Patents

Literature

335results about How to "Improve focus accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

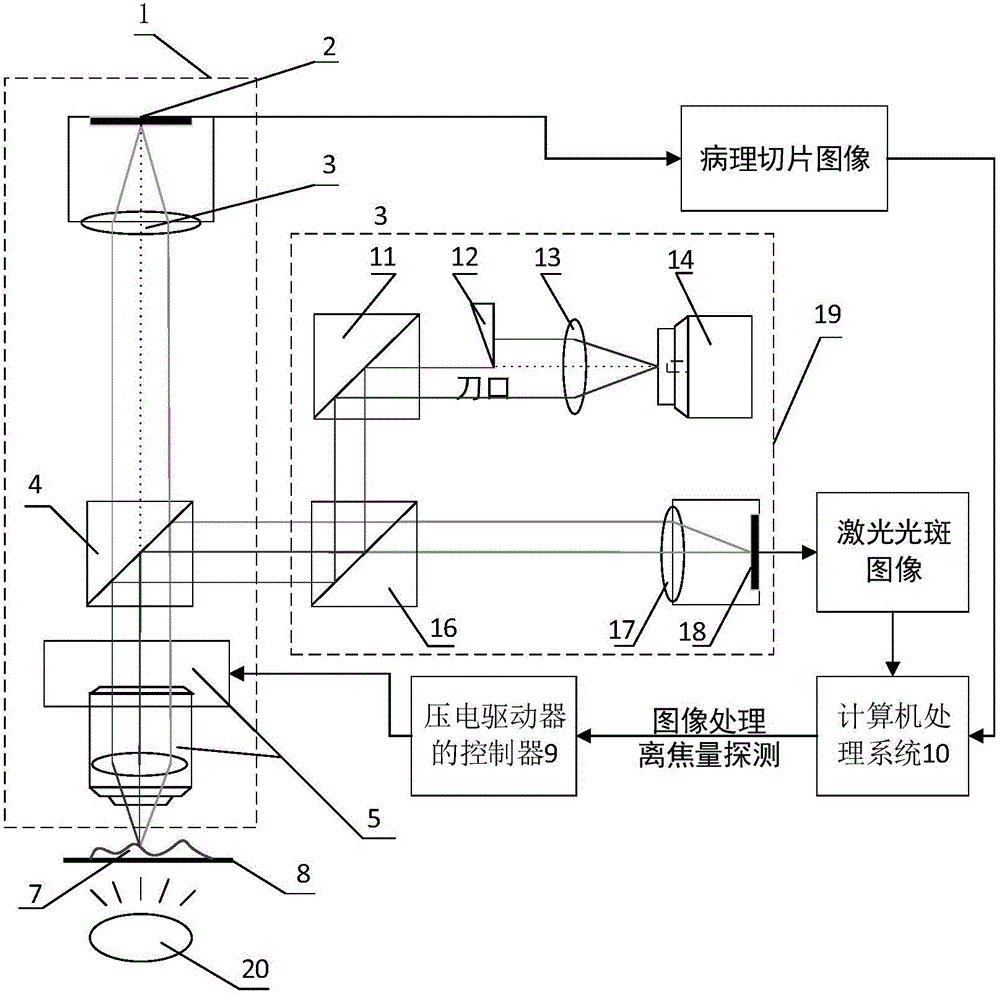

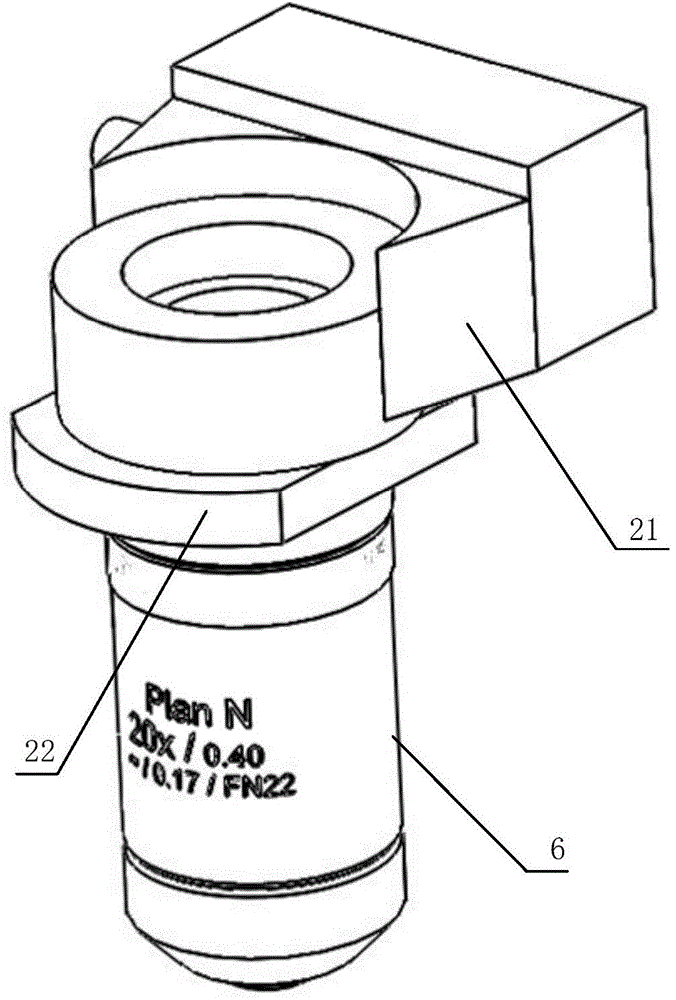

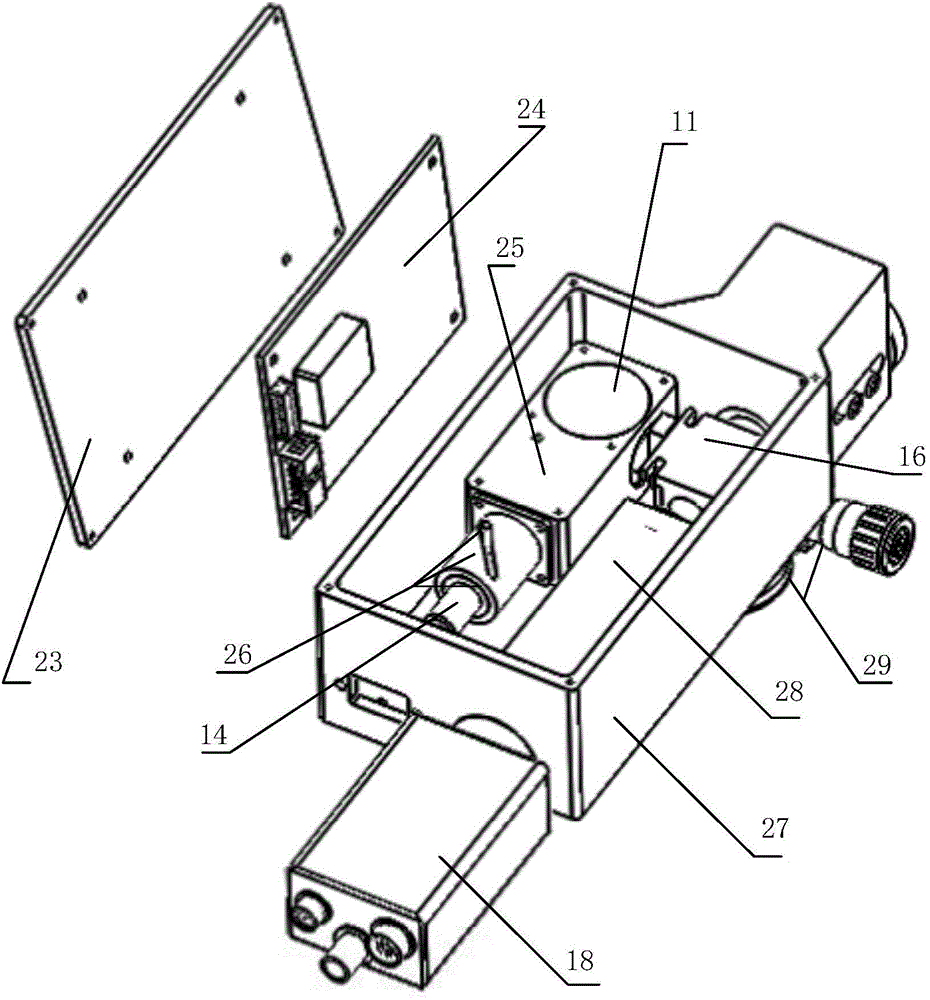

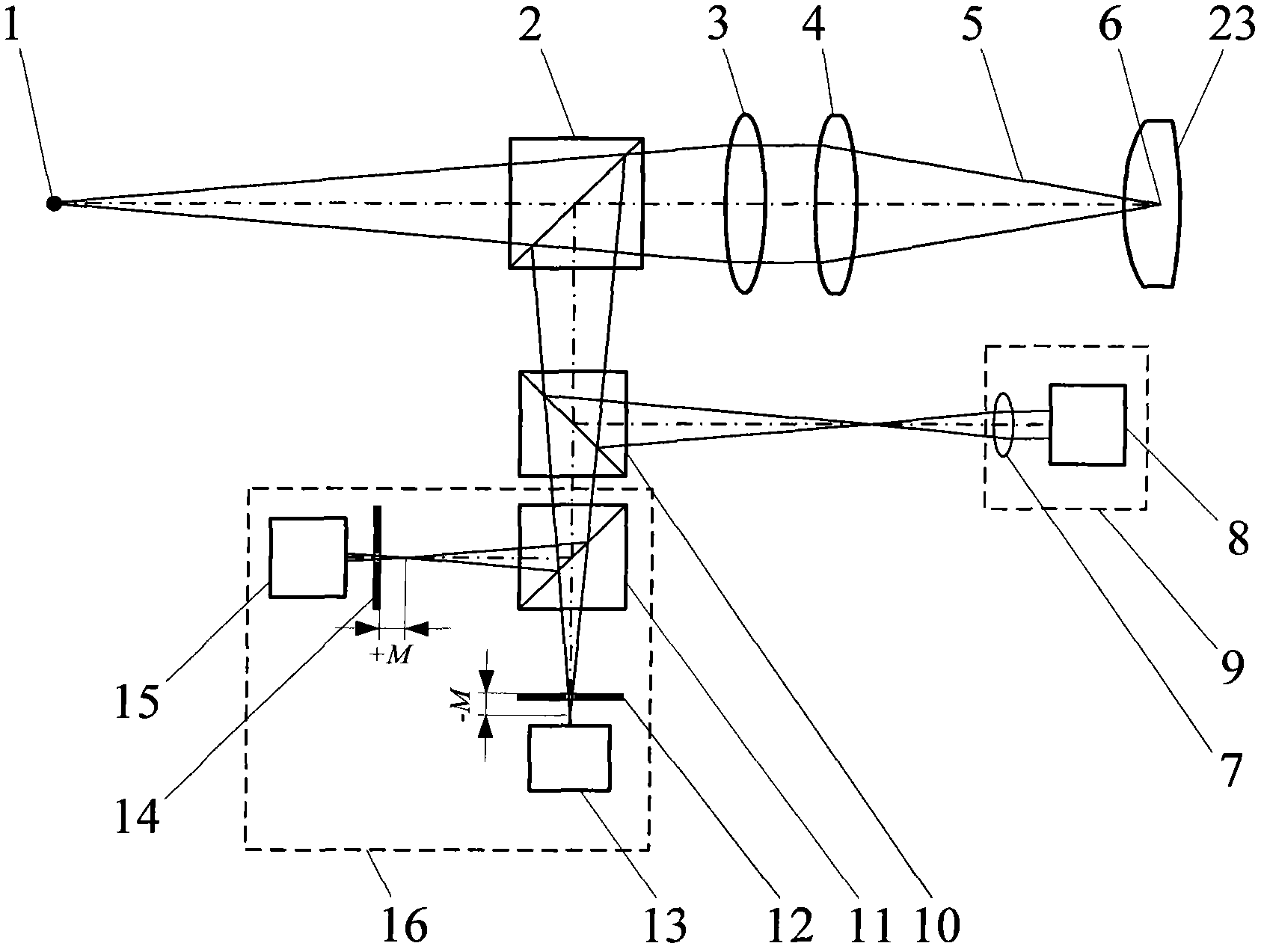

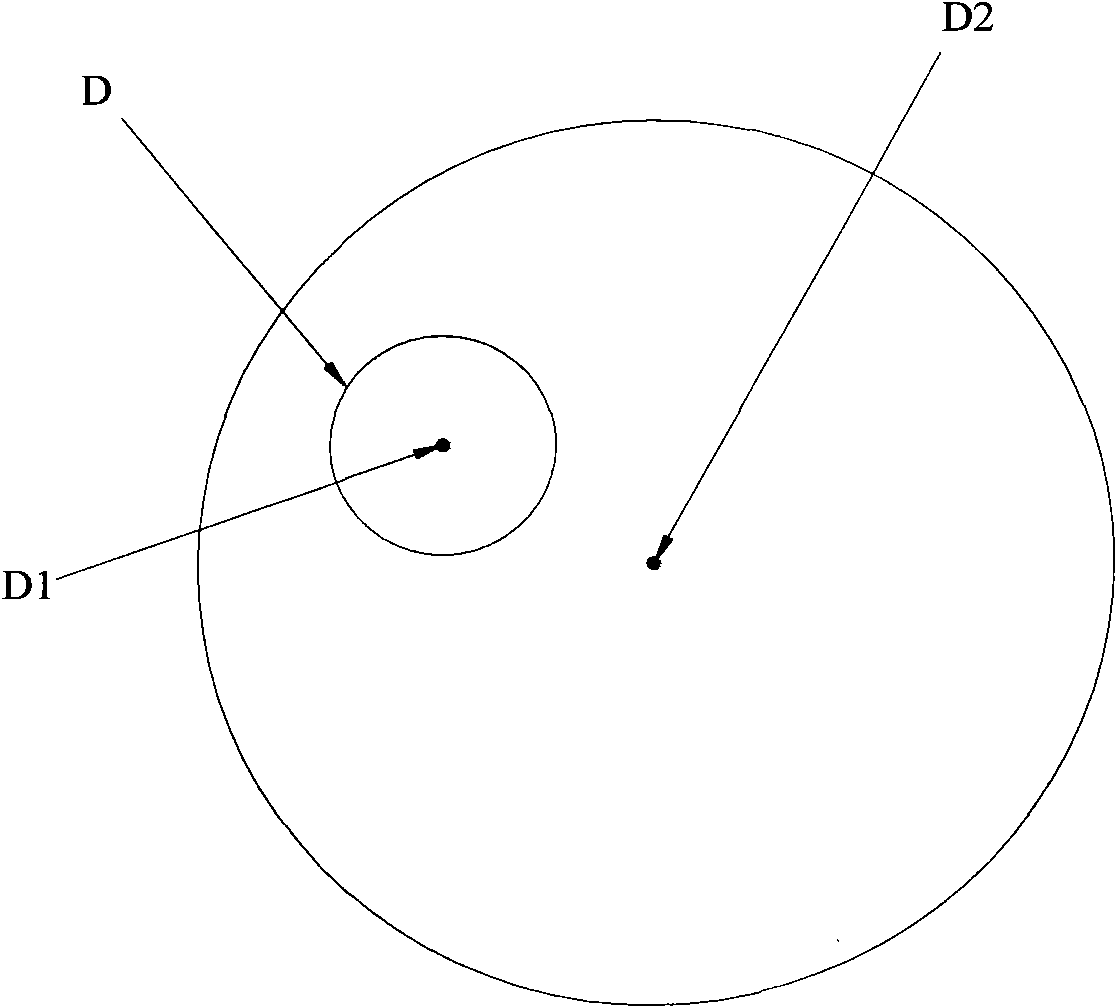

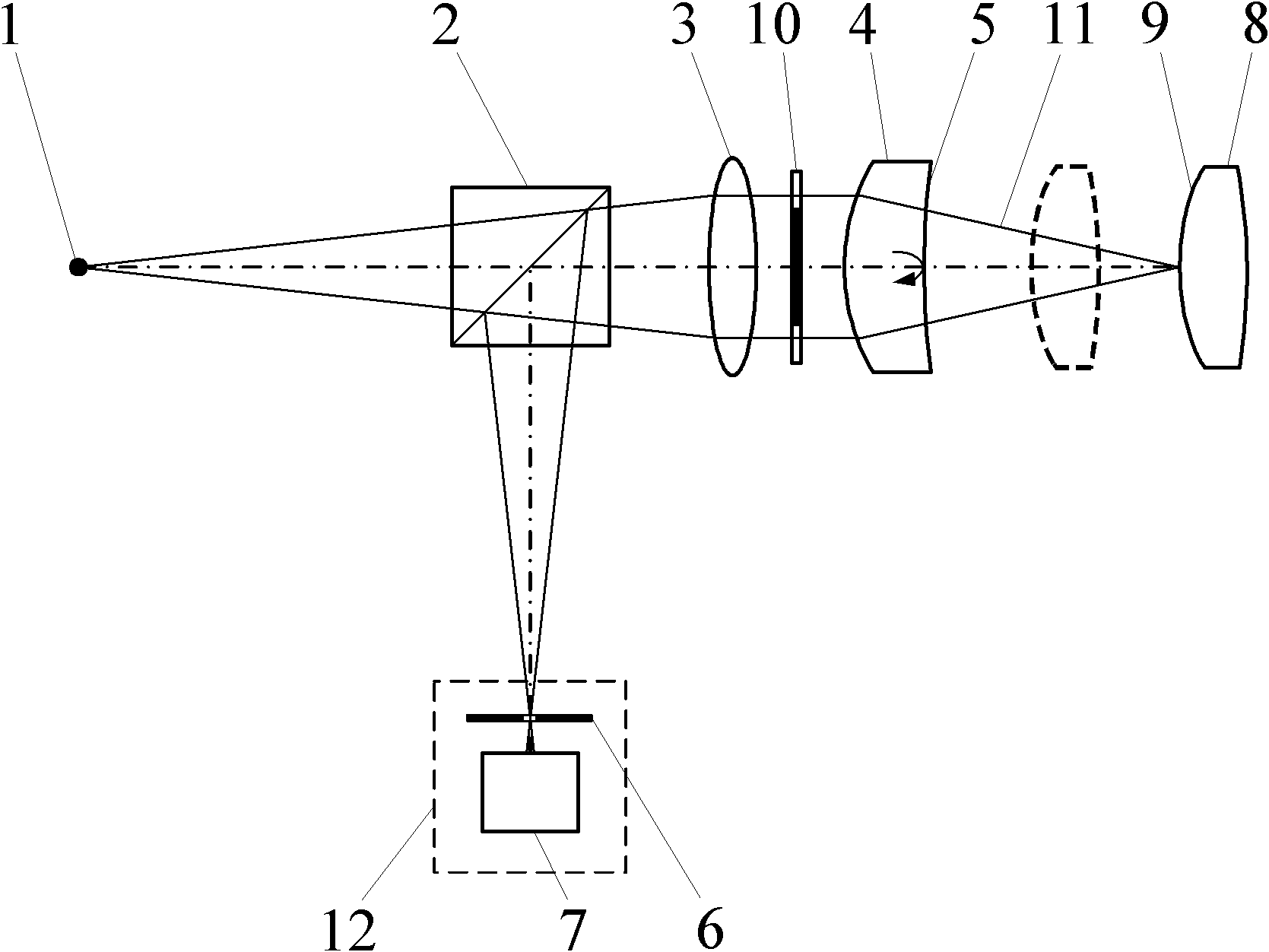

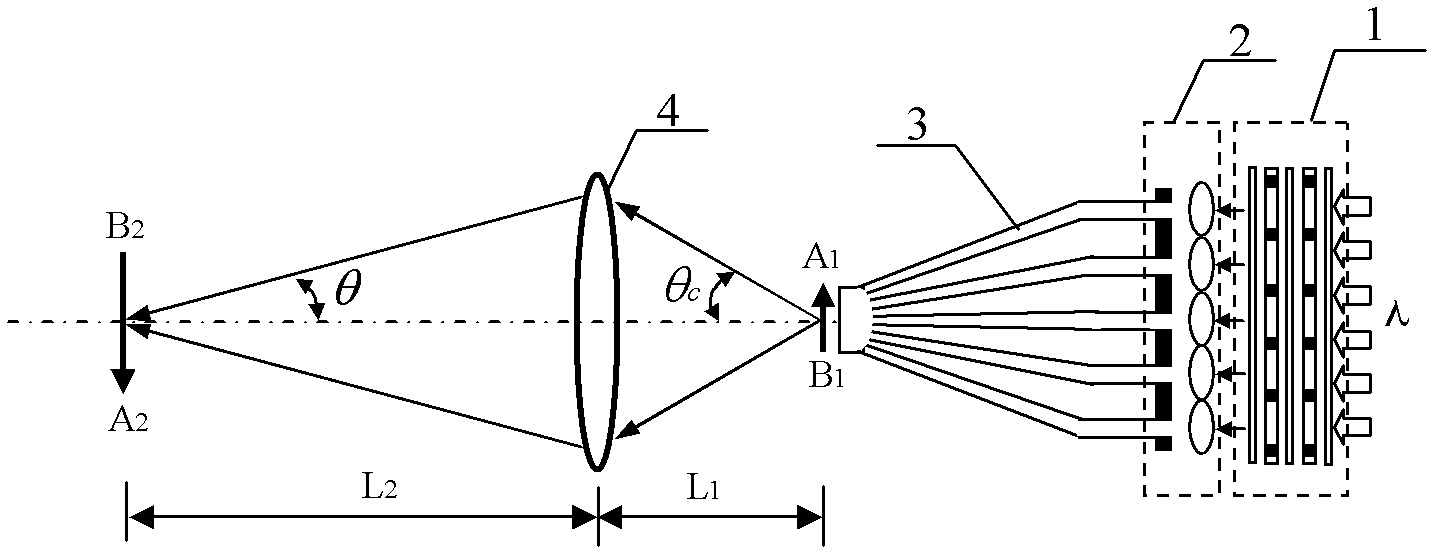

Automatic focusing microscope based on eccentric beam method and focusing method thereof

ActiveCN104932092AImprove noise immunityHigh precisionMicroscopesMicroscopic imageLinear relationship

The invention discloses an automatic focusing microscope based on an eccentric beam method and a focusing method thereof. The hardware comprises an eccentric beam defocus amount detection module, a microscopic imaging module, a piezo lens drive, an XY stage and a computer processing system. The defocus amount detection module transmits a semicircular laser beam to irradiate the surface of a sample and acquire a semicircular spot image formed by sample reflection. The computer processing system uses self-adaptive median filtering, Canny edge detection based on OSTU, the least square fitting and other algorithms to process the grayscaled spot image to acquire spot radius. According to a radius-defocus amount linear relationship model, the sample defocus amount in a field of vision can be calculated. The piezo lens drive drives a lens to compensate the defocus amount. After focusing, the microscopic imaging module acquires a clear sample image. The automatic focusing microscope based on the eccentric beam method and the focusing method thereof, which are provided by the invention, have the advantages of fast focusing speed, high focusing accuracy and large linear range, and can meet the requirement of fast and precise focusing of the microscope under a high power lens.

Owner:SHANGHAI JIAO TONG UNIV

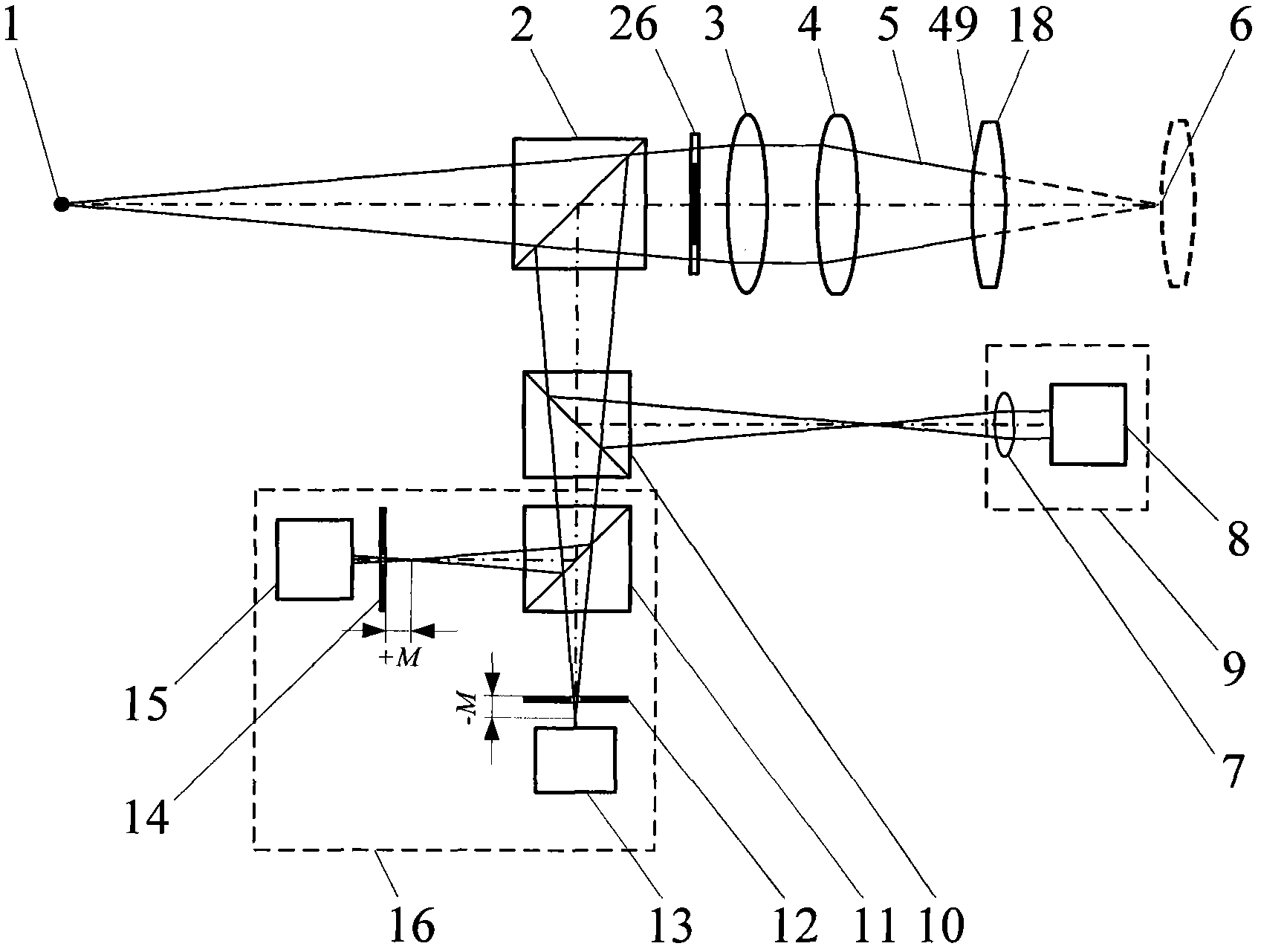

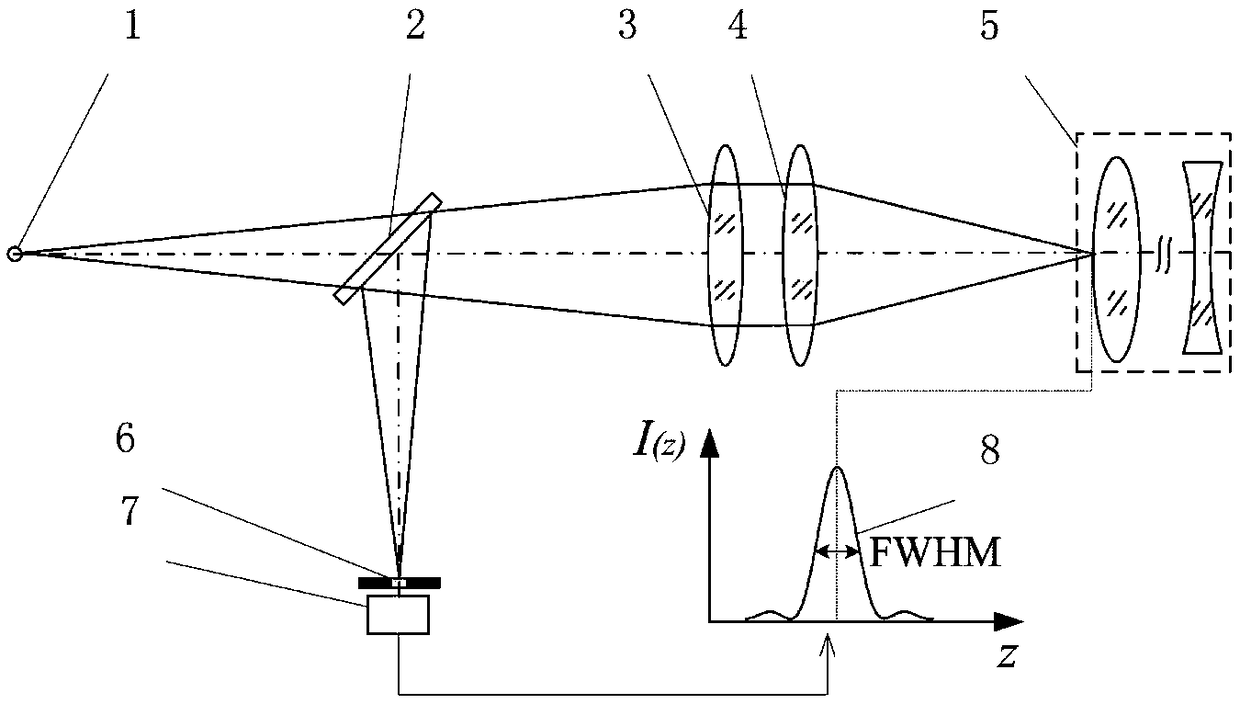

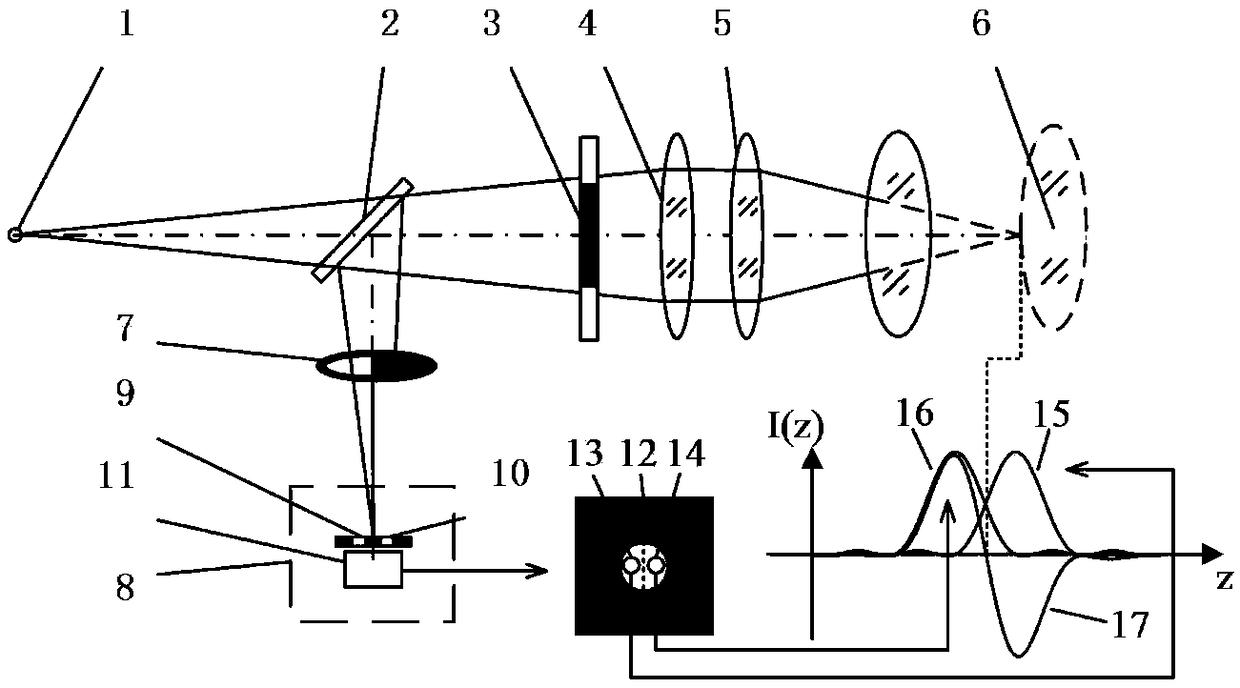

Method and device for measuring multiple element parameters in differential con-focus interference manner

ActiveCN102147240ARealize simultaneous measurementAchieve precise positioningPhase-affecting property measurementsUsing optical meansConsMeasurement precision

