Method and device for measuring multiple element parameters in differential con-focus interference manner

A differential confocal and interference element technology, which is used in measurement devices, geometric characteristics/aberration measurement, and optical devices, etc., to achieve the effects of improving fixed focus accuracy, fast measurement speed, and improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

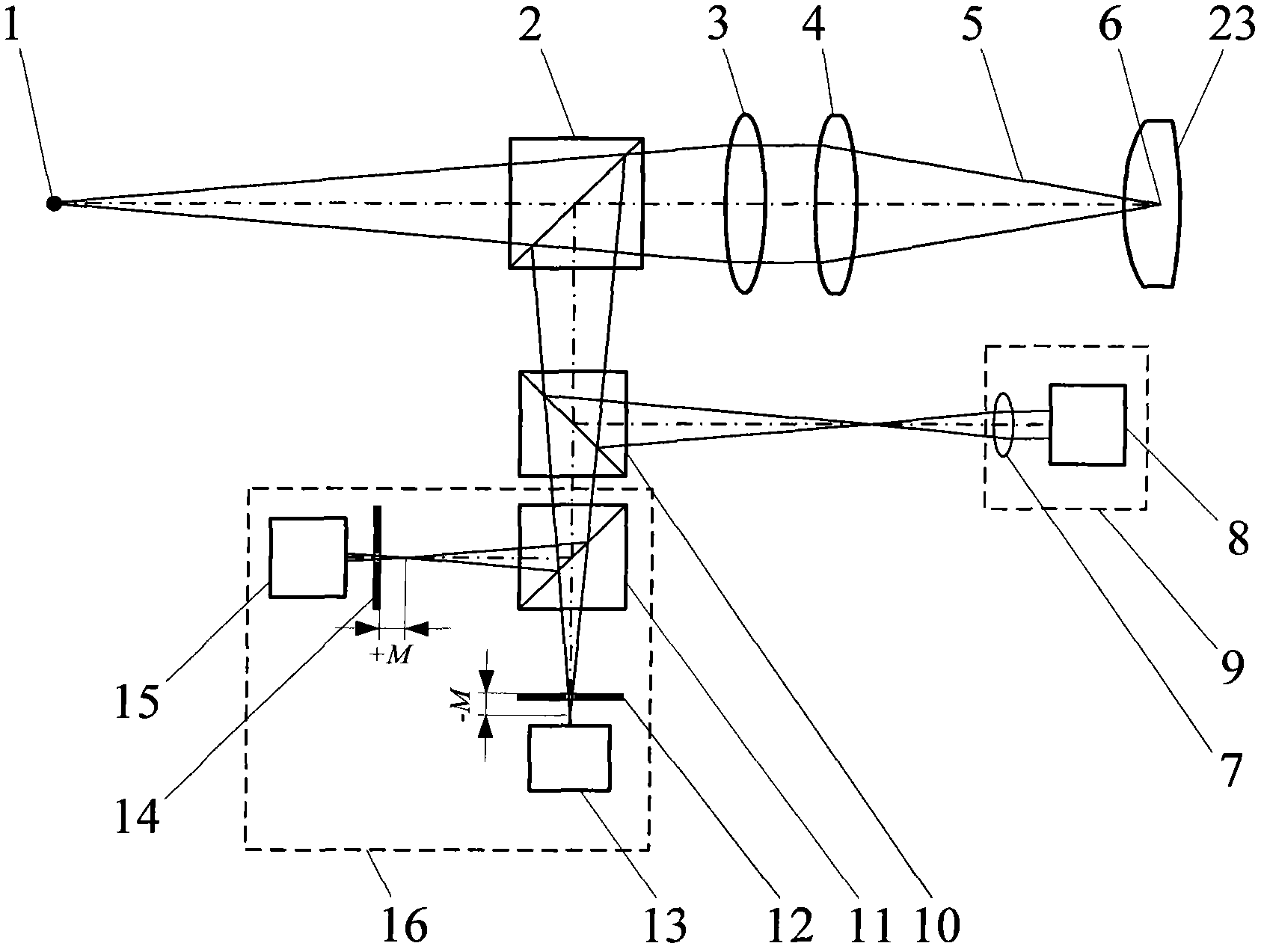

Embodiment 1

[0079] When the measured parameter is the radius of curvature of the convex sphere, as attached Figure 10 As shown, the differential confocal interferometric element multi-parameter measurement device, the measurement steps are:

[0080] (a) Start the measurement software in the main control computer 32, turn on the laser 37, and the light emitted by the laser 37 is transmitted through the optical fiber 38 to form a point light source 1. The light emitted by the point light source 1 forms a measuring beam 5 after passing through the first beam splitter 2, the collimating lens 3 and the converging lens 4;

[0081] (b) The measured spherical element 18 is fixed on the five-dimensional adjustment frame 39, the measuring beam 5 is irradiated on the measured spherical element surface 49, and the light reflected by the measured spherical element surface 49 passes through the converging lens 4 and the collimating lens After 3, it is reflected by the first beam splitter 2 and shoots...

