Focusing positioning method based on initial laser processing position and laser processing device

A laser processing and initial position technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory finishing, focus pattern distortion, and low accuracy, and achieve convenient laser processing operations and auxiliary focusing and positioning, to meet the effect of finishing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

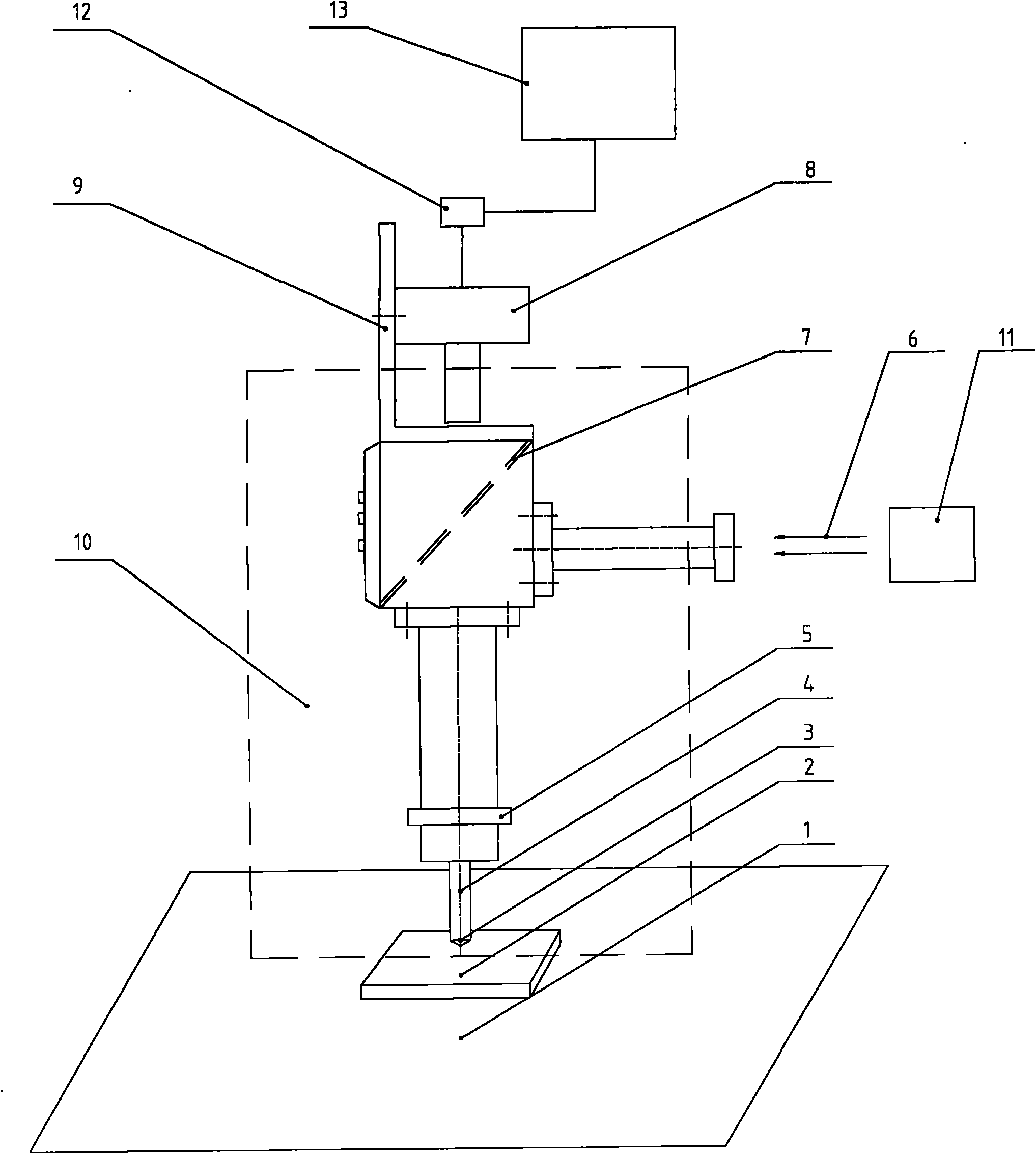

