Patents

Literature

3005results about "Material strength using steady bending forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

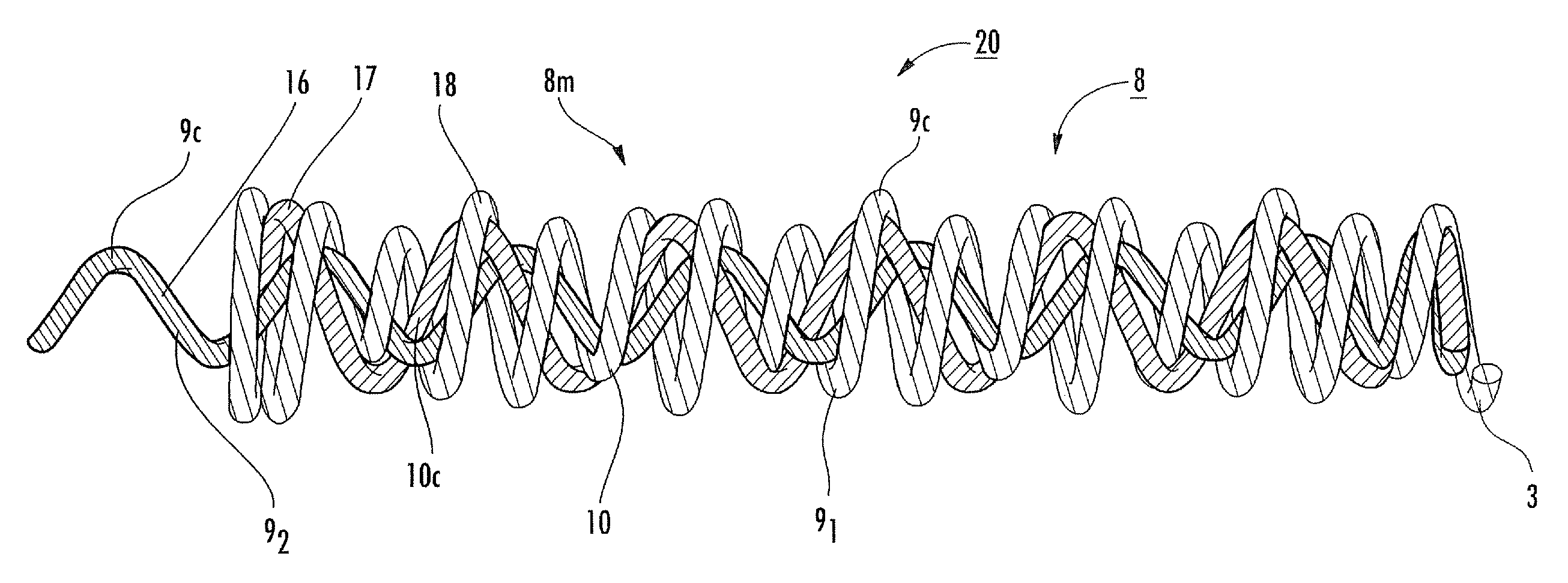

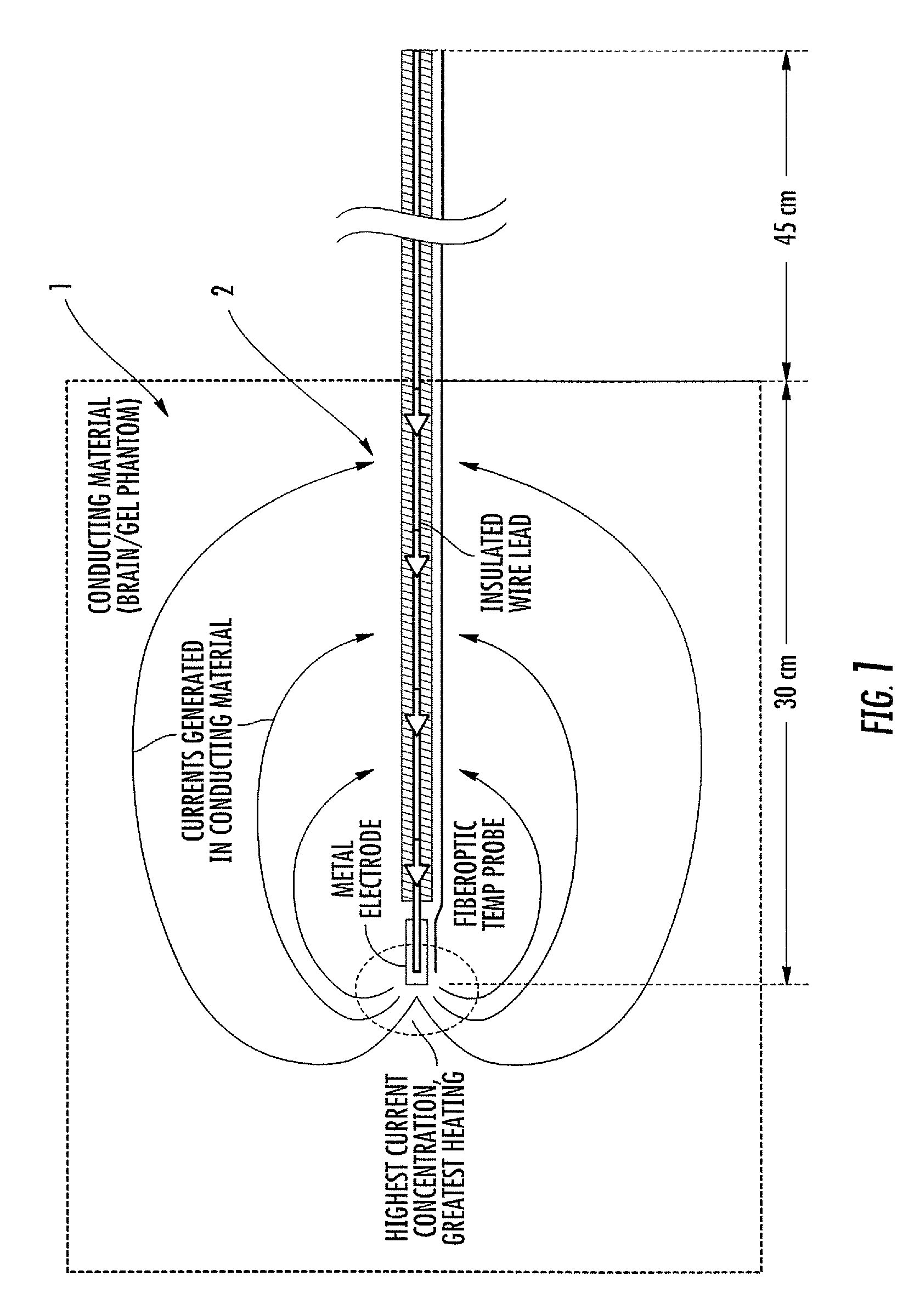

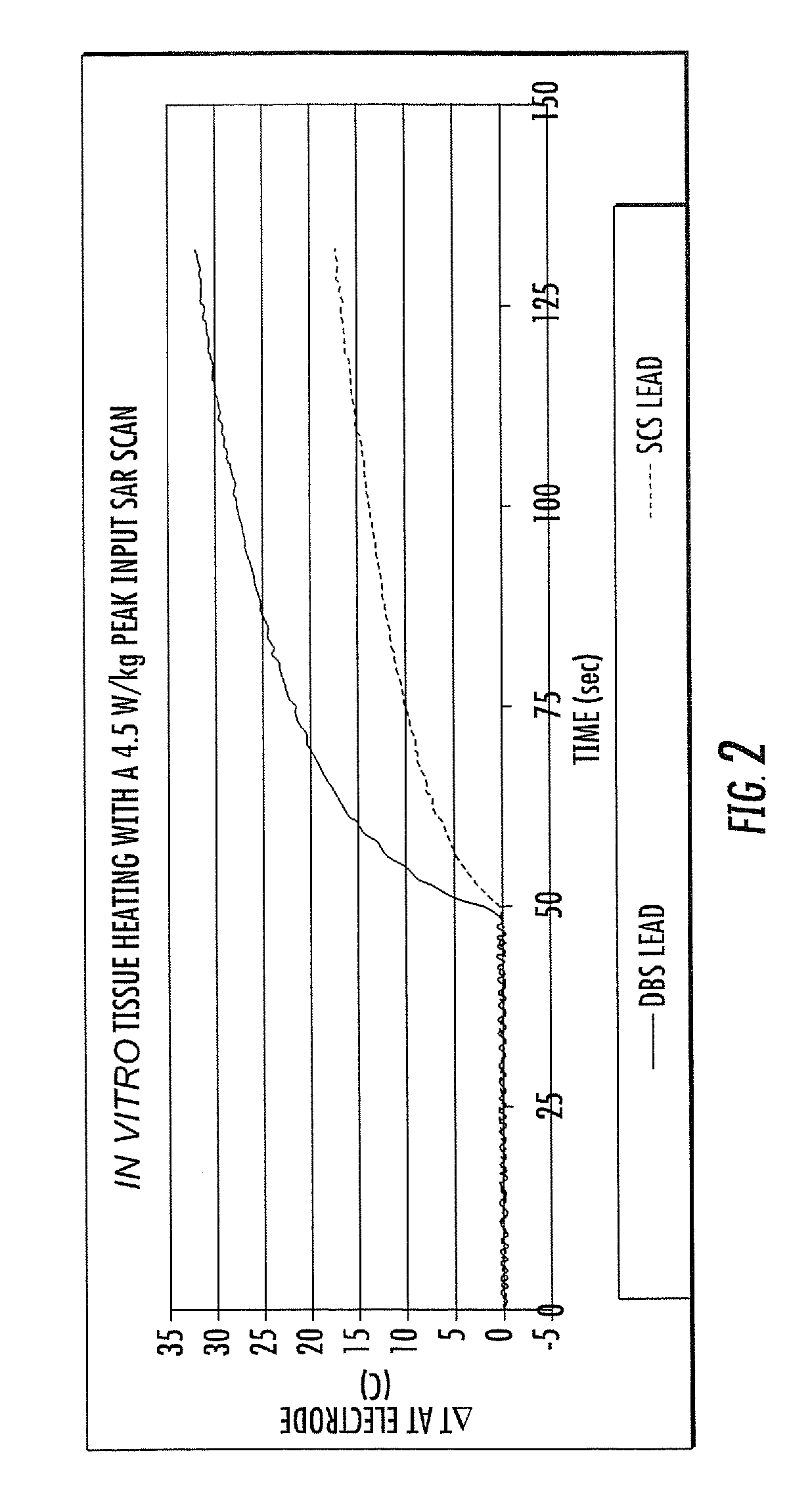

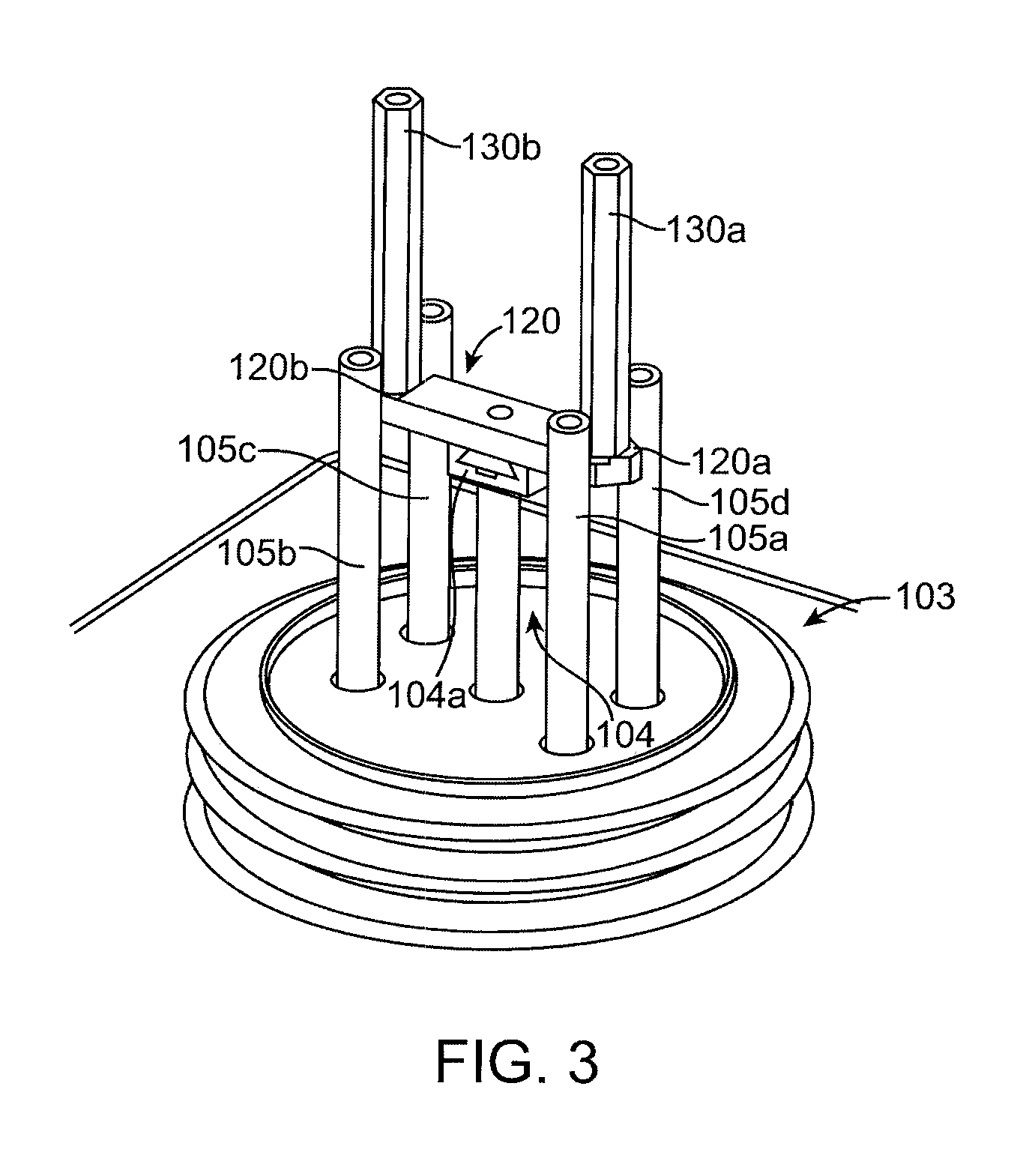

Methods and apparatus for fabricating leads with conductors and related flexible lead configurations

ActiveUS20080262584A1Prevent undesired heatingEasy to useInternal electrodesMaterial strength using steady bending forcesElectrical conductorDegree Celsius

MRI / RF compatible leads include at least one conductor, a respective conductor having at least one segment with a multi-layer stacked coil configuration. The lead can be configured so that the lead heats local tissue less than about 10 degrees Celsius (typically about 5 degrees Celsius or less) or does not heat local tissue when a patient is exposed to target RF frequencies at a peak input SAR of at least about 4 W / kg and / or a whole body average SAR of at least about 2 W / kg. Related leads and methods of fabricating leads are also described.

Owner:MRI INTERVENTIONS INC +1

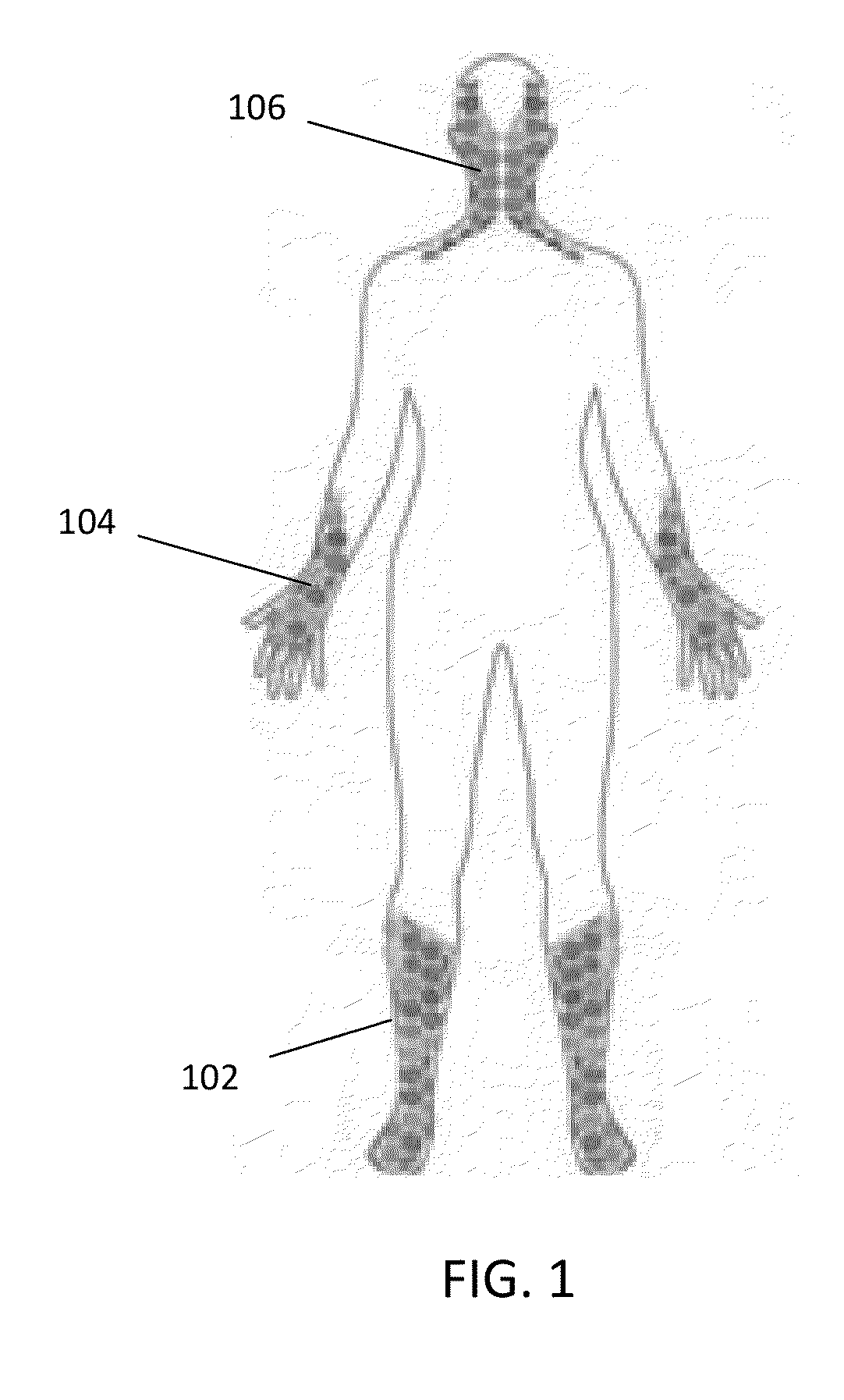

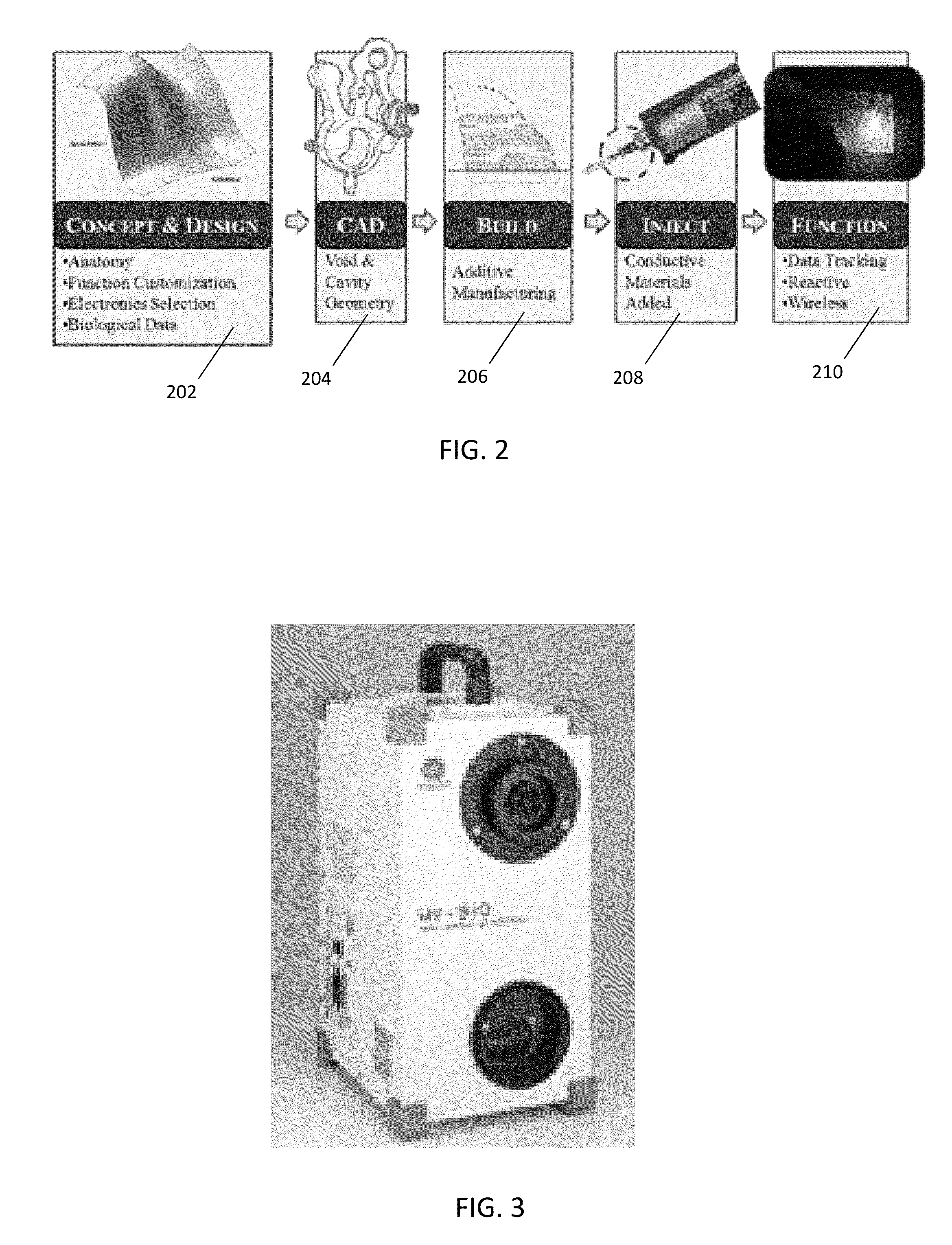

Customizable Embedded Sensors

InactiveUS20130079693A1Force measurement by permanent gauge deformationMeasurement apparatus componentsEngineeringEngineering physics

