Heat dissipation structure of computed tomography (CT) device

A heat dissipation structure and equipment technology, applied in X-ray equipment, radiological diagnostic equipment, medical science, etc., can solve the problems of large and clumsy CT equipment, increase the height of the frame shell, and reduce the heat dissipation performance, etc., to achieve Avoid floating around, reduce installation size, and improve heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

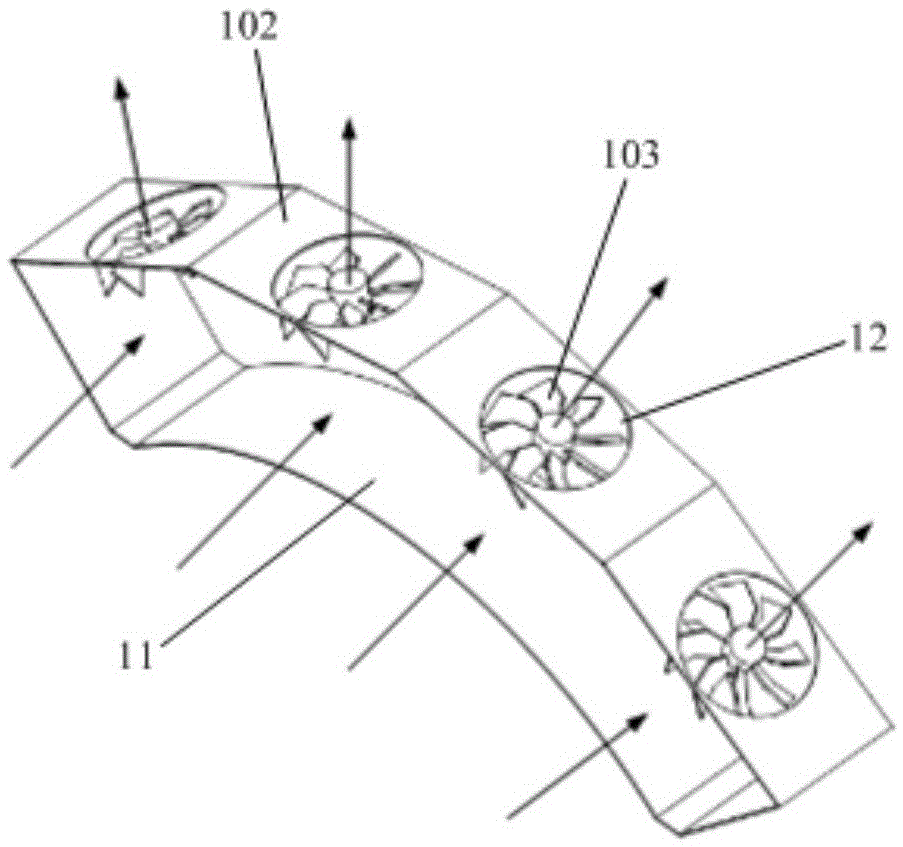

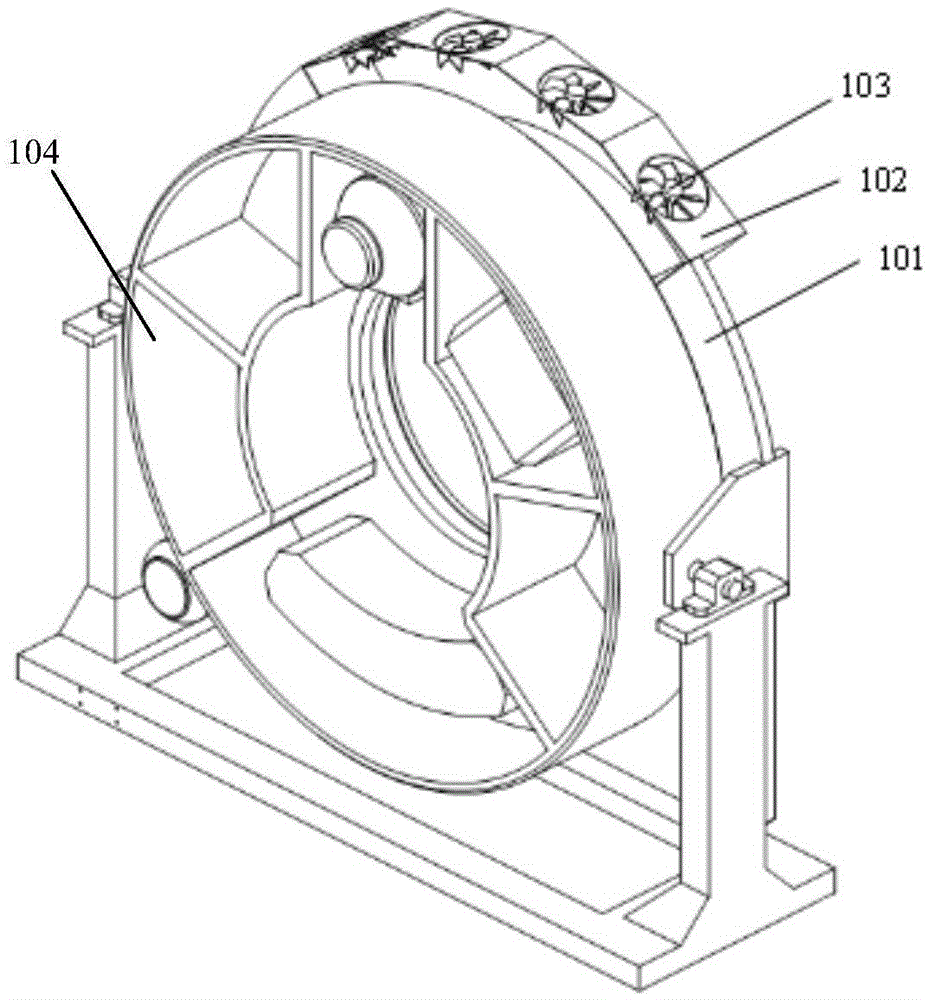

[0042] like Figures 1 to 3 As shown, in an embodiment of the present invention, the entire surface of the air duct 102 close to the front side of the support plate 101 is the air inlet 11, and the upper surface of the air duct 102 is provided with at least For one of the air outlets 12, the number of the fans 103 is the same as the number of the air outlets 12, and they are respectively arranged in the corresponding air outlets 12, and the other surfaces of the air duct 102 are closed surfaces. The integrated wide air inlet design of the air duct 102 significantly reduces the air inlet wind resistance, greatly improves the heat dissipation efficiency of the fan 103, and at the same time significantly reduces the working noise. Therefore, the air in the air duct 102 will not be disturbed, so that the heat dissipation effect of the heat dissipation structure of the CT equipment will not be affected.

