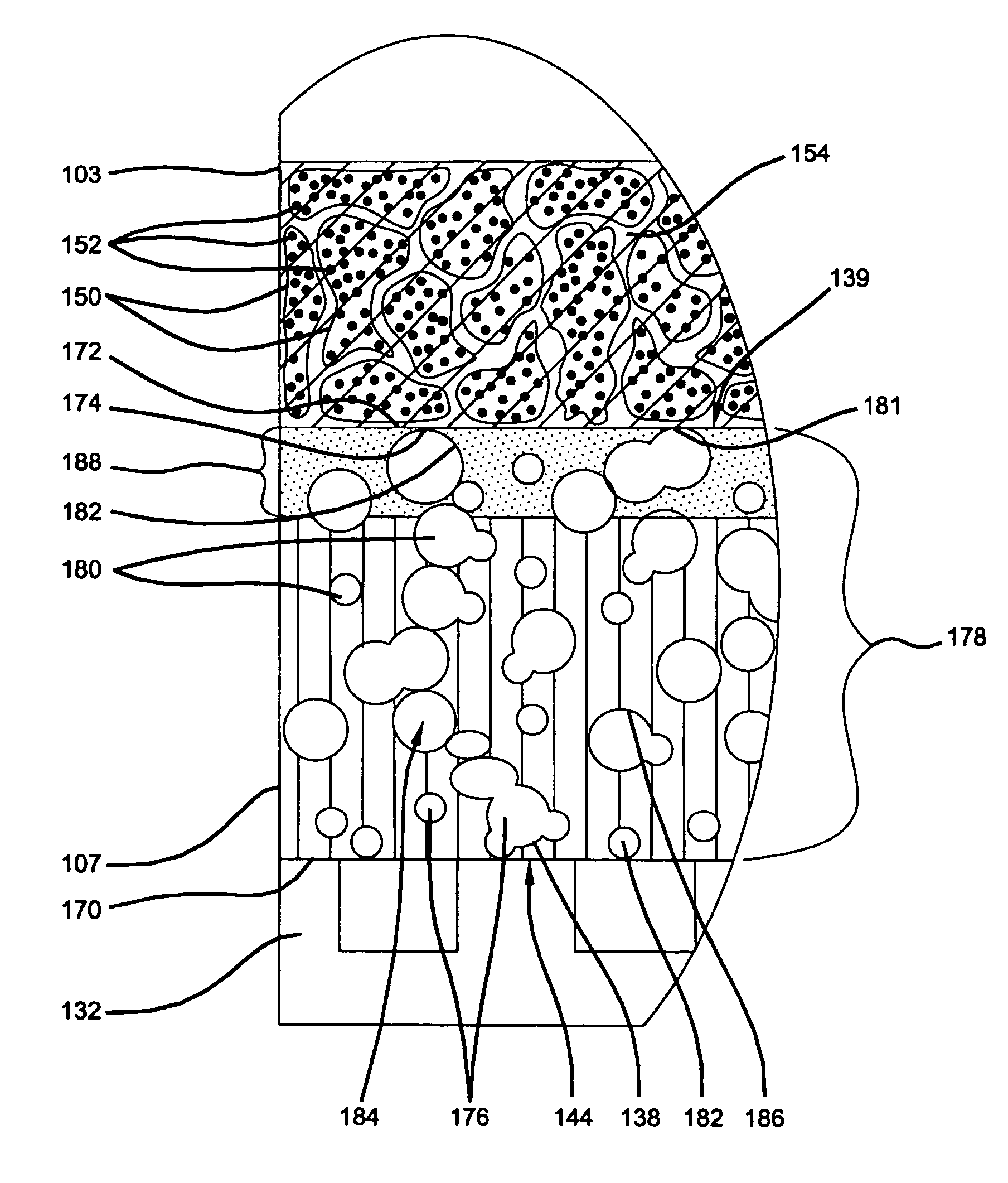

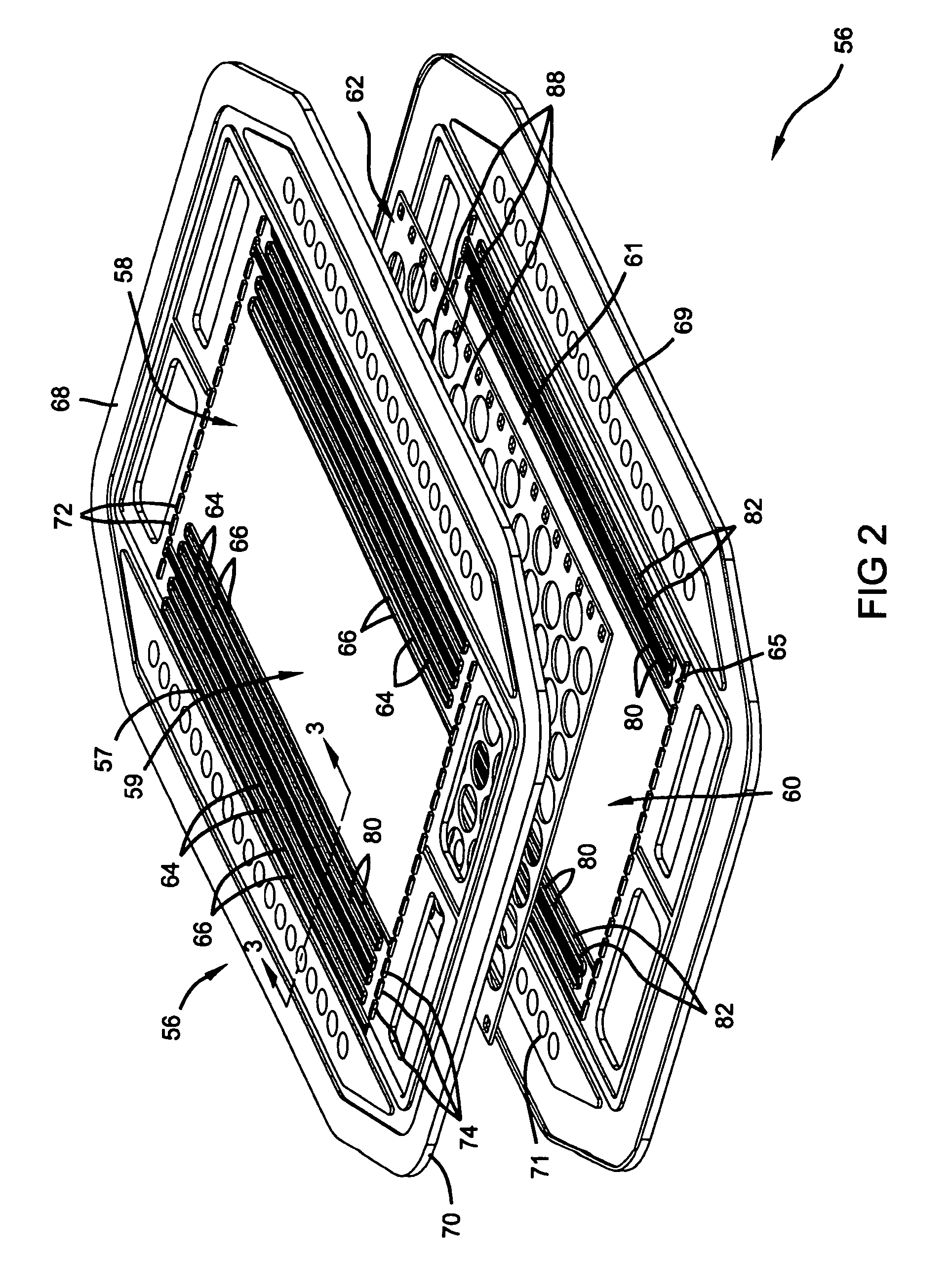

Novel approach to make a high performance membrane electrode assembly (MEA) for a PEM fuel cell

ActiveUS20050260484A1Improve water managementReduction and elimination of needLayered productsFuel cell auxillariesFuel cellsPorous medium

An electrically conductive fluid distribution element for use in a fuel cell having a conductive non-metallic porous media having a surface with an electrically conductive metal deposited along one or more metallized regions. The metallized regions are arranged to contact a membrane electrode assembly (MEA) in a fuel cell assembly, and thus improve electrical conductance at contact regions between the MEA and the fluid distribution media. Methods of making such a fluid distribution element and operating fuel cell assemblies are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Scale inhibitor used in cracked gasoline hydrogenation system

ActiveCN102071061AAdaptableStrong targetingTreatment apparatus corrosion/fouling inhibitionOrganic solventScavenger

The invention relates to a scale inhibitor used in a cracked gasoline hydrogenation system. The scale inhibitor can solve the technical problems, thus the scale inhibitor can well adapt to the complicated operating conditions of the cracked gasoline hydrogenation system, the generation of scale in the cracked gasoline hydrogenation system can be effectively inhibited, the scale adhered to the surface of the equipment can be dispersed in the material, the life of the hydrogenation catalyst can be prolonged and the operational cycle of the cracked gasoline hydrogenation equipment can be prolonged. The scale inhibitor of the invention comprises the following components by weight percent: 5-25% of metal-ion deactivator, 5-30% of antioxidant, 5-30% of radical scavenger, 5-35% of dispersant and35-60% of organic solvent. The preparation method of the scale inhibitor comprises the following steps: heating the raw materials, stirring, fully dissolving and mixing, and cooling.

