Patents

Literature

50results about How to "Realize two-way sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

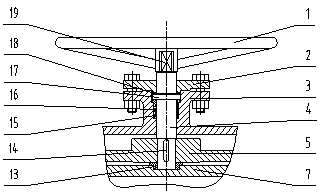

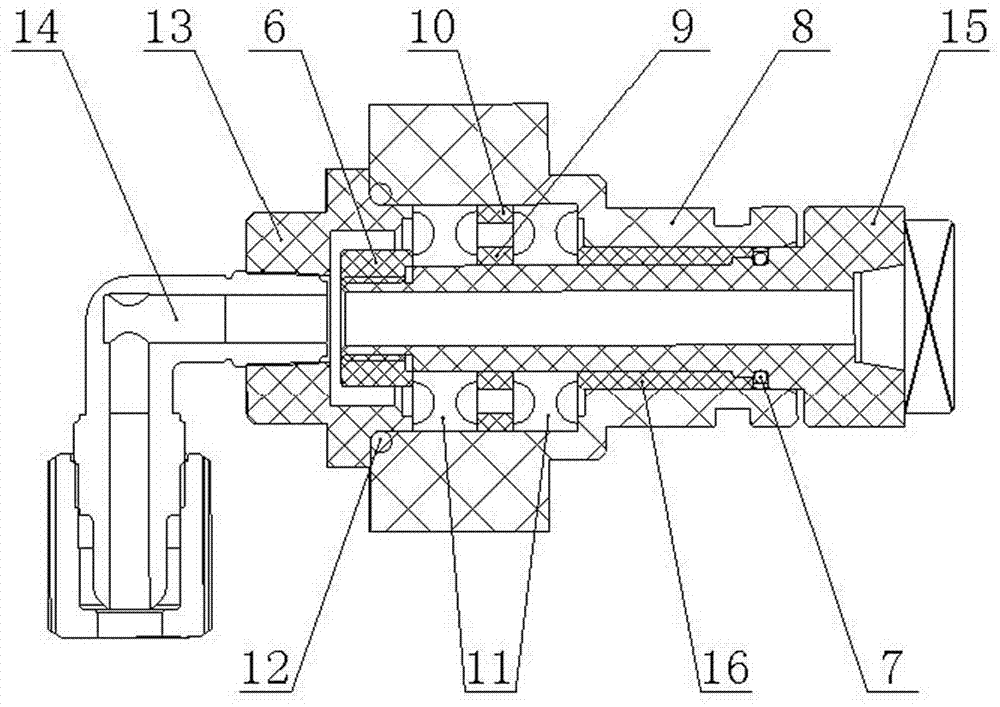

Electronic expansion valve

ActiveCN103867732AGood sealing performanceGood sealing effectSpindle sealingsOperating means/releasing devices for valvesValve openingEngineering

