Patents

Literature

267results about How to "Small installation size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

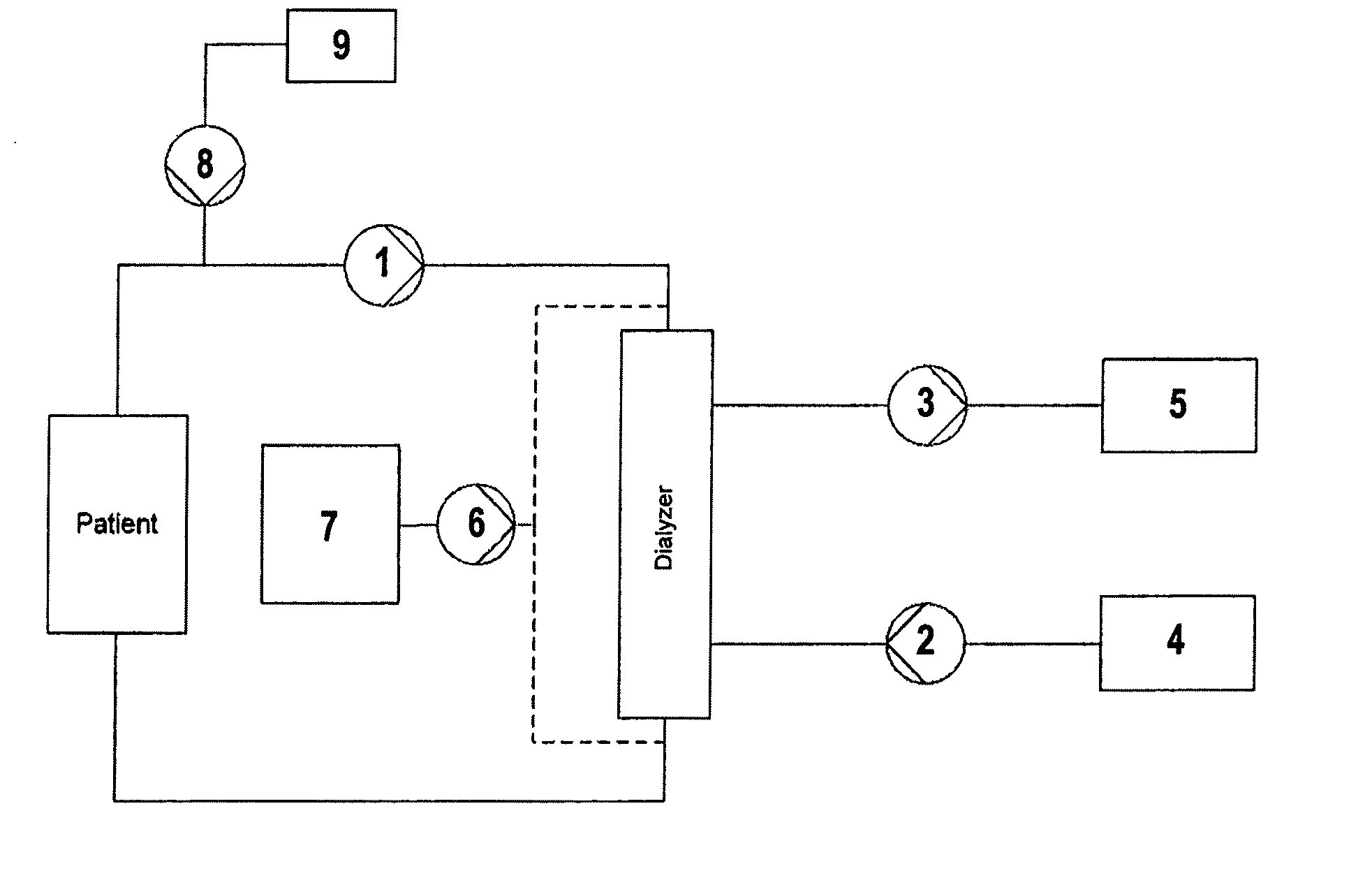

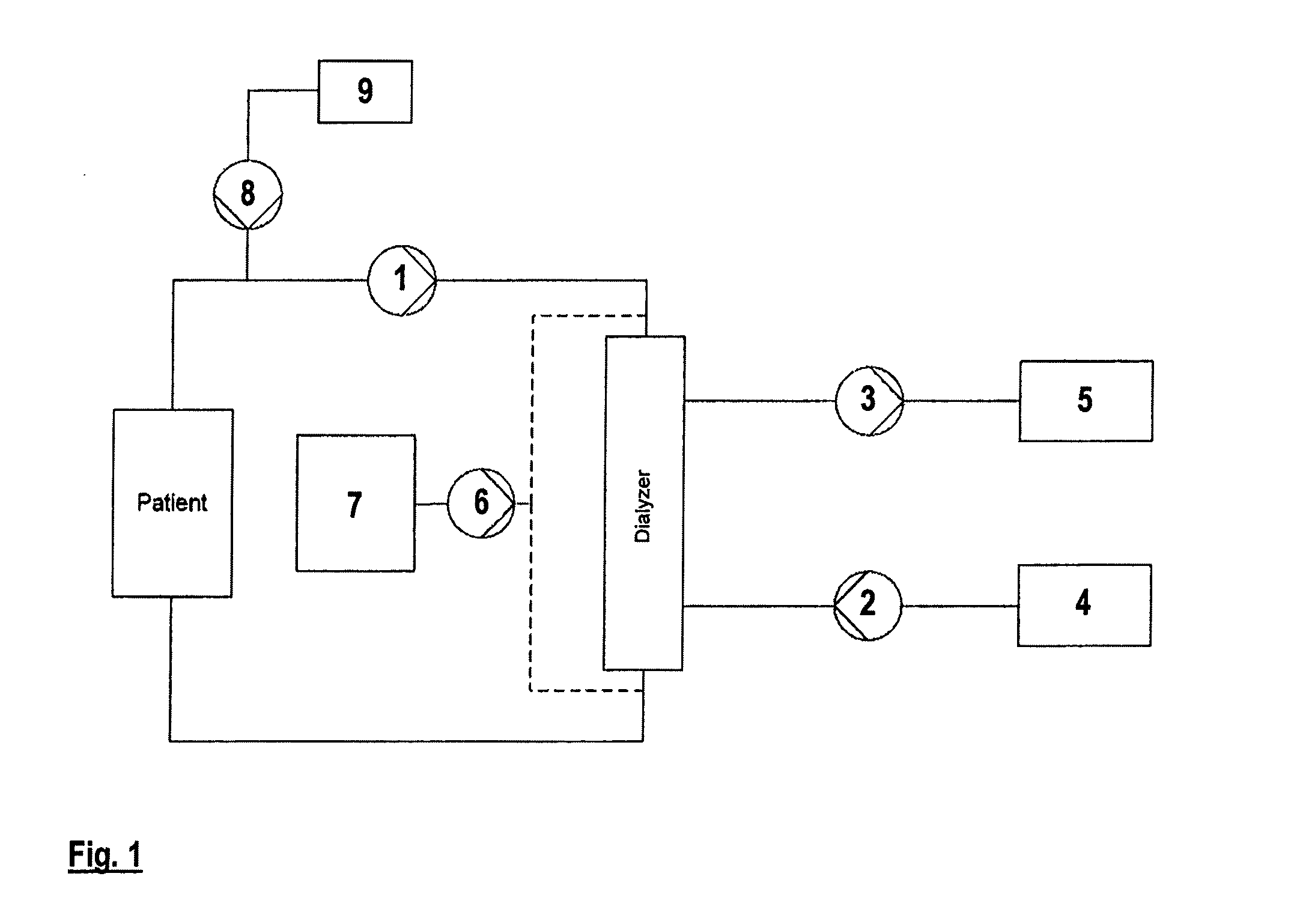

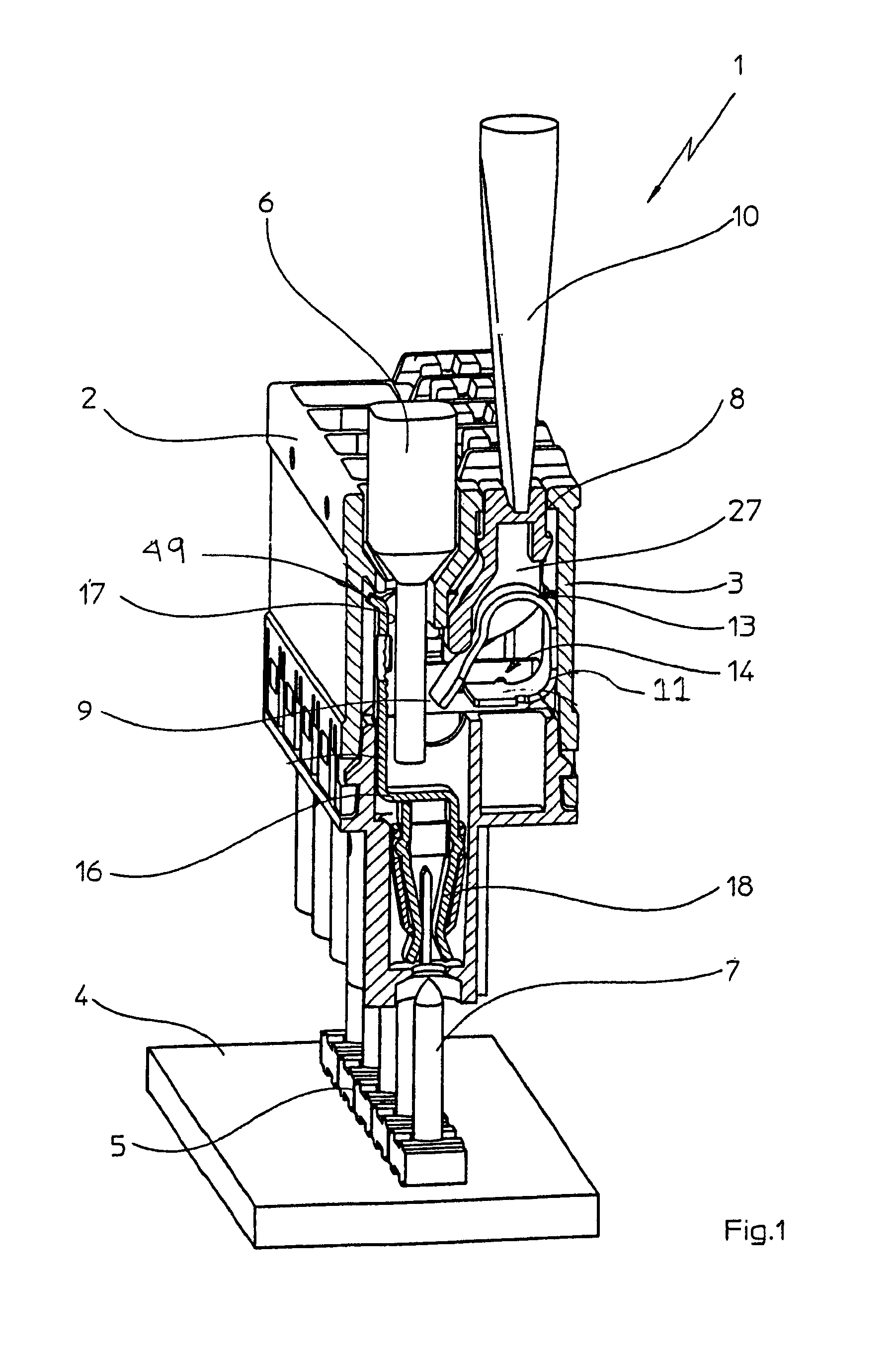

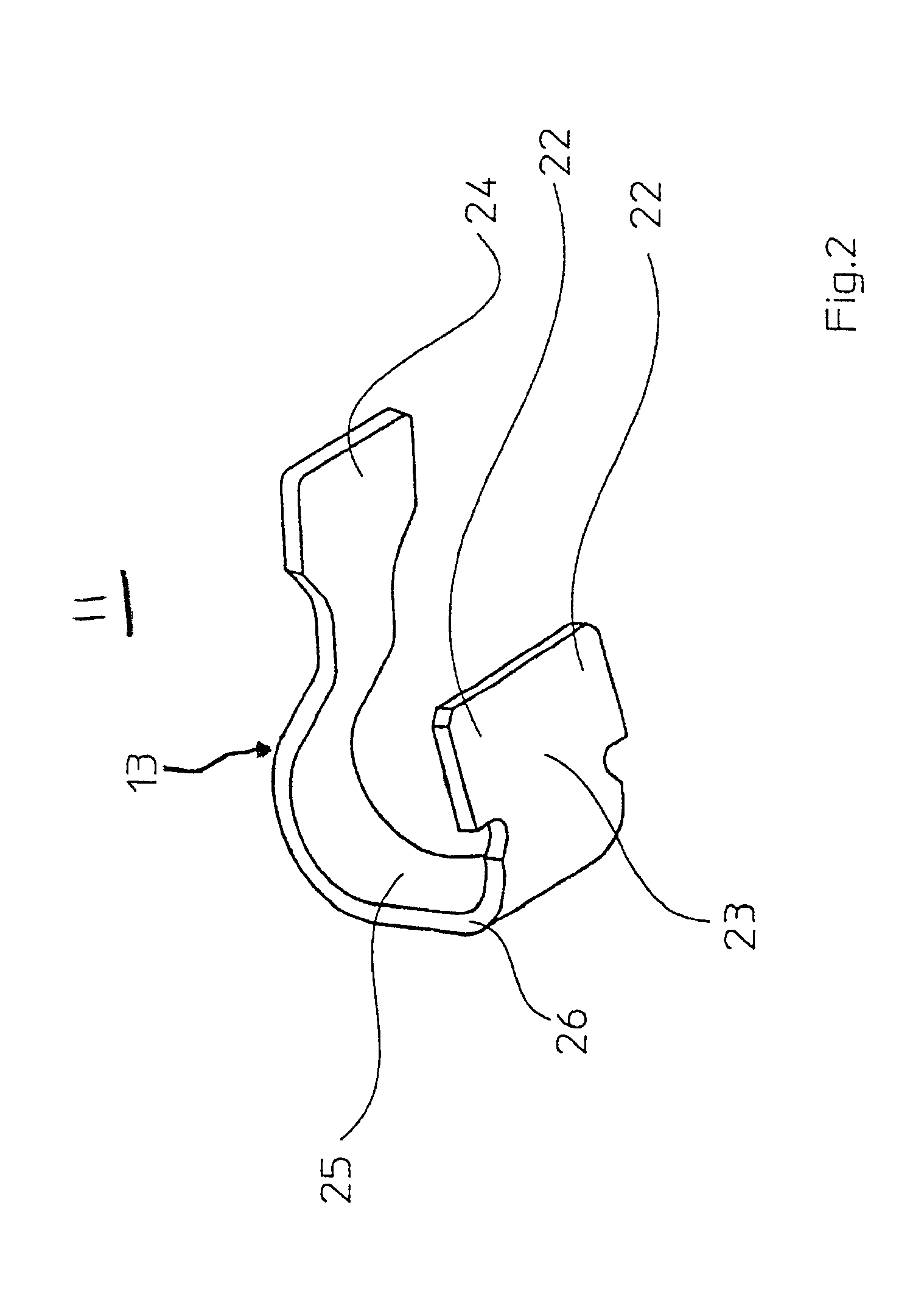

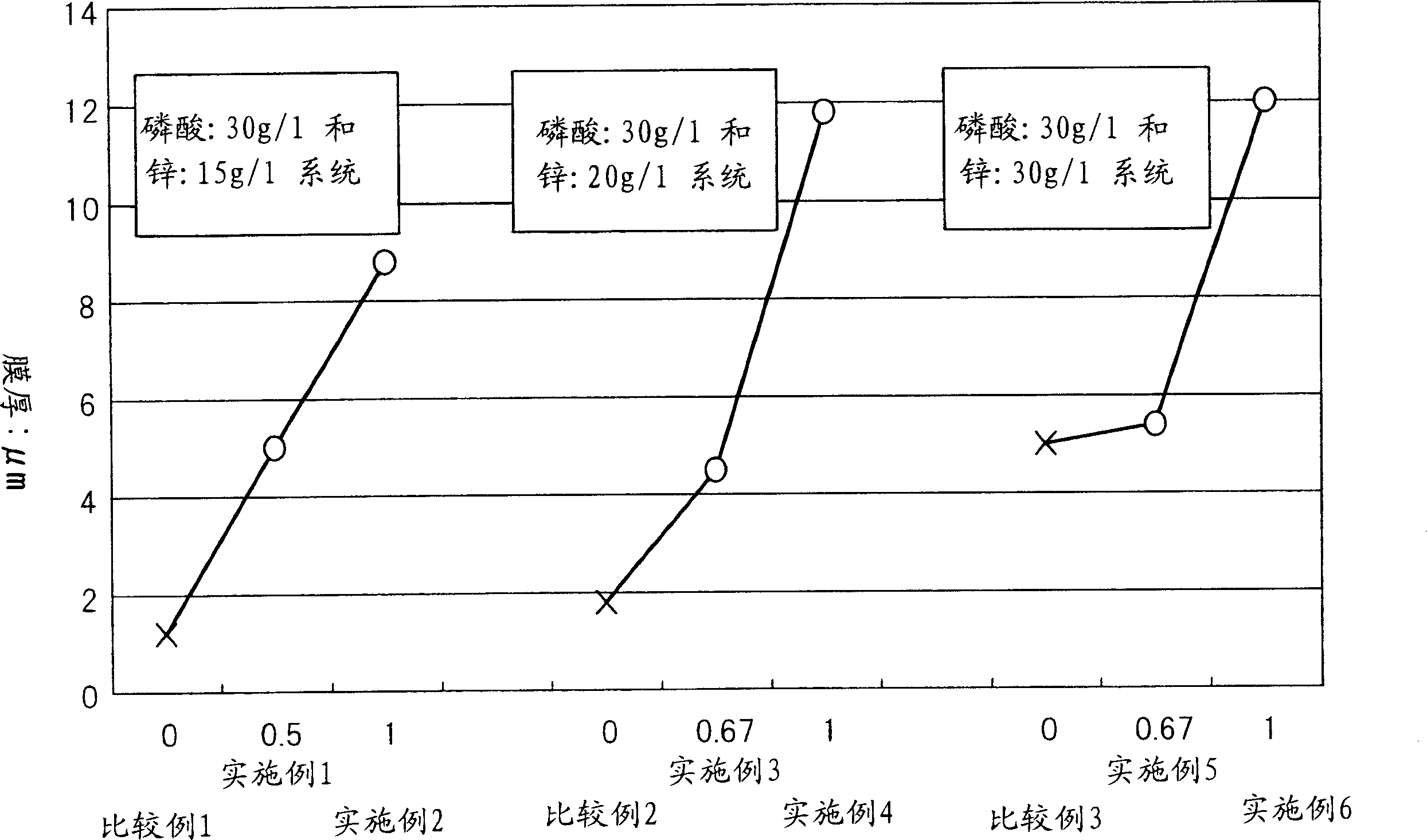

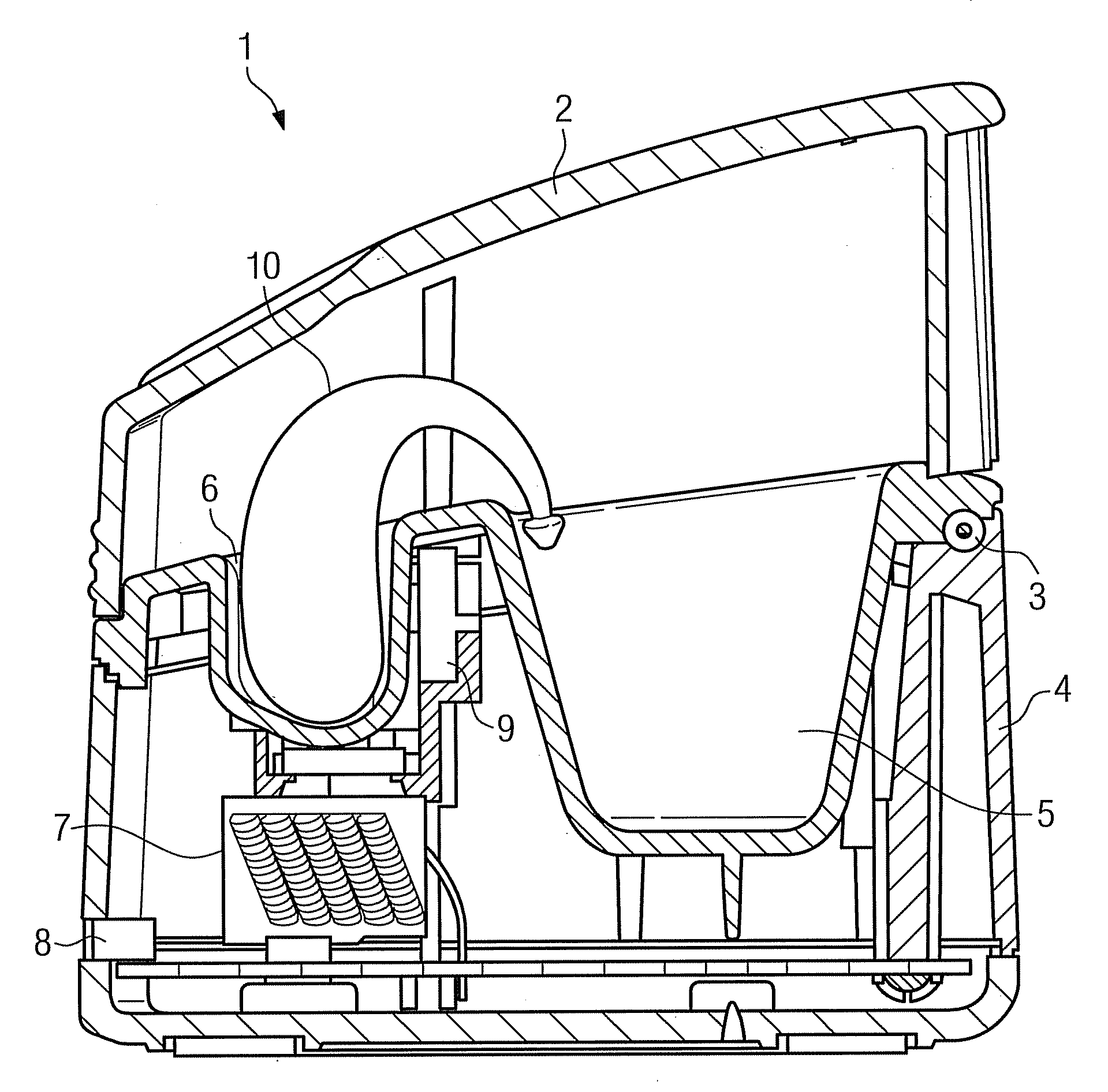

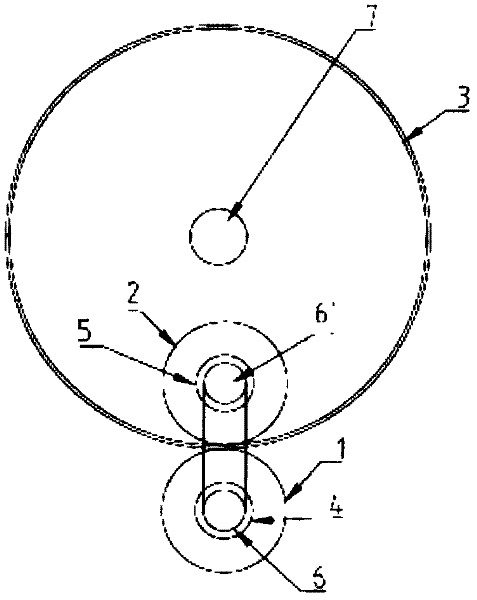

Dialysis device

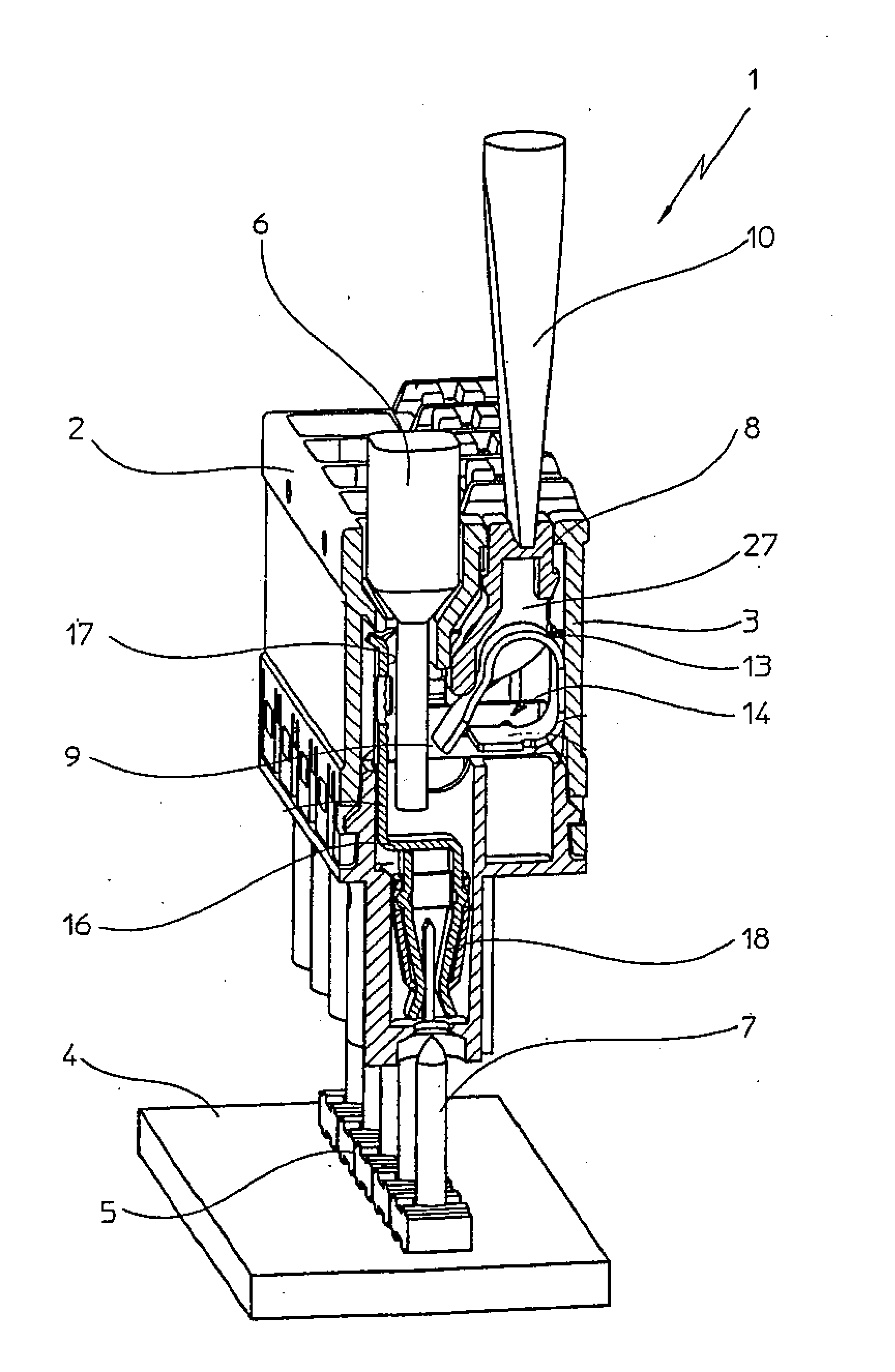

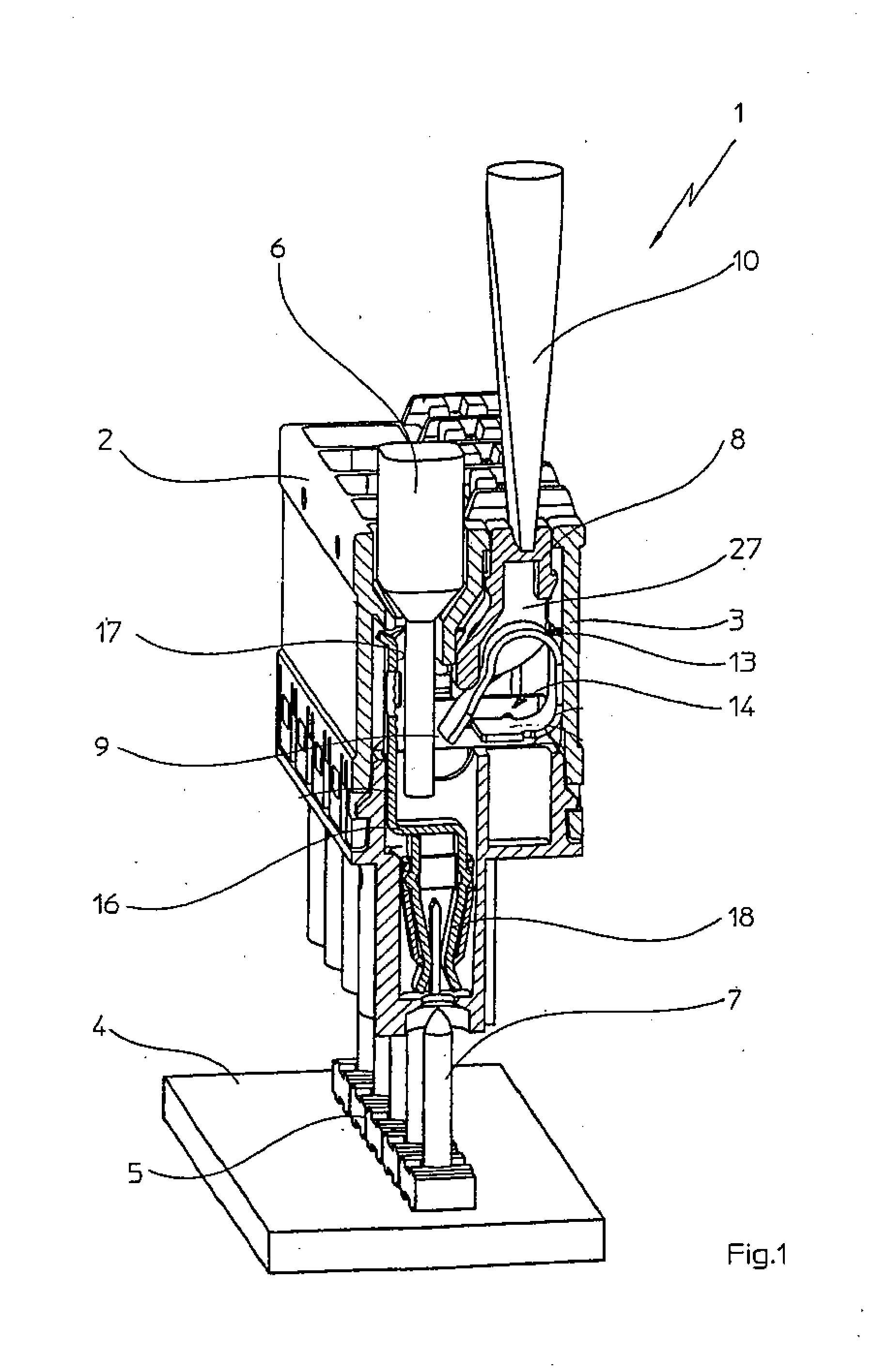

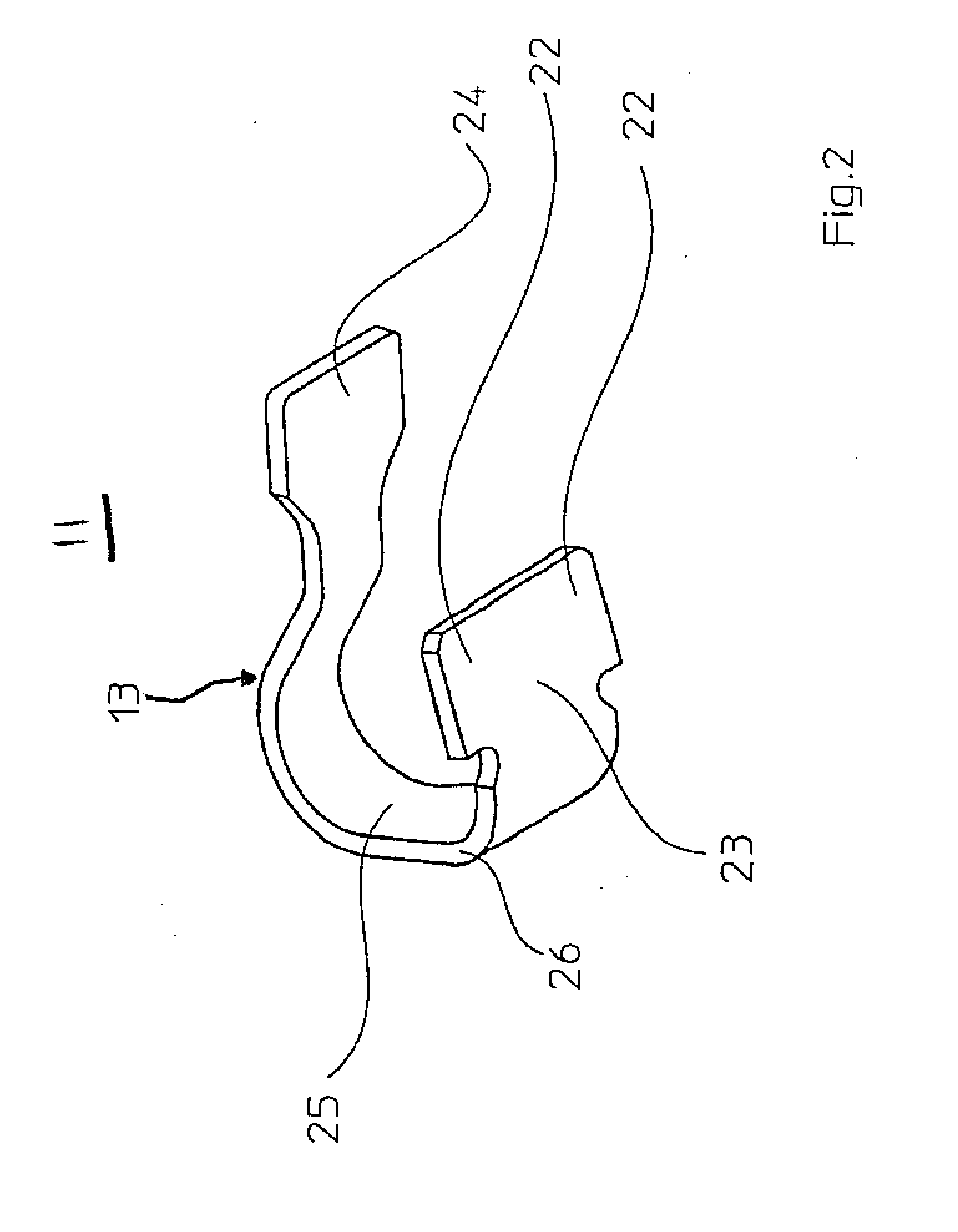

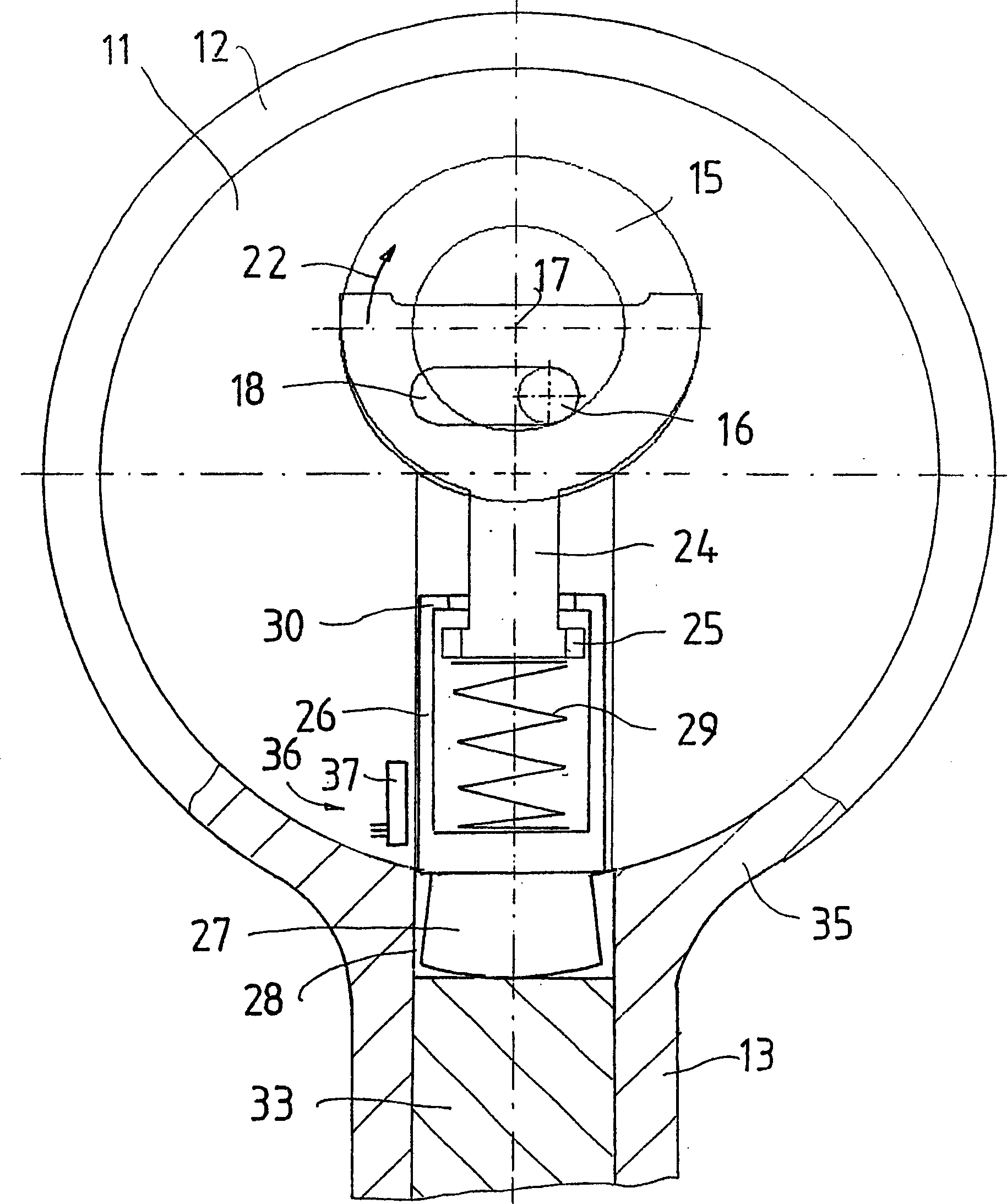

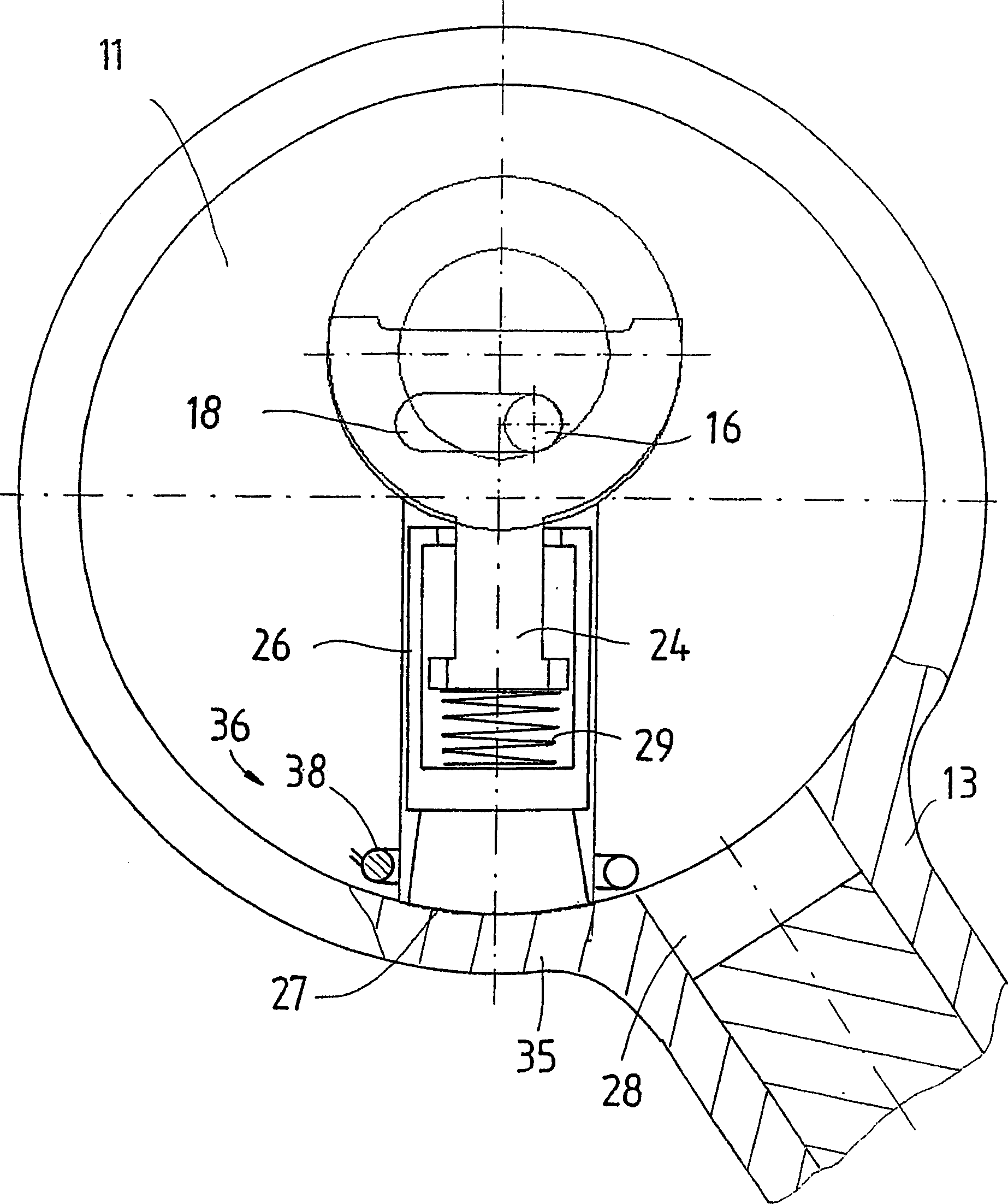

InactiveUS20110105981A1Easy to replaceSmall installation sizeFlexible member pumpsBlood pumpsPeristaltic pumpPiezoelectric actuators

The present invention relates to dialysis devices comprising peristaltic pumps of linear build with piezoelectric actuators.

Owner:GAMBRO LUNDIA AB

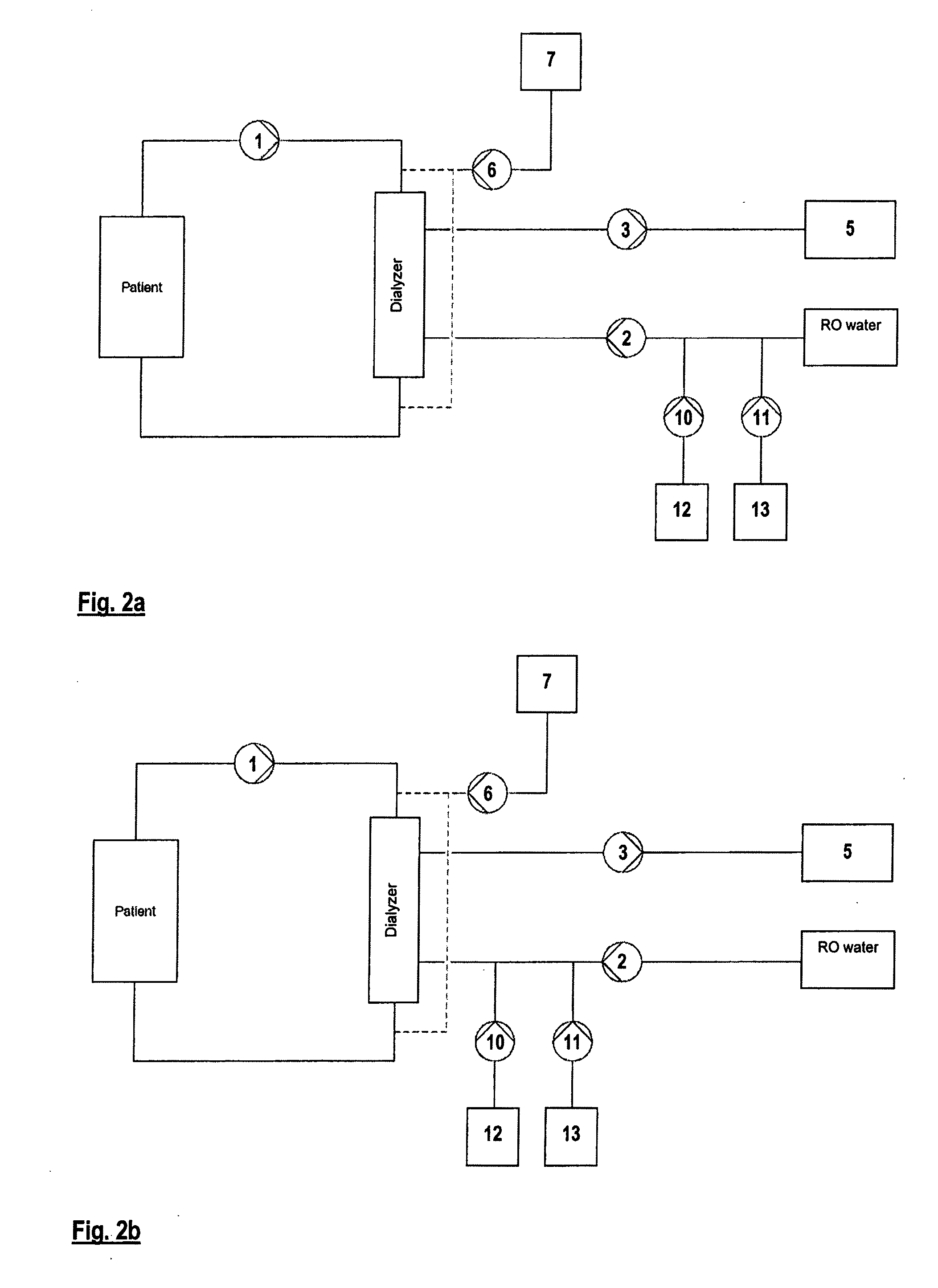

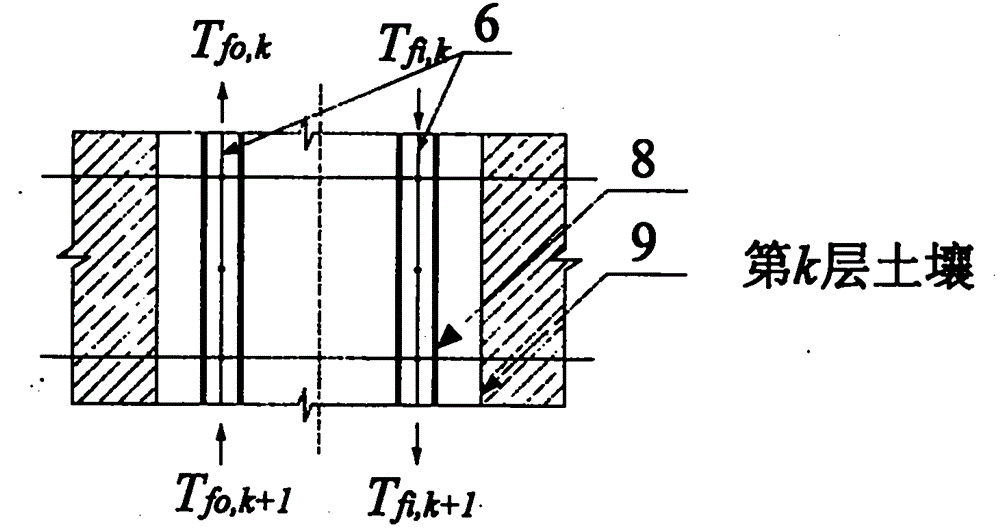

In-situ thermal response testing method of stratified thermal properties of underground rock and soil

InactiveCN102721722AAccurate dataHigh sensitivityMaterial heat developmentThermal response testGround testing

The invention relates to an in-situ thermal response testing method of stratified thermal properties of underground rock and soil. The invention relates to an in-situ thermal response testing device of the stratified thermal properties of the underground rock and soil. According to the in-situ thermal response testing device disclosed by the invention, a U-shaped pipe is buried, an optical fiber temperature sensor is inserted into two branch pipes of the U-shaped pipe, the U-shaped pipe is connected with an inlet and outlet of a circulating water pipeline of a ground testing device, water temperatures in the two branch pipes, namely the water inlet branch pipe and the water outlet branch pipe of the U-shaped pipe in different depth layers are respectively measured, the power of a heater is kept constant, and measured data of the water temperatures and the flow rates of circulating water in the two branch pipes of the U-shaped pipe in different depth layers at different times, as well as the corresponding heating power of the heater is recorded, so that a heat conduction coefficient, volume specific heat and a drilling thermal resistance value of soil in each layer can be obtained. According to the in-situ thermal response testing device disclosed by the invention, the defects that the distribution of the thermal properties of the rock and