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

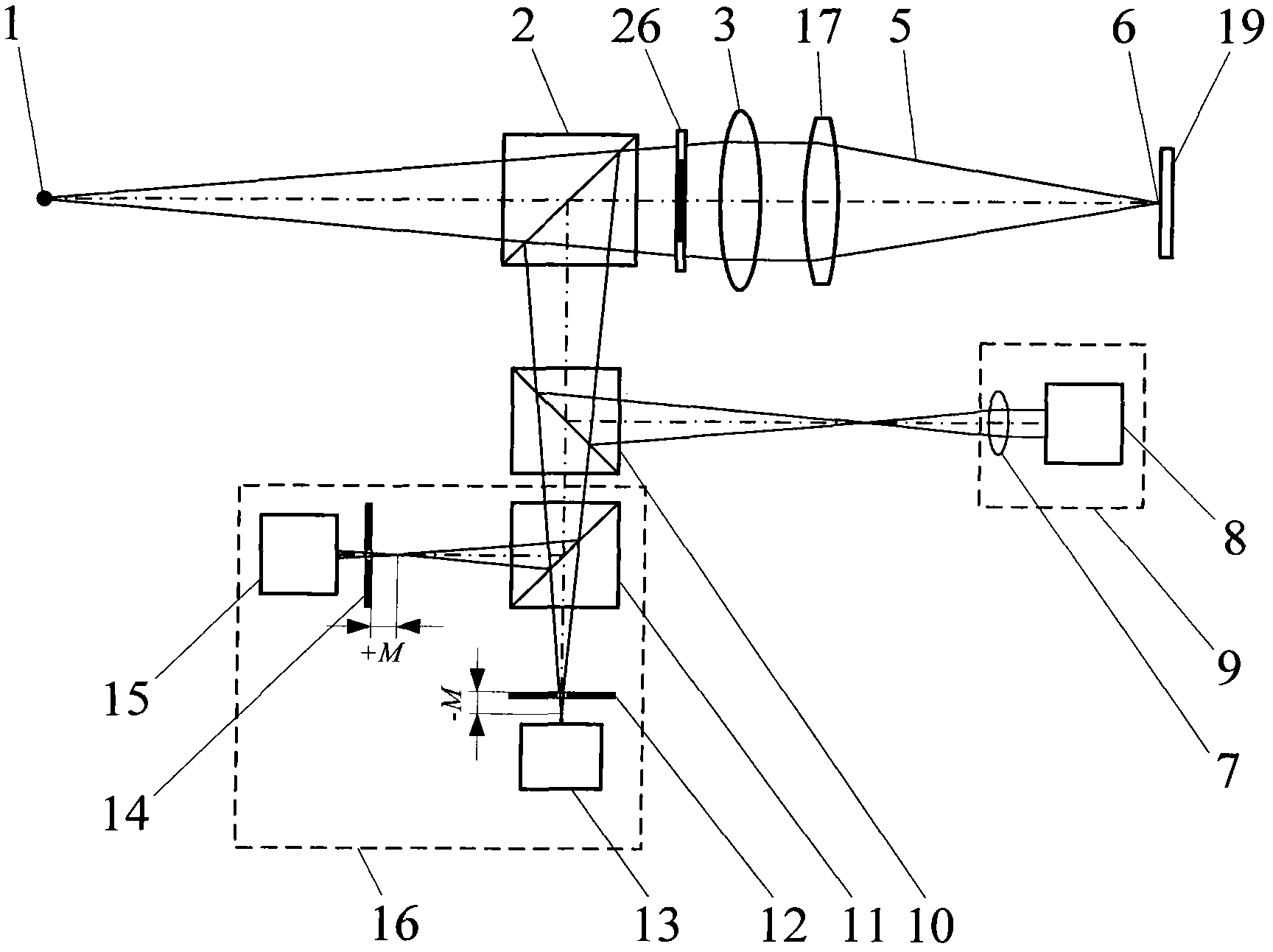

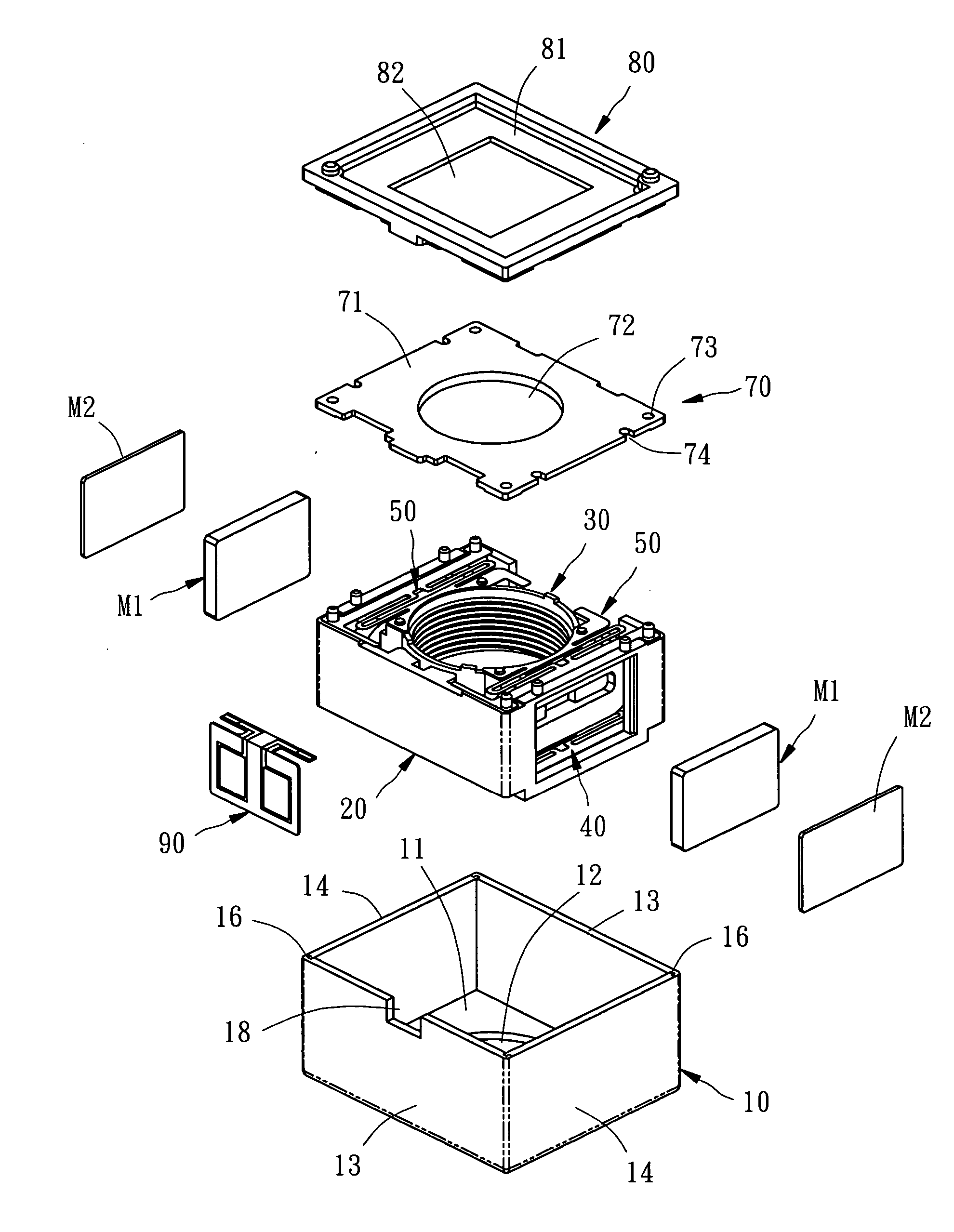

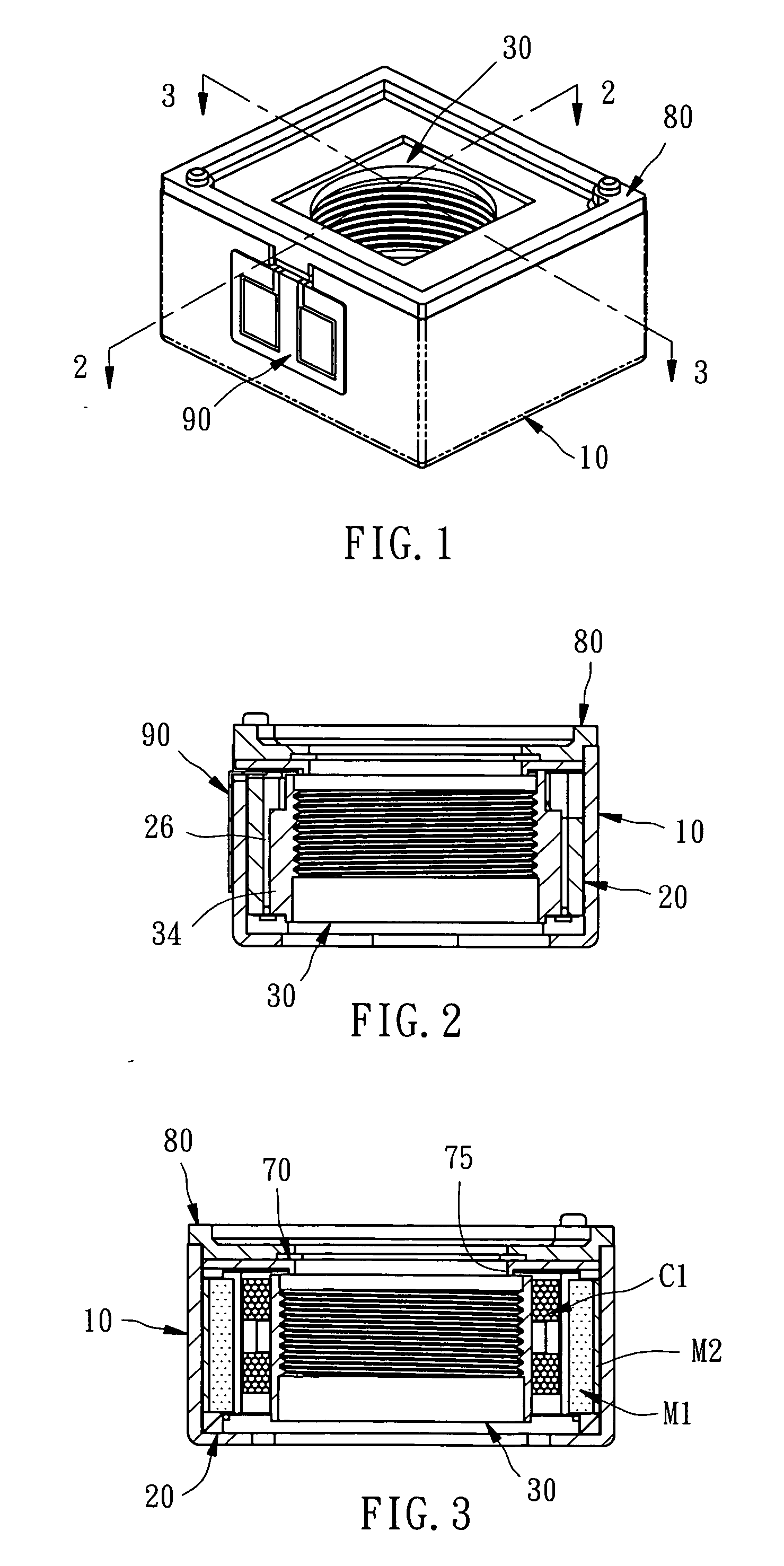

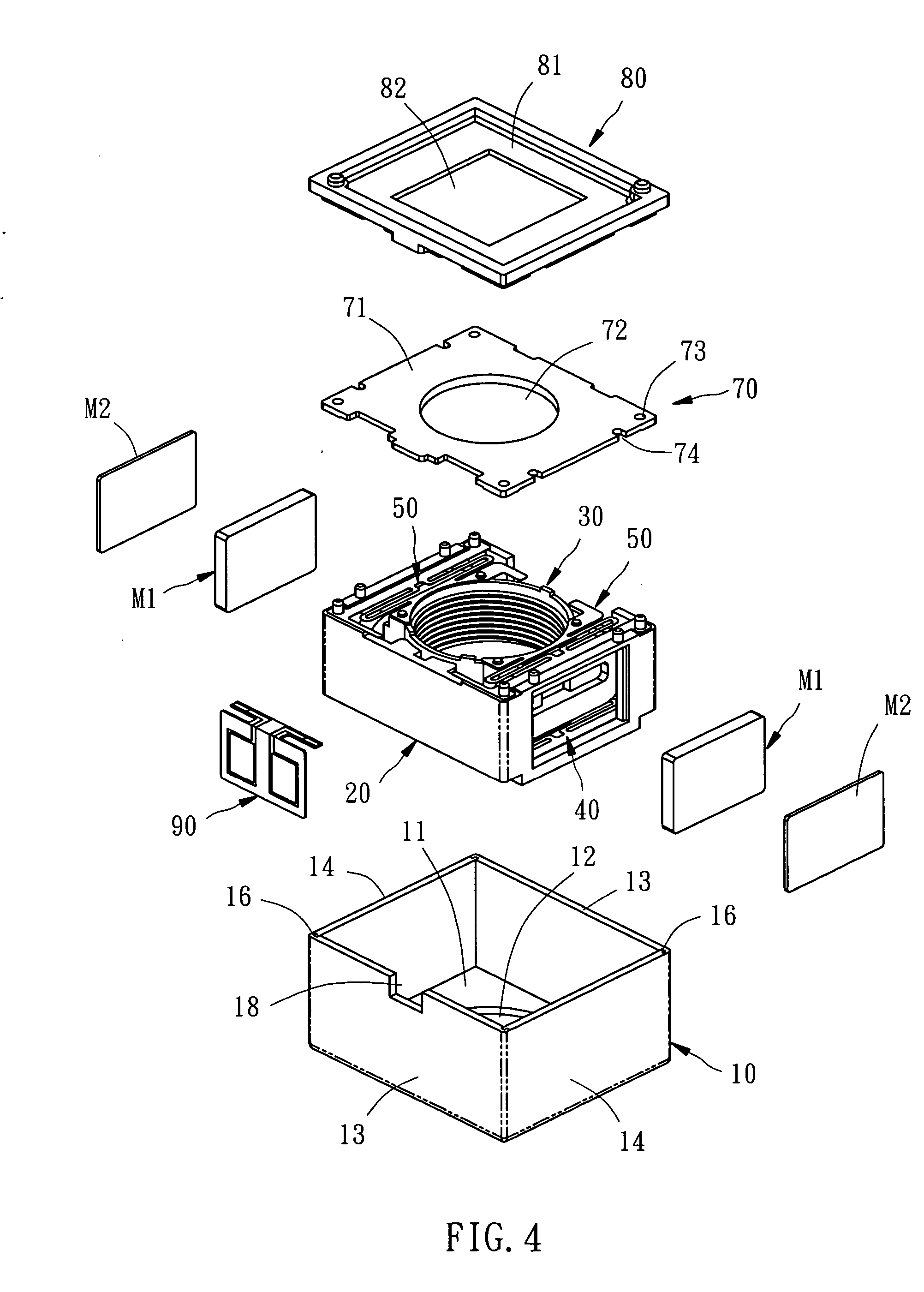

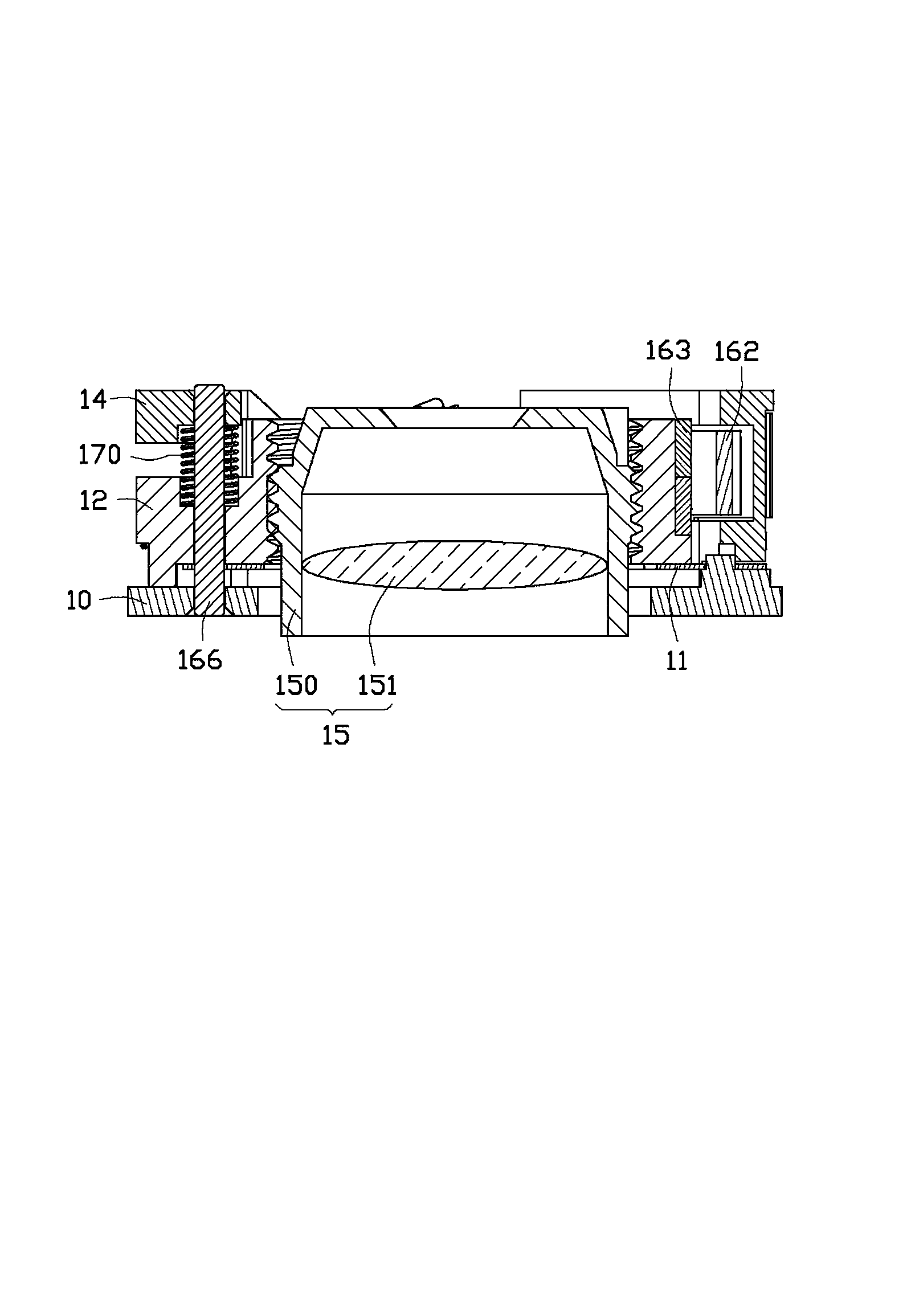

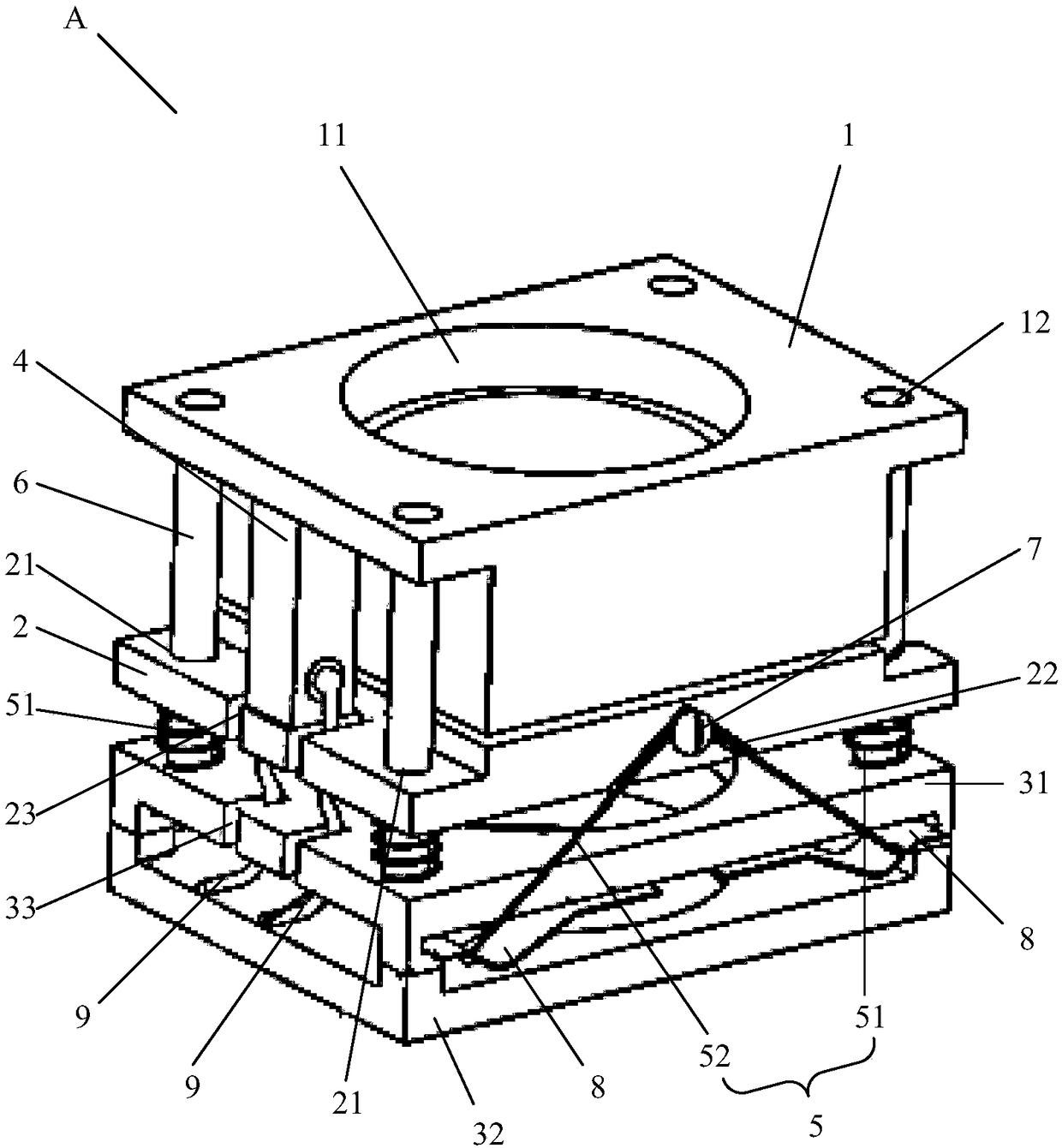

Voice coil motor type focusing actuator

A voice coil motor type focusing actuator, which includes a fixed unit formed of a bracket having a rectilinear sliding groove and two magnets mounted in the bracket at two sides, a movable unit formed of a lens holder holding a lens and mounted inside the bracket and slidably coupled with its rectilinear sliding rail to the rectilinear sliding groove of the bracket and two coils respectively mounted on two sides of the lens holder corresponding to the magnets of the fixed unit, and a resilient holding down unit connected between the fixed unit and the movable unit to hold down the movable unit on the inside of the fixed unit.

Owner:TRICORE CORP

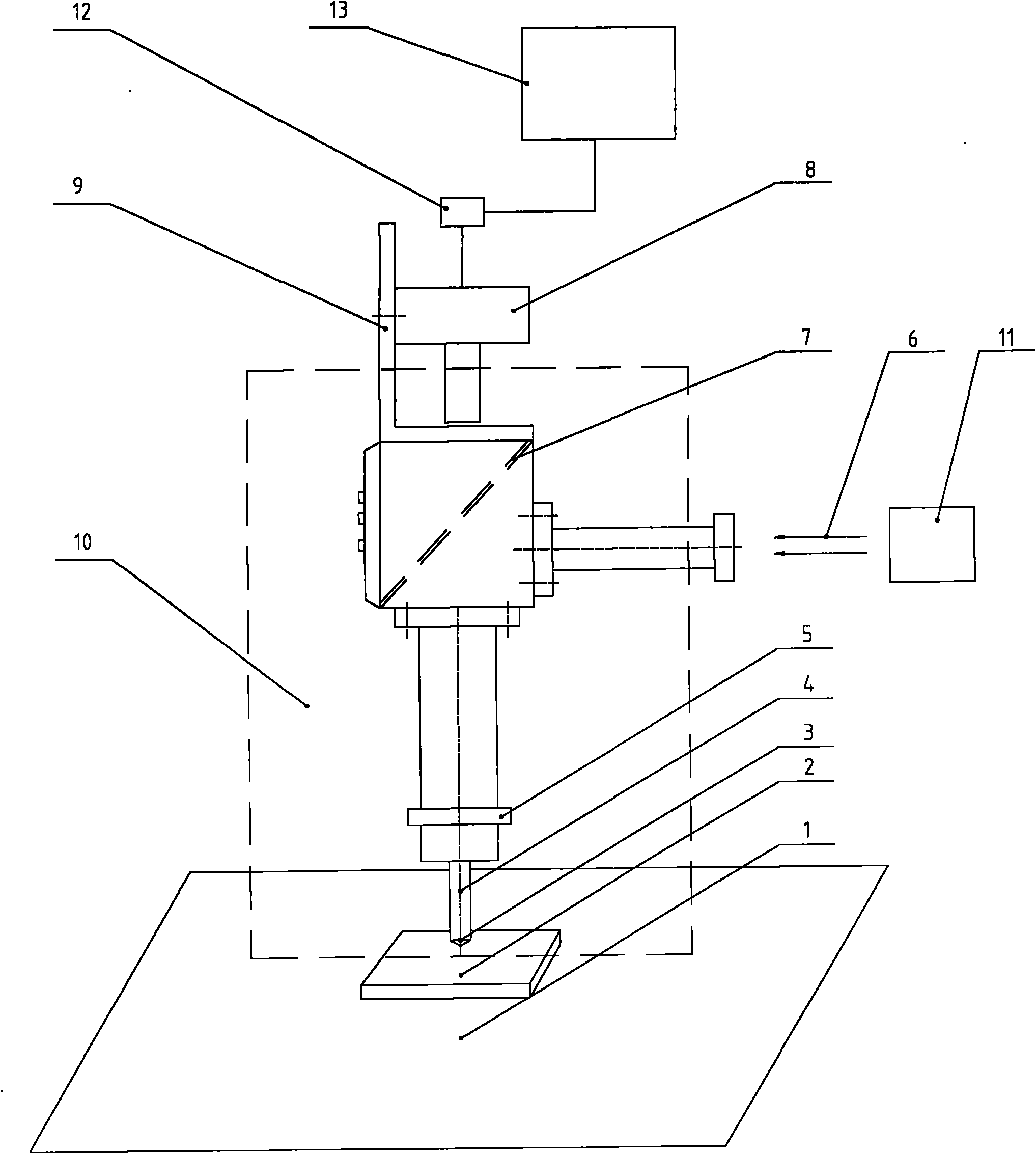

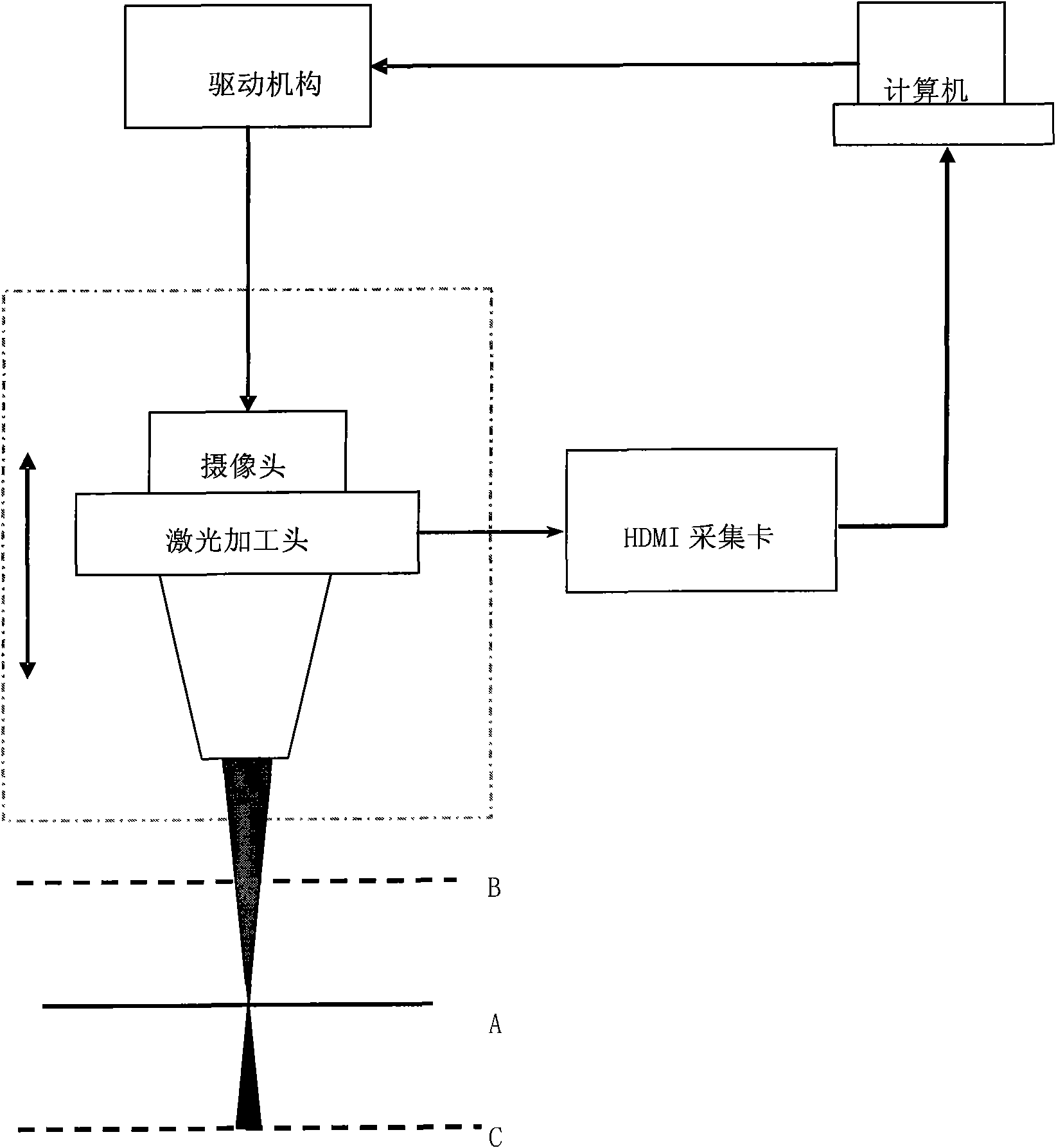

Focusing positioning method based on initial laser processing position and laser processing device

InactiveCN101856773AHigh precisionHigh positioning accuracyLaser beam welding apparatusLaser processingLight spot

The invention discloses a focusing positioning method based on an initial laser processing position. In the method, a beam emitted by a laser is projected on the surface of a work piece to be processed to form a light spot through the optical system of the laser processing head, light spot images are promptly collected through moving the laser processing head and using a camera, the properties of the light spot images are then compared with a computer to find out a light spot image on a focal plane, and then the laser processing head is moved according to the moving distance of the laser processing head corresponding to the light spot image, thereby completing the focusing; and the position relationship between the center of the initial processing point and the center of the light spot is determined by the computer, and the laser processing head is moved according to the position relationship, thereby obtaining the accurate positioning of the initial processing position. Compared with the prior art, the invention has high accuracy in focusing and positioning of the initial processing position, and can satisfy finishing requirements. Simultaneously, the invention also discloses a laser processing device, which has the functions of auxiliary focusing and positioning, thereby facilitating the laser processing operation.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

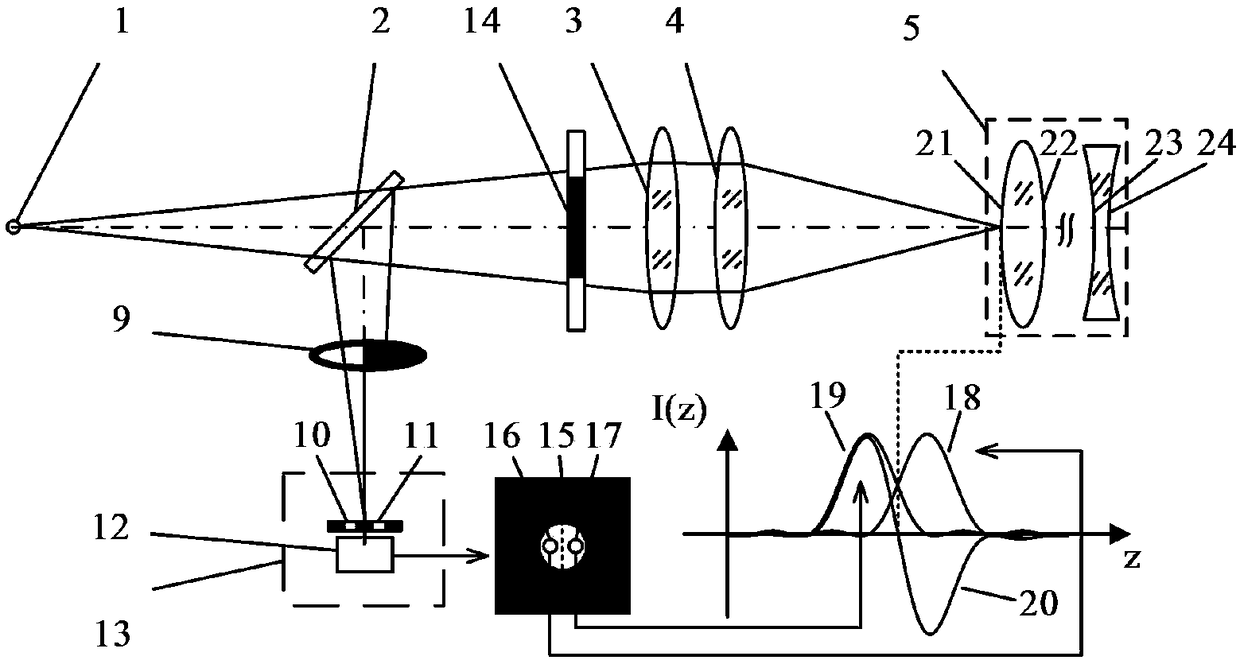

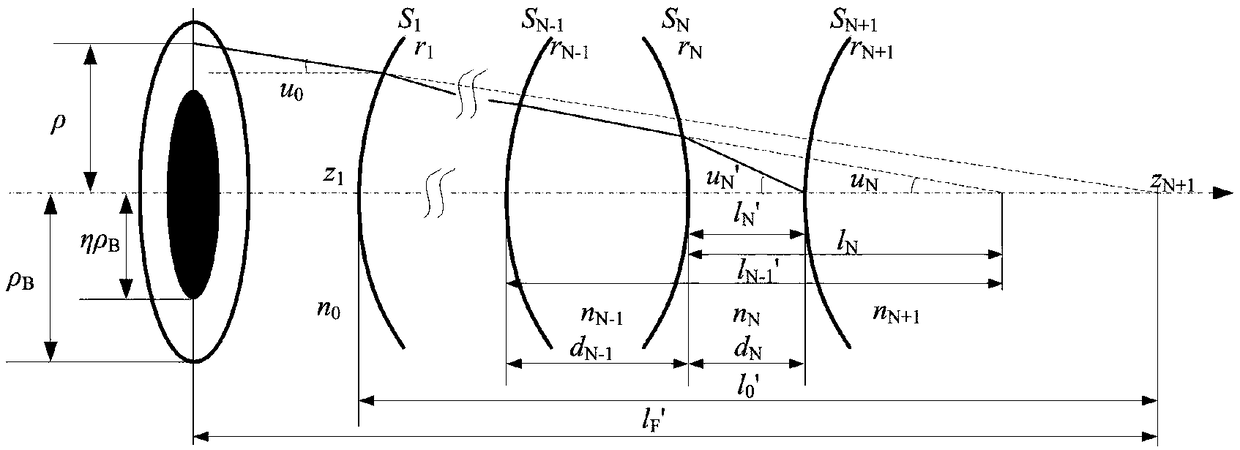

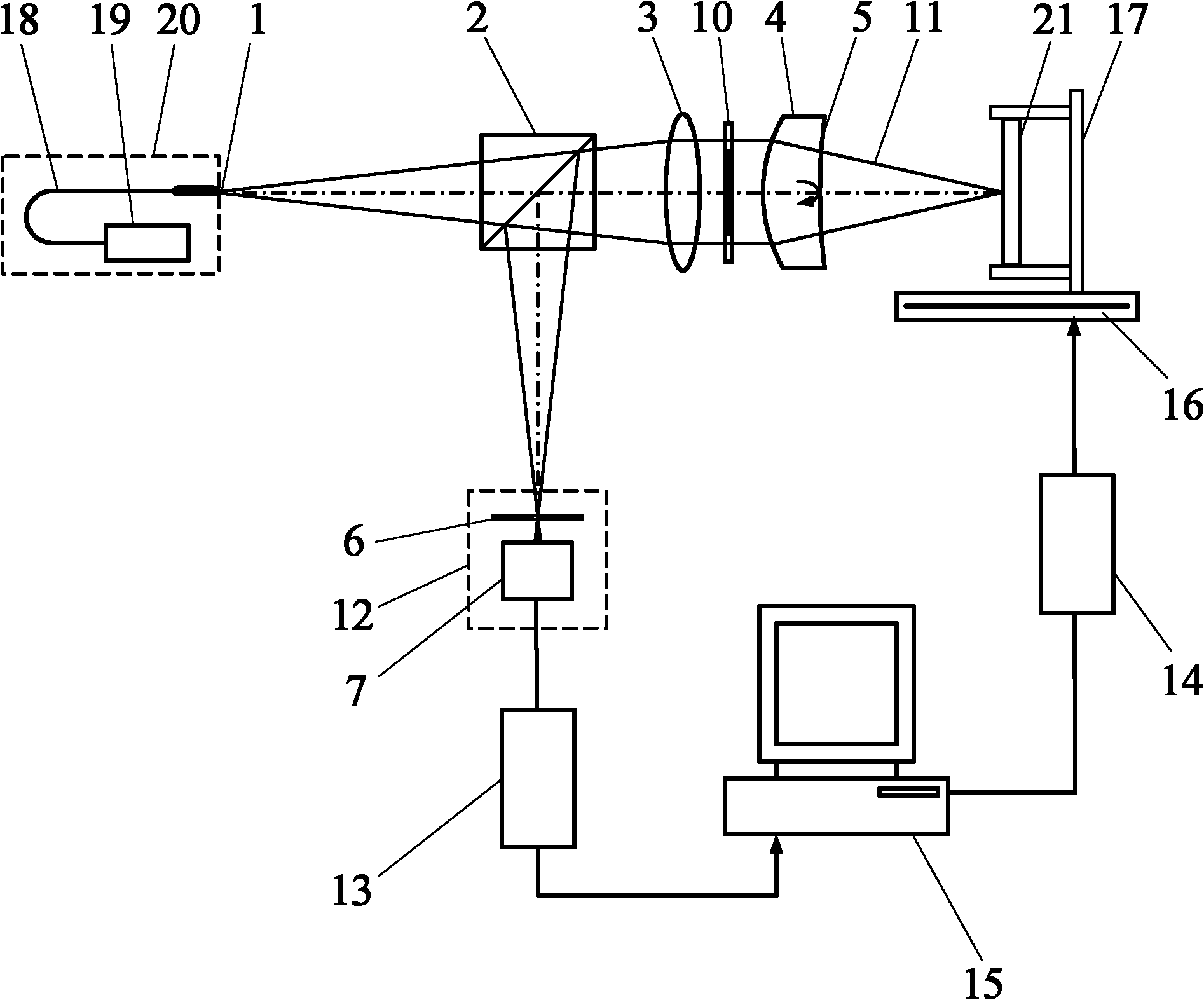

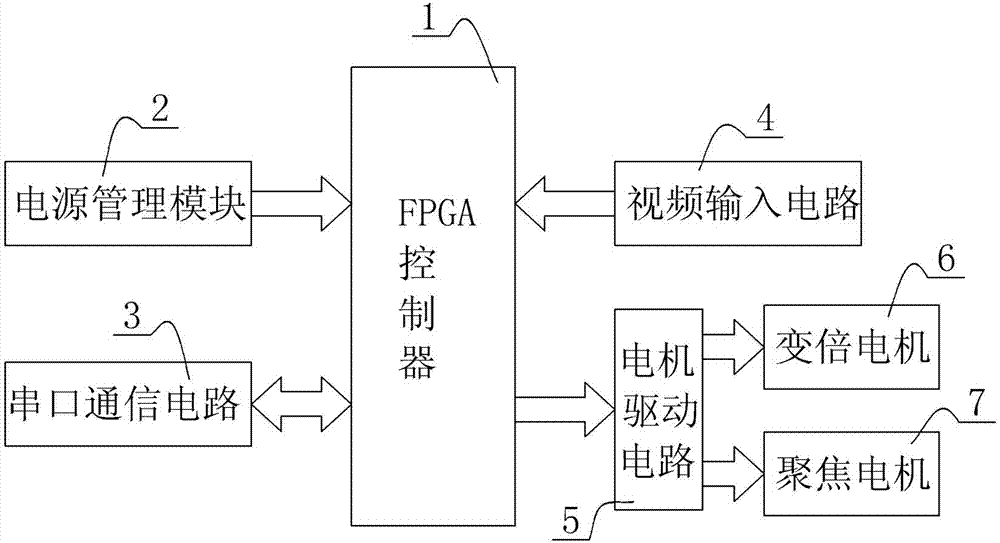

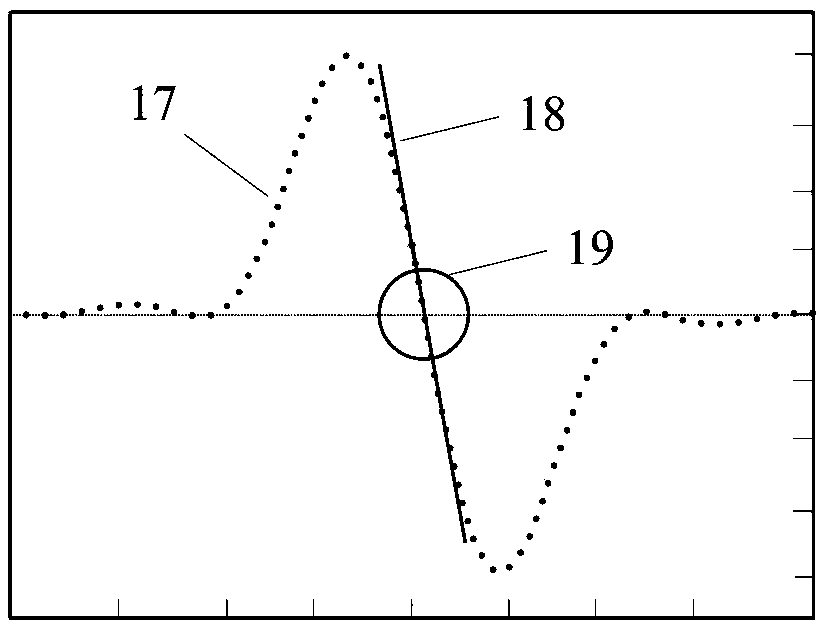

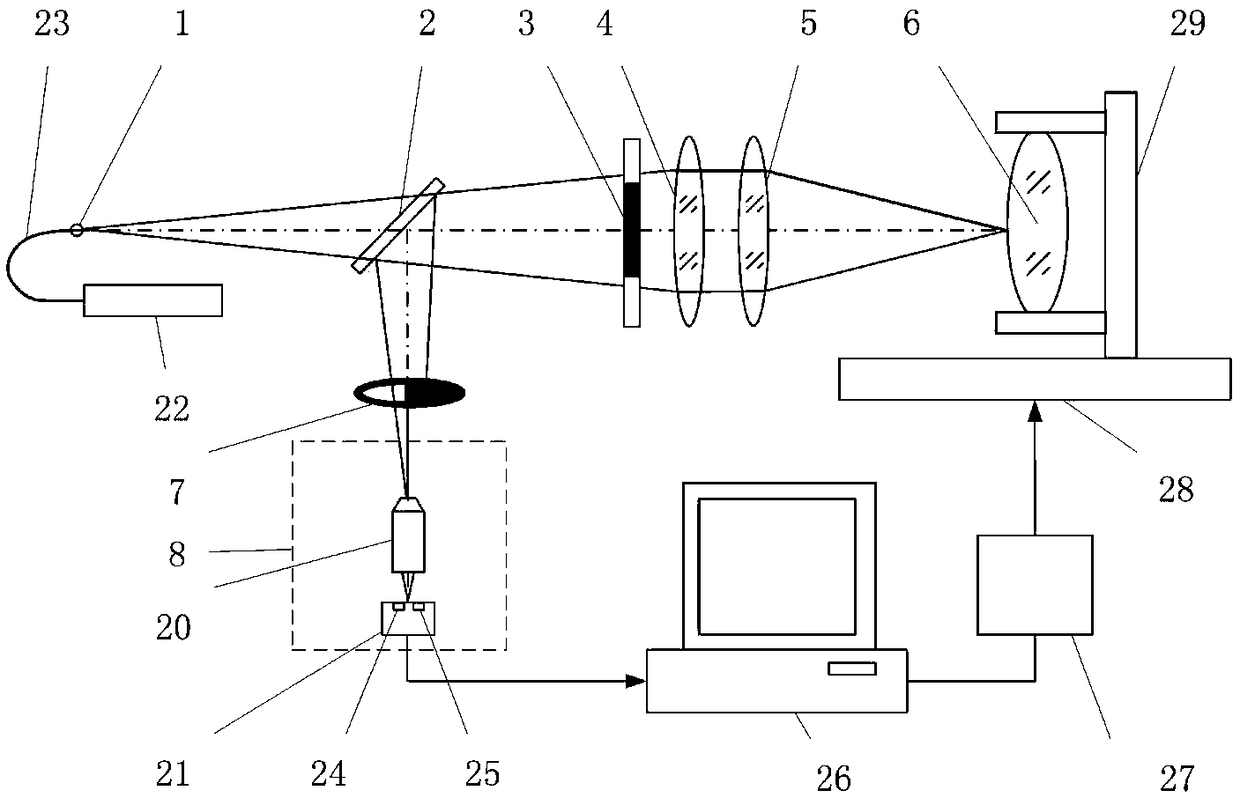

Laser differential confocal tomography focusing method and device

ActiveCN109253989AImprove focus accuracyReduce the impactAnalysis by material excitationLight beamTomography