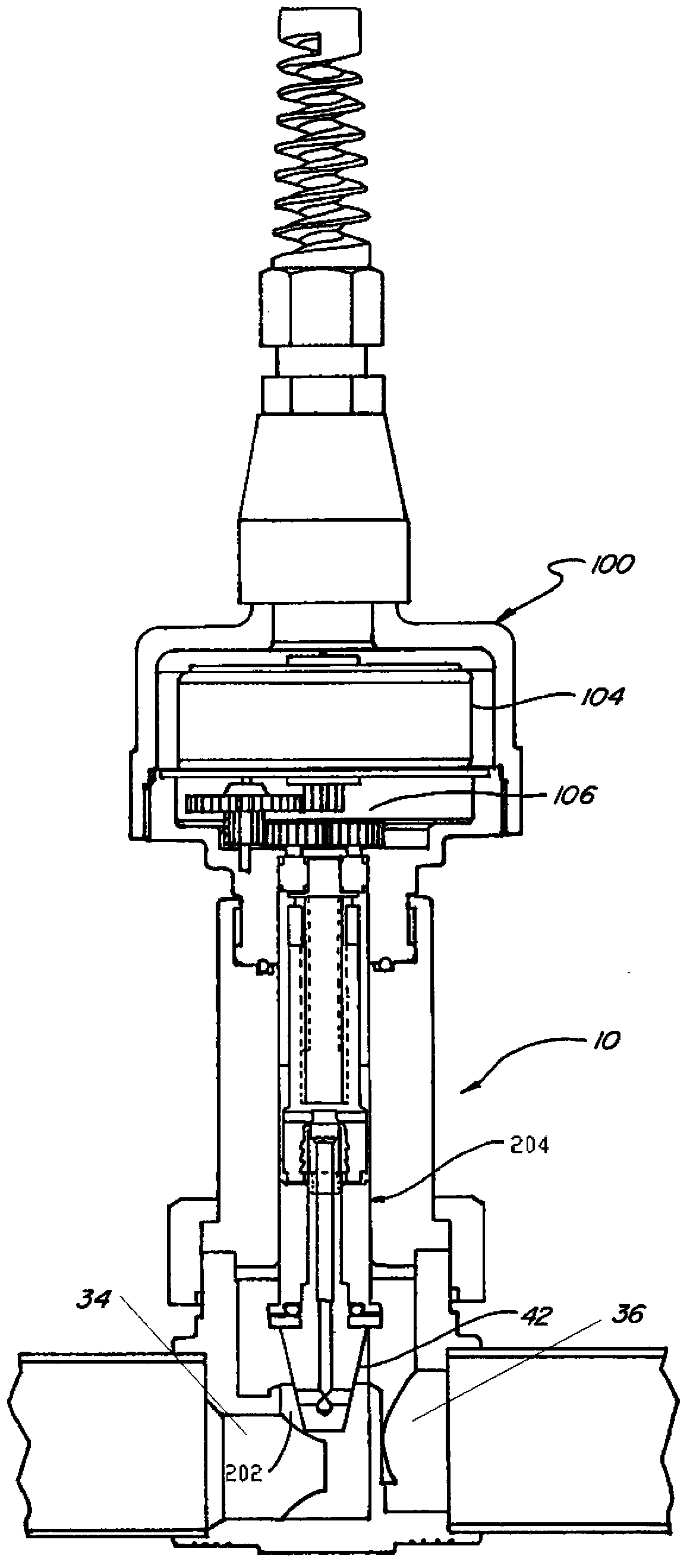

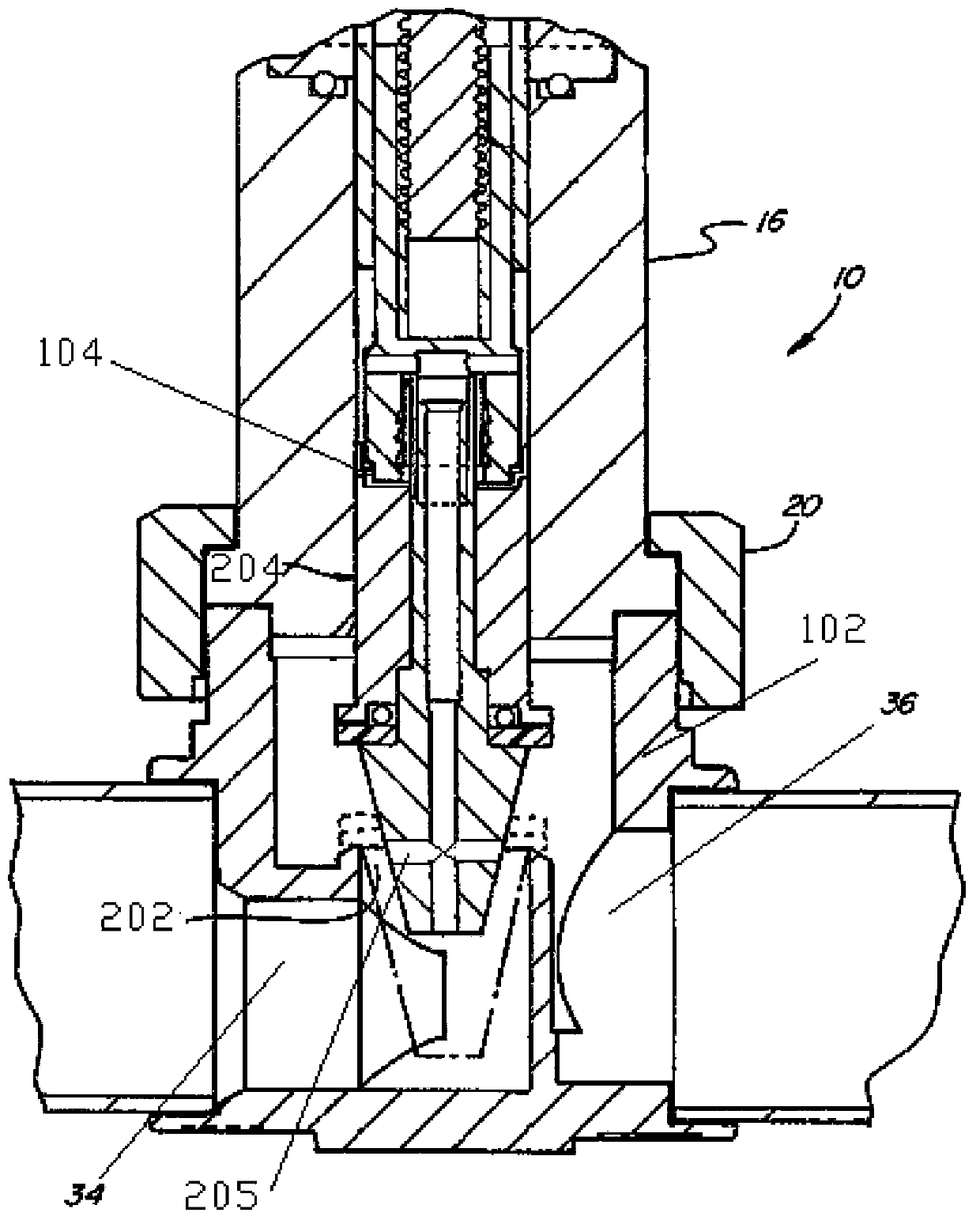

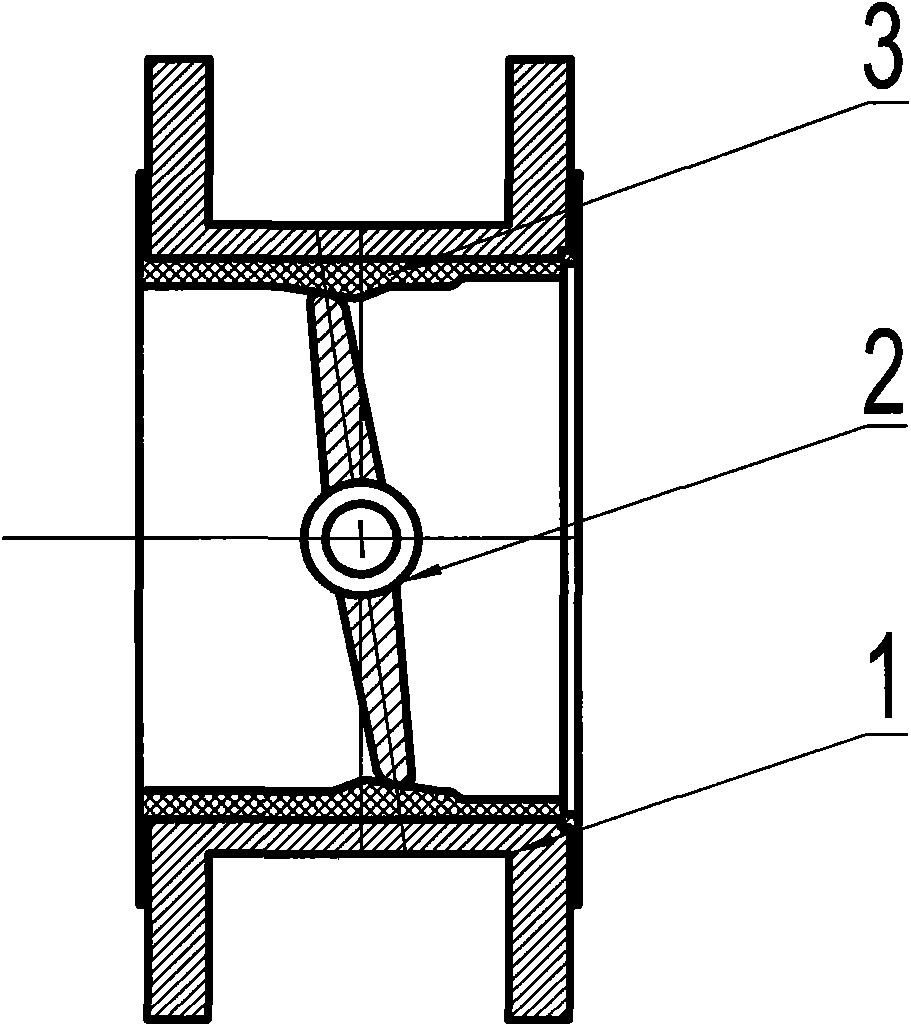

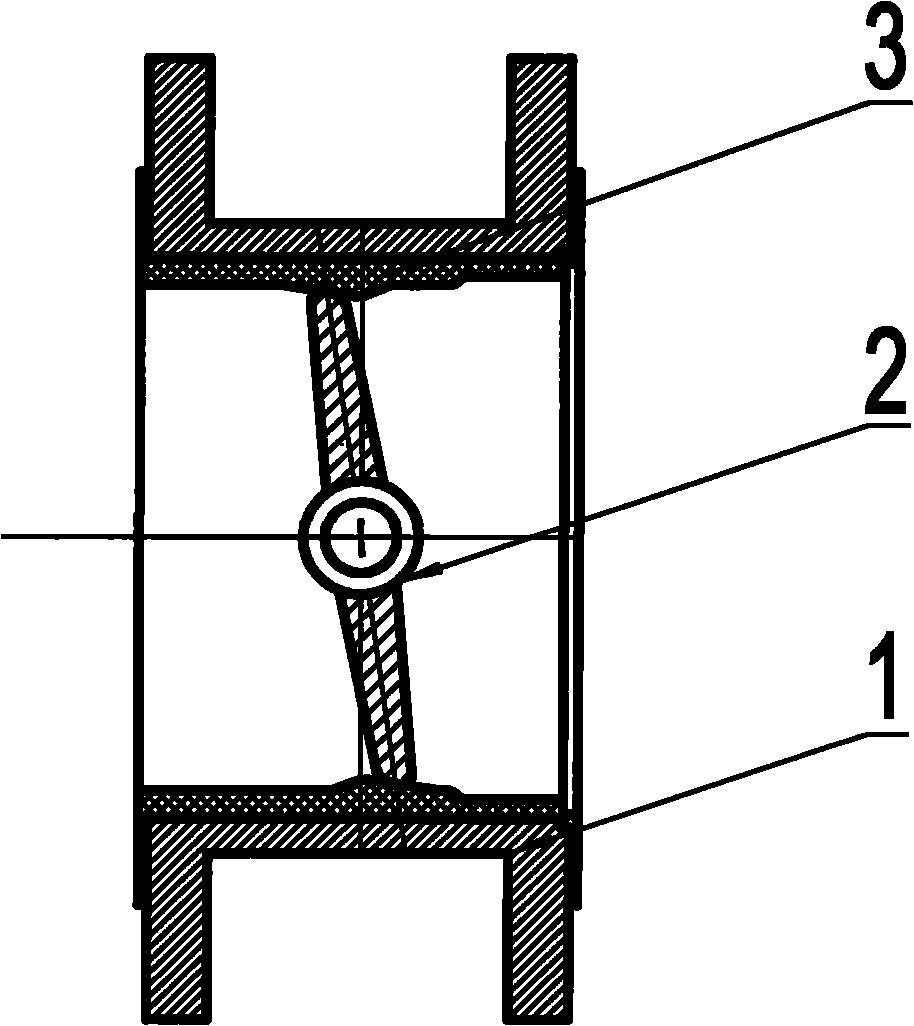

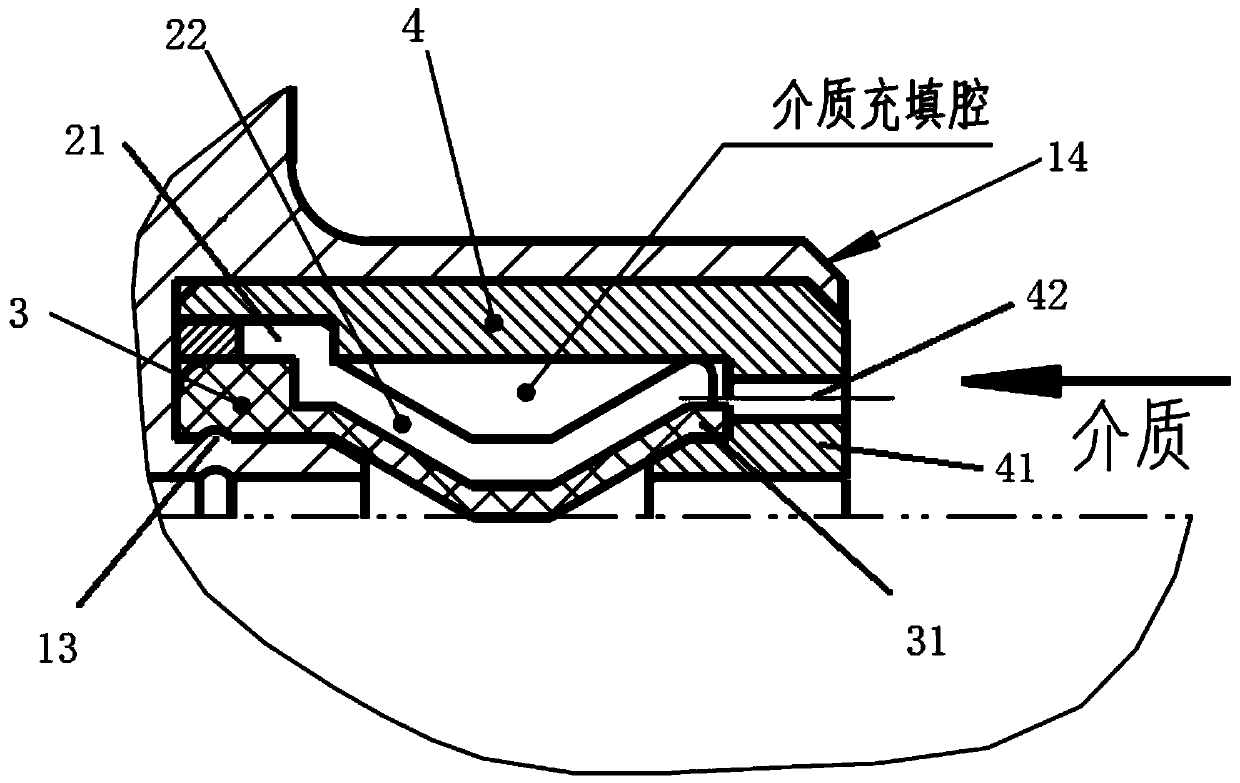

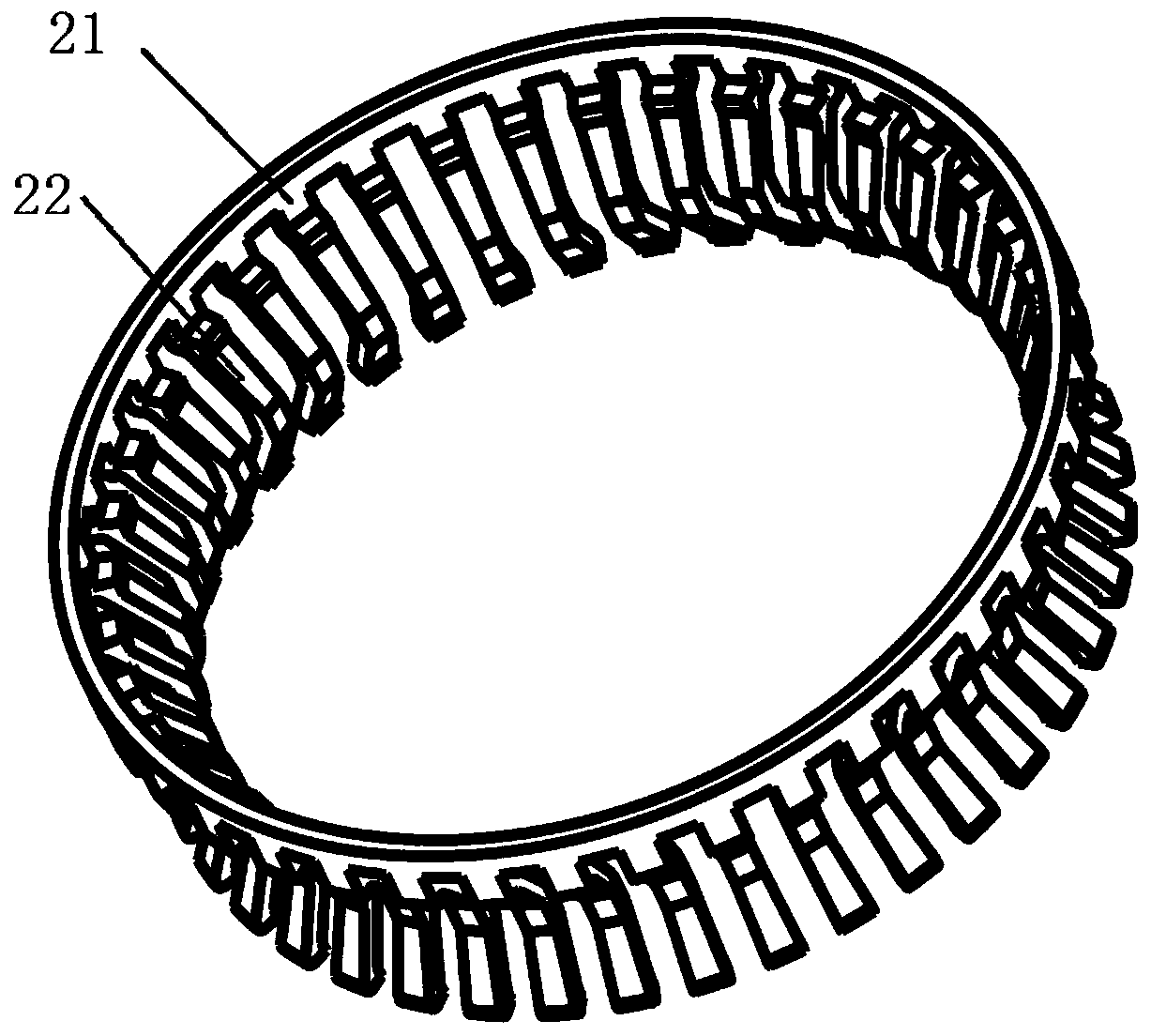

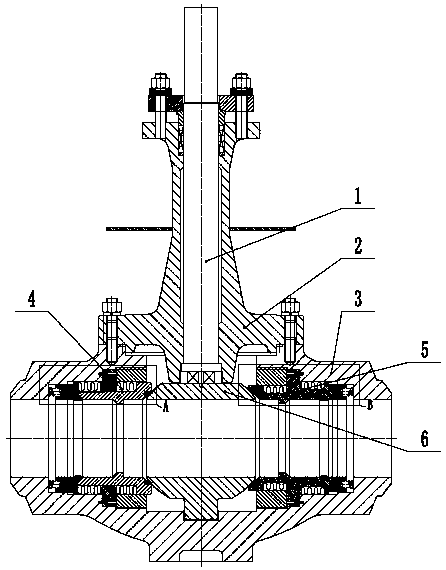

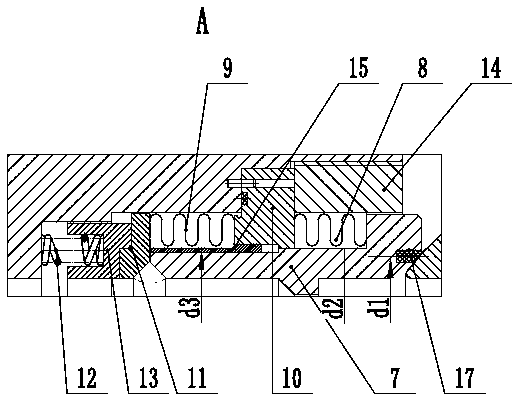

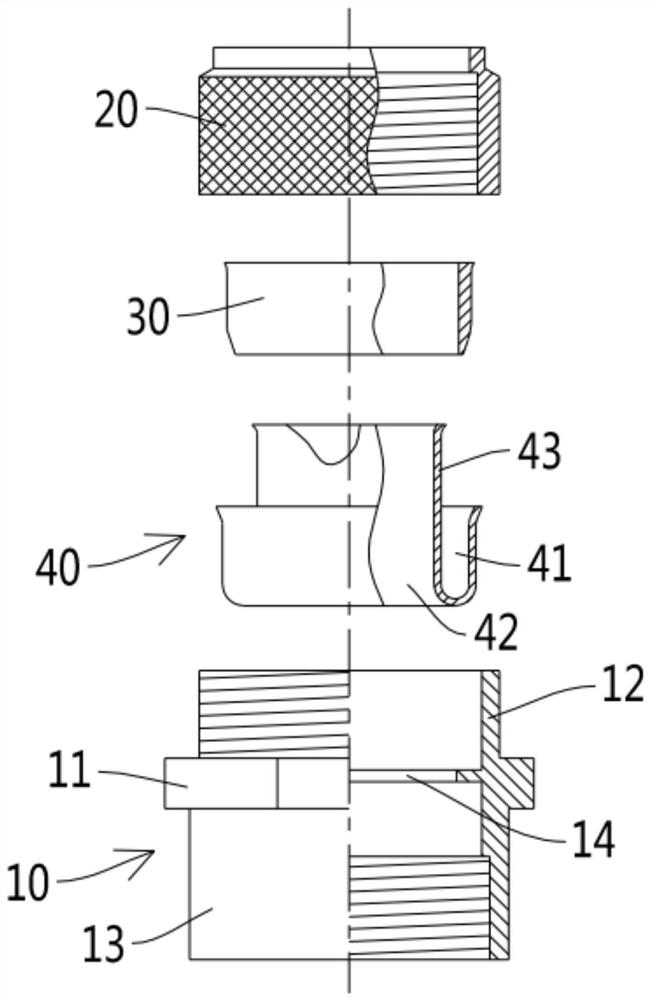

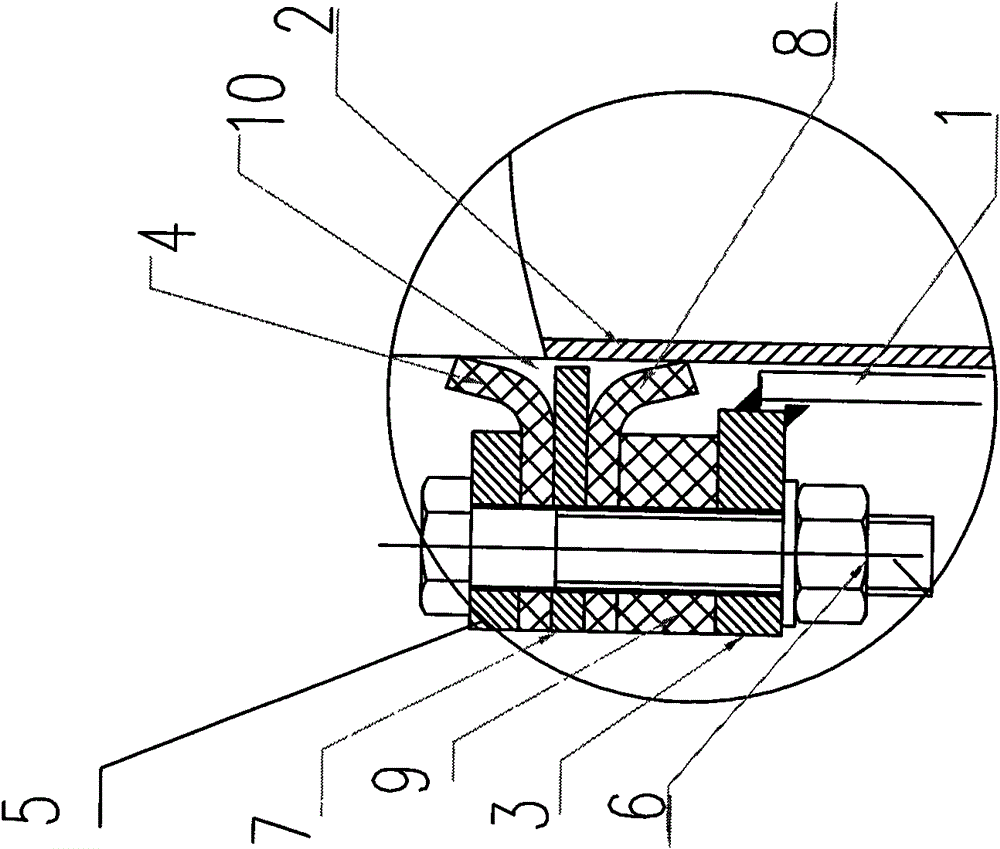

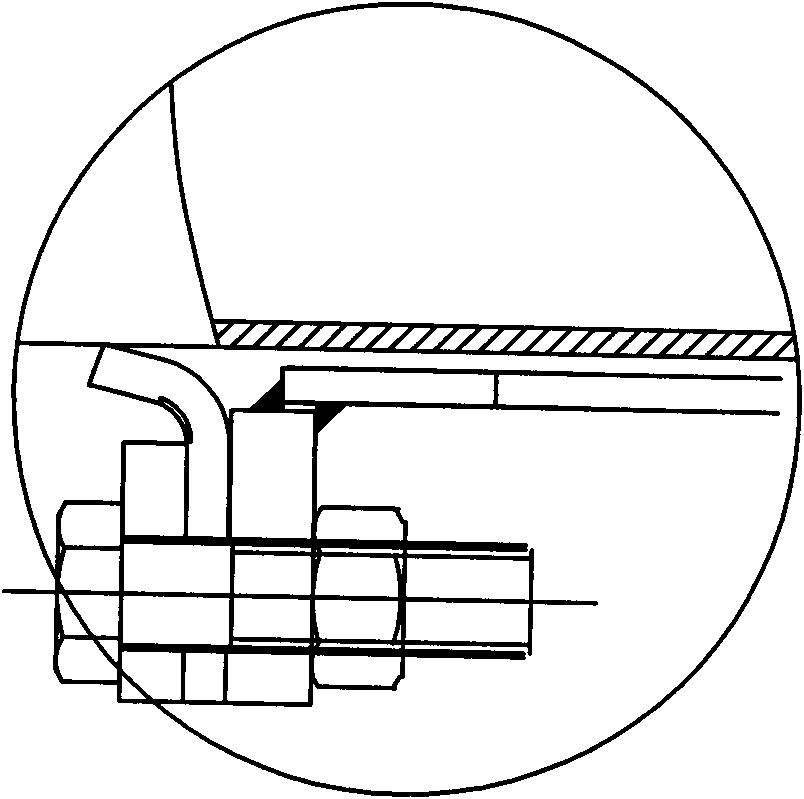

The invention discloses an electronic expansion valve. The electronic expansion valve comprises a valve seat and a valve housing which are assembled to form a valve chamber; the electronic expansion valve also comprises a valve rod which is located in the valve chamber; the valve seat comprises an axial through hole and is provided with a valve opening; the valve rod is inserted into the axial through hole and can move along the axial direction to open or close the valve opening; one of the inner side wall of the axial through hole of the valve seat and the outer side wall of the valve rod is provided with an installing groove; a sealing ring is arranged in the installing groove. The electronic expansion valve is provided with the installing groove, the sealing ring is arranged in the installing groove, and accordingly the sealing performance between the valve seat and the valve rod can be good due to the sealing ring. Compared with a mode that sealing is performed through a bowl-shaped plastic piece in a background technology, two-way sealing can be achieved due to the sealing ring and the good sealing effect can be maintained regardless of the refrigerant flow.

Owner:浙江三花商用制冷有限公司

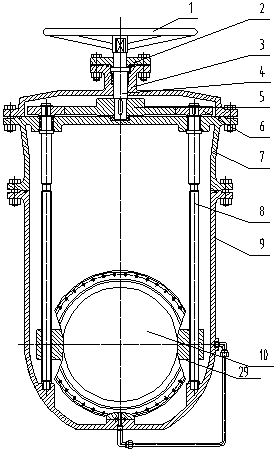

Ceramic double-gate feed valve

ActiveCN106090273AThe overall structure design is concise and clearReliable sealingSlide valveDouble gateLinear motion

The invention discloses a ceramic double-gate feed valve. The ceramic double-gate feed valve comprises two side flanges made of metal, a middle valve body, a graphite gasket, an O-shaped ring, a valve rod, a stuffing box assembly, a stuffing gland, a ceramic valve seat, a ceramic ring, metal disc-shaped gates, a spring seat, supporting ejector rods, a stand column, a pneumatic actuator, an inner hexagonal bolt and a double-ended bolt and nut, wherein the metal disc-shaped gates and the ceramic ring jointly form the gates of the ceramic double-gate feed valve; the ceramic ring and the ceramic valve seat form a ceramic sealing pair; the pneumatic actuator pushes the valve rod and the spring seat, and drives the gates to move up and down, so that opening and closing action of the valve is completed; in the movement process of the gates, a spring enables the gates cling to the surface of the ceramic valve seat through the supporting ejector rods, so that stable and reliable sealing is guaranteed; and meanwhile, the gates generate autoroatation during linear motion due to the function of friction force, so that the ceramic double-gate feed valve has self-grinding performance and self-cleaning performance.

Owner:中一节能耐磨技术宜兴有限公司

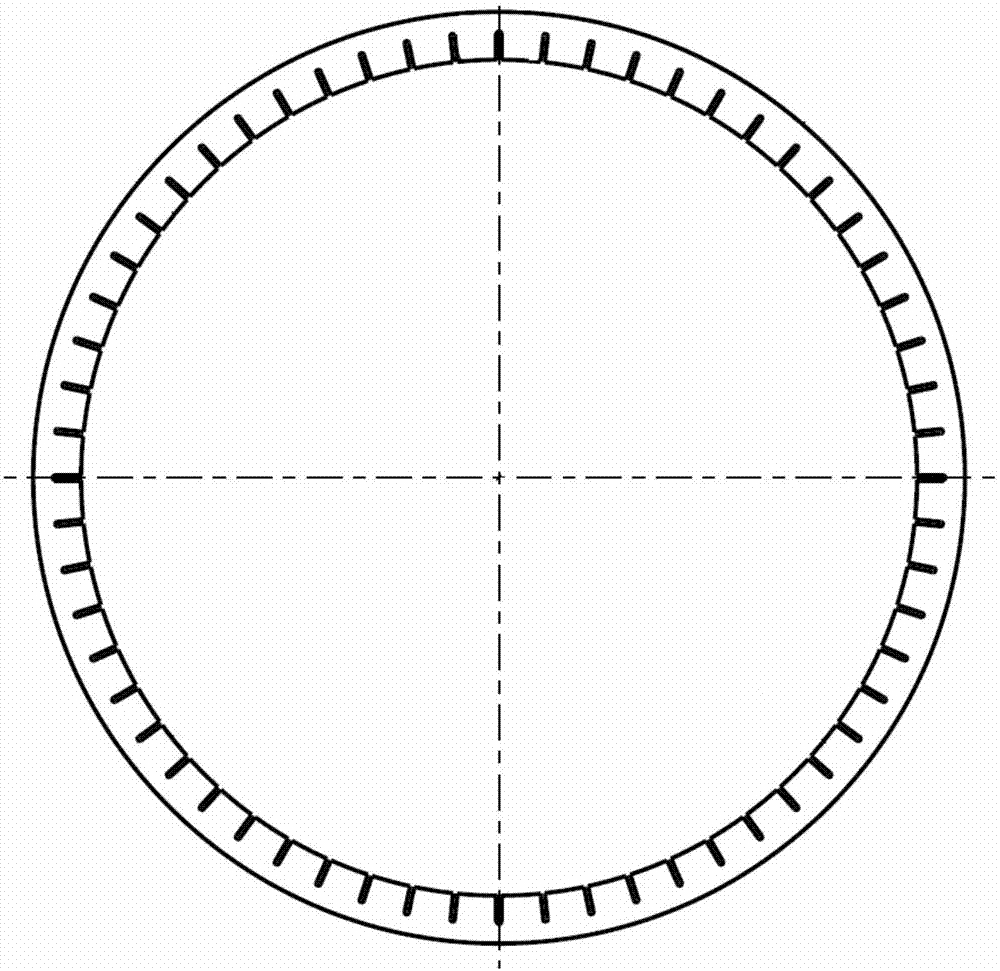

Two-way sealing butterfly valve

The invention provides a bidirectional sealing butterfly valve, comprising a valve seat, a rubber sealing ring, a butterfly board and a pressure board. The rubber sealing ring is fixed on the butterfly board through the pressure board by the bolts, the sealing surface of the valve seat is a plane, the contact place of the rubber sealing ring and the pressure board has a groove, and air holes are uniformly distributed along a circle on the pressure board corresponding to groove of the rubber sealing ring. The butterfly valve has the advantages of simple product structure, low cost and realizing bidirectional sealing reliably.

Owner:JIANGSU SHENTONG VALVE

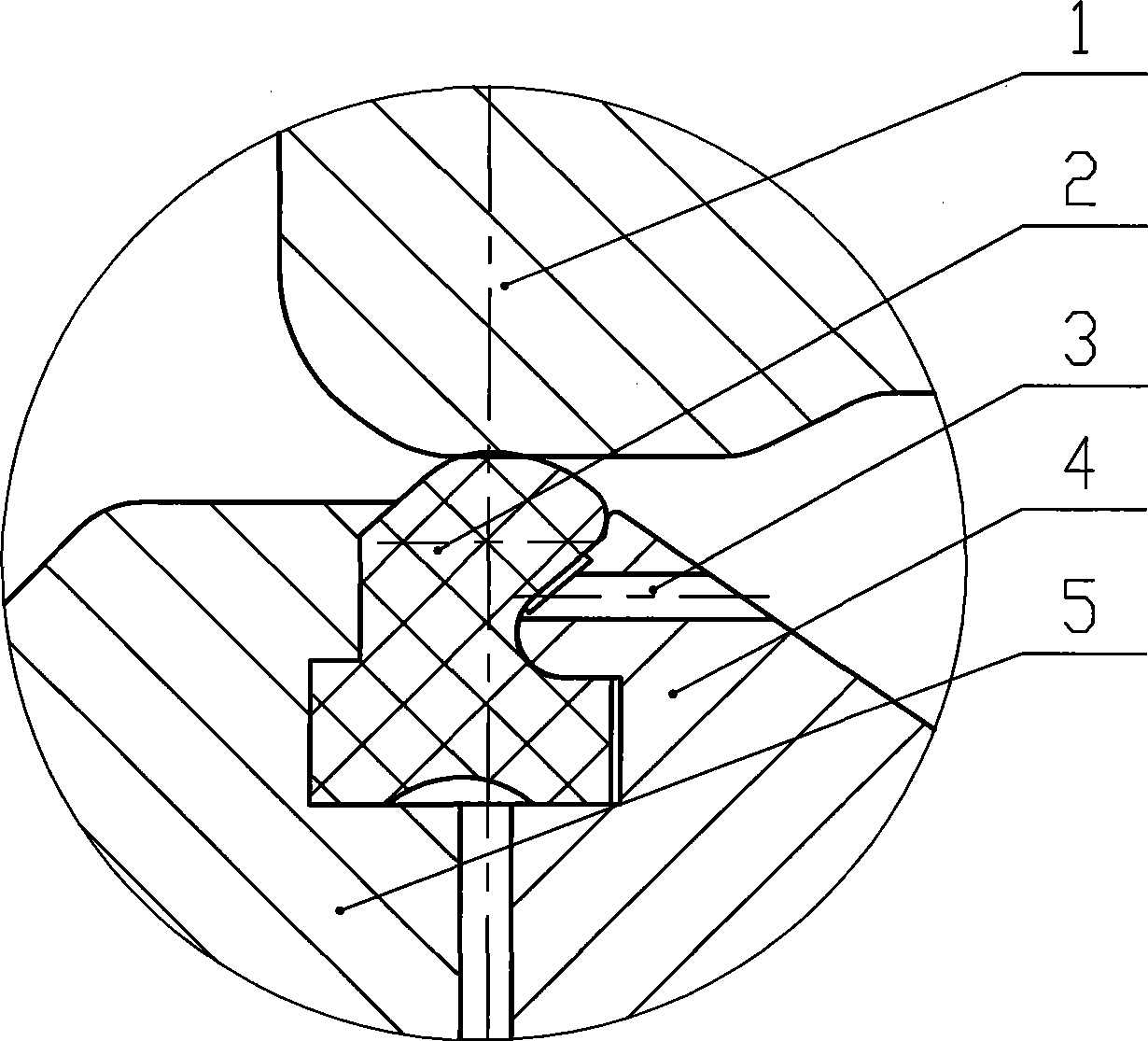

Bidirectional soft and hard seal eccentric half-ball valve

The invention discloses a bidirectional soft / hard sealing eccentric half-ball valve, comprising a valve body which is connected with a valve cover; the valve body is internally provided with an eccentric crankshaft which passes through the valve cover and is hermetically connected with the valve cover; the eccentric crankshaft is connected with a spherical crown; a runway at one side of the valve body is connected with a valve base which is used for positive hard sealing; the valve base is internally provided with a sealing trough which is internally provided with a sealing ring used for reverse soft sealing; the sealing trough is communicated with the runway at the side of the sealing trough; one side of the eccentric half-ball valve corresponding to the runway adopts two sealing structures: soft sealing and hard sealing, which have different directions; therefore, the bidirectional sealing of the eccentric half-ball valve is achieved, the eccentric half-ball valve can be installed in the positive direction or the reverse direction and the applicable range of the eccentric half-ball valve is enlarged; during the reverse sealing, the sealing ring is closely combined with the spherical crown under the water pressure; the bidirectional soft / hard sealing eccentric half-ball valve has simple and reasonable structure and smart arrangement, and is an eccentric half-ball valve with completely new sealing structure.

