Energy-saving ultra low emission dual-mode homogeneous compression-ignition engine based on fully variable valve mechanism

A valve train, homogeneous compression ignition technology, used in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as low fuel utilization, narrow operating conditions, and reduced mechanical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

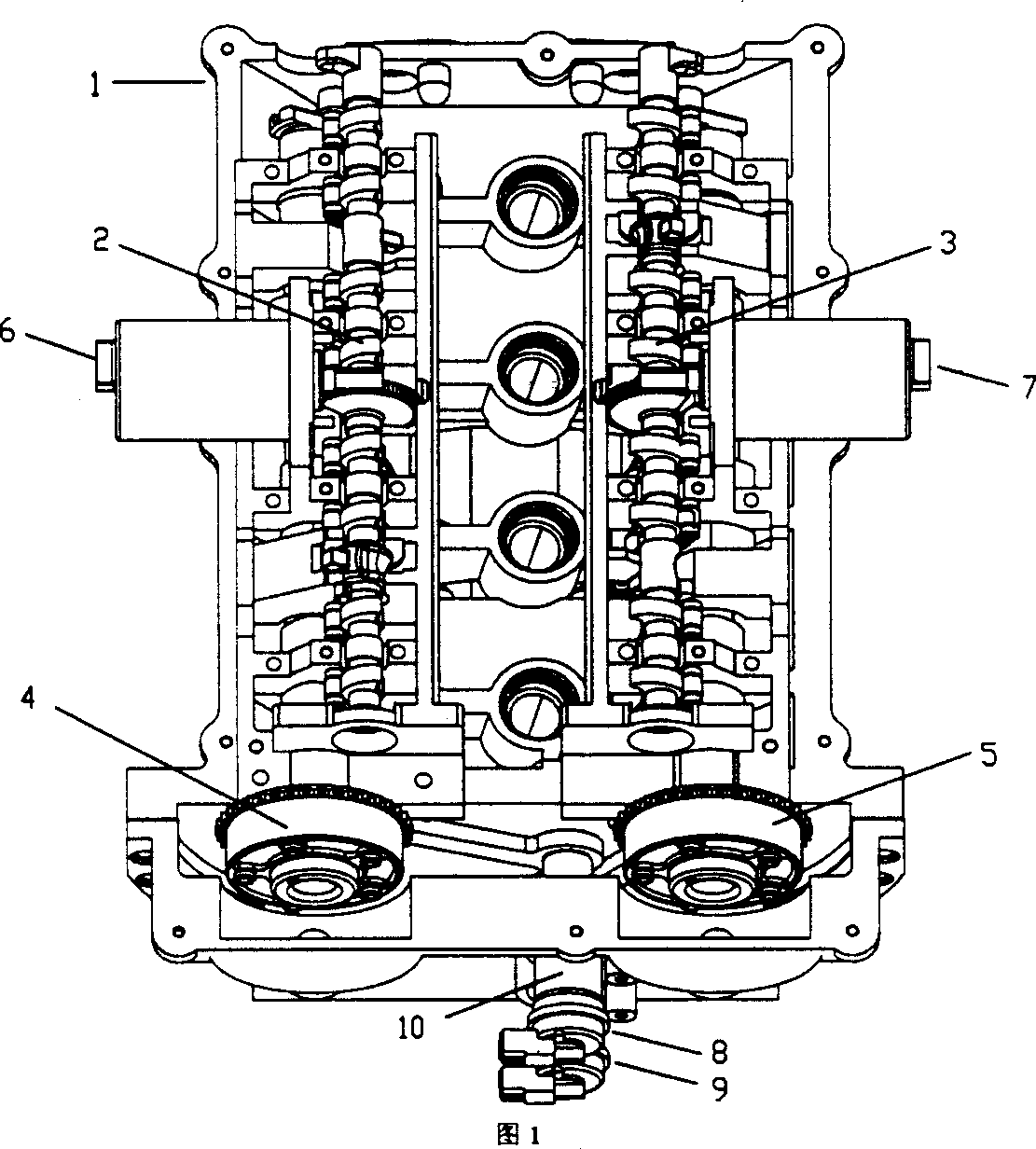

[0020] engine structure

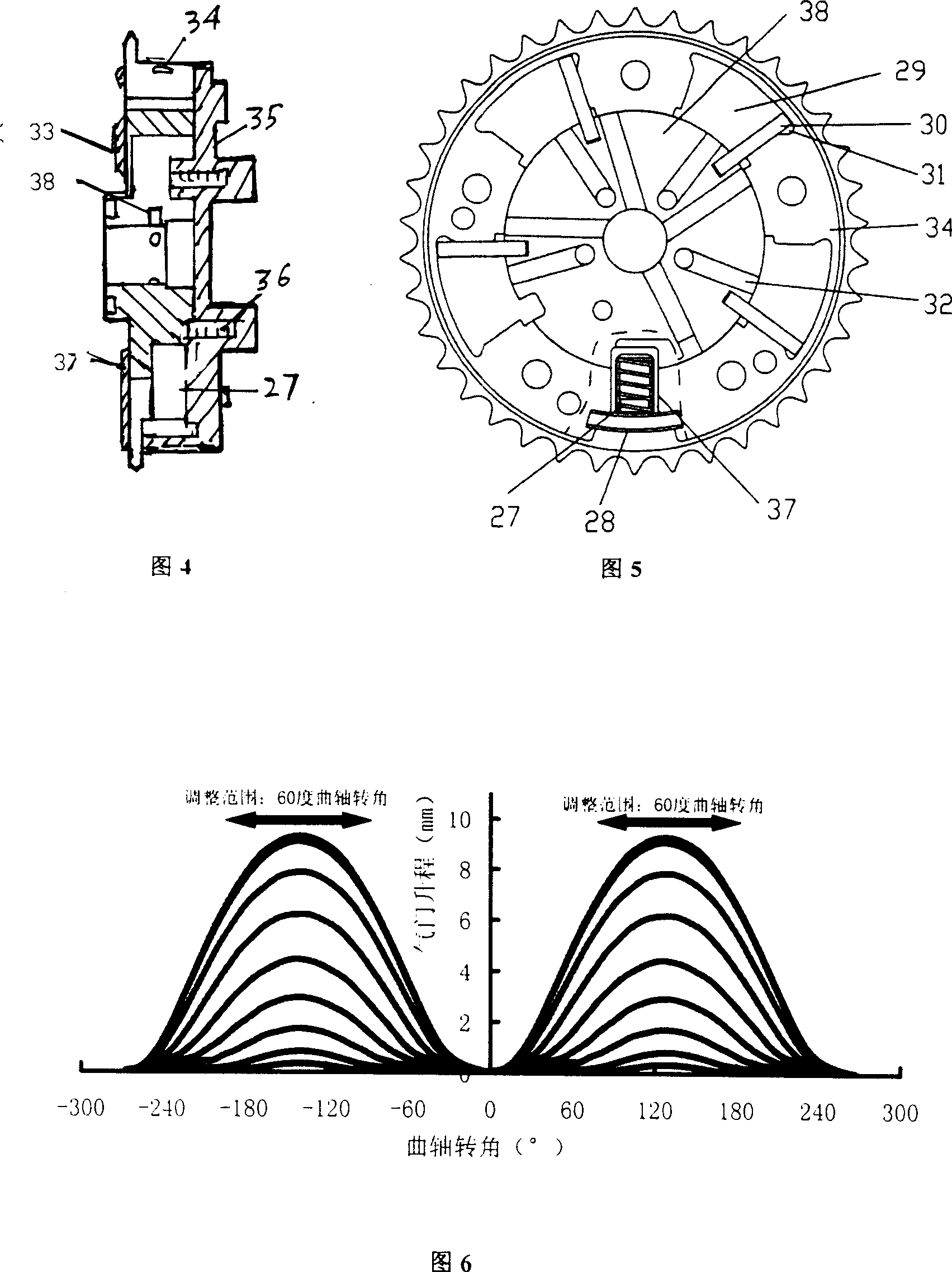

[0021] On the basis of the common port injection spark ignition gasoline engine, a fully variable valve cylinder head 1 is used, on which are arranged two sets of continuously variable valve lift mechanisms 2 and 3, and two sets of continuously variable valve timing systems 4 and 5, as shown in Figure 1. The valve mechanism electronic control unit receives commands such as intake and exhaust valve lift and phase from the engine electronic management unit, and adopts a closed-loop control strategy to control the servo motors 6 and 7 and the high-speed solenoid valves 8 and 9 respectively to achieve a given intake valve. Lift, exhaust valve lift, intake valve phasing, and exhaust valve phasing.