soil in different depths can not be obtained, the testing precision can not be improved, an optimal design method of the underground buried pipe can not be improved and the like in the prior art can be solved; furthermore, values of the thermal properties of the underground rock and soil, the types of the rock and soil, the contents of underground water and the seepage situations in the different depths can be obtained, and the in-situ thermal response testing device further has the advantages of high sensitivity, strong anti-interference property, corrosion resistance, small installation size, no requirements on a power supply and low testing cost.

Owner:YANGZHOU UNIV

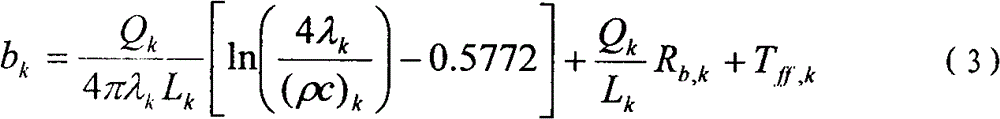

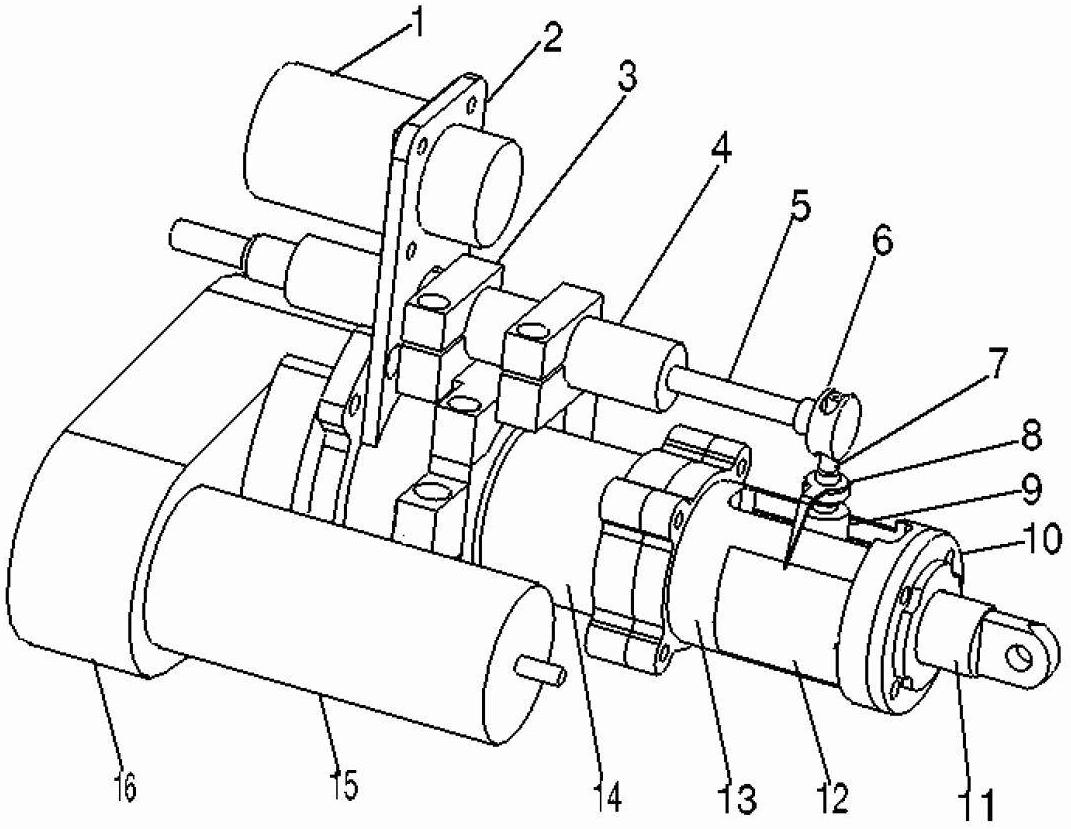

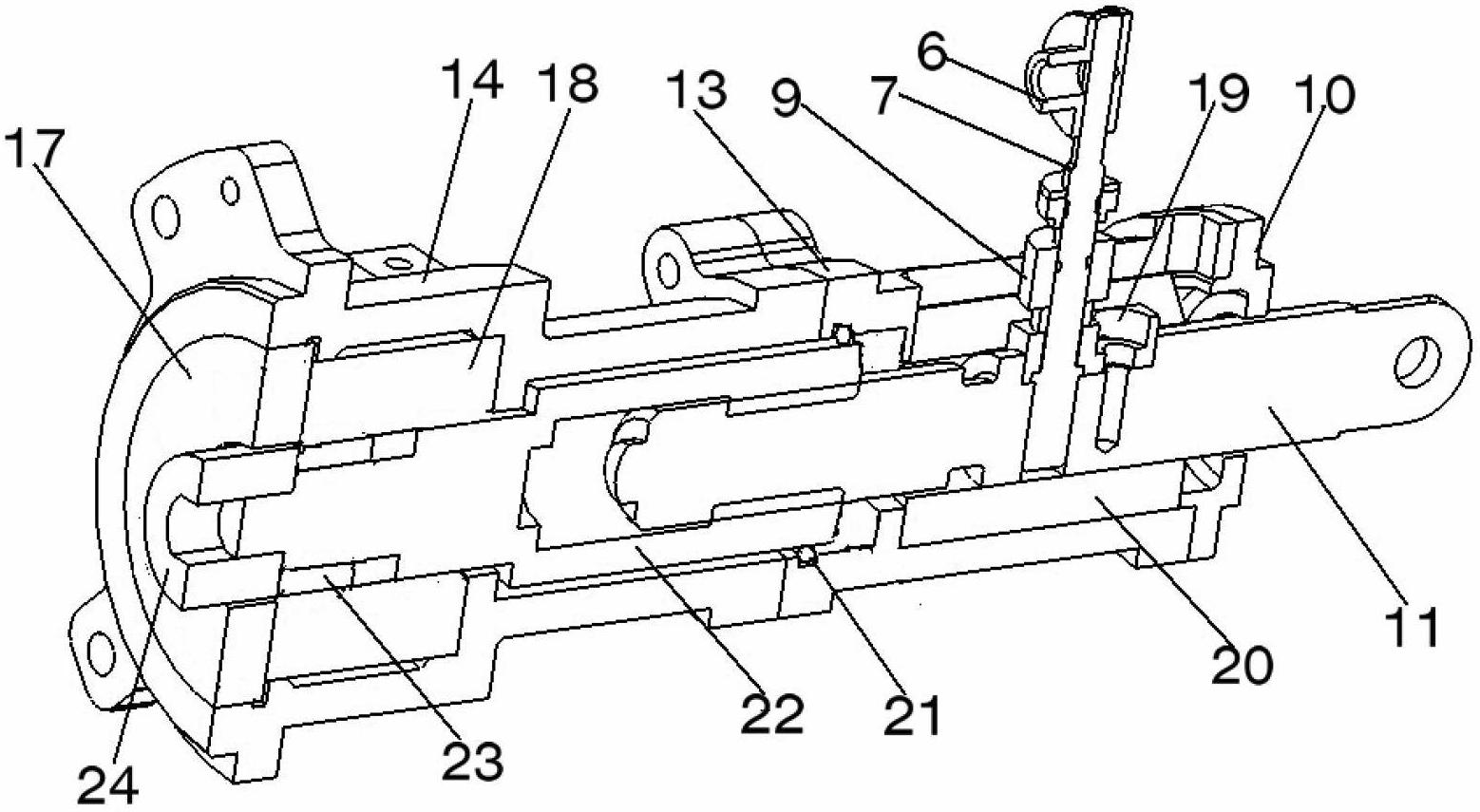

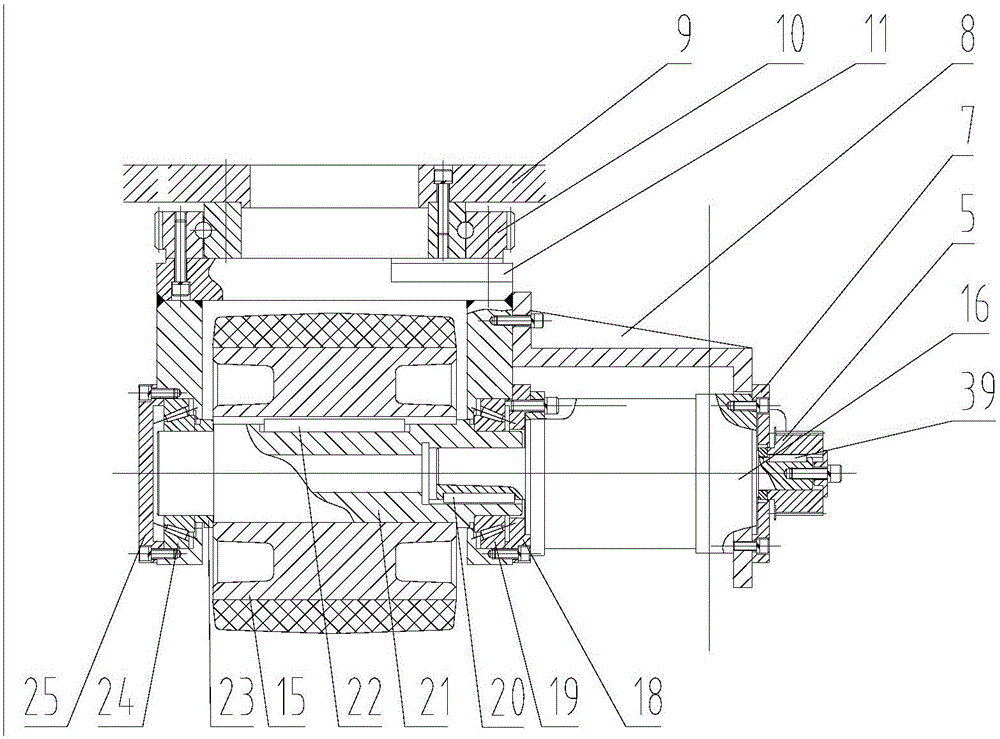

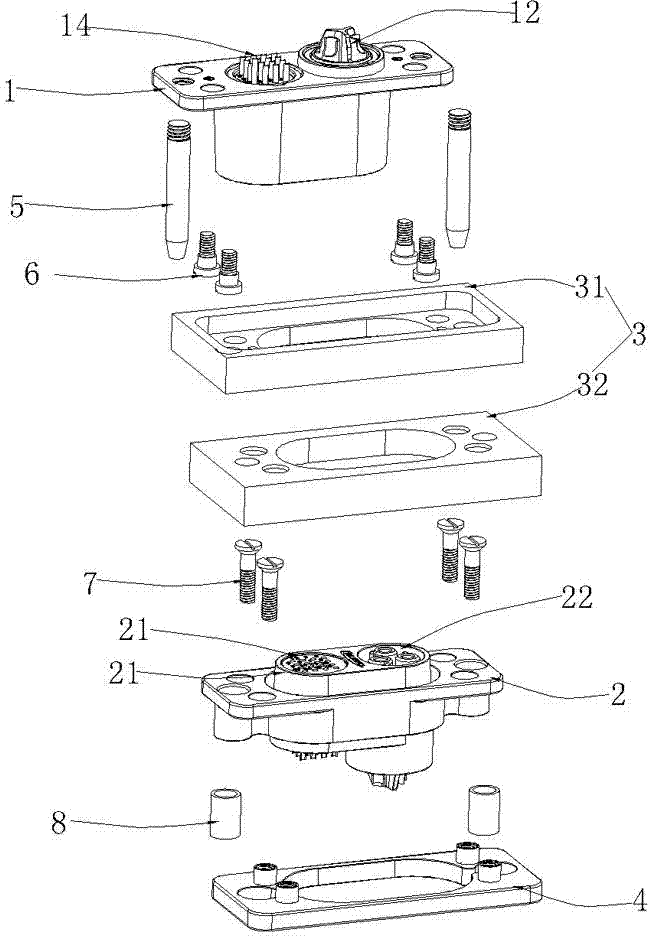

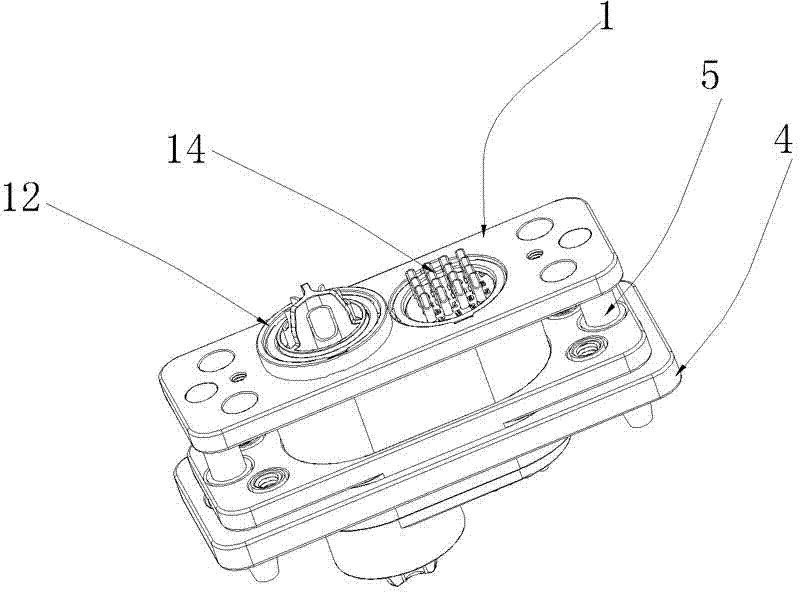

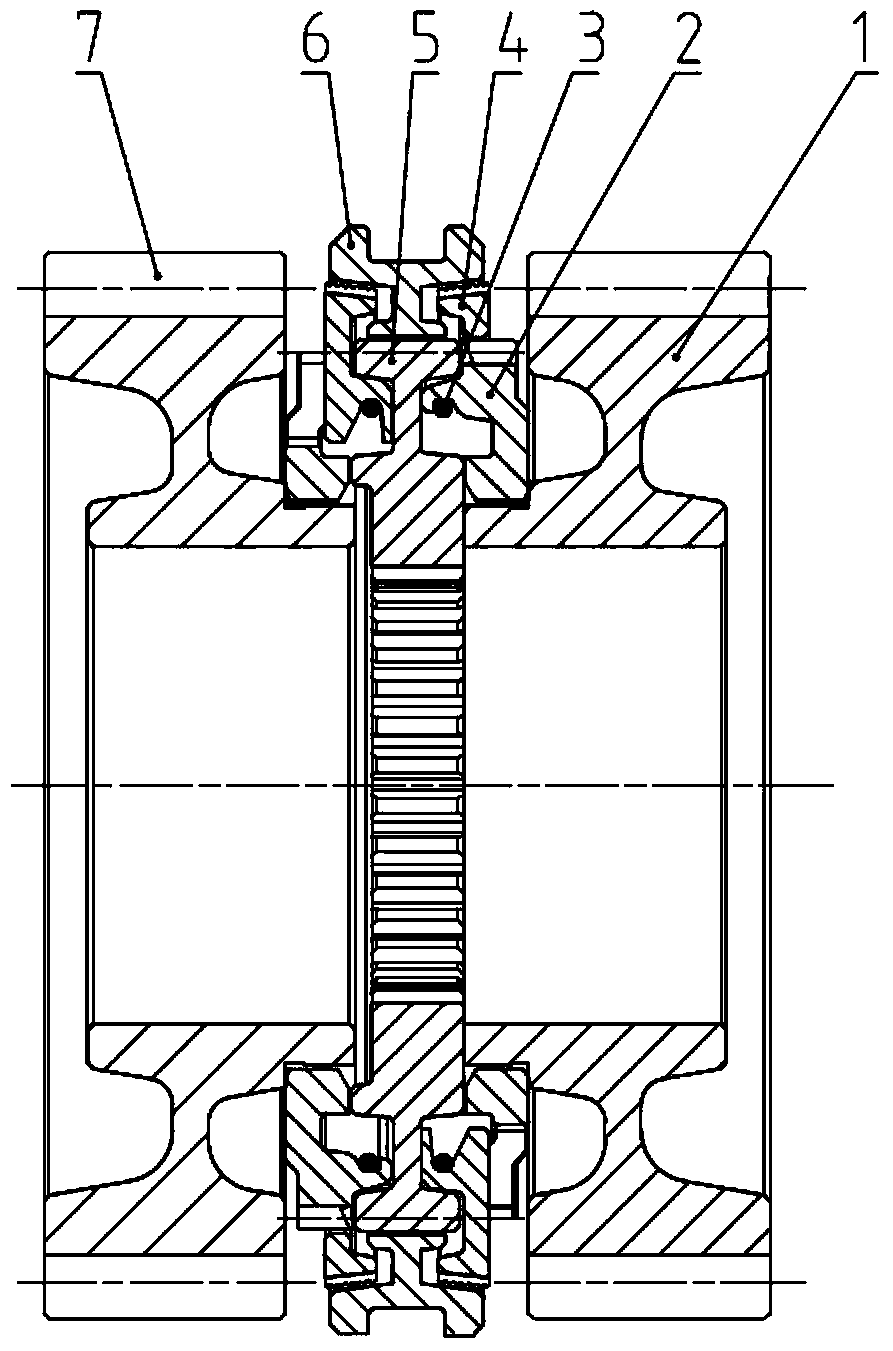

Steering engine for underwater vehicle

ActiveCN102632988AReliable mechanical self-lockingImprove response speedSteering ruddersBall bearingSelf locking

The invention discloses a steering engine for an underwater vehicle. A speed reducer, a lead screw nut, a resistive position sensor and a connector are located on one side of the speed reducer; a lead screw and a nut are coaxially arranged; the steering engine has a compact structure, and the mounting size of the steering engine is reduced. A travel insert block is embedded into the middle part of the lead screw; when the lead screw extends out for a certain distance, the travel insert block is tightly attached to the inner wall of an outer end cover to limit the extension distance of the lead screw; at one end of the lead screw matched with a drive nut, a blind hole in the drive nut has certain depth; and when the lead screw retreats, a travel boss at the end of the lead screw close to the nut is tightly attached to the end surface of the inner hole of the drive nut to limit the retreat distance of the lead screw. According to the invention, through a reverse travel self-locking of a lead screw nut mechanism, the steering engine realizes firm mechanical self-locking to maintain the stability of a rudder surface. The adopted hollow cup DC (direct current) motor has small rotational inertia, the lead screw nut mechanism is supported and guided by a deep groove ball bearing, a ball and a linear bearing, the frictional resistance is reduced, and the response speed of the steering engine is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

