Patents

Literature

172results about How to "Clever layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

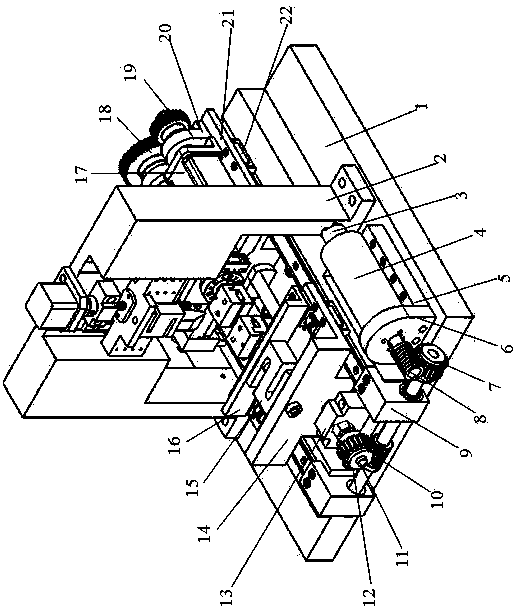

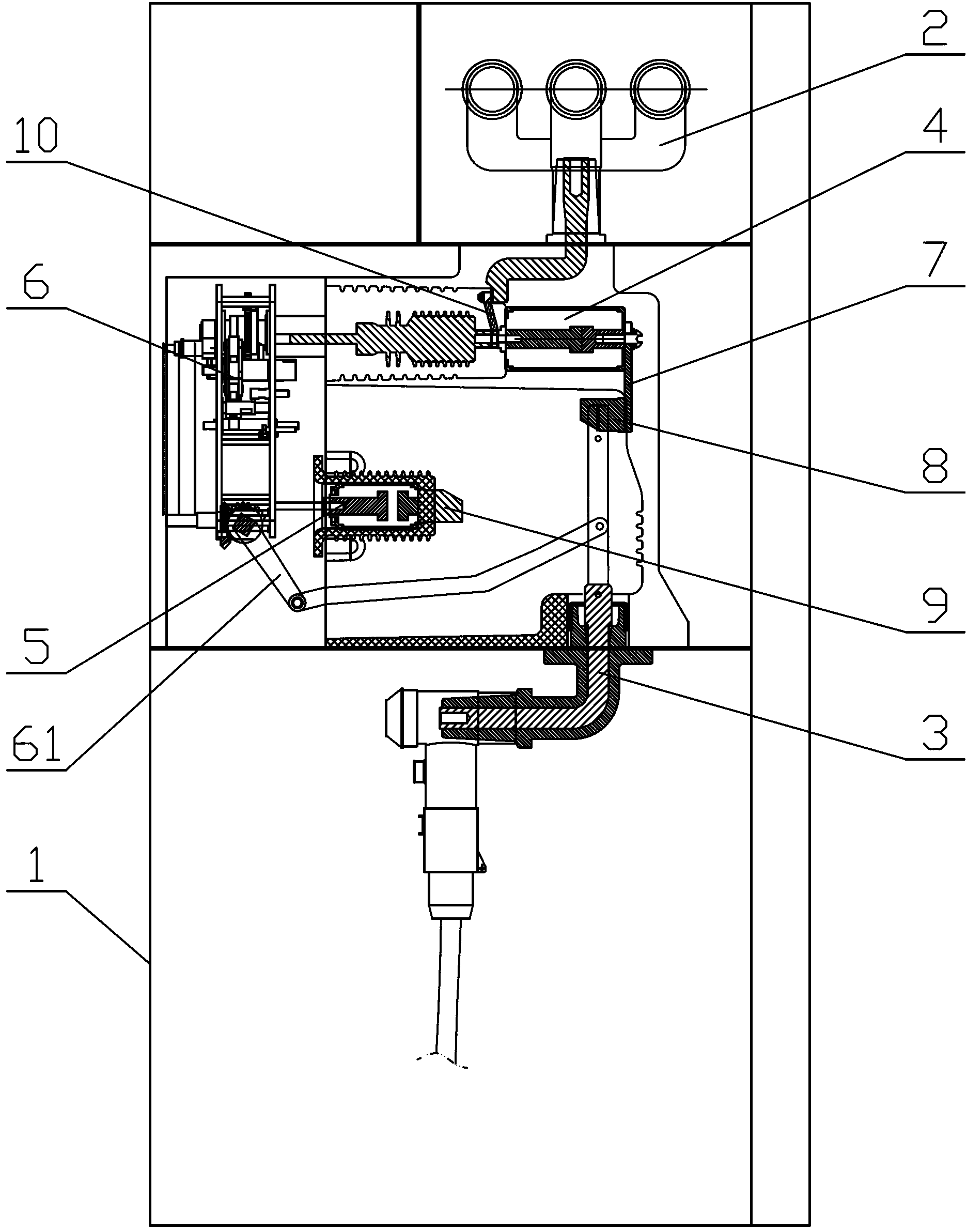

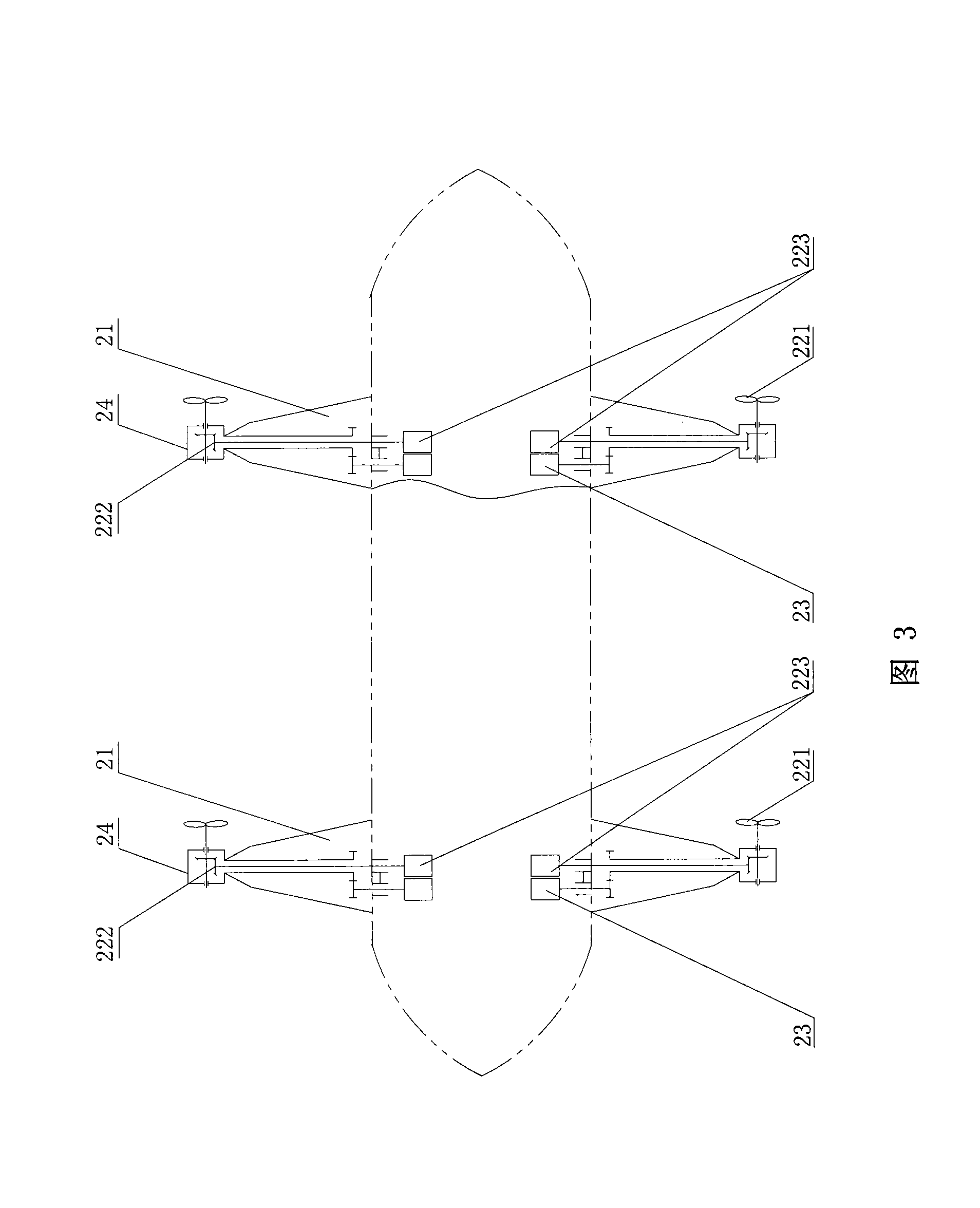

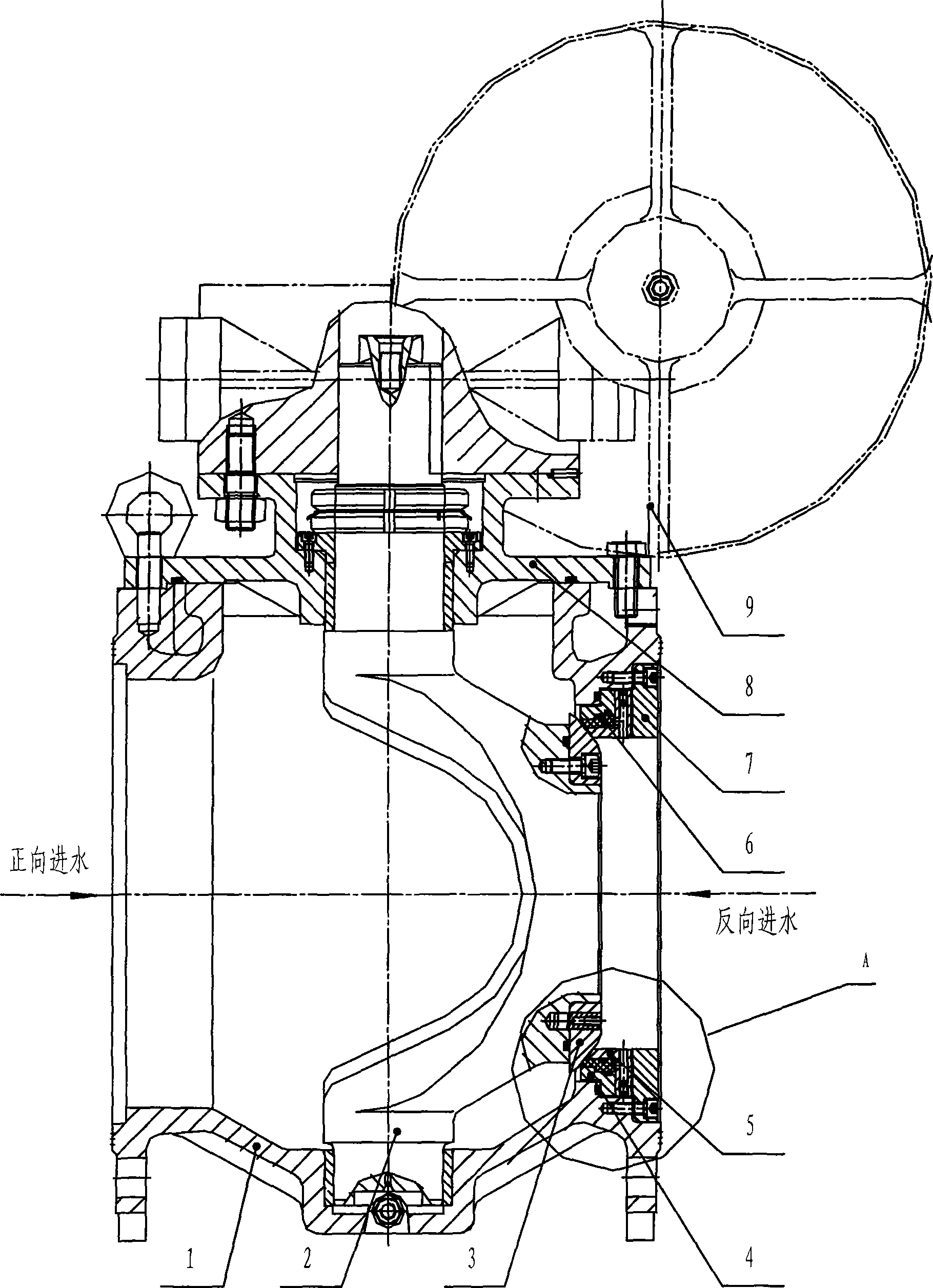

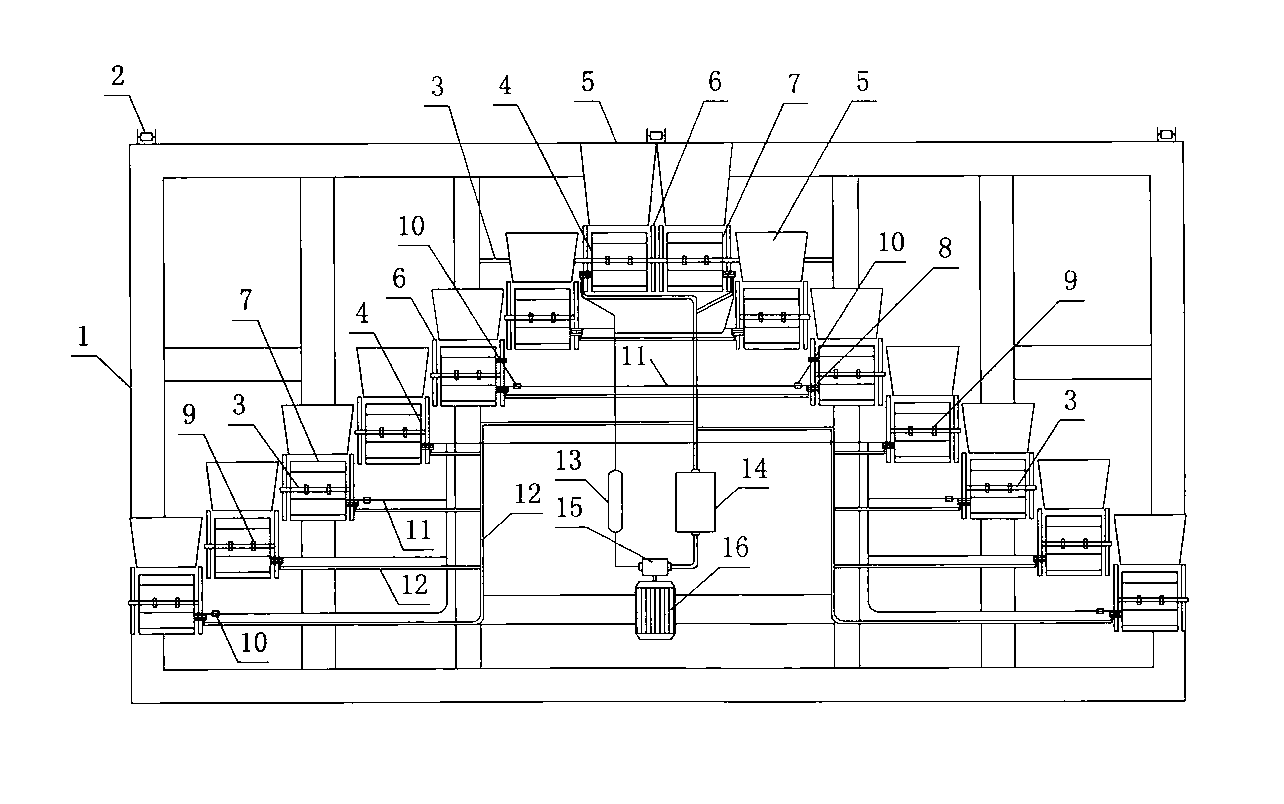

Micro material mechanical performance testing platform under stretching-bending-twisting multi-loads

ActiveCN103389243ANovel ideaCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectromechanicsStress level

The invention relates to a micro material mechanical performance testing platform under stretching-bending-twisting multi-loads, and belongs to the field of electromechanics. The micro material mechanical performance testing platform comprises a tension and compression module, a bending module, a twisting module, a detection control module and a test-piece clamping module, wherein the testing platform takes the tension and compression module as a basic function module; the twisting module is arranged at one end of the tension and compression module; the test-piece clamping module is arranged on the tension and compression module; the bending module is independently arranged at one side of a portal frame. The micro material mechanical performance testing platform can be taken as a material mechanical performance test device with an independent stretching / compressing mode or an independent bending mode or independent twisting mode, namely a single load testing mode, and can be applied to a material mechanical performance test of a twisting load under the given stretching / compressing stress level or a material mechanical performance test of a bending load under the given stretching / compressing stress level, namely a composite load testing mode. The stress strain process of a material under the effect of a composite load can be detected by the collection of a load / displacement signal by using the detection control module.