Owner:WUHAN DAYU VALVE

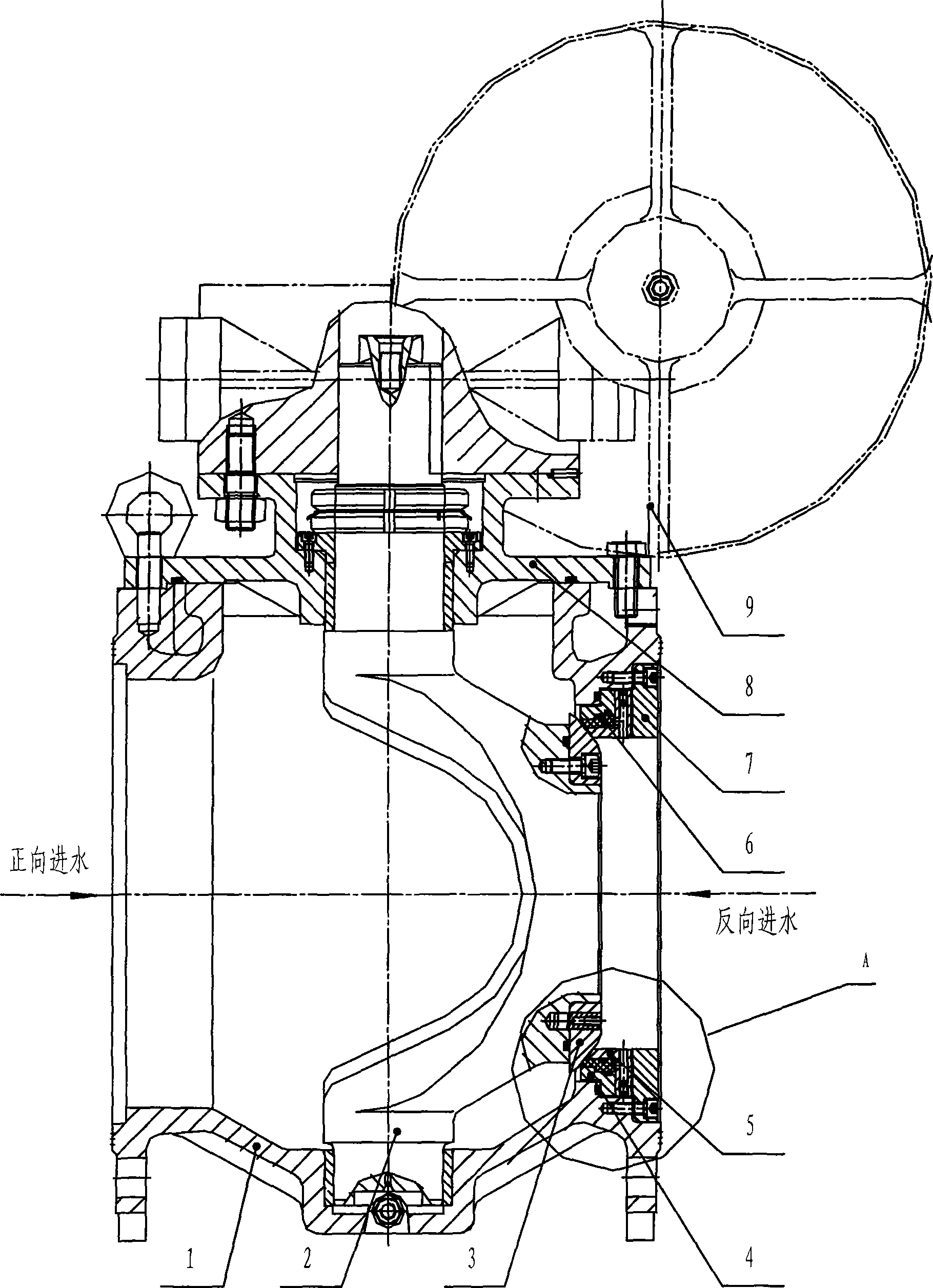

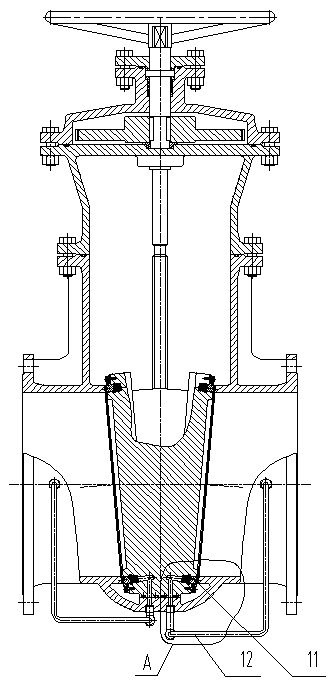

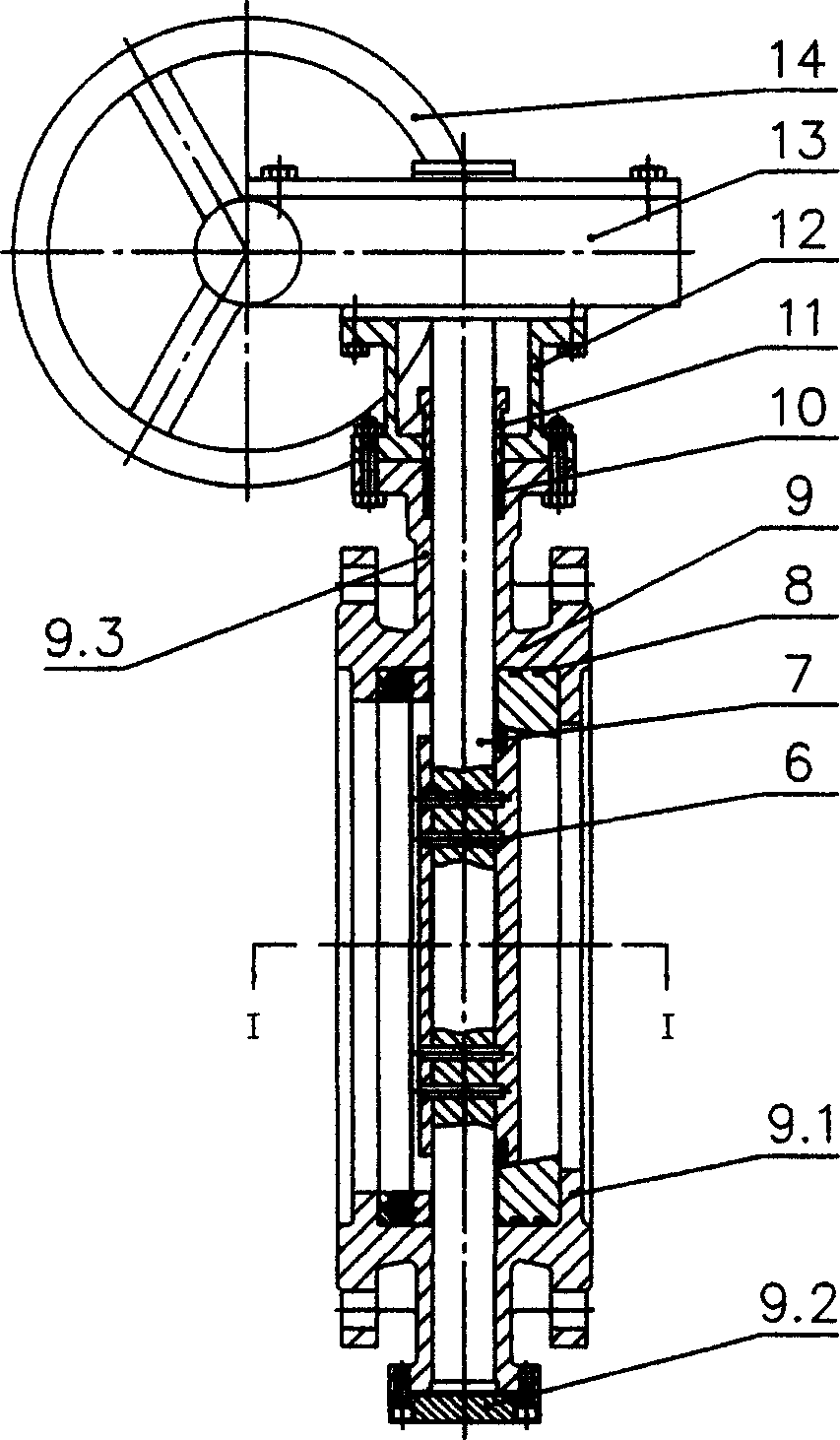

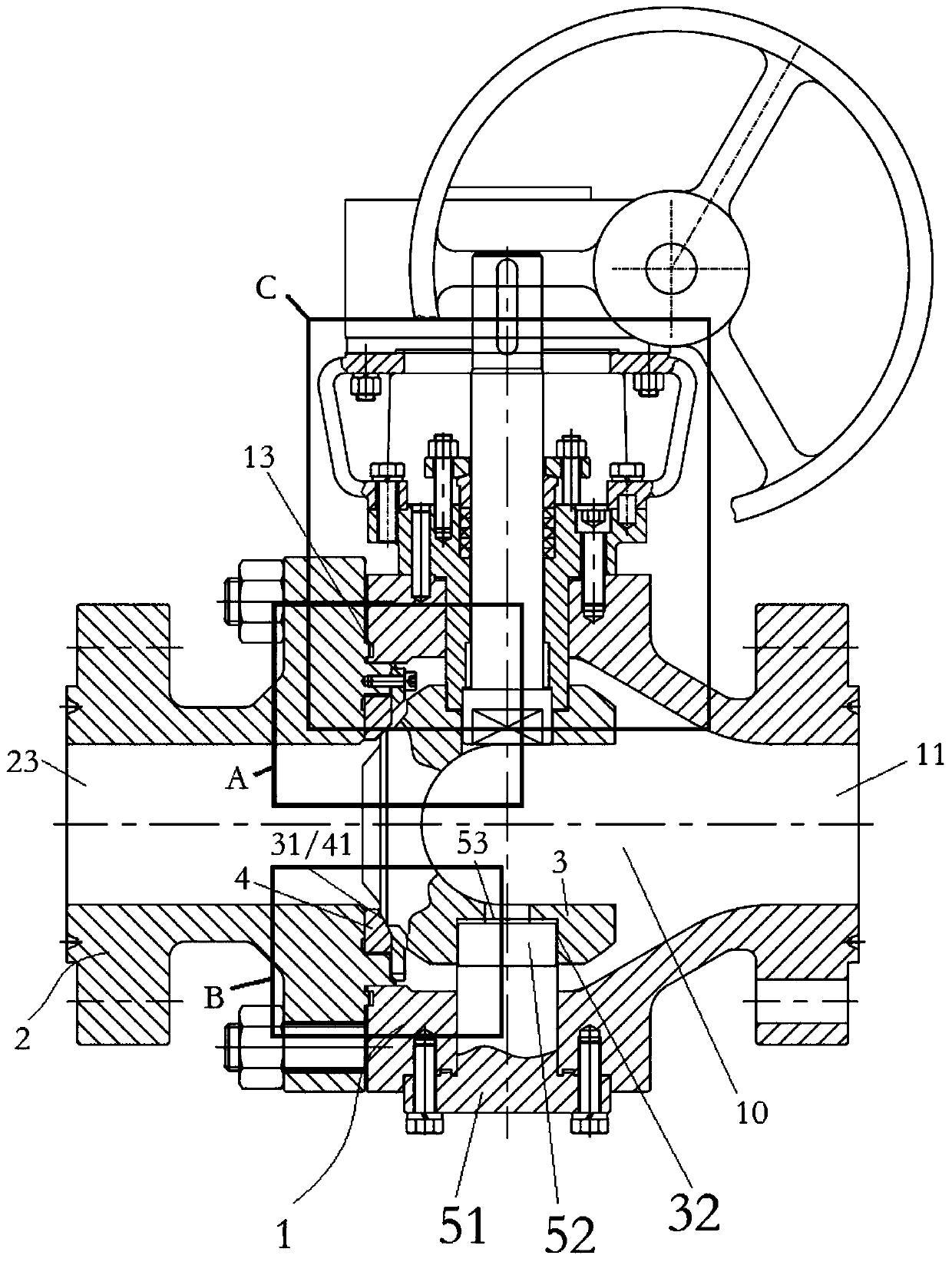

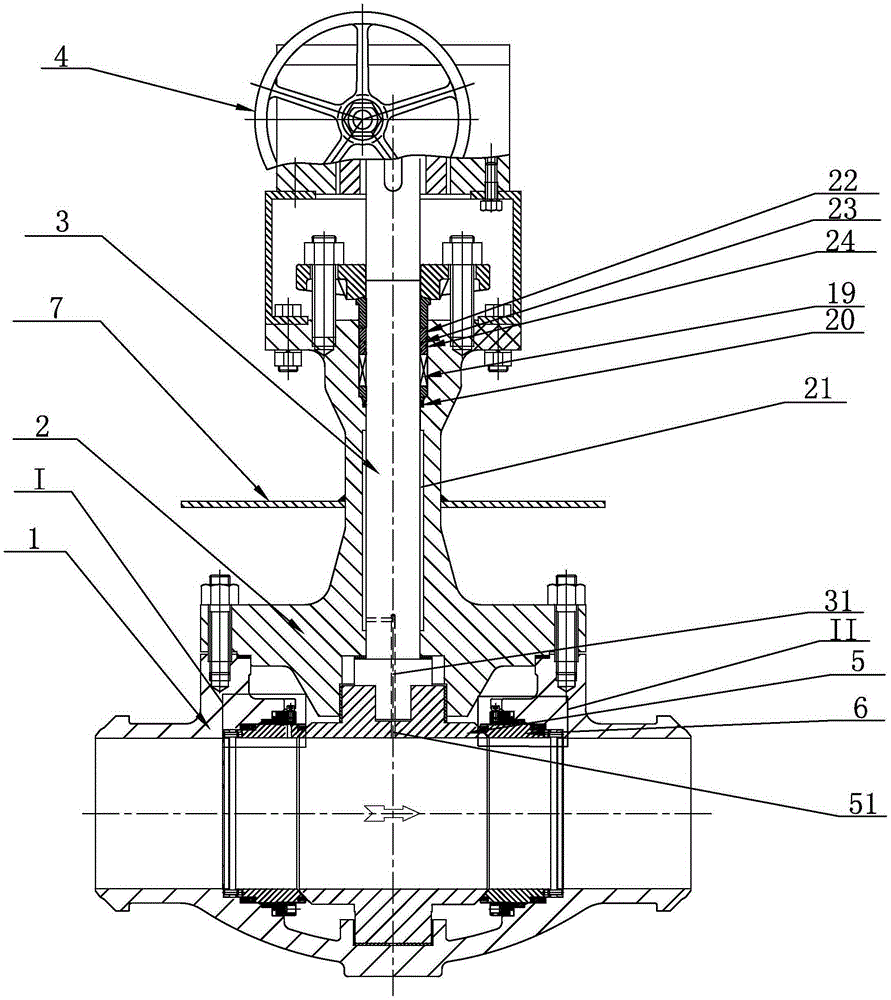

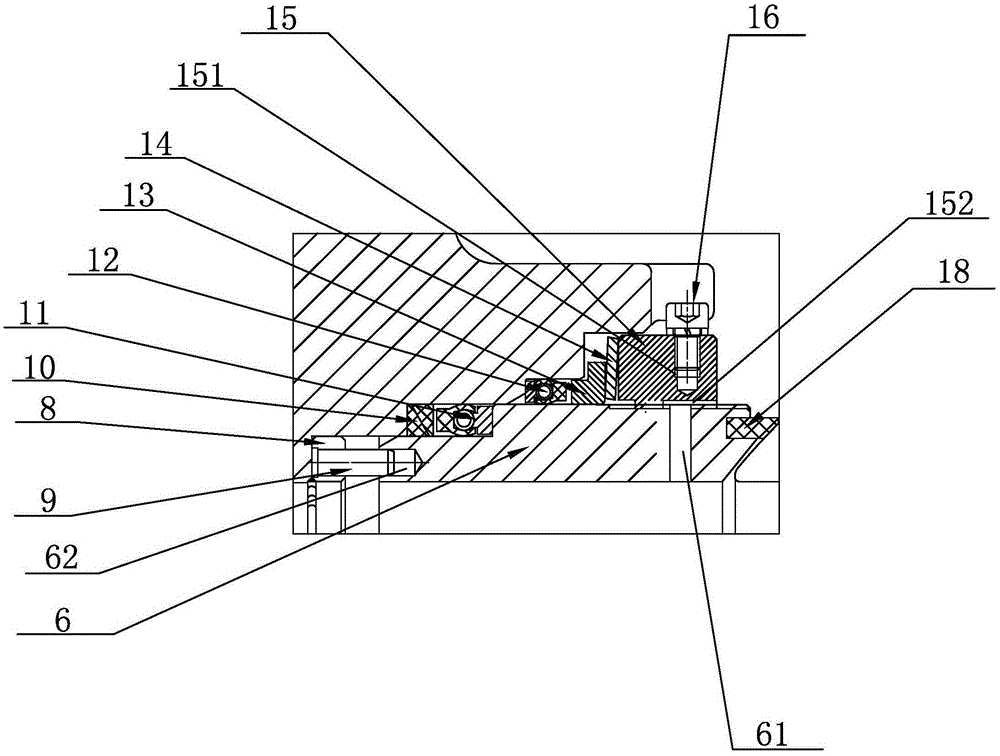

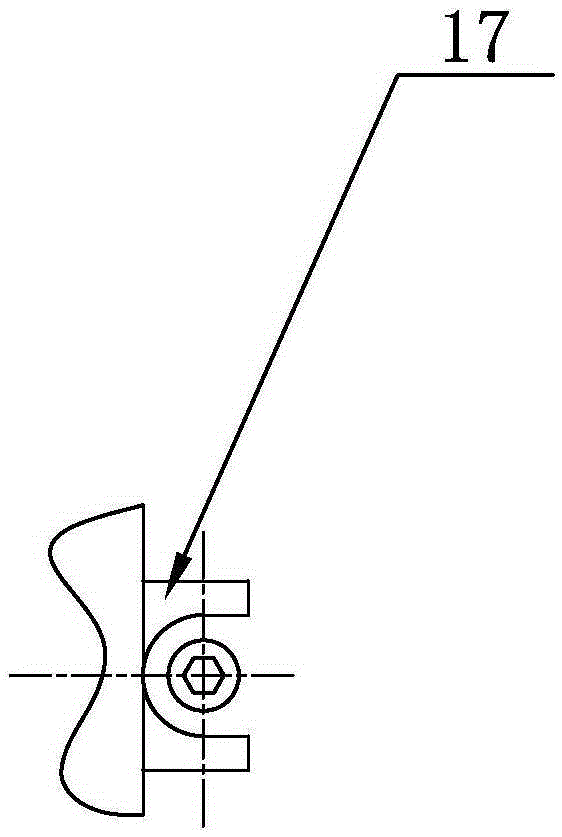

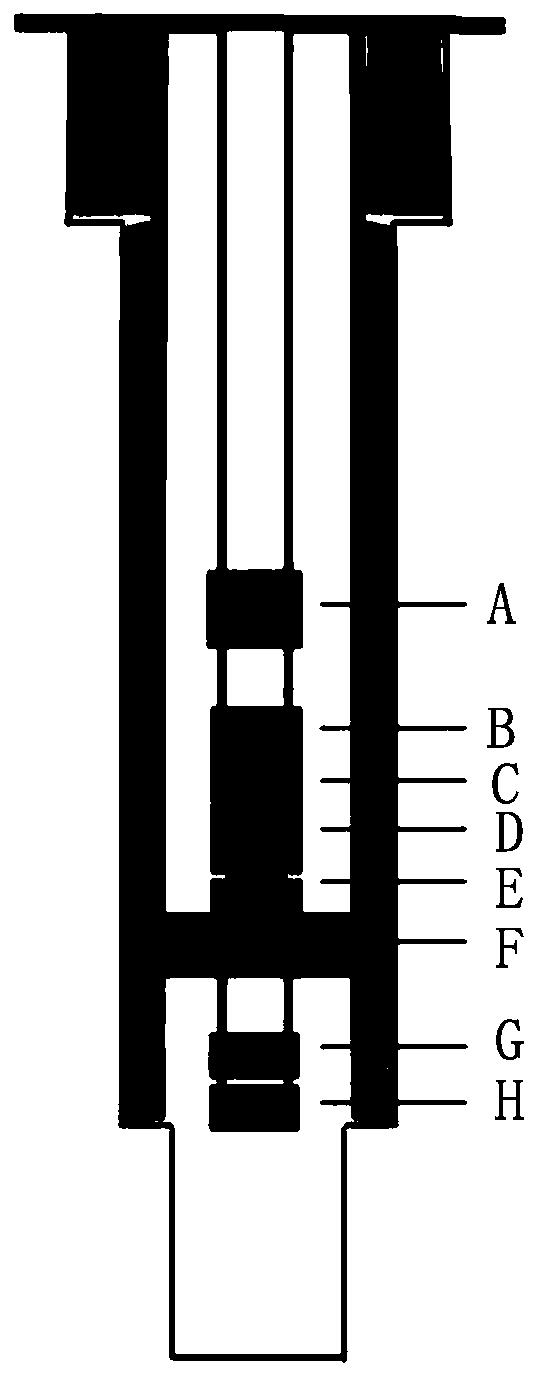

Bidirectional sealing gate valve and using method thereof

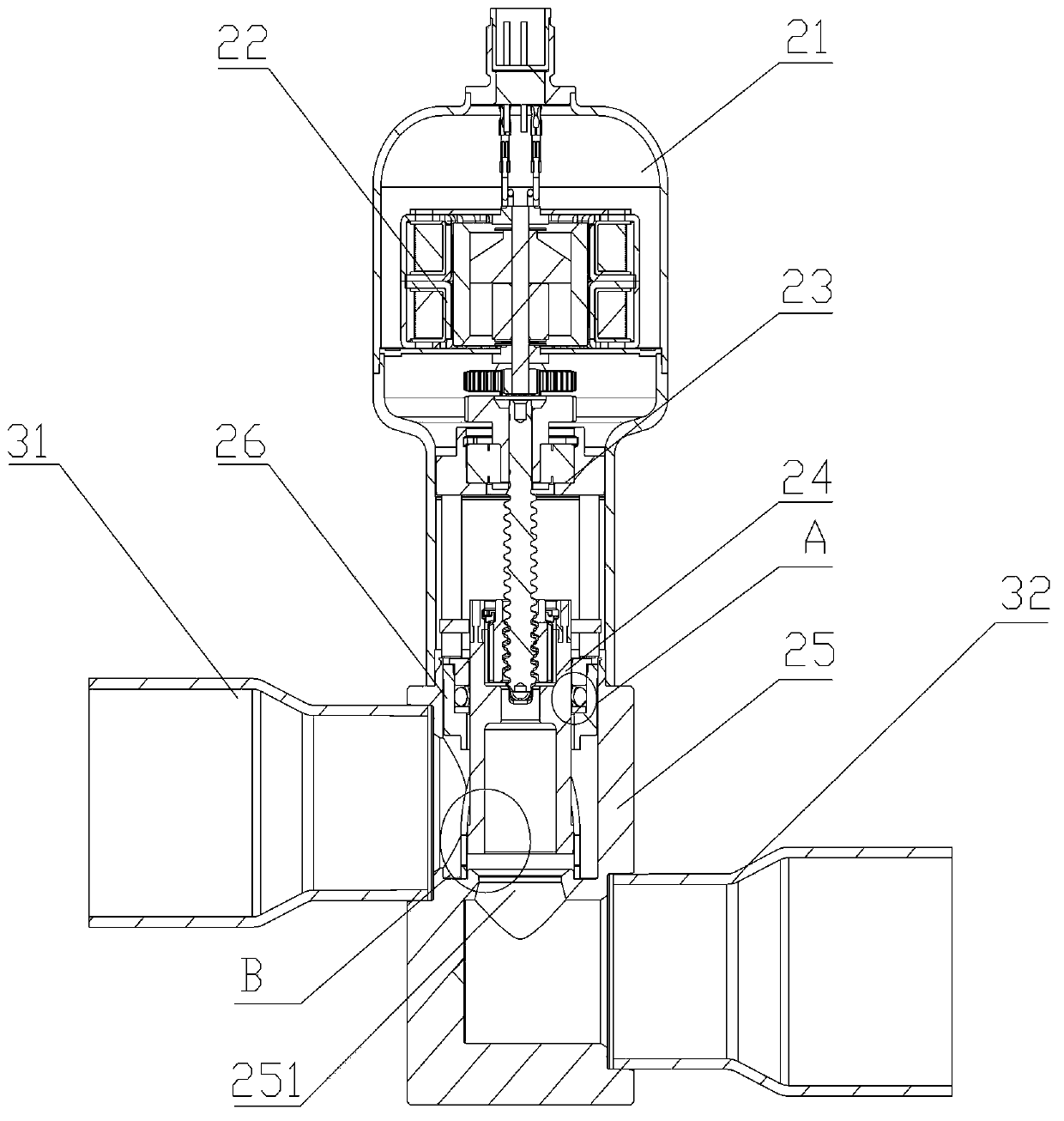

PendingCN109163110AHigh matching precisionSmooth up and down motionOperating means/releasing devices for valvesSlide valveWheel driveGear drive

The invention discloses a bidirectional sealing gate valve and a using method thereof. The bidirectional sealing gate valve comprises a valve deck, a valve shaft, a valve body, a valve plate, a valveseat, a valve body sealing surface and a valve seat sealing surface, wherein the valve seat is connected to the valve plate through a valve seat gland in a floating mode, an elastic connecting piece is arranged between the inner end face of the valve seat and the valve plate, a gear box cover is fixedly connected to the valve deck, the gear box cover is fixedly connected with a valve shaft gland,the part, located below the gear box cover, of the valve shaft is connected with a center gear in a key mode, the outer edges of the two sides of the center gear are meshed with a left gear and a right gear respectively, the left gear and the right gear are connected with screw rods which penetrate through the valve deck to extend downwards through flat keys respectively, and the tail ends of thescrew rods are rotationally connected with the inner surface of the valve body. The bidirectional sealing gate valve has the beneficial effects that 1, a hand wheel drives the gear, the gear drives the screw rods, the screw rods drive a gate plate, the matching precision is high, and due to the fact that the gate plate is supported at the two ends of the screw rods, the gate plate moves up and down stably; and 2, after the gate plate is closed, the valve seat realizes bidirectional sealing of the gate valve under the double acting force of the spring force and the thrust of a medium on the valve seat.

Owner:YINGNUOWEI VALVE IND

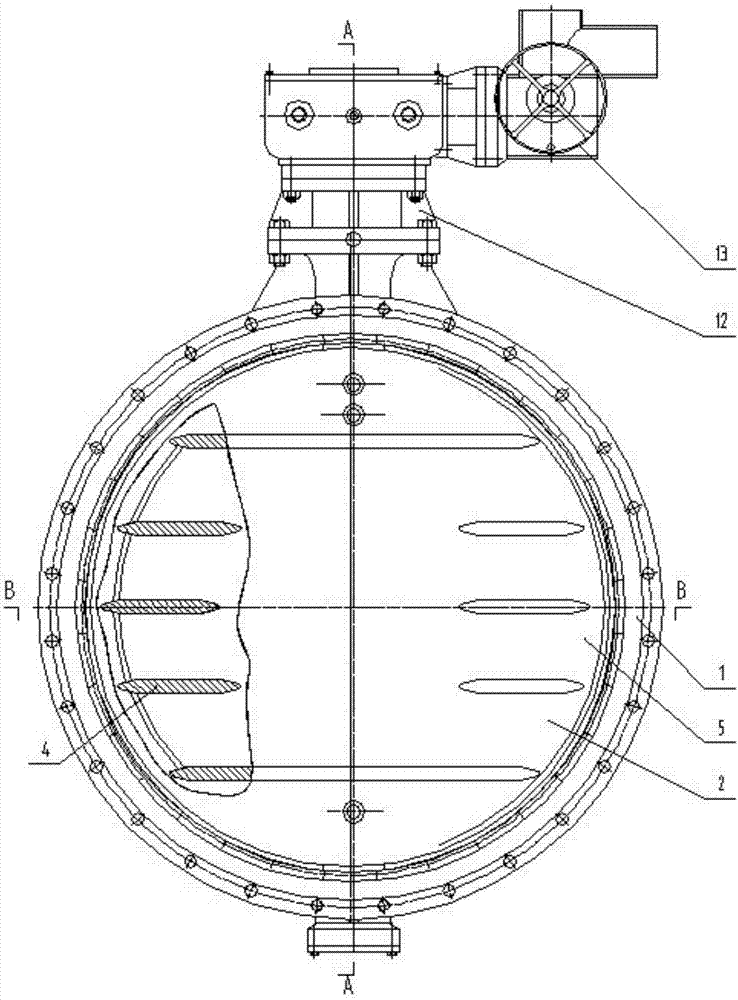

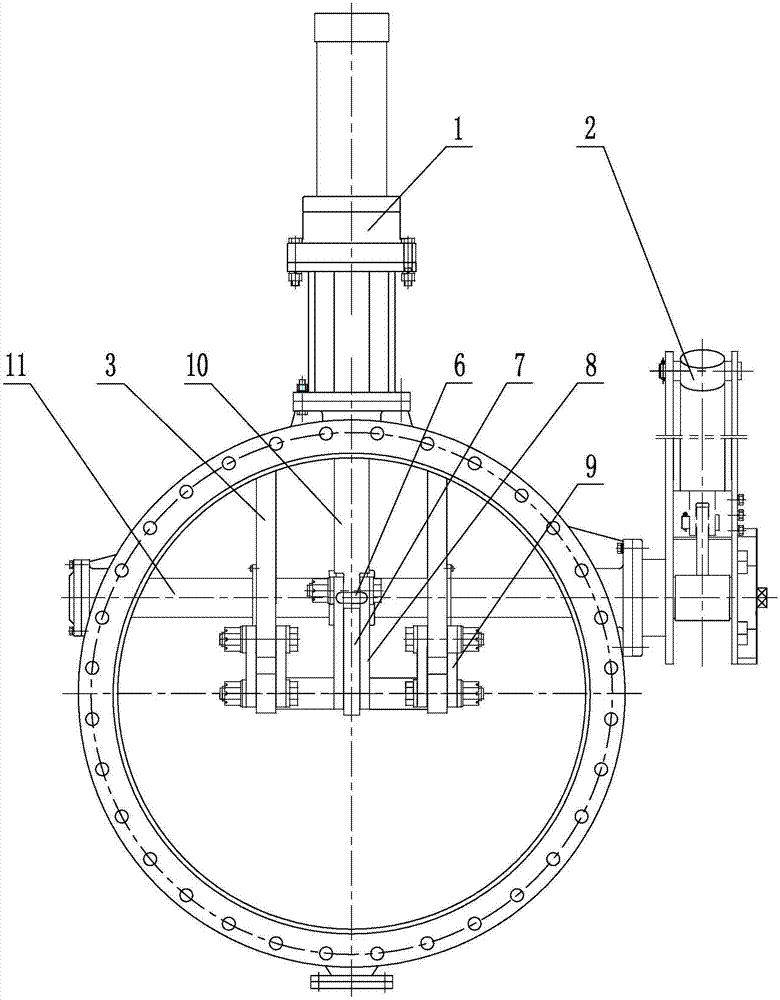

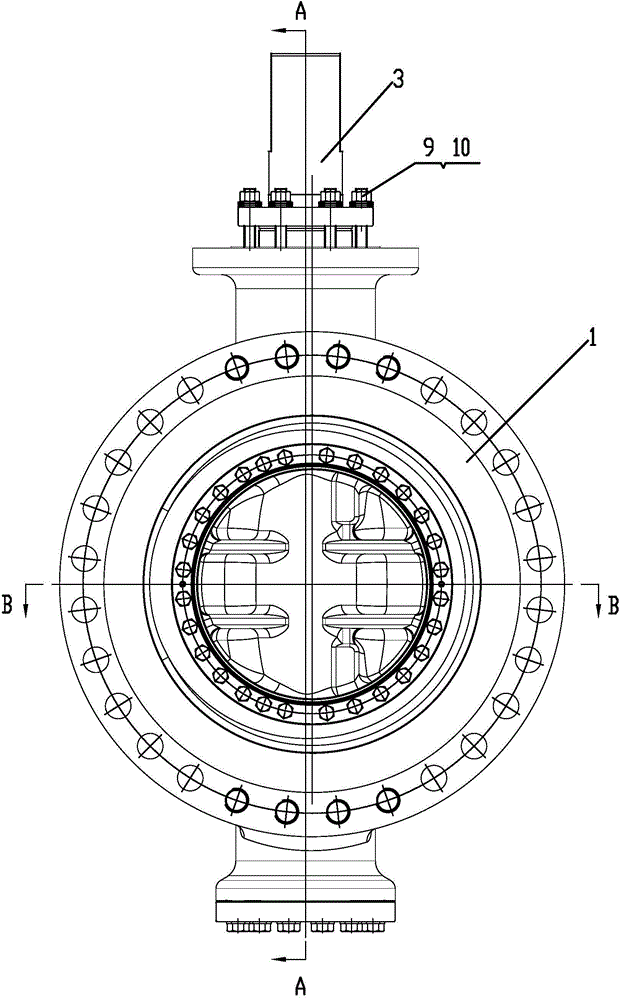

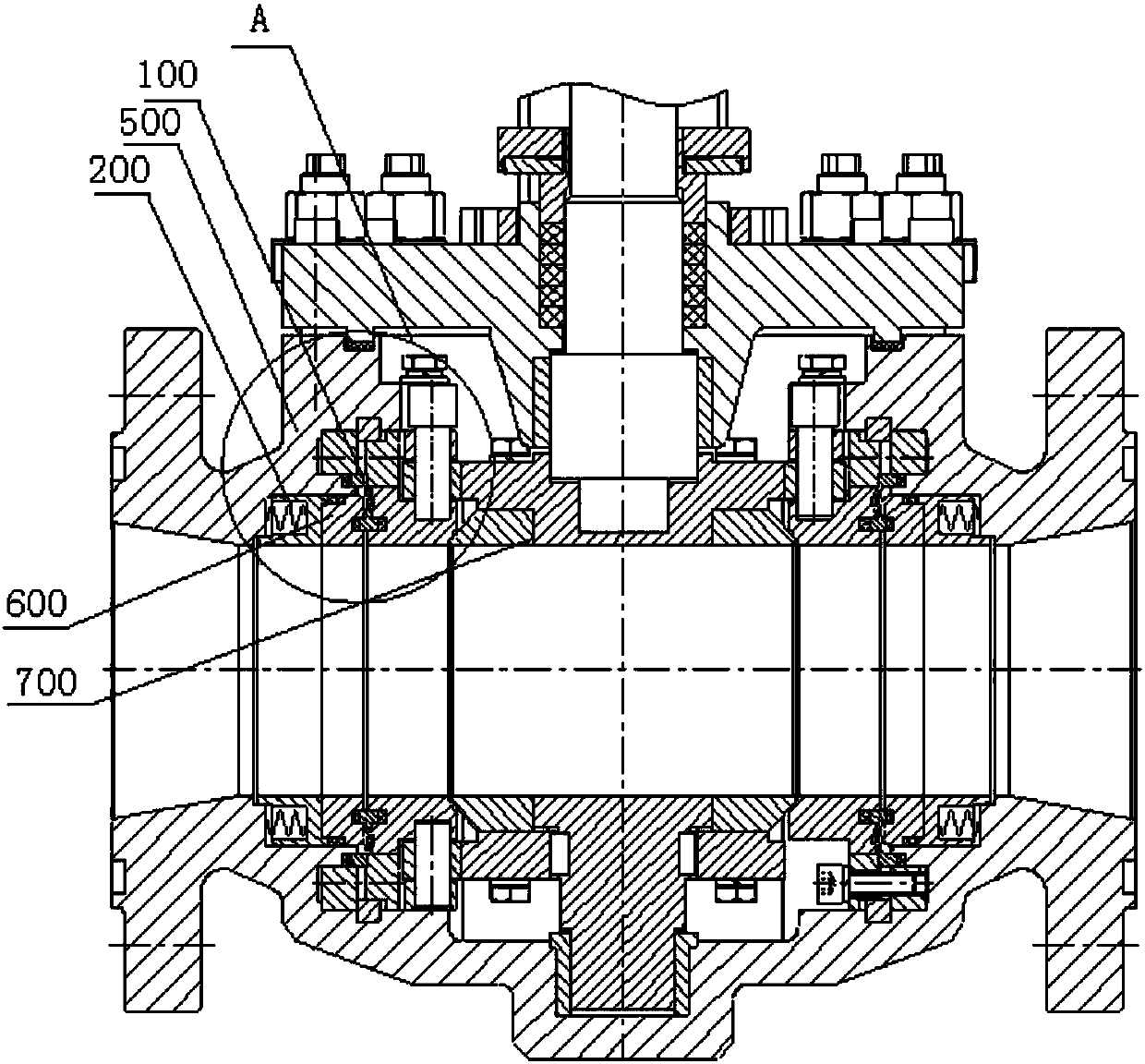

Double-plate double-valve-seat bi-directional metal-sealed butterfly valve

InactiveCN107355548AScientific and reasonable structure designSimple structureLift valveCircular discEngineering

The invention relates to a double-plate double-valve-seat bi-directional metal-sealed butterfly valve, which comprises a drive device, a support, a filler, a filler gland, a bottom cover, a valve body, a butterfly plate, an upper valve shaft, a lower valve shaft, a valve shaft pin, valve seats, a butterfly plate metal seal ring, a pressing plate, a valve seat pressing plate, a check ring and an adjustable valve seat seal ring. The valve seats are oppositely arranged between a disk and the valve body at two sides of the upper valve shaft; the valve seats are oppositely arranged between the disk and the valve body at two sides of the lower valve shaft; and the valve seats are fixed valve seat and / or adjustable valve seats. The butterfly valve has a scientific and reasonable structure design, a simple structure, easiness in processing and manufacturing, large caliber, high flow capacity, high pressure resistance, high temperature resistance, corrosion resistance, diversion stability, small vibration, low noise, long service life, and capability of on-line overhauling and replacing a sealing element, and a double-sealed pair works cooperatively or independently when at a two-way alternative pressure-bearing state so as to further realize two-way sealing.

