A Rotary Sealing Structure Capable of Two-way Sealing

A rotary sealing and two-way sealing technology, which is applied to engine sealing, engine components, mechanical equipment, etc., can solve problems such as narrow working temperature range, high lubricant dependence, and inability to balance high and low temperature resistance, and achieve a wide applicable temperature range , Lubrication conditions are low, and the effect of reducing frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

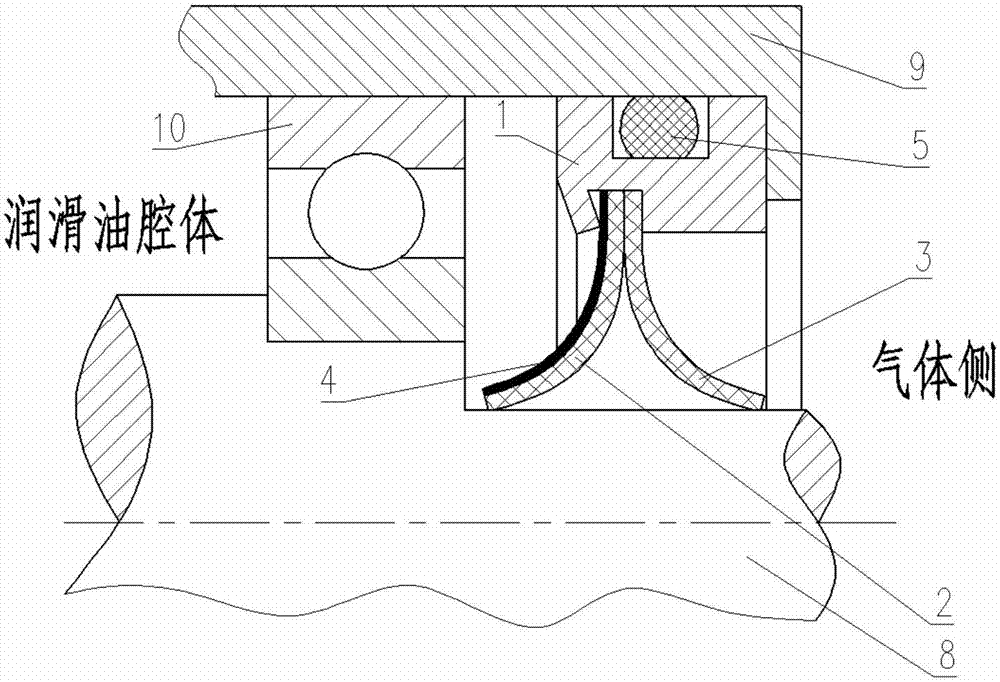

[0042] This embodiment provides an installation structure of the rotary sealing structure. The partial section diagram of the installation is attached image 3 As shown, the process of function realization is as follows:

[0043] The outer surface of the base body 1 is provided with an annular groove, and the O-ring 5 is installed in the annular groove.

[0044] The base body 1 is mounted on the inner surface of the end cap 9 without relative rotation between them, and the base body 1 and the end cap 9 are statically sealed through the O-ring 5 .

[0045] The inner surface of the base 1 is provided with an annular groove, and the rebound device 4 and the sealing lip 2 and the sealing lip 3 are pressed and installed in the annular groove on the upper inner surface of the base 1. Under moderate compression force, the connection between them is airtight.

[0046] The rotating shaft 8 is supported and positioned with the end cover 9 through the bearing 10 . After the installat...

Embodiment 2

[0050] This embodiment provides a combined structure in which two rotary seal structures are used at the same time, and is especially suitable for rotary seals that separate air passages in mechanical structures. The partial sectional view of the installation is attached Figure 4 As shown, the process of function realization is as follows:

[0051] as attached Figure 4 As shown: the base body 11 can be regarded as an extended deformation of the base body 1, and there are two annular grooves on the left and right sides of the outer surface of the base body 11, and the O-rings 5 are installed in the annular grooves.

[0052] The base body 11 is installed on the inner surface of the rotating body 14 , achieves a static seal with the rotating body 14 through the O-ring 5 , and rotates together with the rotating body 14 .

[0053] There are two annular grooves on the left and right sides of the inner surface of the base body 11, and the sealing lip 2, the sealing lip 3 and th...