The present invention relates to a laser differential confocal tomography focusing method and device, and relates to the technical field of optical imaging and detection. The method uses a rear pupilto block half of a measurement beam, uses a spectroscopic differential confocal detection system to detect the unblocked measurement beam, and uses an absolute zero point of a differential confocal response curve to achieve high precision tomographic focusing. The method organically combines a laser differential confocal technique and a ray tracing technique to establish a ray tracing and compensation model to eliminate influence among each fixed focal surface parameters, and achieves fast trigger of focus through data near a linearly fitting absolute zero point. The method can obtain the differential confocal response curve by using only one detector, and realizes the tomographic focusing through the absolute zero point of the differential confocal response curve, greatly simplifies system structure, in the same time, avoids error introduced by adjustment inaccuracy, and greatly improves precision of focusing. The method will provide a new technical approach to the field of confocal imaging / detection.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

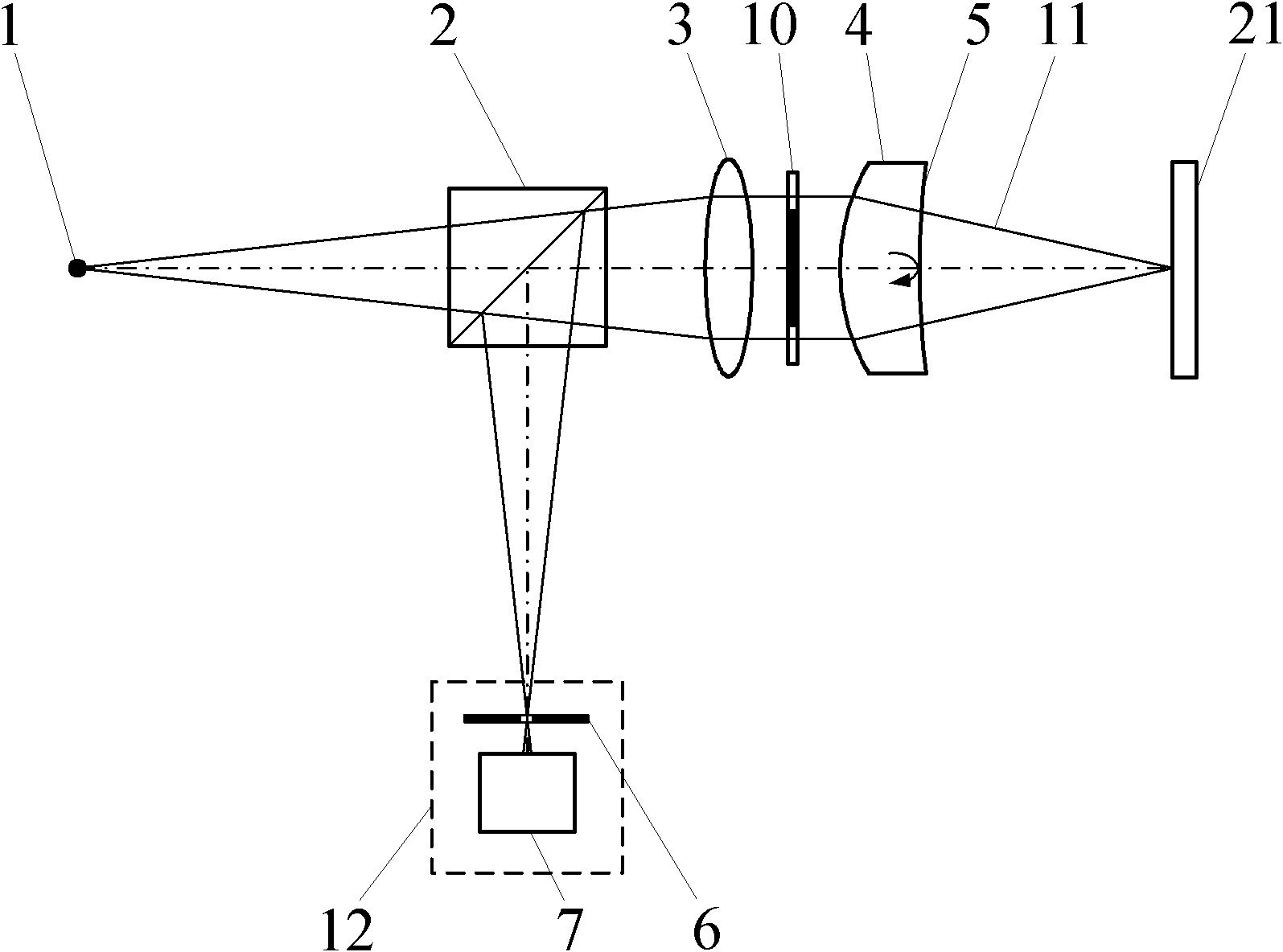

Method for fixing focus and measuring curvature radius by confocal interference

InactiveCN102175426AReduce the impactImprove focus accuracyUsing optical meansTesting optical propertiesOptical measurementsInterference microscopy

The invention relates to a method for fixing a focus and measuring a curvature radius by confocal interference, and belongs to the technical field of optical precision measurement. The method comprises the following steps of: introducing interfering reference light based on a confocal light path; precisely positioning an apex of the surface of a tested spherical element and a location of the centre of a sphere by using the maximum value of a confocal interference response curve to obtain the curvature radius of the surface of the tested spherical element; and maximumly sharpening a main lobe of the confocal response curve. By the invention, the traditional confocal interference microscopy imaging technique is first applied to improvement on the fixed-focus precision of an optical measuring system, so that the optical measuring system has a higher axial resolution and a simple structure, and the research and development costs of the system device are reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

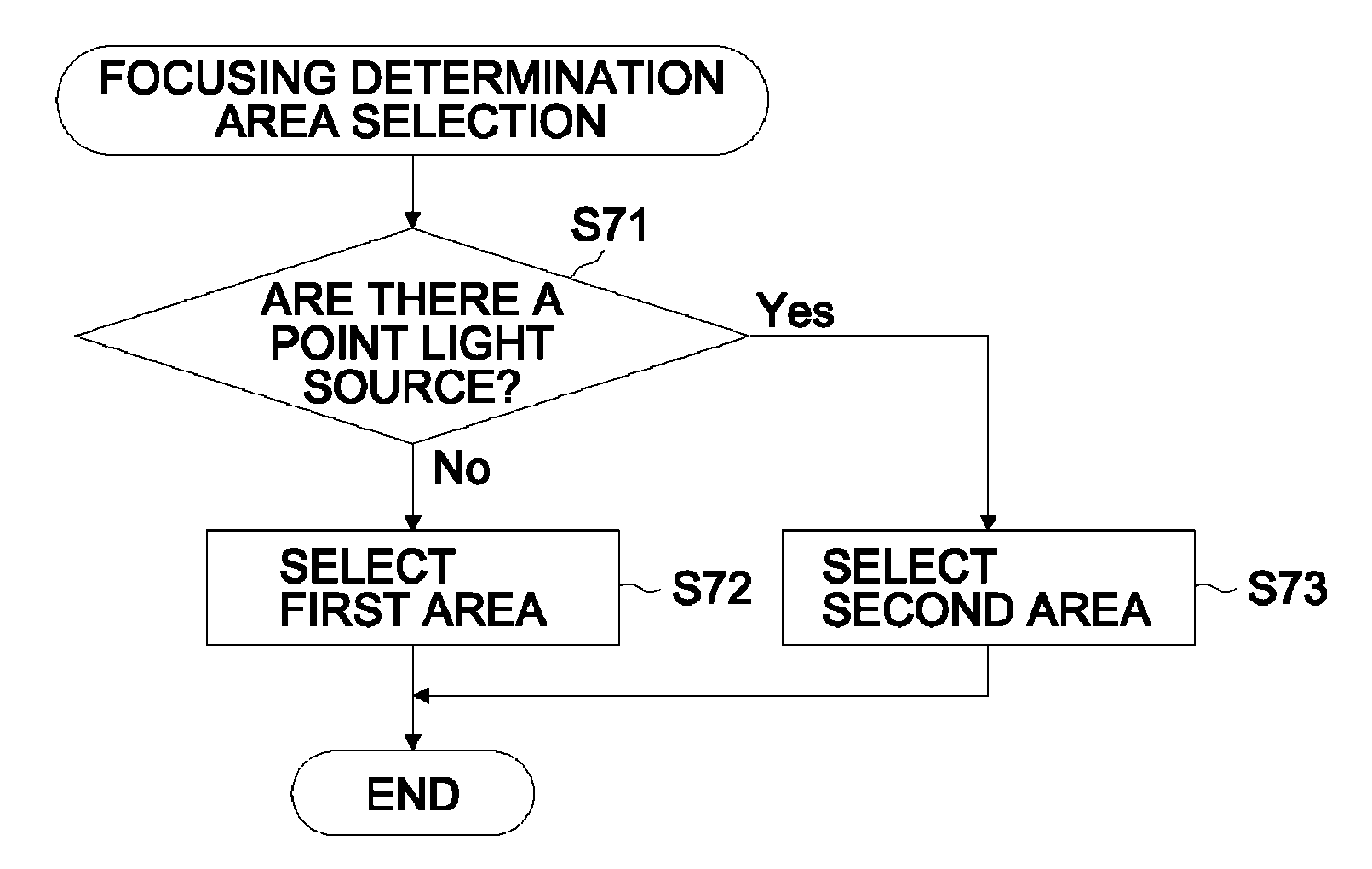

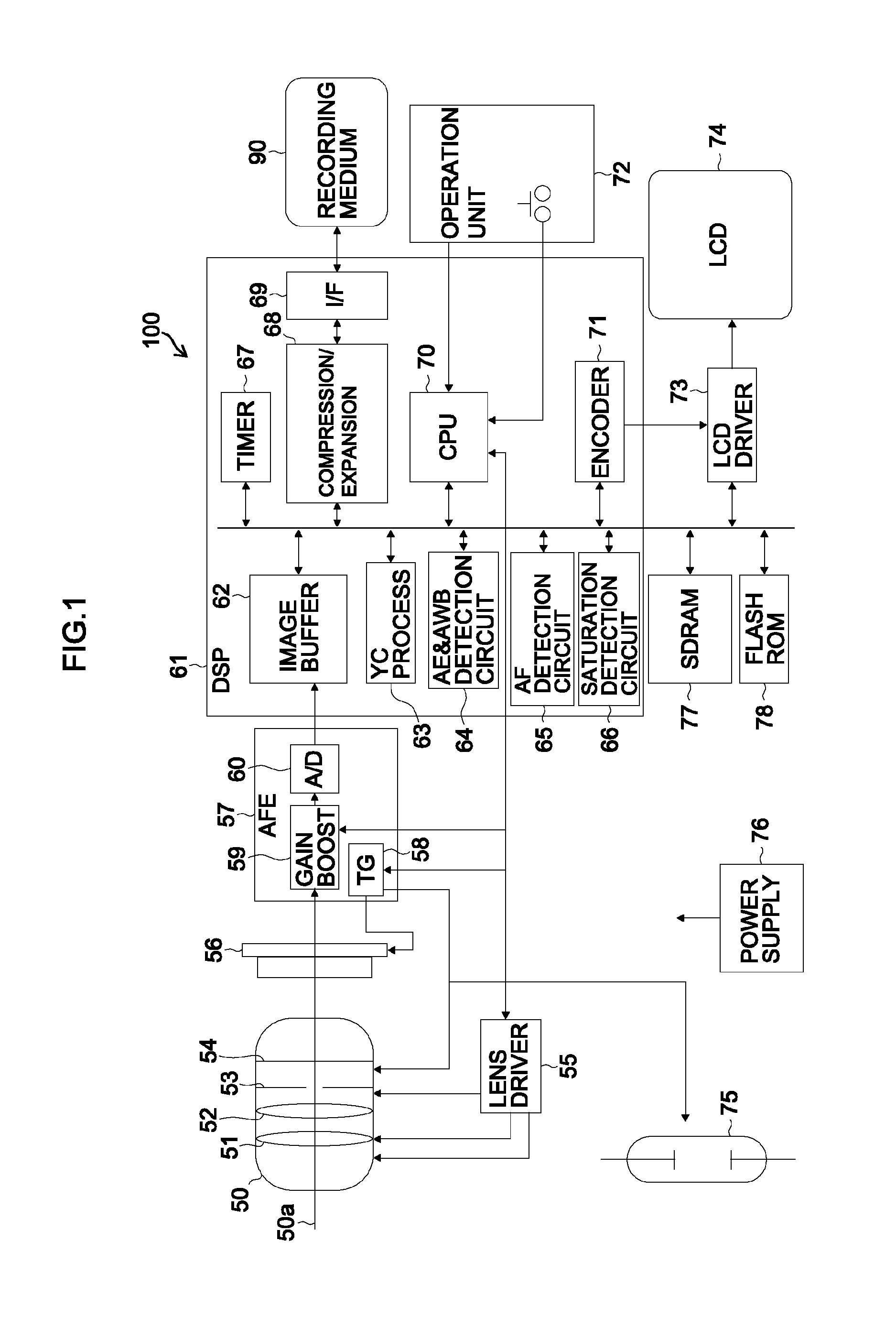

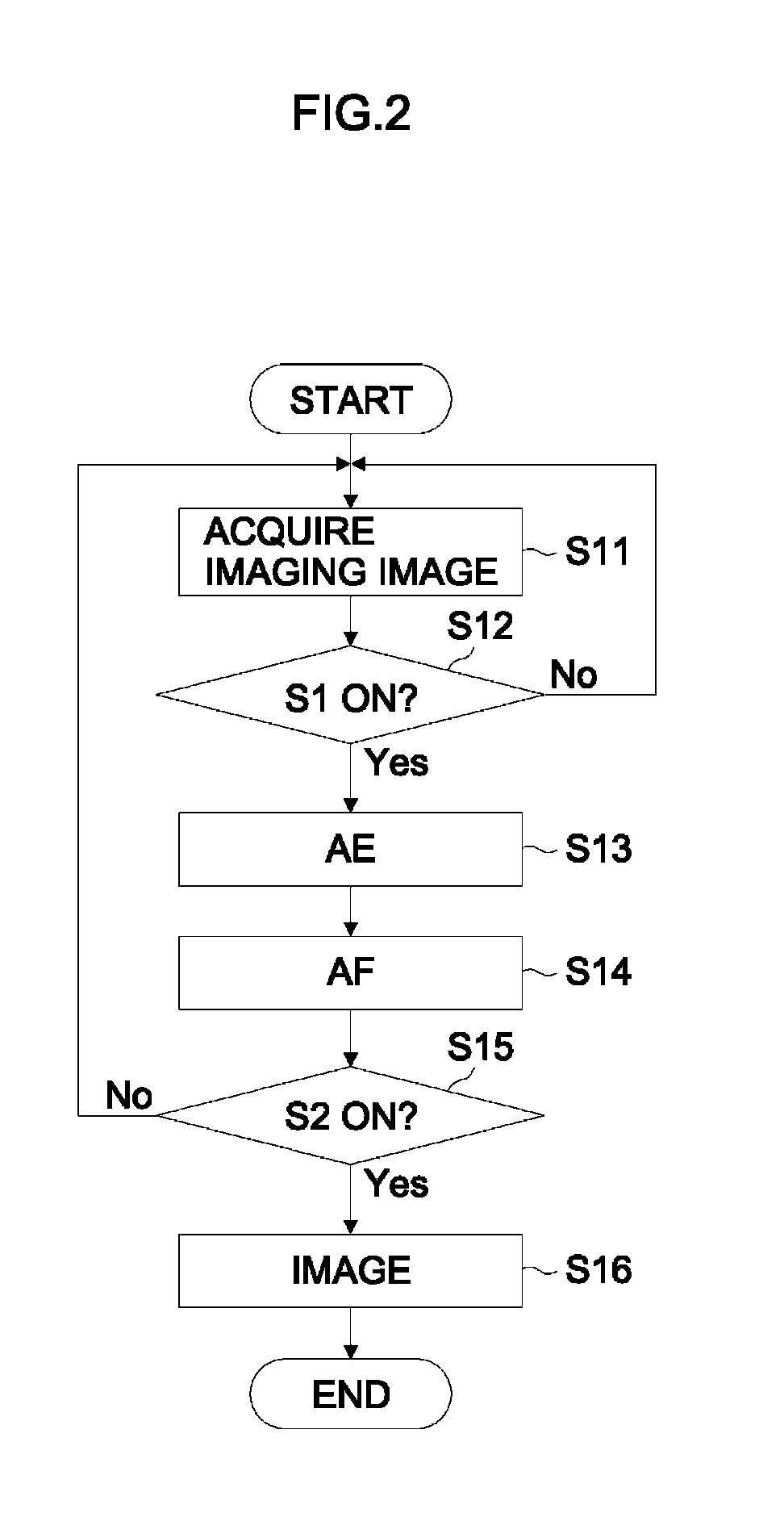

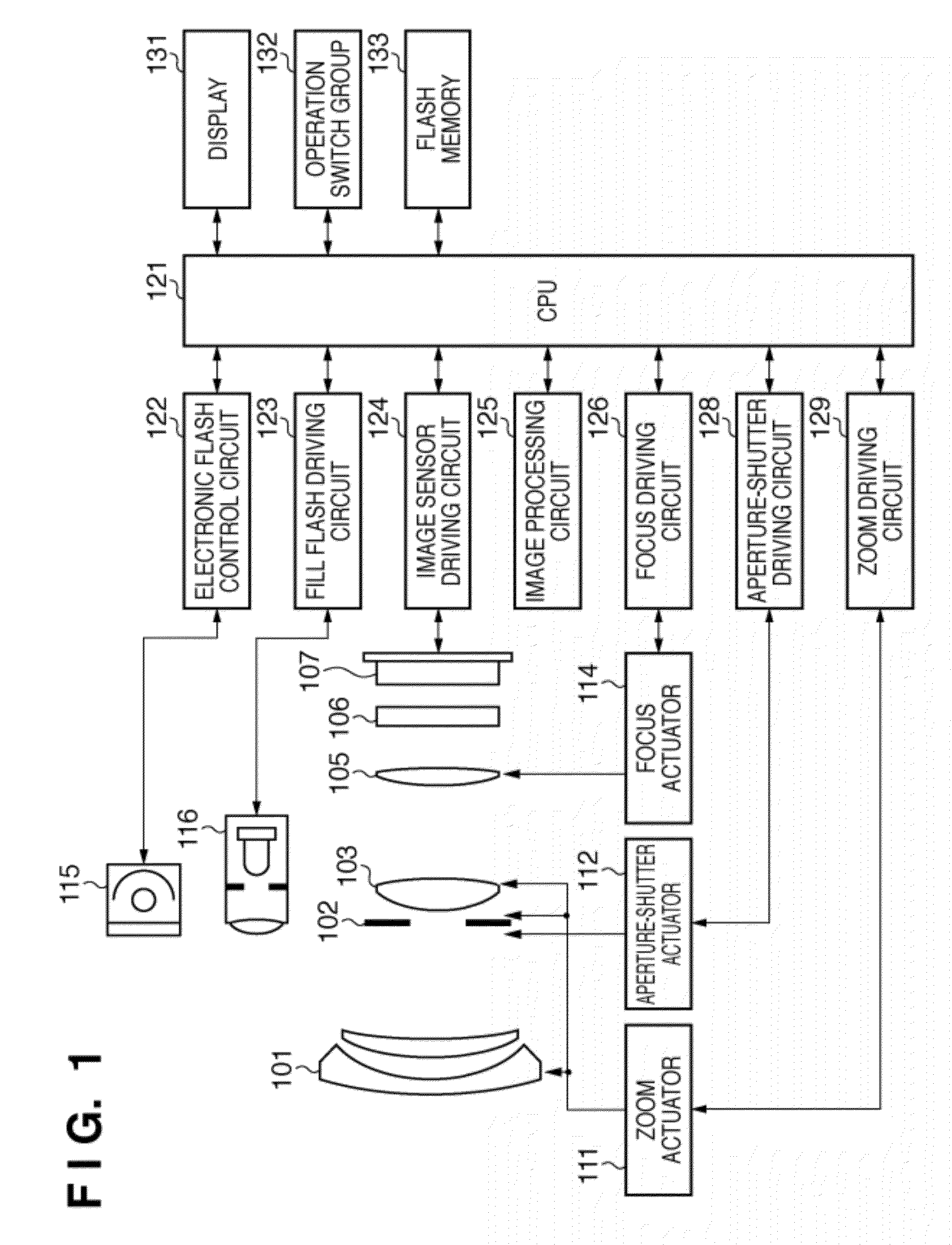

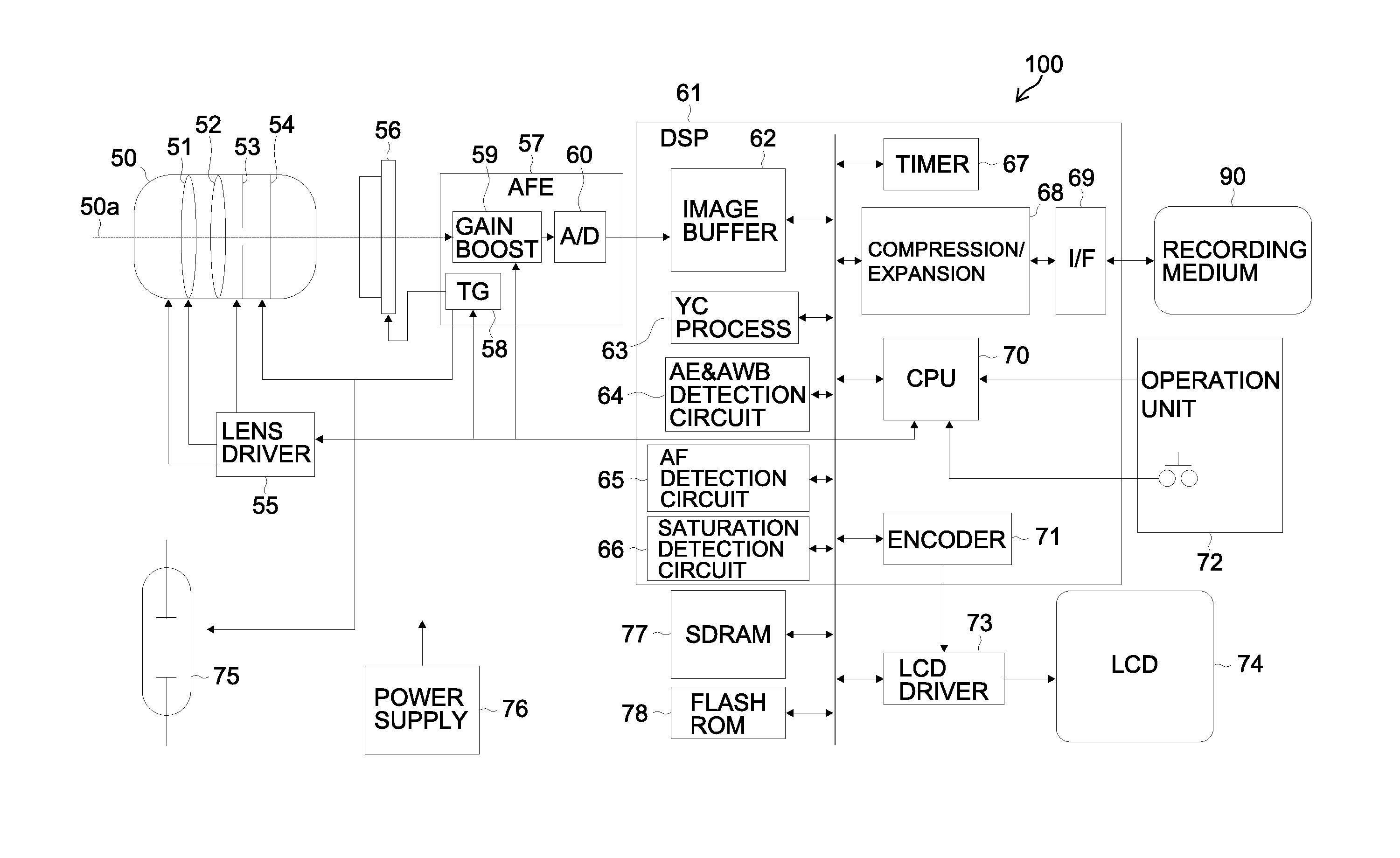

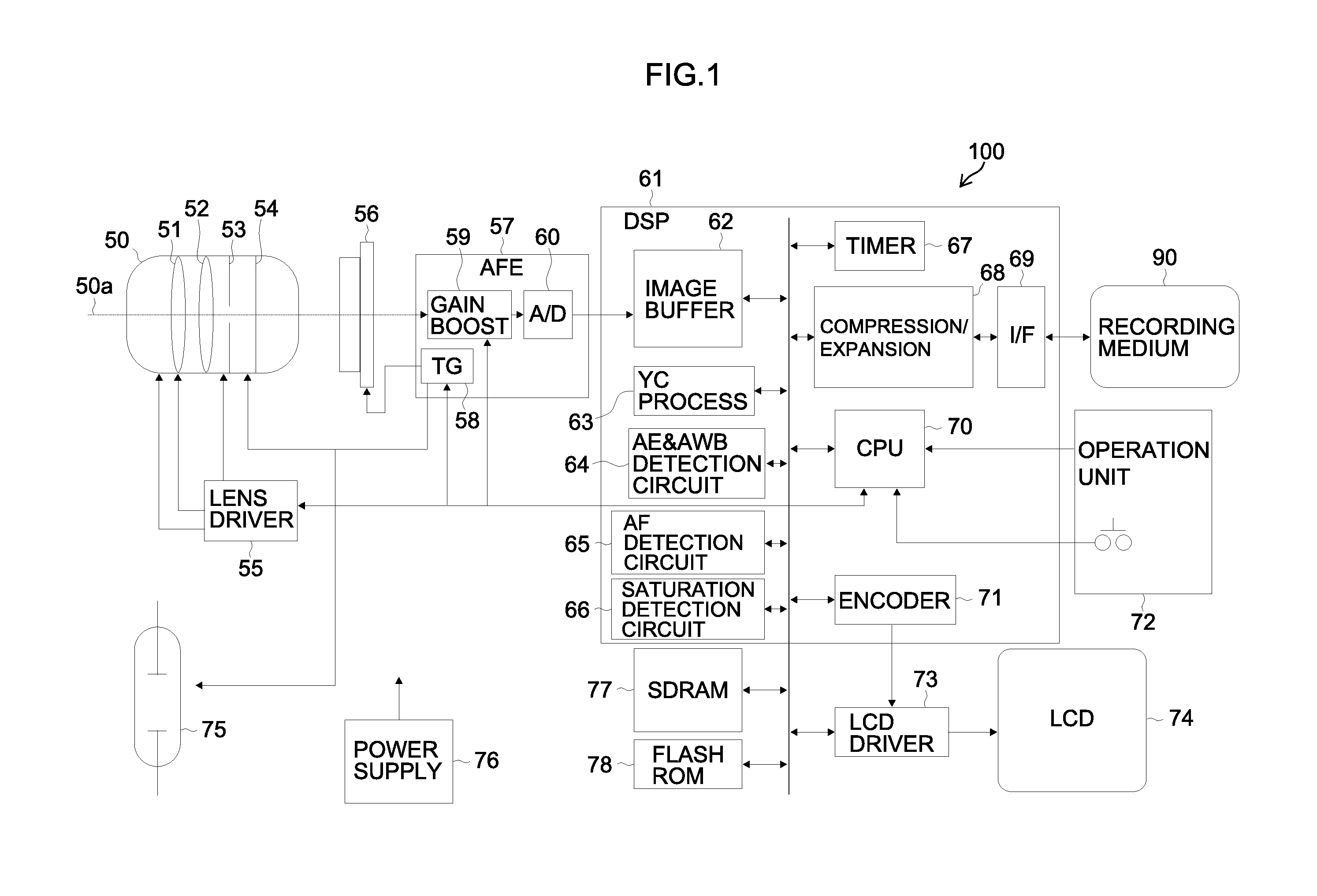

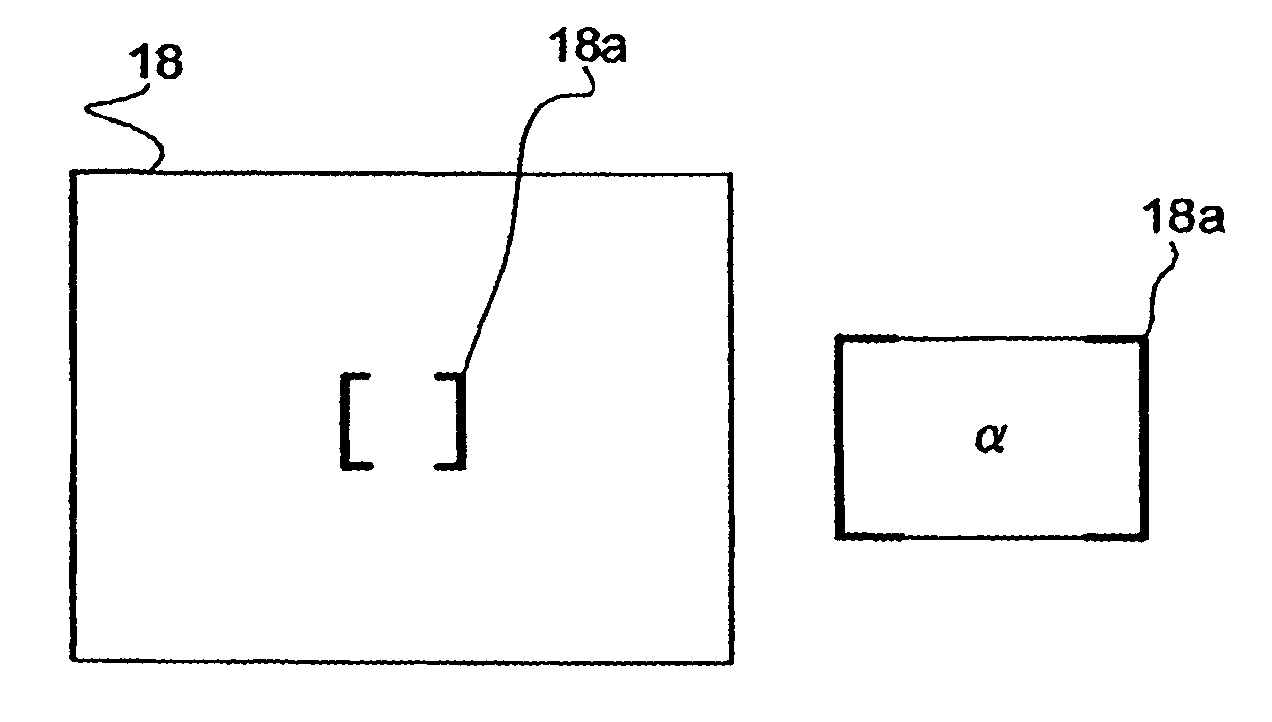

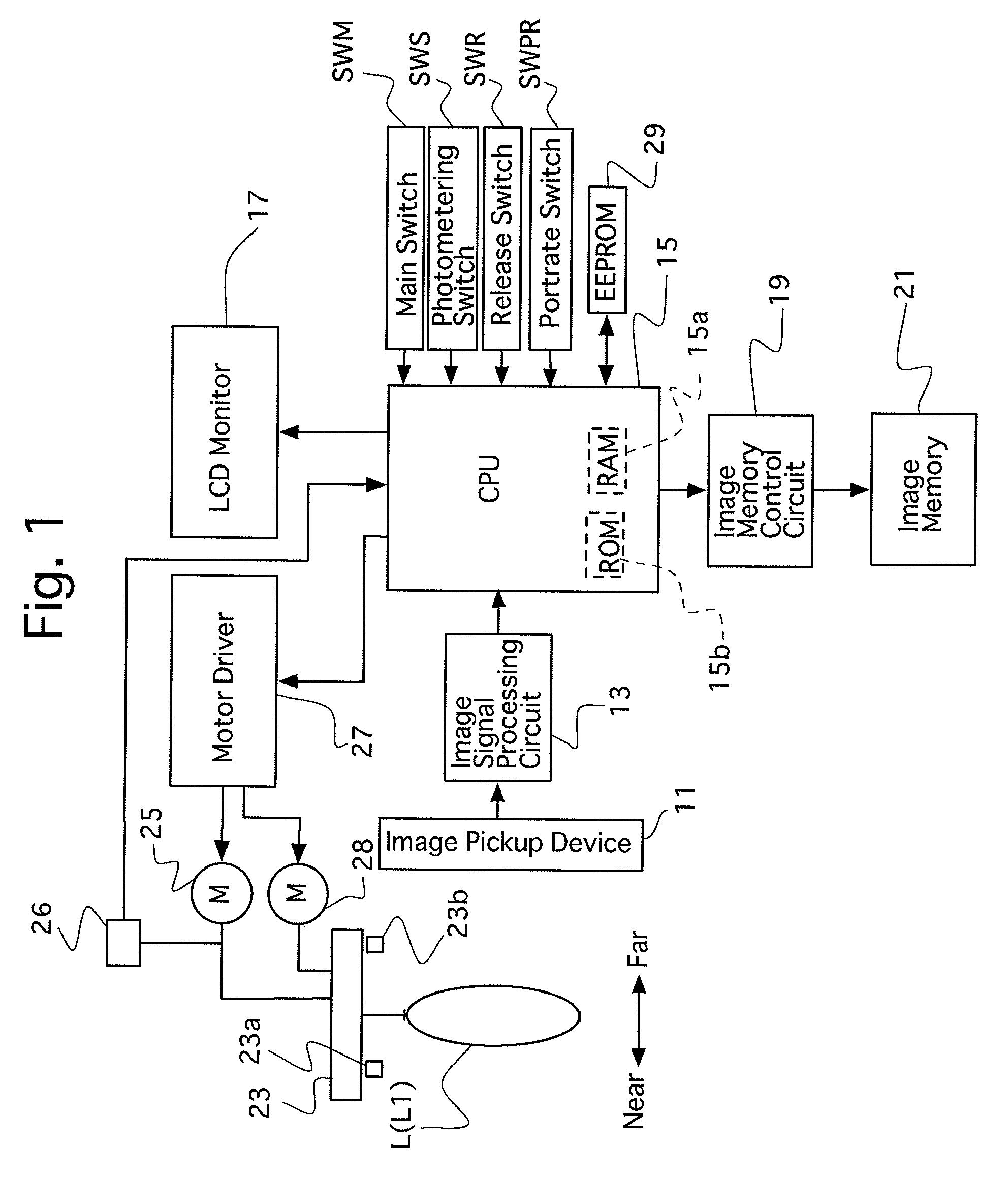

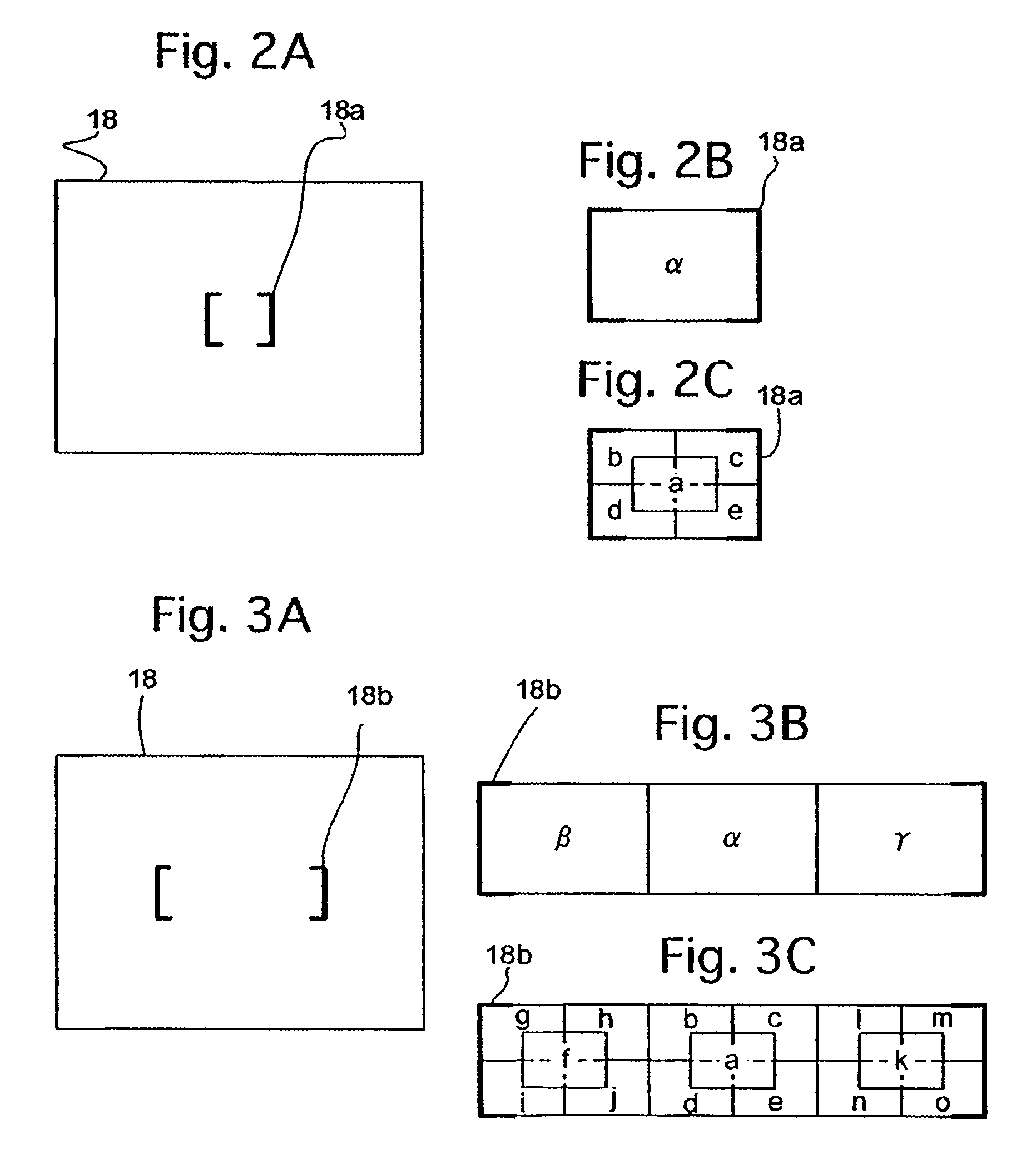

Imaging apparatus and imaging control method for focusing by determining a focusing position