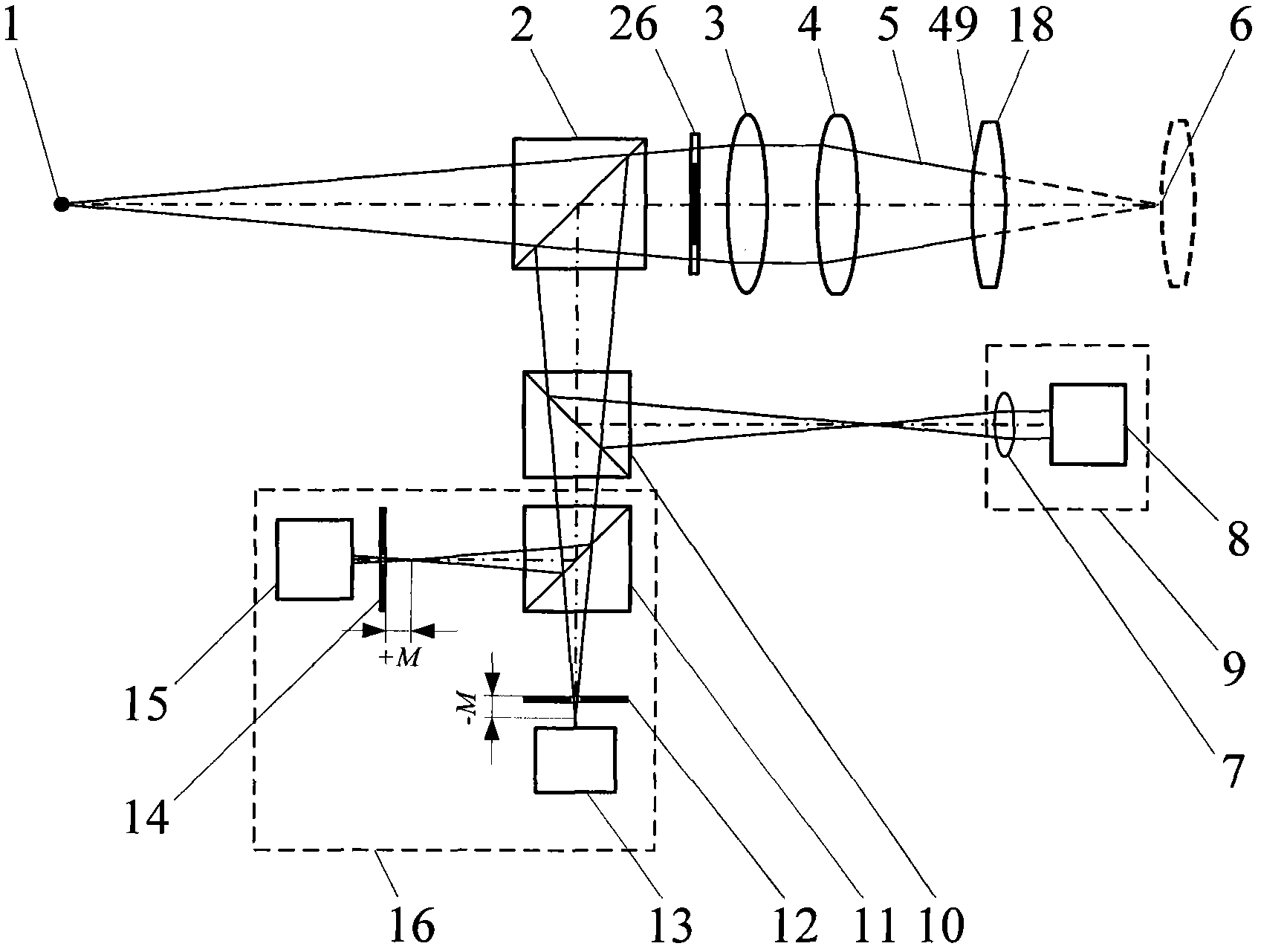

Embodiment 2

[0091] When the measured parameter is the top focal length of the convex lens, as attached Figure 11 As shown, the differential confocal interferometric element multi-parameter measurement device, the measurement steps are:

[0092] (a) Start the measurement software in the main control computer 32, turn on the laser 37, and the light emitted by the laser 37 is transmitted through the optical fiber 38 to form a point light source 1. The light emitted by the point light source 1 passes through the first beam splitter 2 and the collimator lens 3 to form a parallel beam;

[0093] (b) Take off the condensing lens 4, place the measured lens 17 at the parallel optical path where the collimating lens 3 exits, adjust the measured lens 17 so that it has a common optical axis with the collimating lens 3, and the parallel light passes through the measured lens 17 After forming the measurement beam 5;

[0094] (c) plane reflector 19 is fixed on the five-dimensional adjustment frame 39,...