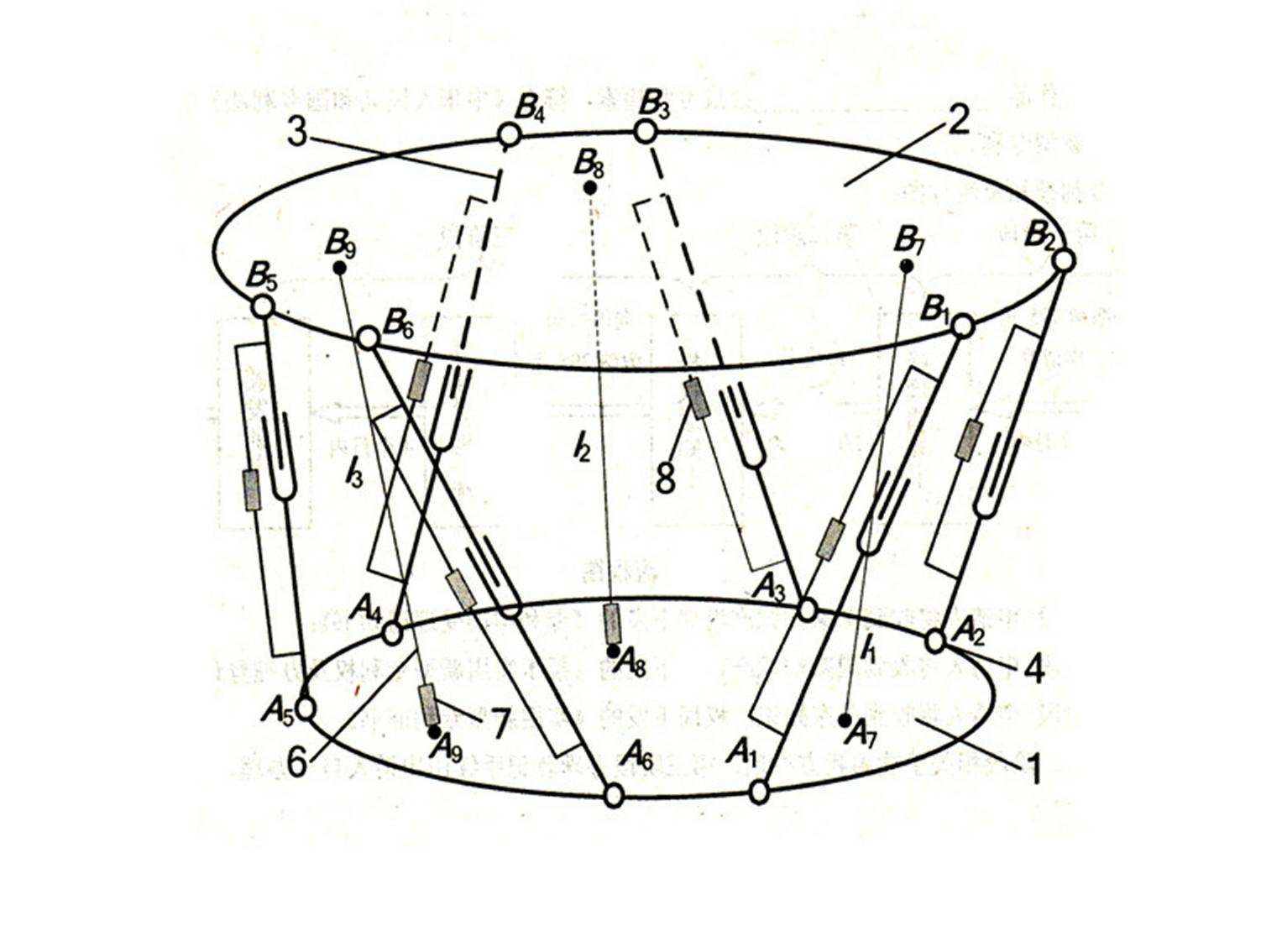

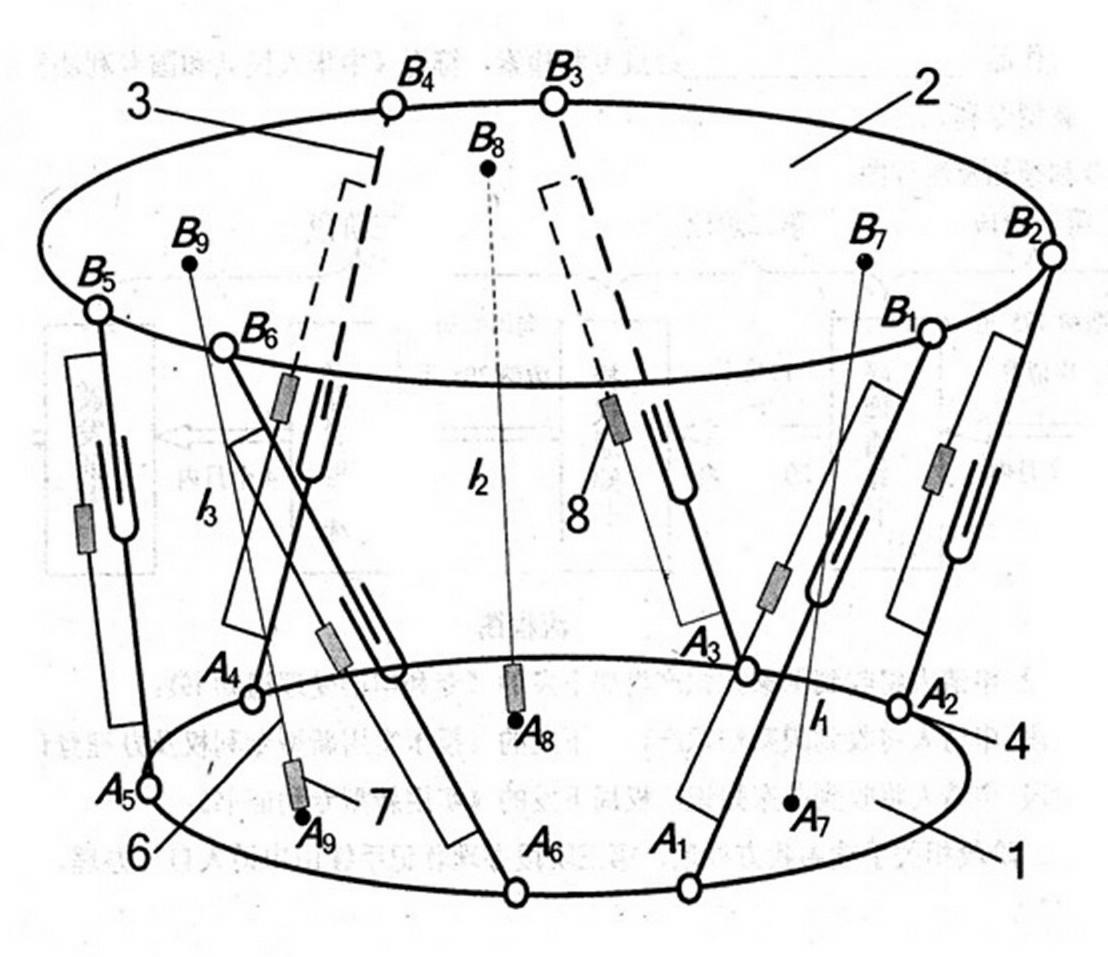

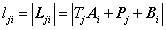

Self-calibration method for parallel robot

InactiveCN102278963ASmall installation sizeCompact structureMeasurement devicesRelative variationEngineering

The invention discloses a self-calibration method of a parallel robot. The method comprises the following steps of: arranging a displacement sensor on each driving branch of the parallel robot, additionally arranging a measuring branch between a fixed platform and a movable platform of the parallel robot, arranging a rope sensor on the measurement branch, establishing a function relation between the relative variation of displacement of the drive branches and the measuring branch and parameters of pose of the movable platform and mechanism parameters of all the branches, driving the parallel robot to carry out pose transformation, enabling the number of established equations to be greater than or more to the number of the mechanism parameters to be identified, and carrying out numerical value solving to obtain poses of the movable platform in any state and mechanism parameter errors and further realize self-calibration. The self-calibration method has the advantage of low cost, convenience for operation and freedom from restriction of distance, hardly has restriction to mechanism design and is a good choice for calibration schemes of the parallel robots.

Owner:YANSHAN UNIV

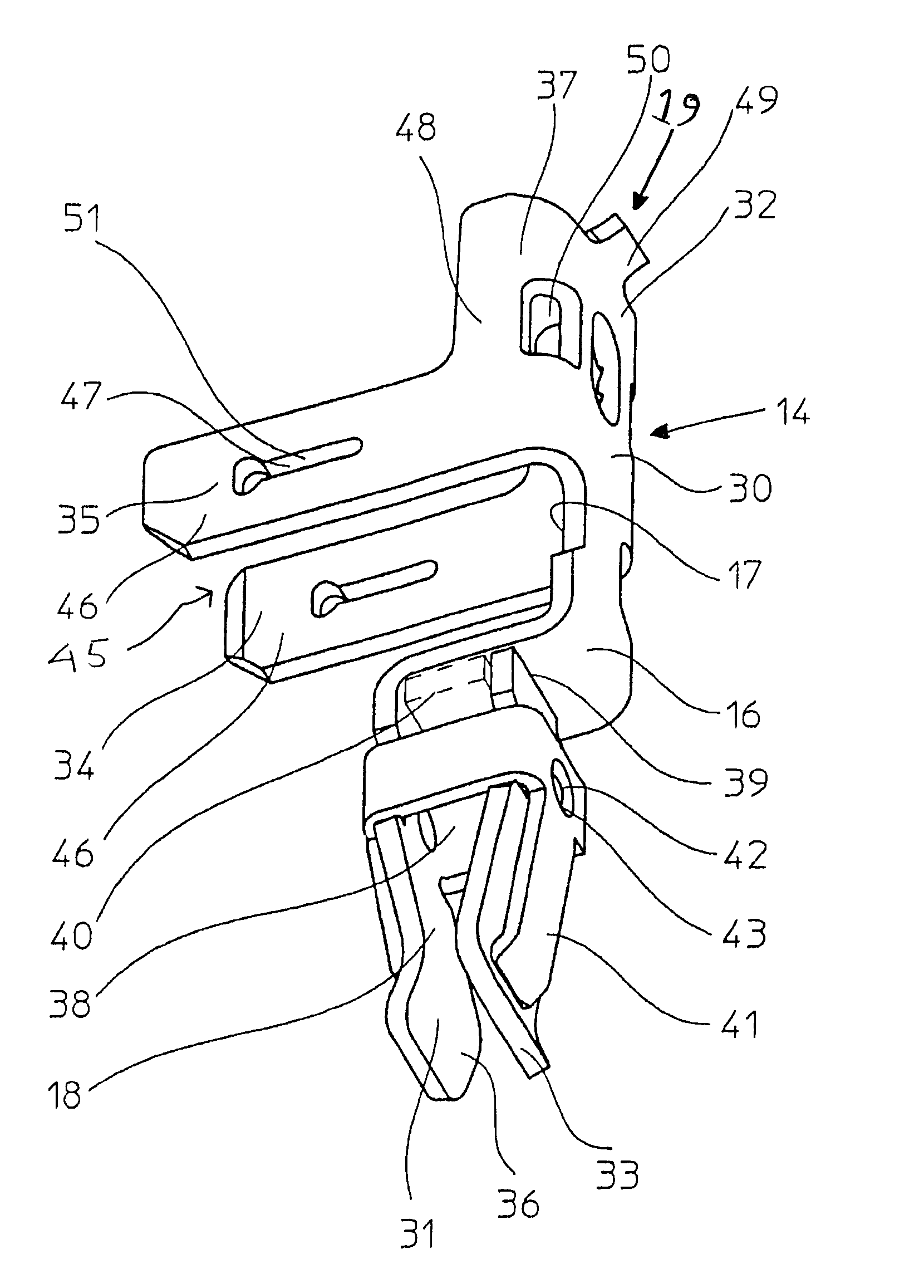

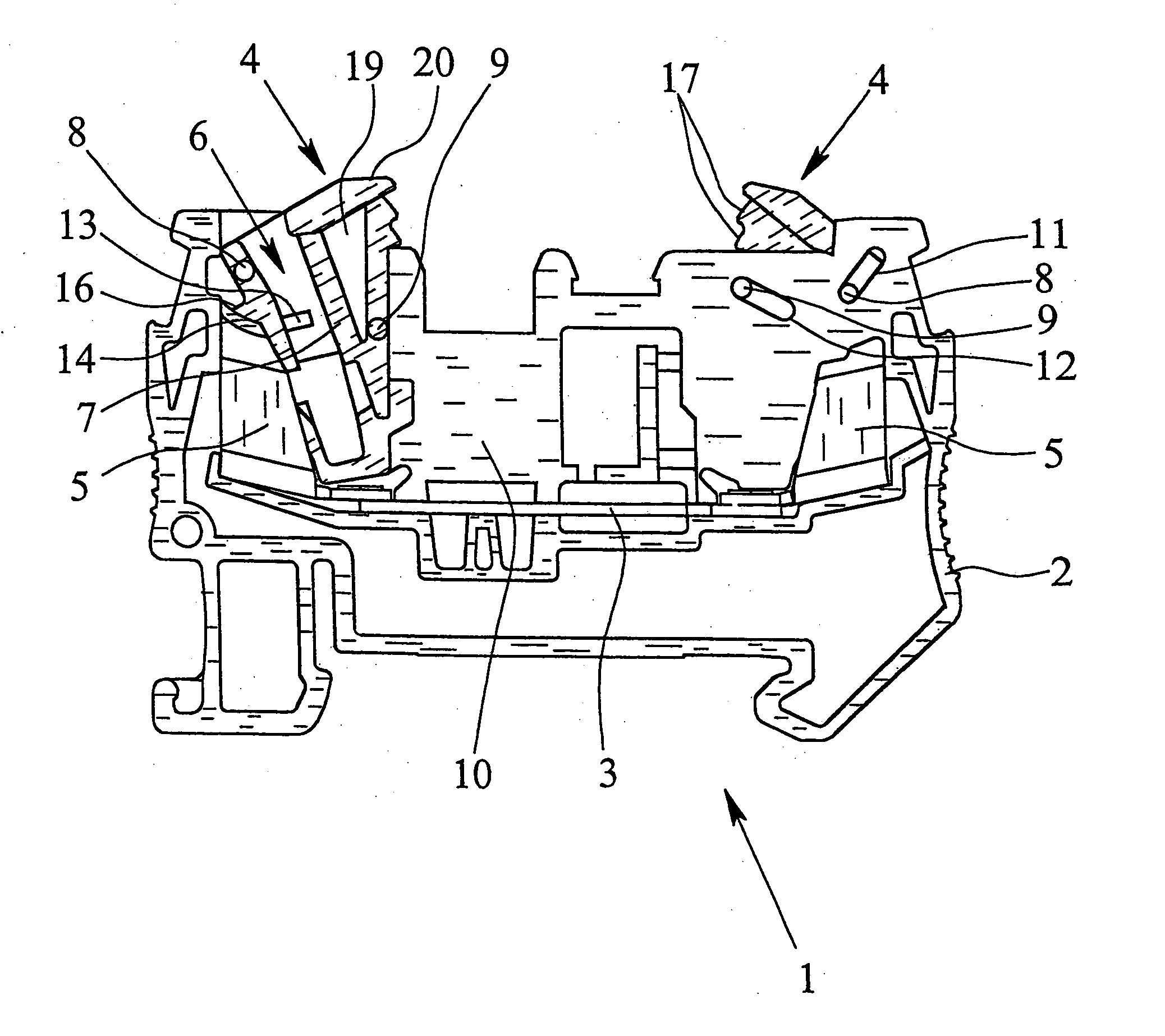

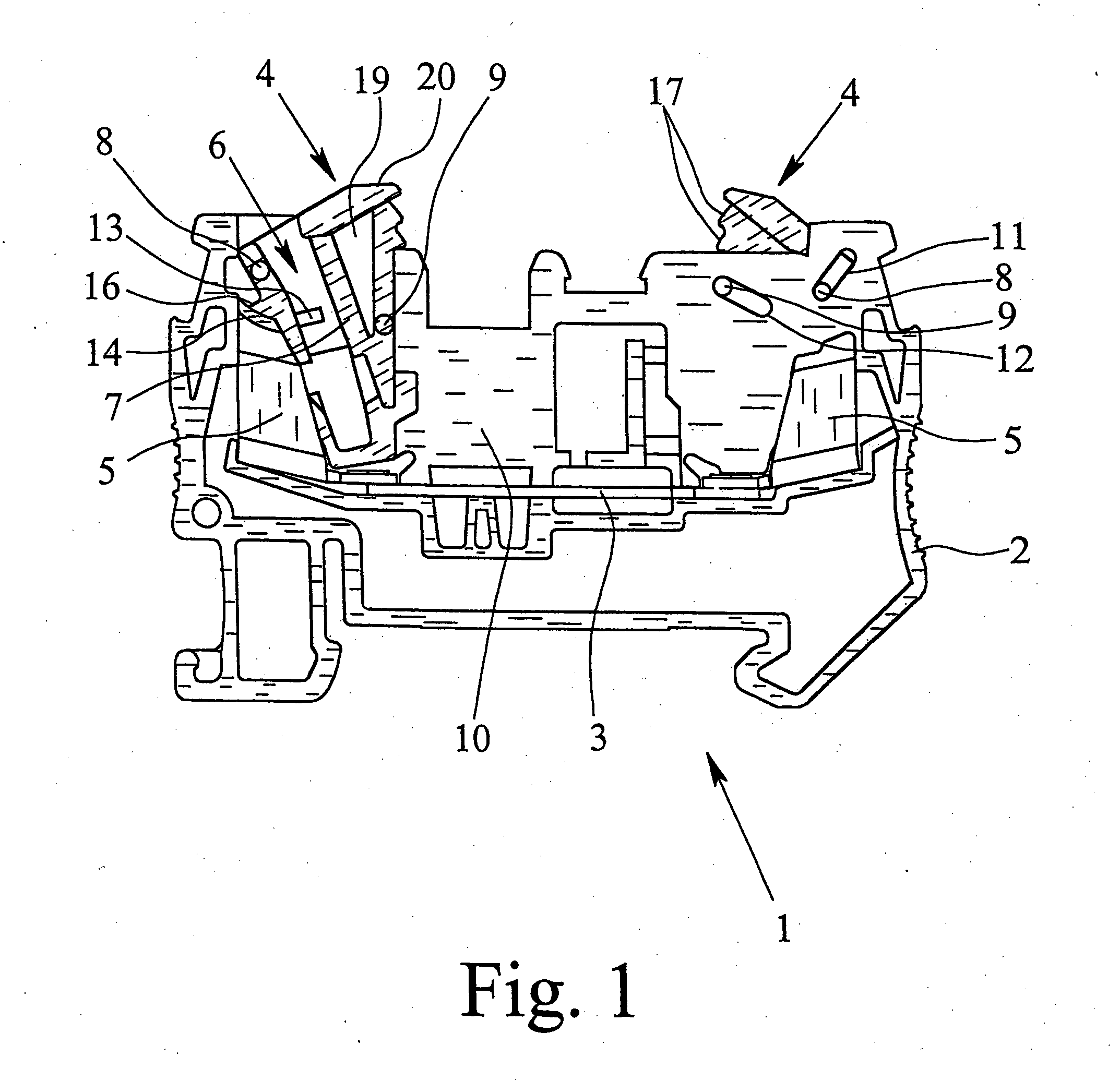

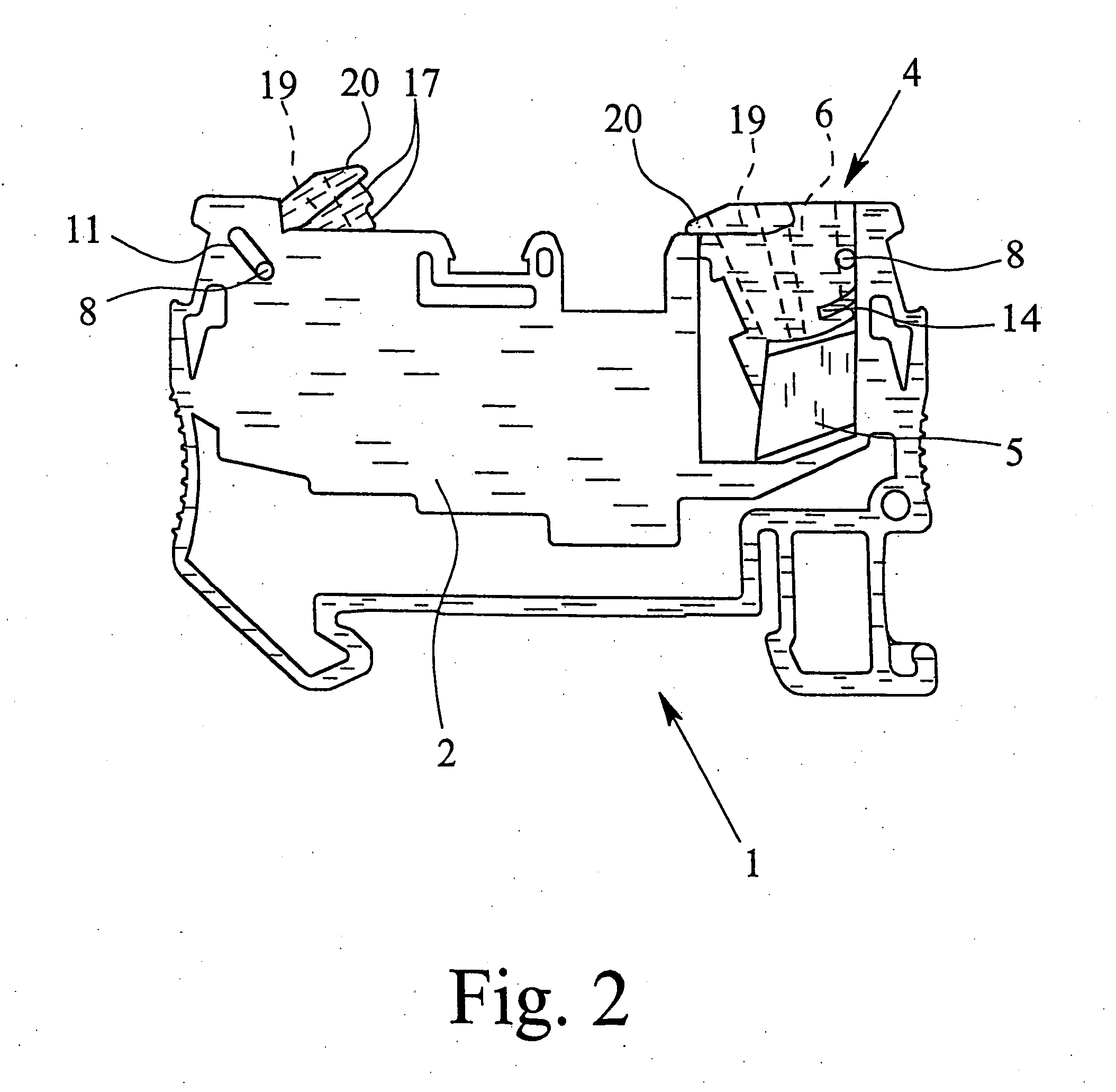

Connecting terminal for printed circuit boards

InactiveUS20100173531A1Simple functional designSmall installation sizeElectrically conductive connectionsCoupling contact membersSpring forcePrinted circuit board

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

Connecting terminal for printed circuit boards

InactiveUS7993156B2Simple functional designSmall installation sizeCoupling contact membersContact members penetrating/cutting insulation/cable strandsSpring forceEngineering

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

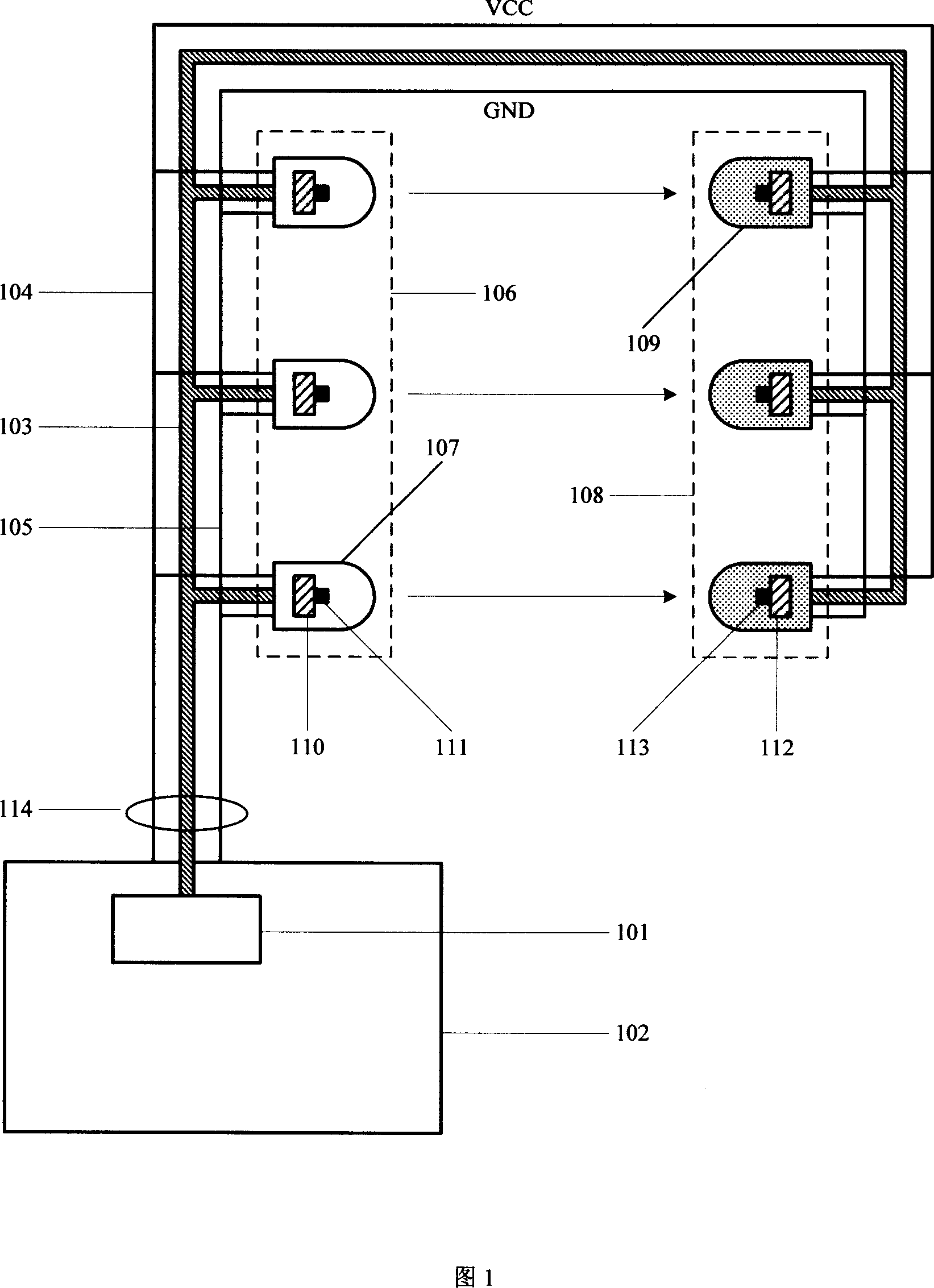

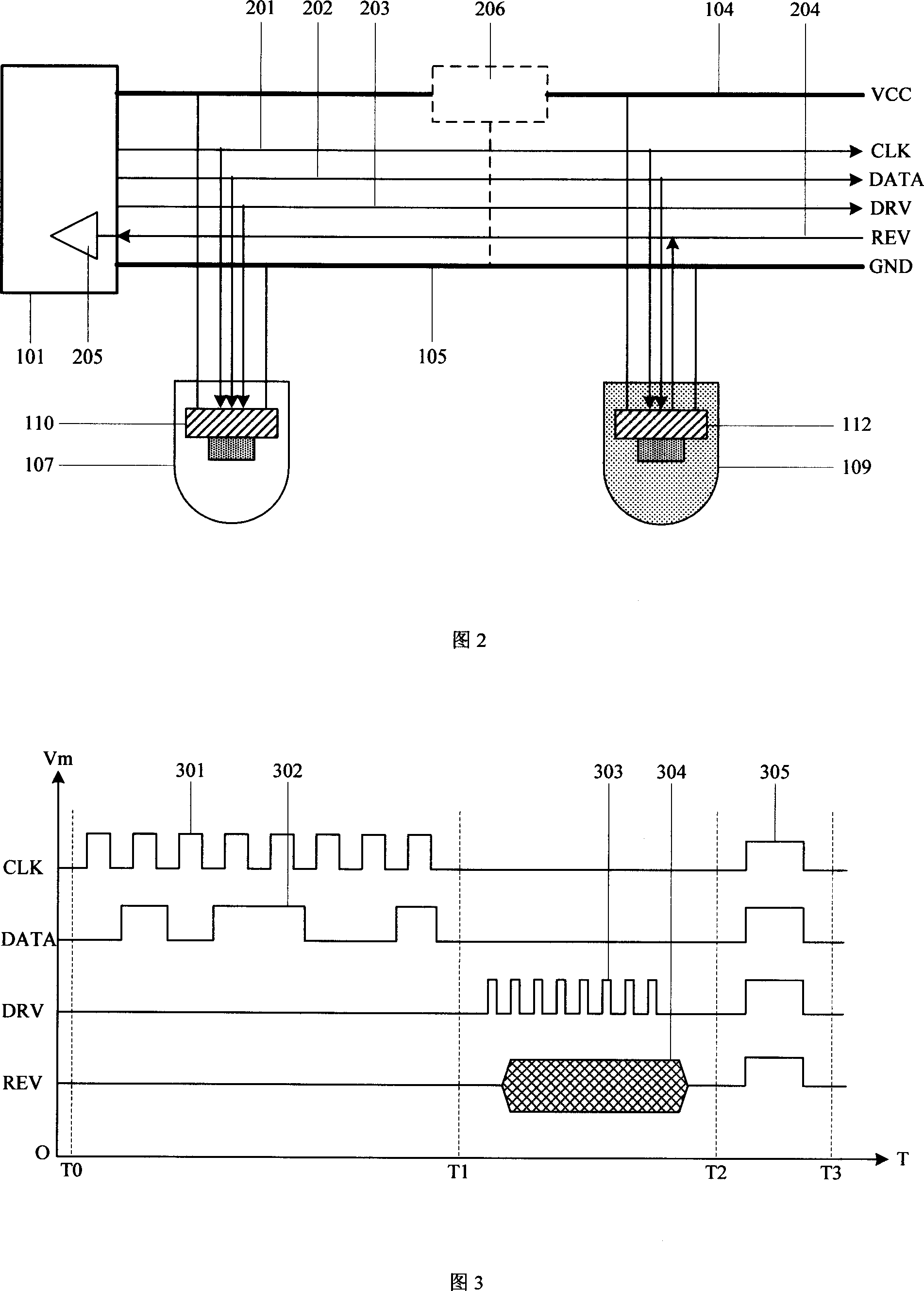

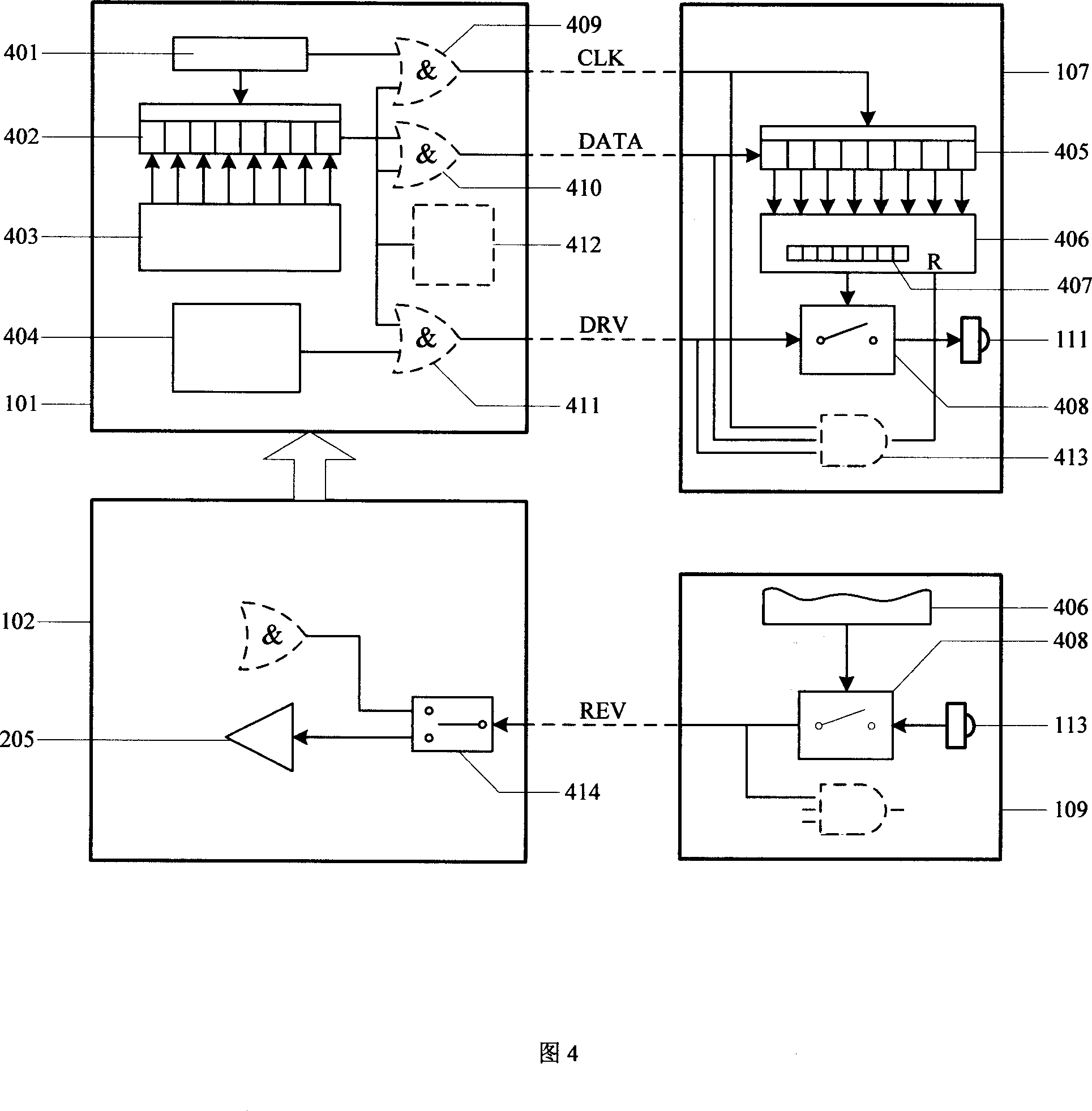

Infrared touch screen for realizing scan driving by bus organized structure

InactiveCN101082850ASmall installation sizeSmall sizeElectronic switchingInput/output processes for data processingDisplay deviceSerial code

The invention discloses an infrared touching screen to realize scanning driving through bus structure, which is characterized by the following: setting a serial code coder of infrared launching and receiving pipe address scanning code in the micro-controller system; inserting decoding chip of decoder corresponding to the coder and address comparing unit of each address value corresponding to scanning address of infrared launching and receiving pipe in the infrared element; connecting address line, driving line or signal line system bus between coder and infrared launching and receiving pipe array; the serial code coder connects the circuit board with infrared launching pipe array and infrared receiving pipe array through connector. The invention reduces the breadth of frame to the maximum degree, which can be assembled on random display for kinds of occasion.