ActiveUS8243191B2Improve focus accuracyTelevision system detailsColor television detailsRegion selectionOptical axis

Owner:FUJIFILM CORP

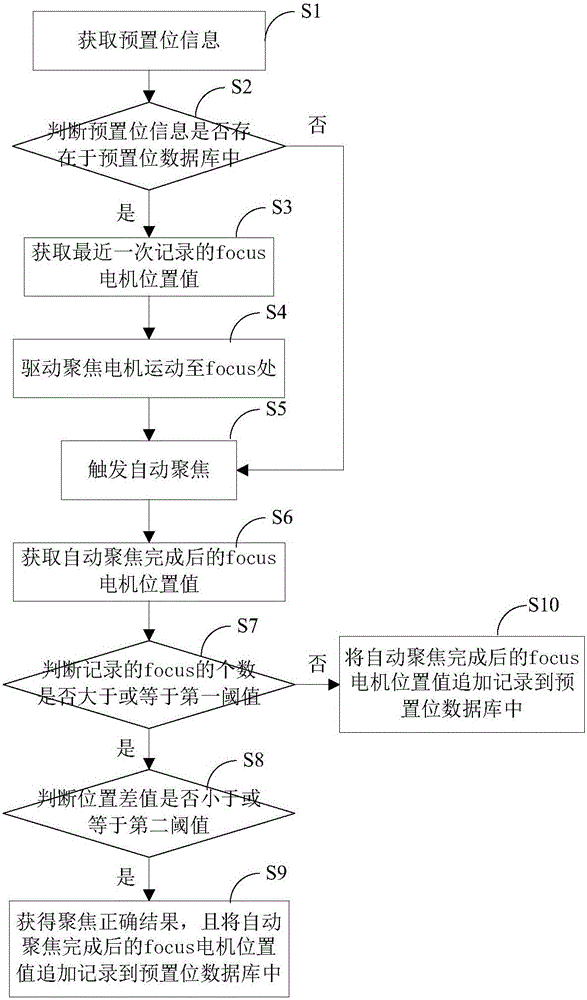

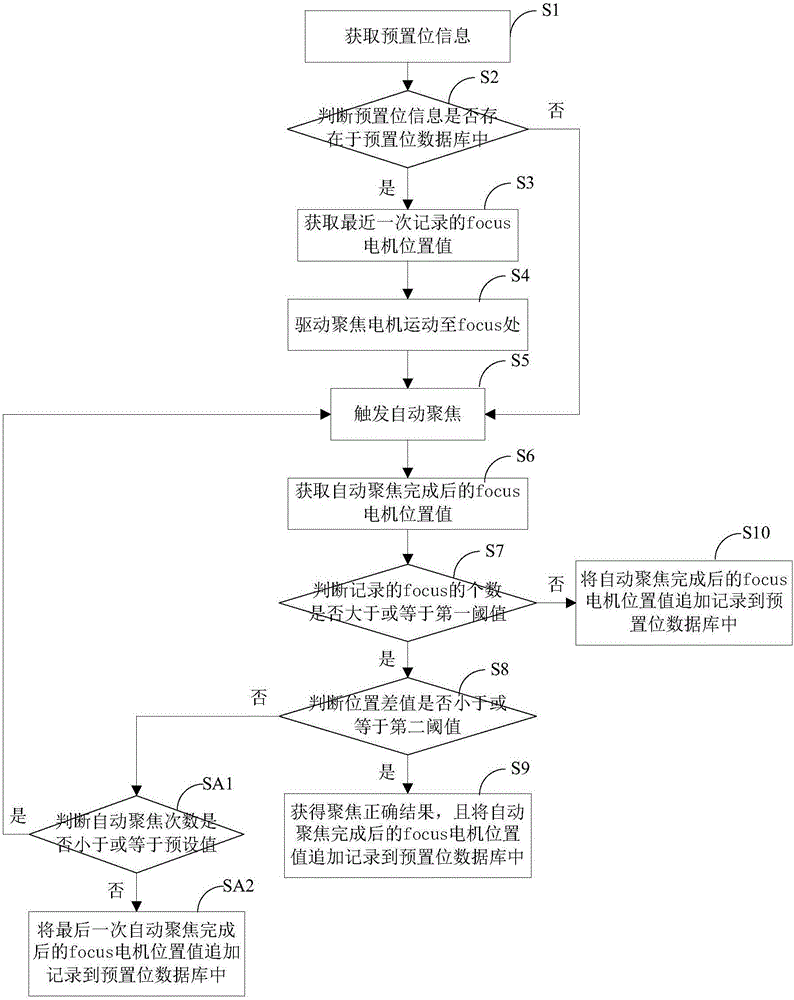

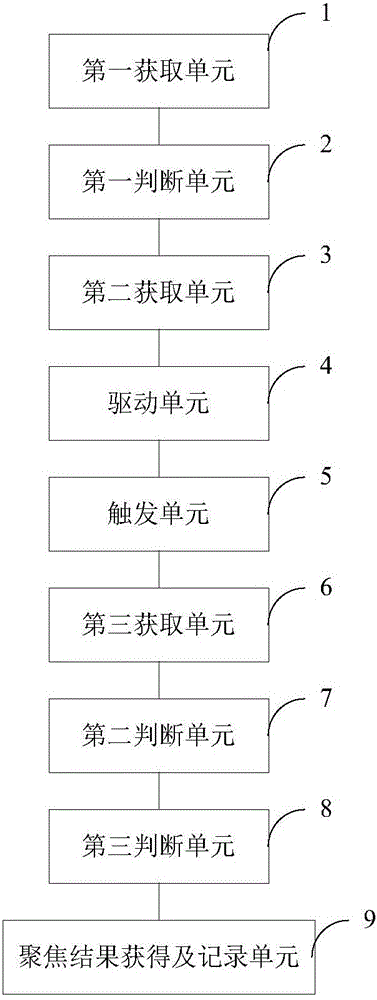

Focusing method and apparatus, cameras and camera system

ActiveCN105763795AImprove stabilityAccurately obtainedTelevision system detailsColor television detailsComputer scienceVideo camera

The invention discloses a focusing method and apparatus, a cameras and a camera system. The focusing method comprises the steps of acquiring preset position information; determining whether the preset position information is in a preset position database; if so, acquiring a latest recorded focus motor positional value corresponding to the preset position information from the preset position database; driving a focus motor to move to the focus motor positional value; triggering automatic focusing; acquiring a focus motor positional value after the automatic focusing is completed; determining whether the number of focus motor positioning values, corresponding to the preset position information, recorded in the preset position database is greater than or equal to a first threshold; if the number is greater than or equal to the first threshold, determining whether the positional difference is less than or equal to a second threshold; and if the positional difference is less than or equal to the second threshold, acquiring a focusing correct result. The invention has the advantages of high correct rate of preset position focusing adjustment, real-time update of historical data, quick acquisition of clear images.

Owner:SUZHOU KEDA TECH

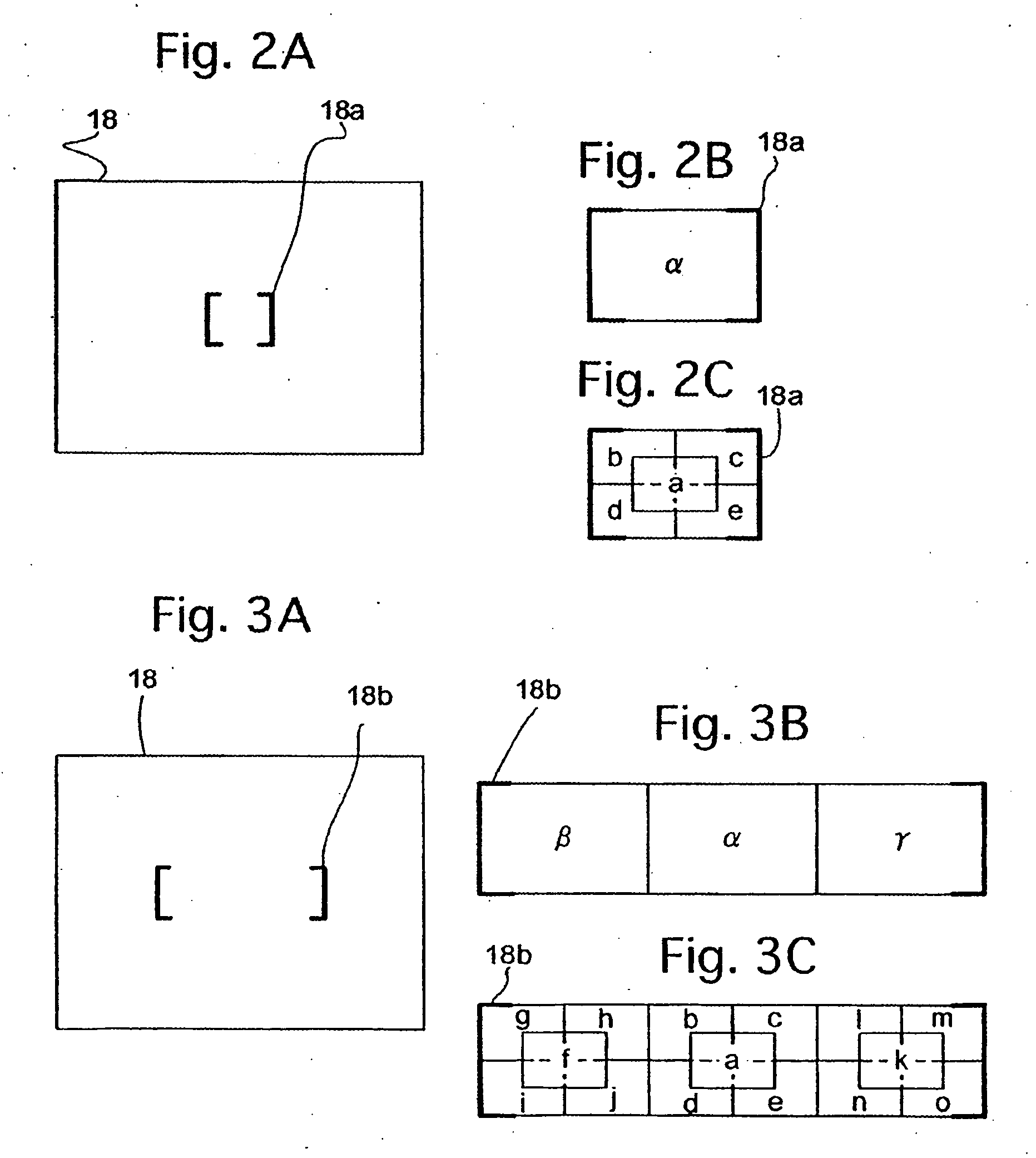

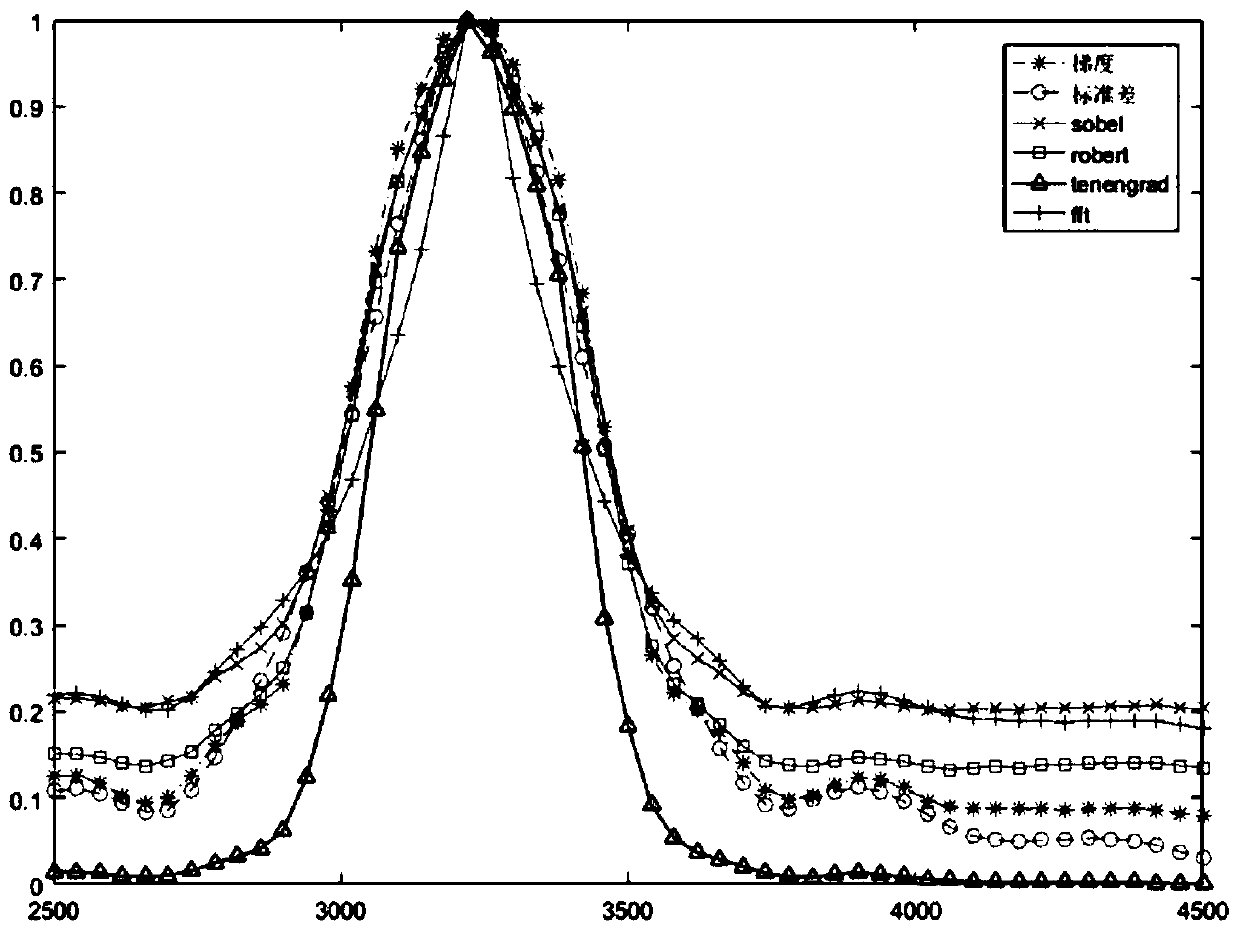

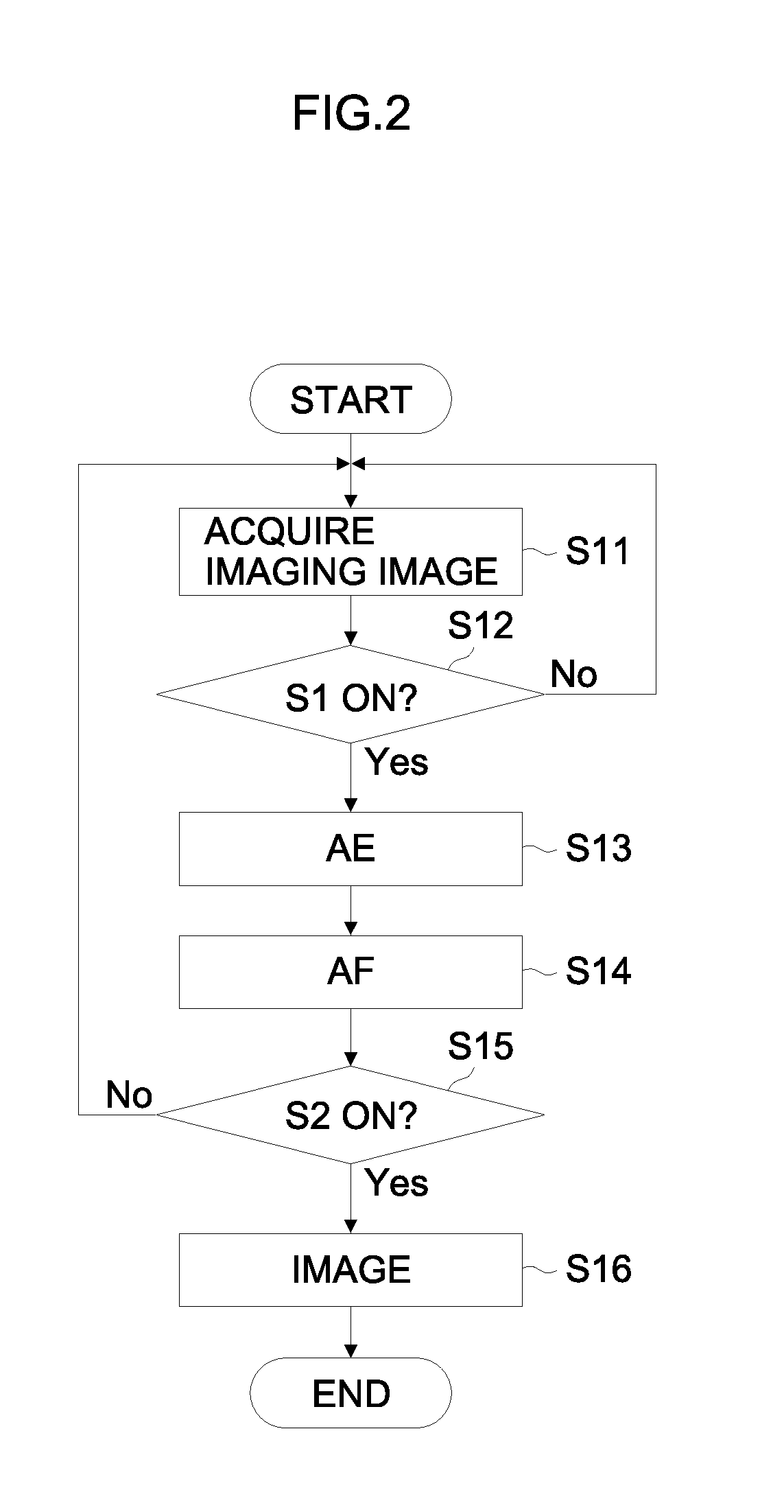

Focus adjusting method and focus adjusting device

InactiveUS20090028539A1Improve focus accuracySpeed up the focusing operationTelevision system detailsProjector focusing arrangementFocal positionComputer vision

A focus adjusting method for adjusting focus by moving a focusing lens group of a photographing optical system, wherein the focus adjusting method includes a first search stage at which a focus search operation is performed based on an image formed in a large focus area while the focusing lens group is moved stepwise over an entire range of movement thereof from the near extremity to the far extremity, and a second search stage at which the focus search operation is performed, based on images formed in small focus areas, at front and rear close vicinities of the in-focus position while the focusing lens group is moved stepwise over a portion of the entire range of movement thereof.

Owner:RICOH IMAGING COMPANY

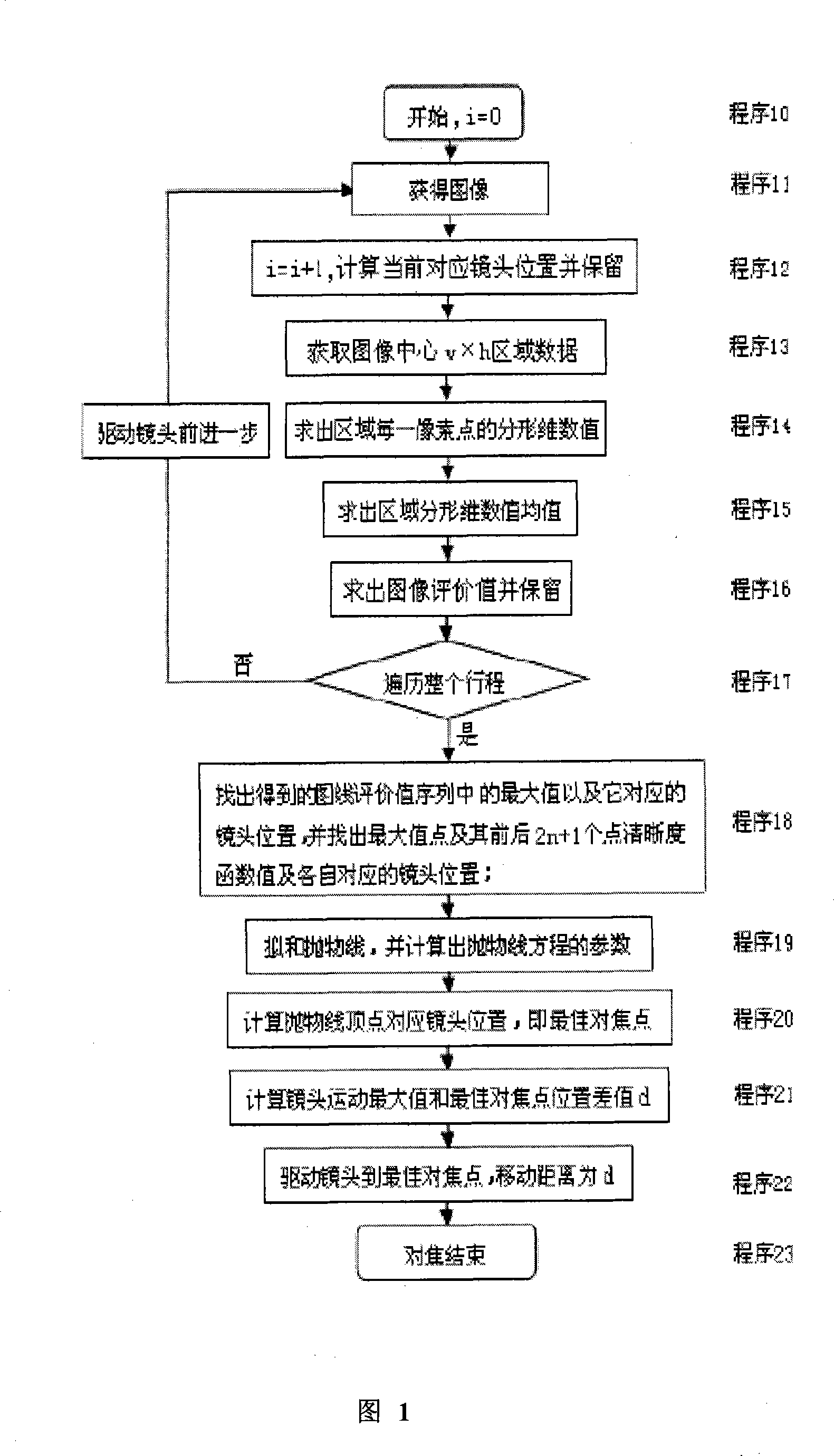

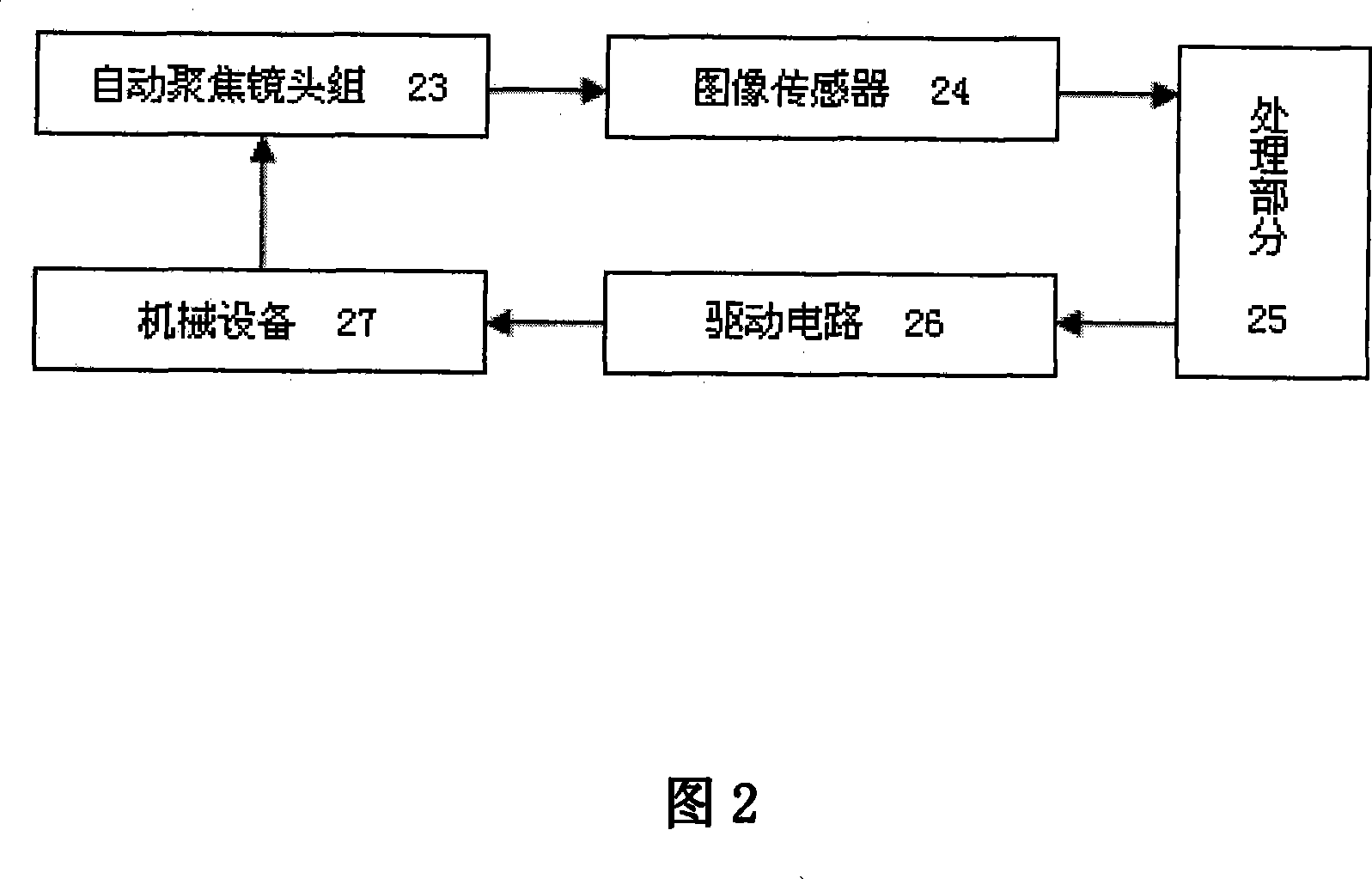

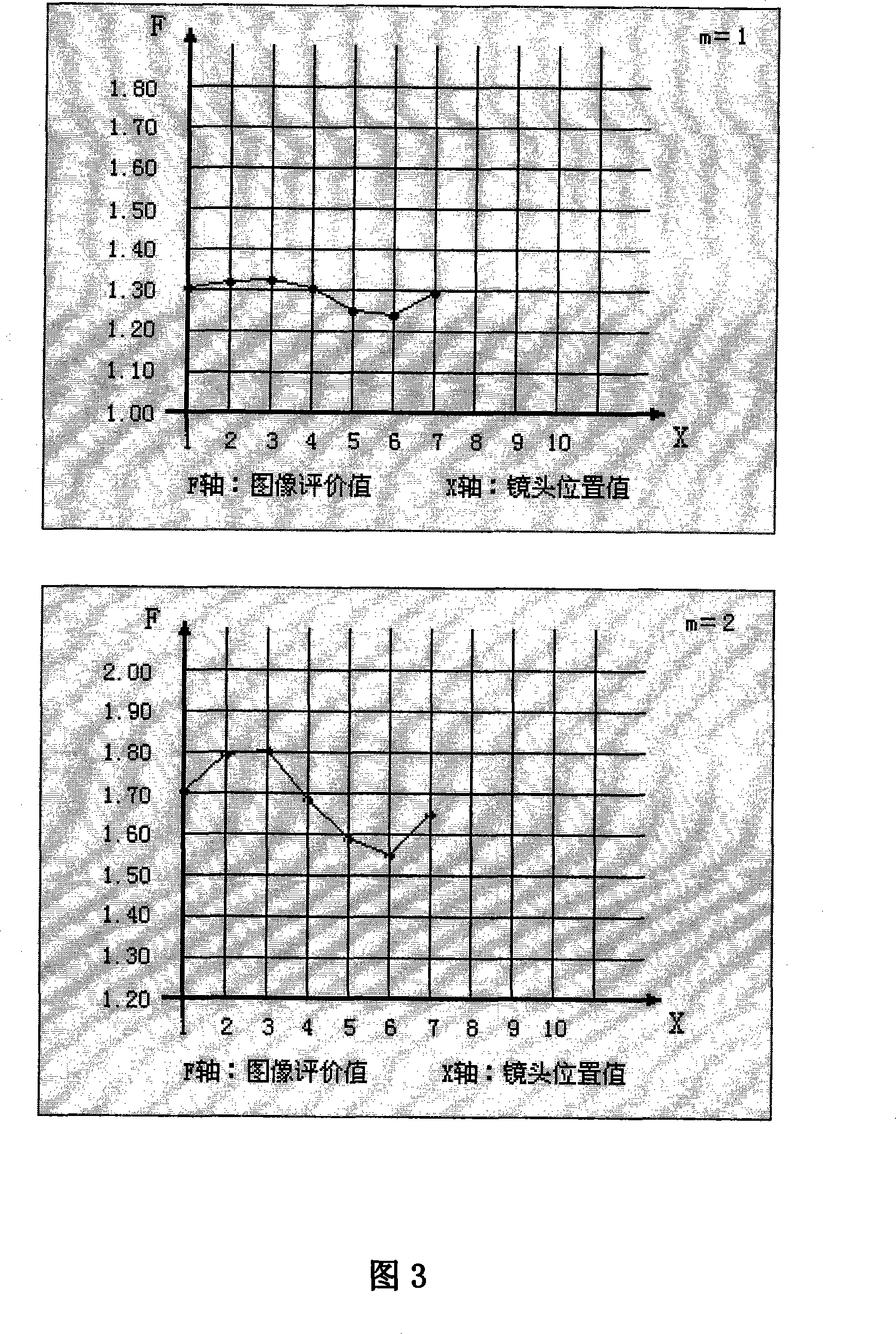

Automatic focusing process

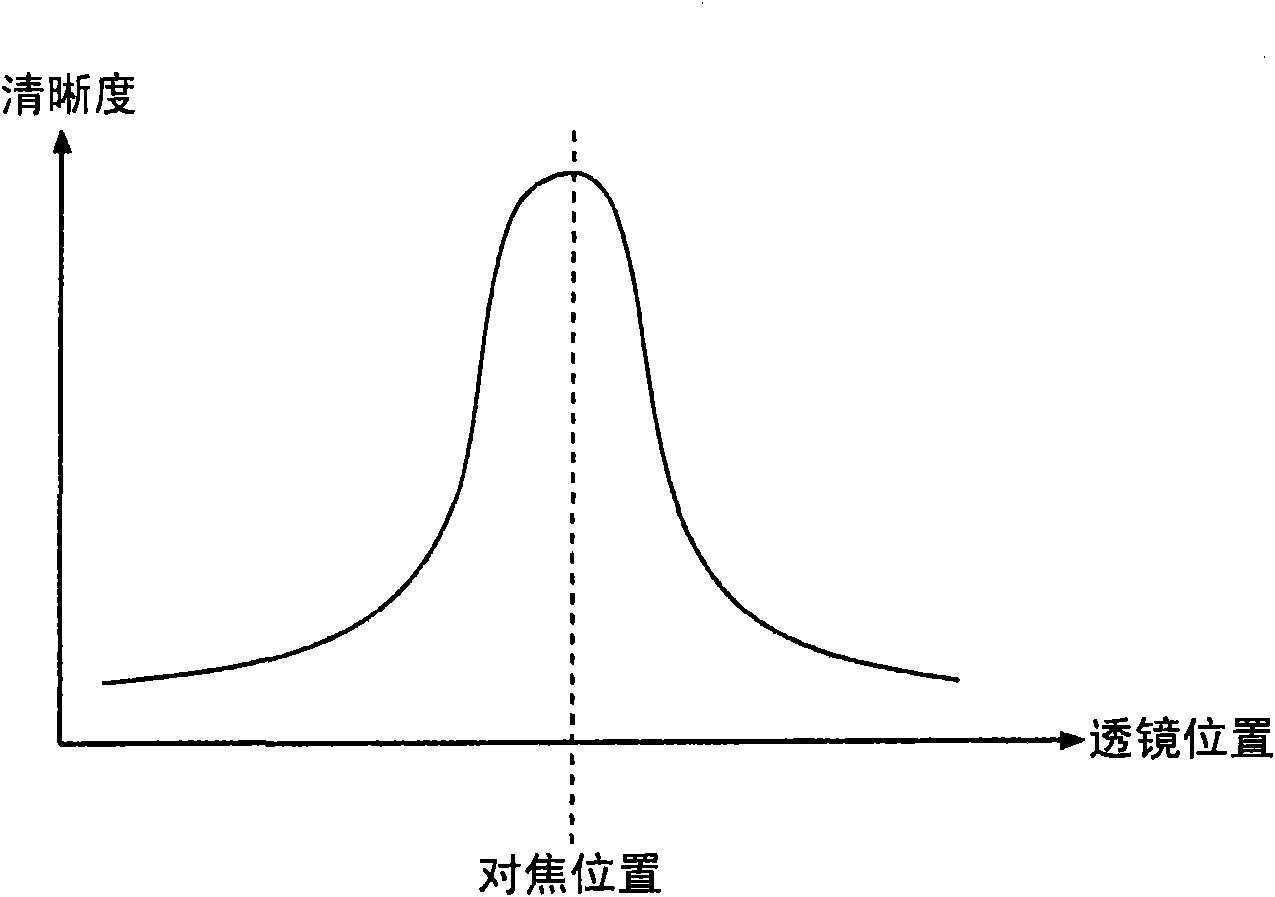

The invention discloses an auto focusing method comprising following steps: driving the lens to move in the whole range can be reached with a predetermined step width, obtaining an image at the initial position of the lens and at the position of each step of the lens; comparing each obtained image, memorizing corresponding lens position, and calculating the fractal dimension value of each pixel in a certain area therein; calculating the image evaluation value by using the fractal dimension value, thereby obtaining an image evaluating sequence; finding out the maximum value, and the values corresponding to the front and post n (n is a positive integer) steps in the sequence, making a parabolic curve according to the 2n+1 evaluating values and the corresponding lens position values; and calculating the corresponding lens position of the parabola vertex which is the lens focusing position. The invented auto focusing method can analyze image detail information well with good adaptability, focusing accuracy is increased, focusing position can be found out quickly, and the invented method can be used broadly in diversified cameras.