Owner:JILIN UNIV

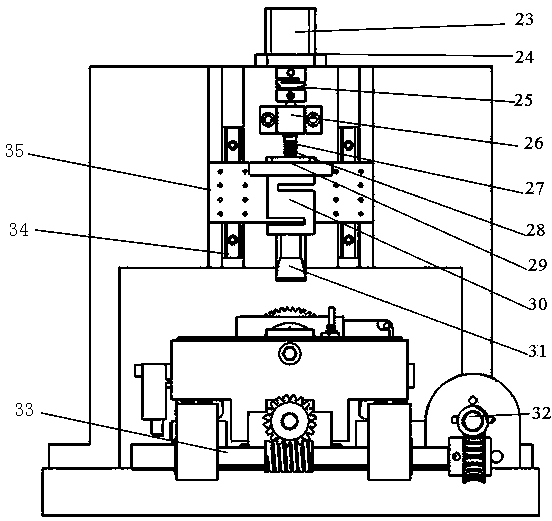

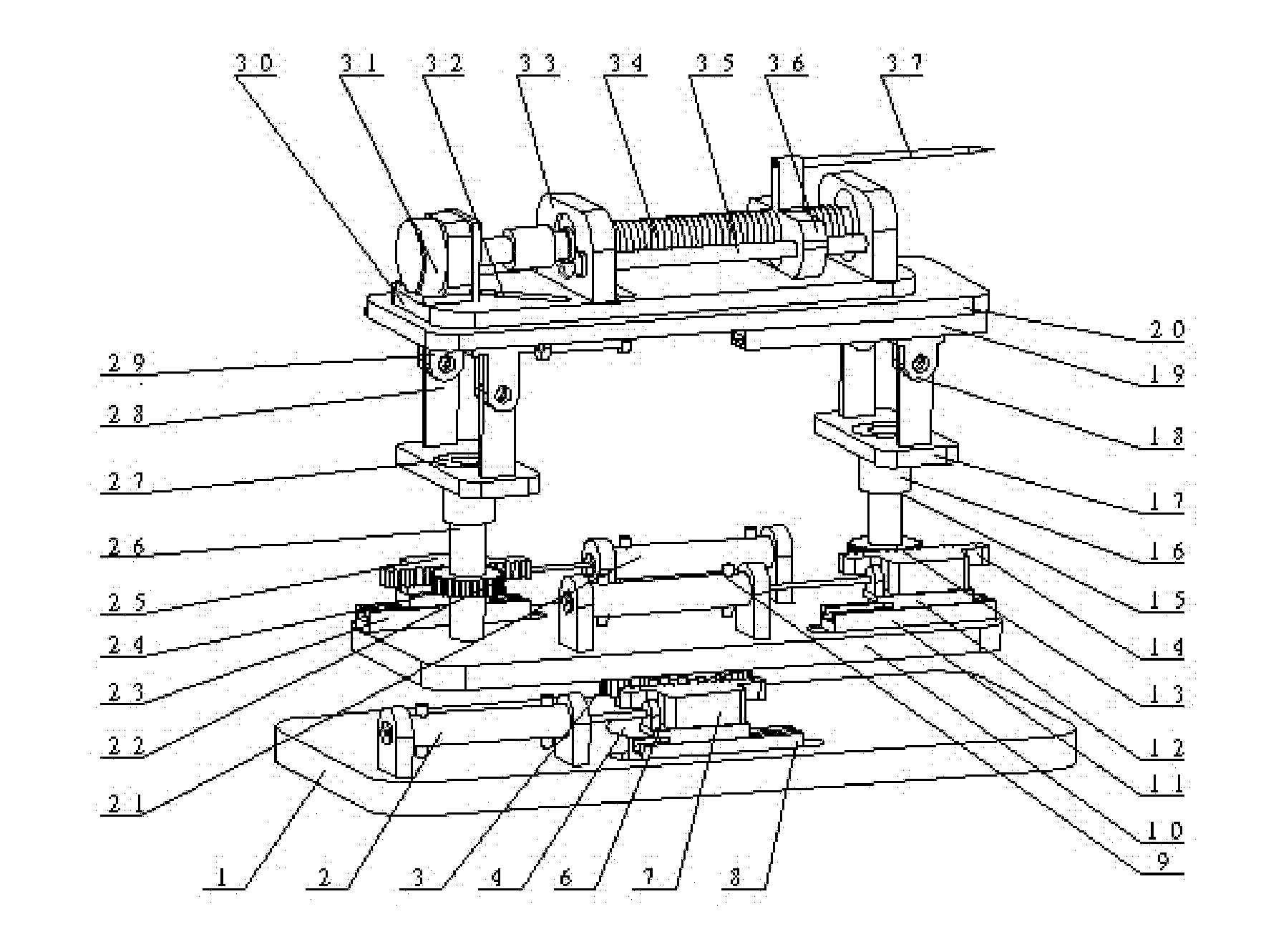

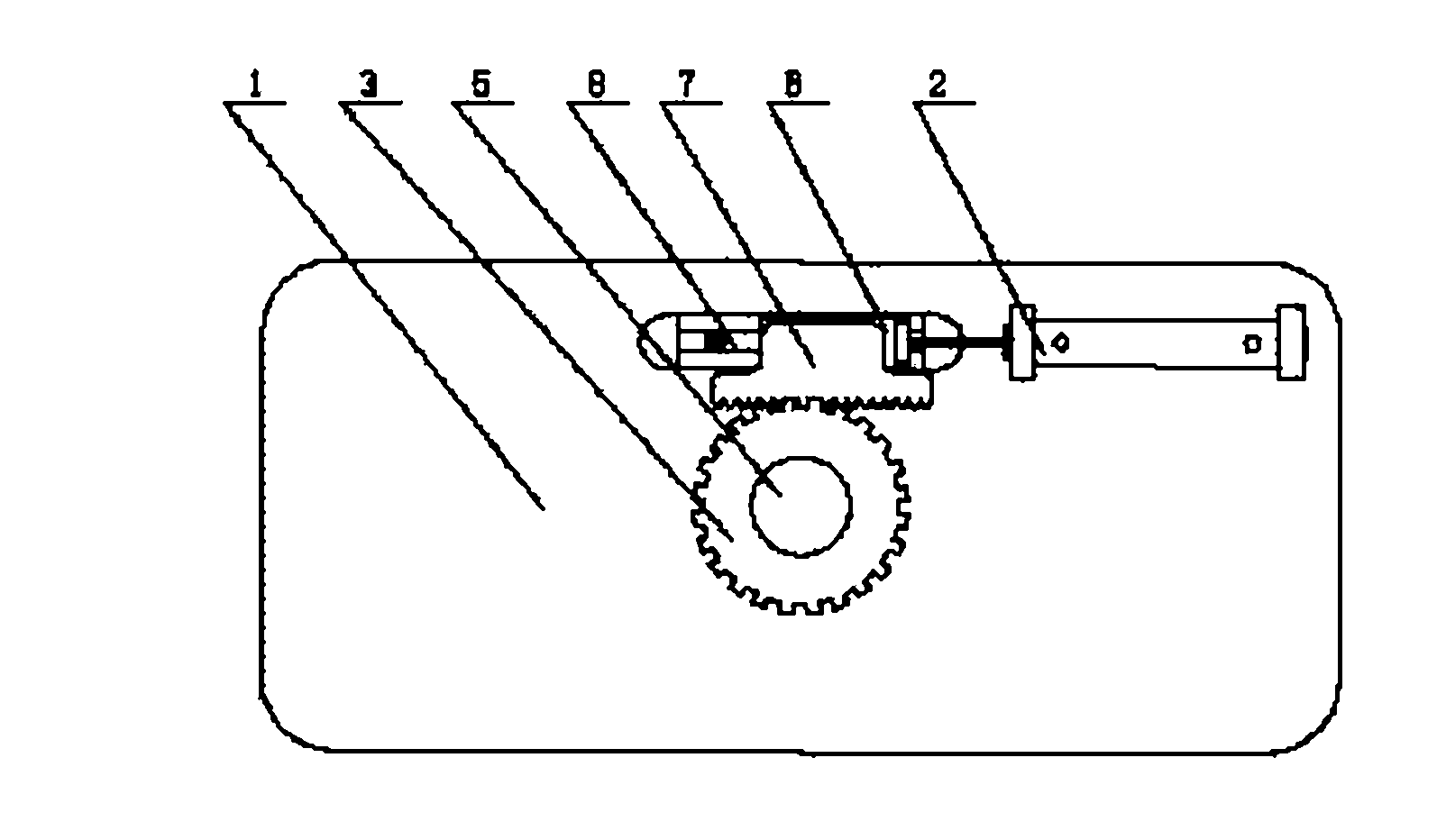

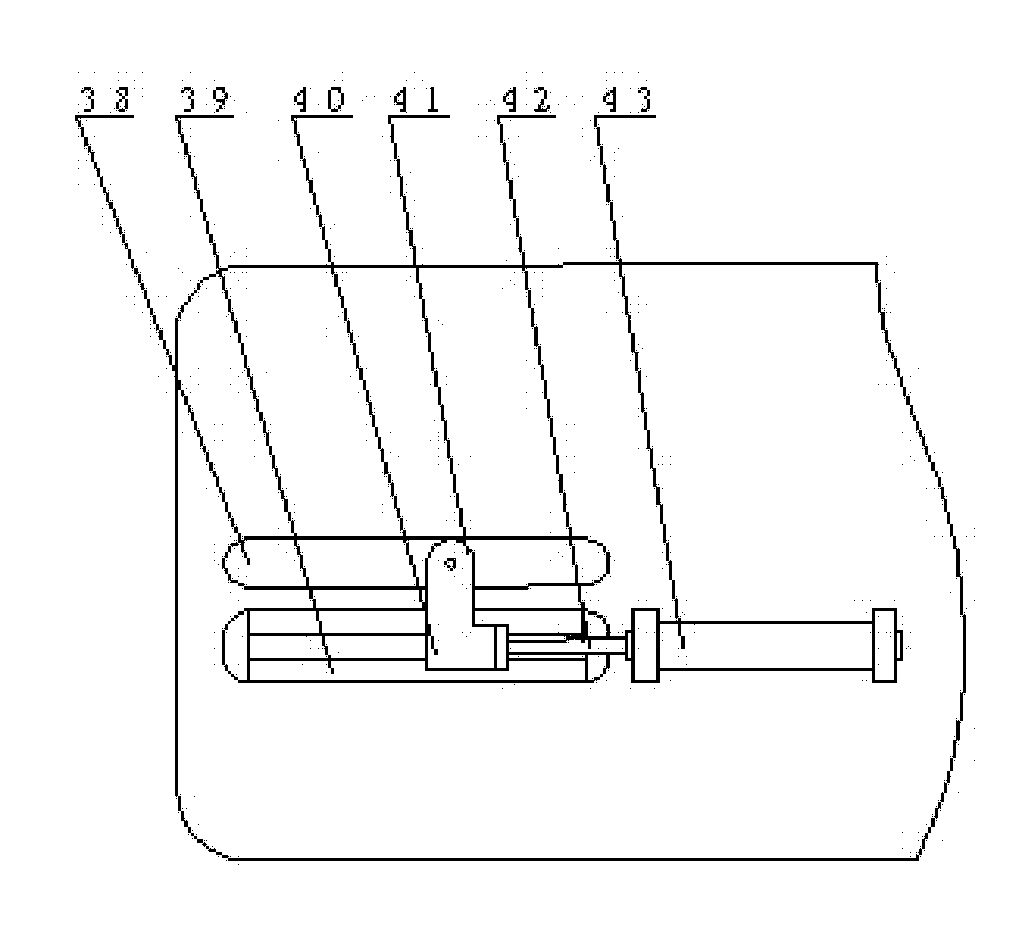

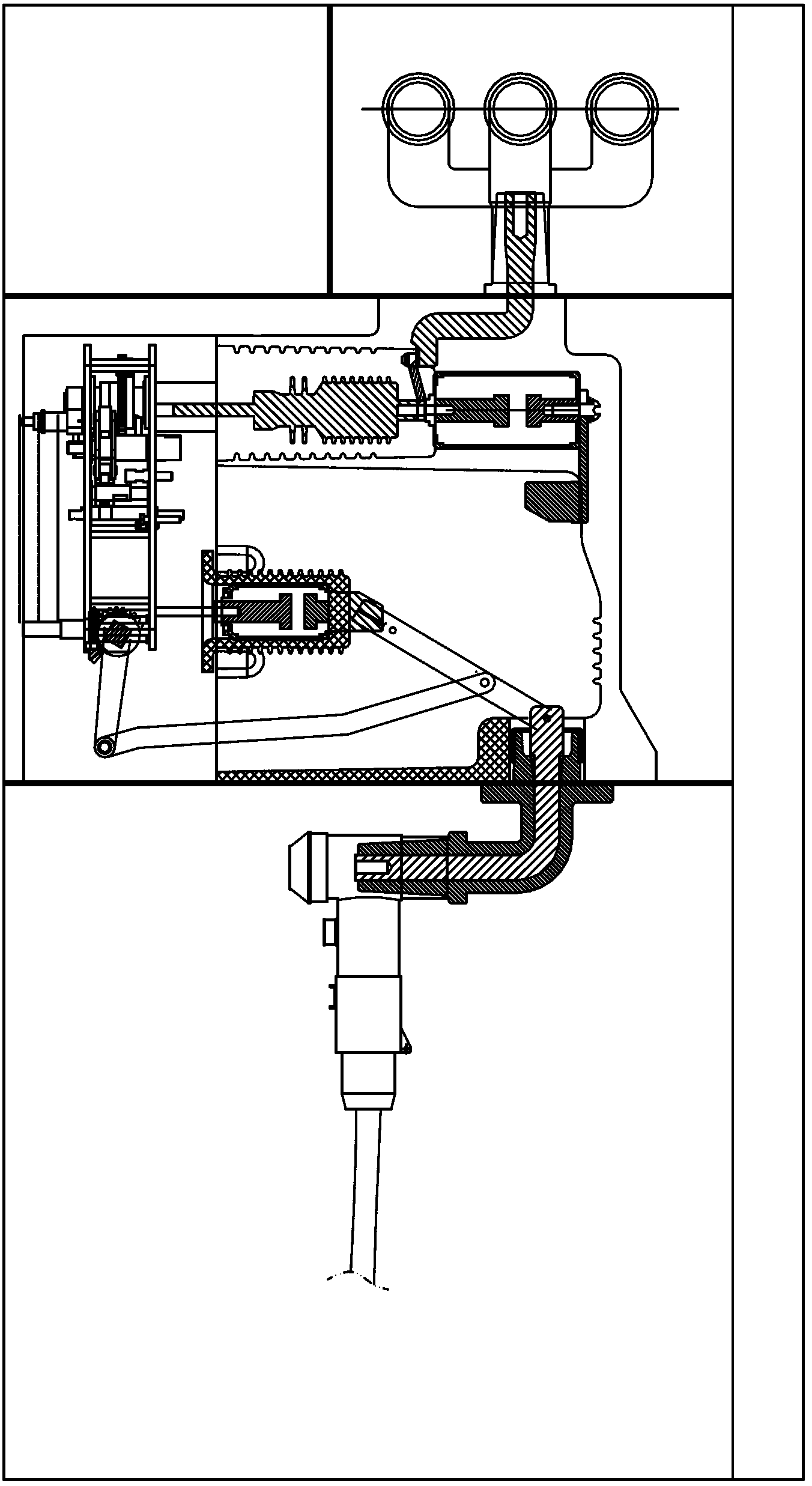

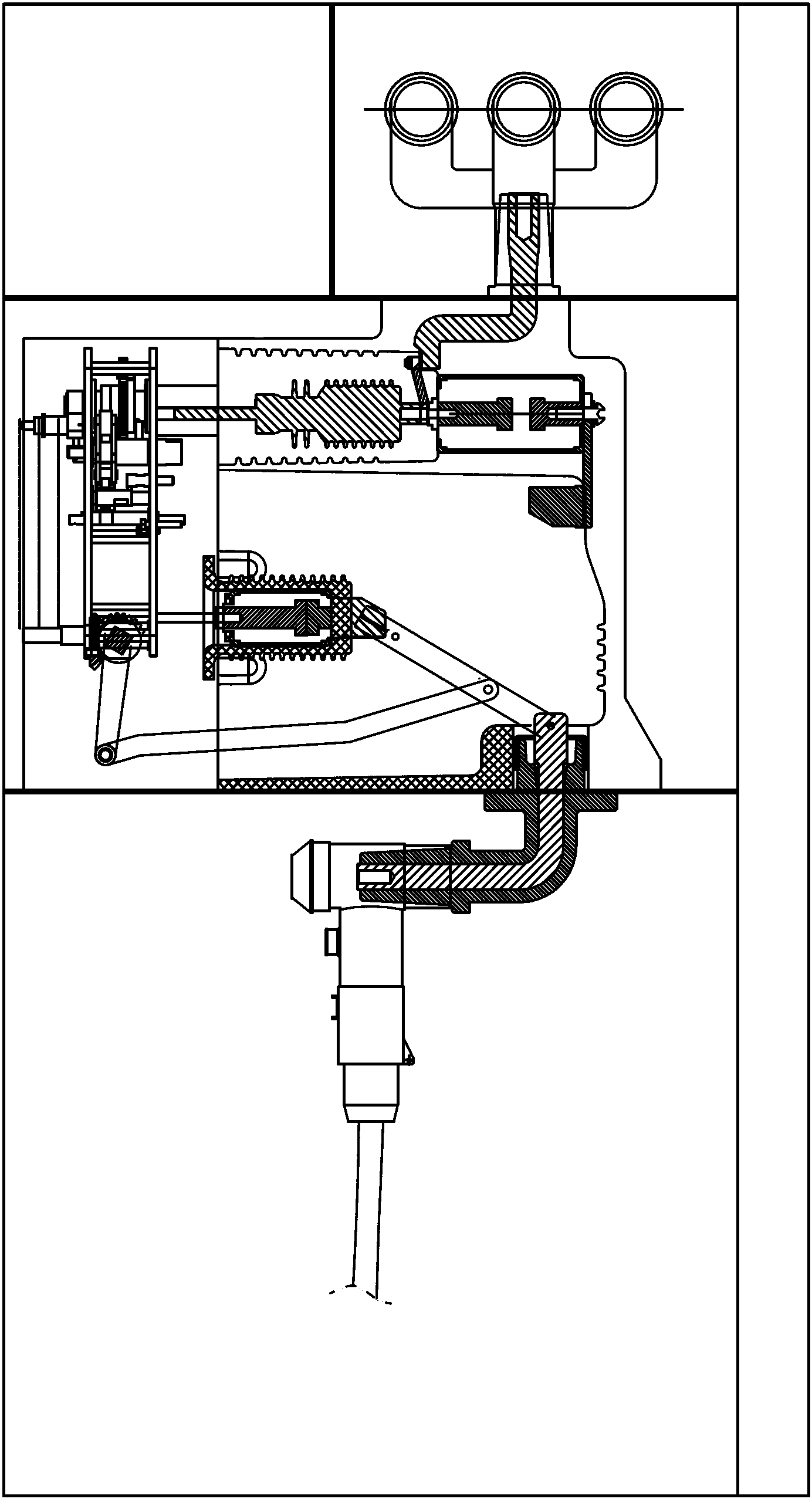

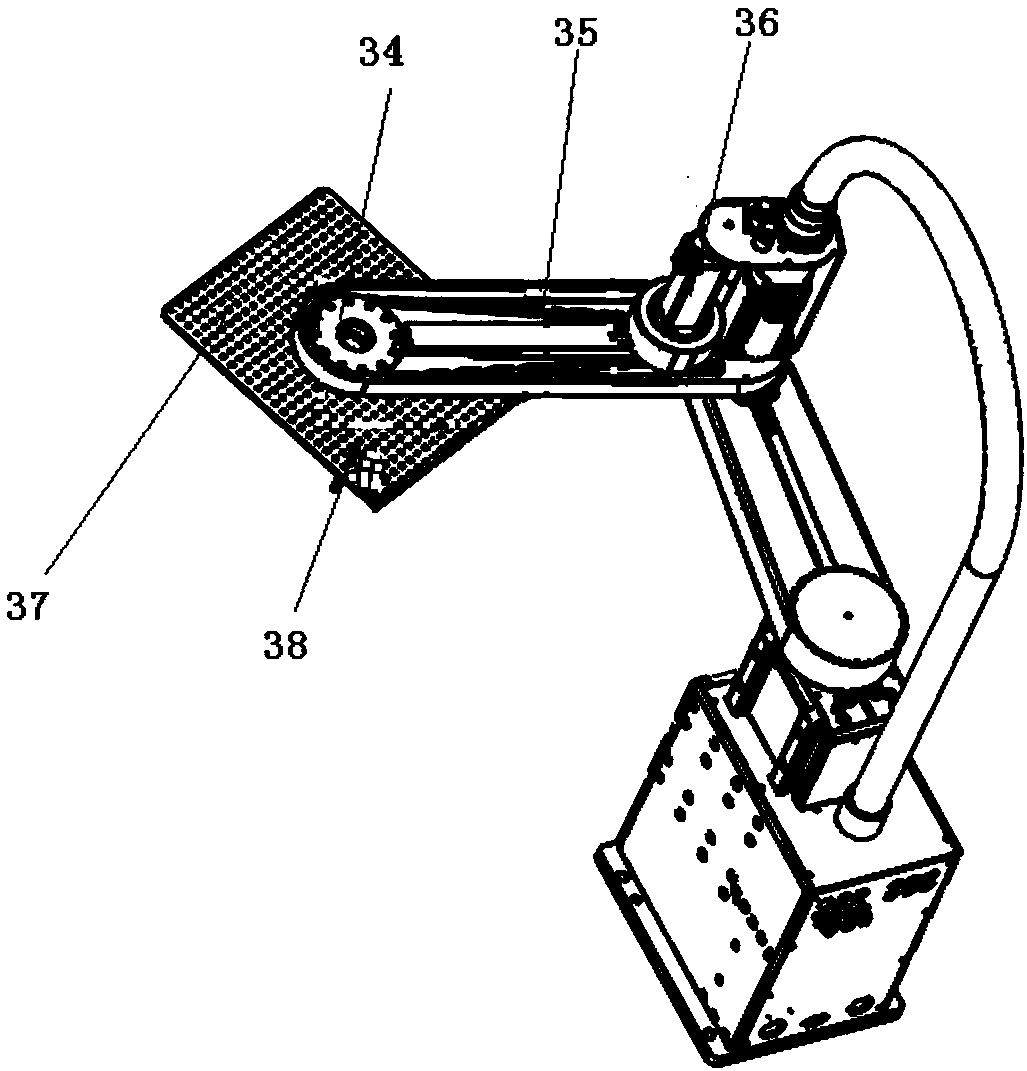

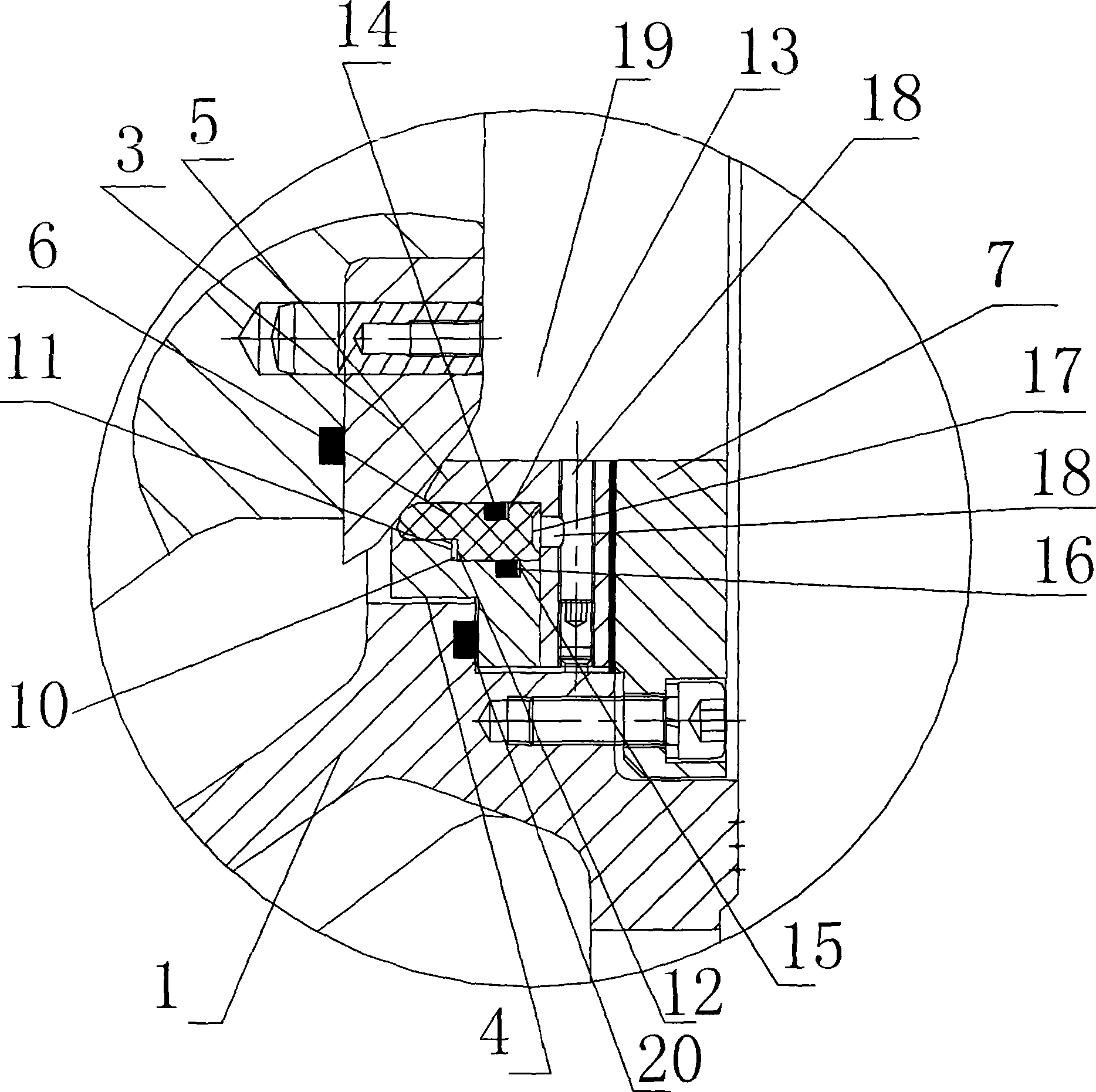

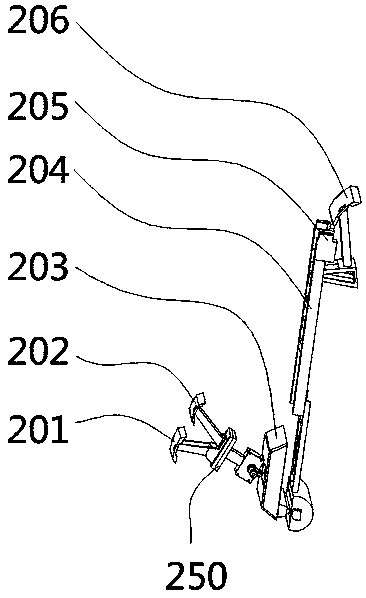

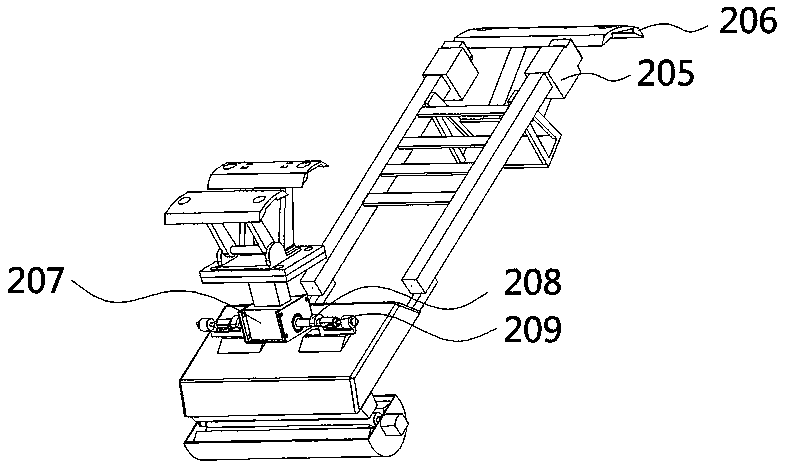

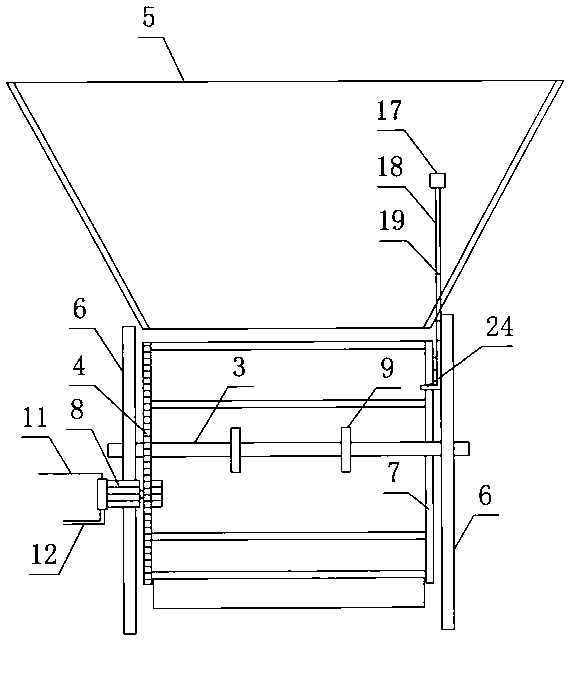

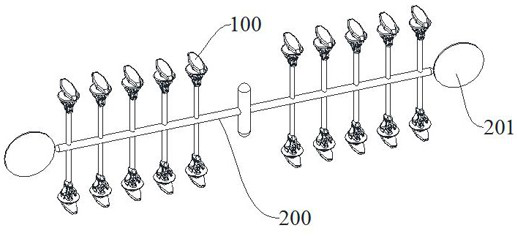

Five degrees of freedom minimally invasive acupuncture surgery guidance mechanism

InactiveCN102258826AHigh precisionFlexible structureDiagnosticsSurgical needlesAcupunctureGear wheel

The invention discloses a five-freedom degree minimally invasive acupuncture operation guiding mechanism. The mechanism is sequentially provided with four platforms from bottom to top, a bottom platform, a middle platform, an upper platform and an acupuncture platform respectively, wherein a bottom module comprises the bottom platform, the middle platform as well as a push rod slide rail mechanism and a gear rack mechanism which are arranged between the bottom platform and the middle platform, and a swinging rotating freedom degree of a device around a vertical shaft is realized by pushing byvirtue of a first cylinder under the coaction of the push rod slide rail mechanism and the gear rack mechanism; a middle module comprises the middle platform, the upper platform as well as two sets of push rod slide rail mechanism-gear rack mechanism-screw nut mechanism which are parallel and are arranged between the middle platform and the upper platform; and an upper module comprises the upper platform, the acupuncture platform and push rod slide rail mechanism-swing rod sliding chute mechanism arranged between the upper platform and the acupuncture platform. The mechanism disclosed by the invention has flexible structure, four cylinders are used for realizing up-down, left-right, tilting and swinging movements in a large range, an ultrasonic motor and the screw nut mechanism are used for realizing acupuncture movement in an operation; and the two sets of gear rack-screw nut mechanisms are used in a parallel manner, and lifting and tilting movements of the mechanism are expertly realized.

Owner:TIANJIN UNIV

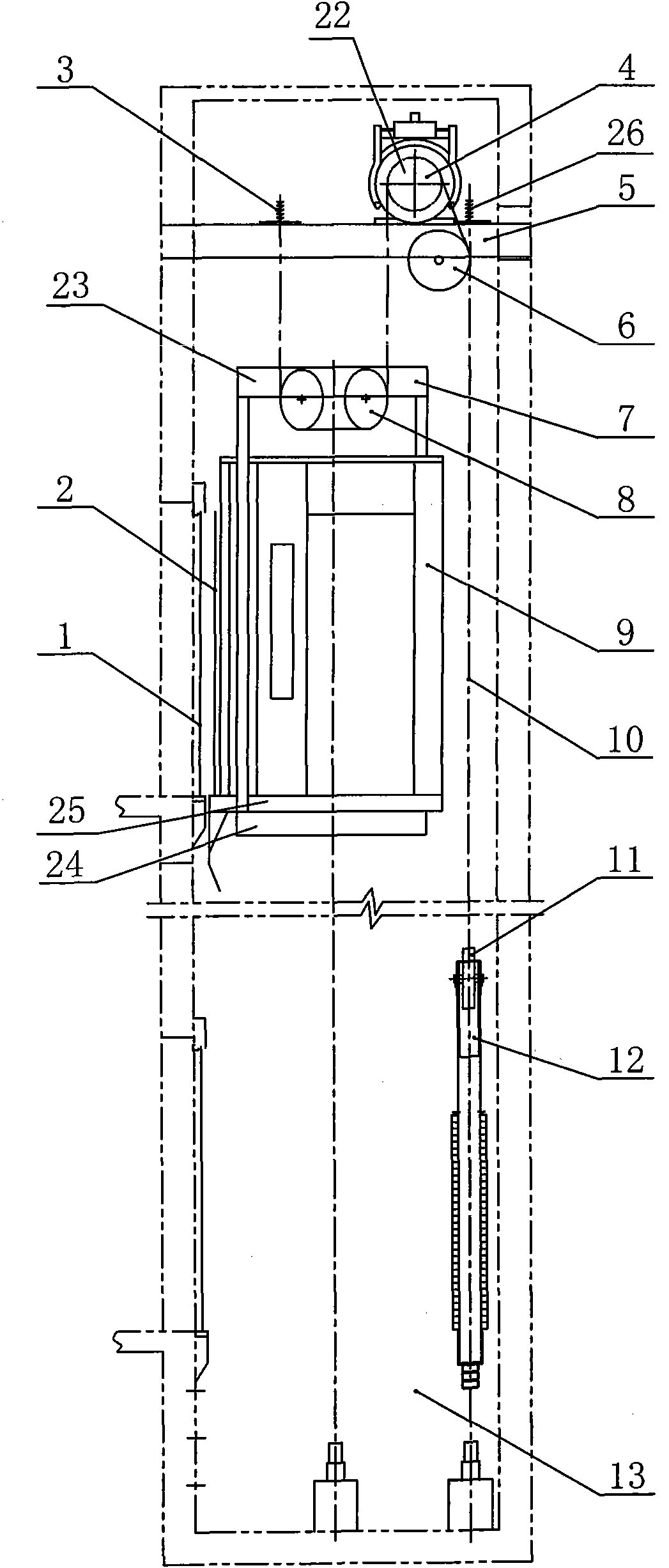

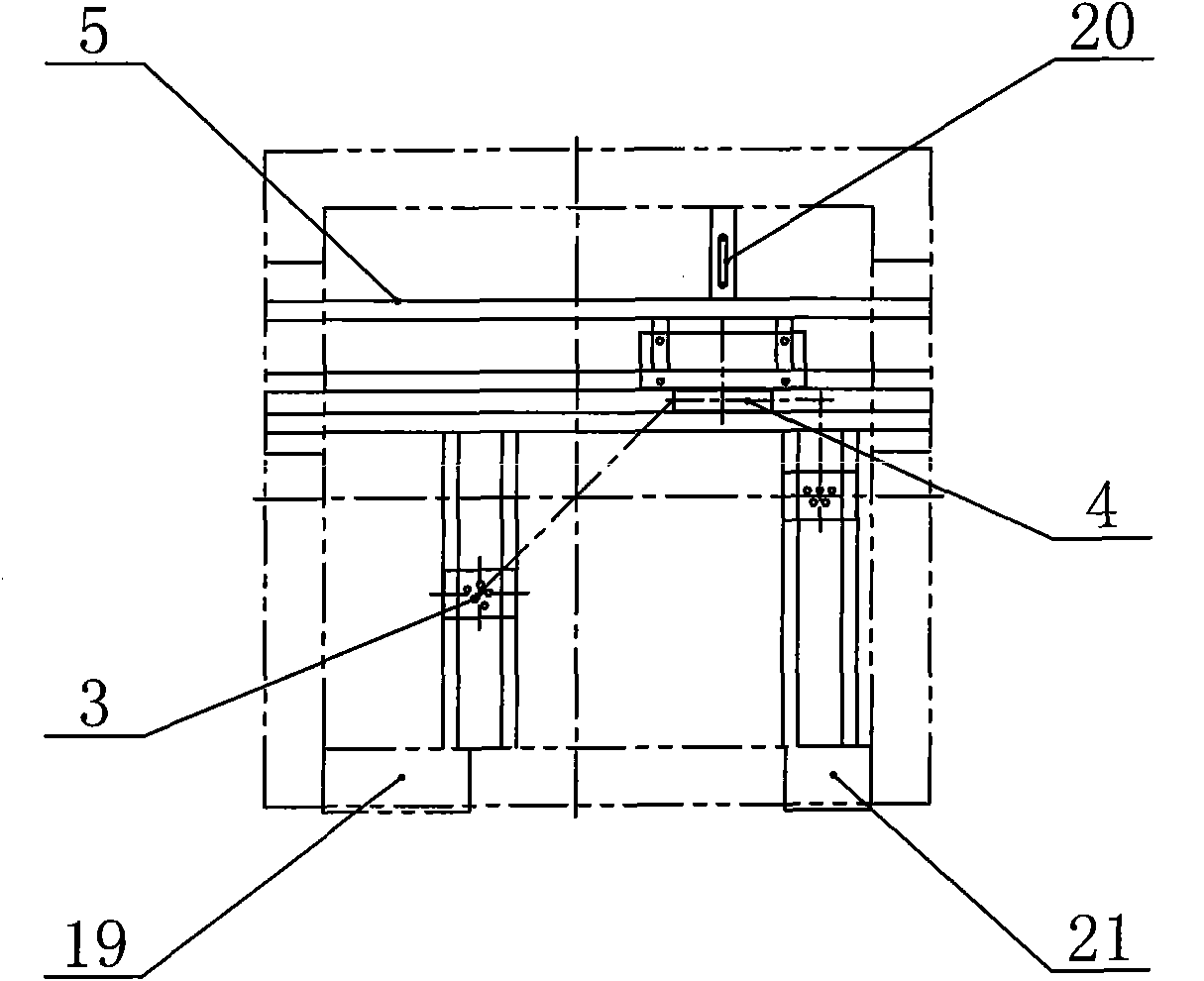

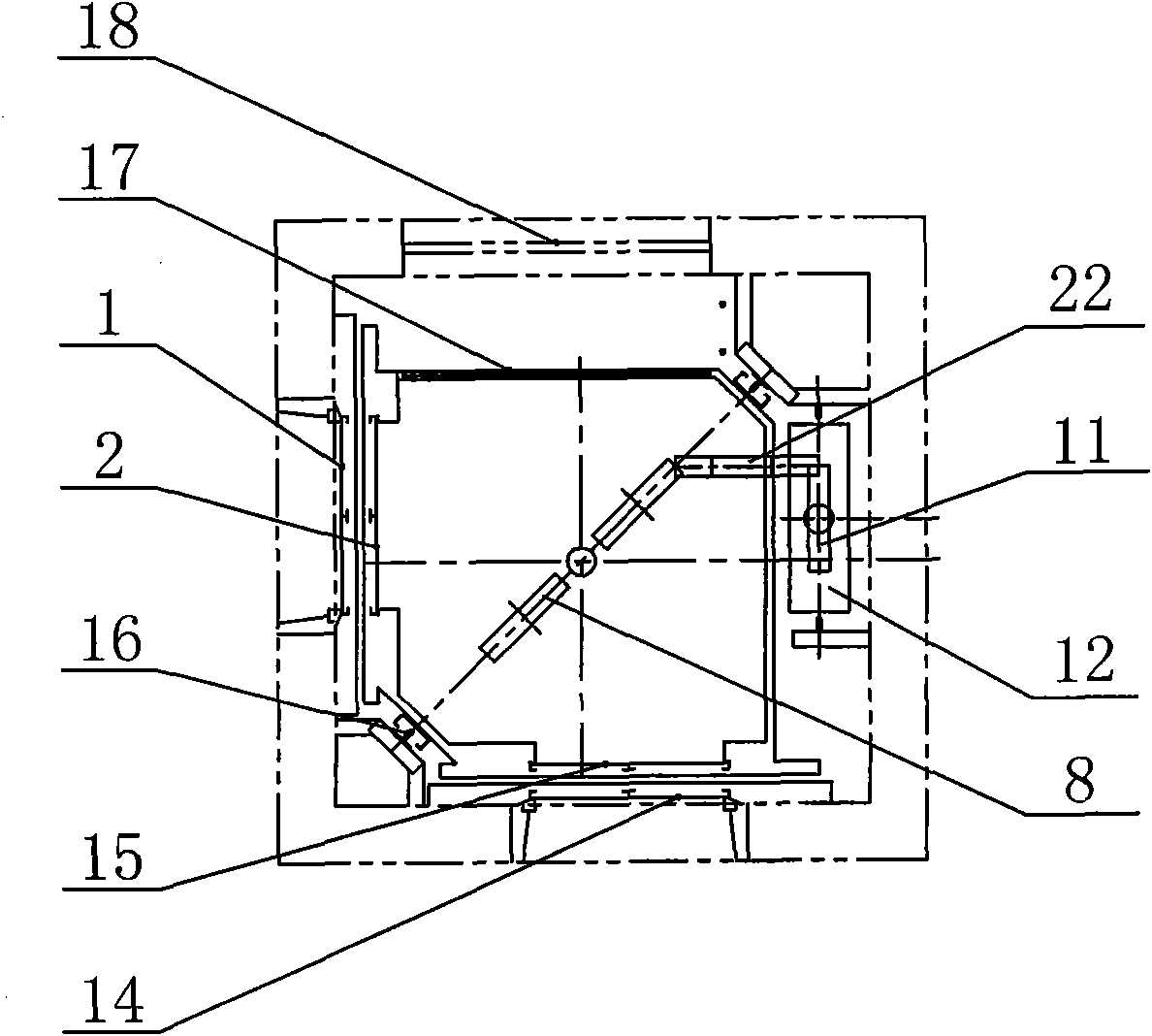

Machine room-less right-angle opening sightseeing elevator

InactiveCN101992988AClever layoutMeet the requirements for placing sightseeing elevatorsElevatorsBuilding liftsEngineeringTractor

The invention relates to a machine room-less right-angle opening sightseeing elevator, comprising a lift car arranged in an elevator lift shaft, a tractor arranged on a bearing steel girder, a counterweight and traction steel wire ropes for connecting the lift car, the tractor and the counterweight, wherein the front side and the left side of the lift car are respectively provided with a front car door and a side car door, the elevator lift shaft is provided with a front layer door and a side layer door respectively corresponding to the front car door and the side car door, lift car guide rails matched with the lift car are arranged at inclined angles located in the front side and the left side of the elevator lift shaft and the opposite angles of the included angles, the back side of the lift car is provided with lift car sightseeing glass, and the elevator lift shaft is provided with a lift shaft sightseeing wall corresponding to the sightseeing glass. The invention provides a solution for customers under special situations with the needs of machine room-less arrangement and right-angle opening in a building under restrictions.

