Bulk material distributing device

A technology for distributing devices and bulk materials, applied in packaging, transportation and packaging, furnaces, etc., can solve the problems of high production cost and complex structure, and achieve the effect of low manufacturing cost, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

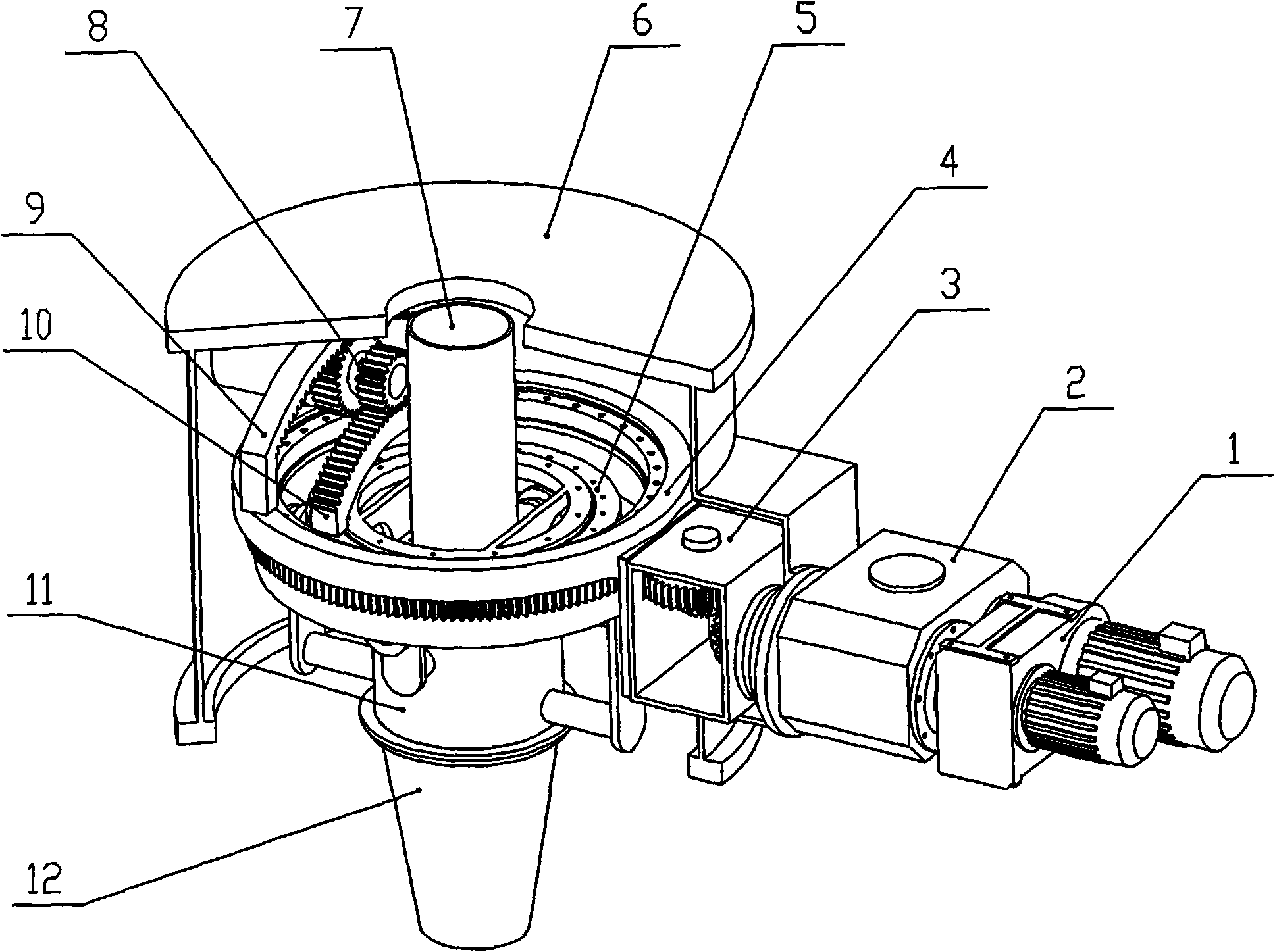

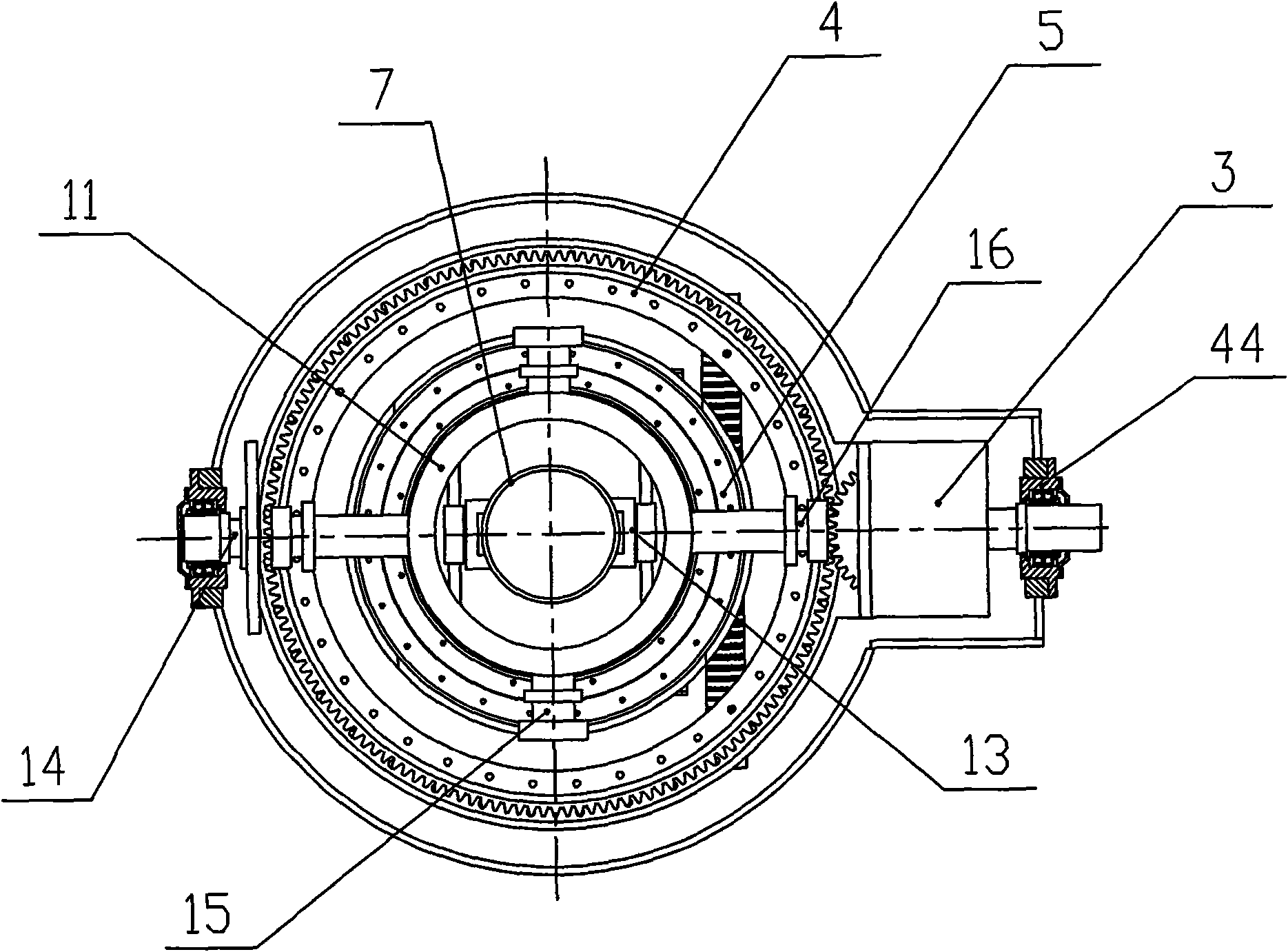

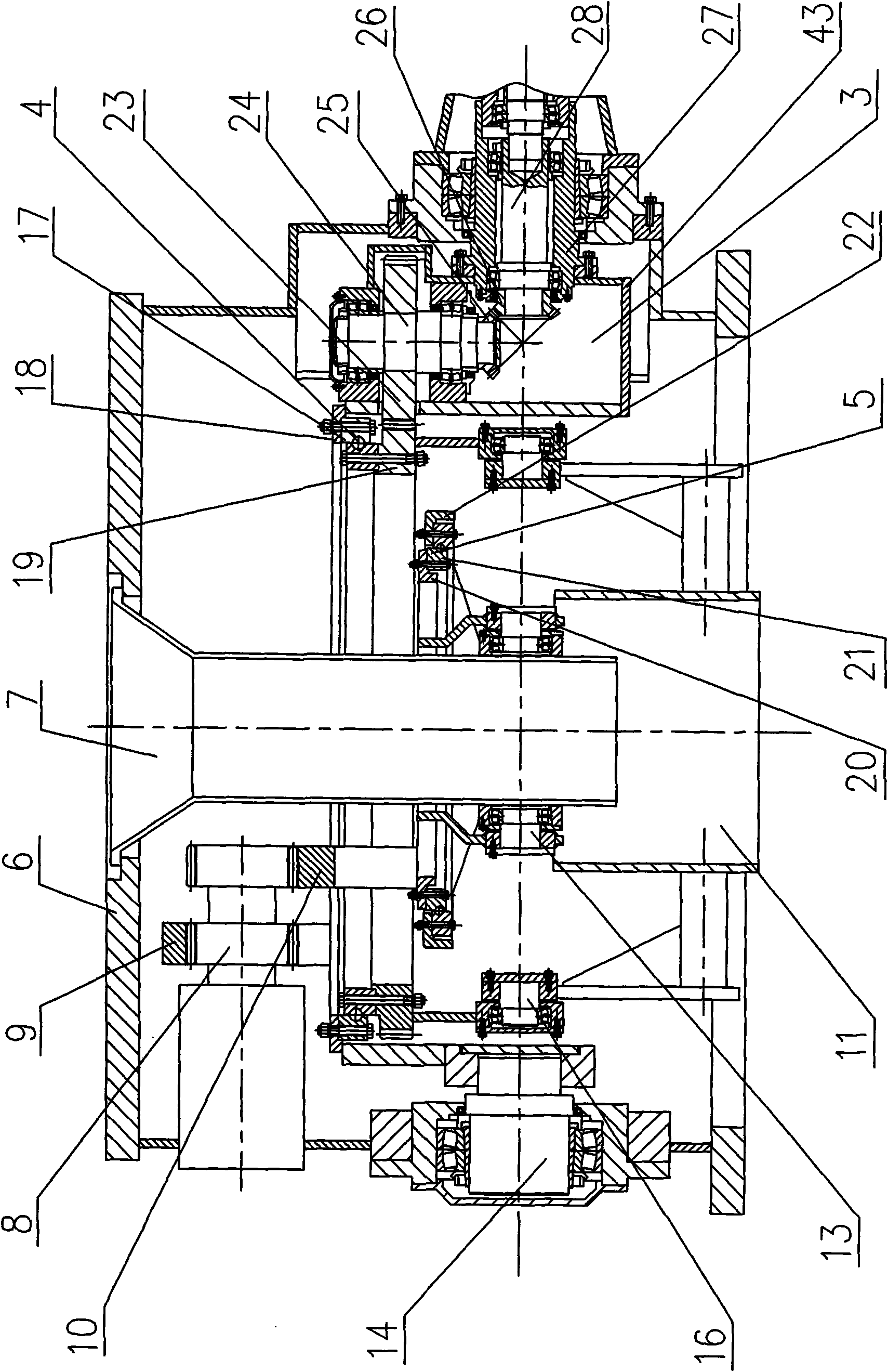

[0024] Embodiment 1: as Figure 1 to Figure 6 As shown, a bulk material distributing device includes a geared motor 1 (including a rotating motor and a tilting motor), a gear box 2, a rotating drive gear box 3, an outer ring 4, an inner ring 5, a housing 6, and an upper fixed chute 7. Gear A8, cross feeding pipe 11, lower fixed chute 12, rotating device A15, rotating device B16, rotating supporting device A14 and rotating supporting device B44; wherein, the lower fixing chute 12 is installed on the cross feeding pipe 11; the cross feeding tube 11 is installed on the inner ring 5 and the outer ring 4 through the rotating device A15 and the rotating device B16, so that the cross feeding tube 11 surrounds the inner ring 5 and the centerline of the outer ring 4 rotate to drive the lower fixed chute 12 to rotate; the outer ring 4 and the inner ring 5 are arranged concentrically; the inner ring 5 is fixed to the upper fixed chute 7; The ring 4 is connected to the housing 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com