Owner:浙江杭化科技股份有限公司

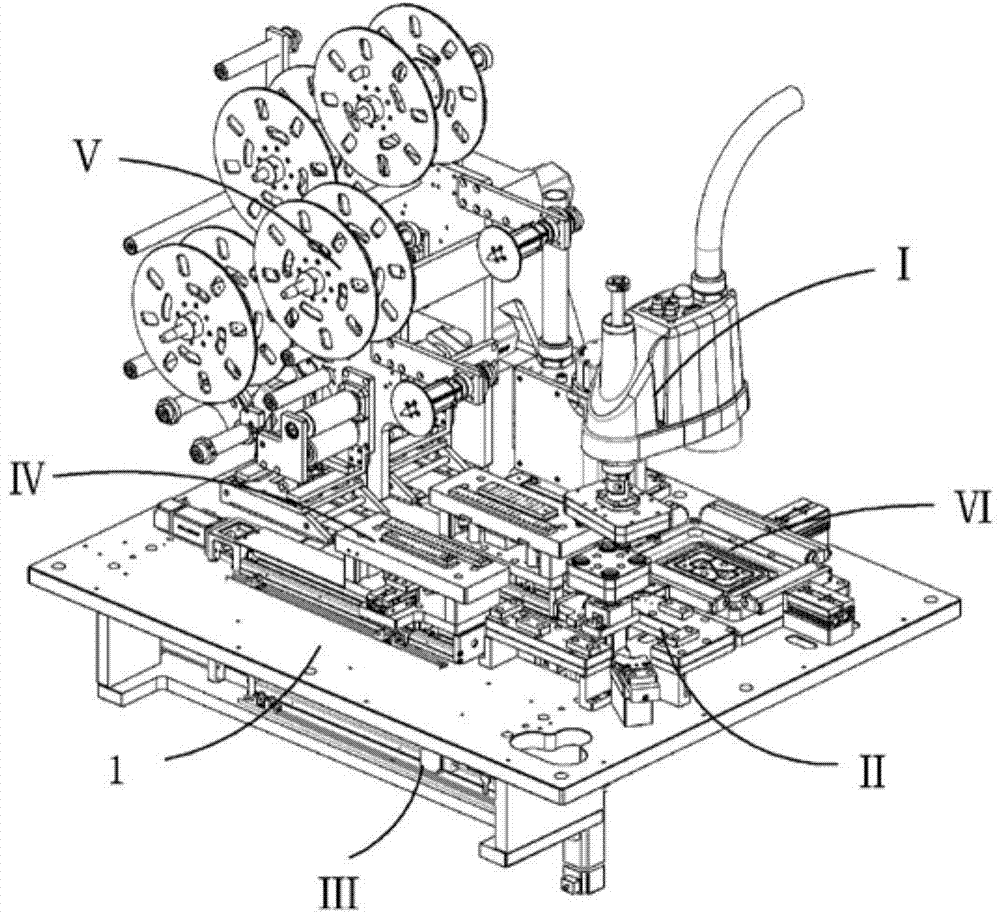

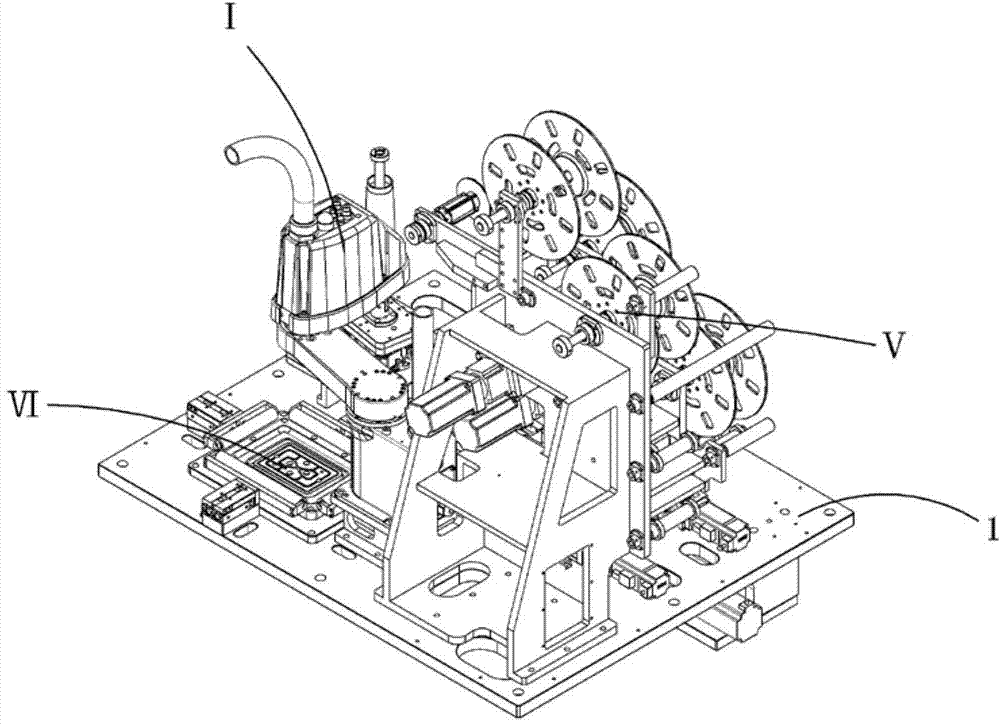

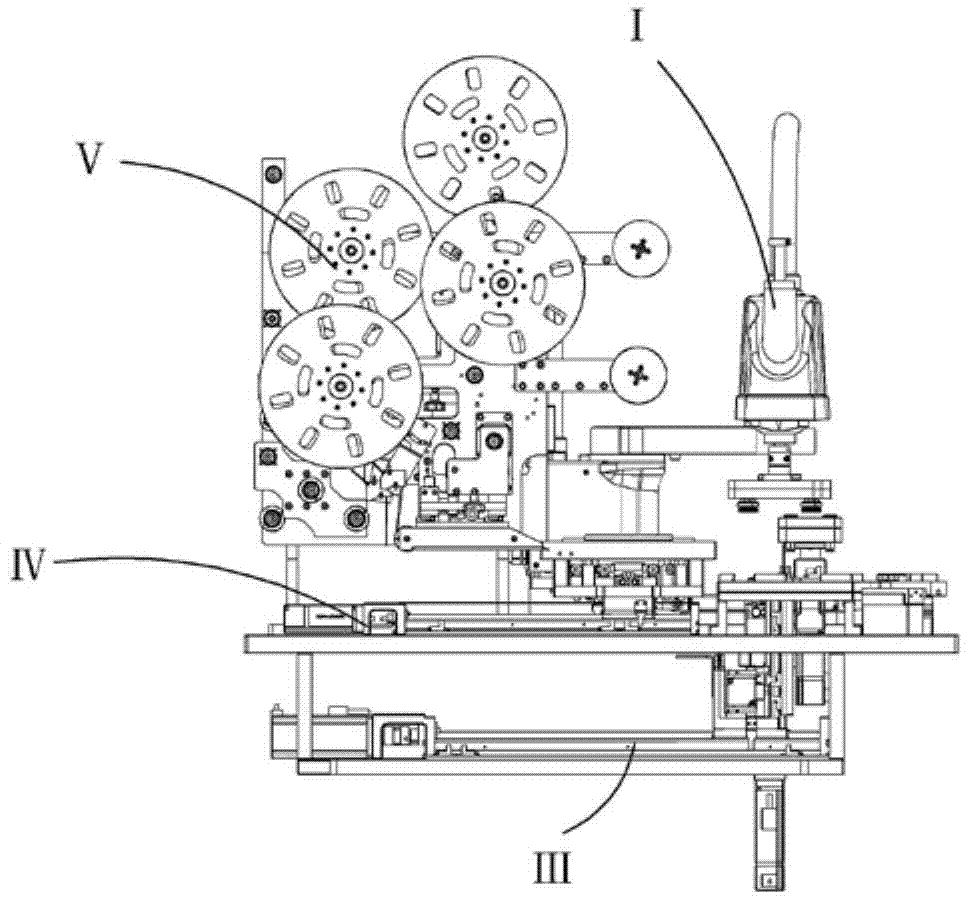

Electronic product film sticking machine

ActiveCN103786917AAccurate correctionIncrease productivityWrapping material feeding apparatusArticle deliveryAssembly lineManipulator

The invention relates to an electronic product film sticking machine which comprises a base plate, a mechanical hand, a correction mechanism, a conveying mechanism, a film taking and sticking mechanism, an inner and outer layer rolling material separating mechanism and a film rolling mechanism. The mechanical hand sucks up electronic products from an assembly line, the electronic products are placed on the correction mechanism firstly, the conveying mechanism is arranged below the correction mechanism, after the positions of the electronic products are corrected, a suction cup on an R-axis mechanism of the conveying mechanism sucks up the electronic products, the electronic products reach the lower portion of the film taking and sticking mechanism under guidance of an X-axis mechanism, a Y-axis mechanism and a Z-axis mechanism, the inner and outer layer rolling material separating mechanism is driven by a motor to separate films and film sticking paper by a strip bar and stick the films and the film sticking paper on the film taking and sticking mechanism at the moment, then the suction cup of the conveying mechanism drives the products, a film on the parallel side is firstly stuck on the film taking and sticking mechanism, then, the film on the other parallel side is stuck, after sticking, the mechanical hand sucks up the products again, the products are conveyed to the film rolling mechanism, the film rolling mechanism rolls the films stuck well to be flat from four sides, and finally the mechanical hand takes the film stuck out of the film rolling mechanism.