Owner:蒋燕青

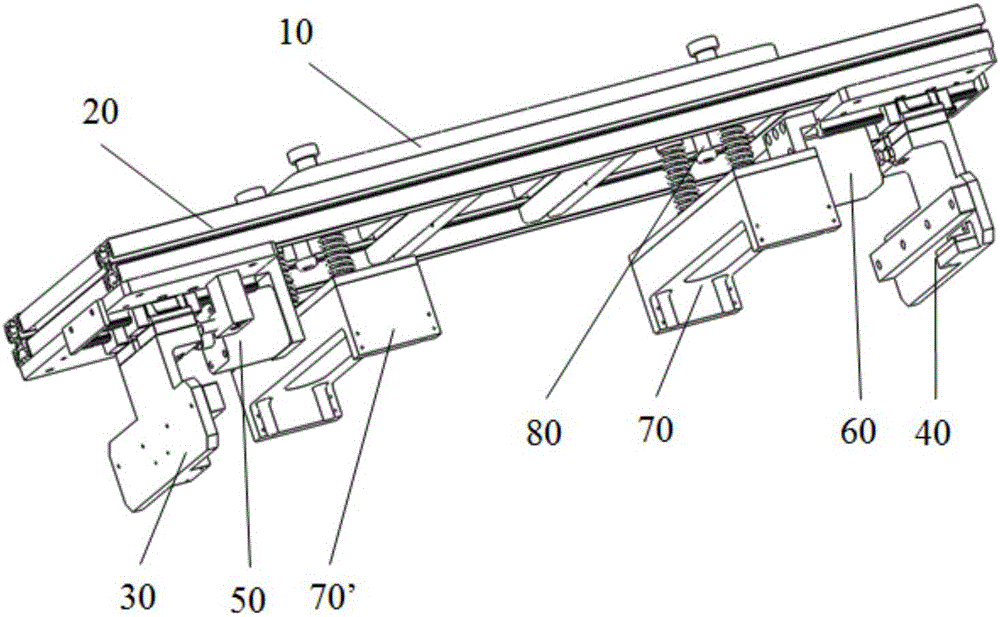

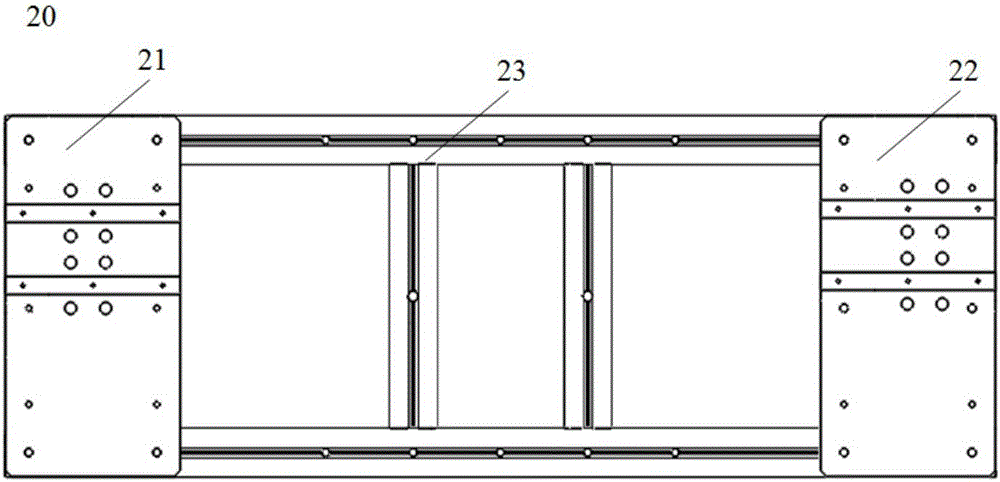

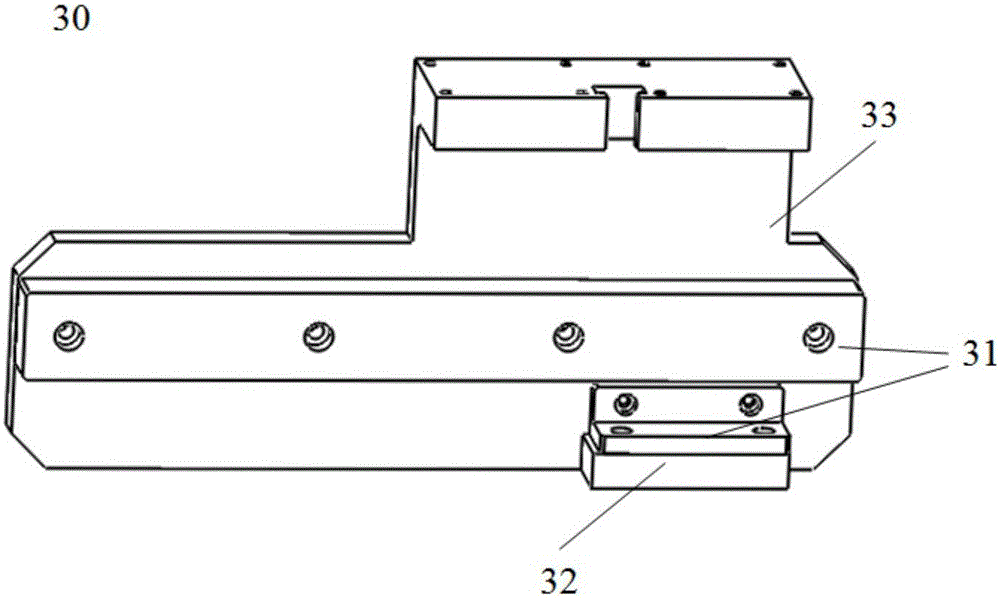

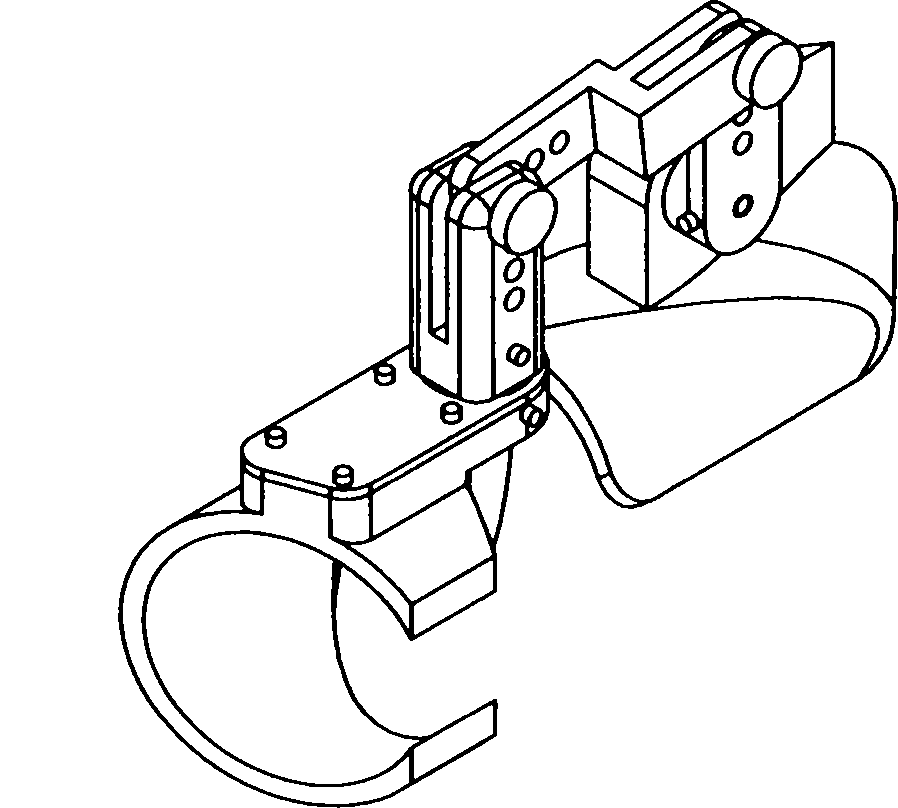

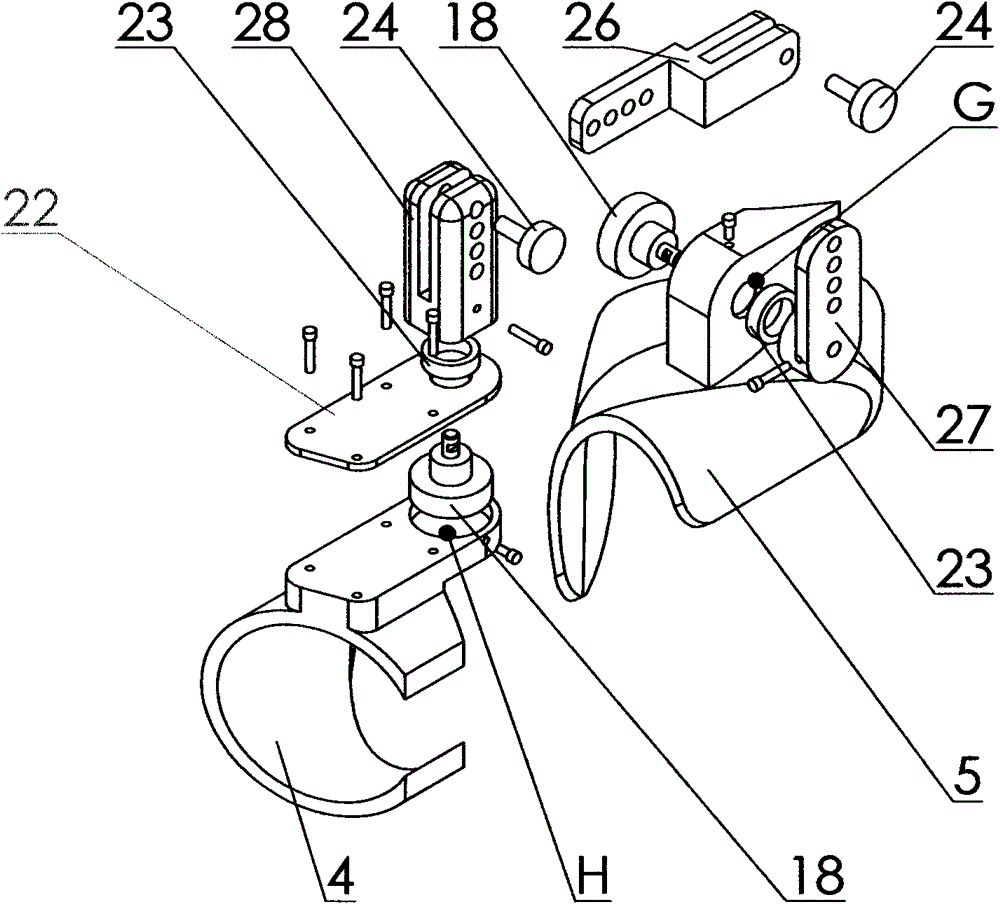

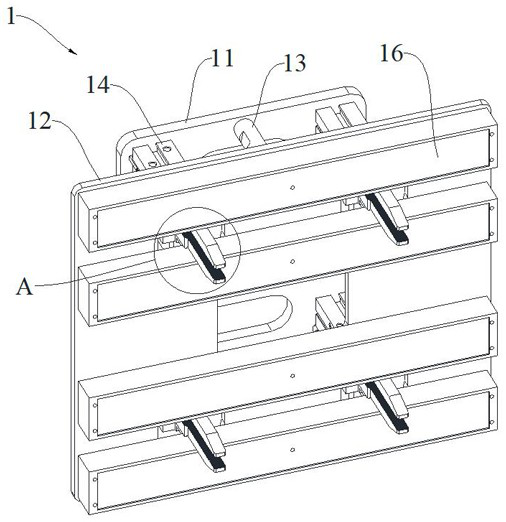

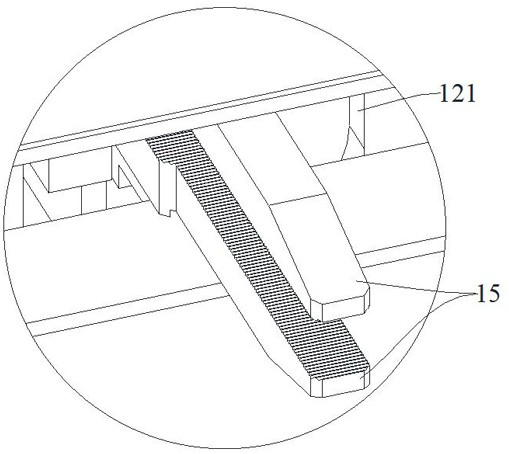

Intelligent transfer fixture

InactiveCN106002970ASimple structureCompact structureProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention belongs to the field of air conditioner external unit assembling, and particularly relates to an intelligent transfer fixture, which comprises a fixed rack, a fixed plate arranged on the fixed rack and connected with the tail end of a mechanical arm, and a first gripper, a second gripper, a first positioning clamping jaw, a second positioning clamping jaw, a first gripper drive device, a second gripper drive device and stop screws commonly integrated on the fixed rack. The first positioning clamping jaw and the second positioning clamping jaw firstly realize the positioning of a width direction of an air conditioner external unit; the drive devices drive the first gripper and the second gripper to move and fasten a handle of the air conditioner external unit, so that the clamping on a length direction of the air conditioner external unit is realized. Through the intelligent transfer fixture provided by the invention, the compactness of overall layout of the product, the highly integration of functions, and the fixed clamping of the air conditioner external unit in the length and width directions are realized; and meanwhile, the intelligent transfer fixture also has the characteristics of simple structure, convenience in operation, convenience in use, and the like.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

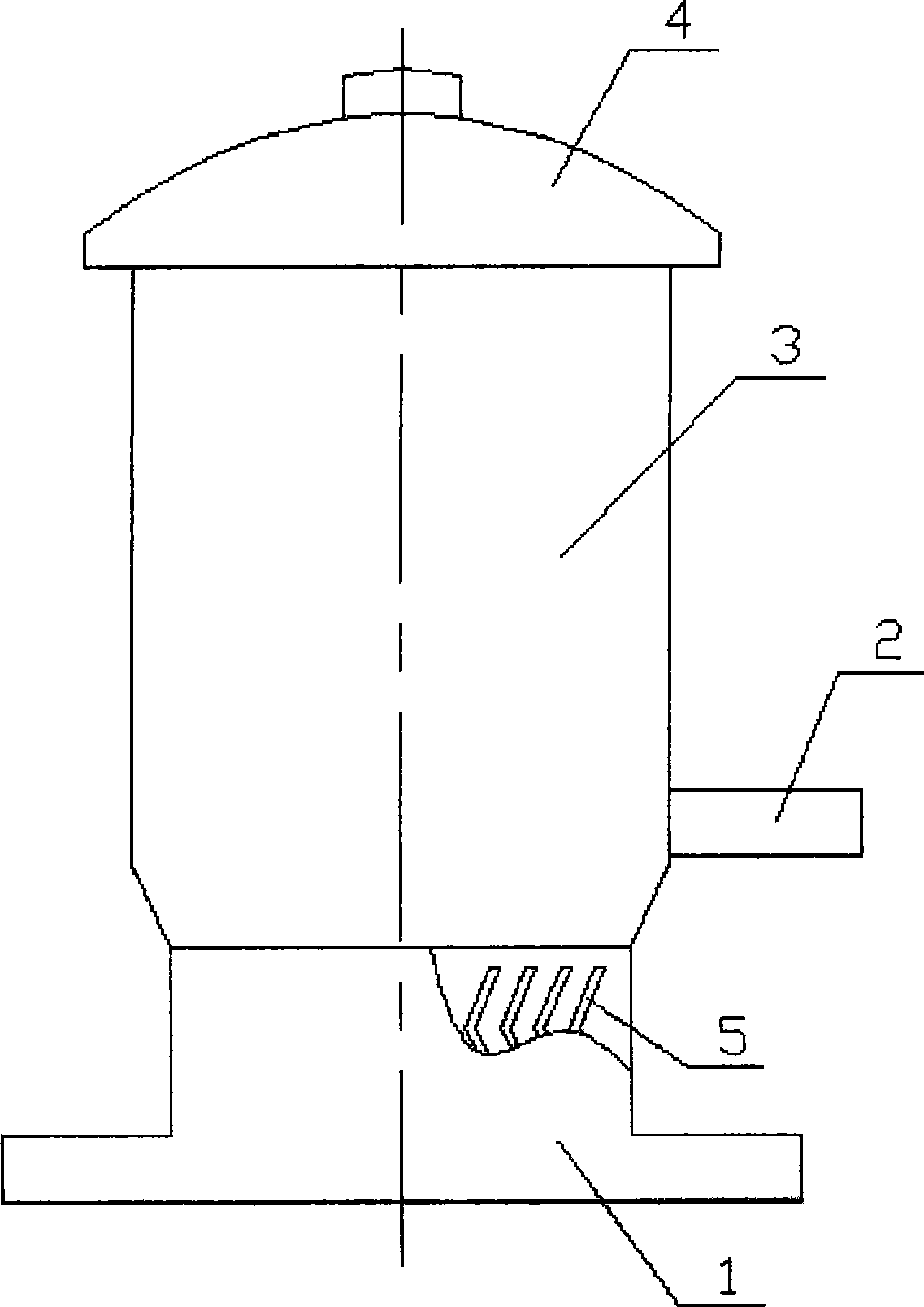

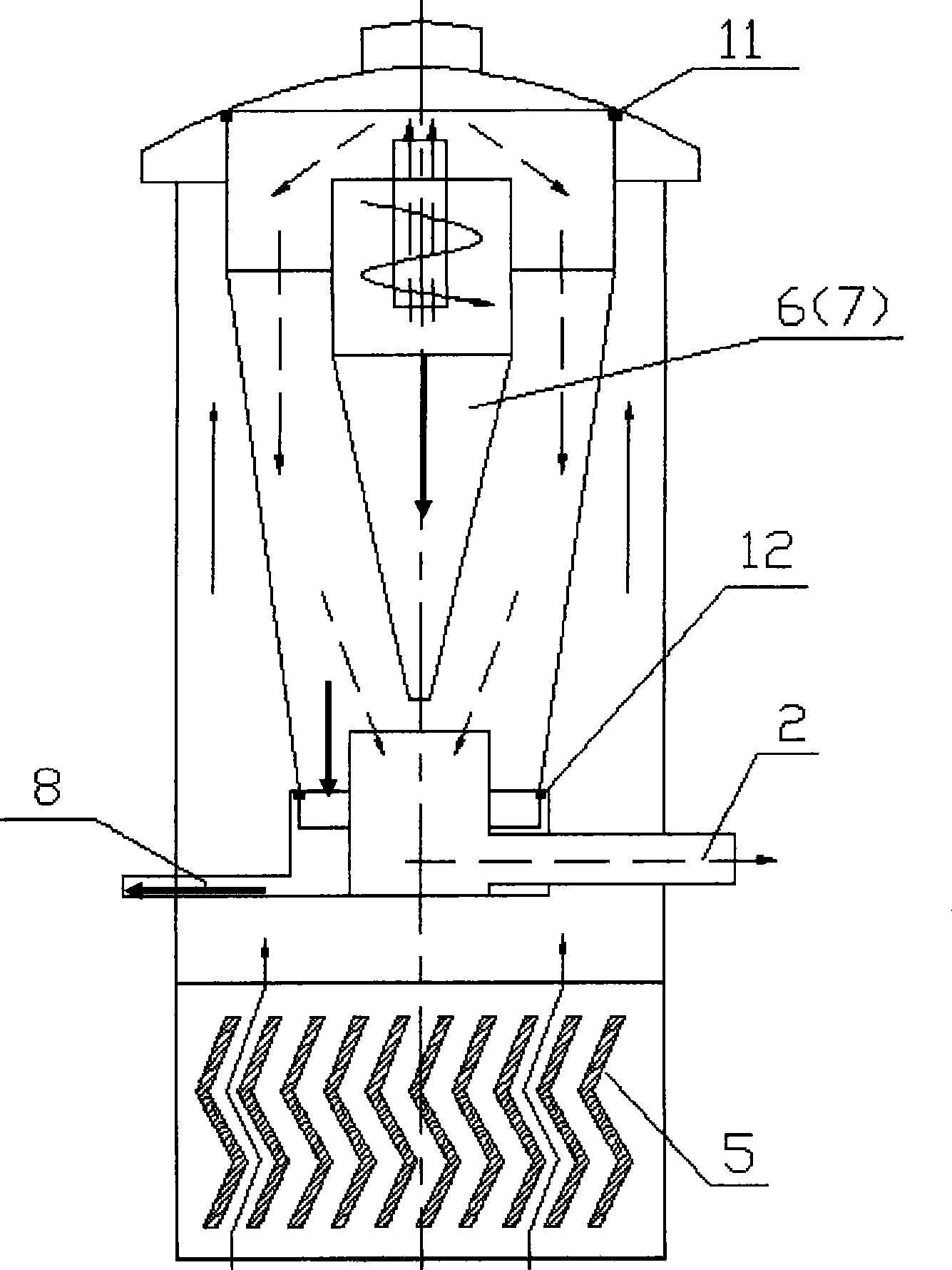

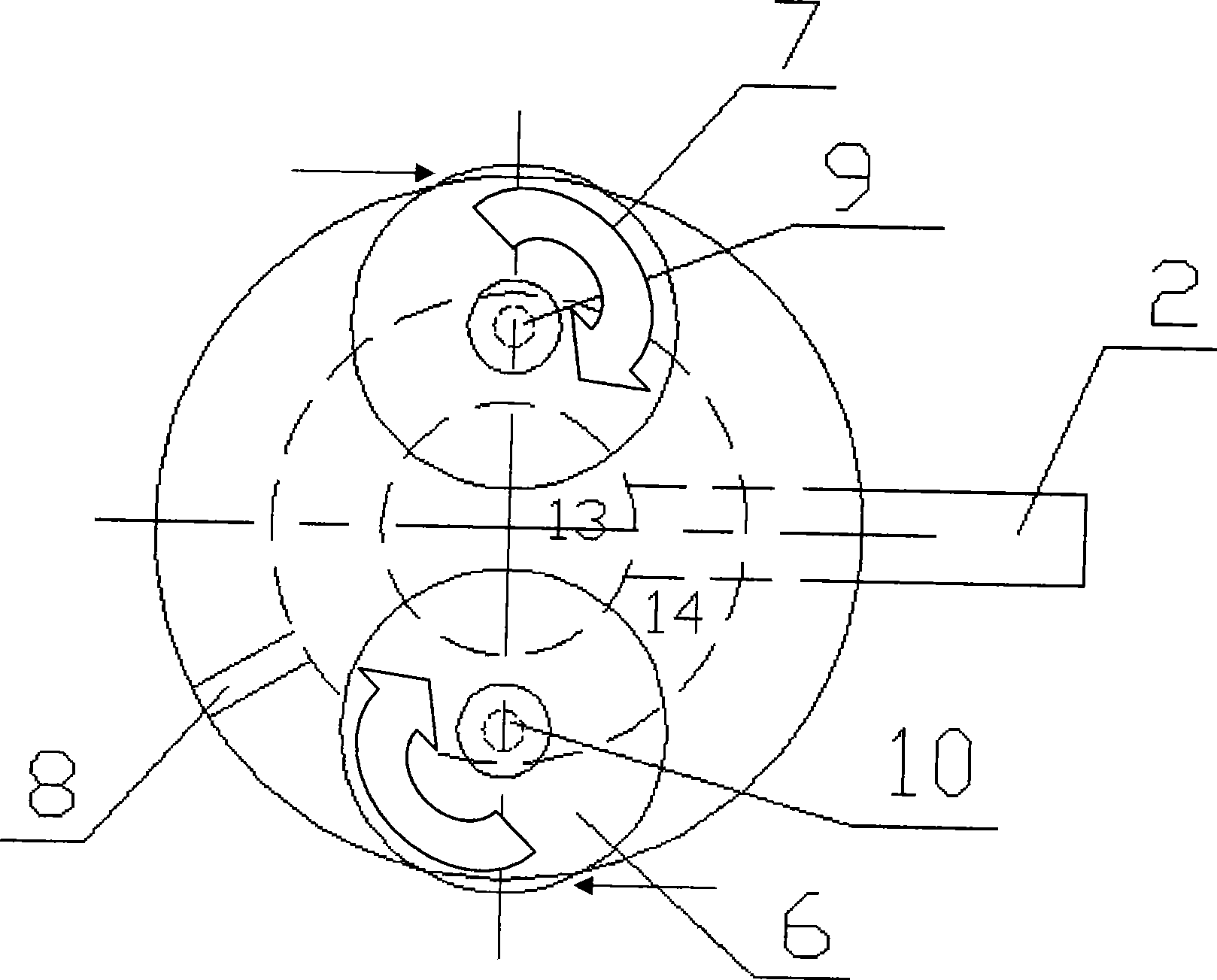

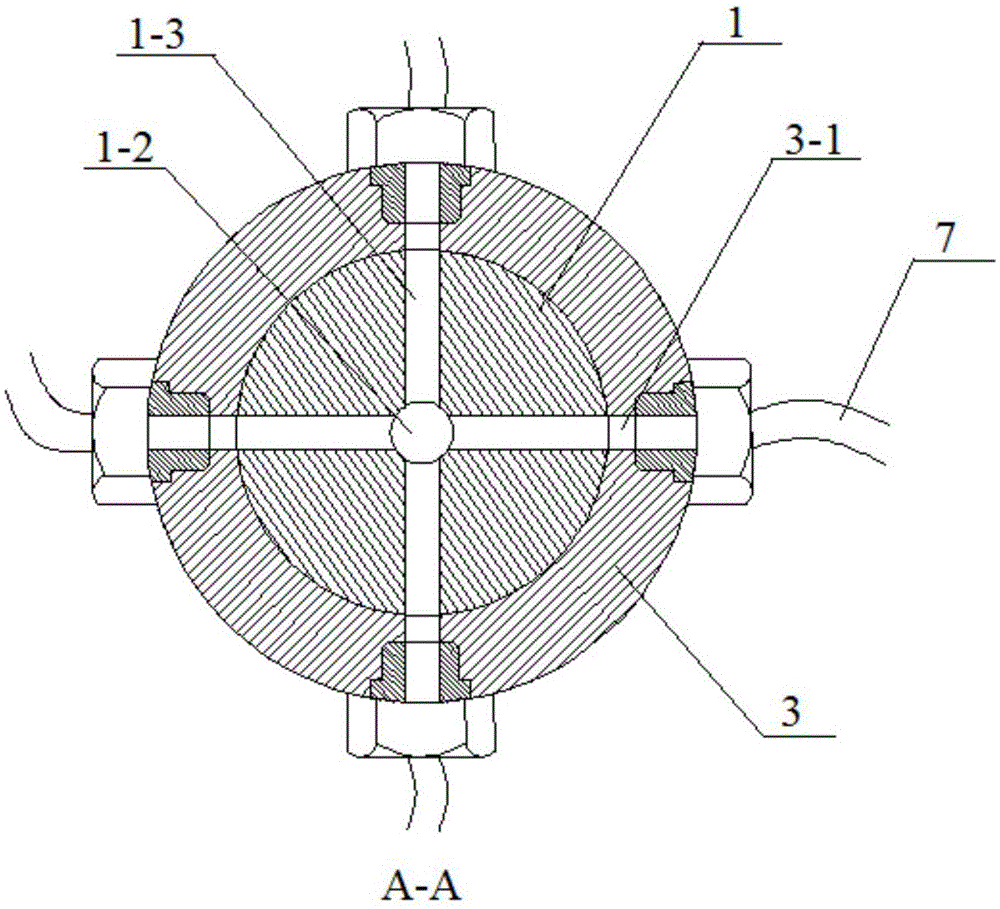

Two stage oil-gas separator

InactiveCN101457680ASignificant application advantagesEasy to separateMachines/enginesEngine lubricationCrankcaseCylinder block

The invention discloses a double-stage oil gas separator comprising a main separator, a preseparator and a base, wherein, the base is fixed on a cylinder body by bolts, and the preseparator is installed in the base and is directly communicated with a crankcase; and the preseparator is an S-shaped wavy labyrinth which comprises a plurality of S-shaped oil block bent plates. The main separator comprises a main separator housing, a main separator cover, two cyclone separators, a gas outlet pipe and an oil outlet pipe, wherein, the bottom of the main separator is sealed with the oil return part and the gas outlet part by a bottom seal packingring, and the top of the main separator is sealed with the main separator cover by a top seal packingring. The double-stage oil gas separator has novel structure, and compared with the other double-stage oil gas separators, the double-stage oil gas separator of the invention occupies little space, is in favor of overall arrangement, thoroughly separates oil and gas and not only can reduce the pollutant discharge but also can reduce the consumption of lubricating oil, thereby reducing the running cost.

Owner:CHERY AUTOMOBILE CO LTD

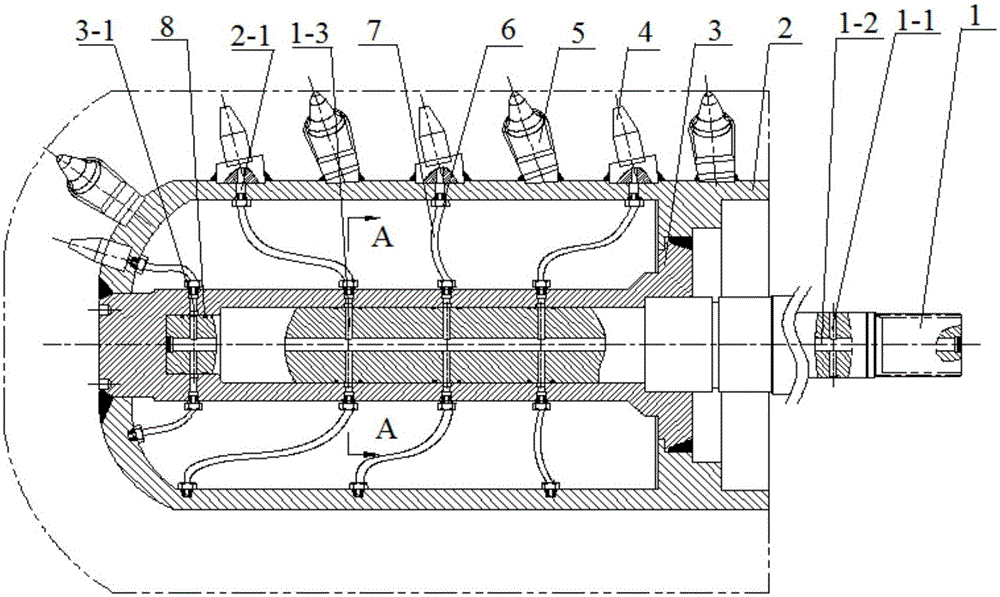

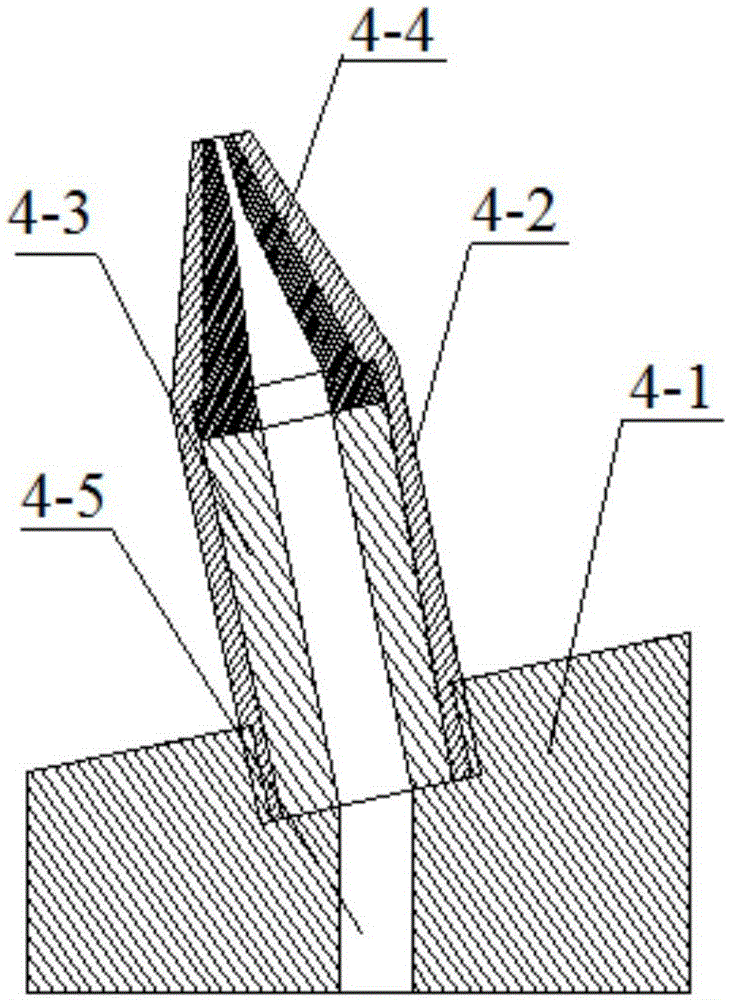

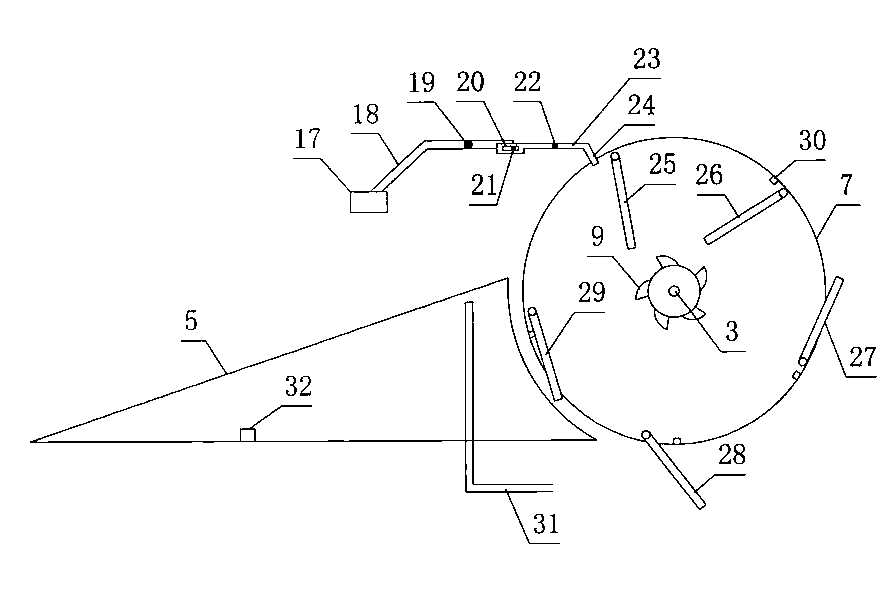

Pre-fixing abrasive and water jet united cutting tooth type roller of coal mining machine

InactiveCN105041309AClever layoutReasonable arrangementCutting machinesEngineeringHigh pressure water

A pre-fixing abrasive and water jet united cutting tooth type roller of a coal mining machine comprises a cutting shaft, a barrel, a high-pressure hose, cutting teeth, a spray head assembly and a core sleeve. The barrel sleeves the periphery of the core sleeve, and the cutting shaft sleeves a matched inner cavity in the core sleeve to drive a cutting head to move. The two ends of the high-pressure hose are in threaded connection with the core sleeve and the barrel respectively. A nozzle base flow channel, a sleeve and a nozzle are arranged in the spray head assembly. The cutting shaft is provided with a water inlet hole, a main flow channel and a water outlet hole. One end of the water inlet hole is connected with a high-pressure water source, the other end of the water inlet hole is communicated with the main flow channel, one end of the water outlet hole is connected with the main flow channel, the other end of the water outlet hole is communicated with a core sleeve flow channel, and the barrel is provided with a barrel flow channel. A mixture of water and abrasive enters the main flow channel through the water inlet hole, passes through the core sleeve flow channel through the water outlet hole, flows into the barrel flow channel through the high-pressure hose, then flows into the spray head assembly, successively passes through the nozzle base flow channel and the sleeve in the spray head assembly to enter the nozzle, and forms a high-pressure abrasive and water jet. The efficiency of mining a thin coal seam can be effectively improved, and cutter wear is reduced.