Owner:BEIJING UNITOP NEW TECH CO LTD

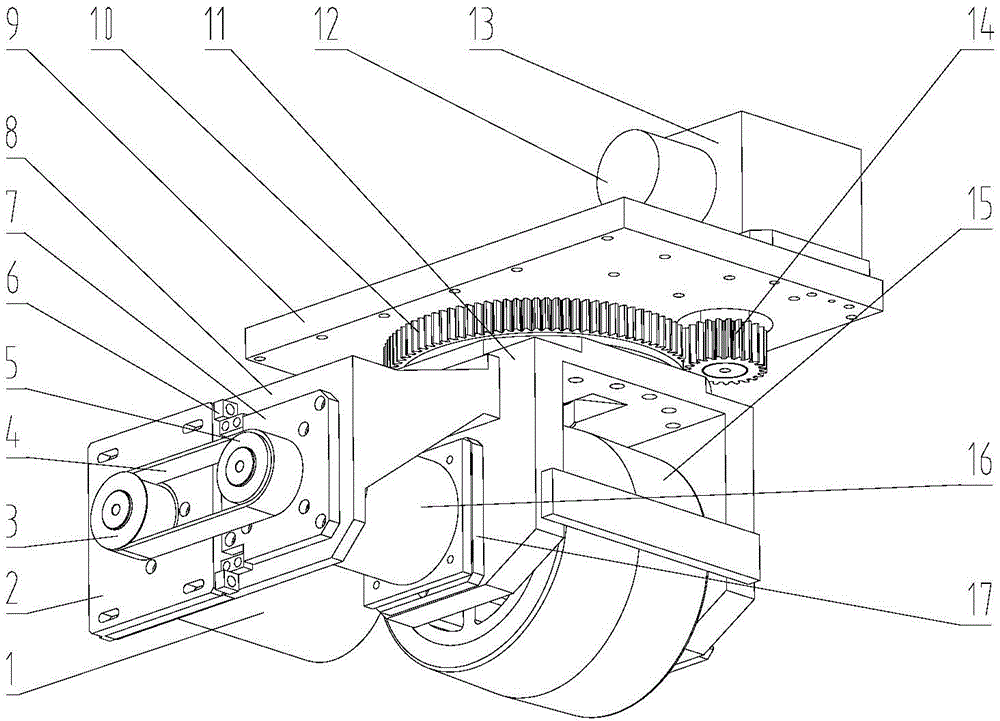

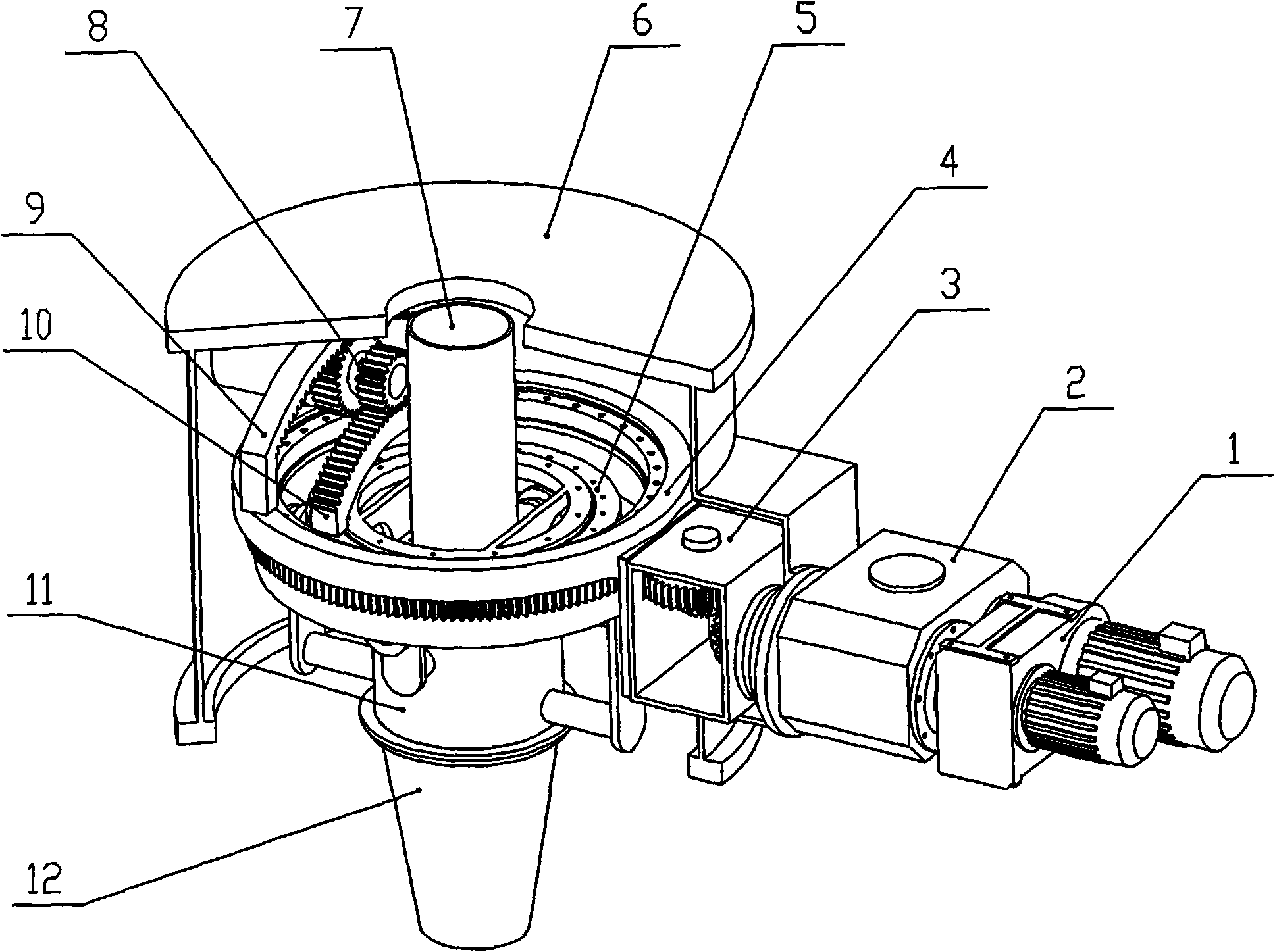

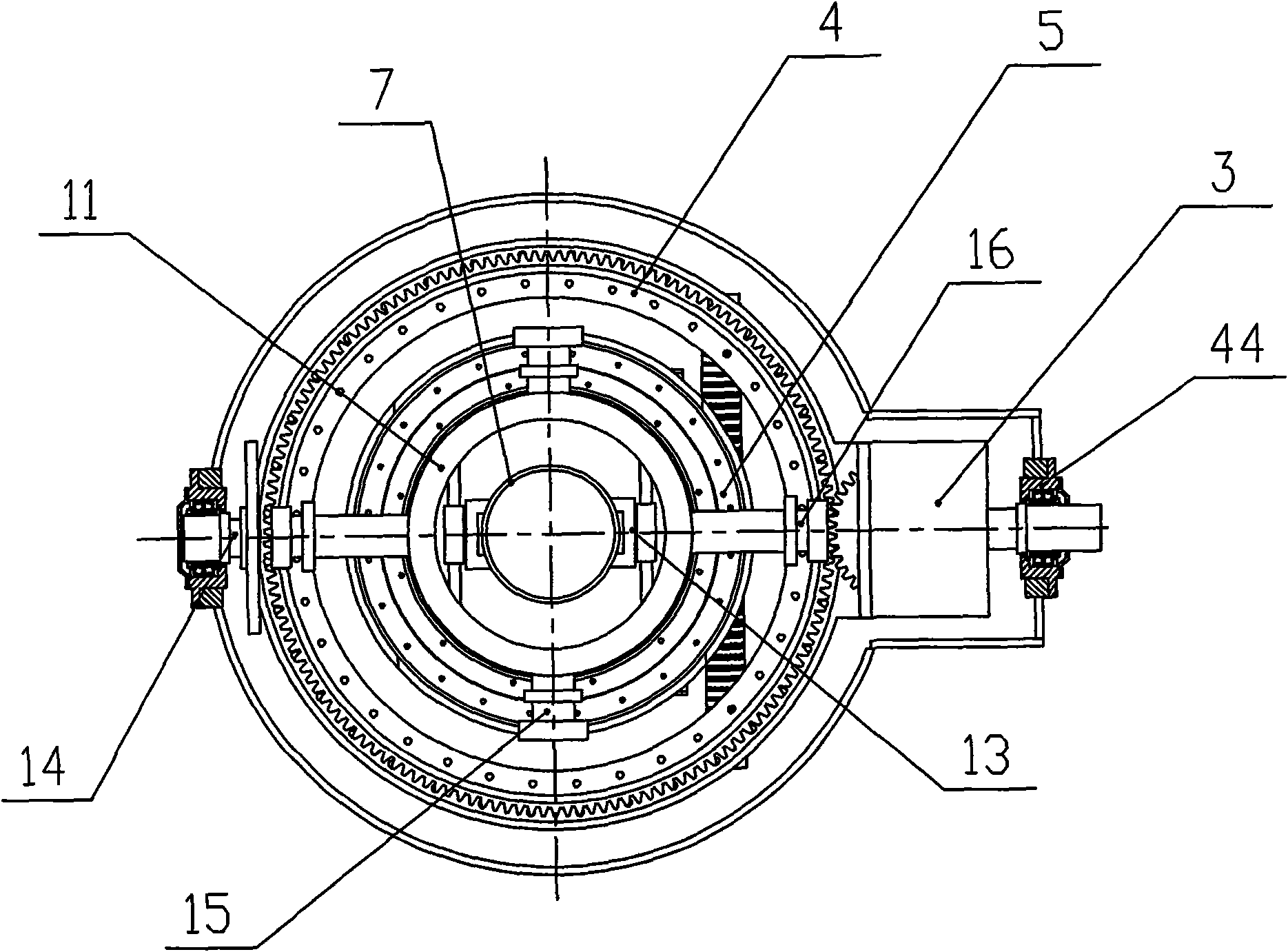

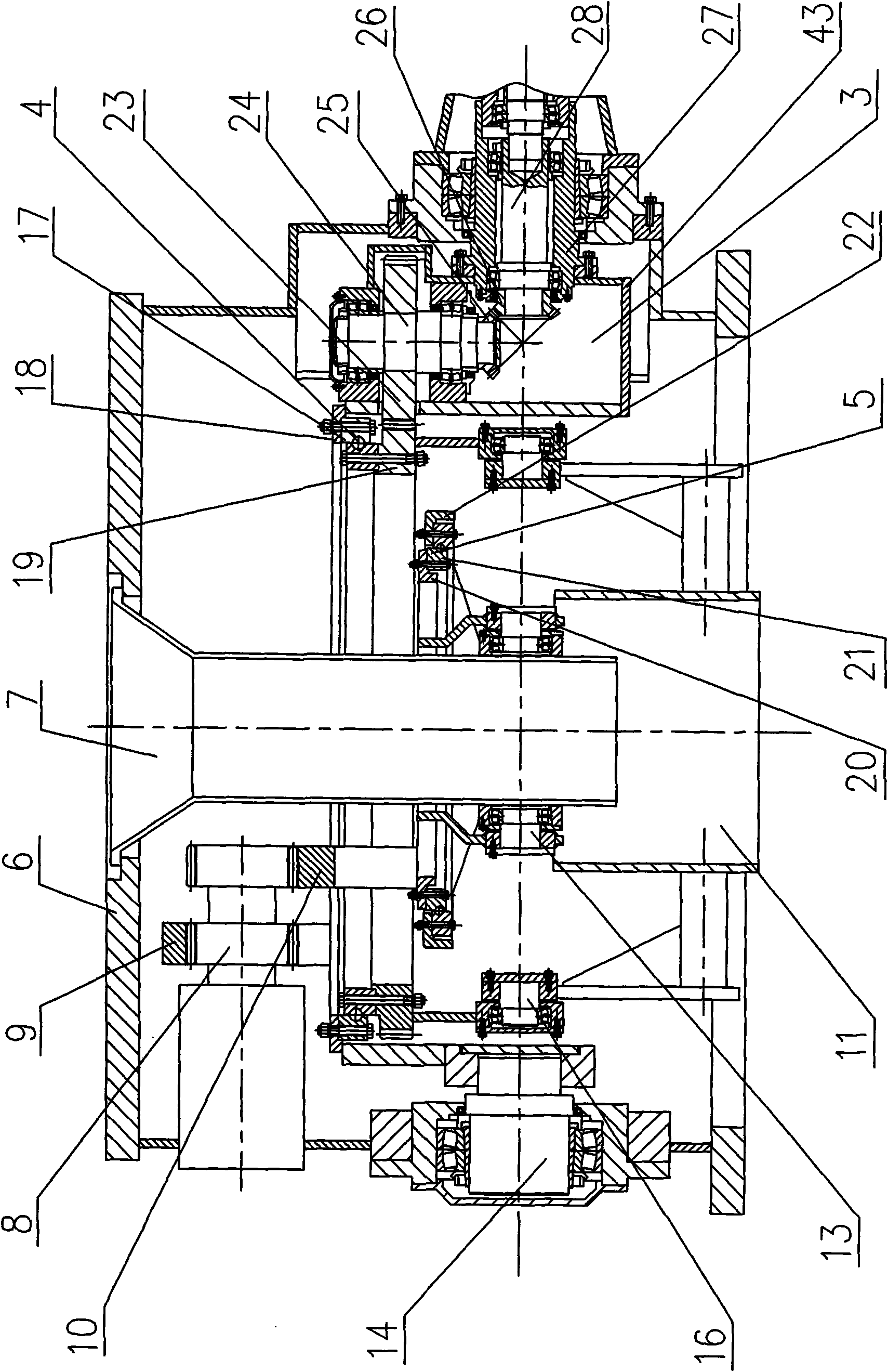

Wheel set integrating driving function and steering function

InactiveCN104527323AAchieving a modular designEasy maintenanceDeflectable wheel steeringWheelsDrive wheelModular design

The invention provides a wheel set integrating the driving function and the steering function. The wheel set integrates a dual-direction omni-bearing steering mechanism and a walking driving mechanism, integration of a dual-direction omni-bearing steering mechanism is improved, modular design of the driving wheel set is achieved, all the parts are installed on a base, the integration level is high, the installation size is reduced, integral installation and integral detachment are achieved, and installation, maintenance and the like of the driving device are convenient; multiple driving wheel sets are jointly used or a single wheel set and auxiliary supporting wheel sets are jointly used, and small-space transport adjustment such as heavy-load and intermediate-range transport, small turning radius and even in-situ rotation, transverse movement and the like of transport equipment can be achieved.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

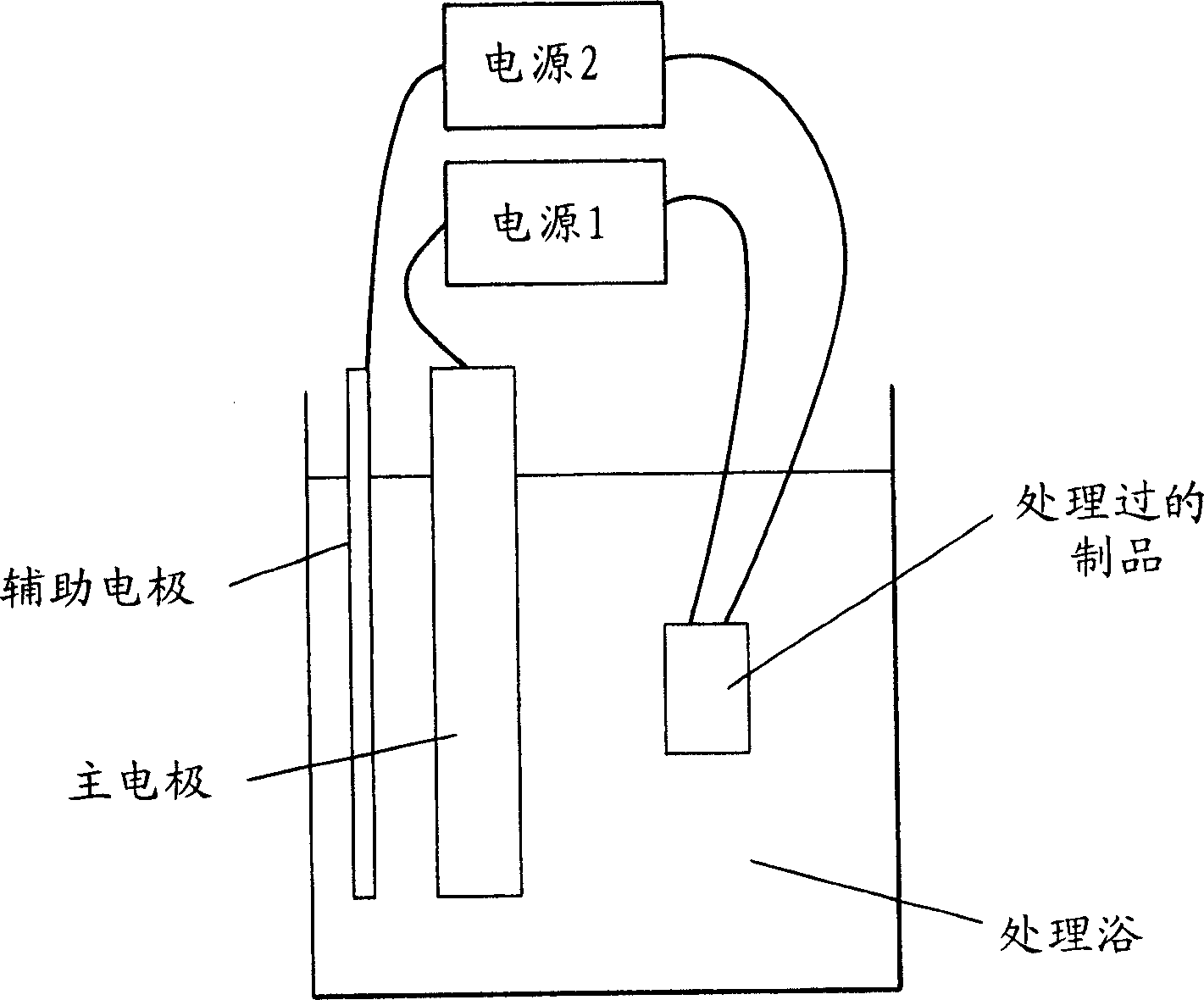

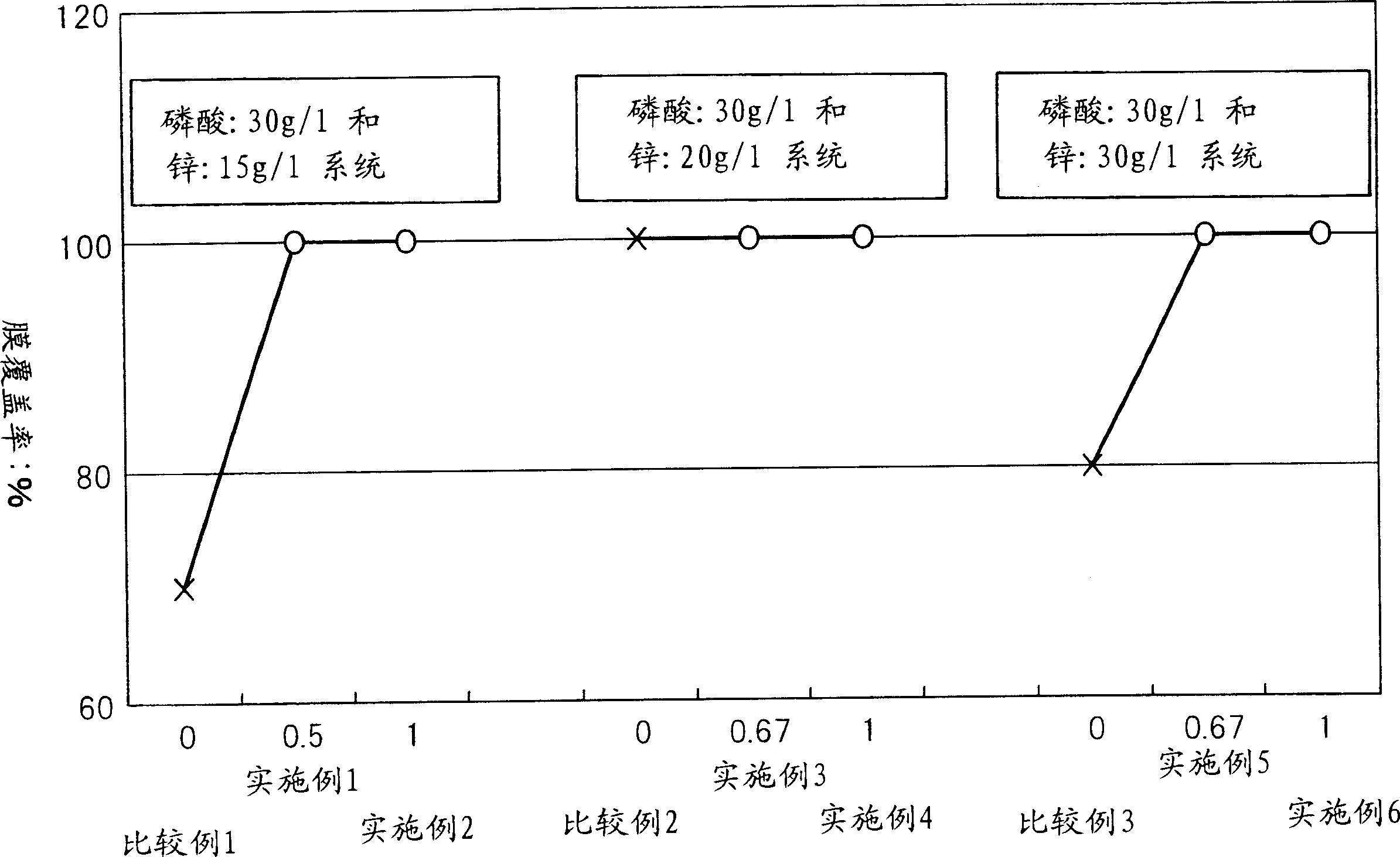

Electrolytic phosphating process

InactiveCN1891865AShorten phosphating treatment timeSmall sizeElectrolytic inorganic material coatingPhosphatisationPhosphate ionPhosphoric acid

This invention provides a phosphating process that can form a film suitable for a cold forging foundation within 60 seconds and preferably 30 seconds or less. The process uses a treatment bath that is formed of a phosphate ion solution (H2PO4-+Zn2+), made by dissolving zinc in phosphoric acid, contains phosphoric acid (H3PO4), phosphate ions, zinc ions and nitrate ions, may contain at least one kind of metal ion selected from the group consisting of nickel ions, cobalt ions, copper ions, manganese ions and iron ions, and further contains 0.5 g / l or below of metal ions other than the film forming components. The process involves electrolytic treatment by applying a voltage between a metal as a positive electrode and a treated article as a negative electrode and forms a phosphate film on the surface of the treated article. The phosphate ion solution prepared by dissolving zinc in phosphoric acid (H2PO4-+Zn2+) is a solution obtained by dissolving 8 parts by mass to a maximum dissolution concentration of zinc in 100 parts by mass of phosphoric acid.

Owner:DENSO CORP

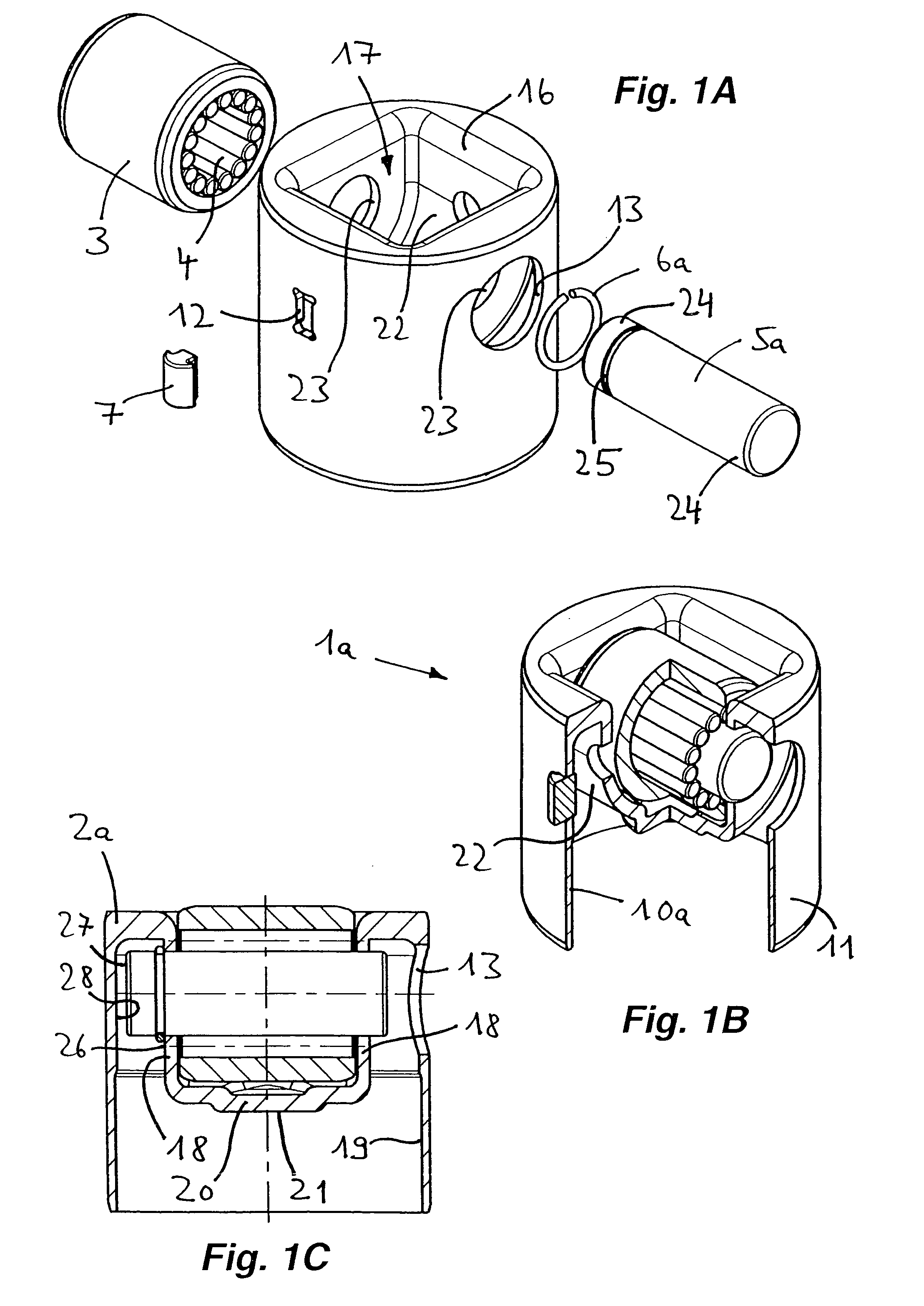

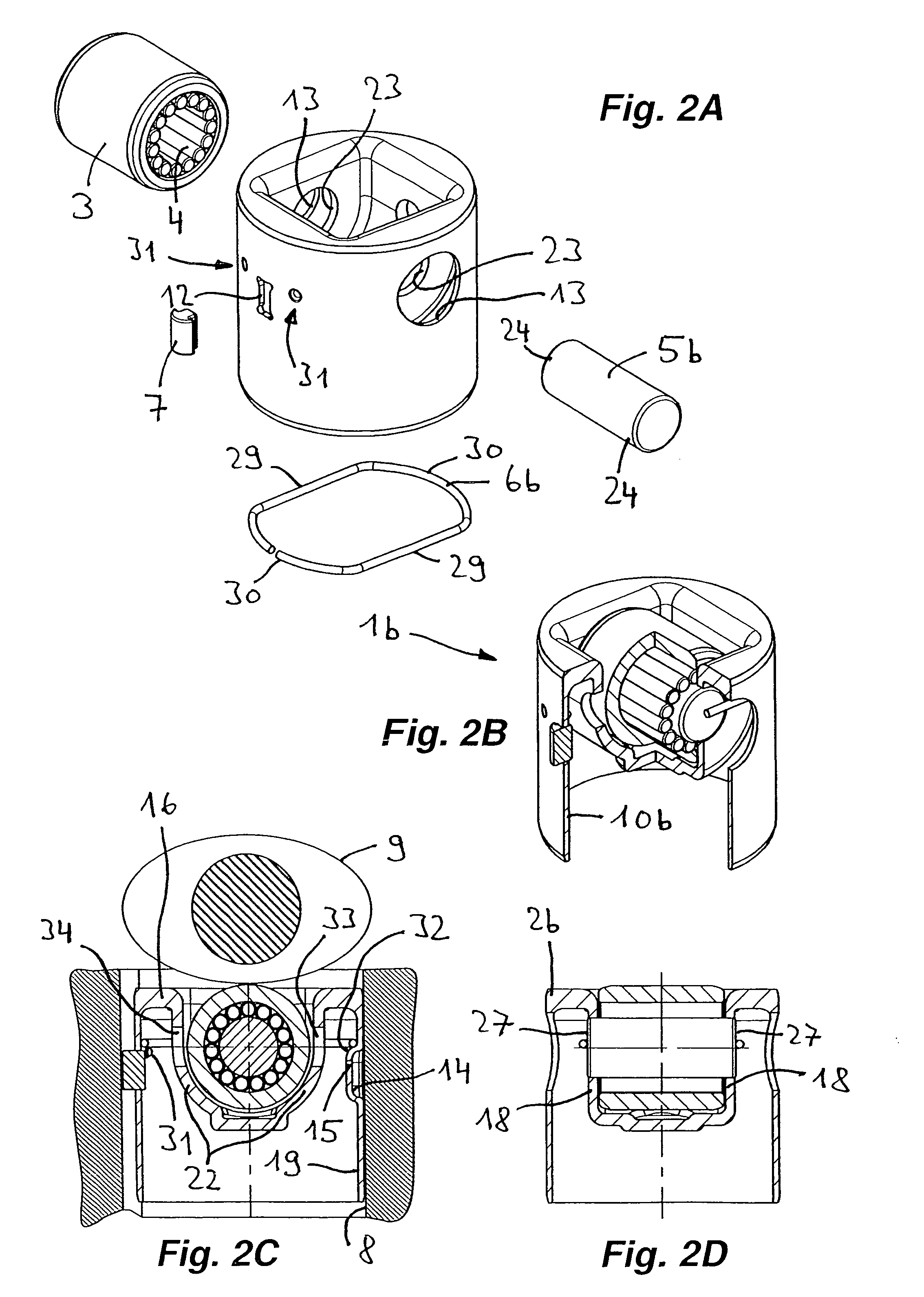

Mechanical roller tappet for an internal combustion engine

InactiveUS20100012065A1High shape stabilityEliminate drawbackValve drivesMachines/enginesEngineeringCam