Owner:NORTHEASTERN UNIV

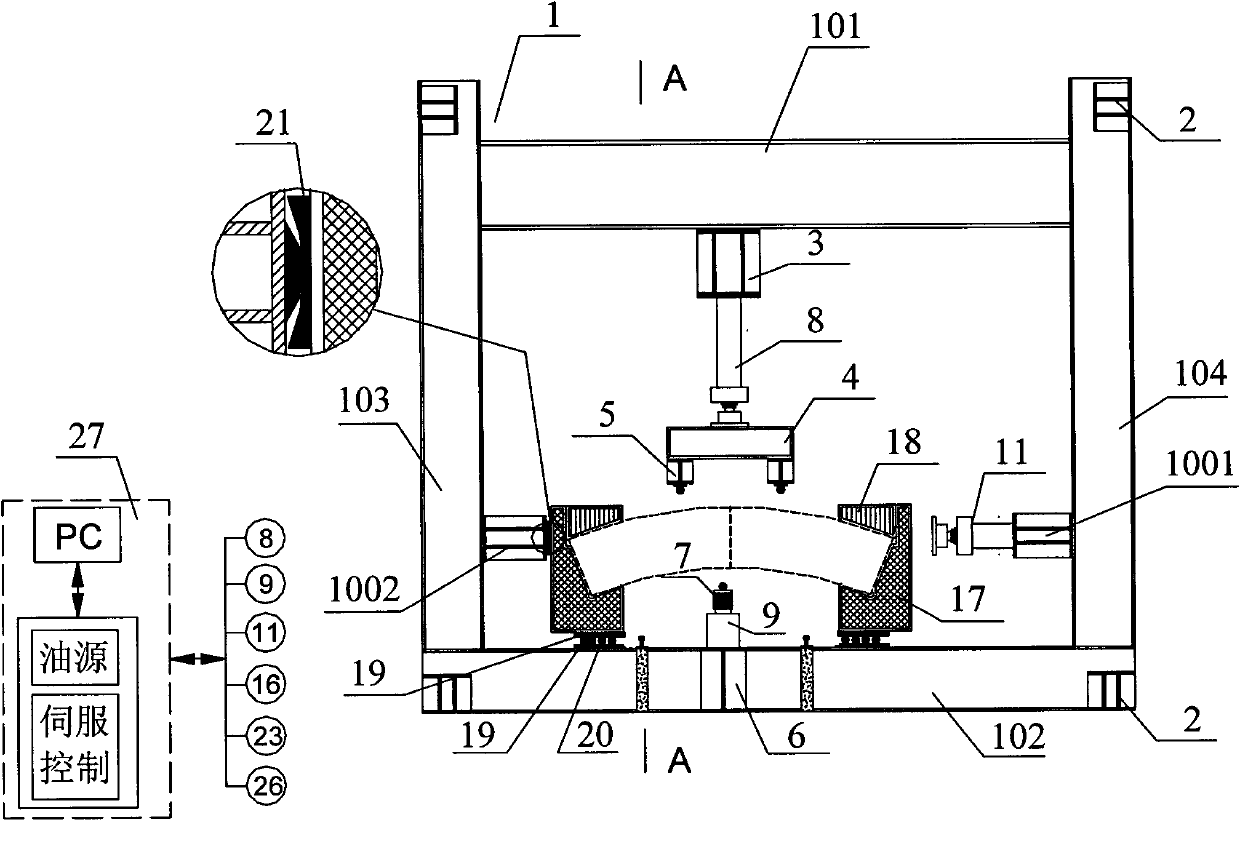

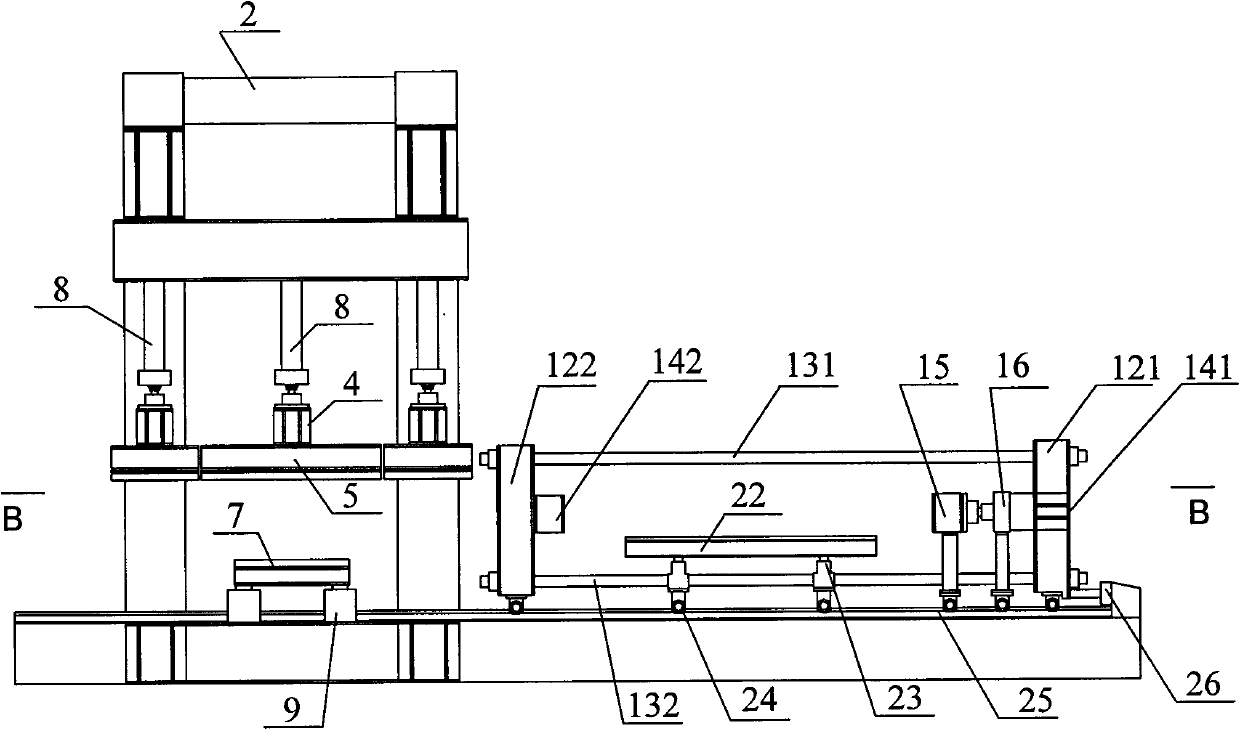

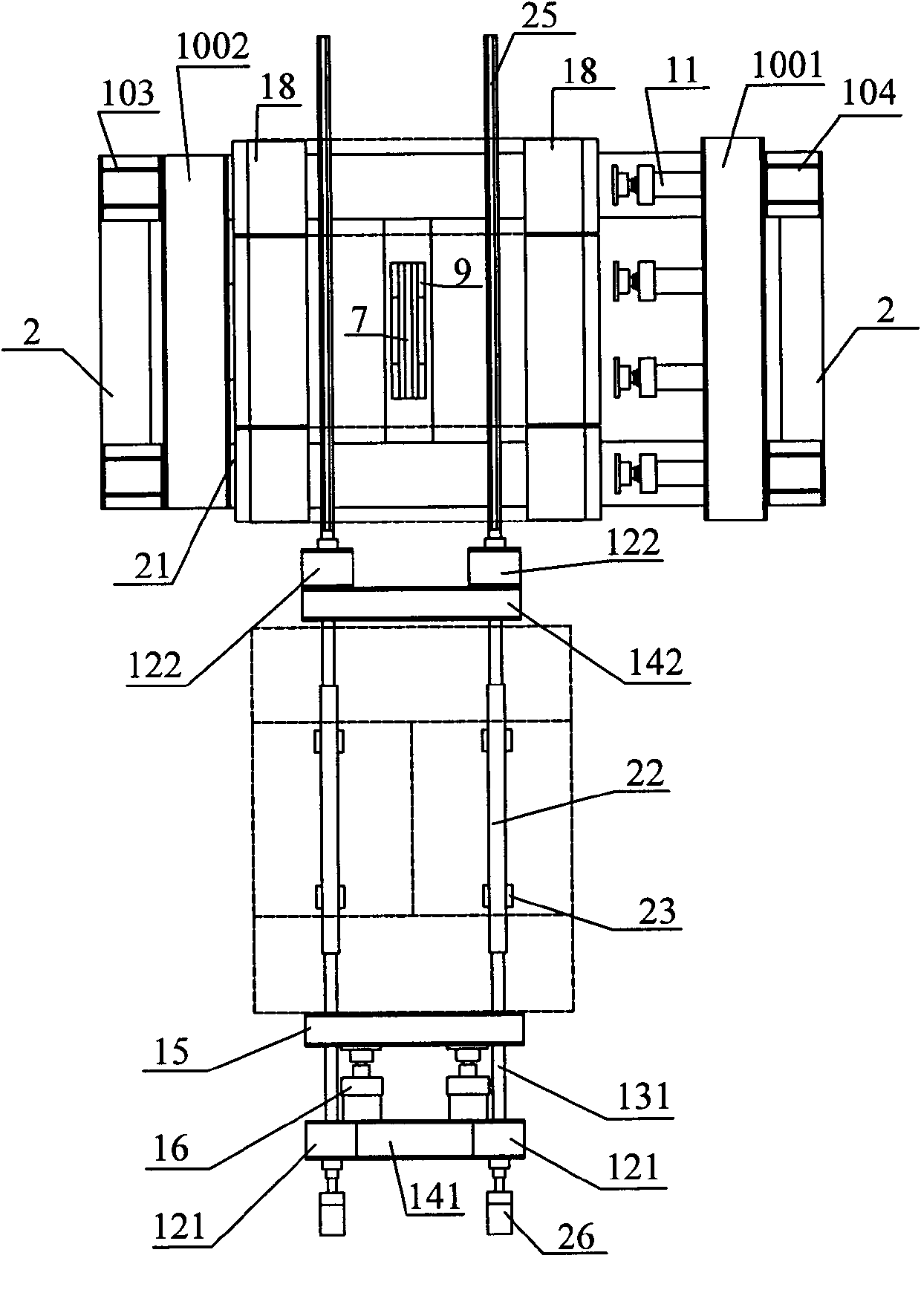

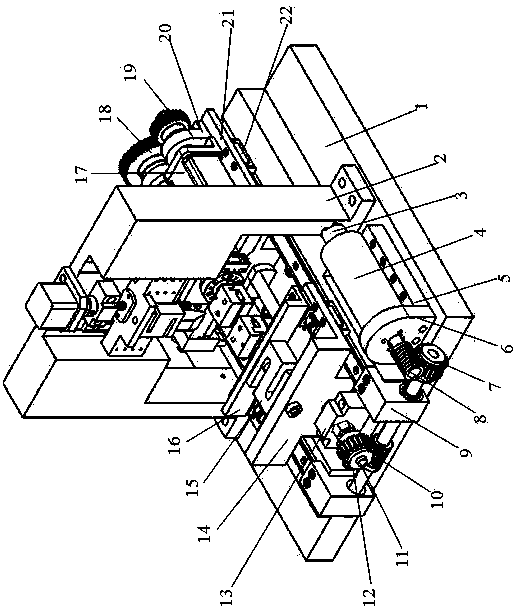

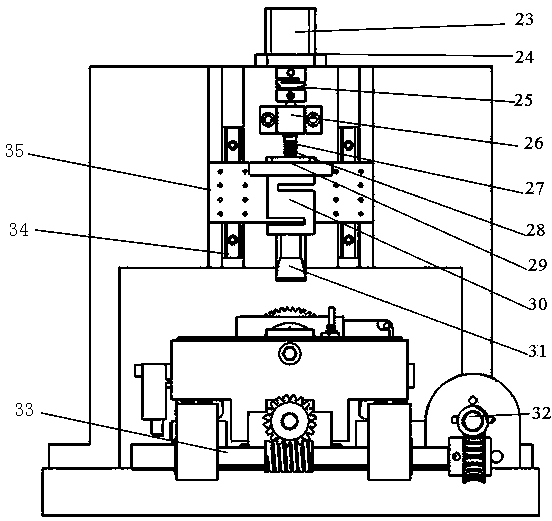

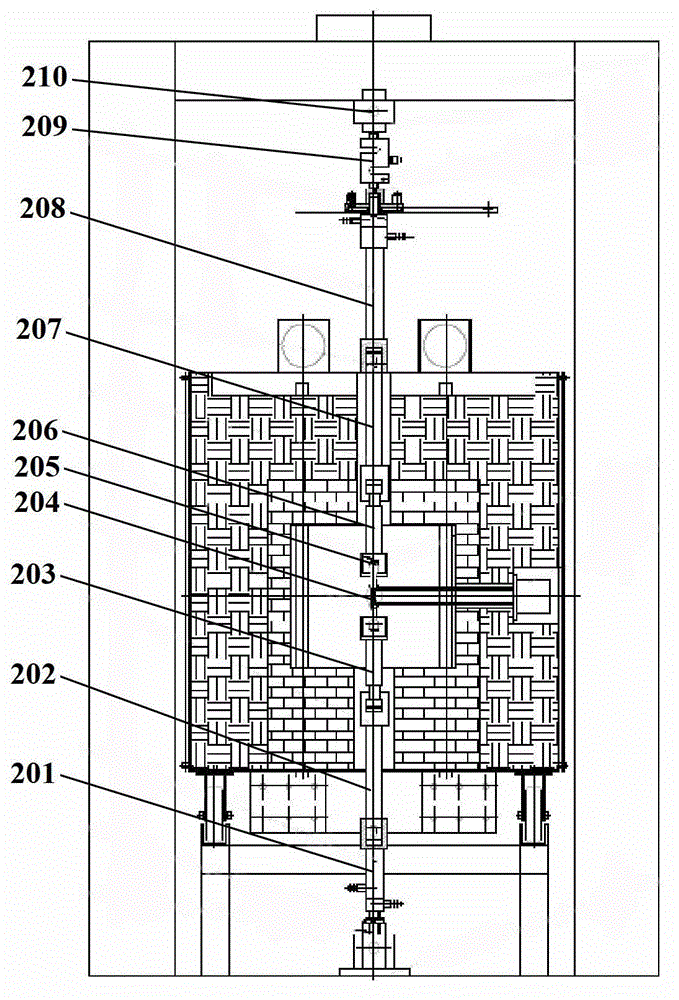

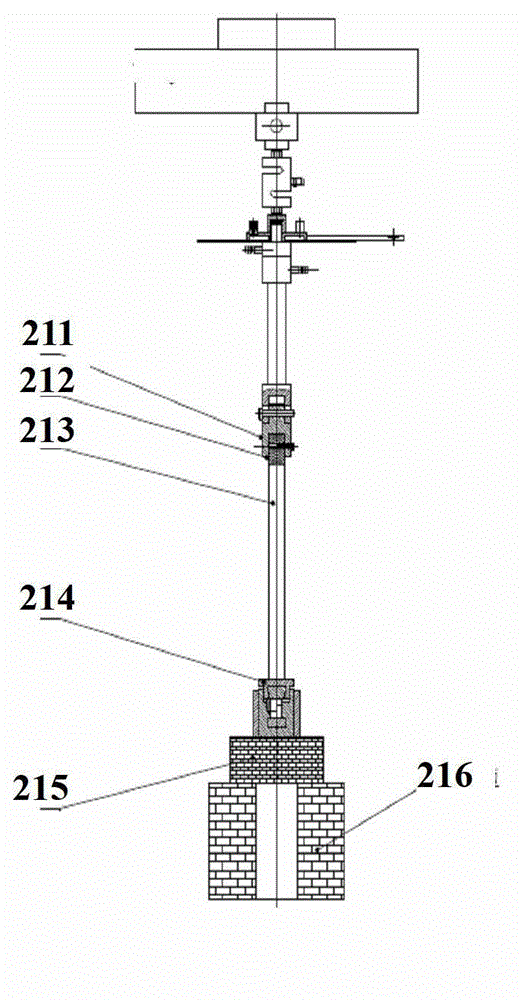

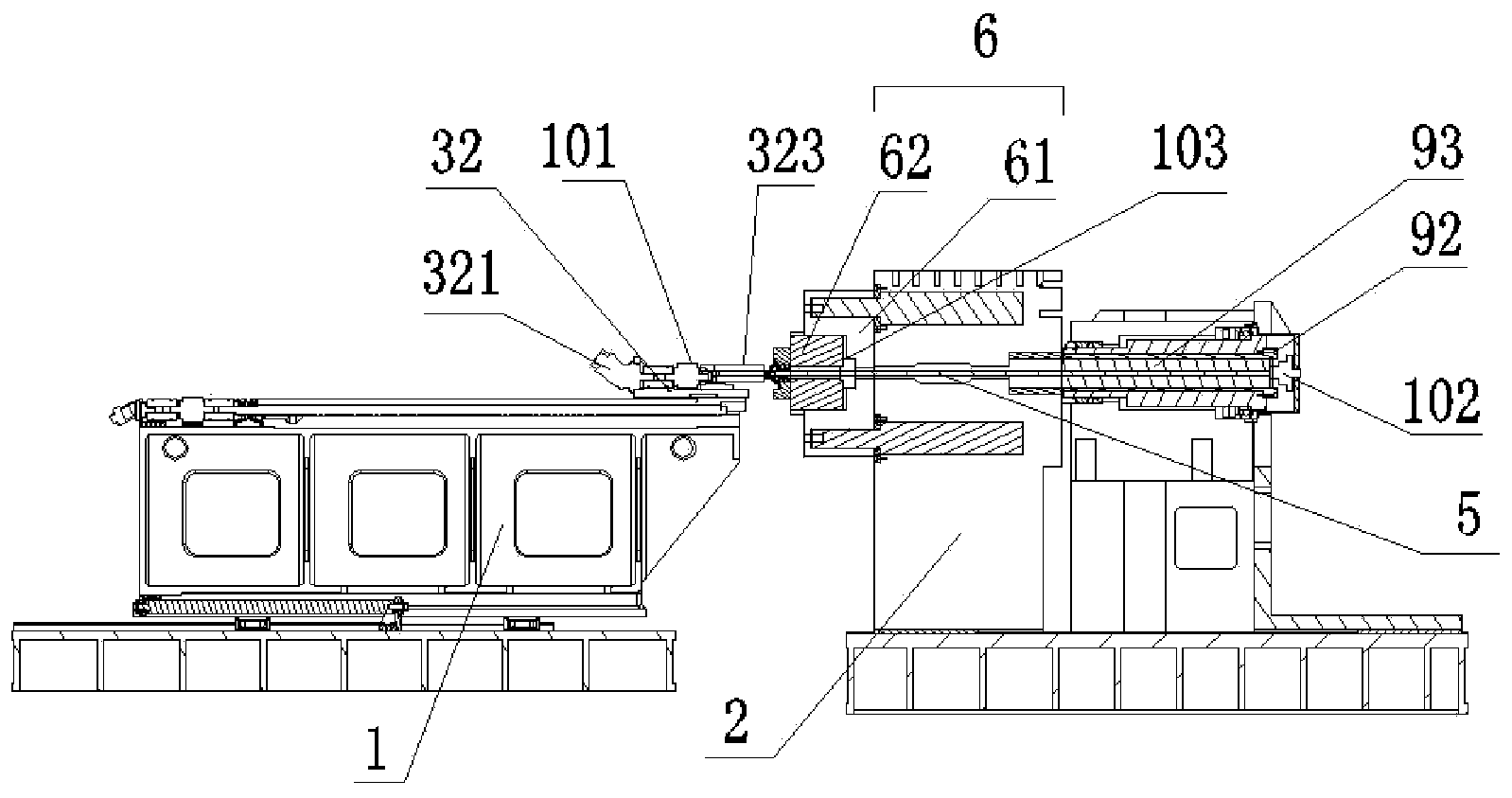

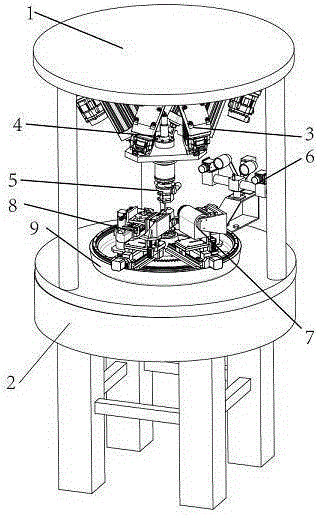

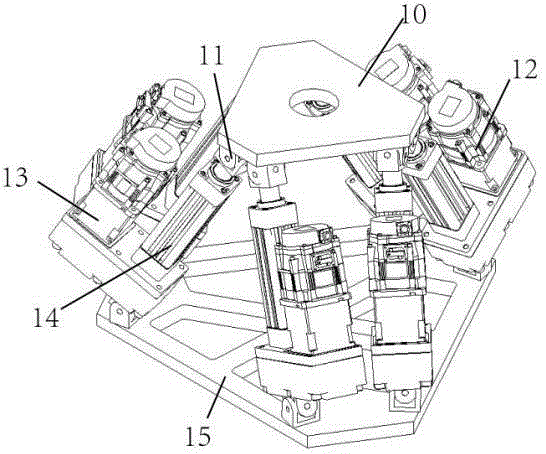

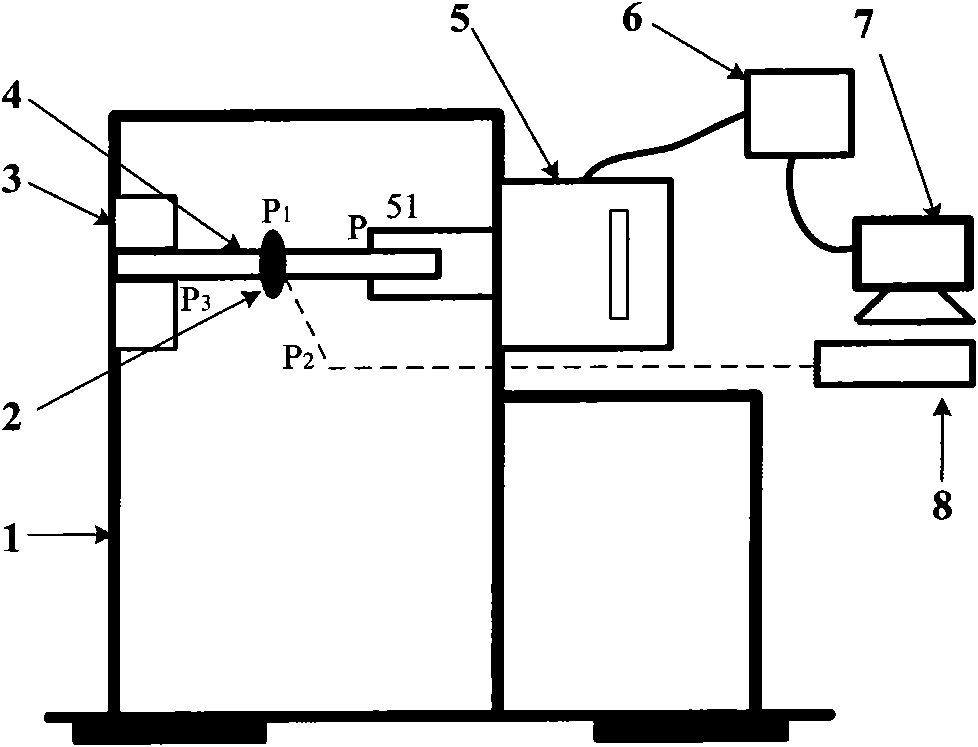

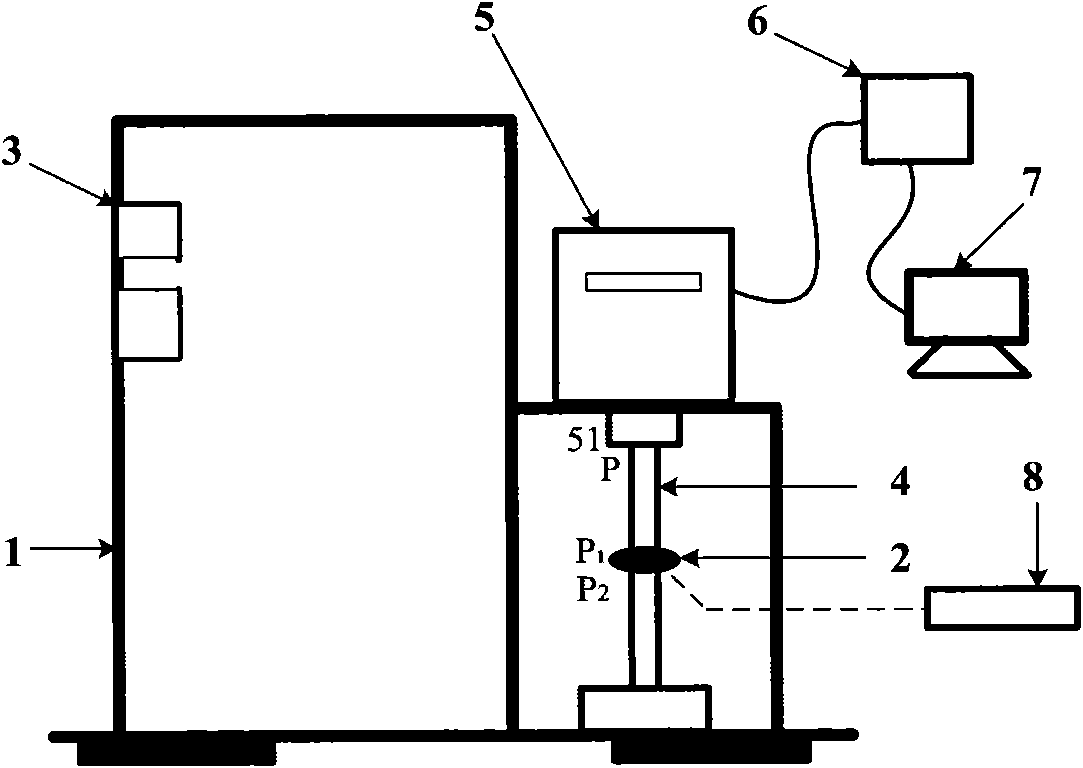

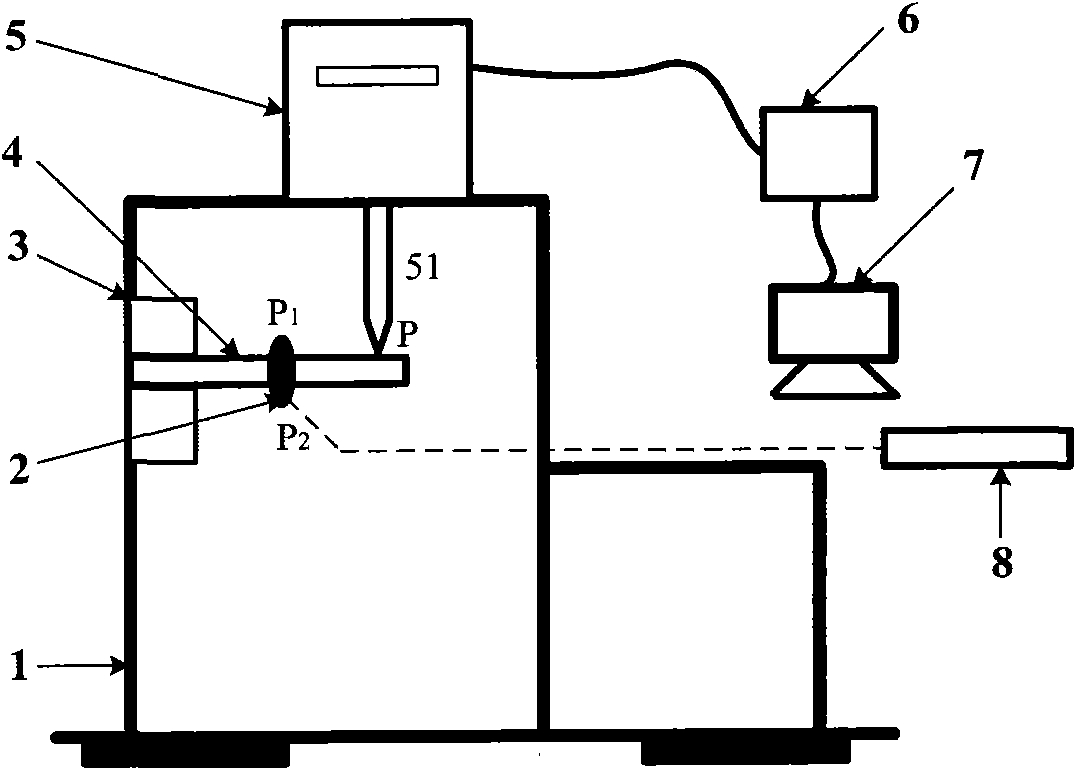

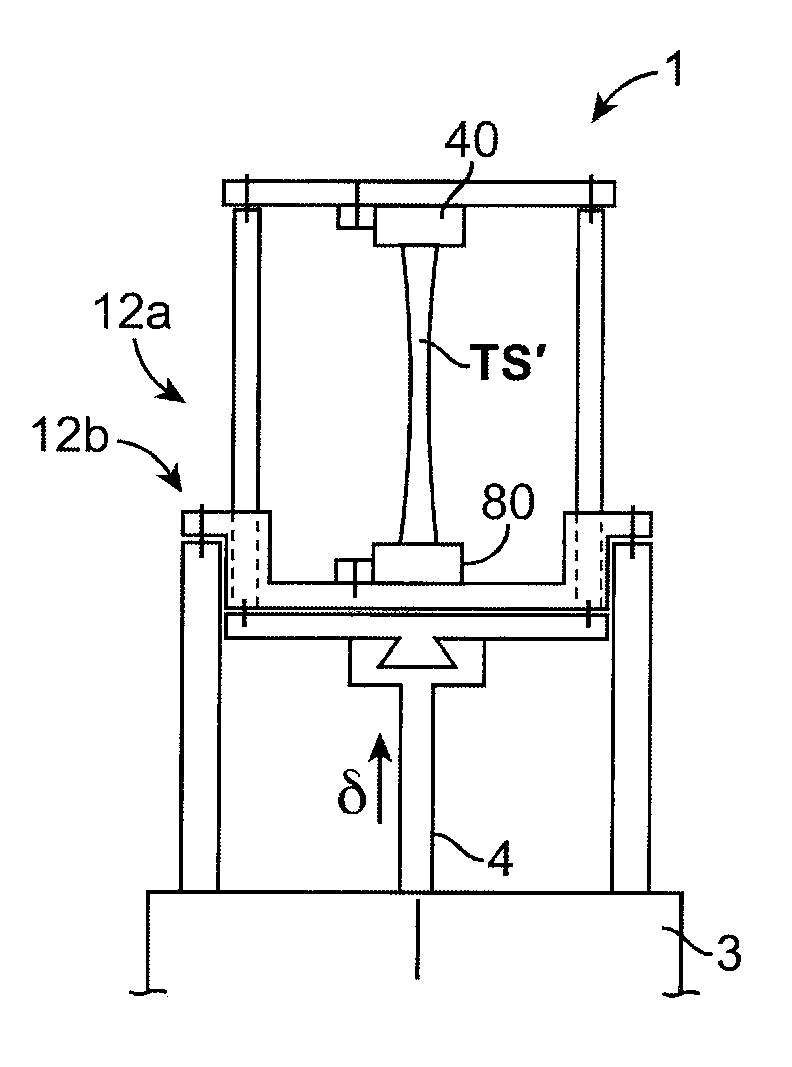

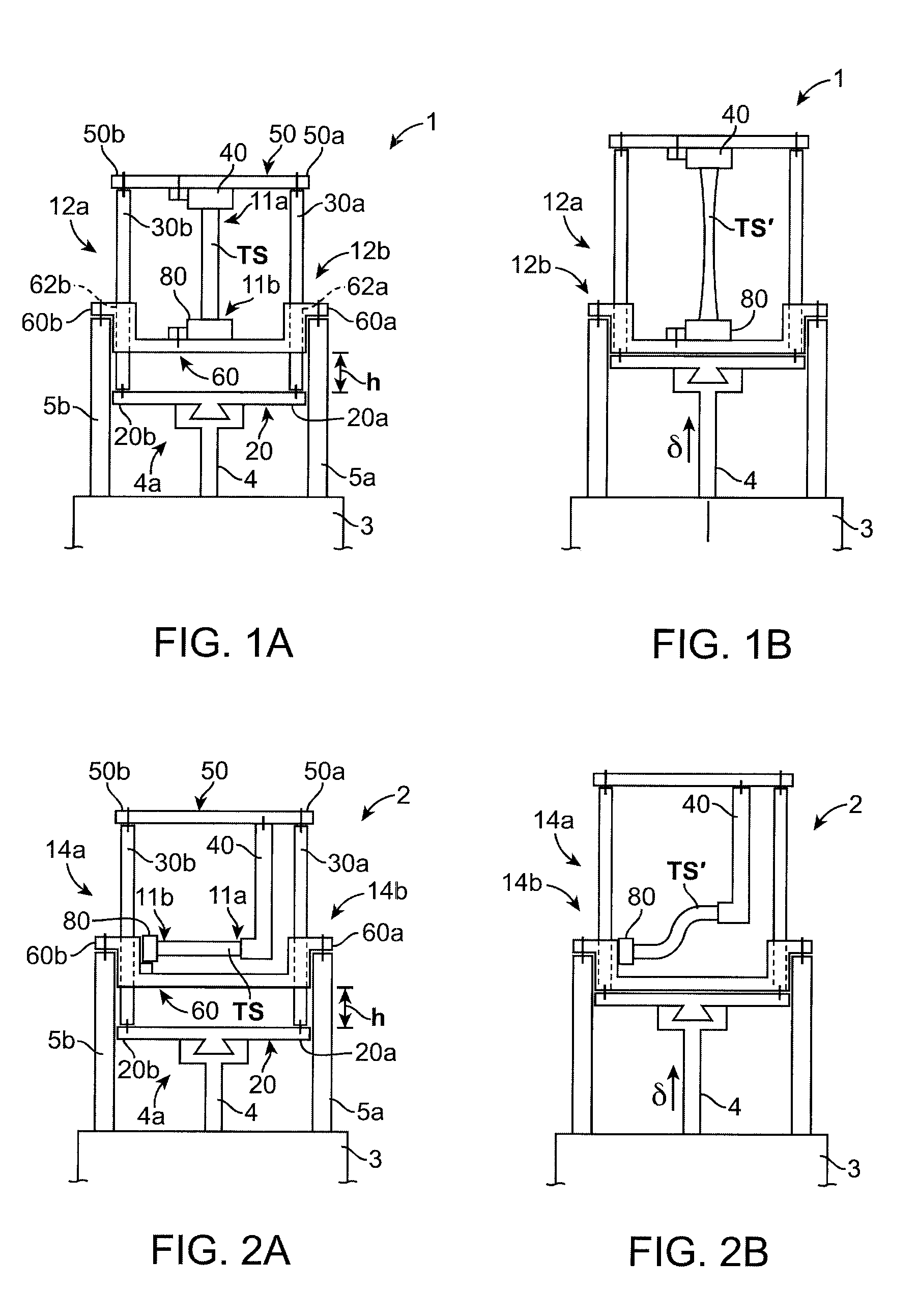

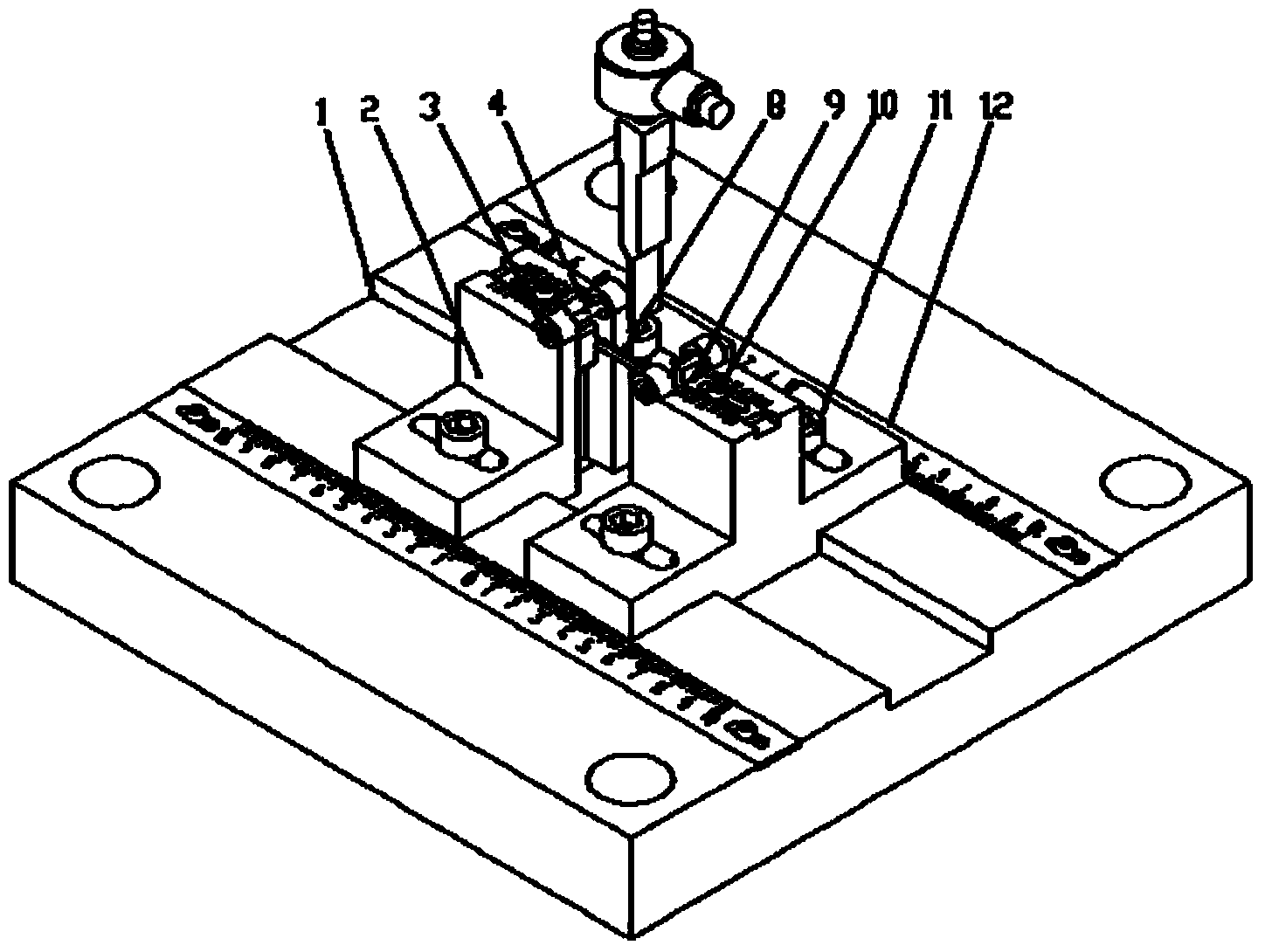

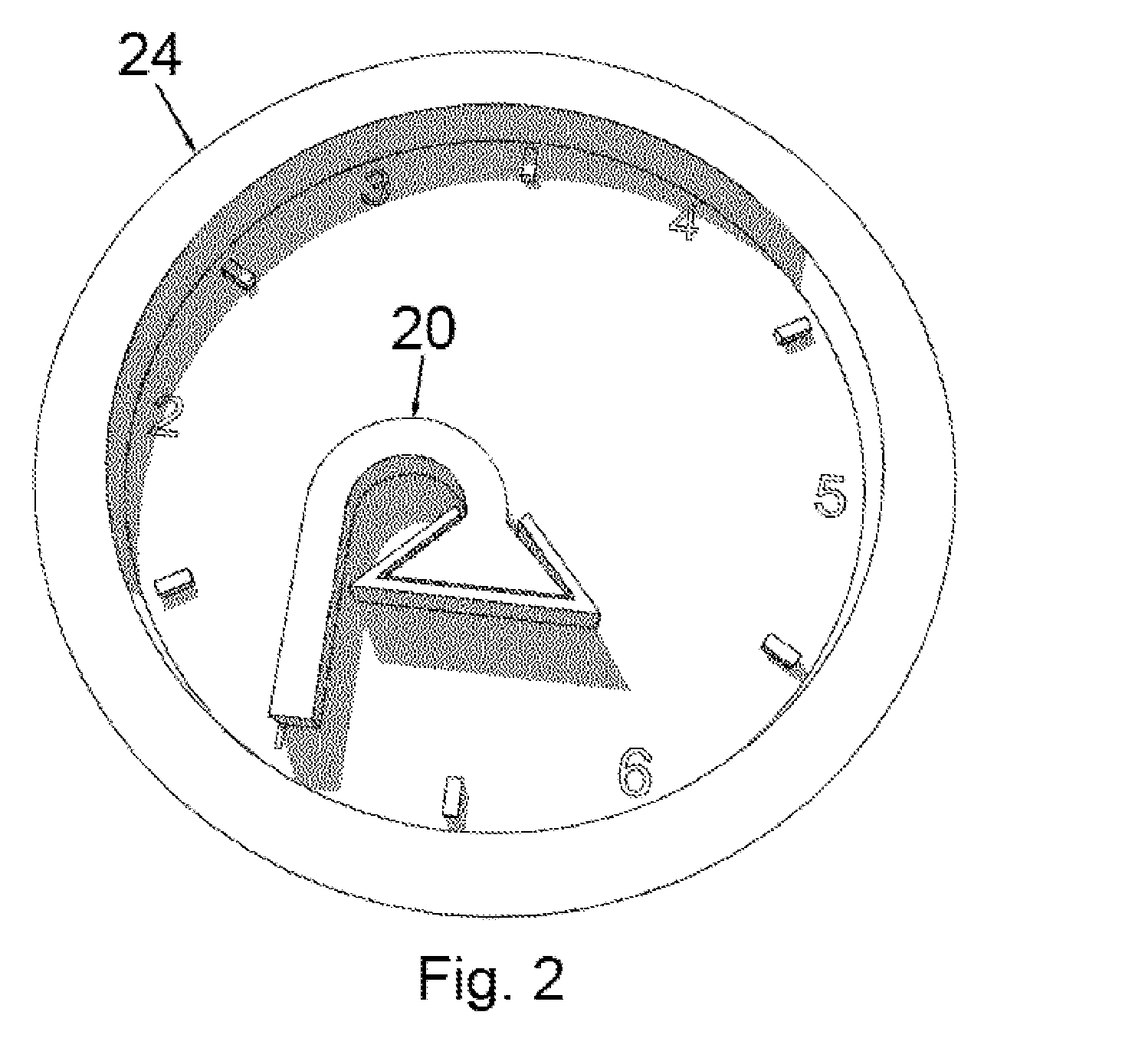

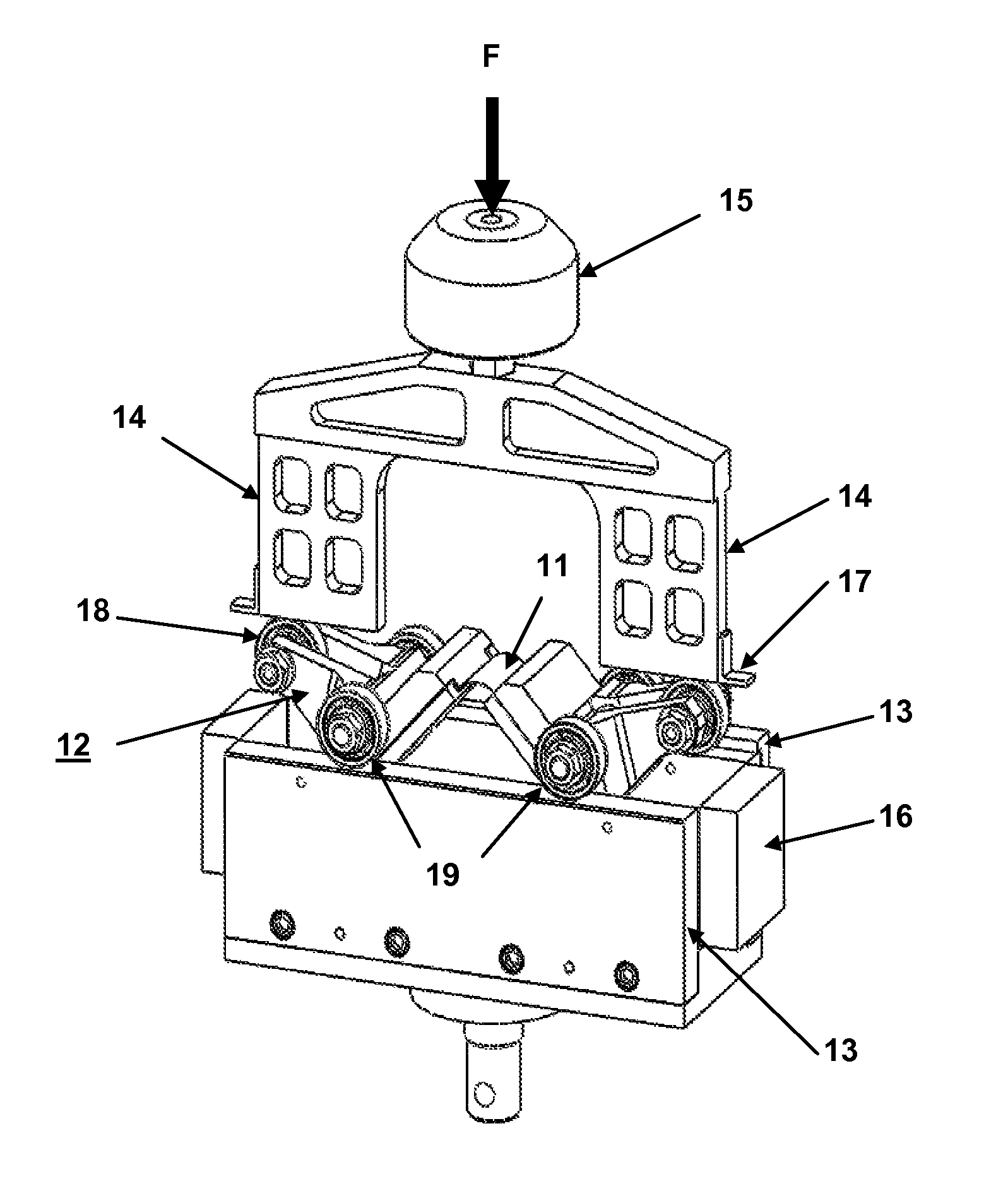

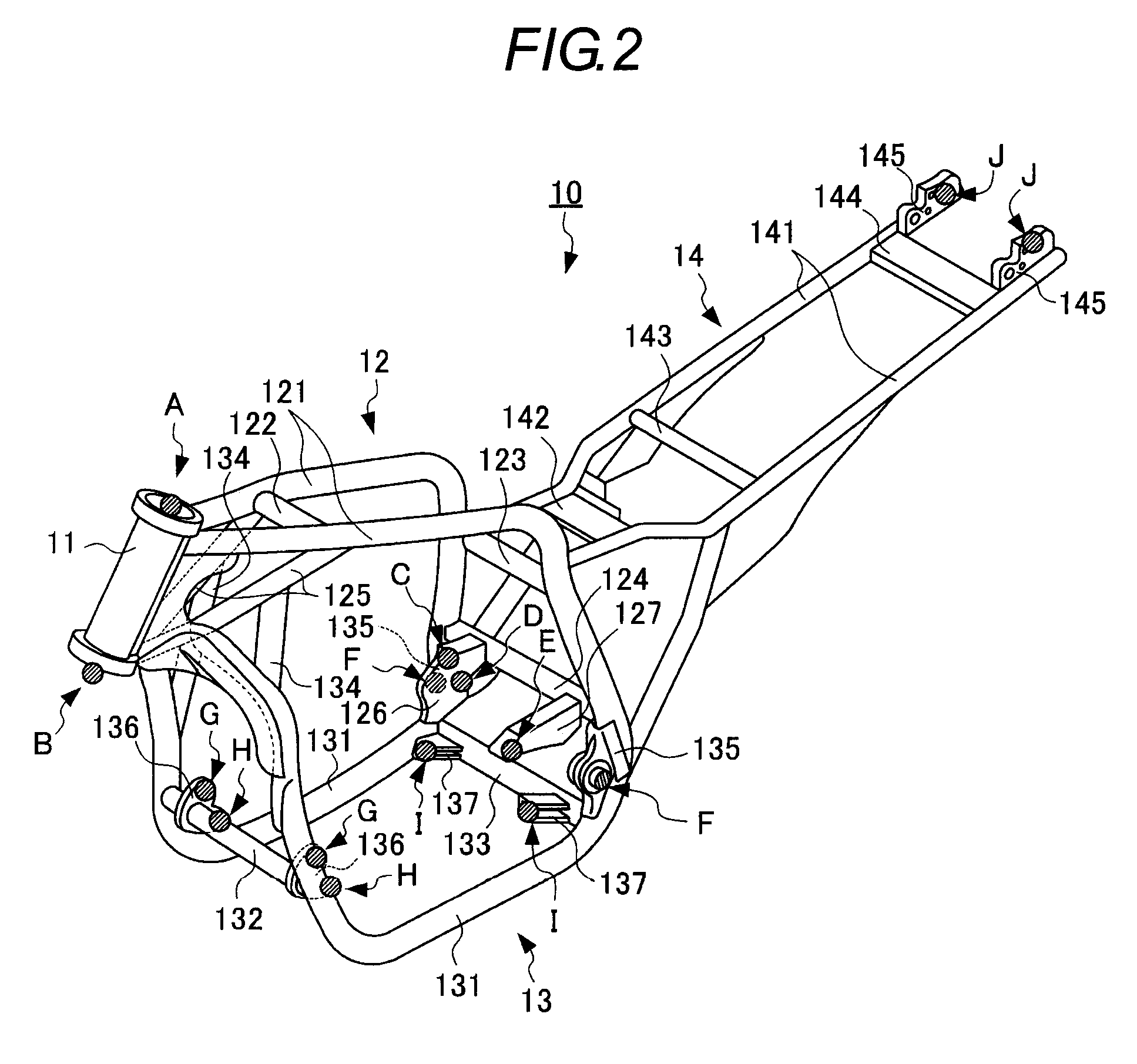

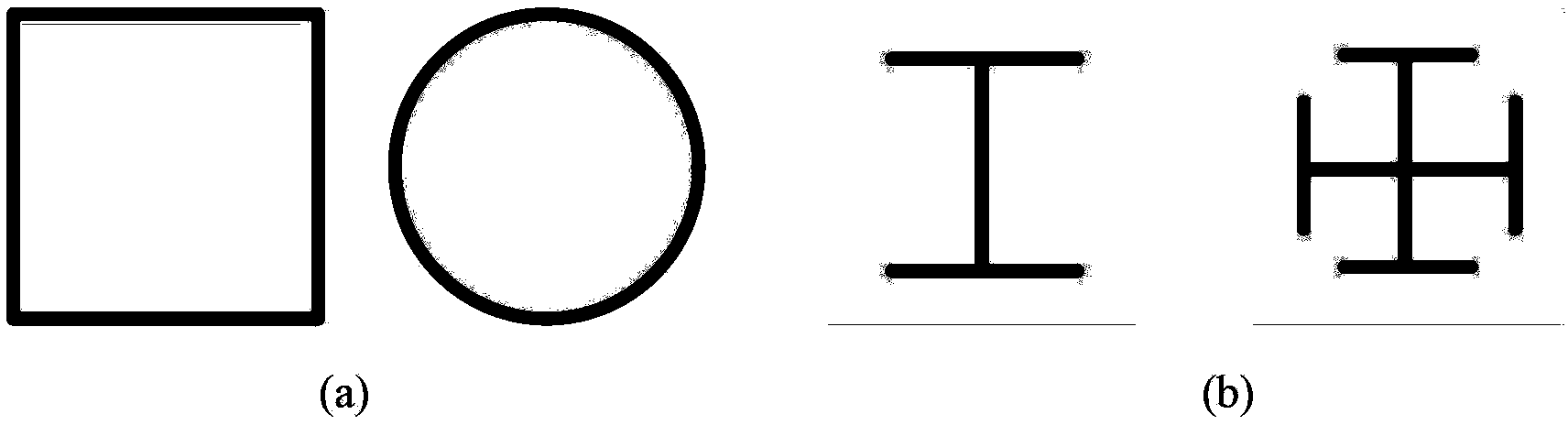

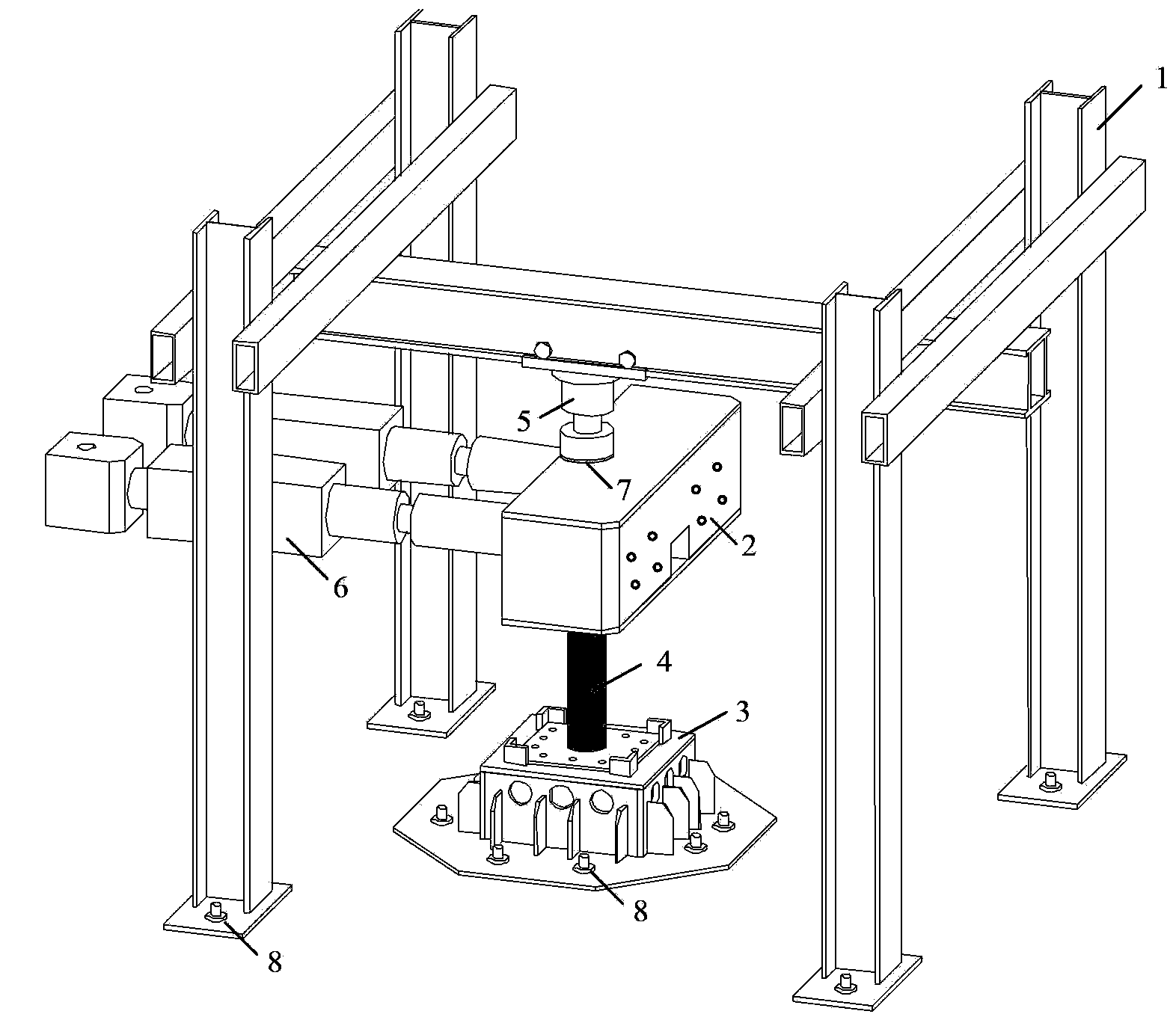

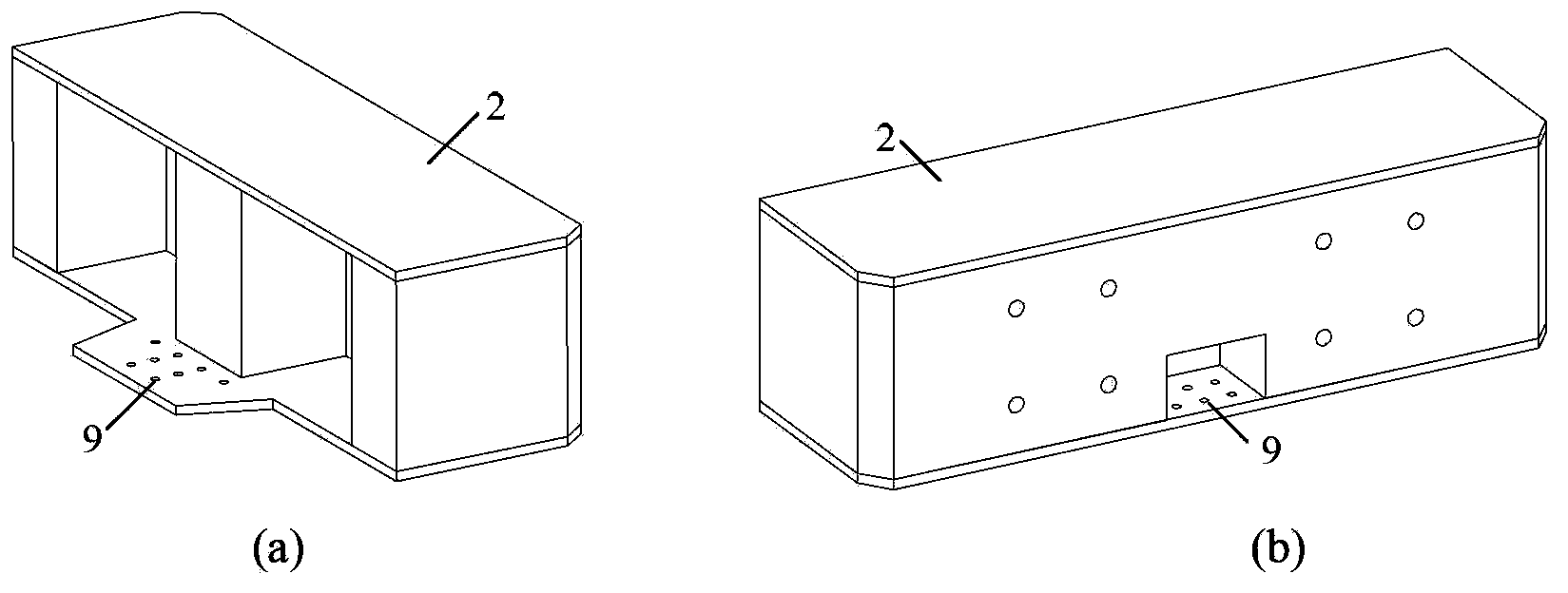

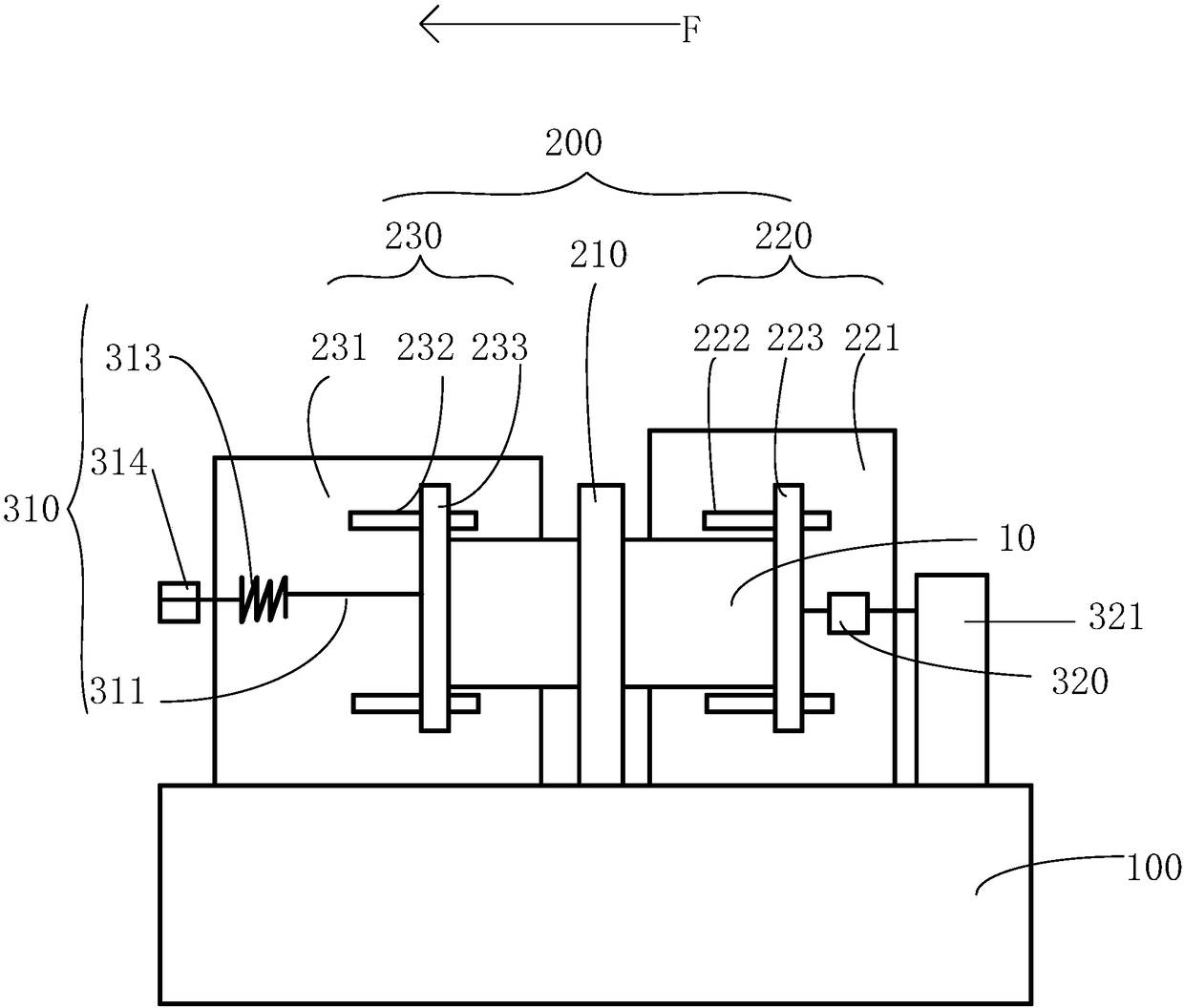

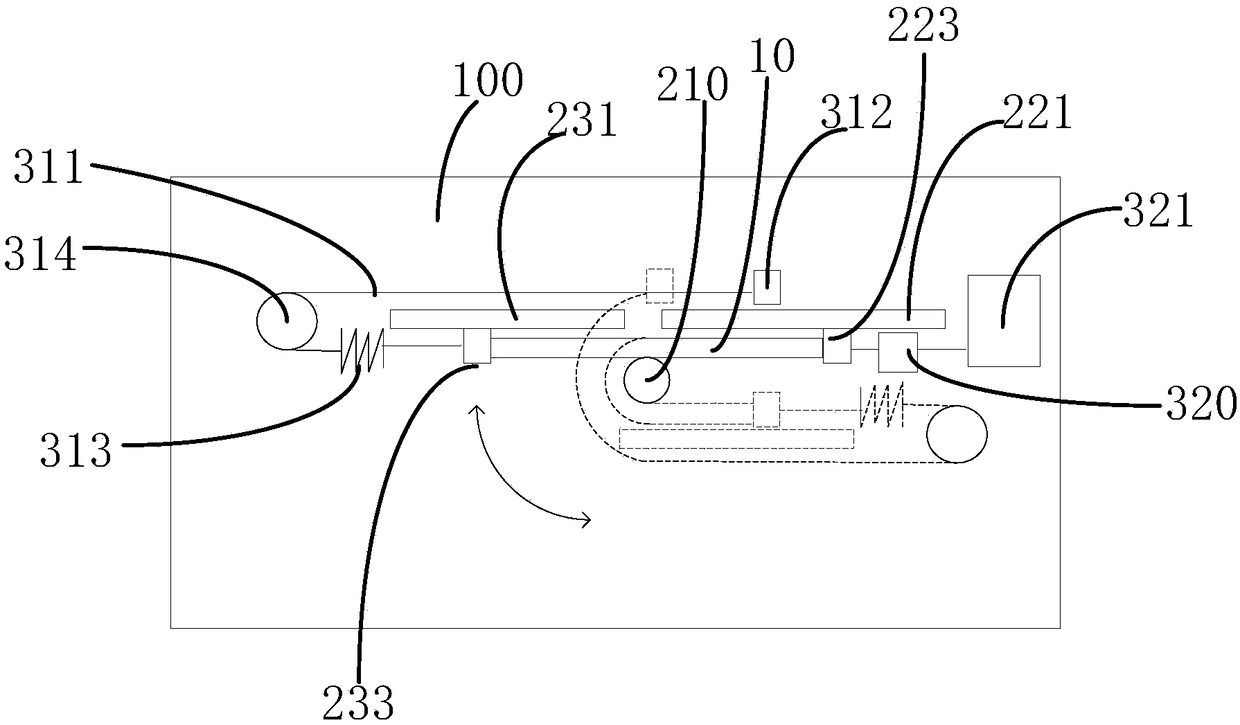

Three-way loading mechanical property test system of multifunctional lining segment joint

ActiveCN102004054AHigh simulationDisplacement boundary conditions are consistentMaterial strength using steady bending forcesMaterial strength using steady shearing forcesPilot systemModular design

The invention provides a three-way loading mechanical property test system of a multifunctional lining segment joint, which mainly comprises a self-balancing frame sub-system, a loading sub-system, a test-piece support sub-system, a test-piece transporting sub-system, a loading control sub-system and a data acquisition sub-system. The loading sub-system adopts a modular design and can finish a shield tunneling lining segment inter-ring shearing test, a bending moment transferring test, a longitudinal joint corner rigidity test, a longitudinal joint radial shearing test and the like by different combinations. The system of the invention can preferably imitate three-way stress states of the shield tunneling lining segment joint in actual conditions and can finish various different loading modes to obtain mechanical parameters of the shield tunneling lining segment joint and mechanical properties of other similar structures.