Owner:CHINA UNIV OF MINING & TECH

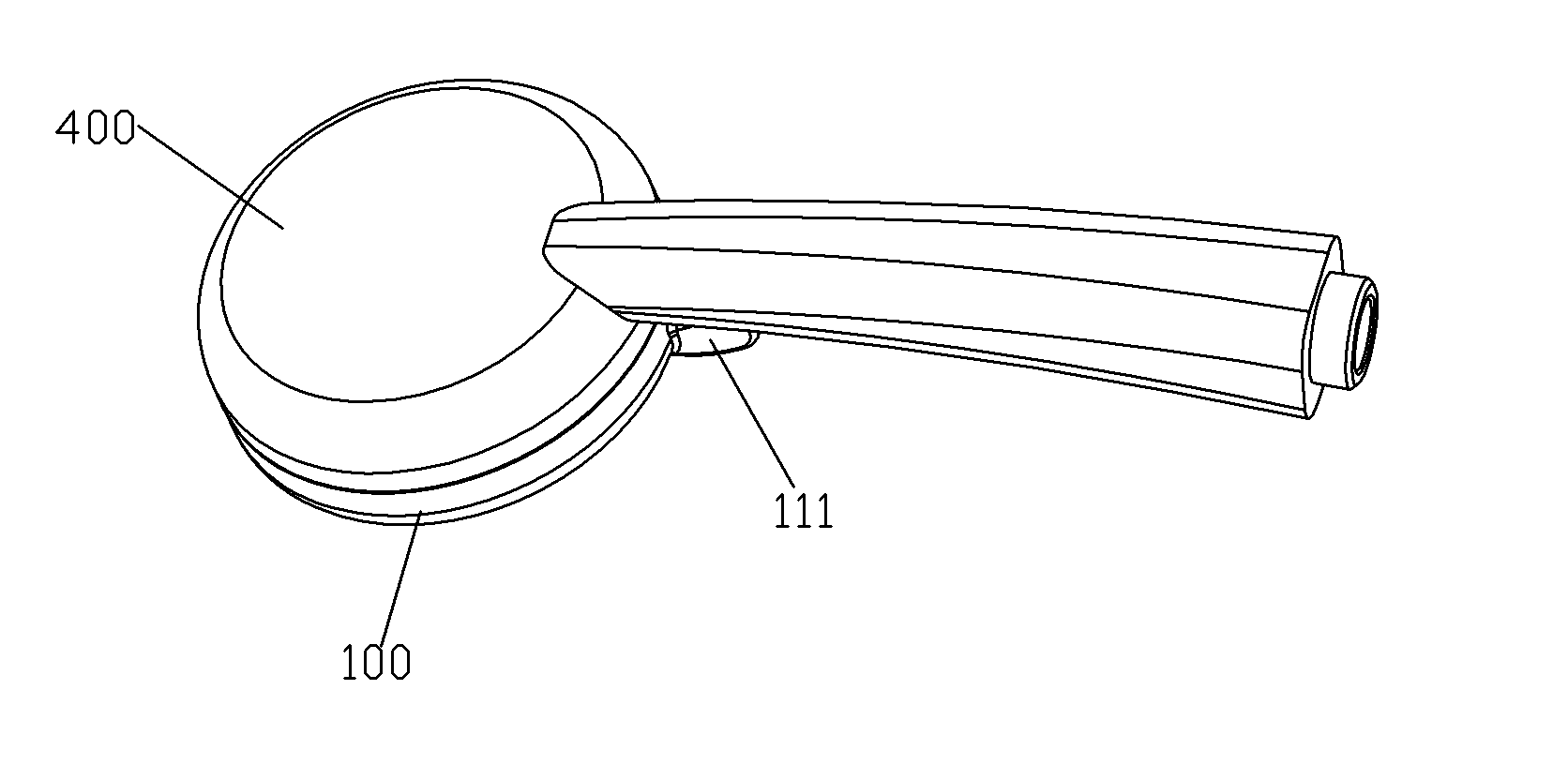

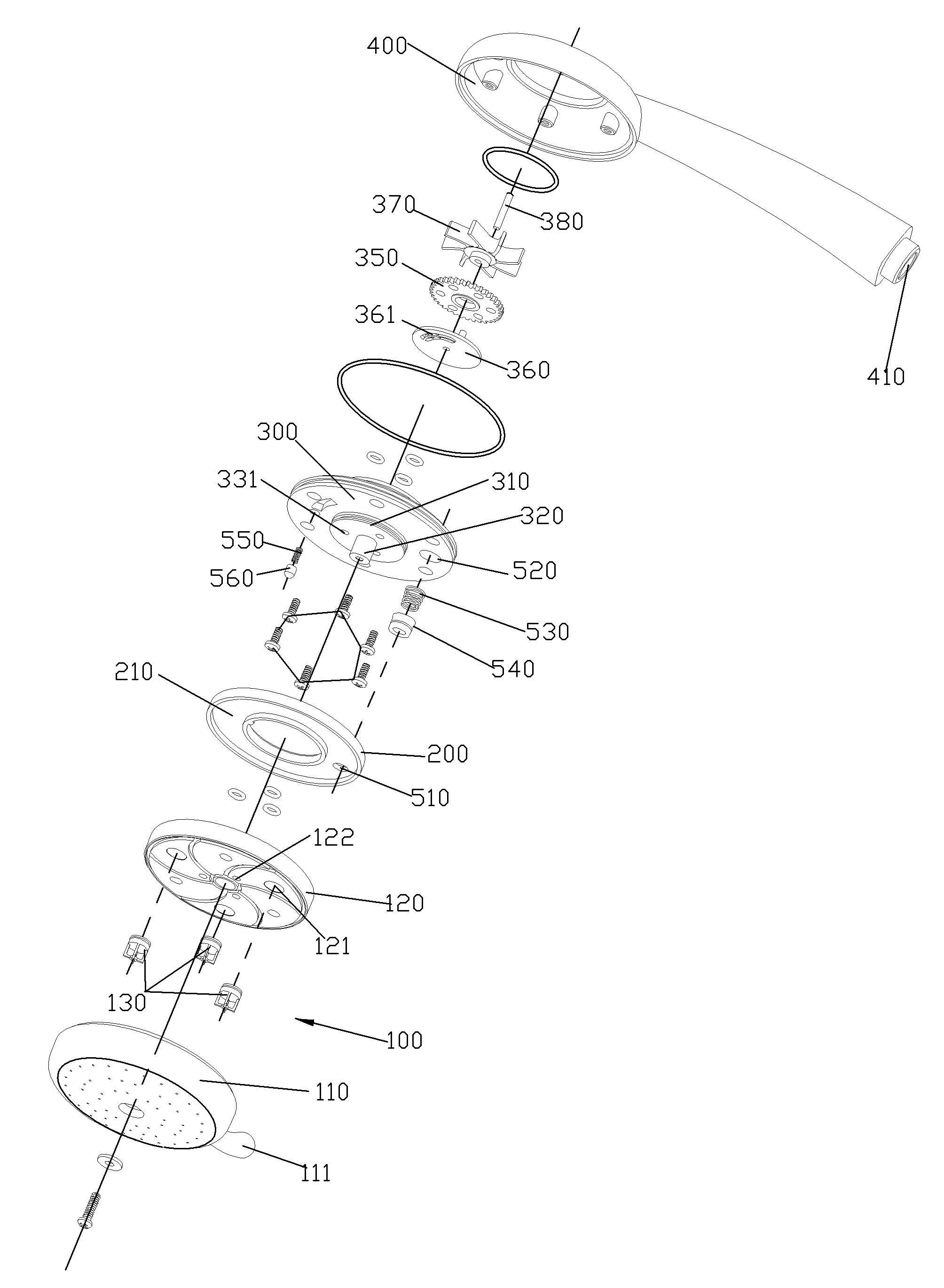

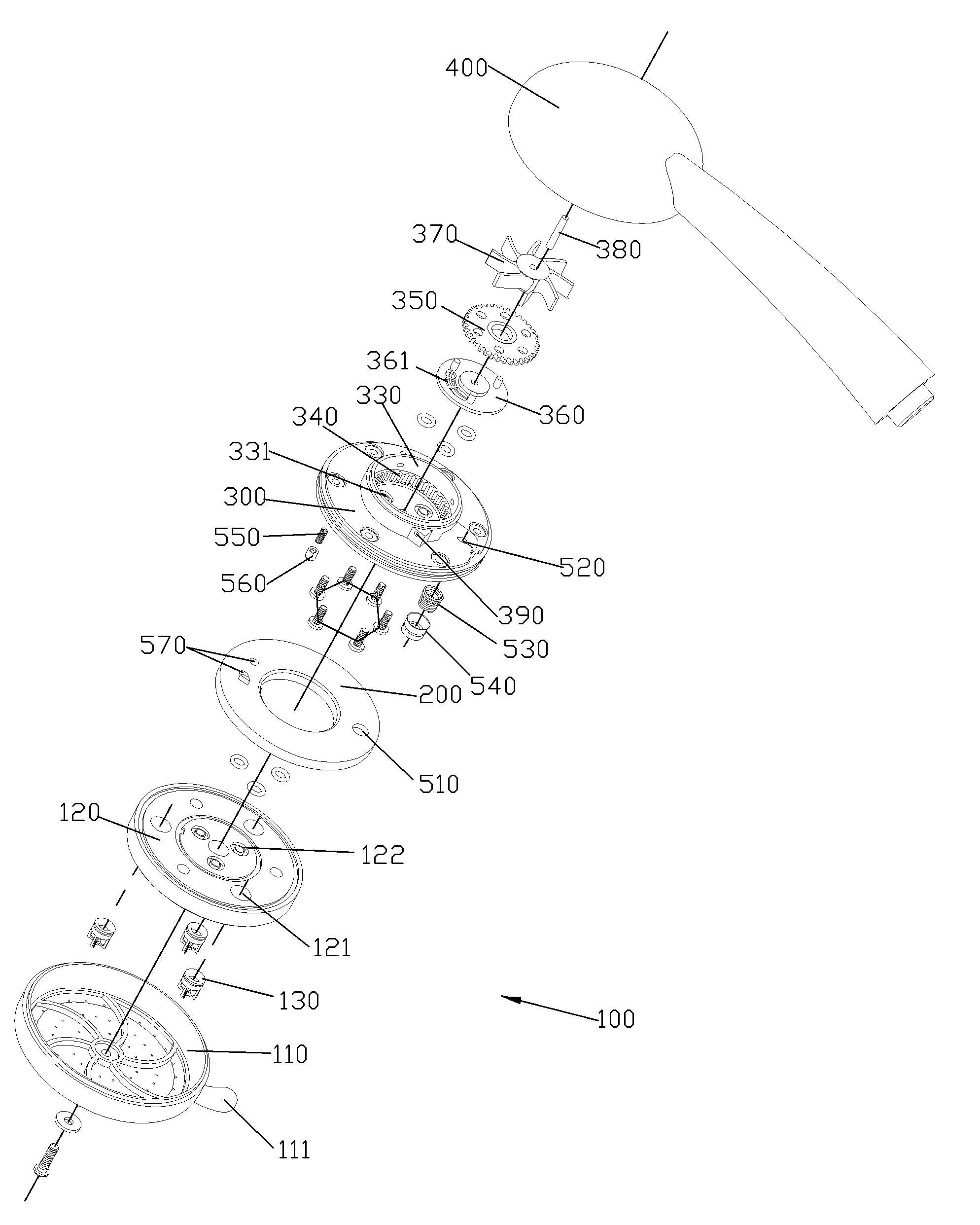

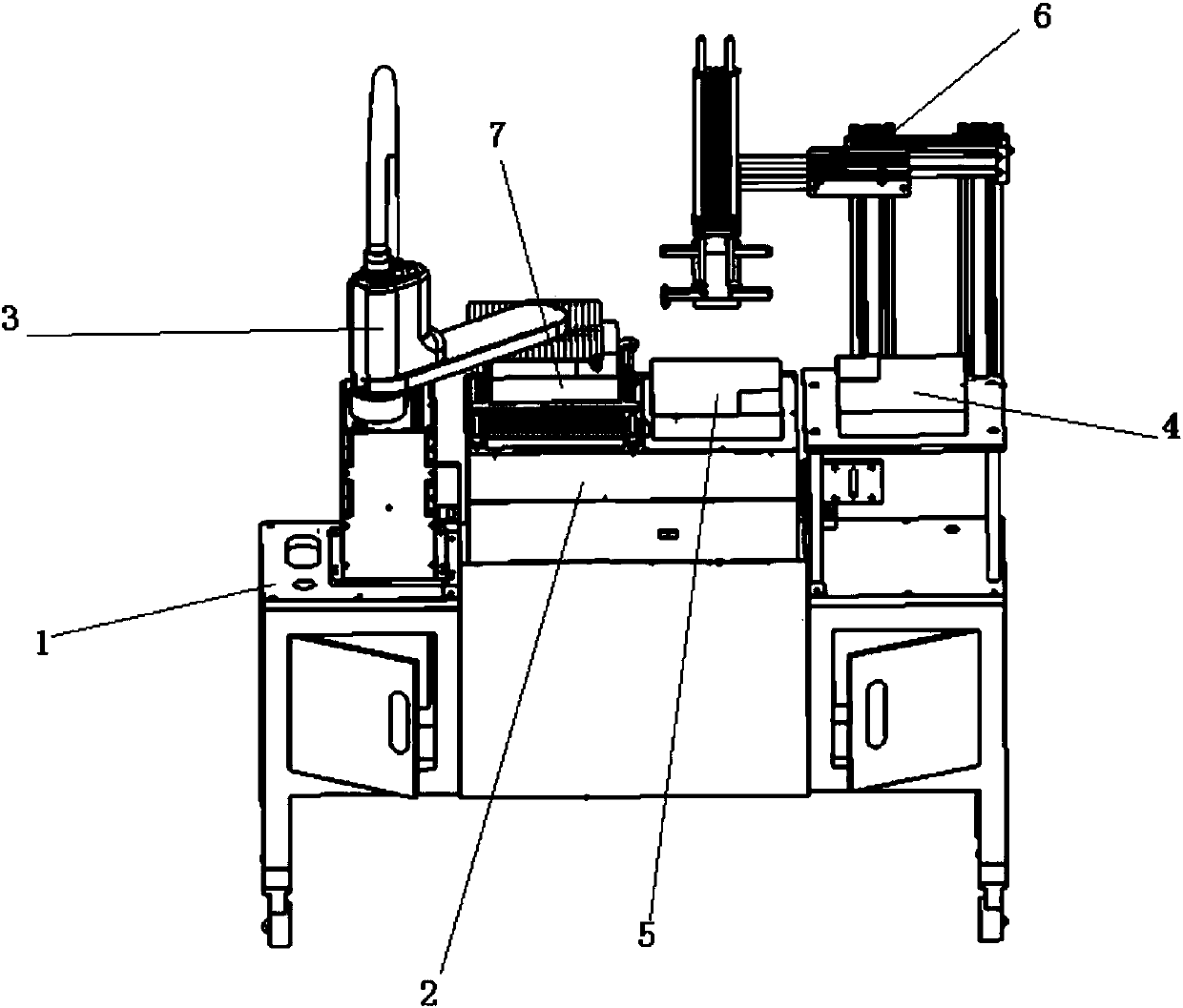

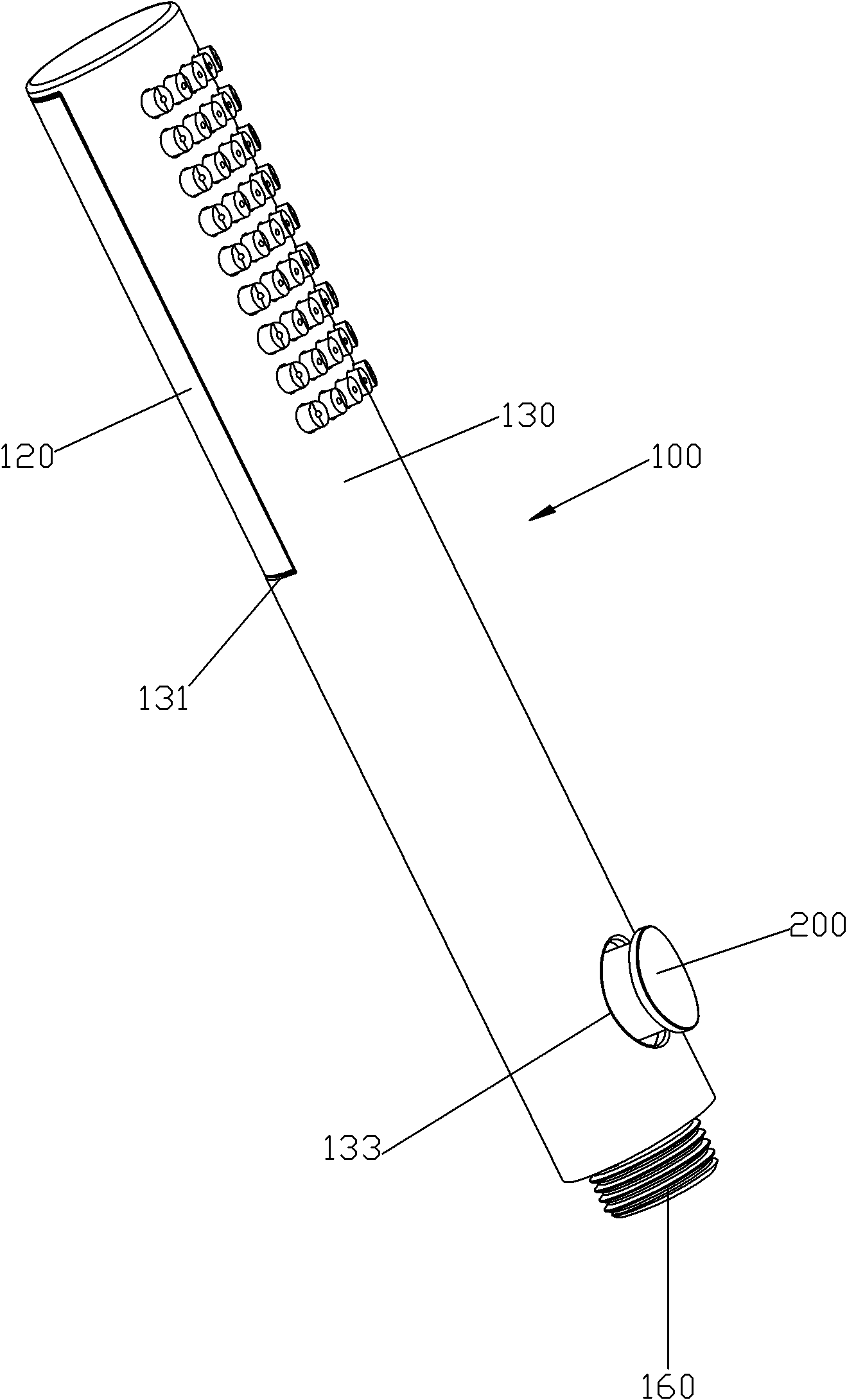

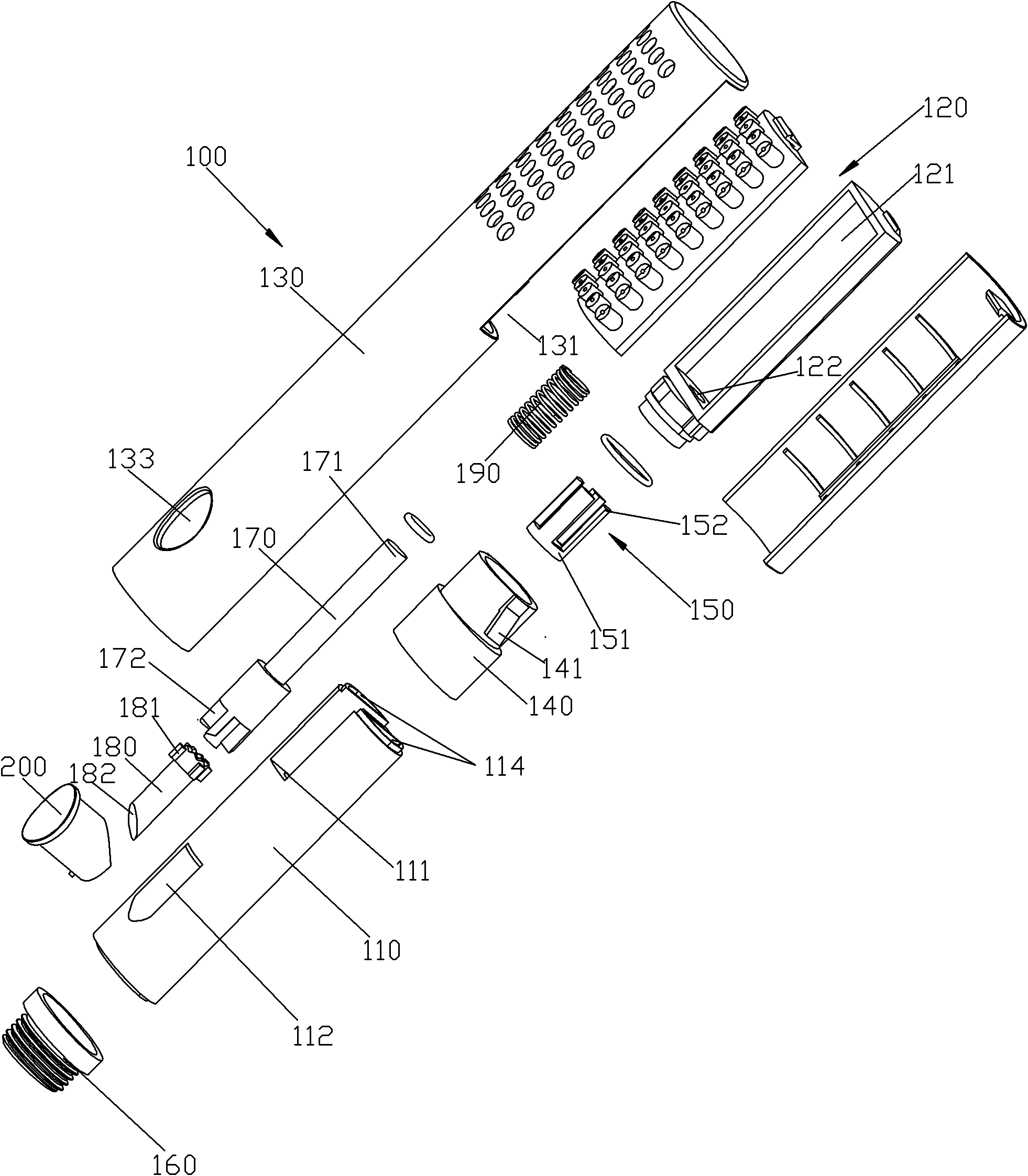

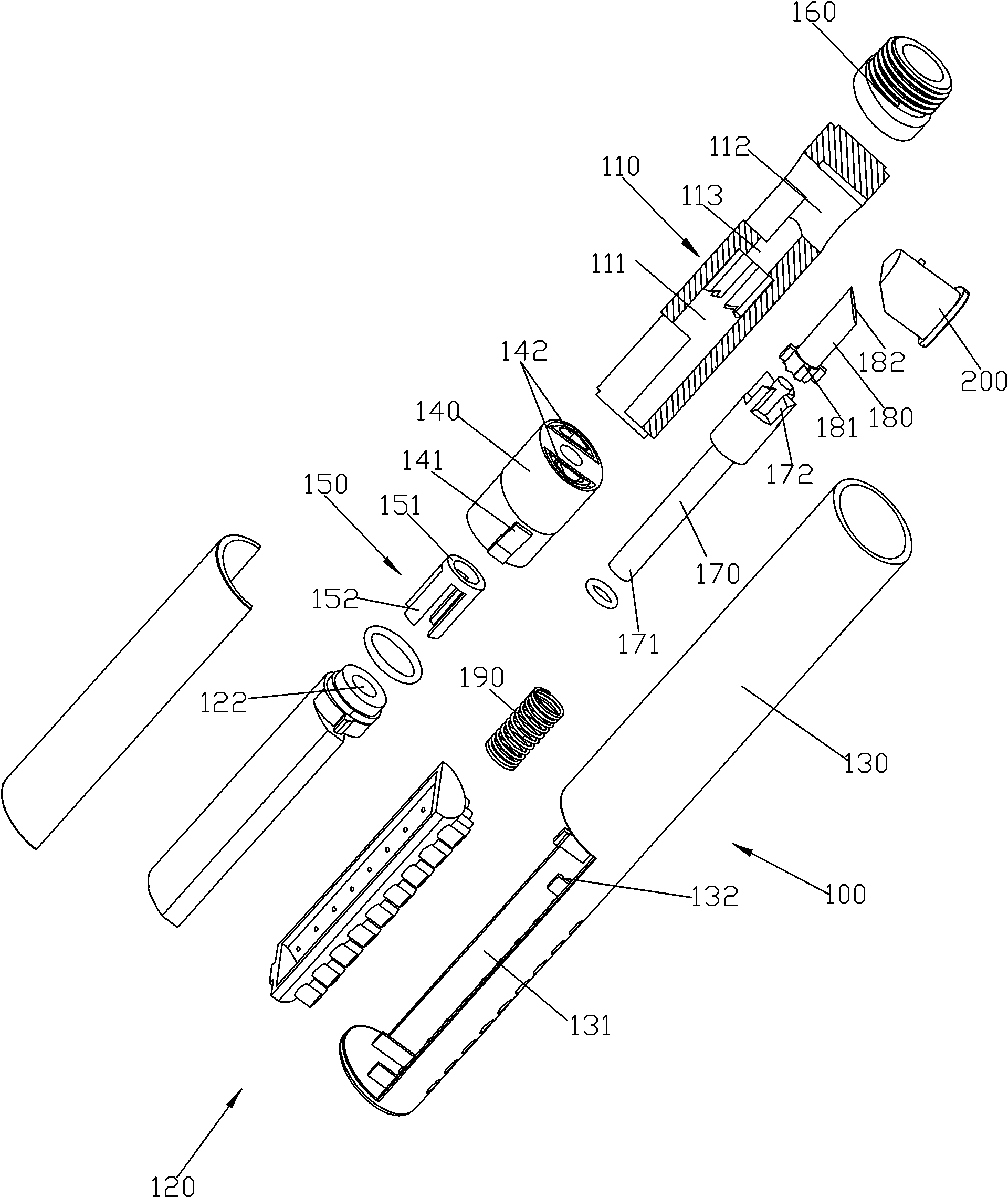

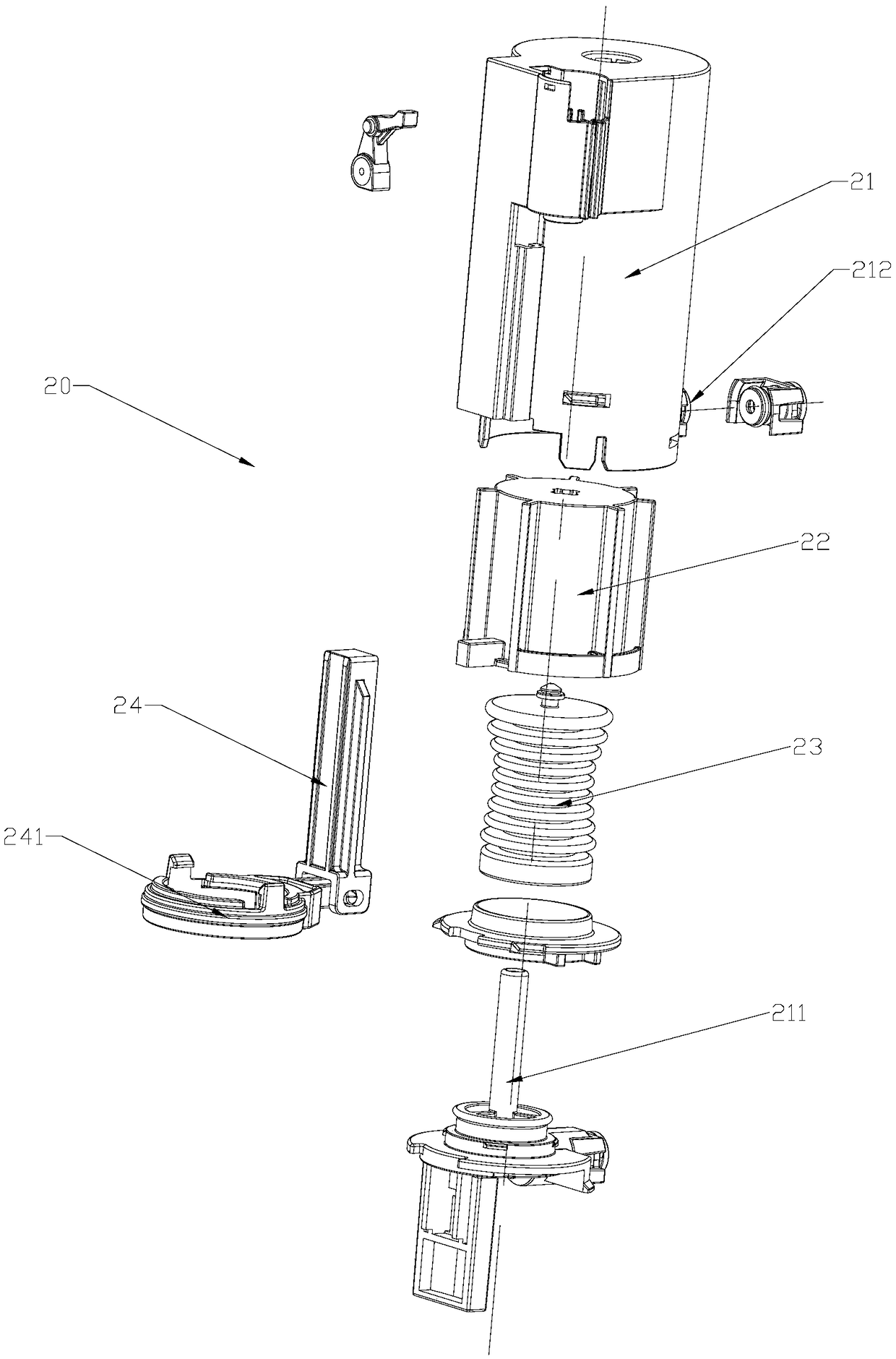

Multifunctional water outlet mechanism

The invention discloses a multifunctional water outlet mechanism which comprises a main body unit, a switching mechanism and a control mechanism. The main body unit comprises a water inlet passage, two water outlet passages and a water outlet terminal; the water outlet terminal is provided with a plurality of water diversion cavities, and at least two of the water diversion cavities are provided with non-return valves; the first water outlet passage is communicated with multiple non-return valves; and when the water pressure of the first water outlet passage is larger than the water pressure controlled by the non-return valves, the non-return valves are opened, and the water flow of the first water outlet passage flow to the water diversion cavities for water inflow. The switching mechanism and the control mechanism are both arranged on the main body unit, the switching mechanism is used for being controlled by a user to at least allow the first water outlet passage and the second water outlet passage to be switched to be communicated with the water inlet passage, and the control mechanism is used for allowing the plurality of water diversion cavities to be switched to be communicated with the second water outlet passage. The multifunctional water outlet mechanism provided by the invention has the following advantages: when water flows out from the first water outlet passage, the non-return valves are opened, the water flows in the water diversion cavities with the non-return valves and flows out from the water diversion cavities with the non-return valves, and the water also flows out from the water diversion cavities without the non-return valves, so that the water outlet area is large; and when the water flows out from the second water outlet passage, the non-returnvalves are closed, and the water flows out from the corresponding water diversion cavities controlled by the control mechanism.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

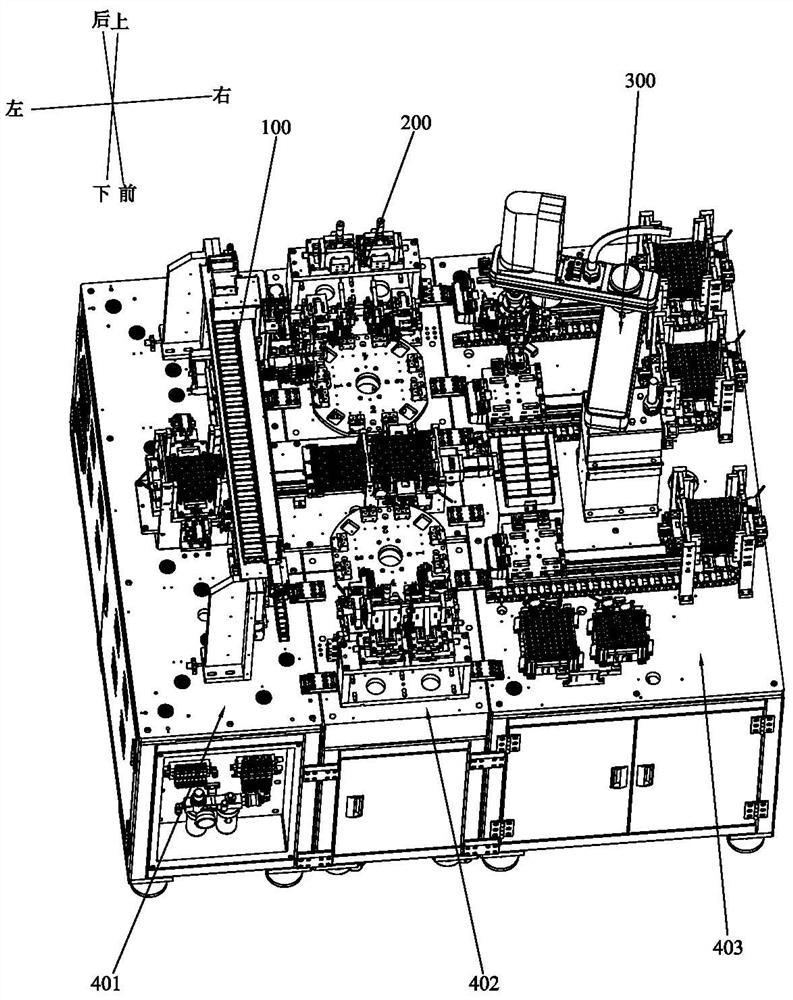

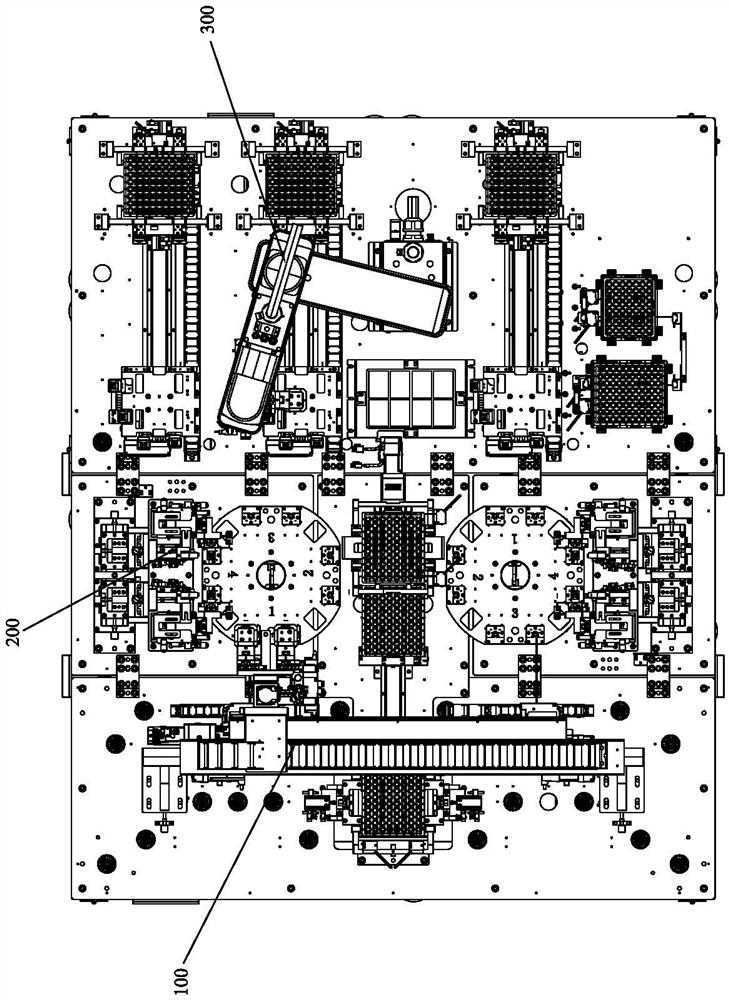

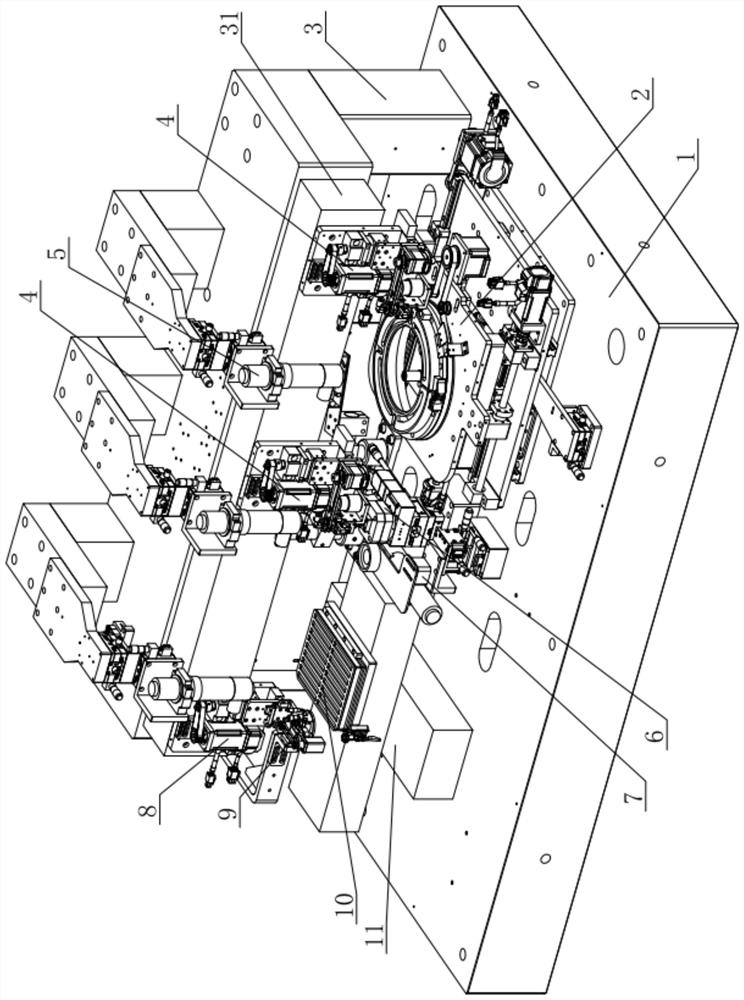

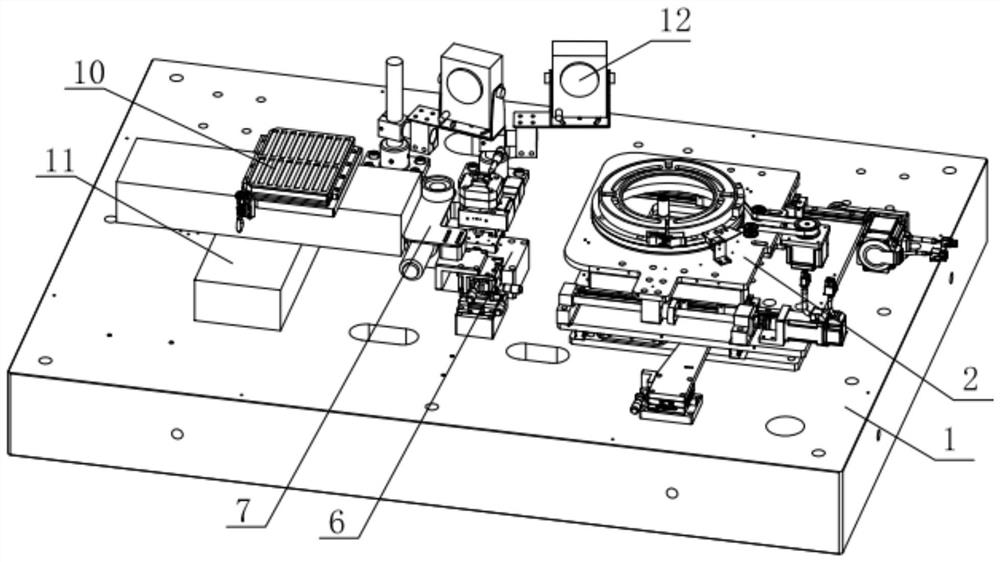

Double-turntable full-automatic detection machine and detection method thereof

PendingCN112517417AReduce labor intensityImprove detection efficiencySortingControl engineeringProcess engineering

The invention discloses a double-turntable full-automatic detection machine and a detection method thereof. The double-turntable full-automatic detection machine comprises a detection machine and an automatic feeding system, an automatic detection system and an automatic discharging system which are arranged on the detection machine. The automatic feeding system is provided with a feeding mechanism and a feeding chuck. The automatic detection system is provided with a first detection station and a second detection station which are each provided with a turntable and a detection mechanism. Eachturntable is provided with a loading jig. The automatic discharging system is provided with a discharging chuck. The feeding chuck grabs products from the feeding mechanism and places the products inthe loading jigs on the turntables, the first detection station and the second detection station detect the products on the corresponding turntables, and after detection is completed, the dischargingchuck grabs the products in the loading jigs and places the products in corresponding good product areas or defective product areas according to detection results to complete discharging. Therefore,compared with the prior art, the double-turntable full-automatic detection machine has the advantages that the automation degree is higher, and the detection efficiency is multiplied.