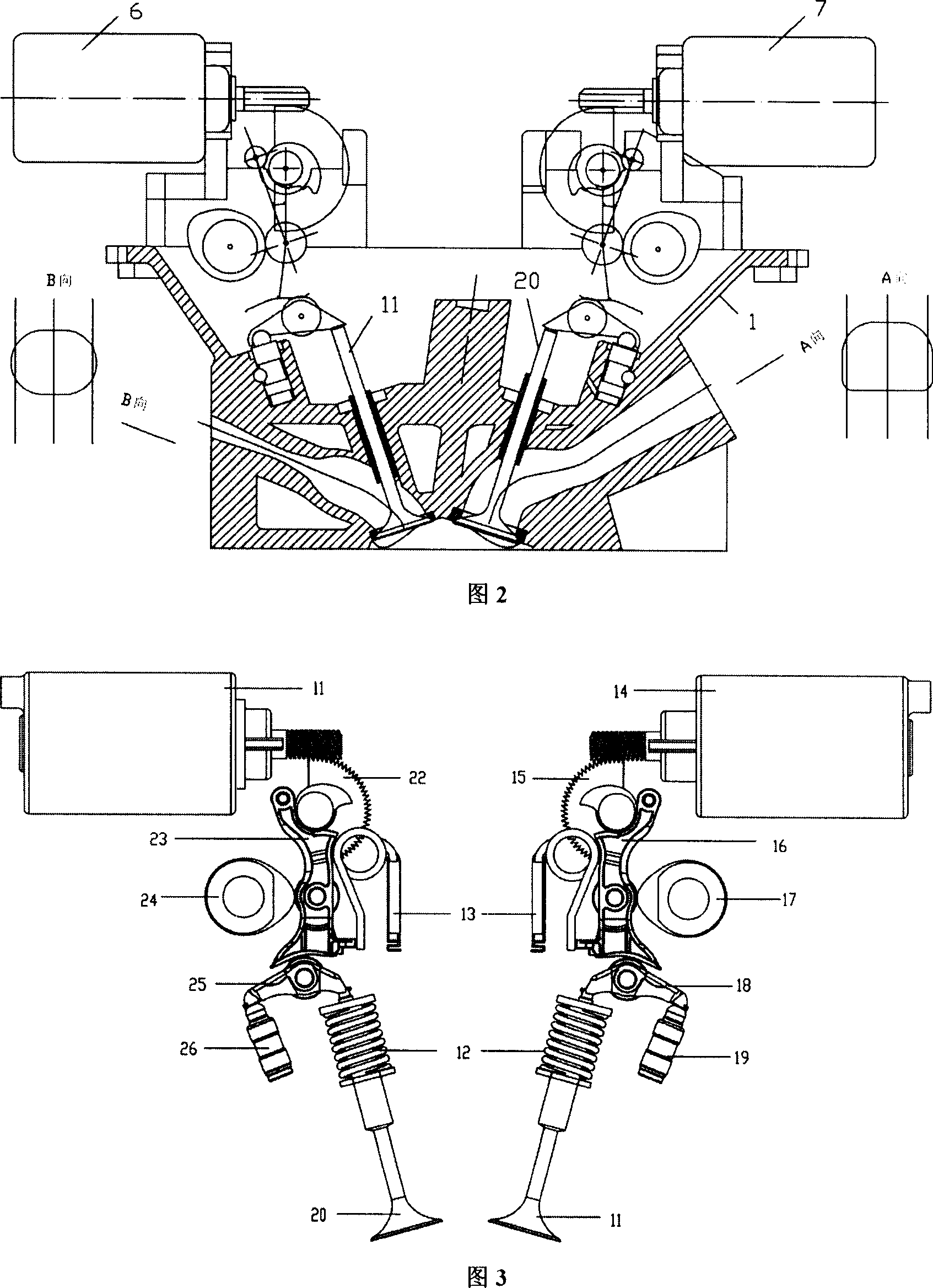

[0022] The variable valve lift mechanism is mainly composed of a servo motor, an eccentric shaft and an intermediate swing rod, and its structure is shown in Figure 3. The movement of the intermediate swing rod is jointly controlled by the camshaft and the ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com