Owner:SCHAEFFLER TECH AG & CO KG

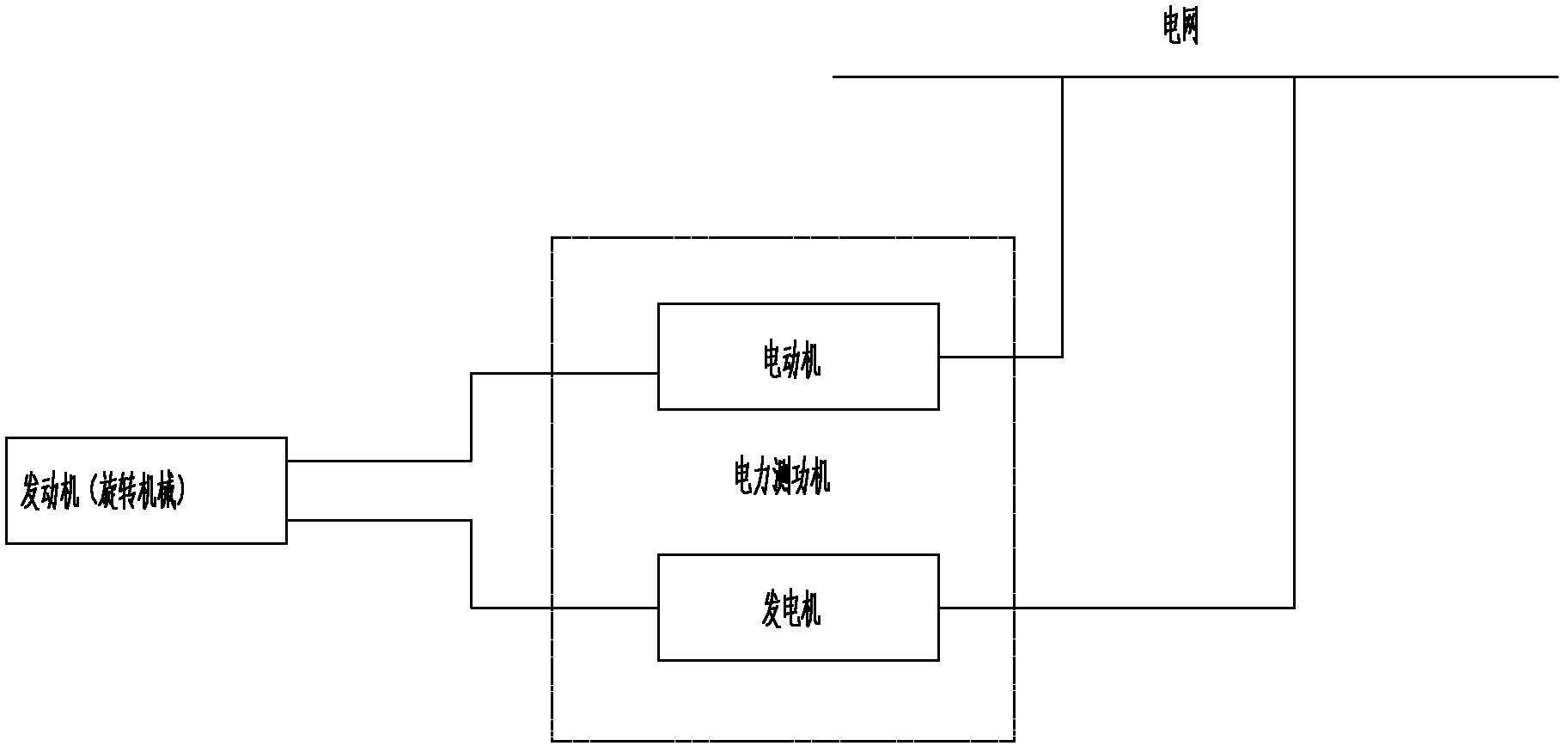

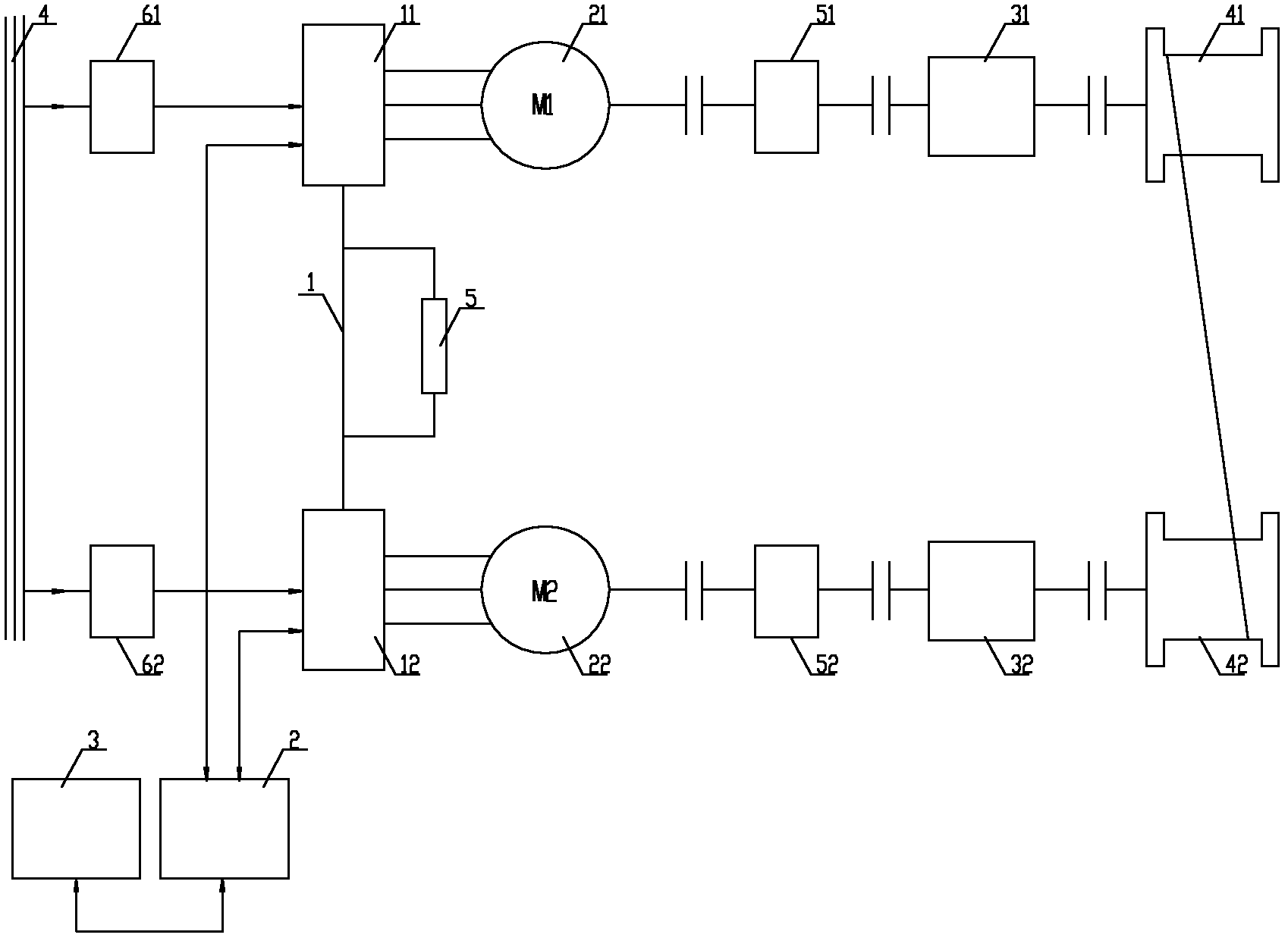

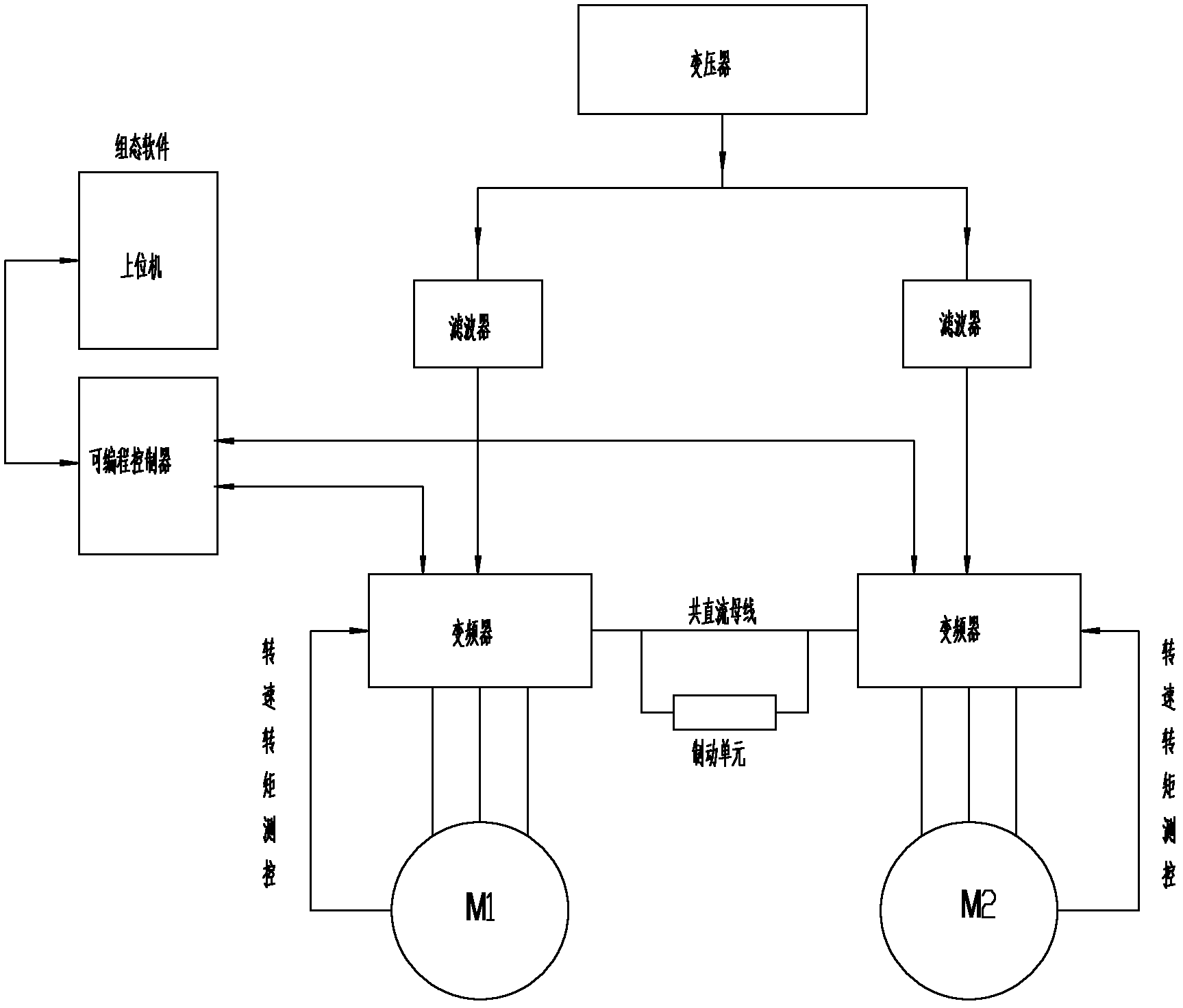

Electric dynamometer

InactiveCN102494820ARealize positive and negative dragCompact structureWork measurementTorque measurementDynamometerVariable-frequency oscillator

The invention discloses an electric dynamometer, which comprises a mechanical transmission system and a frequency conversion control system. The mechanical transmission system comprises two sets of transmission subsystems. The two sets of transmission subsystems are symmetrically arranged and connected in a way of rotating in the same direction, and forwards and backwards drive each other. Each set of transmission subsystem comprises a variable frequency motor and a speed reducer or an accelerator. The speed reducer or accelerator of one set of transmission subsystem is connected with a tested rotating part, and the speed reducer or accelerator of the other set of transmission subsystem is connected with an accompanying-tested rotating part. The tested rotating part and the accompanying-tested rotating part are flexibly connected, and synchronously rotate. The frequency conversion control system comprises two frequency converters. A frequency converter is connected with the variable frequency motor of each set of transmission subsystem. The two frequency converters are connected through a direct current bus. The frequency conversion control system performs closed loop control on the variable frequency motors through the frequency converters. The electric dynamometer is used for solving the problems of high cost, incapability of realizing forward and backward driving, low energy utilization rate and the like.

Owner:BEIJING SANY HEAVY MASCH CO LTD

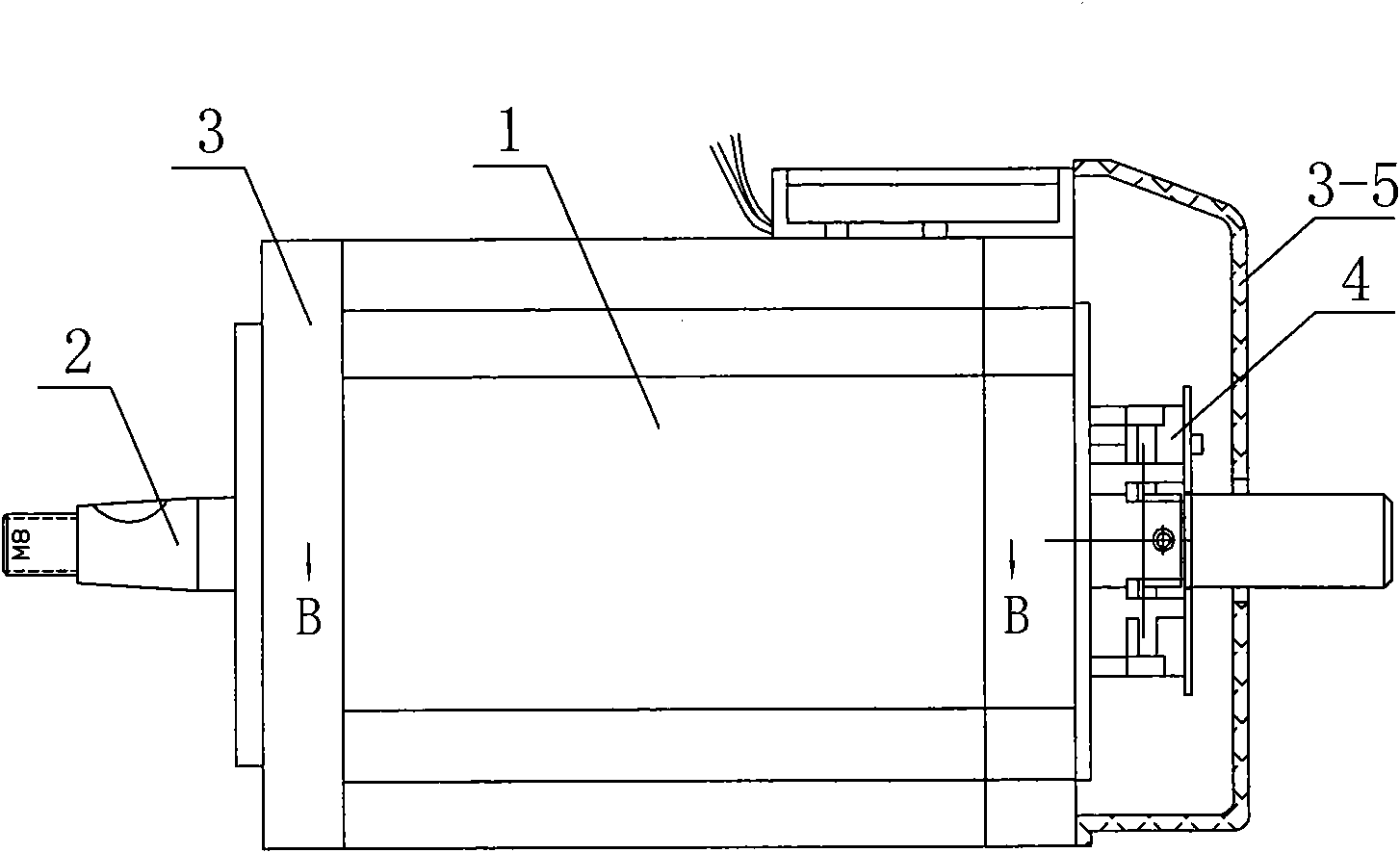

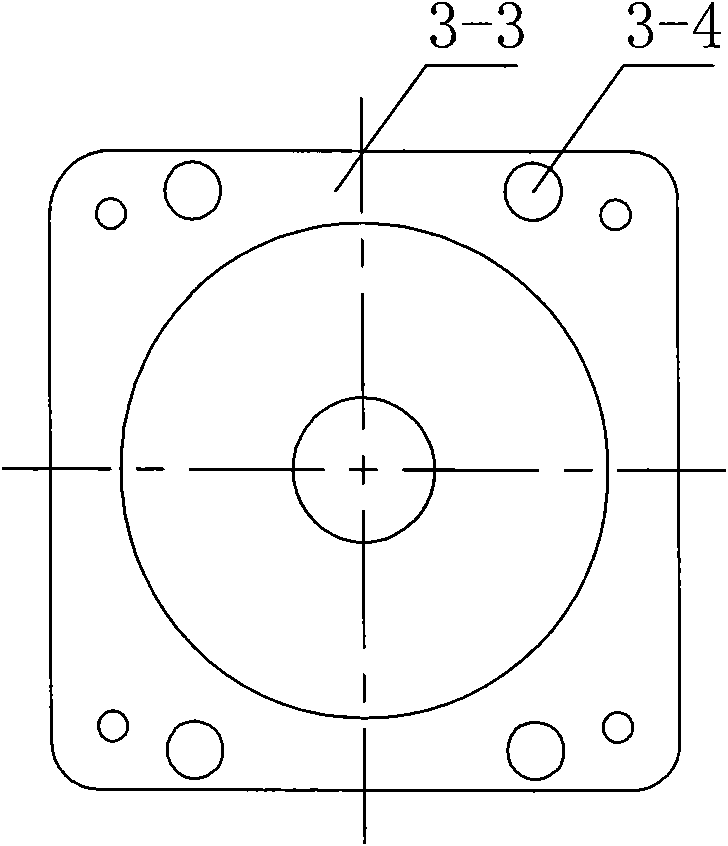

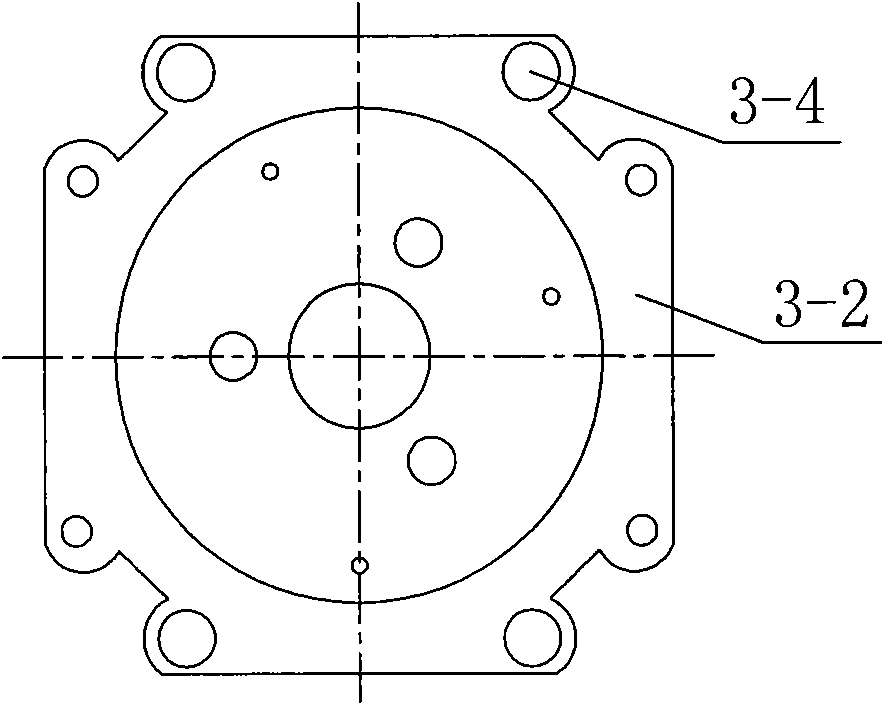

Great-torque miniature DC permanent-magnet synchronous servo motor

InactiveCN101951103ASolve the position control accuracySolve key technologies such as position control accuracyMagnetic circuit rotating partsSynchronous machine detailsElectric machineEngineering

The invention aims to provide a great-torque miniature DC permanent-magnet synchronous servo motor to ensure that the output power and the torque can drive great-load sewing equipment, such as a thick material machine, and the like, and the motor can be lightweight, portable and small. The invention adopts the technical scheme that the great-torque miniature DC permanent-magnet synchronous servo motor is provided with a shell and provided with a stator on the inner wall, wherein a rotor is coaxially embedded in the stator, and a motor output shaft is provided with a photoelectric coder. The great-torque miniature DC permanent-magnet synchronous servo motor is characterized in that the rotor comprises a rotating shaft which penetrates through a bearing, is mounted on the shell and is coaxially provided with a cylindrical rotor core, the outer circumferential surface of the rotor core is evenly provided with a group of axial slots in which matched permanent magnets are inserted, and cylindrical fasteners for fastening the permanent magnets and the rotor core are arranged at both ends of the rotor core. The invention is mainly used for high-speed sewing equipment, particularly a high-speed thick material machine and a synchronization car servo control system.

Owner:杭州励磁自动化技术有限公司

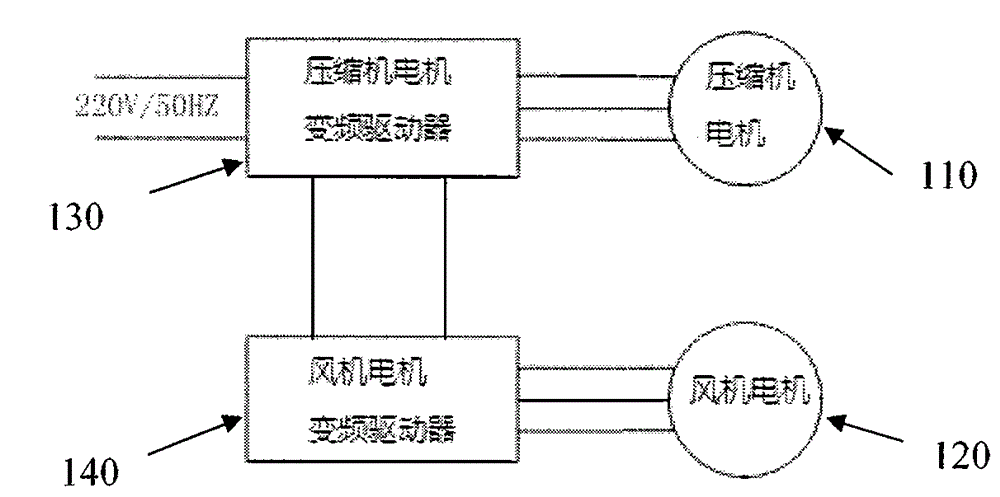

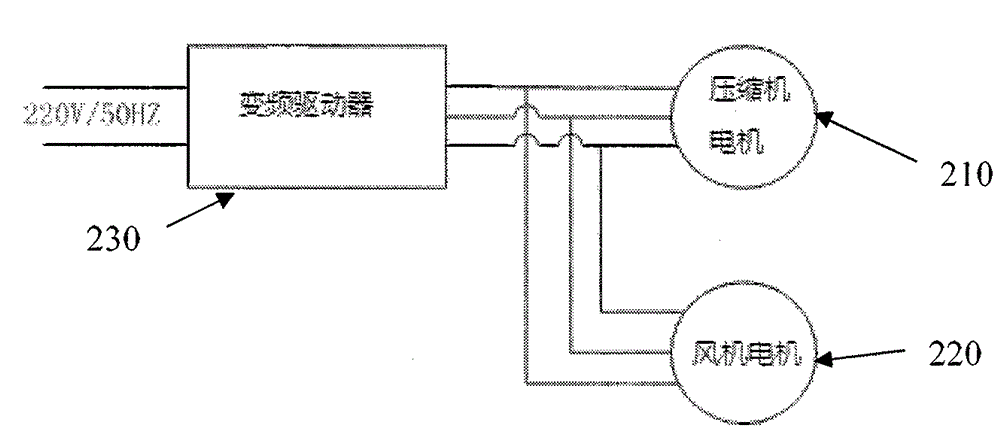

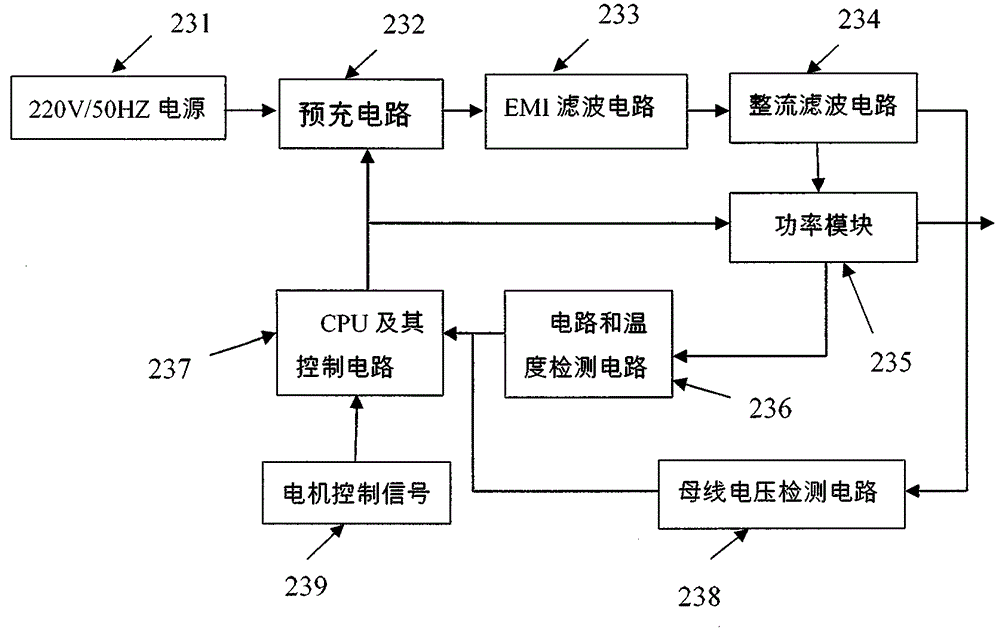

Air conditioner frequency-conversion driving control system and air conditioner using same

InactiveCN103822334ASmall installation sizeLower control costsCompressorSpace heating and ventilation safety systemsBusiness efficiencyControl system

The invention discloses an air conditioner frequency-conversion driving control system and an air conditioner using the same. The air conditioner frequency-conversion driving control system comprises a compressor motor, a fan motor and a single frequency-conversion driver. An output shaft of the frequency-conversion driver is simultaneously connected with the compressor motor and the fan motor, so that the compressor motor and the fan motor are simultaneously controlled. The control cost is greatly reduced on the premise that the running efficiency and the energy efficiency ratio of the air conditioner frequency-conversion driving control system are equivalent to those of a double-frequency-conversion air conditioner driving system, and the mounting size of the air conditioner frequency conversion system is effectively reduced.

Owner:傅先凤

Apparatus for drying hearing aids

InactiveUS20100011613A1Reduce running noiseKeep dryDrying solid materials with heatDrying gas arrangementsLow noiseEngineering

The invention relates to an apparatus for drying hearing aids. According to the invention, the drying apparatus includes a housing and in the housing a hearing aid shell for inserting the hearing aid and a fan, with the fan accelerating air by means of an electro-aerodynamic pump. The electro-aerodynamic pump is advantageously embodied to generate gas ions and to accelerate the gas ions through an electrical field. The electro-aerodynamic fan is advantageous in that it requires little space and, except for the air flow, operates at a low noise level.

Owner:SIEMENS MEDICAL EQUIPMENT

Bulk material distributing device

ActiveCN101633438ASimple structureReduce manufacturing costLarge containersCharge manipulationEngineering

Owner:CISDI ENG CO LTD

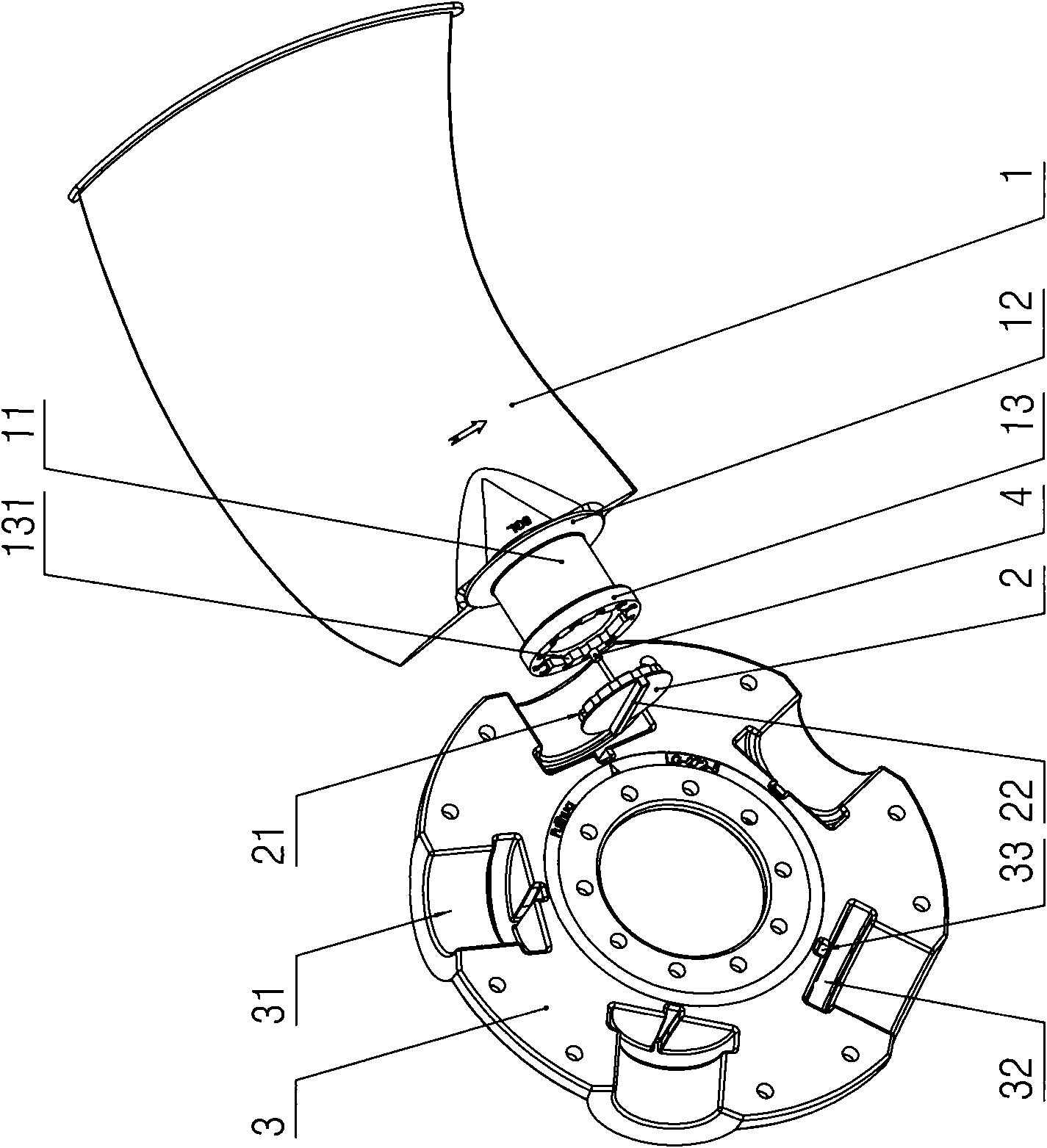

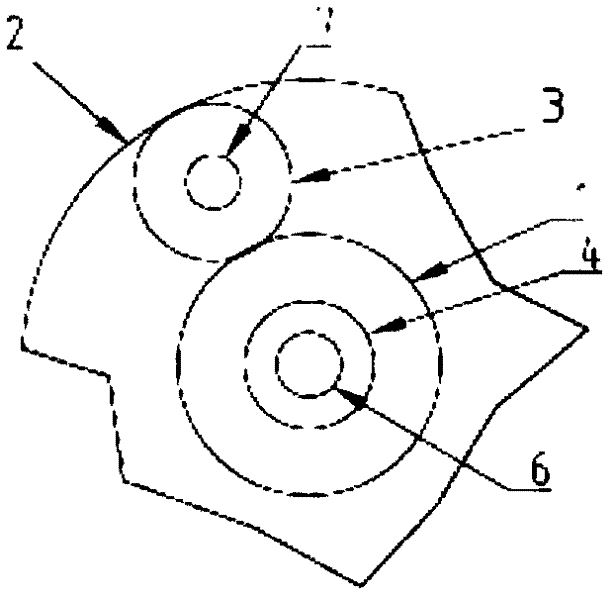

Impeller

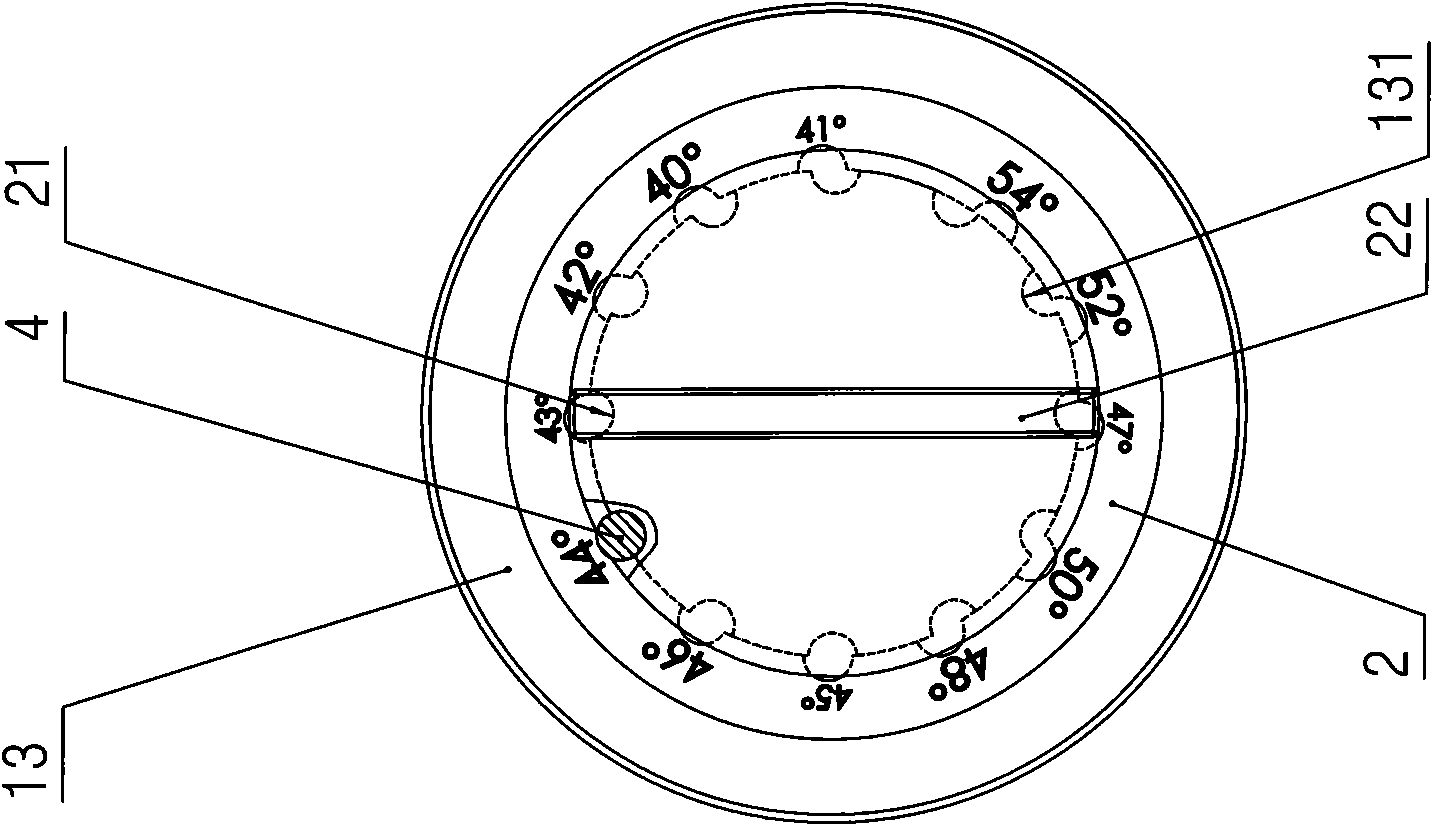

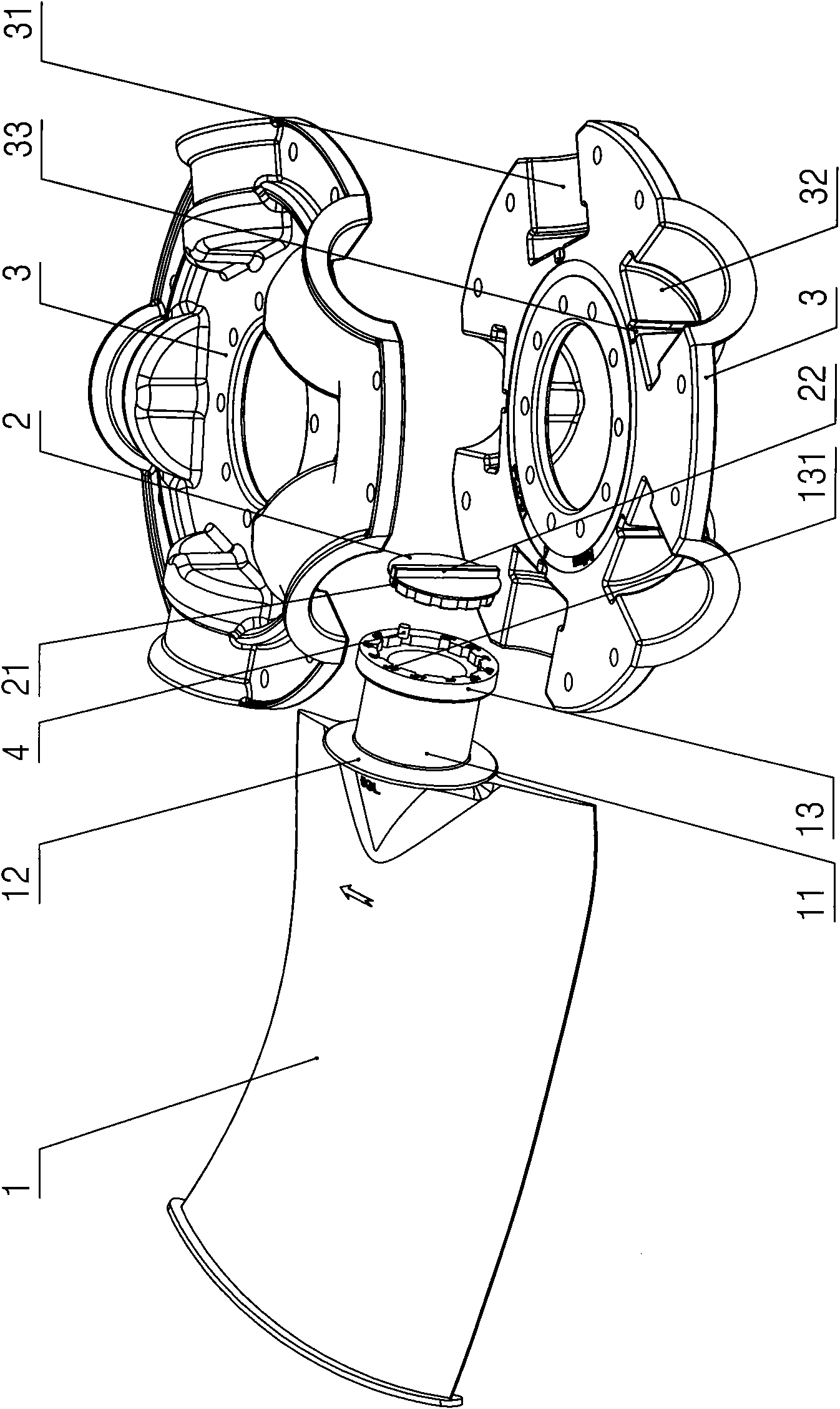

InactiveCN101634311APrecise positioningSmall installation sizePump componentsPumpsCircular discImpeller

The invention discloses an impeller allowing fan blades to be firmly clamped in wheel hub discs at different angles, which comprises a pair of wheel hub discs and at least two fan blades, wherein each fan blade comprises a blade and a blade stem; each blade stem comprises a cylindrical supporting arm, a positioning edge and a positioning seat; the outer edge of the inner end face of each positioning disc is provided with at least two equant inner semi-cylindrical grooves; the outer end faces of the positioning discs are provided with positioning keys; the positioning discs are arranged in accommodating cavities on the end face of the positioning seats; the circumferential walls of the accommodating cavities are provided with outer semi-cylindrical grooves corresponding to the inner semi-cylindrical grooves one by one; one positioning seat and one positioning disc are closed together by cylindrical pins arranged in one pair of inner and outer semi-cylindrical grooves; each wheel hub is provided with front semi-cylindrical grooves which are used for mounting the supporting arms and the same as the fan blades in number and rear semi-cylindrical grooves which are used for mounting the positioning seats and the positioning discs and the same as the fan blades in number; and the rear walls of the rear semi-cylindrical grooves are provided with key slots of the positioning keys. The impeller is mainly used in axial flow fans.