Owner:皓星智能装备(东莞)有限公司

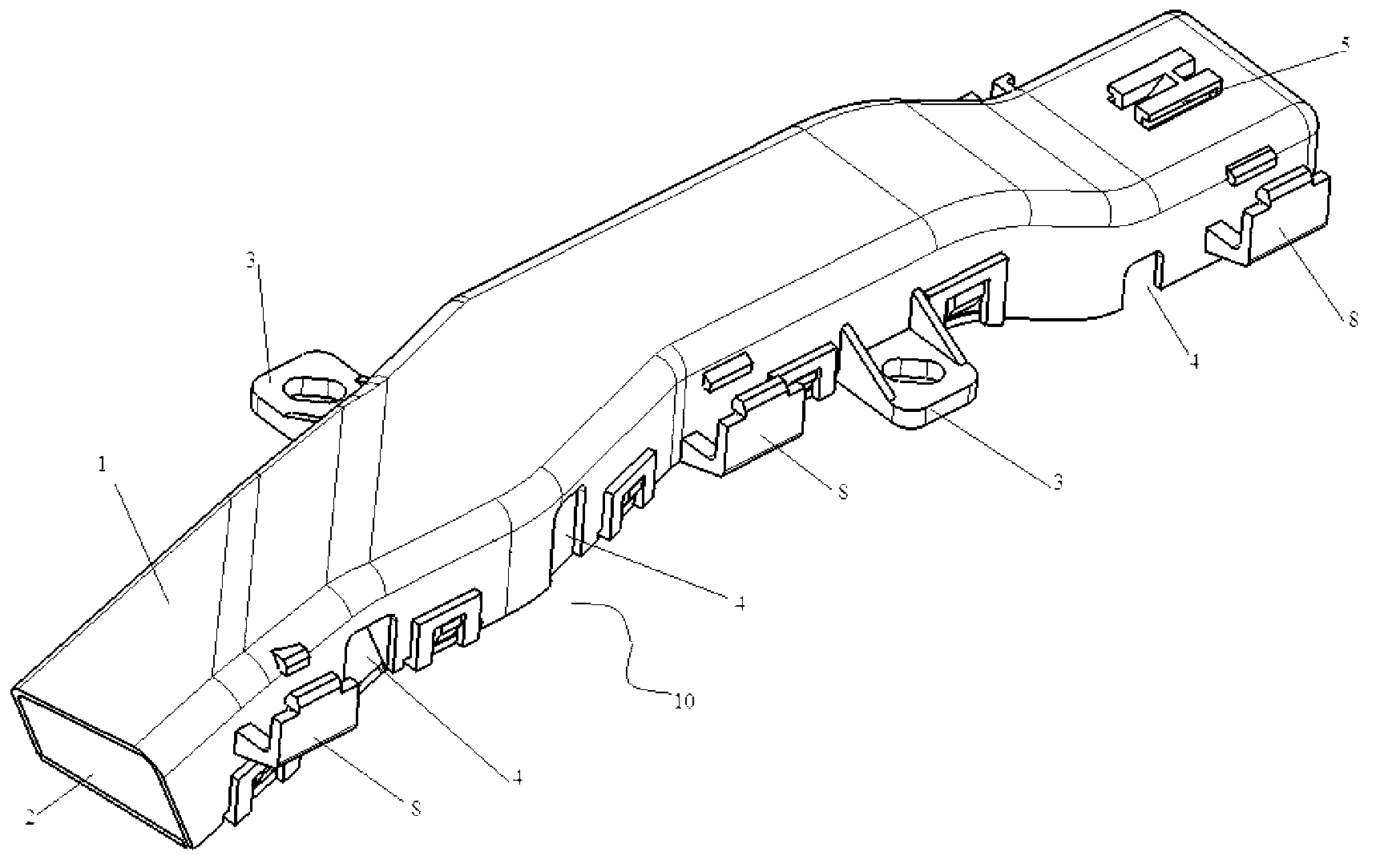

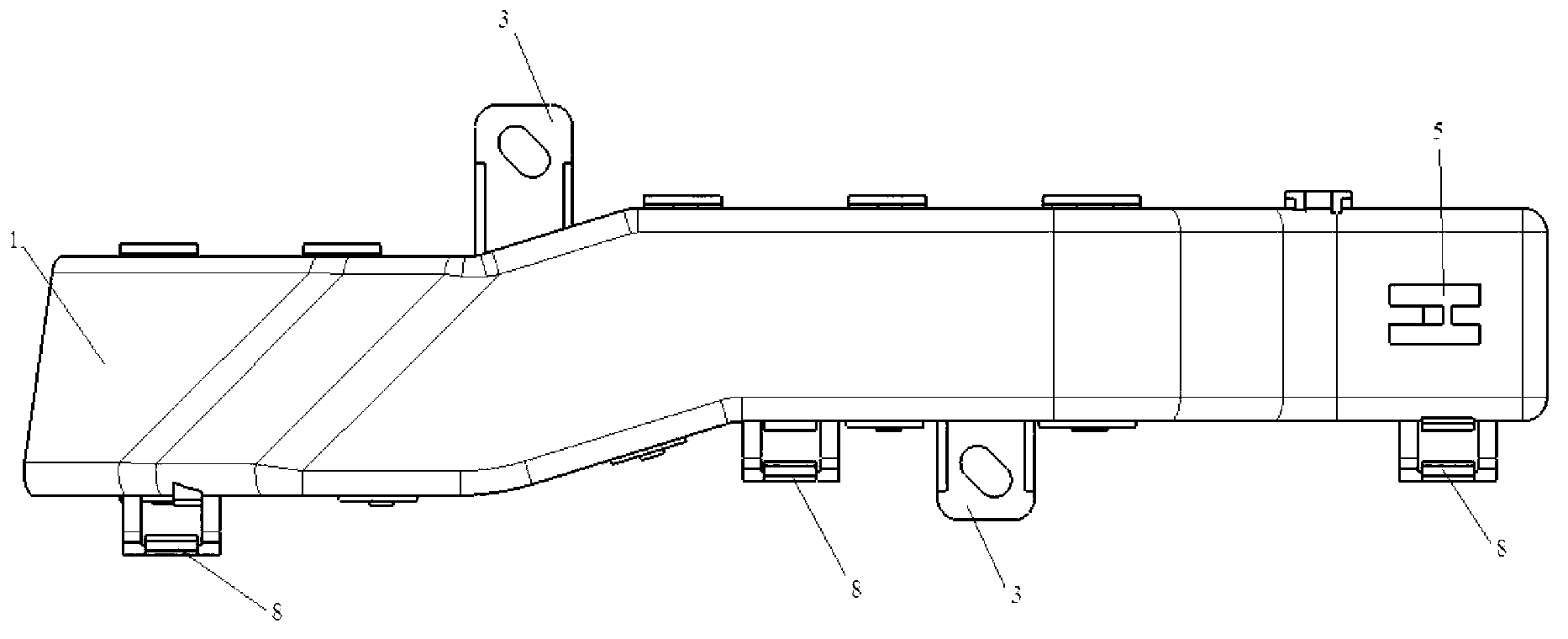

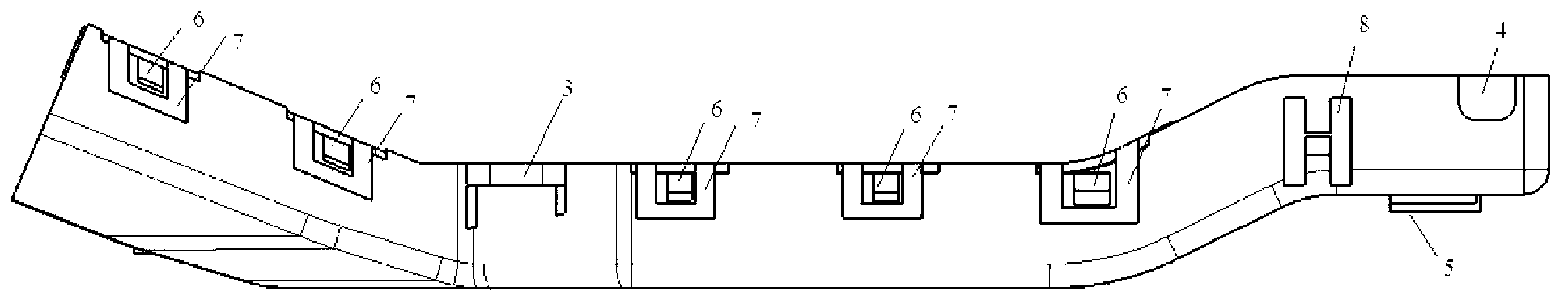

Automobile wire harness fixing support

InactiveCN103269045AImprove reliabilityImprove protectionElectrical apparatusElectric/fluid circuitInterior spaceMain channel

The invention provides an automobile wire harness fixing support. The automobile wire harness fixing support comprises a support body composed of an upper frame and a lower frame, wherein the upper frame is a U-shaped groove plate, the lower frame is of a plate shape, and the lower frame and the upper frame are fixedly connected to form a wire harness main channel. According to the automobile wire harness fixing support, the support body composed of the upper frame and the lower frame is used, so that the automobile wire harness fixing support is convenient to dismount and mount; the overall structure of the automobile wire harness fixing support is designed according to interior space and a wire harness trend, and therefore the layout is ingenious, the structural design is reasonable and simple, and operation is reliable. The automobile wire harness fixing support can enhance the stability of a main wire harness on a pipe beam framework and improve the reliability of the fixation of the wire harness, has an accurate control function on the wire harness trend, and plays a good role in protecting the wire harness to some extent. The automobile wire harness fixing support is fixed on the pipe beam framework through two nuts, so that assembly efficiency is improved, and the wire harness is prevented from being abraded by an instrument board at the same time.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Modular solid insulation ring network cabinet

ActiveCN103219666AGuaranteed accuracyGuaranteed stabilitySwitchgear arrangementsRing networkComputer module

The invention discloses a modular solid insulation ring network cabinet which comprises a cabinet body, an insulated bus module, an isolation module, a main body module, a grounding module and an operating mechanism for controlling the main body module and the grounding module to actuate, wherein the operating mechanism is arranged on the side wall of the cabinet body, the main body module is connected with the operating mechanism through an insulated pull rod, the grounding module is arranged below the main body module, the grounding module is connected with the operating mechanism through a grounding pull rod, the isolation module is arranged at the right lower side of the grounding module, the isolation module comprises an isolation blade and an isolation pull rod movably connected with the isolation blade, and the isolation pull rod is movably connected with a rotating swing rod at the bottom of the operating mechanism. By adopting the modular design, the modular solid insulation ring network cabinet is flexible in production process, convenient to mount and maintain, and compact in structure and small in size as a fully-sealed structure is adopted in the mounting process; and in addition, the modular solid insulation ring network cabinet is provided with a working state monitoring device which can be used for avoiding an electric shock risk, thereby being high in safety.

Owner:BEIJING BOE VACUUM ELECTRONICS CO LTD

Thumb metacarpophalangeal joint movement detection device

InactiveCN104571597ALow costClever layoutInput/output processes for data processingMeasurement pointFinger joint

The invention relates to a data glove for detecting finger movement state of human hands, in particular to a thumb metacarpophalangeal joint movement detection device, and aims to solve the problem that an existing data glove is high in sensor price, complex in system, difficult to maintain and the like. The device which clings to the outside of a human hand to detect joint movement is designed, and a unique connecting mode and ingenious joint measuring point layout are adopted, so that impedance and influence, on finger movement of an operator, of a detection mechanism are lowered or eliminated; when the operator uses the device, flexibility and lightness in movement of fingers can be maintained to greatest extent, and movement state of joints can be accurately detected, so that finger joints of a controlled slave hand and corresponding finger joints of the operator are enabled to act coordinately, and complex control on the slave hand with multiple degrees of freedom is enabled to be visual, simple and convenient.

Owner:苏茂

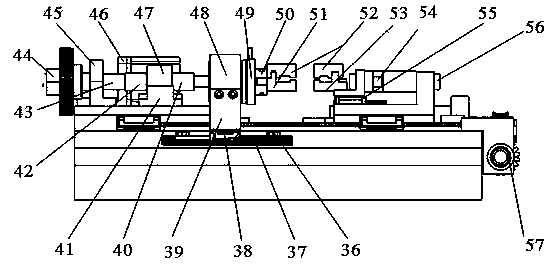

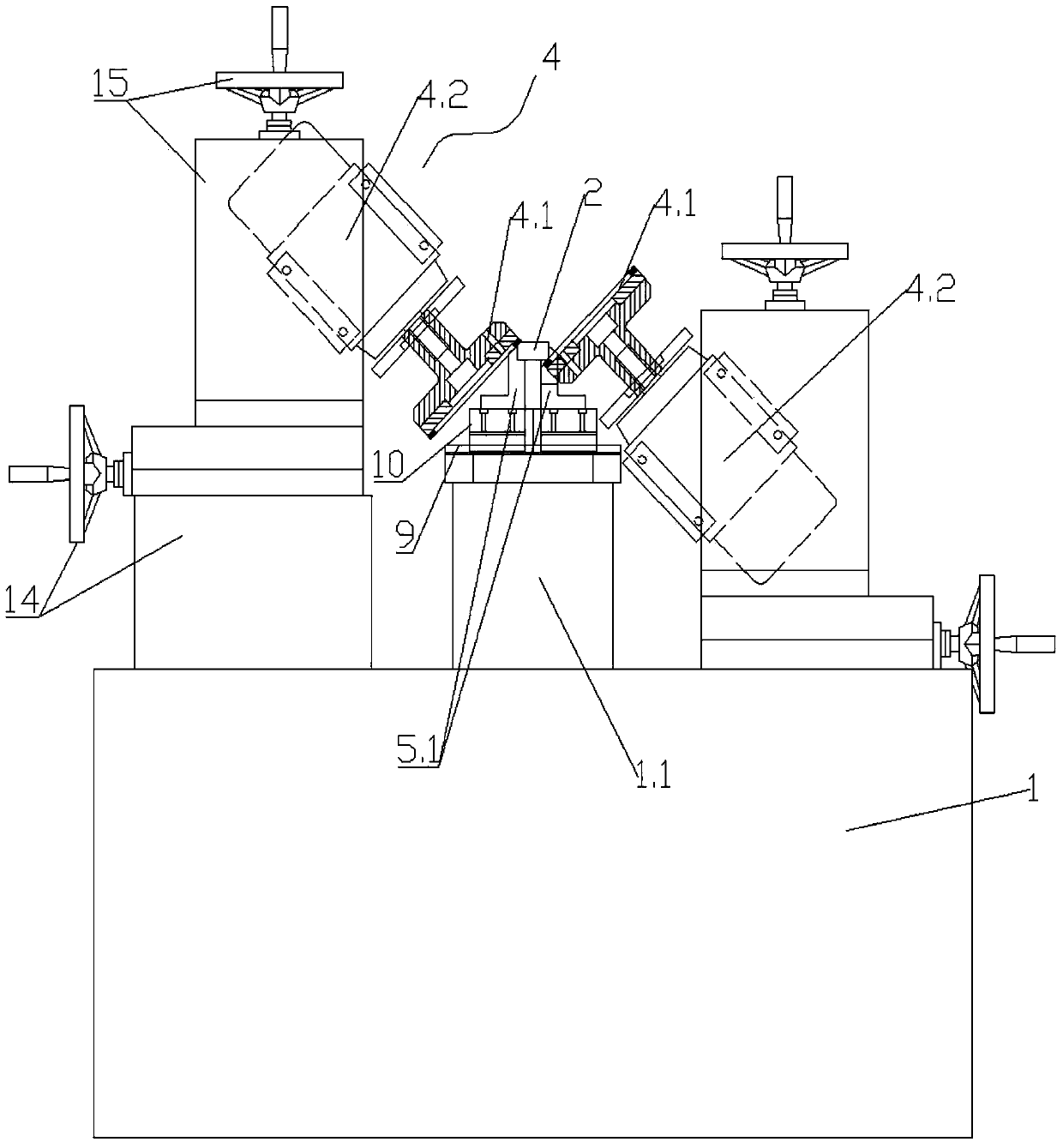

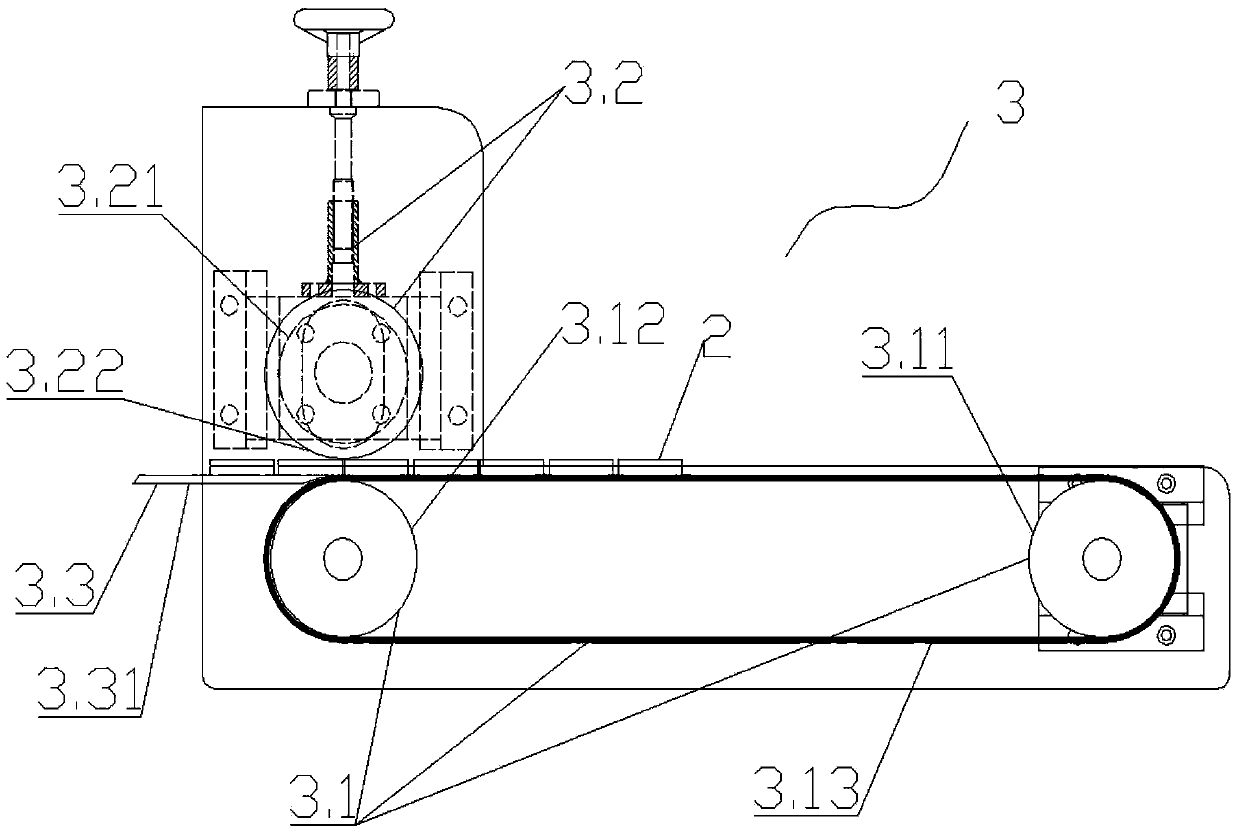

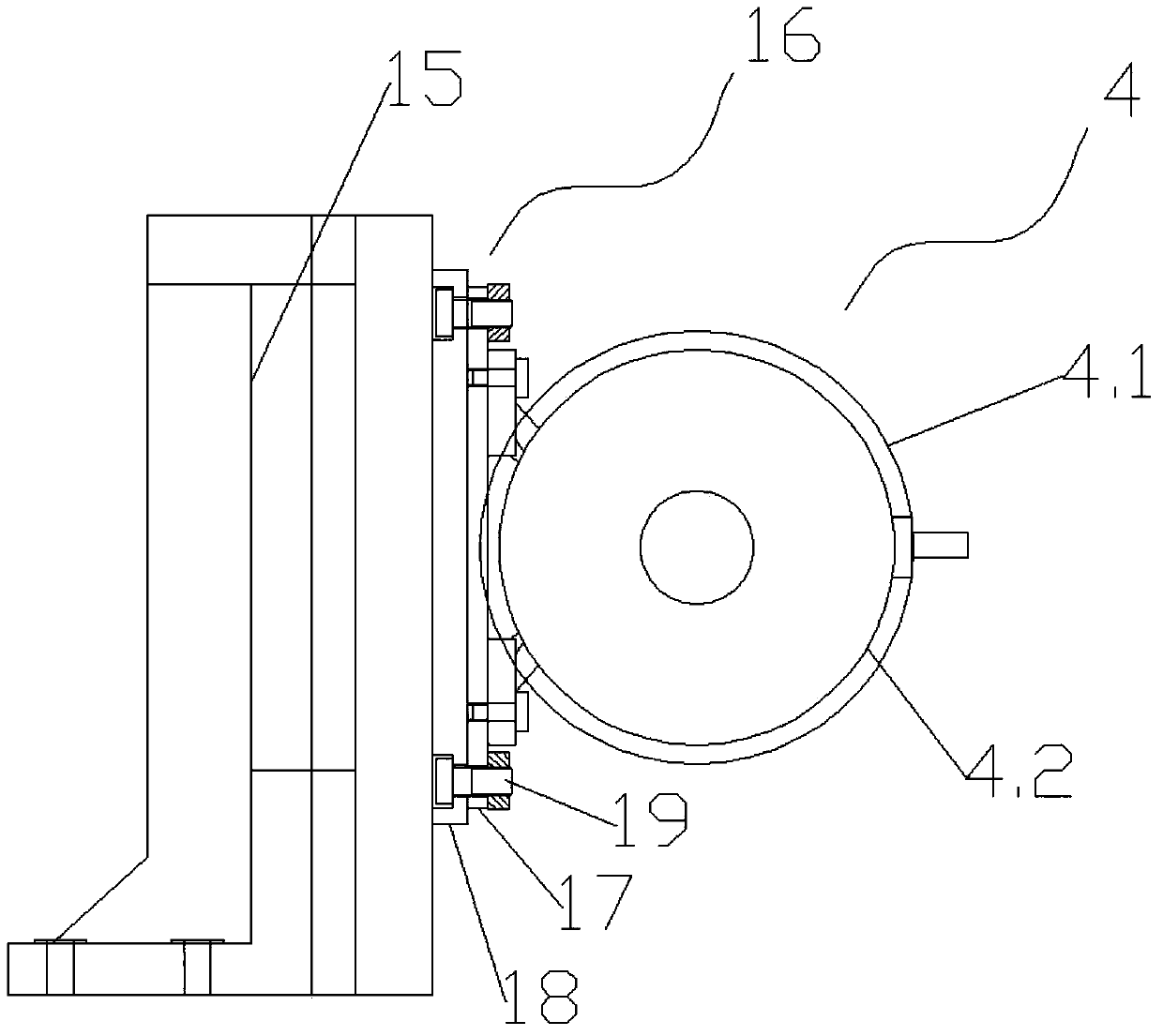

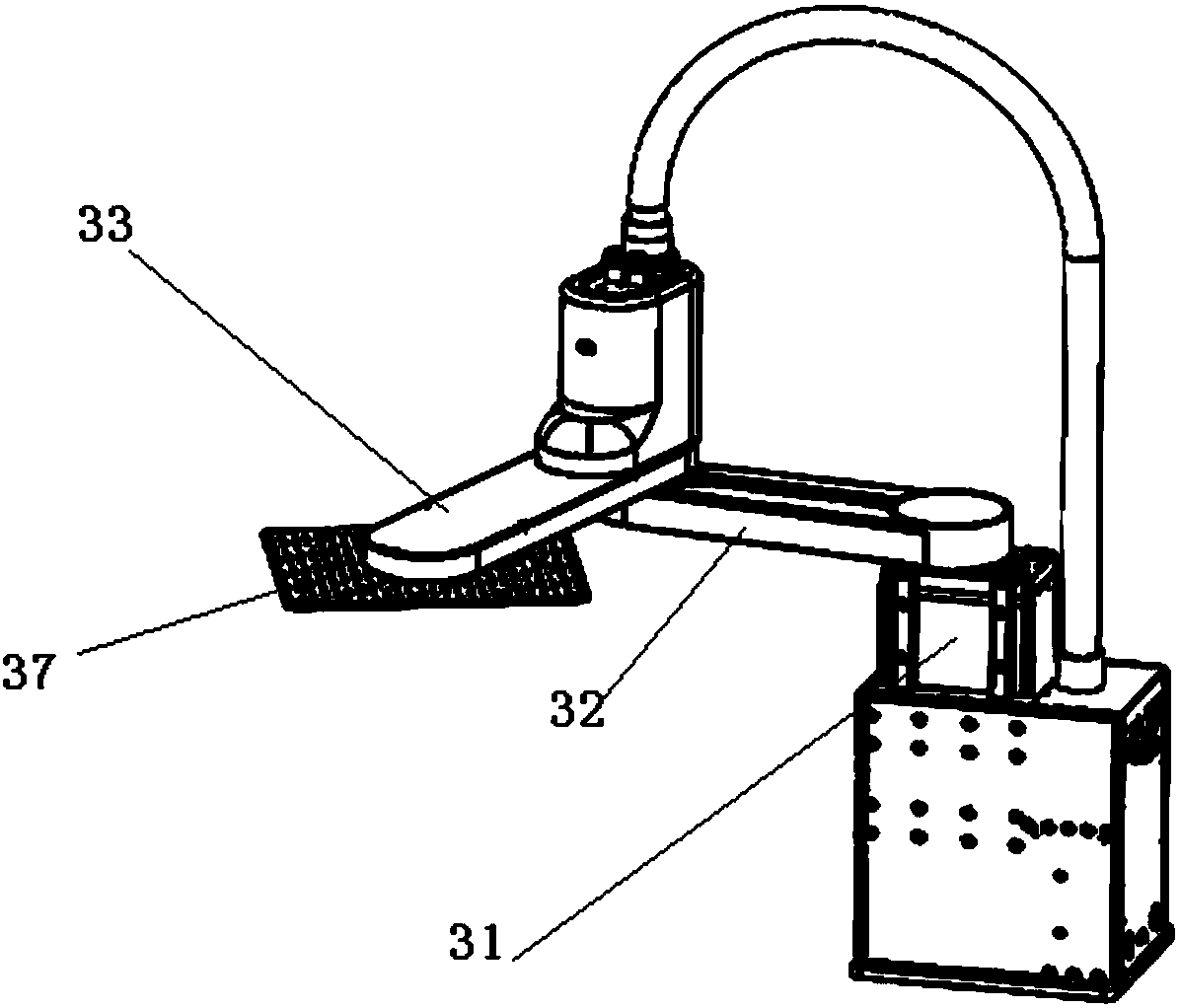

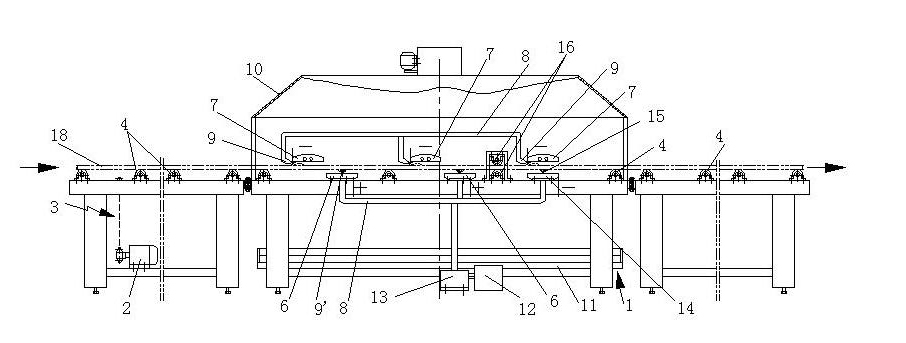

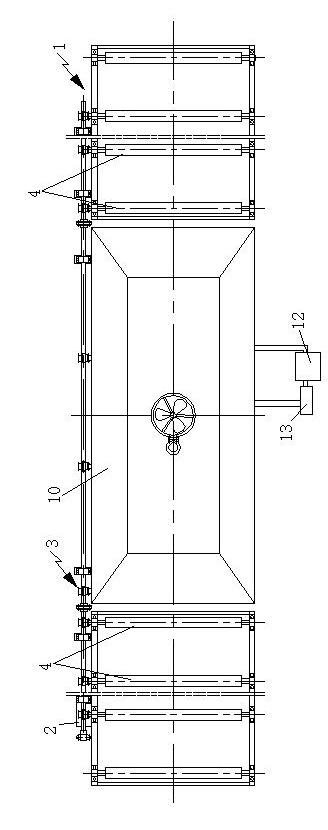

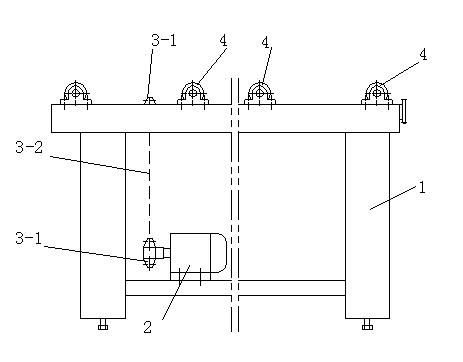

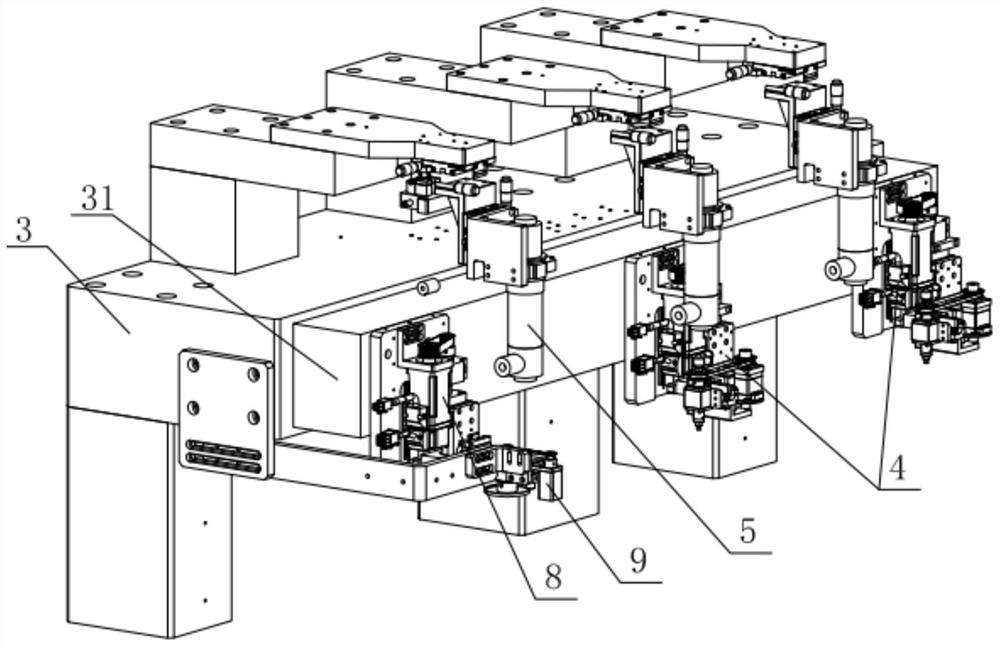

Automatic chamfering machine

ActiveCN103737443AQuality improvementThere will be no unevennessEdge grinding machinesGrinding carriagesTime segmentEngineering

The invention discloses an automatic chamfering machine. The chamfering machine comprises an engine base (1), a conveying mechanism (3), four sand wheel chamfering mechanisms (4) and a guide rail clamping mechanism (5), wherein the conveying mechanism (3) is arranged at one end of the engine base (1) and is used for conveying a work-piece (2), the four sand wheel chamfering mechanisms (4) are arranged on the engine base (1) and simultaneously chamfer the two groups of long opposite sides (2.1) of the workpiece (1), and the guide rail clamping mechanism (5) is used for clamping and smoothly moving the clamped work-piece (2) and is arranged on the working table (1.1) of the engine base (1); two of the sand wheel chamfering mechanisms (4) are respectively located at one group of long opposite sides (2.1) used for processing the work-piece (2) at the two sides of the guide rail clamping mechanism (5) in parallel, and the other two sand wheel chamfering mechanisms (4) are respectively located at the other group of long opposite sides (2.1) used for processing the work-piece (2) at the two sides of the guide rail clamping mechanism (5) in parallel. The automatic chamfering machine is not manually operated, can simultaneously chamfer the two groups of long opposite sides of the work-piece, and can continuously work for a long time segment, and has the advantages of good chamfering quality and high efficiency.