Embodiment 3

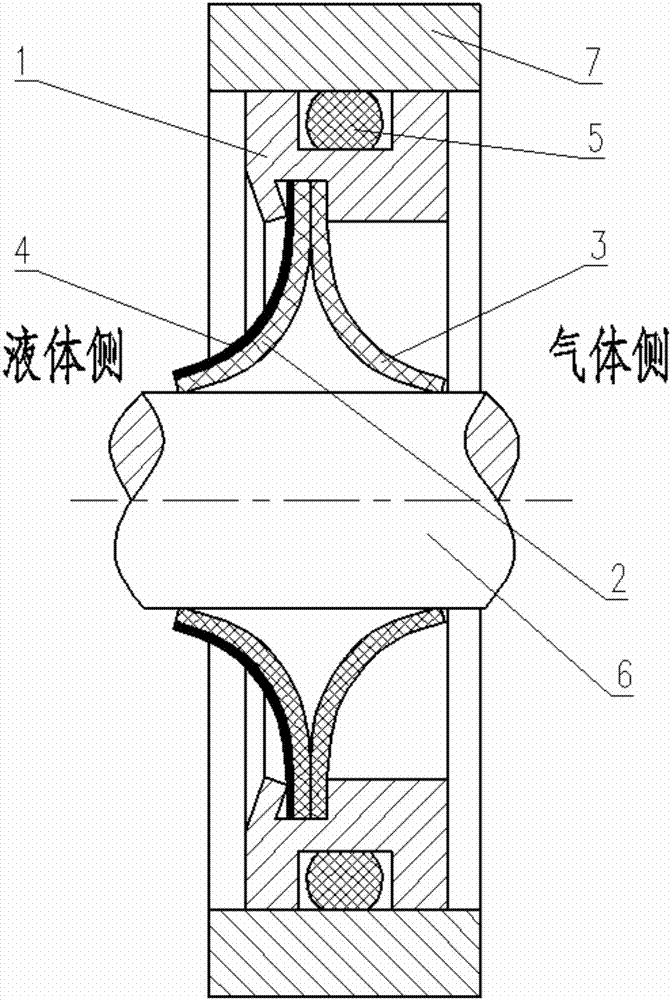

[0060] This embodiment provides a rotary sealing structure, such as figure 1 As shown, the rotary sealing structure includes: a base body 1 , a first sealing lip 2 , a second sealing lip 3 , a rebound device 4 , and an O-ring 5 .

[0061] The outer surface of the base 1 is provided with an annular groove, and the O-ring 5 is installed in the annular groove on the upper outer surface of the base 1 .

[0062] The inner surface of the base body 1 is also provided with an annular groove, the rebound device 4 is installed on one side of the sealing lip 2, the rebound device 4 and the sealing lip 2, the sealing lip 3 It is installed in the annular groove on the upper inner surface of the base body 1, and the connection between them is sealed, so that gas and liquid cannot pass through the rebound device 4, the sealing lip 2, and the sealing lip 3 connection with the substrate 1.

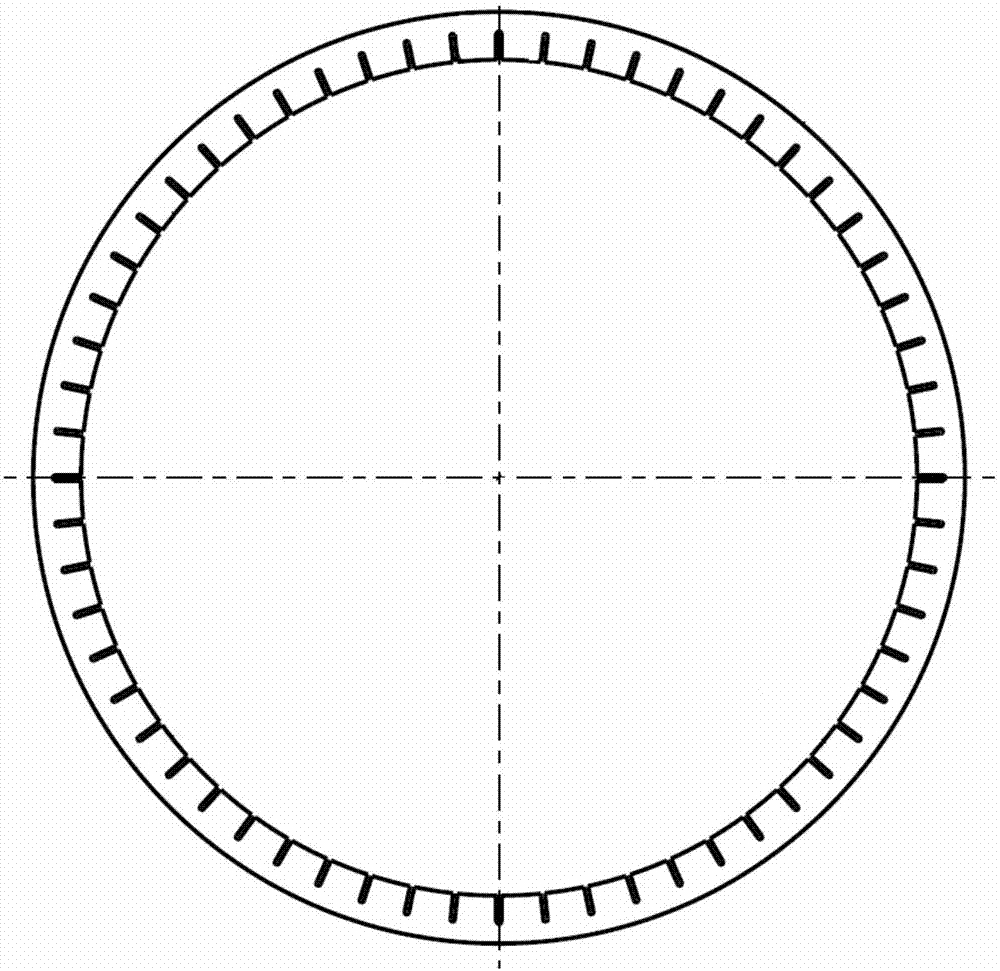

[0063] The sealing lip 2 and the sealing lip 3 are circular thin slices, the inner diameters of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com