Owner:RUITAI OPTICAL CHANGZHOU CO LTD

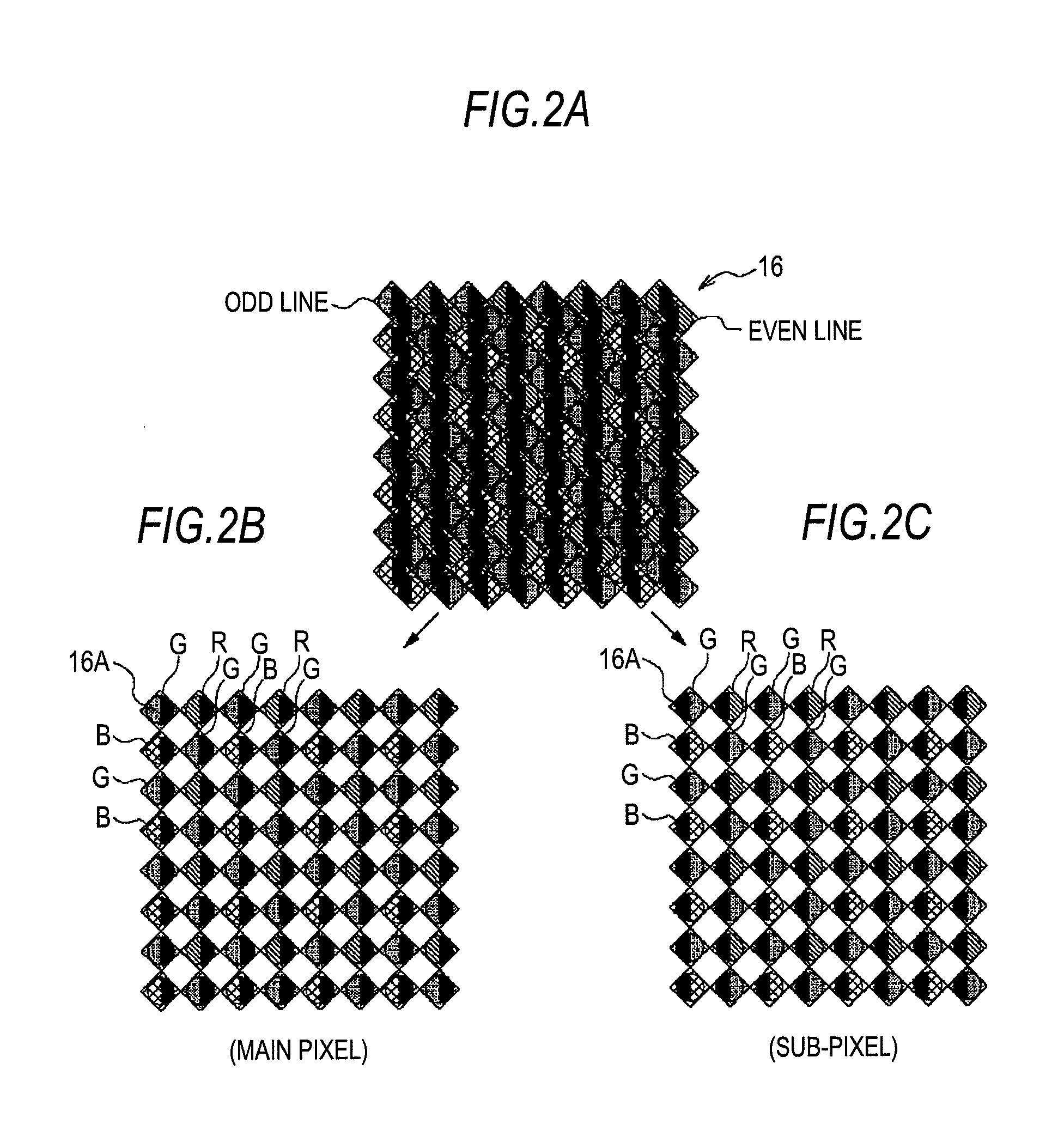

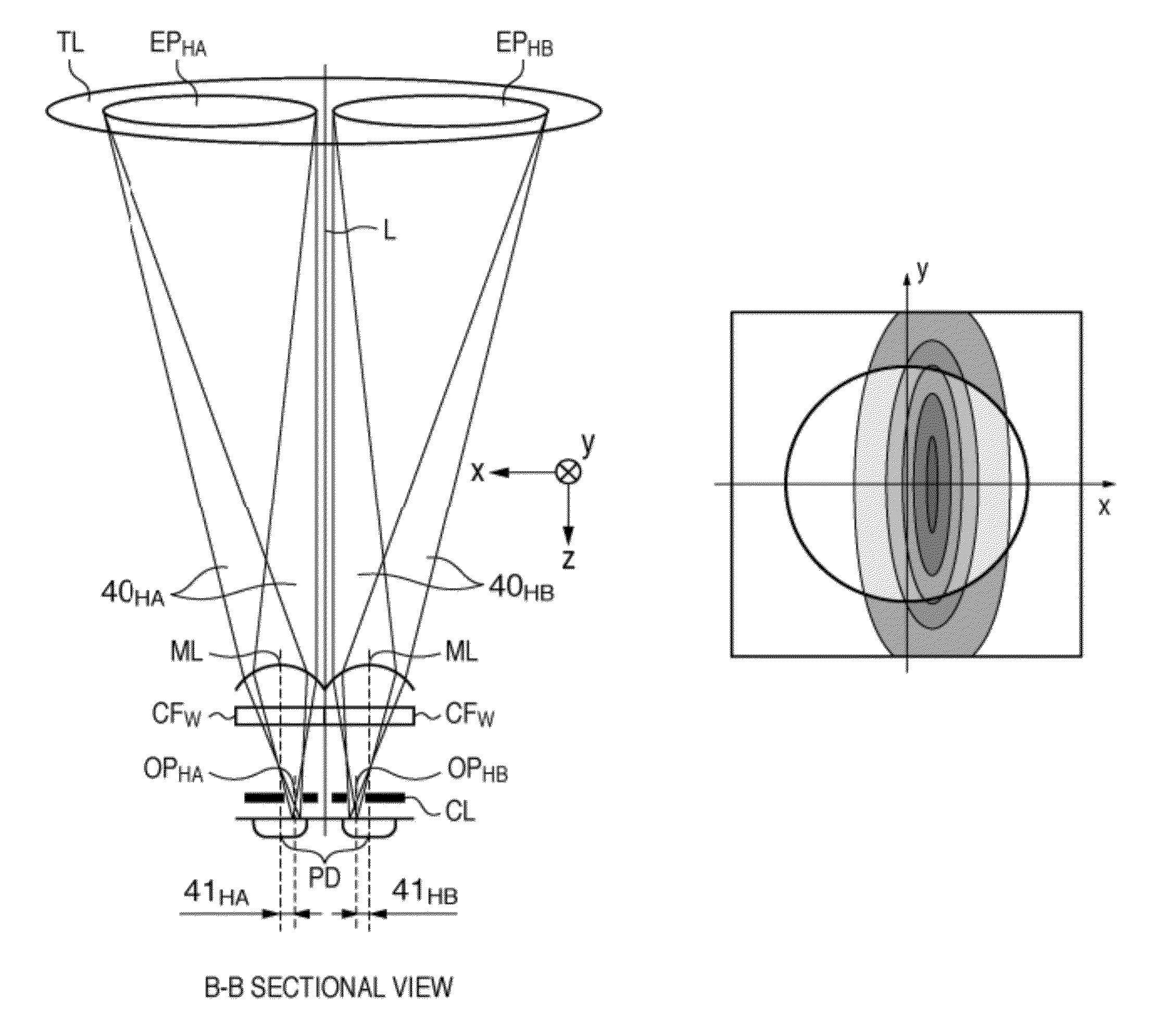

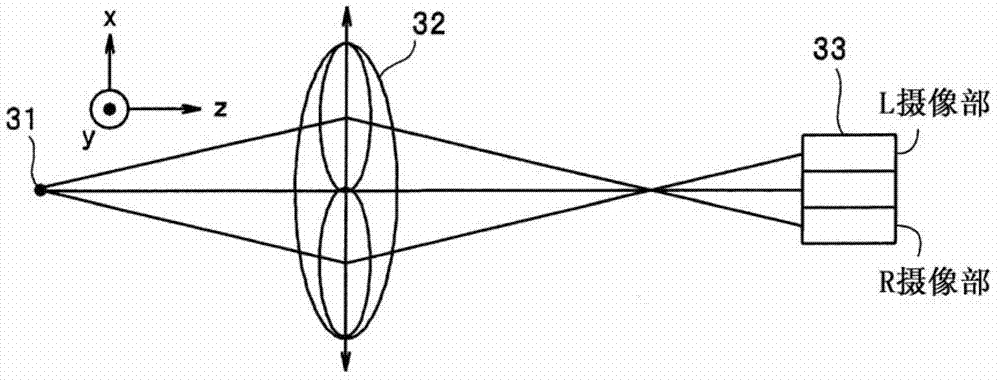

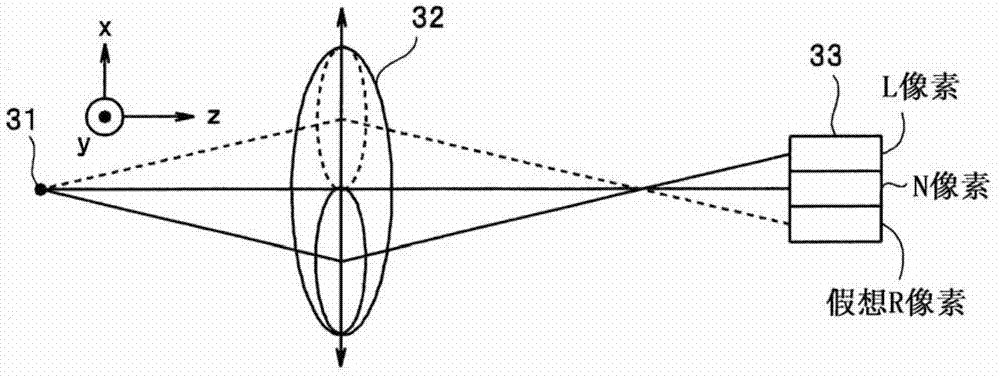

Stereoscopic imaging apparatus

ActiveUS20110228053A1Decrease in sizeAccelerate processTelevision system detailsSteroscopic systemsStereoscopic imagingPixel image

A stereoscopic imaging apparatus which uses contrast AF to obviate disadvantages of phase-difference AF, shorten processing time of contrast AF, and improve focusing accuracy. A phase-difference CCD in which object images having passed through different regions in a predetermined direction of a single photographing optical system are pupil-split and imaged subjects the object images having passed through the respective regions to photoelectric conversion to obtain a main pixel image and a sub-pixel image which have a mutual phase difference. Contrast AF is performed using only one of the main pixel image and the sub-pixel image. Which one of the main pixel image and the sub-pixel image will be used for the contrast AF is determined depending on whether the position of an AF area in the angle of view belongs to a main pixel AF area or a sub-pixel AF area.

Owner:FUJIFILM CORP

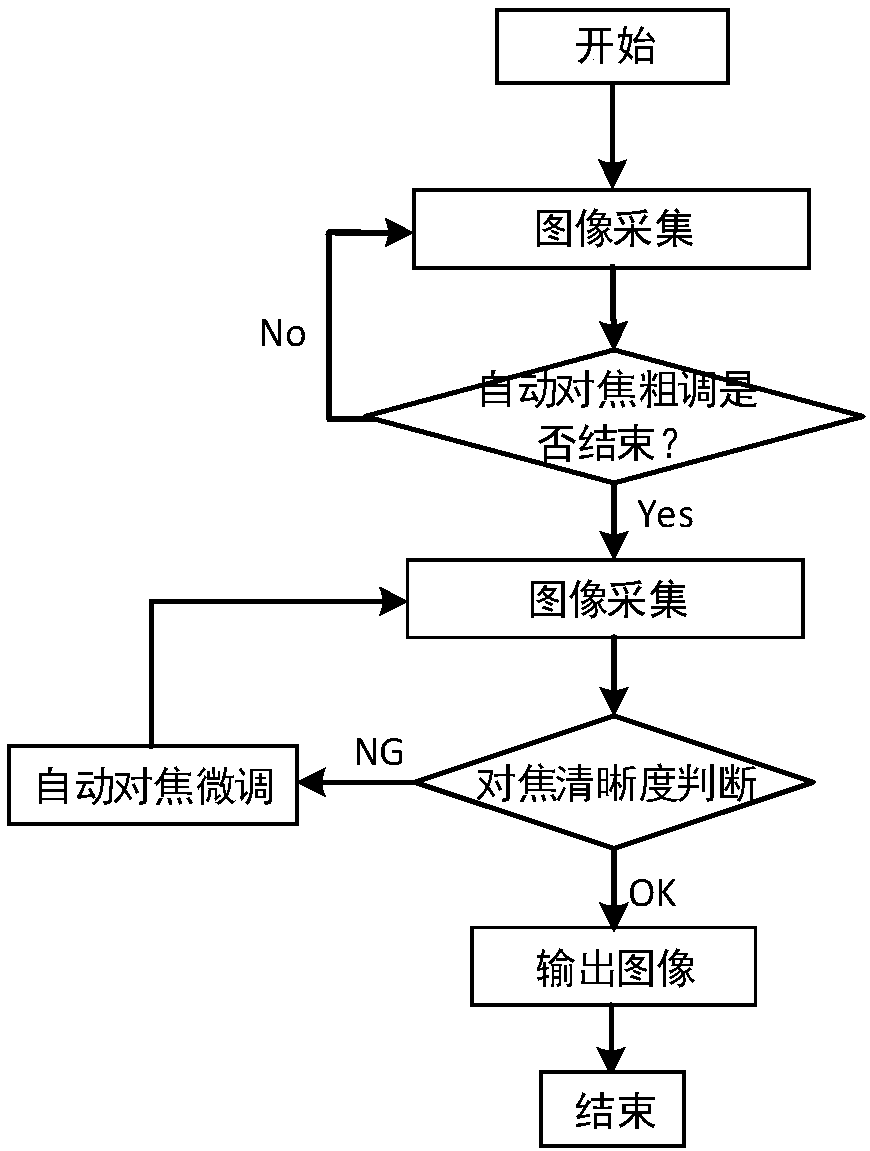

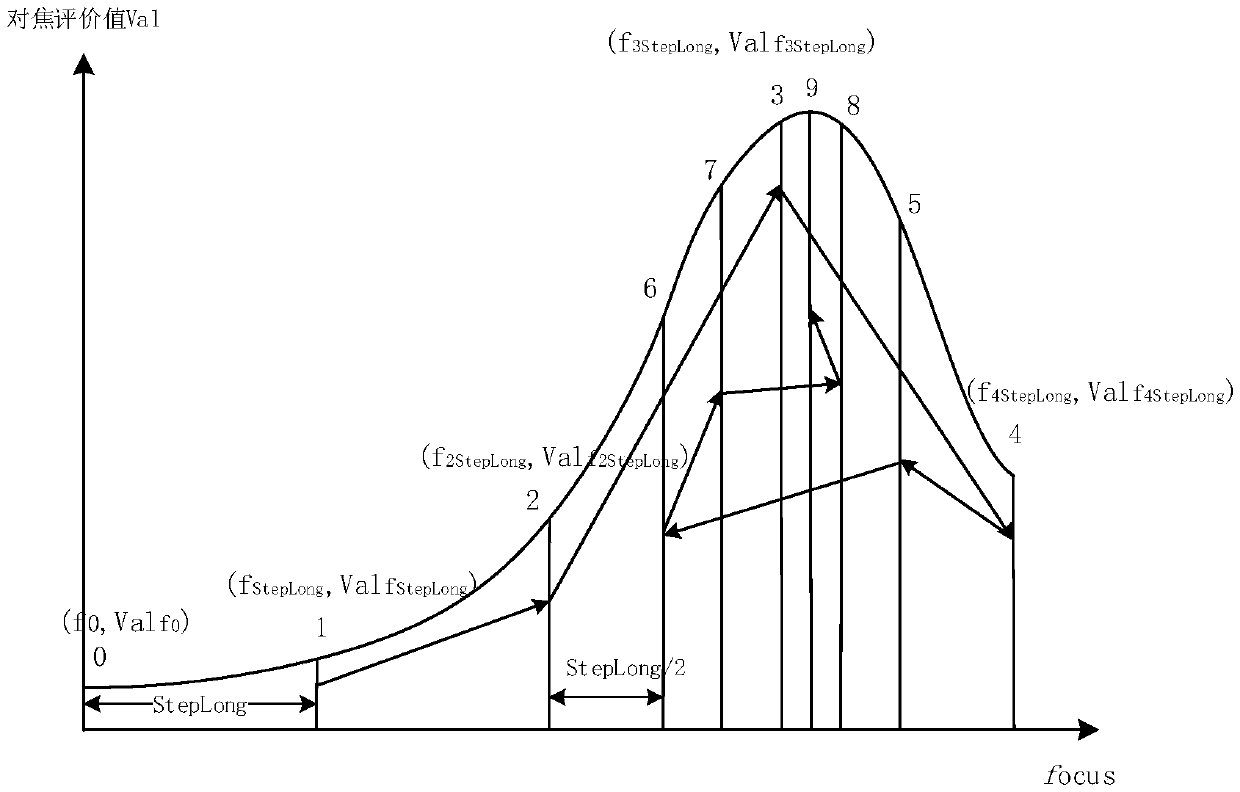

Fast auto-focusing method based on display panel

ActiveCN109696788AAvoid influenceImprove focus accuracyTelevision system detailsColor television detailsAutofocusFine-tuning

The invention belongs to the technical field of display panel defect detection, and discloses a fast auto-focusing method based on a display panel. The method includes the following steps: a focusingscreen image of a display panel is collected, focusing is carried out by dichotomy in the full focal range, the clear focusing range of the image is determined by long-step focusing, and the clear focusing position is determined in the focusing range by short-step focusing; an image corresponding to the clear focusing position is collected at the clear focusing position, and the focusing clarity is judged; if the focusing clarity satisfies a preset threshold requirement, the image is output; and otherwise, an image is collected and the focusing clarity is judged again after auto-focusing fine-tuning until the focusing clarity satisfies the preset threshold requirement, and the image is output. According to the auto-focusing method provided by the invention, the clear focusing position is calculated through coarse focusing, and fine-tuning is carried out according to the clarity of the image at the focusing position. Therefore, the focusing accuracy is improved, error focusing is prevented, the accuracy of defect detection is improved, and the detection time is shortened.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

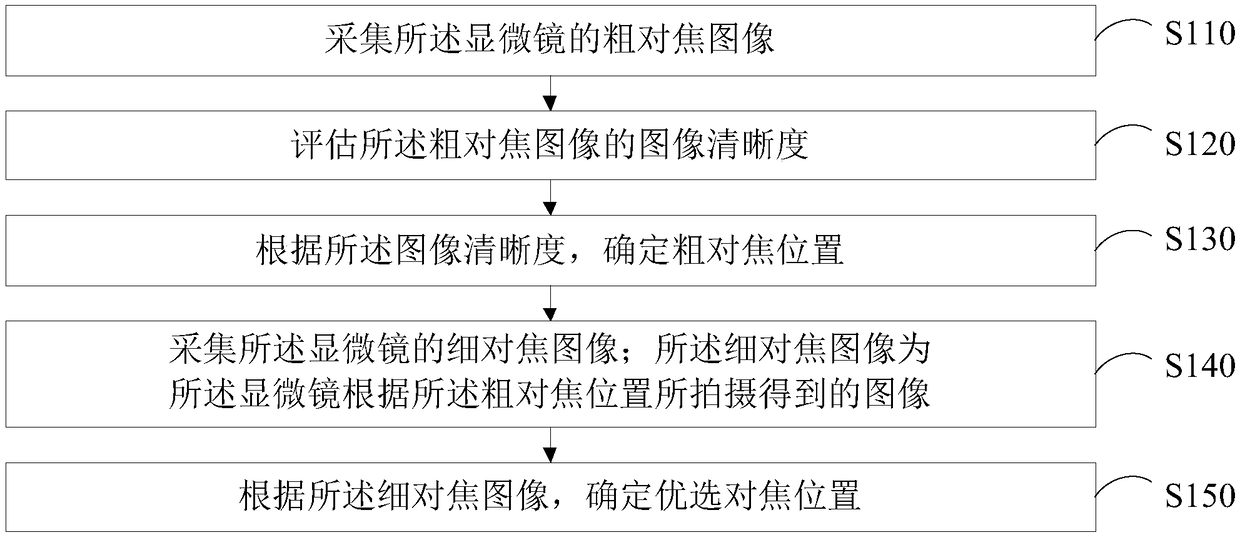

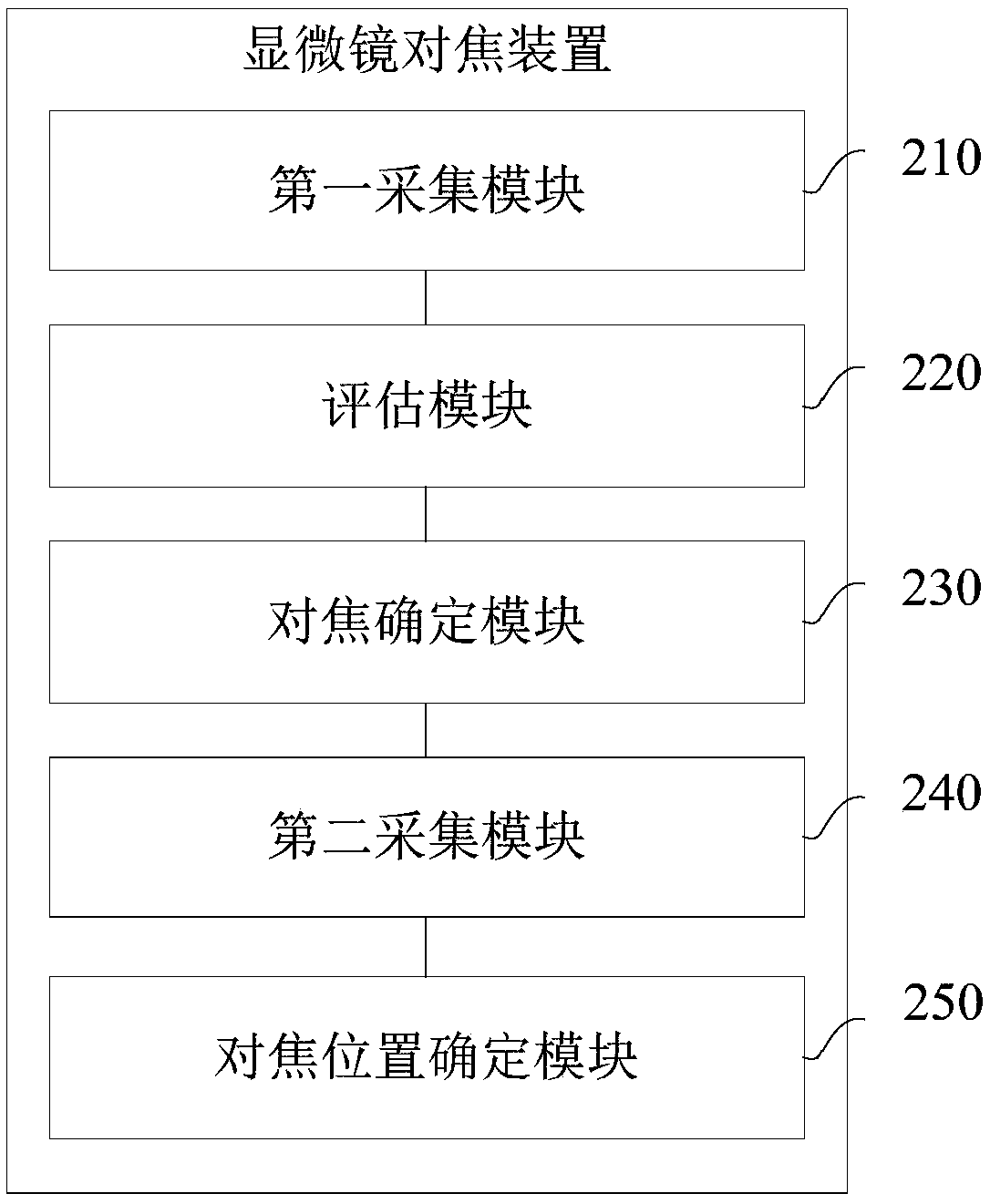

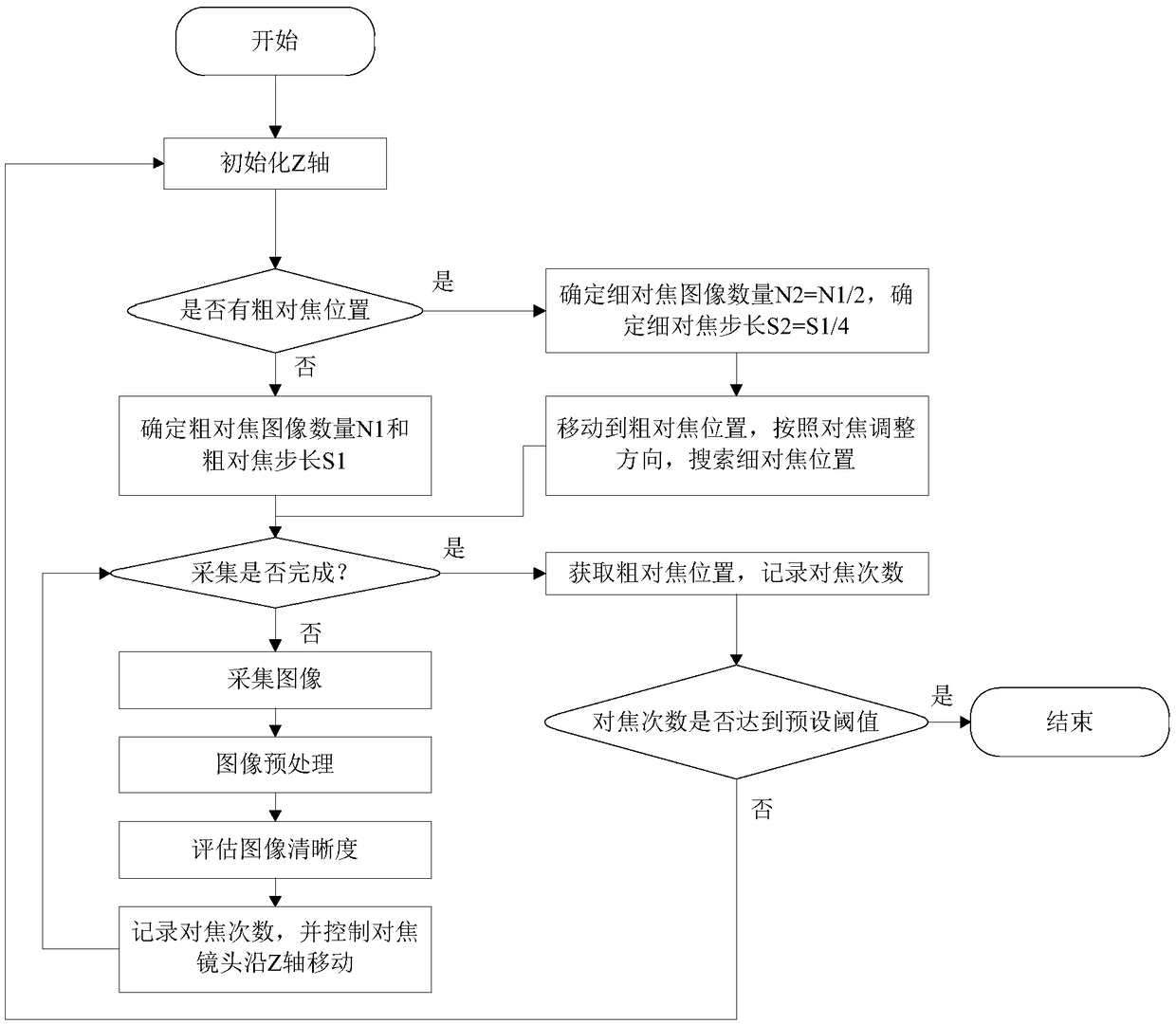

Microscope focusing method and apparatus, computer apparatus, and storage medium

PendingCN109116541AReduce focusing timeImprove focusing efficiencyMicroscopesMountingsComputer scienceMicroscope

The application relates to a microscope focusing method and apparatus, a computer apparatus, and a storage medium. The method includes: collecting a coarse focusing image of a microscope; evaluating the image sharpness of the coarse focusing image; determining a coarse focusing position and a focusing adjustment direction according to the image sharpness; acquiring a fine focusing image, being animage shot by the microscope based on the coarse focusing position, of the microscope; and according to the fine focusing image, determining an optimal focusing position. According to the embodiment of the application, the optimal focusing position can be searched directly in the search range determined according to the coarse focusing position; repeated multi-focusing is avoided; the focusing time is saved; and the focusing efficiency is improved.

Owner:GUANGZHOU HONGQI OPTICAL INSTR TECH

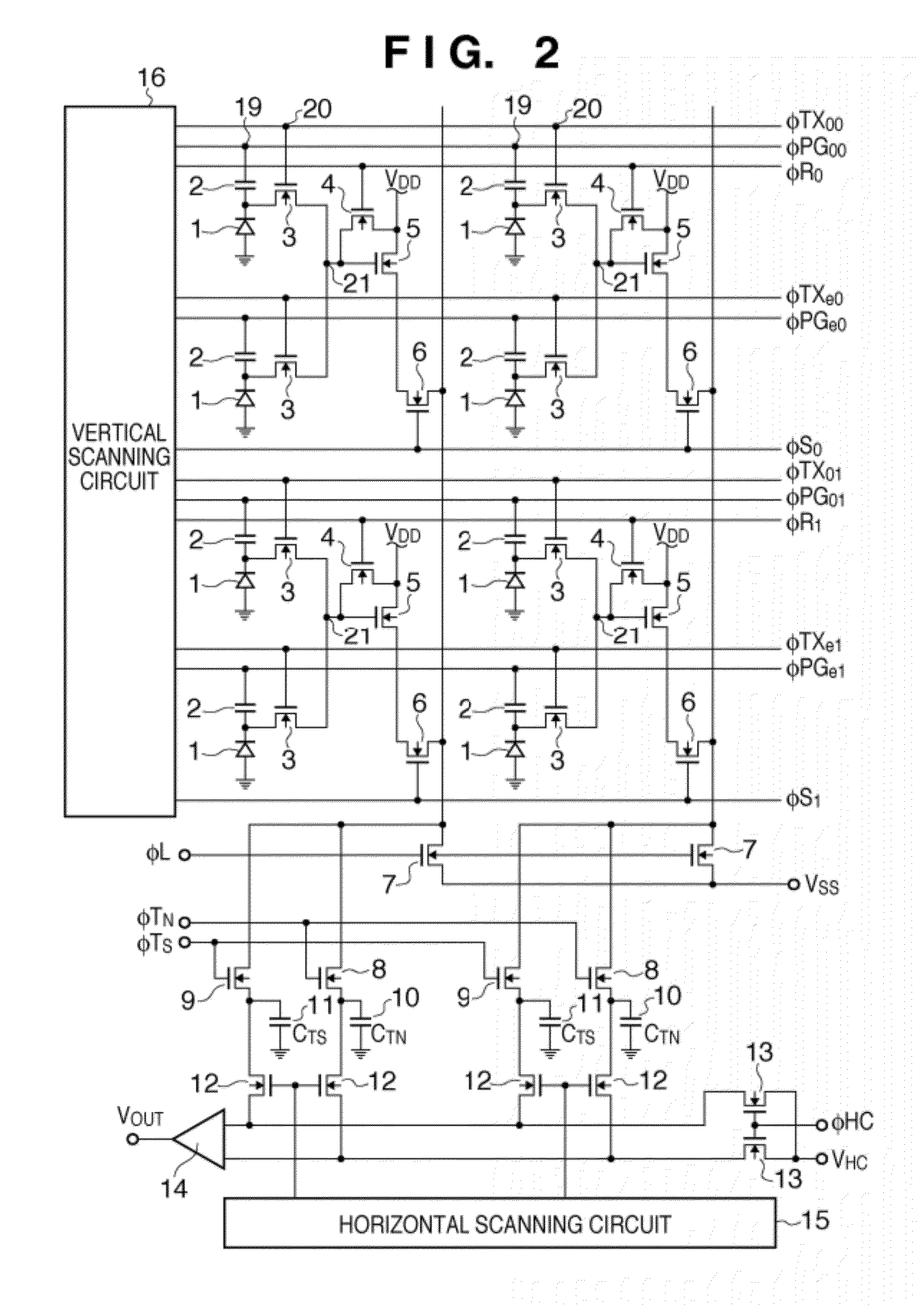

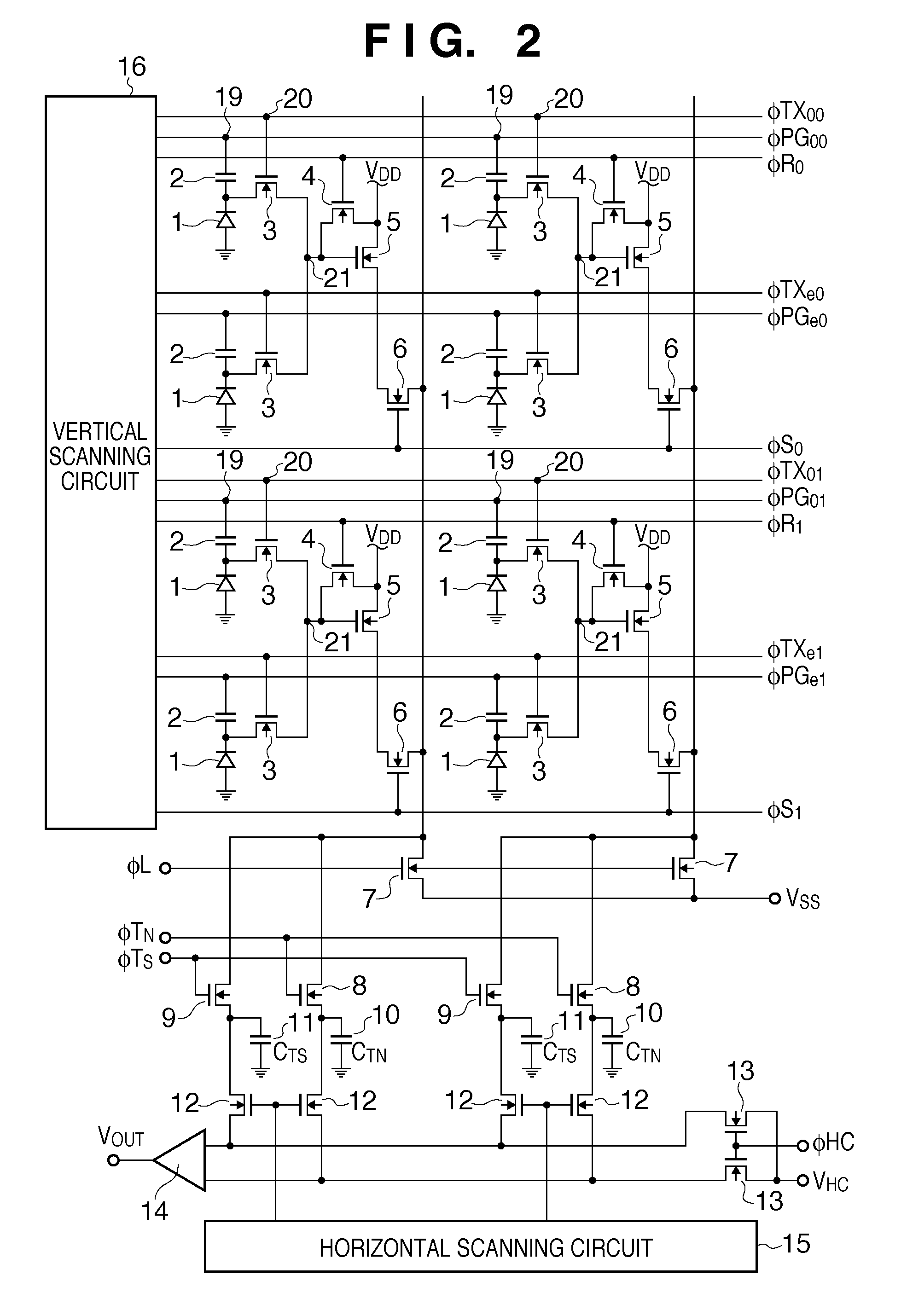

Focus detection apparatus, focus detection method, and image sensing apparatus

InactiveUS8159599B2Simple calculationImprove focus accuracyTelevision system detailsProjector focusing arrangementPhase differenceLuminous flux

A focus detection apparatus includes an image sensor which includes a pair of pixel groups, outputs a first image signal from one of the pair of pixel groups, and outputs a second image signal from the other of the pair of pixel groups, where the pair of pixel groups receive luminous fluxes passing different pupil regions of an imaging optical system which forms an object image; a calculation unit which generates a first corrected image signal by subtracting the second image signal multiplied by a coefficient from the first image signal and generates a second corrected image signal by subtracting the first image signal multiplied by a coefficient from the second image signal; and a focus detection unit which detects a defocus amount based on a phase difference between the first corrected image signal and the second corrected image signal generated by the calculation unit.