Owner:JIANGSU FULIHUA GENERAL EQUIP

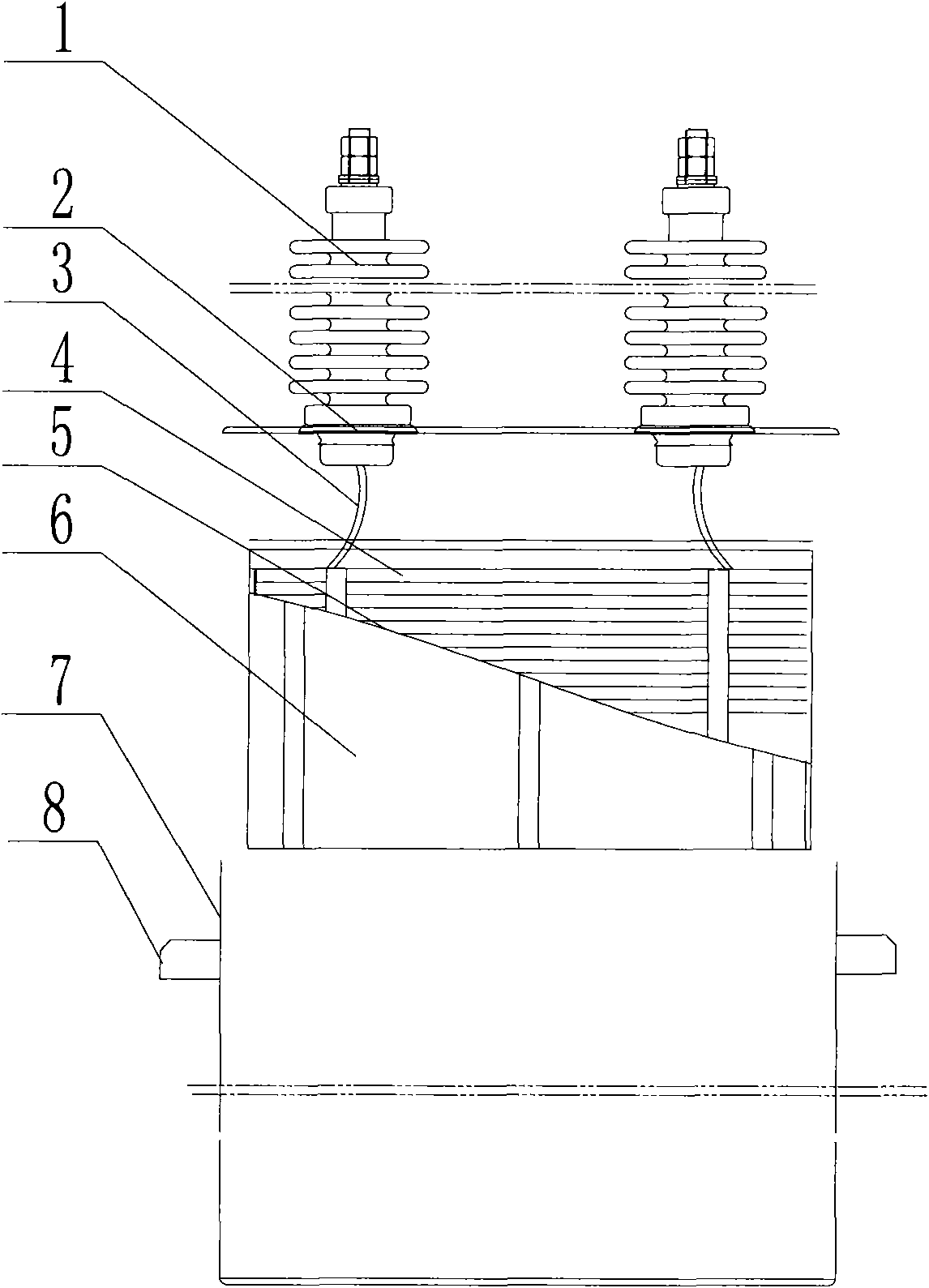

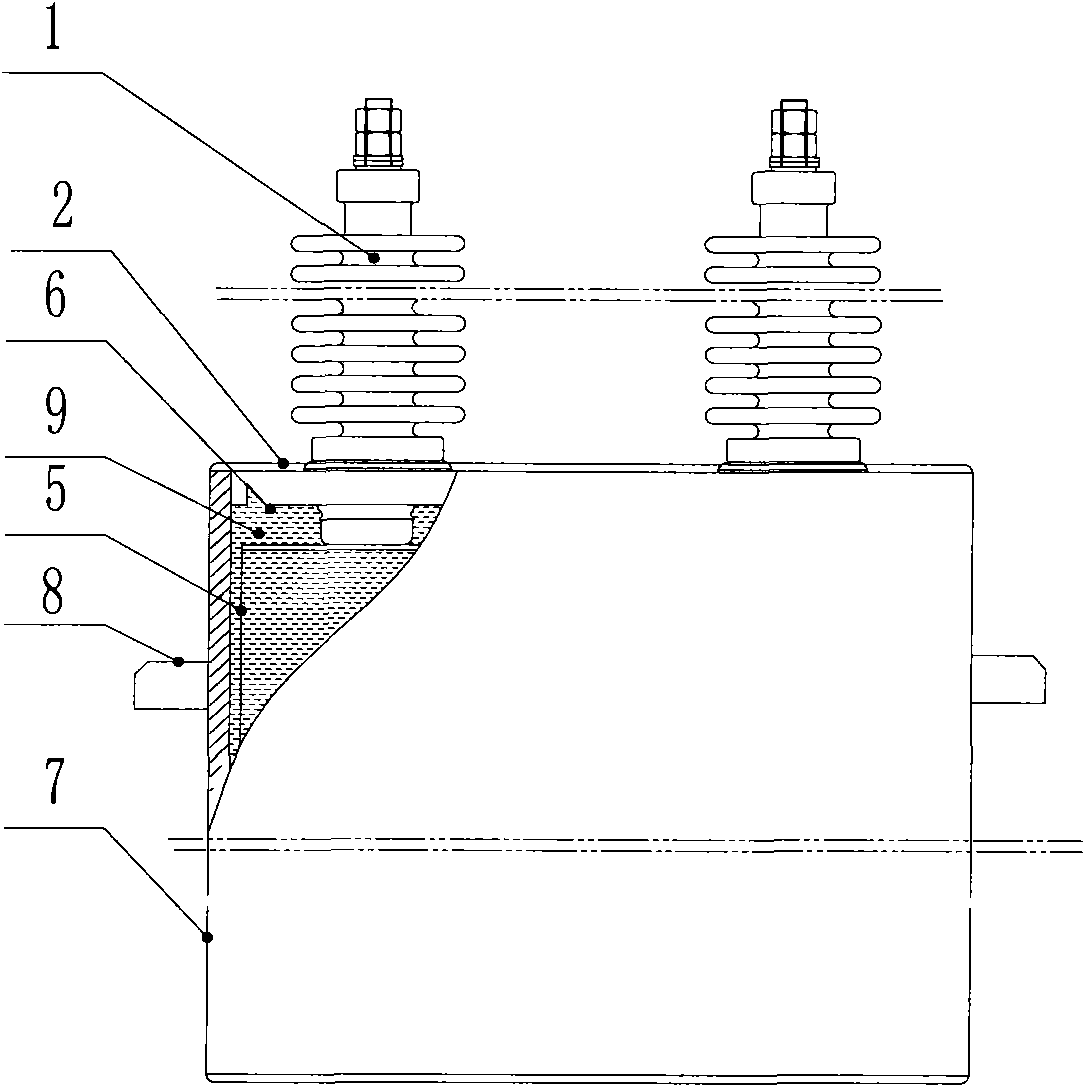

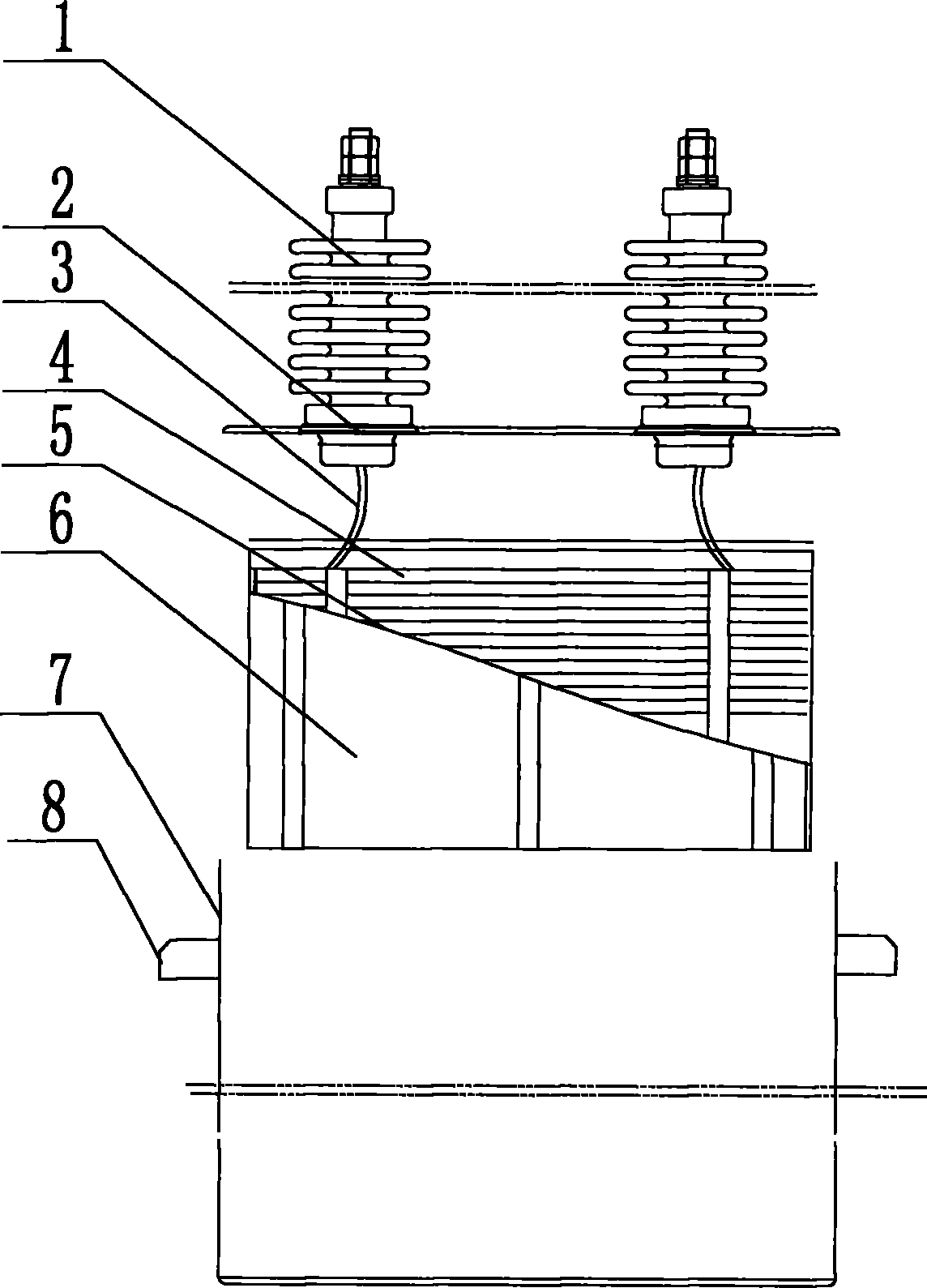

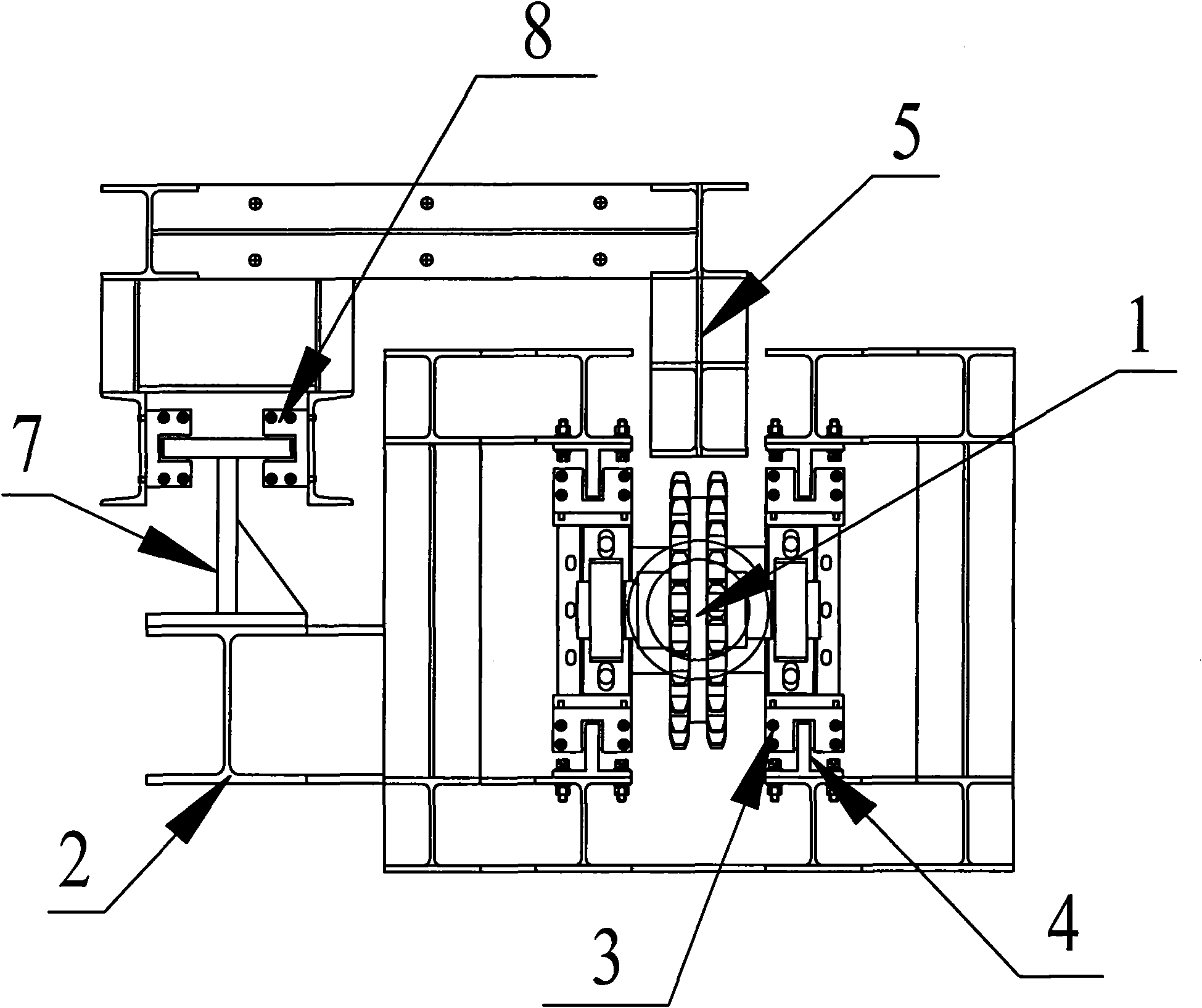

High-voltage power capacitor device and manufacturing method thereof

InactiveCN101950670AHigh rated voltageSmall installation sizeMultiple fixed capacitorsFixed capacitor housing/encapsulationEngineeringHigh pressure

The invention provides a high-voltage power capacitor device and a manufacturing method thereof. The device comprises an outlet sleeve, a box cover, a capacitor element, a capacitor core, a box body and insulating oil. The device is characterized in that: the capacitor core is formed by connecting capacitor elements in series and parallel by connecting plates, wherein the capacitor elements are formed by winding an aluminum foil and a polypropylene film on a winder and pressing; the capacitor core is packed by using a packing insulator and arranged in the box body; the outlet sleeve is fixed on the box cover; the connecting plates are connected with down leads of the outlet sleeve; the box cover is welded on the box body; and the insulating oil is filled in the box body. The box body of the device can be directly grounded, and the device is suitable for a common cabinet capacitor structure and is convenient to install and produce.

Owner:QINGDAO ZHONGZI ZHONGCHENG GROUP CO LTD

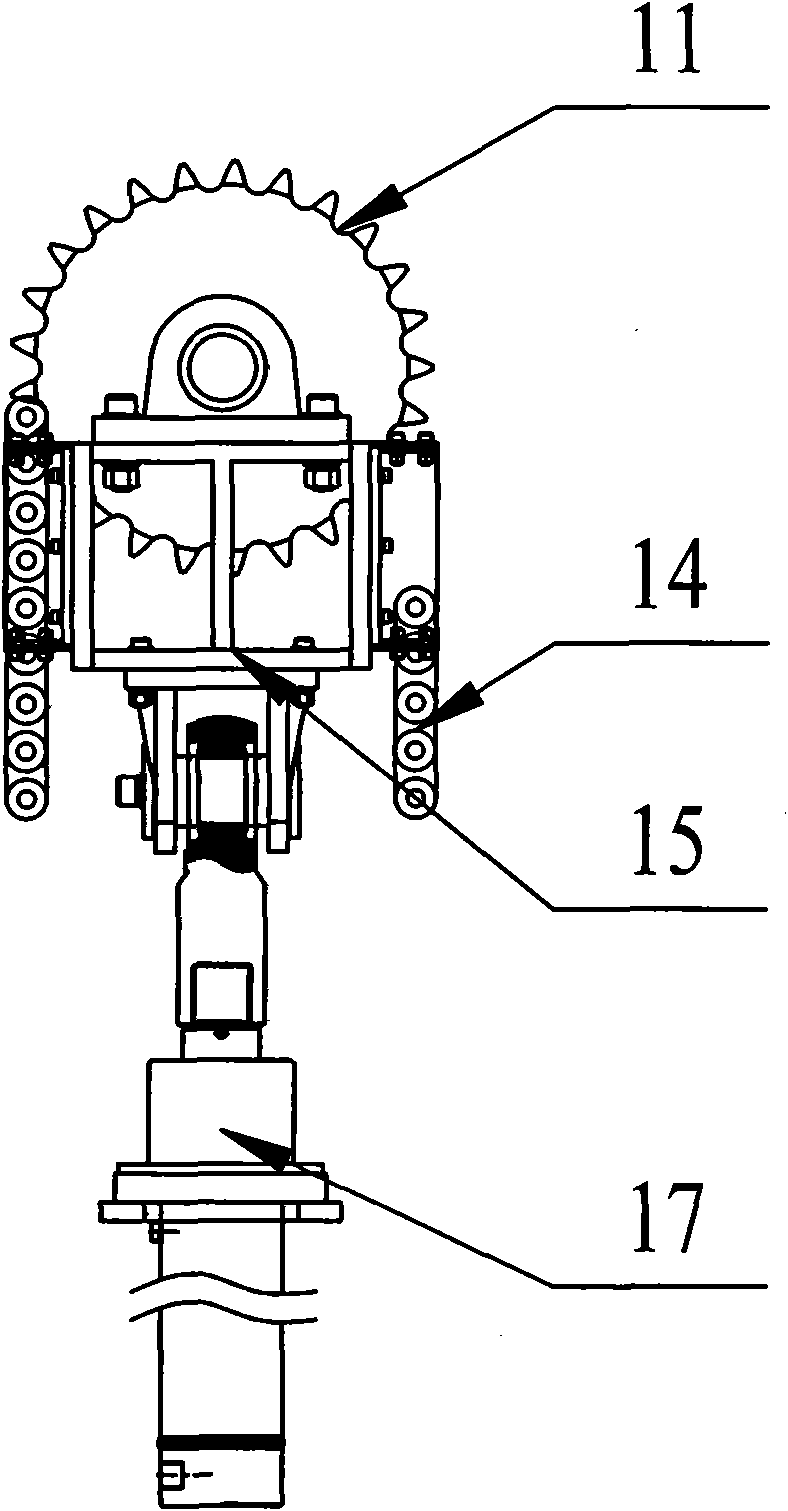

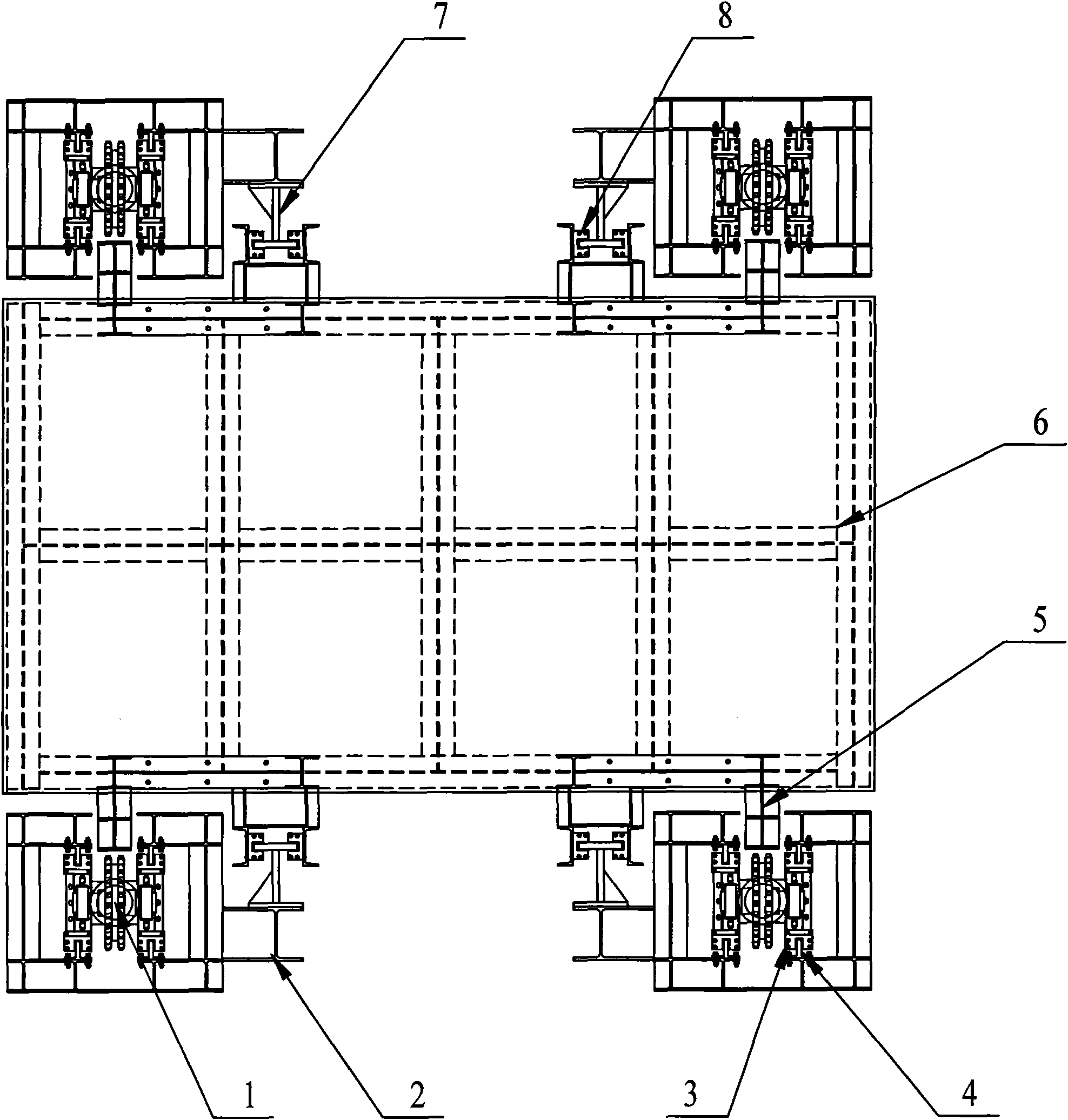

Lifting device and stage structure using same

The invention relates to a lifting device and a stage structure using the same. The lifting device comprises a fixing support for being connected with an operating platform, a guide frame, a chain wheel assembly and a drive unit, wherein, the chain wheel assembly comprises a chain wheel and a chain wound on the chain wheel, one end of the chain is fixedly connected with the fixing support, the other end of the chain is fixedly connected on the guide frame, and the chain wheel is arranged on the guide frame in relative slip and relative rotation manners; and the drive unit drives the chain wheel to rise and fall along the guide frame so that the chain drives the fixing support to rise and fall so as to realize lifting operation of the operating platform. The lifting device has the advantages that motion stroke of an oil cylinder is increased by means of the chain wheel and the chain, thus reducing installation size of the lifting device; and the operating platform can stably rise and fall under guidance of guide shoes and guide rails.

Owner:华强方特(深圳)智能技术有限公司

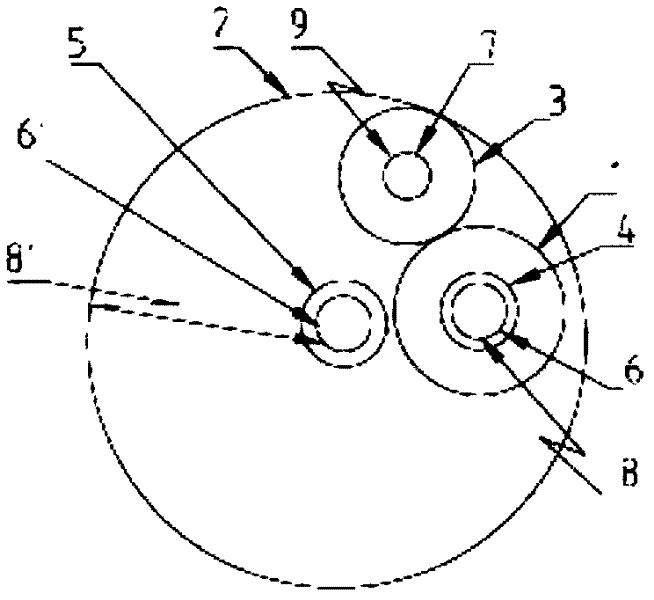

Unidirectional output conversion device

The invention discloses a unidirectional output conversion device, and aims to provide a unidirectional output conversion device which has the advantages of simple structure and low manufacture cost, is convenient to arrange and is flexible to install. The unidirectional output conversion device provided by the invention comprises an input shaft, an output shaft, a first spin wheel, a second spin wheel, a third spin wheel, a first overrun clutch and a second overrun clutch, wherein the third spin wheel is externally meshed with the first spin wheel and is internally meshed with the second pin wheel; the first spin wheel and the second spin wheel are connected with a respective rotation shaft respectively by the first overrun clutch and the second overrun clutch; and the clutching directions of the first overrun clutch and the second overrun clutch are opposite. Therefore, according to the unidirectional output conversion device, back-and-forth swinging and continuous rotation are converted into fixed-direction output.

Owner:黄盛华

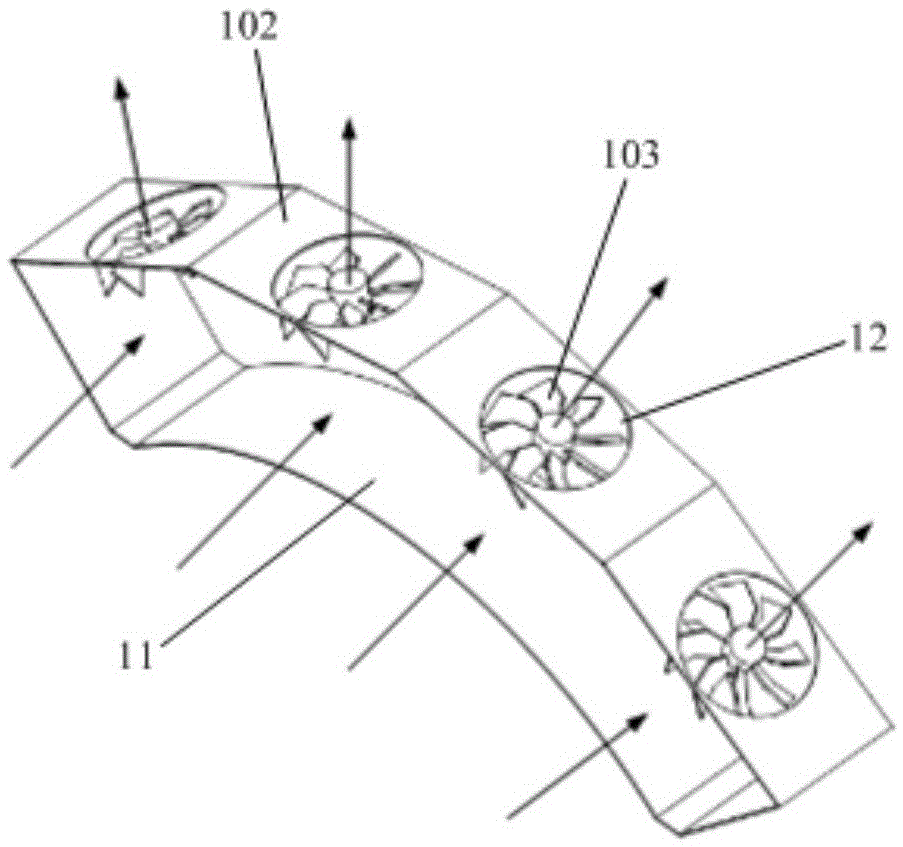

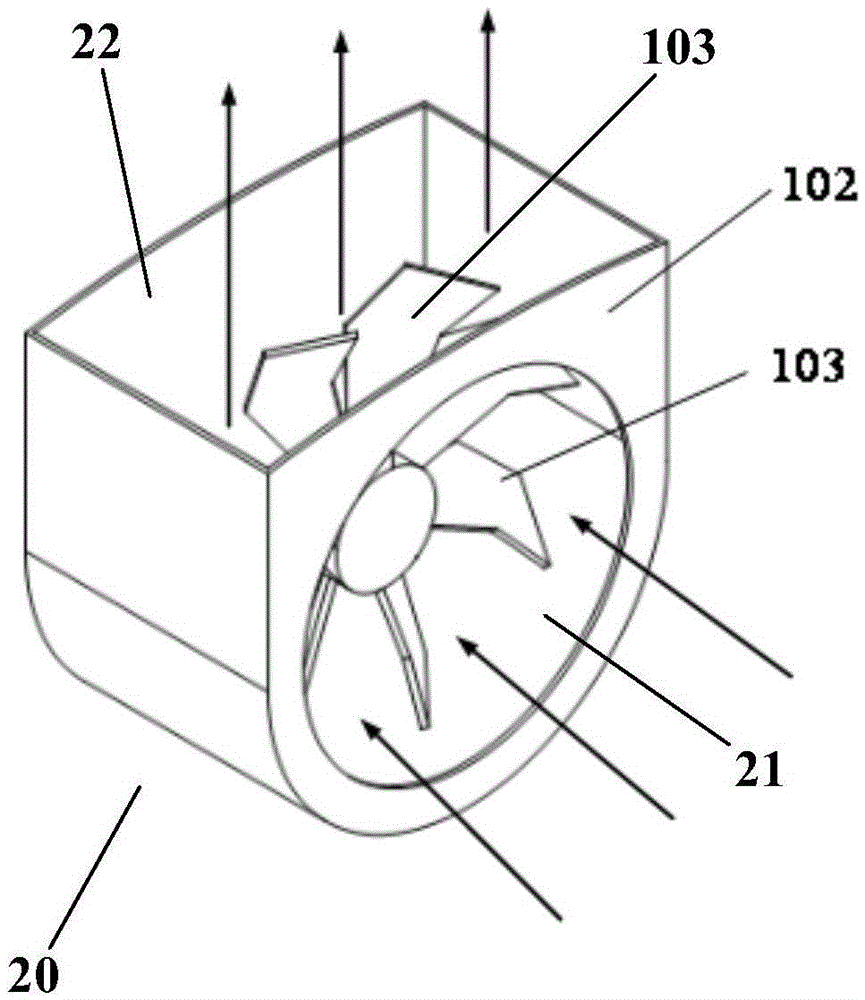

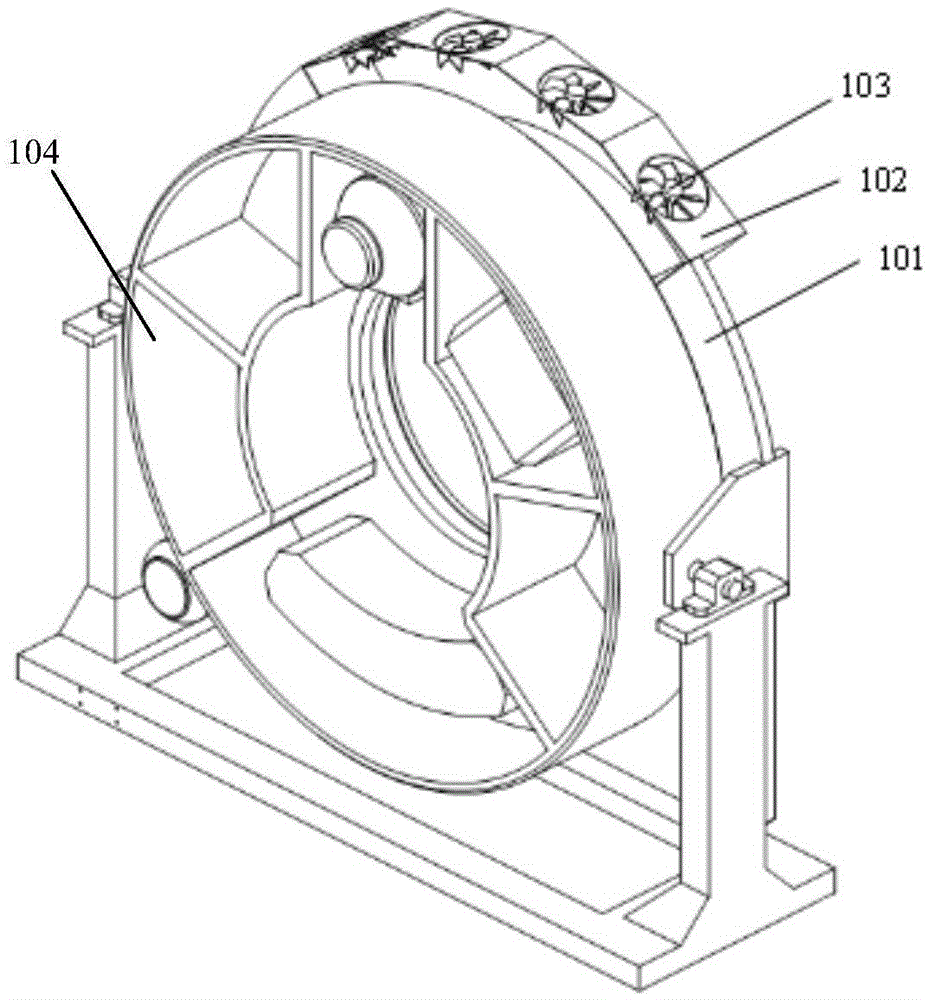

Heat dissipation structure of computed tomography (CT) device

ActiveCN105530751AWill not affect each otherSmall installation sizeX-ray apparatusRadiation diagnosticsScrapComputed tomography

