Three-way loading mechanical property test system of multifunctional lining segment joint

A lining segment and test system technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable bending force, scientific instruments, etc., can solve unreasonable test results and loading control system Low-level, complex test loading system and other problems, to improve the accuracy of data and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

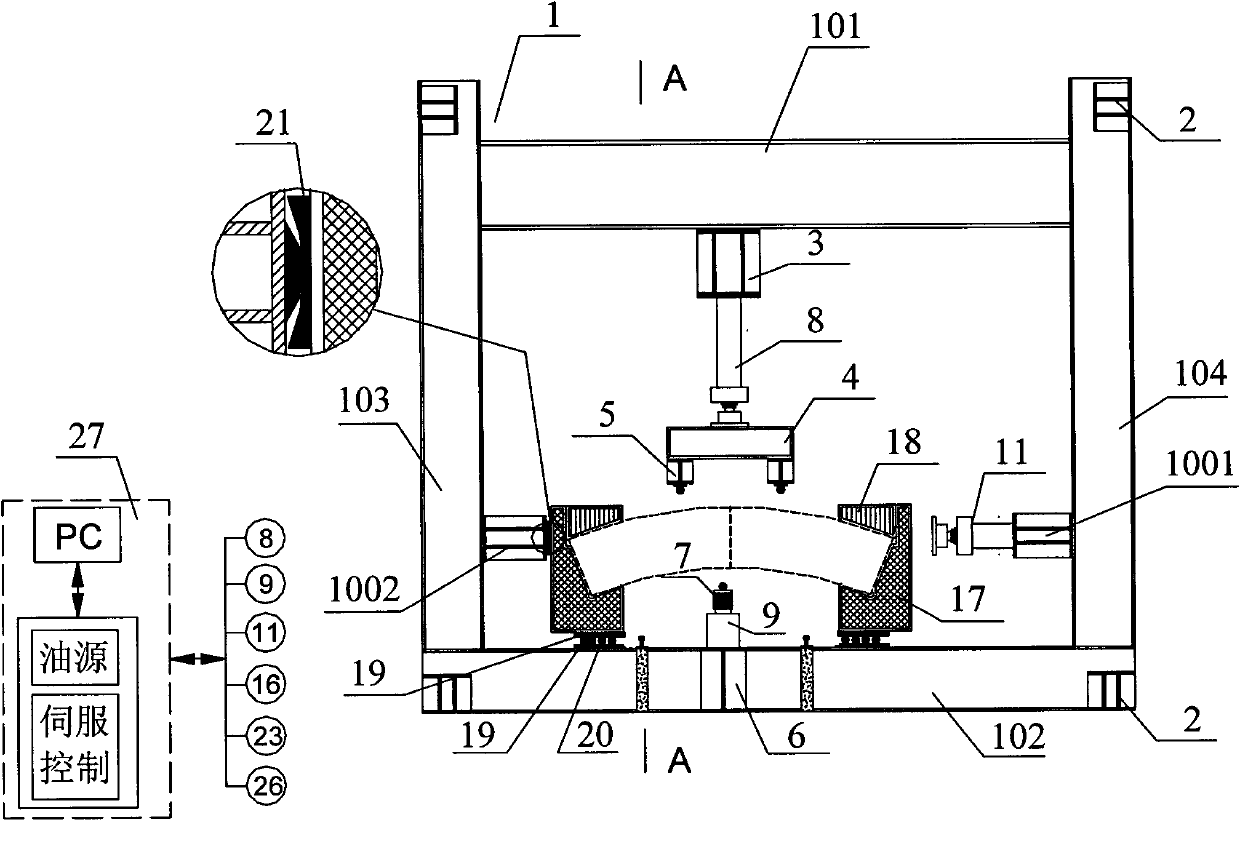

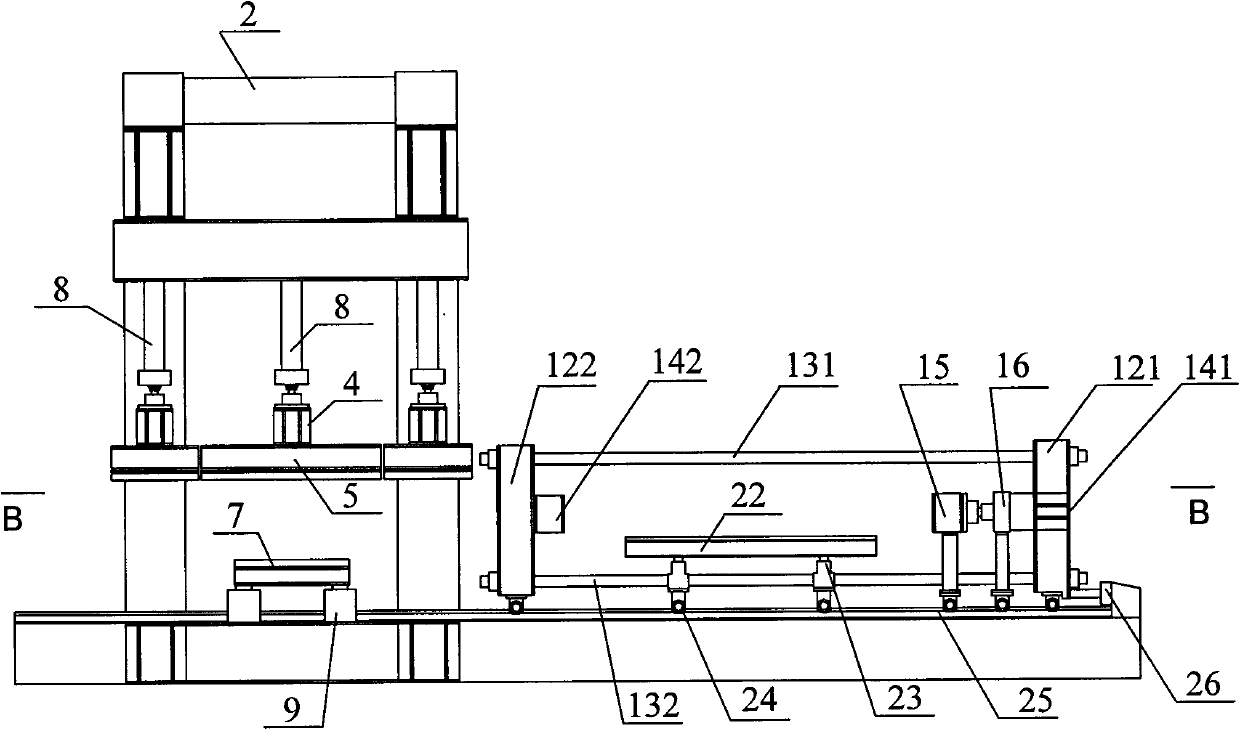