Owner:王中杰

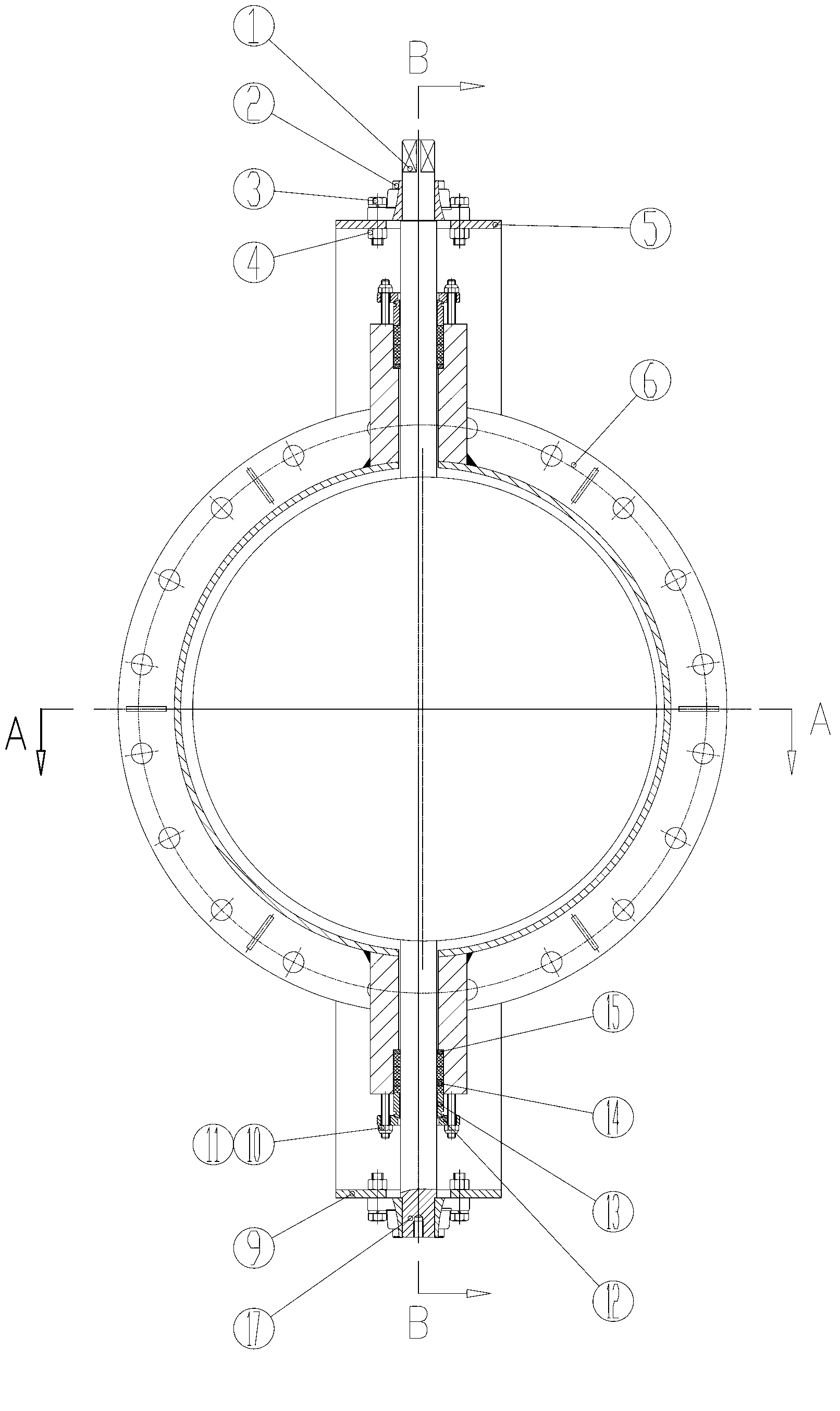

Improved connecting rod drive mechanism of butterfly valve plate

ActiveCN107035872ATo achieve the effect of no cross-breathingImprove reliabilityOperating means/releasing devices for valvesLift valvePhysicsDrive shaft

The invention belongs to butterfly valve components and particularly relates to an improved connecting rod drive mechanism of a butterfly valve plate. The improved connecting rod drive mechanism comprises a valve body, a valve plate and a push-pull drive shaft which is located in the valve body and longitudinally driven by a parallel push-pull mechanism. The valve plate is located in the valve body, a triangular plate is perpendicular to the valve plate and a main shaft, the top end of the triangular plate is connected with the main shaft in a matched manner, the inner end of the lower portion of the triangular plate is hinged to a fixing base on the valve plate, the outer end of the lower portion of the triangular plate and the lower end of the push-pull drive shaft are movably assembled, and the valve plate achieves sealed locking or separating in a manner that the push-pull drive shaft drives the triangular plate and a medium conveying channel formed in the valve body. The two ends of the main shaft are in rotation fit with the inner wall of the valve body, the main shaft is driven by a rotary drive mechanism, and the main shaft and the triangular plate synchronously rotate in the radial direction. The improved connecting rod drive mechanism effectively solves the technical problem that in the prior art, the reverse sealing effect is poor due to single drive. The improved connecting rod drive mechanism has the beneficial effects that bi-drive can effectively increase force, and a certain reverse sealing property is achieved while the forward sealing effect is guaranteed.

Owner:SHITSZJACHZHUAN SANKHUAN VEHLV KORPOREHJSHEN

Metal seal three-eccentric center butterfly valve

ActiveCN111043332AElastic contact sealing effect is goodGood self-sealingLift valveButterfly valveMechanics

The invention discloses a metal seal three-eccentric center butterfly valve. The valve is characterized in that the inner diameter of a metal seal ring is larger than the diameter of a mounting boss,a floating space is formed between the metal seal ring and the mounting boss, two end faces of the metal seal ring are in sliding seal fit with a butterfly plate and a limiting part, and multiple through holes are formed in the limiting part, and communicate with the floating space. The butterfly valve has the advantages that due to the floating space, the metal seal ring can slightly move and elastically deform in the radial direction, the floating space can better adapt to a valve base seal face, when the floating space is in seal fit with the valve base seal face, the better seal effect isachieved, meanwhile, a medium can pass through a through hole to enter the floating space, medium pressure is provided for the metal seal ring, the self seal effect is achieved, the seal effect of thespace and the valve base seal face can be further ensured, dual-way seal is achieved, and no leakage exists.