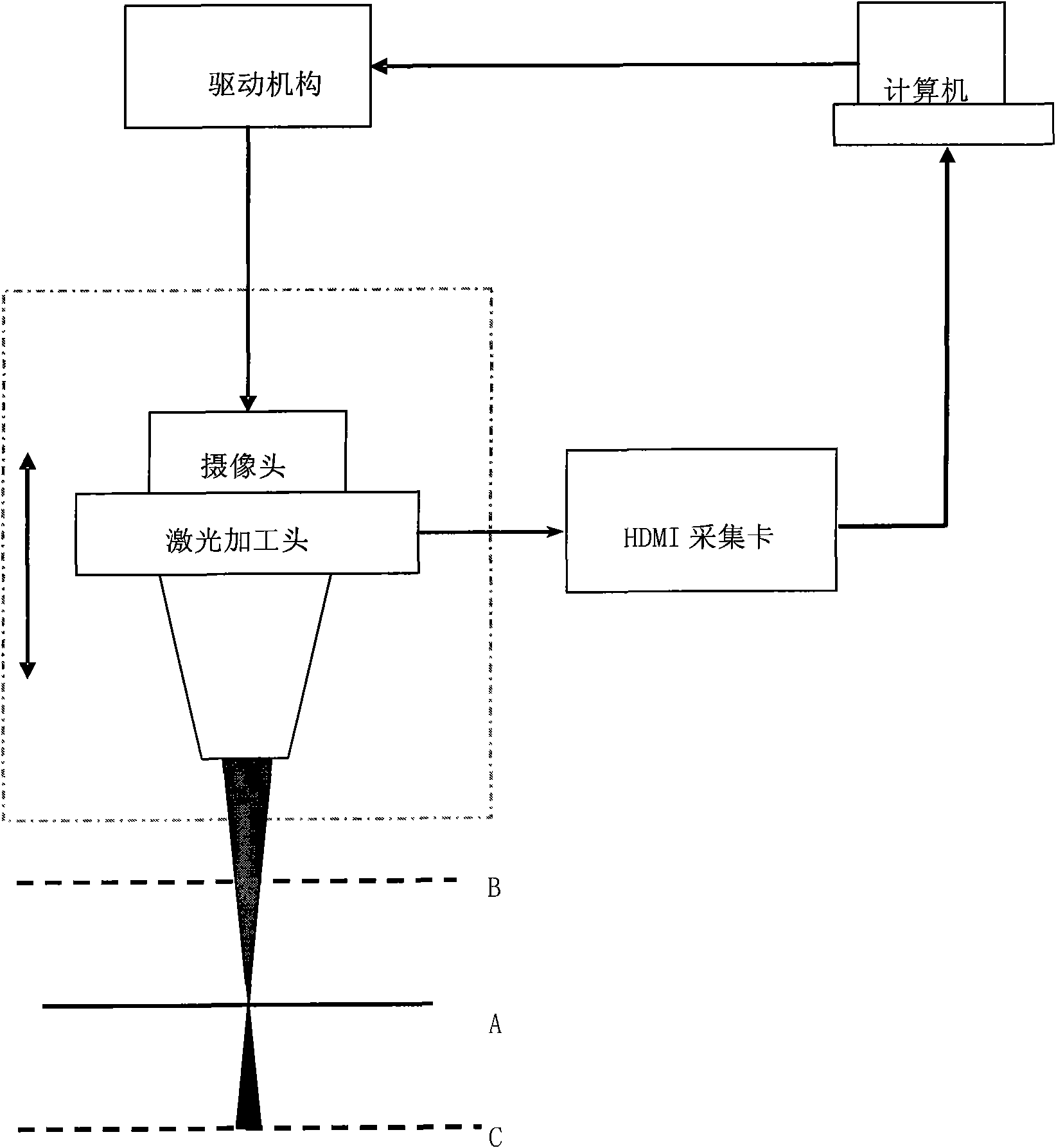

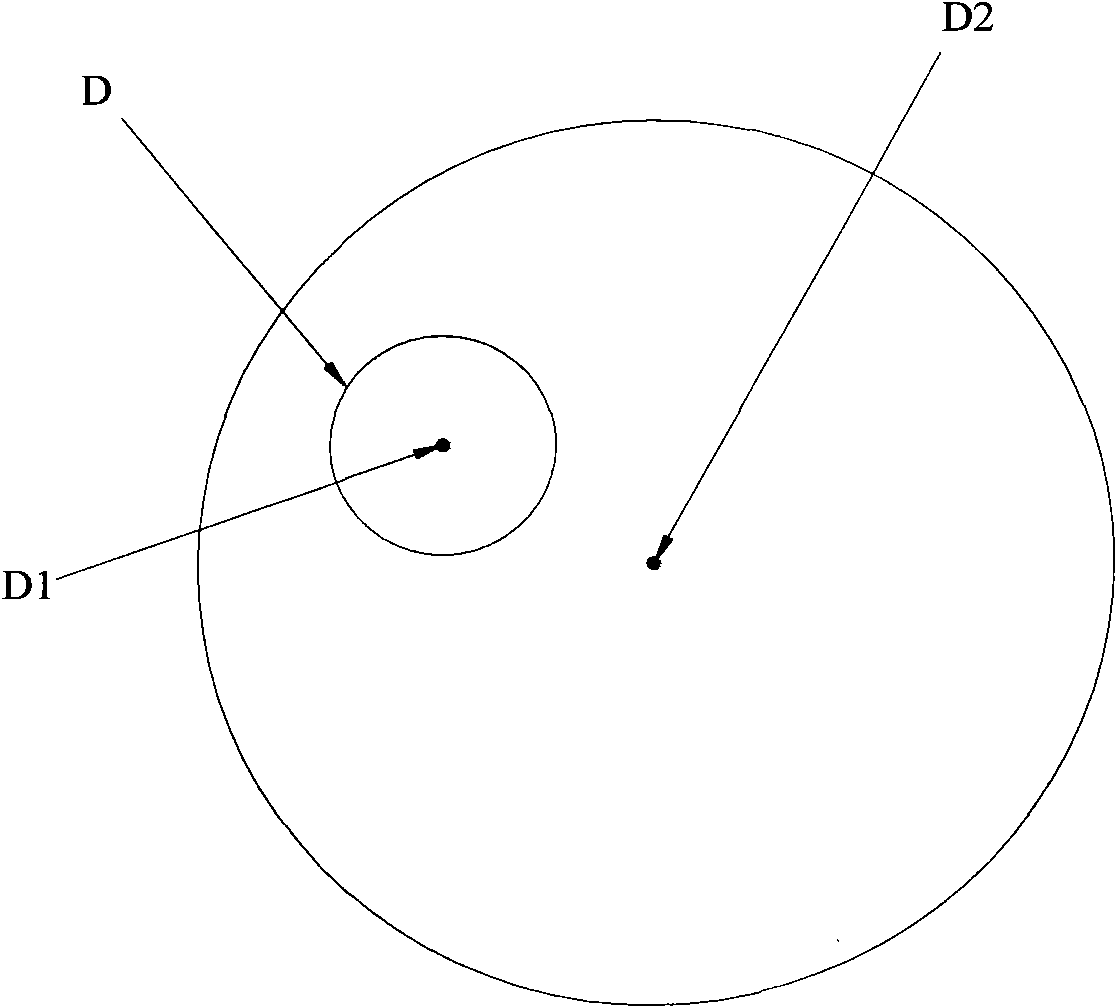

[0022] See figure 1 , the laser processing device of the embodiment of the present invention is mainly made up of processing platform 1, laser device 11, laser processing head 10, camera 8, HDMI acquisition card 12 and computer 13, wherein laser processing head 10 is vertically arranged on the top of processing platform 1, A laser 11 is arranged on the side of the laser processing head 10, and a camera 8 is installed on its top through a bracket 9. The camera 8 is connected to a computer 13 through an HDMI acquisition card 12, and the computer 13 is connected to a driving mechanism. Camera 8 is a CCD camera. The laser 11 and the camera are linked synchronously with the laser processing head 10, and can be moved synchronously by the drive mechanism for focusing and positioning. The driving mechanism of this embodiment adopts a robot arm, and its repeated posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com