Owner:宁波市鄞州启威机械科技有限公司

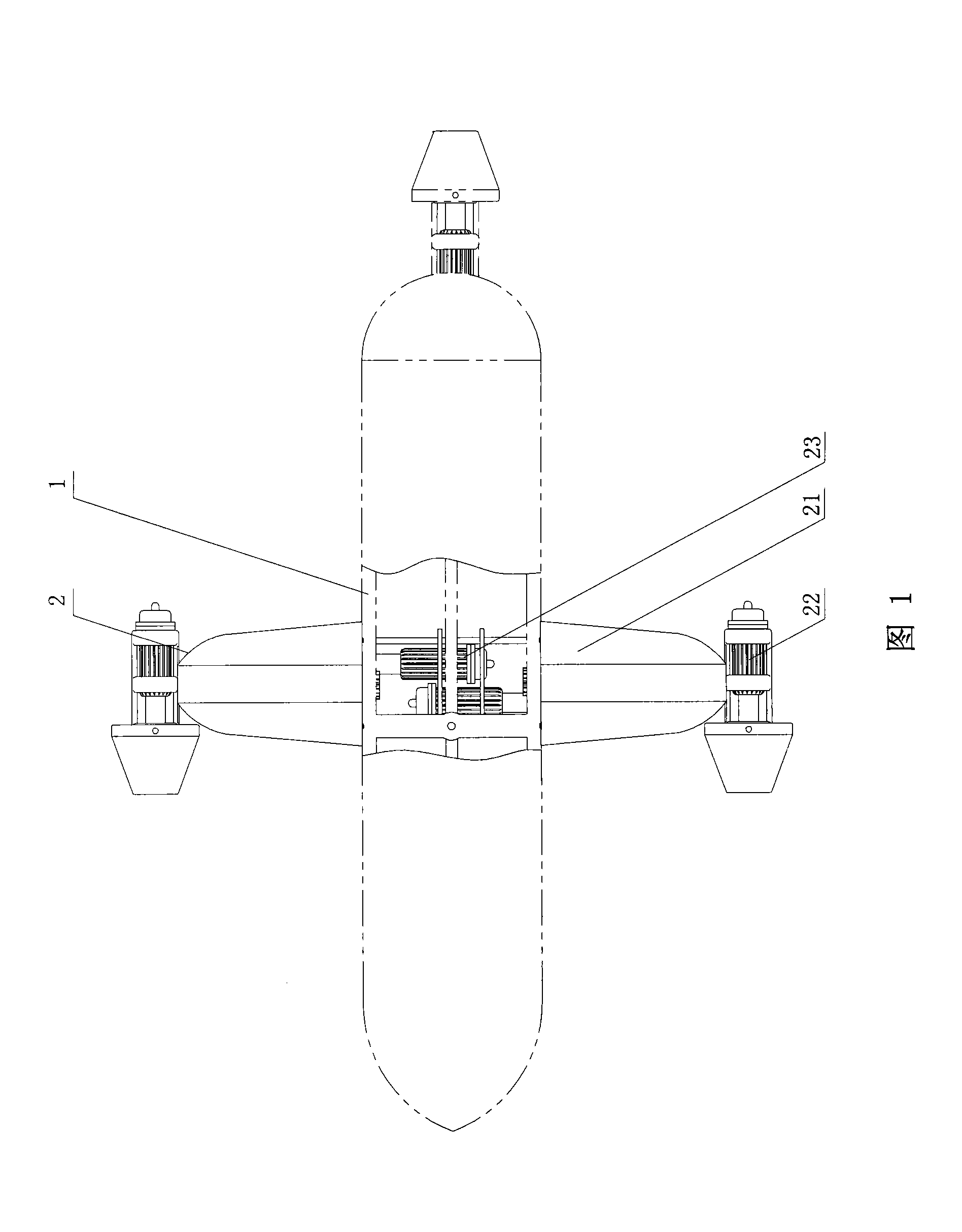

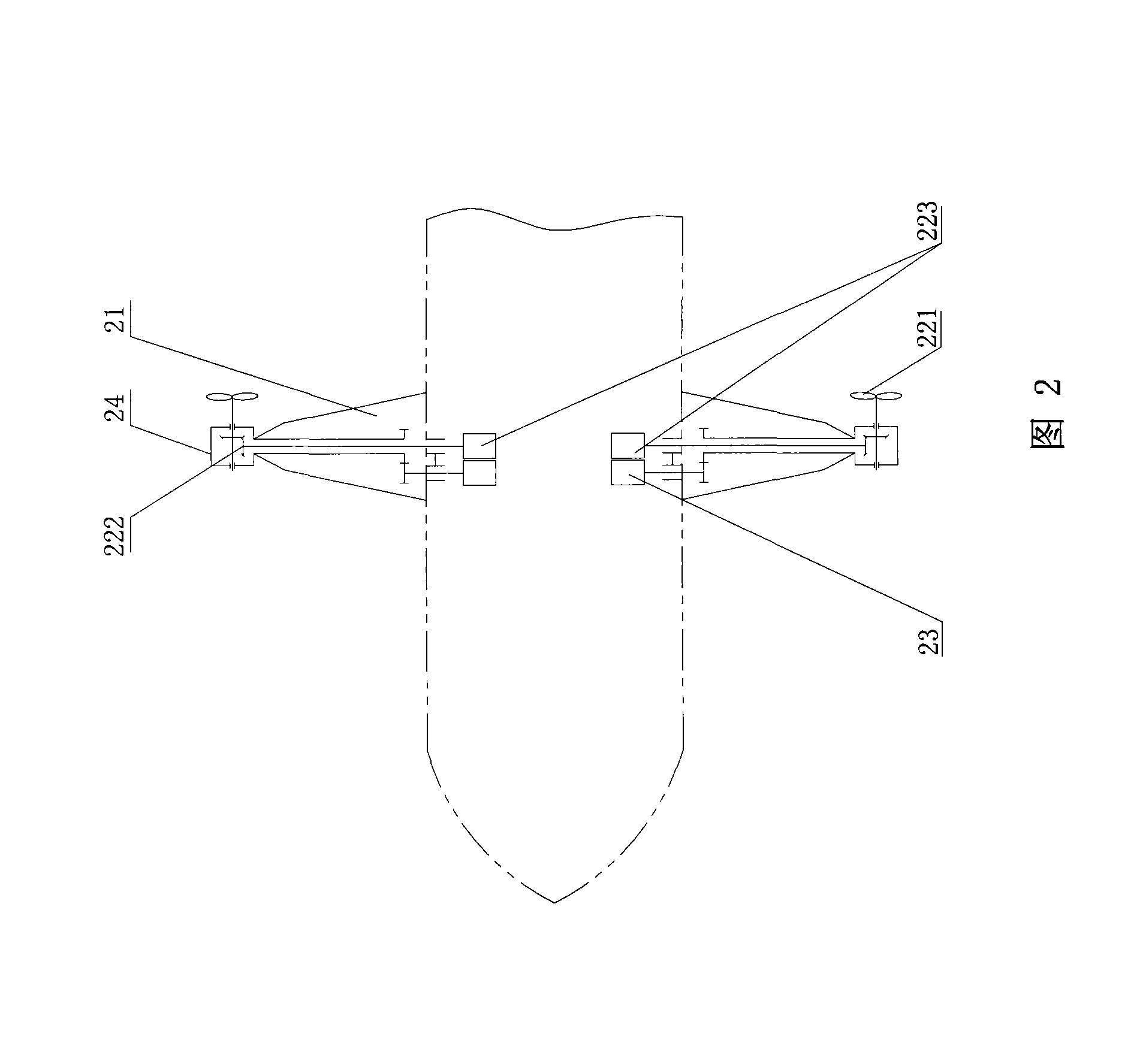

Tilt rotor vector propulsion device used in underwater propeller

InactiveCN101513926AClever layoutCompact structureUnderwater vesselsUnderwater equipmentPropellerDrive motor

Owner:NAT UNIV OF DEFENSE TECH

Single-arm robot stamping and carrying apparatus

ActiveCN107801307AGuaranteed positioning accuracyPerfect protection functionProgramme-controlled manipulatorLaminating printed circuit boardsStampingEngineering

The invention discloses a single-arm robot stamping and carrying apparatus. The single-arm robot stamping and carrying apparatus comprise a machine table; a linear lifting platform is arranged in themiddle part of the machine table; a liftable robot carrying apparatus is arranged at one end, positioned on the linear lifting platform, of the machine table; an isolation paper placement plate and anisolation paper carrying apparatus for carrying isolation paper to a finished product placement plate one by one are arranged at the other end, positioned on the linear lifting platform, of the machine table; the finished product placement plate is positioned on the linear lifting platform; and the linear lifting platform is also provided with a supplied material plate structure with a compensating and lifting function. The single-arm robot stamping and carrying apparatus is mainly specific to flexible FPC board stamping and carrying. The apparatus is a four-axis robot with a liftable base; the Z axis of the robot is positioned on the base, so that the robot can walk in the narrow space of upper and lower modules of a punch conveniently; a suction cup is arranged at the tail end of the robot, and a product protection function is added at the suction cup adsorption position; the suction cup is rotatable, so that a secondary stamping function of the symmetrical products can be realizedconveniently; and the four-axis robot with the liftable base is mainly used for material carrying.

Owner:东莞市本润机器人科技股份有限公司

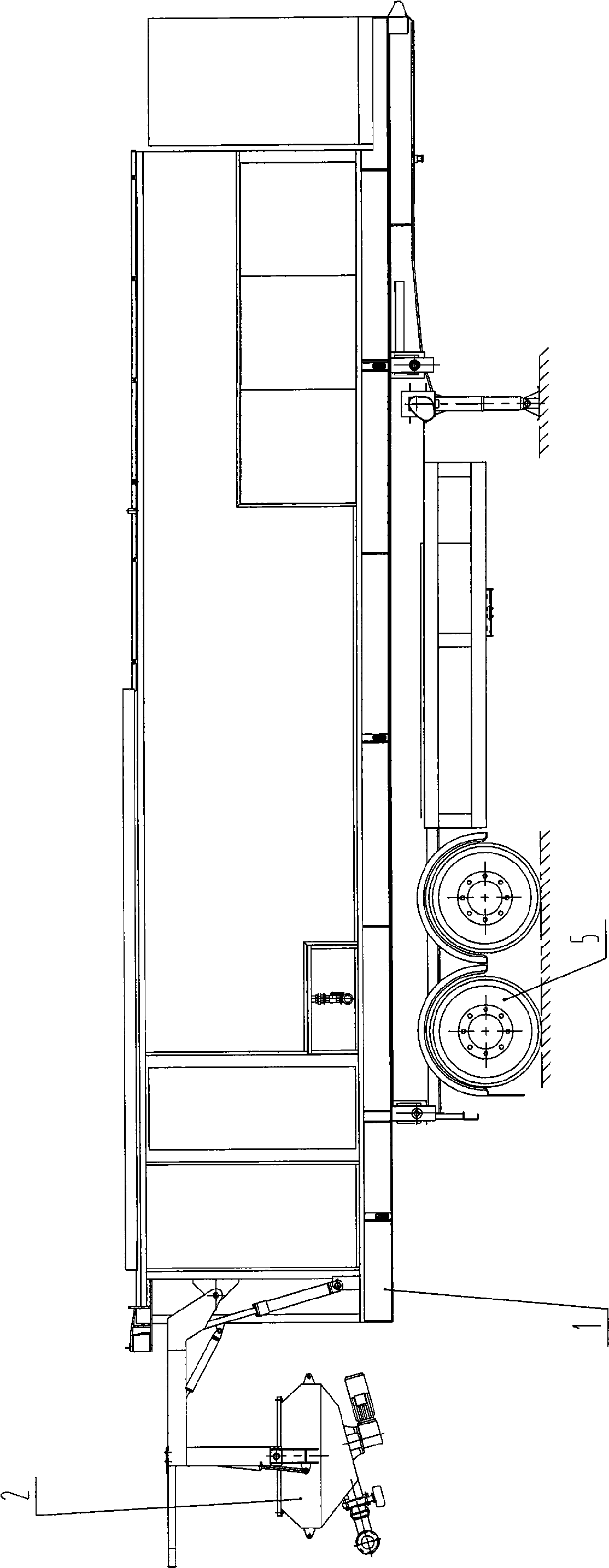

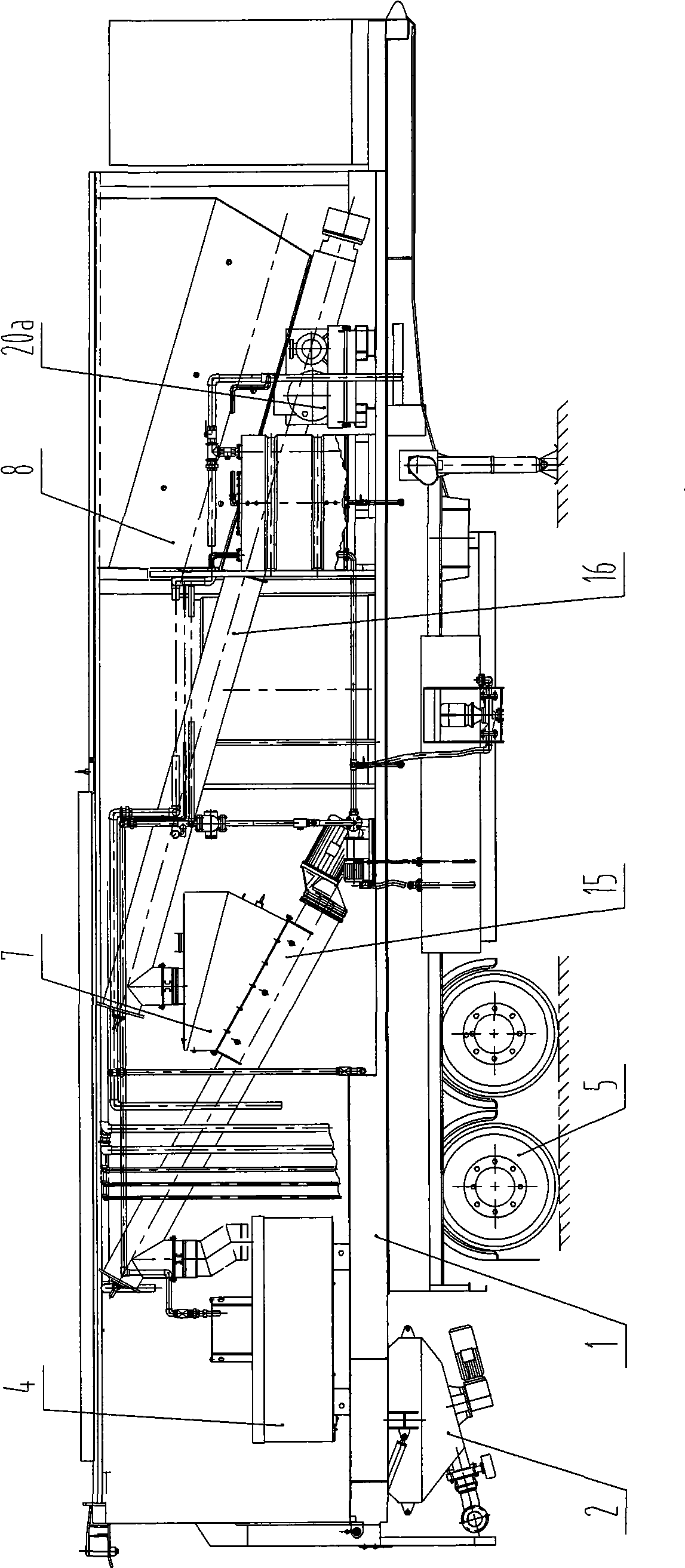

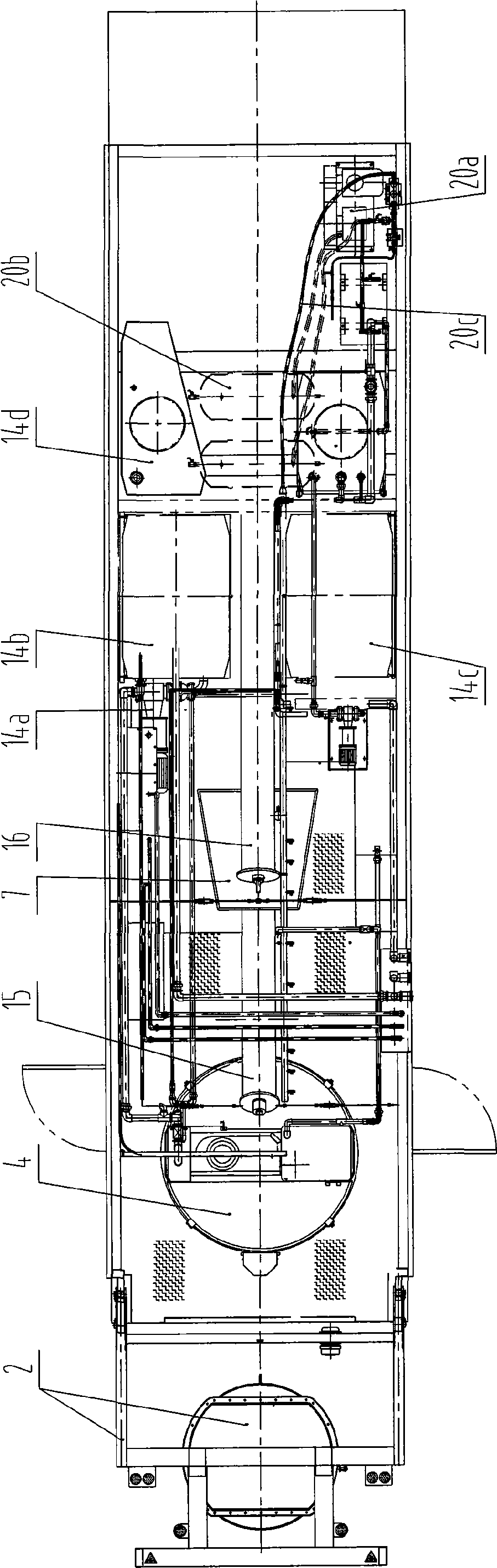

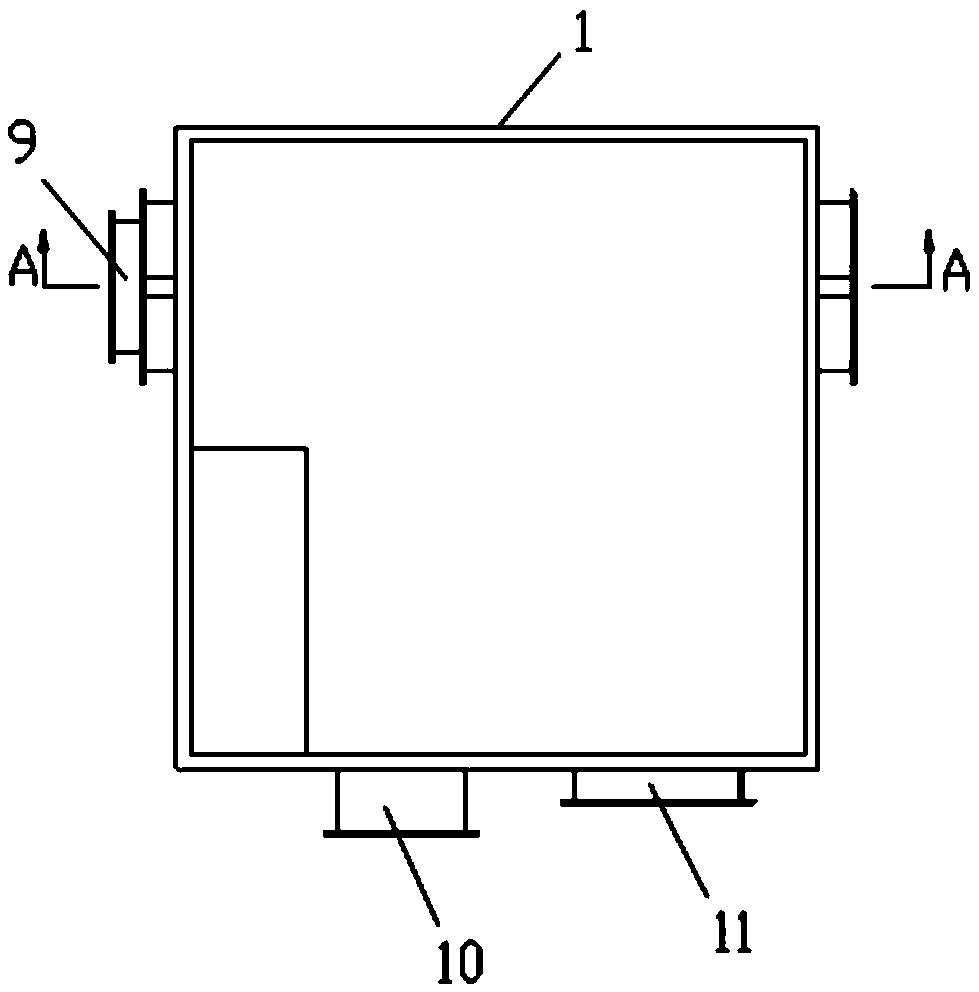

Mortar vehicle for concrete and asphalt

InactiveCN101531034ACompact structureClever layoutCement mixing apparatusLiquid ingredients supply apparatusEmulsionControl system

The invention relates to a mortar vehicle for concrete and asphalt, comprising a bottom disc and upper components arranged on the bottom disc; the upper components comprise an assembly for weighing and charging dry powder, an assembly for measuring and charging asphalt, an assembly for measuring and charging water, an assembly for measuring and charging additives, an assembly for measuring and charging P emulsion, an assembly for a stirring main machine, an assembly for a mortar grouting plate, a power system and a control system; the two sides of a dry powder delivery screw machine in the assembly for weighing and charging dry powder are provided with a first asphalt storing tank and a second asphalt storing tank; the two sides below a dry powder storage bin are respectively provided with a third asphalt storing tank and a P emulsion storing tank in the assembly for measuring and charging P emulsion; three asphalt storing tanks are communicated to form an asphalt storing tank in the assembly for measuring and charging asphalt; and a water tank and a water pump in the assembly for measuring and charging water and an air reservoir in the power system are fixed on the bottom disc below the upper components. The mortar vehicle has the advantages of compact structure, ingenious layout, accurate measurement and wide application range and the like, can produce mortar with high modulus of elasticity and also can produce mortar with low modulus of elasticity.

Owner:SANY HEAVY IND CO LTD (CN) +1

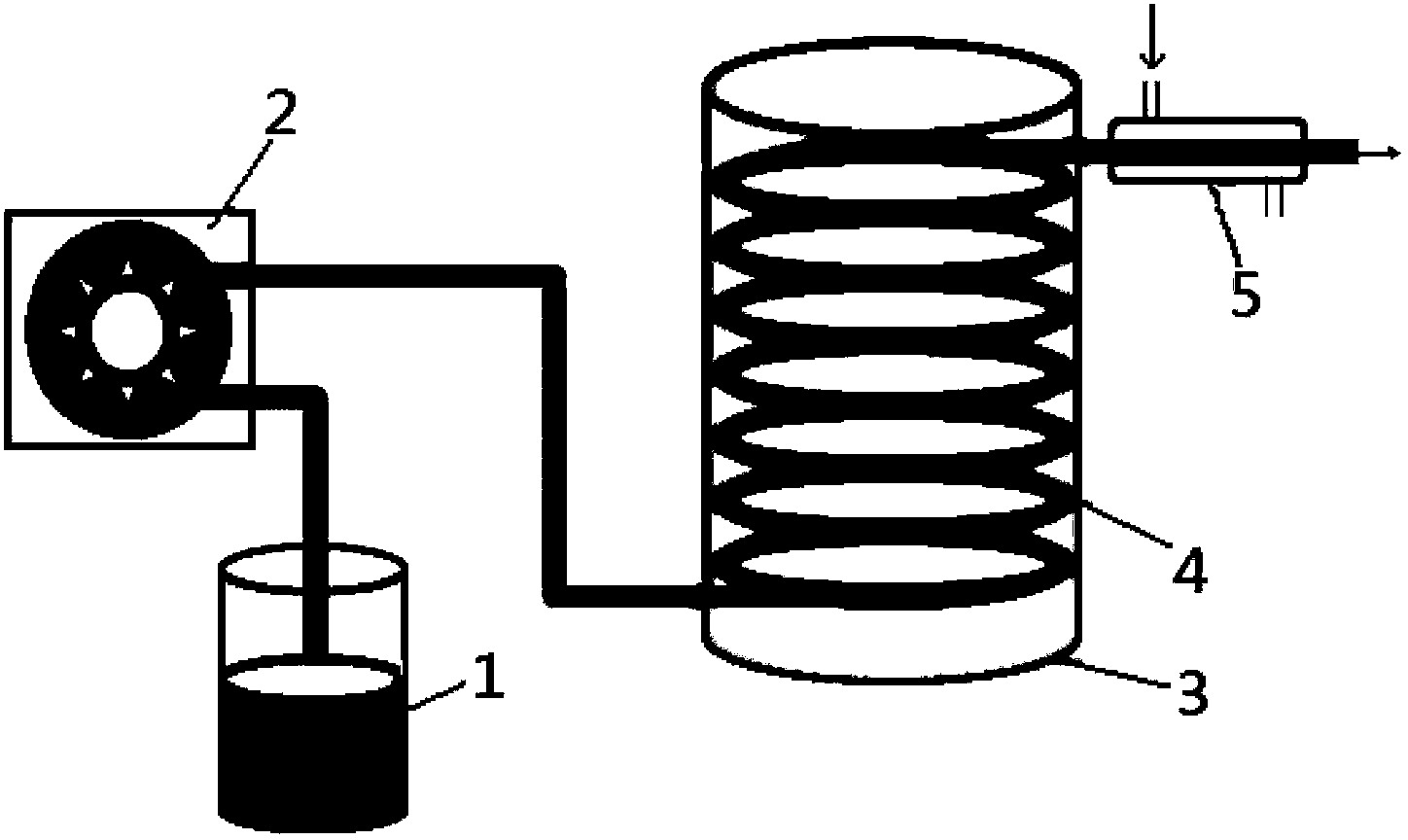

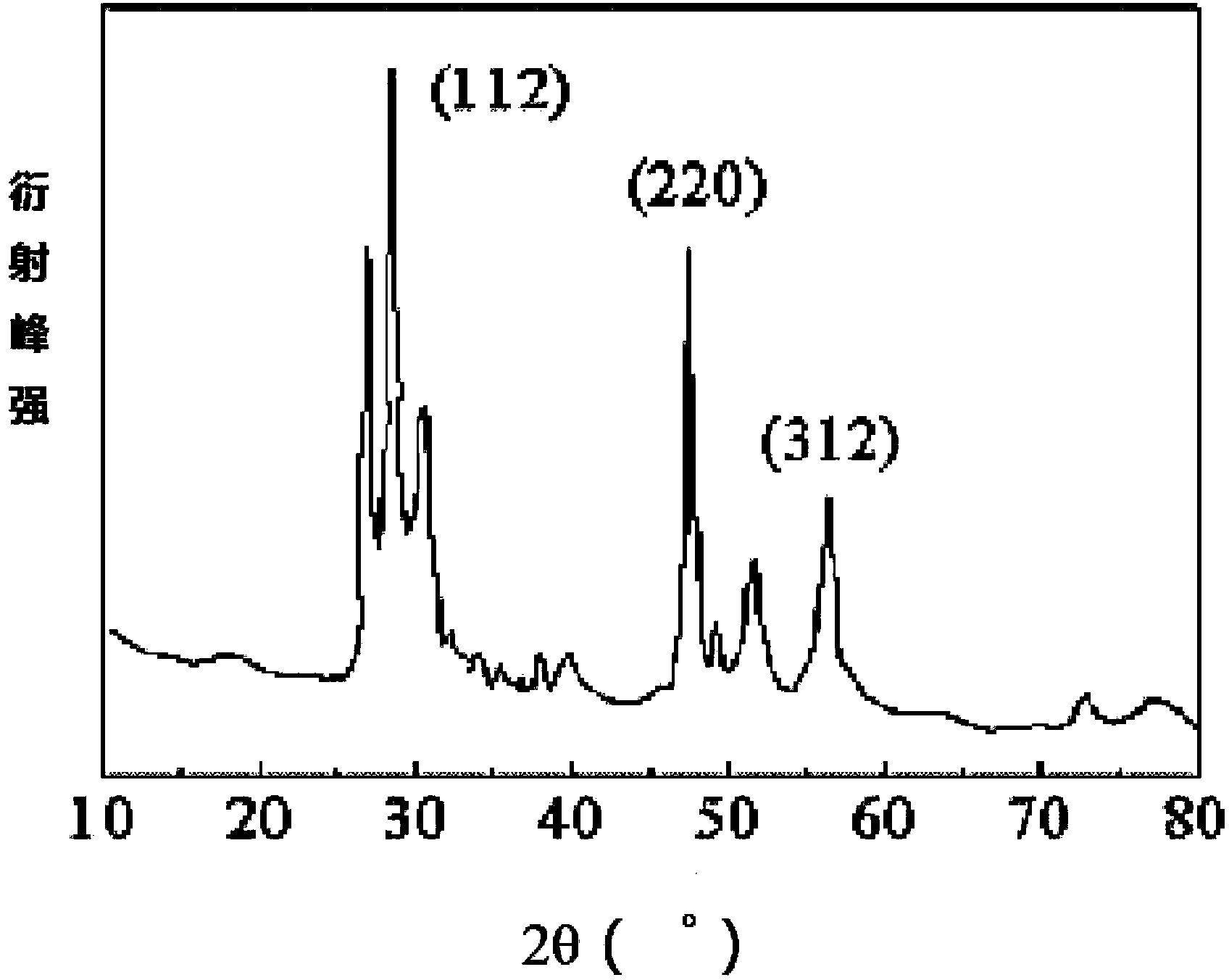

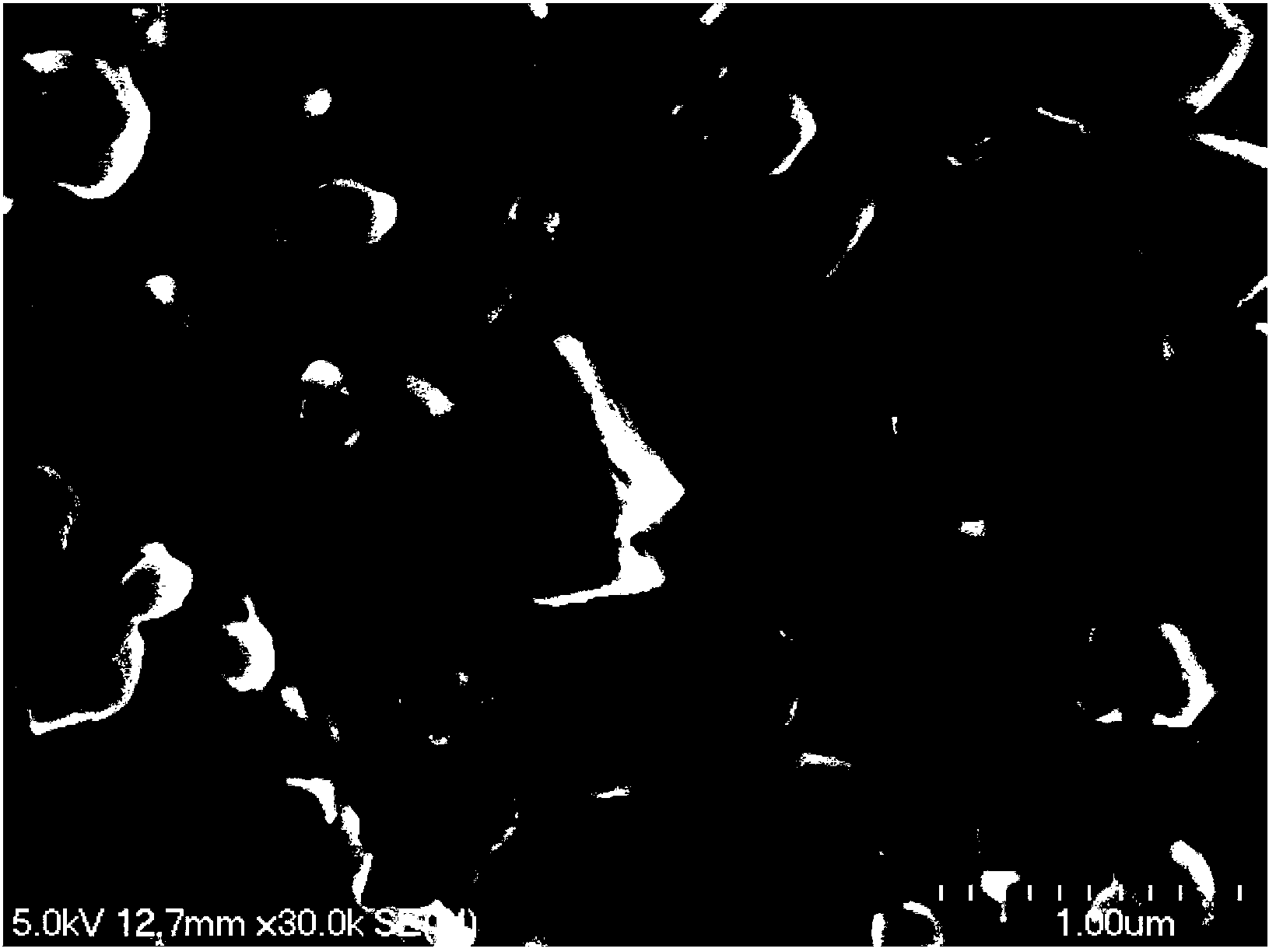

Method for continuous preparation of copper zinc tin sulfur film

The invention discloses a method for continuous preparation of a copper zinc tin sulfur (CZTS) film. The method comprises the preparation steps of: preparation of a reaction precursor solution, continuous preparation of CZTS nanocrystals, purification of the CZTS nanocrystals, blending of a CZTS ink, coating drying and selenation sulfurization annealing treatment. Specifically, the means of continuous preparation of the CZTS nanocrystals makes the continuous and mass preparation of the CZTS film come true, and the preparation is free of the problems of uneven heating and limited heat and mass transfer. At the same time, the selenation sulfurization annealing treatment endows the prepared film with high photoelectric conversion efficiency and strong stability. And the method has the advantages of simple operation and low cost, thus being suitable for marketing production.