Owner:KCM VALVE

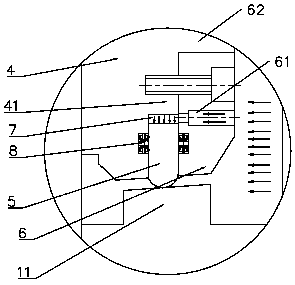

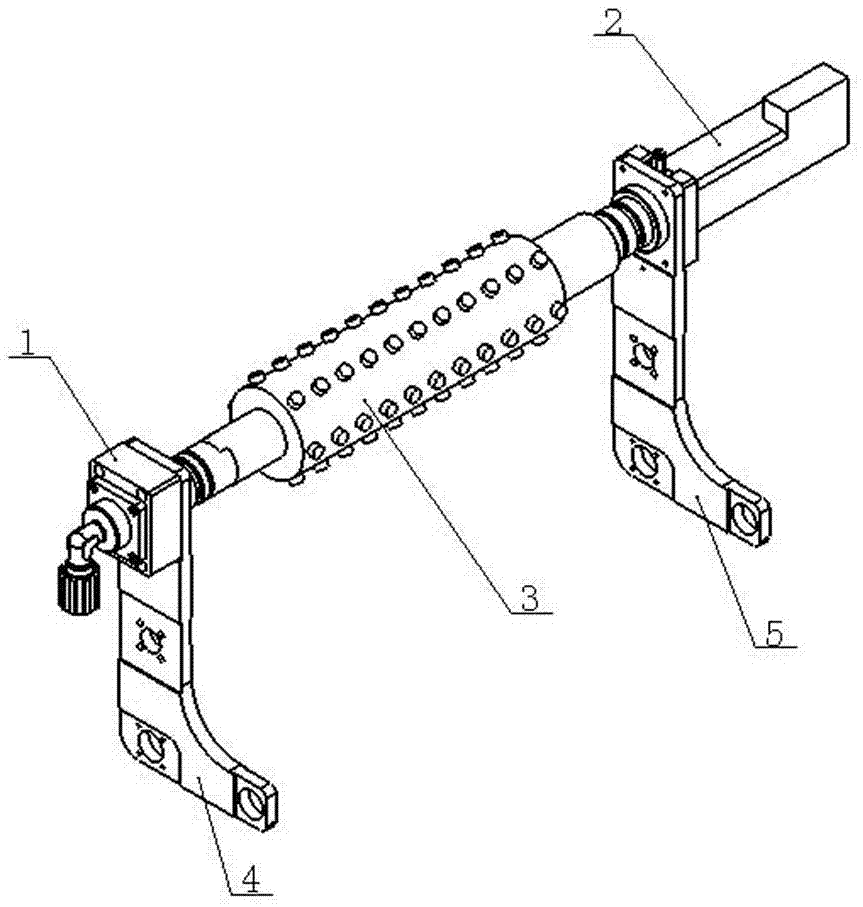

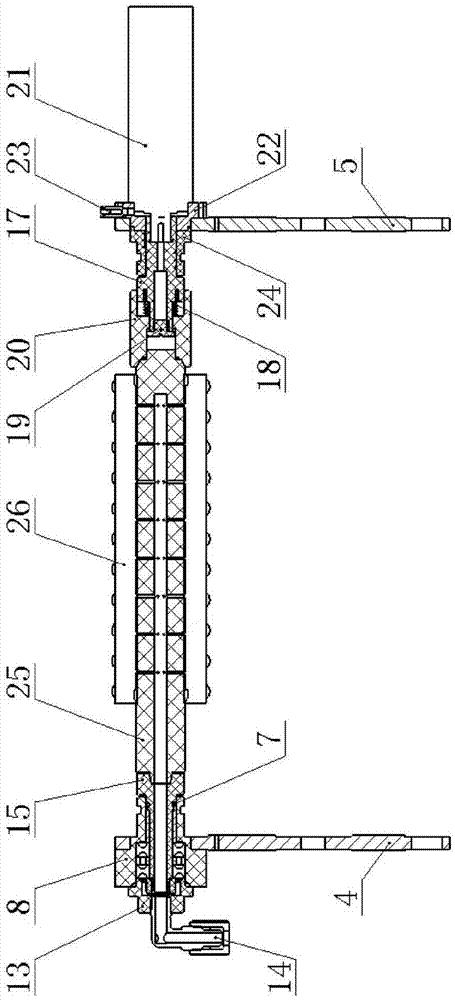

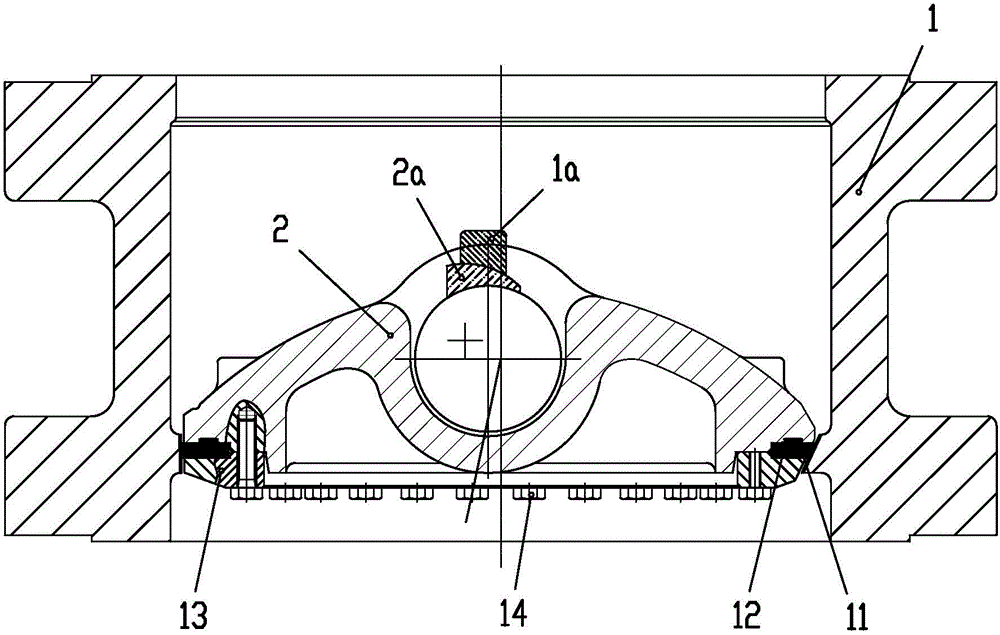

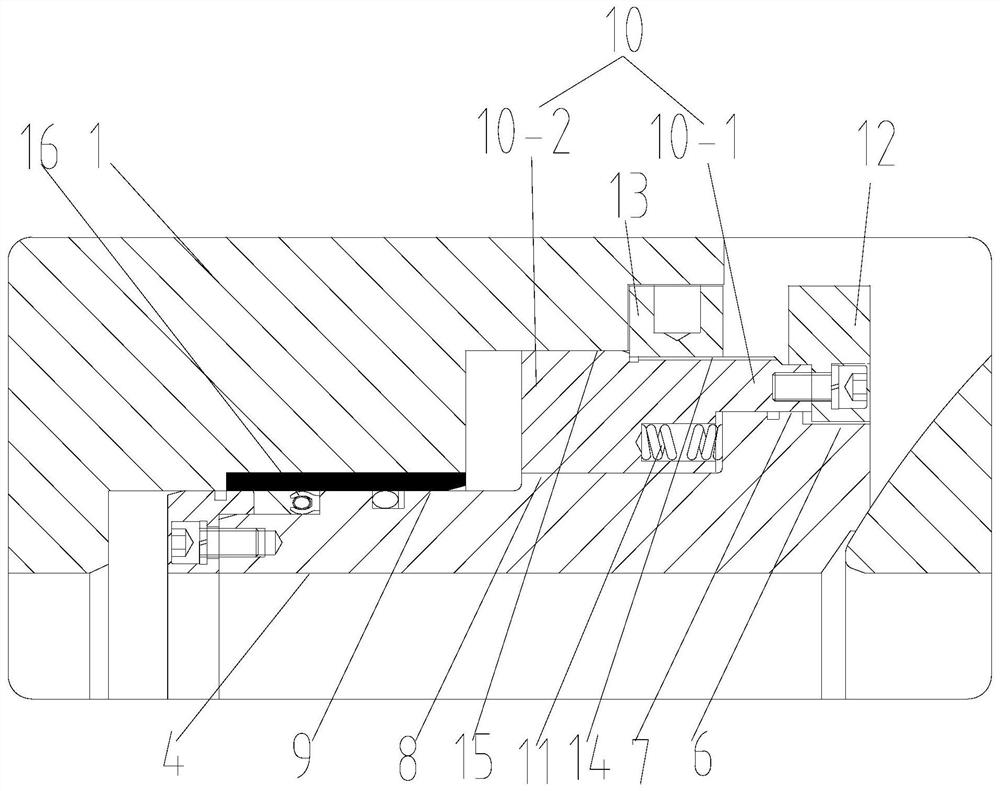

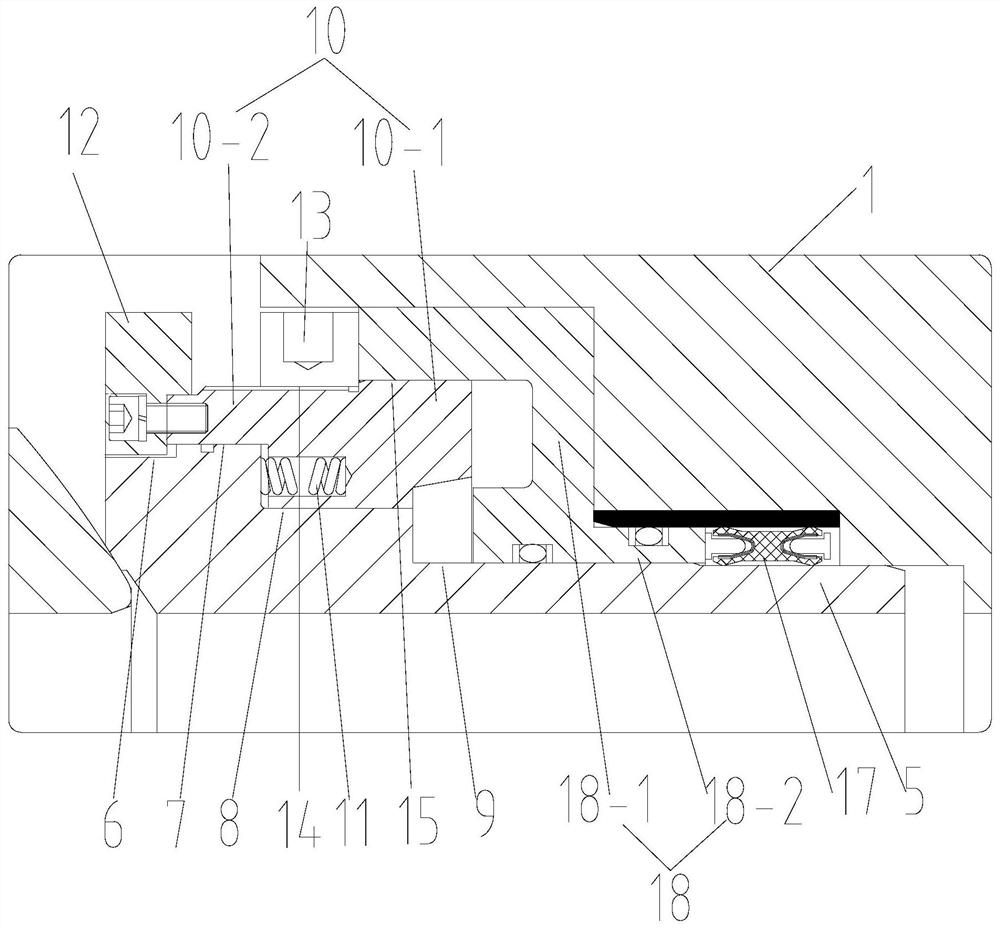

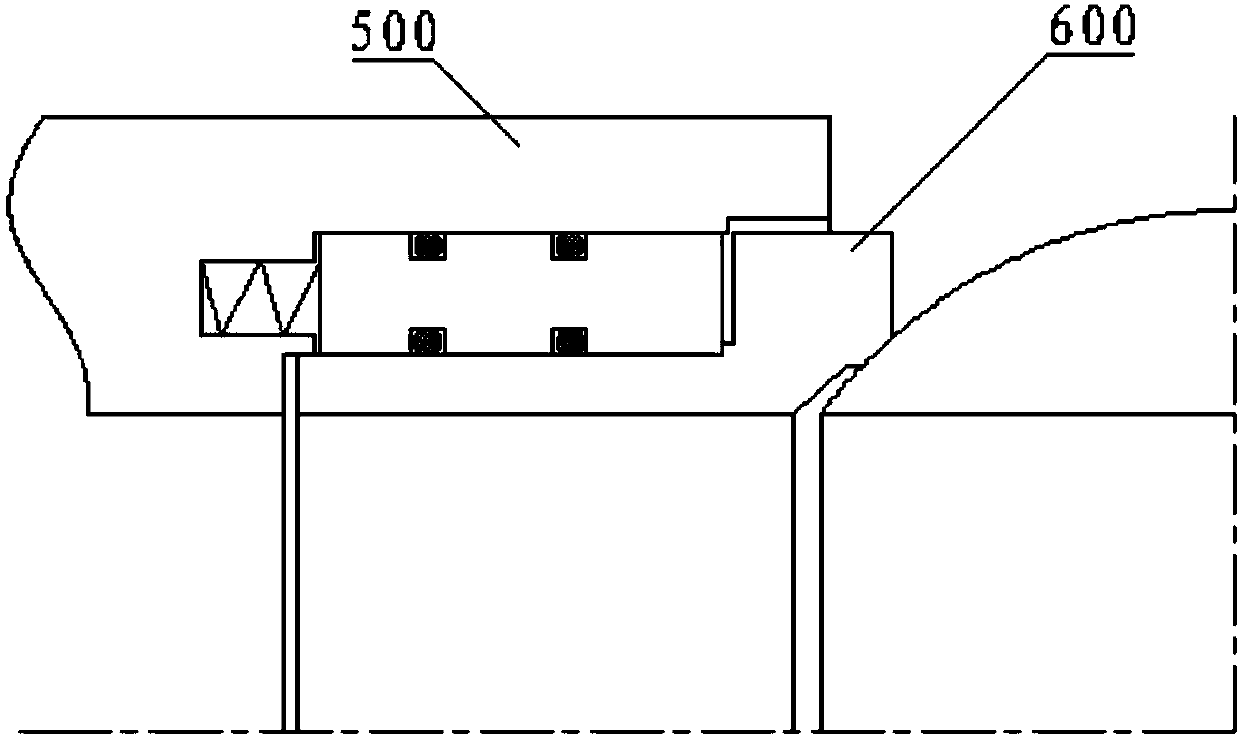

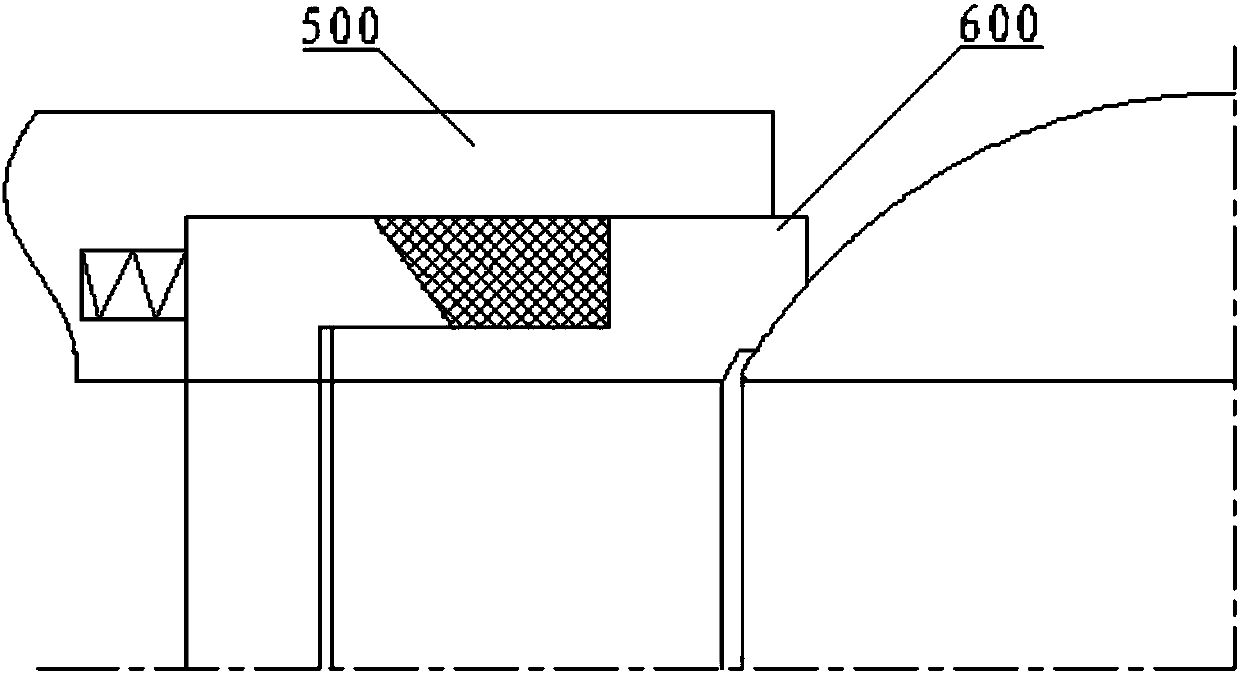

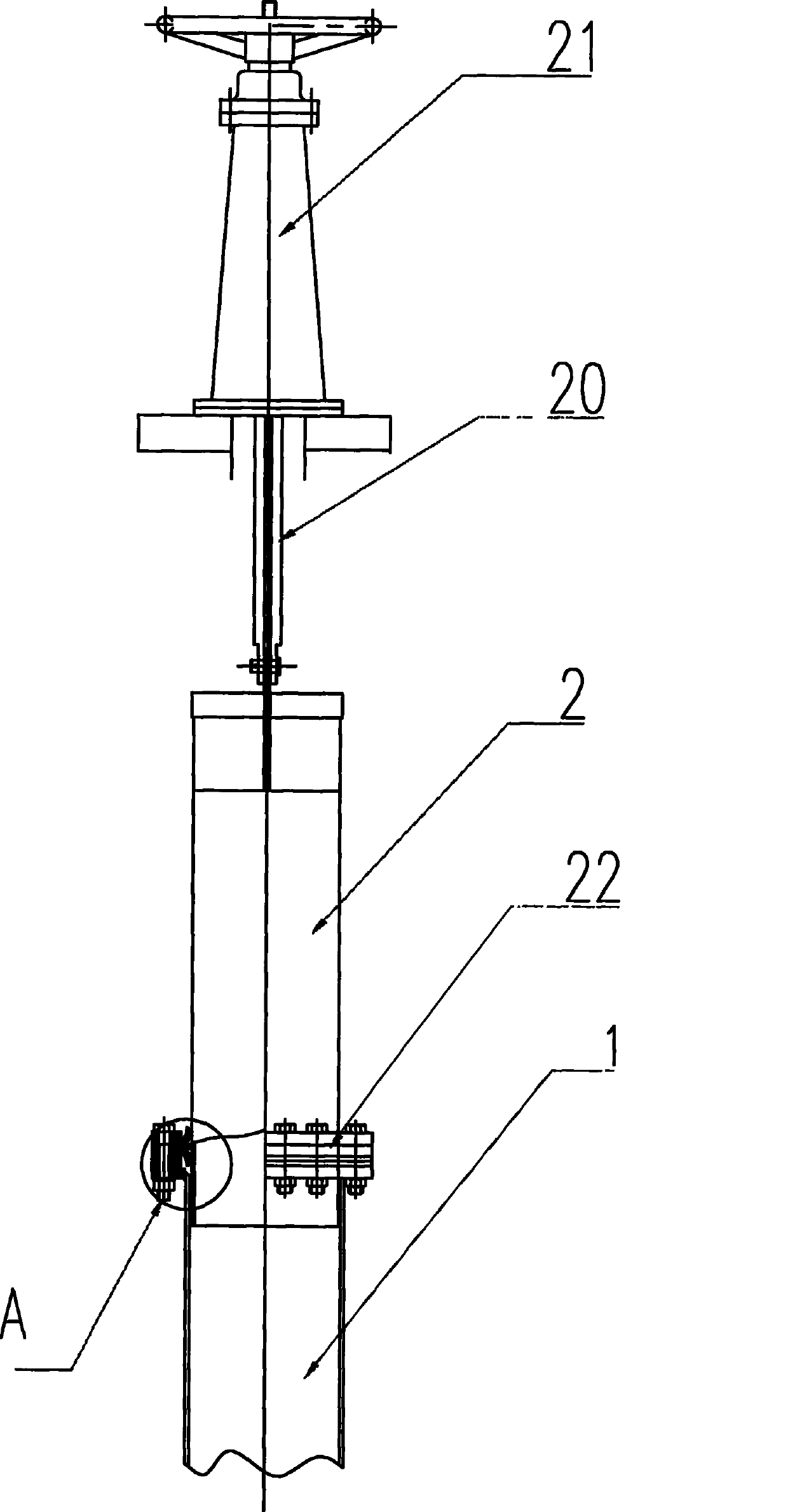

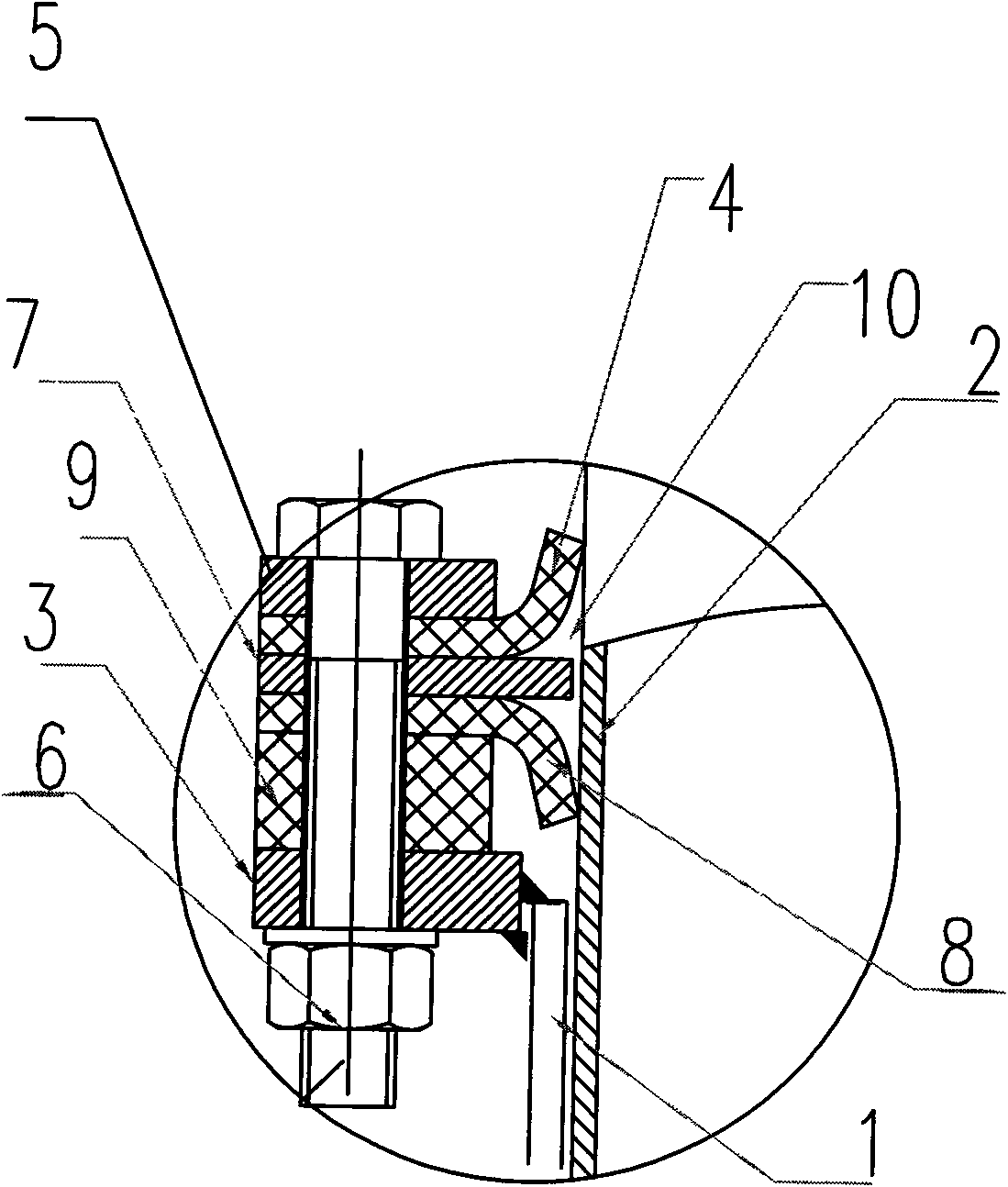

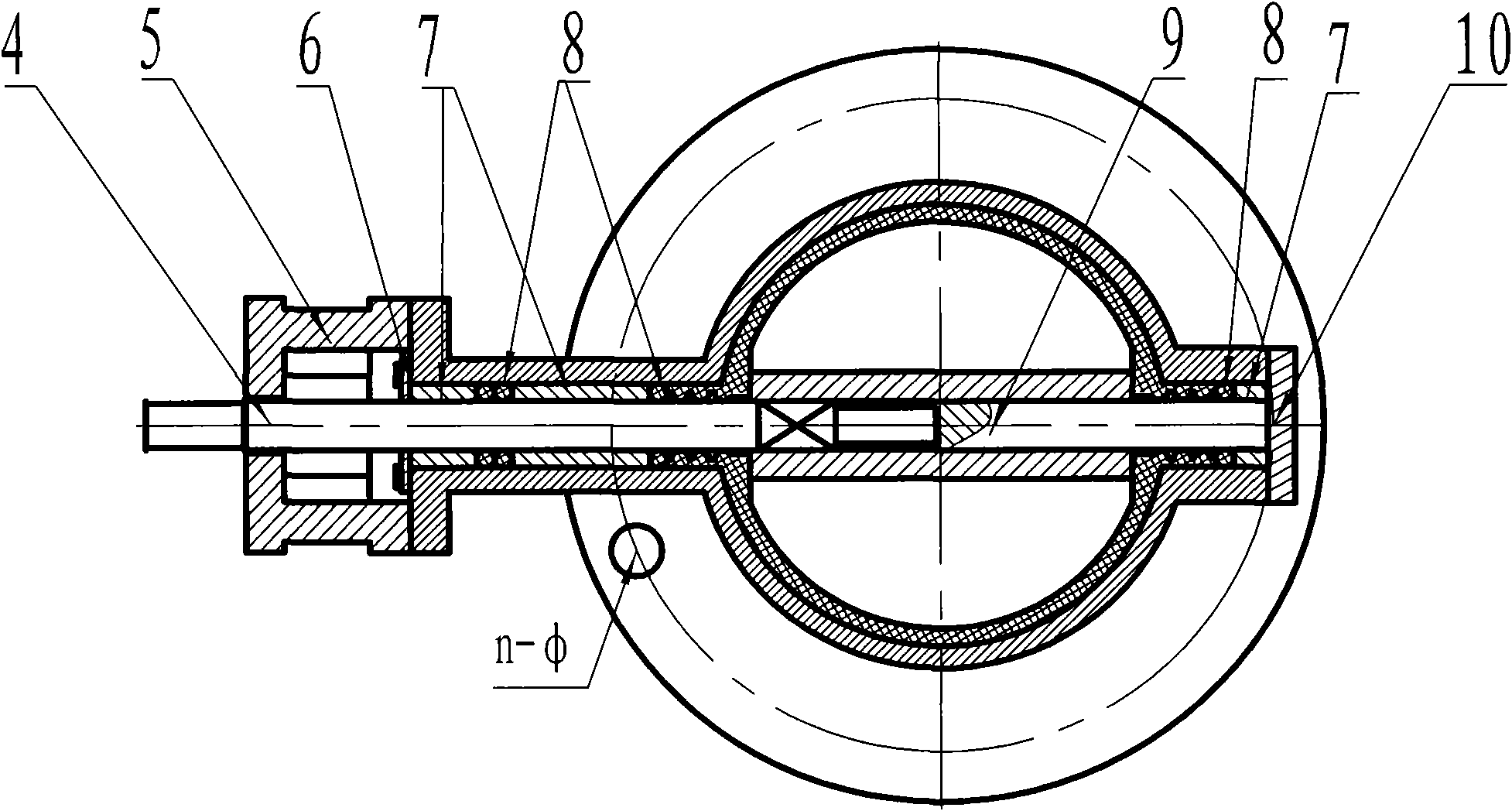

Roller brush unit concentric snapping structure for cleaning wafers

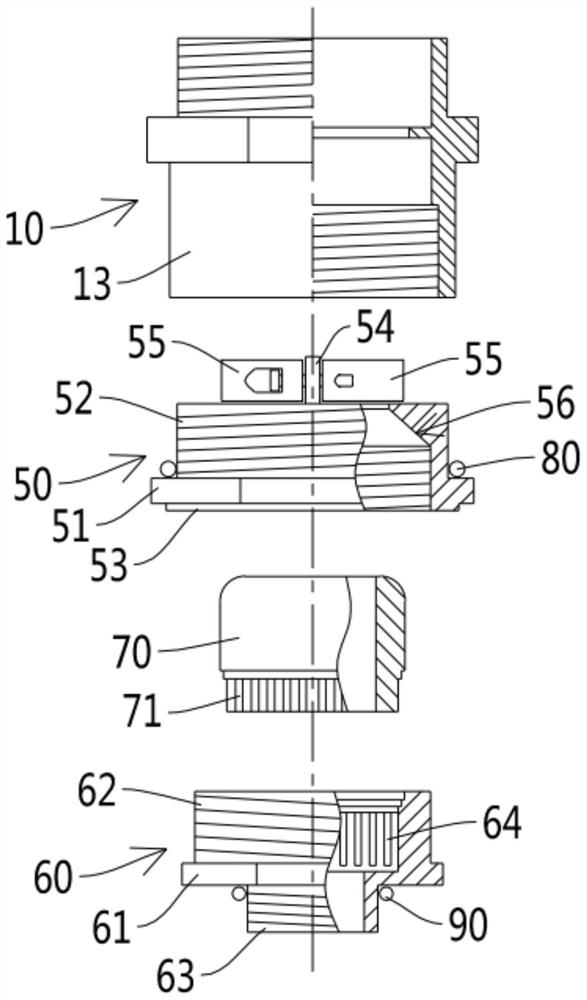

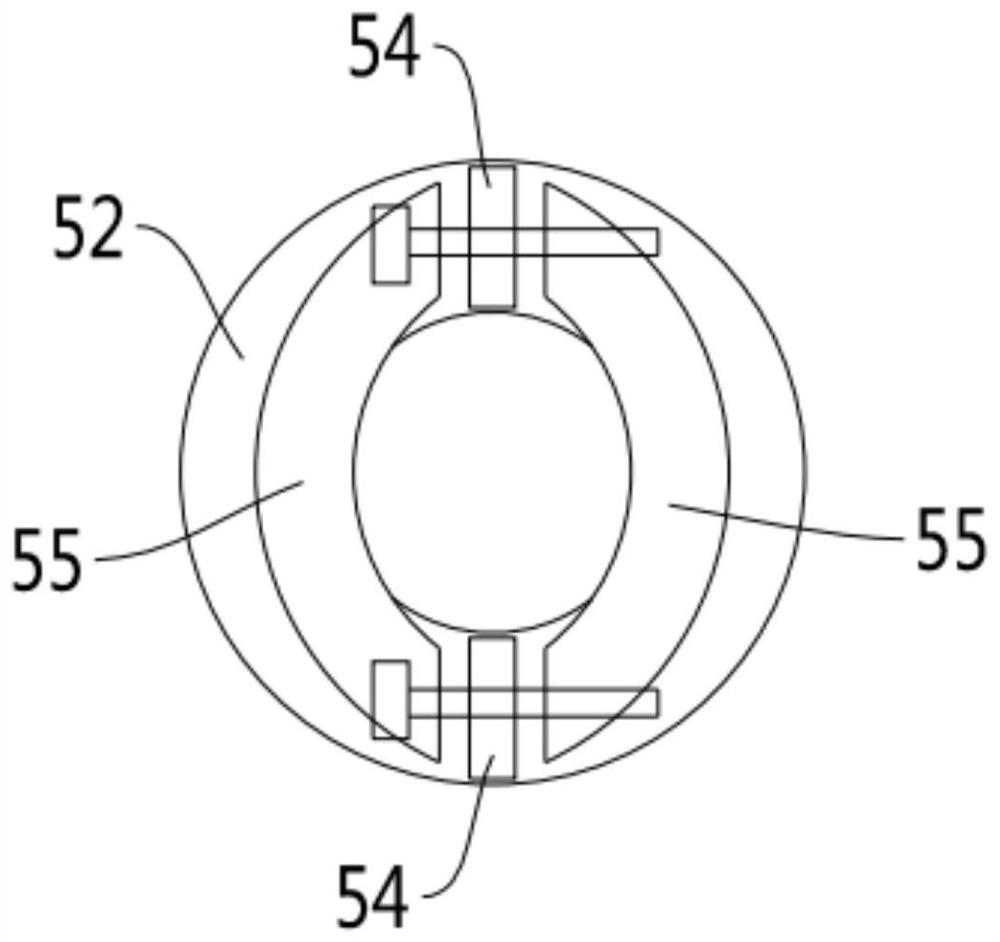

InactiveCN107275262AEliminate impact damageQuick releaseSemiconductor/solid-state device manufacturingCleaning using toolsDrive shaftWafer Product

The invention provides a roller brush unit concentric snapping structure for cleaning wafers. An elastic telescopic snapping structure is arranged on a driving unit for realizing quick snapping and changing. The roller brush unit concentric snapping structure reduces a non-coaxiality manufacturing tolerance between a driving shaft and an idle shaft. The rotating shaft and the driving shaft or the idle shaft of the roller brush utilize a structure form in which a conical hole and a conical shaft are connected in a flexible concentric positioning manner and a square hole and a square shaft are connected in a rigid engaging force transmission manner, thereby reducing a rigid connection degree and the rotating shaft, the driving shaft and the idle shaft of the roller brush, attenuating rotation bounce of the rotating shaft of the roller brush, and eliminating impact of roller brush bounce to a wafer. A glyd ring is arranged for realizing bidirectional sealing. Not only is bidirectional leakage of the idle shaft is settled, but also a function of supporting the idle shaft in concentric rotation is performed. The roller brush unit concentric snapping structure for cleaning the wafers is used for a cleaning system after chemically mechanical polishing (CMP) of the wafer, thereby preventing impact damage of the wafer by the roller brush, improving wafer product quality, reducing sealing gasket changing frequency and prolonging maintenance period of the cleaning equipment.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

Hard sealing two-way disc valve

The present invention relates to one kind of hard sealed bi-directional butterfly valve. The valve has clearance fitted valve seat with conic inner hole, inner step and compression spring in the inner cavity; and butterfly plates on the valve rod inside the valve body with outer sealing surface fitting the conic inner surface of the valve seat to form sealing pair. The butterfly plates may be closed hollow structure including the left plate with curved outer surface, inside reinforcing ribs for connection with the left plate and right planar plate. The upper part of the valve body may have drive mechanism with hand wheel for the operation of opening and closing the valve. The present invention has bi-directional sealing, small flow resistance, high sealing performance, long service life, simple structure and other advantages, and may be used widely in various medium conveying pipelines.

Owner:陈国顺

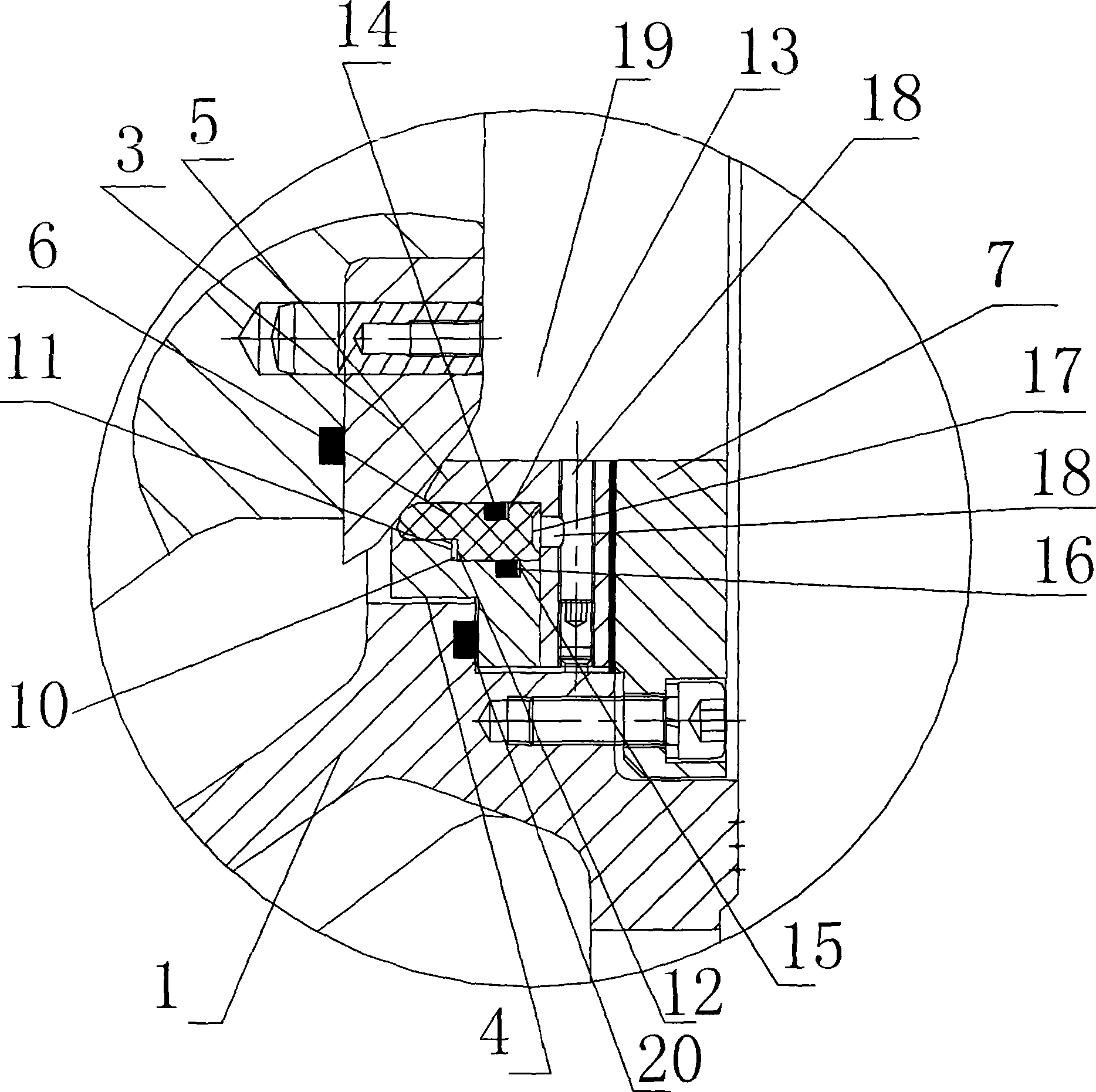

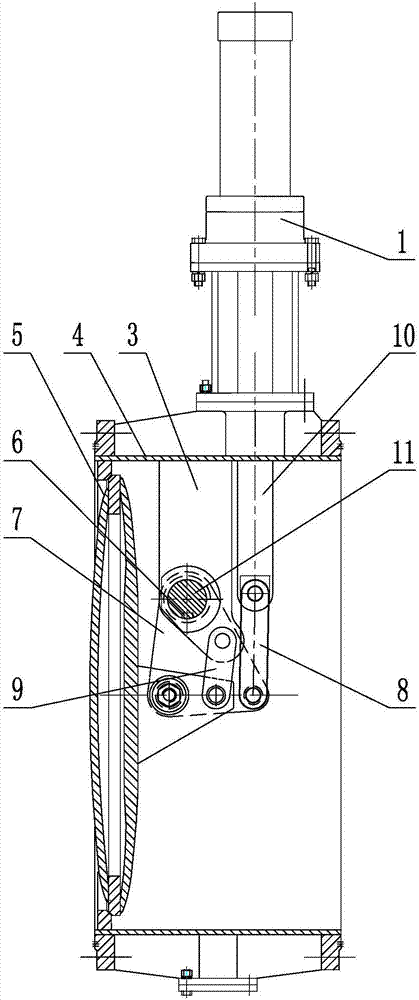

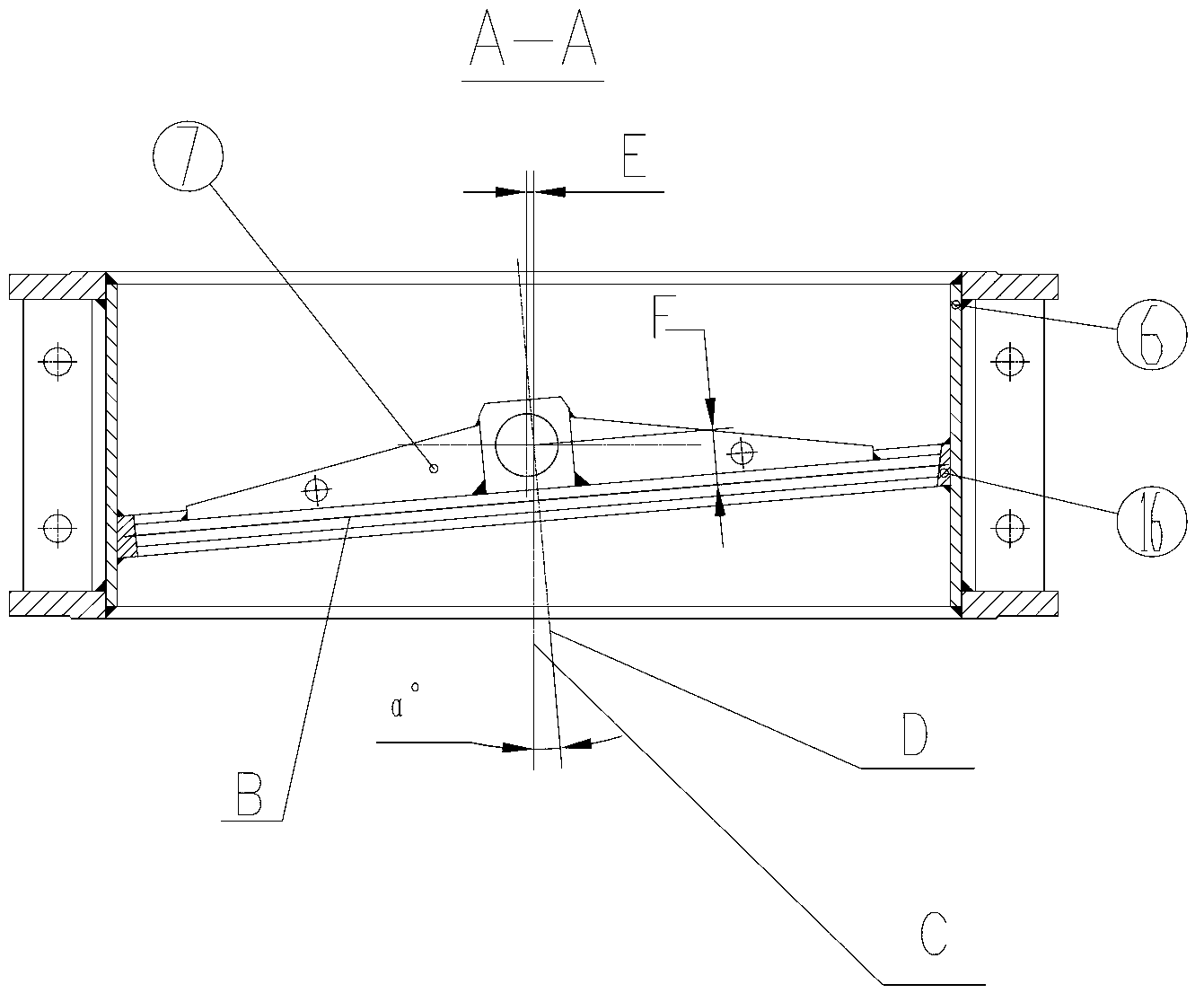

Four-eccentricity double-way sealing butterfly valve

ActiveCN104633142AEven by forceRealize two-way sealingSpindle sealingsLift valveFluid controlEngineering