Owner:CANON KK

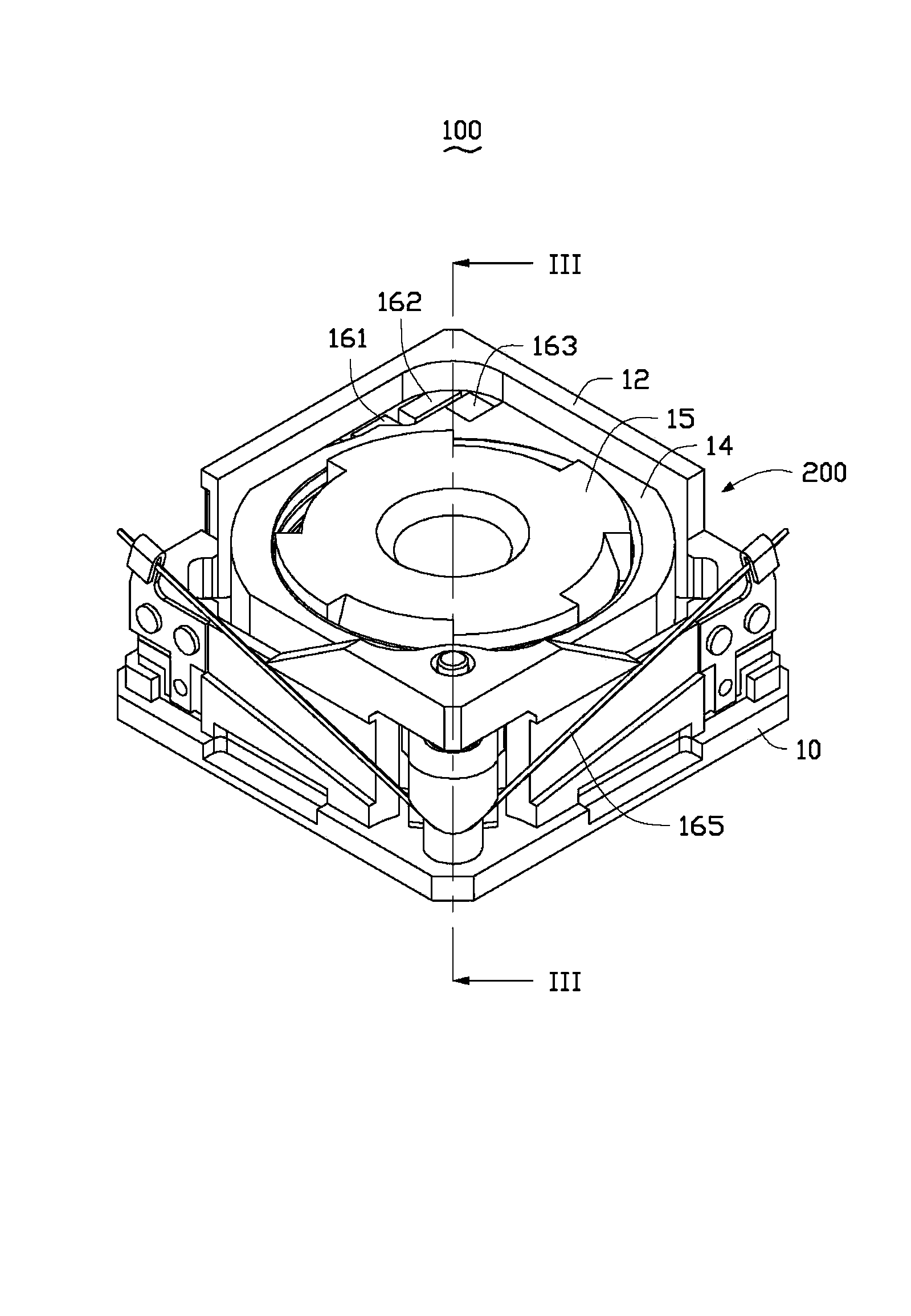

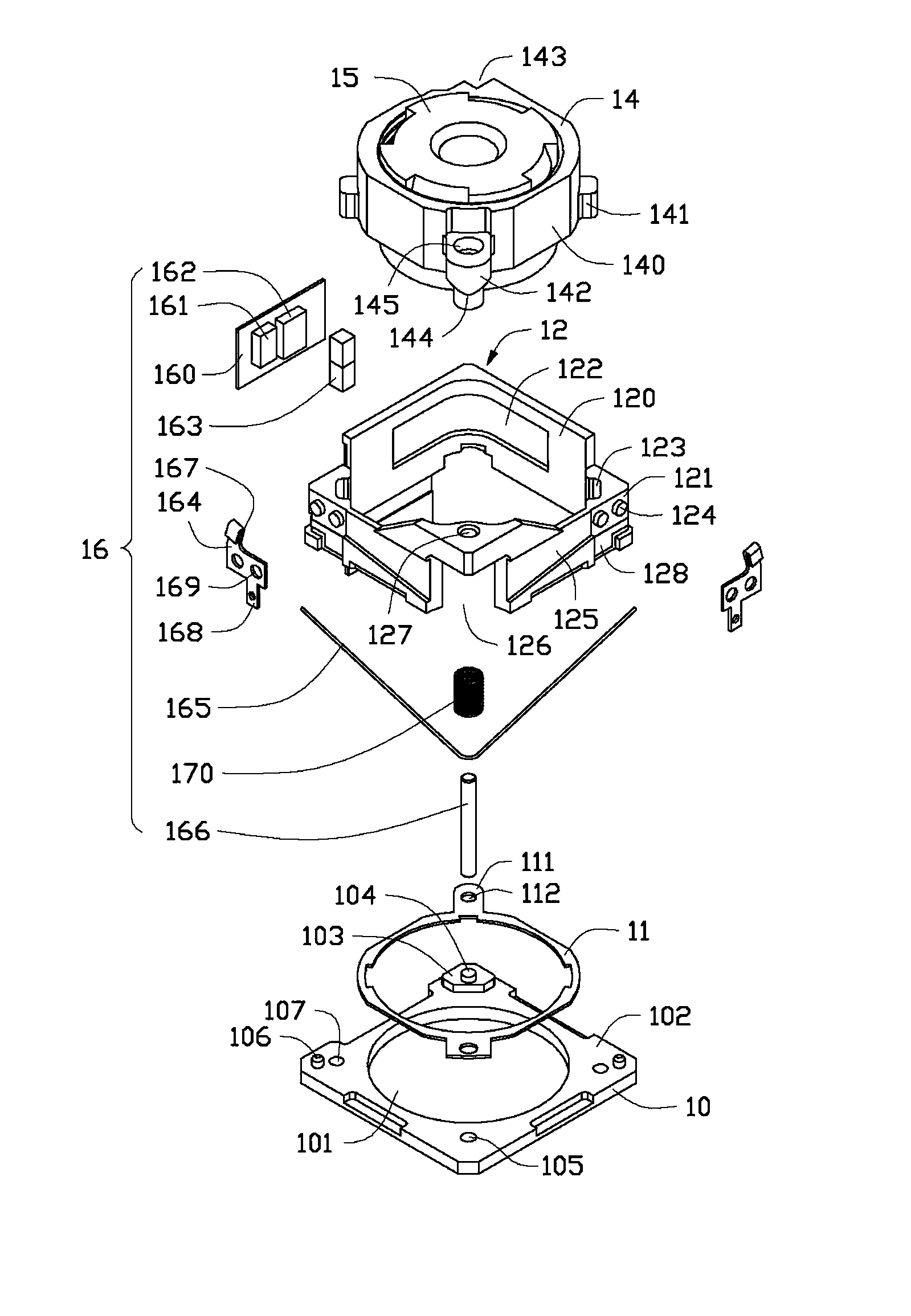

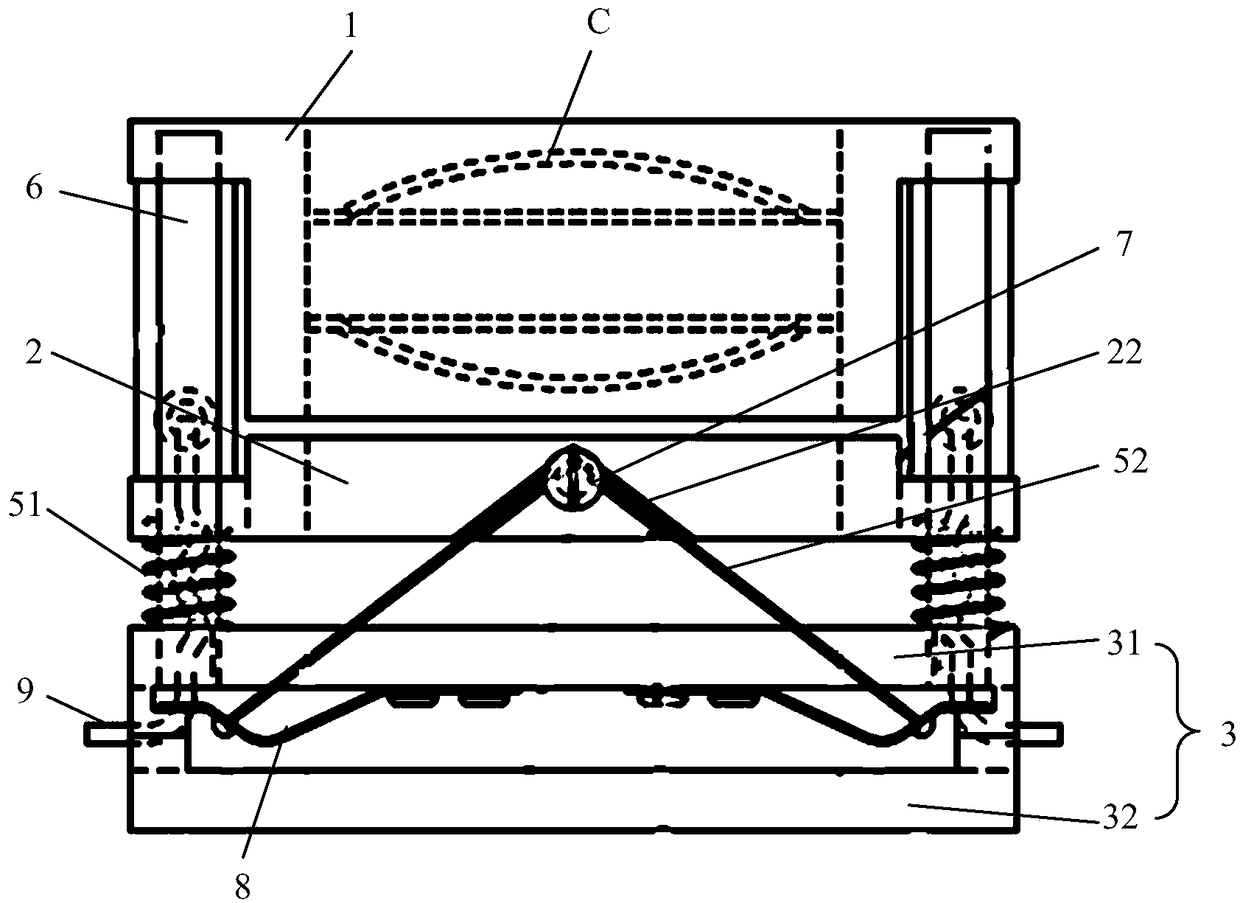

Actuator and camera module provided with actuator

The invention relates to an actuator including a base, a fixing frame, a movable frame and a drive unit. The fixing frame is fixedly arranged on the base. The movable frame is accommodated in the fixing frame and loaded on the base. The movable frame includes an abutting face which faces the base. The drive unit includes an SMA wire, a controller, a position sensor and a guide rod. The SMA wire includes a bending part arranged between two ends, wherein the bending part contacts the abutting face. The guide rod passes through the movable frame and is fixed on the base. The controller is used for applying current to heat the SMA wire and change the length of the SMA wire so as to drive the movable frame to move along the guide rod. The position sensor is used for sensing the position of the movable frame and transmitting the sensing result to the controller. The controller is also used for adjusting the size of the current according to the sensing result.

Owner:郑州联创电子有限公司

Focus detection apparatus, focus detection method, and image sensing apparatus

InactiveUS20110164165A1Improve focus accuracyTelevision system detailsColor television detailsLuminous fluxPupil

A focus detection apparatus includes an image sensor that has a first pixel group which receives a luminous flux passing a first pupil area of an imaging optical system, and a second pixel group which receives a luminous flux passing a second pupil area different from the first pupil area; a storage unit that stores first and second distribution functions corresponding to the first and second pupil areas, respectively; a calculation unit that generates a first image signal by performing calculations on a first subject image, obtained from the first pixel group, using the second distribution function, and generates a second image signal by performing calculations on a second subject image, obtained from the second pixel group, using the first distribution function; and a focus state detection unit that detects a focus state of the imaging optical system based on the first and the second image signals.

Owner:CANON KK

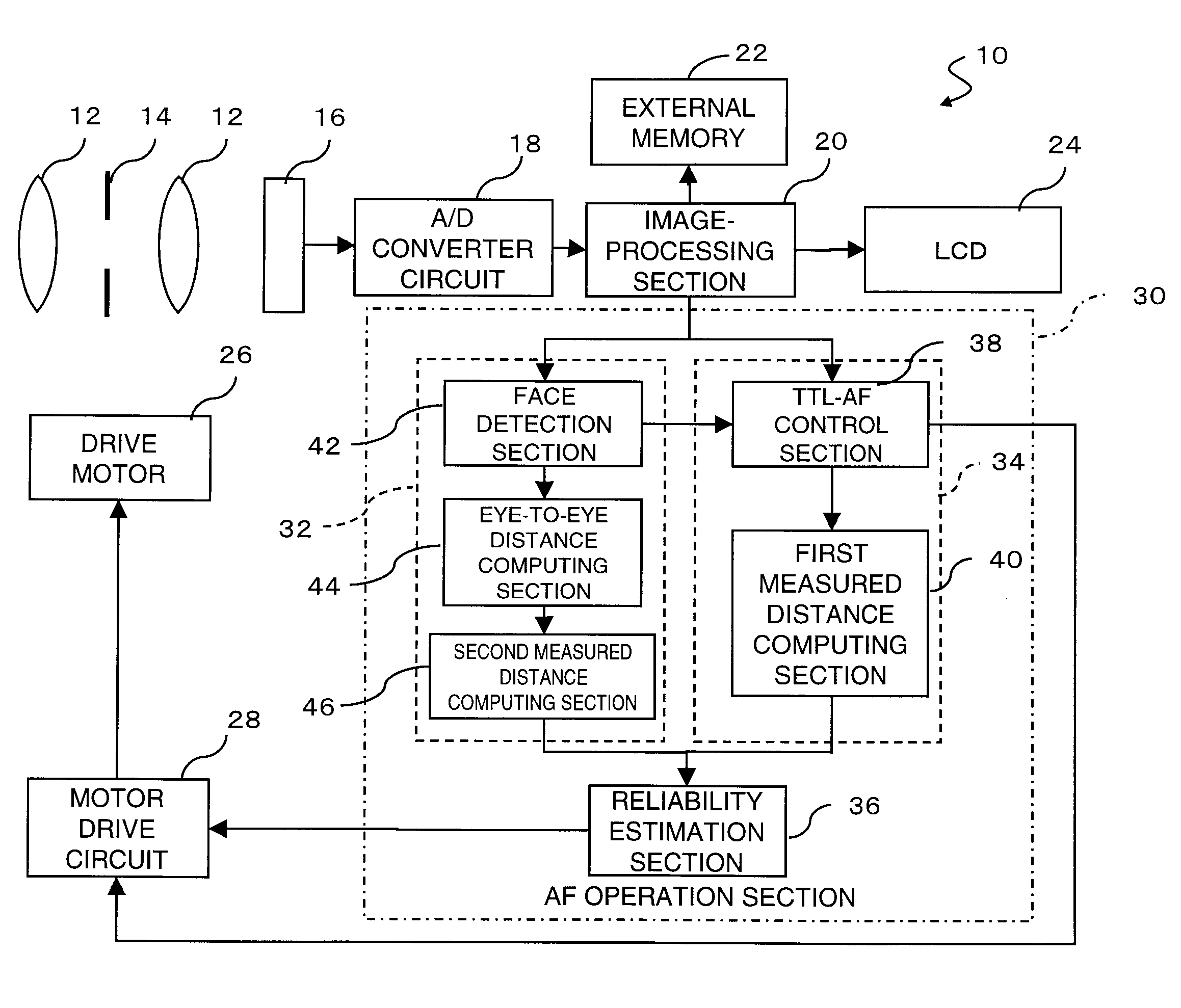

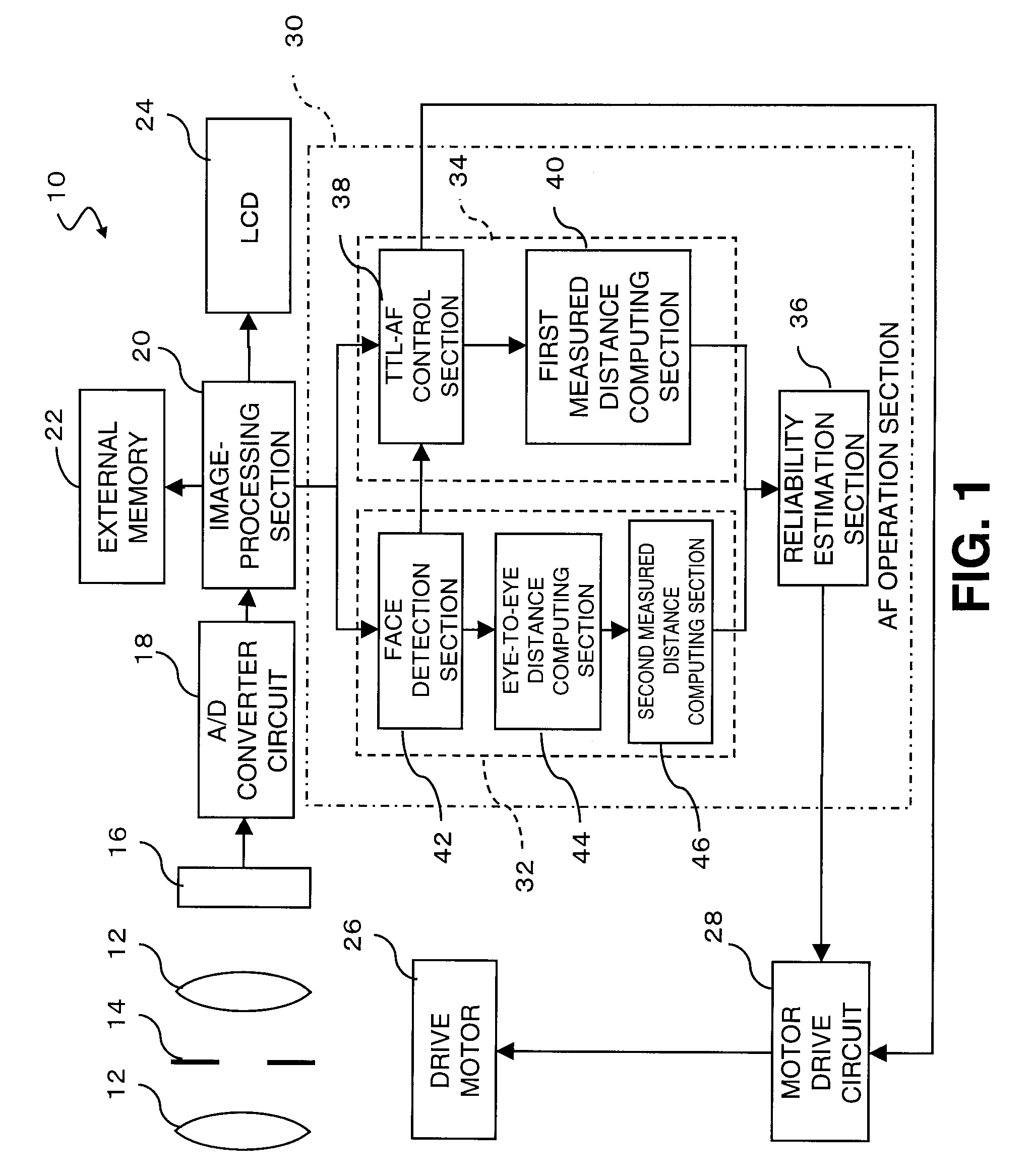

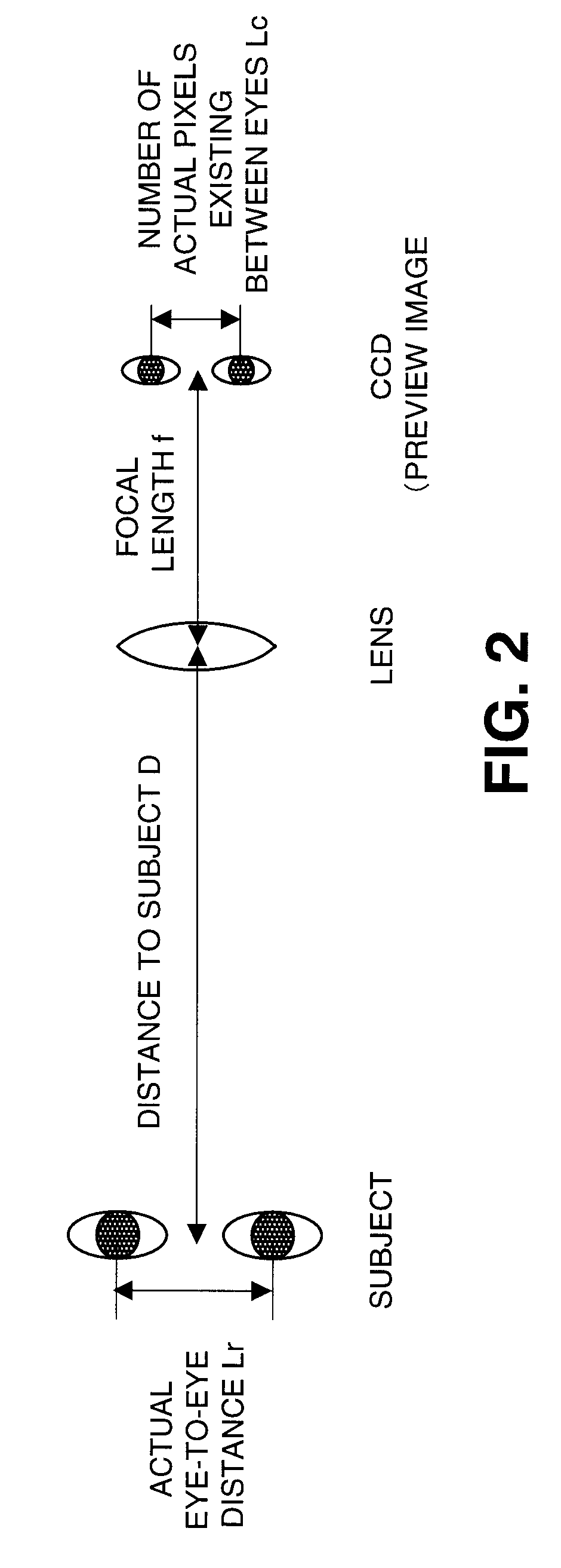

Imaging apparatus

InactiveUS20080050108A1Improve accuracyImprove focus accuracyTelevision system detailsProjector focusing arrangementEngineeringImaging equipment

The accuracy of focus adjustment operation is enhanced further. When focus adjustment operation is performed, a first measured distance acquired by utilization of TTL-AF and a second measured value acquired by utilization of a distance between the eyes have been computed in advance. The degree of reliability of the first measured distance is compared the degree of reliability of the second measured distance in accordance with a result of a determination as to whether or not a face is detected (S10), a result of a determination as to whether or not an ambient brightness value Br is equal to or less than a reference value (S12), a result of a determination as to whether or not a focal length “f” is equal to or less than a reference value (S16), and a result of a determination as to whether or not a second measured distance De is less than a first measured distance Dt (S18). Focus adjustment operation is performed in accordance with a measured distance determined to be more reliable.

Owner:MONUMENT PEAK VENTURES LLC

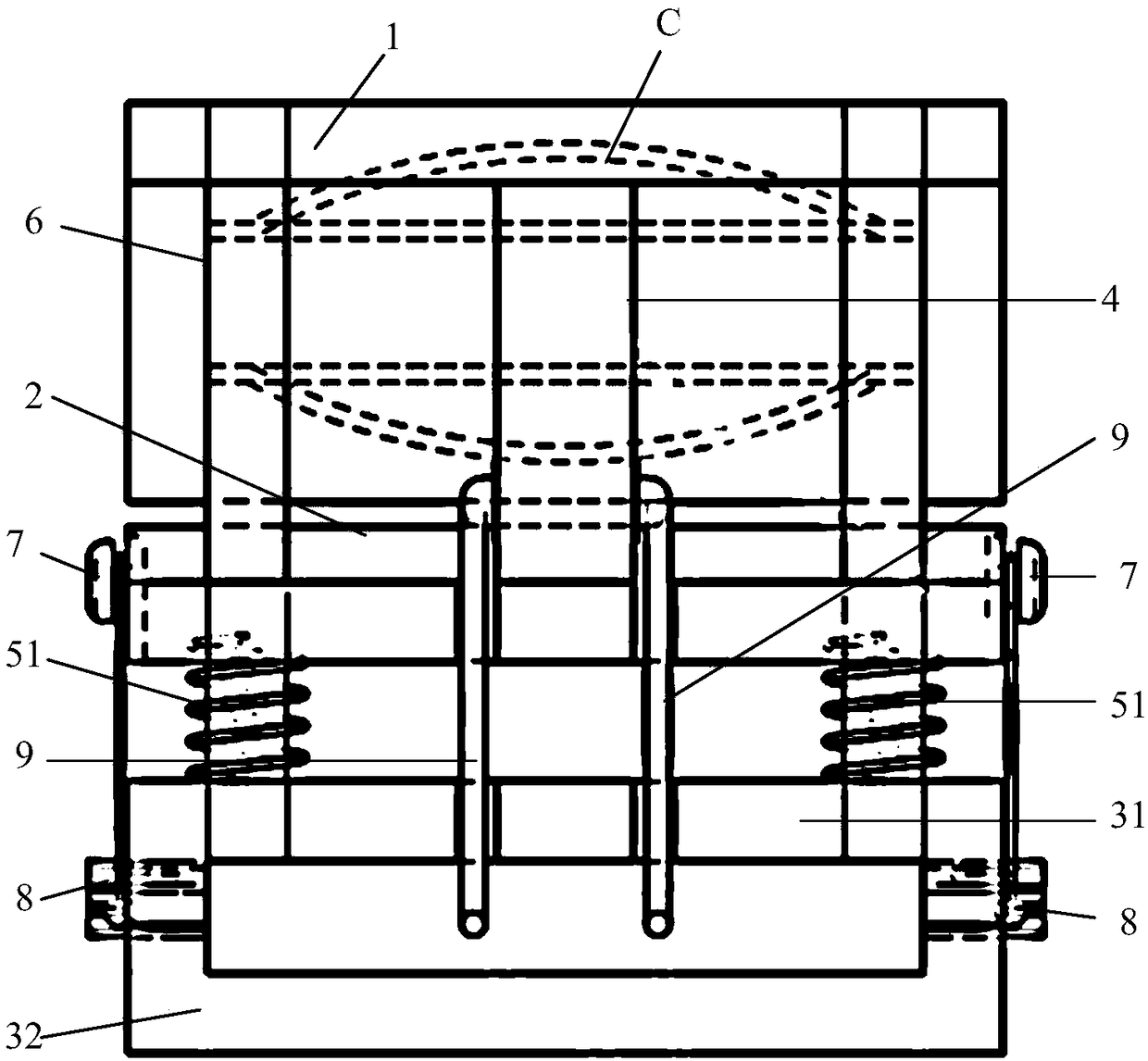

Lens driving device and camera shooting module

PendingCN109061829AHigh adjustment accuracyImprove focus accuracyTelevision system detailsProjector focusing arrangementCamera lensOptical axis

The invention discloses a lens driving device and a camera shooting module. A first driving module is connected with a first bracket and a second bracket, and a gap is formed between the first bracketand the second bracket; a driving line is connected with a third bracket and the second bracket; and an elastic part is arranged between the third bracket and the second bracket. By applying a driving signal to the first driving module and / or the driving line, the first driving module is controlled and / or the driving line is controlled to stretch for driving the first bracket and the second bracket to relatively move along an optical axis and / or controlling a distance between the third bracket and the second bracket. Therefore, accurate and coarse adjustment of displacement between the brackets can be achieved; the adjustment precision of the displacement between the brackets is improved; and the focusing precision of an optical lens group is improved.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

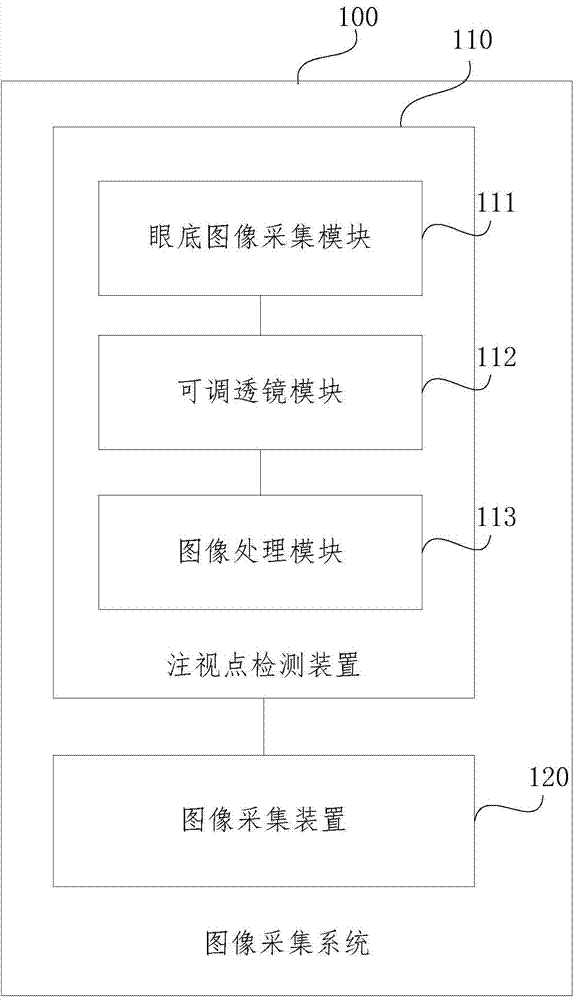

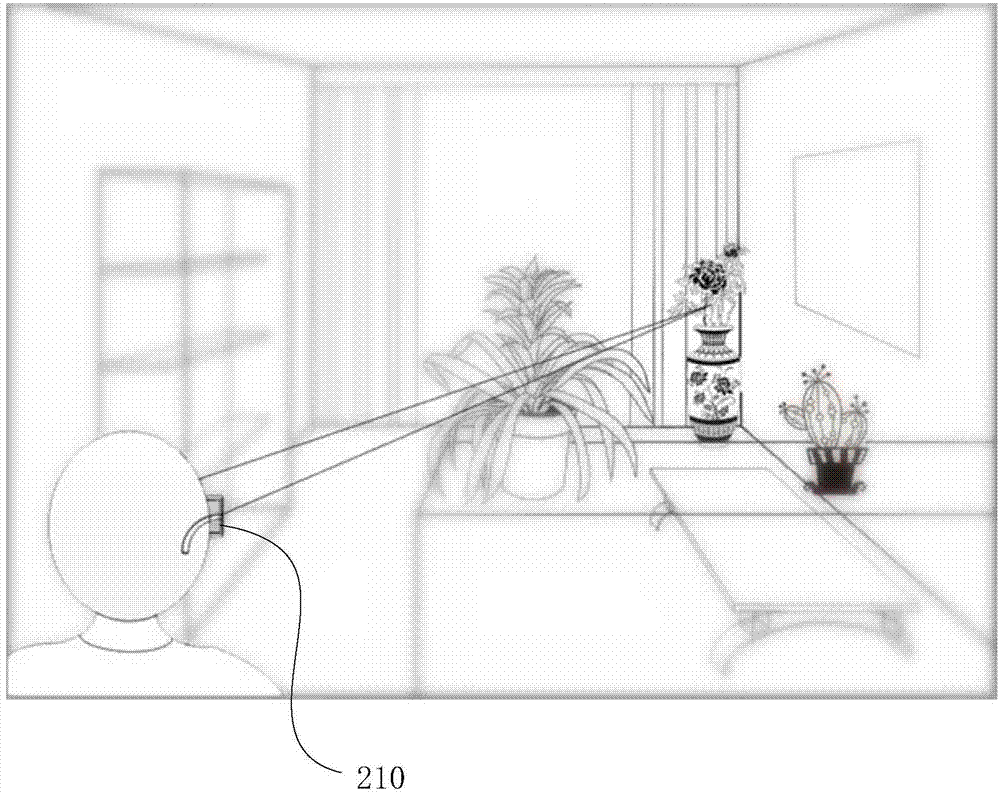

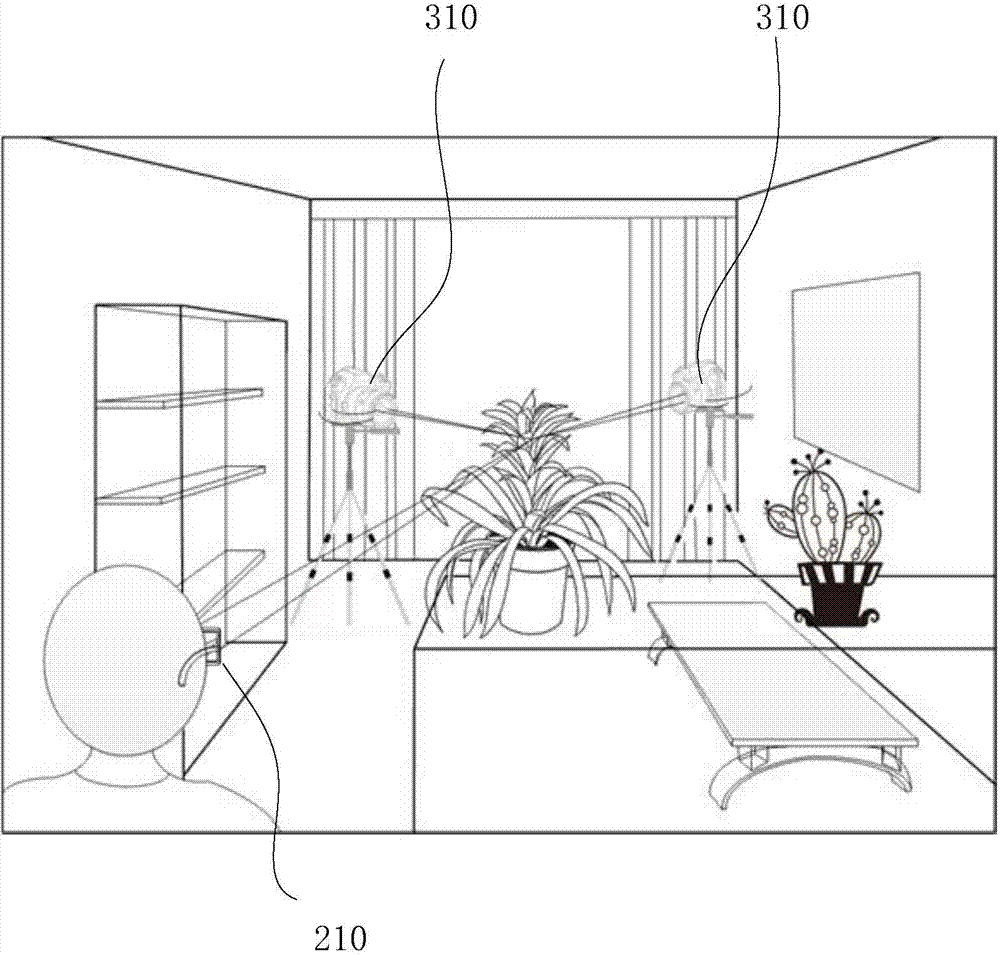

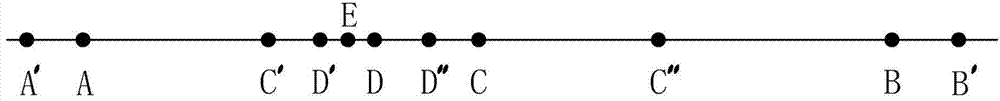

Image collecting system and image collecting method

ActiveCN103501406AHigh focus accuracyAccelerateImage enhancementTelevision system detailsOptical pathOptical axis

The invention discloses an image collecting system and an image collecting method. The system comprises a fixation point detection device and an image collecting device, wherein the fixation point detection device is used for detecting the position, relative to a user, of a user current fixation point, and the image collecting device is used for conducting focusing and image collecting according to the position, relative to the user, of the fixation point. The fixation point detection device comprises an eye fundus image collecting module, an adjustable lens module and an image processing module, the eye fundus image collecting module is used for collecting an image of the eye fundus of the user, the adjustable lens module is used for adjusting imaging parameters of a light path between the eye fundus image collecting module and the eyes so as to enable the eye fundus image collecting module to obtain the clearest image, and the image processing module is used for calculating the position, relative to the user, of the user current fixation point according to the imaging parameters of the light path between the eye fundus image collecting module and the eyes and the optical axis direction of the eyes when the clearest image is obtained. According to the mage collecting system and the image collecting method, the focusing accuracy and the focusing speed of the image collecting device can be improved.

