Pneumatic drain valve and air channel control device thereof

A technology of air circuit control and drain valve, which is applied in water supply installations, flushing equipment with water tanks, buildings, etc., can solve the problems of restricted right above, inapplicability, confusion, etc., to achieve air circuit switching, novel structure and function reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0050] The first embodiment (the limiter 50 is used to limit the movement stroke of the valve core 15 of the drain valve, and the gas flowing out of the second air outlet 36 drives the limiter 50 to move from the limit position to the relief position):

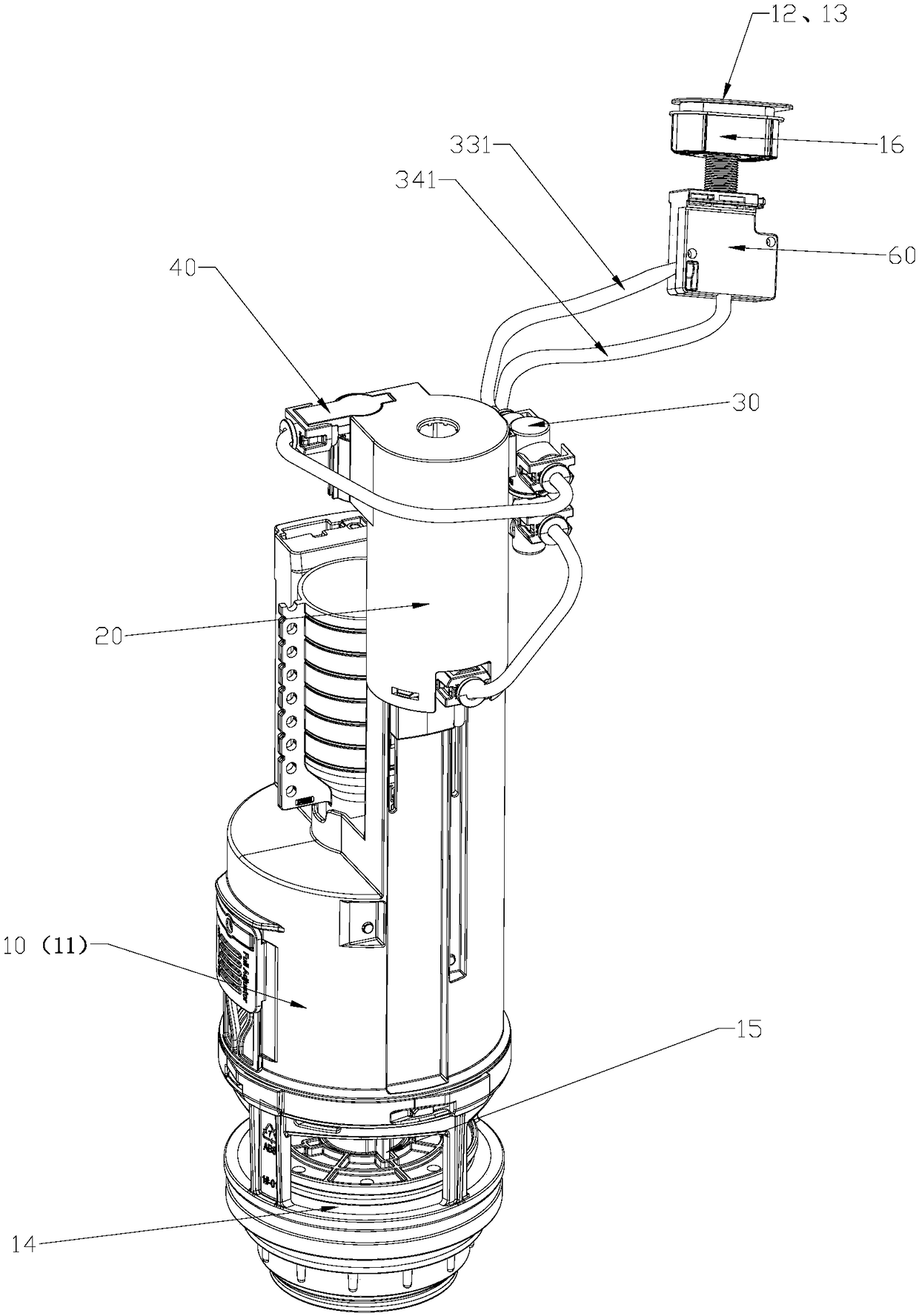

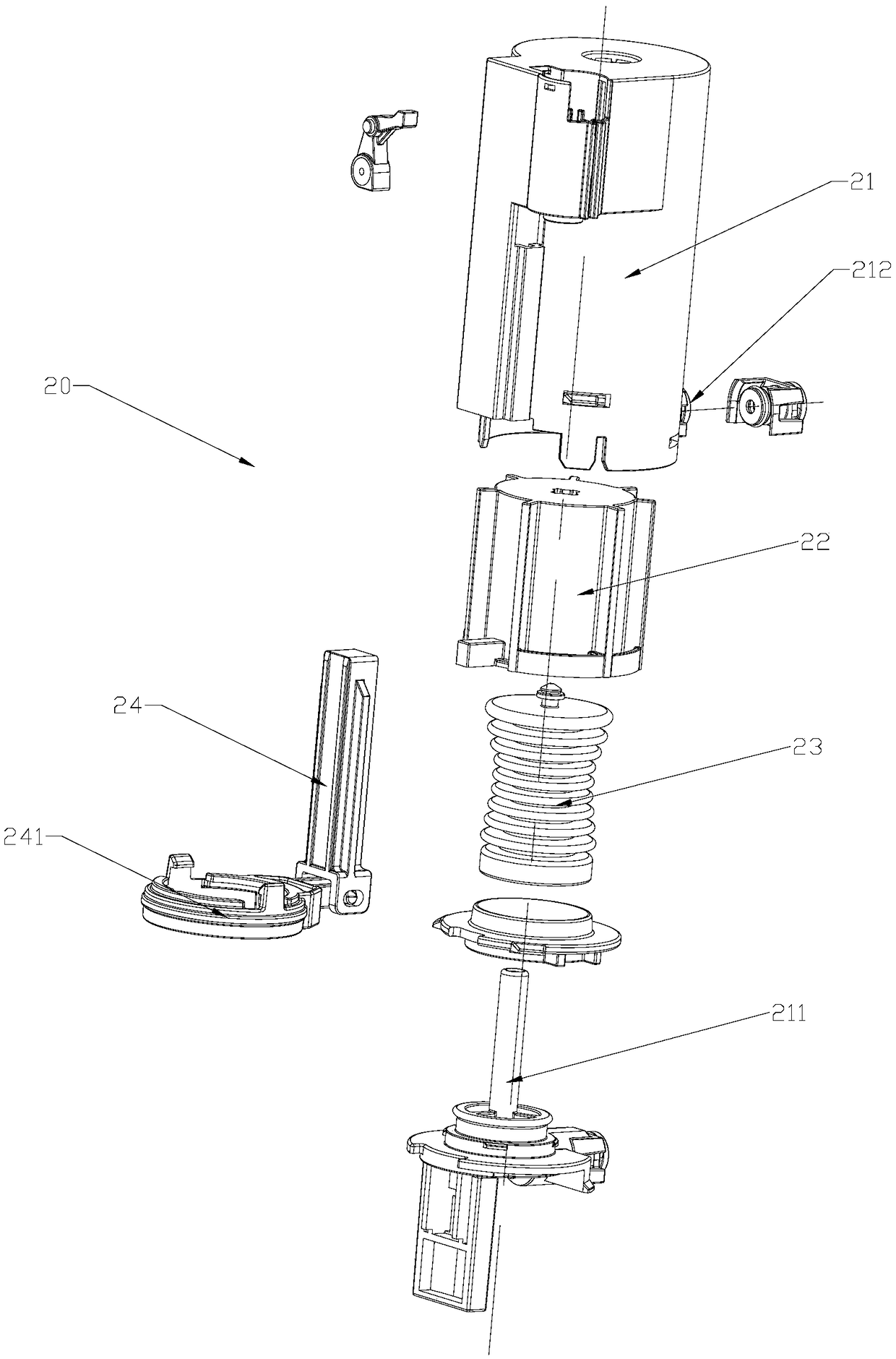

[0051] Such as Figure 1 to Figure 13 As shown, the air circuit control device of the pneumatic drain valve according to the first embodiment of the present invention includes a full drain switch 12 for controlling the drain valve 10 to start full drain, and a half drain switch 13 for controlling the drain valve 10 to start half drain , a switching valve 30 , an air supply source 60 , and a limiting member 50 .