The invention belongs to the field of fluid control valves and relates to a valve body which can achieve double-way sealing, in particular to a four-eccentricity double-way sealing butterfly valve. The four-eccentricity double-way sealing butterfly valve comprises a valve body, a valve plate, a valve rod and a sealing ring, the valve plate is mounted in the valve body, the valve rod is rotatably arranged in a shaft hole of the valve body, the valve plate is fixedly connected with the valve rod through a pin, and thereby, synchronous rotation of the valve plate and the valve rod can be achieved; a packing assembly, a packing gland and a packing pressure plate are sequentially arranged at a position of a packing box of the valve body and fixed and sealed through lock nuts and screws; a gasket, the sealing ring and a pressure ring are sequentially mounted on the valve plate and locked and fixed through hexagon bolts; a boss is arranged at two ends of a shaft shell of the valve plate respectively, and groove stands which are matched with the bosses are disposed in an inner cavity of the valve body. By means of the four-eccentricity double-way sealing butterfly valve, double-way sealing, good abrasive resistance, small required torque and long service life can be achieved, and stable and safe operation of devices can be guaranteed.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

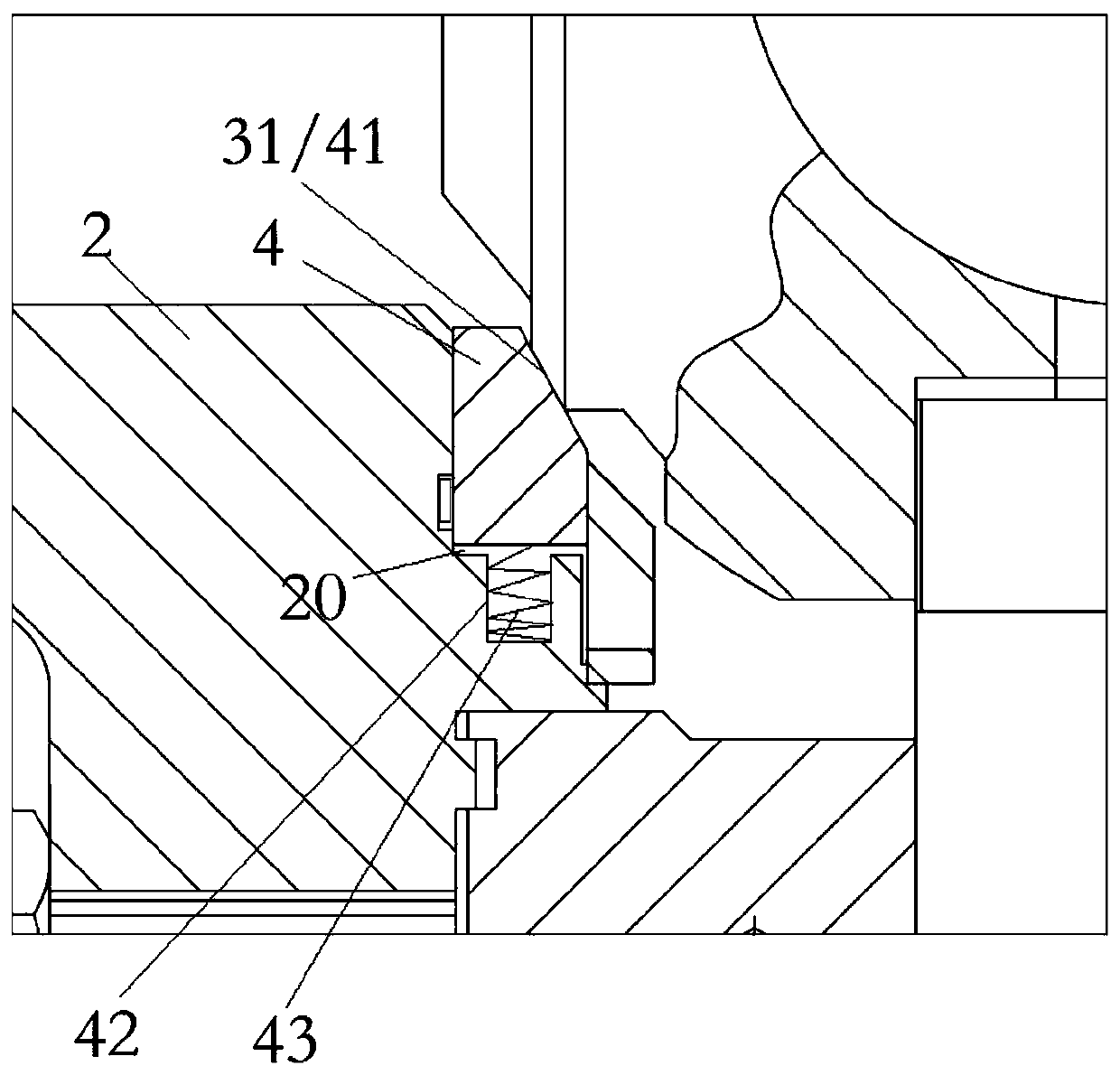

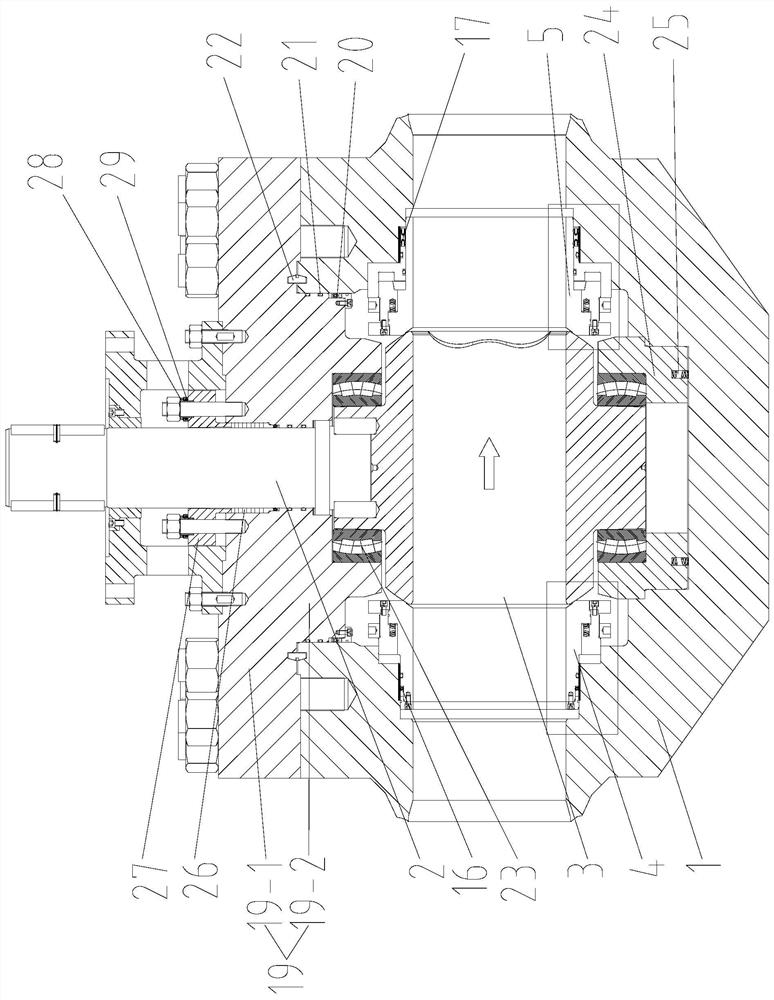

An eccentric ball valve

ActiveCN108980400BReduce the difficulty of assemblyAchieve high-precision bidirectional sealing performancePlug valvesValve housingsEngineeringValve seat

The invention provides an eccentric ball valve. The eccentric ball valve comprises a valve body, a valve cover, a valve ball and a valve seat; the valve body is provided with a middle cavity and a first fluid channel communicating with the middle cavity; the valve cover is detachably connected with the valve body and is provided with a second fluid channel; after the valve cover and the valve bodyare connected, the second fluid channel communicates with the middle cavity; the valve ball is rotationally installed inside the middle cavity through an operation mechanism and is provided with a valve ball sealing face; the valve seat is installed on the valve cover and is provided with a valve seat sealing face capable of extruding the valve ball sealing face to seal the second fluid channel;and the valve seat is installed on the valve cover through an adjustable installing structure in a manner of being capable of finely moving, under driving of the operation mechanism, the valve ball rotates to enable the valve ball sealing face and the valve seat sealing face to be in extrusion contact gradually, the valve seat can finely move, and even-pressure sealing can be achieved between thevalve ball sealing face and the valve seat sealing face. By means of the eccentric ball valve, continuous abrasion of the valve ball and the valve seat can be avoided, and the good sealing performanceis achieved.

Owner:SHANDONG AFA FLOW CONTROL

Top-mounted gas storage metal hard sealing ball valve capable of being maintained online

ActiveCN113154077ABig spaceSmall reciprocating strokePlug valvesValve housingsEngineeringFire prevention

The invention provides a top-mounted gas storage metal hard sealing ball valve capable of being maintained online. The top-mounted gas storage metal hard sealing ball valve comprises a valve body, a ball body, a valve rod and a valve seat; a first low plane, a first step and a second low plane are sequentially arranged on the outer side face of the valve seat; a moving space used for containing a spring seat is formed between the outer side face of the valve seat and the valve body; the spring seat comprises an extending section and a moving section; the length of the extending section is larger than that of the first step; a first spring is arranged in the face, making contact with the first step, of the moving section; a spring pressing plate is fixed to the end of the extending section; a limiting part is fixed to the inner side face of the valve body; the outer side face of the spring seat comprises a third low plane and a second step; the limiting part is located on the third low plane; the spring seat slides towards the ball body; and the limiting part abuts against the second step. The ball valve is in a top-mounted type, the sealing performance is stable and reliable, fire prevention and static prevention are achieved, the total torque of the valve is small, a second spring energy storage sealing ring and a first spring energy storage sealing ring are arranged so that bidirectional sealing can be achieved, and downstream inspection and maintenance are facilitated.

Owner:NEWTORK FLOW CONTROL CO LTD +1

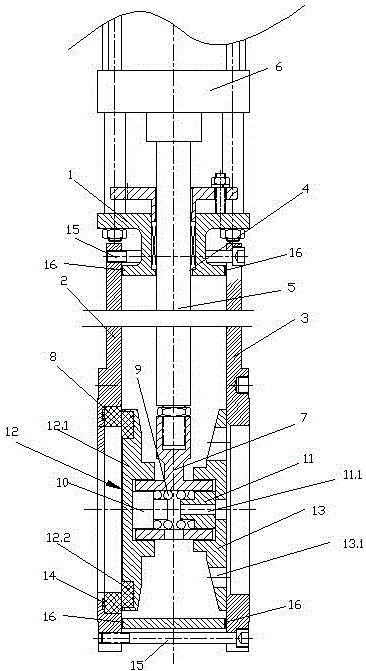

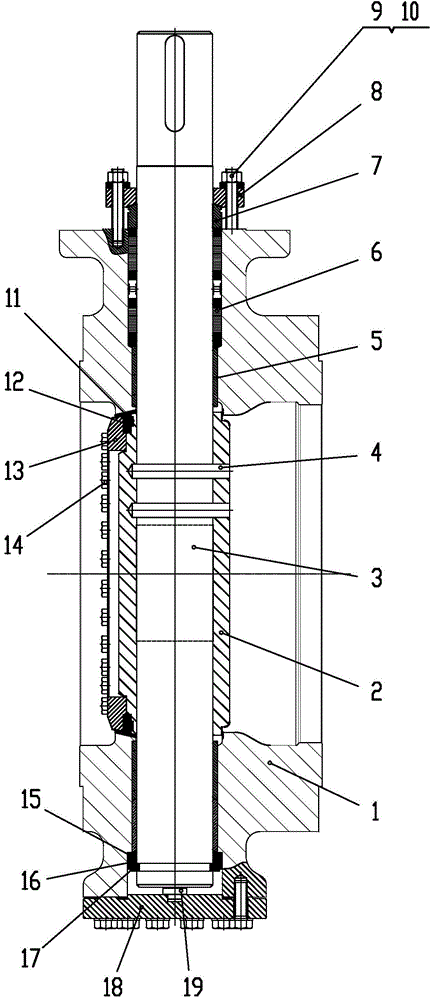

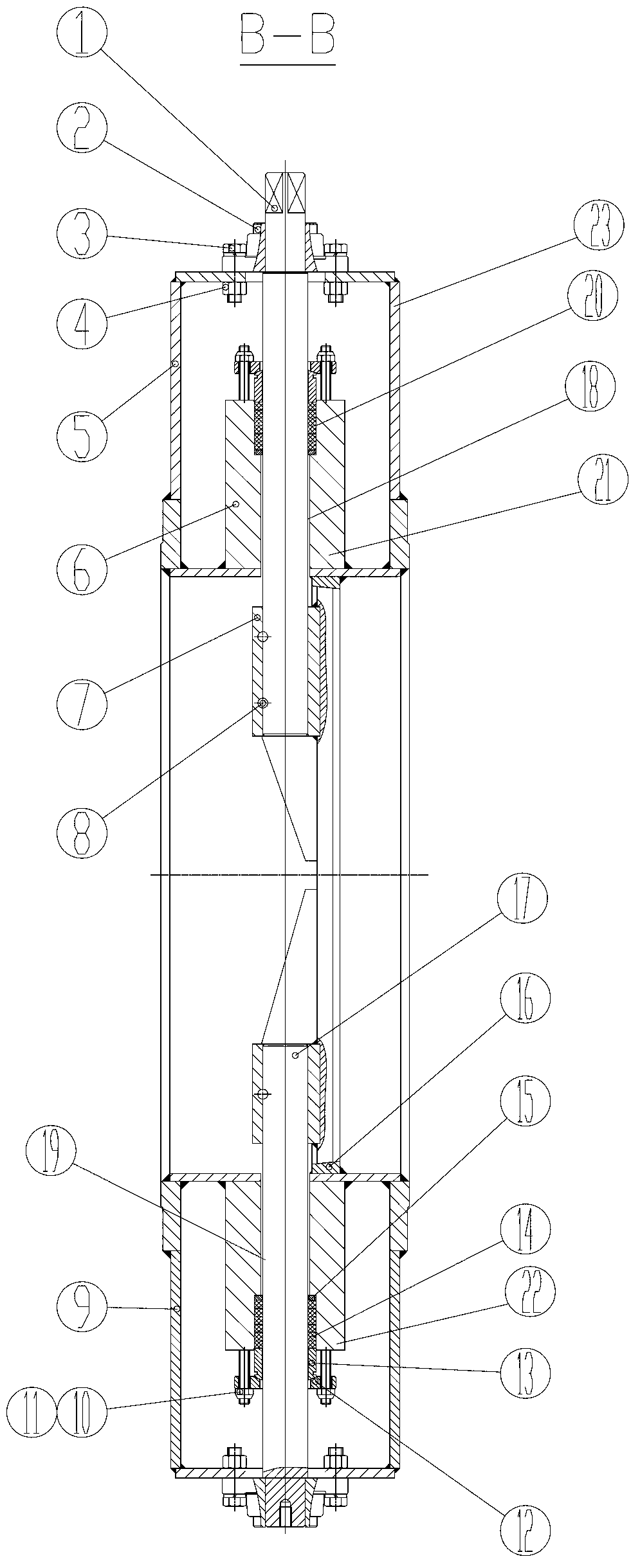

Ultra-low-temperature top entry ball valve and assembly method thereof

InactiveCN105257859ARealize two-way sealingPrevent Liquefaction BoostSpindle sealingsPlug valvesGraphiteEngineering

The invention discloses an ultra-low-temperature top entry ball valve and an assembly method thereof. The ball valve comprises a valve body, a valve cover, a valve rod and an operation mechanism, wherein the valve cover is connected with the valve body in a dismountable manner; a valve ball and a valve holder are arranged in a valve-body middle cavity of the valve body; the lower end of the valve rod penetrates through the valve cover and is connected with the valve ball; a drain board is welded to the valve cover; a steam cavity is arranged in the valve cover; a first pressure relief hole is formed in the valve rod; a second pressure relief hole is formed in the valve ball; the steam cavity, the first pressure relief hole and the second pressure relief hole are communicated with each other; a positioning ring, a positioning pin, an oblique triangular graphite sealing ring, a first lip-shaped sealing ring, a second lip-shaped sealing ring, a pressing ring, a disc spring, a threaded sleeve and an anti-rotation screw are arranged between the inner wall surface of the valve body and the valve holder; the anti-rotation screw penetrates through a positioning member and is connected with a threaded hole of the threaded sleeve; a valve holder sealing ring is fixedly arranged on the valve body and tightly presses the outer surface of the valve ball. Through the technical scheme, the ball valve disclosed by the invention is reasonable in structural design, simple in structure, good in sealing property, safe and reliable in use, and long in service life.

Owner:WUZHOU VALVE

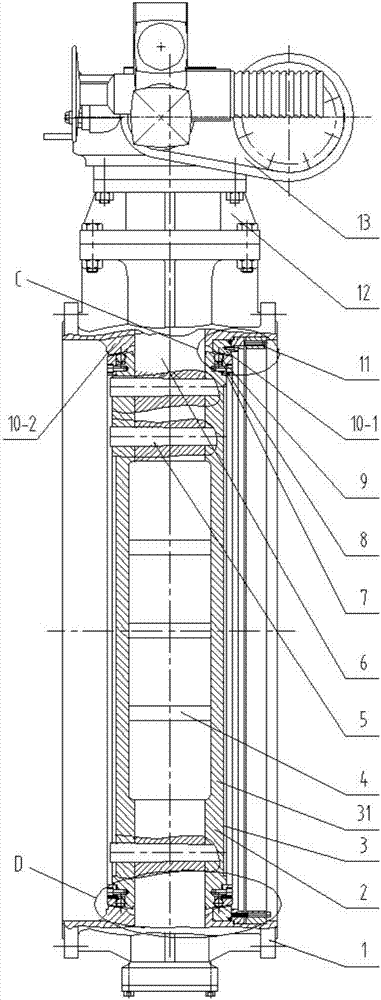

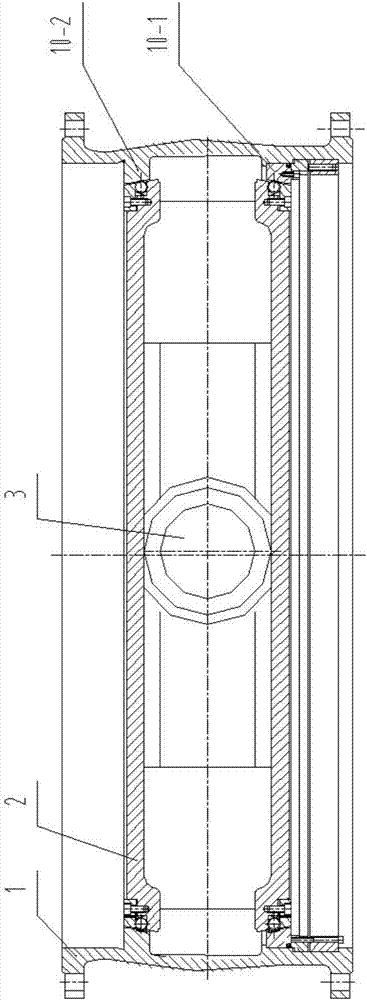

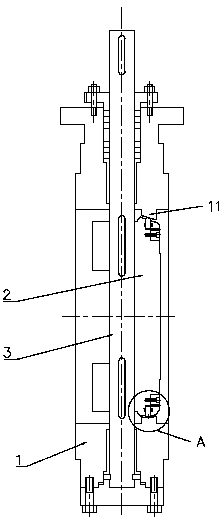

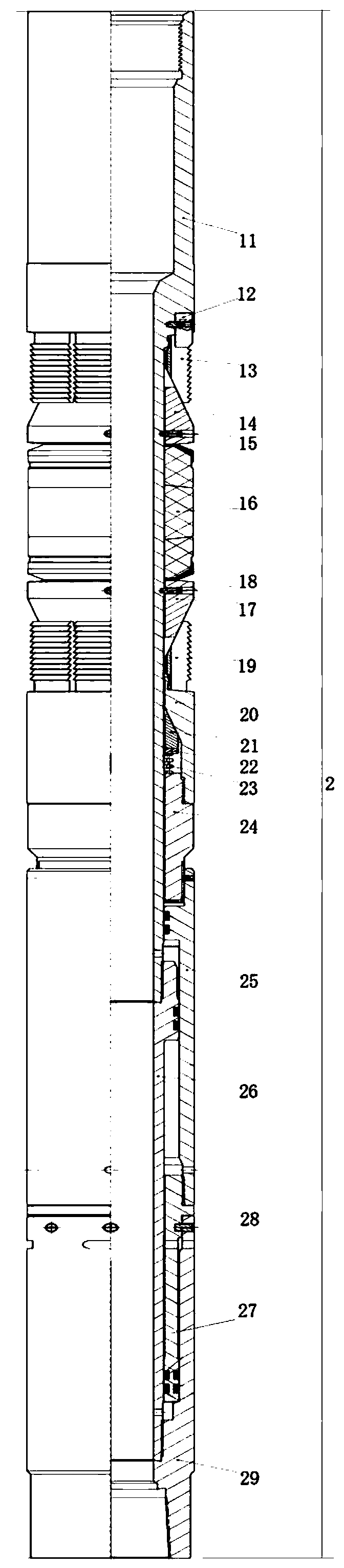

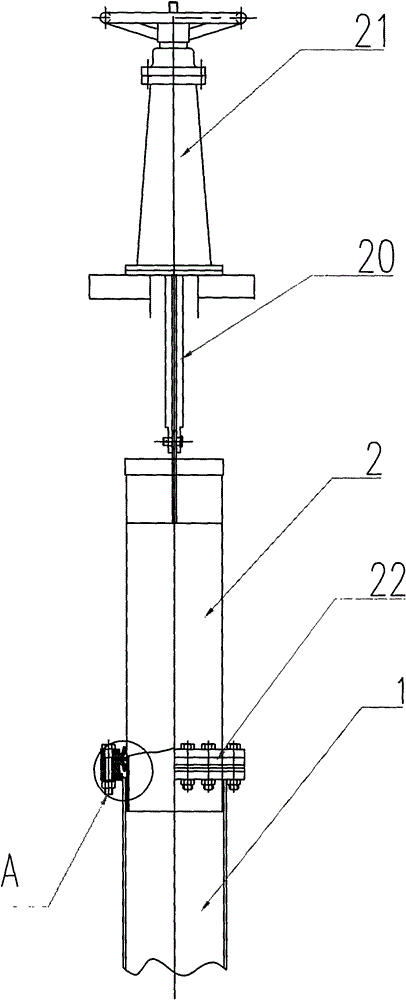

Integrated downhole operation tool based on bidirectional slip hydraulic permanent packer

The invention provides an integrated downhole operation tool based on a bidirectional slip hydraulic permanent packer. The operation tool comprises a test valve, a pressure gauge supporting cylinder,a liquid replacing valve, a plugging valve and the bidirectional slip hydraulic permanent packer, wherein the packer comprises an upper mandrel, a lower mandrel, an upper hydraulic outer cylinder, a lower hydraulic outer cylinder, a first shearing fixing piece, a second shearing fixing piece, a third shearing fixing piece, an upper slip, an upper cone, a rubber cylinder, a lower cone, a lower slip, a lock ring assembly, a double-male short section and an annular piston, wherein the upper slip, the upper cone, the rubber cylinder, the lower cone, the lower slip, the lock ring assembly and the double-male short section are sequentially arranged on the upper mandrel in a sleeving mode from top to bottom, and the annular piston is arranged on the lower mandrel in a sleeving mode. The upper endof the test valve can be connected with the upstream of the integrated downhole operation tool, the lower end of the test valve is connected with the upper end of a pressure gauge, the lower end of the pressure gauge is connected with the upper end of the liquid replacing valve, the lower end of the liquid replacing valve is connected with the upper end of the plugging valve, and the lower end ofthe plugging valve is connected with the bidirectional slip hydraulic permanent packer. The integrated downhole operation tool has the functions of oil testing and well completion production.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Multi-operating-condition valve sealing structure

The invention discloses a multi-operating-condition valve sealing structure. The multi-operating-condition valve sealing structure comprises a valve element front end sealing structure, a membrane, graphite seal rings and a pressing mechanism. The valve element front end sealing structure is located between valve seats and a valve body. The two sides of the membrane are provided with the graphiteseal rings correspondingly. The pressing mechanism is arranged on the radial outer side of the membrane. The membrane and the graphite seal rings are pressed onto a step structure of the valve body and the valve seats in the radial direction. A spring preload structure is arranged between the valve body and the valve seats. The multi-operating-condition valve sealing structure provided by the invention is applied to a ball valve or gate valve sealing system. The multi-operating-condition valve sealing structure makes a ball valve or a gate valve to realize bidirectional sealing under the condition of coexistence of two symmetric valve seats as the detachable sealing structure between the valve seats and the valve body. Under the combined action of medium force of the valve element front end sealing structure and spring force of the spring preload structure, the multi-operating-condition valve sealing structure applies pressure to the valve seat to achieve the sealing effect.