Owner:TONGJI UNIV

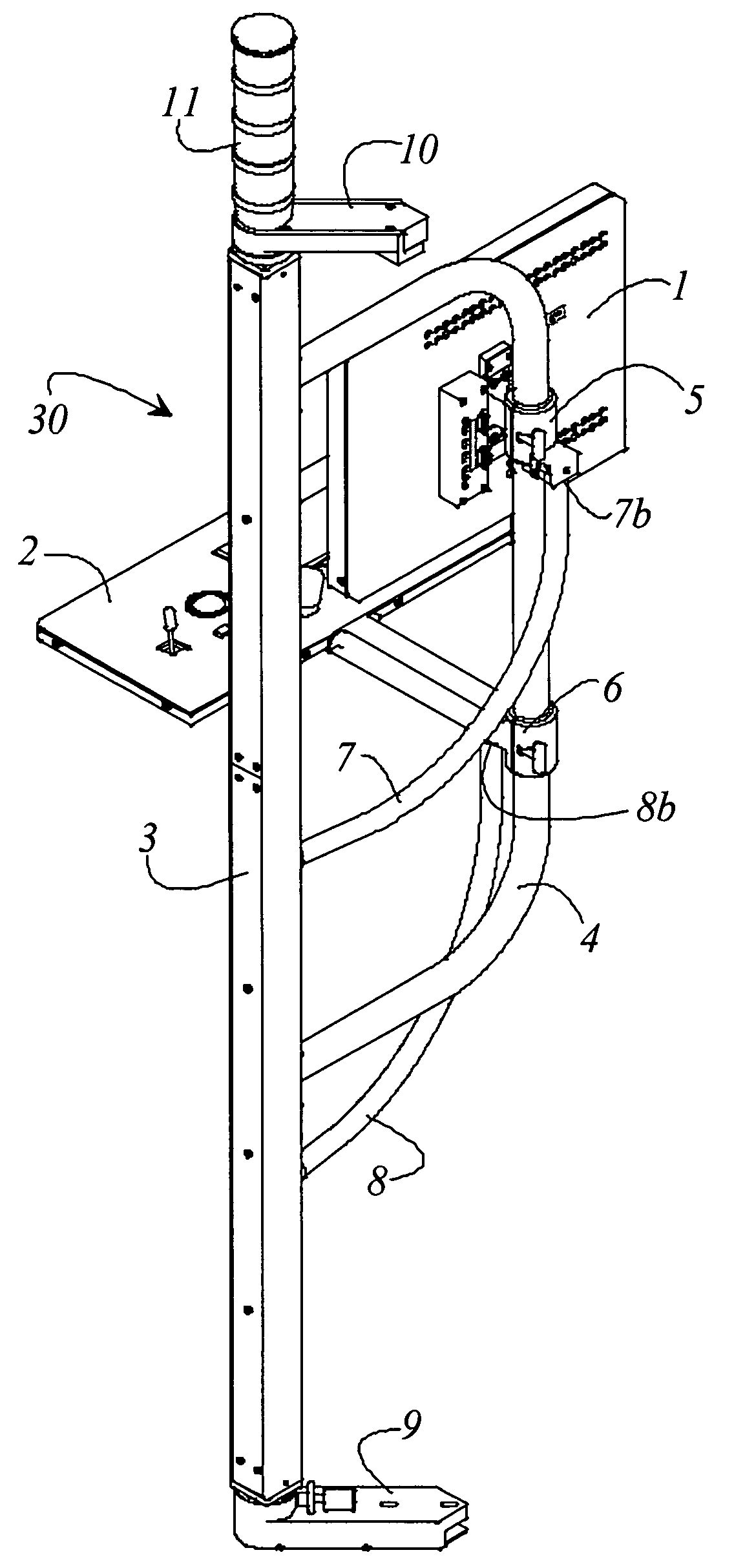

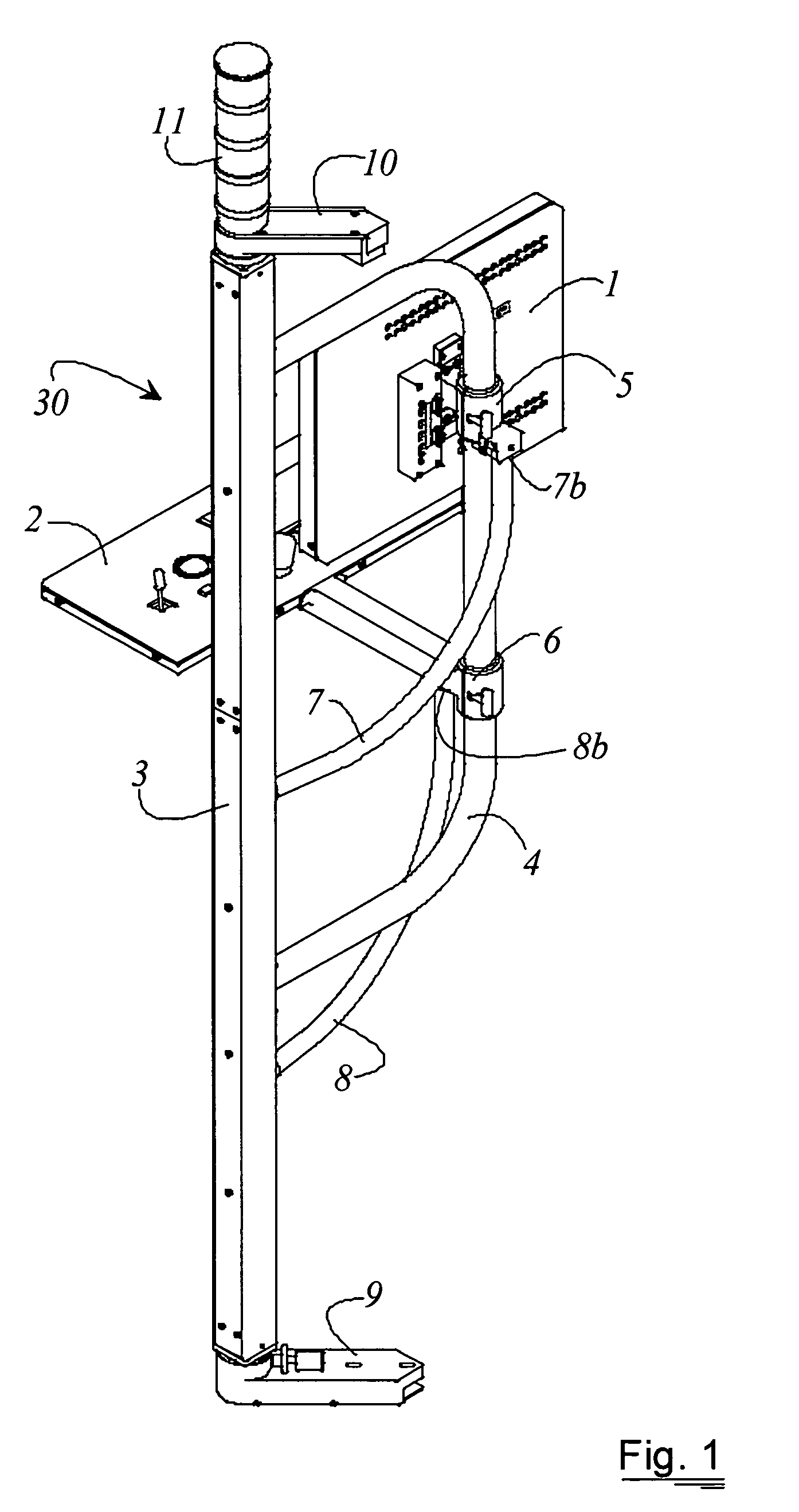

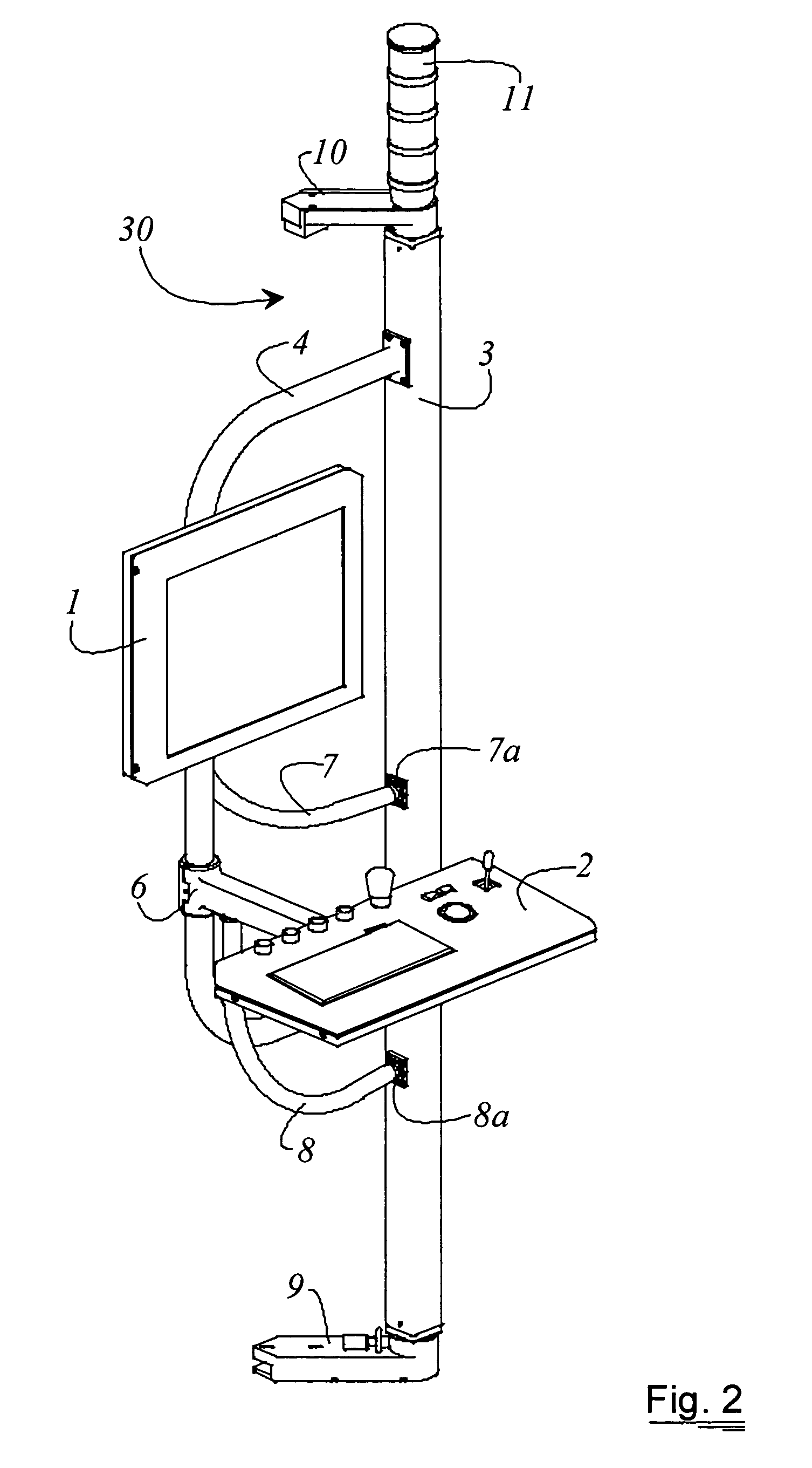

System operating unit

InactiveUS7152488B2Attachment is possiblePipe supportsSemiconductor/solid-state device manufacturingEngineeringVertical axis

The invention concerns a system operating unit (30) having a column (3) that is attachable by way of at least two supports (9, 10) to different points of a system housing (14). In the preferred embodiment, this column is attached laterally to the housing, the supports serving for attachment to the housing of the system. In addition, a retaining bracket (4) is connected to the column (3) in such a way that a horizontal deflection of the retaining bracket (4) about a vertical axis is possible.

Owner:LEICA MICROSYSTEMS SEMICON GMBH

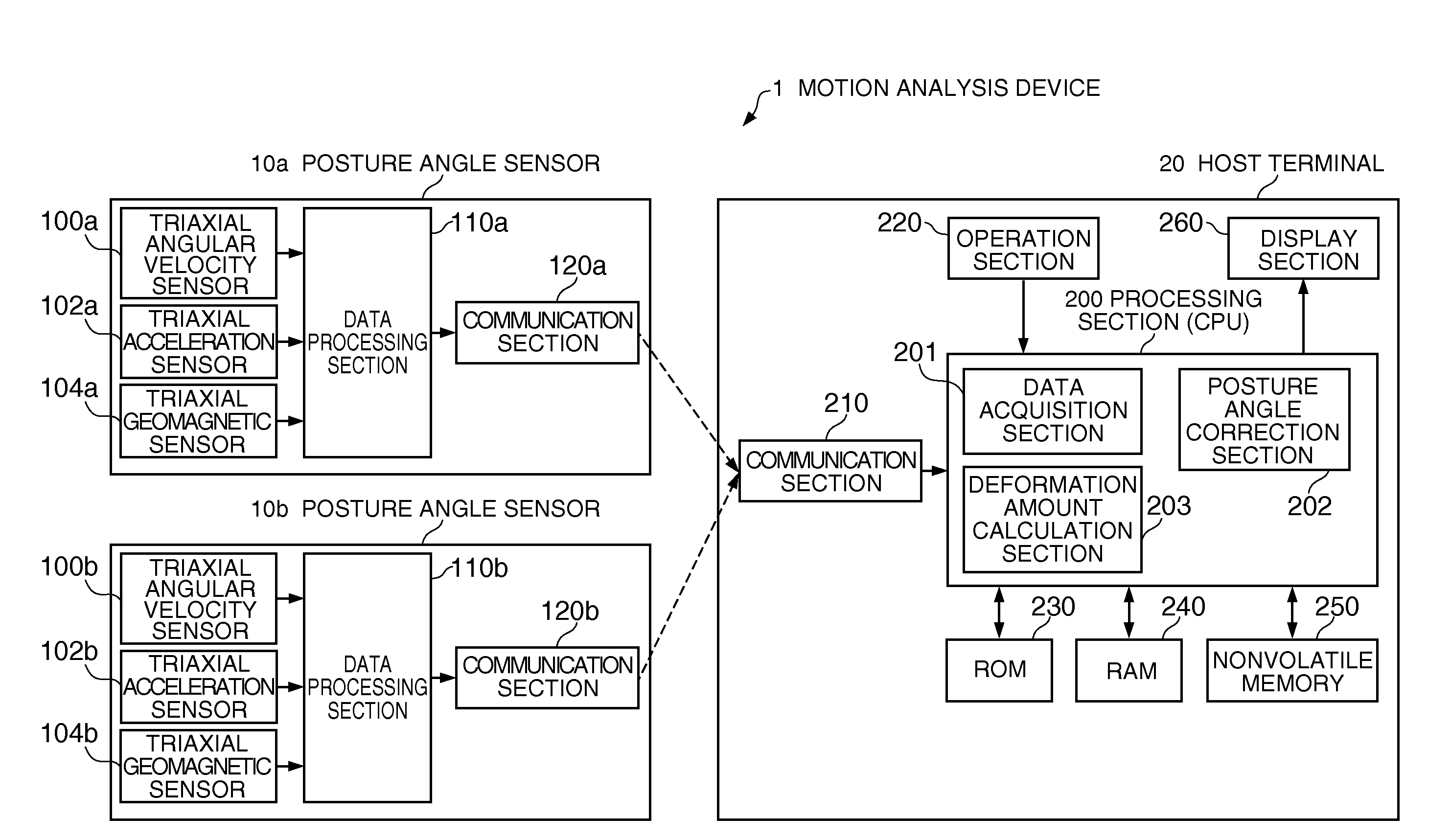

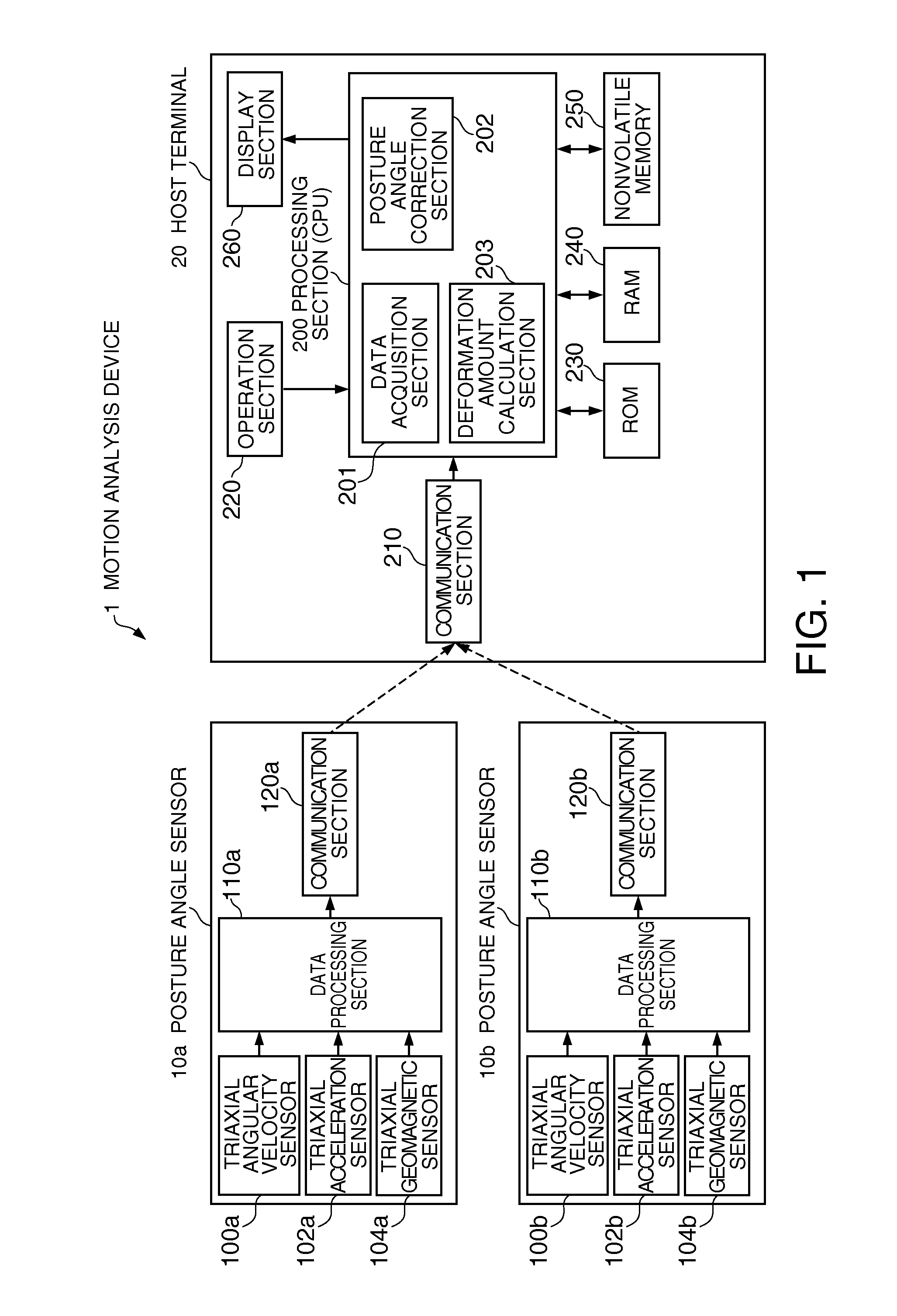

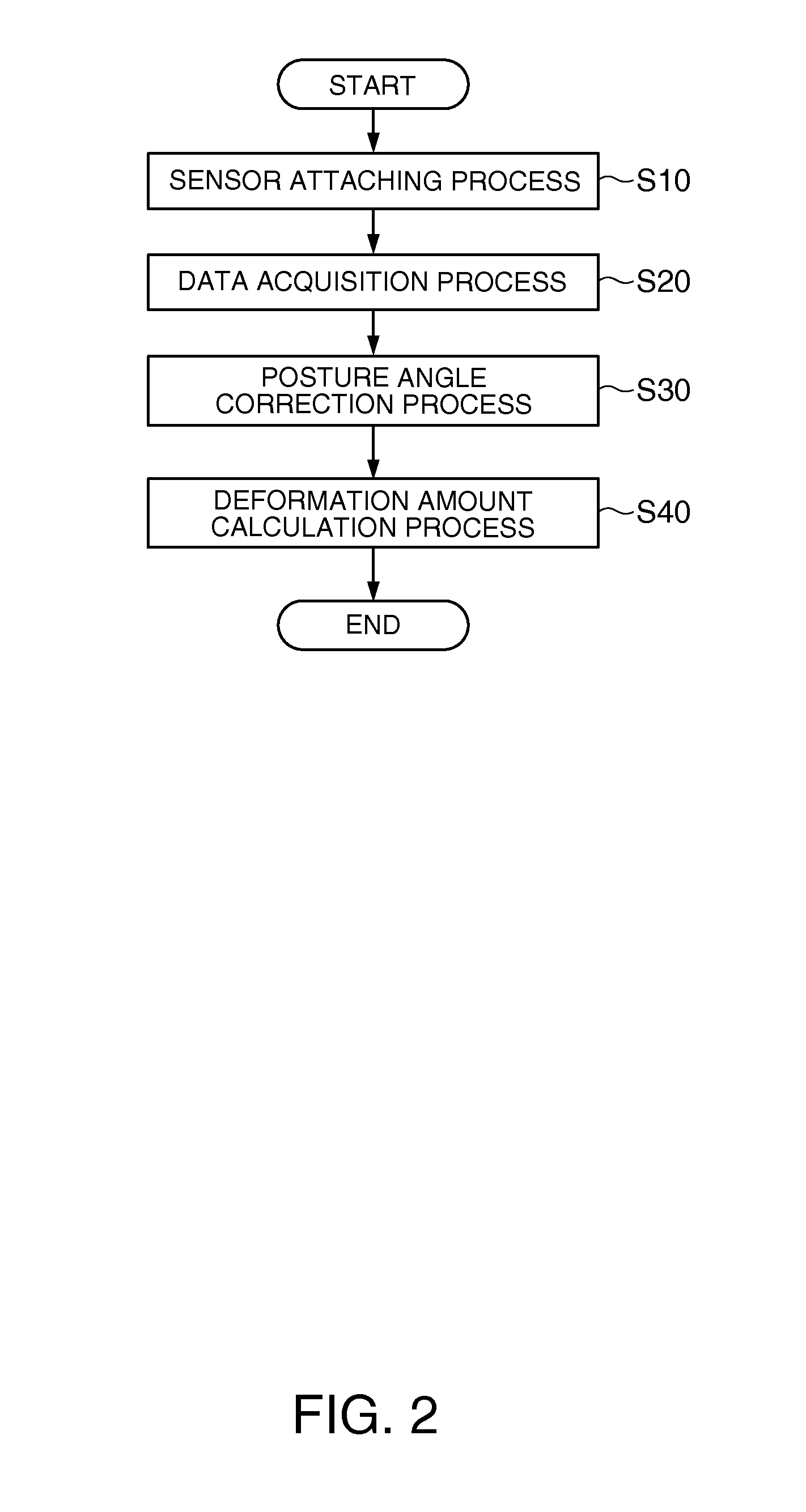

Motion analysis device and motion analysis method

ActiveUS20120179418A1Accurate calculationImprove accuracyGymnastic exercisingDigital computer detailsObject basedData acquisition

A motion analysis device includes two posture angle sensors attached to a measurement object at locations distant from each other, a data acquisition section, a posture angle correction section, and a deformation amount calculation section. The data acquisition section acquires data of a first posture angle and a second posture angle respectively detected by the posture angle sensors. The posture angle correction section corrects a difference between the first posture angle and the second posture angle after starting a motion of the measurement object in accordance with a difference between the first posture angle and the second posture angle before starting the motion of the measurement object. The deformation amount calculation section calculates a deformation amount of the measurement object based on a difference between the first posture angle and the second posture angle corrected by the posture angle correction section.