Owner:徐东

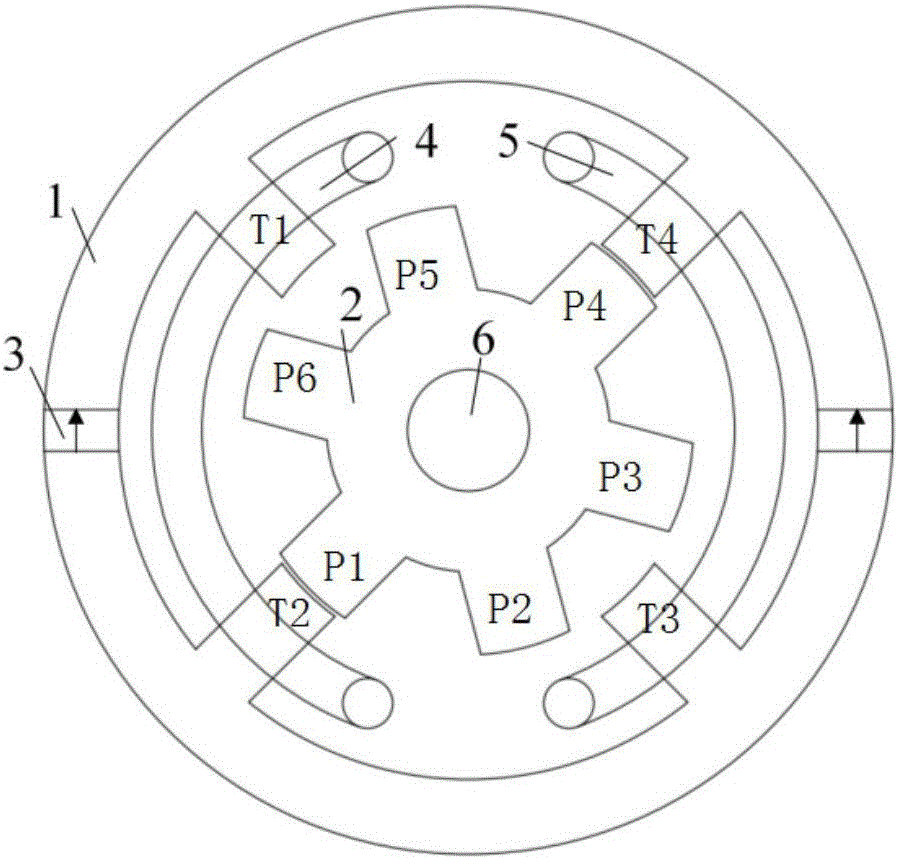

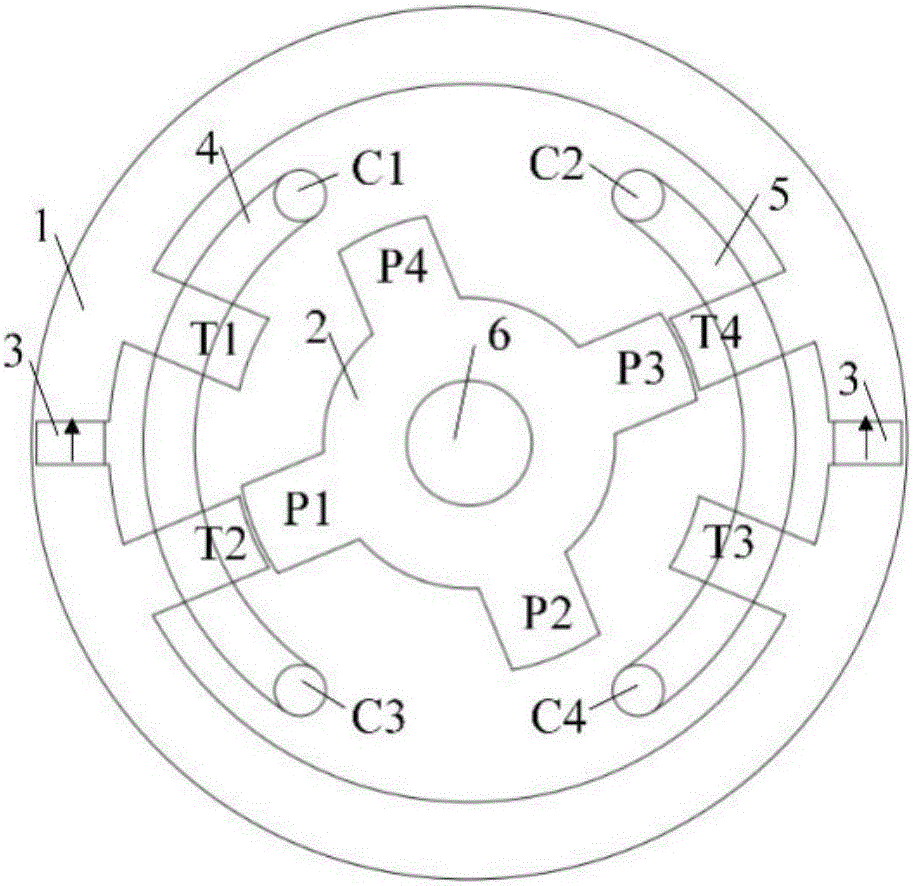

Doubly salient permanent magnet synchronous motor with unequally spaced stator poles

ActiveCN105932793AIncrease the effective areaIncrease the number of turnsMagnetic circuit rotating partsSynchronous machine detailsPhysicsDoubly salient

The invention belongs to the field of doubly salient permanent magnet synchronous motors and discloses a doubly salient permanent magnet synchronous motor with unequally spaced stator poles. The doubly salient permanent magnet synchronous motor comprises a stator, a rotor, a permanent magnet, an armature winding and a rotating shaft, wherein the rotor is arranged in the stator and rotates relative to the stator; the rotating shaft is arranged in the rotor and rotates along with the rotor; the permanent magnet is symmetrically arranged at a yoke part of the stator and provides excitation for the air-gap field of the motor; the armature winding is coiled on the stator poles of the stator, and after the armature winding is energized, the magnetic field of the armature winding interacts with the magnetic field of the permanent magnet to rotate the rotor. Through the doubly salient permanent magnet synchronous motor, a problem that the motor cannot be started in a bidirectional way in the prior art is solved, and the stator poles are unequally spaced, so that the output torque is improved, and furthermore, through superposition on a multi-module structure, the output torque can be superposed, so that the toque pulsation is reduced, and the fault tolerance and the reliability are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

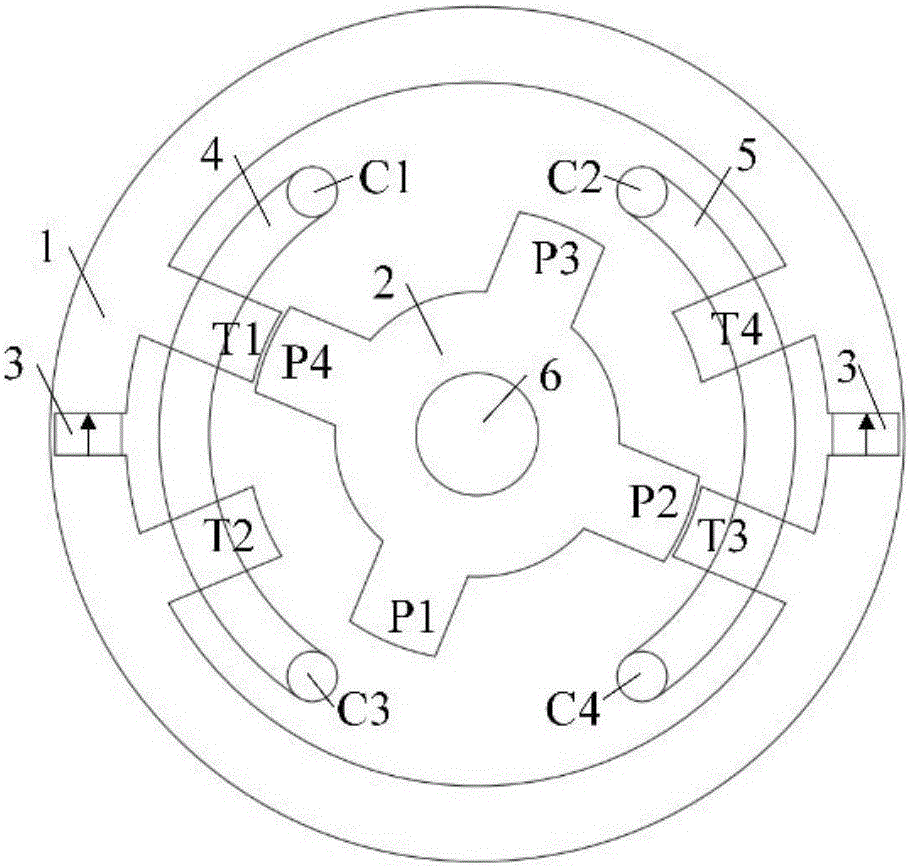

Bidirectional soft and hard seal eccentric half-ball valve

The invention discloses a bidirectional soft / hard sealing eccentric half-ball valve, comprising a valve body which is connected with a valve cover; the valve body is internally provided with an eccentric crankshaft which passes through the valve cover and is hermetically connected with the valve cover; the eccentric crankshaft is connected with a spherical crown; a runway at one side of the valve body is connected with a valve base which is used for positive hard sealing; the valve base is internally provided with a sealing trough which is internally provided with a sealing ring used for reverse soft sealing; the sealing trough is communicated with the runway at the side of the sealing trough; one side of the eccentric half-ball valve corresponding to the runway adopts two sealing structures: soft sealing and hard sealing, which have different directions; therefore, the bidirectional sealing of the eccentric half-ball valve is achieved, the eccentric half-ball valve can be installed in the positive direction or the reverse direction and the applicable range of the eccentric half-ball valve is enlarged; during the reverse sealing, the sealing ring is closely combined with the spherical crown under the water pressure; the bidirectional soft / hard sealing eccentric half-ball valve has simple and reasonable structure and smart arrangement, and is an eccentric half-ball valve with completely new sealing structure.

Owner:WUHAN DAYU VALVE

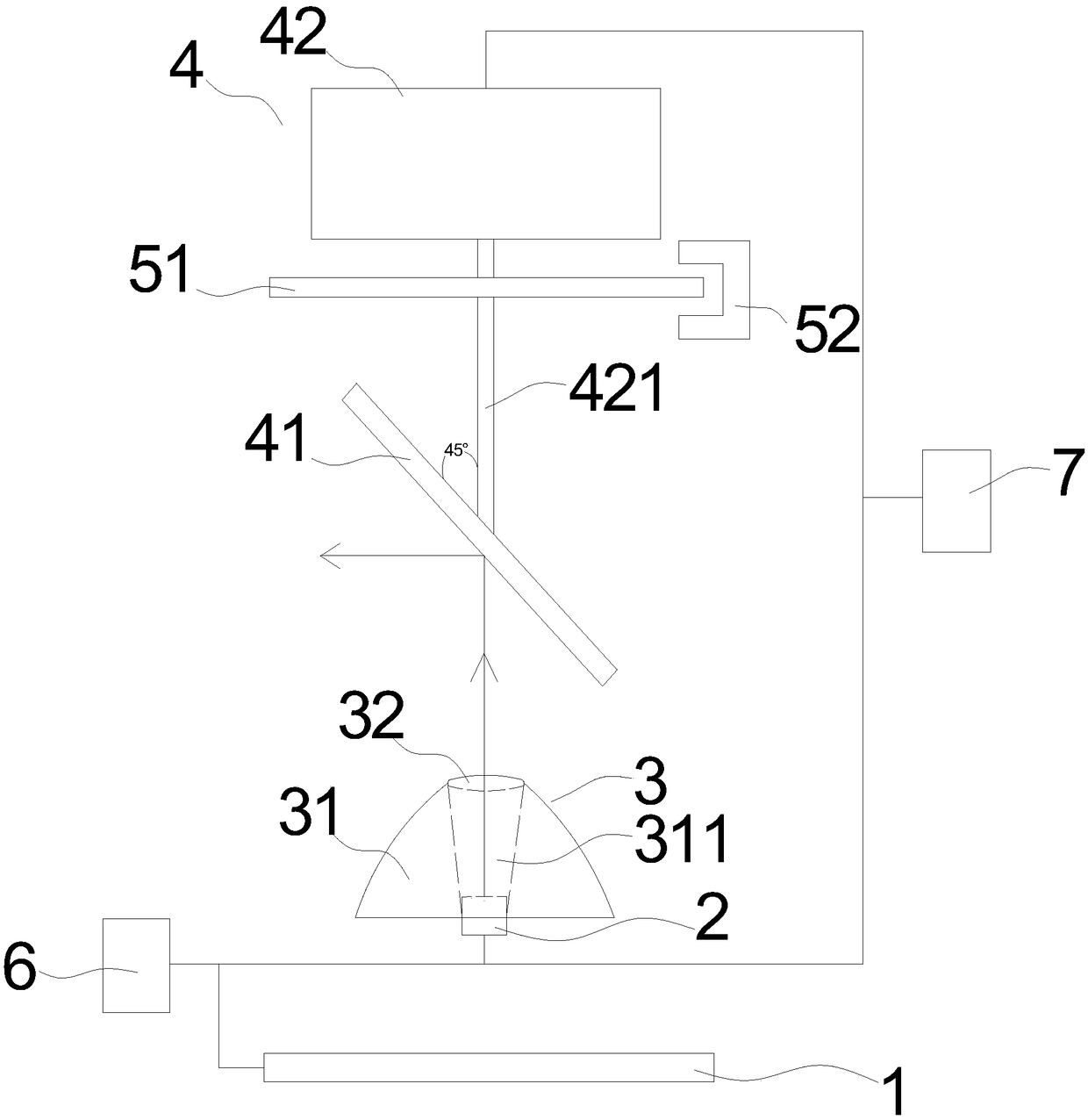

Transceiving combine lens based two-dimensional scanning laser ranging radar

PendingCN108710134AOptical path independentClever layoutElectromagnetic wave reradiationLaser rangingOptoelectronics

The invention discloses a transceiving combine lens based two-dimensional scanning laser ranging radar and mainly solves problems of large size and low space utilization rate of scanning laser radar in the prior art due to separated placement of a transmitting part and a receiving part. The transceiving combine lens based two-dimensional scanning laser ranging radar comprises a receiving sensor, alaser, a combined lens and a rotating reflection component in sequential arrangement. The laser is used for lasing, the combined lens is used for collimation of emitted laser and convergence of received laser, the transmitting component is capable of rotating during lasing, and the receiving sensor is used for receiving laser. By adoption of the technical scheme, the problems are well solved, andthe transceiving combine lens based two-dimensional scanning laser ranging radar can be used for laser ranging radar.

Owner:SUZHOU UNION INTELLIGENT TECH CO LTD

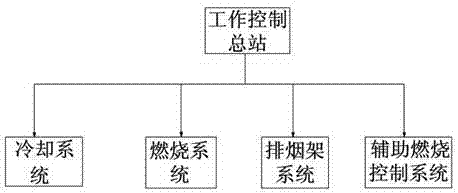

Carbon roaster control system with combustion assistance function and implementation method of system

The invention discloses a carbon roaster control system with a combustion assistance function, and solves the problems of the conventional carbon roaster control system that resources are waste and environment is polluted as the temperature control of a preheating zone of a roaster is inaccurate, and combustible substance can not burn out. The control system comprises a work control master station connected with a combustion system, a smoke evacuation system, a cooling system and a combustion assistance control system, The combustion assistance control system comprises a PLC (Programmable Logic Controller) control cabinet connected with the work control master station, a temperature control device and a fire detection device which are both connected with the PLC control cabinet, and a combustible gas pipeline device connected with the temperature control device and the fire detection device simultaneously. The carbon roaster control system provided by the invention seamlessly joints the traditional carbon roaster control mode with the added combustion assistance control system, and operation and control are carried out, thereby achieving the purpose that the temperature of the carbon roaster preheating zone is accurately controlled, and the combustible substance is fully burned so that pollution is avoided, and therefore the invention is suitable for being popularized for use.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

Method and device for carrying out electrolytic etching on metal plate

ActiveCN102181915AImprove production environmentReasonable structureElectrolysis componentsElectrolysisEtching

The invention discloses a method and device for carrying out electrolytic etching on a metal plate. The method comprises the following steps: putting a metal plate onto a delivery roll, and delivering to an electrolysis region; arranging at least one negative electrode above the electrolysis region to serve as an upper electrode, and arranging at least one positive electrode below the electrolysis region to serve as a first lower electrode, wherein the upper electrode and the first lower electrode are staggered in the vertical direction; injecting electrolyte into the clearance between the upper surface of the metal plate and the negative electrode, and simultaneously injecting electrolyte into the clearance between the lower surface of the metal plate and the positive electrode; and applying a voltage to conduct the positive electrode and the negative electrode through the electrolyte and the metal plate, wherein the discharging part is provided with an ash-removing negative electrode which is used as a second lower electrode to carry out ash-removing electrolytic treatment on the lower surface of the metal plate. The device comprises a framework, a motor, a transmission gear, the delivery roll, the positive electrode and the negative electrode, wherein at least one ash-removing negative electrode is arranged at the discharging side of the positive electrode close to the discharging part of the metal plate on the framework. The invention can be used for carrying out ash-removing treatment on the metal plate in the electrolytic etching process, and has a reasonable structure.

Owner:常州正成机电科技有限公司

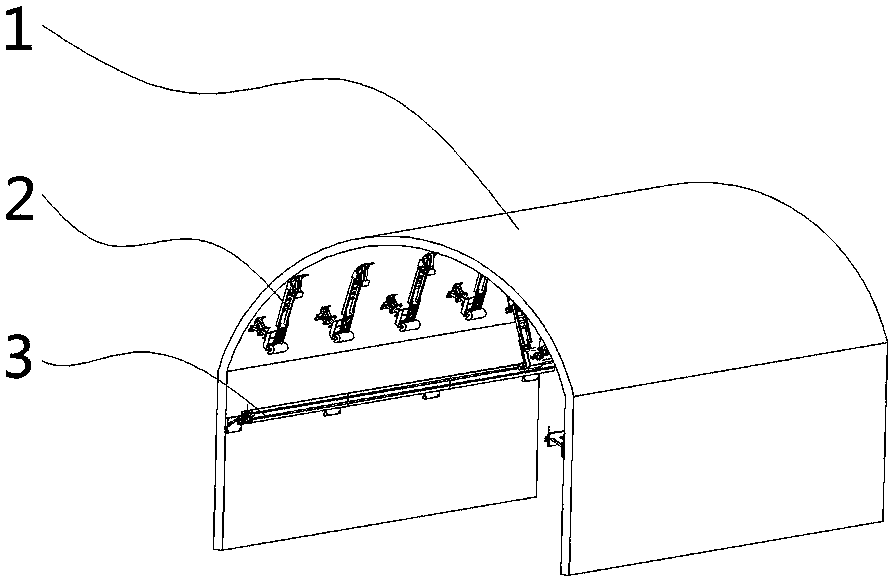

Tunnel light cleaning and replacing device and construction method thereof

ActiveCN107559777AEasy to operateClever layoutLighting elementsOutdoor lightingTraffic flowMechanical engineering

The invention discloses a tunnel light cleaning and replacing device which comprises a tunnel main body. A light cleaning and replacing mechanism is mounted in the tunnel body. The tunnel light cleaning and replacing device is characterized in that the light cleaning and replacing mechanism comprises a bracket; a mounting arm and a movable arm locked on the tunnel main body are arranged on one side of the bracket while a motor control cabinet is mounted on the other side of the bracket; bearings extend on two sides of the motor control cabinet; spring mechanism bayonet locks are connected to the tail ends of the bearing; a push rod arranged on the back side of a tunnel light is inserted into each of the spring mechanism bayonet locks; a spring lock arranged on one end of the push rod is locked in each of the spring mechanism bayonet locks while an outer barrel of a telescopic rod is mounted on the other end; and a spring propping push rod is arranged in the outer barrel of the telescopic rod. The tunnel light cleaning and replacing device disclosed by the invention has the beneficial effects that the tunnel light cleaning and replacing device is simple to operate and skillful in layout, can be folded and unfolded flexibly to clean the tunnel light automatically quickly, and the tunnel is not closed, so that normal traffic flow is not affected, and therefore, the tunnel light cleaning and replacing device is suitable for being popularized and used.

Owner:甘肃中太信息科技有限公司

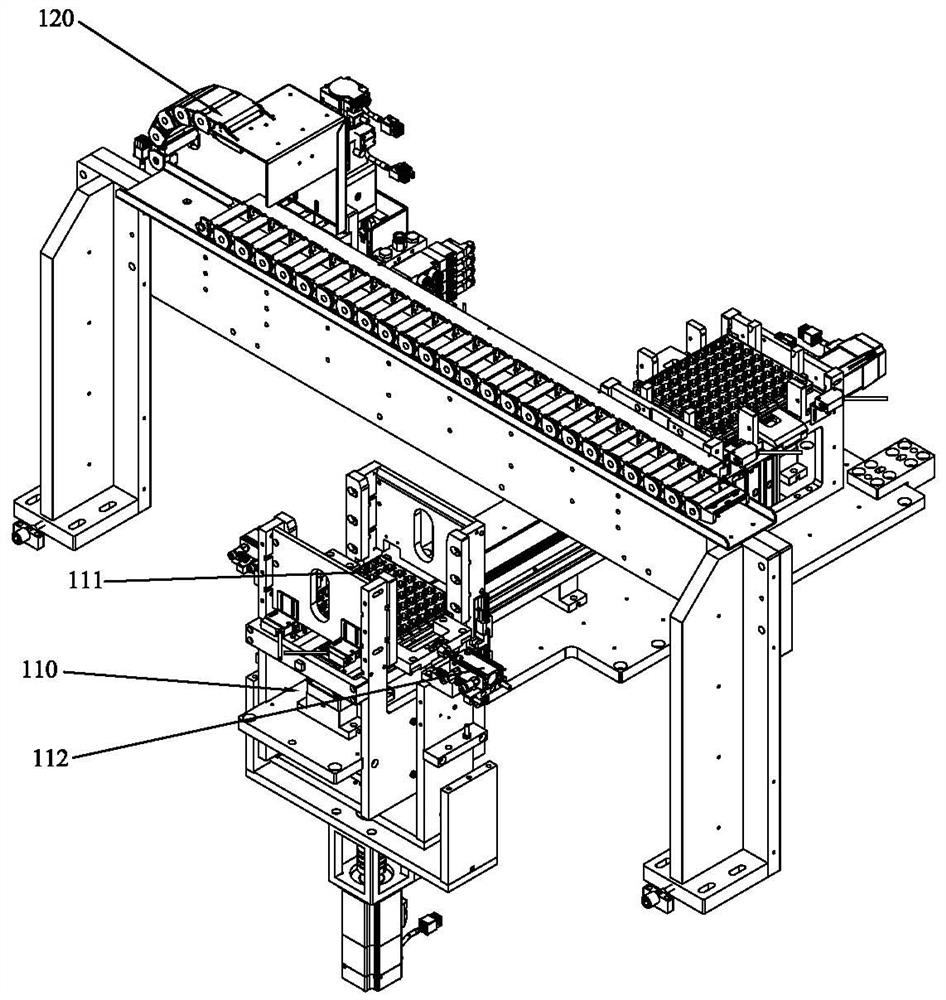

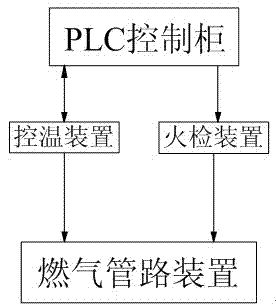

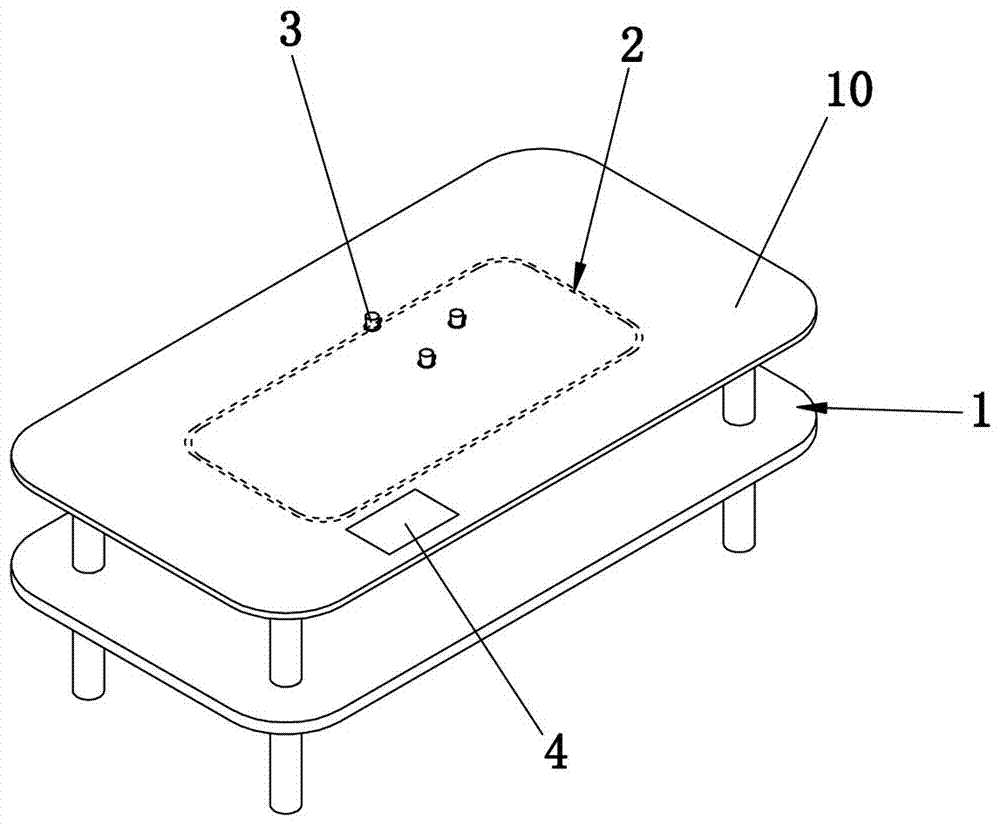

Multi-chip intelligent mounting equipment and using method thereof

PendingCN111883470ACompact structureReasonable structureSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingEngineering

The invention relates to multi-chip intelligent mounting equipment and a using method thereof. The multi-chip intelligent mounting equipment comprises a working platform, wherein a feeding area, a preset platform and a discharging area are sequentially arranged on the working platform in the Y-axis direction, a supporting frame is installed on the working platform located outside the ends of the feeding area, the preset platform and the discharging area, and a Y-direction linear guide rail is installed on the front side face of the supporting frame in the length direction; a welding head assembly is movably installed on the Y-direction linear guide rail, and a gluing assembly is further installed on the Y-direction linear guide rail located above the discharging area. A plurality of firstcamera assemblies are further installed at the top of the supporting frame, and second camera assemblies are installed on the working platform located on the front side of the preset platform. One setof welding head assembly picks up the chips in the feeding area to the preset platform, the other set of welding head assembly picks up the chips on the preset platform to the discharging area, and the substrate in the discharging area is glued by the gluing assembly before the chips are placed, so high-precision mounting of the wafers on the substrate is realized, the automation degree is high,the mounting efficiency is greatly improved, and the surface mounting quality is guaranteed.

Owner:恩纳基智能科技无锡有限公司

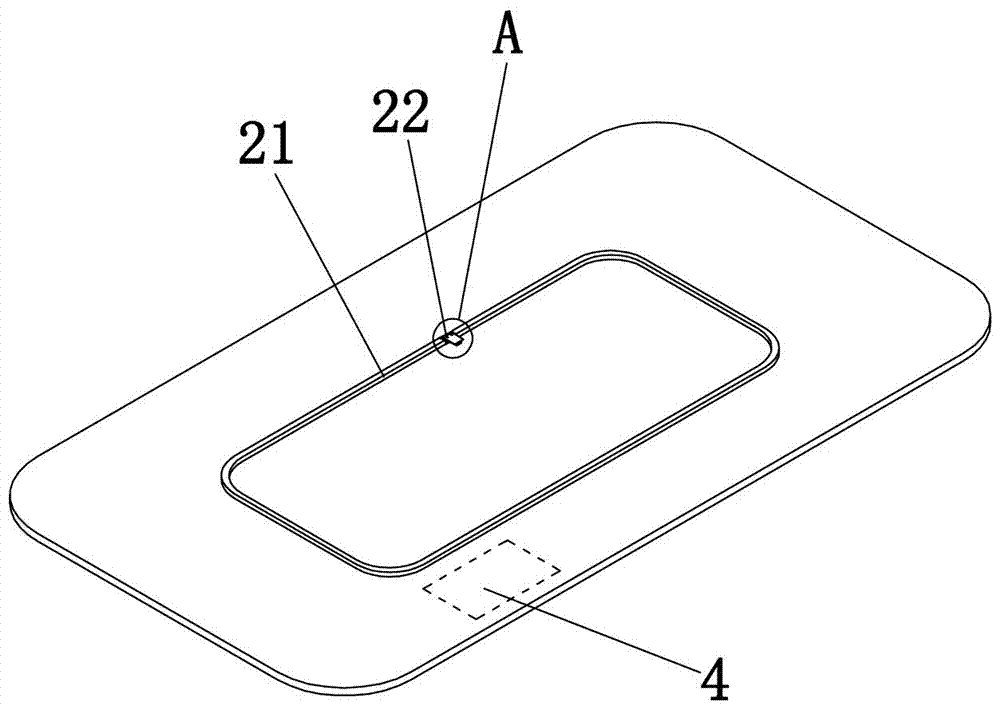

Intelligent tea table and working method thereof

The invention discloses an intelligent tea table and a working method thereof, relating to the field of tea set. The intelligent tea table comprises a tea table and a tray, wherein the tea table comprises a glass table top, an electric sliding rail mechanism is arranged at the bottom of the glass table top and consists of a circular orbit and at least one slider, the circular orbit is arranged at the bottom of the glass table top, a mounting plate is arranged on the slider, one end of the mounting plate is horizontally extended out of the slider and is provided with an electromagnet towards the bottom of the glass table top, a permanent magnet and three spherical clamp slots distributed triangularly are arranged at the bottom of the tray, a ball is arranged in each spherical clamp slot in a clamping manner, and a human body inductor is arranged on the surface of the tray. The intelligent tea table has the beneficial effects that by means of the attraction action of the electromagnet and the permanent magnet, the tray is adsorbed on the slider across the glass table top, when the slider moves along the circular orbit, the tray carrying tea cups can move in face of a tea drinker along with the slider, no tea drinker walks and delivers tea, and the intelligent tea table has the advantages of being smart to distribute, and hidden and safe in design.