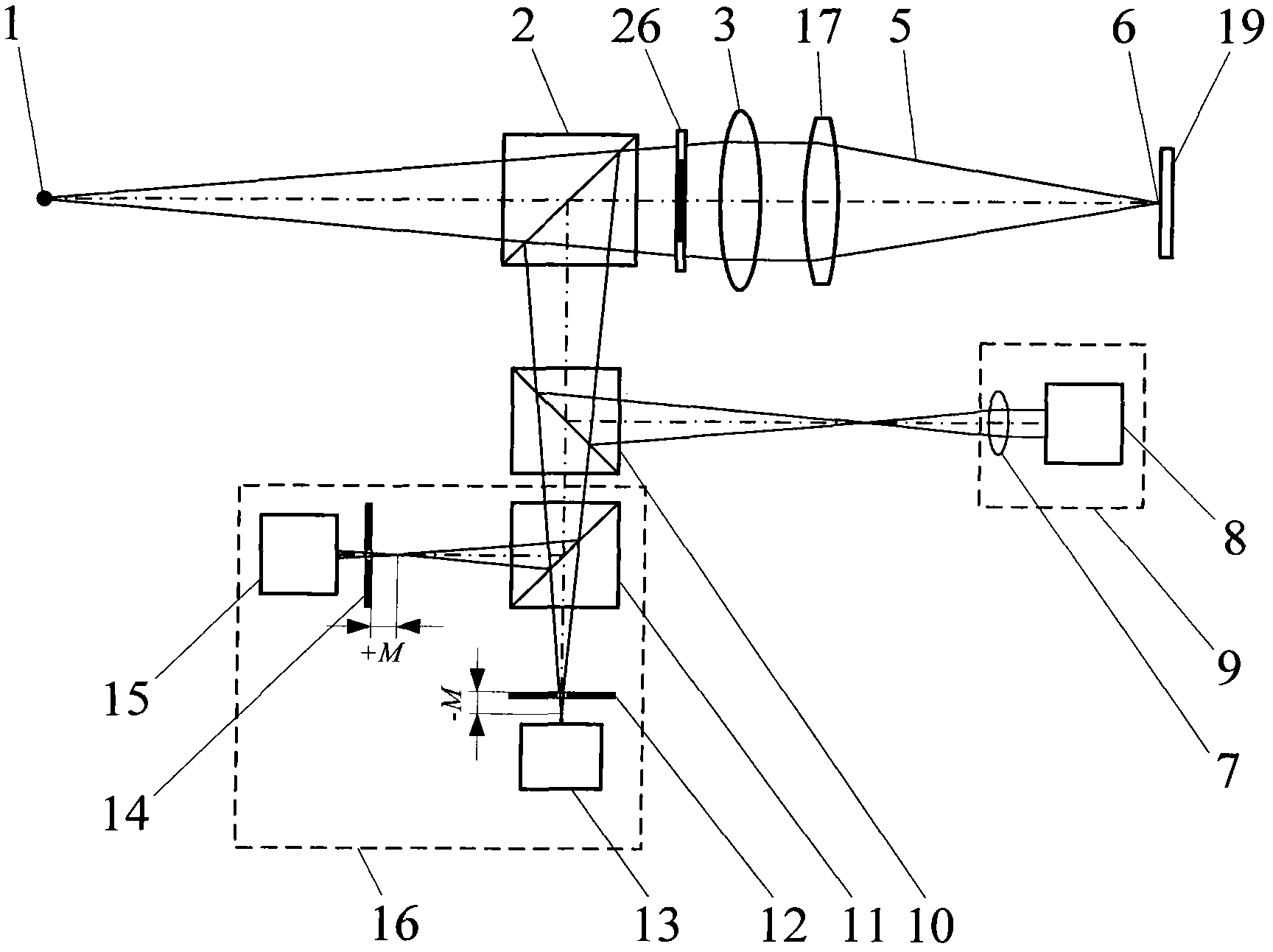

Embodiment 3

[0101] When the measured parameters are the refractive index and thickness of GCL-0101K9 plano-convex lens, as attached Figure 12 As shown, the differential confocal interferometric element multi-parameter measurement device, the measurement steps are:

[0102] (a) Start the measurement software in the main control computer 32, turn on the laser 37, and the light emitted by the laser 37 is transmitted through the optical fiber 38 to form a point light source 1. The light emitted by the point light source 1 forms a measuring beam 5 after passing through the first beam splitter 2, the collimating lens 3 and the converging lens 4;

[0103] (b) Fix the measured lens 17 on the five-dimensional adjustment frame 39, fix the plane reflector 19 behind the measured lens 17, adjust the measured lens 17 so that it has a common optical axis with the measuring beam 5, and adjust the plane reflector 19, making it perpendicular to the optical axis of the measuring beam 5;

[0104] (c) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com