Owner:SEIKO EPSON CORP

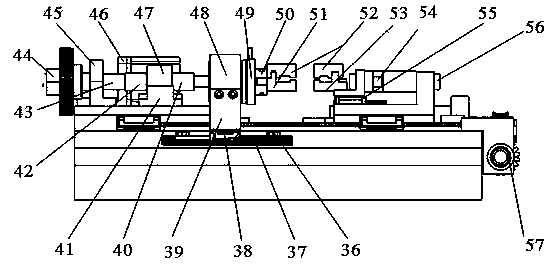

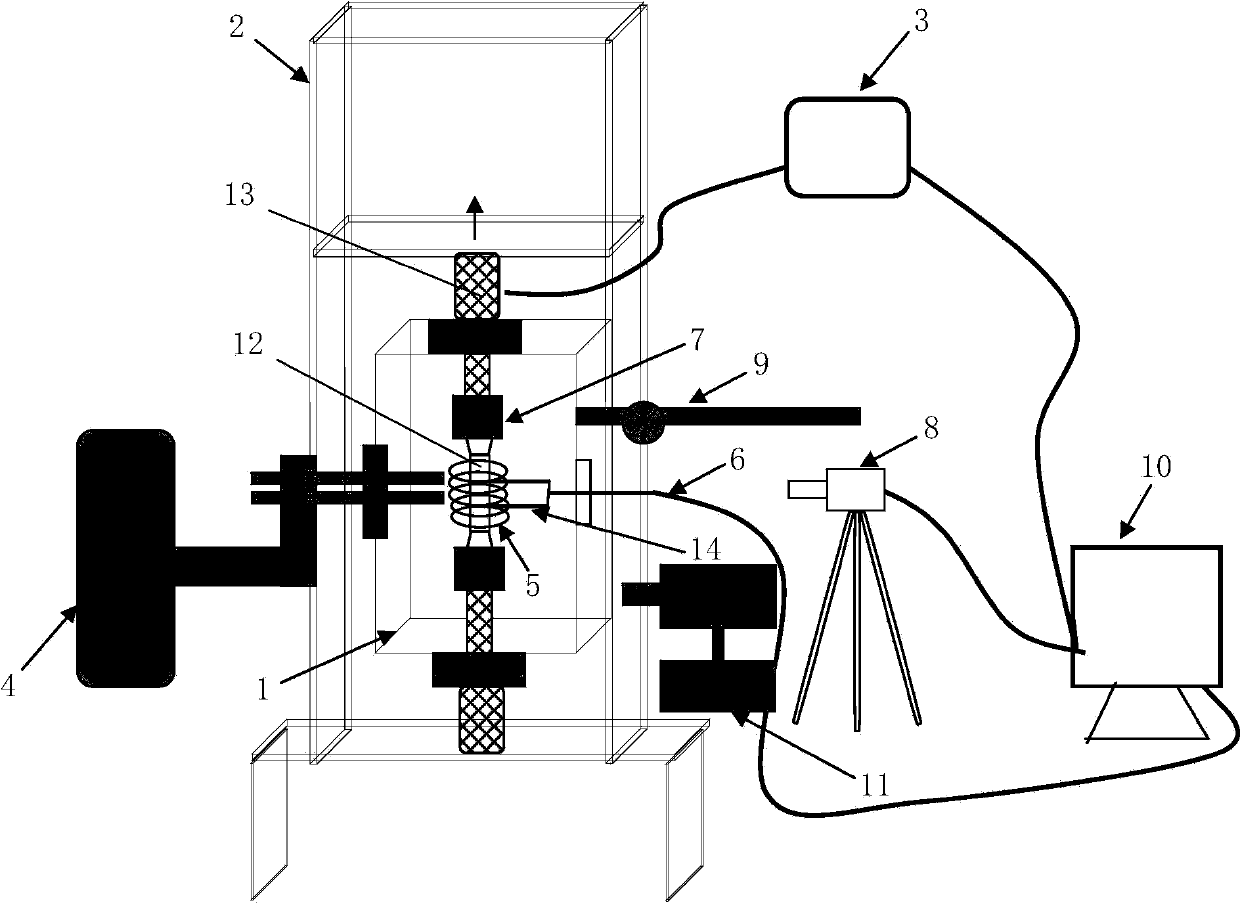

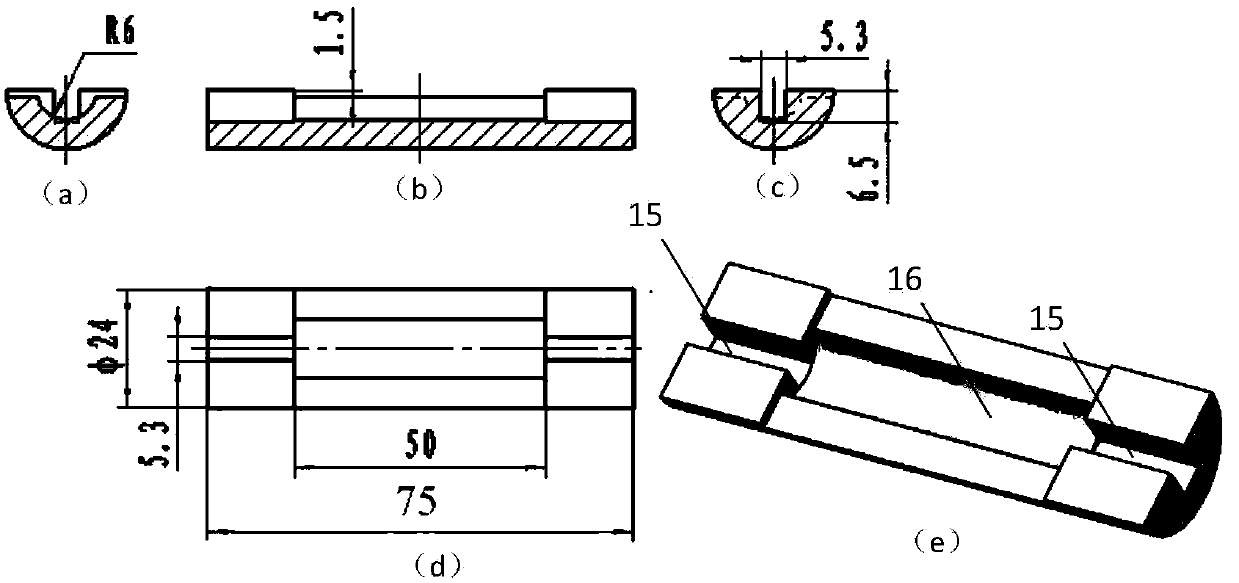

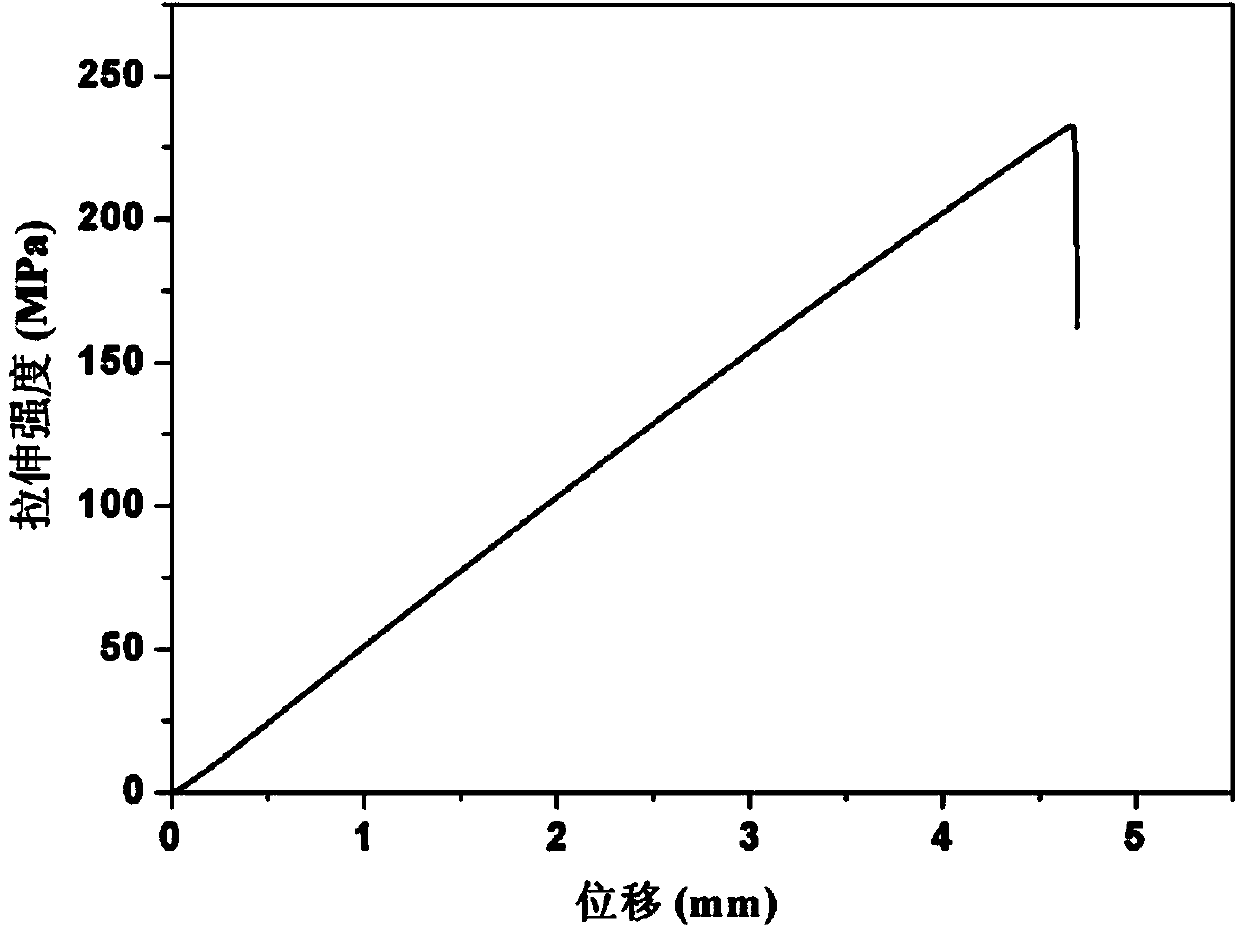

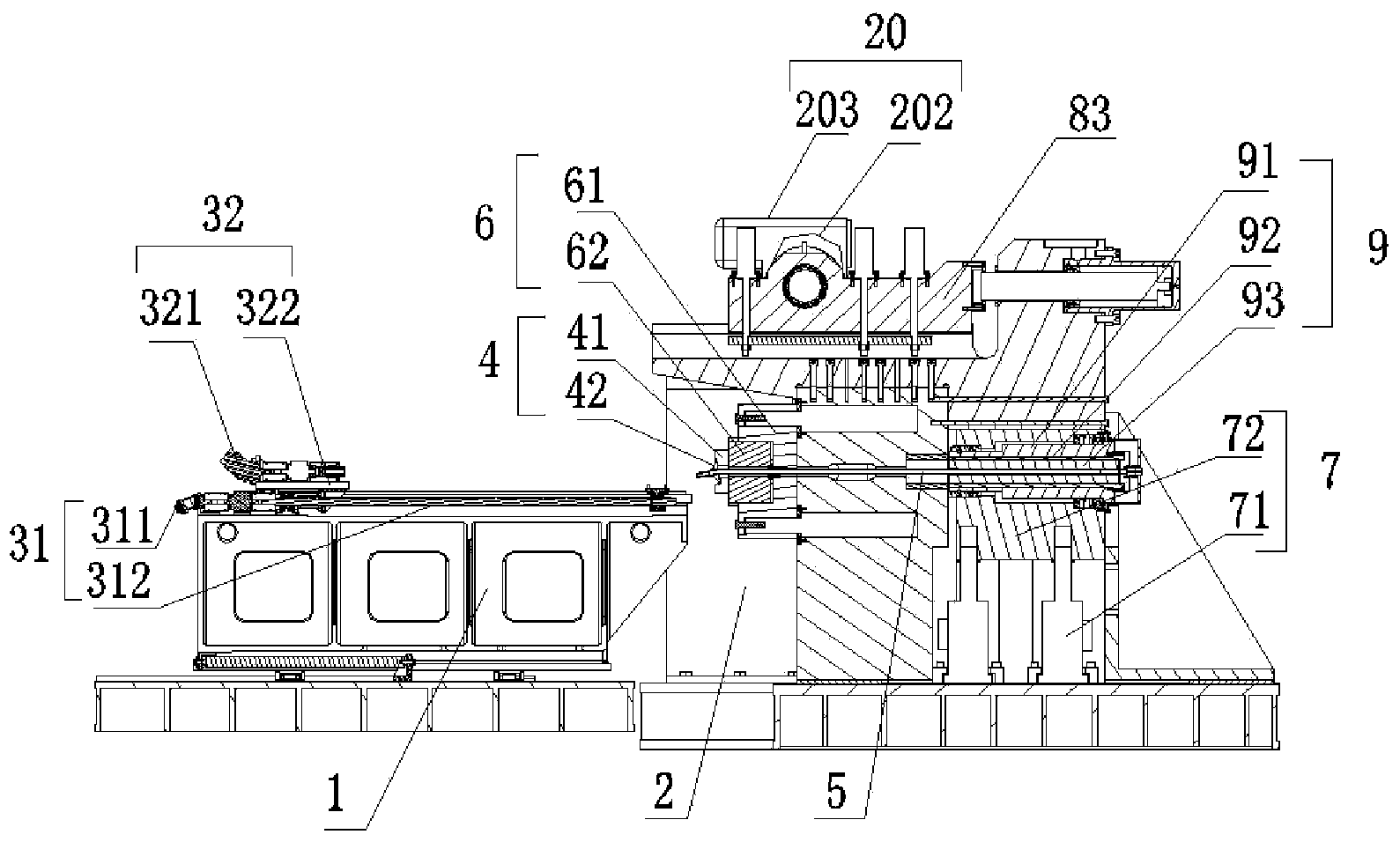

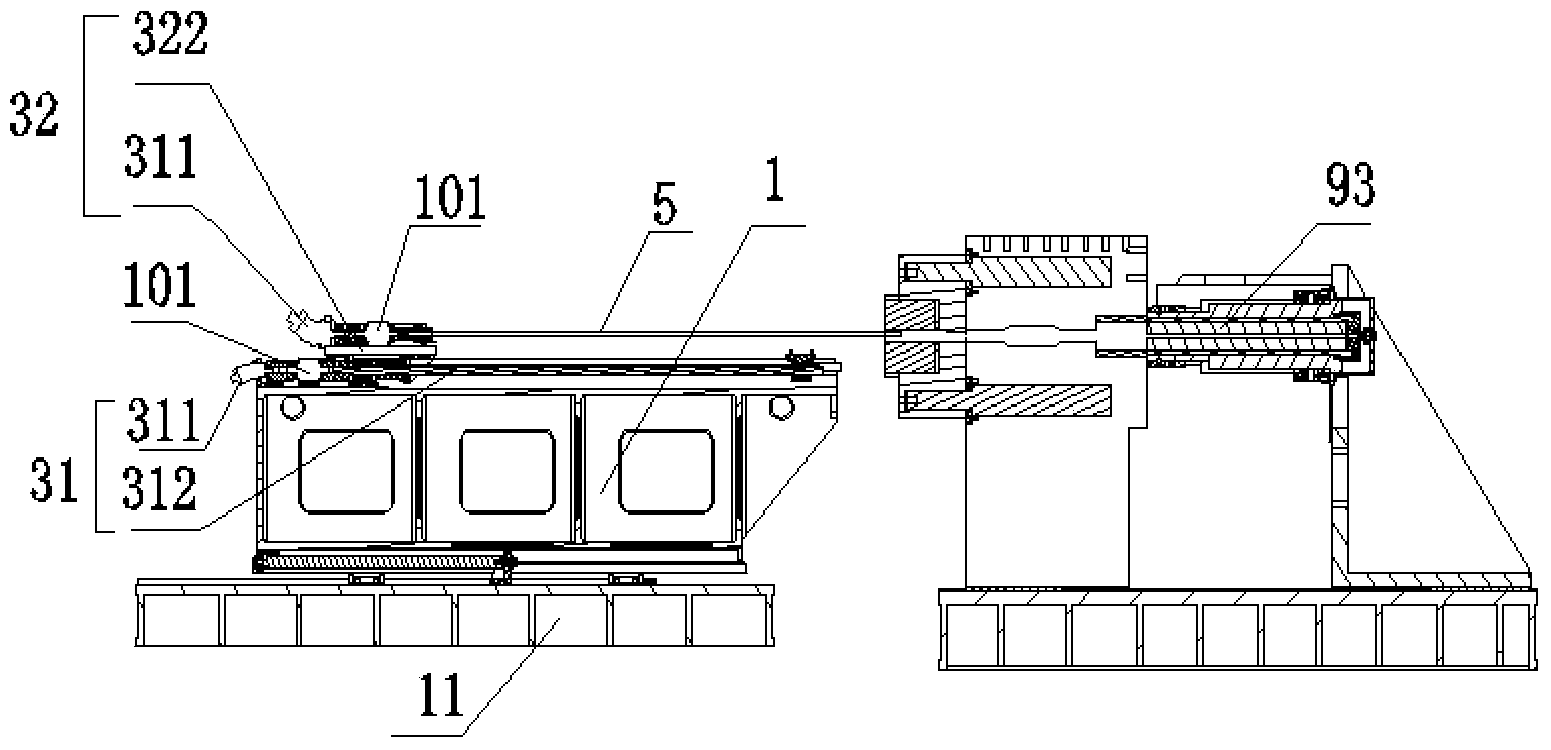

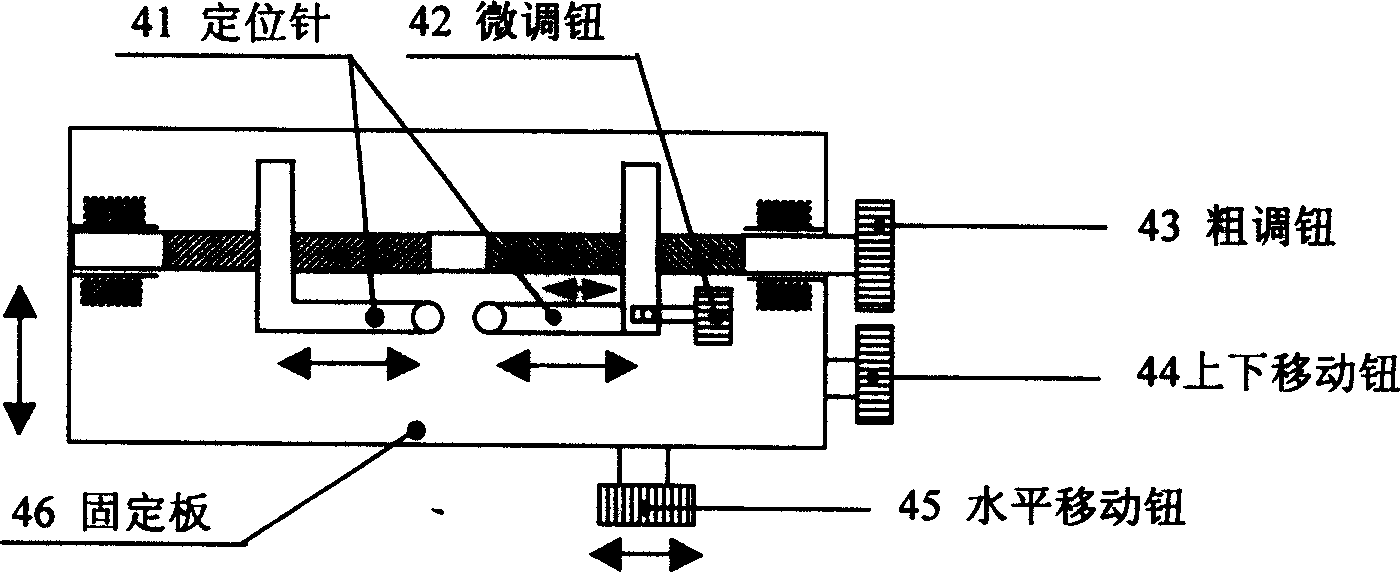

Micro material mechanical performance testing platform under stretching-bending-twisting multi-loads

ActiveCN103389243ANovel ideaCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectromechanicsStress level

The invention relates to a micro material mechanical performance testing platform under stretching-bending-twisting multi-loads, and belongs to the field of electromechanics. The micro material mechanical performance testing platform comprises a tension and compression module, a bending module, a twisting module, a detection control module and a test-piece clamping module, wherein the testing platform takes the tension and compression module as a basic function module; the twisting module is arranged at one end of the tension and compression module; the test-piece clamping module is arranged on the tension and compression module; the bending module is independently arranged at one side of a portal frame. The micro material mechanical performance testing platform can be taken as a material mechanical performance test device with an independent stretching / compressing mode or an independent bending mode or independent twisting mode, namely a single load testing mode, and can be applied to a material mechanical performance test of a twisting load under the given stretching / compressing stress level or a material mechanical performance test of a bending load under the given stretching / compressing stress level, namely a composite load testing mode. The stress strain process of a material under the effect of a composite load can be detected by the collection of a load / displacement signal by using the detection control module.

Owner:JILIN UNIV

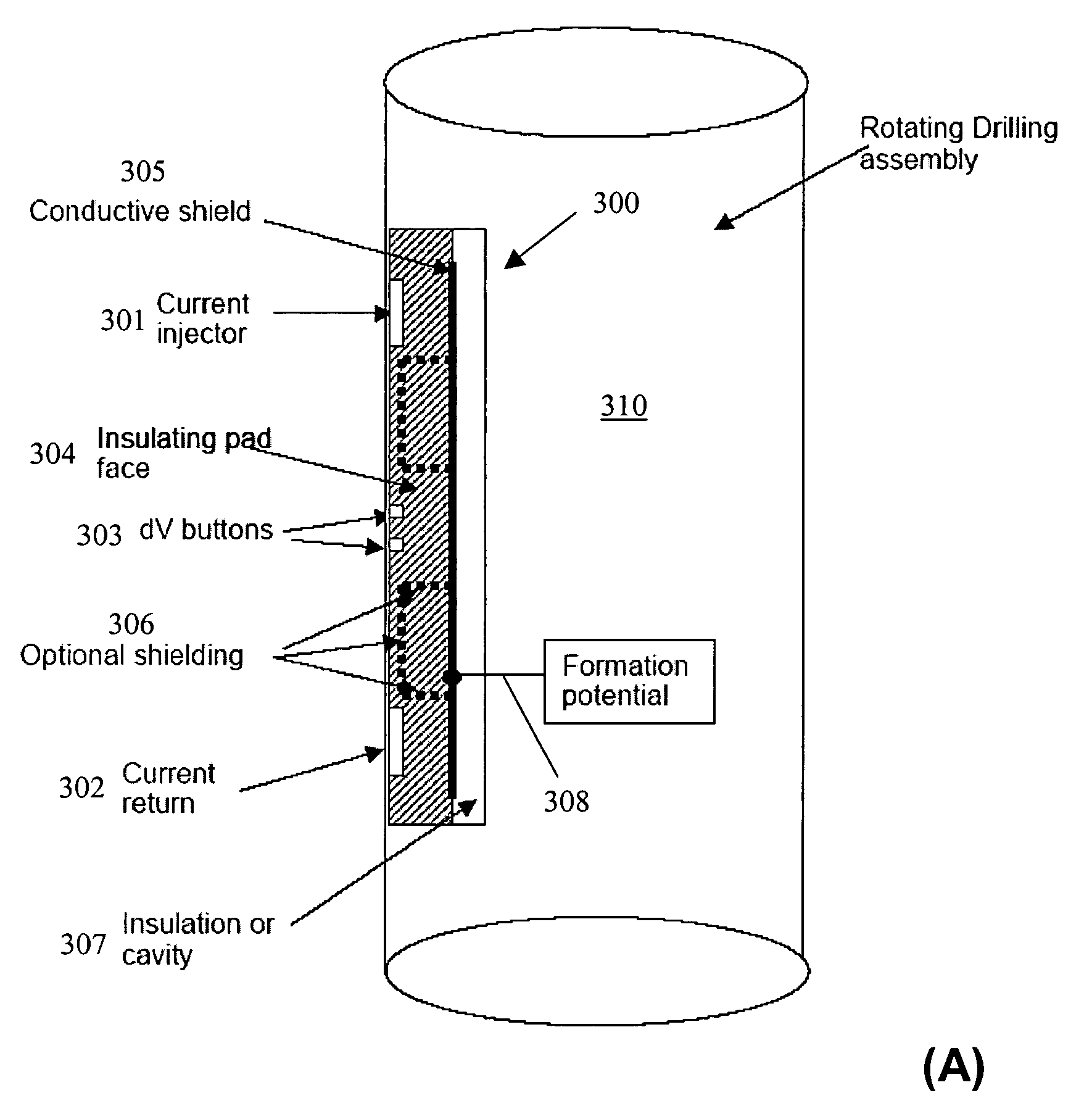

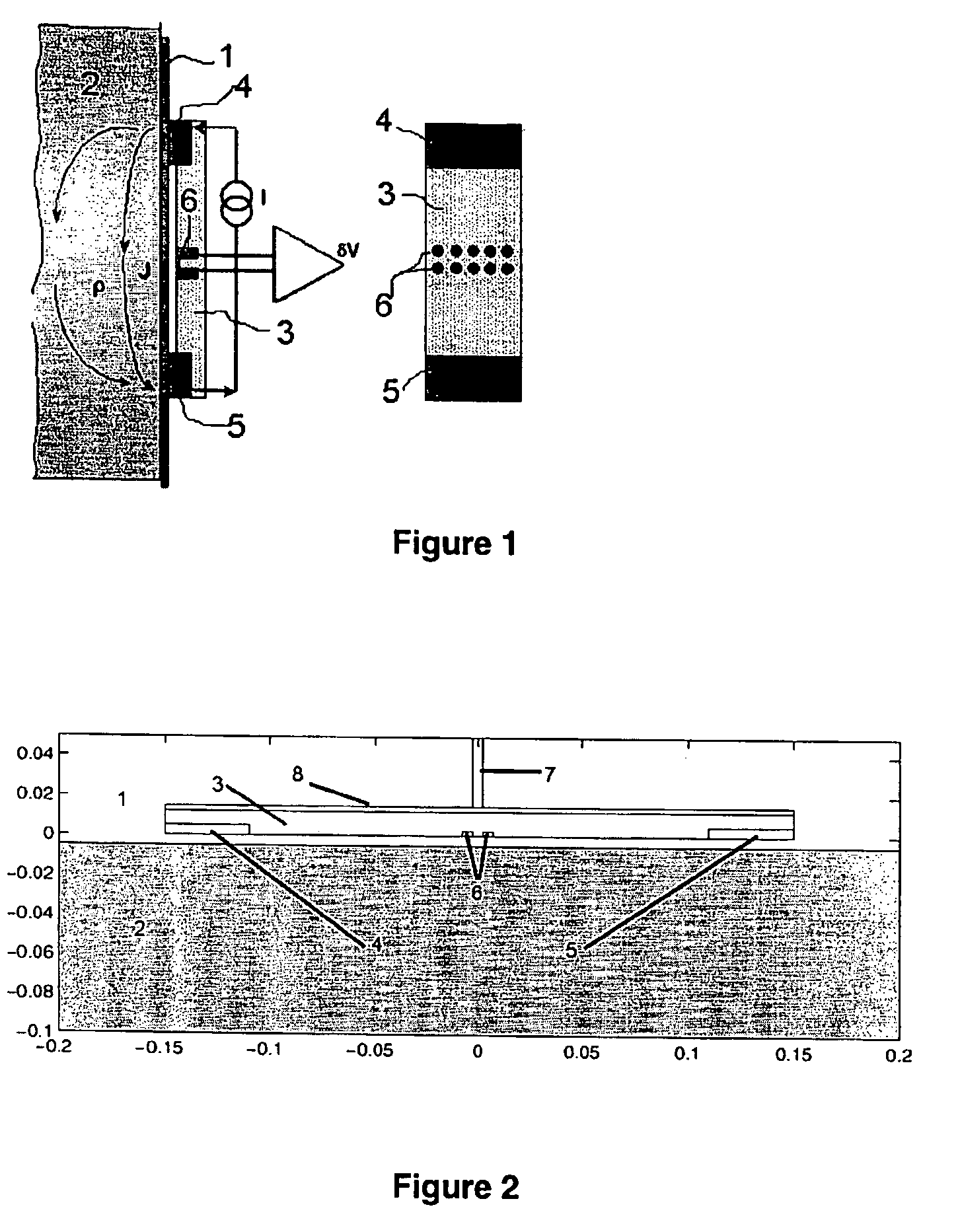

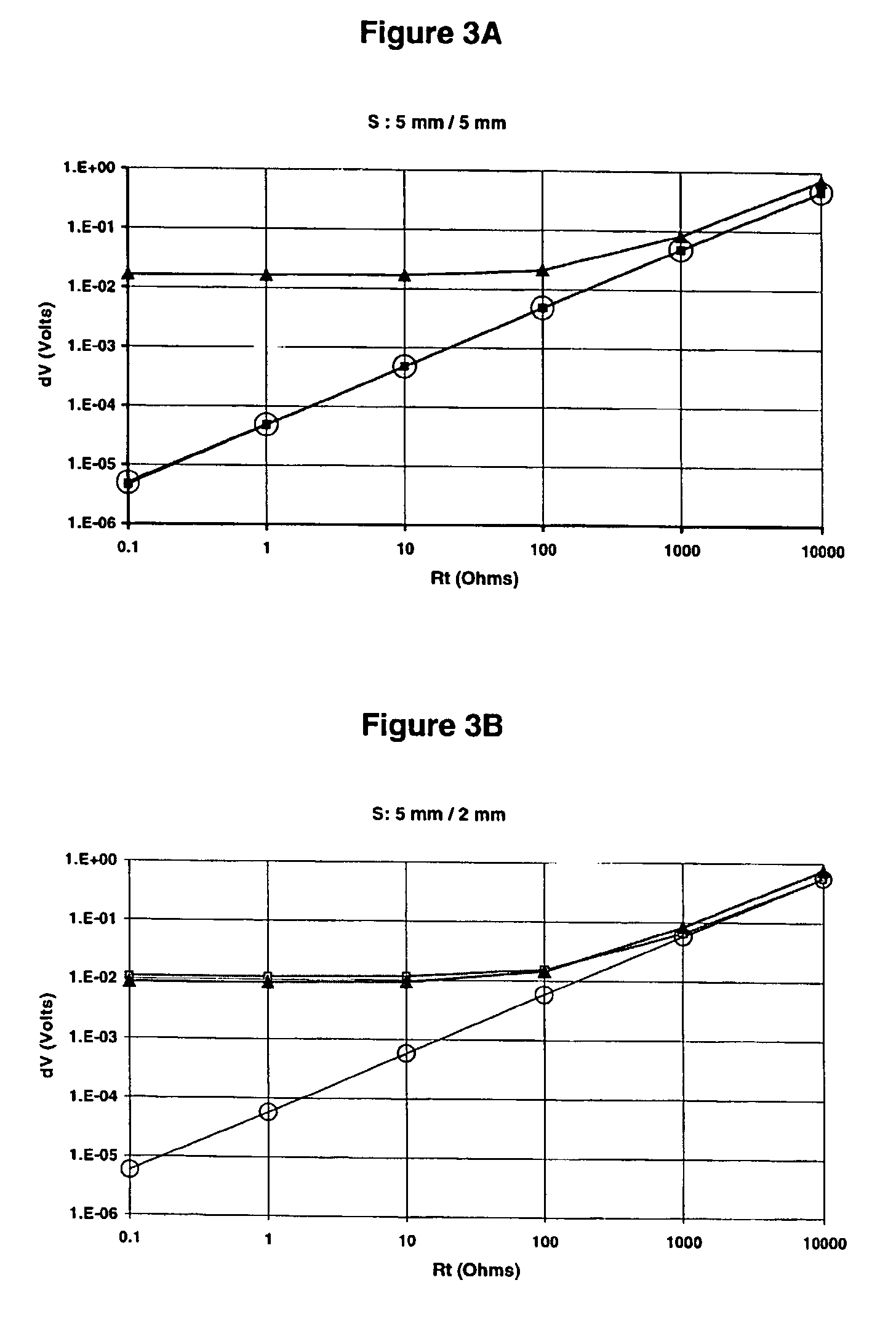

Formation imaging while drilling in non-conductive fluids

InactiveUS7242194B2Electric/magnetic detection for well-loggingMaterial strength using steady bending forcesConductive materialsEngineering

A resistivity tool for investigating a wall of a borehole drilled with a non-conductive mud includes a tool body adapted to be incorporated in a logging-while-drilling tool assembly; a resistivity sensor disposed on the tool body, wherein the resistivity sensor comprises a sensor pad supporting a current injector electrode, a current return electrode, and an array of measurement electrodes, and a circuitry for controlling current injection from the current injector electrode and for measuring voltage difference between electrodes in the array of measurement electrodes, wherein the current injector electrode and the current return electrode are disposed near opposite ends of the sensor pad and the array of measurement electrodes is disposed between the current injector electrode and the current return electrode, wherein the sensor pad is constructed of an insulating material and includes a conductive shielding member, or wherein the sensor pad is constructed of a conducting material and includes insulating sections around the electrodes.