Owner:BOZHON PRECISION IND TECH CO LTD

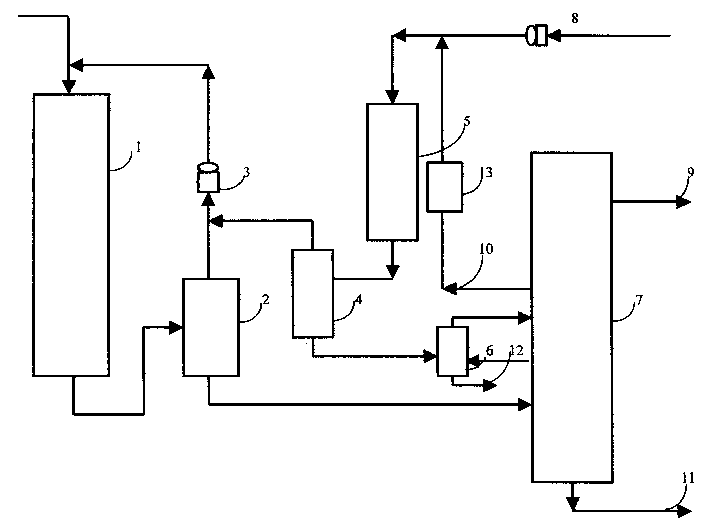

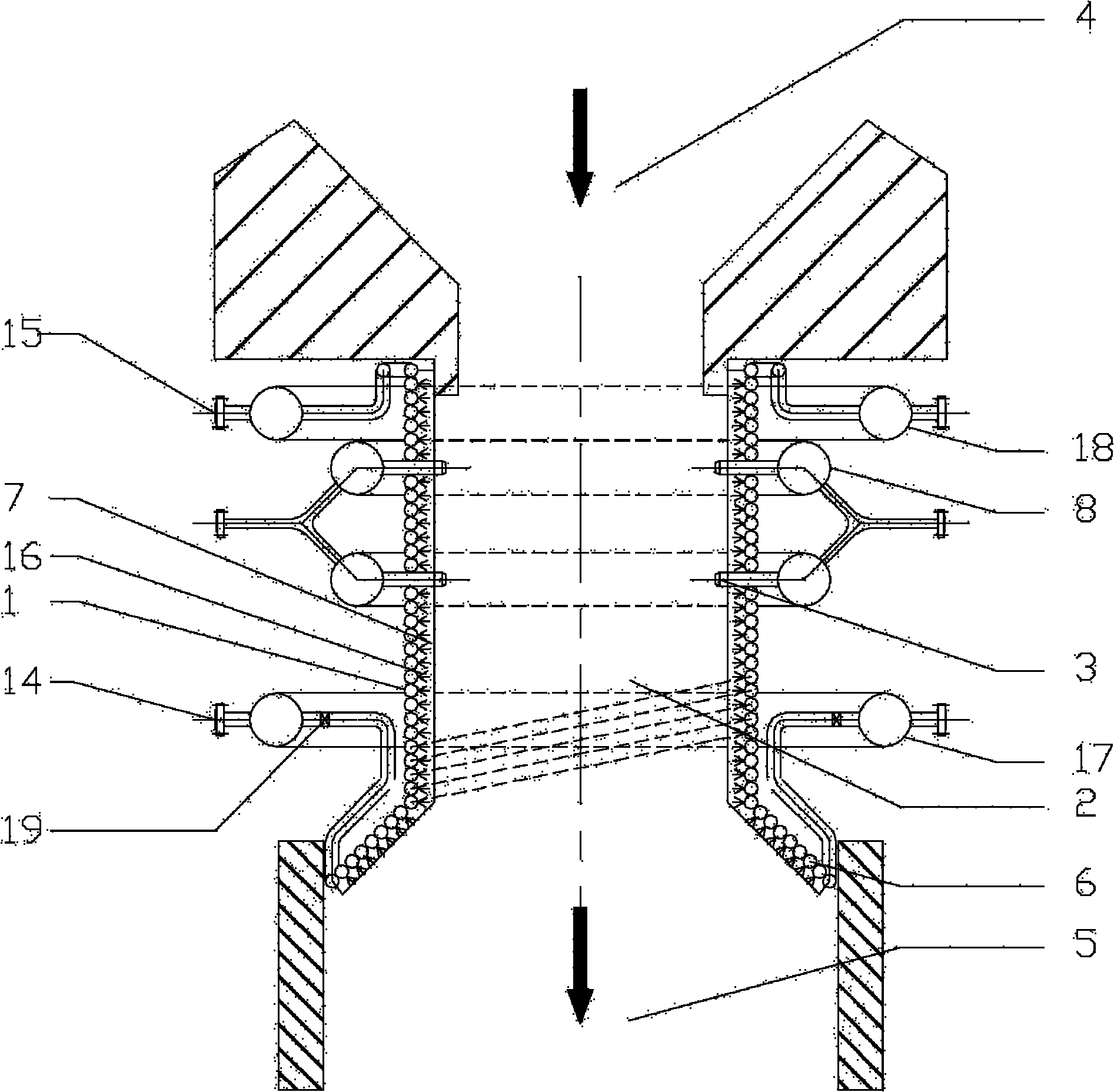

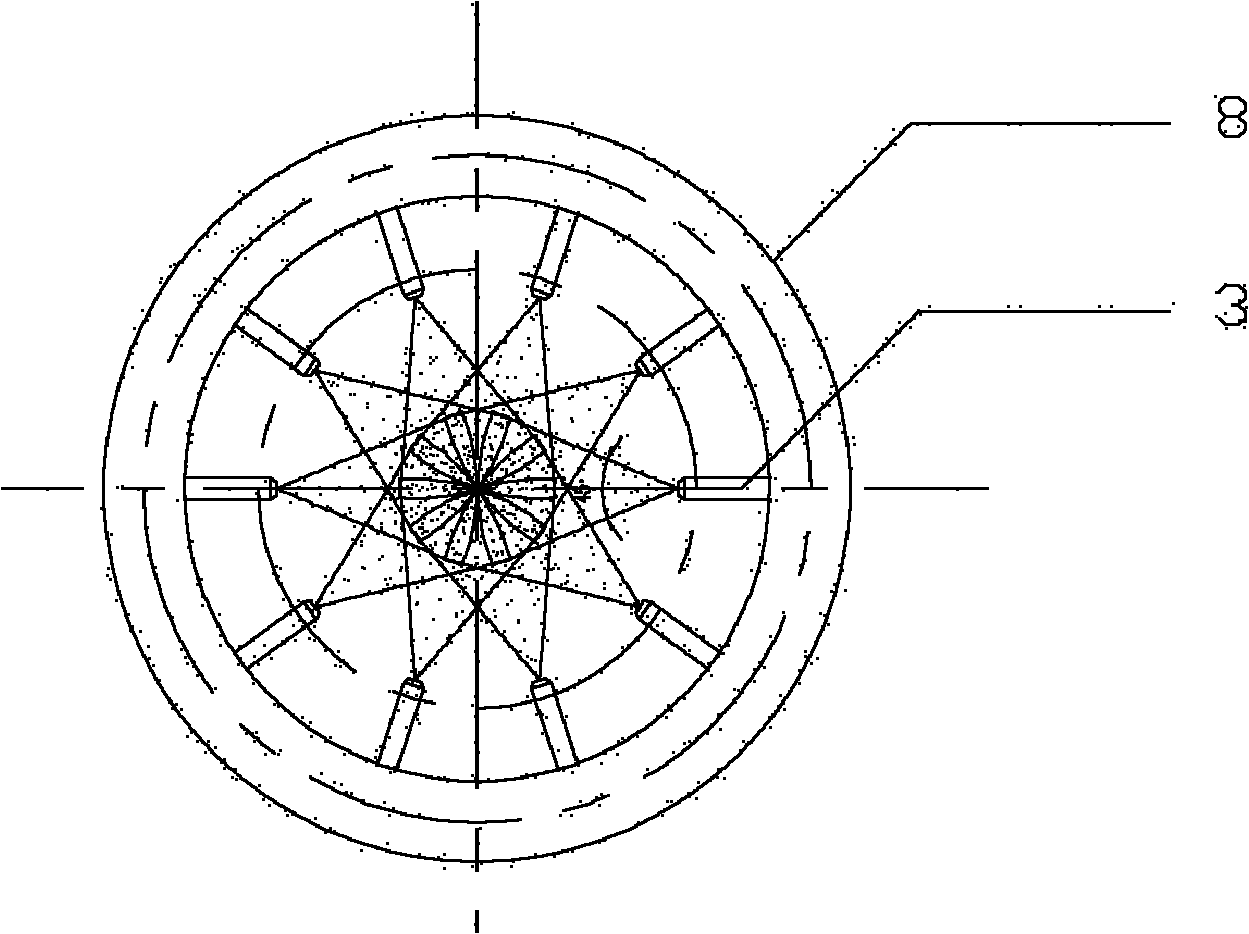

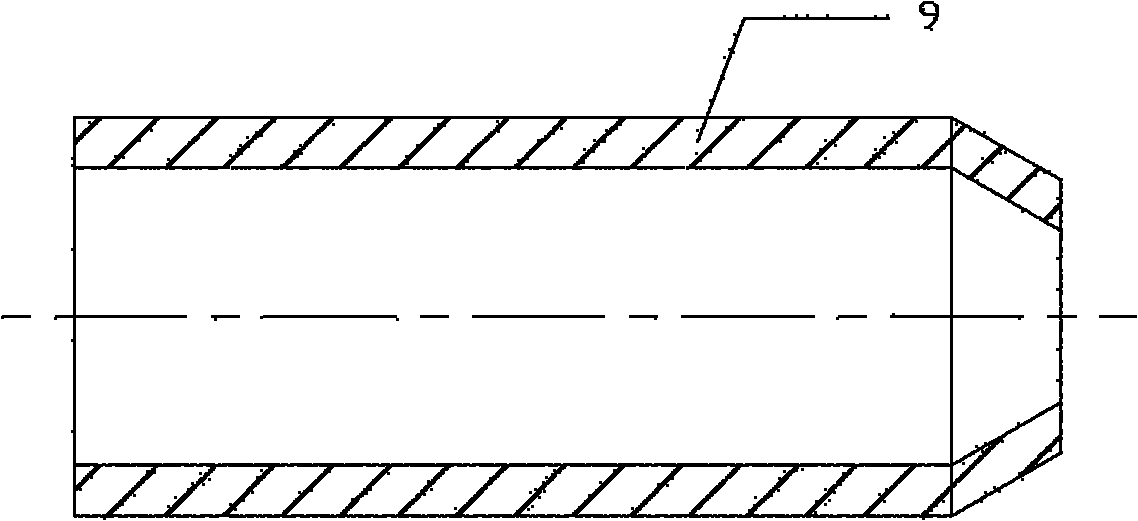

High-temperature crude synthesis gas chilling device

ActiveCN102140372AIncrease contact areaSimple structureChemical industryCombustible gas productionWear resistantChiller

The invention relates to a high-temperature crude synthesis gas chilling device, which comprises a gas flow channel of a chiller and an atomizing nozzle arranged on the side wall of the gas flow channel, wherein the gas flow channel is connected with a reaction chamber and a cooling chamber of a gasification furnace and provides a mixing space for a chilling medium and high-temperature crude synthesis gas; the atomizing nozzle is a single-flow-channel pressure nozzle or a double-flow-channel gas-liquid two-phase nozzle, and is partitioned into 1-20 layers; each layer is uniformly distributed on the circumference and is used for uniformly spraying the chilling medium into the high-temperature crude synthesis gas and chilling the synthesis gas to be in a specific temperature range; the gas flow channel is a water cooled-wall or a fire-resistant and wear-resistant liner or the combination of the water-cooled wall and the fire-resistant and wear-resistant liner; and the gas flow channel has a cylindrical structure or a conical structure or the combination of the cylindrical structure and the conical structure. The chilling device has the advantages of high chilling efficiency, large gas-liquid contact area, high chilling rate, small dosage of the chilling medium, mature manufacturing technology, high reliability and capability of reducing the consumption and the discharge of cleaning black water, and relates to an environmentally-friendly and-energy saving technology.

