Method for measuring disconnecting switch contact finger pressure based on optical fiber Bragg grating sensor

A technology of grating sensor and isolating switch, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problem of inaccurate judgment of the safe closing position of the moving contact and the inability to reflect the isolation in time Changes in the contact finger pressure of the switch, the inability to implement real-time online safety monitoring of the contact finger pressure of the isolation switch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to facilitate the understanding of technical personnel.

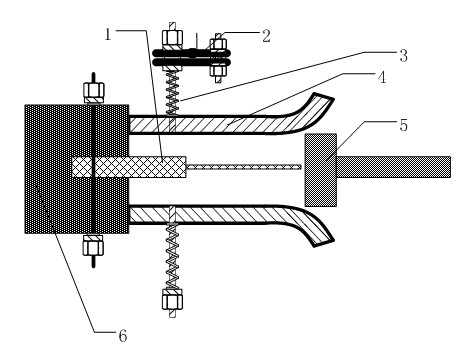

[0024] Such as figure 1 Shown: The method for measuring the contact finger pressure of the disconnector based on the optical fiber Bragg grating sensor is carried out according to the following steps:

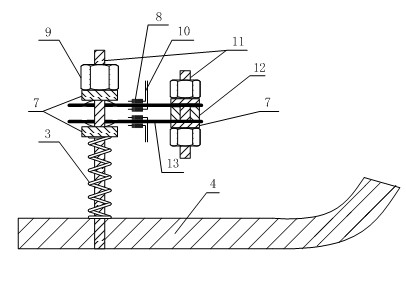

[0025] (1) Use the optical fiber Bragg grating displacement sensor 1, the optical fiber Bragg grating pressure sensor 2 and the isolation switch to form a measuring device, fix the optical fiber Bragg grating displacement sensor 1 on the contact wall 6 of the static contact of the isolation switch, and fix the optical fiber Bragg grating pressure sensor 2 On the outside of the isolation switch spring 3;

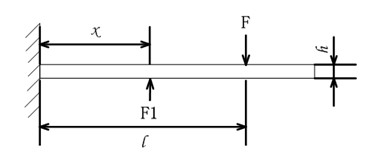

[0026] (2) Implement closing action on the isolating switch, make the moving contact of the displacement sensor 1 touch the moving contact 5 of the isolating switch, use the spectrum analyze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com