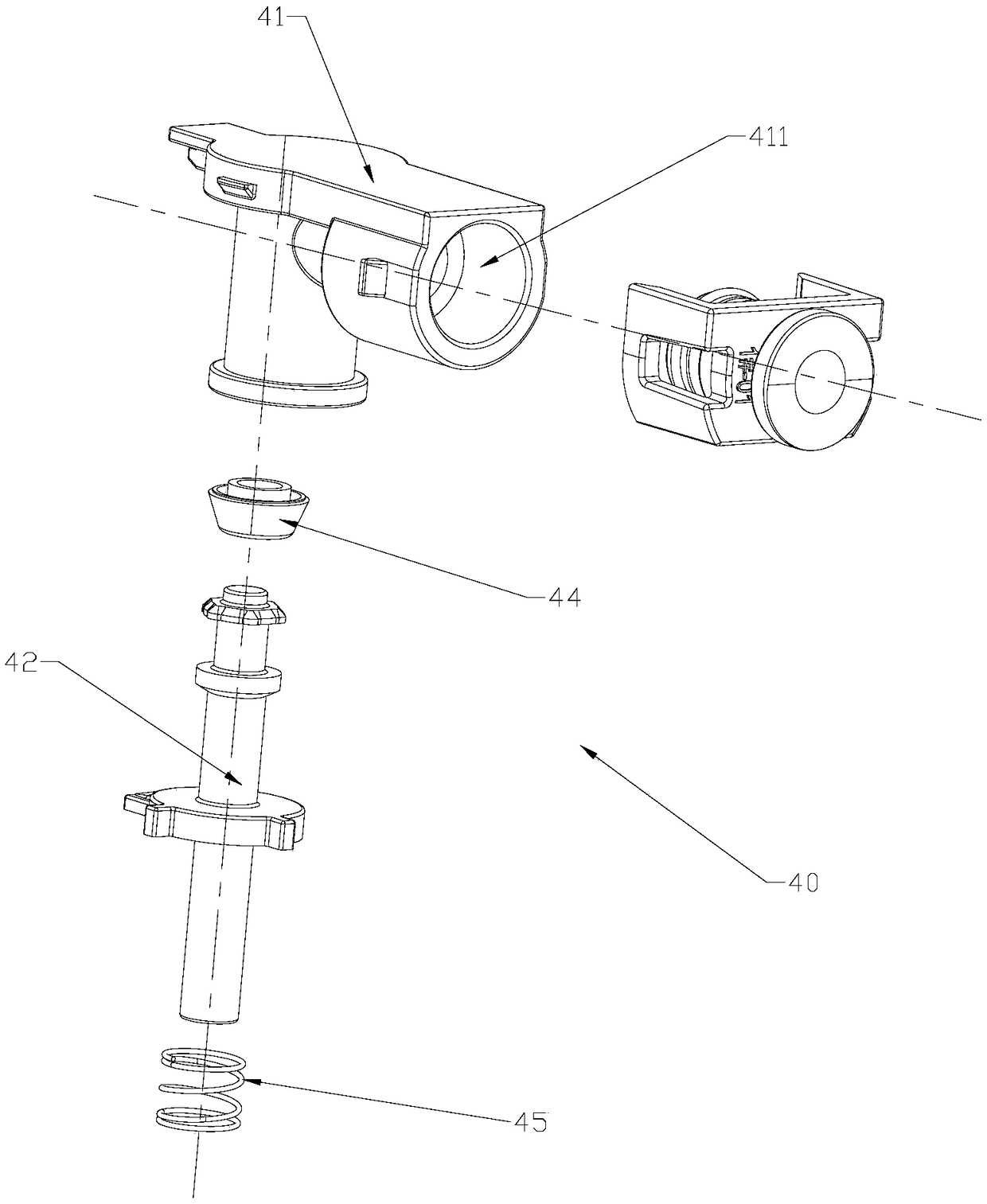

[0052] Such as Figure 4 to Figure 6 As shown, the switching valve 30 includes a switching body 31 and a switching core 32, and the switching body 31 has a first air inlet 33, a second air inlet 34, a first air outlet 35, and a second air outlet 36; The switching core 32 is movably disposed in the switching body 31 ...

no. 2 example

[0066] The second embodiment (the stopper 50 is used to limit the full row of floating buckets of the drain valve, and the gas flowing out of the second air outlet 36 drives the stopper 50 to move from the limit position to the relief position)

[0067] The main difference between the air circuit control device of the pneumatic drain valve of the second embodiment of the present invention and the first embodiment is that the first embodiment controls the drainage by restricting or giving way to the movement of the valve core 15 by the limiting member 50 The valve performs half drainage or full drainage, but in this embodiment, the floating bucket of the full row of the drainage valve is restricted or given way by the limiter 50 to control the drainage valve to perform full drainage or half drainage, that is, this embodiment The principle of the drain valve realizing full drain and half drain is different from that of the first embodiment.

[0068] Specifically, in this embodim...

no. 3 example

[0070] The third embodiment (the stopper 50a is used to limit the movement stroke of the spool 15 of the drain valve, and the gas flowing out of the second air outlet 36 drives the stopper 50a to move from the abdication position to the limit position):

[0071] Such as Figure 14 and Figure 15 As shown, the air circuit control device of the pneumatic drain valve of the third embodiment of the present invention is mainly different from the first embodiment in that: in this embodiment, the limiting member 50a adopts a push rod that slides back and forth, and the first The gas flowing out from the second air outlet 36 is used to drive the limiting member 50a, so that the limiting member 50a moves from the evacuation position to the limiting position. Such as Figure 14 As shown, when the switching core 32 is in the first position, the limiting member 50a is located in the relief position, and the limiting member 50a makes way for the valve core 15 so that the drain valve 10 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com