Owner:BEIJING ZHIGU RUI TUO TECH

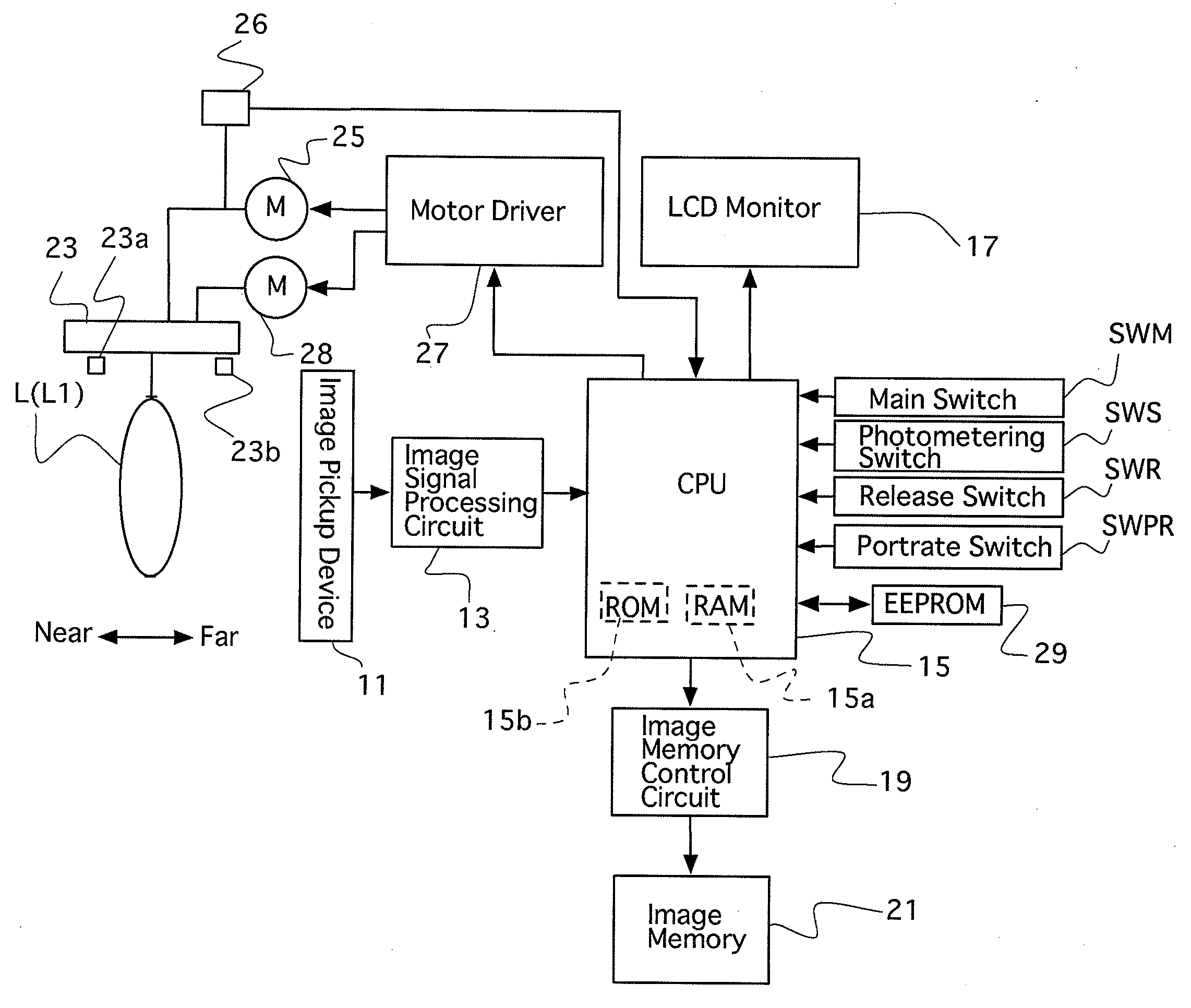

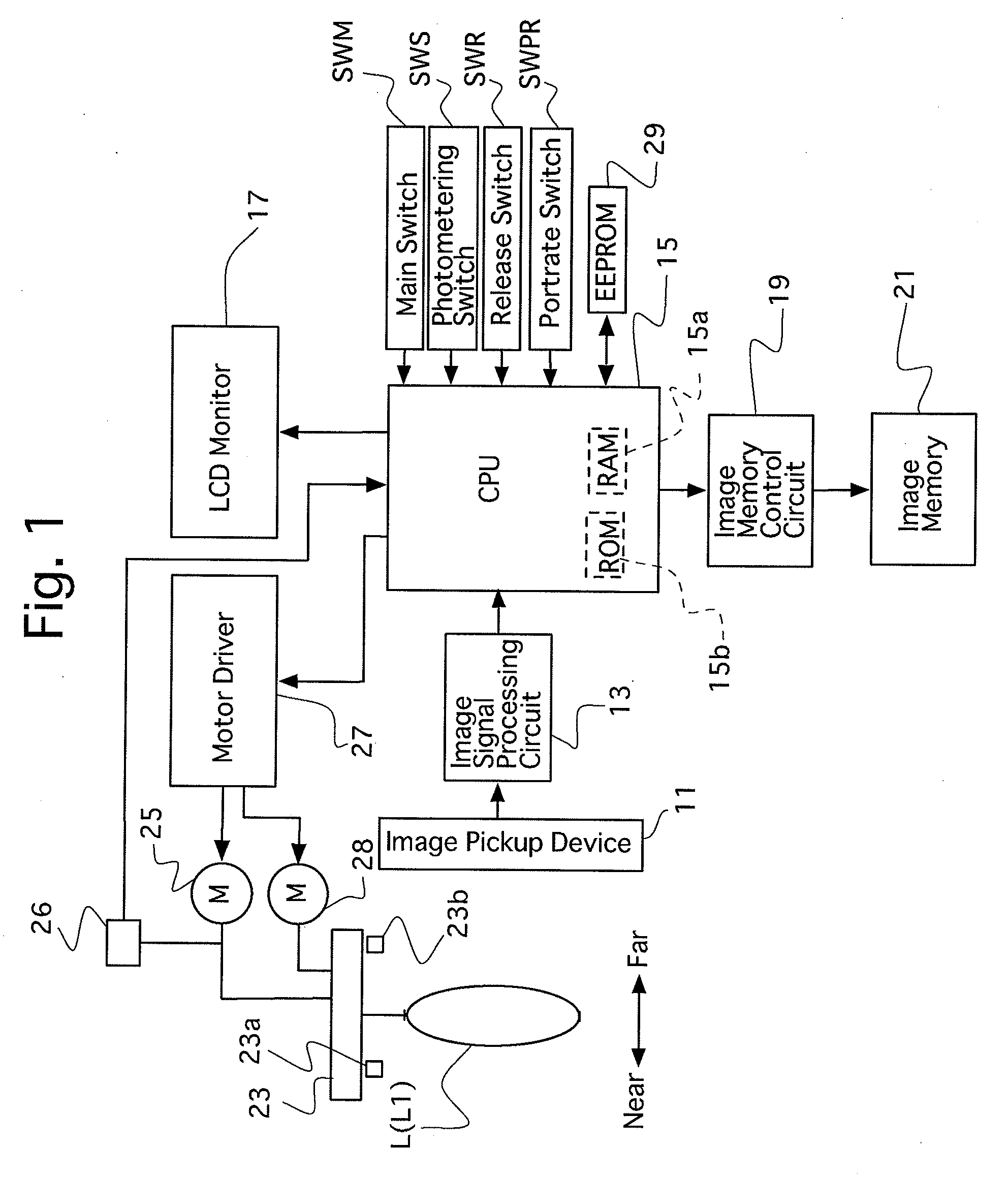

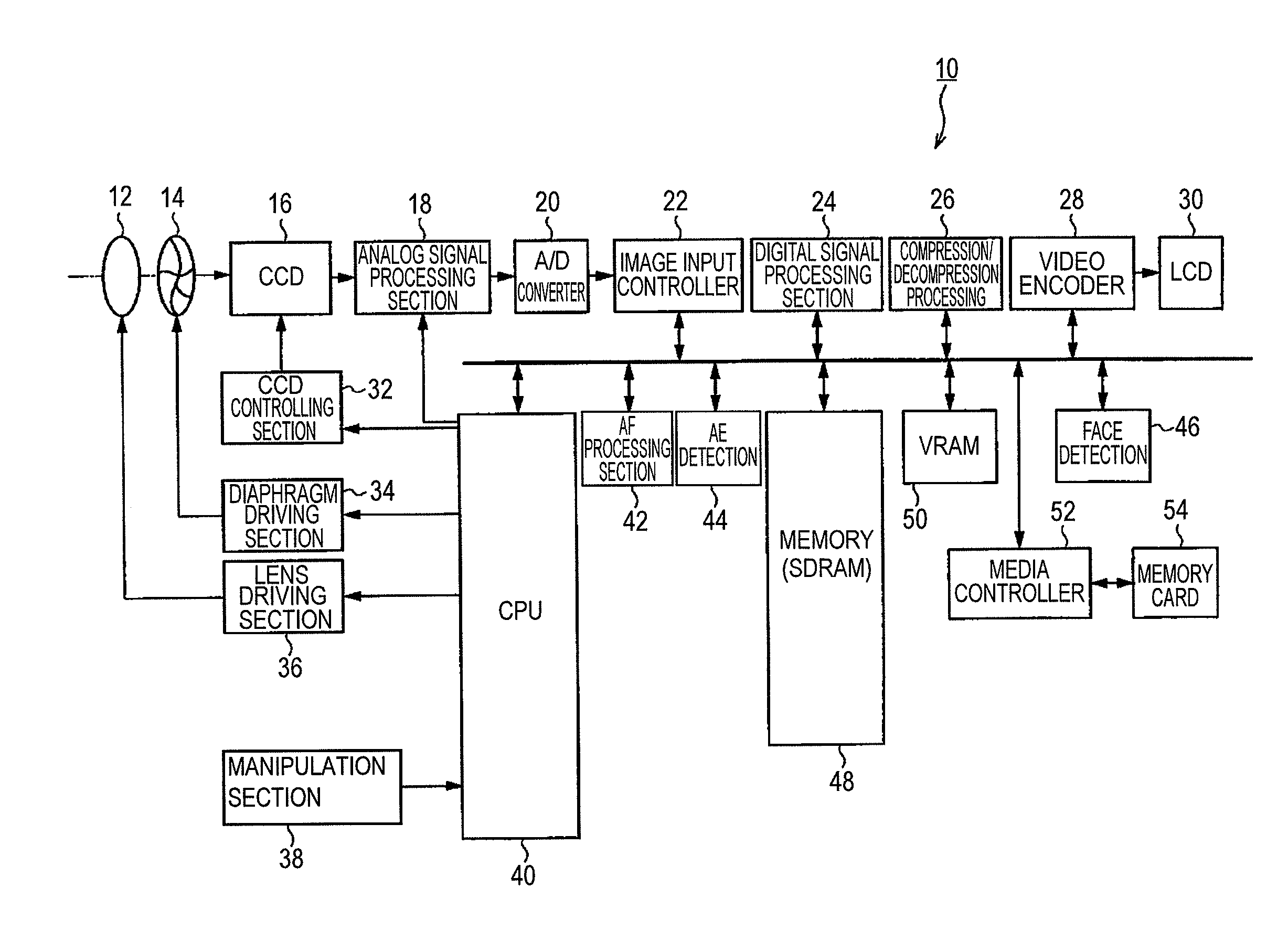

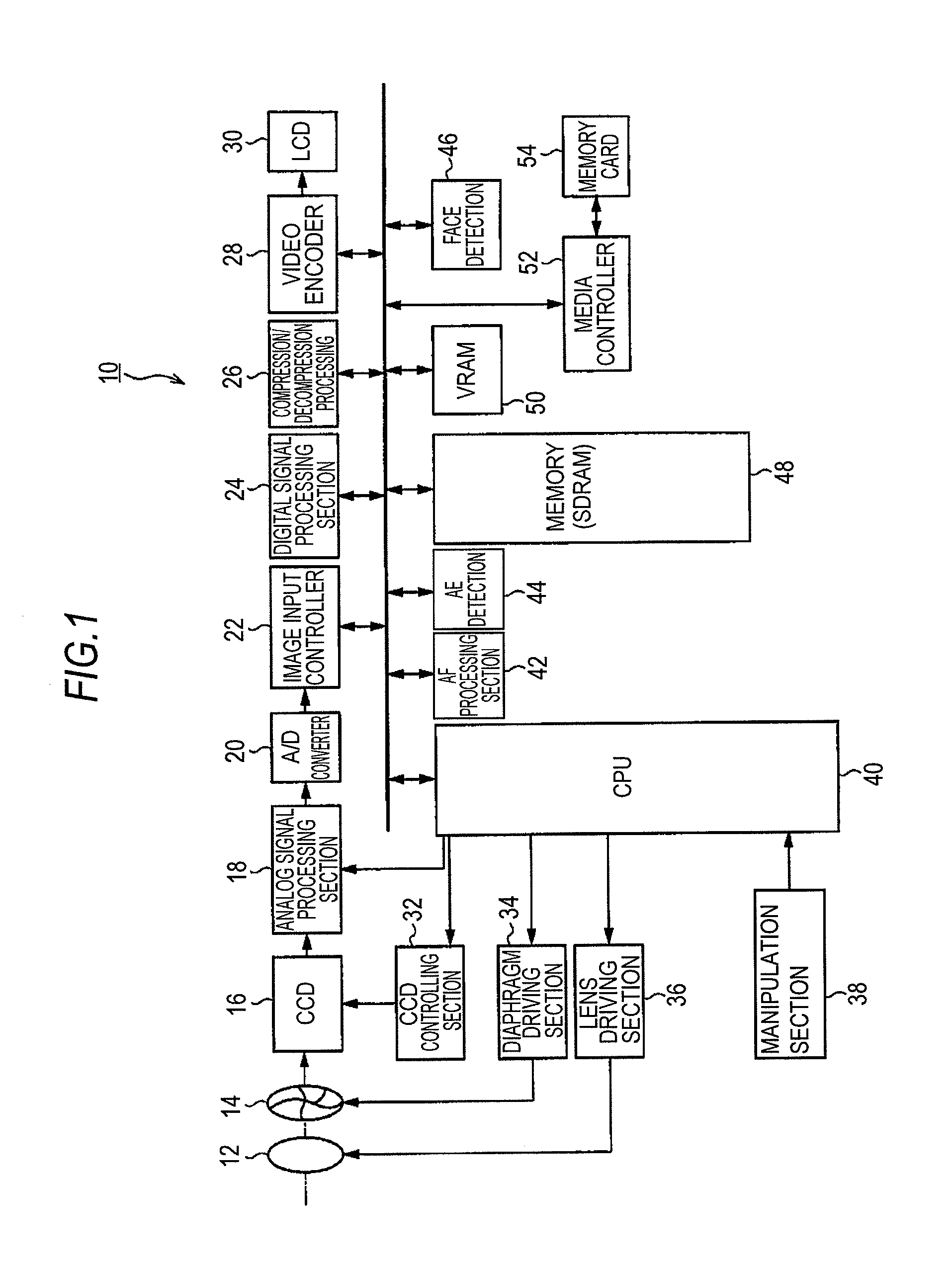

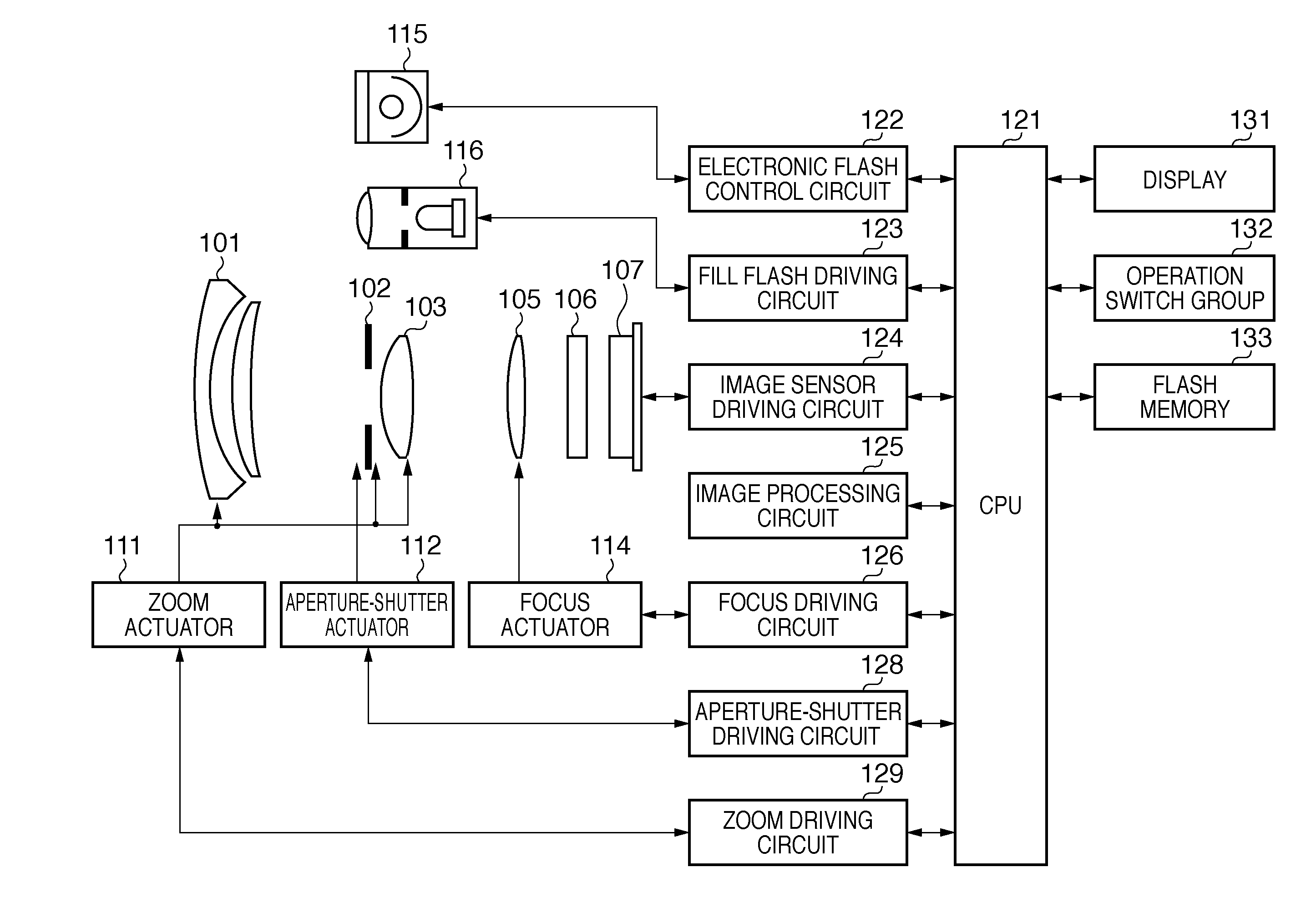

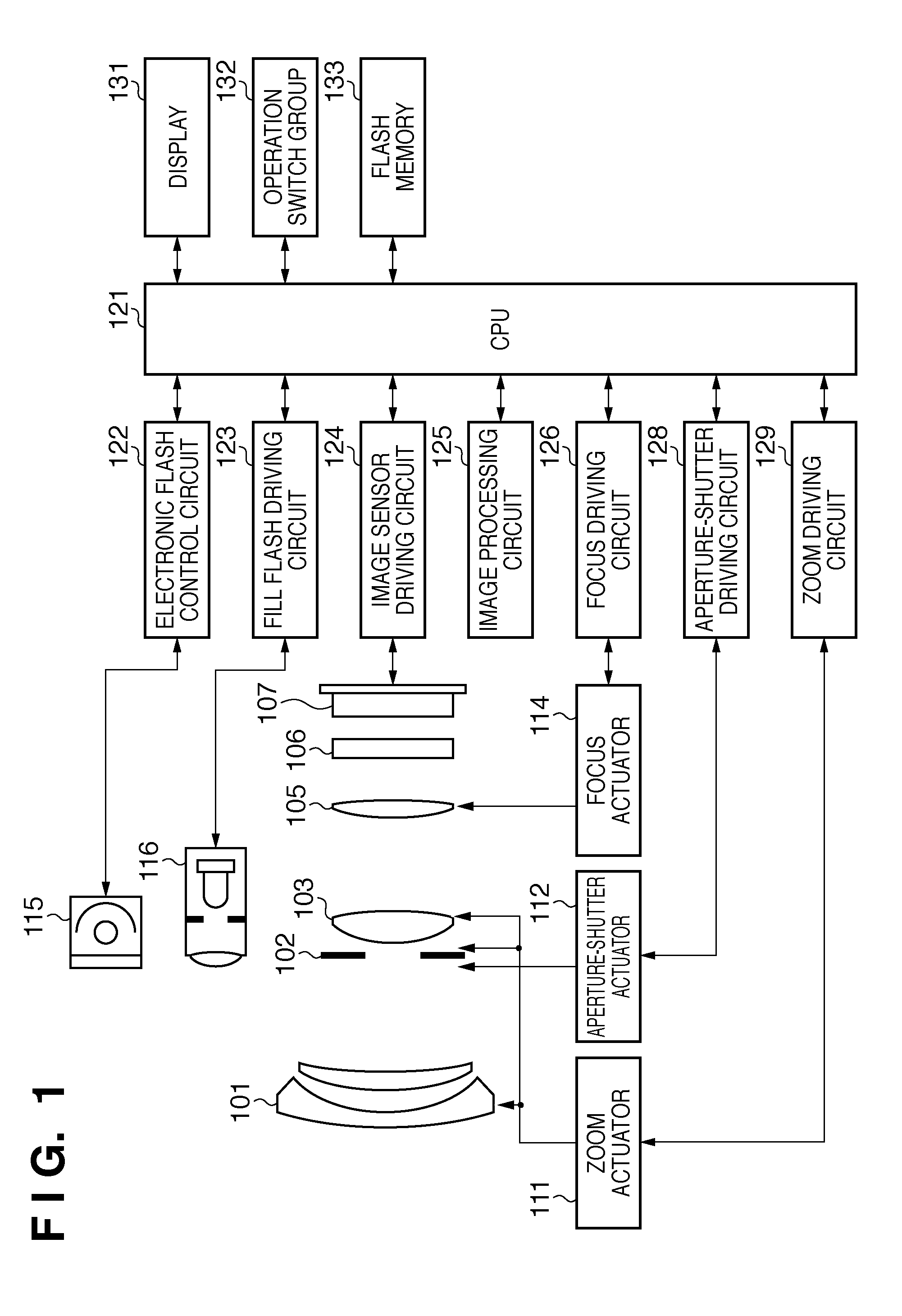

Imaging apparatus and imaging control method

ActiveUS20100315514A1Improve focus accuracyTelevision system detailsColor television detailsRegion selectionOptical axis

An imaging apparatus includes: an imaging optical system including a focus lens; an imaging element generates an image indicating an object image; a lens drive device which moves the focus lens along an optical axis direction of the imaging optical system; an evaluation value calculation device which calculates an evaluation value of a contrast for each of a plurality of evaluation value calculation areas while moving the focus lens; a point light source presence / absence determination device which determines a presence or absence of a point light source in a specific region of the image; an area selection device which selects a focusing determination area based on the presence or absence of the point light source; and a focusing control device which determines the focusing position of the focus lens based on the evaluation value in the focusing determination area and moves the focus lens to the focusing position.

Owner:FUJIFILM CORP

Image pickup apparatus and image pickup device

ActiveCN102883093AImprove focus accuracySufficient focus accuracyTelevision system detailsColor television detailsComputer vision

An image pickup apparatus includes: an image pickup device that includes a pixel used for focus detection, a plurality of the pixels being arranged in a matrix; a correction memory that stores correction information used for correcting a difference in amounts of received light that depend on pixel positions of the pixels used for focus detection; a correcting section that reads the correction information to correct a pixel value of the pixel used for focus detection; and a focus detecting section that detects a focal point by using the pixel value corrected by the correcting section. Focus accuracy is increased by correcting the pixel value for an AF pixel depending on the pixel position.

Owner:OLYMPUS CORP

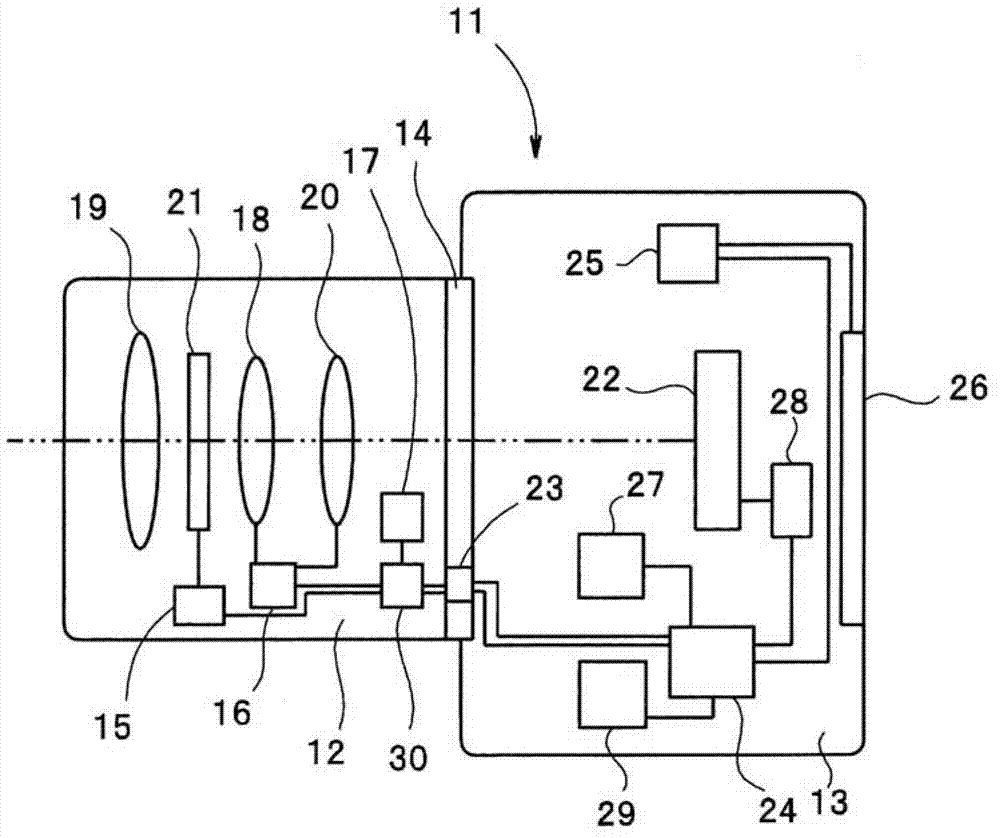

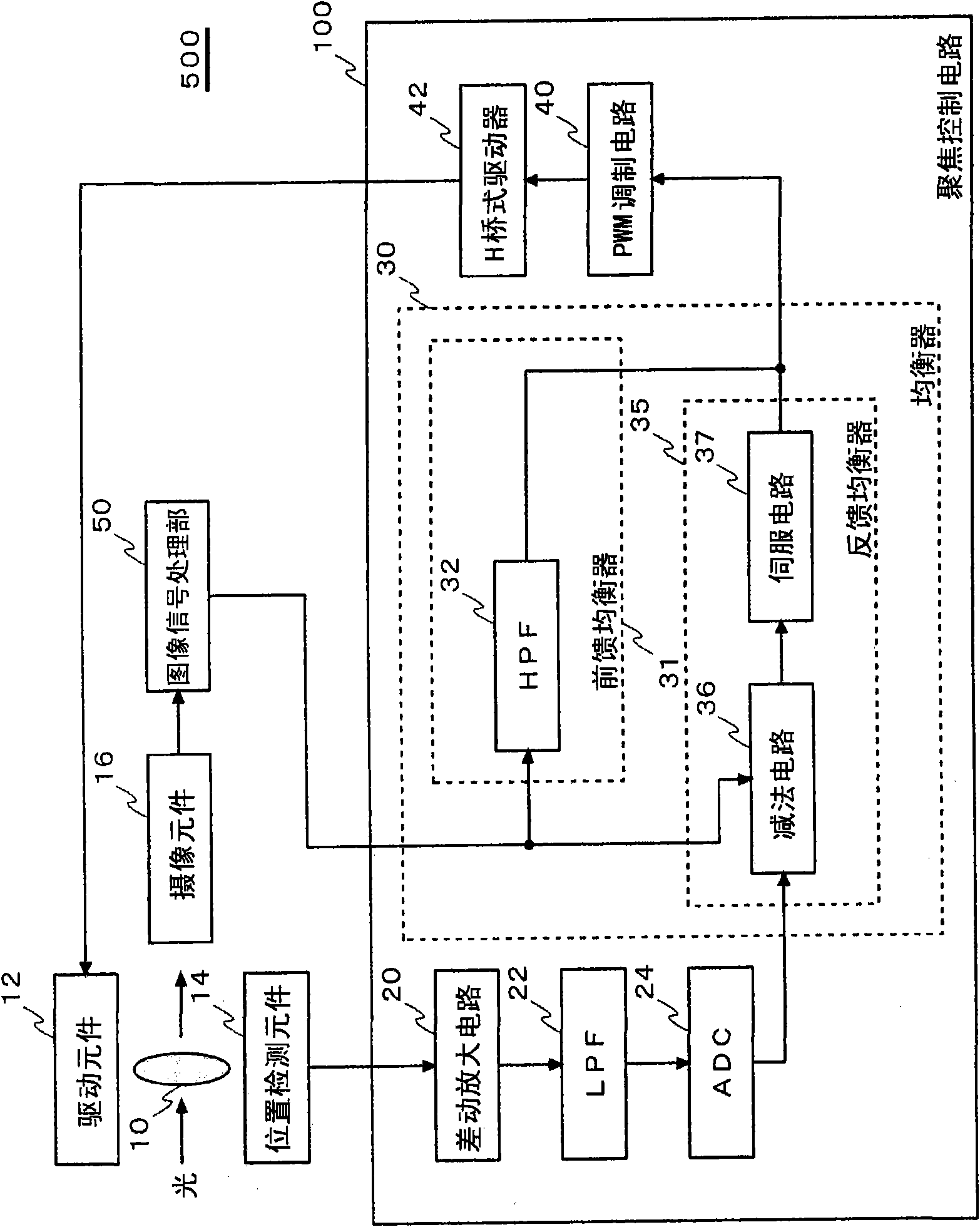

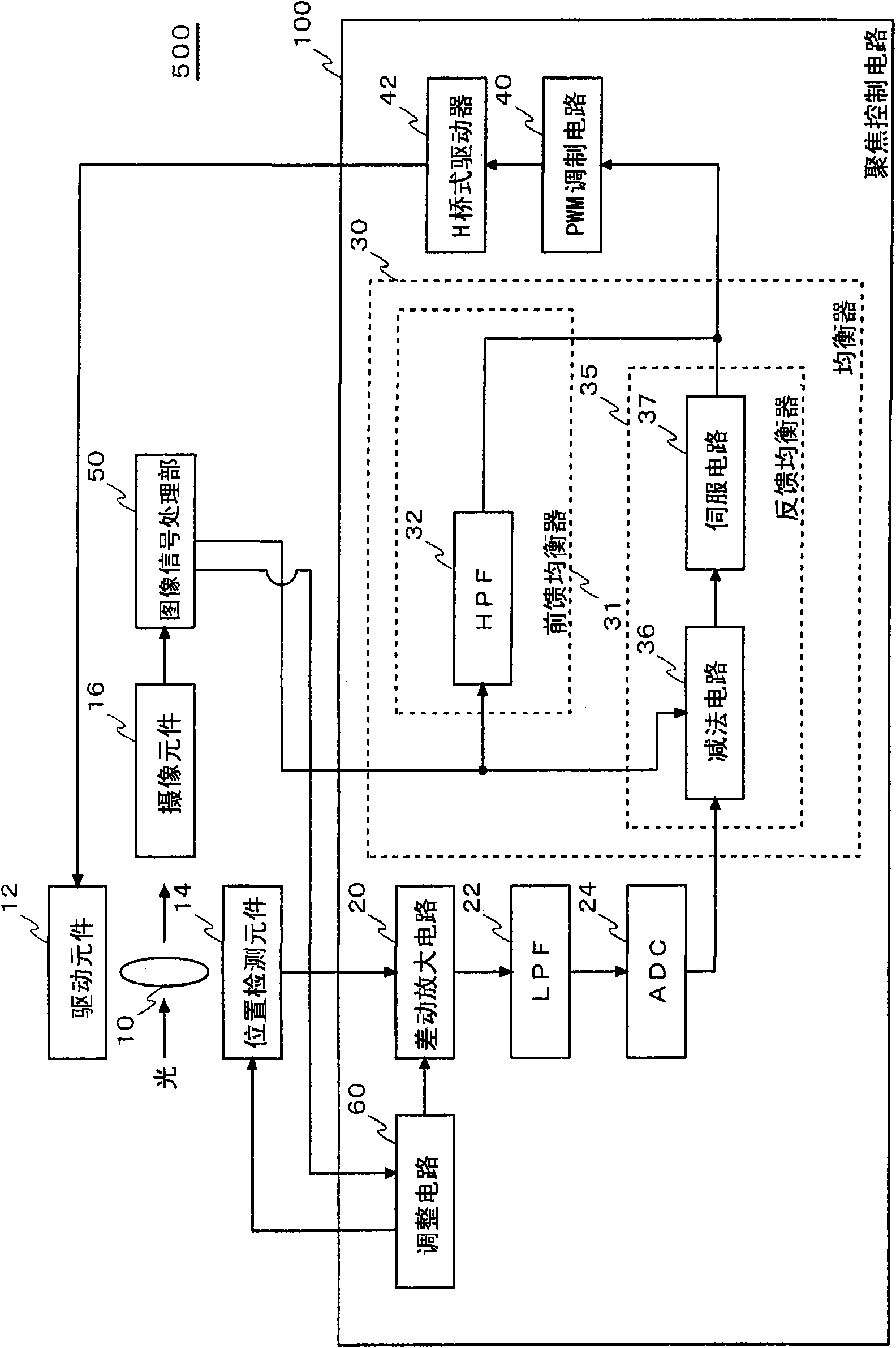

Focus control circuit

ActiveCN101930150AImprove focus accuracyTelevision system detailsProjector focusing arrangementLocation detectionControl circuit

The invention provides a focus control circuit (100) installed in an image pickup apparatus (500) including a lens (10), a driver element (12) for adjusting the position of the lens (10), and a position detecting element (14) for detecting the position of the lens (10). A feedback equalizer (35) included in the focus control circuit (100) generates a drive signal used to adjust the position of the lens (10) to a target position, based on a difference between the position of the lens (10) identified by the output signal of the position detecting element (14) and the target position of the lens (10) set externally, and controls the driver element (12).

Owner:SANYO ELECTRIC CO LTD +1

Focus adjusting method and focus adjusting device

InactiveUS7831138B2Improve focus accuracySpeed up the focusing operationTelevision system detailsProjector focusing arrangementFocal positionComputer vision

A focus adjusting method for adjusting focus by moving a focusing lens group of a photographing optical system, wherein the focus adjusting method includes a first search stage at which a focus search operation is performed based on an image formed in a large focus area while the focusing lens group is moved stepwise over an entire range of movement thereof from the near extremity to the far extremity, and a second search stage at which the focus search operation is performed, based on images formed in small focus areas, at front and rear close vicinities of the in-focus position while the focusing lens group is moved stepwise over a portion of the entire range of movement thereof.

Owner:RICOH IMAGING COMPANY

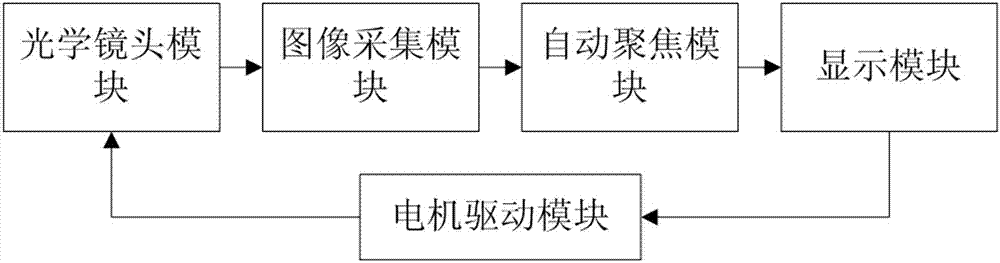

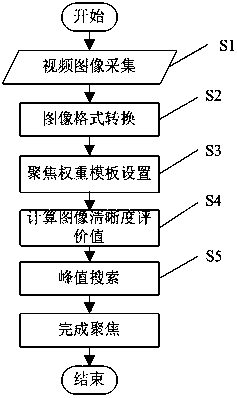

Auto-focus device and method for visible light lens

ActiveCN103945133AFast focusingShorten speedTelevision system detailsColor television detailsCamera lensMotor drive

The invention relates to an auto-focus device for a visible light lens. The auto-focus device comprises an FPGA (field programmable gate array) controller, a video input circuit, a power management module, a motor driving circuit and a serial port communication circuit, wherein the FPGA controller drives a focus motor to move to the best focus position through the motor driving circuit. A focus method includes the steps: a) determining the farthest clear position and setting the position of the motor as A; b) determining the nearest clear position and setting the position of the motor as B; c) determining the whole focus course between the two points A and B; d) judging whether trigger signals are generated or not; e) moving to the nearest local end point; f) seeking a primary focus clear point; g) seeking a secondary focus clear point; h) seeking a tertiary focus clear point. According to the auto-focus device and the method, the focus mode of the maximum stroke of a focus motor in the past is avoided, focus speed is high, the focus motor successively approximates the focus position by gradually decreasing the speed and the step length of the focus motor, so that the final focus position is more accurate, and images are clearer.

