Micro material mechanical performance testing platform under stretching-bending-twisting multi-loads

A test platform and micromechanics technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/compression, and analyzing materials, etc., can solve the difficulty of ensuring the synchronization of composite loads and research and observation methods Immaturity, measurement accuracy is difficult to guarantee and other problems, to achieve the effect of ingenious design, novel ideas, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

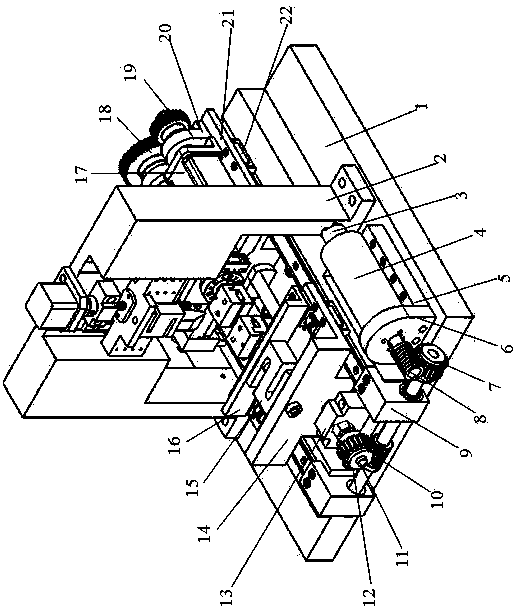

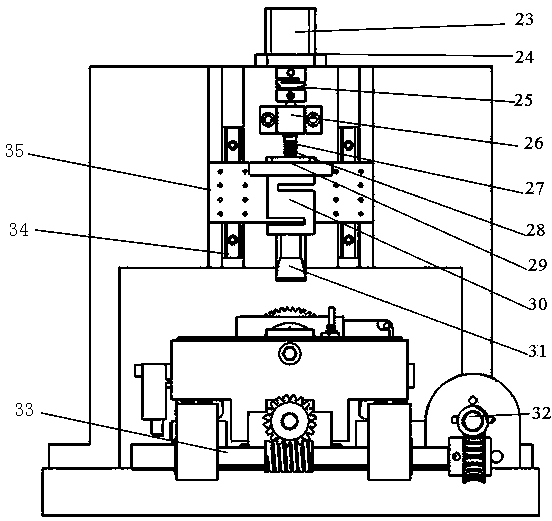

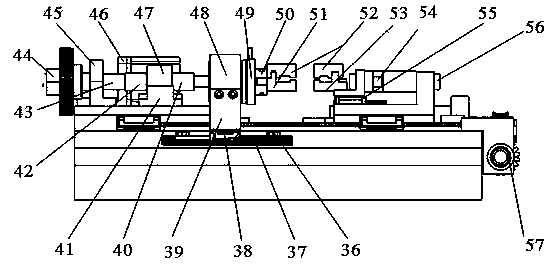

[0036] see Figure 1 to Figure 5 As shown, the tensile-bending-torsion material micromechanical property testing platform under multiple loads of the present invention includes a tension-compression module, a bending module, a torsion module, a control detection module, and a specimen clamping module; the test platform is based on a tension-compression module It is a basic functional module, the torsion module is arranged at one end of the tension-compression module, and its function can be independent or related to the function of the tension-compression module, the specimen clamping module is arranged on the tension-compression module, and the bending module is independently arranged on the test platform. On the side, the function is independent of the tension and compression modules, and the control and detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com