Owner:SCHLUMBERGER TECH CORP

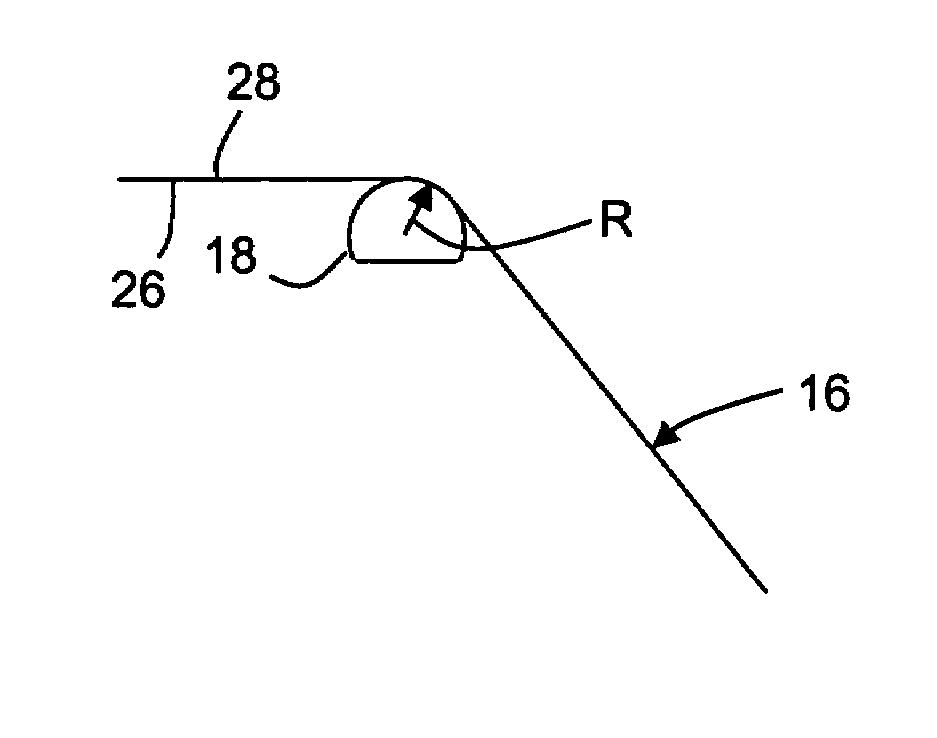

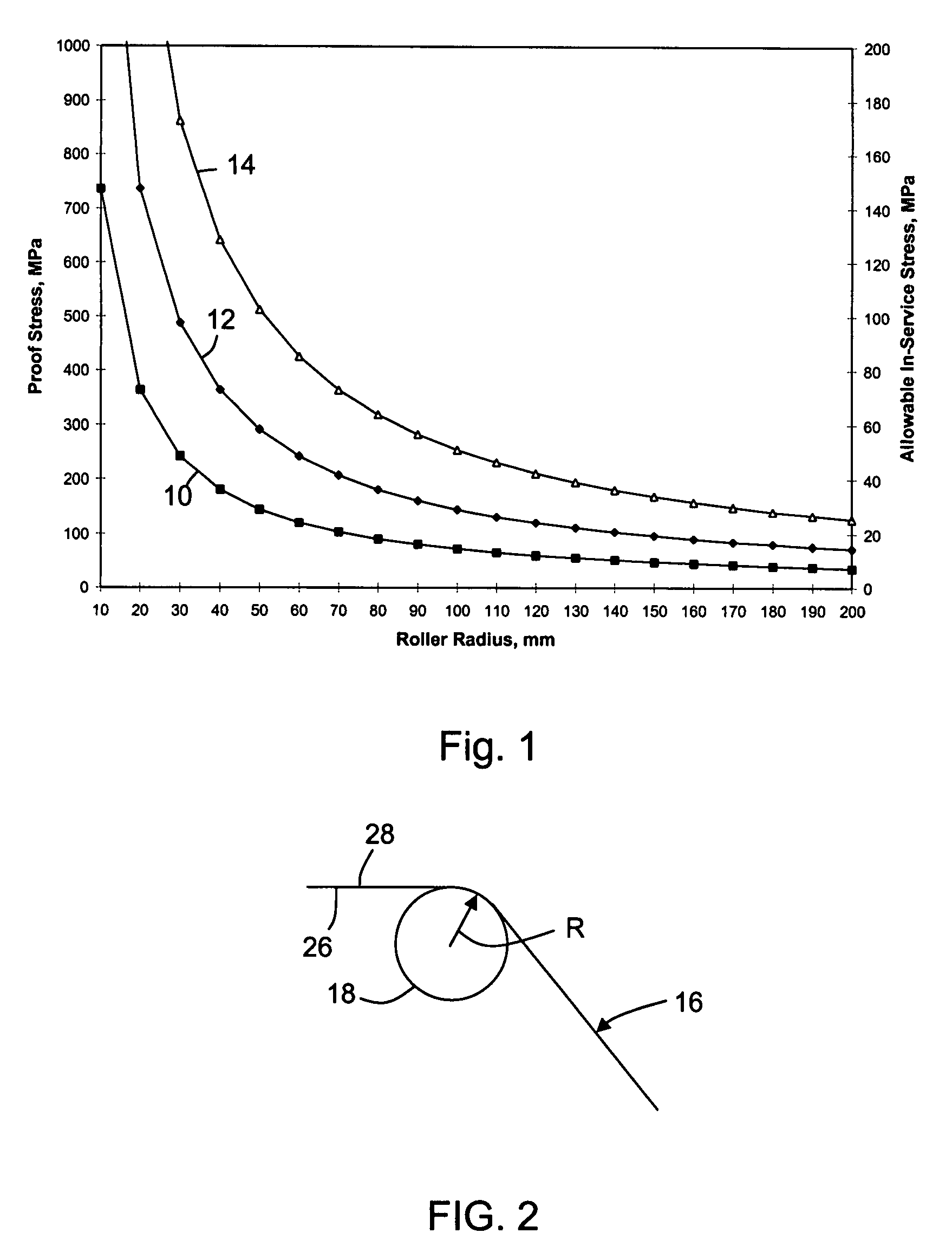

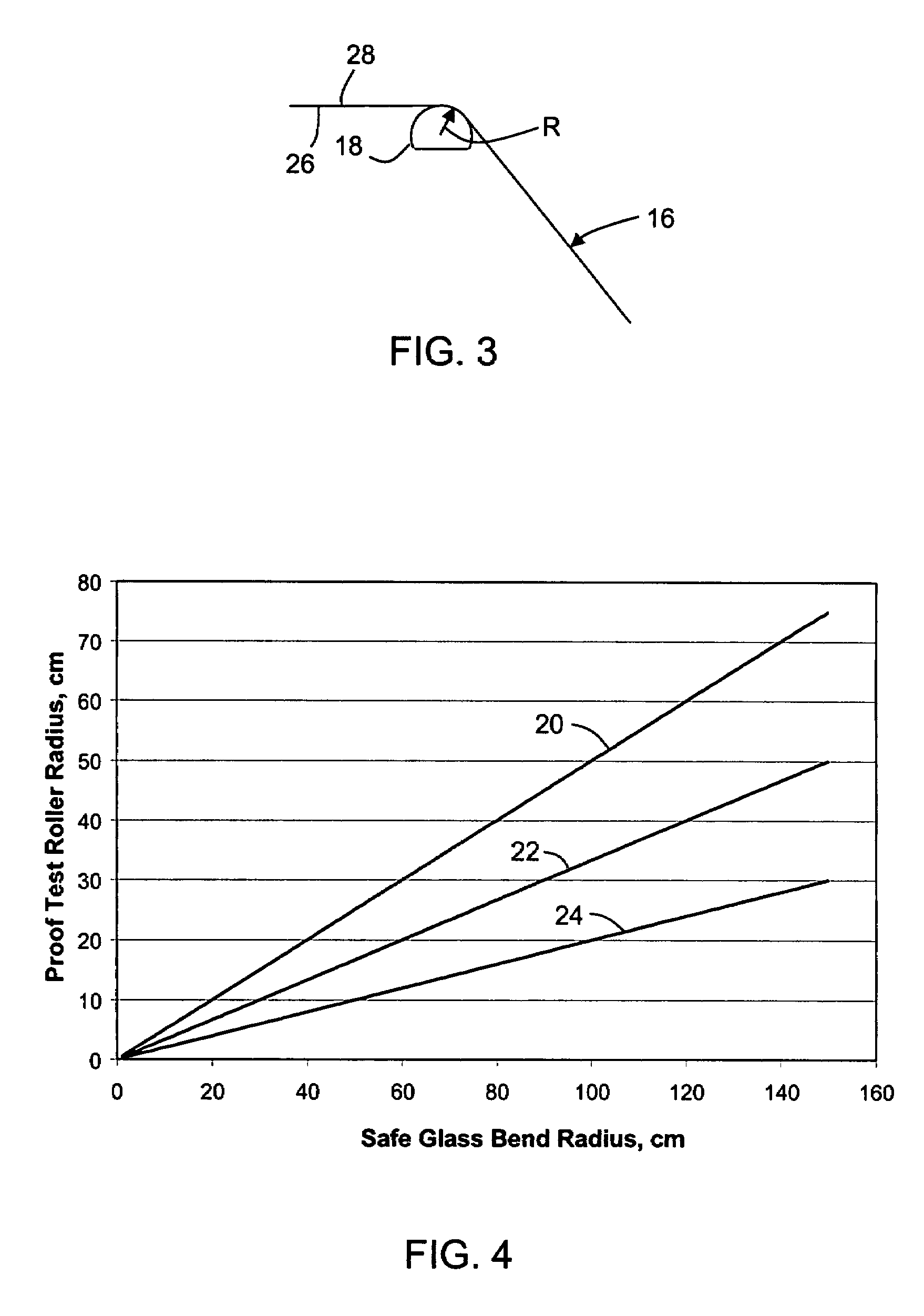

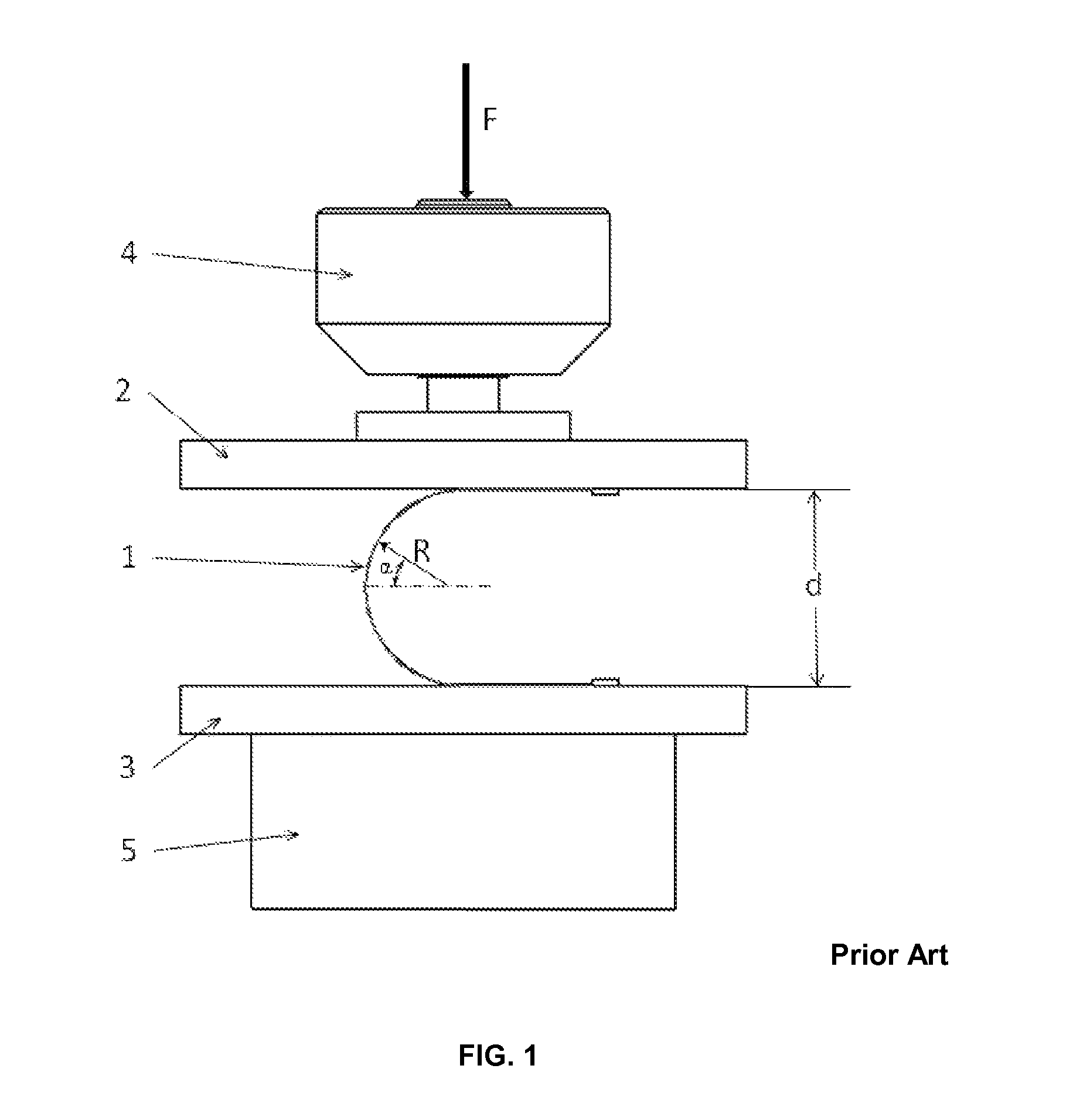

Method and apparatus for proof testing a sheet of brittle material

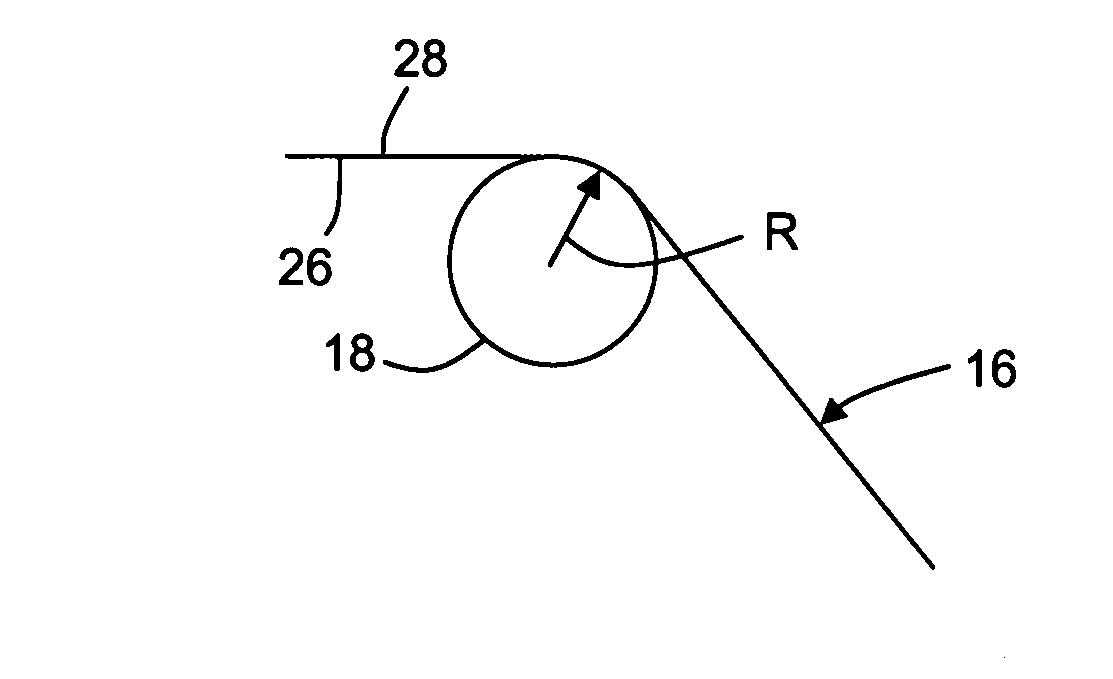

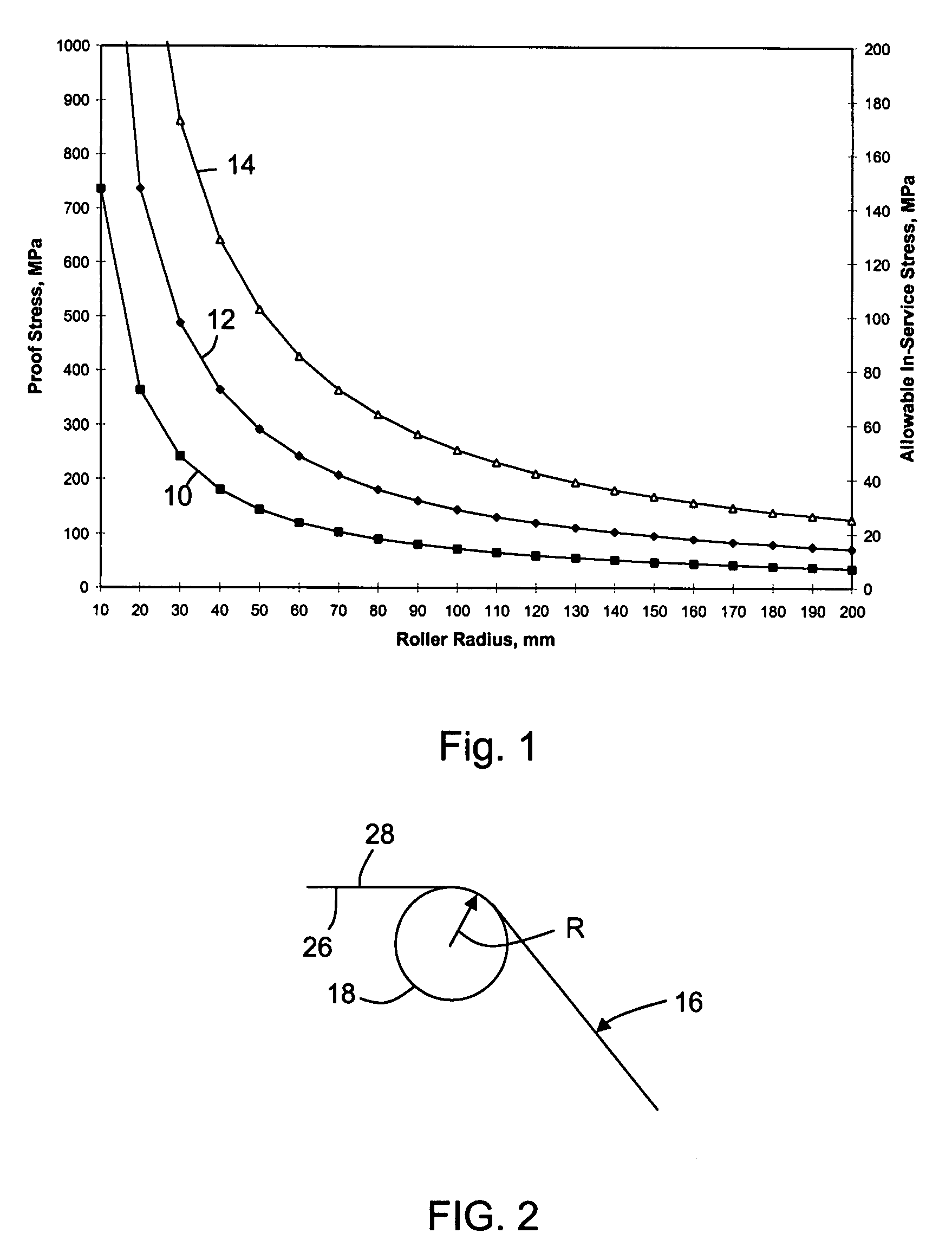

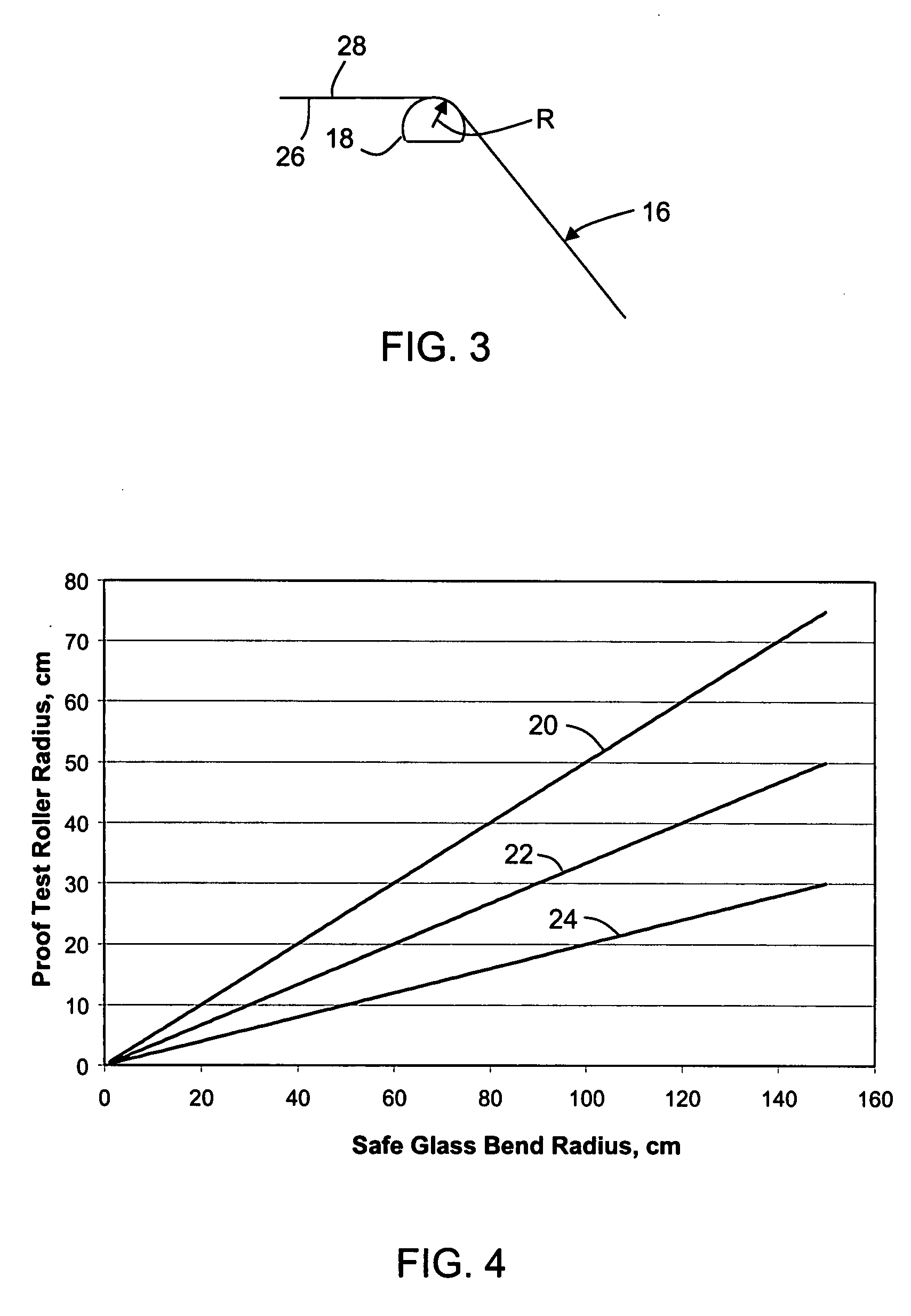

InactiveUS7461564B2Force measurementMaterial strength using tensile/compressive forcesStress inducedRelative motion

Disclosed is a method of proof testing a sheet of brittle material such as a glass or glass-ceramic based material. The method comprises bending the glass sheet over at least one arcuate member to detect sheets having a strength greater than a predetermined value. The method includes imparting a bend to the sheet and producing relative motion between the sheet and the bend such that the bend traverses the sheet, and wherein tensile stress induced in a surface of the sheet by the bend corresponds to the predetermined strength value. An apparatus for performing the proof testing is also disclosed.

Owner:CORNING INC

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

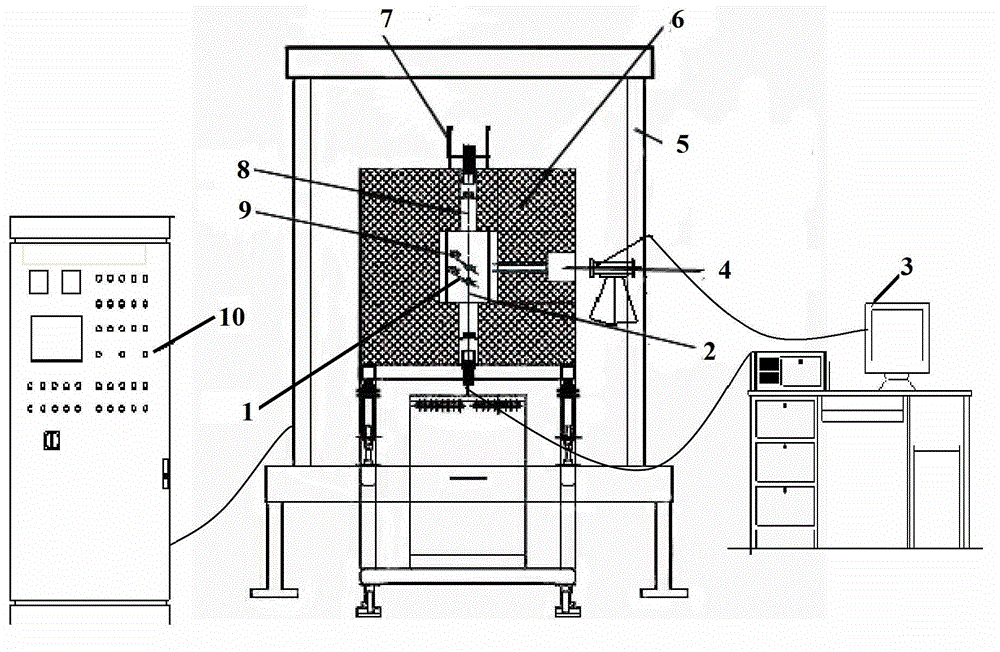

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

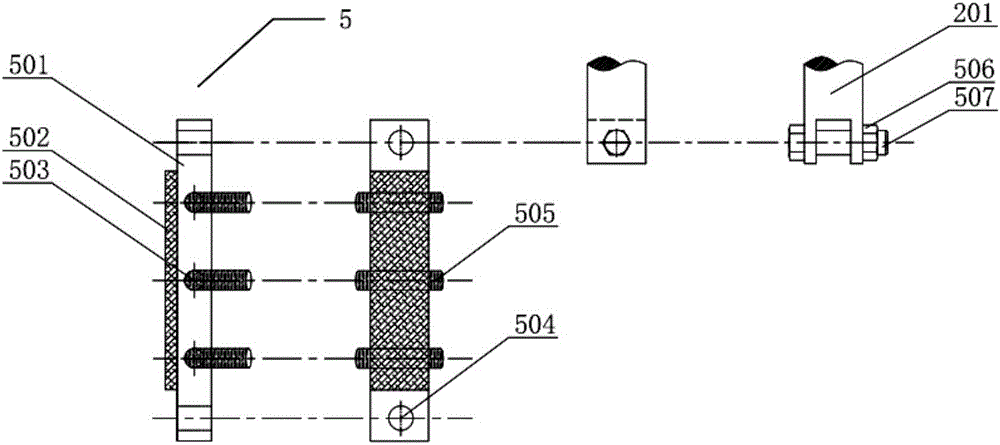

Test bed for testing integrated mechanical properties of anchor rod and test method

ActiveCN104075943AImprove reliabilityValid testMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesEngineeringSingle measure

The invention relates to the technical field of mine support, and particularly relates to a test bed for testing integrated mechanical properties of an anchor rod and a test method. The test bed comprises a pushing and mixing test mechanism, an installation pretension test mechanism, a bending load test mechanism, an axial load test mechanism, a shearing load test mechanism and an impact load test mechanism, wherein the pushing and mixing test mechanism and the installation pretension test mechanism are arranged on an installation test bed, and the bending load test mechanism, the axial load test mechanism, the shearing load test mechanism and the impact load test mechanism are arranged on a work test bed. By using the test bed, the installing and working process of the anchor rod can be simulated in a laboratory, and one or multiple combined external forces such as torsion, stretching, bending, shearing and impact are applied to the anchor rod; and mutually independent loading systems are adopted to apply corresponding loads to the anchor rod, so as to carry out independent experiments of various loads in the installing and working process of the anchor rod or a combined loading test of a plurality of any working stresses such as stretching, shearing and impact caused by installation stress and surrounding rock deformation, thereby effectively testing the integrated mechanical properties of the anchor rod under the combined action of various different external forces.

Owner:CCTEG COAL MINING RES INST

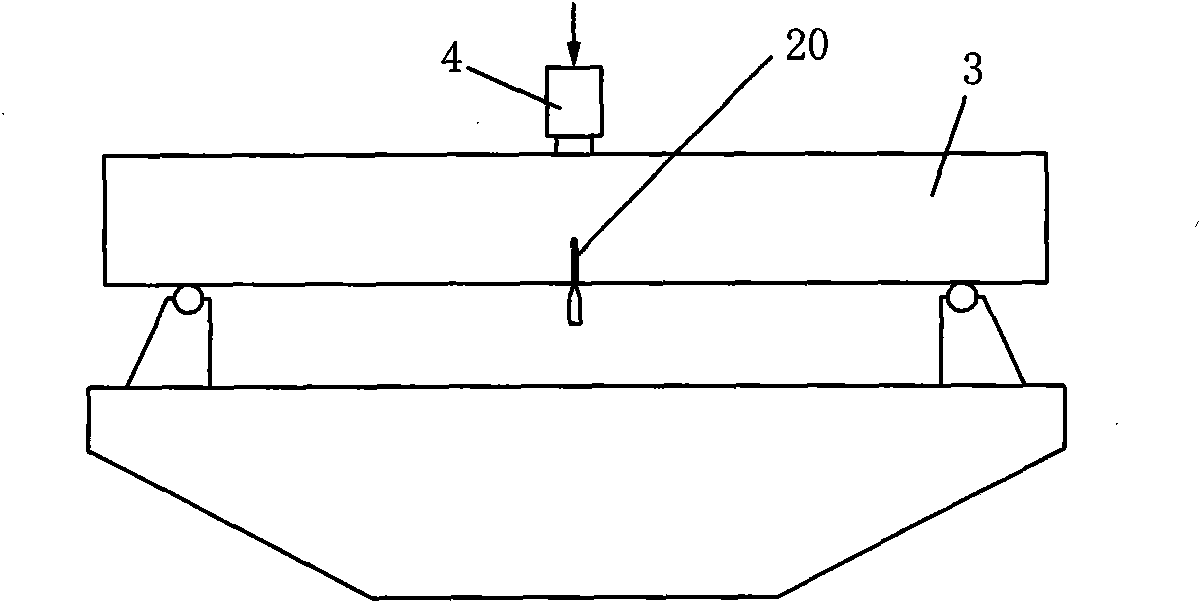

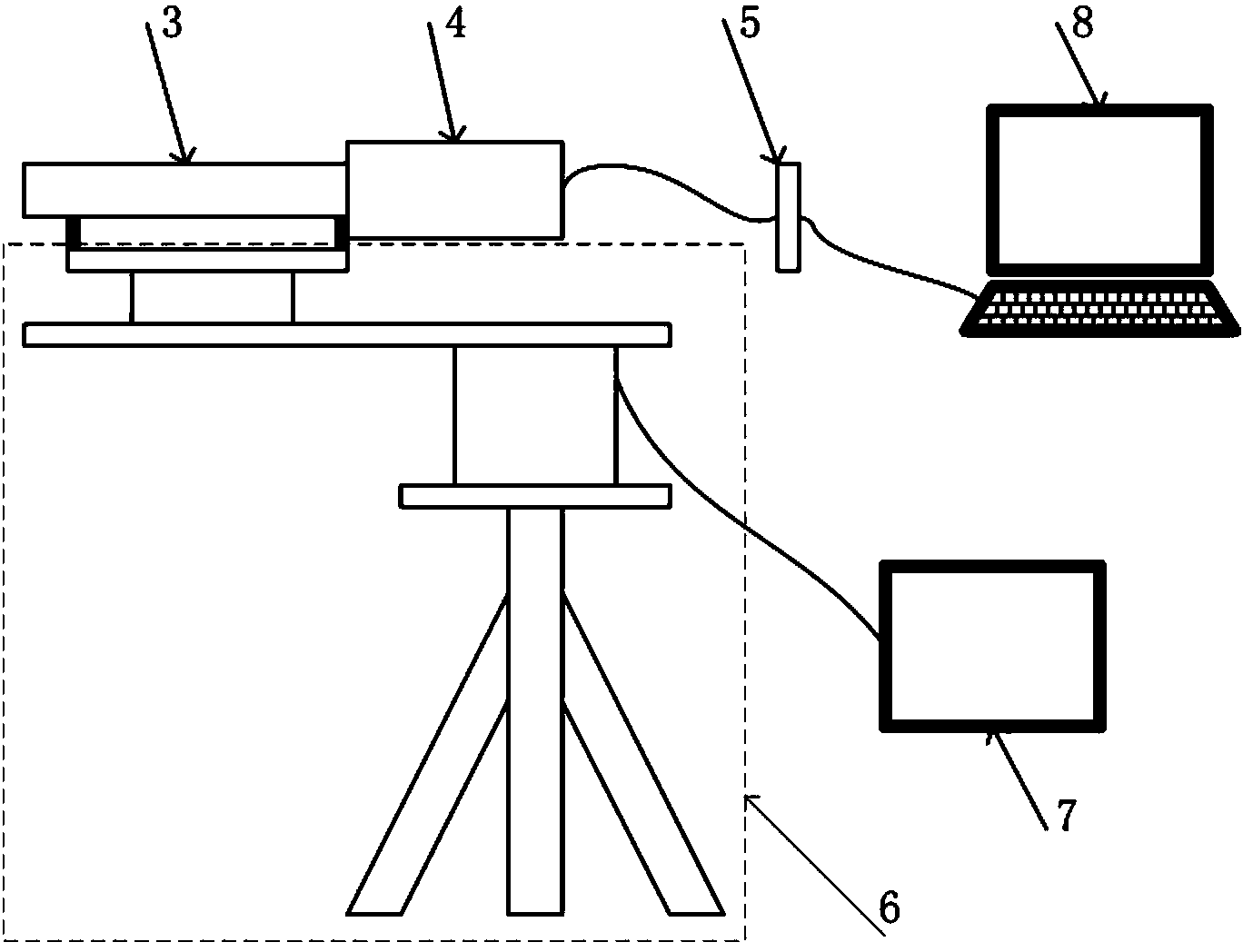

Concrete fracture test system and test method thereof

InactiveCN101975701ASmall loadMeet load rate requirementsMaterial strength using steady bending forcesContact pressureData acquisition

The invention relates to a concrete fracture test system and a test method thereof, and belongs to the technical field of concrete material performance test. The system comprises a measurement system and a data acquisition and processing system; a support for supporting a concrete test piece and even cushion posts symmetrically positioned on the surrounding side of the concrete test piece are arranged on a pressure tester platform of the measurement system; and springs which extend out of the tops of the cushion posts and are higher than pressure sensors are sleeved on the cushion posts. The method comprises the following steps of: when a top plate moves relative to the platform by adopting the system, making the top plate contact the springs and then contact the pressure sensors; when the top plate is contacted with the pressure sensors, controlling the load loaded onto the concrete test piece to be continuously loaded with low loading rate till the concrete test piece cracks, destabilizes and is damaged; and meanwhile, acquiring a load signal and a crack opening displacement signal and transmitting the signals to a computer. The system and the method can acquire a fine load-displacement curve so as to calculate an accurate concrete double-K fracture parameter.