Owner:WISON ENG

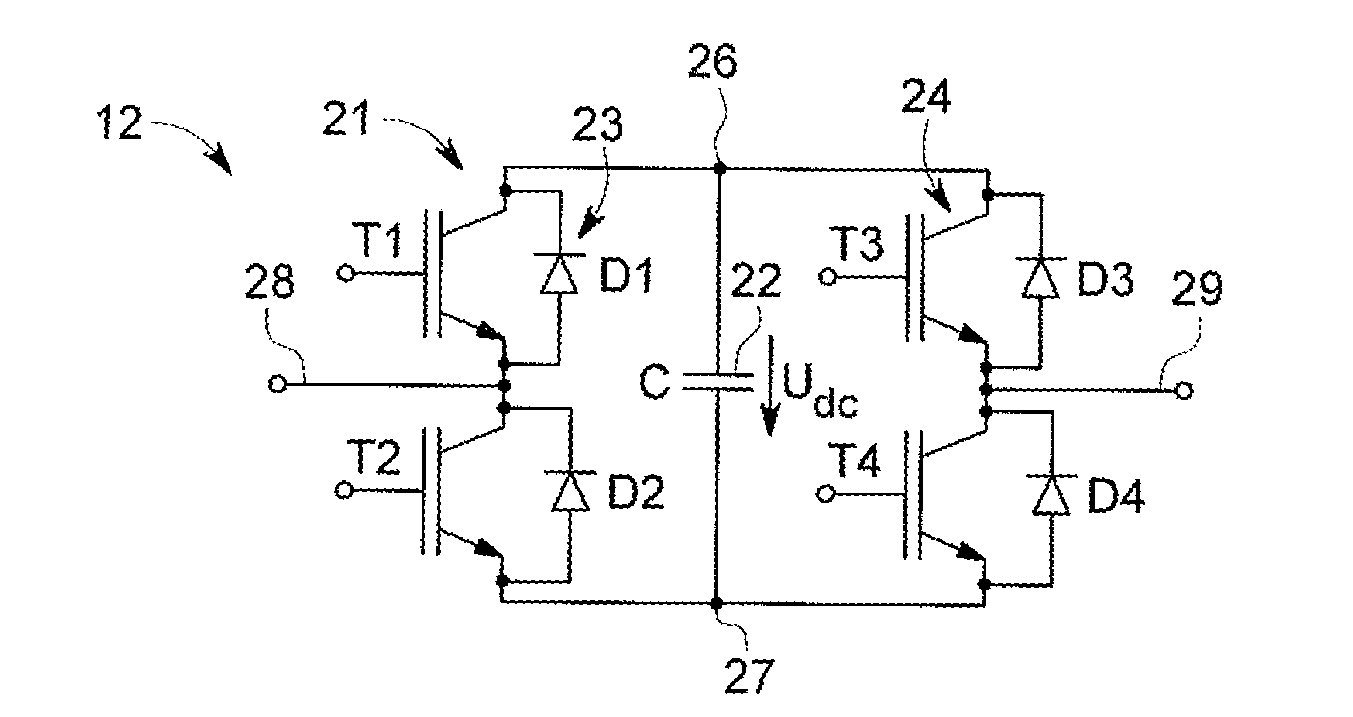

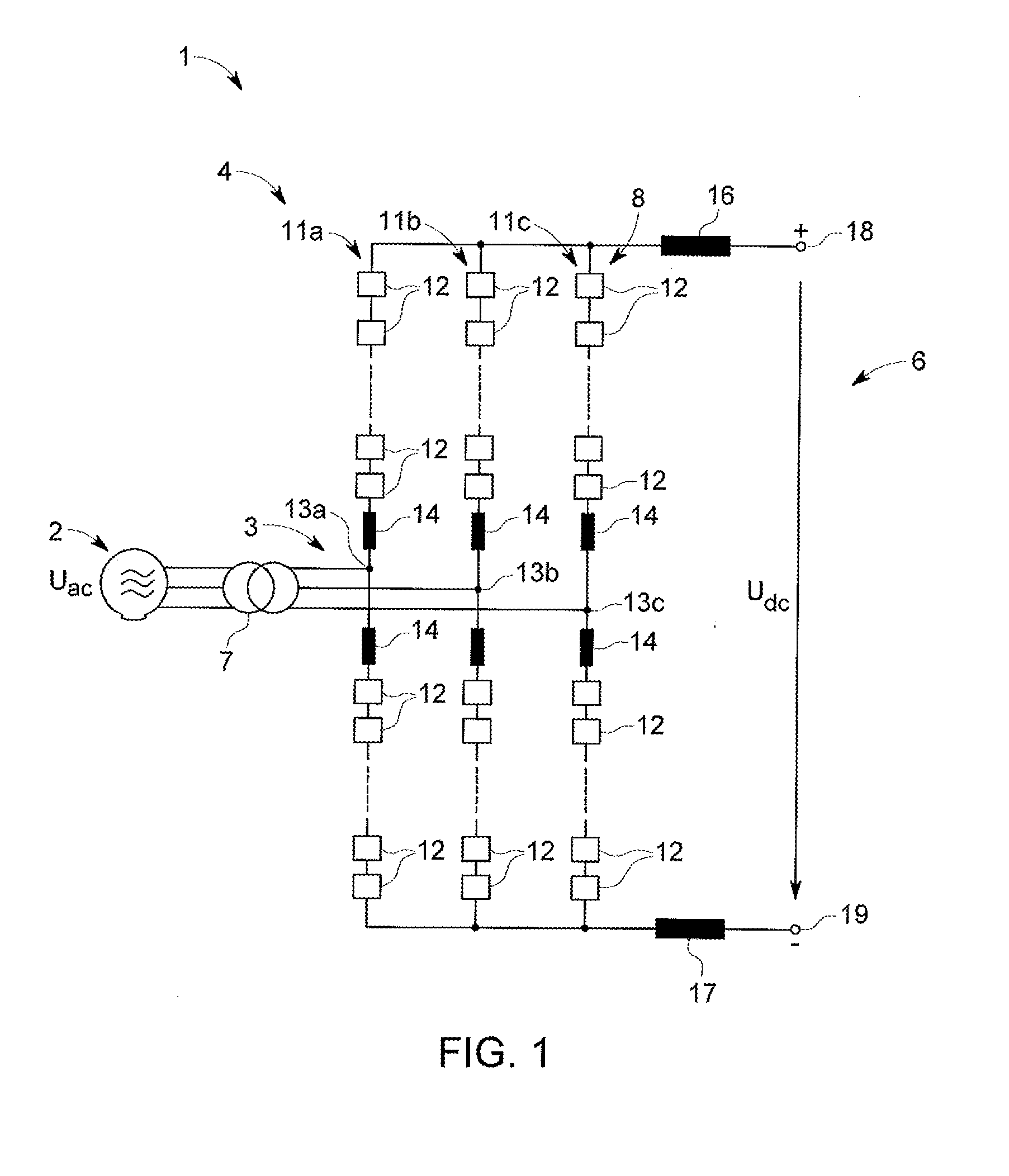

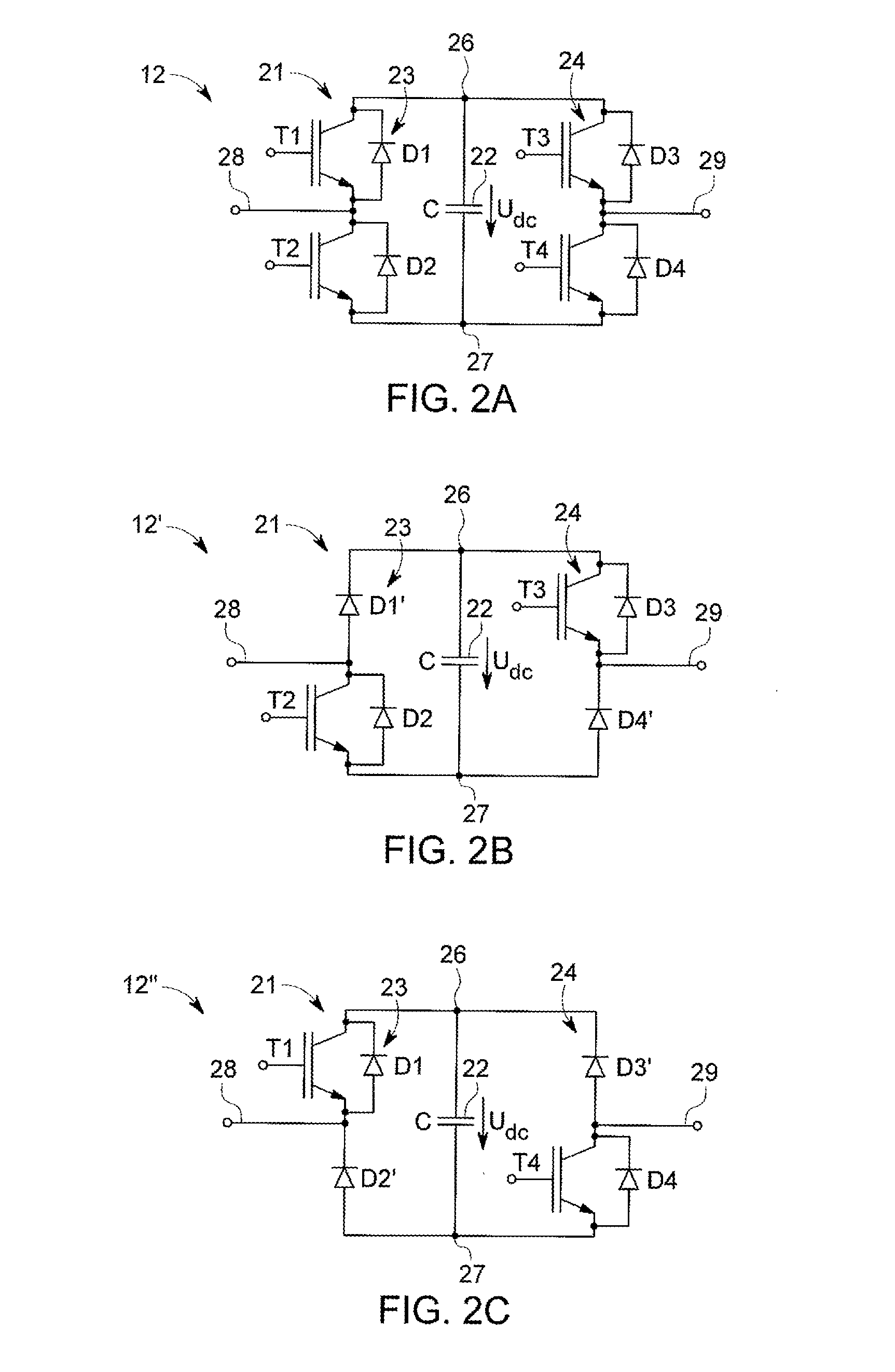

Converter submodule with short-circuit device and power converter having same

ActiveUS20160365787A1Low effortShort-circuitedSpark gap detailsSpark gaps with auxillary triggeringPower semiconductor deviceFlyback diode

A short-circuit device and a protection method for a submodule for a power converter are disclosed. The submodule includes a bridge circuit having at least one power semiconductor branch extending between a first and a second DC voltage node and at least one controllable power semiconductor switch disposed therein to which a freewheeling diode is connected in anti-parallel, and a capacitor connected in parallel to the bridge circuit. The short-circuit device has at least one selected of the freewheeling diodes anti-parallel to the power semiconductor switches of the bridge circuit, wherein the at least one selected freewheeling diode is manufactured in press pack design and rated such that, when a fault occurs in the submodule, the at least one selected freewheeling diode breaks down due to the fault conditions and provides a durable, stable, low-impedance short circuit path between a first and a second AC voltage connection of the submodule.

