Electronic product film sticking machine

A technology for electronic products and laminating machines, used in external support, transportation and packaging, sending objects, etc., can solve the problems of inaccurate lamination position, low work efficiency, poor product quality, etc., to achieve simple and convenient organization, improve production efficiency, and process The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

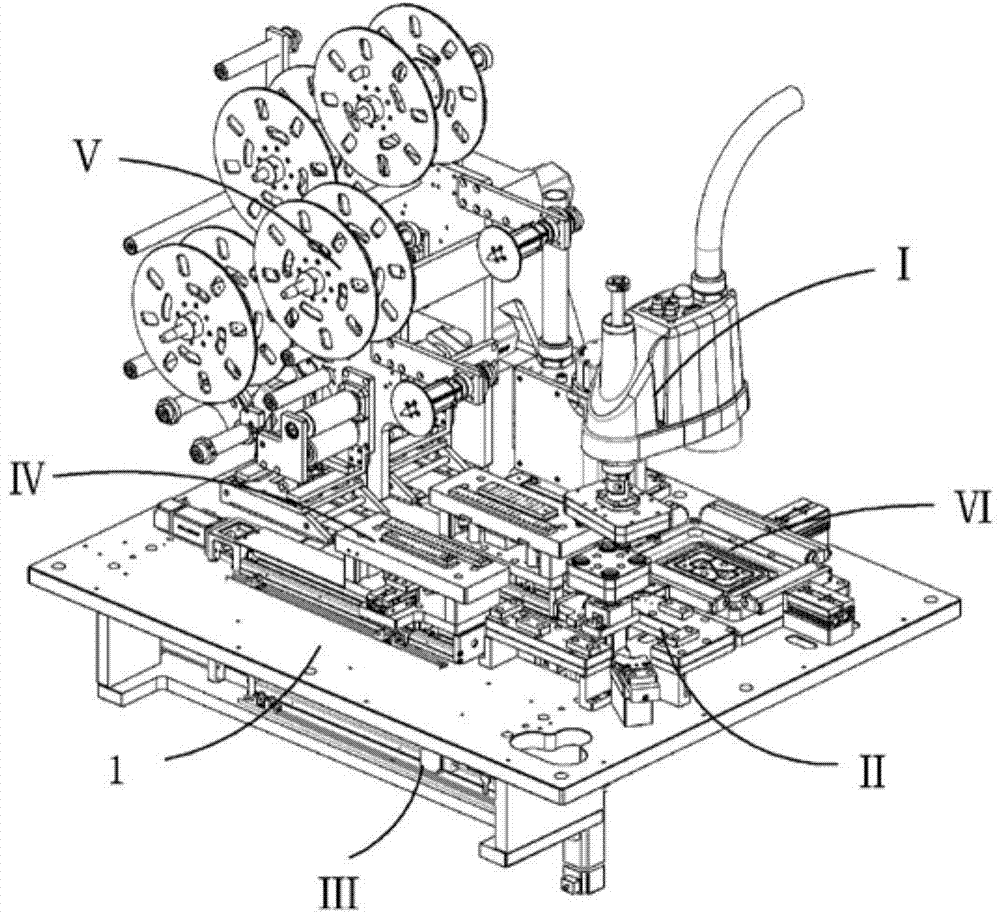

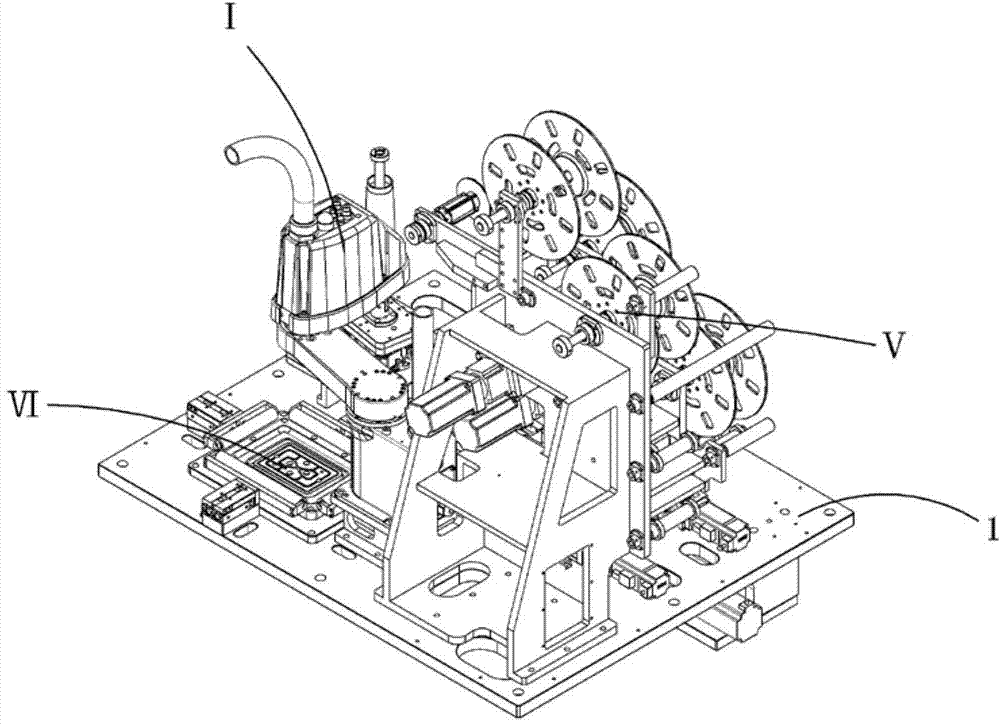

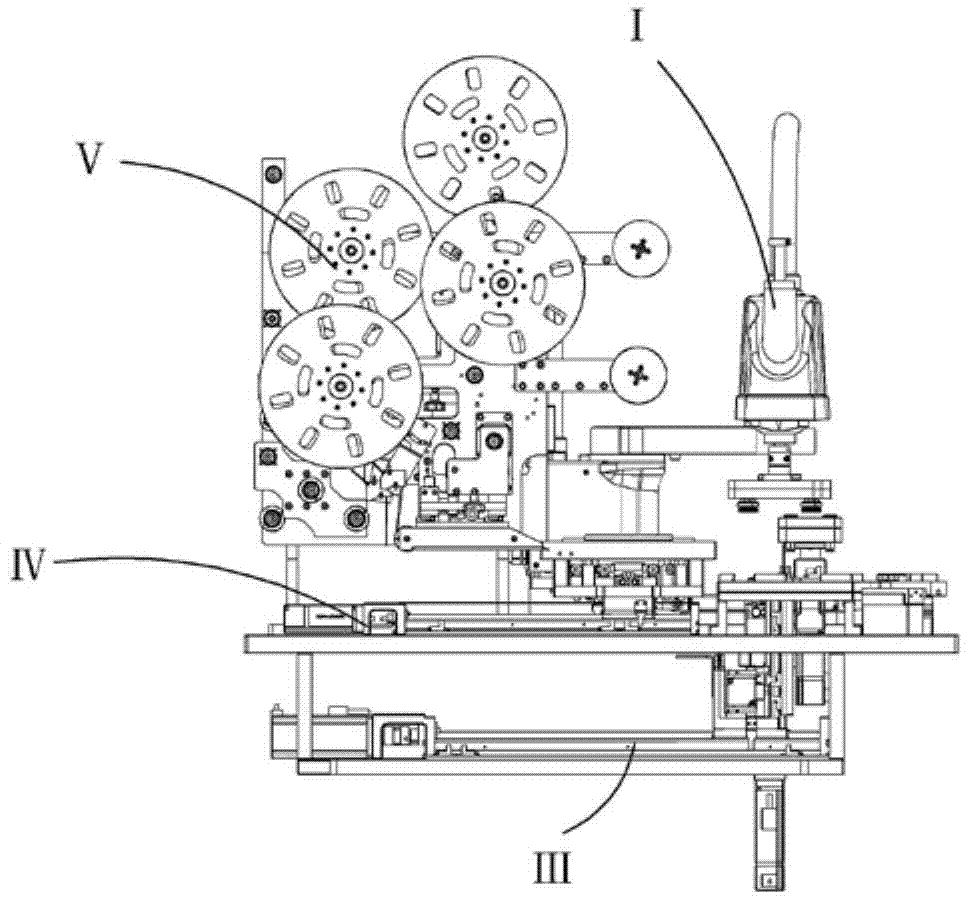

[0045] Examples, see attached Figure 1-20 , a film laminating machine for electronic products, which includes a bottom plate 1, a manipulator I, a correction mechanism II, a transport mechanism III, a film taking and laminating mechanism IV, an inner and outer material roll separation mechanism V, and a film rolling mechanism VI, the manipulator is installed on the bottom plate ; The correction mechanism is installed on the bottom plate, and is located in the right front of the bottom plate, the product can be placed on the correction mechanism, and the product is clamped and corrected.

[0046] See attached Figure 4 , the correction mechanism includes a front support 2, a rear support 3, a front base plate 4, a rear base plate 5, a front correction base plate 6, a rear correction base plate 7, a left limit block 8, a right limit block 9, a front limit block Block 10, rear limit block 11, correction base 12, limit cylinder 13, correction connecting plate 14, correction plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com