Owner:胡少伟

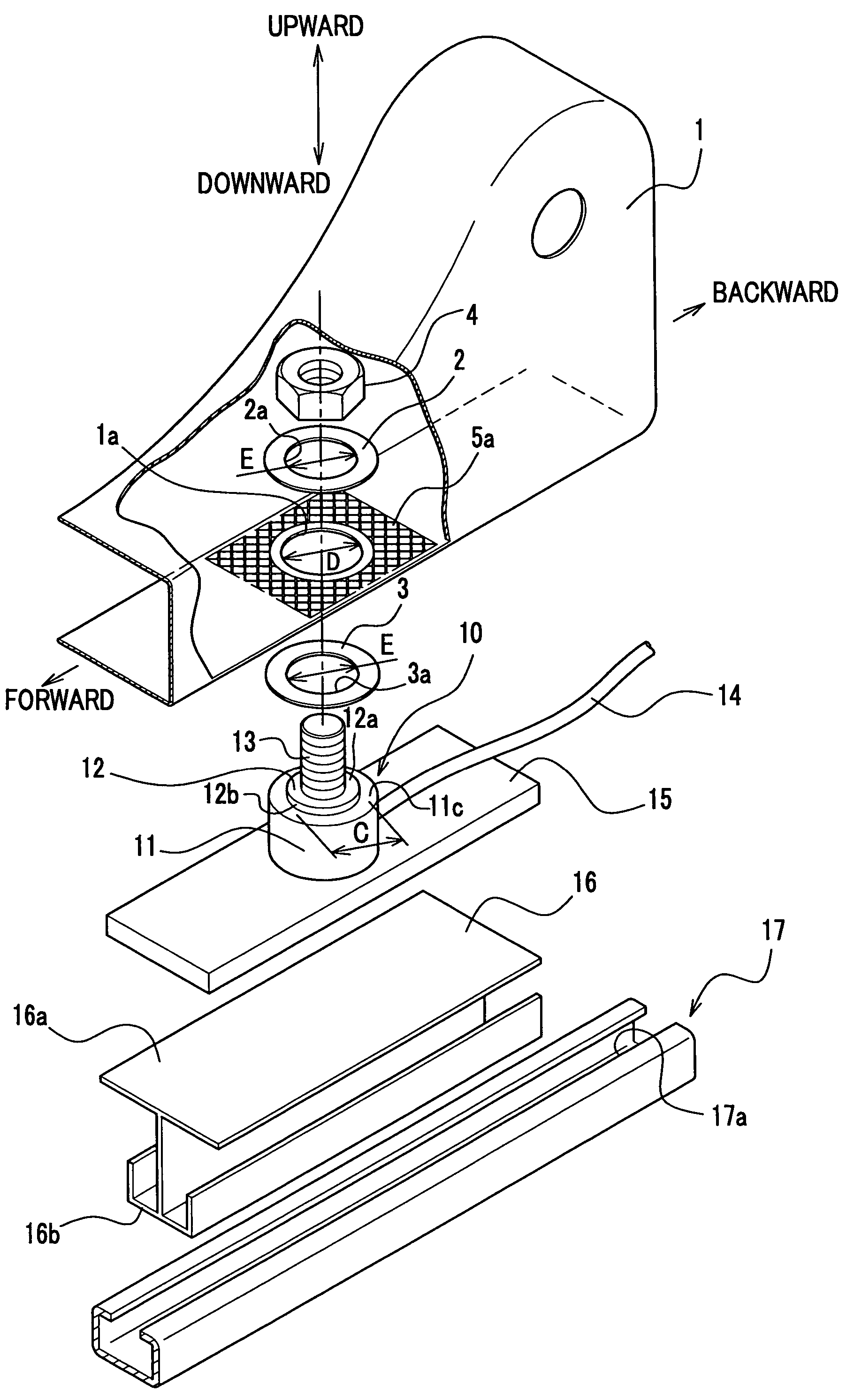

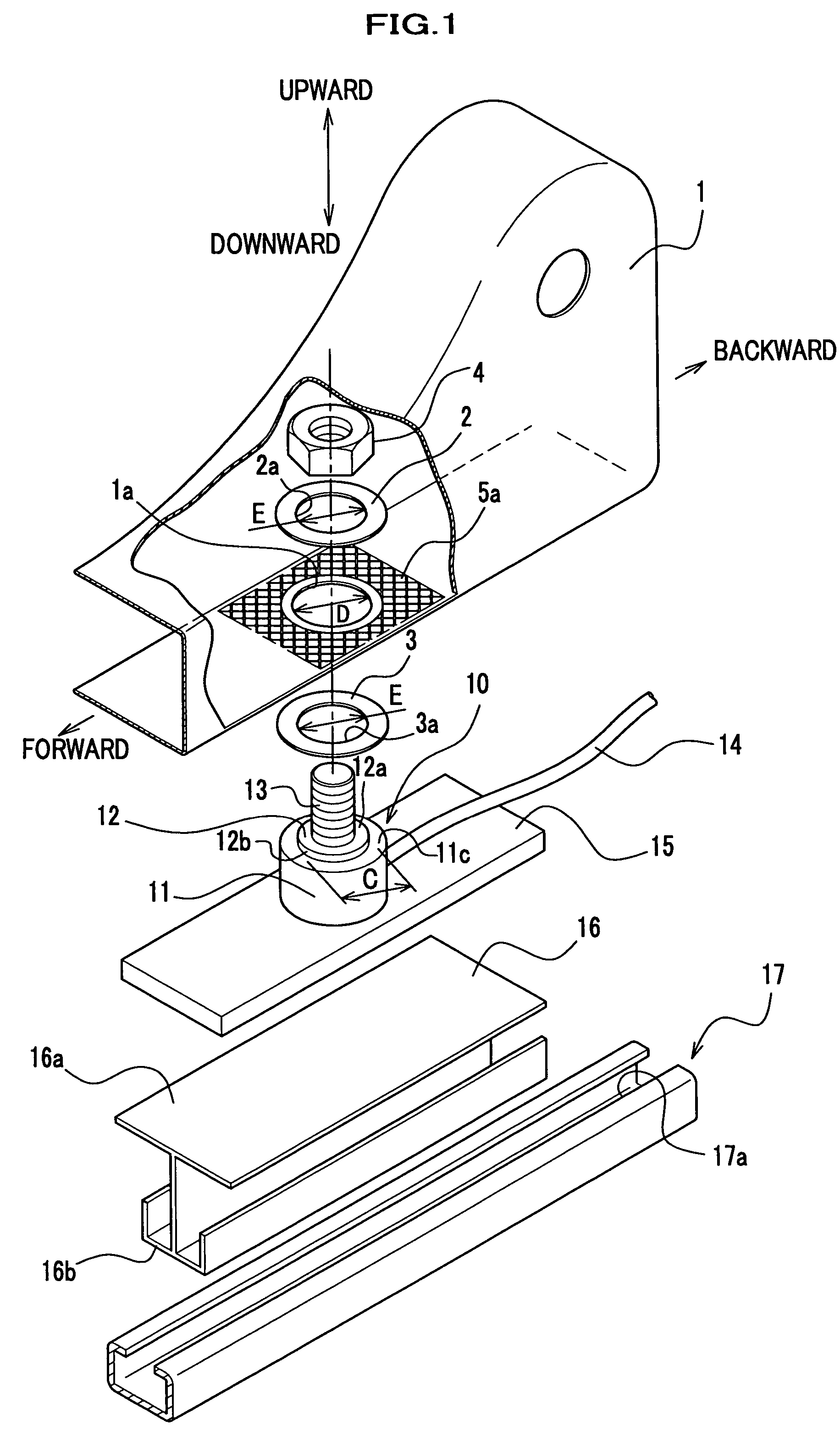

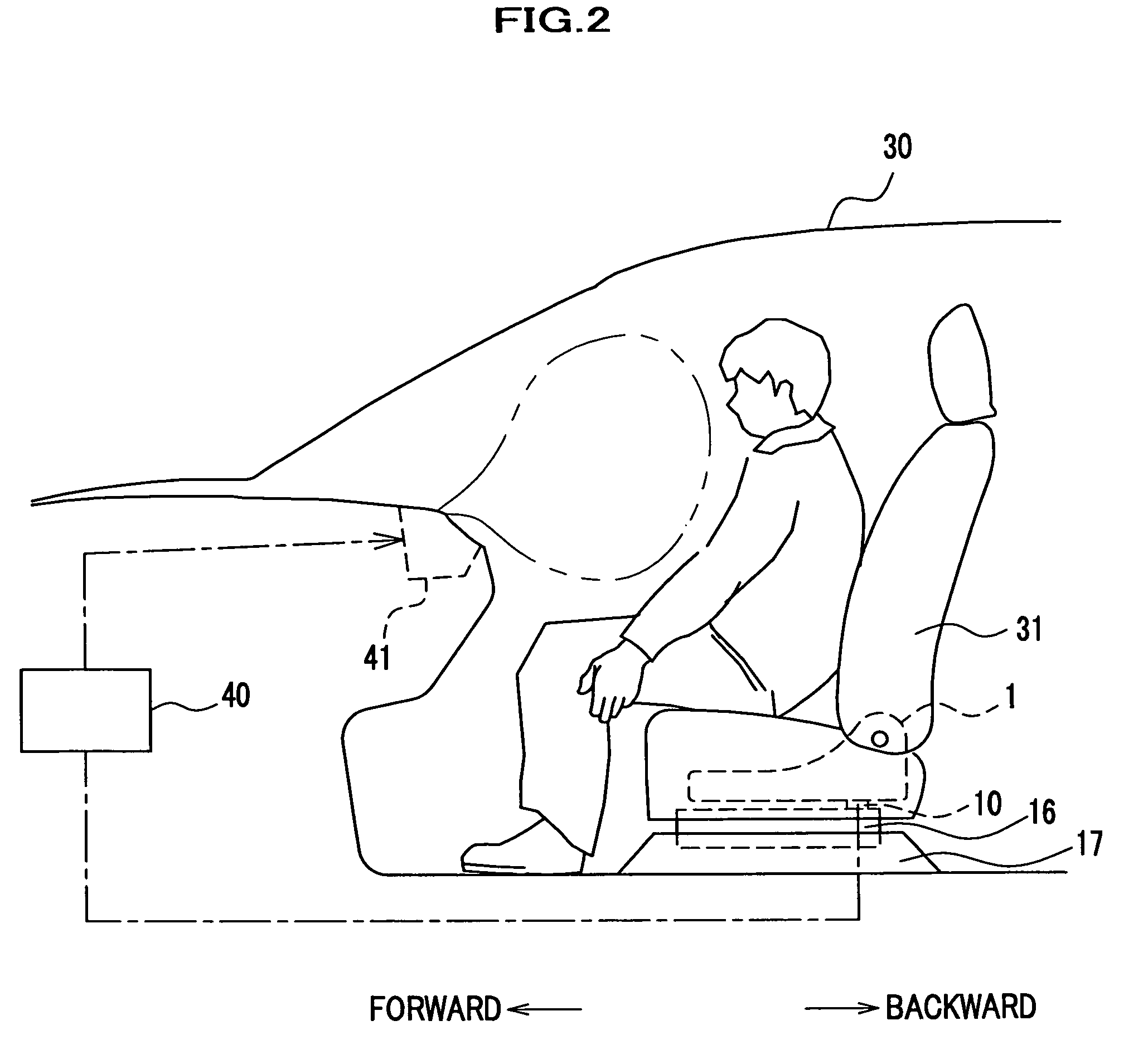

Force sensor assembly

InactiveUS7210358B2Stable controlNot be excessively tightened onto the threaded portionVehicle seatsLoad modified fastenersScrew threadForce sensor

A force sensor assembly includes a force sensor, a first support member, a threaded portion, an opening made in the first support member, a nut, a restricting member and a spacer. The nut is screwed onto the threaded portion which is inserted through the opening. The restricting member is provided between the force sensor and the nut. The spacer, which is provided between the force sensor and the nut, is deformable in a direction of its thickness. The shape of the spacer is adapted to avoid interference with the restricting member. Before the nut is tightened onto the threaded portion, a summation of thickness for the first support member and the spacer is adapted to be not less than a height of the restricting member. The nut is tightened up with a predetermined fastening torque until the spacer deforms so that the nut strikes the restricting member.

Owner:HONDA MOTOR CO LTD

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

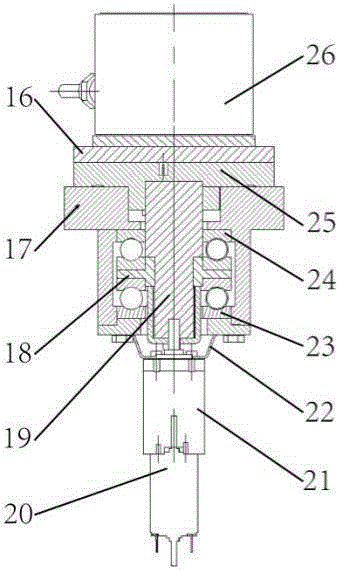

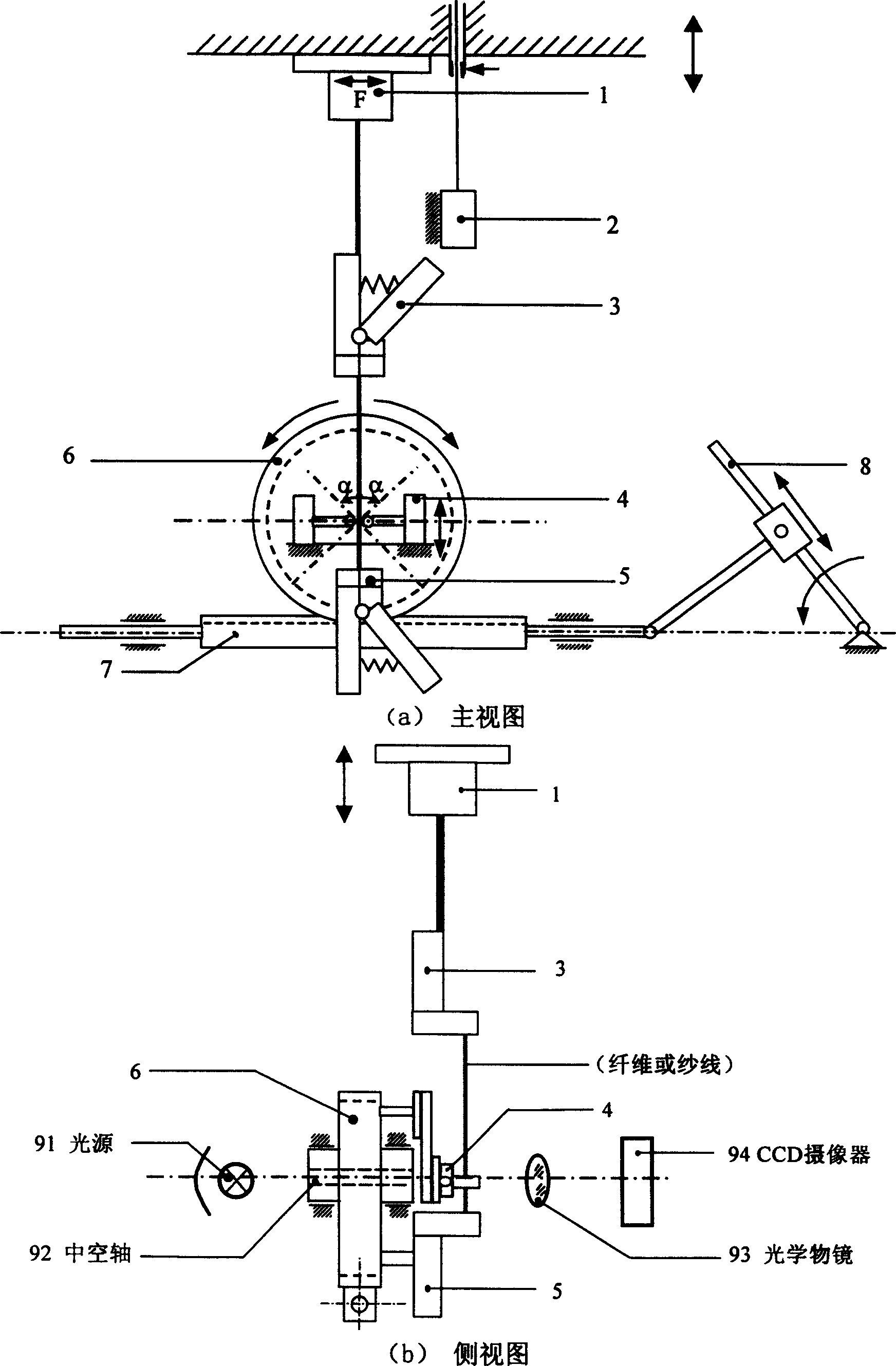

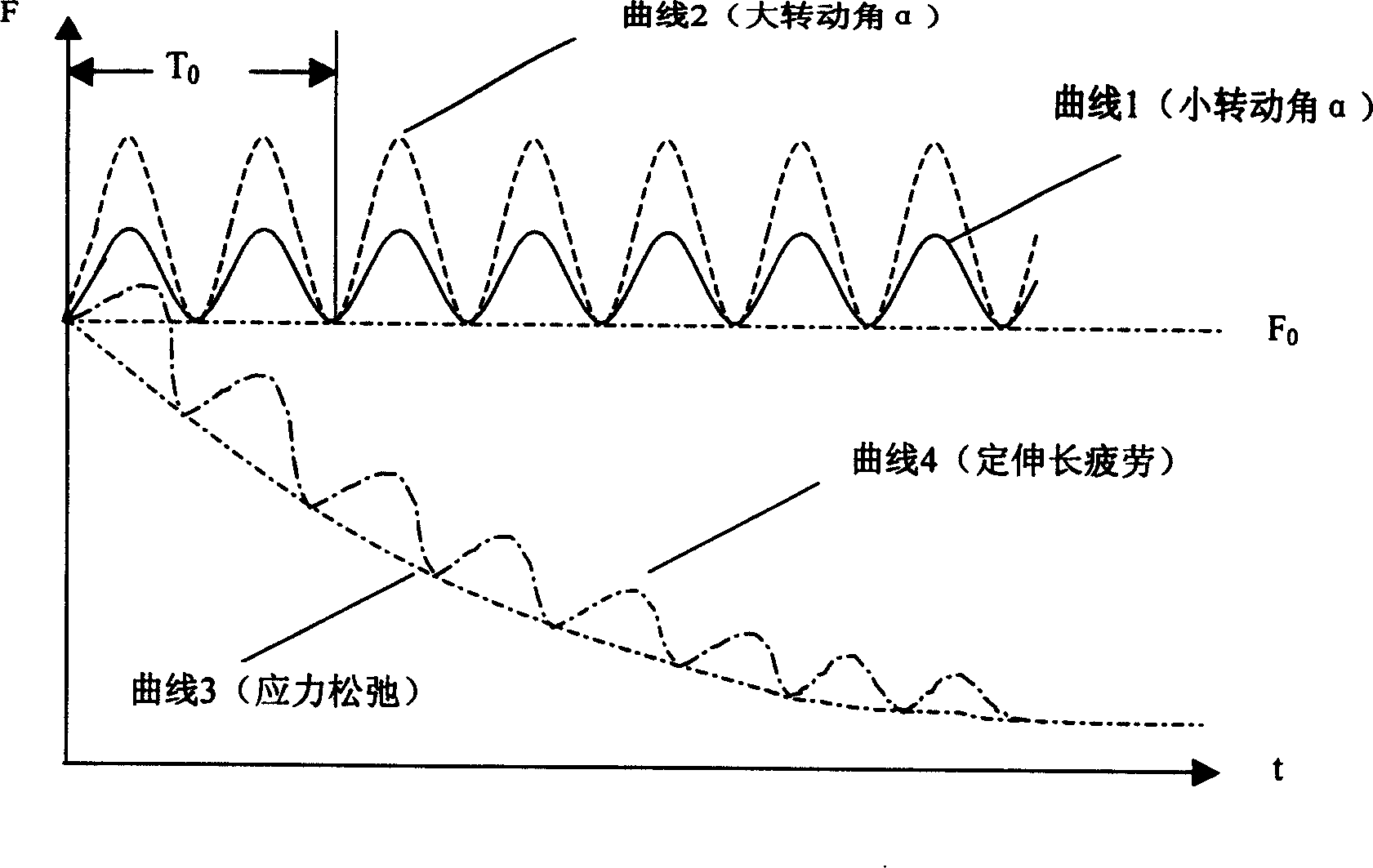

Measuring device for flexural fatigue property of flexible material

InactiveCN1587967AEffective bending fatigue measurementAccurate Bending Fatigue MeasurementsMaterial strength using steady bending forcesUsing mechanical meansMeasurement deviceCollection system

The invention is an apparatus used for measuring flexible material flexural fatigue, with property of being consisted of crank block rack mechanism, force and displacement sensor, upper and lower cartridge, optical plummet centering system, up-and-down and rotation driving system and control circuit, program and signal collection system, finishing measurement of fixed point flexural fatigue and relaxation creep behaviour of flexible material with stationary load and stretch effectively and accurately. The index property measured are endurance failure time, endurance limit strength and limiting strain, relaxation time, sample thickness or diameter. The apparatus has simple but practical structure, convenient installation and replacement, many tunable parameters containing sample length, fixed points position and their distance, bending rotational angle and angular frequency, original load and stretch, accurate measurement, and can avoid influence of move of application point in bending, offset of sample and vibration.

Owner:DONGHUA UNIV

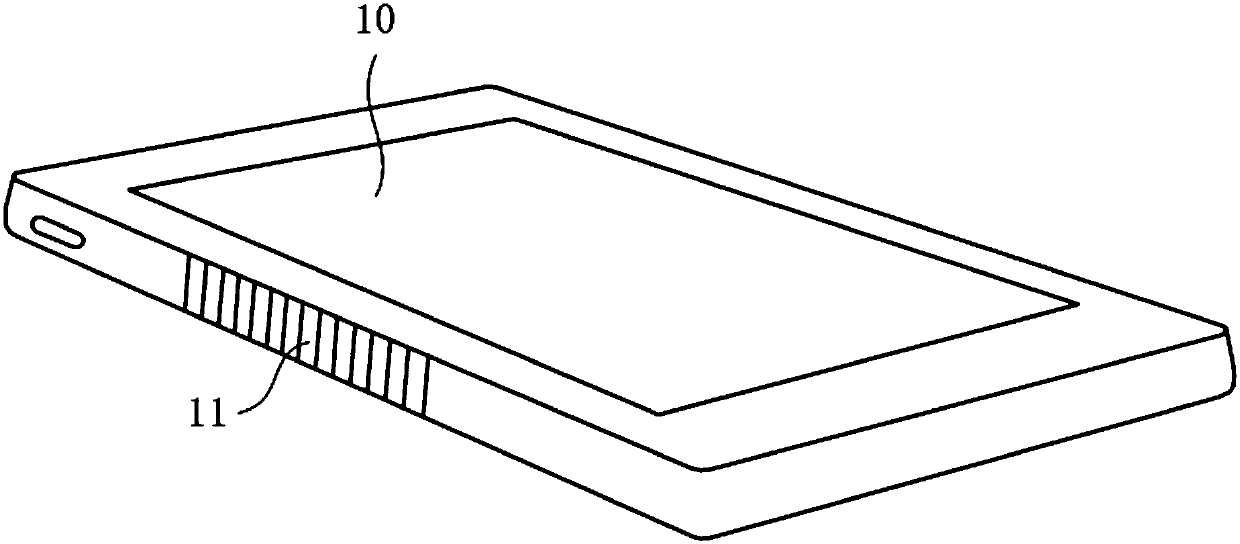

Flexible display device bending test equipment and system

InactiveCN107631861AIntuitive detection of bending stressSimple structureMaterial strength using steady bending forcesOptical apparatus testingFlexible displayTest equipment

The invention provides a flexible display device bending test equipment and system. The equipment comprises a bending device, wherein the bending device comprises a bent shaft, an upper bending boardand a lower fixing board, the bent shaft is arranged between the upper bending board and the lower fixing board, the upper bending board is connected with the bent shaft, an upper clamping board is arranged on the surface of the upper bending board, the upper clamping board can slide along the surface of the upper bending board, the surface of the upper clamping board opposite to the upper bendingboard is an upper portion disposing surface of a flexible display device, the upper portion disposing surface of the flexible display device is provided with a first fixing clamp used for fixing an upper portion of the flexible display device, a lower clamping board is arranged at the surface of the lower fixing board, the lower clamping board can slide along the surface of the lower fixing board, the surface of the lower clamping board opposite to the lower fixing board is a lower portion disposing surface of the flexible display device, the lower portion disposing surface of the flexible display device is provided with a second fixing clamp used for fixing a lower portion of the flexible display device, a first voltage testing element is connected with one end of the upper clamping board, and a second voltage testing element is connected with one end of the lower clamping board.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Method for detecting mechanical properties of local heating loading test material under high temperature oxidation environment and device thereof

ActiveCN101936854ASimple test operationSave test costMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesFlexural strengthMechanical property

The invention provides a test method capable of simply and conveniently testing mechanical properties of tensile strength, compressive strength, bending strength and fracture toughness of ceramic material and composite material thereof under superhigh temperature oxidation environment with the temperature of more than 1500 DEG C and a test device thereof. The test device is composed of a test frame, a fixed sample system, a loading system, a superhigh temperature flaming heating system, a record display system and a non-contact type infrared temperature measuring system. The method includes that acetylene or gasoline aeration flaming technology is adopted to locally and rapidly heat a sample, so that local temperature thereof reaches more than 1500 DEG C, a portable tester is utilized to apply bending, stretching or compressive load on the sample, and load value is recorded, thus obtaining mechanical properties of material. The invention has the advantages that operation is simple, the technology of local high temperature and synchronous loading on superhigh temperature sample is realized, superhigh temperature mechanical properties which can not be tested before such as strength and toughness of material can be conveniently measured under superhigh temperature oxidation environment by utilizing the test device of the invention.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

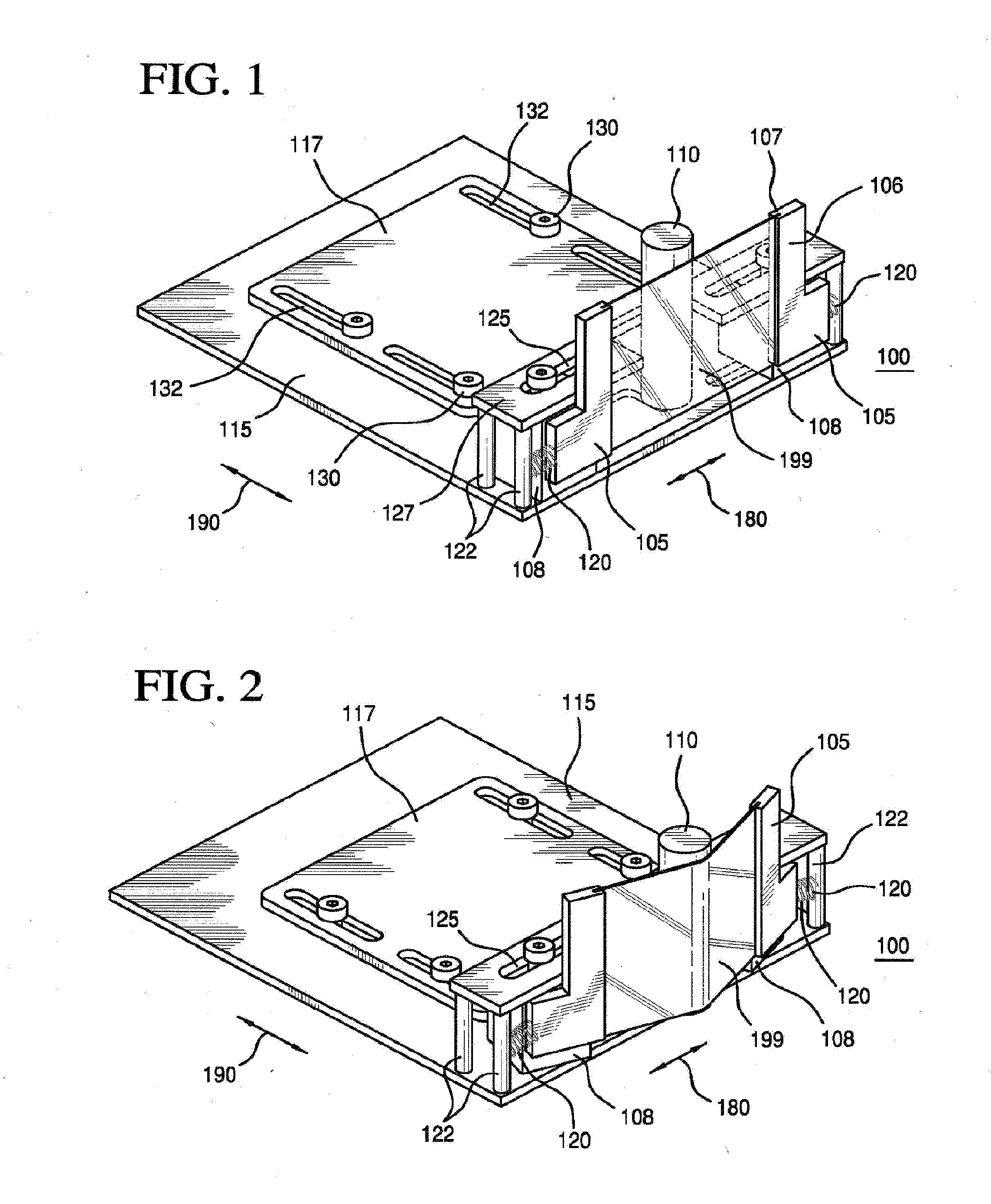

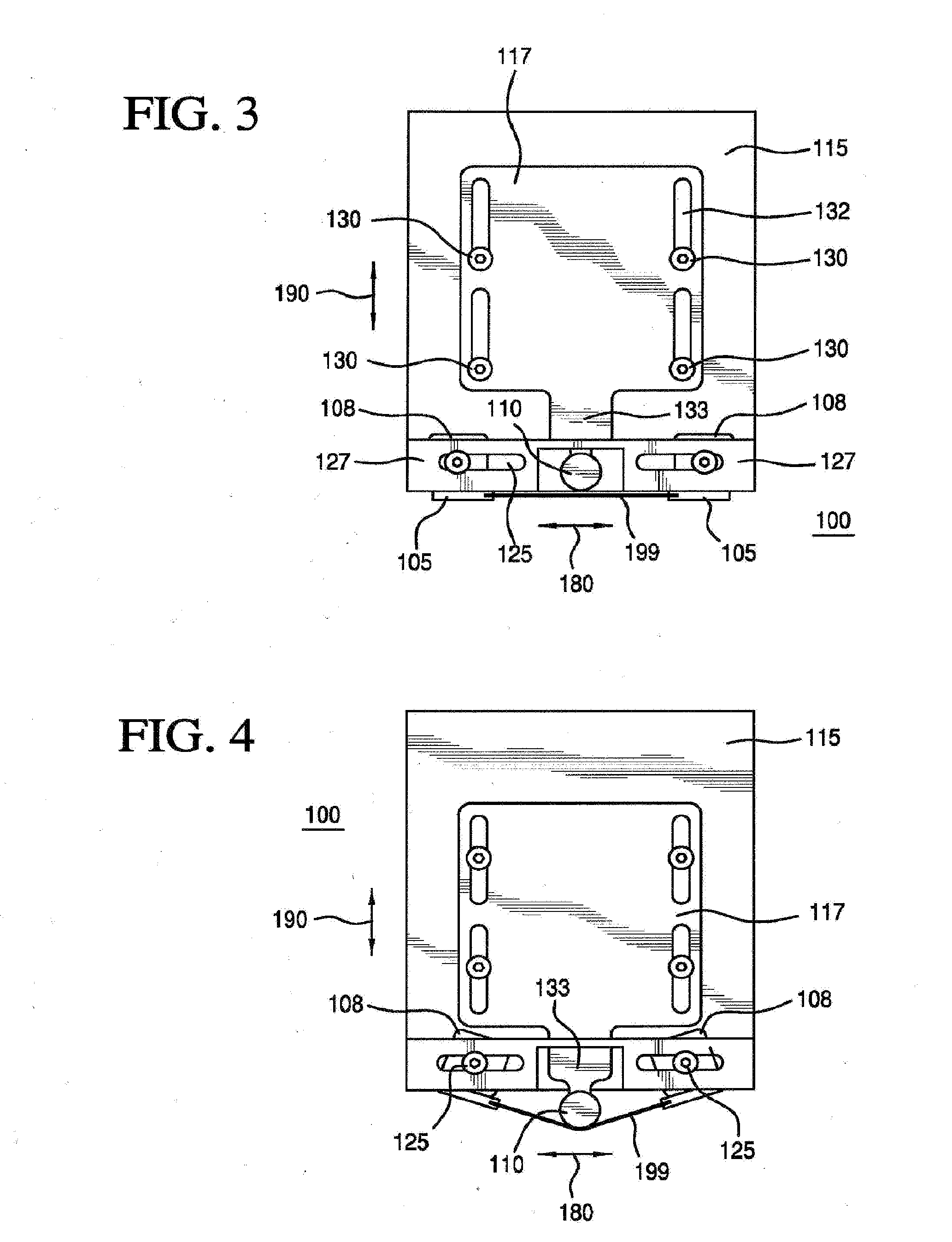

Display bender and method of testing flexible display

InactiveUS20120067134A1Force measurement by measuring optical property variationStructural/machines measurementDisplay deviceFlexible display

Some embodiments include an apparatus for testing flexible displays. The apparatus can include: (a) a first clamp configured to receive a first end of the flexible display; (b) a second clamp configured to receive a second end of the flexible display, wherein the second end of the flexible display is opposite the first end of the flexible display; and (c) a test column. Other embodiments and methods are disclosed herein.