Owner:GE ENERGY POWER CONVERSION TECH

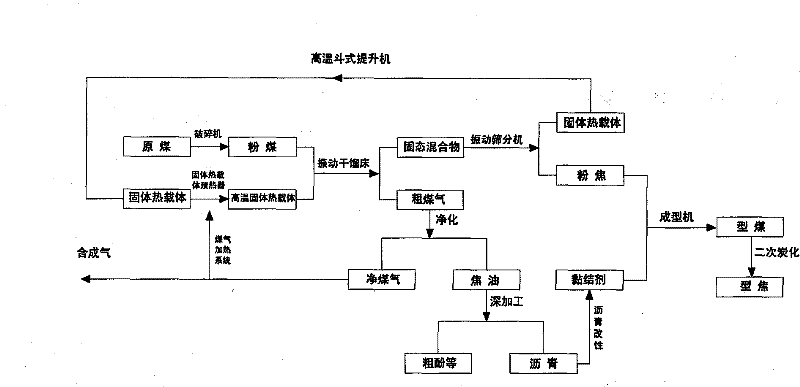

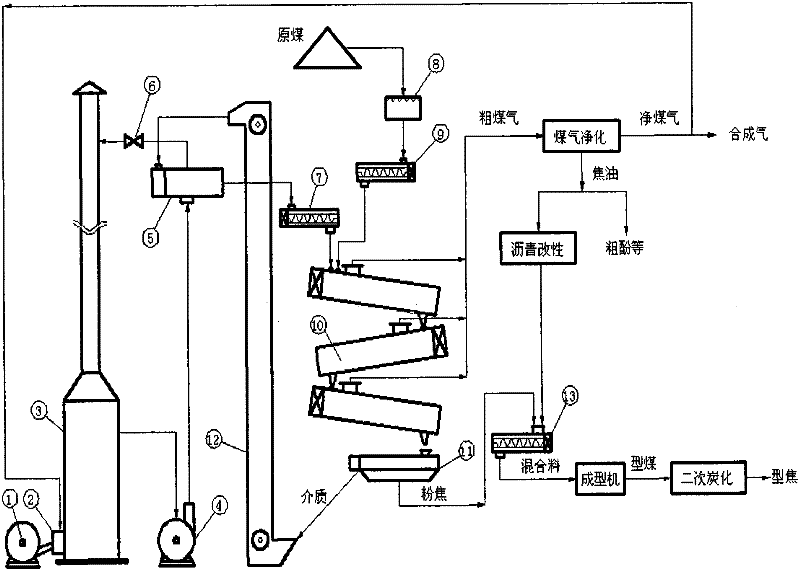

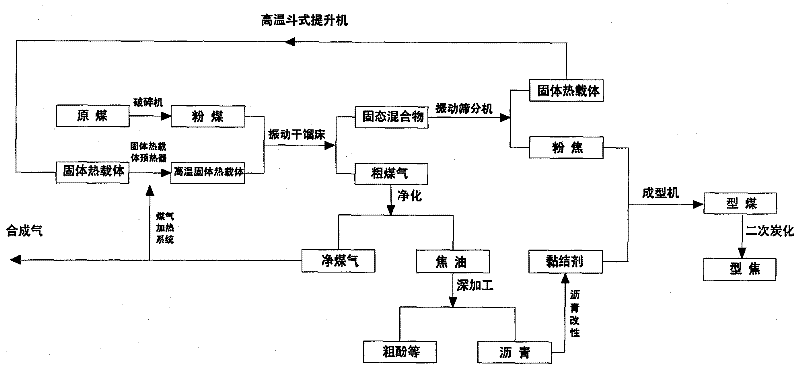

Poly-generation process for pyrolyzing solid thermal carrier via low-rank coal vibration bed

InactiveCN102453489AFast pyrolysisExtended service lifeDirect heating destructive distillationSolid fuelsGeneration processTar

The invention provides a poly-generation process for pyrolyzing a solid thermal carrier via a low-rank coal vibration bed. The process flow is as follows: mixing and retorting coal powder and a high-temperature solid thermal carrier in a vibration carbonization bed; introducing crude gas generated in the retorting process into a gas purification section; carrying out tar deep processing and asphalt modification on the separated tar to prepare crude phenol, an asphalt binder and the like; and carrying out formation and ball pressing on a retorted product powder semi-coke and the asphalt binder as well as other additives, and secondarily carbonizing to prepare a formed coke. In the process provided by the invention, a burning or oxidization phenomenon is not generated during the period of retorting; the product powder semi-coke is low in ash content, high in gas thermal value and high in useful component; the relative motion speed of the solid thermal carrier and the coal powder is small; crude gas does not carry fine coke particles, thereby avoiding adhesion of tar and fine particles on the inner wall of a pipeline and ensuring the long-term operation of a system; and the solid thermal carrier is surrounded by the powder coal, the probabilities of friction and collision between the solid thermal carriers are reduced, and the service life is prolonged. The process provided by the invention is the poly-generation process for pyrolyzing the solid thermal carrier via the low-rank coal vibration bed, and the poly-generation process is practicable in the aspects of technology, materials, cost and the like.