Owner:山东神戎电子股份有限公司

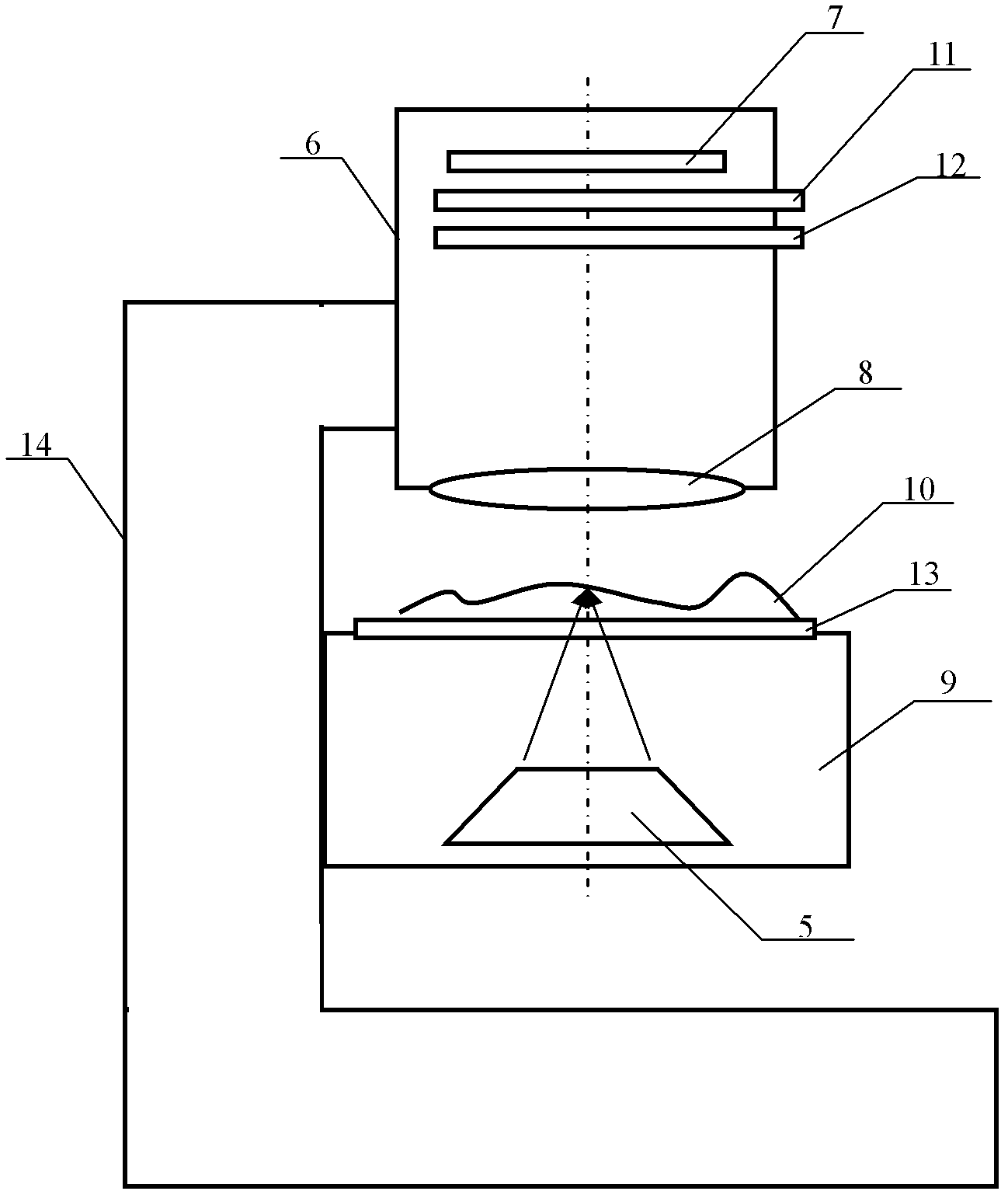

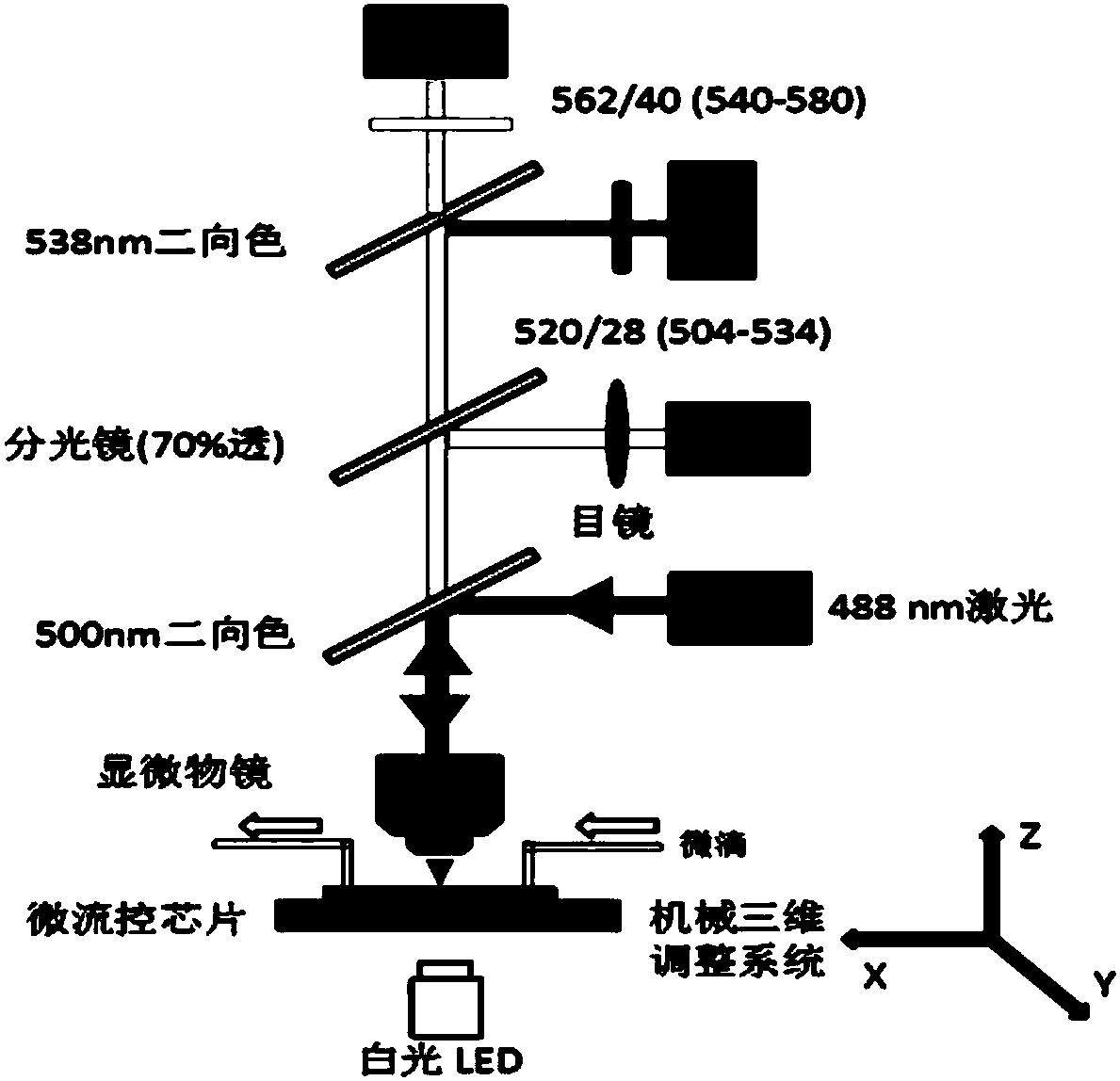

Laser optical tweezer microscope

InactiveCN102436063AImprove focus accuracyHigh positioning accuracyRadiation/particle handlingMicroscopesMicroscopic imageMicroscope

The invention relates to a laser optical tweezer microscope. The microscope comprises: a lens cone, an image sensor, a microscopic objective lens, an objective table which can move up and down, a carrying substrate, a support and a digital optical phase conjugate apparatus which is used to generate laser optical tweezer and focus the optical tweezer on an object. The lens cone is fixed on the support. The objective table which can move up and down is connected with the support through a rack. The carrying substrate is placed on the objective table which can move up and down. The microscopic objective lens, which is used to carry out amplification imaging to the object placed on the carrying substrate, is installed on a bottom of the lens cone. The image sensor, which is used to record and amplify the microscopic image, is arranged in the lens cone and is located above the microscopic objective lens. By using the microscope of the invention, focusing accuracy and positioning accuracy of the optical tweezer can be increased. A precision machinery motor is not needed to increase a moving speed of the optical tweezer. An optical tweezer number can be increased. Any one optical tweezer can be independently operated. Through cooperation of a plurality of the optical tweezers, a high-precision complex microscopic operation can be realized.

Owner:李志扬

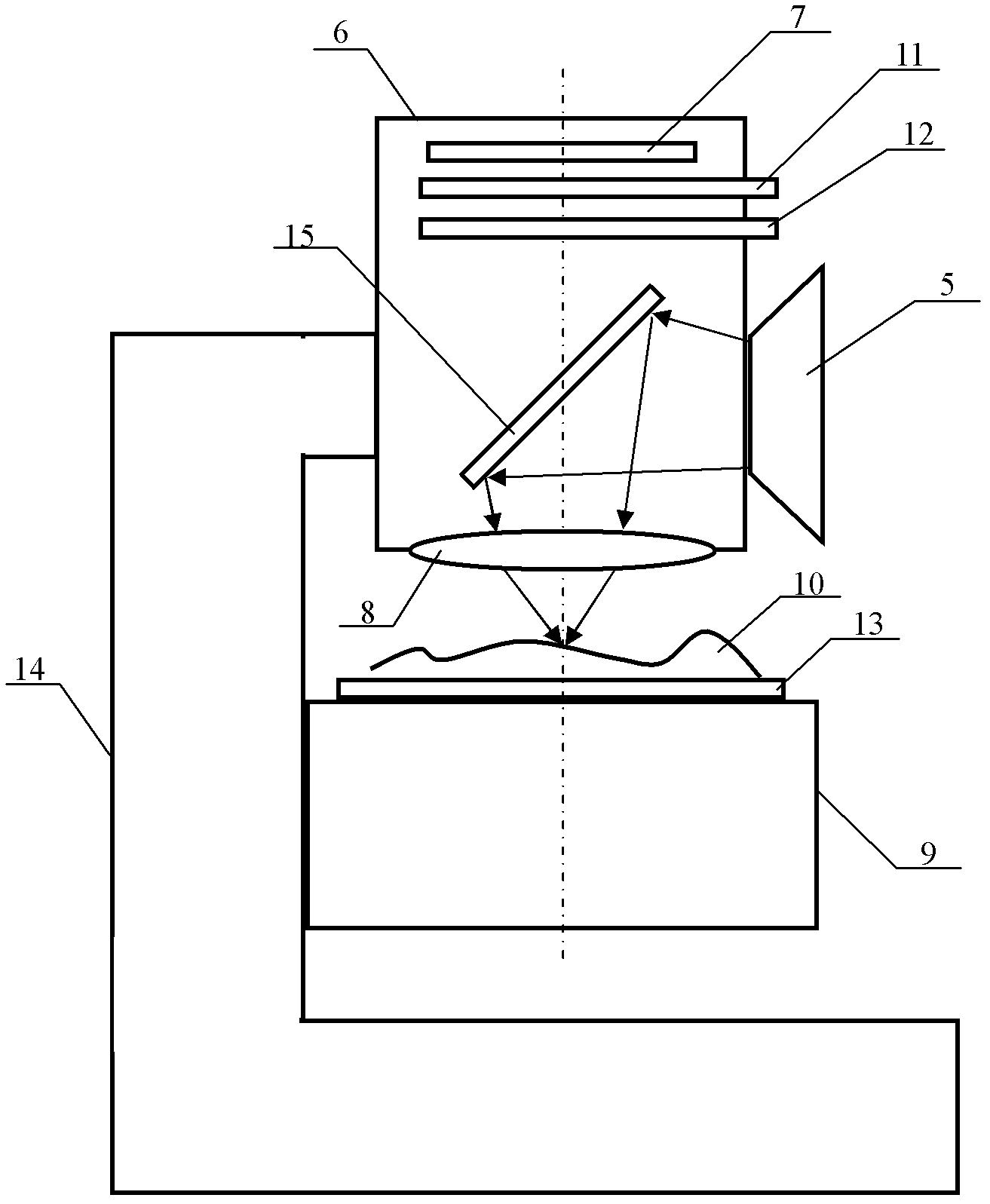

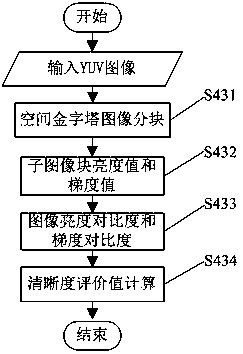

Method and device for improving automatic focusing accuracy and speed of camera

PendingCN110166692AEvenly distributedOffset the effect of sharpness evaluation valueTelevision system detailsColor television detailsBrightness contrastHill climbing

The invention relates to the field of image processing and food monitoring, and particularly discloses a method and a device for improving the automatic focusing accuracy and speed of a camera. The method for improving the automatic focusing accuracy and speed of the camera is characterized by sequentially comprising the steps of video image collection, image format conversion, focusing template setting, night vision low-illumination scene definition evaluation value calculation, daytime scene definition evaluation value calculation, peak searching and motor-driven lens focus finding. The threshold value of the change of the definition evaluation value in the hill climbing algorithm is adaptively adjusted according to the brightness contrast, the gradient contrast and the ISO value, the change trend of the current evaluation value can be effectively judged, the peak value can be found more quickly, and the automatic focusing speed and accuracy of night vision and low-illumination scenes are improved.

Owner:JINAN JOVISION TECH CO LTD

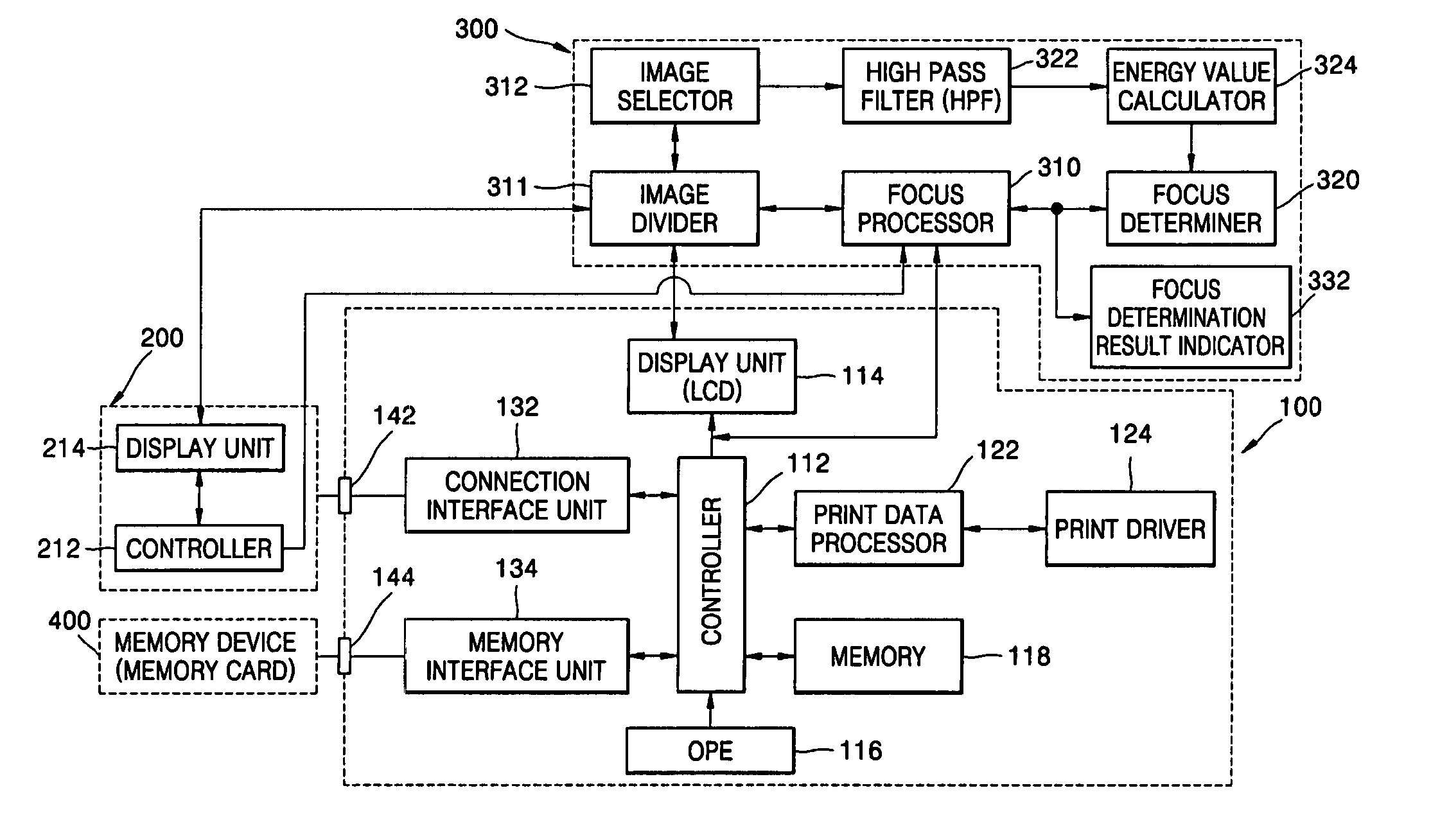

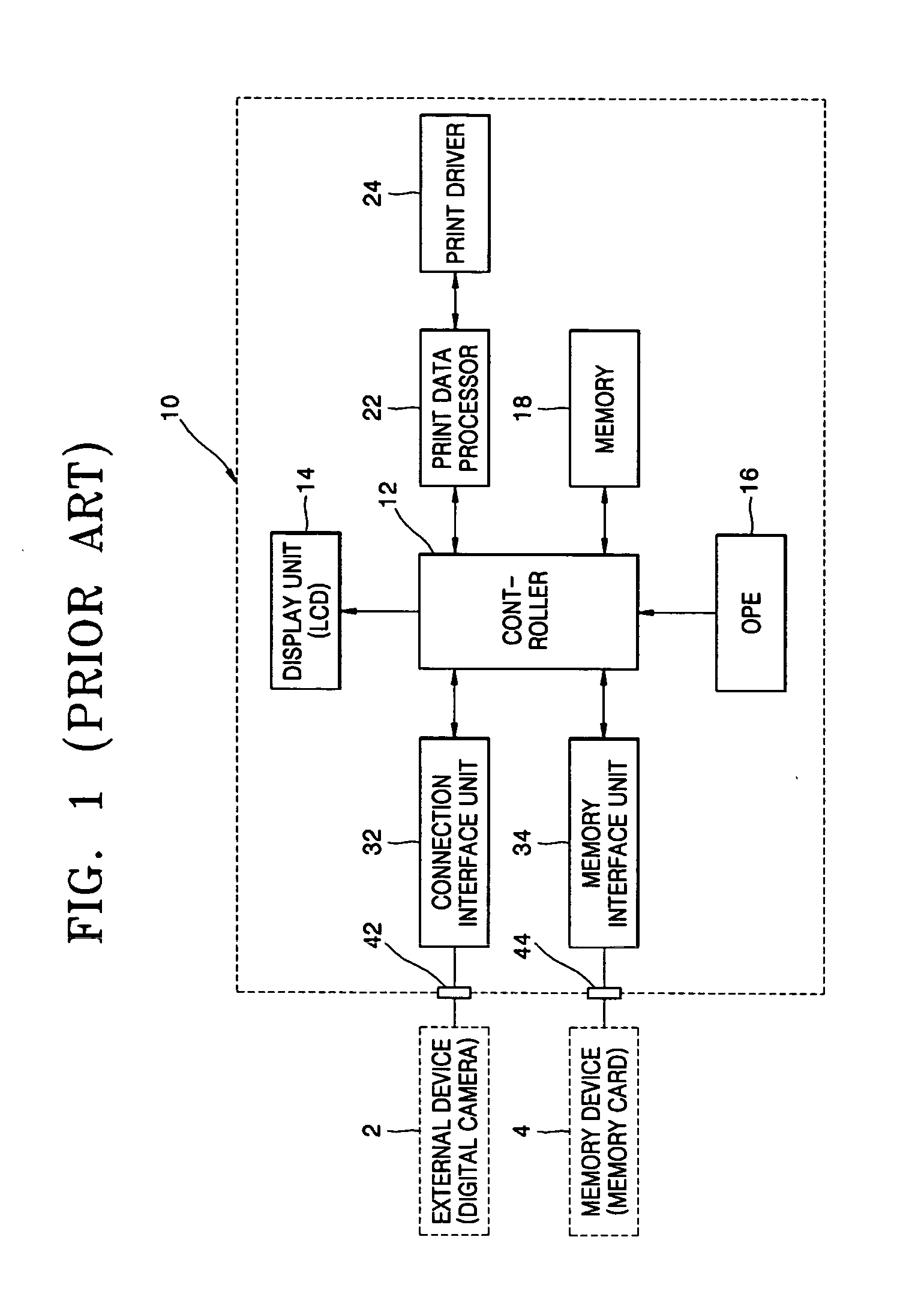

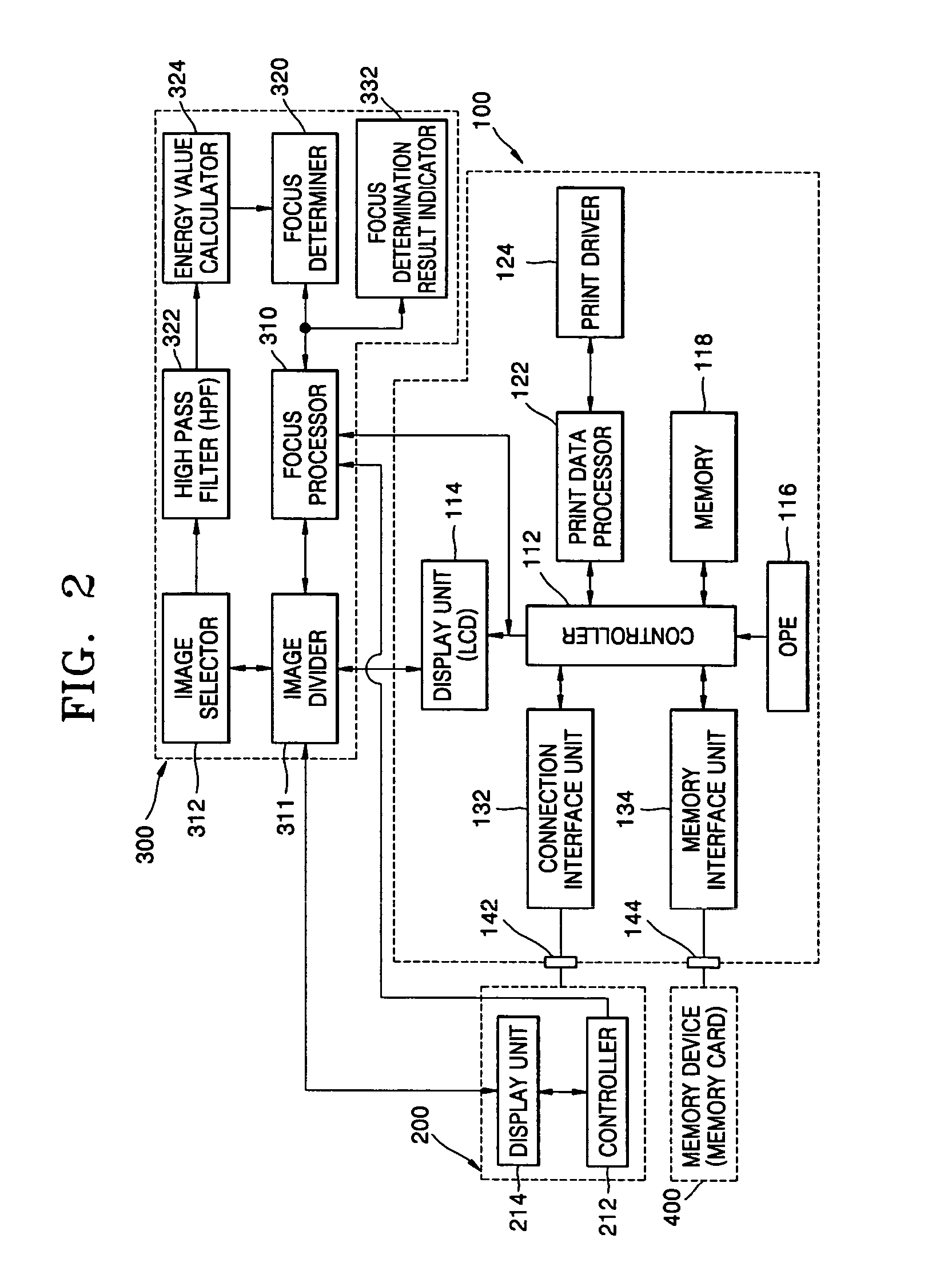

Image processing device and method, and image forming apparatus and image capturing apparatus including an image processing device

InactiveUS20050110892A1Improve focus accuracyTelevision system detailsProjector focusing arrangementImaging processingComputer printing

An image processing device and method in which only an image or part(s) of an image in adequate focus may be printed through an image forming apparatus such as a printer, are provided. The image processing device includes a focus determiner for determining whether a focus accuracy of an image displayed on a display unit is greater than a predetermined focus accuracy, and a focus processor for processing the image to be printed only if it is determined that the focus accuracy of the image is greater than the predetermined focus accuracy.

Owner:SAMSUNG ELECTRONICS CO LTD

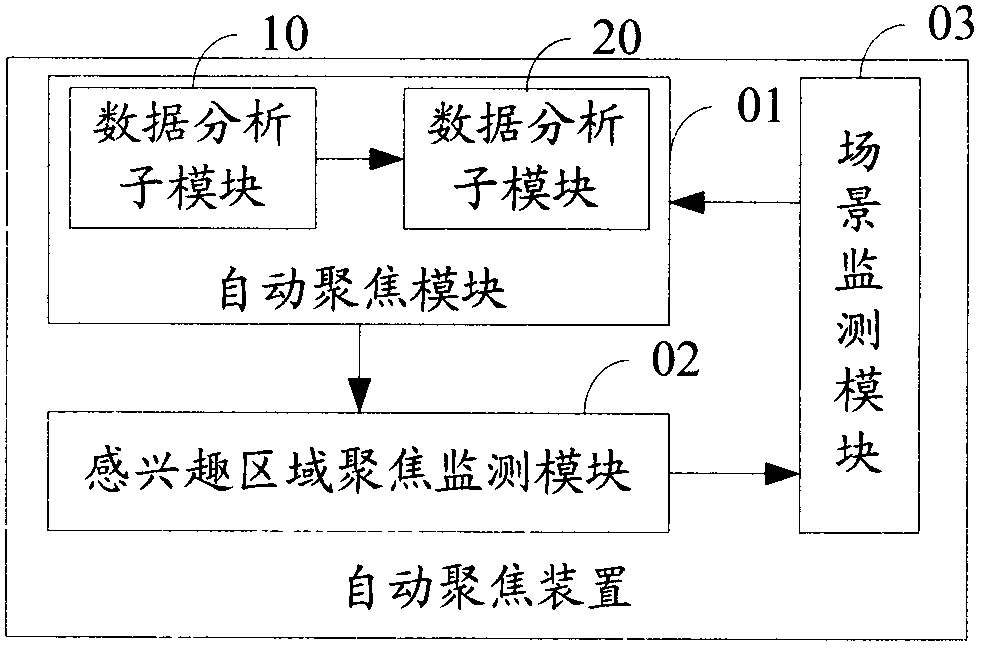

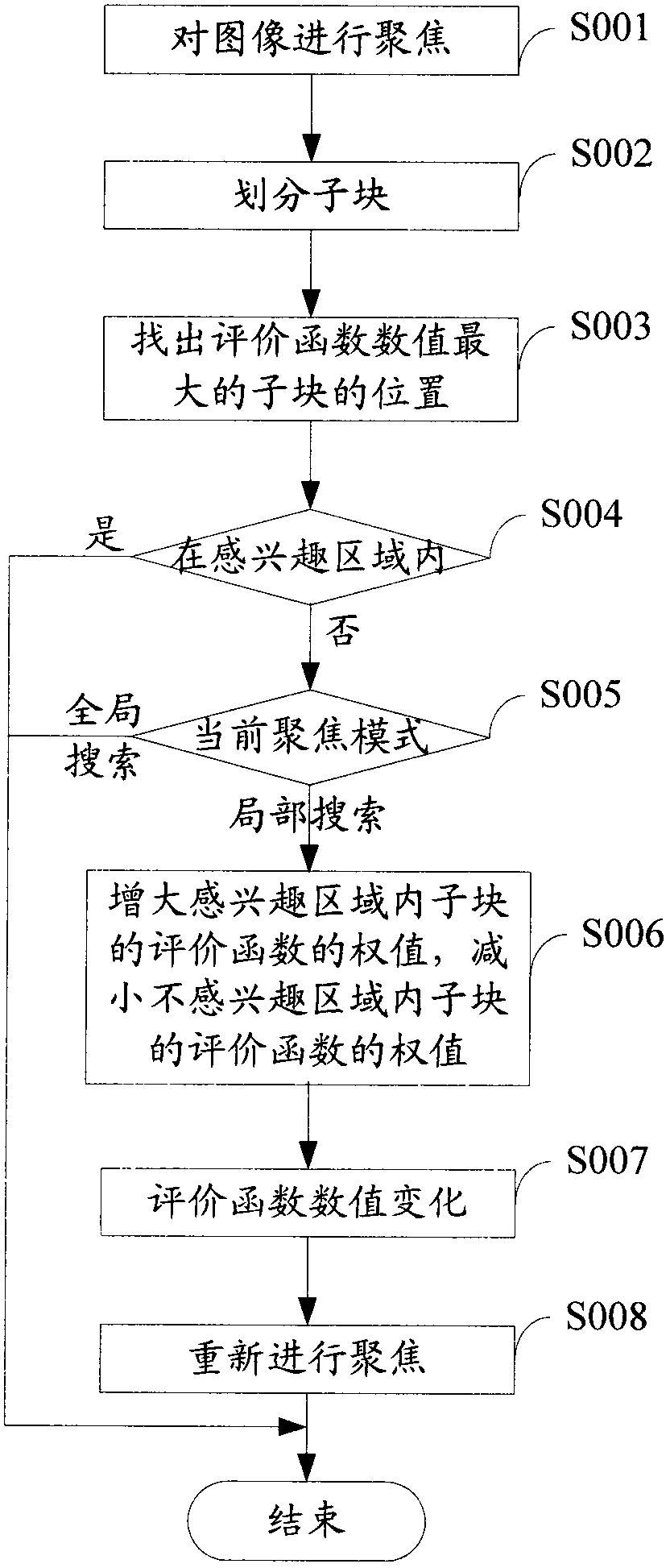

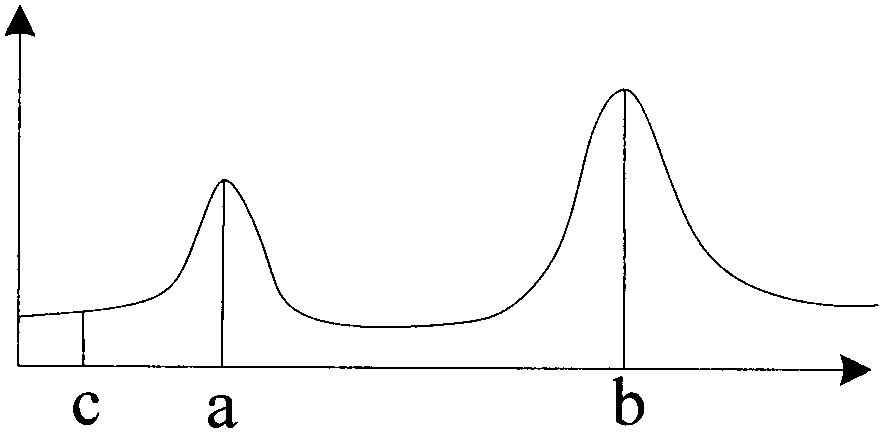

Method and apparatus for automatic focusing

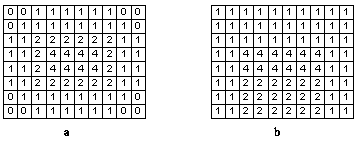

InactiveCN103424953AAchieving Auto FocusImprove focus accuracyMountingsFocusing aidsAutomatic testingRegion of interest

The invention relates to a method and apparatus for automatic focusing. The method comprises the following steps that: a focused image is divided into more than two sub blocks; a position of one sub block with the maximum evaluation function value is found out and whether the position which the sub block is located at is in a region of interest; and if the position which the sub block is located at is not in a region of interest and the current focusing mode is a local searching mode, weighting processing is carried out on the evaluation function of the image and re-focusing is carried out on the image. The provided apparatus consists of an automatic focusing module, a region of interest focusing monitoring module, and a scene monitoring module. automatic focusing of the region of interest can be realized and the focusing precision is improved.

Owner:ZTE CORP

Laser differential confocal curvature radius measuring method and device

The invention relates to a laser differential confocal curvature radius measuring method and a laser differential confocal curvature radius measuring device, which belong to the technical field of optical precision measurement. The laser differential confocal curvature radius measuring method utilizes a post-positioned pupil to block half of a measuring beam, uses a light splitting pupil differential confocal detection system for detecting a measuring beam to obtain a differential confocal response curve, and utilizes an absolute zero point of the differential confocal response curve to perform precise focus fixation on a surface vertex position and a sphere center position of a spherical element separately, so as to obtain a curvature radius of the element. According to the laser differential confocal curvature radius measuring method and the laser differential confocal curvature radius measuring device, the post-positioned light splitting pupil laser differential confocal technologyis applied to the high-precision detection of the curvature radius of the spherical element for the first time, the differential confocal focus fixation and curvature radius measurement is realized byusing only one path of detector, the system structure is simple, the assembly and debugging difficulty is reduced, the possible decrease of focus fixation precision caused by replacement of a measured lens is avoided, further the measurement precision is improved; and data near a zero point of the differential confocal response curve is subjected to linear fitting, so as to achieve fast triggering of the focus fixation and measurement, thus the measurement speed and precision as well as the scattering resistance are greatly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

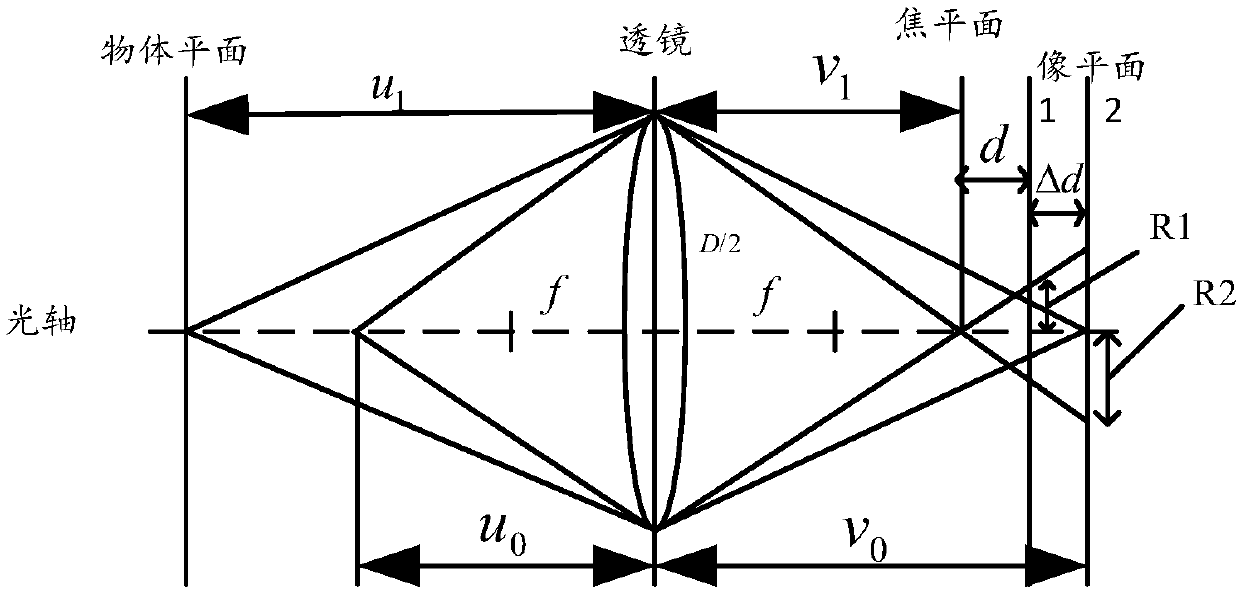

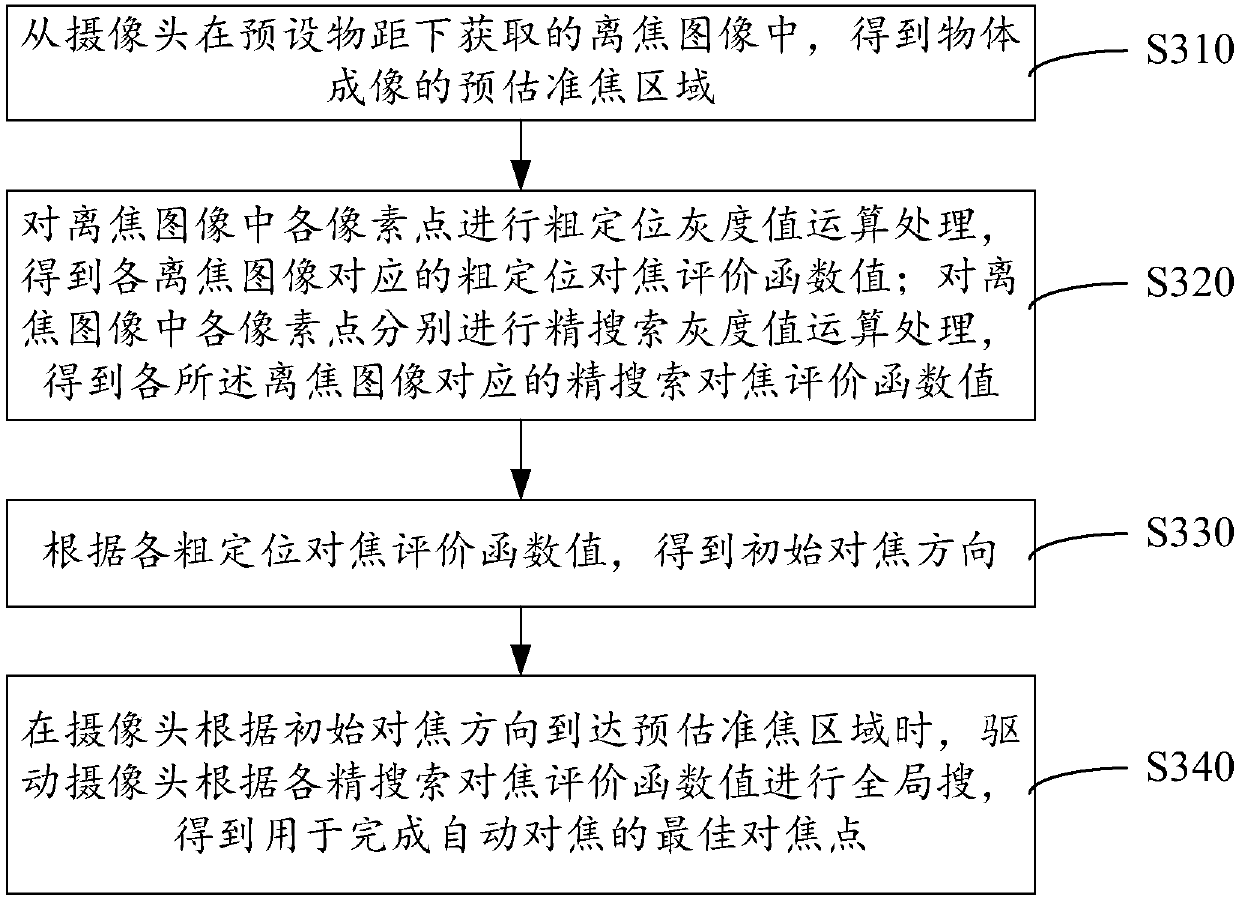

Automatic focusing method, device and system

ActiveCN107664899AImprove focus accuracyHigh speedMountingsFocusing aidsComputer graphics (images)Evaluation function

The invention relates to an automatic focusing method, a device and a system; the method comprises the following steps: obtaining an object imaging pre-estimated focusing area from out-of-focus imagesobtained by a camera under a preset object distance; calculating a coarse positioning gray value for each pixel point in the out-of-focus image, and obtaining a coarse positioning focusing evaluationfunction value corresponding to each out-of-focus image; respectively calculating a precise searching gray value of each pixel point in the out-of-focus image, thus obtaining a precise searching focusing evaluation function value corresponding to each out-of-focus image; obtaining an initial focusing direction according to each coarse positioning focusing evaluation function value; driving the camera to make global searches according to each precise searching focusing evaluation function value when the camera reaches the pre-estimated focusing area according to the initial focusing direction,thus obtaining the best focusing point for finishing the automatic focusing. The automatic focusing method, device and system are high in focusing precision, and fast in speed.

Owner:GUANGDONG SHUNDE IND DESIGN INST GUANGDONG SHUNDE INNOVATIVE DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com