Owner:ARIZONA STATE UNIVERSITY

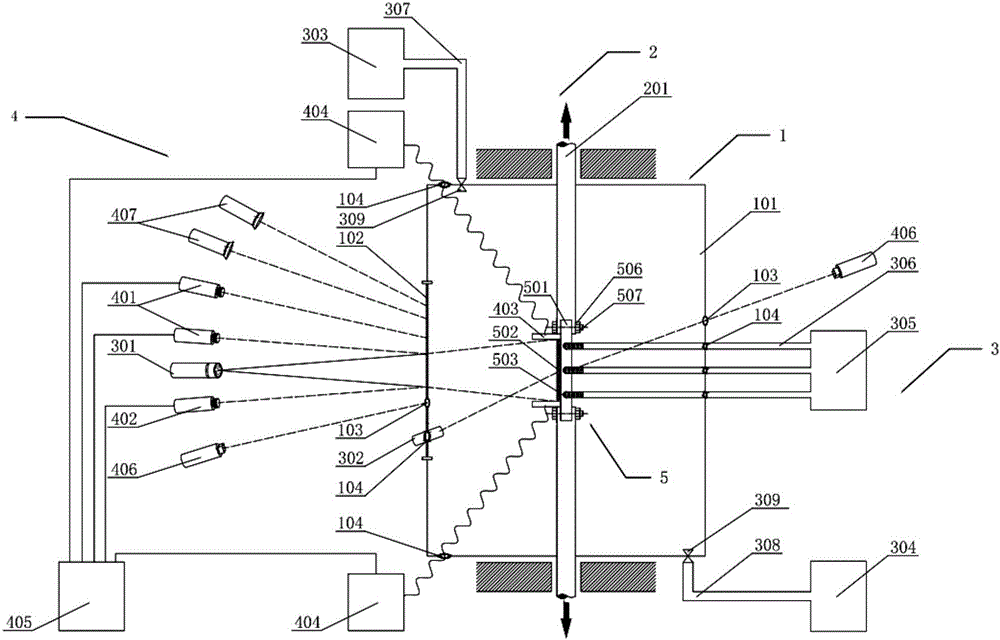

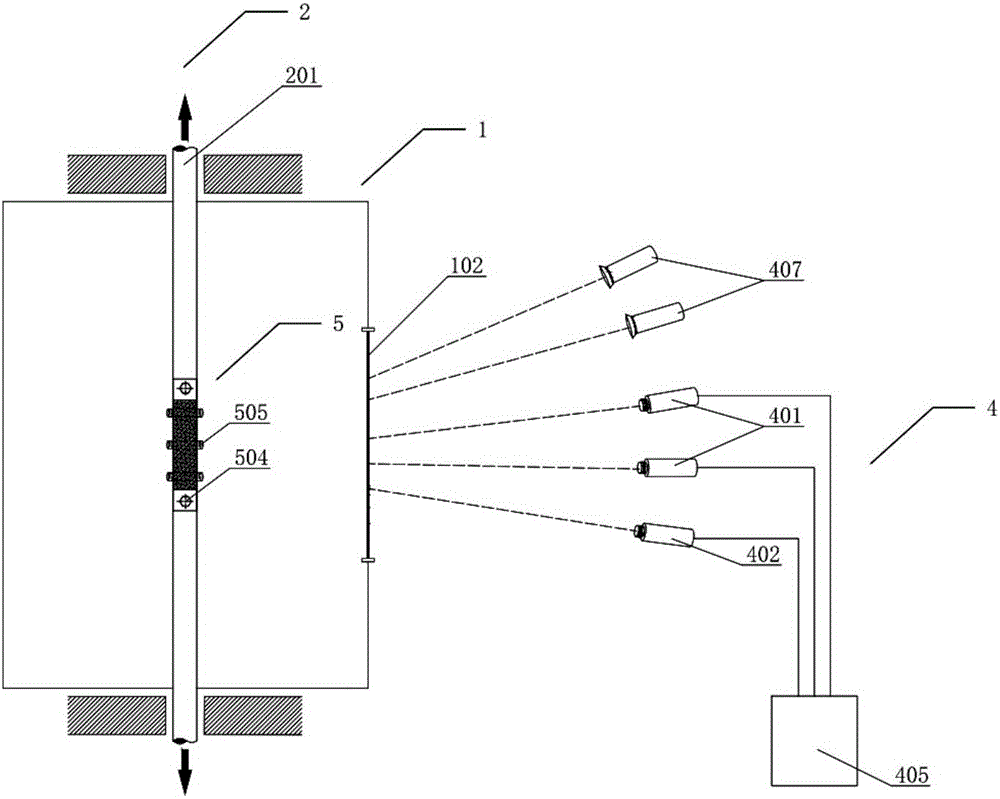

Multi-field coupled environment simulating and online monitoring/observing system

ActiveCN105973690AFast heating and cooling rateIncreased limit temperatureWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMulti fieldX-ray

The invention discloses a multi-field coupled environment simulating and online monitoring / observing system. The system comprises: a main body test box provided with a quartz observing window and an infrared window; a mechanical loading module comprising two coaxially arranged mechanical loading shafts and respectively connected with the main shafts of a universal testing machine and a sample clamping device; a multi-field service environment module arranged outside the main body test box and comprising an infrared laser rapid heating device, an X-ray radiation device, a corrosion gas box and a cooling system and respectively used for realizing heating, irradiating, corroding and cooling environments; and a damage online monitoring / observing module comprising a surface / interface strain real-time observation system, an in-situ fracture behavior observation system, a damage signal collecting system and an infrared thermodetector which are arranged outside the main body test box, and damage signal detectors arranged at the upper end and the lower end of a tested sample, and wherein devices contained in the damage online monitoring / observing module are respectively used for real-time capturing of strain information, in-situ fracture image information, damage information and temperature information, and synchronously run through a cynchronous control system.

Owner:XI AN JIAOTONG UNIV

Fixture for mechanical analysis of a hollow tube

InactiveUS7770467B1Accurate measurementPrevent crashMaterial strength using steady bending forcesTest fixtureMechanical property

A test fixture for use with a Dynamic Mechanical Analyzer (DMA) restrains a hollow cylindrical tube for purposes of performing either a tensile or transverse / bending load test. The fixture includes a clamp that is configured to restrain the tube without imparting a preload or changing a mechanical property of the tube.

Owner:ABBOTT CARDIOVASCULAR

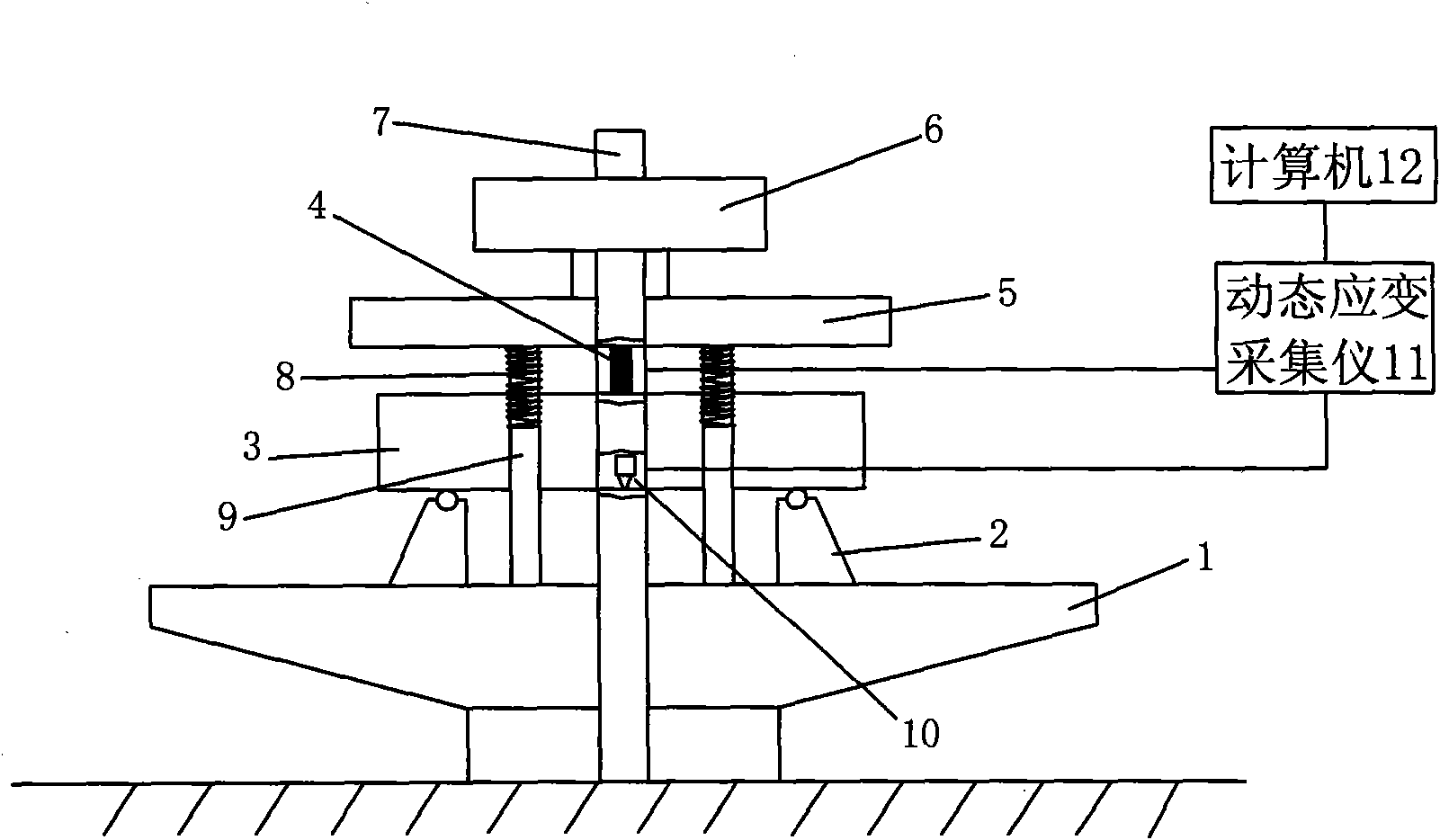

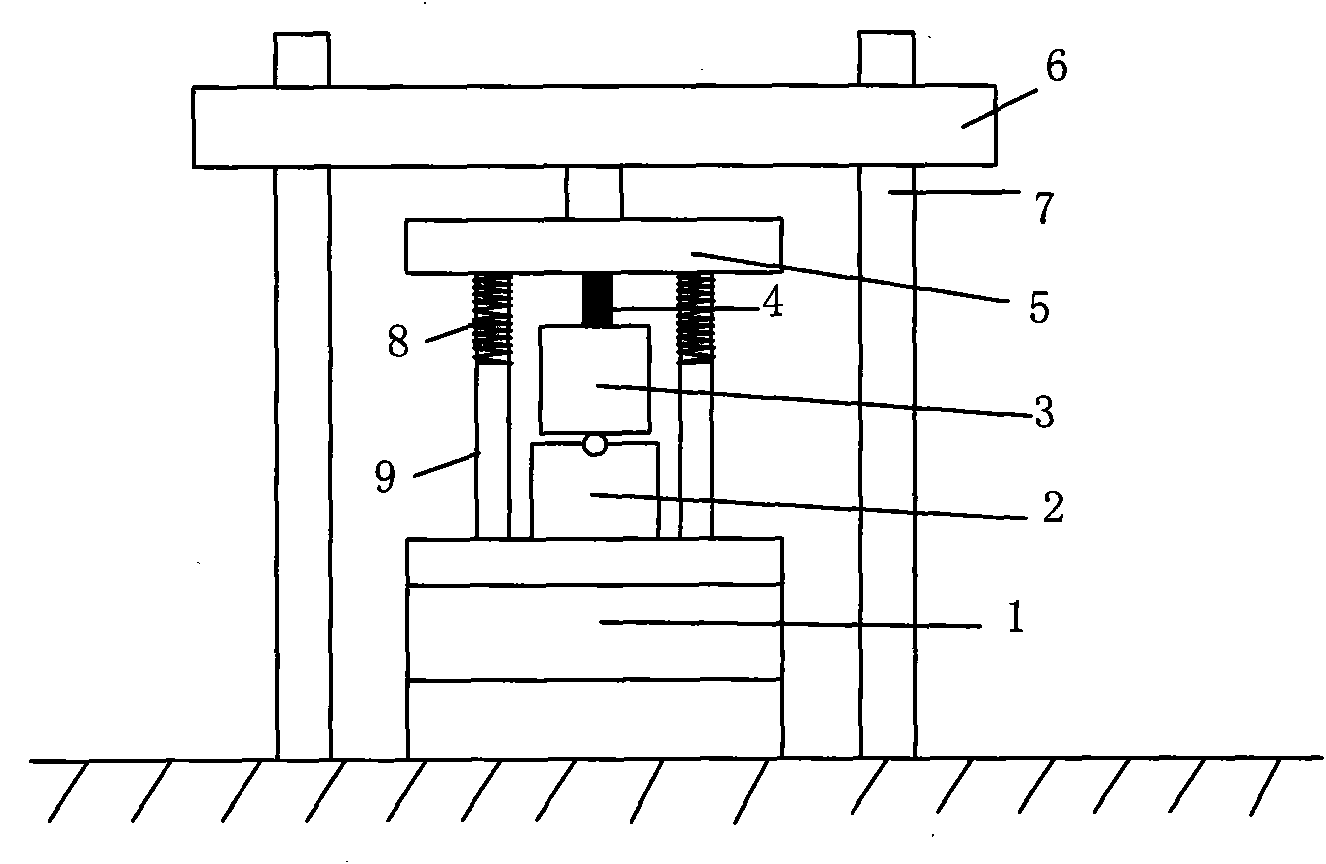

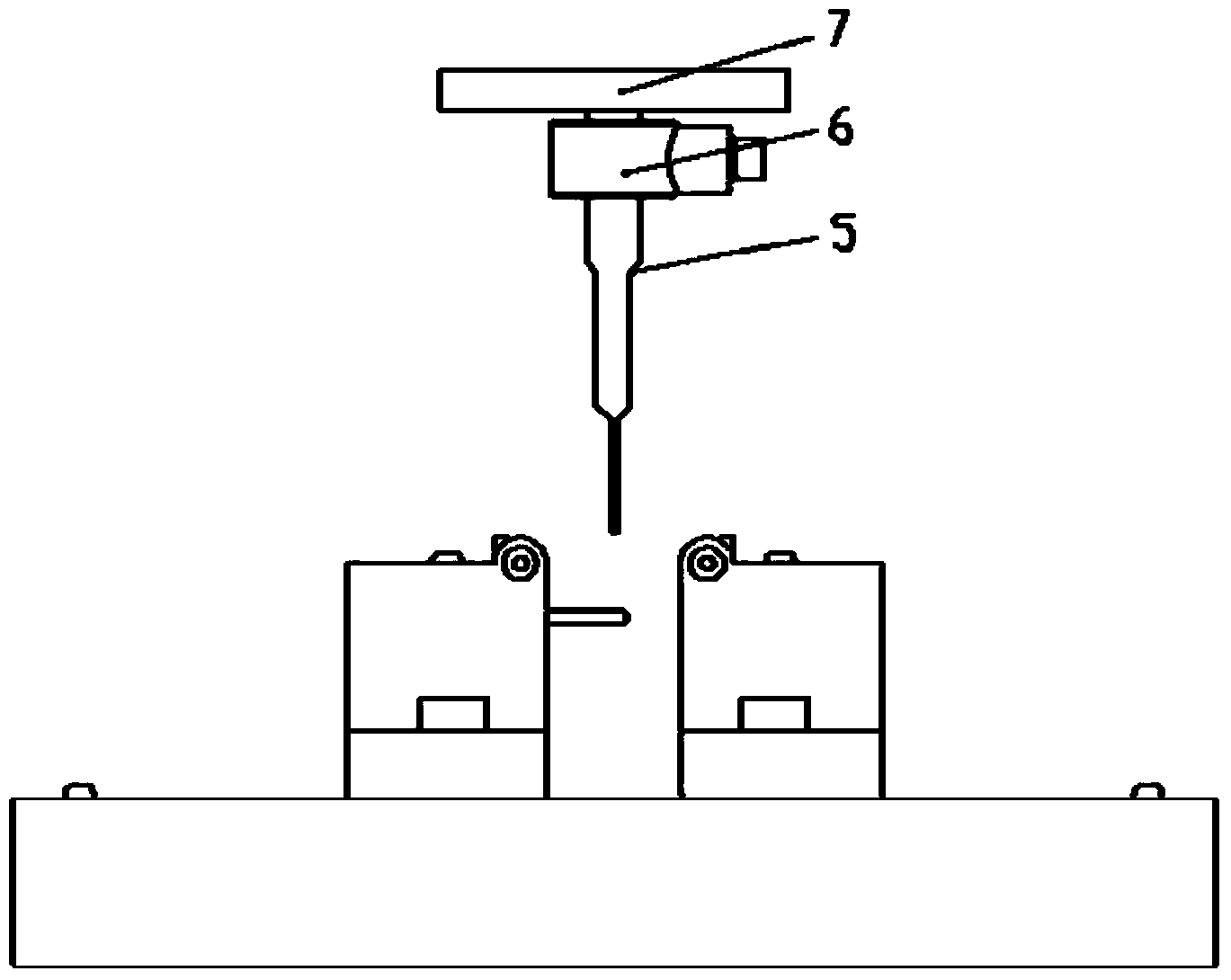

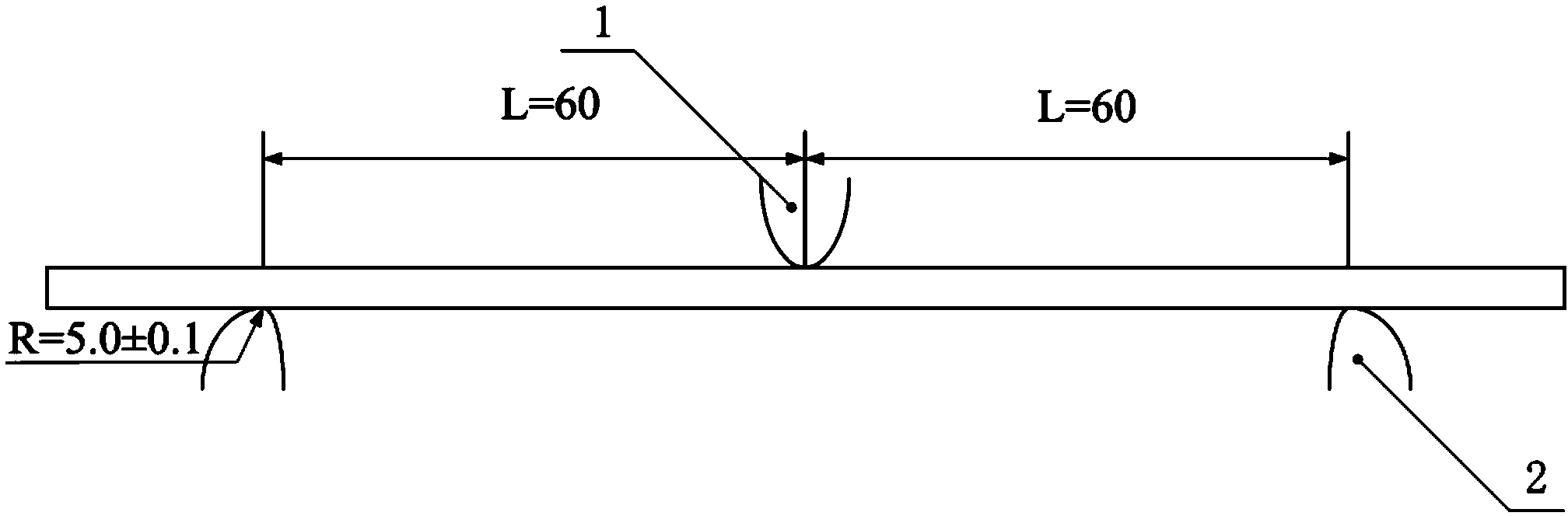

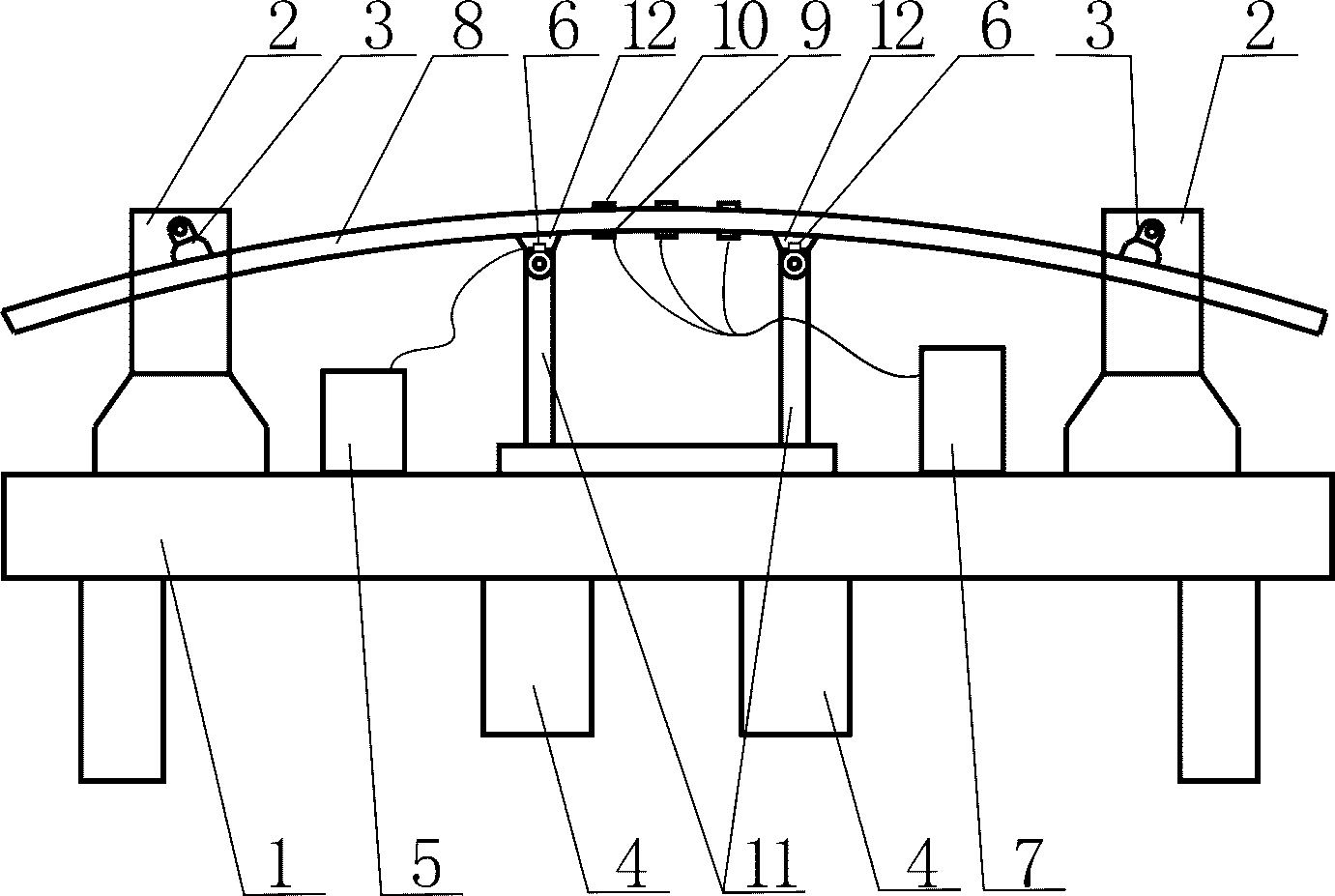

Bearing-type damage biomechanic three-point bending test device and bearing-type damage biomechanic three-point bending method

InactiveCN103760037AReduce distortionThe test data is accurateMaterial strength using steady bending forcesRolling resistanceElement model

The invention provides a bearing-type damage biomechanic three-point bending test device. The bearing-type damage biomechanic three-point bending test device is characterized by comprising a base (1), a support base (2), support bearings (3), support shafts (4), a pressing head (5), a sensor (6), a connecting plate (7), a travel switch (8), a baffle (9), a baffle fixing screw (10), a support base fixing screw (11) and a dividing rule (12). The bearing-type damage biomechanic three-point bending test device provided by the invention has the advantages that a pair of support shafts and the support bearings can support a biological sample, the rolling friction is formed among the support shafts and the support base, the biological sample free bending constraint caused by the friction in a test process is reduced, the transformation of the biological sample on a supporting position is relieved, more accurate test data can be obtained, and a terminal condition more easily set in a finite element model so as to perform material parameter reverse engineering.

Owner:HUNAN UNIV

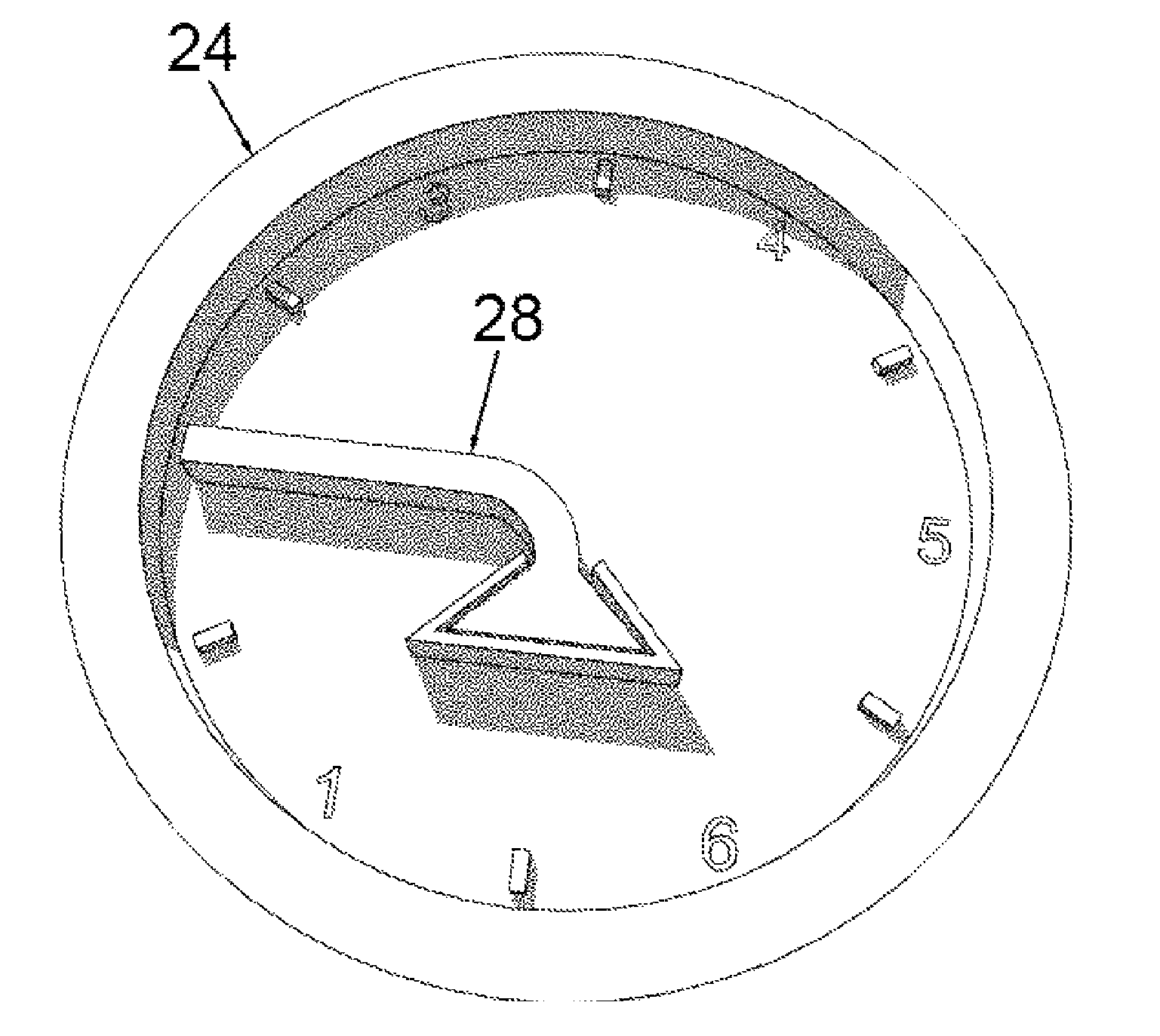

Environmental condition cumulative tracking integration sensor using shape memory polymer

InactiveUS8033237B2Easy to readInexpensive and effective regulatoryThermometer detailsAnalysis using chemical indicatorsEngineeringVisual perception

Owner:CORNERSTONE RES GROUP

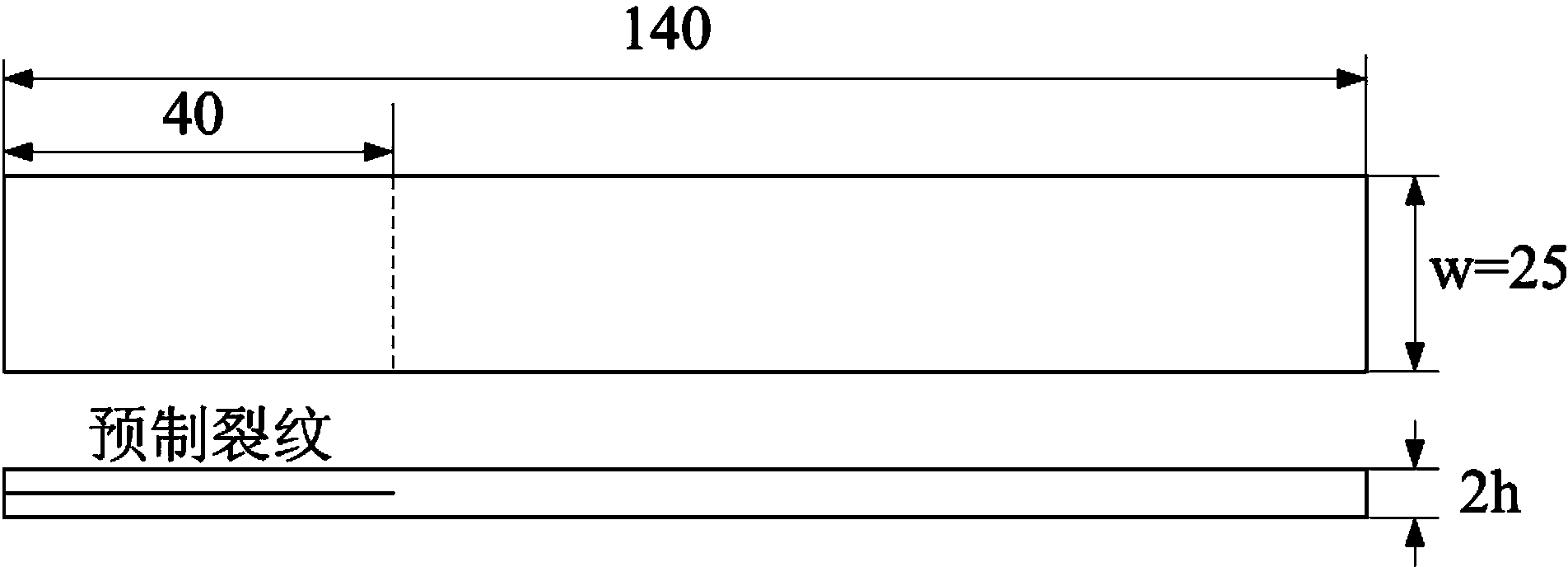

Composite material II type crack growth rate measuring method capable of acquiring crack growth S-N curve

InactiveCN103439194ASimplified Determination Method of Cracking ThresholdReduce testing costsMaterial strength using steady bending forcesFiberCrack growth resistance curve

A composite material II type crack growth rate measuring method capable of acquiring a crack growth S-N curve comprises five steps: 1, a single end-notched flexure (ENF) composite material sample is selected and formed through molding fiber cloth and resin; 2, the sample is tested through a three-point bending manner; 3, a triaxial movable high power digital measurement system is adopted to observe and measure the crack growth length, and the test load, the cycle index and the corresponding crack growth length are recorded; 4, the constant interface shear stress of a neutral surface of the composite material is worked out according to the engineering beam theory, and a three-parameter power function is adopted to fit the crack growth interface shear stress and the corresponding cycle index so as to obtain the crack growth S-N curve; 5, a dual-growth exponent function is utilized to fit the test load cycle index and the a-N curve of a corresponding crack growth length, and the crack growth rate is obtained after derivation; a Paris model and an energy release rate formula are adopted, and a crack growth rate curve is obtained through least-squares approximation.