[0043] Further, the shape of the air outlet 12 is a circle matching the shap...

Embodiment 2

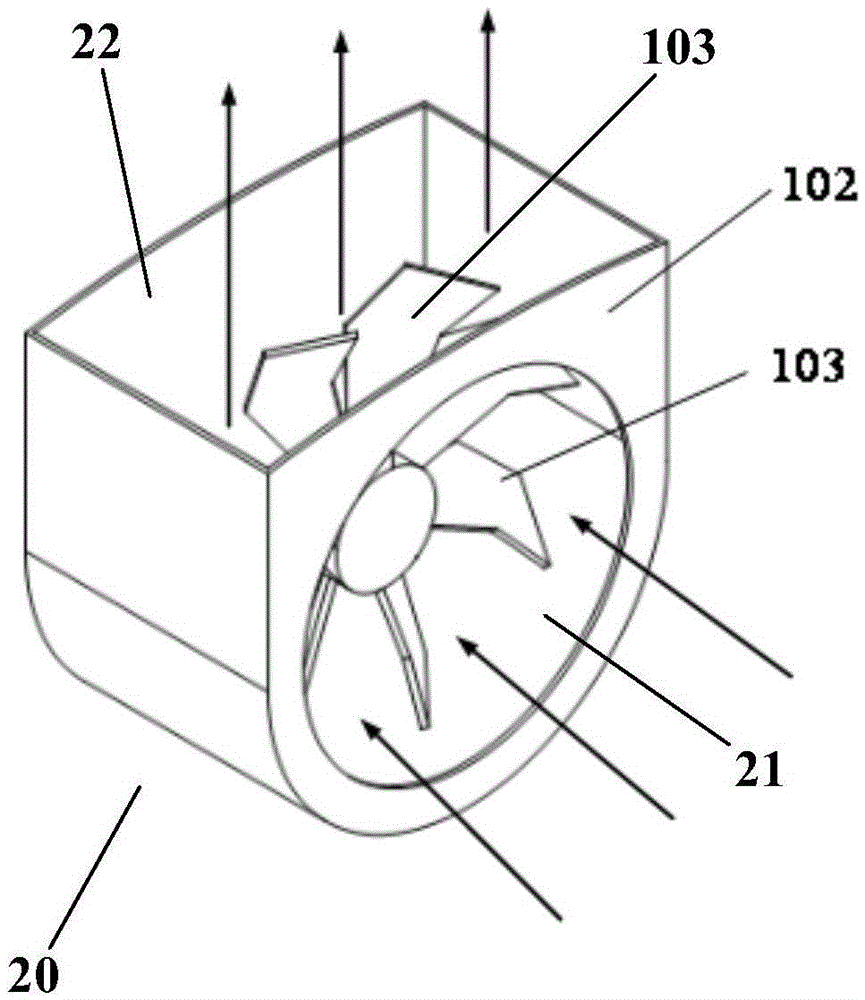

[0046] like Figures 4 to 6 As shown, in another embodiment of the present invention, the air duct 102 includes at least one independent air duct unit 20, and the at least one air duct unit 20 is located on the rear side of the support plate 101. The air inlet 21 is opened on one surface of the air duct unit 20 close to the support plate 101 . In the air inlet 21, the support plate 101 is provided with a corresponding opening 10 near the air inlet 21, and the entire upper surface of the air duct unit 20 is the air outlet 22. The air duct unit The remaining faces of 20 are closed faces. The independent air duct design of the air duct unit 20 can further avoid the mutual influence between the fans 103, so as not to affect the heat dissipation effect of the heat dissipation structure of the CT equipment.

[0047] Further, the shape of the air inlet 21 is a circle that matches the shape of the fan 103 , so that the exhaust efficiency of the fan 103 can be improved.

[0048] Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com