Owner:CHINA UNIV OF MINING & TECH

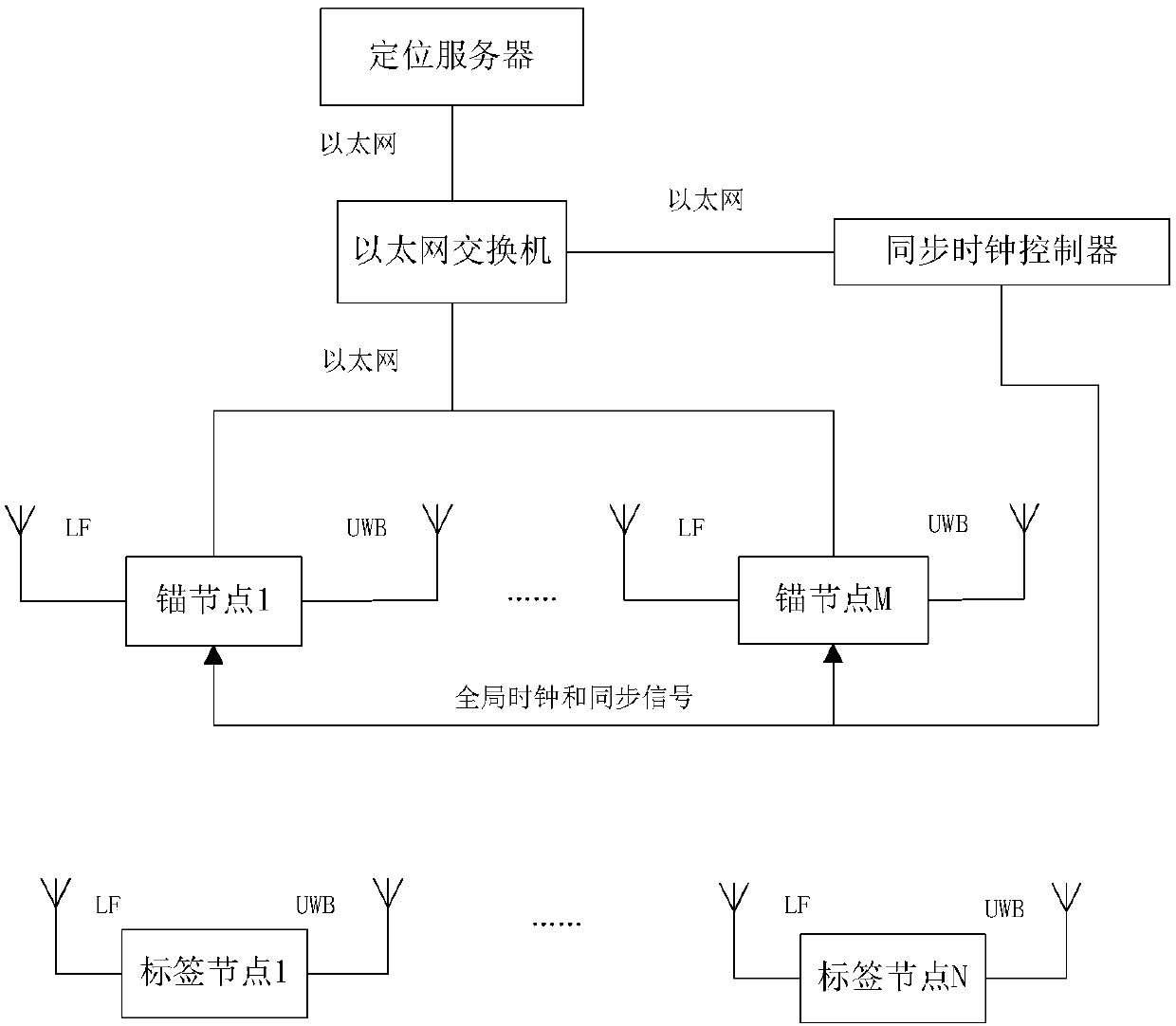

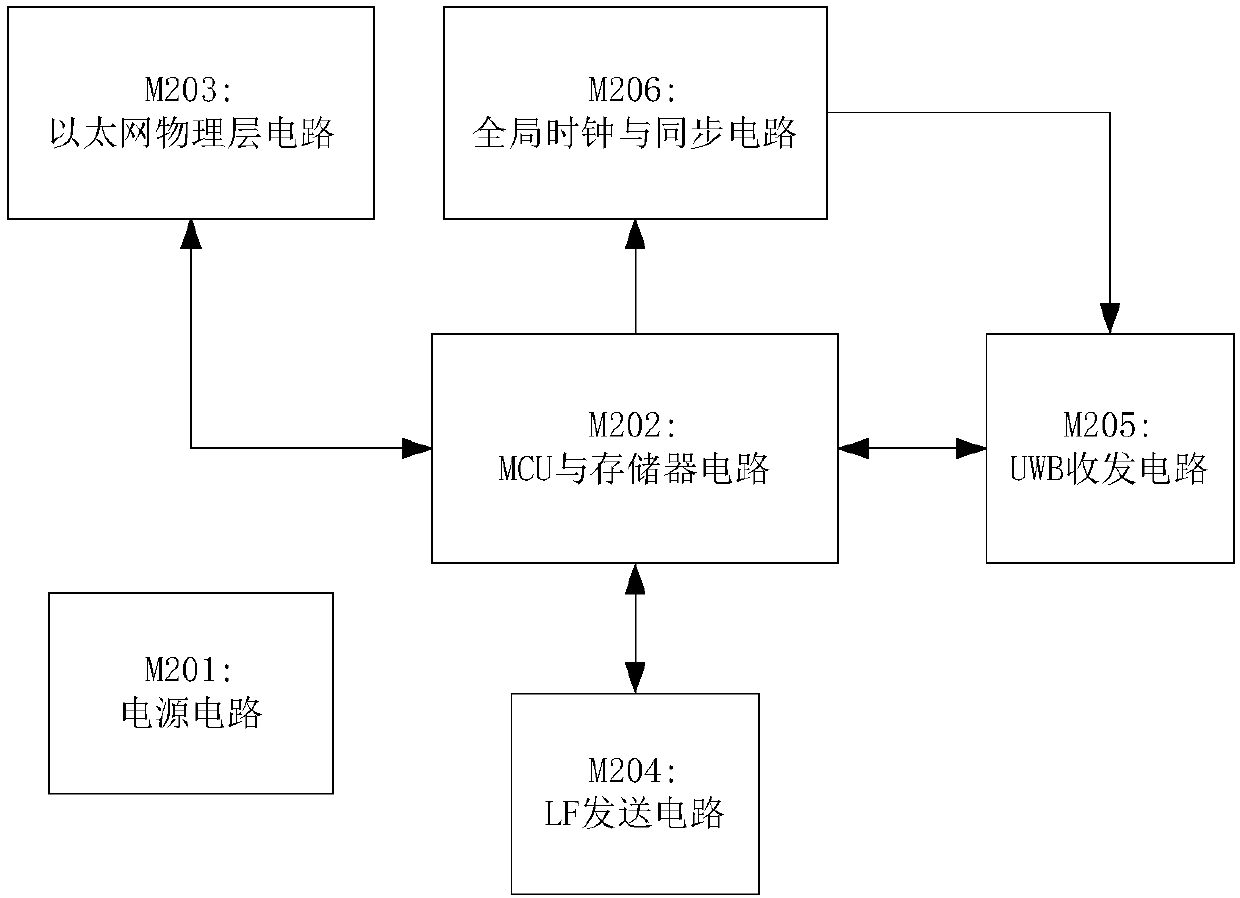

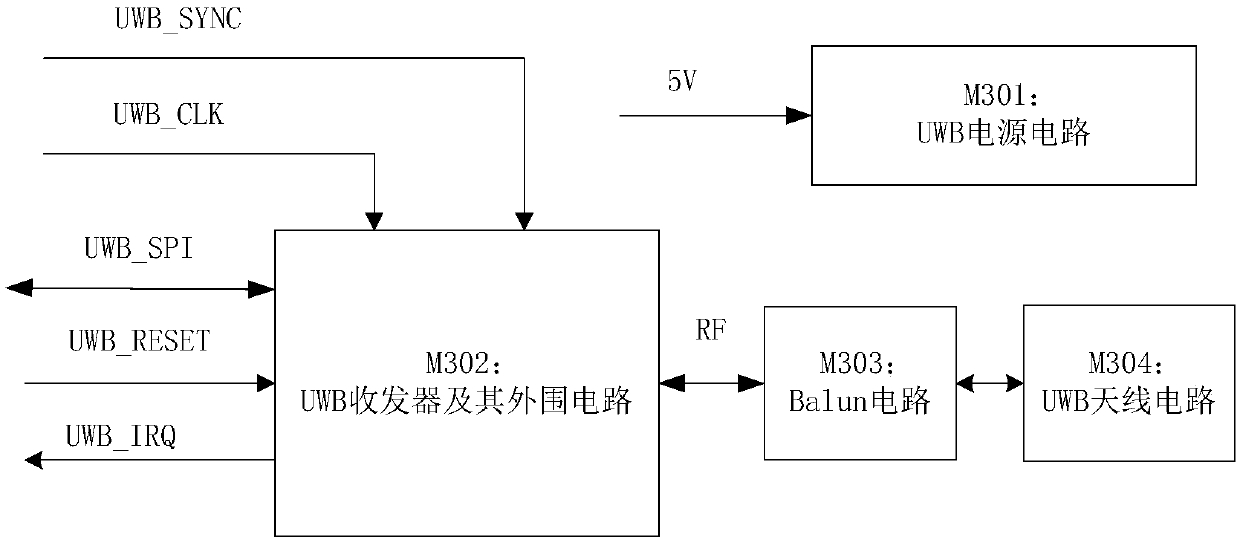

Positioning system and positioning method of indoor high-density mobile tags

ActiveCN107635283AHigh densityReduce power consumptionPower managementPosition fixationHigh densityDouble frequency

The invention discloses a positioning system and a positioning method of indoor high-density mobile tags. The positioning system comprises a positioning server, an Ethernet switch, a synchronous clockcontroller, anchor nodes and tag nodes; an LF and UWB double-frequency communication mode is adopted between the anchor nodes and the tag nodes, UWB realizes uplink communication from the tag nodes to the anchor nodes, and LF realizes downlink communication from the anchor nodes to the tag nodes; the positioning server, the synchronous clock controller and the anchor nodes are communicated via awired Ethernet, and the positioning server, the synchronous clock controller and the anchor nodes are respectively connected with the Ethernet switch; and the synchronous clock controller is connectedwith each anchor node, provides a UWB transmitting-receiving circuit clock for each anchor node and finishes synchronization of positioning timers among all the anchor nodes in the system. Accordingto the positioning system and the positioning method of the indoor high-density mobile tags, advantages of LF and UWB are combined, the bandwidth required by UWB positioning communication is reduced,and power consumption of mobile tags is reduced.