Owner:BEIHANG UNIV

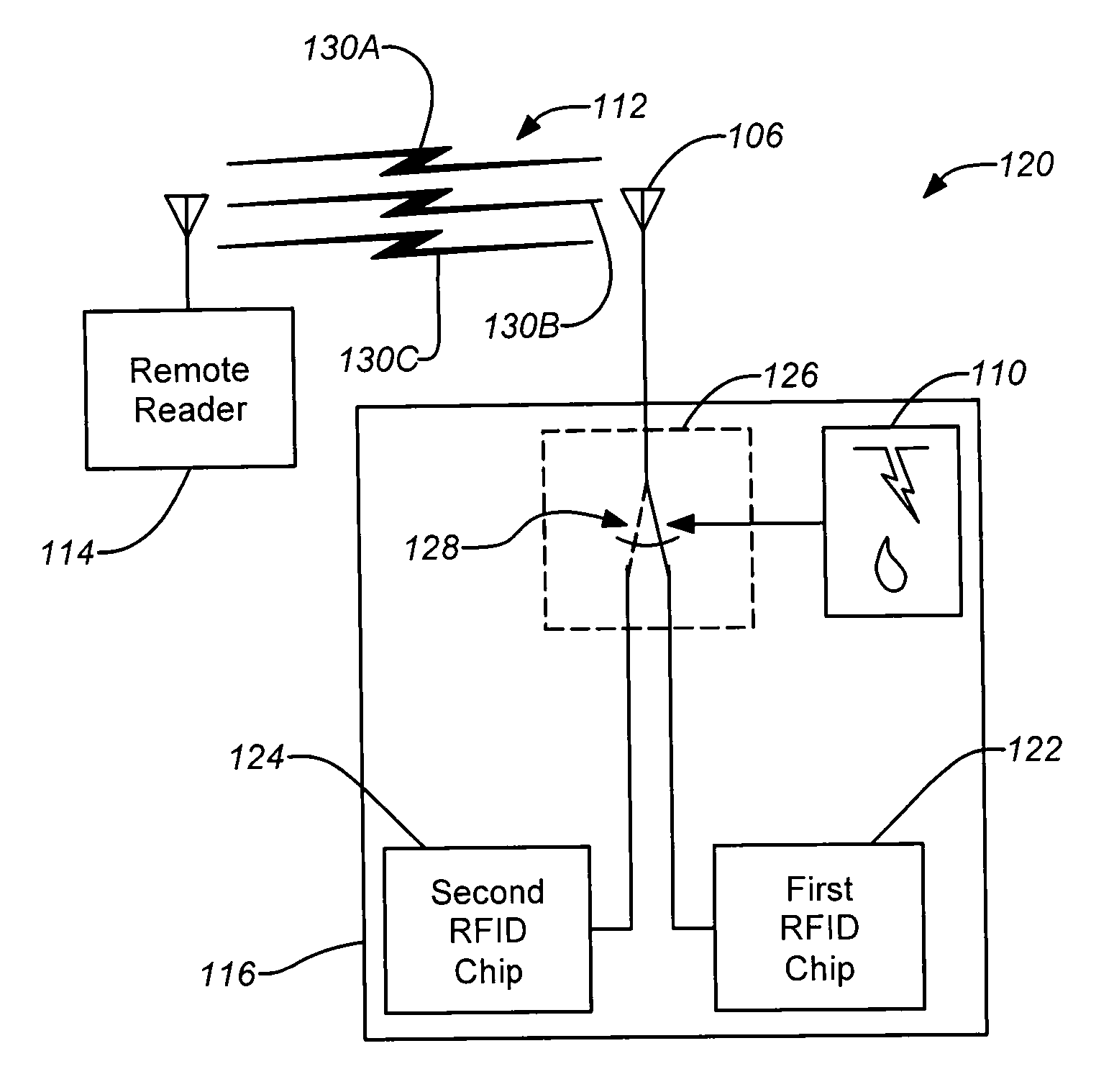

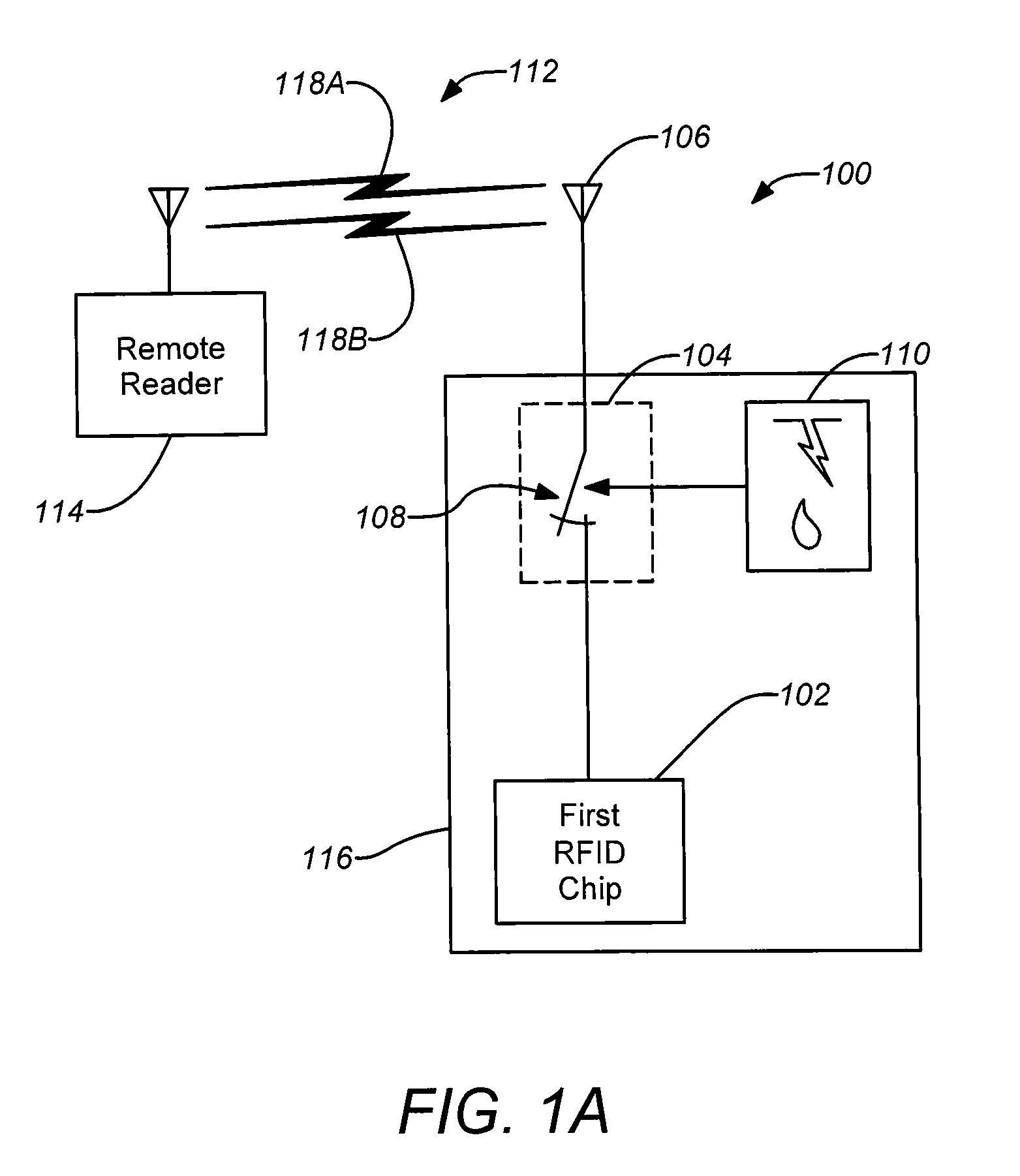

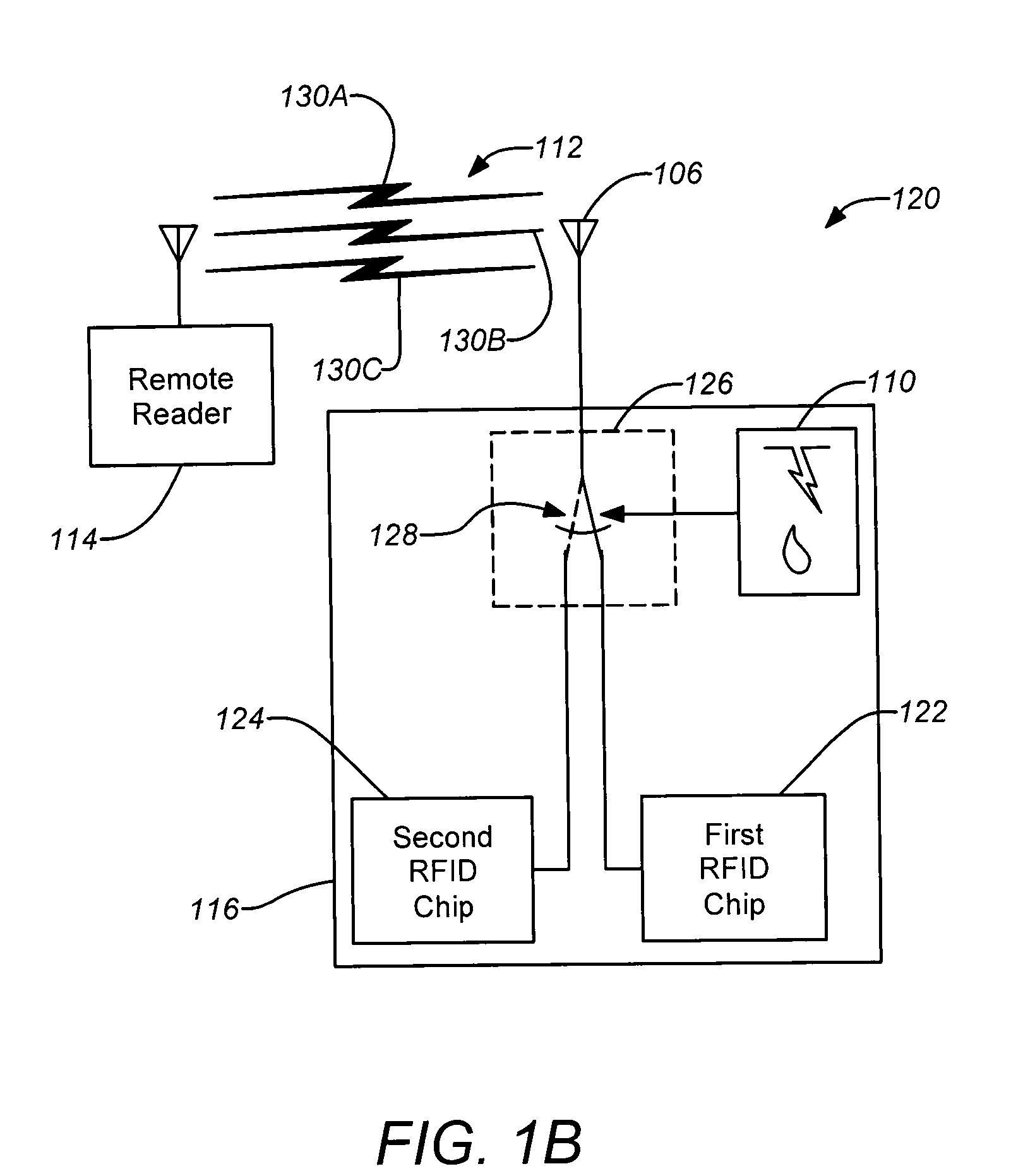

Rfid-based corrosion and moisture detection

ActiveUS20100123583A1Analysing solids using sonic/ultrasonic/infrasonic wavesBurglar alarm by openingStructural health monitoringEngineering

Structural health monitoring apparatuses and methods are disclosed. One or more structural health sensors may be used to disconnect and / or connect one or more RFID chips to an antenna such that wireless communication with the one or more RFID chips (or the absence of wireless communication) through the antenna indicates the structural health status. Example structural health sensors may be moisture detecting or fracture detecting. A remote reader may be used to establish the wireless communication with the one or more RFID chips to determine the structural health. The sensors and RFID chips may be passive and powered through the wireless communication from the remote reader. Such apparatuses and methods may be applied to any large structures requiring regular inspection, such as aircraft, ships, automobiles or buildings.

Owner:THE BOEING CO

Four-point bending test device for full-size metal composite tube

InactiveCN103308397ASimple structureReasonable designMaterial strength using steady bending forcesFour point flexural testStrain gauge

The invention relates to a four-point bending test device for a full-size metal composite tube. The four-point bending test device for the full-size metal composite tube mainly comprises a base, two load supporting columns, clamping buckles for a detected metal composite tube, two loading oil cylinders, a controller, a sensor, a strain foil and a strain gauge, wherein intervals between the two loading oil cylinders and the adjacent load supporting columns are equal; the sensor is used for transmitting the pressure and stroke of each loading oil cylinder to the controller; and the strain foil transmits the local strain and stress size of the detected metal composite tube to the strain gauge. According to the structure, the whole full-size metal composite tube can be tested; the ends of the piston rods of the loading oil cylinders are hinged with the clamping buckle, so that the clamping buckle can be automatically changed and regulated along with a bending angle of a steel tube; and the clamping buckles for the detected metal composite tube can longitudinally rotate relative to the load supporting columns, so that a clamp can be always in surface contact with the steel tube. Therefore, the four-point bending test device for the full-size metal composite tube has the characteristics of simple structure, reasonable design and convenience in operation and application, and can detect the strain size and the stress size.

Owner:CHINA NAT OFFSHORE OIL CORP +1

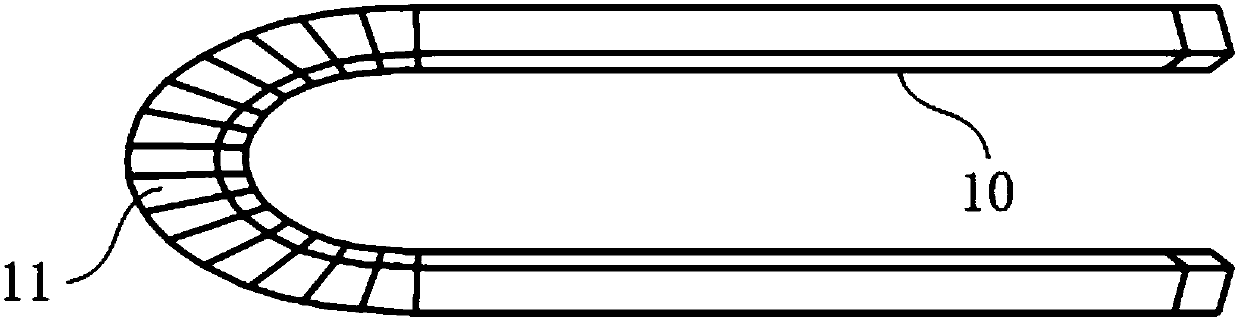

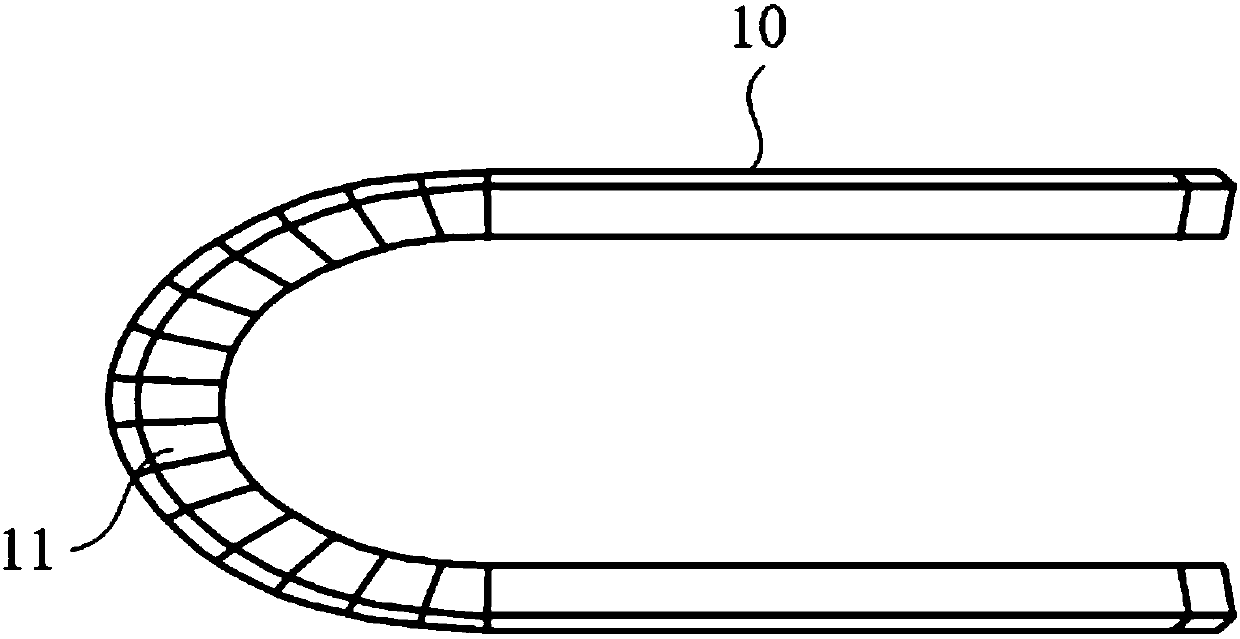

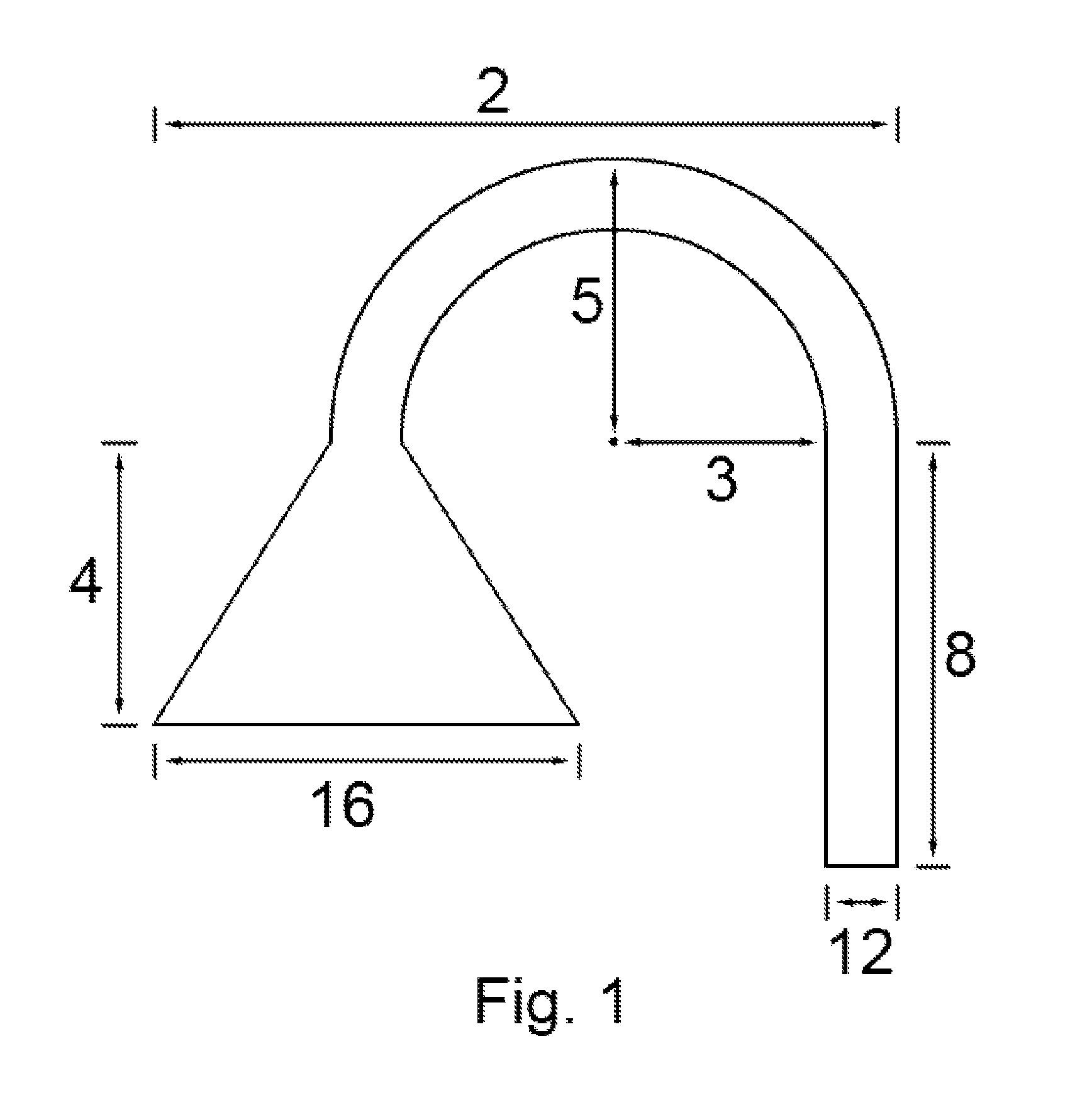

Method and apparatus for proof testing a sheet of brittle material

InactiveUS20080083288A1Force measurementMaterial strength using tensile/compressive forcesStress inducedEngineering

Disclosed is a method of proof testing a sheet of brittle material such as a glass or glass-ceramic based material. The method comprises bending the glass sheet over at least one arcuate member to detect sheets having a strength greater than a predetermined value. The method includes imparting a bend to the sheet and producing relative motion between the sheet and the bend such that the bend traverses the sheet, and wherein tensile stress induced in a surface of the sheet by the bend corresponds to the predetermined strength value. An apparatus for performing the proof testing is also disclosed.

Owner:CORNING INC

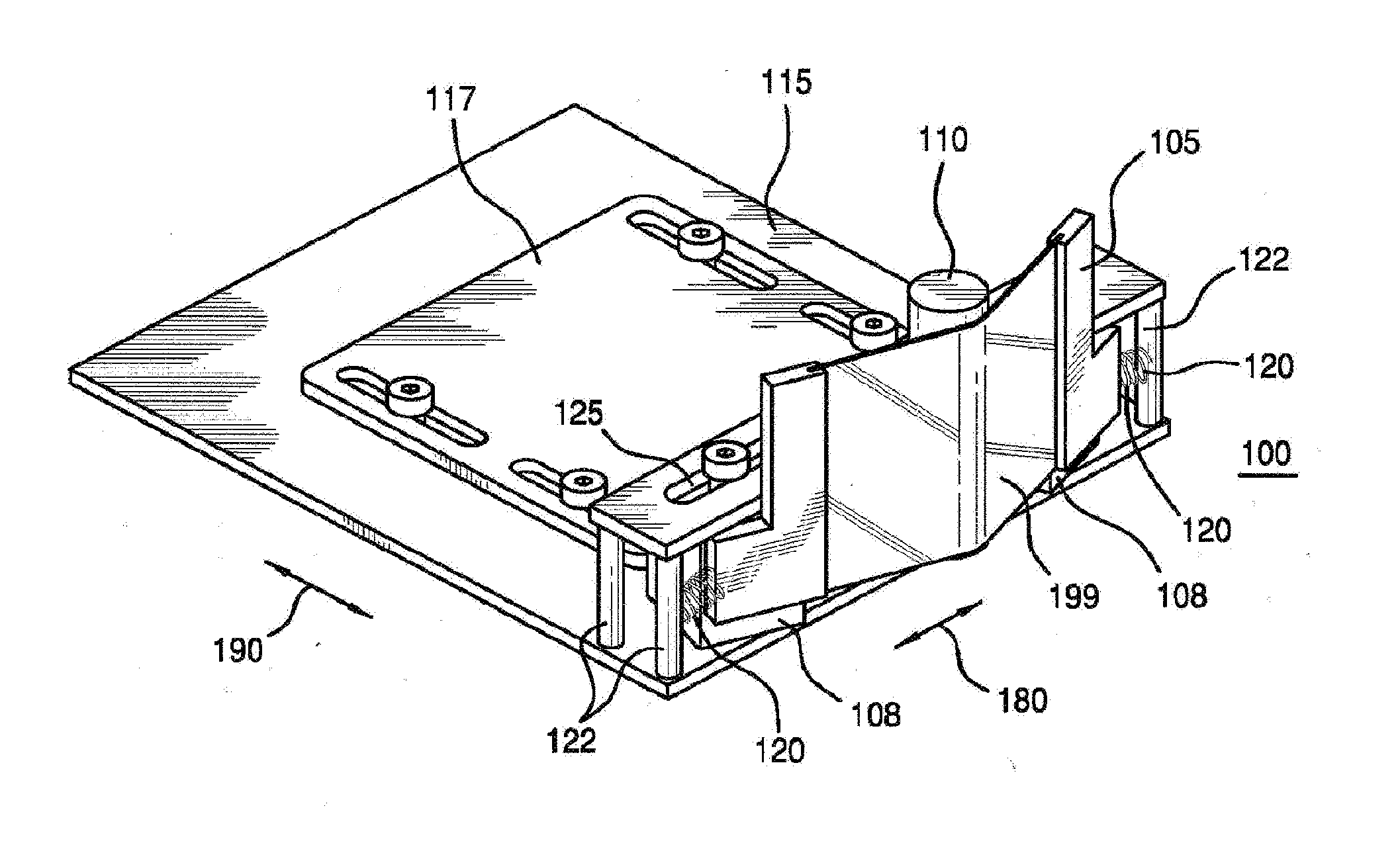

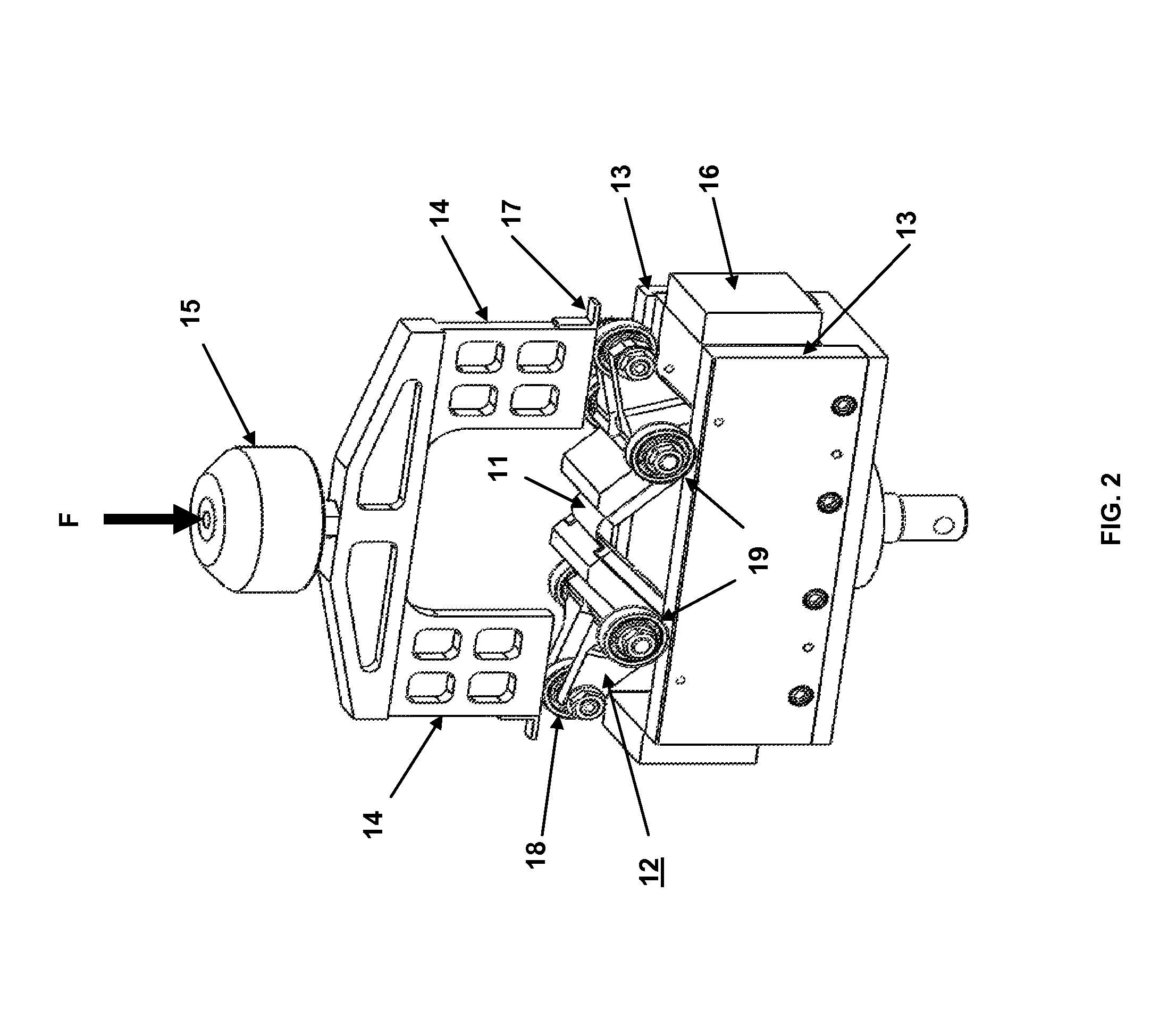

Device for testing thin specimens in pure bending

An improved test fixture to evaluate thin composite laminates commonly used in deployable space structures. The fixture is designed to impart a pure moment into the coupon, a necessary improvement to prior test methods where results are obtained by fitting material properties in a nonlinear structural analysis of the test. Fixture mechanics allow for direct calculation of the coupon flexural modulus and allowable flexural strain based on two key measurements, fixture displacement and applied load.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

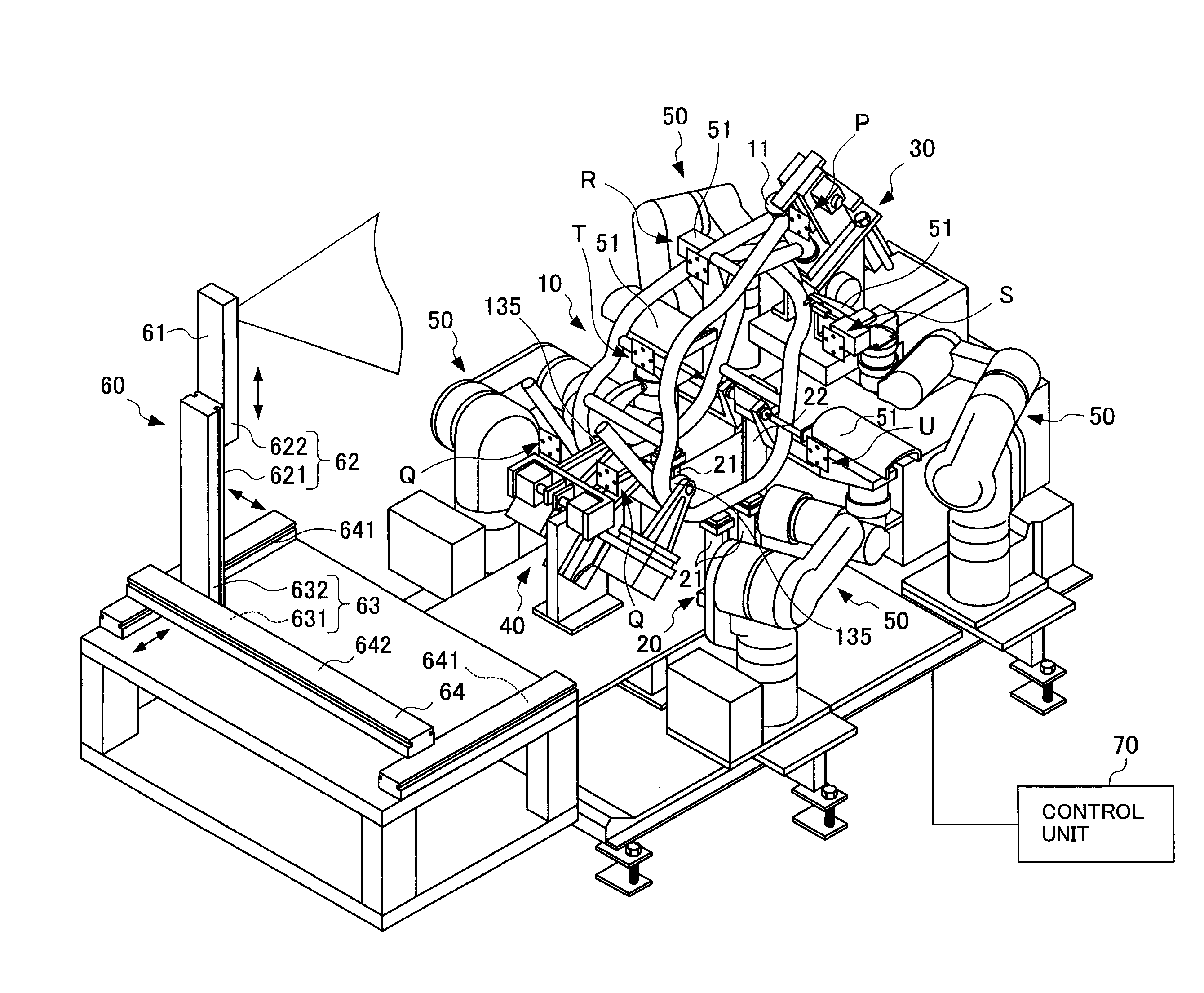

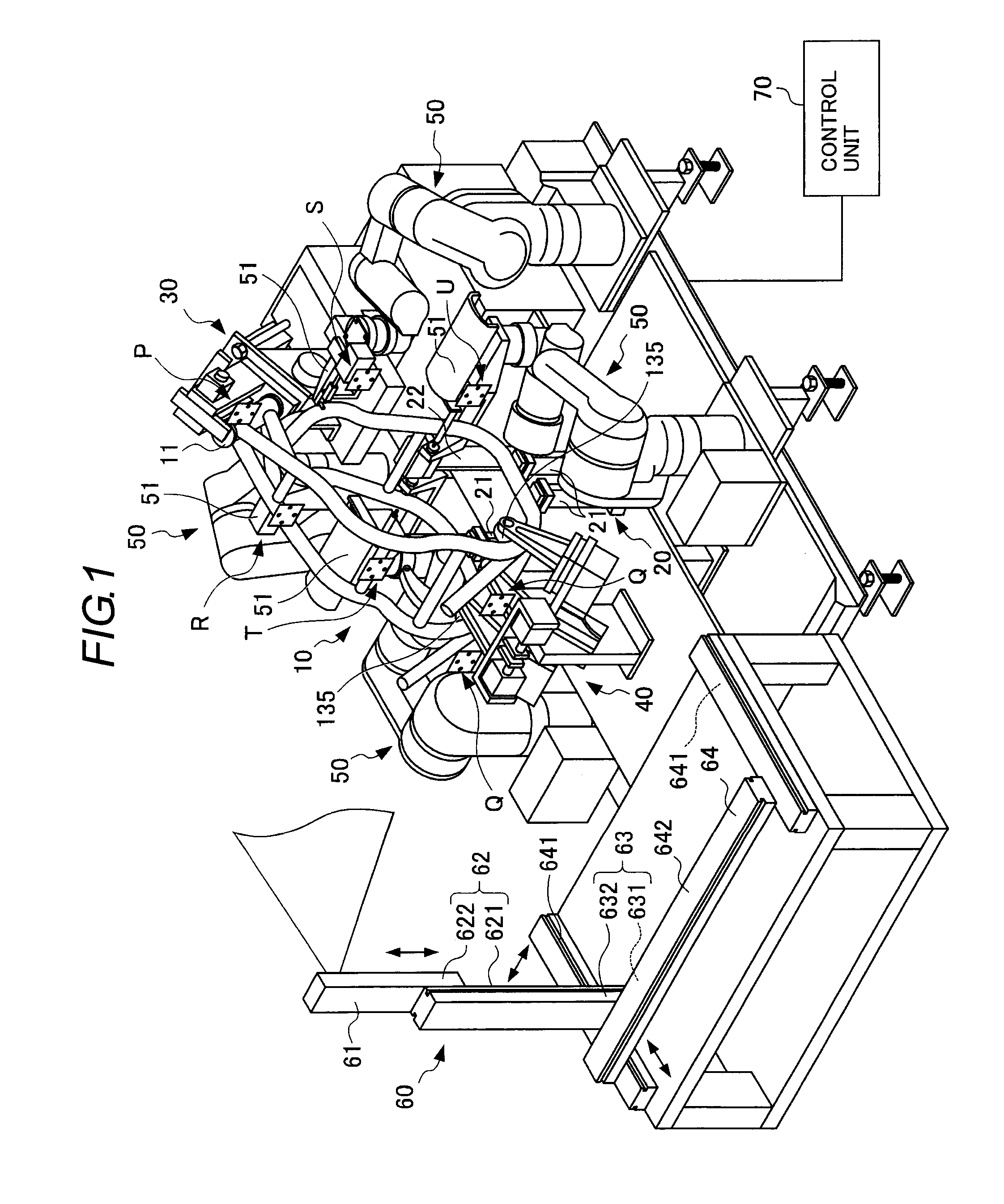

Sensing method, accuracy control method, workpiece positioning system and workpiece positioning method

InactiveUS20100154193A1Precise positioningProgramme-controlled manipulatorWelding/cutting auxillary devicesVehicle frameEngineering

Owner:HONDA MOTOR CO LTD

Steel-concrete composite column anti-seismic anti-torsion test loading device and manufacturing method thereof

InactiveCN103398908AGuaranteed to twist freelyFor quick replacementMaterial strength using steady bending forcesServo actuatorTorsion test

The invention relates to a steel-concrete composite column anti-seismic anti-torsion test loading device and a manufacturing method thereof, and belongs to the technical field of structure engineering. The steel-concrete composite column anti-seismic anti-torsion test loading device comprises a loading frame, a top beam, a base, an antifriction plate, a thrust jack, and two electro-hydraulic servo actuators. The loading frame is obtained by welding steel plates. All column bases of the loading frame are provided with bolt holes and are fixedly connected to the ground by ground anchor bolts. The top beam is obtained by welding steel plates. The bottom of the top beam is provided with bolt holes and is fixedly connected to a top steel plate of a test piece by bolts. The base is obtained by welding steel plates. The top of the base is provided with bolt holes and is connected to a bottom steel plate of the test piece by bolts. An upper end of the thrust jack is connected to the loading frame by a rolling bearing. The antifriction plate is horizontally arranged in the center of the top of the top beam. The electro-hydraulic servo actuators are arranged horizontally and are fixedly connected to the top beam. The steel-concrete composite column anti-seismic anti-torsion test loading device solves the problem of the prior art, has a simple structure, is convenient for use, has strong universality, can be used for anti-seismic anti-torsion tests on various steel-concrete composite columns, and has wide application prospects.

Owner:TSINGHUA UNIV

Bending test device and bending test method

ActiveCN108225938AReal-time detection of aging parametersShorten test timeMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesTest efficiencyEngineering

The invention provides a bending test device and a bending test method. The bending test device comprises a bearing platform, a bending unit and a parameter detection unit, wherein the bearing platform is used for bearing a to-be-tested object; the bending unit is used for controlling the first end of the to-be-tested object to swing repeatedly relative to the second end, so as to bend the to-be-tested object repeatedly; the bending unit is arranged on the bearing platform; the parameter detection unit is used for detecting the aging parameter of the to-be-tested object in the bending processof the to-be-tested object; the parameter detection unit is connected with the to-be-tested object. The invention aims to provide a bending test device and a bending test method, the performance change of the to-be-tested object can be visually monitored in a process of repeatedly bending a flexible display screen and other to-be-tested objects, then the aging degree of the to-be-tested object canbe visually judged according to the performance change in the bending test process, thereby improving the test efficiency and the test result accuracy.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com