Owner:SHANGHAI VALVE FACTORY

Low-load type cut-off butterfly valve

The invention relates to a low-load type cut-off butterfly valve, in particular to a low-load cut-off butterfly valve which is developed for working conditions that the nominal pressure is low and cutting off is required, and belongs to the field of fluid control valves. A valve plate is mounted in a valve body; the valve body comprises sleeves provided with stuffing boxes, a stuffing component is arranged in each stuffing box, filler pressure plates are arranged on the outer side of the stuffing components, and the filler pressure plates are fixed at the end parts of a first sleeve and a second sleeve through screw rods and lock nuts; a first shaft hole and a second shaft hole are formed on the valve body, wherein the first shaft hole and the second shaft hole penetrate the first sleeve and the second sleeve respectively, a valve rod is arranged in the first shaft hole, and a driven shaft is arranged in the second shaft hole; a valve seat is arranged in the inner chamber of the valve body; the upper end and the lower end of the valve plate are in rotational connection with the valve rod and the driven shaft respectively; the valve seat is embedded in the inner chamber of the valve body to form a certain angle; the valve plate is an integral part with a triple eccentric structure; and when at open and middle positions, the valve seat is not in contact with the valve plate and dose not interfere with the valve plate.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

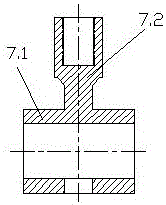

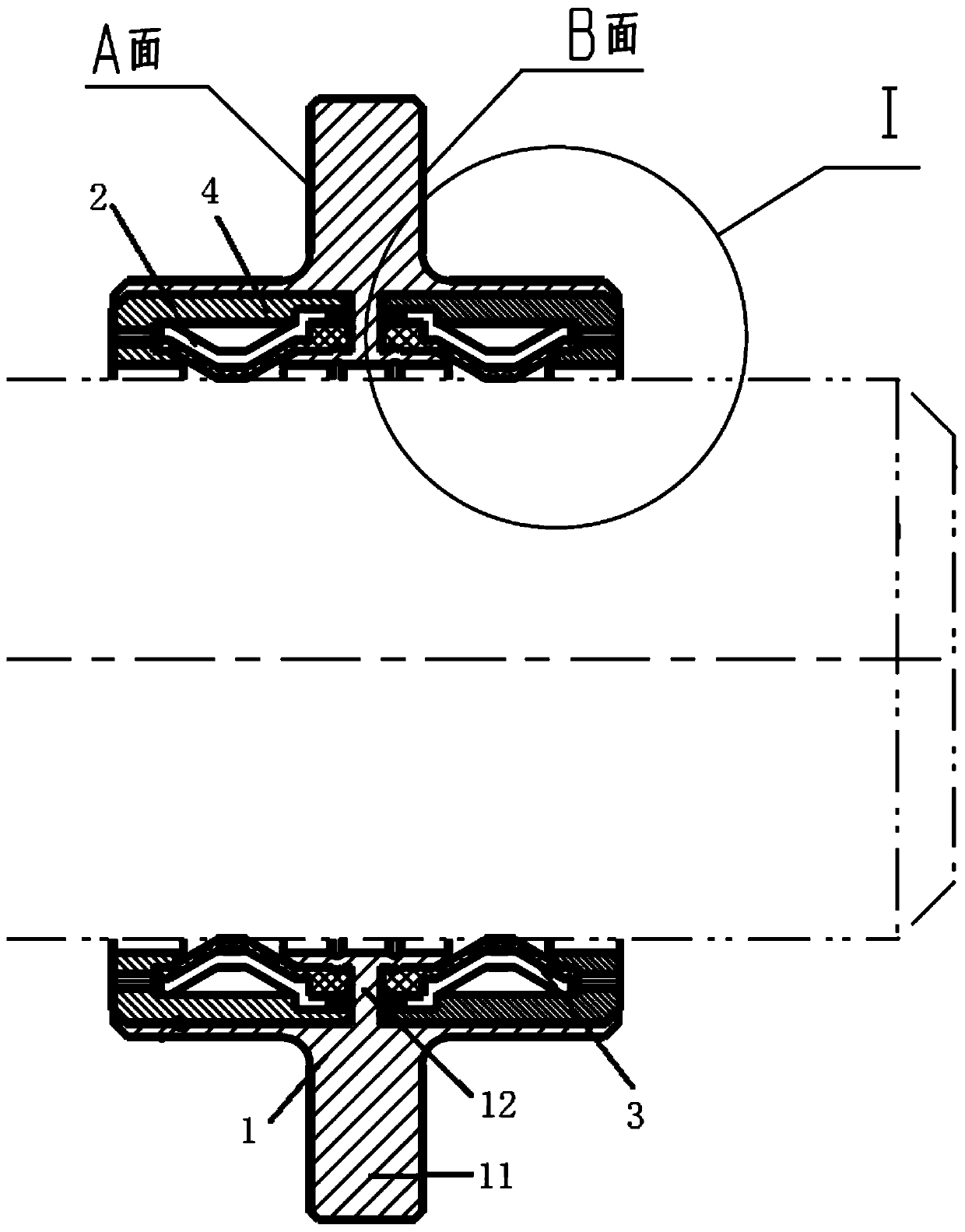

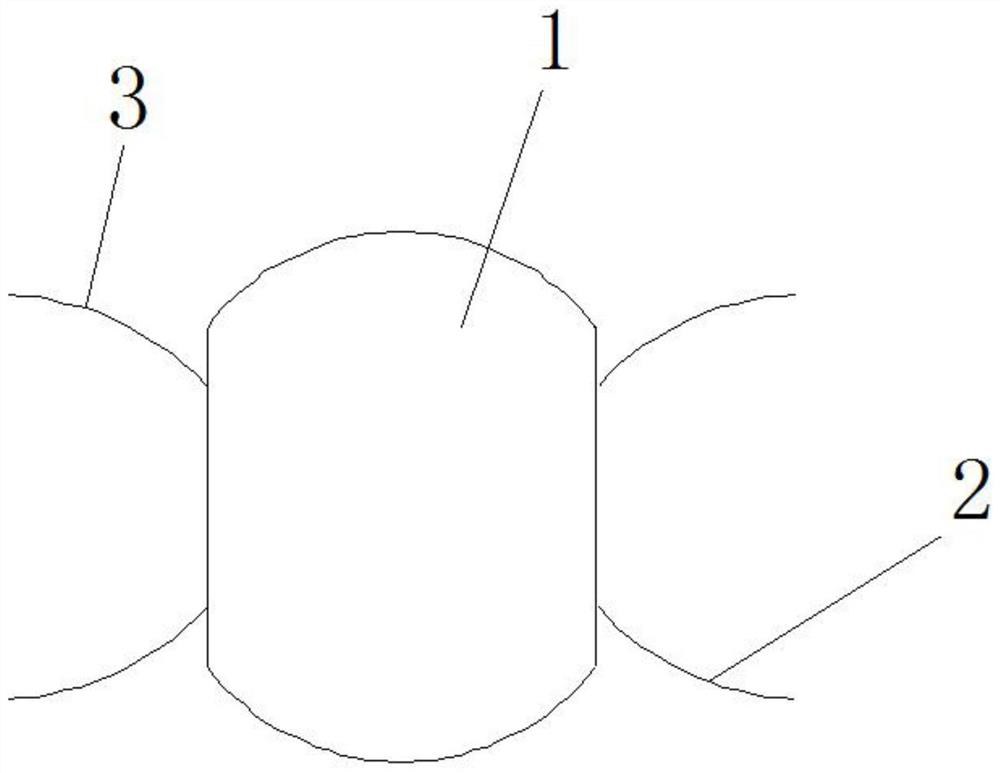

Novel bidirectional sealing sleeve

PendingCN107342575ARealize two-way sealingFree hold tightEngine sealsCable fittings in presence of gas/oilSafety coefficientEngineering

Disclosed in the invention is a novel bidirectional sealing sleeve comprising a sealing sleeve body. The sealing sleeve body consists of an axial sealing element and a radial sealing element that are connected mutually and have elasticity; and the axial sealing element and the radial sealing element are integrated into one. The axial sealing element is a cylindrical sleeve body holding the surface of an insulating shielding layer of a cable to form axial sealing. The radial sealing element is an annular gasket body that is compressed between a sealing flange and an inner tube flange of a cable terminal by the sealing flange to form horizontal sealing. The annular gasket body is arranged at the periphery of the cylindrical sleeve body and the center of the annular gasket body is overlapped with the center of the cylindrical sleeve body. Therefore, the sealing effect is improved; the potential safety hazard of oil leakage is reduced; the product quality and the safety coefficient of accessory operation of the cable are improved; and sealing of cables with different specifications can be realized by using a few of specifications.

Owner:JIANGSU ZHONGTIAN TECH CABLE ACCESSORIES CO LTD

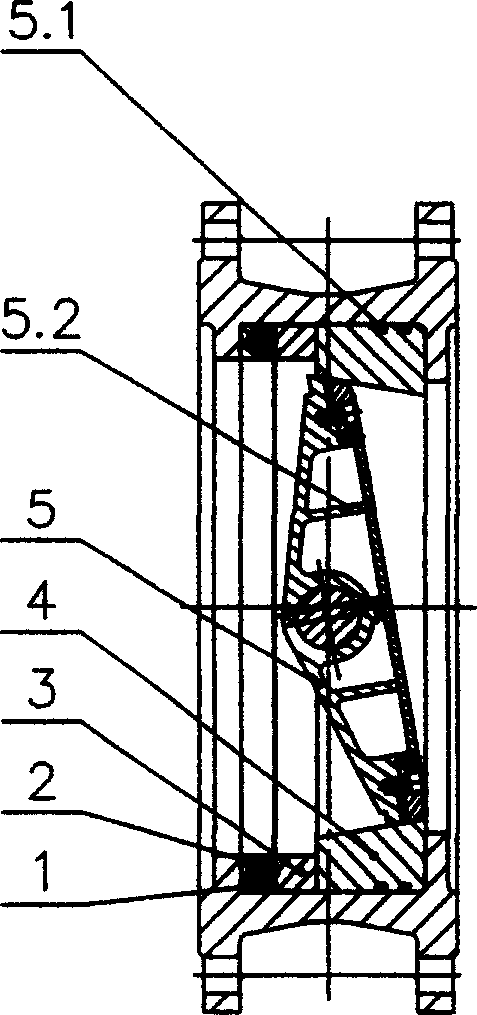

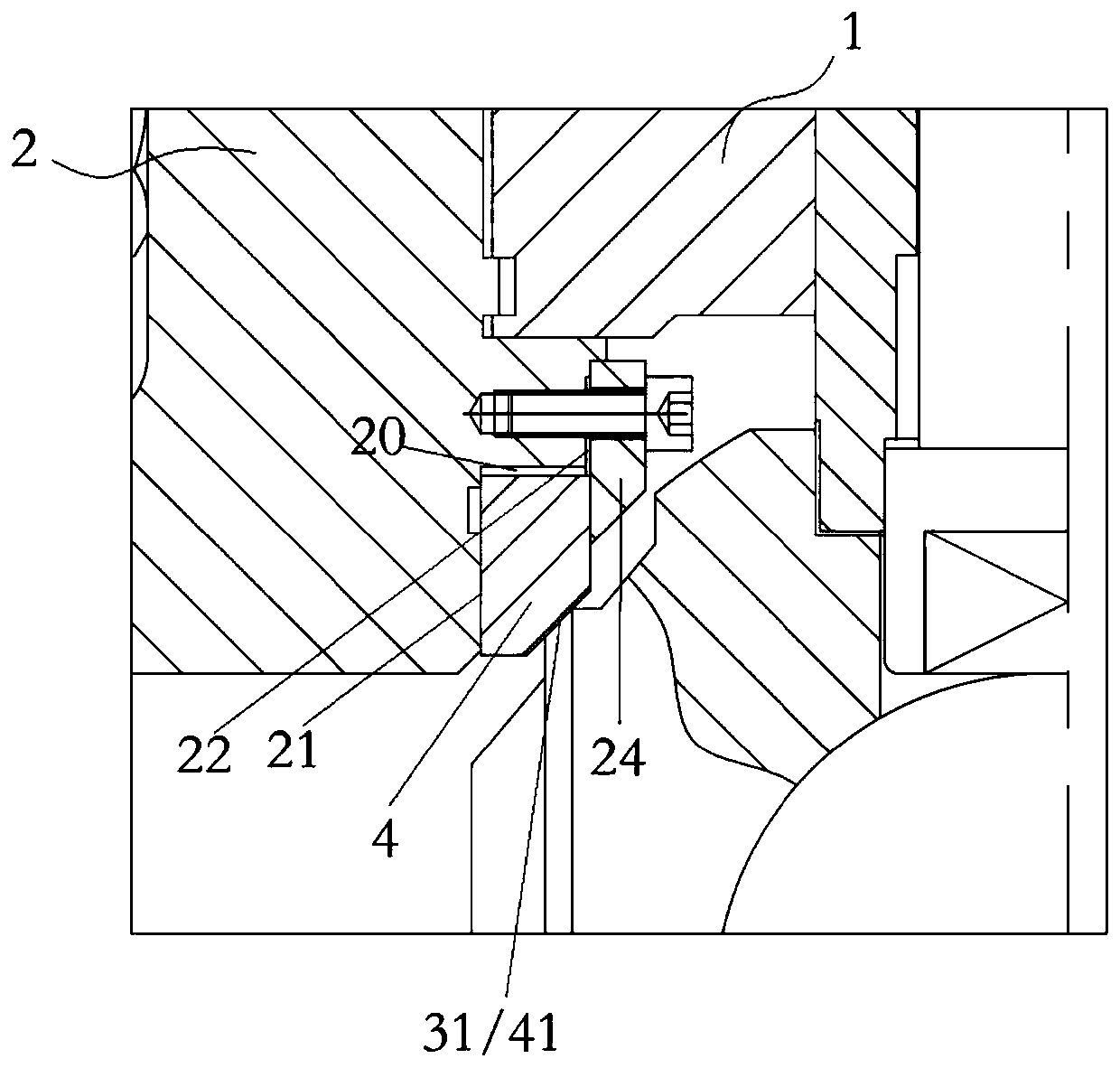

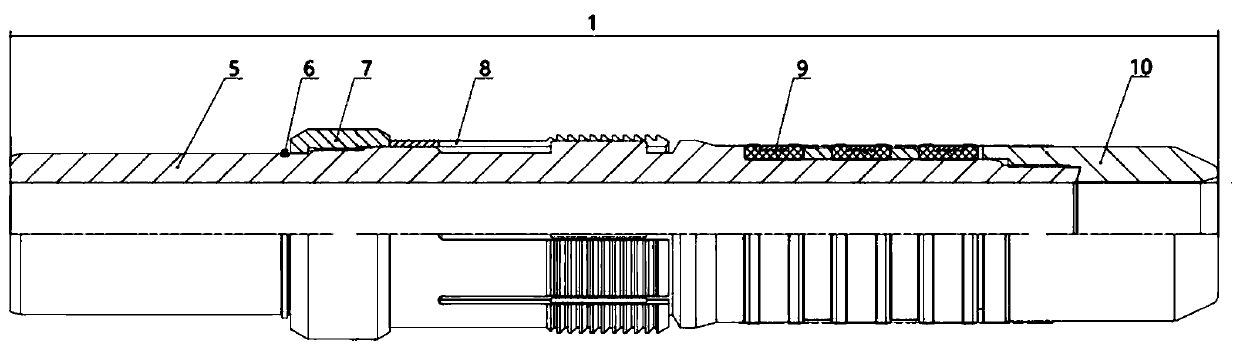

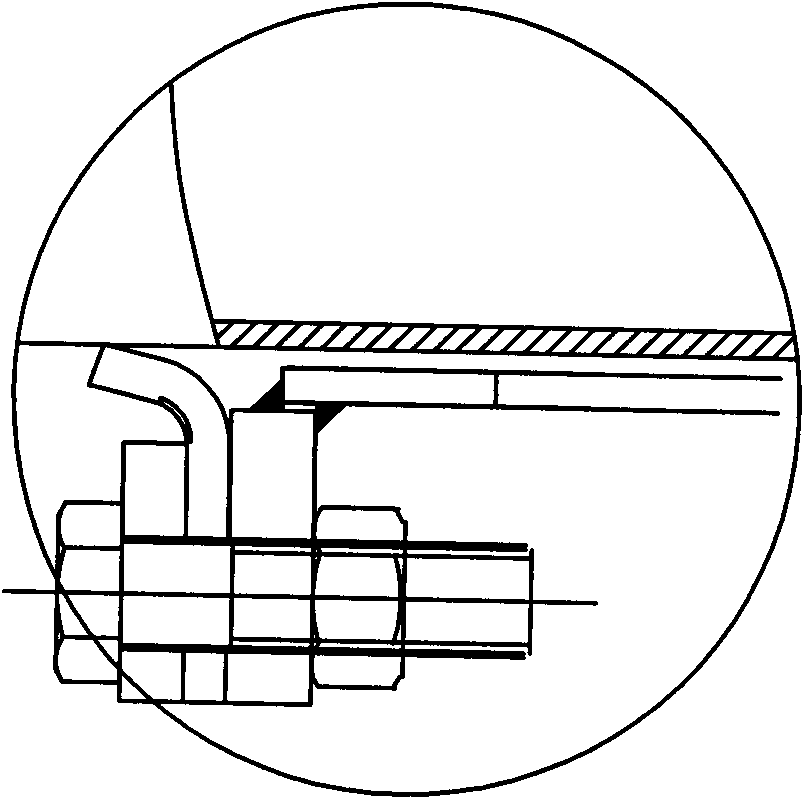

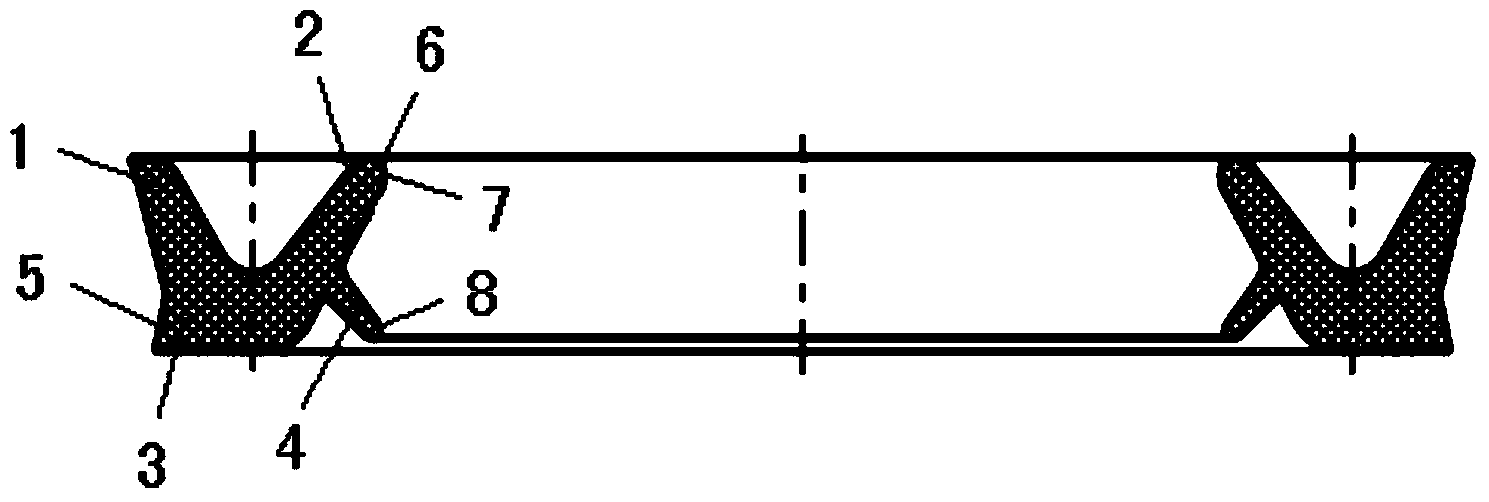

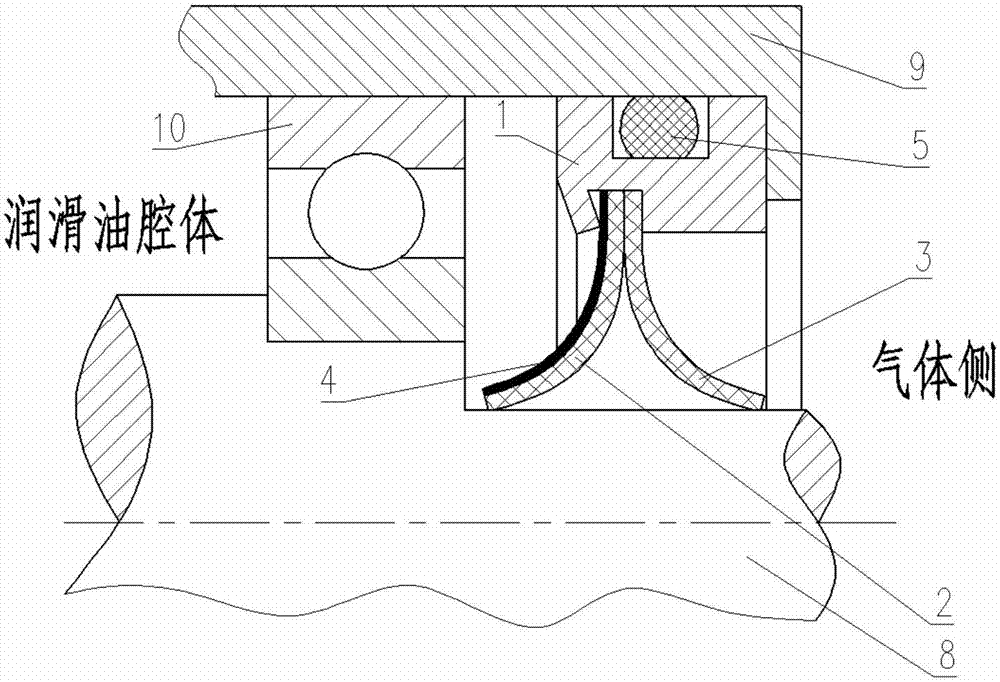

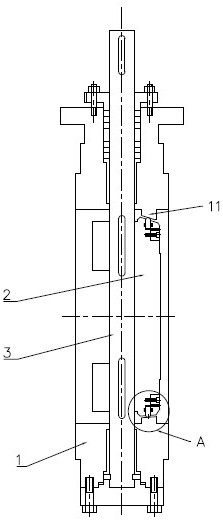

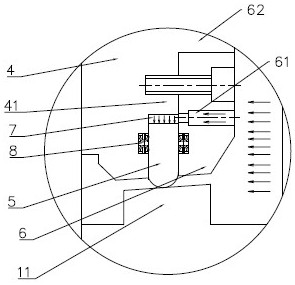

Sleeve valve

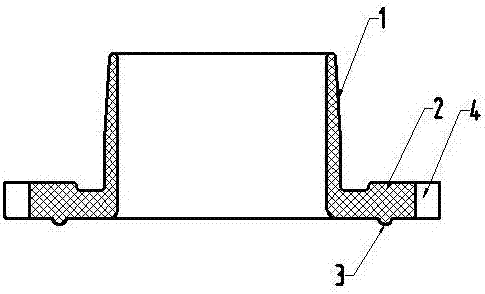

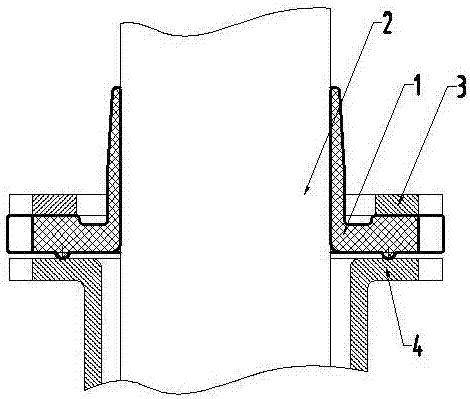

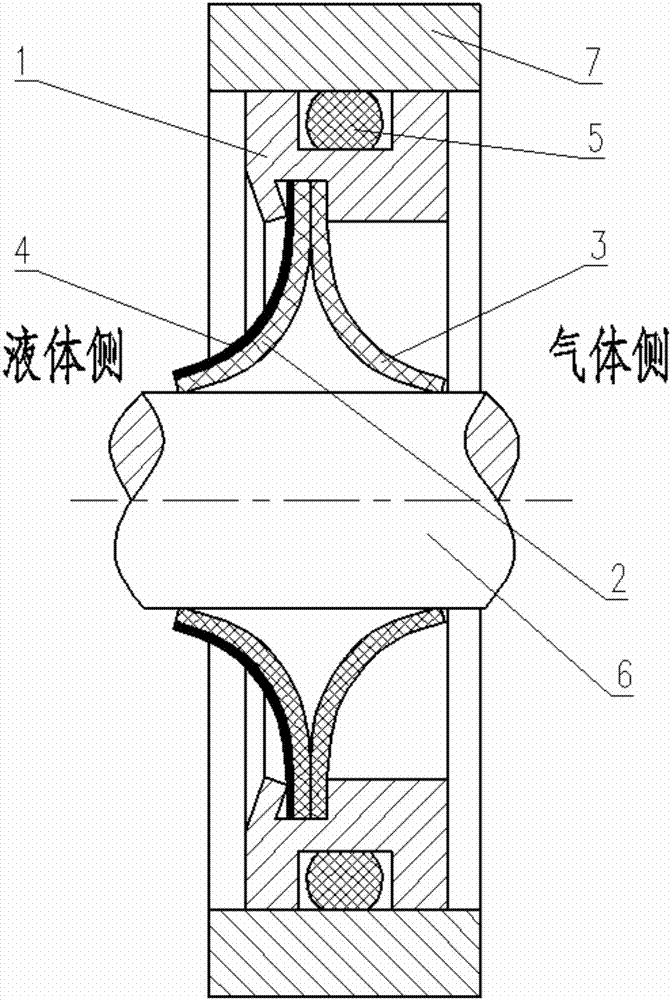

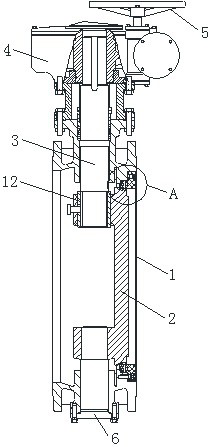

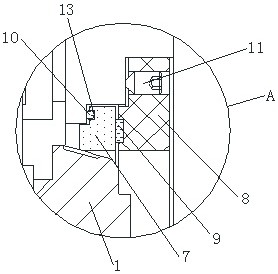

ActiveCN102691792APrevent backflowPrevent leakageValve arrangementsEngine sealsSleeve valveEngineering

The invention relates to a sleeve valve, which comprises an outer barrel (1) and an adjustment barrel (2) which can relatively slide up and down in the outer barrel (1), wherein a sealing device consisting of a flange (3), an upper sealing ring (4) of which the inner edge is upwards bent and a pressing plate (5) is arranged at the end of the outer barrel (1); and a lower sealing ring (8) of which the inner edge is downwards bent is arranged between the upper sealing ring (4) and the flange (3). An oil storage tank can store more lubrication oil, and the sealing effect is relatively good.

