A New Bellows Sealed Ball Valve

A technology for sealing ball valves and bellows, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of unusable, rubber sealing components not resistant to high temperature and low temperature, to extend service life and prevent torsion Invalidation, the effect of increasing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

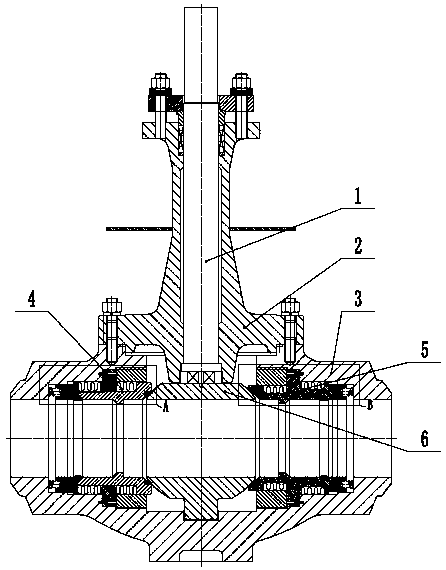

[0028] Such as figure 1 , 2 , 3, a new type of bellows-sealed ball valve, including a valve body 3, a ball 6 is arranged in the inner cavity of the valve body 3, and a valve stem that is linked with the ball 6 and protrudes from the top of the valve body 3 is also arranged in the valve body 3 1. The valve stem 1 is supported and limited by the valve cover 2, and the valve seat assembly A4 and the valve seat assembly B5 are respectively arranged on both axial sides of the ball 6,

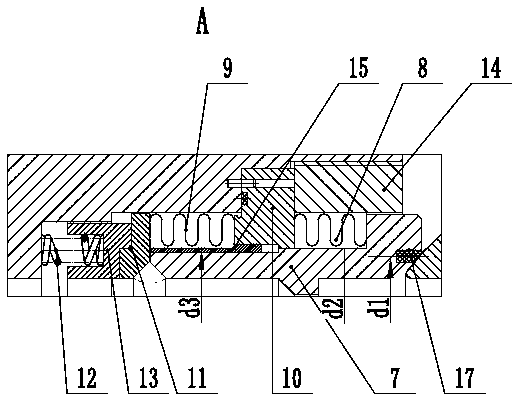

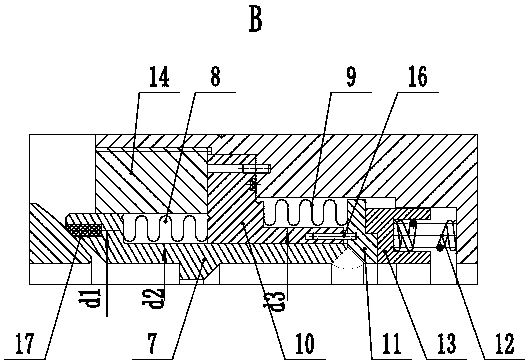

[0029] Both the valve seat assembly A4 and the valve seat assembly B5 include a valve seat body 7, on which a sealing ring 17 forming a sealing pair with the sphere 6 is arranged, and two bellows are set on the outer ring of the valve seat body 7 in sections , are respectively bellows I8 and bellows II9, the two bellows are respectively welded on both sides of the cage 10, the other end of the bellows I8 is welded to the stepped surface of the outer ring of the valve seat body 7, the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com