Owner:SOUTH CHINA UNIV OF TECH

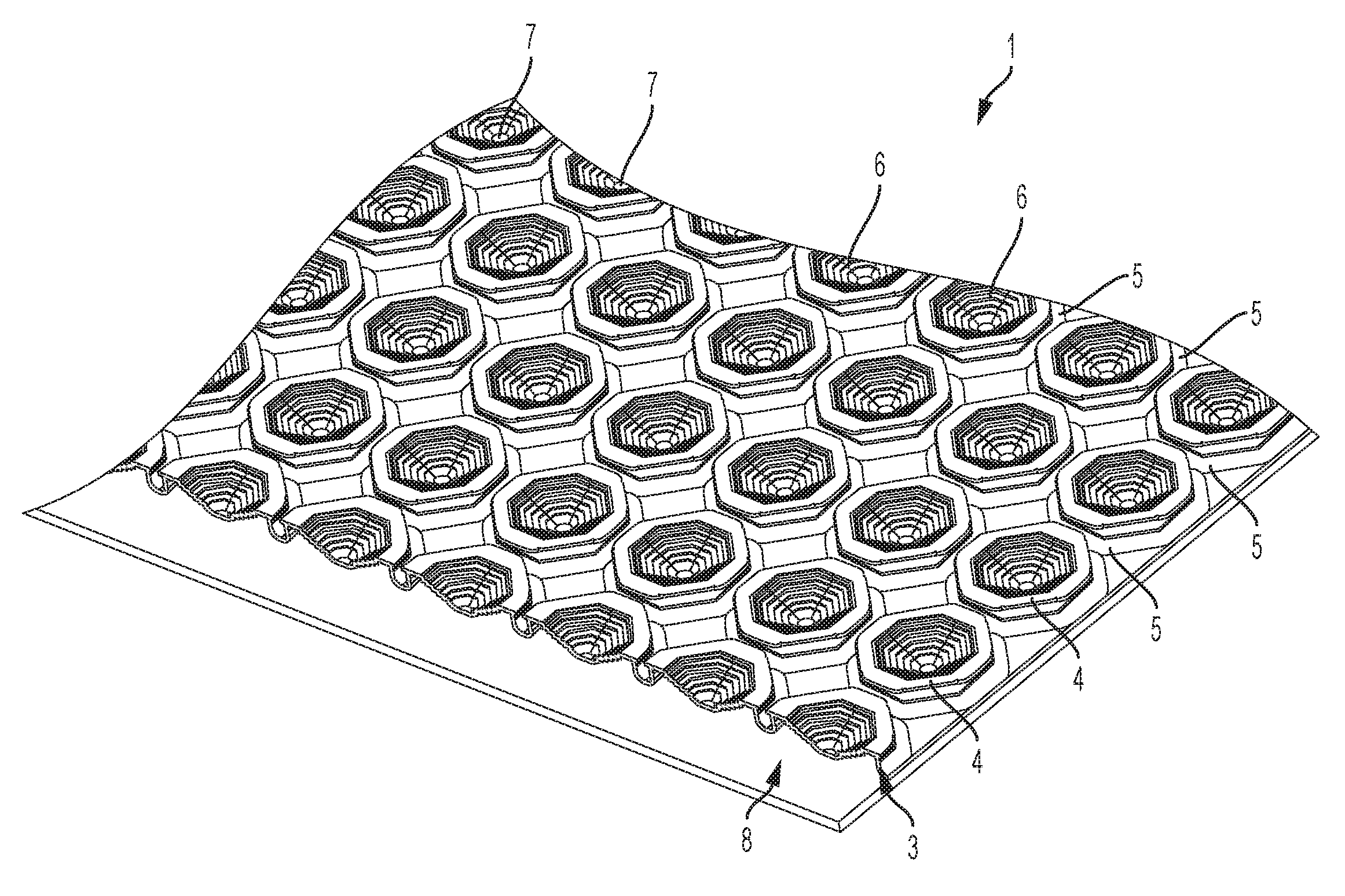

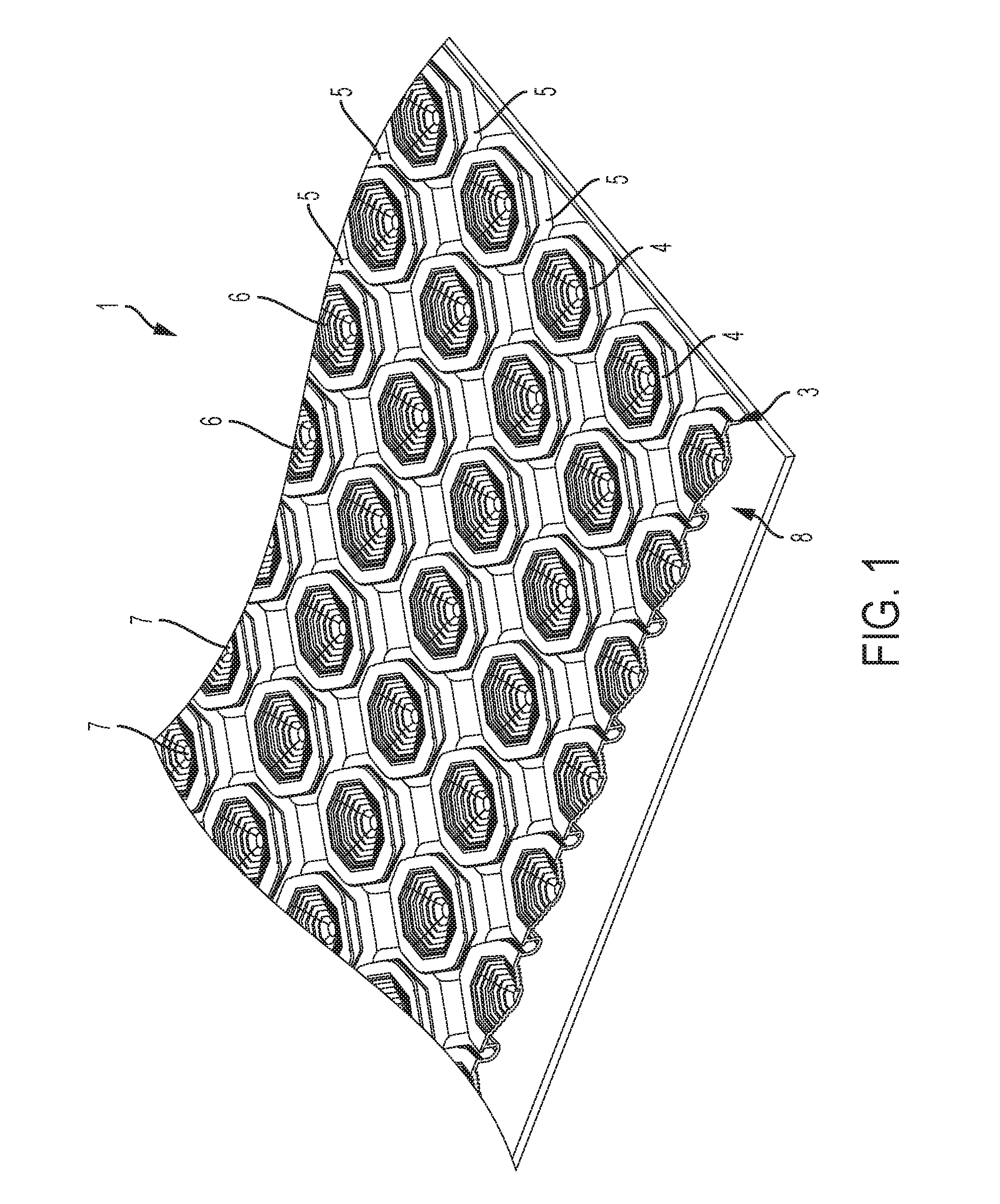

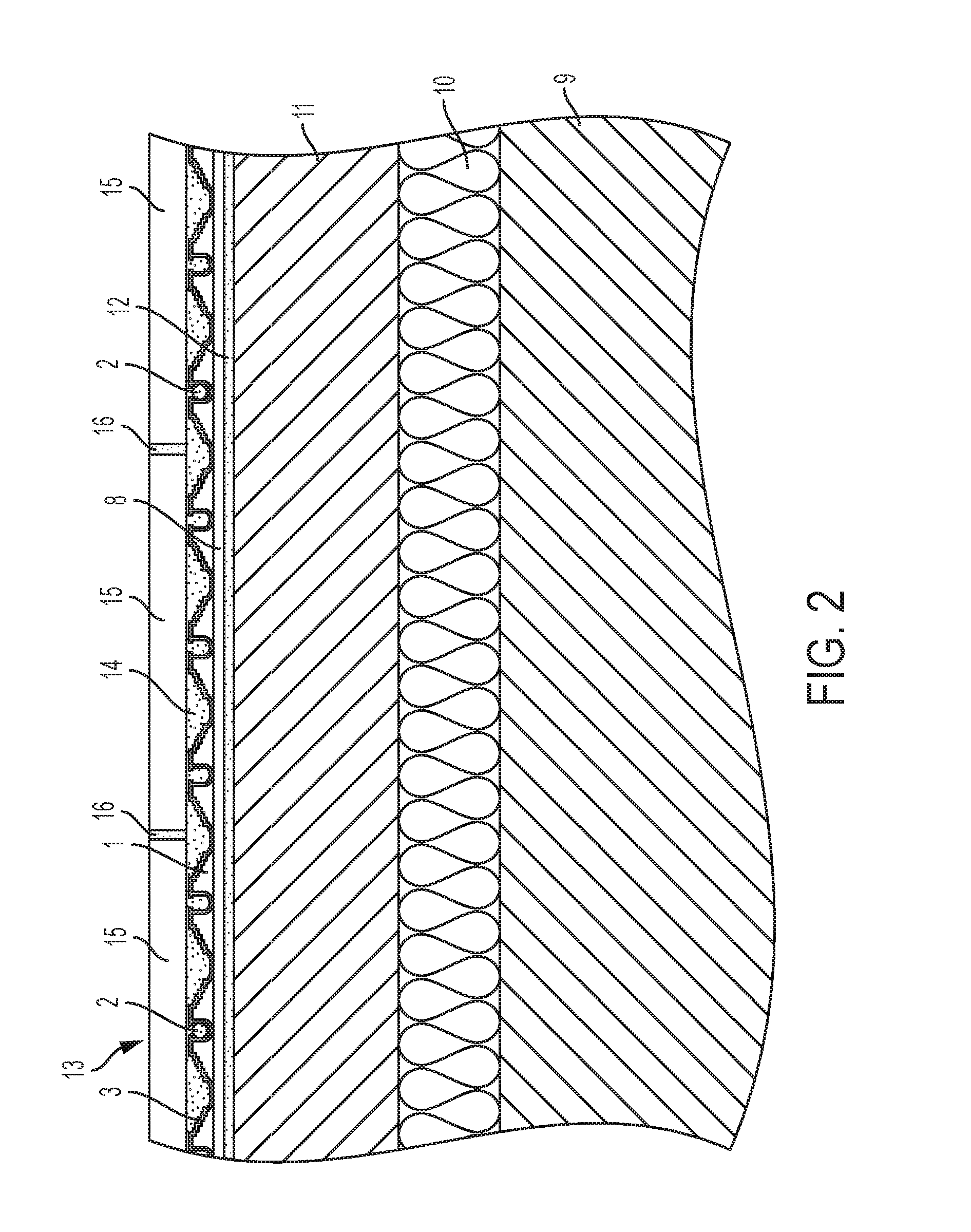

Support structure for electric cables of a surface heater

InactiveUS20160192443A1Easily transferFacilitate attachmentCable installations on groundDomestic stoves or rangesElectric heatingElectric cables

A support structure for electric heating cables of a surface heater includes a film-like support layer with projections that extend upward and that define heating cable receiving channels therebetween for receiving the electric heating cables. A thermal barrier layer is fastened to the bottom side of the support layer.

Owner:SCHLUTER SYST LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com