Owner:JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

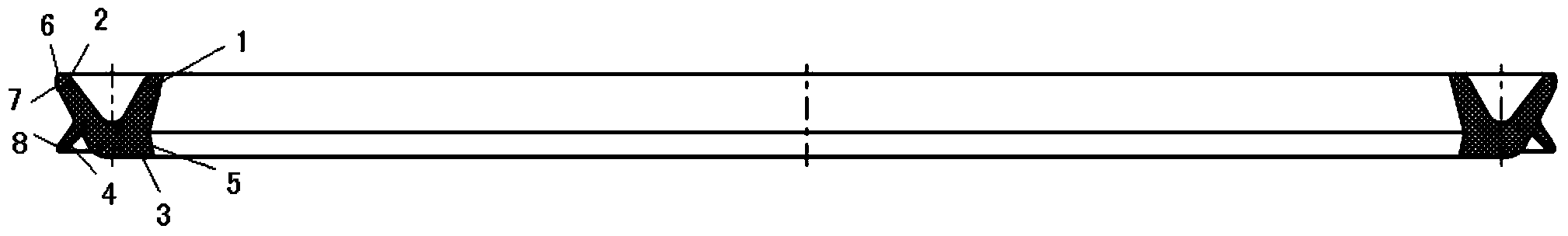

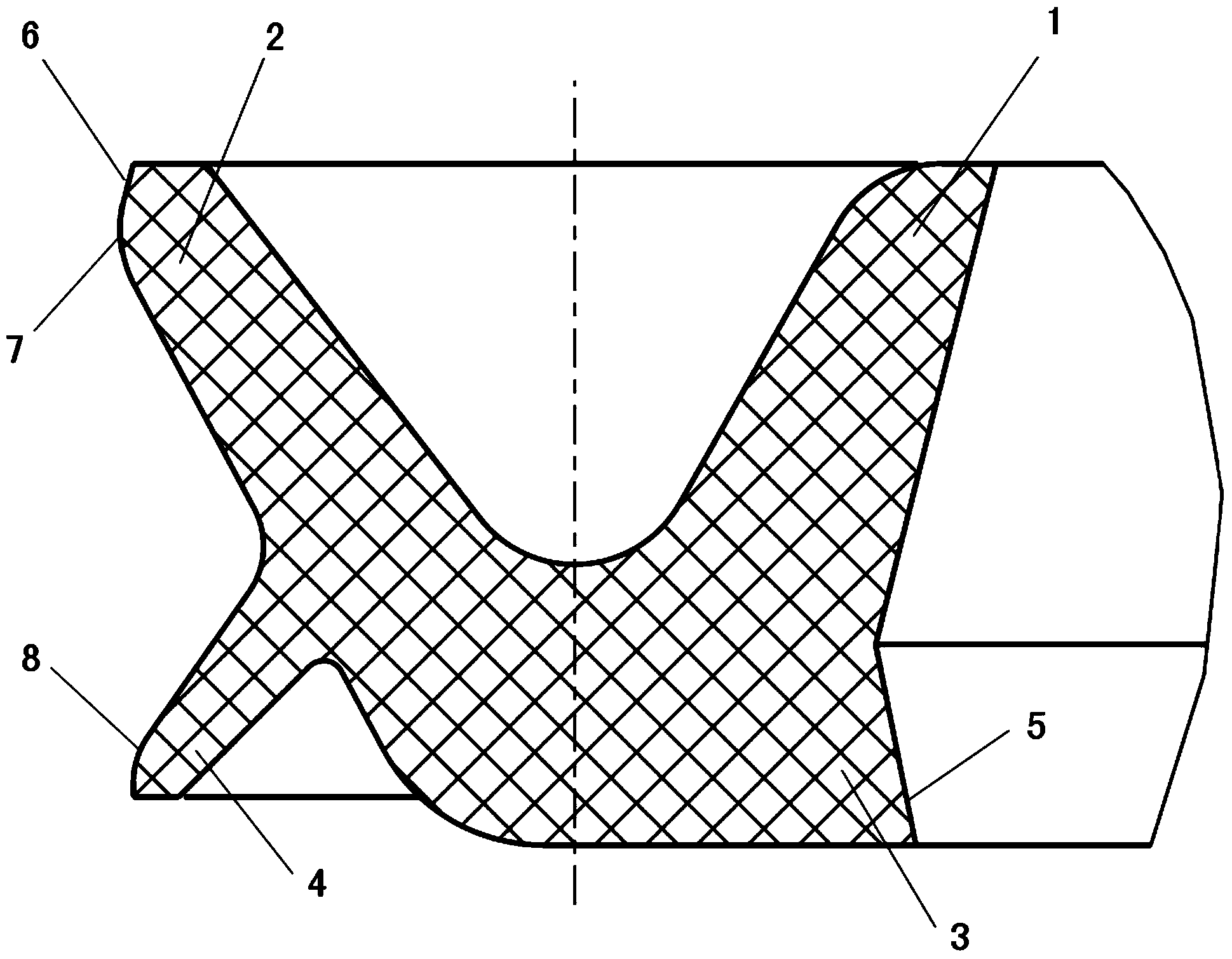

Pneumatic seal ring with irregularly-shaped cross section

ActiveCN103671930ARealize two-way sealingReduce resistanceEngine sealsFluid-pressure actuatorsLubricationMechanical engineering

The invention relates to a pneumatic seal ring with an irregularly-shaped cross section. The pneumatic seal ring comprises a sealing lip, a main sealing lip, a seal ring root portion and an auxiliary sealing lip, wherein the sealing lip, the main sealing lip, the seal ring root portion and the auxiliary sealing lip form a whole through injection molding. A groove is formed between the sealing lip and the main sealing lip, the seal ring root portion is located on the lower portion of the sealing lip, and the tail end of the main sealing lip turns upwards. An arc-shaped face serving as a contact face is arranged at the position, adjacent to the tail end of the main sealing lip, of one side of the main sealing lip, the auxiliary sealing lip is located below the main sealing lip, and the sealing direction of the auxiliary sealing lip is opposite to that of the main sealing lip. Another arc-shaped face serving as a contact face is arranged at the tail end of the auxiliary sealing lip. The pneumatic seal ring can realize bidirectional sealing, and when used in cooperation of other parts, can achieve the purpose of keeping lubrication grease on a seal working face. The pneumatic seal ring can be widely applied to sealing of pistons and piston rods.

Owner:北京隆轩橡塑有限公司

Full lining bidirectional composite soft sealing butterfly valve

InactiveCN101858441AGuaranteed anti-corrosion performanceExtended service lifeLift valveValve member-seat contactsWastewaterFresh water

The invention discloses a full lining bidirectional composite soft sealing butterfly valve, belonging to the butterfly valves for pipelines of a large-scale water supply and drainage engineering, sea water and wastewater treatment, fresh water, gases and the like. The full lining bidirectional composite soft sealing butterfly valve comprises a valve body, a valve seat, valve shafts, a valve plate, a connecting seat, a pressing cover, bushes, a seal ring and a rear end cover, wherein the valve seat is arranged on the valve body; the valve shafts are arranged on the central line of the valve body; the valve plate is connected with the valve shaft; the connecting seat, the pressing cover, the bush and the seal ring are mounted on the upper part of the valve body; and the rear end cover is arranged at the bottom of the valve body. The full lining bidirectional composite soft sealing butterfly valve is characterized in that the valve shaft is formed by connection of an upper valve shaft (4) and a lower valve shaft (9); the valve seat (3) adopts a composite off-center inclined plane sealing form to be directly vulcanized on the valve body (1) and fully cover the valve body (1); the valve plate (2) is an inclined plate sphere; the upper and lower supports of the valve body (1) are sealed through an O-shaped seal ring (8); and the bushes (7) are respectively installed in the upper and lower supports of the valve body (1). The invention has the advantages of corrosion resistance, long service life and good sealing property while avoiding lock or setover of closure.

Owner:SHANDONG LULIN VALVE

Ultralow-temperature high-bearing bidirectional sealing device

The invention relates to an ultralow-temperature high-bearing bidirectional sealing device. The device solves the problems of short service life, high cost and poor sealing performance of an existingshaft hole sealing structure. The device comprises a sealing framework and two dynamic sealing units; each dynamic sealing unit comprises a spring leaf, a plastic ring and a pressing sleeve; the sealing framework is of a sleeve structure, an annular sealing plate is arranged on the outer end surface of the sleeve structure, the two end surfaces of the annular sealing plate are in contact with a sealed device to form static sealing surfaces, a partition plate is arranged on the inner surface of the sleeve structure and divides a sleeve inner cavity symmetrically into two sealing cavities, the sealing units are in the sealing cavities correspondingly, the pressing sleeves are arranged in the sealing cavities, annular bosses are arranged on the inner surfaces of the tail ends of the pressingsleeves, and axial pressure guide holes are formed in the annular bosses; the front end of each plastic ring is arranged on the partition plate of the sealing framework, the middle part of the plasticring is pressed on a mounting shaft, and the tail end of the plastic ring is arranged on the annular boss of the corresponding pressing sleeve; and the spring leaves are arranged between the plasticrings and the pressing sleeves in a sleeve mode, and each spring leaf comprises a fixing ring and multiple elastic membrances.

Owner:XIAN AEROSPACE PROPULSION INST

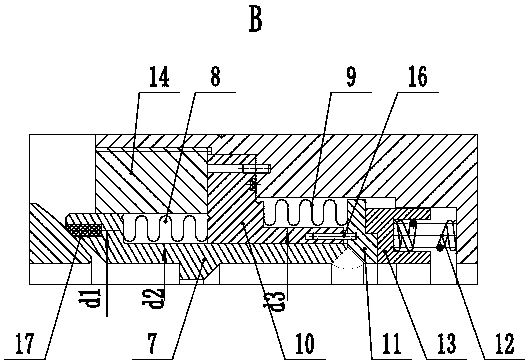

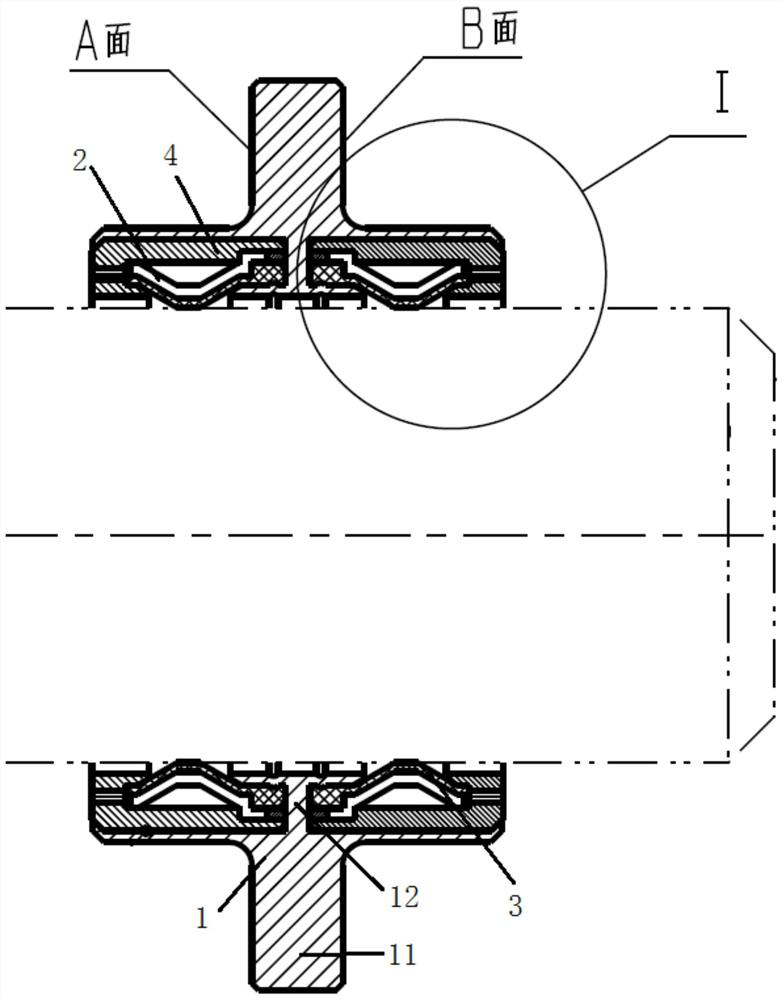

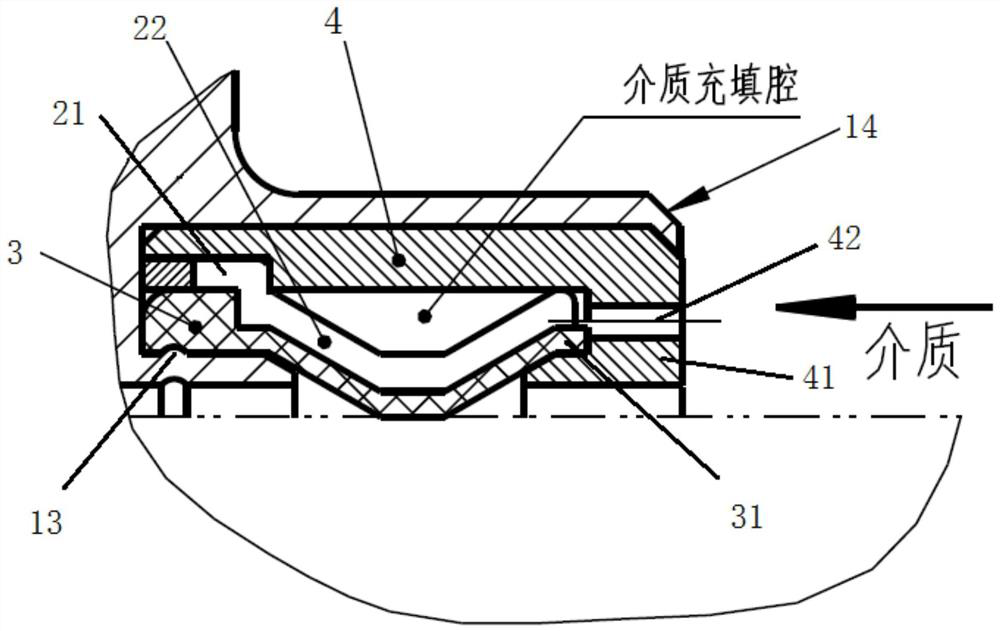

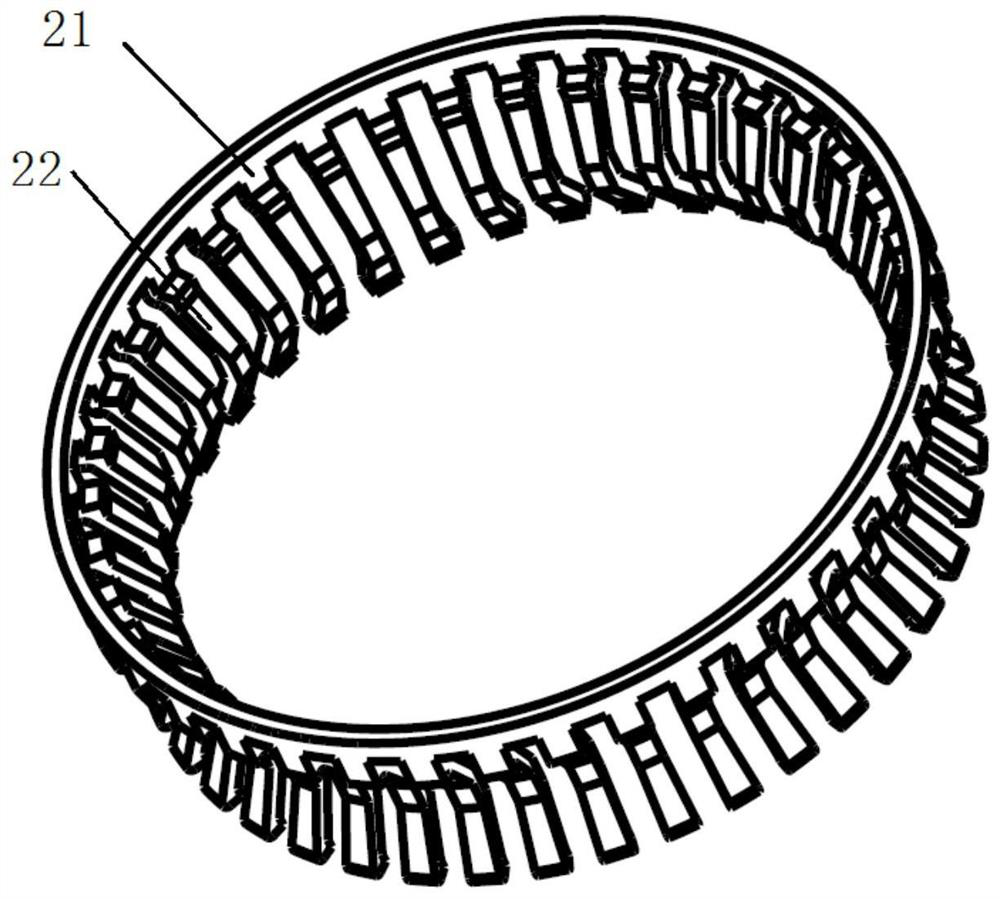

A New Bellows Sealed Ball Valve

ActiveCN105697808BRealize two-way sealingRealize automatic pressure reliefPlug valvesValve housingsVALVE PORTValve seat

The invention discloses a novel sealing ball valve with corrugated pipes. A valve seat assembly A and a valve seat assembly B are arranged on the two axial sides of a valve body respectively and respectively comprise a valve seat body, each valve seat body is provided with a sealing ring forming a sealing pair with a ball body, two corrugated pipes, namely the corrugated pipe I and the corrugated pipe II are installed on the outer ring of each valve seat body in a sectional mode and a sleeving mode and are welded to the two sides of a holder respectively, the other end of each corrugated pipe I is welded to the step surface on the outer ring of the corresponding valve seat body, the other end of each corrugated pipe II is welded to a valve seat check ring, the inner diameters of the corrugated pipe I and the corrugated pipe II of the valve seat assembly A are greater than the inner diameter of the sealing ring of the valve seat assembly A, the inner diameter of the corrugated pipe I of the valve seat assembly B is smaller than the inner diameter of the sealing ring of the valve seat assembly B, and the inner diameter of the corrugated pipe II of the valve seat assembly B is greater than the inner diameter of the sealing ring of the valve seat assembly B. The novel sealing ball valve has the beneficial effect of being applicable to severe working conditions, and valve seats on one side or both sides can realize the bidirectional sealing function.

Owner:JIANGSU SHENTONG VALVE

A two-way sealing device with ultra-low temperature and high load

The invention relates to an ultra-low temperature and high load-bearing bidirectional sealing device, which solves the problems of short service life, high cost and poor sealing performance of the existing shaft hole sealing structure. The device includes a sealing frame and two sets of dynamic sealing units, the dynamic sealing unit includes a spring sheet, a plastic ring and a pressing sleeve; the sealing frame is a sleeve structure, the outer end surface of the sleeve structure is provided with an annular sealing plate, and the two end surfaces of the annular sealing plate It is in contact with the sealed device to form a static sealing surface; the inner surface of the sleeve structure is provided with a partition, which separates the inner cavity of the sleeve into two symmetrical sealing chambers, and the sealing units are respectively arranged in the sealing chambers; the pressing sleeve is arranged in the In the sealing cavity, the inner surface of the end is provided with an annular boss, and the annular boss is provided with a pressure-inducing hole along the axial direction; the front end of the plastic ring is installed on the partition plate of the sealing frame, and the middle part is pressed on the installation shaft. The end is installed on the annular boss of the pressing sleeve; the spring sheet is sleeved between the plastic ring and the pressing sleeve, which includes a fixing ring and a plurality of elastic diaphragms.

Owner:XIAN AEROSPACE PROPULSION INST

Anti-tensile high-voltage electric box hose coupler

PendingCN112161132ARealize two-way sealingFirmly connectedJoints with sealing surfacesCable junctionsStructural engineeringScrew thread

The invention discloses an anti-tensile high-voltage electric box hose coupler. The anti-tensile high-voltage electric box hose coupler comprises a main amplitude pipe with a first rotary knob part; afirst connecting end with an external thread on the outer surface is arranged at one end of the main amplitude pipe; a second connecting end with an internal thread on the internal surface is arranged at the other end of the main amplitude pipe; the first connecting end is in threaded connection with a packing nut; a clamping ring and a hose sheath are arranged between the packing nut and the first connecting end; the hose sheath is embedded into the first connecting end; the hose sheath comprises an external bowl; a bowl opening is formed in the bottom of the external bowl; a bowl opening isextended to form a bowl pipe; the bowl pipe is sleeved with the clamping ring; and the clamping ring is embedded into the external bowl. The electric box hose coupler has the characteristics of excellent sealing performance and firm connection; the global function is perfect; and the practicability is high.

Owner:浙江雷诺尔电气有限公司

A Rotary Sealing Structure Capable of Two-way Sealing

Owner:CHINA NORTH VEHICLE RES INST

Bidirectional sealing strip and oil-immersed transformer with same

PendingCN113555187AFix leaksImprove working stability and service lifeTransformers/inductances coolingTransformers/inductances casingsPower equipmentEngineering

The invention relates to the technical field of power equipment, and discloses a bidirectional sealing strip which comprises a sealing strip body, and the two sides of the sealing strip body extend outwards to form a forward elastic sealing part and a reverse elastic sealing part respectively. Compared with the prior art, the bidirectional sealing strip or sealing ring has the following advantages that bidirectional sealing can be achieved, when a sealing leakage point appears in main sealing of a sealing container, the forward elastic sealing part and the reverse elastic sealing part seal the leakage point under the action of pressure, and the sealing state is formed. The leakage problem of a sealing system is effectively solved, and the service life and working stability of the transformer are improved.

Owner:广东中顺电气制造有限公司

a sleeve valve

ActiveCN102691792BPrevent backflowPrevent leakageValve arrangementsEngine sealsSleeve valveEngineering

The invention relates to a sleeve valve, comprising an outer cylinder (1), an adjusting cylinder (2) that can slide up and down in the outer cylinder (1), and a flange (3), A sealing device composed of an upper sealing ring (4) with an inner edge bent upward and a pressure plate (5), and a lower sealing ring with an inner edge bent downwards is also provided between the upper sealing ring (4) and the flange (3) (8). The invention can store more lubricating oil in the oil storage tank, and the sealing effect is better.

Owner:JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

Seal rotary ball valve with anti-loose press ring and valve seat capable of floating in single direction

PendingCN111828675ARealize two-way sealingEasy to manufacturePlug valvesOperating means/releasing devices for valvesValve seatPhysics

The invention relates to a seal rotary ball valve with an anti-loose press ring and a valve seat capable of floating in a single direction. The seal rotary ball valve comprises a valve body and a valve plate. The valve plate is located in the valve body, a valve rod is installed in the valve body, a driving device is installed on the upper portion of the valve body, and a hand wheel is installed on the top end of the driving device. The upper end of the valve rod is in transmission connection with the driving device, the lower end of the valve rod is connected with the upper end of the valve plate, and the bottom end of the valve body is fixedly provided with a seal base. The valve seat is arranged in the valve body and located on the top of the valve plate, and the press ring is embeddedin one side of the valve body and located on the outer side of the valve seat. According to the seal rotary ball valve, through cooperation arrangement of the valve seat, the press ring, a first sealblock, a second seal block and a locking screw, dual-direction seal between the valve body and the valve plate can be achieved, a spline housing is welded to the valve plate, so that the valve rod isconnected with the valve plate through the spline housing, and accordingly the rotary ball valve is more easily manufactured.

Owner:ZHENGZHOU ALDU VALVE CO LTD

Metal seal triple eccentric butterfly valve

ActiveCN111043332BElastic contact sealing effect is goodGood self-sealingLift valveEngineeringButterfly valve

Owner:KCM VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com