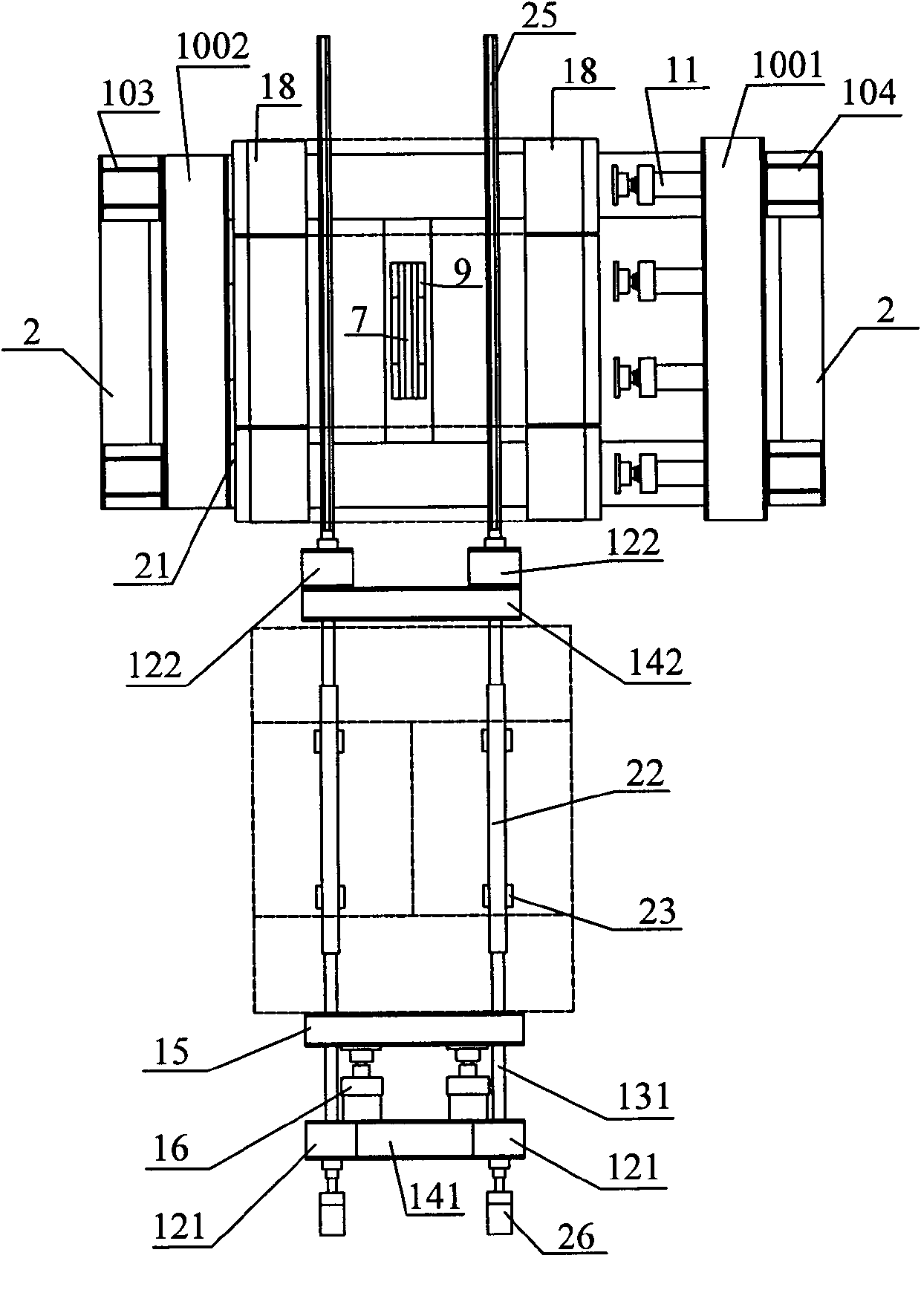

[0041] Such as Figure 1 to Figure 3 Shown, test system of the present invention mainly comprises following six parts:

[0042] 1. The self-balancing frame subsystem mainly includes the main frame 1 and the connecting beam 2 that constitute the balanced frame structure. The main frame 1 includes two frame top beams 101, two frame bottom beams 102, two left frame columns 103 and two The right frame column 104, two connecting beams 2 are arranged between the two left frame columns 103, and two connecting beams 2 are arranged between the two right frame columns 104;

[0043] 2. The loading subsystem mainly includes the X-direction loading subsystem, the Y-direction loading subsystem, and the Z-direction loading subsystem, wherein: the X-direction loading subsystem mainly includes the X-direction loading actuator 11 and the X-direction loading right reaction beam 1001. The left reaction beam 1002 is loaded in the X direction, and the two ends of the right reaction beam 1001 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com