Owner:泉州创源机电科技有限公司

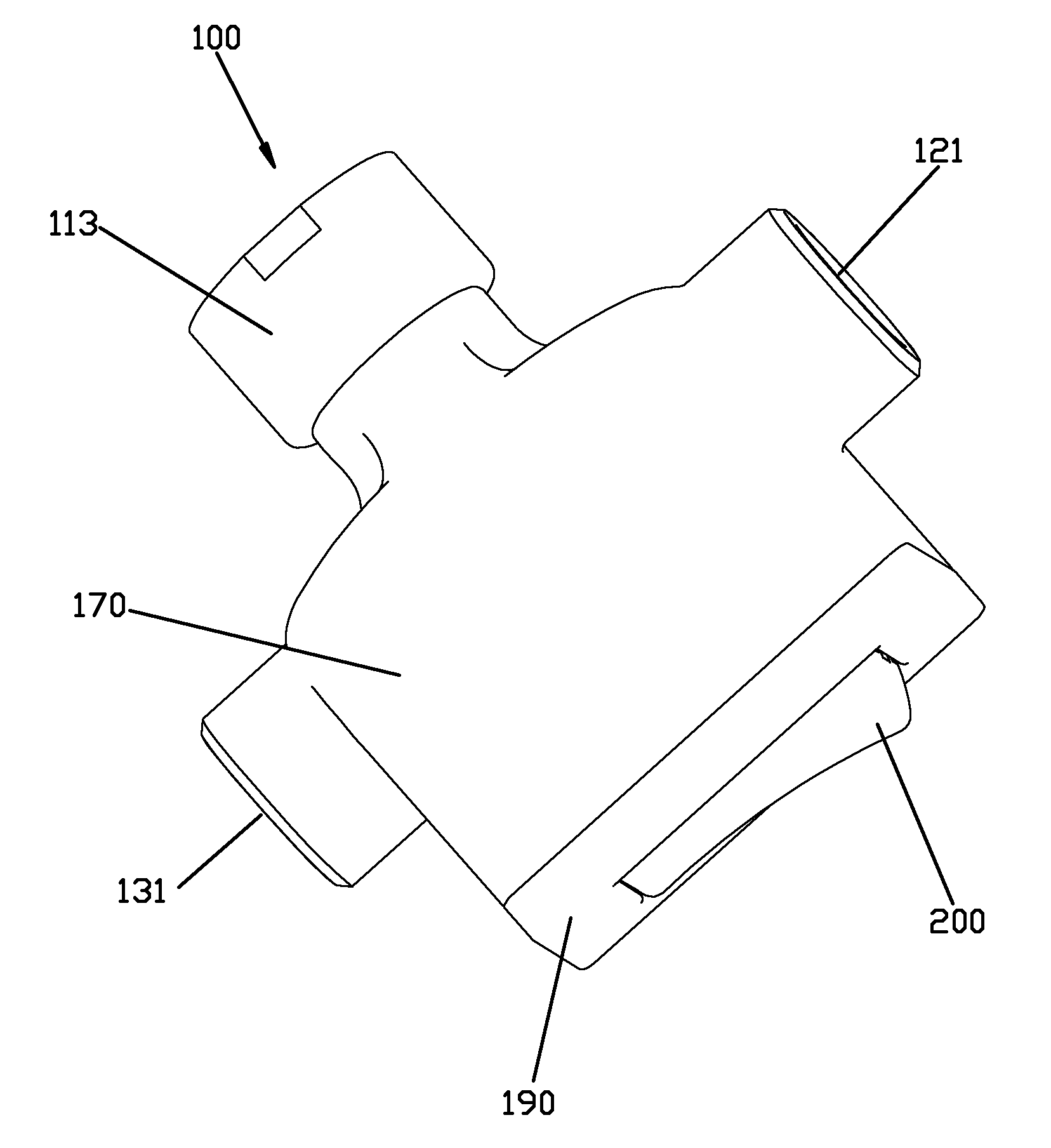

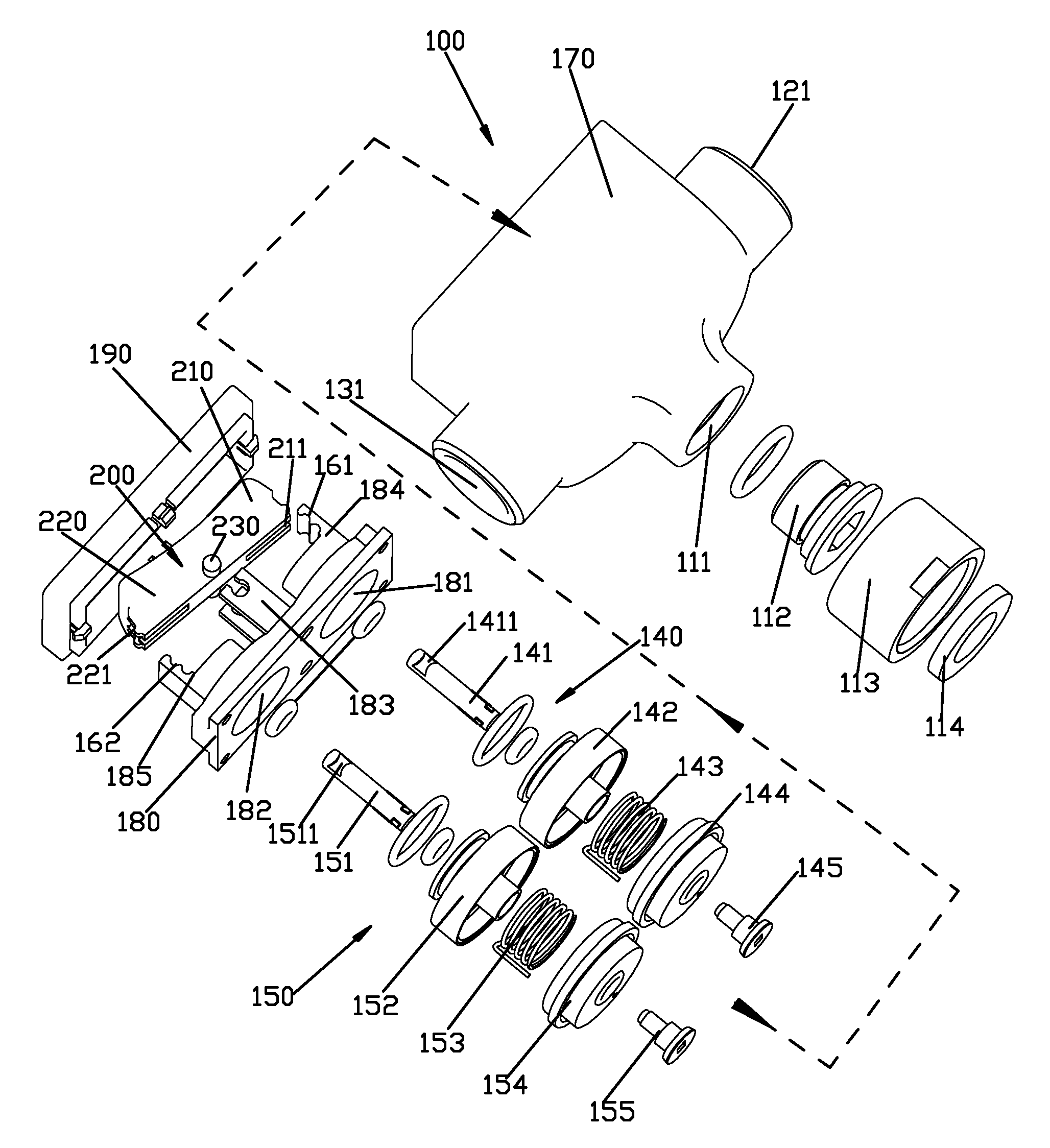

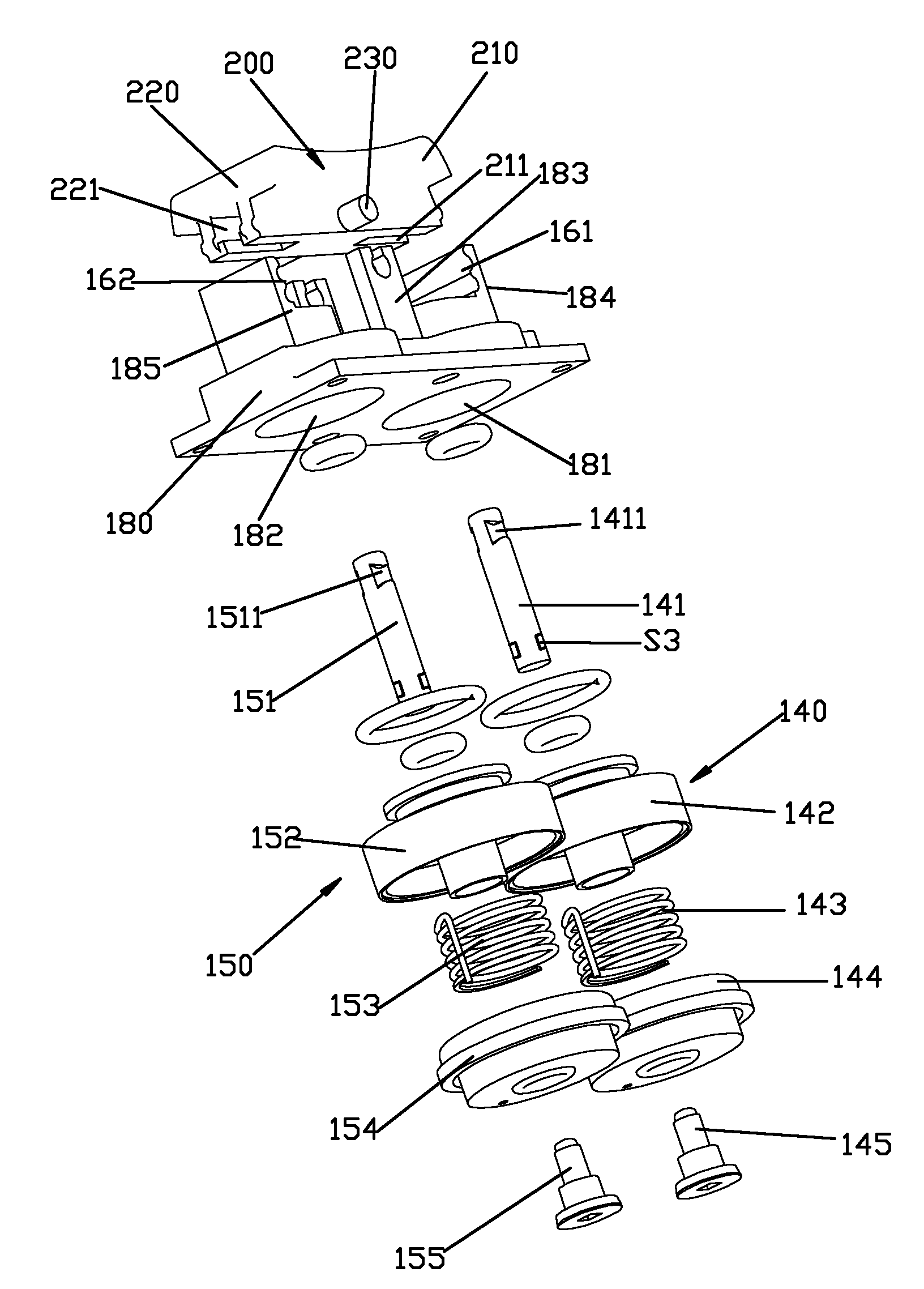

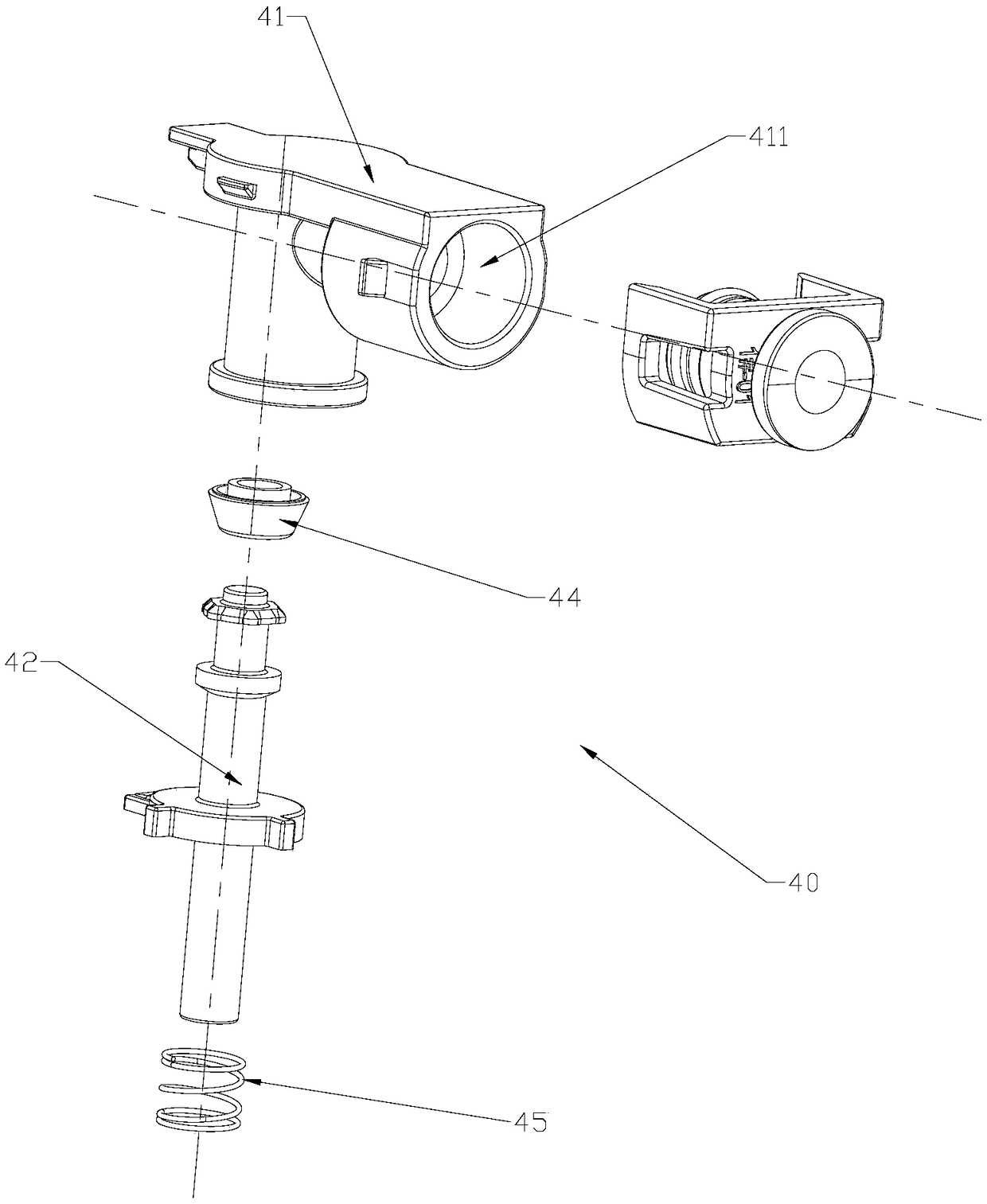

Button switching three-way valve

The invention discloses a button switching three-way valve which comprises a fixed unit (100), wherein the fixed unit (100) is provided with a water inlet path (110) and two water outlet paths (120) and (130); pilot valves (140) and (150) are connected between the water outlet paths (120,130) and the water inlet path (110); the pilot valves (140) and (150) are provided with valve shafts (141) and (151); the on-off control between the water outlet paths (120) and (130) and the water inlet path (110) is realized by controlling the valve shafts (141) and (151) to slide; the fixed unit (100) is provided with two opposite control surfaces (161) and (162), and each of the two control surfaces (161) and (162) is provided with a clamping groove; the button switching three-way valve is also provided with a button (200) which is provided with a middle part and two connecting parts (210 and 220) which are positioned at both sides of the middle part; the middle part is pivoted at the fixed unit (100); the two connecting parts (210) and (220) are respectively connected with the two valve shafts (141) and (151) to control the two valve shafts (141) and (151) to slide; and the outer sides of the two connecting parts (210) and (220) are provided with clamping teeth which are adapted to clamping grooves. The invention has the advantage of convenience for switching.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

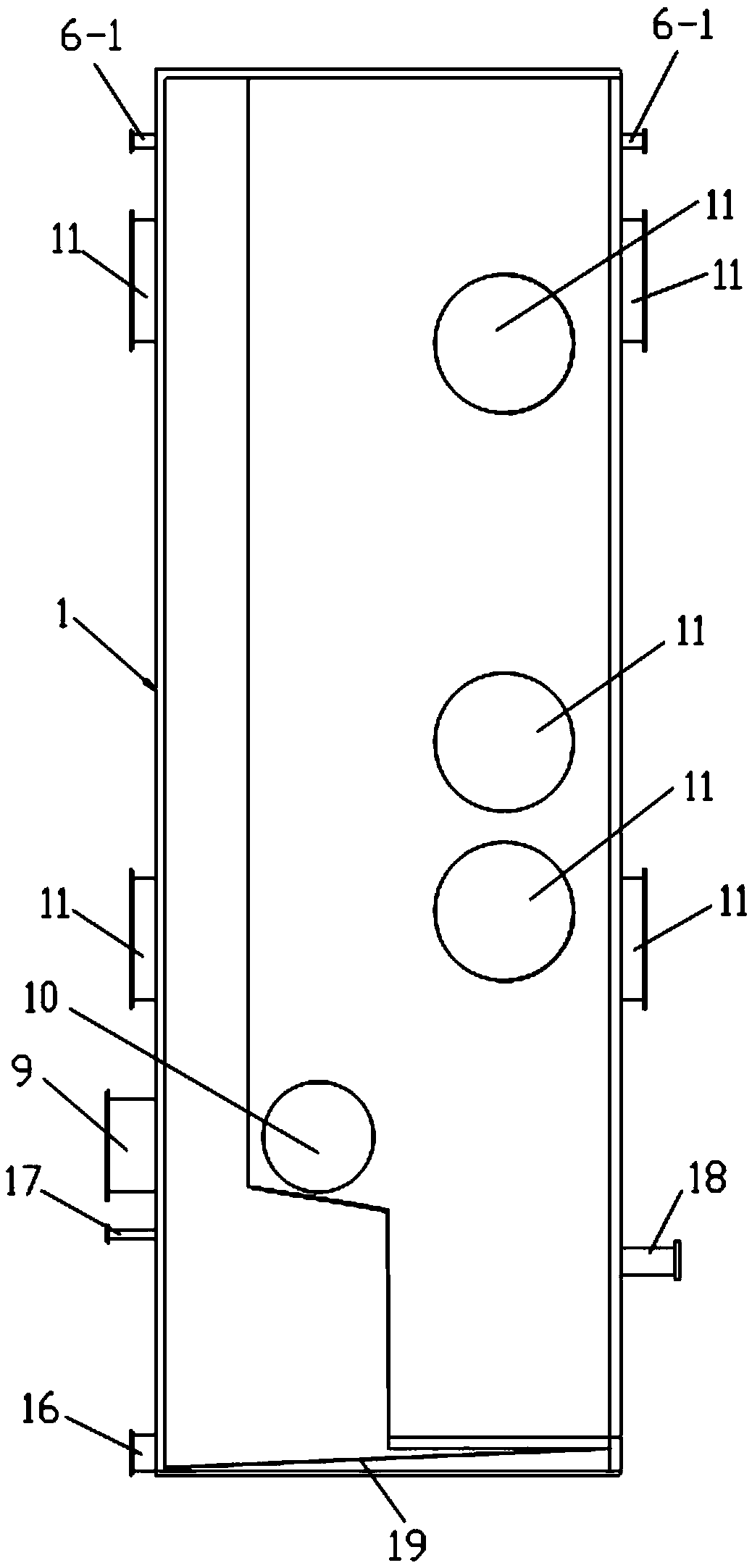

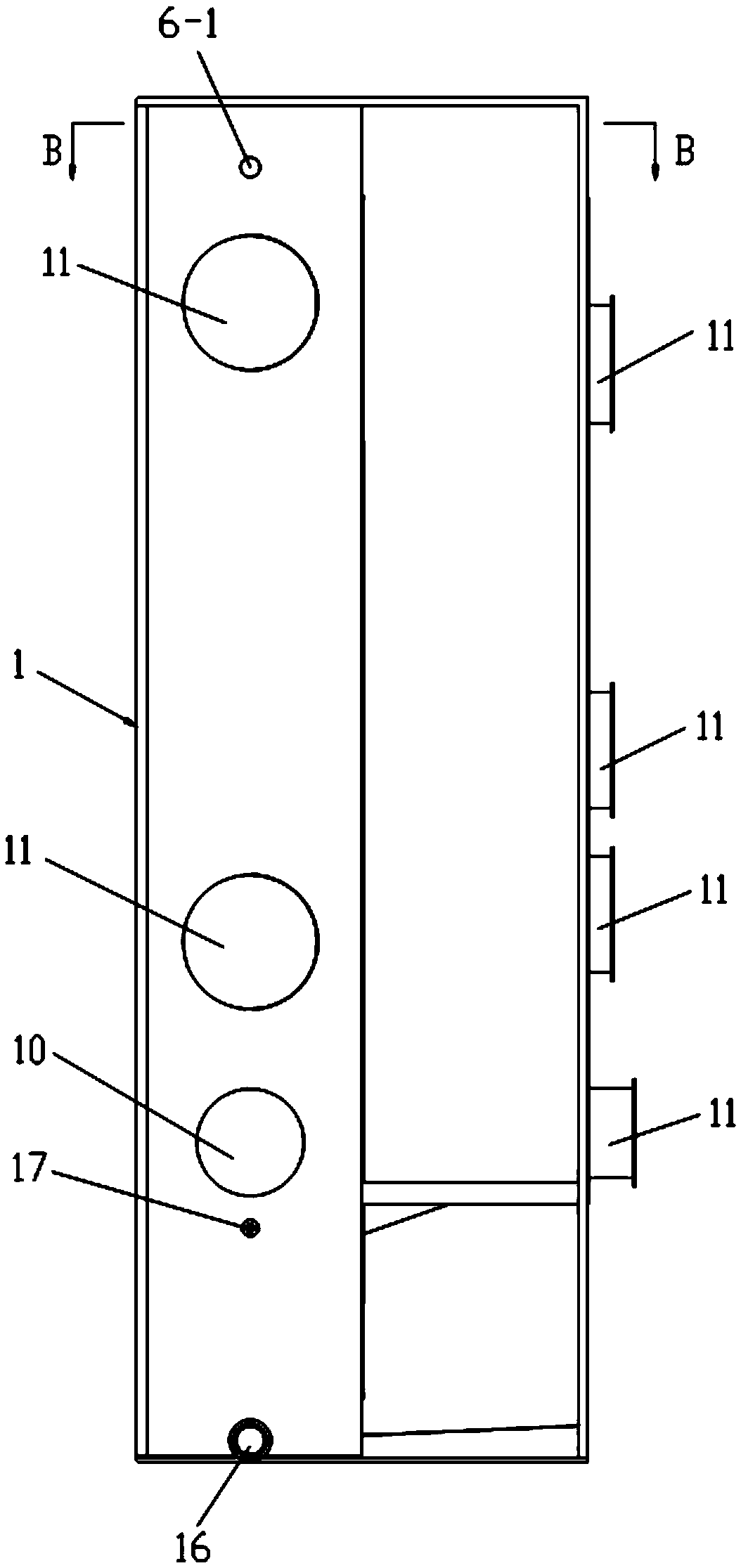

Container-type low-concentration organic waste gas purification treatment device

ActiveCN105498524ASmall footprintSmall pipe connectionGas treatmentDispersed particle separationEngineeringEnvironmental engineering

The invention discloses a container-type low-concentration organic waste gas purification treatment device which comprises a framework with the boundary dimension equal to that of a standard container. The framework is vertically arranged and internally provided with a first biological membrane drip filter area, a second biological membrane drip filter area, a demisting and adsorbing area, a spray liquid circulation water tank and the like. A gas inlet is formed in the lower portion of the first biological membrane drip filter area, and the top of the first biological membrane drip filter area is communicated with the lower portion of the second biological membrane drip filter area through a first gas delivery channel. A demisting unit and an adsorbing unit are sequentially arranged in the demisting and adsorbing area from bottom to top. The top of the second biological membrane drip filter area is communicated with the lower portion of the demisting and adsorbing area through a second gas delivery channel, the top of the demisting and adsorbing area is communicated with a third gas delivery channel, and an exhaust port is formed in the third gas delivery channel. The waste gas purification treatment device is arranged in the container framework and has the advantages of being compact in structure, small in occupied area, not prone to leakage, low in energy consumption and manufacturing cost, convenient to transport, install and debug and the like.

Owner:广东致顺化工环保设备有限公司

Deepwater wave power generation device

ActiveCN103321823ASimple structureReasonable designMachines/enginesEngine componentsImpellerHydraulic motor

The invention discloses a deepwater wave power generation device. Seven groups of impeller supports are arranged at the upper end of a buoy rack, an impeller is arranged in each impeller support, large toothed discs are disposed on two sides of each impeller, a hydraulic pump is arranged on the upper side of each large toothed disc, a small gear is arranged on each hydraulic pump and meshed with each large toothed disc, a hydraulic motor is disposed at the back end of a pressure storage tank, a generator is arranged at the back end of the hydraulic motor, and an oil collection tank is disposed at the front right end of the hydraulic motor.

Owner:江苏天能海洋重工有限公司

Automatic line production equipment

ActiveCN112277270AClever layoutAutomatically realize the demoulding operationDomestic articlesSortingRobot handProcess engineering

The invention discloses automatic line production equipment. The automatic line production equipment comprises a clamp, a manipulator, a case, a detection mechanism and a separation mechanism; t he clamp is arranged on the manipulator, and the detection mechanism and the separation mechanism are both arranged on the case; the manipulator is used for controlling the clamp to clamp injection moldingwaste with automobile clasp nails from an injection mold, controlling the clamp to drive the automobile clasp nails to face the detection mechanism and controlling the clamp to place the injection molding waste on the separation mechanism from top to bottom; the detection mechanism is used for detecting whether the automobile clasp nails connected with the injection molding waste are qualified ornot; and the separation mechanism cuts off the automobile clasp nails from the injection molding waste from top to bottom. The automatic line production equipment provided by the invention is ingenious in layout, the automobile clasp nails with the injection molding waste can be automatically taken out of an injection mold, the automobile clasp nails can be automatically detected and screened, the automobile clasp nails can be automatically separated from the injection molding waste, and the equipment is easy and convenient to control, high in efficiency, high in automation degree and small in requirement for labor force.

Owner:宁波天安汽车零部件有限公司

Button flow regulating device

InactiveCN102095017ASmall radial spacingLow pressureOperating means/releasing devices for valvesWater channelWater flow

The invention discloses a button flow regulating device which comprises a fixed unit with a water channel, and a button, wherein the fixed unit is provided with a move shaft, a pushing rod and a spring internally; the move shaft and the pushing rod can move relatively to the fixed unit; the moving directions of the move shaft and the pushing rod are in parallel with the water flow general direction of the water channel; the flow area of the water channel is changed through the relative movement between the move shaft and the fixed unit, and the flow regulating function is realized, wherein the fixed unit, the move shaft, the pushing rod and the spring are matched to form an automatic ball-point pen move mechanism; the button is slidingly connected with the fixed unit; the sliding direction of the button is vertical to the sliding direction of the move shaft; and the button and the tail end of the pushing rod constitute a linkage structure. The button flow regulating device has the advantages that the sliding direction of the move shaft and the pushing rod and the flow water general direction of the water channel are in parallel, the layout is smart, the radial interval of the fixed unit is small, the occupation area is small, the pressing strength for the users can be reduced, and the button flow regulating device is convenient to switch.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD +1

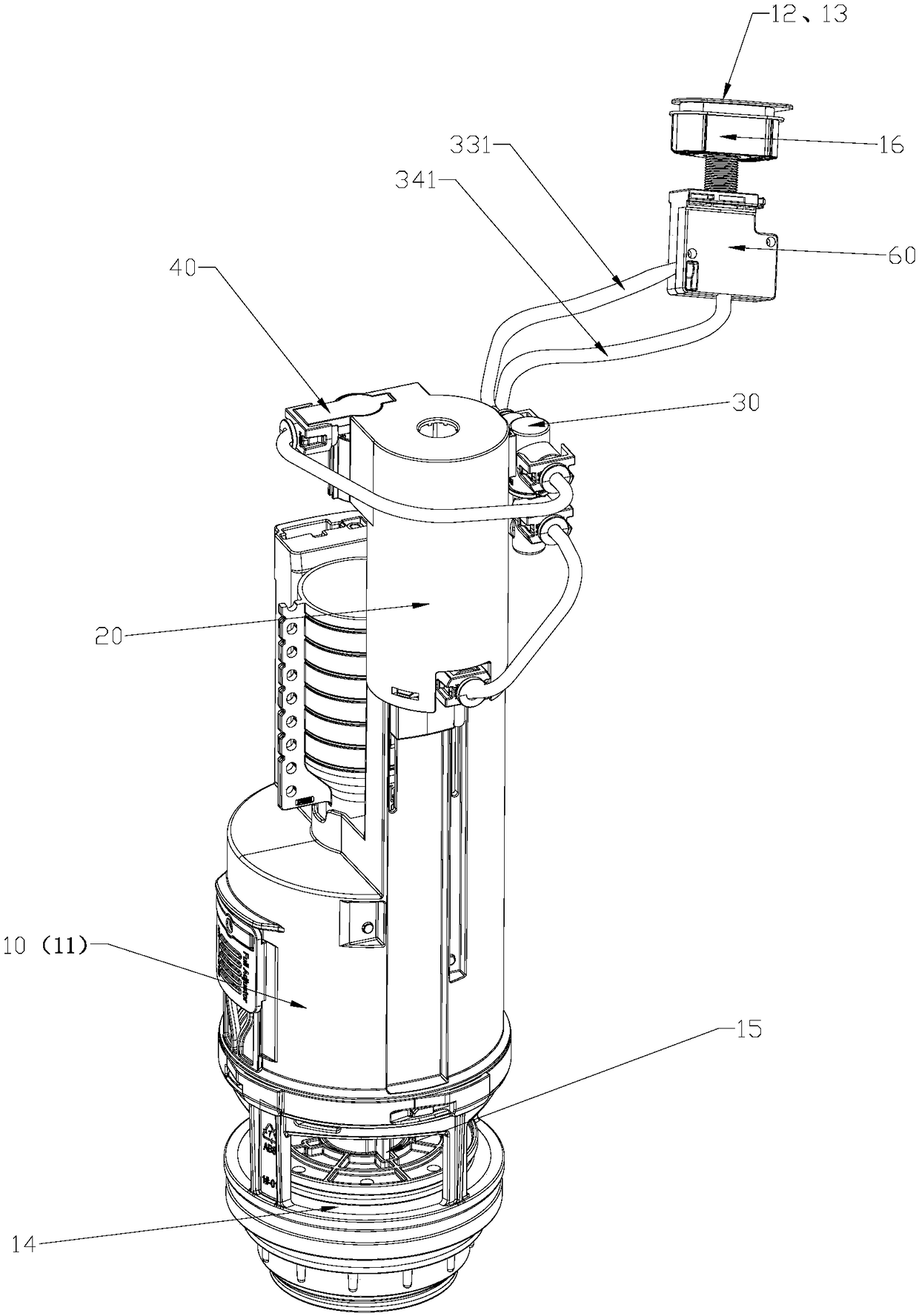

Pneumatic drain valve and air channel control device thereof

The invention discloses a pneumatic drain valve and an air channel control device thereof. A switching body of a switching valve of the pneumatic drain valve is provided with a first air inlet, a second air inlet, a first air outlet and a second air outlet; a switching core of the switching valve is movably arranged in the switching body; one of a half-drain switch and a full-drain switch controlsan air supply source to supply air to the first air inlet so that the switching core moves a first position, communicated with the first air outlet, of the first air inlet, the air flowing out from the first air outlet drives and controls the drain valve to correspondingly perform half drain or full drain; the other one of the half-drain switch and the full-drain switch controls the air supply source to supply air to the second air inlet so that the switching core moves a second position, communicated with the first air outlet and the second air outlet simultaneously, of the second air inlet,the air flowing out from the first air outlet and second air outlet jointly drives and controls the drain valve to correspondingly perform full drain or half drain; the structural layout is more flexible, and the operation is more convenient; the air channel switching can be achieved, and the function is more reliable.

Owner:XIAMEN R&T PLUMBING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com