The invention provides a heat dissipation structure of a computed tomography (CT) device. Due to the structural design of an air duct and fans, fans do not interfere with each other. The fans and the air duct are fixed on a support plate, the rear space of the support plate is fully used, and the fans and the air duct are not directly installed over a heat dissipation component, so that the installation size above a CT device rack can be effectively reduced, and the overall height of the rack is lowered. Due to cooperation of the air duct and the support plate, the impact of the fans on the air of the rear space of the support plate is effectively prevented, independence of the front space and the rear space of the support plate is realized, worn scraps of a transmitting belt at the rear side of the support plate and carbon powder on a slide ring carbon brush are prevented from blowing up and flying around so as not to pollute the whole rack system, the rotation noise of a rotation component at the front side of the support plate is lowered, and the heat dissipation efficiency is improved. Through adoption of the structural design of the air duct, inlet air resistance in the heat dissipation structure can be reduced obviously, the heat dissipation efficiency of the heat dissipation structure is greatly improved, and the working noise of the heat dissipation structure is lowered remarkably.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

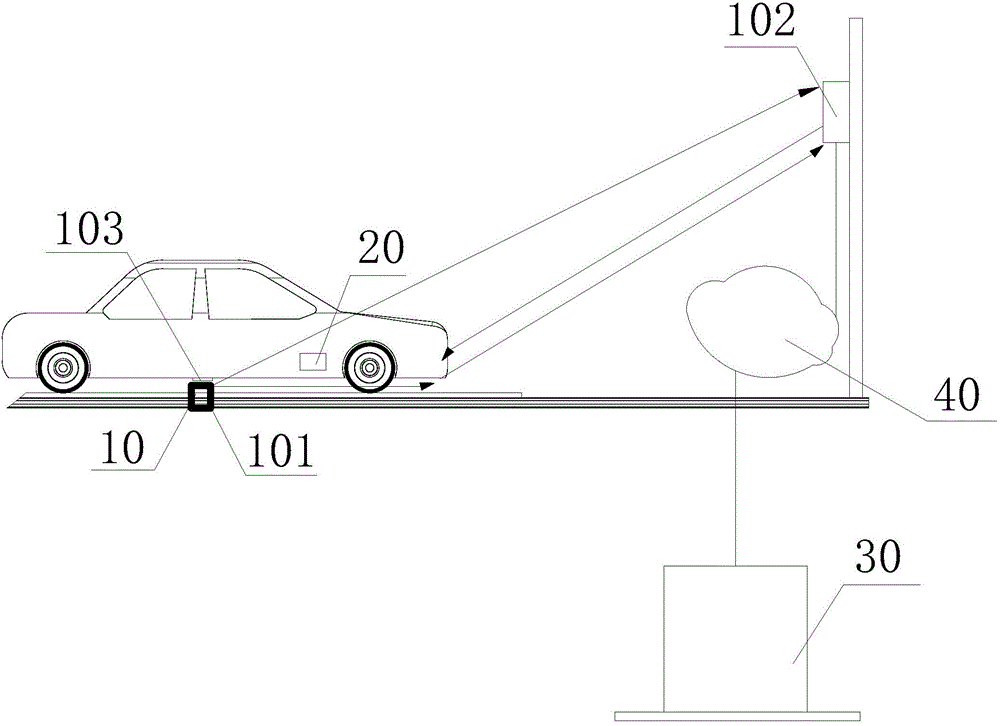

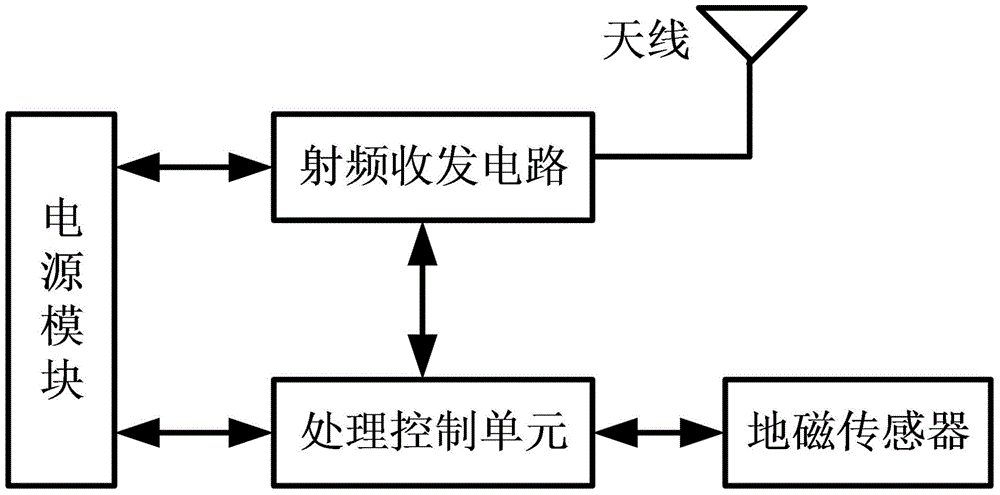

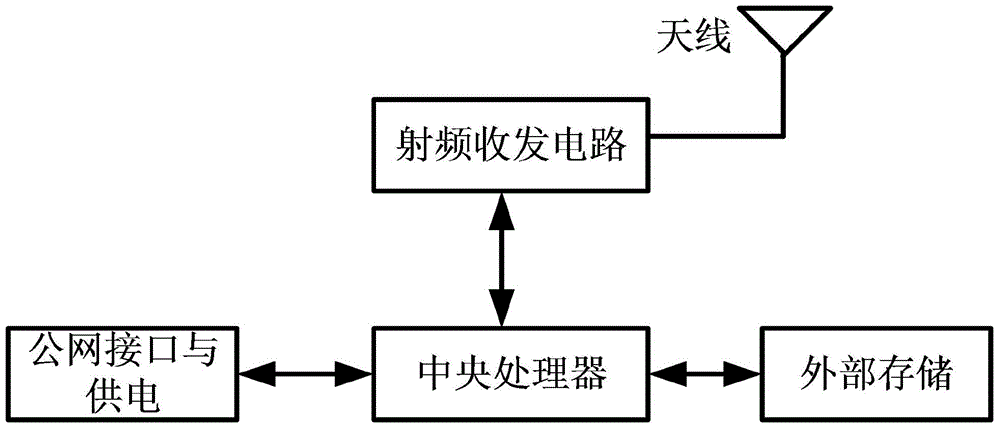

Intelligent management monitoring system for convenient parking in urban areas

InactiveCN104900060AImprove reliabilityAvoid damageTicket-issuing apparatusDetection of traffic movementParking areaDriver/operator

The invention discloses an intelligent management monitoring system for convenient parking in urban areas. The intelligent management monitoring system comprises a sensing and induction system installed on a parking lot, an induction system installed on a vehicle and a big data server, wherein the big data server stores and analyzes parking lot information in an entire city area, and stores and analyzes vehicle and vehicle owner information. The intelligent management monitoring system provides data interface for combing parking information and map navigation, and provides data and interface for paying parking fees to a bank. Garages and parking lot information in the urban areas can be collected by the sensing and induction system and fed back to the big data server through a network. In this way, parking stall information in all parking lots in an urban area can be obtained. The parking information is pushed to map navigation in combination with the map navigation, so that a driver can rapidly find an appropriate parking place. Automatic parking charging can be realized by binding a parking stall and a vehicle one by one through the induction system on the vehicle.

Owner:贺杰

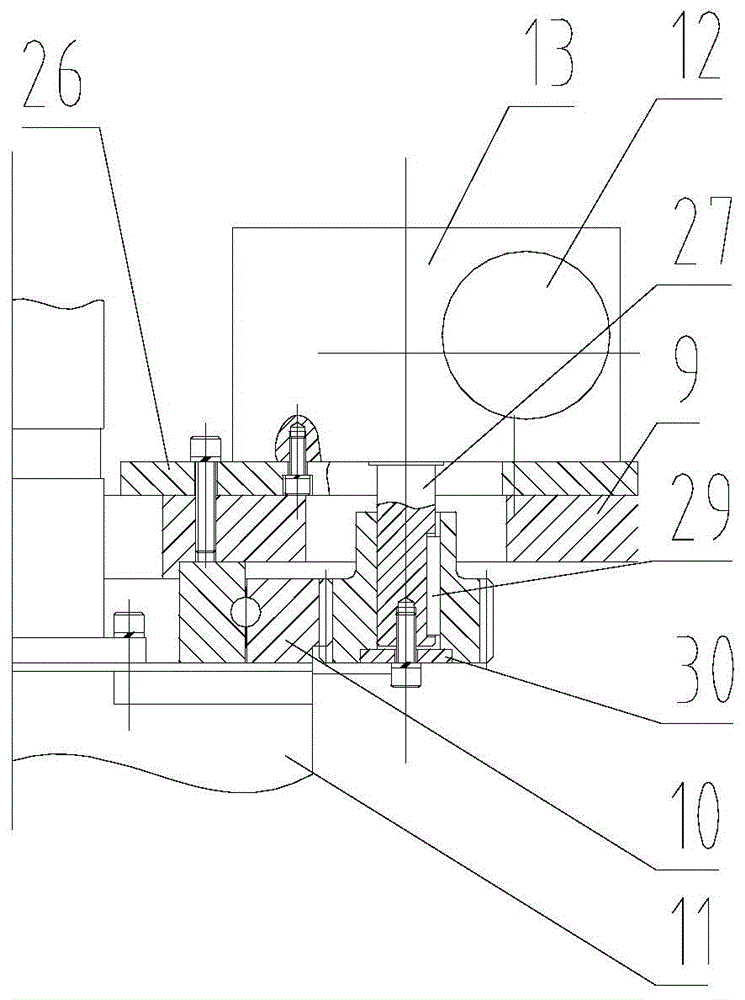

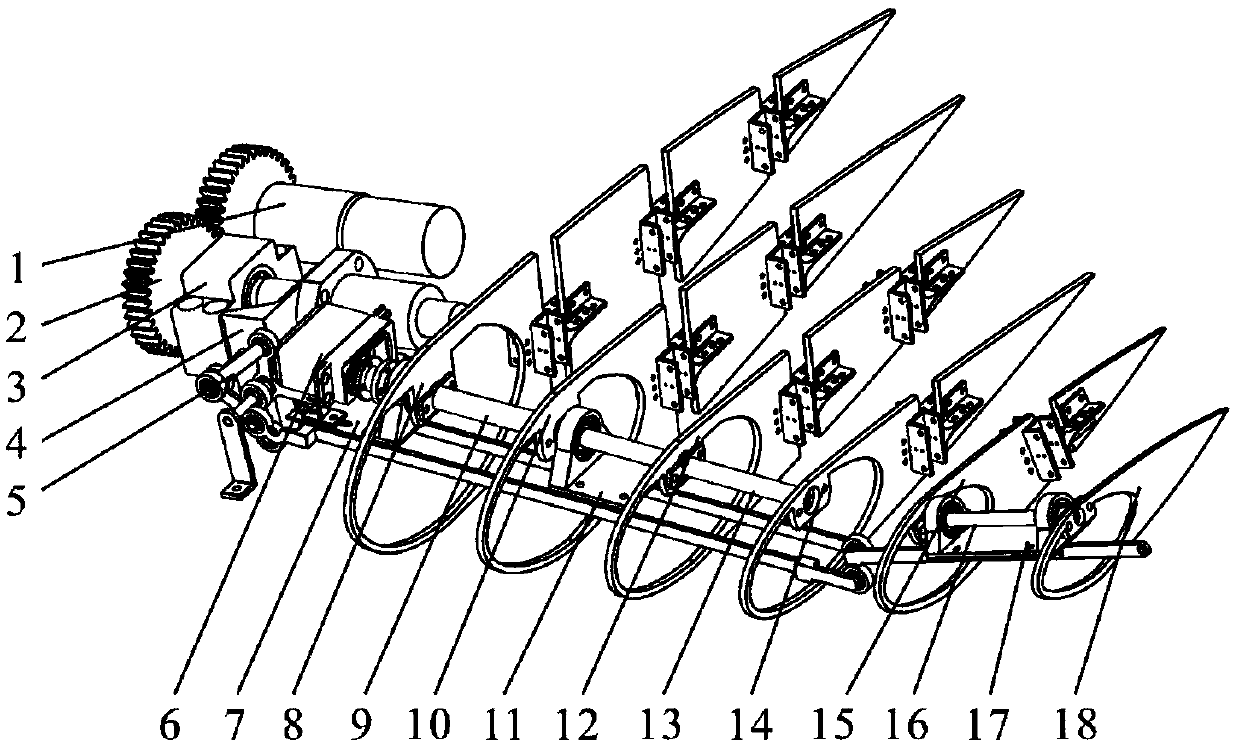

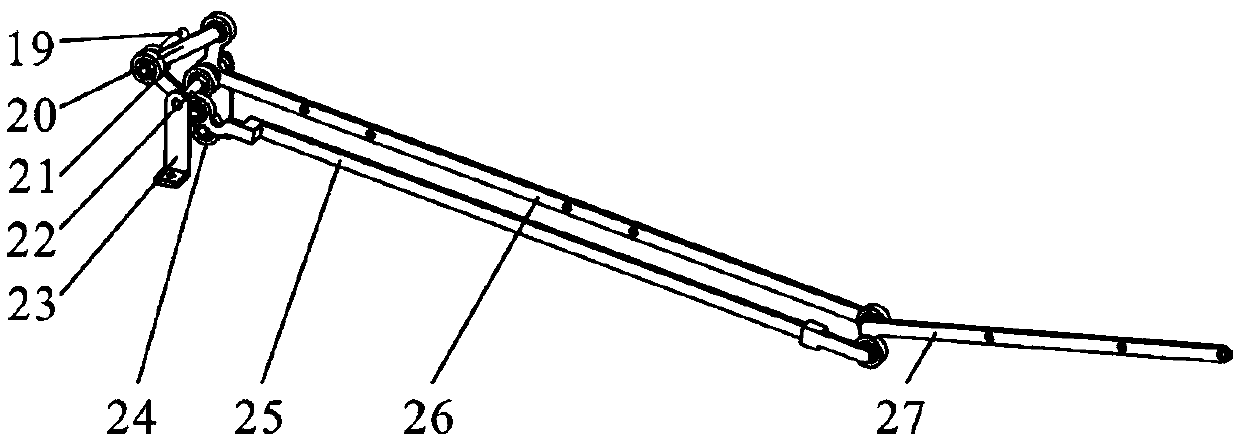

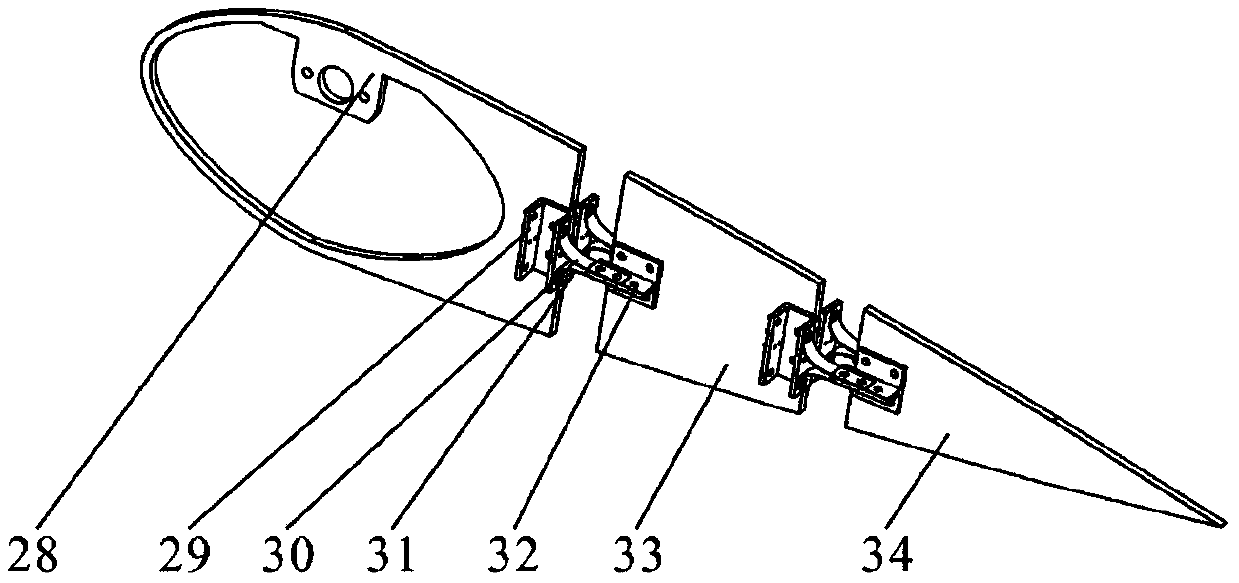

Bionic underwater vehicle flapping wing propulsion device

ActiveCN109533249AReduce development difficultySmall sizeSteering ruddersPropulsive elements of non-rotary typeFlapping wingBall screw

The invention discloses a bionic underwater vehicle flapping wing propulsion device. An underwater vehicle comprises a drive motor assembly, a transmission gear set, a ball screw, a steering engine, asteering shaft, an adaptive under-actuated flexible wing framework, a single-sliding block and double-rocker mechanism, and a fixing seat, the drive motor assembly, the ball screw and the fixing seatare connected with an underwater vehicle body separately, the drive motor assembly is composed of a motor, a speed reducer and an encoder, the ball screw is composed of a screw rod, a screw nut and ascrew fixing seat, and an output shaft of the speed reducer is connected with a driving gear of the transmission gear set; a driven gear of the transmission gear set is connected with the screw rod of the ball screw, and the motor drives the screw rod to rotate through the transmission gear set. The bionic underwater vehicle flapping wing propulsion device has the advantages that the integral structure is provided with a front end swing and a rear end swing, the whole device has two degrees of freedom, and propulsion, turning, floating, submergence and other movements of the underwater vehicle can be achieved.

Owner:TIANJIN UNIV

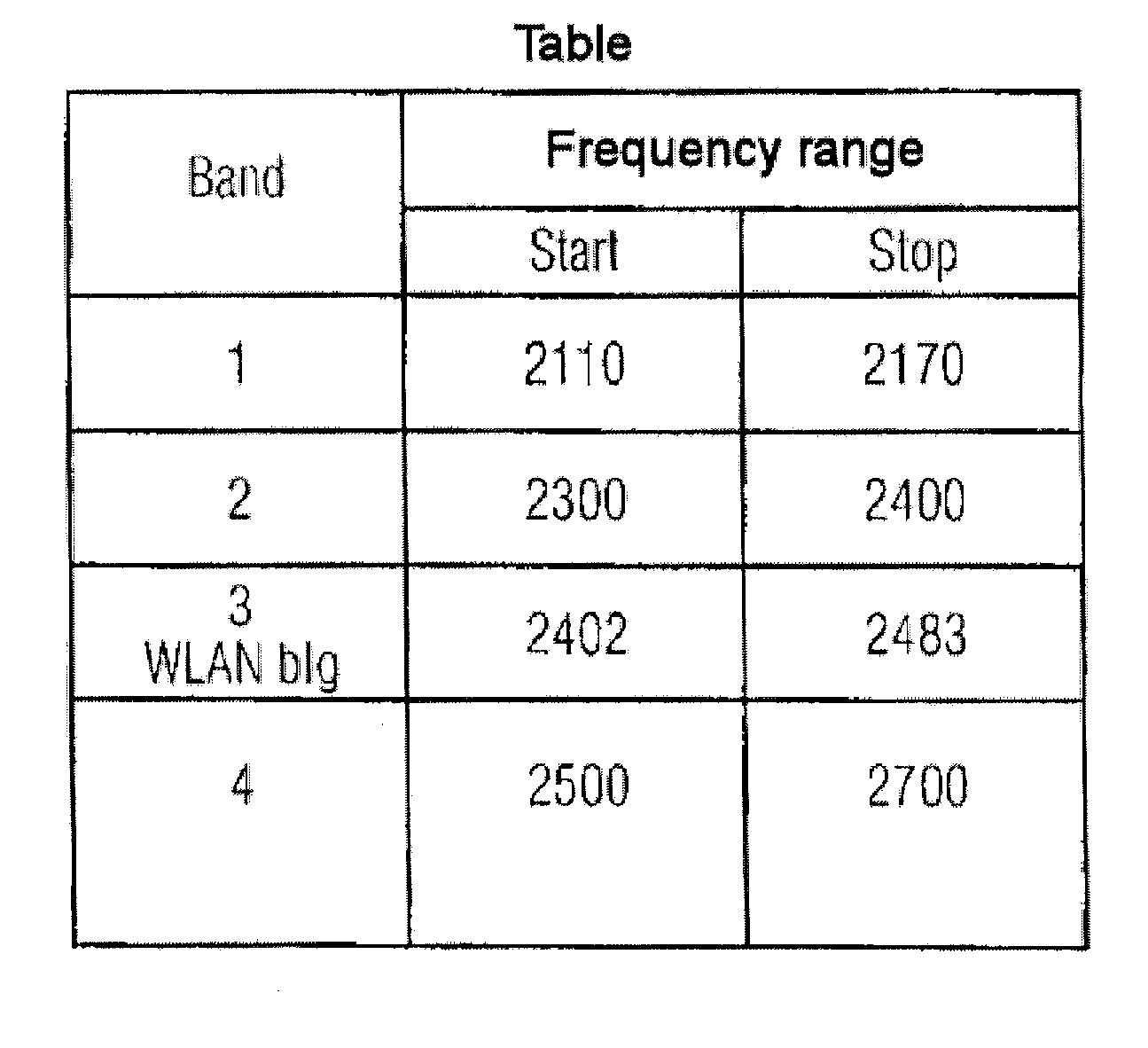

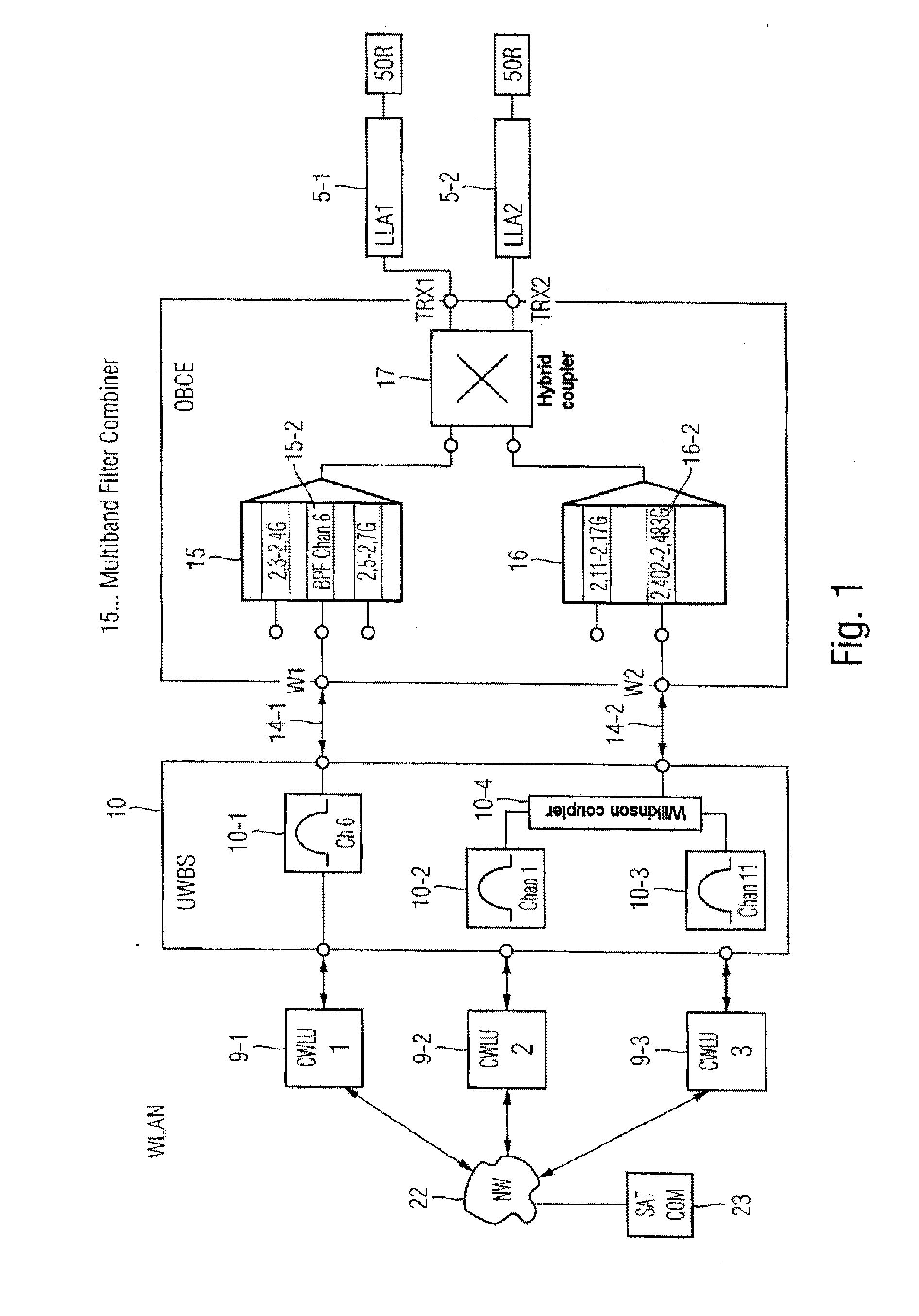

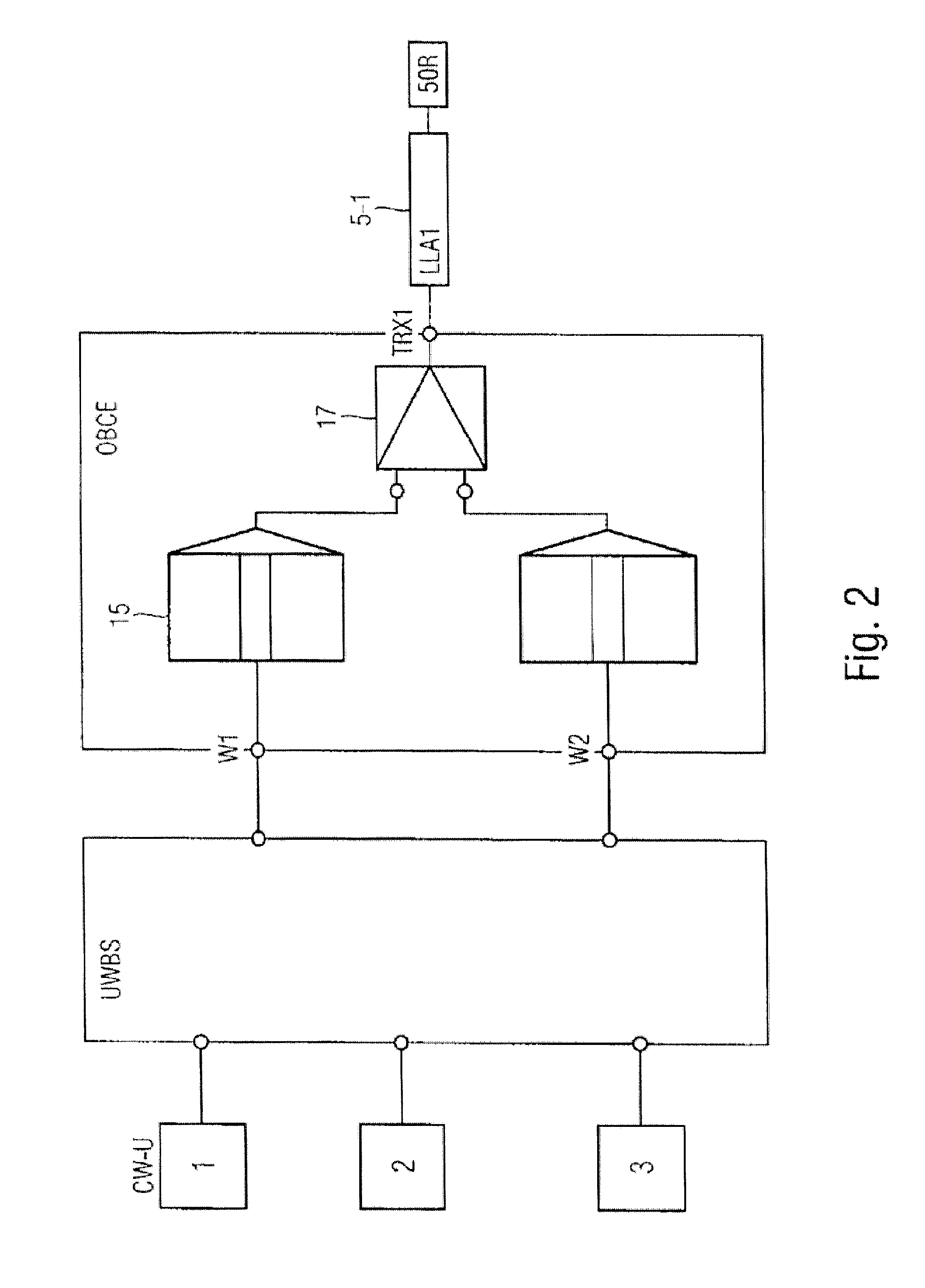

Device for providing radiofrequency signal connections

InactiveUS20120327921A1Control performanceWithout having negative effectNetwork topologiesWeight reductionMobile radioVIT signals

What is disclosed is a device for providing radiofrequency signal connections for users, wherein the device comprises a plurality of access points which transmit or receive radiofrequency signals in different predetermined radiofrequency bands and are each connected via a transmission and reception signal path to at least one shared transmitting and receiving antenna, filter means being provided in the transmission and reception signal paths respectively and isolating the radiofrequency bands sufficiently from one another and from predetermined mobile radio frequency bands.

Owner:AIRBUS OPERATIONS GMBH

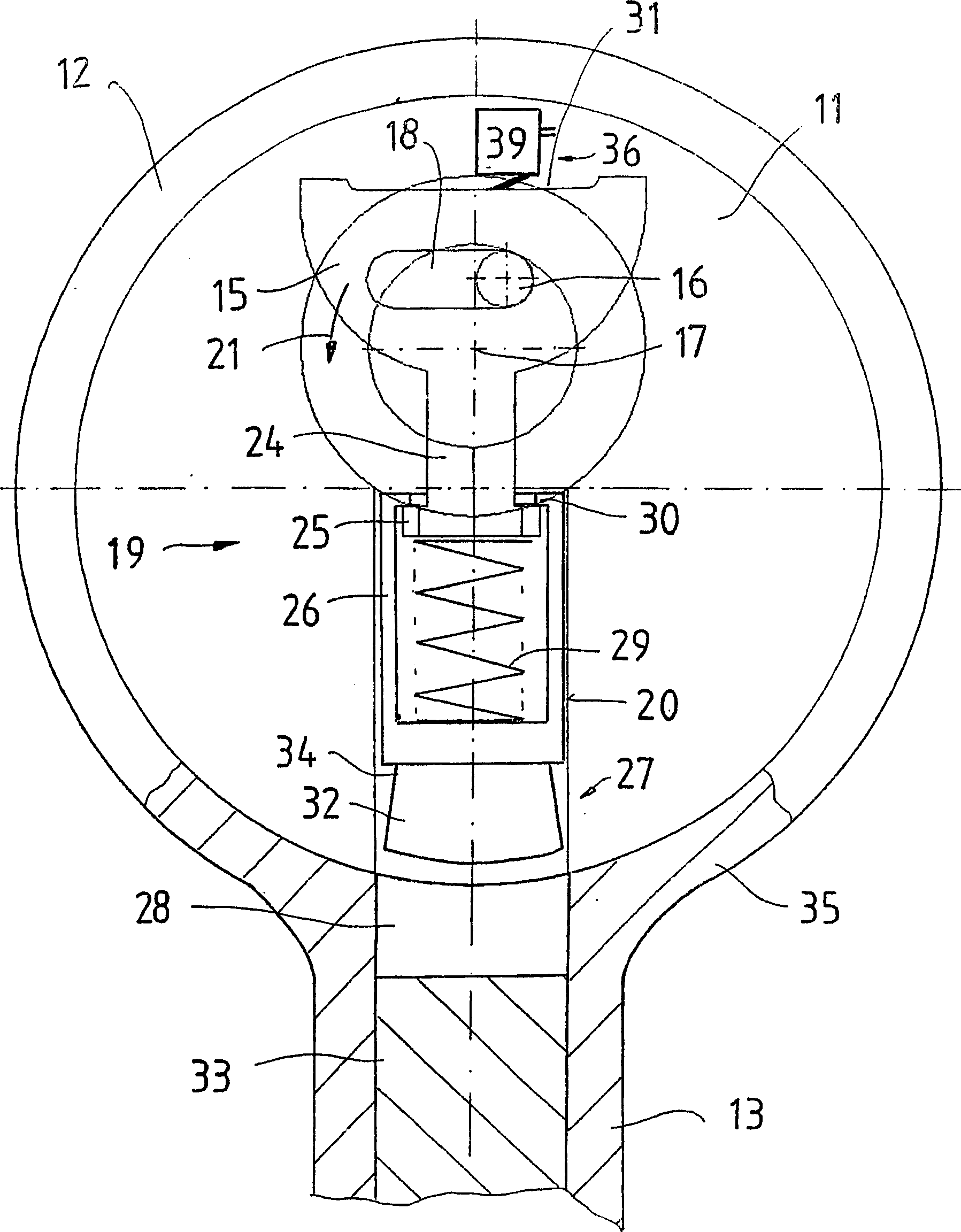

Electromechanical lock cylinder

InactiveCN1813114AEasy to controlReduce consumptionNon-mechanical controlsSpherical shapedEngineering

The invention concerns an electromechanical lock cylinder that cooperates with evaluation electronics to recognize access authorization and has a housing that includes two opposite cylindrical receptacles, in which a lock core, which can be operated by a key, or a knob shaft, which is connected to rotate in unison with a know, are mounted to rotation, in which the lock core and / or knob shaft cooperate with a lock tab, which operates, in particular, a bolt or latch with a door lock, and, with a fitting key or access authorization, an electromechanically driven blocking or coupling element is moved from the rest position to an operating position and produces a splined connection between the key or knob and the lock tab, characterized by the fact that the lock tab is freely rotatable relative to the two lock cores or the two knob shafts in the rest position of the blocking or coupling element.

Owner:ASSA ABLOY AB

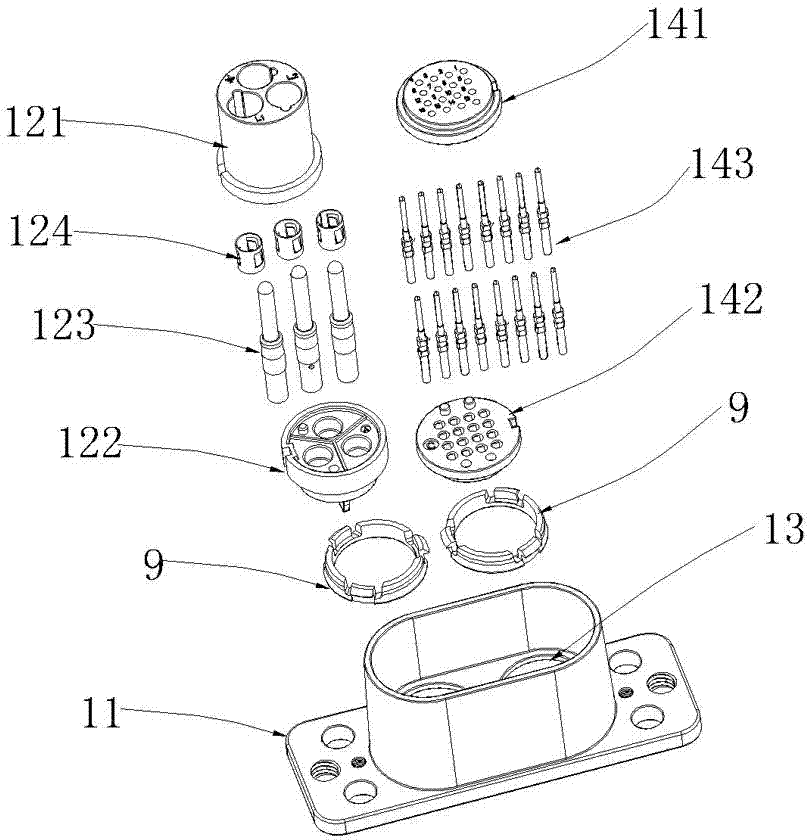

Plug-socket integrated connector with board-to-board butting compatibility function

ActiveCN104518352AAvoid misalignmentSeamless connectionSecuring/insulating coupling contact membersEngineeringMechanical engineering

Owner:SHENZHEN LINKO ELECTRIC

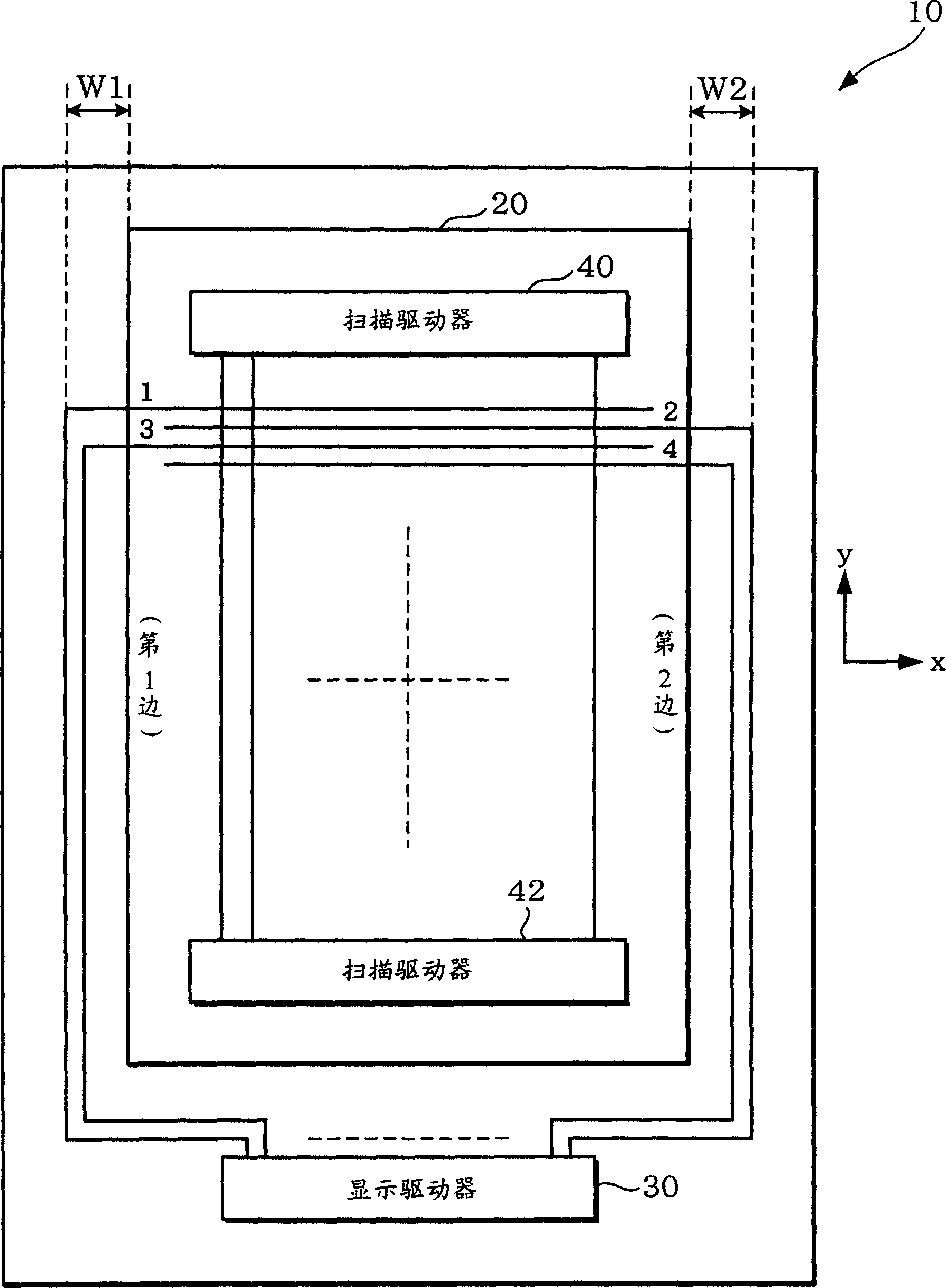

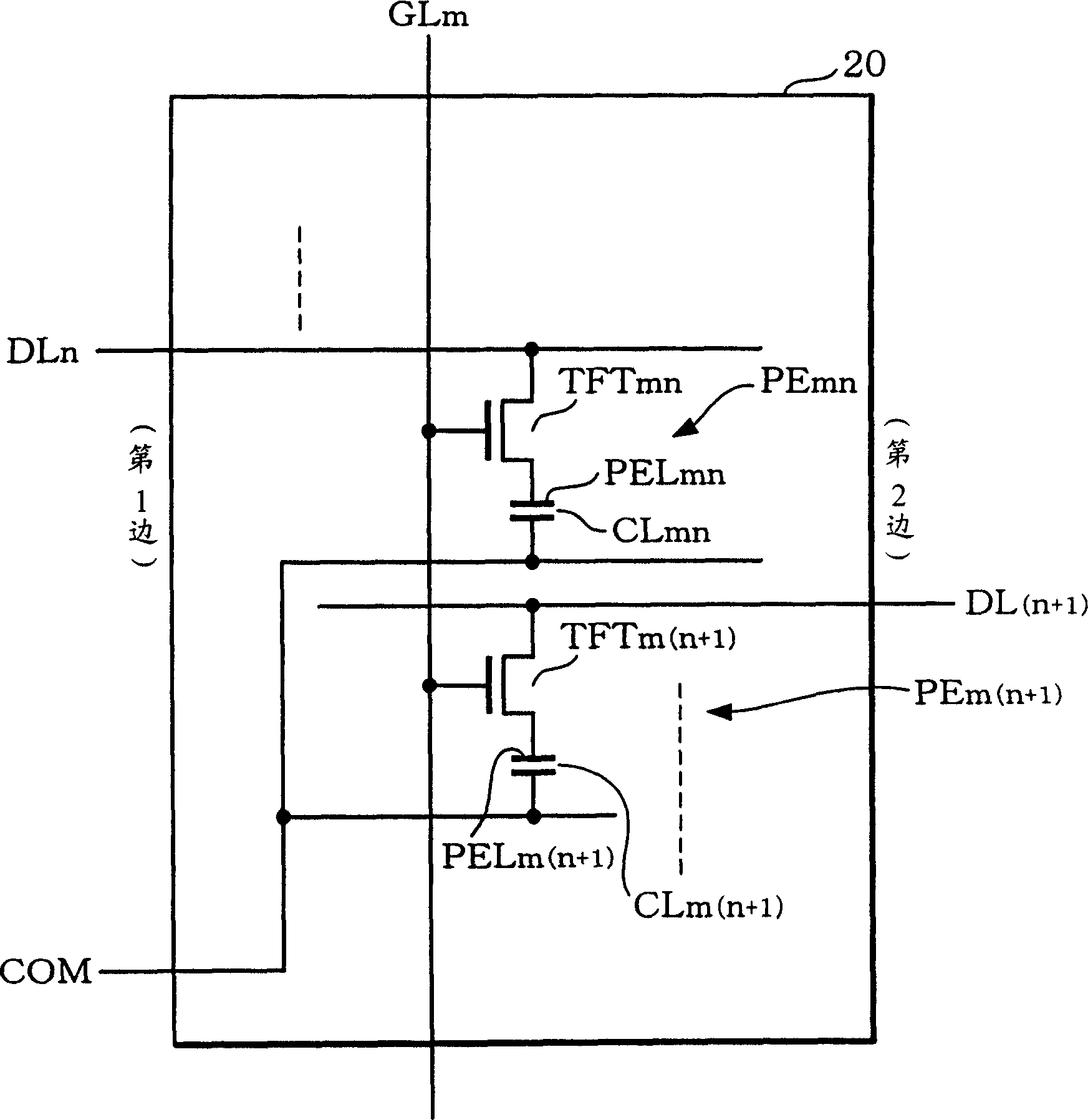

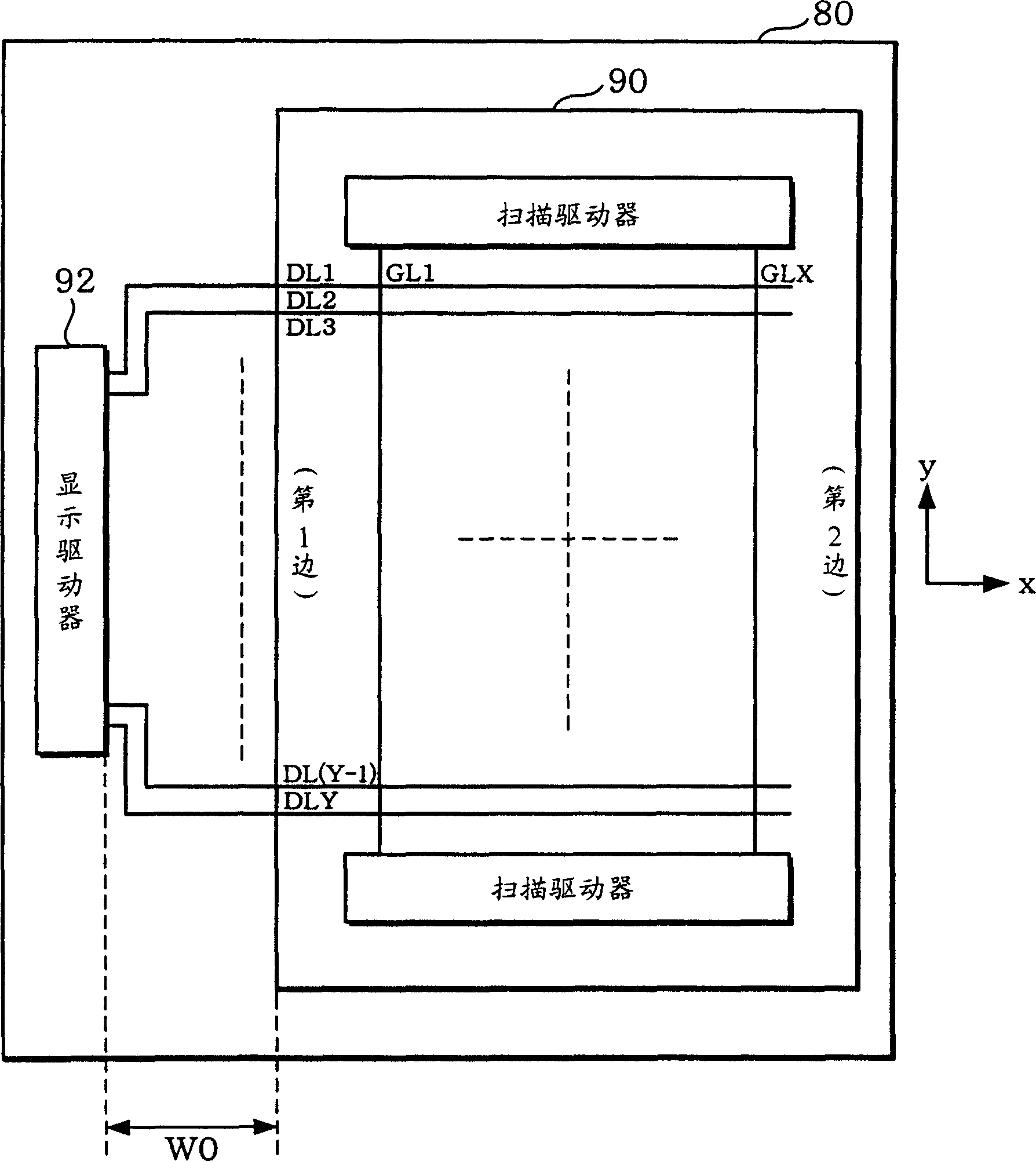

Displaying driver and photoelectric device

InactiveCN1530908AImprove picture qualitySmall installation sizeCathode-ray tube indicatorsShift registerMultiplexing

A display driver (200) multiplexes gray-scale data captured by a data latch (300) and outputs a data signal to a comb-tooth distributed data line. The data latch (300) includes a gray-scale bus (310) to which the gray-scale data for first to third color components is supplied corresponding to the arrangement order of the data lines. A first data latch, a second data latch, a first shift register, a second shift register, a first clock signal line, and a second clock signal line are N multiplexed. A multiplexer (380) multiplexes N sets of gray-scale data captured by the first and second data latches. The display driver (200) outputs the data signal corresponding to first or second multiplexed data to a data signal supply line.

Owner:SEIKO EPSON CORP

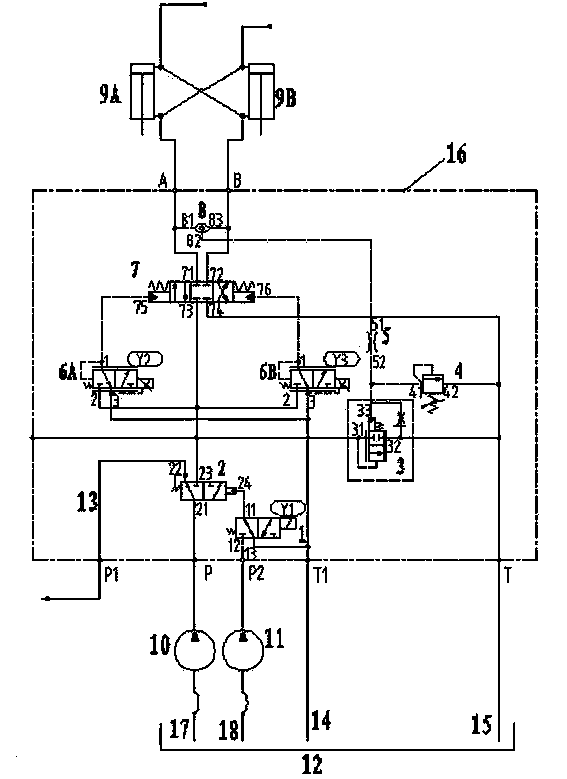

Steering electrohydraulic control system for remote control loading machine

InactiveCN103671364ALow calorific valueCommutation smoothServomotor componentsFluid-pressure actuator componentsRemote controlControl system

The invention relates to a steering electrohydraulic control system for a remote control loading machine. The steering electrohydraulic control system for the remote control loading machine comprises an oil tank, a steering metering pump, a pilot pump, a solenoid directional valve, a three-way pressure compensator, an overflow valve, a throttling valve, a shuttle valve, two hydraulic directional valves, two three-way solenoid proportional reducing valves and two steering oil cylinders. An inlet of the steering metering pump is connected with an oil outlet of the oil tank, the outlet of the steering metering pump is connected with a first oil inlet of the first hydraulic directional valve, the first hydraulic directional valve is respectively connected with the three-way pressure compensator and the two three-way solenoid proportional reducing valves, and the two three-way solenoid proportional reducing valves are connected with the second hydraulic directional valve, the shuttle valve and the two steering oil cylinders in sequence. The steering electrohydraulic control system for the remote control loading machine is stable in steering and free of impact and clamping stagnation phenomena, reduces the heat emitting amount and reduces waste of power of an engine, and thus the purposes of reducing oil consumption and saving energy are achieved finally.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

Electrical terminal

InactiveUS20050079753A1Simple structureGood and reliable handlingCouplings bases/casesContact members penetrating/cutting insulation/cable strandsBusbarEngineering

An electrical terminal has a housing including at least one side wall with two elongated holes, the two elongated holes are positioned spaced apart on a common circular path. The terminal also includes a busbar and at least two insulation piercing elements which produce electrical contact between the inserted conductor and the busbar. The electrical terminal includes at least two actuating elements arranged so as to turn relative to the insulation piercing elements in the electrical terminal. The actuating elements further includes two journals. Each journal is located in a corresponding one of the elongated holes and is restricted so that the actuating element, when pivoted out of a first position in which the insertion of an incoming conductor is possible into a second position in which the conductor makes contact with the insulation piercing element, is guided and restricted by the movement of the journals within the elongated holes.

Owner:PHOENIX CONTACT GMBH & CO KG

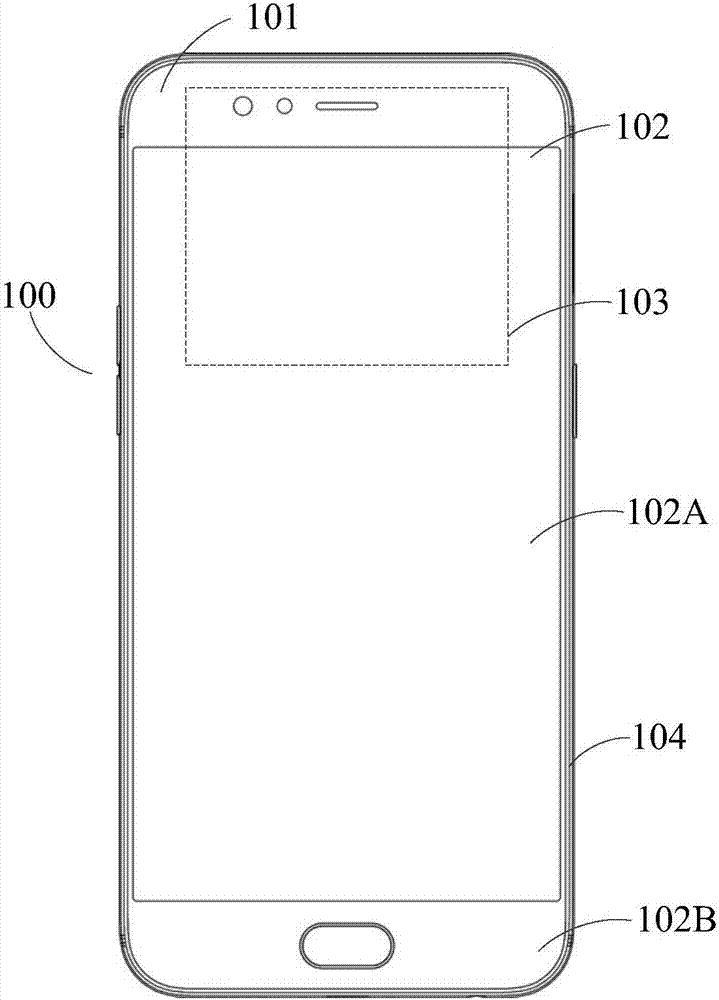

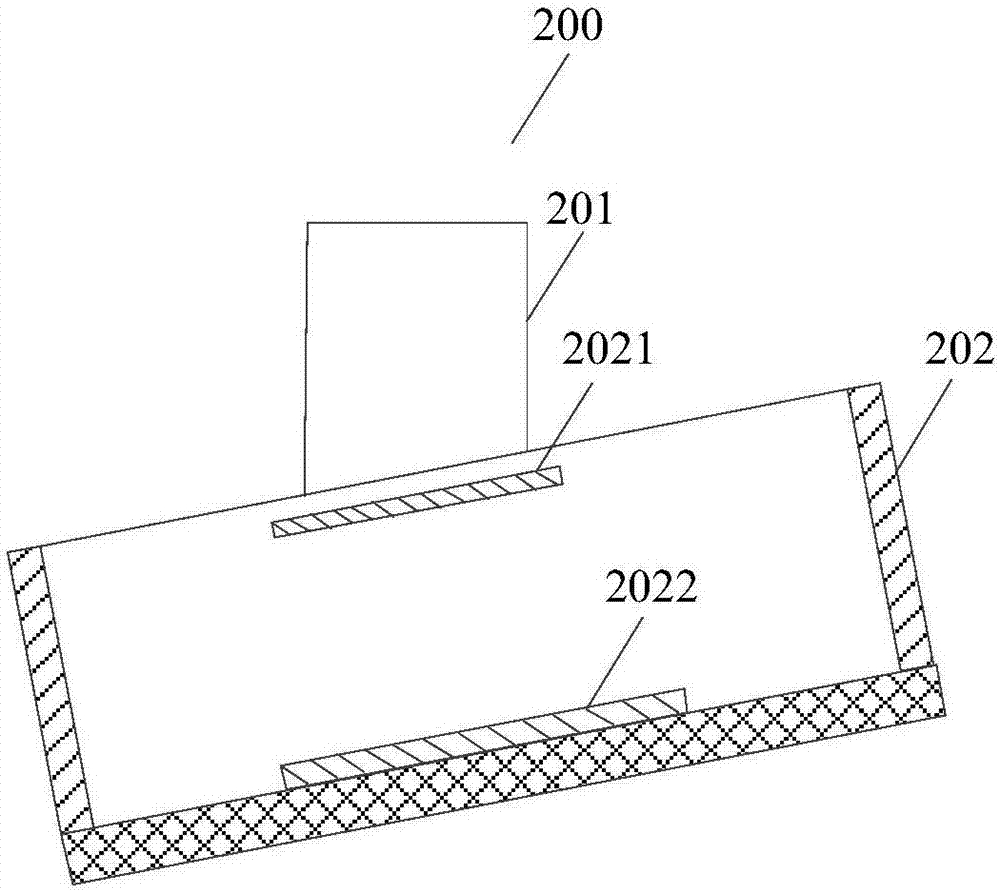

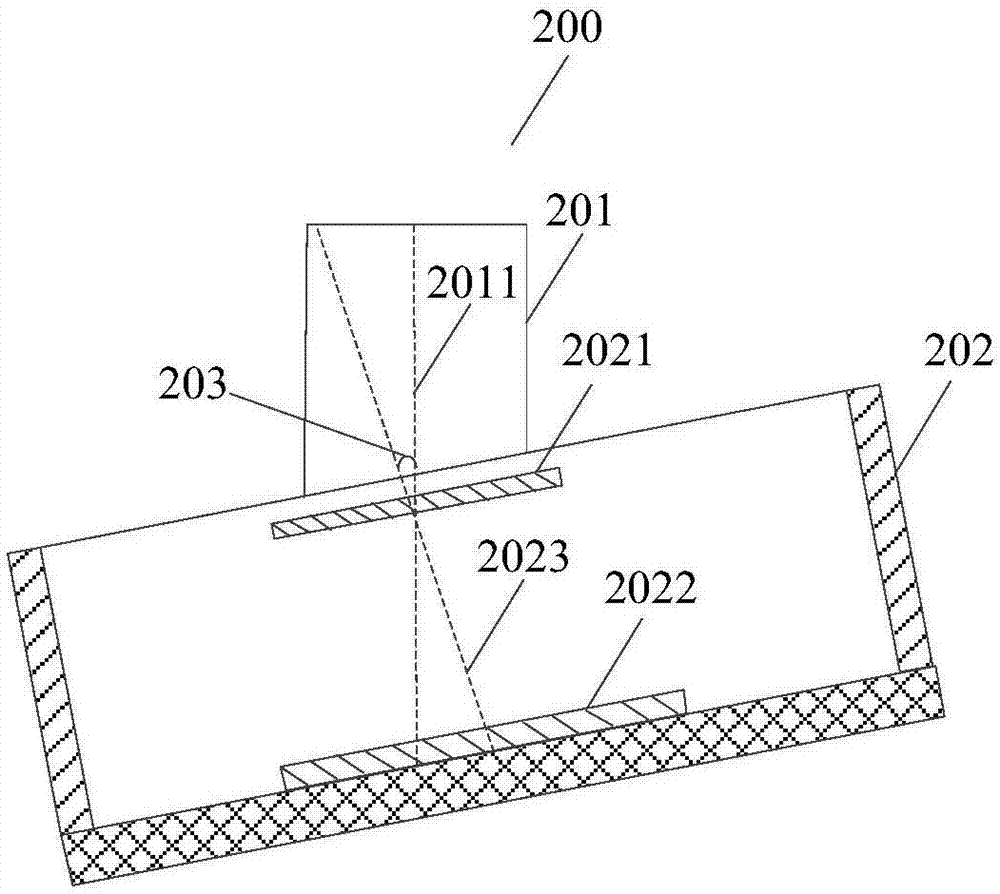

Camera module and electronic device

PendingCN107277332AIncrease the screen ratioSmall installation sizeTelevision system detailsColor television detailsLight guideEngineering

The invention provides a camera module and an electronic device. The camera module comprises at least one lens, at least one light guide part, at least one photosensitive chip and a base. At least one lens is obliquely arranged on the base. At least one light guide part and at least one photosensitive chip are arranged in the base. At least one light guide part is used to adjust the angle of the light incident from at least one lens, so that the light is perpendicularly introduced onto at least one photosensitive chip. According to the invention, the lens is obliquely arranged on the base, so that the base can be obliquely arranged on the electronic device; the installation size of the bottom of the base is reduced; and the screen proportion of the electronic device is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

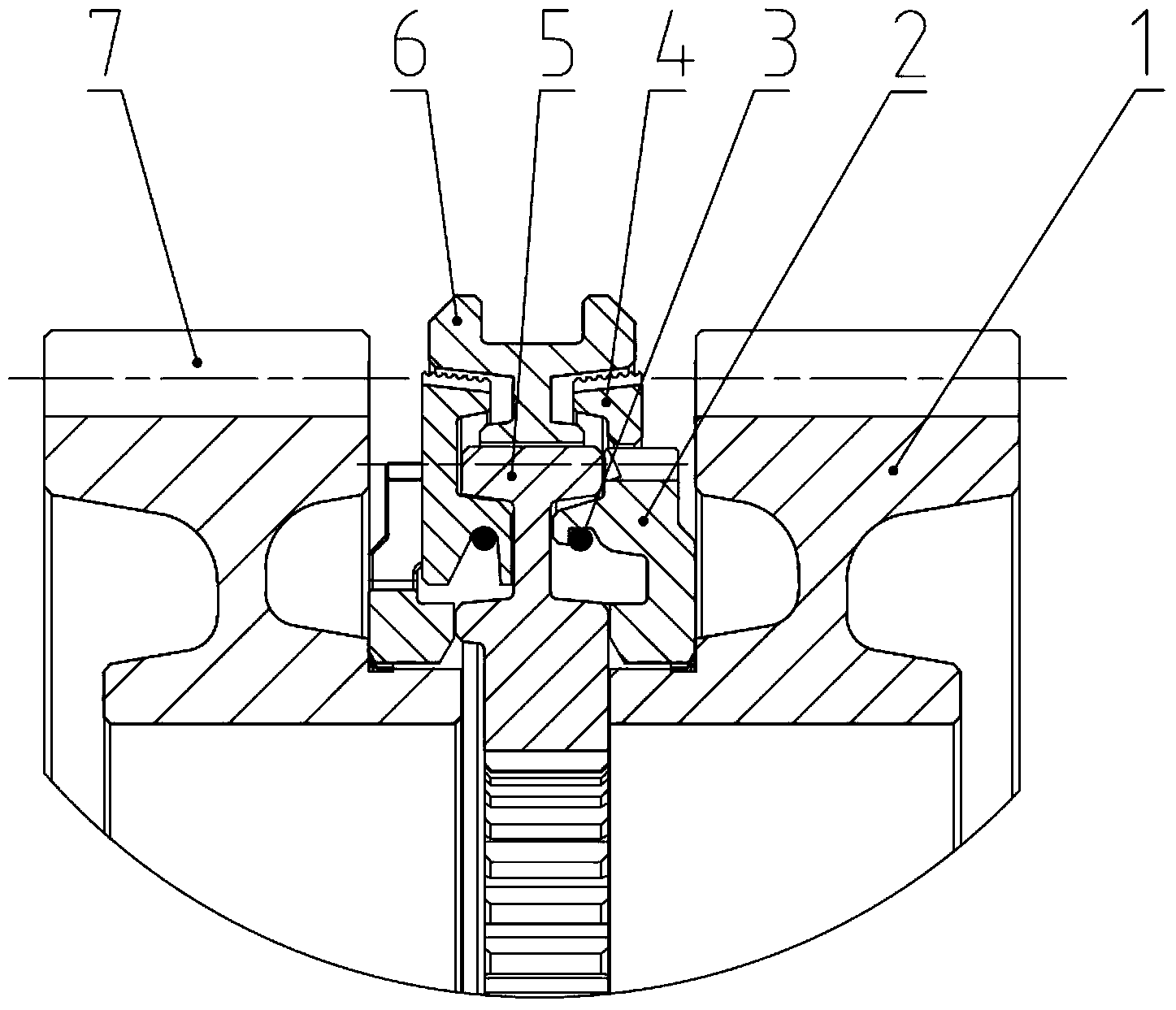

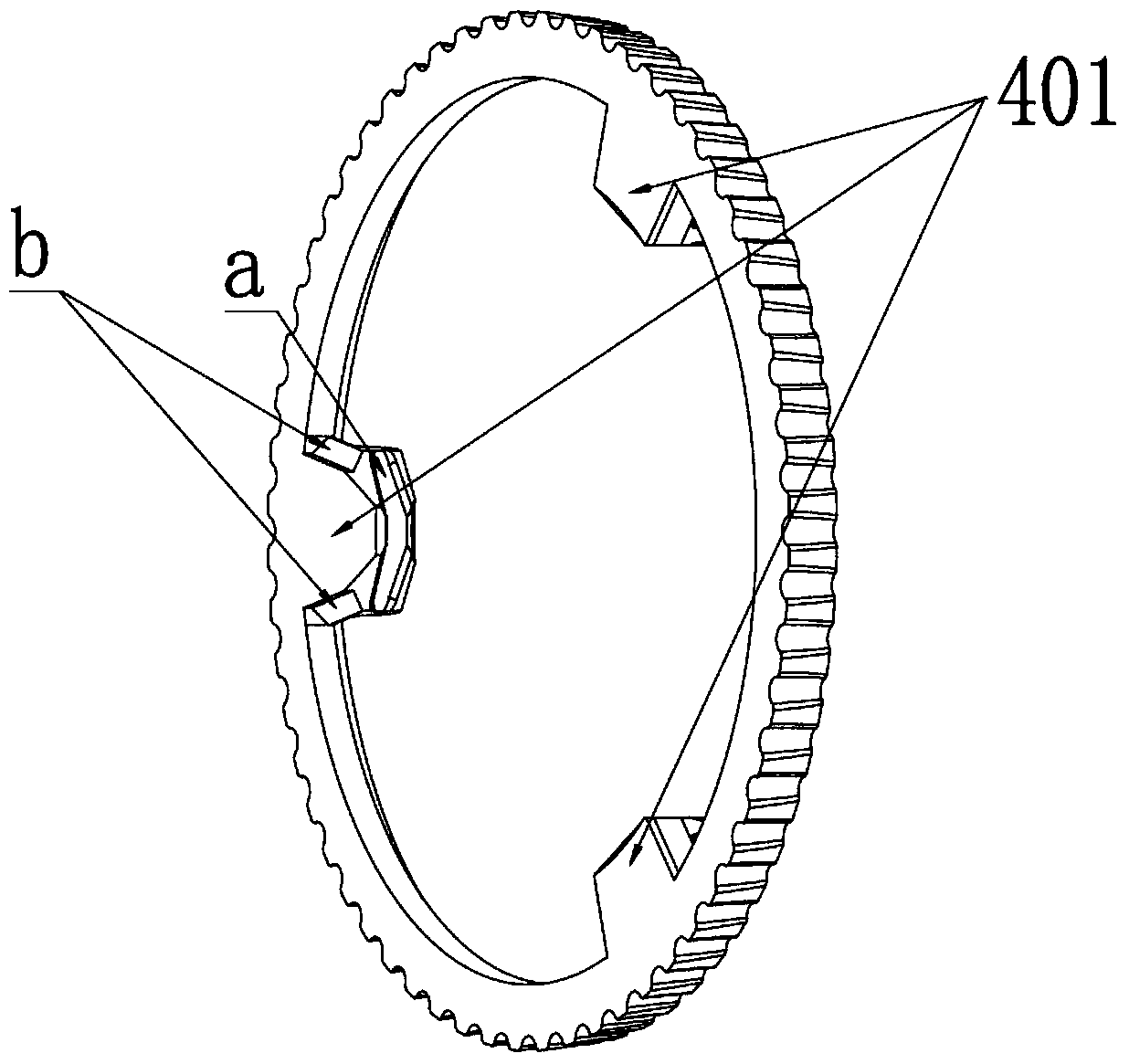

Lock ring type synchronizer and synchronizing method thereof

The invention provides a lock ring type synchronizer and a synchronizing method thereof. The synchronizer comprises gear hubs, slide sleeves, return springs, synchronous conical rings and jointed gear rings. The slide sleeves sleeve the gear hubs, the inner walls of the synchronous conical rings are provided with a plurality of locking bosses uniformly distributed, each locking boss is provided with a first locking slope, the side walls of the jointed gear rings are provided with annular bosses extending axially, the annular bosses are provided with locking grooves matched with the locking bosses on the inner walls of the synchronous conical rings, the locking grooves are provided with second locking slopes, the slide sleeves slide from one sides of the gear hubs to the jointed gear rings so as to push the synchronous conical rings and the jointed gear rings to be matched, and the synchronous conical rings are driven to overpass the jointed gear rings by the return springs, so that internal splines of the slide sleeves are meshed with outer splines of the jointed gear rings. The lock ring type synchronizer is compact in integral structure and small in axial size, and has larger friction radius than that of conventional lock ring synchronizers due to the fact that the slide sleeves are provided with frictional conical surfaces, that is, larger capacity of the synchronizer is achieved, and a transmission is higher in operation comfortableness and reliability and lower in cost.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com